Patents

Literature

857results about How to "Improve stripping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

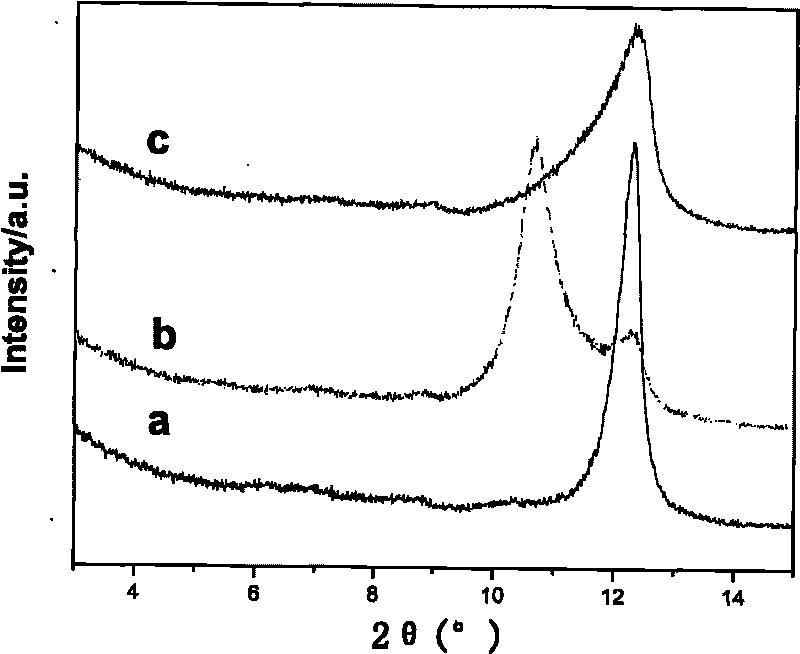

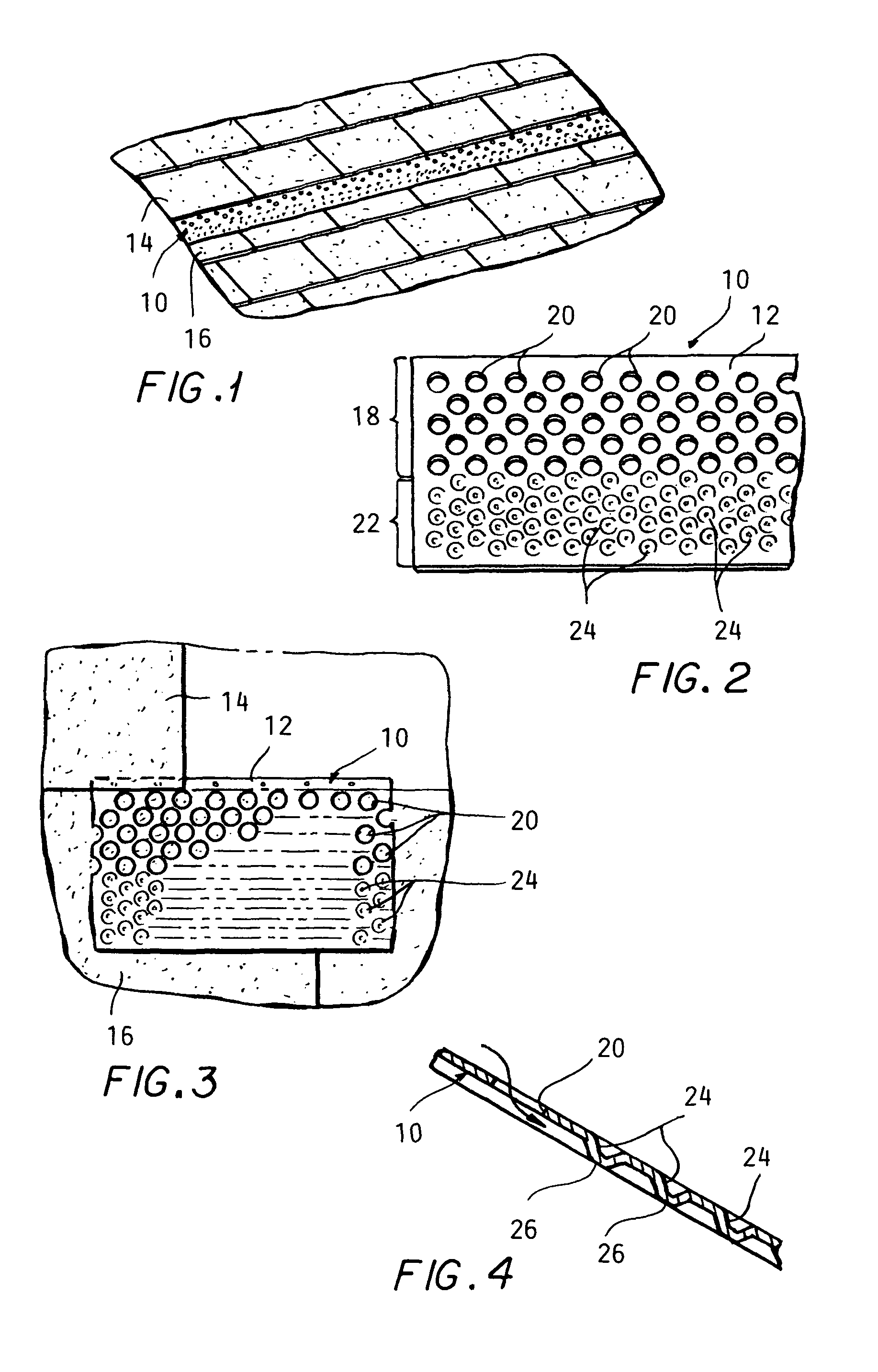

Method for preparing graphene compounds and graphene oxide compounds with high efficiency

The invention relates to a method for preparing graphene compounds and graphene oxide compounds with high efficiency, relating to the method for preparing the graphene compounds and the graphene oxide compounds. The invention solves the problems of easy composition of graphene or graphene oxide per se and many process steps, higher cost and difficult dispersedness for preparing the graphene compounds and the graphene oxide compounds by the traditional method at the same time. The invention adopts a mechanical stripping method to obtain the graphene compounds and the graphene oxide compounds. In the invention, an automatic machine is utilized, solid particles are used for assisting stripping, the contact area and the stripping number of the stripping process are greatly increased, and carbon material powder experiences a lot of stripping processes through the action of shear and impact, thereby obviously improving the stripping efficiency and achieving the purpose of uniform dispersedness to the composites. The method is suitable for industrial mass production of the graphene compounds and the graphene oxide compounds.

