Patents

Literature

58results about How to "Improve product distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

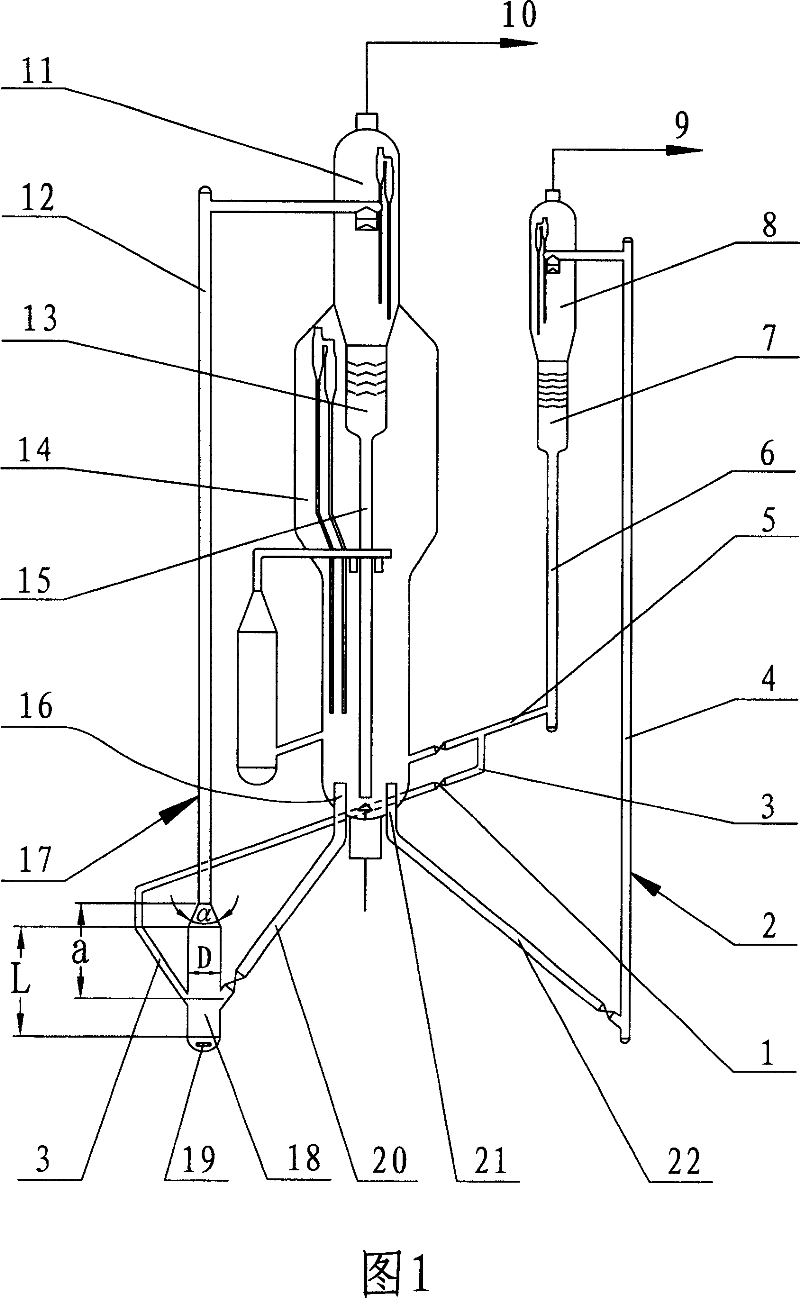

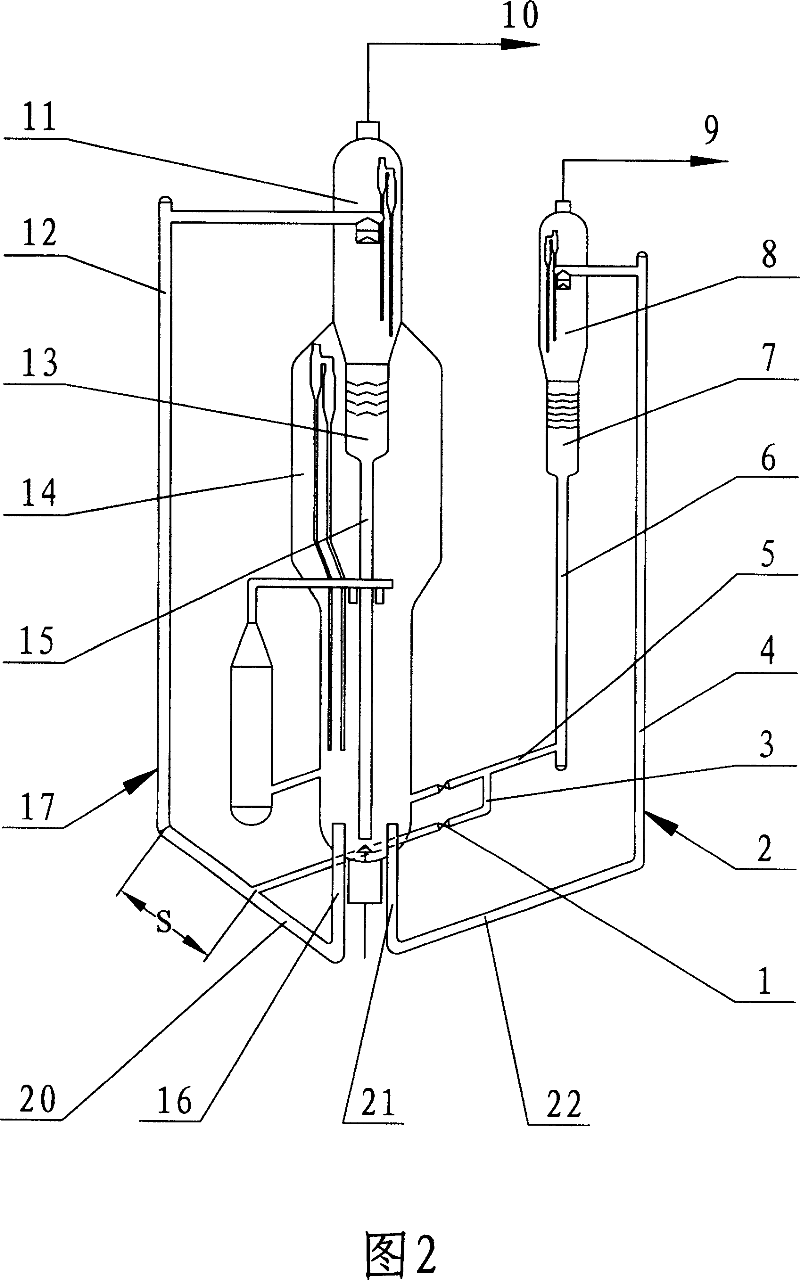

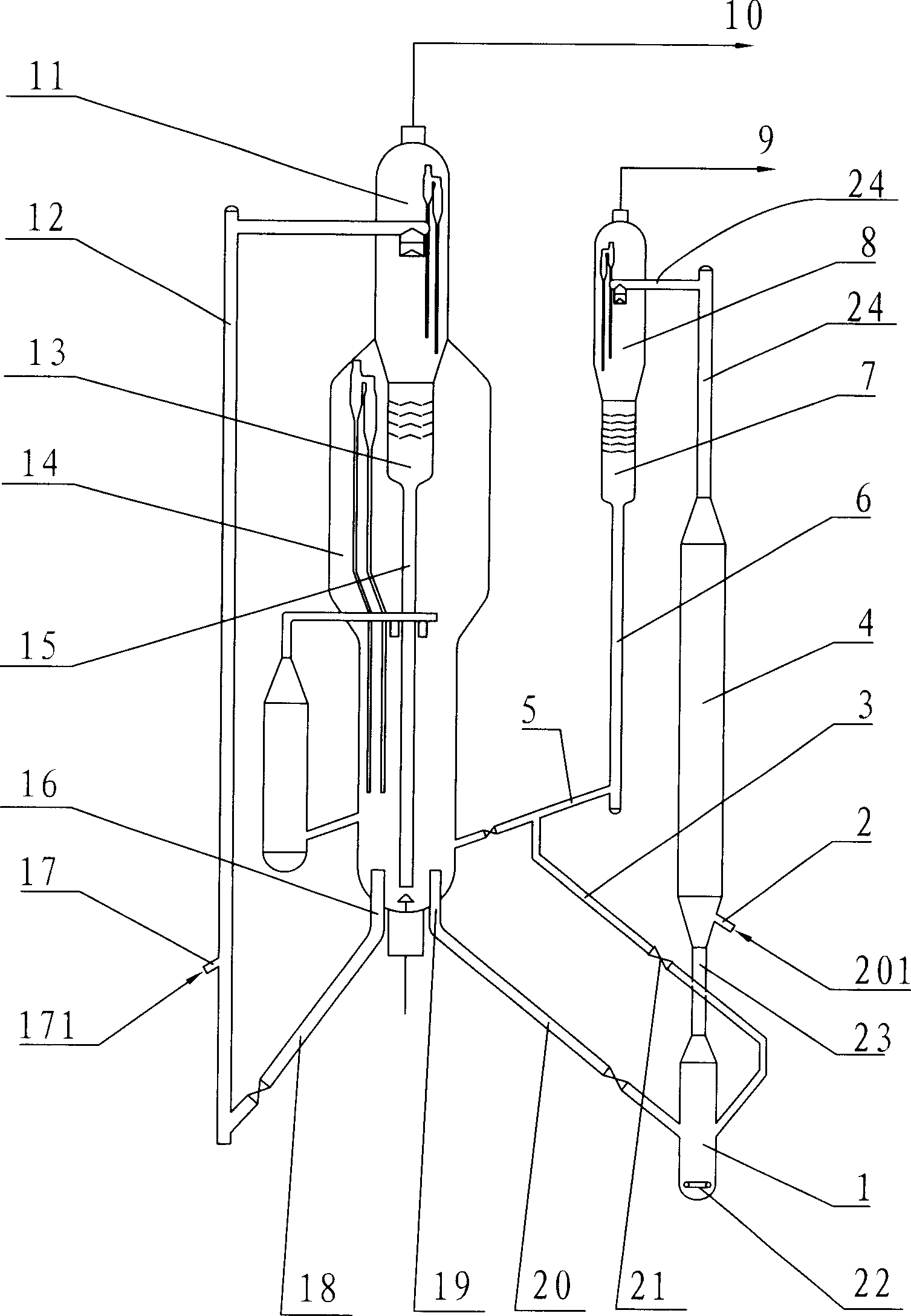

Catalytic cracking method and apparatus

ActiveCN100338185CReduce carbon contentHigh activityCatalytic crackingChemical industryControl valves

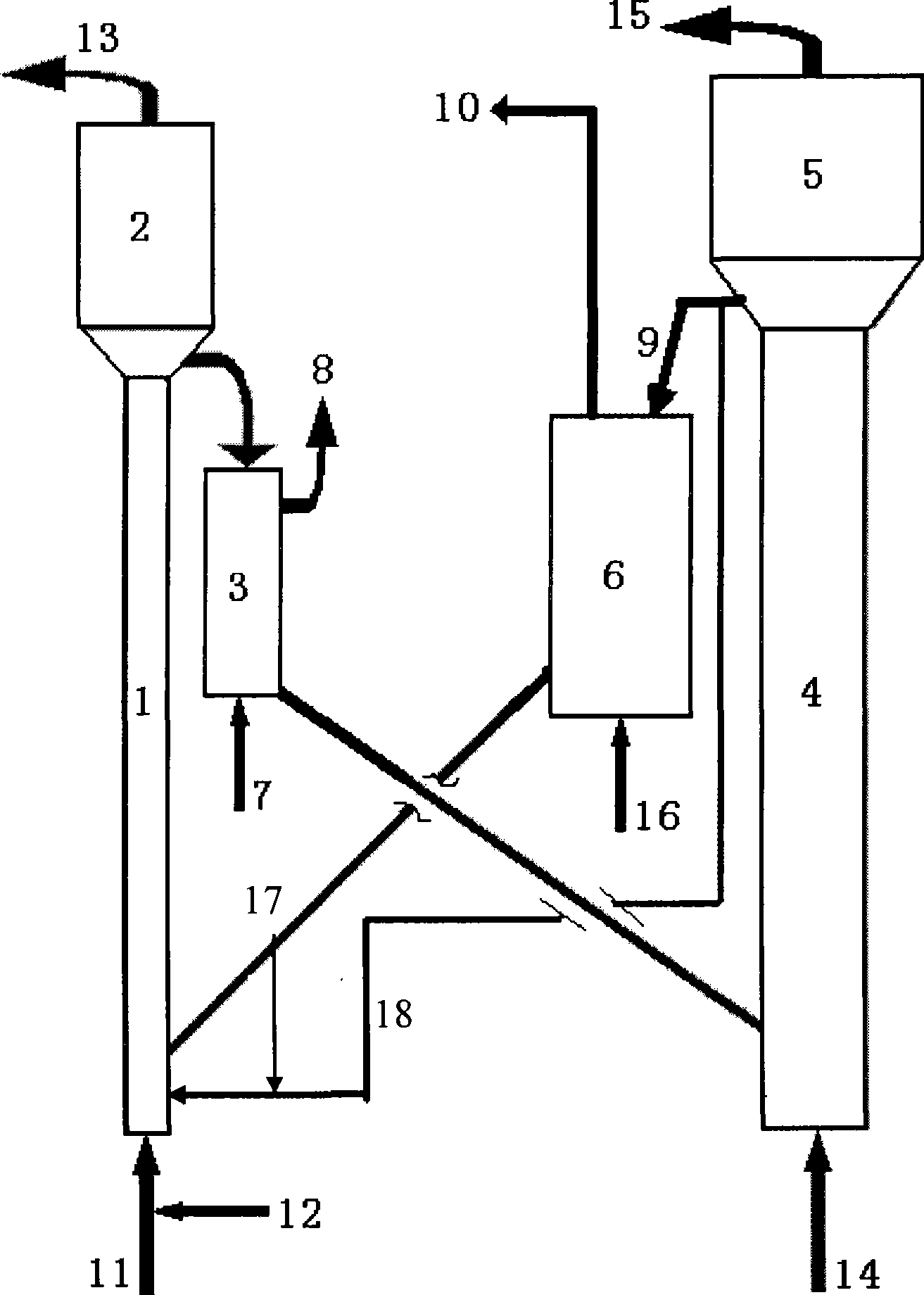

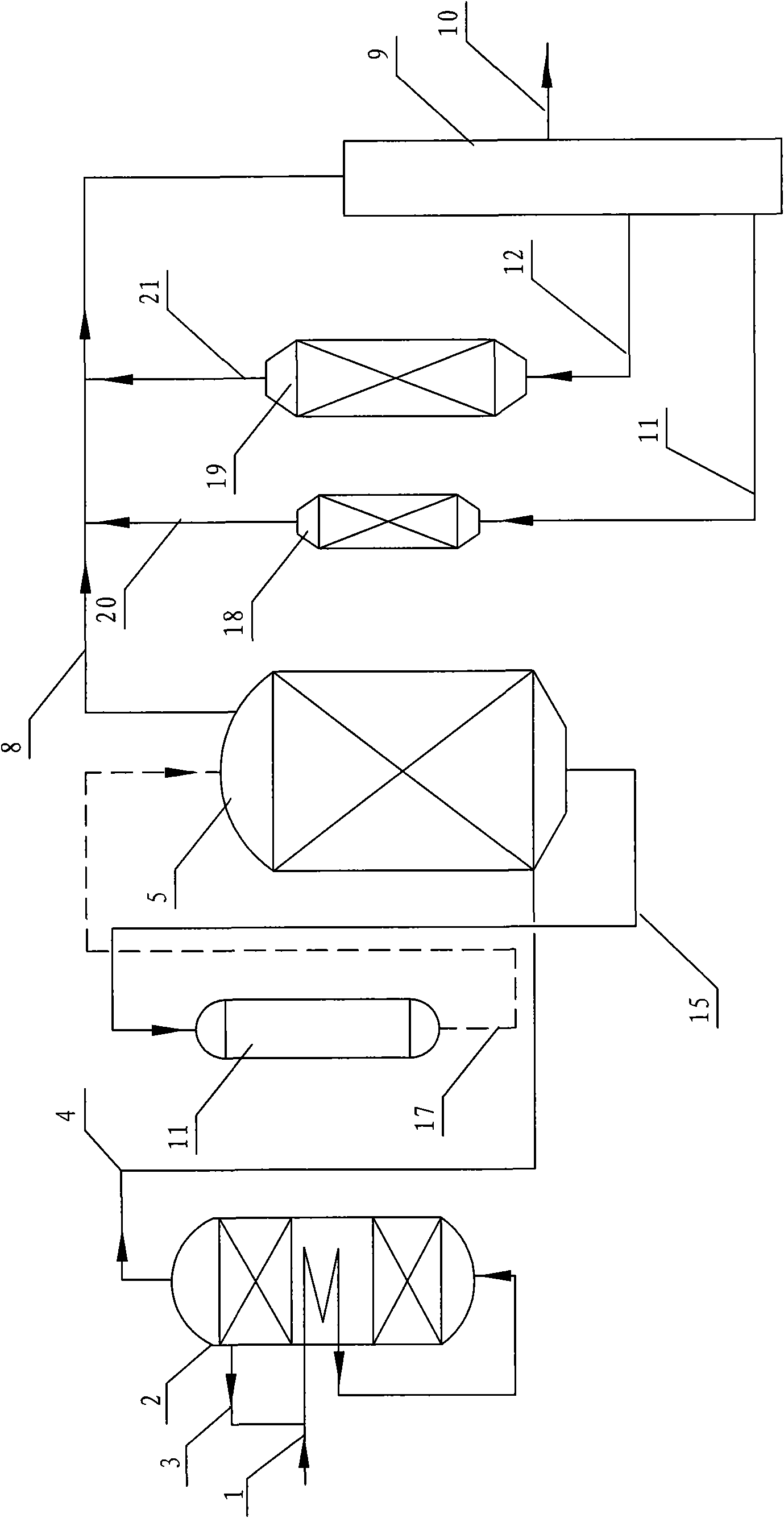

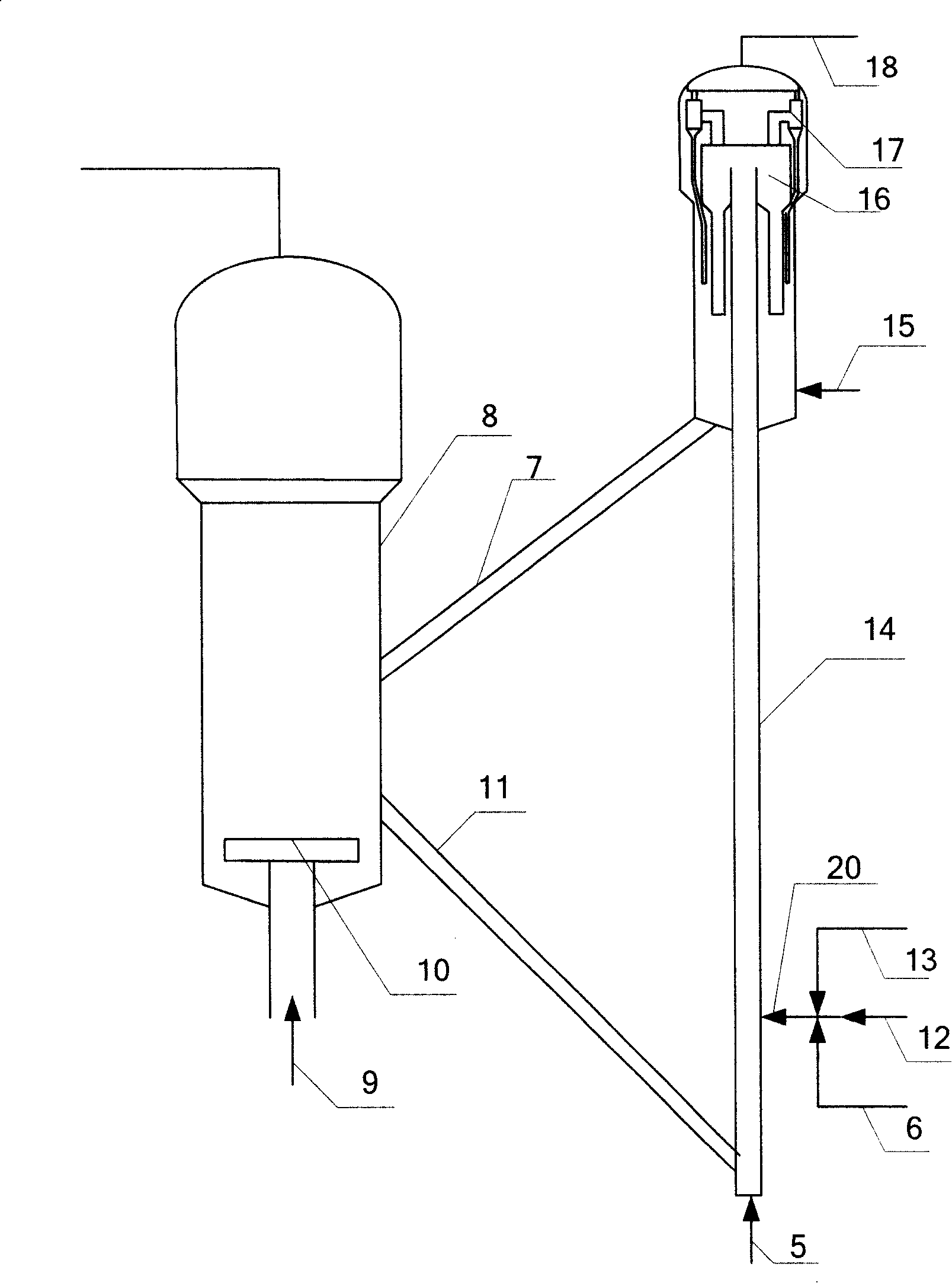

The invention discloses a kind of catalysis crack method and its device in petroleum chemical industry, to solve the problems as the whole activeness reduction of mixed catalysts and the flexibility lack of adjusting the agent-oil proportion of heavy oil riser reactor caused by the mixing wise of the spend catalyst and regenerating catalyst of the present two-riser catalysis crack device. The main characteristics of the invention method are: part of the spent catalyst from the light hydrocarbon riser reactor (4) gets into catalyst mixer through the spent catalyst duct (3) set flow control valve (1) after water vapour stripped in the stripping section (7) of the second settler, and gets into heavy oil riser reactor (12) to react after mixed by the effect of water vapour with the regenerating catalyst form regenerator (14) in catalyst mixer. The method of the invention is suitable to be used in the two-riser catalysis crack craft and the three-riser catalyst crack craft set heavy oil riser reactor; the invention has disclosed related devices.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

Owner:CHINA PETROCHEMICAL CORP +1

Hydrocarbon oil conversion method

ActiveCN101457152AIncrease productionImprove product distributionHydrogenCatalytic crackingForming gasHydrogen

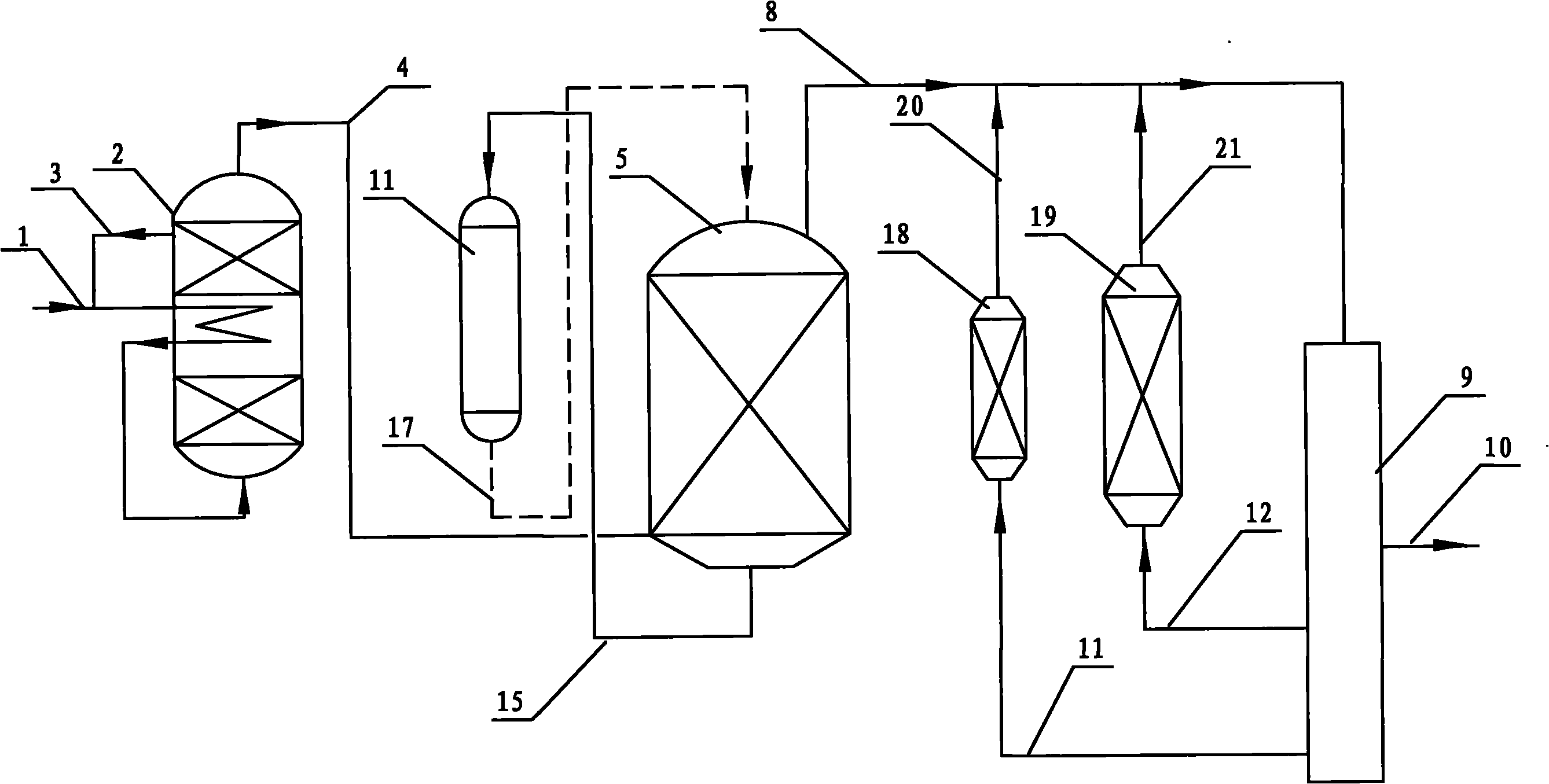

The present invention discloses a hydrocarbon oil convert method, wherein the method includes the following procedures: under cracking condition, contact hydrocarbon oil with energizing agent in a reactor to obtain reaction product and spent catalyst; separate the reaction product and spent catalyst, and contact the spent catalyst with water vapor and oxygen-containing gas inside a gasifying stove to obtain forming gas and semi-regenerated catalyst; separate the forming gas with the semi-regenerated catalyst, and transmit at least part of the semi-regenerated catalyst into the reactor for periodic duty, wherein reaction temperature inside the gasifying stove is from 500 DEG C to lower than 800 DEG C. The hydrocarbon oil convert method provided in the invention makes spent catalyst contactwith water vapor and oxygen-containing gas in the temperature from 500 DEG C to lower than 800 DEG C, and that can increase production quantity of carbon monooxide and hydrogen; carbon monooxide can be converted to hydrogen in the following course of working to obtain higher hydrogen rate of production; the energizing agent that regenerated in the temperature from 500 DEG C can improve hydrogen rate of production and improve product distribution of hydrocarbon oil reaction product.

