Patents

Literature

279results about How to "Speed up the construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

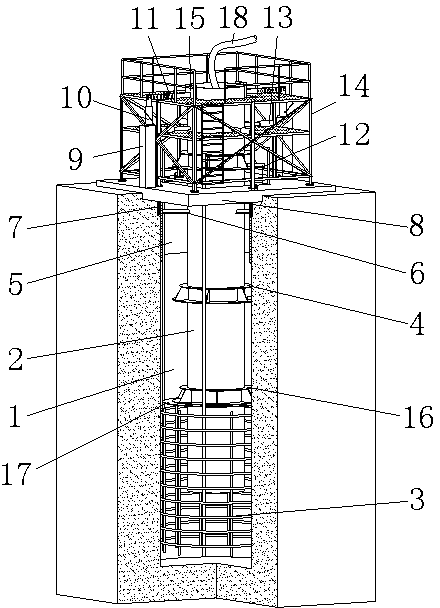

Construction method and structure for mounting reverse-construction steel pipe column in rotary drilled pile hole

The invention discloses a construction method and structure for mounting a reverse-construction steel pipe column in a rotary drilled pile hole. The construction method comprises the steps as follows: 1, drilling the pile hole; 2, mounting a reinforced concrete bearing platform; 3, hoisting a pile foundation reinforcement cage; 4, hoisting the steel pipe column; 5, mounting a concrete pouring platform; 6, cleaning the pile hole; 7, adjusting the elevation, the center position and the perpendicularity of the steel pipe column; 8, completing pouring of concrete in a pile foundation and the steel pipe column. The method is simple and practical, the construction period can be shortened, the project cost can be reduced, and the problem that the construction period is longer due to the fact that the pile foundation and the steel pipe column are constructed separately is solved. By the aid of the construction method and structure, the construction period is shortened while the project quality is guaranteed. The construction method and structure have the good social benefit and the good economic benefit. According to the construction method and structure, the high-efficiency construction requirement is met, the construction cost is saved, the project cost is reduced, the problem of continuous construction of rotary drilling and the steel pipe column in basement reverse construction is effectively solved, and the construction method and structure have the wide practicability and the popularization performance.

Owner:CHINA CONSTR FOURTH ENG DIV

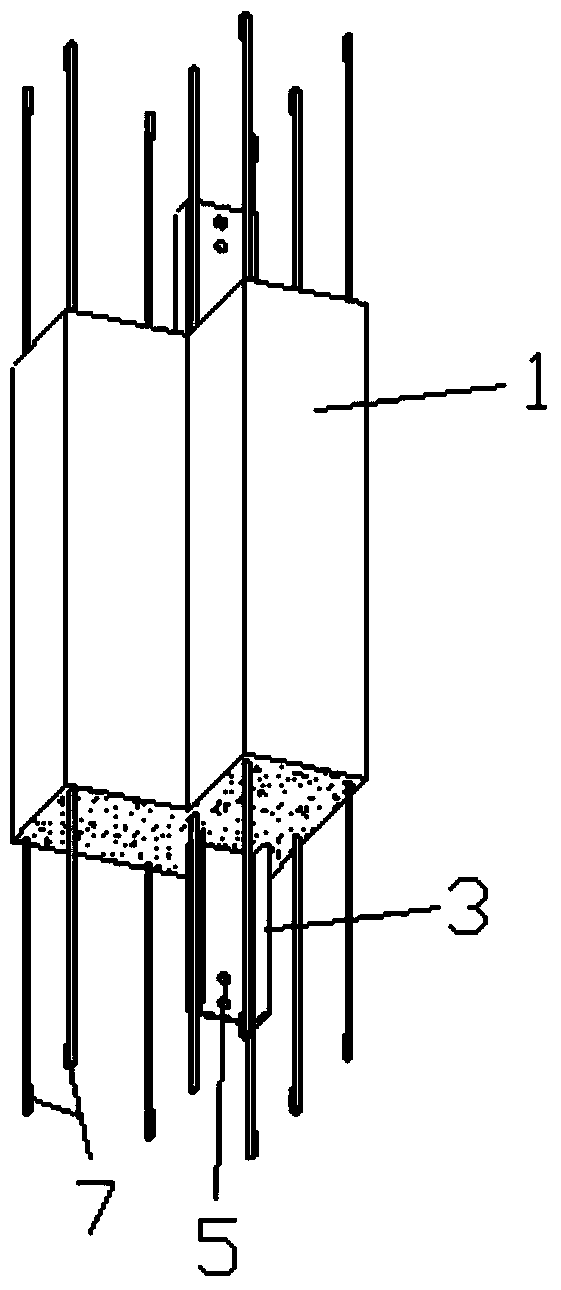

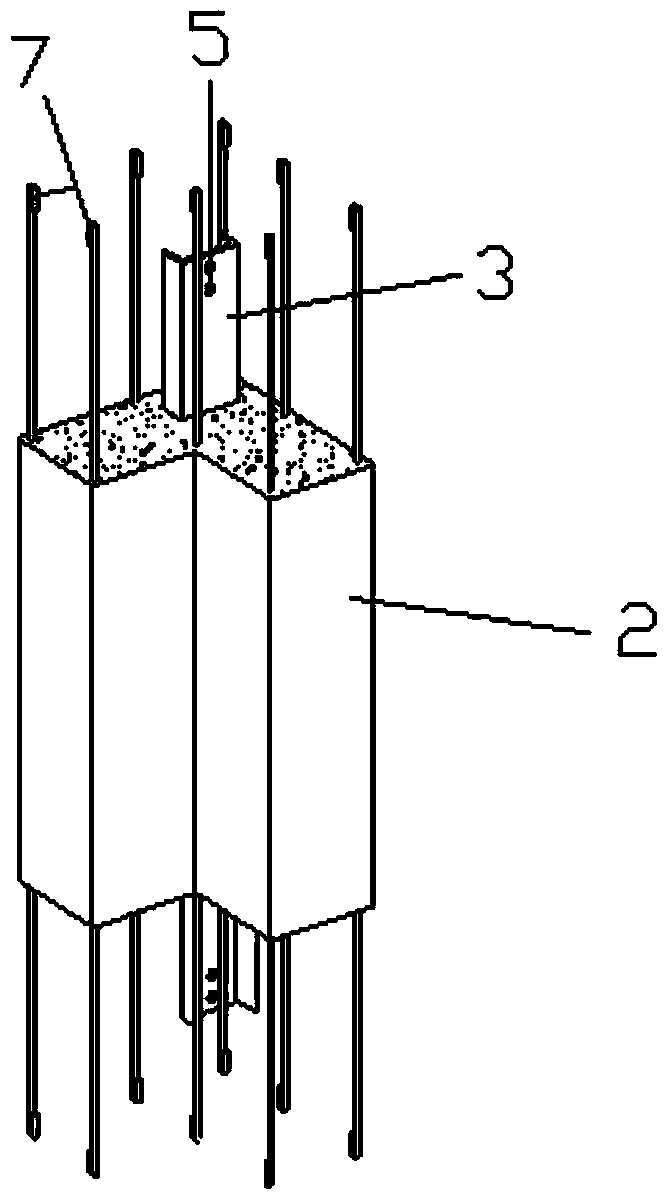

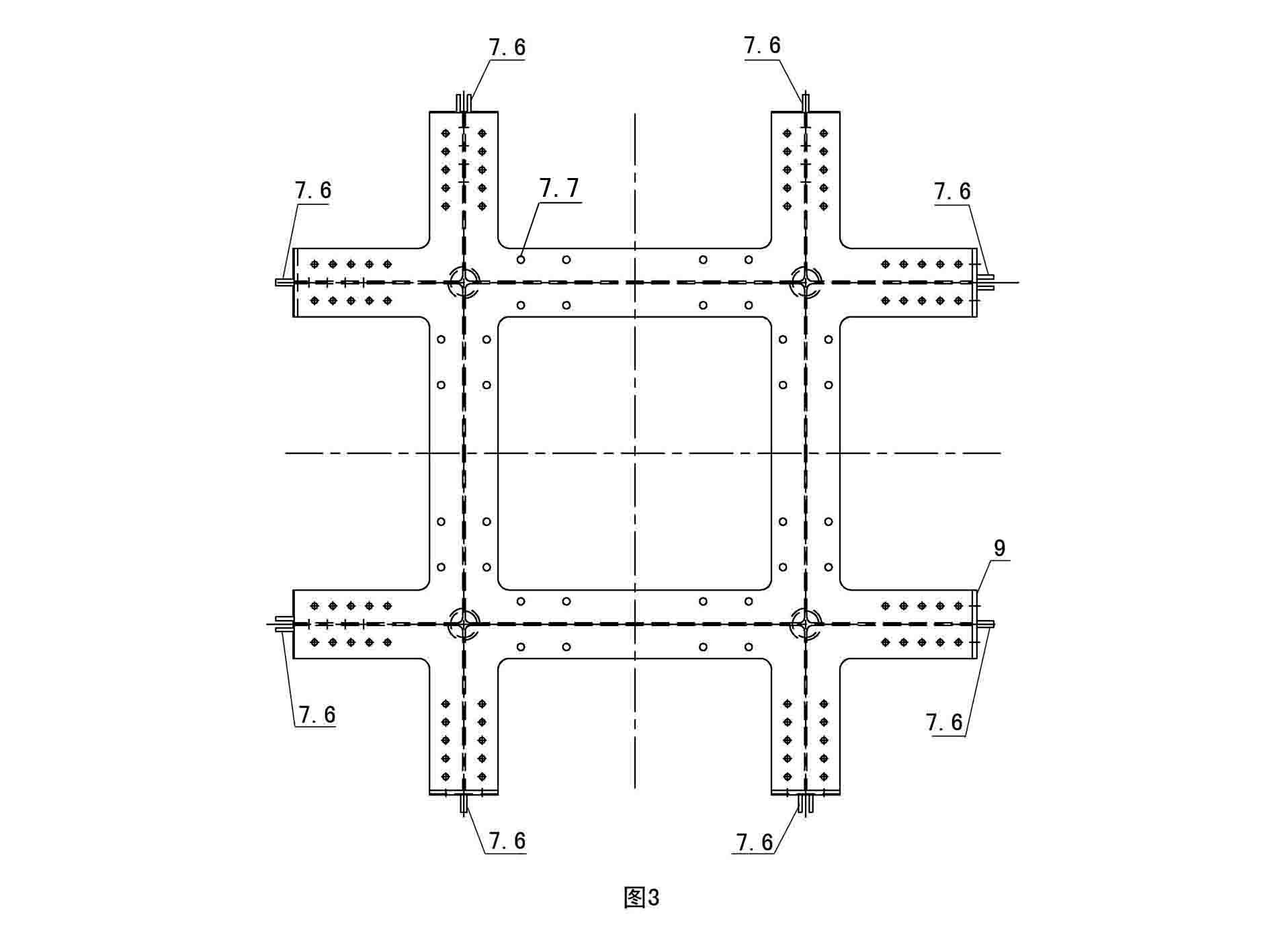

Prefabricated, assembled and integrated type special-shaped column structure and jointing construction method thereof

InactiveCN103850350AImprove integrityEliminate weaknessBuilding material handlingWhole bodyBolted joint

The invention discloses a prefabricated, assembled and integrated type special-shaped column structure and a jointing construction method of the column structure. The prefabricated, assembled and integrated type special-shaped column structure comprises a prefabricated upper column, a prefabricated lower column and a prefabricated laminated beam, wherein the prefabricated upper column and the prefabricated lower column are respectively provided with channel steel in an embedding manner, reserved bolt holes are formed in each channel steel, the adjacent prefabricated upper column and prefabricated lower column are connected through the channel steel by bolts to form an upper and lower through special-shaped column provided with a cast-in-place area, and reinforcing hoops are arranged in the cast-in-place area; the prefabricated laminated beam is anchored in the abnormal column through a longitudinal rib of the prefabricated laminated beam; cast-in-place concrete is injected in the cast-in-place areas of the adjacent two prefabricated upper column and prefabricated lower column and a part, not pouring the concrete, of the prefabricated laminated beam, so as to form a beam and column combined whole body. According to the prefabricated, assembled and integrated type special-shaped column structure and the jointing construction method of the column structure, which are disclosed by the invention, the problems that the vibration of concrete in joint core area of the special-shaped column is not dense and is difficult can be remarkably modified, so that the vibration resistance of joints can be improved; furthermore, the construction speed further can be increased, the construction period is shortened, and the development of building industrialization is facilitated.

Owner:NANJING TECH UNIV +1

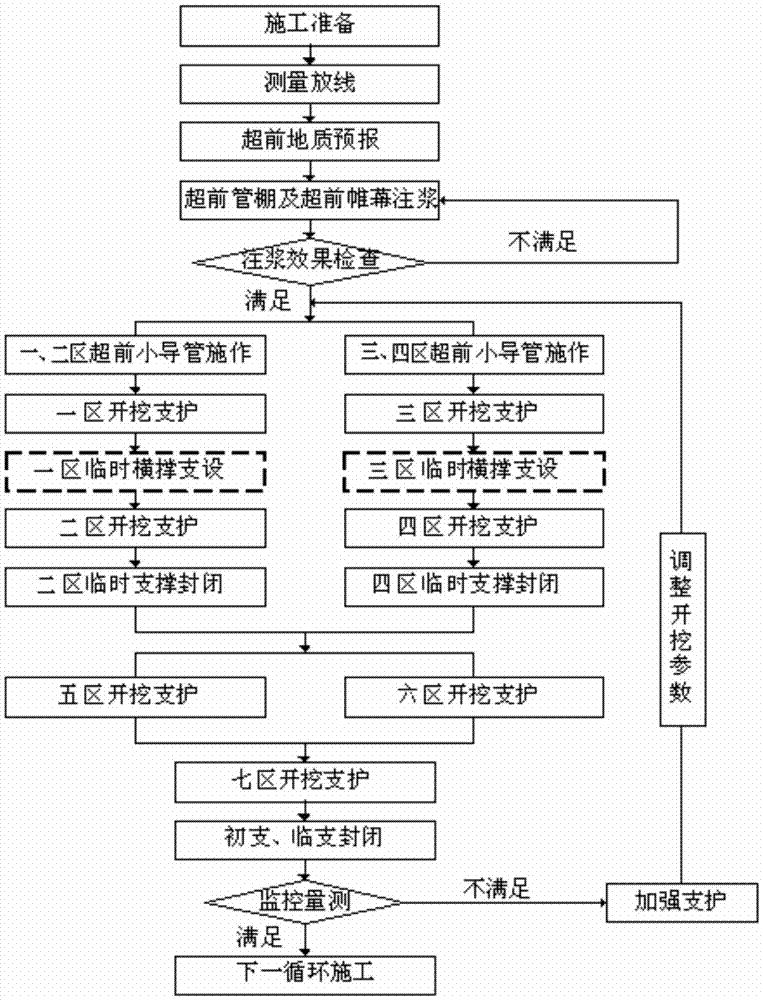

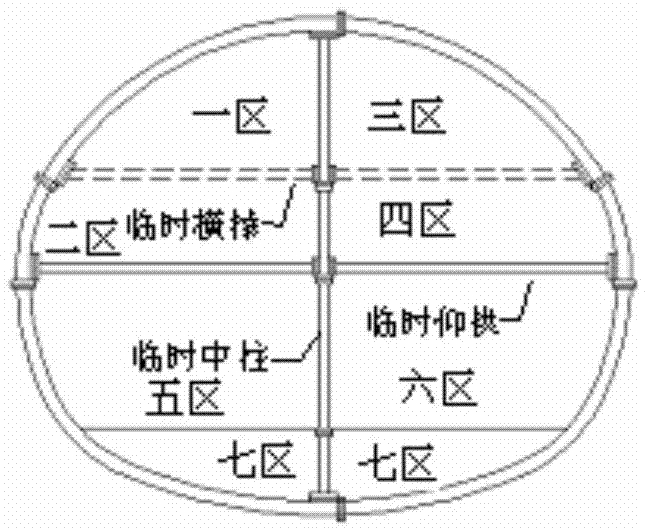

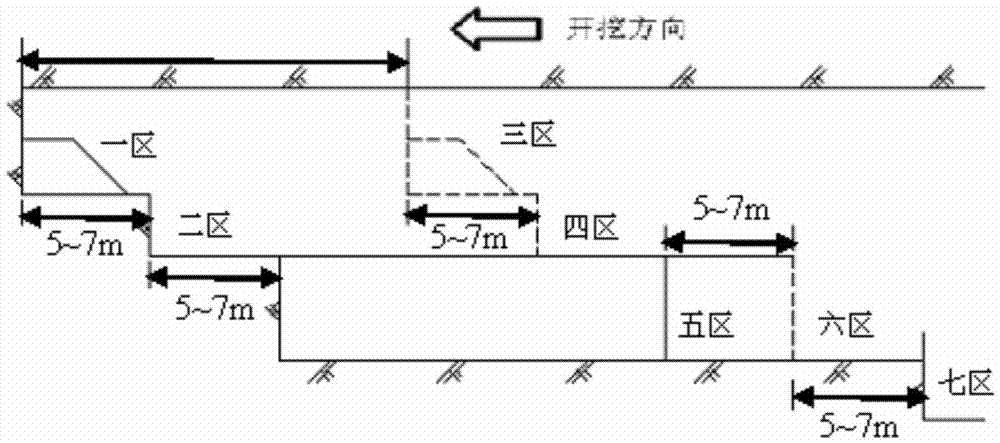

Construction method of shallow-buried subsurface-excavated cross-shaped cross-strut tunnel

ActiveCN105443132AEasy to operateQuality is easy to controlUnderground chambersTunnel liningConstruction designEnvironmental geology

The invention discloses a construction method of a shallow-buried subsurface-excavated cross-shaped cross-strut tunnel. The method includes the following steps of conducting construction preparation, conducting measurement and pay-off on a tunnel advanced support and the tunnel contour line according to construction design requirements, conducting advanced geological forecasting through the geophysical prospecting advanced geological forecasting and drilling advanced geological forecasting combined mode, conducting advanced pipe shed grouting and advanced curtain grouting, checking the grouting effect, entering the next procedure if the grouting effect meets the construction requirement, conducting advanced pipe shed and advanced curtain grouting again if the grouting effect does not meet the construction requirement, conducting excavation support construction on construction areas on by one from top to bottom and from left to right, conducting primary support and temporary support sealing and conducting monitoring and measuring after the primary tunnel transverse end face construction is completed, repeatedly executing the steps for the next circulation of construction if the design requirement is met, conducting support strengthening if the design requirement is not met, and regulating excavation parameters to conduct excavation support construction again till the design requirement is met.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

Construction method of subway station

ActiveCN105926669ARealize turnkey constructionSimple forceArtificial islandsUnderwater structuresSupporting systemSubway station

The invention provides a construction method of a subway station. The construction method is characterized in that a temporary support system does not need to be set; the situations that in a temporary support system in a conventional construction method, supports are difficult to disassemble and change are prevented through utilizing plates, comprising top plates, layer plates and bottom plates, in all layers of a station with a permanent structure; and a lot of temporary materials are saved. According to the construction method, the problem that the structure is unstable due to conversion of a structure stress system caused by support disassembly and support changing is avoided, a conventional station structure longitudinal beam system is changed into a system horizontally and integrally bearing stress, and the structure is constructed at a time, and is simple, clear, safe and reliable.

