Patents

Literature

354results about How to "Guaranteed molding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

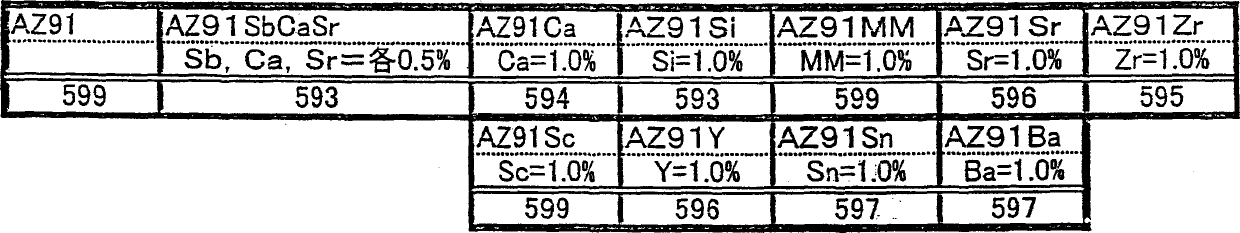

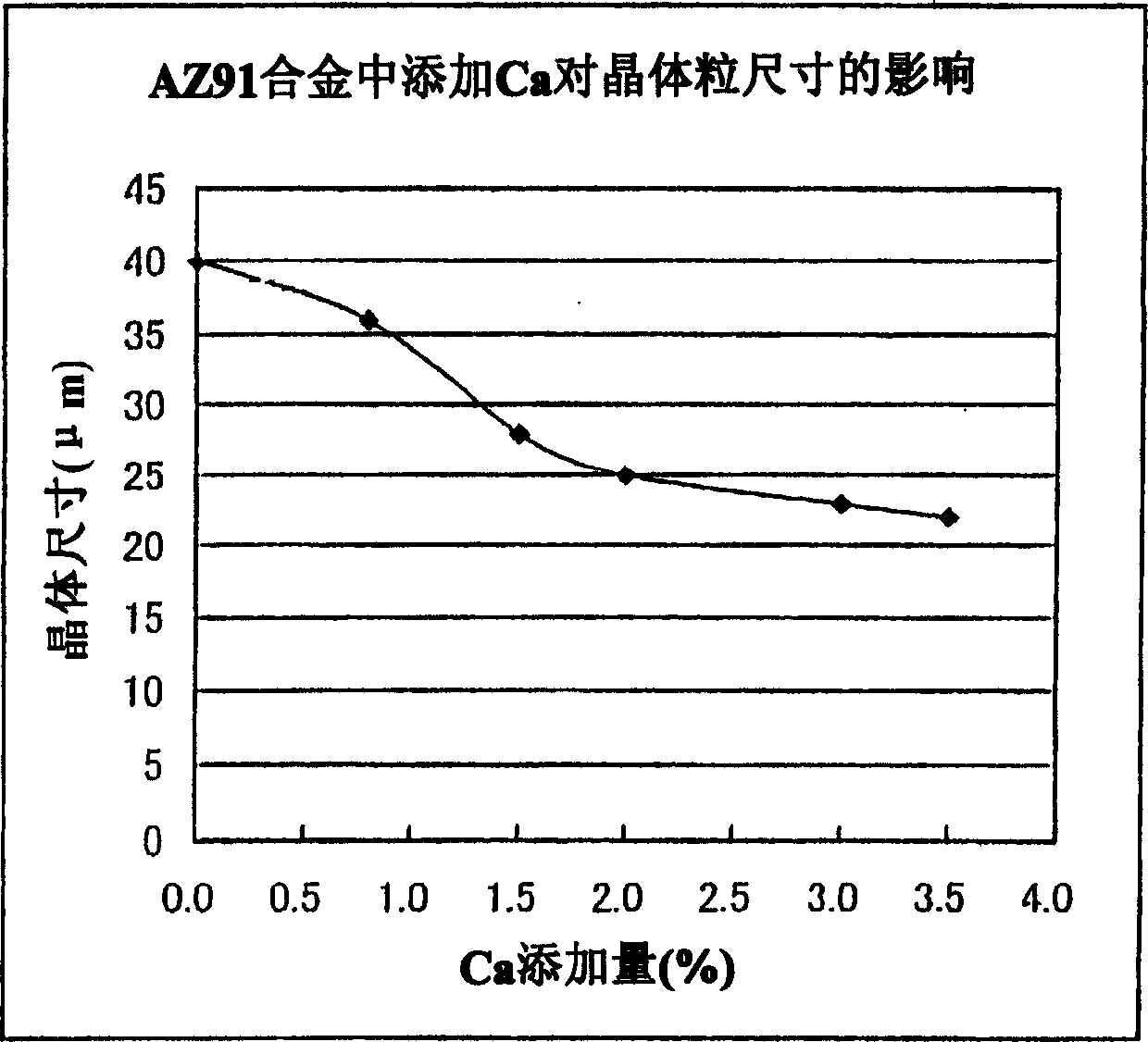

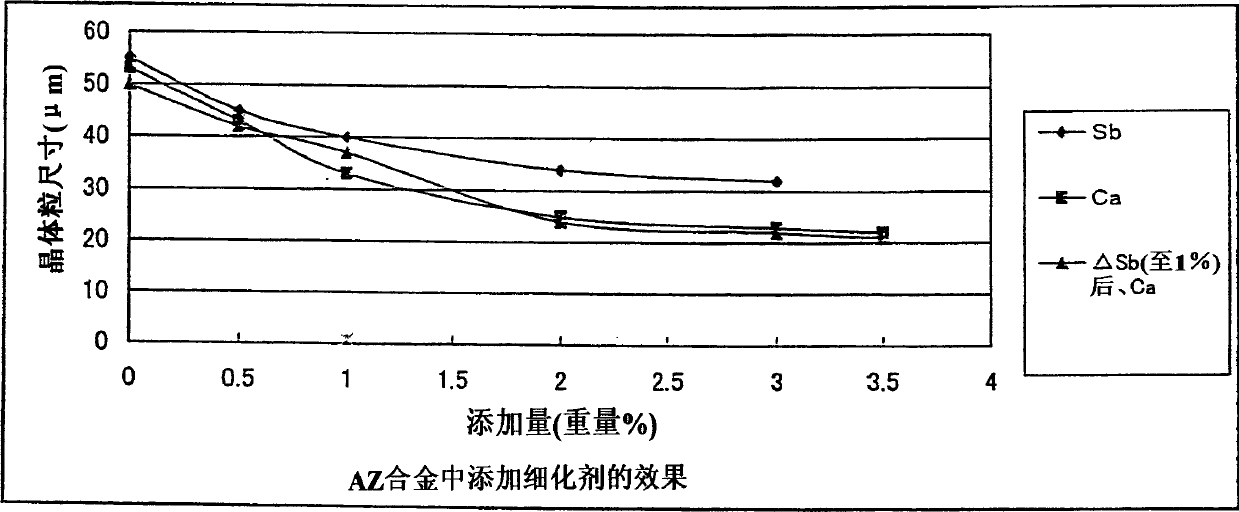

Die casting magnesium alloy and magnesium die casting

InactiveCN1637160ALarge particle sizePrevention of reduction in strength characteristicsUnderwater structuresReceptacle cultivationRare-earth elementMischmetal

The invention provides a magnesium alloy for die-casting that can improve the high-temperature creep performance without reducing the strength at room temperature, and a magnesium die-cast product using the alloy. Manufacture of magnesium die-casting products using a magnesium alloy for die-casting, wherein the magnesium alloy for die-casting is an AZ91 series alloy of 6.0 to 11.0% by weight of aluminum, 0.1 to 2.5% by weight of zinc, and 0.1 to 0.5% by weight of manganese, and added silicon: 0.1 to 1.5% by weight 1. At least one of misch metal containing rare earth elements: 0.1-1.2% by weight, zirconium: 0.2-0.8% by weight, made into an AZ91-based matrix alloy, and adding 0.1-1.5% by weight of antimony to the AZ91-based matrix alloy and at least one of 0.05 to 3.5% by weight of calcium, and 0.1 to 2.5% by weight of strontium, and other components are unavoidable components.

Owner:ADVANCED TECH +1

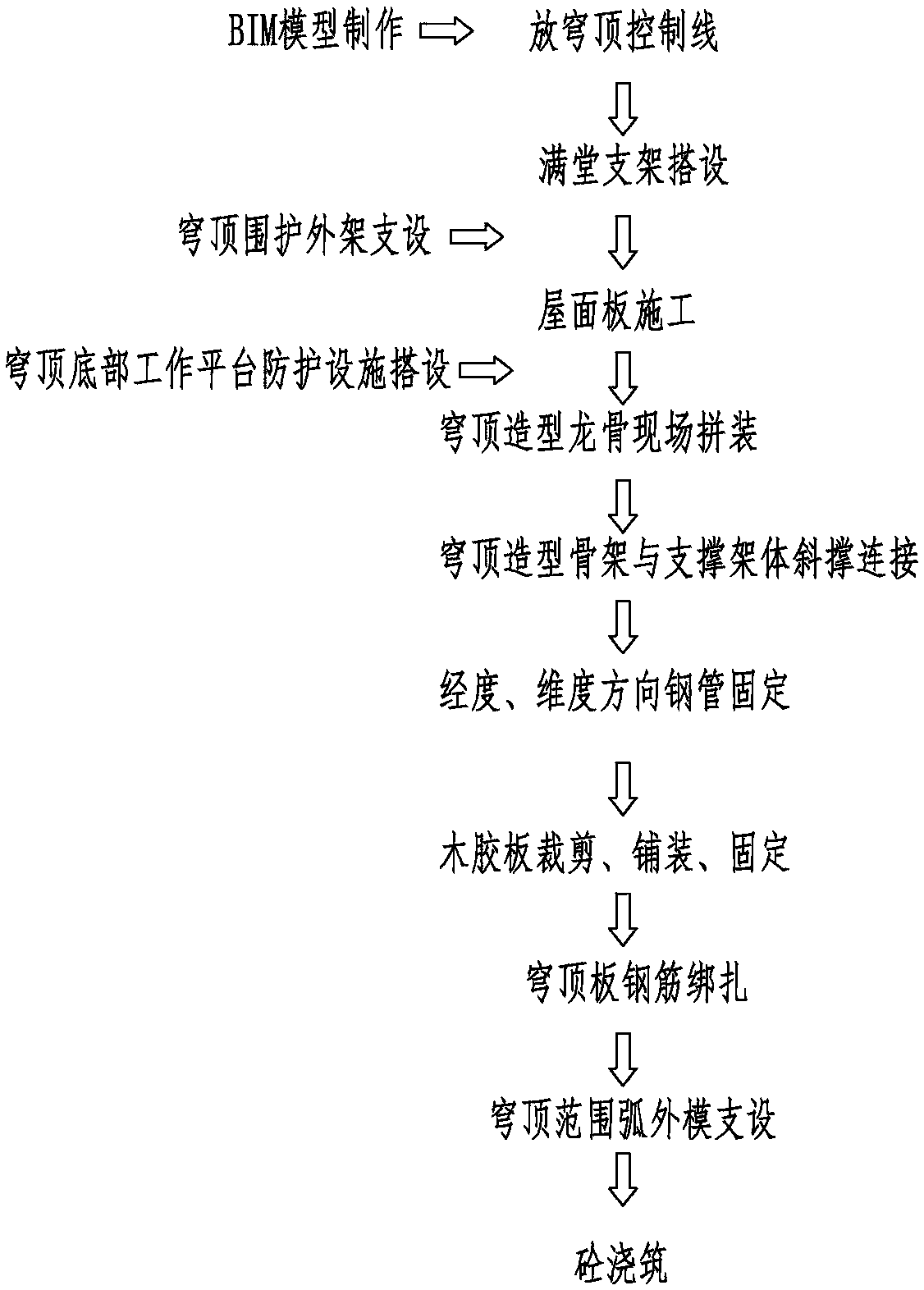

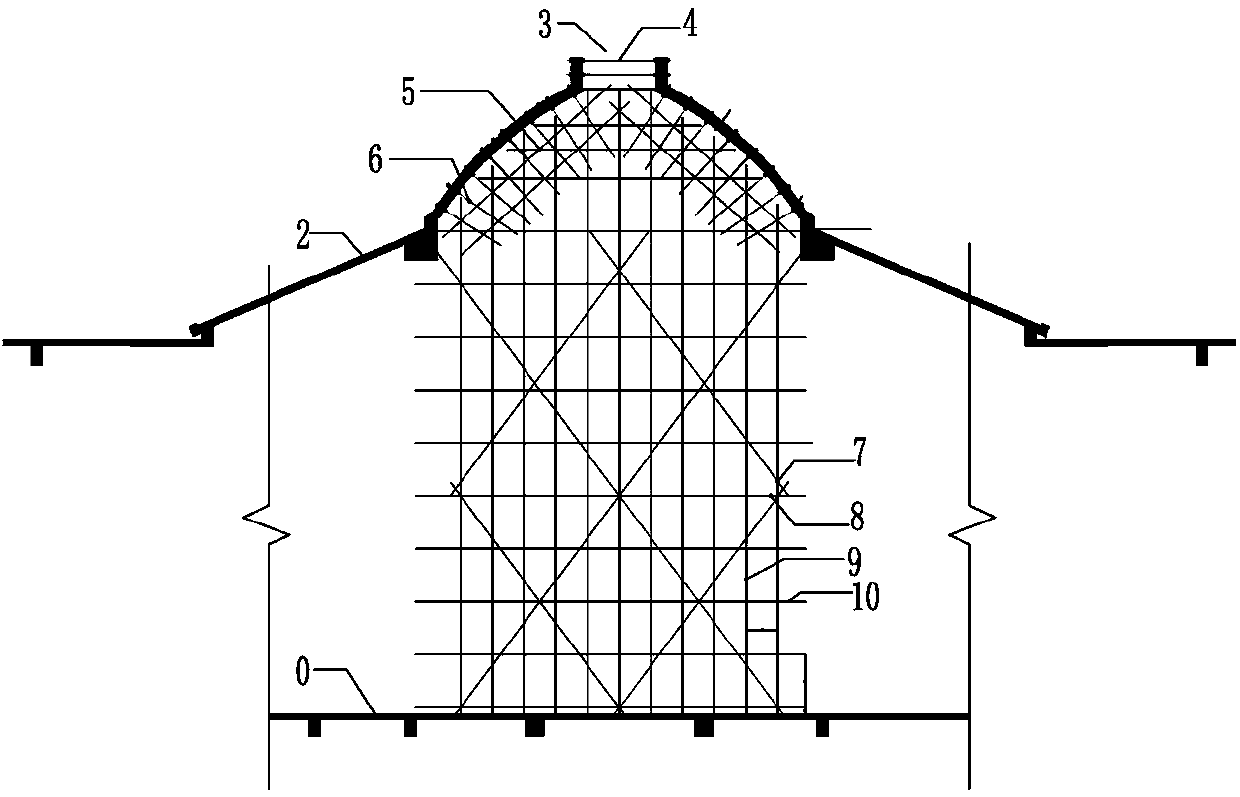

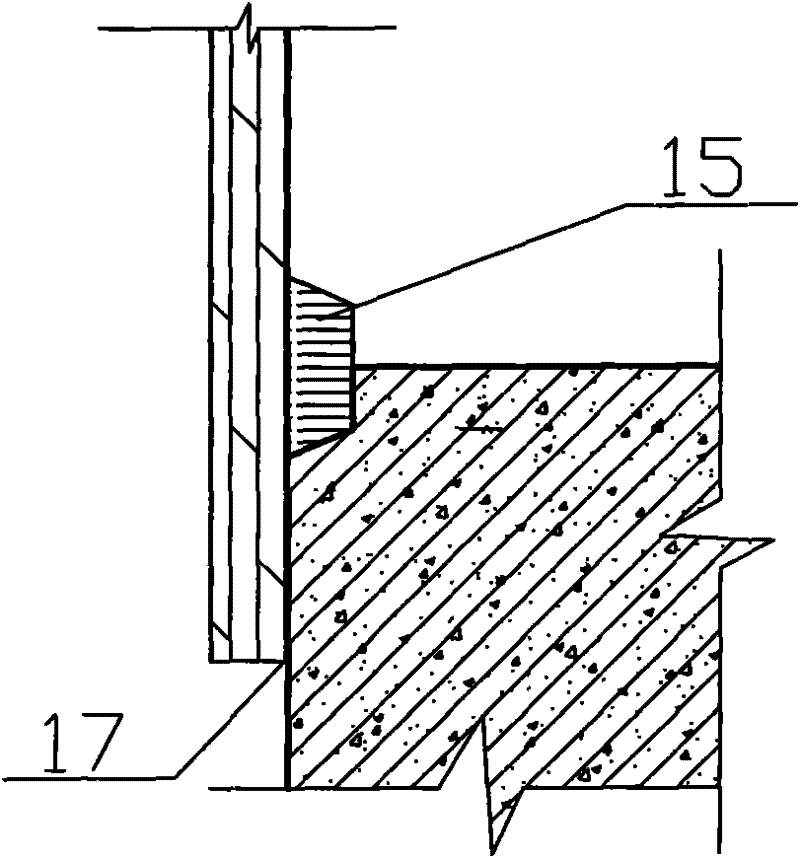

Wide-span semispherical reinforced concrete dome structure and construction method thereof

PendingCN108678258AImprove securityControl free fall heightBuilding roofsForms/shuttering/falseworksSupporting systemReinforced concrete

The invention relates to a wide-span semispherical reinforced concrete dome structure and a construction method thereof. The wide-span semispherical reinforced concrete dome structure comprises a semispherical reinforced concrete dome. The construction method thereof comprises the steps of delivering dome control lines, erecting a full framing, installing keels of the dome, splicing templates andpouring concrete. The steel pipe fastener-type full framing is adopted as a support system of an overall dome roof. The structure is highly safe. The prefabricated templates are adopted and subjectedto bending operation so that high dimensional accuracy is obtained. The templates are formed by splicing of dual-layer curved templates. Seam splicing positions are filled and smeared flat by putty inorder to prevent leakage of slurries and reduce repair cost in the later period.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

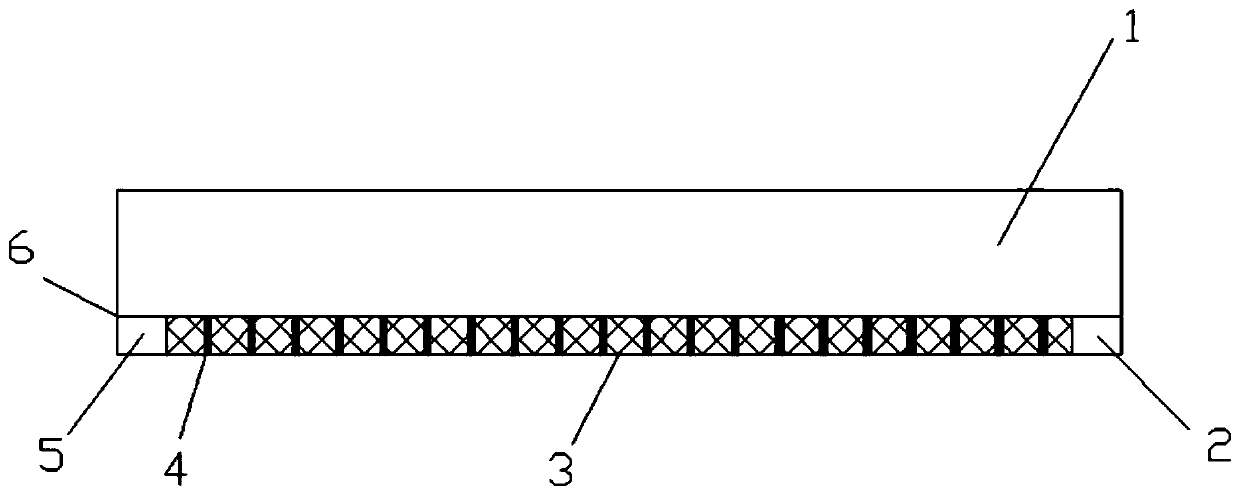

Environmental-friendly recyclable basalt fiber and jute fiber composite plate for automotive interiors and production method thereof

