Concrete single-bin utility tunnel horizontal forming mold and system, and tunnel molding method

A technology of integrated pipe gallery and forming mold, applied in the direction of mold, ceramic forming core, ceramic forming machine, etc., can solve the problems of shortening the service life of underground pipelines, affecting the bearing capacity and durability of structures, and affecting the use function of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0203] According to the third embodiment provided by the present invention, there is provided a method for molding a concrete single-storage integrated pipe gallery or using the above-mentioned horizontal forming mold for a concrete single-storage integrated pipe gallery to mold a concrete single-storage integrated pipe The method of corridor, this method comprises the following steps:

[0204] 1) Mold assembly: clean the mold, apply the release agent, place the steel frame, close the side mold 2, close the socket end mold 4, close the socket end mold 3, close the inner tank mold 5, place the inner tank bottom template 508, lock the lock Tightening device 11 and positioning locking device 12;

[0205] 2) Feeding and vibrating: concrete pouring and vibrating; concrete molding and plastering;

[0206] 3) steam curing;

[0207] 4) Demoulding: Demoulding in the reverse order of mold assembly.

[0208] Preferably, the method also includes:

[0209] 5) Secondary maintenance of p...

Embodiment 1

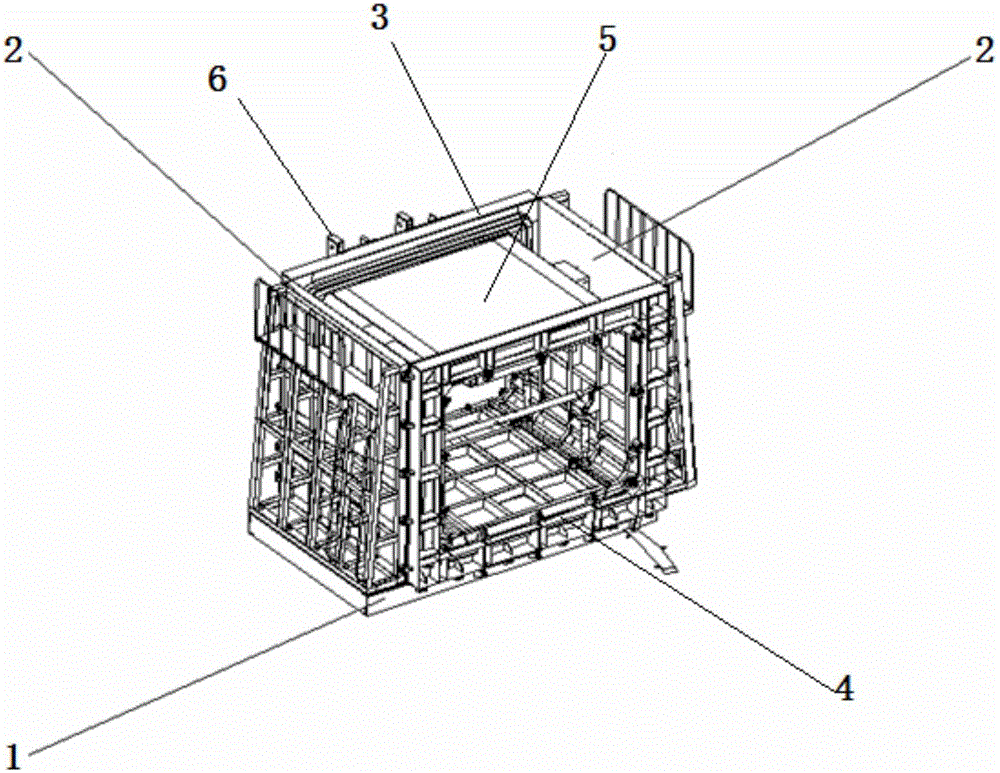

[0213] The horizontal forming mold for the concrete single warehouse comprehensive pipe gallery includes a mold base 1, a side mold 2, a socket end mold 3, a socket end mold 4, an inner tank mold 5, and a support frame 6. Wherein: the mold base 1 is fixed on the ground. The side molds 2 are arranged on both sides of the mold base 1 . The socket end die 3 and the socket end die 4 are independently arranged at the front and rear ends of the die base 1 . The socket end die mold 4 is fixed on the support frame 6 . The liner mold 5 is arranged on the support frame 6 . The supporting frame 6 is arranged on the ground or the mold base 1 .

