Patents

Literature

97results about How to "Improve octane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

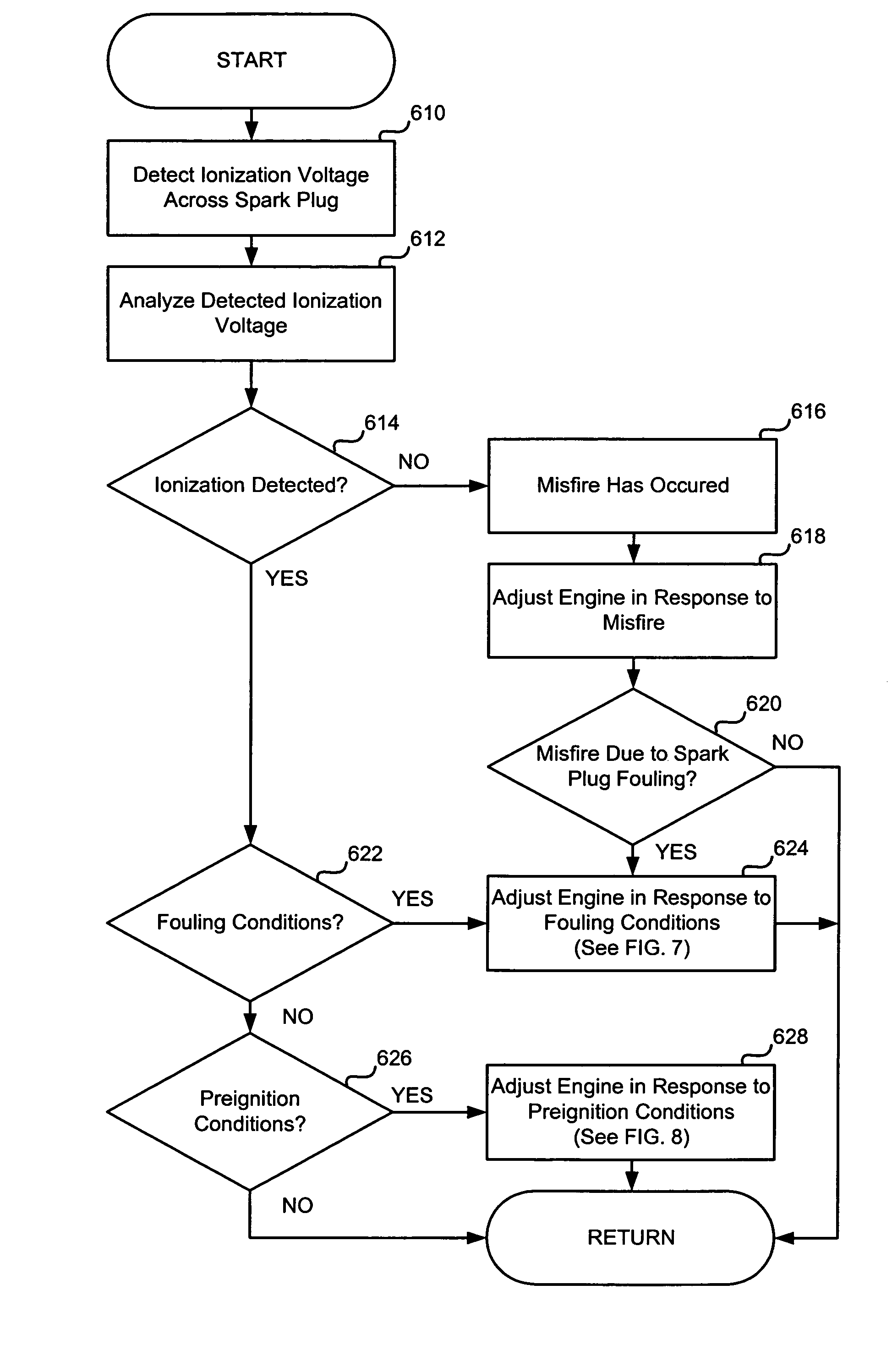

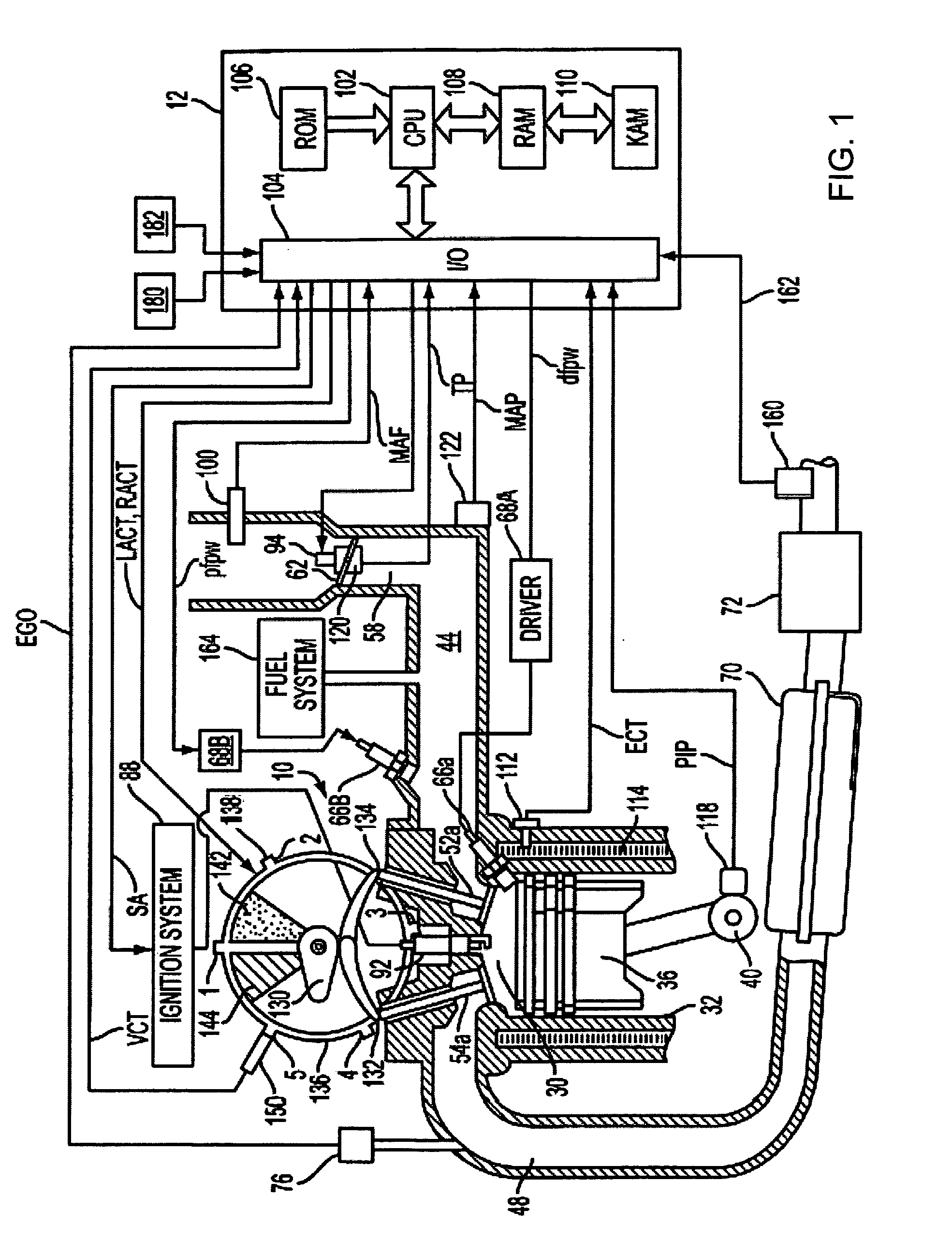

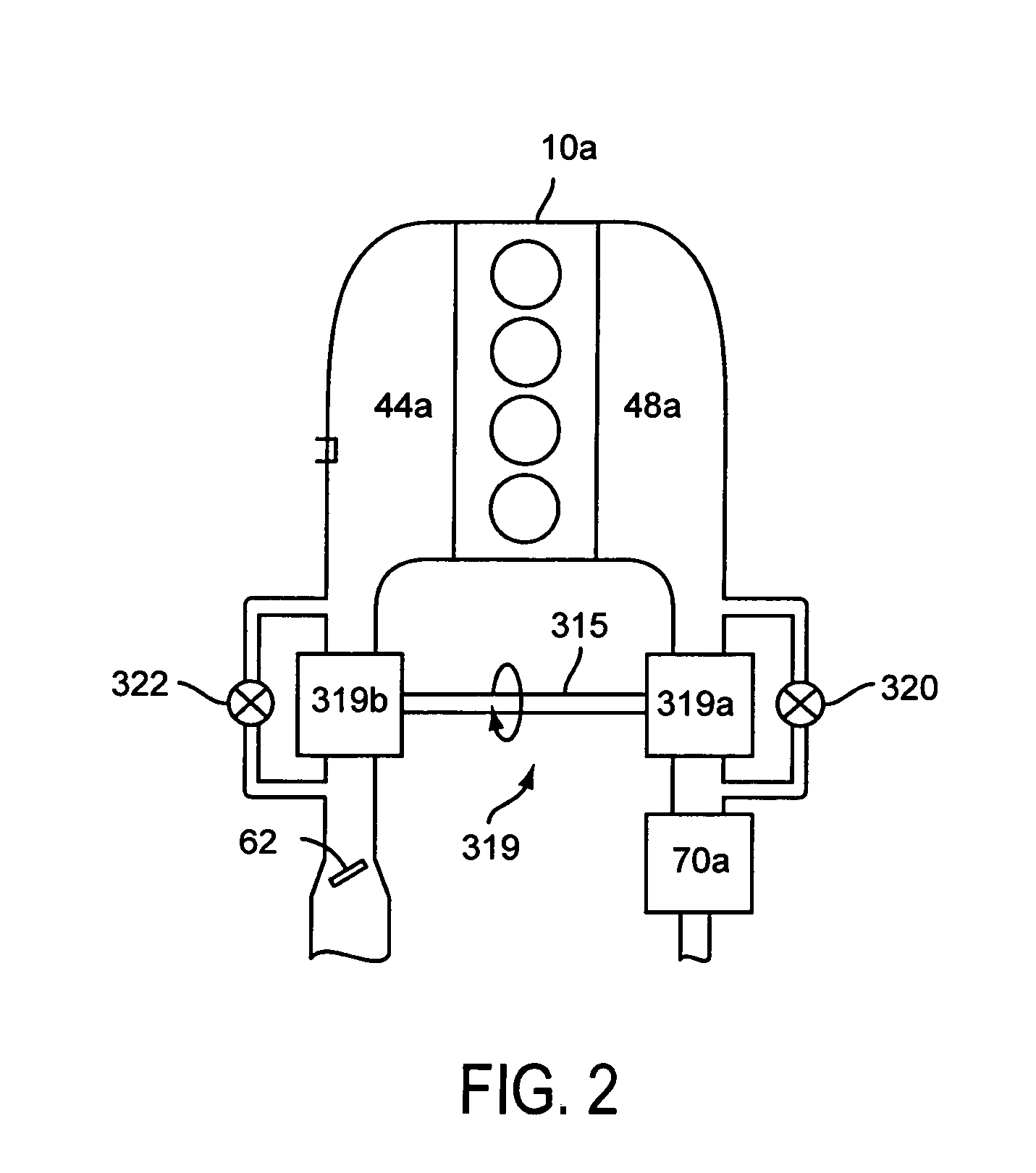

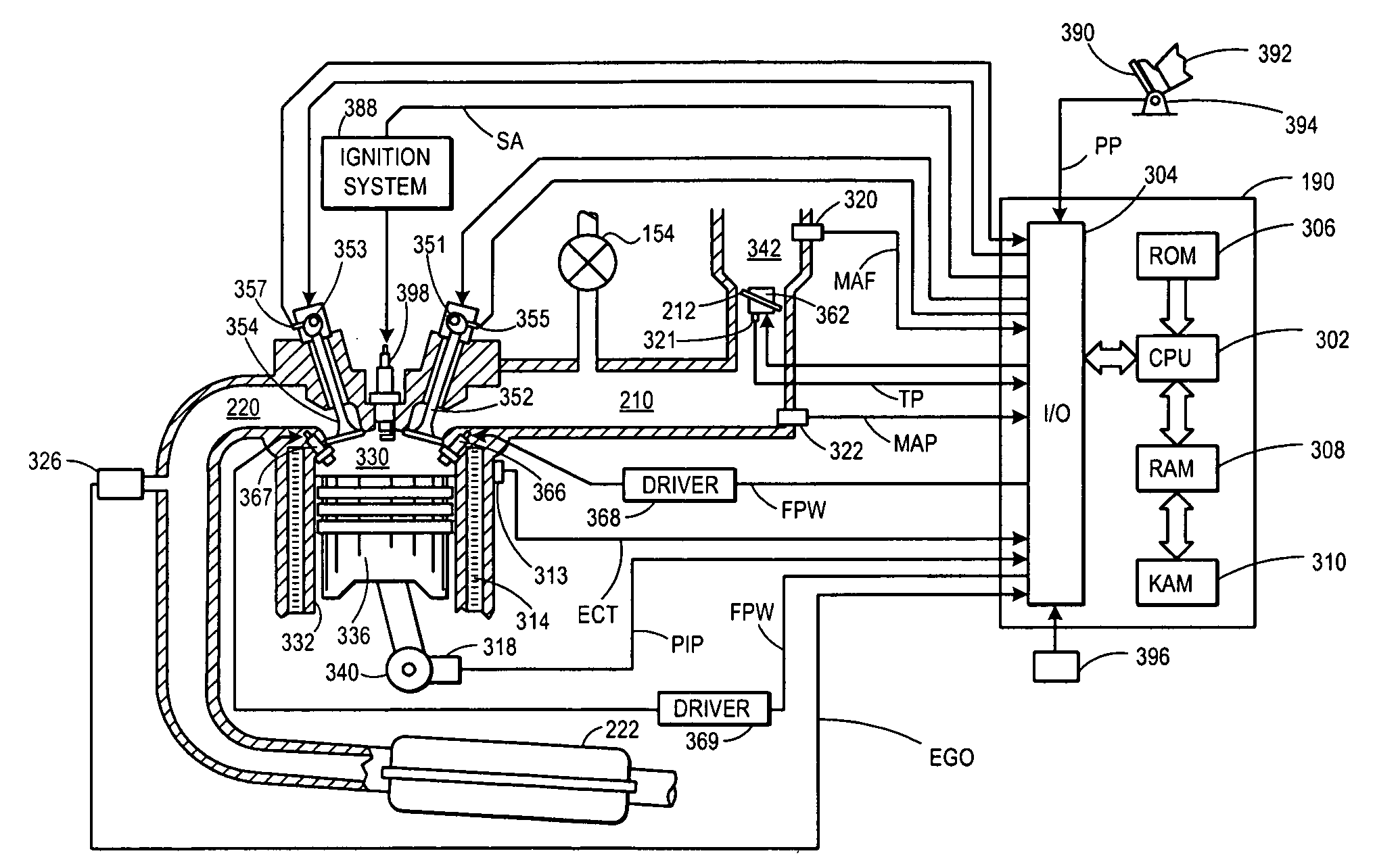

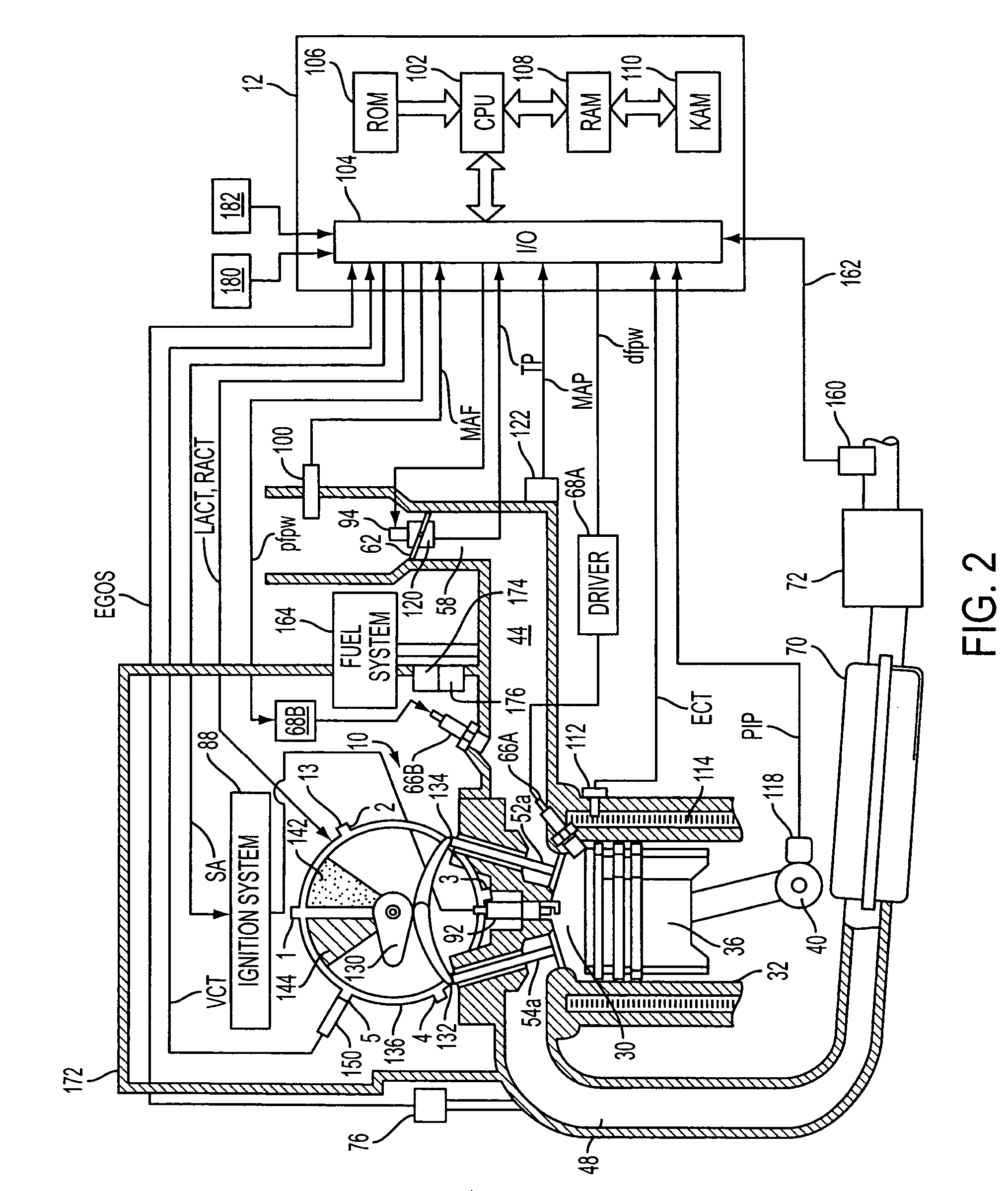

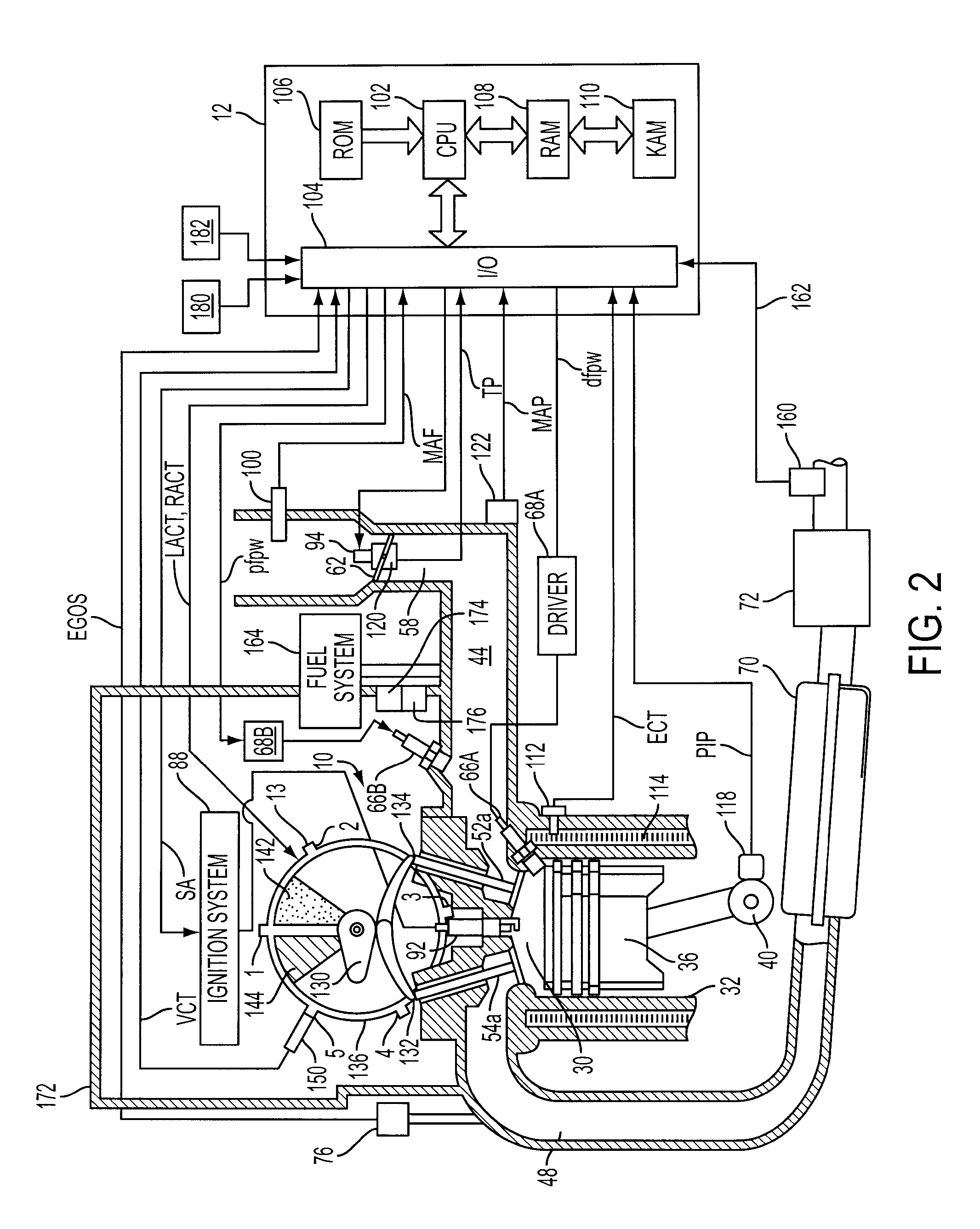

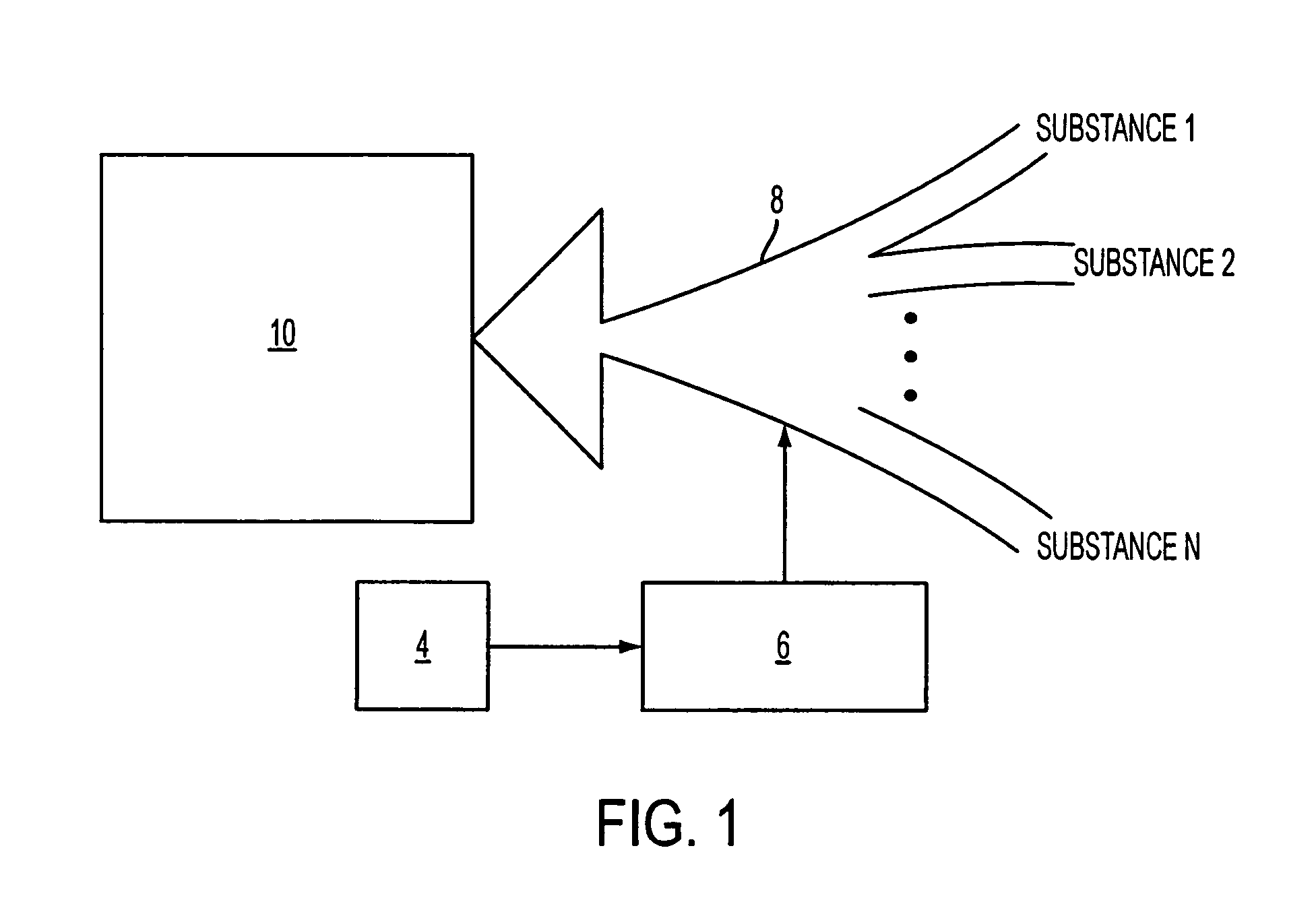

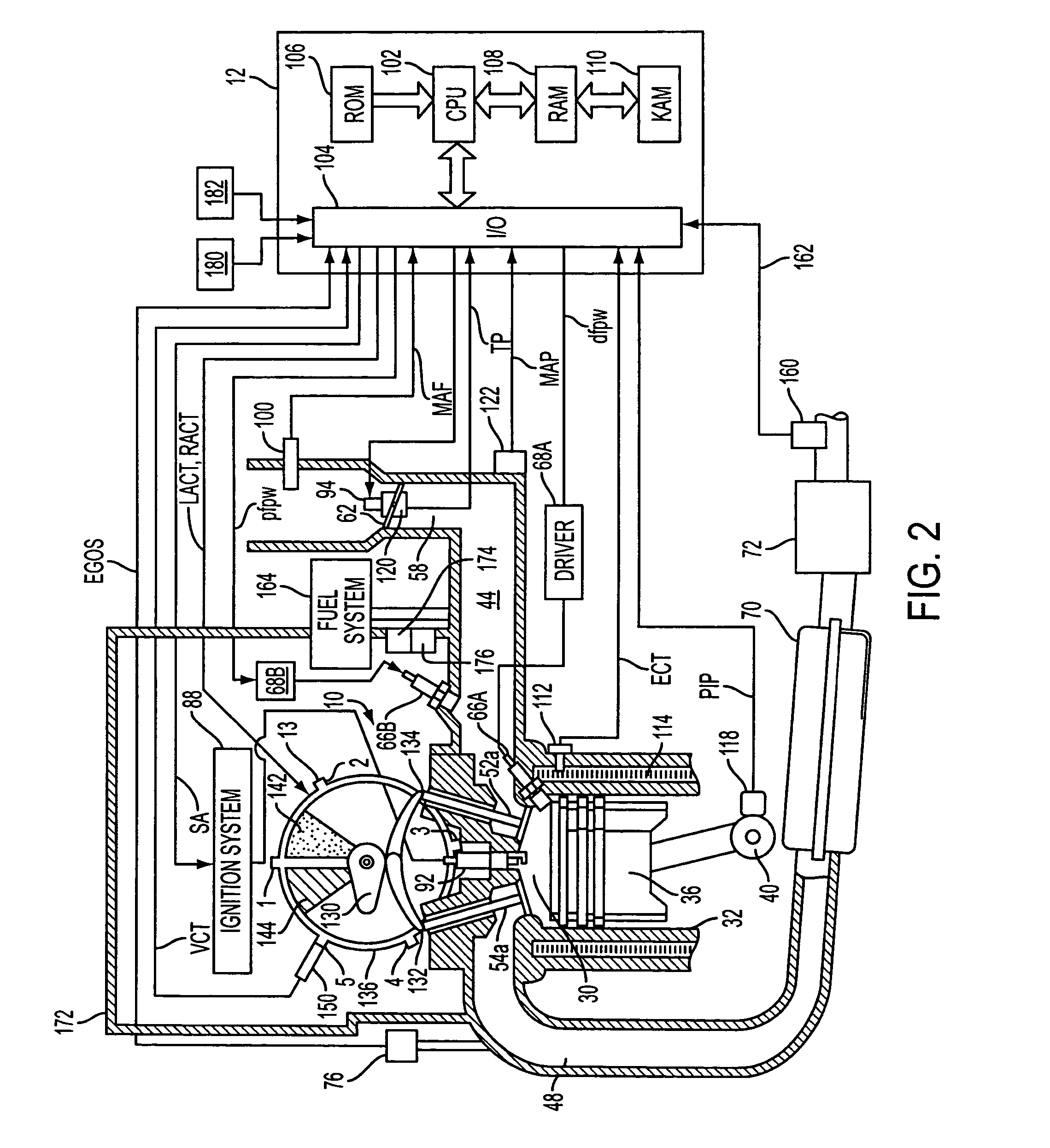