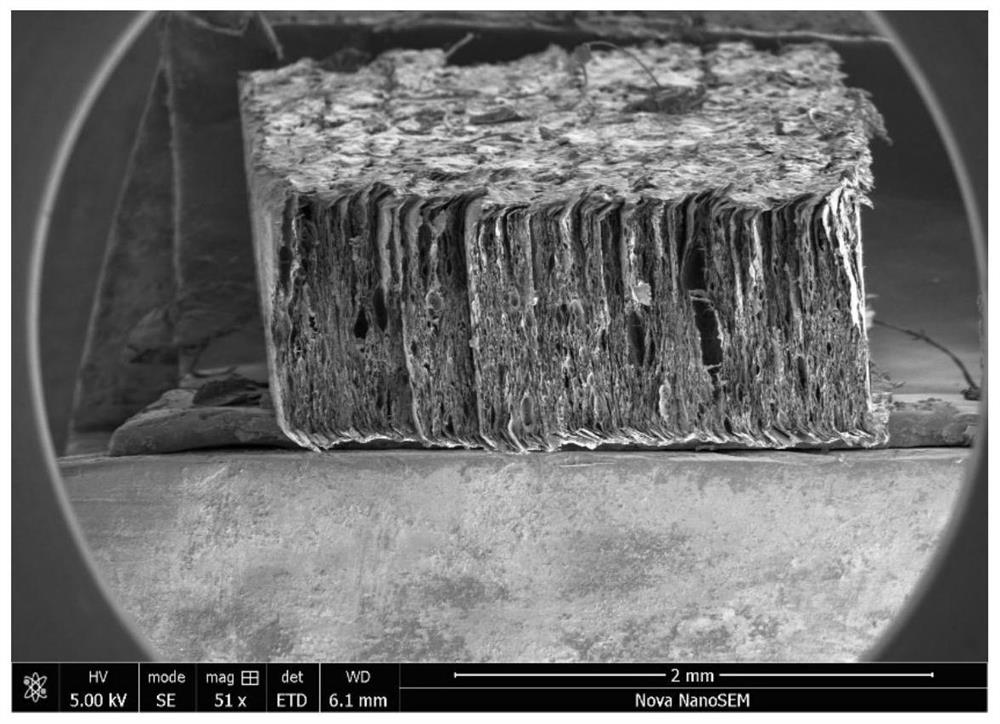

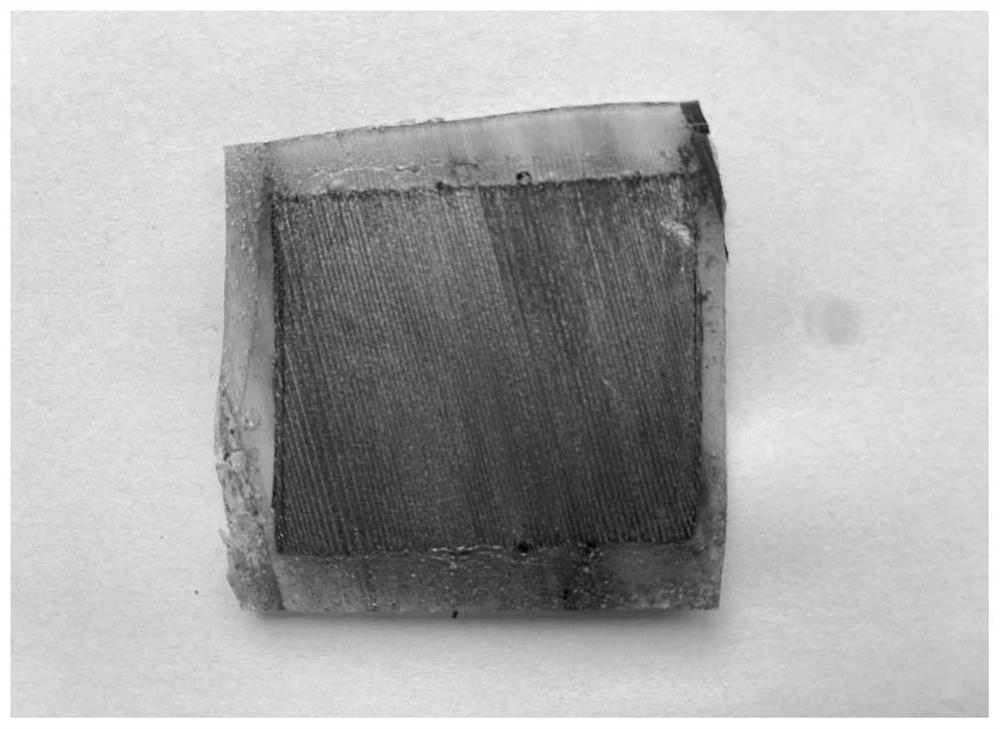

ActiveCN102145553AGuaranteed mechanical strengthGuaranteed molding effectLaminationLamination apparatusEnvironmental resistanceSurface layer

The invention relates to an environmental-friendly recyclable basalt fiber and jute fiber composite plate for automotive interiors and a production method thereof. The environmental-friendly recyclable basalt fiber and jute fiber composite plate is produced by manufacturing a felt by combining a surface layer with a core layer and then carrying out hot-press forming. The core layer is manufactured by lapping and needling two natural fibers, i.e. basalt fibers and jute fibers, and mixtures of two chemical fibers, i.e. polyster fibers and polypropylene fibers; and the core layer comprises the following components in percentage by weight: 10%-30% of the basalt fibers, 10%-30% of the jute fibers, 20%-30% of the polyster fibers and 30%-40% of the polypropylene fibers. The invention has the advantages of low density, light weight, low cost, high strength, good toughness, large deformation, high safety, environment friendliness, recyclability, and the like.

Owner:CHANGCHUN BOCHAO AUTOMOTIVE PARTS CO LTD

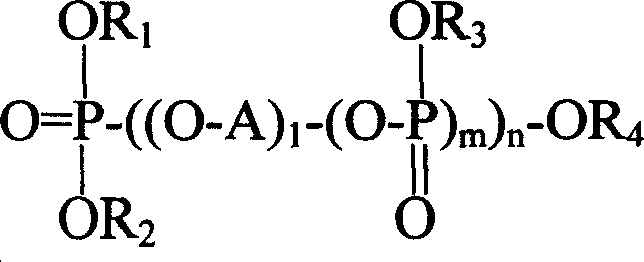

Resin composition for plating substrate and resin moldings using the same, and metal plated parts

InactiveCN1513028ANo plating swellingHigh Plating Adhesion StrengthCoatingsThin material handlingPhosphatePolyresin

The resin composition for a platable substrate of the present invention comprises 100 parts by weight of a resin composition (C) comprising 10 to 60% by weight of a graft copolymer (A) prepared by graft polymerization of a rubbery polymer (A1) and a monomer component (A2) containing an aromatic alkenyl compound monomer unit (a) and a vinyl cyanide compound monomer unit (b) and 40 to 90% by weight of the other polymer (B) (provided that the total amount of the components (A) and (B) is 100% by weight), and 5 to 40 parts by weight of a phosphate ester flame retardant (D) having a molecular weight of more than 326 or 2 to 40 parts by weight of a red phosphorus flame retardant (D'). The resin composition for a platable substrate of the present invention is excellent in production stability such as moldability, dimensional stability, mechanical strength and plating properties, and is also environmentally friendly. Excellent plated parts having good thermal conductivity can be provided by forming a metal plating layer on a resin molded article obtained by molding the resin composition for a platable substrate using a plating treatment. The resulting plated parts are suitable for use as housings for laptop PC and portable devices.

Owner:大科能宇菱通株式会社

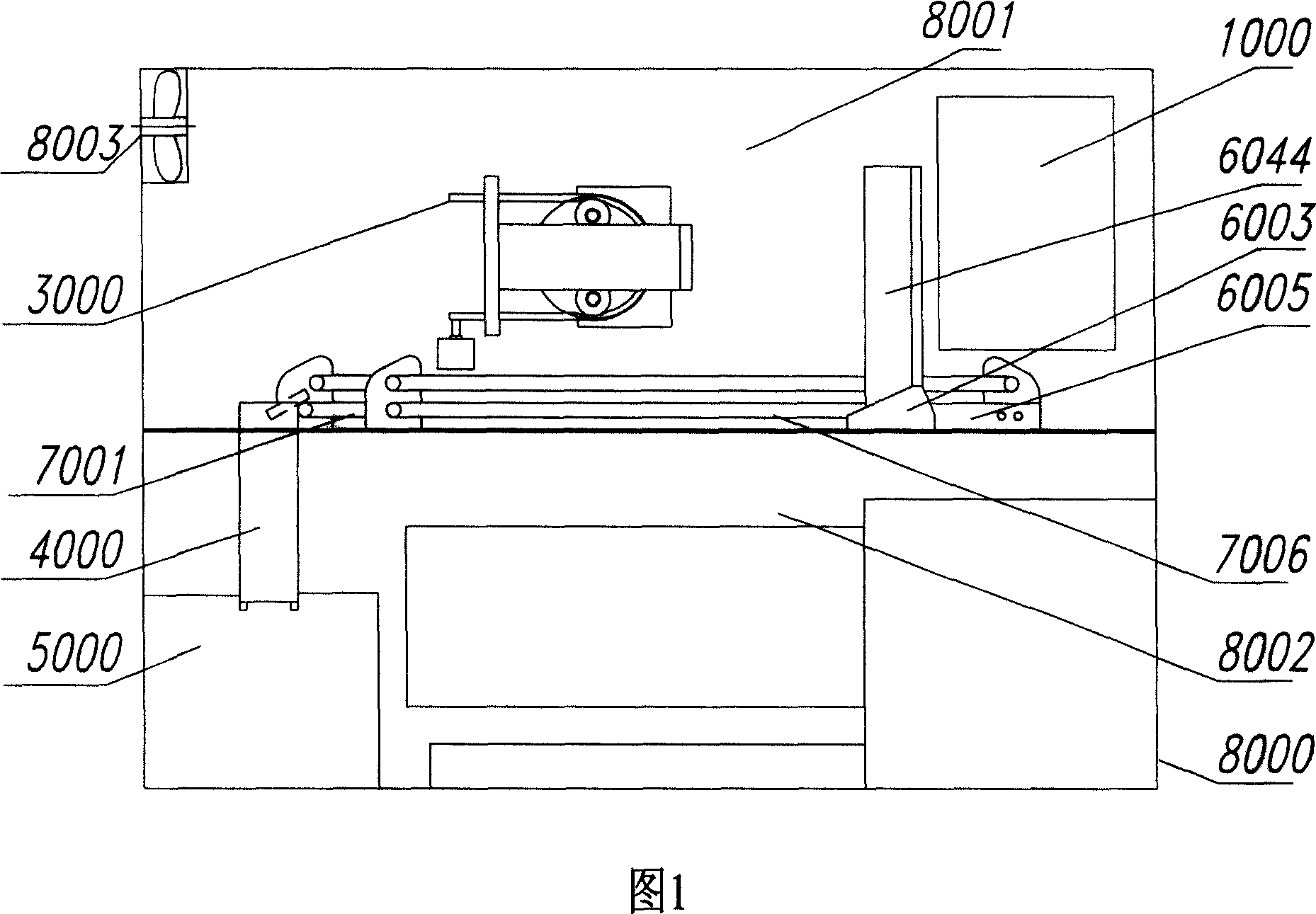

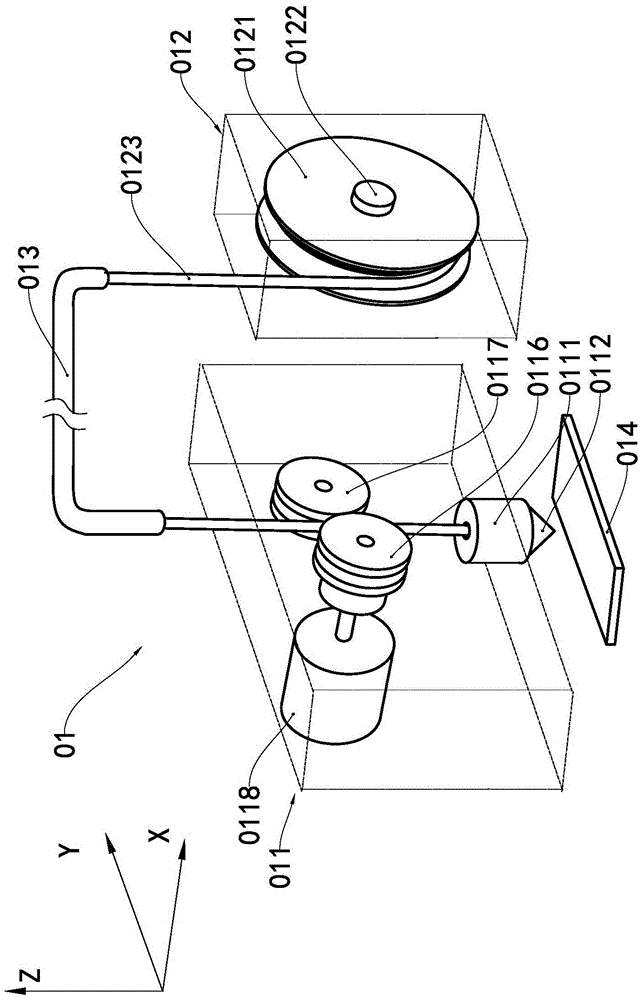

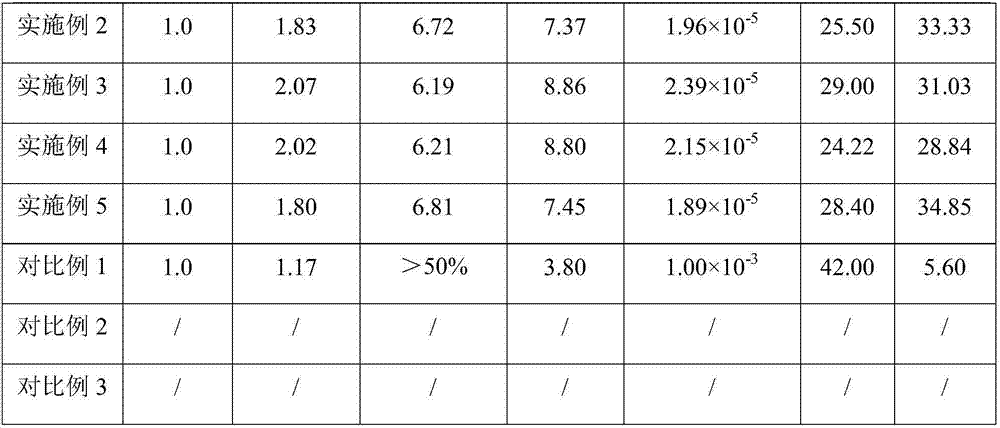

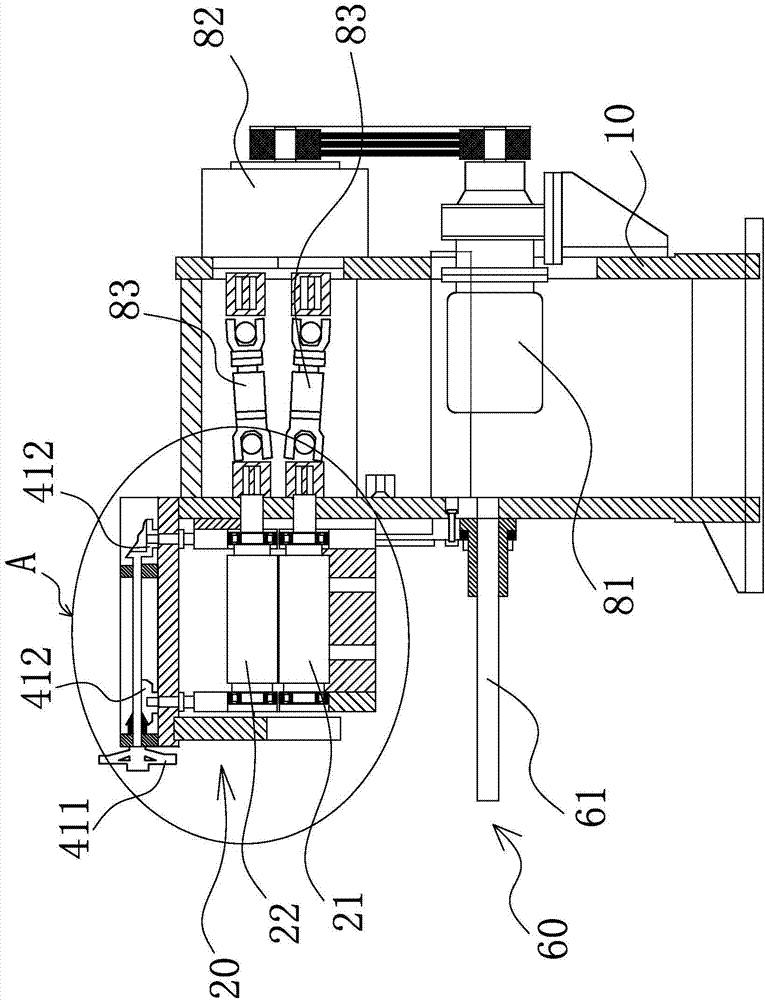

Automatic counting instrument for body cell of milk / bacteria through direct microscopic method

InactiveCN101050416ASimple structureImprove counting accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsMilk sampleEngineering

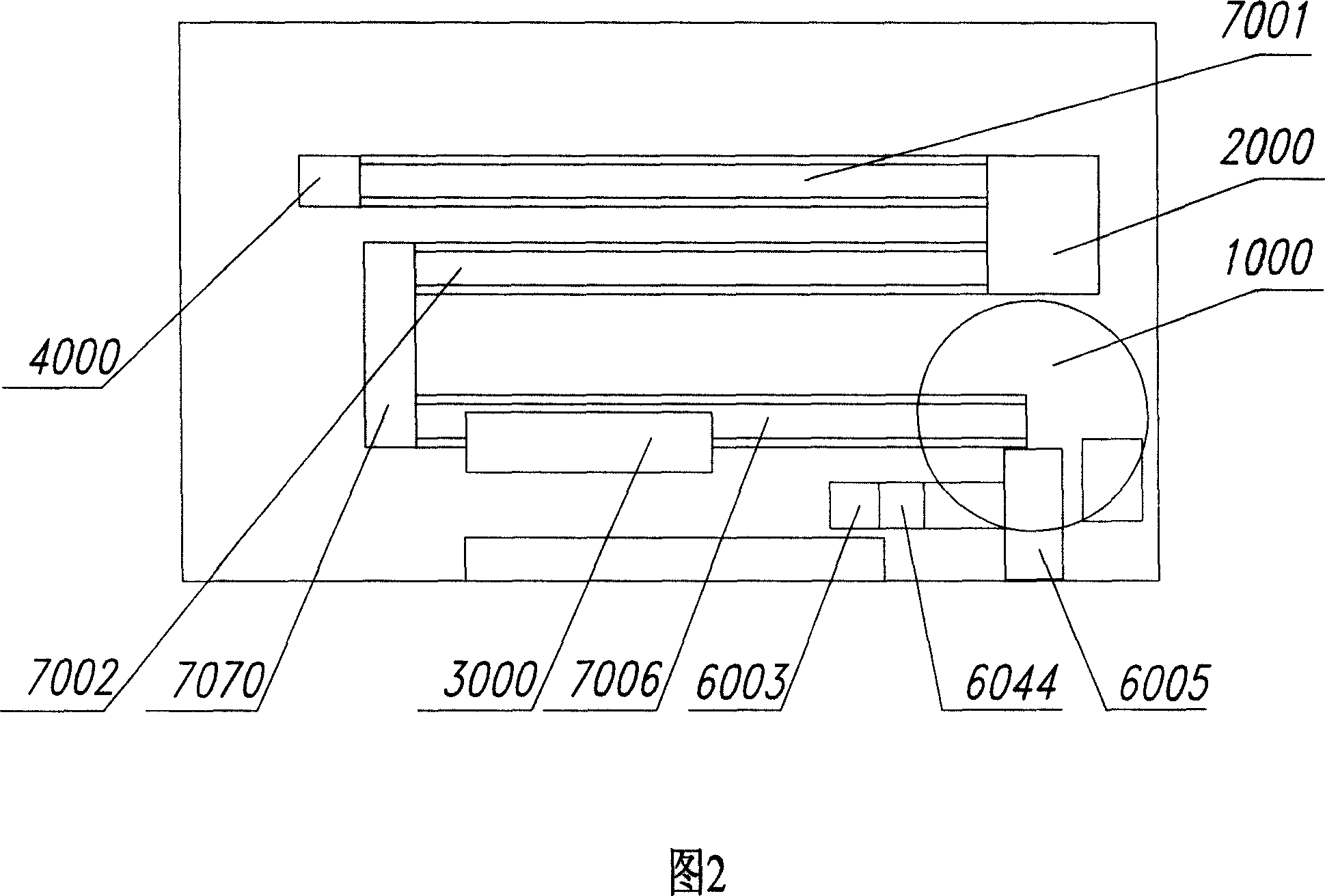

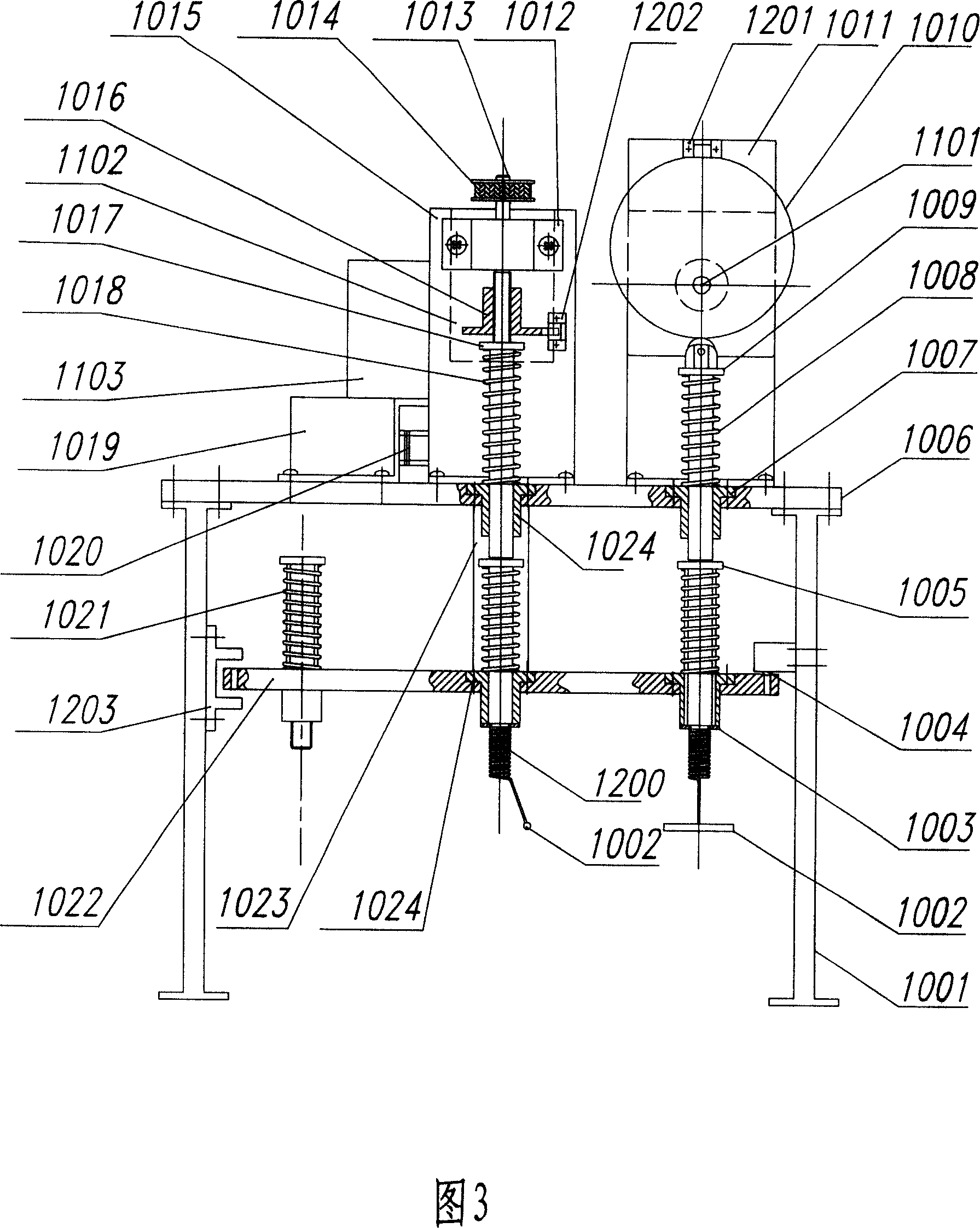

This invention provides a direct microscopic examination method milk somatic cells / bacteria automatic counter. The automatic counter comprises: a sampling / smearing apparatus, a dyeing apparatus, a washing / drying apparatus, a microscopic detecting apparatus, a convey apparatus for conveying the milk sample as well as glass slide to and out of the sampling / smearing zone, and another convey apparatus for conveying the smeared glass slide to the dyeing zone, washing / drying zone and microscopic detecting zone, which comprises multi-stage glass slide convey mechanisms and glass slide running mechanisms. The automatic analyzer comprises a smearing apparatus, a dyeing apparatus, a washing / drying apparatus a microscopic detecting apparatus and a control apparatus for convey apparatuses. This invention divides direct microscopic examination method milk somatic cells / bacteria analysis and assay into multiple mechanical actions performed by different apparatuses, and sets corresponding working positions and working zones. The working positions and working zones are connected via the convey apparatuses, and can reasonably and effectively perform automatic detection under the control of the control apparatus. The automatic counter has high counting precision and repeat precision, and the working efficiency is largely increased.