Owner:GUANGZHOU METRO DESIGN & RES INST

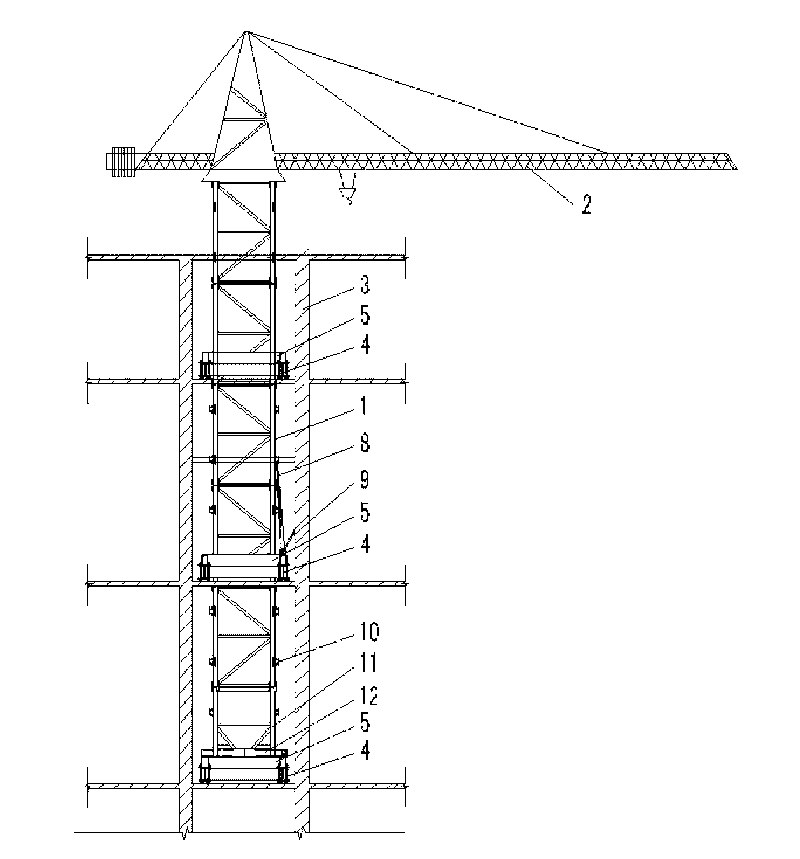

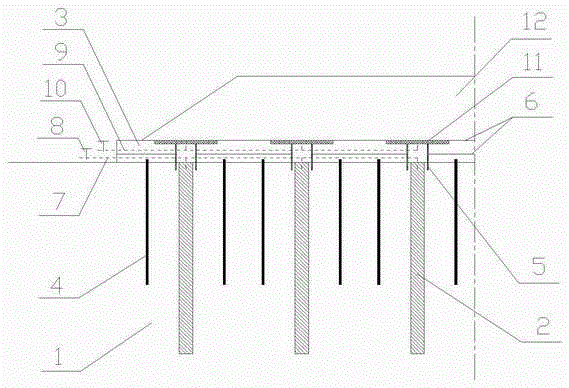

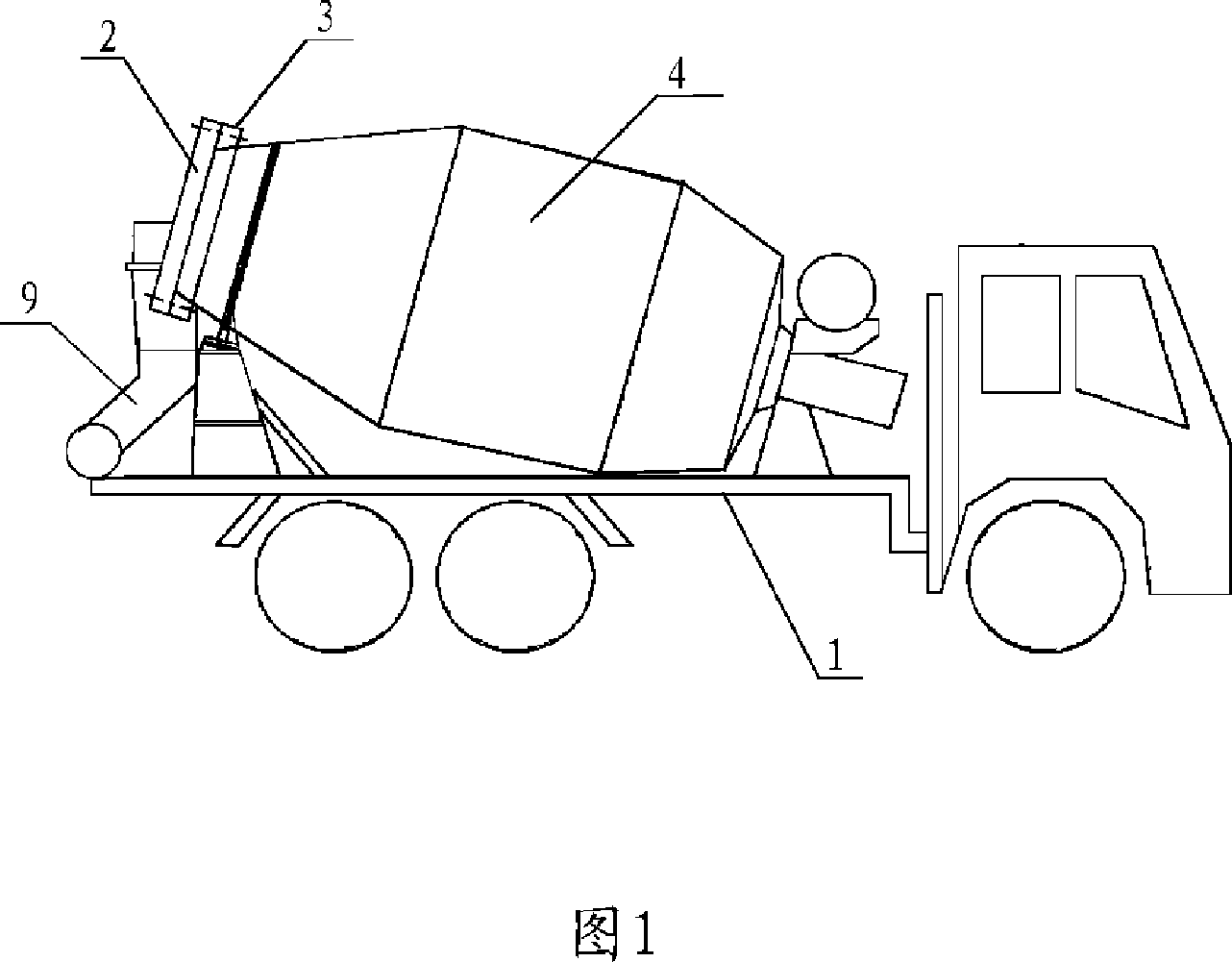

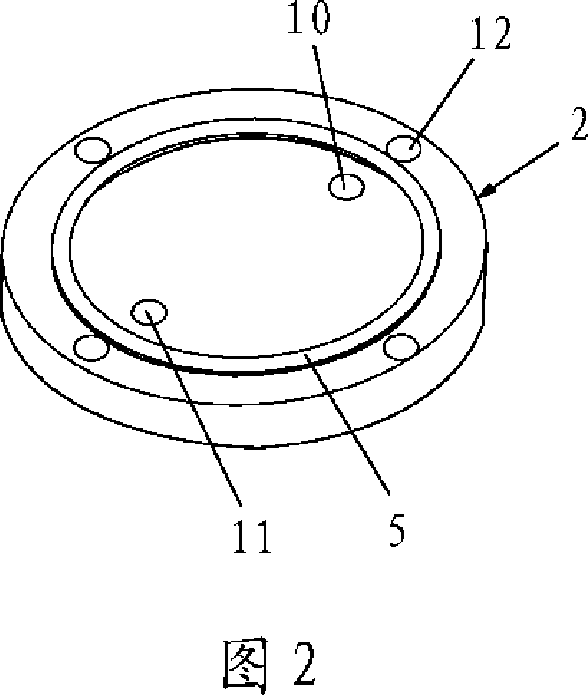

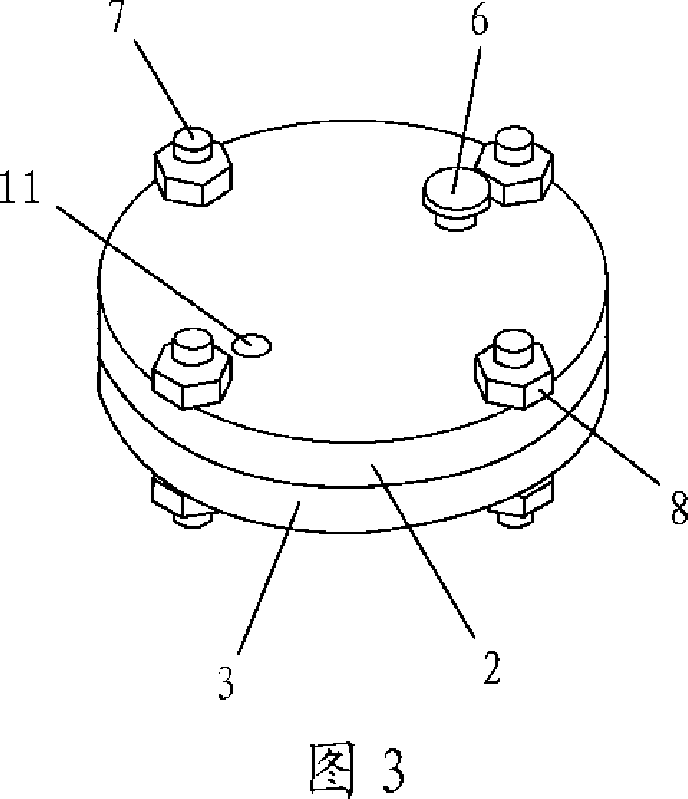

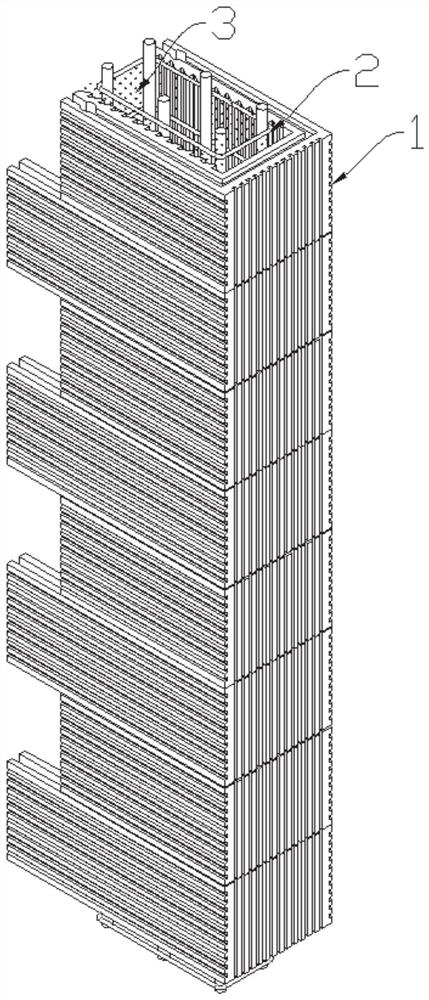

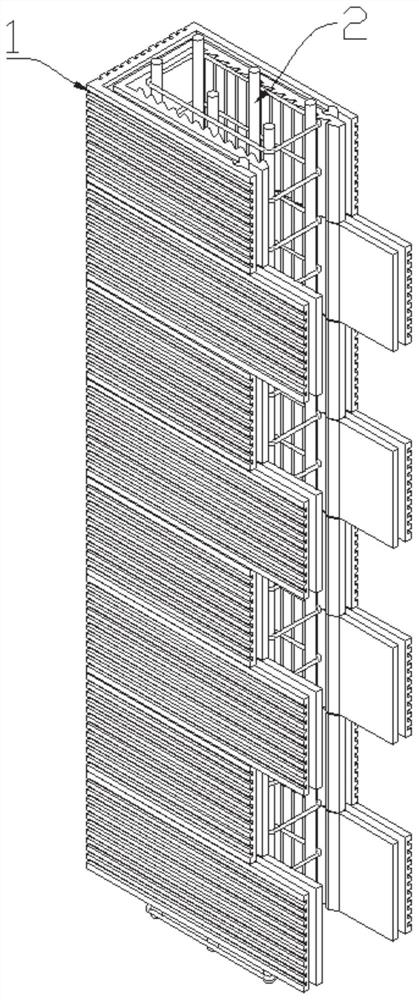

Self-climbing tower crane

InactiveCN101691191AHave vertical transportation requirementsMeet vertical transportation requirementsCranesSocial benefitsTower crane

The invention discloses a self-climbing tower crane, which comprises a tower body (1), a hoisting arm (2) and a climbing mechanism, wherein the climbing mechanism comprises a main stressed supporting steel beam (4) and a steel structure climbing attached frame (5); the steel structure climbing attached frame (5) is fixedly connected on the main stressed supporting steel beam (4) and is provided with a jacking cylinder (8) and a supporting steel beam (9); and a tower body supporting tread (10) is arranged on a tower body (1), and the bottom of the tower body (1) is provided with a climbing base section (11). The self-climbing tower crane can climb upward along a constructed structure by using the constructed building structure as a support, meet the requirements of superhigh-rise and out-of-code tall buildings on vertical transportation at the whole construction height, contribute to construction efficiency, construction period reduction, steel conservation and energy conservation and create obvious economic and social benefits.

Owner:CHINA CONSTR FOURTH ENG DIV

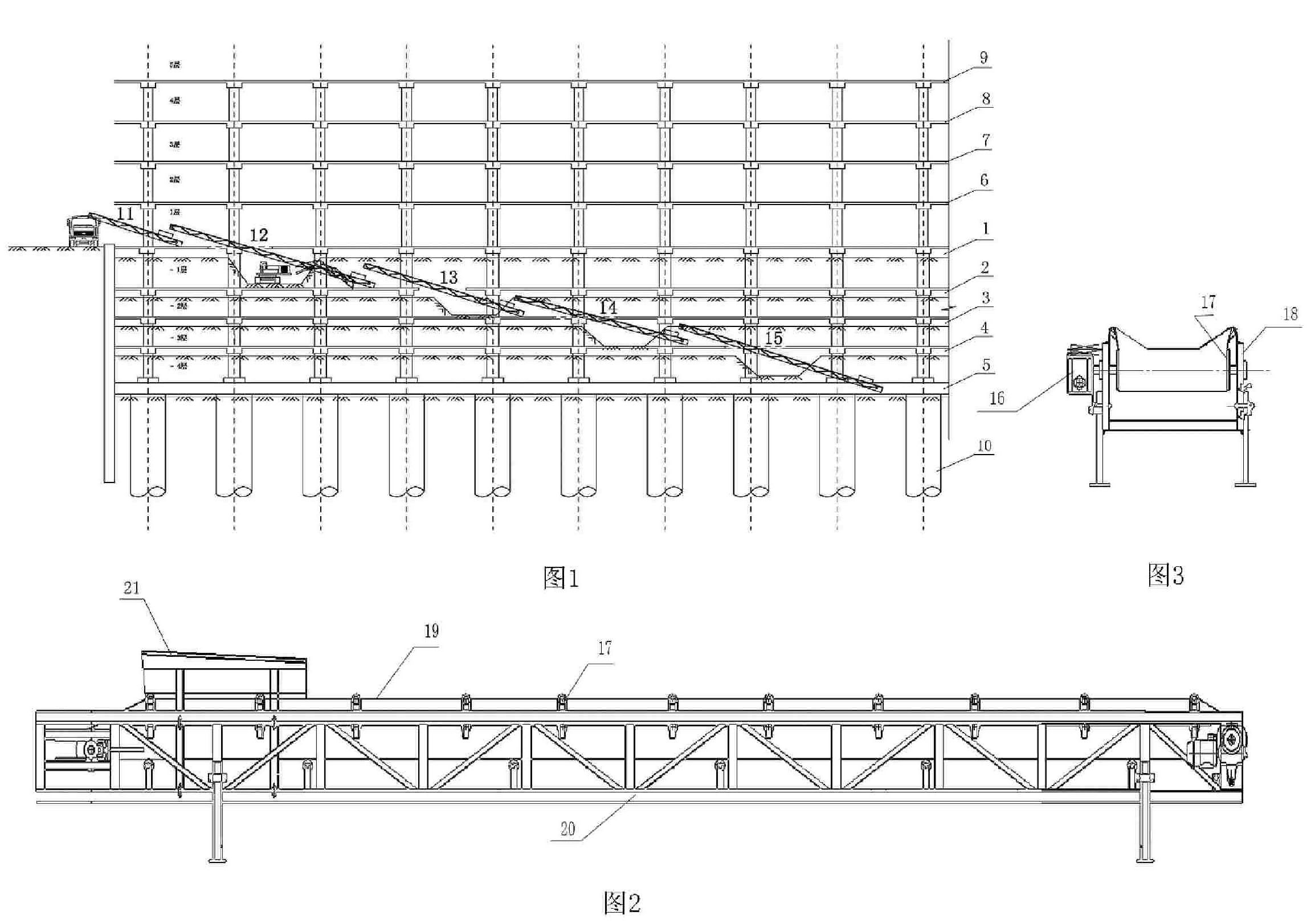

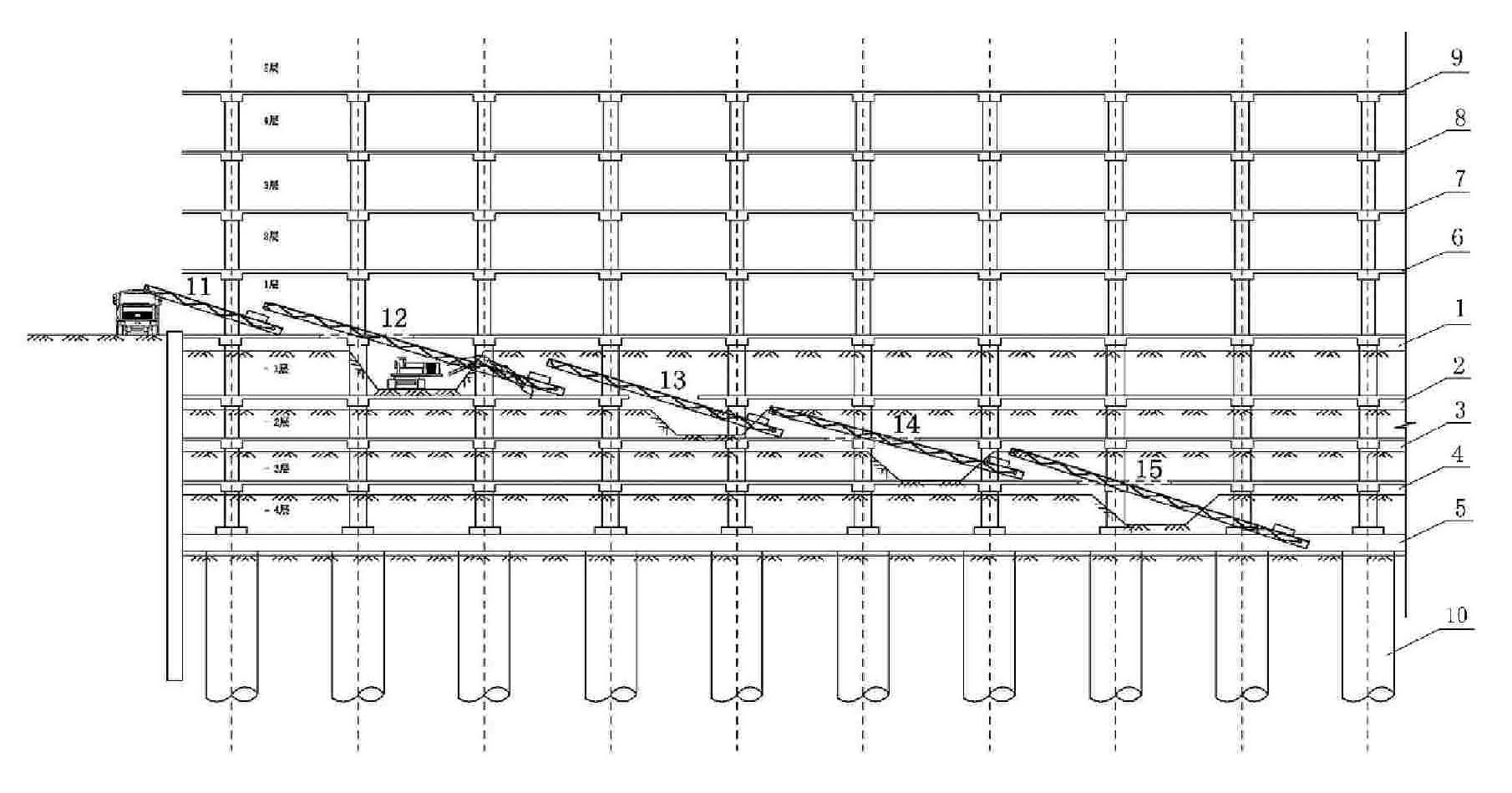

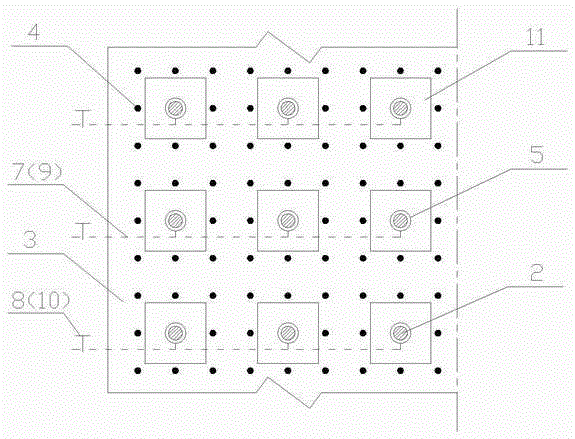

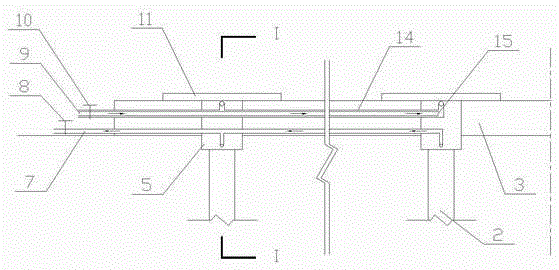

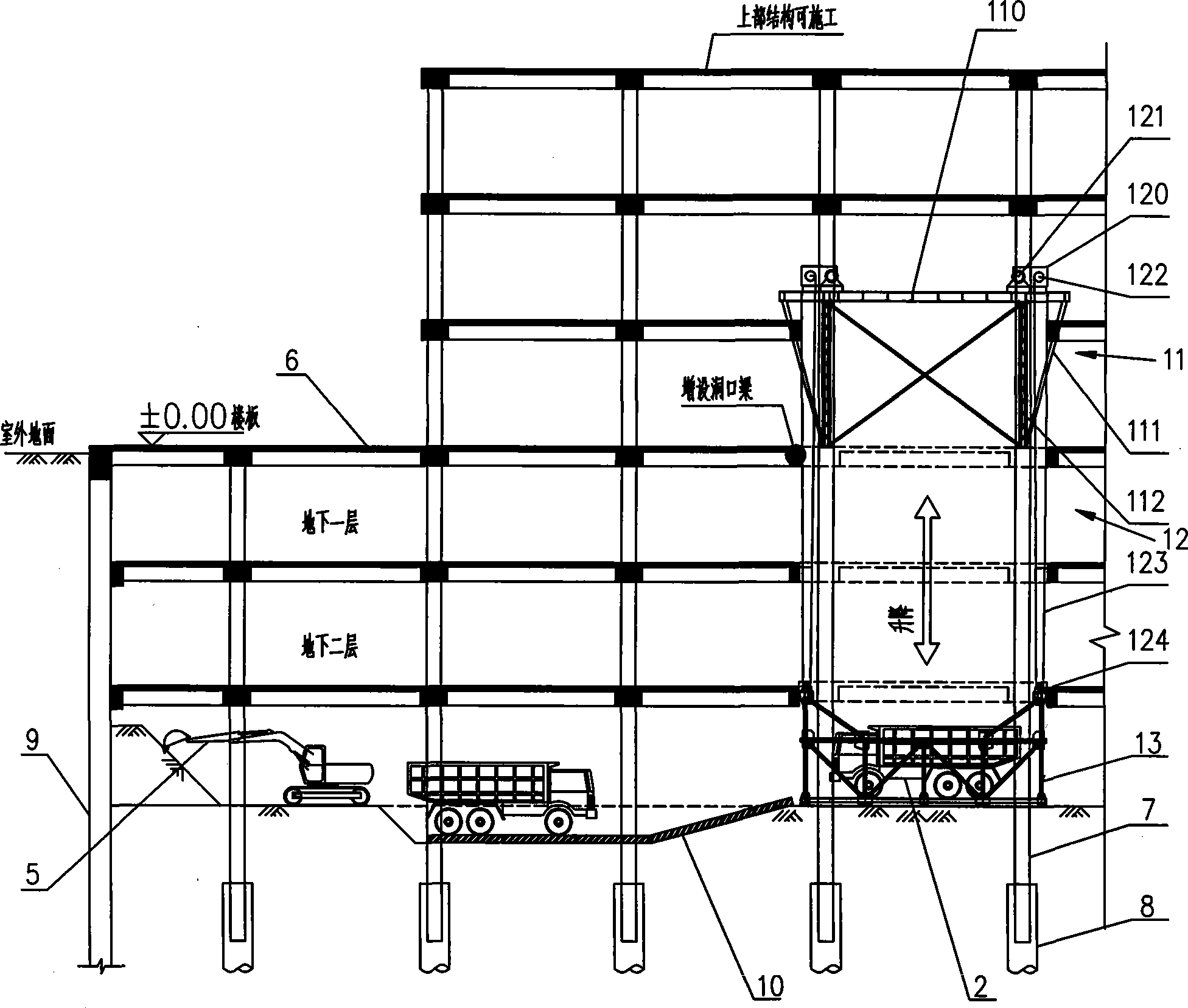

Device and method for vertically transporting earthwork by reverse construction method

InactiveCN101775821AImprove digging efficiencyReduce hole sizeSoil-shifting machines/dredgersExcavationsFloor slabConveyor belt

The invention relates to a device and a method for vertically transporting earthwork by a reverse construction method, which belong to the field of civil construction. In the device, segmental belt-type conveyor belts are adopted as earthwork transporting tools in a deep foundation pit; the conveyor belts pass through reserved holes of floor slabs on each floor; and the earthwork is transported to a dump truck obliquely from the bottom to the top by the conveyor belts. The device is formed by connecting independently segmented and obliquely arranged belt-type conveyor belts end to end; and each floor is provided with at least one conveyor belt which consists of an electric motor, a conveyor belt rack, an unloading tank, a scraping plate, a roller wheel, a roller wheel shaft bracket, a belt, a feeding funnel and an emergency brake device. The device and the method for vertically transporting the earthwork by the reverse construction method can effectively increase the earth volume in single vertical transport, effectively improve excavation efficiency, reduce excavation machines, reduce excavation cost, and simultaneously, reduce the influence of the construction of underground excavation on the simultaneous construction of an upper structure to the minimum.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

Steel pipe-batten plate combined building column and construction technology thereof

PendingCN107227822AReduce steel consumptionImprove economyStrutsBridge structural detailsReinforced concrete columnArchitectural engineering

The invention provides a steel pipe-batten plate combined building column and a construction technology thereof. The steel pipe-batten plate combined building column comprises a column skeleton and formworks detachably mounted outside the column skeleton, wherein the column skeleton comprises square steel pipes arranged at corners of the column skeleton and batten plates arranged between adjacent square steel pipes; the batten plates are arranged in the vertical directions of the square steel pipes according to certain intervals. The square steel pipes and the batten plates are combined to form the column skeleton, the steel pipe is arranged at each corner of the whole column skeleton, the formworks are arranged among the steel pipes, and then concrete is cast in place to form the steel-concrete combined column; the steel pipes are arranged at the corners of the column skeleton, while only batten plates are arranged at the middle positions of the column skeleton, so that when a beam is connected with an independent column, steel bars can freely extend into the column body and thus a fighting phenomenon of steel bars in the conventional reinforced concrete column is avoided; after the concrete is poured, a whole is formed, so that the rigidity in a node area is better.

Owner:SHANGHAI OPEN STEEL JOIST

Combined-type composite foundation with controllable rigidity piles, drainage materials and reinforced cushion

ActiveCN106759223AImprove stabilityReduce differential settlementSoil preservationSupporting systemPile cap

Disclosed is a combined-type composite foundation with controllable rigidity piles, drainage materials and a reinforced cushion. The reinforced cushion is laid on the surface of a soft soil foundation. The vertical drainage materials and the rigidity piles with caps are arranged in the foundation. Grouting tubes are installed between pile tops and the pile caps to form a controllable supporting system. When grouting is not conducted on the grouting tubes, drainage consolidation is conducted through the soft soil foundation under the effect of an upper load so as to improve the bearing capacity. The bearing effect of the rigidity piles is difficult to play due to the fact that the rigidity piles are stabbed into the grouting tubes. When the grouting tubes are grouted and after slurry is hardened, the pile caps, the slurry and the rigidity piles form a rigidity support, and the goal that the load is undertaken by the piles and soil together to reduce settlement is realized. Meanwhile, the reinforced cushion has the effects of restraining the horizontal displacement of the piles and the soil, limiting the local deformation of a dyke and a dam and the like. According to the composite foundation, the bearing force of the foundation soil can be given full play; the using amount of the rigidity piles is reduced; the stability of the foundation is improved; the post-construction settlement and differential settlement are reduced; the construction period is shortened; and the composite foundation can be applied to projects such as highways, railways and earth-rock dams.

Owner:WUYI UNIV

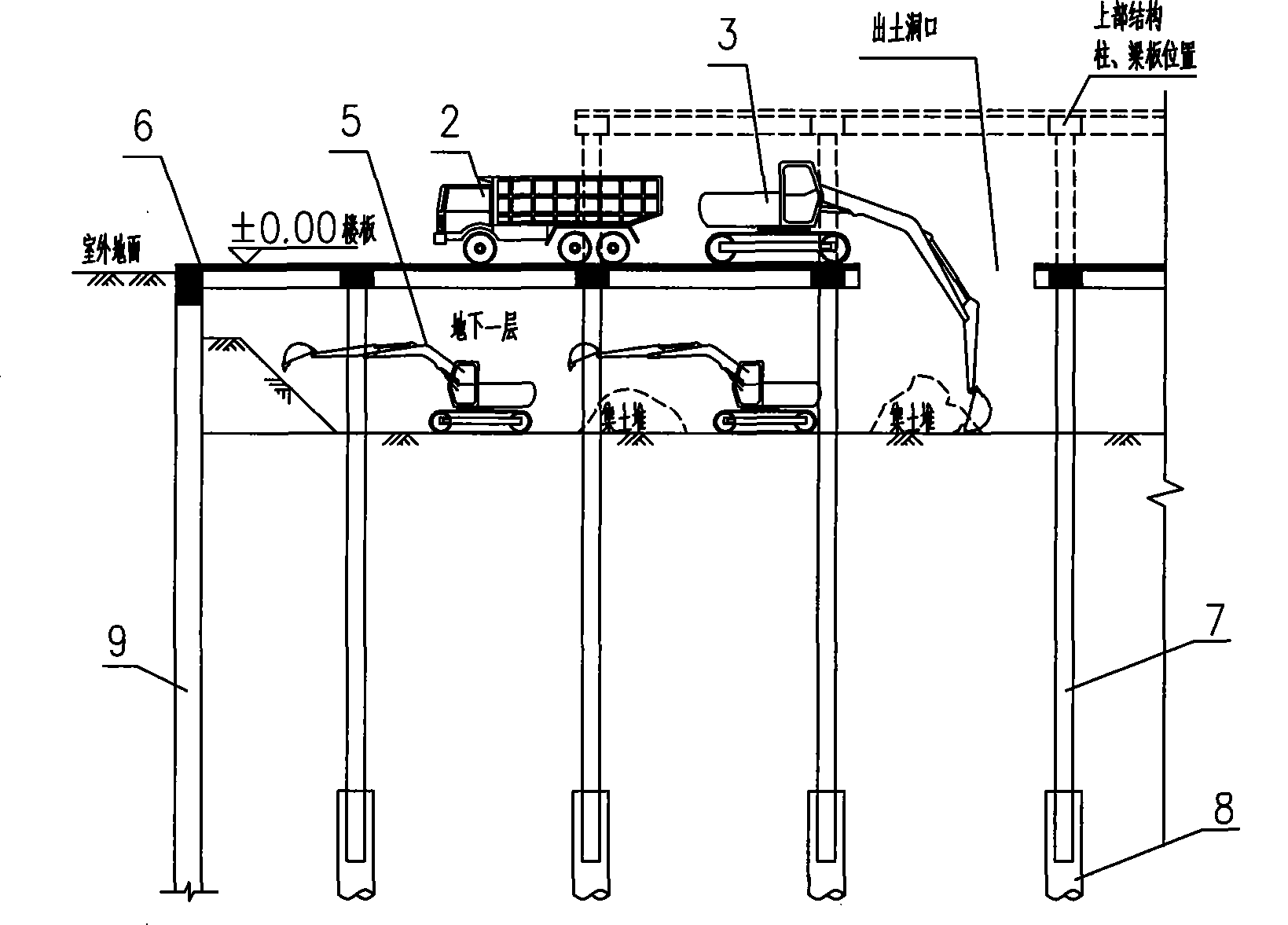

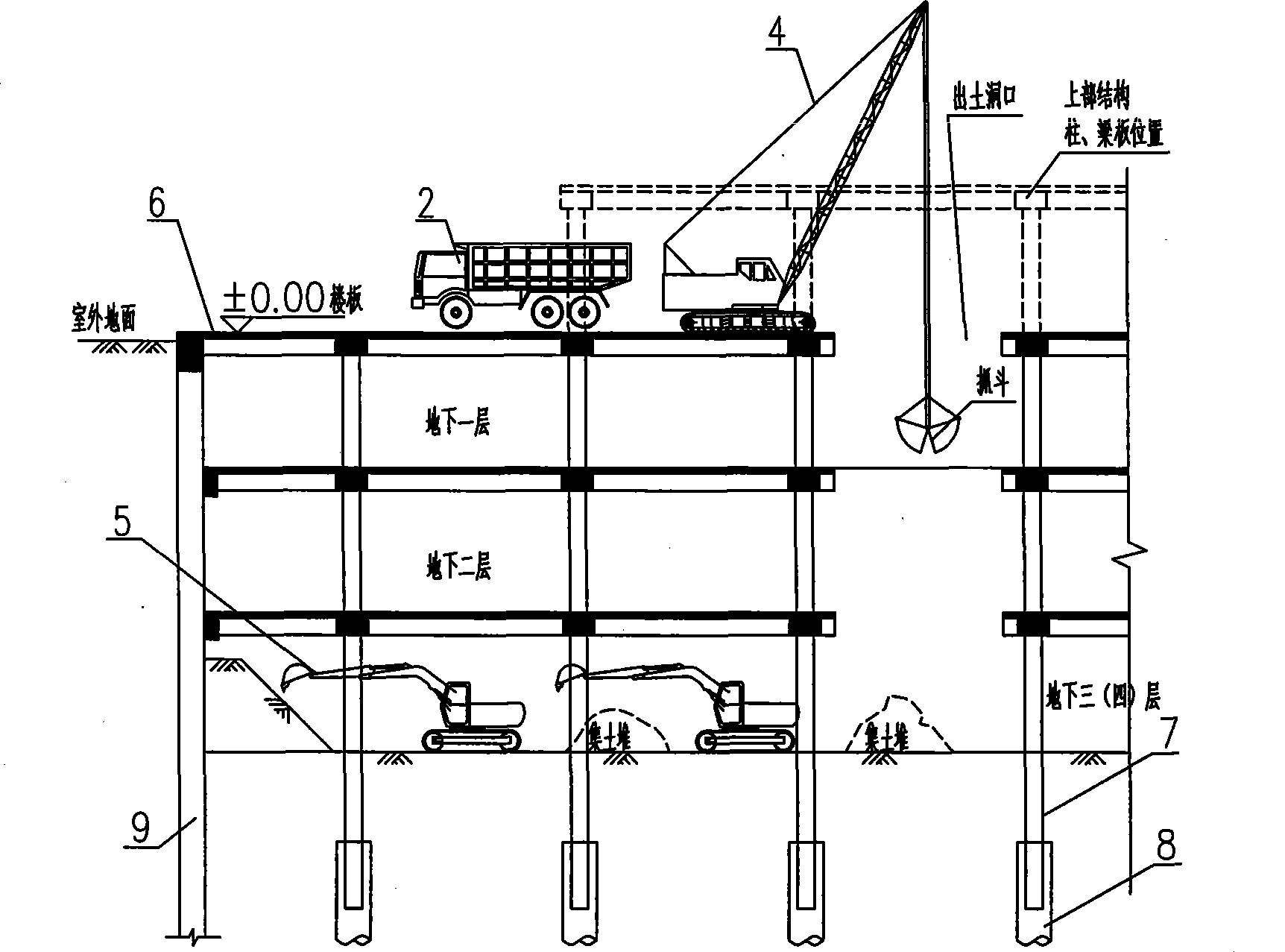

Elevator for deep foundation pit excavation by inverse construction method, and excavation system and method

InactiveCN101434358AAvoid smallReduce the process of digging and bargingExcavationsBuilding liftsBasementExcavator

The invention relates to the field of civil engineering construction, in particular to equipment, a system and a method used by deep foundation pit excavation construction, and discloses a lifter used by deep foundation pit excavation using a topdown construction method. The lifter comprises a bracket, a lifting mechanism and a lift car, wherein, the bracket is fixed on a basement top plate; the lifting mechanism is fixed on the bracket; the lift car is connected with the lower end of the lifting mechanism which drives the lift car to move up and down; and the lift car can load heavy construction vehicles. The invention also discloses a system and a method used by deep foundation pit excavation construction using the topdown construction method, which comprise heavy construction machinery, wherein, the heavy construction machinery comprises an earth transporting vehicle, an excavator excavating on the excavation working face of the bottom of the foundation pit as well as the lifter arranged on the basement top plate; and the heavy construction machinery realizes excavating, earth loading and earth transporting by the reciprocating transportation of the lifter between the basement top plate and the bottom of the foundation pit. The invention can effectively improve the excavation efficiency, reduce the excavation cost and reduce the influence of the underground excavation construction on the synchronous superstructure construction to the minimum.