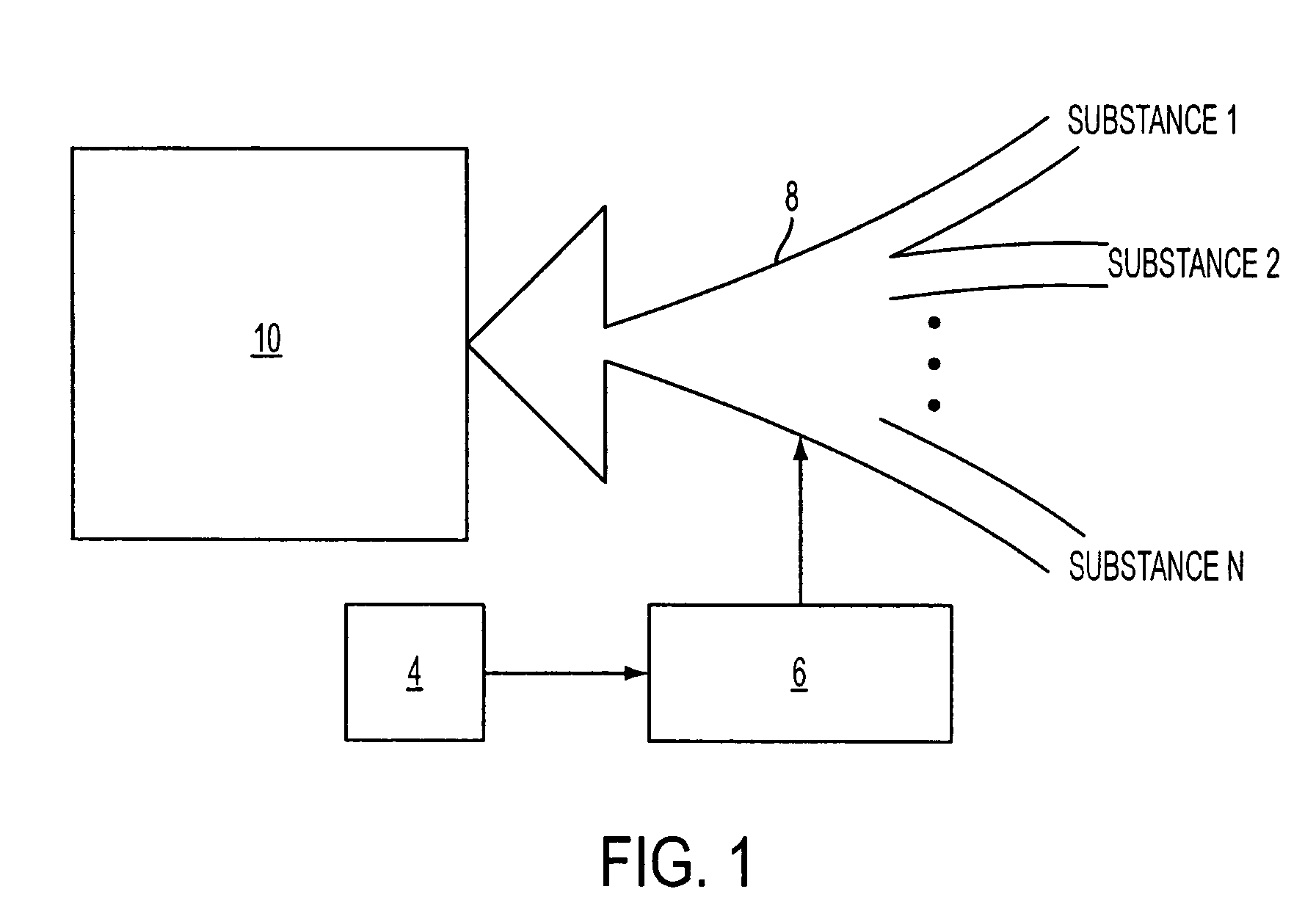

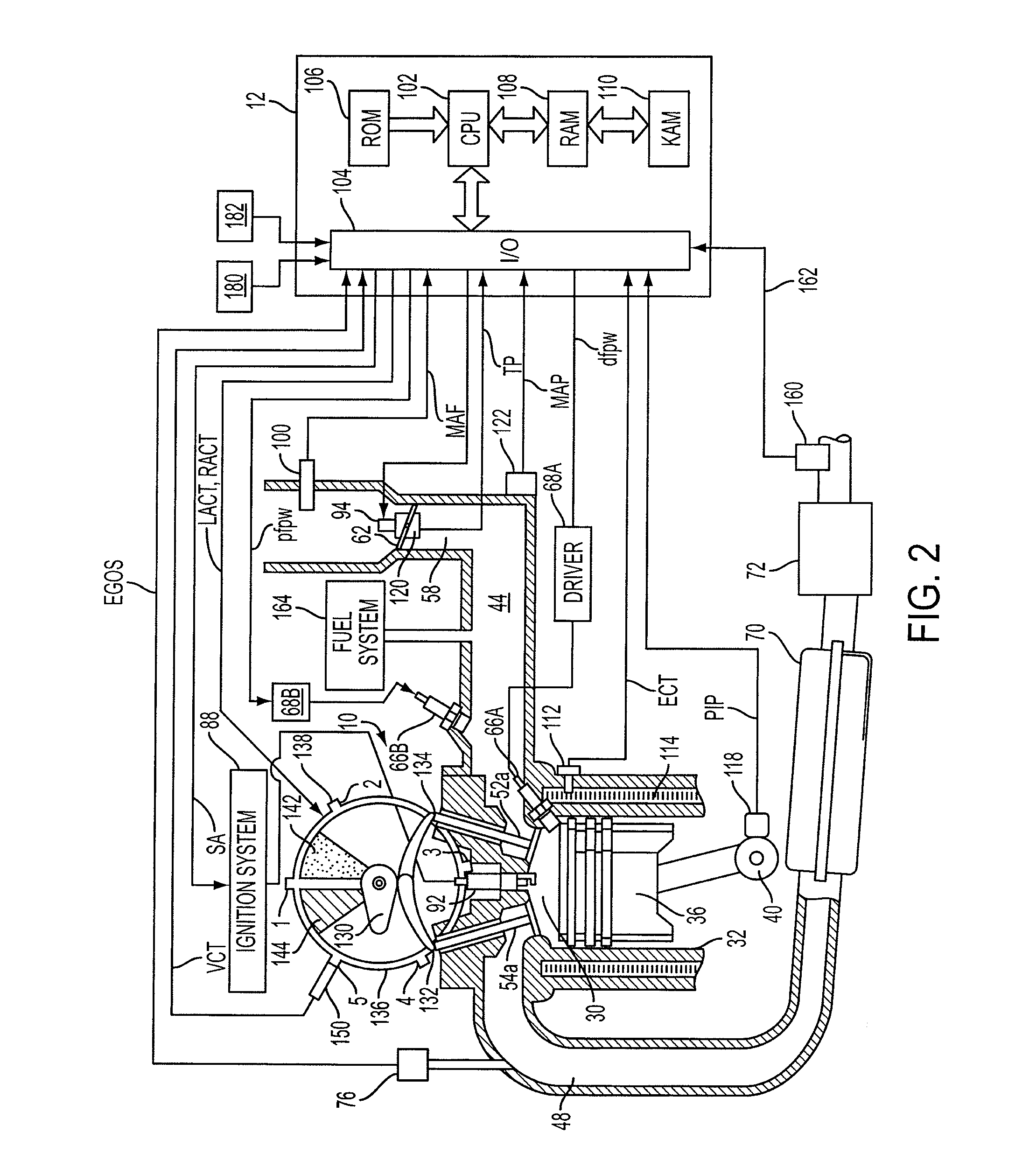

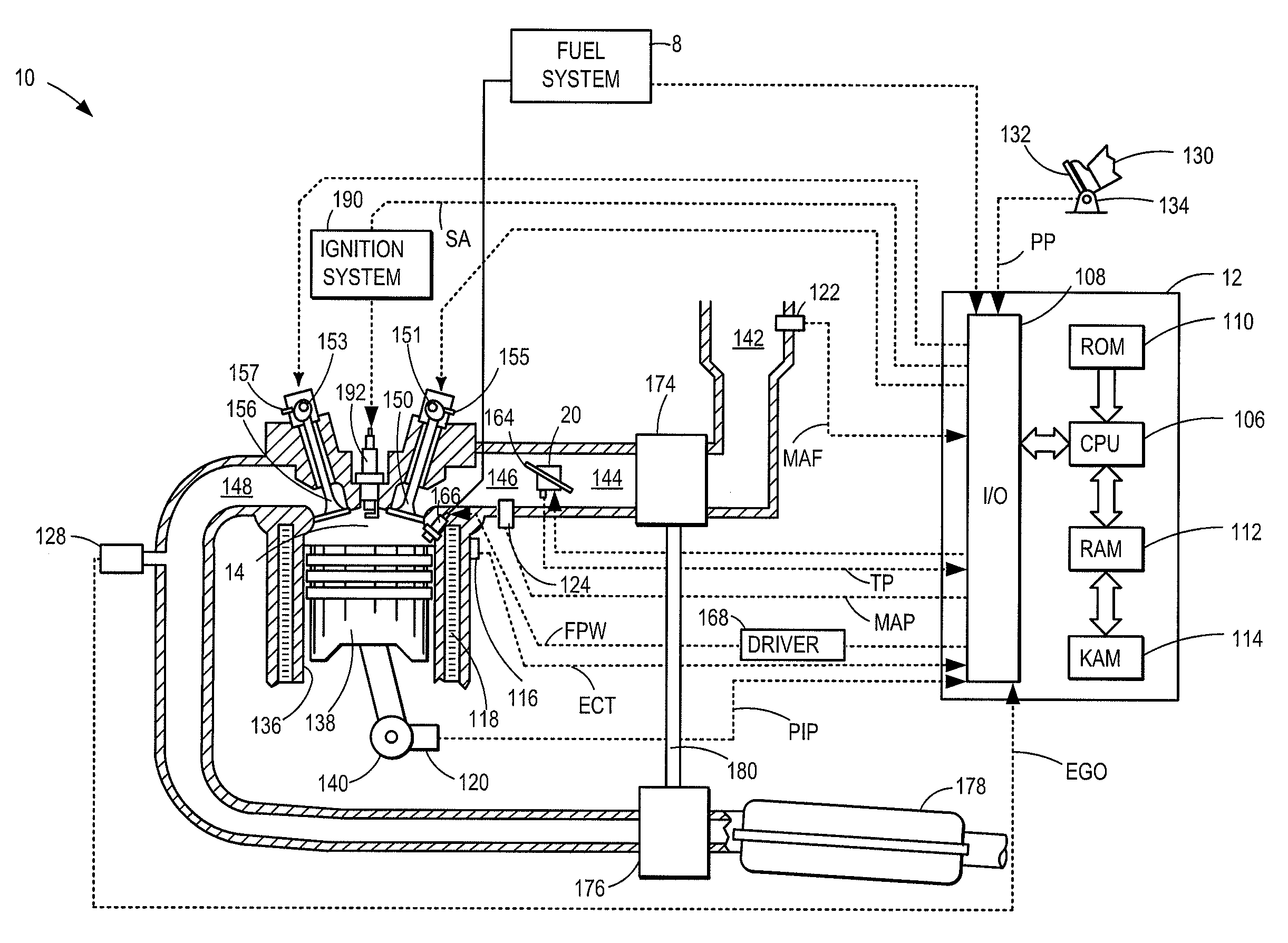

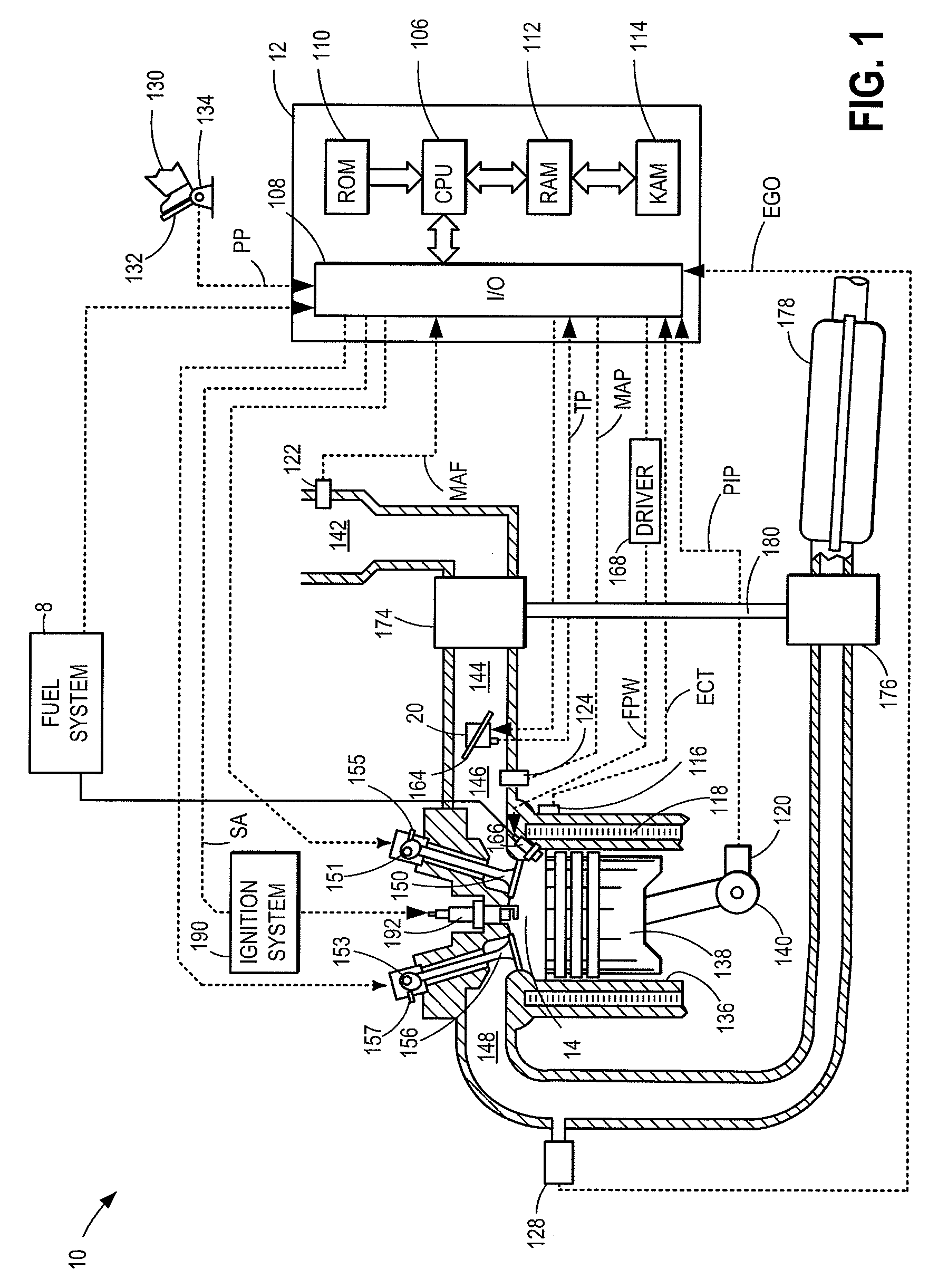

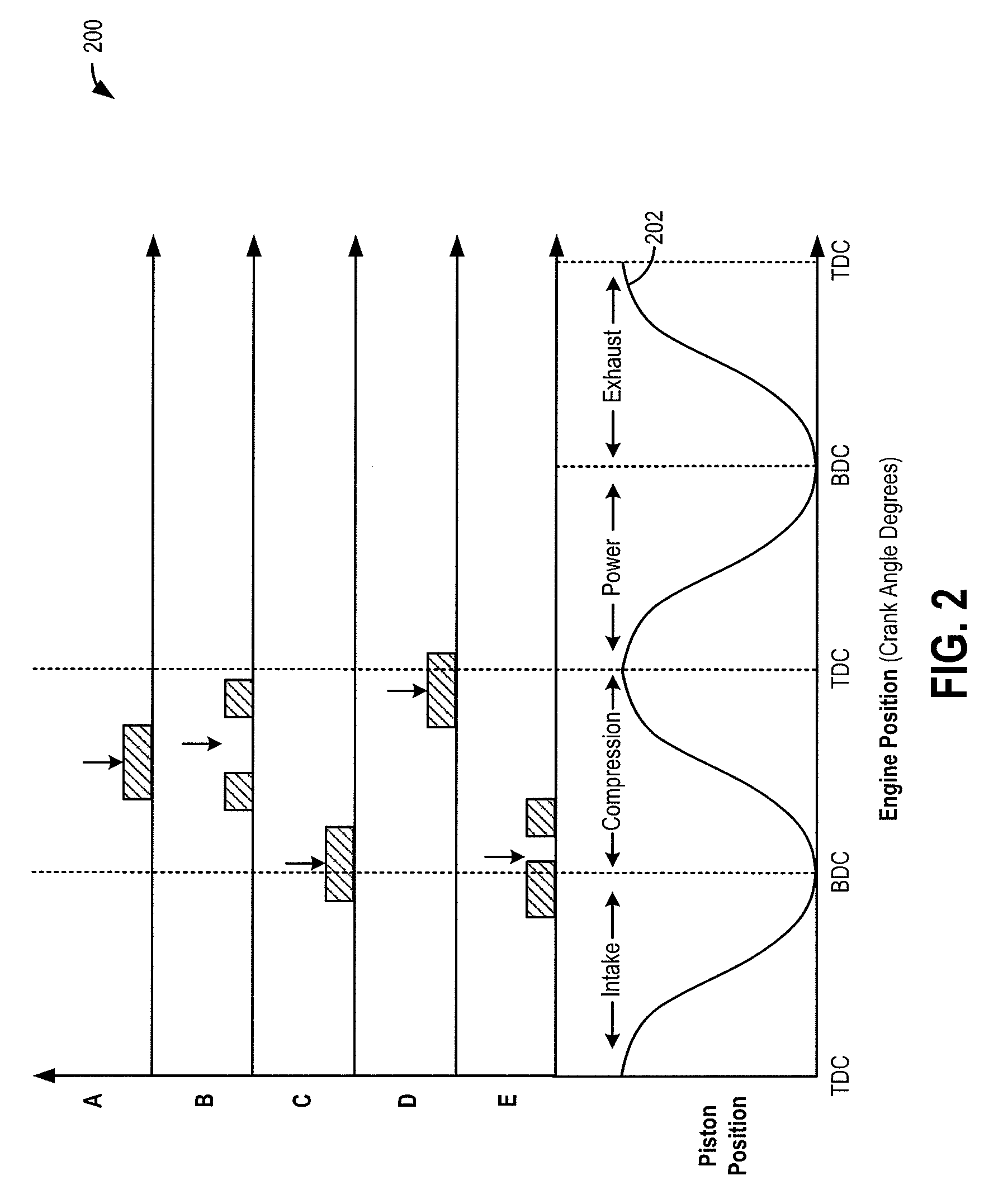

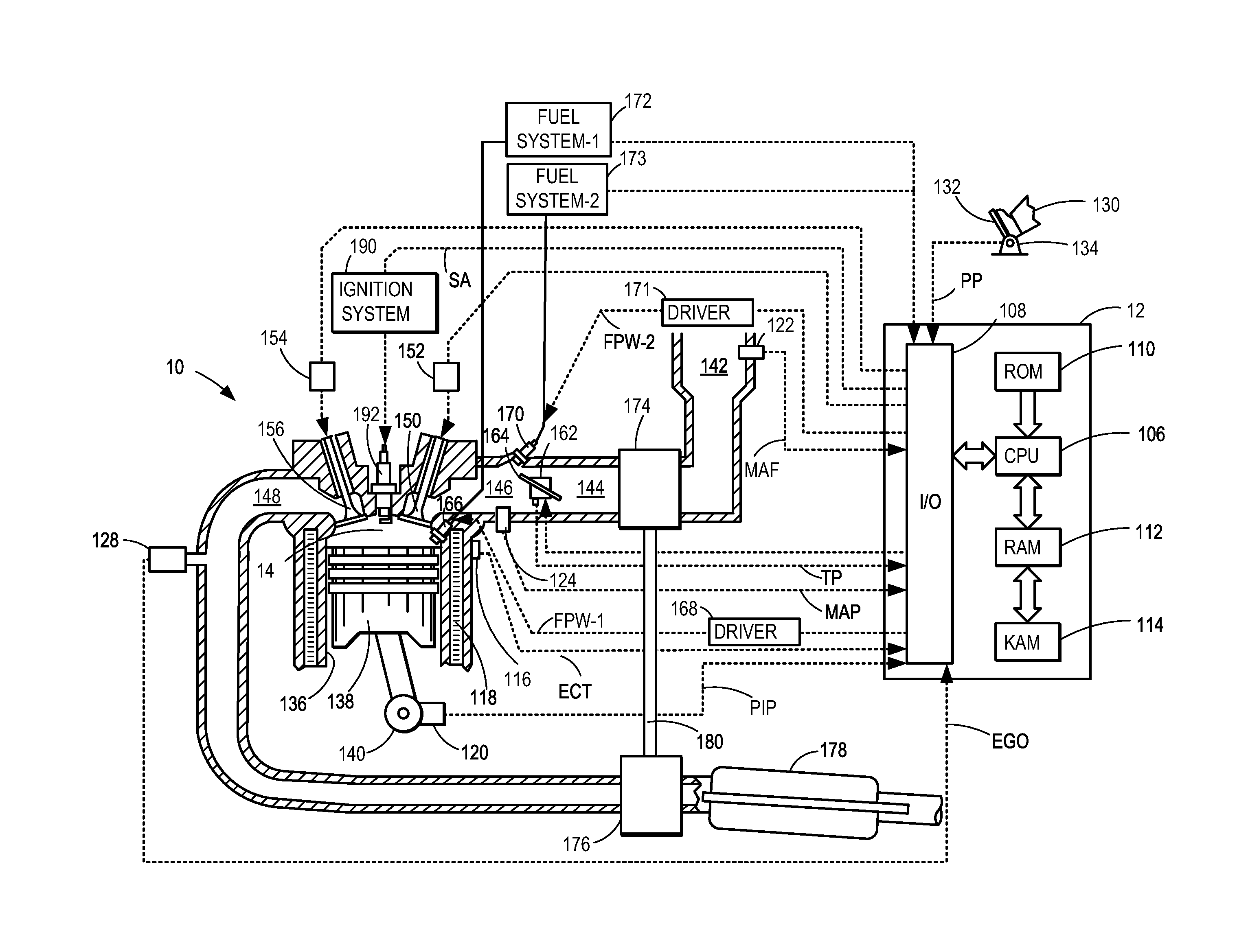

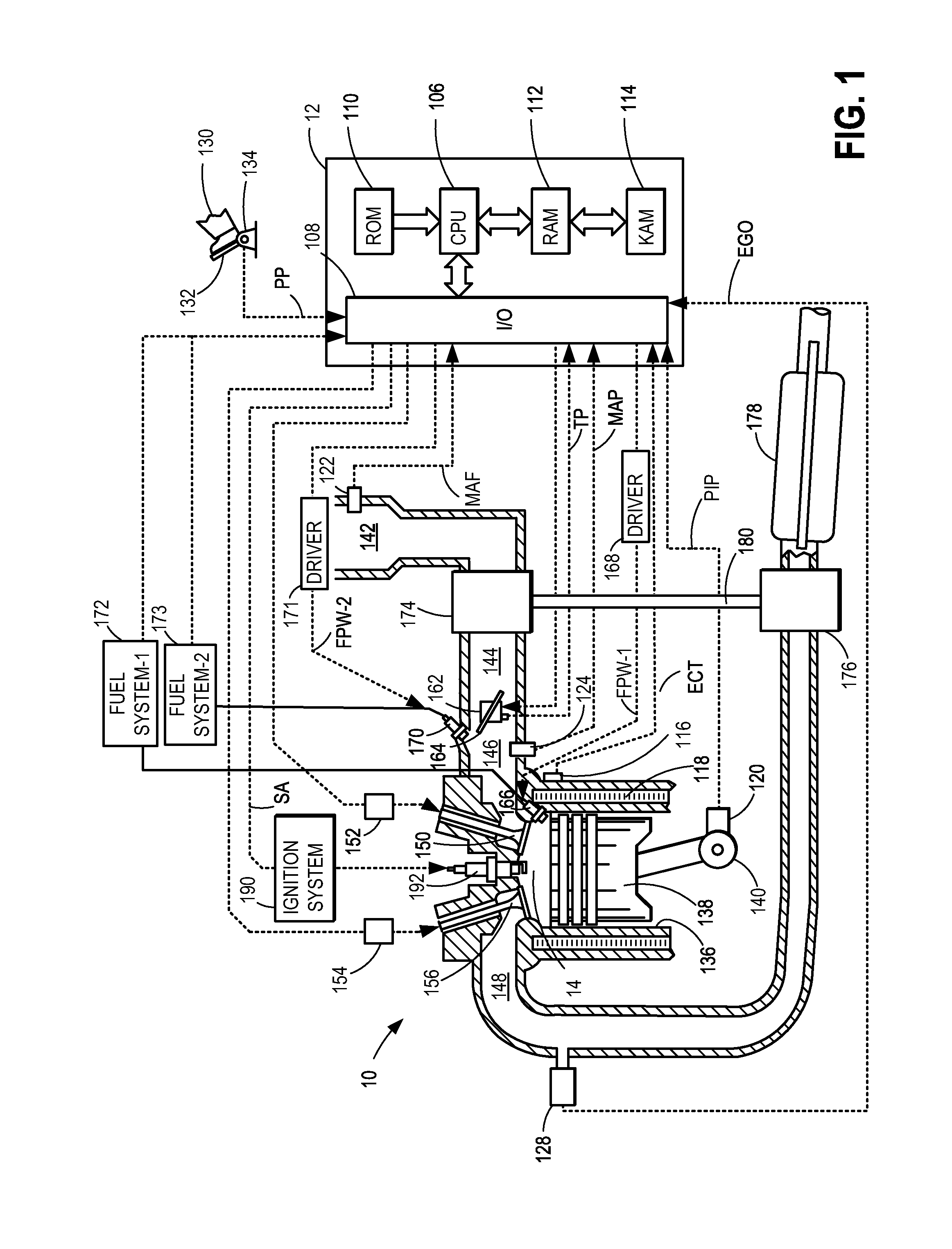

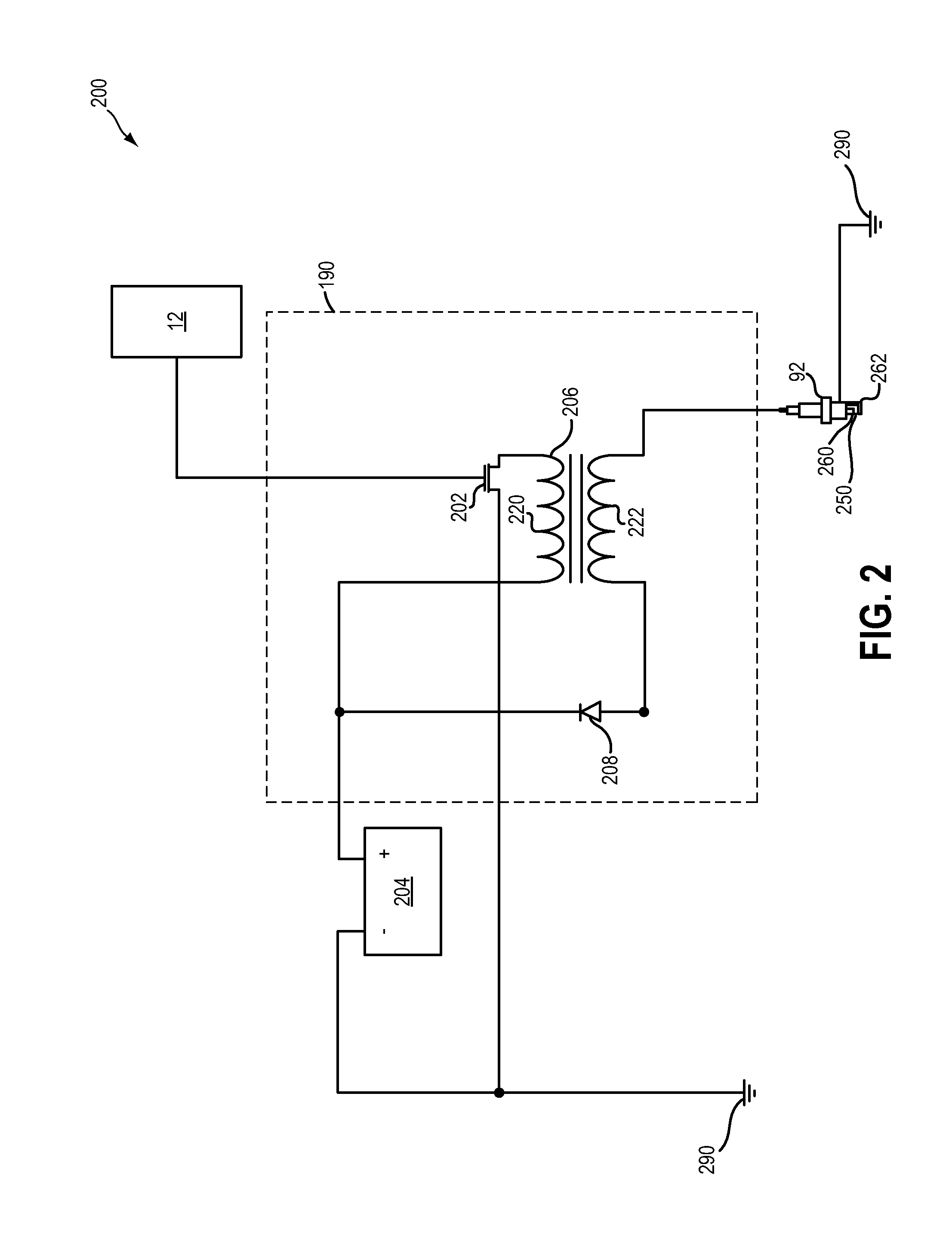

Spark control for improved engine operation

InactiveUS20070215130A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberControl system

