Patents

Literature

645 results about "Utility tunnel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A utility tunnel, utility corridor, or utilidor is a passage built underground or above ground to carry utility lines such as electricity, steam, water supply pipes, and sewer pipes. Communications utilities like fiber optics, cable television, and telephone cables are also sometimes carried. One may also be referred to as a services tunnel, services trench, services vault, or cable vault. Smaller cable containment is often referred to as a cable duct or underground conduit. Direct-buried cable is a major alternative to ducts or tunnels.

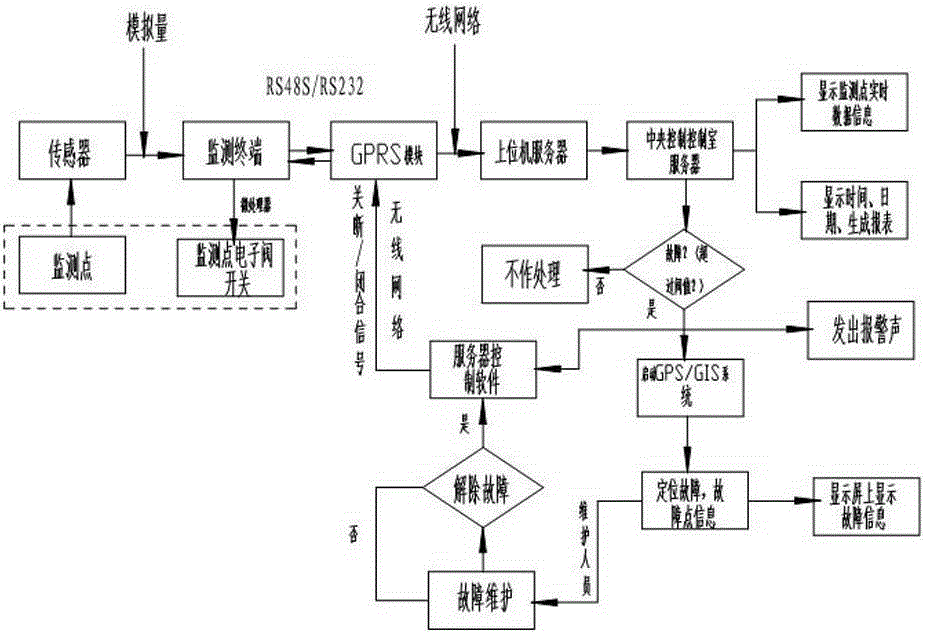

GPRS-based urban underground integrated pipe gallery water supply pipeline online monitoring system

InactiveCN105223890AImprove operational efficiencyImprove running qualityProgramme controlComputer controlAutomatic controlComputer-aided

The invention relates to a GPRS-based urban underground integrated pipe gallery water supply pipeline online monitoring system which mainly comprises four parts: pipeline monitoring sites, a GPRS data transmission network, a central control room, and an automatic control link. Monitoring data is transmitted to the central control room through a GPRS network. Pressure, flow, liquid level and residual chlorine data of a water supply pipeline is collected and processed, and the operation state of the water supply pipeline is analyzed based on the data transmitted back wirelessly. When the data of the pipeline is abnormal, alarm is raised, and meanwhile, computer-aided control software is started automatically to close a switching valve installed at a faulty site, and the operation state of the underground integrated pipe gallery water supply pipeline is detected, diagnosed and controlled online. When the pipeline fails, the position of the faulty site is located accurately by using a GIS and a GPS, and fault information is displayed on the display screen of a monitoring center. Therefore, the damage caused by accidents is reduced, and the operation efficiency and quality of the water supply pipe are improved.

Owner:遵义长征电力科技股份有限公司

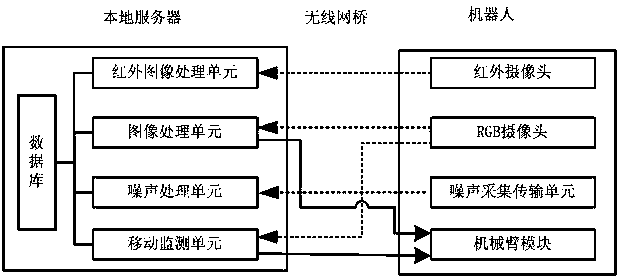

Utility tunnel inspection system based on robot and interactive system

InactiveCN108356818AJudgment of health statusProgramme-controlled manipulatorMeasurement devicesTreatment resultsEngineering

The invention provides a utility tunnel inspection system based on a robot and an interactive system. The utility tunnel inspection system based on the robot comprises a remote infrared monitoring anddiagnosis module, a remote image monitoring and diagnosis module, a remote sound monitoring and diagnosis module, a navigation positioning and motion control module, and a database. The remote infrared monitoring and diagnosis module is used for detecting the temperature of equipment in a utility tunnel, and sending equipment information exceeding an alarm value to the database after judgement ismade; the remote image monitoring and diagnosis module is used for collecting images of the equipment and moving bodies in the utility tunnel, analyzing the images and sending abnormal results to thedatabase; the remote sound monitoring and diagnosis module is used for collecting noise of electrical equipment in the utility tunnel, analyzing the noise and sending the noise to the database; and the navigation positioning and motion control module is used for obtaining the operating path of the robot. According to the utility tunnel inspection system, known targets and unknown targets can be detected through surrounding environment information obtained through sensors and treatment on the environment information, and treatment results are displayed on a system interface.

Owner:史聪灵

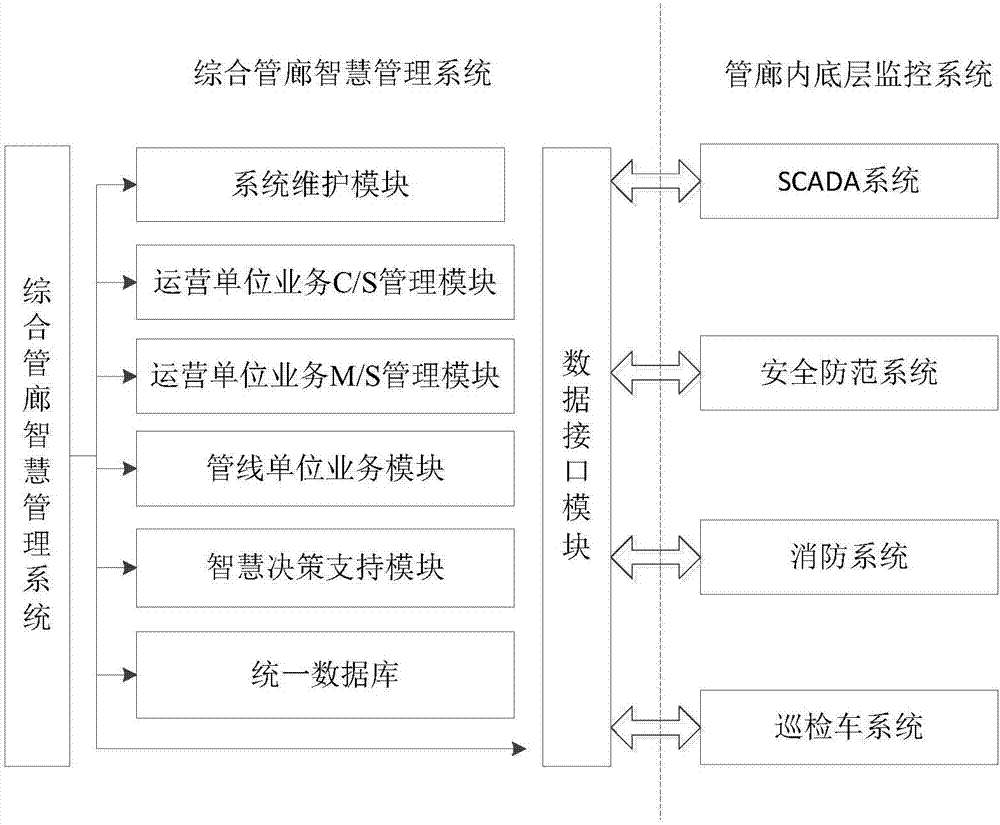

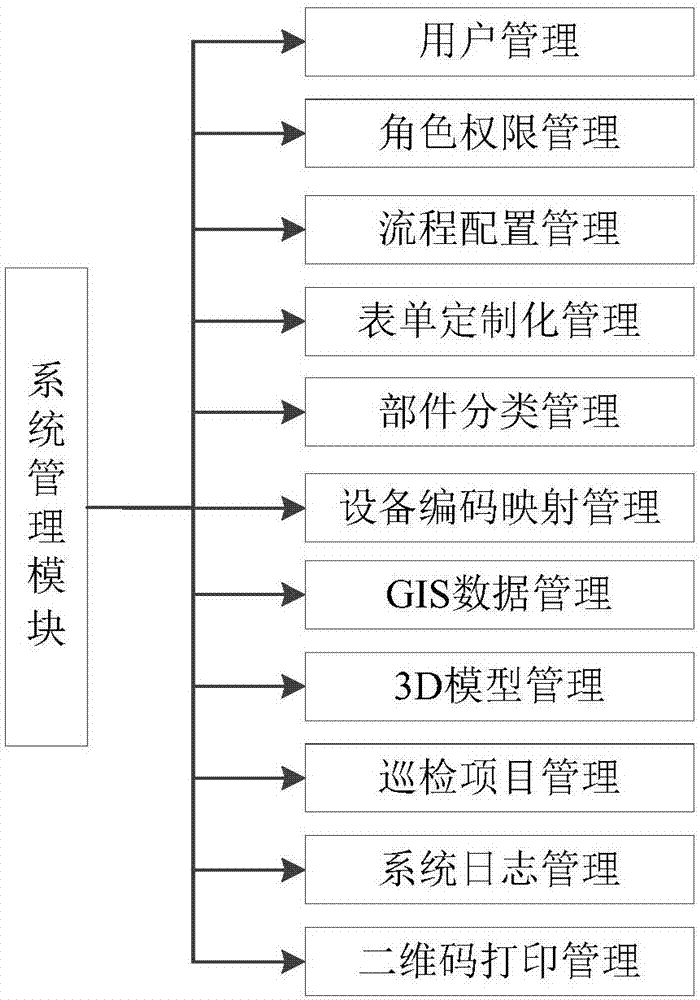

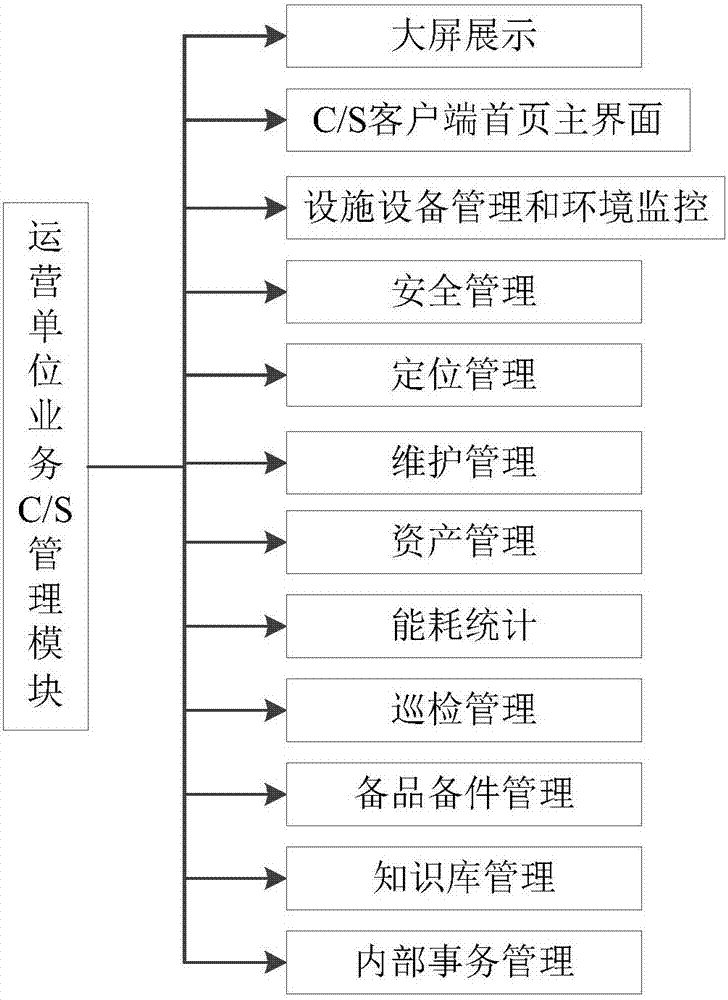

Utility tunnel intelligent management system

InactiveCN107016502AReduce operation and management costsImprove service levelResourcesDaily operationFull life cycle

The invention discloses a utility tunnel intelligent management system, which comprises a system maintenance module, an operation department service C / S management module, an operation department service M / S management module, a pipeline department service module, a data interface module, an intelligent decision-making support module and a unified database, and is characterized in that the system maintenance module is used for performing support management on a utility tunnel intelligent operation management platform; the operation department service C / S management module is used for performing management on a desktop terminal used by a utility tunnel operation department in the process of operating utility tunnels; the operation department service M / S management module is used for performing management on daily operation and maintenance services of the utility tunnels; the pipeline department service module is used for performing management on an operating system of a utility tunnel using department; the data interface module is used for performing data exchange with a utility tunnel inner bottom monitoring system; the intelligent decision-making support module is used for providing auxiliary decision-making support for utility tunnel operation management; and the unified database is used for storing data in full life cycle of the utility tunnels. The utility tunnel intelligent management system realizes intelligent operation management for the utility tunnels by using advanced information technologies, can avoid occurrence of major disaster accidents as far as possible, and promotes sustainable development of the utility tunnel operation work.

Owner:CHINA CONSTR UNDERGROUND SPACE

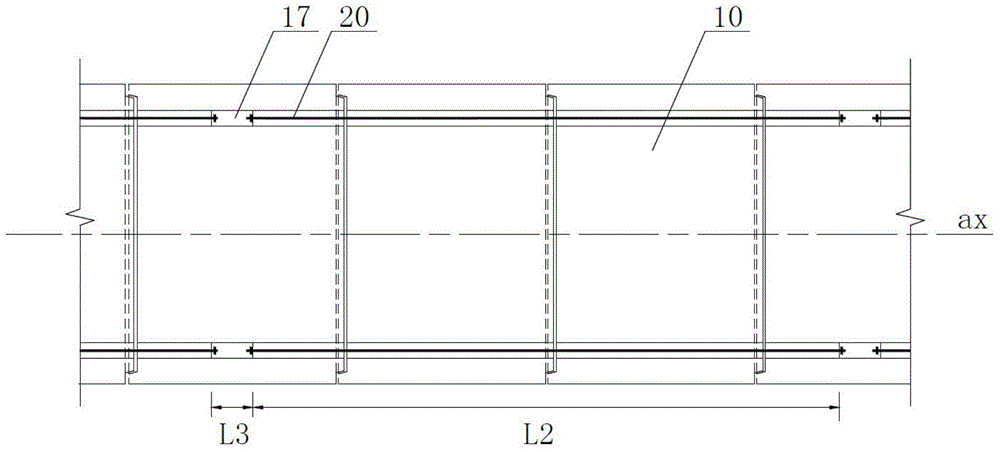

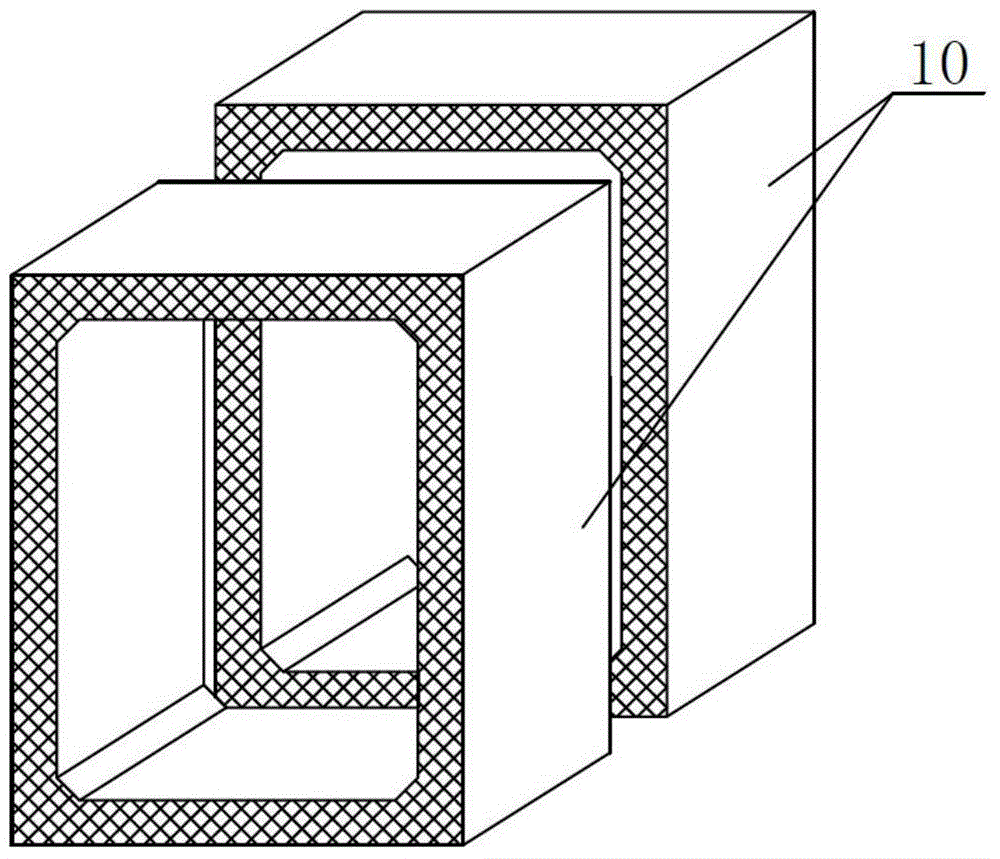

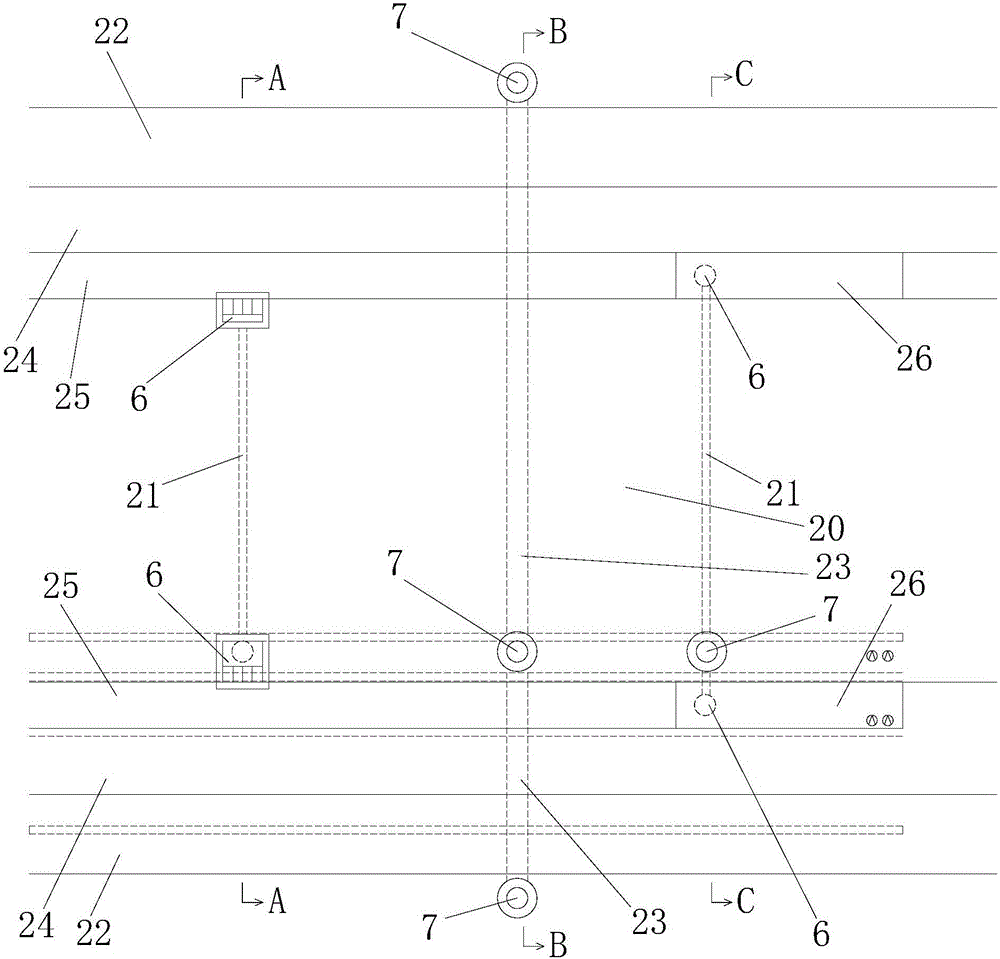

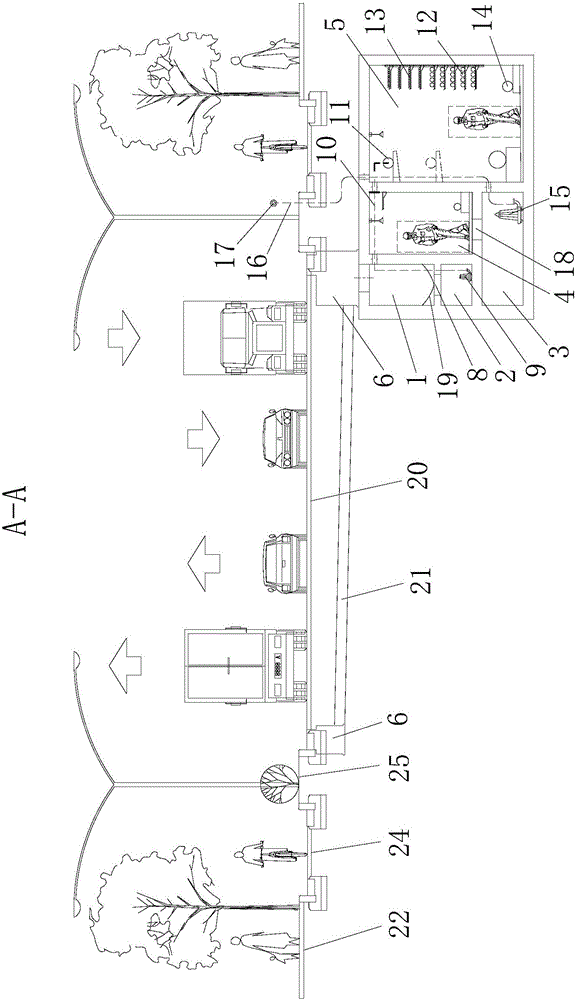

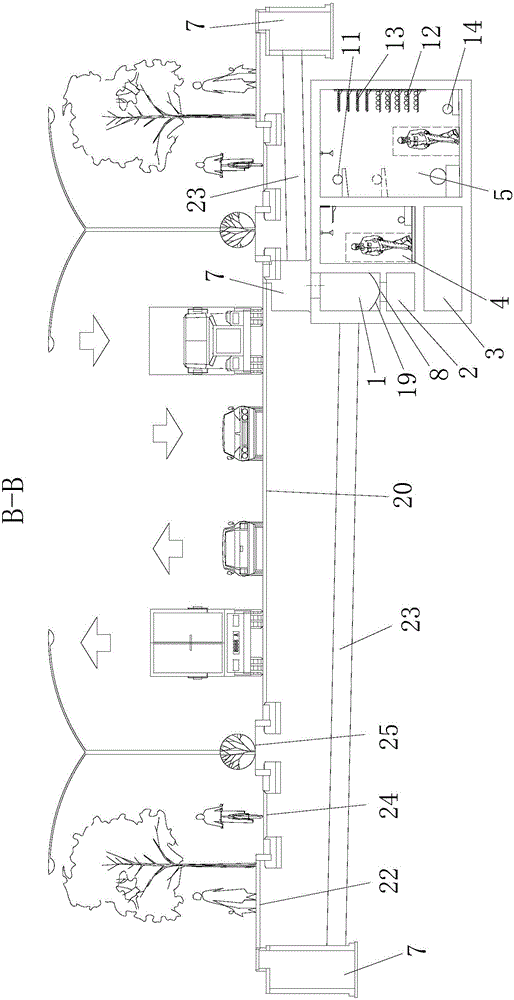

Pre-assembled single-compartment municipal tunnel and construction method thereof