Owner:CHINA PETROLEUM & CHEM CORP +1

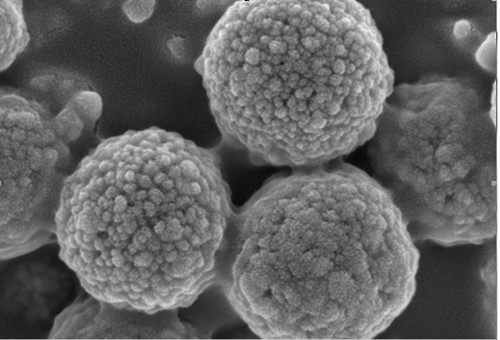

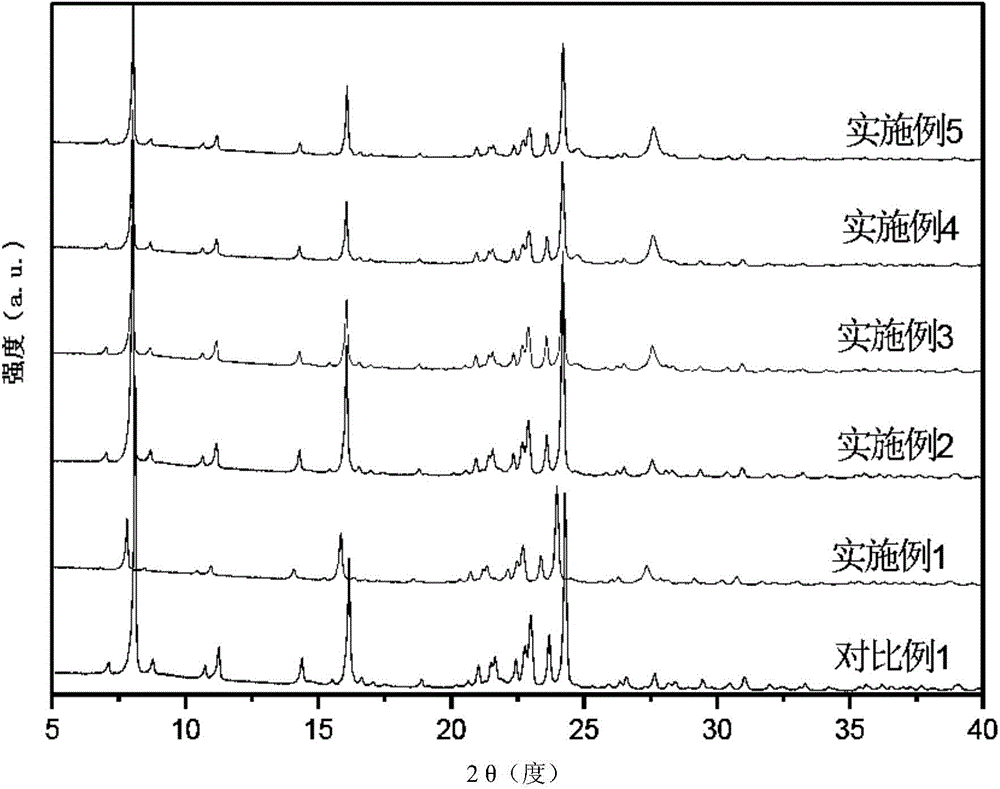

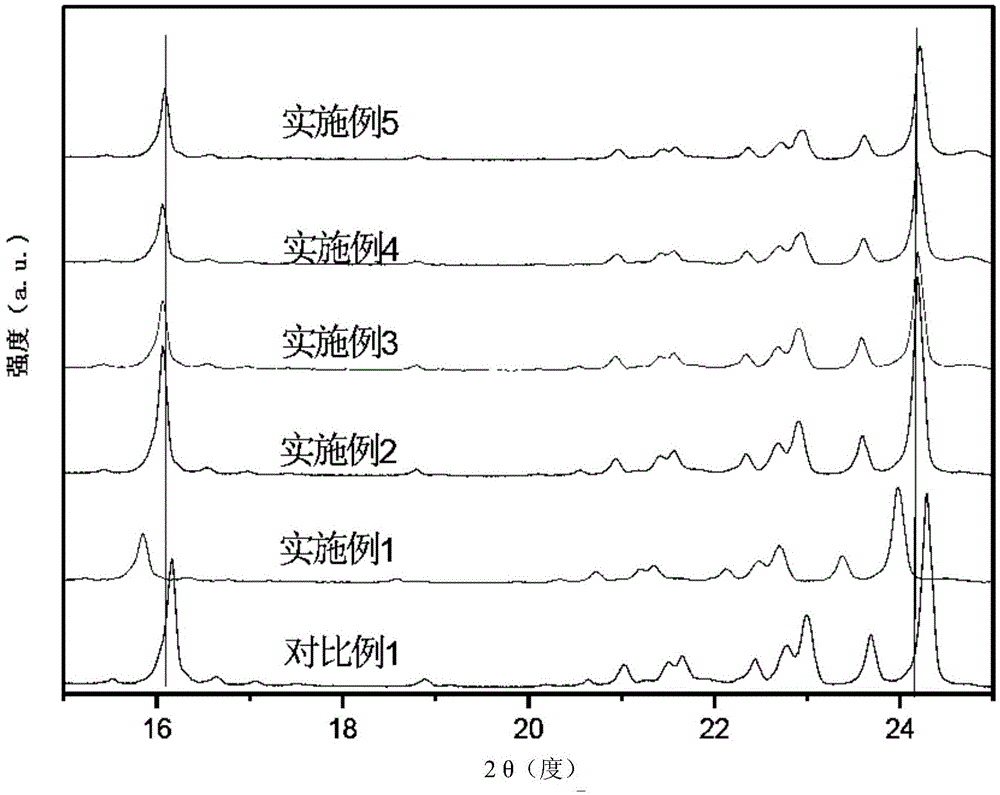

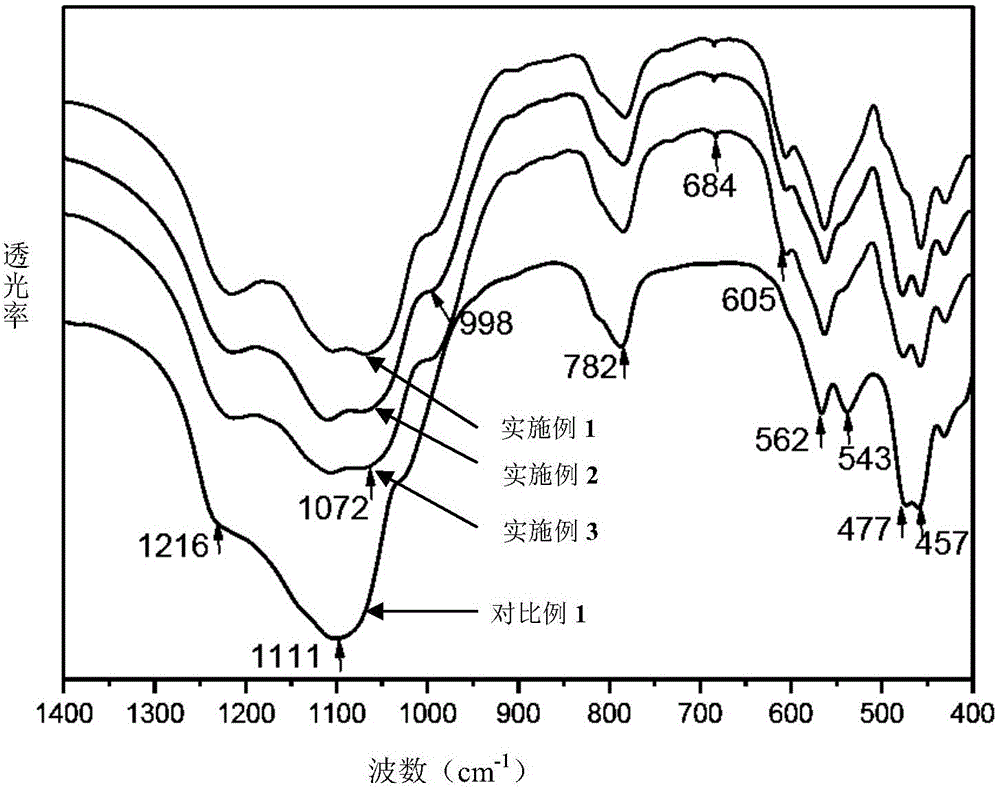

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657711AIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveGas phase

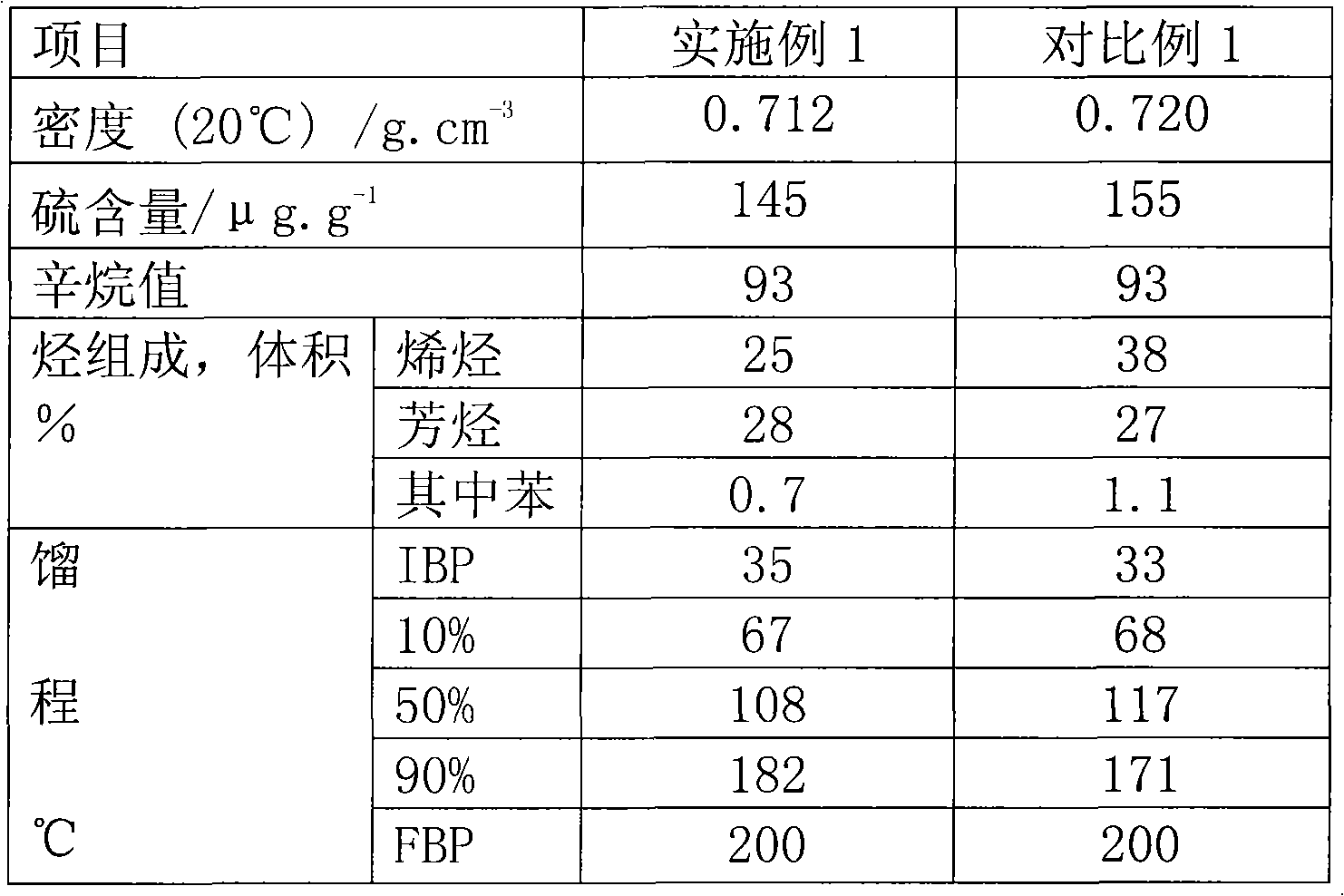

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component a first Y-type molecular sieve, a second Y-type molecular sieve and a third Y-type molecular sieve; the first Y-type molecular sieve is a rare-earth Y-type molecular sieve, the rare-earth content in the first Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50; the second Y-type molecular sieve is a rare-earth-containing gas-phase overstable Y-type molecular sieve; and the third Y-type molecular sieve is a rare-earth-containing DASY molecular sieve. The preparation method comprises the following steps: preparing a slurry containing the cracking activity component, adhesive and clay, and carrying out spray drying. The catalyst has higher conversion rate and gasoline yield, and can reduce the consumption of the molecular sieves, thereby lowering the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