Owner:SHANGHAI CONSTRUCTION GROUP

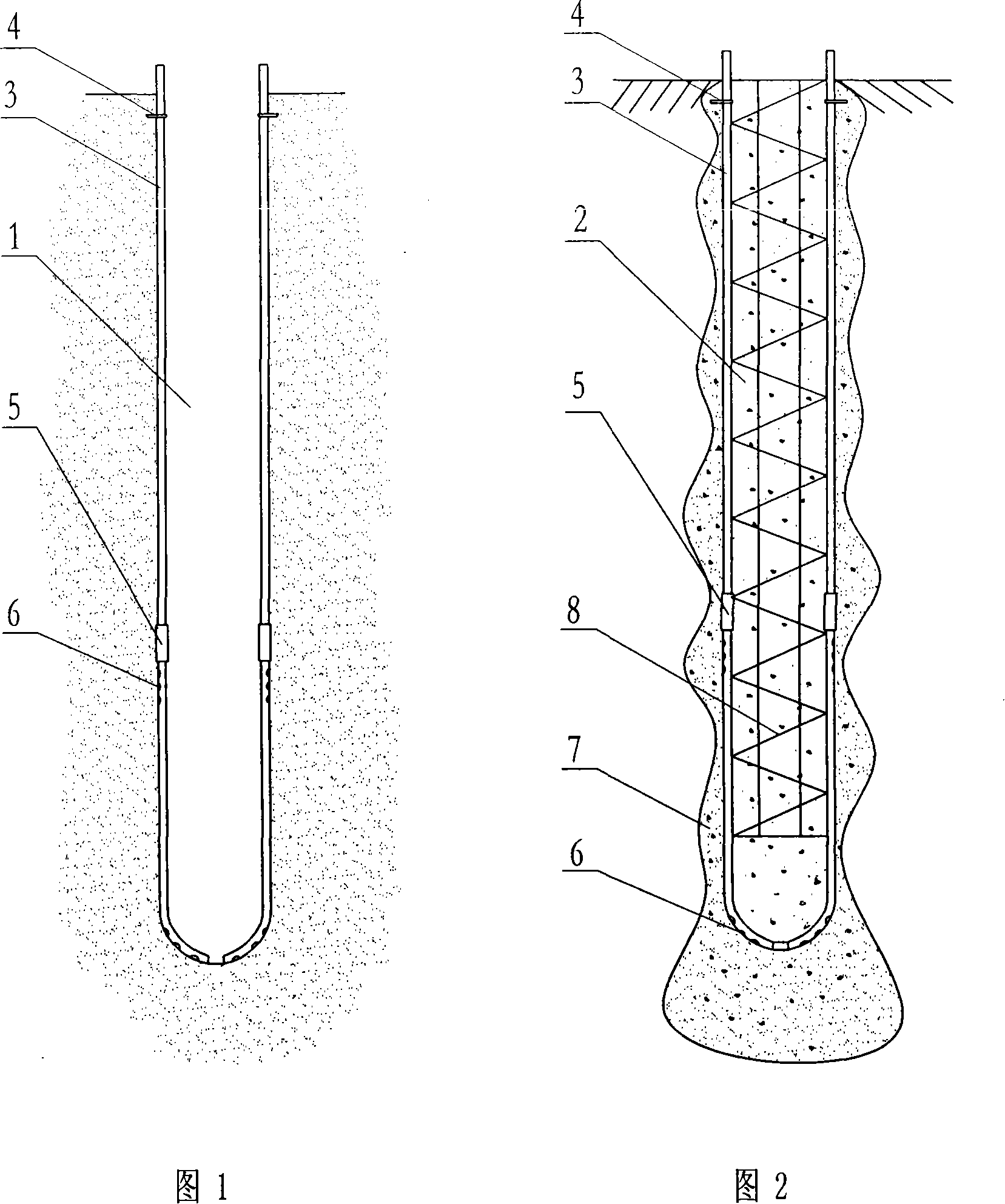

Construction method for increasing dry auger boring pouring pile bearing capacity

InactiveCN101148874AIncrease frictionImprove pile end bearing capacityBulkheads/pilesPressure groutingRebar

The construction process of raising the bearing capacity of auger boring pile includes setting two grouting pipes symmetrically beside the side wall of pile hole, setting reinforcing cage and grouting concrete with concrete pumping agent in 1-1.5 wt% of cement, and pressure grouting cement slurry with concrete pumping agent in 1 wt% of cement and concrete expanding agent in 5 wt% of cement in the pumping pressure of 200-300 kg / sq cm in 8-24 hr after filing until cement slurry overflows from the top end beside the pile. The process can raise the bearing capacity of the pile by over 1 time, reduce the length of the pile, save material, lower cost and reduce construction pollution.

Owner:李树源

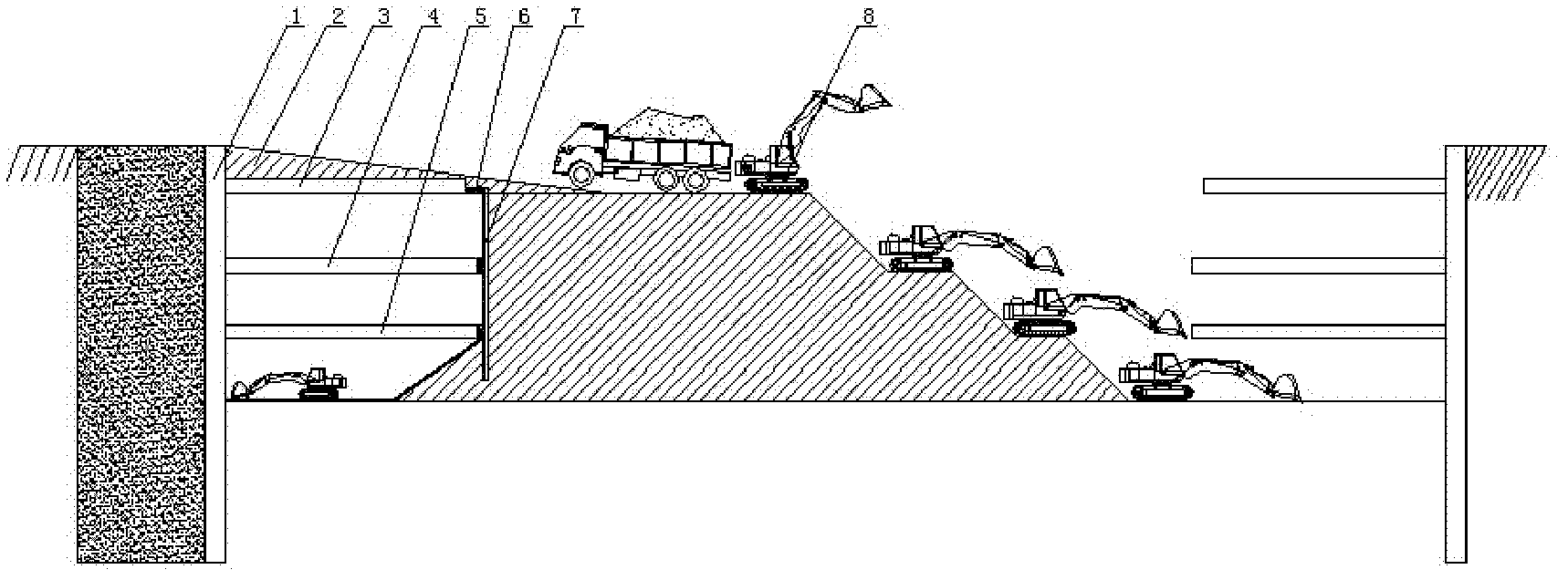

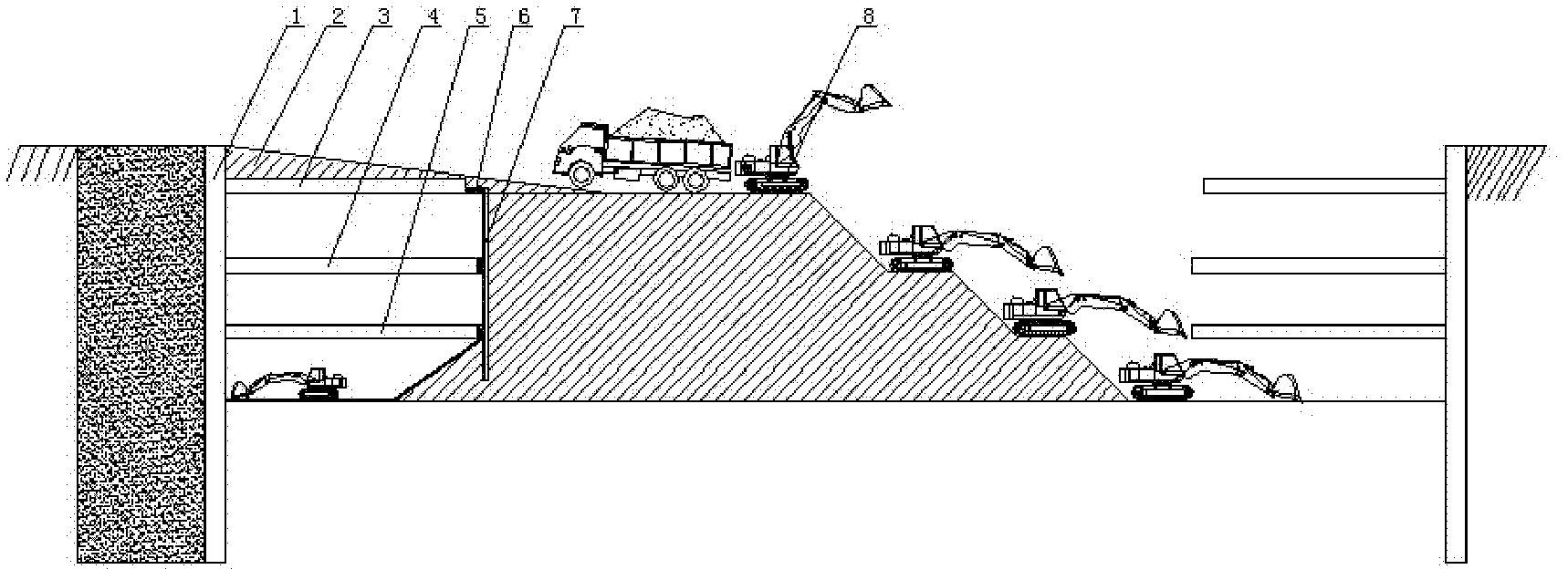

Deep foundation pit earthwork digging method

ActiveCN102425173AEnsure safetyAvoid repeated digging and fillingExcavationsBulkheads/pilesBuilding constructionSteel plates

The invention relates to a deep foundation pit earthwork digging method. The method comprises the following steps of: (1) after paying-off measurement of a deep foundation pit is finished, designing N layers of horizontal supporting steel plates according to the deep foundation pit engineering conditions in the deep foundation pit from top to bottom, and digging the foundation pit earthwork layerby layer by adopting an island type digging method, wherein N is more than or equal to 1 and less than or equal to 20; (2) downwards driving an outside steel plate pile along the wall of the deep foundation pit; and (3) digging the earthwork above the first layer of horizontal supporting steel plate, welding one end of the first layer of horizontal supporting steel plate to the outside steel plate pile, downwards driving an inside steel plate pile at the other end of first layer of the horizontal supporting steel plate and the like, constructing the Nth layer of horizontal supporting steel plate, building a ramp, digging the earthwork below the Nth layer of horizontal supporting steel plate, regressing, digging the ramp, removing the inside steel plate pile, digging the rest earthwork, and thus finishing digging the earthwork of the deep foundation pit. The construction method is simple and feasible; a trestle is not required, the construction period is effectively quickened, and the digging cost of the earthwork of the deep foundation pit is reduced; and the deep foundation pit earthwork digging method is safe and reliable.

Owner:MCC TIANGONG GROUP

Construction method for going through subway station by double circular shielding

A construction method for passing the dual-circle shield machine the subway station includes such steps as earlier stage preparation, installing movable base, putting the dual-circle shield machine on the base, temporary fixing, installing two 200-ton jacks behind said dual-circle shield machine, welding the back-base to the preburied bottom plate of station, pushing the dual-circle shield machine along with its base forward by 3 m, restoring the jacks, arranging a supporter between jack and back-base, and repeating said steps.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

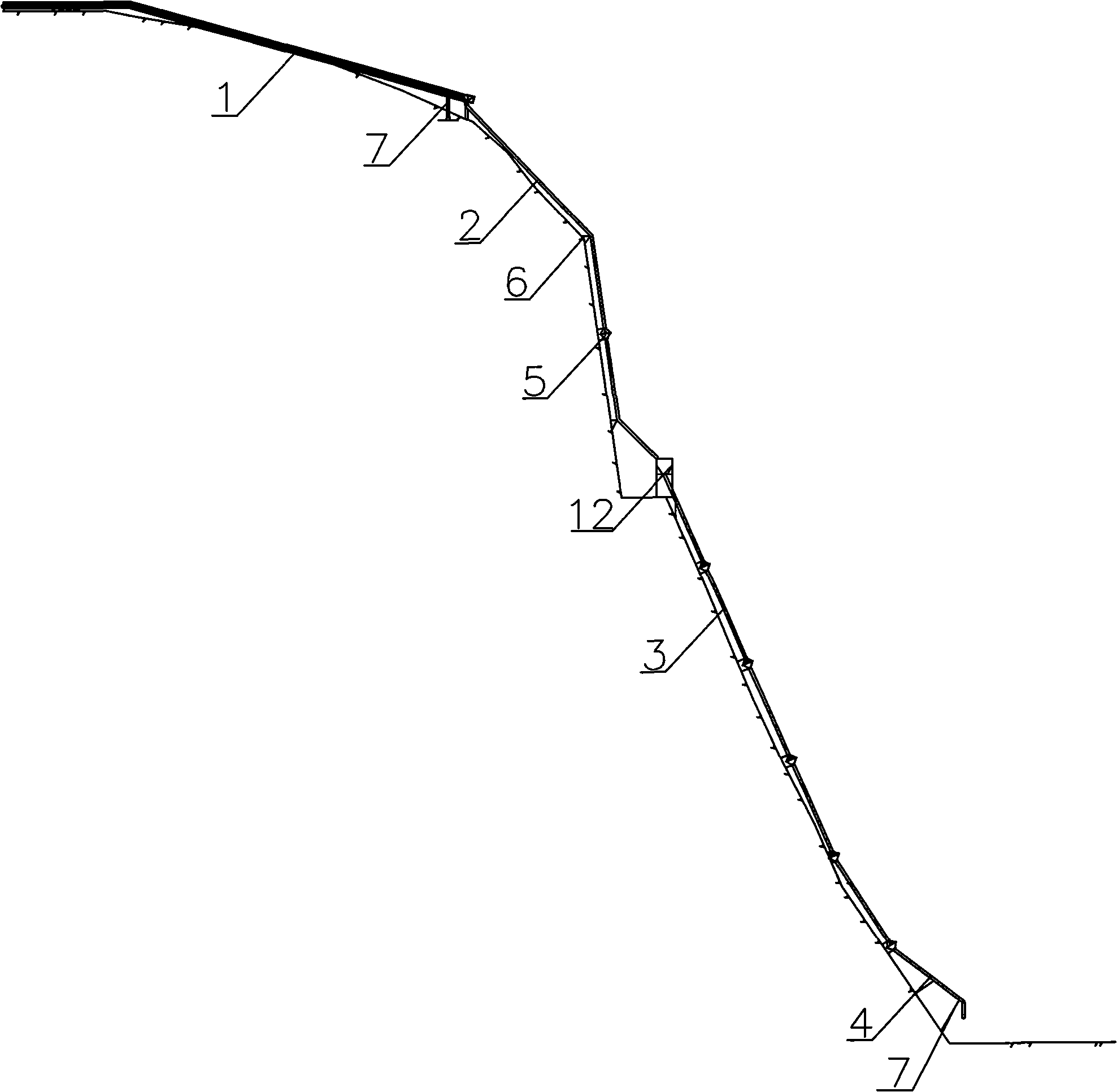

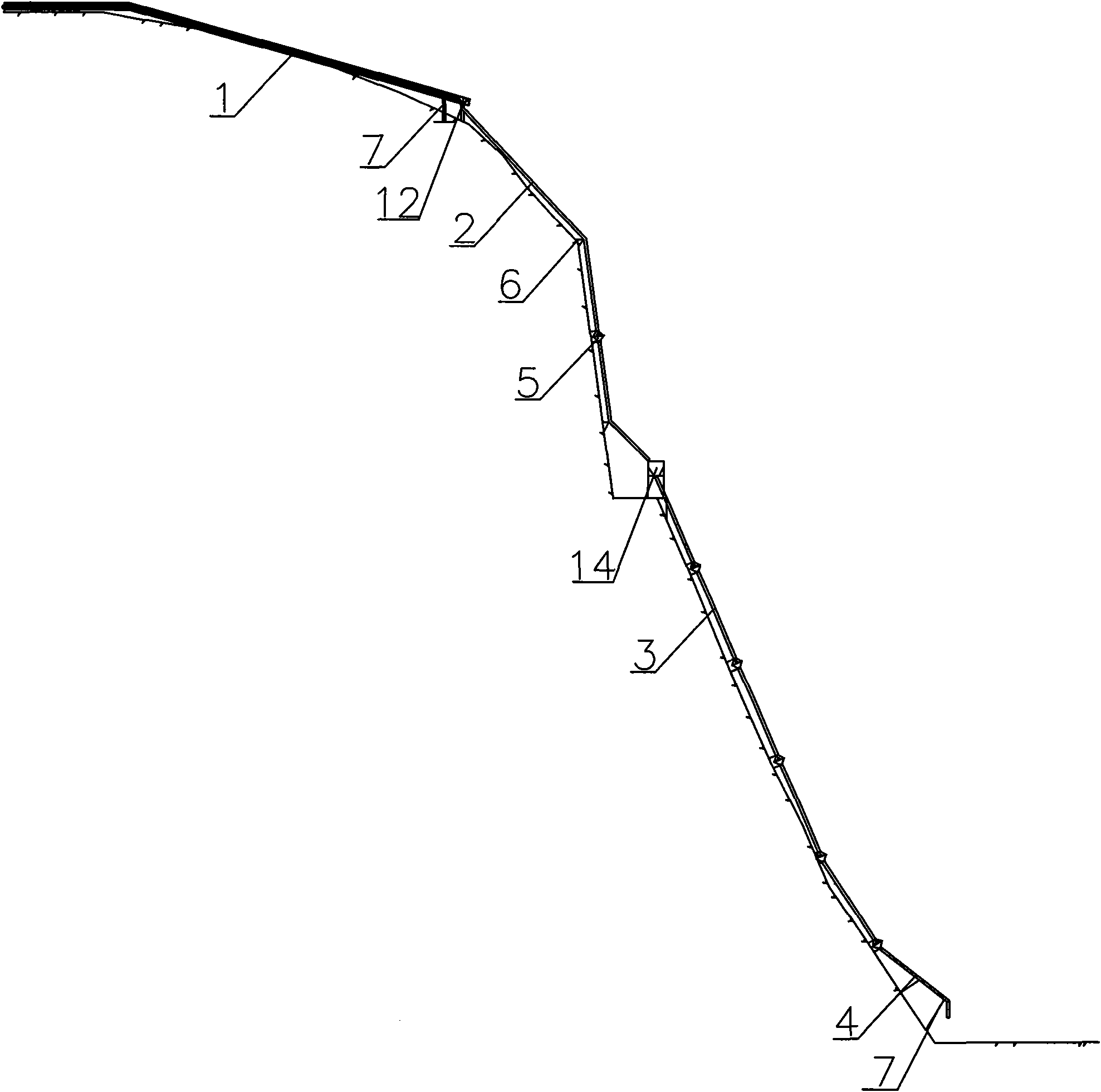

High-slope large-scale steel penstock mounting and unloading device and steel penstock mounting method

ActiveCN106151682ASolve the difficulty of installationSimple structural designPipe laying and repairTerrainPenstock

The invention discloses a high-slope large-scale steel penstock mounting and unloading device which comprises a trolley with a rotary part, a rail and a traction device for dragging the trolley. A high-slope large-scale steel penstock mounting method comprises the following steps: (1) carrying out foundation measurement and rail laying; (2) designing and arranging the traction device; (3) manufacturing and mounting the trolley and carrying out a load test; (4) transporting steel penstocks to unloaded positions; (5) swerving the trolley and the steel penstocks; (6) unloading the steel penstocks at a first abrupt slope section; (7) swerving the trolley and the steel penstocks at a gentle slope plane; (8) unloading the steel penstocks at a second abrupt slope section; (9) putting the steel penstocks in position; and (10) disassembling and moving out the trolley. According to the high-slope large-scale steel penstock mounting and unloading device and the high-slope large-scale steel penstock mounting method, the technological problems including laying of the rail and the traction device for mounting the steel penstocks at a complicated massif terrain, design of the mounting and unloading device, horizontal transportation, right-angle swerving, unloading in a high-slope, plane swerving and in-position unloading of the steel penstocks can be solved, construction is safe and efficient, and economy and practicality are realized.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

Large-span self-anchored suspension bridge hoisting construction method and temporary tower-girder anchoring device

InactiveCN104652285ASave on Interference FeesReduce risk factorBridge erection/assemblyHorizontal forceSteel frame

The invention provides a temporary tower-girder anchoring device. One end surface of a first grid is arranged opposite to one end surface of a second grid, so that acting surfaces of force transfer supports are formed; the two oppositely arranged end surfaces of the first grid and the second grid are supported by the force transfer supports to transfer force, so that horizontal force applied on a side span girder can be transferred to a bridge tower in the process of construction; a jack is mounted in a telescopic sleeve composed of an inner barrel and an outer barrel, one end of the jack is fixedly connected with a steel frame arranged on the end of the outer barrel far from the inner barrel, and an oil tube of the jack enters the outer barrel through an oil tube port arranged on the sidewall of the outer barrel. A large-span self-anchored suspension bridge hoisting construction method adopting the temporary tower-girder anchoring device transfers the horizontal force applied on the side span girder to the bridge tower by means of the temporary tower-girder anchoring device in the process of construction.