PendingCN104947709ADoes not affect structural reinforcementGuaranteed StrengthArtificial islandsUnderwater structuresButt jointSpatial structure

The invention discloses a pre-assembled single-compartment municipal tunnel and a construction method thereof, relates to the technical field of pre-assembled municipal spatial structure and construction and solves the problem that a cast-in-place structure of an existing tunnel is long in construction period and quality is hard to control. The pre-assembled single-compartment municipal tunnel is assembled by several pre-assembled pipe joints arranged on a concrete cushion layer and provided with longitudinal joints in sequence via butt joint, a plurality of supports with through holes are embedded in the corner of the edge of the inner wall of each pre-assembled pipe joint, pipe joint connectors with pre-stressed rebars inside sequentially penetrate the supports of the pre-assembled pipe joints along the axis, and two ends of the pipe joint connectors are anchored on the supports on the outer side respectively. The construction method includes structurally calculating according to the geological conditions and the surroundings of the tunnel; preassembling pipe joints, excavating a foundation pit of the tunnel, casting the concrete cushion layer in the foundation pit in place, sequentially docking the pre-assembled pipe joints above the concrete cushion layer via the longitudinal joints, and filling the soil back to the foundation pit.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

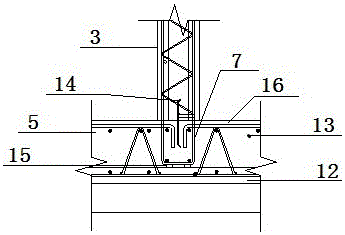

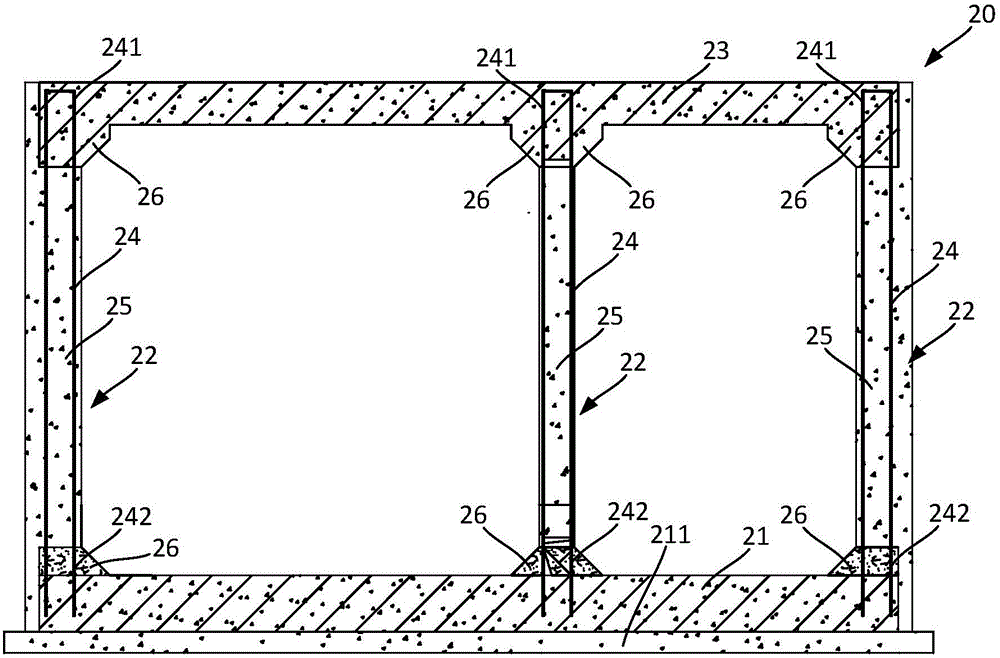

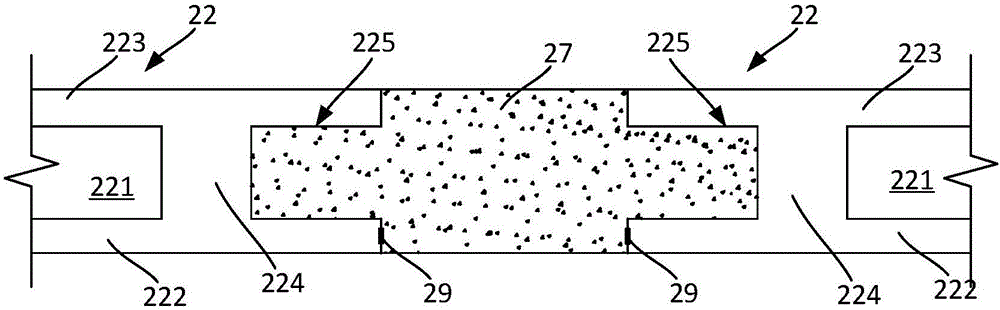

Total-prefabricated superimposed assembly type underground pipe gallery and connecting node thereof

InactiveCN105839666AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresEngineeringUtility tunnel

The invention discloses a total-prefabricated superimposed assembly type underground pipe gallery and a connecting node thereof. A bottom plate of the underground pipe gallery is a prefabricated superimposed bottom plate. A side wall or a side wall and middle wall body is a prefabricated sandwich superimposed wall. A top plate of the underground pipe gallery is a prefabricated superimposed plate. The bottom plate, the side wall or the side wall and middle wall body and the top plate are connected in a cast-in-place manner to form the underground pipe gallery. The shop prefabrication way and the superimposed cast-in-place way are combined, the advantages of the shop prefabrication way and the advantages of the cast-in-place way are fully taken, defects and deficiencies are overcome, especially the defects of low production efficiency and small transportation amount of a traditional prefabricated pipe gallery are overcome, the purposes of template-free cast-in-place construction, environmental protection, material saving, high quality and high efficiency are achieved, and the underground pipe gallery has high water resistance.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

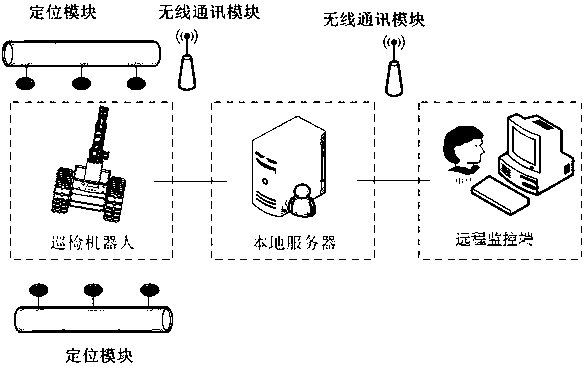

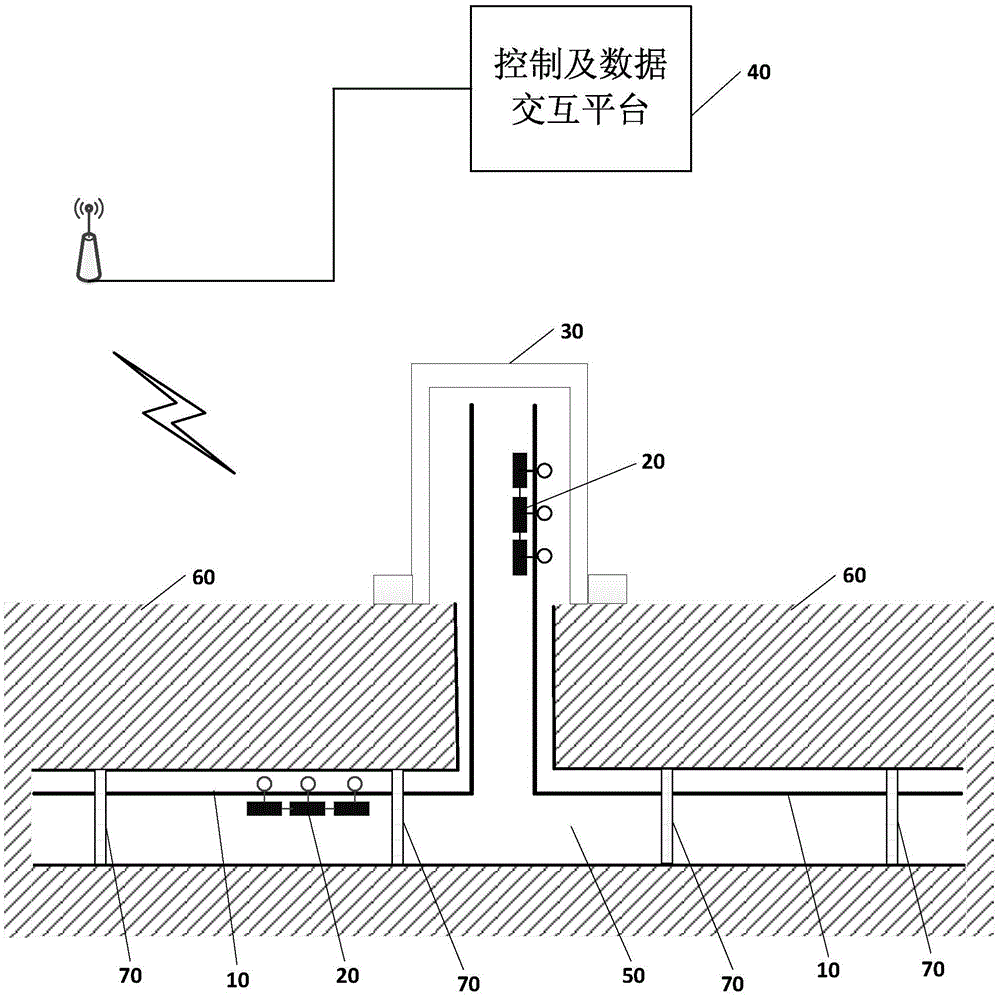

Intelligent pipe network system bases on railway robot

InactiveCN105487507AEasy maintenanceReduce operating costsTransmissionProgramme total factory controlDocking stationIntelligent Network

The invention is suitable for the field of pipe network municipal management and provides an intelligent pipe network system based on a railway robot. The intelligent pipe network system comprises shuttling railways, a mobile robot, a robot docking station and a control and data interaction platform. The shuttling railways are fixedly arranged in cabins of a comprehensive pipeline corridor, paved along the axis direction of the comprehensive pipeline corridor and pass through a fireproof door; the railway robot can movably and fixedly arranged on the shuttling railways, and is used for patrolling conditions in the comprehensive pipeline corridor and repairing the fault; the robot docking station provides charging, is used for assembly and establishing work, and serves as a communication relay for enabling the control and data interaction platform and the robot to be communicated; and the control and data interaction platform is used for carrying out analysis and storage on the received data, providing search and display service, and sending instruction data for executing the task to the mobile robot. The intelligent pipe network system, compared with an intelligent pipe network adopting a sensor fixed-point layout mode, has the advantages of simple maintenance, low operation cost and wide detection range, and can carry out safety patrol inspection instead of workers.

Owner:SHENZHEN SCHRODER INDUSTYR MEASURE & CONTROLS EQUIP CO LTD +1

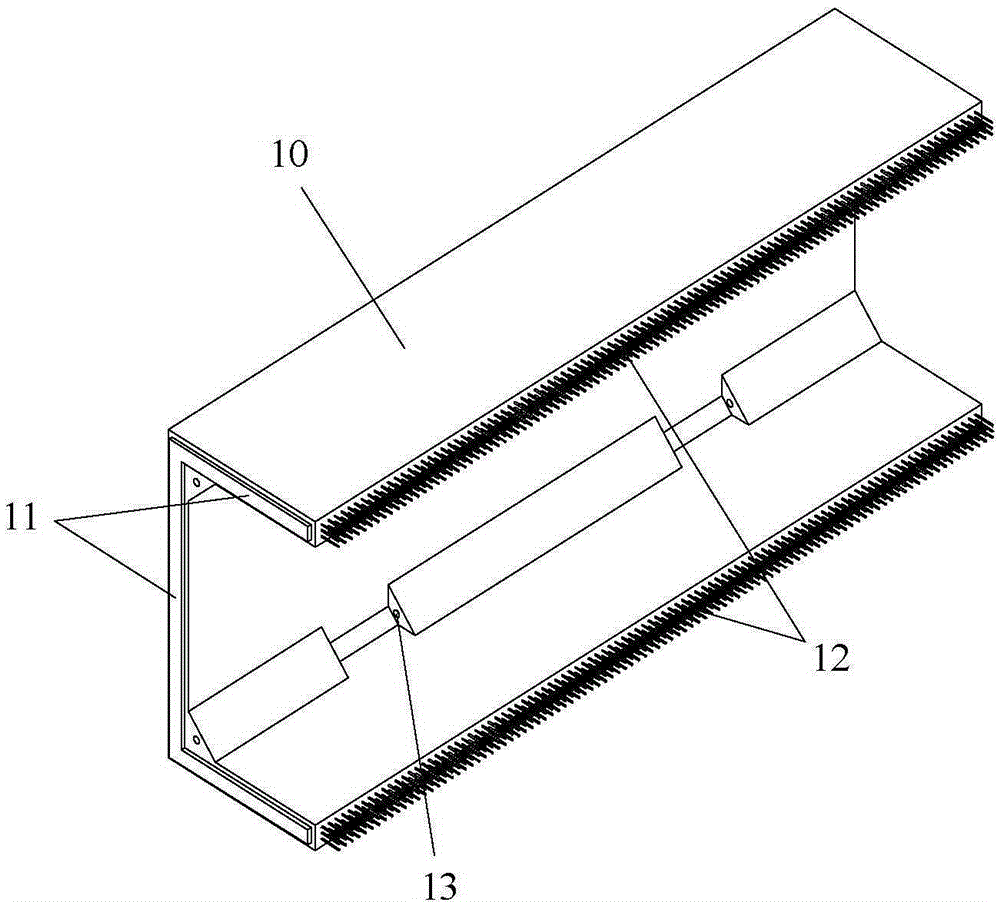

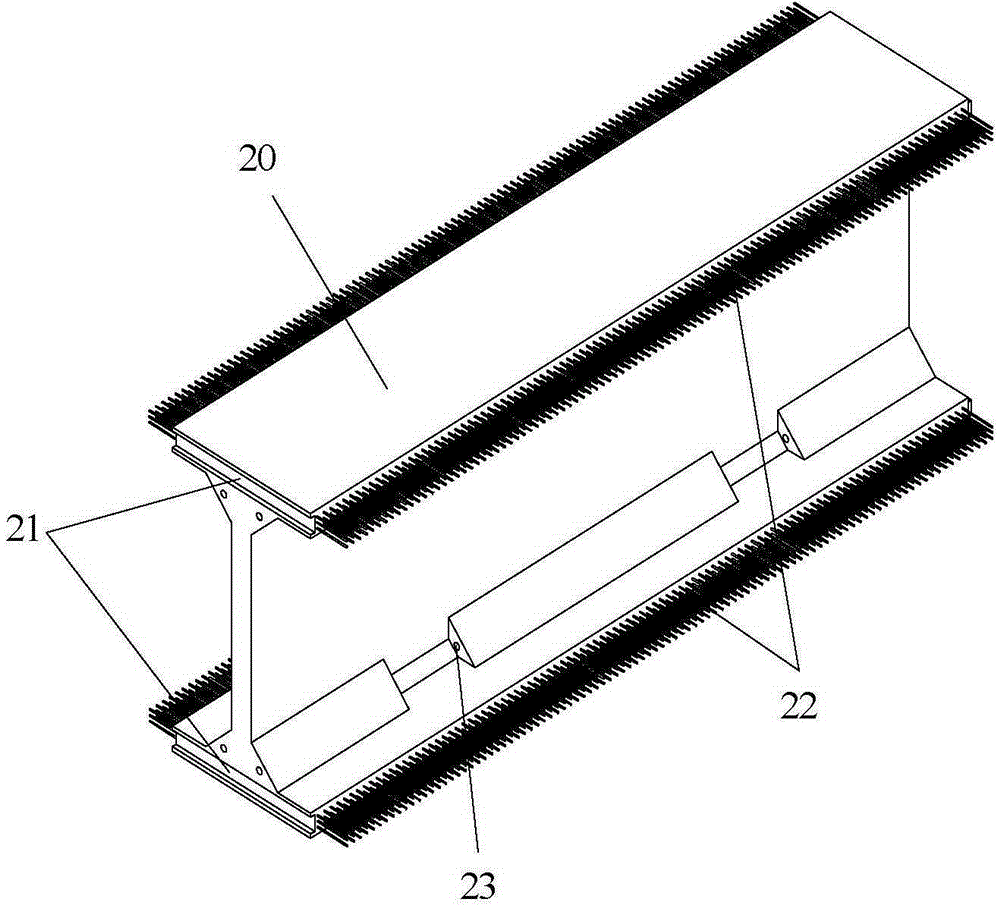

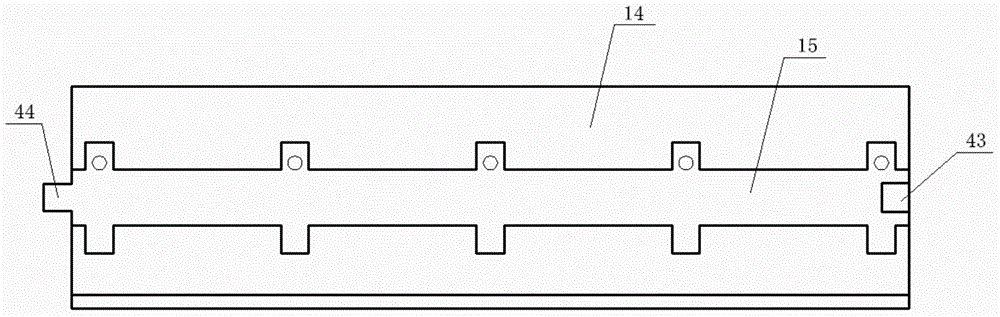

Pipe gallery prefabricated members and prefabricated comprehensive pipe gallery

ActiveCN105256838AEasy to transportStable structural strengthArtificial islandsUnderwater structuresPre stressUtility tunnel

The invention discloses pipe gallery prefabricated members and a prefabricated comprehensive pipe gallery. The pipe gallery prefabricated members comprise groove type prefabricated members. Each groove type prefabricated member comprises a web plate, a wing plate, internal reinforcing steel bars, connecting and sealing structures and longitudinal stress structures, wherein the connecting and sealing structures and the longitudinal stress structures are arranged at the two ends of the web plate and the wing plate; the height of the web plate meets the use requirement of the pipe gallery; the transverse side of the wing plate comprises a reinforcing steel bar reserved end; the connecting and sealing structures are plug-in structures, and the longitudinal stress structures are prestress steel cable connecting structures, or the connecting and sealing structures and the longitudinal stress structures are cast-in-place structures. According to the plug-in structures, prefabricated member are connected through the convex and concave plug-in structures in the longitudinal direction. According to the prestress steel cable connecting structures, a prestress steel cable passes through a prestress steel cable hole to be in prestress connection with the longitudinally matched prefabricated members. According to the cast-in-place structures, the prefabricated members are connected through the reinforcing steel bar reserved ends and then poured with concrete. The pipe gallery is assembled through the prefabricated members. Both the structure completeness and convenience of transportation and installation of the prefabricated members are achieved, the pipe gallery is stable in structural strength, convenient to transport, low in transportation and installation cost and flexible to assemble.