Owner:HARBIN INST OF TECH

Method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping

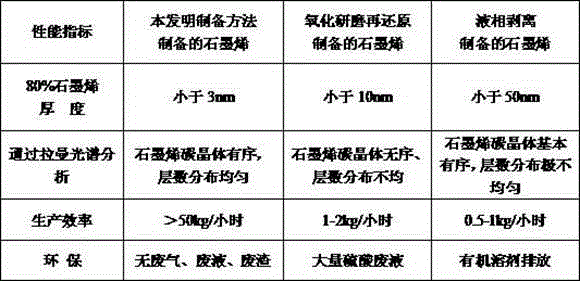

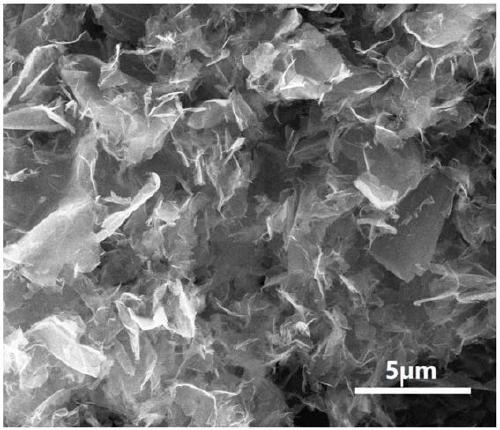

