Patents

Literature

106results about How to "High gasoline yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic cracking catalyst and its prepn

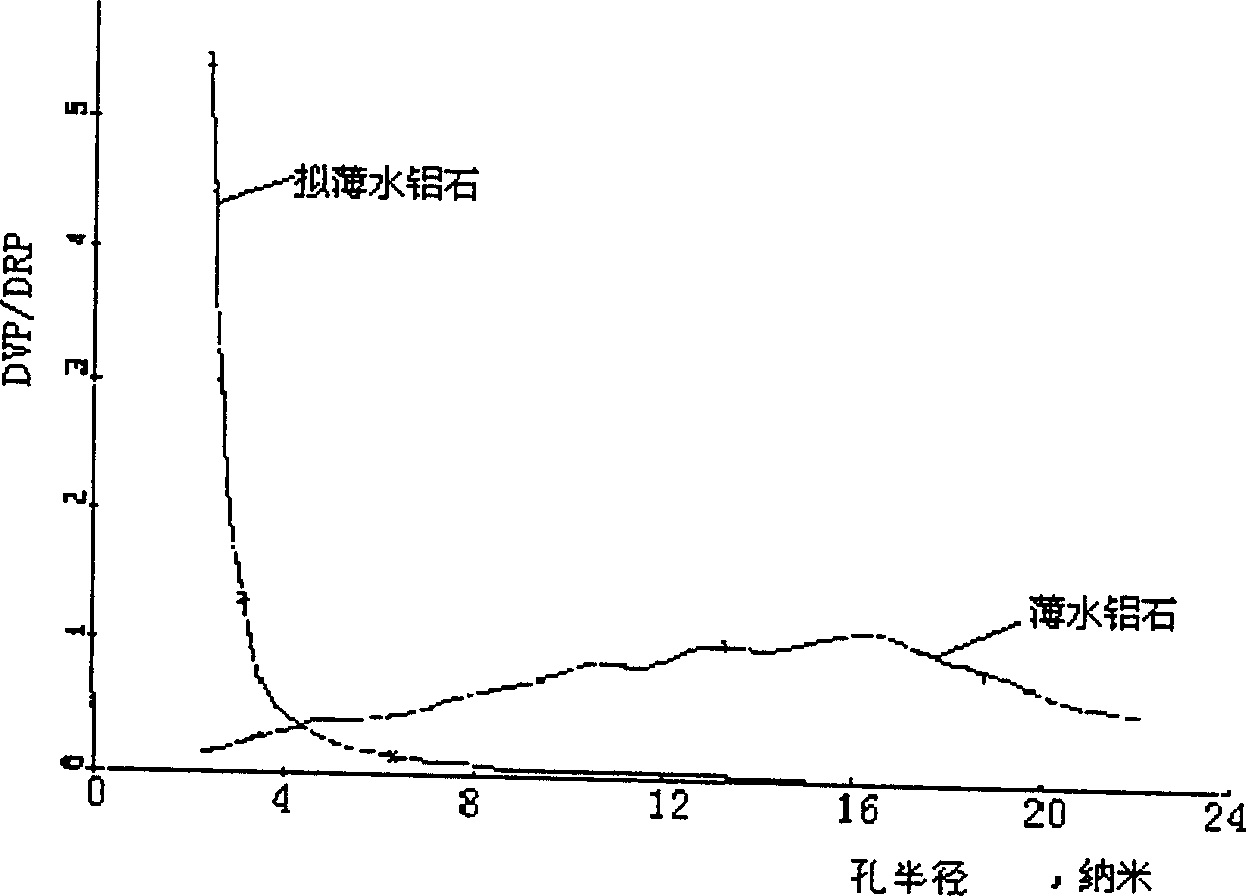

The catalytic cracking catalyst contains medium and large pore alumina with average pore size not smaller than 3 nm 5-60 wt%, zeolite 5-60 wt%, adhesive 5-40 wt% and clay 5-85 wt%. The preparation process includes mixing the said materials, spraying, roasting, washing and drying. Compared with conventional catalyst, the catalyst has strengthened heavy oil converting capacity, obviously improved gasoline and coke selectivity and strengthened heavy metal nickel resistance.

Owner:PETROCHINA CO LTD

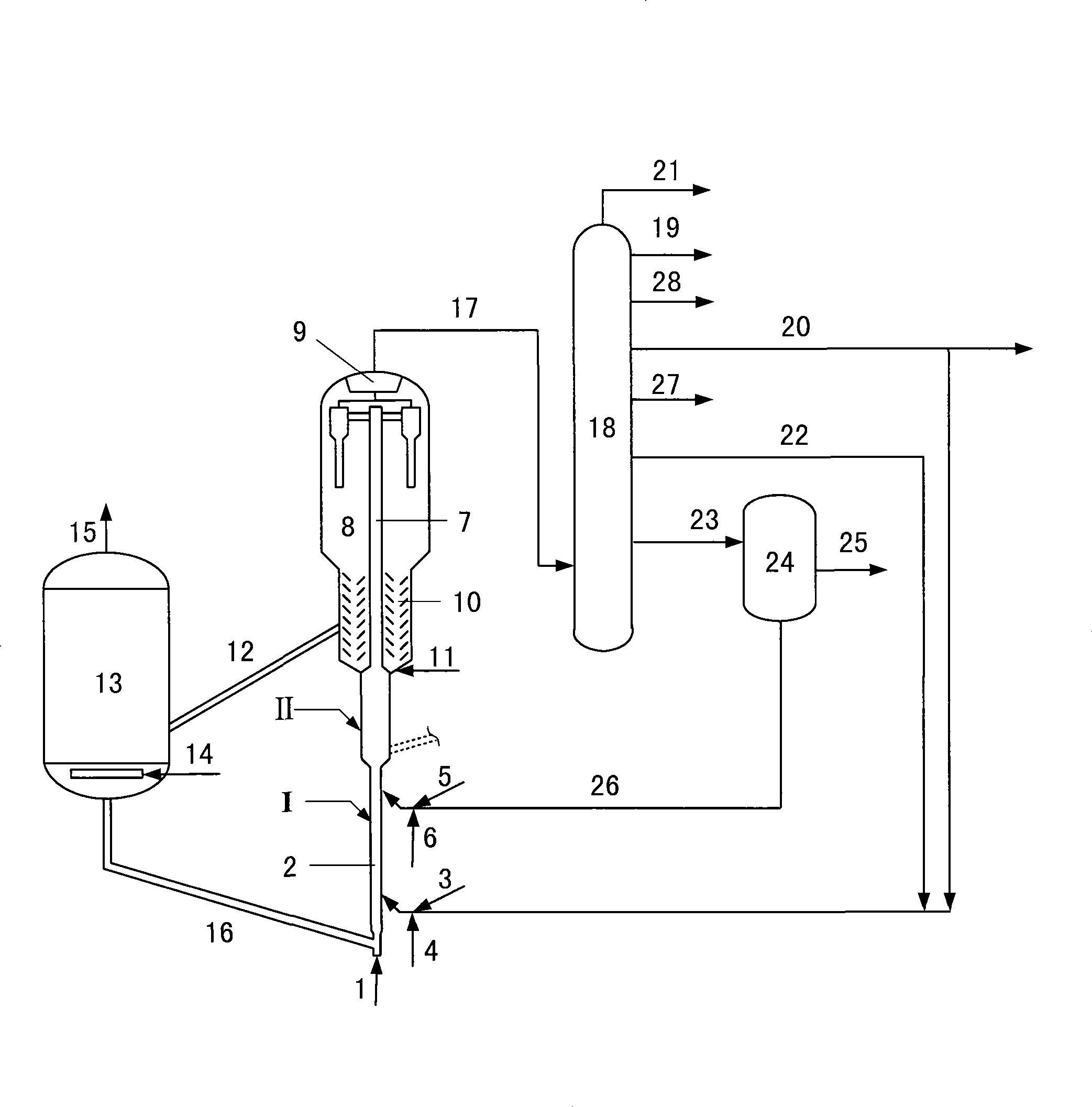

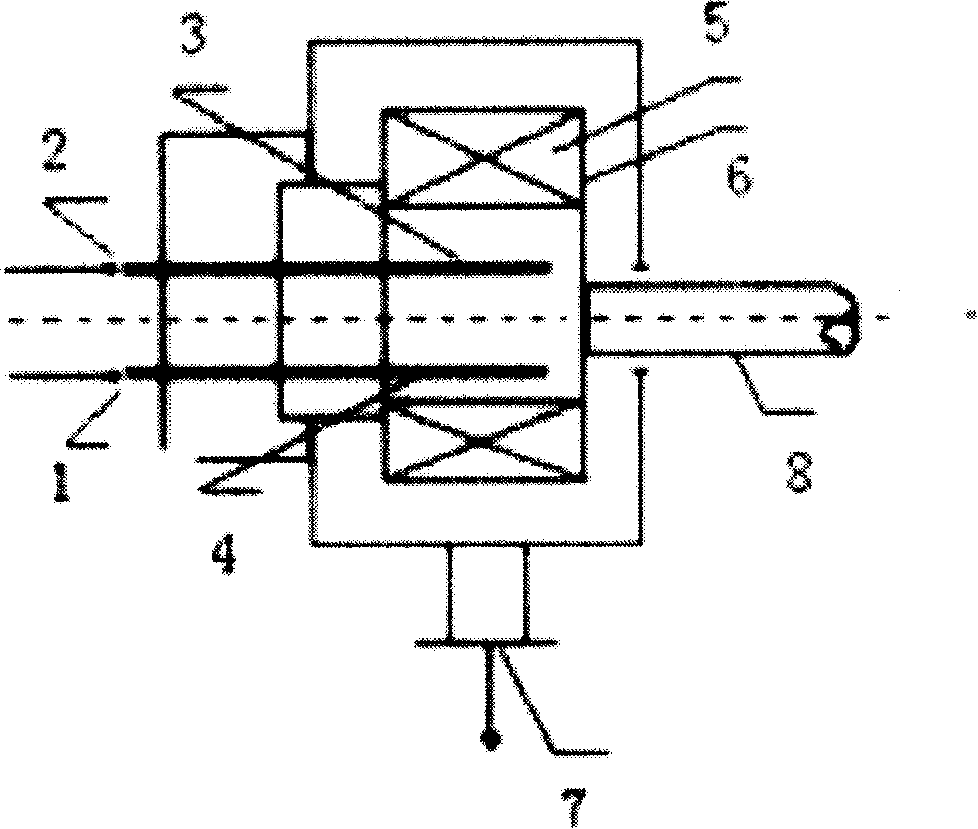

Catalytic conversion method for preparing propone and high-octane number gasoline

The invention provides a catalysis conversion method used for preparing propylene and high octane gasoline; raw material which is difficult to be cracked contacts a thermal regeneration catalyst; the cracking reaction is carried out under the conditions of 600-750 DEG C of temperature, 100-800h<-1> of weight hourly space velocity, 0.10-1.0MPa of pressure, 30-150 of weight ratio of catalyst to raw material and 0.05-1.0 of weight ratio of water vapour to raw material; the reaction matter flow is mixed with the raw oil which is easy to be cracked and the cracking reaction thereof is carried out under the condition of 450-620 DEG C of temperature, 0.1-100h<-1> of weight hourly space velocity, 0.10-1.0MPa of pressure, 1.0-30 of weight ratio of catalyst to raw material and 0.05-1.0 of weight ratio of water vapour to raw material; after spent catalyst is separated from reaction oil gas, the spent catalyst enters a stripper and is returned to a reactor after being stripped, burned and regenerated; the reaction oil gas is separated so as to gain the object outcome: propylene, high octane gasoline and re-cracked raw material; the re-cracked raw material comprises distillate with the distillation range of 180-260 DEG C and heavy aromatic raffinate oil. The method greatly increases the yield and selection of propylene, obviously improves the yield and octane of the gasoline and leads the reduction range of yield of the dry gasoline to achieve more than 80% by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic composition for hydrotreating of hydrocarbons and method for hydrotreating

InactiveUS20090283443A1Improve rendering capabilitiesPoint becomes highMolecular sieve catalystsHydrocarbon oil crackingTitaniumCrystallinity

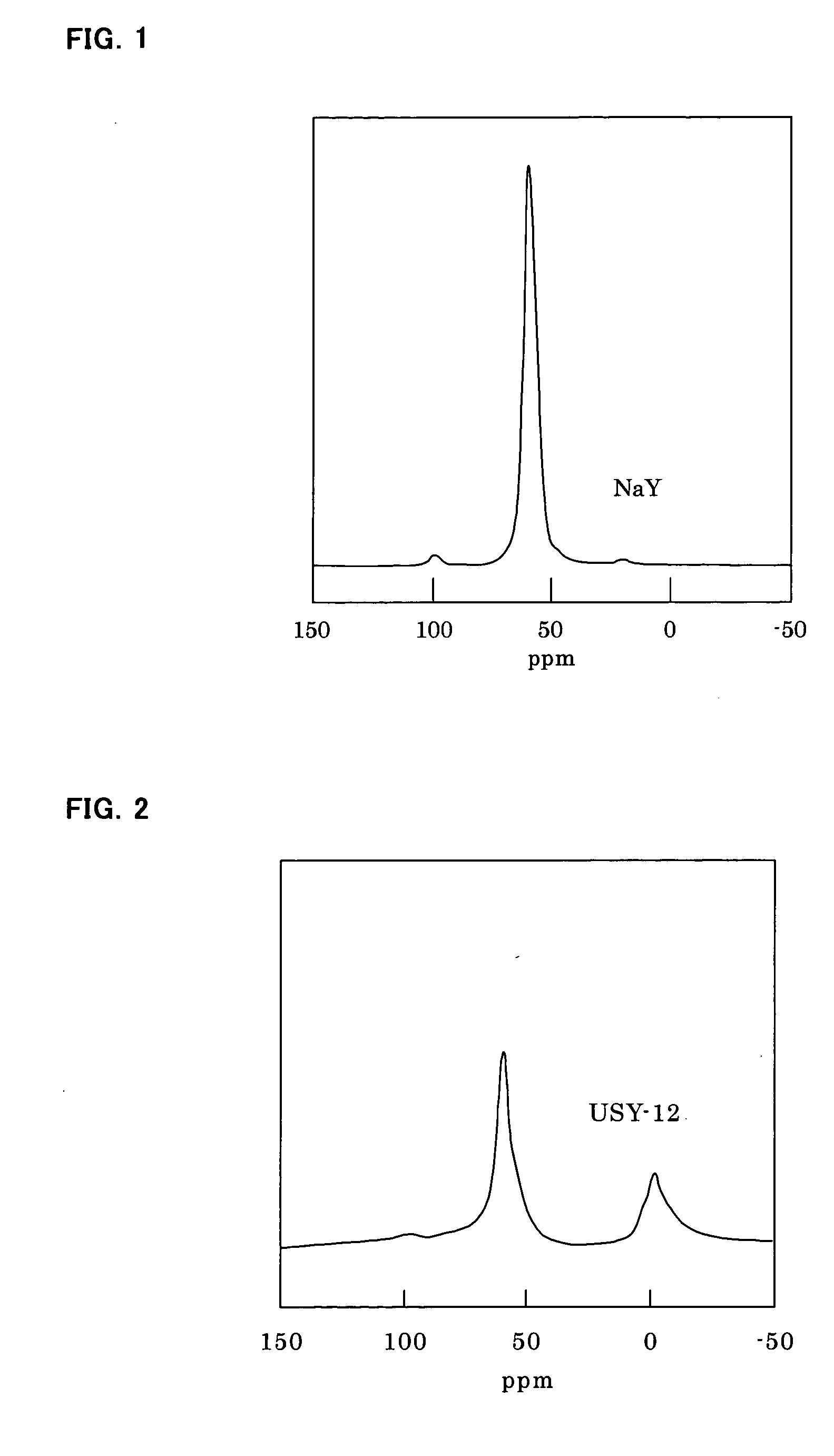

A catalytic composition for hydrotreating of hydrocarbons in which a metallic component for hydrogenation is carried on a carrier comprising zeolite Y with aluminum and titanium inserted therein and a porous inorganic oxide, the zeolite Y having the following characteristics: (a) unit cell dimension (UD) in a range from 24.25 to 24.60 Å, (b) crystallinity of 95% or more, (c) specific surface area (SA) of 500 m2 / g or more, (d) total pore volume (PVt) of a group of pores each having a diameter of 600 Å or below in a range from 0.45 to 0.70 ml / g, (e) pore volume (PVm) of a group of pores each having a diameter in a range from 100 to 600 Å in a range from 0.10 to 0.40 ml / g, (f) pore volume (PVs) of a group of pores each having a diameter in a range from 35 to 50 Å in a range 0.03 to 0.15 ml / g, and (g) percentage of 4-coordinate aluminum atoms against total aluminum atoms in the zeolite of 60 atom % or more.

Owner:JGC CATALYSTS & CHEM LTD +1

Catalytic cracking catalyst

The present invention relates to a cracking catalyst. Its composition contains (by wt%) 10%-50% of high rare earth ultrastable Y-type molecular sieve, 10%-40% of aluminium oxide adhesive and 10%-70% of clay. The preparation method of described high rare earth ultrastable Y-type molecular sieve includes the following steps: fully mixing ultrastable Y-type zeolite and acid solution whose equivalent concentration is 0.01N-2N according to the solid-liquid ratio of 20:4 at temperature range of 20deg.C-100deg.C, stirring them for 10min-300min, then washing, filtering, adding rare earth salt solution to make rare earth ion exchange, after the exchange washing, filtering and drying so as to obtain the high rare earth ultrastable Y-type molecutar sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

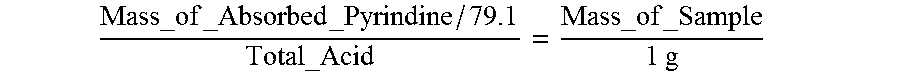

Hydrocracking catalyst, preparation method and use thereof, and method for hydrocracking catalytic diesel oil

