Patents

Literature

1695results about "Ceramic shaping mandrels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

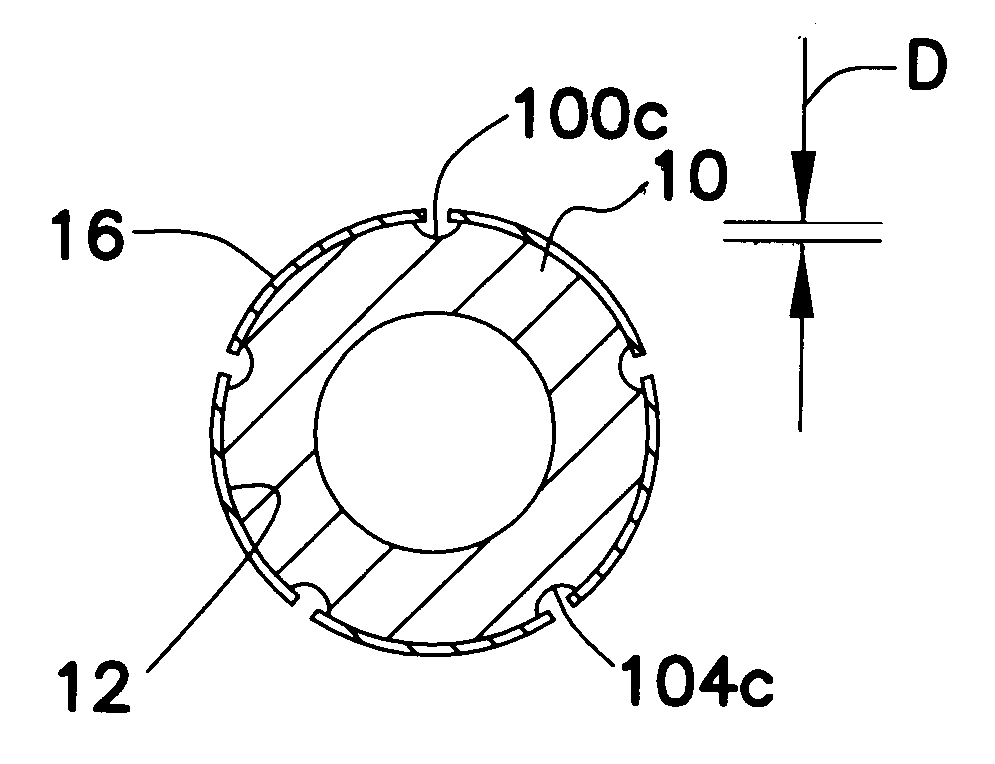

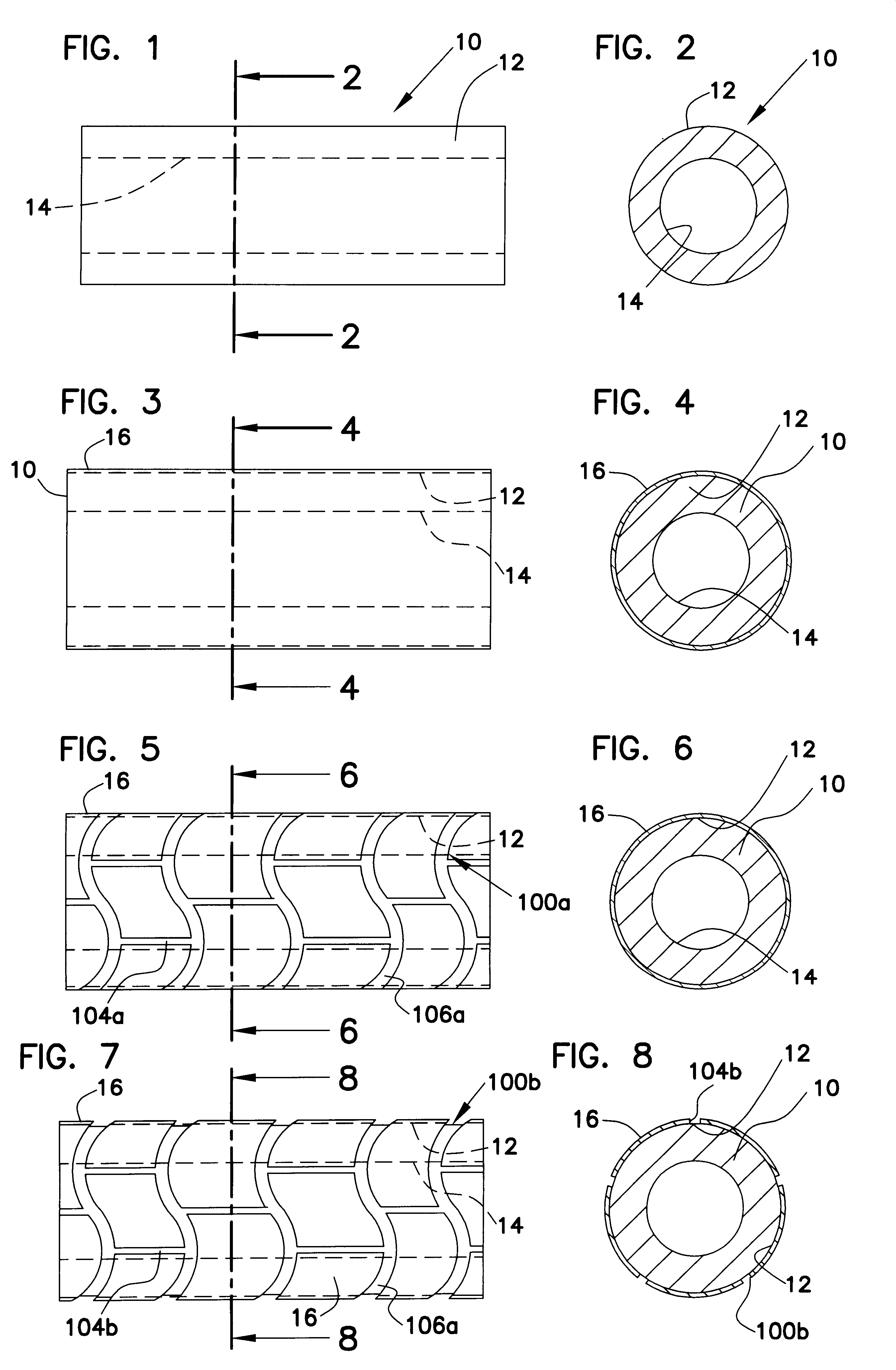

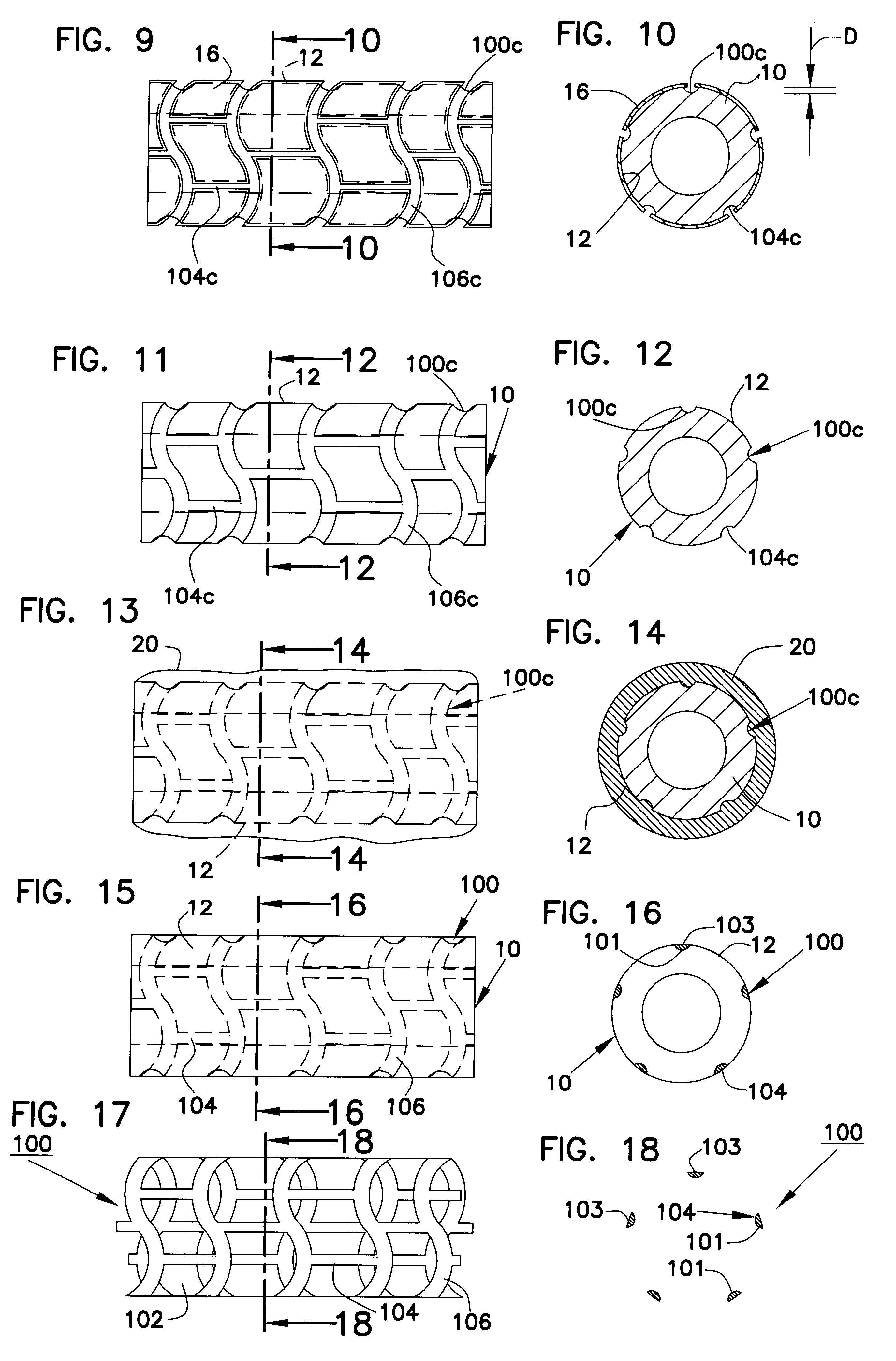

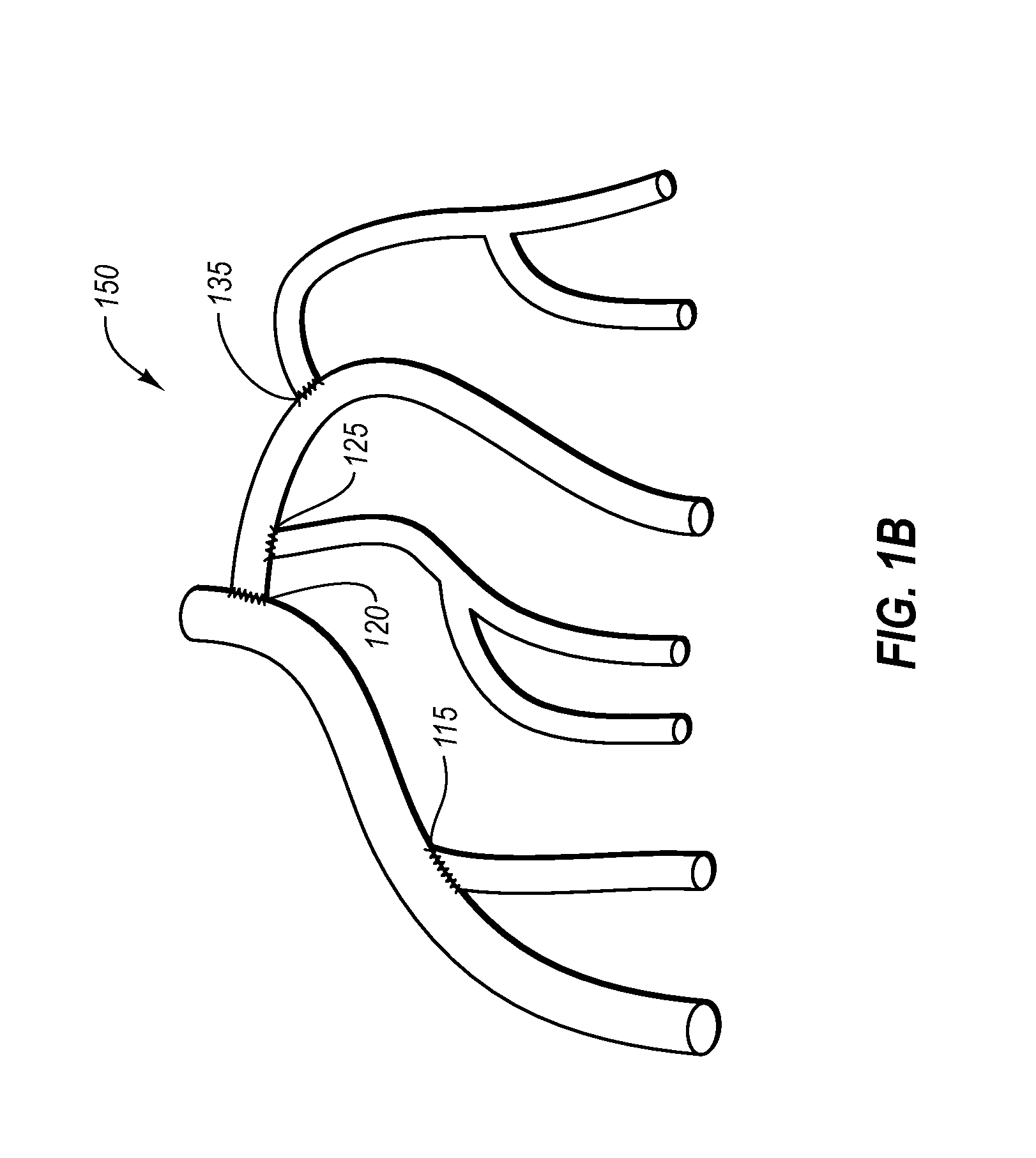

Method for manufacturing intraluminal device

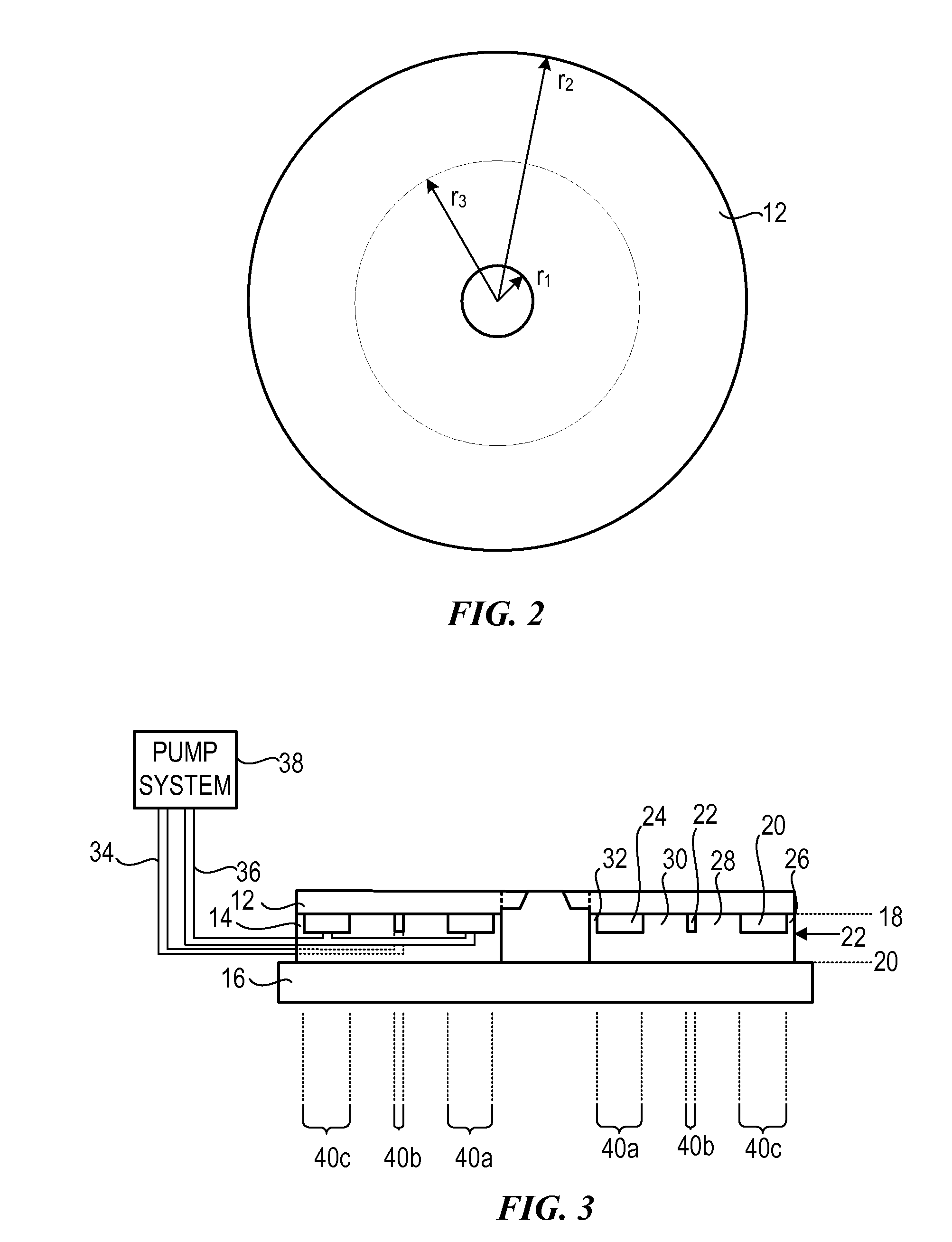

A generally tubular device (e.g., a stent or catheter) for placement in a lumen of a patient's body is made by forming a depressed pattern in an external surface of a mold. The depressed pattern corresponds to a desired shape of the generally tubular device. A material is deposited in the depressed pattern for the material to form the generally tubular device conforming to the depressed pattern. The generally tubular device is separated from the mold.