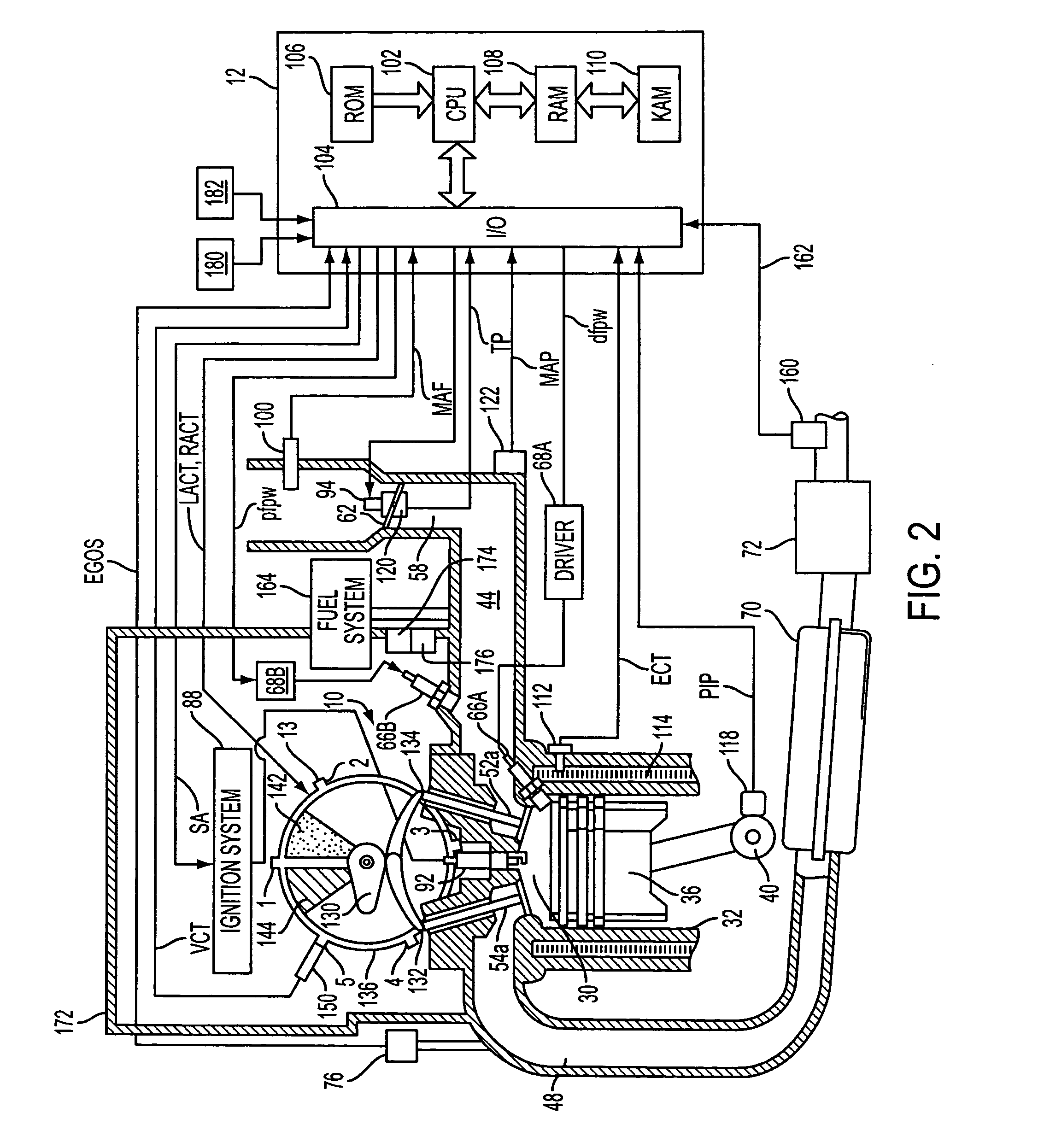

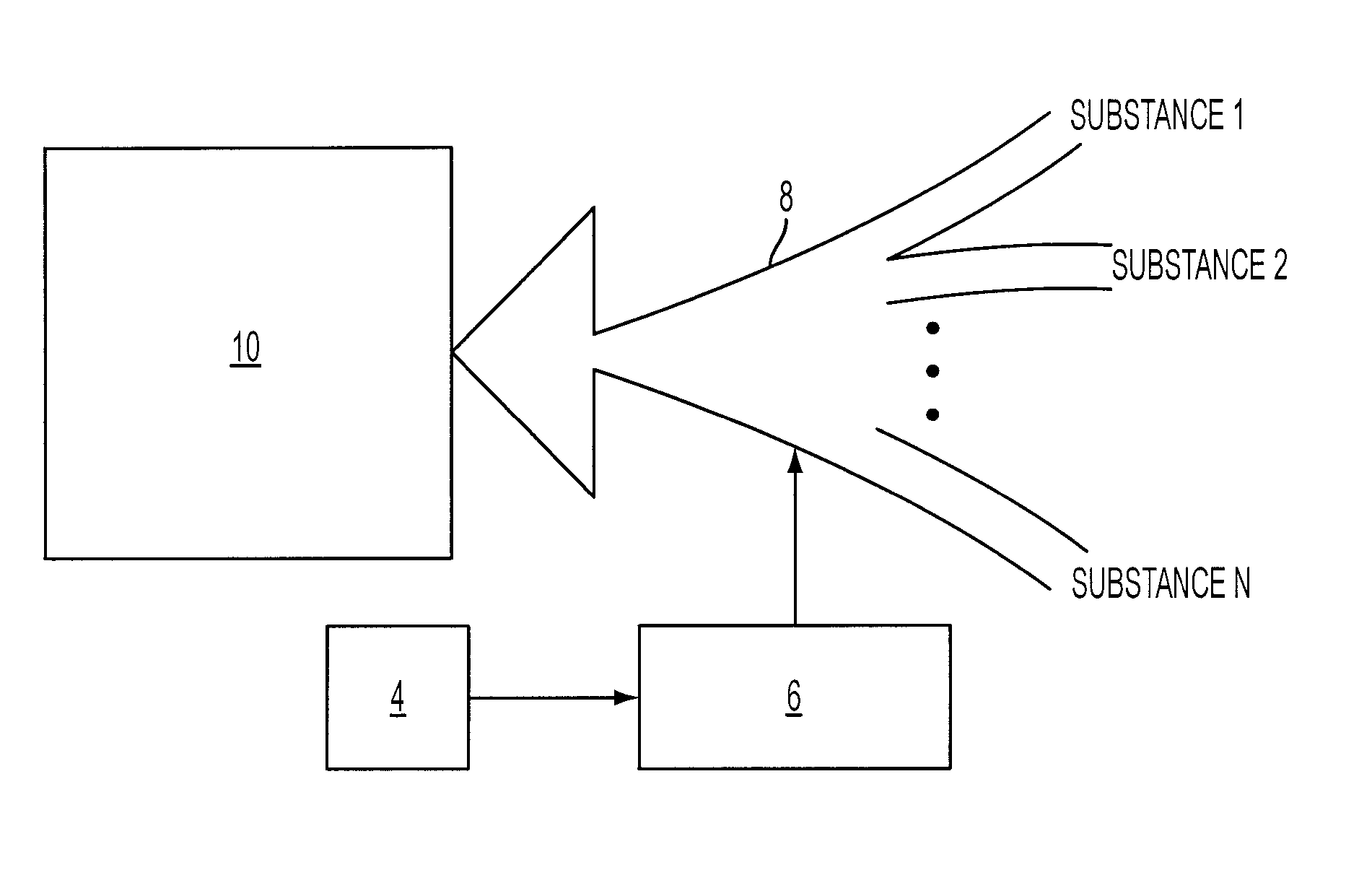

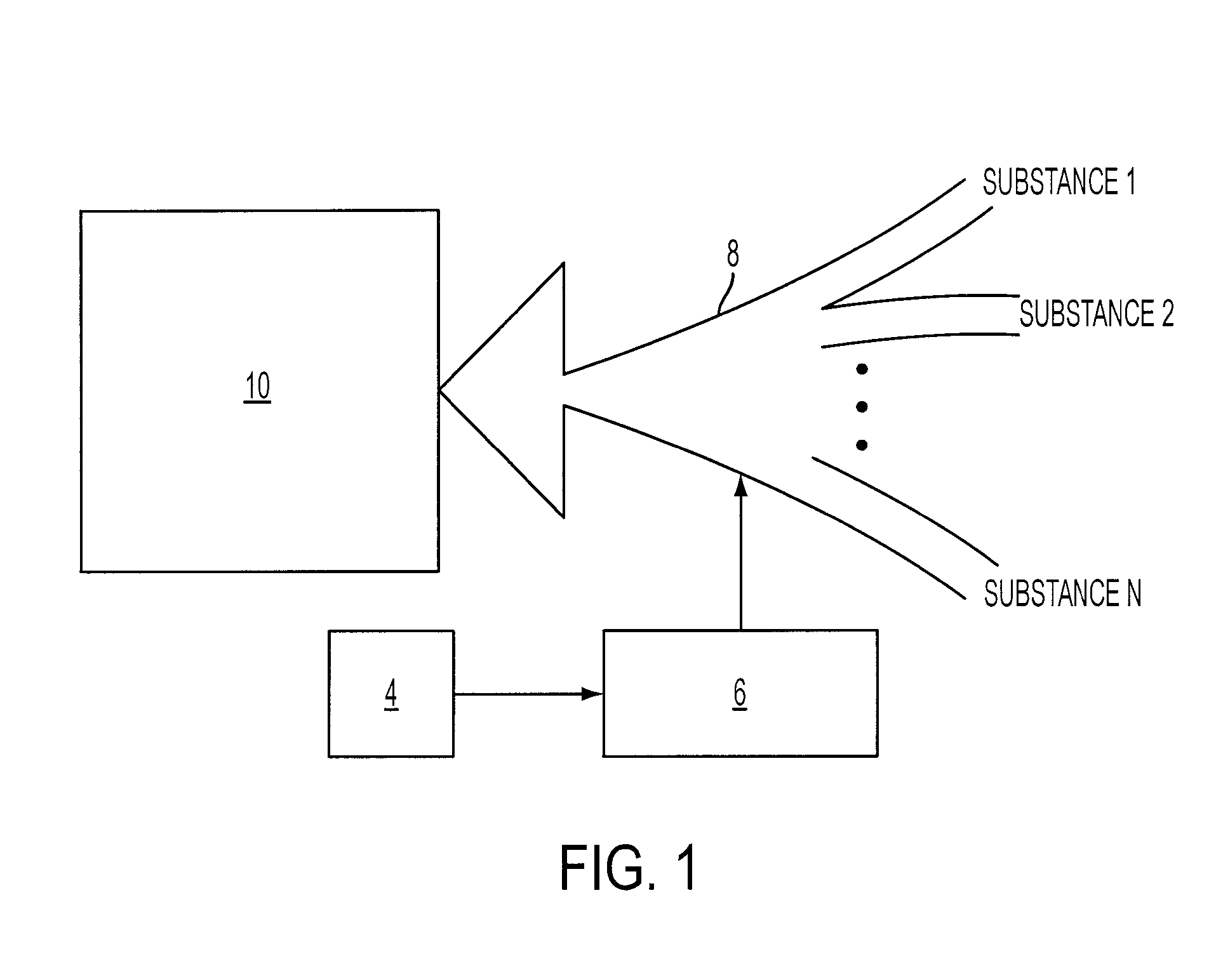

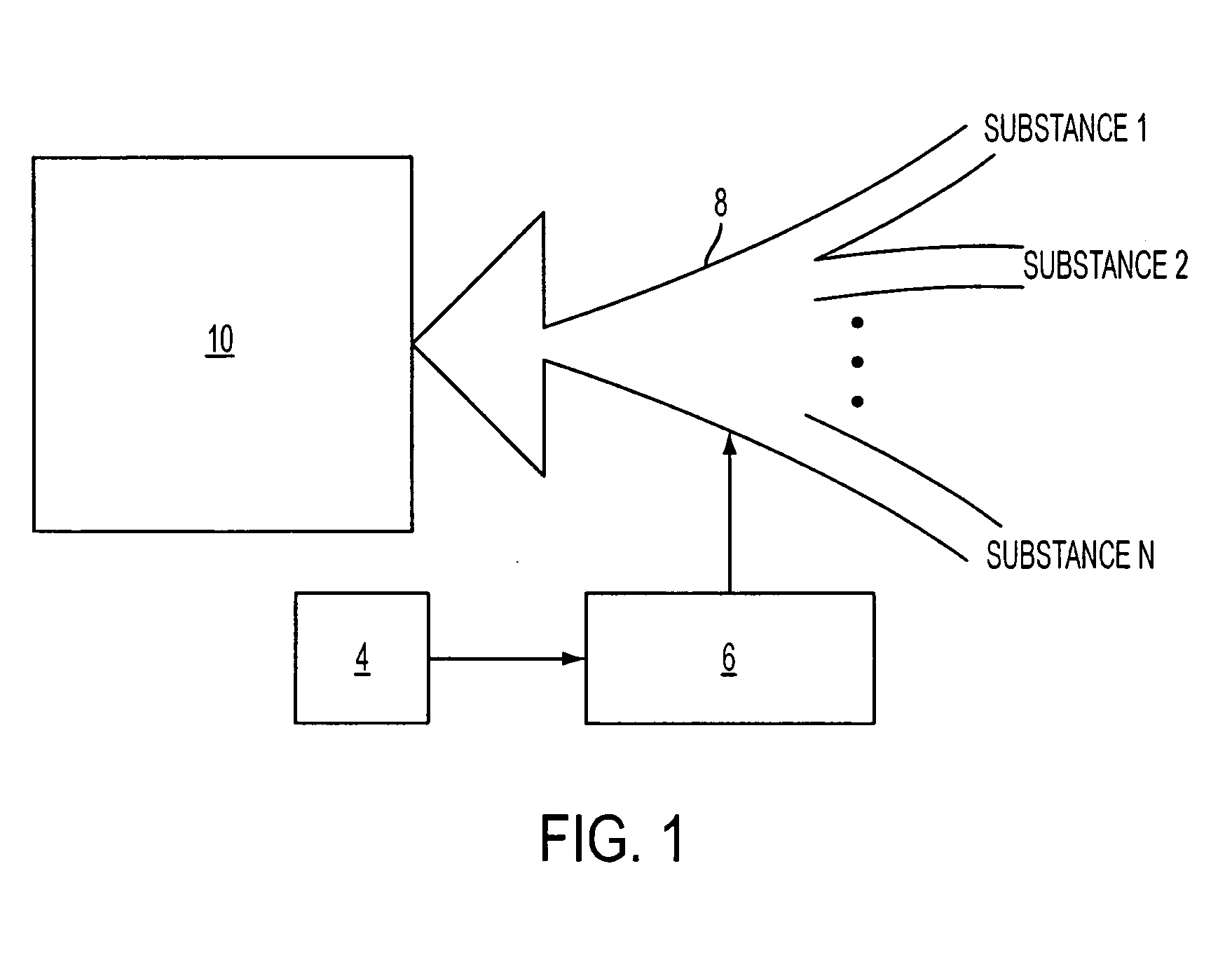

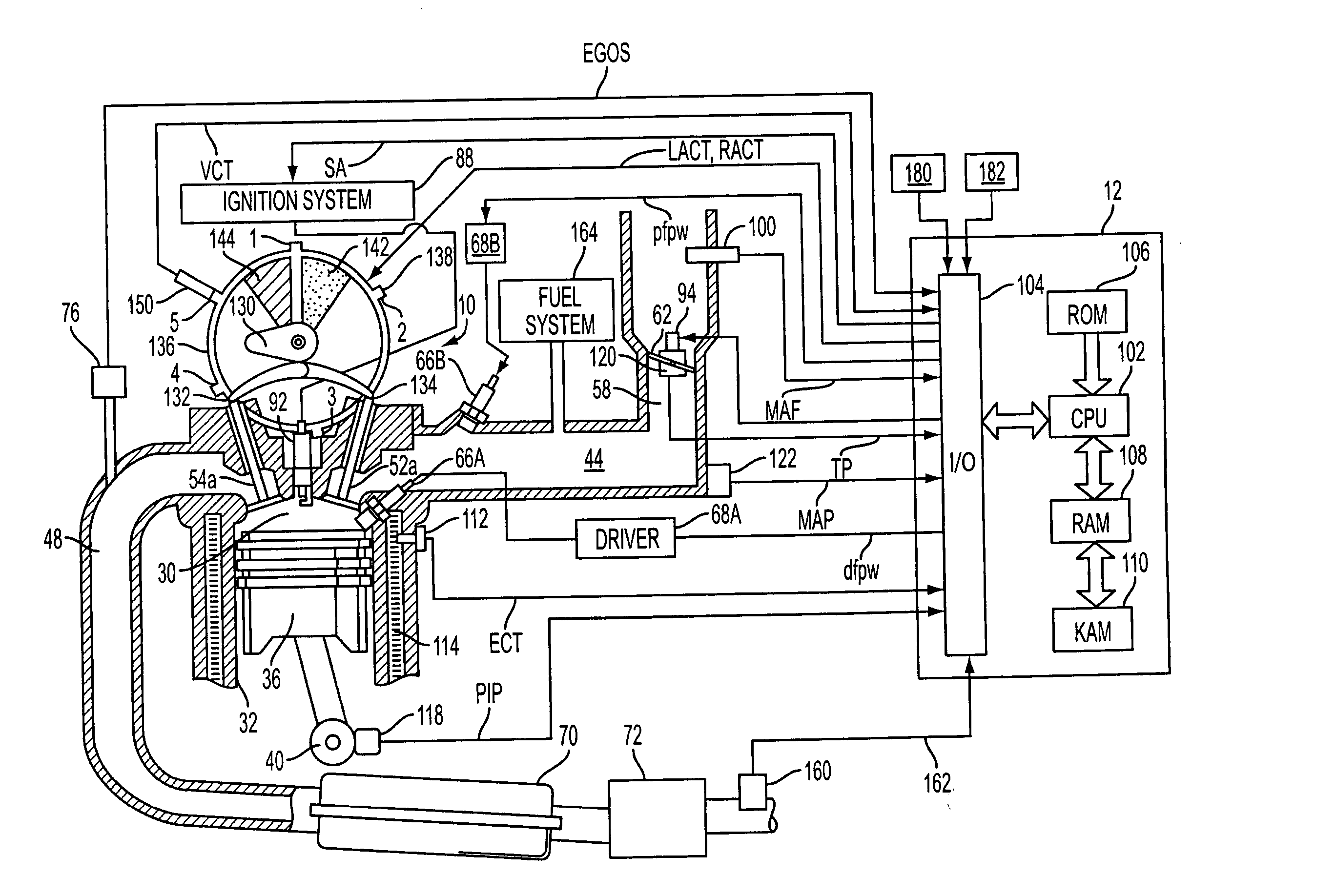

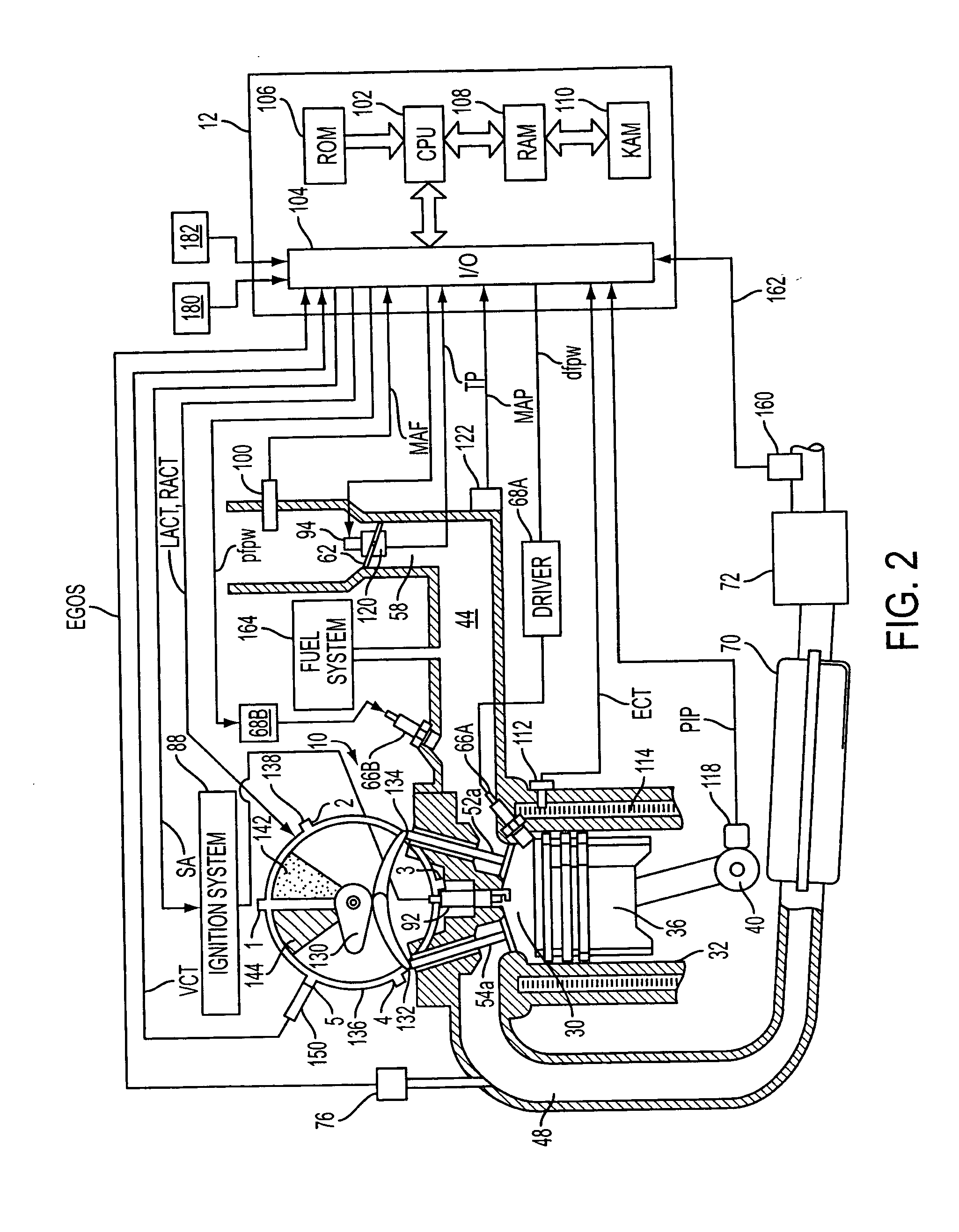

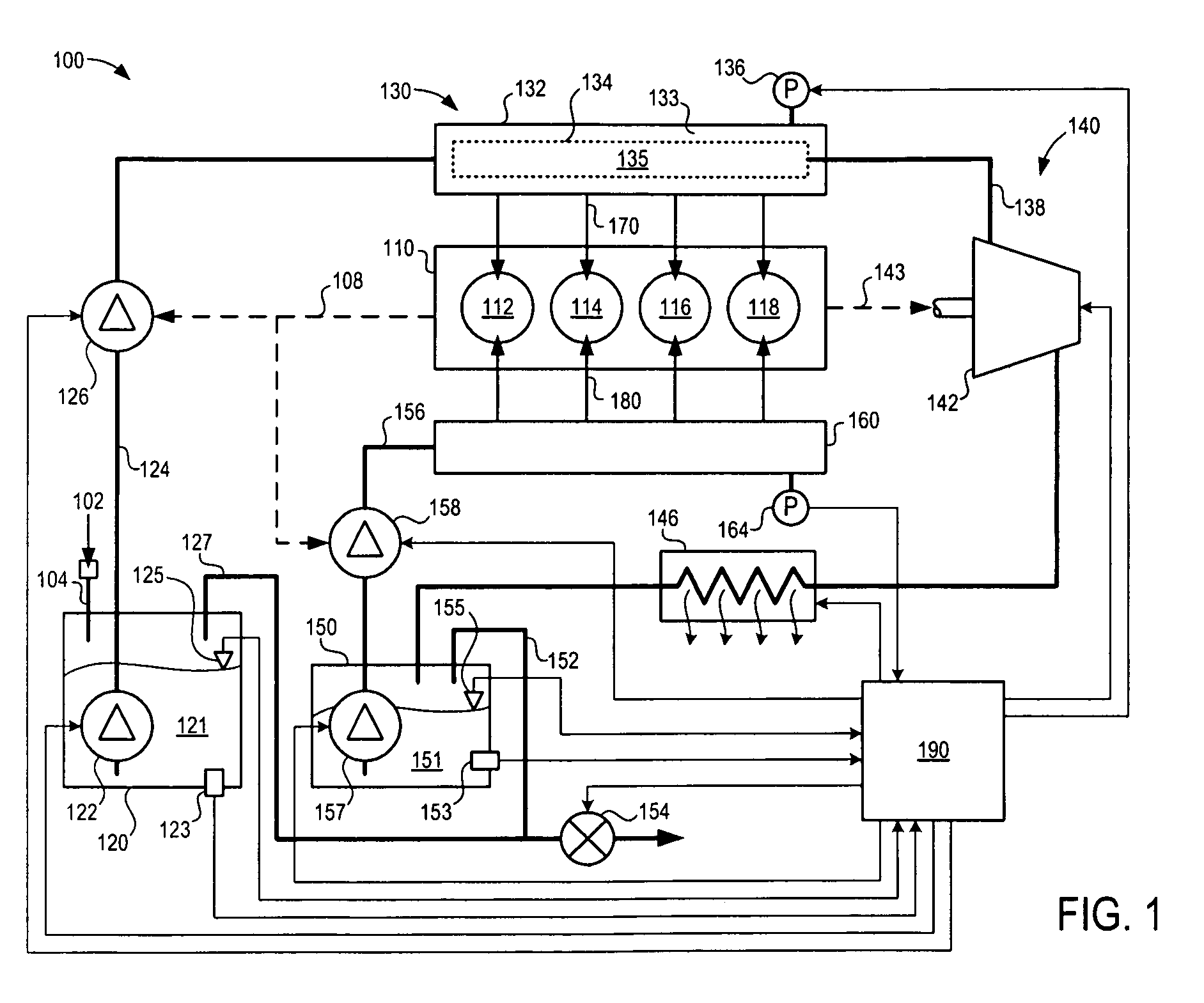

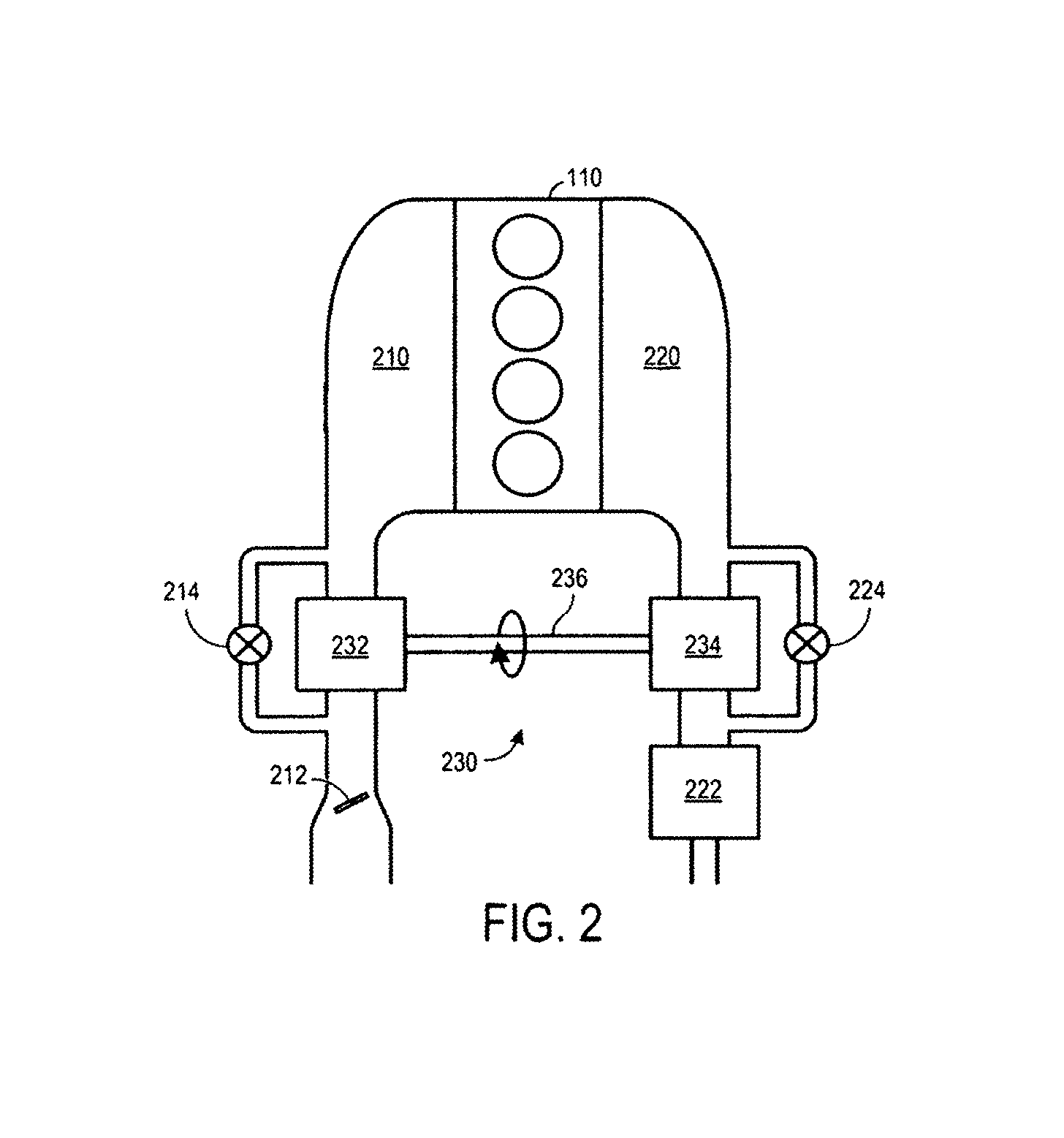

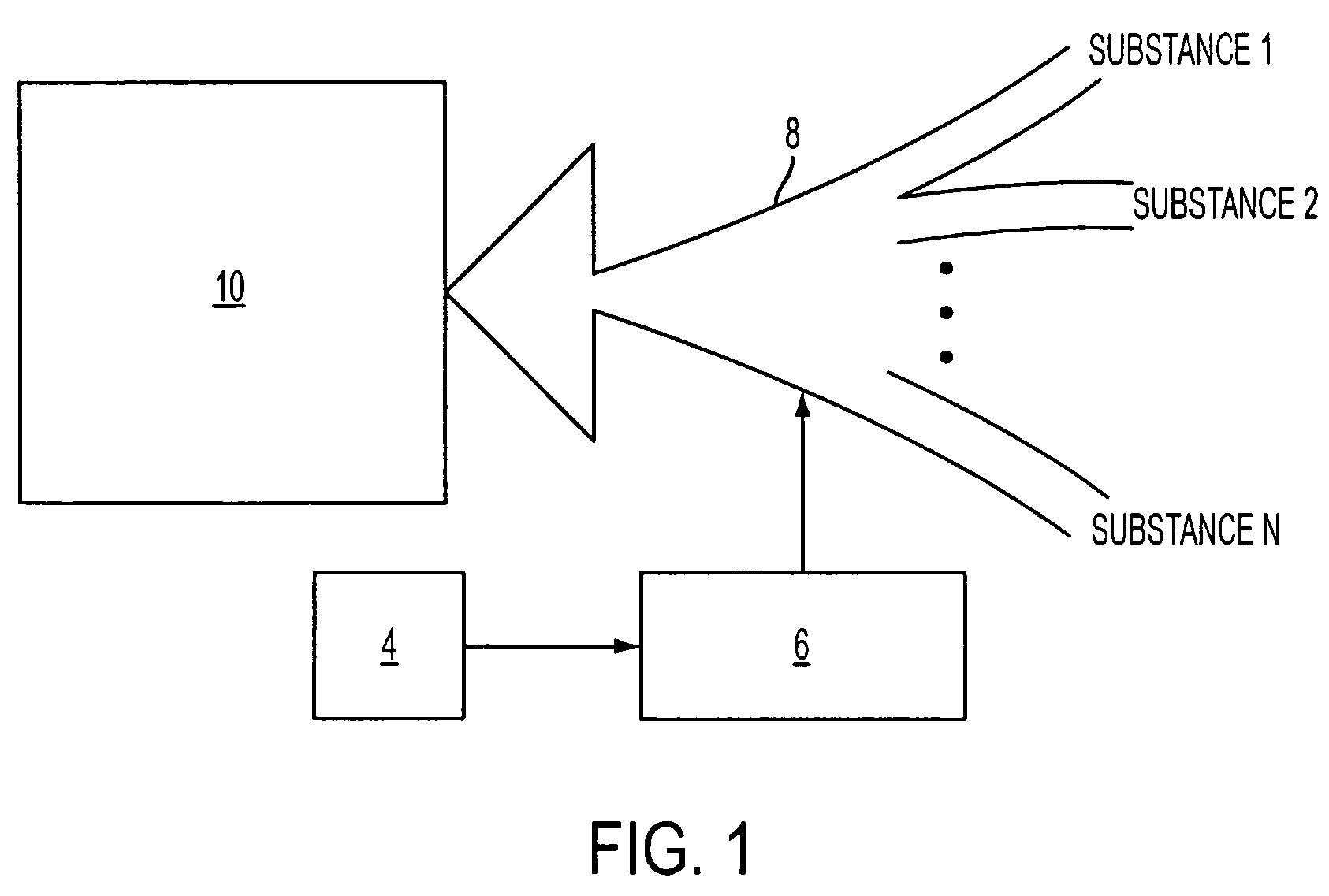

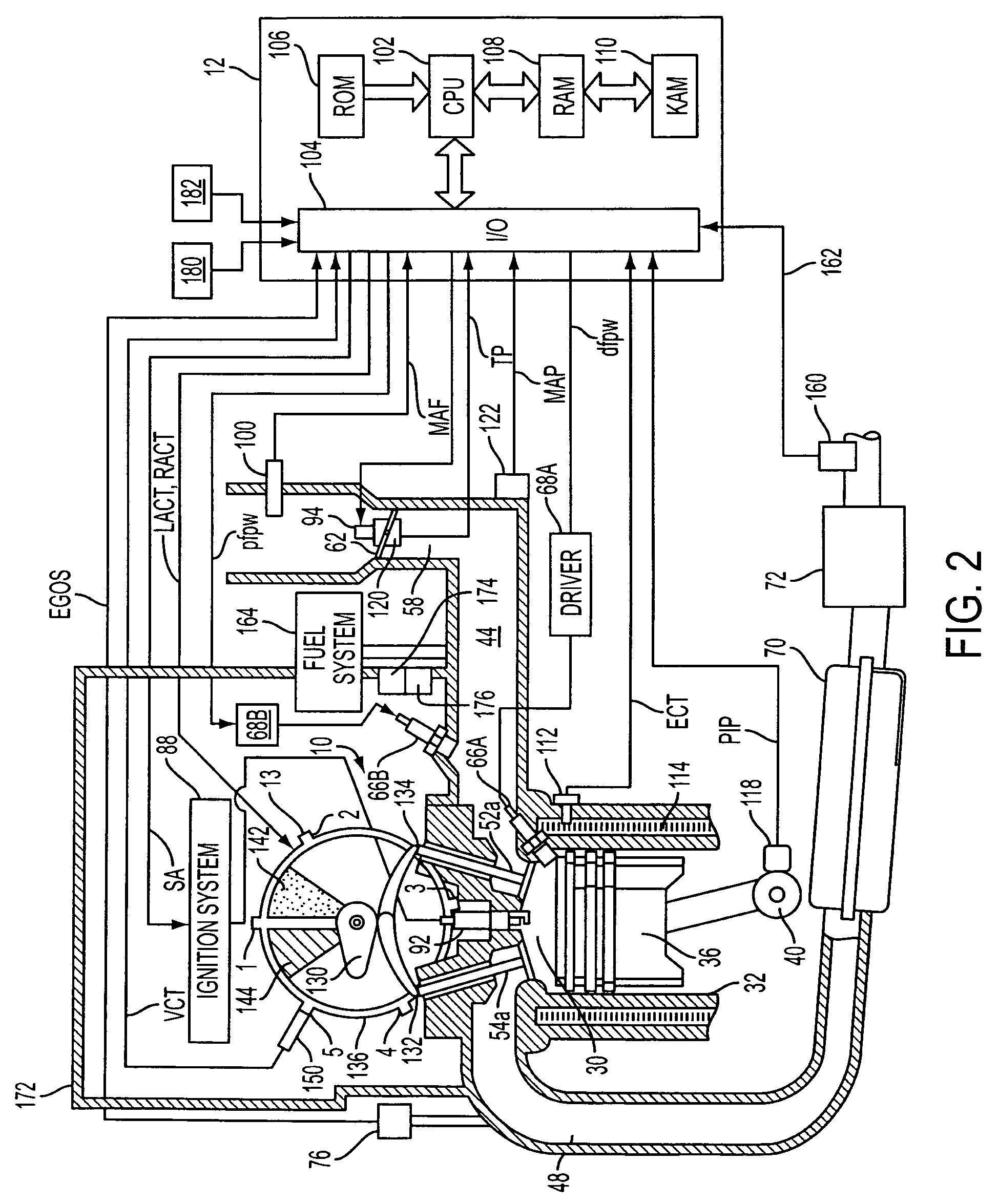

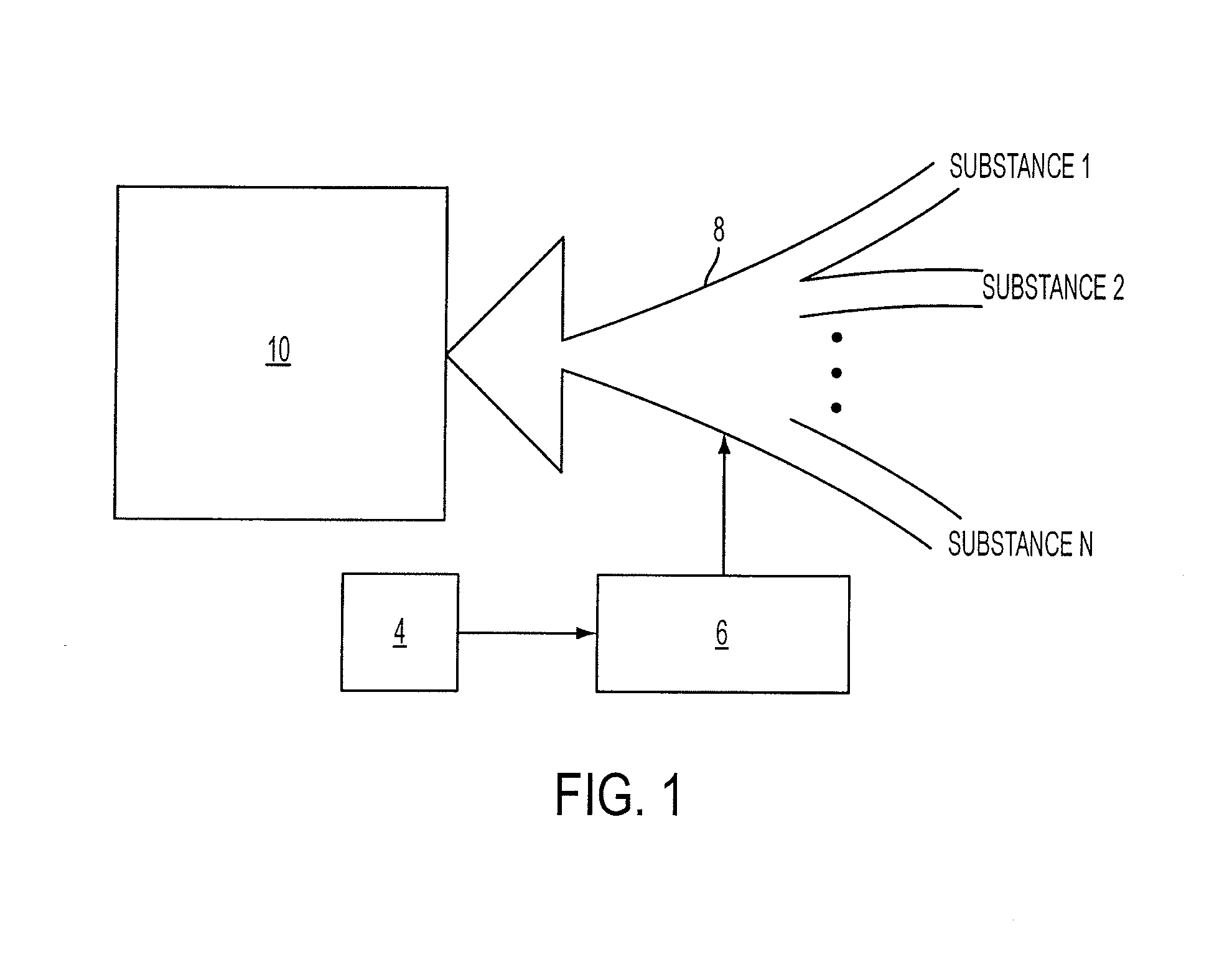

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a substance to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, and a control system configured to vary a number of sparks performed by the spark plug in relation to a combustion event of the combustion chamber responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

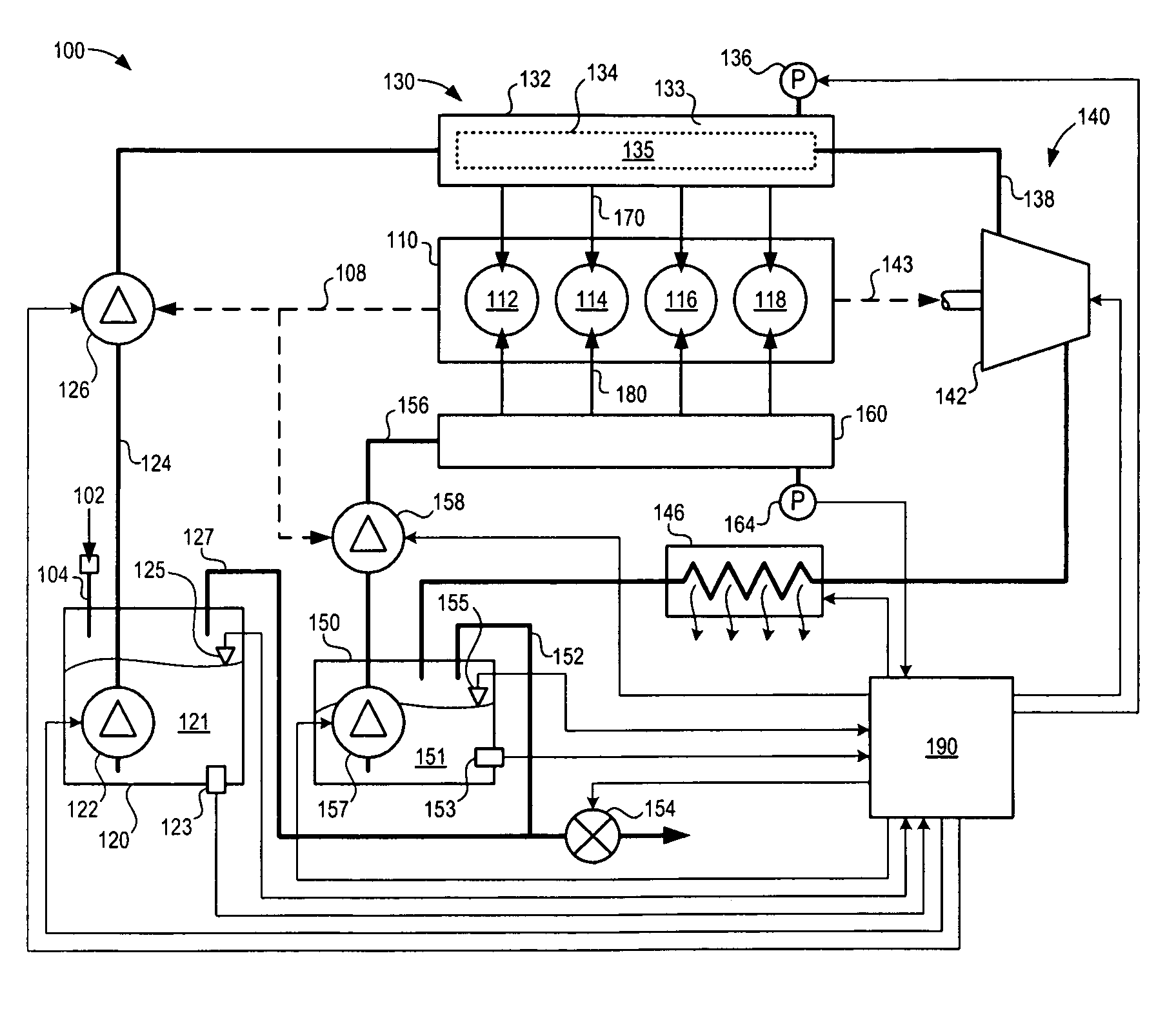

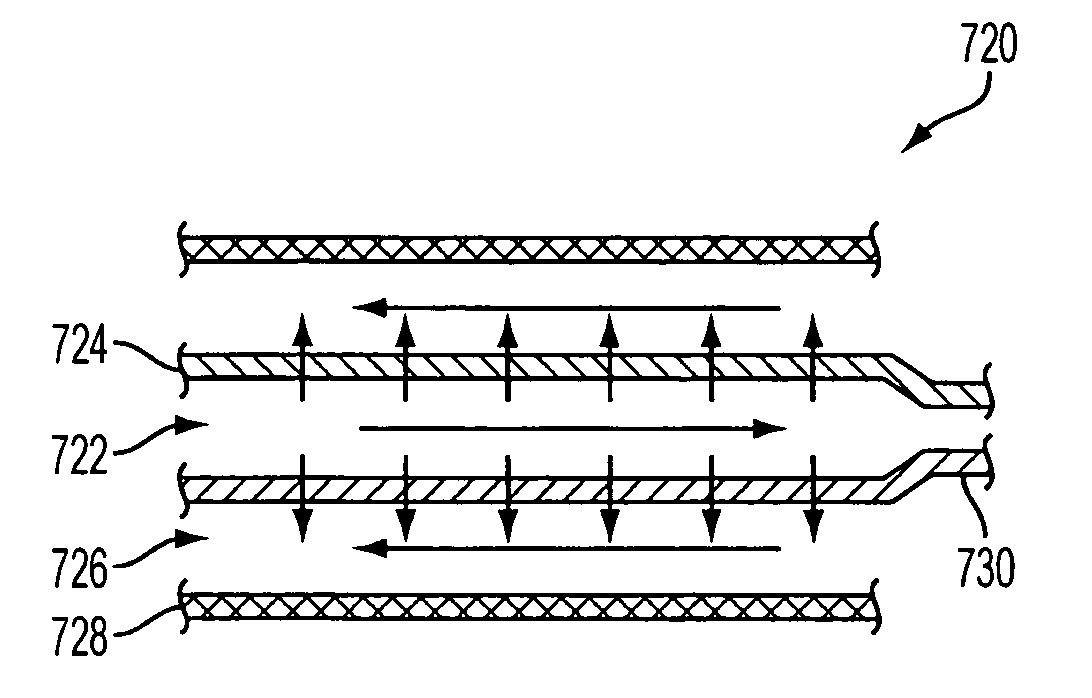

Fuel Rail Assembly Including Fuel Separation Membrane

InactiveUS20090159057A1Reduce constraintsLow costElectrical controlInternal combustion piston enginesHigh rateAlcohol

As one example, a fuel rail assembly for supplying pressurized fuel to a plurality of cylinders of an engine is provided. The fuel rail assembly includes a fuel rail housing defining an internal fuel rail volume having at least a first region and a second region; a fuel separation membrane element disposed within the fuel rail housing that segregates the first region from the second region. The membrane element can be configured to pass a first component of a fuel mixture such as an alcohol through the membrane element from the first region to the second region at a higher rate than a second component of the fuel mixture such as a hydrocarbon. The separated alcohol and hydrocarbon components can be provided to the engine in varying relative amounts based on operating conditions.

