Patents

Literature

62results about How to "Ratio is limited" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

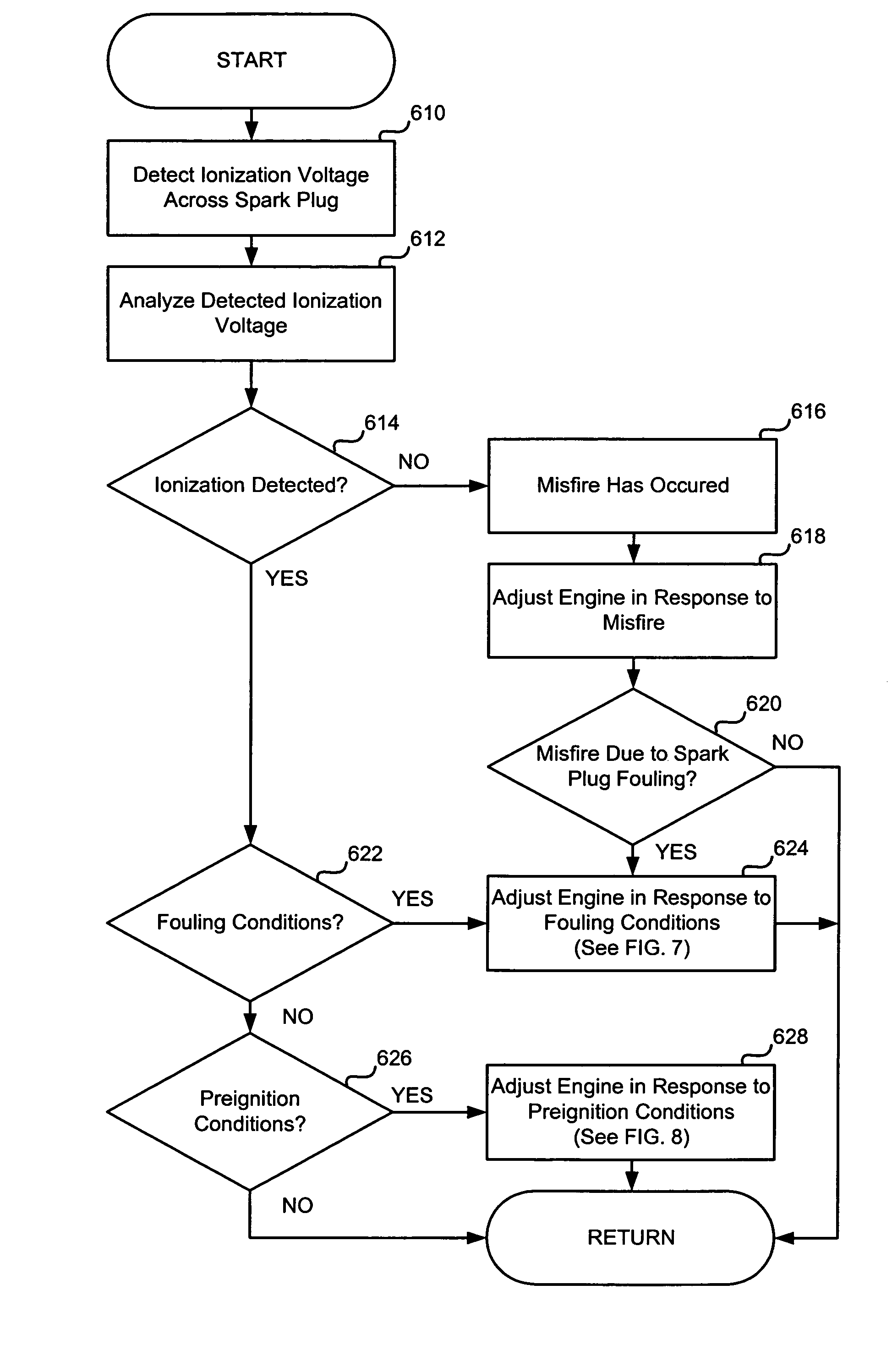

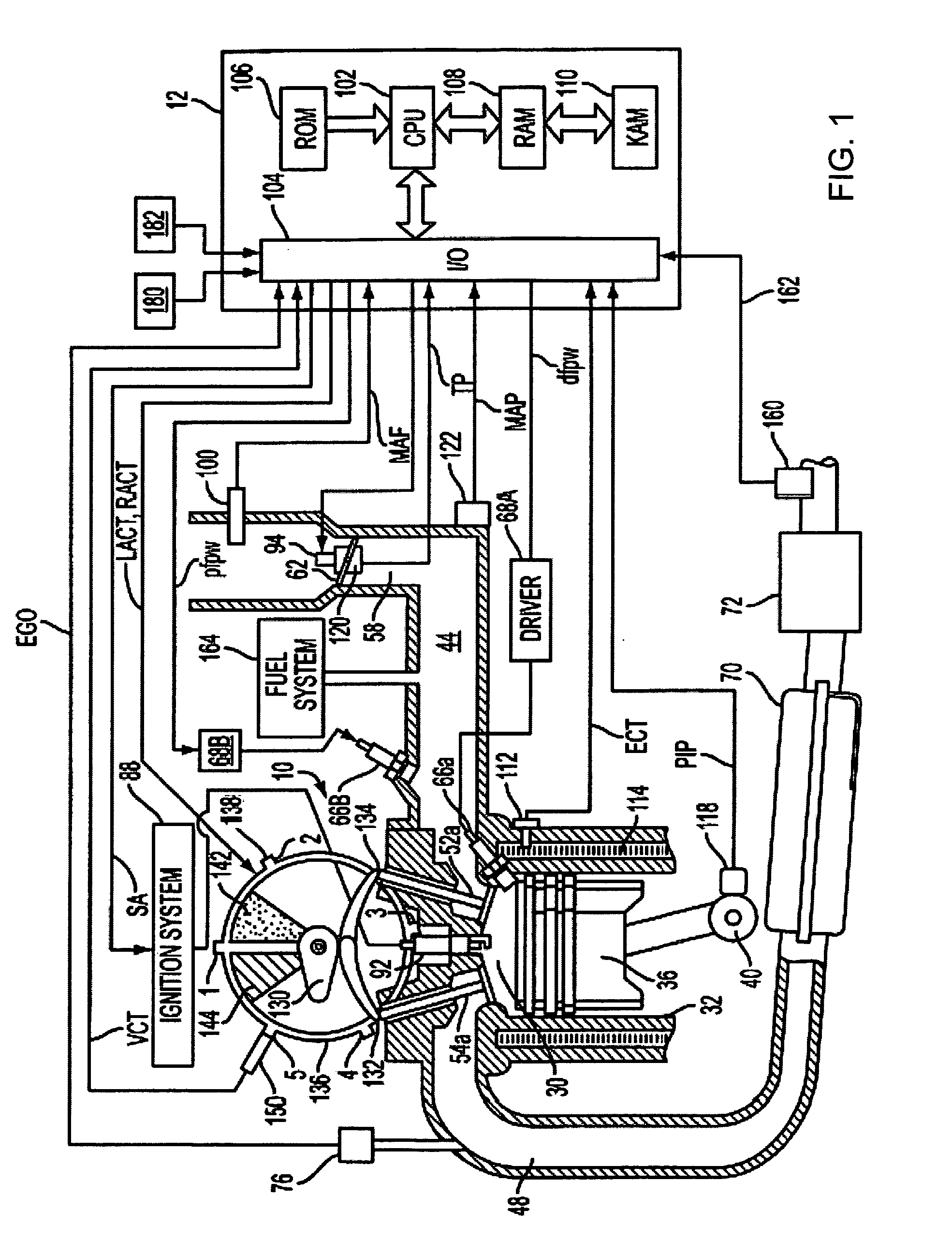

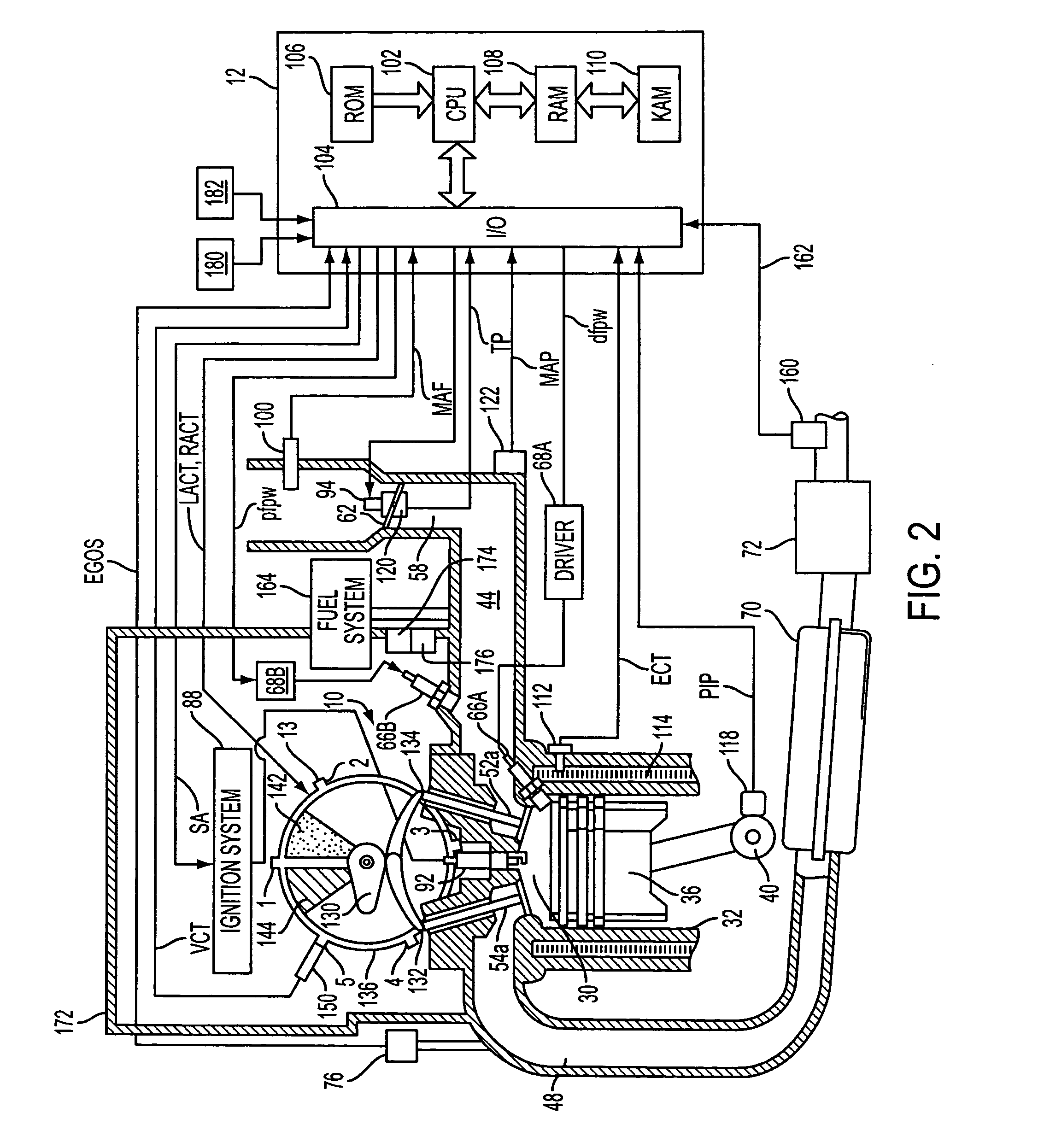

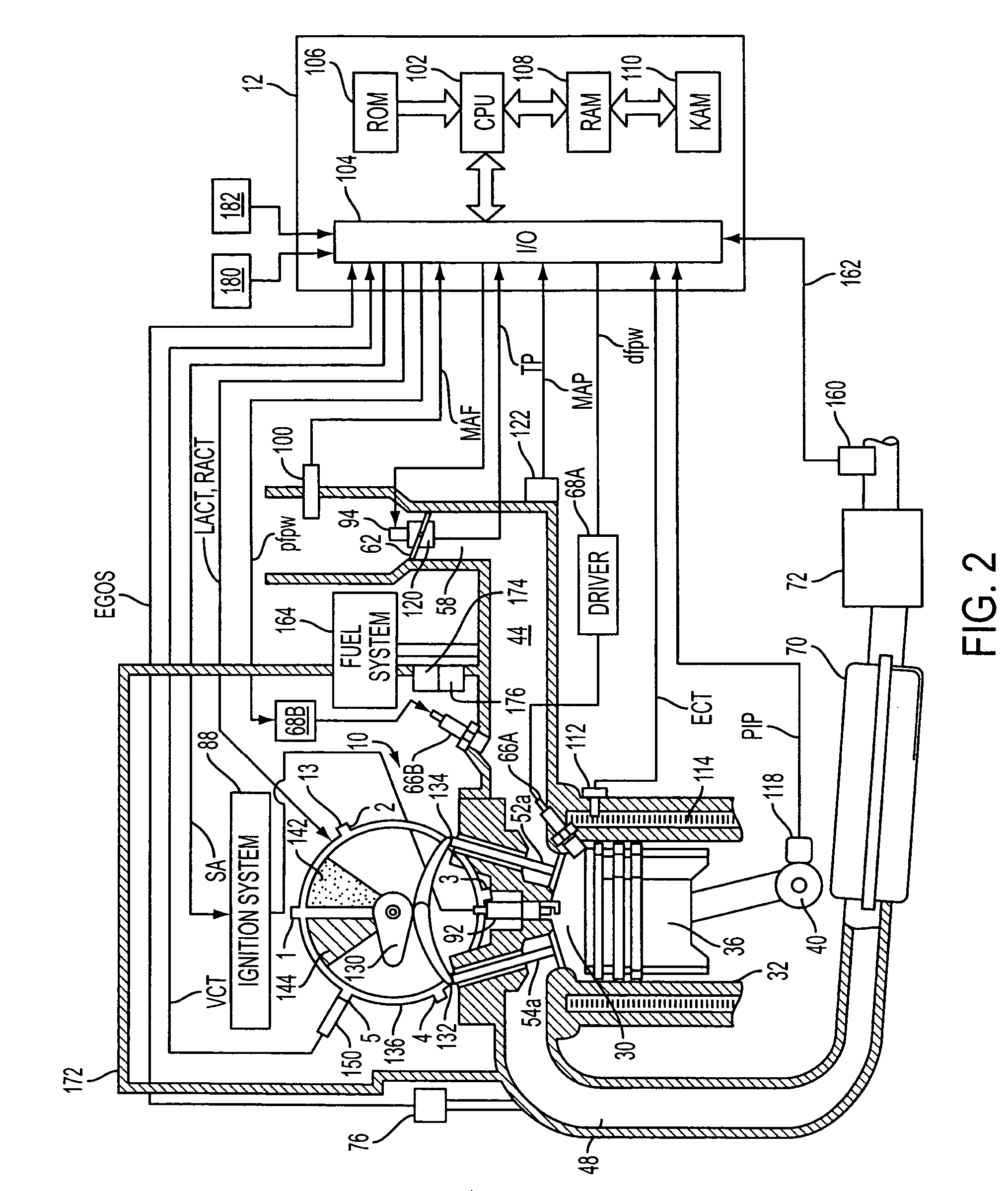

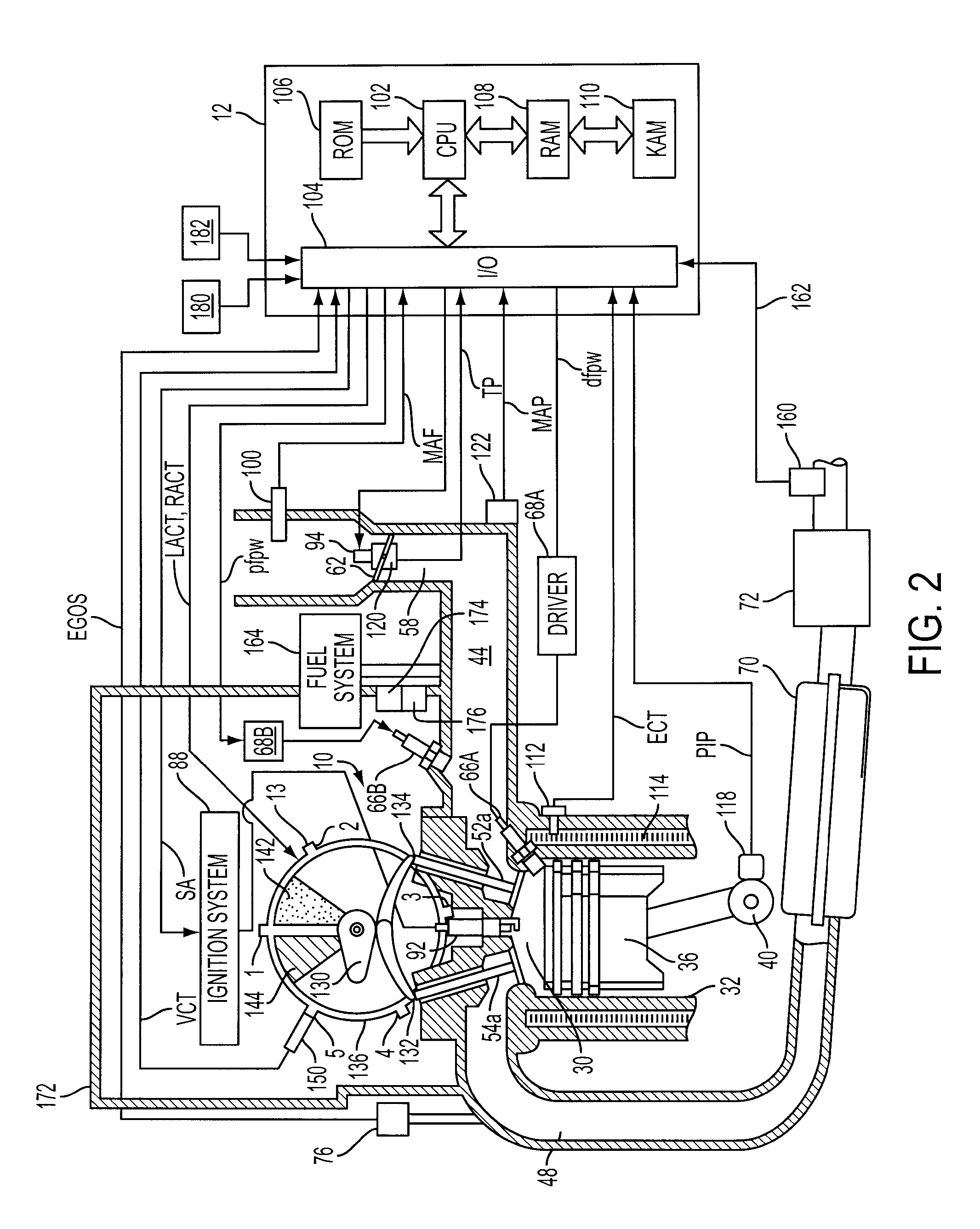

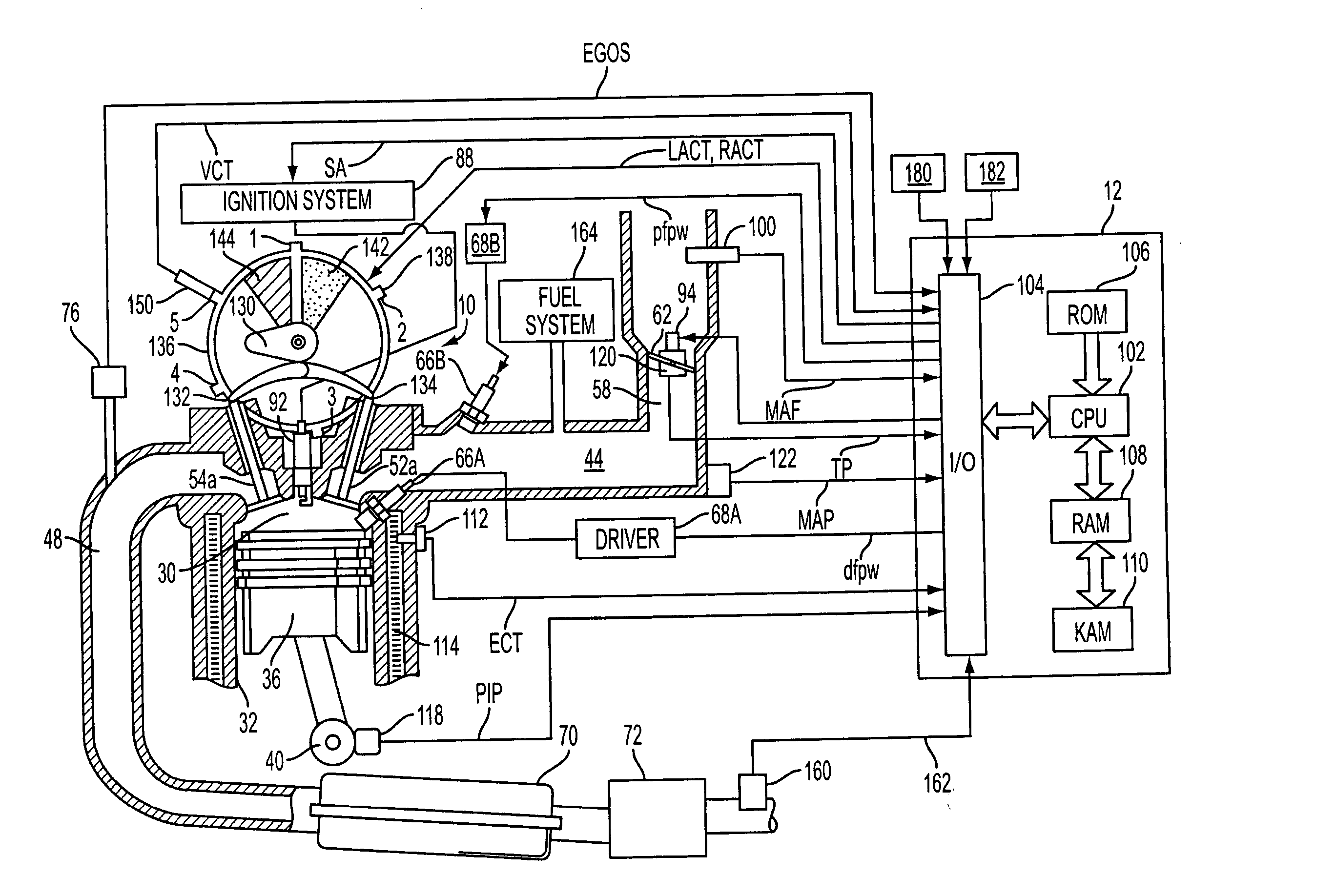

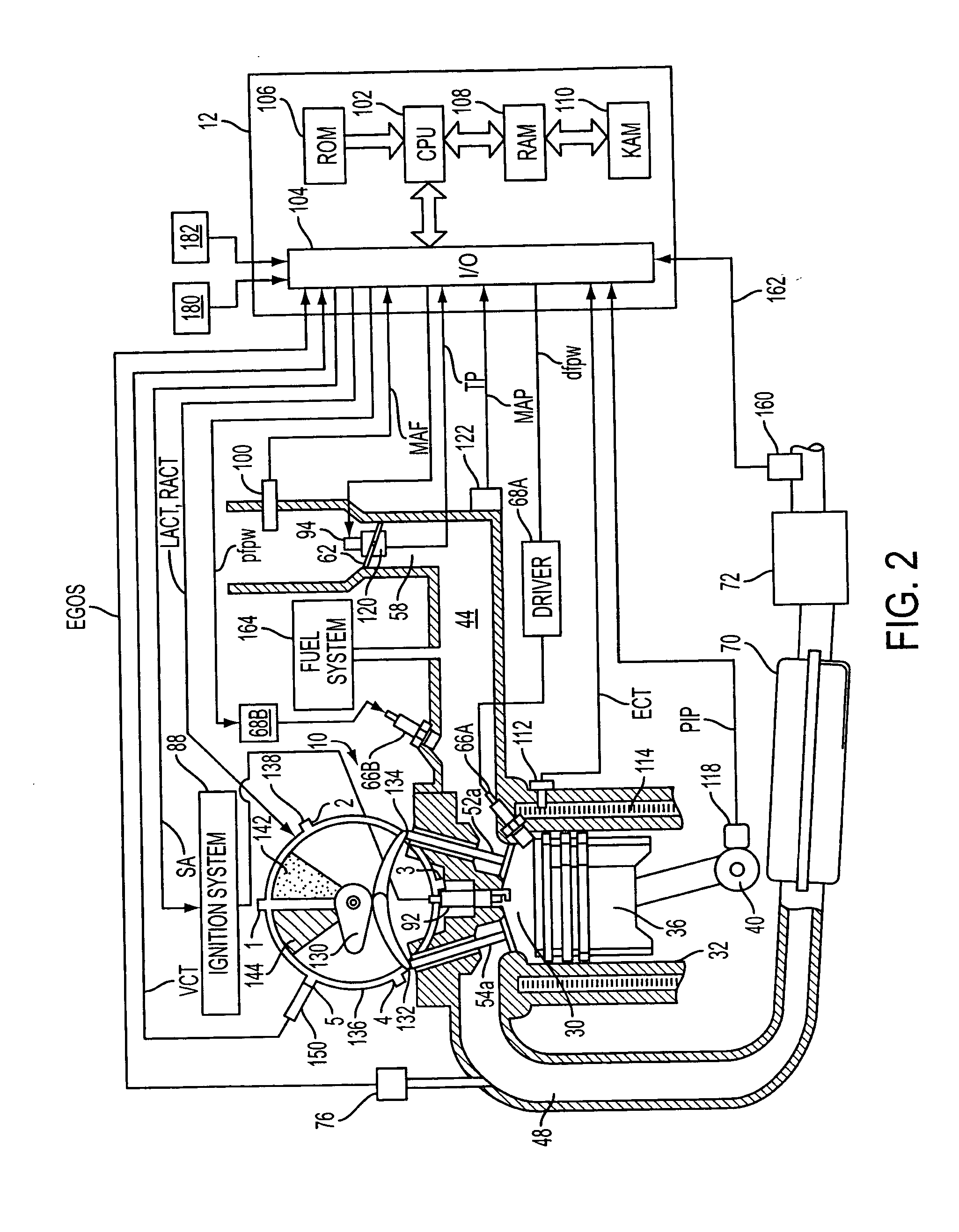

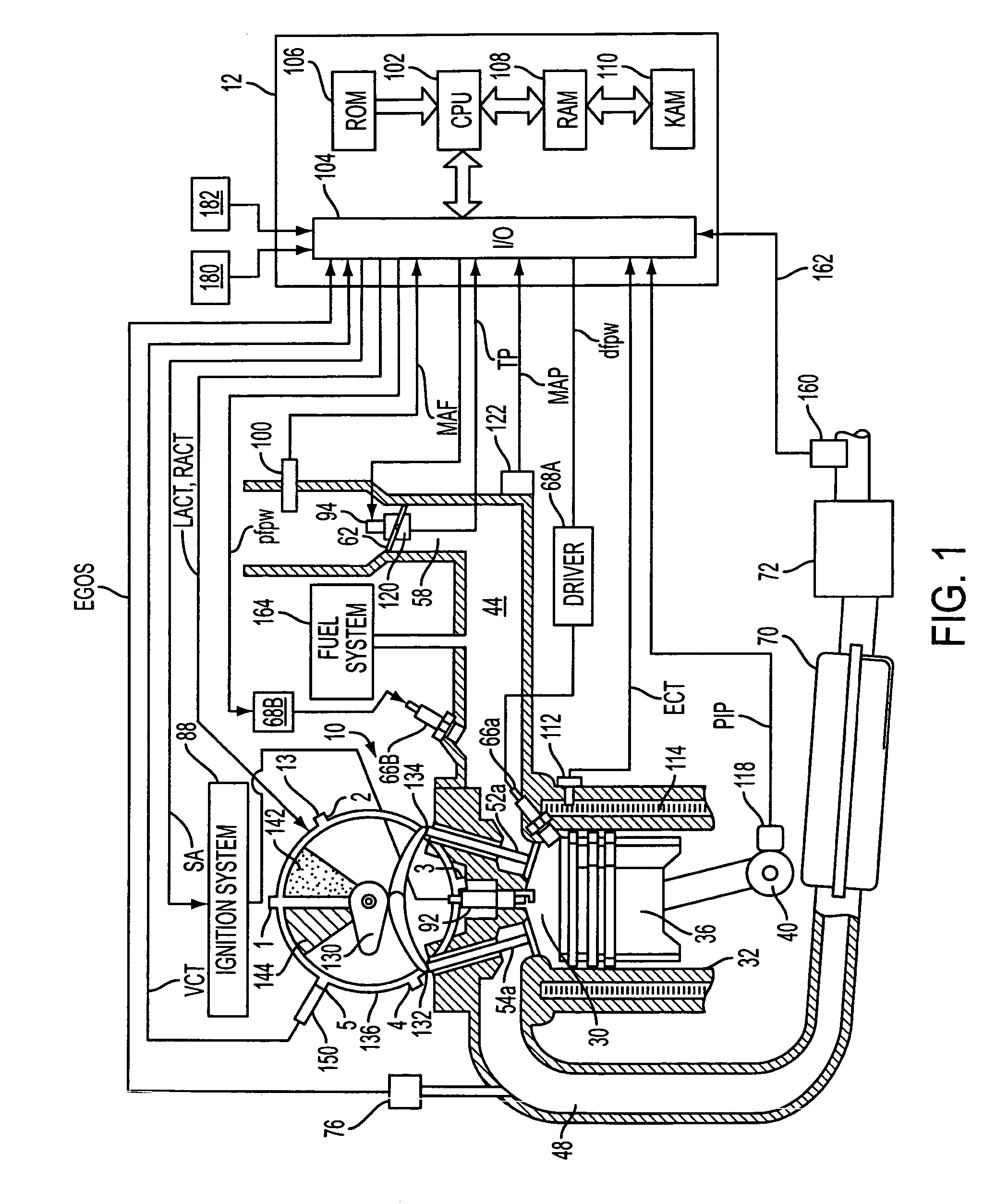

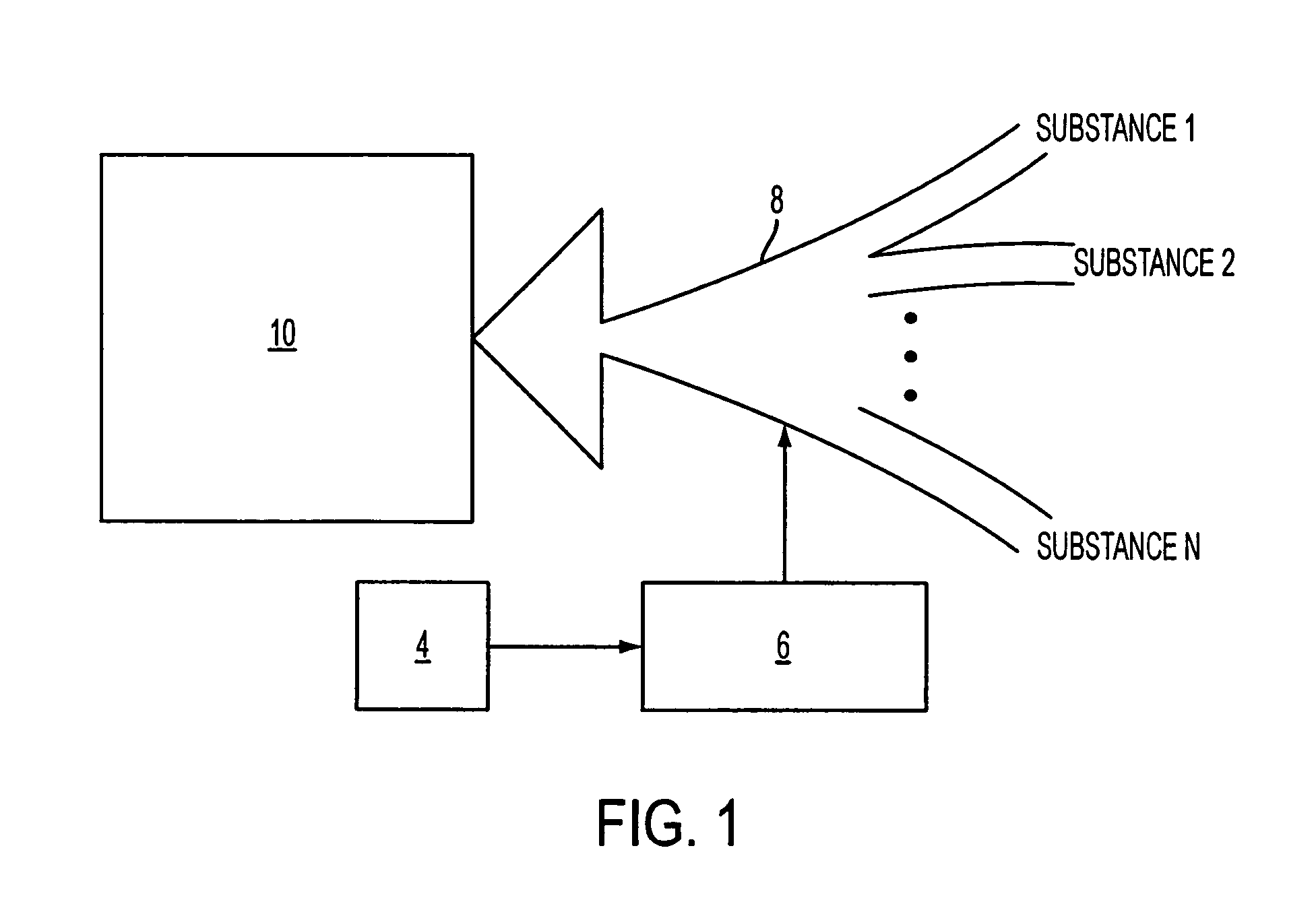

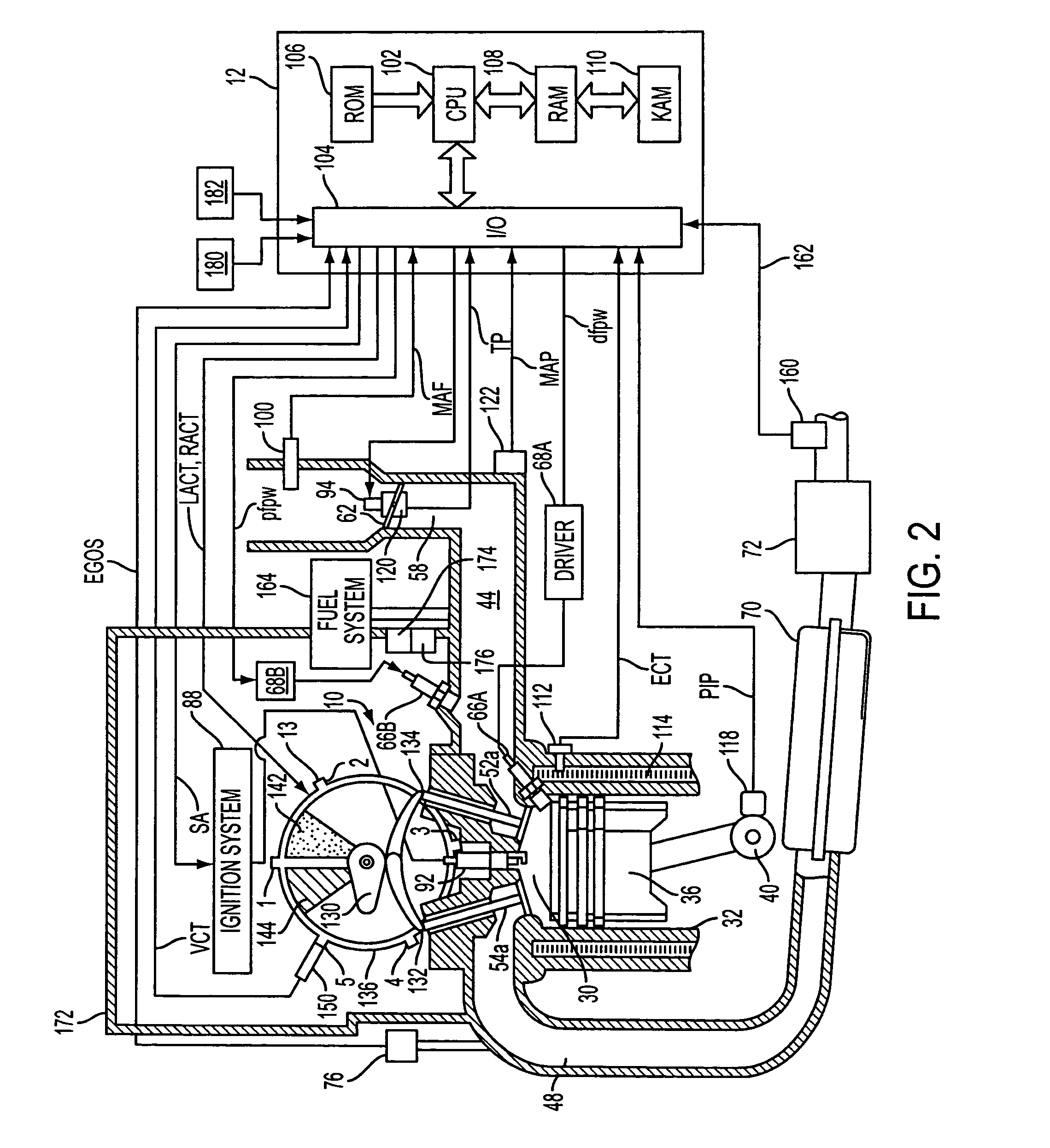

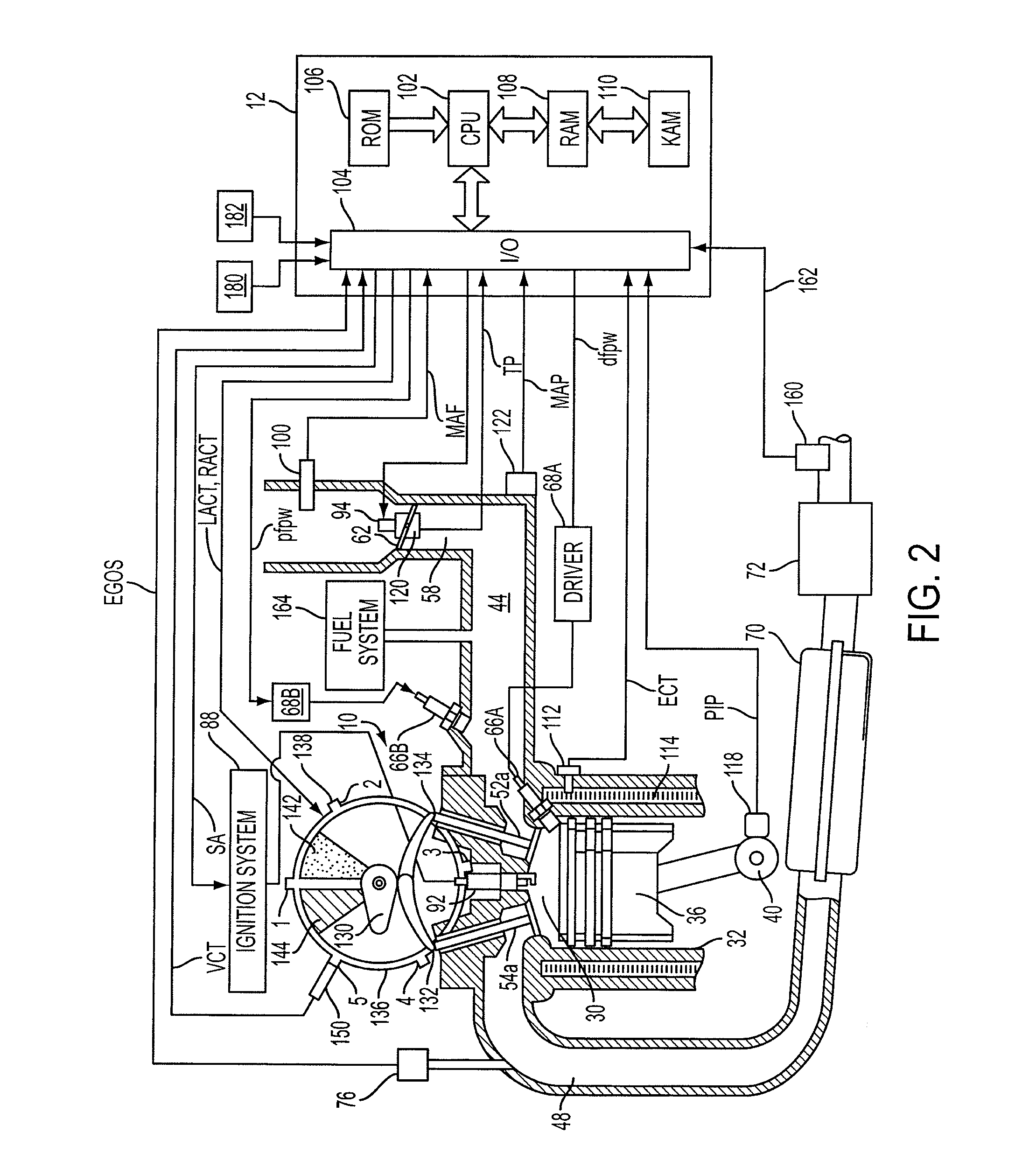

Spark control for improved engine operation

InactiveUS20070215130A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberControl system