Owner:EV3 PERIPHERAL +1

Method and apparatus for lining a conduit

Owner:HEAGY RICHARD T +3

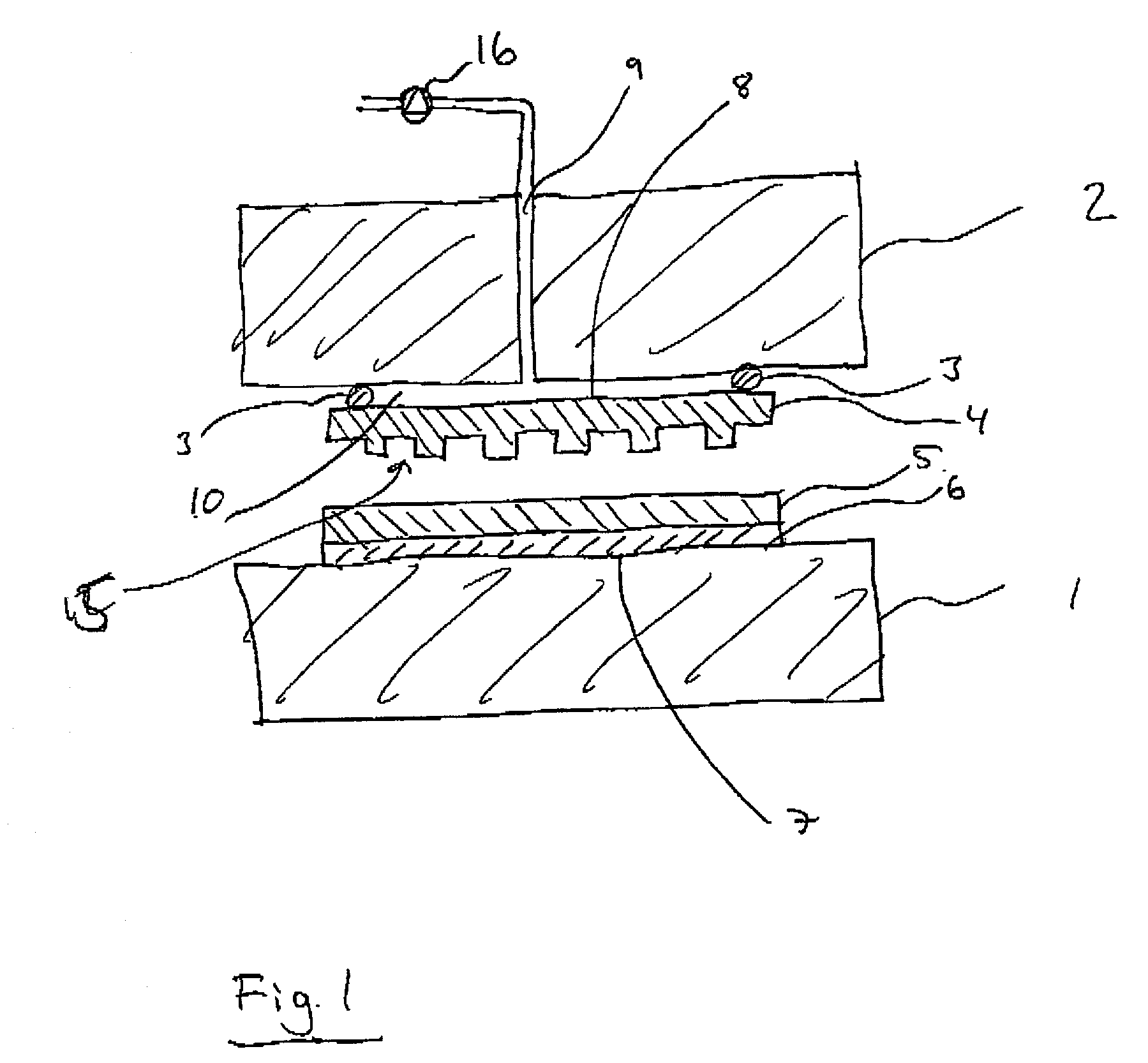

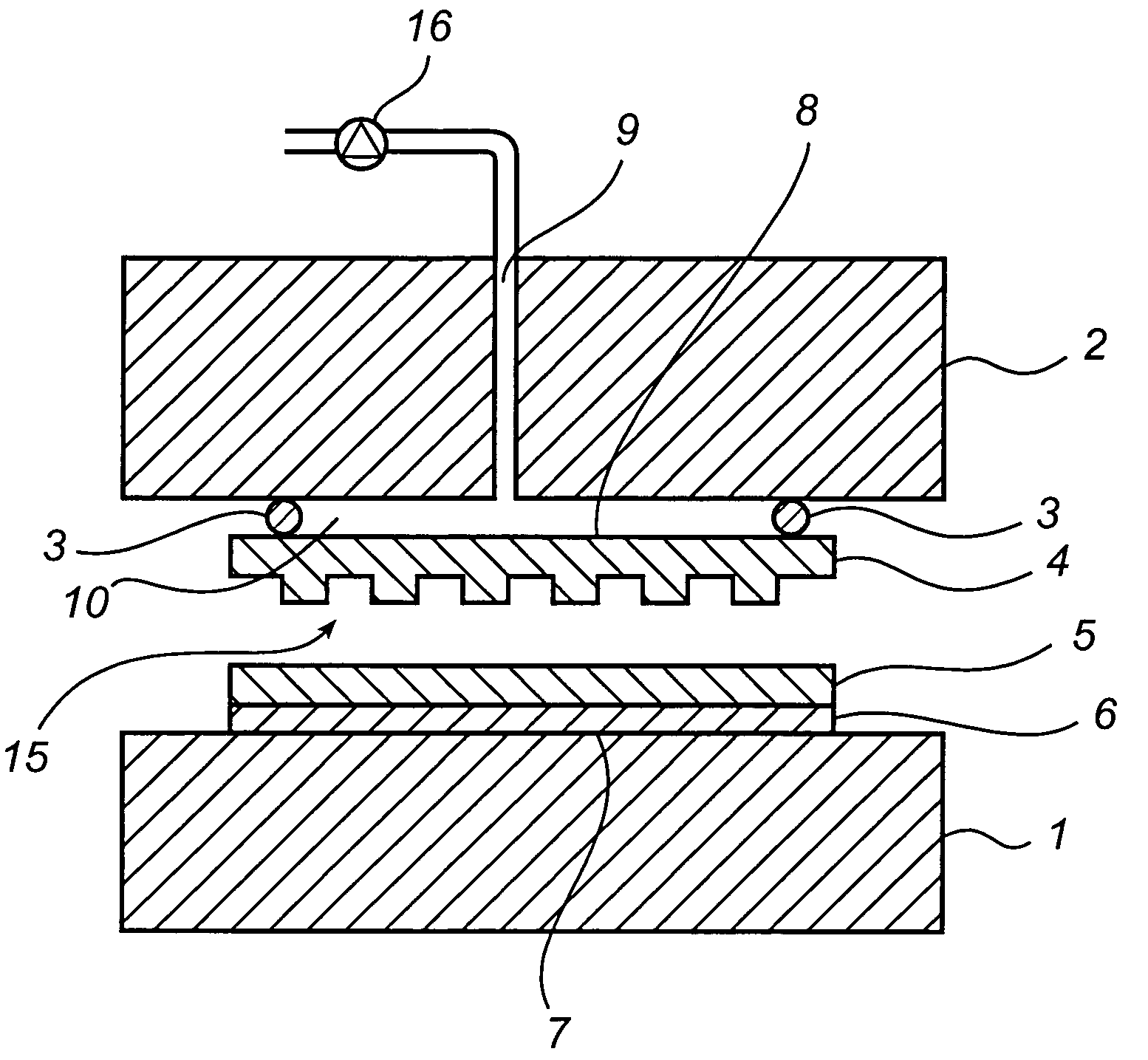

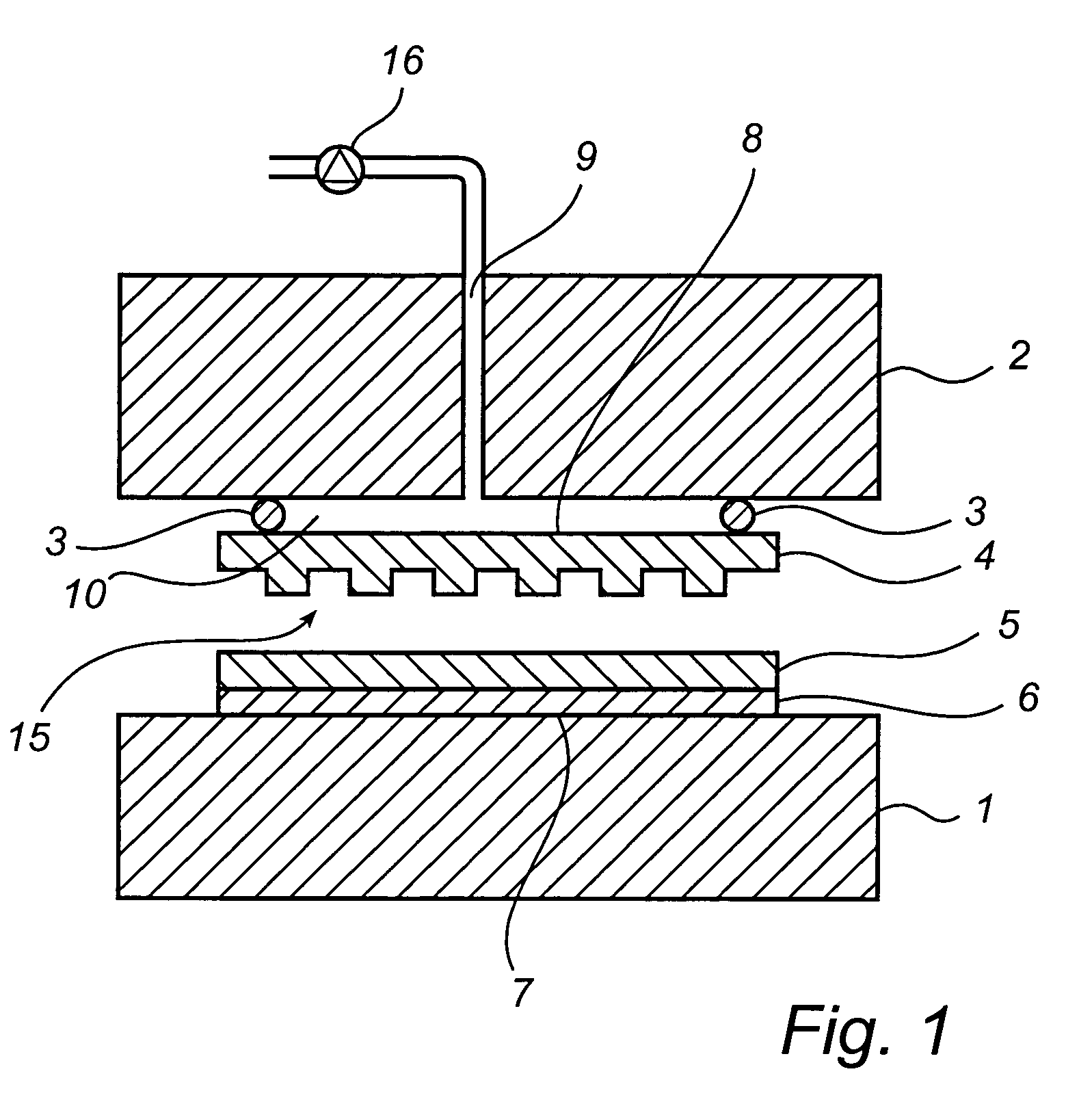

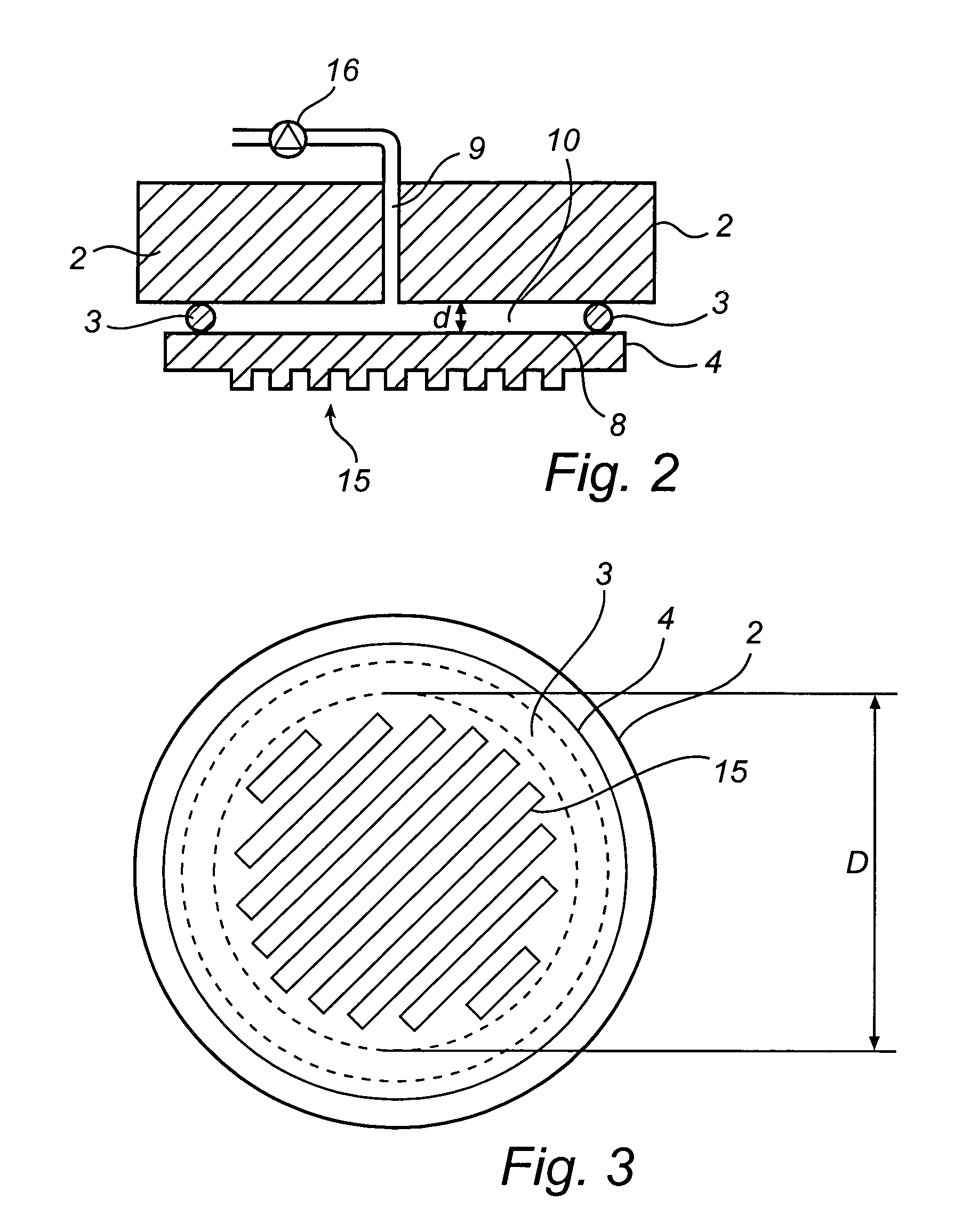

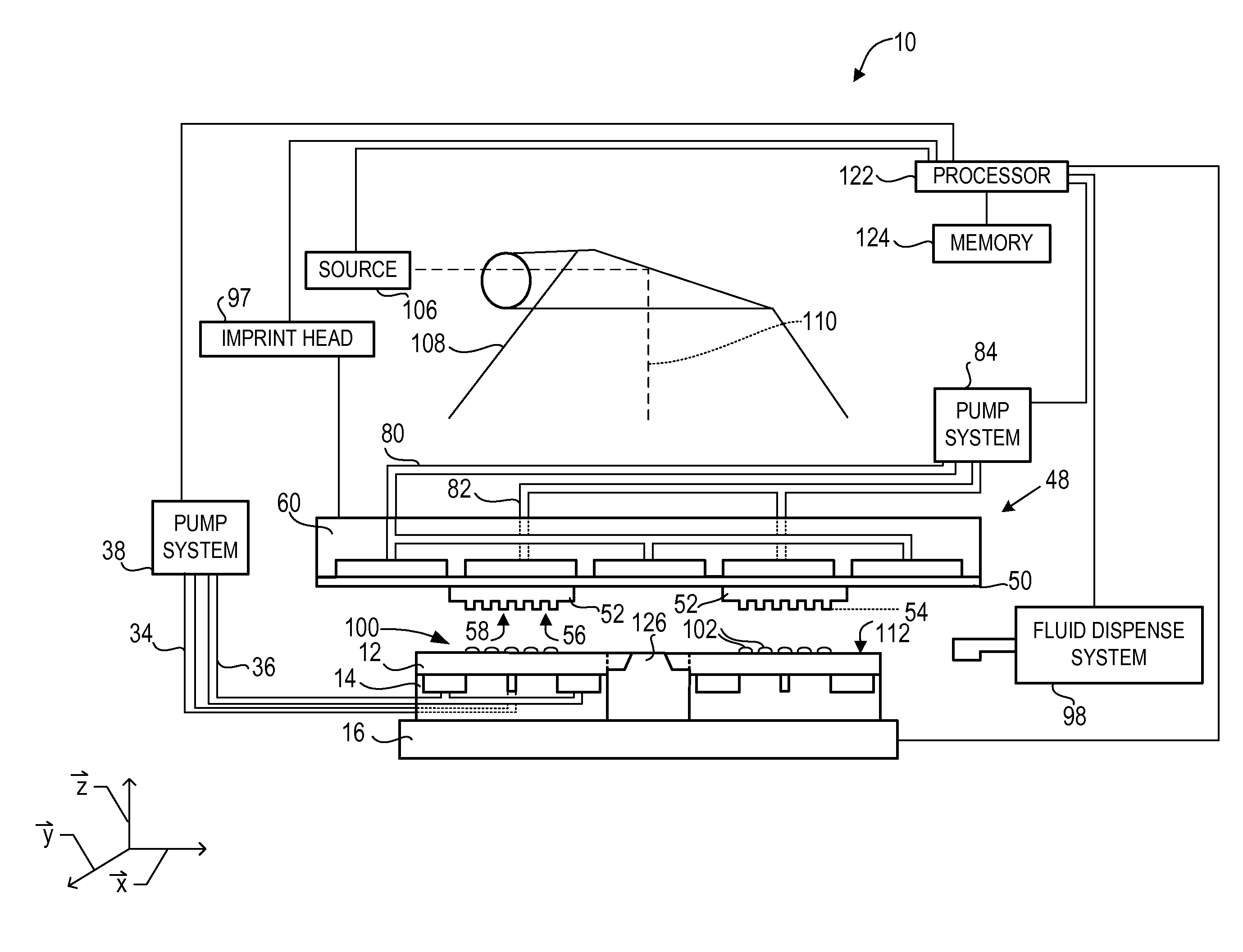

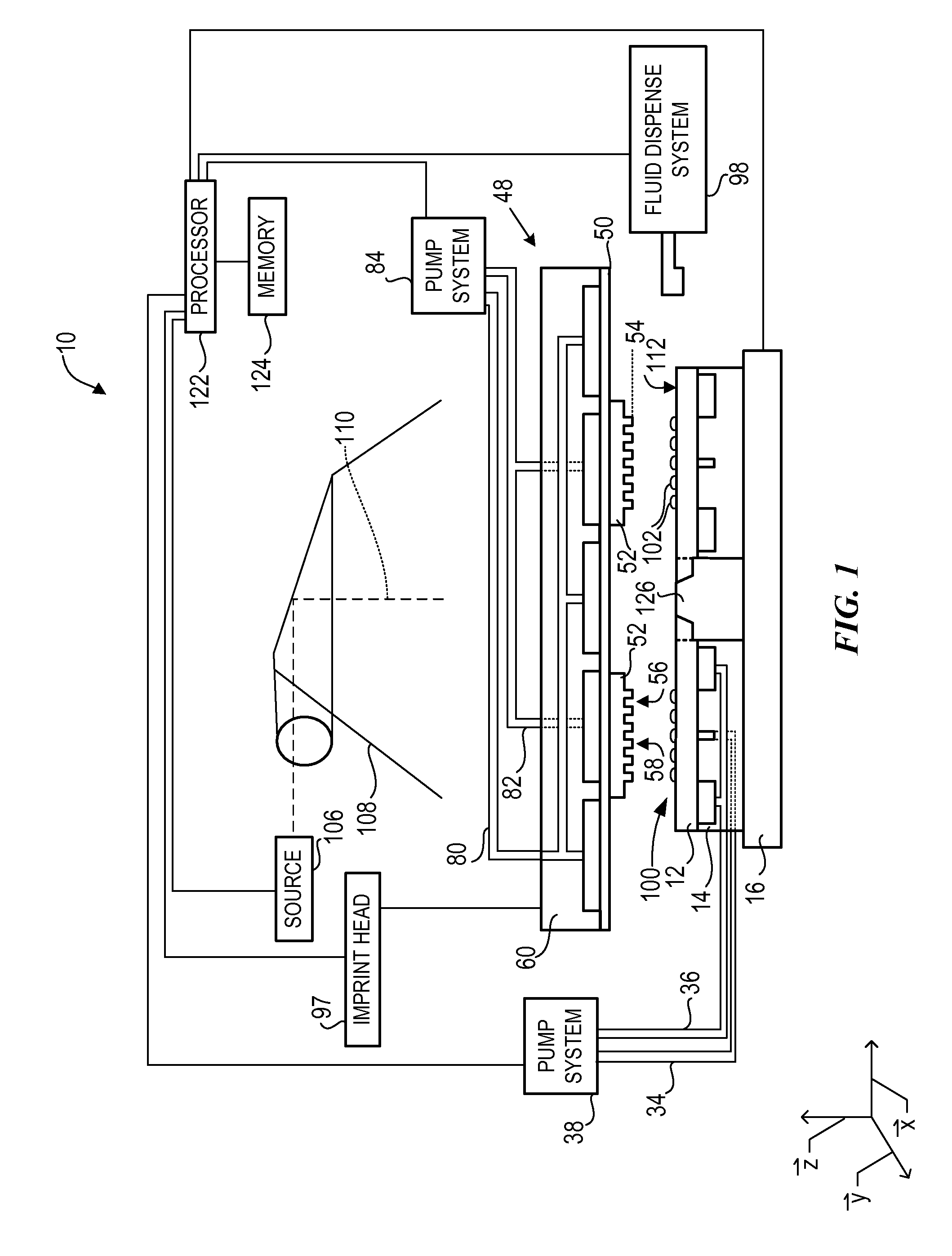

Imprint method and device

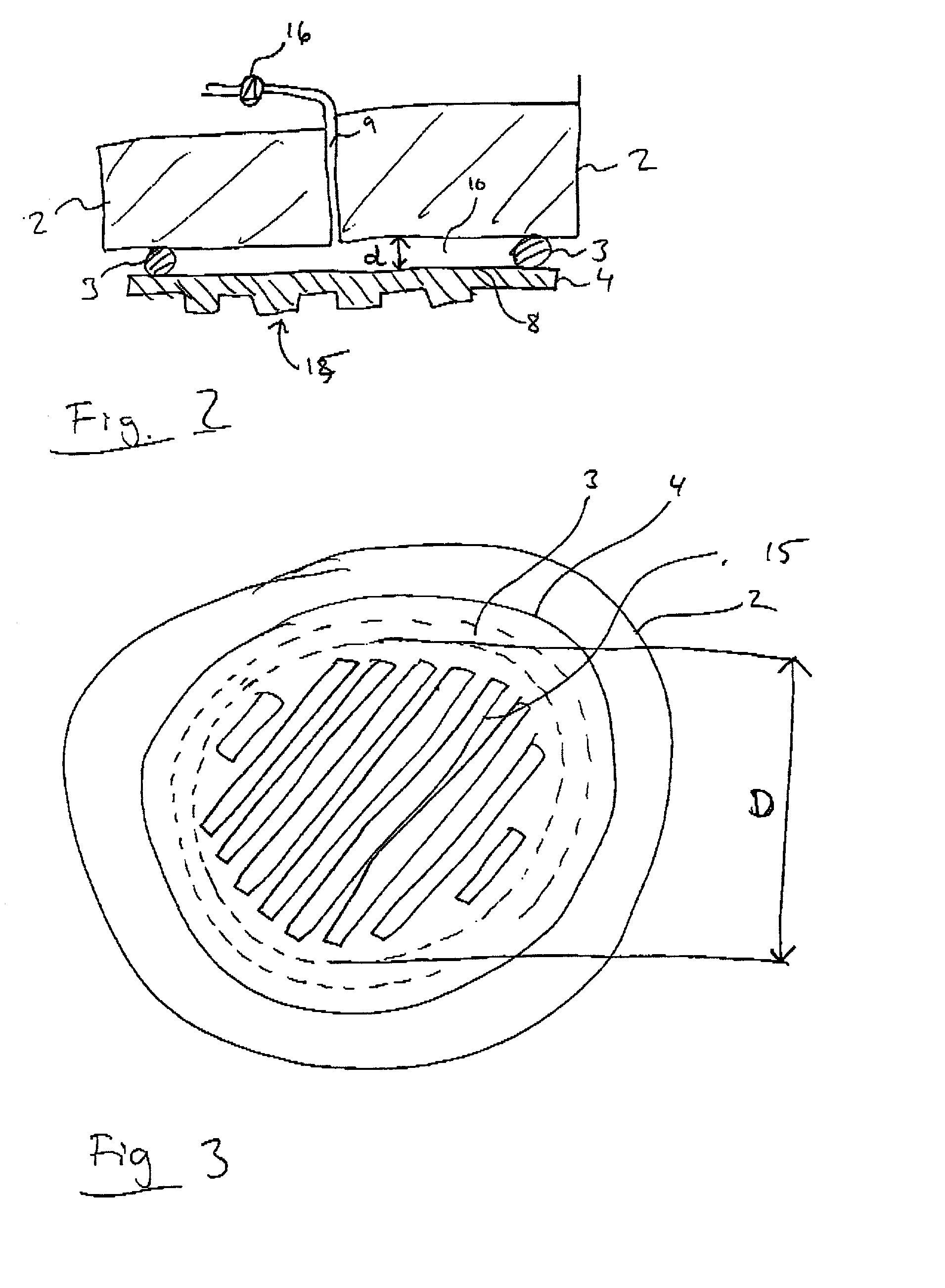

An imprint process comprises the step of aligning a substrate, supported on a first support member, with a template, supported on a second support member. The substrate has at least one essentially plane surface provided with a moldable film. The template has at least one essentially plane surface provided with a relief pattern. The relief pattern is adapted to interact with the moldable film. The process further comprises the step of arranging a sealing gasket between the template and the second support member, such that a pressure cavity is defined by the second support member, the template and the sealing gasket. The process also comprises the step of applying a static gas pressure to the pressure cavity, in order to provide a pressure between the template and the substrate. The pressure is sufficient to form a pattern in the moldable film. An imprint device is also disclosed.

Owner:OBDUCAT AB SE

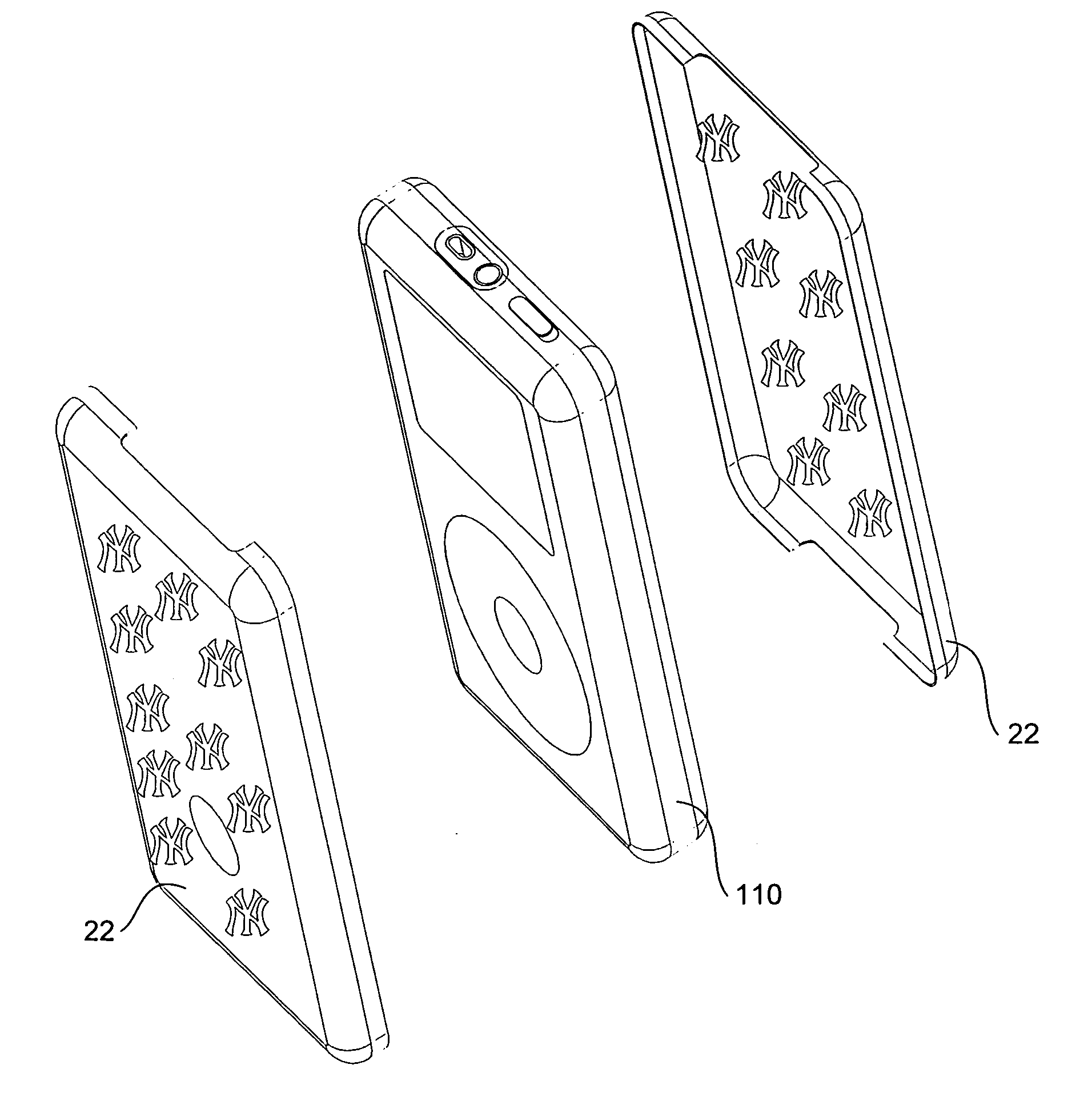

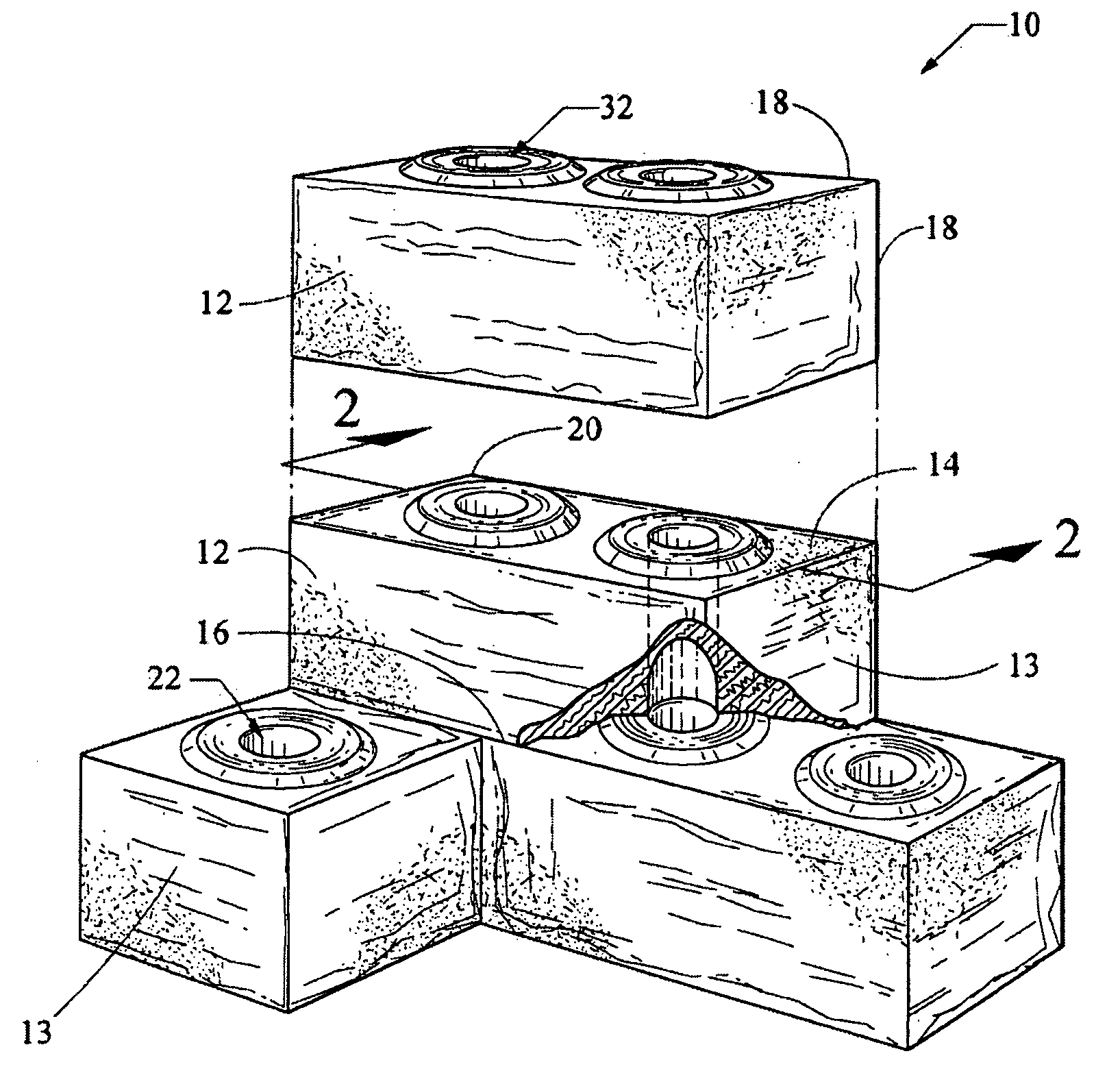

Apparatus and method for making form-fitted molded protective cases for products

A method and apparatus for making inexpensive, form-fitted, protective cases of thermal plastic or polycarbonate material that can be easily printed with decorative imagery and / or electronic circuitry for a variety of products, such as portable music players or radios, cell phones, lap-top computers, and the like. The method involves creating a tool having substantially the same surface dimensions of a product. An element is then molded from bulk film of thermoplastic material using the tool. Once the element is molded, it is trimmed from the bulk film. The resulting apparatus is a protective case intended to form-fit over the surface features and dimensions of the actual product used to define the tool.

Owner:SIK

Casting preforms for optical fibres

InactiveUS20050089670A1Difficult and expensive to produceButtonsCladded optical fibreOptoelectronicsPolymer

This invention relates to a method of preparing a preform for an optical fibre, and more particularly to a method of preparing a preform for a polymer holey optical fibre. The invention provides a method of preparing a preform for manufacture of a polymer holey optical fibre comprising casting a preform body in a mould from a suitable material, said mould including at least one protrusion adapted to form a corresponding hole within the preform, and subsequently separating the preform body and mould. The invention also provides a method of preparing a preform for manufacture of a polymeric holey optical fibre comprising separately casting one or more elements of a preform in respective mould(s) from a suitable material, and separating said elements from said respective mould(s) and combining said elements to construct a preform having a plurality of holes therein, each hole being formed in an element or formed by the combination of two or more elements.

Owner:THE UNIV OF SYDNEY +2

Method of making a part of large dimensions out of composite material

InactiveUS6264877B1Avoid disadvantagesRisk of pollutionFinal product manufactureLaminationGlass fiberFiber

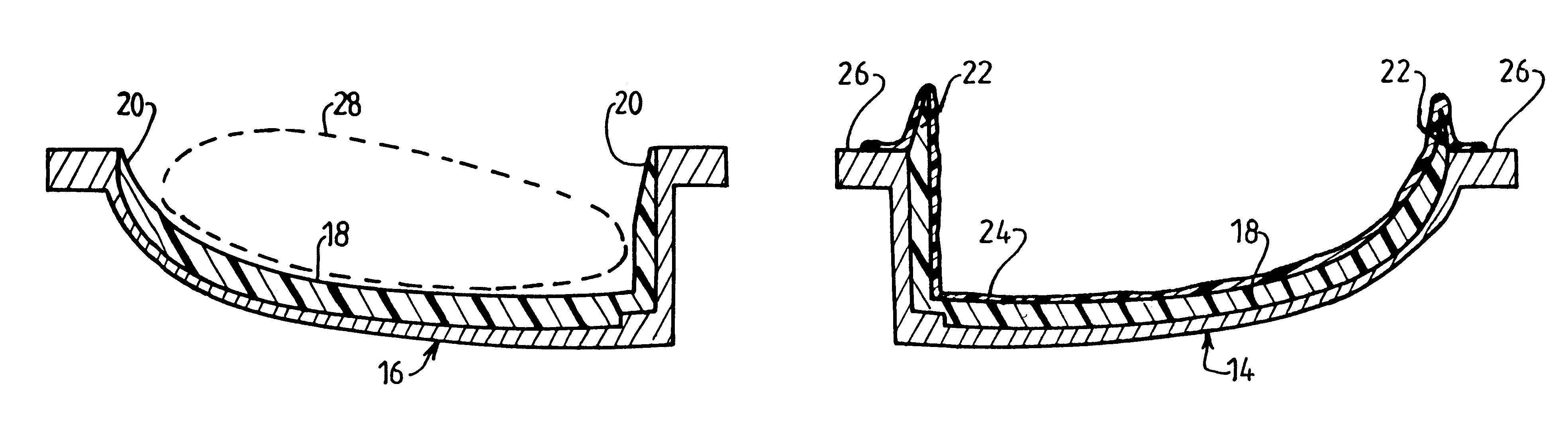

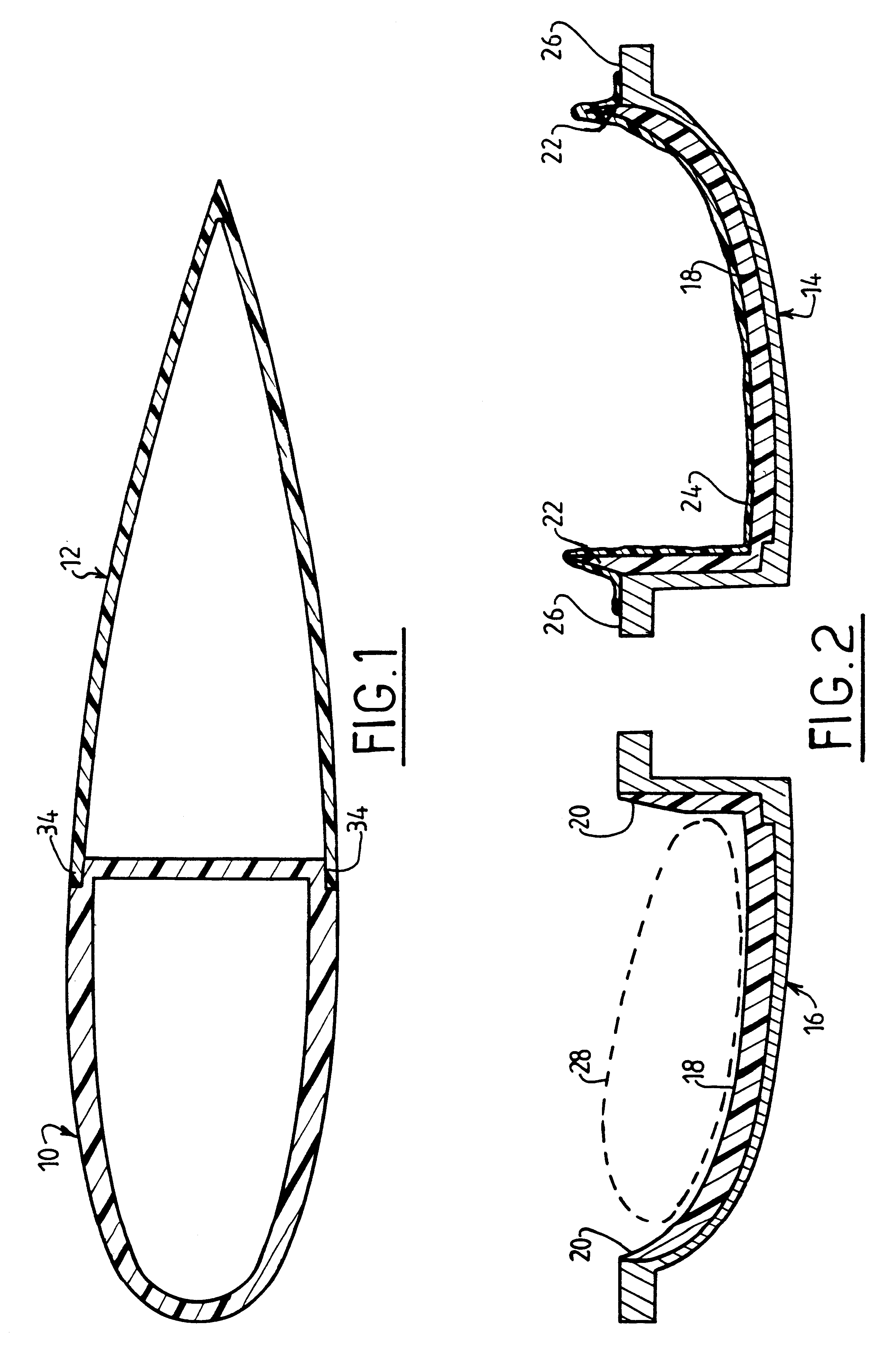

A method of making a composite material part, in particular a wind turbine blade of great length, consists in placing a thickness of a cloth made up of threads comprising a mixture of polypropylene threads or fibers and of glass fibers or threads in two mold portions having the shape of the part that is to be made, placing an inflatable envelope on the cloth inside one of the mold portions, in closing the mold, in placing it in an enclosure fed with hot gas under pressure to melt the polypropylene of the cloth, thereby embedding the glass fibers or threads, then in allowing it to cool, and in unmolding.

Owner:ALTERNATIVES ENERGIES

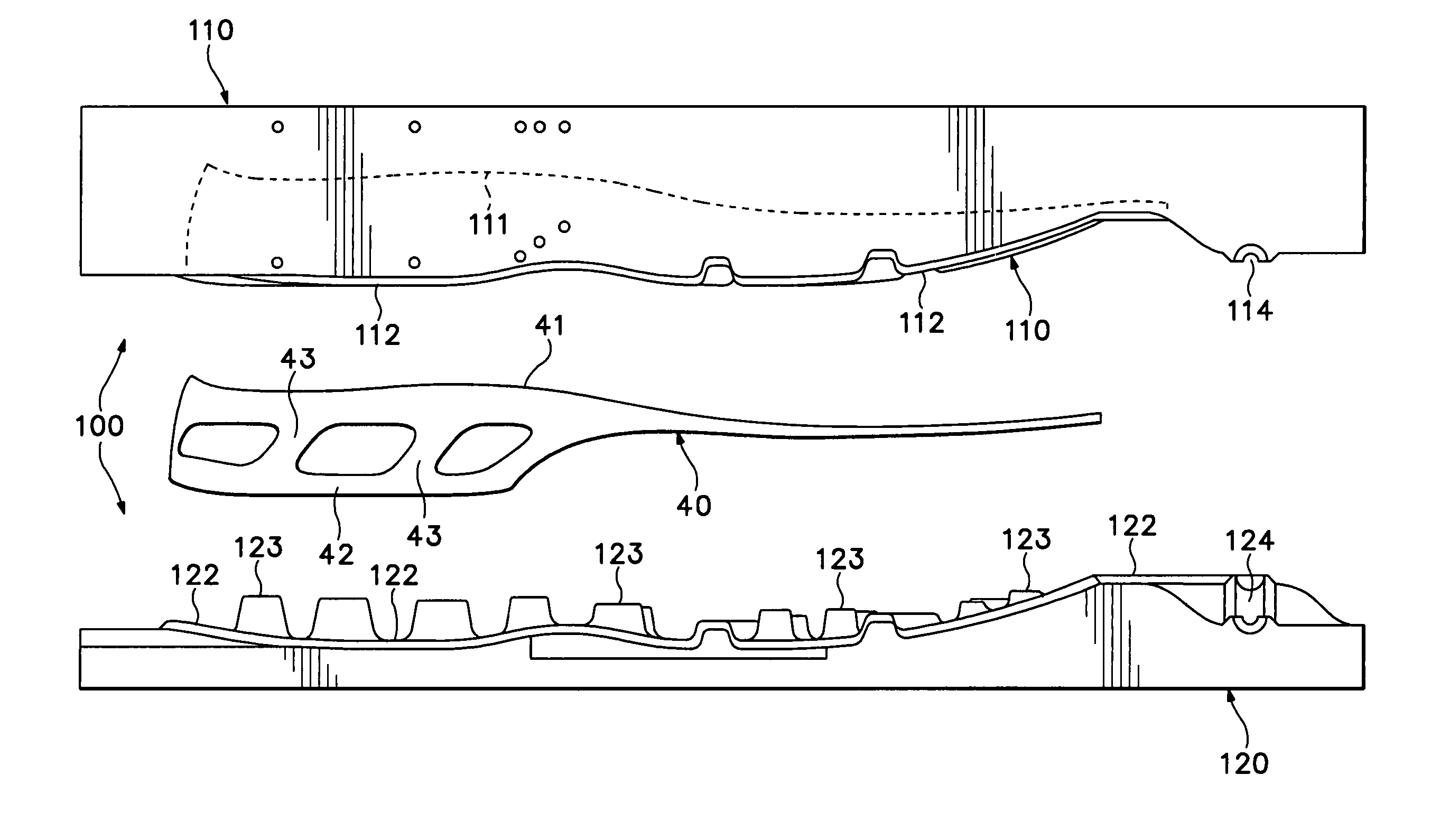

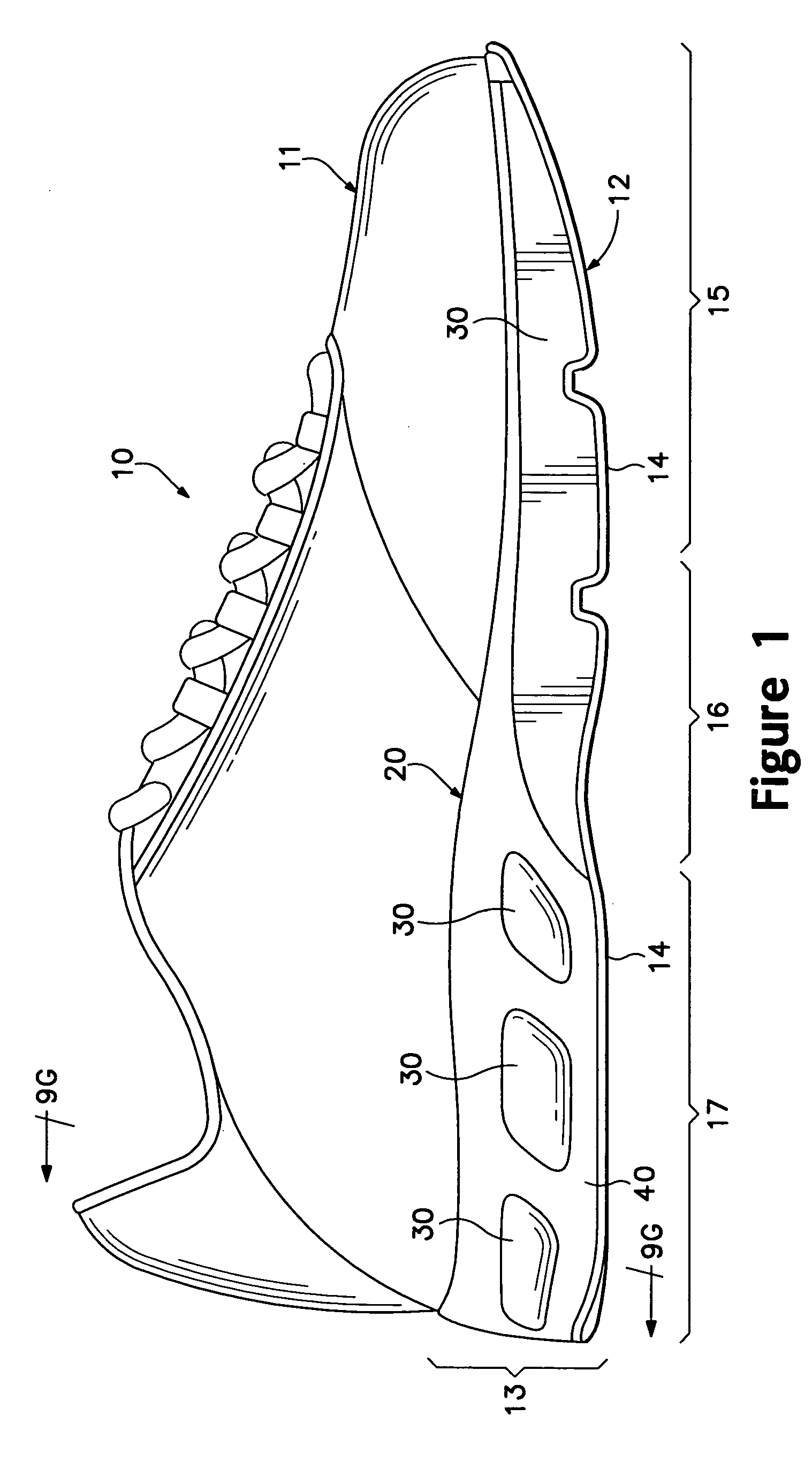

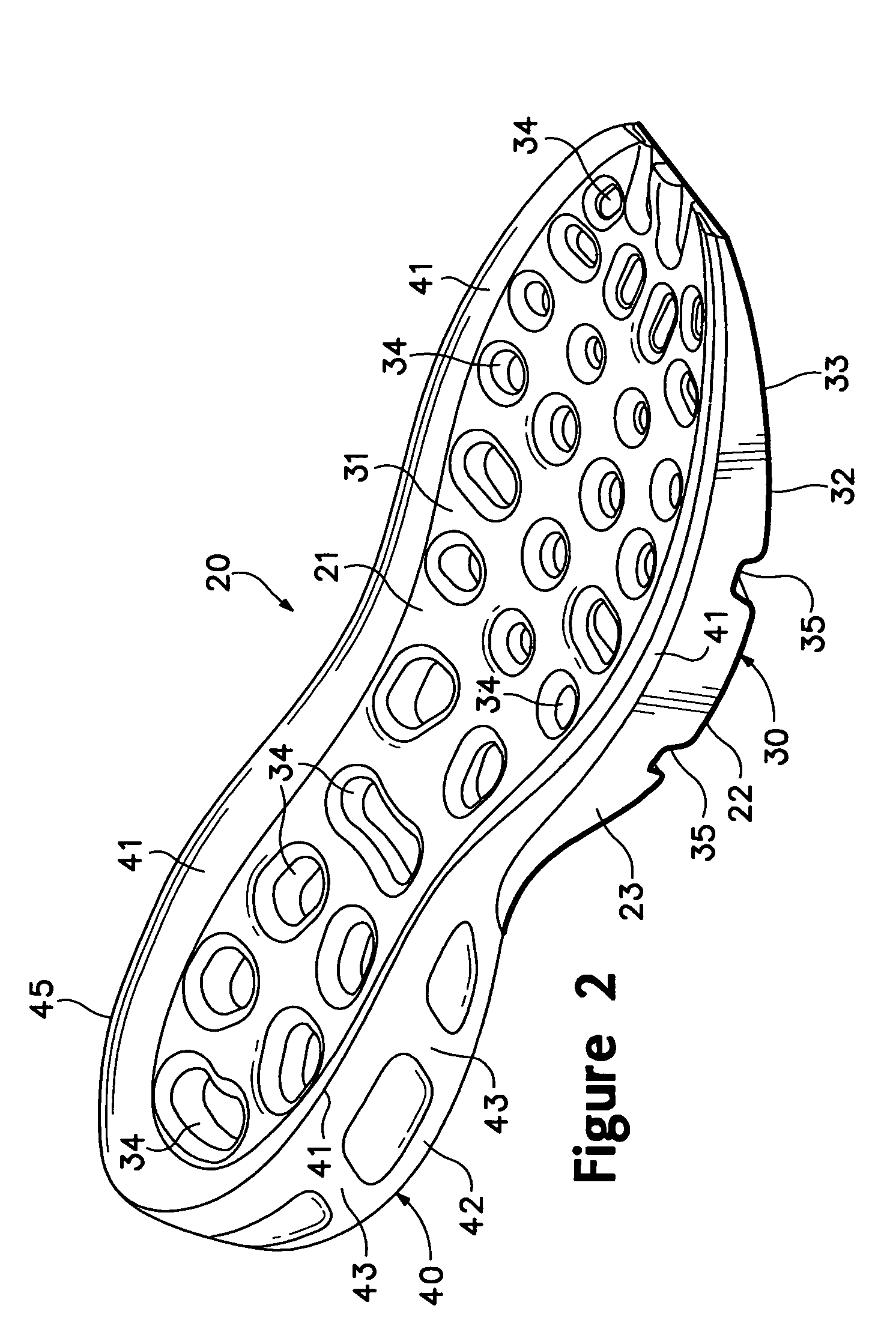

Method of making article of footwear having a fluid-filled bladder with a reinforcing structure

Owner:NIKE INC

Method for making prosthetic residual limb socket

A definitive socket for residual limb prosthetic use is formed in a single molding step by compressive pressure casting or molding a pre-formed, moldable, hardenable socket material over a residual limb and curing the socket material to a load-bearing hardened condition while it is maintained under peripheral compressive pressure against the residual limb and while the residual limb is tensioned in a distal direction during the casting process. The combination of pressure casting the socket material and applying tension to the residual limb in a distal direction while the socket material is curing results in forming a definitive socket that fits well to the residual limb after curing without substantial rectification. Pressure relief formations, socket coverings, and a prosthesis coupler may be compression molded simultaneously with the socket.