Owner:FORD GLOBAL TECH LLC

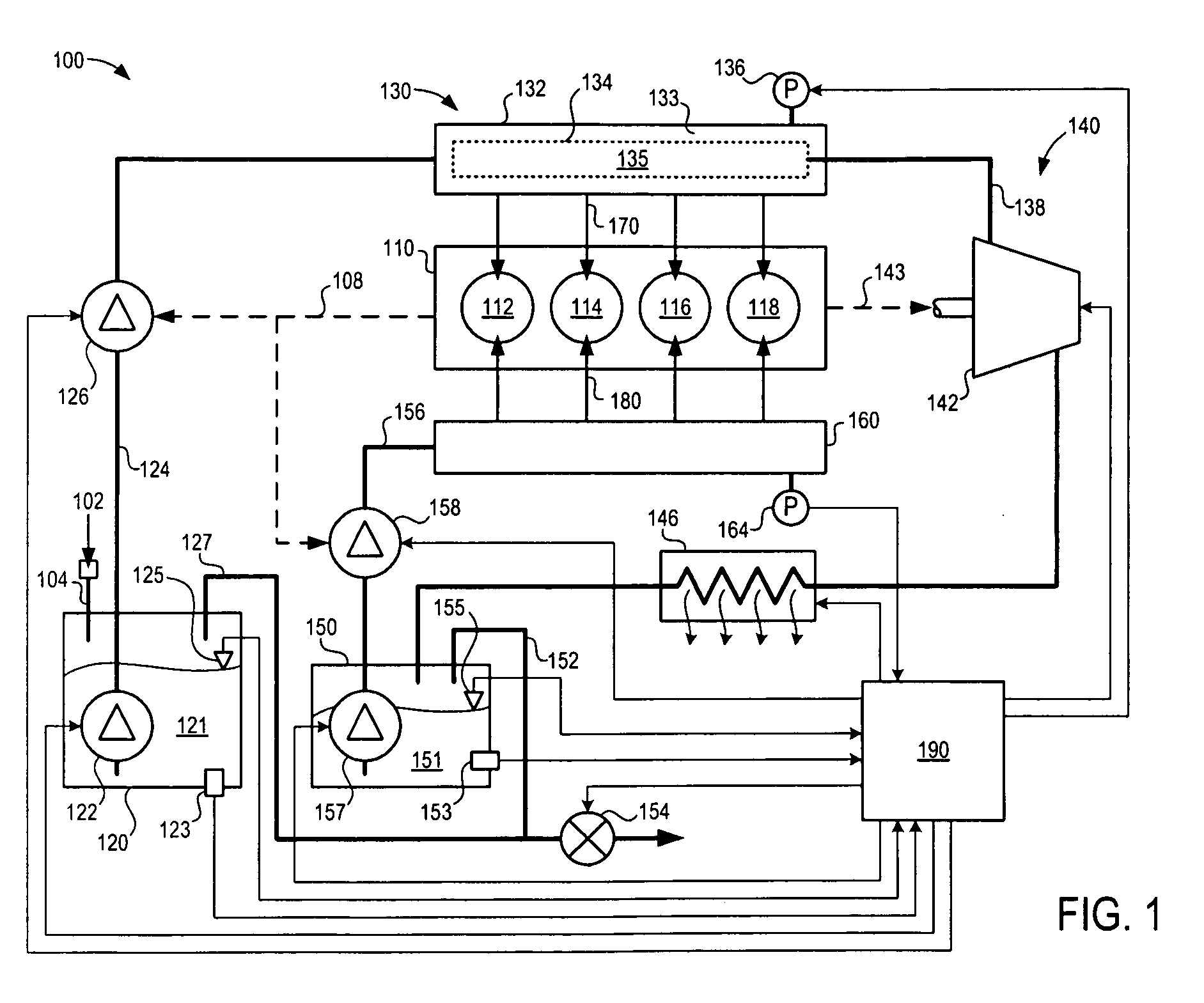

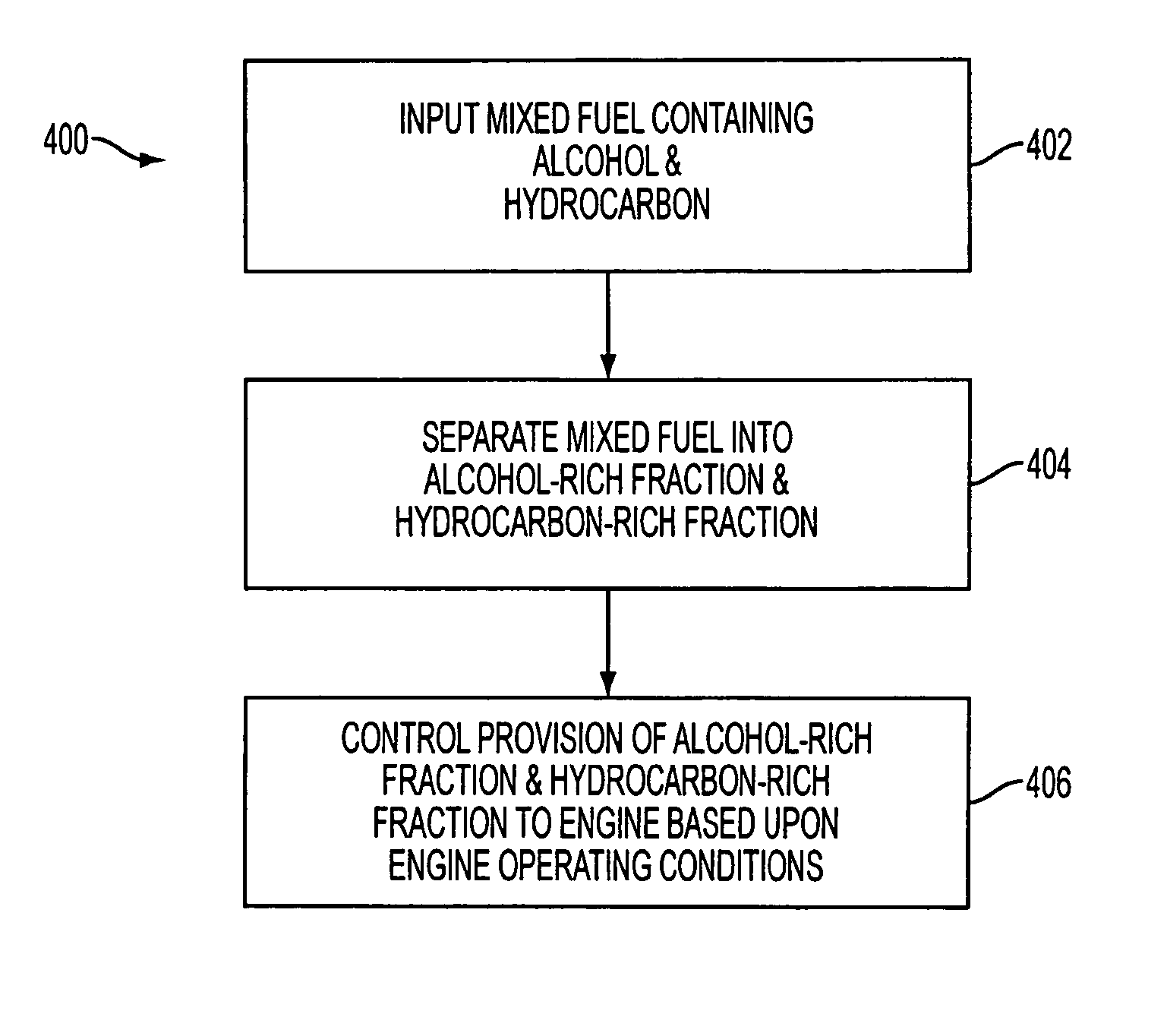

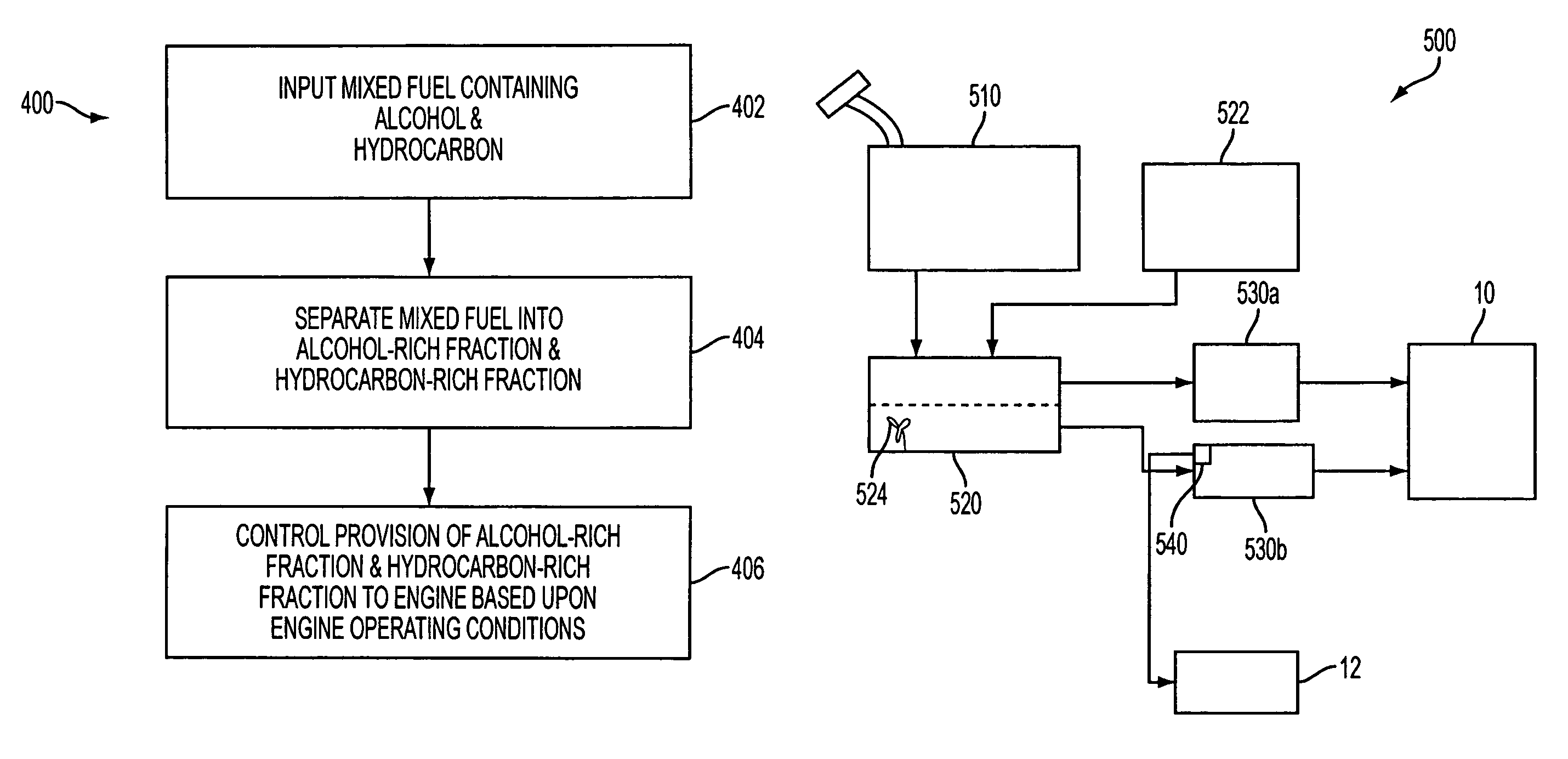

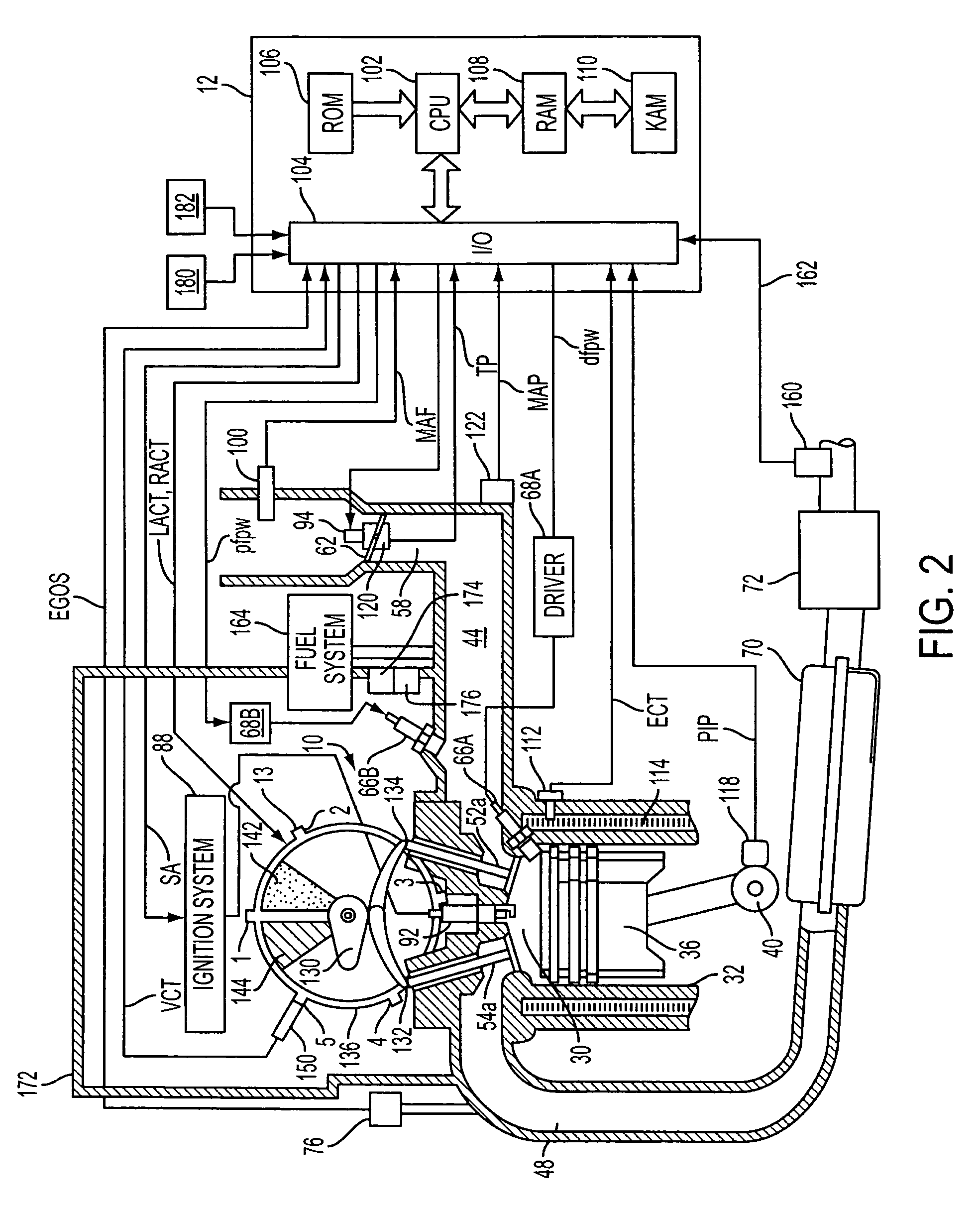

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215072A1Low costImprove charge cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelFuel tankElectrical polarity

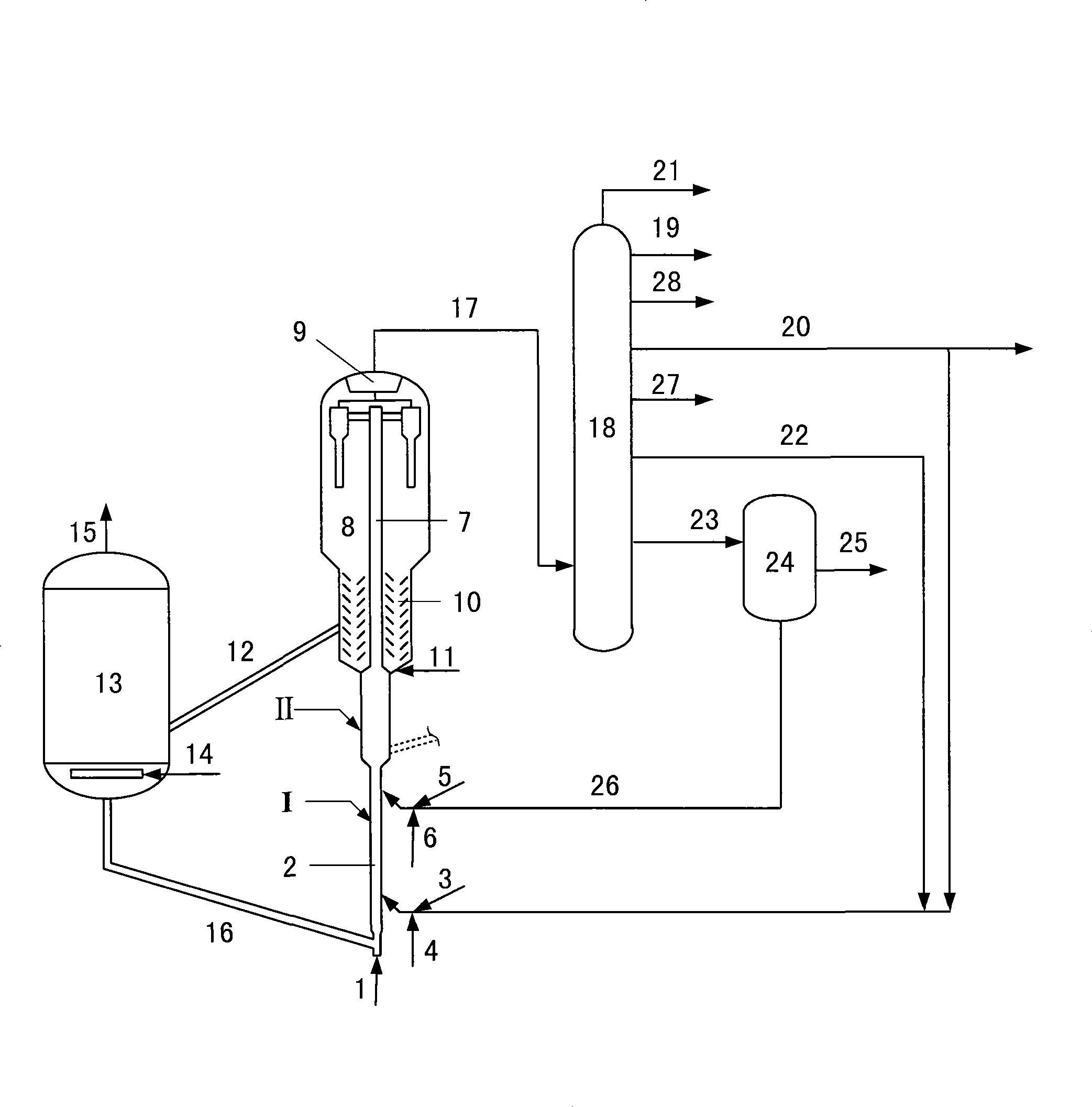

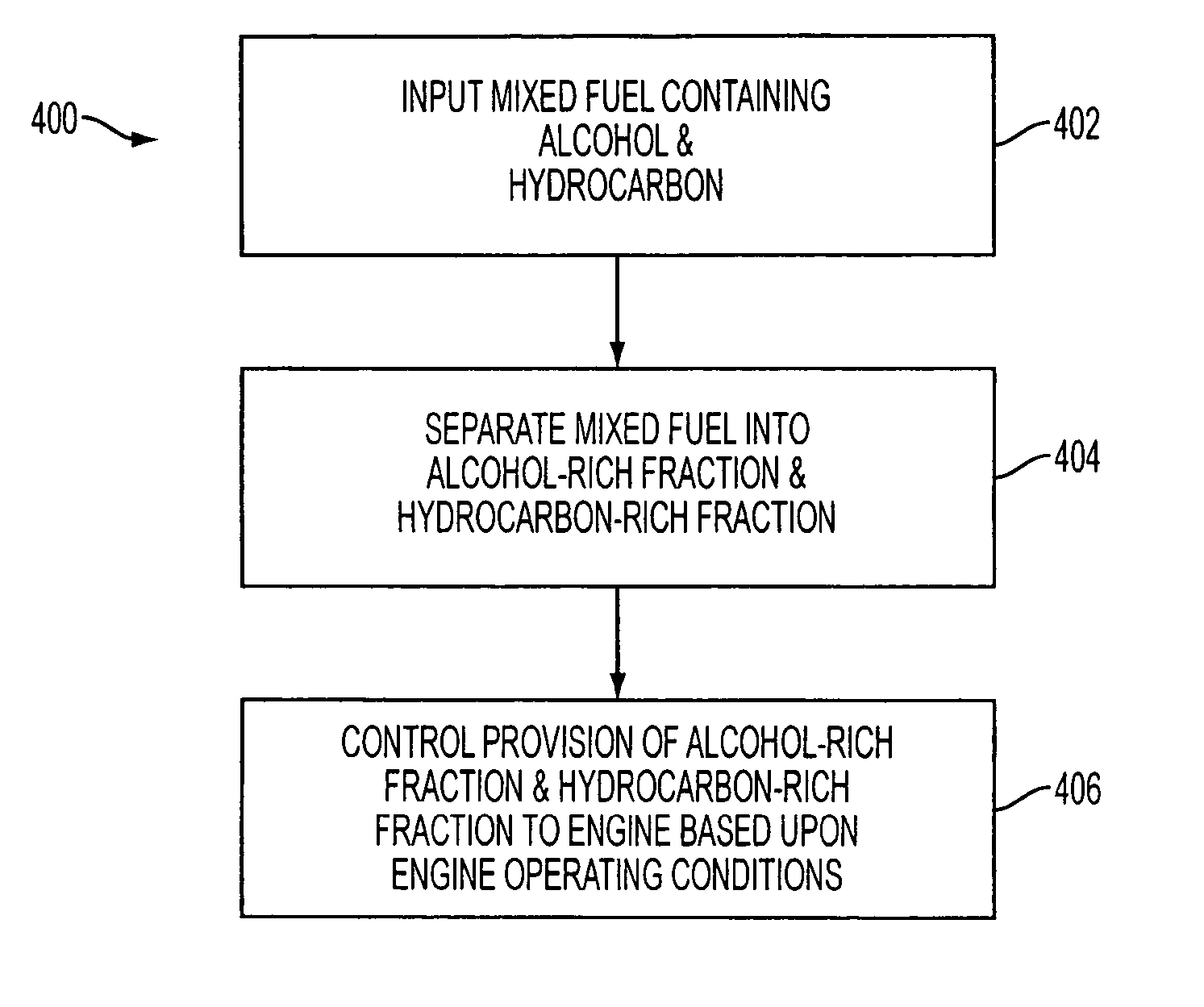

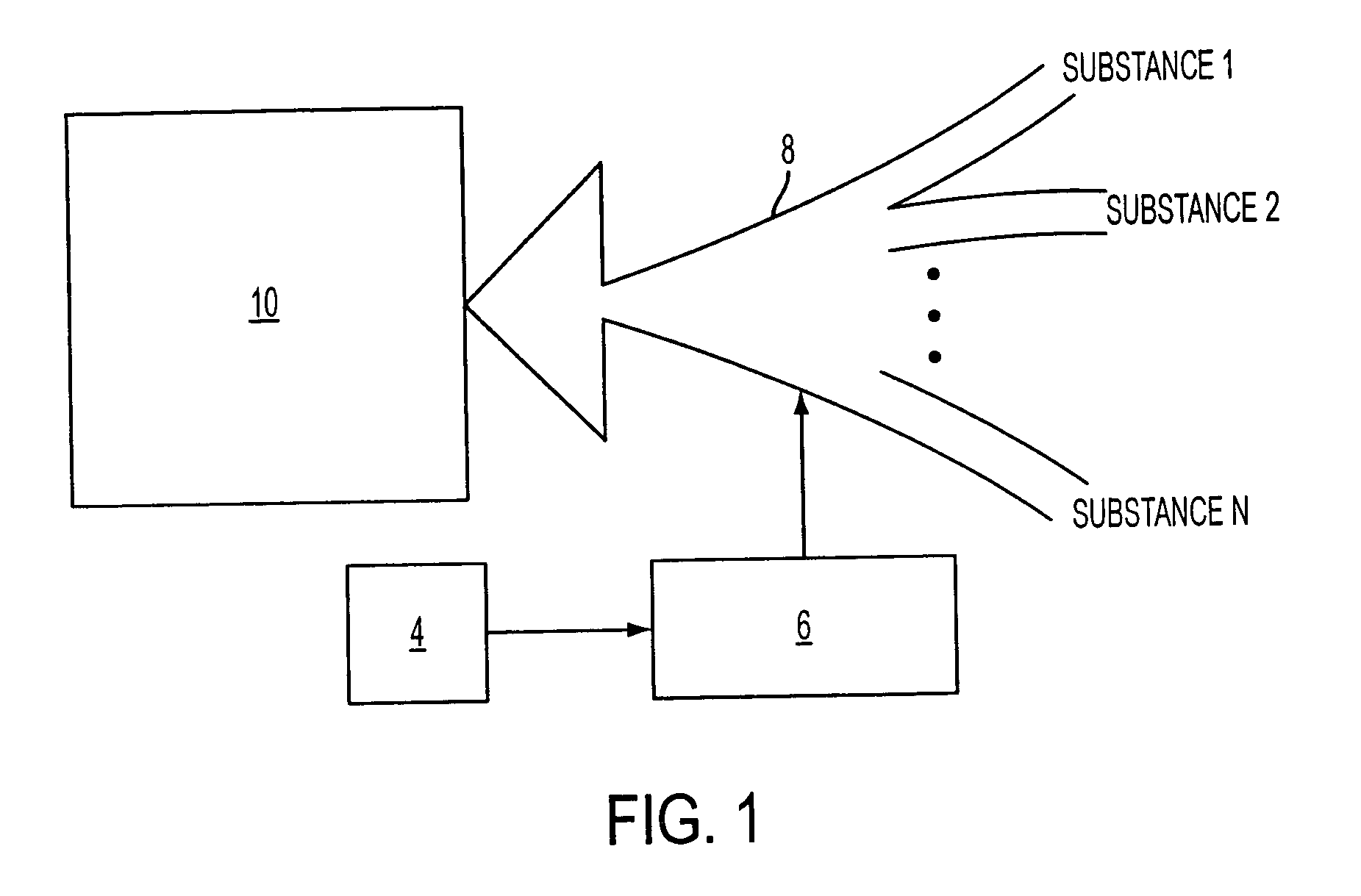

In an apparatus having an internal combustion engine, a fuel tank, and an extractor disposed fluidically between the fuel tank and the engine, a method of operating the apparatus is disclosed, wherein the method comprises adding a volume of a mixed fuel into the extractor from the fuel tank, wherein the mixed fuel contains at least one substantially nonpolar fuel component and at least one polar fuel component, adding a volume of a polar solvent to the extractor, extracting at least a portion of the polar fuel from the mixed fuel into the polar solvent, thereby forming a first fuel mixture with an enriched concentration of the polar fuel and a second fuel mixture with an enriched concentration of the substantially nonpolar fuel, and providing the first fuel mixture and the second fuel mixture to the engine in a ratio selected based upon engine operating condition.

Owner:FORD GLOBAL TECH LLC

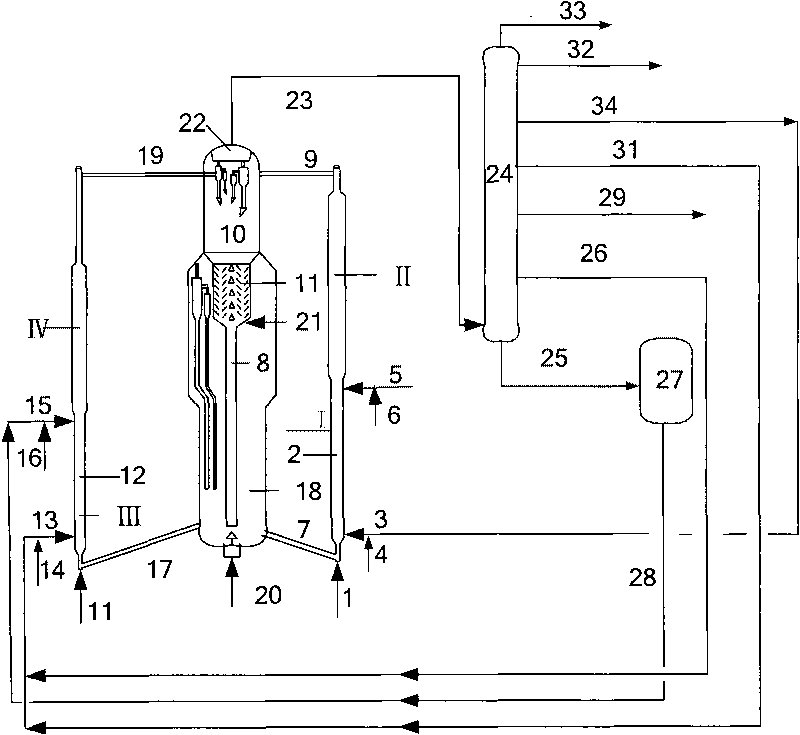

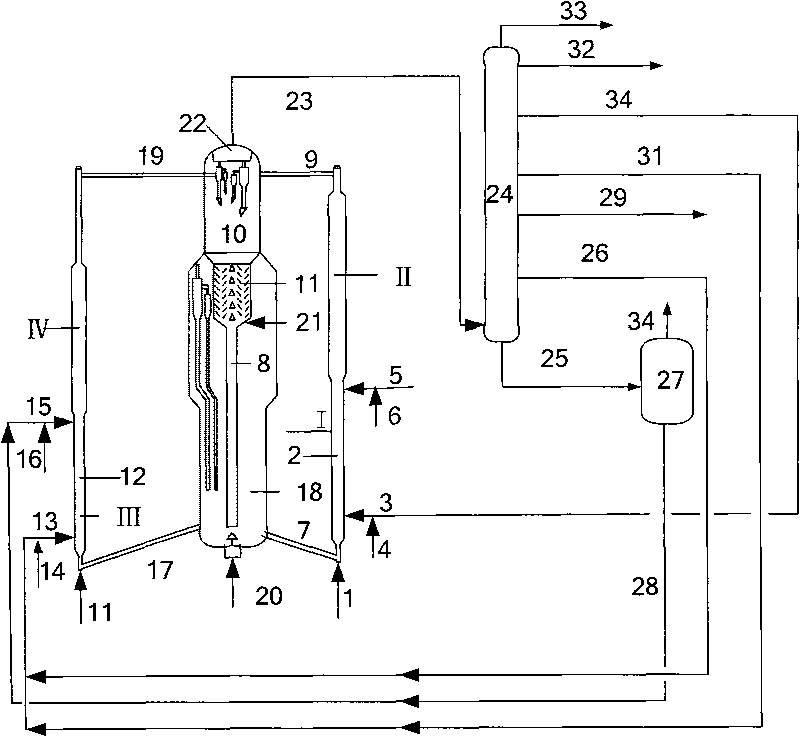

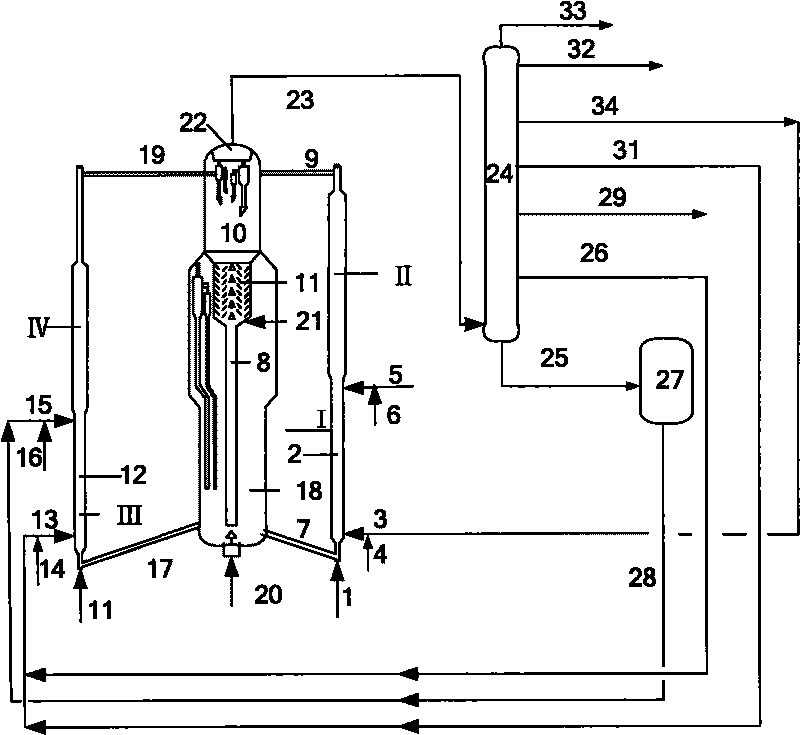

Catalytic conversion method for preparing propone and high-octane number gasoline

The invention provides a catalysis conversion method used for preparing propylene and high octane gasoline; raw material which is difficult to be cracked contacts a thermal regeneration catalyst; the cracking reaction is carried out under the conditions of 600-750 DEG C of temperature, 100-800h<-1> of weight hourly space velocity, 0.10-1.0MPa of pressure, 30-150 of weight ratio of catalyst to raw material and 0.05-1.0 of weight ratio of water vapour to raw material; the reaction matter flow is mixed with the raw oil which is easy to be cracked and the cracking reaction thereof is carried out under the condition of 450-620 DEG C of temperature, 0.1-100h<-1> of weight hourly space velocity, 0.10-1.0MPa of pressure, 1.0-30 of weight ratio of catalyst to raw material and 0.05-1.0 of weight ratio of water vapour to raw material; after spent catalyst is separated from reaction oil gas, the spent catalyst enters a stripper and is returned to a reactor after being stripped, burned and regenerated; the reaction oil gas is separated so as to gain the object outcome: propylene, high octane gasoline and re-cracked raw material; the re-cracked raw material comprises distillate with the distillation range of 180-260 DEG C and heavy aromatic raffinate oil. The method greatly increases the yield and selection of propylene, obviously improves the yield and octane of the gasoline and leads the reduction range of yield of the dry gasoline to achieve more than 80% by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215127A1Low costImprove charge cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesHigh rateFuel tank

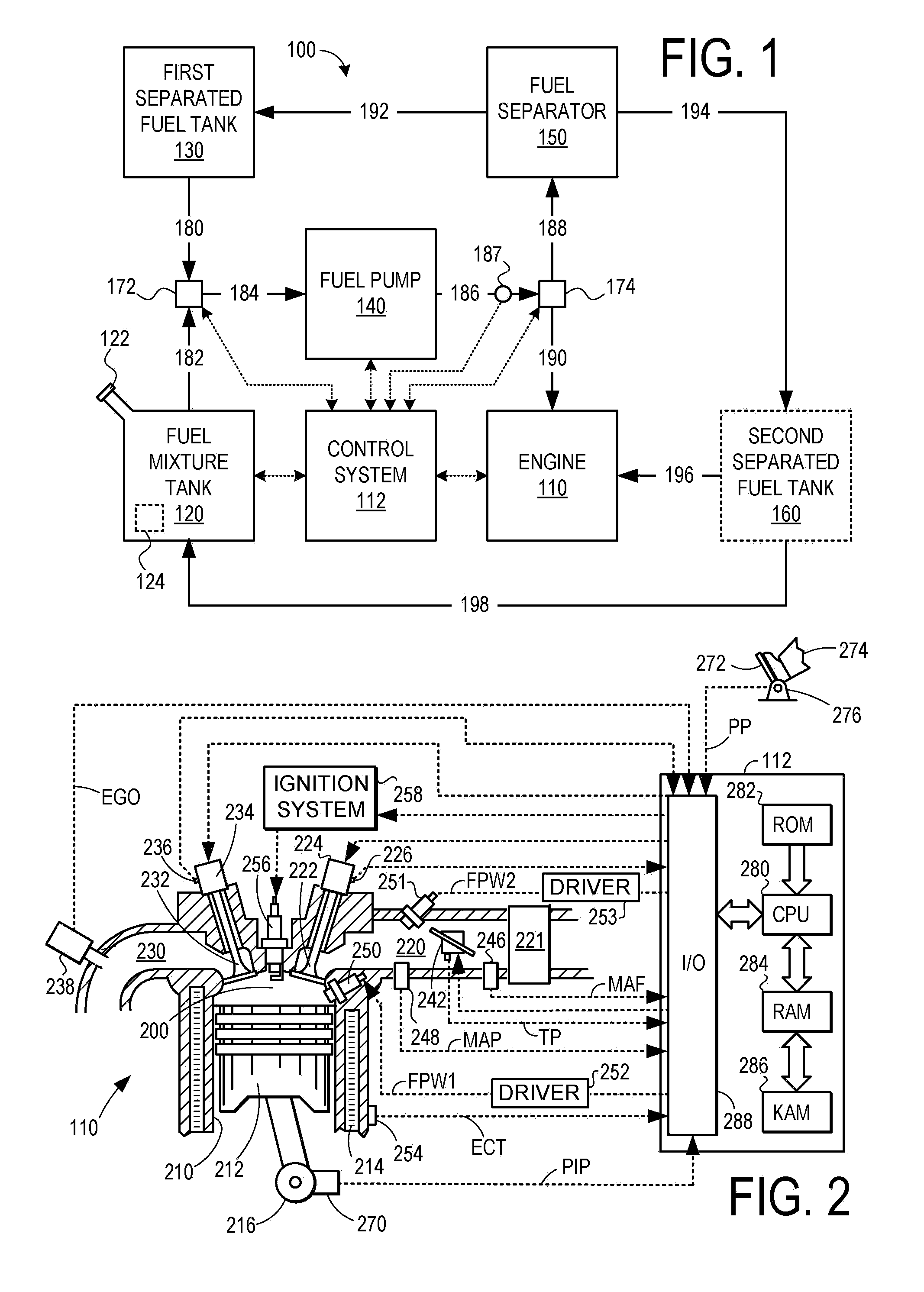

An apparatus comprising an internal combustion engine, a fuel tank, a fuel separator disposed fluidically between the fuel tank and the engine, wherein the fuel separator comprises first and second passageways separated at least partially by a selective barrier that selectively transports a first fuel in a fuel mixture at a higher rate than a second fuel in the fuel mixture, and wherein the first passageway is configured to receive an input of fuel from the fuel tank, and an extraction fluid source in fluid communication with the second passageway of the fuel separator.

