Tunnel arch installation vehicle

An arch installation and operation vehicle technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of difficult steel arch movement and accurate positioning, long construction period, low installation efficiency, etc., and achieve processing and production. The effect of convenient installation and layout, low investment cost, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

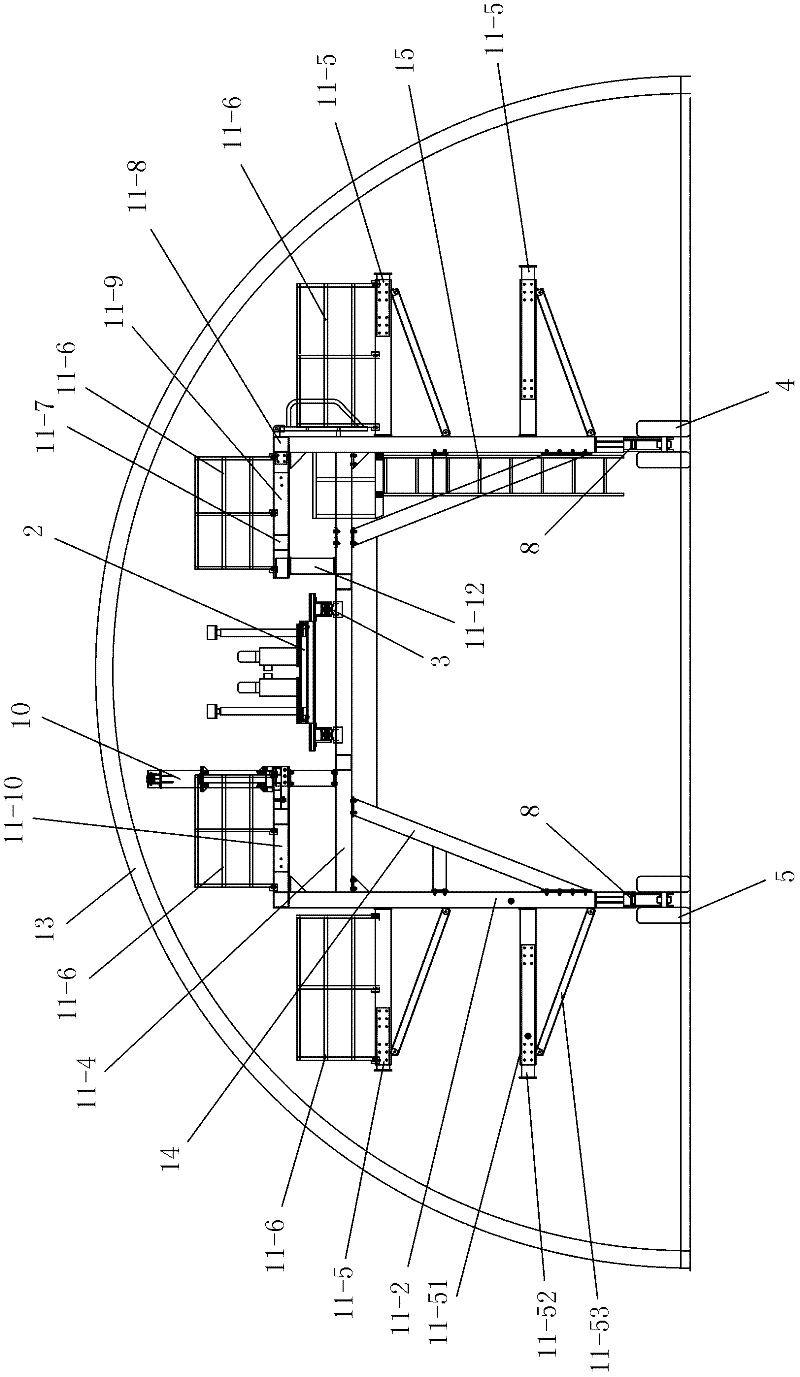

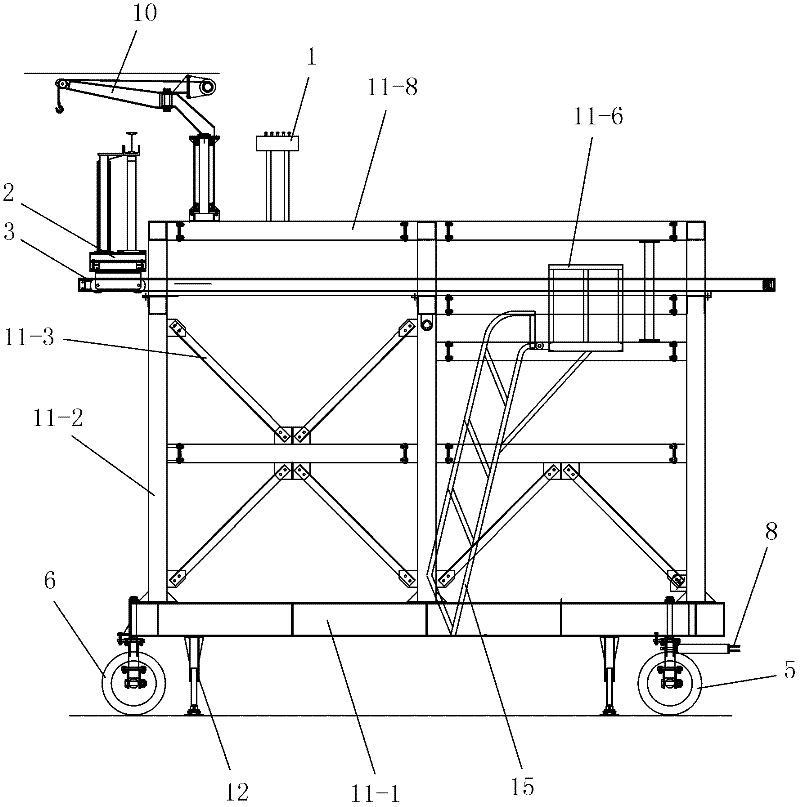

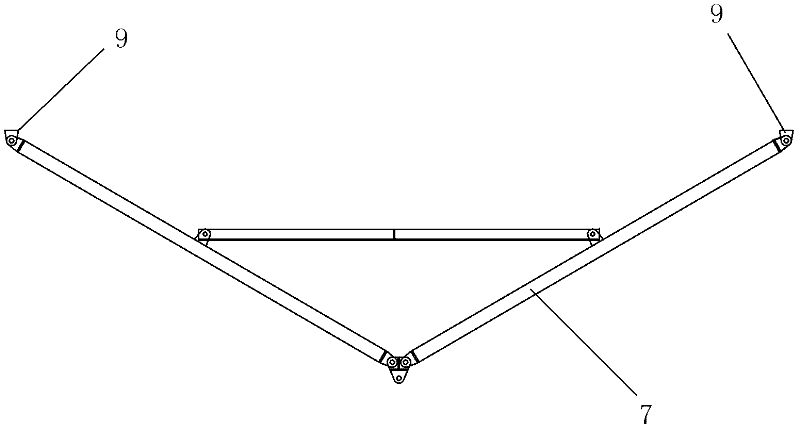

[0053] Such as figure 1 , figure 2 As shown, the present invention includes a frame, a traveling mechanism that drives the frame to move back and forth along the center line of the tunnel under construction, a traction mechanism that is connected in transmission with the traveling mechanism, and a tunnel that needs to be installed behind the frame. The arch lifting device for lifting the arches one by one and the arch transfer mechanism 2 for transferring the tunnel arches lifted by the arch lifting device to the designed installation position one by one through alignment adjustment. The arch transfer mechanism 2 includes a translation trolley that can move back and forth on the upper part of the frame, a lifting mechanism that can smoothly lift the tunnel arch, and a horizontal movement that can move left and right on the translation trolley. Simultaneously drive the left and right moving mechanism of the lifting mechanism to move left and right synchronously, the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com