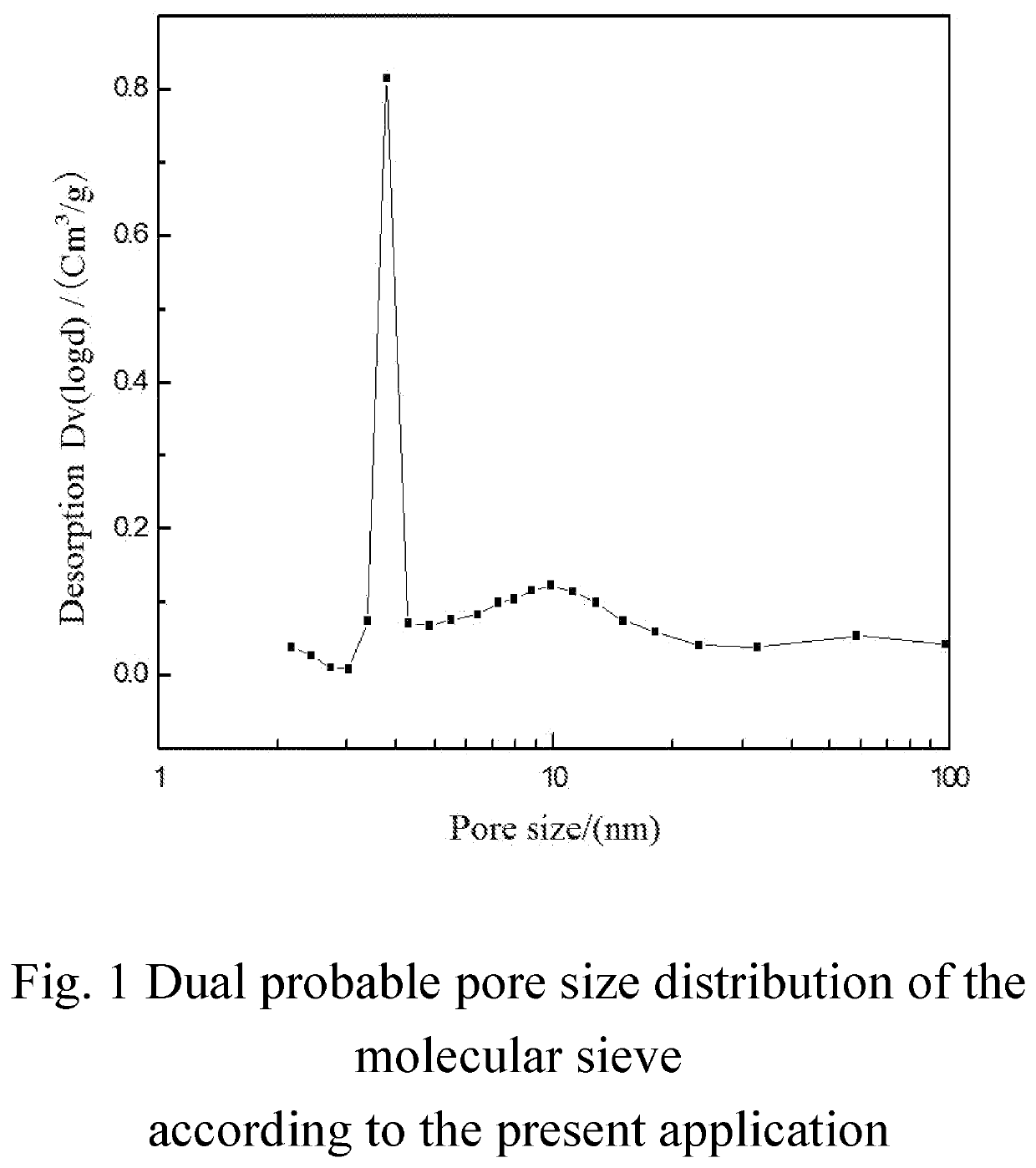

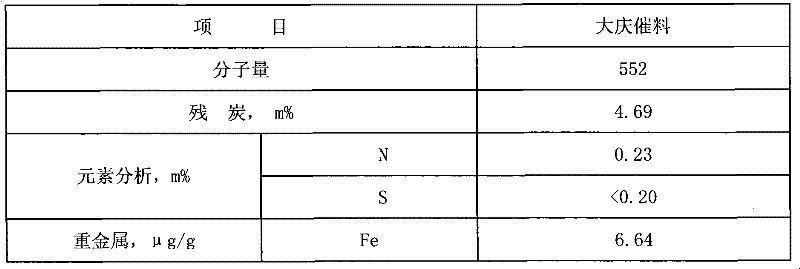

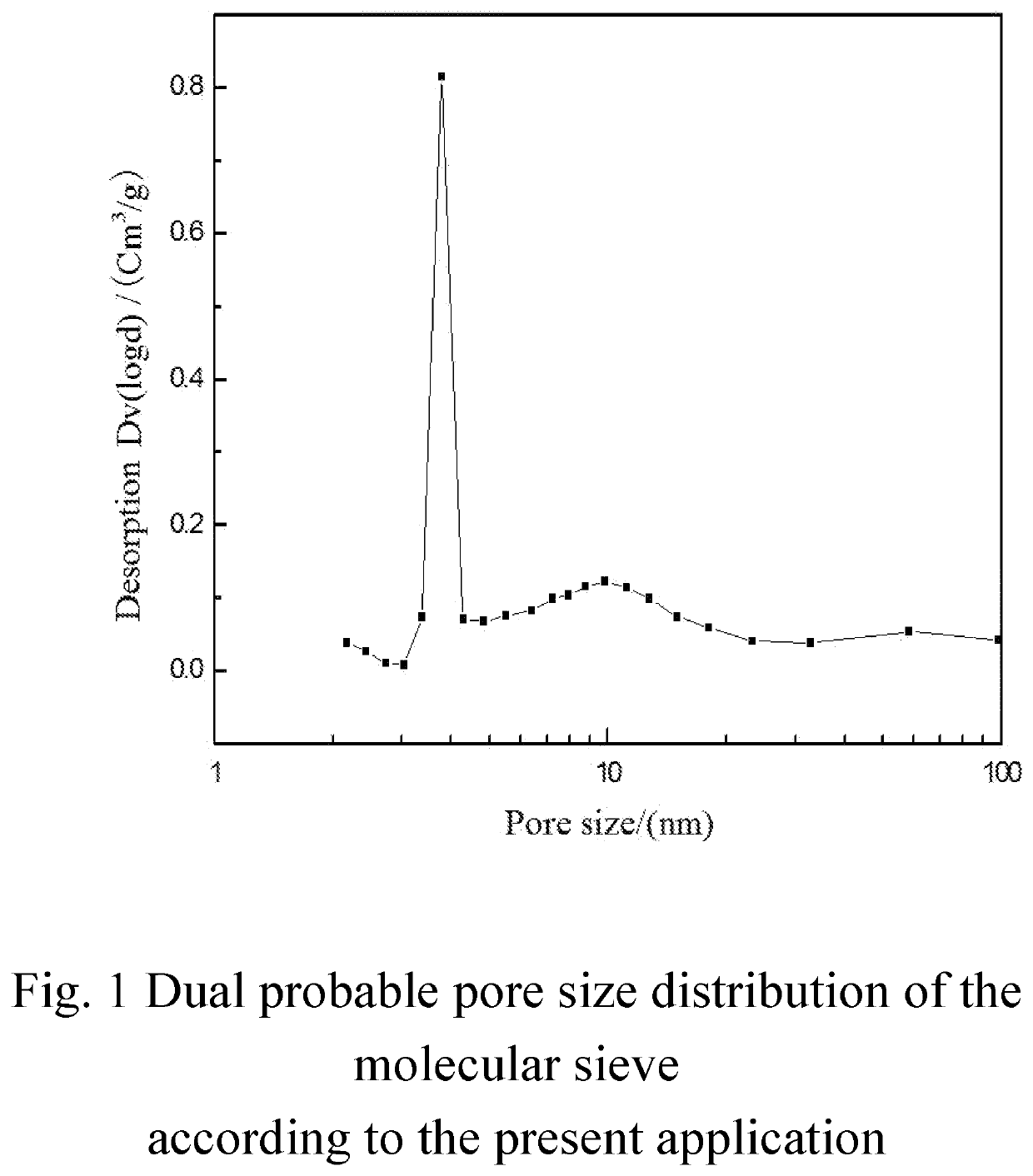

ActiveUS20170128919A1Good effectImprove catalytic stabilityMolecular sieve catalystsCatalyst activation/preparationDesorptionEstimation methods

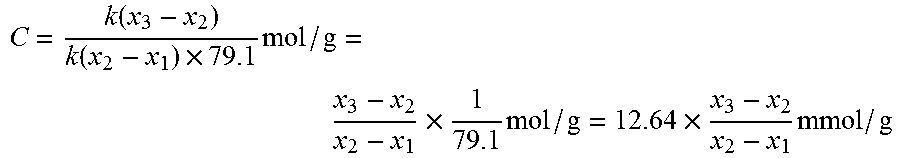

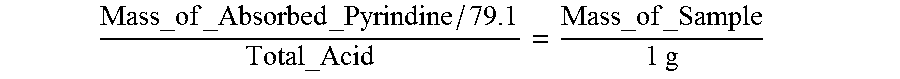

The present disclosure provides a hydrocracking catalyst, a method for preparing the same and a use of the same, and a method for hydrocracking catalytic diesel oil. The catalyst comprises a support, an active metal component, and carbon, wherein, based on the total weight of the catalyst, the content of the support is 60 to 90 wt %, the content of the active metal component calculated in metal oxides is 15 to 40 wt %, and the content of carbon calculated in C element is 1 to 5 wt %; measured with an infrared acidimetric estimation method, the acid properties of the hydrocracking catalyst are: the total infrared acid amount is 0.4 to 0.8 mmol / g, wherein, the infrared acid amount of strong acid with desorption temperature greater than 350° C. is 0.08 mmol / g or lower, and the ratio of the total infrared acid amount to the infrared acid amount of strong acid with desorption temperature greater than 350° C. is 5 to 50.

Owner:CHINA PETROCHEMICAL CORP +1

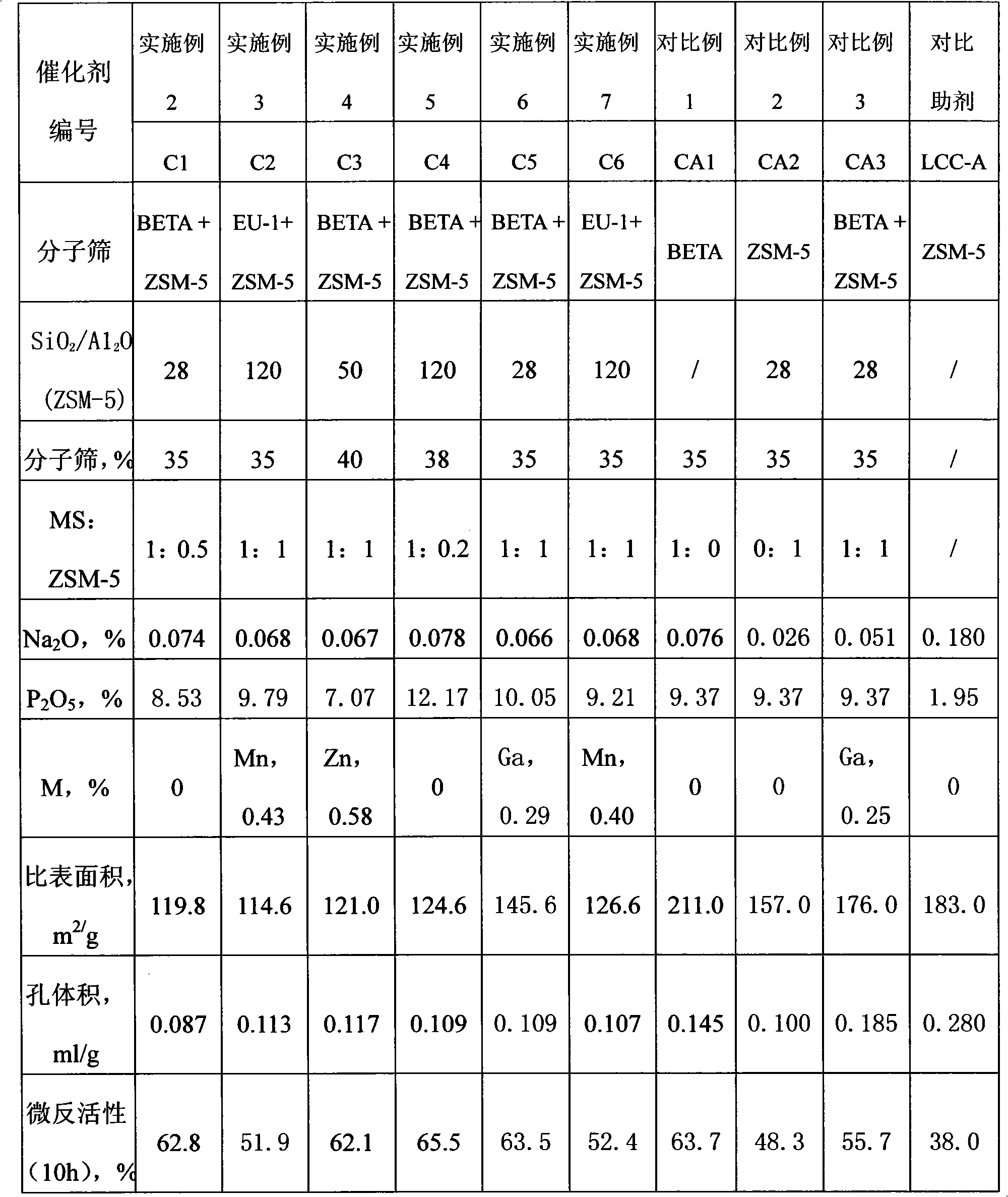

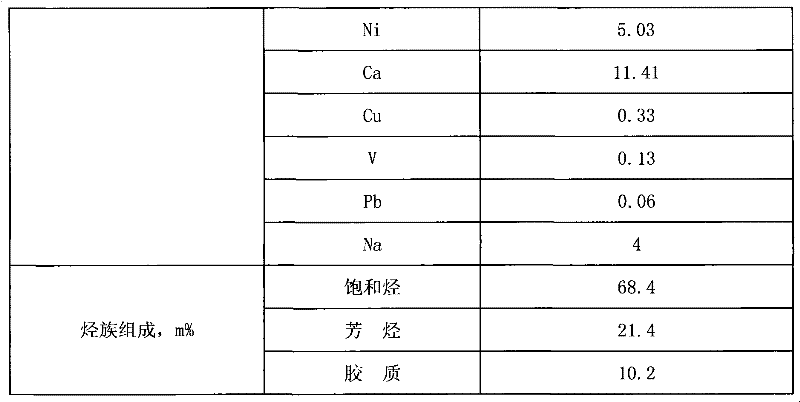

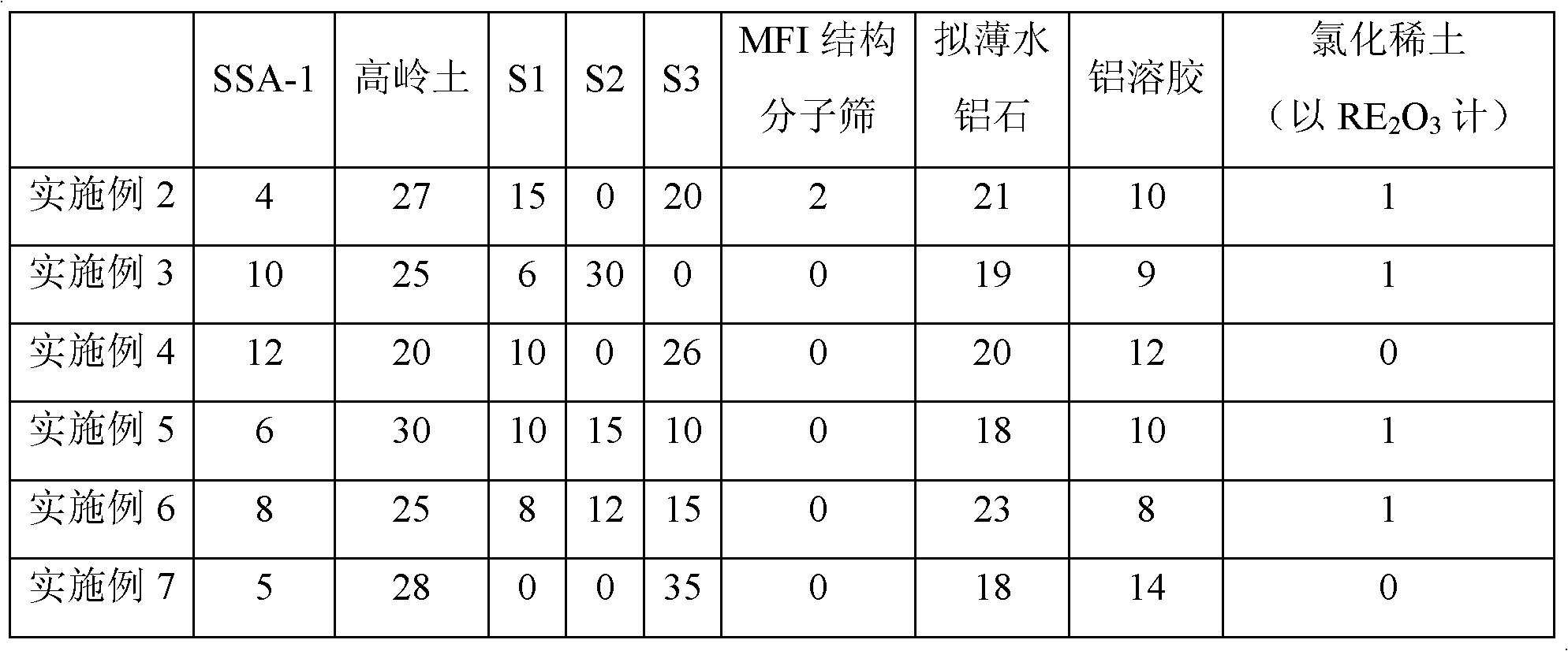

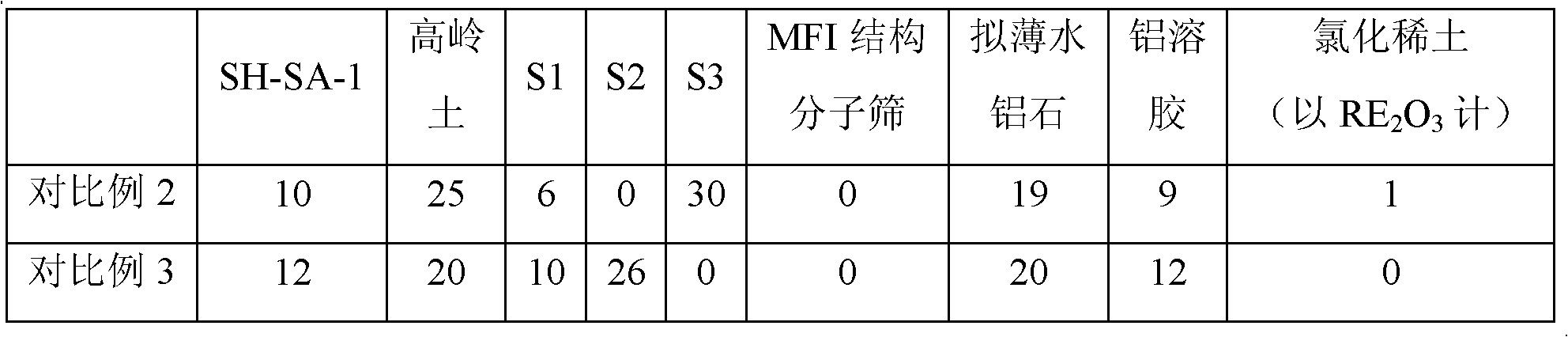

RFCC high octane gasoline additive and preparation method thereof

ActiveCN102049290AHigh strengthSimple preparation processCatalytic crackingMolecular sieve catalystsHydrogenAdditive ingredient

RFCC (Resid Fluid Catalytic Cracking) high octane gasoline additive contains the following ingredients by weight percentage taking the total weight of the additive as 100%: 5-90 of H-type (Hydrogen) composite molecular sieve, 1-60 of BETA or EU-1 molecular sieve, 1-30 of ZSM-5 molecular sieve adopting modified or non-modified chemical elements, 2-60 of clay, and 7.0-15.0 of P(calculated based on P205) wherein the precursor of the P is aluminum phosphate sol; and 2-10 of A1 and 5-15 of P are contained in the aluminum phosphate sol, and the PH value of the aluminum phosphate sol is 1.0 to 2.5; and 2-20 of the aluminum phosphate sol is calculated based on HNO3. By adopting the preparation method provided by the invention, the activity of the FCC additives is significantly enhanced; and owing to mixing use with main catalytic agent, the product distribution can be improved, the gasoline octane value is improved, and the gasoline productivity is improved at the same time.

Owner:PETROCHINA CO LTD

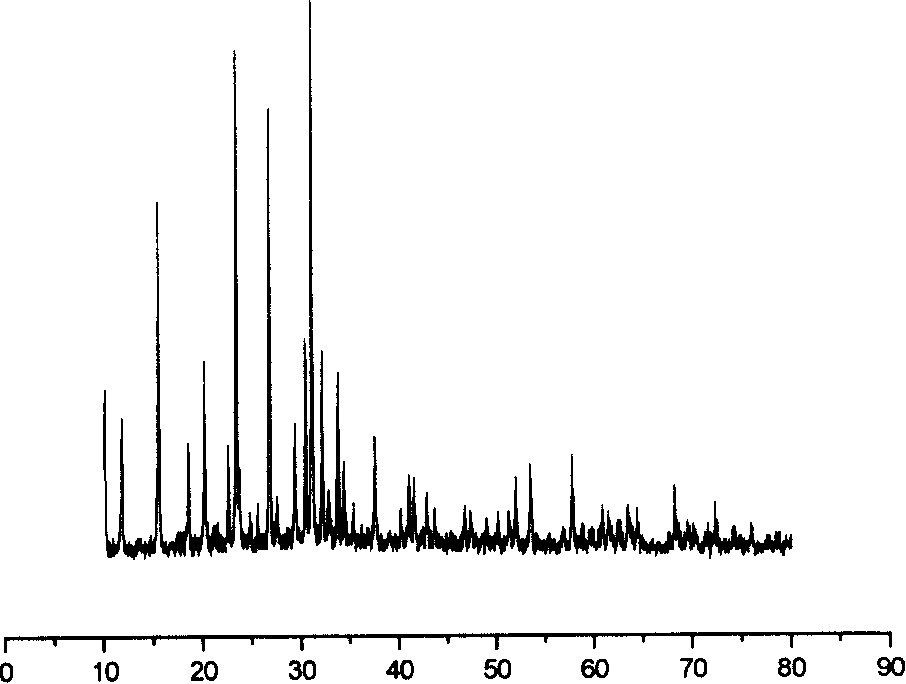

Method for preparing nano NaY molecular sieve

InactiveCN101177281AHigh product purityWell dispersedFaujasite aluminosilicate zeoliteSodalitesChemistryMolecular sieve

The invention relates to a preparation method of nanometer NaY molecular sieve, which is as follow: under the hypergravity condition of the revolving bed, performing guiding agent preparation, mother solution preparation, and mixing of guiding agent and mother solution, and the sequent crystallization of the reaction product. The invention enables to shorten the crystallization reaction time, simplify the technological process and prepare the high-quality nanometer NaY molecular sieves. The nanometer NaY molecular sieve catalyst prepared through the method can be used for the catalytic cracking of the heavy oil. Compared with the normal industrial molecular sieve, the nanometer NaY molecular sieve has the advantages of great increase of gasoline productivity, diesel fuel productivity, clean oil yield and total-liquid yield, improvement of the product selectivity, and obvious improvement of the product distribution.