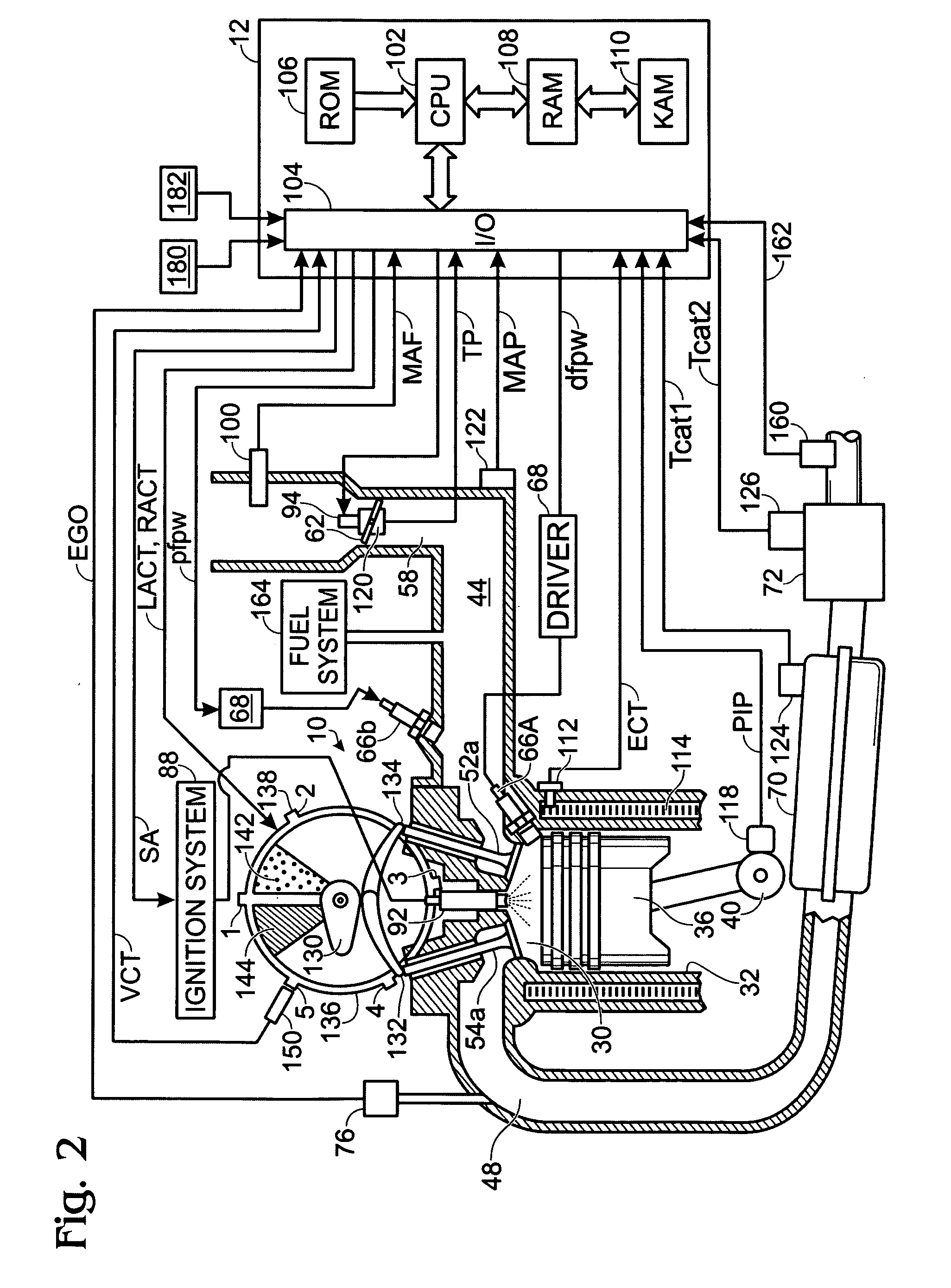

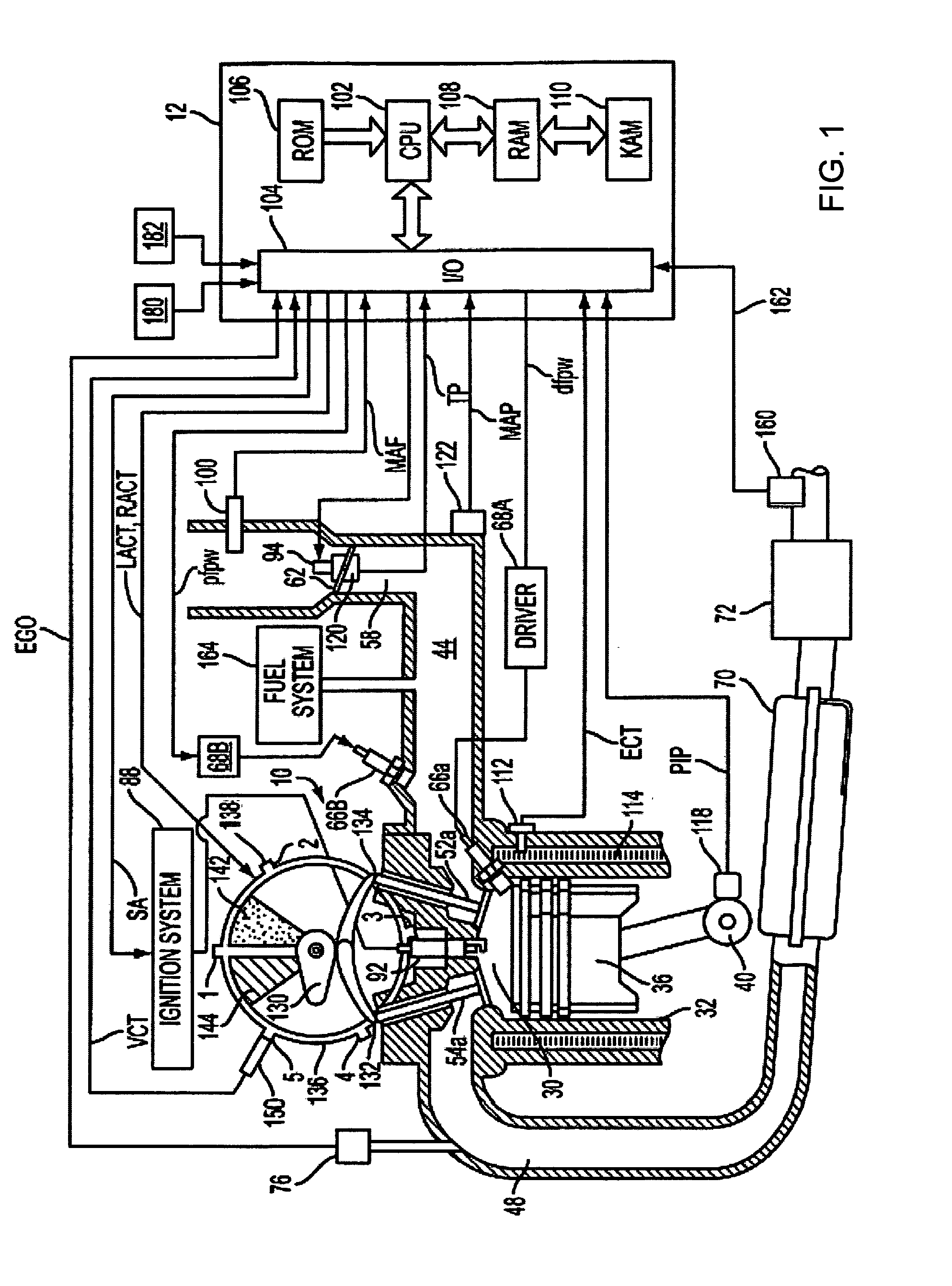

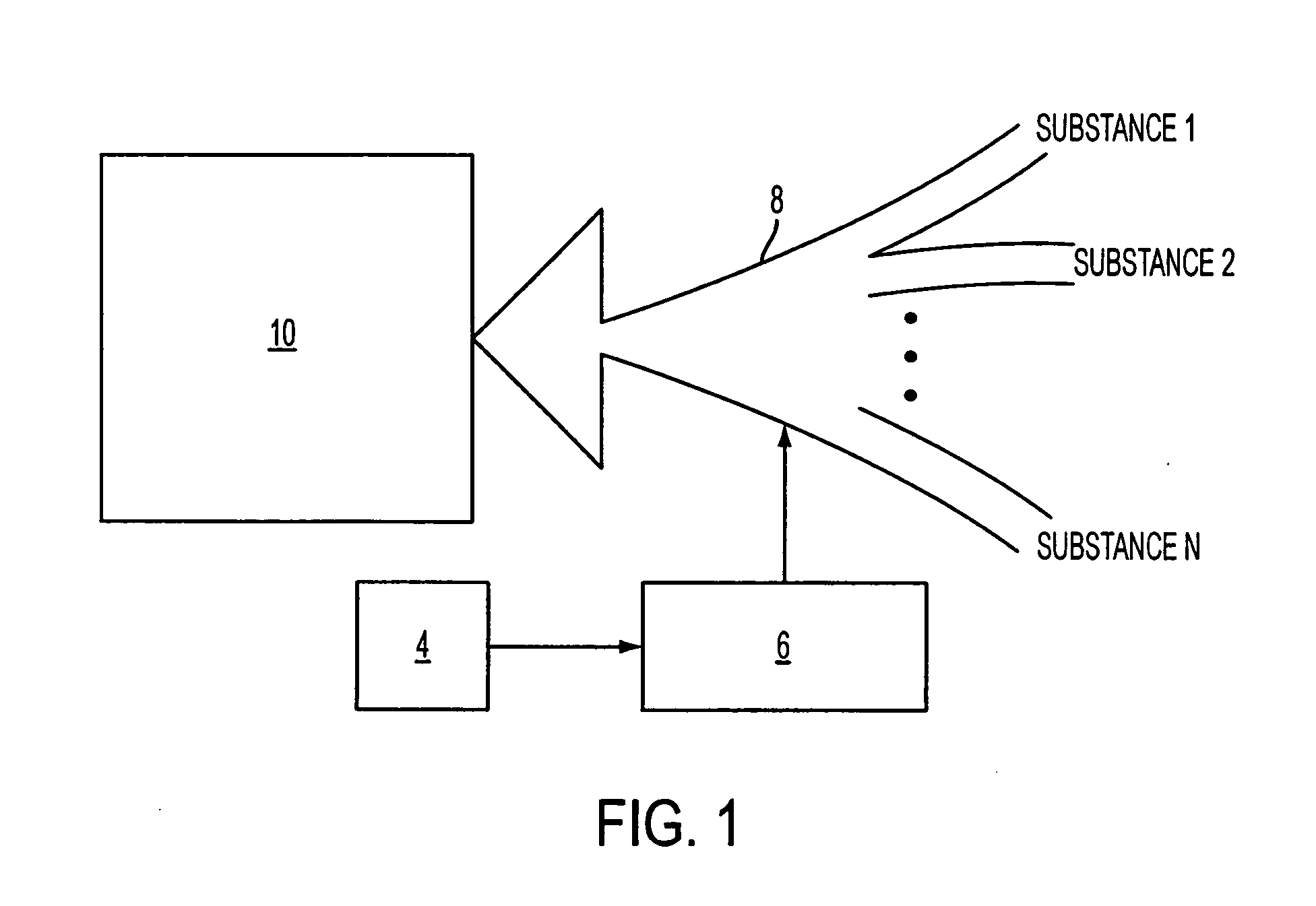

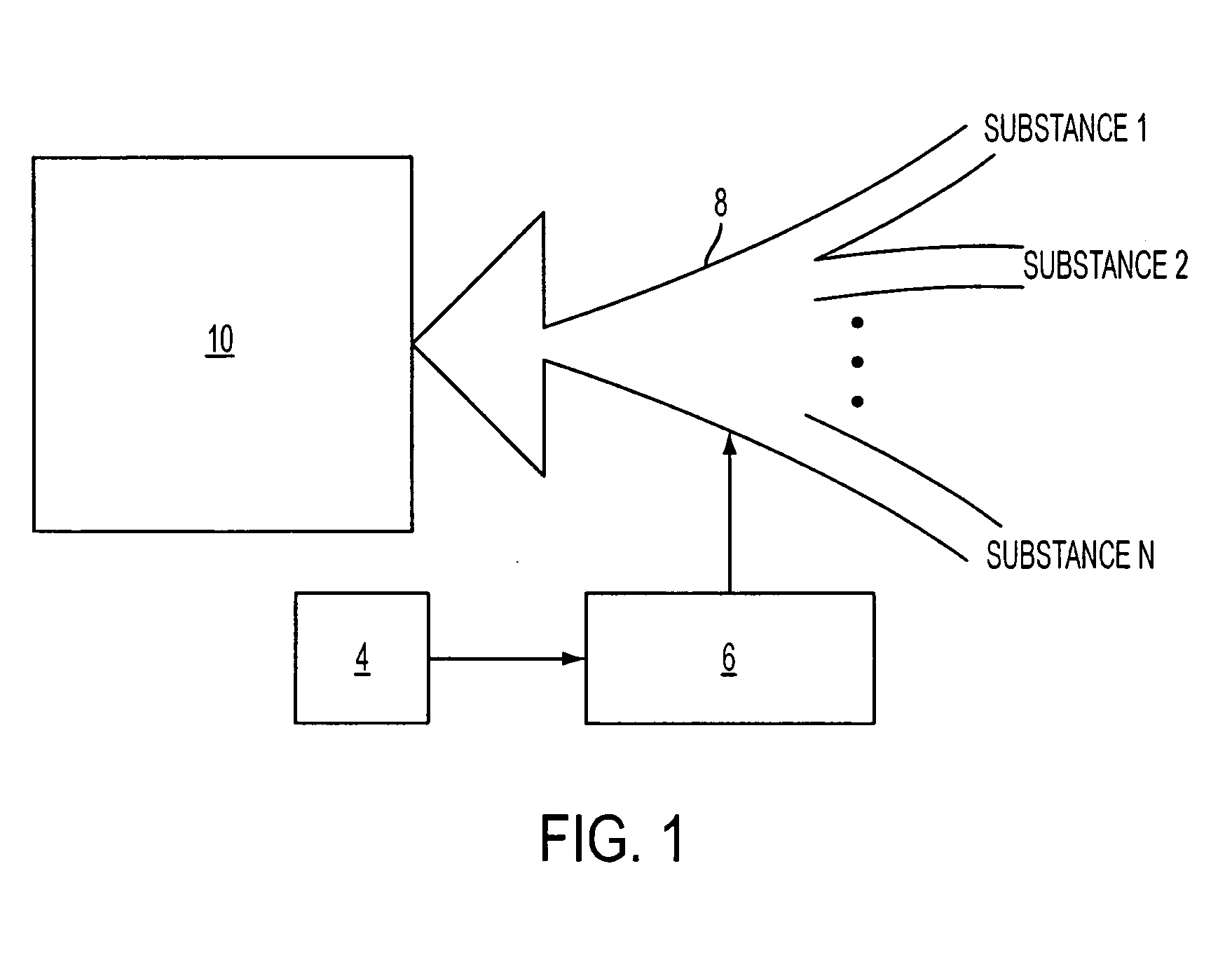

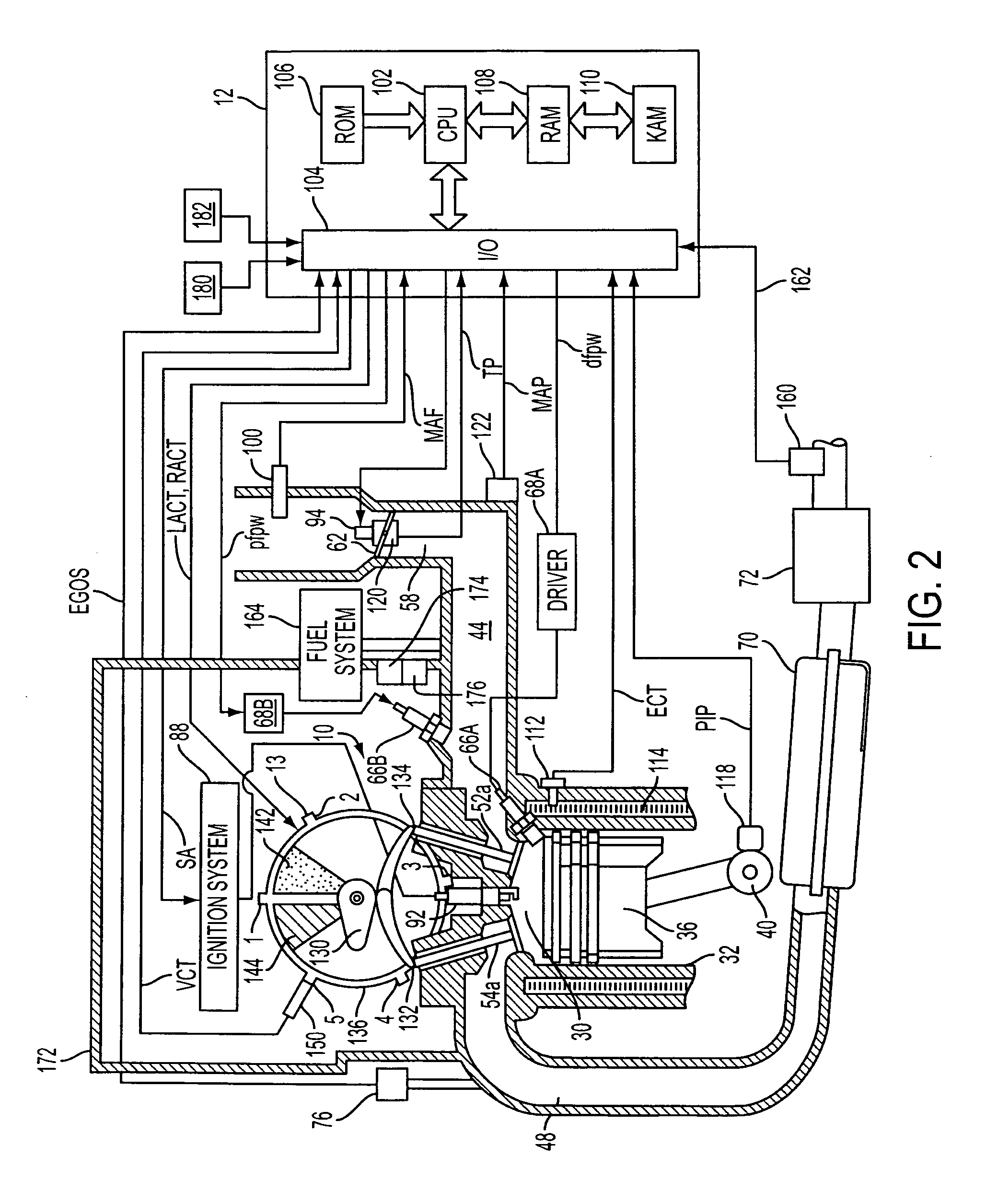

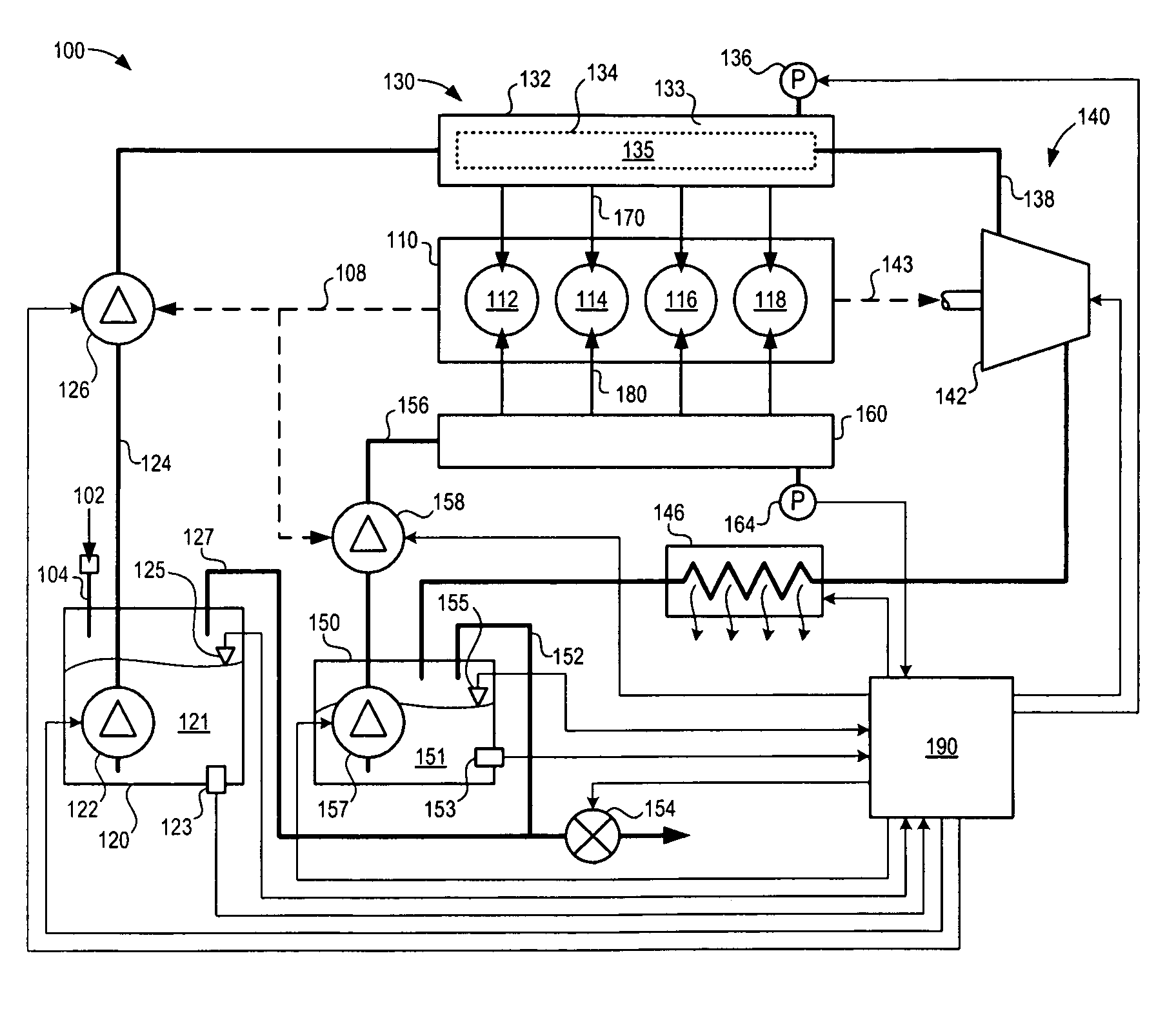

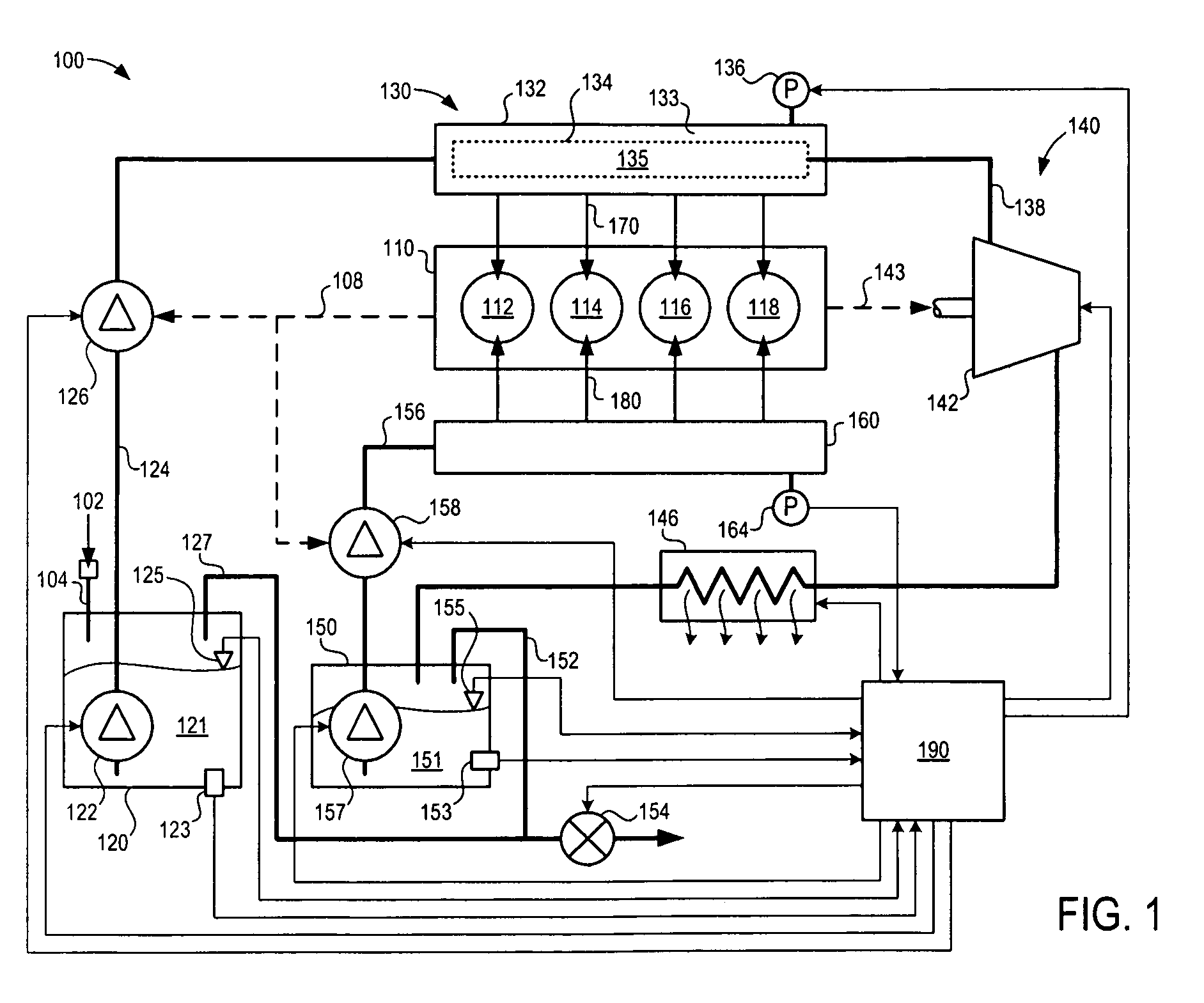

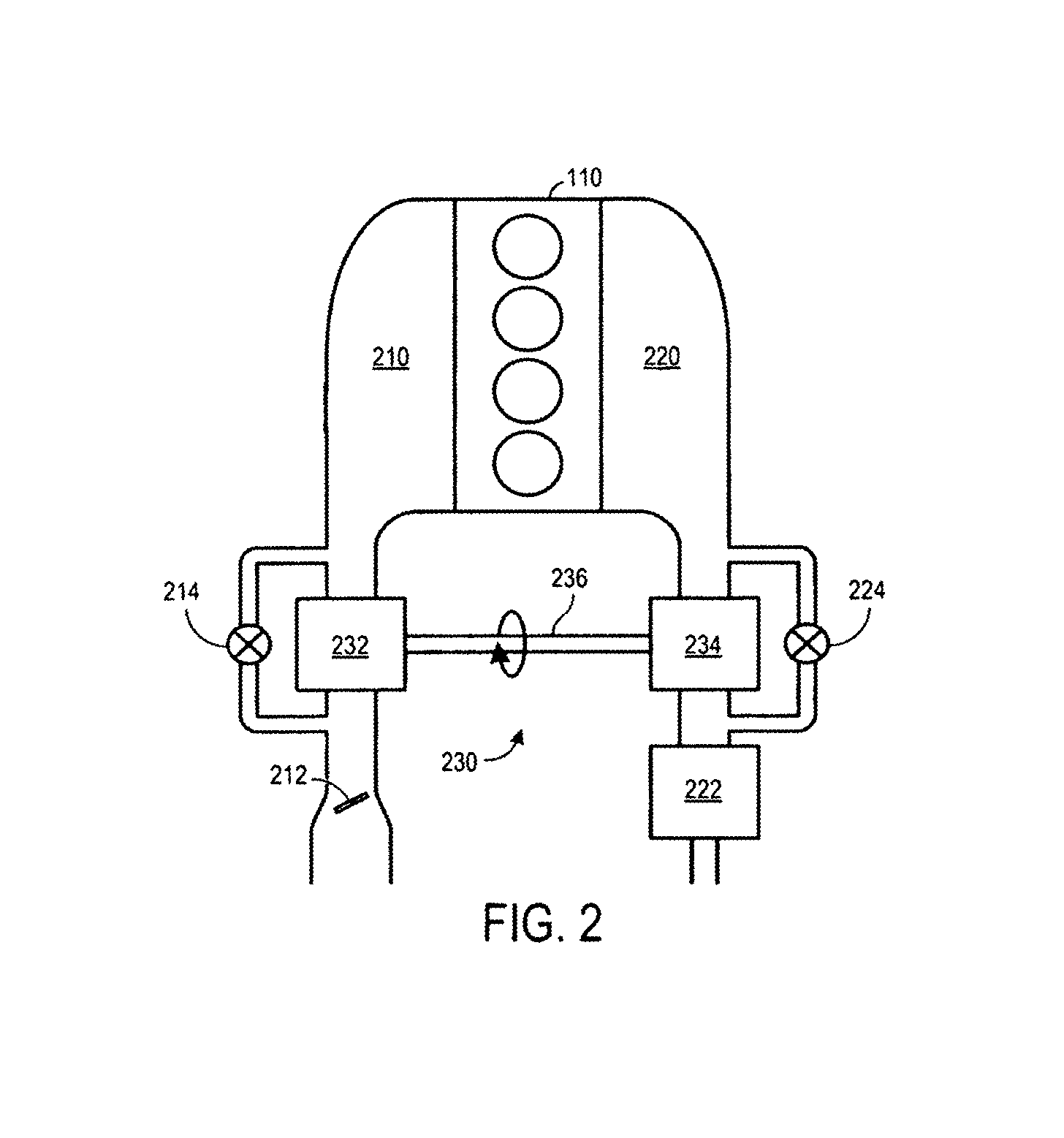

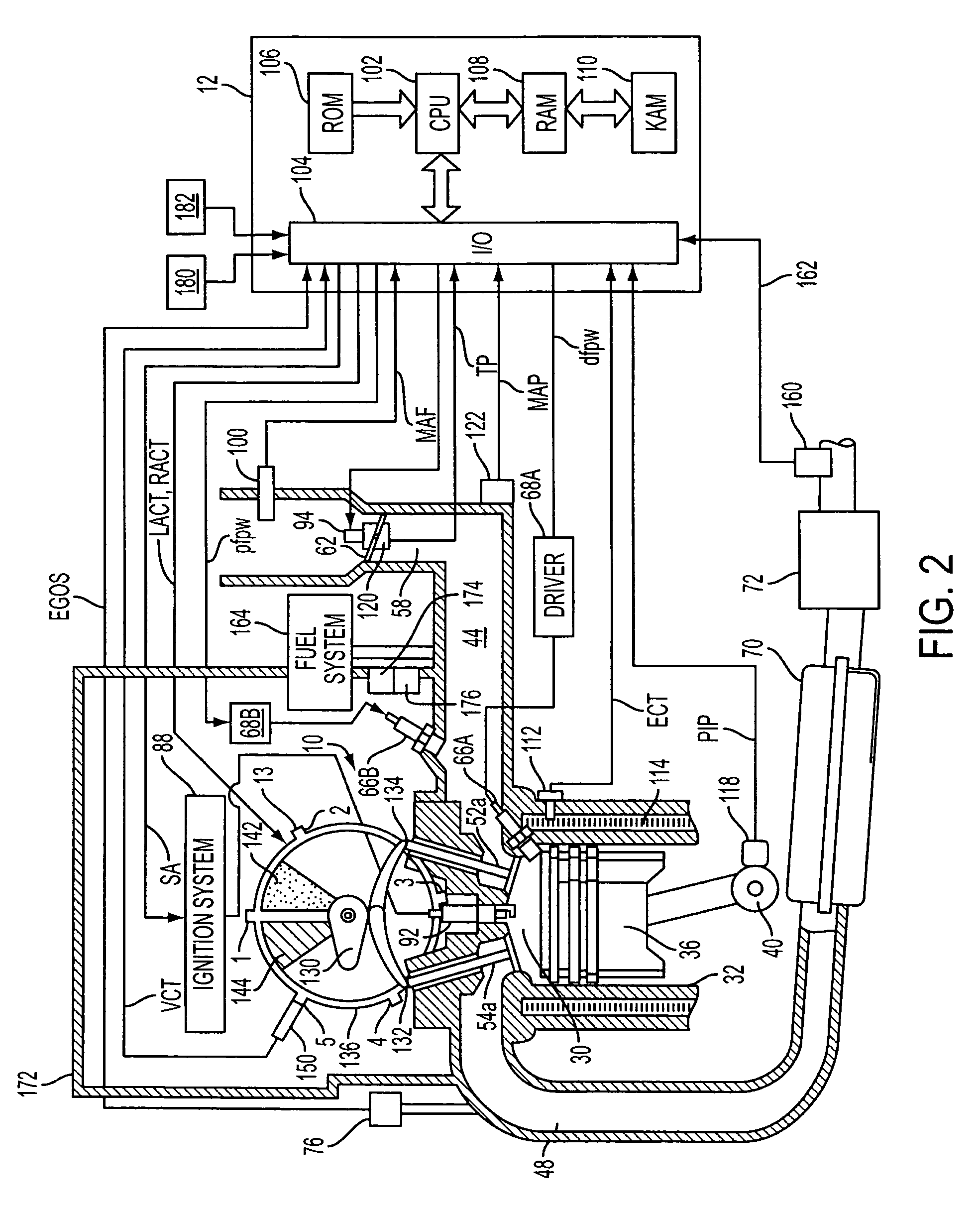

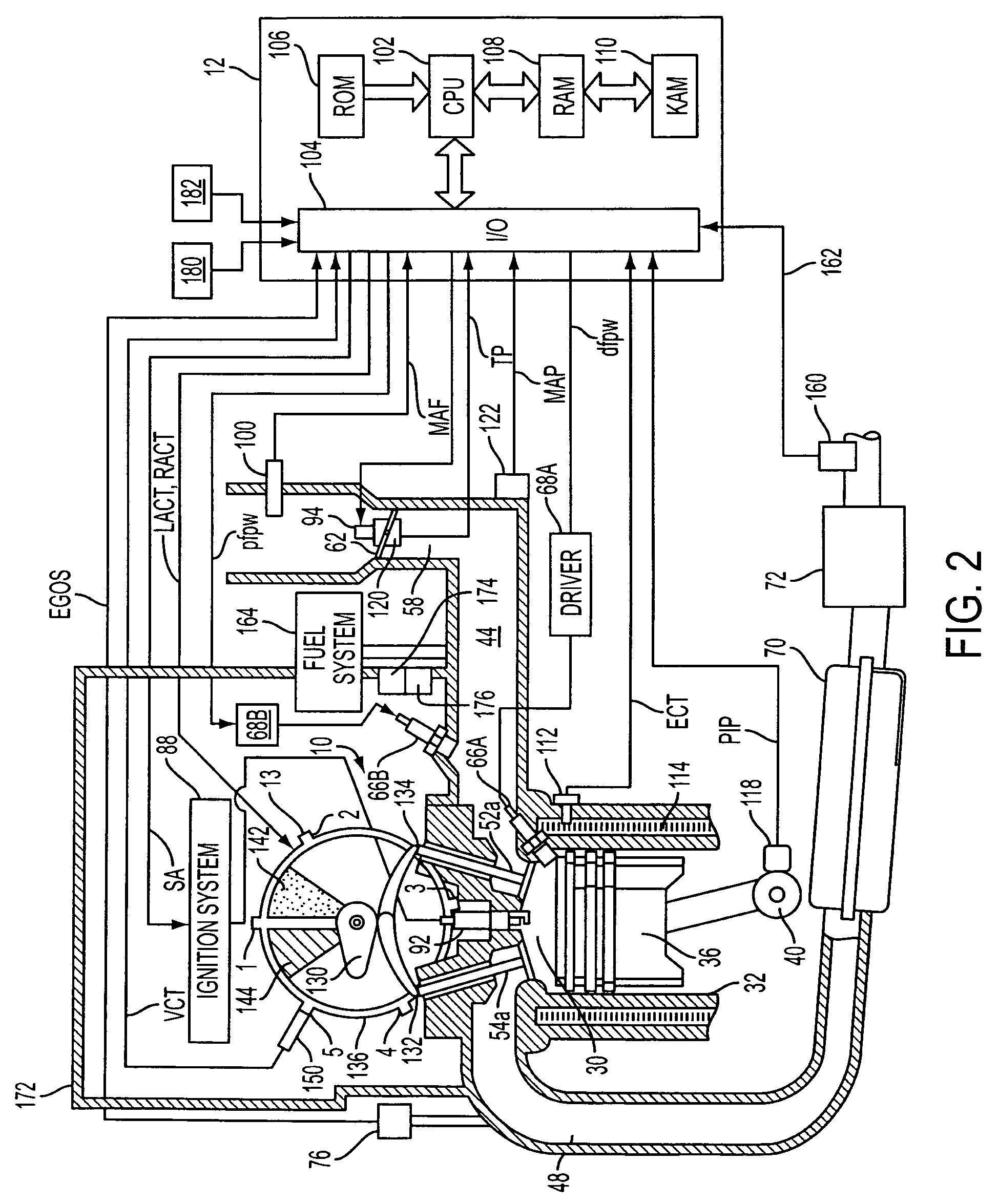

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a substance to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, and a control system configured to vary a number of sparks performed by the spark plug in relation to a combustion event of the combustion chamber responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