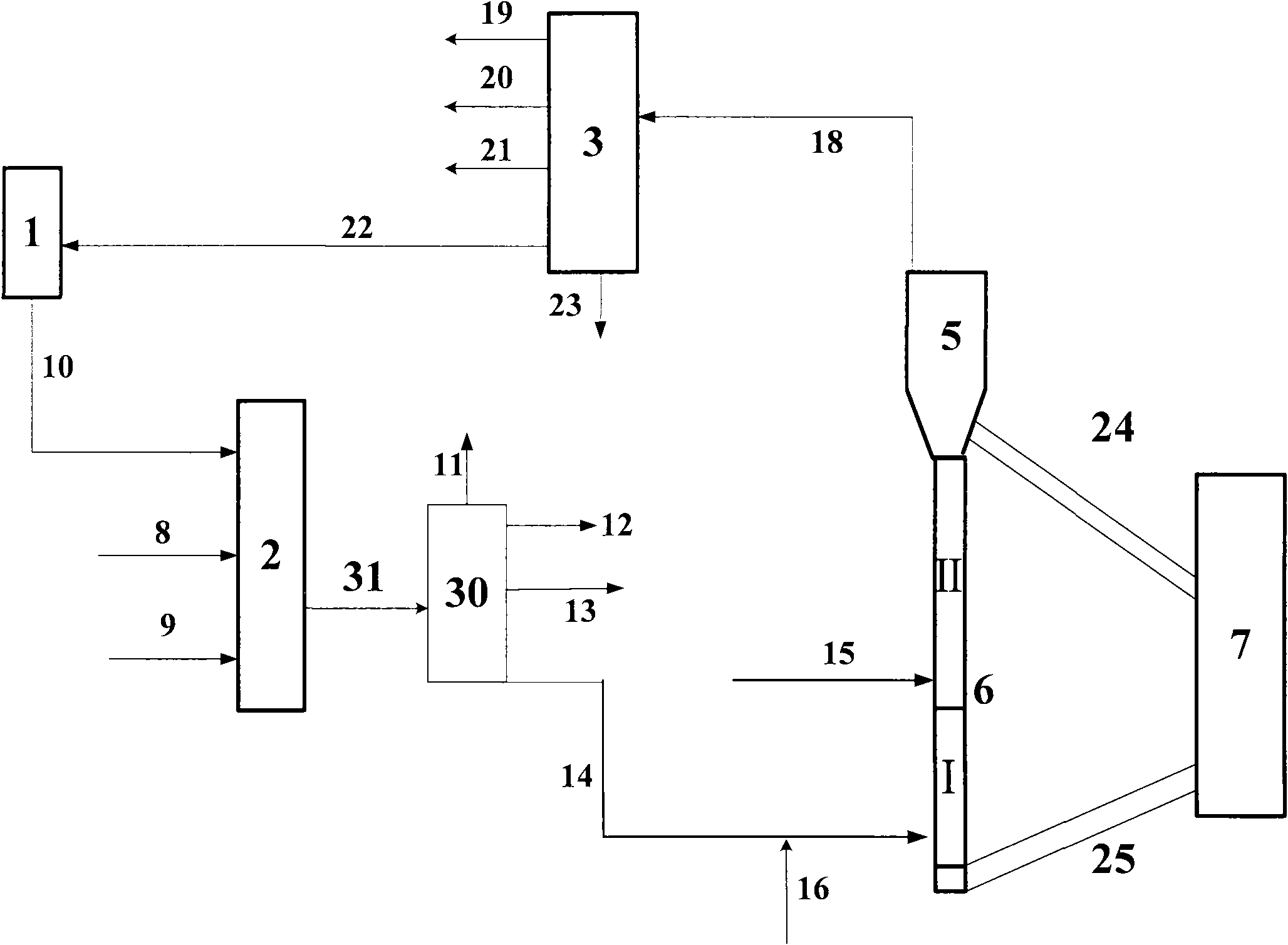

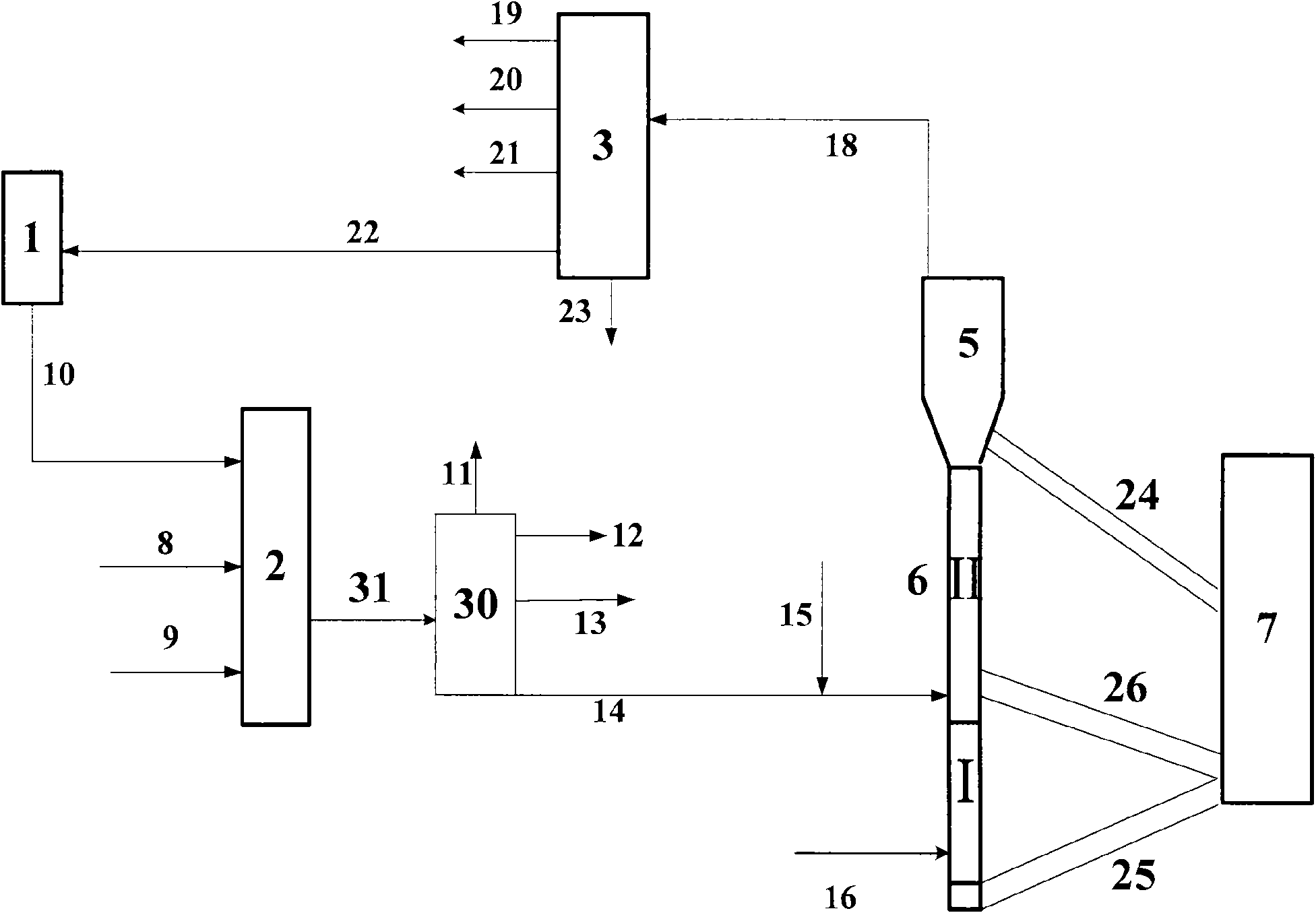

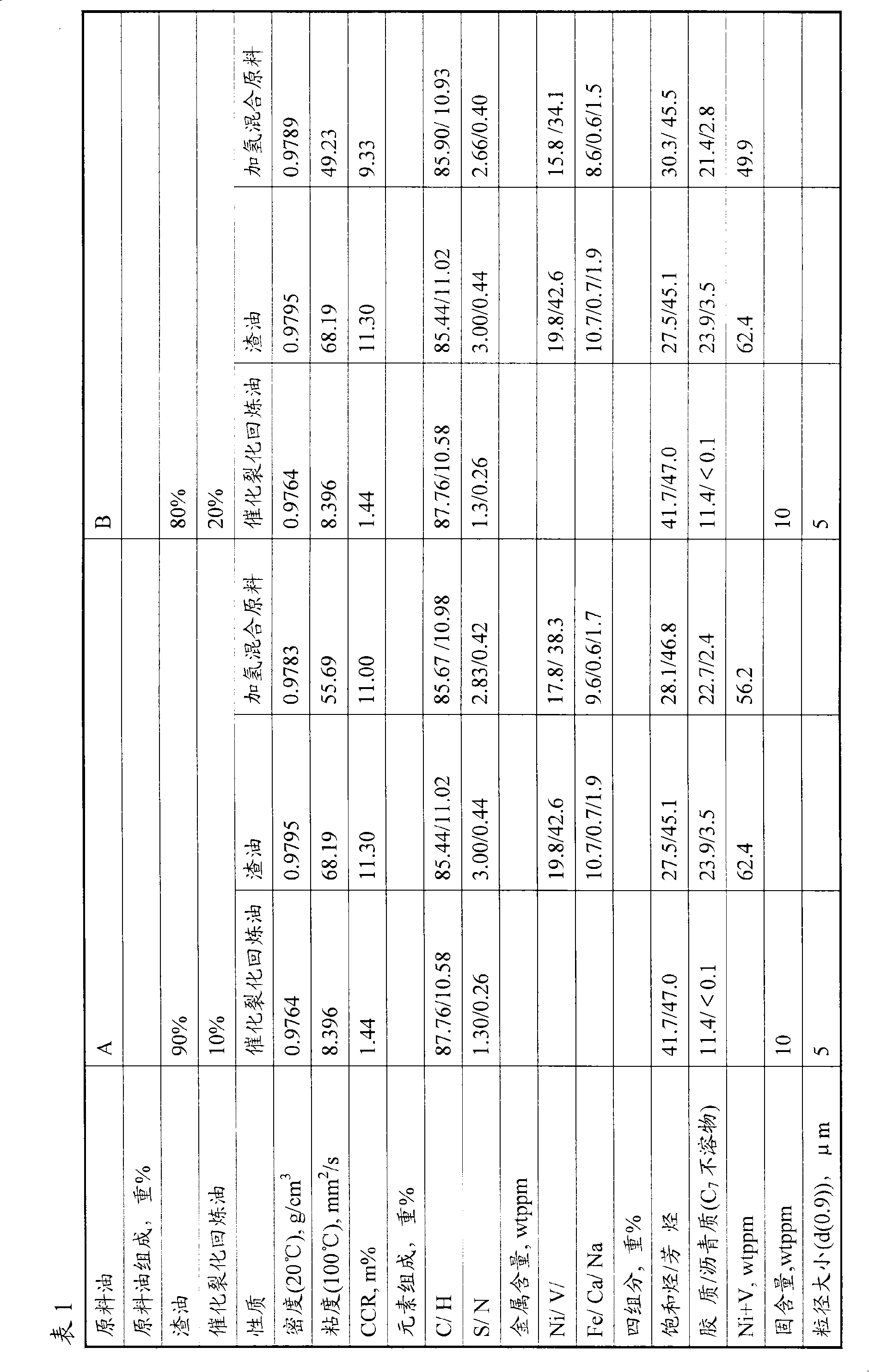

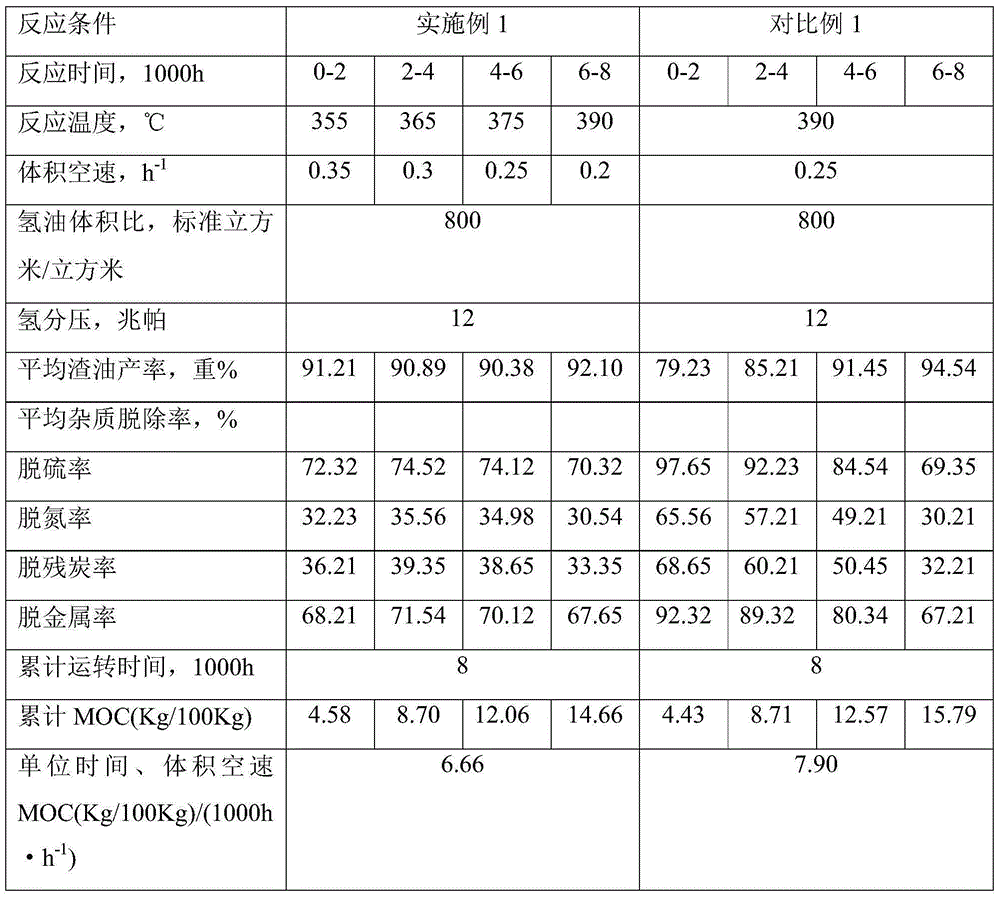

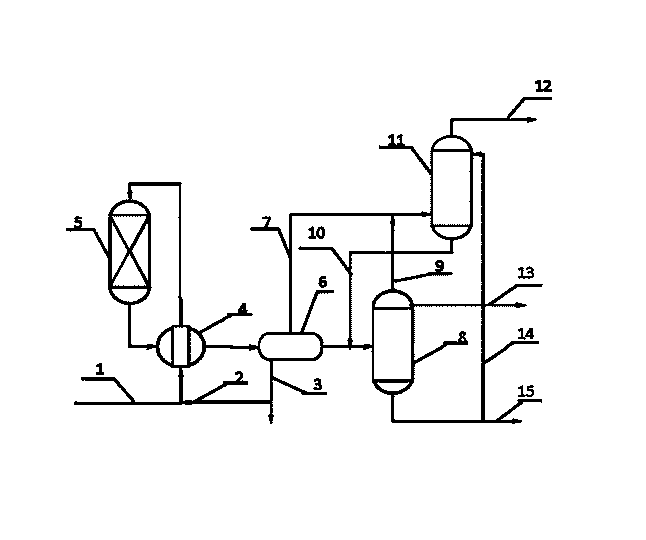

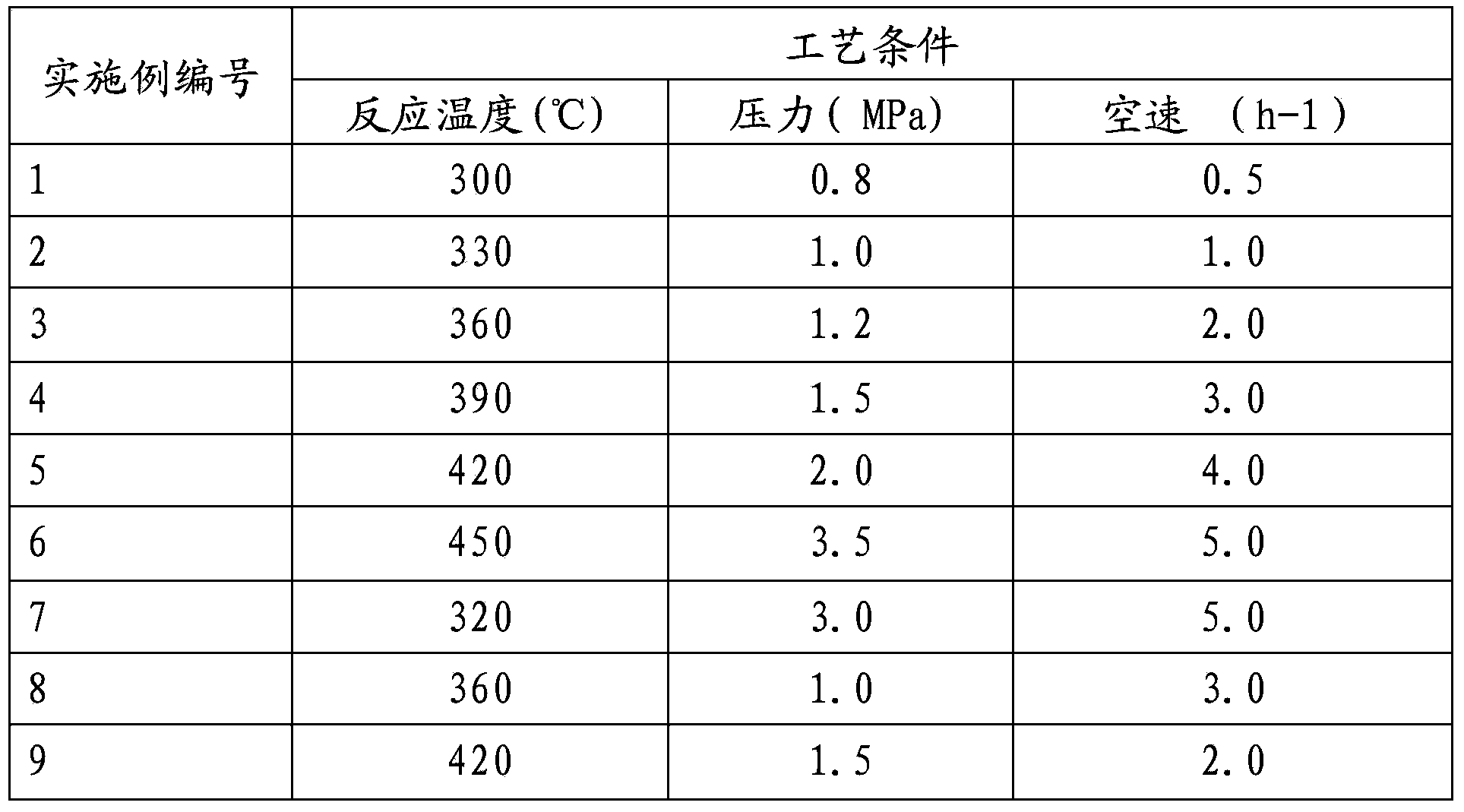

Improved hydrotreatment and catalytic cracking combination method for hydrocarbon oil

ActiveCN101538481AEnhanced dissociationImprove efficiencyTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses an improved hydrotreatment and catalytic cracking combination method for hydrocarbon oil, which comprises the following steps that: under reaction conditions of the presence of hydrogen and the hydrotreatment, the contact reaction of residual oil, catalytic cracking cycle oil, optional distillate oil and a hydrotreating catalyst is performed, and gas, hydrogenerated naphtha, hydrogenerated diesel oil and hydrogenerated tail oil are obtained after a reaction product is separated; under catalytic cracking reaction conditions, the contact reaction of the optional conventional catalytic cracking raw oil, the hydrogenerated tail oil and a catalytic cracking catalyst is performed, and dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking cycle oil are obtained after a reaction product is separated; and the conventional catalytic cracking raw oil is light or heavy distillate oil, and the contact reaction with the catalytic cracking catalyst is that the heavy raw oil and light raw oil are optionally and orderly performed along with the hydrogenerated tail oil in a reactor comprising at least two reaction regions (I and II) along the flowing direction of reaction materials respectively. The method is suitable for hydrocarbon oil conversion to produce more gasoline and diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking desulfur method of faulty gasoline and device thereof

ActiveCN1903989AHigh activityModerate operating conditionsCatalytic crackingOil processingIt equipment

The present invention discloses a catalytic cracking desulfurization method of low-grade gasoline in the field of petroleum processing technology and its equipment. It is characterized by that the invented gasoline upgrading reactor adopts gasoline fast bed reactor with cylindrical structure, a portion of spent catalyst can be passed through spent catalyst coveying pipeline with flow control valve and fed into catalyst mixer, and is mixed together with regenerated catalyst coming from regenerator under the action of aqueous vapor, then fed into gasoline fast bed reactor and is contacted with low-grade gasoline feed so as to make reaction to greatly reduce sulfur content of low-grade gasoline.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Method for preparing olefin by dehydration of methanol

ActiveCN102060644AImprove reaction separation efficiencyLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCarbonization

The invention discloses a method for preparing olefin by dehydration of methanol, which overcomes the shortcoming of low olefin yield in the prior art, the shortcoming that a catalyst is susceptible to inactivation due to carbonization during reaction and the like. The method provided by the invention comprises: heating the methanol to generate vapor; allowing the vapor to enter a catalytic distillation rector to contact with a zeolite molecular sieve (ZSM)-5 catalyst and react; allowing the reaction product to enter a moving-bed reactor to contact with the catalyst and react; separating the reaction products; after ethylene and propylene products are separated out, allowing a material flow containing C4 hydrocarbons and a material flow containing C5-C7 hydrocarbons to enter two fixed-bedrectors respectively to contact with the catalyst and react; regenerating the inactive catalyst in the moving-bed reactor by burning and then recycling the regenerative catalyst. The method provided by the invention has the advantages of high olefin yield, high catalyst activity and high stability.