Owner:KAUPTHING BANK

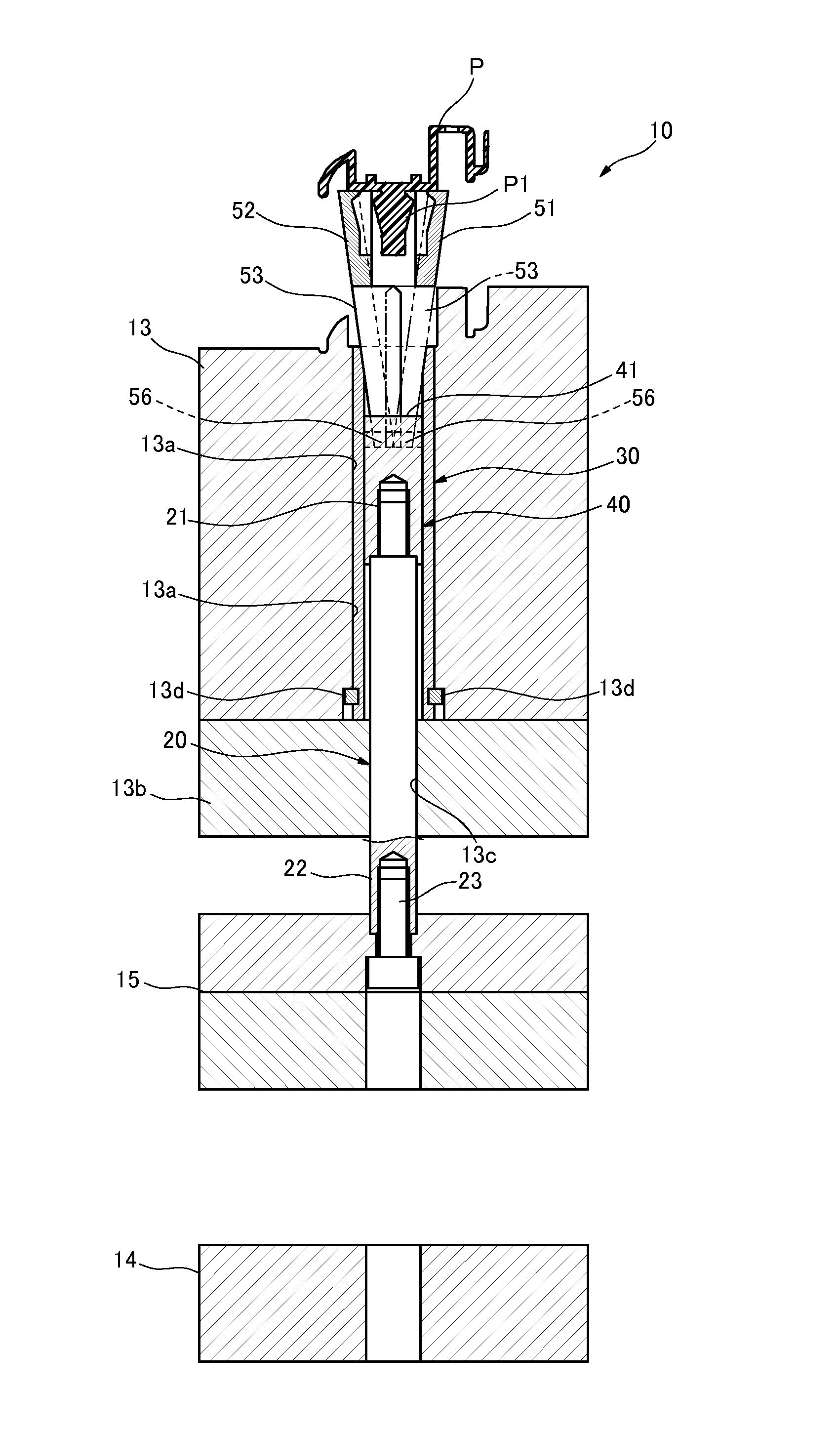

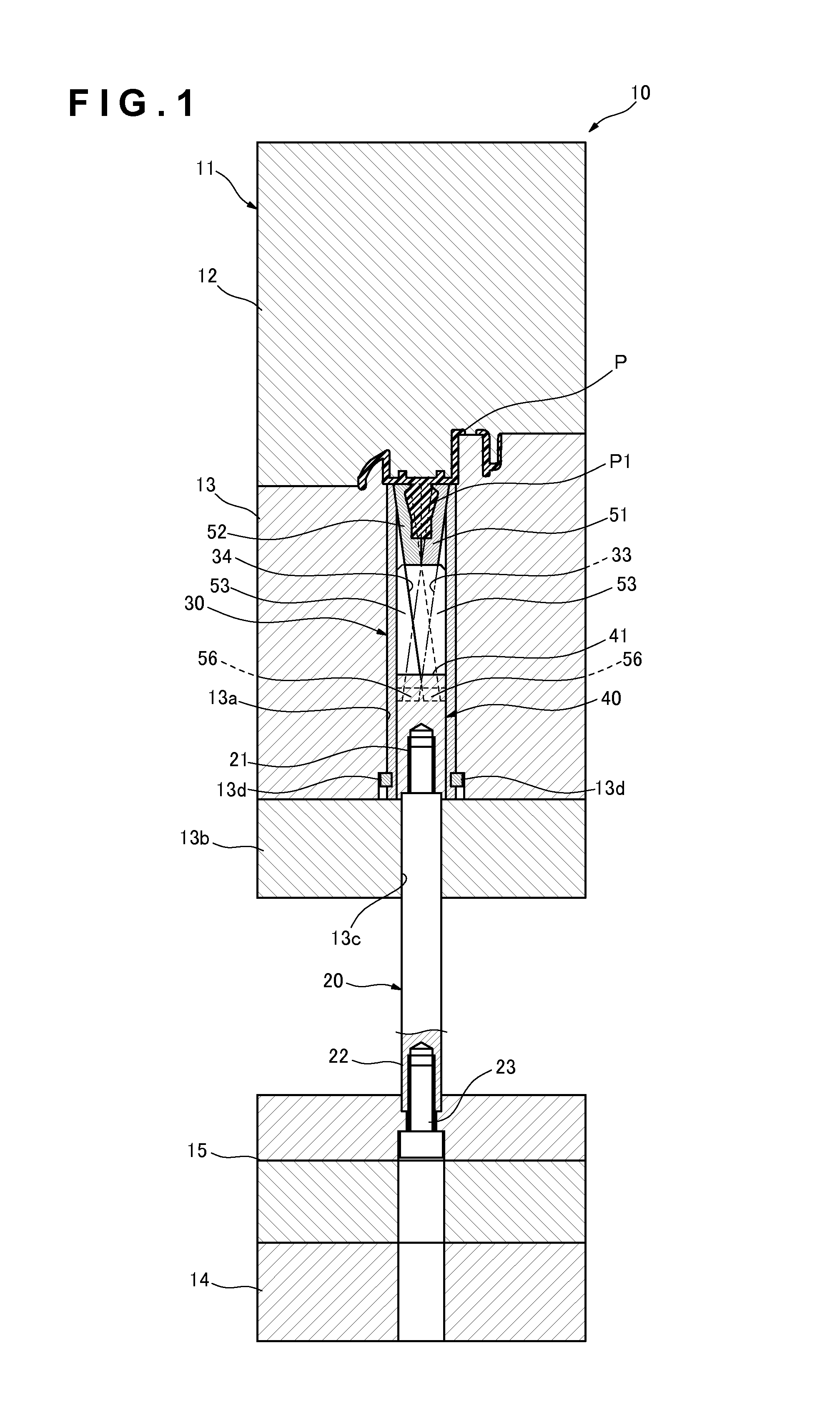

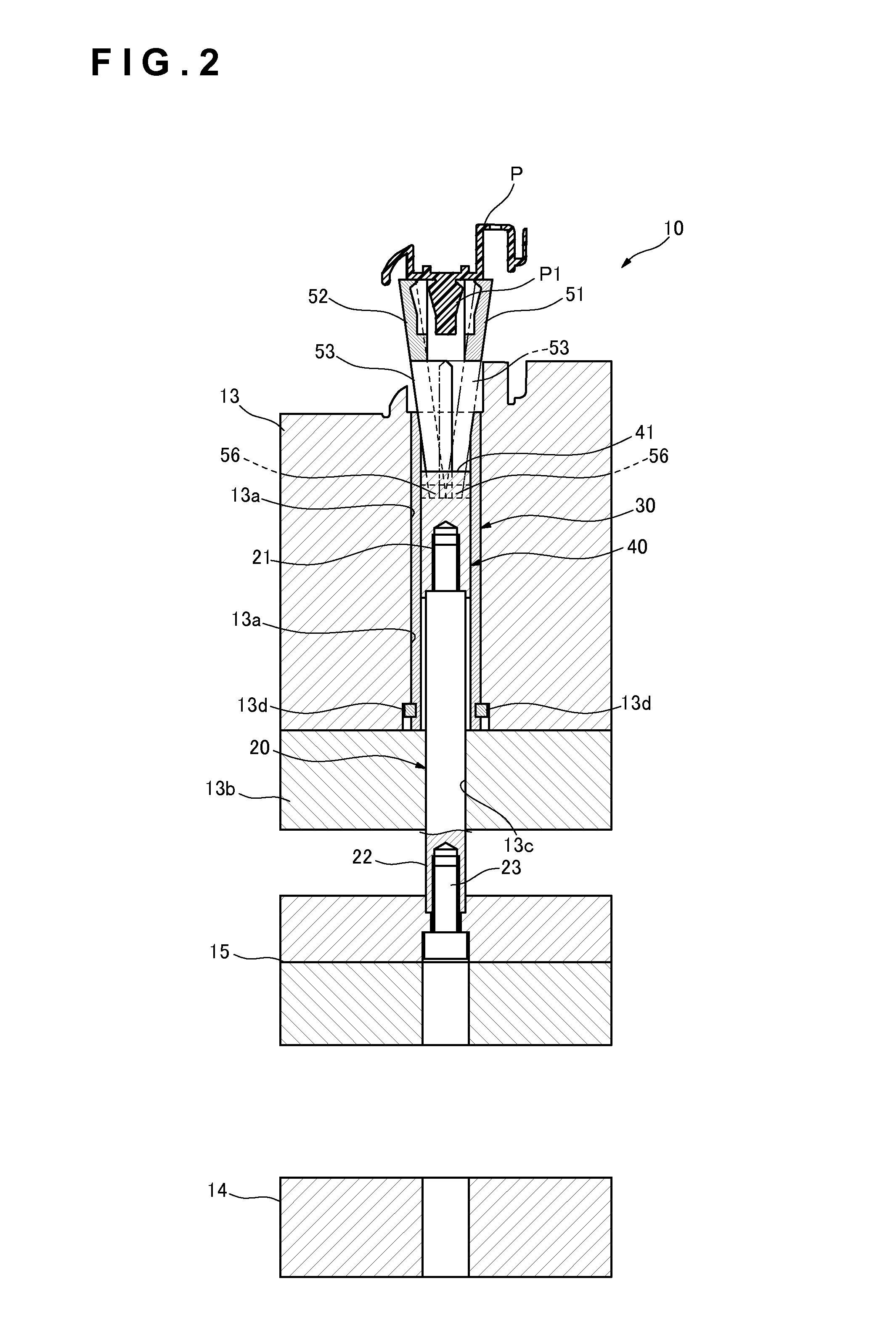

Undercut processing mechanism

A pair of mold cores (51, 52) for molding an undercut portion (P1) in a holder (30) installed inside a movable mold (13) are connected to and supported by a retaining piece (40) which is moved in the demolding direction, and at the time of demolding, the respective mold cores (51, 52) are guided by guide means (33, 34) from the molding position, where they are contacted with each other, to the mold release position, where they are separated from each other, being moved from one end side to the other end side of the retaining piece (40), in the mutually opposite directions so as to pass each other in the back and forth direction.

Owner:TECHNOCRATS CORP

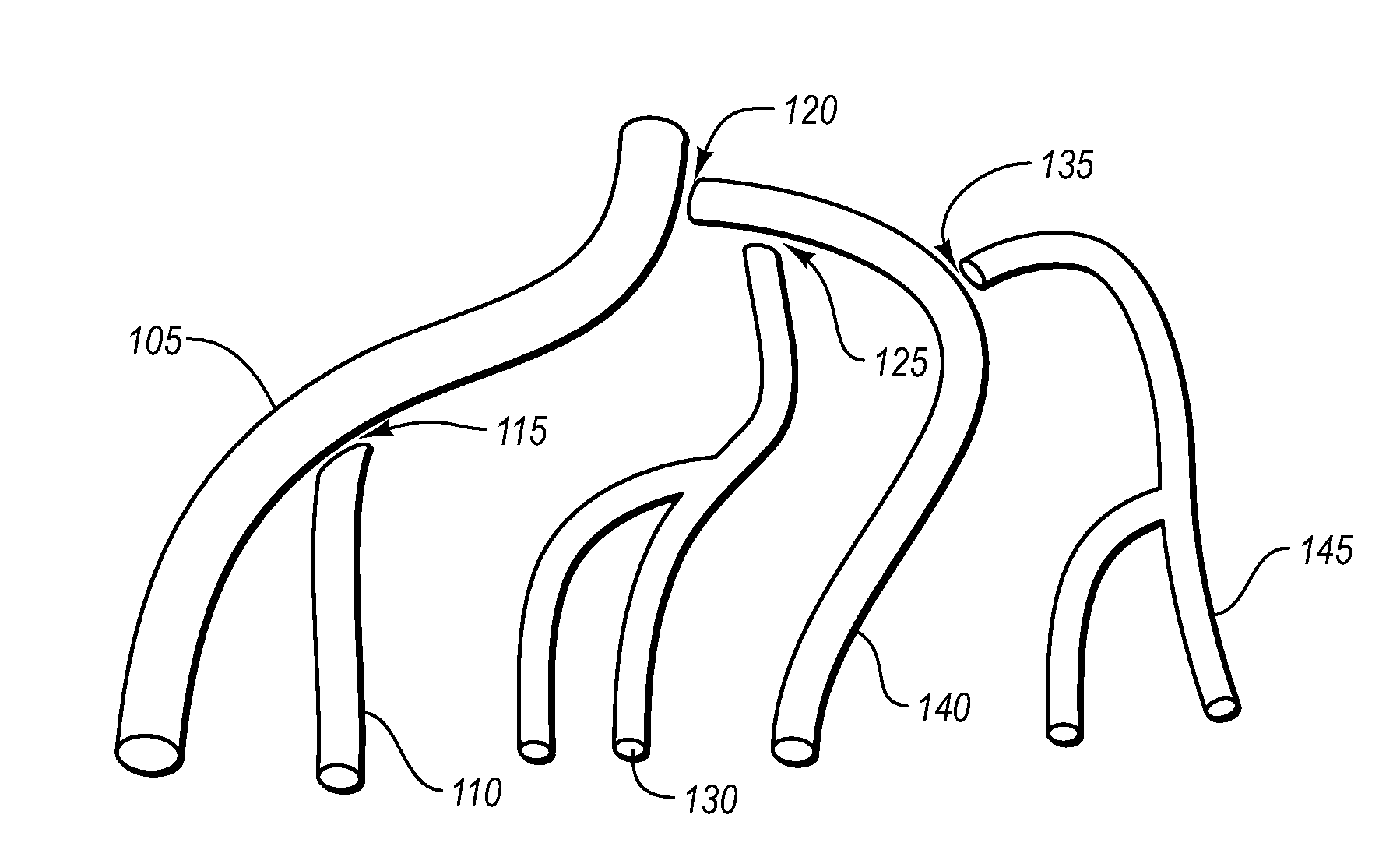

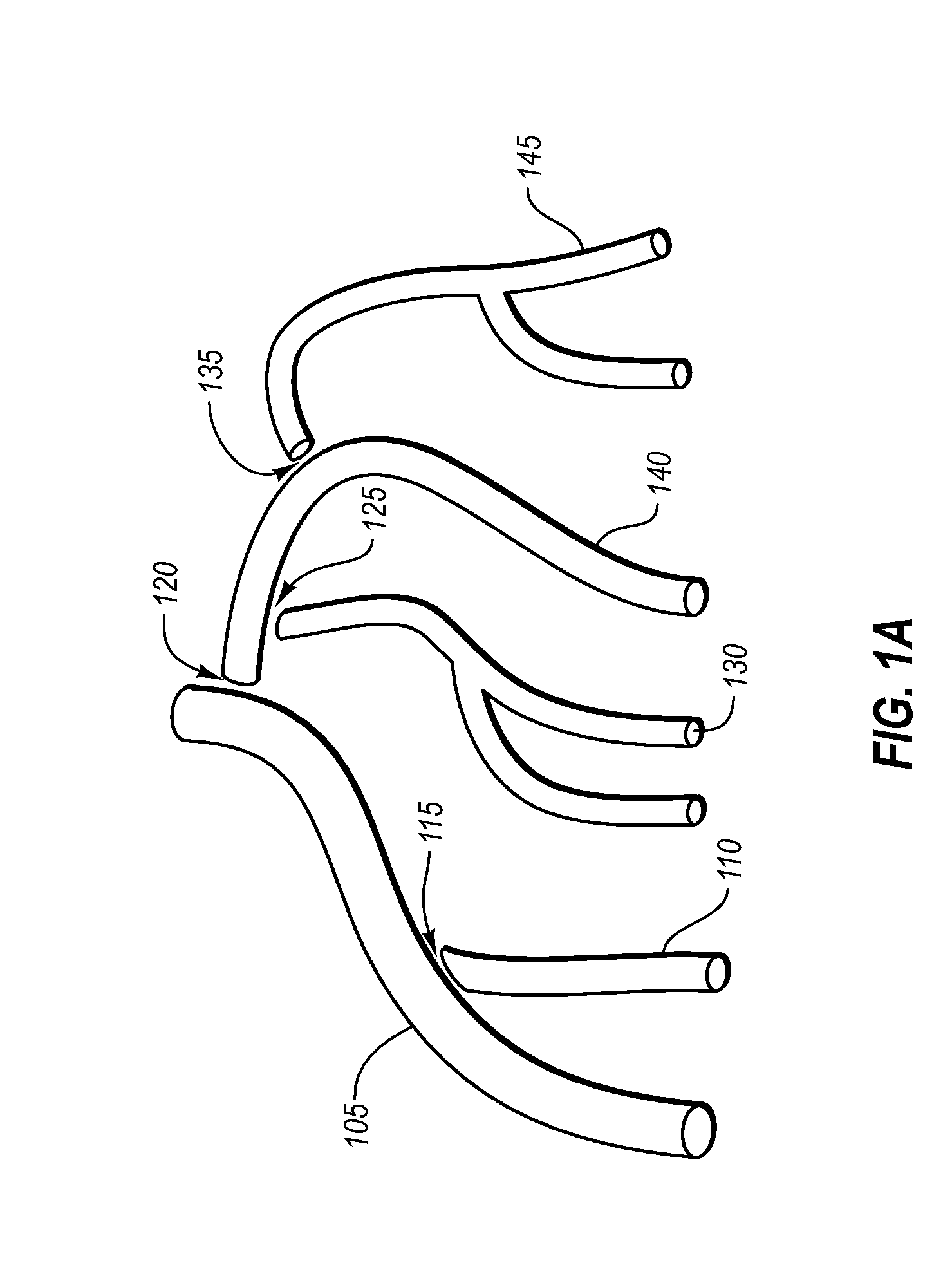

Forming vascular diseases within anatomical models

InactiveUS20080076101A1Improve radial strengthArtificial flowers and garlandsSynthetic resin layered productsVascular diseaseAnatomical structures

Anatomical models are provided with simulated plaque, lesion, chronic total occlusion, as well as other vascular diseases that more accurately replicate these abnormalities. In such embodiment, the vascular disease may be formed separate from the structured anatomical model. The formed vascular disease material may then be bonded to or within a PVA material in a separate process from forming this simulated vascular disease, thus providing a replicated specific anatomy structure with an abnormality for demonstrating, testing, and / or developing medical functions and / or devices.

Owner:ABBOTT LAB INC

Imprint method and device

InactiveUS7144539B2Eliminate disadvantagesConfectioneryNanoinformaticsShell moldingMembrane interaction

An imprint process comprises the step of aligning a substrate, supported on a first support member, with a template, supported on a second support member. The substrate has at least one essentially plane surface provided with a moldable film. The template has at least one essentially plane surface provided with a relief pattern. The relief pattern is adapted to interact with the moldable film. The process further comprises the step of arranging a sealing gasket between the template and the second support member, such that a pressure cavity is defined by the second support member, the template and the sealing gasket. The process also comprises the step of applying a static gas pressure to the pressure cavity, in order to provide a pressure between the template and the substrate. The pressure is sufficient to form a pattern in the moldable film. An imprint device is also disclosed.

Owner:OBDUCAT AB SE

Method for producing upsized frp member

InactiveUS20040130072A1Improve mass productionReduce manufacturing costLamination ancillary operationsLaminationAir cycleFiber

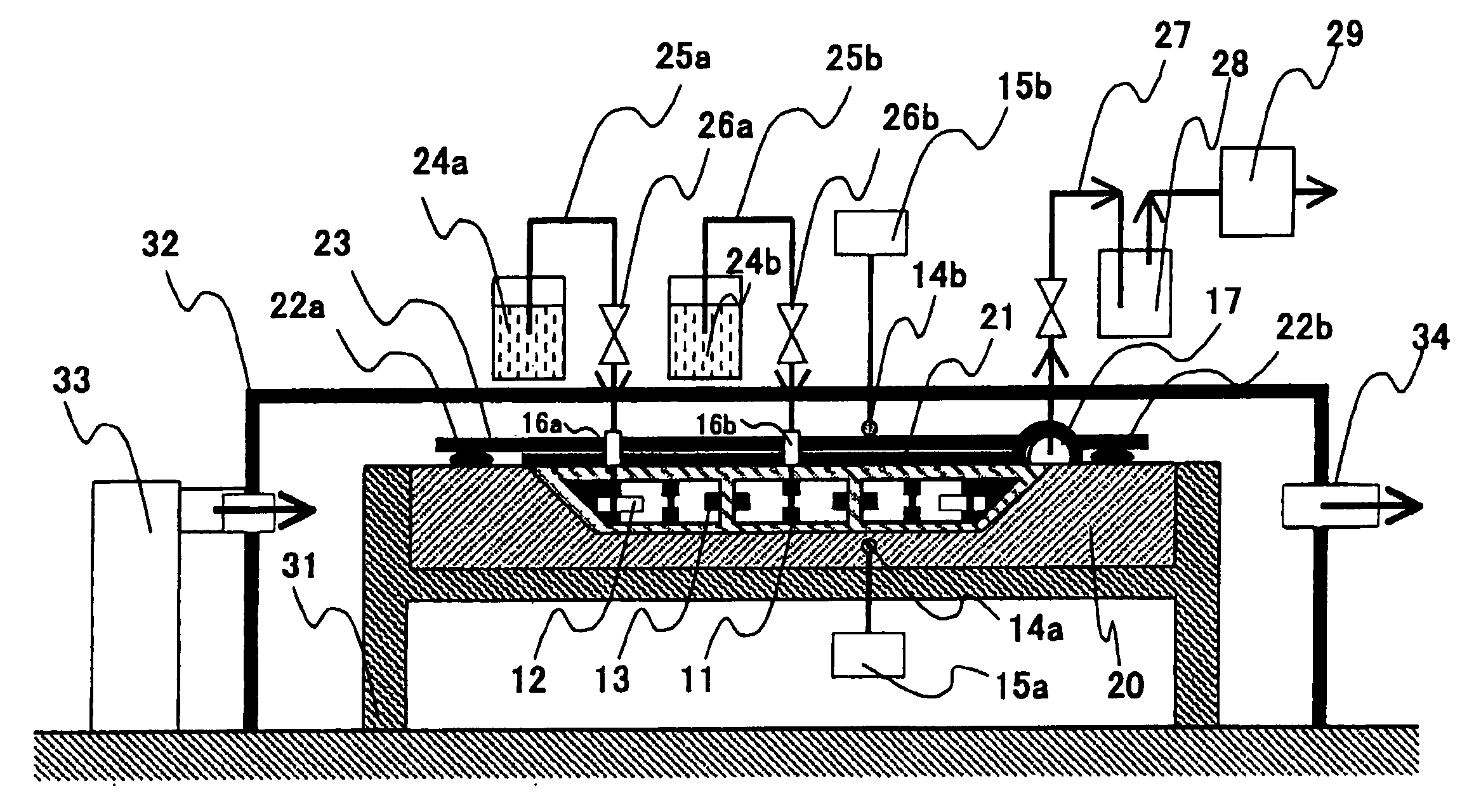

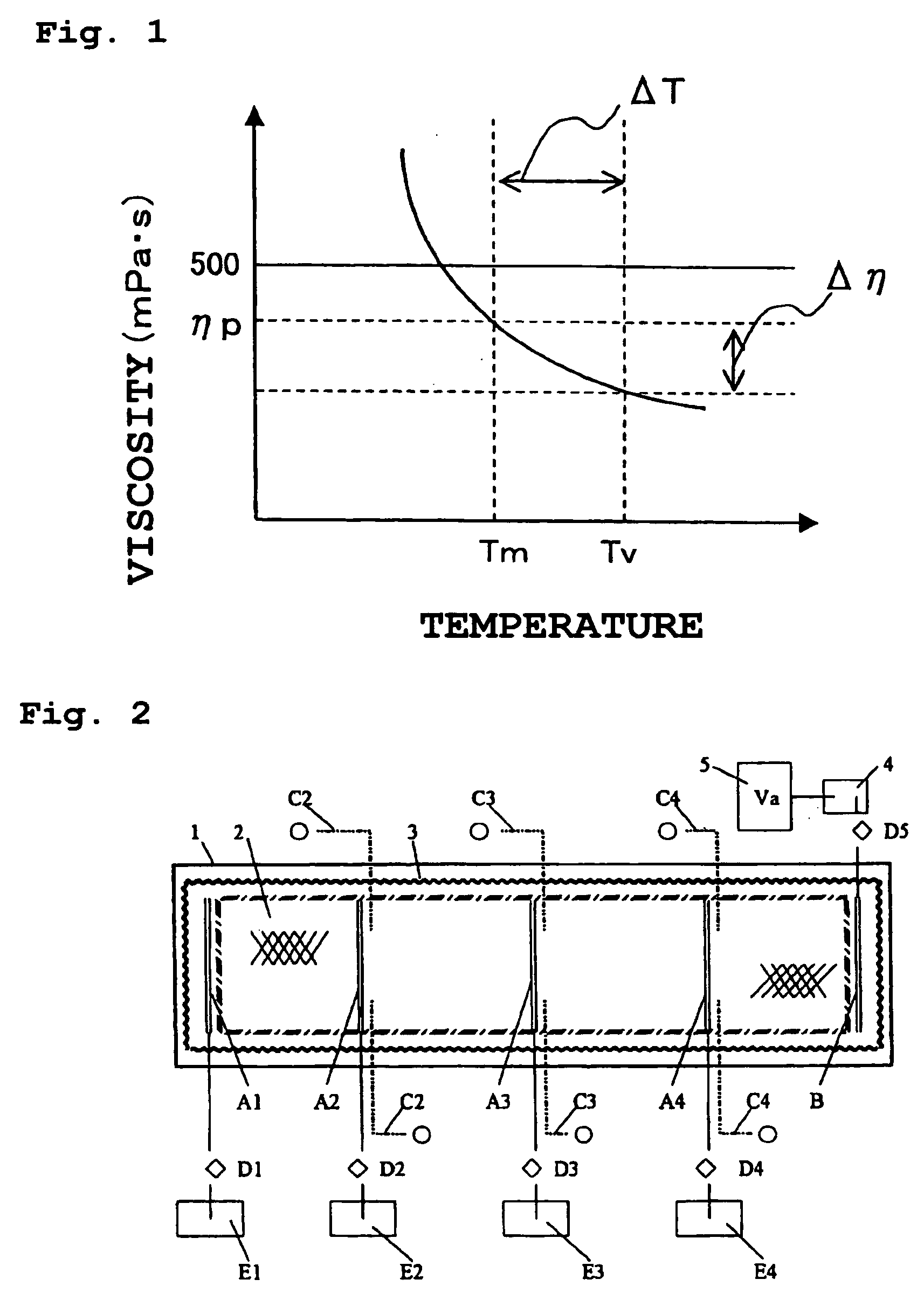

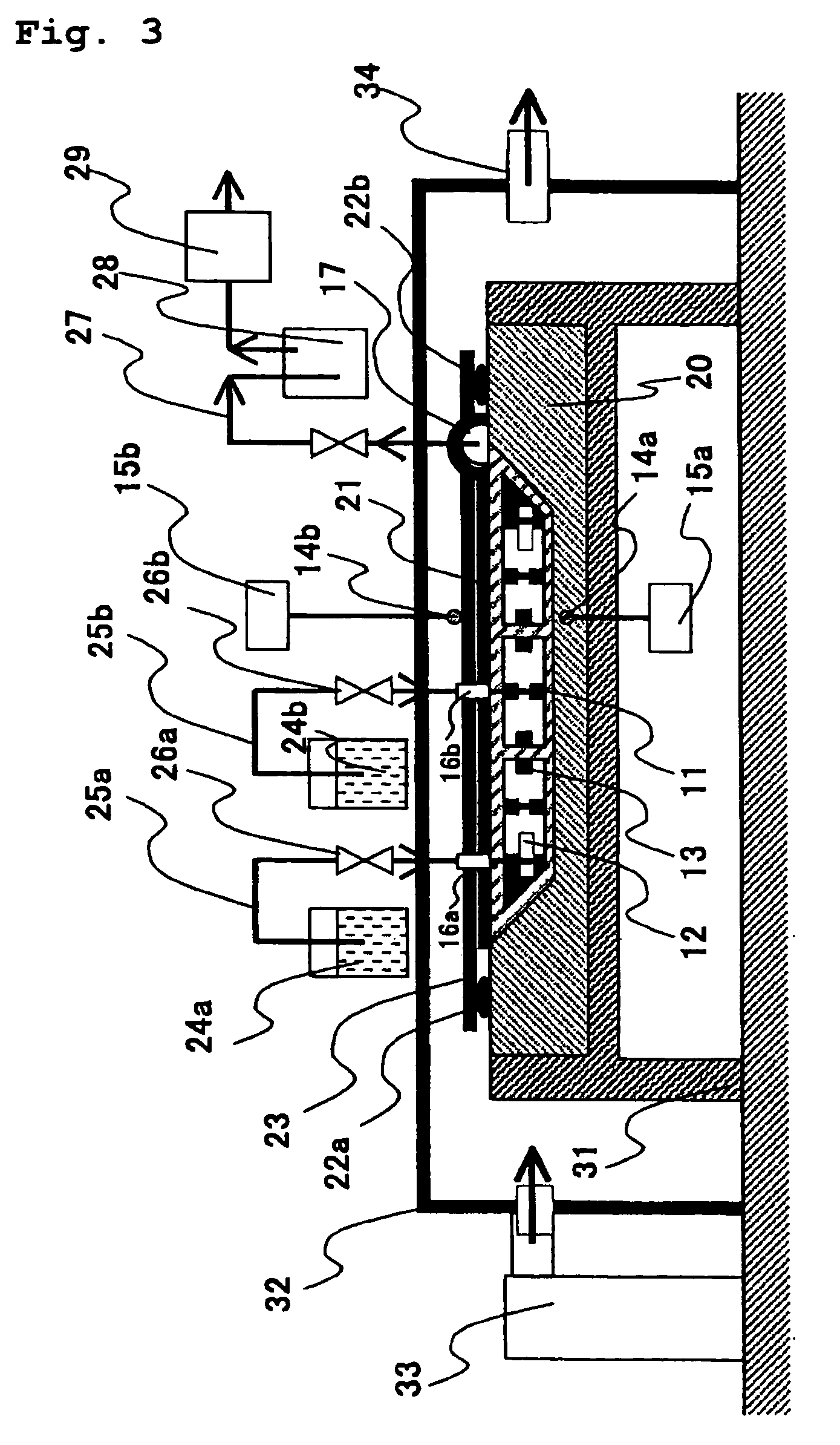

The present invention relates to a method for manufacturing a large FRP member and has the following structure. The method for manufacturing a large FRP member, comprising the following steps (A) to (F). They are: setting step (A) of disposing a preform containing a reinforcing fiber base material on a surface of a molding die; sealing step (B) of covering a molding portion with a bagging material or a mold and providing at least one suction port and at least one resin injection port for sealing; evacuating step (C) of evacuating the molding portion through the suction port; hot-air heating step (D) of heating the molding portion by hot air; resin injection step (E) of injecting a thermosetting resin from the resin injection port for impregnating the reinforcing fiber base material with the resin while a temperature Tm of the molding die and a temperature Tv of the bagging material or the mold are both set to room temperature or more, and a difference DeltaT in temperature between the Tm and the Tv is set to 10° C. or less; and curing step (F) of curing the resin by maintaining the molding portion at a predetermined temperature Tpc which is equal to or more than room temperature. Preferably, the preform described above includes the reinforcing fiber base material and a resin distribution medium. In addition, it is preferable that in the hot-air heating step (D), the molding die be placed in a sealed chamber which is heat insulated with a heat insulating material, the hot air be circulated and supplied, and timing of starting the injection of the resin from a plurality of the resin injection ports be controlled in accordance with signals supplied from resin detection sensors provided in the molding die. The present invention provides a method for manufacturing a large FRP member having superior quality at an inexpensive cost and with high production yield, in which non-impregnated portions and voids are unlikely to be formed.

Owner:TORAY IND INC

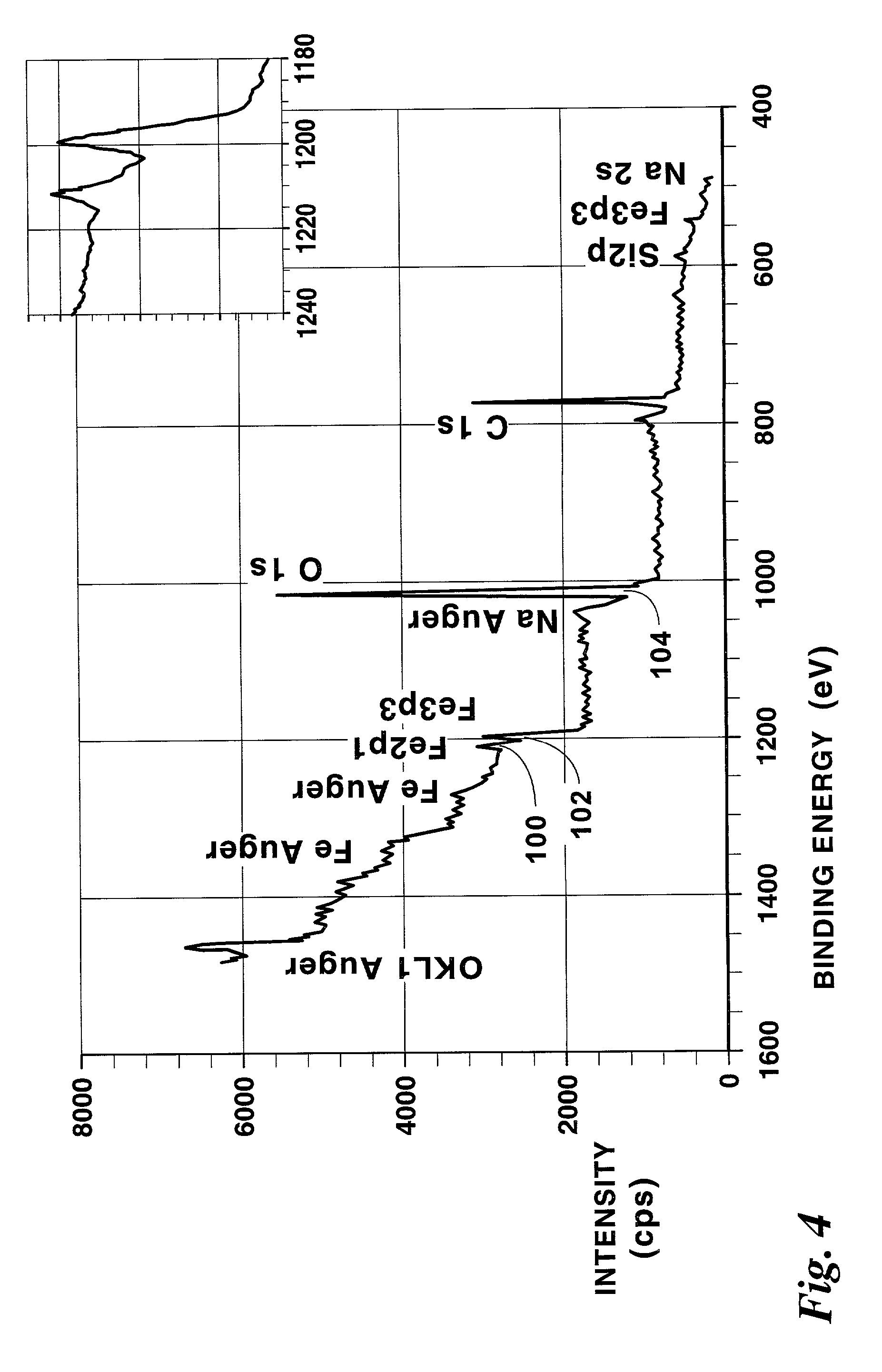

Cement-based materials system for producing ferrous castings using a three-dimensional printer

ActiveUS20110177188A1Improve accuracyHigh strengthAdditive manufacturing apparatusAlkali metal silicate coatingsMaterials scienceMaterial system

Owner:MASSACHUSETTS INST OF TECH

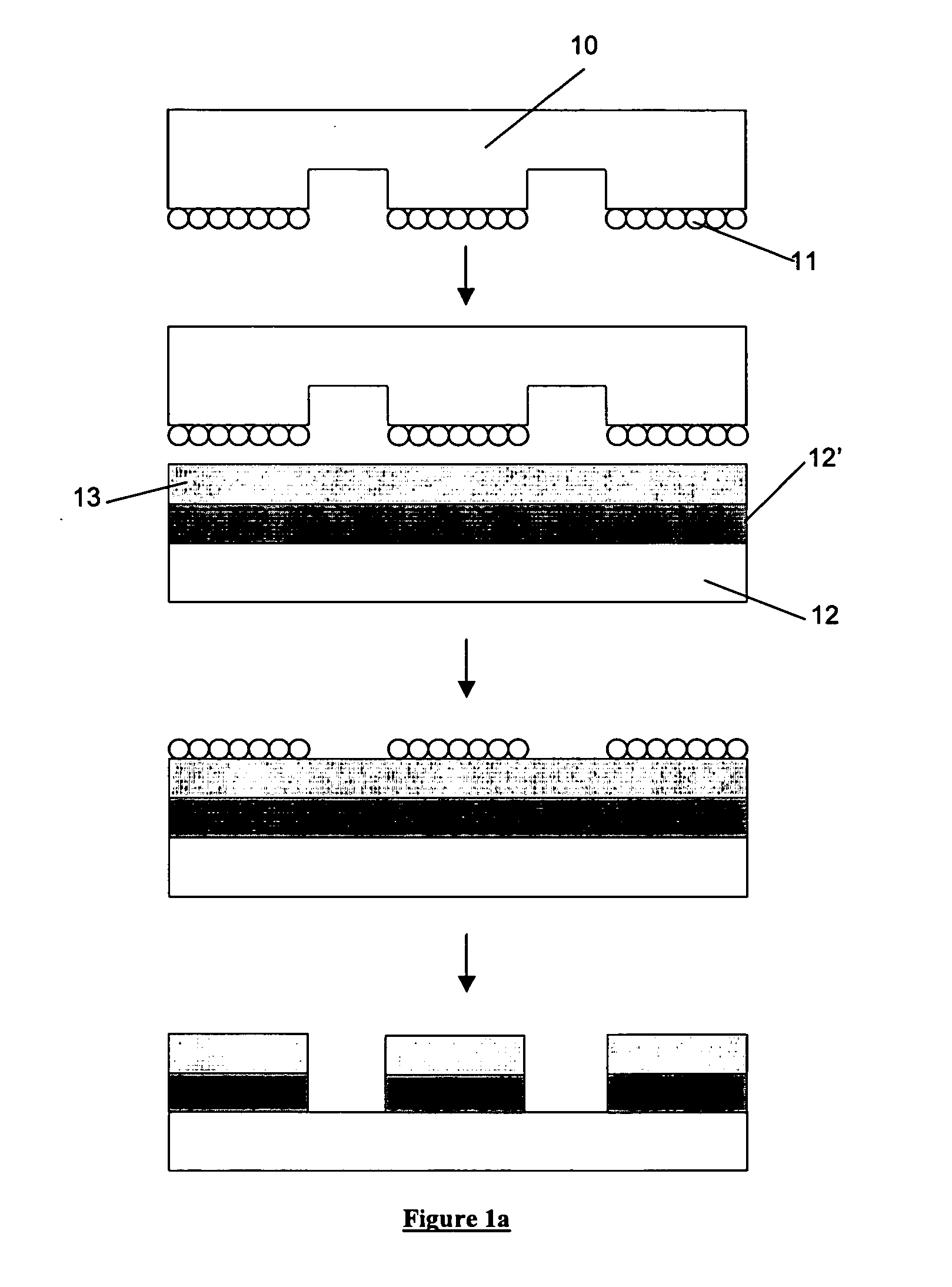

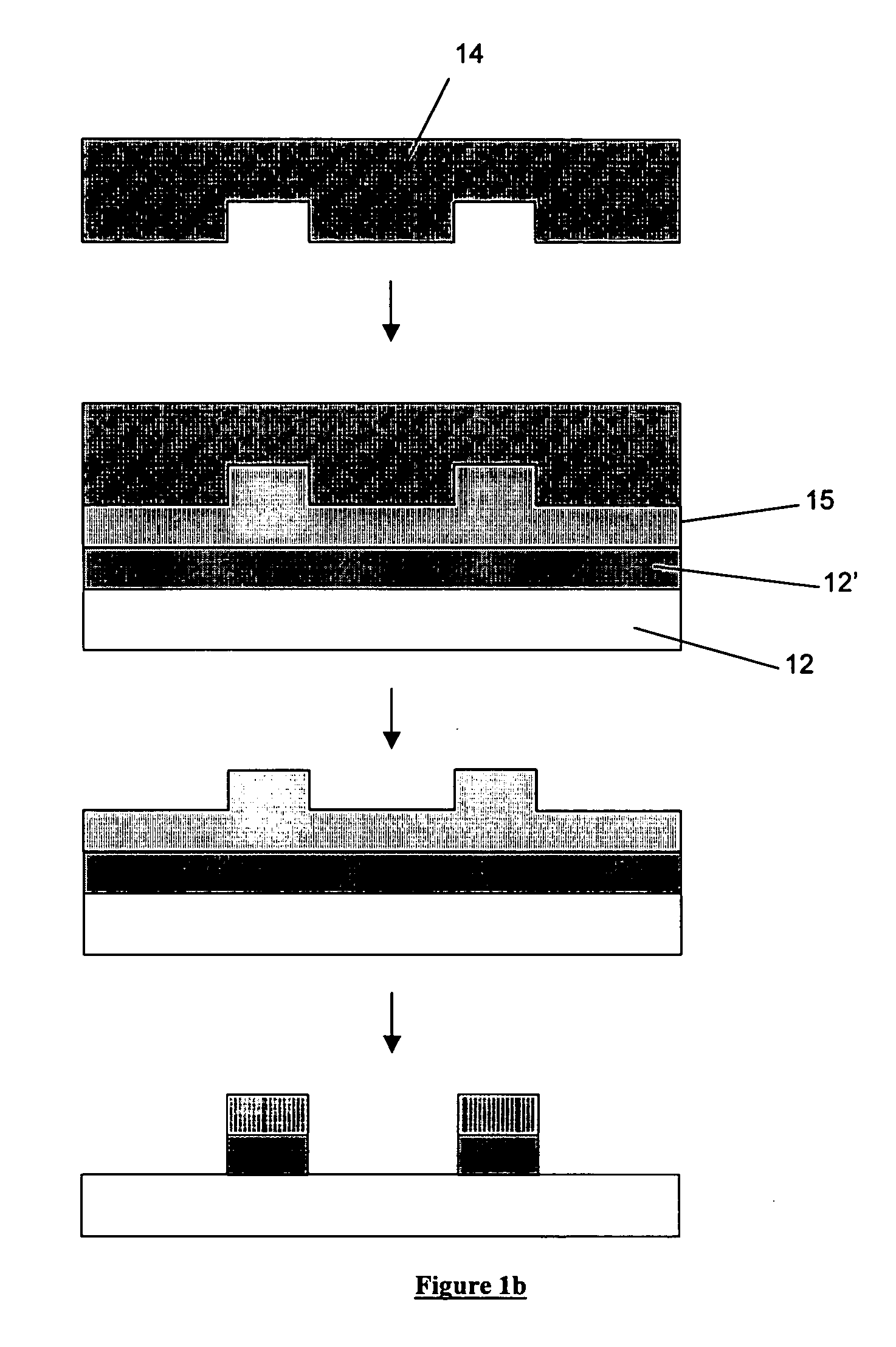

Imprint lithography

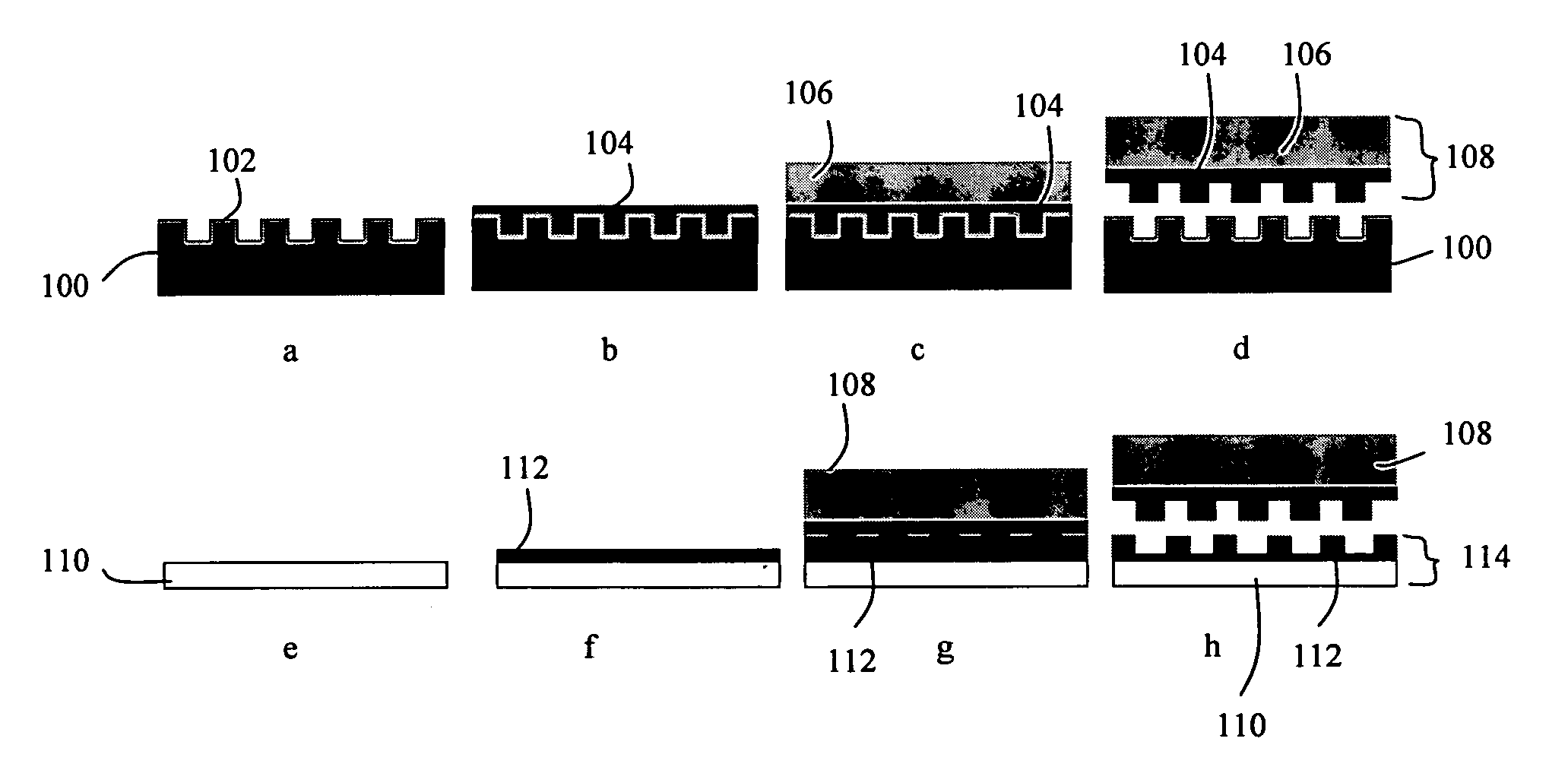

A method of making an imprint lithography template includes applying a curable material to a patterned surface of a master imprint template, allowing the curable material to cure and thereby forming a second imprint template having a patterned surface which is the inverse of the patterned surface of the master imprint template; removing the second imprint template from the master imprint template; applying inorganic sol-gel to a substrate; imprinting the inorganic sol-gel with the second imprint template; allowing the inorganic sol-gel to cure; and removing the second imprint template from the cured inorganic sol-gel, such that the inorganic sol-gel forms a third imprint template having a patterned surface which corresponds with the patterned surface of the master imprint template.

