Shear wall template structure and construction method

A shear wall and formwork technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, wall, etc., can solve problems such as increased workload, difficult manual movement, and impact on turnover times. , to achieve the effect of reducing the punching process, ensuring the appearance quality, and increasing the number of turnovers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with embodiments and drawings.

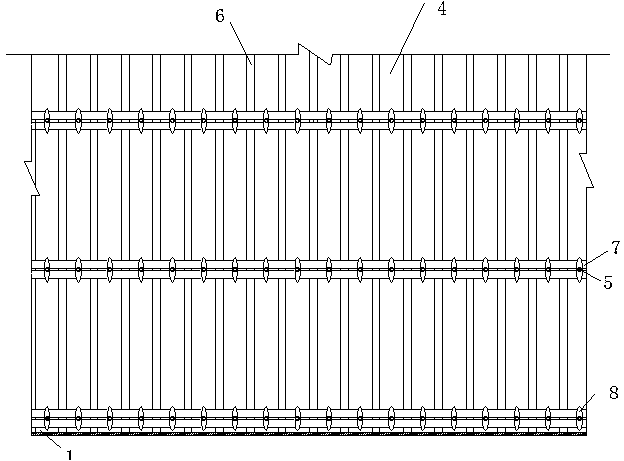

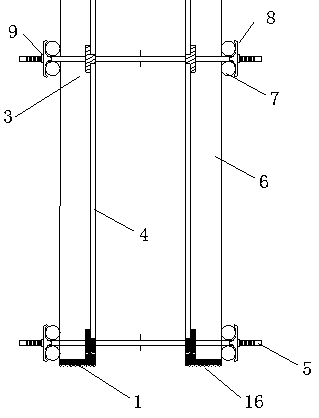

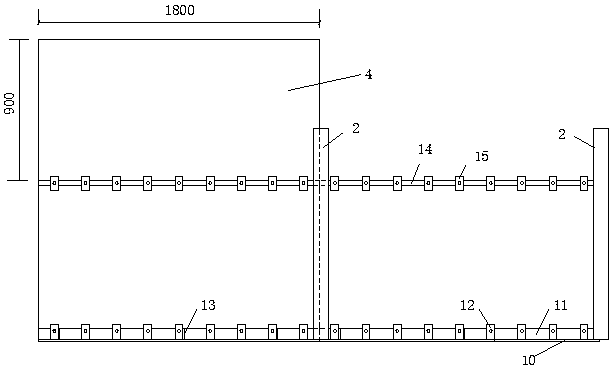

[0033] A shear wall formwork structure, which is mainly formed by splicing several formwork 4, the bottom row of formwork 4 is erected on a shaped bottom clamp 1, the shaped bottom clamp 1 is L-shaped, and the shaped bottom clamp A number of first locking plates 12 are evenly arranged along the length of the inner side of the member 1, and each first locking plate 12 is provided with a pair of bolt holes; the shaped bottom clamping member 1 includes a horizontally arranged presser foot plate 10 and a vertical A straightly arranged first bead 11, the first bead 11 and the presser foot plate 10 are connected by nails into an L-shape (that is, an angle steel structure), and the first locking plate 12 is vertically arranged on the inner side of the first bead 11; A triangular stiffening plate 13 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com