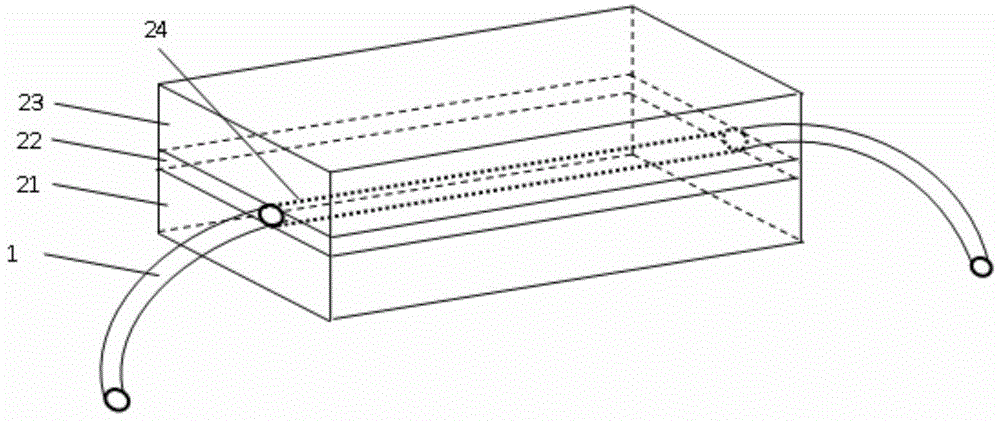

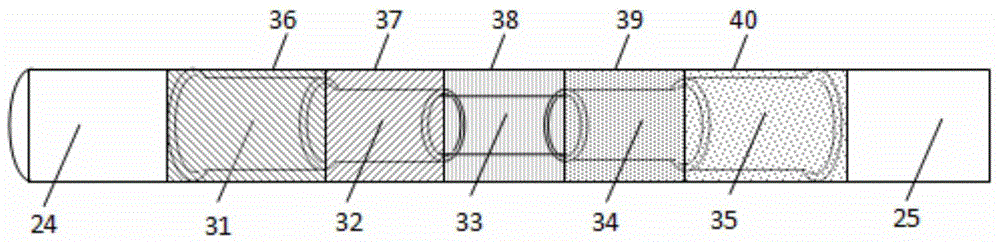

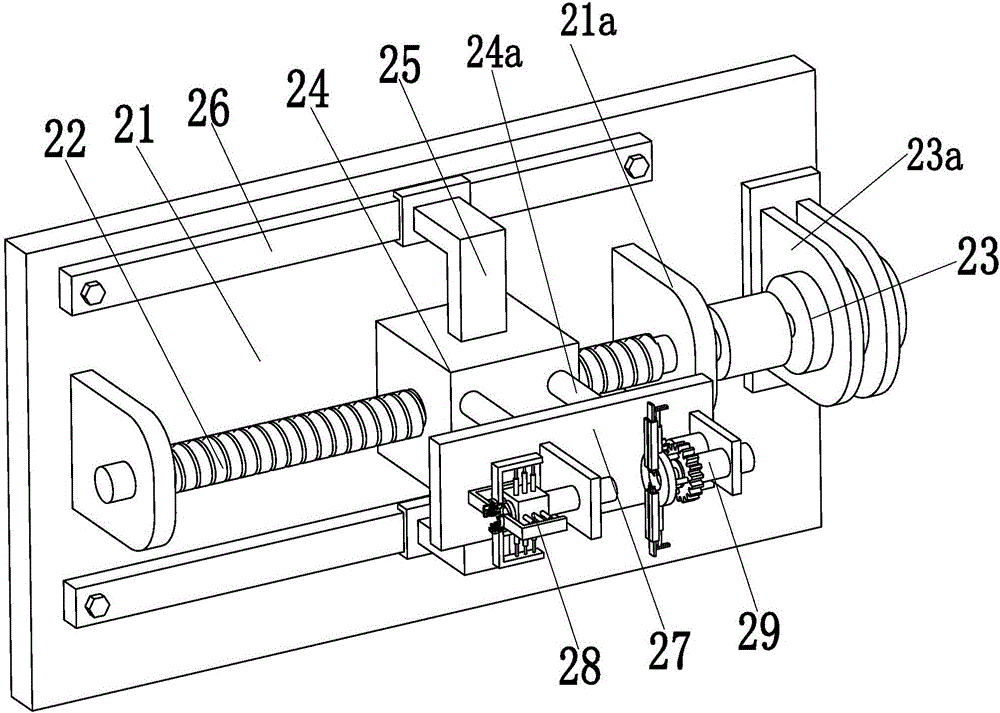

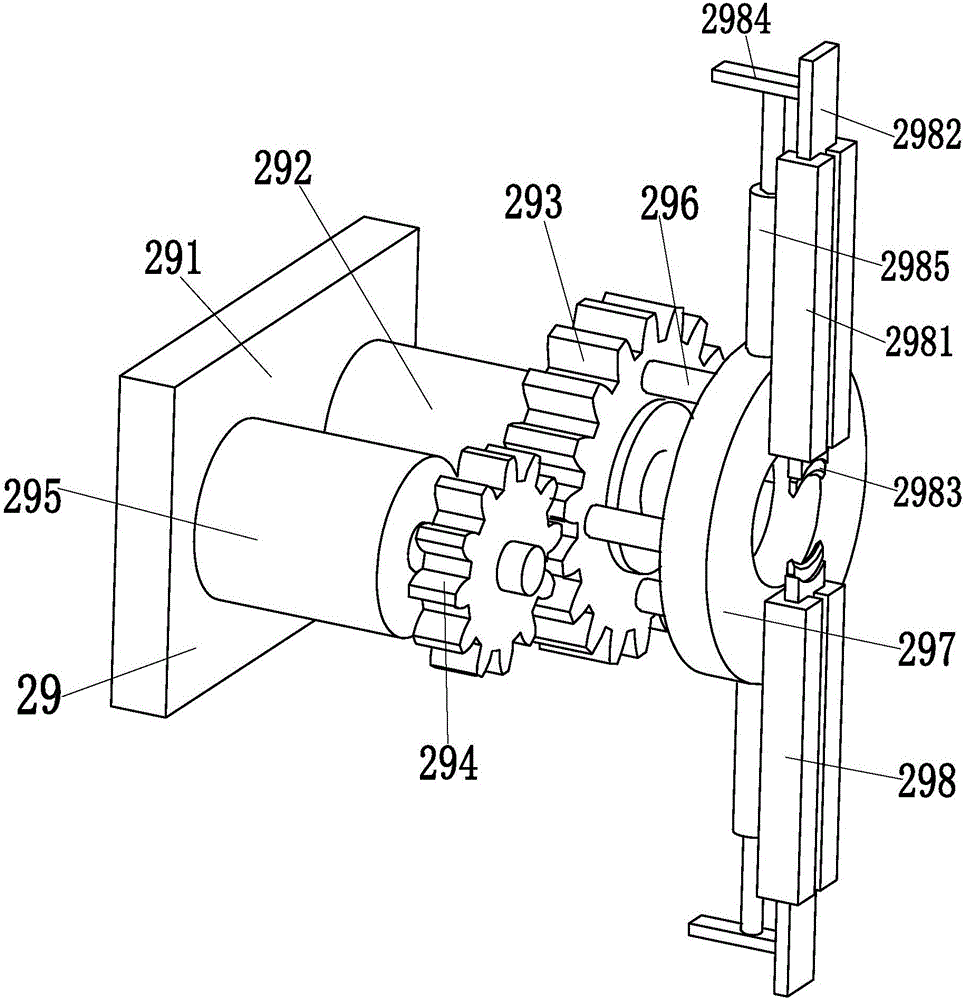