Owner:CHINA PETROCHEMICAL CORP +1

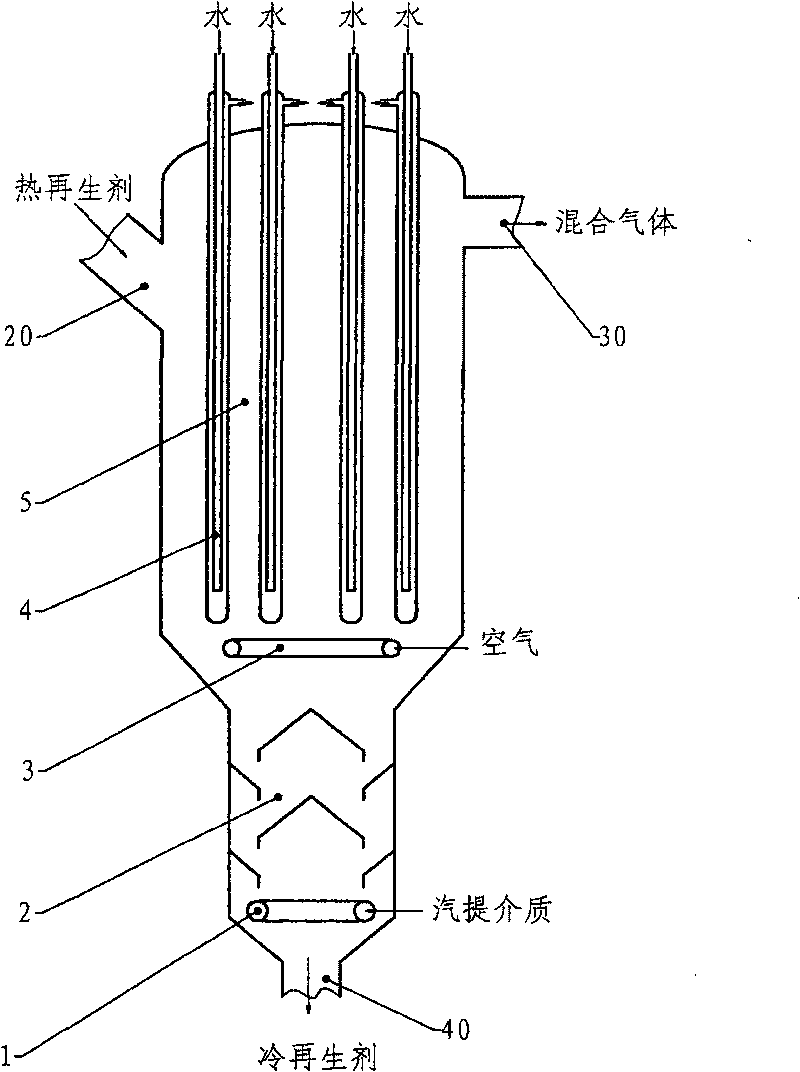

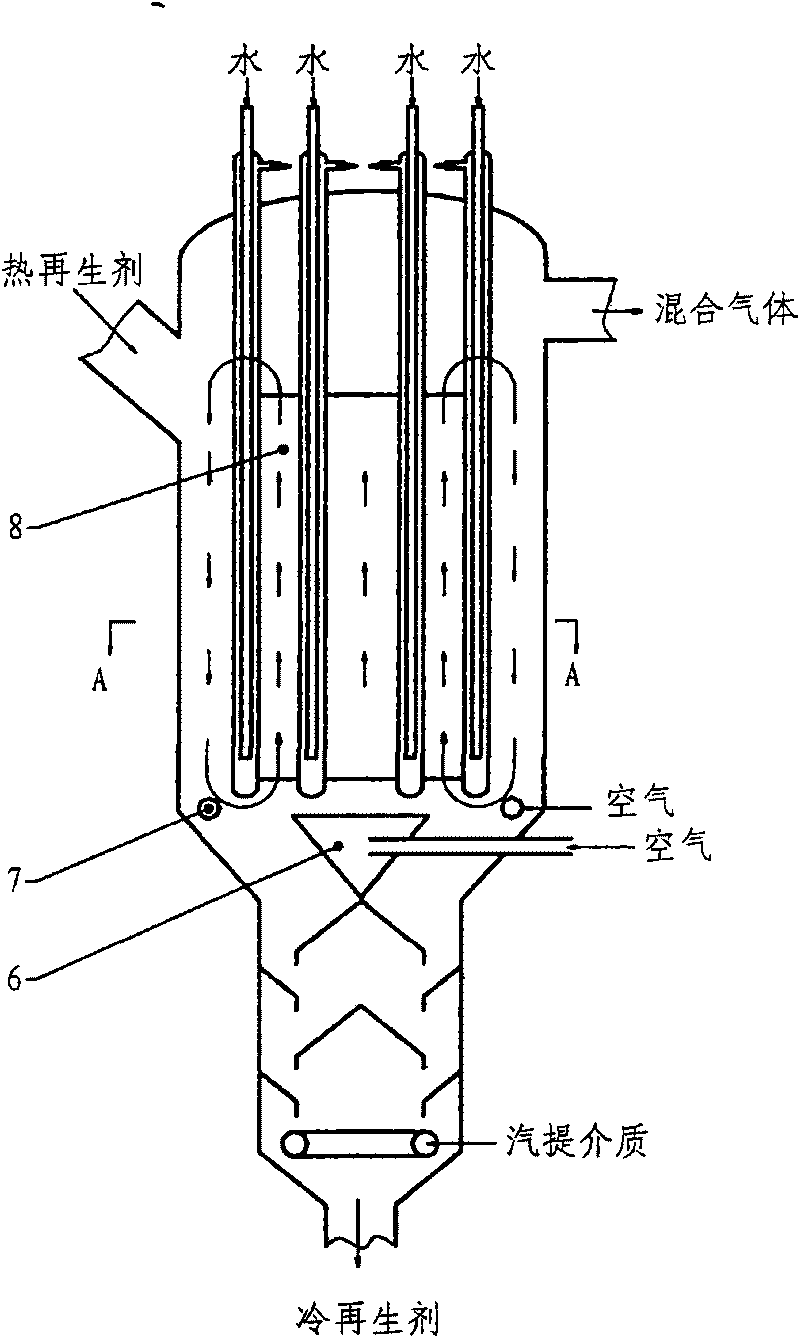

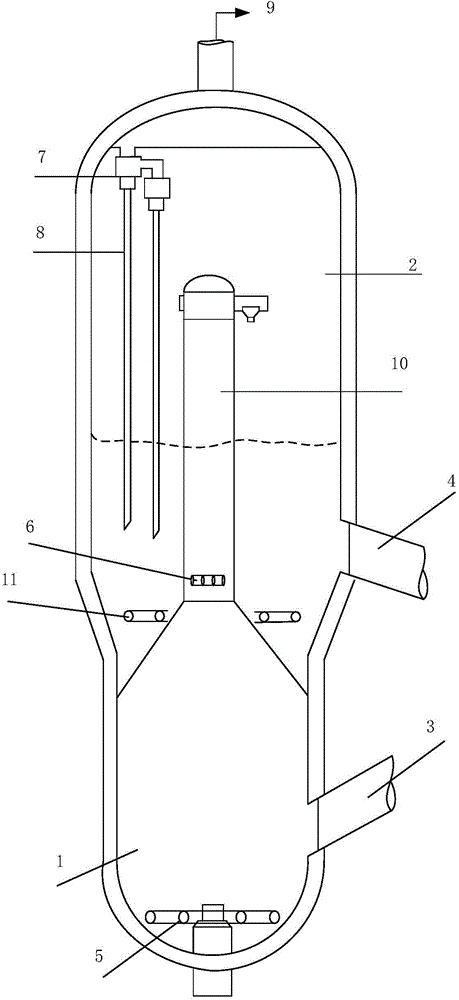

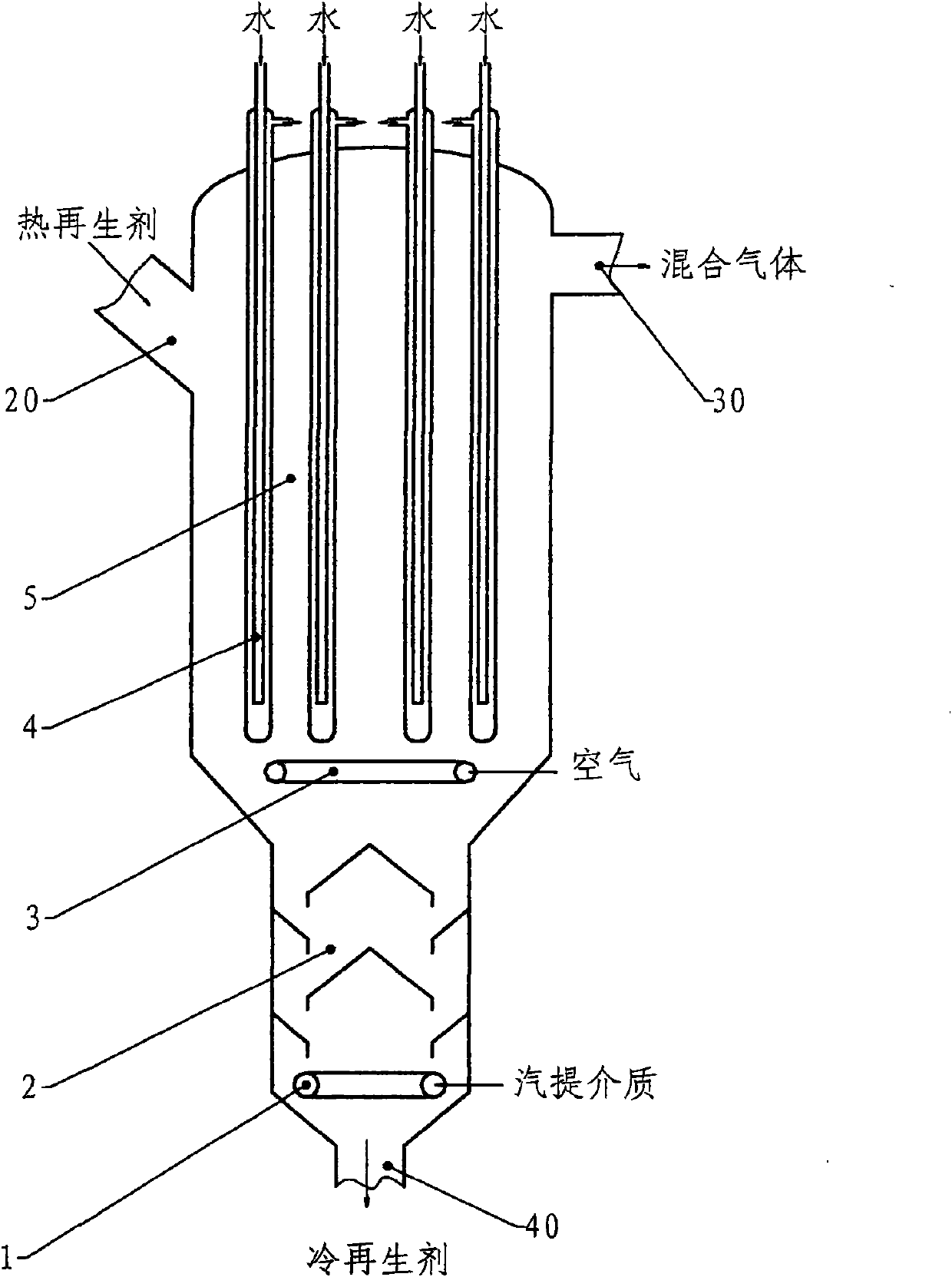

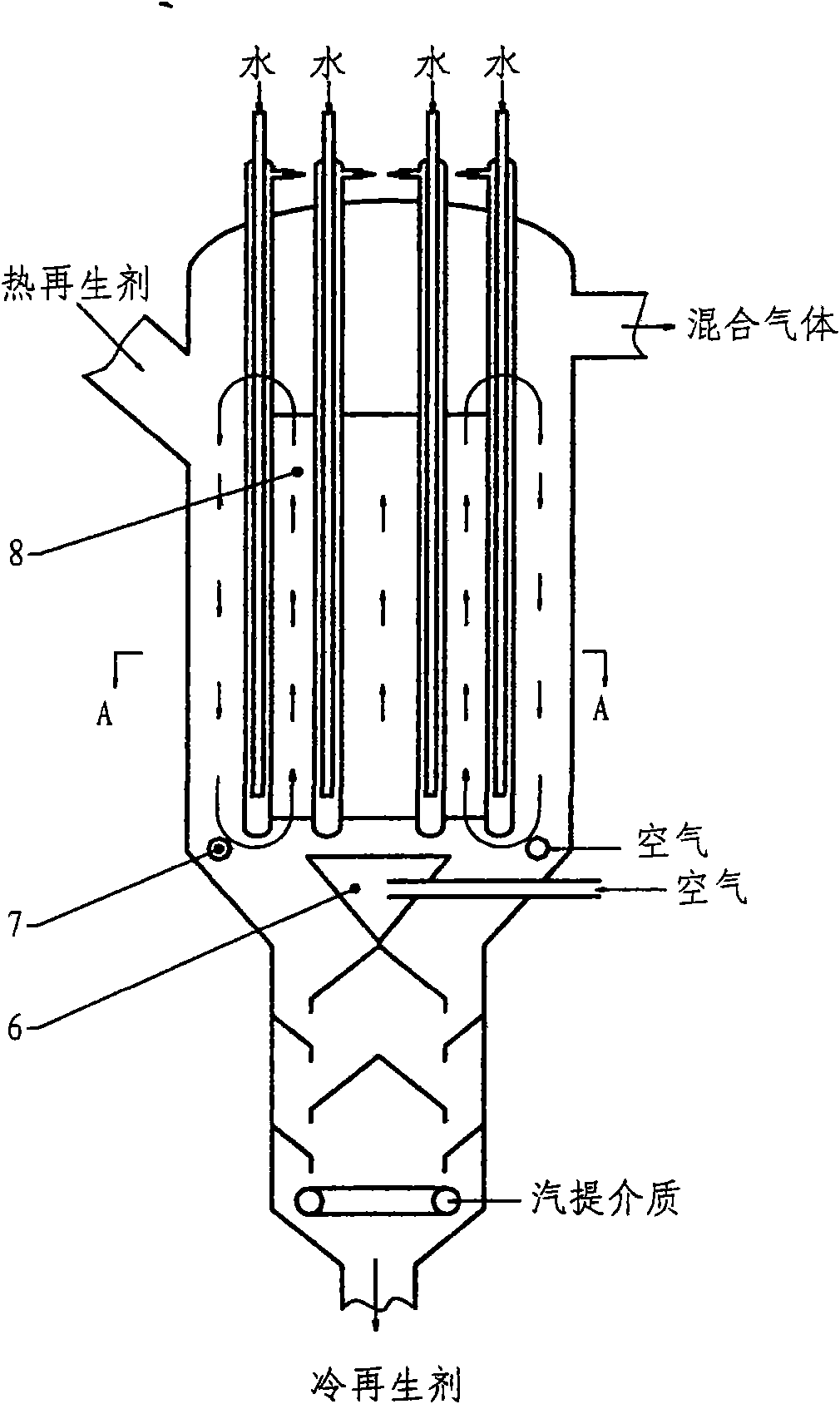

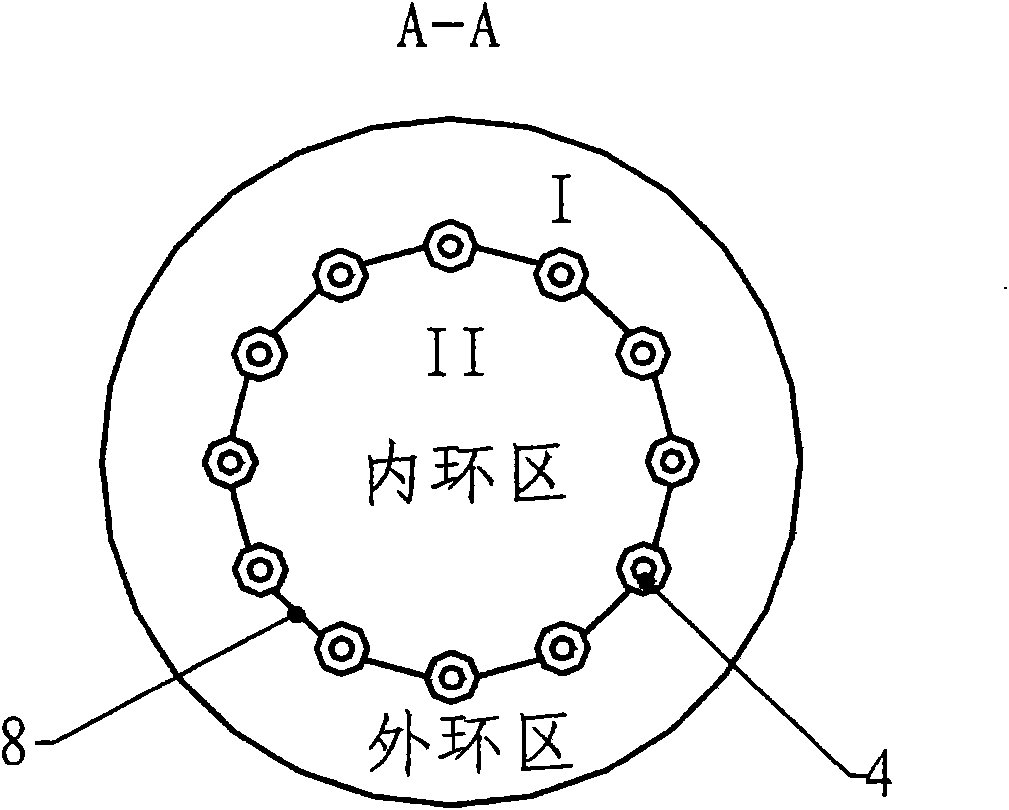

Coupling equipment for realizing temperature adjustment and stripping of catalytic cracking regenerant

InactiveCN101760229AImprove heat extraction and heat exchange efficiencyInhibitory inactivation effectCatalytic crackingFlue gasEngineering

The invention provides coupling equipment for realizing the temperature adjustment and the stripping of catalytic cracking regenerant, which comprises a temperature adjustment section arranged at the upper part and a stripping section arranged at the lower part; the temperature adjustment section is provided with a built-in heat exchange component and at least an air distributor; and the temperature adjustment section extends downwards and reduces the circulation area to form the stripping section. By coupling the stripping area with quite small circulation area at the lower part of the temperature adjustment section, the invention can realize the function of flue gas removal without or only with a small amount of stripping steam, and can best inhibit the inactivation of the regenerant under the steam atmosphere. The coupling equipment of the invention can be arranged in a regenerant circulating pipeline of a catalytic cracker, so that the regenerant directly enters a rise reactor after the temperature is adjusted and the flue gas is removed, thereby not only significantly improving the oil ratio, the regeneration temperature and the raw material pre-heating temperature of the catalytic cracker and facilitating the improvement of product distribution, but also having the function of glue gas removal and reducing the load of a rich gas compressor and the energy consumption of the device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Directional reactive catalysis thermal cracking method for direct converting low carbon alkane without need of oxygen

ActiveCN1696249AFunctionalImprove product distributionCatalytic crackingChemical recyclingAlkaneCarbon deposit

A directional catalytic thermocracking reaction for non-oxygen direct conversion of low-carbon alkane includes reaction between the preheated heavy petroleum hydrocarbon and hot cracking catalyst from the first generator in the first reactor to obtain the oil gas and carbon deposited catalyst, stripping the catalyst, regenerating in the first generator, delivering the oil gas in the following product separation system, feeding low-carbon alkane in the second reactor, reacting on the aromatizing catalyst from the second regenerator to obtain arylhydrocarbon and H2, regenerating the catalyst, and separating arylhydrocarbon from H2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low energy consumption catalytic conversion method of hydrocarbon oil

The invention provides a low energy consumption hydrocarbon oil catalytic conversion method, wherein, material oil and an atomizing medium are mixed and sprayed in a reactor by a nozzle, and contact and react with high temperature regenerated catalyst, the oil gas and the catalyst are separated after the reaction, the isolated oil gas enters into a product fractionating system, the isolated deactivated catalyst which undergoes or does not undergo the steam stripping enters into a regenerator for charring regeneration, the catalyst which regains the activation returns to the reactor for cycling use; the atomizing medium contains C3 - C5 alkane. By adopting the method of the invention, on the basis of not changing reaction operating conditions, the product distribution is optimized and the energy consumption of atomizing steam is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Double lift pipe catalytic cracking method and device for modifying inferior patrol

ActiveCN1298812CReduce olefin contentReduce hydrocarbon contentCatalytic crackingOil processingGasoline

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

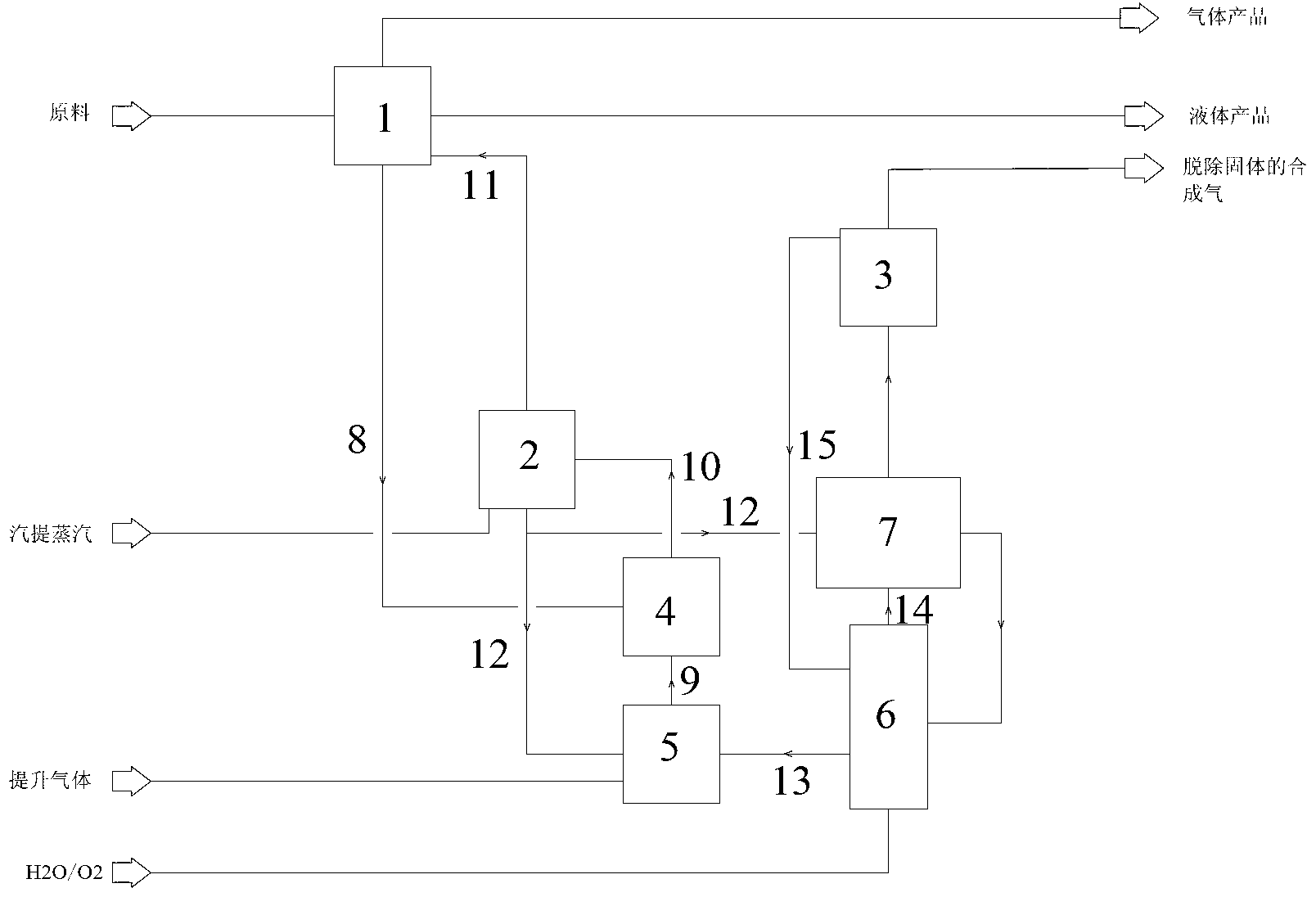

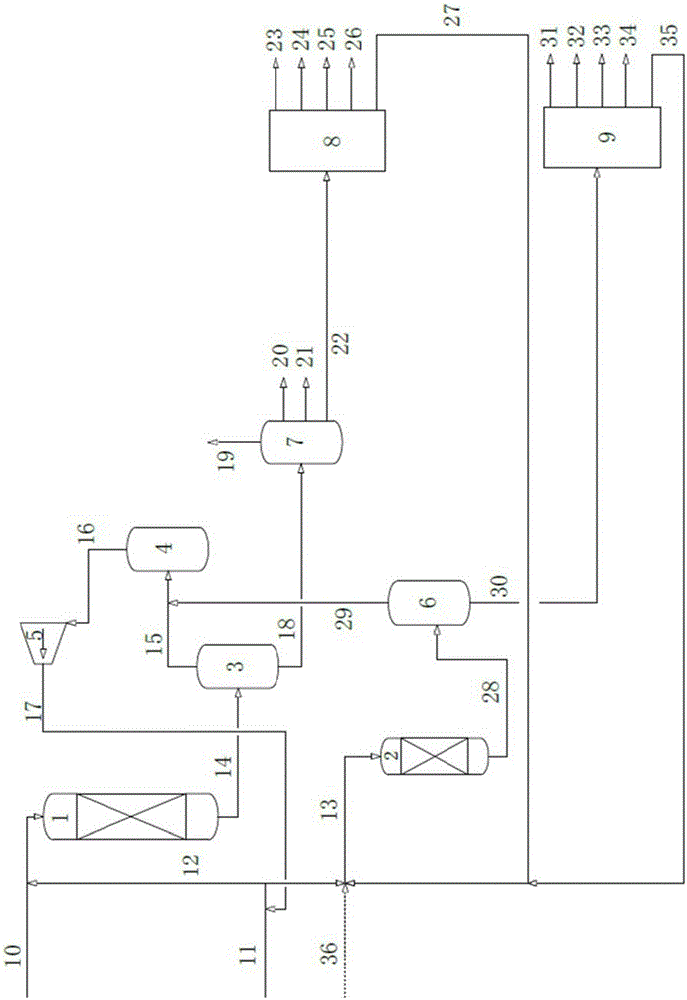

Inferior heavy oil fluidization conversion technology

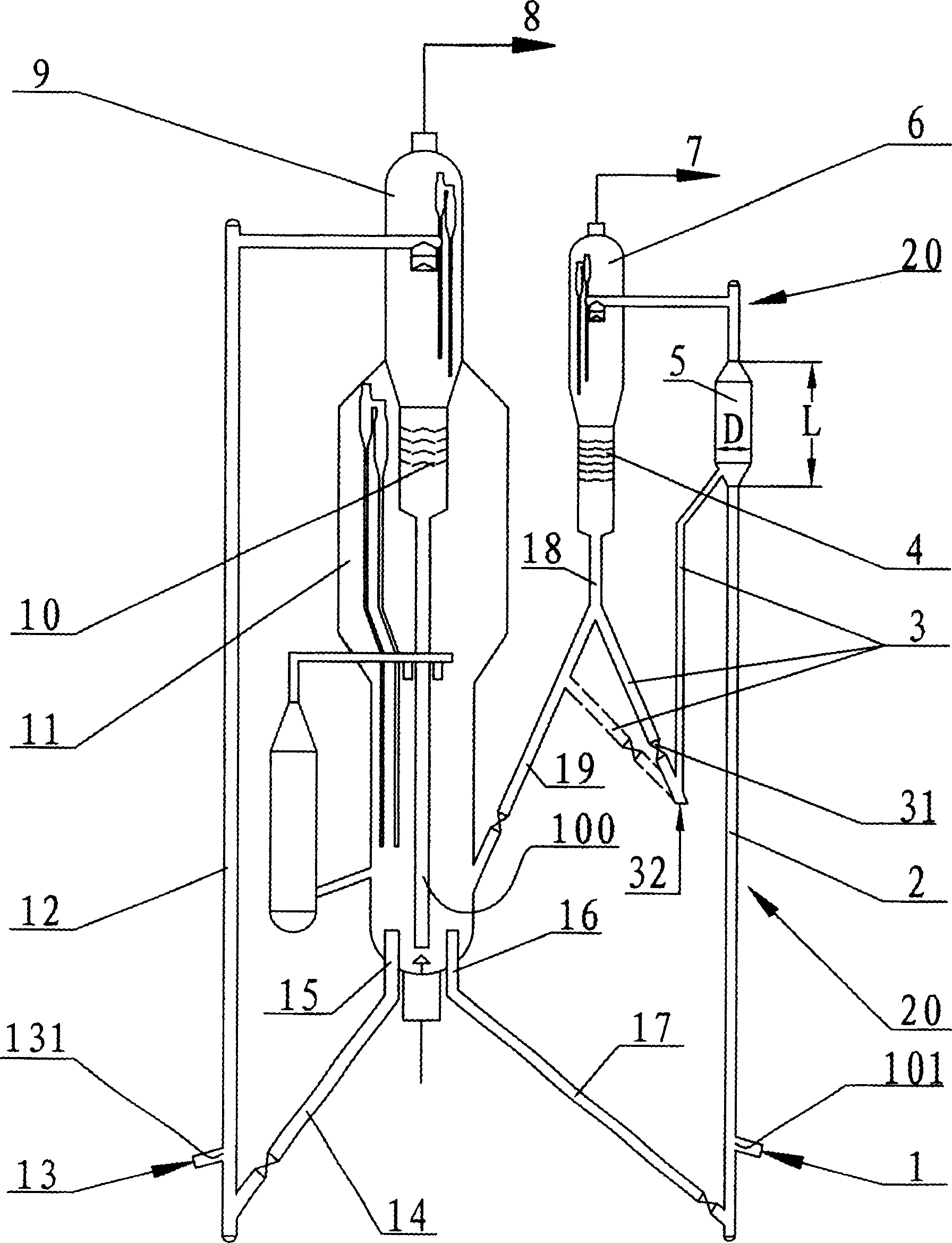

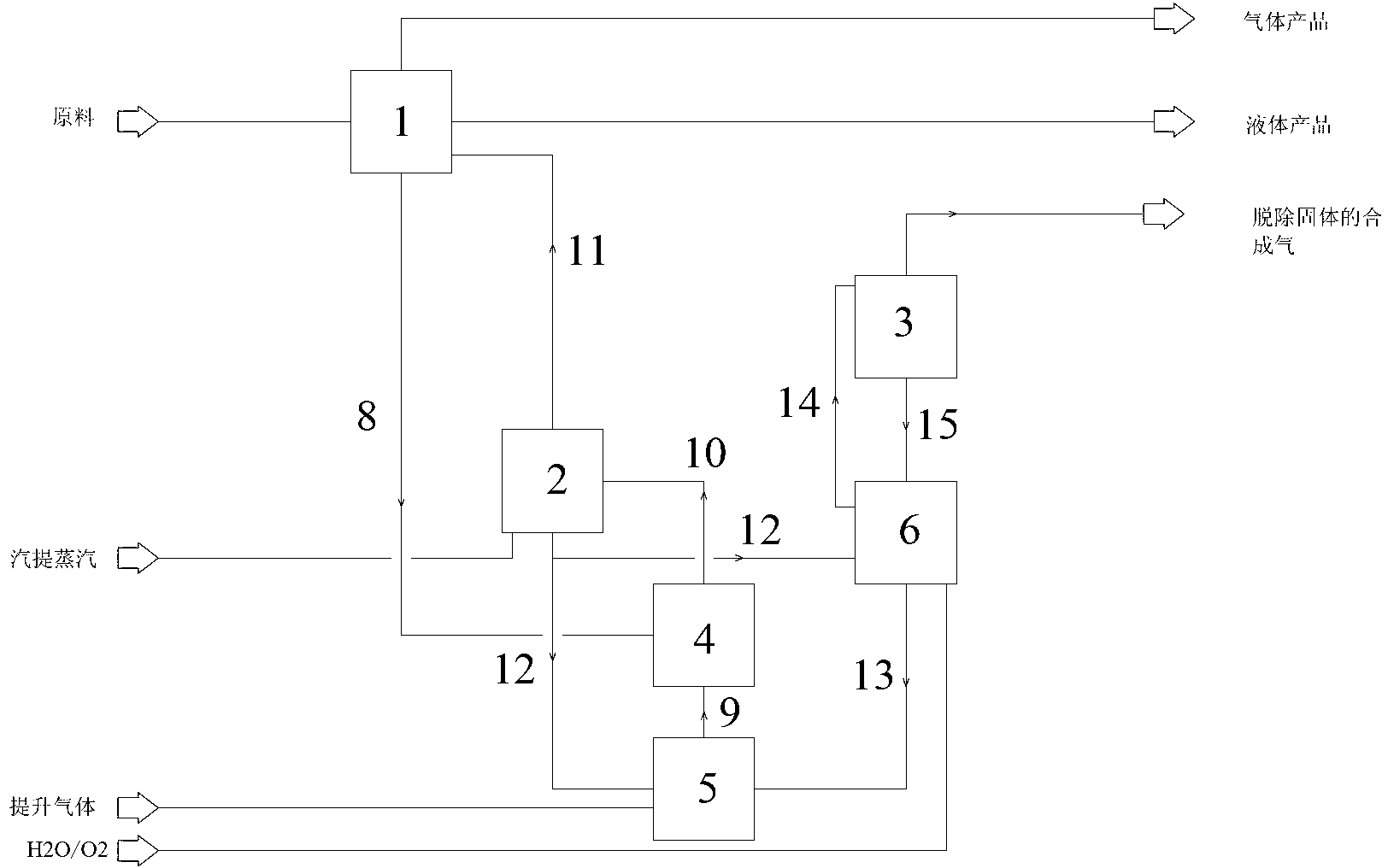

ActiveCN103224808ALow calorific valueQuality improvementTreatment with plural serial stages onlyGranular/pulverulent flues gasificationSyngasThermal energy

The invention relates to an inferior heavy oil fluidization conversion technology. The inferior heavy oil fluidization conversion technology comprises that raw material oil is treated by a fractionating tower, then enters into a lifting pipe reactor, undergoes a contact reaction with coke carriers from a coke carrier mixer, then enters into a first gas-solid separation device and is separated; the separated reaction oil gas is fed into the fractionating tower and is subjected to product division; the coke carriers with coke is stripped and is divided into two parts, one of the two parts is fed into the coke carrier mixer, then is mixed with the high-temperature coke carriers from a vaporizer and then is fed back to the lifting pipe reactor, and other one of the two parts is fed into the vaporizer, contacts with oxygen-containing gas and water vapor and undergoes a gasification reaction; the produced synthetic gas is separated by a second gas-solid separation device, is fed into a follow-up section, and is subjected to heat recovery and conversion; and the vaporized coke carriers are fed into the coke carrier mixer and is mixed with the coke carriers with the coke. Compared with the prior art, the inferior heavy oil fluidization conversion technology has the advantages of simple process, low investment, strong raw material adaptability, good product distribution and good environmental benefits.