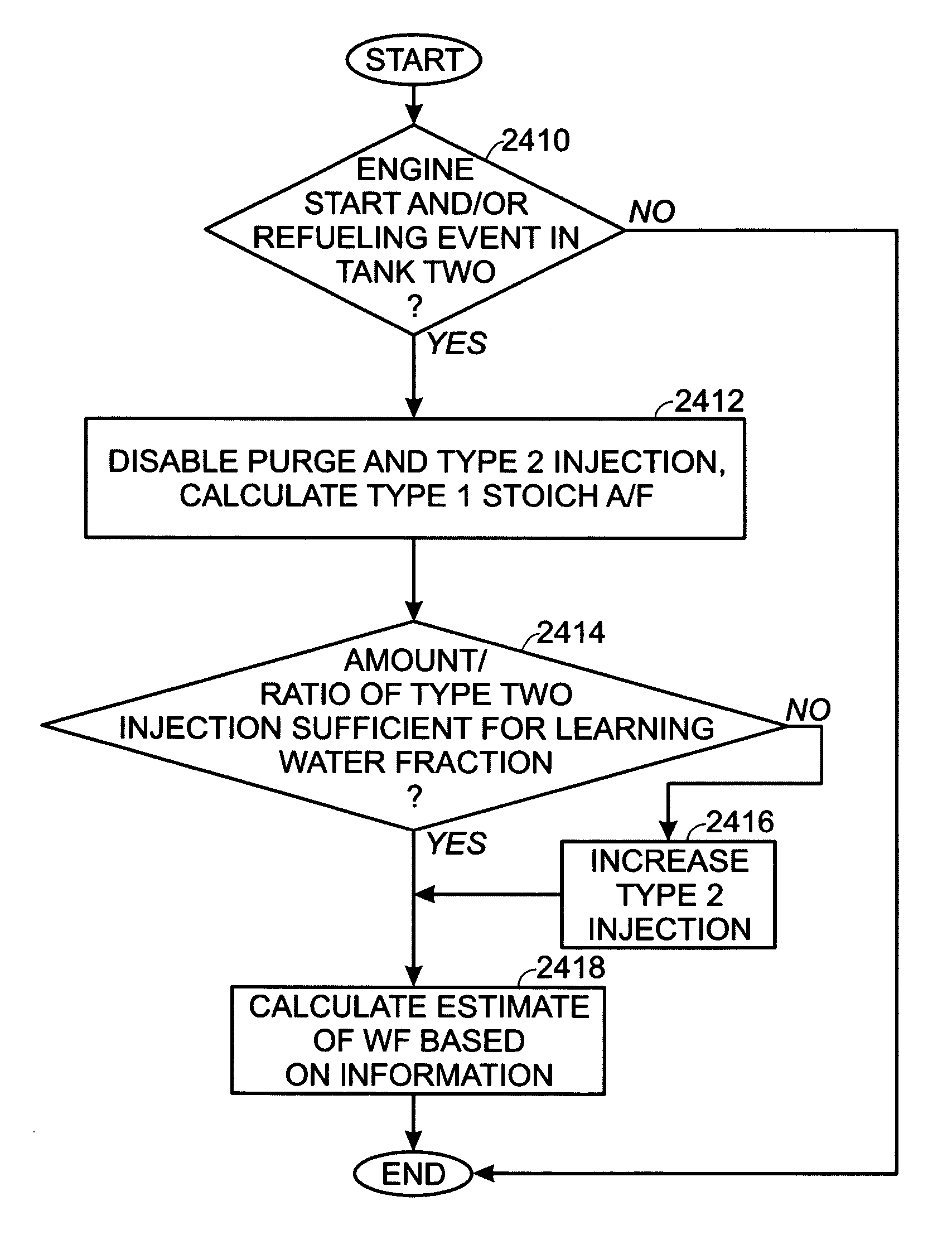

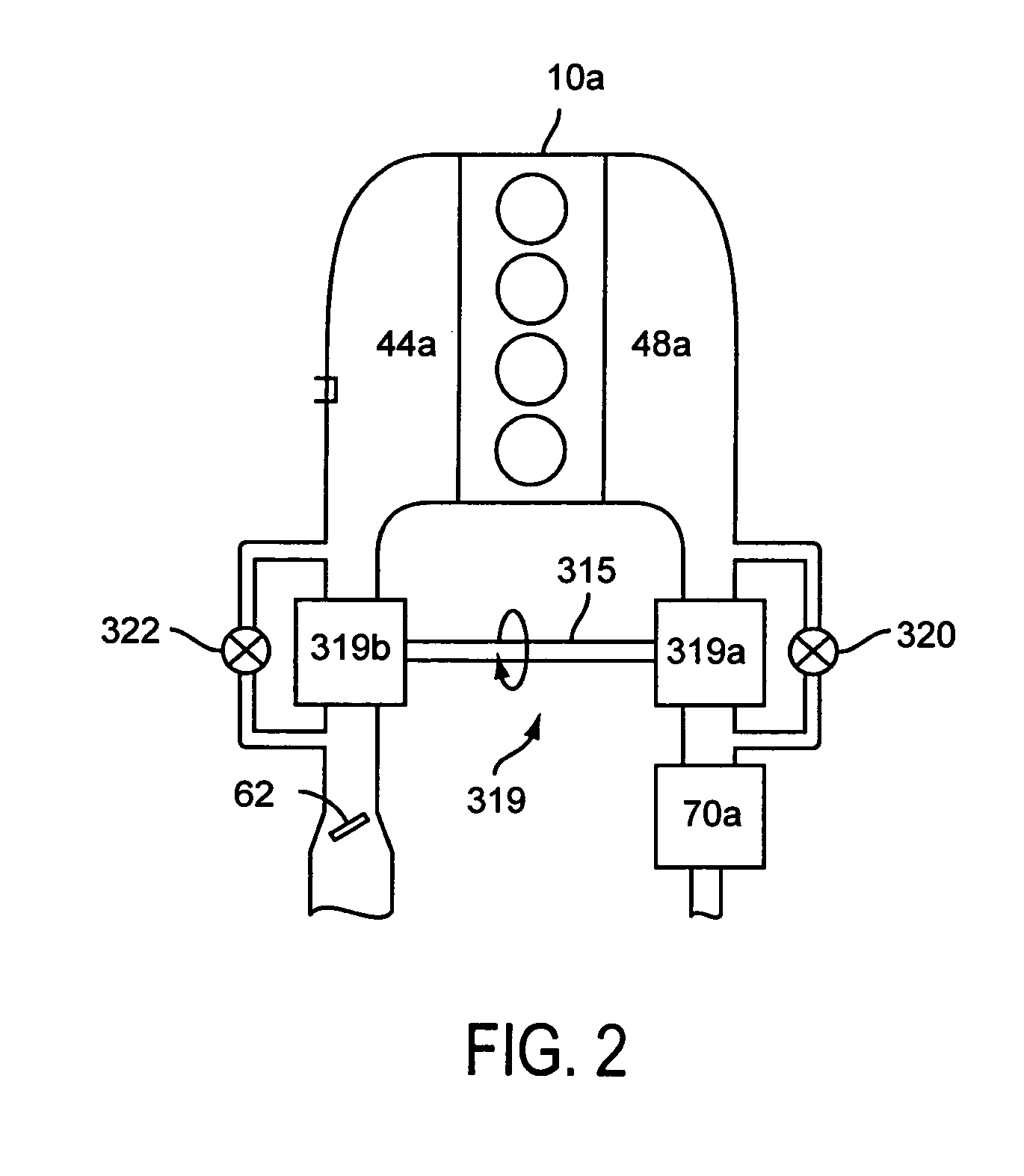

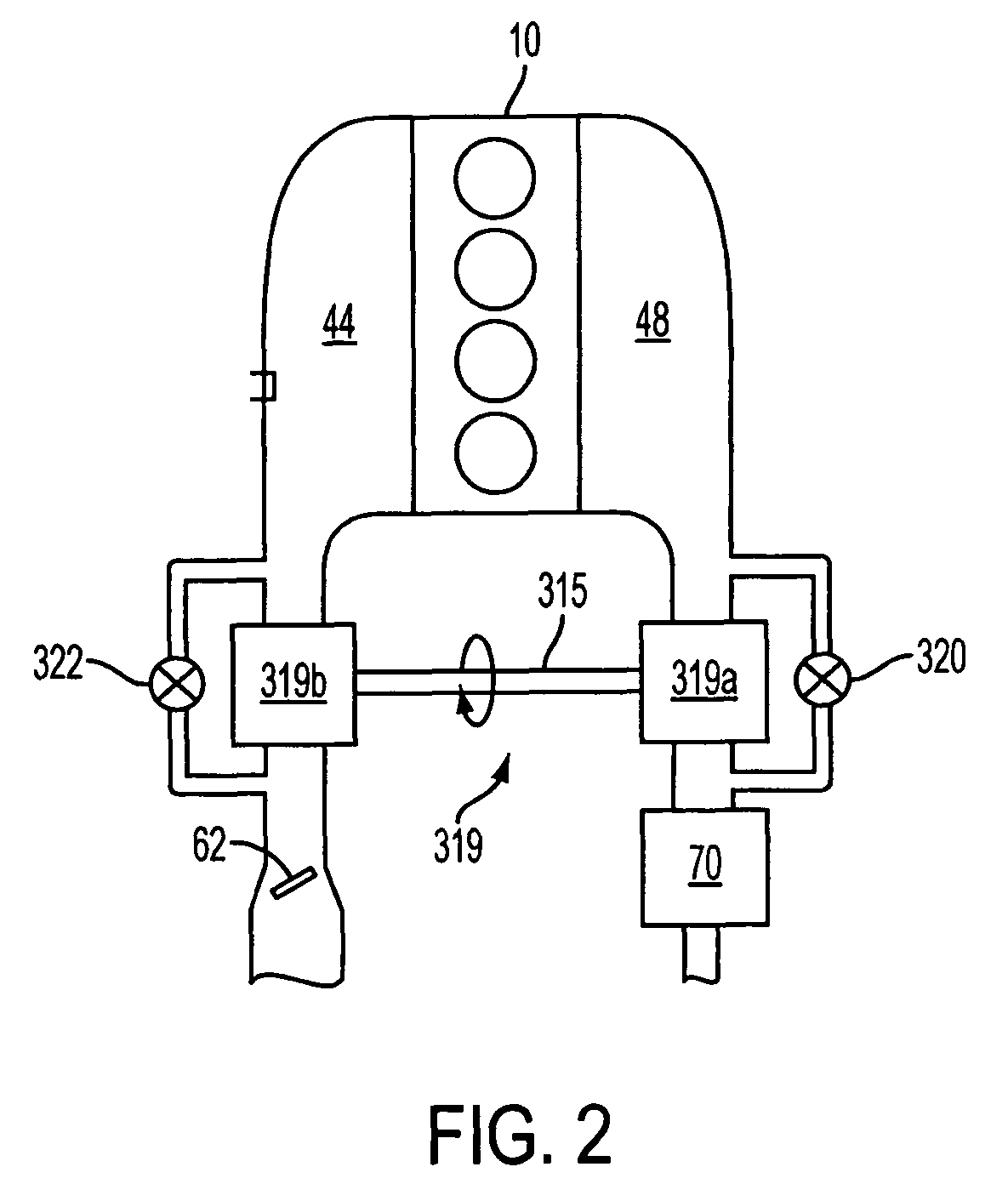

Fuel mass control for ethanol direct injection plus gasoline port fuel injection

ActiveUS20070119394A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesPort fuel injectionOperant conditioning

A system for an engine of a vehicle traveling on the road, comprising of a cylinder located in the engine, a delivery system configured to delivery fuel and a fluid to at least an engine cylinder of the while the vehicle is traveling on the road, said fluid containing at least some water, and a controller for varying an engine operating parameter based on an amount of water in said fluid, where said amount is determined based on an operating condition.

Owner:FORD GLOBAL TECH LLC

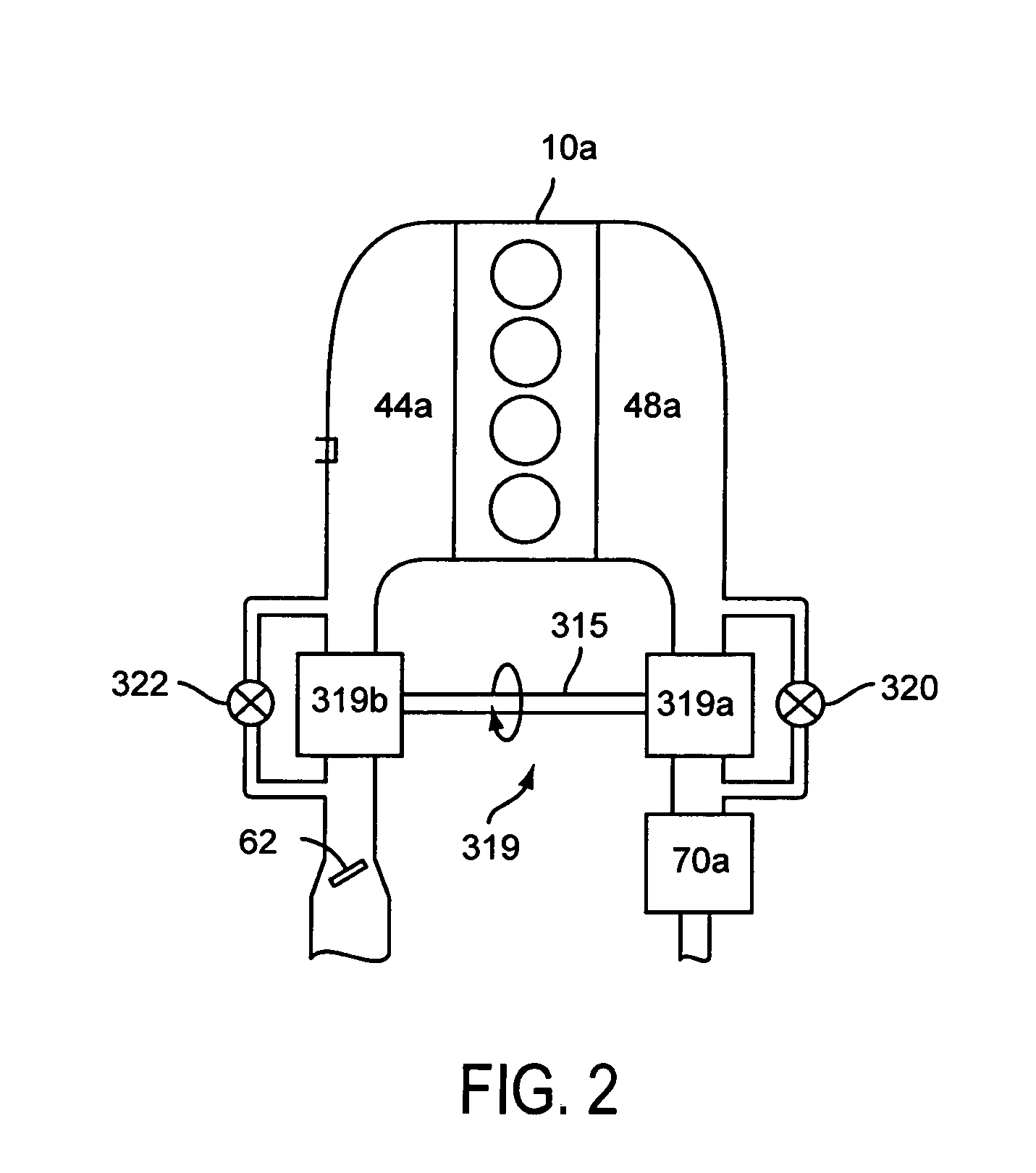

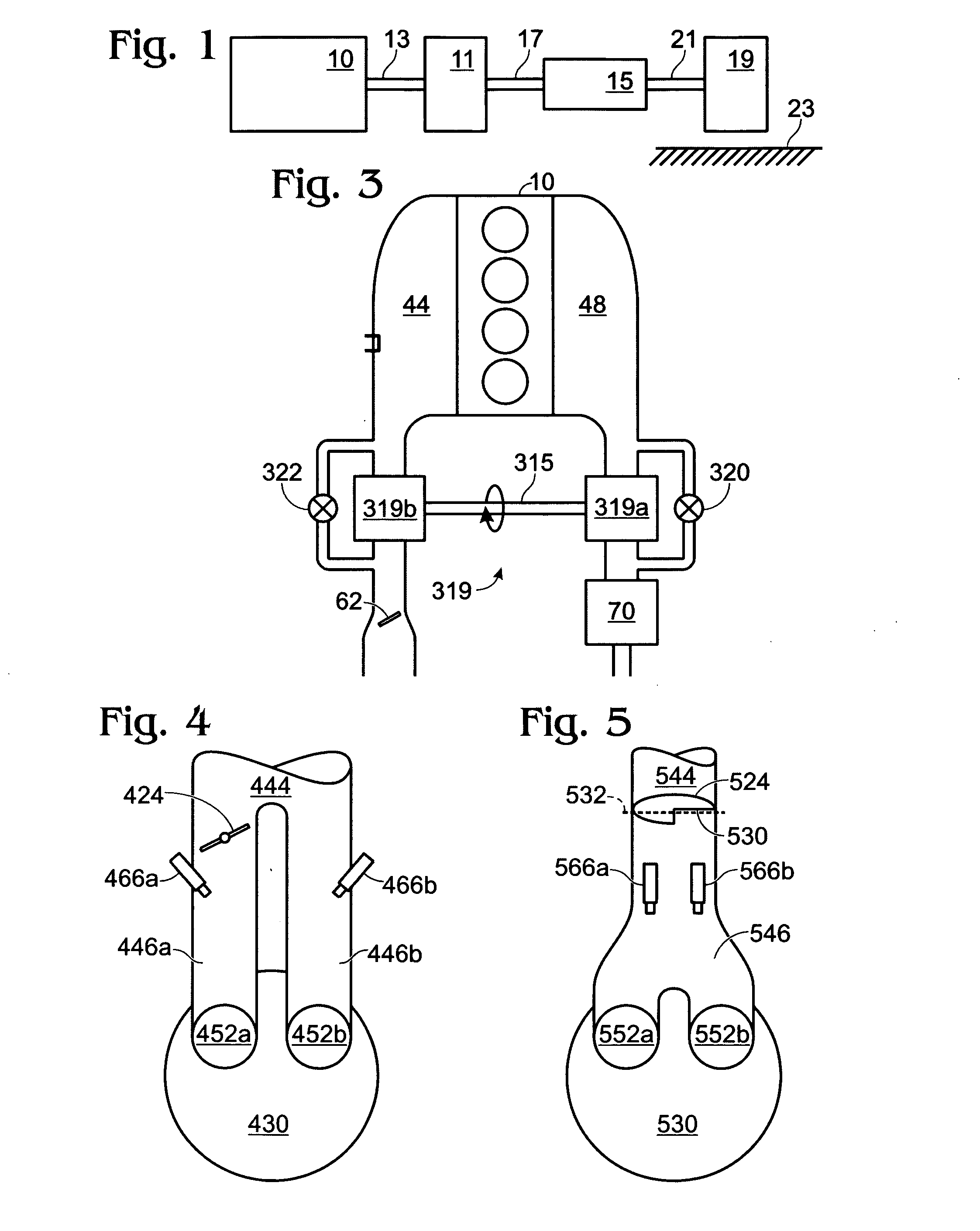

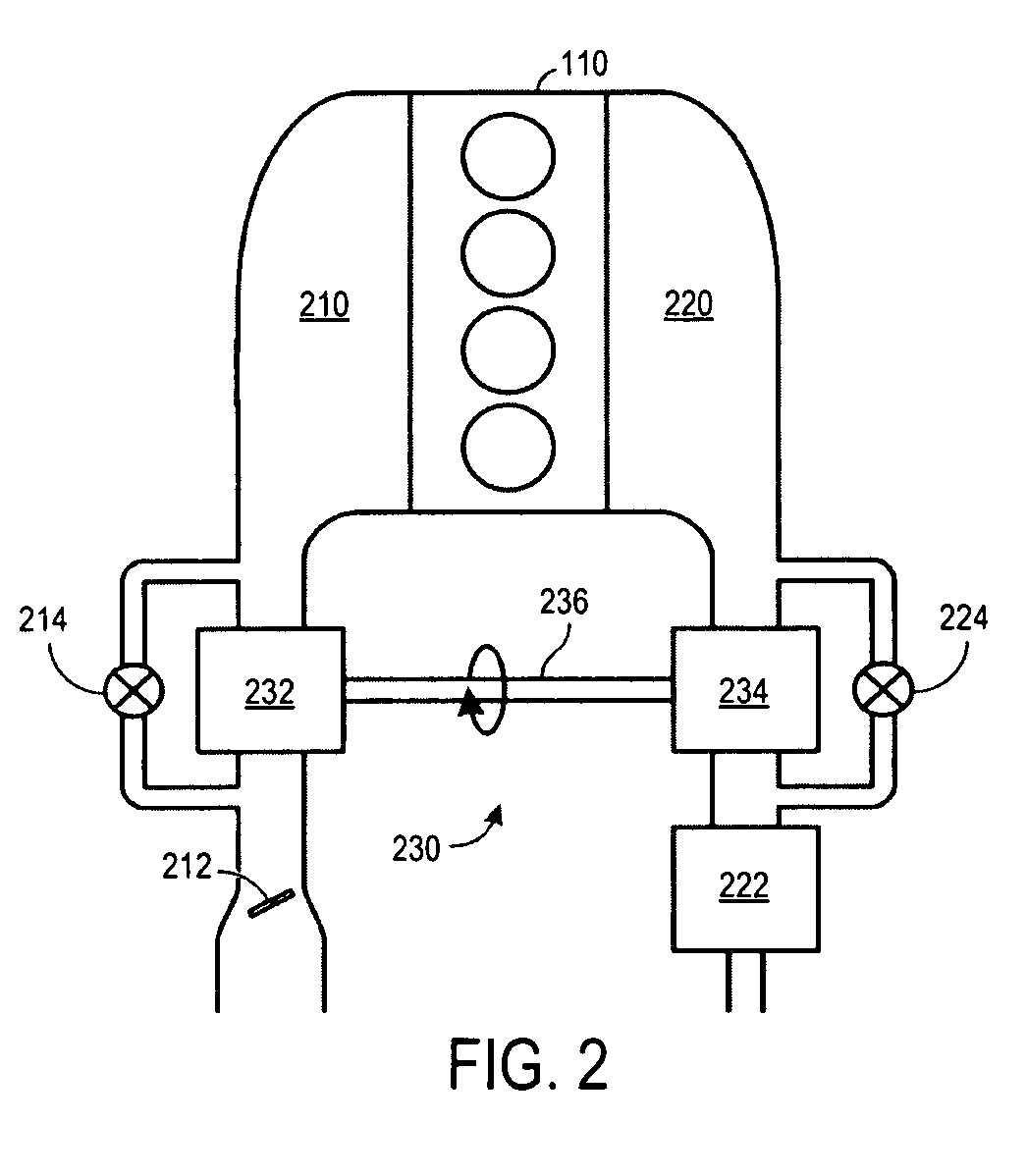

First and second spark plugs for improved combustion control

InactiveUS20070215102A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberHydrocotyle bowlesioides

An engine system, comprising of a combustion chamber; a first spark plug configured to perform a spark within the combustion chamber, said first plug configured to have a first heat range; a second spark plug configured to produce a spark within the combustion chamber, said second plug configured to have a second heat range different from said first heat range of said first plug; and a delivery system configured to deliver a hydrocarbon fuel and a fluid including an alcohol to the combustion chamber in varying resulting ratios.

Owner:FORD GLOBAL TECH LLC

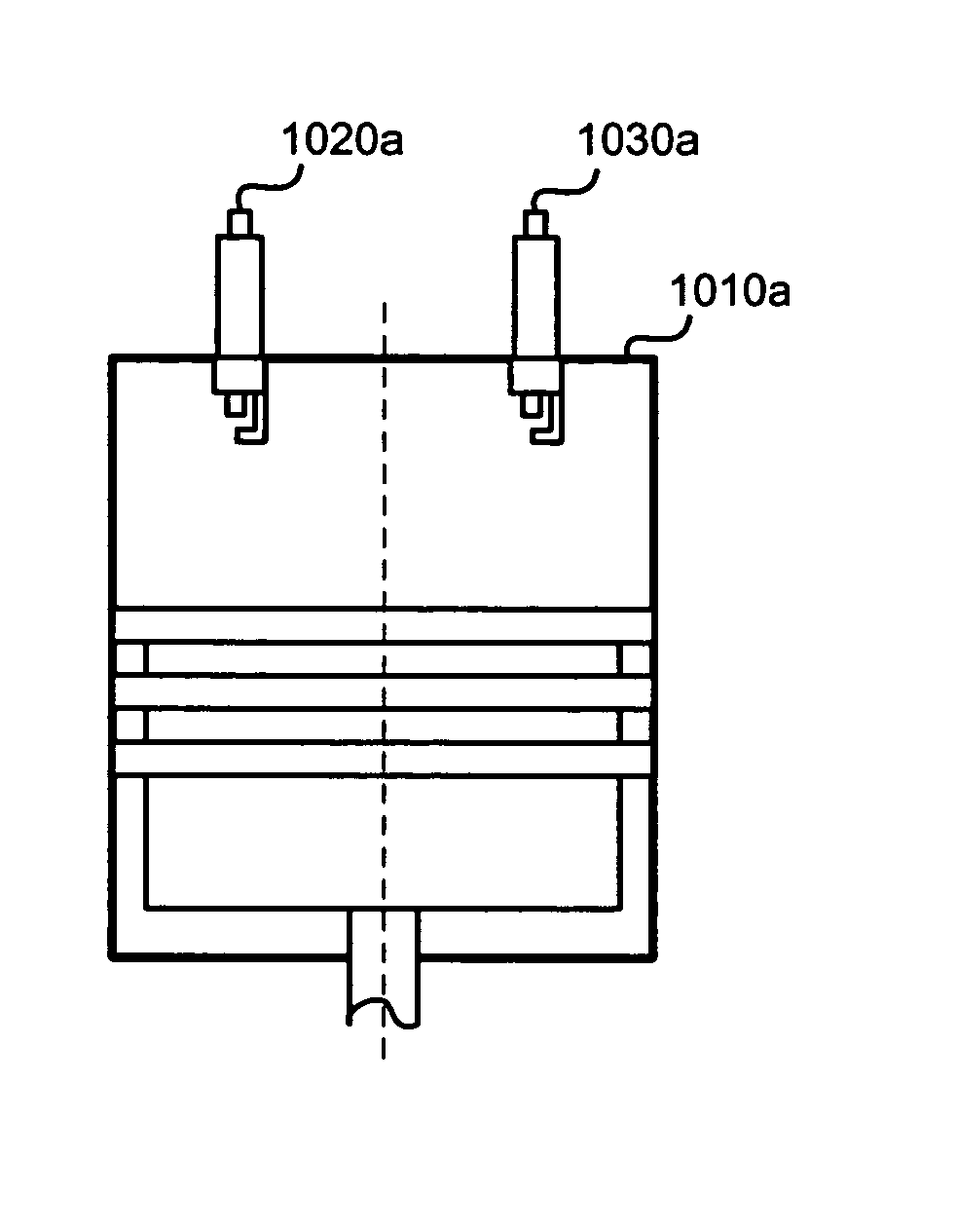

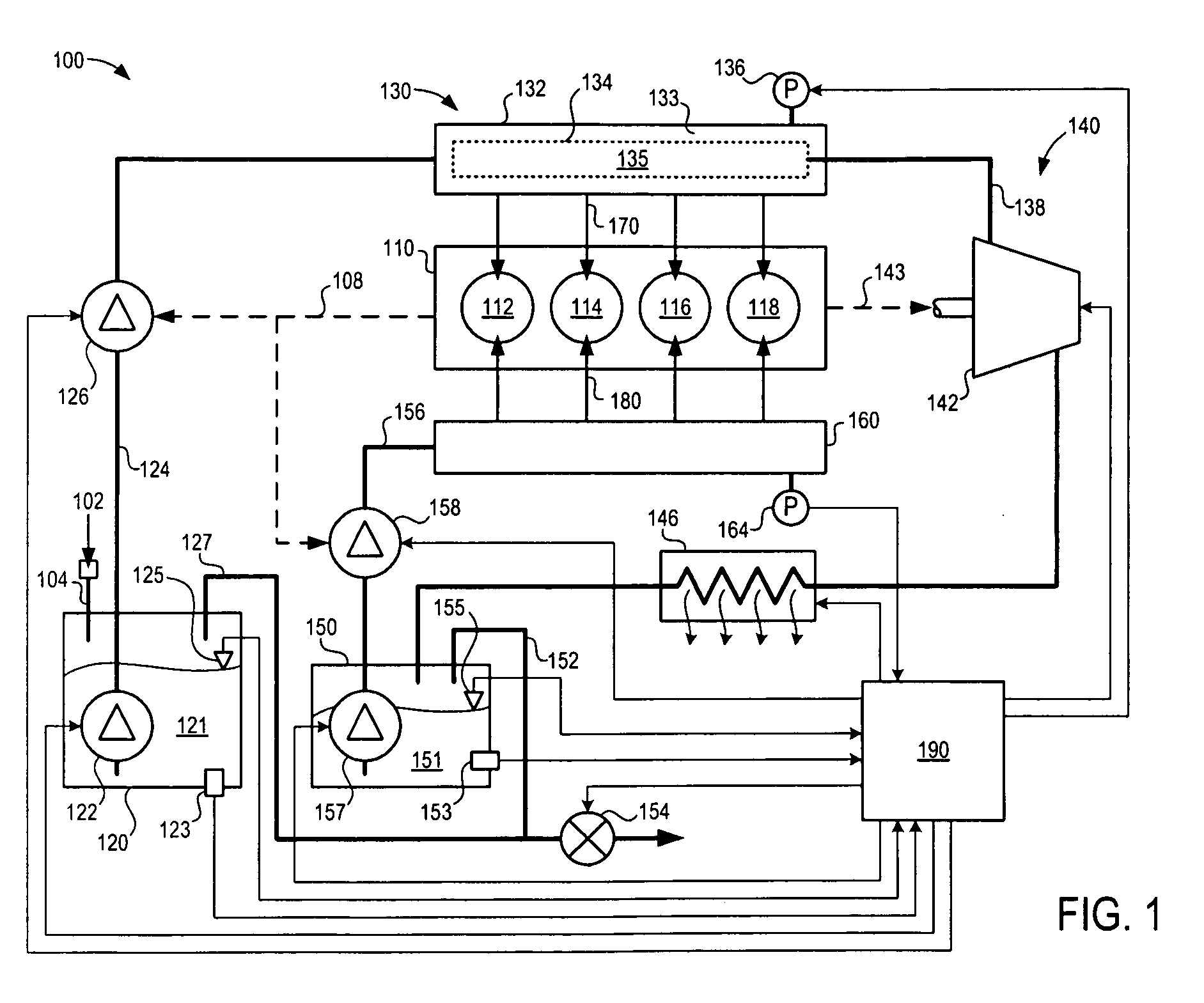

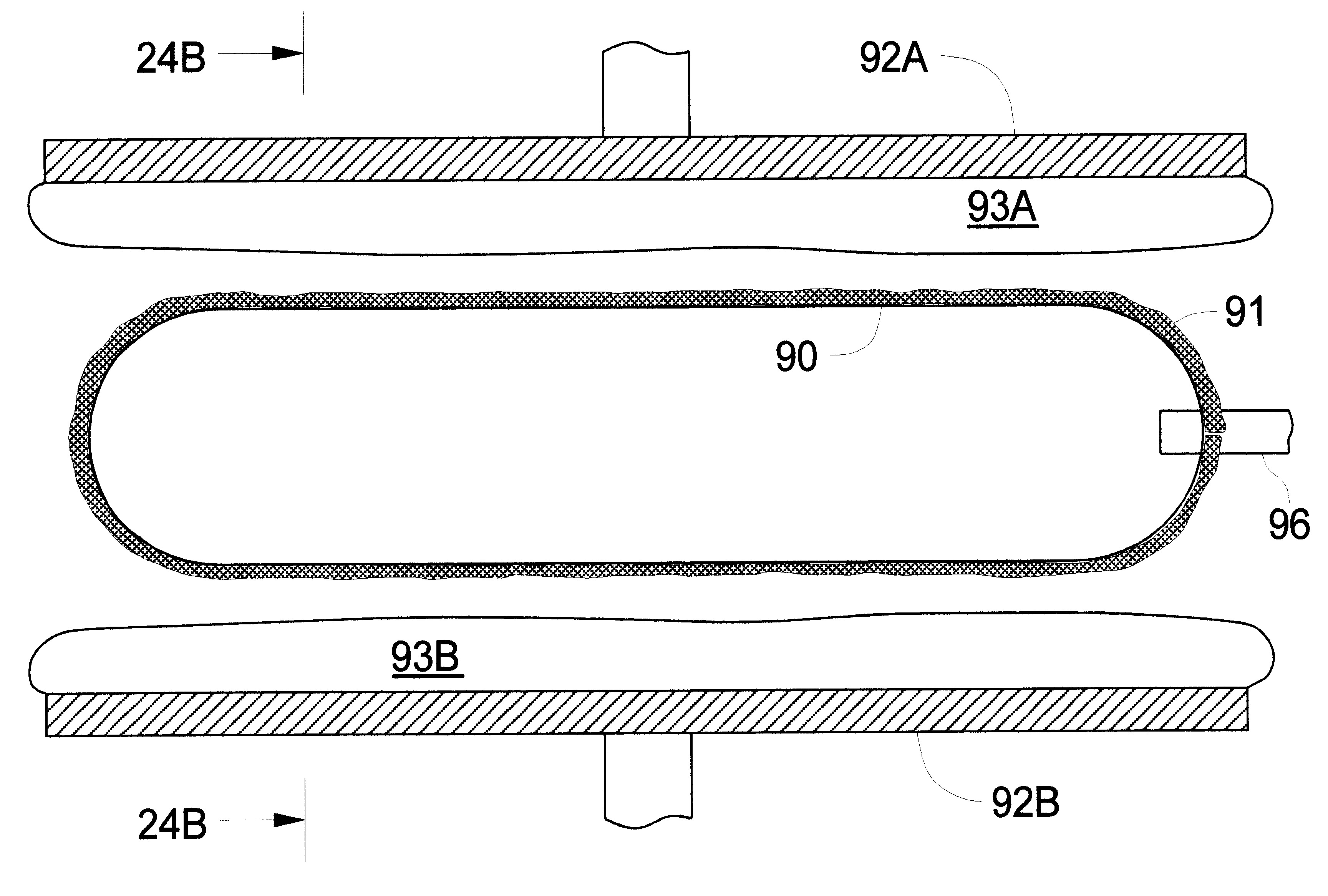

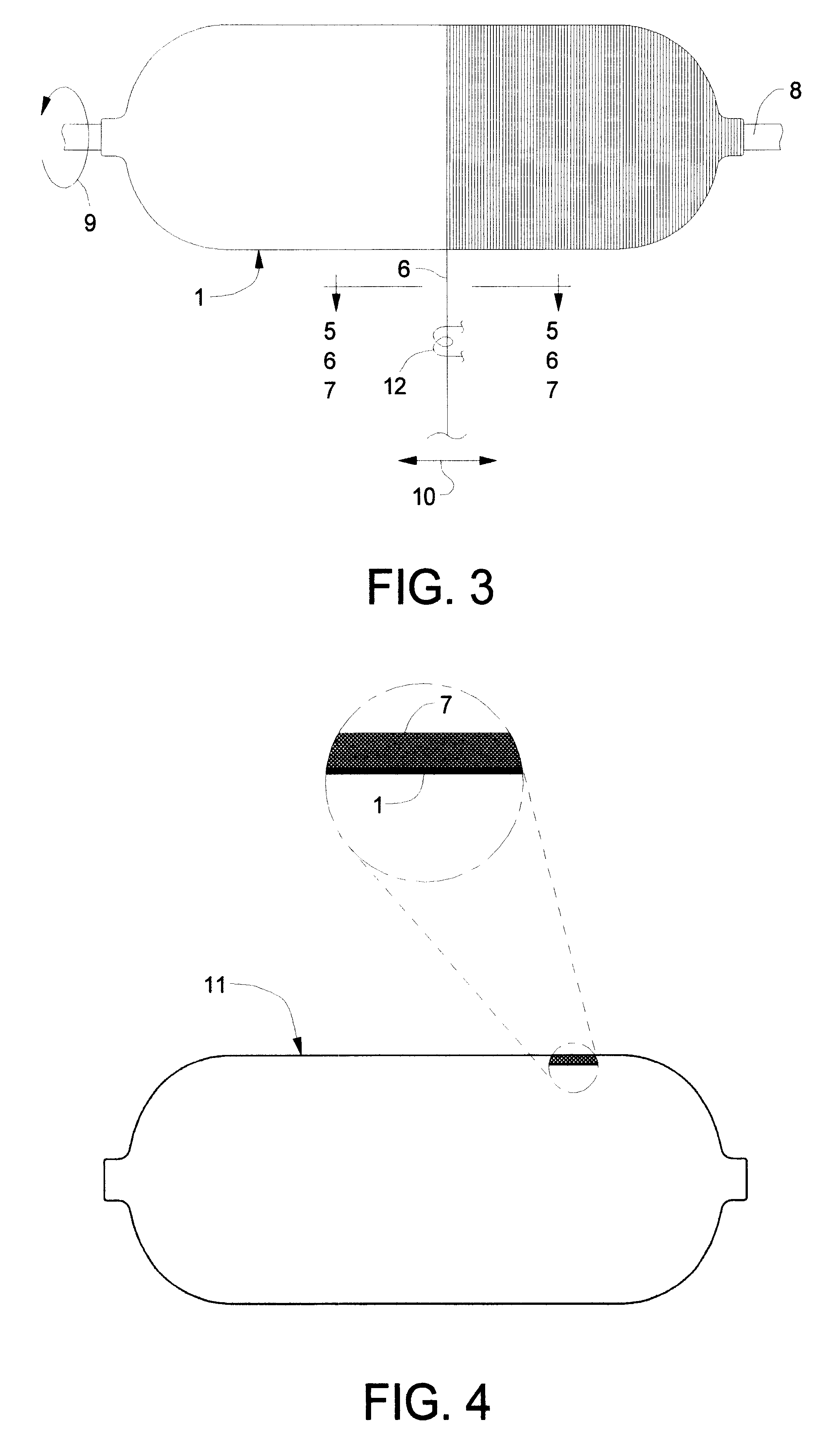

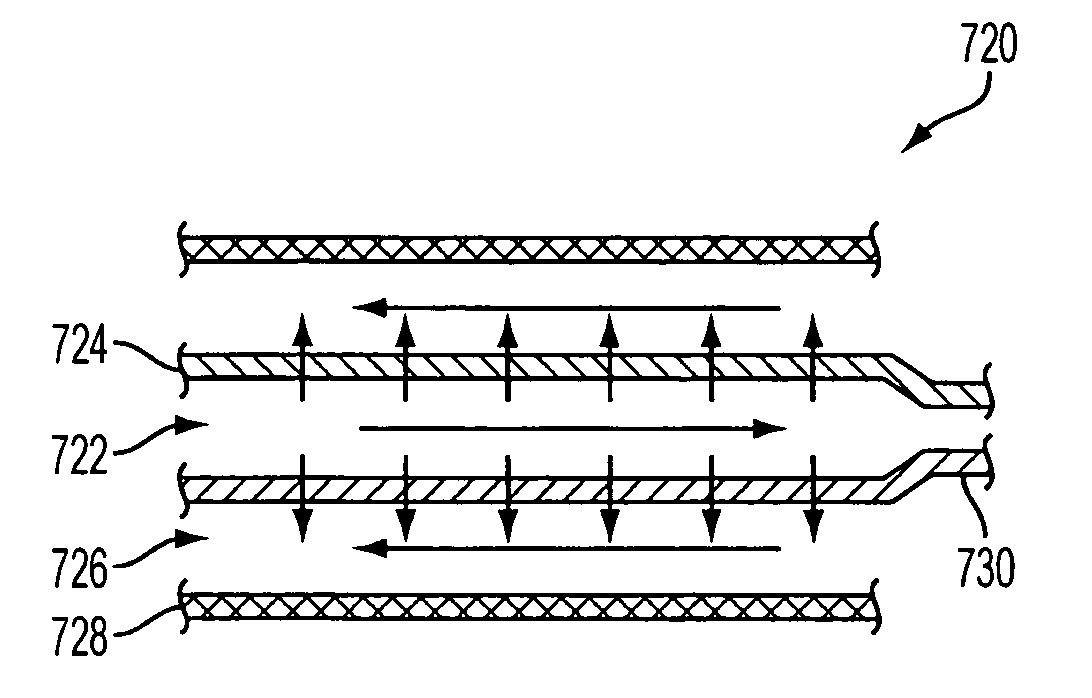

Fuel Rail Assembly Including Fuel Separation Membrane

InactiveUS20090159057A1Reduce constraintsLow costElectrical controlInternal combustion piston enginesHigh rateAlcohol

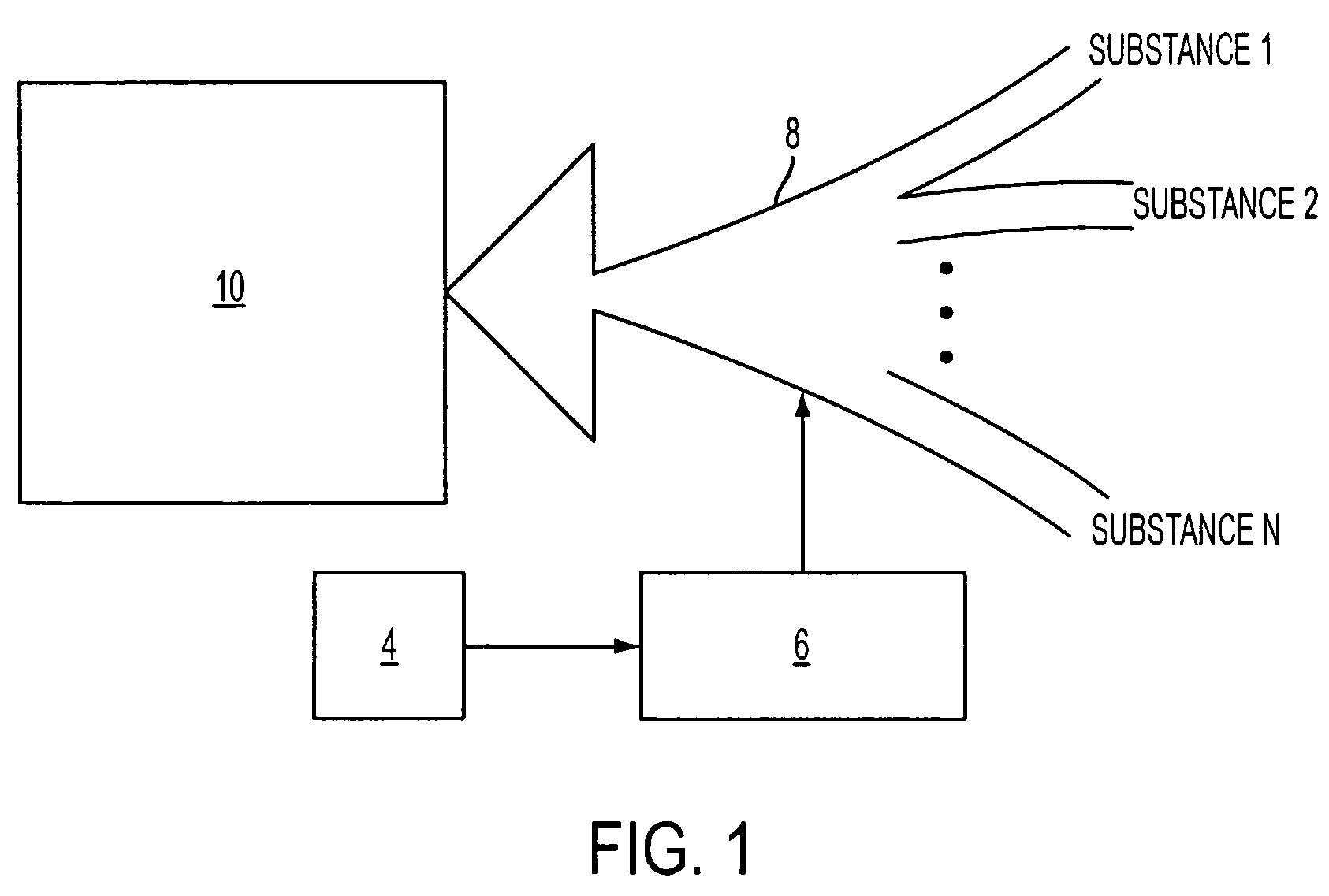

As one example, a fuel rail assembly for supplying pressurized fuel to a plurality of cylinders of an engine is provided. The fuel rail assembly includes a fuel rail housing defining an internal fuel rail volume having at least a first region and a second region; a fuel separation membrane element disposed within the fuel rail housing that segregates the first region from the second region. The membrane element can be configured to pass a first component of a fuel mixture such as an alcohol through the membrane element from the first region to the second region at a higher rate than a second component of the fuel mixture such as a hydrocarbon. The separated alcohol and hydrocarbon components can be provided to the engine in varying relative amounts based on operating conditions.