Owner:CHANGAN UNIV

Vertical concrete conveying system of small and medium hydropower station at high steep slopes

InactiveCN101812845ASolve shipping problemsReduce displacementFoundation engineeringSteep slopeHead drop

The invention discloses a vertical concrete conveying system of a small and medium hydropower station at high steep slopes, relating to a concrete conveying system. Through flexibly combining a belt conveying section, a chute conveying section, a chute barrel conveying section and an upright post chute conveying section, the concrete conveying system solves the problems of concrete conveying under the environment of large angles, great head drops and high steep slopes, and is in particular suitable for a concrete conveying task of a project in high-mountain gorge zones. Through improvement on the technology of the conventional concrete vertical conveying, the concrete vertical conveying system saves the materials, shortens the construction periods, reduces the construction difficulty and ensures the construction security.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

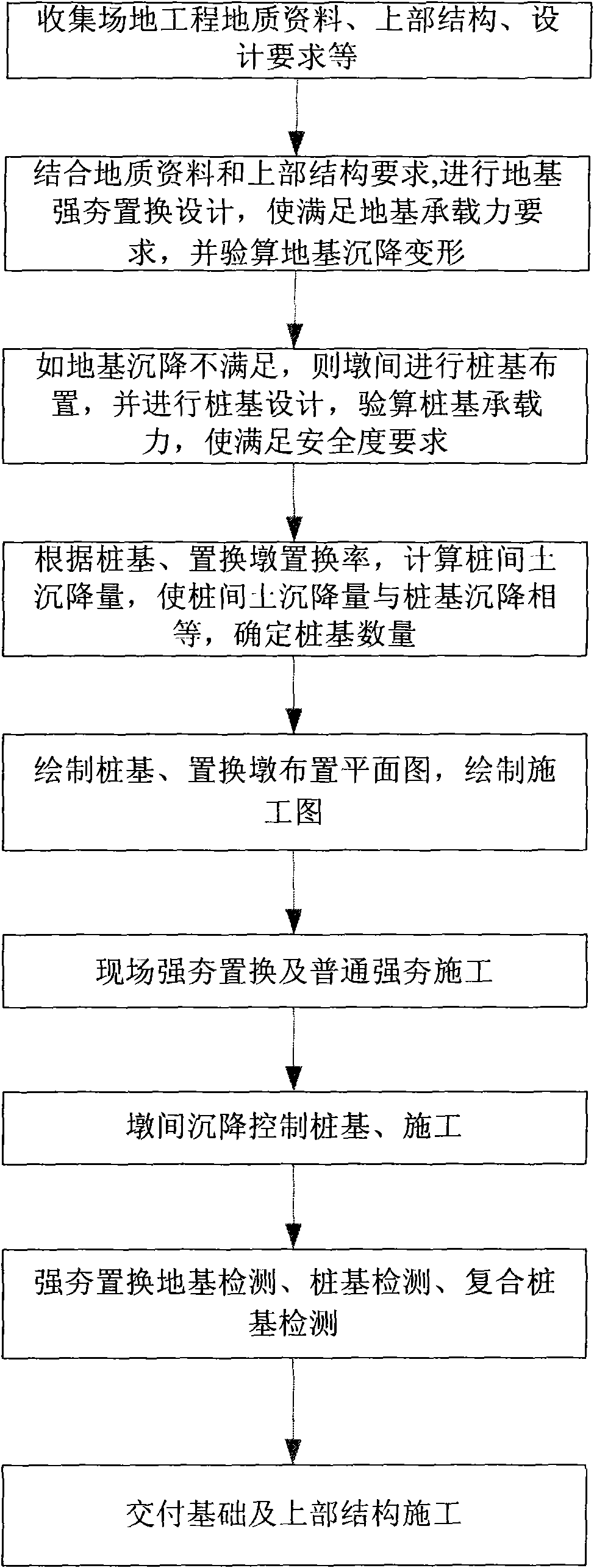

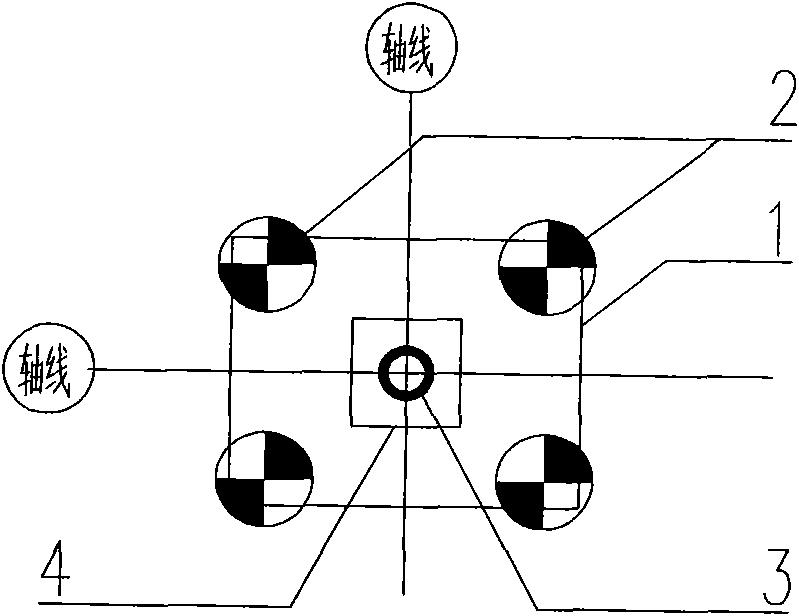

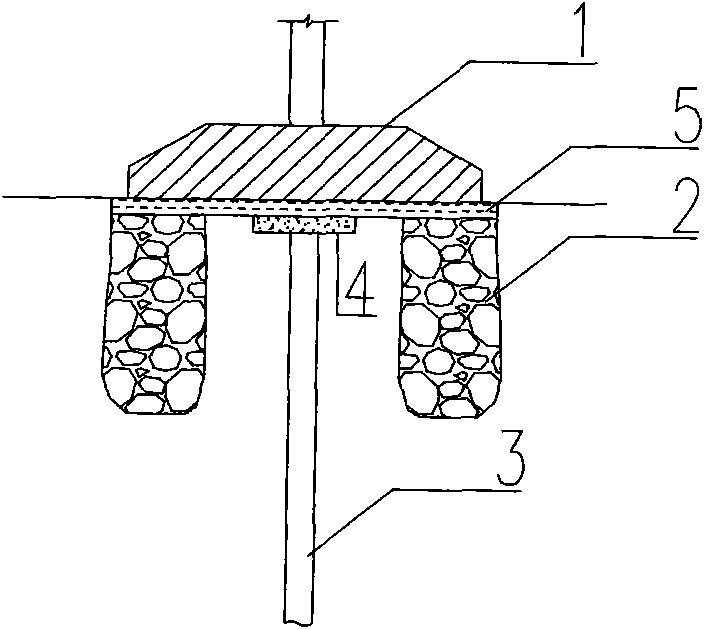

Method for processing long-pile short-pier composite foundation

InactiveCN101591903ALow costSpeed up the construction periodBulkheads/pilesSoil preservationCut and fillEngineering

The invention relates to a method for processing a long-pile short-pier composite foundation, which sets pier-changing and inter-pier pitching piles in the foundation to satisfy the foundation bearing capacity and deformation requirements, performs pier setting mainly through a forced ramming or forced ramming displacement method, and sets sedimentation control piles between the piers. The principle of displacing pier distribution points comprises the following steps: symmetrically setting one or more displacement points for changing the piers in the length direction of an independent foundation, and setting the sedimentation control piles between the displacement points as the inter-pier pitching piles; evenly setting a plurality of displacement points for changing the piers in the length direction of a strip foundation, and arranging the sedimentation control piles between the displacement points according to the designed separation distance; and on the basis of a large size, calculating the required displacement ratio of rectangular or quincuncial distribution points for the displacing pier distribution points according to the bearing capacity, calculating the required pile number for the sedimentation control piles according to sedimentation, and arranging the piles according to rectangular or quincuncial shapes between the displacing piles. The method has the advantages of manufacturing cost saving, mature construction experience, simple process and remarkable effect, and economically and effectively solves the problems that the bearing capacity of deep made ground or a soft soil foundation is insufficient and the foundation deformation is large and uneven.