Owner:HANGZHOU ULTRASUN TECH

Anti-slagging biomass solid granular fuel

The invention discloses an anti-slagging biomass solid granular fuel and solves a problem that a biomass solid granular fuel in the prior art is liable to slag and is low in combustion efficiency. The anti-slagging biomass solid granular fuel is prepared from following raw materials, by weight, 60-70 parts of crop straws, 10-15 parts of wood chips, 5-10 parts of bagasse, 3-5 parts of a combustion-promoting agent and 1-3 parts of an anti-slagging agent. The anti-slagging biomass solid granular fuel is simple in components, reasonable in formula, low in cost, high in combustion efficiency and low in slagging rate.

Owner:江山华隆能源开发有限公司

Steel automobile wheel balancing block with large gram weight and manufacture method thereof

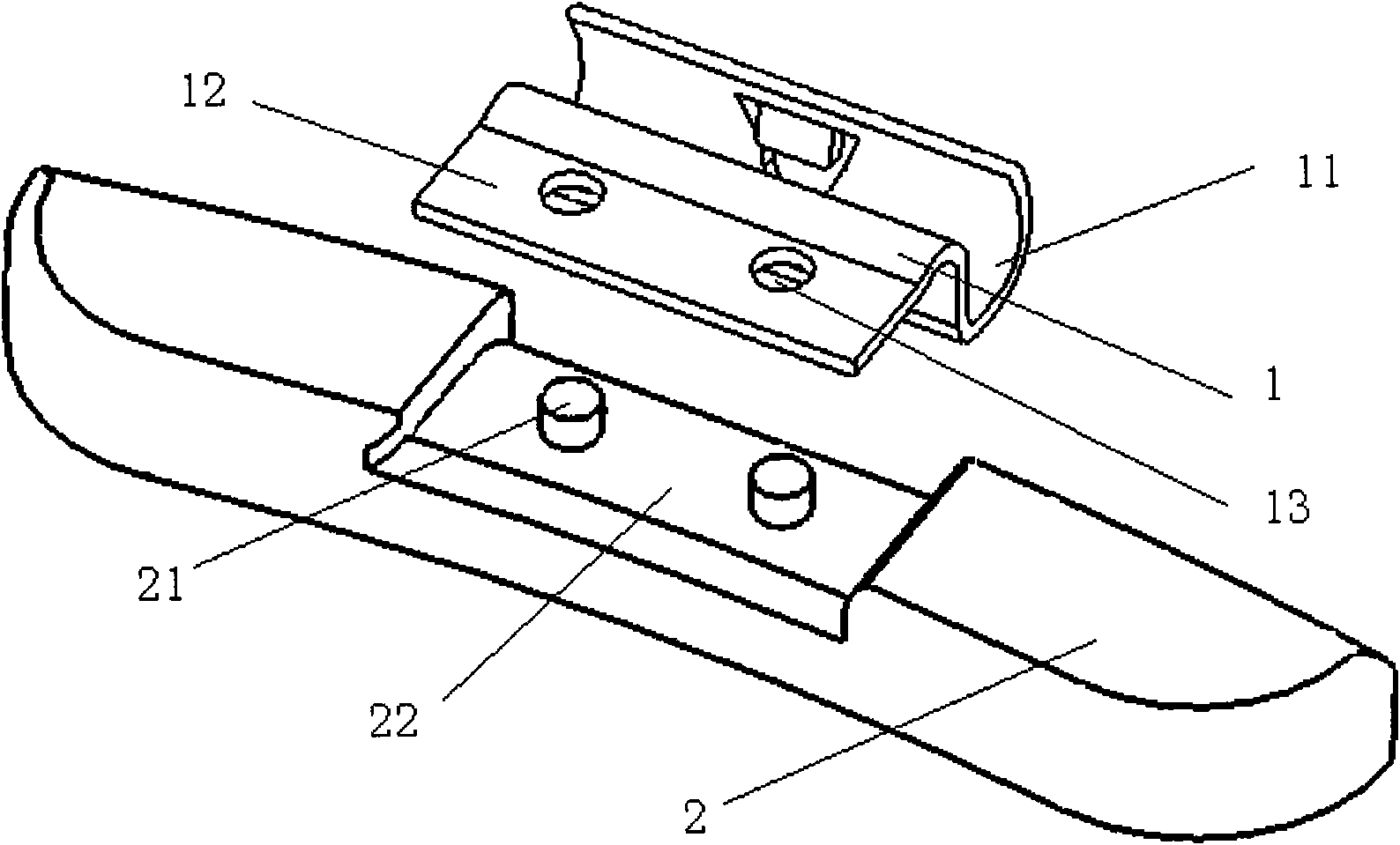

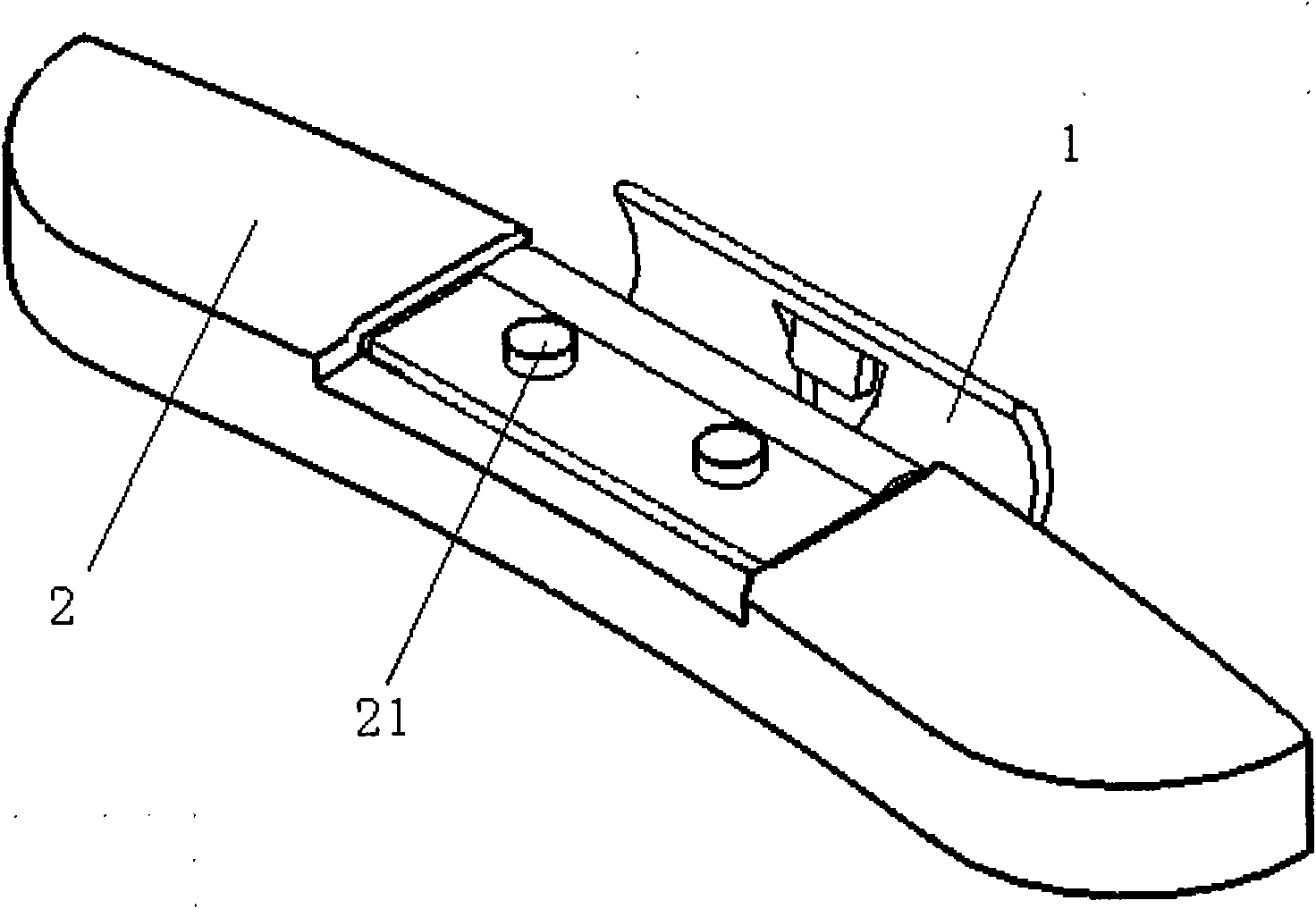

InactiveCN101596835AGuaranteed molding accuracyGuaranteed molding effectWheel-ballasting weightsGramEngineering

The invention discloses a steel wheel balancing block with single weight of more than 60 grams (containing 60 grams), comprising a balancing weight block and a spring hook, wherein the upper part of the spring hook is provided with a clamping part, the lower part of the spring hook is provided with a combination part which is fixed with the balancing weight block together, the upper surface of the balancing weight block is provided with a positioning groove, a protrusion is at least arranged on the bottom surface of the positioning groove, and the lower surface of the balancing weight block corresponding to the protrusion is a plane; and a rivet hole which is matched with the protrusion of the balancing weight block is arranged on the combination part of the spring hook so as to enable the spring hook to be riveted with the balancing weight block together by the protrusion. The invention also discloses a manufacture method of the balancing weight block in the balancing block, comprising the following steps: blanking and punching the positioning groove; bending blanks; cleaning the surfaces of the bent blanks; preheating; coating a lubricant; heating by induction; carrying out temperature plastic molding; deburring; carrying out surface shot blasting; pressing characters on the surface of the balancing weight block; riveting and fixing with a spring hanger; and painting on the appearance.

Owner:SHANGHAI UNIV OF ENG SCI +1

Hot-press molded protective film with shinning and antistatic effects and preparation method thereof

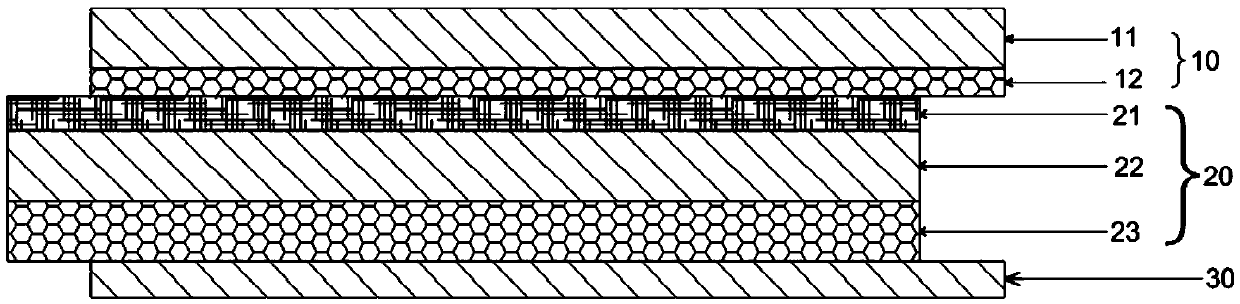

InactiveCN105522799AImprove the effect of hot pressingGuaranteed molding effectSynthetic resin layered productsAntistatic agentAcrylic resin

The invention discloses a hot-press molded protective film with shinning and antistatic effects and a preparation method thereof. The protective film can be used for comprehensively protecting a curved screen, and has an attractive appearance since shinning and antistatic effects are extra added. The protective film comprises a film protecting layer, an application layer and a release layer from top to bottom, wherein the application layer comprises a UV hardened layer, a base material A and an adhesive layer A; the principle component of the UV hardened layer is an acrylic resin layer, the base material A is a PET film, and the principle component of the adhesive layer is an organic silicone pressure-sensitive adhesive layer; and the thickness of the UV hardened layer is 2-10 mu m, the thickness of the base material A is 20-200 mu m, and the thickness of the adhesive layer A is 20-100 mu m. The hot-press molded protective film has shining and antistatic effects since shining particles and an antistatic agent are added into the application layer, and has high flexibility and cannot rebound after hot press since high-elasticity high-viscosity organic silicone pressure-sensitive adhesive is utilized in the adhesive layer.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Construction method of large-span double-sided arc-shaped aluminum plate curtain wall

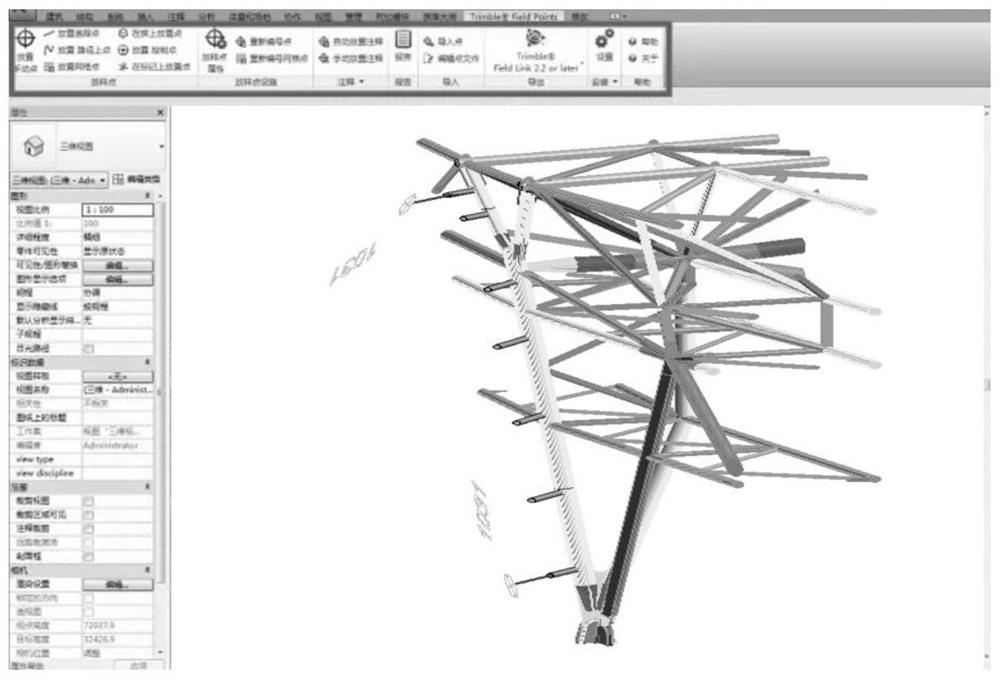

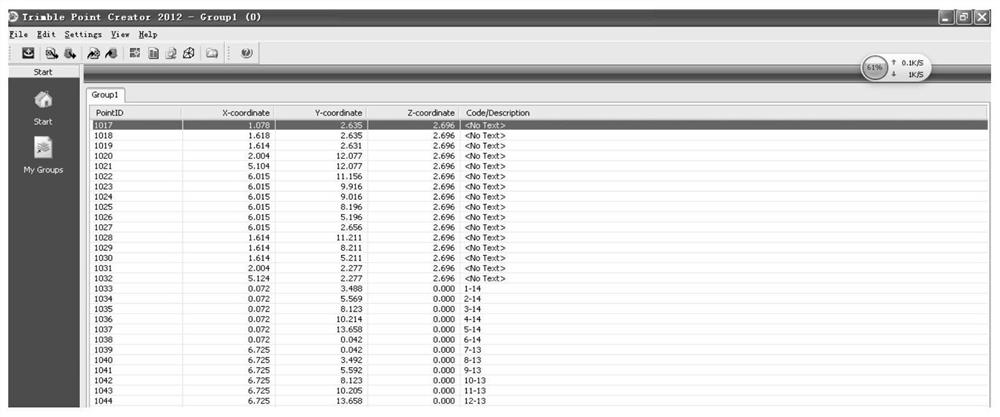

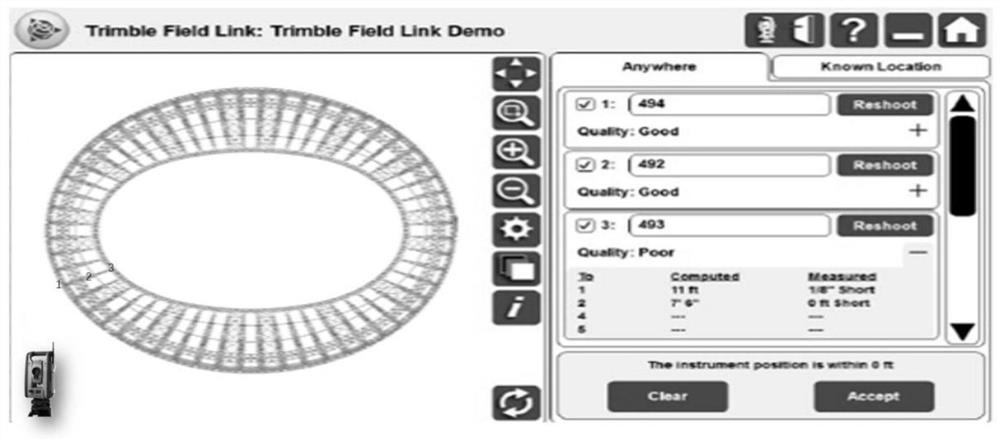

InactiveCN112431420AImprove installation accuracySpeed up the construction periodGeometric CADWallsLong spanMechanical engineering

The invention provides a construction method of a large-span double-sided arc-shaped aluminum plate curtain wall. Through the comprehensive application of a BIM technology and a lofting robot, curtainwall units are reasonably partitioned, adapting parts are reasonably arranged, and then a moulding bed, a curtain wall keel steel truss, the adapting parts and large-span double-sided arc-shaped aluminum plate curtain wall unit plates are accurately and rapidly positioned in an auxiliary mode, so that rapid on-site assembly and positioning installation are realized. According to the constructionmethod of the large-span double-sided arc-shaped aluminum plate curtain wall, the molding effect and precision of the large-span double-sided arc-shaped aluminum plate curtain wall molding are ensuredby adopting a field segmented integral molding bed preprocessing and assembling technology; through the comprehensive application of a BIM model and the lofting robot, the curtain wall keel steel truss and the adapting parts are quickly positioned and welded on site, so that the problem of positioning and mounting of a large number of adapting parts of different specifications on site is solved,the mounting accuracy is greatly improved, and the construction period is greatly shortened; and a segmented hoisting mode is adopted, and through the comprehensive application of the BIM model and the lofting robot, a curtain wall unit panel is accurately positioned, and the hoisting precision and the efficiency are improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

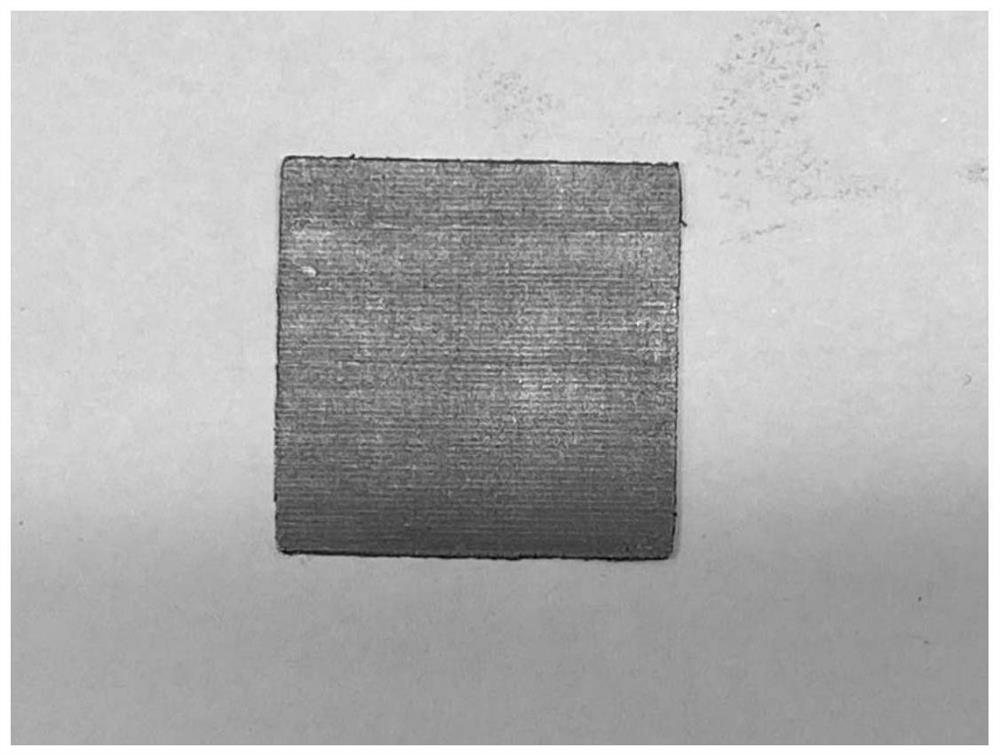

Graphene composite heat-conducting gasket and preparation method thereof

ActiveCN113510979AReduce gum contentImprove reliabilityLamination ancillary operationsLaminationPolymer scienceGraphite

The invention provides a graphene composite heat-conducting gasket which comprises a plurality of layers of graphene foam films arranged in the thickness direction and an adhesive, and the graphene foam films account for 50 wt.%-95 wt.%. The invention also provides a preparation method of the graphene composite heat-conducting gasket, wherein the preparation method comprises the steps: stacking the graphene foam films layer by layer and putting the graphene foam films into a mold, and applying pressure to tightly fit the films; uniformly coating the periphery of the graphene heat-conducting foam films subjected to pressure application with the adhesive, so as to completely coating a plurality of layers of graphene heat-conducting foam films into a block body; after the block body is cured and formed, cutting the block body into sheets along the stacking direction; dipping the cut sheets in dipping glue, taking out the sheets, and carrying out hot press molding on the taken-out sheets; and trimming the edge of the formed sheets, and removing an adhesive bonding area on the edge to obtain the graphene composite heat-conducting gasket. The heat-conducting gasket is low in density, high in heat conductivity in the thickness direction and low in heat resistance.