Owner:FORD GLOBAL TECH LLC

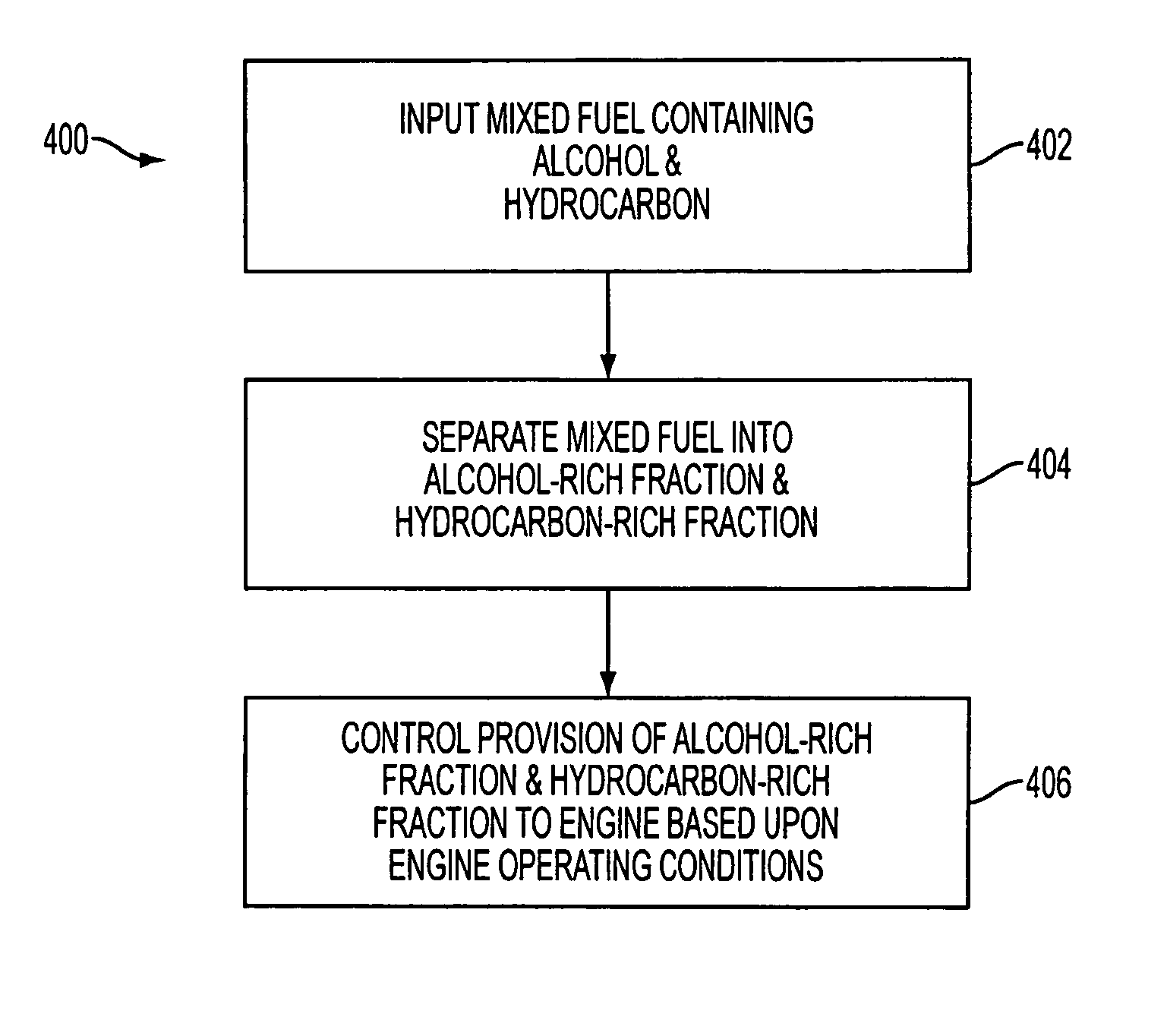

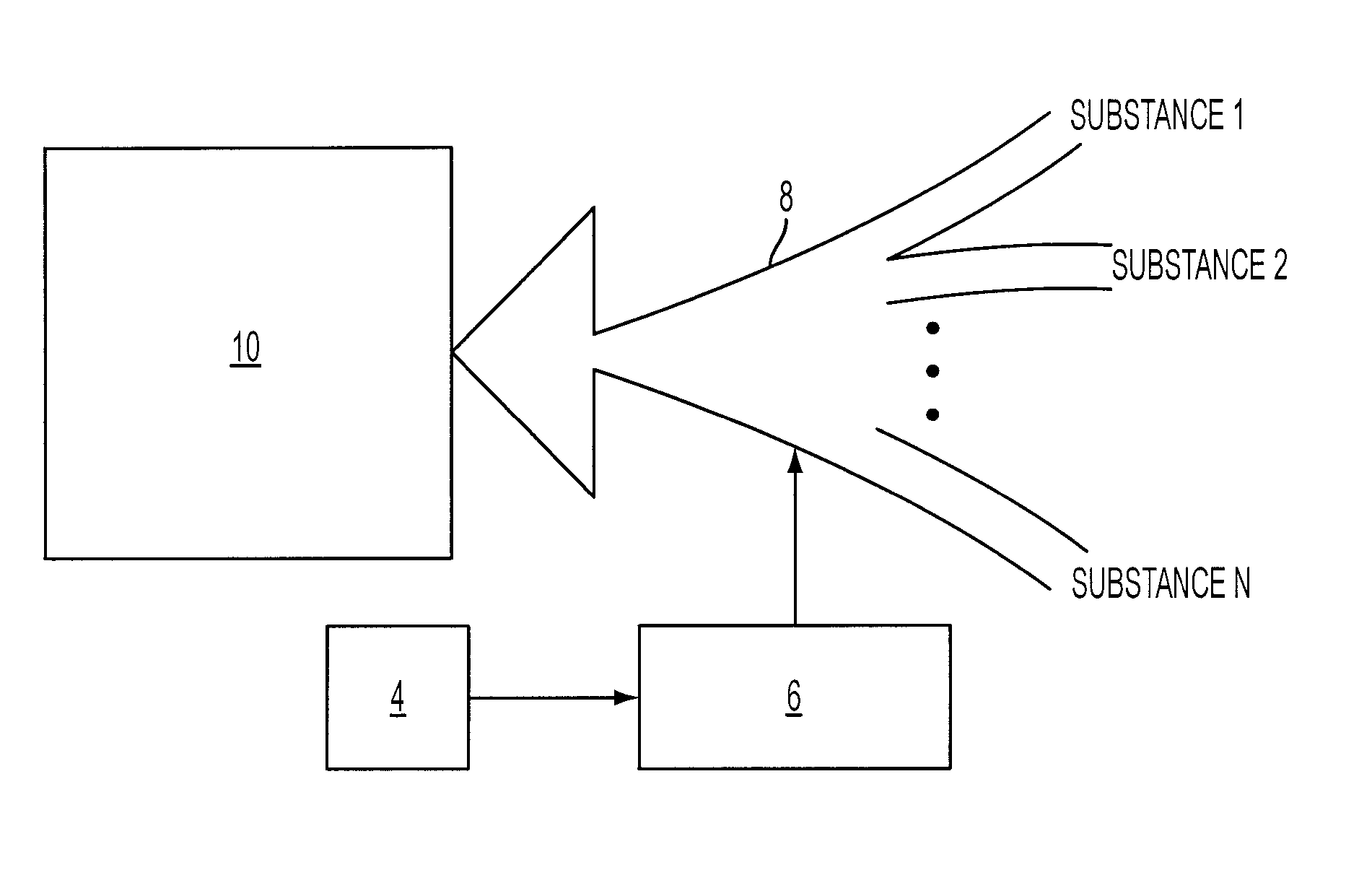

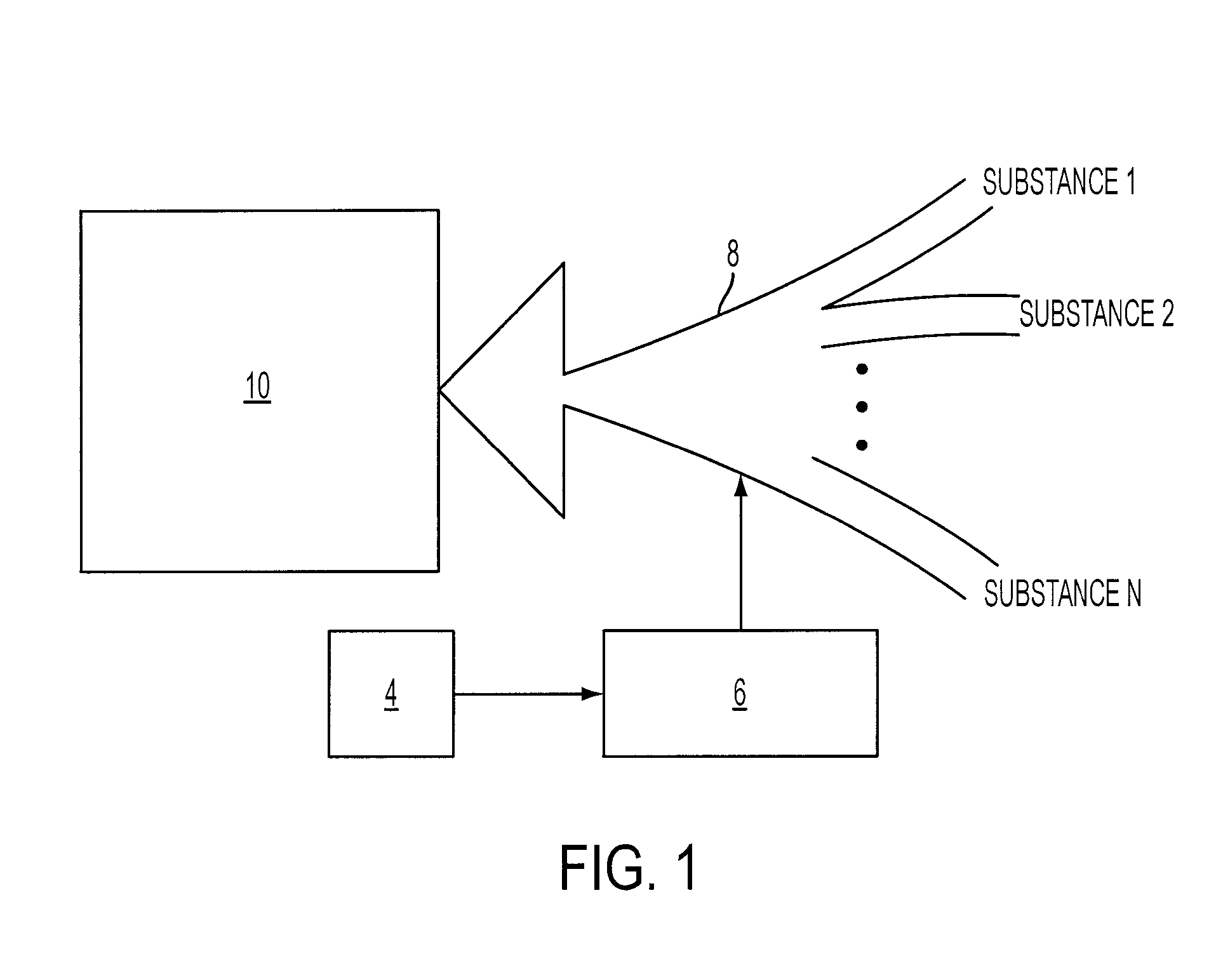

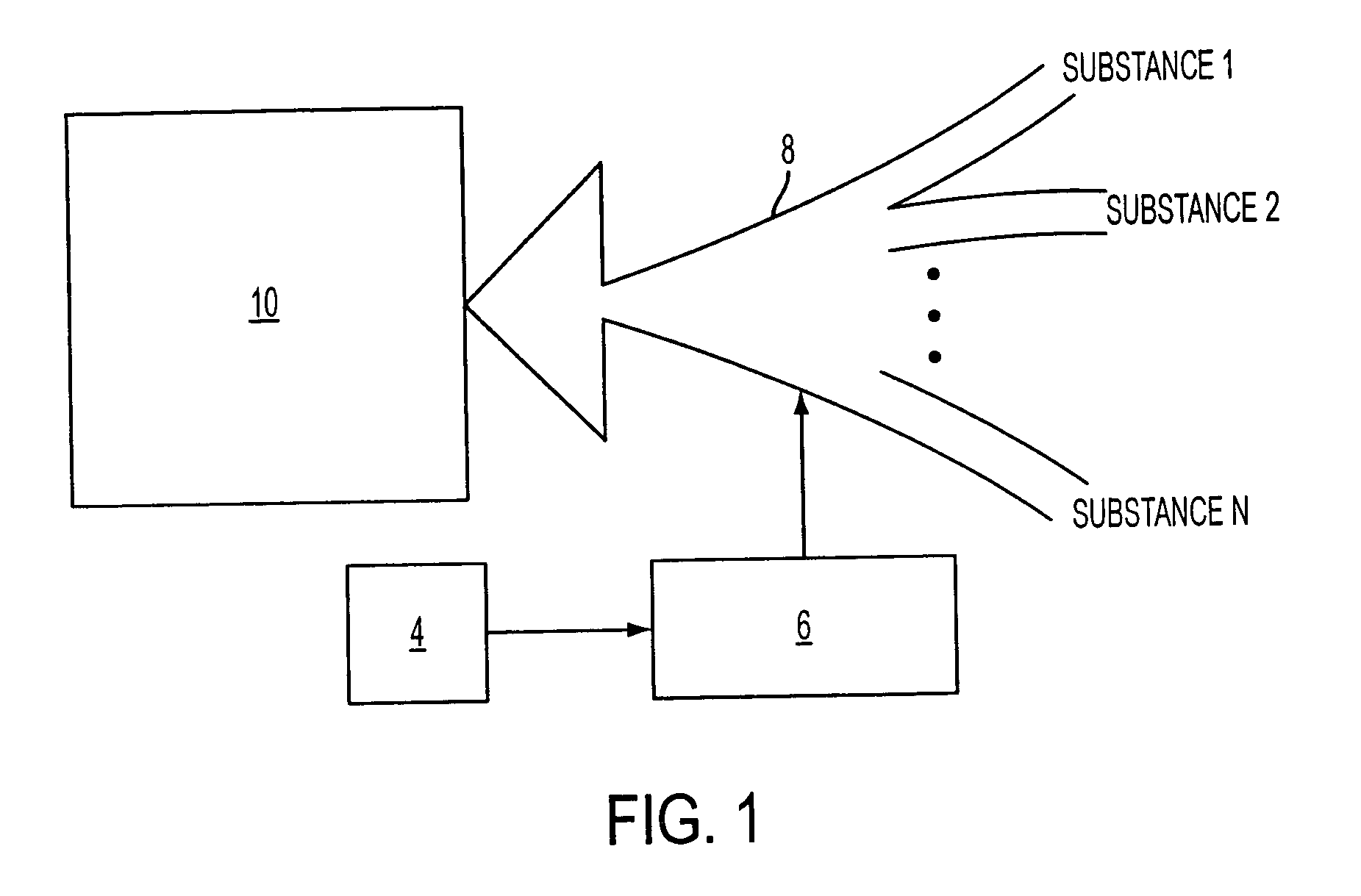

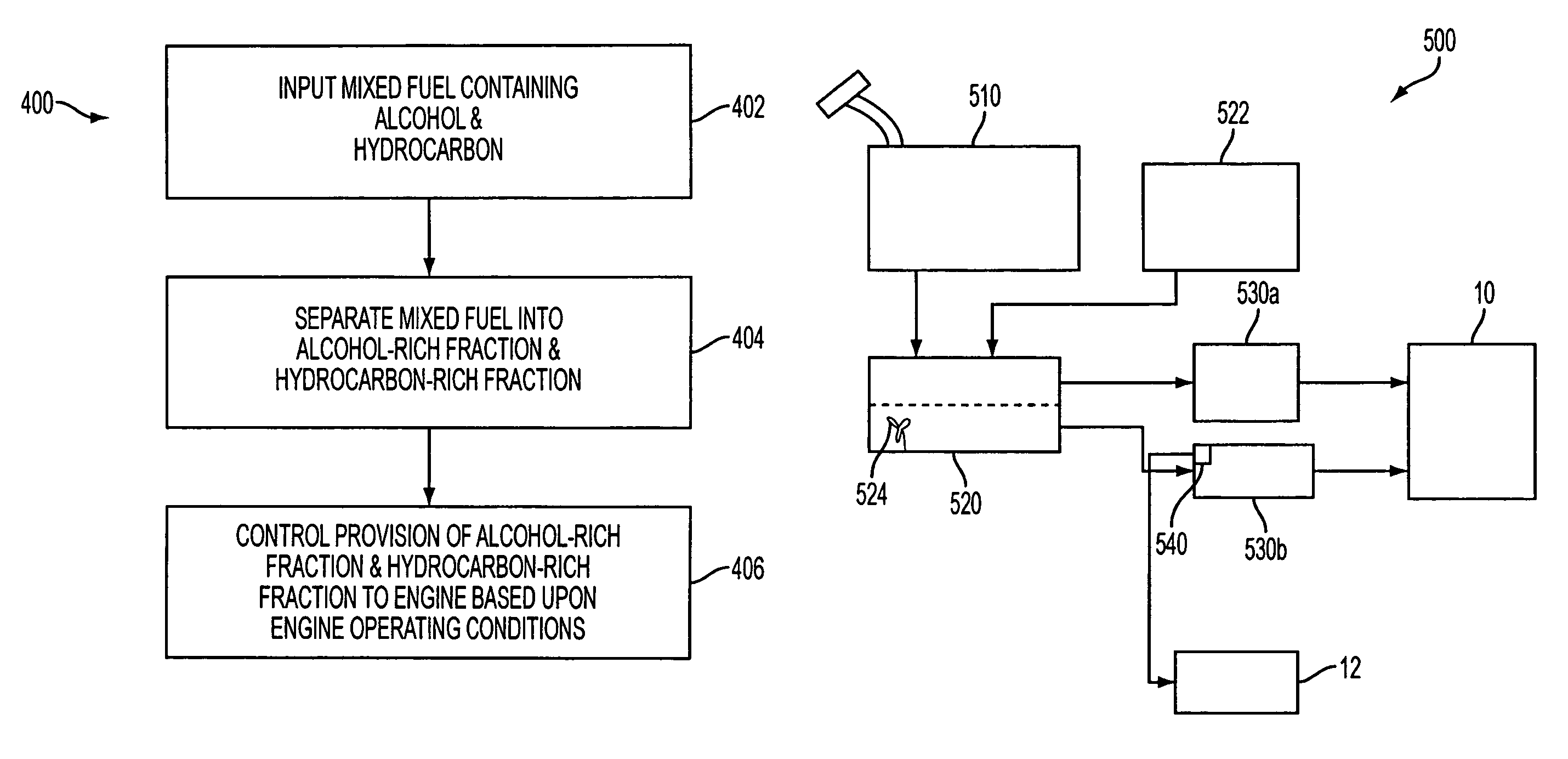

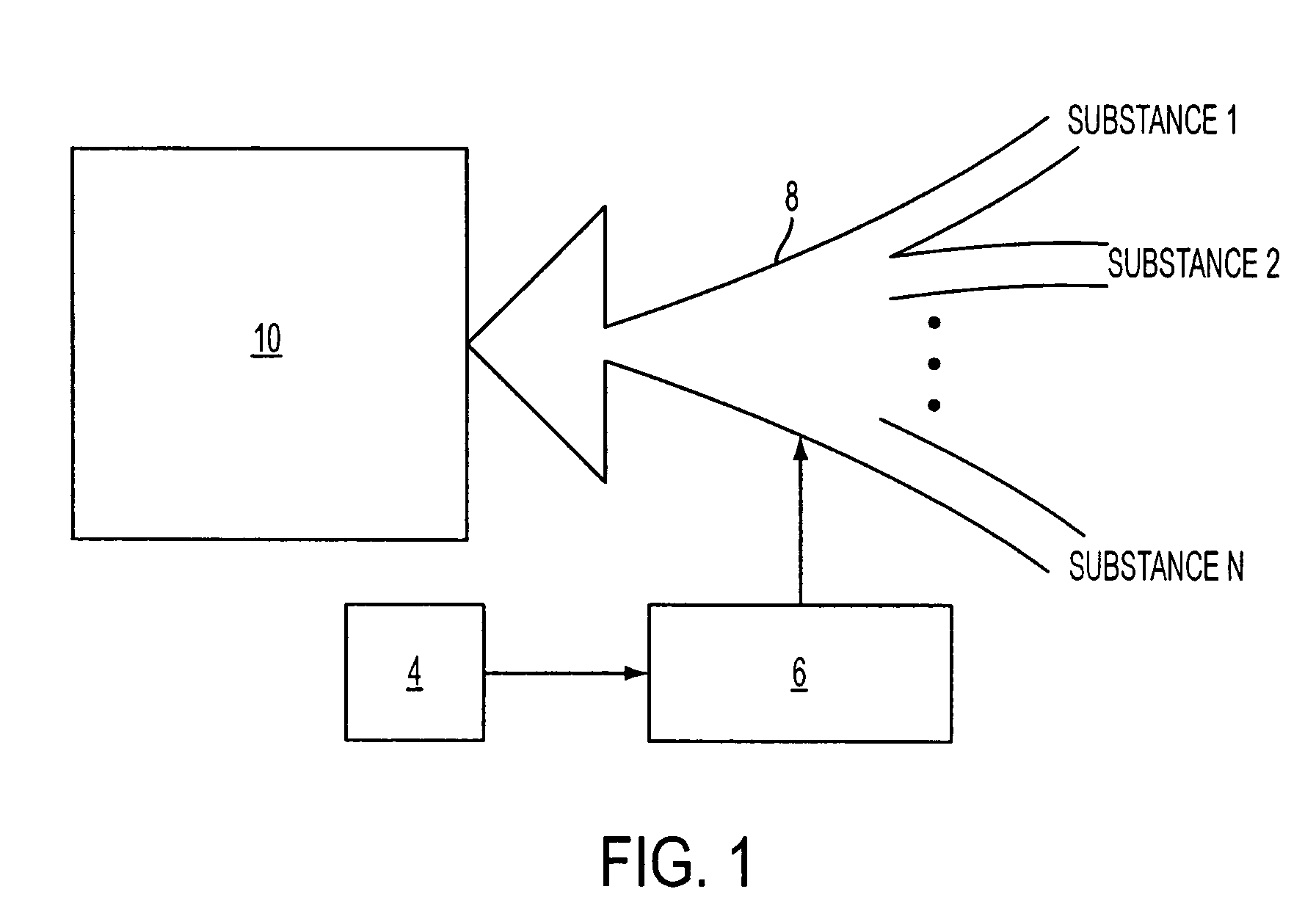

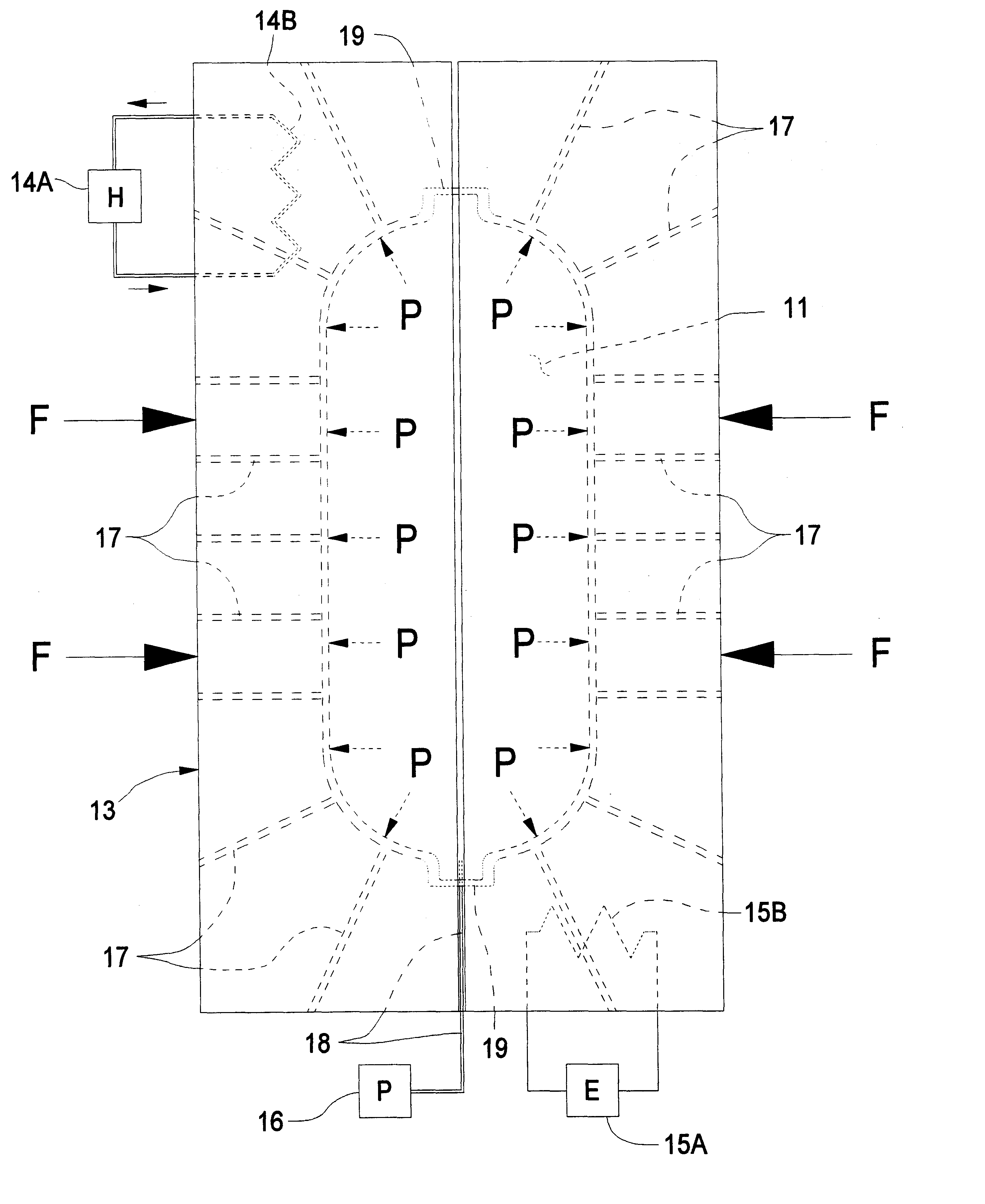

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215072A1Low costImprove charge cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelFuel tankElectrical polarity

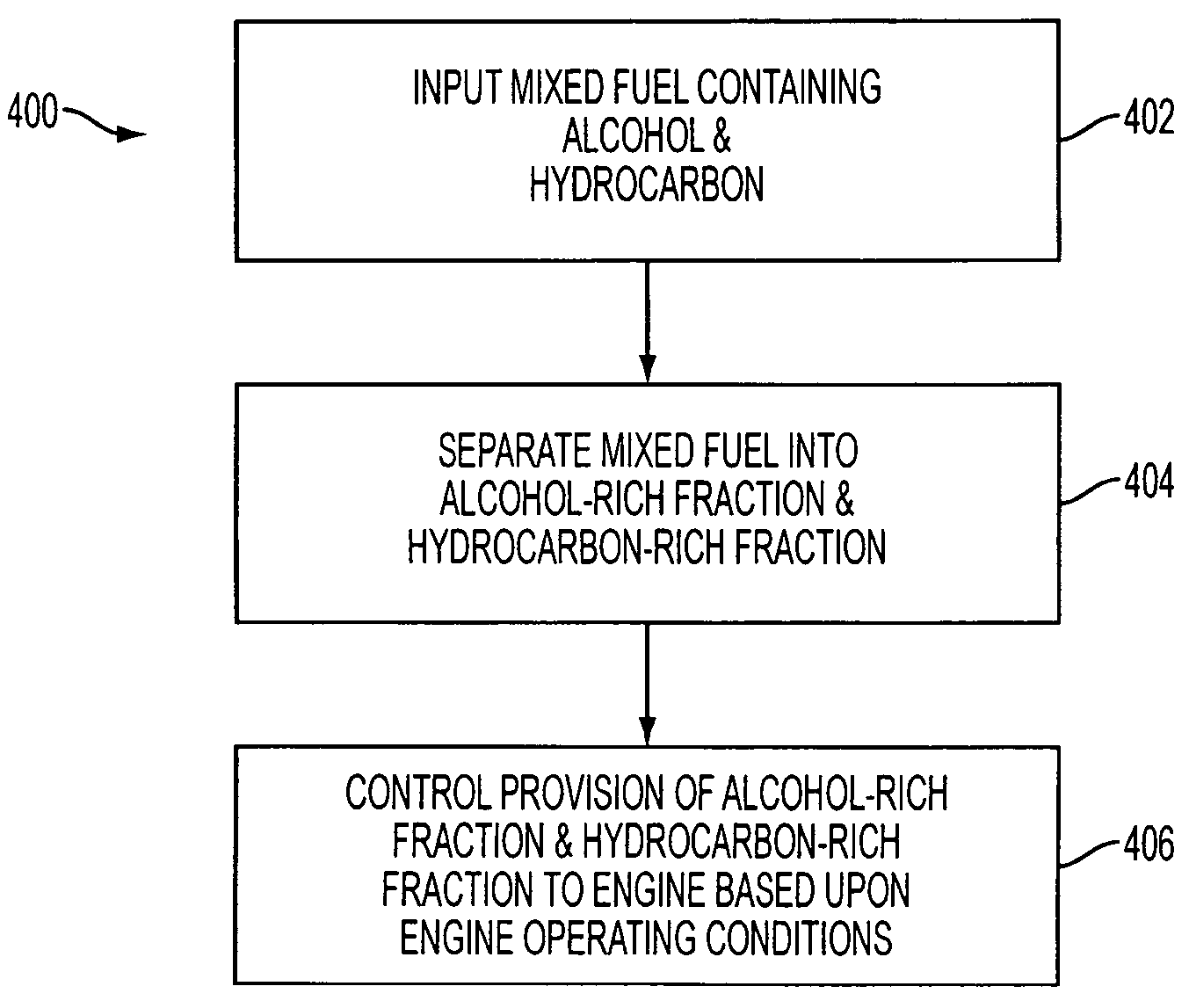

In an apparatus having an internal combustion engine, a fuel tank, and an extractor disposed fluidically between the fuel tank and the engine, a method of operating the apparatus is disclosed, wherein the method comprises adding a volume of a mixed fuel into the extractor from the fuel tank, wherein the mixed fuel contains at least one substantially nonpolar fuel component and at least one polar fuel component, adding a volume of a polar solvent to the extractor, extracting at least a portion of the polar fuel from the mixed fuel into the polar solvent, thereby forming a first fuel mixture with an enriched concentration of the polar fuel and a second fuel mixture with an enriched concentration of the substantially nonpolar fuel, and providing the first fuel mixture and the second fuel mixture to the engine in a ratio selected based upon engine operating condition.