Owner:上海现代建筑设计(集团)有限公司 +2

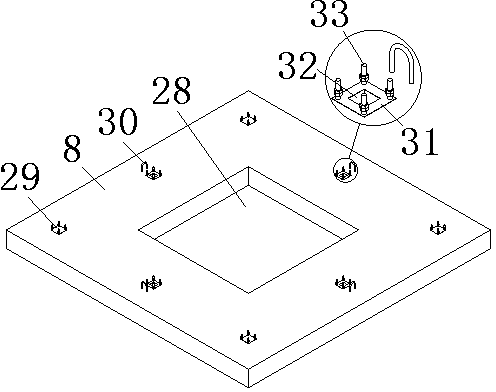

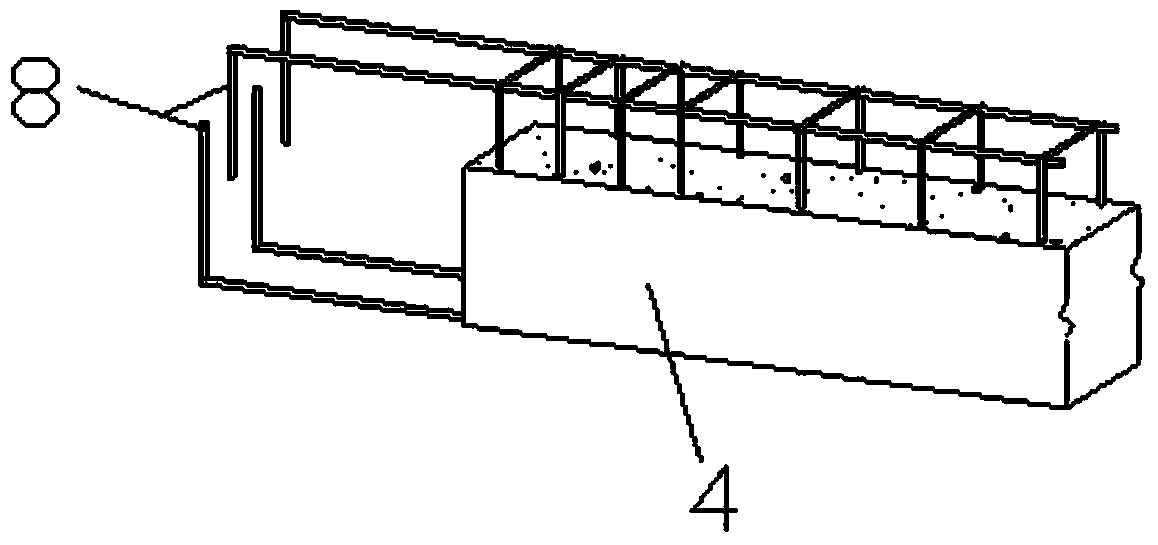

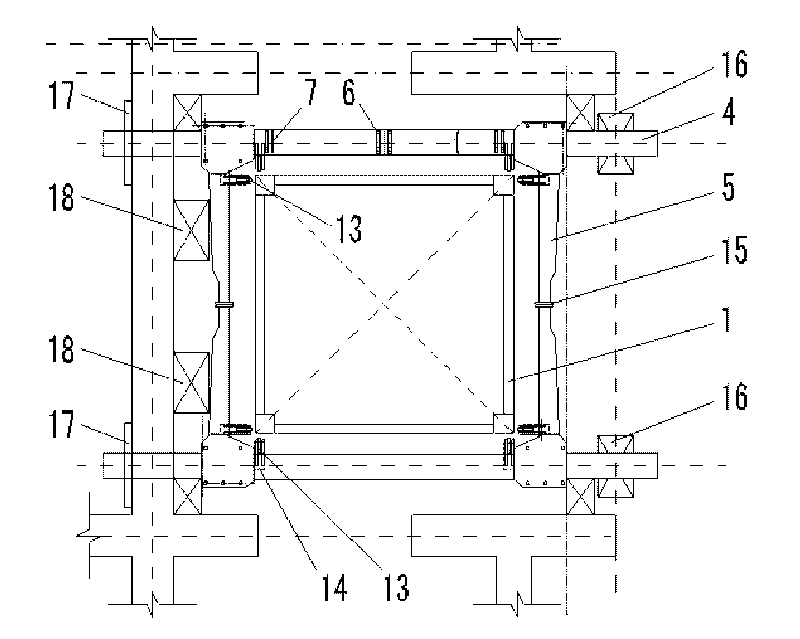

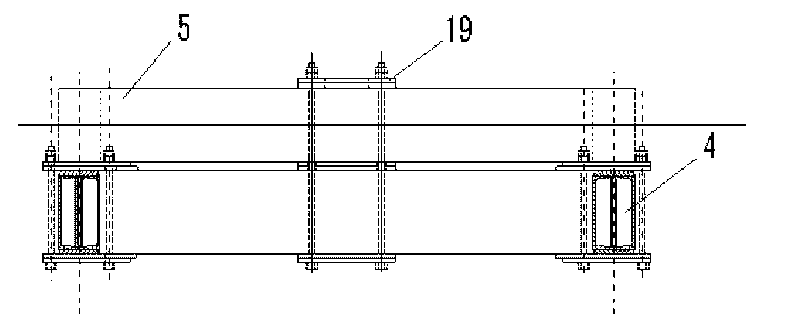

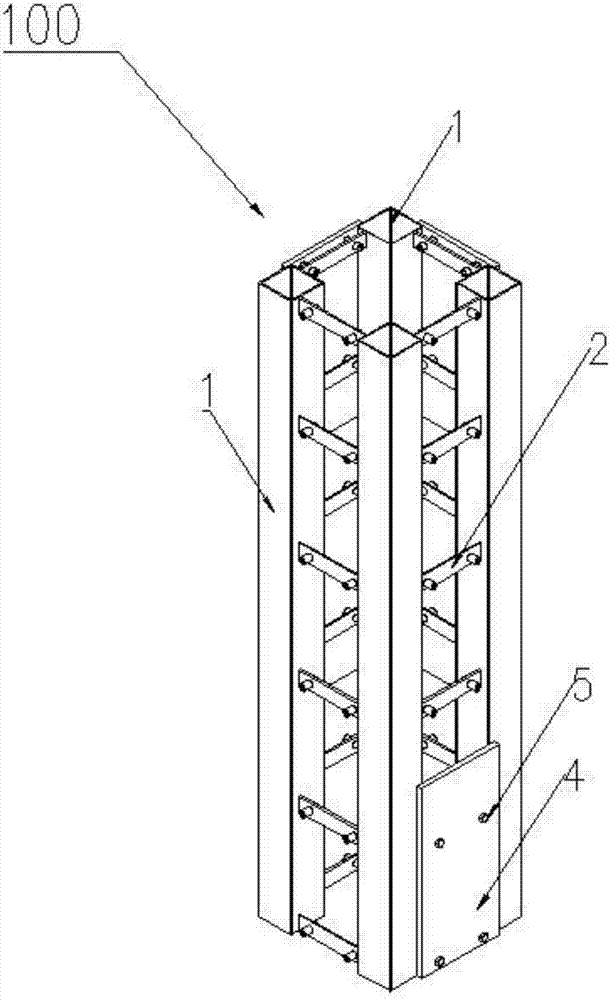

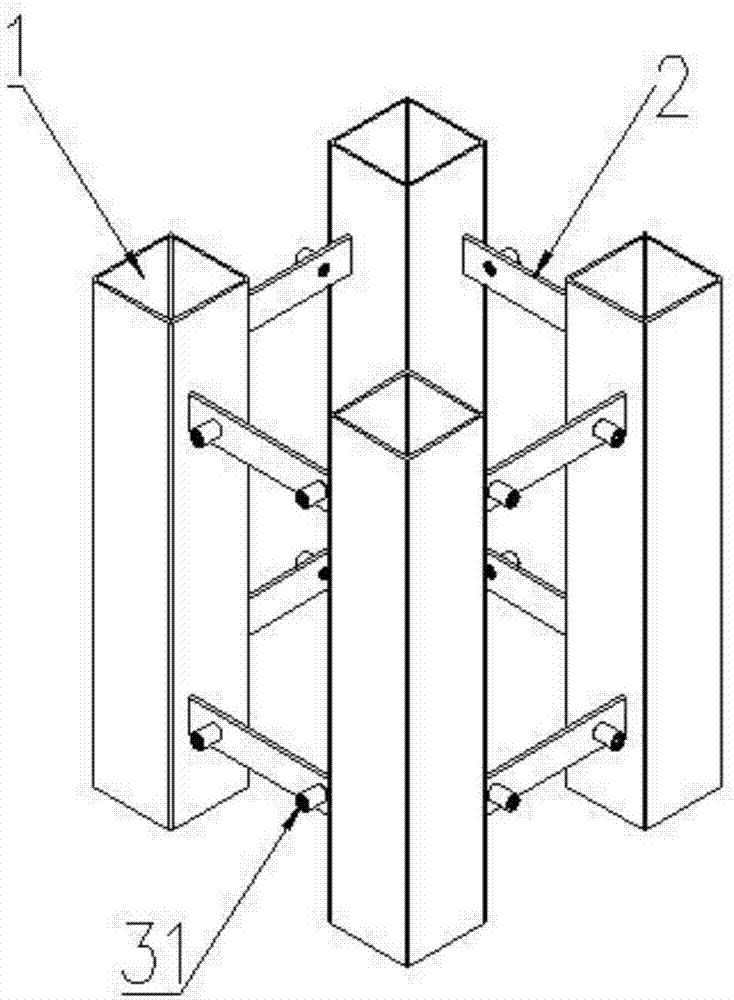

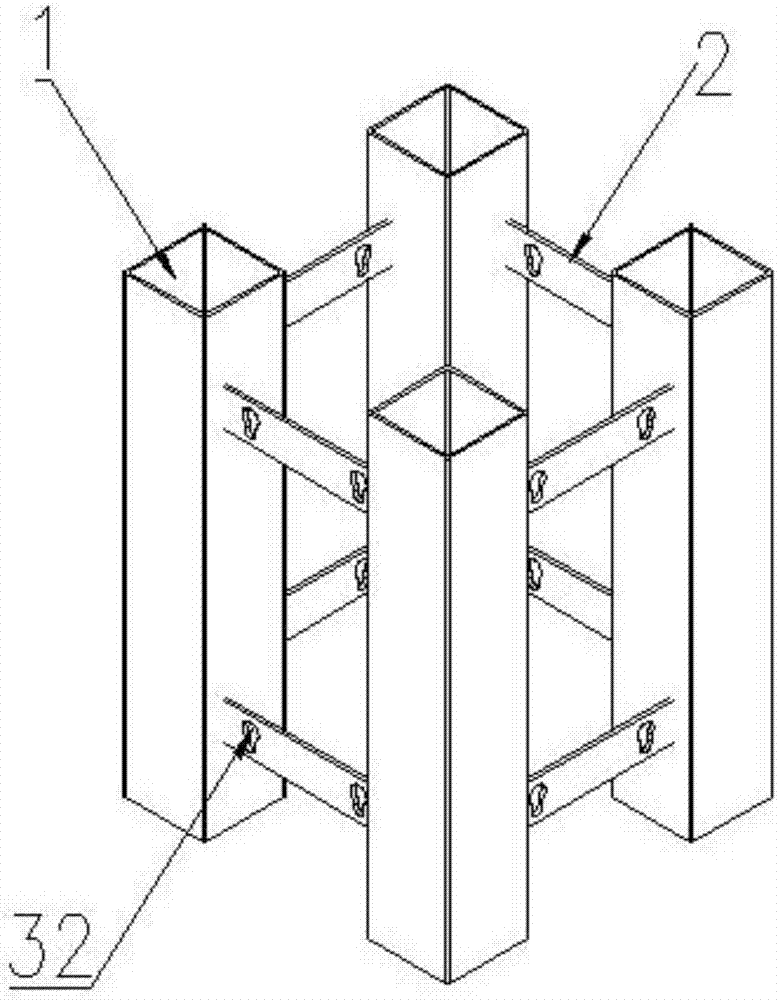

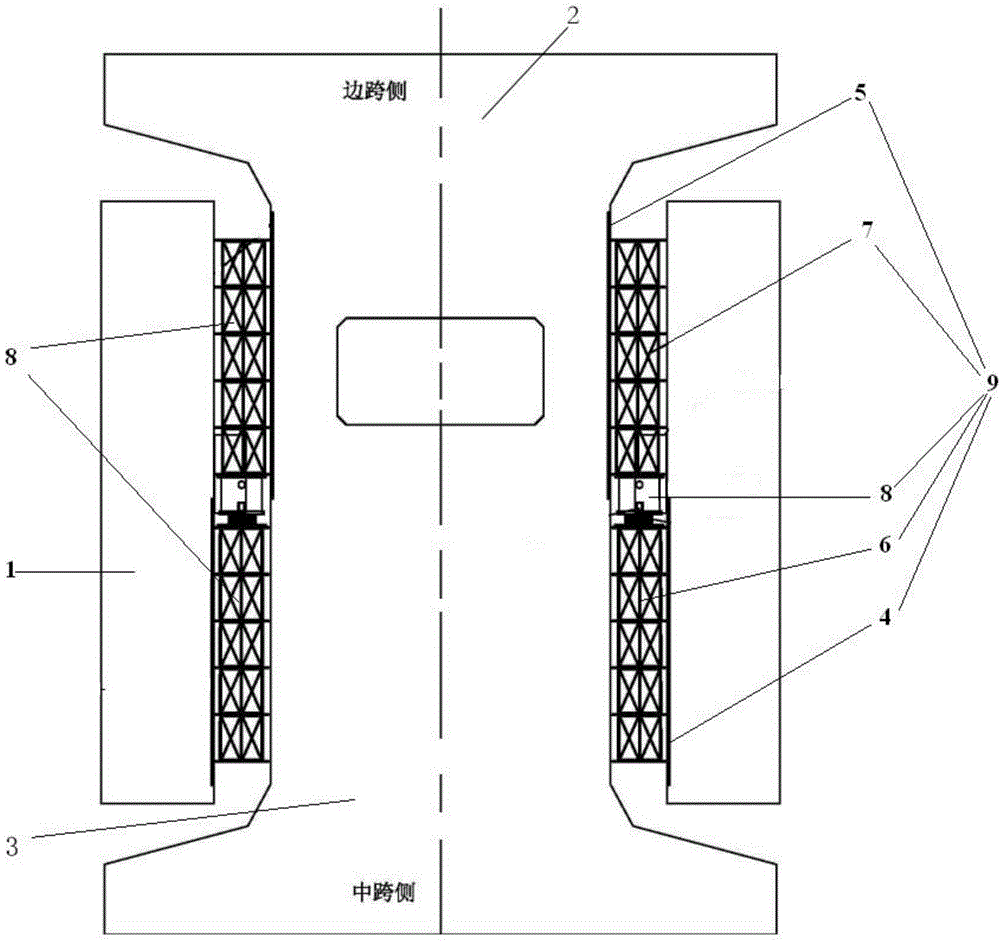

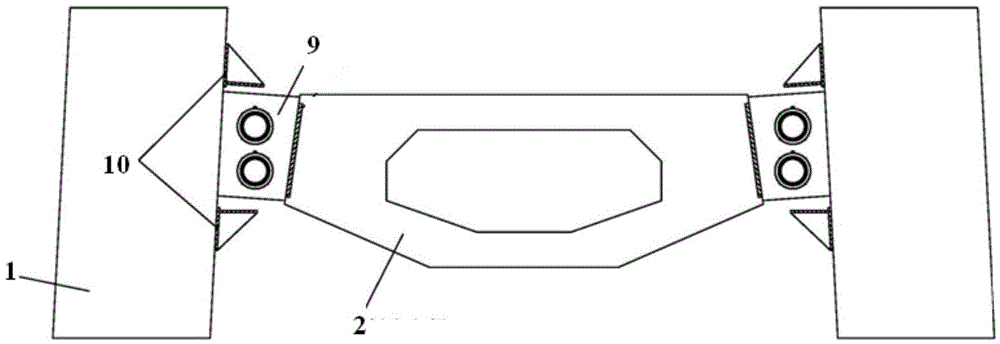

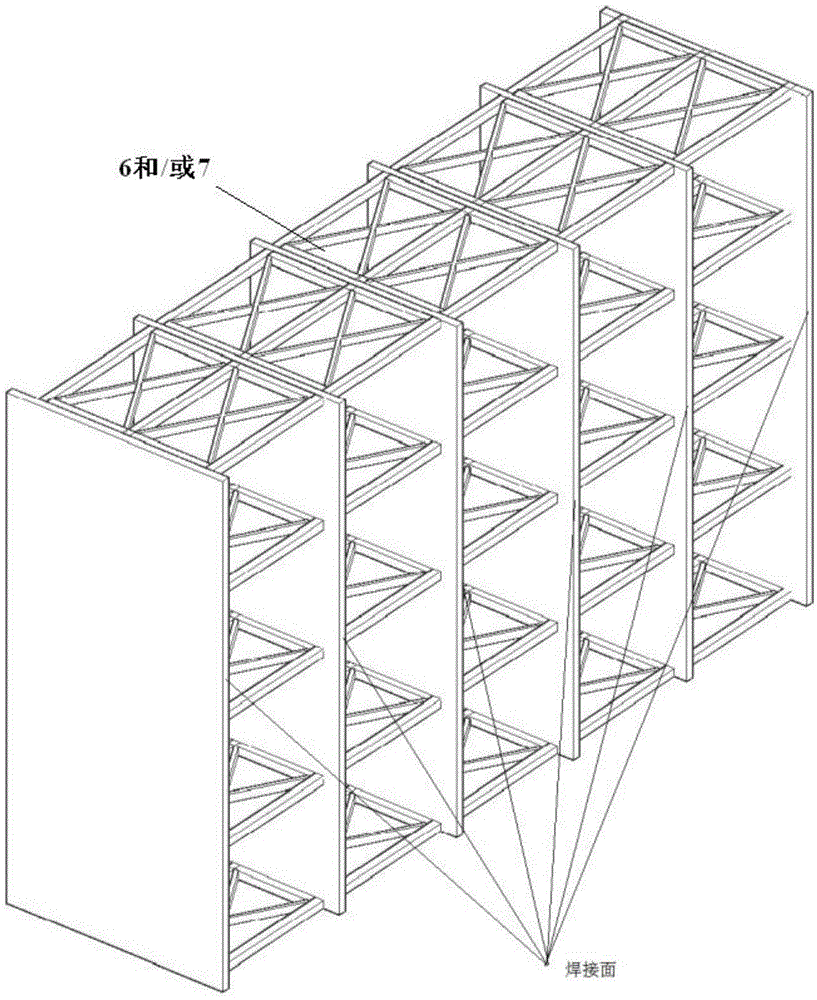

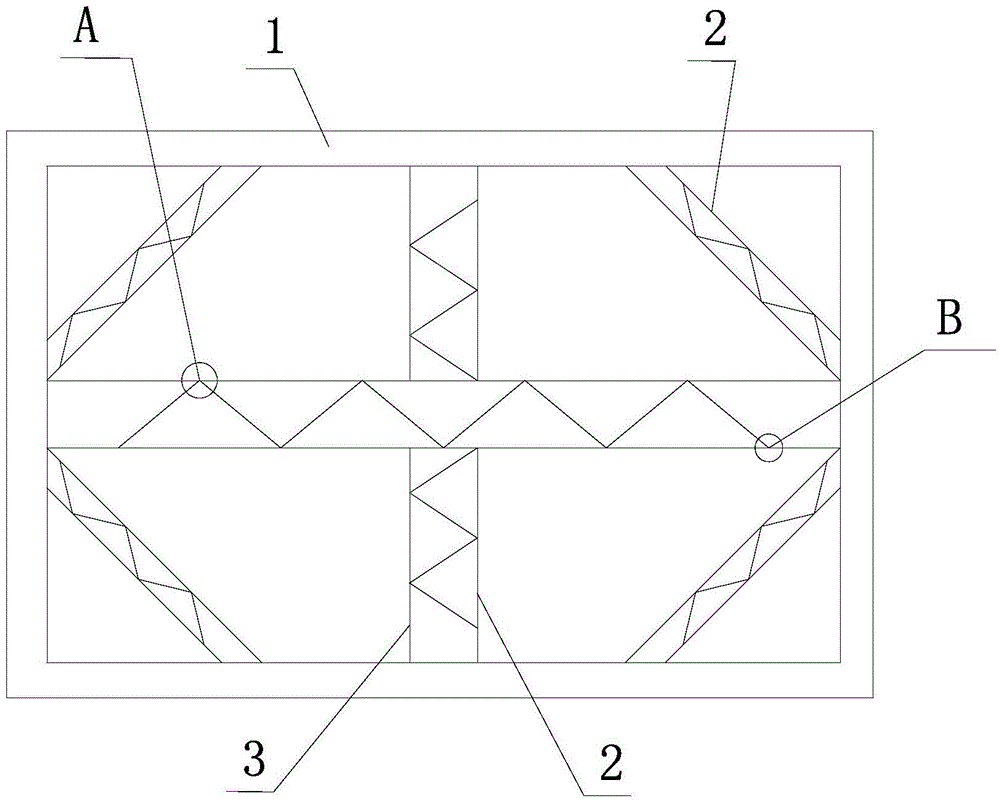

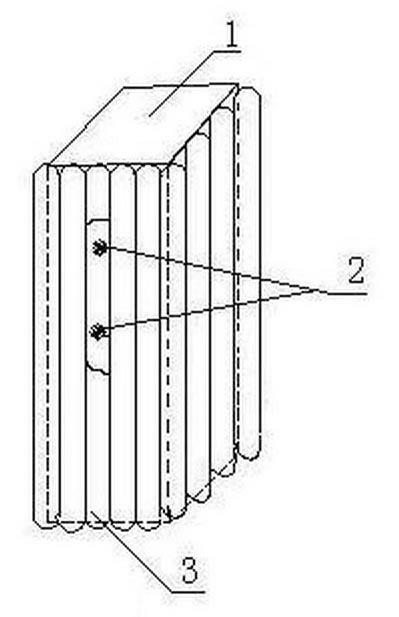

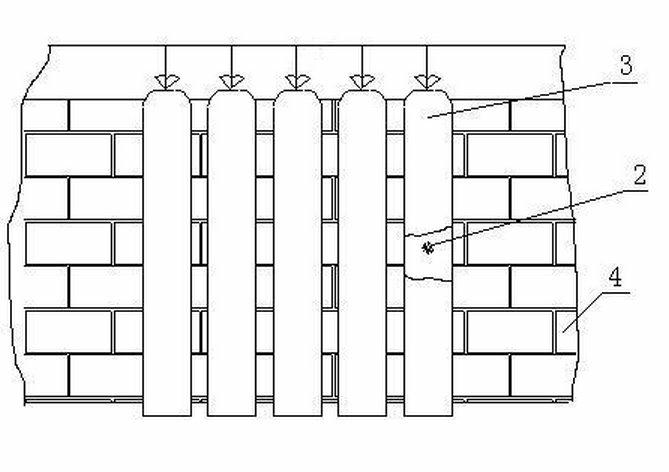

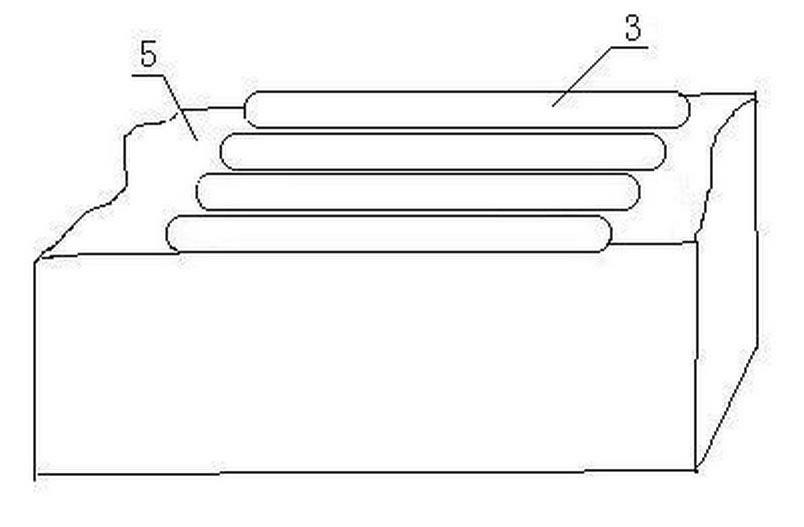

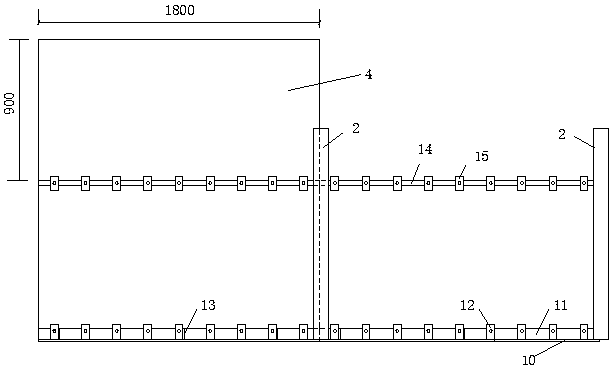

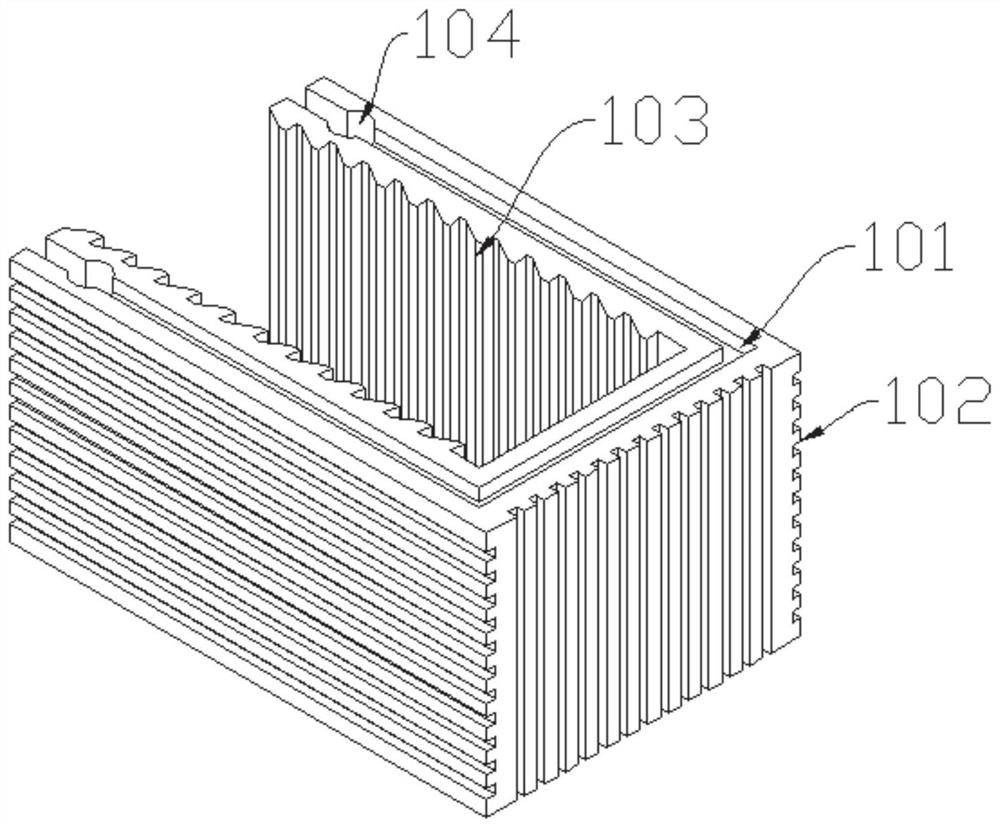

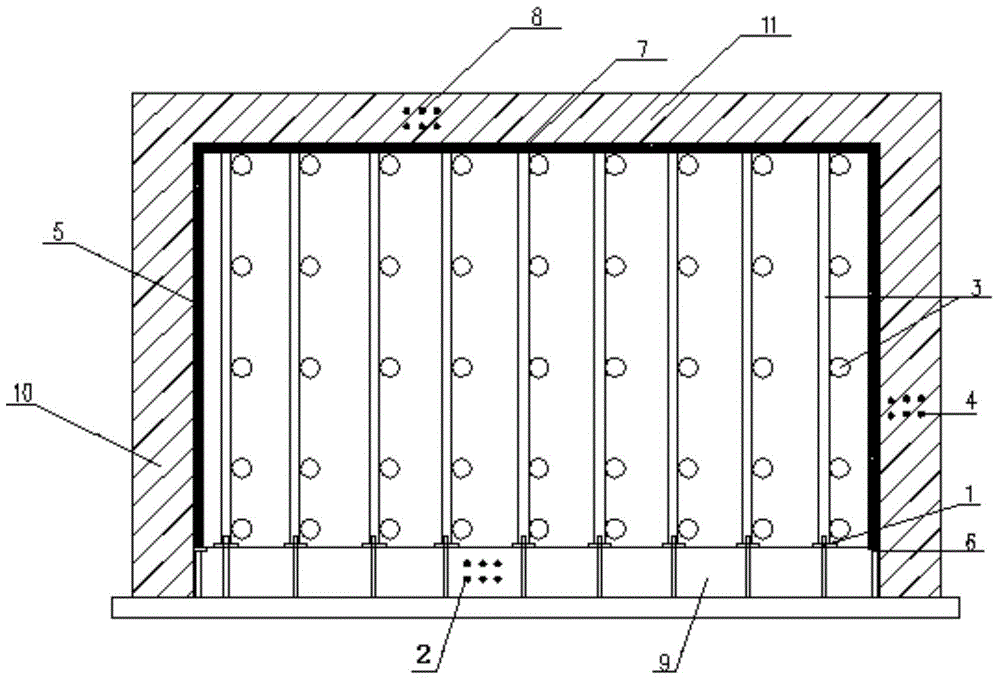

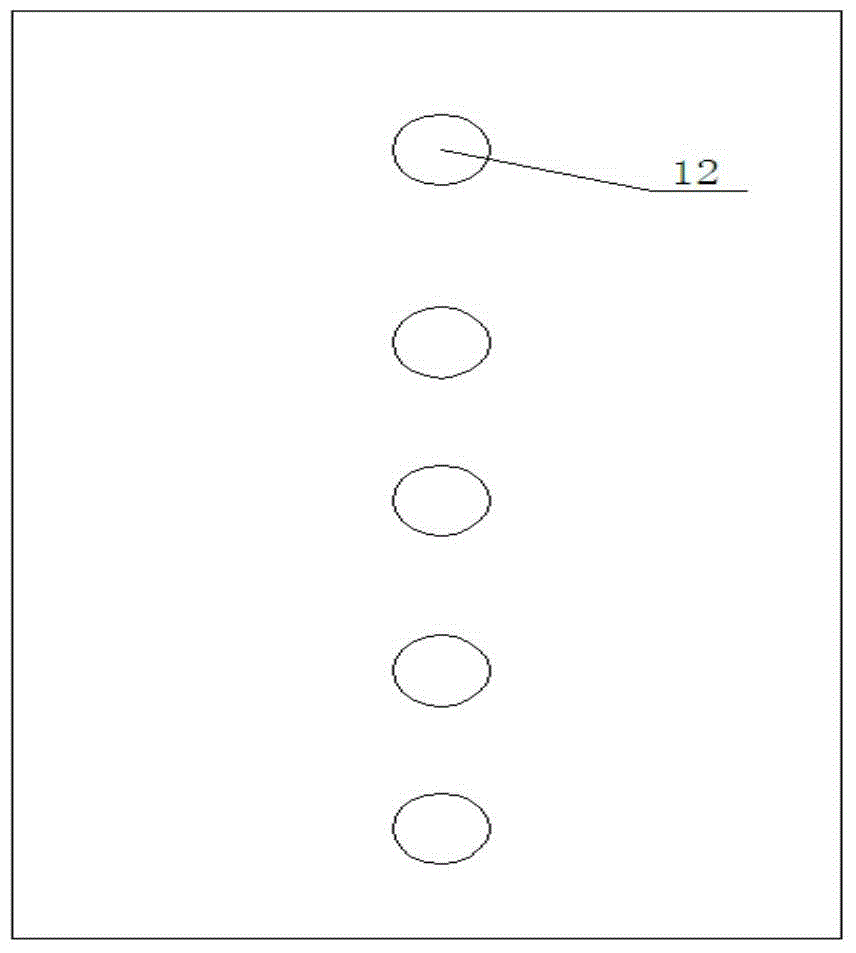

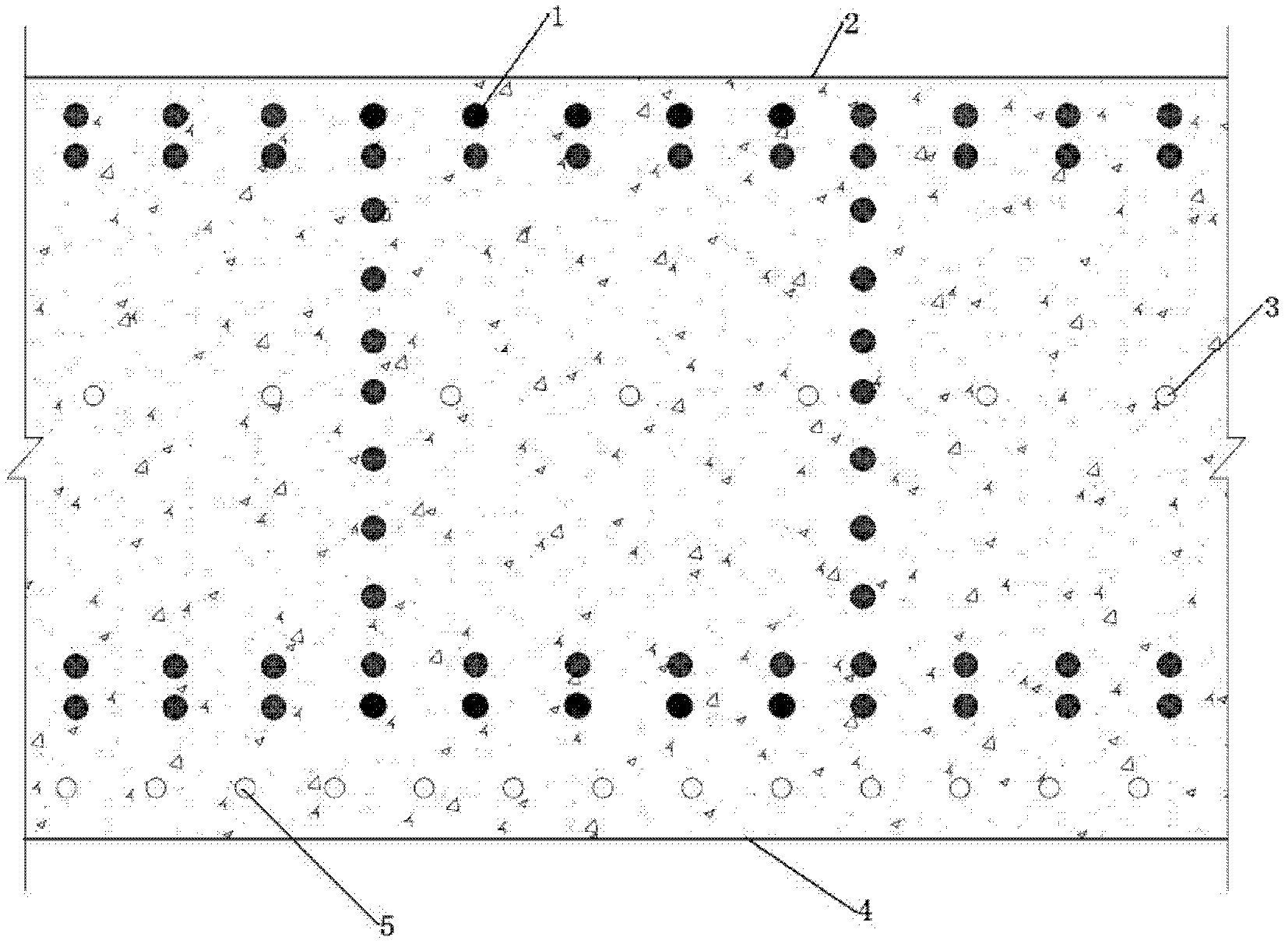

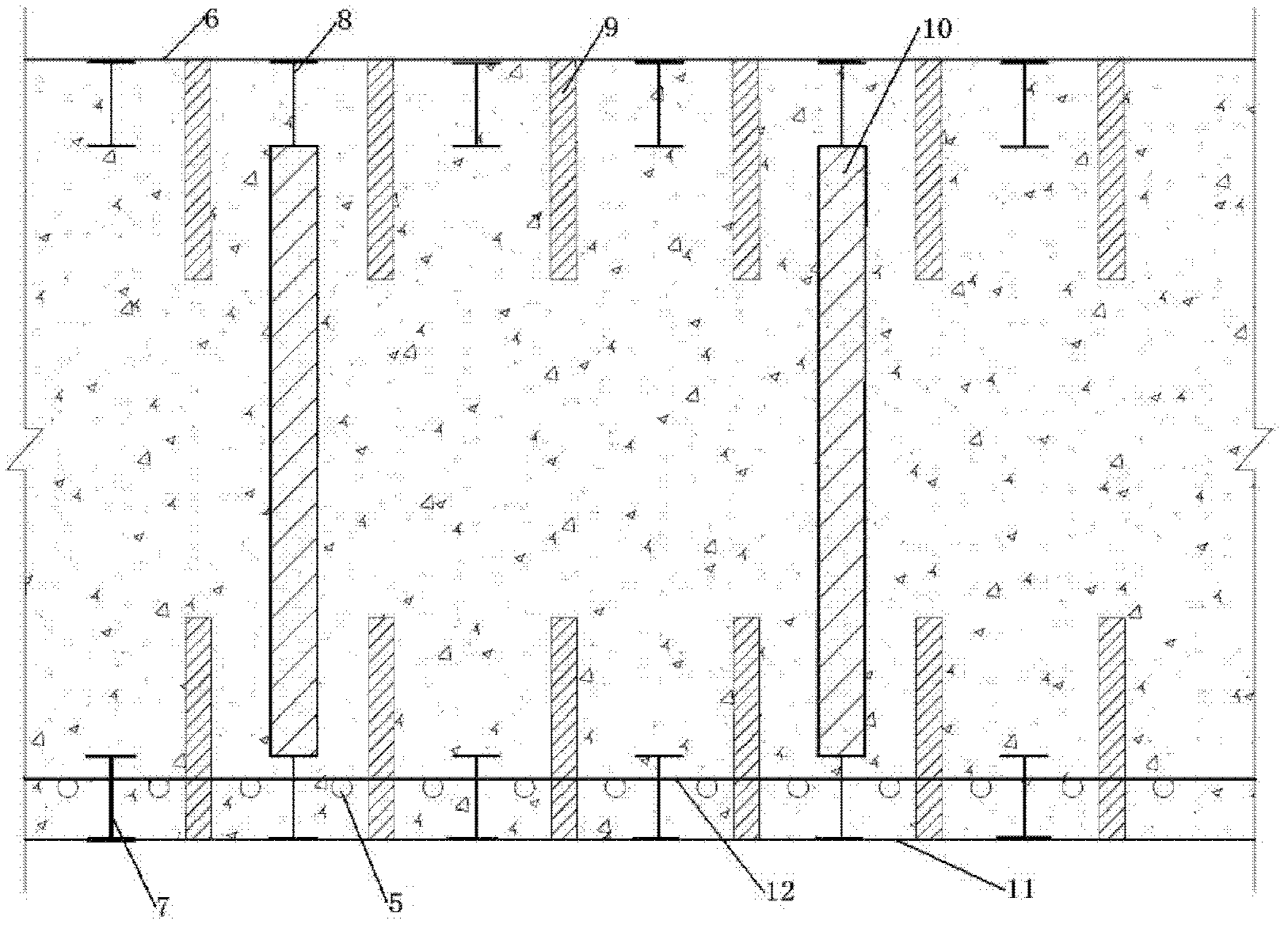

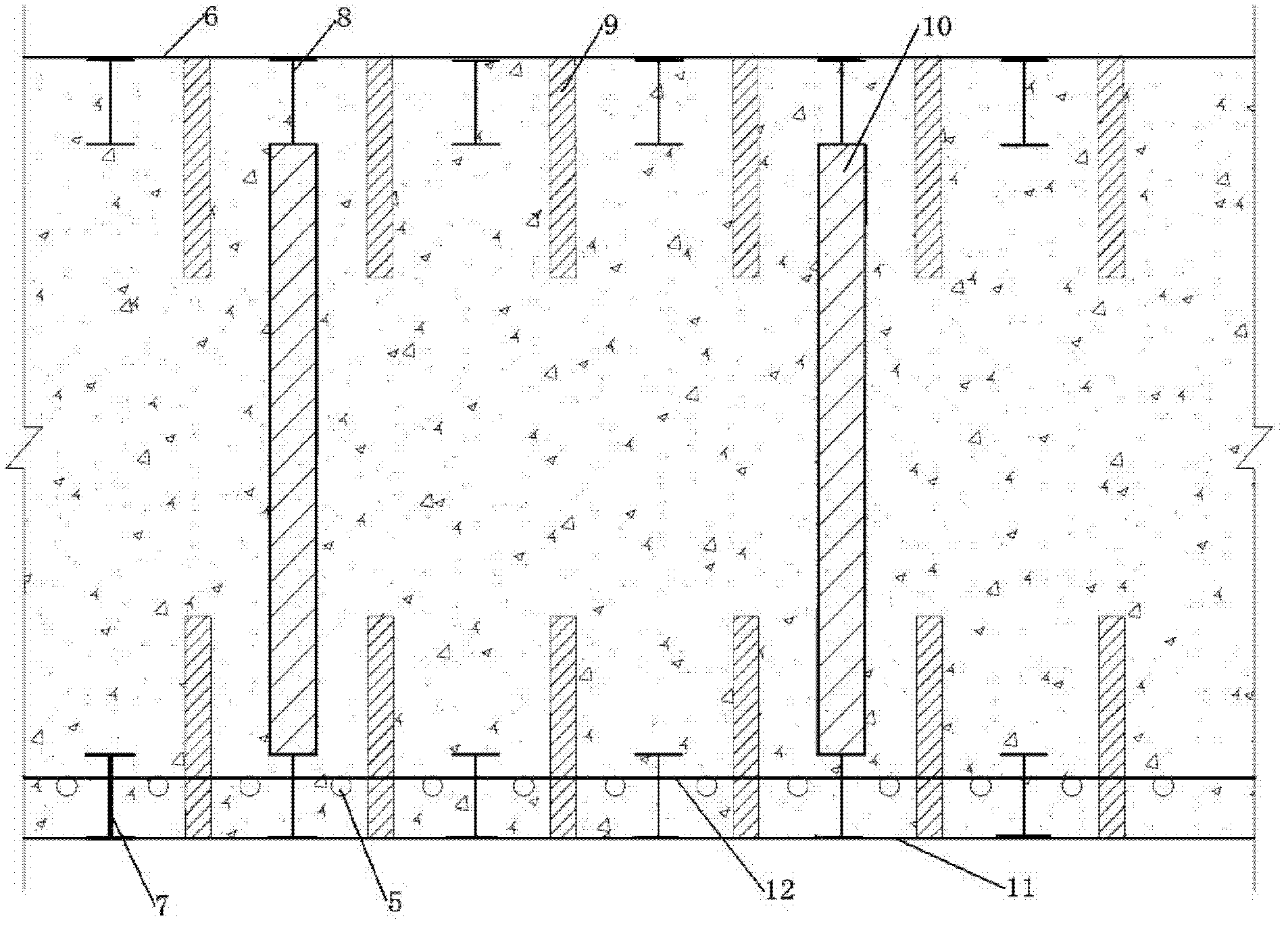

Prefabricated internal support system and construction method for foundation pit support system