Owner:SHANGHAI HOTO PETROCHEM ENG

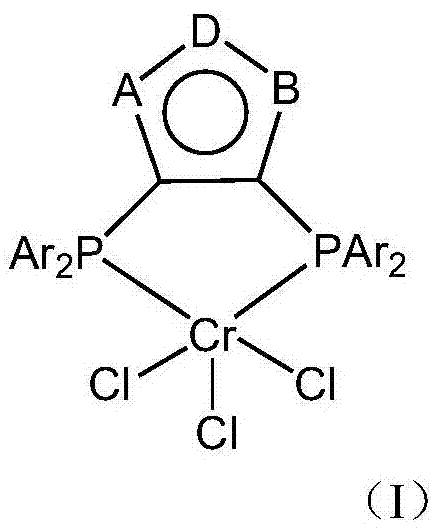

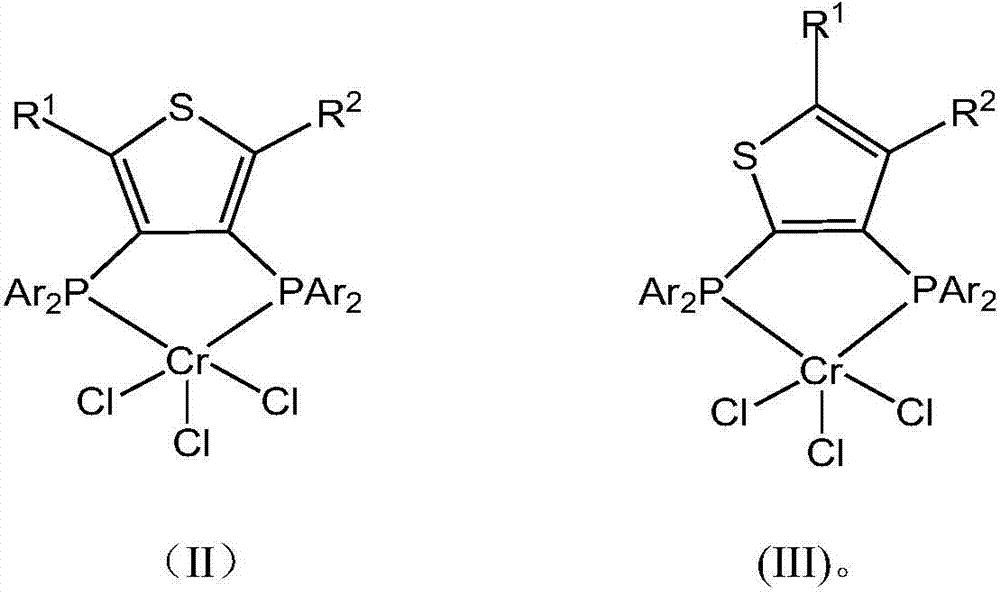

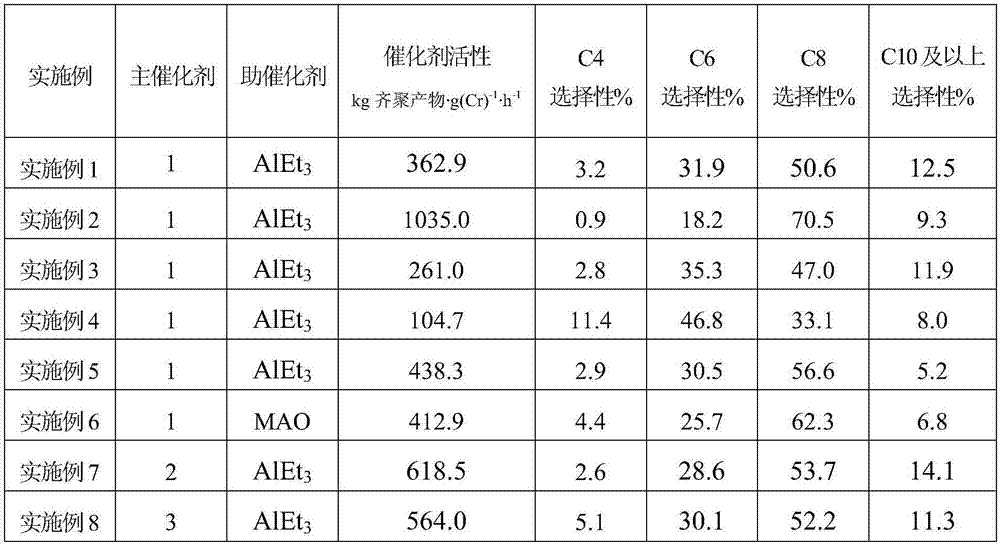

Ethylene oligomerization catalyst and application thereof

ActiveCN107149947AImprove distributionHigh product contentOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsArylHydrogen

The invention relates to an ethylene oligomerization catalyst. The ethylene oligomerization catalyst comprises a main catalyst represented by general formula (I) shown in the description and an aluminum-containing cocatalyst; in the formula (I), one of A, B and D is S, the remaining two of A, B and D are independently selected from CR<1> and CR<2>; the R<1> and the R<2> are same or can be different, and are respectively selected from hydrogen, an alkyl group, a cycloalkyl group and halogen, and atoms in the alkyl group and the cycloalkyl group are optionally substituted with hetero atoms or are not substituted; and Ar is an aryl group or a substituted aryl group. The catalyst provided by the invention has the advantages of good oligomerization activity and good product distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing content of olefin in gasoline in catalytic cracking process

InactiveCN1600832ASimple technical solutionImprove product distributionCatalytic crackingProduct recoveryChemistry

This invention provides a method for lowering the content of gasoline olefines in catalystic cracking process. The inert termination medium, not taking part in the reaction, is fed into life-pipe, mixed with reactant-flow already in the life-pipe, then up-flowing along said pipe. The produced products stream is proceeded with oil-separation and products-recovery. Wherein, the volume of the termination medium fed-in is of 2-8 wt.% of the capacity of the catalystic cracking installation, and the feeding-point is at 1.0-2.0 seconds point of oil-contacting in lift-pipe. In this invention, light wt. petro-hydrocarbon can be used as termination agent, with its feeding valume being 5-15 wt%, and feeding-point being at 1.0-2.0 seconds point of oil-contacting time point. This invention is easy to operate, with lower olefines content in gasoline, and increases iso-hydrocarbons normal hydrocarbons ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst regeneration method and device

ActiveCN105521834AAvoid local overheatingAvoid overheatingCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsCombustionProduct gas

The invention relates to a catalytic cracking catalyst regeneration method and a catalytic cracking catalyst regeneration device. The method comprises the following steps: (1) a spent catalyst contacts a first oxygen-containing gas, and coke burning is carried out; (2) a mixture obtained after coke burning contacts methanol, and combustion is carried out; and (3) the mixture obtained after combustion contacts a second oxygen-containing gas, and coke-burning regeneration is continued. The regeneration device comprises a coke burning tank and a regenerator. The inner space of the regenerator is divided into a catalyst dense phase zone positioned in the lower part and a catalyst dilute phase zone positioned in the upper part. The top of the coke burning tank is communicated with the catalyst dilute phase zone of the regenerator through a delivery pipe, such that the mixture obtained through the coke burning process in the coke burning tank can be delivered to the regenerator. A methanol distributor is arranged in the delivery pipe, and is used for introducing methanol into the delivery pipe. With the method provided by the invention, regeneration device local overheating and over-temperature phenomena caused by dilute phase tail burning can be avoided, such that regeneration device stable operation can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for bad-quality raw oil

ActiveCN106590744AExtend your lifeExtended operating cycleTreatment with hydrotreatment processesWaxNaphtha

The invention discloses a treatment method for bad-quality raw oil. The method includes the steps that 1, the bad-quality raw oil is subjected to a superficial hydrogenation reaction, so that gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil are obtained, wherein with the bad-quality raw oil being a standard, the productivity of the hydrogenated residual oil is controlled to be 85-95 wt%; b, the obtained hydrogenated residual oil in the step a is subjected to a first catalytic cracking reaction, so that first dry gas, first liquefied gas, first gasoline, first diesel oil and first wax oil are obtained; c, the first wax oil obtained in the step b is subjected to a hydrogenation reaction of wax oil, so that hydrogenated wax oil is obtained; d, the hydrogenated wax oil obtained in the step C is subjected to a second catalytic cracking reaction, so that second dry gas, second liquefied gas, second gasoline, second diesel oil and second wax oil are obtained. Compared with the prior art, the method can prolong the running period of a hydrogenation device for the bad-quality raw oil and lower chemical hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Directional reactive catalysis thermal cracking method for direct converting low carbon alkane without need of oxygen

ActiveCN1296459CFunctionalImprove product distributionCatalytic crackingHydrocarbon by hydrocarbon condensationAlkaneOxygen

A directional catalytic thermocracking reaction for non-oxygen direct conversion of low-carbon alkane includes reaction between the preheated heavy petroleum hydrocarbon and hot cracking catalyst from the first generator in the first reactor to obtain the oil gas and carbon deposited catalyst, stripping the catalyst, regenerating in the first generator, delivering the oil gas in the following product separation system, feeding low-carbon alkane in the second reactor, reacting on the aromatizing catalyst from the second regenerator to obtain arylhydrocarbon and H2, regenerating the catalyst, and separating arylhydrocarbon from H2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and application

InactiveCN1915518BReduced hydrogen transfer activityIncrease concentrationMolecular sieve catalystsBulk chemical productionMolecular sieveActive component

A catalyst for catalytic cracking process is composed of active component (15-65 Wt %), adhesive (10-40) and carrier (15-70). Said active component is the HZSM-5 molecular sieve modified by two or more of P, Mg, Ga and Ge and the modified Y molecular sieve (0.1-10 Wt %) which is the REY molecular sieve prepared by RE metal ion exchange. It has low hydrogen transfer activity.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

