Method for preparing nano NaY molecular sieve

A molecular sieve and nanotechnology, applied in the field of preparation of nano-NaY molecular sieve, can solve the problems of uneven particle size distribution, larger particle size, long crystallization time, etc., and achieve improved product distribution, narrow particle size distribution, and light oil yield. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

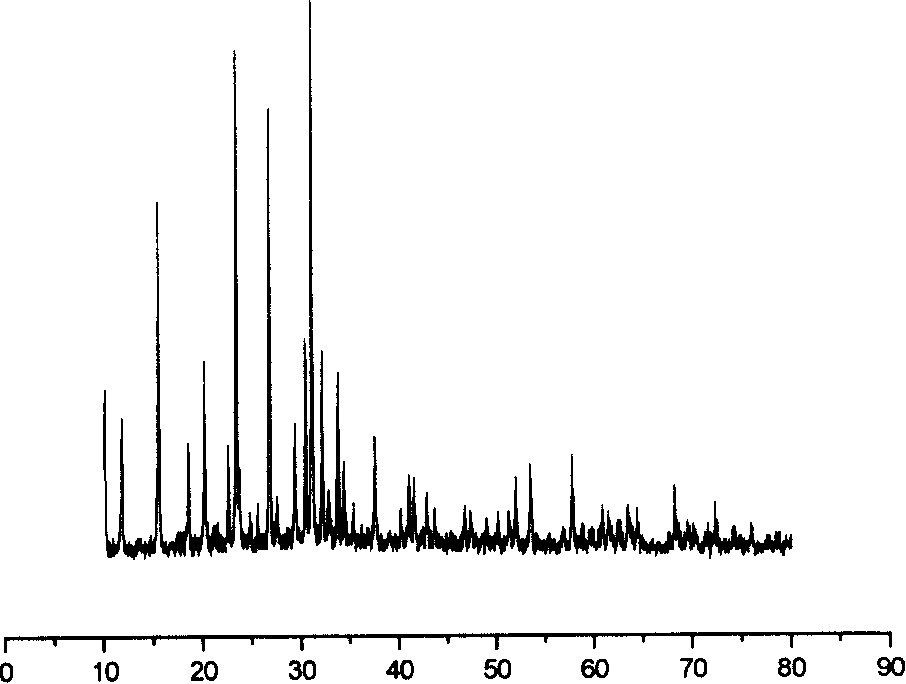

[0049] In the high-gravity rotating bed with a rotating speed of 600r / min, the directing agent with a silicon-aluminum ratio of 7:1 (mixing 0.88mol / L sodium silicate 725ml with 0.91mol / L sodium aluminate 100ml) was prepared respectively, and the silicon-aluminum ratio was 4:1 (mixing 0.75mol / L sodium silicate 4250ml with 1.21mol / L sodium aluminate 1300ml) mother liquor, and mixing the two in a rotating bed to form a reaction solution, and aging at room temperature for 24h, and then in crystal Crystallization at a temperature of 100°C for 12 hours in a chemical reactor; washing to make the pH value reach 7-9, drying; roasting at 600°C for 3 hours to form NaY molecular sieves. The specific surface area is 701m 2 / g.