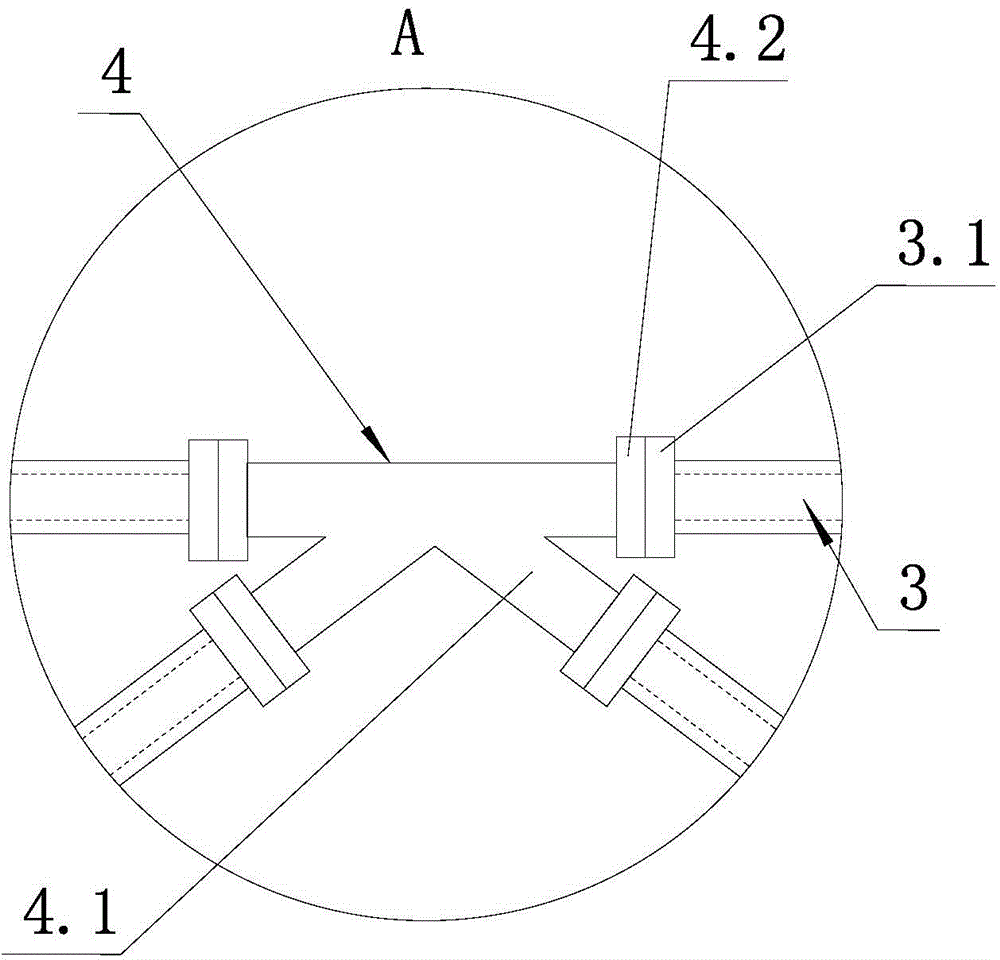

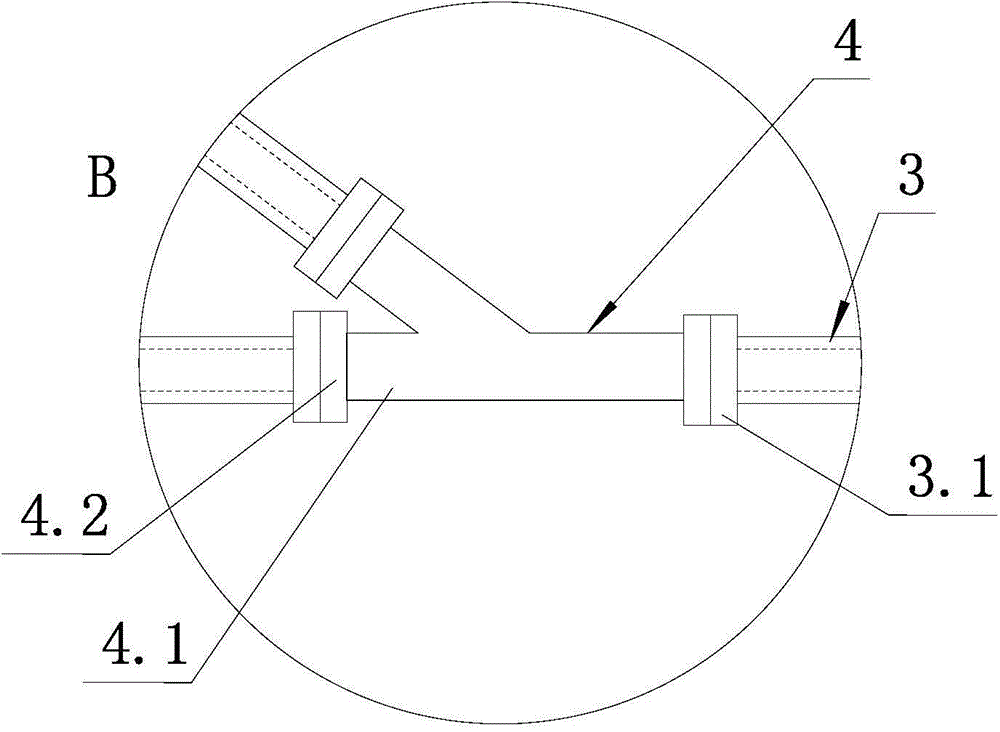

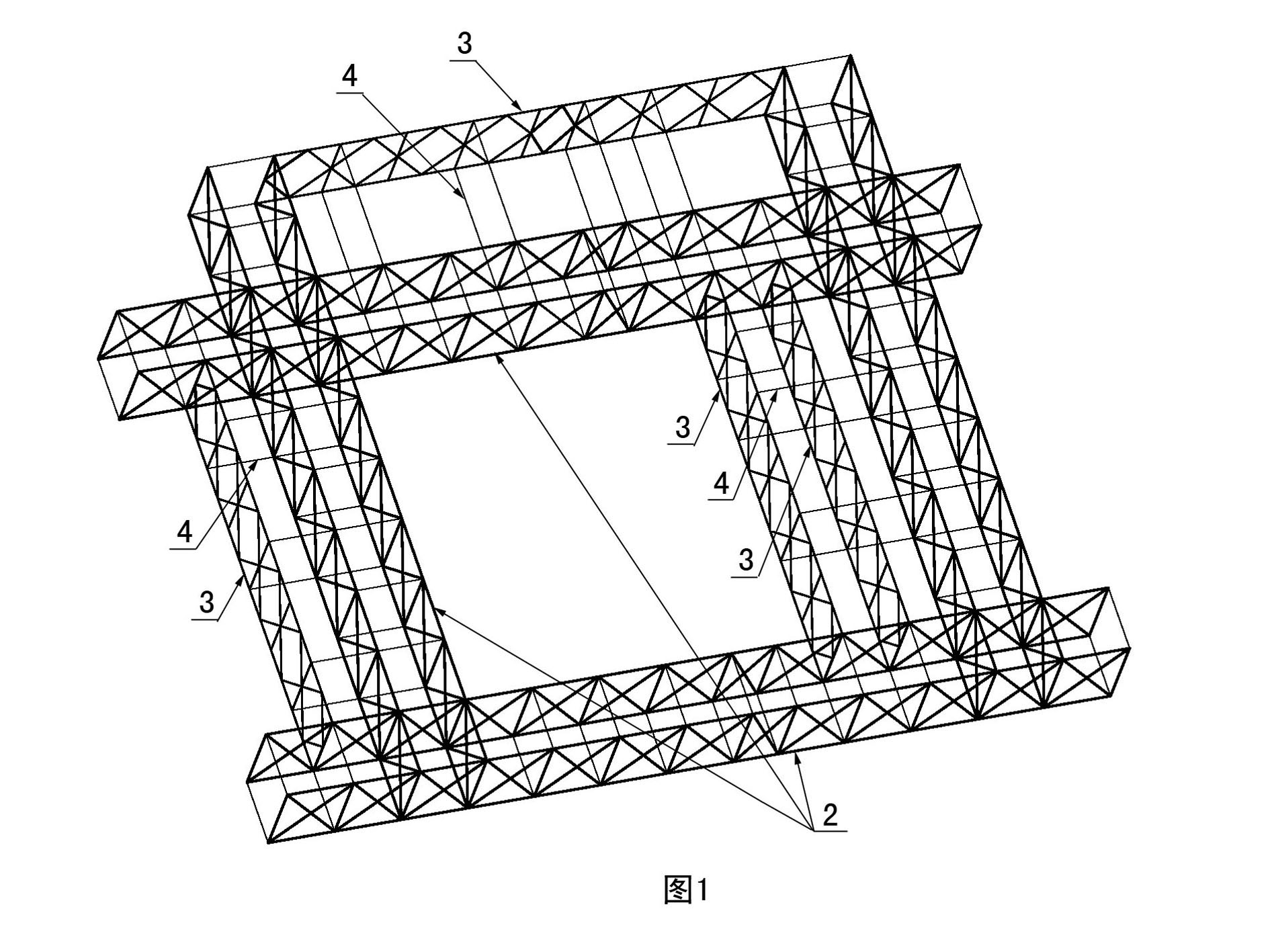

The invention discloses a prefabricated internal support system and a construction method for a foundation pit support system. The prefabricated internal support system comprises a top beam (1), an enclosing purline and an inner support (2), wherein the inner support (2) is a truss type inner support (2) assembled by splicing a pre-stressed hollow square pile (3) and a node connecting piece; first end plates on the two ends of the truss type inner support (2) are in screwed connection with a connecting plate on the top beam (1), and the rest of the first end plates are in screwed connection with second end plates of the node connecting piece; the construction method comprises the key points that the pre-stressed hollow square pile (3) and the node connecting piece are assembled into the truss type inner support (2) in a splicing manner, and the two ends of the truss type inner support (2) are connected with the top beam (1). The prefabricated internal support system and the construction method for the foundation pit support system has the advantages that the system and the method are convenient and efficient, the construction speed is high, the construction period is short, the follow-up earth cutting and earth discharging are convenient, the dismounting process is also convenient, efficient and labor-saving, no safety potential hazard is caused, the system can be recycled, and the material is saved.

Owner:宁波冶金勘察设计研究股份有限公司

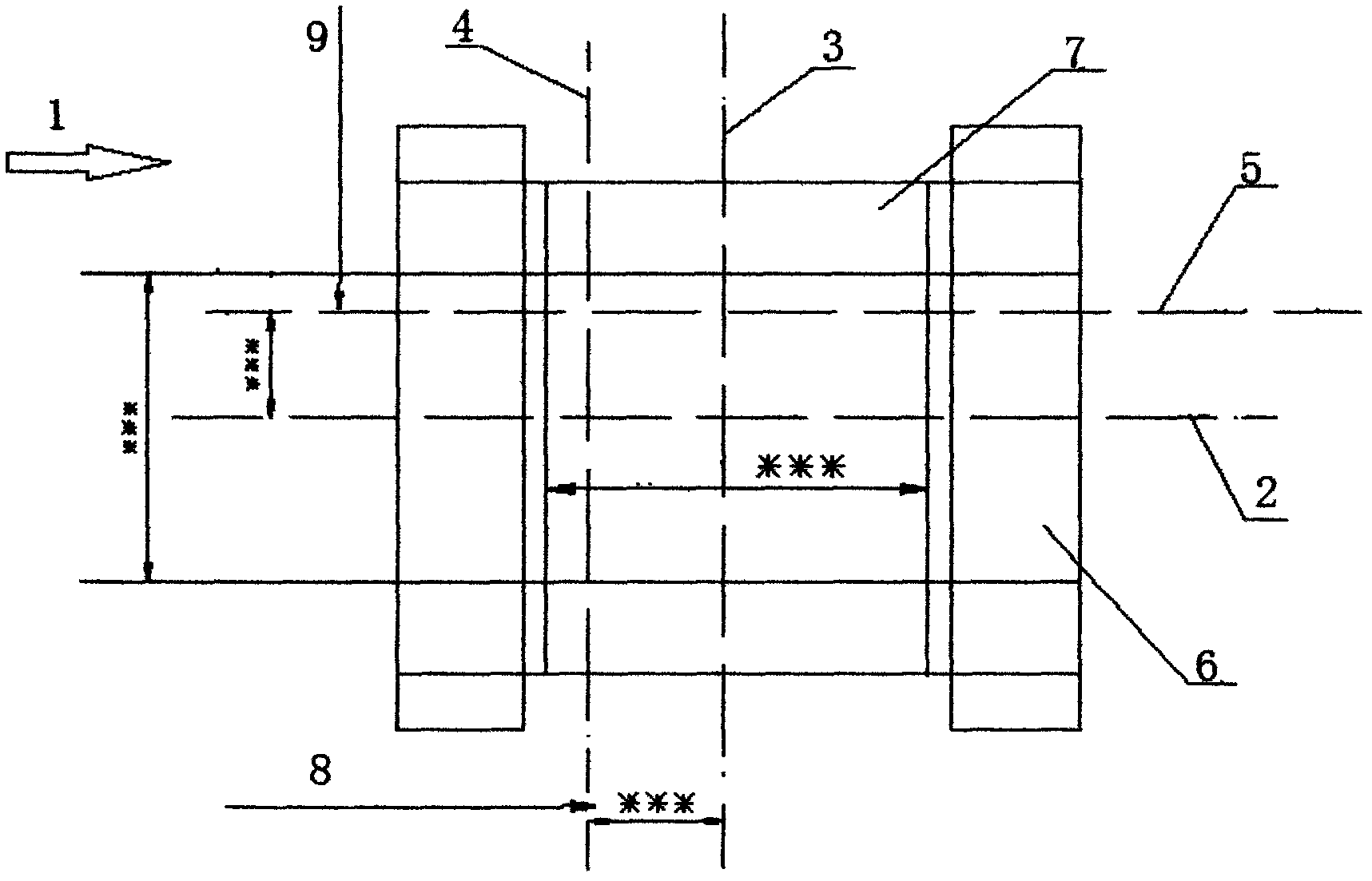

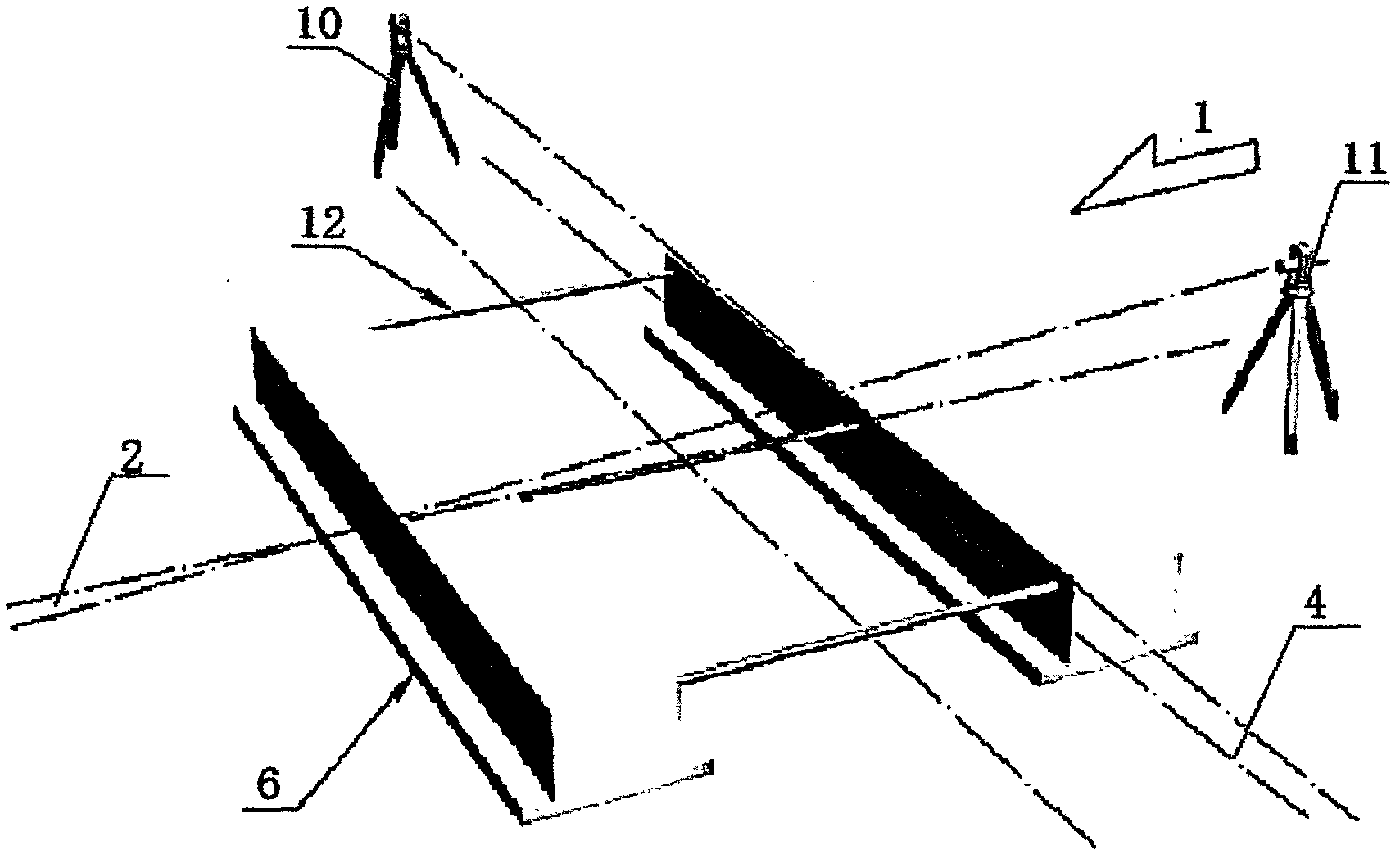

Assembly type variable steel girder platform, distribution method and assembly method thereof

ActiveCN101824905AEasy to set upSpeed up the construction periodBuilding support scaffoldsWork periodDistribution method

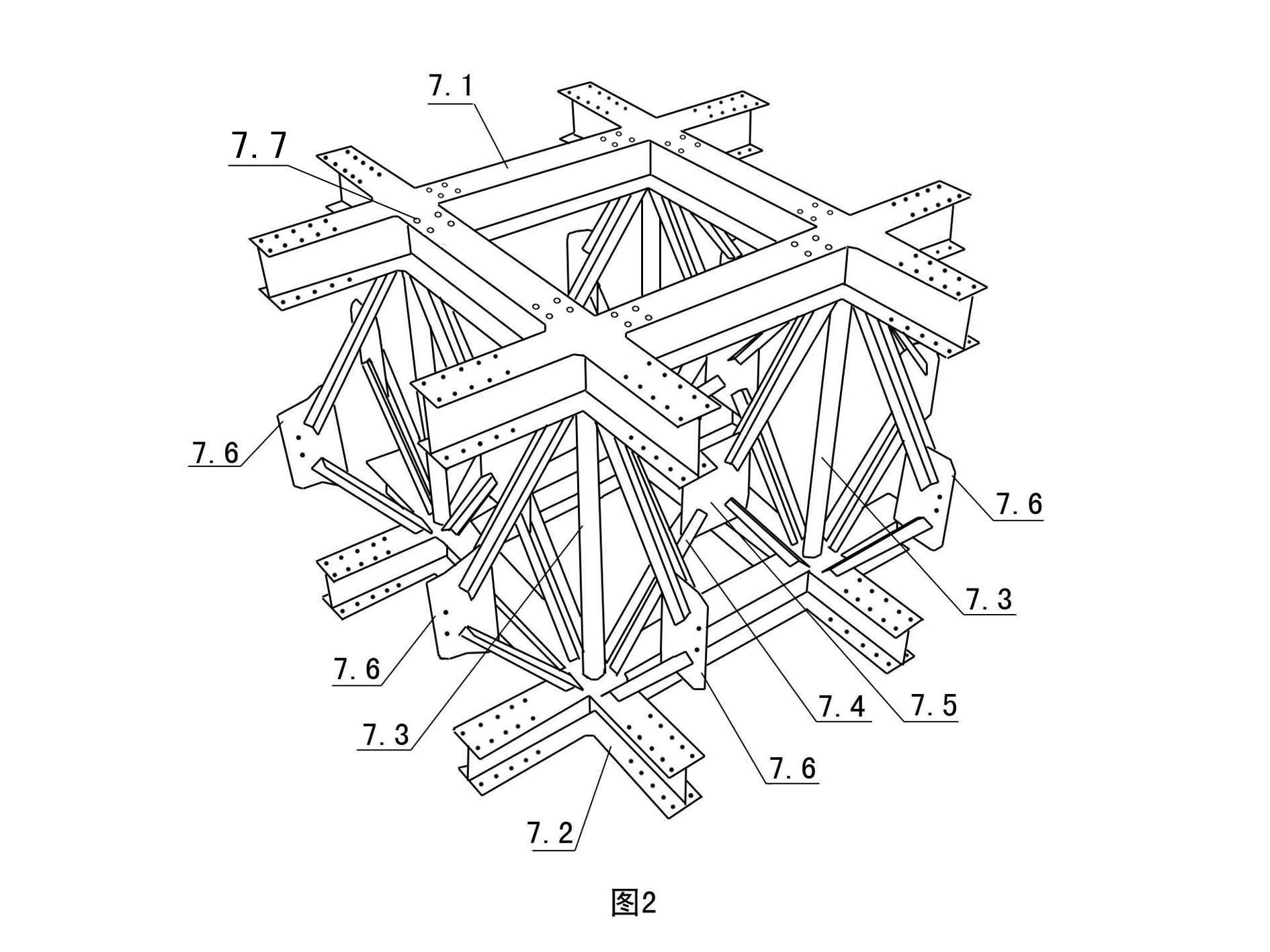

The invention relates to an assembly type variable steel girder platform, a distribution method and an assembly method thereof. The platform is supported on a core tube, and is formed by sectional steel grinders through being fixedly connected, and the sectional steel grinders mainly consist of main stress grinders, sub stress grinders and support rods between grinders, wherein the main stress grinders are formed by main grinder standard nodes and main grinder groined node standard nodes through being dismountably connected via node plates with bolt holes, end sealing plates with bolt holes and screw bolts, the sub stress grinders are formed by sections of sub grinder standard sections through being dismountably connected end to end, and in addition, the sub stress grinders are dismountably connected between two main stress grinders. The platform can be applied to template lifting construction of high and superhigh building core tube steel platforms, and can also be used as platforms for large-area spanning construction operation and construction machine pile carrying and placement, the construction is very easy, the work period of the construction is greatly accelerated, and the construction cost is reduced.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

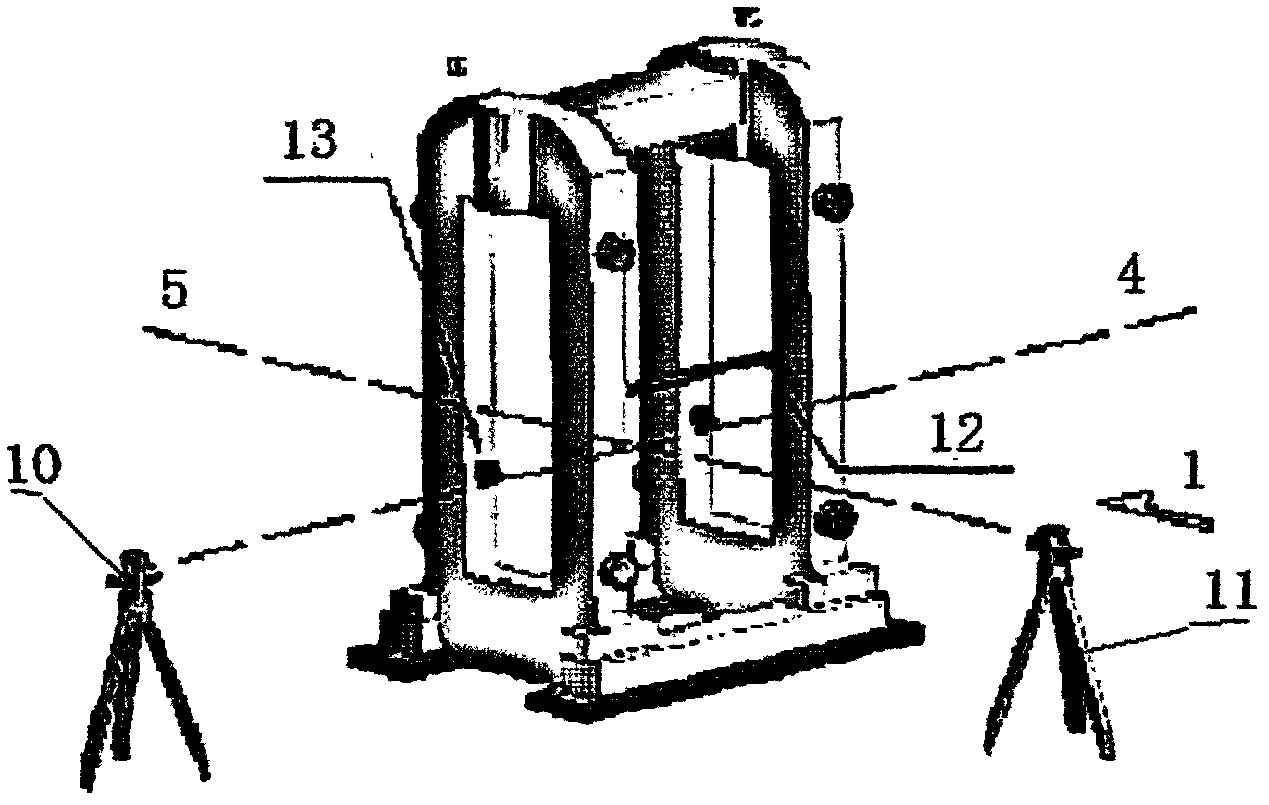

Rolling mill equipment installing method

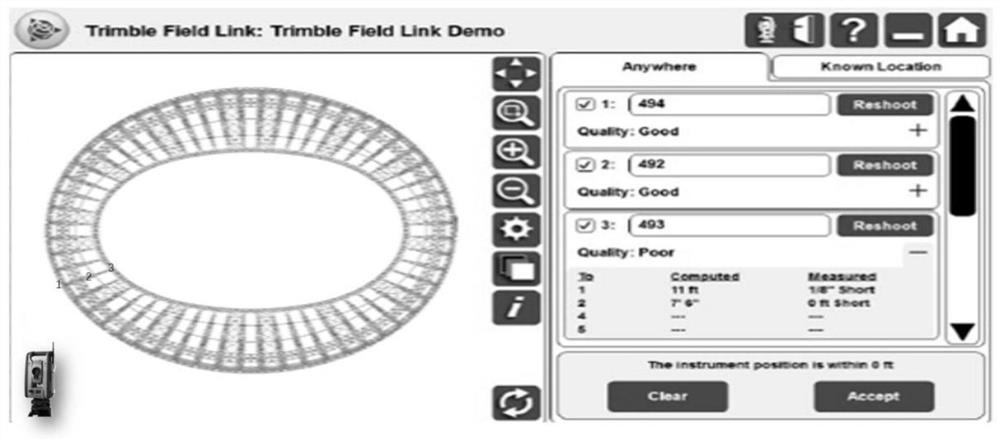

ActiveCN103203364AMeet the requirements of the installation accuracy levelSpeed up the construction periodMetal rolling stand detailsMetal rolling arrangementsWork periodTheodolite

A rolling mill equipment installing method is used for installing and debugging equipment by performing measuring and paying off according to the main central line of a rolling mill foundation and a designed auxiliary parallel central line, utilizing a measuring method for installing and adjusting a rolling mill base and a rolling mill rack and utilizing a transit cross marking line to inspect verticality and a central line according to the main central line of a rolling mill foundation, and has the effects of meeting the installing accuracy class requirement of foreign rolling mills, and the requirements on work period, quality and safety, thus shortening the work period and lowering the construction cost.