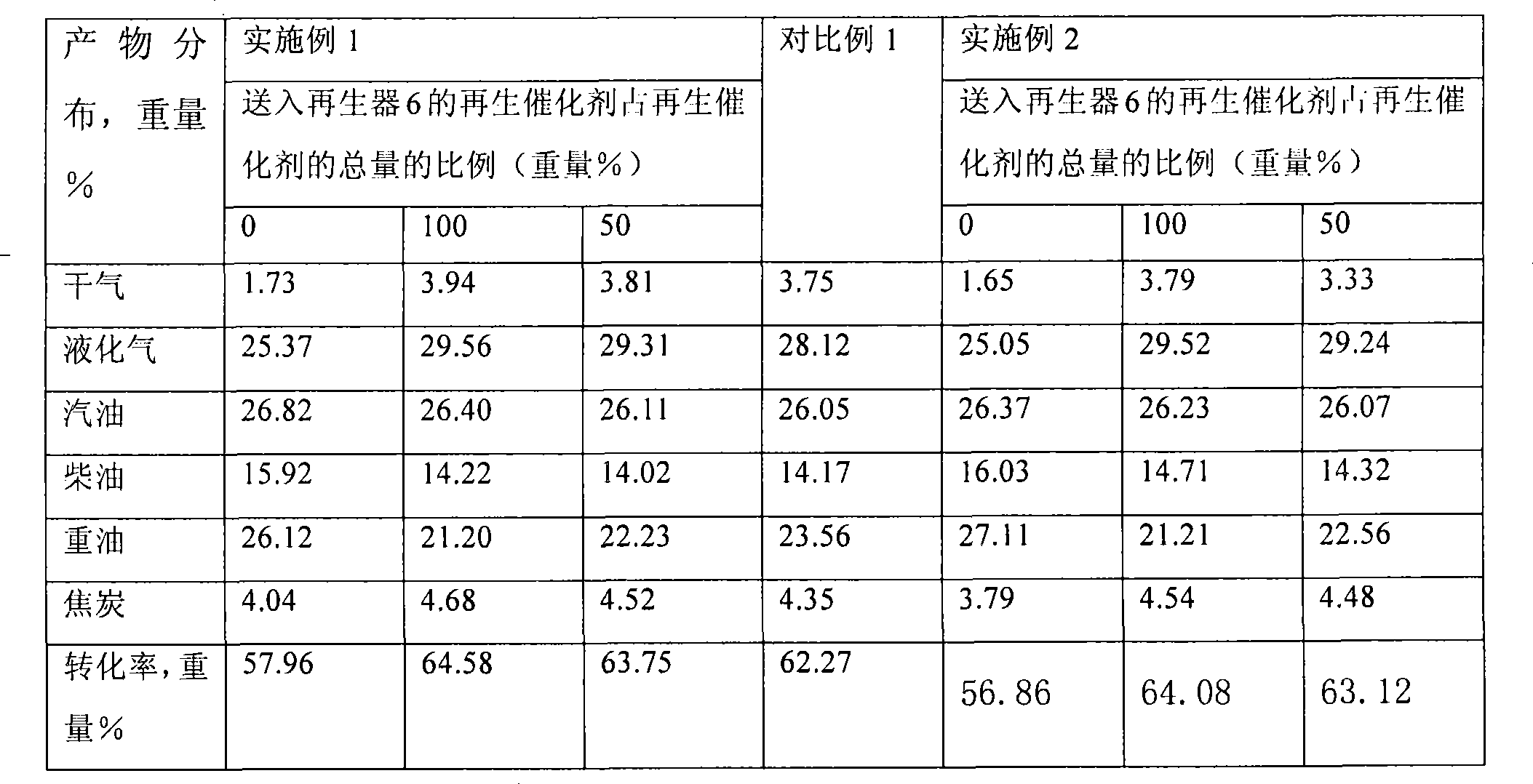

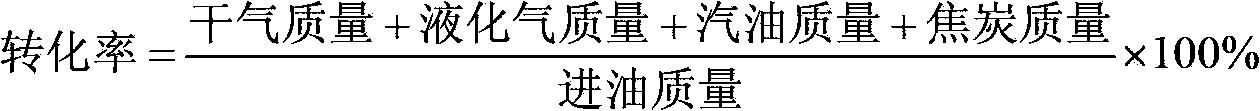

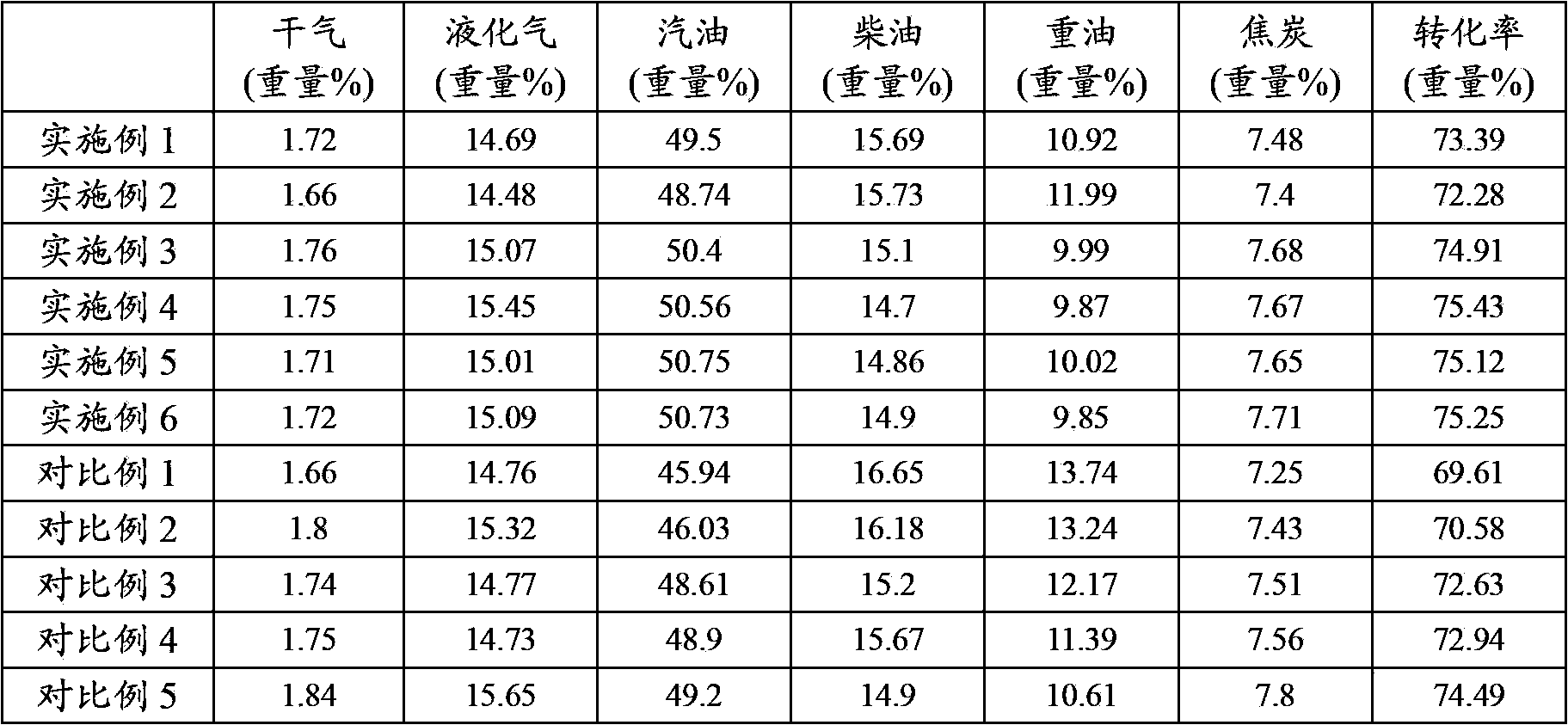

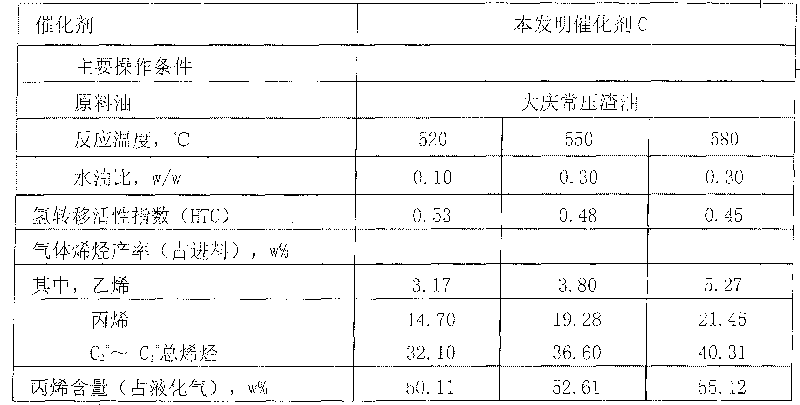

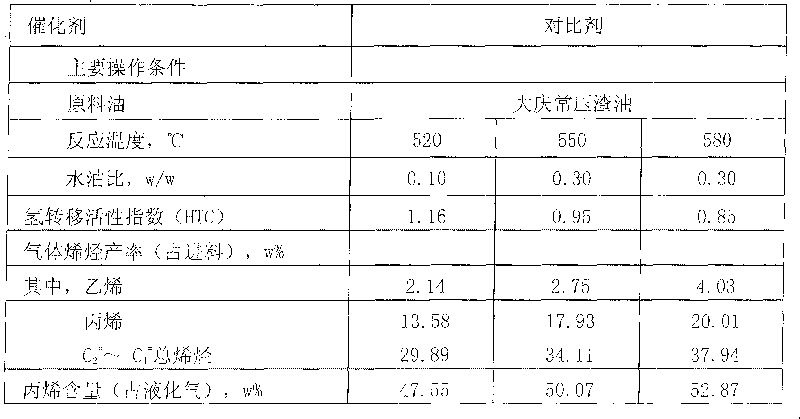

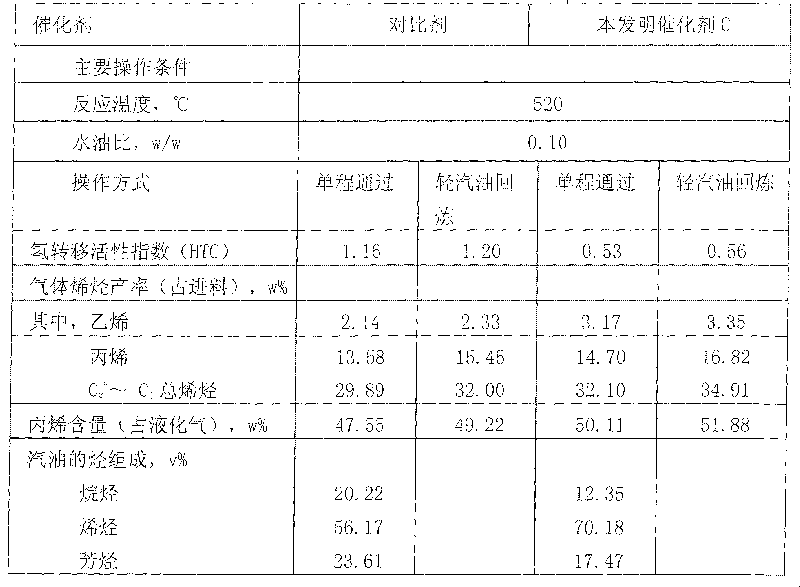

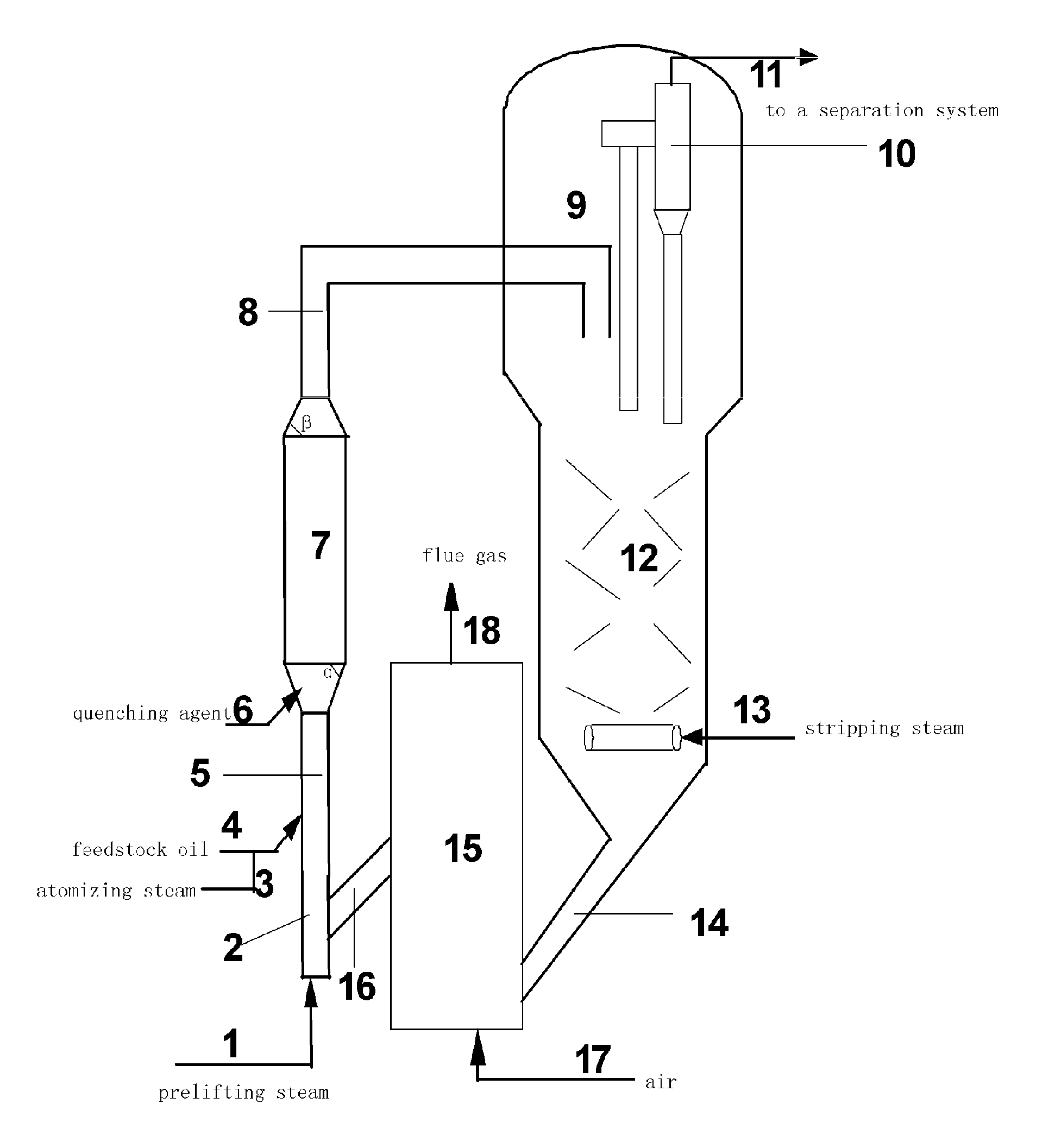

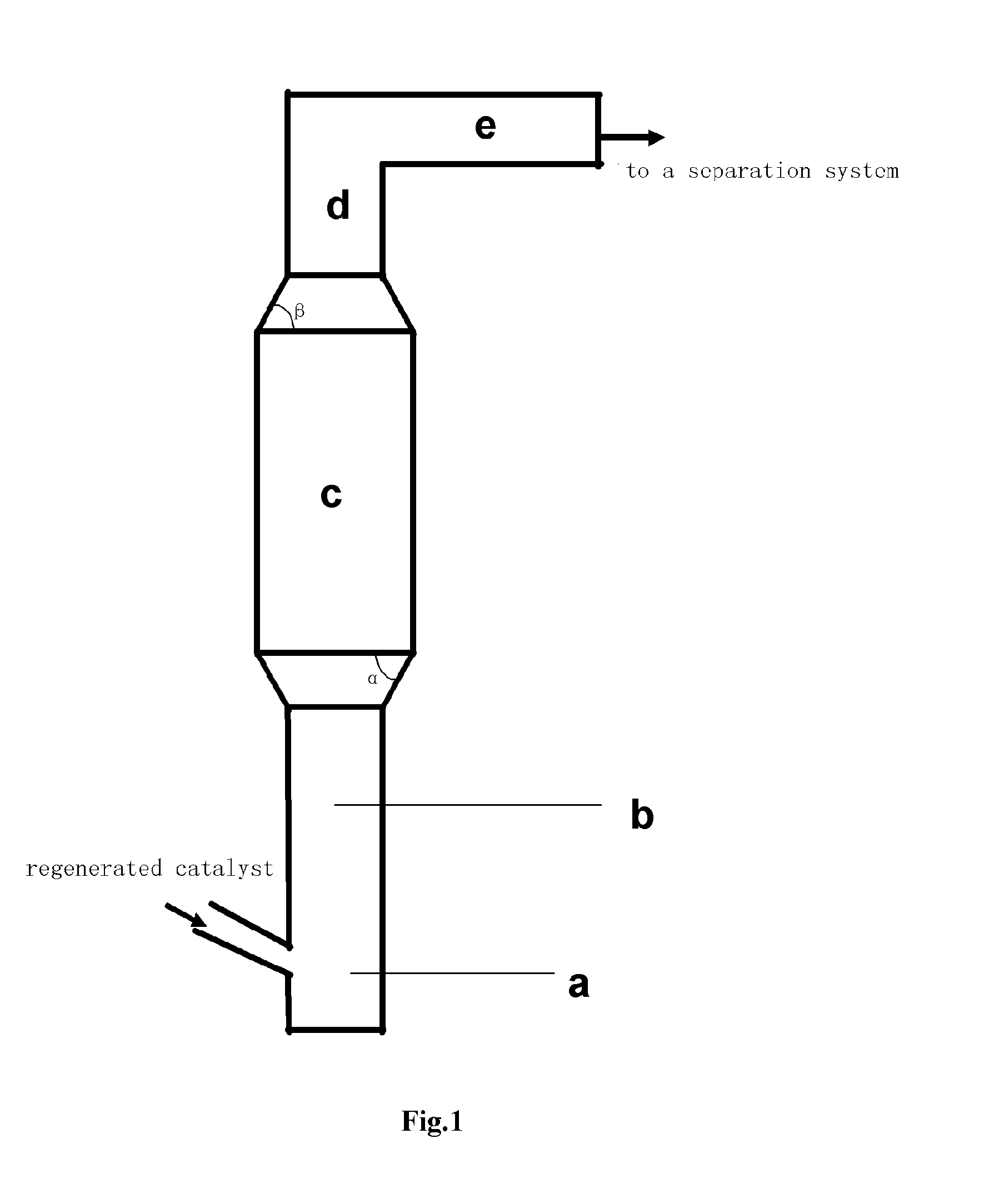

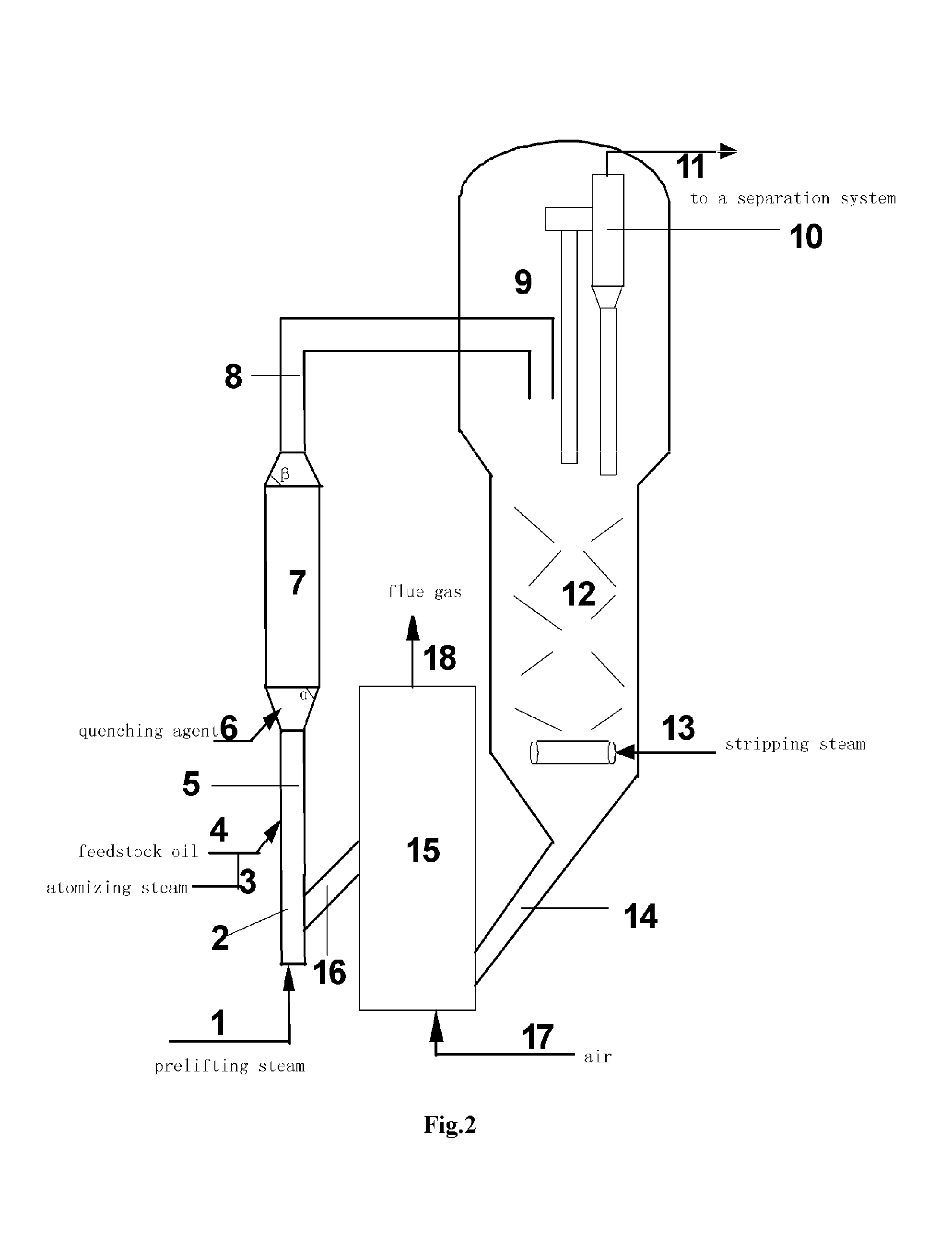

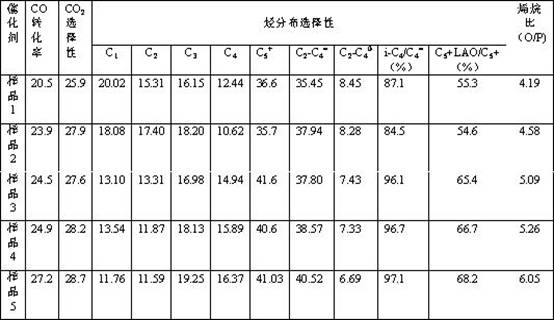

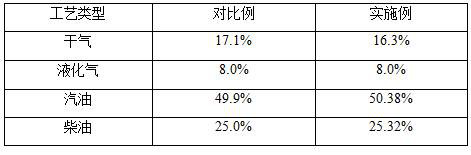

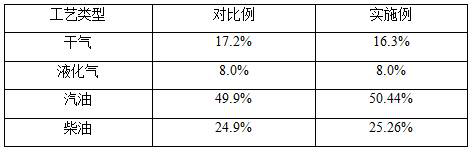

Catalytic conversion method for improving product distribution

ActiveUS20130211167A1Improve product distributionIncreasing isobutene contentCatalytic crackingHydrocarbonsPtru catalystCracking reaction

The present invention relates to a catalytic conversion process for improving the product distribution, characterized in that a feedstock oil of good quality is contacted with a hot regenerated catalyst having a lower activity in a reactor to carry out a cracking reaction, the reaction product is separated from the spent catalyst to be regenerated, then the reaction product is fed into a separation system, and the spent catalyst to be regenerated is stripped, regenerated and recycled in the process. The isobutene content in the liquefied petroleum gas (LPG) produced by the process is increased by a factor of more than 30%, and the olefin content in the gasoline composition may be increased to more than 30 wt. %. The product distribution is optimized, and the yields of dry gas and coke are decreased, so as to sufficiently utilize the petroleum resources.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

Coupling equipment for realizing temperature adjustment and stripping of catalytic cracking regenerant

InactiveCN101760229BRealize the function of removalInhibitory inactivation effectCatalytic crackingFlue gasGas compressor

The invention provides coupling equipment for realizing the temperature adjustment and the stripping of catalytic cracking regenerant, which comprises a temperature adjustment section arranged at the upper part and a stripping section arranged at the lower part; the temperature adjustment section is provided with a built-in heat exchange component and at least an air distributor; and the temperature adjustment section extends downwards and reduces the circulation area to form the stripping section. By coupling the stripping area with quite small circulation area at the lower part of the temperature adjustment section, the invention can realize the function of flue gas removal without or only with a small amount of stripping steam, and can best inhibit the inactivation of the regenerant under the steam atmosphere. The coupling equipment of the invention can be arranged in a regenerant circulating pipeline of a catalytic cracker, so that the regenerant directly enters a rise reactor after the temperature is adjusted and the flue gas is removed, thereby not only significantly improving the oil ratio, the regeneration temperature and the raw material pre-heating temperature of the catalytic cracker and facilitating the improvement of product distribution, but also having the function of glue gas removal and reducing the load of a rich gas compressor and the energy consumption of the device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing olefin by dehydration of methanol

ActiveCN102060644BImprove reaction separation efficiencyLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCarbonizationCatalytic distillation

The invention discloses a method for preparing olefin by dehydration of methanol, which overcomes the shortcoming of low olefin yield in the prior art, the shortcoming that a catalyst is susceptible to inactivation due to carbonization during reaction and the like. The method provided by the invention comprises: heating the methanol to generate vapor; allowing the vapor to enter a catalytic distillation rector to contact with a zeolite molecular sieve (ZSM)-5 catalyst and react; allowing the reaction product to enter a moving-bed reactor to contact with the catalyst and react; separating the reaction products; after ethylene and propylene products are separated out, allowing a material flow containing C4 hydrocarbons and a material flow containing C5-C7 hydrocarbons to enter two fixed-bedrectors respectively to contact with the catalyst and react; regenerating the inactive catalyst in the moving-bed reactor by burning and then recycling the regenerative catalyst. The method provided by the invention has the advantages of high olefin yield, high catalyst activity and high stability.

Owner:CHINA PETROCHEMICAL CORP +1

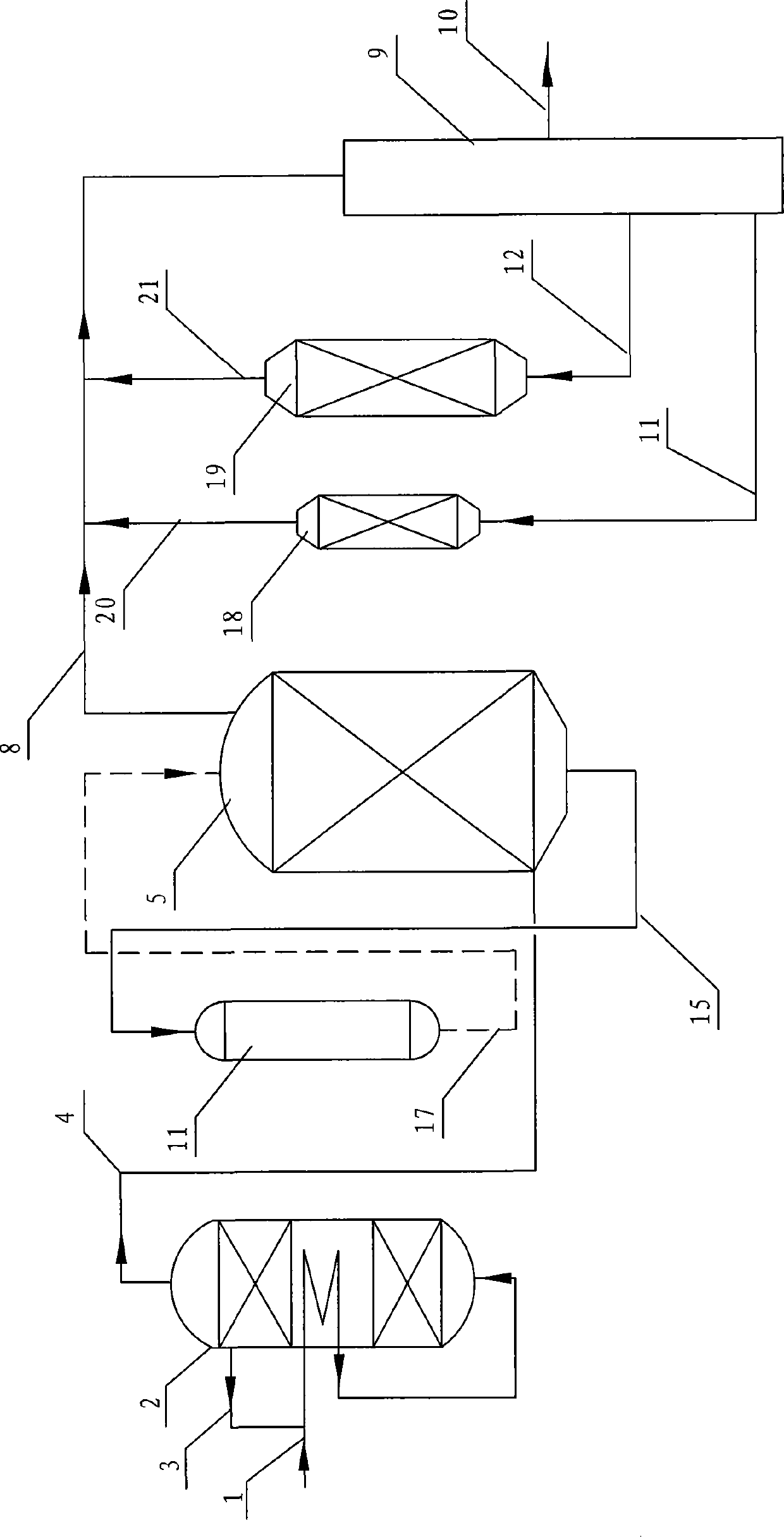

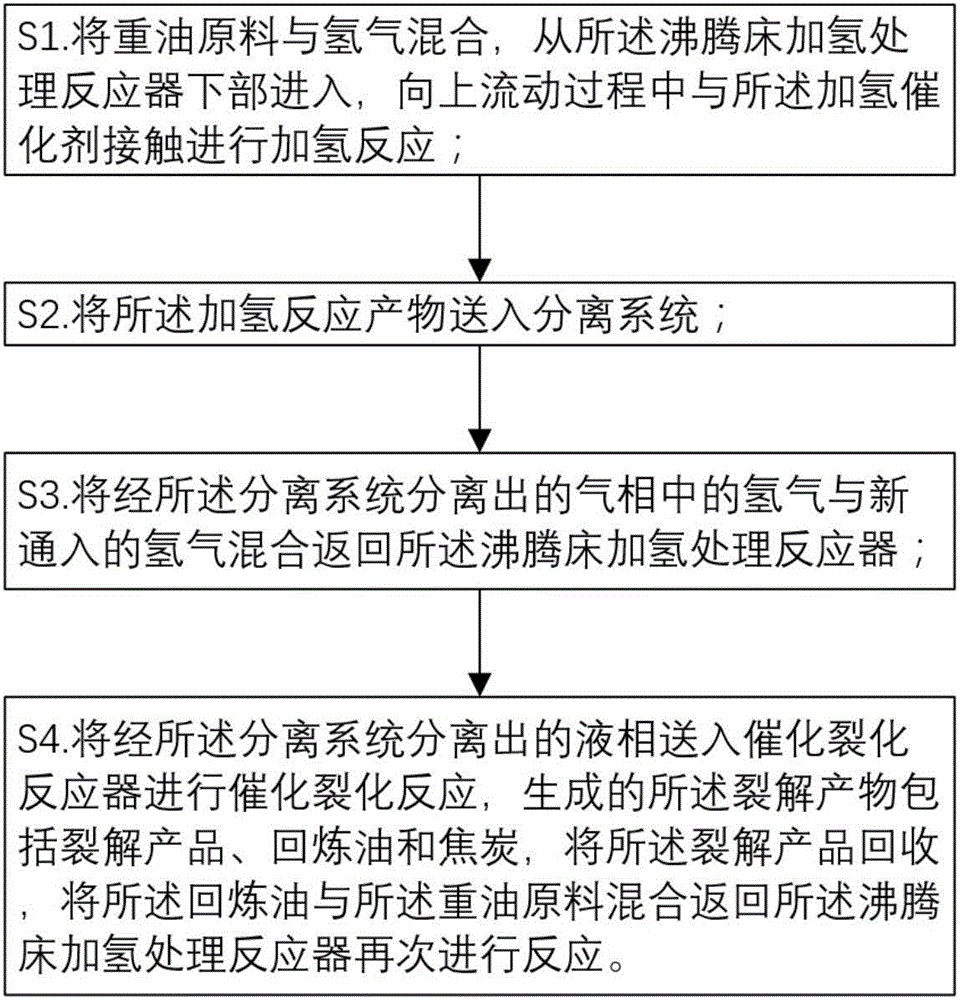

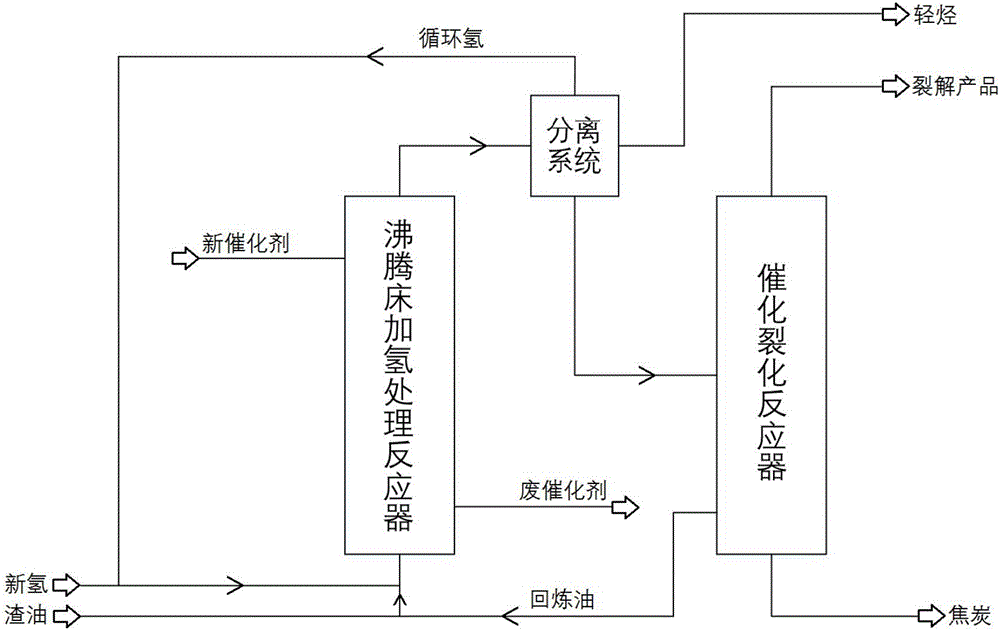

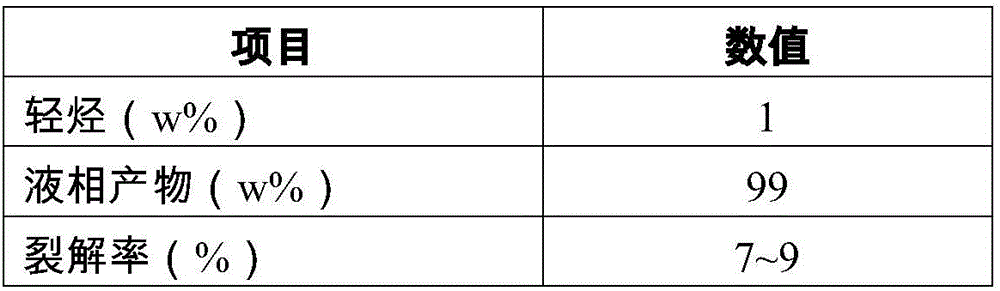

Fluidized bed hydrogenation and heavy oil catalytic cracking combining method and hydrogenation catalyst

InactiveCN106833741AReduce yieldHigh yieldTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsGas phaseSlurry

The embodiments of the present invention provide a combined method of ebullating bed hydrogenation and heavy oil catalytic cracking and a hydrogenation catalyst. The heavy oil raw material and hydrogen are subjected to hydrogenation reaction under the catalysis of hydrogenation catalyst, the hydrogenation reaction product is subjected to gas-liquid separation, the hydrogen in the separated gas phase is recycled for hydrogenation reaction, and the separated liquid phase is further catalyzed Cracking reaction, recovering the cracking products in the cracking products, mixing and recycling the recycled oil and heavy oil raw materials in the cracking products for hydrogenation reaction; the hydrogenation catalyst is a particle supported by silicon-aluminum oxide, with a particle size range of 0-300 μm, Directed hydrogenation of aromatic rings in heavy oil molecules, including gums, can be performed. The technical scheme of the invention improves the quality of catalytic cracking raw materials, improves the distribution of products, greatly reduces the oil slurry yield of catalytic cracking, or does not produce oil slurry, and can greatly improve the economic benefits of the combined process.