Owner:CHANGZHOU FUXI TECH CO LTD

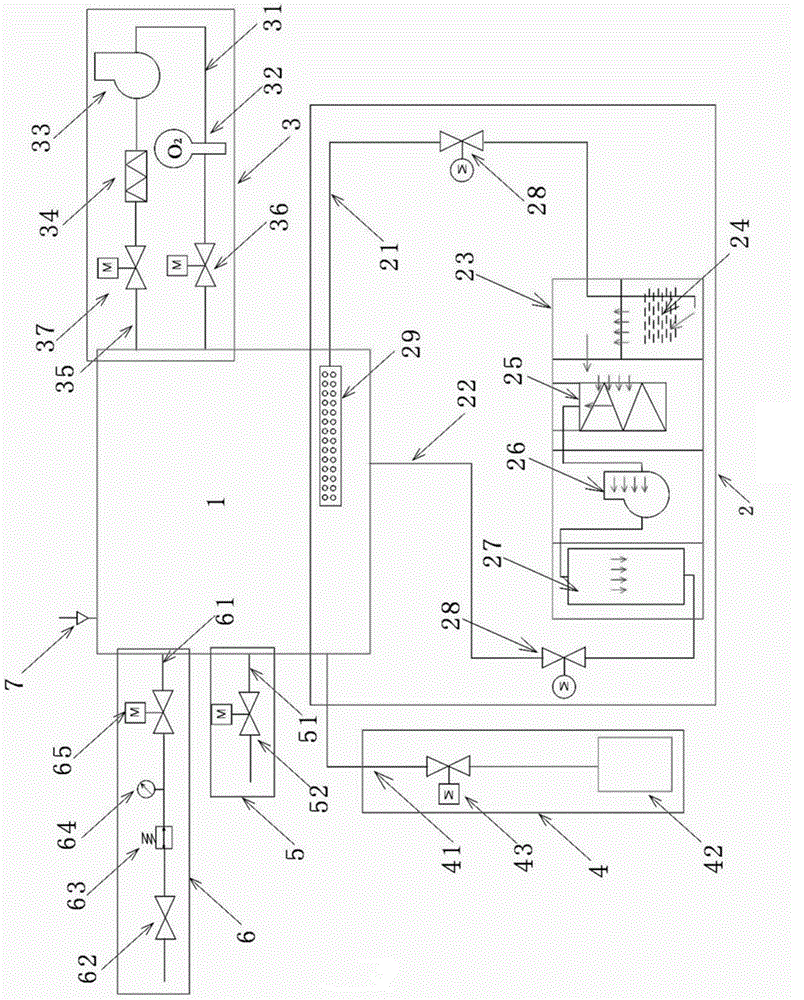

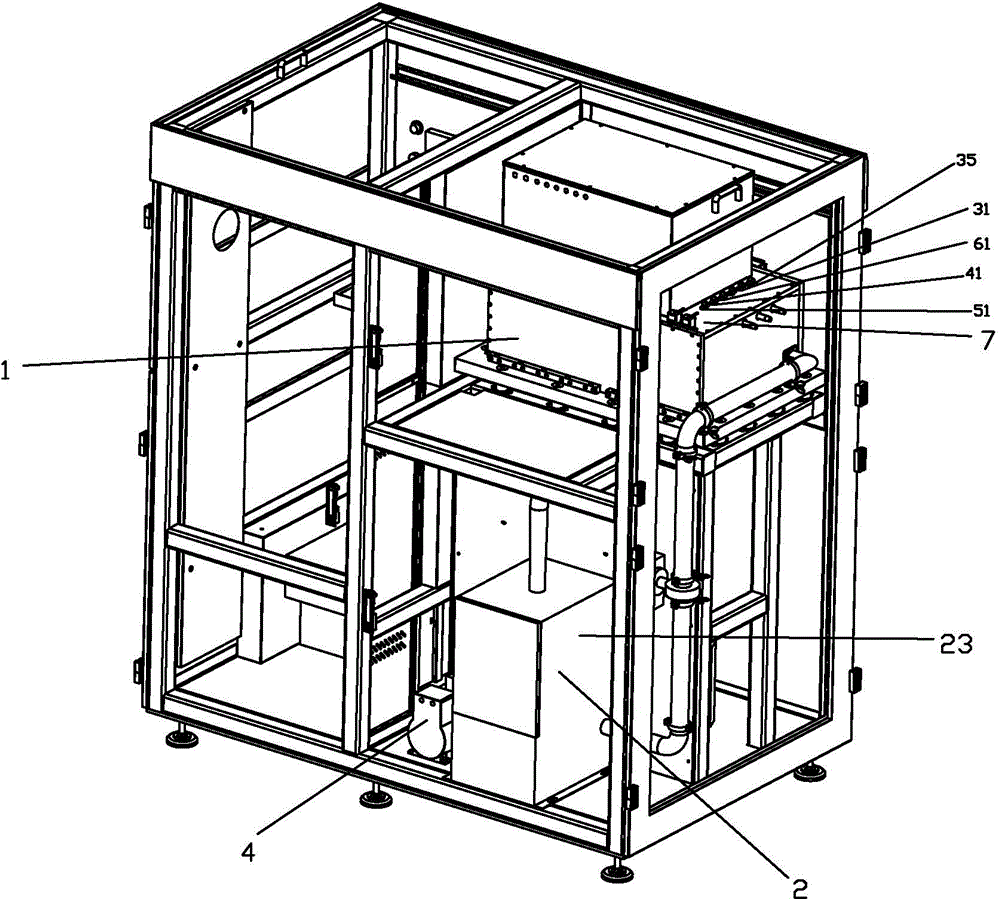

Gas protecting system of metal powder laser quick forming machine

InactiveCN104550951AReduce consumptionGuarantee the oxygen content of the environmentWater filterEngineering

The invention discloses a gas protecting system of a metal powder laser quick forming machine. The metal powder laser quick forming machine comprises a sealing forming bin, the gas protecting system comprises a gas circulating purifying mechanism, the gas circulating purifying mechanism comprises an explosive-proof and smoke dust-removal purifier, the explosive-proof and smoke dust-removal purifier is connected with the sealing forming bin through a gas inlet pipe and a gas outlet pipe to form the gas circulating purifying, and is sequentially provided with a water filtering device, a filtering element device, a circulating fan device and a drying machine from an inlet to an exit, and electric valve switches are respectively arranged on the gas inlet pipe and the air outlet pipe. The gas protecting system has the advantages that the oxygen content of the forming environment is controlled to be less than 100ppm, the smoke dust produced in the forming process can be filtered to balance the gas pressure of the forming bin, and the compactness of the formed part reaches 100%; the bright metal luster is realized, and the oxidizing is avoided; the consumption amount of inert gas is saved, the consumption amount of gas is only equal to 2 / 100 of the consumption amount of gas of the prior art, and the economic benefit is higher.

Owner:GUANGDONG HANBANG 3D TECH CO LTD

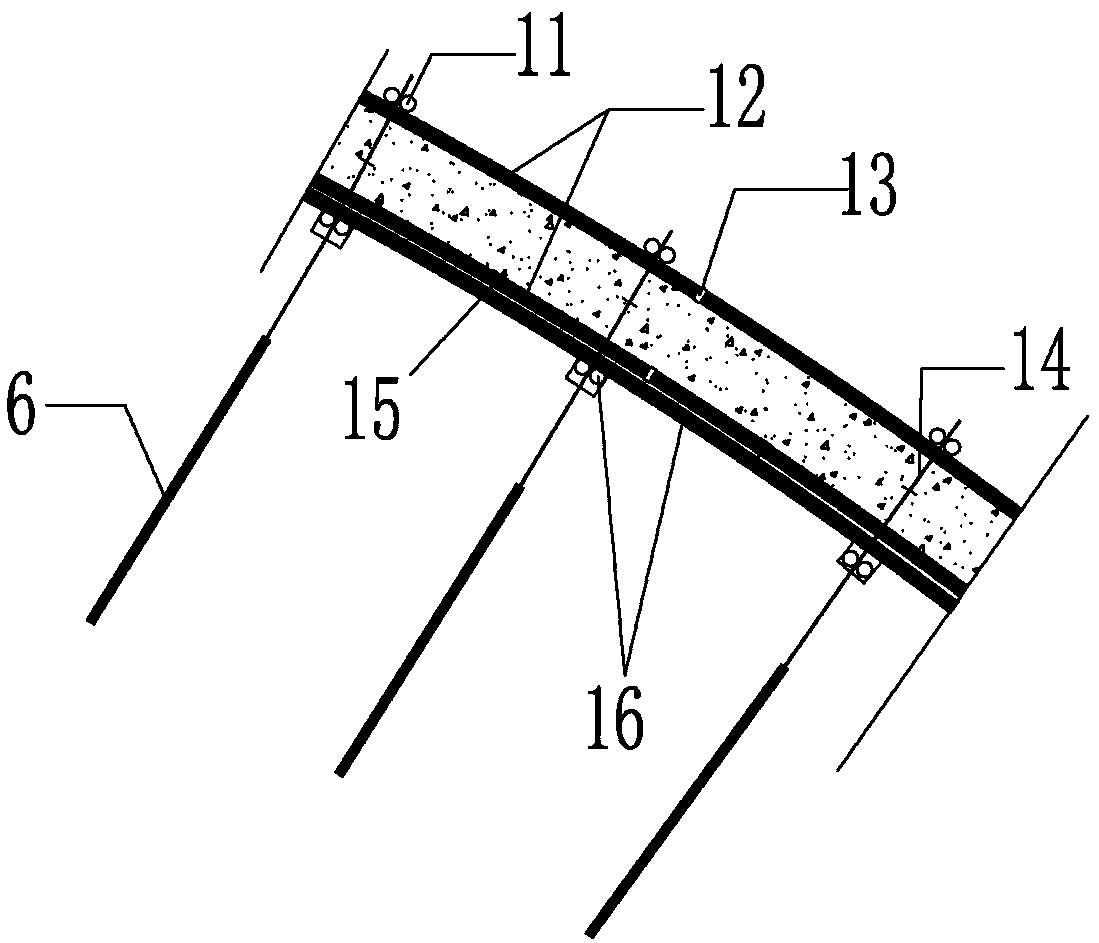

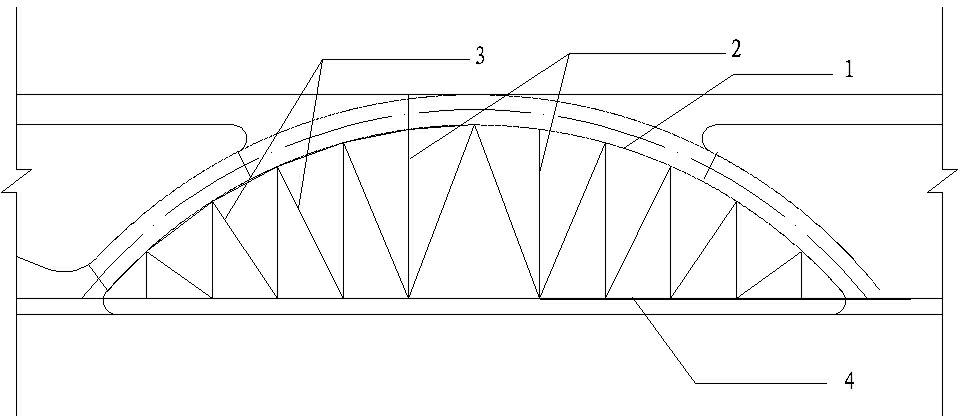

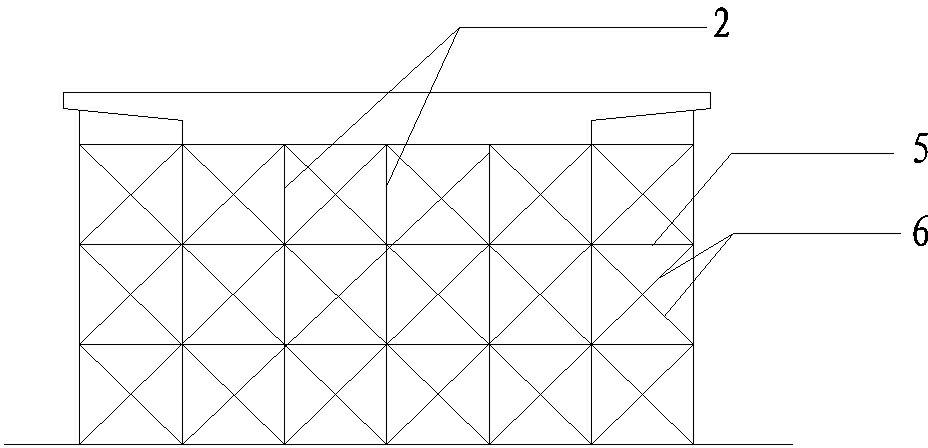

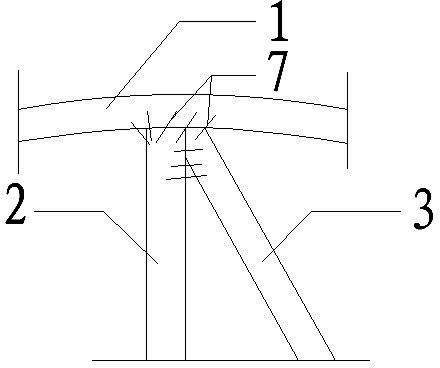

Wood truss support structure for arch cap formwork of rigid frame arch bridge and construction method of wood truss support structure

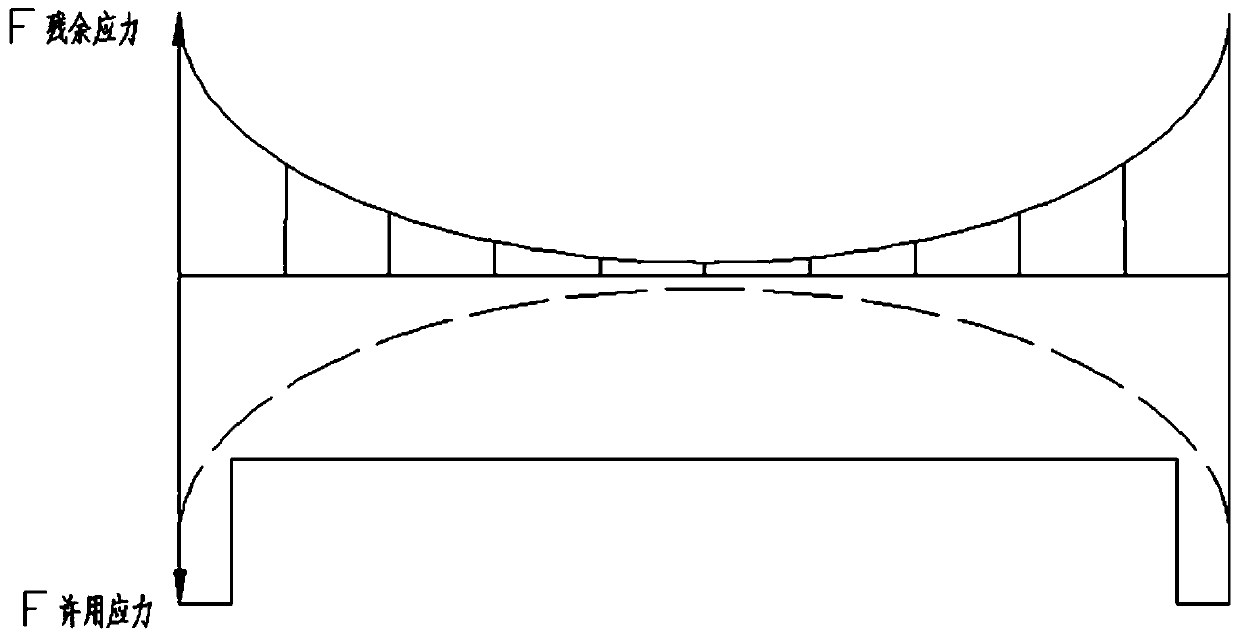

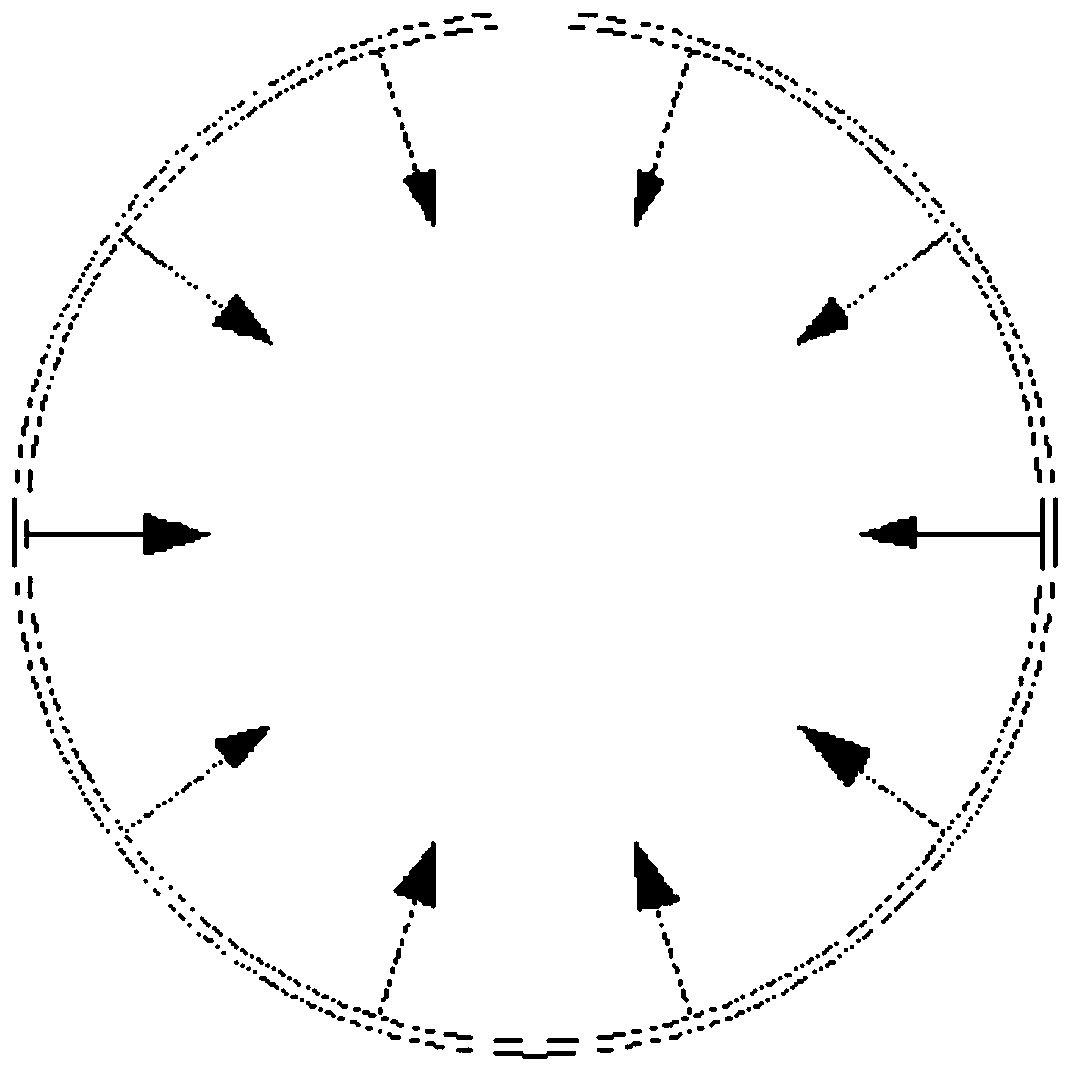

InactiveCN102433839AVibrate compactVibration formingBridge erection/assemblyConstant loadArchitectural engineering

The invention relates to a wood truss support structure for an arch cap formwork of a rigid frame arch bridge and a construction method of the wood truss support structure. The structure comprises a lower suspension pull and support rod and an upper suspension arc longitudinal beam, wherein the two ends of the upper suspension arc longitudinal beam are fixedly connected with the two ends of the lower suspension pull and support rod to form a closed bowstring structure, a plurality of vertical wood rods are fixedly connected between the lower suspension pull and support rod and the upper suspension arc longitudinal beam, inclined support rods are arranged among the vertical wood rods, the lower suspension pull and support rod, the upper suspension arc longitudinal beam, the vertical wood rods and the inclined support rods are fixedly connected with one another to form a truss with multiple triangular stable structures, and horizontal pull rods and vertical bridging rods are arranged among a plurality of trusses and are pulled to form an integrated structure. The construction method comprises the following steps of: reinforcing a foundation; constructing arch foot bearing table; elastically setting a control line; installing the lower suspension pull and support rod; and symmetrically installing the plurality of trusses and the like. The structure has a combined effect of effectively supporting a constant load and a construction load, and the construction safety and the shaping quality of an arch cap structure of the rigid frame arch bridge are improved.