Owner:CHINA SIXTH METALLURGICAL CONSTR

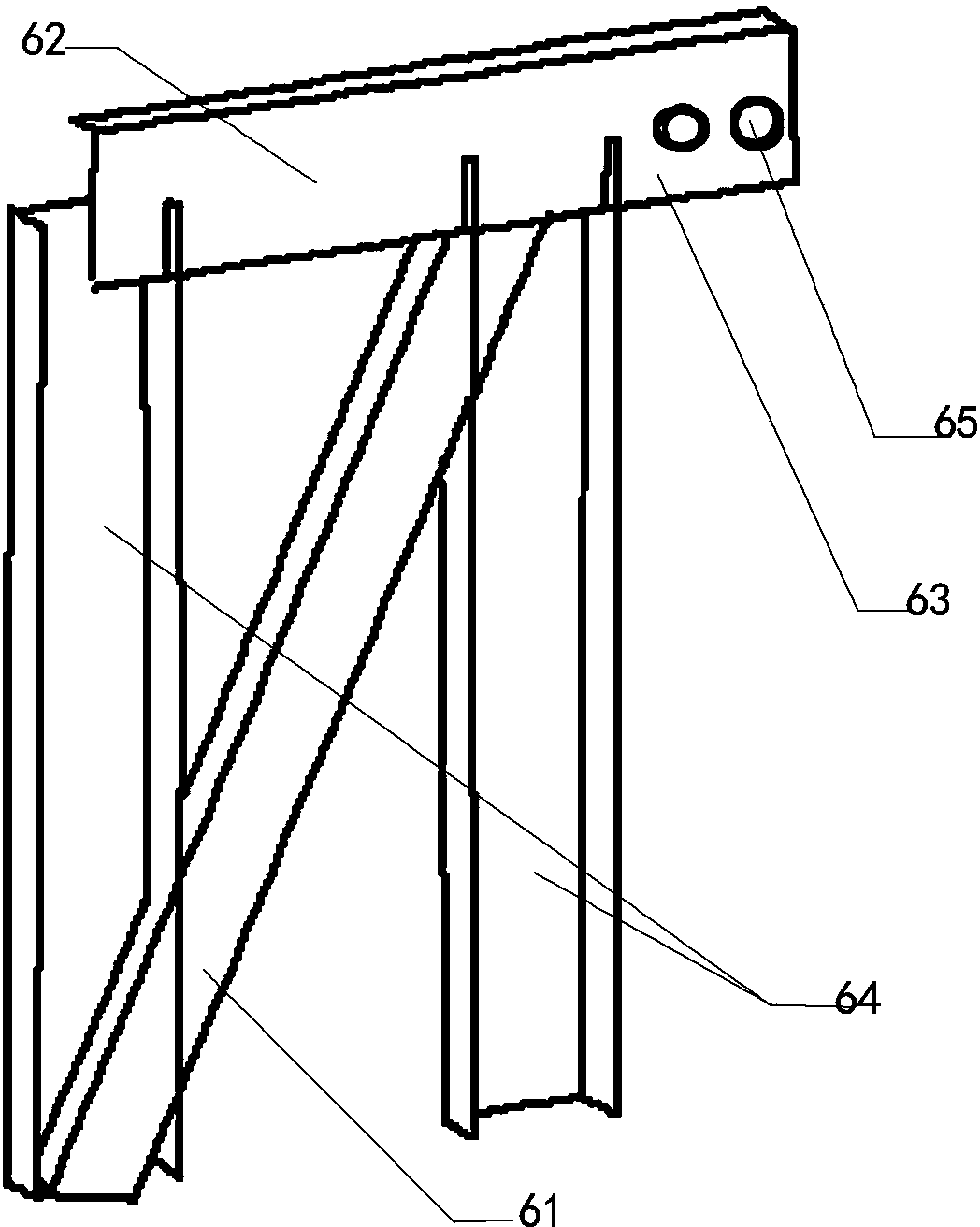

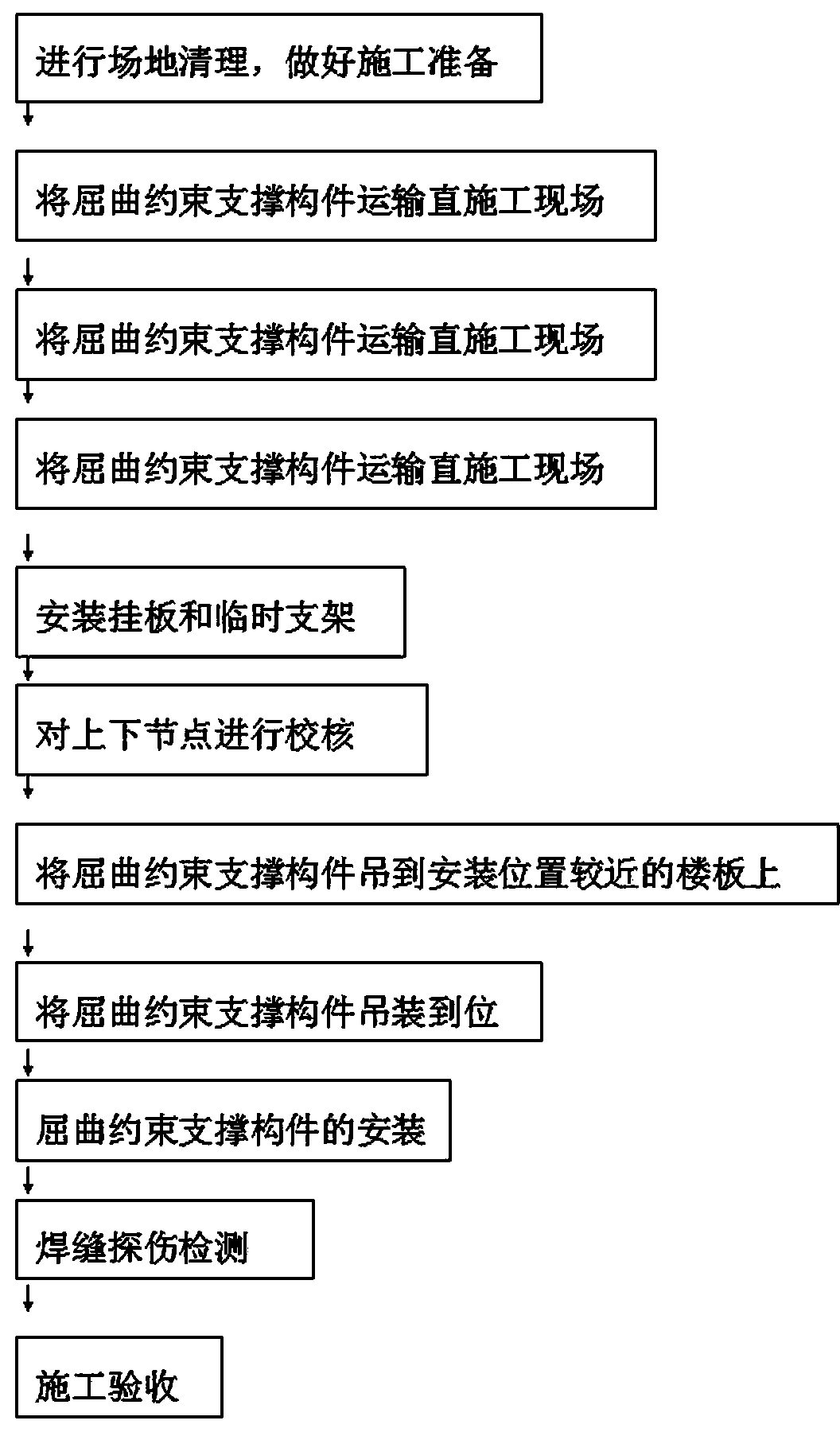

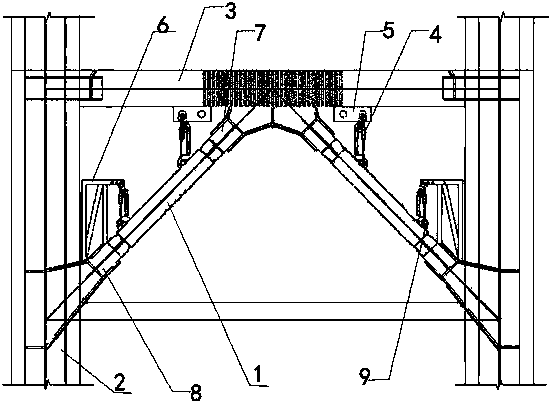

Lifting installation system for buckling restrained supporting member and construction method thereof

ActiveCN103643800ASimple structureEasy maintenanceBuilding material handlingBuckling-restrained braceEngineering

The invention provides a lifting installation system for a buckling restrained supporting member and a construction method of the lifting installation system for the buckling restrained supporting member. In the installation system, chain blocks used for lifting the buckling restrained supporting member are fixed to a beam or supporting stand columns of the buckling restrained supporting member to be installed respectively through hanging plates or temporary supports. The hanging plates and the temporary supports are simple in structure and can be used repeatedly, construction is convenient, manpower and material resources are saved, and the problems that in the current construction, the rate of progress is low, the construction can be finished only with cooperation of several persons, waste of manpower and material resources is caused, and engineering cost is high are solved. The invention further provides the normative construction method. The problems that in the prior art, construction specifications are relatively lacked, and construction methods are different and operation are not standard in current construction are solved. In addition, lifting installation performed on the buckling restrained supporting member can be finished under the condition of narrow spaces, and the problems that in the current construction, the chain blocks are applied with high requirements for spaces of construction environments, and adaptability to the narrow spaces of construction is not high are solved.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

Dust control method for blasting demolition of building

InactiveCN102587691ACompletely brokenSpeed up the construction periodBuilding repairsFloor slabDust control

The invention discloses a dust control method for blasting demolition of a building, which includes the steps: covering blast holes with water bags, setting a range for the water bags covering the blast holes to be larger than 30cm in radius, building a water tank 13cm high along the wall with each floor as a bottom, and filling the water tank with water 10cm in depth; drilling the floors, and drilling holes on each floor at intervals of 4-5m<2>, wherein the depth of each drilled hole is three quarters of the thickness of each floor slab; allowing the drilled holes to be communicated with cavities in the floor slabs, and injecting water into the drilled holes to fully wet the floor slabs; reserving a skylight on each floor; using water to fully wet an expected blast dreg collapse area and an expected blast wave impact range with water; suspending plastic water containers 5kg in weight at intervals of 4-5m<2> on each floor, and filling the plastic water containers with explosive. By the dust control method, blast dust can be reduced effectively, the building can be broken thoroughly, construction period is quickened, and cost is saved.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

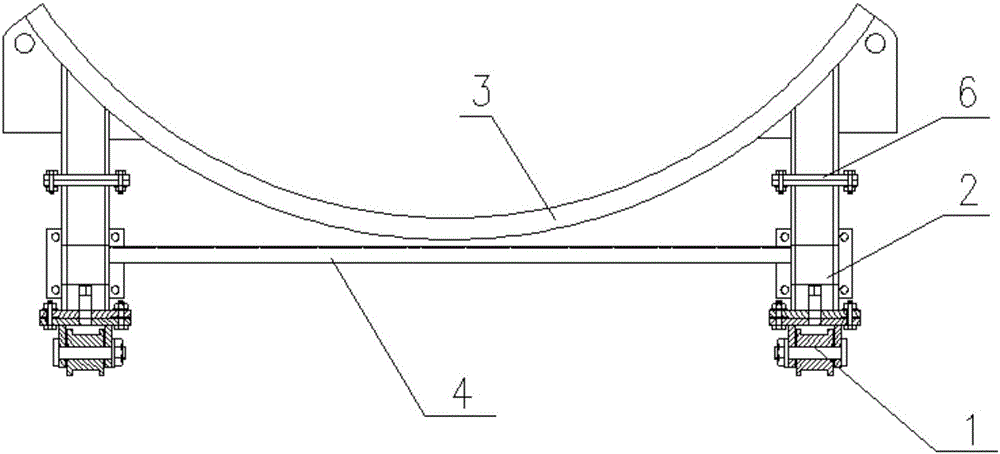

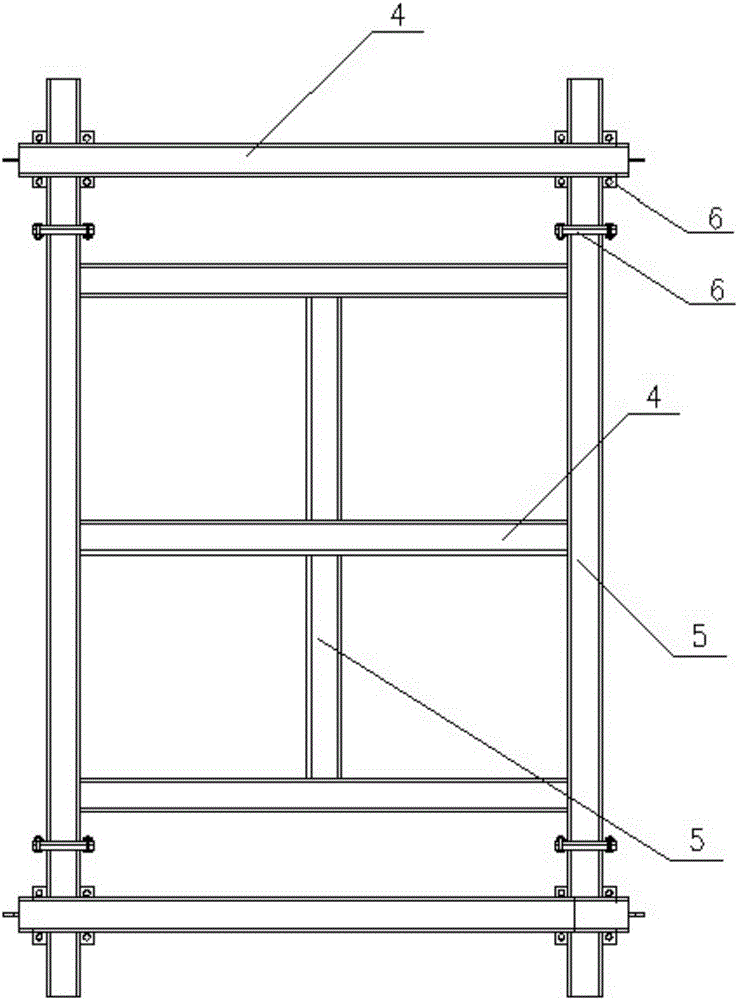

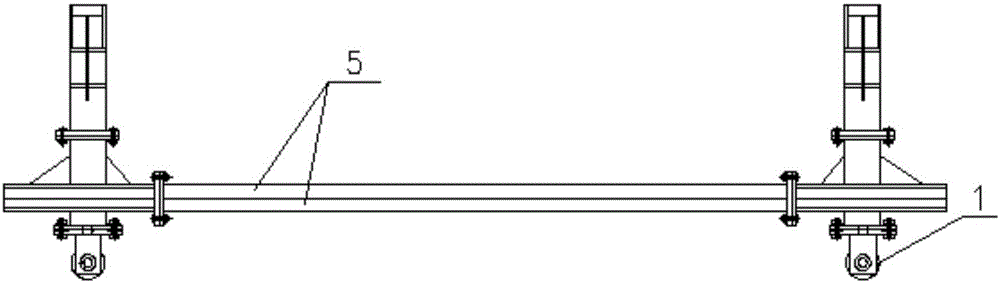

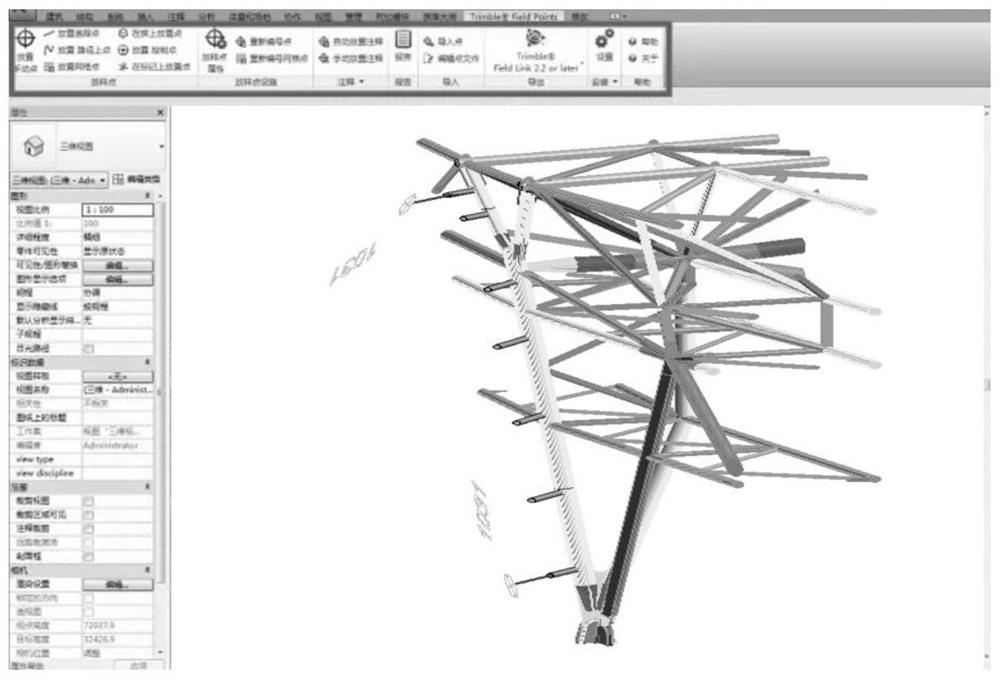

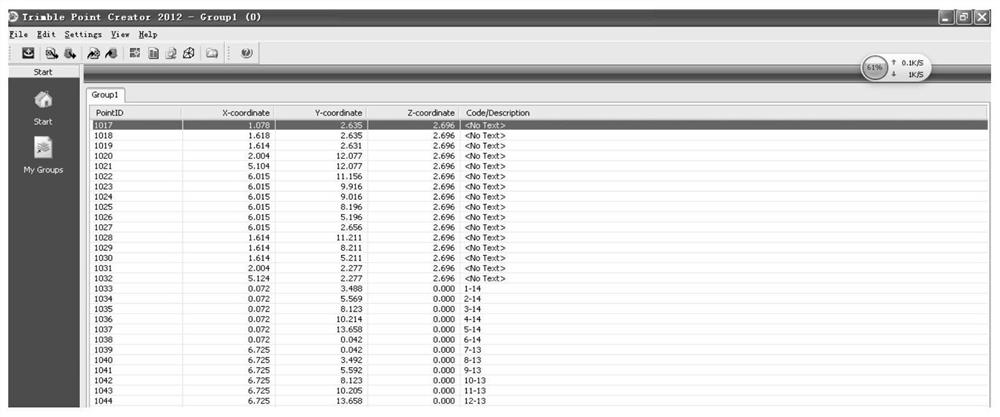

Construction method of large-span double-sided arc-shaped aluminum plate curtain wall

InactiveCN112431420AImprove installation accuracySpeed up the construction periodGeometric CADWallsLong spanMechanical engineering

The invention provides a construction method of a large-span double-sided arc-shaped aluminum plate curtain wall. Through the comprehensive application of a BIM technology and a lofting robot, curtainwall units are reasonably partitioned, adapting parts are reasonably arranged, and then a moulding bed, a curtain wall keel steel truss, the adapting parts and large-span double-sided arc-shaped aluminum plate curtain wall unit plates are accurately and rapidly positioned in an auxiliary mode, so that rapid on-site assembly and positioning installation are realized. According to the constructionmethod of the large-span double-sided arc-shaped aluminum plate curtain wall, the molding effect and precision of the large-span double-sided arc-shaped aluminum plate curtain wall molding are ensuredby adopting a field segmented integral molding bed preprocessing and assembling technology; through the comprehensive application of a BIM model and the lofting robot, the curtain wall keel steel truss and the adapting parts are quickly positioned and welded on site, so that the problem of positioning and mounting of a large number of adapting parts of different specifications on site is solved,the mounting accuracy is greatly improved, and the construction period is greatly shortened; and a segmented hoisting mode is adopted, and through the comprehensive application of the BIM model and the lofting robot, a curtain wall unit panel is accurately positioned, and the hoisting precision and the efficiency are improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

Lightweight aggregate pretreatment method and its device

InactiveCN101077596AAccelerate the pre-wetting speedImprove preprocessing efficiencyCement mixing apparatusPre treatmentPretreatment method

The present invention is light aggregate pre-treating process and apparatus. The light aggregate is first pressurized and humidified in a sealed pressure container as the light aggregate pre-treating apparatus in the pressure of 5-8 MPa for 30-120 min to reach water absorbing rate of 60-80 %; and then shell forming treated through mixing with cement for 90-180 min, with the cement adding amount being 50-100 kg for 1 cu m of aggregate without free water, to form watertight shell in the surface of the aggregate. The present invention has high aggregate pre-treating speed, high efficiency, and capacity keeping free water amount and maintaining high pumpability of the concrete.

Owner:北京东方建宇混凝土科学技术研究院有限公司 +2

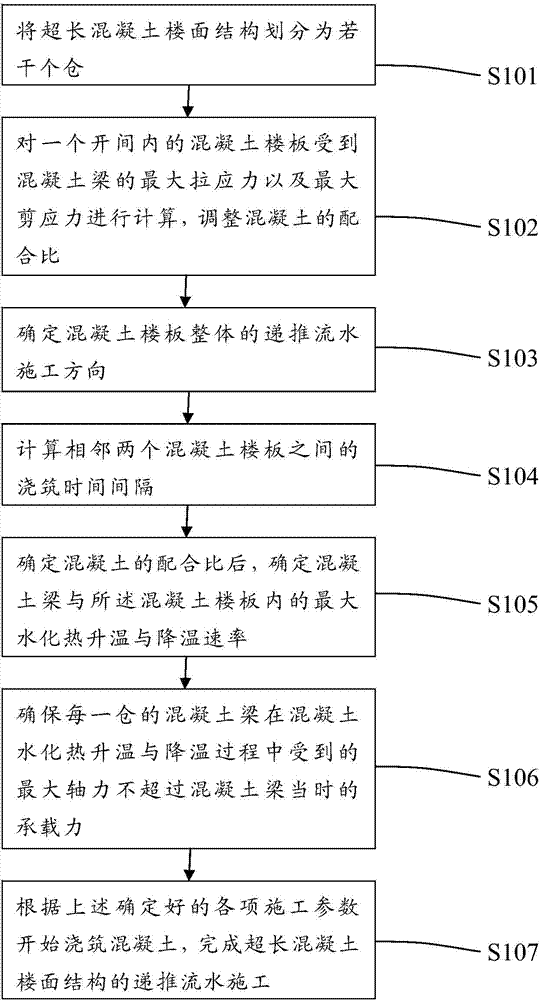

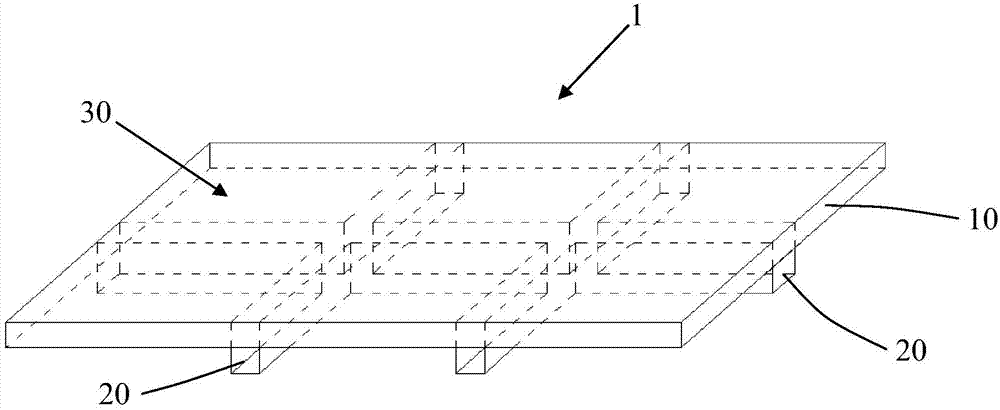

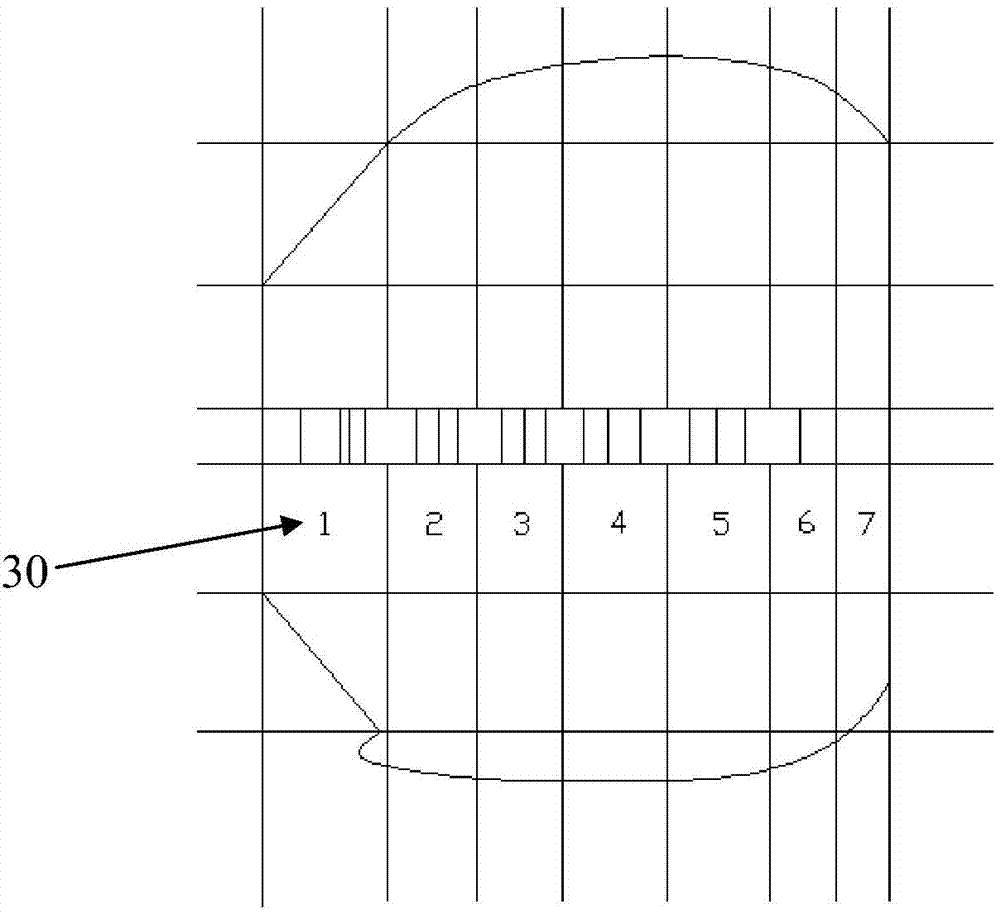

Recursive flow process construction method for ultra-long concrete floor structure

ActiveCN103669868AControl shrinkage stressReduce crackingBuilding material handlingShear stressStructure of the Earth

The invention discloses a recursive flow process construction method for an ultra-long concrete floor structure. The method includes the following steps that the ultra-long concrete floor structure is partitioned; maximum tension stress and maximum shear stress of a concrete beam on a concrete floor in each bay are calculated, and the mixing proportion of concrete is adjusted; the recursive flow process construction direction of the overall concrete floor is determined; the pouring time interval between every two adjacent concrete floors is calculated; the rate of maximum hydration heat temperature raising and temperature lowering in the concrete beam and the concrete floor is determined; it is guaranteed that the maximum axial force applied to the concrete beam in the concrete hydration heat temperature raising and temperature lowering process does not exceed the bearing capacity at that time; concrete pouring is performed, and recursive flow process construction of the ultra-long concrete floor structure is completed. According to the construction method, when concrete is mixed, constraining force of the concrete beam on the concrete floor is strictly measured, if requirements are not met, the mixing proportion of the concrete is readjusted, and thus the construction quality is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