Owner:FORD GLOBAL TECH LLC

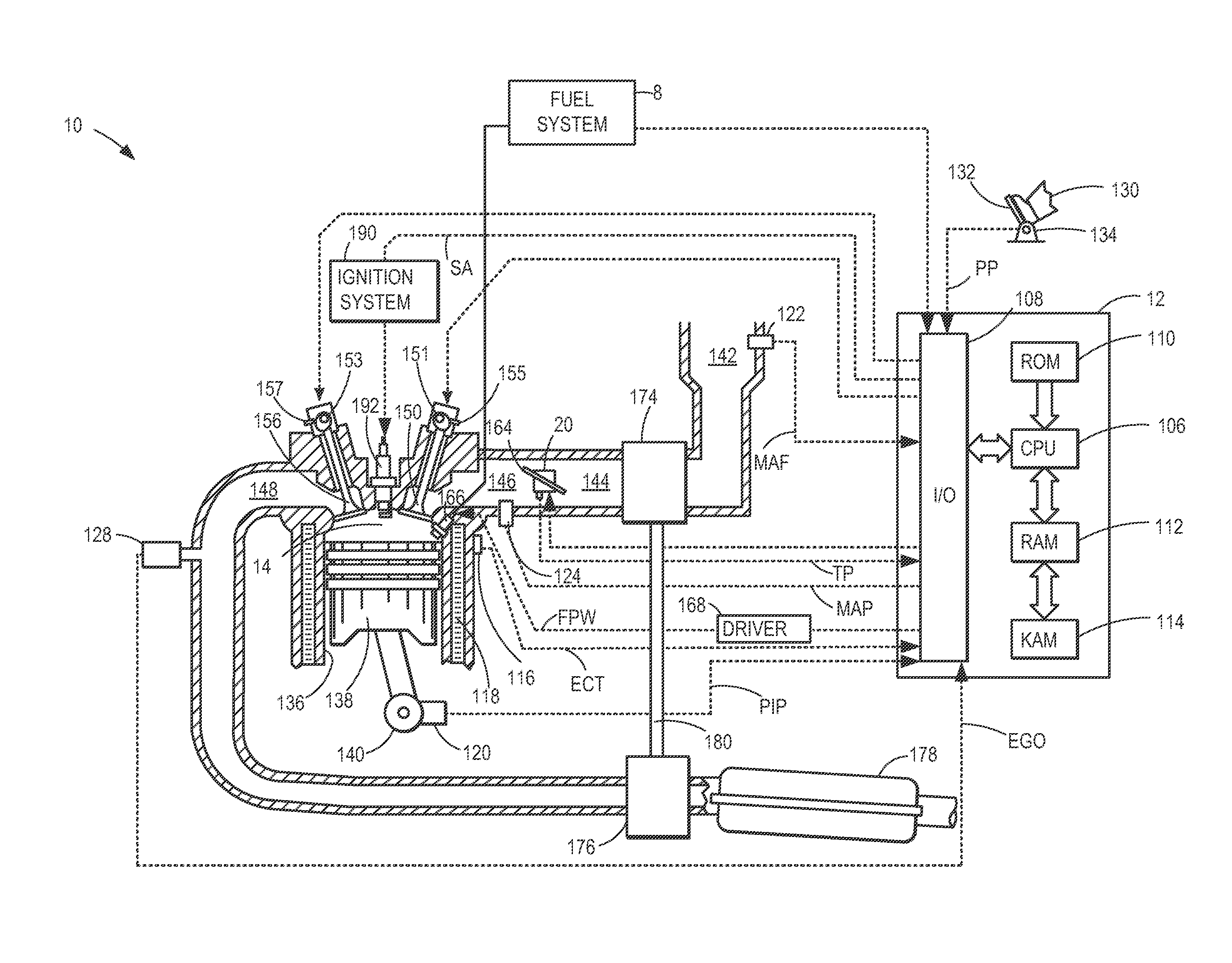

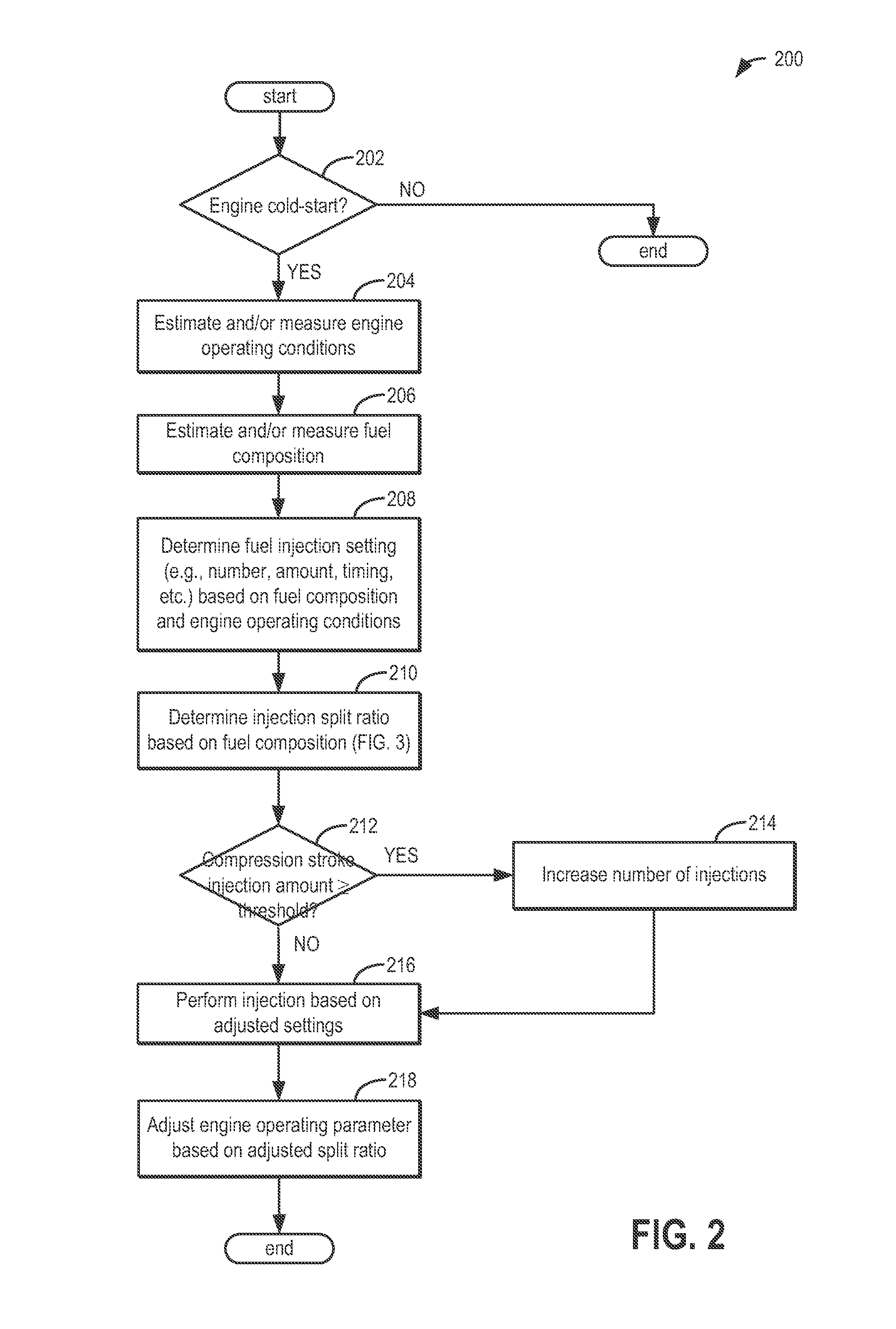

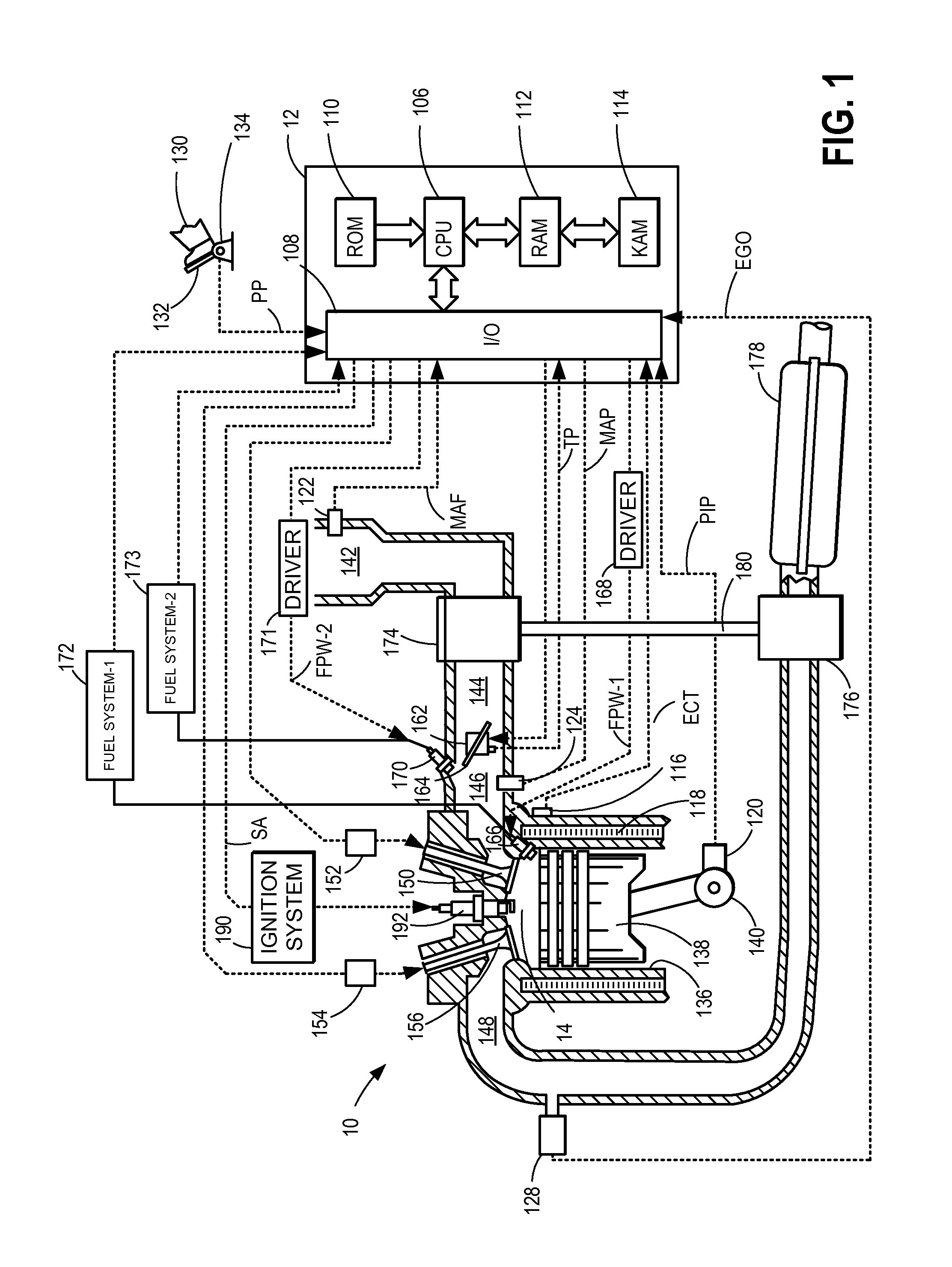

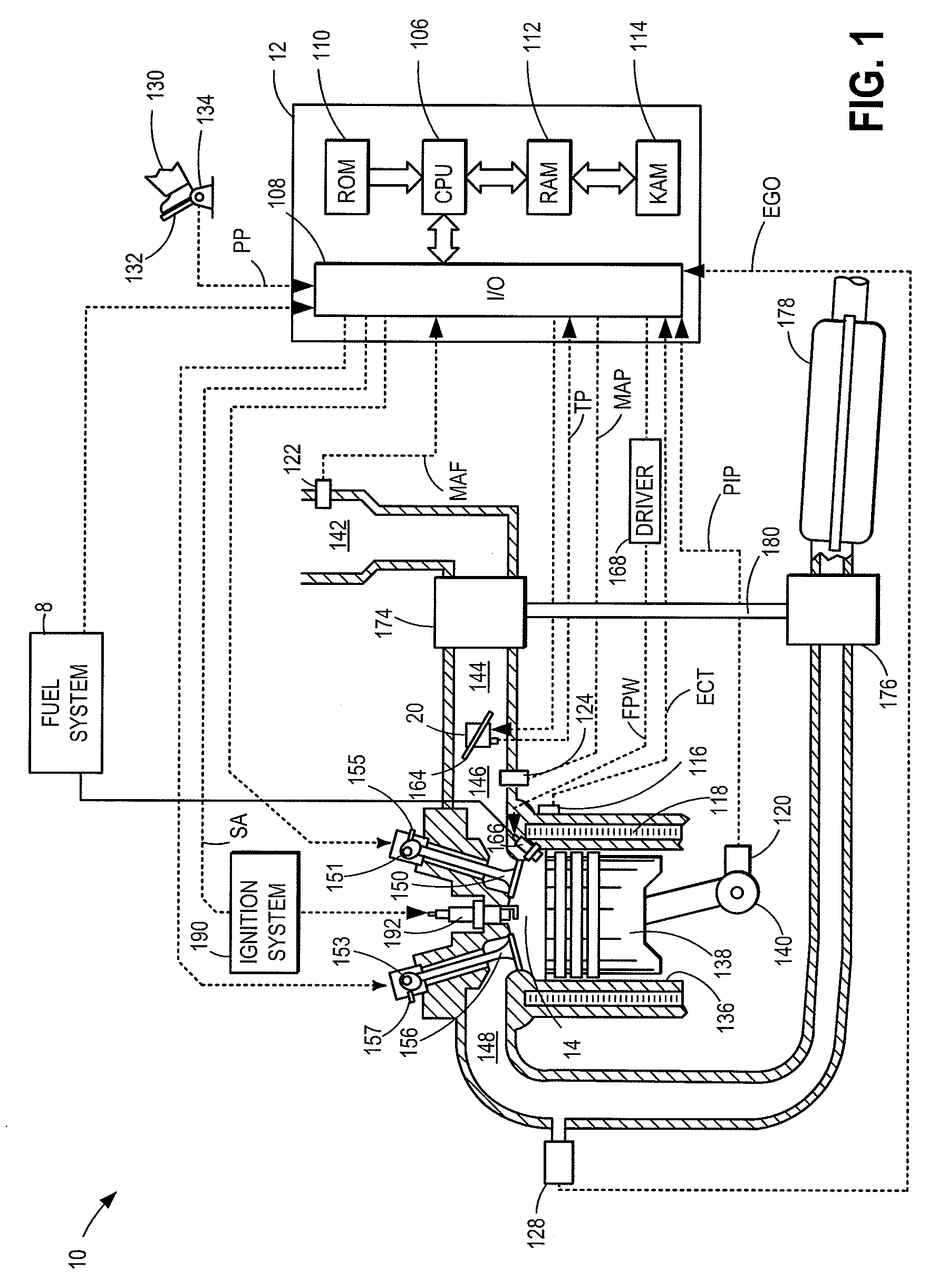

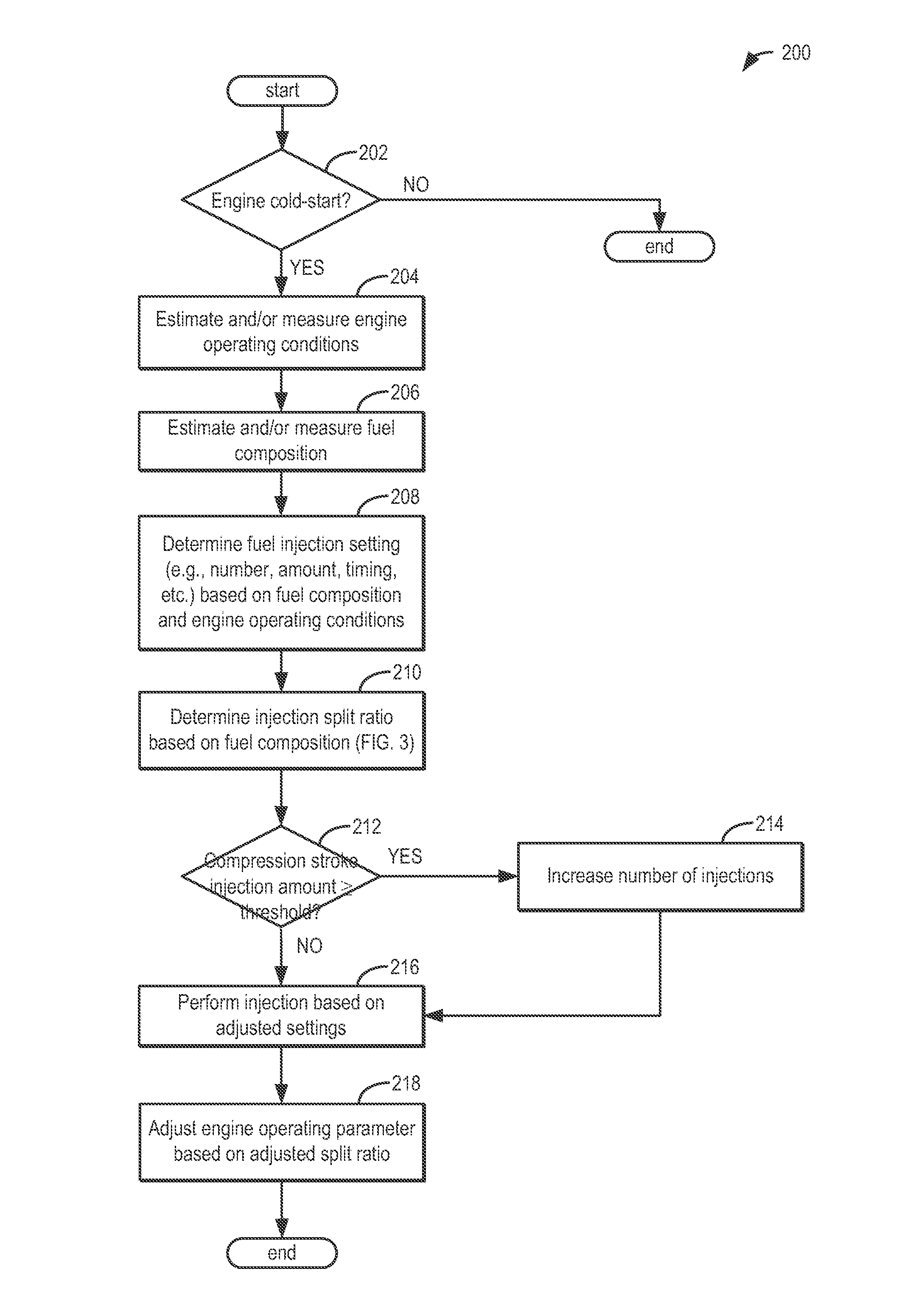

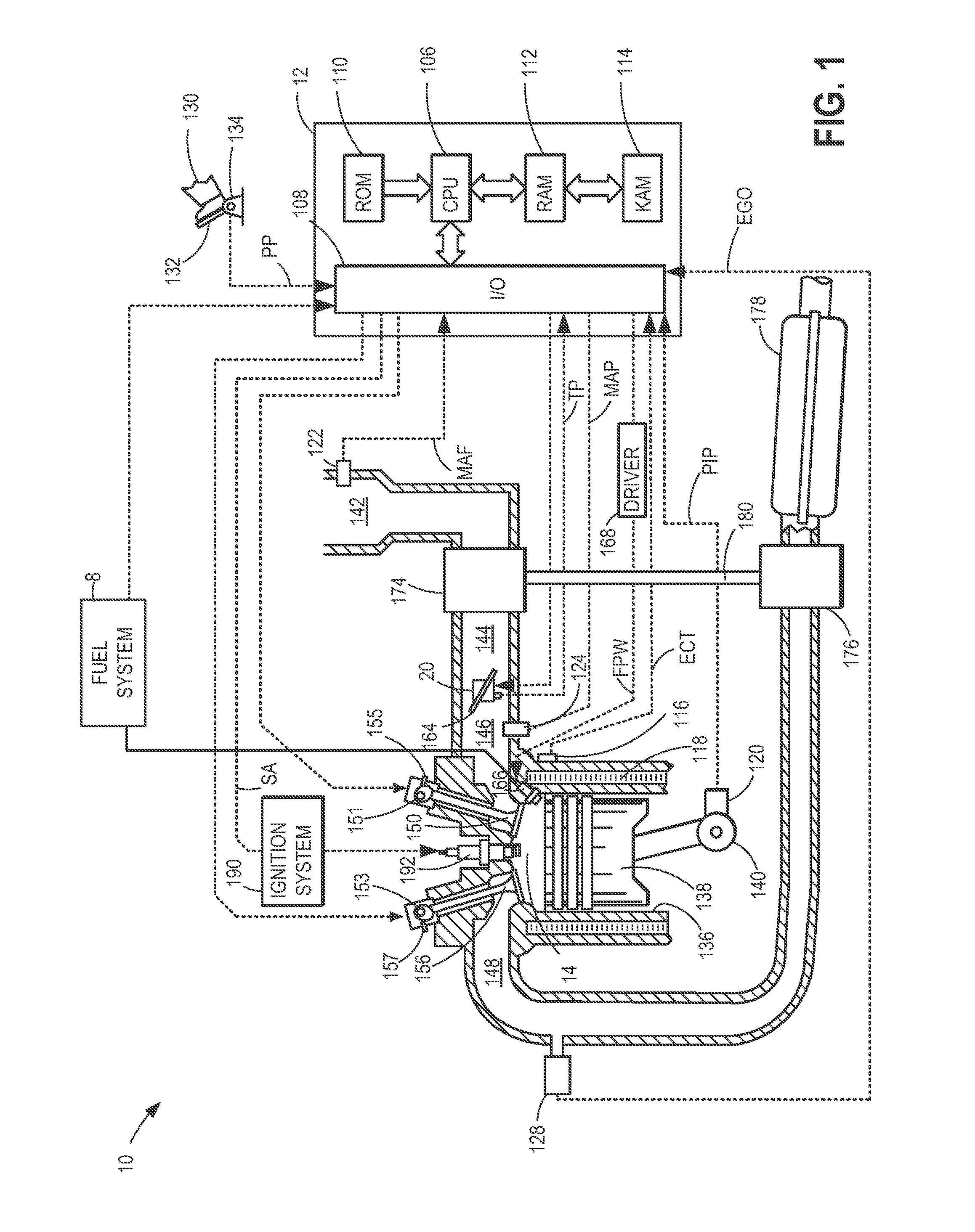

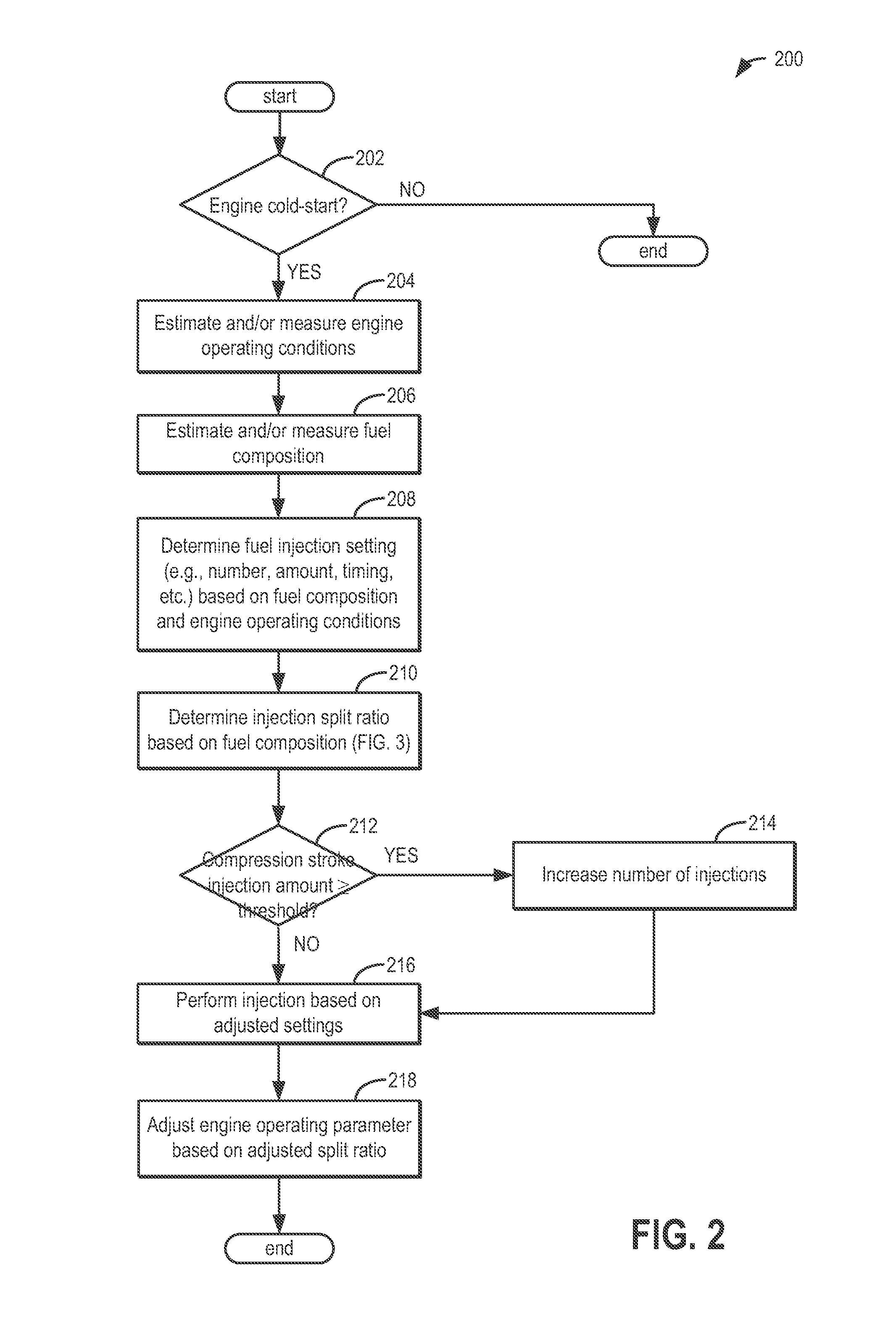

Fuel-based injection control

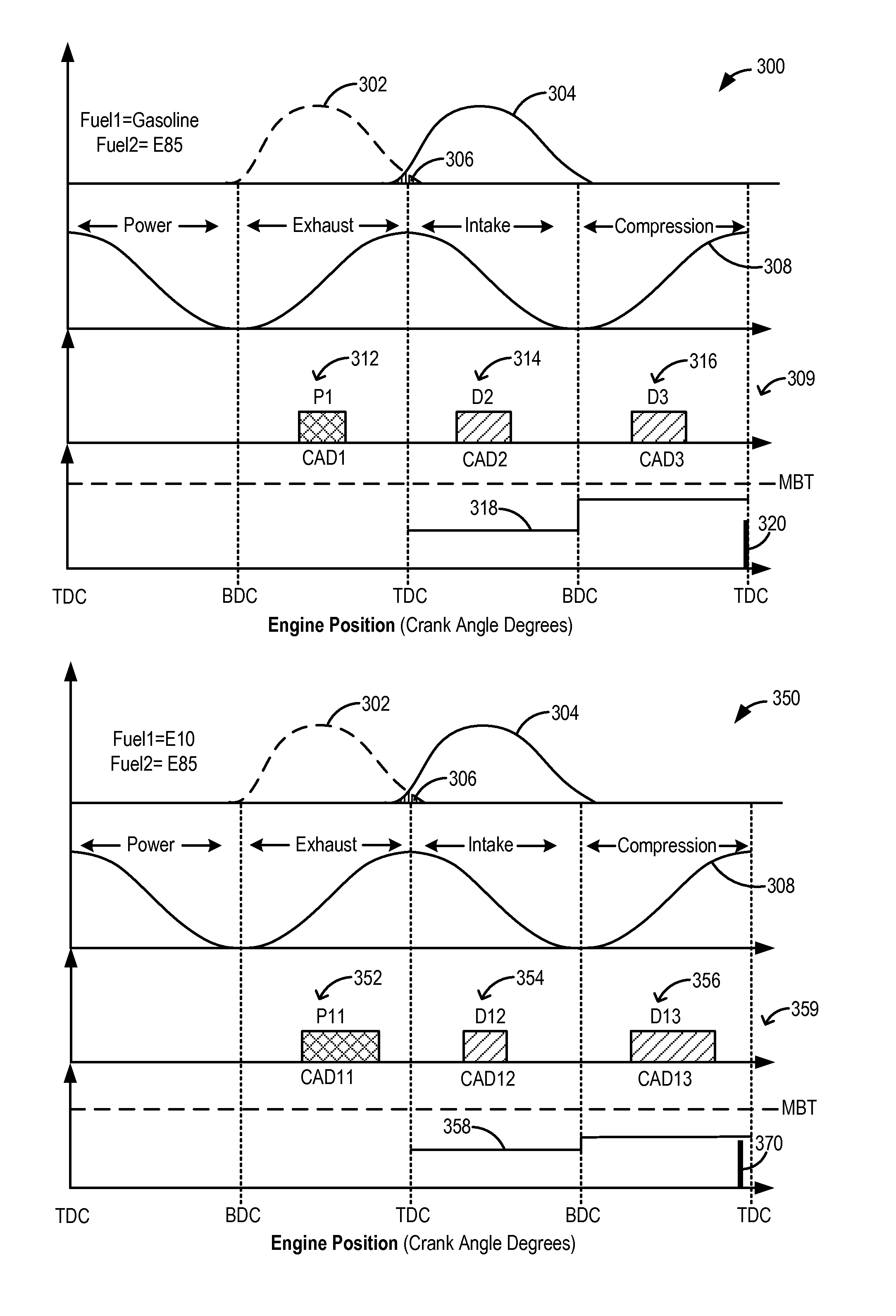

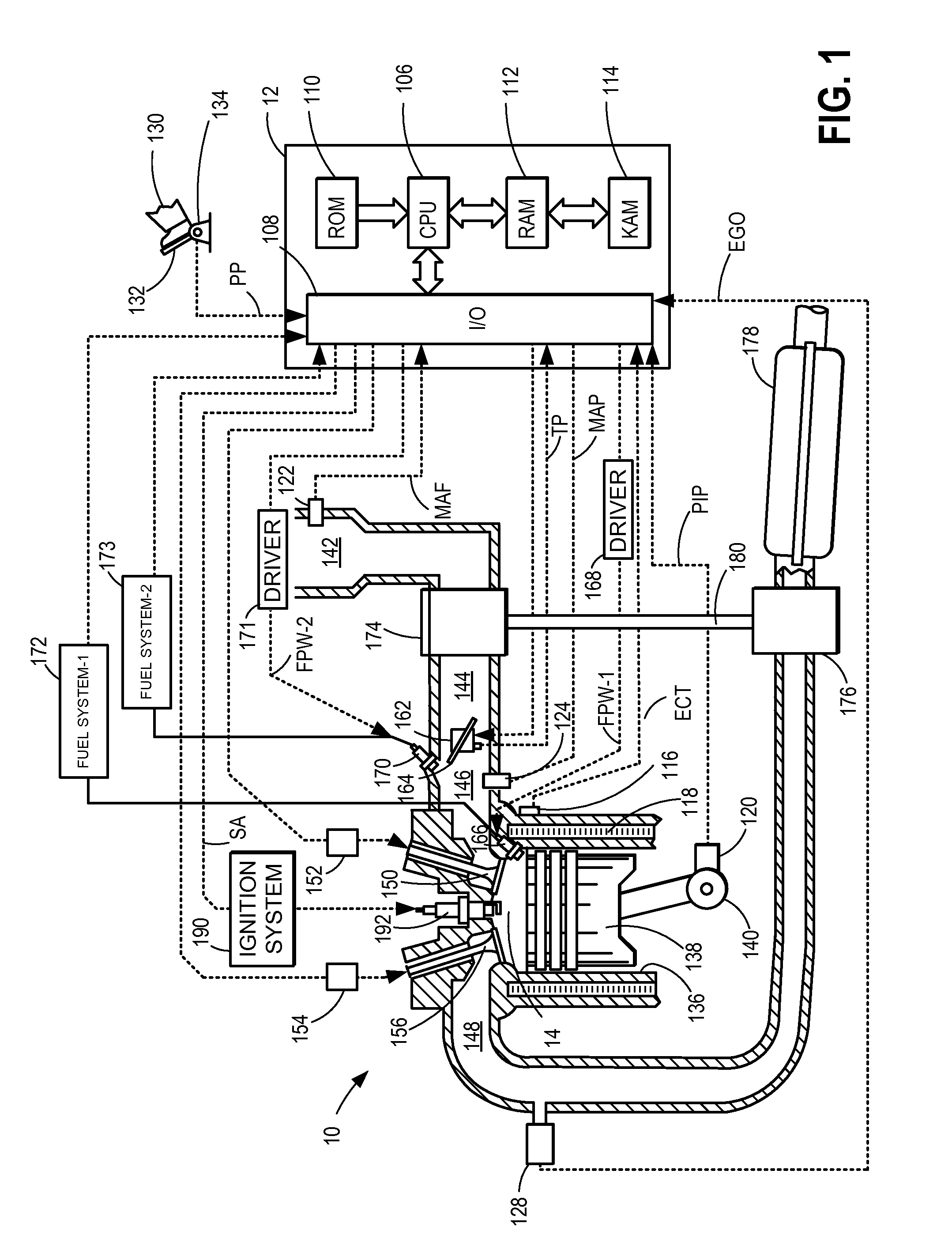

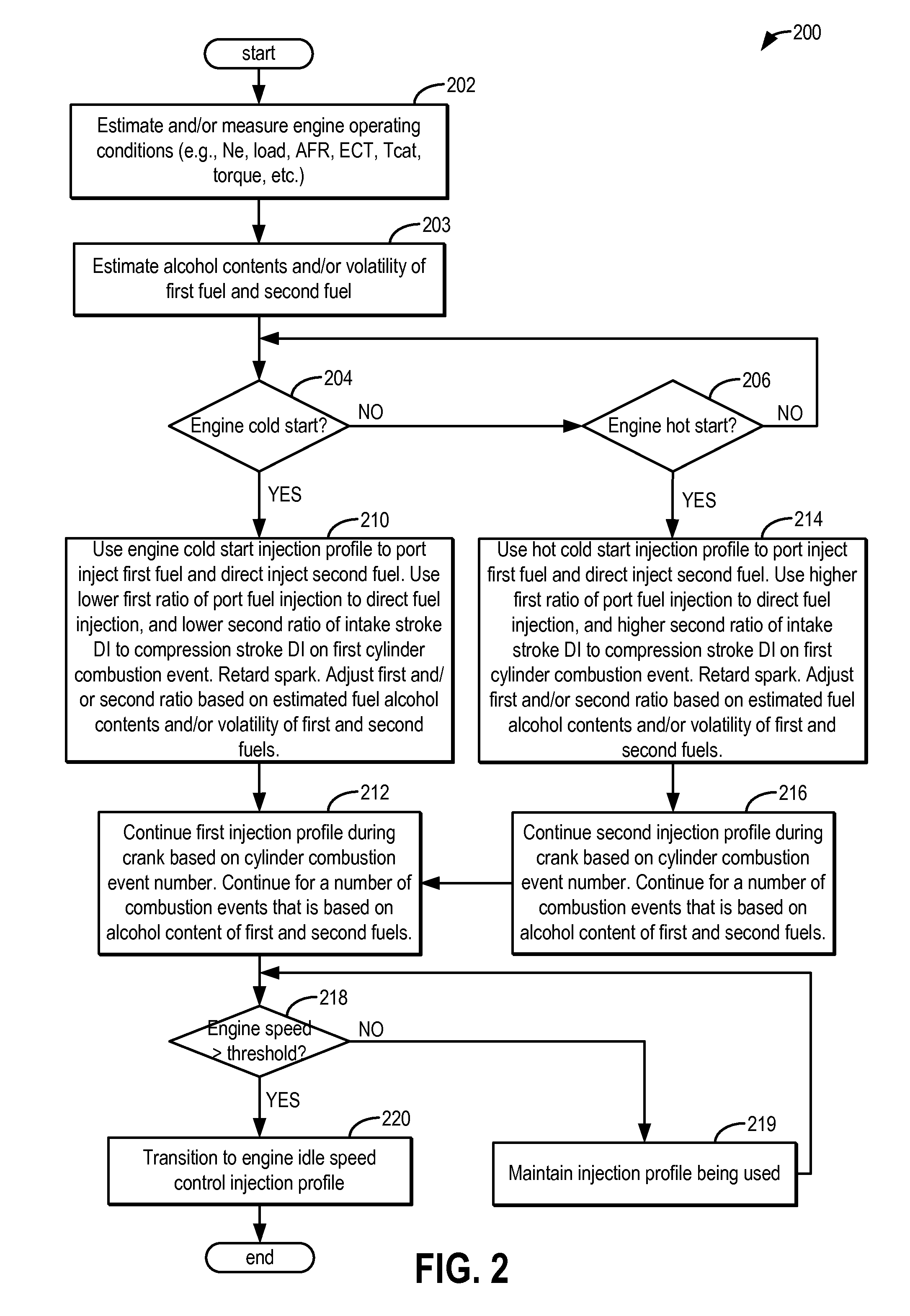

ActiveUS20110184629A1High latent heatImprove peak torque output of engineElectrical controlInternal combustion piston enginesAlcohol contentControl system