Owner:ASML NETHERLANDS BV +1

Heat curable, thermally expandable composition with high degree of expansion

Compositions containing at least one liquid epoxy resin, at least one solid epoxy resin, at least one propellant, at least one curing agent and at least one mica-containing filler produce expandable, thermally curable binder systems which may be used without the addition of hollow glass beads for the production of stiffening and reinforcing laminates and for the production of stiffening and reinforcing mouldings. Said laminates according to the invention are suitable for the stiffening and reinforcing of components, in particular in the automotive industry, such as car body frames, doors, boot lids, engine bonnets and / or roof parts. In addition, the mouldings that may be produced from said binders are suitable for the stiffening and reinforcing of hollow metal structures, in particular of hollow car body parts such as body frames, body supports and posts or doors in the automotive industry.

Owner:HENKEL KGAA

Method of assembling a single piece co-cured structure

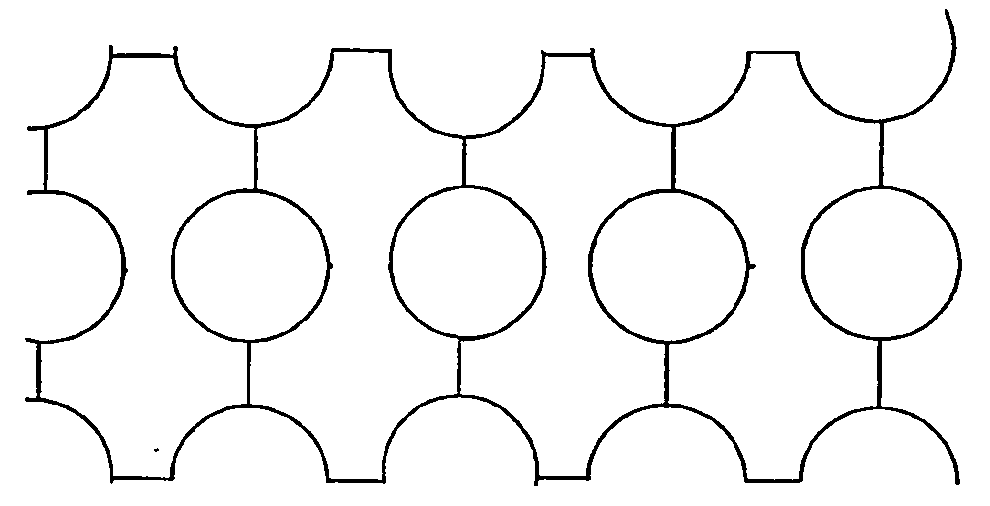

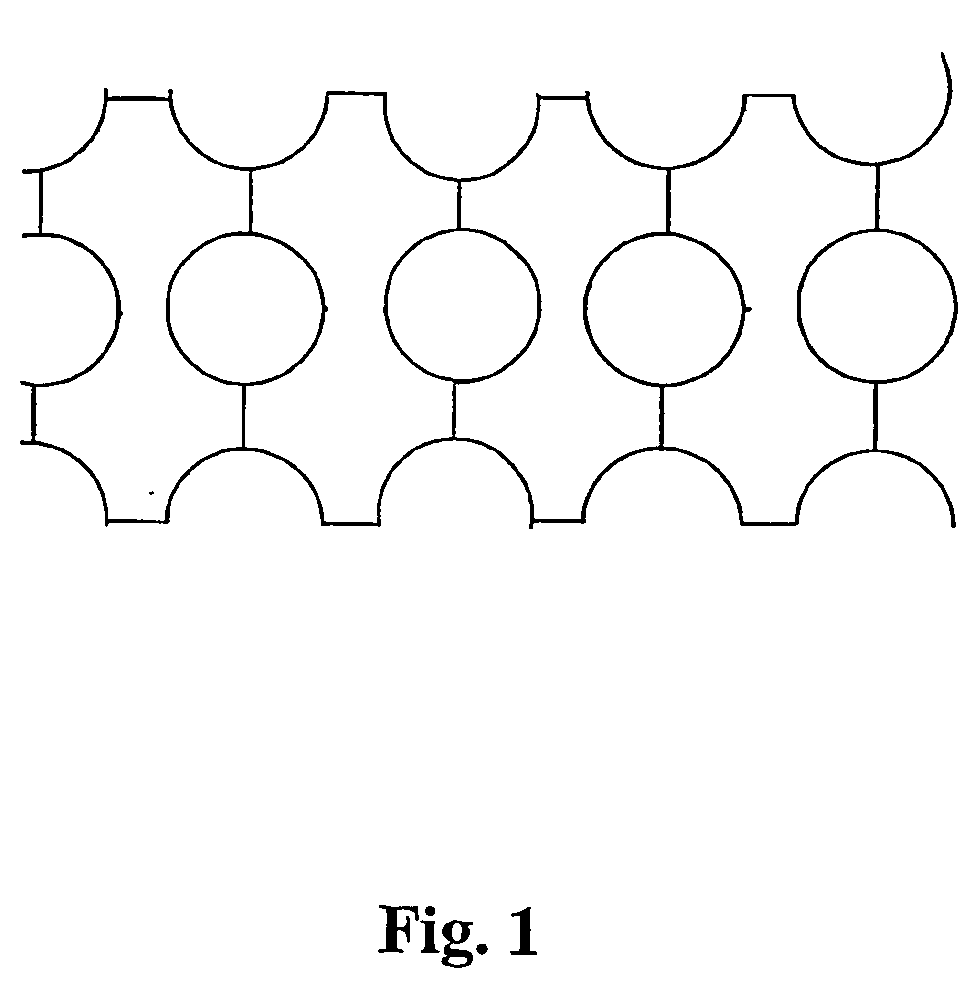

InactiveUS20040070108A1Low costProcess economyConfectioneryWood working apparatusGrid patternEngineering

A method for manufacturing a composite structure is disclosed herein. The process uses a frame and selectively pressurizable forms. The forms define the interior members of the composite structure and frames define the exterior surface of the composite structure. Composite material is wrapped around the forms and the forms and composite material are placed in the frame. Selective forms are then pressurized and the composite material is co-cured together. A single piece co-cured fuselage incorporating a plurality of stiffeners is also disclosed in the application. The stiffeners are co-cured to the fuselage and may be in various patterns. The patterns may include an iso-grid pattern, and ortho-grid pattern, and a hoop-grid pattern.

Owner:SPECTRUM AERONAUTICAL +1

Receptacle for handling molten metal, casting assembly and manufacturing method

InactiveUS20130334744A1Simpler and less cumbersomeEasy to manufactureMelt-holding vesselsDischarging arrangementRefractoryEngineering

A receptacle for handling molten metal is provided. The receptacle has bottom and side walls and includes a refractory defining a cavity within which the molten metal is conveyed or contained. The receptacle has at least one channel extending within at least one of its walls. The channel has an inlet and an outlet. The inlet is connectable to a source for circulating a fluid within the channel. The outlet allows the fluid to be expelled from said channel. The channel allows, when the fluid is circulated in it, to regulate the temperature of the refractory and thereby of the metal conveyed or contained. A casting assembly and a method for casting the refractory are also provided.