Owner:SHENZHEN HUAHAN GUANLANG PROPERTY SERVICES CO LTD

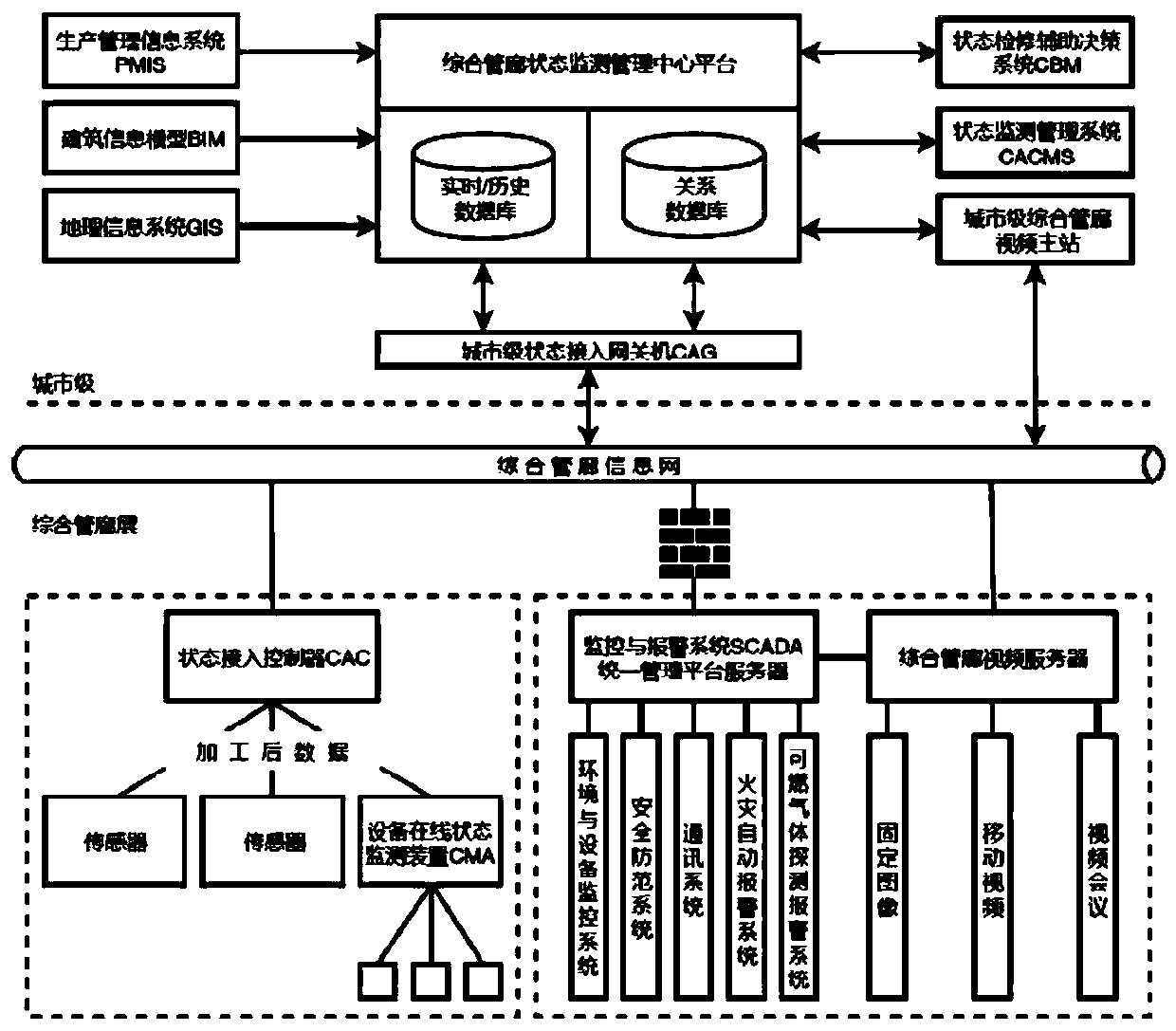

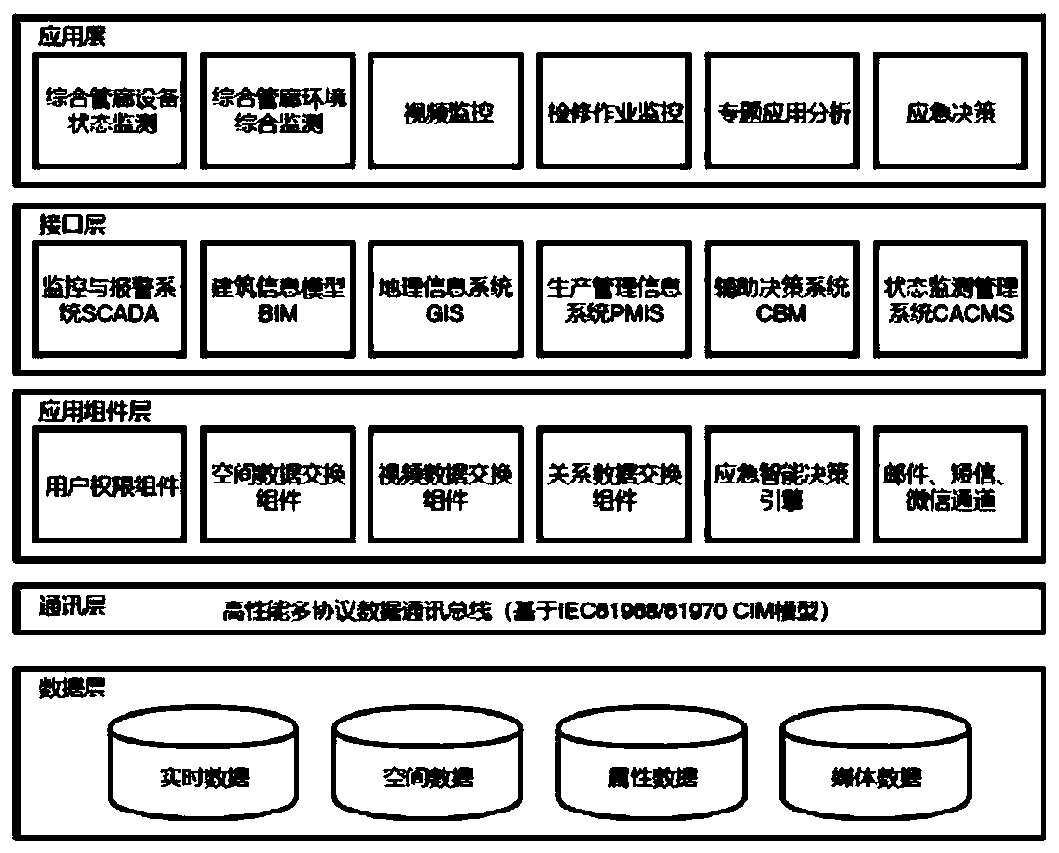

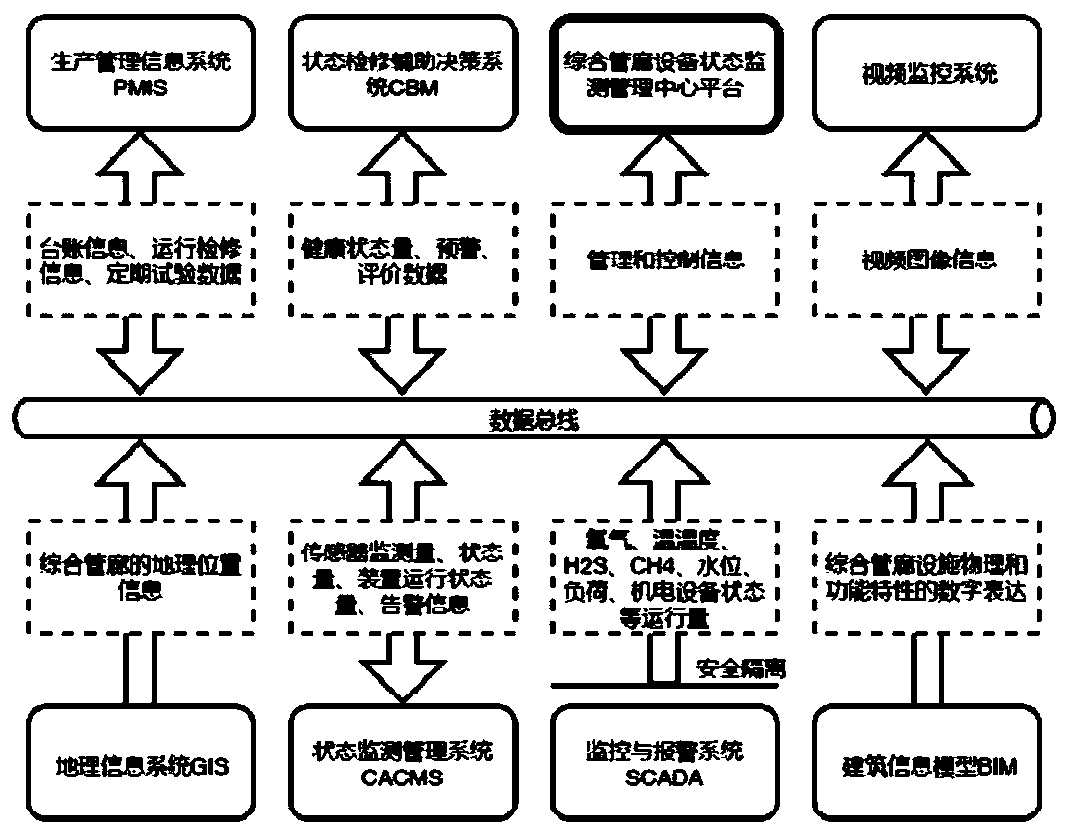

Comprehensive pipe gallery equipment state monitoring and management system

PendingCN110428135AComprehensive and timely information serviceImprove operational efficiencyRegistering/indicating working of machinesHardware monitoringTime informationData warehouse

The invention discloses a comprehensive pipe gallery equipment state monitoring and management system which is characterized by comprising a comprehensive pipe gallery layer system and a city-level system. According to the invention, a real-time database, a data warehouse and an intelligent platform tool are used as key technical means; a centralized and unified integration and sharing platform isprovided for various real-time information and production management information; a comprehensive pipe gallery equipment state unified centralized monitoring system is established; real-time information and business information based on manual work are effectively collected, converted, integrated, loaded and displayed, and more comprehensive and timely information services are better provided forvarious business fields such as comprehensive pipe gallery production operation commanding, emergency disposal, gallery entry professional pipeline operation management and state maintenance.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

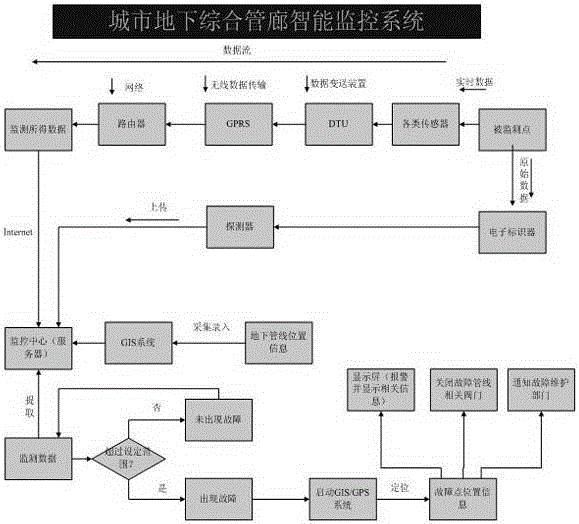

Urban underground comprehensive pipe gallery intelligent monitoring system

InactiveCN105351754AImprove running qualityImprove operational efficiencyPipeline systemsTraffic capacityMonitoring system

The invention relates to an urban underground comprehensive pipe gallery intelligent monitoring system. The urban underground comprehensive pipe gallery intelligent monitoring system mainly comprises a data collecting module, a data processing module, a data transmission module, a display and fault early warning module, a fault point positioning and processing module and a power source module. During construction, electronic markers are arranged on a pipeline monitoring point, and the basic information of a pipeline including the diameter, position, material, purpose, buried depth, types of conveying media, pressure, flow amount, flow direction, laying data, construction company and the like is recorded into the electronic markers. Each marker has a unique ID, and after the markers are buried, the IDs and global position system (GPS) coordinates of the marks are recorded on site. A detector is used for obtaining the information of the electronic markers and uploading the IDs, basic information and GPS coordinates of the markers to a server building database, and the information is stored in a monitoring center server. By means of the urban underground comprehensive pipe gallery intelligent monitoring system, the operation quality and efficiency of an urban underground pipe gallery can be greatly improved.

Owner:遵义长征电力科技股份有限公司

Method for constructing urban utility tunnel

InactiveCN107142960AReduce duplicationReduce formwork constructionArtificial islandsUnderwater structuresArchitectural engineeringJackscrew

The invention discloses a method for constructing an urban utility tunnel. The method comprises the steps that firstly, a base plate of the utility tunnel and a 50+ / -10cm side wall are poured; secondly, after concrete pouring for the first time is completed, and the strength of concrete reaches 80+ / -5% of the design strength, a movable formwork rail of the utility tunnel is laid on the base plate of the utility tunnel; then, a utility tunnel body is erected on the movable formwork rail of the utility tunnel; the residual part of the side wall and a top plate of the utility tunnel are poured with concrete on the utility tunnel body, after the strength of the concrete reaches 80+ / -5% of the design strength, a jackscrew is adjusted to be lower, and a split bolt is disassembled; when a side template of an inner mold is naturally drooping under the gravity, a movable formwork structure of the utility tunnel is driven to move to a next station so as to realized synchronous forward movement; finally, an outer template is suspended by adopting a crane, the crane moves along a lower sliding rail to the next station; and the above steps is repeated to complete the construction of the whole urban utility tunnel. The invention provides the method for the utility tunnel of a formwork framework capable of being repeatedly used and automatically walking. The method has the advantage that repeated construction of frame bodies and templates can be reduced.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

Assembled and combined cabin concrete structure of shallow-buried 0815-type underground comprehensive pipe gallery

ActiveCN105113543AAvoid hidden dangers in fire protection technologyEnsure safetyArtificial islandsUnderwater structuresUtility tunnelSewage

The invention discloses an assembled and combined cabin concrete structure of a shallow-buried 0815-type underground comprehensive pipe gallery. The assembled and combined cabin concrete structure comprises a first-class main line pipe gallery provided with multiple standard segments; each standard segment comprises an upper cabin and a lower cabin, the upper cabin is of an upper cabin concrete structure which is formed by assembling two same L-shaped bracket column connection plate side walls and an inspection beam connection plate cabin cover, the two side walls are symmetrically distributed on the two sides of the upper cabin to form a U-shaped connection body, and the cabin cover covers the top of the U-shaped connection body in a jointed mode to form the upper cabin to contain municipal pipelines; the lower cabin is of a boat-shaped groove concrete structure formed by assembling two same inverted-T-shaped structure ground beams, and the two structure ground beams are symmetrically distributed on the two sides of the lower cabin and connected to form an inverted-pi-shaped connection body for containing rainwater pipelines and sewage pipelines; the upper cabin is detachably installed on the lower cabin. Assembling moulds of the assembled and combined cabin concrete structure are easier to demould, hoist, transport and install, high in anti-seismic performance and commonality and mature in technology and can be applied to unified management of the municipal pipelines.

Owner:赵洪志

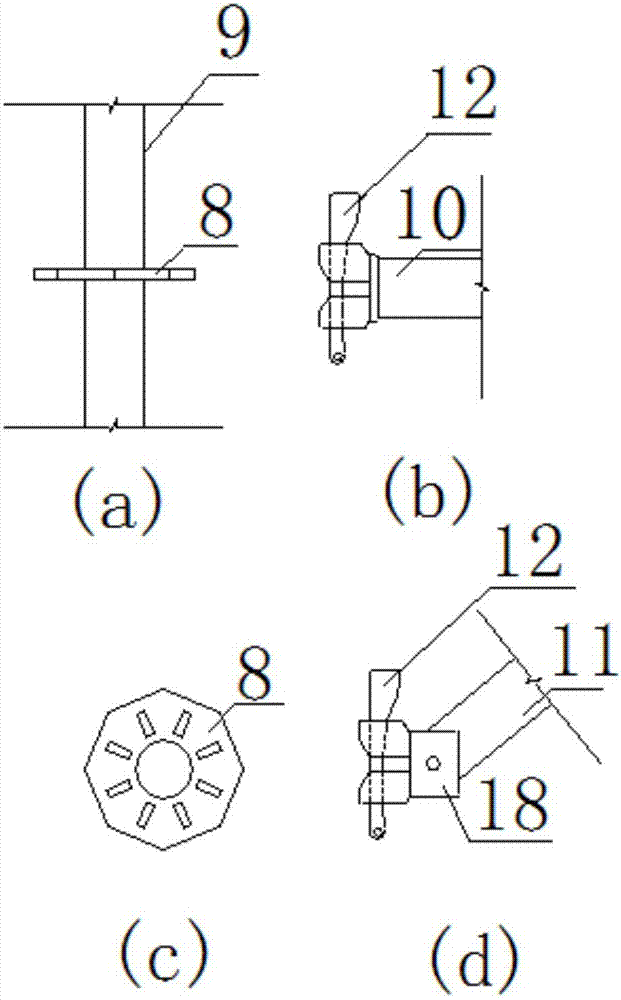

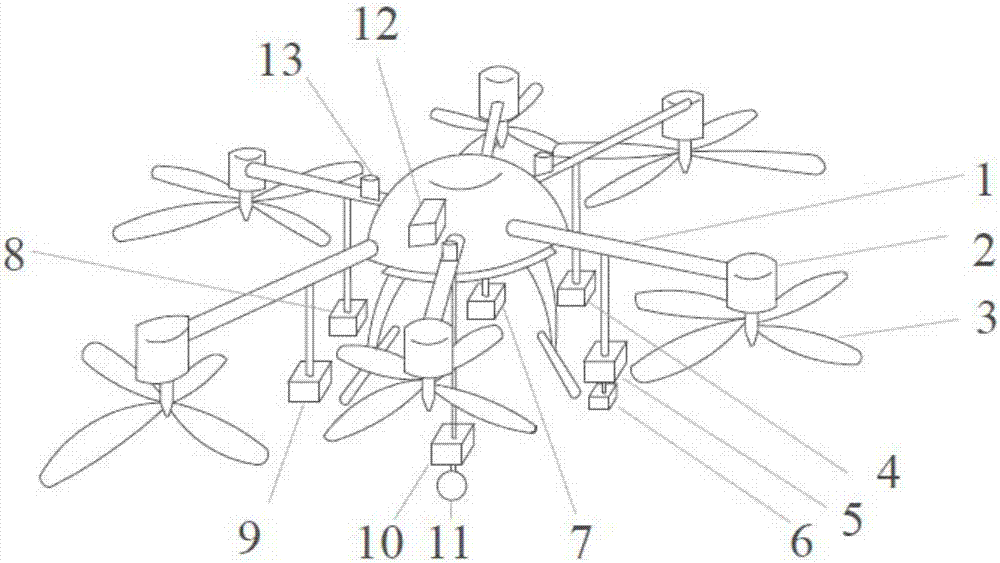

Six-rotor flying robot used for detecting underground utility tunnel

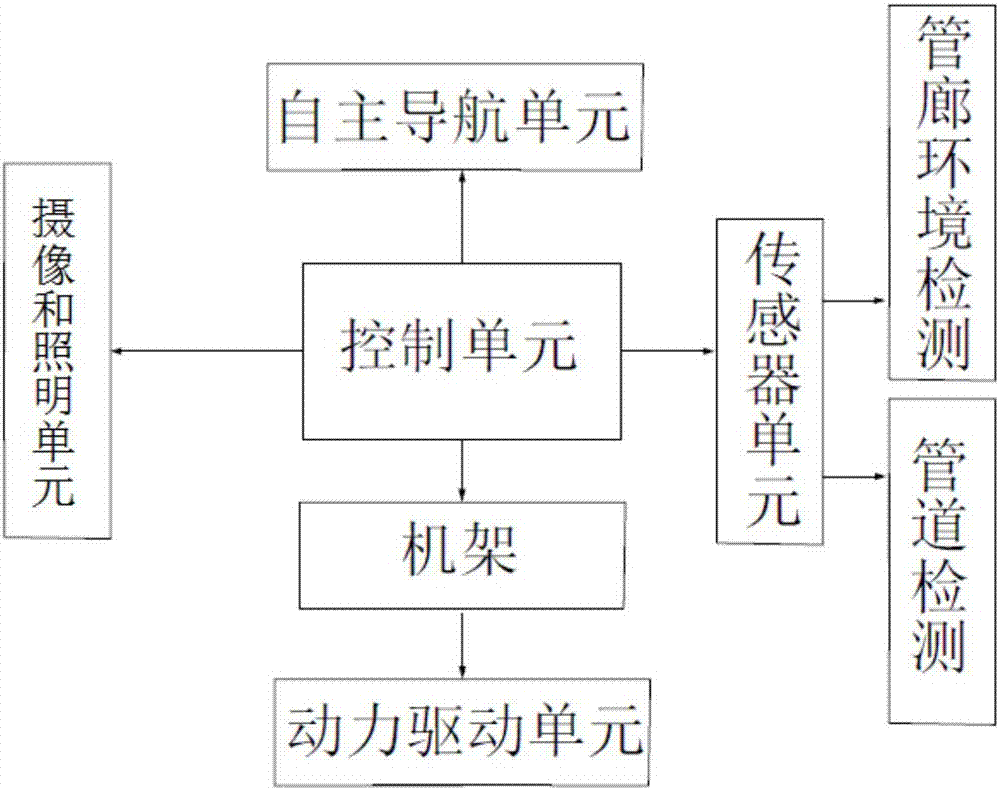

InactiveCN106864739AOvercome the incomplete defect of inspectionComprehensive detectionAircraft componentsNavigation by speed/acceleration measurementsControl cellMachine

The invention discloses a six-rotor flying robot used for detecting an underground utility tunnel comprising a machine frame, a power driving unit, a sensor unit, an autonomous navigation unit, a camera shooting and illuminating unit, a control unit and a storage unit. The invention uses the six-rotor flying robot as a skeleton, and carries different types of sensors for detecting the interior environment, fuel gas, fuel oil, water pipes and heat networks in the underground utility tunnel. Videos of inner walls, floors, various pipelines and attachments in the underground utility tunnel are shot by the camera shooting and illuminating unit, and stored in the storage unit for later comprehensive analysis and processing by means of computers after being pre-processed by the control unit. On the one hand, the six-rotor flying robot used for the detecting the underground utility tunnel is labor-saving and can be used for routine detection of the underground utility tunnel; on the other hand, the same can be used for detecting and sending back the information inside the underground utility tunnel in the case of disasters, so that following personnel can enter the underground utility tunnel to handle the disasters and to make decisions for rescue. The six-rotor flying robot uses an autonomous navigation method by a combination of laser radar and IMU, so as to overcome the limitation of no GPS signals in underground space.

