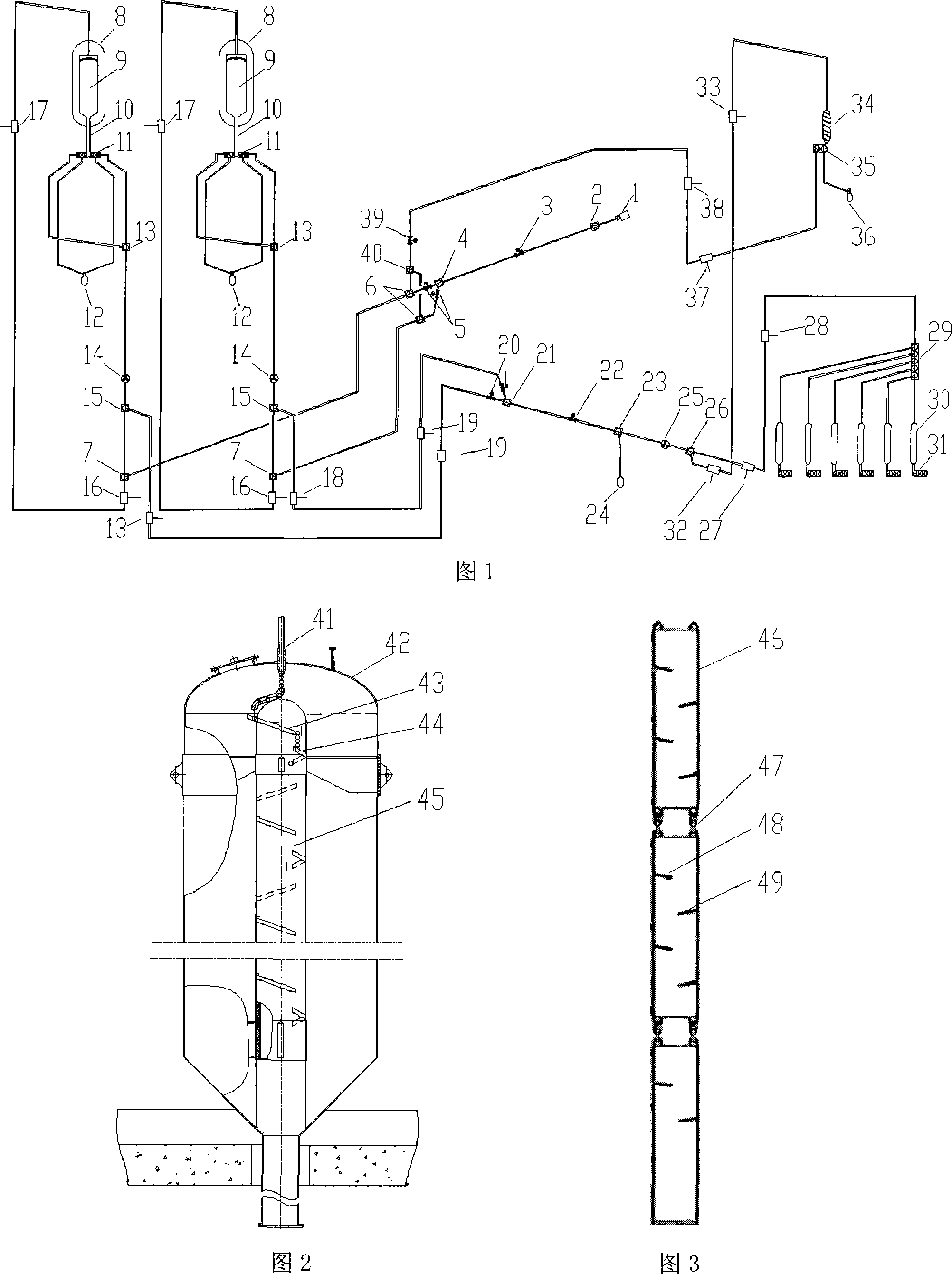

Ball bed high-temperature gascooled reactor online reloading system

A high-temperature gas-cooled reactor and pebble bed technology, which is applied in the field of reactor engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0089] The on-line refueling system of the pebble bed high temperature gas-cooled reactor proposed by the present invention has main functions including loading new fuel elements for the pebble bed high temperature gas-cooled reactor, unloading spent fuel elements, and circulating the fuel elements in the reactor through the core and the reactor stack for multiple times. Emptying and reloading of fuel elements in the core, etc.

[0090] In the on-line refueling system of the pebble bed high-temperature gas-cooled reactor, the new fuel elements are simplified at the charging port 1 and then loaded into the new fuel loading system. After the atmosphere is switched, the air atmosphere under normal pressure is switched to that under high pressure Helium atmosphere. Through the distributor 4 after the atmosphere switching pipe section, the fuel elements are distributed to the two reactor systems, and then enter the core fuel cycle main system through the collector 7, and are pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com