Owner:BEIJING UNIV OF CHEM TECH

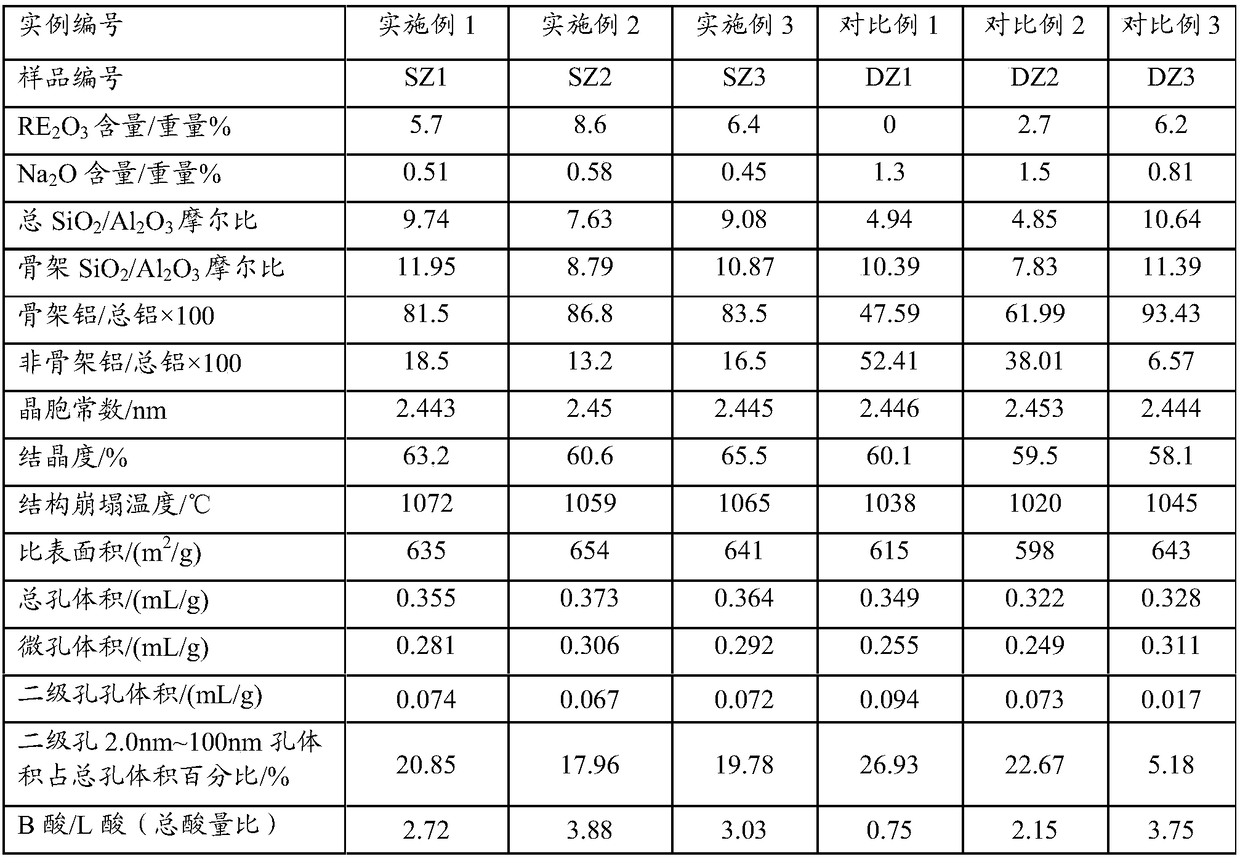

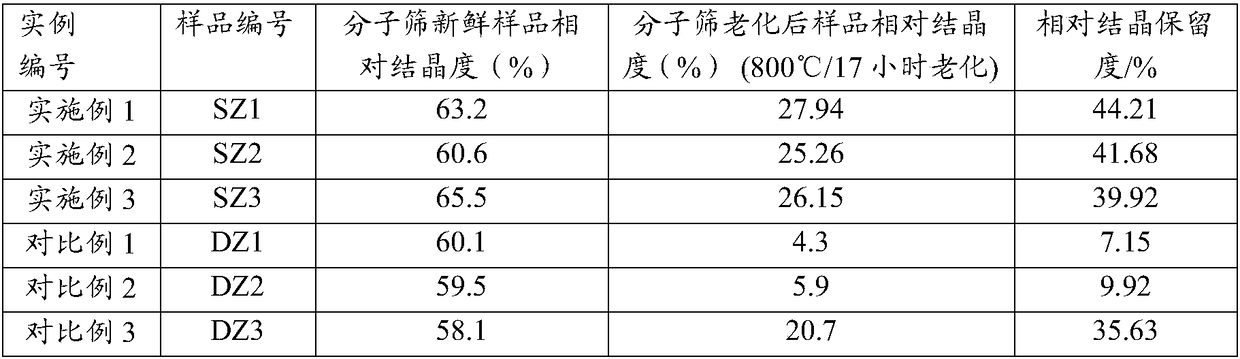

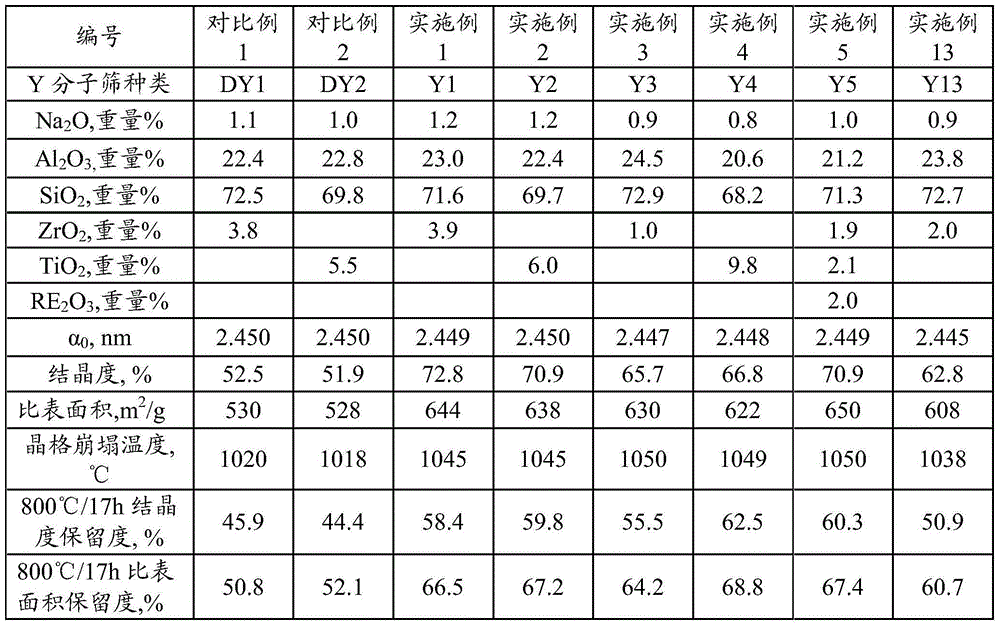

Modified Y-Type Molecular Sieve, Preparation Thereof and Catalyst Comprising the Same

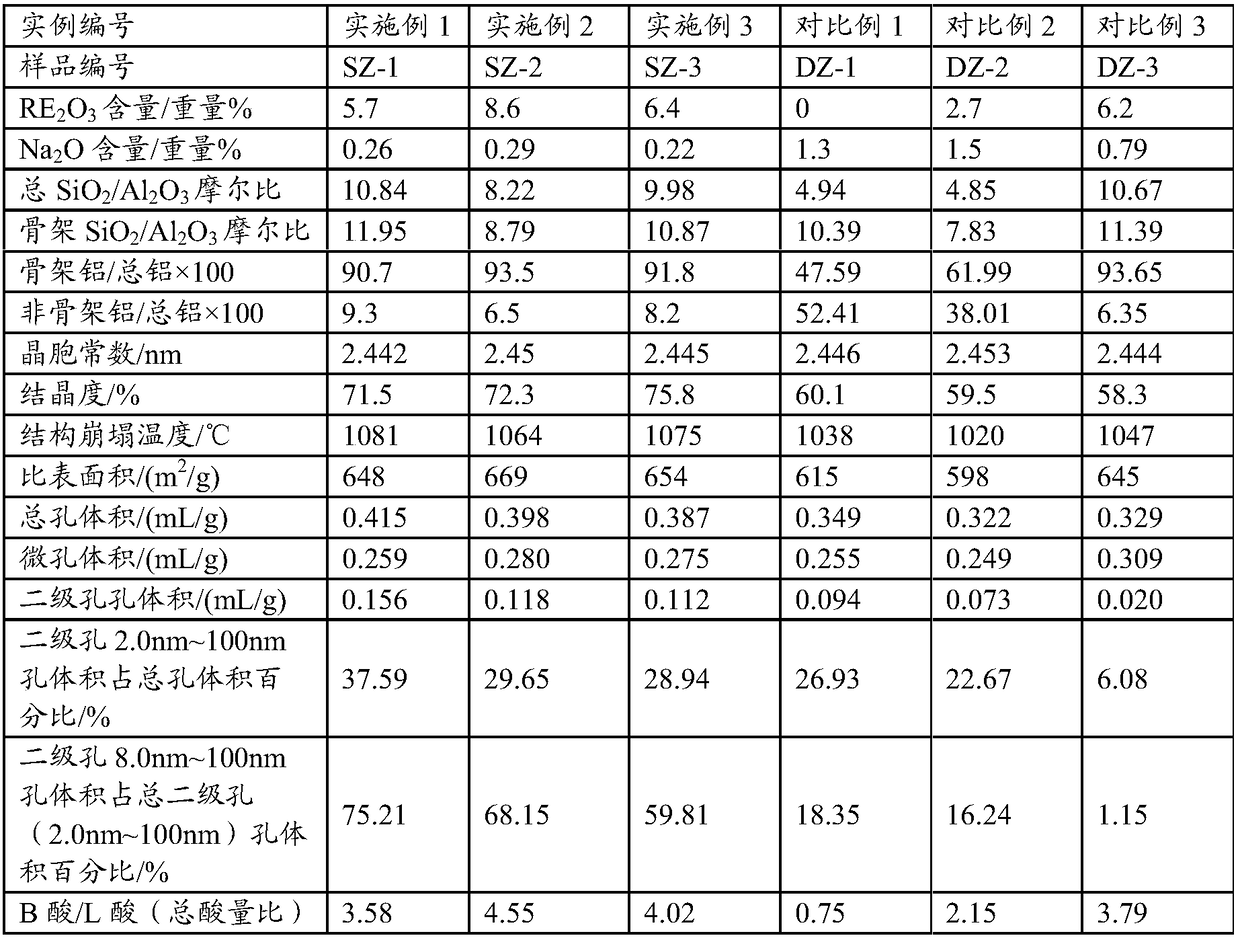

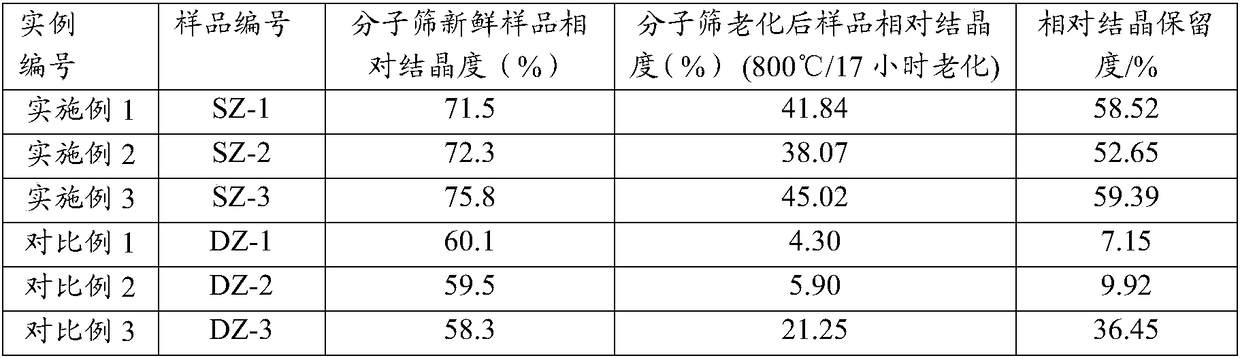

ActiveUS20200009541A1Increase lytic activityGood coke selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

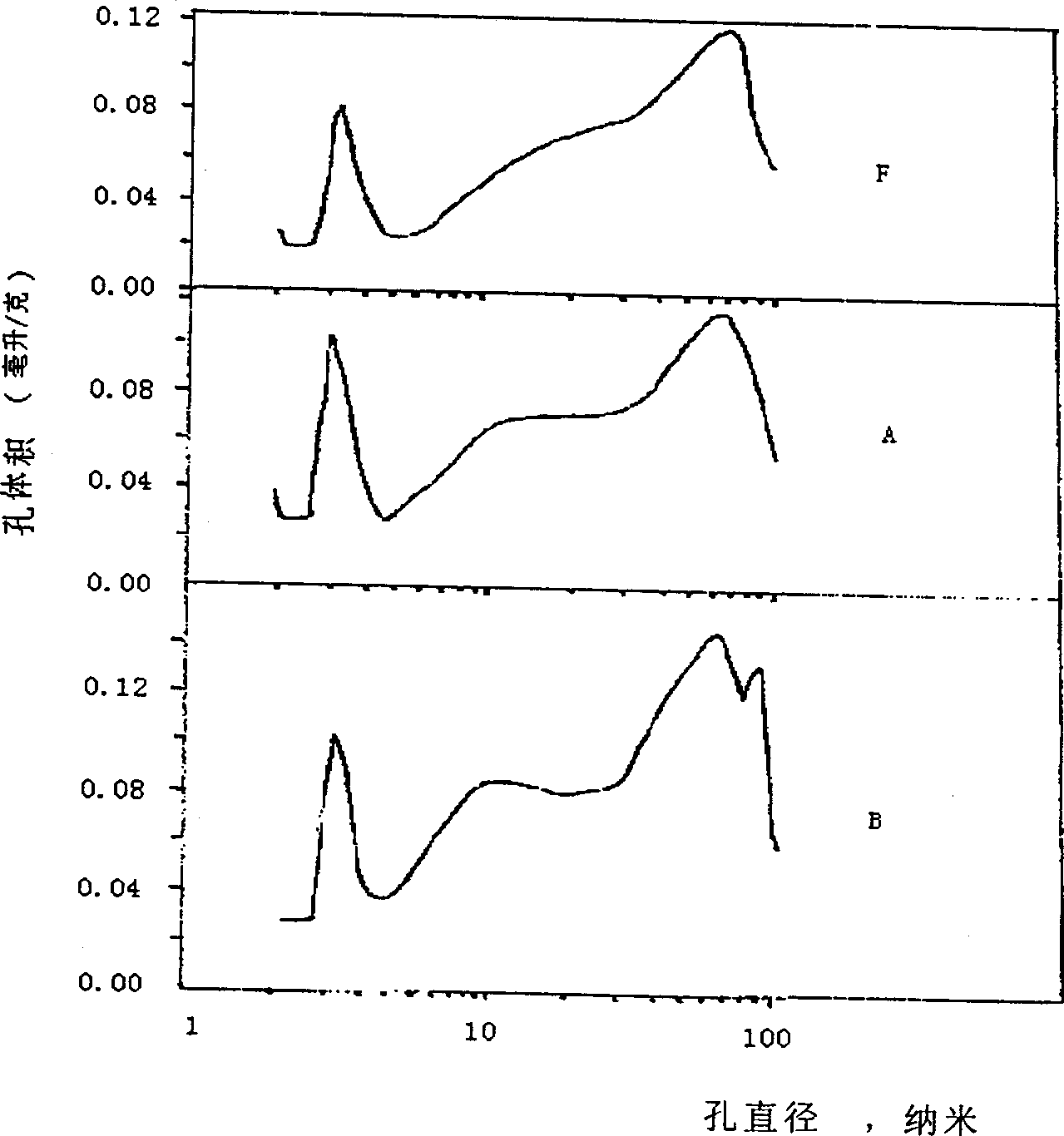

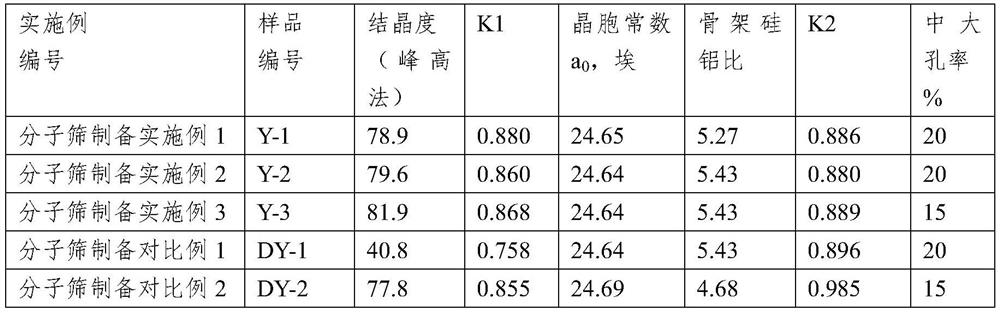

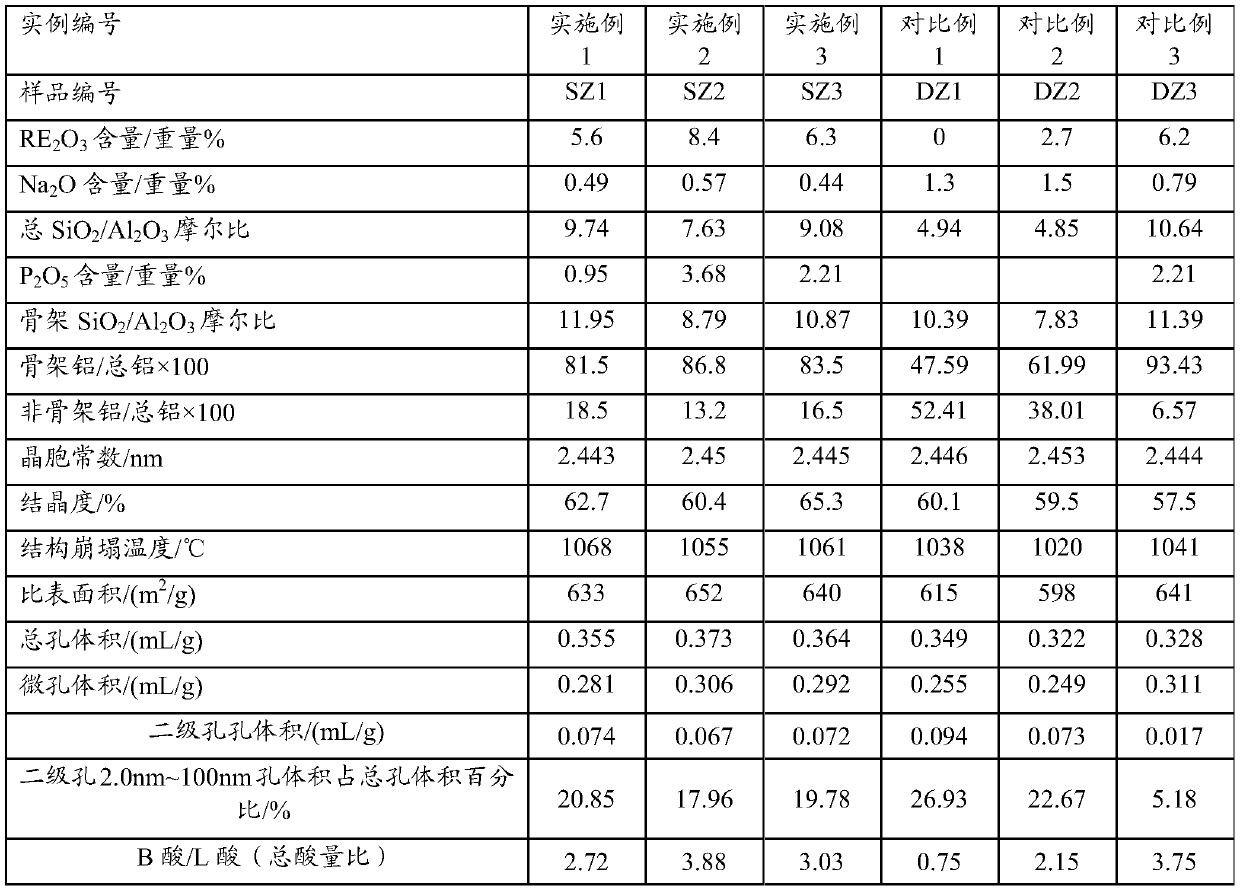

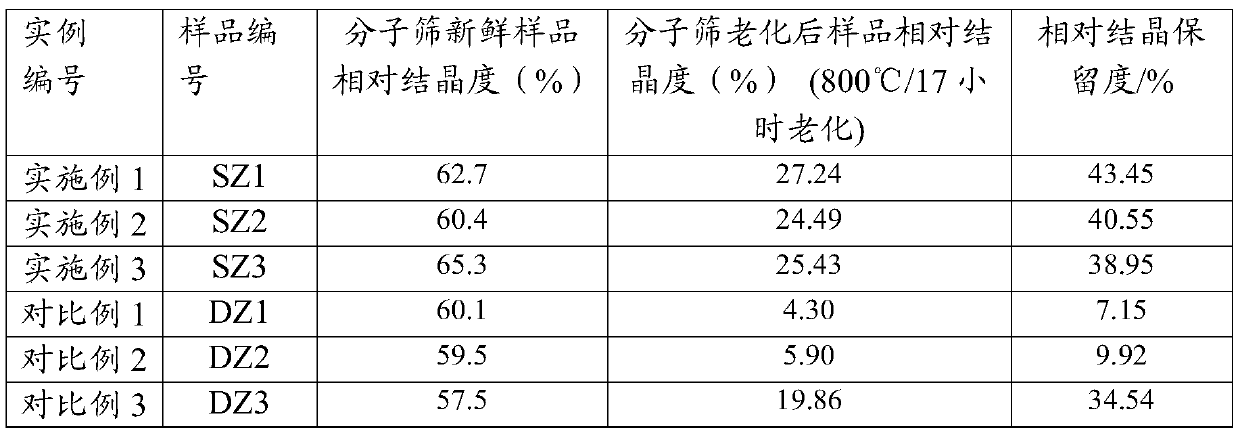

A modified Y-type molecular sieve has a rare earth oxide content of about 4% to about 12% by weight, a phosphorus content of about 0% to about 10% by weight, a sodium oxide content of no more than about 1.0% by weight, a total pore volume of about 0.36 to 0.48 mL / g, a percentage of the pore volume of secondary pores to the total pore volume of about 20% to about 40%, a lattice constant of about 2.440 nm to about 2.455 nm, a percentage of the non-framework aluminum content to the total aluminum content of no more than about 10%, a lattice collapse temperature of not lower than about 1060° C., and a ratio of B acid to L acid of no less than about 3.50. The preparation of the molecular sieve includes ion-exchange with rare earth, hydrothermal roasting, gas phase ultra-stabilization, acid treatment, and an optional phosphorus modification.