Owner:ANHUI HUALI CONSTR GRP

Titaniferous stainless steel electroslag remelting casting powder

The invention discloses titaniferous stainless steel electroslag remelting casting powder which is prepared from the raw materials in parts by weight as follows: 46.0-50.0 parts of fluorite, 20.0-24.0 parts of alumina powder, 18.5-22.5 parts of lime, 3.5-5.5 parts of fused magnesite, 2.0-4.0 parts of titanium dioxide as well as other components: 0.0-0.6 part of SiO2, 18.0-22.0 parts of CaO, 20.0-24.0 parts of Al2O3, 4.2-5.8 parts of MgO, 2.0-4.0 parts of TiO2, 45.0-51.0 parts of CaF2, less than 0.03 part of S and less than 0.03 part of C. Slag is formed by the casting powder according to strict quality control standard so as to ensure that the impurity content is low, the purity is high and the slag is dry and free from moisture. In the electroslag remelting process, desulfuration and deoxygenation effects are enhanced, the resistivity is improved, and the casting powder is free from cutoff in arcing, good in lubrication and relatively easy to popularize and apply.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

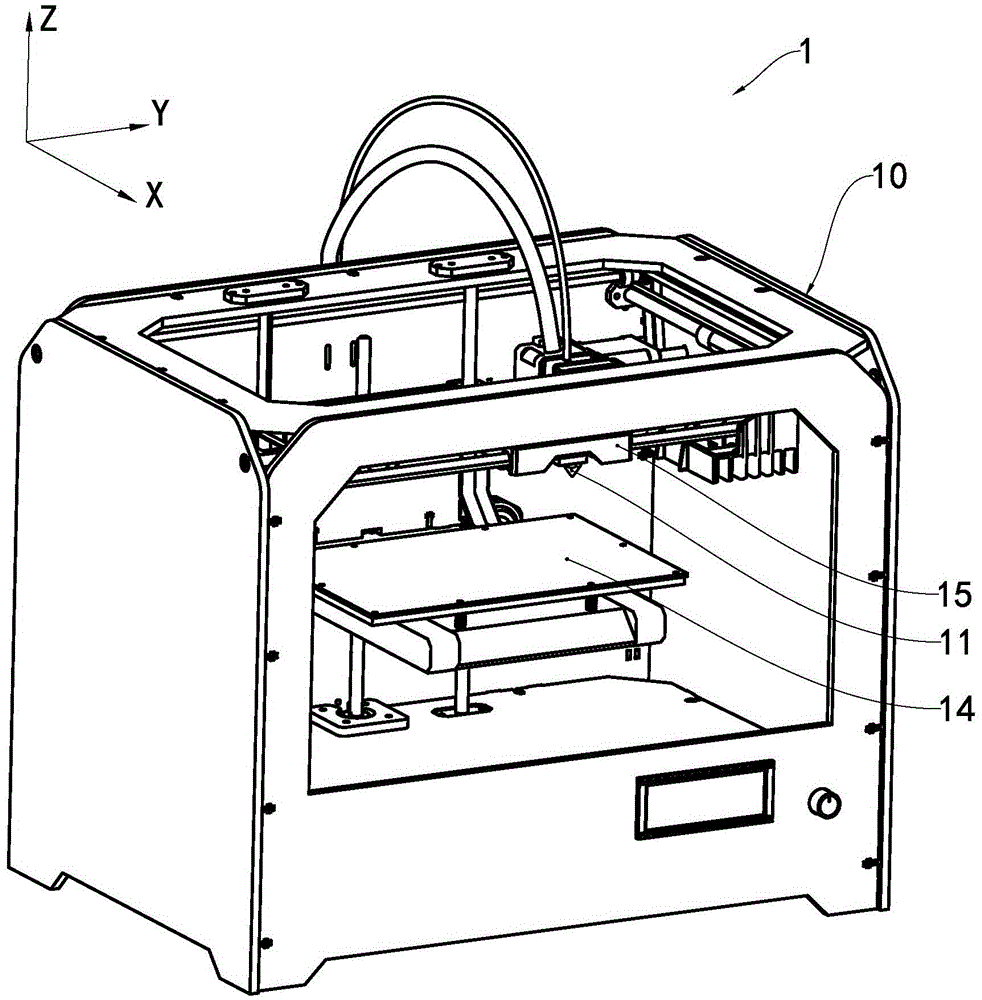

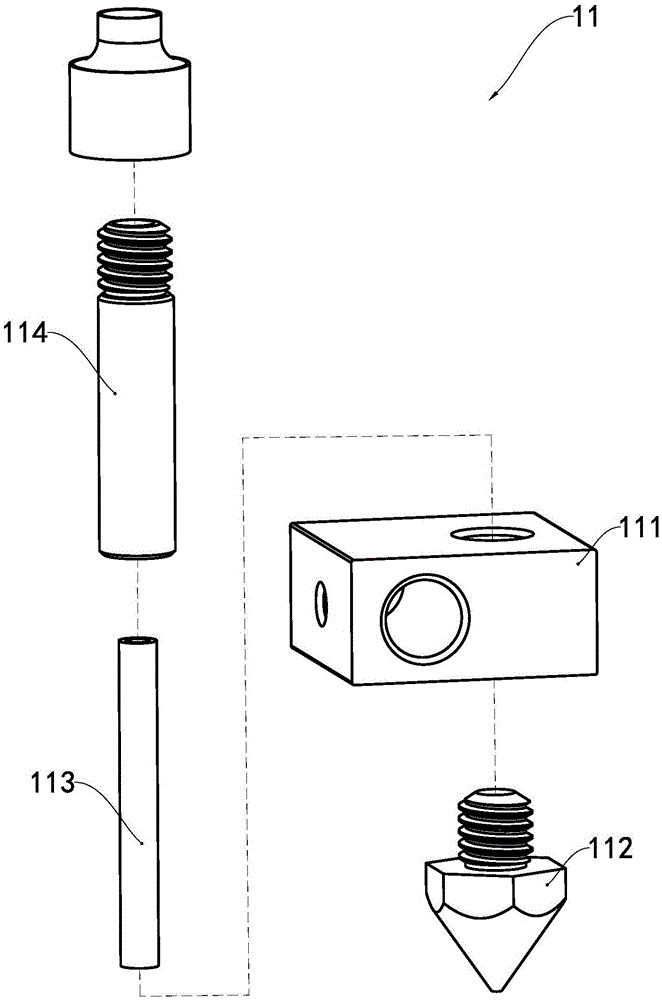

Printing head and three-dimensional printer

ActiveCN105459402APrevent adhesionAvoid condensationAdditive manufacturing apparatusEngineeringElectrical and Electronics engineering

The invention relates to a printing head for a three-dimensional printer. The printing head comprises a heating block, a throat tube fixedly connected with the heating block and a spraying nozzle, and further comprises a Teflon pipe located in the throat tube in the mode of being coaxial with the throat tube. The section, near a spraying opening, of a melting pipe of the spraying nozzle is a hole expanding outwards. The printing head can effectively prevent extruded fuse wires from adhering and agglomerating to the periphery of the spraying opening, improve printing accuracy and guarantee the forming effect of a three-dimensional object. The invention further provides the three-dimensional printer including the printing head.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Low-VOC natural fiber composite as well as preparation method and application of composite

ActiveCN104690979AGuaranteed mechanical strengthGuaranteed molding effectVehicle componentsMelt spinning methodsNatural fiberLow density

The invention relates to a low-VOC natural fiber composite as well as a preparation method and application of the composite. The preparation method comprises the following steps: carrying out blend spinning on nano-clay and resin to prepare modified synthetic fibers, mixing the modified synthetic fibers and natural fibers or the natural fibers and other fibers to prepare mixed fibers, and carrying out opening, mixing, mesh placement, acupuncture and hot pressing treatment to prepare the low-VOC natural fiber composite. The low-VOC natural fiber composite can be applied to automotive interior trims and has the characteristics of low VOC, small density, light weight, low cost, high strength, good toughness, high deformation, high safety, environmental protection, capability of recovering and the like.