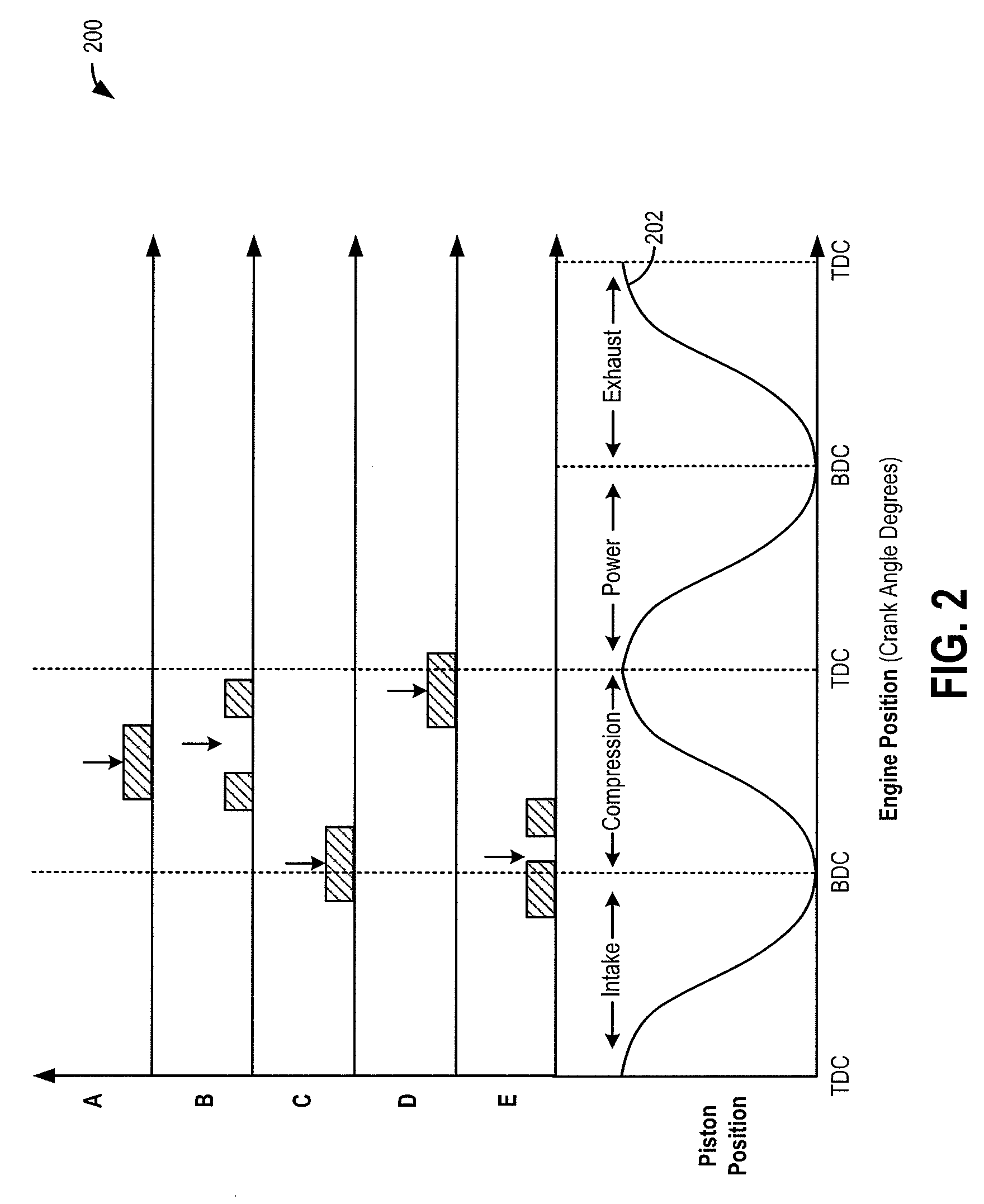

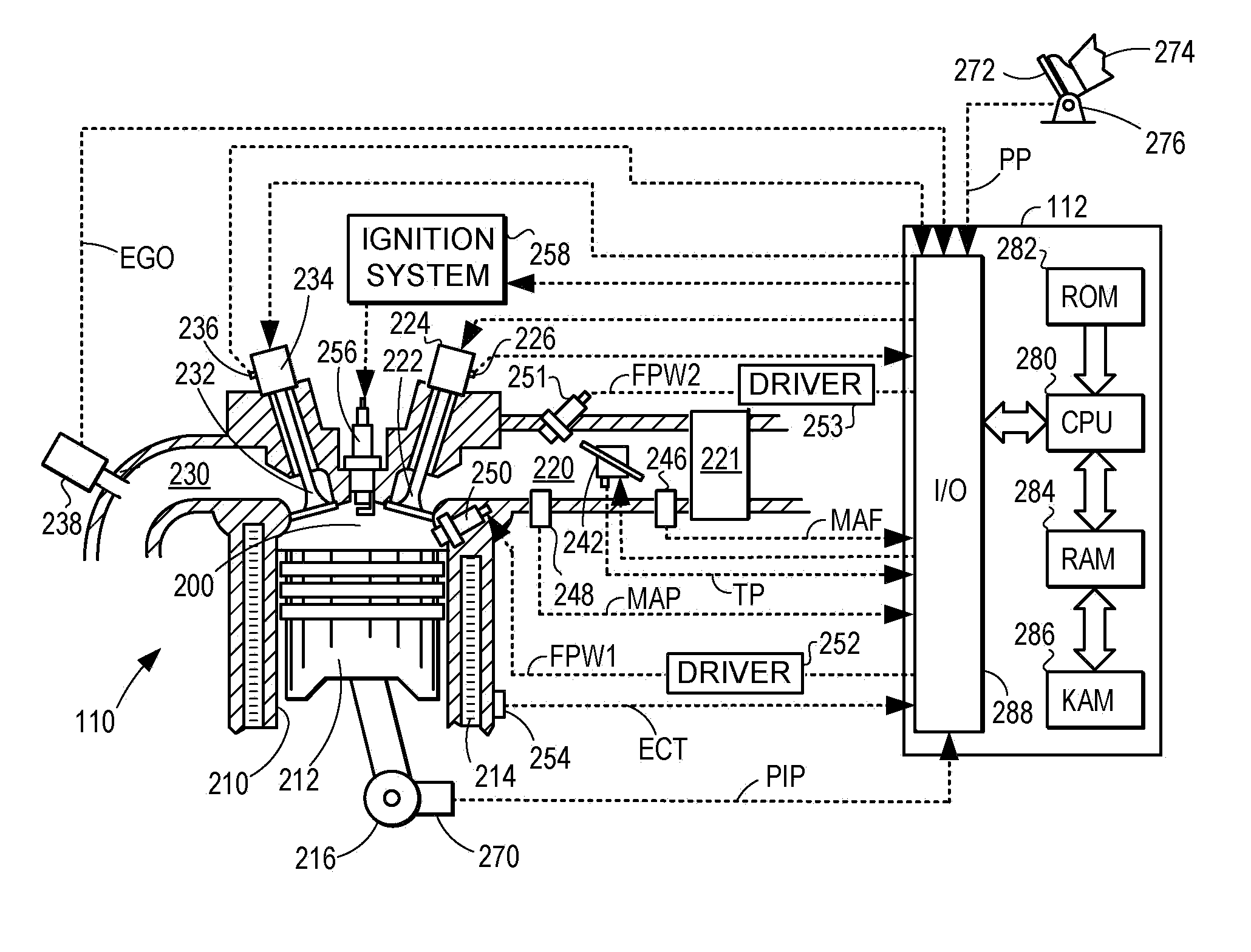

Systems and methods of operating an engine with a varying fuel composition. In one example, a split injection is performed during engine cranking with at least some fuel injected in the intake stroke and some fuel injected in the compression stroke. Further, a split ratio of the injection is adjusted based on the alcohol content of the injected fuel.

Owner:FORD GLOBAL TECH LLC

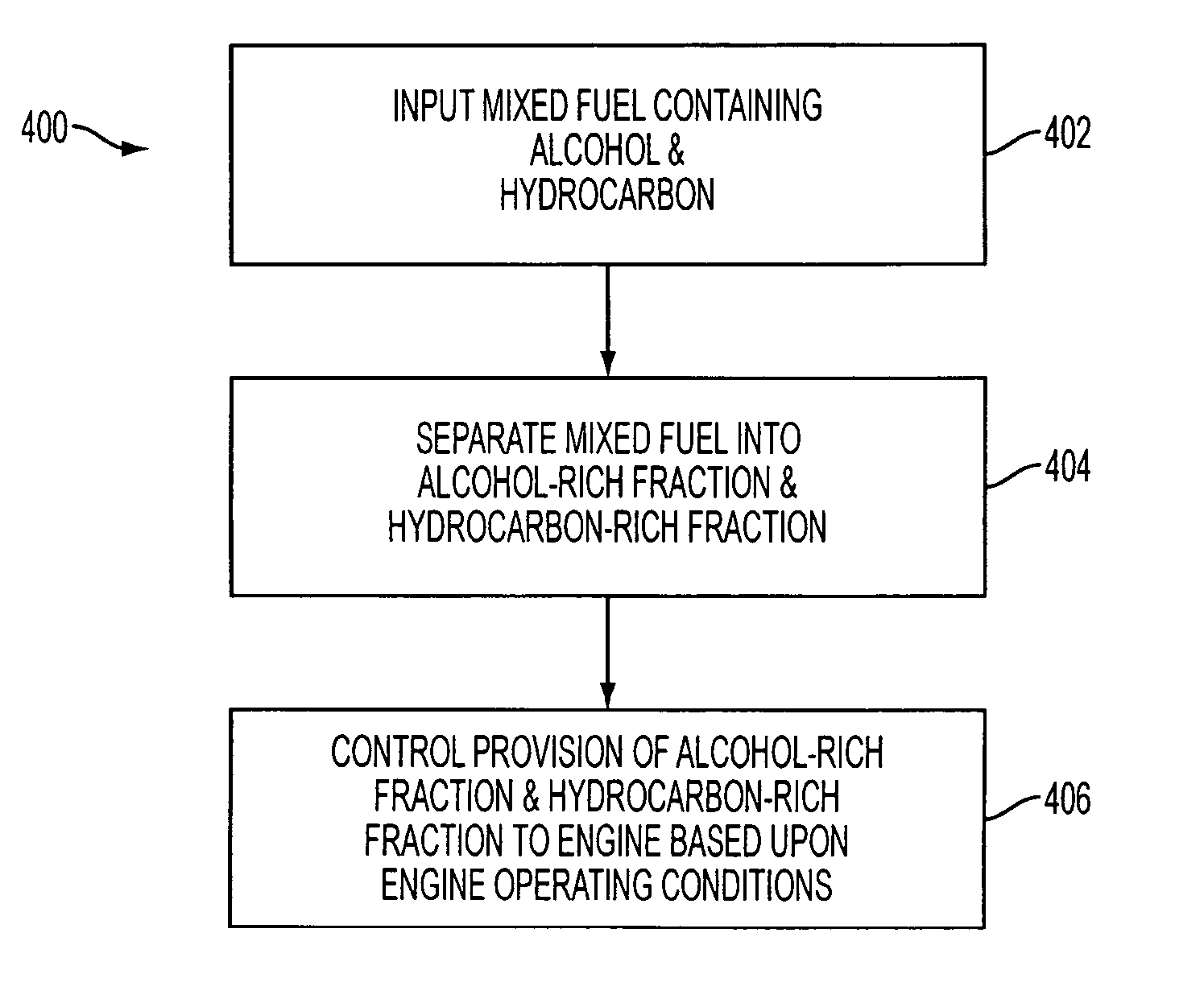

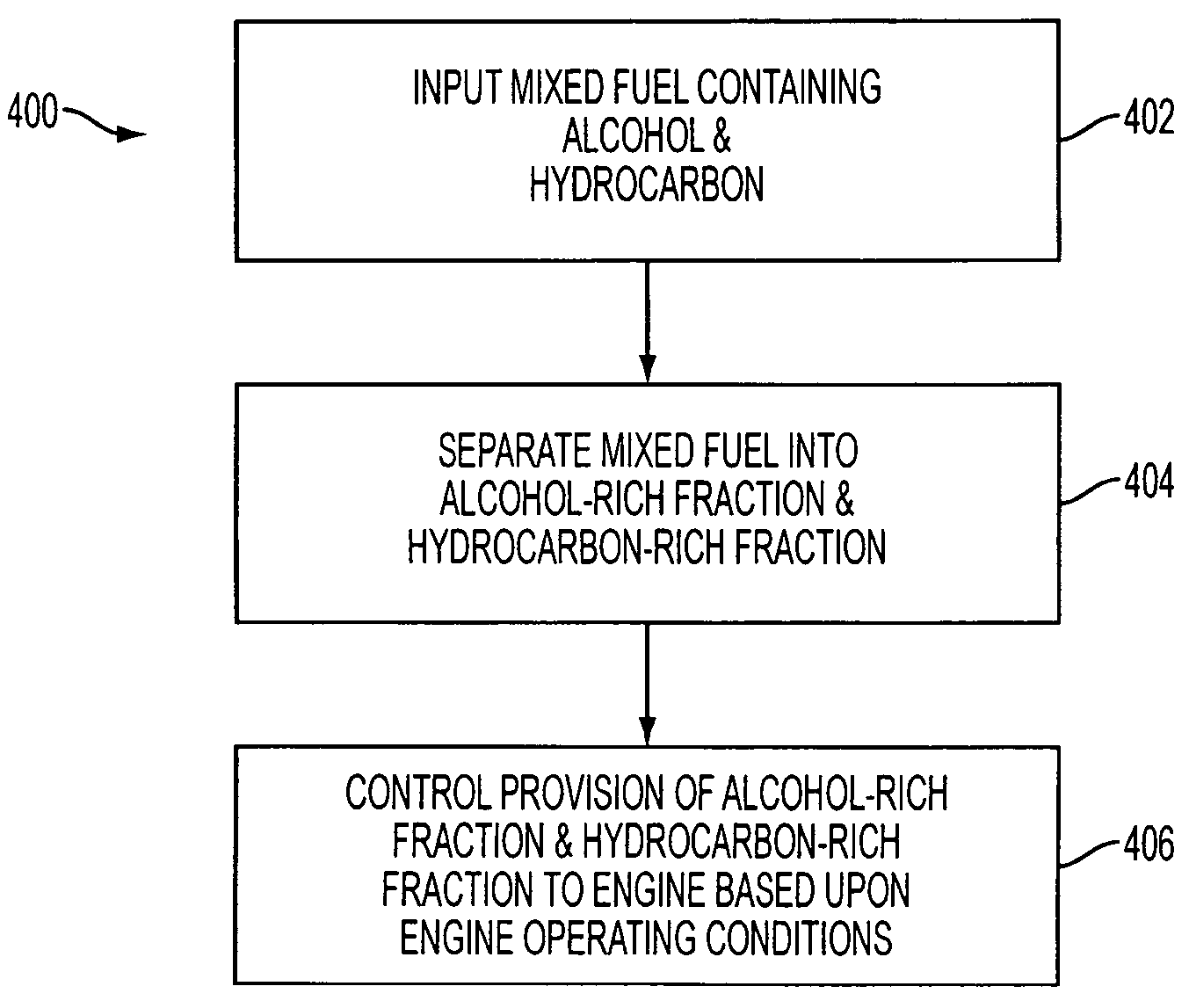

Apparatus with Mixed Fuel Separator and Method of Separating a Mixed Fuel

InactiveUS20070234976A1Increase heatIncrease profitElectrical controlNon-fuel substance addition to fuelInternal combustion engineMixed fuel

A method of operating a vehicle system including an internal combustion engine is disclosed, the method comprises separating a second fuel from a first fuel, the second fuel having a greater concentration of at least one component than the first fuel; combusting at least the first fuel at least during a first engine load; and combusting at least the second fuel at least during a second engine load higher than the first engine load.

Owner:FORD GLOBAL TECH LLC

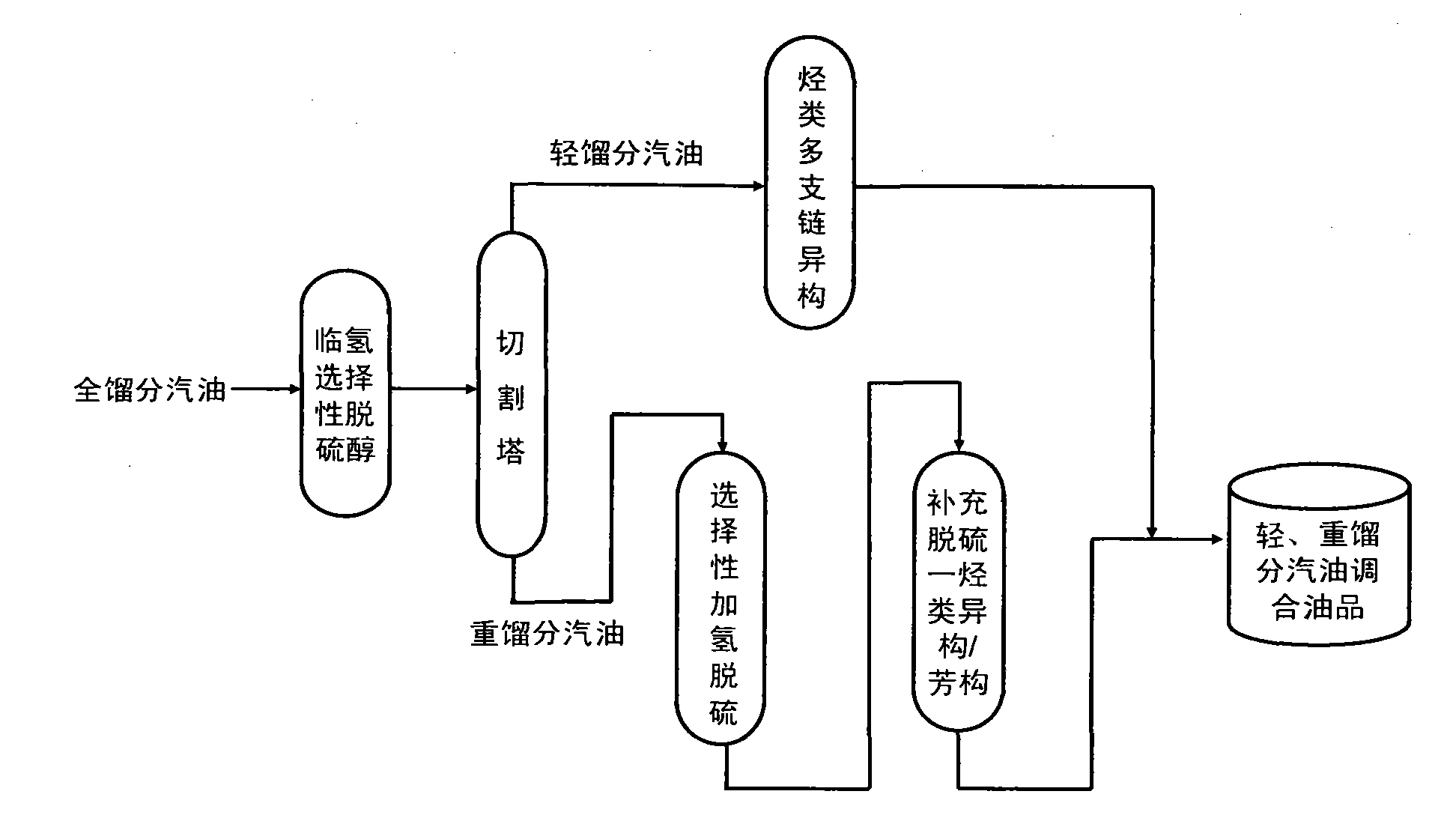

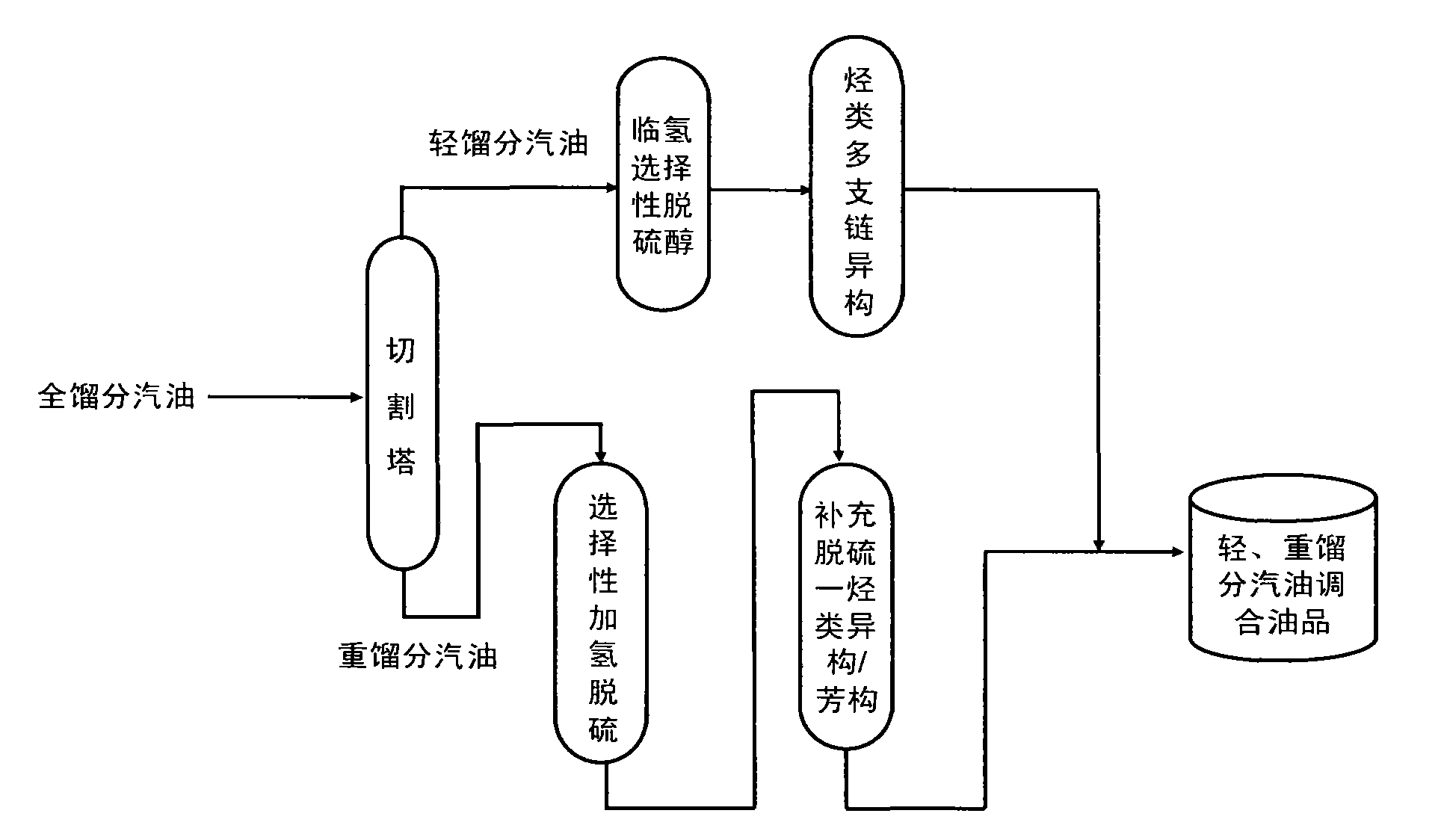

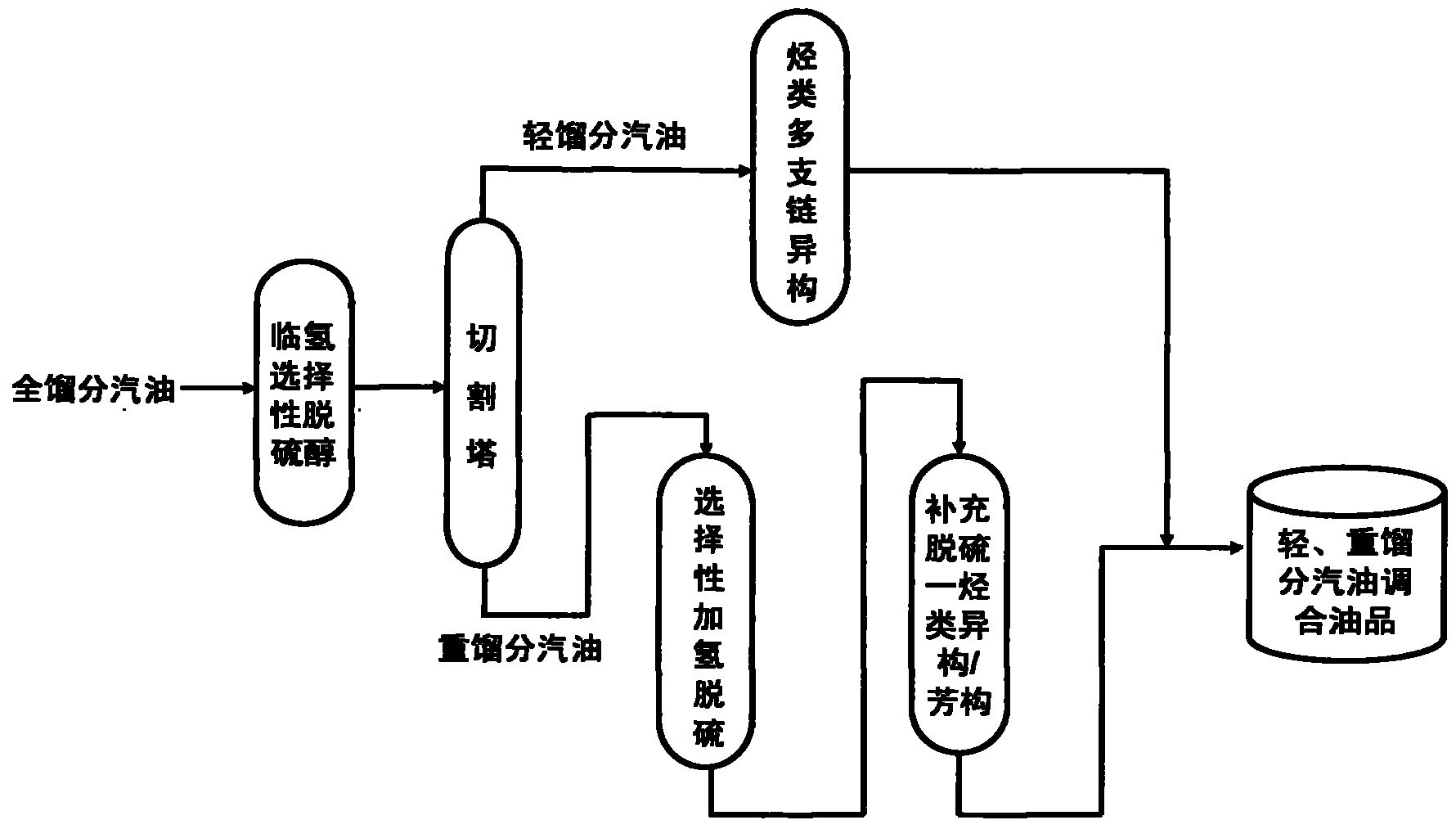

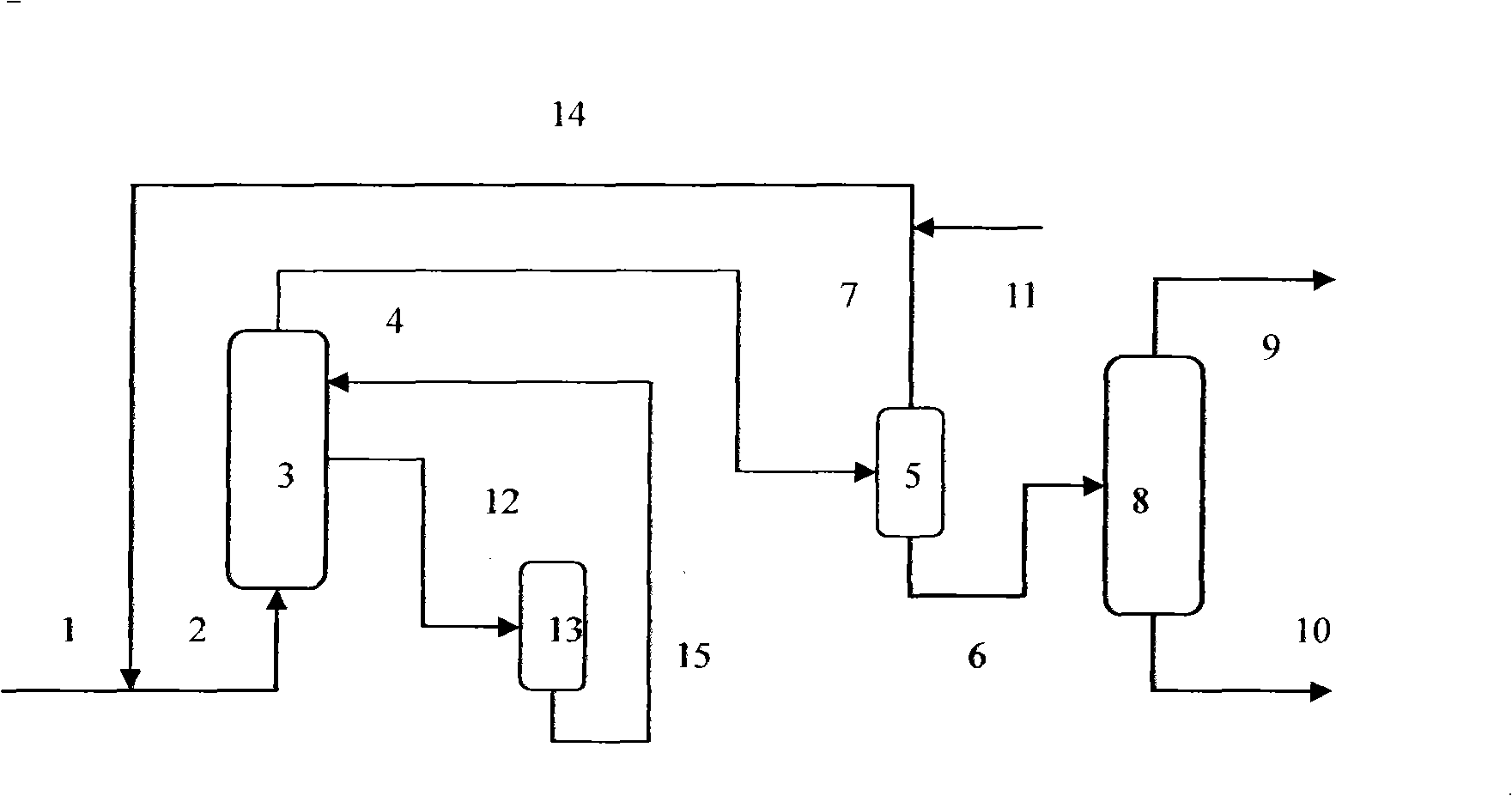

Efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and high octane number

ActiveCN101885983AImprove octaneOctane recoveryTreatment with hydrotreatment processesIsomerizationAlcohol

The invention relates to an efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and a high octane number. The method comprises the following steps of: distilling inferior full cut gasoline at 50-90 DEG C to obtain light cut gasoline and heavy cut gasoline; making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst; making the heavy cut gasoline contact with a selective hydrogenation desulfurization catalyst and a complement desulfurization isomerization / aromatization catalyst sequentially; and finally, mixing the treated light cut gasoline with the treated heavy cut gasoline to obtain the gasoline with the ultra-low sulfur and the high octane number. The method further comprises the step of: before the distillation, making the inferior full cut gasoline contact with a hydro-selective desulfurization alcohol catalyst, or, before making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst, making the light cut gasoline contact with the hydro-selective desulfurization alcohol catalyst. The efficient coupling hydro-upgrading method is suitable for the hydro-upgrading treatment of inferior gasoline with ultrahigh sulfur and high olefin, reduces the sulfur content after the upgrading treatment to below 5mu g / g (no sulfur substantially) and can maintain the octane number and higher yield of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

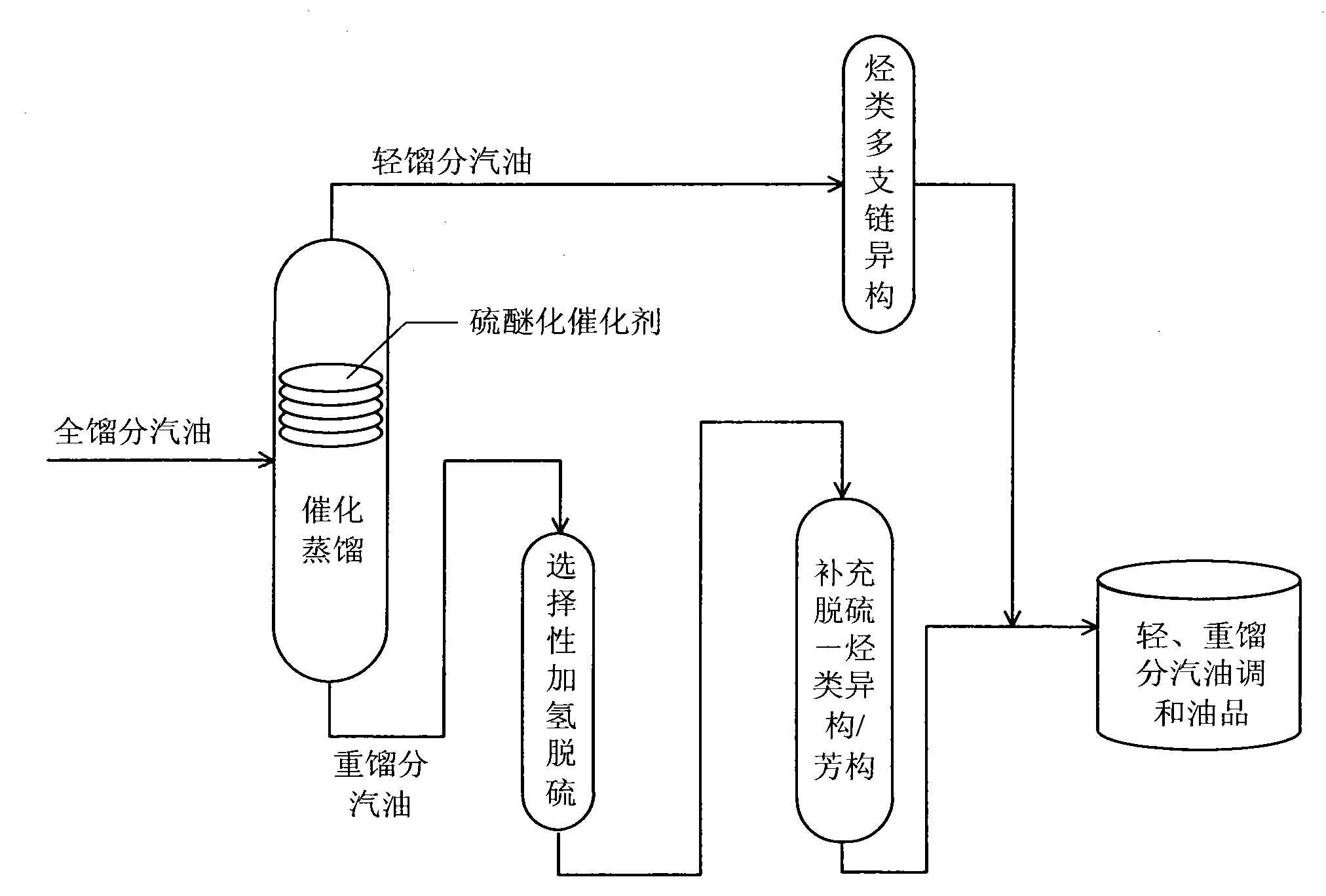

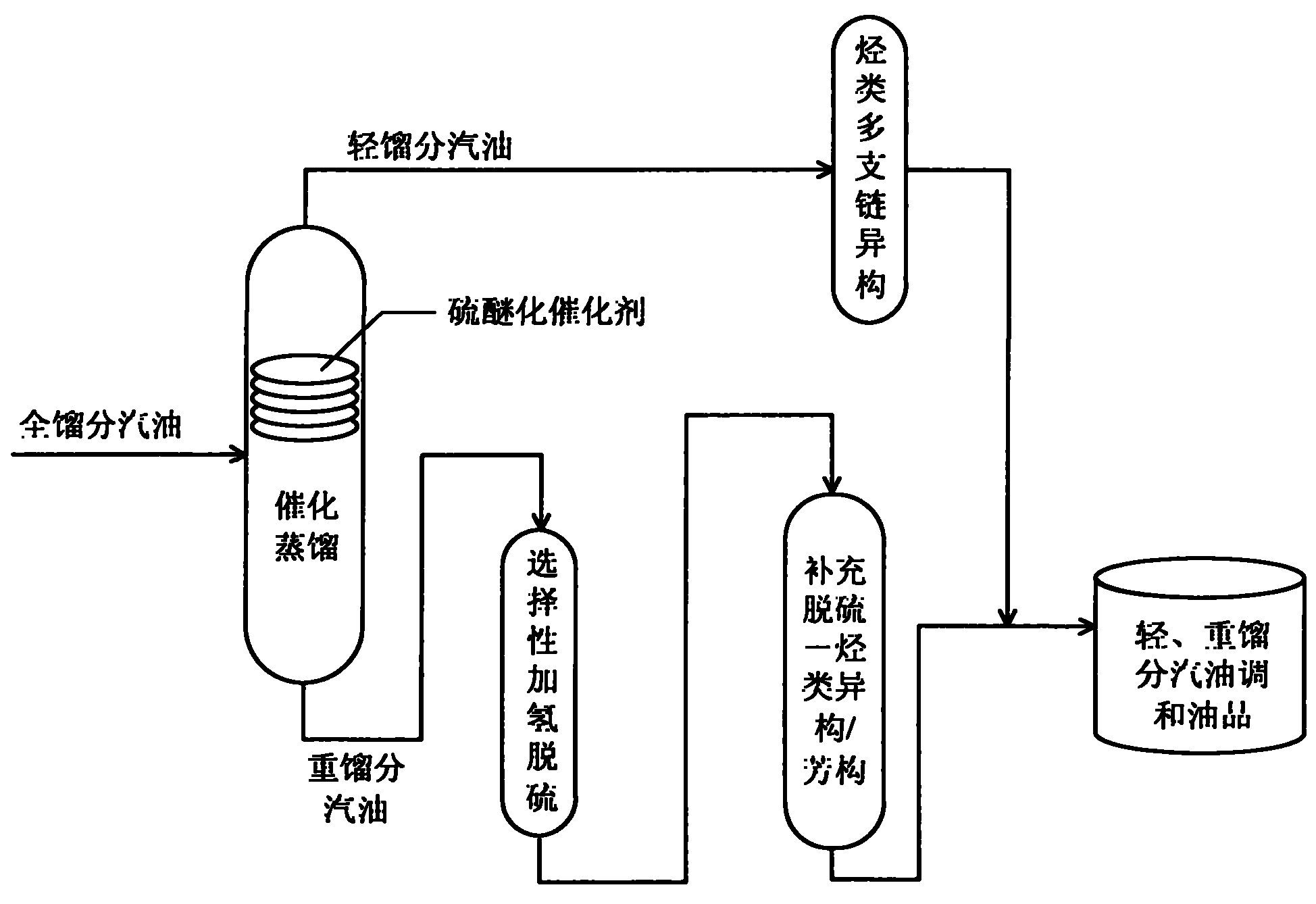

Production method for ultra-low sulfur and high-octane number gasoline

ActiveCN101885985ATake advantage ofIncrease temperatureTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a production method for ultra-low sulfur and high-octane number gasoline. The method comprises the following steps of: filling a poor-quality full range gasoline raw material in a reaction distillation column to contact the material with a sulfoether catalyst to perform a sulfur ether reaction and fraction cutting so that low-boiling point sulfides, such as thiol and thiophene, are converted into high-boiling point sulfoether which is then transferred into heavy fraction gasoline, wherein the cutting fractionation temperature of light fraction gasoline and the heavy fraction gasoline is 50 to 90 DEG C; contacting the light fraction gasoline with a hydrocarbon highly branched isomerization catalyst; contacting the heavy fraction gasoline with a selective hydrodesulfurization catalyst and a desulfurization-hydrocarbon isomerization / aromatization catalyst; and mixing the treated light fraction gasoline and the heavy fraction gasoline to obtain the ultra-low sulfur and high-octane number gasoline. The method is suitable for modifying poor-quality gasoline, can reach better desulfurization and olefin reduction effects on ultra-high sulfur and high-olefin poor-quality catalytic gasoline, and can maintain or increase the octane number of the product and keep a higher product yield after reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS20070215125A1Improve charge cool effectReduce knock limitNon-fuel substance addition to fuelInternal combustion piston enginesMixed fuelFuel tank

In an apparatus having an internal combustion engine, a method of operating the engine is disclosed, comprising providing a mixed fuel from a fuel tank to a separator, separating at least a portion of the hydrocarbon fuel component from the mixed fuel by transporting a hydrocarbon fuel component through a material in the separator that selectively transports the hydrocarbon fuel component, thereby forming a first oxygenated fuel component-enriched fuel fraction and a second hydrocarbon-enriched fuel fraction, and providing fuel from the first fuel fraction and fuel from the second fuel fraction to the engine in a ratio based on an engine operating condition.