Owner:CHINA PETROCHEMICAL CORP +1

Composite molecular sieve catalyst capable of improving octane number of gasoline and preparation method of composite molecular sieve catalyst

ActiveCN102451753AA component and B component adjustmentMeet the different needs of the distributionCatalytic crackingMolecular sieve catalystsProduction rateCompound a

The invention relates to a composite molecular sieve catalyst for preparing high-octane gasoline. The catalyst comprises 5-60 parts by weight of molecular sieve dry basis, and the molecular sieve comprises 1-45% of BETA molecular sieve, 1-40% of ZSM-5 molecular sieve, and the balance being clay and other molecular sieves selected from one or more of EU-1, NU-87, SAPO-11, L, and the ITQ, MCM-22, MCM-49, MCM-56, USY and REUSY according to 100%; and a compound A containing the BETA molecular sieve and a compound B containing the ZSM-5 molecular sieve are respectively prepared and are mixed according to the weight ratio of 1:0.1 to 10 to obtain the composite molecular sieve catalyst. In a catalytic cracking unit, the catalyst is used as an addition agent to be mixed with a main catalyst to prepare high-octane gasoline, the gasoline production rate is high, and the production rate of liquefied petroleum can be flexibly adjusted.

Owner:PETROCHINA CO LTD

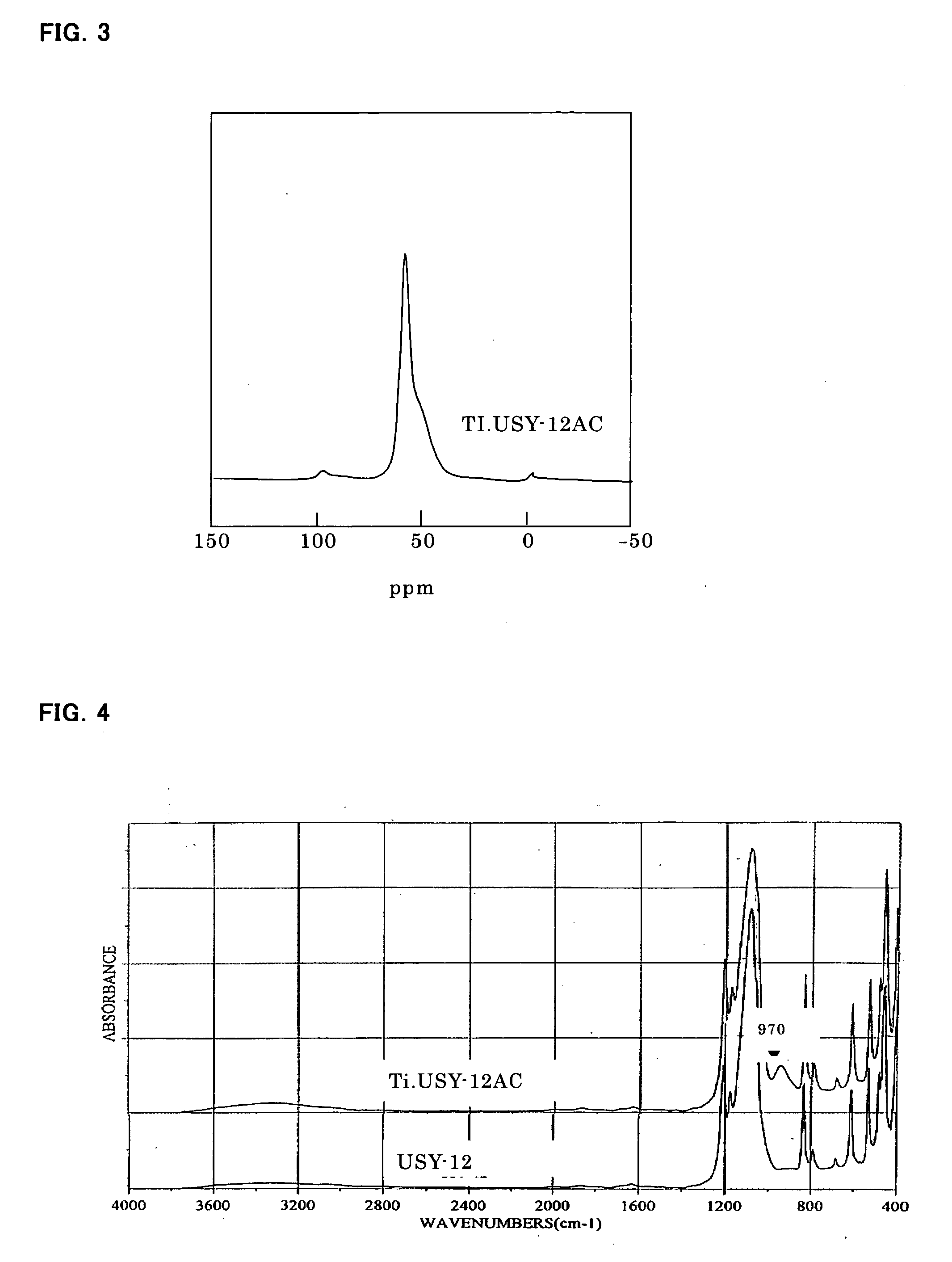

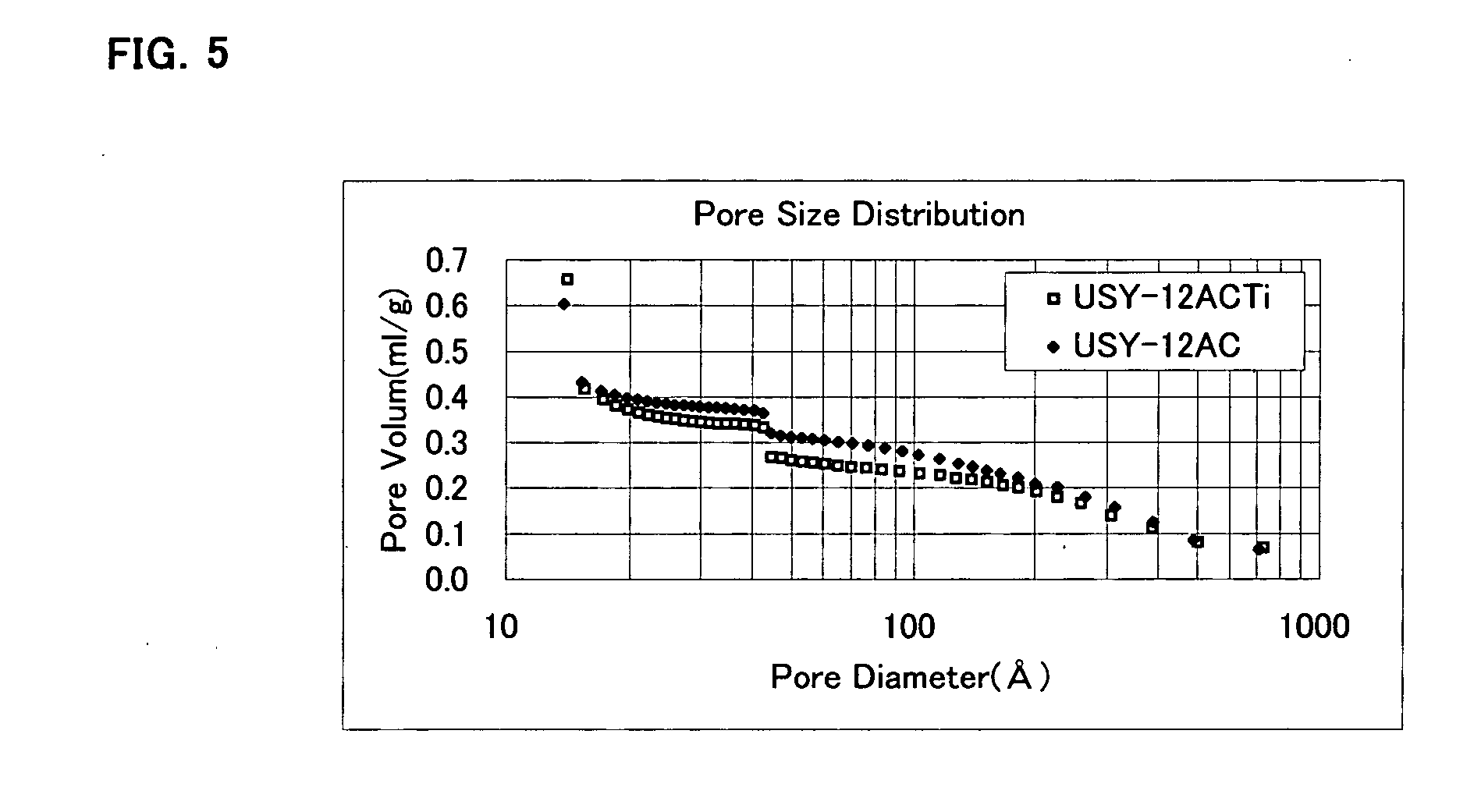

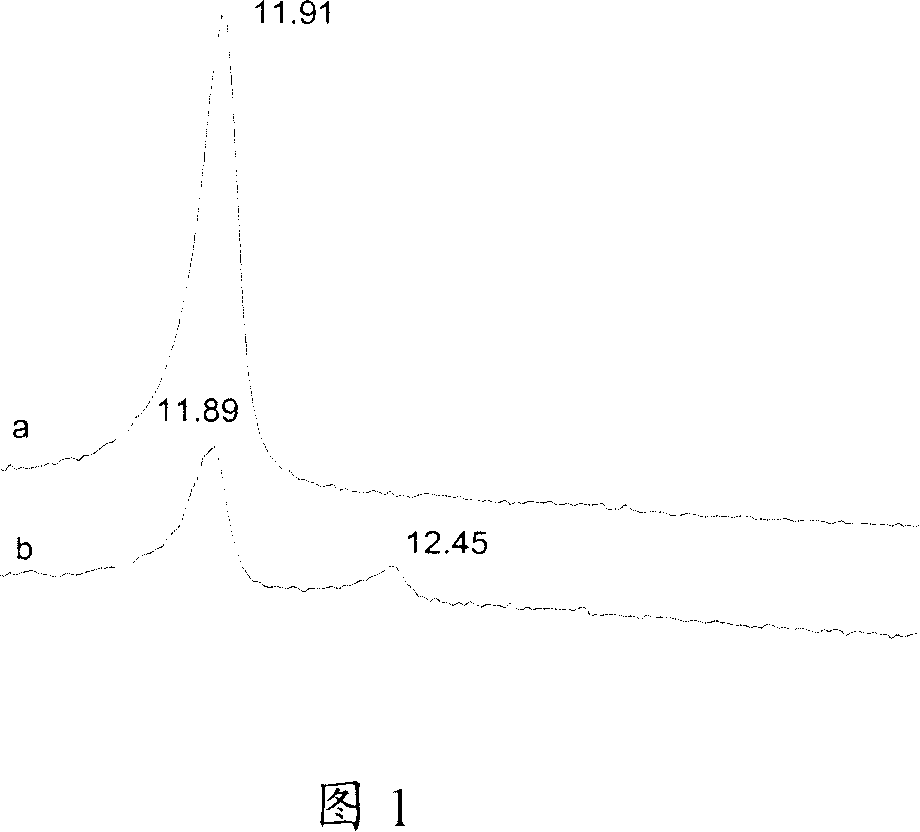

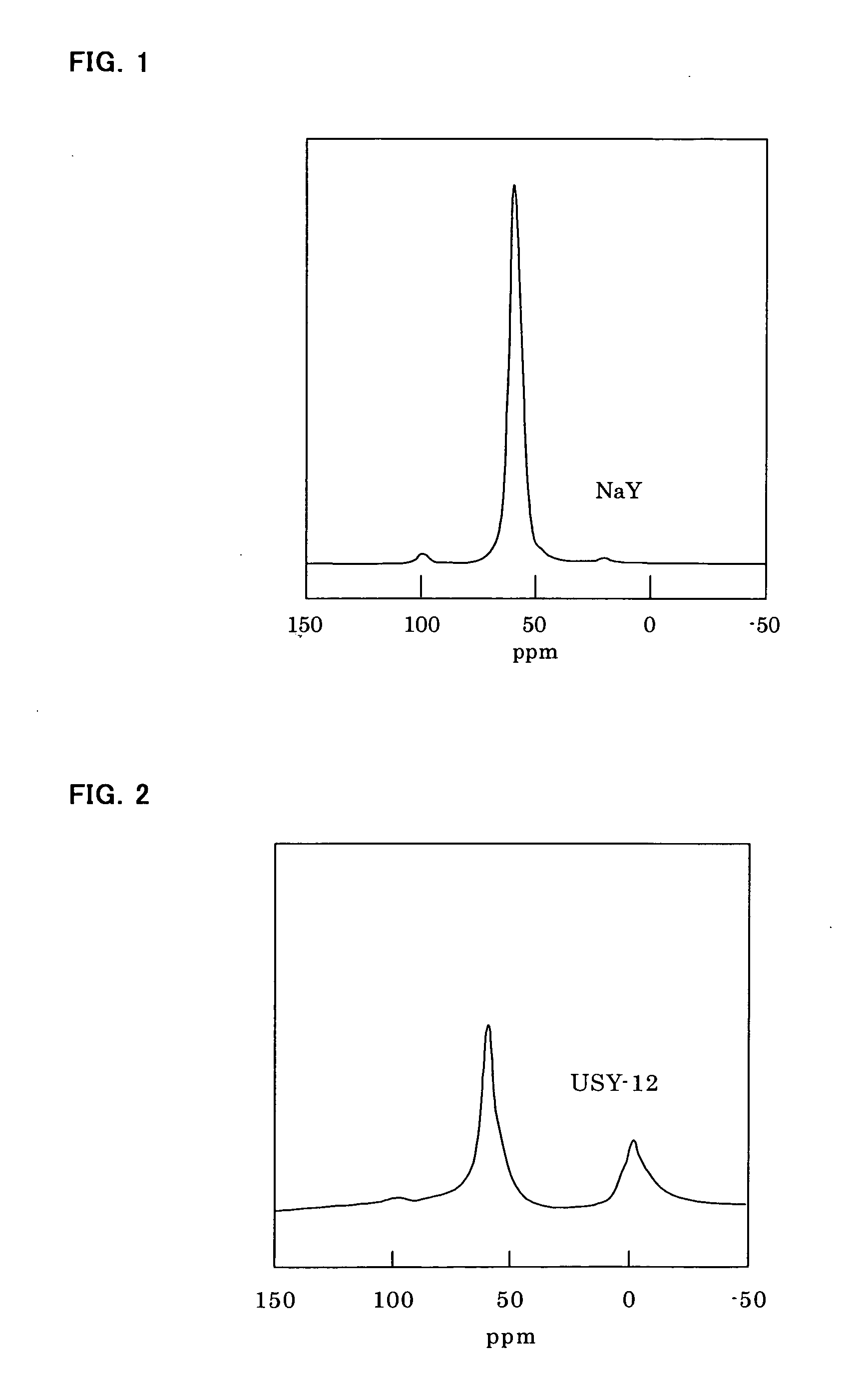

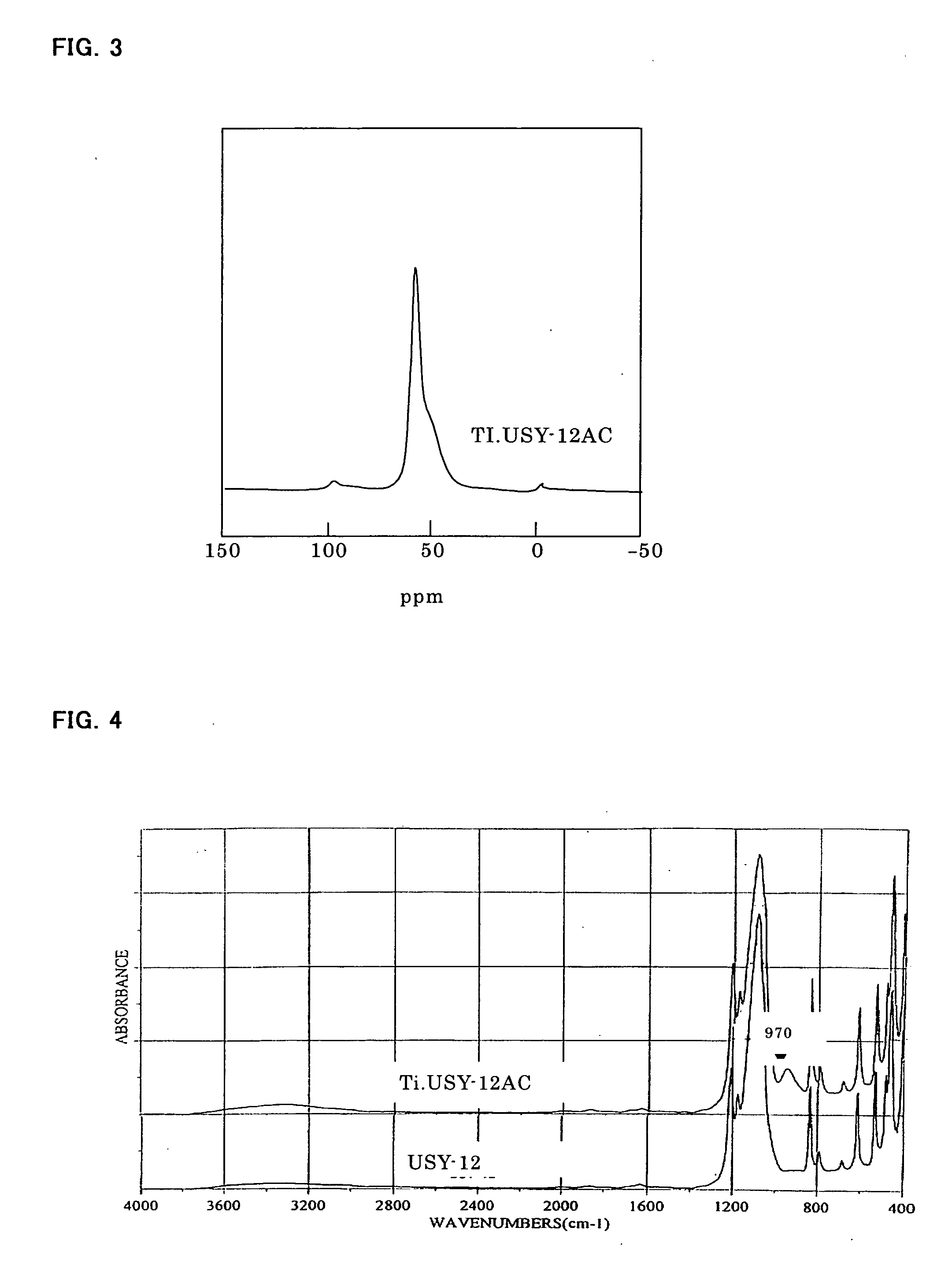

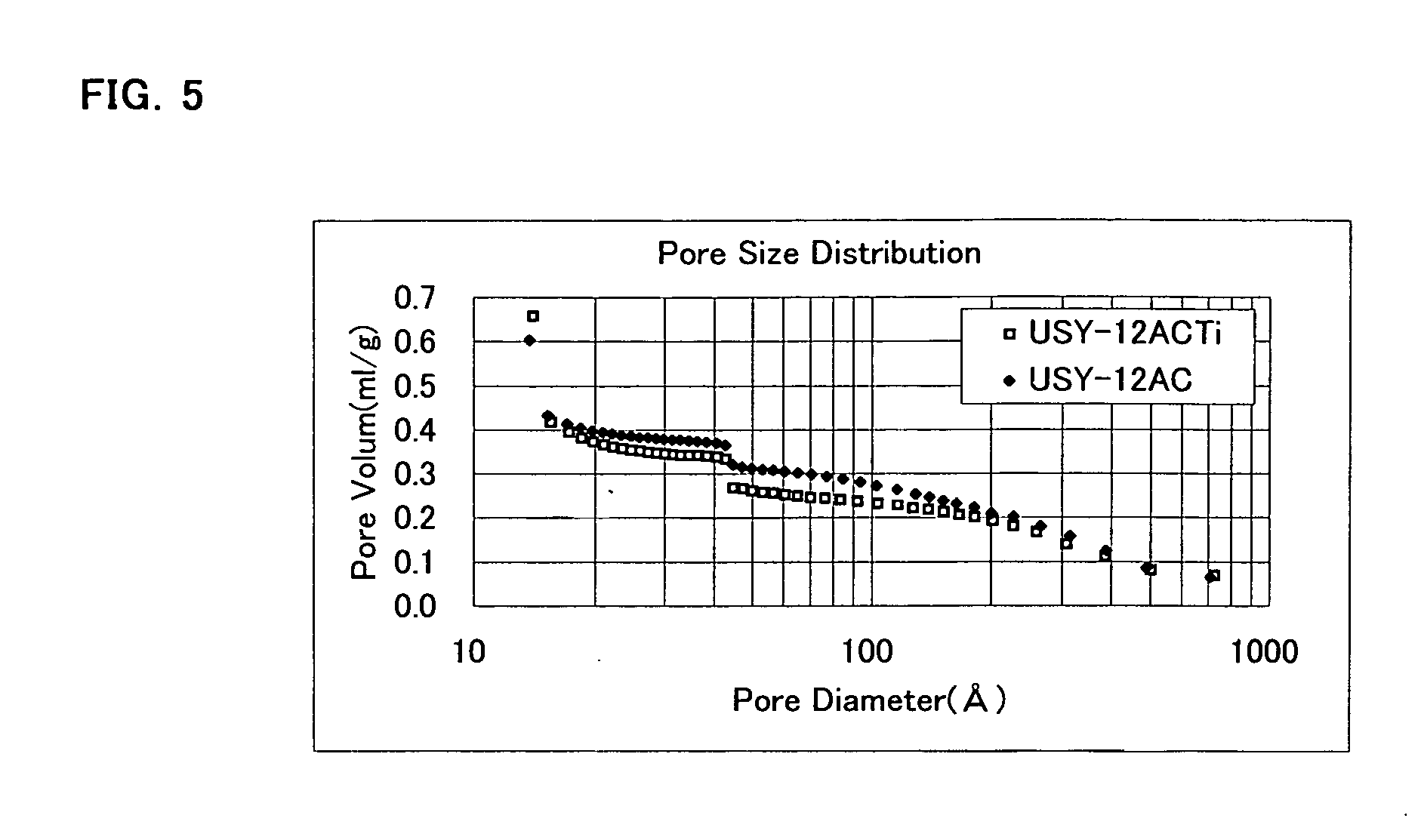

Method for manufacturing zeolite Y with aluminum and titanium inserted therein

ActiveUS20110251049A1Improve rendering capabilitiesPoint becomes highMolecular sieve catalystsHydrocarbon oil crackingTitaniumCrystallinity