Owner:扬州超峰汽车内饰件有限公司

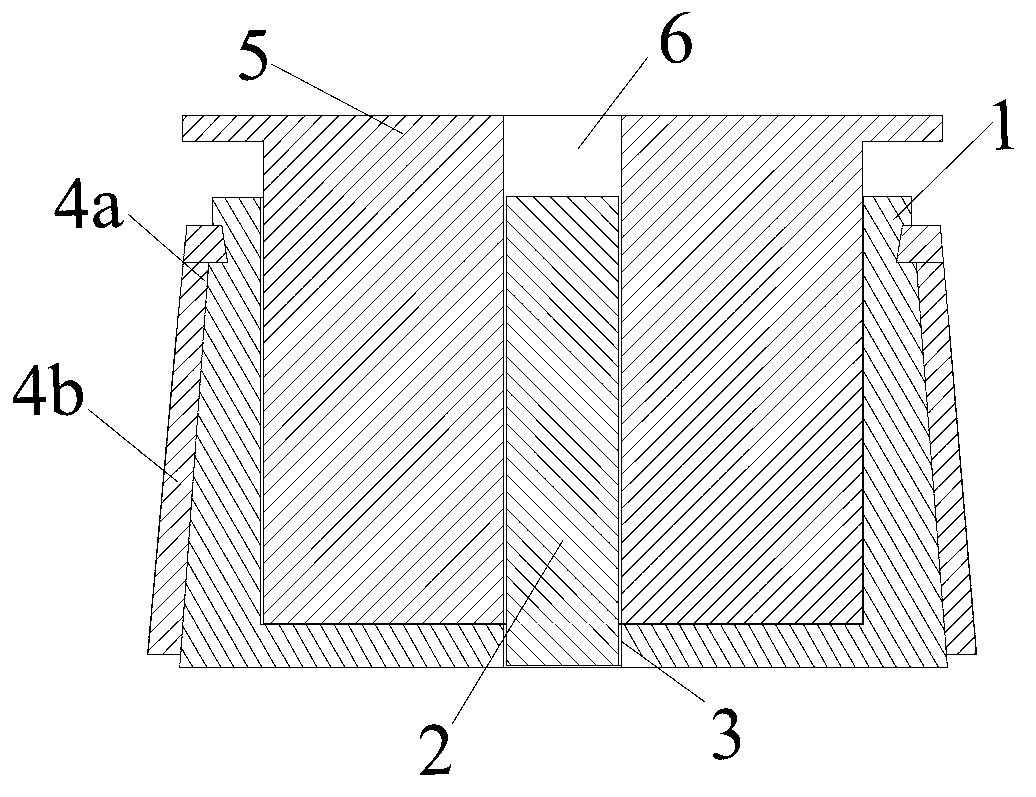

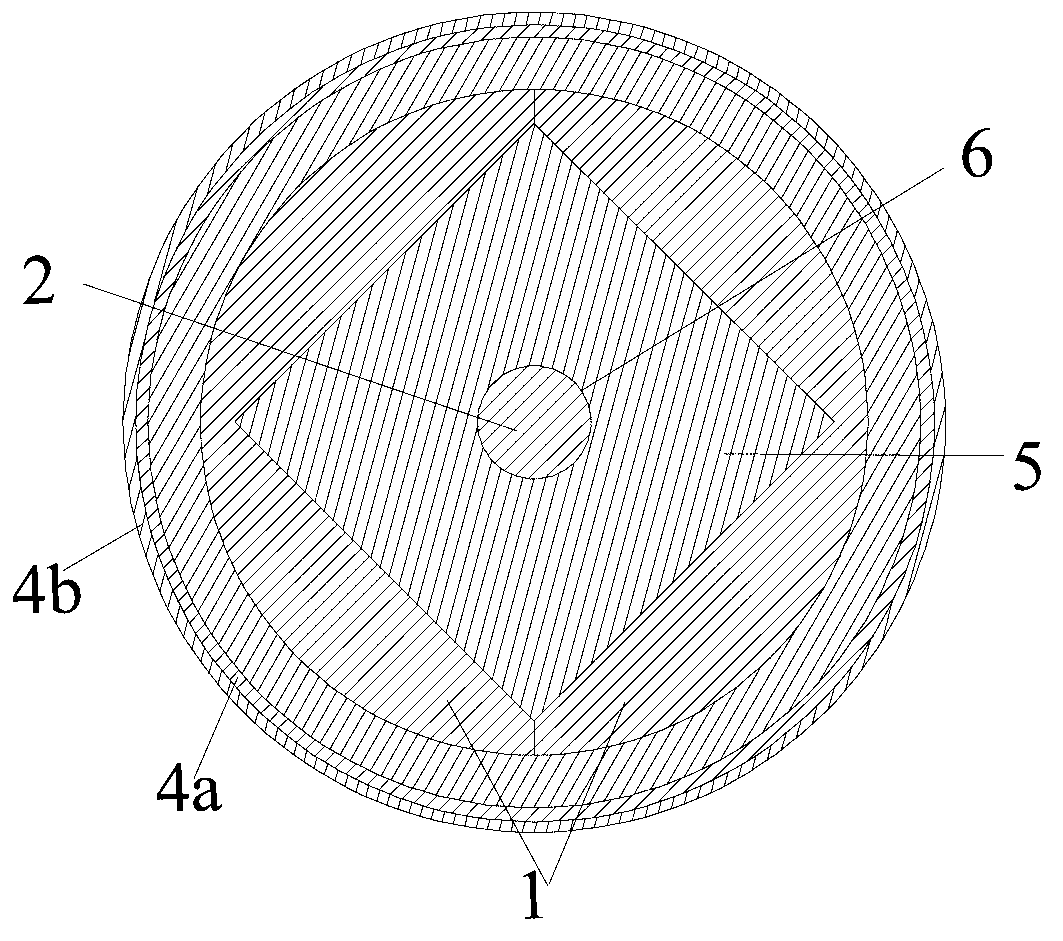

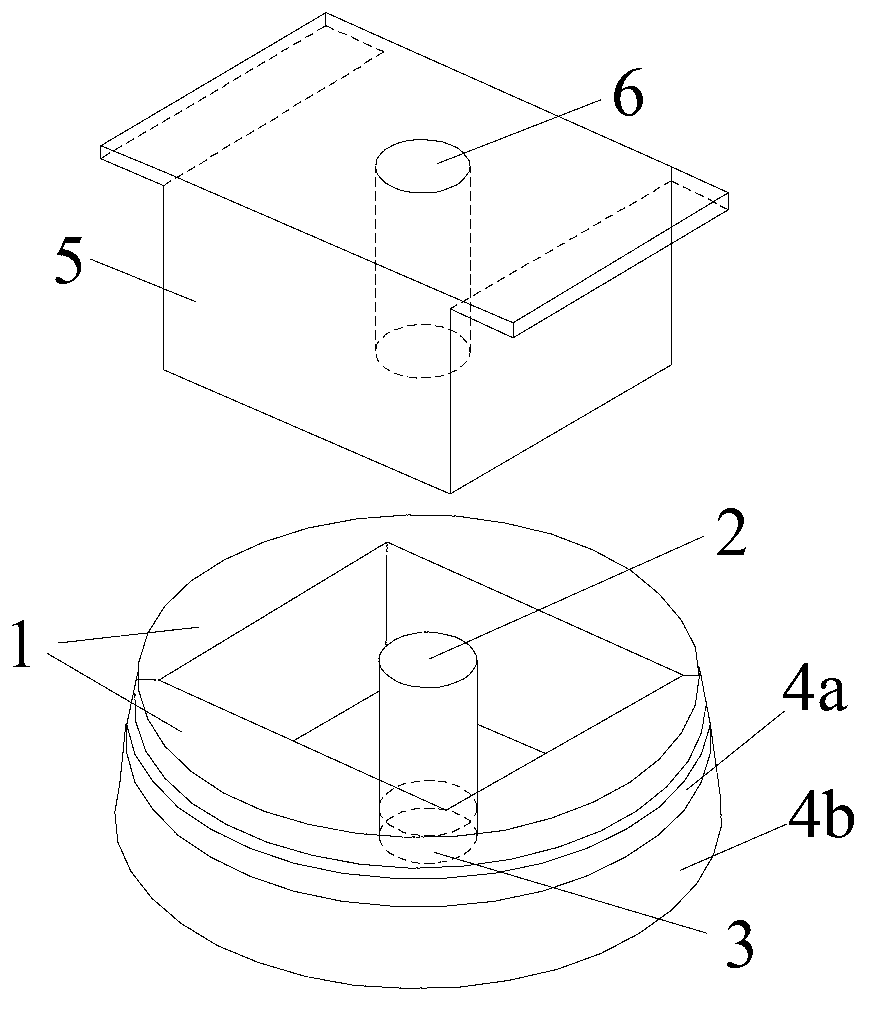

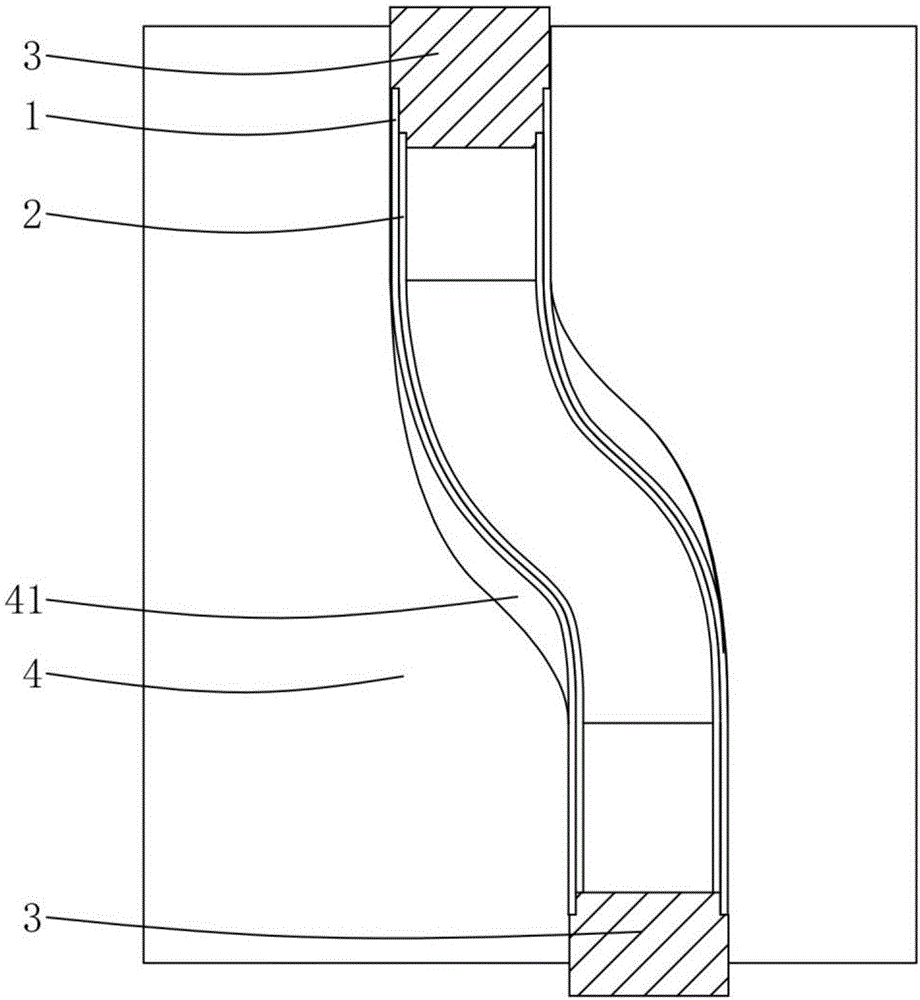

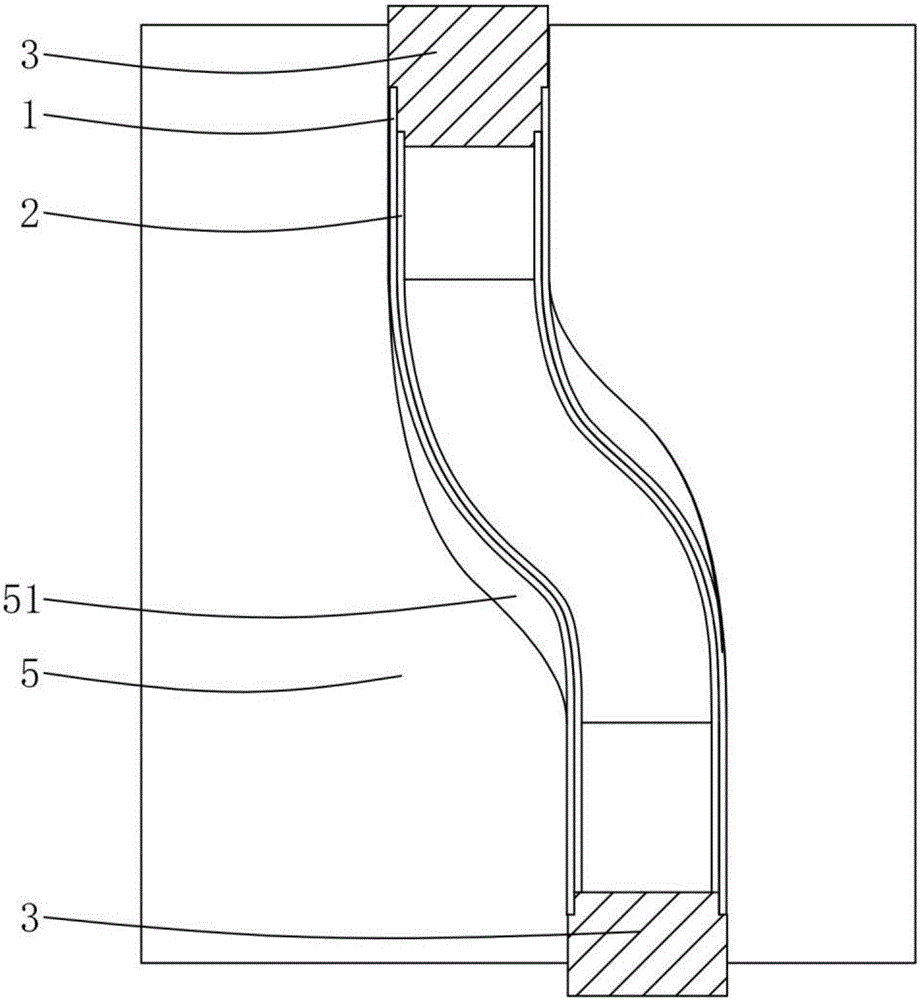

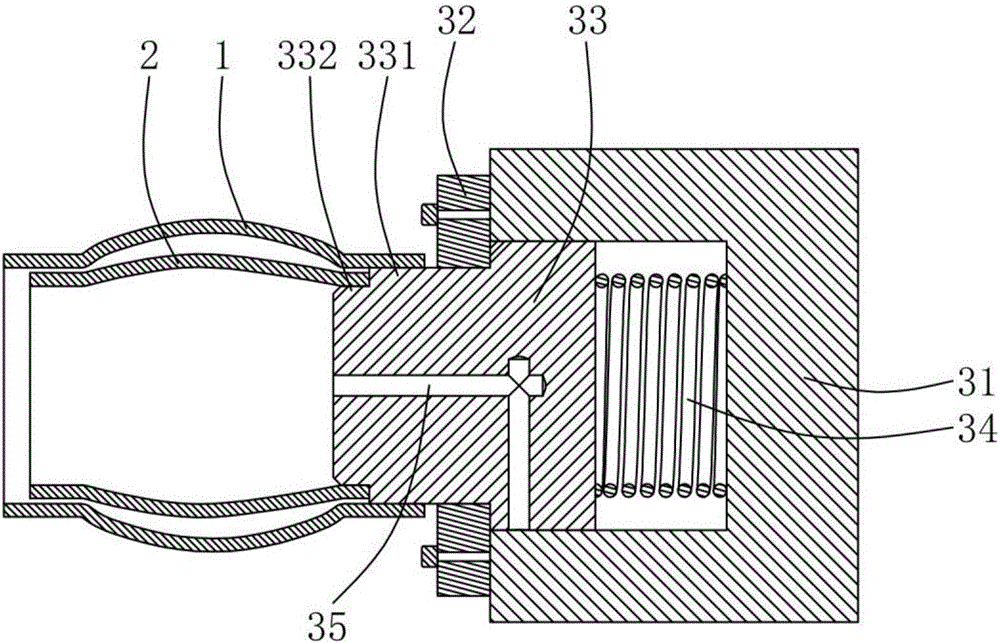

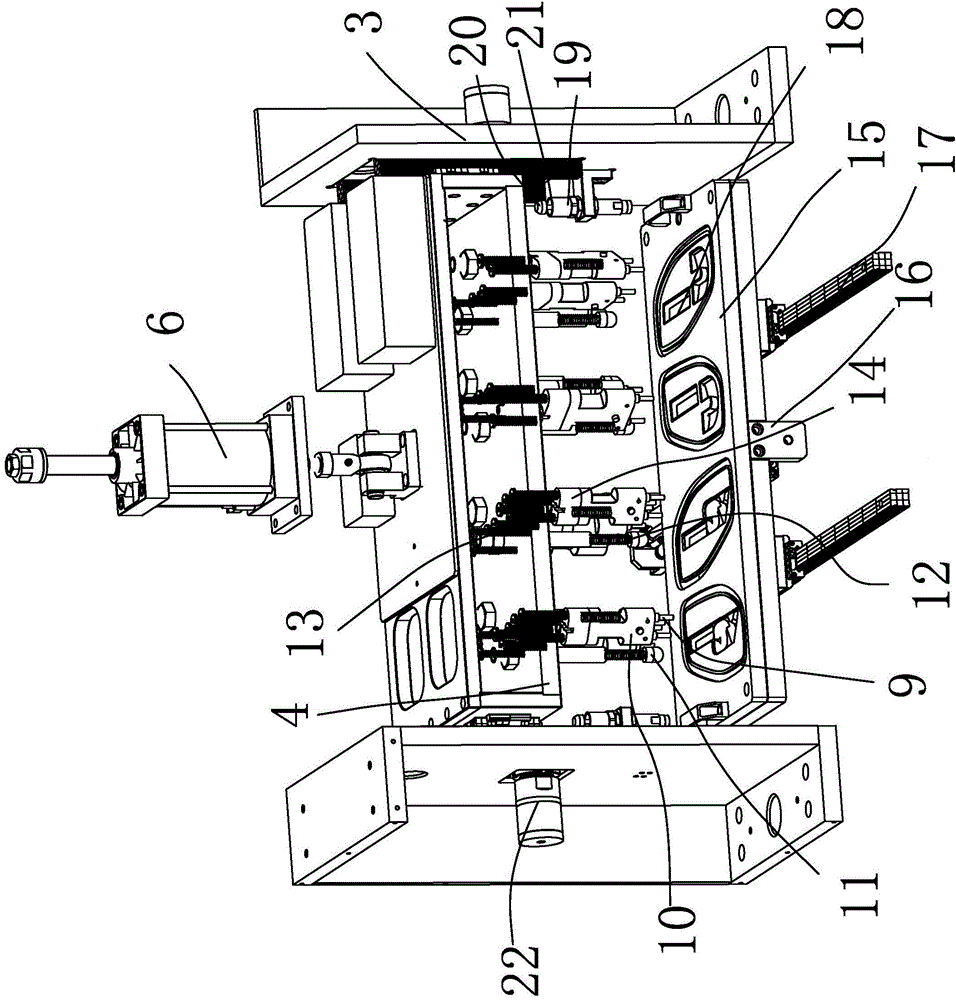

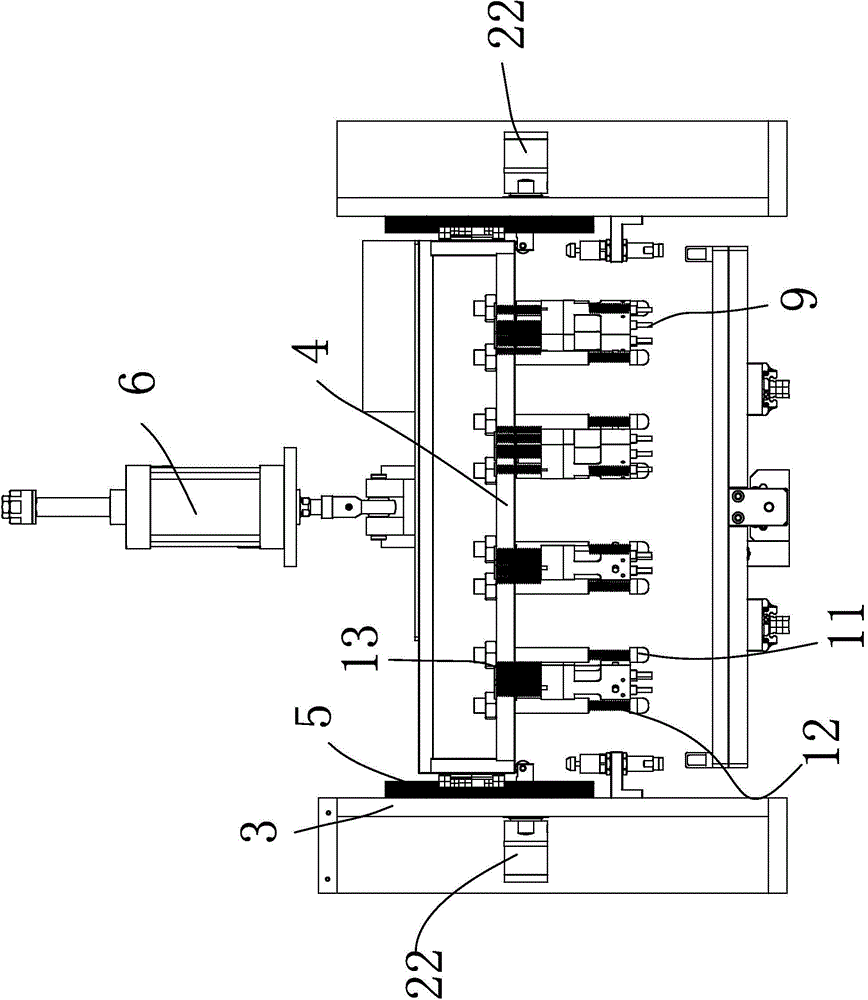

Reserved chamber simulating test piece manufacturing die assembly and method used for manufacturing test piece

InactiveCN103278360AEasy to assemble and disassembleEasy to demouldPreparing sample for investigationBiochemical engineering

The invention discloses a reserved chamber simulating test piece manufacturing die assembly and a method used for manufacturing a test piece. The die assembly comprises a model shell, a solid cylinder, a round through hole, clamps, a bearing plate and a cylinder containing cavity, wherein the model shell has a splitting structure and is formed by two symmetrical parts; a hexahedral sample adding cavity is arranged at the upper part of the model shell, and a press is used for compacting and shaping a sample in the cavity by the bearing plate. The die assembly has a simple structure, and is convenient to disassemble, and the sample can be subjected to mold release conveniently. The invention also discloses the method for manufacturing the test piece by adopting the reserved chamber simulating test piece manufacturing die assembly. The method comprises the steps of assembling a mold, adding the sample, pressurizing the sample, separating the mold, and disassembling the mold. According to the test piece manufactured by adopting the method for manufacturing the test piece by the die assembly, the test piece can be subjected to mold release conveniently, and the pressurized shaping effect of the test piece is good.

Owner:SHANDONG UNIV OF SCI & TECH

Machining process for double-layer composite metallic tube

The invention discloses a machining process for a double-layer composite metallic tube. The process sequentially comprises the following steps that an outer metallic tube body and an inner metallic tube body are placed into an inner tube model cavity; high-pressure water is led into the inner metallic tube body so as to finish inner high-pressure forming of the inner metallic tube body, and a primary semi-finished double-layer composite metallic tube is prepared; the primary semi-finished double-layer composite metallic tube is placed into an outer tube model cavity; high-pressure water is led into the outer metallic tube body so as to finish inner high-pressure forming of the outer metallic tube body, and a secondary semi-finished double-layer composite metallic tube is prepared; and end post-treatment is conducted on the secondary semi-finished double-layer composite metallic tube, so that the finished double-layer composite metallic tube is prepared. Two passes of inner high-pressure forming are adopted, the forming effects of the inner metallic tube body and the outer metallic tube body are guaranteed, the machining procedures are optimized, and the machining process is more concise, so that the machining efficiency is improved, the profit rate is increased, and the product rejection rate is decreased.

Owner:山东辛丁管理咨询有限公司

Environment-friendly recyclable basalt fiber and fibrilia automobile door plate and preparation process thereof

ActiveCN102145554AGuaranteed molding effectGuaranteed sound insulationLayered productsNon-woven fabricsSurface layerHigh intensity

The invention relates to an environment-friendly recyclable natural fiber automobile door plate which is formed by the steps of preparing a composite felt material by a core layer and a surface layer; and performing hot-press and forming. The natural fiber automobile door plate is characterized in that the core layer is prepared by mixing two kinds of natural fibers, namely a basalt fiber and fibrilia, and two kinds of chemical fibers, namely a polyster fiber and a polypropylene fiber, lapping and needling. The core layer comprises the following components in percentage by weight: 10 to 30 percent of basalt fiber, 10 to 30 percent of fibrilia, 20 to 30 percent of polyster fiber, and 30 to 40 percent of polypropylene fiber. The invention also provides a preparation process for the environment-friendly recyclable natural fiber automobile door plate. The environment-friendly recyclable natural fiber automobile door plate has the characteristics of low density, light mass, low cost, high intensity, high toughness, high safety, environmental-friendliness and the like, and can be deformed heavily and recycled.

Owner:CHANGCHUN BOCHAO AUTOMOTIVE PARTS CO LTD

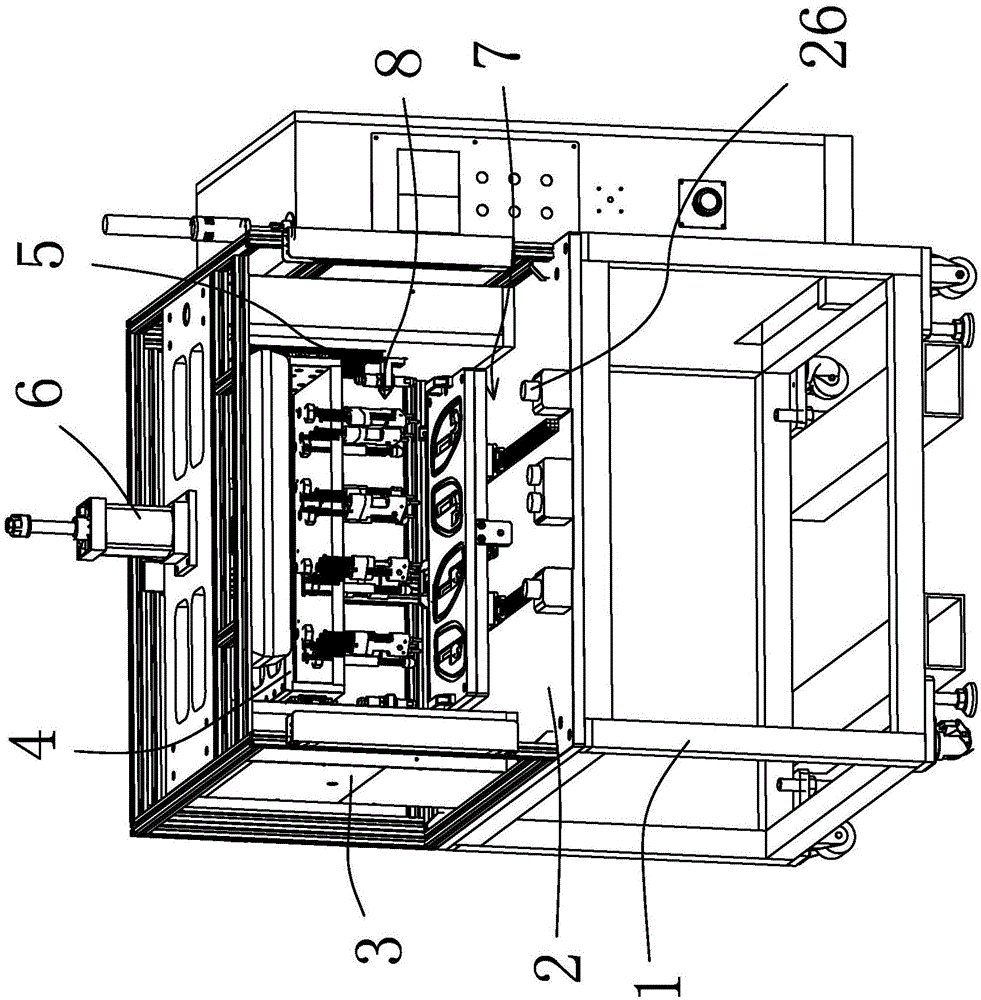

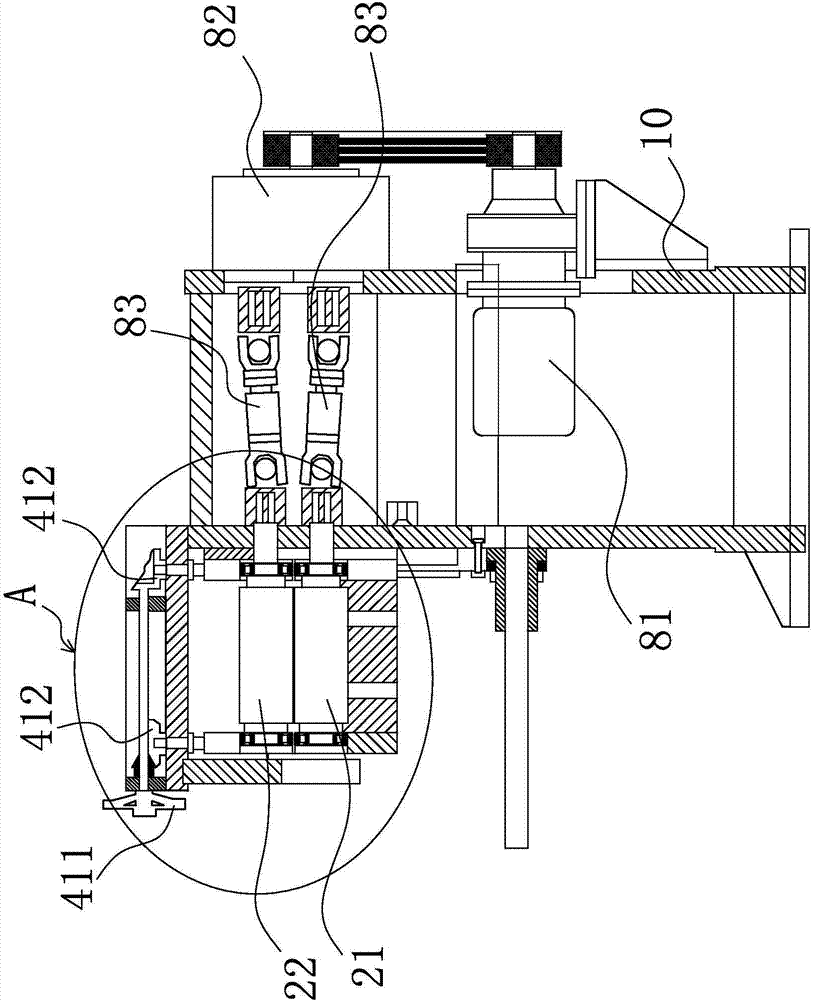

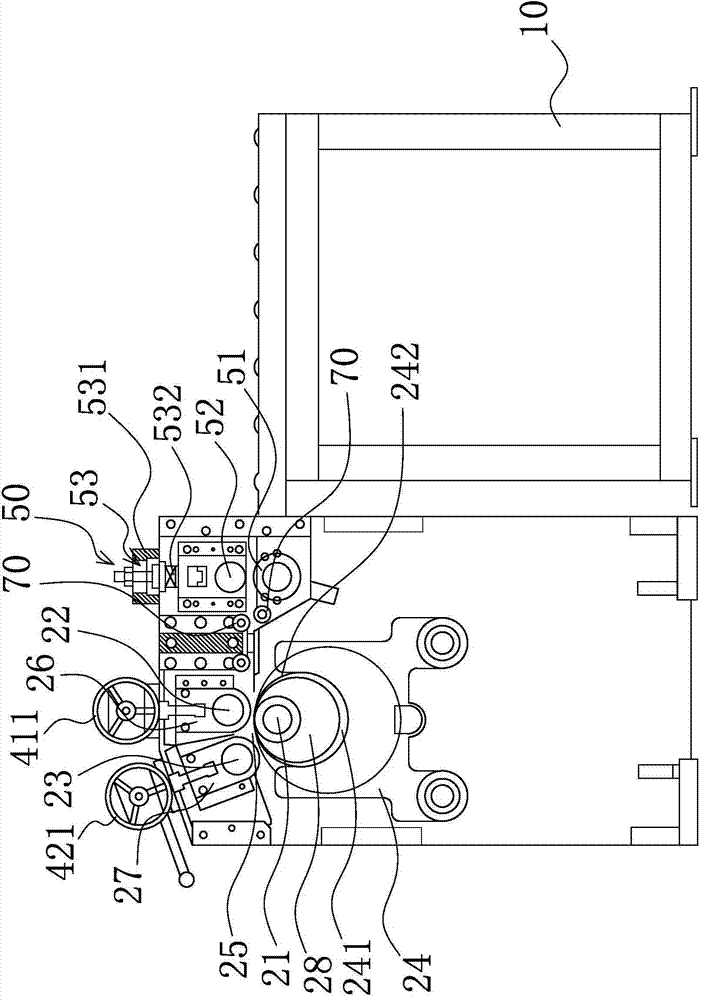

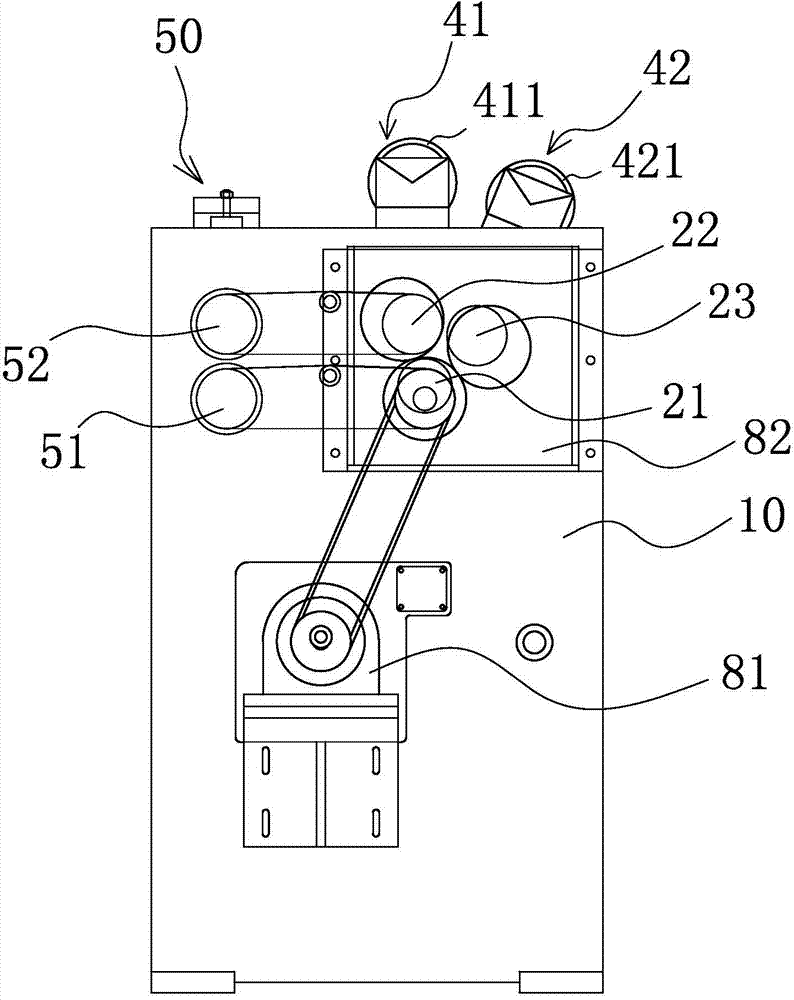

Hot melt special machine and hot melt method using the hot melt special machine

The invention belongs to the technical field of automobile part hot melt equipment, and provides a hot melt special machine and a hot melt method using the hot melt special machine. The hot melt special machine comprises a frame and a product work bench arranged on the frame; an installation rack, an upper mould fixing plate, an up-down movement guide rail, and an up-down movement cylinder are arranged on the product work bench, the bottom surface of the product work bench is provided with a lower mould storage mechanism, the lower part of the upper mould fixing plate is provided with a mechanism for heating and melting rivets, and the mechanism is opposite to the lower mould storage mechanism and is provided with a secondary buffer mechanism. The hot melt special machine has the advantages that a secondary buffer mechanism is added to guarantee the moulding effect and the rivet force so as to reduce the generation rate of substandard products. Furthermore, an electric and heat insulation block is designed to electrically disconnect the heating body of the hot melt head and the frame so as to eliminate the safety hazard. A gas-cutting baffle mechanism is added to guarantee the safety during sudden interruption of gas supply.