Owner:CHINA UNIV OF MINING & TECH

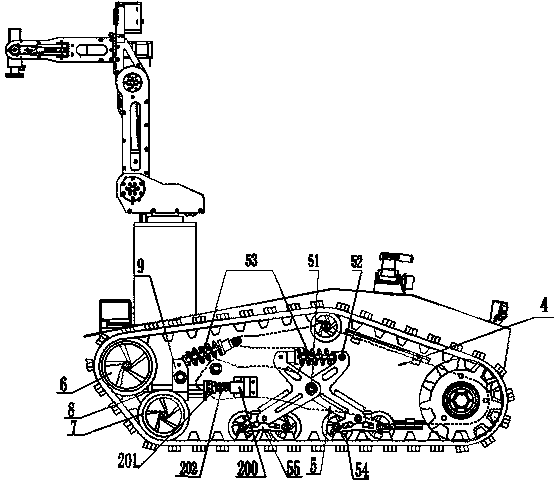

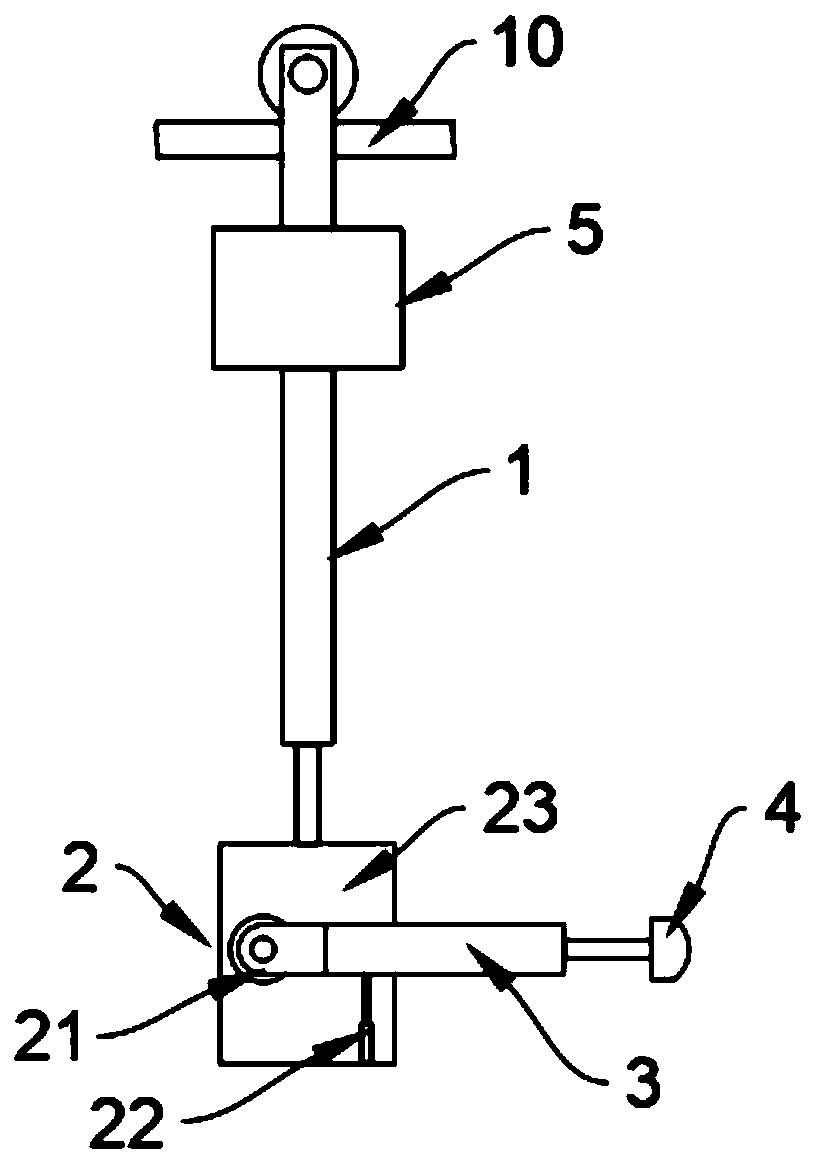

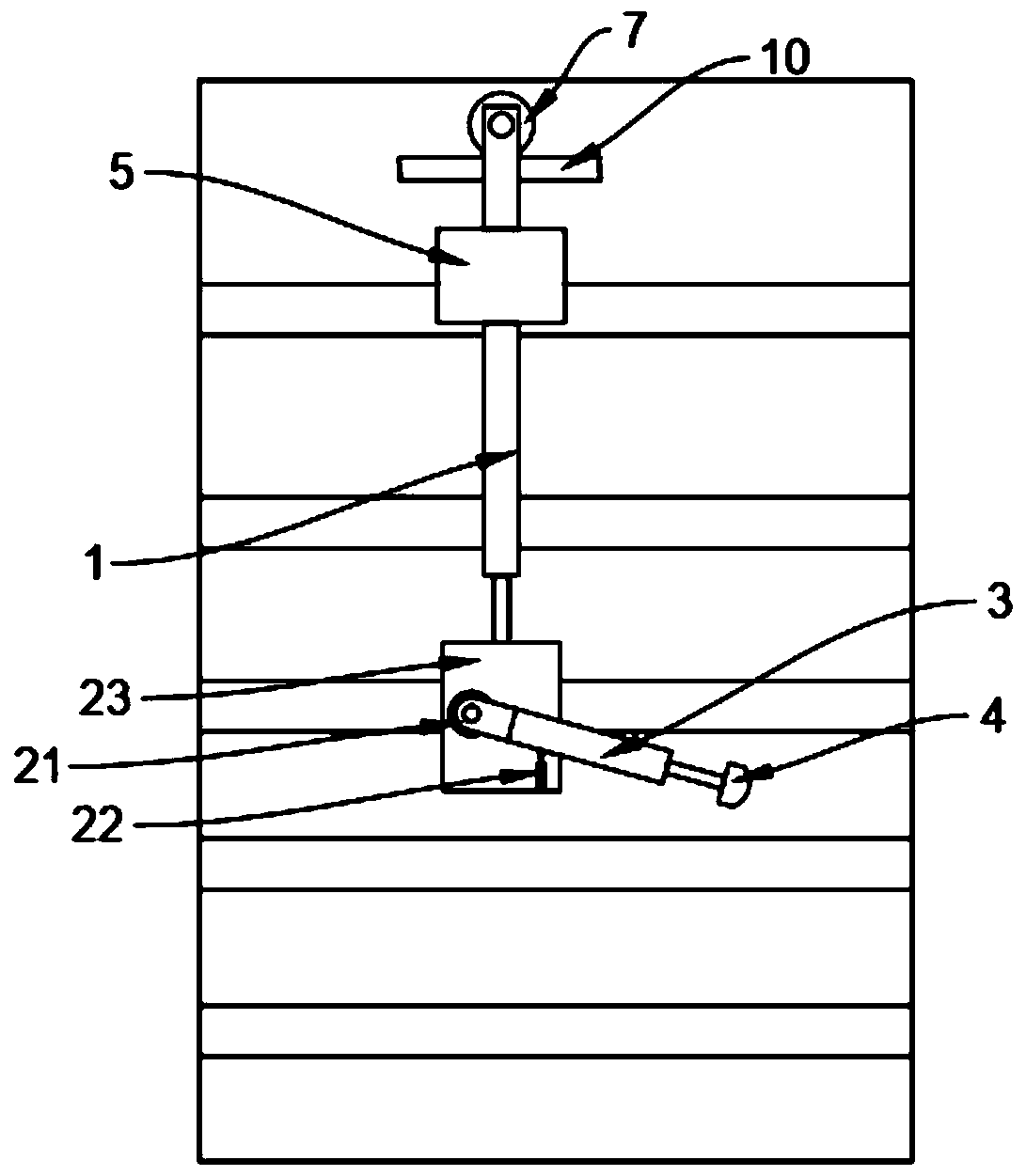

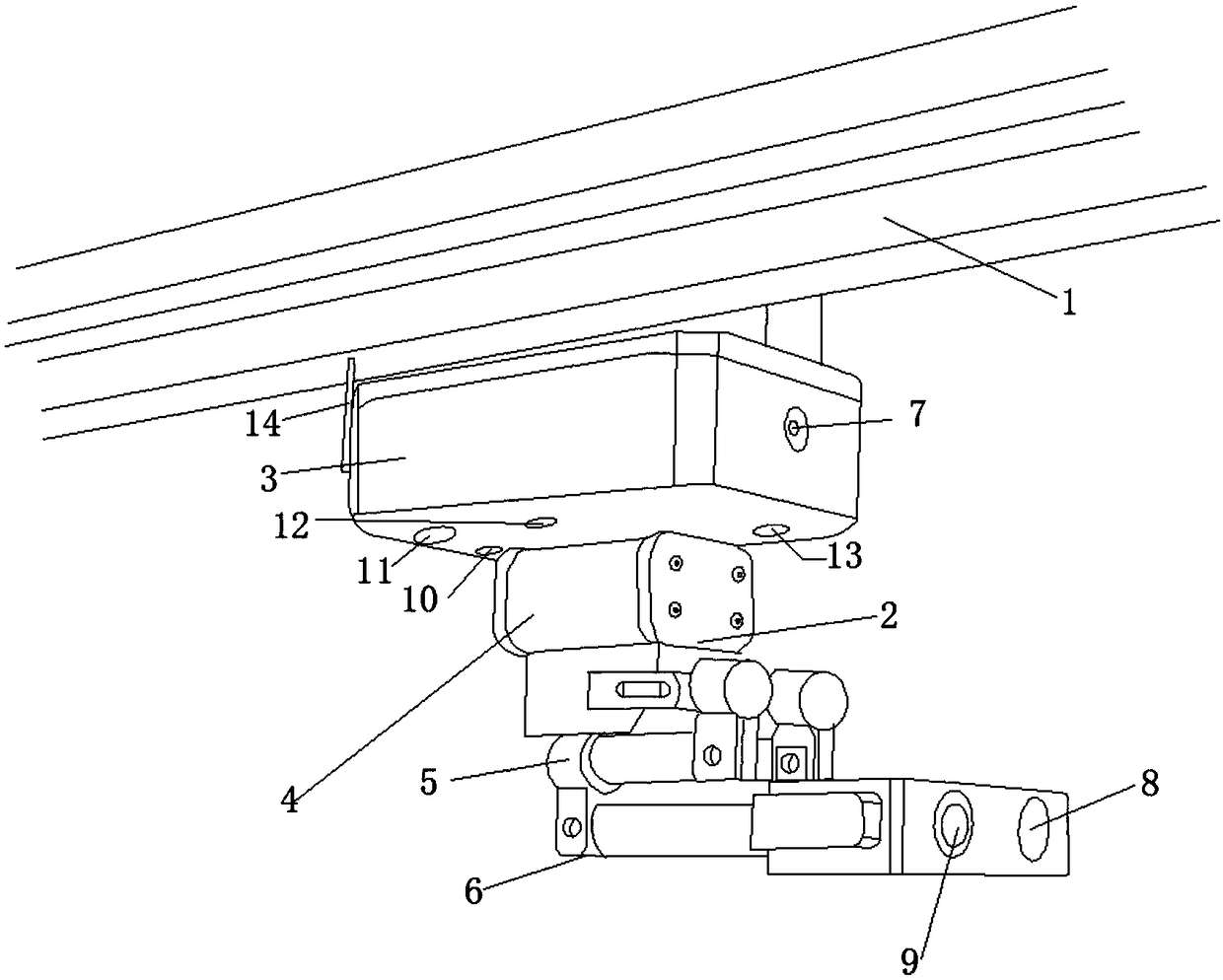

Intelligent tour inspection robot for utility tunnel

PendingCN111300453AAvoid collection blind spotsCollection in depthProgramme-controlled manipulatorFire alarm smoke/gas actuationControl engineeringUtility tunnel

The invention discloses an intelligent tour inspection robot for a utility tunnel. The intelligent tour inspection robot comprises a control system and a robot body controlled by the control system, wherein the robot body comprises an information collection unit and a lifting mechanism, an extendable mechanism and a rotating mechanism connected with the information collection unit, the lifting mechanism controls the information collection unit to lift, and the extendable mechanism and the rotating mechanism jointly control the position of the information collection unit in the horizontal direction; and the control system comprises a central control system, an information processing unit and a mobile control unit, information collected by the information collection unit is received by the central control system, and processed by the information processing unit, and finally, the robot body is controlled to move by the mobile control unit, so that a specific part or abnormal information is collected again. According to the intelligent tour inspection robot for the utility tunnel, one the one hand, a tour inspection dead zone is eliminated, and on the other hand, the abnormal part is reinspected repeatedly.

Owner:中科信同科技集团有限公司

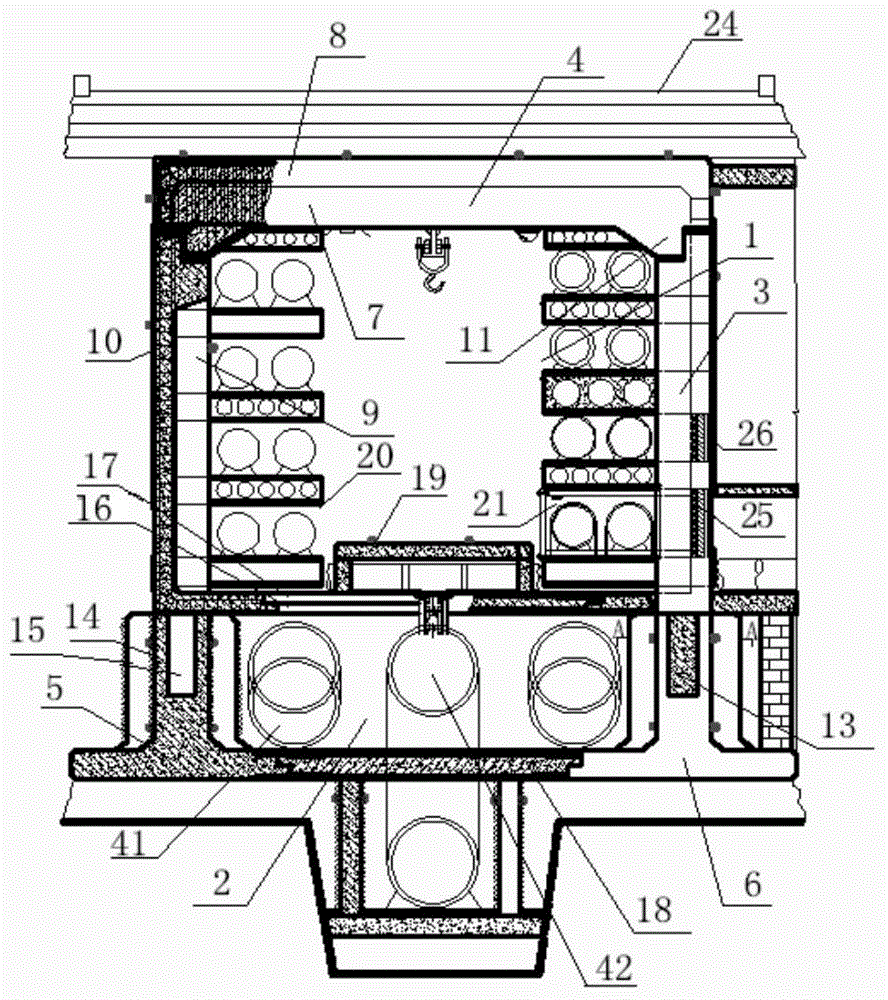

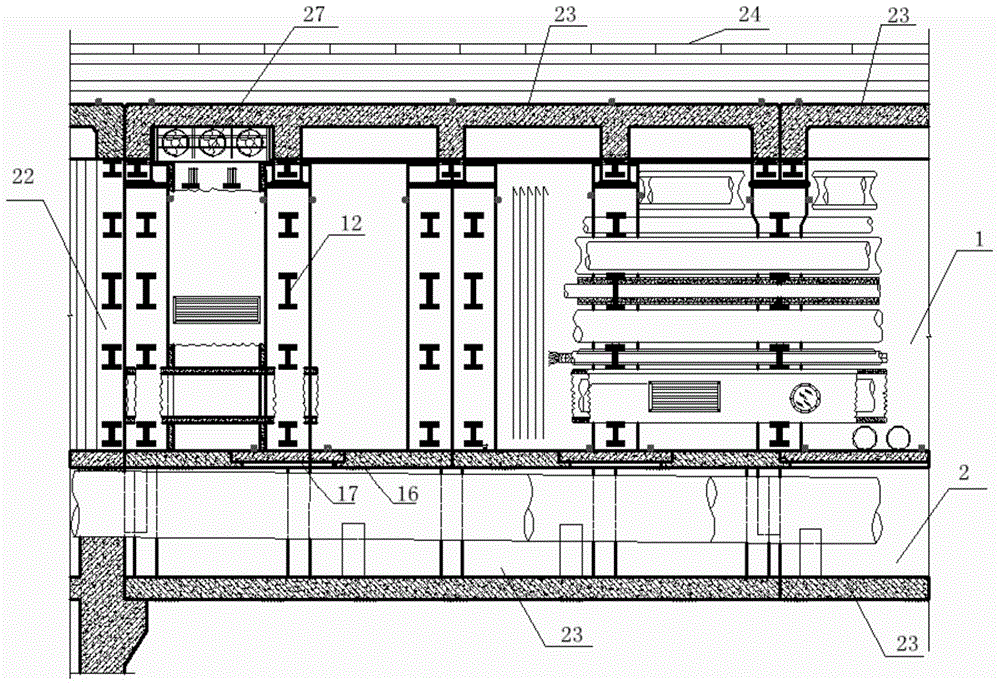

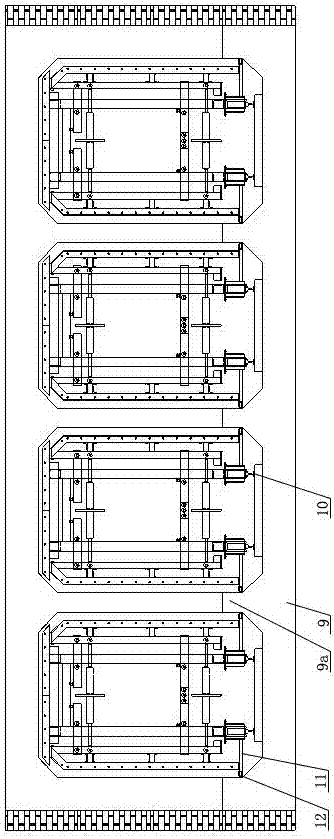

Combined underground pipe gallery space fire safety research model device

ActiveCN109345938ARealistic reproduction of flow conditionsMeet the requirements of the ventilation modeEducational modelsSource typeEngineering

The invention relates to a combined underground pipeline space fire safety research model device. The device is formed by freely combining a plurality of integrated pipe gallery modules which are of the same structure and detachably assembled together. The combined module includes a variable-frequency ventilation device, a fire source device, a slope adjustment device, a fire detection device anda fire fighting system. One end of main pipe galleries is fixed on a support frame, and the other end is supported by a jack and the slope thereof can be adjusted. A mobile trolley equipped with a burning oil pan and a cable rack can slide in the pipe galleries to change the position of the fire source. The pipe gallery modules can be disassembled and assembled freely. Combined modules can be combined to form a multilayer or multi-compartment pipe gallery. After the fire detection device issues a warning, corresponding fire extinguishing media (such as water or gas) can be provided for fires of different fire source power through the control on the fire fighting system. The device provides an integrated, convenient and flexible small-size comprehensive pipe gallery scale experimental model, which can realize arbitrary combination of different pipe gallery structures, fire fighting systems, fire detection devices, ventilation modes, fire source types and pipe gallery slopes and meet theneeds of experimenters to carry out simulation experiments on the fire conditions of various complex pipe galleries.

Owner:BEIJING UNIV OF TECH

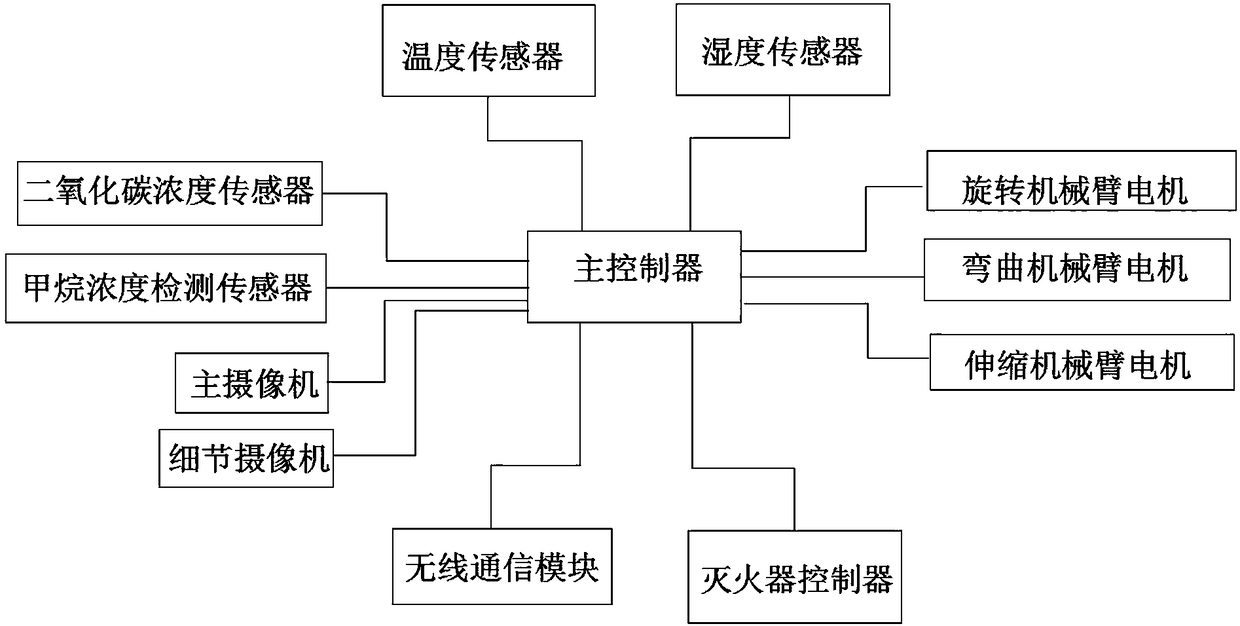

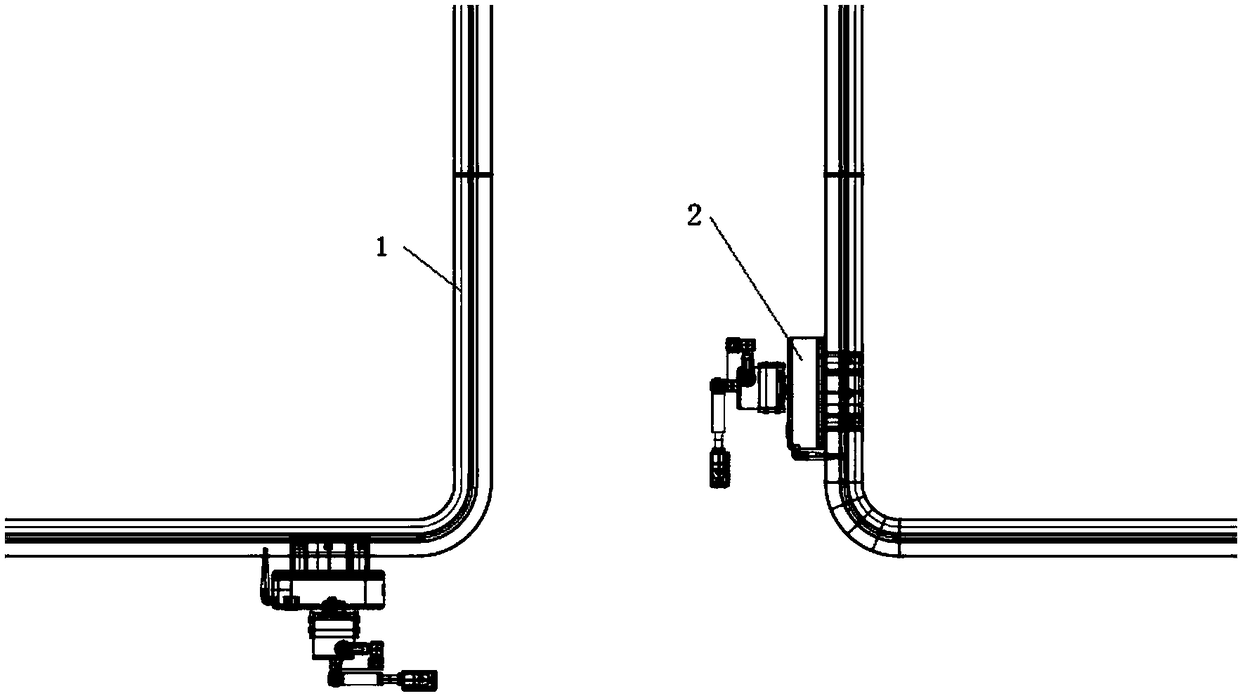

Urban utility tunnel robot

InactiveCN108227591AEasy maintenanceEasy to shoot detailsProgramme controlTelevision system detailsUnderground tunnelFire extinguisher

The invention provides an urban utility tunnel robot and relates to the technical field of tunnel robots. The robot comprises a guide rail, a tunnel robot and a safety island, wherein the safety island is mounted at a tunnel vent port, and a tunnel robot charging pile is mounted in the safety island; the guide rail is L-shaped, and one branch rail of the L-shaped guide rail is perpendicularly mounted in the safety island; the tunnel robot comprises a host, a rotary mechanical arm, a bent mechanical arm and a telescopic mechanical arm; a master controller and a master camera are mounted on thehost; the bottom end of the host is connected with the rotary mechanical arm; one side of the rotary mechanical arm is connected with the bent mechanical arm; the bent mechanical arm is connected withone end of the telescopic mechanical arm; a detachable fire extinguisher nozzle and a detachable detail camera are arranged at the other end of the telescopic mechanical arm. A maintenance man is notrequired to reach underground tunnels to maintain the robot, the shooting range is wide, detail shooting can be performed, and the robot is simple in structure, convenient to operate, accurate in detection and high in reliability.

Owner:HEBEI DABAI ROBOT TECH CO LTD

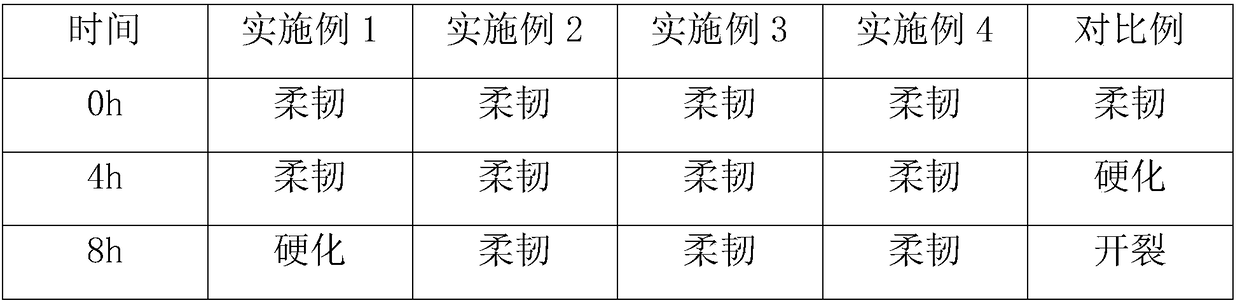

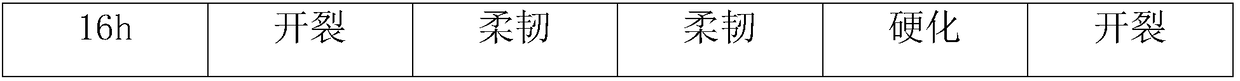

Modified acrylate spray membrane waterproofing material and preparation method thereof

The invention discloses a modified acrylate spray membrane waterproofing material and a preparation method thereof. Raw materials for preparation of the waterproofing material comprise (by weight): 100 parts of an acrylate aqueous solution, 10-100 parts of an aqueous emulsion, 0.5-10 parts of an oxidizing agent, 0.5-10 parts of a reducing agent, 0-100 parts of a pigment and 0-10 parts of an auxiliary agent. According to the invention, the problem that a film of an acrylate spray membrane waterproofing material is easy to crack at low humidity can be effectively solved. By professional equipment for construction, toughness of the acrylate spray membrane waterproofing material can be maintained for a long time, and the acrylate spray membrane waterproofing material is applicable to waterproofing works of subway, urban underground utility tunnels, tunnels and underground engineering, etc.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Large-section cable laying method

ActiveCN105896398AReduce frictionReduce the difficulty of layingApparatus for laying cablesCable trayEngineering

The invention provides a large-section cable laying method, belongs to the field of cable laying, and aims at reducing the cable laying difficulty in a comprehensive tube lane, improving the laying efficiency and reducing the construction cost. The method comprises the following steps: (1) laying a cable bridge in the comprehensive tube lane by an upright post; (2) installing a cable reel at the starting point of the cable bridge, and arranging an electric winching or a winding engine at the end point of the cable bridge; (3) fabricating a roller device; (4) binding the end of a traction wire rope on the electric winching or the winding engine and the end of a cable firmly; (5) starting the electric winching or the winding engine and pulling the cable in place along the laying path; and (6) binding the cable on the cable bridge segment by segment. By the large-section cable laying method, the cable can be pulled to move along the laying path under the action of relatively small traction force; manpower, a hoisting device and the like do not need to be input in the comprehensive tube lane in the overall laying process; the laying difficulty is reduced; the laying efficiency is improved; and the construction cost is reduced.