Owner:FORD GLOBAL TECH LLC

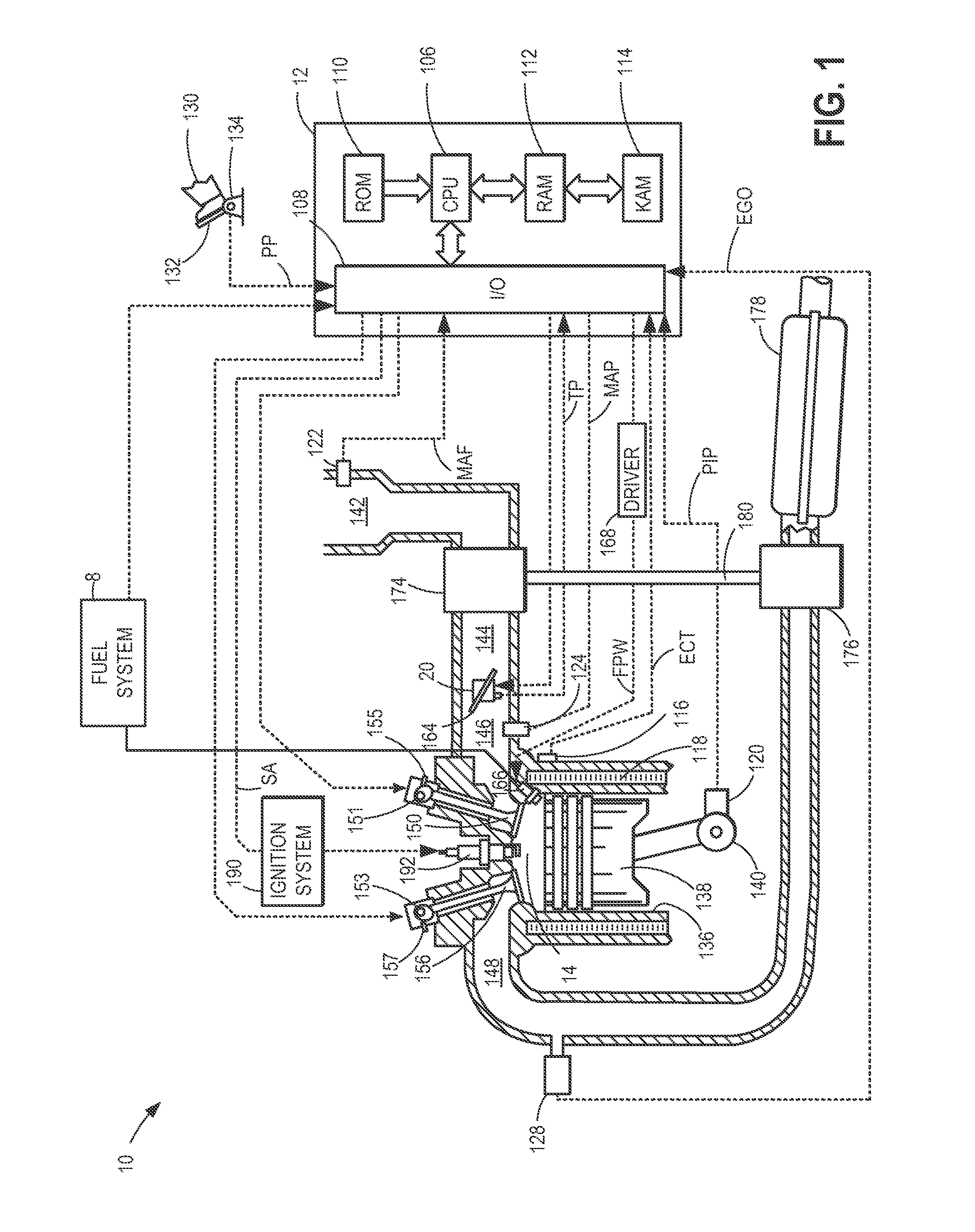

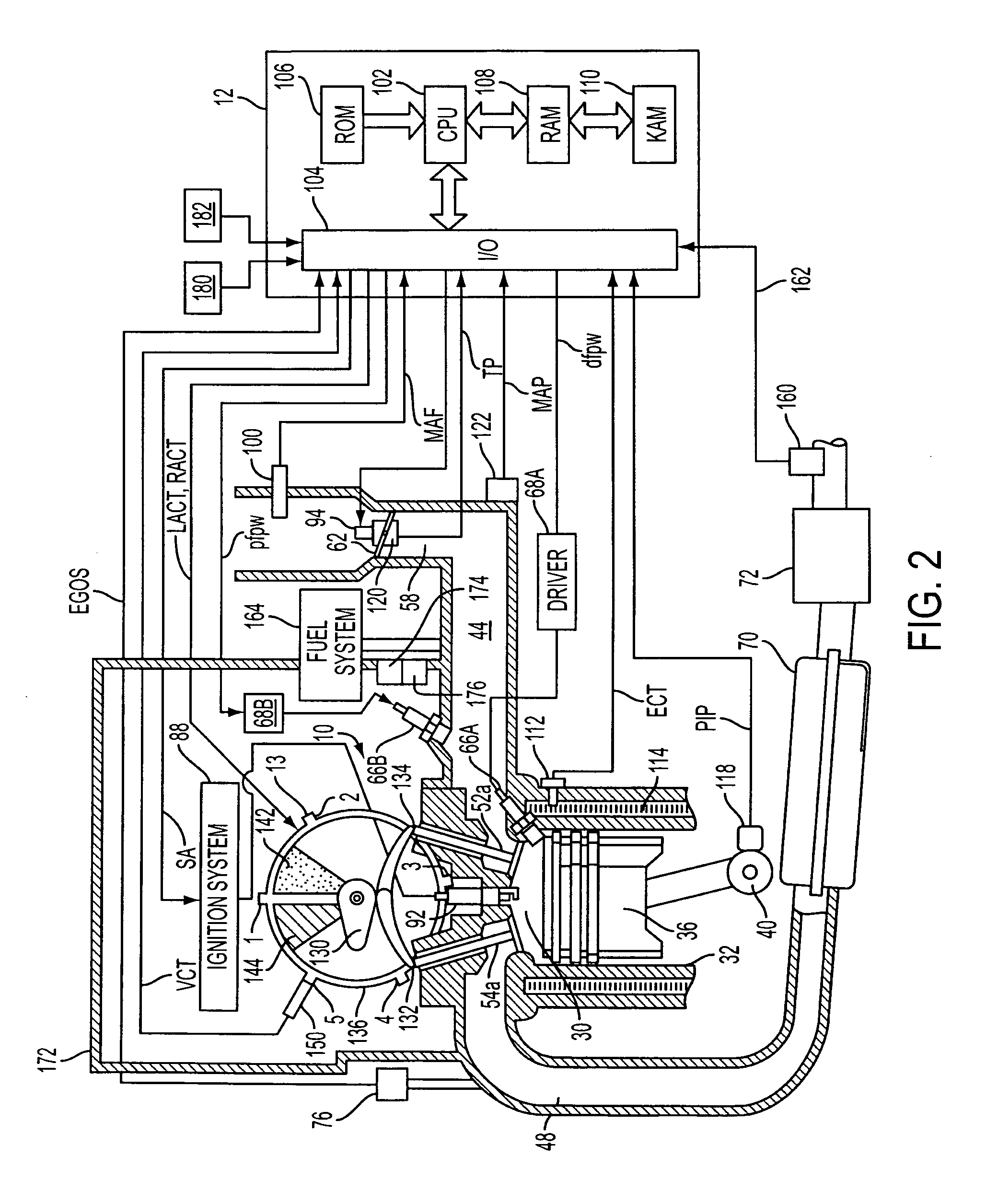

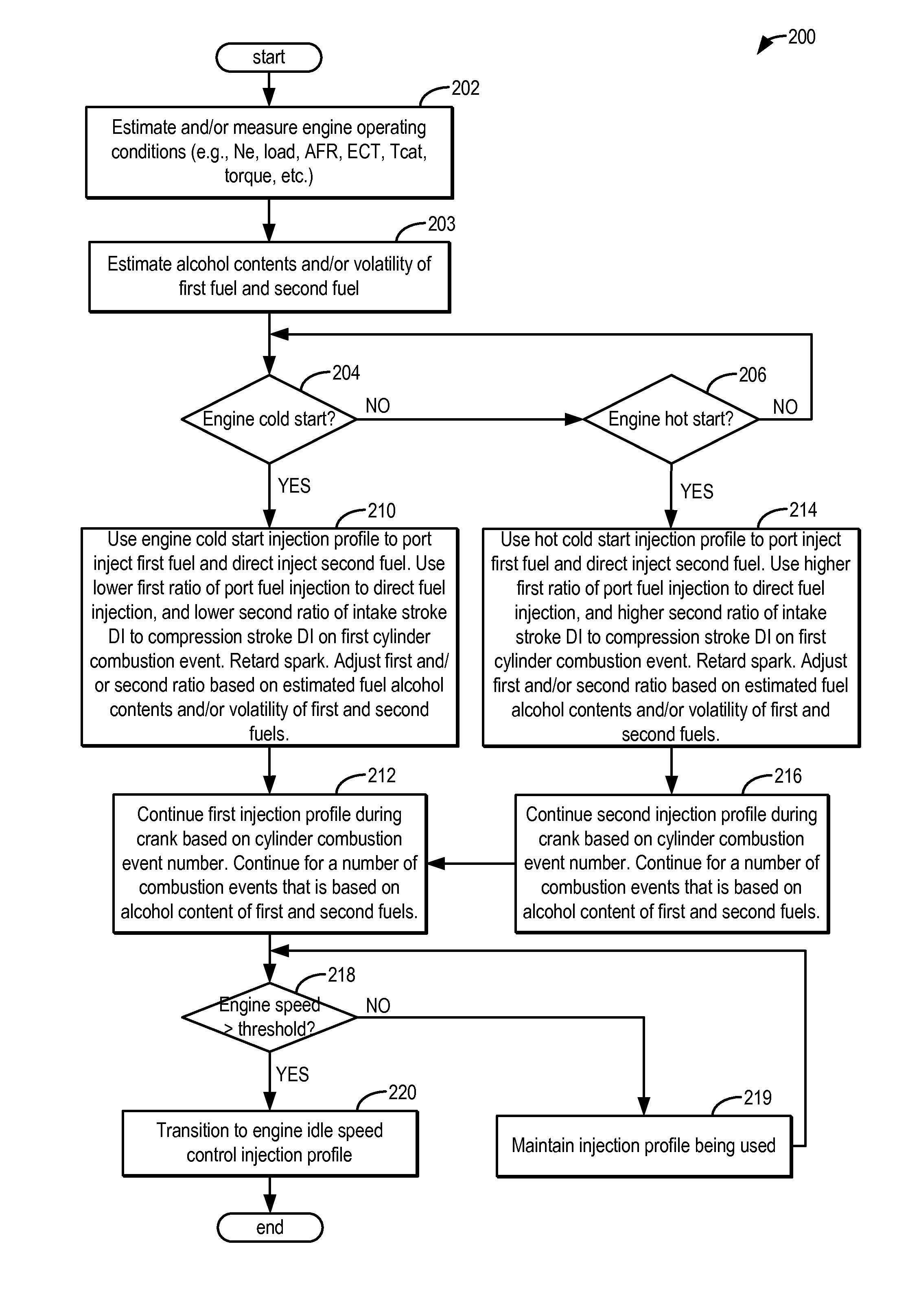

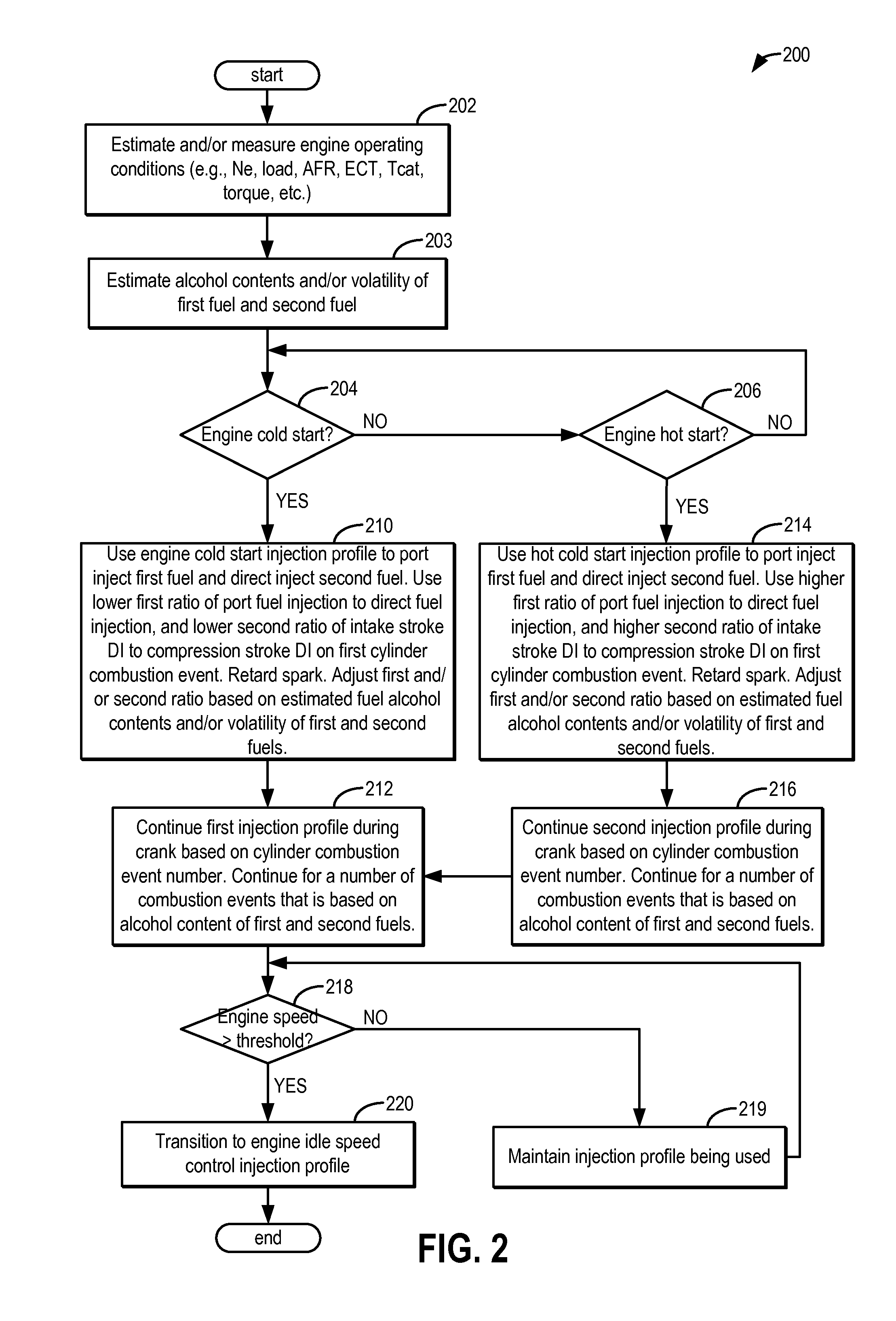

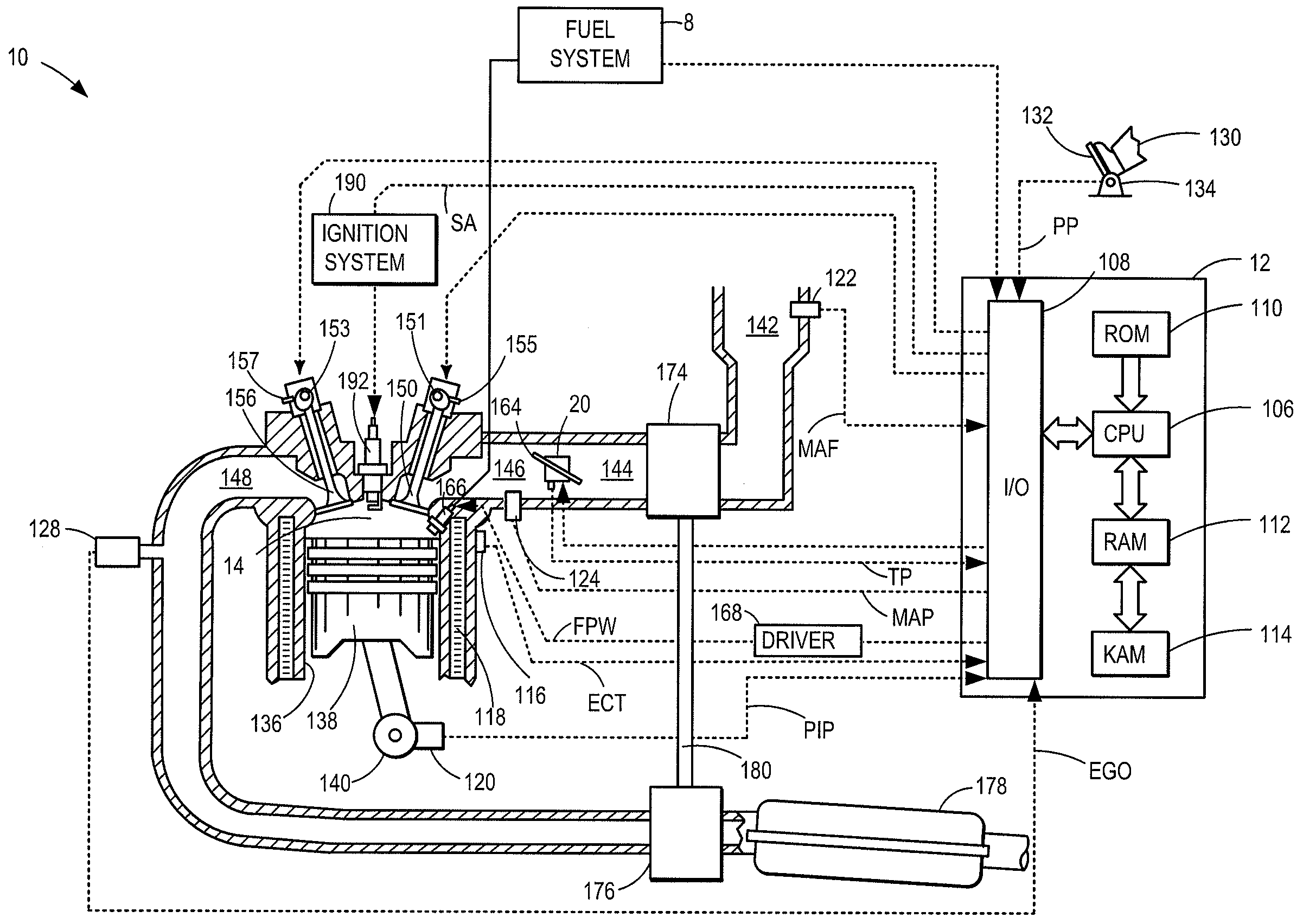

Method and system for engine control

ActiveUS20140297159A1Improve cooling effectIncrease heatValve arrangementsElectrical controlAlcohol contentMultiple injection

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for different fuels injected into an engine cylinder from different fuel injectors during engine start and crank. By splitting fuel injection during start and cranking so that fuel of lower alcohol content is port injected and fuel of higher alcohol content is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved.

Owner:FORD GLOBAL TECH LLC

Fuel-Based Injection Control

ActiveUS20100294236A1Improve atomizationIncrease it fuel contentAnalogue computers for vehiclesElectrical controlInjectorFuel injection

Systems and methods of operating an engine, the engine including an injector configured to directly inject fuel into an engine cylinder. One example method comprises, during an engine cold start, performing compression direct fuel injection, and retarding a timing of the compression injection as a fuel alcohol content of the fuel increases.

Owner:FORD GLOBAL TECH LLC

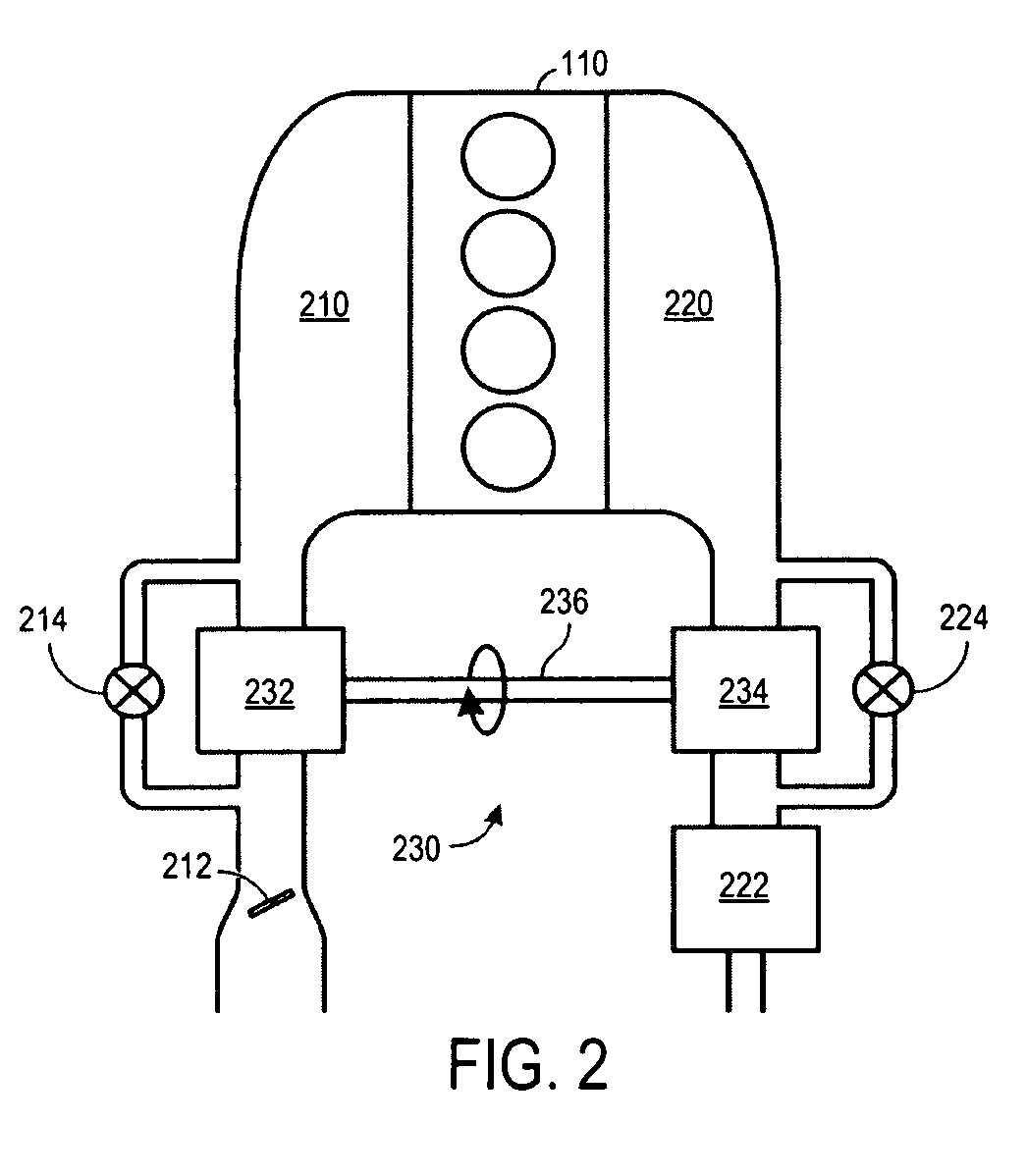

Control of peak engine output in an engine with a knock suppression fluid

InactiveUS20070219674A1Low costImprove charge cooling effectAnalogue computers for vehiclesElectrical controlOn boardHigh alcohol

A method for a vehicle traveling on the road, comprising of receiving a fuel mixture, said mixture having at least some alcohol, separating said fuel mixture into at least a first and second mixture on board the vehicle, where said first mixture has a higher alcohol concentration than said second mixture, delivering a first amount of said first mixture and a second amount of said second mixture to the engine in different ratios as an operating condition varies, and adjusting an engine operating parameter in response to availability of said first mixture.

Owner:FORD GLOBAL TECH LLC

Catalytic conversion method for preparing propylene and high octane gasoline

ActiveCN101760227AHigh selectivityHigh yieldCatalytic crackingChemical recyclingGasolineCracking reaction

The invention discloses a catalytic conversion method for preparing propylene and high octane gasoline. Raw oil of different cracking properties enters different reaction regions of a first riser reactor to contact with catalytic cracking catalysts for carrying out cracking reactions so as to separate a spent catalysts from reaction oil gas; the reaction oil gas is separated for obtaining a product comprising the propylene, gasoline and a re-cracking raw material, wherein the re-cracking raw material is transmitted into a second riser reactor to contact with hot regenerated catalysts for carrying out catalytic conversion; and after the spent catalysts in the two riser reactors are burned in a same regenerator, the spent catalysts are respectively returned to the two riser reactors. In themethod, the yields of the propylene and the gasoline are obviously increased; the octane value of the gasoline is also obviously improved. Under the condition of largely increasing the yield of the propylene, the yield of dry gas is obviously reduced by more than 80% by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for deep desulfurization olefin hydrocarbon reduction of gasoline

ActiveCN101492609AStructuring reaction does not affectReduced responseRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization catalyst and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS8015951B2Increase heatIncrease profitNon-fuel substance addition to fuelInternal combustion piston enginesSolventOperant conditioning

Systems and methods are provided for extracting components of a mixed fuel into at least one substantially non-polar component and at least one polar fuel component. In one example approach, a volume of a mixed fuel is added to an extractor and a polar solvent is used to extract components of the mixed fuel. The extracted components may be selectively provided to an engine in a ratio based upon engine operating conditions.

Owner:FORD GLOBAL TECH LLC

Fuel rail assembly including fuel separation membrane

InactiveUS8550058B2Increase heatIncrease profitElectrical controlInternal combustion piston enginesAlcoholHigh rate

As one example, a fuel rail assembly for supplying pressurized fuel to a plurality of cylinders of an engine is provided. The fuel rail assembly includes a fuel rail housing defining an internal fuel rail volume having at least a first region and a second region; a fuel separation membrane element disposed within the fuel rail housing that segregates the first region from the second region. The membrane element can be configured to pass a first component of a fuel mixture such as an alcohol through the membrane element from the first region to the second region at a higher rate than a second component of the fuel mixture such as a hydrocarbon. The separated alcohol and hydrocarbon components can be provided to the engine in varying relative amounts based on operating conditions.

Owner:FORD GLOBAL TECH LLC

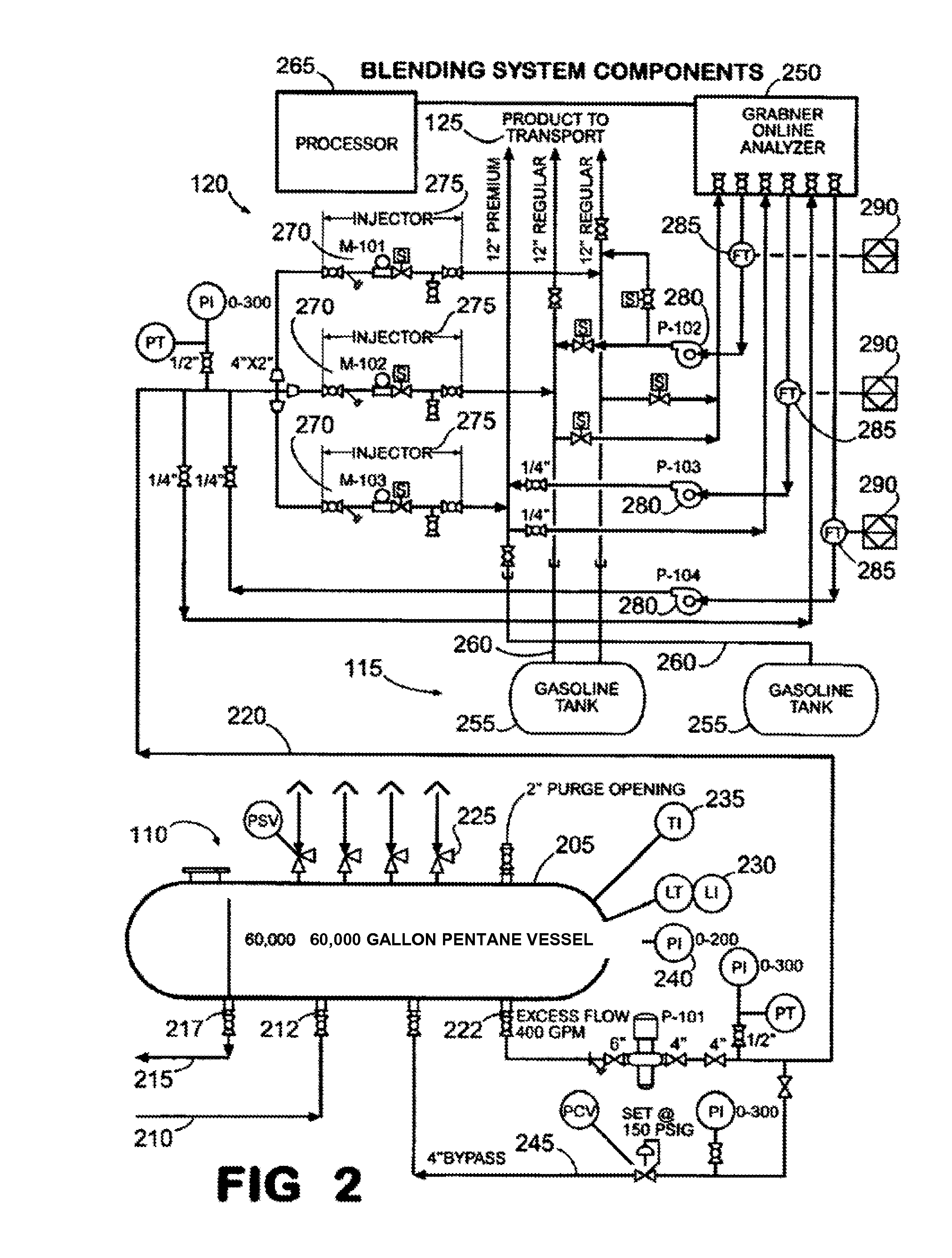

Expansion of fuel streams using mixed hydrocarbons

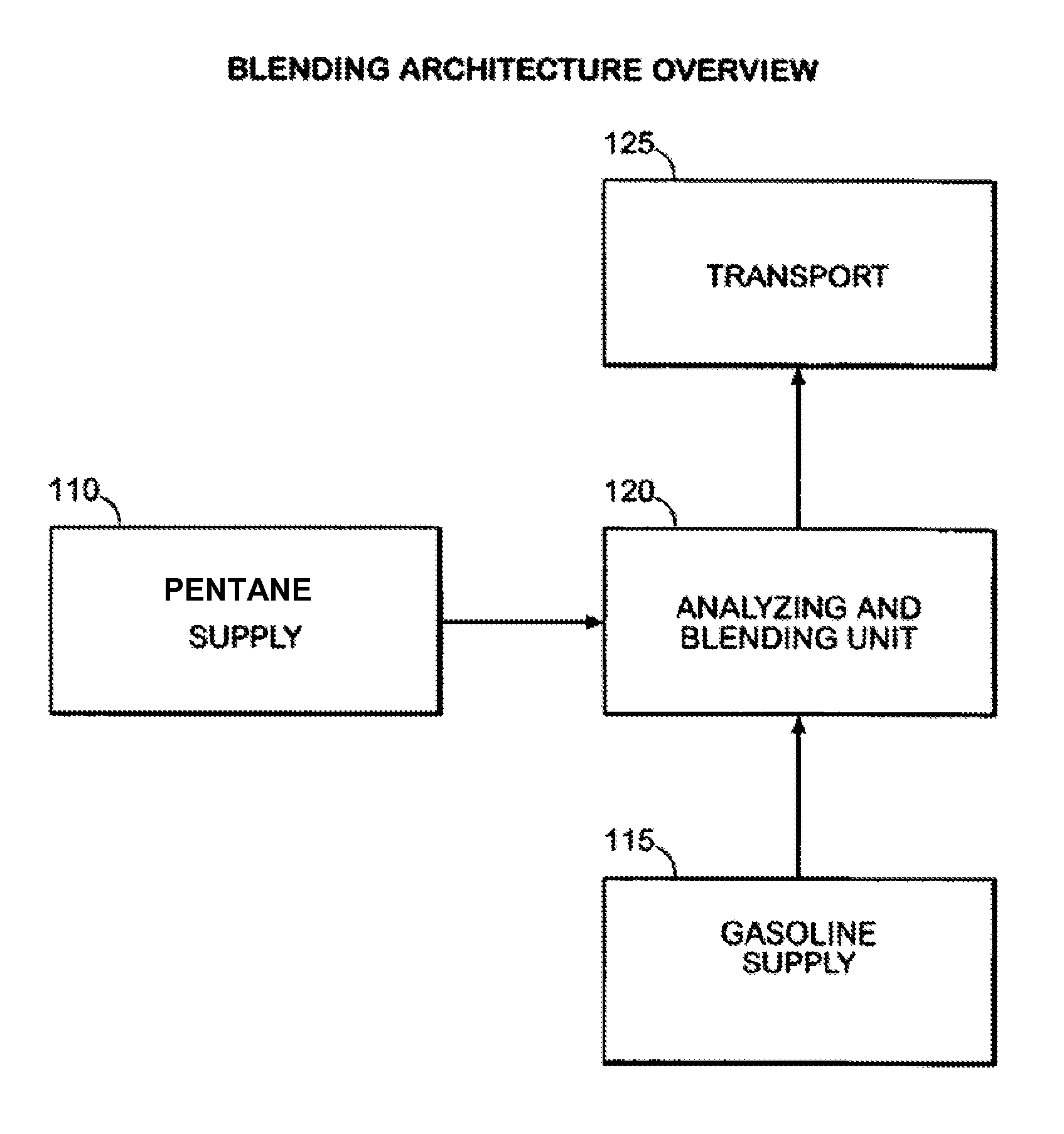

ActiveUS8597380B2Improve octaneReducing octaneLiquid fillingHydrocarbon purification/separationOil refineryHydrocarbon