Owner:SHANGHAI HOTO PETROCHEM ENG

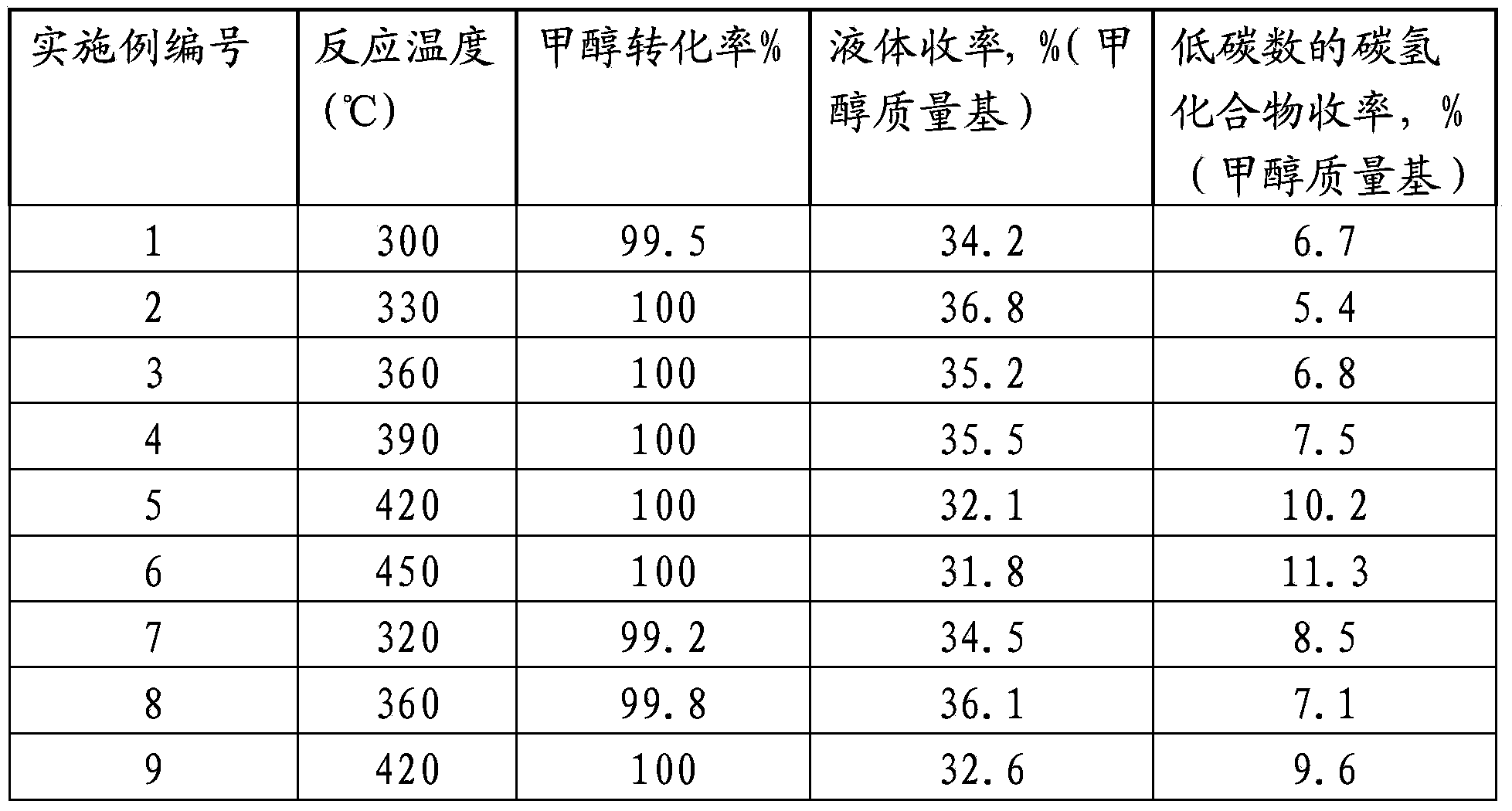

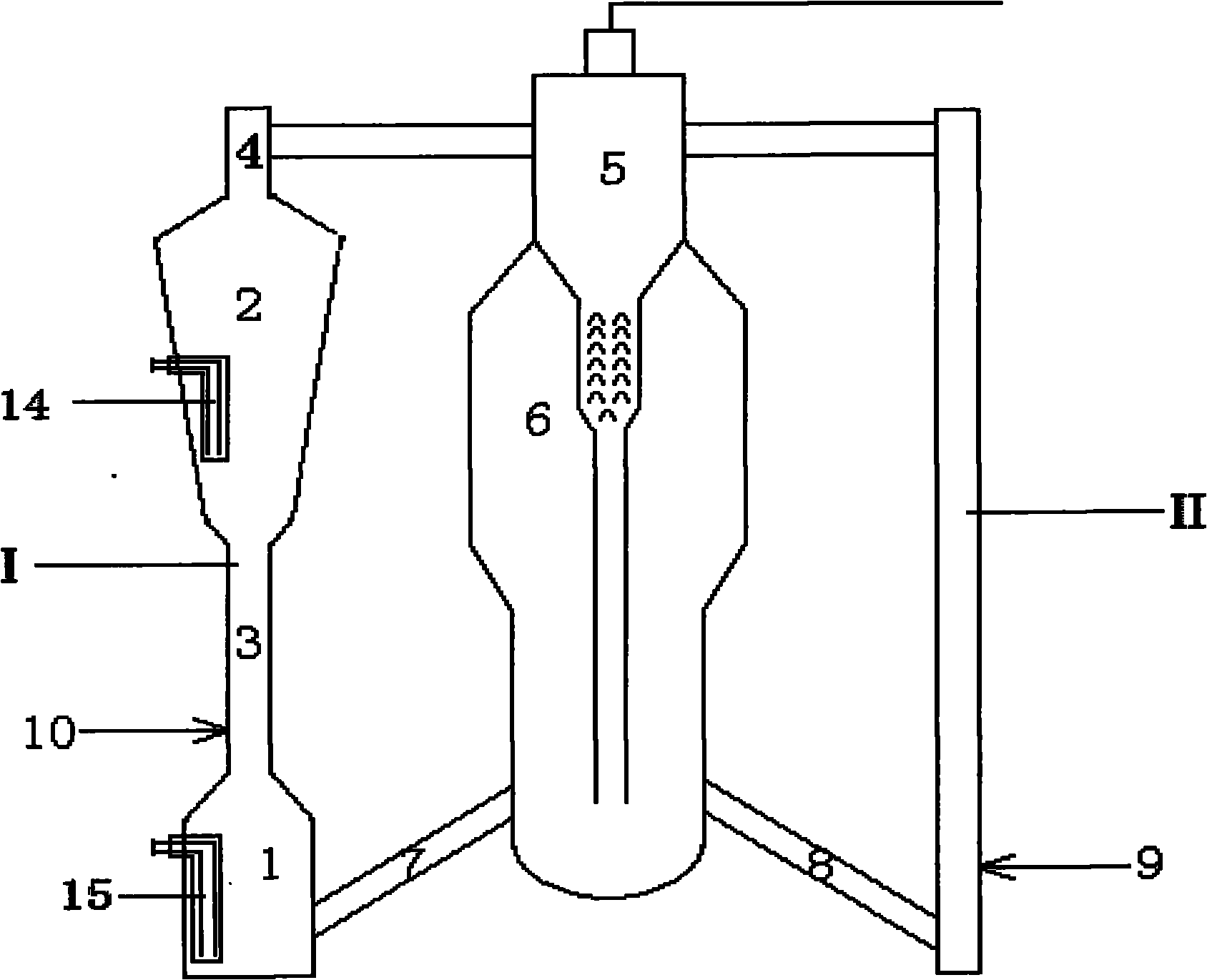

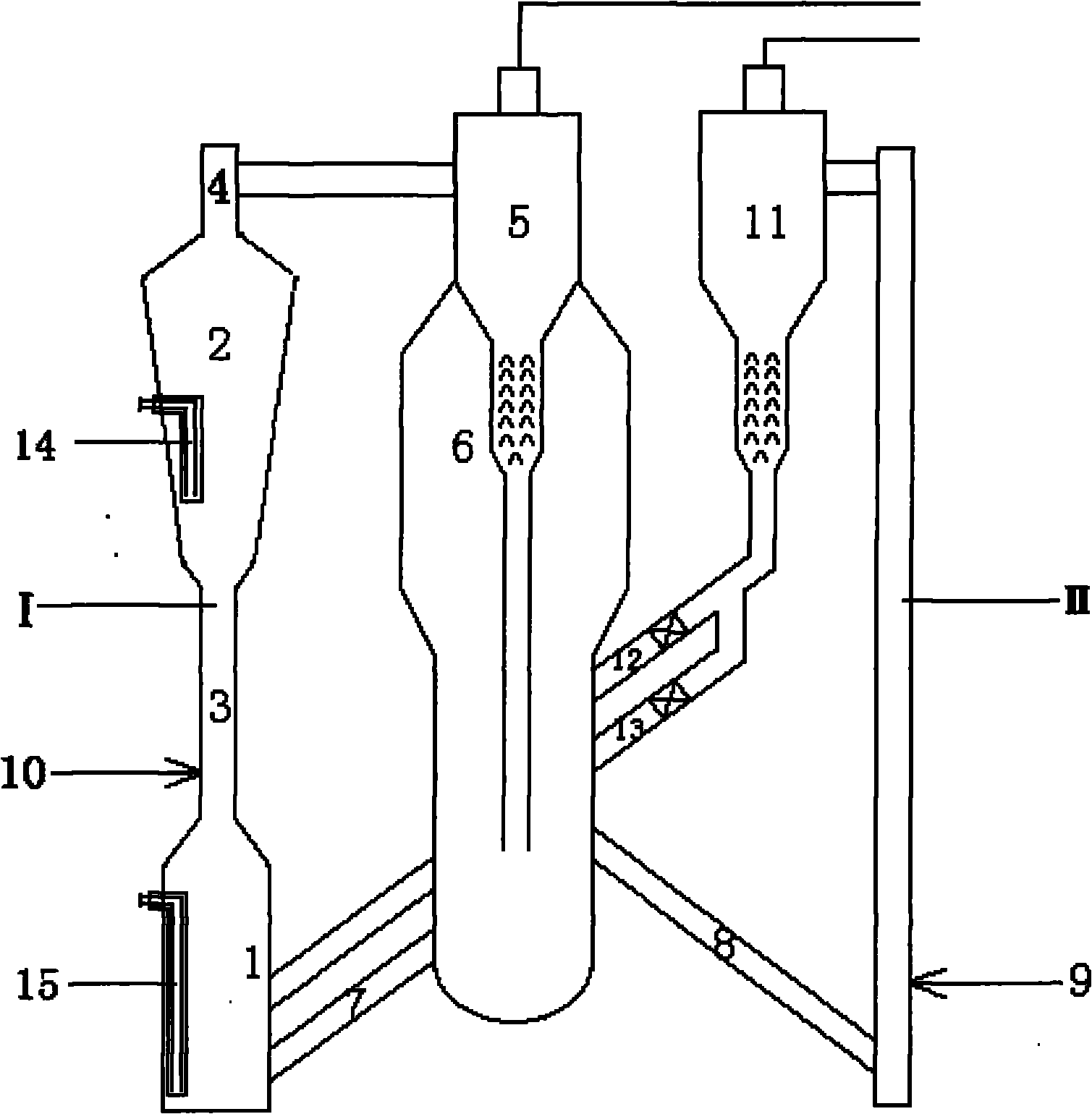

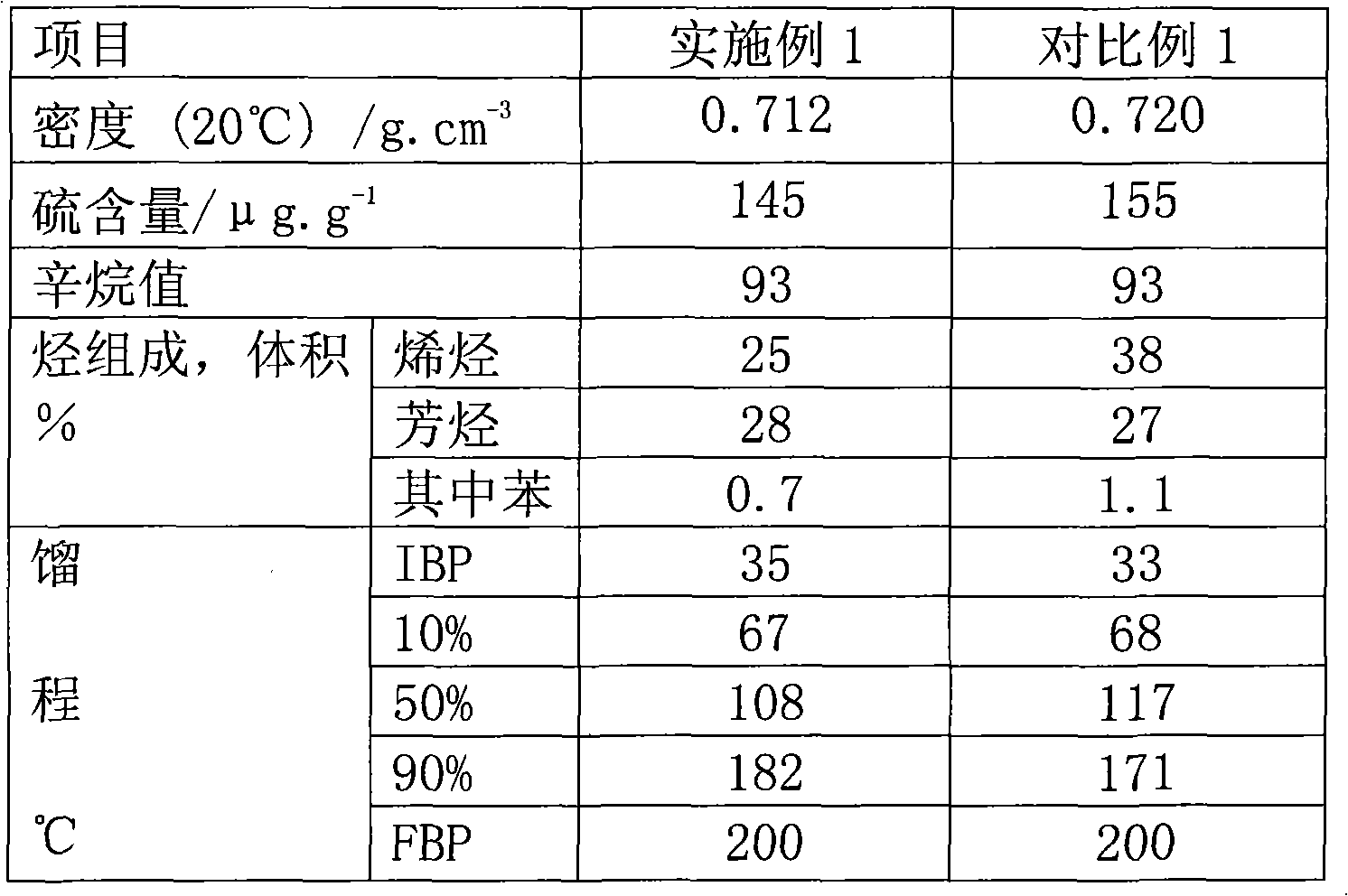

Technique method for producing gasoline by using methanol through one-step method

InactiveCN103881748AImprove conversion rateShort processLiquid hydrocarbon mixture productionBio-feedstockLiquid productGasoline

The invention relates to a technique method for producing gasoline by using methanol through a one-step method. The technique method comprises the following steps: (1) heating methanol and water and then feeding in a reactor, wherein the methanol is converted into C1-C12 hydrocarbon products under proper conditions; (2) carrying out heat exchange to the C1-C12 hydrocarbon products and then feeding in a separator, to obtain generation water, non-condensable gas and a liquid product containing C3-C12, wherein the liquid product is pumped into a stabilizing tower through a pump; (3) separating out gasoline fraction and liquefied gas in the stabilizing tower, discharging non-condensable gas from the tower top, wherein the gasoline fraction serves as a gasoline product and a gasoline absorbent; (4) feeding the non-condensable gas in an absorption tower, recovering C<3+> by using the gasoline absorbent, separating out dry gas from the tower top, and returning the gasoline absorbent to the stabilizing tower. According to the technical scheme, the technique method has the advantages of short technique flow, small equipment investment, low operation cost, high methanol conversion rate, high gasoline productivity being more than 36%, and greatly improved product distribution.

Owner:洛阳市科创石化科技开发有限公司

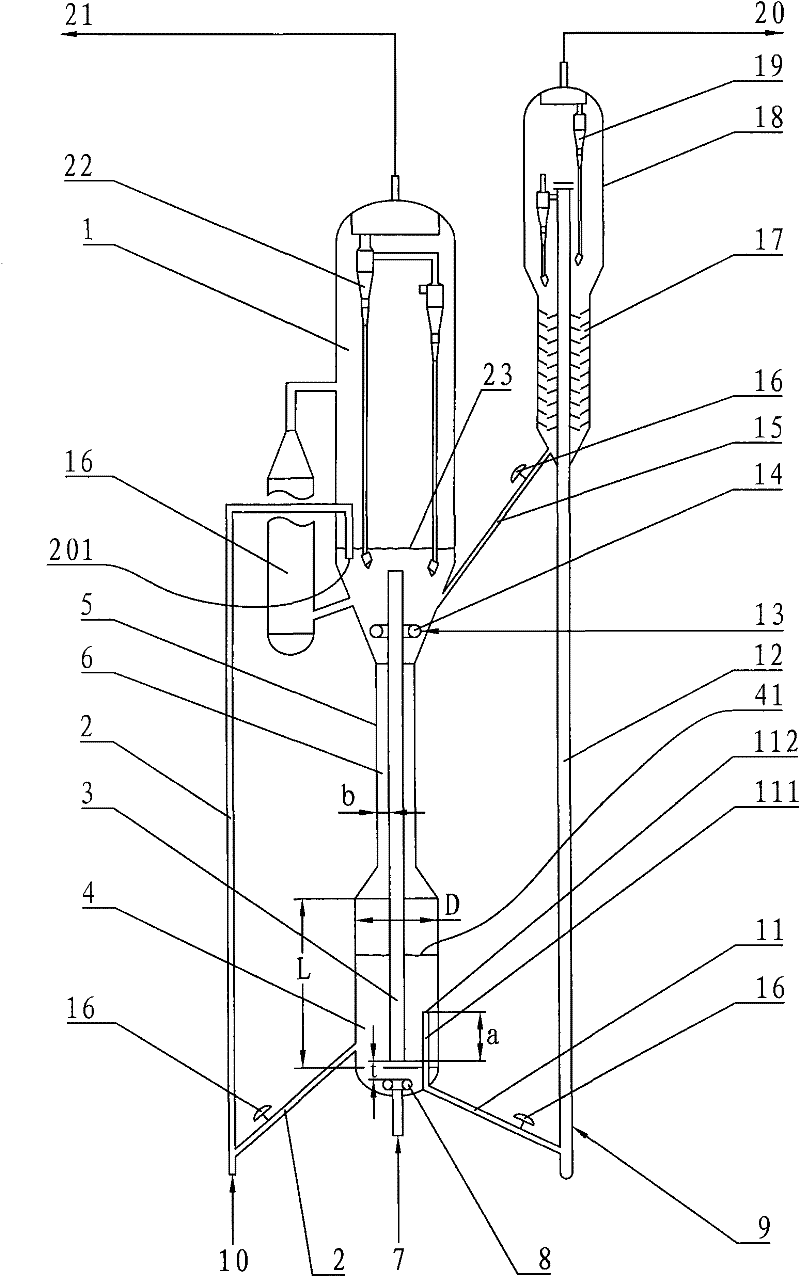

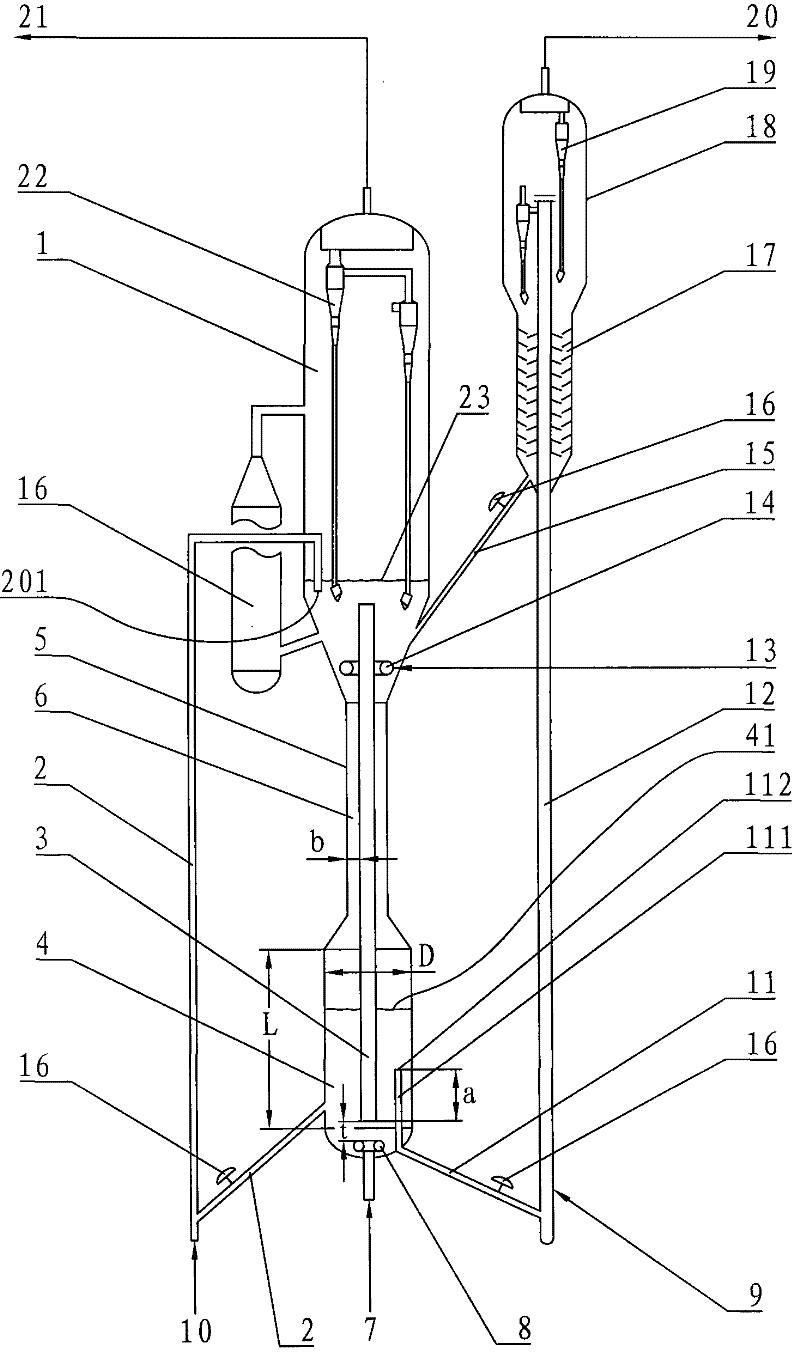

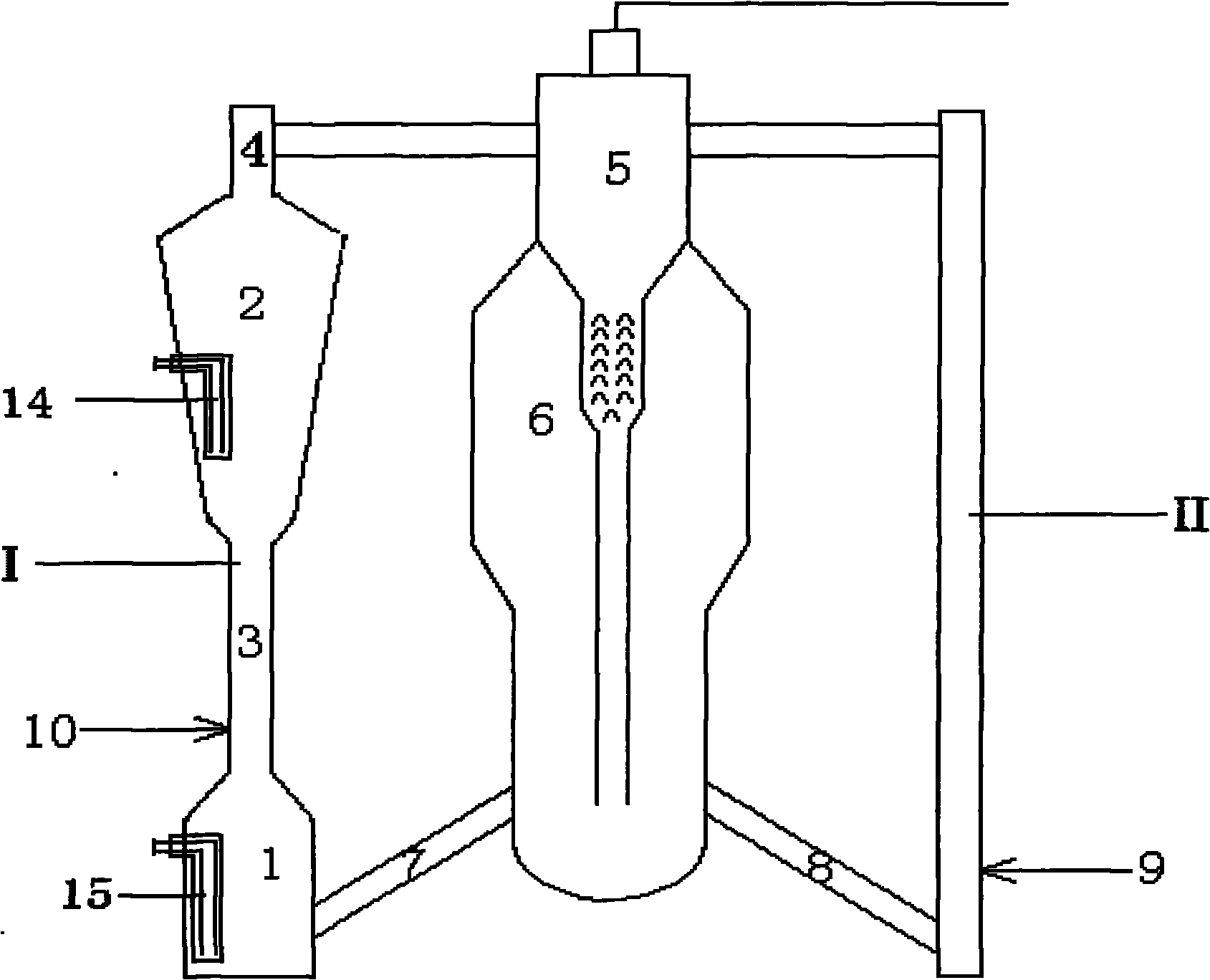

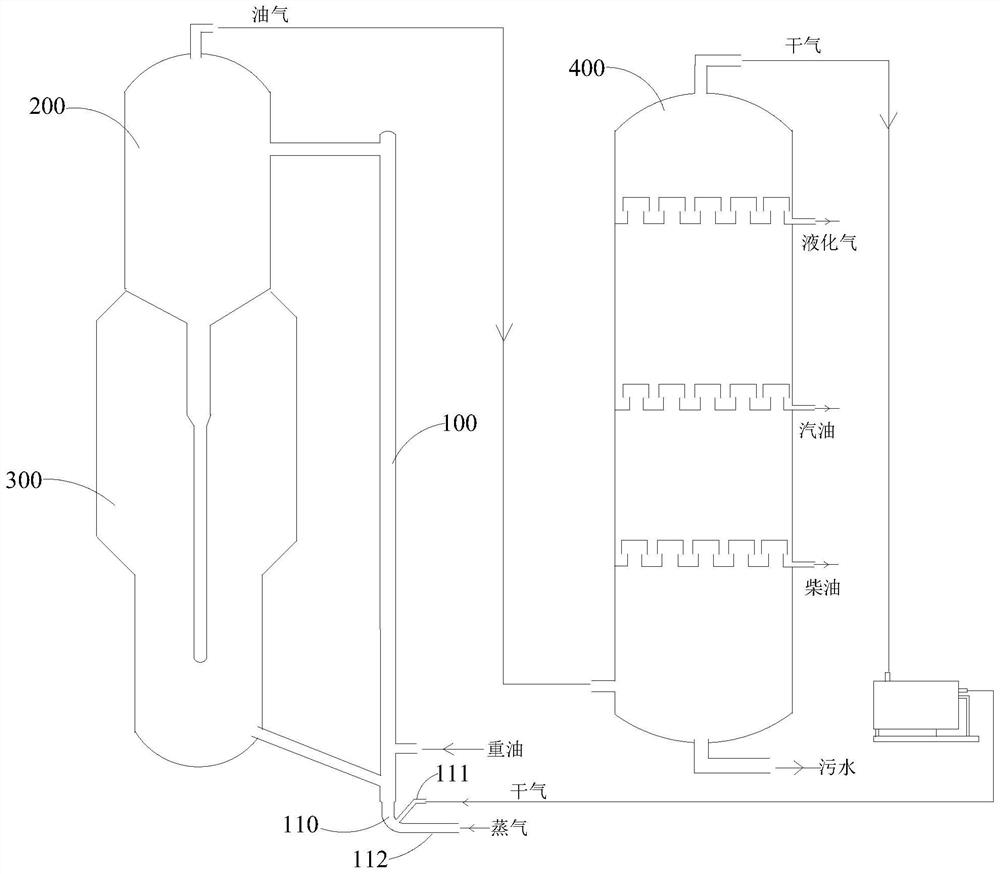

Catalytic cracking method and device thereof

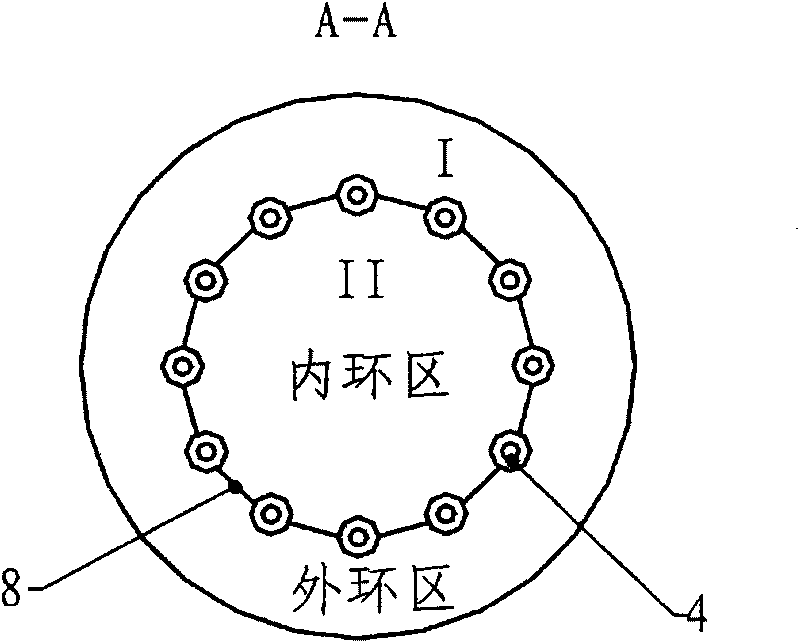

InactiveCN101993709AUniform radial distributionImprove contact effectCatalytic crackingGasolineChemistry

The invention discloses a catalytic cracking method and device. The method comprises the following steps of extracting the heat of a catalyst from a regenerator at a mixing section, mixing the catalyst subjected to heat extraction with heavy raw oil, entering a riser reactor, an isokinetic bed reactor and a precipitator of a reactor I, entering a fractionator by oil gas, and entering the regenerator by the catalyst for regeneration; mixing the other part of the catalyst from the regenerator with light raw oil, entering a reactor II, entering the precipitator by a compound of reaction oil gas and the catalyst, entering the fractionator by the oil gas, entering the regenerator by the catalyst for regeneration, producing qualified gasoline by the reactor I, and producing olefin by the reactor II, and thus, a set of devices is utilized to satisfy the needs for producing the gasoline and a chemical material.