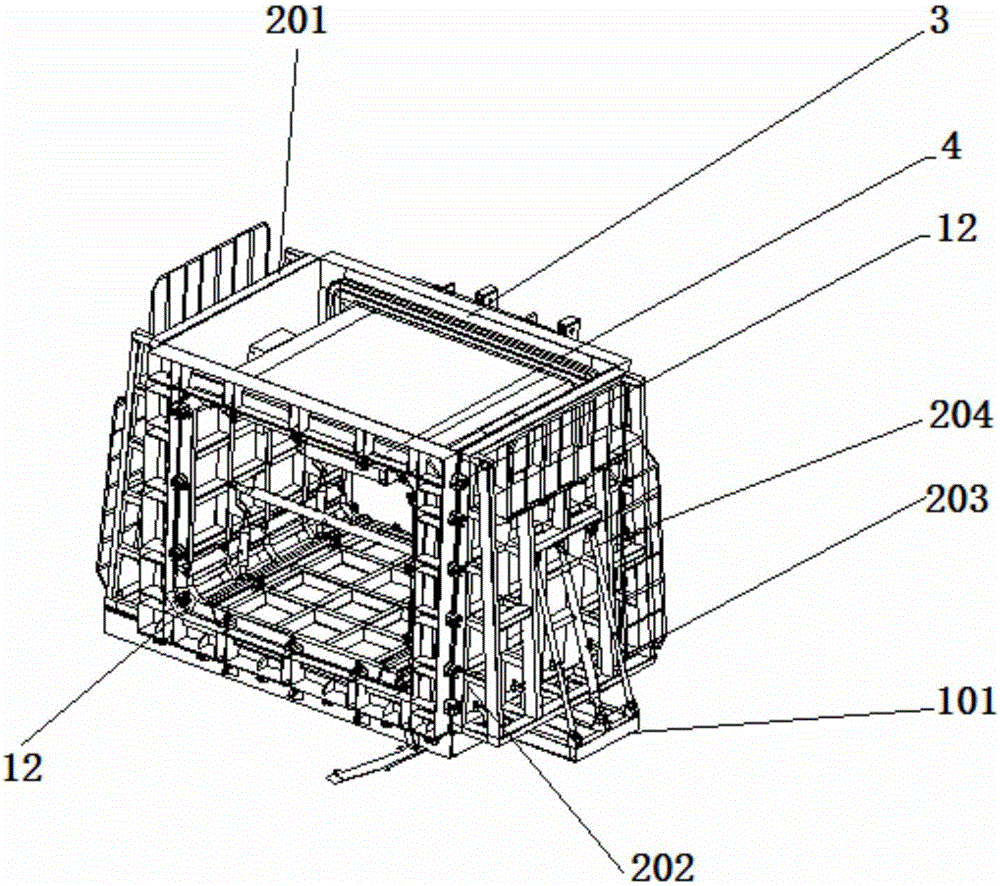

[0214] The side form 2 includes a fixed side form 201 and a movable side form 202 . The fixed side mold 201 is fixedly connected with the mold base 1 . The movable side mold 202 is hingedly connected with the mold base 1 . A corner device 203 is provided under the movable side mold 202, and the corner device 203 is connected with the movable...

Embodiment 2

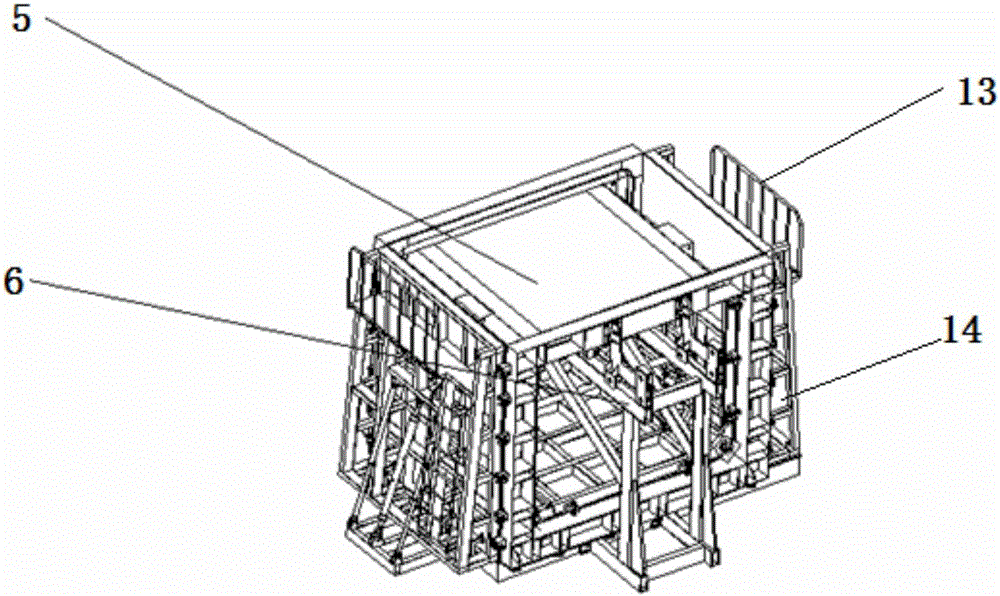

[0221] Repeat Example 1, except that the socket end mold 3 is fixed on the support frame 6, and the side mold 2 is two movable side molds 202. The movable side mold 202 is hingedly connected with the mold base 1 . A corner device 203 is provided under the movable side mold 202, and the corner device 203 is connected with the movable side mold 202 and the mold base 1 respectively, the side of the mold base 1 is provided with a support plate 101, and one end of the two-way screw mandrel 204 is connected with the movable side mold 202, The other end of the two-way screw rod 204 is connected to the support plate 101 .

[0222] The socket end die mold 3 adopts a socket end die parallel movable door frame mold opening structure 305 . The outer side of the socket end die mold 3 is provided with a socket end die track 306 . The socket end mold track 306 is connected with the support frame 6 . The socket end mold parallel movable door frame mold opening structure 305 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com