Owner:PYROTECK INC

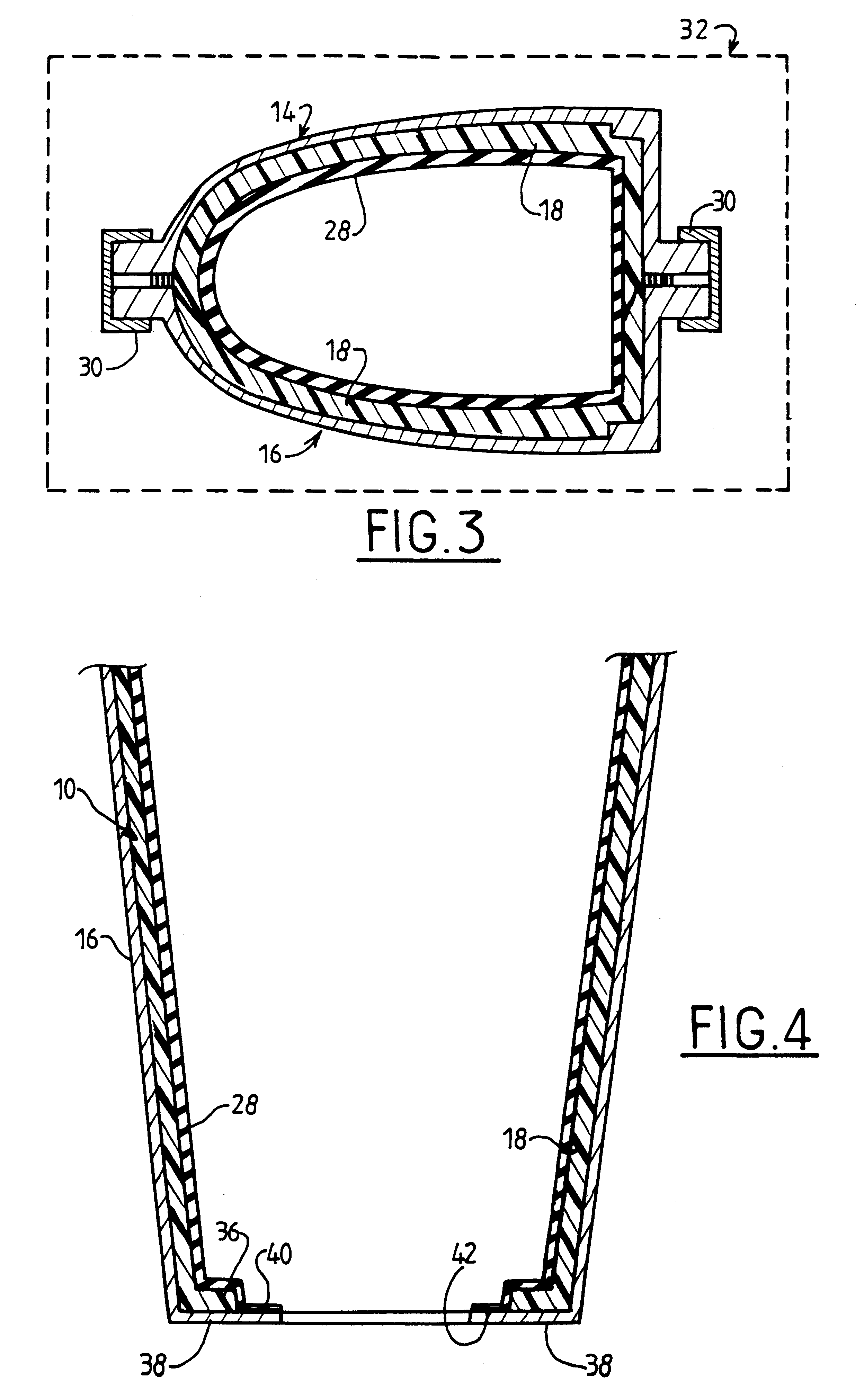

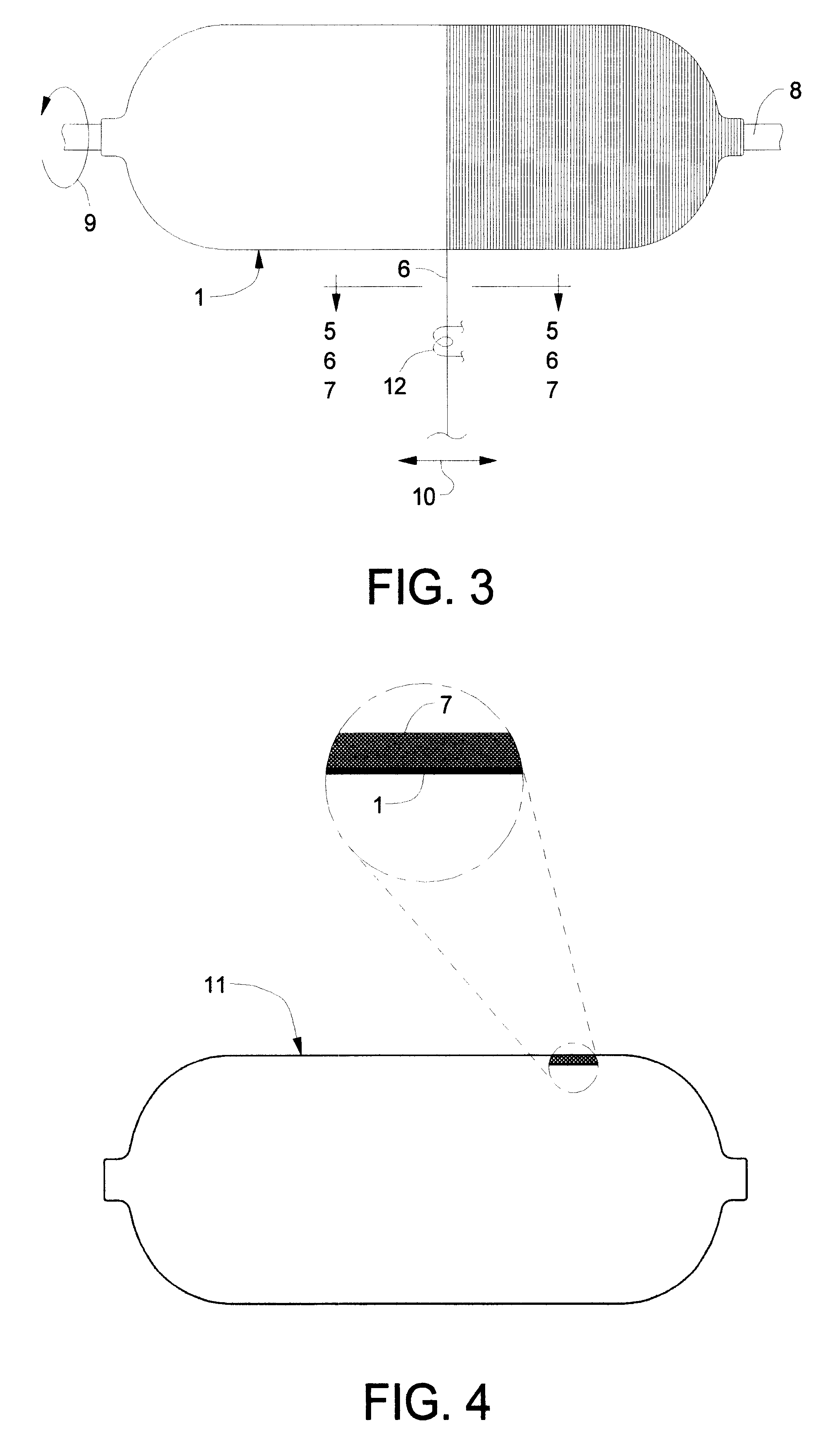

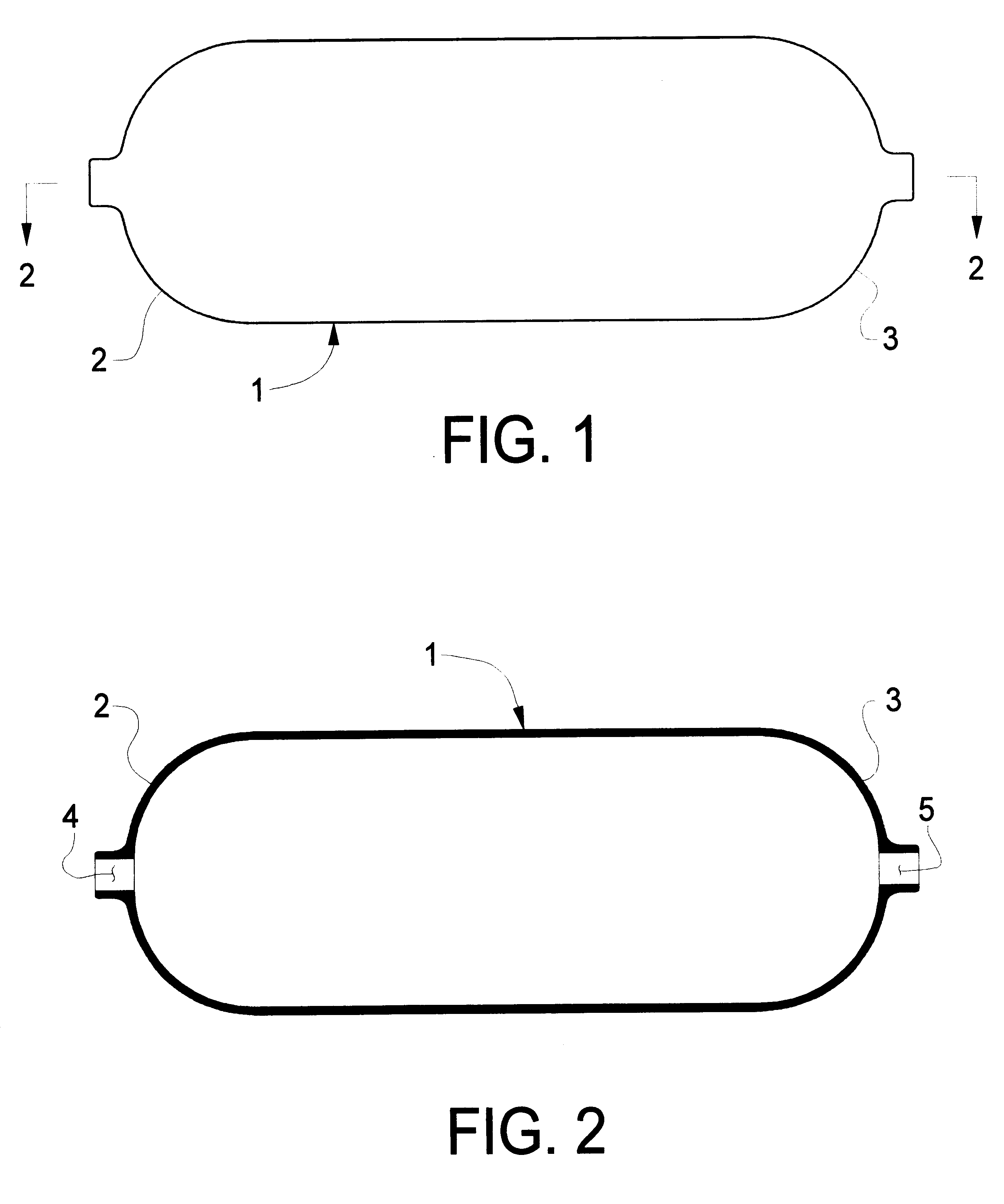

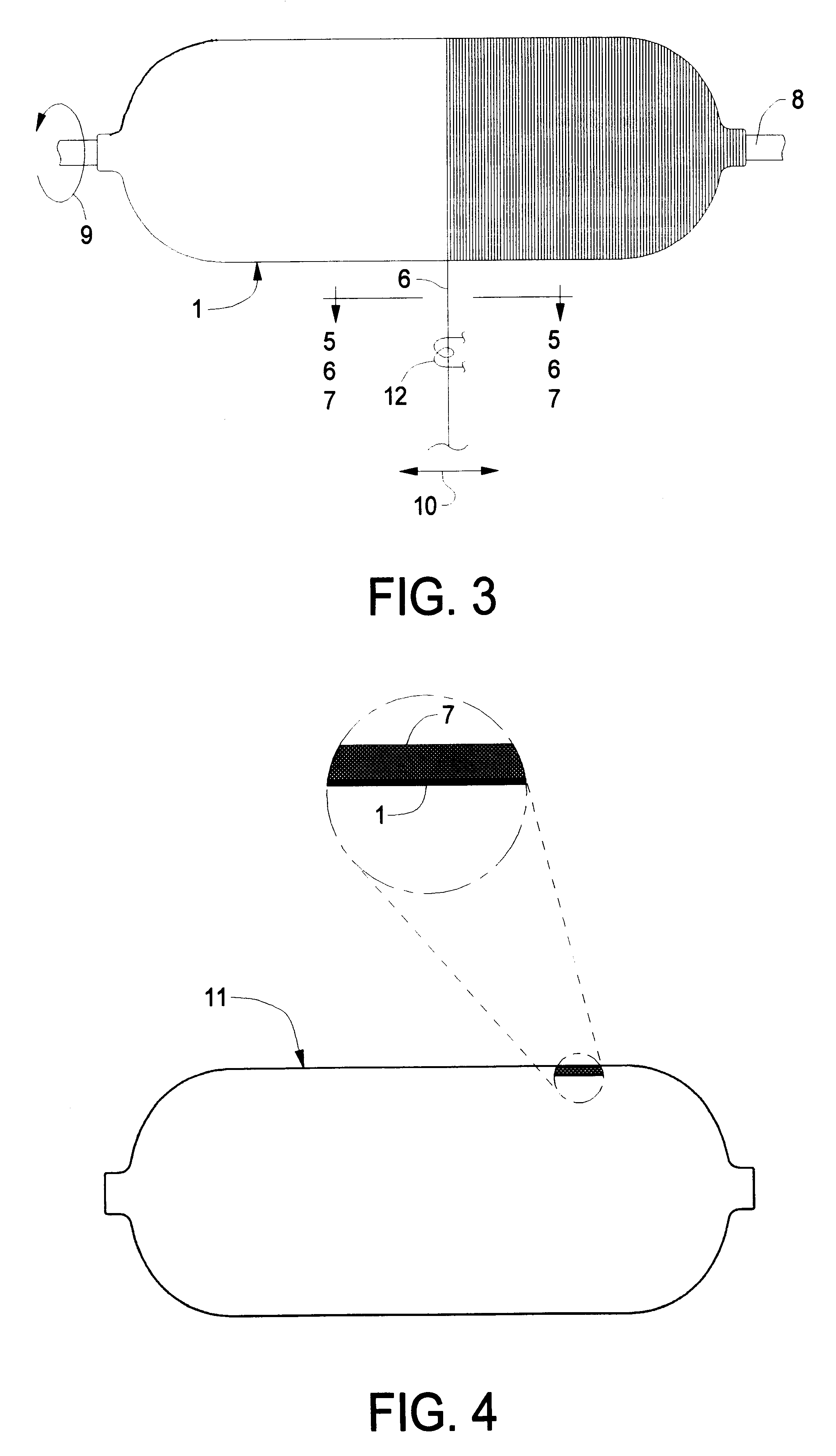

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

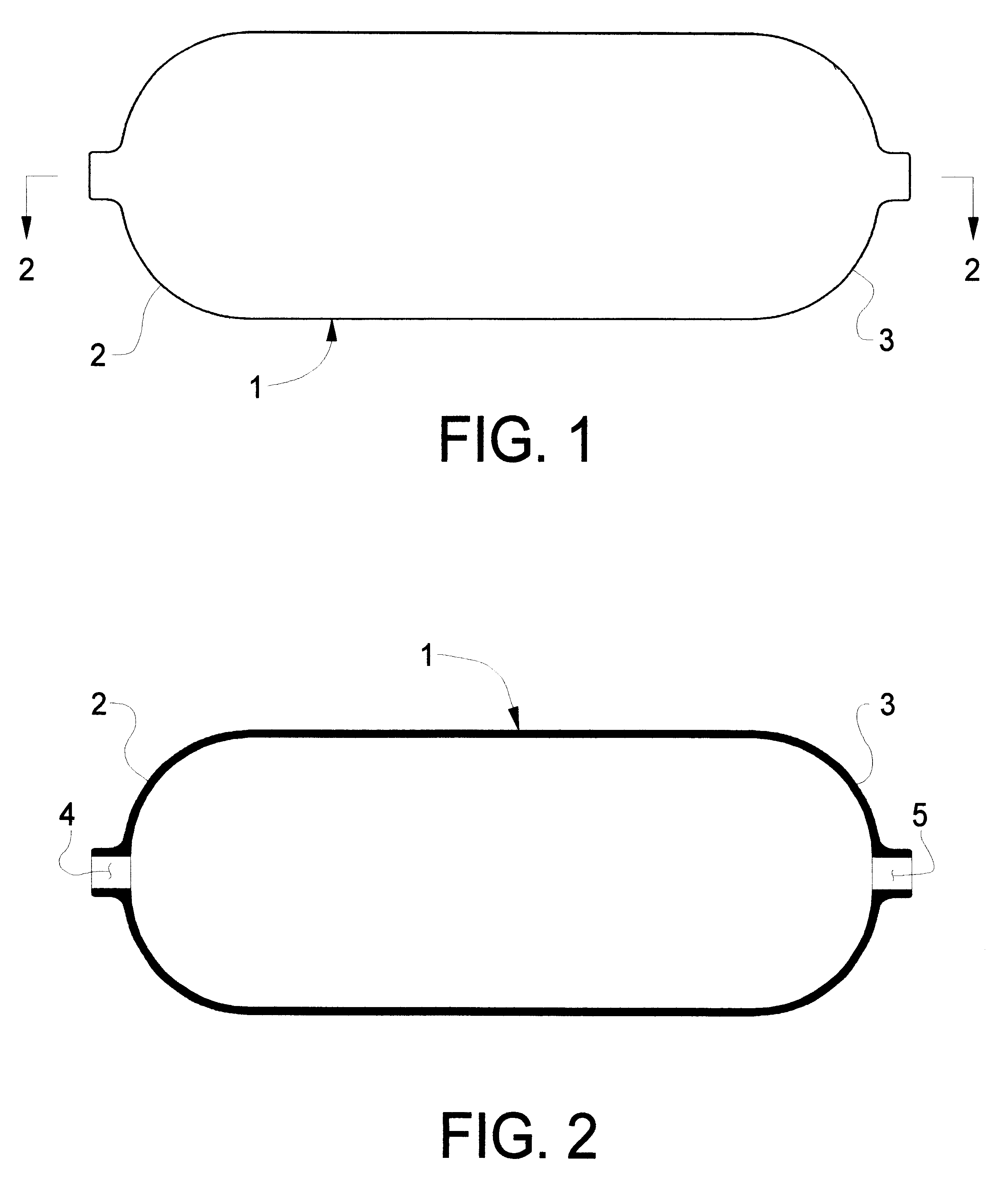

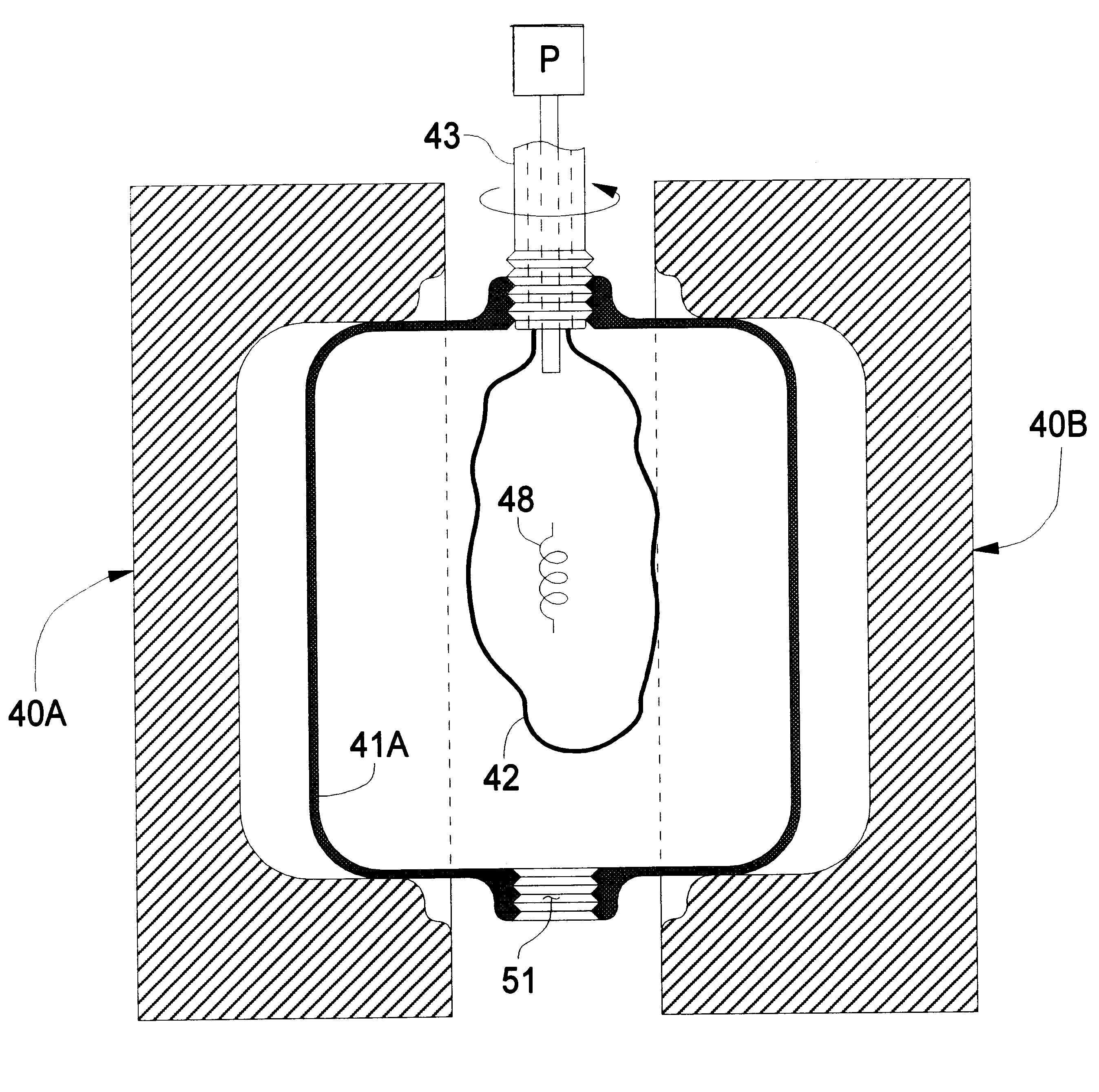

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

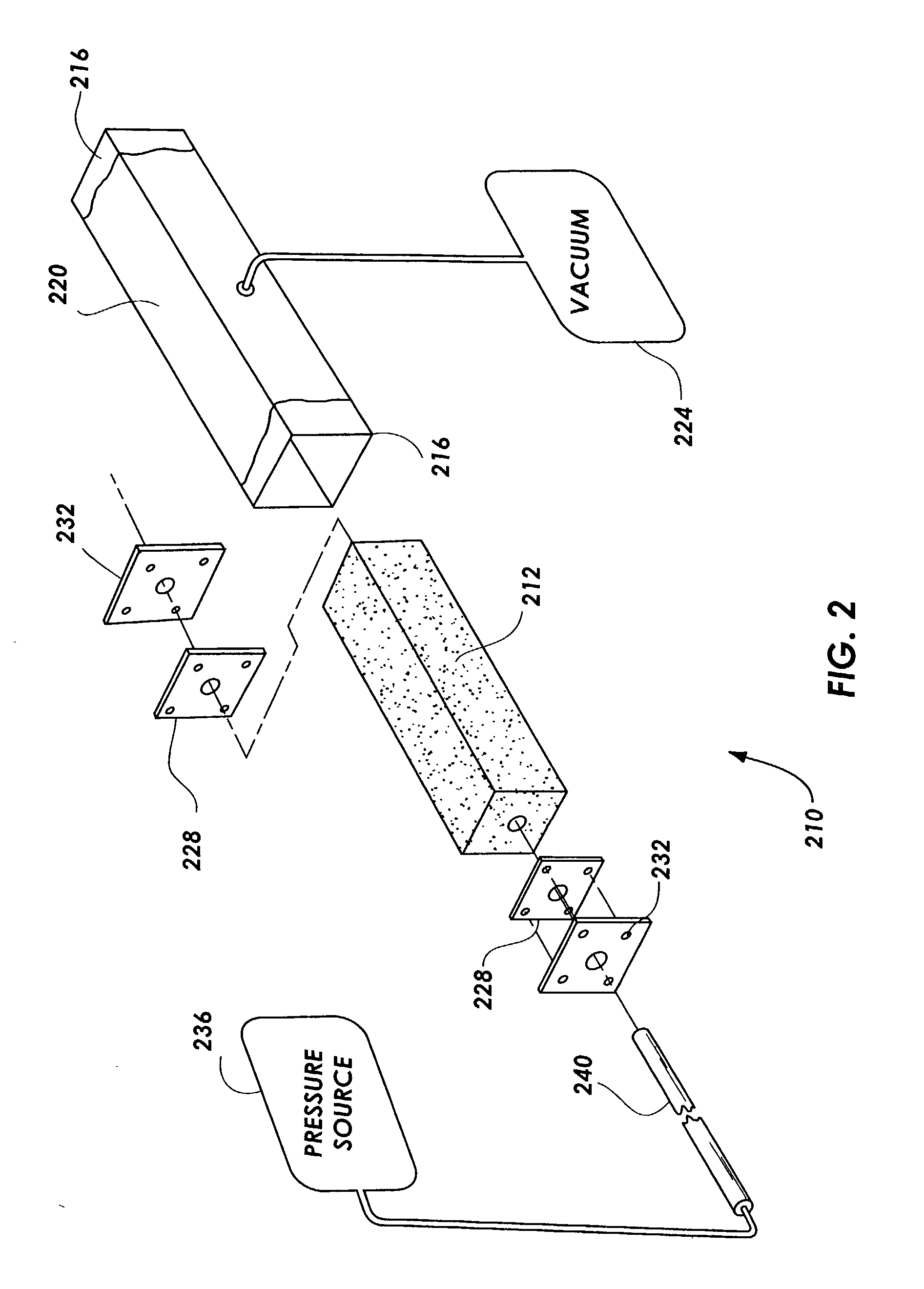

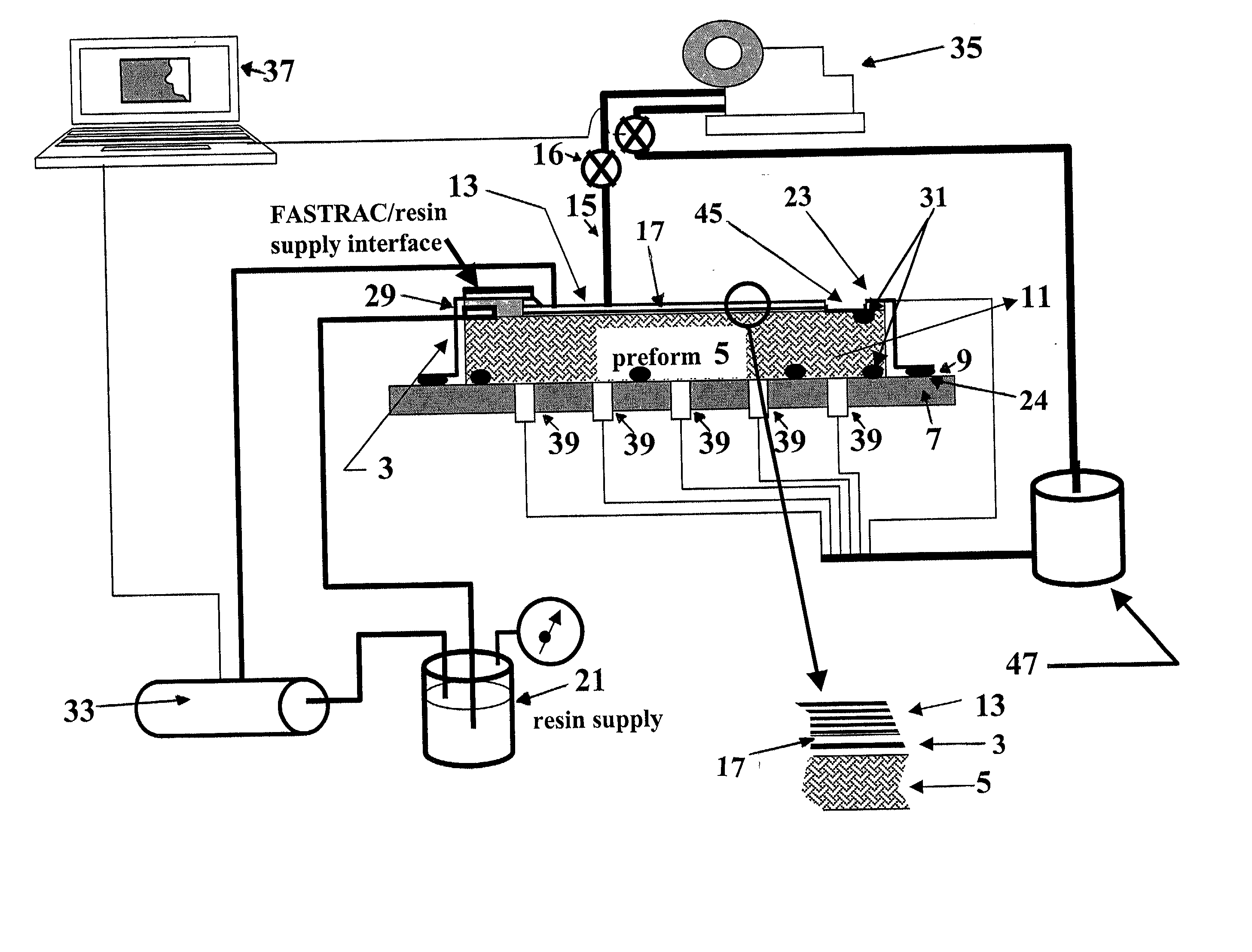

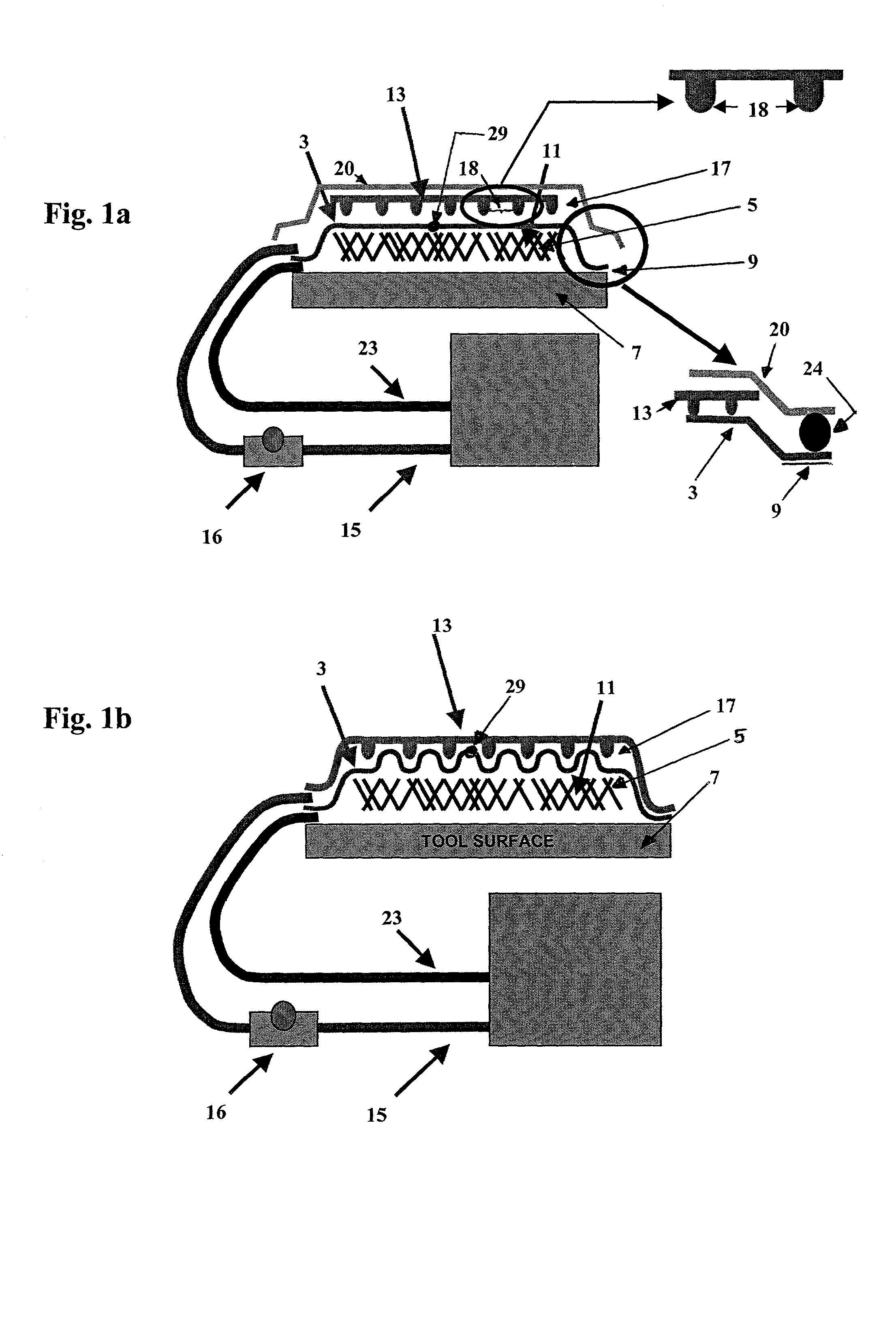

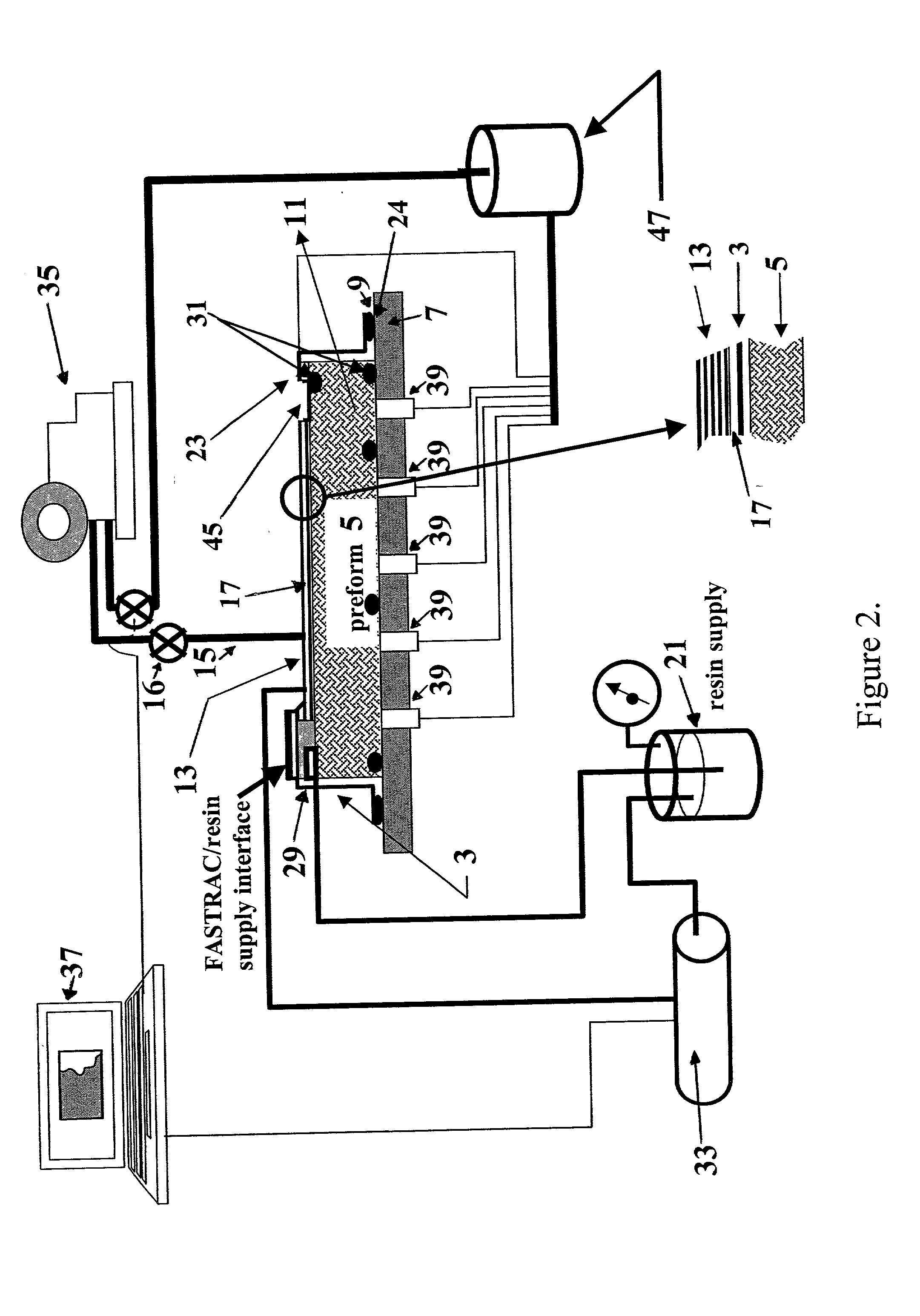

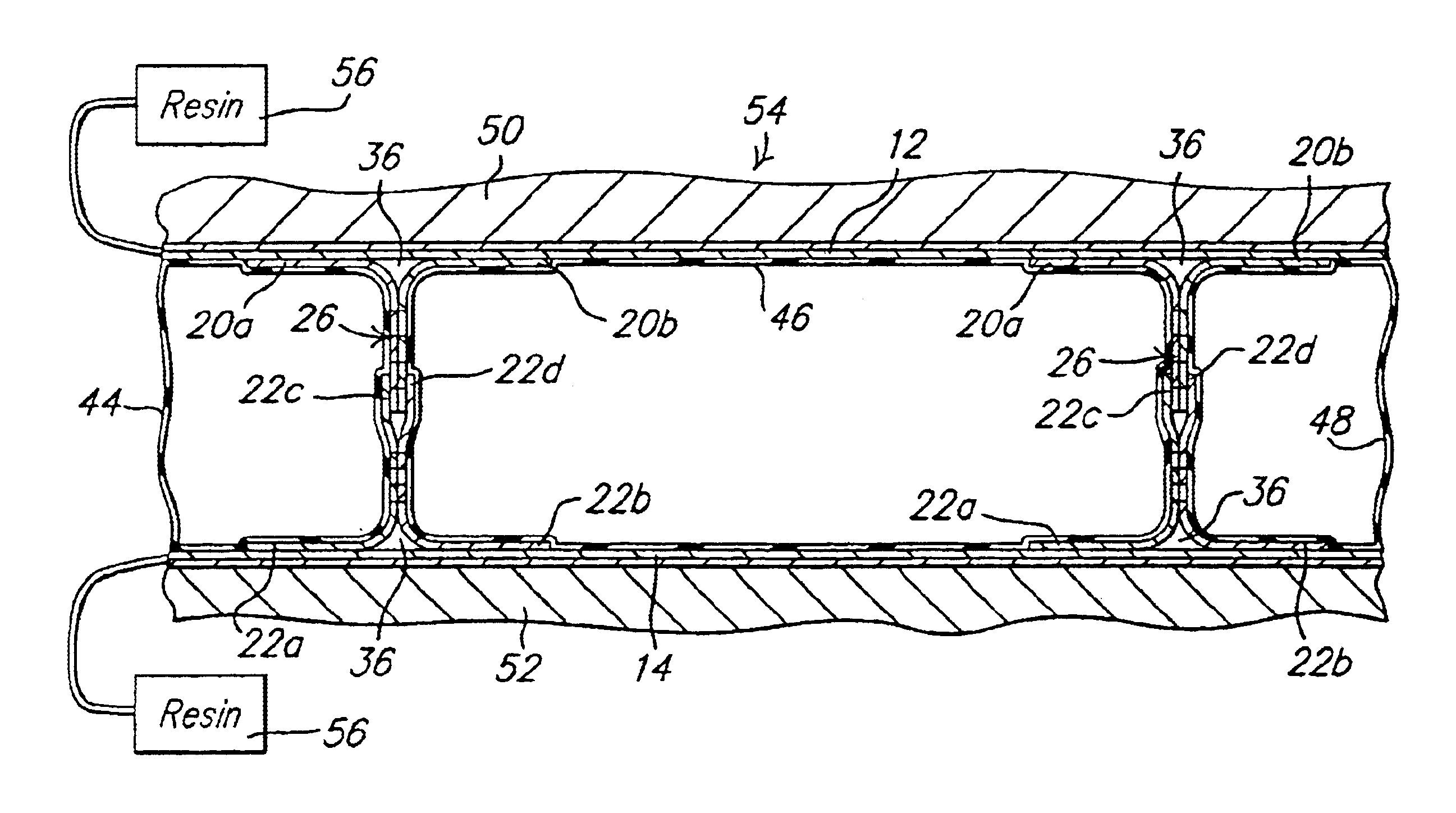

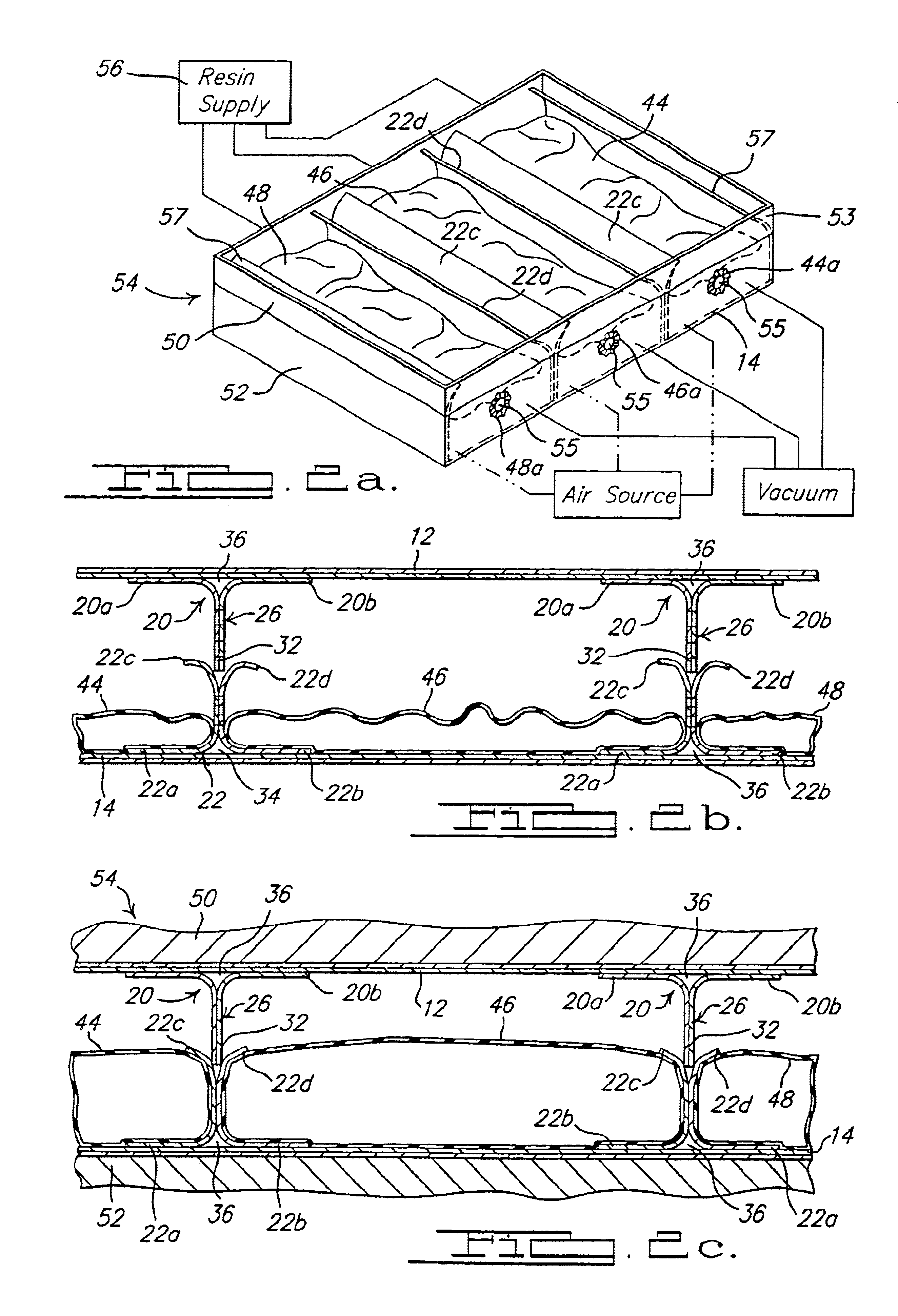

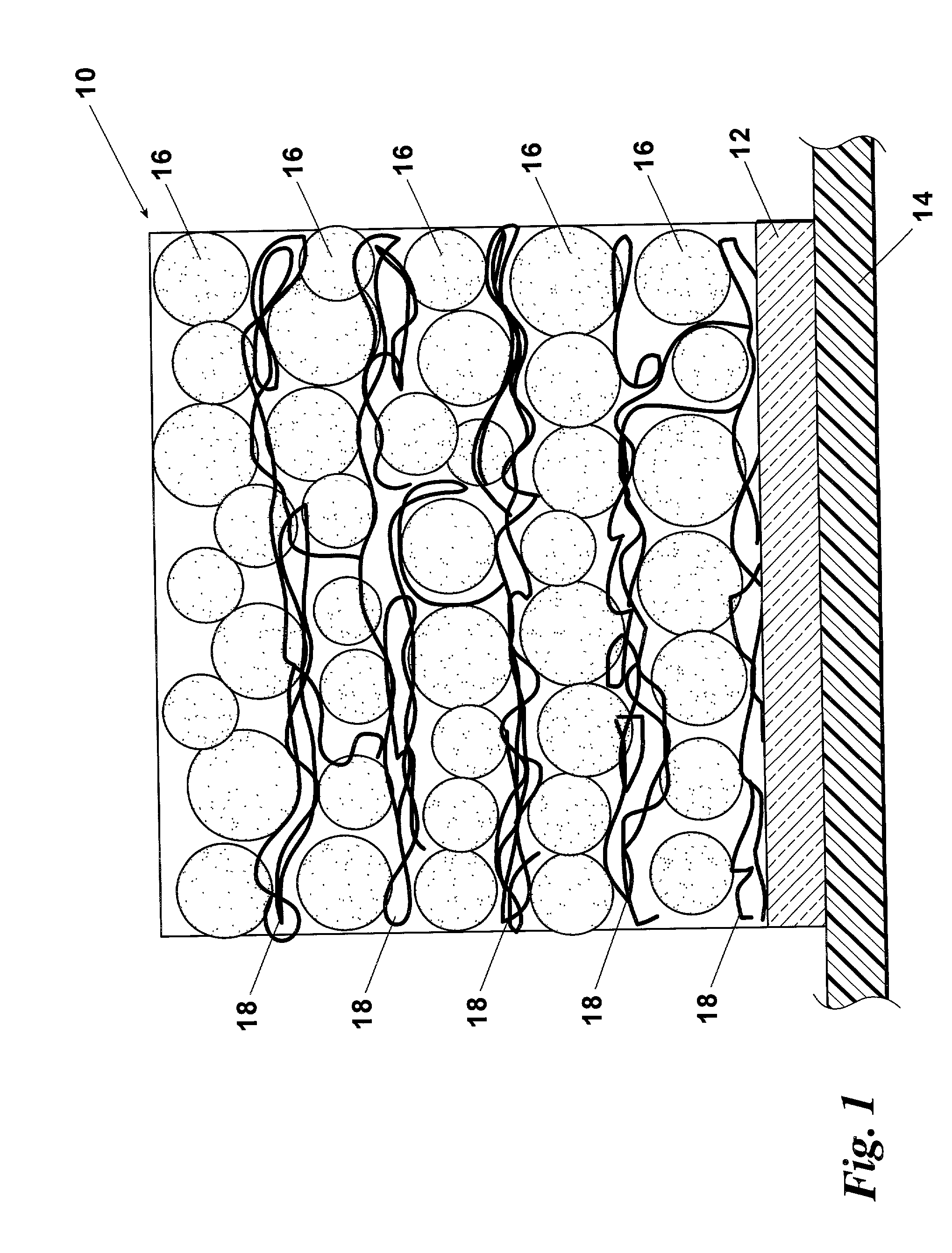

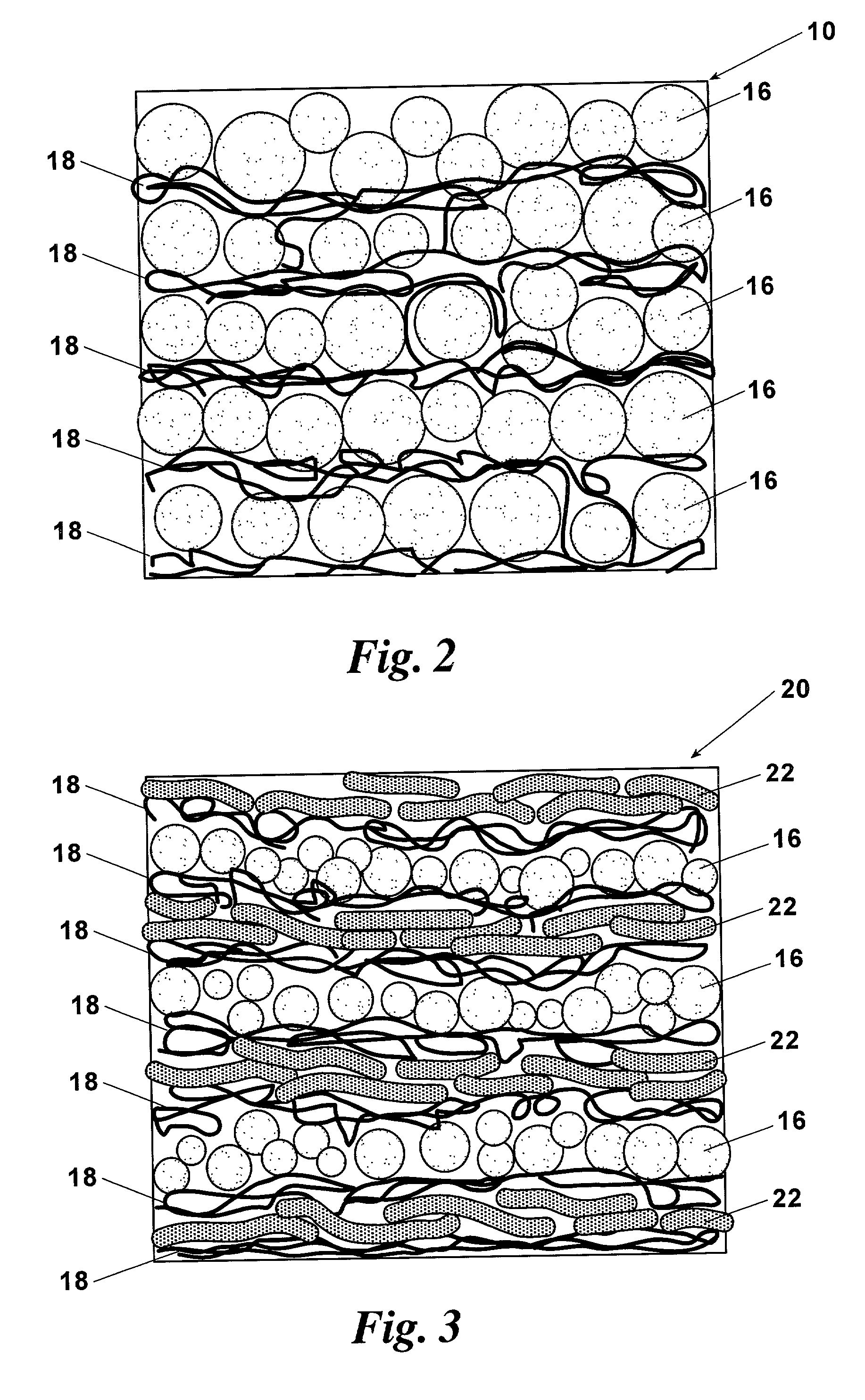

Apparatus and method for selectively distributing and controlling a means for impregnation of fibrous articles

InactiveUS20020155186A1Quick configurationMinimize and eliminate wasteTailstocks/centresConfectioneryFiberLine tubing

A process and apparatus for producing fiber reinforced resin structures using vacuum assisted resin transfer molding technology, wherein the apparatus and process employ a first fluid impervious flexible sheet containing therein a resin port; a fiber containing preform; a primary vacuum line; a resin channeling means; and a secondary vacuum line. The fluid impervious flexible sheet is placed over or around the fiber containing preform to form a chamber to which the primary vacuum line is connected. The resin channeling means is positioned on top of the fluid impervious flexible sheet, exterior to the chamber containing the preform in a fashion so as to form a pocket between or around the resin channeling means and said fluid impervious flexible sheet to which the secondary vacuum is applied. Activation of the secondary vacuum causes formation of channels in the fluid impervious flexible sheet. These channels increase the speed and efficiency of resin impregnation of the fiber containing preform.

Owner:UNITED STATES OF THE ARMY AS REPRESENTED BY THE SEC OF THE

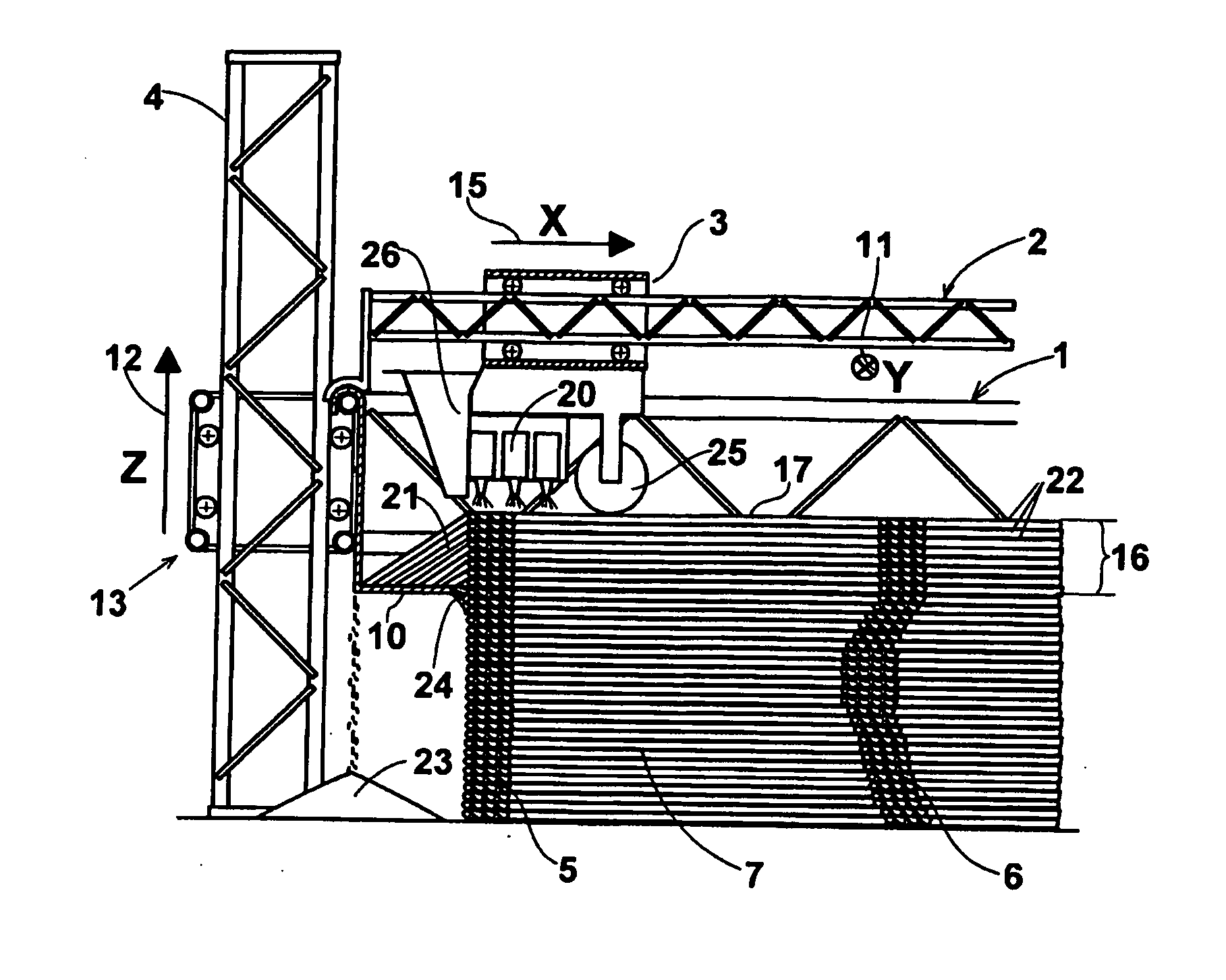

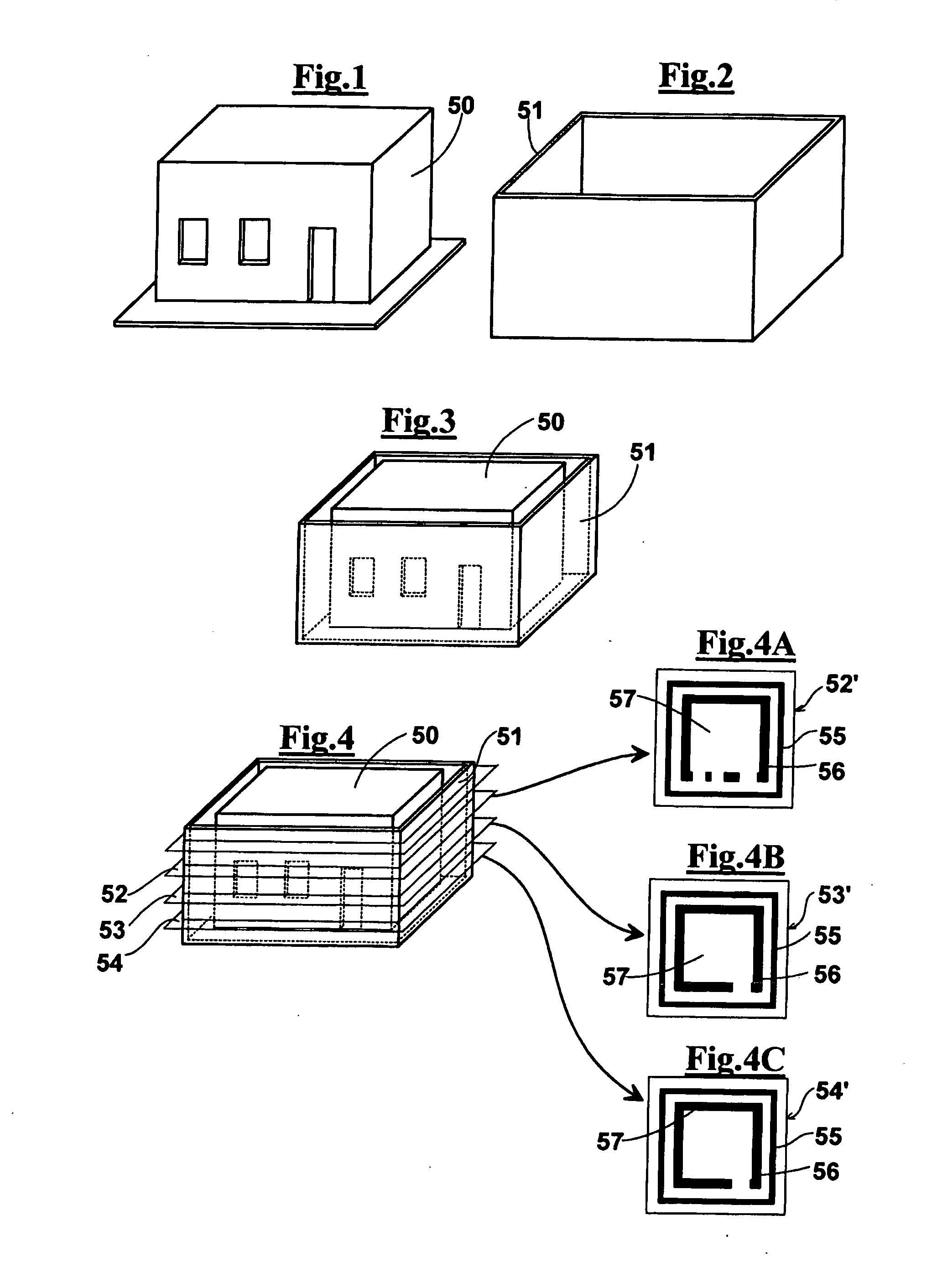

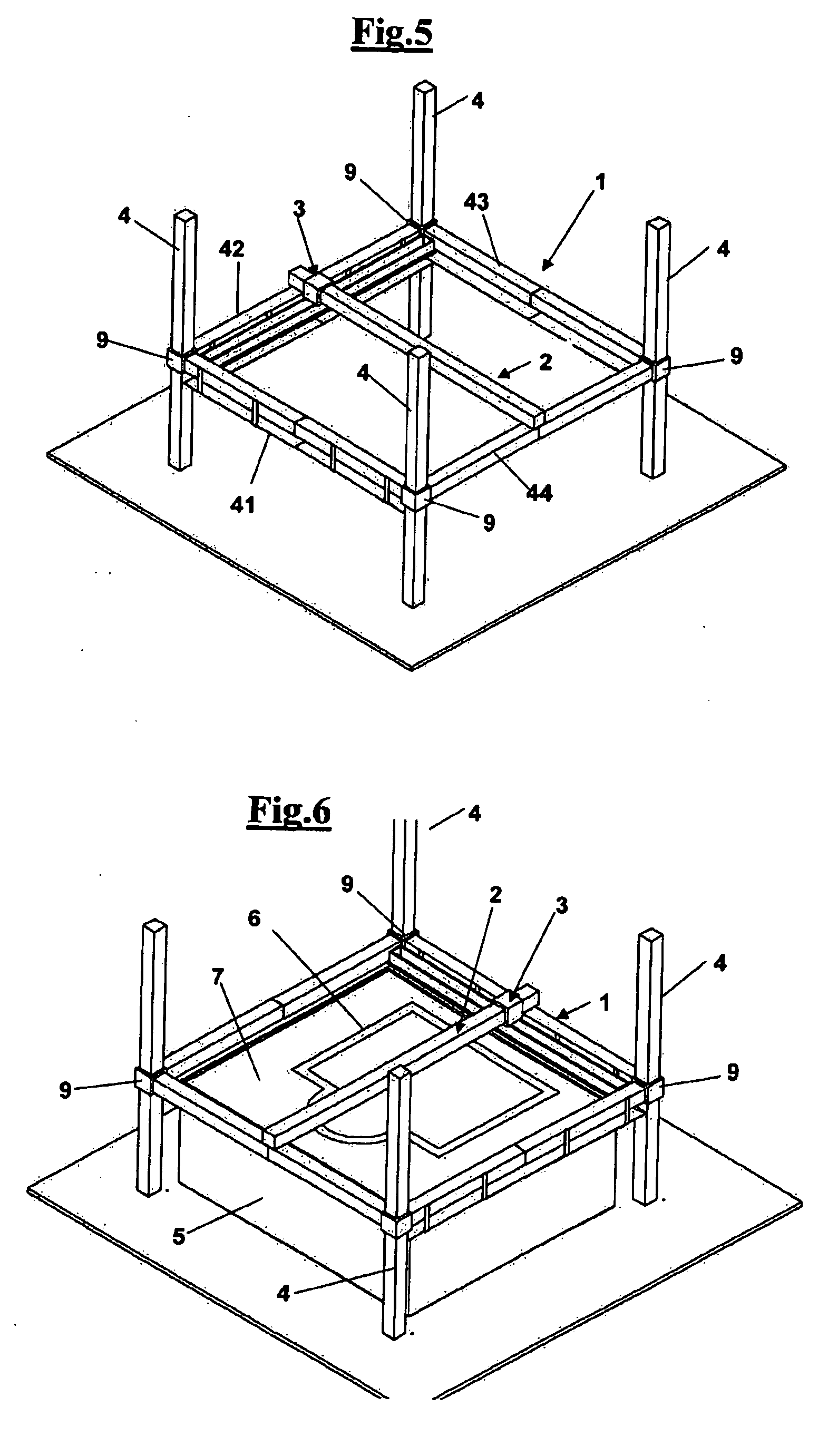

Method for automatically producing a conglomerate structure and apparatus therefor

InactiveUS20100207288A1Improve efficiencyReduce decreaseAdditive manufacturing apparatusMouldsSection planeEngineering

A method and an apparatus for automatically making conglomerated structures (6). The method comprises a) modelling a building structure and a containing shell about the structure by a computer using a CAD software thus obtaining a file; b) extracting sections of modelled structure and of modelled containing shell, by means of horizontal planes spaced apart of a predetermined pitch, such that a plurality of section planes is generated, said planes being sorted from below towards above with respect to the model of the structure and of the model of the shell; c) depositing by a moving unit (3) on a ground a bottom-to-top plurality of layers of granular material (22) alternate to a binding material liquid sprayed on the layers at filled areas corresponding to filled portions of the of the structure and of the containing shell, according to a predetermined path; d) vertically raising the moving unit (3) according to a pitch between a deposited layer and the following layer; e) repeating the step of depositing granulating material and repeating the step of spraying the binding material on a granulated material at filled areas of the structure and of the shell as many times as the planar cross sections into which said structure and the containing shell have been divided, each of said times for a different and consecutive section plane until the last layer (17) is complete; f) demolishing the containing shell (5) and removing unbound granular material (7) accumulated in the shell (5), thus releasing a conglomerate structure (6) that reproduces accurately said modelled structure. The apparatus comprises a horizontal frame (1), a bridge (2) sliding on guide on the horizontal frame (1), a moving unit (3) sliding along the bridge (2) or integral to the bridge (29) and have a spraying head (20). The horizontal frame (1) is moved along uprights (4) by a step actuator. The apparatus comprises a plurality of “skirts” (10) that surround the containing shell (5) and are integral to the horizontal frame (1). Such skirts scrape the outer surface of the containing shell (5) collecting the granular material (21) deposited out of the shell (5). Such skirts (10) can comprise an brush-like edge (20) suitable for externally sweeping the containing shell (5).

