Catalytic cracking method and device thereof

A catalytic cracking device and catalytic cracking technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve problems such as complex processes, achieve the effects of increasing production rate, maximizing benefits, and improving oil-gas contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

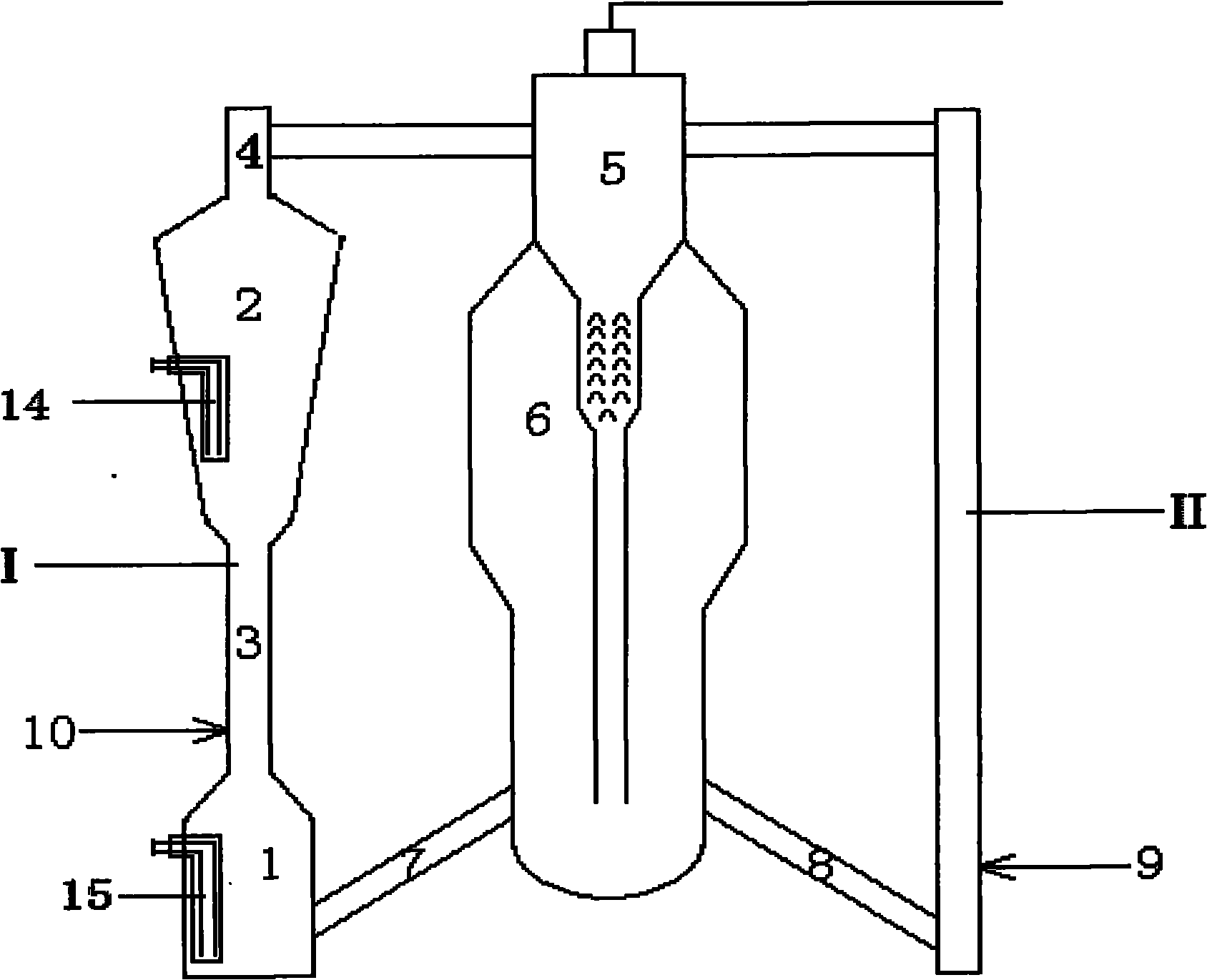

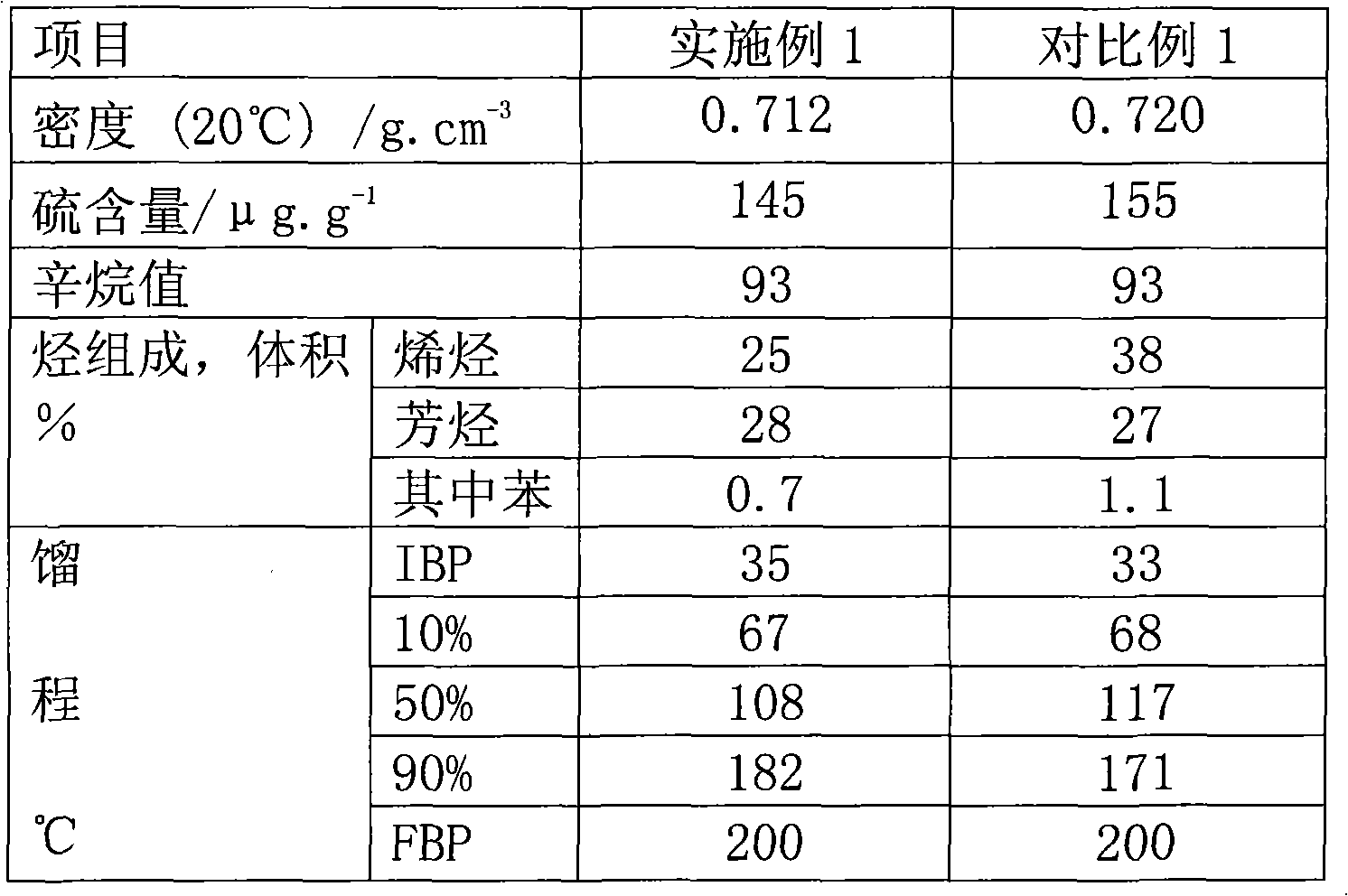

[0044] The main properties of the heavy feedstock oil A used are listed in Table 1, and the light feedstock is the liquefied gas produced by the cracking of the heavy feedstock oil A. The experiment adopts the operation method of one-way pass, and the experiment is carried out in figure 1 The device is carried out, and the catalyst is RSC-2006. Heavy stock oil A is carried out in reactor I, and the reaction temperature of the riser reactor in reactor I is 515 ℃, and reaction pressure is 0.11Mpa (gauge pressure), and water-oil ratio is 0.05, and the reaction time is 1.1s, The agent-oil ratio is 9.5; the reaction temperature in the constant velocity bed reaction section is 500°C, the reaction pressure is 0.11MPa (gauge pressure), and the reaction space velocity is 1.5h -1 The light raw material C4 liquefied gas reacts in the light raw material reactor II, the reaction temperature of the reactor II is 610°C, the reaction pressure is 0.11Mpa (gauge pressure), the water-oil ratio ...