A catalytic composition for hydrotreating of hydrocarbons is made in which a metallic component for hydrogenation is carried on a carrier formed of zeolite Y with aluminum and titanium inserted therein and a porous inorganic oxide. The zeolite Y has: unit cell dimension in a range from 24.25 to 24.60 Å, crystallinity of 95% or more, specific surface area of 500 m2 / g or more, total pore volume of a group of pores each having a diameter of 600 Å or below in a range from 0.45 to 0.70 ml / g, pore volume of a group of pores each having a diameter in a range from 100 to 600 Å in a range from 0.10 to 0.40 ml / g, and pore volume of a group of pores each having a diameter in a range from 35 to 50 Å in a range 0.03 to 0.15 ml / g.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

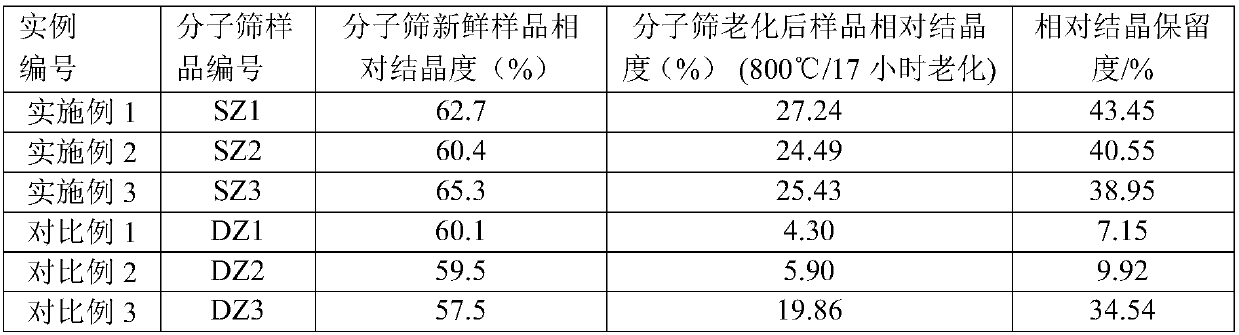

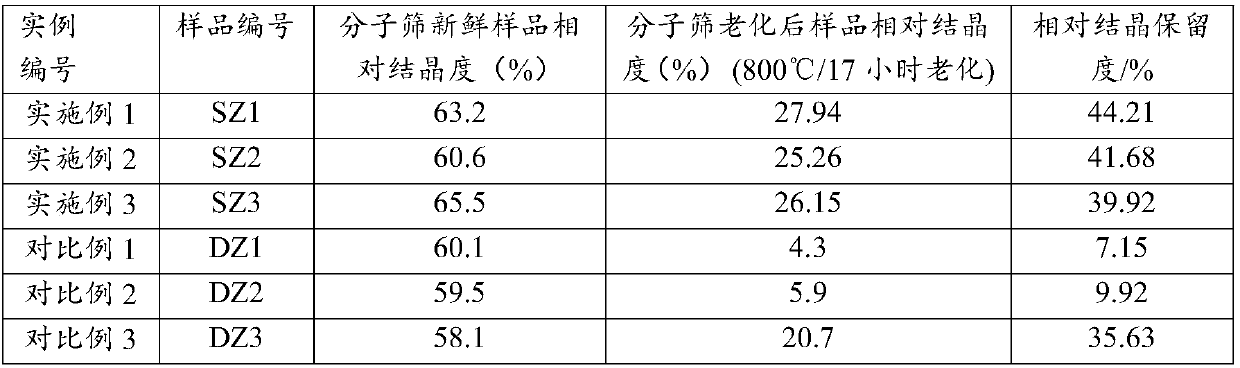

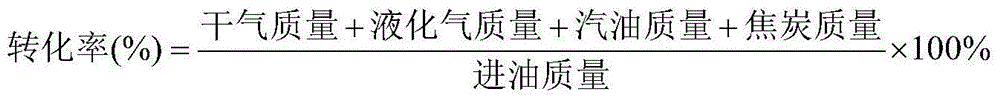

Catalytic cracking catalyst and preparation method thereof

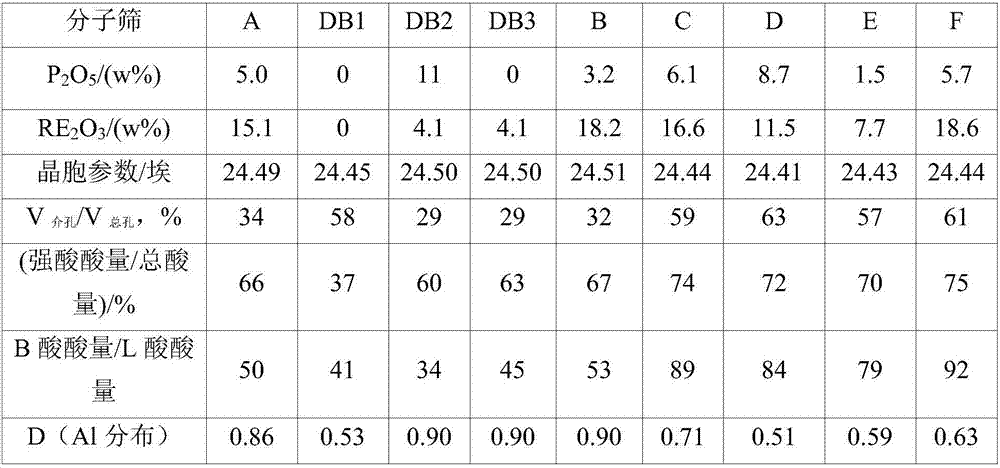

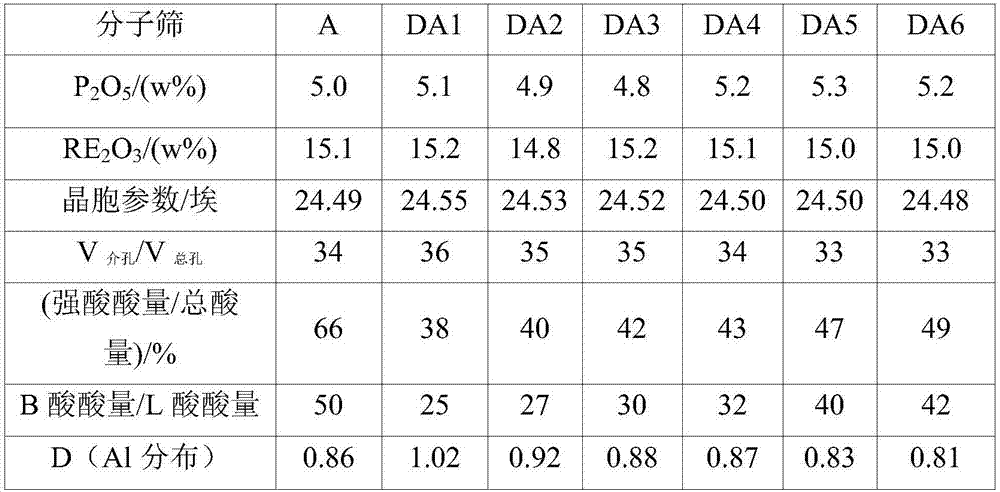

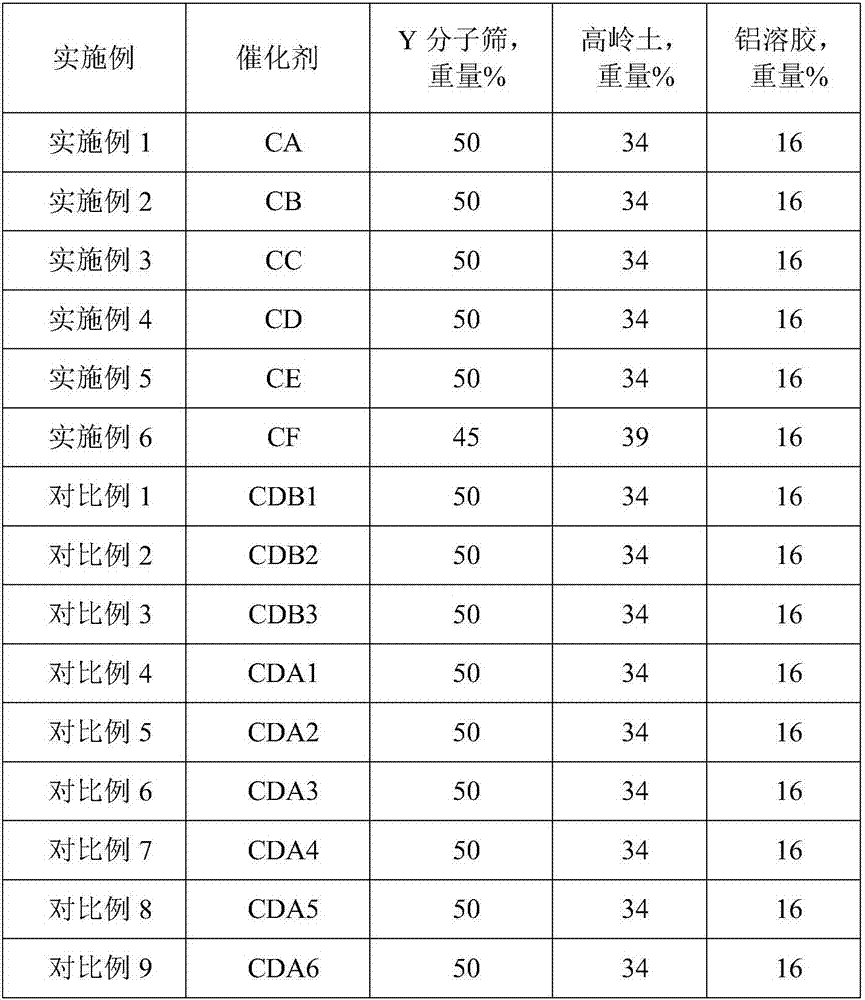

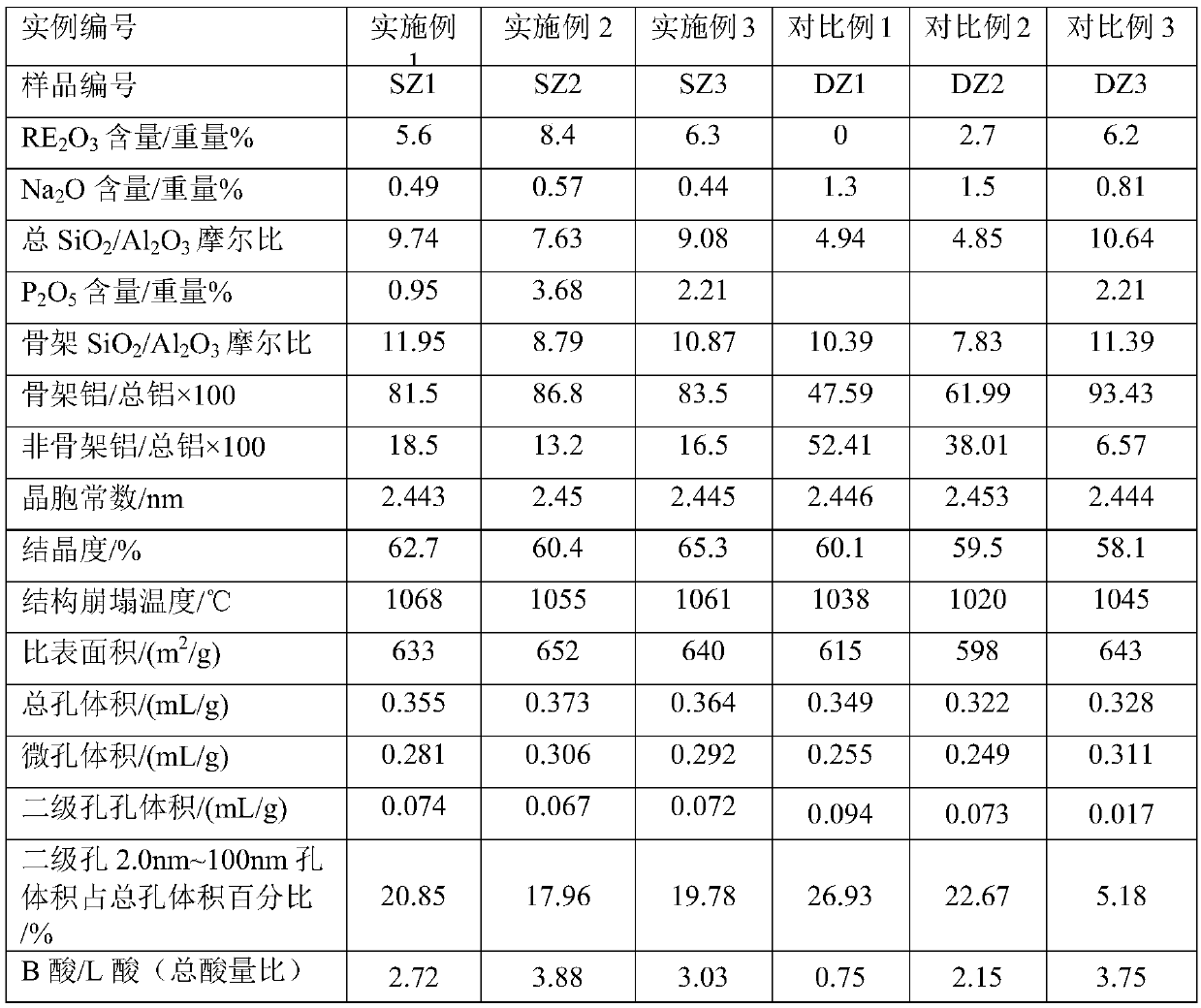

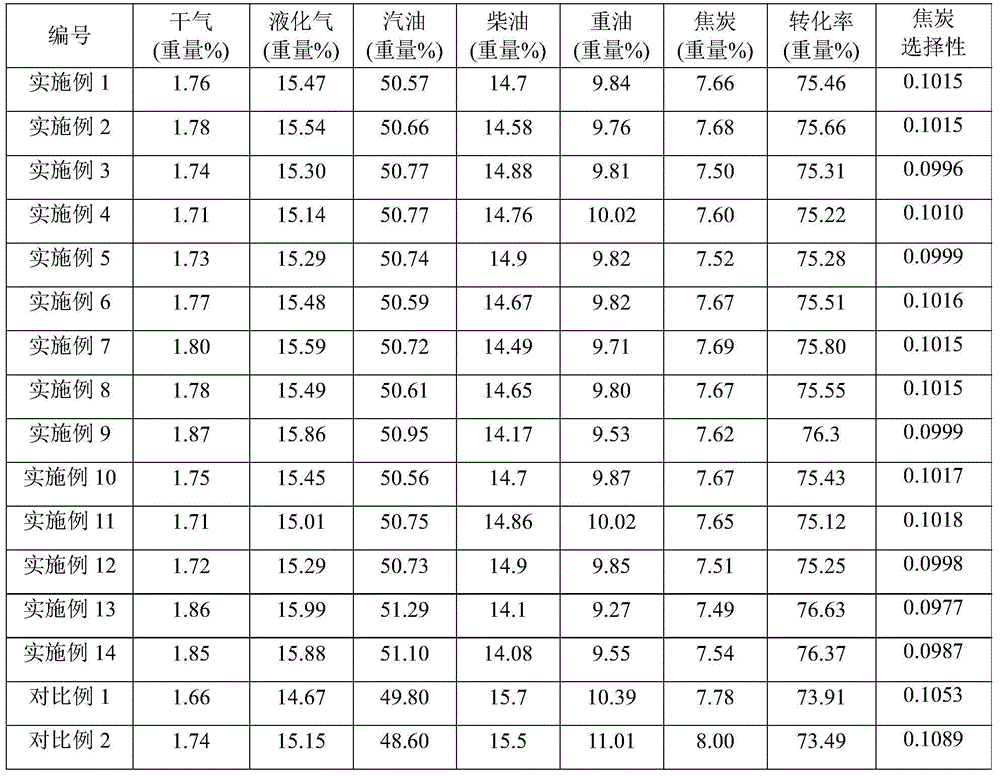

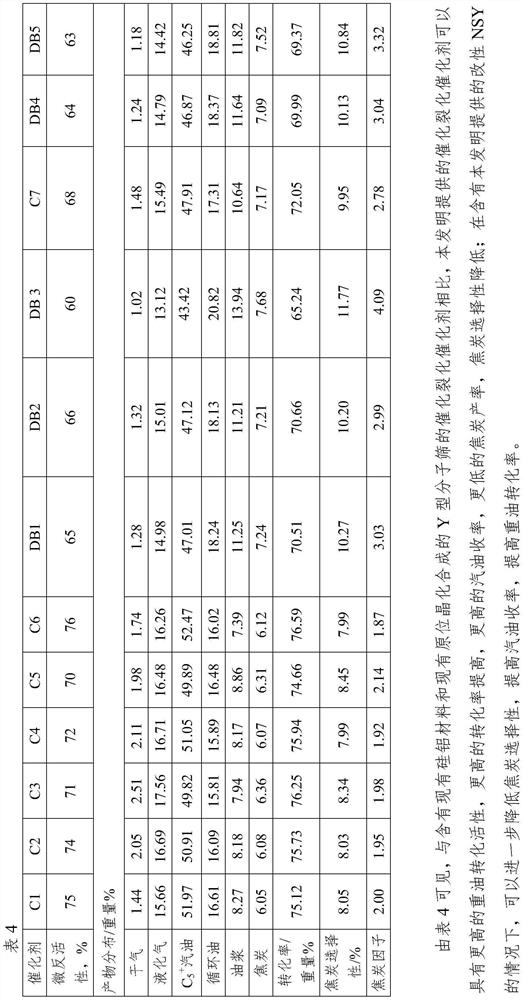

ActiveCN107970974AStrong ability to convert heavy oilHigh gasoline yieldCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

The invention relates to a catalytic cracking catalyst and a preparation method thereof. The catalytic cracking catalyst comprises, 25 to 75 wt% of a Y molecular sieve containing phosphorus and rare earth, 10 to 30 wt% of an inorganic oxide binder and 15 to 65 wt% of natural mineral matters, wherein the Y molecular sieve containing phosphorus and rare earth has a cell parameter of 24.35 to 24.55 angstroms; the phosphorus content of the molecular sieve is 0.3 to 10.0 wt% in terms of P<2>O<5> and on the basis of the dry base weight of the molecular sieve; the rare earth content of the molecularsieve is 0.5 to 19 wt% in terms of RE<2>O<3> and on the basis of the dry base weight of the molecular sieve; the distribution parameter D of Al in the molecular sieve is no less than 0.4 and no more than 0.9; the mesopore volume of the molecular sieve accounts for 25 to 65% of total pore volume; the amount of strong acids in the molecular sieve accounts for 65 to 78% of total acid amount; and a ratio of the amount of the acid B to the amount of the acid L is 21 to 98. The catalytic cracking catalyst provided by the invention has the advantages of excellent heavy oil conversion capability, higher gasoline yield and lower coke yield when applied to catalytic cracking of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petroleum hydrocarbon catalytic cracking catalyst

ActiveCN110193376AImprove conversion rateHigh yieldCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