Owner:CHINA 19TH METALLURGICAL CORP

Tunneling and assembling structure and construction method of comprehensive pipe gallery

ActiveCN104912101ARealize integrated constructionRealize automated constructionArtificial islandsExcavationsArchitectural engineeringUtility tunnel

The invention relates to a tunneling and assembling structure and a construction method of a comprehensive pipe gallery. According to the construction method, shield backrest equipment is arranged at the first end of a foundation pit, a U-shaped shield mechanism is arranged at the second end of the foundation pit, and a middle part is arranged between the shield backrest equipment and the U-shaped shield mechanism. The middle part comprises an expanded jack or a combination of the expanded jack and one or more prefabricated pipe gallery sections, or a section of pit slot or a combination of the section of pit slot and one or more one or more prefabricated pipe gallery sections, or one or more prefabricated pipe gallery sections. The tunneling and assembling structure and the construction method of the comprehensive pipe gallery have the advantages that construction efficiency and economic efficiency of the comprehensive pipe gallery are improved effectively.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

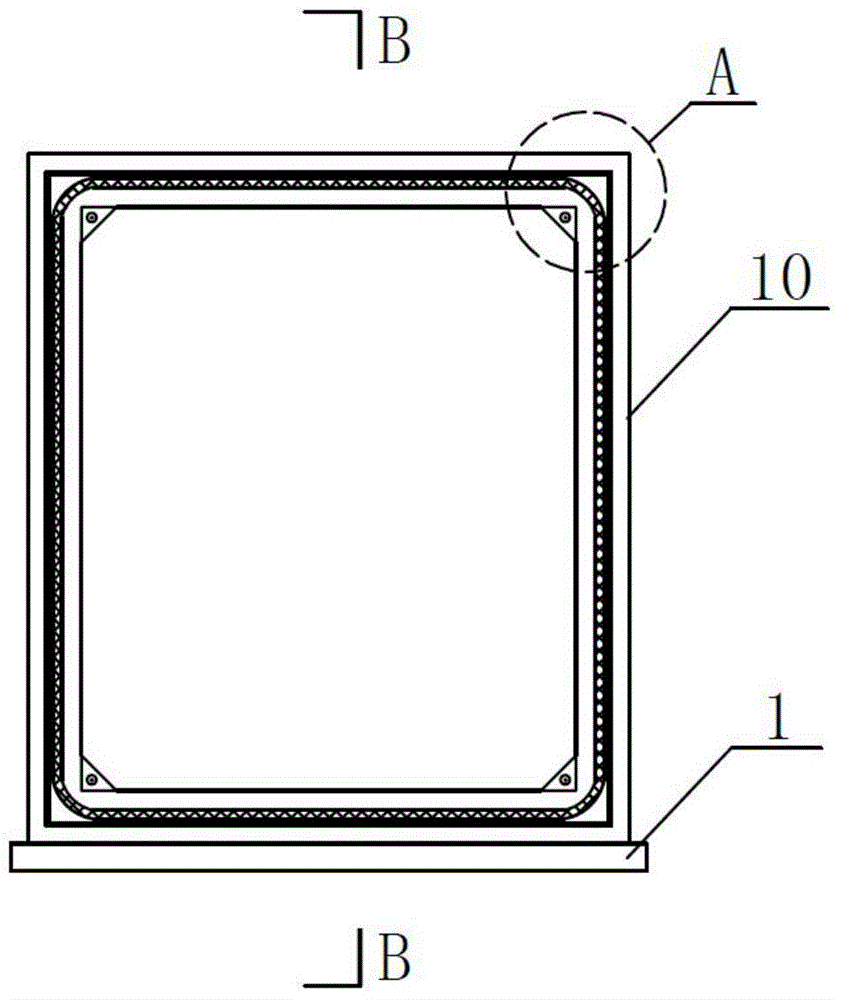

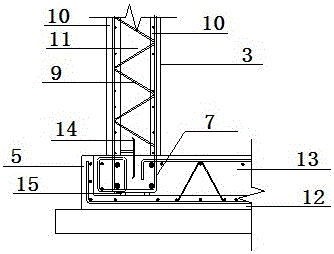

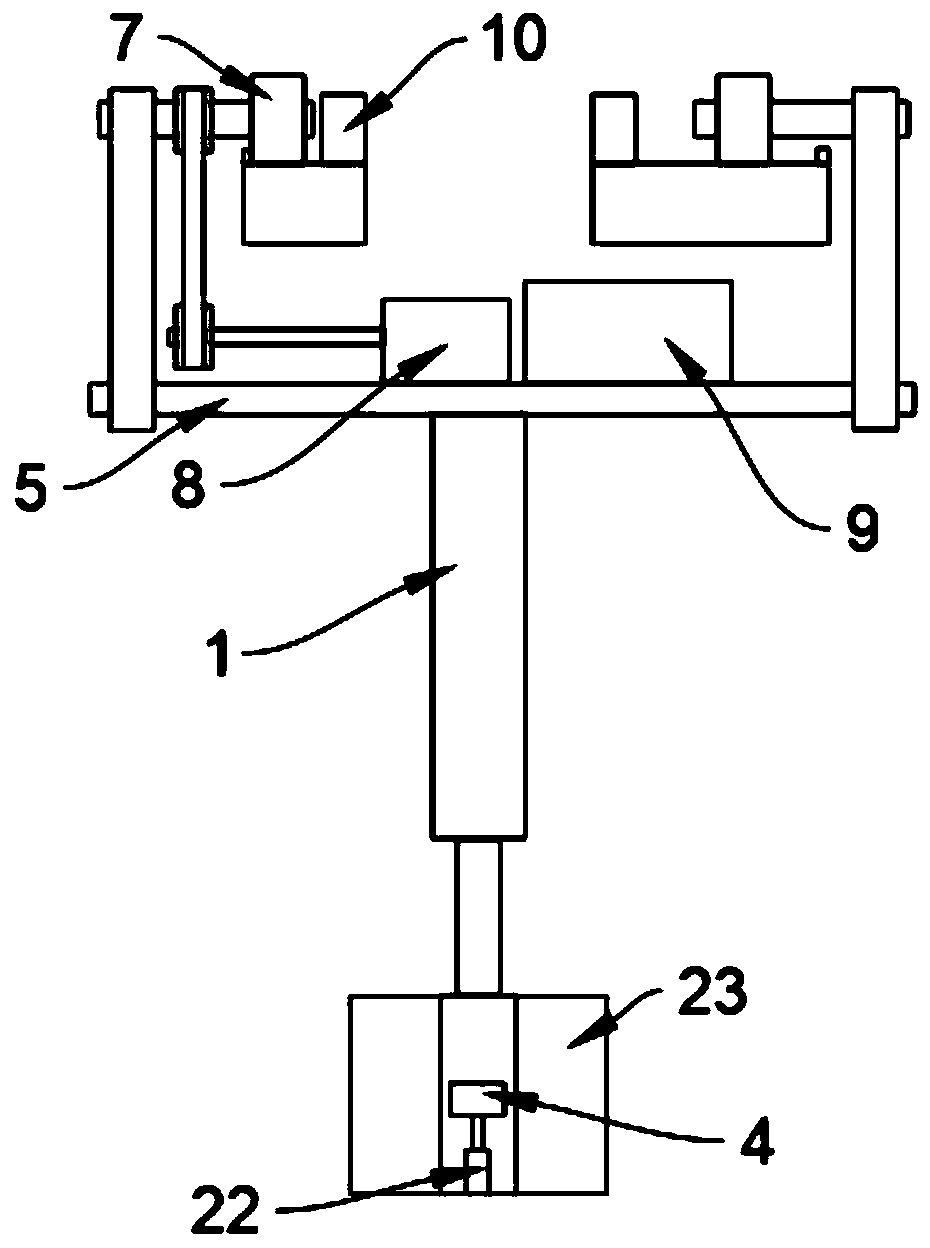

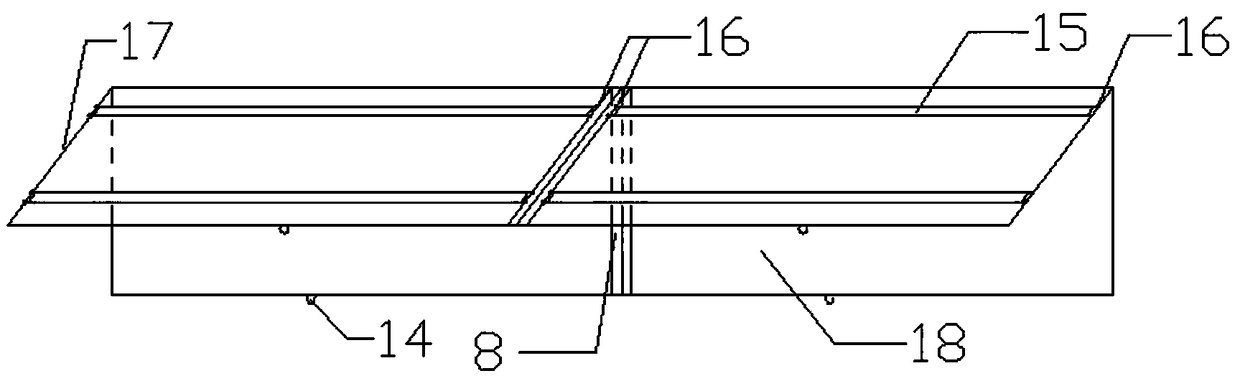

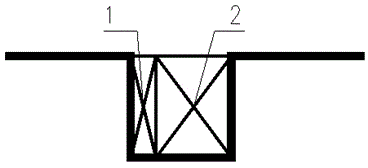

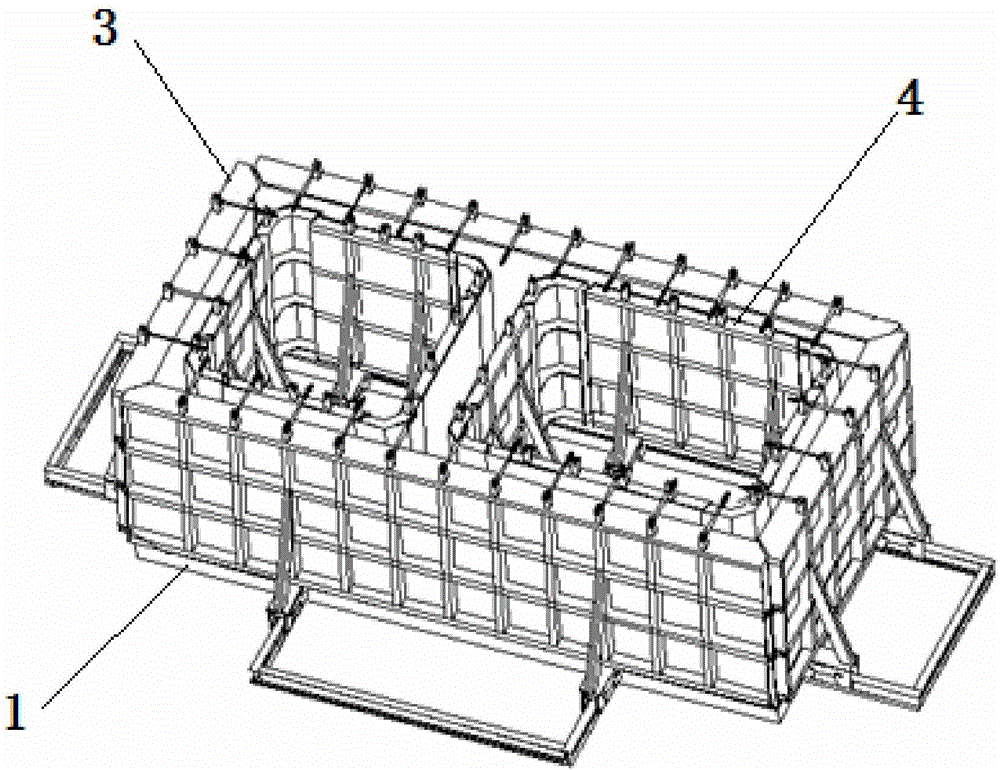

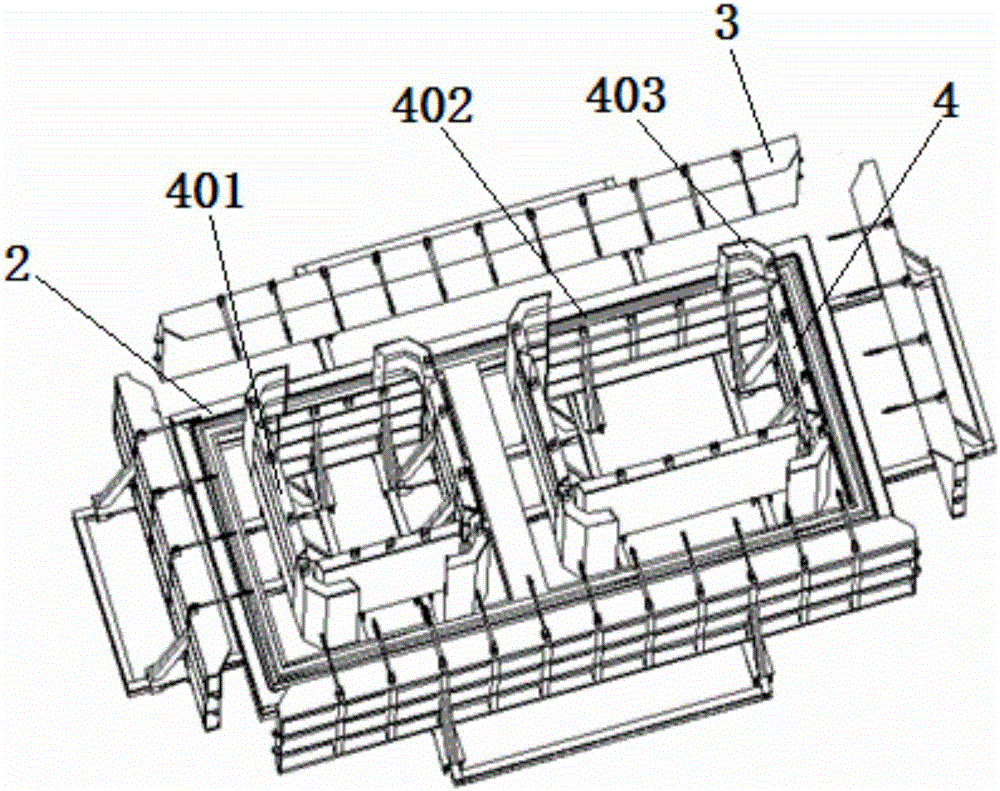

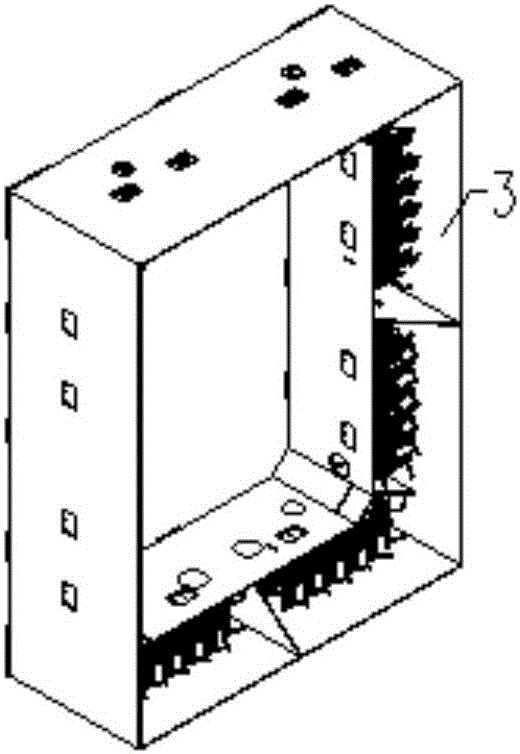

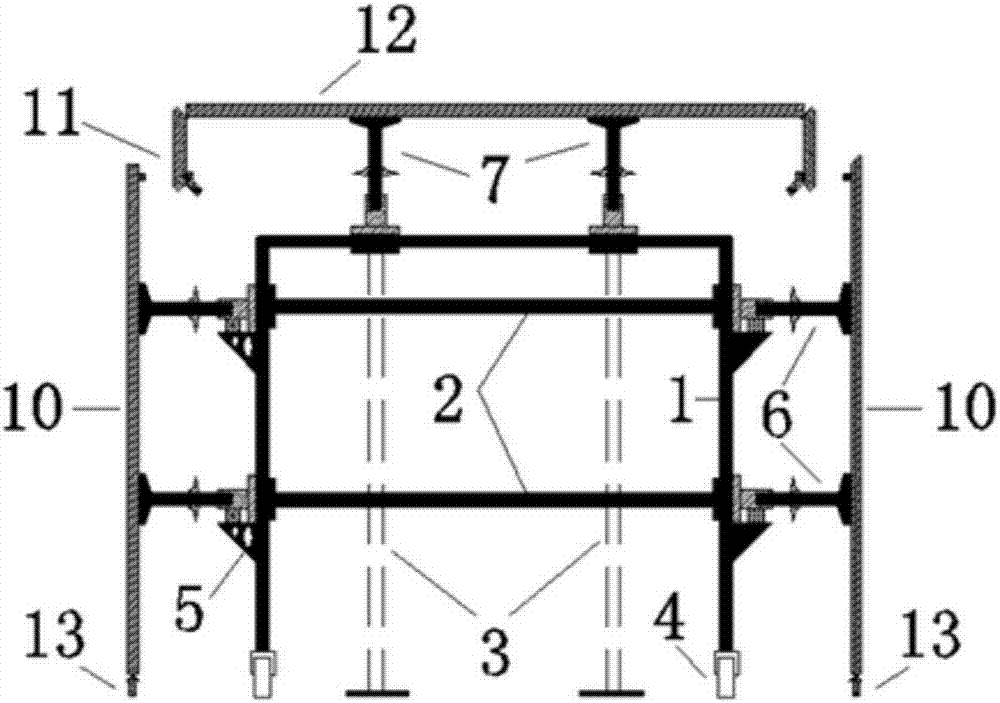

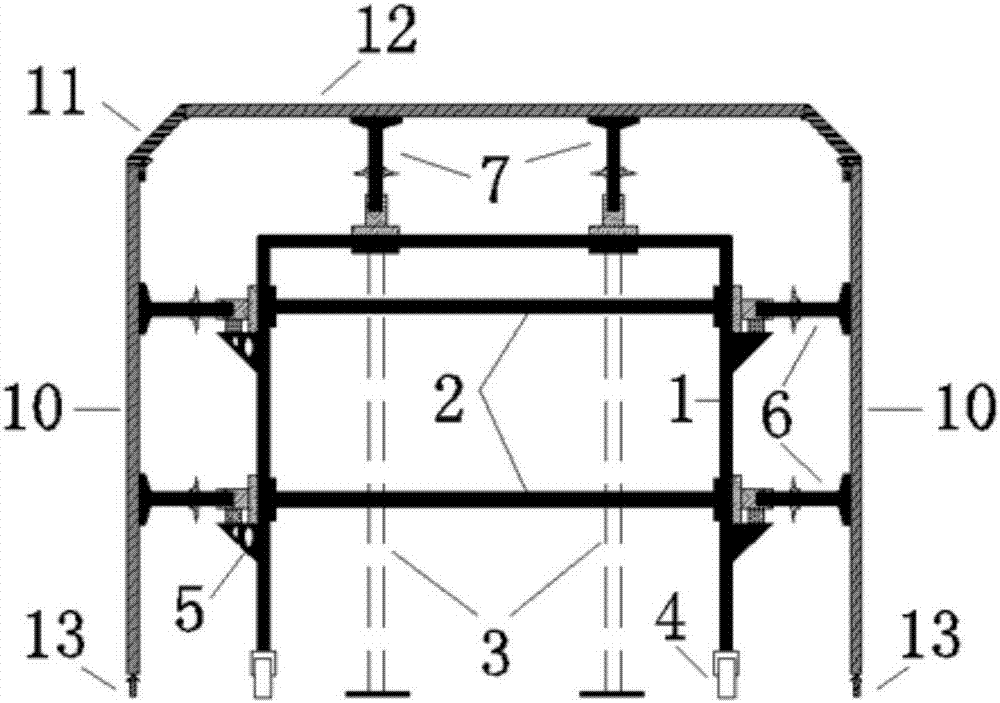

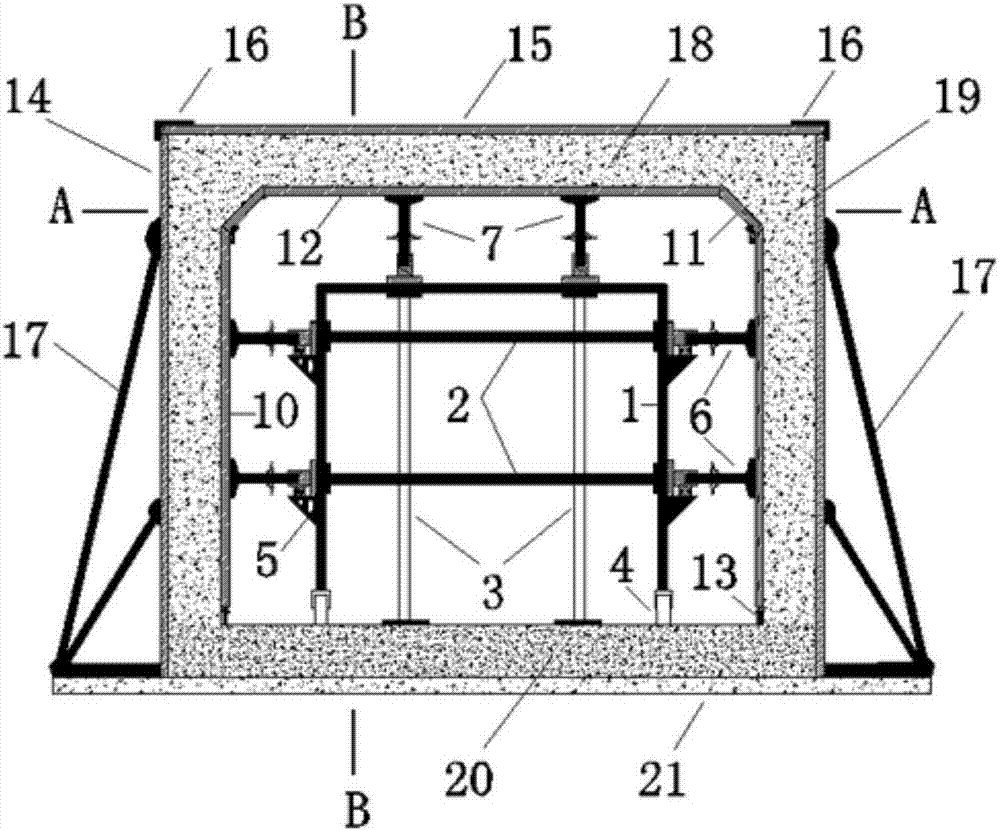

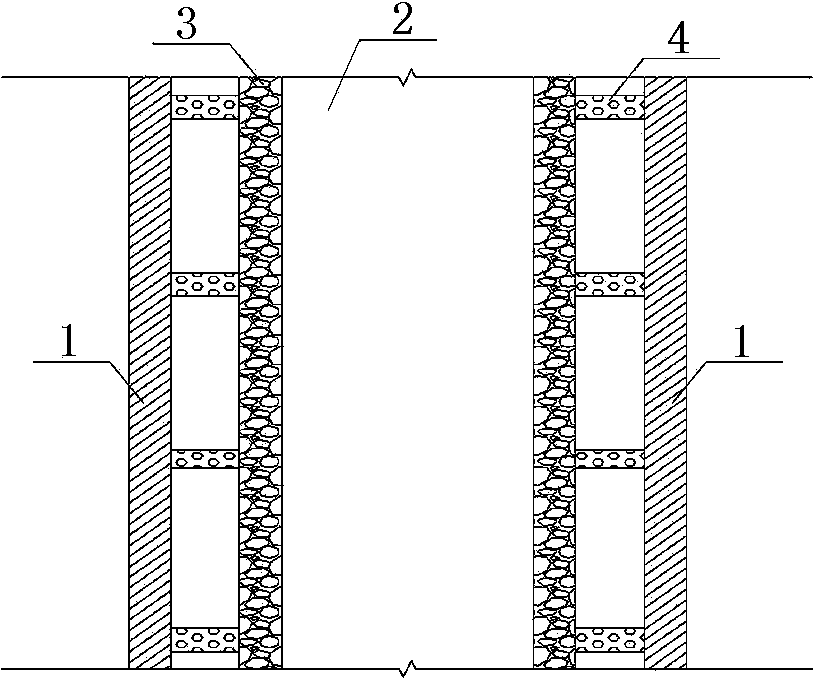

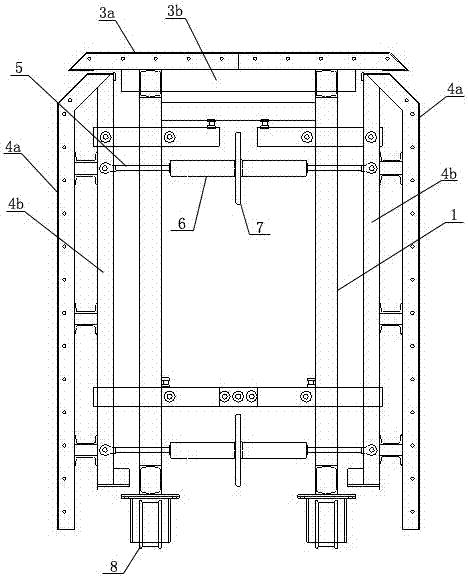

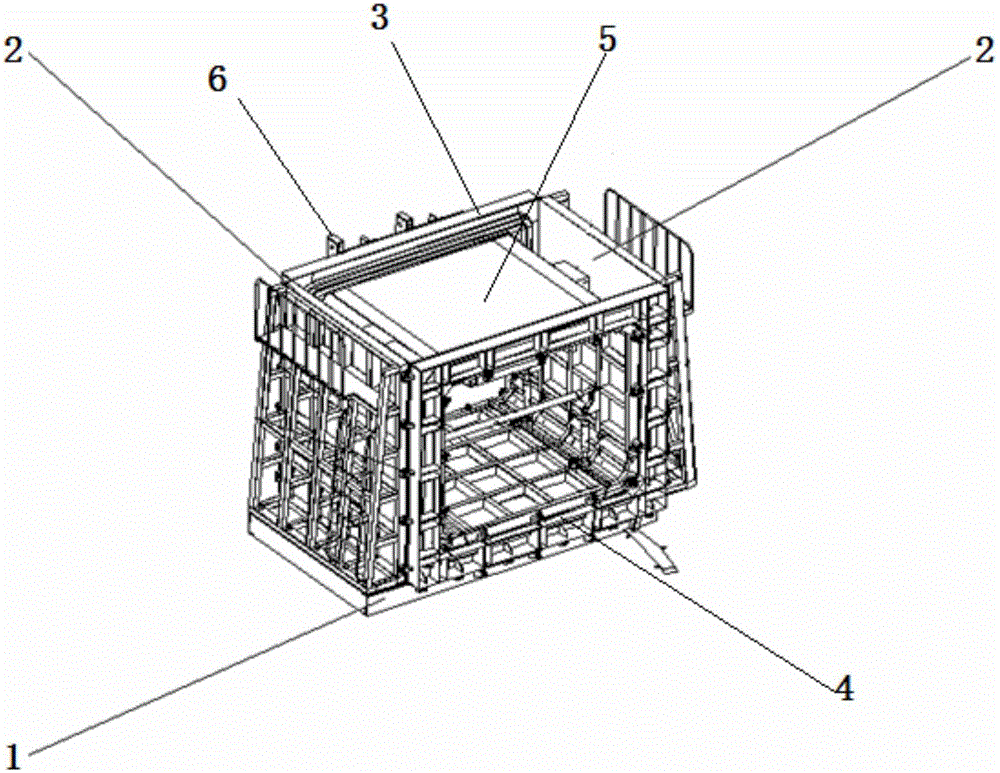

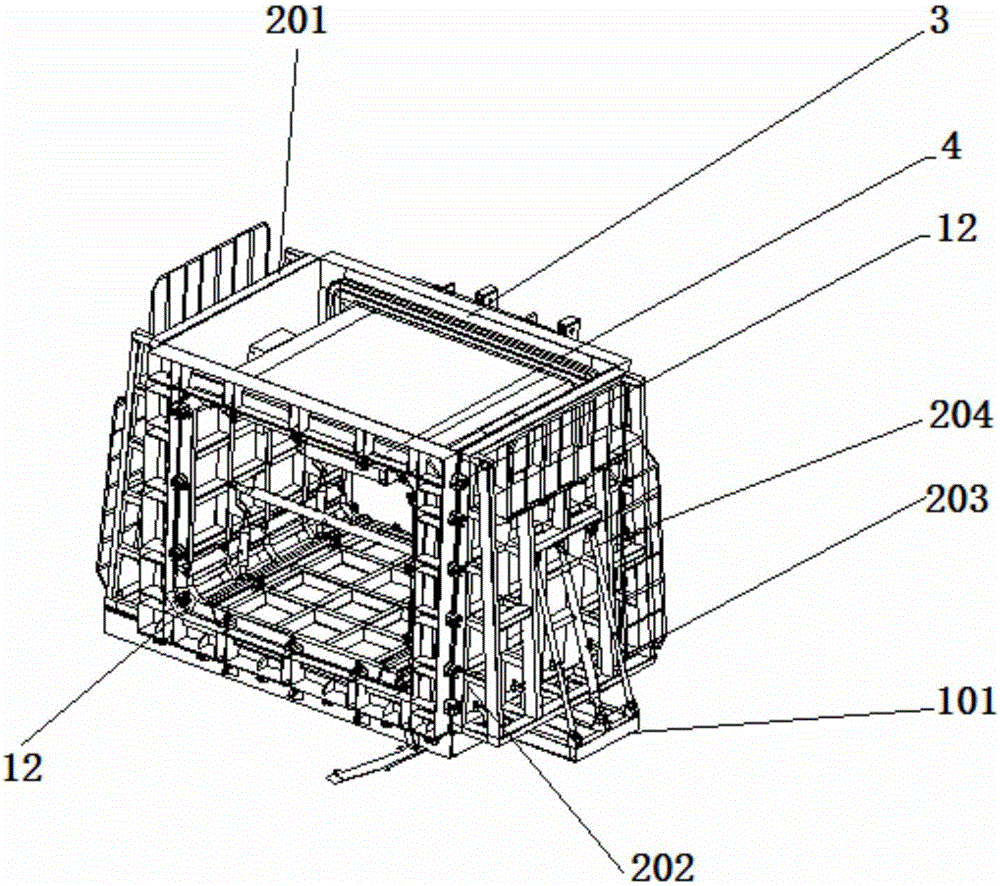

Vertical molding mold and system and application method for concrete utility tunnel

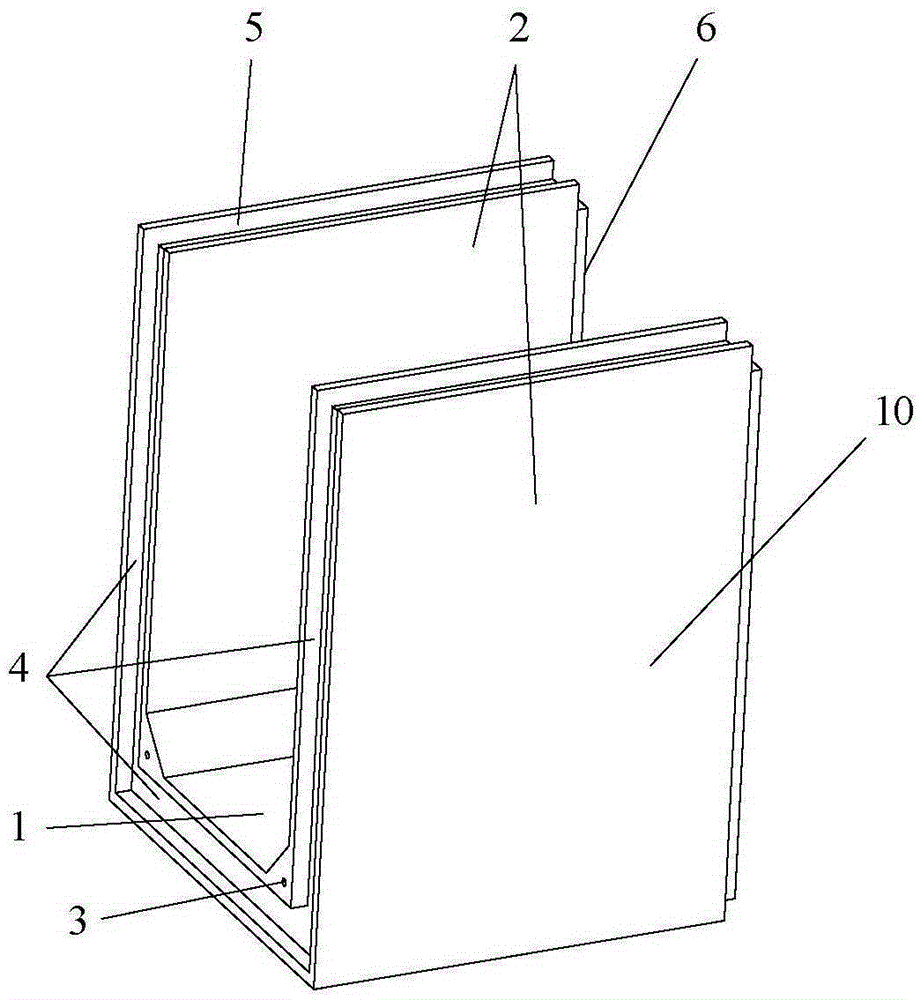

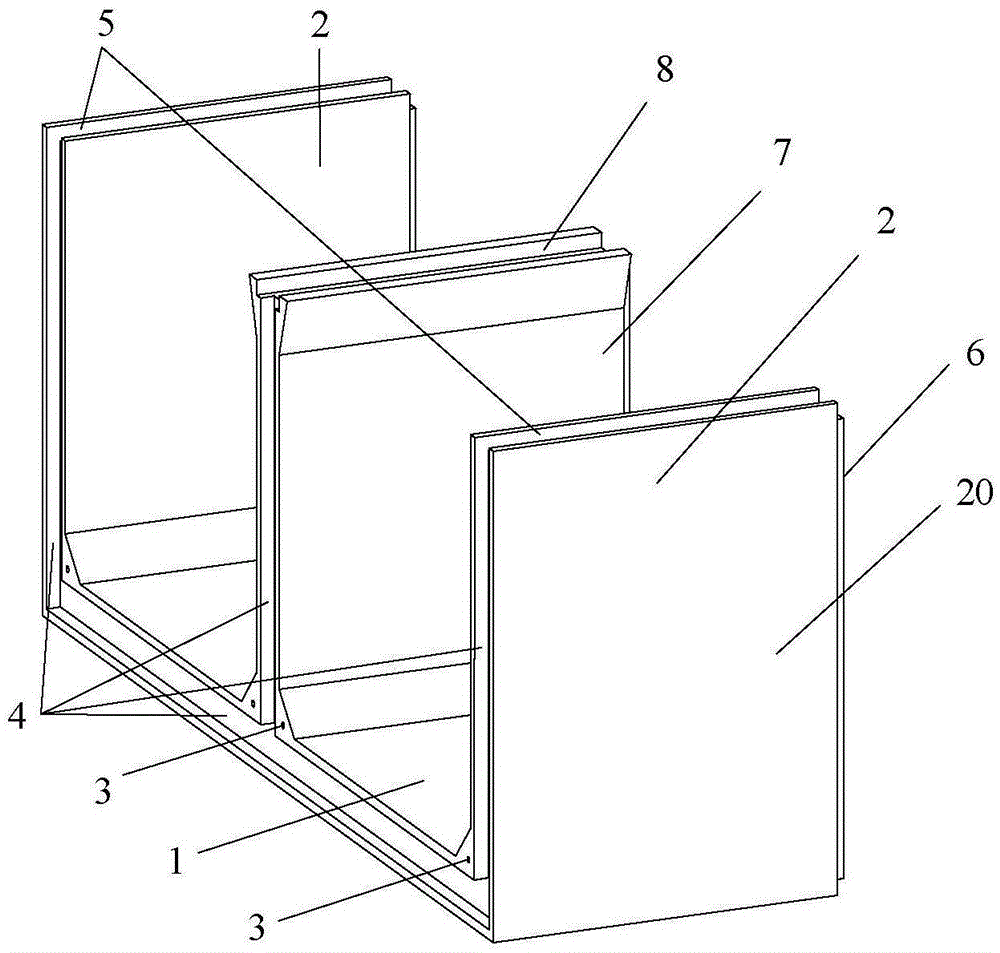

InactiveCN106346595AIncrease production capacityIncrease pouring speedMouldsMould auxillary partsUtility tunnelMaterials science

The invention discloses a vertical molding mold for a concrete utility tunnel. The vertical molding mold comprises a mold base (1), a female end mold (2), an external mold (3) and one or more internal molds (4). The mold base (1) is fixed on the ground, the female end mold (2) is arranged on the mold base (1), the external mold (3) is arranged on the mold base (1) and located on the periphery of the outer side of the female end mold (2), one or more internal molds (4) are arranged on the mold base (1) and located on the periphery of the inner side of the female end mold (2). The molding mold and system and production technology for the concrete single-cabin, dual-cabin and multiple-cabin utility tunnel is high in quality and large in scale and can be rapidly and largely produced.

Owner:CHANGSHA CHUHONG MACHINERY

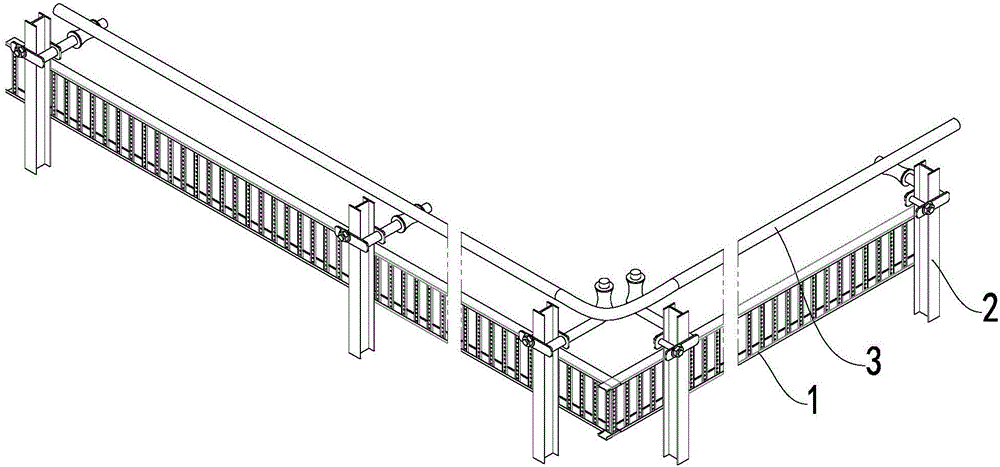

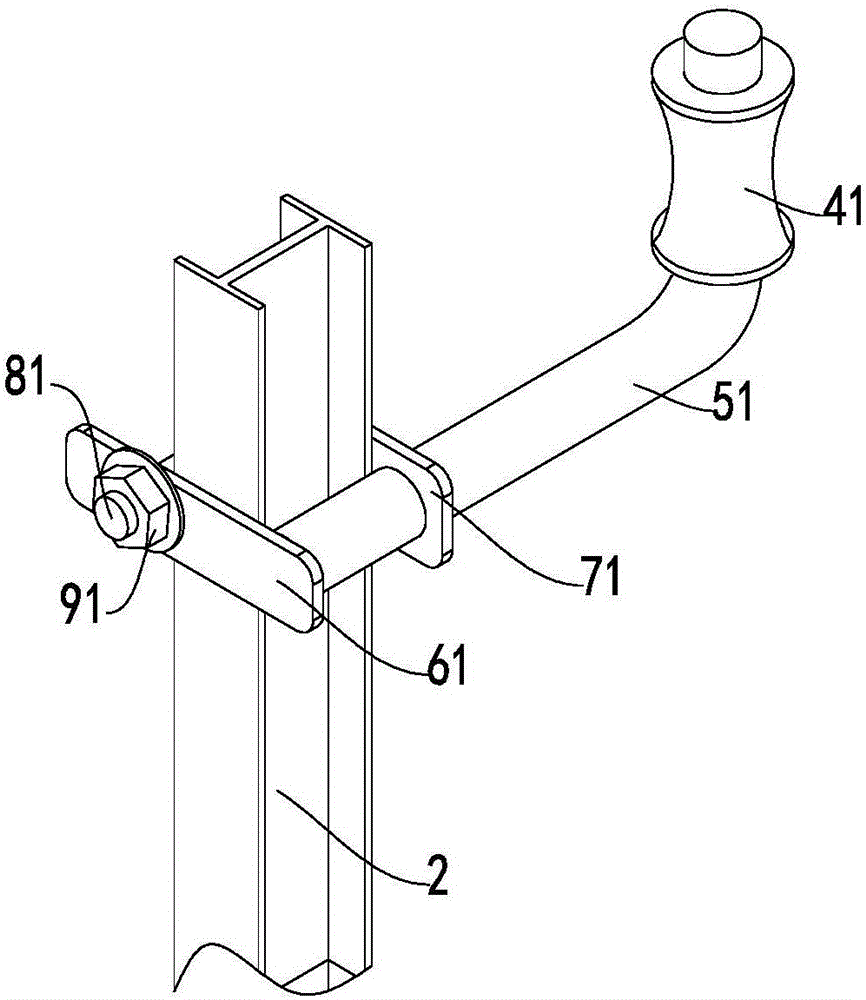

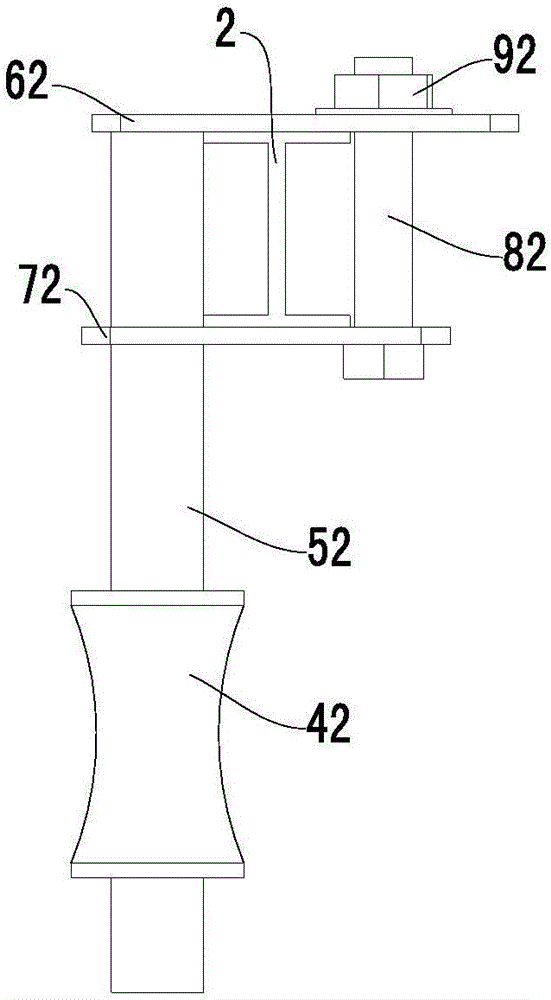

Underground pipe gallery construction device, combination and construction method