Owner:FORD GLOBAL TECH LLC

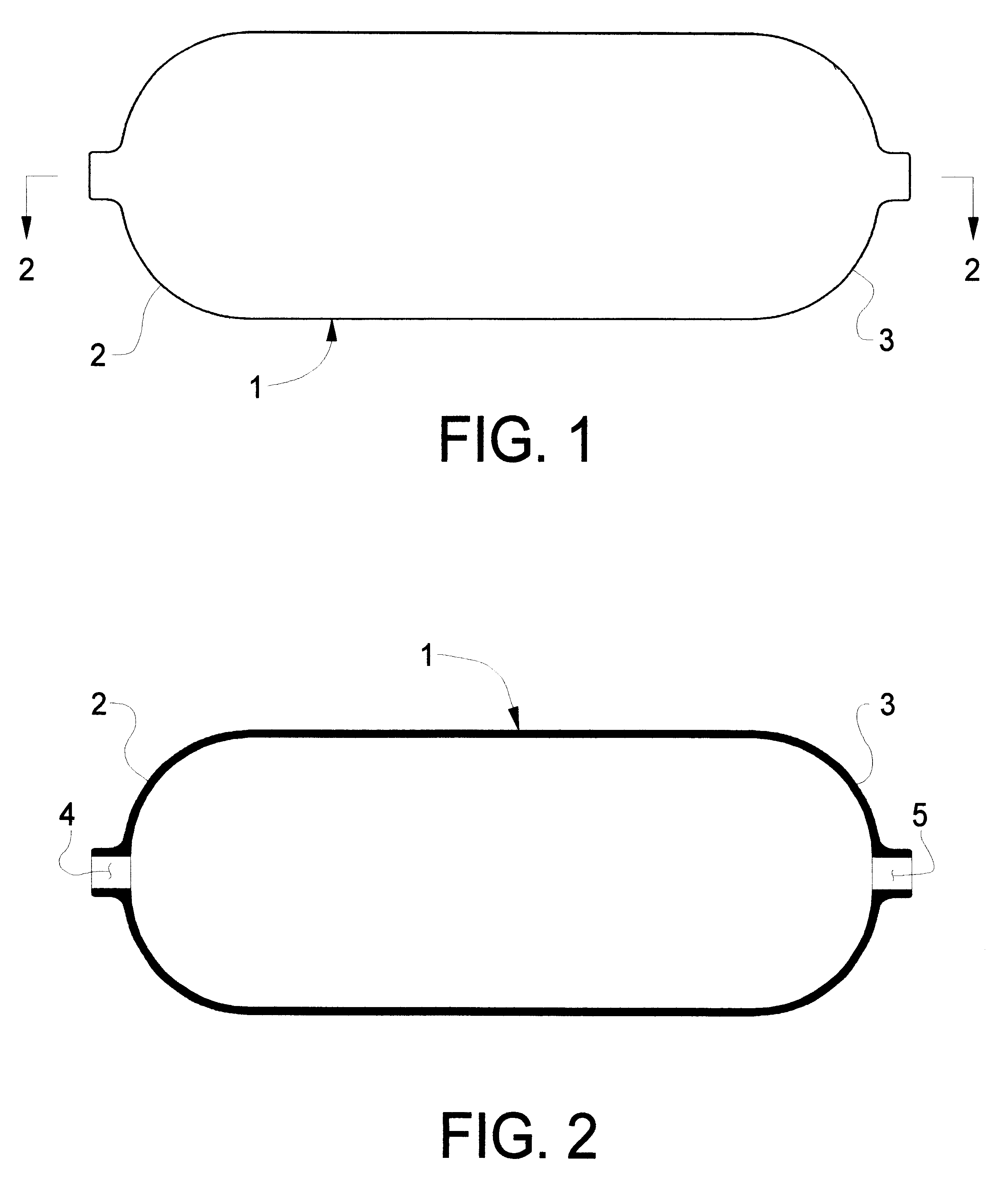

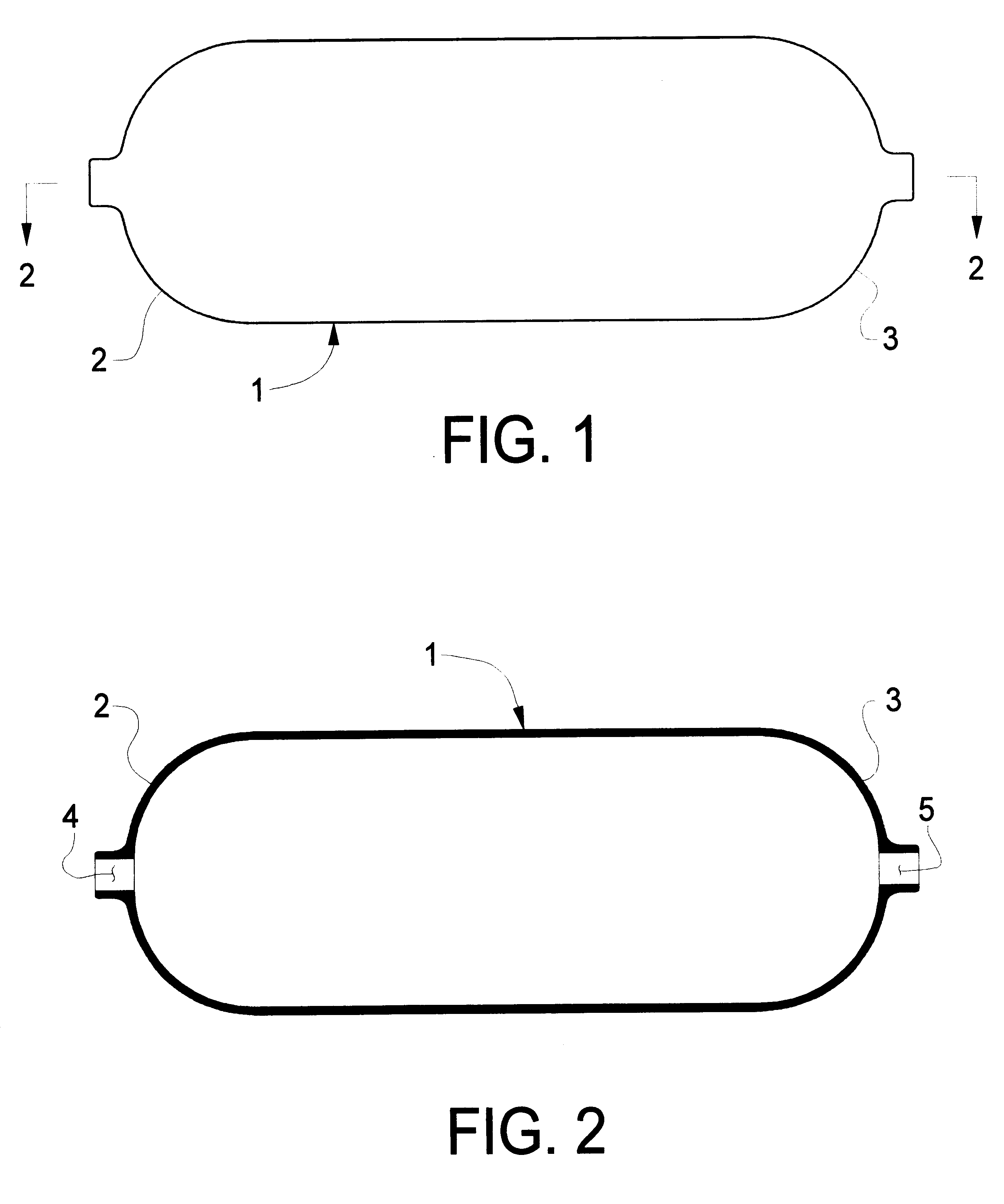

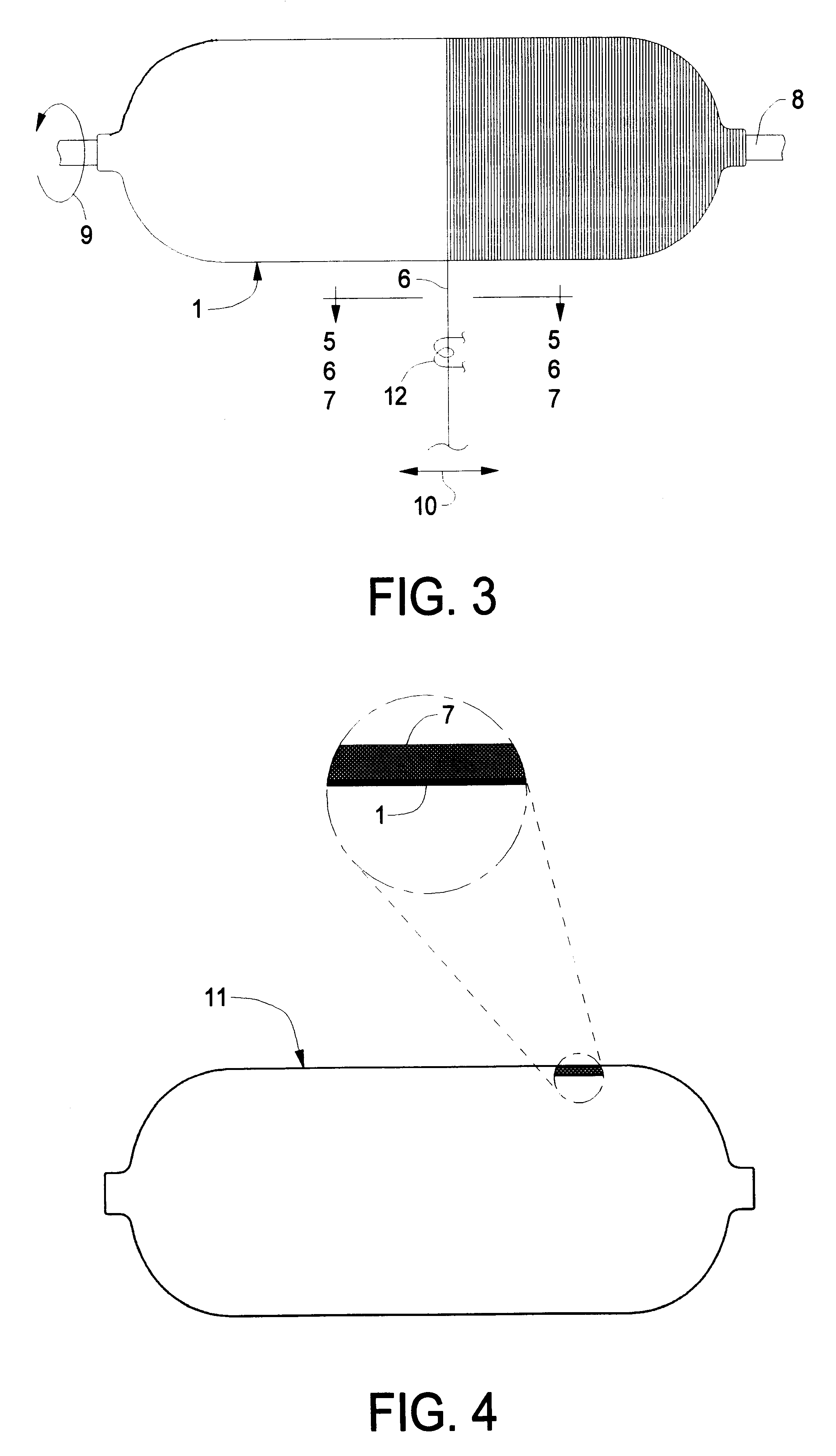

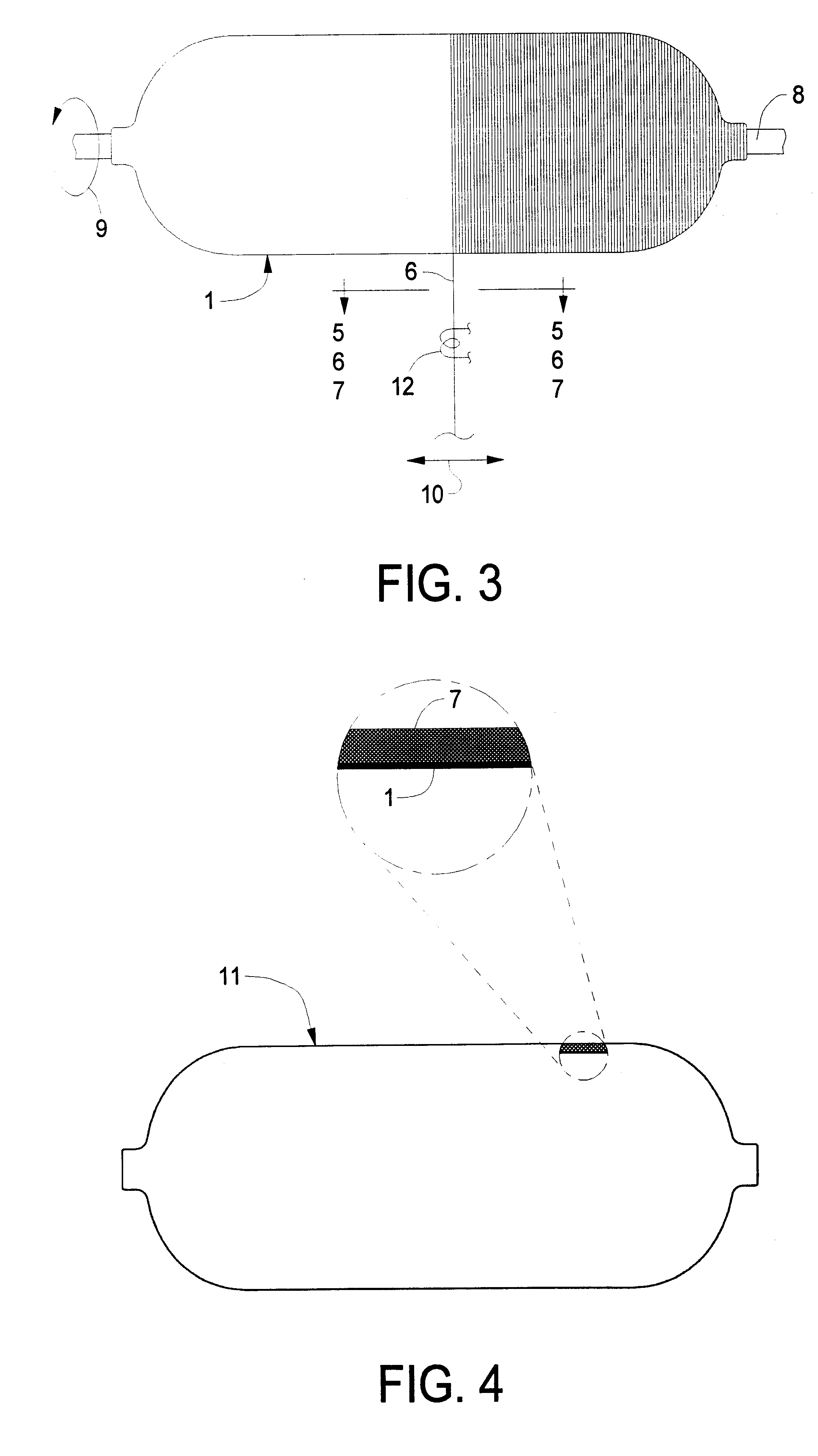

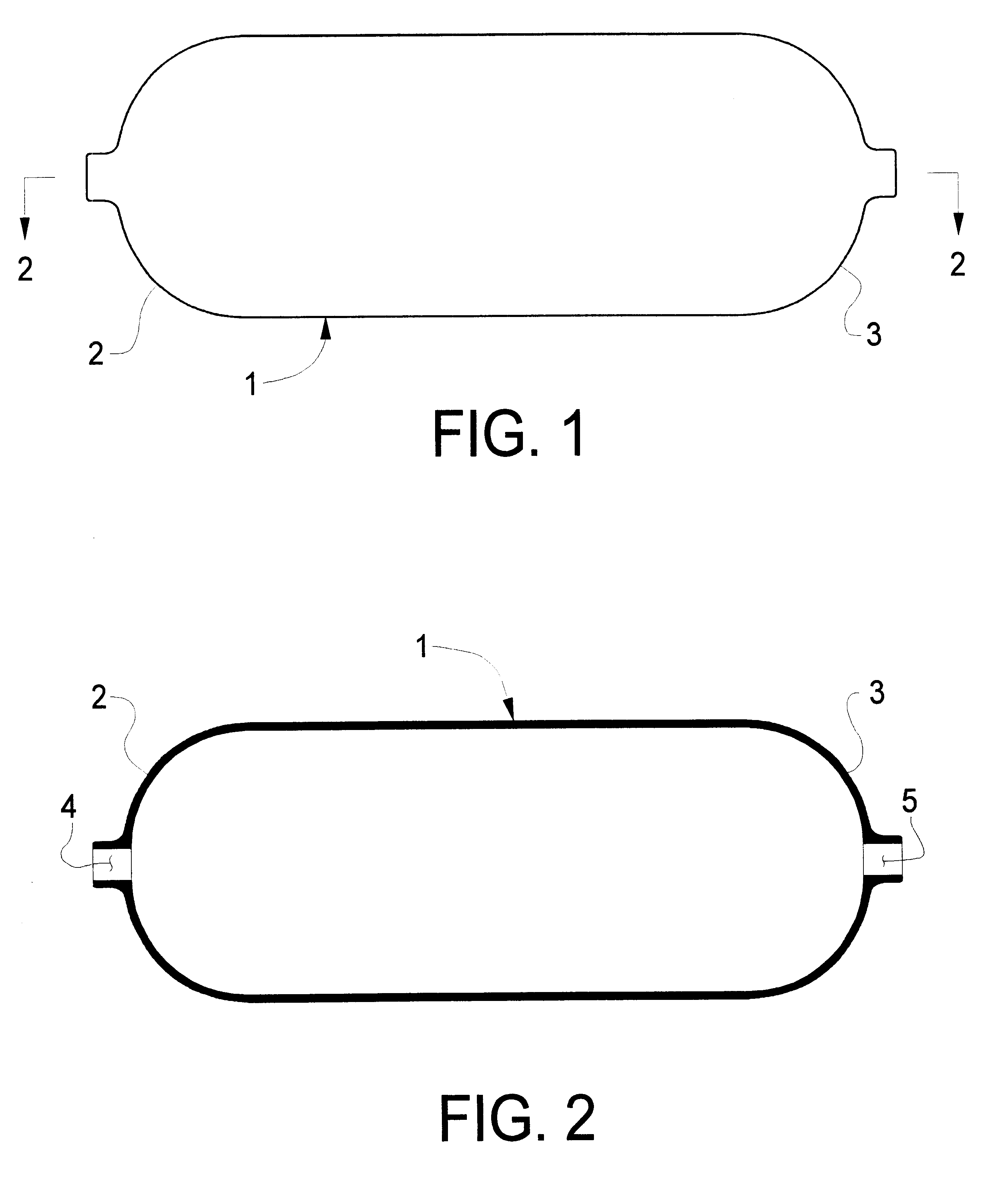

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

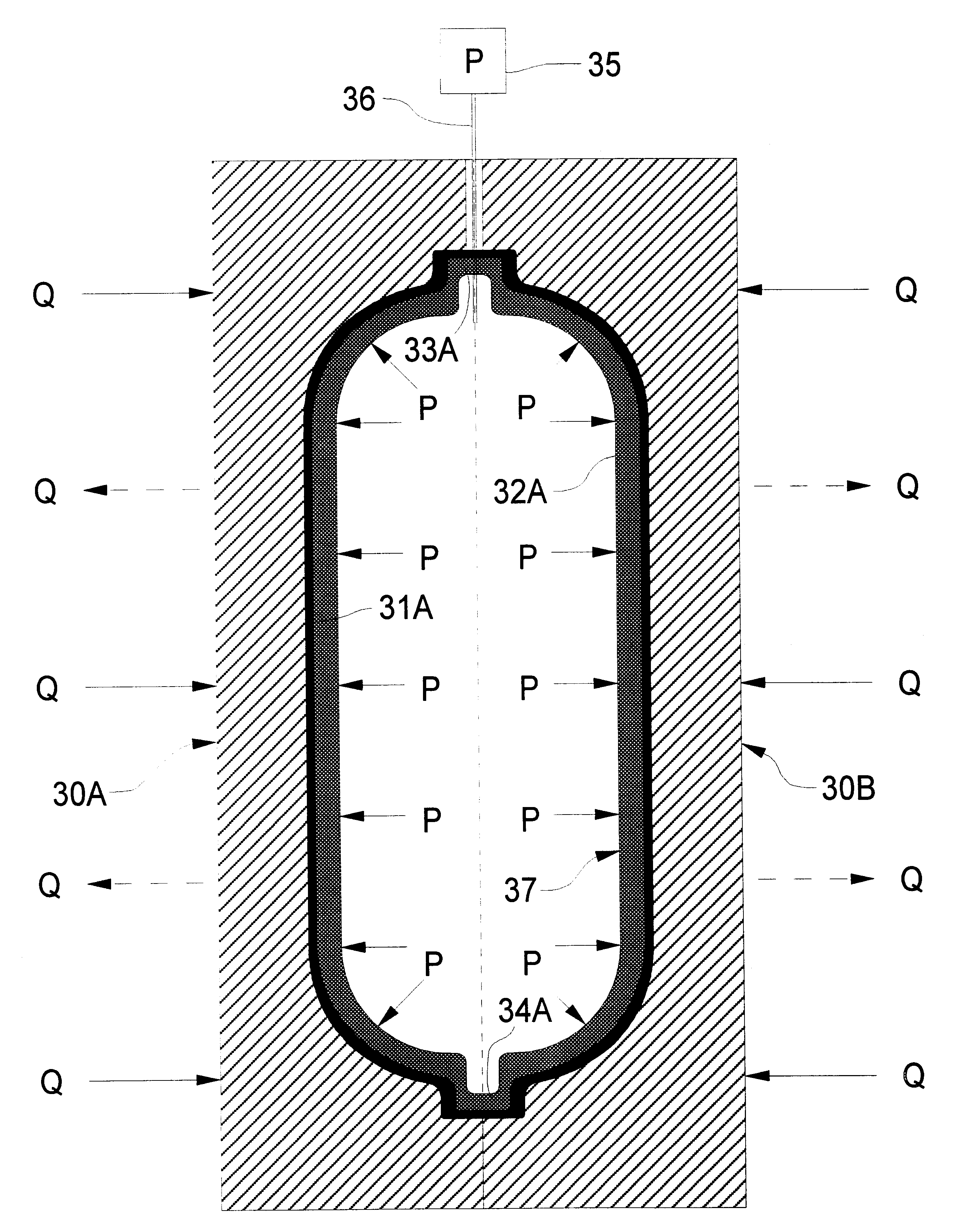

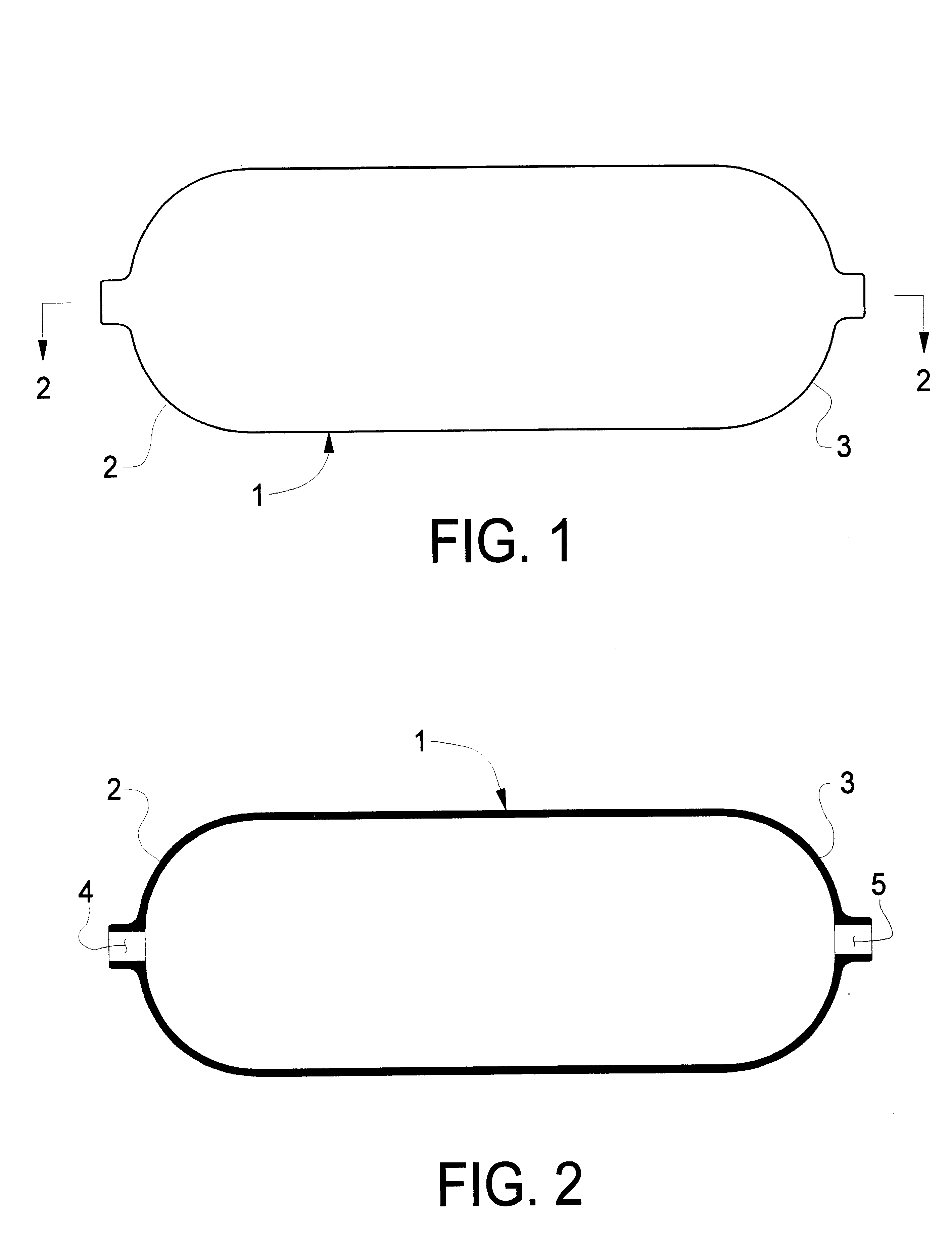

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

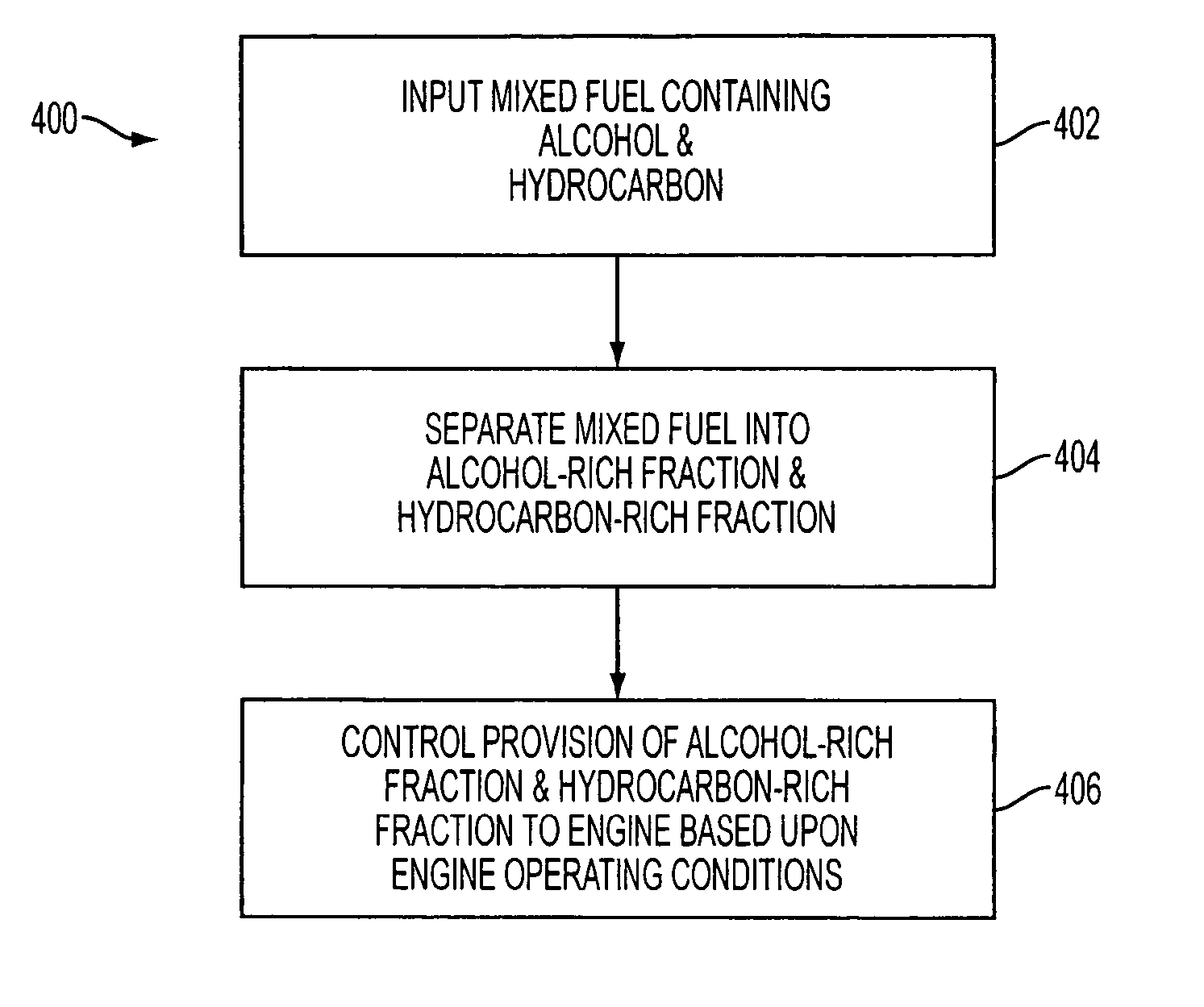

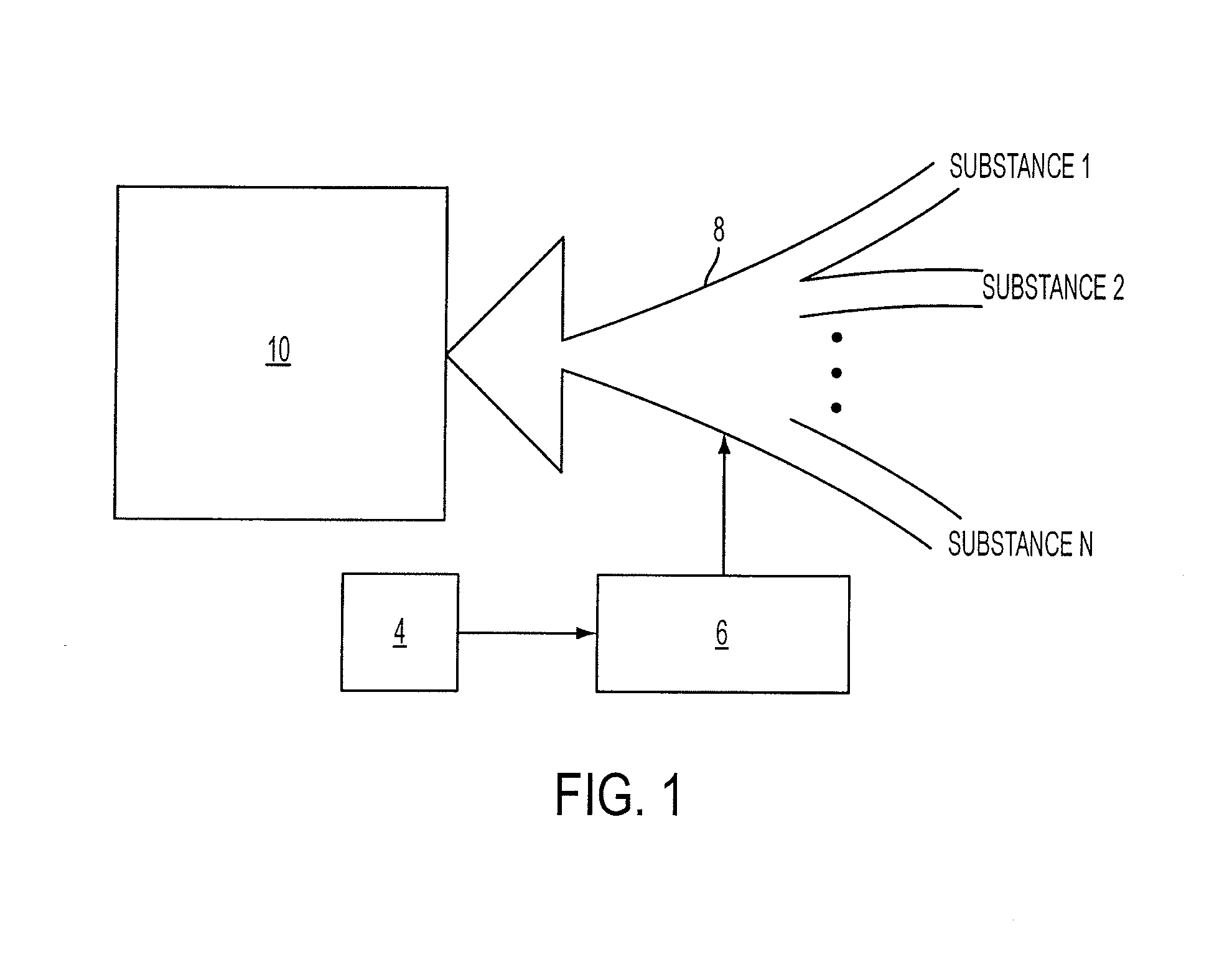

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215127A1Low costImprove charge cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesHigh rateFuel tank

An apparatus comprising an internal combustion engine, a fuel tank, a fuel separator disposed fluidically between the fuel tank and the engine, wherein the fuel separator comprises first and second passageways separated at least partially by a selective barrier that selectively transports a first fuel in a fuel mixture at a higher rate than a second fuel in the fuel mixture, and wherein the first passageway is configured to receive an input of fuel from the fuel tank, and an extraction fluid source in fluid communication with the second passageway of the fuel separator.

Owner:FORD GLOBAL TECH LLC

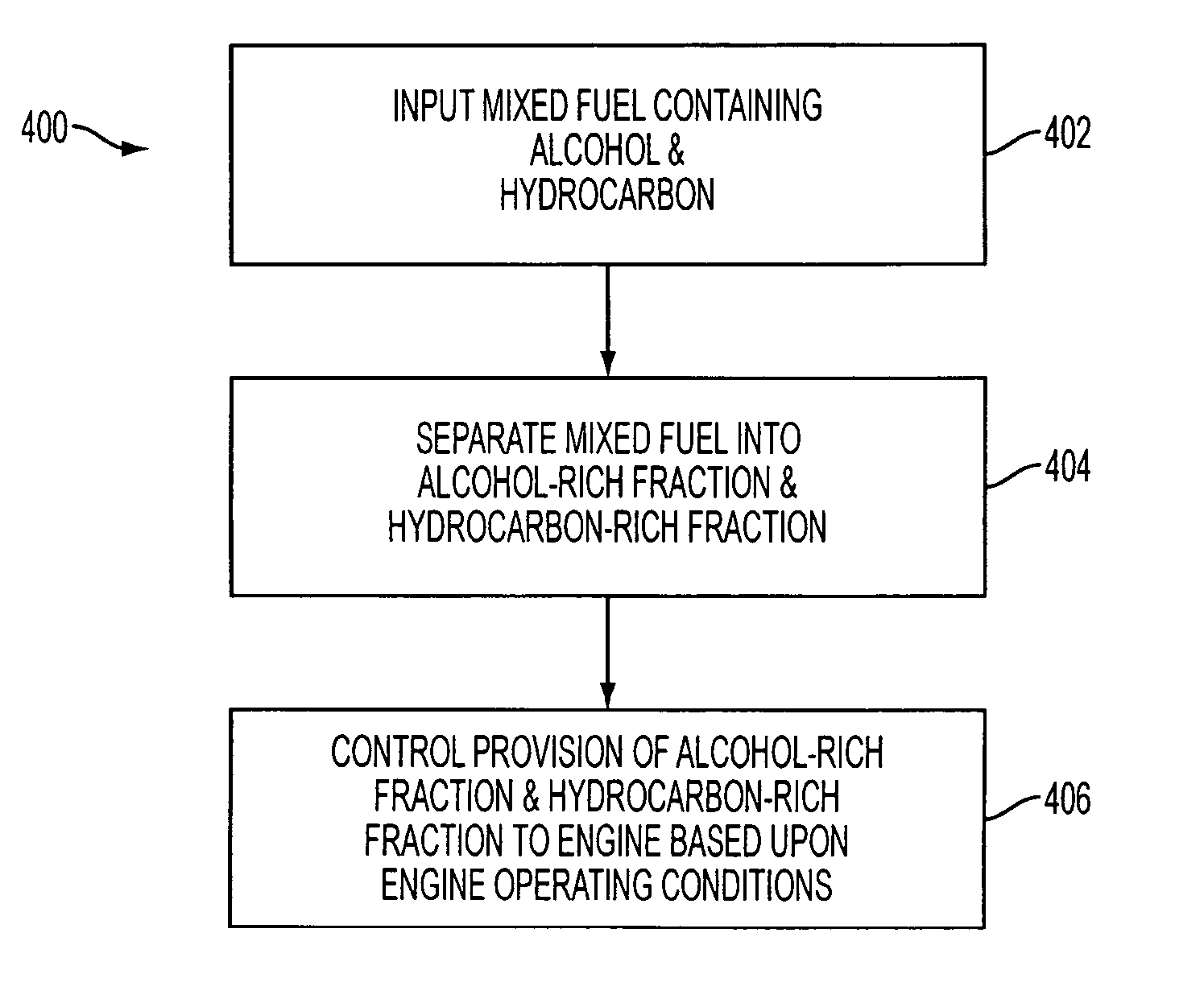

Apparatus with Mixed Fuel Separator and Method of Separating a Mixed Fuel

InactiveUS20070234976A1Increase heatIncrease profitElectrical controlNon-fuel substance addition to fuelInternal combustion engineMixed fuel

A method of operating a vehicle system including an internal combustion engine is disclosed, the method comprises separating a second fuel from a first fuel, the second fuel having a greater concentration of at least one component than the first fuel; combusting at least the first fuel at least during a first engine load; and combusting at least the second fuel at least during a second engine load higher than the first engine load.

Owner:FORD GLOBAL TECH LLC

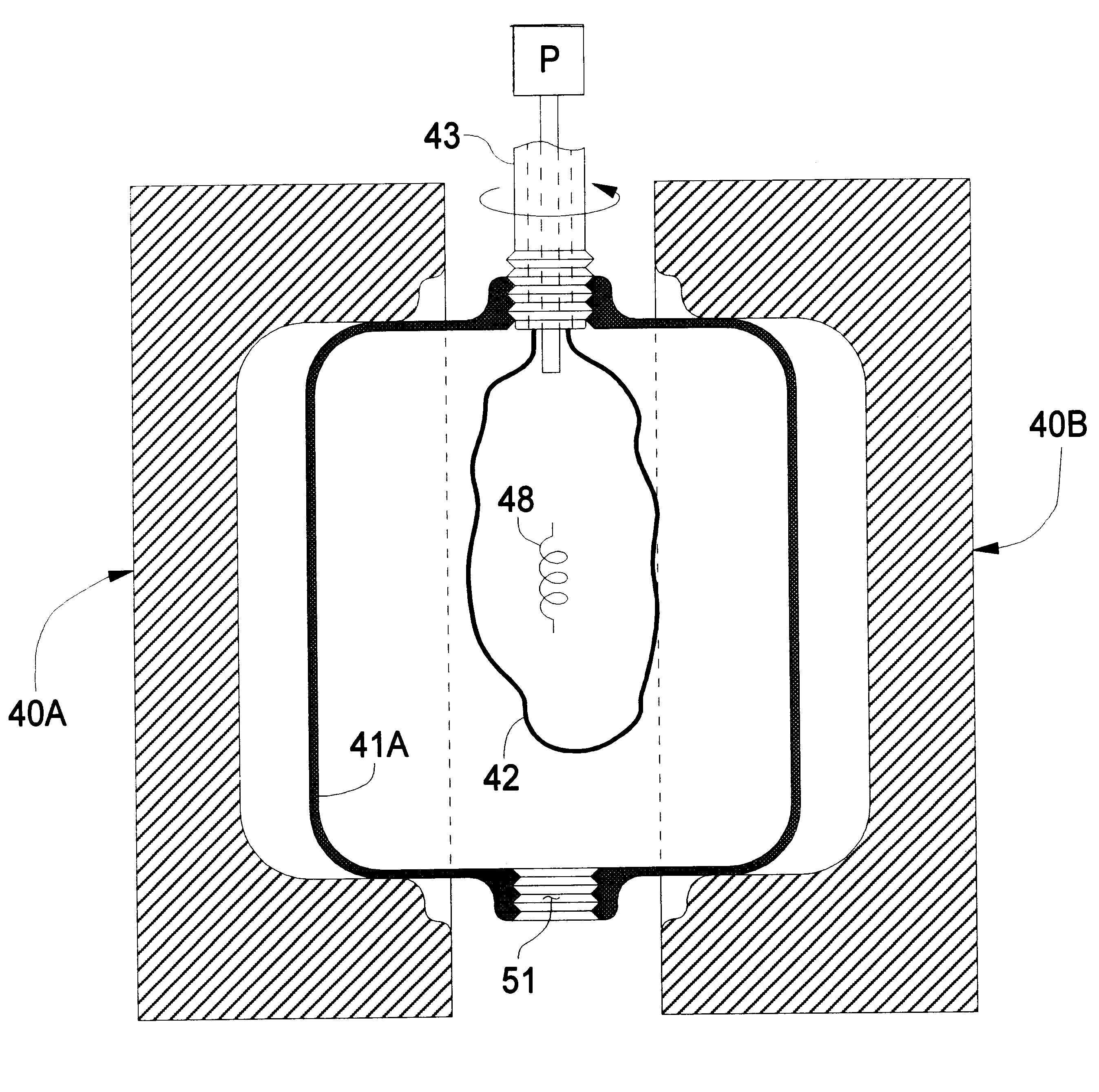

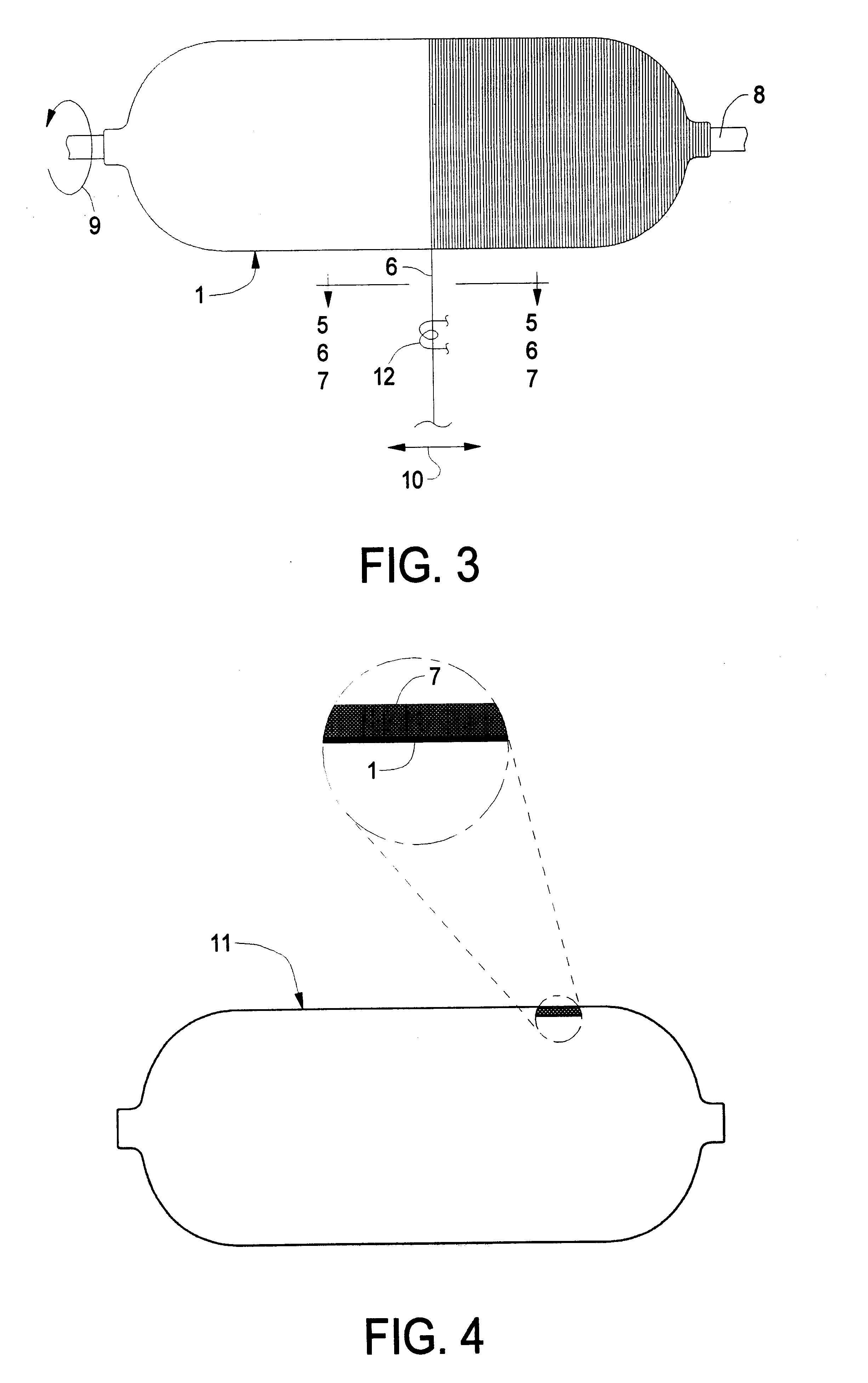

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215125A1Improve charge cool effectReduce knock limitNon-fuel substance addition to fuelInternal combustion piston enginesMixed fuelFuel tank

In an apparatus having an internal combustion engine, a method of operating the engine is disclosed, comprising providing a mixed fuel from a fuel tank to a separator, separating at least a portion of the hydrocarbon fuel component from the mixed fuel by transporting a hydrocarbon fuel component through a material in the separator that selectively transports the hydrocarbon fuel component, thereby forming a first oxygenated fuel component-enriched fuel fraction and a second hydrocarbon-enriched fuel fraction, and providing fuel from the first fuel fraction and fuel from the second fuel fraction to the engine in a ratio based on an engine operating condition.