Owner:DINI ENRICO

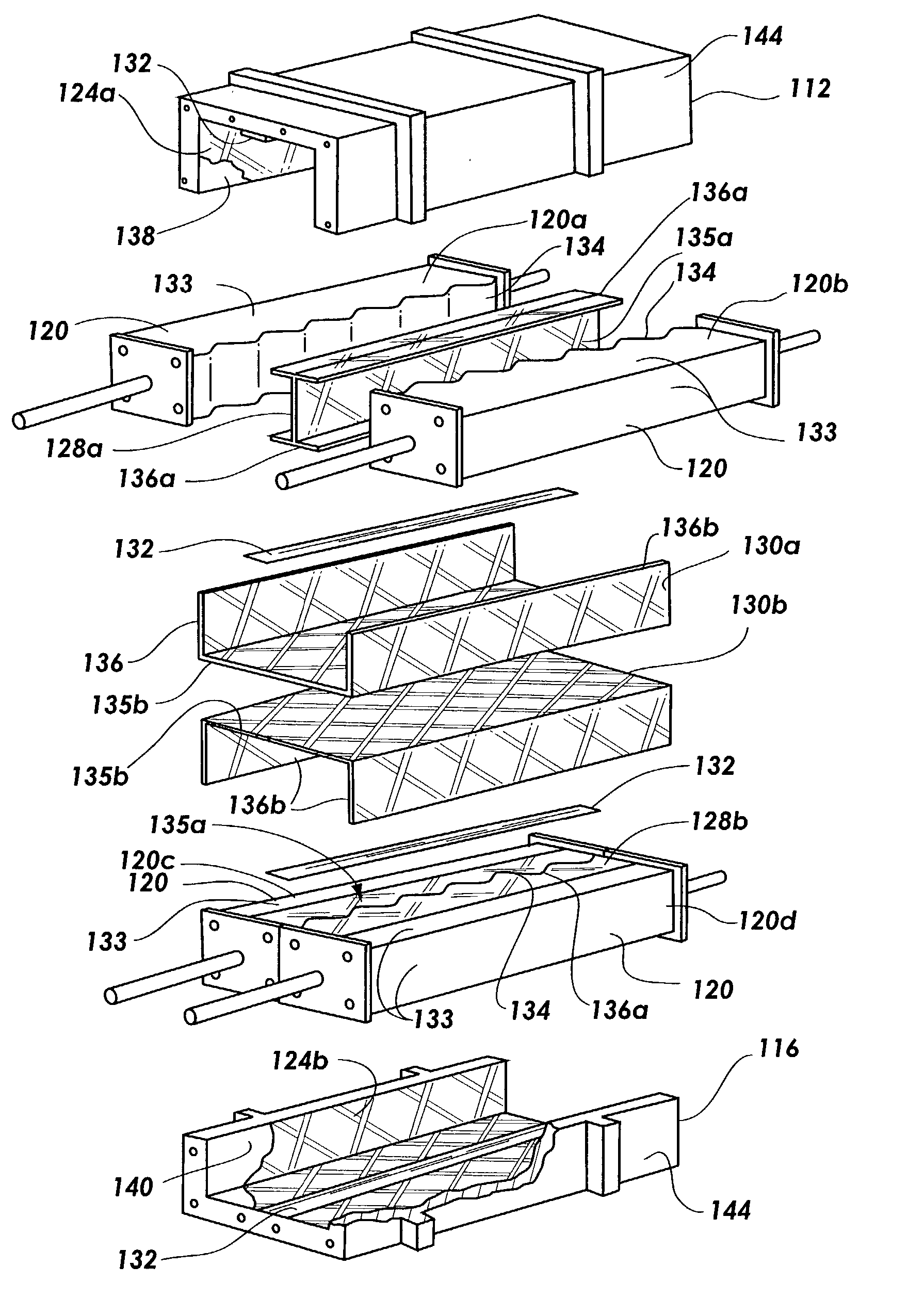

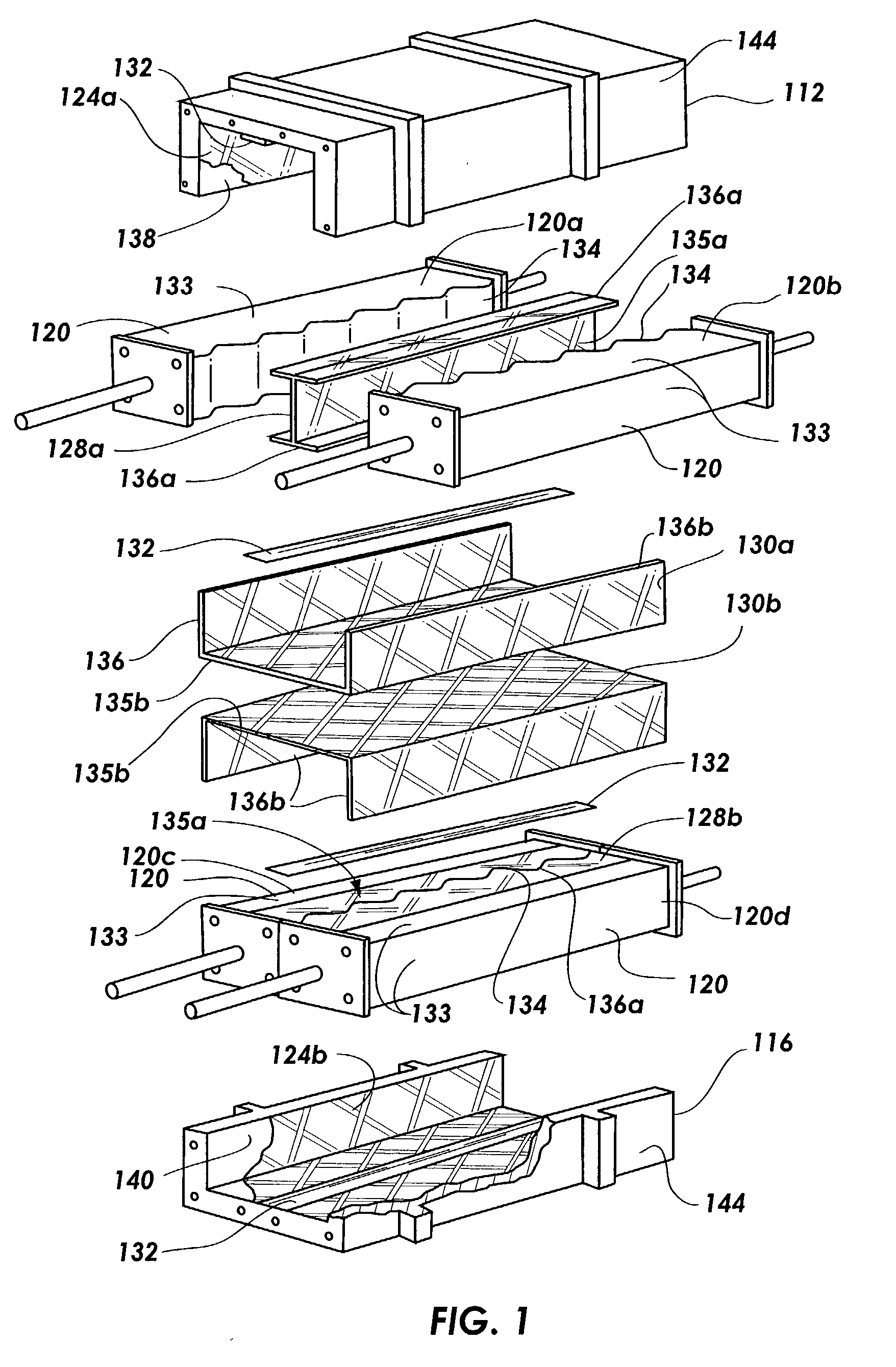

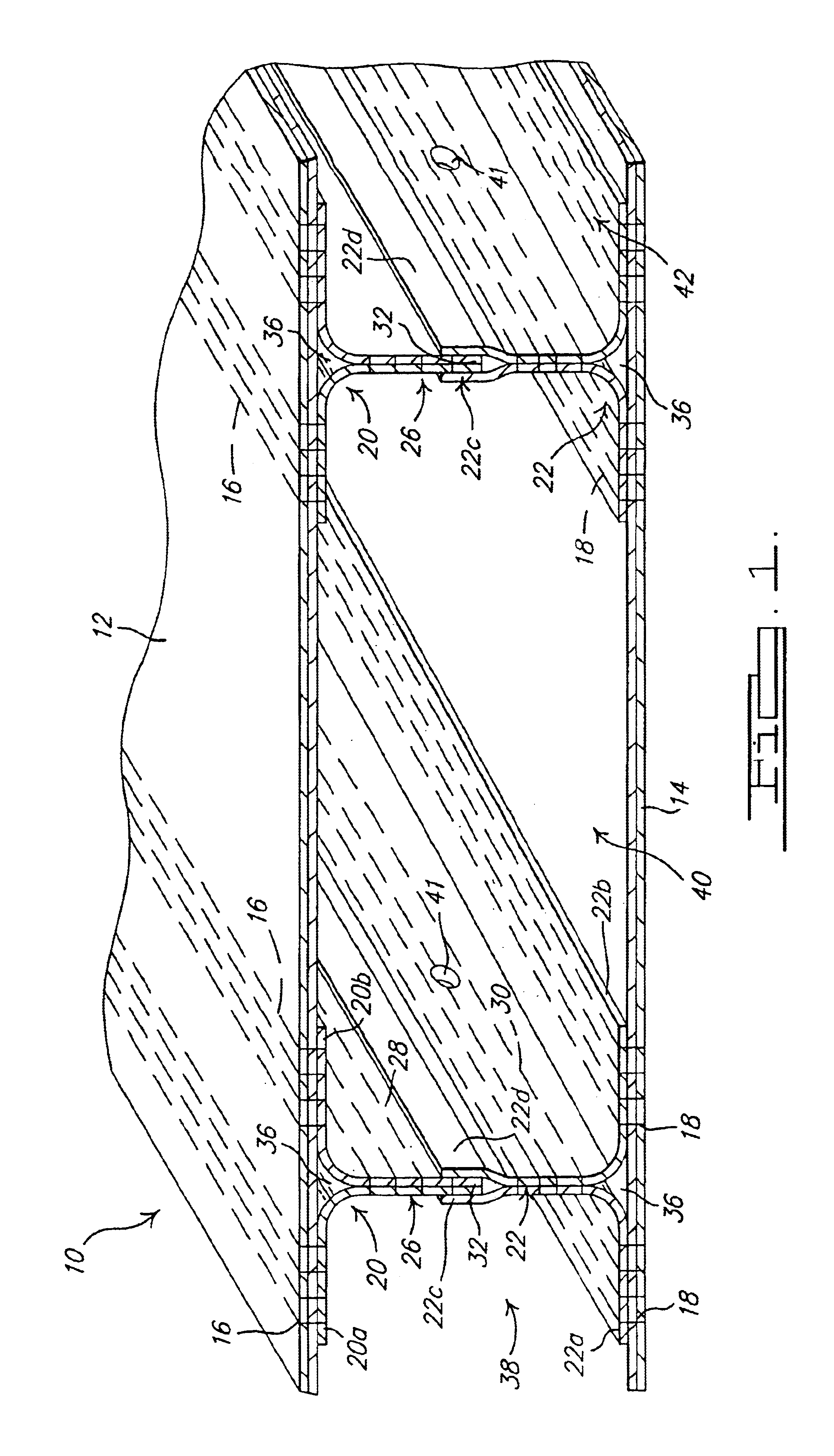

Molding process and apparatus for producing unified composite structures

InactiveUS6896841B2Stable structureManufactured usingLaminationWood working apparatusShell moldingEngineering

A method of forming a unitary, composite structural member, and a member formed in accordance with the process. The process involves stitching a plurality of warp knit panel sections together to generally form a plurality of independent panel sections. The sections are placed within the dies of a molding tool such that a rib portion of each section aligns. Inflatable bladders are then slipped into voids formed in between the various panel sections of the assembly. The bladders are inflated to hold with one another. Resin is then infused into the panels that make up the assembly. The assembly is then cured. When the panels are removed from the molding tool a unitary, complexly shaped, composite structural member is formed.