Owner:JIANGSU HONGJI ENERGY SAVING NEW TECH CO LTD

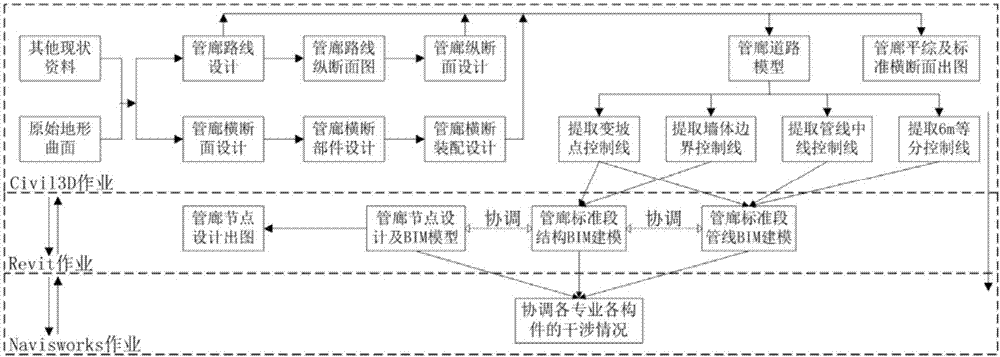

Utility tunnel full-length BIM (building information modeling) collaborative design method combining Civil 3D with Revit

InactiveCN107423518AIncrease valueQuality improvementGeometric CADOffice automationControl lineUtility tunnel

The invention discloses a utility tunnel full-length BIM (building information modeling) collaborative design method combining Civil 3D with Revit. The method comprises: using Civil 3D to draw a tunnel line, generating tunnel vertical section and tunnel standard cross section, and assembling; using the Civil 3D to establish a tunnel road model; using the Civil 3D to extract standard tunnel control line segments from the tunnel line, the tunnel vertical section and the tunnel standard cross section; using Revit to draw a standard utility tunnel segment BIM model in combination with the standard tunnel control line segment; using the Revit to perform tunnel joint BIM design in the standard utility tunnel segment BIM model so as to achieve utility tunnel full-length BIM collaborative design, wherein in Navisworks, the standard utility tunnel segment BIM model and the tunnel joint BIM model are integrated, and interferences between professions and members are collaborated. By fully collaboratively using respective advantages of Civil 3d and Revit, the method herein is capable of establishing the complete utility tunnel full-length BIM model accurately and quickly, thereby arriving at collaborative design.

Owner:中建基础设施勘察设计建设有限公司 +1

Structure of utility tunnel and construction method

InactiveCN106555408AReduce weightStable structureArtificial islandsUnderwater structuresArchitectural engineeringUtility tunnel

The invention relates to a structure of a utility tunnel and a construction method. The structure of the utility tunnel comprises a bottom plate, prefabricated panels, reinforcement cages, reinforced structures and a top plate, wherein the bottom plate is formed by pouring; the prefabricated panels are arranged on the bottom plate; a cavity of which the top and the bottom communicate with each other is formed in each prefabricated panel; each reinforcement cage is inserted in the corresponding cavity; each reinforced structure is formed in the corresponding cavity by pouring; the top plate is formed on the prefabricated panels by pouring; the top plate and the reinforced structures are integrated by pouring; and the bottom plate, the prefabricated panels and the top plate are enclosed to form the utility tunnel. The prefabricated panels with the cavities are adopted, therefore, form boards of all wall boards in a cast-in-situ mode are omitted, and the width of an excavated foundation pit of the utility tunnel is not large; and by the bottom plate and the top plate which are cast in situ, mechanization and industrialization are realized to a maximum extent, and corresponding labor costs can be saved. The utility tunnel is lighter than an integral type prefabricated pipe gallery, the prefabricated panels with the cavities are light in weight and are convenient to hoist and convey, and therefore, large-area construction can be carried out in a construction site.