Embodiment 2

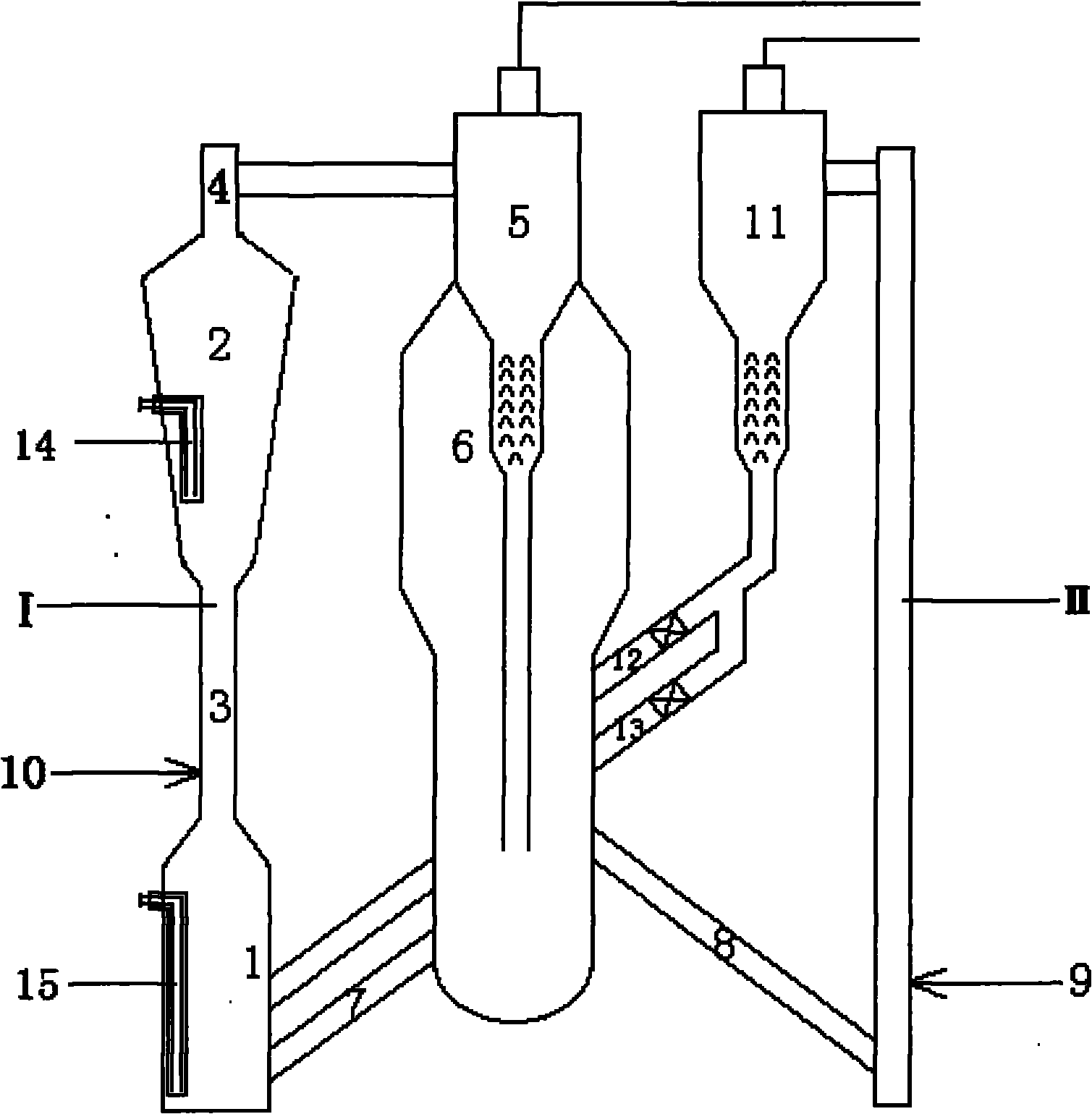

[0047] The main properties of the heavy raw material A used in the experiment and the light raw material are straight-run gasoline are listed in Table 1. The experiment adopts the operation method of one-way pass, and the experiment is similar to figure 2 The experimental device is carried out, and the catalyst is the prolific olefin catalyst of Engelhardt Company. The heavy feed oil A is carried out in the heavy feed oil reactor, the reaction temperature of the riser reaction section in the heavy feed oil reactor is 520°C, the reaction temperature of the constant velocity bed reaction section is 505°C, and the straight-run gasoline is The light raw material reactor is carried out, and the reaction temperature of the light raw material reactor is 620°C. The experimental results are listed in Table 3, and the main properties of gasoline are listed in Table 4. It can be seen from Table 3 and Table 4 that the yields of propylene and gasoline are respectively 4.0% and 1.5% high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com