Owner:FORD GLOBAL TECH LLC

Method for fabricating composite pressure vessels

InactiveUS6171423B1Speed up the processRatio is limitedVessel manufacturingCylinder headsPolytetramethylene terephthalateFiber

A process for fabricating a composite vessel includes the steps of: A) preforming (e.g., by winding fiber and at least one thermoplastic substance onto a thermoplastic liner) a thermoplastic shell which has at least one opening for access to the interior; B) extruding a circular cross section of a fluid parison of thermoplastic material (which preferably is chosen to have a melting point lower than that of the thermoplastic shell) into the interior of the thermoplastic shell through the opening; C) in a mold, applying at least one force (such as gas under pressure) which tends to urge the fluid parison toward the interior walls of the thermoplastic shell (which may be preheated prior to introduction into the mold) such that the fluid parison imparts heat to the thermoplastic shell; D) continuing step C) until the thermoplastic shell and the fluid parison consolidate to form a composite vessel; E) cooling the vessel until it is solidified; and F) removing the vessel from the mold. For some composite vessels, prior to step C), an insert may be introduced into the interior of the parison and positioned in alignment with the opening in the thermoplastic shell such that the insert is rendered integral with the composite vessel during step D). Suitable thermoplastic materials include polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

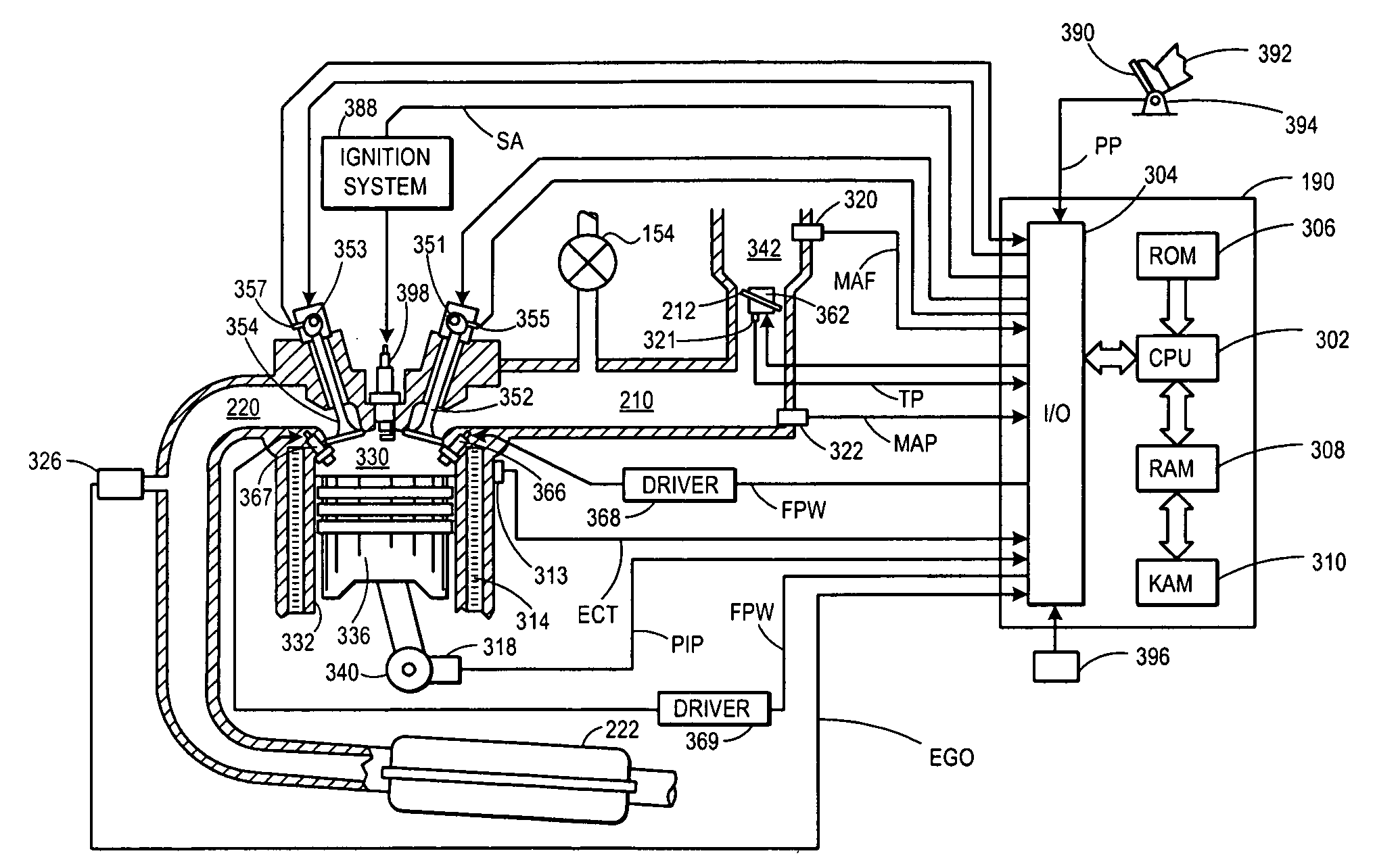

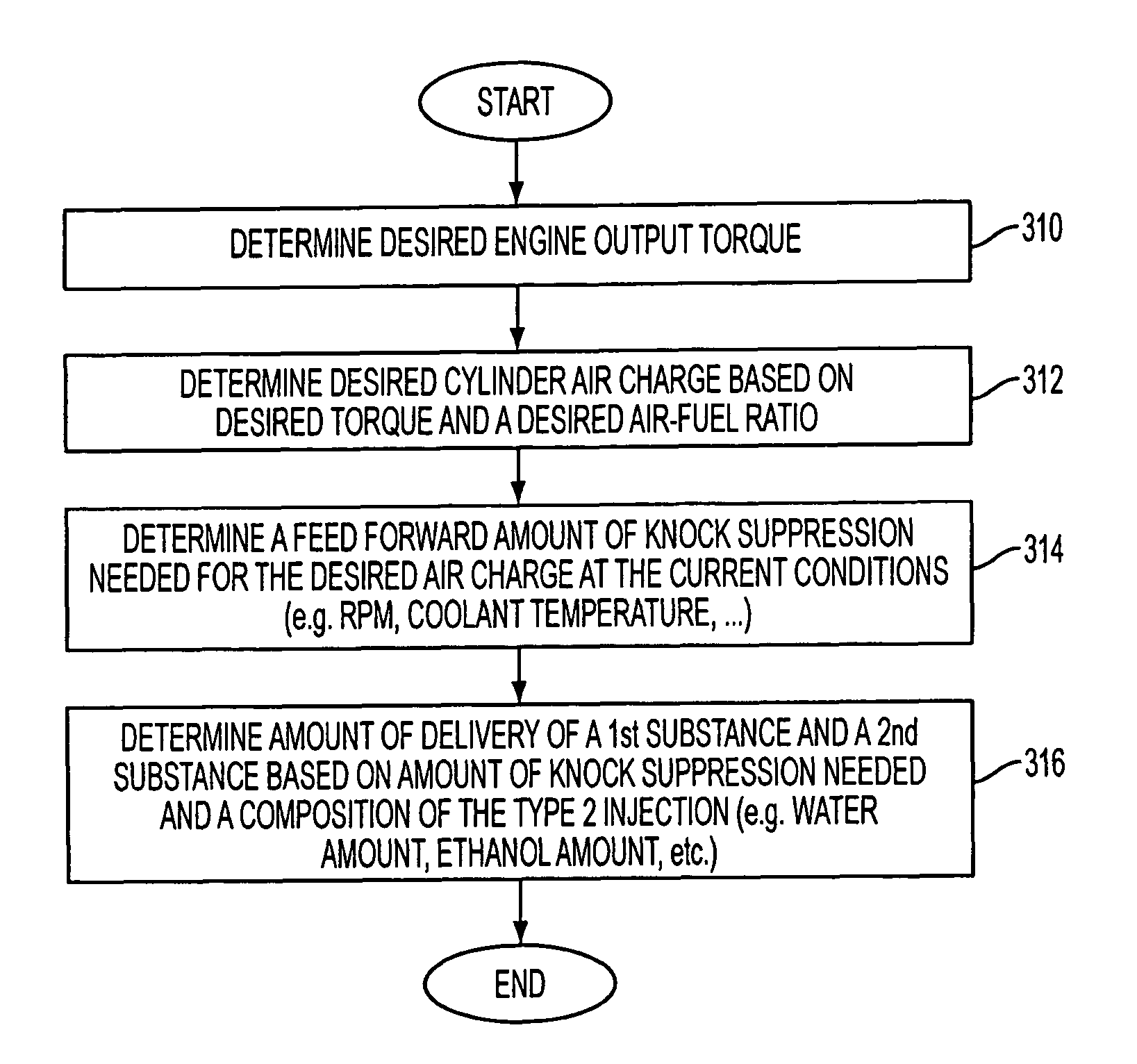

Control of peak engine output in an engine with a knock suppression fluid

InactiveUS20070219674A1Low costImprove charge cooling effectAnalogue computers for vehiclesElectrical controlOn boardHigh alcohol

A method for a vehicle traveling on the road, comprising of receiving a fuel mixture, said mixture having at least some alcohol, separating said fuel mixture into at least a first and second mixture on board the vehicle, where said first mixture has a higher alcohol concentration than said second mixture, delivering a first amount of said first mixture and a second amount of said second mixture to the engine in different ratios as an operating condition varies, and adjusting an engine operating parameter in response to availability of said first mixture.

Owner:FORD GLOBAL TECH LLC

Control for alcohol/water/gasoline injection

ActiveUS8434431B2Increase profitLow costInternal combustion piston enginesNon-fuel substance addition to fuelAqueous alcoholGasoline

A system for controlling an engine is described. In one example, fuel and a fluid are delivered to the engine cylinder, the fluid including at least some water. The amount of fuel and fluid delivered is adjusted in different ratios as a condition varies to address both pre-ignition and knock.

Owner:FORD GLOBAL TECH LLC

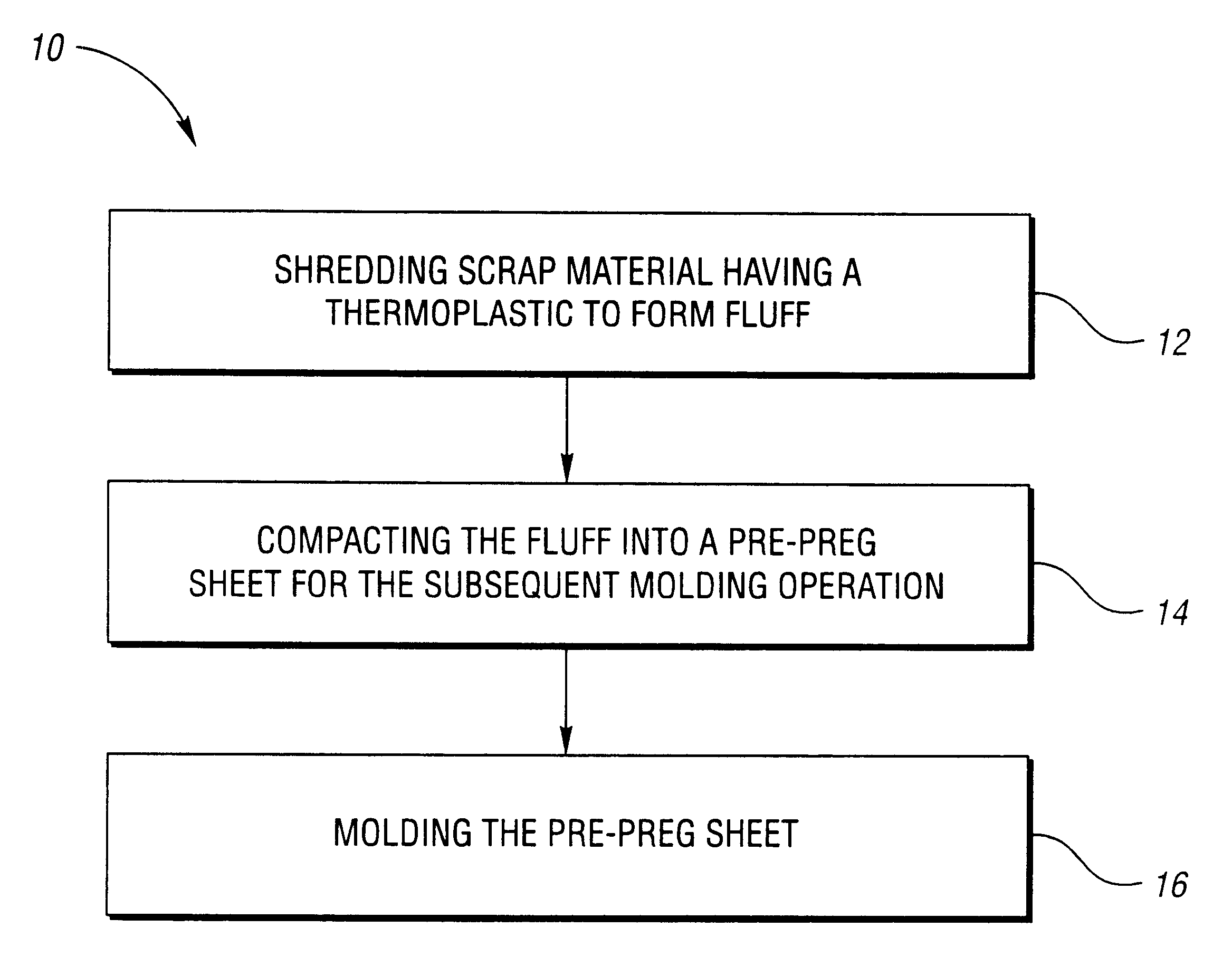

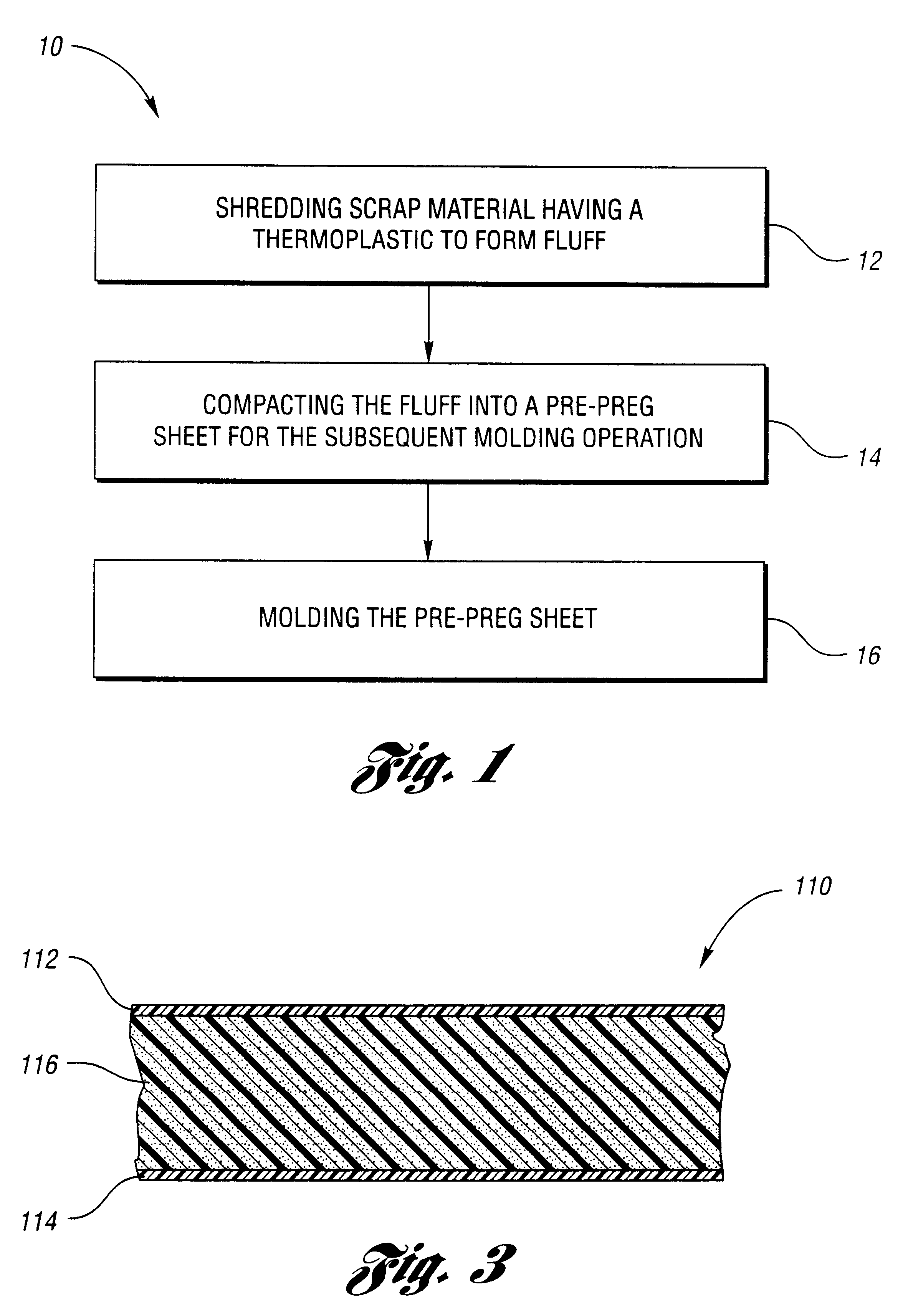

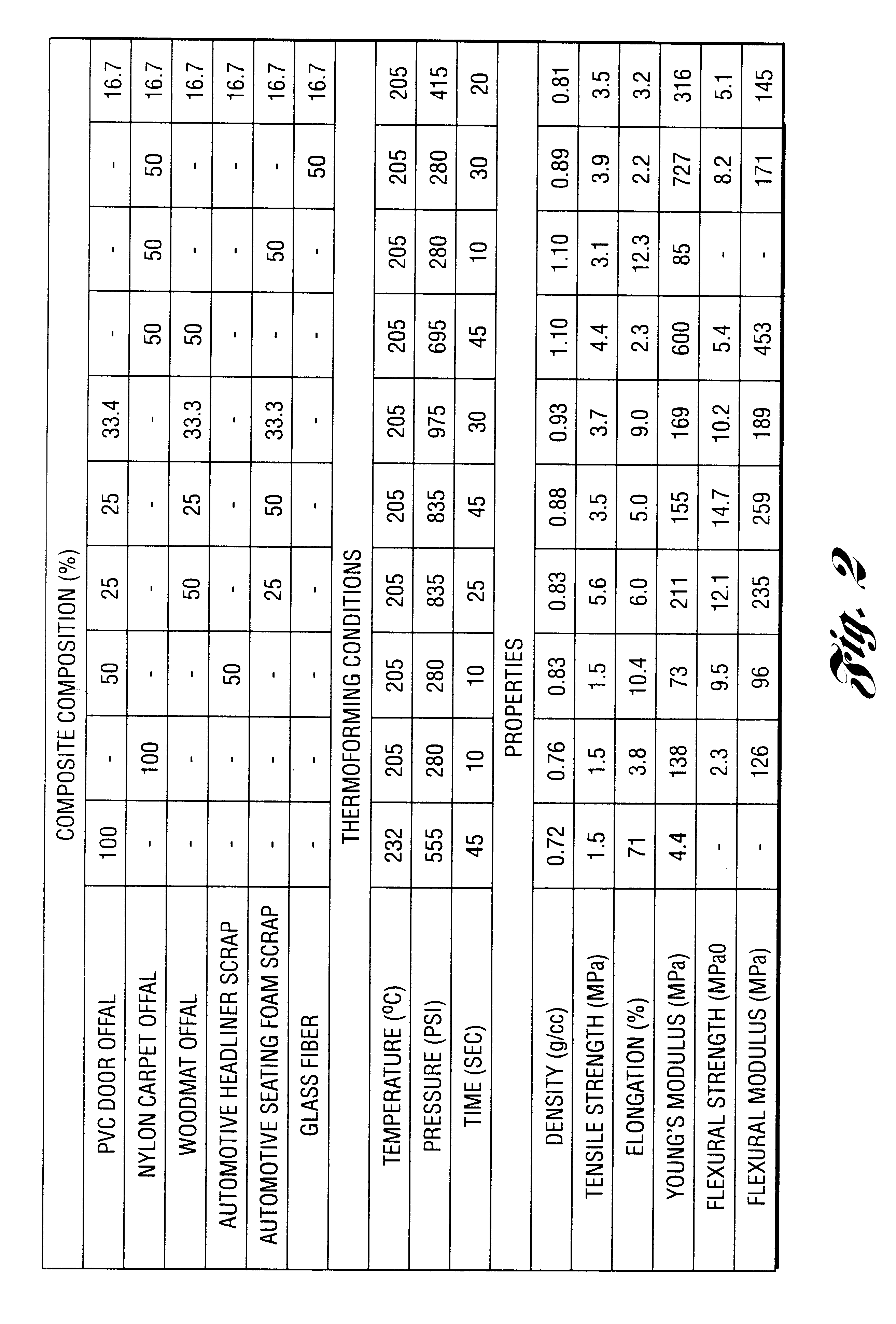

Method of recycling scrap material containing a thermoplastic

InactiveUS6576176B1Ratio is limitedOther chemical processesPlastic recyclingThermoplasticShell molding

The invention involves recycling scrap material having a thermoplastic. The invention includes a method of forming a thermoplastic pre-preg sheet for use in a subsequent molding operation. The method includes shredding a first scrap material having a thermoplastic to form fluff. The fluff has at least about 20 percent weight of thermoplastic. The method further includes sufficiently compacting the fluff into a thermoplastic state sufficient for forming the thermoplastic pre-preg sheet.

Owner:AURIA SOLUTIONS UK I LTD

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS8015951B2Increase heatIncrease profitNon-fuel substance addition to fuelInternal combustion piston enginesSolventOperant conditioning

Systems and methods are provided for extracting components of a mixed fuel into at least one substantially non-polar component and at least one polar fuel component. In one example approach, a volume of a mixed fuel is added to an extractor and a polar solvent is used to extract components of the mixed fuel. The extracted components may be selectively provided to an engine in a ratio based upon engine operating conditions.

Owner:FORD GLOBAL TECH LLC

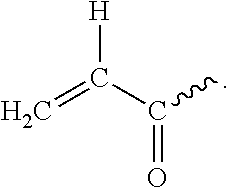

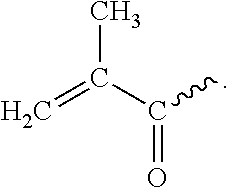

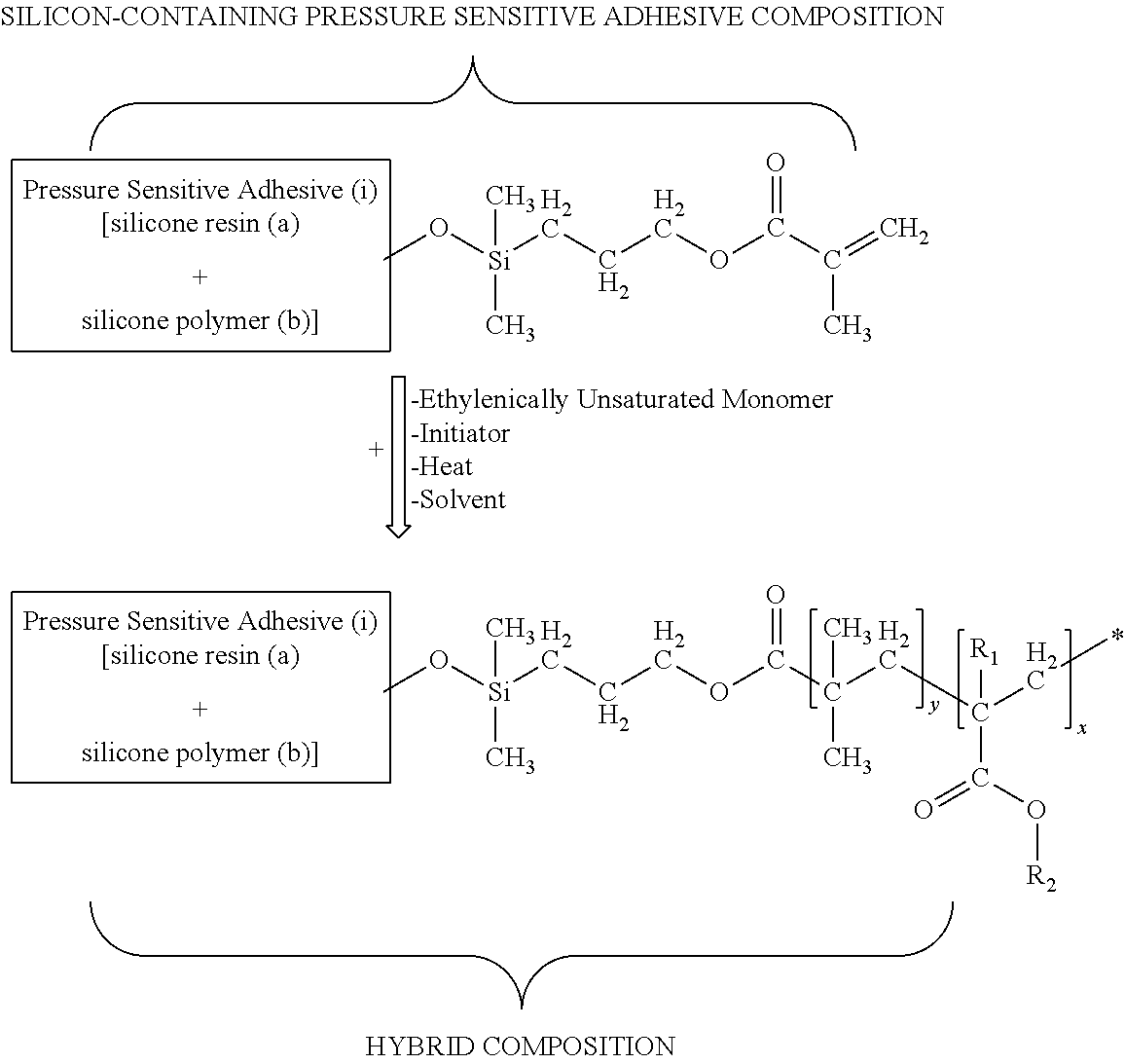

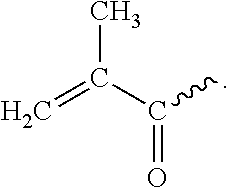

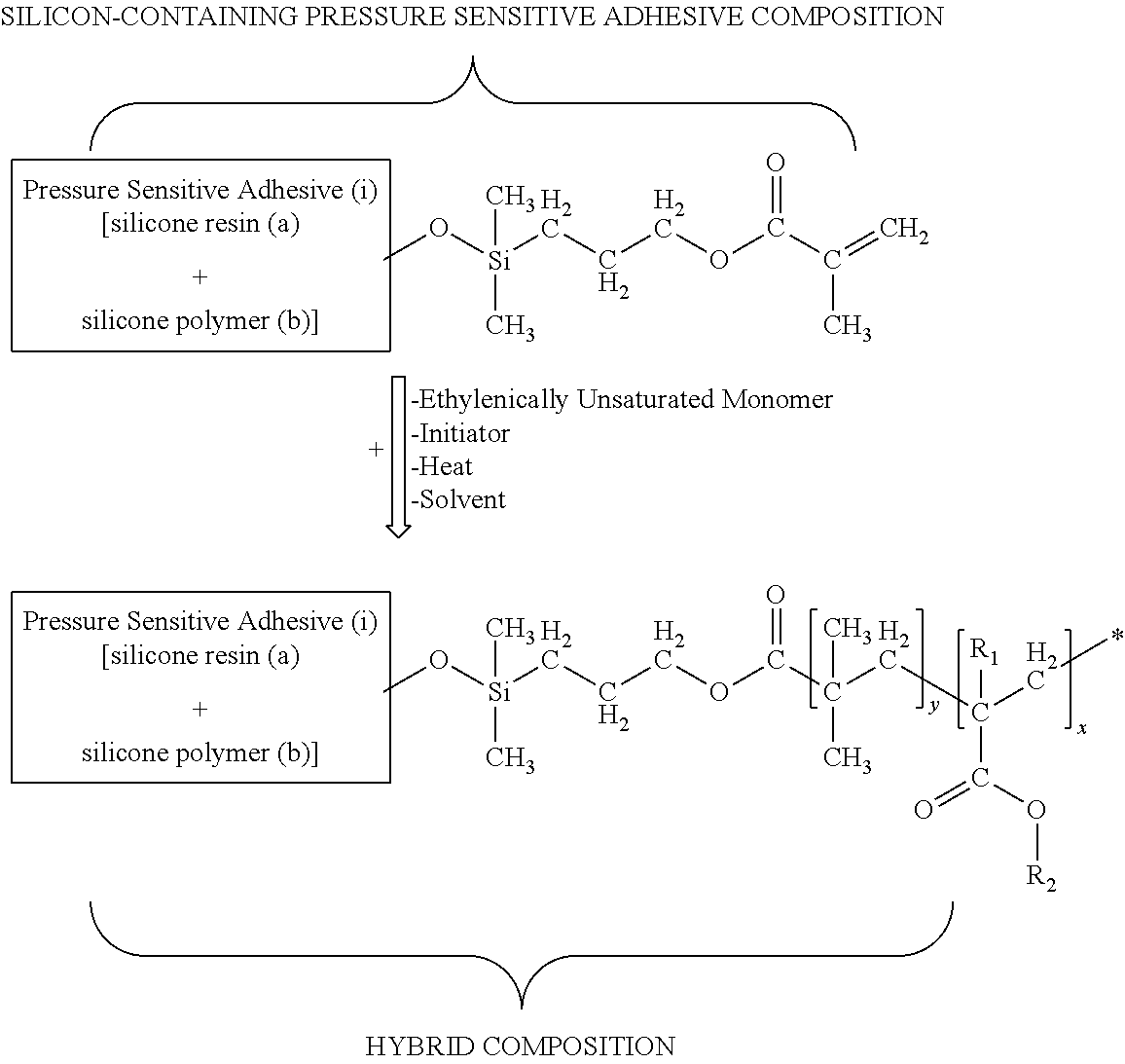

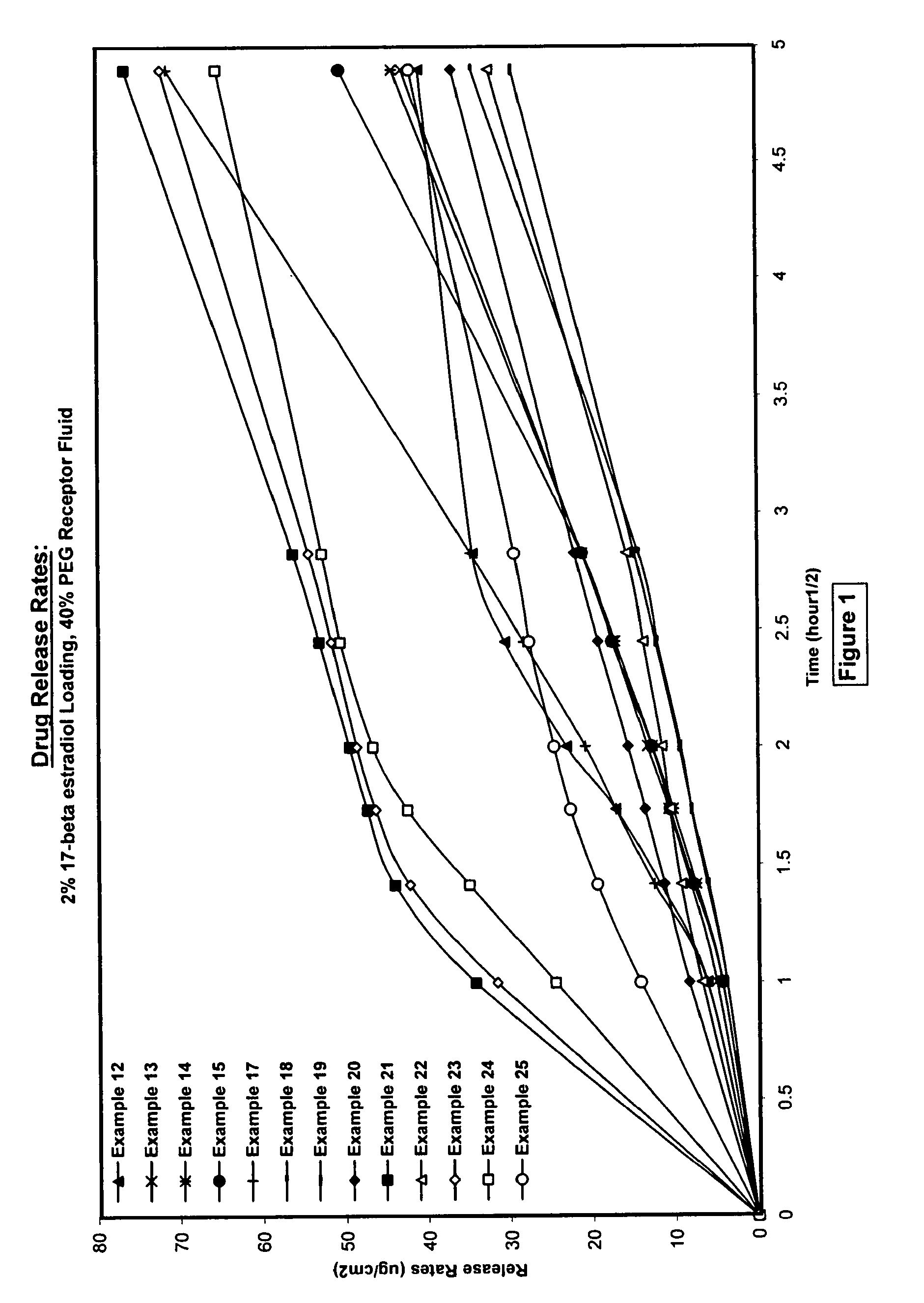

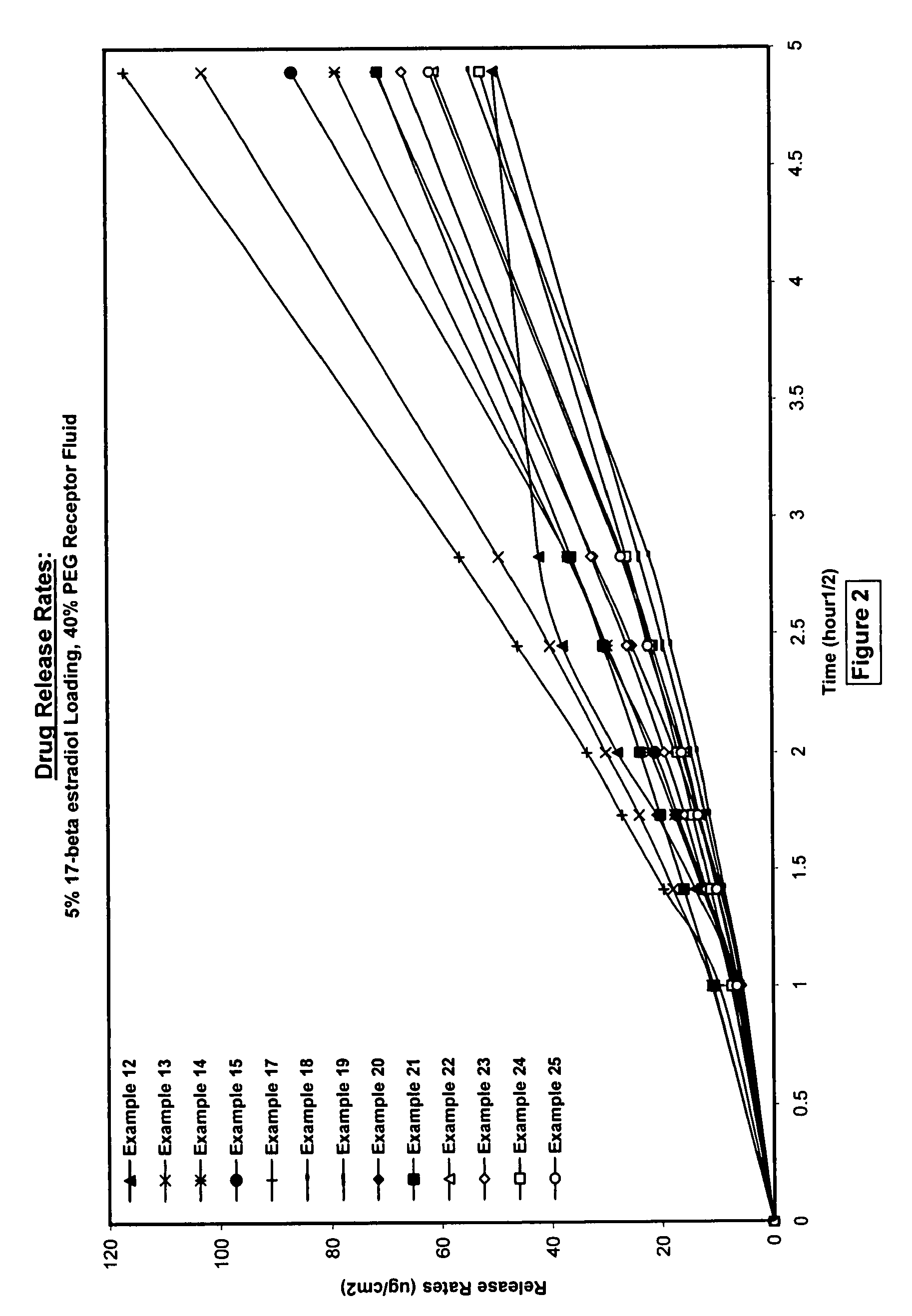

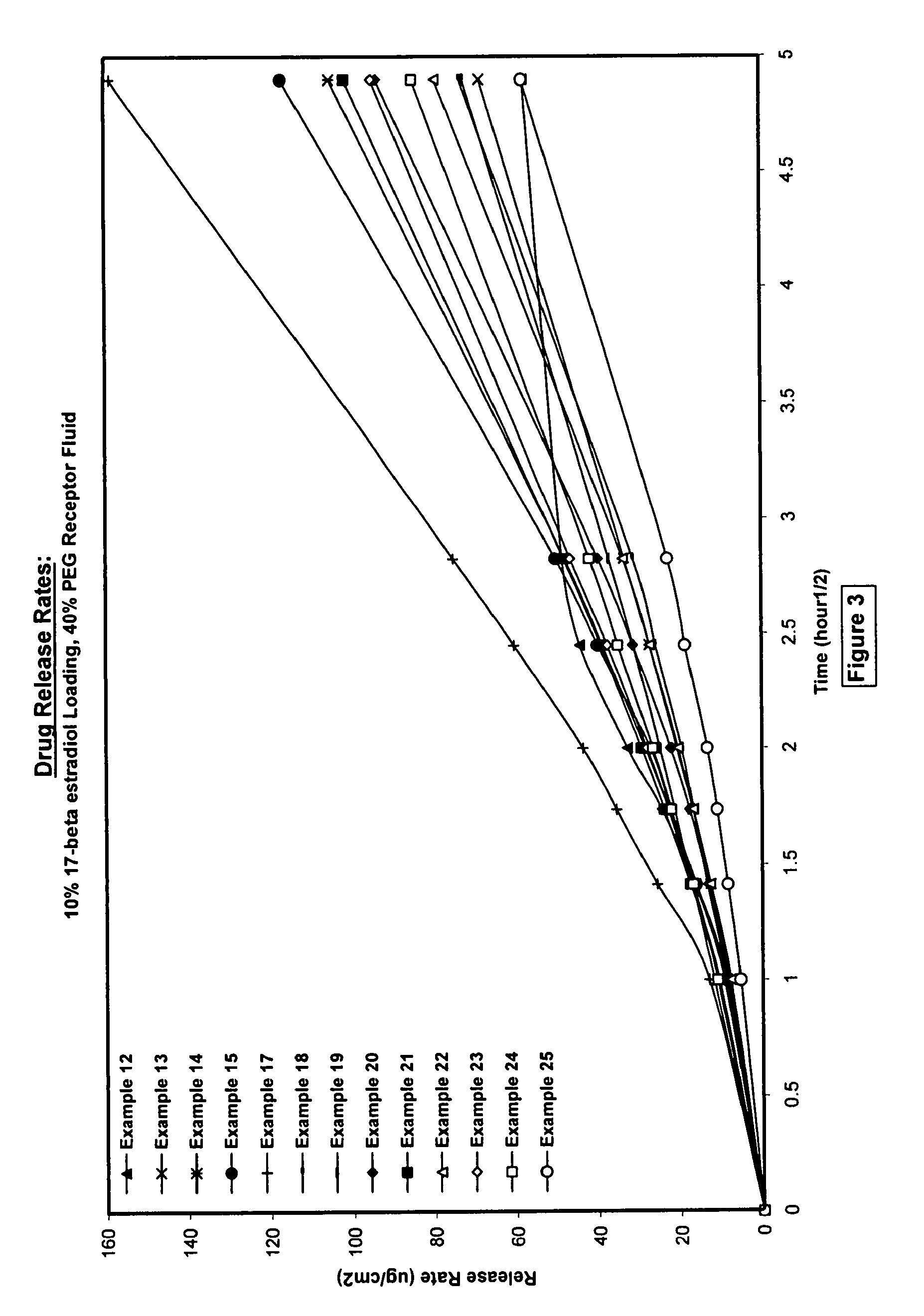

Silicone acrylate hybrid composition and method of making same

ActiveUS20120114737A1Good flexibilityRatio is limitedBiocideOrganic active ingredientsMethacrylateSilicon

A silicone acrylate hybrid composition includes the reaction product of a silicon-containing pressure sensitive adhesive composition, an ethylenically unsaturated monomer, and an initiator. The silicon-containing pressure sensitive adhesive composition includes acrylate or methacrylate functionality. A method of making the hybrid composition includes polymerizing the ethylenically unsaturated monomer and the silicon-containing pressure sensitive adhesive composition in the presence of the initiator.

Owner:DOW CORNING FRANCE +1

Fuel rail assembly including fuel separation membrane

InactiveUS8550058B2Increase heatIncrease profitElectrical controlInternal combustion piston enginesAlcoholHigh rate

As one example, a fuel rail assembly for supplying pressurized fuel to a plurality of cylinders of an engine is provided. The fuel rail assembly includes a fuel rail housing defining an internal fuel rail volume having at least a first region and a second region; a fuel separation membrane element disposed within the fuel rail housing that segregates the first region from the second region. The membrane element can be configured to pass a first component of a fuel mixture such as an alcohol through the membrane element from the first region to the second region at a higher rate than a second component of the fuel mixture such as a hydrocarbon. The separated alcohol and hydrocarbon components can be provided to the engine in varying relative amounts based on operating conditions.