Owner:CHINA PETROCHEMICAL CORP +1

Layered composite material as well as preparation method and application thereof

PendingCN112156784AIncreased hydrogenation conversionHigh selectivityHydrocarbon from carbon oxidesCatalyst activation/preparationWater-gas shift reactionHydrogenation reaction

The invention relates to a layered composite material as well as a preparation method and application thereof, in particular to a Fe-based material for high-selectivity preparation of alpha-olefin. Acatalyst provided by the invention can inhibit secondary hydrogenation reaction of primary olefinand water gas shift reaction WGS, thereby improving olefin selectivity, effectively reducing CO2 generation, regulating and controlling product distribution with high added value, especially improving the yield of alpha olefin, and having significant industrial application value.

Owner:NINGXIA UNIVERSITY

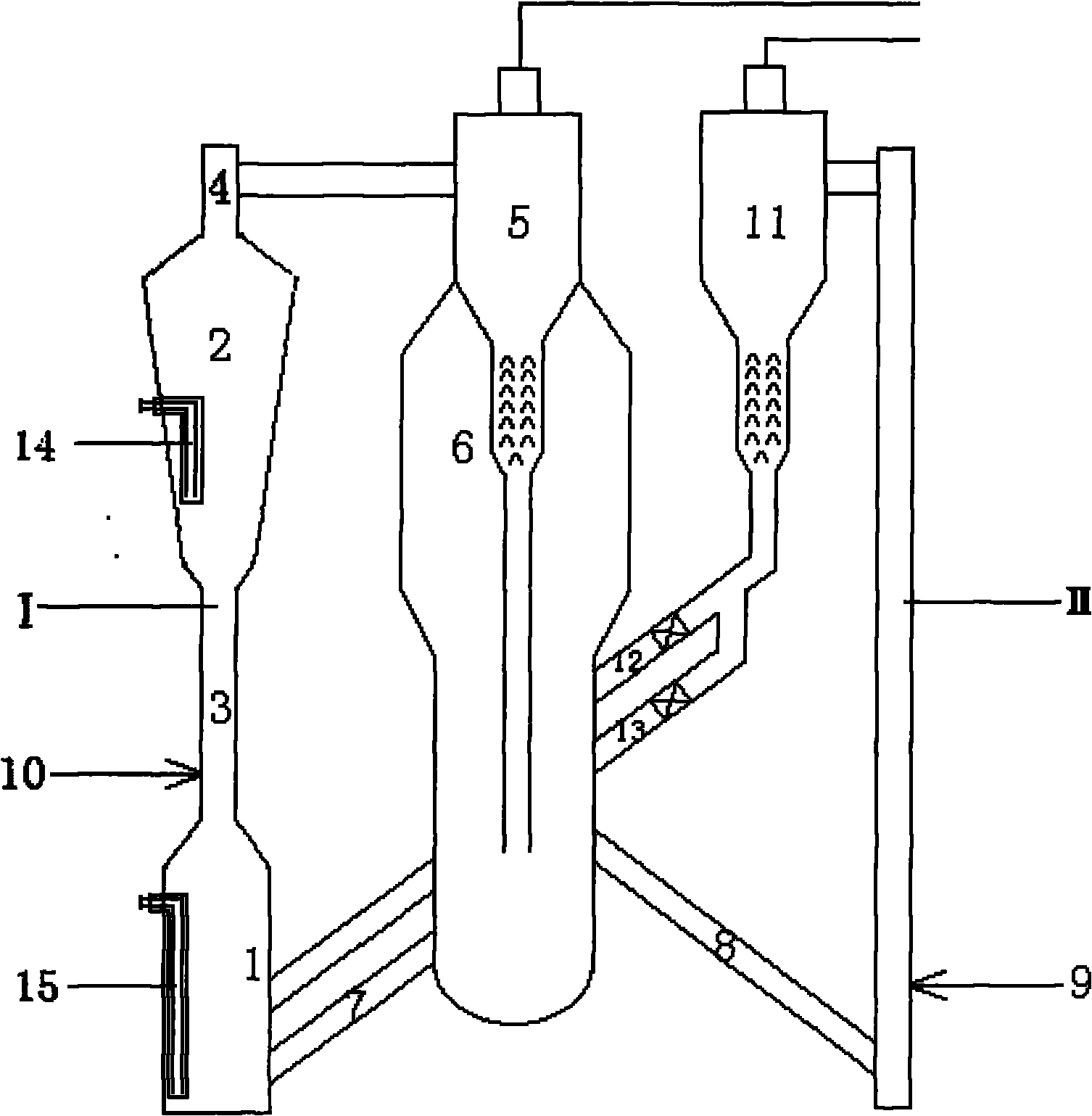

Catalytic cracking method and device

InactiveCN101993708AUniform radial distributionImprove contact effectCatalytic crackingGasolineTower

The invention discloses a catalytic cracking method and a catalytic cracking device. The method comprises the following steps of: heating a catalyst from a regenerator at a mixing section; mixing the catalyst and heavy raw oil and adding the mixture into a riser reactor of a reactor I, a constant-velocity bed reactor and a settling vessel; introducing oil gases into a fractionating tower and adding the catalyst into the regenerator for regeneration; mixing the other part of catalyst from the regenerator and light raw oil and then adding the mixture into a reactor II; and introducing reaction oil gases and adding a catalyst compound into the settling vessel, introducing the oil gases into the fractionating tower, and adding the catalyst into the regenerator for regeneration, wherein the reactor I produces qualified gasoline and the reactor II produces olefins, so the requirements of producing gasoline and chemical raw materials can be met by one set of device.

Owner:CHINA PETROCHEMICAL CORP +1

Rare earth-containing Al-ITQ-13 zeolite and synthesis method thereof

ActiveCN104528756AHigh purityGood repeatabilityCrystalline aluminosilicate zeolitesSynthesis methodsRare earth

The invention provides rare earth-containing Al-ITQ-13 zeolite and a synthesis method thereof. The rare earth-containing Al-ITQ-13 zeolite has a mole ratio of RE2O3 to SiO2 of 0.0005-0.1 and a mole ratio of SiO2 to Al2O3 of 10-2000. The synthesis method comprises the following steps of mixing a rare earth source, germanium oxide, a silicon source and water by stirring, adjusting a pH value, carrying out stirring, adding R(OH)2 into the mixture to obtain A, adding an aluminum source and a fluorine source into distilled water to obtain B, mixing the A and the B, adding crystal seeds into the mixture, carrying out stirring to obtain a gel mixture, and carrying out crystallization to obtain the rare earth-containing Al-ITQ-13 zeolite. The rare earth-containing Al-ITQ-13 zeolite has good hydro-thermal stability, high catalytic cracking activity, good product distribution and good alkene selectivity. The synthesis method has the advantages of good repeatability, rare earth content adjustability, easy penetration of aluminum into a molecular sieve skeleton, high aluminum source utilization rate and silica-alumina ratio adjustability.

Owner:PETROCHINA CO LTD +1

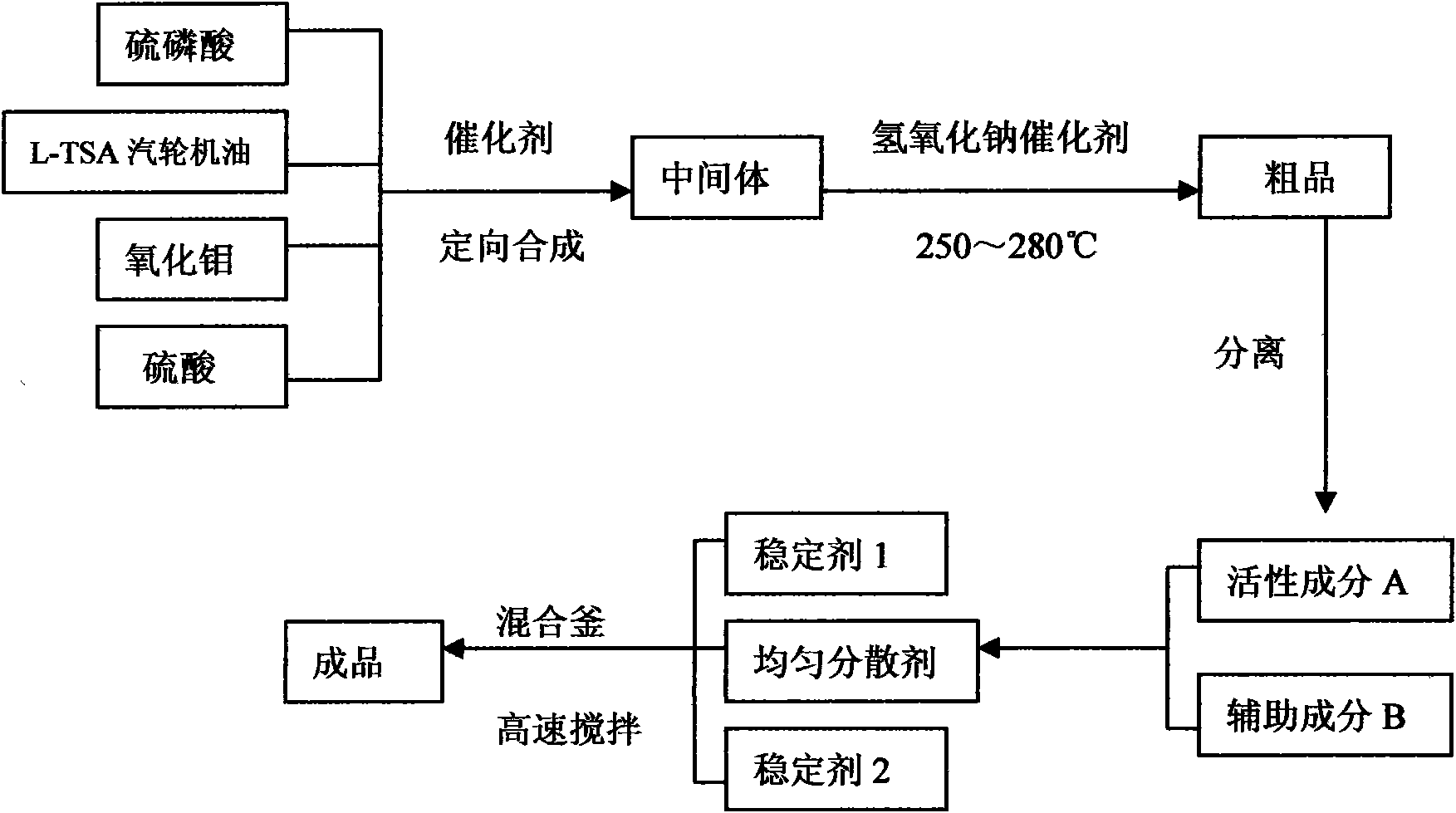

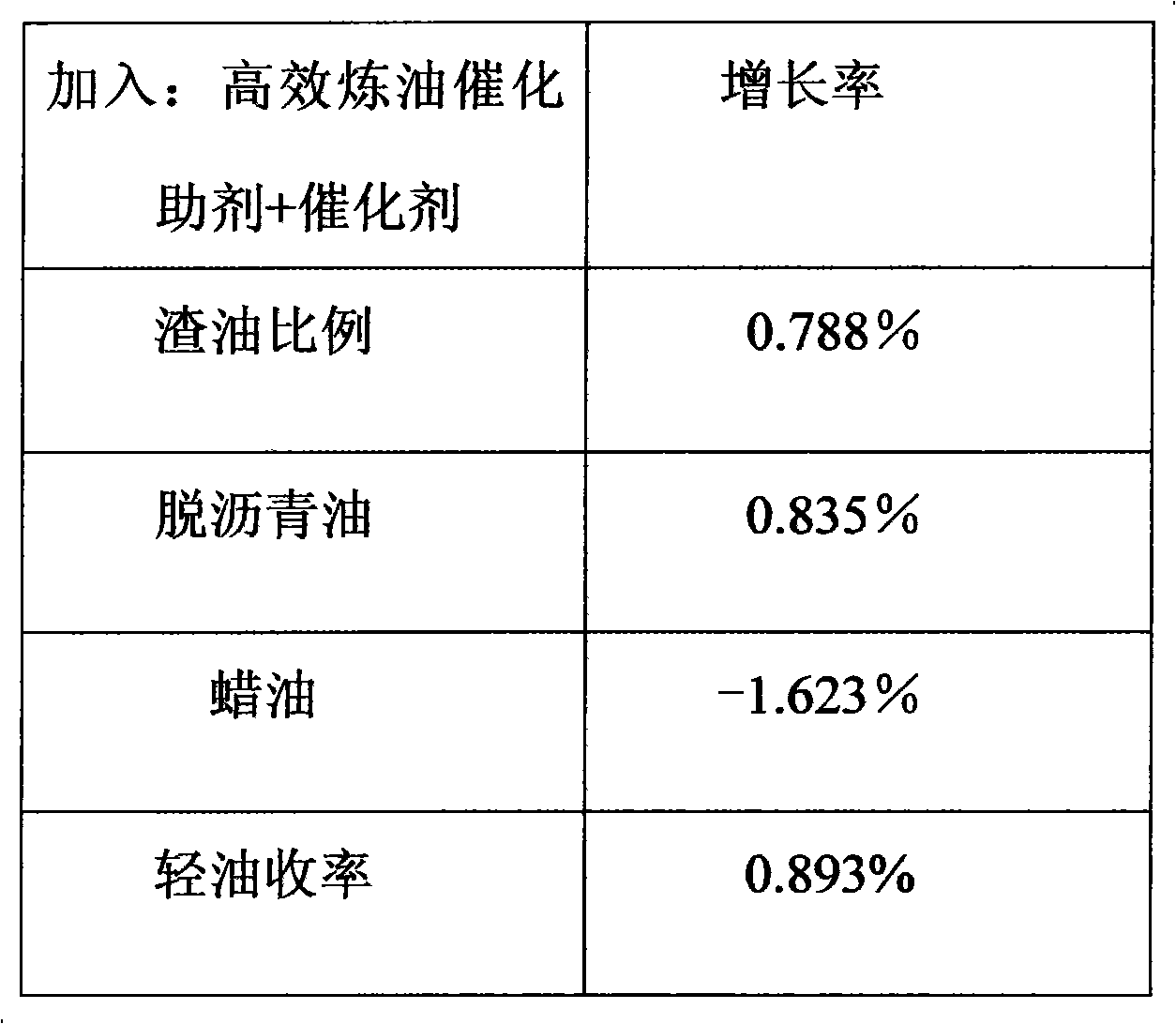

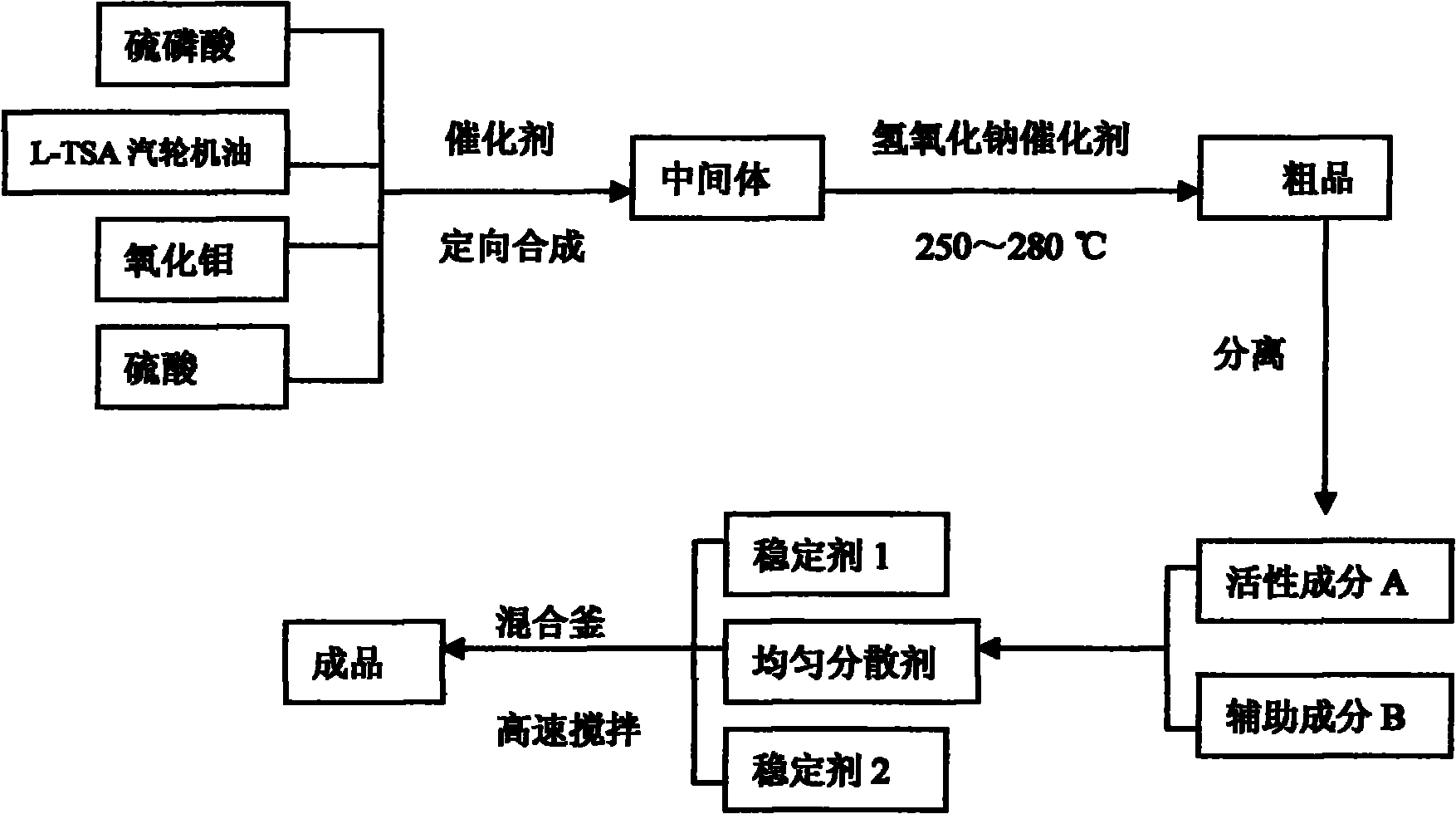

Novel high-efficiency refining catalytic aid and preparation method thereof

InactiveCN101905164AReduce hydrogen contentPoor cracking performanceCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsCompound (substance)Alkyl side chain

The invention discloses a novel high-efficiency refining catalytic aid and a preparation method thereof, and belongs to the field of chemical engineering. The high-efficiency refining catalytic aid contains the following components: thiophosphoric acid, molybdenum oxide, L-STA turbine oil and sulfuric acid. The preparation method comprises the following steps of: mixing the components to prepare an intermediate; mixing the 90 to 95 percent of intermediate with 5 to 10 percent of sodium hydroxide solution with the concentration of 5 to 8 percent, reacting at the temperature of between 250 and 280 DEG C and under the pressure of 2 to 5 MPa for 1 to 2 hours, reducing the temperature to 30 DEG C, and standing for demixing for 2 to 3 hours to prepare an upper oil substance, namely an active ingredient A; and reacting 95 to 98 volume percent of active ingredient A with 2 to 5 volume percent of alkyl side chain-containing auxiliary component B at the temperature of between 50 and 70 DEG C and at the normal pressure for 0.5 to 1 hour, sequentially adding 0.5 to 1 percent of stabilizer 1, 1 to 3 percent of stabilizer 2 and a homogenizing-dispersing agent, and stirring in a mixing kettle at a speed of 300 to 400 revolutions per minute for 1 to 1.5 hours to prepare the finished product of the high-efficiency refining catalytic aid.

Owner:SHANGHAI YOUHAO CHEM

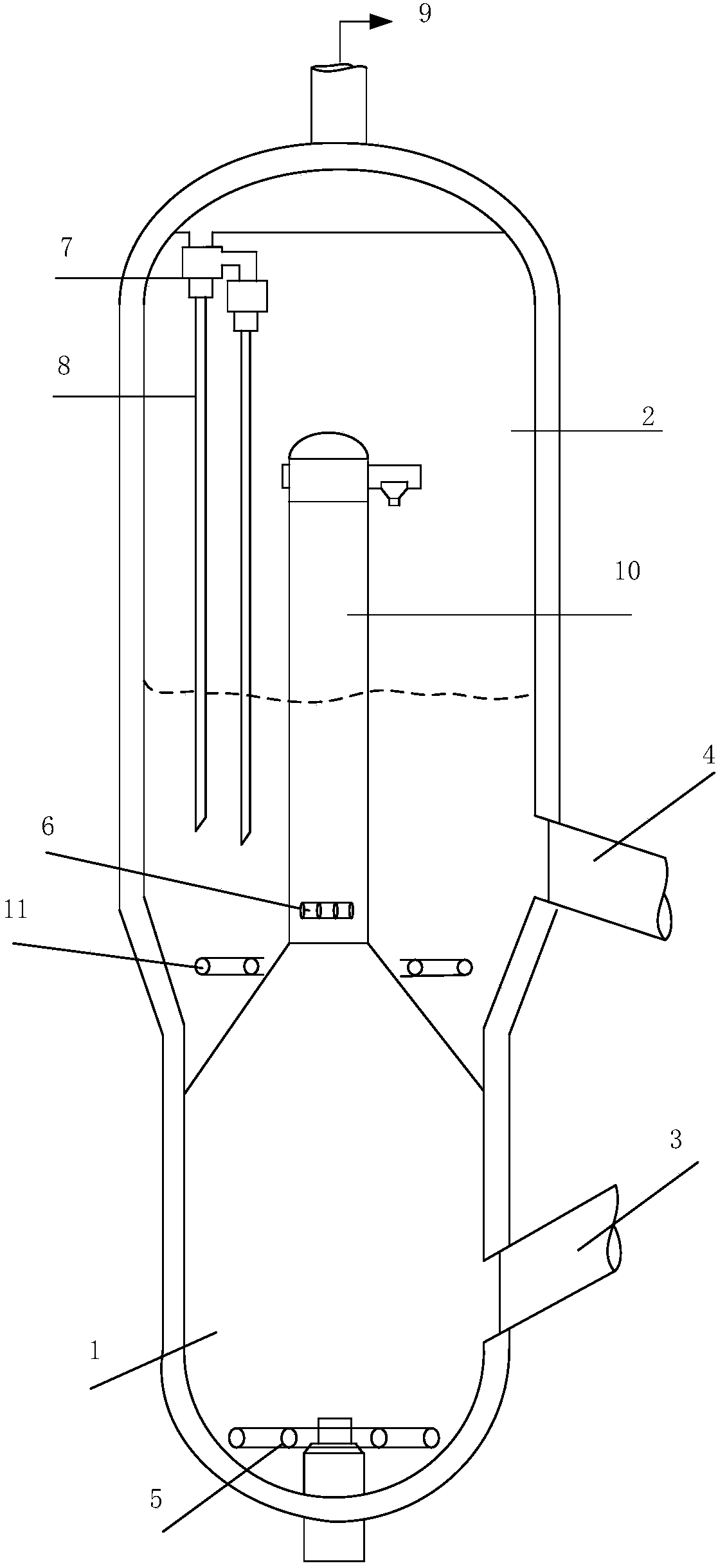

Heavy oil deep processing method and device

PendingCN112940773AHigh activity and selectivityImprove product distributionCatalytic crackingDispersed particle separationProcess engineeringFuel oil

The invention relates to a heavy oil deep processing method and device, and belongs to the technical field of petroleum processing. The method comprises the steps of replacing part of pre-lifting steam with dry gas to form pre-lifting mixed gas, and fully contacting a catalyst with heavy oil under the action of the pre-lifting mixed gas to carry out catalytic cracking reaction. According to the method, the catalyst is protected to a certain extent, cracking of the catalyst is avoided, the activity and selectivity of the catalyst are improved, then product distribution is changed, the yield of gasoline and diesel oil in the product is increased, economic benefits are increased, and meanwhile, sewage discharge is reduced.

Owner:宁夏瑞科新源化工有限公司

A catalytic cracking catalyst regeneration method and equipment

ActiveCN105521834BGuaranteed uptimePromote combustionCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsCombustionOxygen

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com