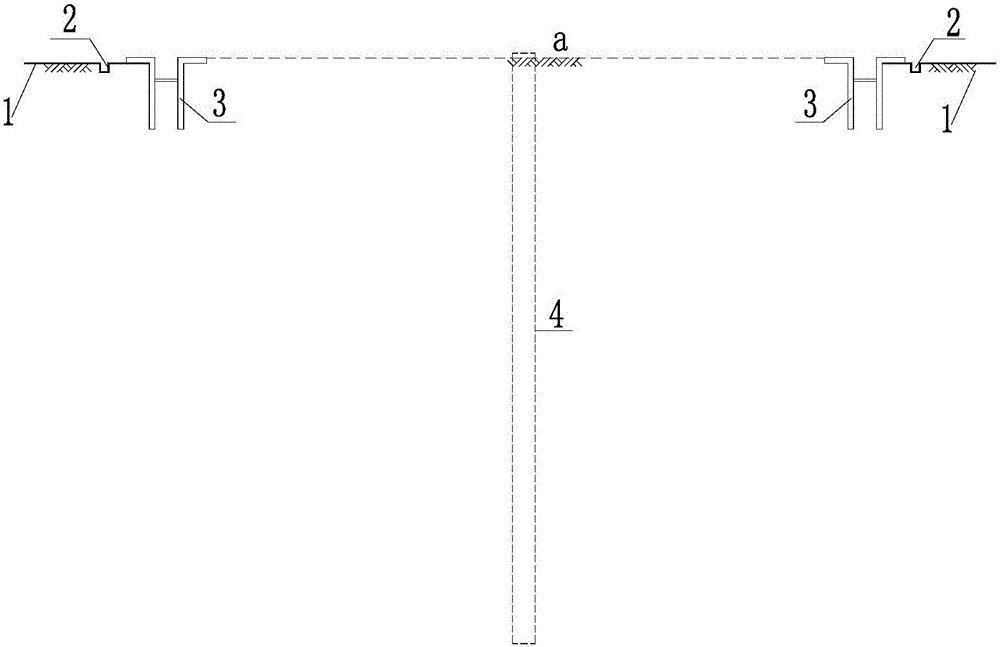

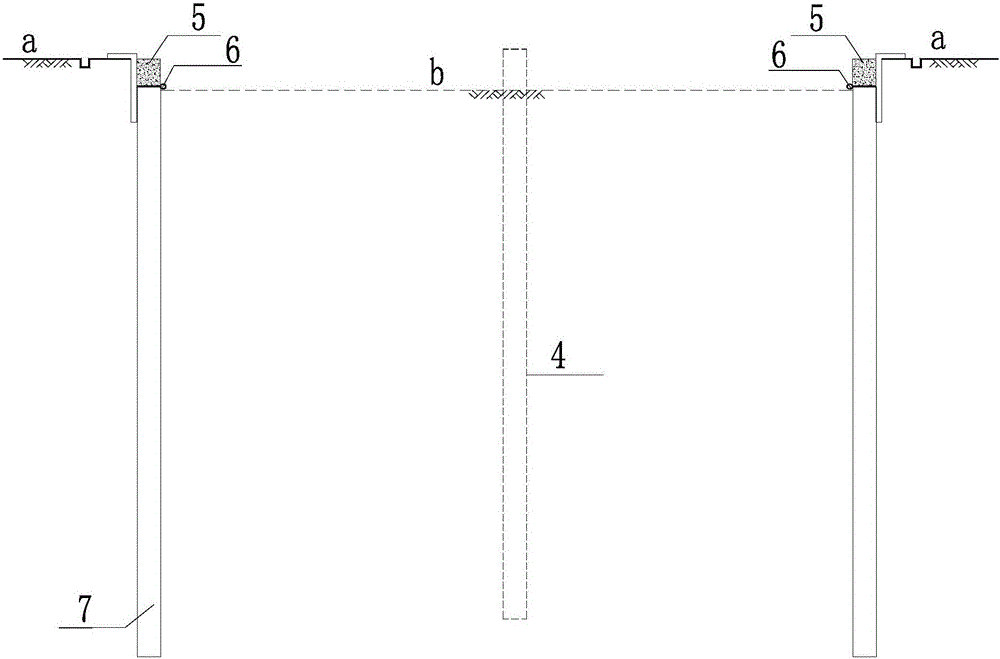

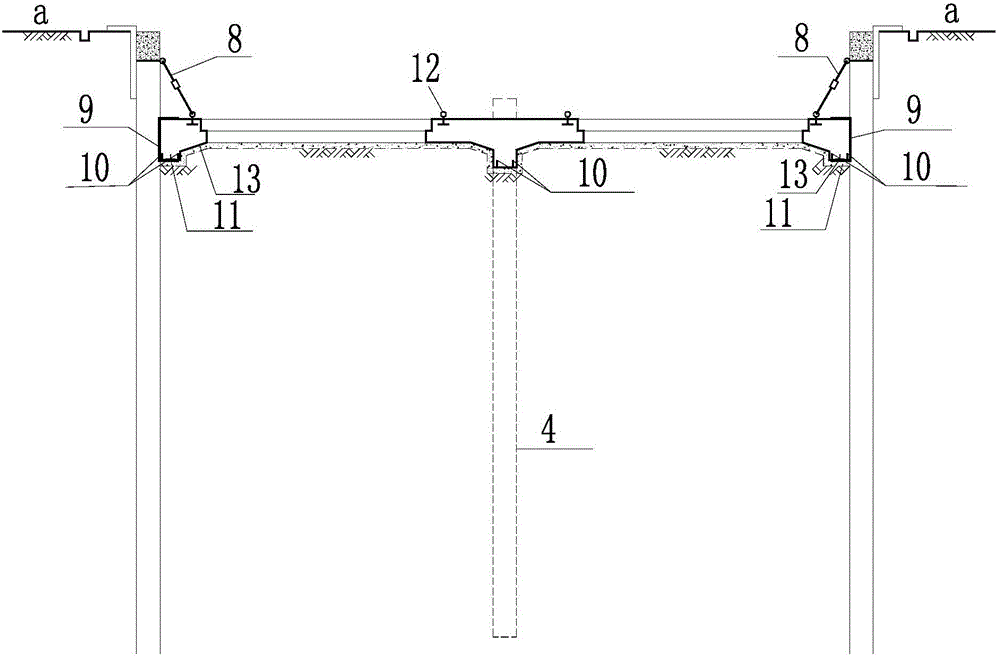

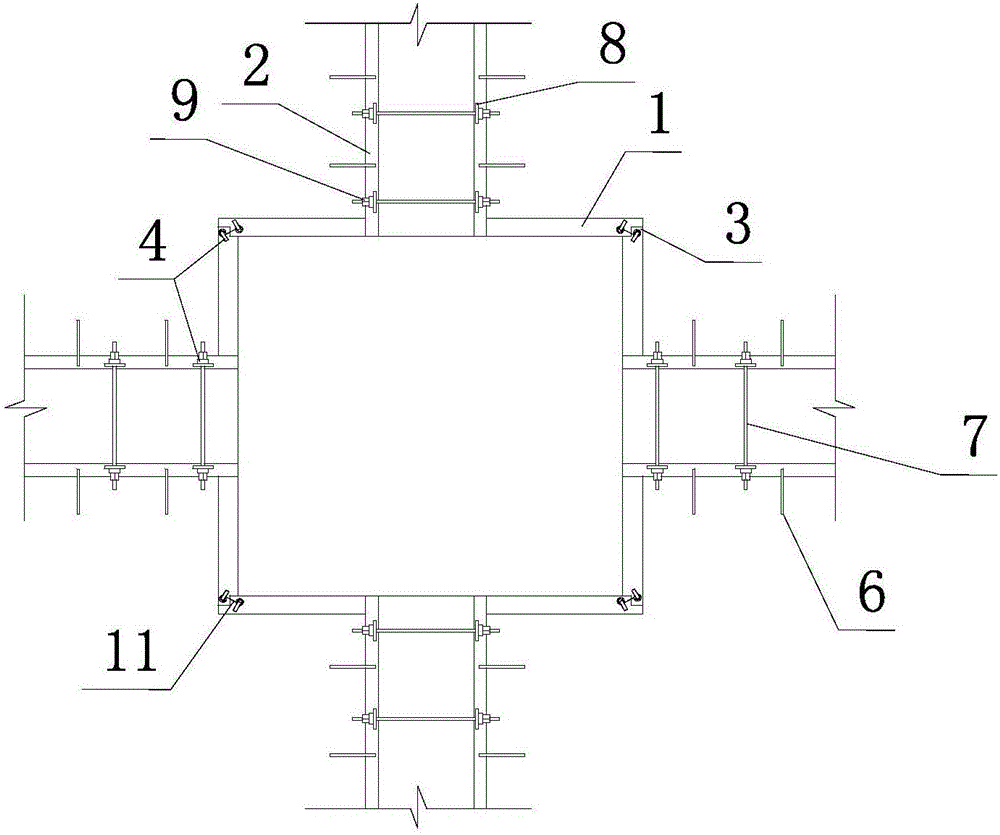

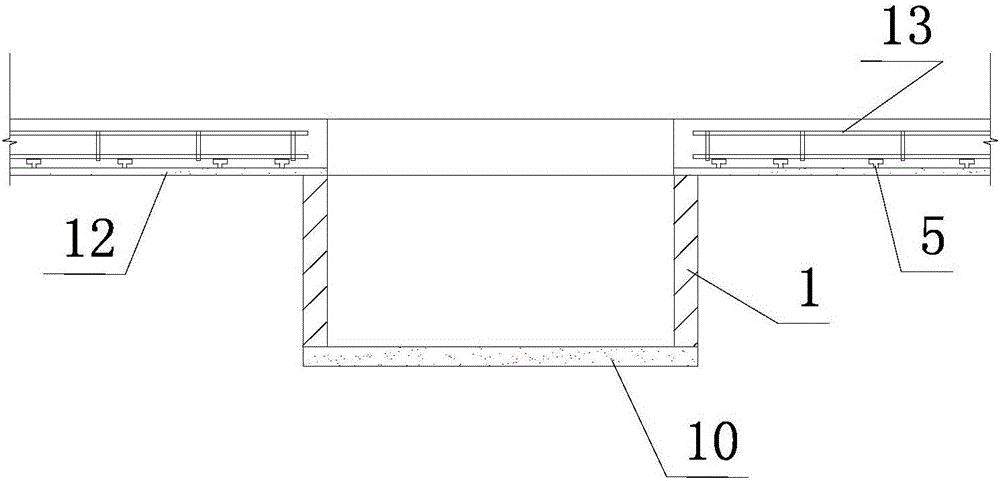

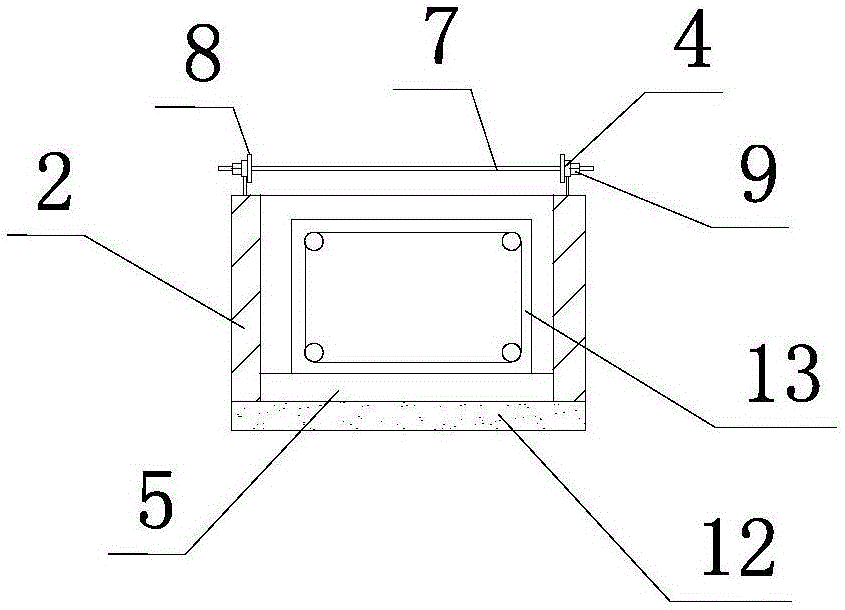

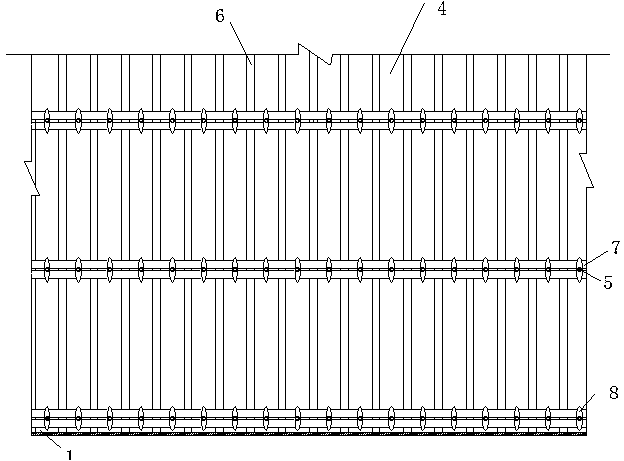

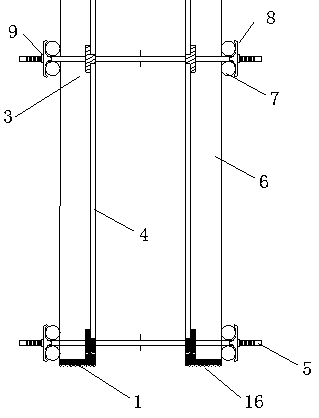

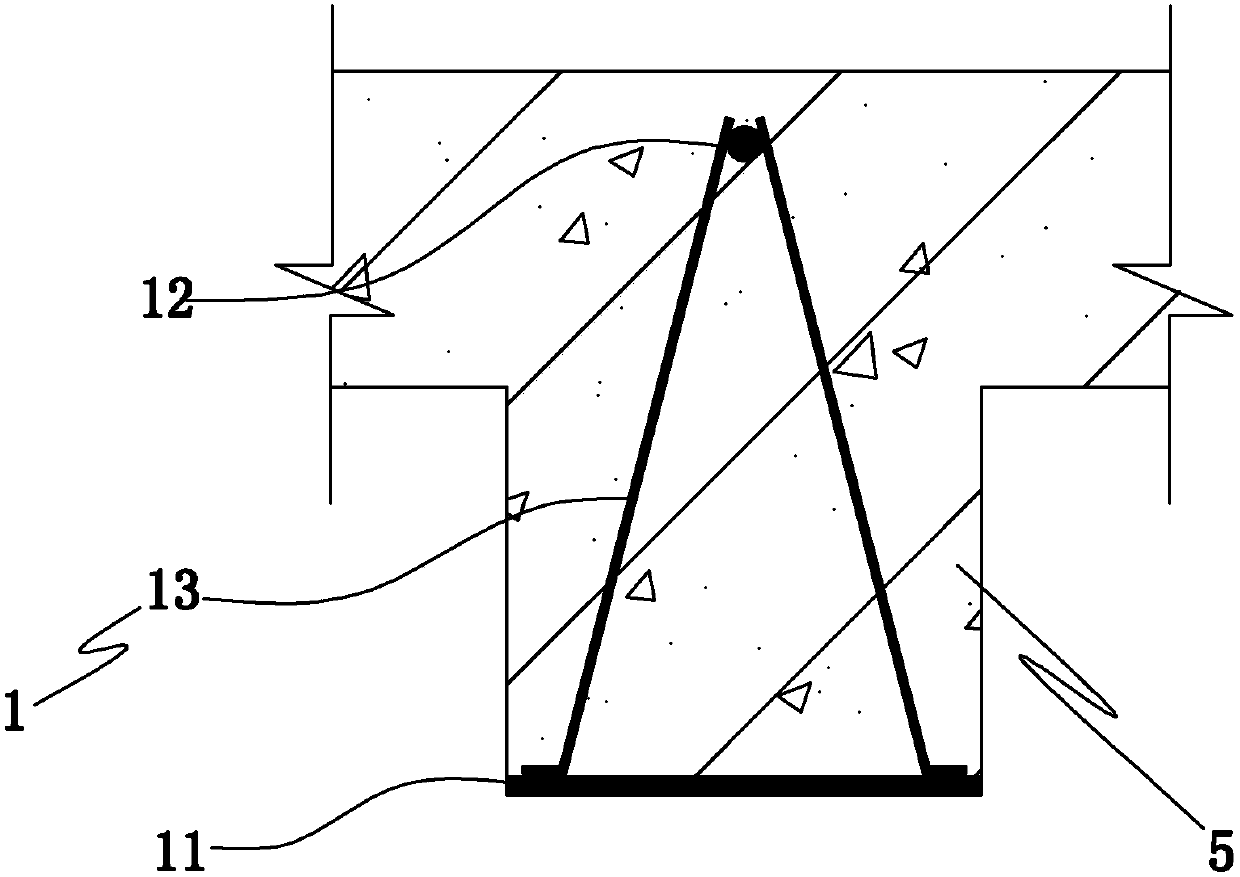

Construction device and method for bearing platform and ground beam structure

PendingCN106836463AAvoid displacementGuaranteed verticalityCellarsForms/shuttering/falseworksRebarReinforced concrete

The invention discloses a construction device and method for a bearing platform and ground beam structure. The device comprises bearing platform side formworks (1) and ground beam side formworks (2) which are of a reinforced concrete structure. A convex strip (3) on each side of each bearing platform side formwork (1) abuts against a convex strip (3) on the adjacent side of the adjacent bearing platform side formwork (1) in a mutually meshing mode. The lower ends of every two parallel ground beam side formworks (2) are supported by concrete supporting blocks. Positioning steel bars (6) bent outwards are fixed to the top edge of each ground beam side formwork (2). Telescopic supporting rods (7) are arranged between every two parallel ground beam side formworks (2). The key of the method lies in that the bearing platform side formworks (1) and the ground beam side formworks (2) which are of the reinforced concrete structure are prefabricated and then are hoisted and strengthened on site. By means of the device and method, the construction intensity of workers can be relieved, the construction process is fast and convenient, and the construction period can be shortened.

Owner:NINGBO DONGXIN CONSTR

Shear wall template structure and construction method

InactiveCN110295738AIntegrity guaranteedHigh turnoverWallsForms/shuttering/falseworksUtility tunnelShear wall

The invention belongs to the field of housing construction and utility tunnel construction, and particularly relates to a shear wall template structure. The shear wall template structure is mainly formed by splicing a plurality of templates, and a row of templates located below are arranged on a setting bottom clamping part which is of an L type; the inner side of the setting bottom clamping partis provided with a plurality of first locking plates in the length direction uniformly, and each first locking plate is provided with a split bolt hole; a setting middle clamping part is arranged between the templates of the upper and lower adjacent layers, and comprises a second long depression bar of which one side is provided with a plurality of second locking plates in the length direction uniformly; each second locking plate is provided with a split bolt hole; and the templates on the both sides of the shear wall are fixed to the position of each split bolt hole through pull screws. According to the shear wall template structure, the drilling procedures of the templates are reduced, and the cost is saved; meanwhile the construction period is shortened, and the construction process issimple; and the shear wall template structure is easy to operate by workers.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction equipment and method for fabricated non-dismantling formwork constructional column and ring beam

ActiveCN113846802ASave the installation and disassembly processImprove construction qualityStrutsWallsBrickArchitectural engineering

The invention relates to the technical field related to buildings, in particular to construction equipment and method for a fabricated non-dismantling formwork constructional column and a ring beam. The fabricated non-dismantling formwork constructional column comprises a plurality of U-shaped brick bodies which are different in length and connected in a staggered mode to form a formwork groove; a steel bar column is placed in the formwork groove, and a concrete pouring layer is poured between the steel bar column and the formwork groove. According to the construction equipment and method for the fabricated non-dismantling formwork constructional column and the ring beam, the design is novel, a U-shaped brick body is adopted to replace a wood formwork, a formwork mounting and dismounting procedure is omitted, the construction quality of the constructional column and the ring beam is improved, the construction efficiency is improved, the construction period is effectively shortened, the construction cost is saved, and the safety risk of edge work of the constructional column and the ring beam is greatly reduced. According to the construction equipment and method for the fabricated non-dismantling formwork constructional column and the ring beam, for the super high-rise edge constructional column, the formwork supporting and disassembling process is omitted, the construction risk is greatly reduced, a large amount of high-altitude edge operation is reduced, and the practicability is high.

Owner:CHINA RAILWAY URBAN CONSTR GRP

Concrete pouring construction method for underground gallery

InactiveCN105401580AImprove turnover rateSave material costFoundation engineeringFalseworkEngineering

The invention discloses a concrete pouring construction method for an underground gallery. The concrete pouring construction method comprises the step of bottom slab concrete pouring, side wall concrete pouring and top slab concrete pouring, an inner formwork and an outer formwork of the side wall are erected to the top at a time, and the step that concrete is poured onto a bottom slab, a side wall and a top slab after scaffolds and top slab formworks are installed completely. Due to the fact that the bottom slab concrete, the side wall concrete and the top slab concrete are poured at a time, stagnant water steel plates do not need to be installed through welding, so that the material cost of the stagnant water steel plates and welding rods as well as the labor cost for welding the stagnant water steel plates are reduced, the turnover rate of the steel formworks and the scaffolds is increased, the construction cost is greatly reduced, and the construction period is shortened; in addition, no horizontal construction seam exists in the wall, and the waterproof performance is improved.

Owner:TIANJIN 20 CONSTR

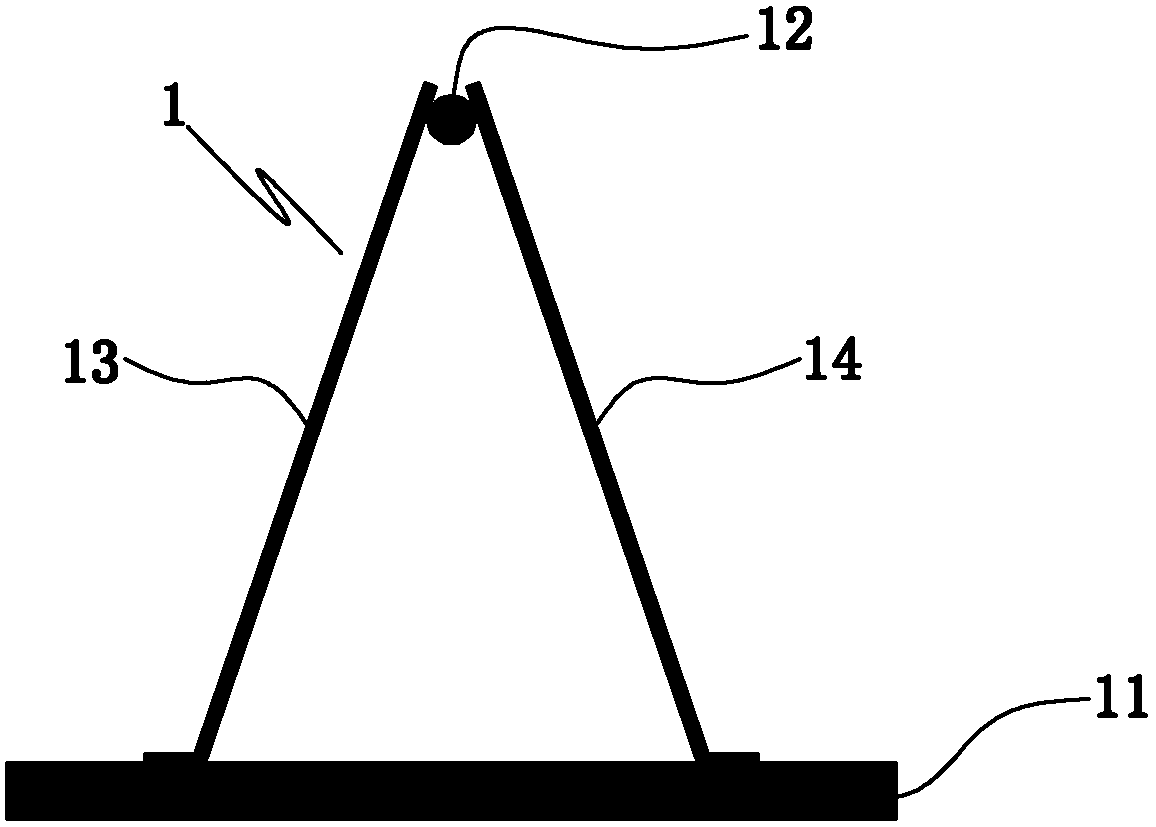

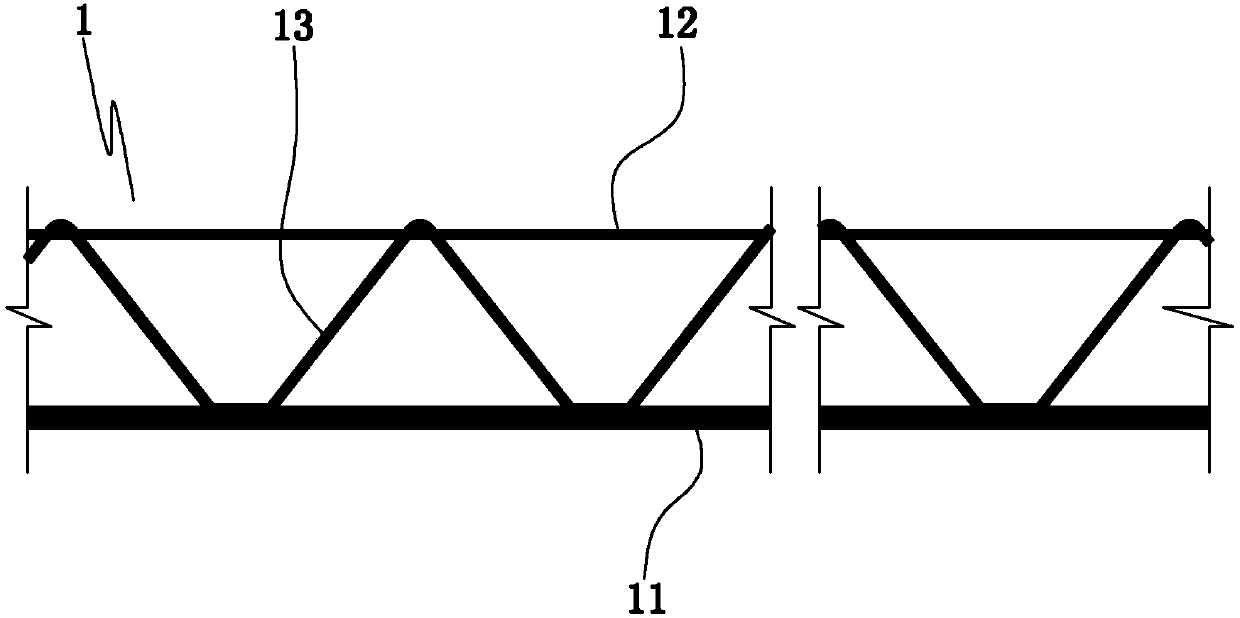

Truss girder, combination beam using truss girders and combination floor system using truss girders

ActiveCN106088480AImprove carrying capacityReduce deformation deflectionFloorsLoad-supporting elementsFloor slabSystem construction

The invention discloses a truss girder, a combination beam using truss girders and a combination floor system using truss girders. The truss girder comprises a lower chord plate, an upper chord member located above the lower chord plate and a connecting web member connecting the upper chord member with the lower chord plate. The combination beam is composed of the truss beams and concrete, and the steel and concrete combination beam is formed through construction. The combination floor system comprises main frame beams, truss beams, a plurality of light plate bottom molds and concrete floors, wherein the truss beams are supported on the main frame beams through lower chord plates, the light plate bottom molds are located between the truss beams, and the concrete floors are located on the light plate bottom molds. The whole floor system construction process does not need supporting, and the truss beams are used for bearing construction loads. The truss beams and the concrete are combined into the steel structure-concrete combined beam which is hidden in the floor system to serve as a hidden ribbed beam and bear the loads in the use stage. The combination floor system has the advantages of being low in cost, high in speed, excellent in heat preservation and noise isolation performance, light, high in strength, environmentally friendly, convenient to industrialize and the like.

Owner:杭州材智建筑科技有限公司

Construction method for steel plate concrete wall of primary loop cabin of high temperature gas cooled reactor

ActiveCN102605951AShorten the critical pathEnsure correct executionWallsBuilding material handlingSteel platesNuclear reactor

The invention relates to a construction method for a steel plate concrete wall of a primary loop cabin of a high temperature gas cooled reactor, which belongs to the technical field of reactor structures. The method includes: arranging inner bearing steel posts, outer bearing steel posts, bearing crossbeams and connecting beams according to design requirements, sequentially arranging shielding cooling water pipes, outer steel plates, inner steel plates and a plurality of transverse shearing nails to form a wall framework module, hoisting the module to the position of the primary loop cabin ofthe high temperature gas cooled reactor, concreting to form a lower-layer steel plate concrete wall module, hoisting an upper-layer module on the lower-layer steel plate concrete wall module, and cycling so to form the wall of the primary loop cabin of the high temperature gas cooled reactor. By the construction method, time of constructional critical paths can be shortened, cross workload on a construction site can be reduced, and work intensity on the construction site is relieved. Further, accurate execution of construction schedule can be guaranteed while construction quality is improved and construction period is shortened.

Owner:CHINERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com