Owner:THE BOEING CO

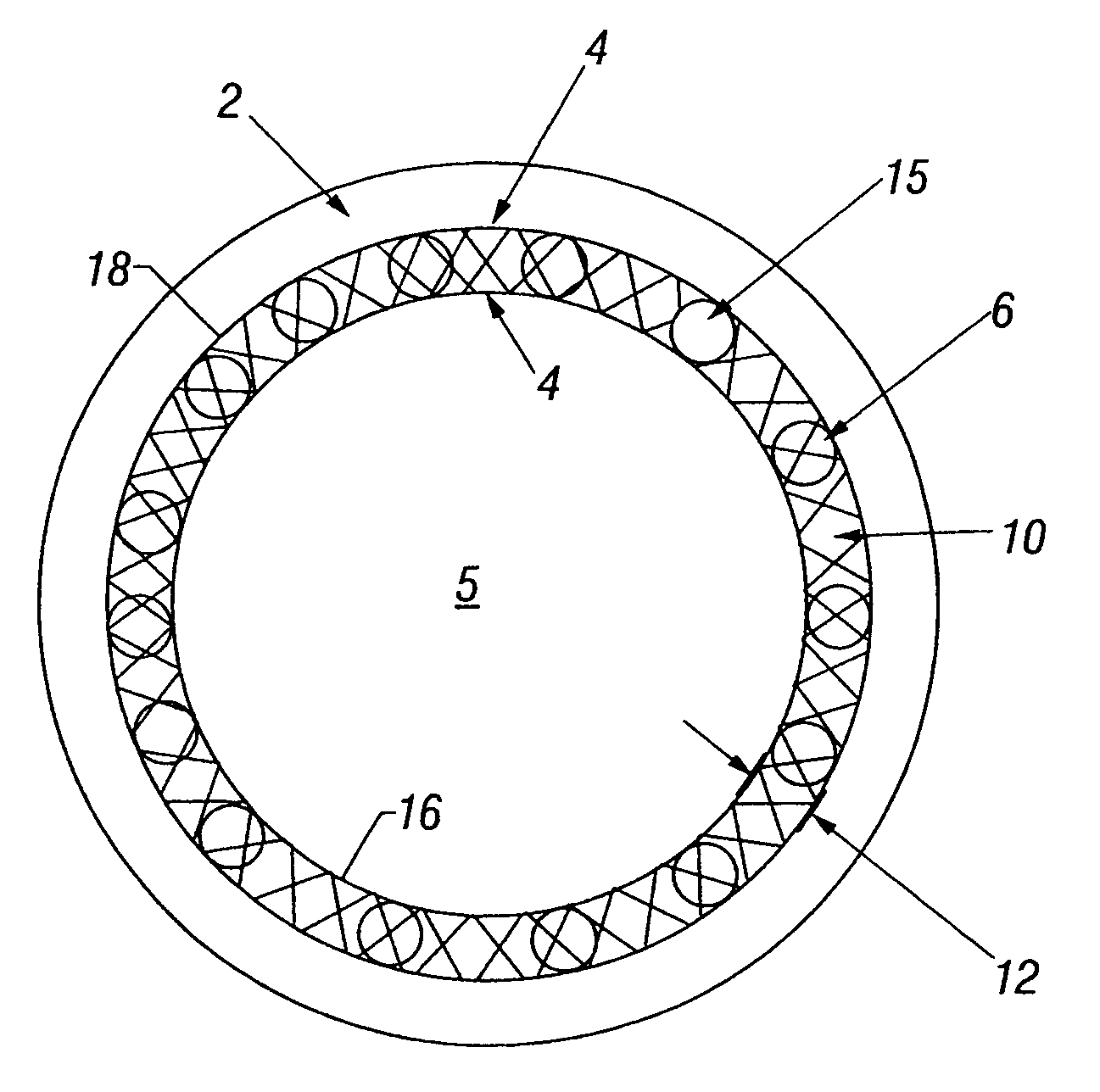

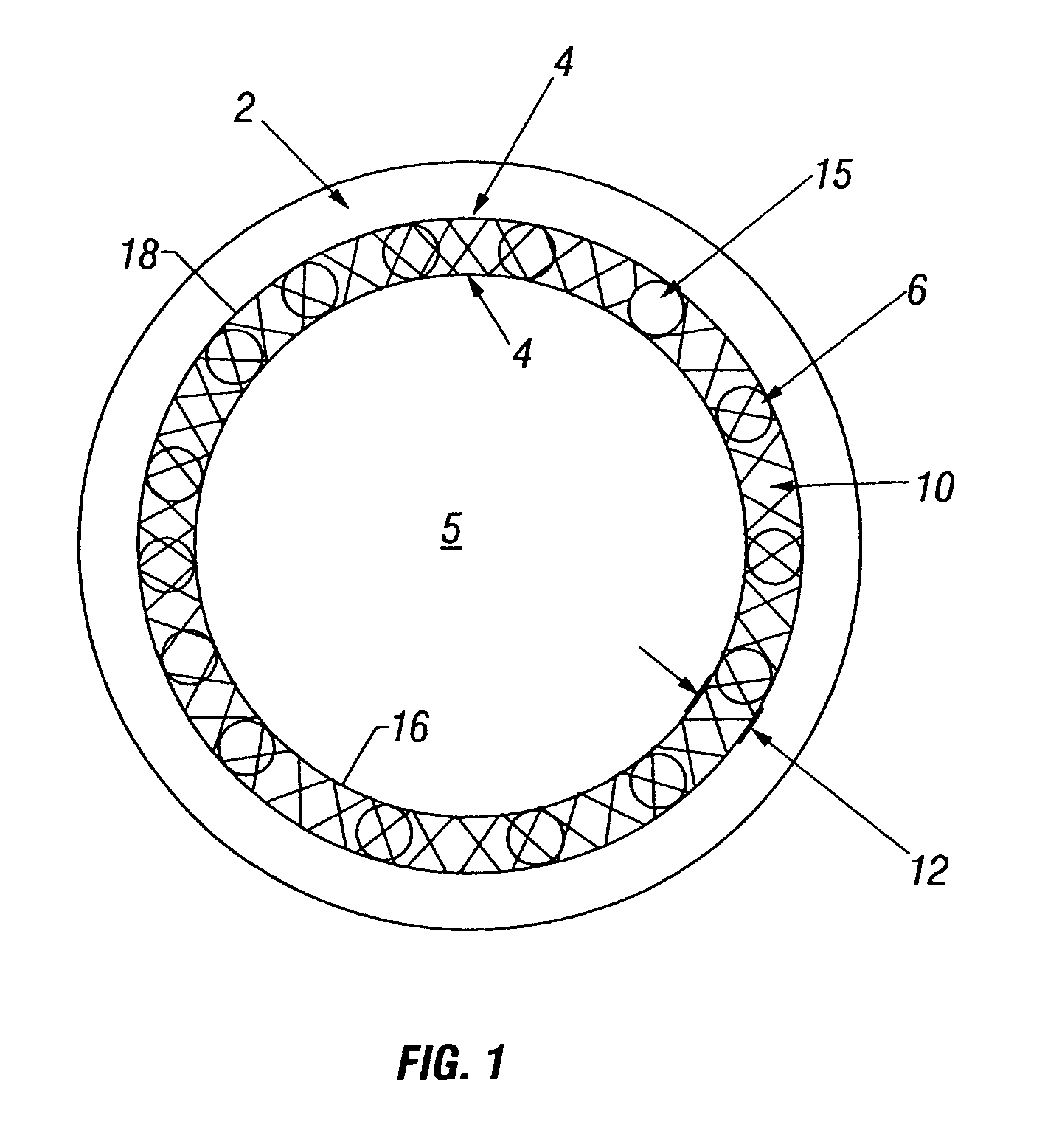

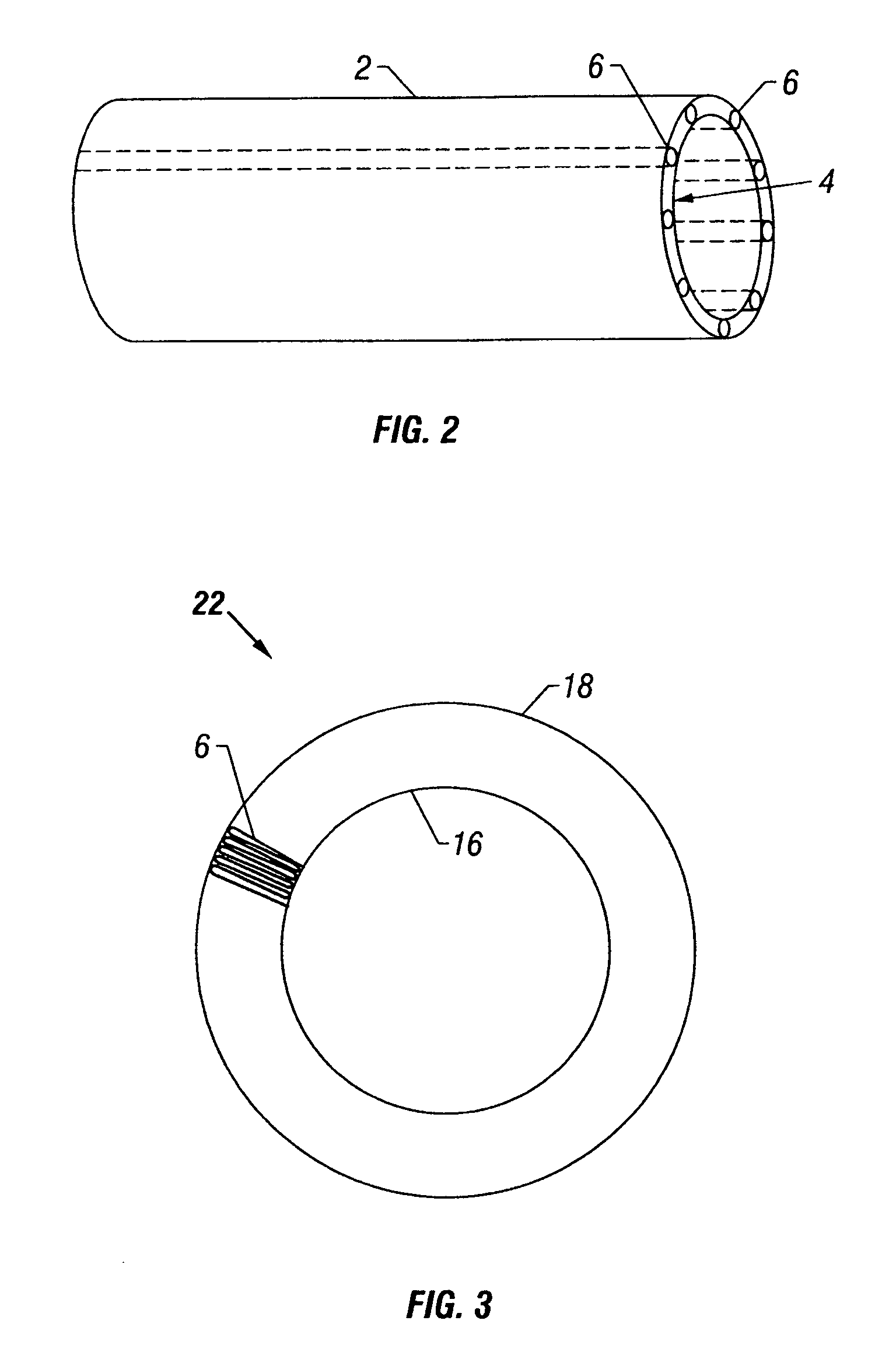

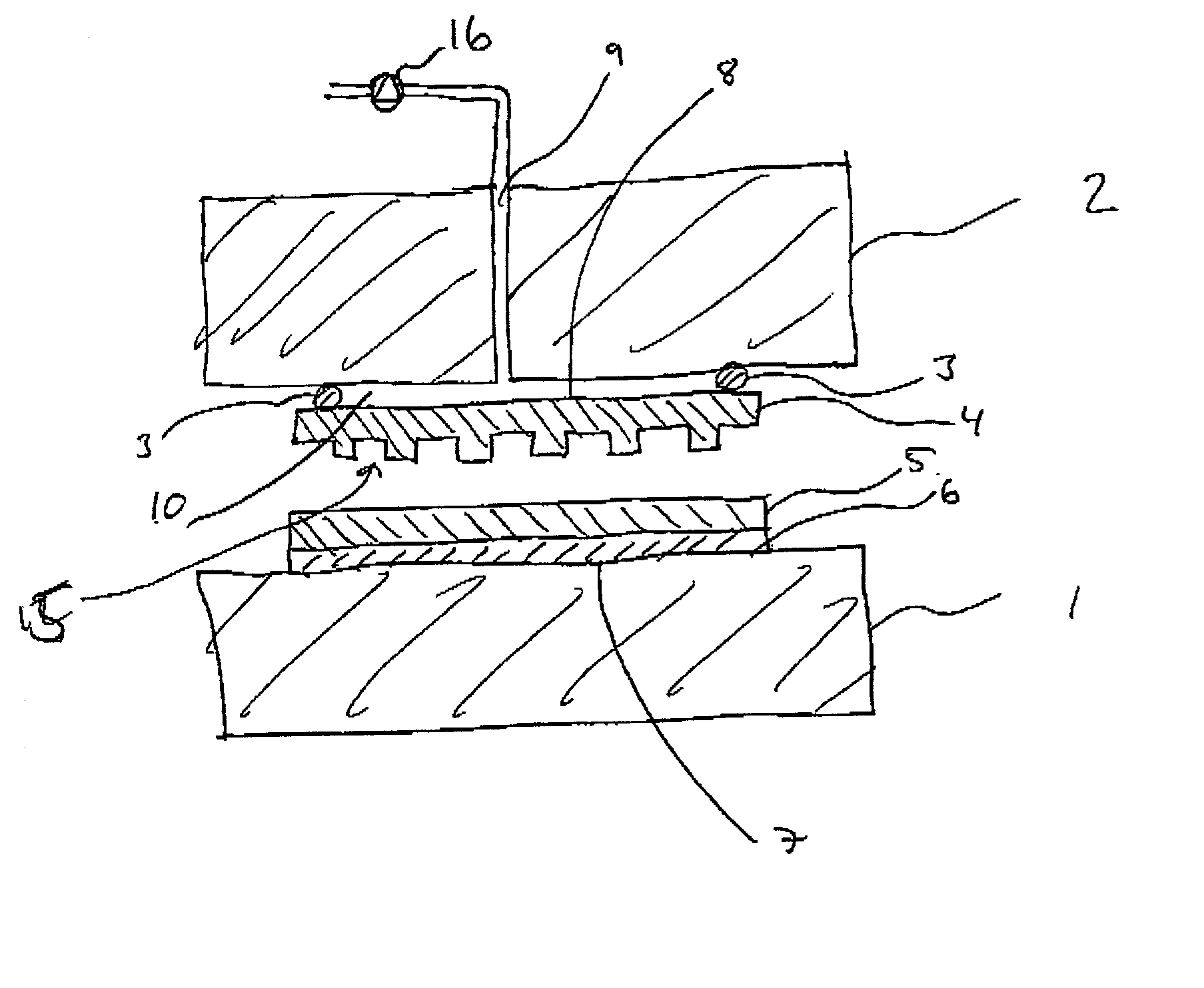

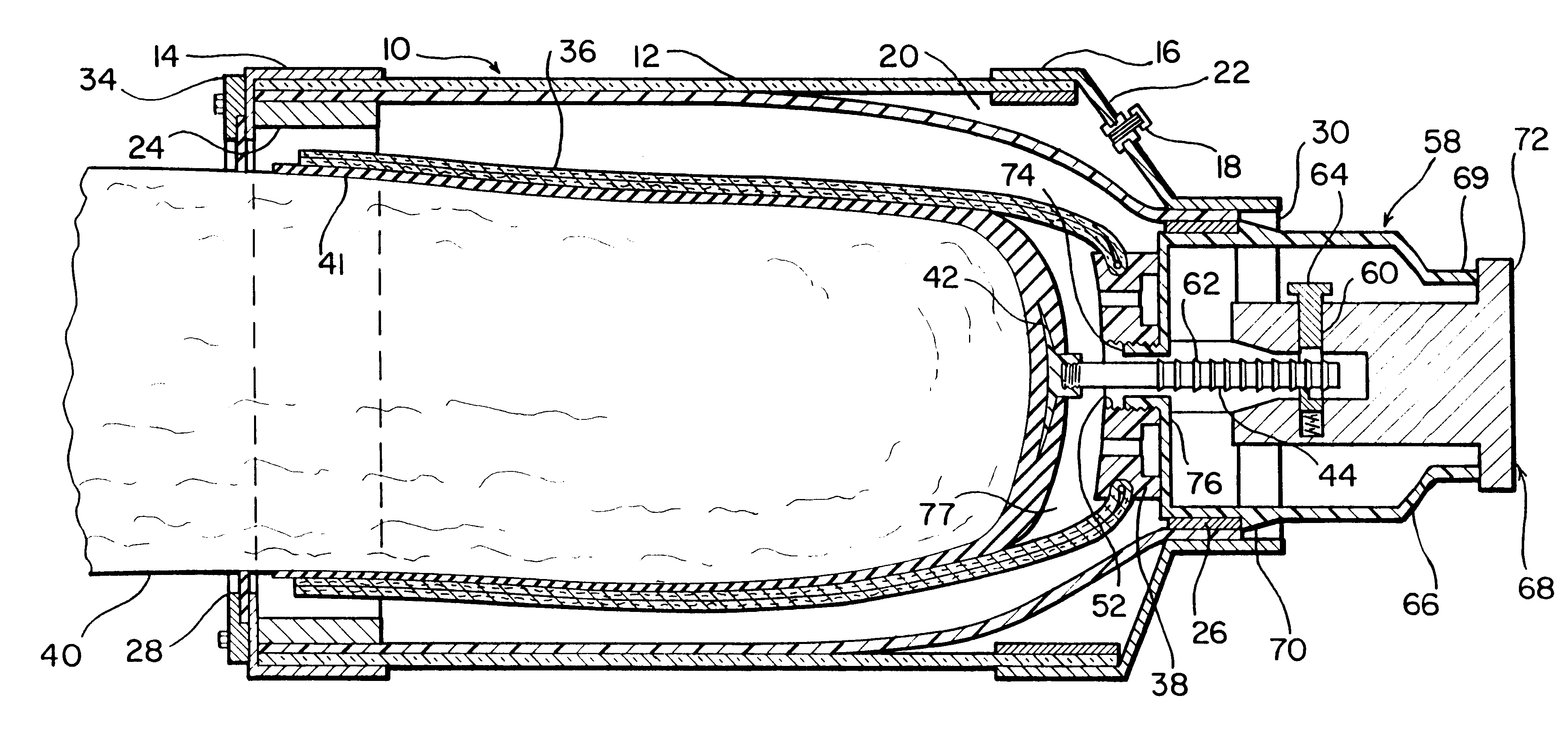

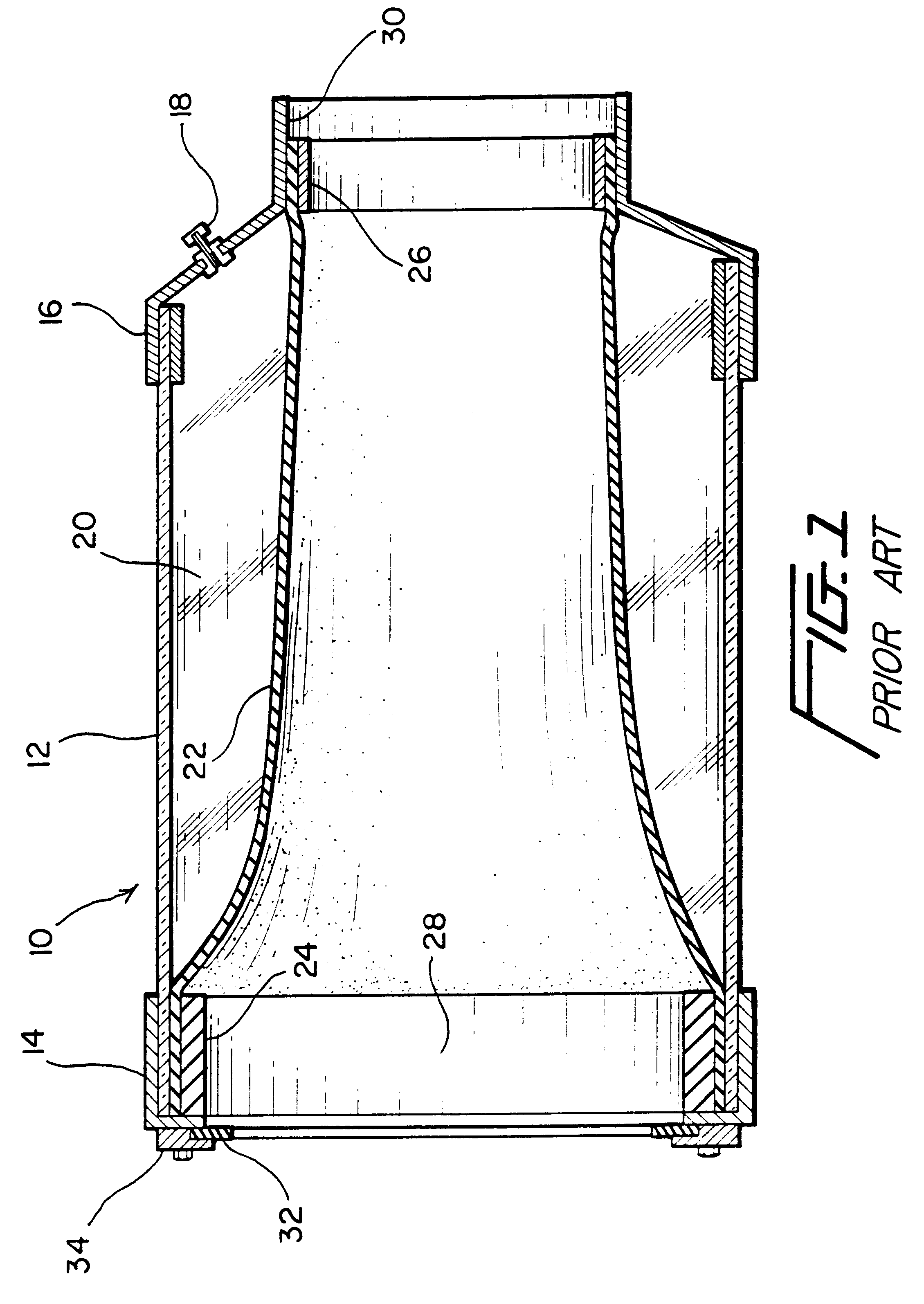

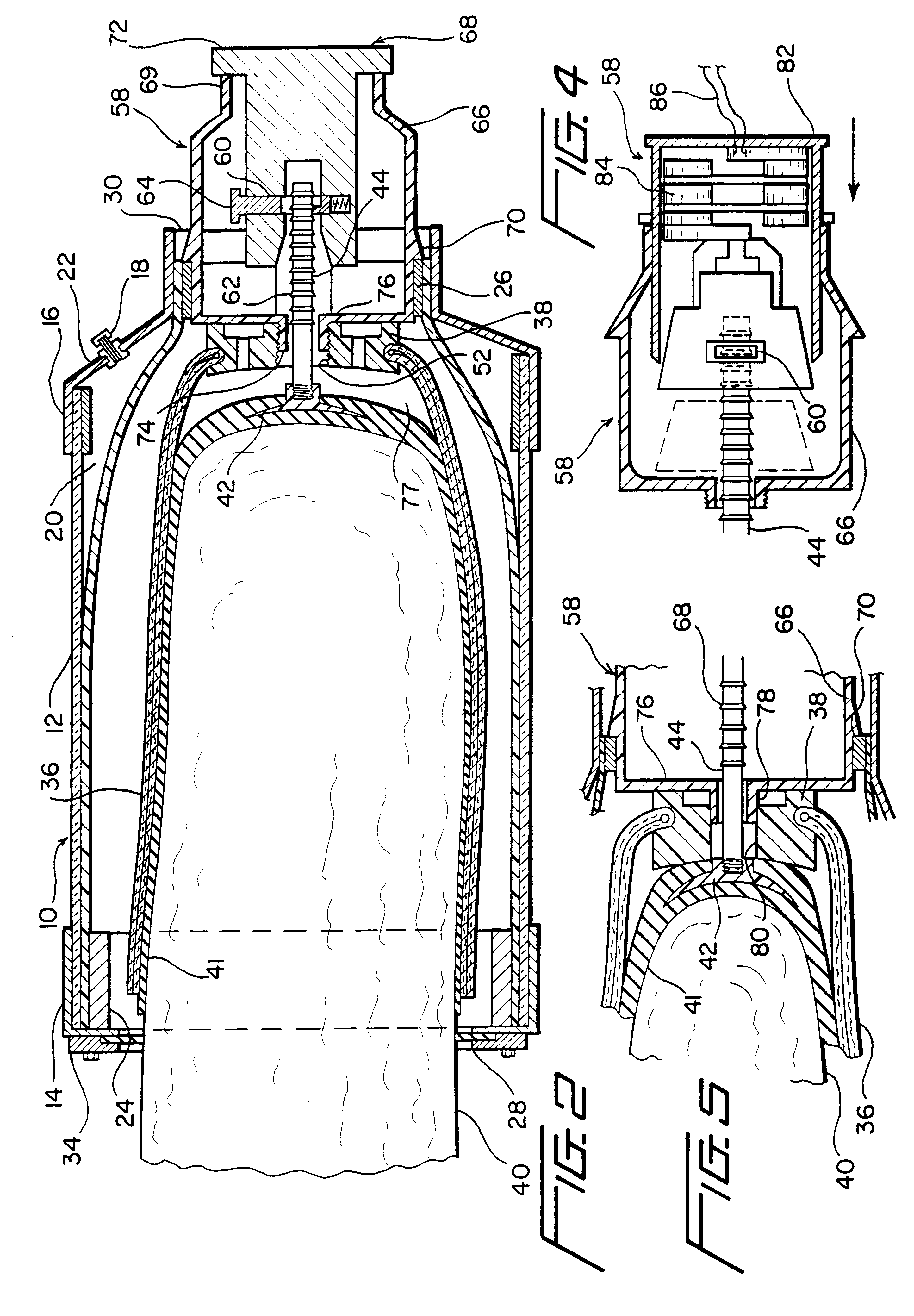

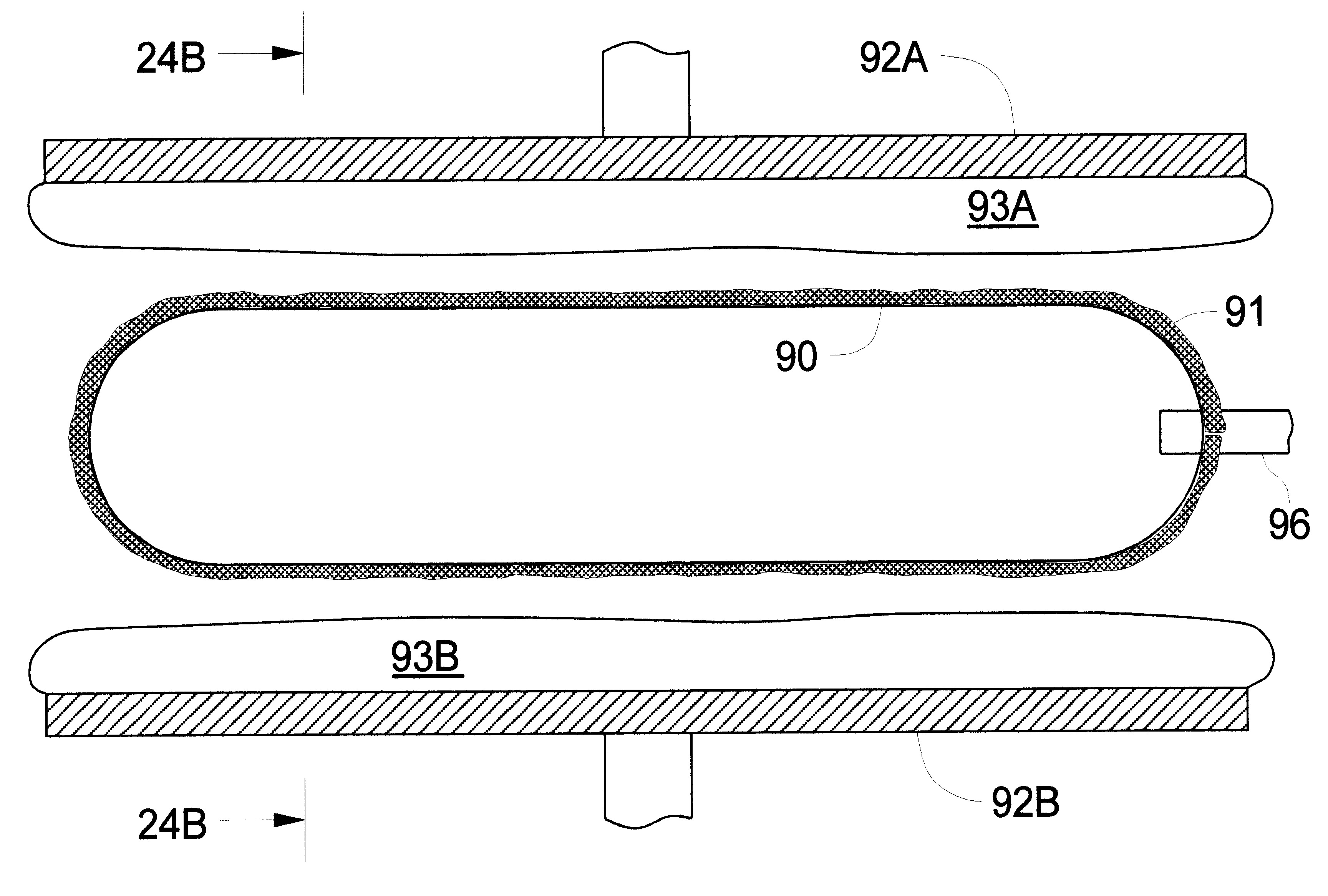

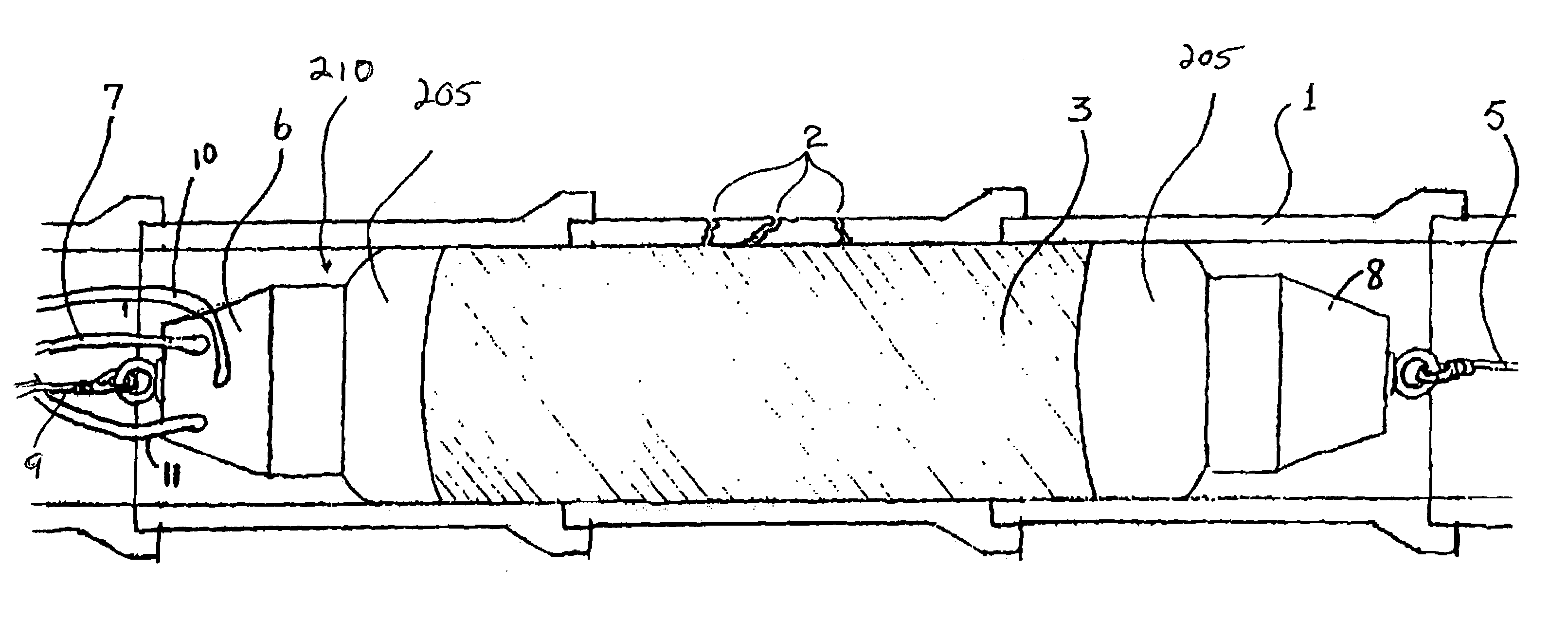

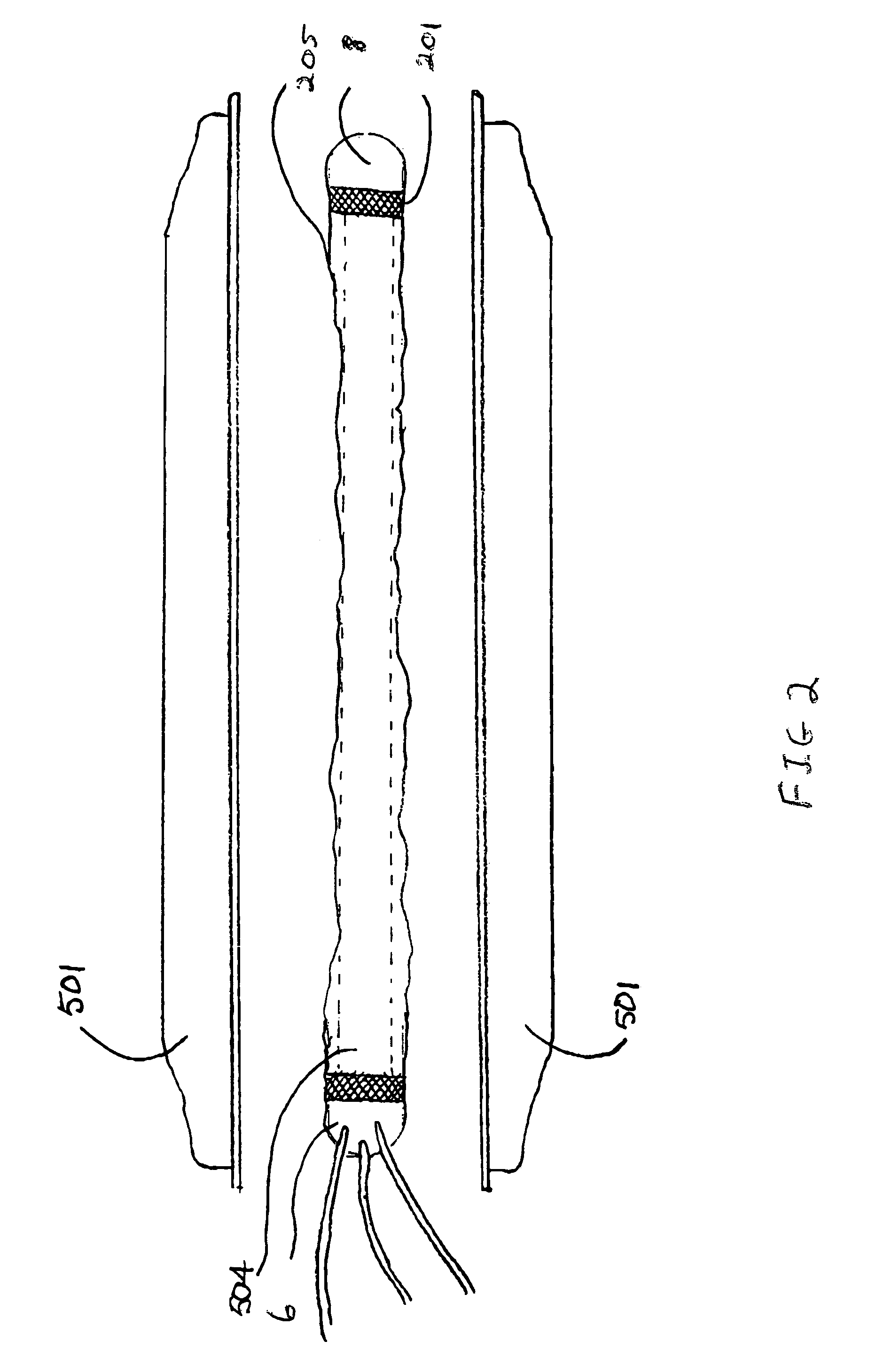

Inflatable heating device for in-situ repair of conduit and method for repairing conduit

InactiveUS7052567B1Extend the life cycleRobust and heatingConfectionerySweetmeatsElastomerResin matrix

The apparatus of the present invention is generally characterized by a heating / inflation module having pressurizable interior and an attached heat curable pre-preg. In particular, an elastomeric, seamless composite is provided that includes a heating element disposed within a thermoset resin matrix. The composite adapted to maintain a consistent temperature profile and an internal air pressure. A first end piece is attached to a first end of the composite and has an air port for communication with a compressed air source, a vacuum port for communication with a vacuum supply source and at least one electrical cable port for communication with a power supply source. A second end piece attached to a second end of the composite. The apparatus further includes a pre-preg removably attached to an outer surface of the composite. The pre-preg includes a structural fiber matrix supporting a heat curable resin. The composite is constructed by applying a liquid silicone matrix to at least one layer of braided or wound and / or tape fibers, wherein a portion of the fibers are electrically conductive. The layer of braided fibers is introduced into a mold, and a removable, expandable inner bladder is then loaded into the mold. The inner bladder is inflated to conform the layer of braided fibers to an interior surface of the mold. An electric current is caused to flow to the conductive fibers to cure the silicone matrix into a stable, elastomeric state. The composite is removed from the mold. A method for repairing a damaged section of a conduit is also disclosed.

Owner:EMS USA HLDG I +1

Assembly of free-standing films using a layer-by-layer process

InactiveUS20010046564A1Easy to controlRetain biological activityMaterial nanotechnologyMouldsCross-linkEngineering

A method for the layer-by-layer assembly of a free standing thin film includes the steps of preparing a support with a suitable substrate; forming a thin film having a plurality of layers onto the substrate utilizing a layer-by-layer assembly process; removing the substrate and thin film from the support; and separating the substrate from the thin film. Various compounds improving the strength, flexibility, tension and other mechanical properties may be included in the assembly to improve the structural quality of the film. Similar effect may also be achieved by cross-linking the applied layers.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

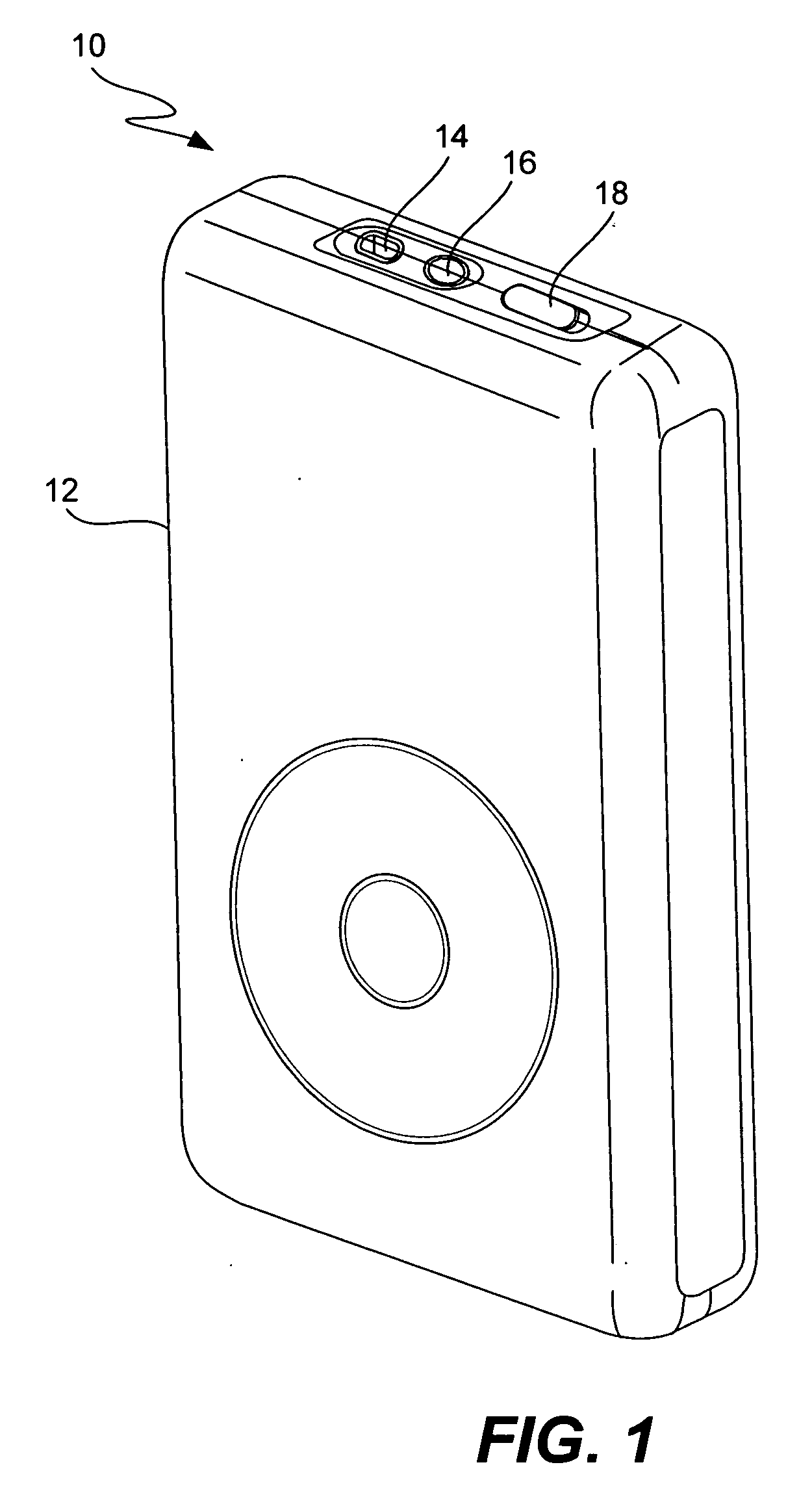

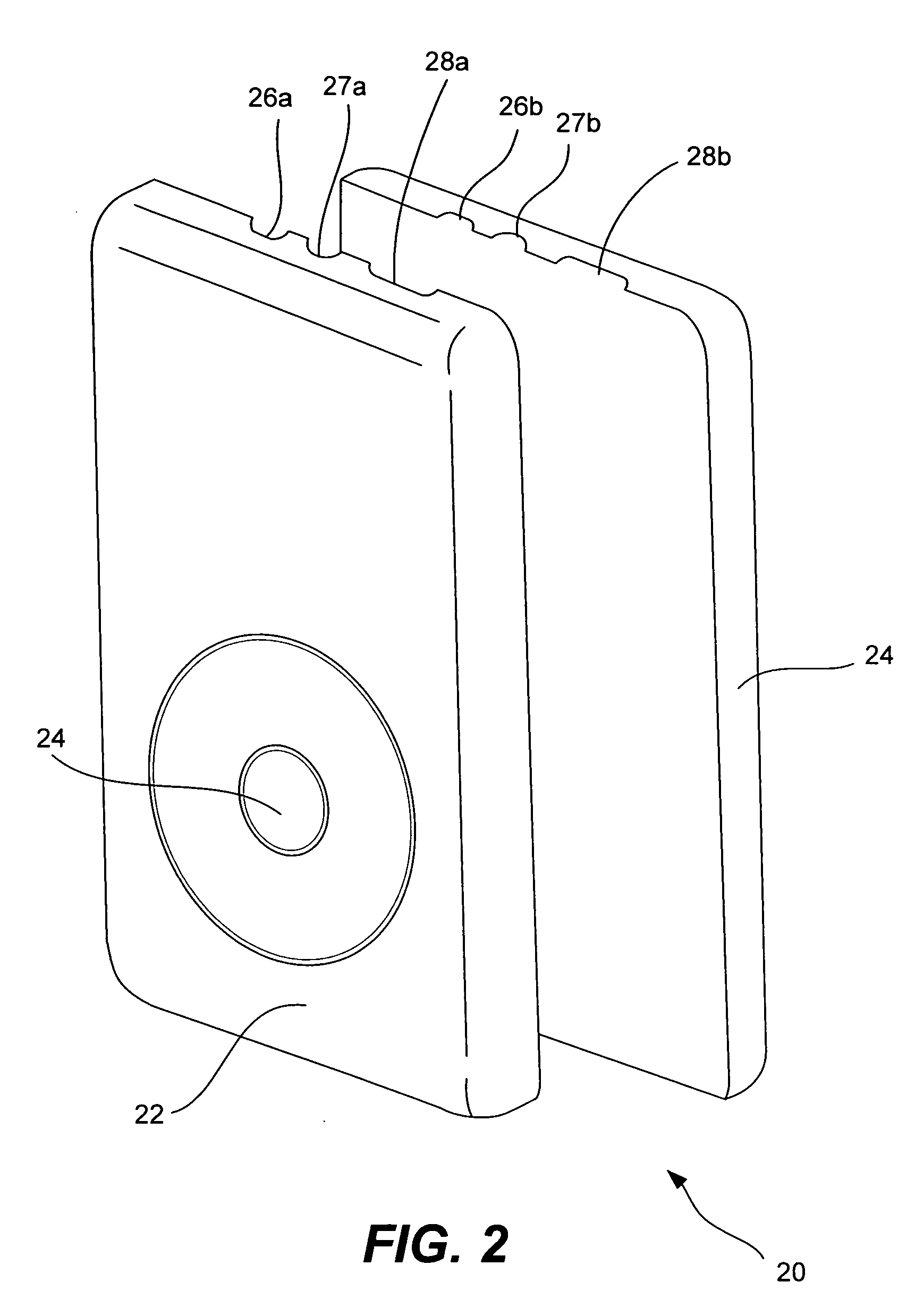

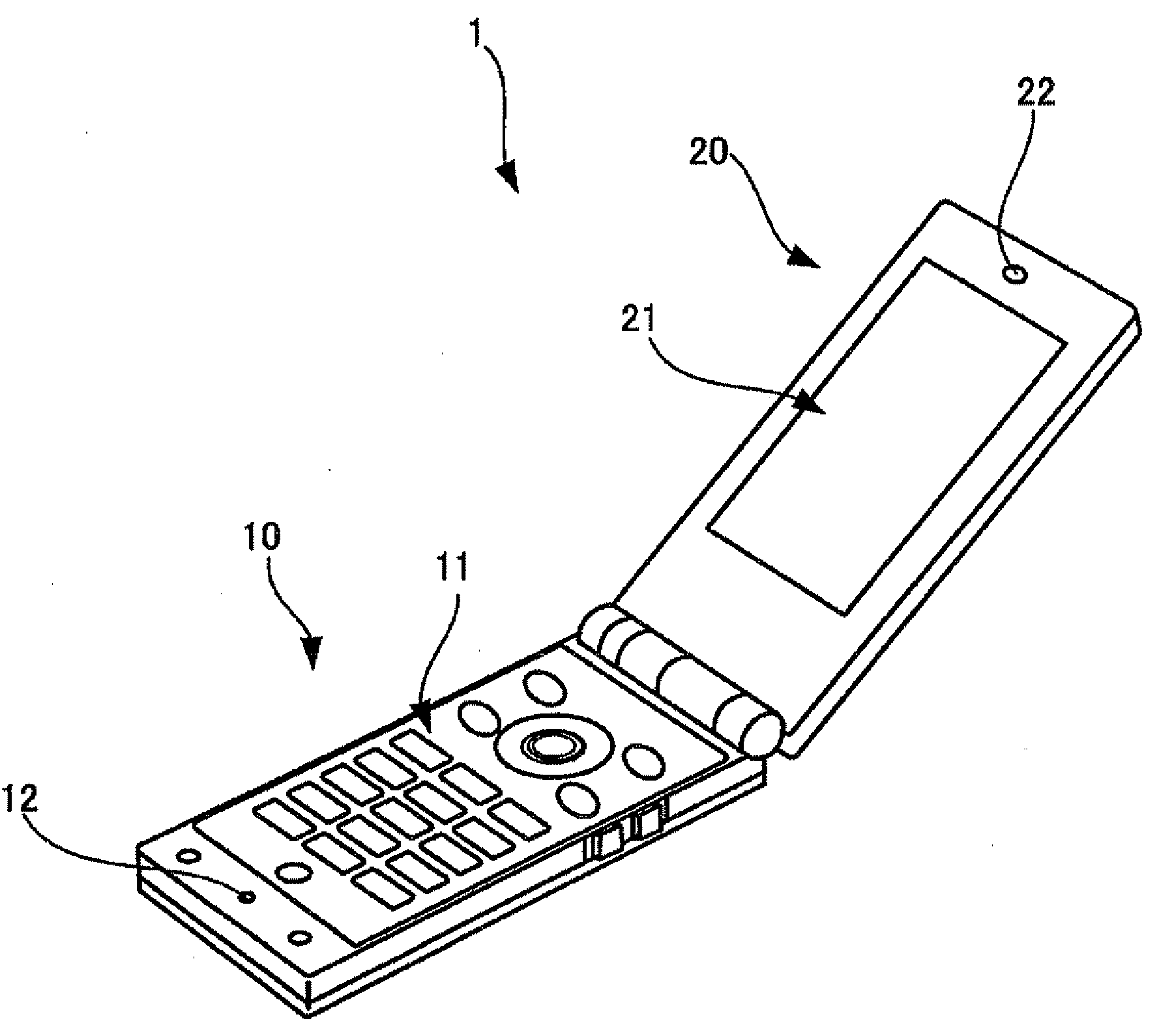

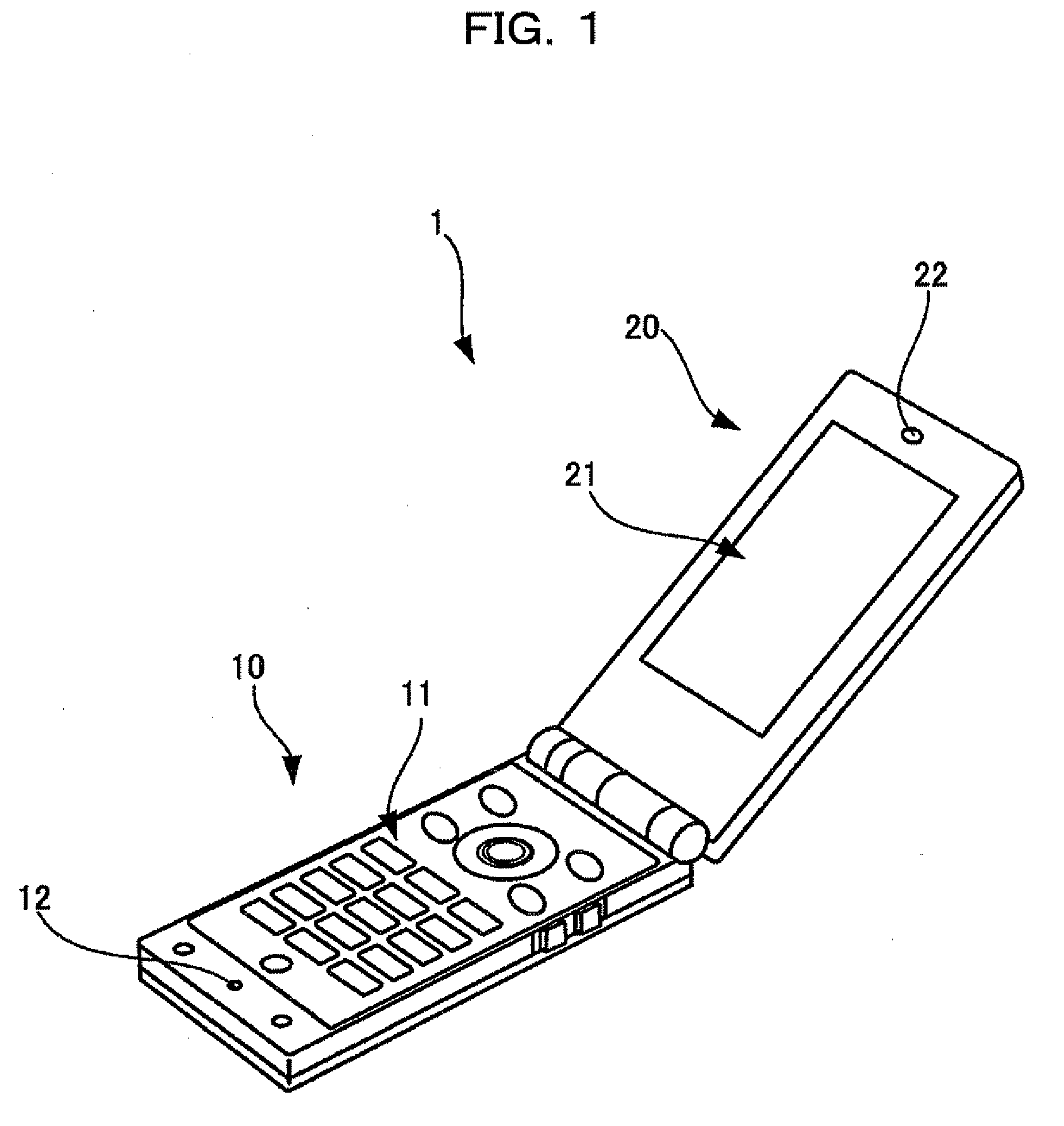

Mobile device

A mobile device having a housing and operating on power supplied from the battery loaded in the battery chamber including: a pair of walls of the housing having hook receiving portions formed a groove; a battery lid covering the battery chamber so as to be freely detached; a pair of positioning hooks serving to position the battery lid by entering the grooves of the corresponding hook receiving portions; overhanging edges serving to regulate position of the cover lid; and a waterproof gasket fixed to the battery chamber side of the cover lid so as to be in contact with all sides of the battery chamber.

Owner:FUJITSU CONNECTED TECH LTD

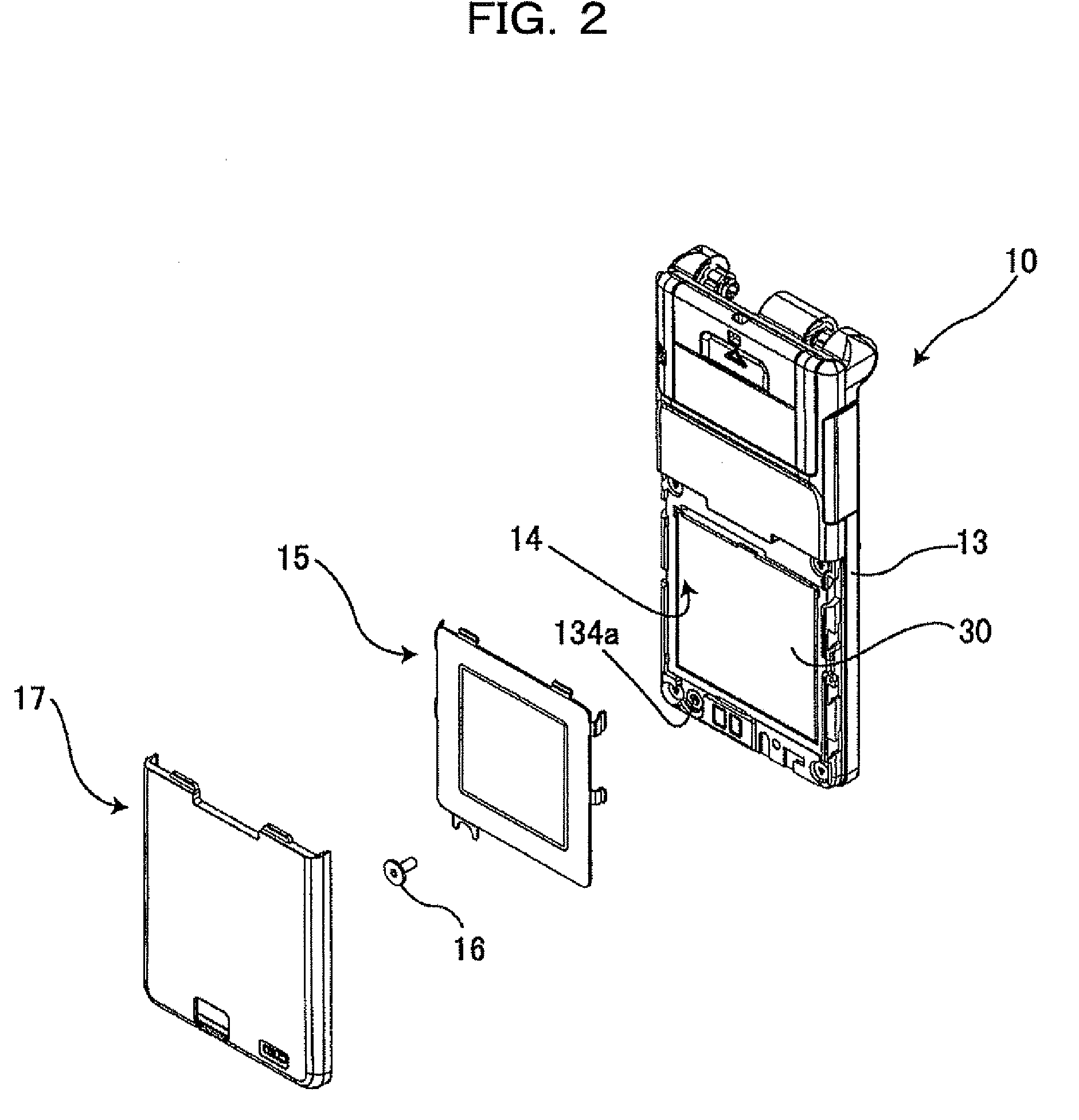

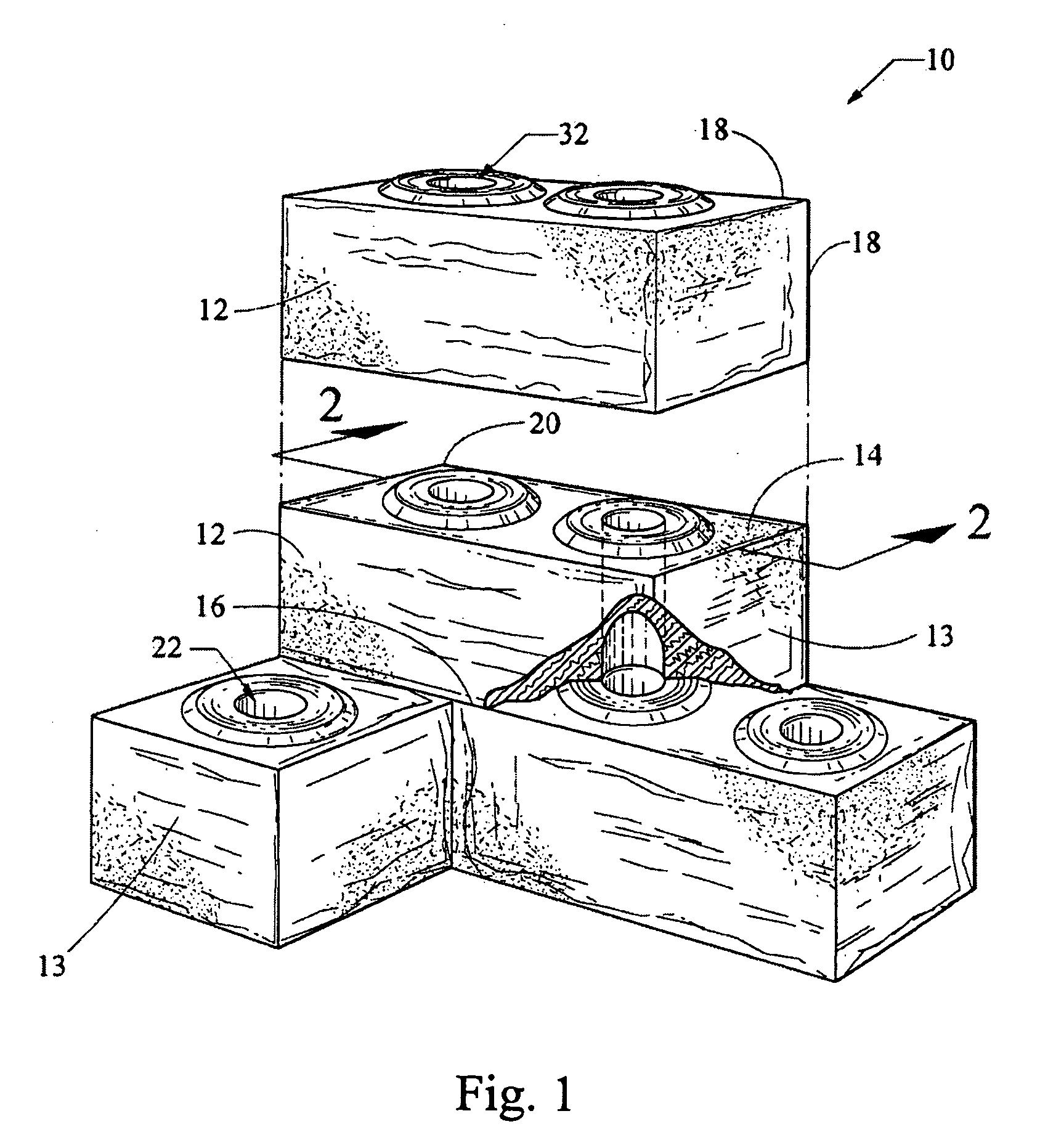

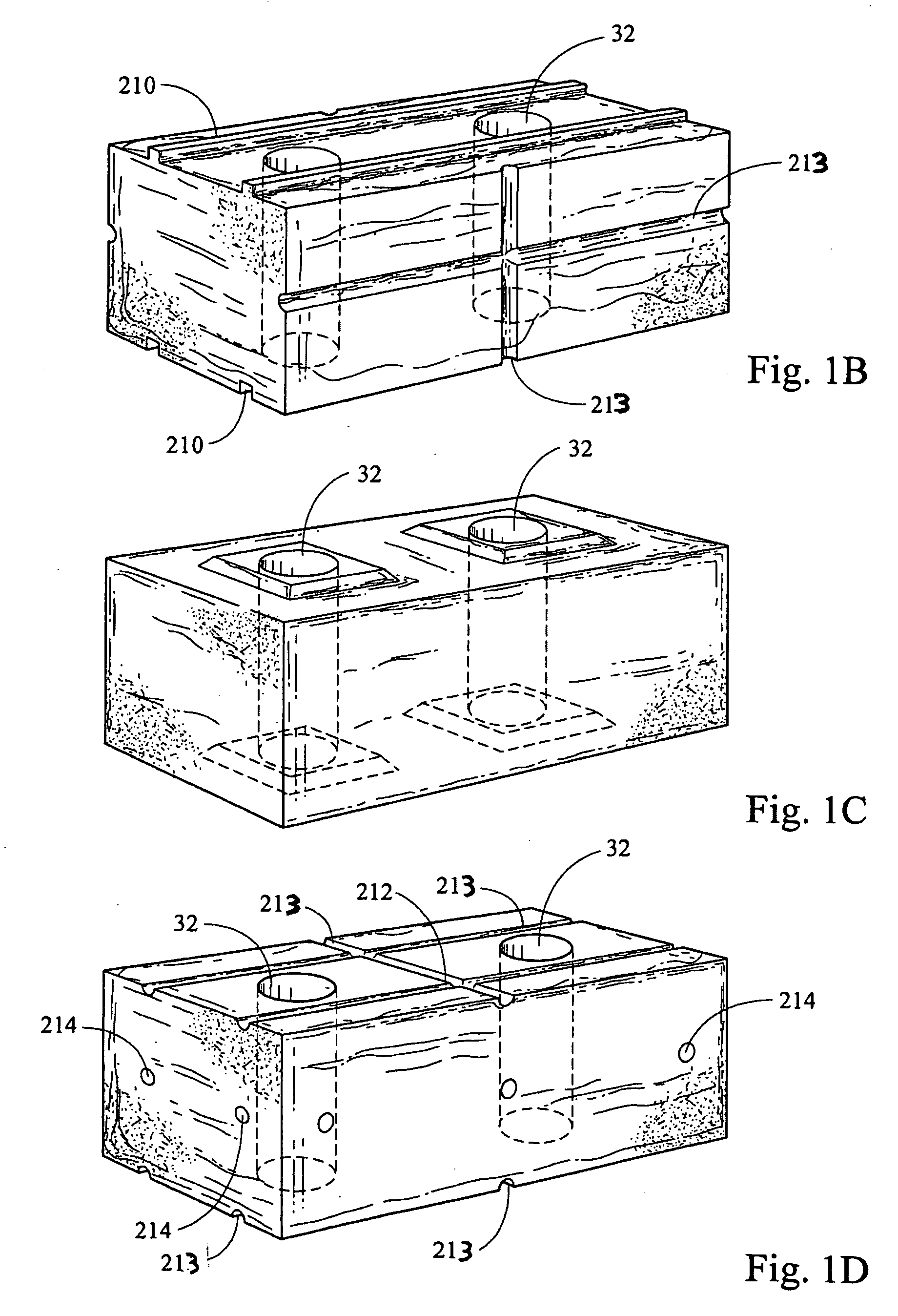

Building block, building block mold, and method for forming building block

InactiveUS20090077920A1Attractive surface finishHigh dimensional tolerance capabilitySolar heating energyConstruction materialStructural degradationHigh dimensional

The present invention provides an improved building block formed of recycled straw stalks, a mold for forming the block, and a method of forming the block. The improved block provides a moisture and pest resistant building block having high dimensional tolerances and being capable of long term use without structural degradation.