Owner:JIAXING XINYUAN PRECISION MOLD TECH

Aerogel ceramic fiber insulation board and preparation method thereof

ActiveCN108585922AIntegrity guaranteedGood insulation performanceCeramicwareFiberWorking temperature

The invention discloses an aerogel ceramic fiber insulation board and a preparation method thereof. A thermal conductivity of the aerogel ceramic fiber insulation board at 25 DEG C is equal to or smaller than 0.021W / (m*K), the thermal conductivity at 500 DEG C is equal to or smaller than 0.050W / (m*K), and the density is 250-350kg / m<3>; and the preparation technology comprises preparing fluid of sol and a gelatinizing agent, beating, molding, gelatinizing and drying. A high-efficiency adiabatic aerogel composite board without organic binder and the preparation method thereof, provided by the invention, can be used in the field with the working temperature of 800 DEG C or 1200 DEG C or over 1200 DEGC.

Owner:响水华夏特材科技发展有限公司

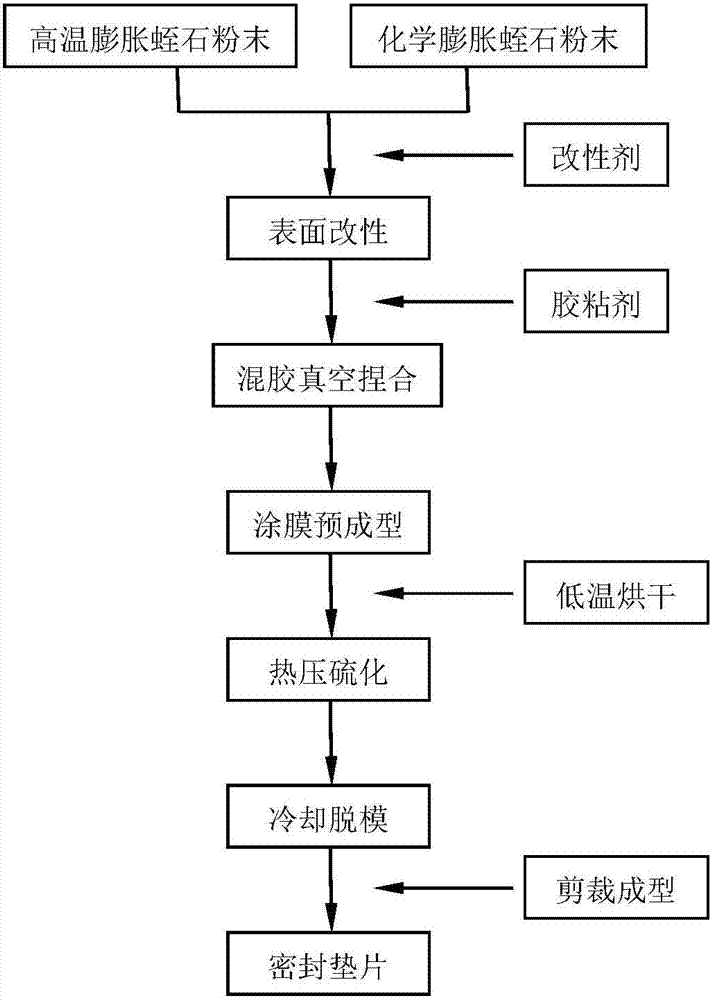

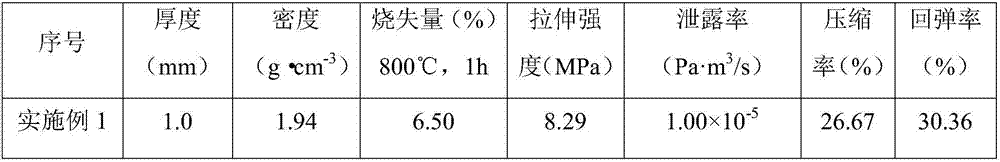

Preparation method of vermiculite-based high temperature-resistant sealing material

The invention relates to a preparation method of a vermiculite-based high temperature-resistant sealing material. The preparation method comprises the following steps: preparing materials: selecting high-temperature expanded vermiculite powder, chemical expanded vermiculite powder, a modifier and an adhesive; uniformly mixing two types of expanded vermiculite powder and water to obtain a mixed material with the mass concentration of 35-45%; sending the mixed material into a vacuum kneading machine, and adding the modifier for performing surface modification for 0.5-2h; adding the adhesive for performing vacuum kneading for 0.5-2.0h, together with the adhesive; performing coating premoulding on a kneaded slurry, and drying, wherein the moulding thickness is 2.0-4.0mm and the drying temperature is 60-75 DEG C; performing hot-pressing vulcanization moulding on a dried premoulded blank on a hot-pressing vulcanizing machine; cooling and demoulding the material, and cutting into shapes to obtain the vermiculite-based high temperature-resistant sealing materials with different thicknesses. According to a process method of performing coating premoulding first and then performing mould-pressing vulcanization molding, the vermiculite content can reach 95%, the contents of other auxiliary agents are low, and the high temperature resistance of the sealing material is effectively improved.

Owner:WUHAN UNIV OF TECH +1

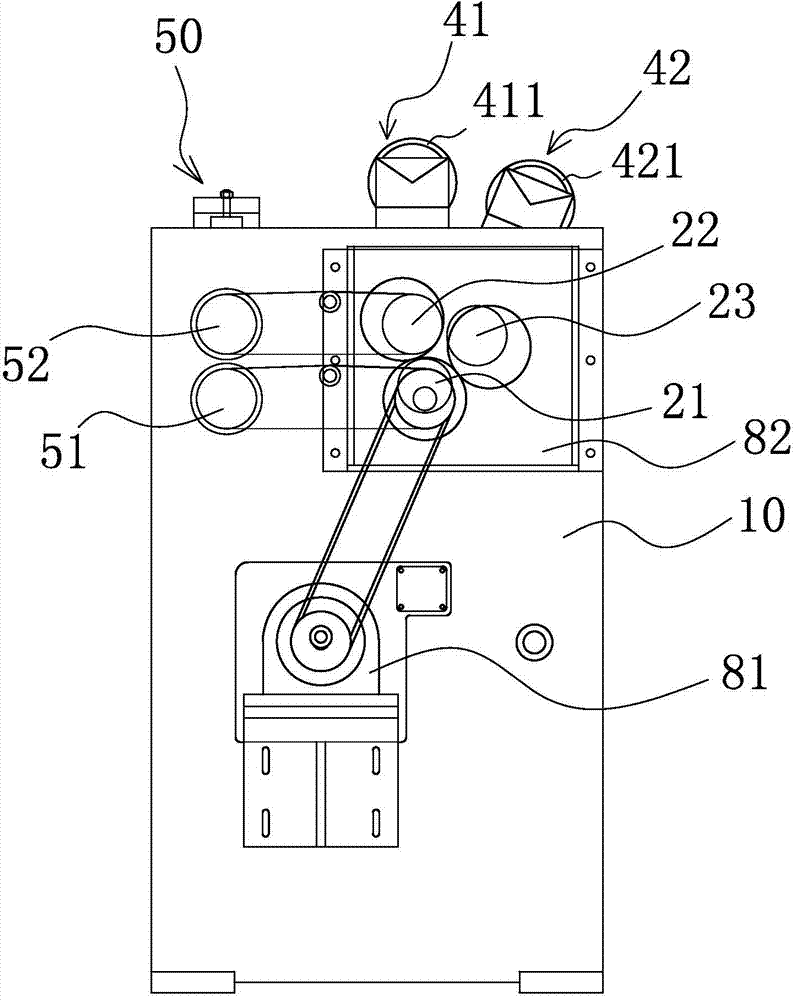

Edge rolling method of edge rolling machine

ActiveCN104772405AGood formabilityReasonable designMetal-working feeding devicesRimsButt weldingEngineering

The invention provides an edge rolling method of an edge rolling machine, and belongs to the technical field of machines. The edge rolling method of the edge rolling machine comprises the following steps: (1) placing bar stocks on a material feeding mechanism, and conveying the bar stocks to a propulsion mechanism by the material feeding mechanism; (2) further pushing the bar stocks which arrive at the propulsion mechanism to enter a transition channel by the propulsion mechanism, in a process that the bar stocks pass through the transition channel, causing a main roll, a first regulation roll and a second regulation roll which rotate according to a preset direction to be in contact with the bar stocks, and beginning to bend the bar stocks; (3) causing the bent bar stocks to enter an arc-shaped channel, and carrying out edge rolling on the bar stocks by the arc-shaped channel to obtain a shape required by a rim; (4) causing the bar stocks subjected to the edge rolling to be separated from the arc-shaped channel; (5) pressing the bar stocks unloaded from the arc-shaped channel into two straight edges on a butt welding hole by a flatting machine. The edge rolling method of the edge rolling machine has the advantages of reasonability in design, convenience in regulation and good forming effect.

Owner:NINGBO LONGTIME MACHINE

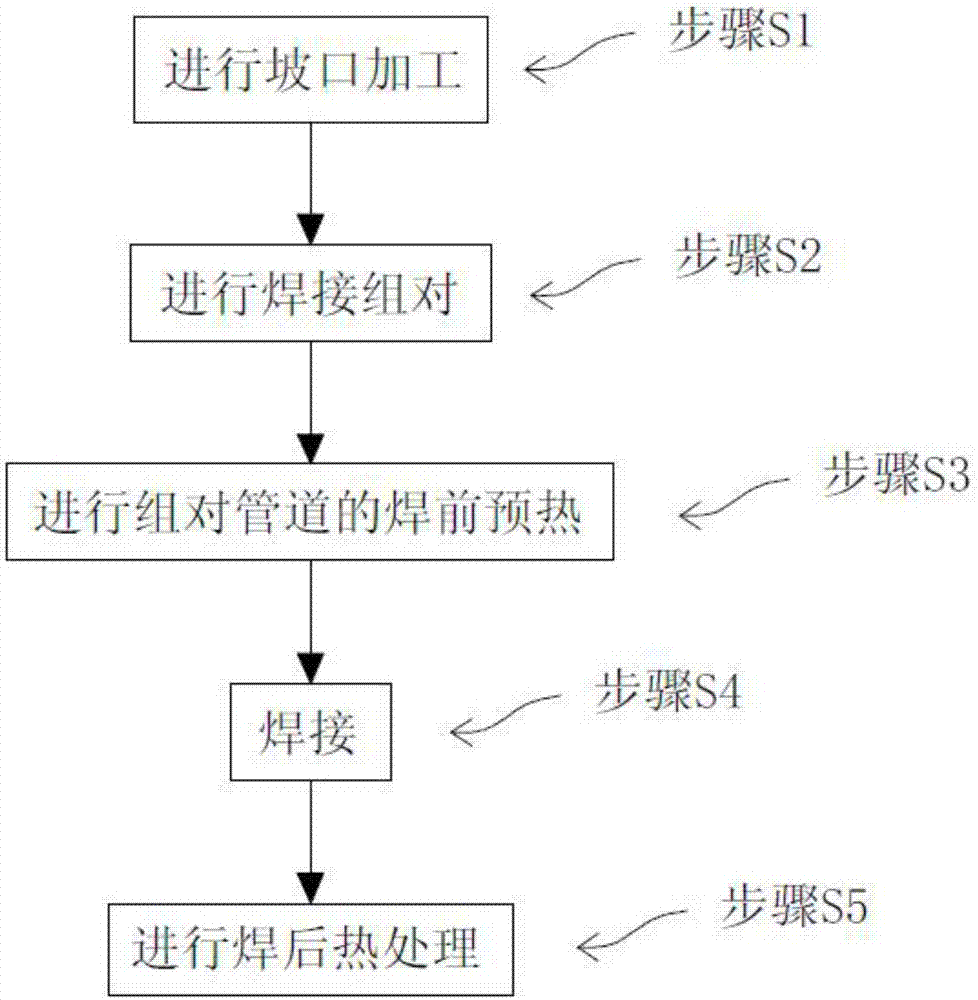

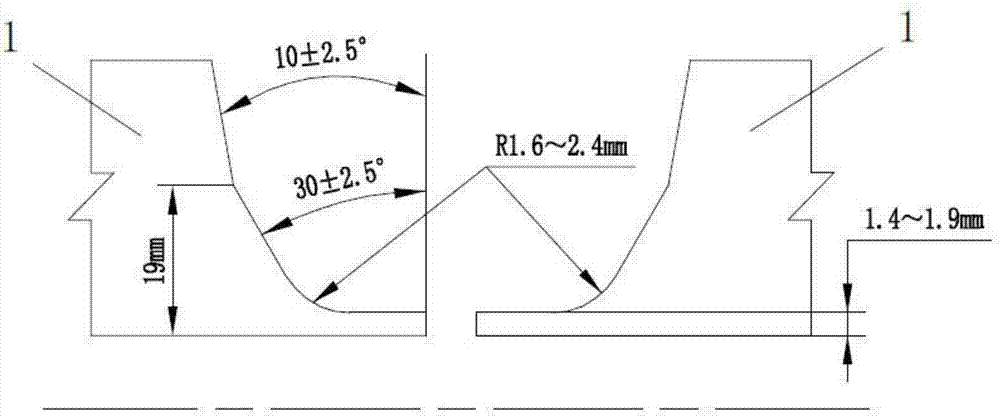

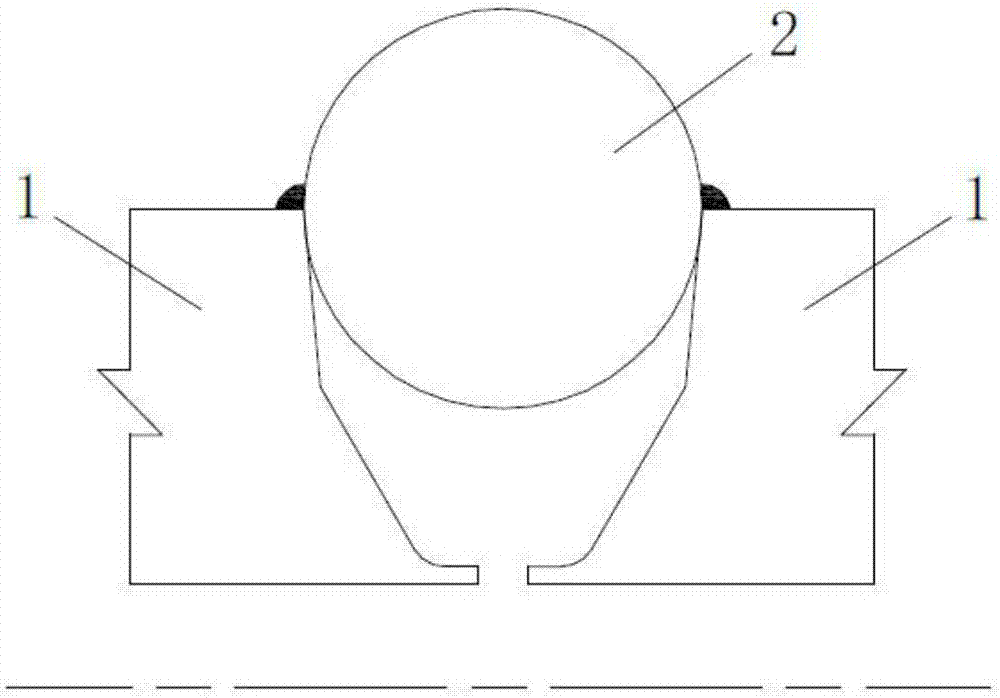

AP1000 main steam pipeline welding method

InactiveCN107457473AAvoid indentation defectsPrevent collapseArc welding apparatusNuclear powerShielding gas

The invention belongs to the technical field of AP1000 nuclear power, and particularly relates to an AP1000 main steam pipeline welding method. In order to solve the problems that an air filling protection device is difficult to install and potential safety hazards exist in the good health of operators when a conventional air filling protection device is used for auxiliary welding of an AP1000 main steam pipeline, the AP1000 main steam pipeline welding method is disclosed. The welding method particularly includes the following several steps of S1, chamfering; S2, welding assembly; S3, weld preheating; S4, welded connection; and S5, postweld heat treatment. When the welding method is used for welding the AP1000 main steam pipeline, through adjustment matching of the groove dimensions and welding parameters, welded joints formed in the welding process can still achieve a continuous and uniform forming effect without the supporting action of backing gas, and therefore installation of the air filling protection device is omitted and the influence on the good health of the operators by protective gas is avoided.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

Concrete test piece forming die capable of adjusting steel bar position and forming method