Owner:SUNOCO PARTNERS MARKETING & TERMINALS LP

Universal synthetic gasoline fuel conditioner additive, method and product-by-process

ActiveUS7931704B2Improve the lubrication effectReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

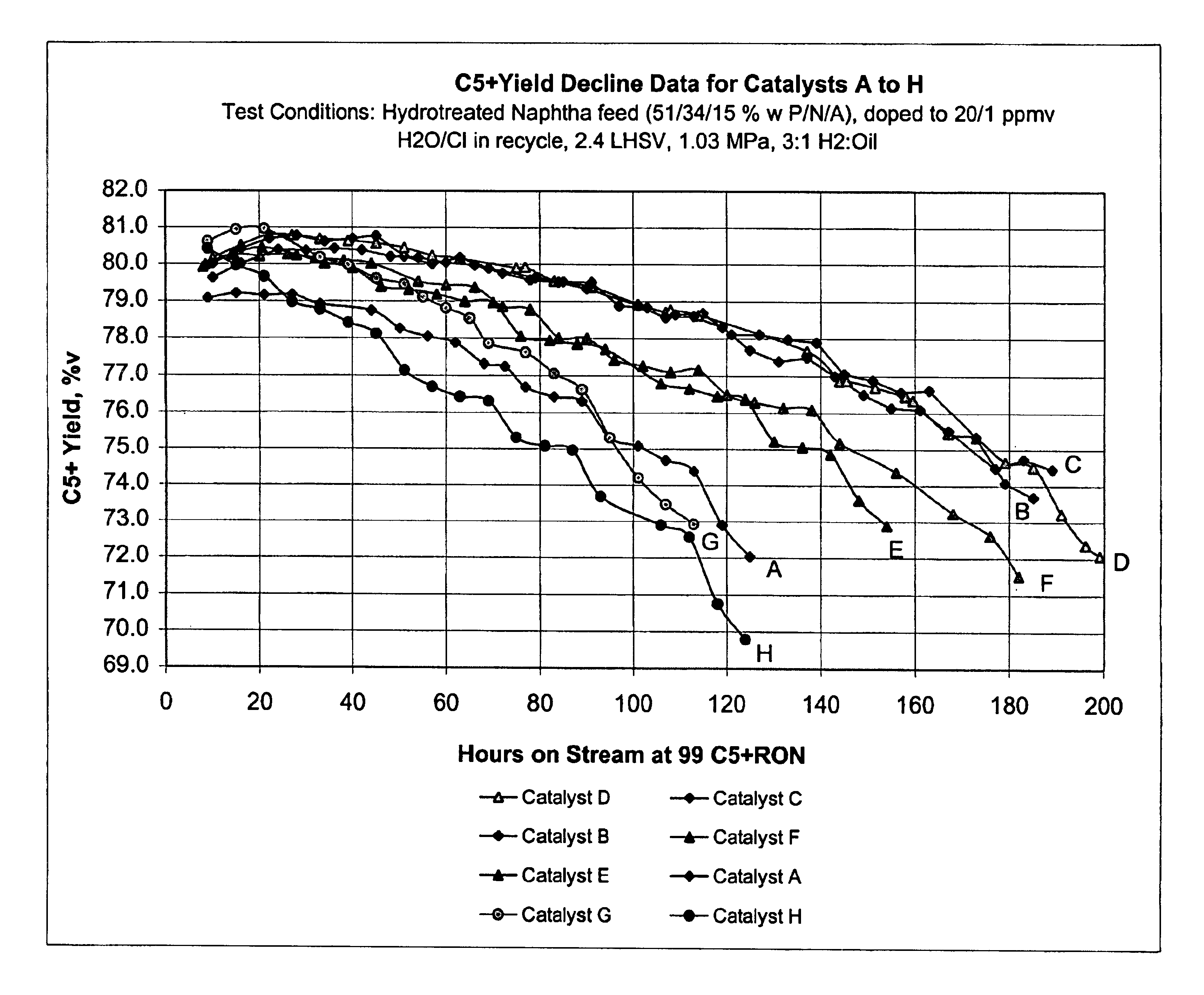

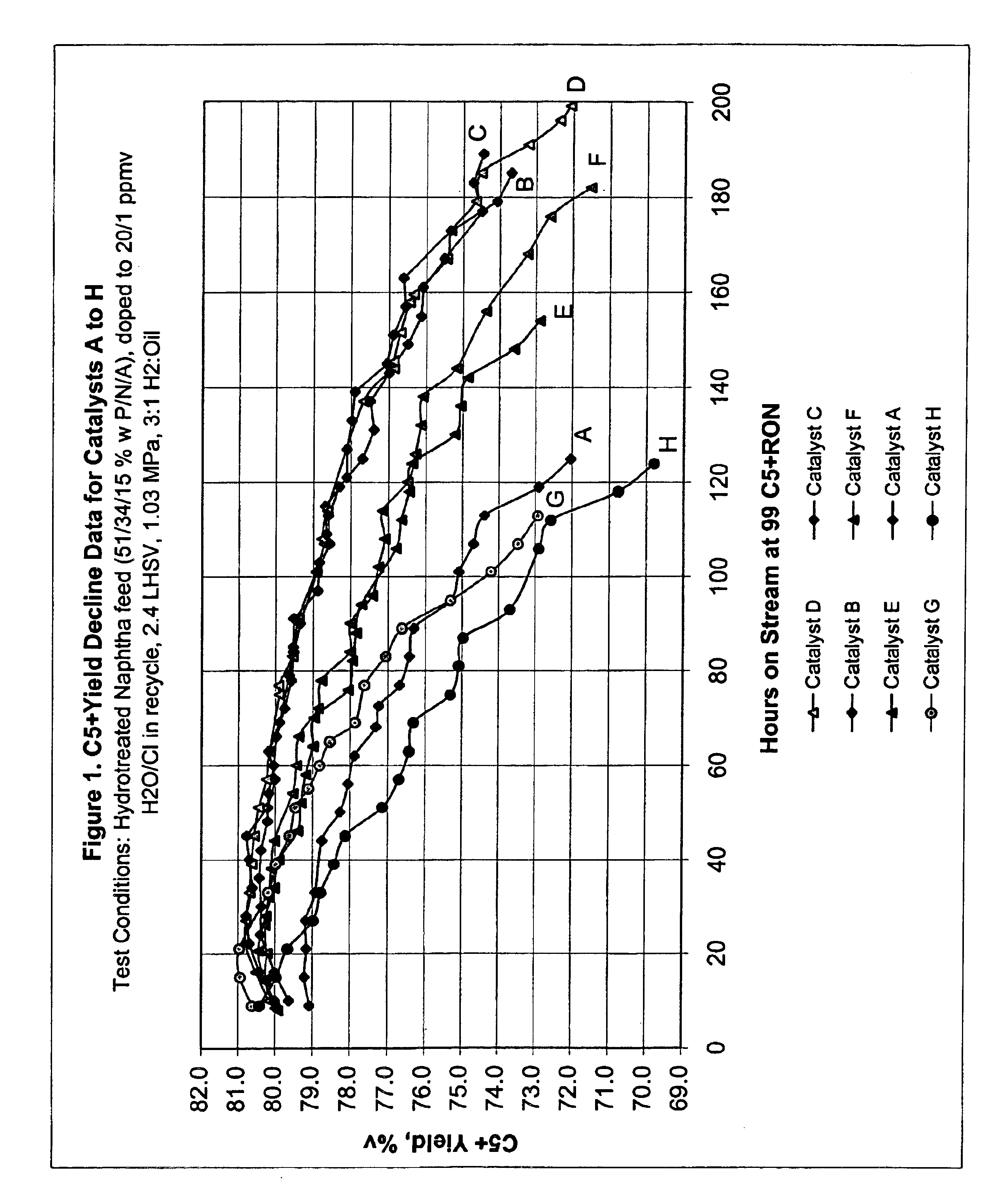

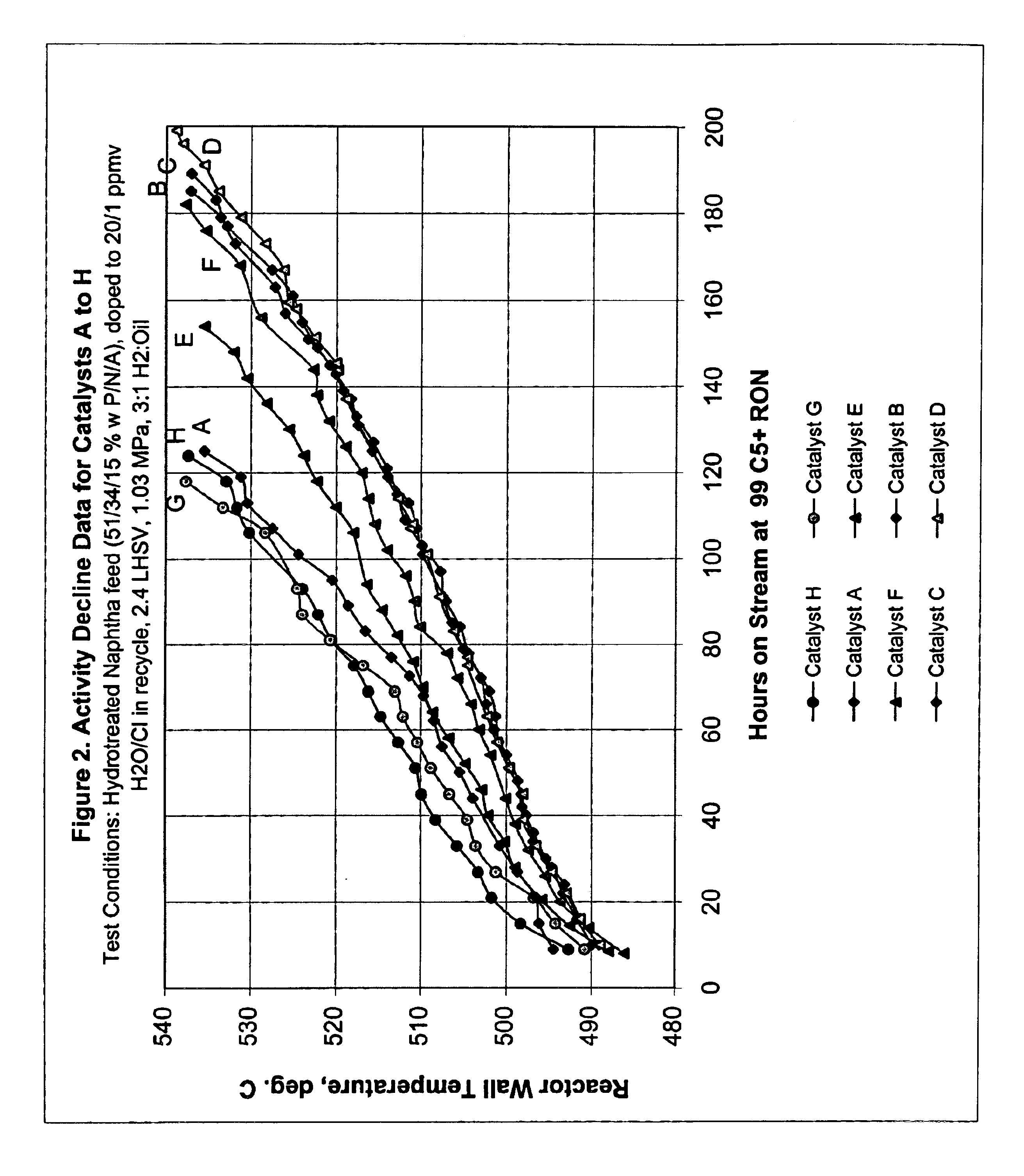

Bismuth- and phosphorus-containing reforming catalysts, method of making and naphtha reforming process

InactiveUS6864212B2Improve octaneReduce coking rateCatalyst carriersOther chemical processesNaphthaEngineering

Bismuth- and phosphorus-containing naphtha reforming catalysts, methods of making such catalysts, and a naphtha reforming process using such catalysts.

Owner:INST FR DU PETROLE

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS7337754B2Increase heatIncrease profitInternal combustion piston enginesNon-fuel substance addition to fuelHigh rateFuel tank

An apparatus comprising an internal combustion engine, a fuel tank, a fuel separator disposed fluidically between the fuel tank and the engine, wherein the fuel separator comprises first and second passageways separated at least partially by a selective barrier that selectively transports a first fuel in a fuel mixture at a higher rate than a second fuel in the fuel mixture, and wherein the first passageway is configured to receive an input of fuel from the fuel tank, and an extraction fluid source in fluid communication with the second passageway of the fuel separator.

Owner:FORD GLOBAL TECH LLC

Apparatus with mixed fuel separator and method of separating a mixed fuel

InactiveUS7665428B2Increase heatIncrease profitNon-fuel substance addition to fuelInternal combustion piston enginesFuel tankEngineering

Owner:FORD GLOBAL TECH LLC

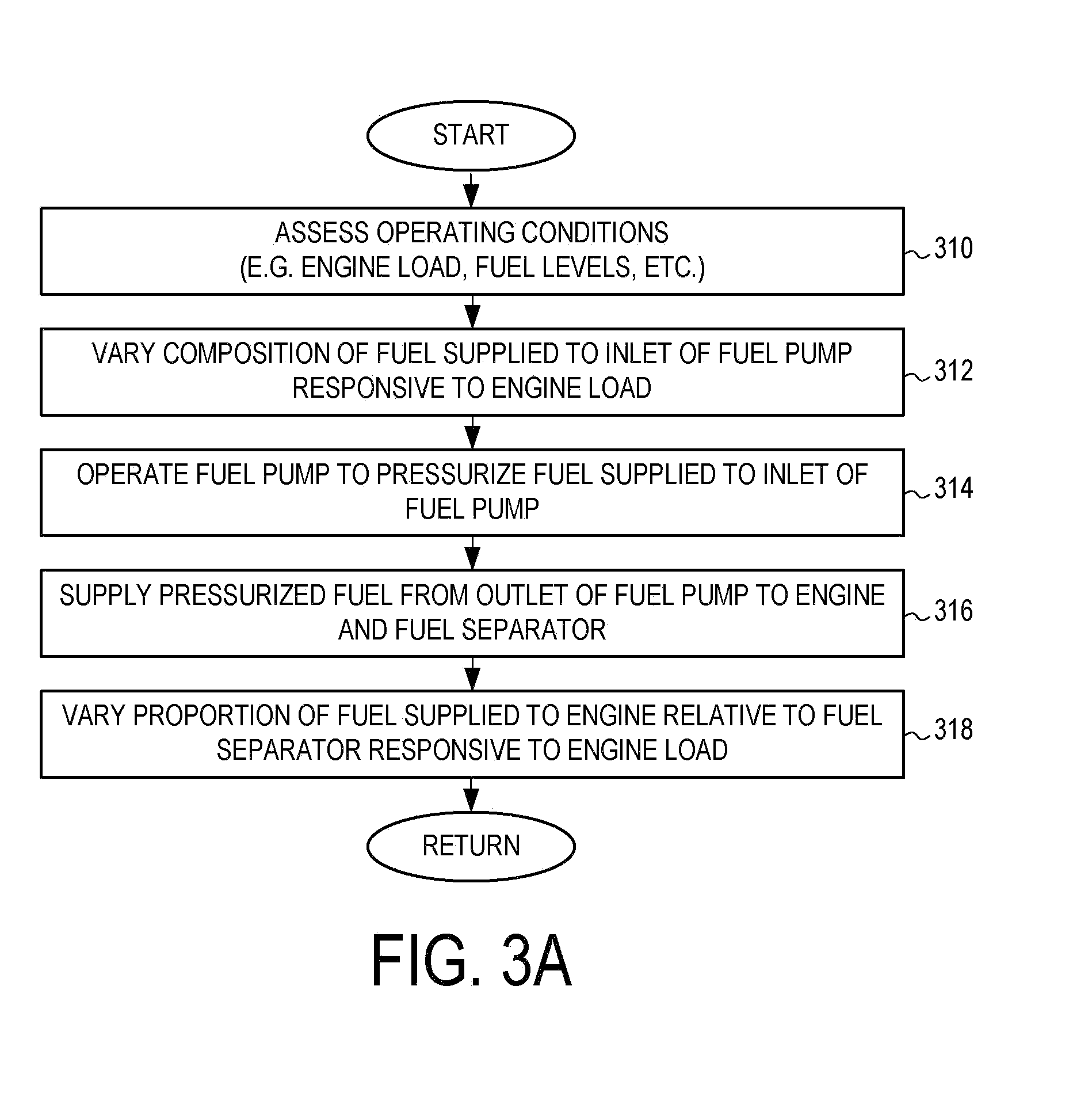

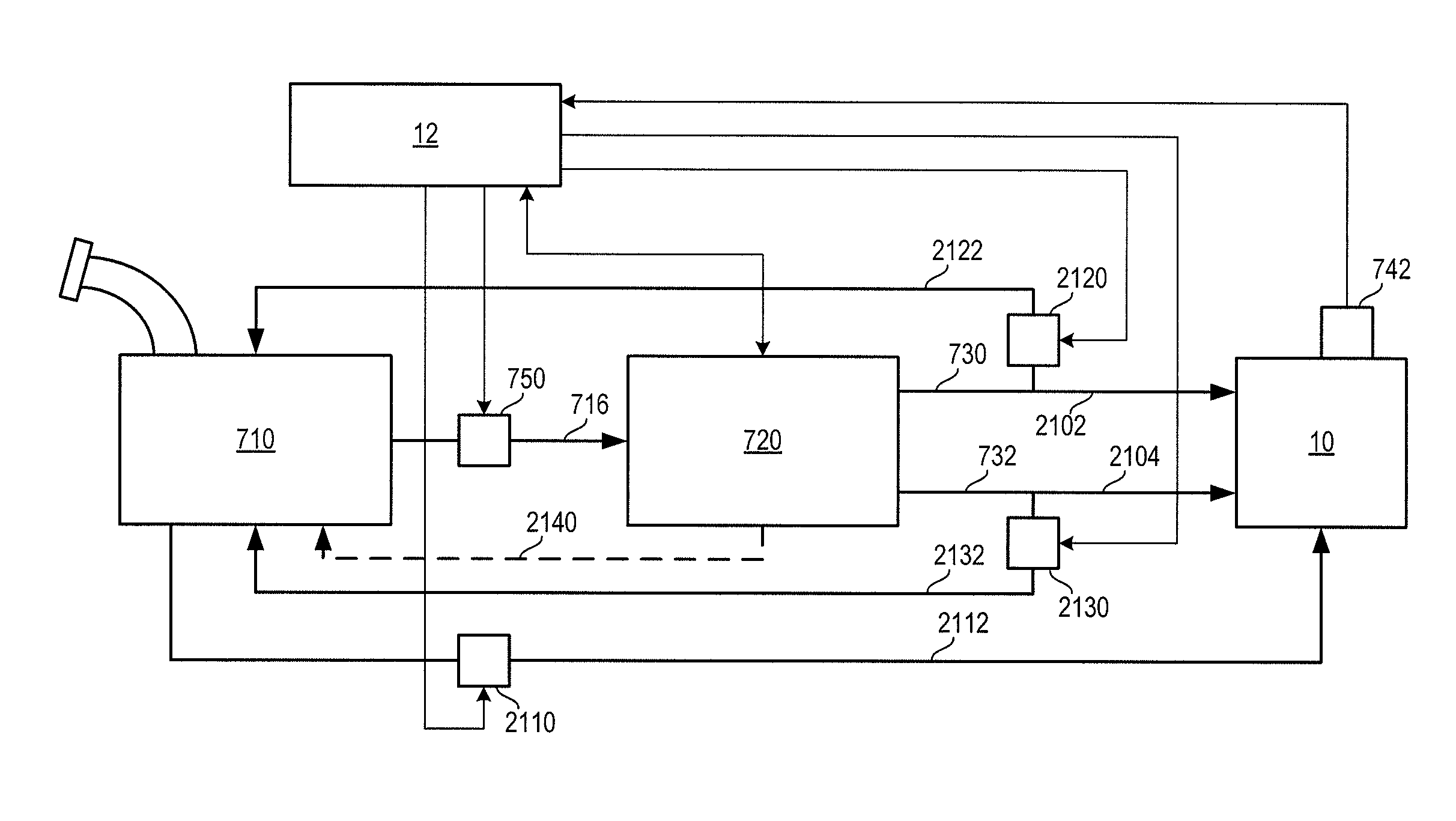

Fuel system for multi-fuel engine

InactiveUS20100024772A1Facilitating fuel separationLow costElectrical controlInternal combustion piston enginesInternal combustion engineFuel supply

A fuel system and a method of operation of the fuel system are described in the context of a multi-fuel internal combustion engine. As a non-limiting example, the method includes: varying a composition of fuel supplied to an inlet of a fuel pump responsive to engine output; operating the fuel pump to provide pressurized fuel at an outlet of the fuel pump using the fuel received at the inlet of the fuel pump; supplying the pressurized fuel from the outlet of the fuel pump to the internal combustion engine and to a fuel separator; and varying a proportion of the pressurized fuel supplied to the internal combustion engine relative to the fuel separator responsive to the engine output.

Owner:FORD GLOBAL TECH LLC

Control for knock suppression fluid separator in a motor vehicle

InactiveUS8267074B2Increase heatIncrease profitElectrical controlInternal combustion piston enginesMobile vehicleMotorized vehicle

Owner:FORD GLOBAL TECH LLC

Universal Synthetic Gasoline Fuel Conditioner Additive, Method and Product-by-Process

ActiveUS20110197499A1Negative effectImprove the lubrication effectLiquid carbonaceous fuelsFuel additivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Fuel-based injection control

ActiveUS8165788B2High latent heatImprove peak torque output of engineAnalogue computers for vehiclesElectrical controlAlcohol contentControl system

Systems and methods of operating an engine, the engine including an injector configured to directly inject fuel into an engine cylinder. One example method comprises, during an engine cold start, performing compression direct fuel injection, and retarding a timing of the compression injection as a fuel alcohol content of the fuel increases.

Owner:FORD GLOBAL TECH LLC

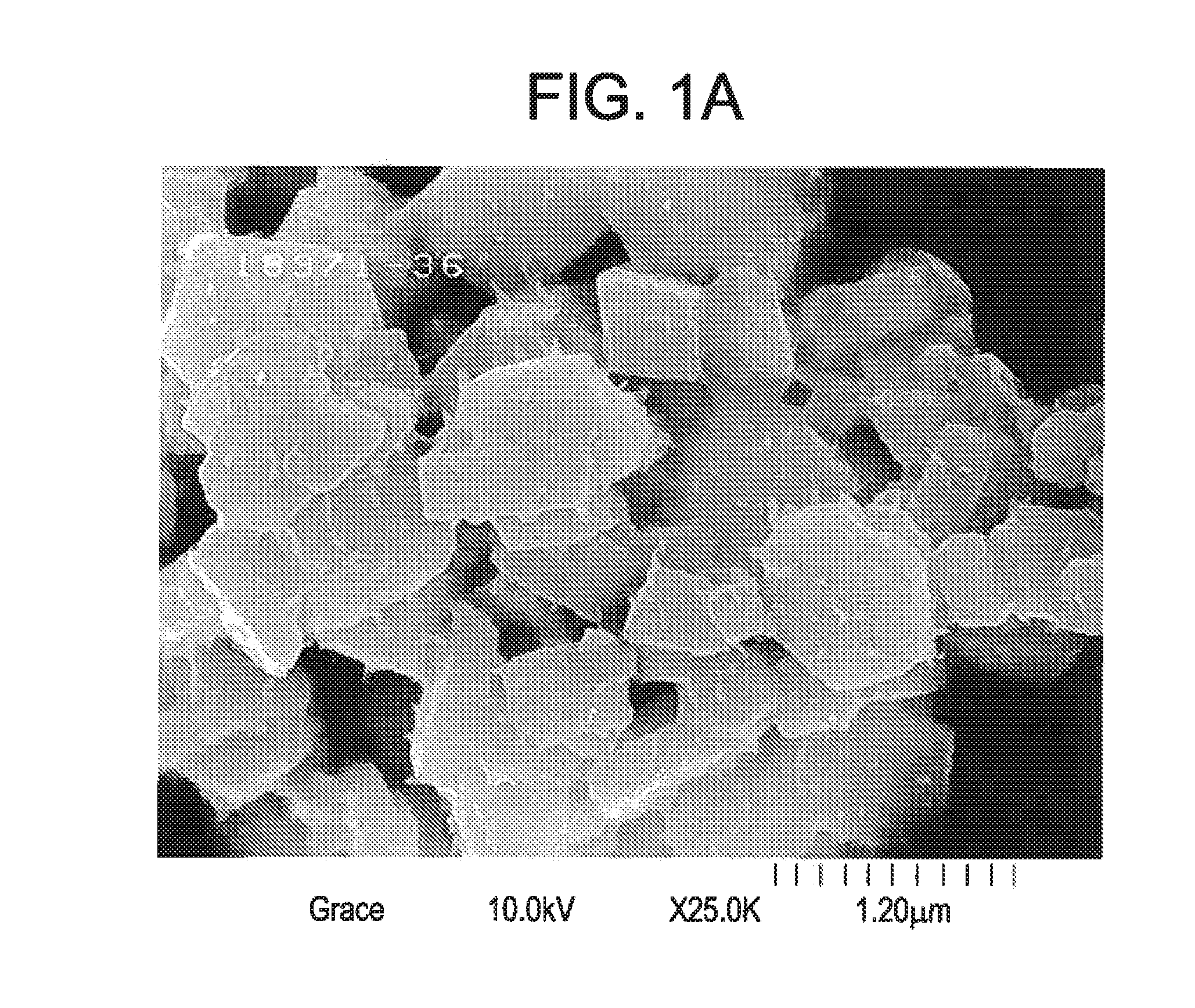

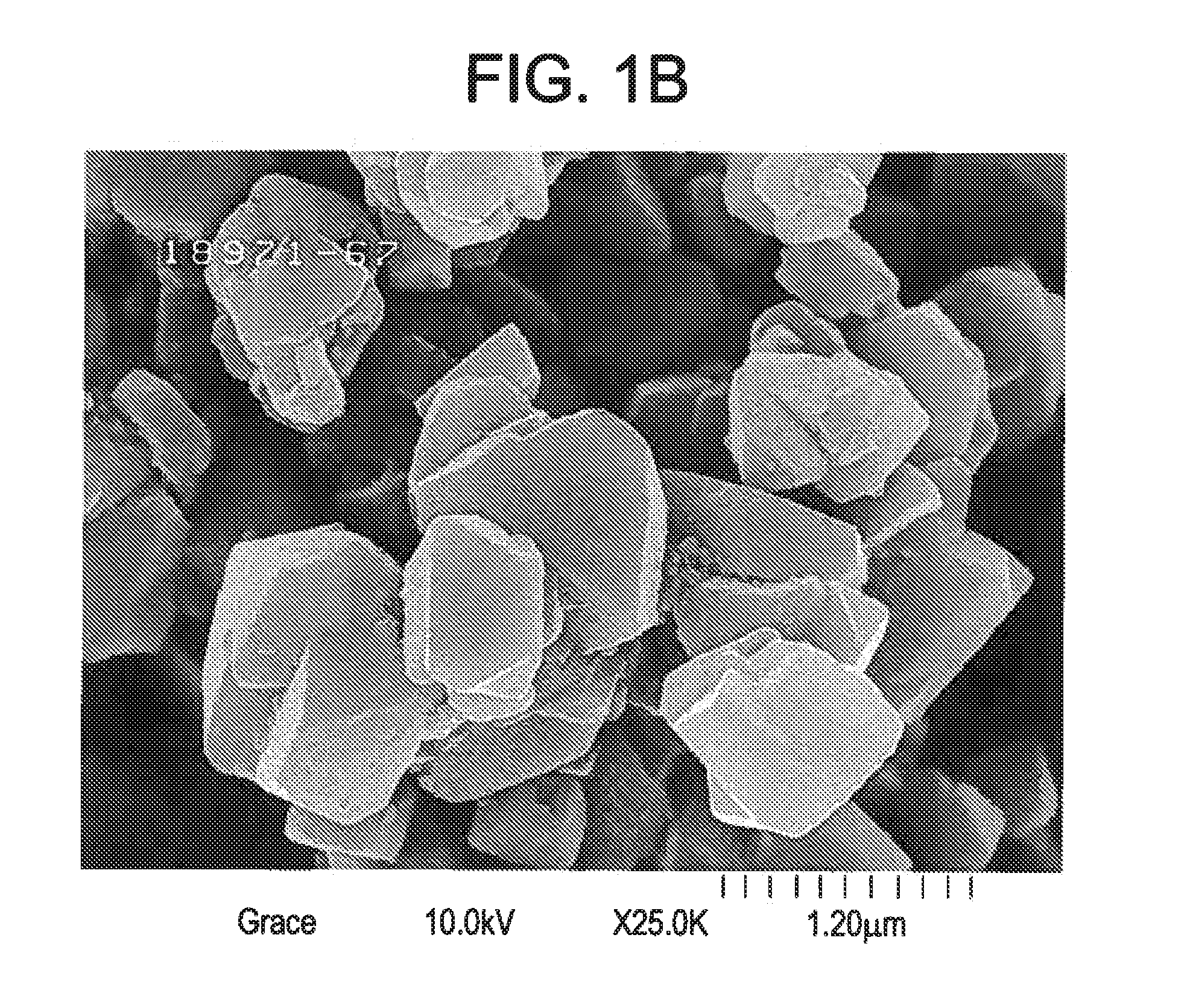

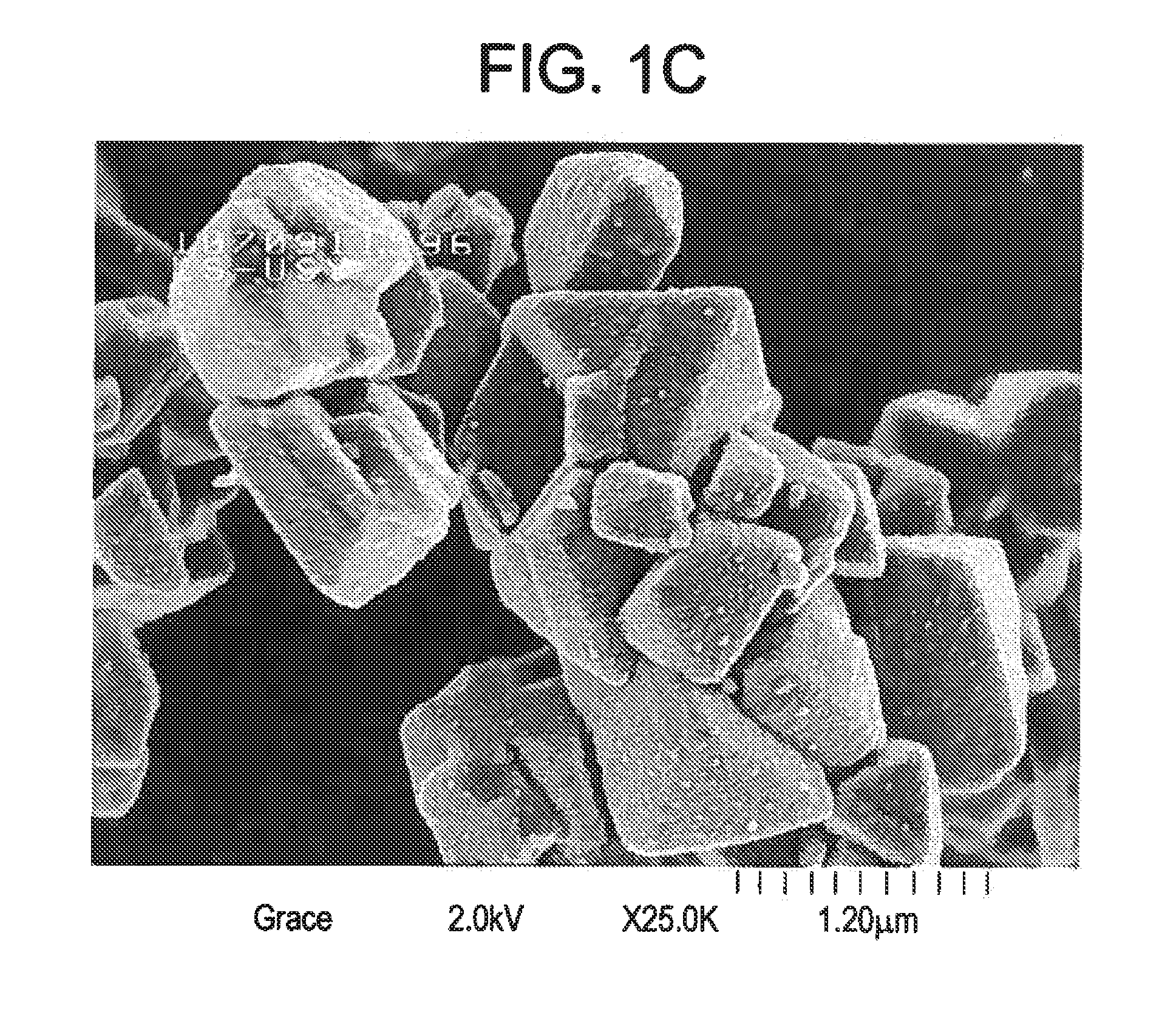

Novel ultra stable zeolite y and method for manufacturing the same

InactiveUS20110224067A1Less coke contaminationEnhance octaneAluminium compoundsCatalytic crackingFluid catalytic crackingZeolite

This invention comprises USY zeolite prepared by treating a USY zeolite under hydrothermal conditions after forming the USY zeolite from heat treating ammonium exchanged zeolite Y, e g, by calcination. When this invention is used in a FCC catalyst, a significant improvement of activity and selectivity in the fluid catalytic cracking (FCC) performance is observed, compared to FCC catalysts containing conventional USY zeolite. The process used to make the invention is efficient and comprises treating the USY zeolite in an exchange bath under the aforementioned hydrothermal conditions. The surface of the resulting USY zeolite has a molar ratio of alumina to silica that is higher than that seen in the bulk USY zeolite and has a unique structure as viewed by SEM and TEM.

Owner:WORMSBECHER RICHARD FRANKLIN +4

Fuel-based injection control

ActiveUS8447496B2High latent heatImprove peak torque output of engineElectrical controlInternal combustion piston enginesAlcohol contentControl system

Systems and methods of operating an engine with a varying fuel composition. In one example, a split injection is performed during engine cranking with at least some fuel injected in the intake stroke and some fuel injected in the compression stroke. Further, a split ratio of the injection is adjusted based on the alcohol content of the injected fuel.

Owner:FORD GLOBAL TECH LLC

Method and system for ignition energy control

ActiveUS20150330290A1Increase energy densityImprove cooling effectElectrical controlInternal combustion piston enginesEnergy controlEngineering

Owner:FORD GLOBAL TECH LLC

Method and system for engine control

ActiveUS9255541B2High power outputImprove cooling effectValve arrangementsElectrical controlMultiple injectionAlcohol content

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for different fuels injected into an engine cylinder from different fuel injectors during engine start and crank. By splitting fuel injection during start and cranking so that fuel of lower alcohol content is port injected and fuel of higher alcohol content is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com