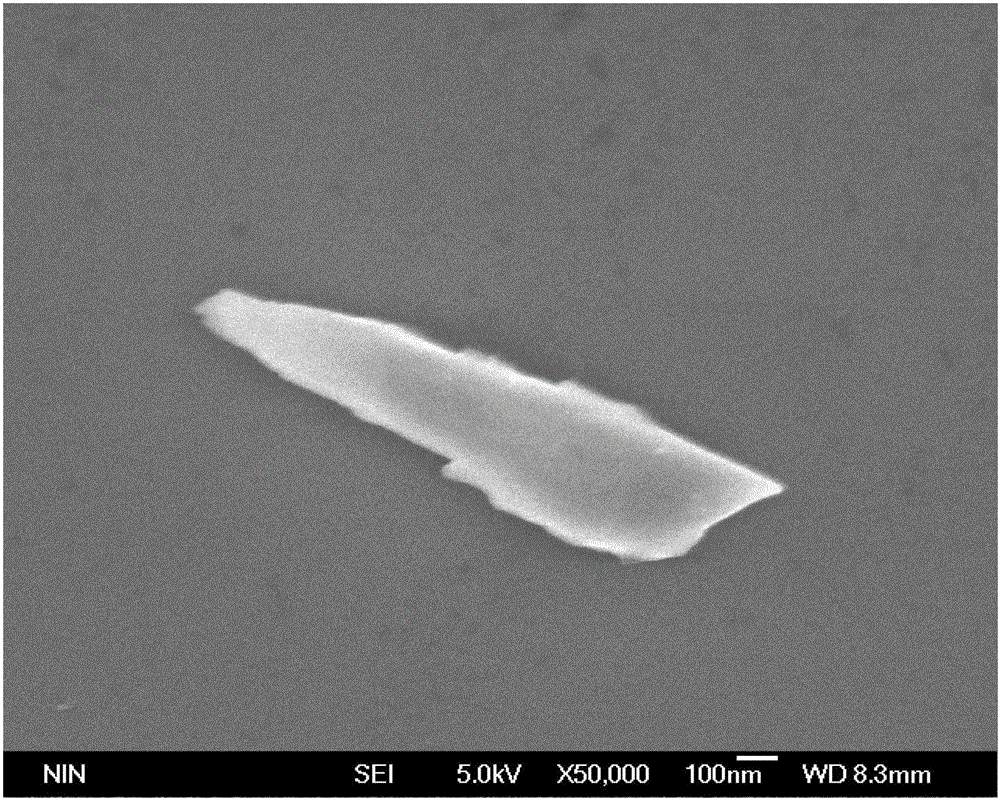

InactiveCN101817516AImprove stripping efficiencyLight in massHigh volume manufacturingSolid particle