Owner:中建科技(北京)有限公司

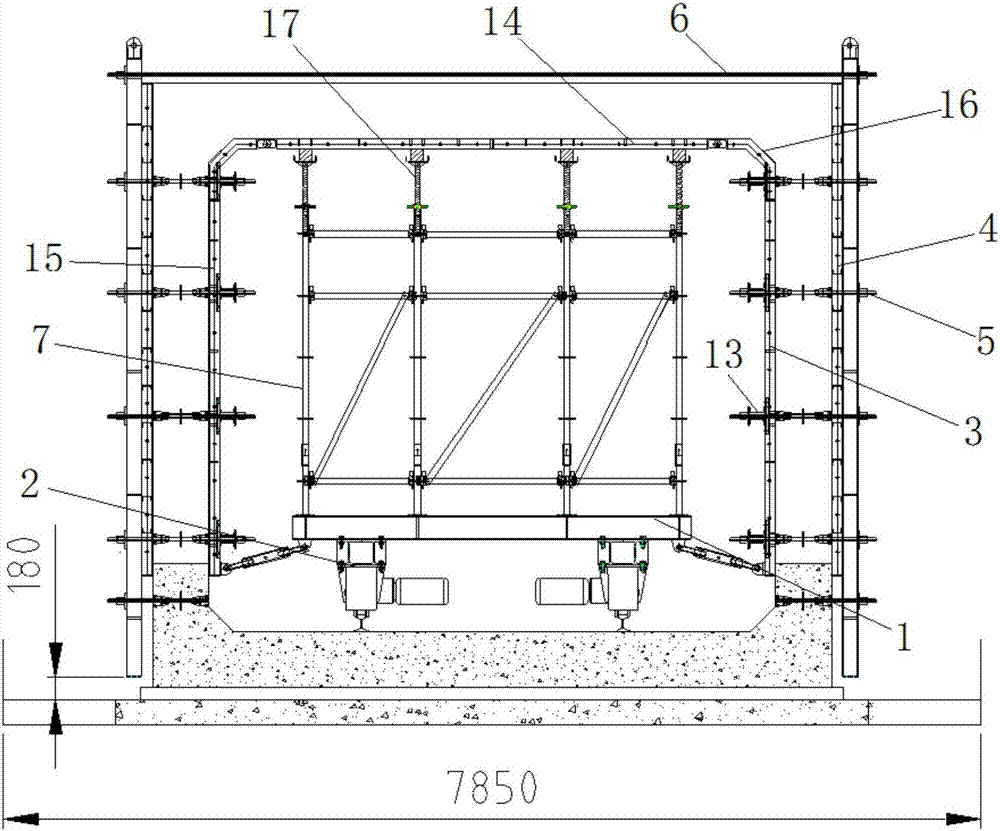

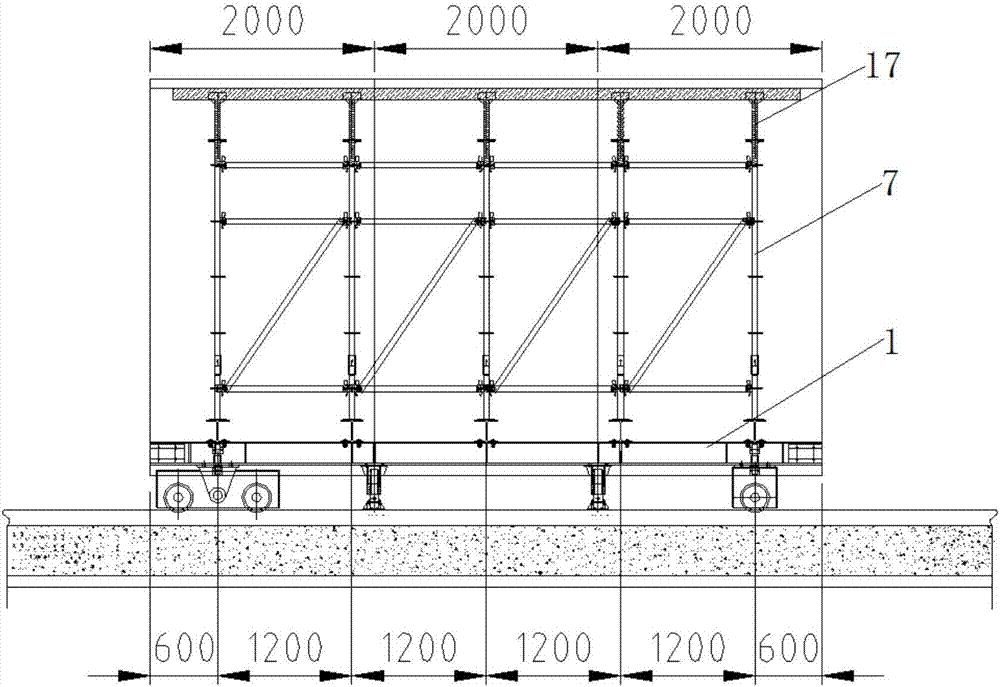

Utility tunnel integral formwork and using method thereof

ActiveCN107119715AImprove construction qualityImprove waterproof performanceArtificial islandsUnderwater structuresSupporting systemEconomic benefits

The invention discloses a utility tunnel integral formwork and a using method thereof. The utility tunnel integral formwork comprises an inner formwork body and an outer formwork body. The inner formwork body comprises an inner supporting frame, wheels, tripods, transverse adjustable jacks, vertical adjustable jacks, inner formwork vertical plates, an inner formwork top plate, inner formwork corner plates and universal wheels. The outer formwork body comprises outer formwork vertical plates, an outer formwork top plate, buckles and inclined struts. According to the utility tunnel integral formwork capable of moving integrally, a traditional supporting system composed of a plurality of anchor rods and a plurality of wooden plates is effectively optimized, the supporting procedures are simplified, the construction efficiency is improved, the construction quality of a utility tunnel can be improved, and the surface waterproofing performance of the utility tunnel can also be optimized. The inner formwork body can move integrally to the next construction section for direct supporting. The construction method is easy and convenient to implement, ordered and high in construction efficiency, does not need much labor or time, and can bring great economic benefits.

Owner:NORTHEASTERN UNIV

Comprehensive pipe rack system with sponge urban function

ActiveCN105926676AUnderstand the purposeLearn about featuresArtificial islandsUnderwater structuresReclaimed waterEngineering

The invention discloses a comprehensive pipe rack system with a sponge urban function. Rainwater inspection wells are arranged above a rainwater cabin; rainwater enter the rainwater cabin through rainwater inlets; people enter the rainwater cabin through the rainwater inspection wells to dredge; an initial rainwater cabin is arranged under the rainwater cabin; the rainwater cabin is connected with the initial rainwater cabin through a plurality of communication holes; a clean water cabin is arranged under the initial rainwater cabin; the rainwater cabin is connected with the clean water cabin through a purification treatment device; a clean water lifting pump is arranged at the tail end of the clean water cabin, and is connected with a sprinkler head on the ground through a reclaimed water pipe; a fuel gas cabin is arranged above the clean water cabin; an inspector hole is formed on a clapboard between the clean water cabin and the fuel gas cabin; a waste water lifting pump is arranged at the tail end of the initial rainwater cabin, and is connected with a sewage pipe arranged at one side in a comprehensive cabin through a waste water pipe; electric power pipes, communication pipes, a water supply pipe and the sewage pipe are also arranged in the comprehensive cabin. The comprehensive pipe rack system with the sponge urban function provided by the invention has the functions of seepage, stagnation, storage, purification, application and drainage, and is strong in practicability, and easy to popularize and use.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

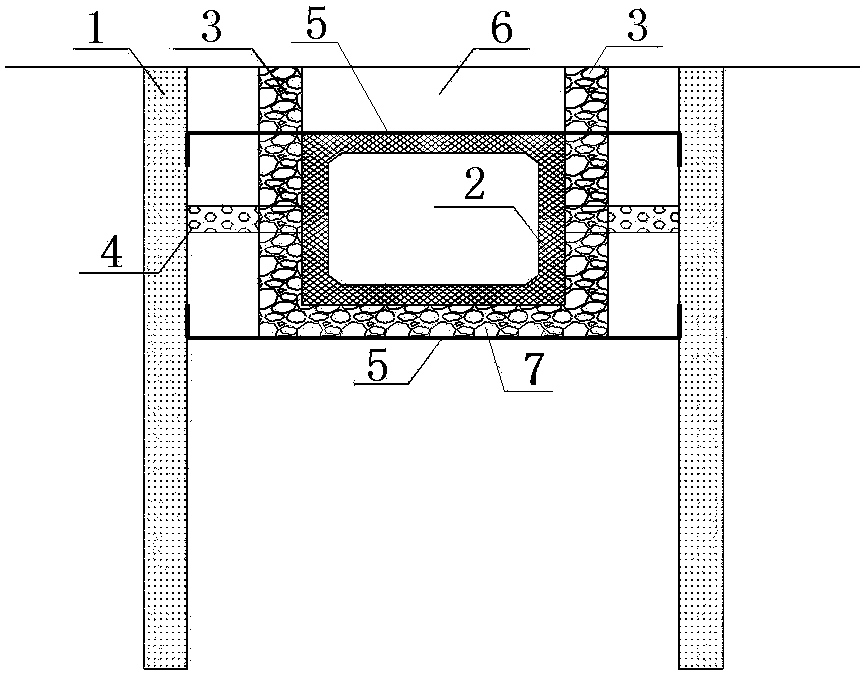

Construction method for preventing deformation of utility tunnel at high-water-level liquefaction region

ActiveCN104234056APrevent liquefactionDrain fastArtificial islandsProtective foundationStructure of the EarthUtility tunnel

The invention discloses a construction method for preventing deformation of a utility tunnel at a high-water-level liquefaction region. The construction method comprises the following steps: arranging enclosure bodies on the two sides of a foundation pit to be excavated; excavating the foundation pit; laying horizontal gravel drainage passages at the bottom of the foundation pit in layers; pouring a bottom plate and wall plates on the two sides of the bottom plate of the utility tunnel on the horizontal gravel drainage passages in sequence; refilling covering soil between the wall plates and the enclosure bodies in layers; meanwhile refilling vertical gravel drainage passages along the wall plates; pouring a roof plate of the utility tunnel after refilling the covering soil and the vertical drainage passages to the position of the roof plate of the utility tunnel; refilling the covering soil on the top of the utility tunnel and refilling the vertical gravel drainage passages to the design ground. The construction method has the advantages that the construction steps are simple and a complex structure consisting of the foundation pit enclosure bodies, the gravel drainage passages and shear connectors is used for achieving the purposes of inhibiting the foundation liquefaction, quickening the drainage of the liquefied foundation and preventing the deformation of the utility tunnel due to floating.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

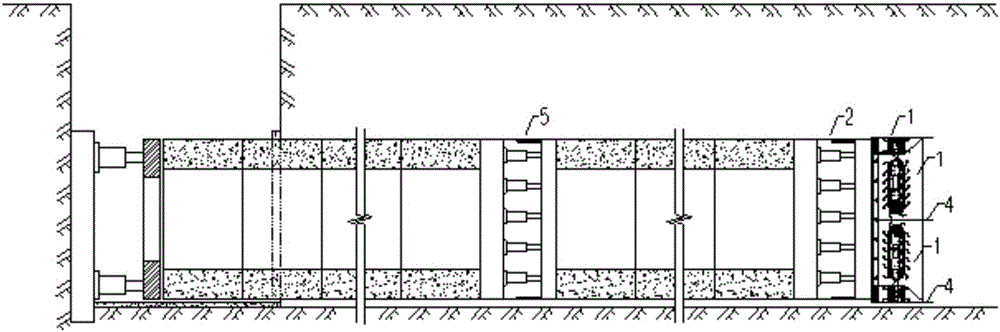

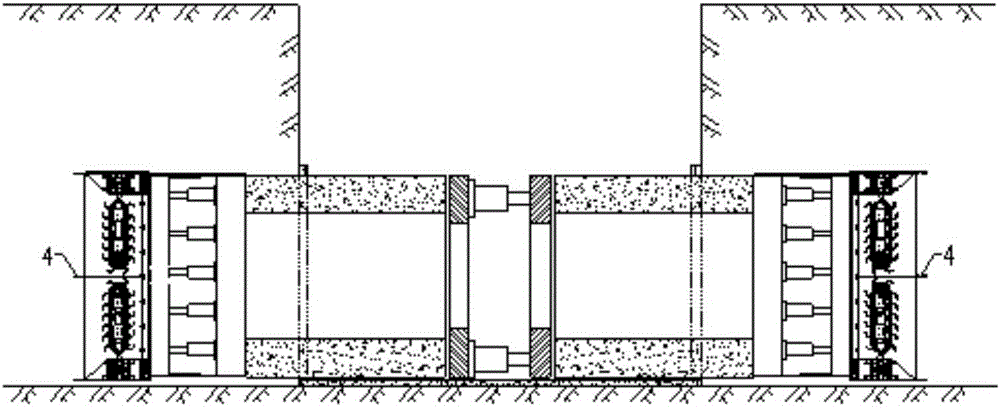

Formwork trolley and sliding formwork construction method for utility tunnel cast-in-place concrete sliding formwork construction

PendingCN107882064AImprove molding qualityAvoid deformationArtificial islandsUnderwater structuresVehicle frameArchitectural engineering

The invention discloses a formwork trolley structure for utility tunnel cast-in-place concrete sliding formwork construction. The formwork trolley comprises a formwork system, a trolley frame, a lateral supporting mechanism, a jacking mechanism and a traveling mechanism. The formwork system is composed of a top formwork assembly and side formwork assemblies. The top formwork assembly is arranged over the trolley frame and connected with the trolley frame. The side formwork assemblies are arranged on the two sides of the trolley frame and connected with the trolley frame through the lateral supporting mechanism. According to the formwork trolley and the sliding formwork construction method, by means of mutual cooperation during pouring of a middle gallery wall of the utility tunnel and large set-shaped steel formworks on all the trolleys, a pouring space of the middle gallery wall of the tunnel is formed between the side formworks of the adjacent trolleys, in addition, the supporting reliability of the formwork structures is guaranteed through the actions of the lateral supporting mechanisms of the trolleys, formwork deformation in the pouring process of the middle gallery wall is avoided, the number of formwork seams is small, and the forming quality of the middle gallery wall is improved; and meanwhile, the formwork trolley is simple in overall structure, labor is saved, and the construction cost is reduced.

Owner:CHENGDU JIANGONG ROAD & BRIDGE CONSTR

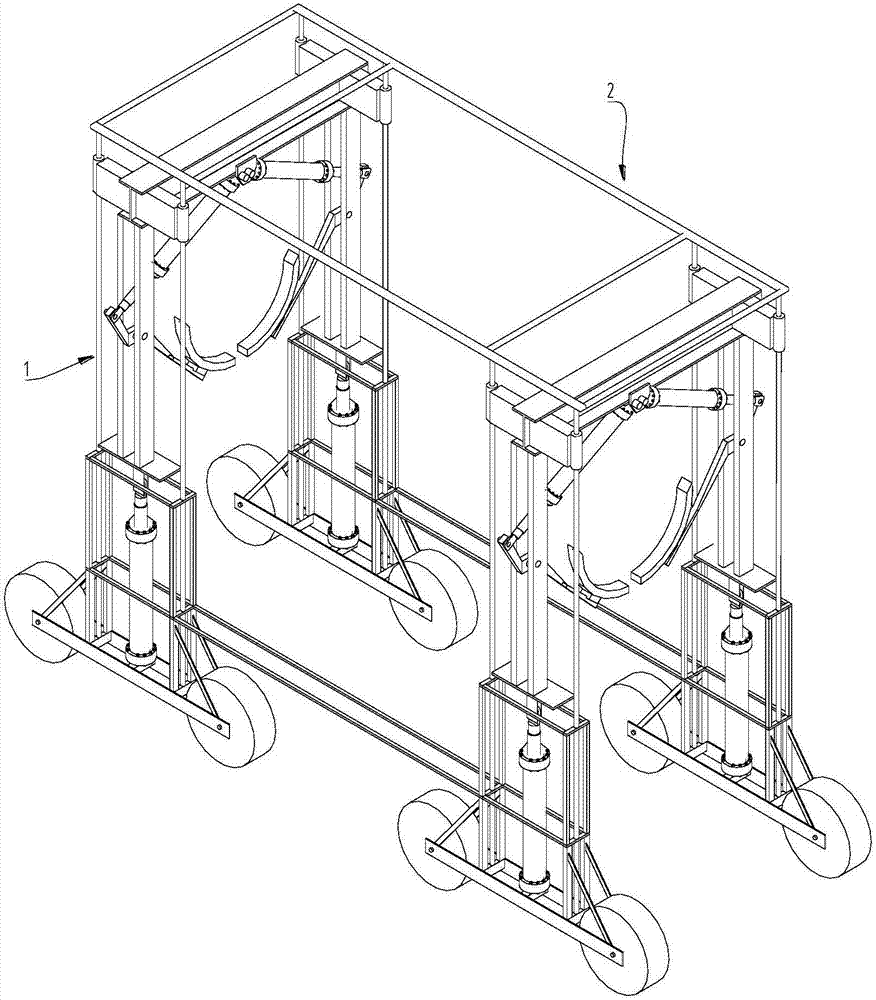

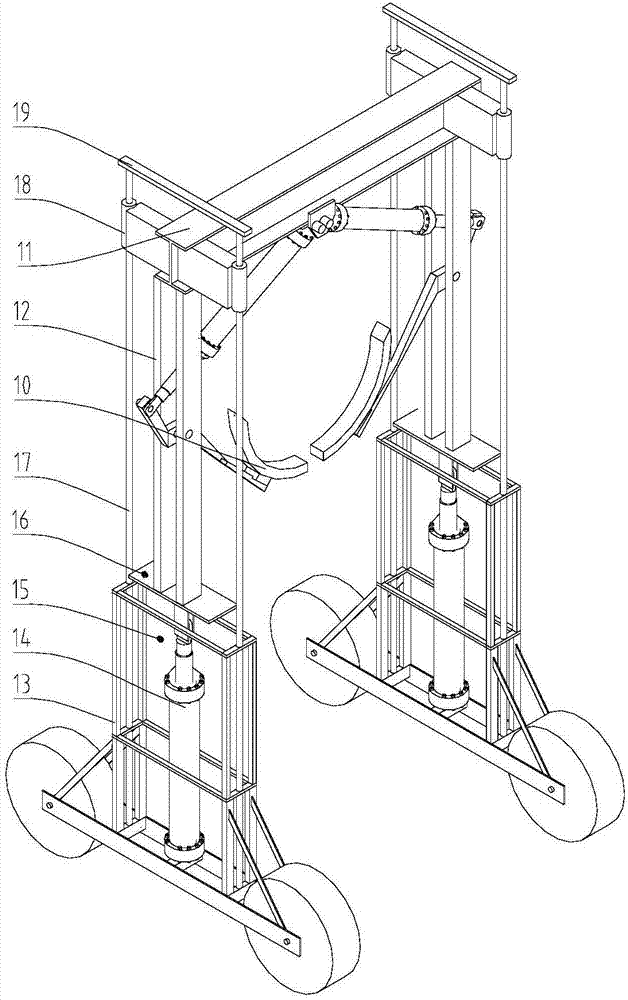

Utility tunnel pipeline transport cart and pipeline transport method thereof

InactiveCN106882112AReduce workloadImprove installation efficiencyVehicle to carry long loadsLifting framesHydraulic cylinderVehicle frame

The invention discloses a utility tunnel pipeline transport cart and a pipeline transport method thereof, belongs to the field of pipeline transport, and aims at providing a utility tunnel pipeline transport cart capable of straddling a concrete pipe pier. Horizontal transport and vertical hoisting of pipelines are integrated, so that the workload is reduced, and the pipeline installation efficiency is improved. The utility tunnel pipeline transport cart comprises N single frames. Each single frame comprises a pipeline clamping mechanism, a beam and supporting pieces, wherein a doorway is defined by the beam and the supporting pieces, stabilizing bar systems for connecting adjacent single frames are arranged on the two sides of the doorway, the pipeline clamping mechanism is installed below the beam, and vertical lifting hydraulic cylinders are installed on the lower supporting pieces. According to the pipeline transport cart, it is unnecessary to use other tools, the workload of transporting the pipelines by a crane is avoided, and thus the pipe installation efficiency is improved; according to the pipeline transport method, the processes of horizontally transporting the pipelines and vertically placing the pipelines on the concrete pipe pier in place are completed in one step, the workload of transferring the pipelines in the horizontal and vertical directions is reduced, and the installation period is shortened.

Owner:CHINA 19TH METALLURGICAL CORP

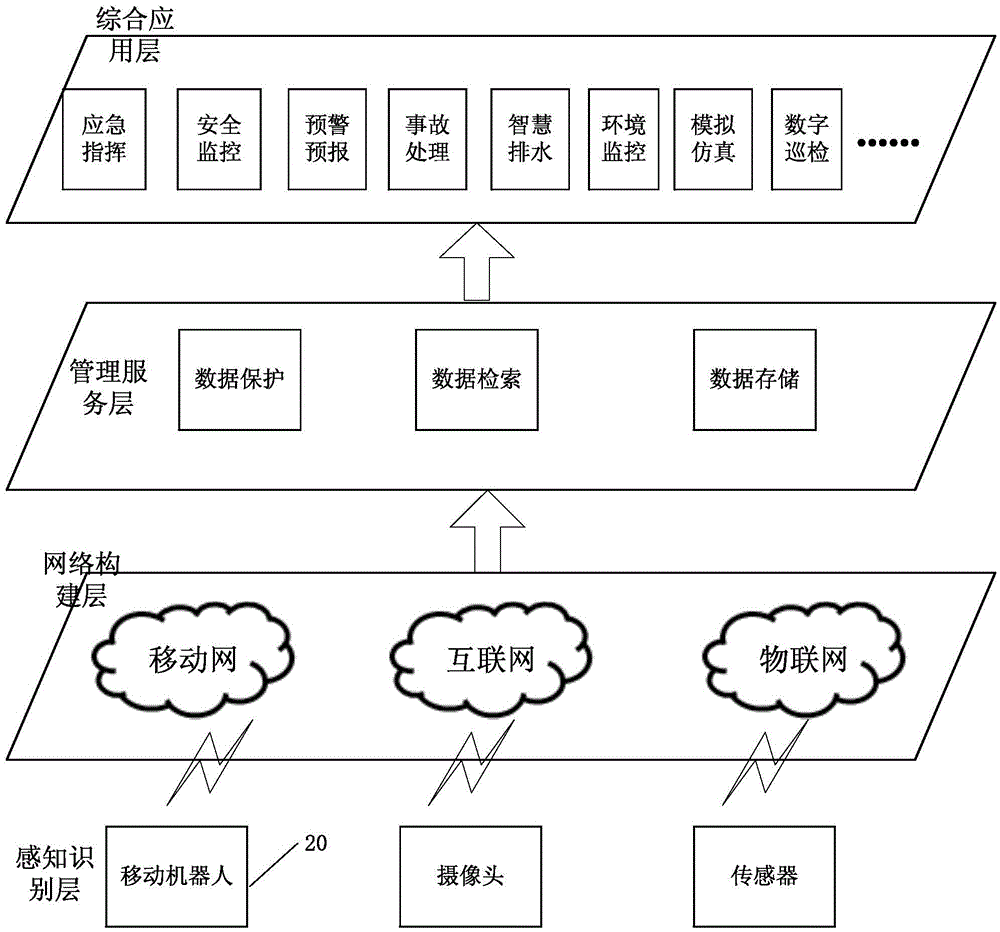

Utility tunnel monitoring and early warning system

InactiveCN106482785AReduce application requirementsReduce in quantityMeasurement devicesEarly warning systemError reporting