A petroleum hydrocarbon catalytic cracking catalyst comprises a carrier, a Y-type molecular sieve, a mesoporous molecular sieve with a M41S structure and a molecular sieve with a pore opening diameterof 0.59-0.73 nanometer. The Y-type molecular sieve comprises an ultra-stable Y-type molecular sieve containing phosphorus and rare earth, the total pore volume of the Y-type molecular sieve is 0.33-0.39 ml / g, the pore volume of secondary pores of 2-100 nm accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the proportion of non-framework aluminum content to thetotal aluminum content is not higher than 20%, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of B acid content to L acid content measured by pyridine adsorption infrared method at 200 DEG C is not lower than 2.50. The catalyst has high heavy oil conversion activity, good coke selectivity, high gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petroleum hydrocarbon catalytic cracking catalyst

ActiveCN110193377AImprove conversion rateHigh yieldMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveGasoline

A petroleum hydrocarbon catalytic cracking catalyst comprises a carrier, a Y-type molecular sieve, a mesoporous molecular sieve with a M41S structure and a molecular sieve with a pore opening diameterof 0.59-0.73 nanometer. The Y-type molecular sieve comprises an ultra-stable Y-type molecular sieve containing rare earth, the total pore volume is 0.33-0.39 ml / g, the pore volume of secondary poreswith pore diameters of 2-100 nm accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the proportion of non-framework aluminum content to the total aluminum content is not higher than 20%, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of B acid content to L acid content measured by pyridine adsorption infrared method at 200 DEG C isnot lower than 2.50. The catalyst has high heavy oil conversion activity, good coke selectivity, high gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method and application thereof

ActiveCN105195218AImprove adhesionHigh matrix activityCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

The invention discloses a catalytic cracking catalyst and a preparation method and application thereof. The catalytic cracking catalyst comprises cracking active components, clay and binders, wherein the cracking active components comprise, by weight, 25%-70% of first Y-type molecular sieves, 10%-70% of second Y-type molecular sieves and 5%-20% of third Y-type molecular sieves; the binders are modified aluminum sol containing Cl and Si, based on the total weight of the modified aluminum sol, the content of Al ranges from 8% to 13% by weight, the content of Cl ranges from 4% to 9% by weight, the weight ratio of Al to Cl is 1.2-2.2 to 1, the content of Si ranges from 0.1% to 1% by weight, and the pH value of the modified aluminum sol ranges from 2.2 to 5.2. The catalytic cracking catalyst has lower coke selectivity and higher catalytic cracking activity in the heavy oil catalytic cracking process, and a higher gasoline yield can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452838AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, alumina containing an additive and a modified Y type molecular sieve. The modified Y type molecularsieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of thetotal pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEGC; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7h; carrying out a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalytic cracking catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y zeolite and preparation and application thereof

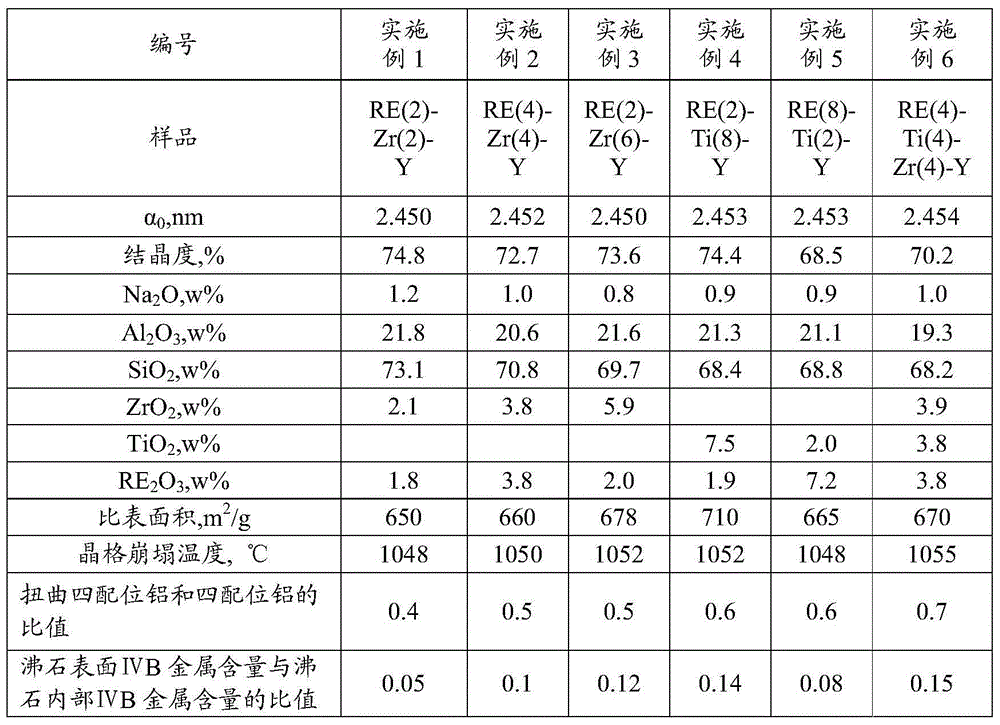

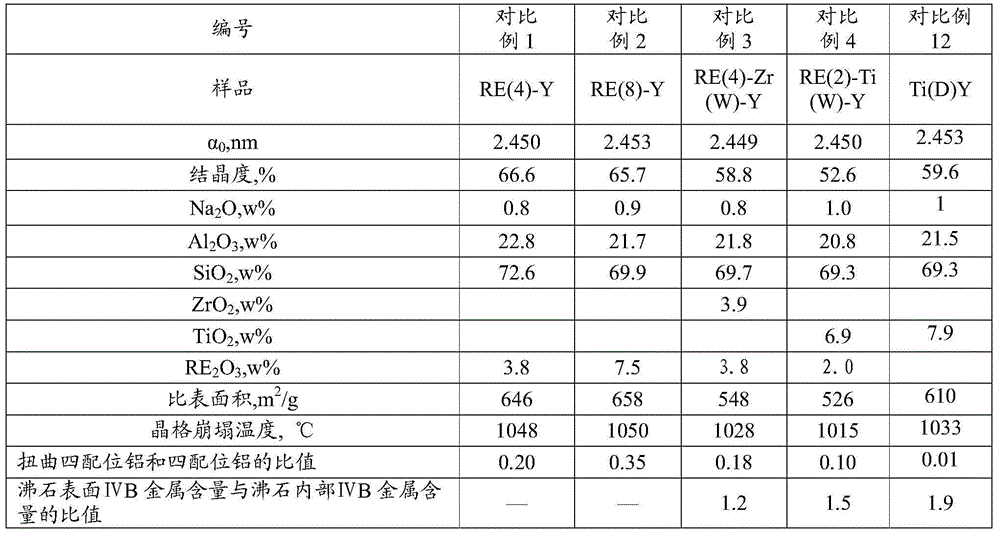

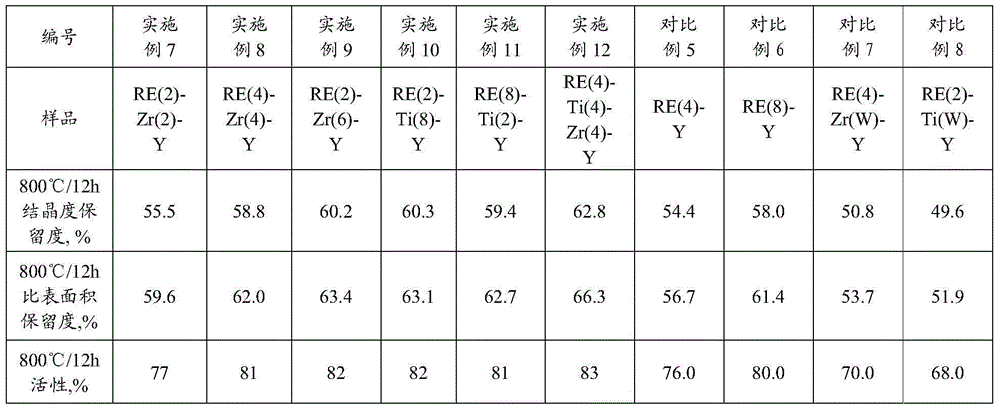

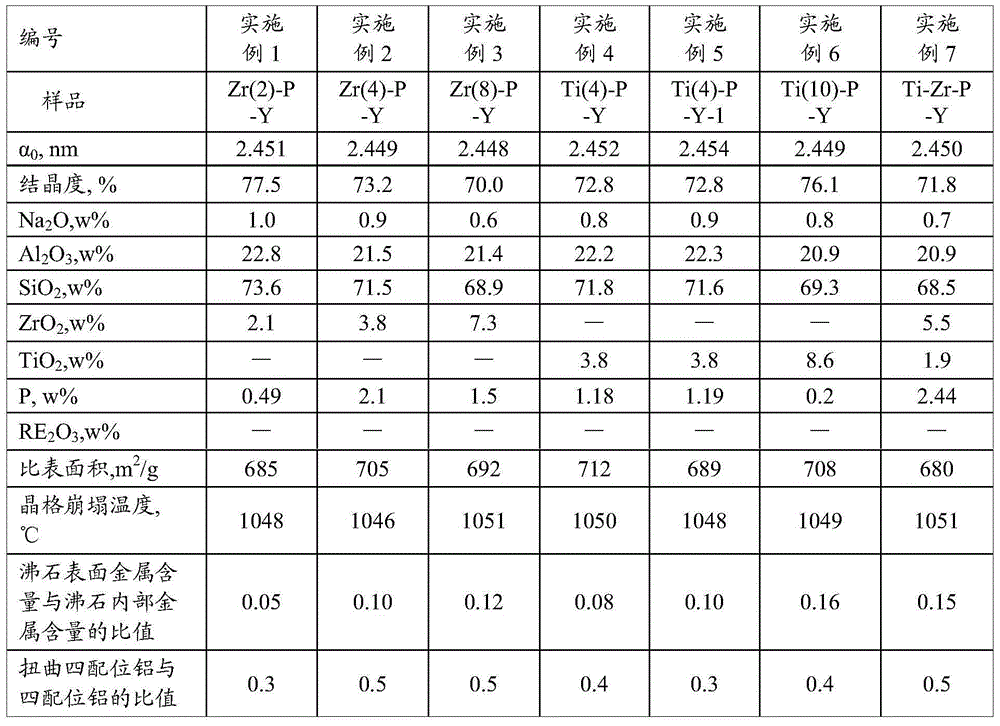

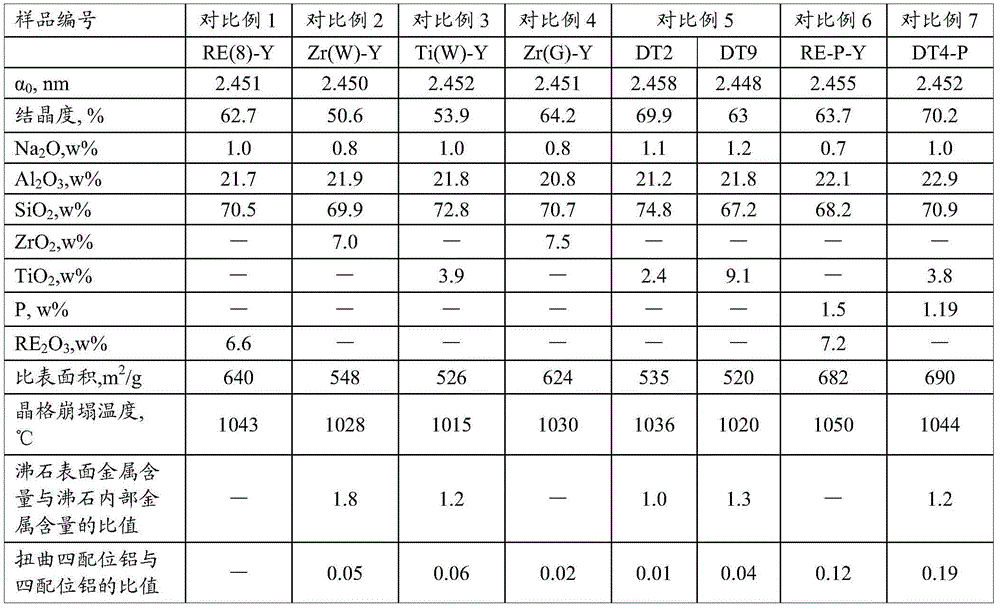

ActiveCN106145153AGood choiceHigh gasoline yieldCatalytic crackingMolecular sieve catalystsMolecular sieveOrganic solvent

Provided are modified Y zeolite and preparation and application thereof. The modified Y zeolite is prepared from, by oxide, 1-15 wt% of group IV B metal and 1-15 wt% of rare earth. The ratio of distorted tetrahedral-coordinated framework aluminum to tetrahedral-coordinated framework aluminum in the lattice structure of the modified Y zeolite is (0.2-0.8):1, and the ratio of the metal content on the surface of the zeolite to the metal content in the zeolite is not larger than 0.2. A preparation method of the modified Y zeolite comprises the steps that rare earth ion exchange calcination is carried out; Y zeolite with the water content not larger than 5 wt% is treated with an organic solvent and a modified metallic compound; calcination is carried out. The modified Y zeolite has high thermal and hydrothermal stability, and a cracking catalyst prepared from the modified Y molecular sieve has good activity and coke selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN102974384AHigh FCC activityImprove conversion rateCatalytic crackingMolecular sieve catalystsIon exchangeRare earth

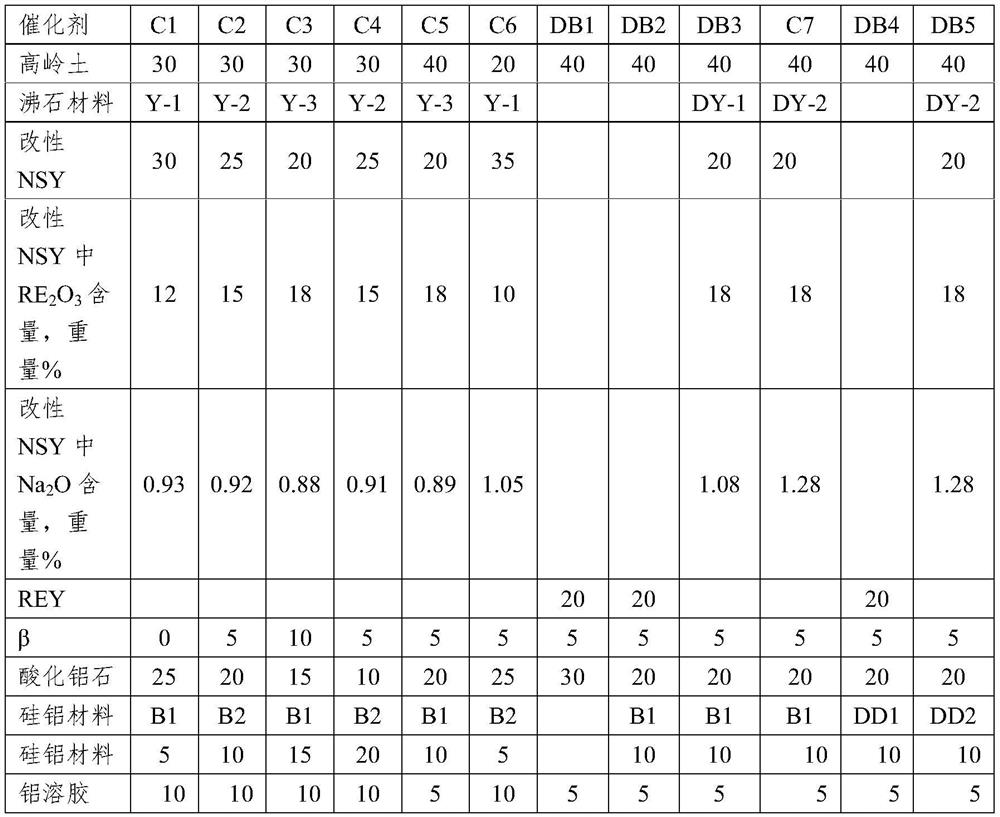

The invention relates to a catalytic cracking catalyst and a preparation method thereof. The catalytic cracking catalyst comprises a cracking-active component, a mesoporous silica-alumina material, clay, and a binder. The preparation method of the mesoporous silica-alumina material comprises the steps that: a mesoporous silica-alumina material without ion exchange is mixed with water, and the mixture is beaten into slurry; and the obtained slurry contacts an inorganic acid under room temperature to 100 DEG C for at least 0.2h, such that the sodium oxide content in the mesoporous silica-alumina material is no higher than 0.2wt%, wherein a weight ratio of the mesoporous silica-alumina material without ion exchange to water to inorganic acid is 1:5-30:0.03-0.3. The cracking-active component comprises 90-100wt% of rare-earth-containing Y-type molecular sieve. During a catalytic cracking treatment process upon raw oil with relatively high basic nitrogen content, the catalytic cracking catalyst shows relatively high catalytic cracking activity, and assists in achieving relatively high conversion rate and especially relatively high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

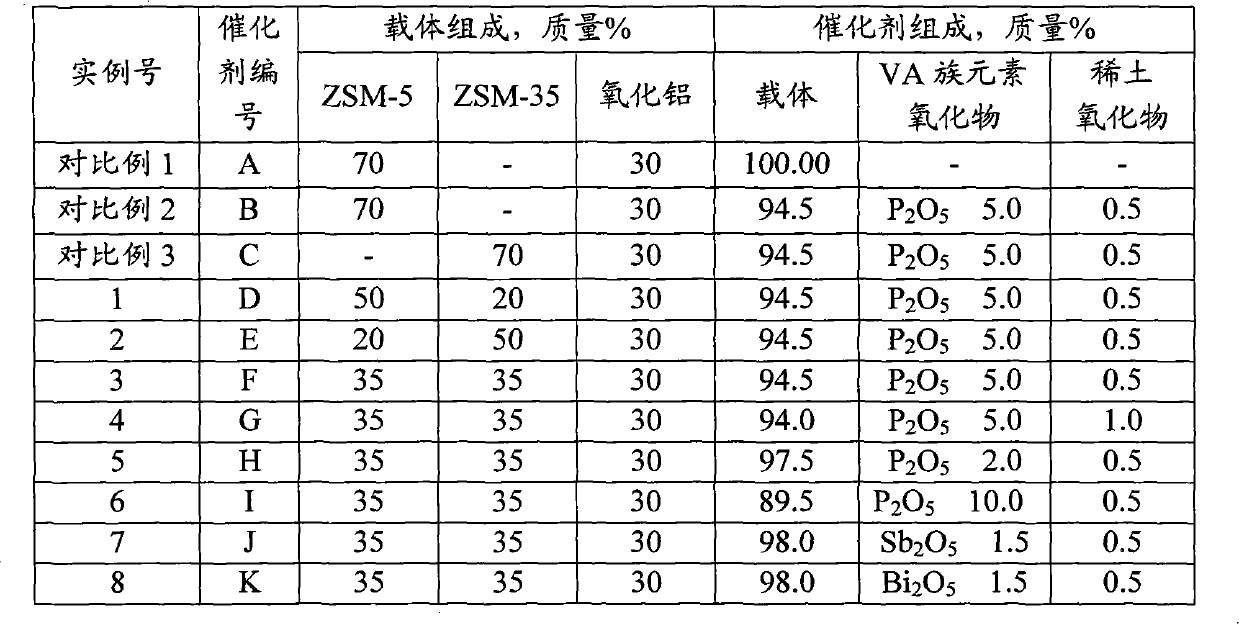

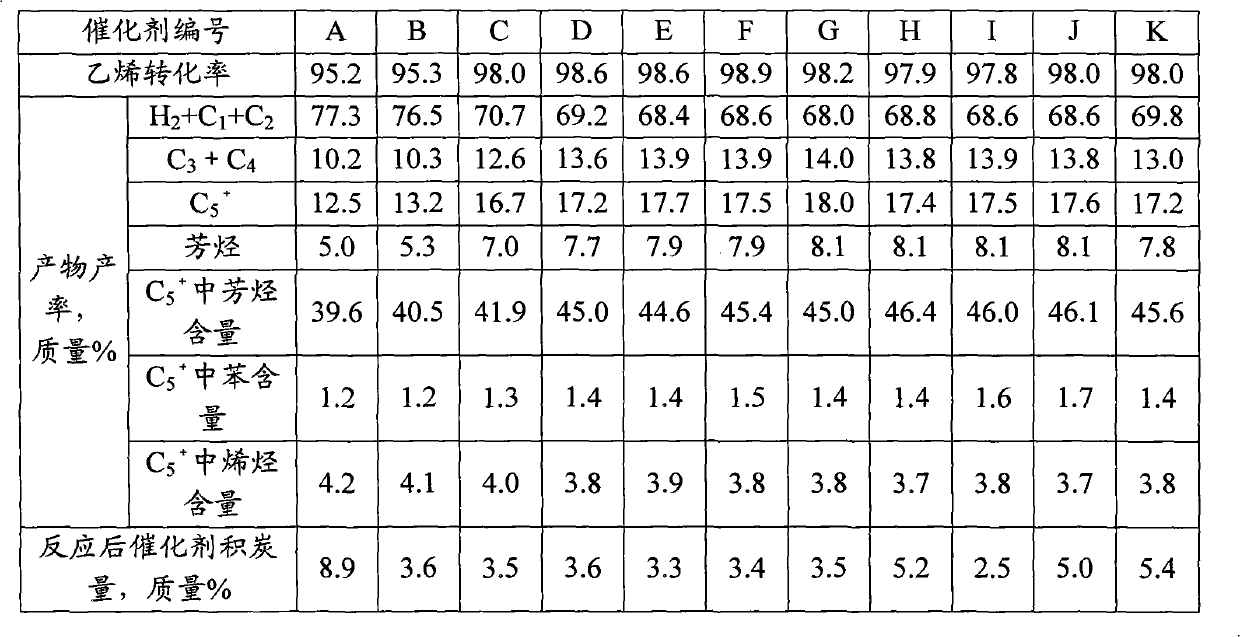

Catalyst for producing gasoline by refinery dry gas and preparation method thereof