Owner:FORD GLOBAL TECH LLC

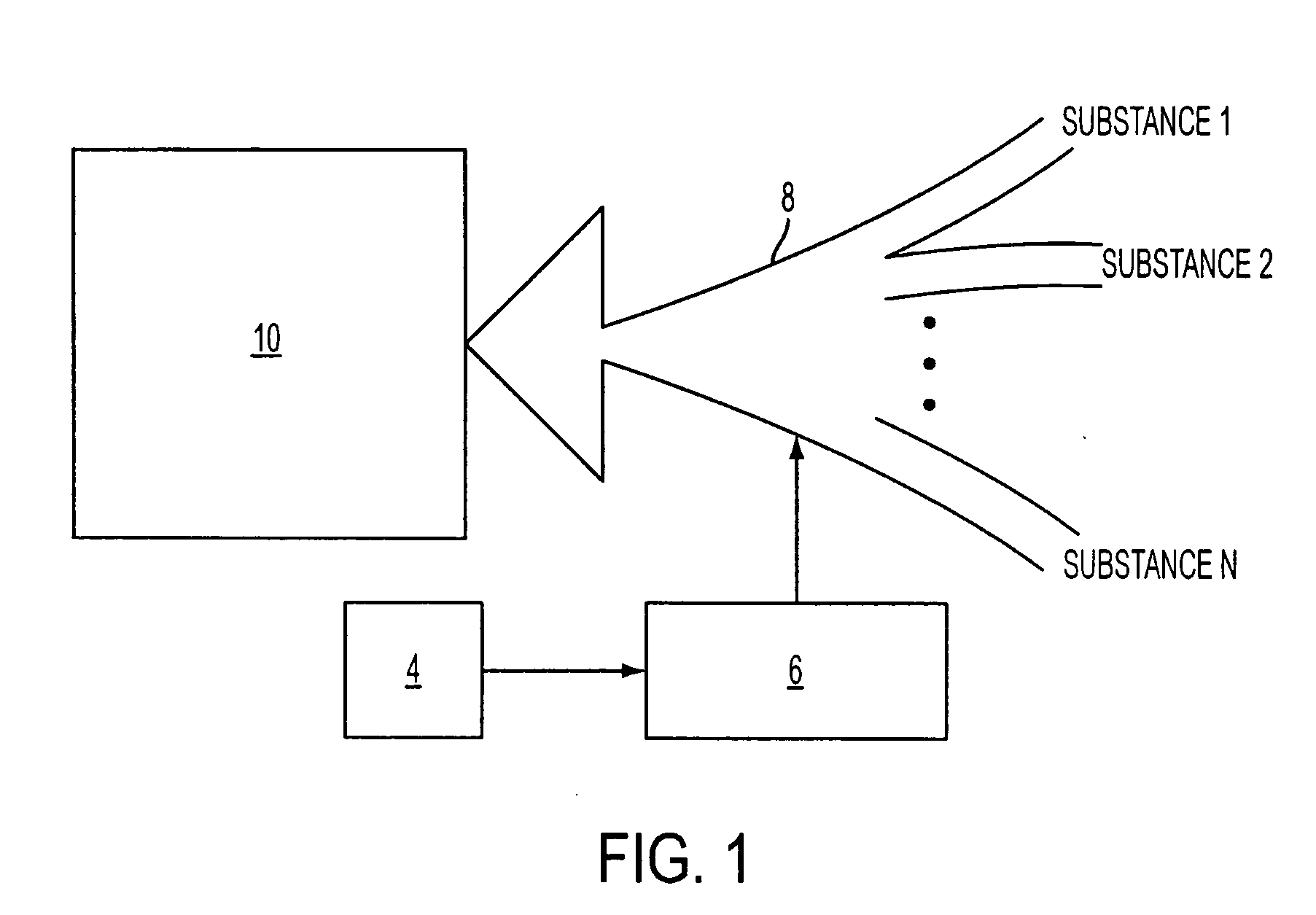

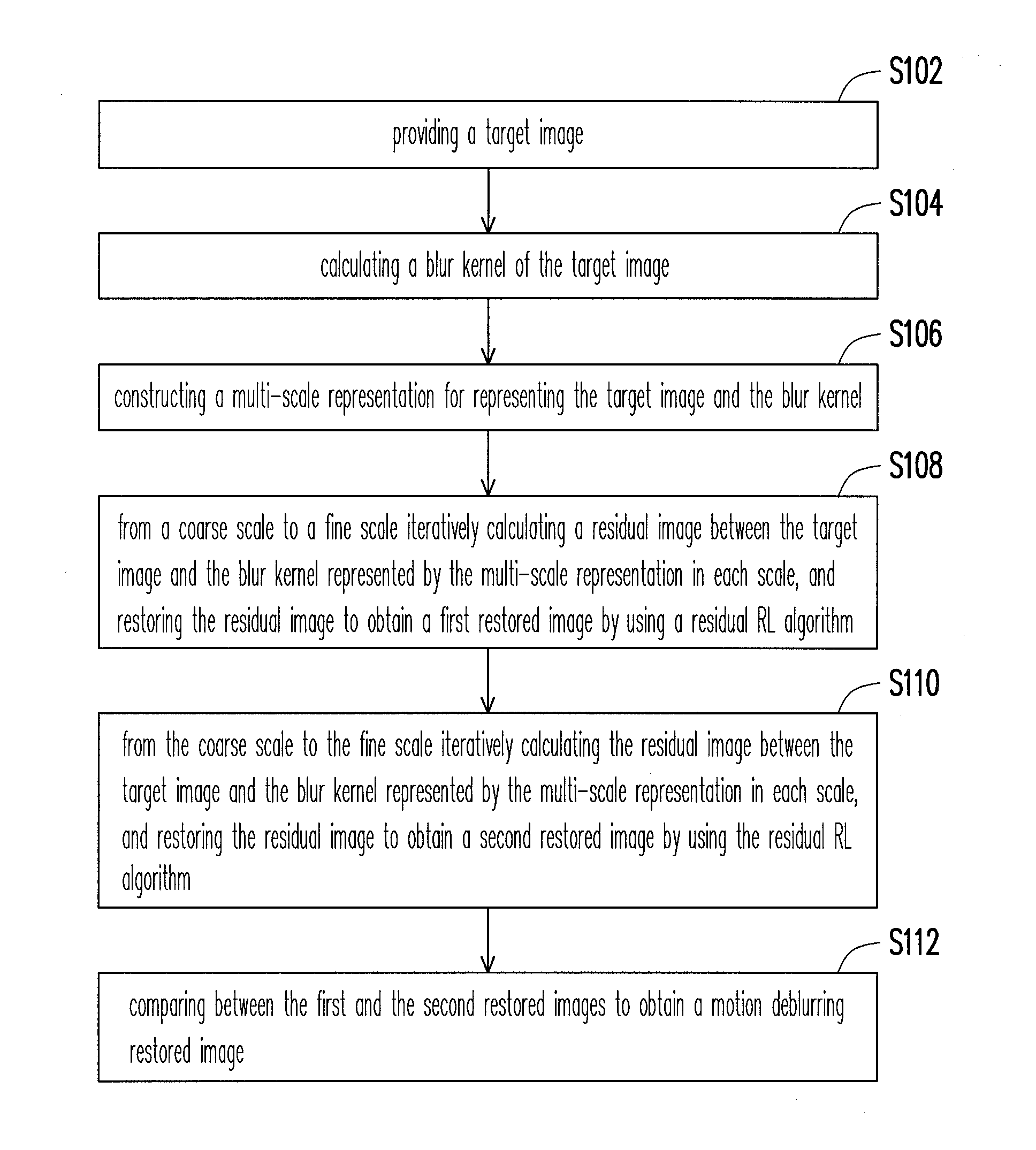

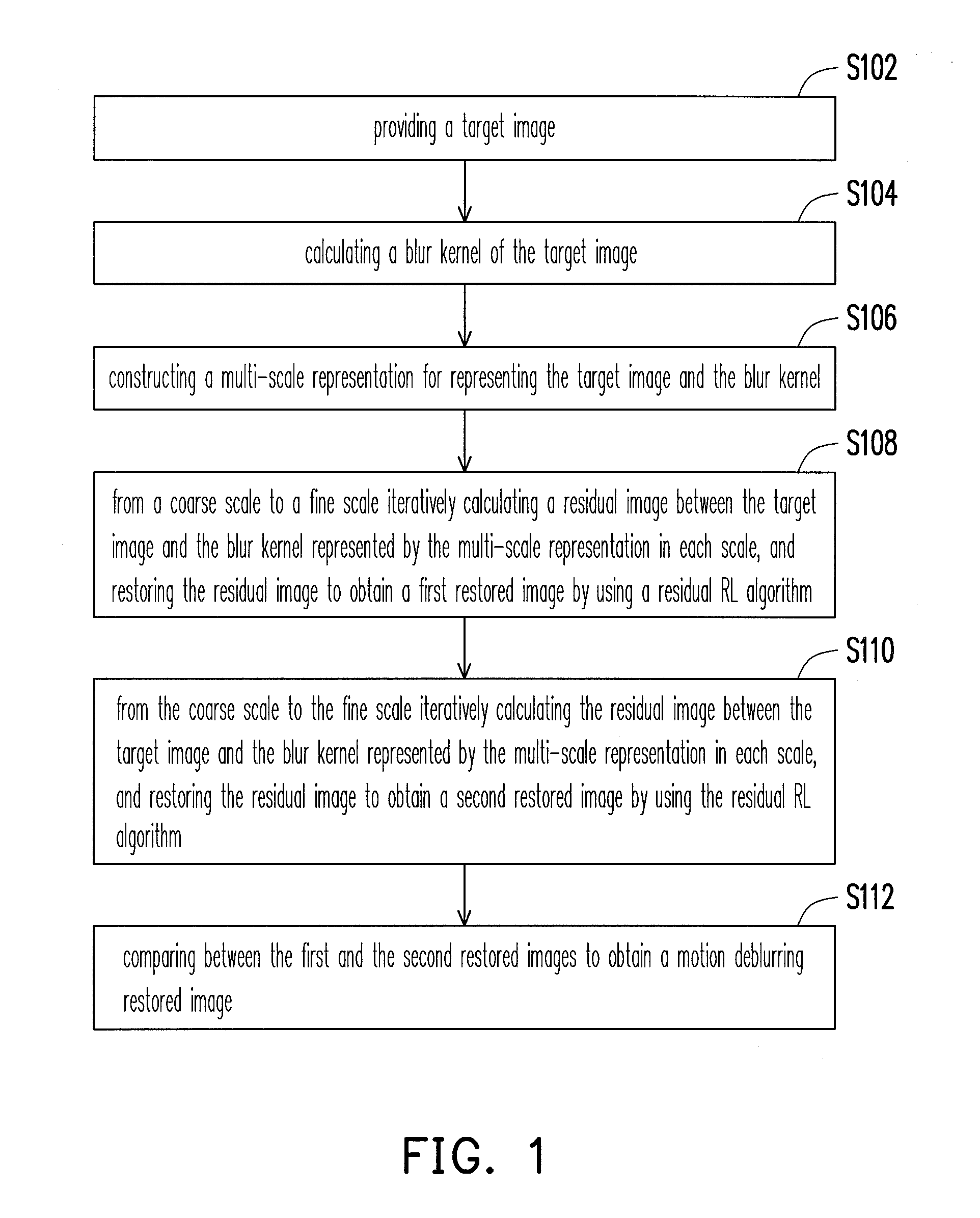

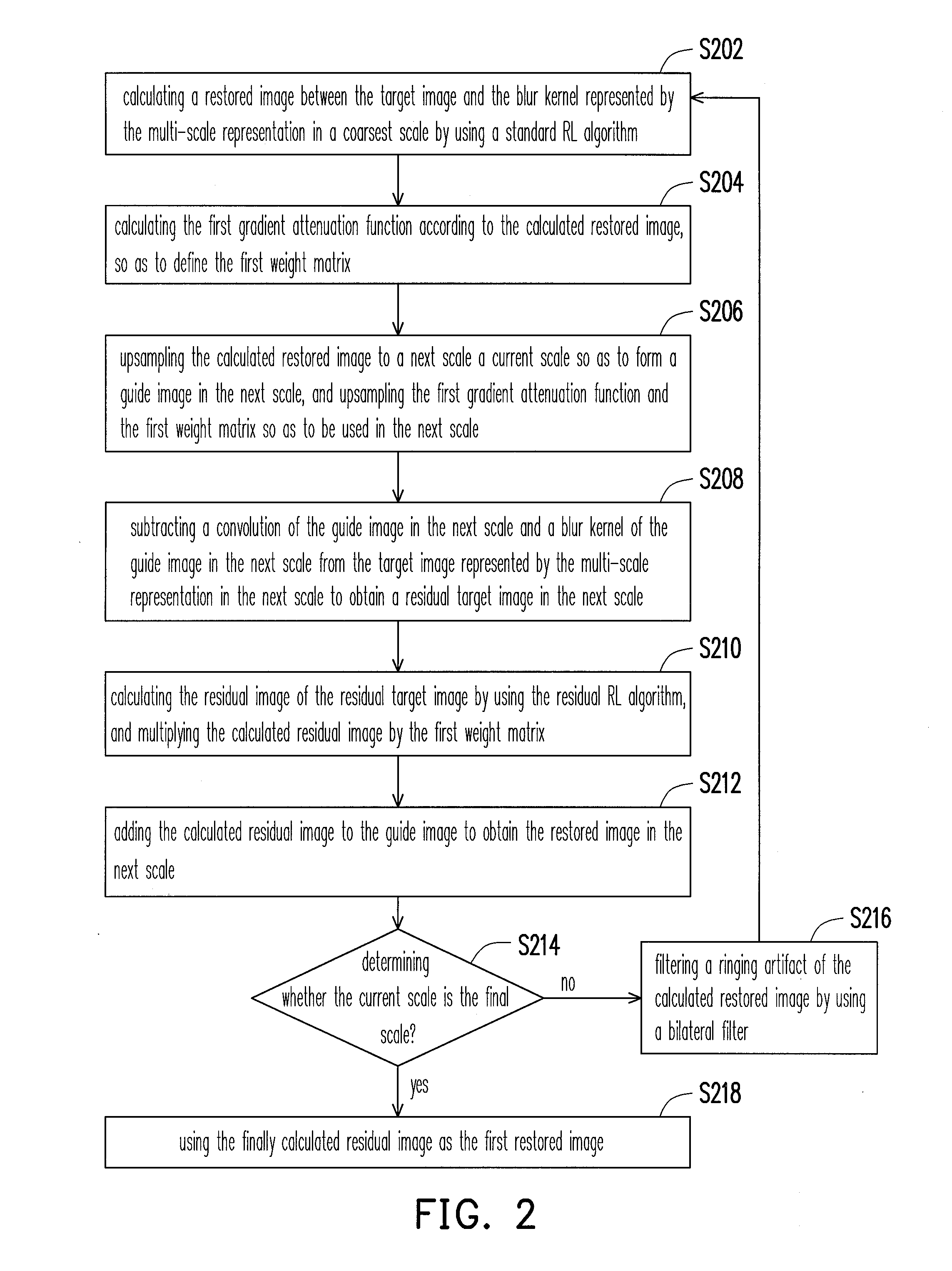

Hierarchical motion deblurring method for single image

InactiveUS20110229044A1Suppressing ringing artifactSuppress artifactsImage enhancementTelevision system detailsSingle imageAttenuation function

A hierarchical motion deblurring method for a single image is provided. In the method, a blur kernel of a target image is calculated and a multi-scale representation for representing the target image and the blur kernel is constructed. Then, a gradient attenuation function and a strong edge suppression function are applied to a residual Richardson-Lucy algorithm, so as to iteratively calculate a residual image between the blur kernel and the target image represented by the representation in each scale and restore the residual image to obtain a first restored image and a second restored image. Finally, the two restored images are compared so as to obtain a motion deblurring image.

Owner:NOVATEK MICROELECTRONICS CORP

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS7337754B2Increase heatIncrease profitInternal combustion piston enginesNon-fuel substance addition to fuelHigh rateFuel tank

An apparatus comprising an internal combustion engine, a fuel tank, a fuel separator disposed fluidically between the fuel tank and the engine, wherein the fuel separator comprises first and second passageways separated at least partially by a selective barrier that selectively transports a first fuel in a fuel mixture at a higher rate than a second fuel in the fuel mixture, and wherein the first passageway is configured to receive an input of fuel from the fuel tank, and an extraction fluid source in fluid communication with the second passageway of the fuel separator.

Owner:FORD GLOBAL TECH LLC

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS7665428B2Increase heatIncrease profitNon-fuel substance addition to fuelInternal combustion piston enginesFuel tankEngineering

Owner:FORD GLOBAL TECH LLC

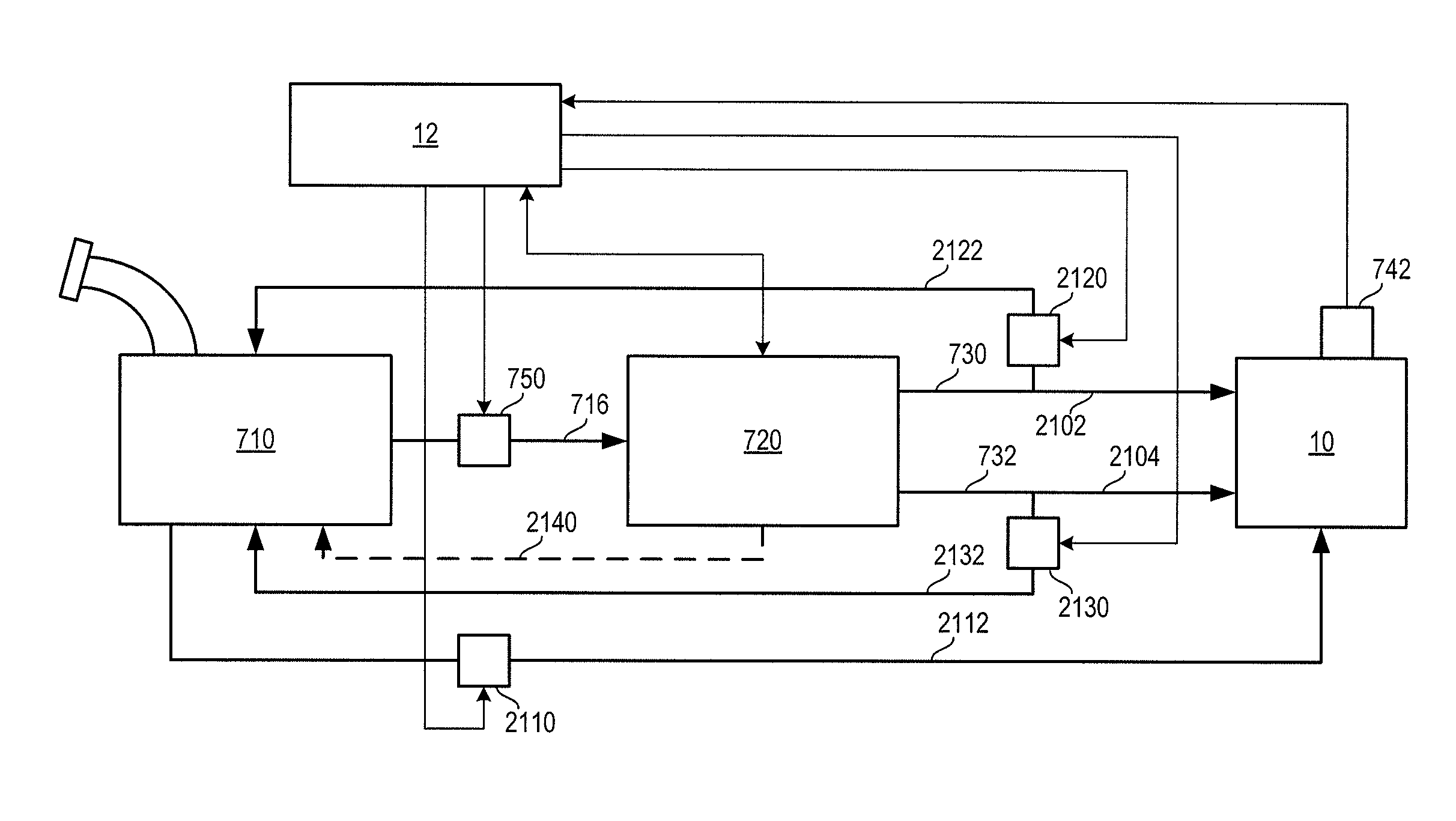

Control for knock suppression fluid separator in a motor vehicle

InactiveUS8267074B2Increase heatIncrease profitElectrical controlInternal combustion piston enginesMobile vehicleMotorized vehicle

Owner:FORD GLOBAL TECH LLC

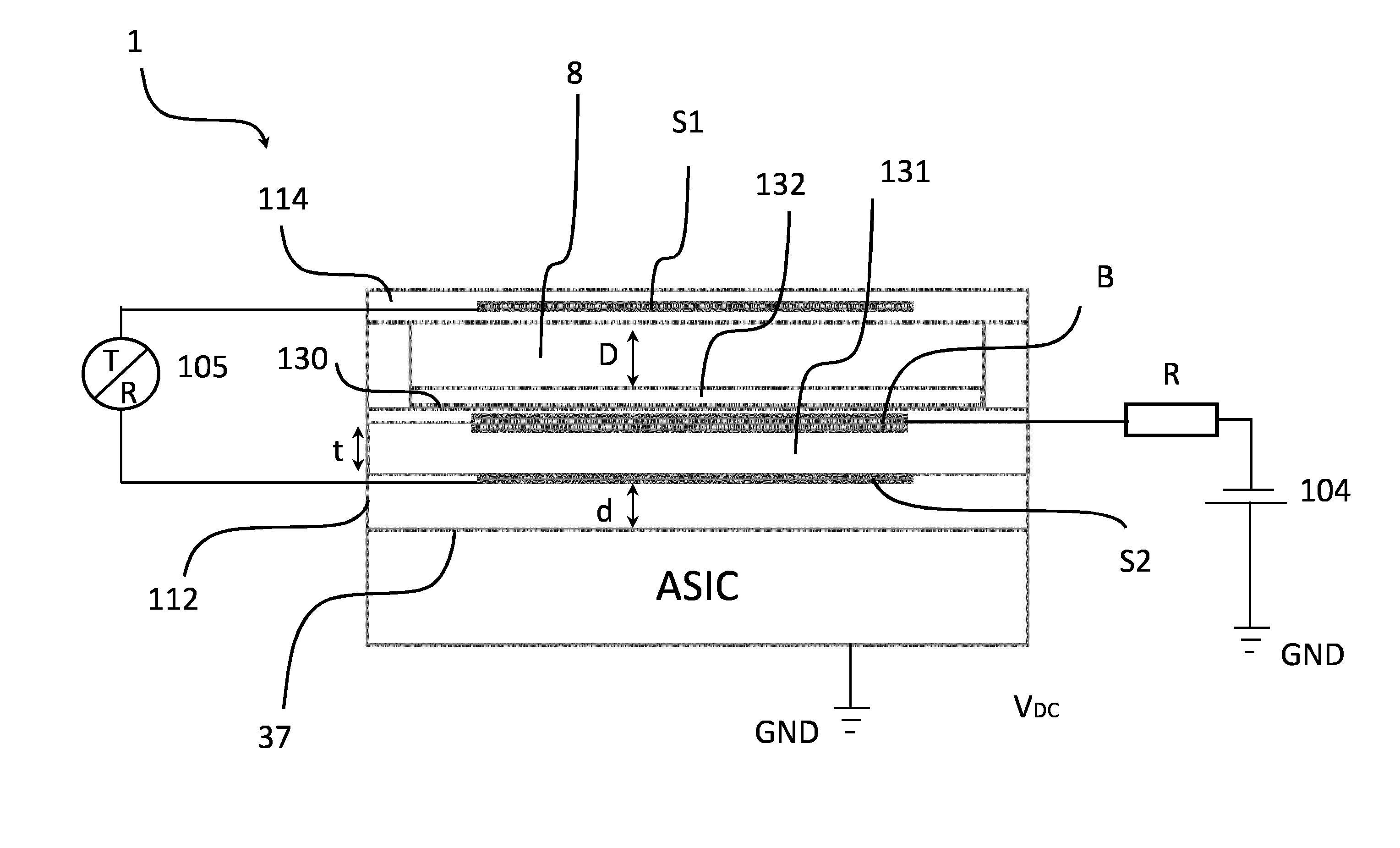

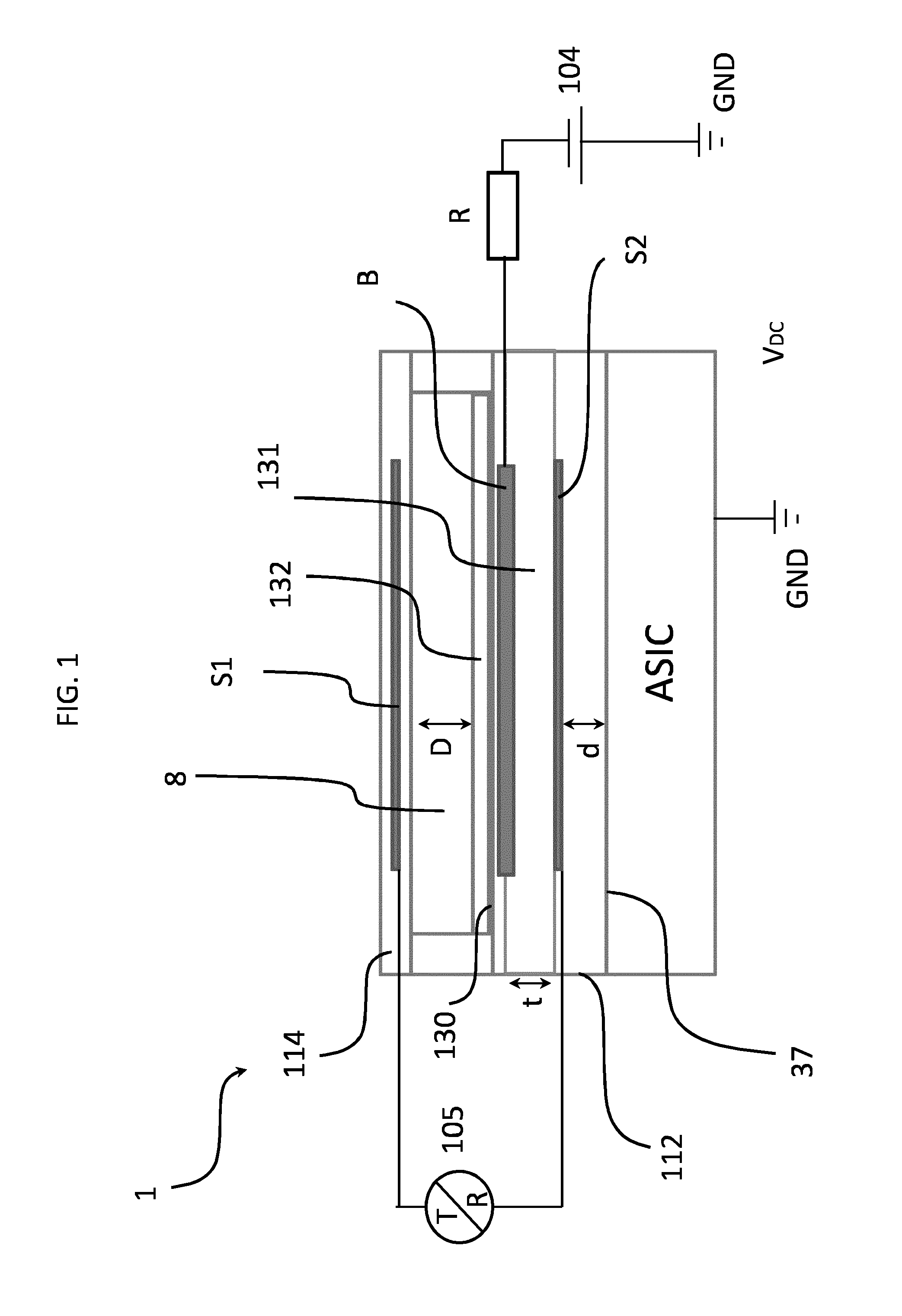

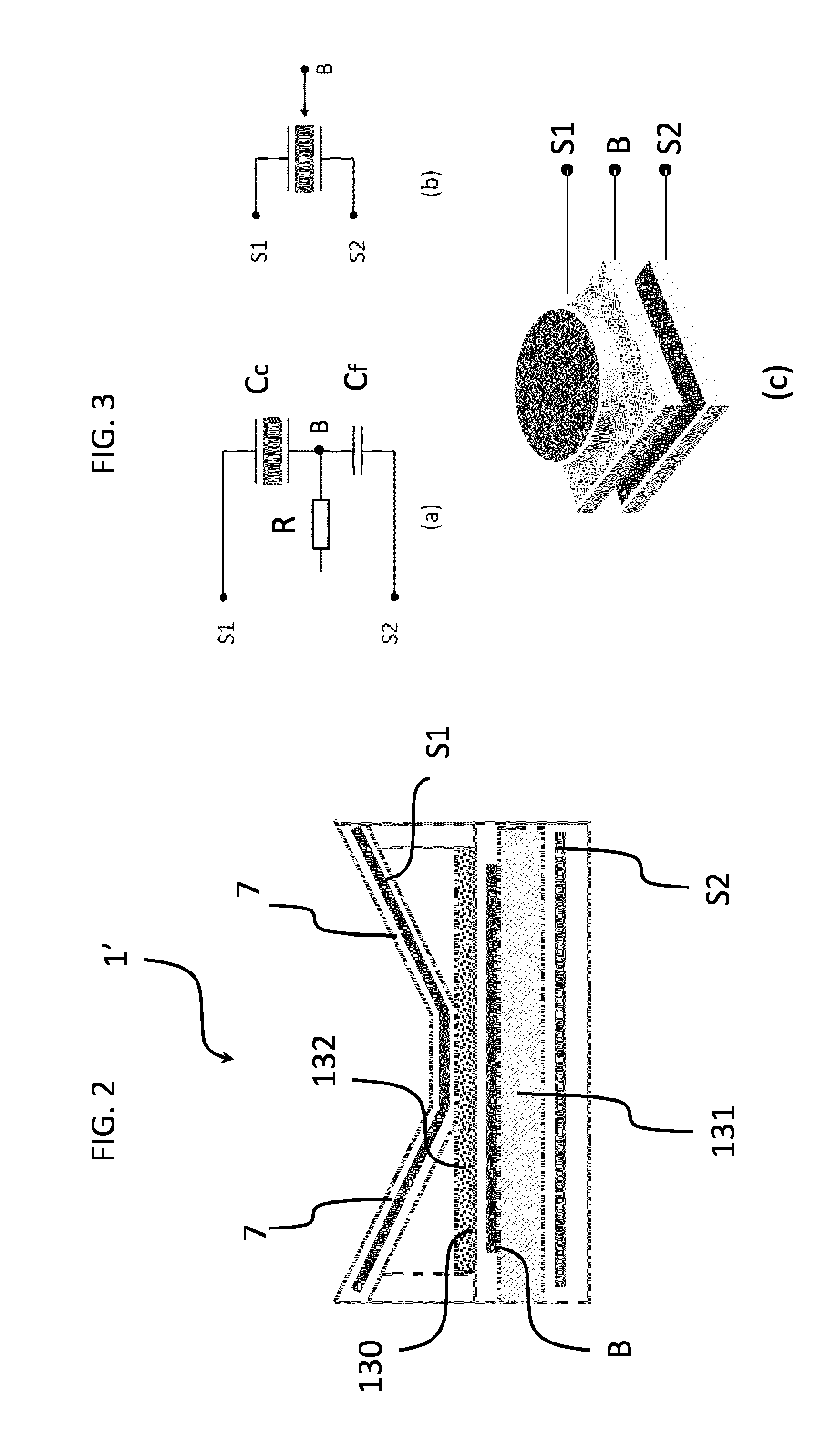

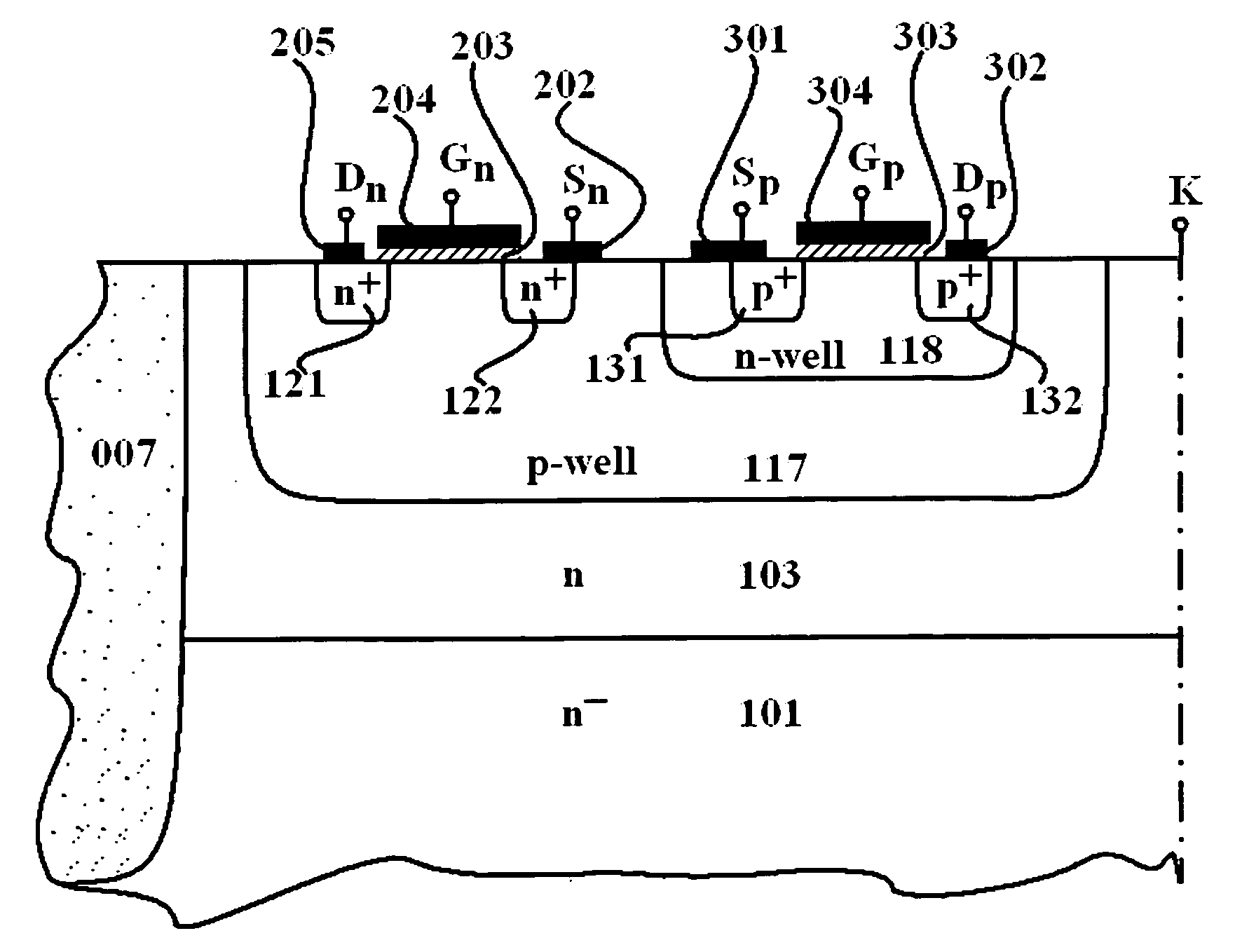

Monolithically integrated three electrode cmut device

ActiveUS20160310992A1Improved and efficient high voltage supplySuitable for miniaturizationUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationCapacitive micromachined ultrasonic transducersCell membrane

A capacitive micromachined ultrasonic transducer (CMUT) cell comprising three electrodes: a first electrode coupled to a cell membrane; a second electrode embedded into a cell floor opposing the first electrode and separated therefrom by a gas or vacuum cavity; and a third electrode opposing the second electrode on the cavity side, wherein a dielectric layer is sandwiched between the second electrode and the third electrode to create a capacitive relation between the second electrode and the third electrode. The three electrode CMUT cell provides an ultrasound transducer with two actively driven (controlled) electrodes.