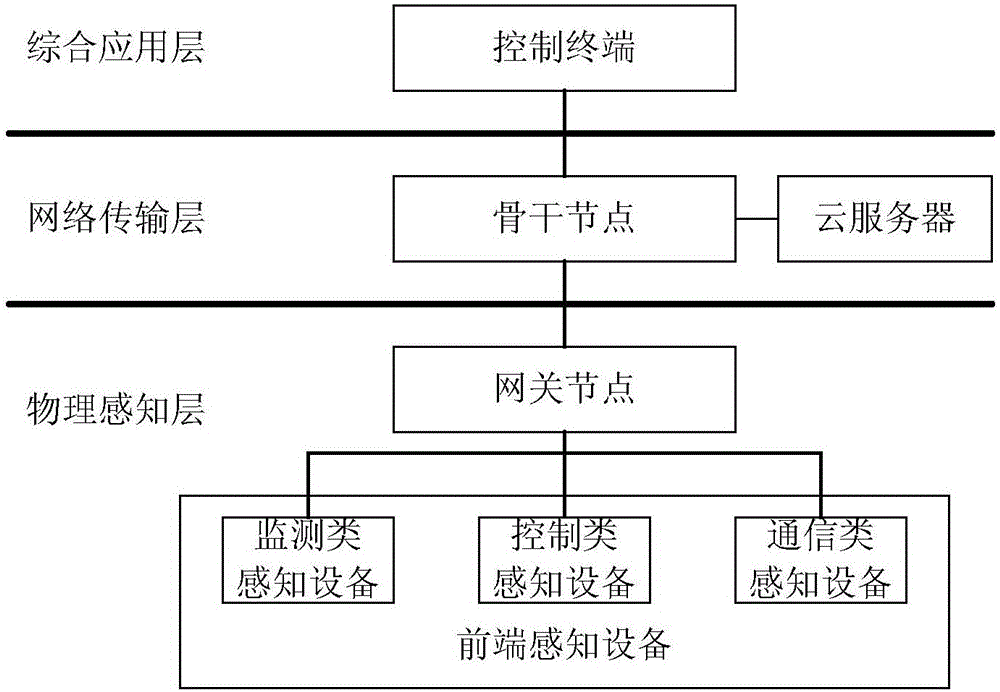

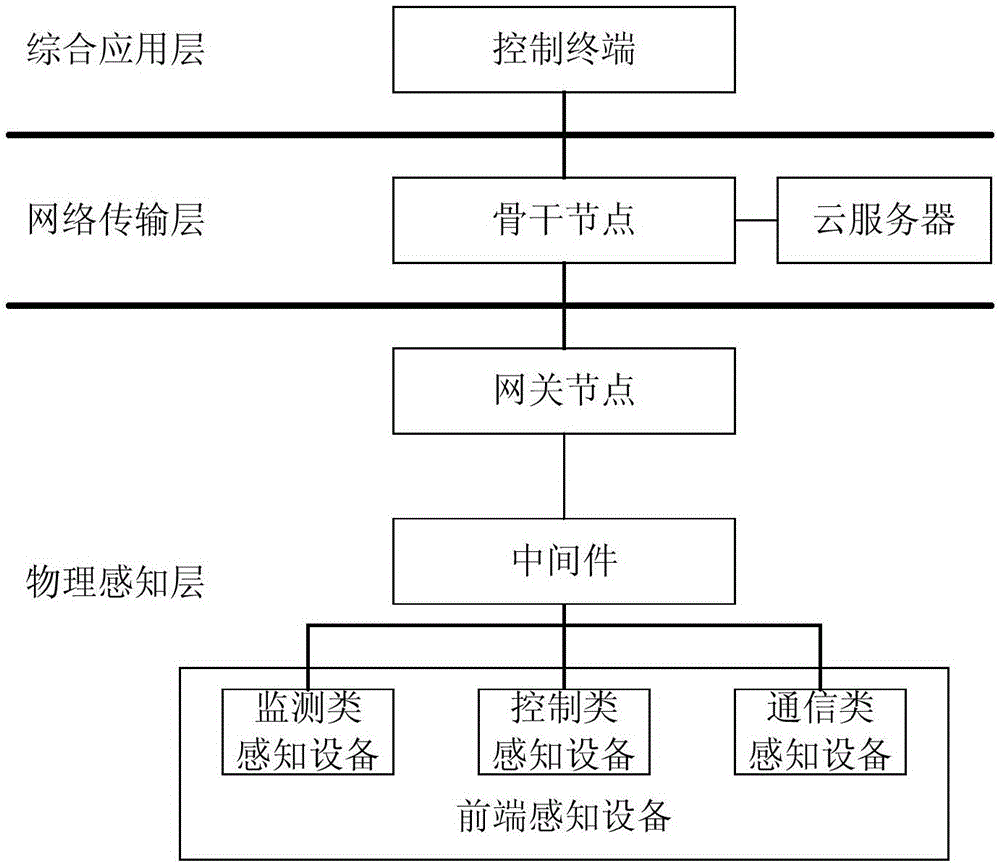

The invention provides a utility tunnel monitoring and early warning system, which comprises a physical perception layer, an integrated application layer and a network transmission layer, wherein the physical perception layer comprises a plurality of front-end perception devices and a gateway node in communication connection with each front-end perception device; the front-end perception device is set to acquire each piece of perception information in the utility tunnel; the gateway node is set to upload the perception information acquired by the front-end perception device to the network transmission layer; the network transmission layer comprises a backbone network node which is set to upload the perception information uploaded by the gateway node to the integrated application layer; the integrated application layer comprises a plurality of control terminals which are set to carry out operation processing on the perception information uploaded by the network transmission layer and provide corresponding application service according to a processing result. Various conditions in the utility tunnel can be monitored in a real-time and online mode, each relevant department can quickly take effective measures, loss caused by error reporting or missed reporting is avoided, the reliability is high, the capital construction input is little, and the maintenance and the operation are convenient and quick.

Owner:上海瀚所信息技术有限公司

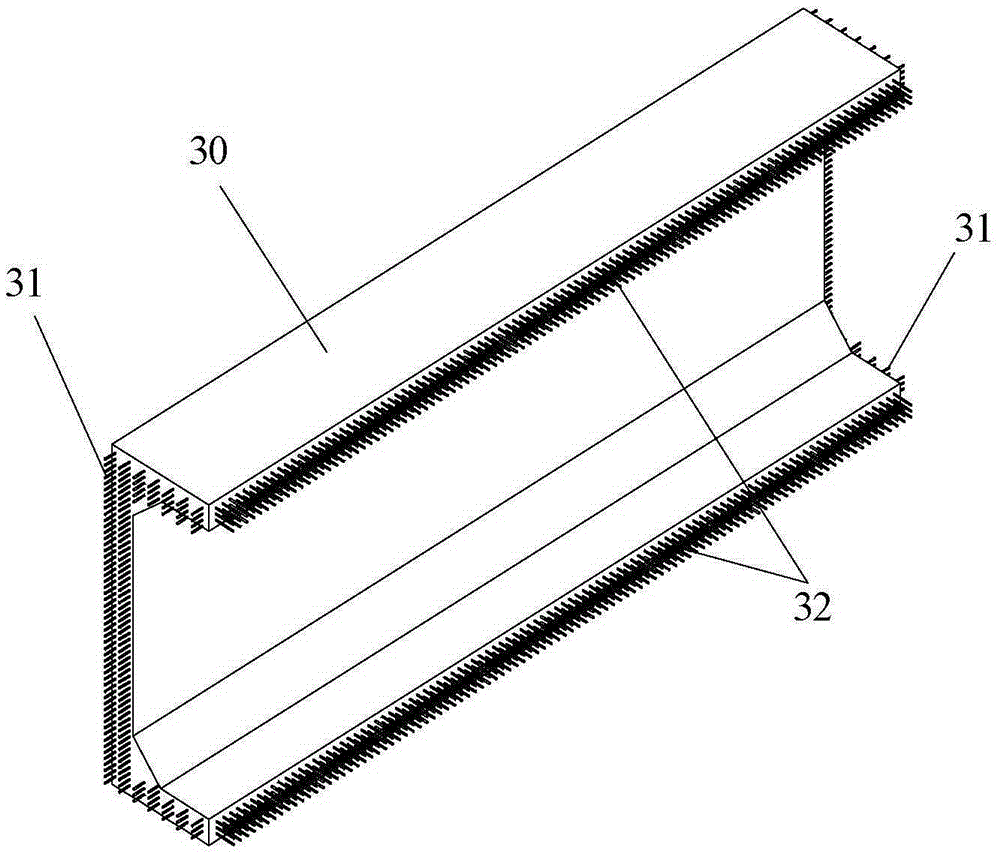

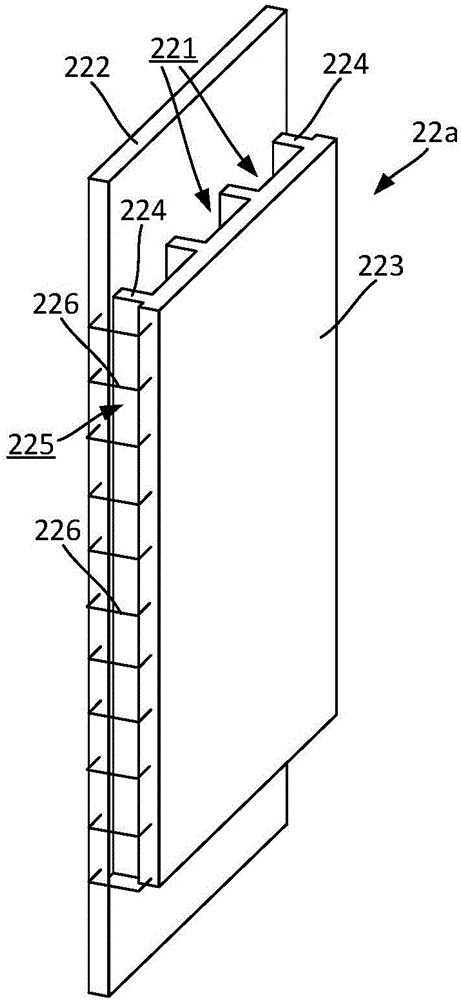

Pipe gallery prefabricated member and assembled comprehensive pipe gallery

InactiveCN105256837AEasy to transportStable structural strengthArtificial islandsUnderwater structuresUtility tunnelEngineering

The invention provides a pipe gallery prefabricated member and an assembled comprehensive pipe gallery. The pipe gallery prefabricated member comprises a bottom frame prefabricated member and a cover board prefabricated member. The bottom frame prefabricated member comprises a bottom board, vertical boards, internal reinforcing pieces of the bottom board and the vertical boards and prestress steel cable holes formed in the inside corners connected with the bottom board and the vertical boards. A U-shaped bin groove is formed by every two adjacent vertical boards and the bottom board. The bottom frame prefabricated member at least comprises one U-shaped bin groove. Grooves A and protrusions A are arranged on the end faces of the portions, on the two sides of each U-shaped bin groove, of the bottom board and the end faces of the vertical boards respectively, wherein the protrusions A are inserted in the grooves A in a matched manner. Grooves B are formed in the upper end faces of the vertical boards of the U-shaped bin grooves. The cover board prefabricated member comprises protrusions B arranged on the bottom face and inserted in the grooves B in a matched manner, grooves C and protrusions C, wherein the two ends of the cover board prefabricated member are provided with the grooves C and the protrusions C, and the protrusions C are inserted in the grooves C in a matched manner. The pipe gallery comprises sealing pads, prestress steel cables, the bottom frame prefabricated member and the cover board prefabricated member. The needed pipe gallery is formed by assembling the bottom frame prefabricated member and the cover board prefabricated member. By the adoption of the pipe gallery prefabricated member and the assembled comprehensive pipe gallery, the site assembling construction load is low, transport and installation cost is low, assembling operation is flexible, and various use requirements are met.

Owner:SHENZHEN HUAHAN GUANLANG PROPERTY SERVICES CO LTD

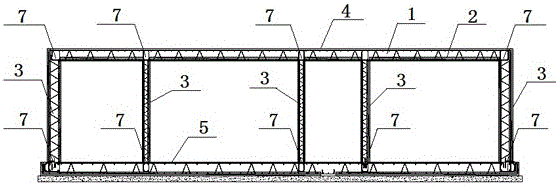

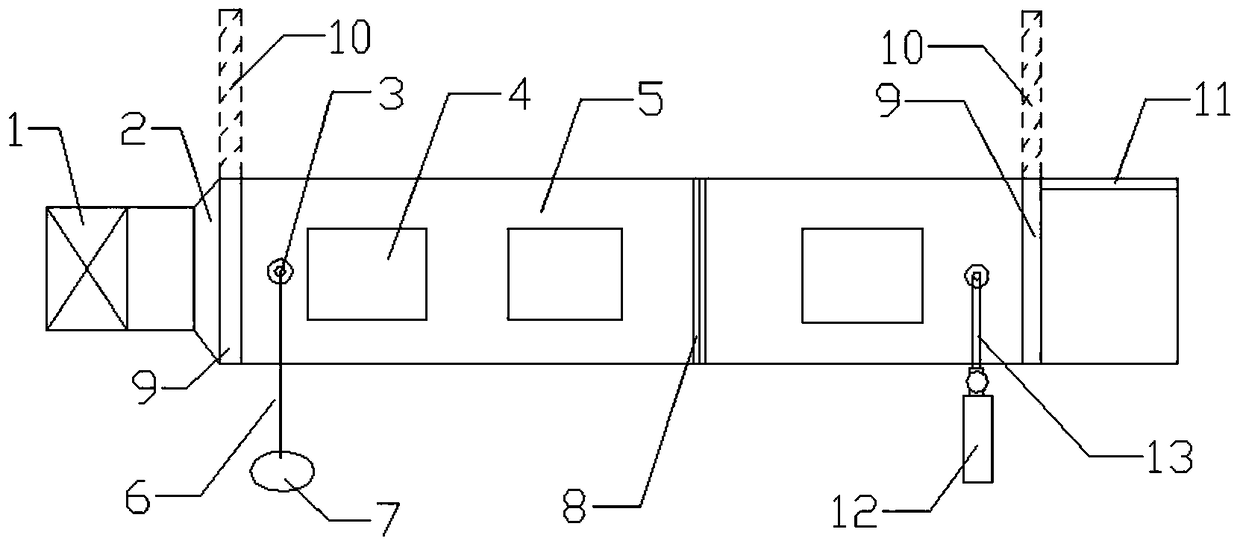

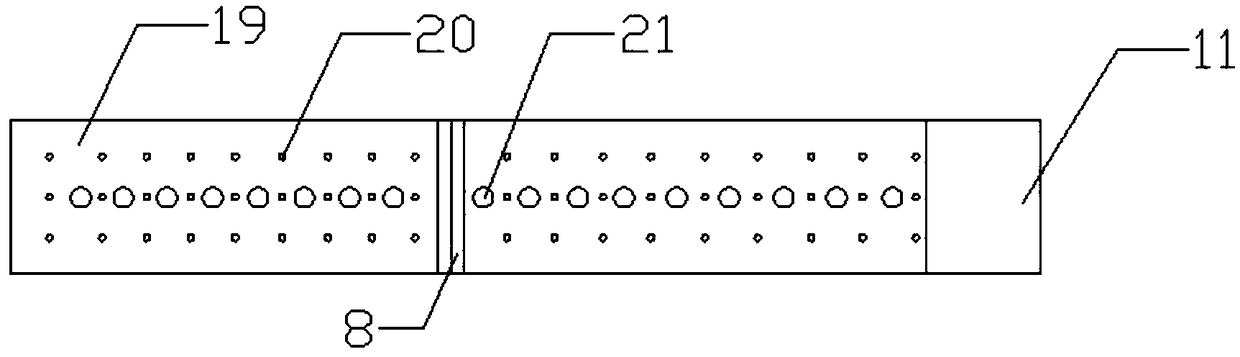

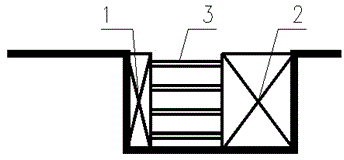

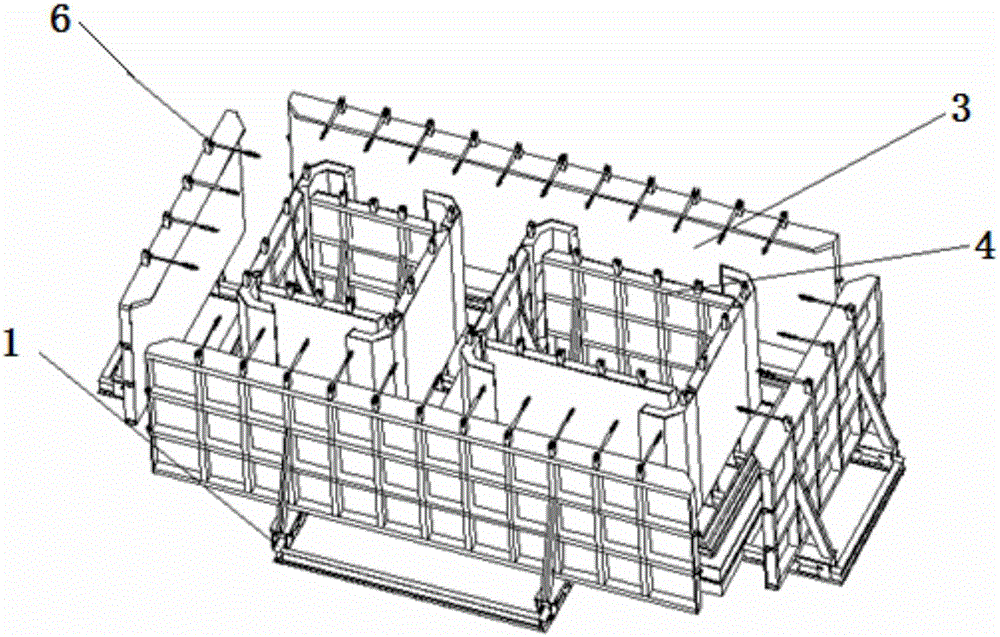

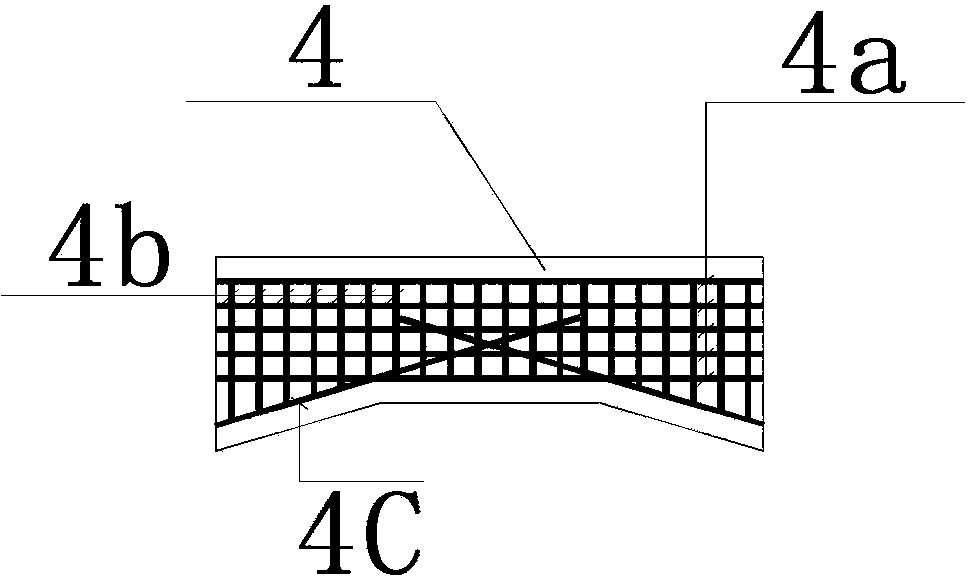

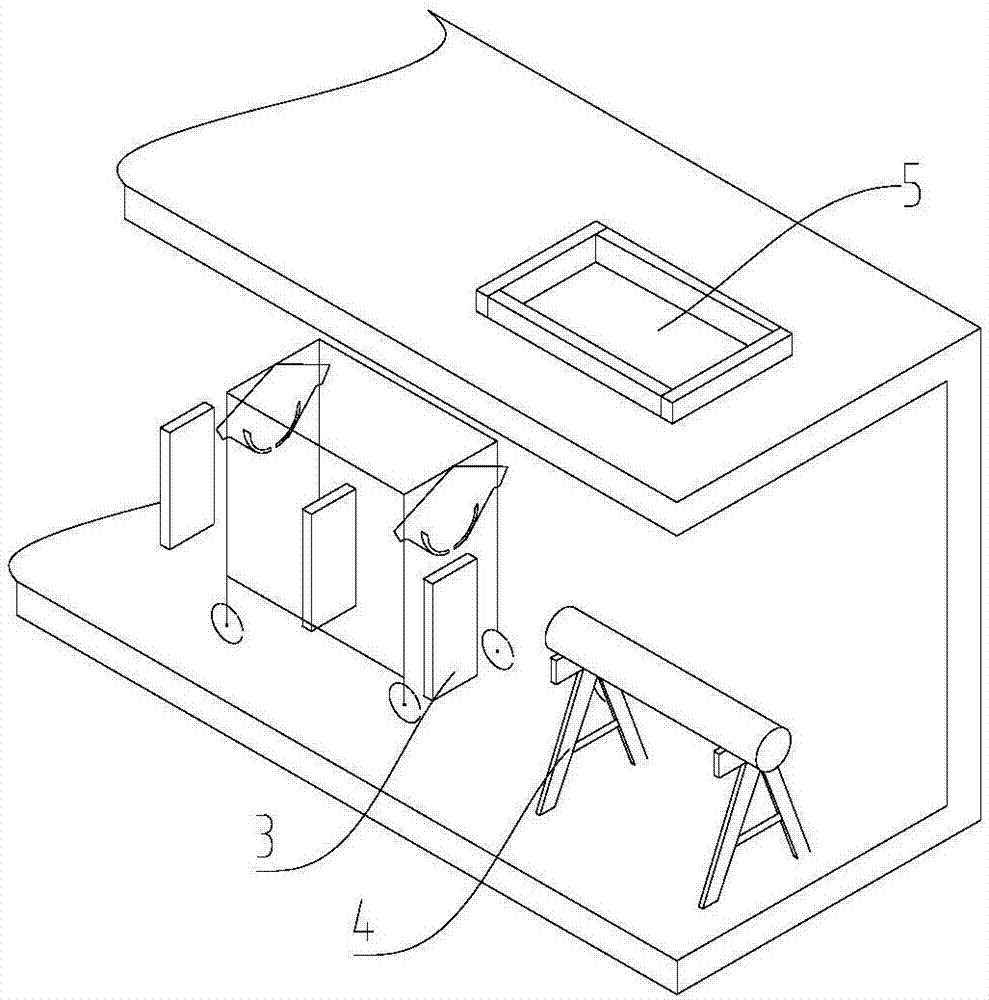

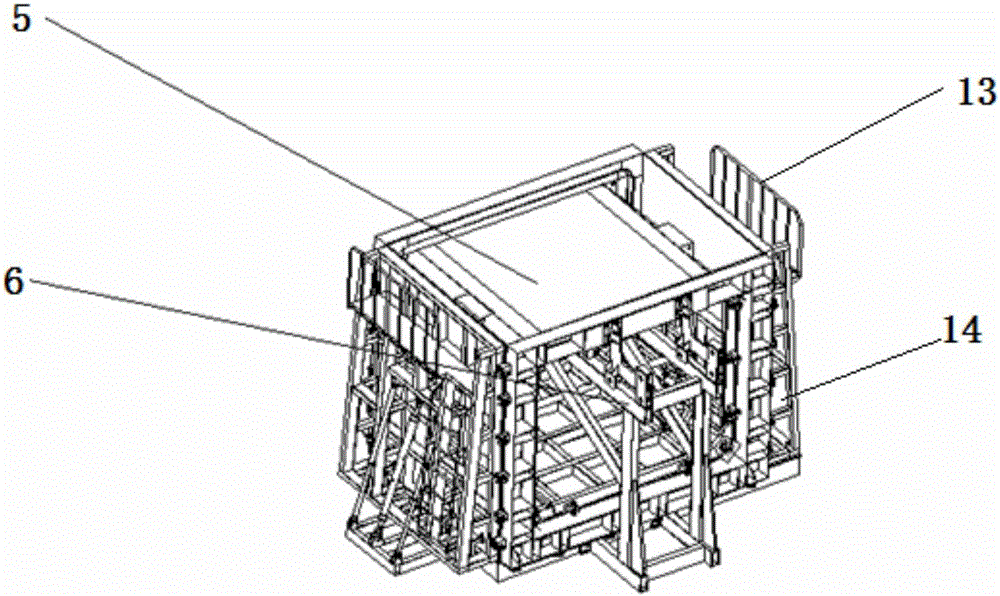

Concrete single-bin utility tunnel horizontal forming mold and system, and tunnel molding method

ActiveCN106182359AEasy to assemble and disassembleImprove efficacyDischarging arrangementMouldsShell moldingUtility tunnel

A concrete single-bin utility tunnel horizontal forming mold comprises a mold base (1), side mold bodies (2), a plug end mold body (3), a socket end mold body (4), an inner container mold body (5) and a supporting frame (6), wherein the mold base (1) is fixed on the ground; the side mold bodies (2) are arranged on two sides of the mold base (1); the plug end mold body (3) and the socket end mold body (4) are independently arranged at the front and rear ends of the mold base (1); the plug end mold body (3) or the socket end mold body (4) is fixed on the supporting frame (6); the inner container mold body (5) is arranged on the supporting frame (6); and the supporting frame (6) is arranged on the ground or the mold base (1). The invention further provides a concrete single-bin utility tunnel horizontal forming system and a production process thereof. The concrete single-bin utility tunnel horizontal forming mold and system as well as the production process have the advantages that the quality is high, the scale is large, and rapid mass production can be achieved.

Owner:CHANGSHA CHUHONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com