ActiveCN102950017AHigh gasoline yieldLong life one wayMolecular sieve catalystsLiquid hydrocarbon mixtures productionZSM-5 zeoliteOxide

A catalyst for producing gasoline by refinery dry gas comprises 1.0-13.0 m% of VA-group element oxides, 0.1-5.0 m% of rare earth oxide, and 86-98.9 m% of a composite carrier; the composite carrier comprises 15-75 m% of ZSM-5 zeolite, 15-75 m% of ZSM-35, and 10-70 m% of a binder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for oligomerizing gasoline with high yield

InactiveUS20150166425A1High recovery rateHigh gasoline yieldMolecular sieve catalystLiquid hydrocarbon mixtures productionGasolinePhotochemistry

Owner:UOP LLC

High-stability modified Y-type molecular sieve and preparation method thereof

ActiveCN108455625AHigh thermal and hydrothermal stabilityImprove transformation activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveWater vapor

The invention relates to a high-stability modified Y-type molecular sieve and a preparation method thereof, wherein the modified Y-type molecular sieve contains 5-12 wt% of RE2O3 and 0.1-0.7 wt% of Na2O, and has the total pore volume of 0.33-0.39 mL / g, the pore volume of the secondary pores with the pore size of 2-100 nm accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the non-framework aluminum content is not more than 20% of the total aluminum content, the lattice collapse temperature is not below 1050 DEG C, and the pyridine adsorption infrared methoddetermination results show that a ratio of the amount of B acid to the amount of L acid is not less than 2.50. The preparation method comprises: ion exchange, modification treatment at a certain temperature under water vapor conditions, and reaction with silicon tetrachloride. According to the present invention, the modified Y-type molecular sieve has advantages of high heavy oil conversion activity, low coke selectivity, high diesel yield, high liquefied gas yield, high light-oil yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

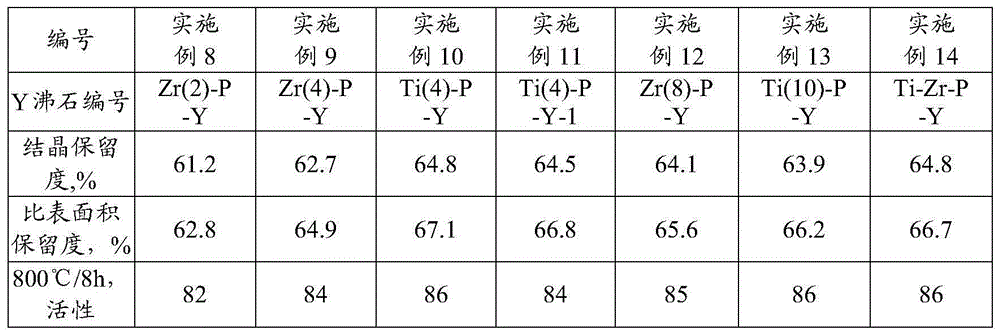

Catalytic cracking catalyst and preparation method thereof

ActiveCN105618107AHigh conversion capacity of heavy oilImprove cracking capacityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveGasoline

A catalytic cracking catalyst and its preparation method are disclosed. With total weight of the catalyst as the reference, the catalyst contains, by weight, 10-60% of titanium and / or zirconium modified Y molecular sieve, 10-60% of clay and 5-50% of a binder. The titanium and / or zirconium modified Y molecular sieve contains 1.0-15.0 wt% of titanium and / or zirconium metal oxide. The preparation method of the catalyst comprises the following steps: preparing the titanium and / or zirconium modified Y molecular sieve, preparing catalyst slurry and spray-drying. The step of preparing the titanium and / or zirconium modified Y molecular sieve comprises the following steps: (1) dispersing a compound containing titanium and / or zirconium in water, and adjusting pH value of the mixture to 3-10; (2) mixing the molecular sieve and the mixture obtained in the Step (1), and stirring; optionally filtering and / or drying; and (3) roasting at 300-700 DEG C. The catalyst has high heavy oil conversion ability and gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing nano NaY molecular sieve

InactiveCN100551825CHigh purityGood dispersionFaujasite aluminosilicate zeoliteSodalitesMolecular sieveGasoline

The invention relates to a preparation method of nanometer NaY molecular sieve. Through the preparation of the directing agent, the preparation of the mother liquor, the mixing of the directing agent and the mother liquor, and the subsequent crystallization of the reaction product under the condition of high gravity in the rotating bed, it provides a preparation that shortens the crystallization reaction time and simplifies the process flow. A method for high-quality nanometer NaY molecular sieves. The nanometer NaY molecular sieve catalyst prepared by the method of the invention is applied to catalytic cracking of heavy oil, and has distinct advantages compared with conventional industrial molecular sieves. Gasoline yield, diesel yield, light oil yield and total liquid yield can all be greatly increased, not only improving product selectivity, but also significantly improving product distribution.

Owner:BEIJING UNIV OF CHEM TECH

Modified Y zeolite and preparation method thereof

ActiveCN106145154AHigh crystallinityLarge specific surface areaCatalytic crackingMolecular sieve catalystsOrganic solventRare earth

The invention provides modified Y zeolite and a preparation method thereof. The modified Y zeolite contains 1-15 wt% of IVB family metal according to oxide and 0.1-10.0 wt% of phosphorus according to P. The ratio of the content of metal on the surface of the zeolite to the content of metal in the zeolite is not higher than 0.2. The preparation method of the modified Y zeolite includes the steps of processing Y zeolite with water content not exceeding 5 wt% through organic solvent and modified metallic compound, conducting calcinating, and then conducting processing through a phosphorous containing compound and acid. The modified Y zeolite has heat and hydrothermal stability not lower than that of the rare earth modified Y zeolite and has higher coke selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