Owner:ORYZATECH

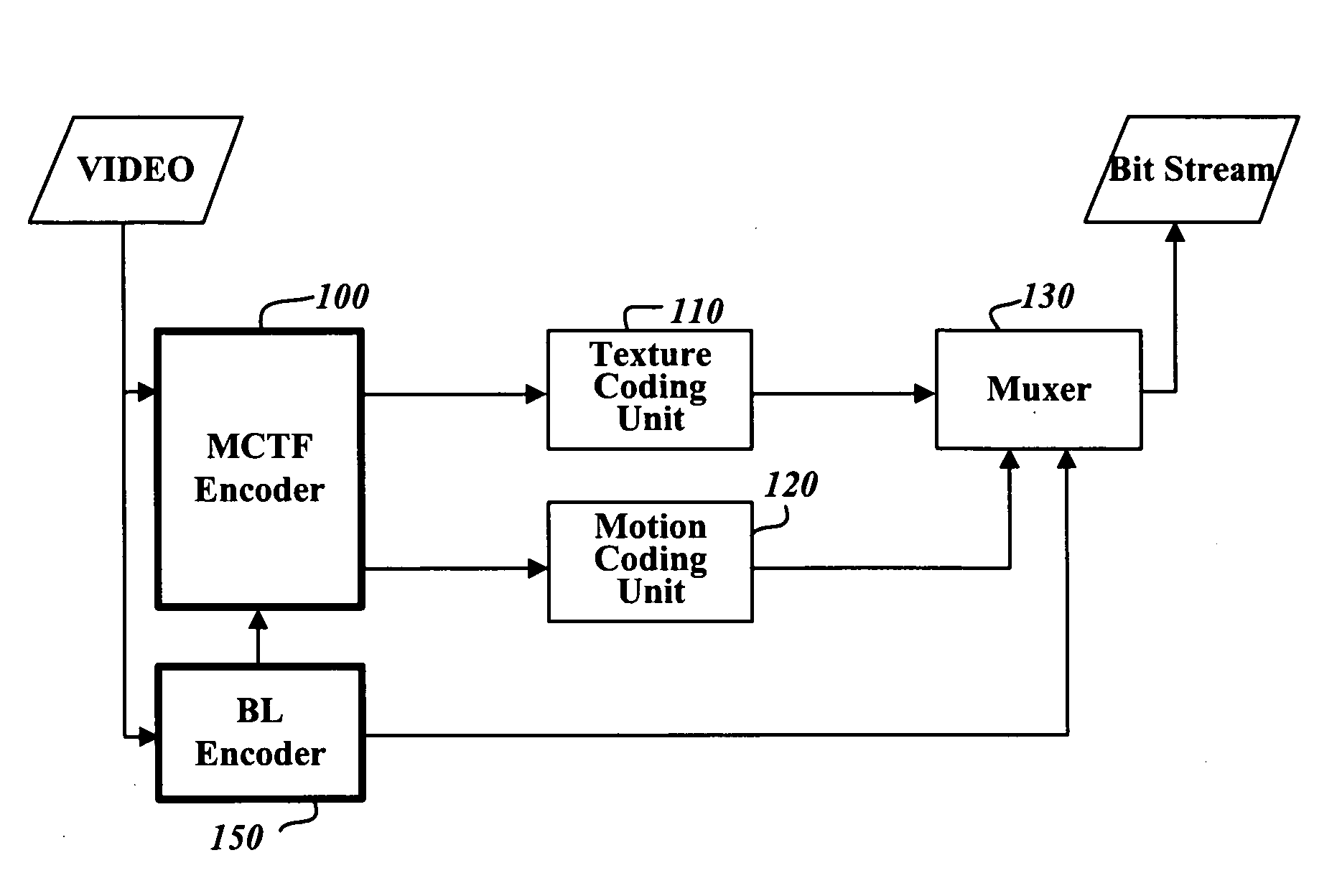

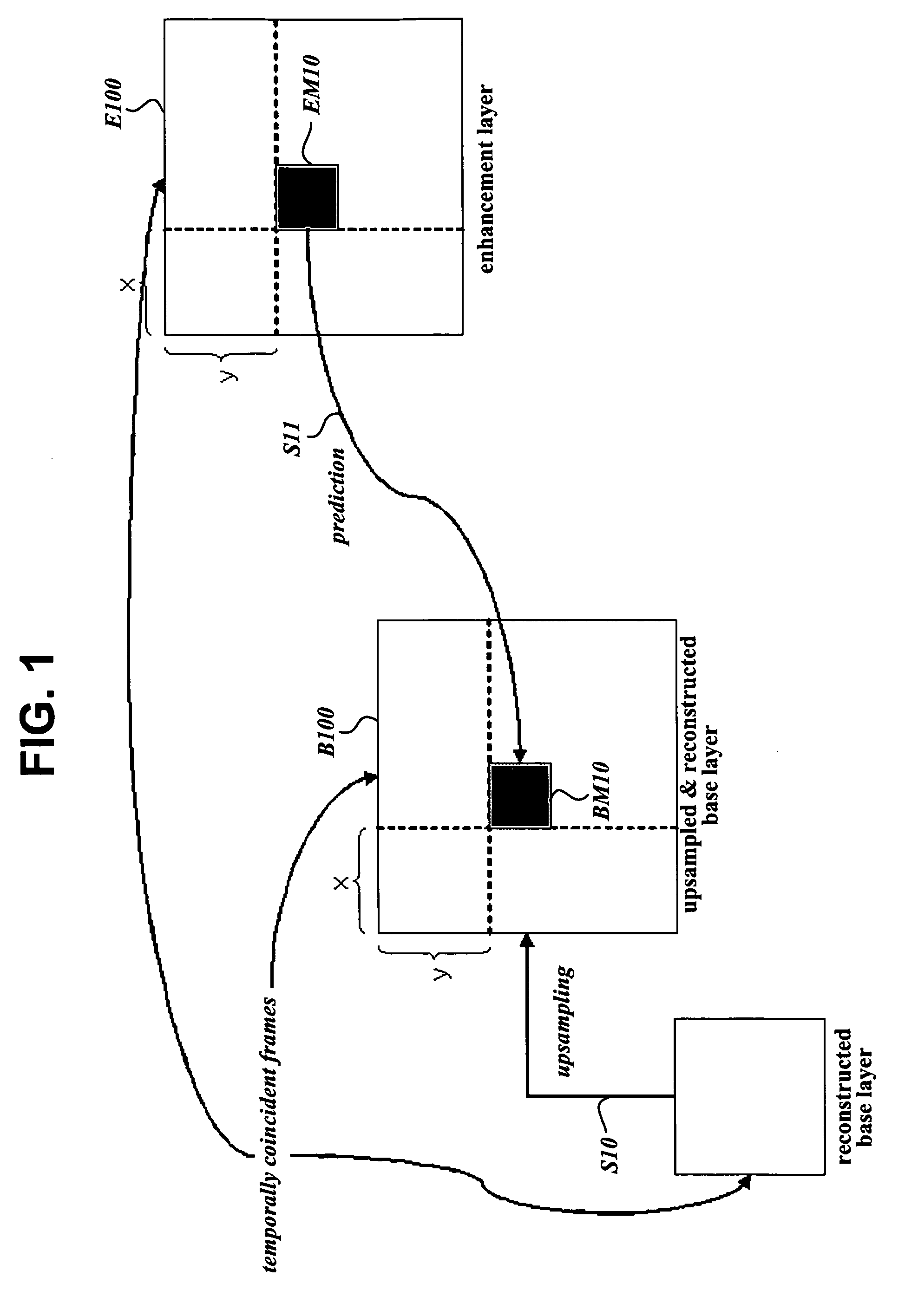

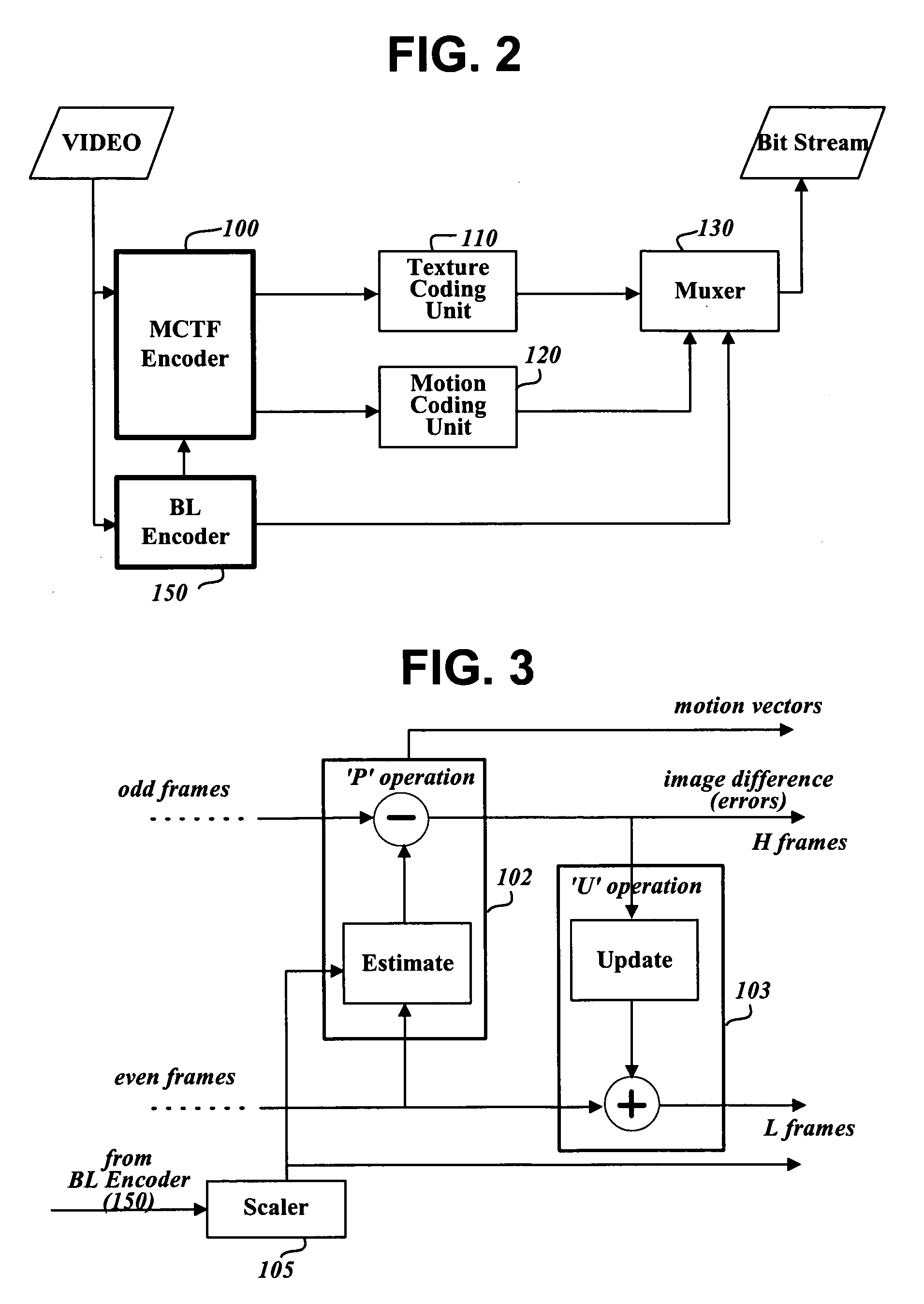

Method for encoding and decoding video signals

InactiveUS20060093036A1MouldsPicture reproducers using cathode ray tubesPattern recognitionFrame sequence

A method for encoding video signals by inverse motion compensated temporal filtering where video frames of a base layer are used to encode video frames of an enhanced layer into predicted images. For each image block in an arbitrary frame in an enhanced layer frame sequence, an area including a block, which is present in a base layer frame temporally coincident with the arbitrary frame and is at the same position as the image block, is enlarged according to the ratio between screen sizes of the two layers. A reference block most highly correlated with the image block is searched for in the enlarged area in the temporally coincident base layer frame through motion estimation and is used to obtain pixel difference values and a motion vector of the image block for encoding the image block into a predicted image, thereby improving coding efficiency.

Owner:LG ELECTRONICS INC

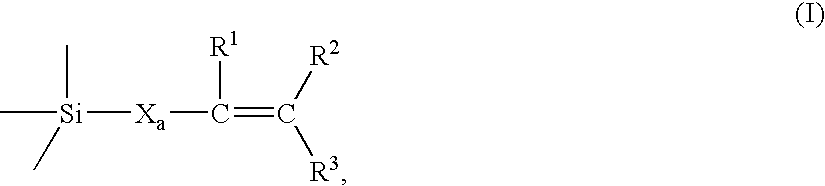

Silicone binders for investment casting

A green product for use in fabricating a ceramic article comprises a ceramic powder immobilized within a silicone matrix, wherein the silicone matrix comprises one or more cross linked or polymerized silicone monomers and / or oligomers, wherein the one or more cross linked or polymerized silicone monomers and / or oligomers have a alkenyl reactive functional group and a hydride reactive functional group. Processes for forming a green product and a ceramic core with the silicone monomers and / or oligomers are also disclosed.

Owner:GENERAL ELECTRIC CO

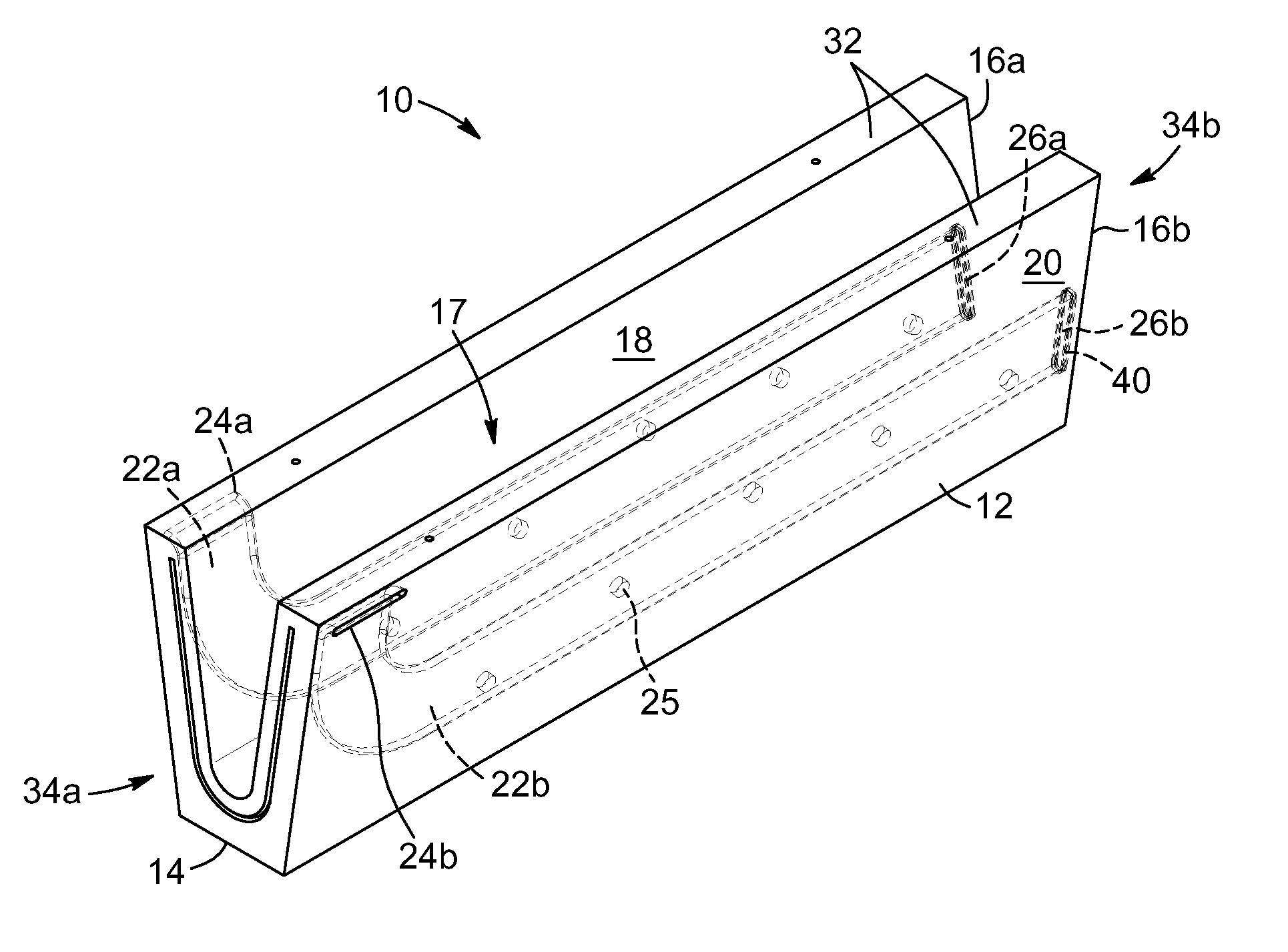

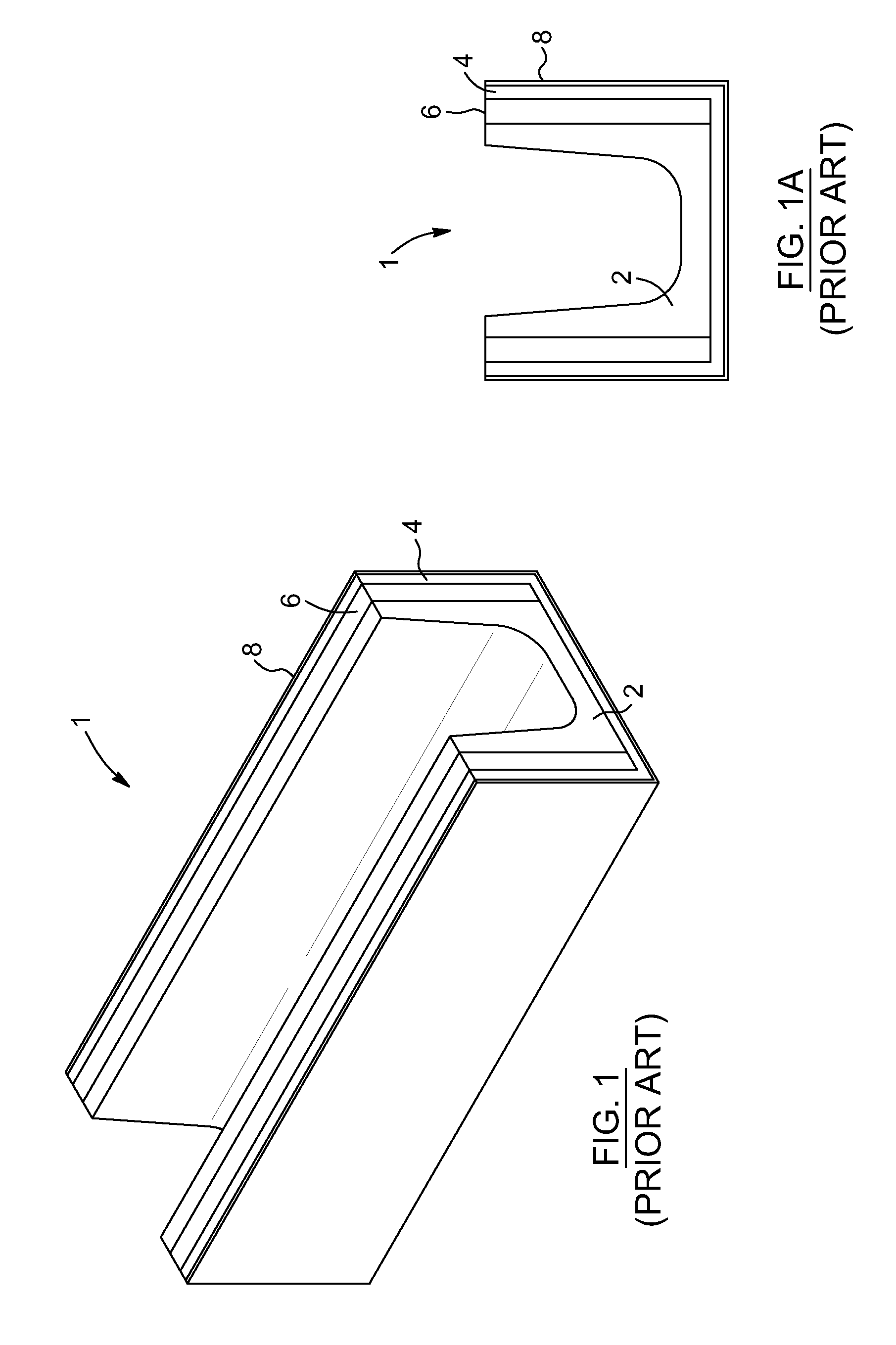

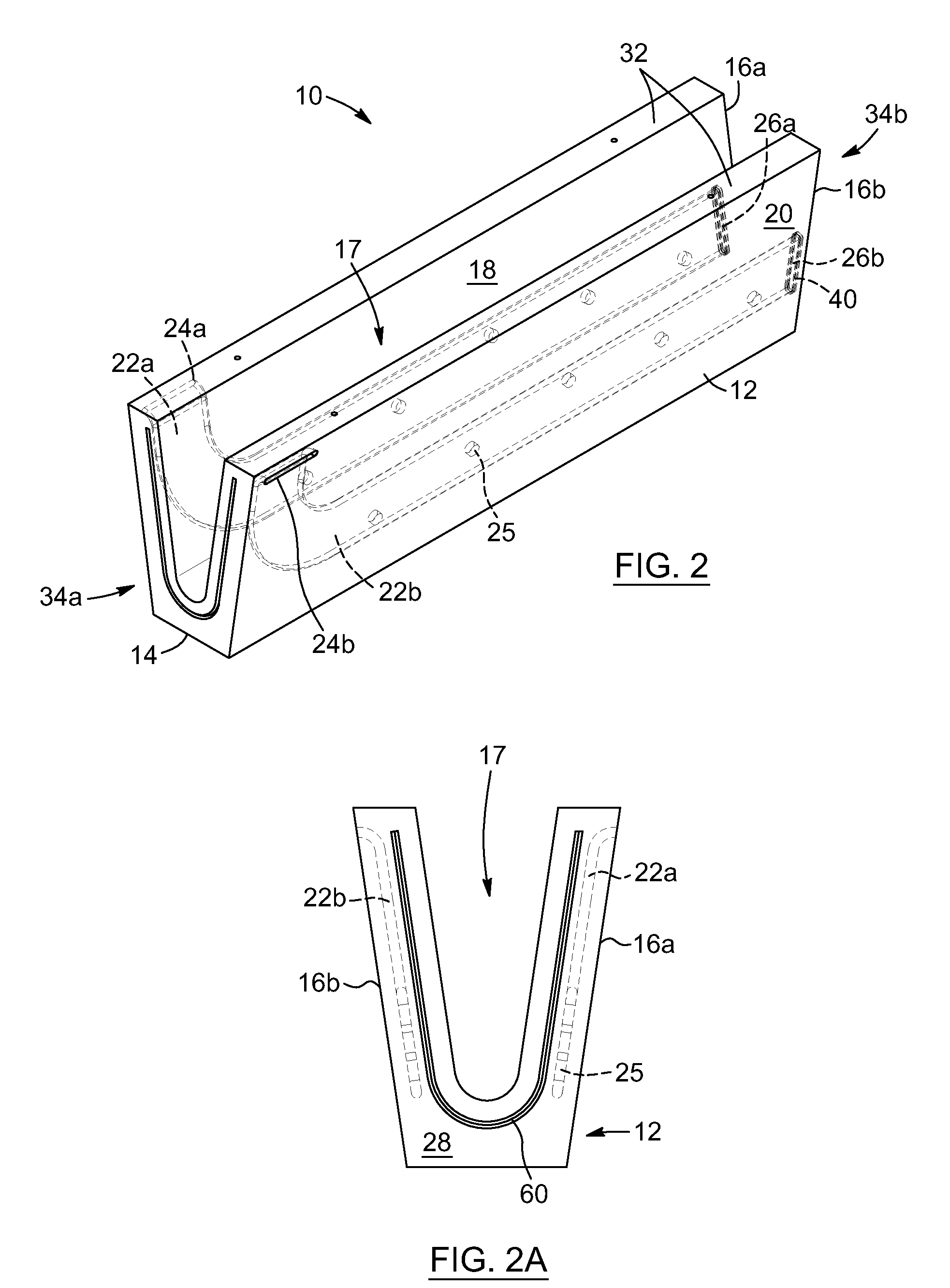

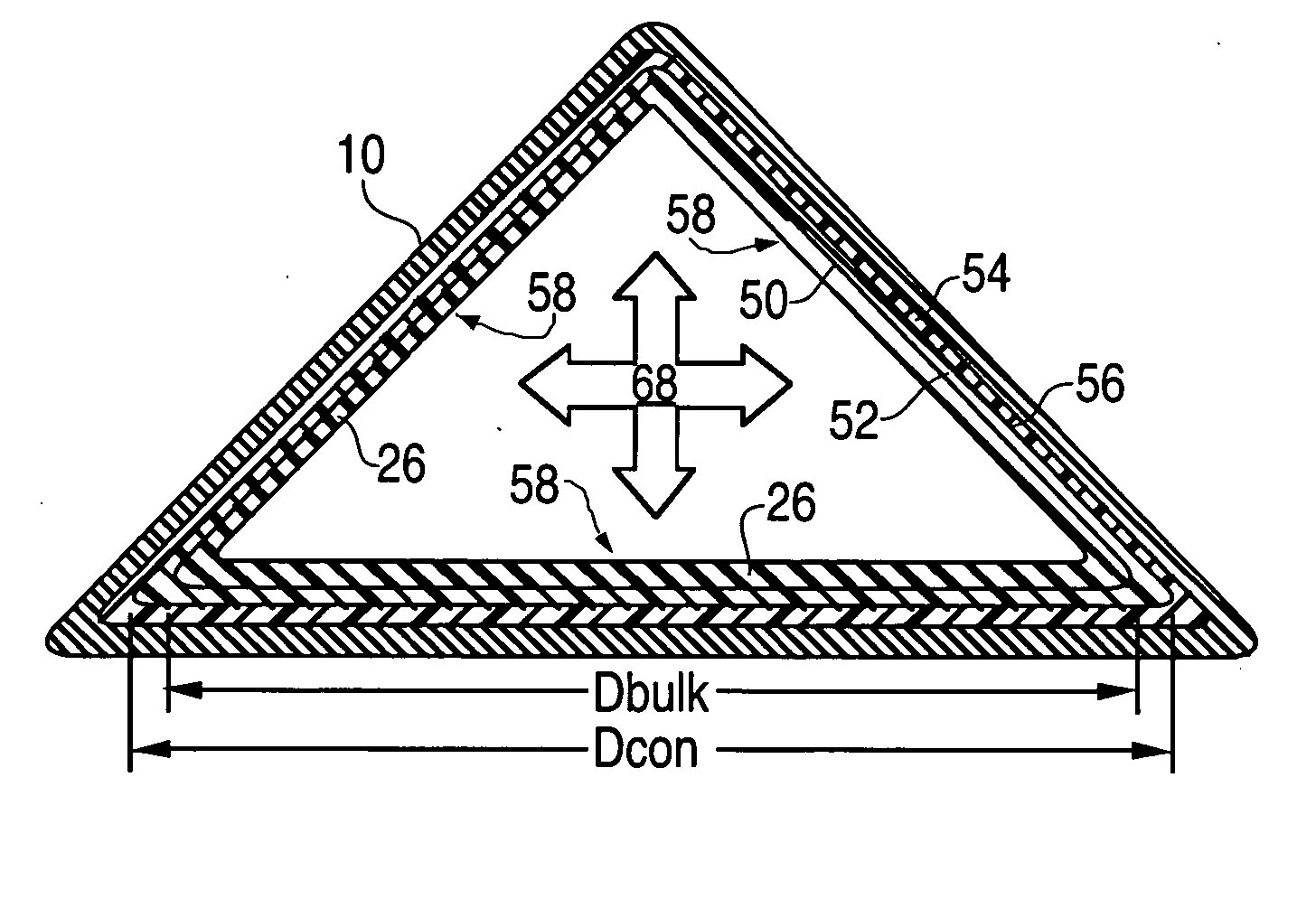

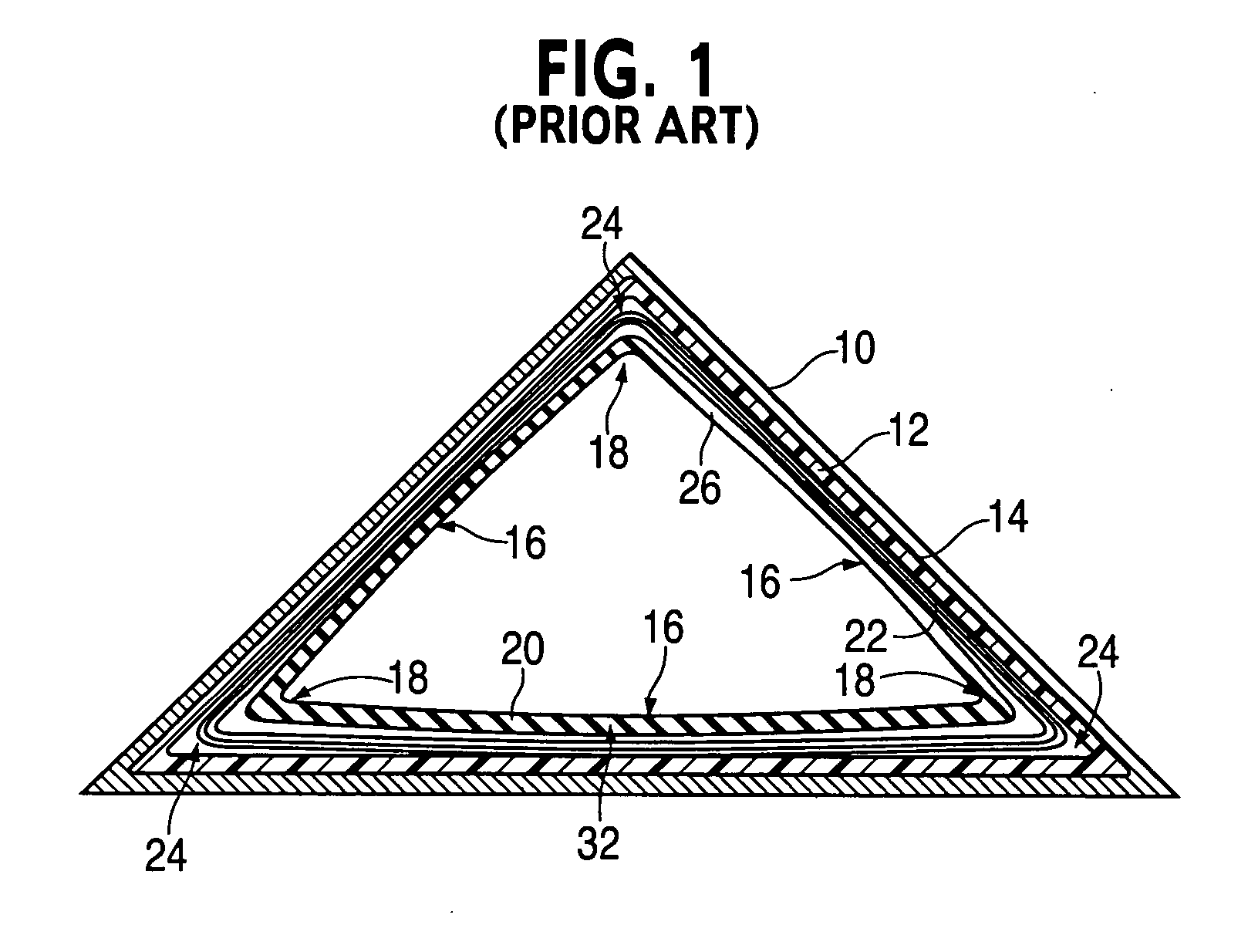

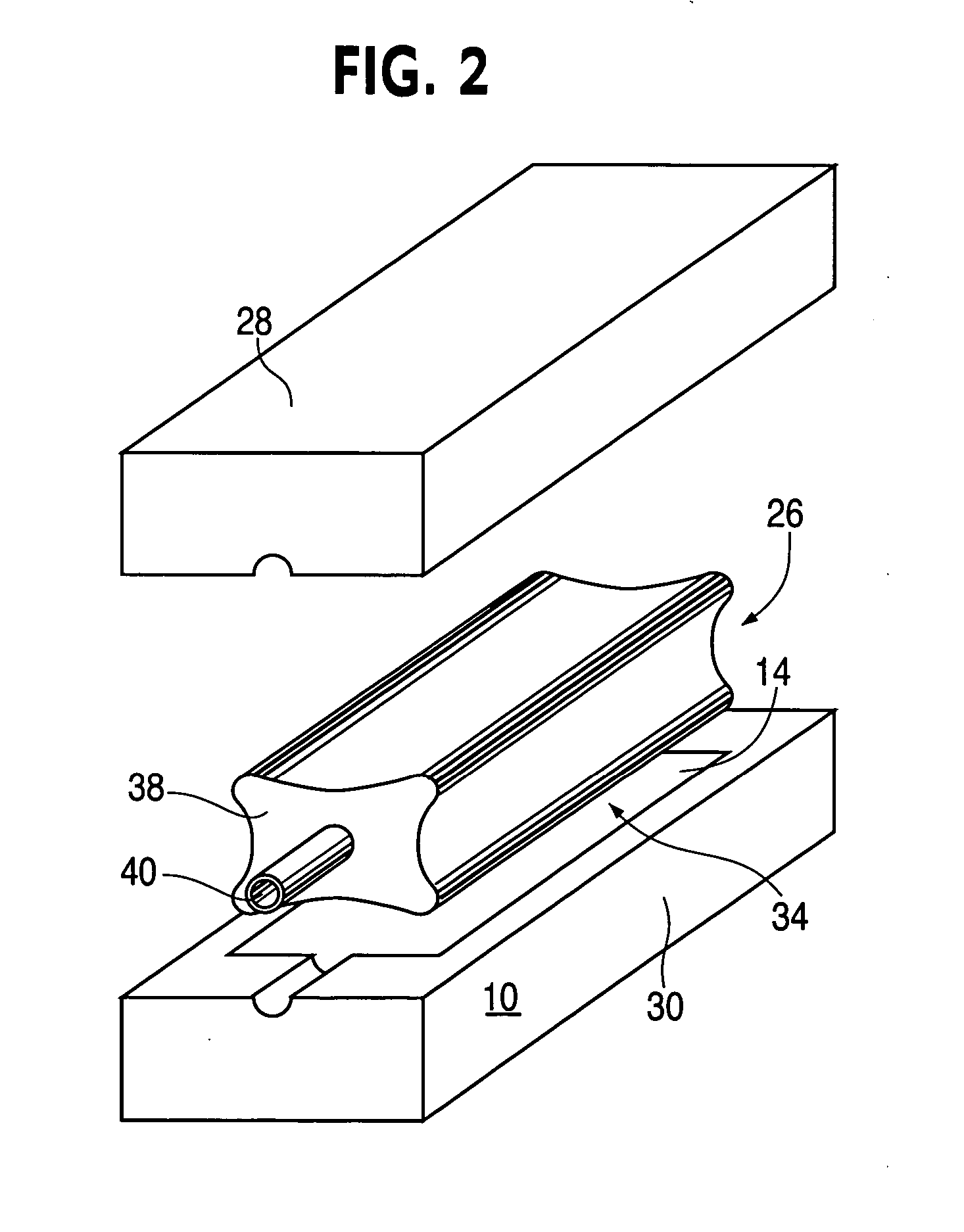

Corner-consolidating inflatable apparatus and method for manufacturing composite structures

ActiveUS20070096368A1Easy and inexpensive to manufactureConfectioneryWood working apparatusEngineeringMechanical engineering

An inflatable compaction tool for consolidating a composite material inside a faceted hollow or tubular mold for a composite part is made from an elastic material. The compaction tool includes relatively flat wall segments conjoined by corner segments that define a sealed chamber. The wall segments curve away from the mold surface toward the midpoint of each wall segment, so that as a pressurized fluid is introduced into the compaction tool, a component of the force exerted on the tool interior surface is transmitted through the wall segments toward the corner segments. Thus, during initial inflation, the corner segments are forced toward the corner regions of the mold before the wall segments contact the composite material, firmly compressing the composite material into the corner regions of the mold before the friction of the wall segments against the composite material inhibits expansion of the corner segments into the mold corner regions.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com