Owner:KONINKLJIJKE PHILIPS NV

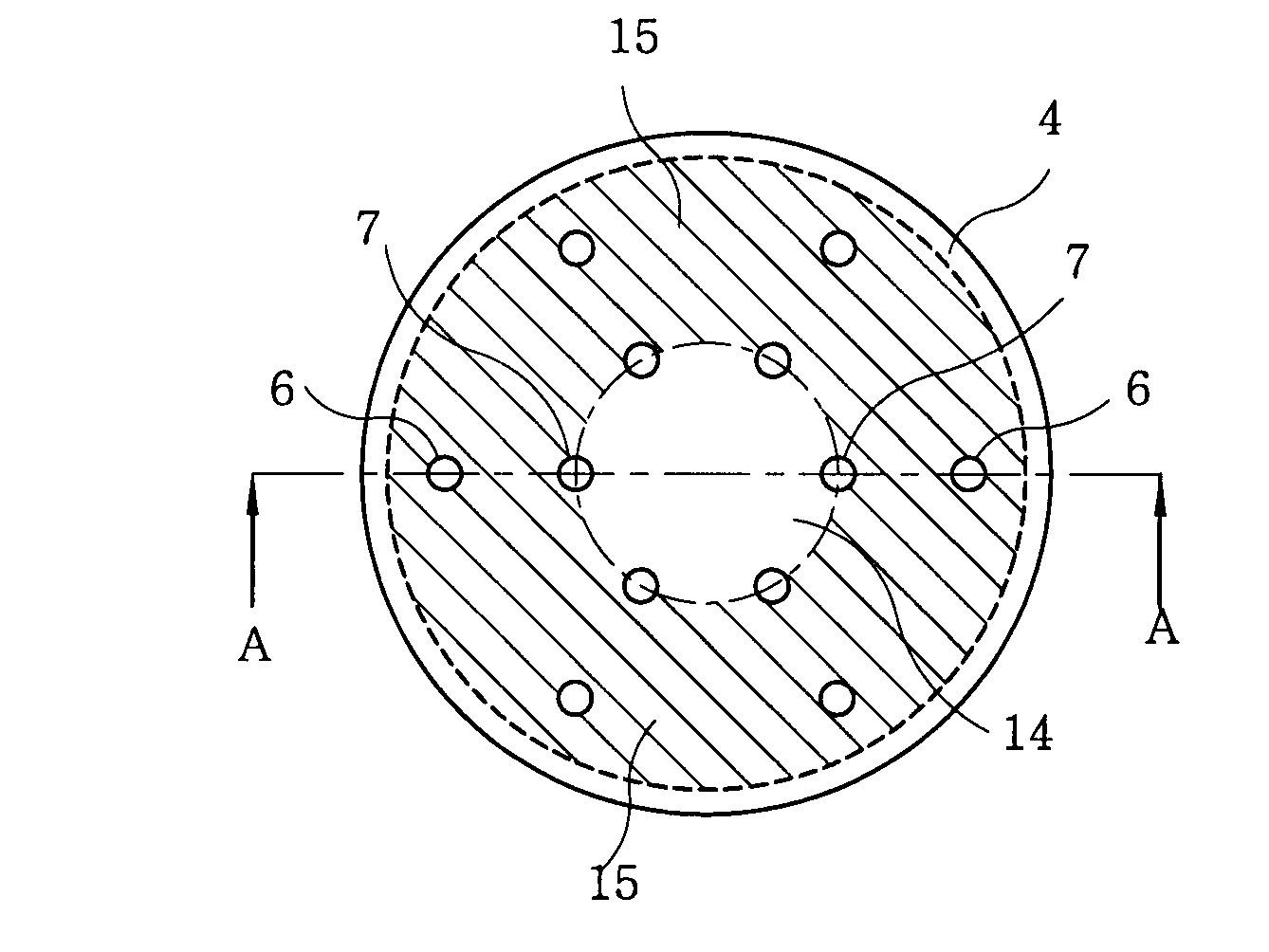

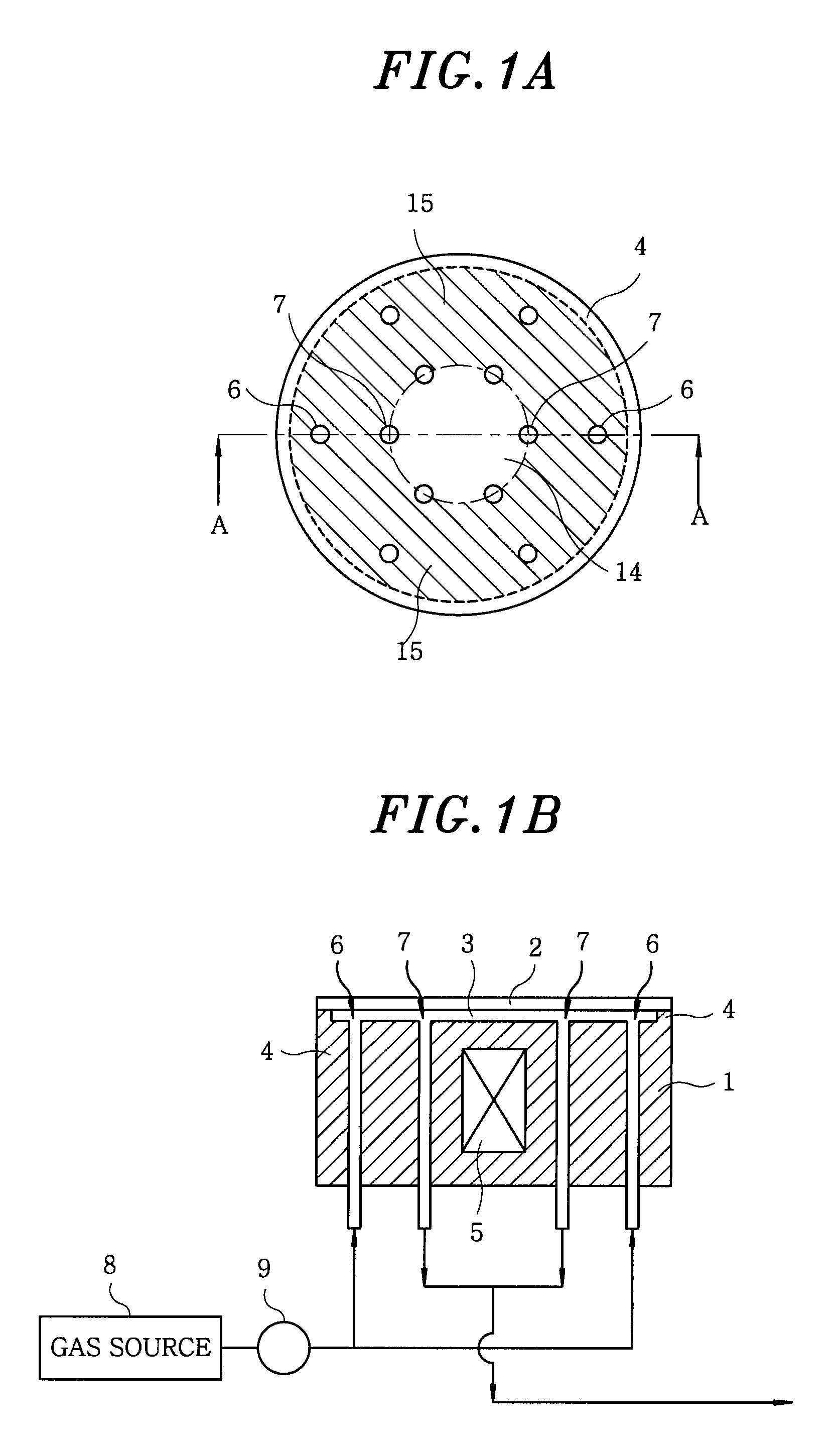

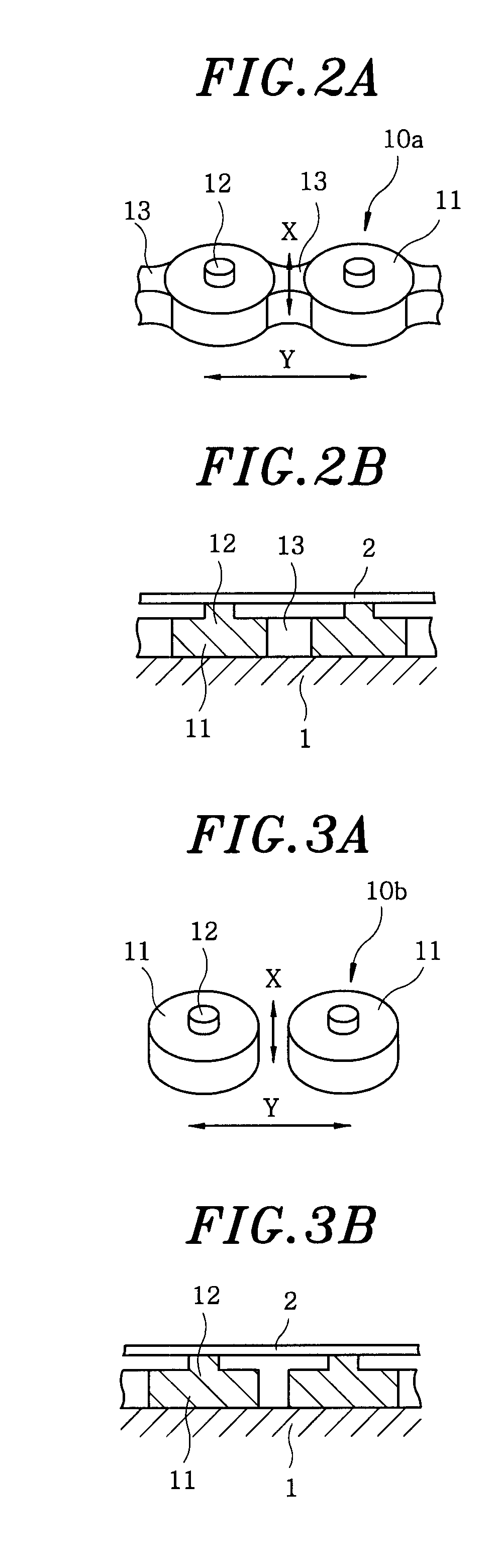

Substrate mounting table, substrate processing apparatus and temperature control method

InactiveUS20090233443A1Ratio is limitedImprove controllabilityElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlPeripheral

A substrate mounting table for mounting a substrate in a substrate processing apparatus, includes a table body having a substrate mounting surface. An annular peripheral ridge portion is formed on the substrate mounting surface of the table body. The annular peripheral ridge portion makes contact with a peripheral edge portion of the substrate and forms a closed space for circulation of a heat transfer gas below the substrate, when the substrate is mounted on the substrate mounting surface of the table body. The table body has a heat transfer gas inlet port formed in a peripheral edge region of the substrate mounting surface, a heat transfer gas outlet port formed in a central region of the substrate mounting surface, and a flow path formed on the substrate mounting surface for forming a conductance C when the heat transfer gas flows from the inlet port to the outlet port.

Owner:TOKYO ELECTRON LTD

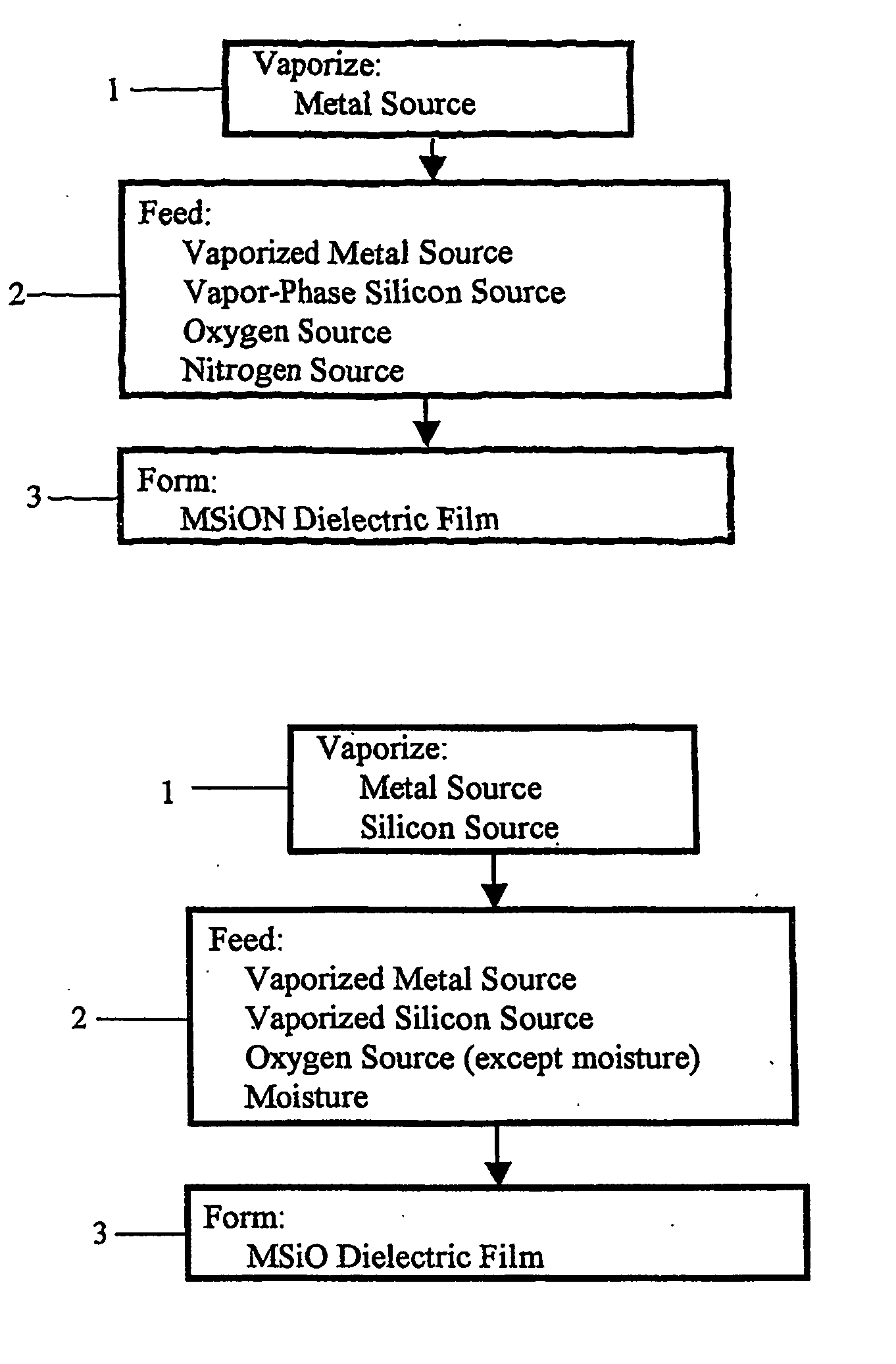

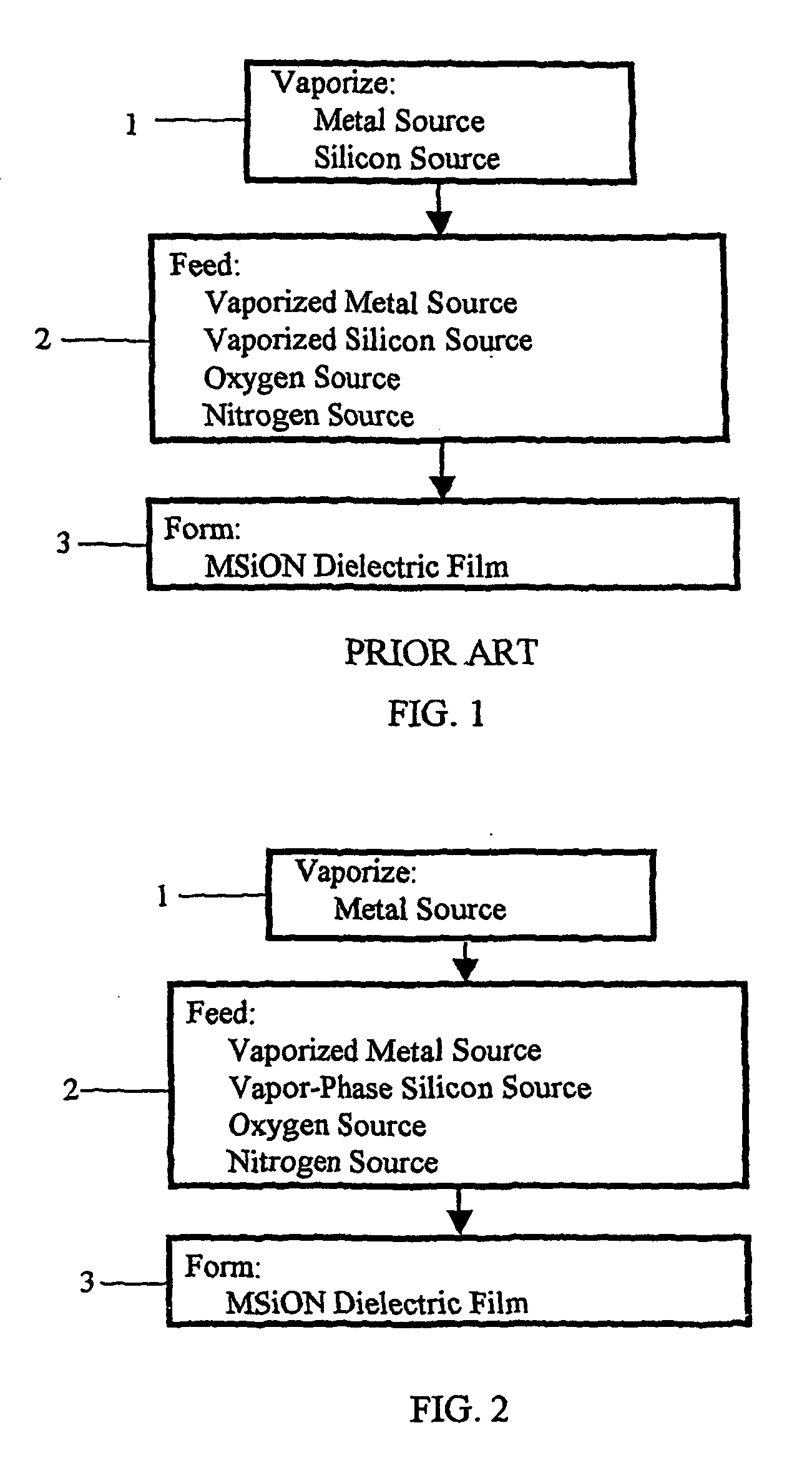

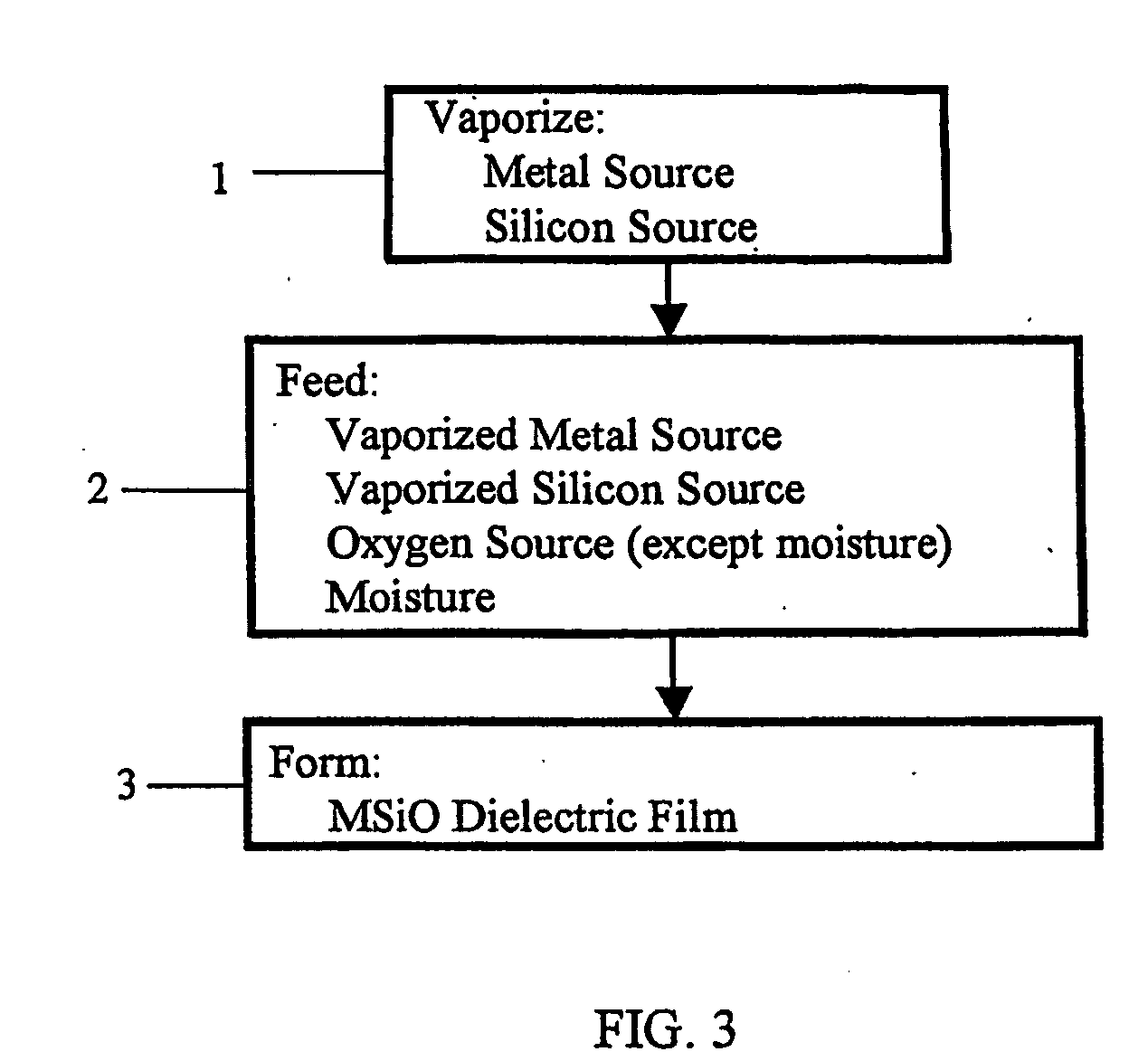

Method for forming dielectric or metallic films

InactiveUS20070190807A1Maintain good propertiesImprove conductivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNitride

Method for producing a metal silicon (oxy)nitride by introducing a carbon-free silicon source (for example, (SiH3)3N), a metal precursor with the general formula MXn (for example, Hf(NEt2)4), and an oxidizing agent (for example, O2) into a CVD chamber and reacting same at the surface of a substrate. MsiN, MSIo and / or MSiON films may be obtained. These films are useful are useful as high k dielectrics films.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Silicone Acrylate Hybride Composition and Method Of Making Same

ActiveUS20090196911A1Ratio is limitedReduce solubilitySenses disorderAntimycoticsMethacrylateSilicon

A silicone acrylate hybrid composition includes the reaction product of a silicon-containing pressure sensitive adhesive composition, an ethylenically unsaturated monomer, and an initiator. The silicon-containing pressure sensitive adhesive composition includes acrylate or methacrylate functionality. A method of making the hybrid composition includes polymerizing the ethylenically unsaturated monomer and the silicon-containing pressure sensitive adhesive composition in the presence of the initiator.

Owner:DOW SILICONES CORP

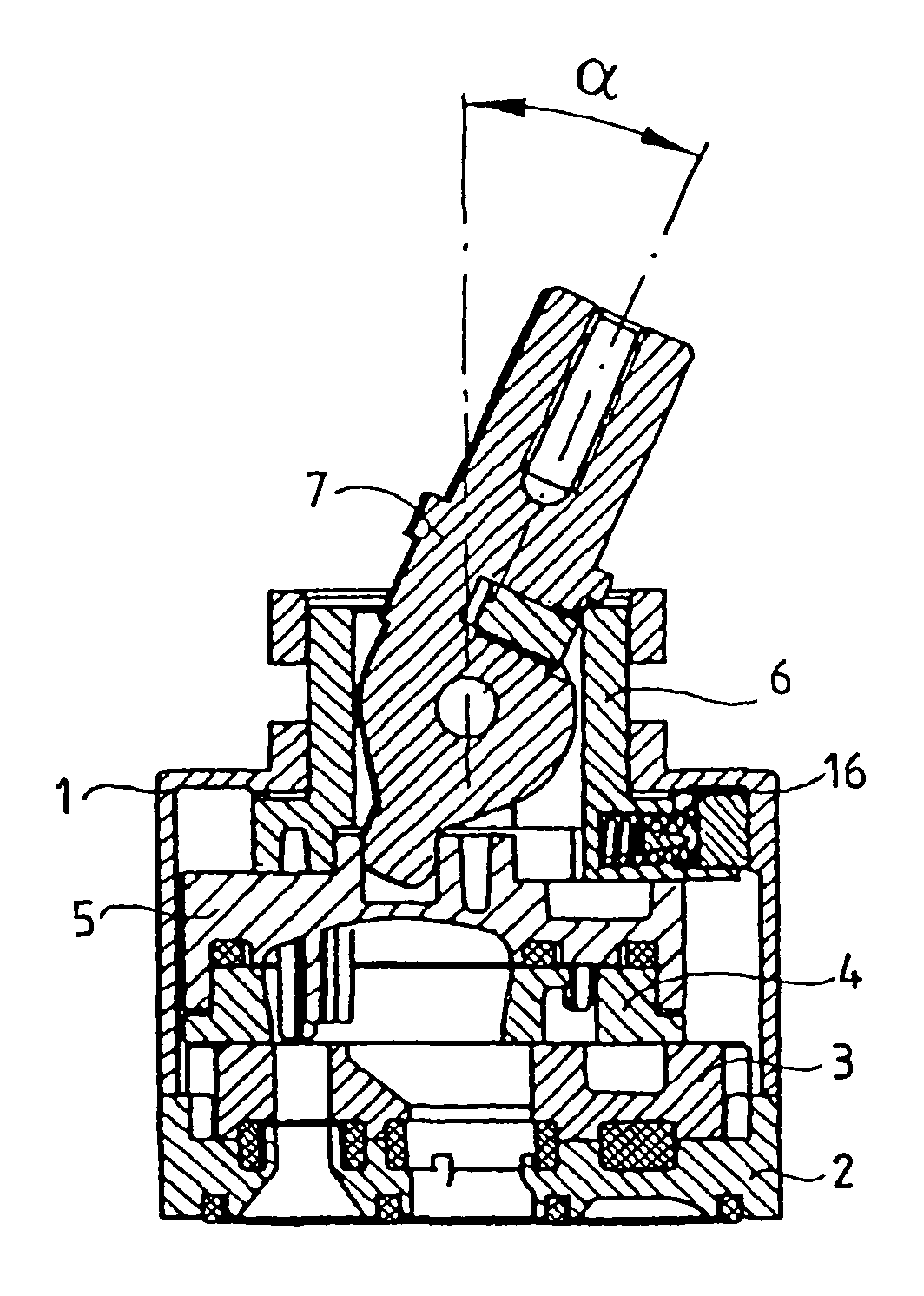

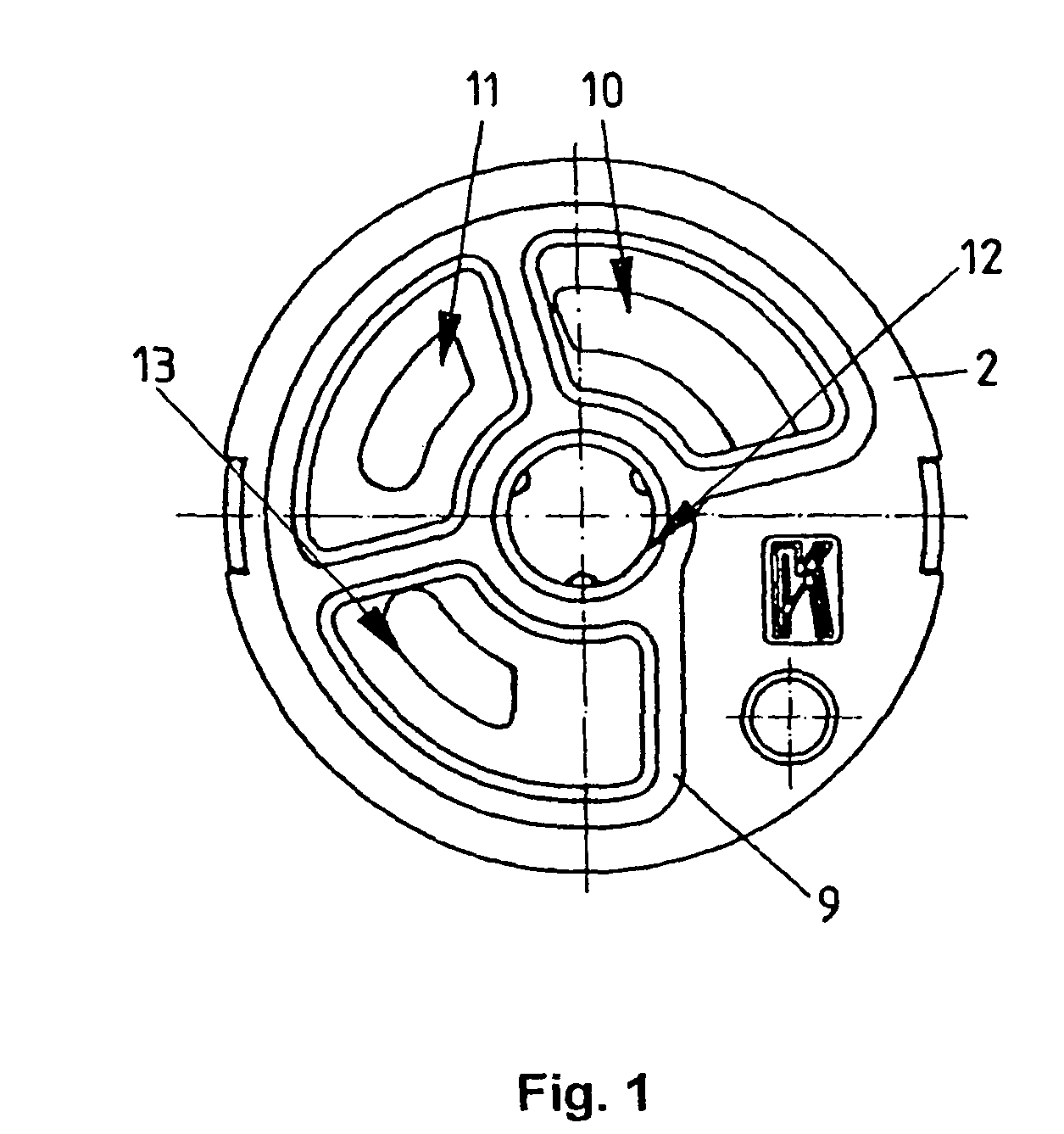

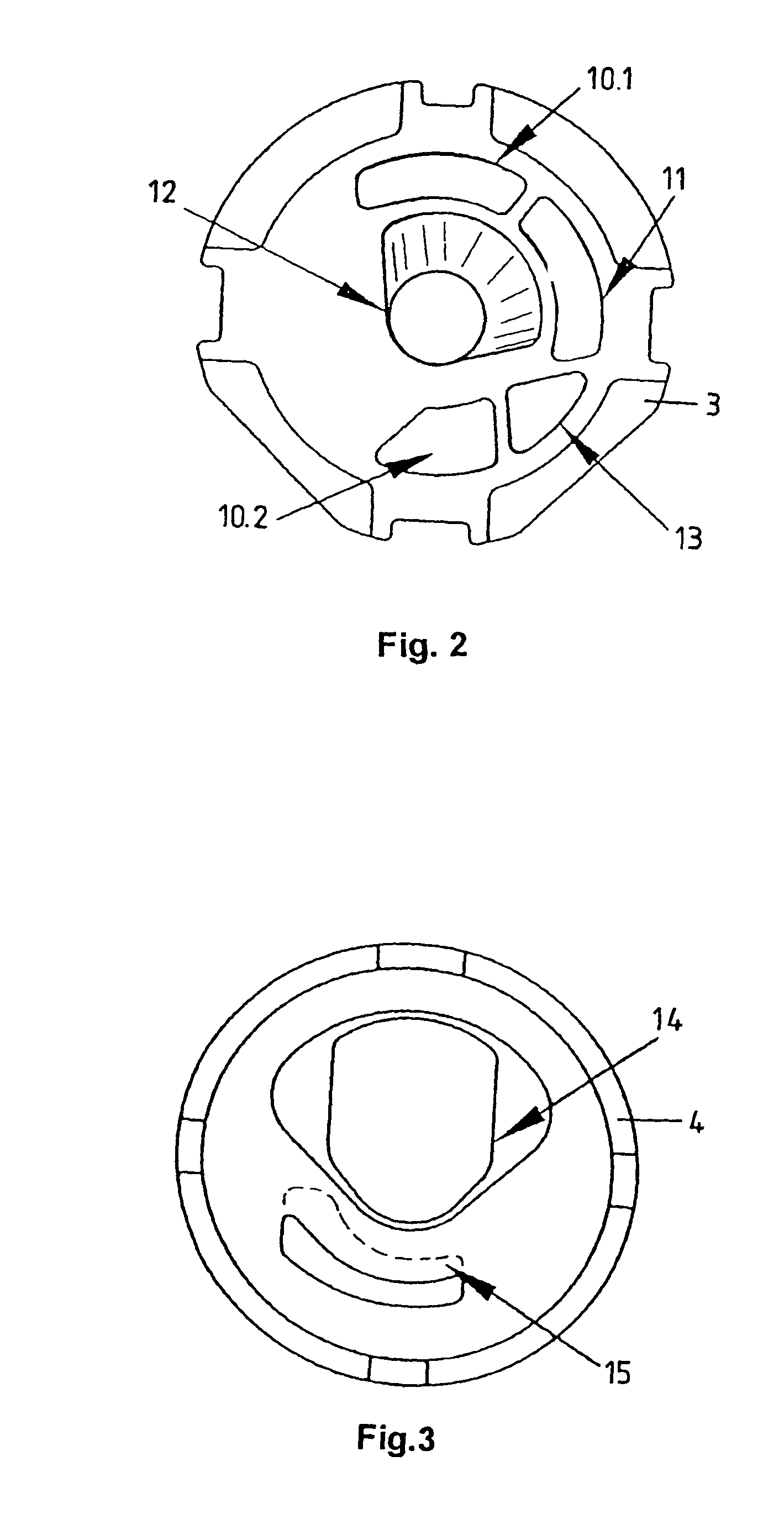

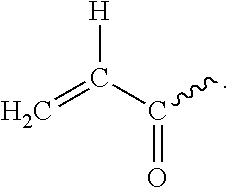

Insertion piece to a single-grip mixing faucet

ActiveUS8109292B2Simple handlingSimplifying developmentWatering devicesMultiple way valvesWarm waterMechanical engineering

An insertion piece to a single-grip mixing faucet developed as a control unit. On one side, the control unit is connected to a footing having warm and cold water inlets. On the other side, the control unit is connected to a driving arm. The control unit includes a fixed inlet disc and a moving control disc arranged above the inlet disc to form together a plane sealing. The side of the inlet disc opposite the control disc is coupled to the footing, whereas the side of the control disc opposite the inlet disc is in connection with a ceramic moving element, which, in turn, is in connection with the driving arm. The inlet disc includes at least one inlet opening for warm water, at least one inlet opening for cold water, and an outlet hole forming at least two outlet openings, preferably one for tub filling and one for shower filling. The driving arm independently controls the separate outlets.

Owner:KEROX IPARI & KERESKEDELMI

Silicone acrylate hybrid composition and method of making same

ActiveUS8614278B2Ratio is limitedReduce solubilityBiocideOrganic active ingredientsMethacrylateSilicon

Owner:DOW CORNING FRANCE +1

Silicone acrylate hybride composition and method of making same

ActiveUS8124689B2Ratio is limitedReduce solubilitySenses disorderNervous disorderMethacrylateSilicon

A silicone acrylate hybrid composition includes the reaction product of a silicon-containing pressure sensitive adhesive composition, an ethylenically unsaturated monomer, and an initiator. The silicon-containing pressure sensitive adhesive composition includes acrylate or methacrylate functionality. A method of making the hybrid composition includes polymerizing the ethylenically unsaturated monomer and the silicon-containing pressure sensitive adhesive composition in the presence of the initiator.

Owner:DOW SILICONES CORP

Method for fabricating composite pressure vessels

InactiveUS6565793B1Speed up the processRatio is limitedLabelling non-rigid containersLaminationFiberPolytetramethylene terephthalate

A process of fabricating a composite vessel includes the steps of: A) fabricating a thermoplastic liner for the vessel; B) overlaying a layer comprising fiber and a thermoplastic material (preferably by winding commingled filaments, rovings or yarns) onto the thermoplastic liner to obtain a composite intermediate structure (the fiber and thermoplastic material can be heated if desired during the overlaying, e.g. winding, step); C) heating the composite intermediate structure in a mold while applying at least one force thereto tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold; D) continuing step C) until the thermoplastic liner and the overlaid layer consolidate to form a composite vessel; E) cooling the mold and composite vessel until the composite vessel is solidified; and F) removing the formed composite vessel from the mold. The at least one force applied during step C) may be obtained by introducing gas pressure into the interior of the composite intermediate structure. Suitable materials for the thermoplastic material include: polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

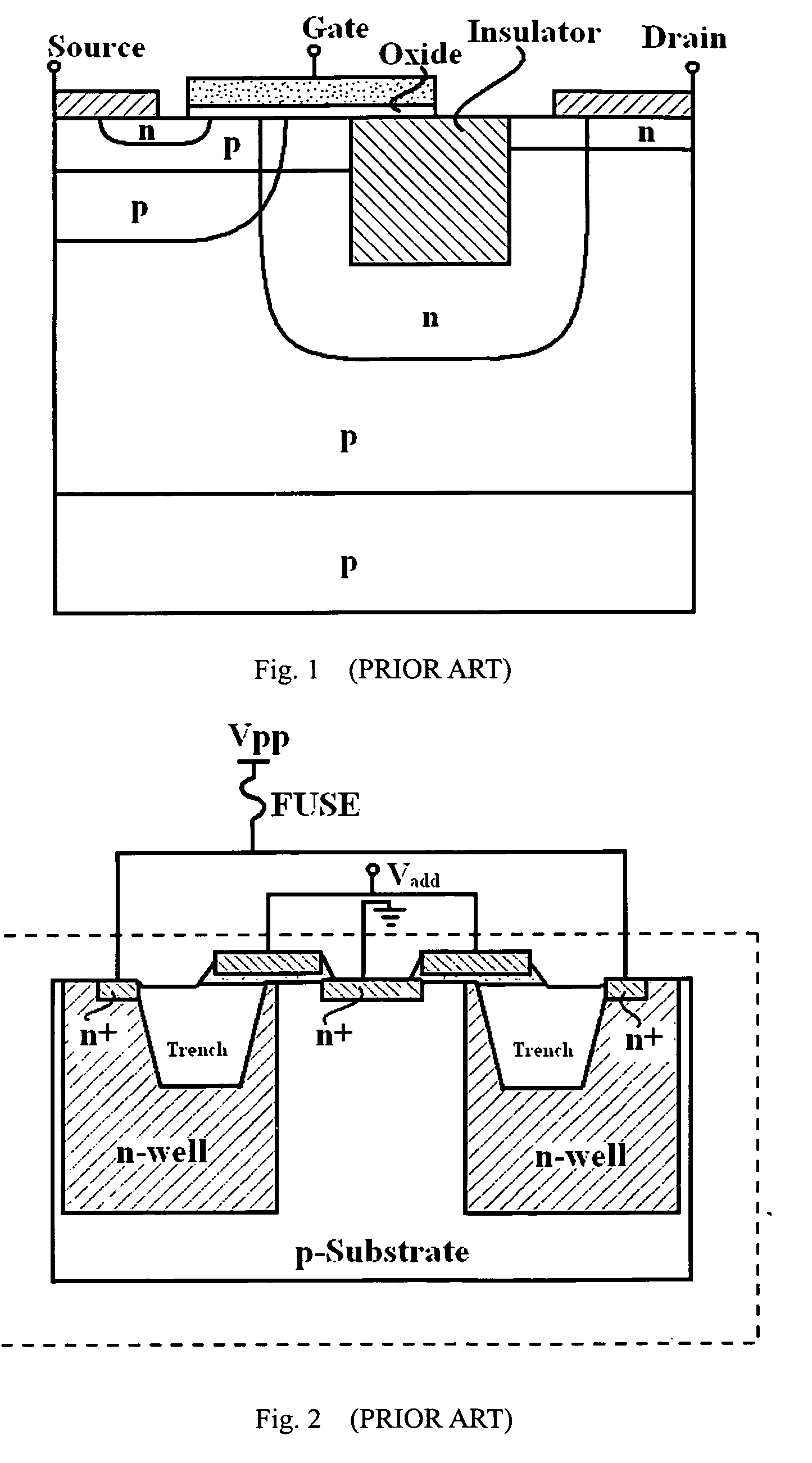

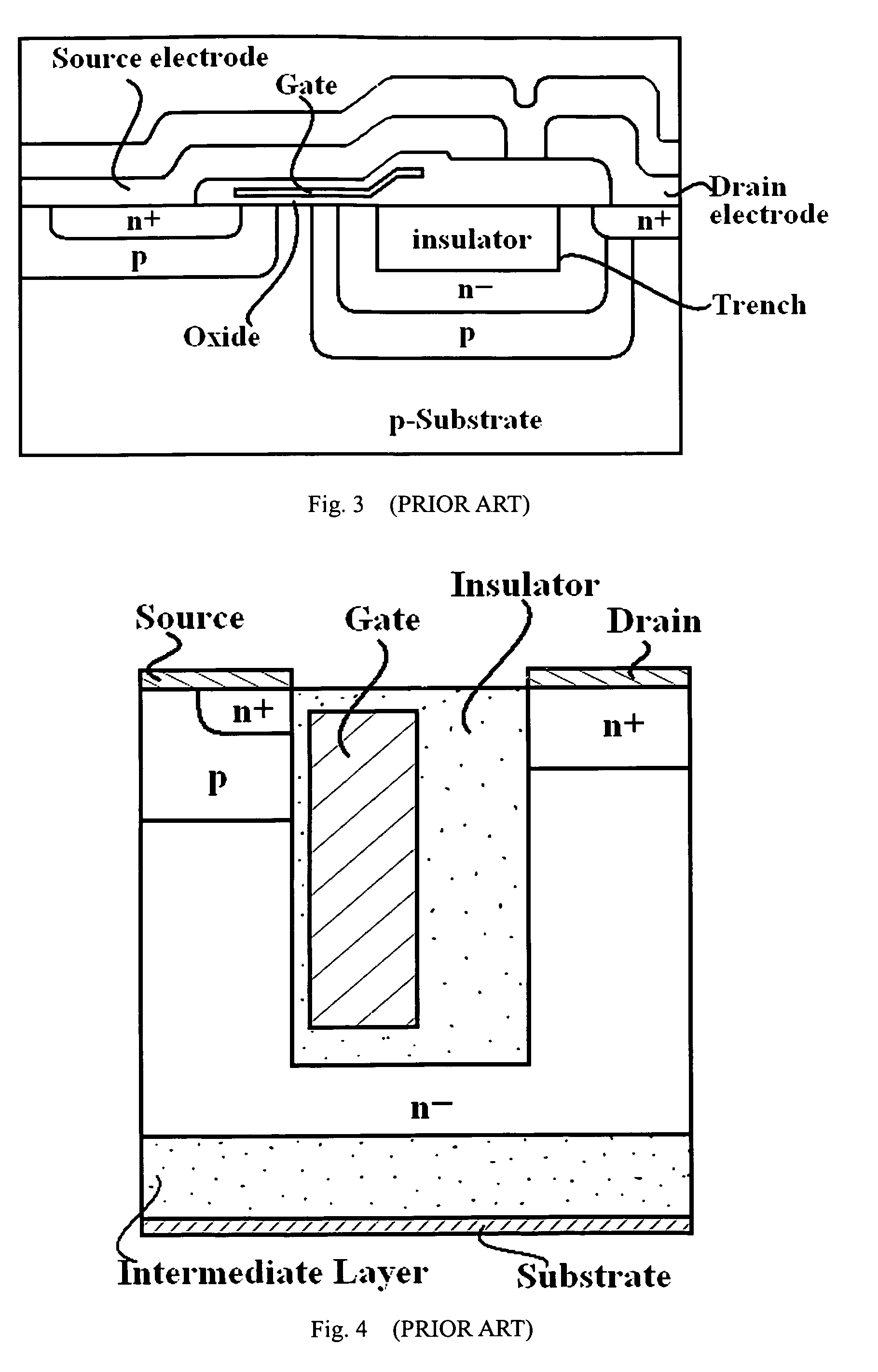

Semiconductor device with a u-shape drift region

InactiveUS20090057711A1Simple processReduce manufacturing costSolid-state devicesSemiconductor devicesDevice materialSemiconductor

A semiconductor device with a U-shape drift region comprises a semiconductor substrate of a first conductivity type, a trench filled with an insulator material formed in a portion of a first main surface of the substrate, a cell of the device including the trench and semiconductor region surrounding the trench. The semiconductor device has at least one cell. Two device-feature regions are formed beneath the first main surface of the substrate, the first one is located at one side and the second one is located at the other side of the trench. At least a region of a second conductivity type and / or a region of metal is formed in the first device feature region and is connected to a first electrode. At least a region of a first conductivity type and / or a region of metal is formed in the second device feature region and is connected to a second electrode. Based on this invention, semiconductor devices, especially, an IGBT without tail during turning-off can be fabricated with a simple process at a low cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com