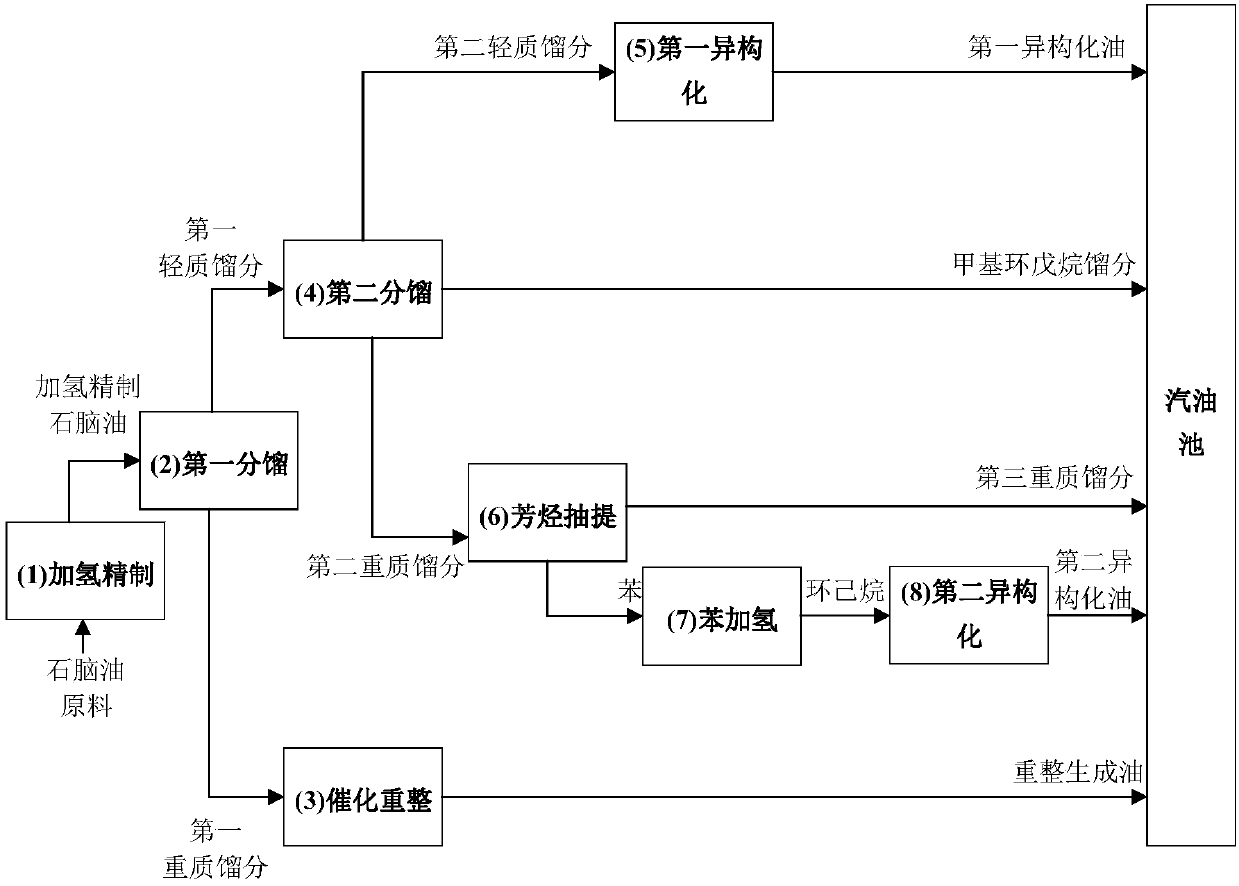

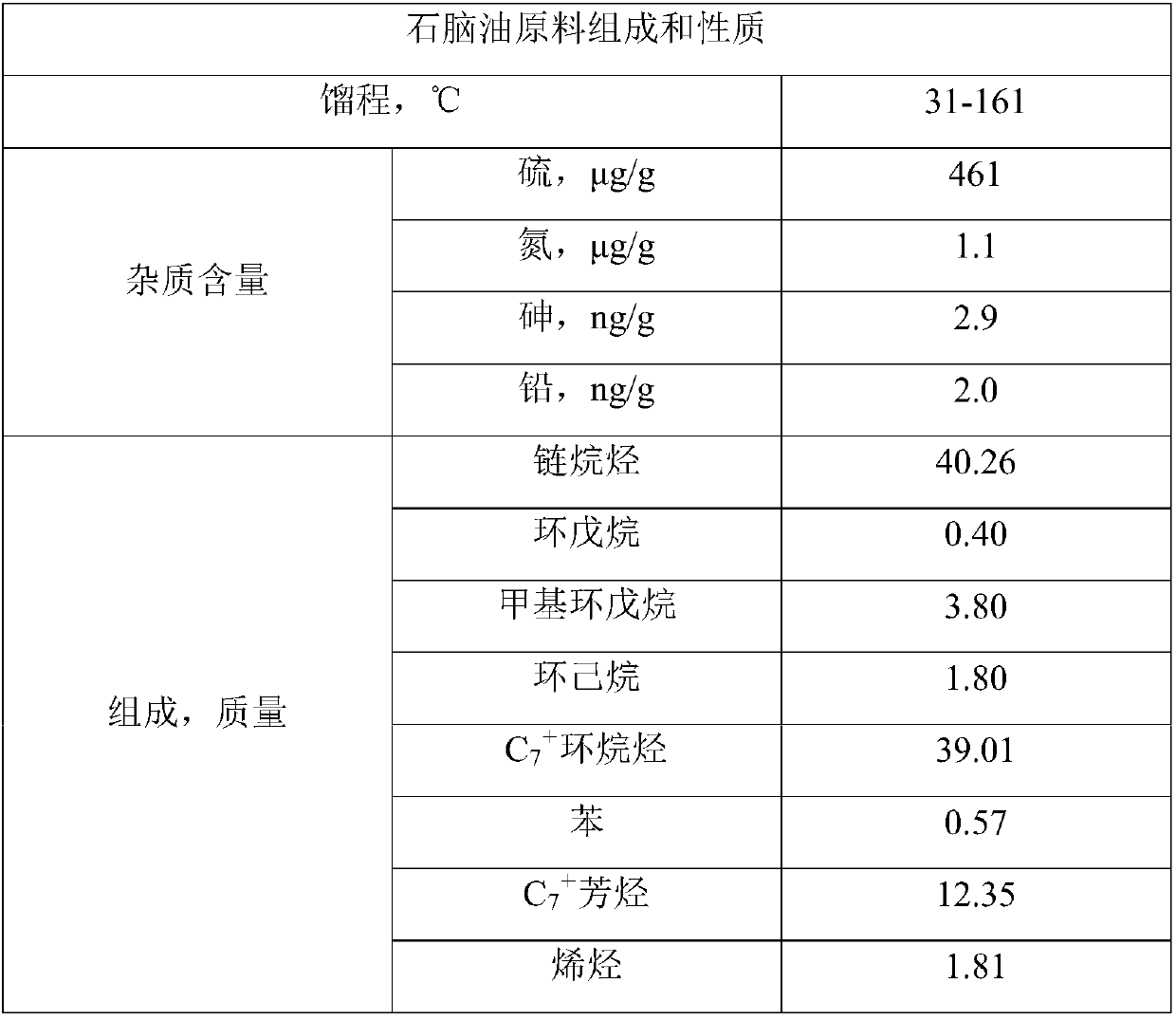

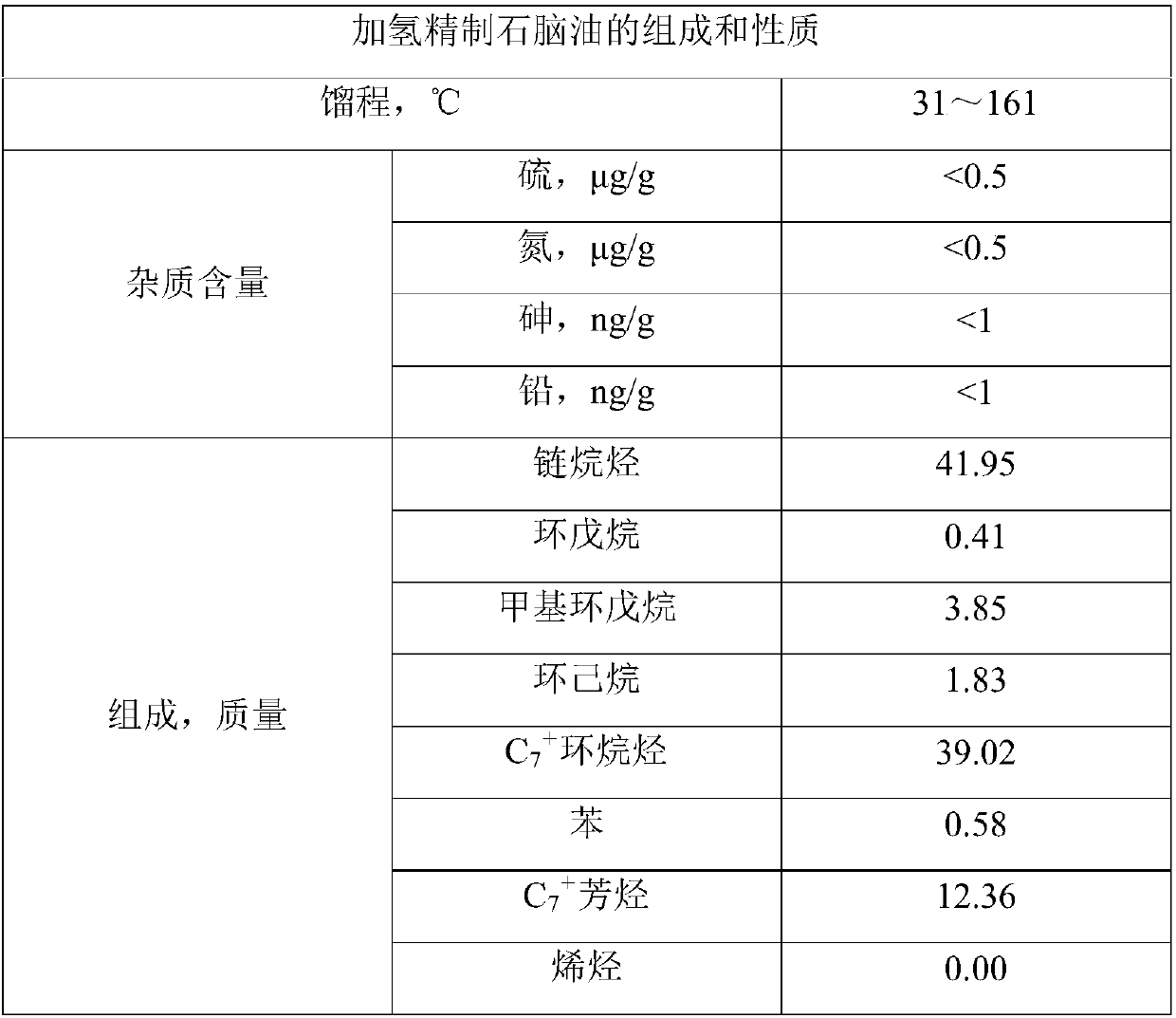

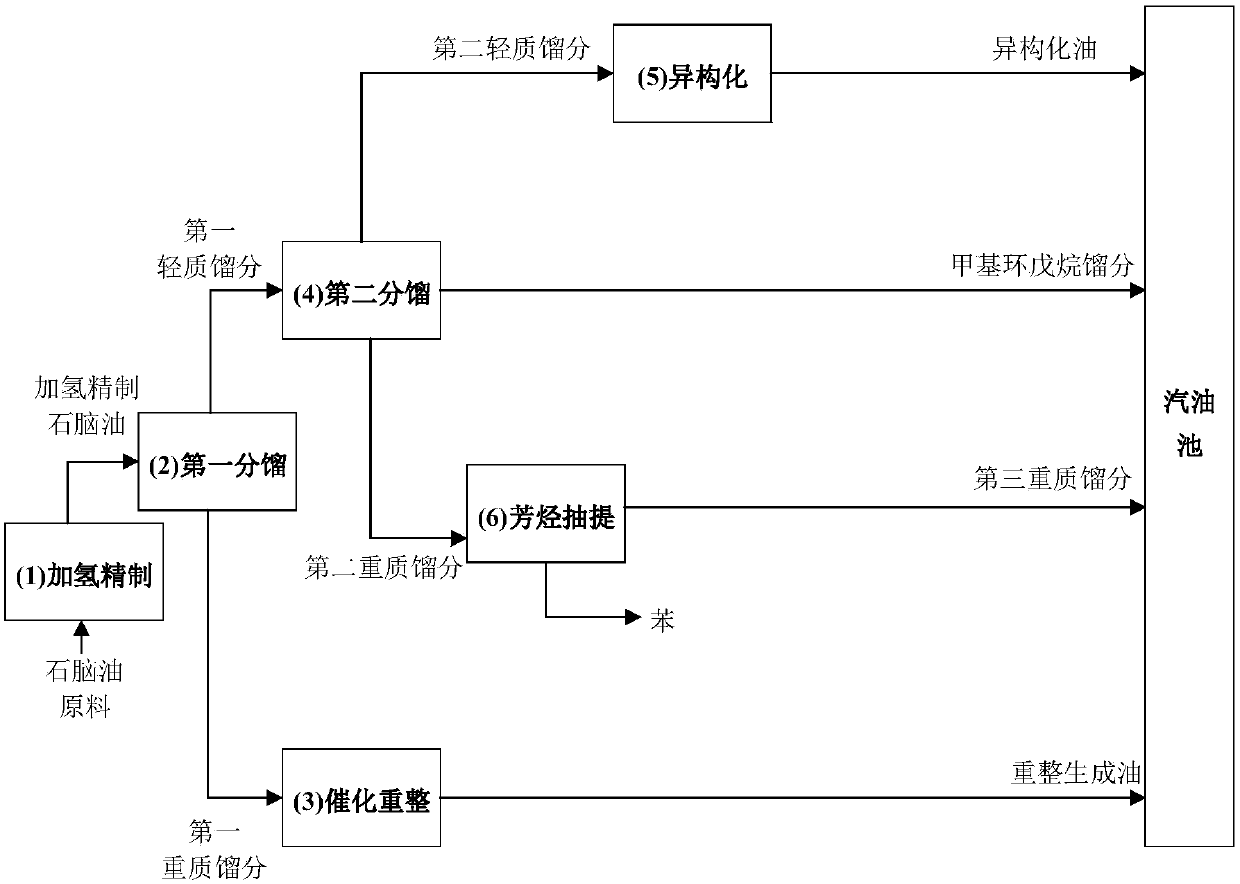

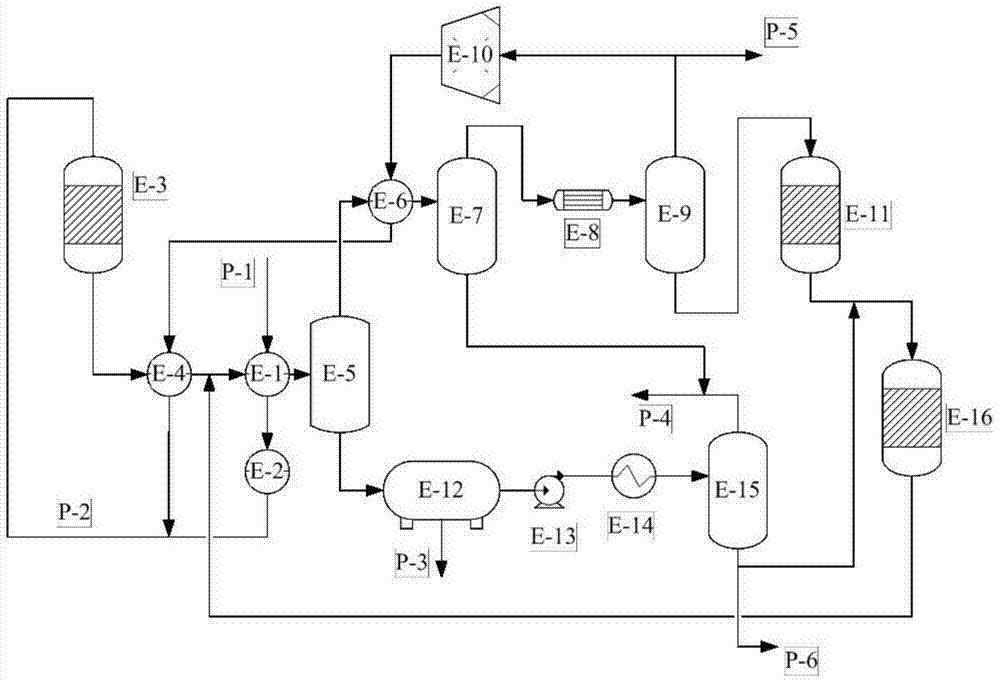

Method for producing high-octane gasoline through naphtha

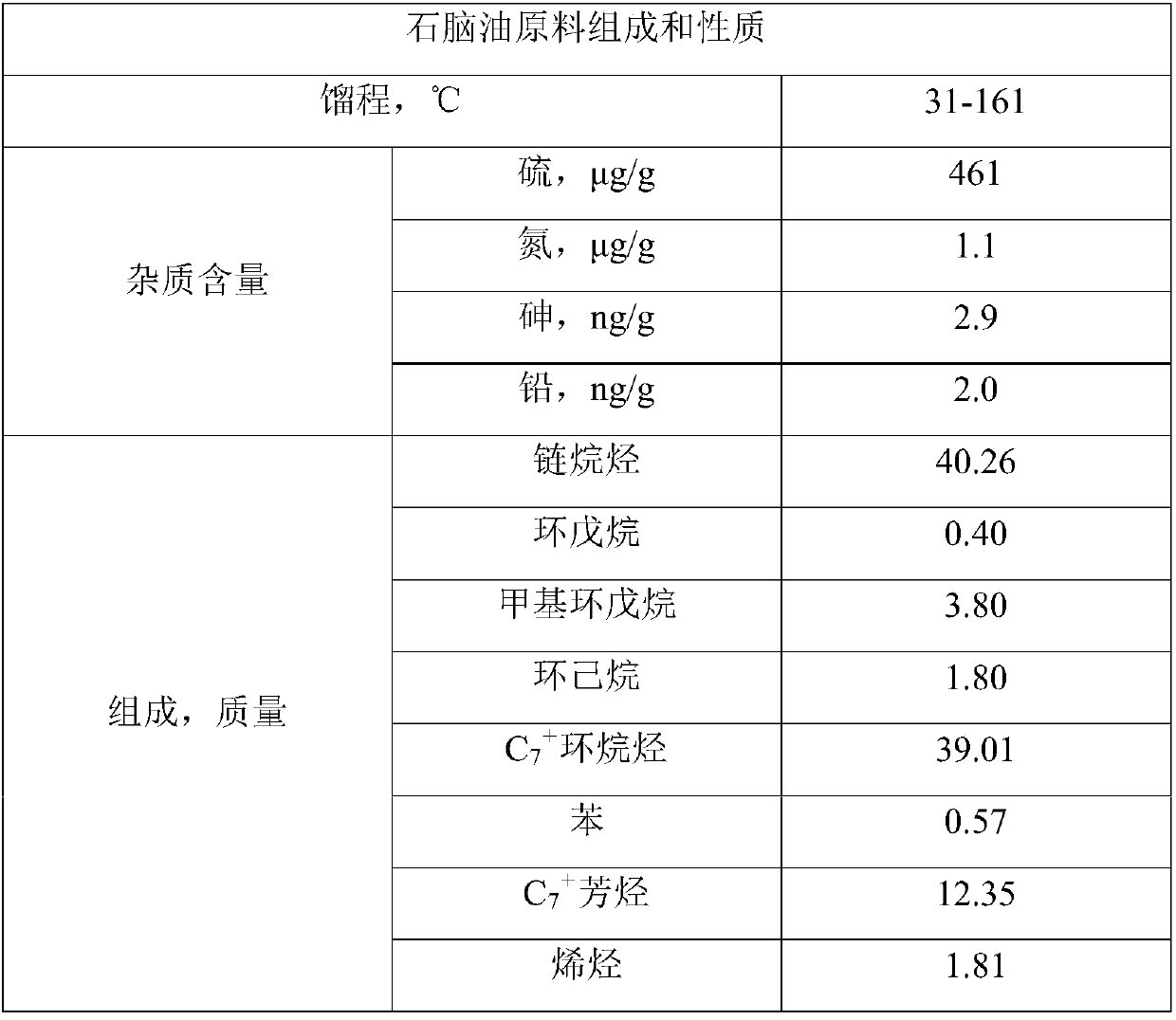

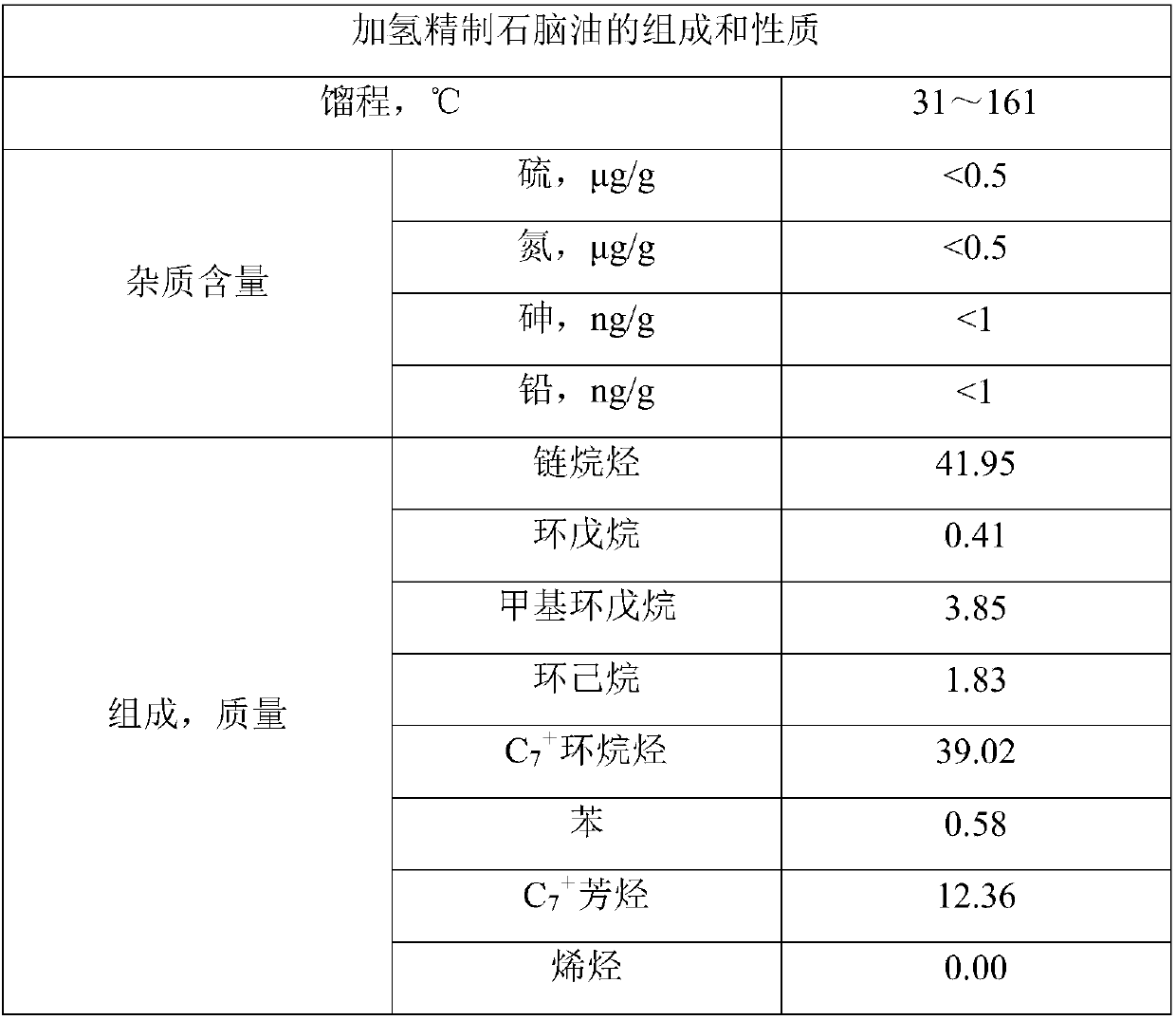

ActiveCN109679691AHigh gasoline yieldSimple compositionTreatment with hydrotreatment processesHydrocarbon oils treatment productsCatalytic reformingAlkane

The invention relates to a method for producing high-octane gasoline through naphtha. The method comprises the steps: a naphtha raw material is subjected to hydrorefining, primary fractionation and secondary fractionation; methylcyclopentane, cyclohexane and multibranched paraffin are directly separated from the naphtha to serve as gasoline components; and then first heavy ends obtained through primary fractionation are subjected to catalytic reforming, second light ends obtained through secondary fractionation are subjected to an isomerization reaction to obtain a gasoline component, and benzene in the naphtha can further be hydrogenated to form the cyclohexane to be isomerized. According to the method, the gasoline yield can be increased, gasoline composition is optimized, the content ofisoparaffin and cycloparaffin in the gasoline is increased, and the content of arene and n-paraffin is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high octane gasoline through naphtha

ActiveCN109679693AHigh gasoline yieldOptimizing Gasoline CompositionTreatment with hydrotreatment processesHydrocarbon oils treatment productsCycloalkaneMethylcyclopentane

The invention relates to the method for producing high octane gasoline through naphtha. The method includes the steps that a naphtha raw material is subjected to hydrorefining, first fractionation andsecond fractionation, methyl cyclopentane, cyclohexane and multi-branched alkane in the naphtha are directly separated to be used as gasoline components, then a first heavy fraction obtained in firstfractionation is subjected to catalytic reforming, and a second light fraction obtained in second fractionation is subjected to an isomerization reaction to obtain gasoline components. According to the method for producing the high octane gasoline through the naphtha, the gasoline yield can be increased, gasoline compositions are optimized, the contents of iso-alkane and cycloalkane in the gasoline are increased, and the contents of arene and normal-alkane are decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic Cracking Catalyst and Preparation Thereof

ActiveUS20190351396A1Increase lytic activityGood coke selectivityCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

A catalytic cracking catalyst has a rare earth modified Y-type molecular sieve, an additive-containing alumina binder, and a clay. The rare earth modified Y-type molecular sieve has a rare earth oxide content of about 12 wt %, a phosphorus content of about 0-10 wt %, a sodium oxide content of no more than about 1.0 wt %, a total pore volume of about 0.36-0.48 mL / g, a percentage of the pore volume of secondary pores having a pore size of 2-100 nm to the total pore volume of about 20-40%, a lattice constant of about 2.440-2.455 nm, a percentage of non-framework aluminum content to the total aluminum content of no more than about 10%, a lattice collapse temperature of not lower than about 1060° C., and a ratio of B acid to L acid in the total acid content of the modified Y-type molecular sieve of no less than about 3.50.

Owner:CHINA PETROCHEMICAL CORP +1

Integrated method for synthetising gasoline from methyl alcohol or dimethyl ether

ActiveCN103865564AReduce energy consumptionSimple processLiquid hydrocarbon mixture productionBio-feedstockAlkyl transferAlcohol

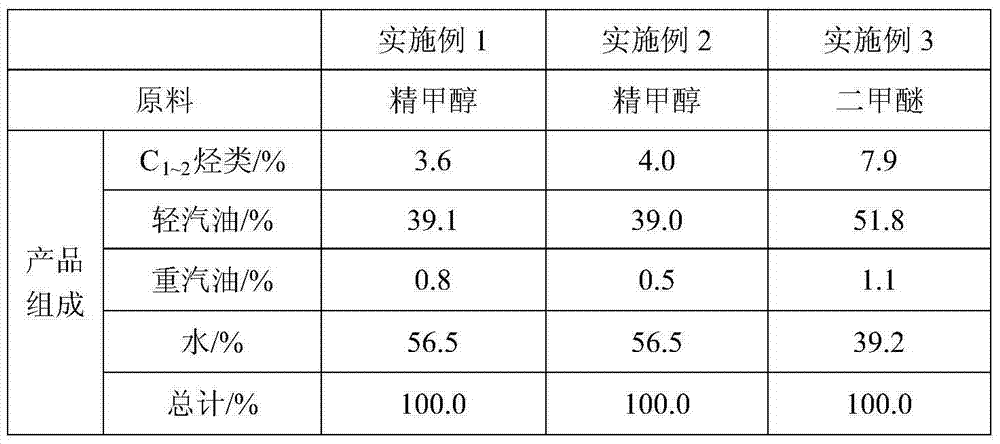

The invention discloses an integrated method for synthetising gasoline from methyl alcohol or dimethyl ether. The integrated method is characterized by comprising the following steps: generating hydrocarbons rich in gasoline components from methyl alcohol or dimethyl ether in a synthesis reactor; separating through a flash tank, a gas-liquid separation tank and a fractionating tower to obtain C1-2 hydrocarbons, C3-4 hydrocarbons, light gasoline components, heavy gasoline components and water, wherein the light gasoline components are discharged as products; entering water into a sewage treatment unit; returning C1-2 hydrocarbons to the synthesis reactor after being supersized by a compressor; aromatizing the C3-4 hydrocarbons again, and then directly mixing the product with the heavy gasoline components to enter an alkyl transfer reactor as the raw material; returning the reaction product to the flash tower; discharging a little of C1-2 and heavy gasoline components as byproducts. The integrated method is simple in technological process, and the system is low in energy consumption; on the basis of fed refined methanol, the yield of the gasoline achieves 36-40%; on the basis of the fed dimethyl ether, the yield of the gasoline achieves 50-54%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Silicon-aluminum material, preparation thereof and low-green-coke high-activity heavy oil conversion catalytic cracking catalyst

PendingCN113830775ALow selectivityHigh average pore sizeMaterial nanotechnologyCatalytic crackingMolecular sievePtru catalyst

The invention belongs to the technical field of catalytic materials, and relates to a silicon-aluminum material, preparation thereof and a low-green-coke high-activity heavy oil conversion catalytic cracking catalyst. The anhydrous weight chemical expression of the silicon-aluminum material is (0-1) Na2O. (15-50) Al2O3. (85-50) SiO2, the most probable pore size is 10-100 nm, the specific surface area is 150-600 m < 2 > / g, the pore volume is 0.5-1.5 ml / g, and the pore volume of pores with the pore diameter of more than 10nm accounts for 70-98% of the total pore volume. The preparation method comprises the steps of adding an alkaline silicon source into an acidic aluminum source, contacting with alkali, and washing. The low-green-coke high-activity heavy oil conversion catalytic cracking catalyst contains the silicon-aluminum material and an in-situ crystallization Y-type molecular sieve. The catalytic cracking catalyst has good coke selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ultra-stable Y-type molecular sieve containing phosphorus and rare earth and preparation method thereof

ActiveCN108452828BHigh crystallinityHigh thermal and hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveHeat stability

An ultra-stable Y-type molecular sieve containing phosphorus and rare earth and a preparation method thereof. The Y-type molecular sieve contains 4 to 11 wt% rare earth, 0.05 to 10 wt% phosphorus, 0.1 to 0.7 wt% sodium oxide, and has a pore volume of 0.33 to 0.39 mL / g, the volume of 2-100nm pores accounts for 15-30% of the total pore volume, the unit cell constant is 2.440-2.455nm, non-framework aluminum accounts for less than 20% of the total aluminum, the lattice collapse temperature is greater than 1050°C, and the B acid content The ratio to the amount of L acid is not less than 2.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earth, roasting it for 4.5-7 hours in an atmosphere of 350-480°C and 30-90 volume % water vapor, phosphorus modification treatment and mixing with silicon tetrachloride gas. Contact reaction steps. The Y-type molecular sieve has good hydrothermal stability, high heavy oil cracking activity, good coke selectivity, and high yields of heavy oil converted into gasoline, liquefied gas and total liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

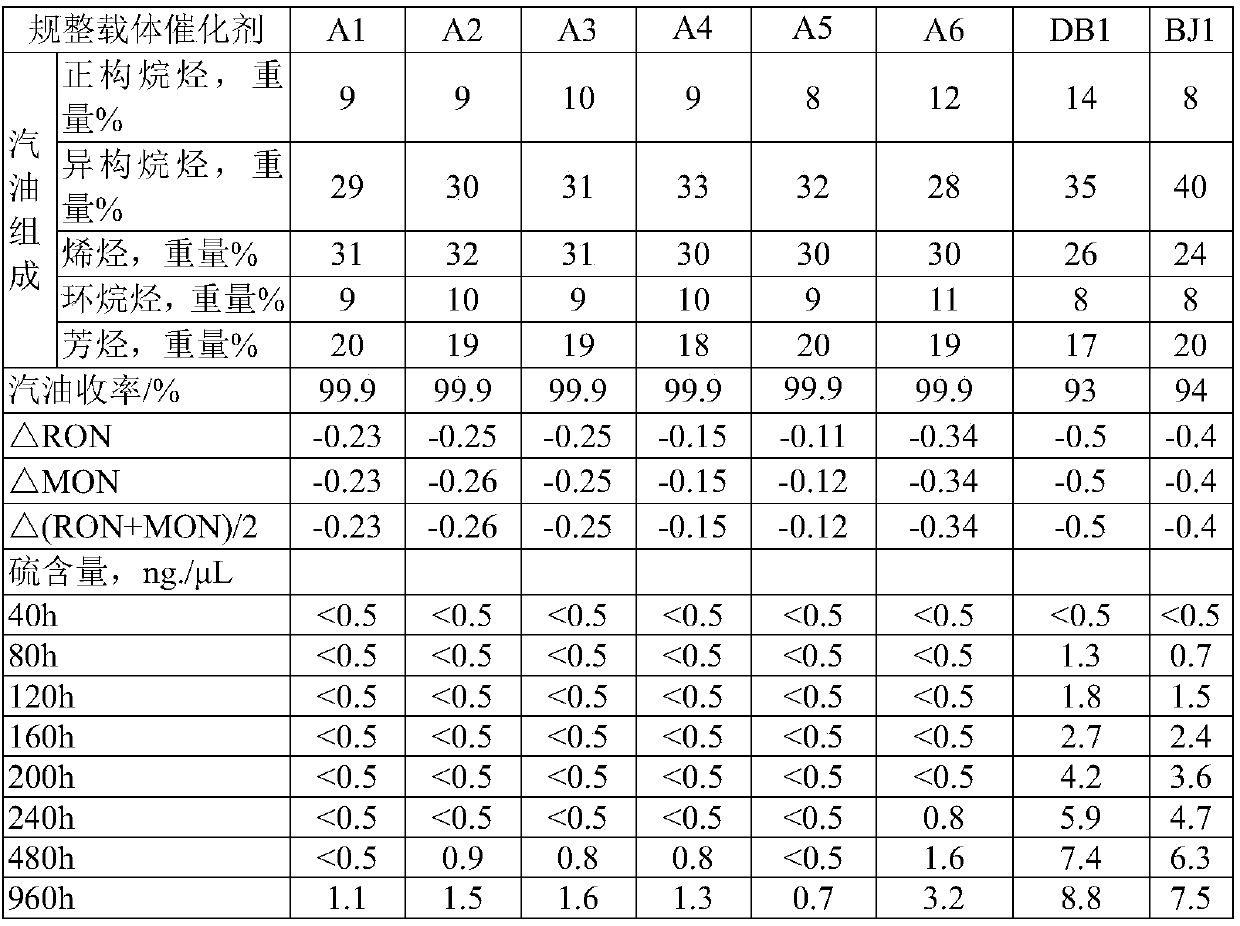

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

PendingCN111085187AHigh activityHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsPtru catalystActive agent

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the surface of the regular carrier, wherein the active coating comprises a matrix containing IIA and IIB group metal oxides and a modified metal film attached to the outer surfaceof the matrix, the modified metal film comprises a modified metal, and the modified metal comprises one or more of Cr, Mo and W. The preparation method comprises the following steps: forming a mixturefrom metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; after the ultrasonic treatment, separating the mixed solution to obtain suspension; contacting the suspension with matrix particles, carrying out freeze drying to obtain matrix particles containing a modified metal film, andcoating the regular carrier with the matrix particles containing the modified metal film to obtain the regular carrier catalyst. The catalyst is used for hydrocarbon hydro-desulfurization, has high desulfurization activity and good stability, and can reduce the octane number loss of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com