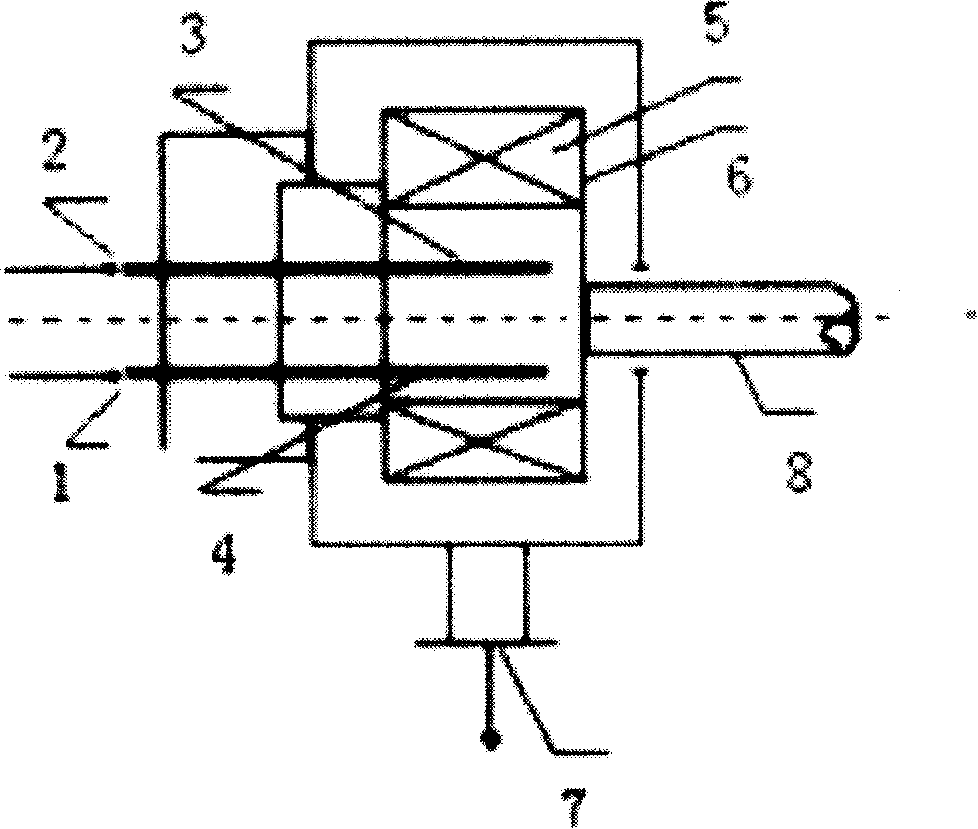

[0050] The present invention is using image 3 During the preparation of NaY molecular sieves in the high-gravity rotating bed reactor shown, the main process is as follows Figure 4 shown. After the high-gravity rotating bed reactor is turned on, the screen pa...

Embodiment 2

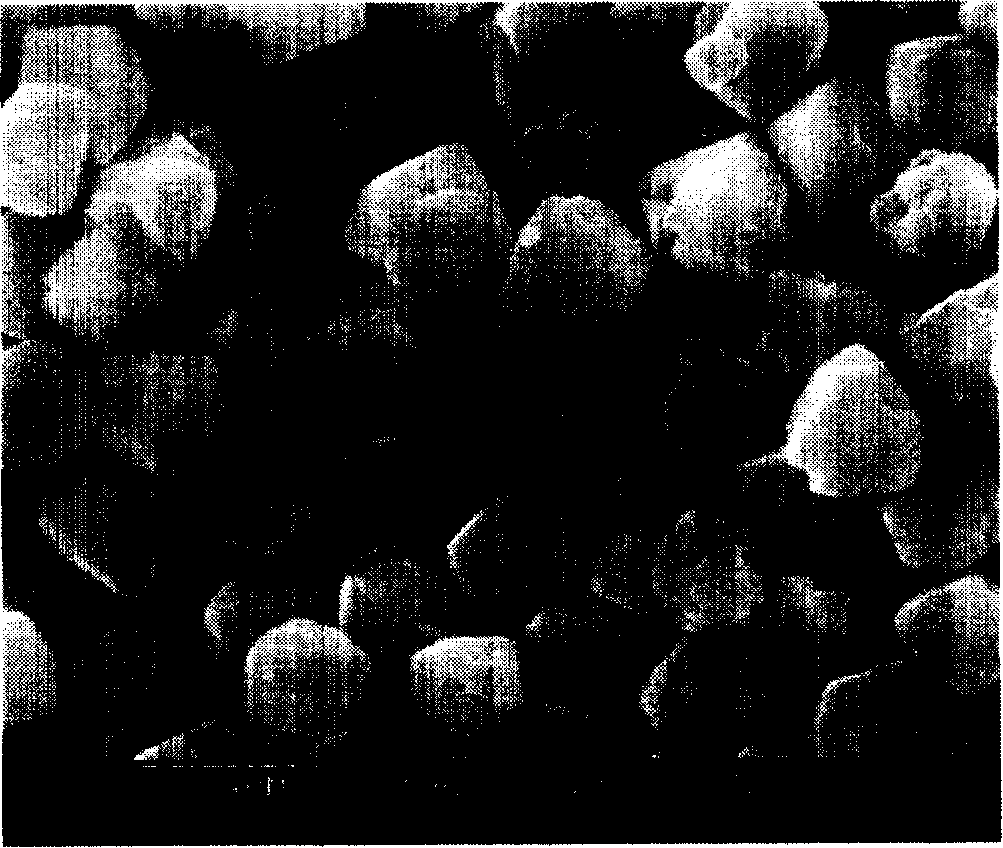

[0053] The rotational speed of the high-gravity rotating bed reactor is 1200r / min, and the rest of the conditions are the same as in Example 1. The specific surface area of the obtained NaY molecular sieve is 743m 2 / g, the SEM photo of the product is as Figure 7 shown.

Embodiment 3

[0055] The rotational speed of the high-gravity rotating bed reactor is 1800r / min, and the rest of the conditions are the same as in Example 1. The obtained NaY molecular sieve has a specific surface area of 735m 2 / g, the SEM photo of the product is as Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com