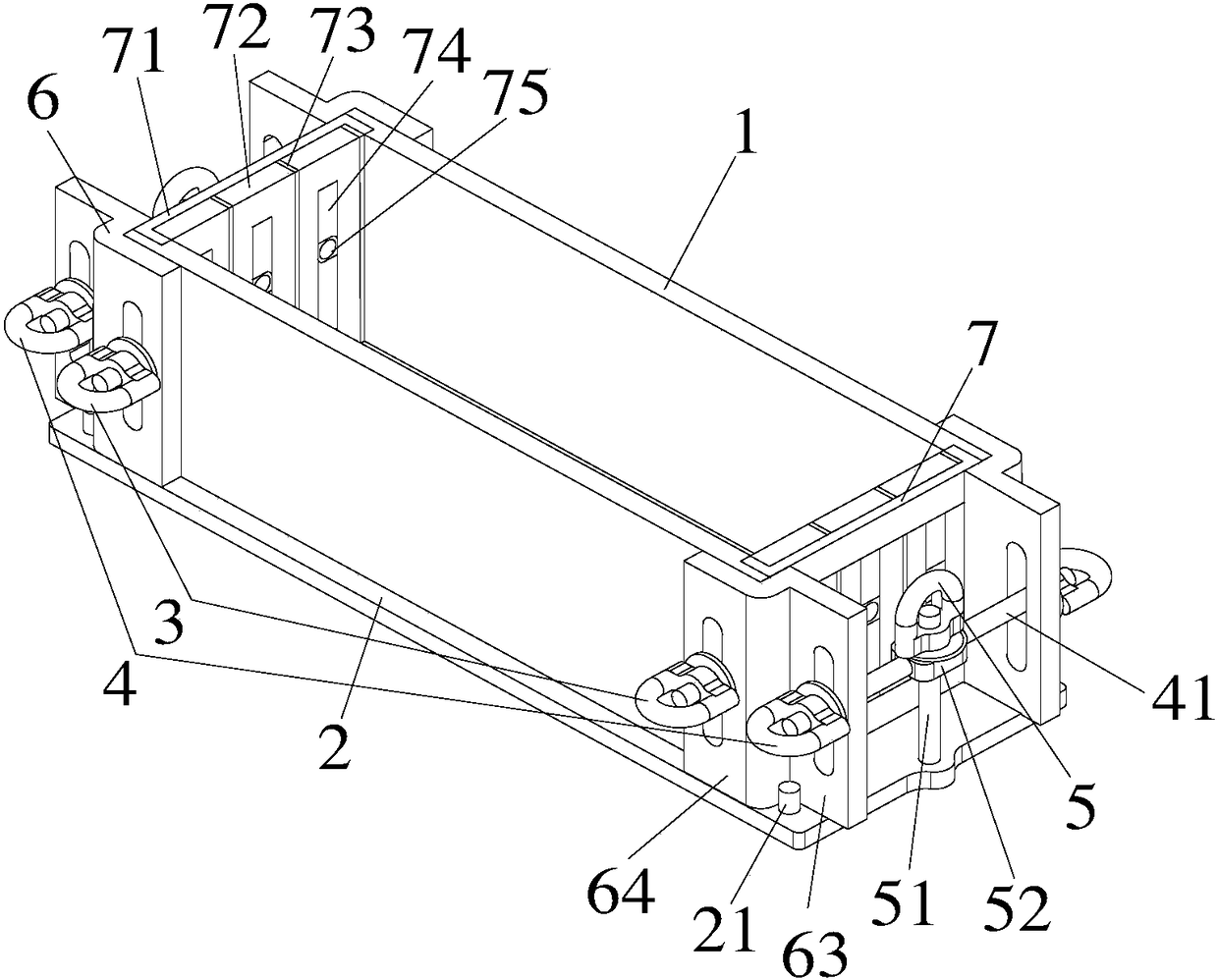

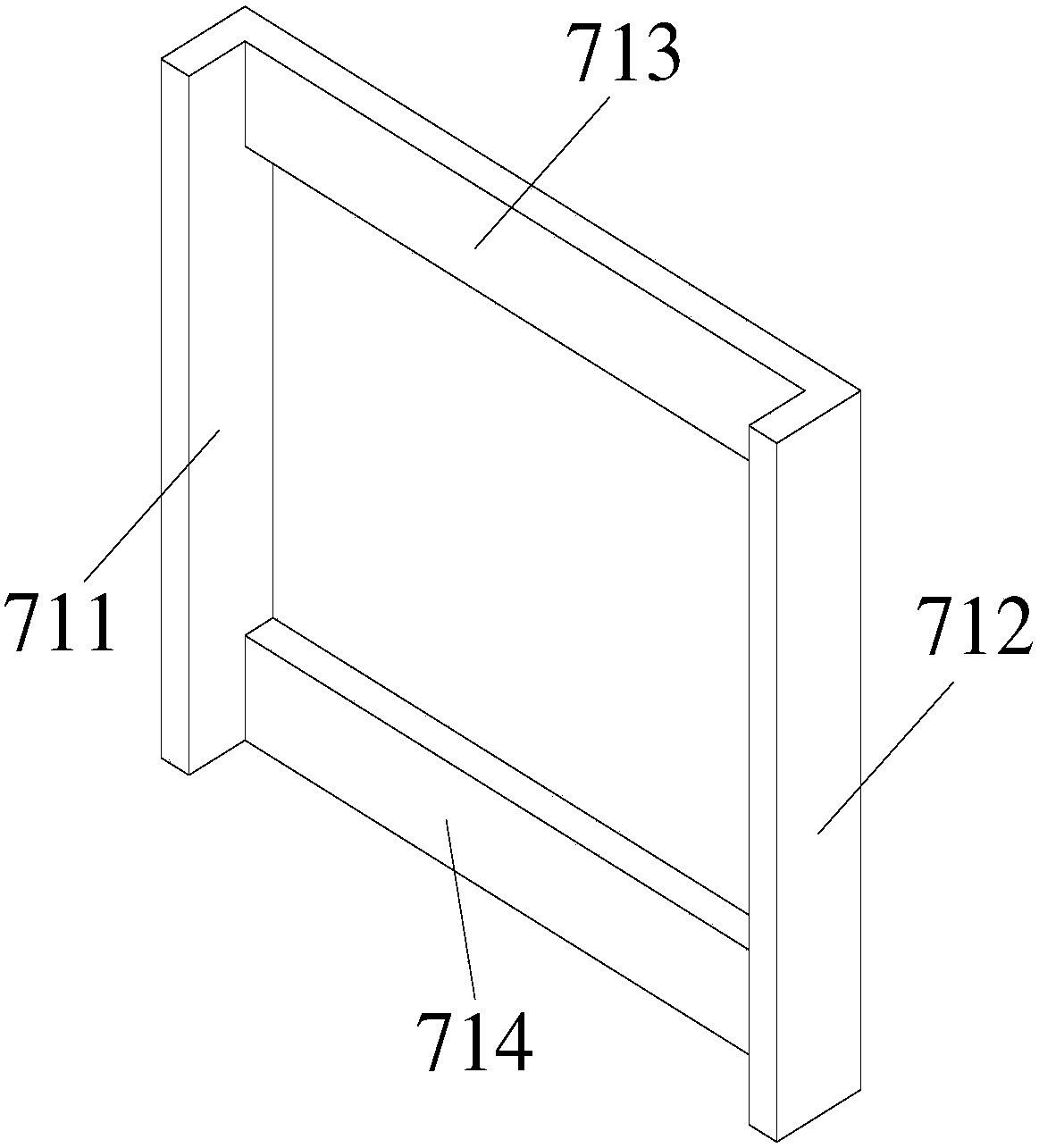

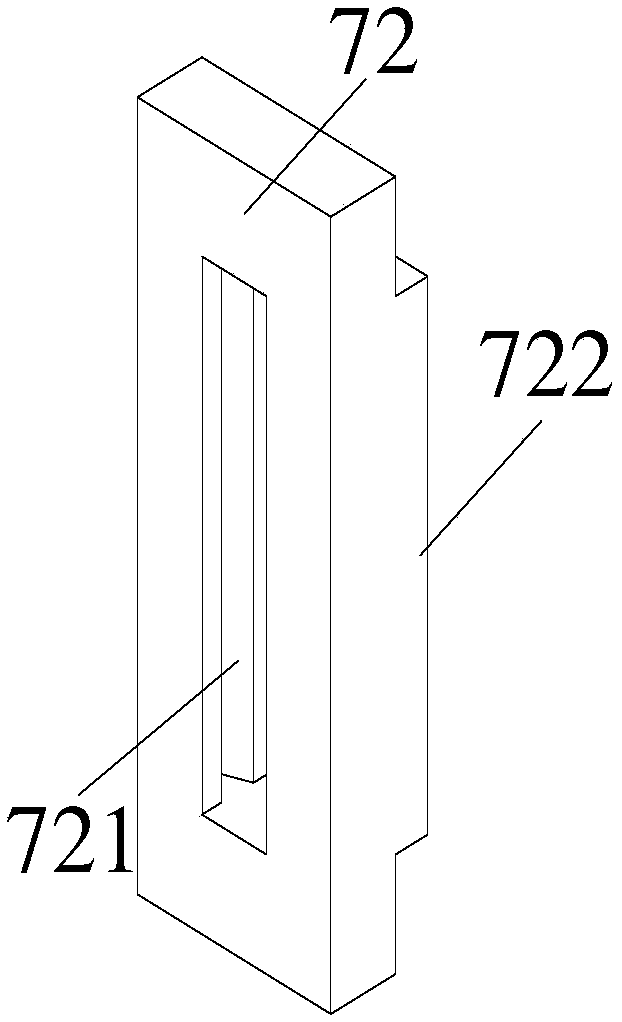

ActiveCN108262839APrecise positioningEasy to operateMouldsMould fastening meansRebarMechanical engineering

The invention relates to a concrete test piece forming die capable of adjusting a steel bar position and a forming method. The forming die comprises a bottom plate, two opposite side plates and two end plates arranged oppositely, and the side plates and the end plates are fixed on the periphery of the bottom plate; the end plates comprises end plate supports and T-shaped adjusting regions, and theT-shaped adjusting regions comprises adjusting area bases and adjusting area bosses extending from one sides of the adjusting area bases; the adjusting area bosses are inserted into the cavities of the end plate supports in the Z-axis direction, and end plates with basically flat inner sides are formed; the T-shaped adjusting regions are formed by connecting a plurality of T-shaped positioning pieces arranged in the X-axis direction in parallel, or through the T-shaped positioning pieces and T-shaped clamping plates arranged and matched at intervals in the X-axis direction; and the middle parts of the T-shaped positioning pieces are provided with reinforcing steel bar positioning holes with axes arranged in the Z-axis direction, and the steel bar positioning holes of the two oppositely-arranged end plates are arranged correspondingly.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

Photosensitive resin for laser 3D printing and preparation method thereof

ActiveCN107698718AHigh temperature resistantSmall shrinkage deformationAdditive manufacturing apparatusEpoxyTemperature resistance

The invention discloses a photosensitive resin for laser 3D printing and a preparation method thereof. The photosensitive resin comprises the following raw materials in parts by weight: 10-40 parts ofacrylic ester with high TG value, 10-65 parts of an epoxy resin, 5-30 parts of a trimethylene oxide compound, 1-10 parts of a cationic photopolymerization initiator, 1-10 parts of a free radical typephotopolymerization initiator and 1-5 parts of a silane coupling agent. The preparation method comprises the following steps: mixing the raw materials according to the weight part ratio, and then heating and stirring at 20-80 DEG C for 30-150 minutes to enable the raw materials to become faint yellow transparent liquid. The photosensitive resin overcomes the defects of a traditional laser 3D printing medium, and has the characteristics of high temperature resistance and small shrinkage deformation, the forming effect of the print parts is guaranteed, and the quality of the print parts is effectively improved; the method is simple to operate and the photosensitive resin is convenient to prepare.

Owner:惠展电子材料(上海)有限公司

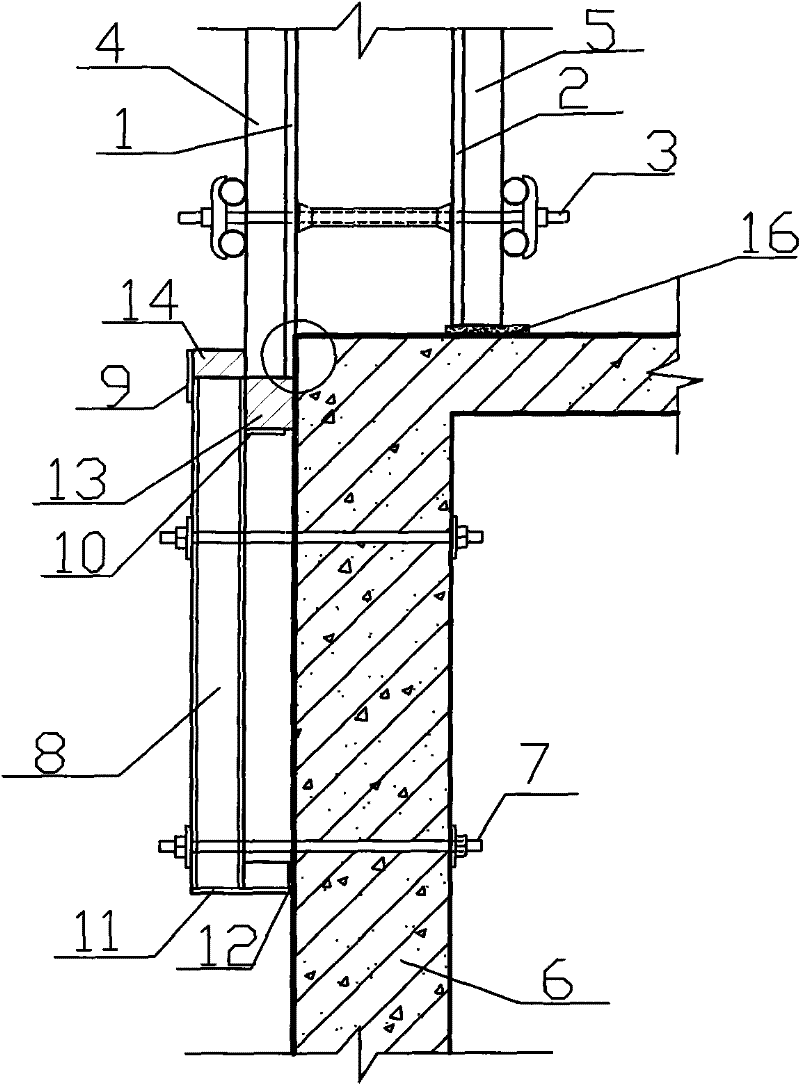

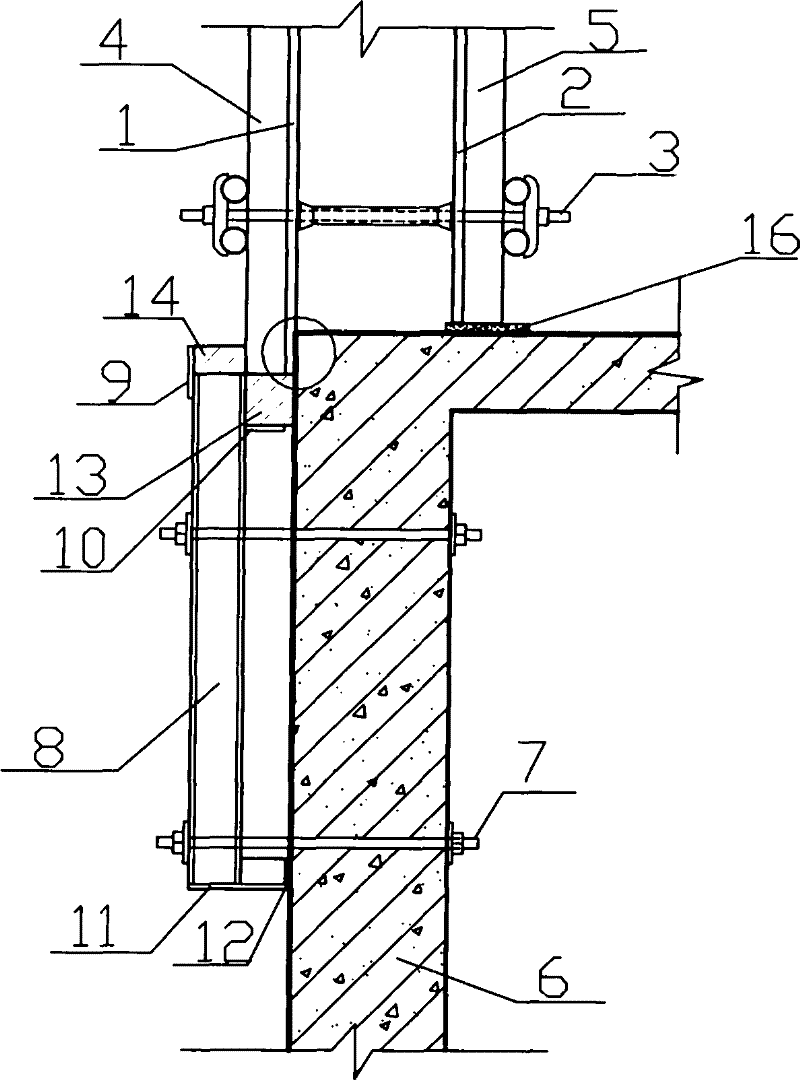

Connecting layer structure of fair-faced concrete outer wall template

InactiveCN101748891AGuaranteed tightEnsure stabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringEngineering

The utility model discloses a connecting layer structure of a fair-faced concrete outer wall template, which comprises a template. The template consists of an outer wall template and an inner wall template which are fixed together by a split bolt; long battens are arranged on both outer sides of the outer wall template and the inner wall template; channel steel is fixedly arranged on the outer side of a lower wall body through a wall penetrating bolt; a steel gasket is arranged on the outer side at the upper part of the channel steel, and a support bracket is arranged on the inner side; a steel gasket is arranged on the inner side at the lower part of the channel steel; a sponge cushion is arranged between the steel gasket and the lower wall body; the bottom part of the outer wall template is fixed on a batten on the support basket of the channel steel, the inner side of the bottom part of the outer wall template is propped against the lower wall body, and a batten is arranged between the long batten on the outer side at the bottom part of the outer wall template and the steel gasket on the outer side at the upper part of the channel steel. In the invention, a connecting layer part of the outer wall template is mainly and specially designed, so that the tightness and the solidness at the connecting layer of the outer wall template are ensured, the mortar leakage and other quality defects at the connecting layer of the outer wall template can be effectively solved, and the forming effect and the apparent mass of fair-faced concrete for the outer wall are ensured.

Owner:QINGJIAN GRP CO LTD

Environment-friendly biomass particle fuel and processing method

The invention relates to the technical field of biomass fuel and specifically relates to environment-friendly biomass particle fuel and a processing method. The particle fuel is prepared from the following raw materials in parts by weight: 45 to 65 parts of woodwork waste mixture, 10 to 20 parts of mulberry stalk, 5 to 15 parts of straw, 5 to 8 parts of tobacco stem, 3 to 5 parts of flame accelerator, 2 to 3 parts of anti-slagging agent and 1 to 2 parts of sulfur fixing agent. The invention further discloses the processing method of the particle fuel. The processing method comprises the steps of preparing the flame accelerator, the anti-slagging agent and the sulfur fixing agent according to selected parts by weight; mixing and smashing; drying: drying an obtained wood pellet mixture at high temperature; extrusion forming: sending the dried solid fuel into a granulator to be extruded and granulated and finally cooling to obtain the environment-friendly biomass particle fuel. The environment-friendly biomass particle fuel and the processing method disclosed by the invention have reliable performance, and the environment-friendly biomass particle fuel can meet the requirement of energy conservation and environmental friendliness and meanwhile has long combustion time and high combustion ratio.

Owner:云南省福仑木业有限公司

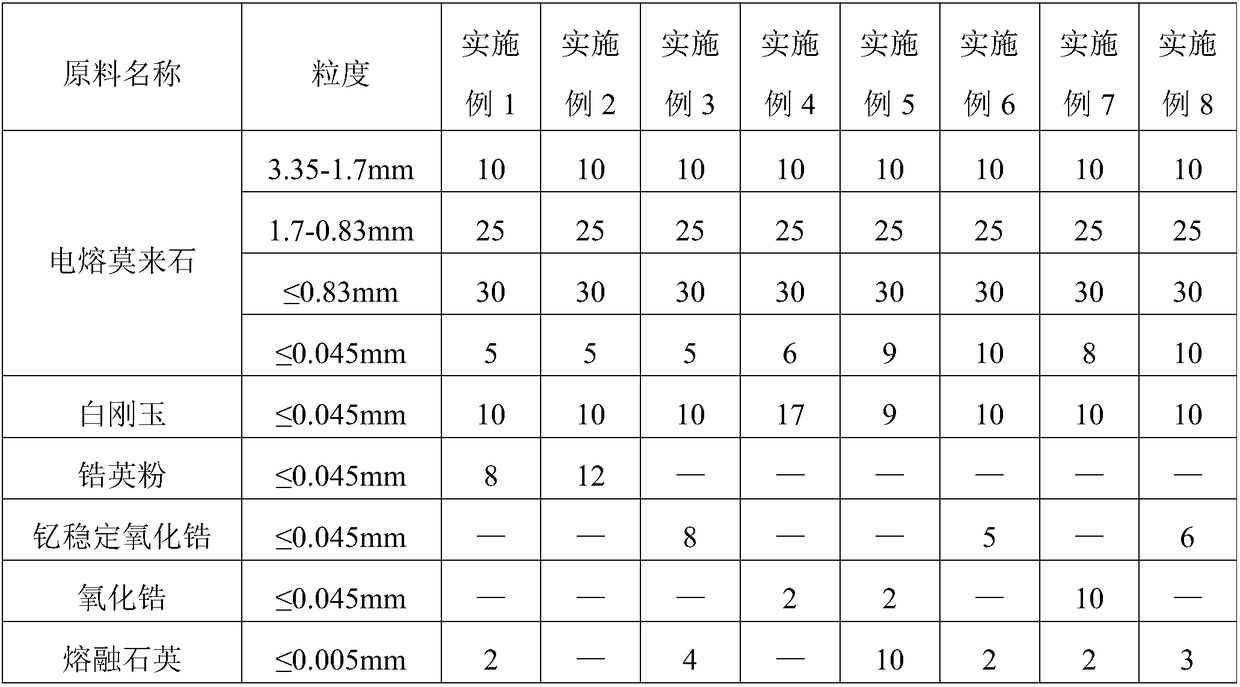

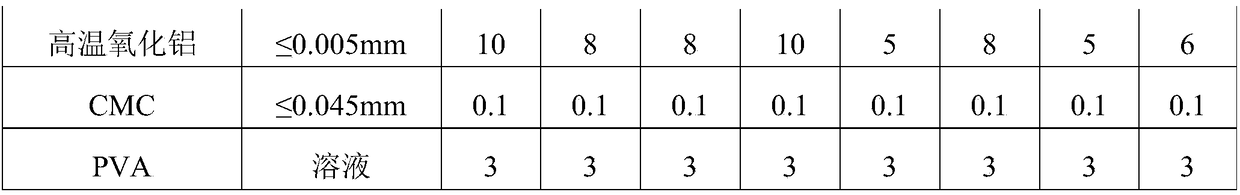

Zirconium-containing re-sintered electrically-fused mullite brick and preparation method thereof

The invention belongs to the technical field of functional materials, and relates to a zirconium-containing re-sintered electrically-fused mullite brick and a preparation method thereof. The brick isprepared from raw materials in percentage by mass as follows: 70%-95% of electrically-fused mullite, 2%-12% of zirconium-containing substances, 0-27% of Al2O3 micro-powder, 0-10% of SiO2 micro-powderand 0.1%-5% of an additive. According to the brick and the preparation method, zirconia is added to the electrically-fused mullite, so that the alkali vapor erosion resistance and the thermal stress impact resistance are improved while the refractoriness under load is high; and the preparation method of the zirconium-containing re-sintered electrically-fused mullite brick is simple, easy to implement, energy-saving and environment-friendly.

Owner:ZIBO GT INDAL CERAMICS

Edge rolling equipment

The invention provides edge rolling equipment, which belongs to the technical field of machines. The edge rolling equipment comprises a rack, a main roll, a first regulation roll, a second regulation roll and a movable seat ,wherein the peripheral side surfaces of the main roll, the first regulation roll and the second regulation roll define a transition channel; the rack is provided with a first regulation mechanism and a second regulation mechanism; the first regulation mechanism and the second regulation mechanism are respectively connected with the first regulation roll and the second regulation roll; the first regulation mechanism can drive the first regulation roll to generate linear displacement; the second regulation mechanism can drive the second regulation roll to generate the linear displacement; the rack is provided with a propulsion mechanism used for pushing bar stocks which are horizontally arranged into the transition channel; the movable seat is movably installed on the rack and is provided with an arc-shaped channel used for carrying out edge rolling on the bar stocks; the transition channel is provided with an inlet and an outlet; the inlet is used for receiving bar stocks sent out by the propulsion mechanism, and the outlet is used for unloading the bar stocks into the arc-shaped channel. The edge rolling equipment has the advantages of reasonability in design, convenience in regulation and good forming effect.

Owner:NINGBO LONGTIME MACHINE

Supporting structure for relieving stress deformation of metal part manufactured through SLM

ActiveCN111318703AGuaranteed molding effectImprove printing accuracyAdditive manufacturing apparatusIncreasing energy efficiencyStructural engineeringMaterials science

The invention provides a supporting structure for relieving the stress deformation of a metal part manufactured through SLM. The supporting structure comprises latticed supporting units, conical supporting units and volume supporting units. A base plate is arranged below the narrow and long suspension face of a part needing to be supported. The latticed supporting units are arranged between the bottom face of the narrow and long suspension face and the base plate. The volume supporting units are arranged at the positions, with the feature residual stress larger than a set threshold value, of the part. According to the supporting structure for relieving the stress deformation of the metal part manufactured through SLM, the three supporting structures of the latticed supporting units, the conical supporting units and the volume supporting units are adopted at the same time to relieve the deformation caused by self-stress of the part in the SLM 3D printing process, so that formation of the part is ensured, and the printing precision of the part is improved.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com