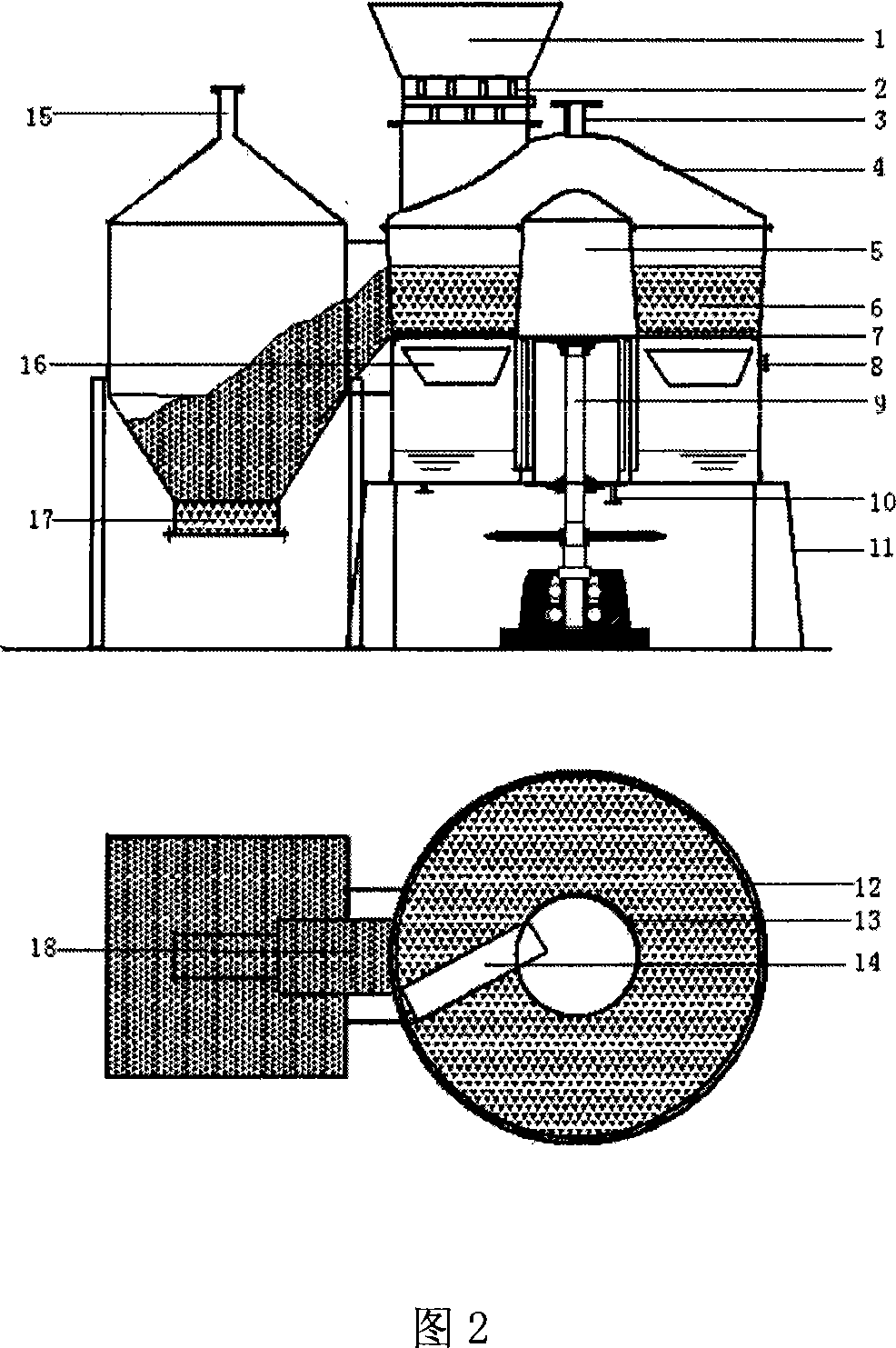

The invention provides a method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping and relates to a preparation method of the graphene or the graphene oxide, solving the problems that the traditional micro-mechanical stripping method has low efficiency and can not be used for large-batch production. The method comprises the following step of separating carbon materials by utilizing solid particles and a liquid working medium (or gas working medium) and adopting mechanical stripping to obtain the graphene or the graphene oxide, wherein the carbon materials comprise graphite powder, expanded graphite, expandable graphite or graphite powder oxide. By using automatic machinery and using a great deal of solid particles for assisting stripping processes, the invention greatly increases the contact areas and the stripping times of the stripping processes, the carbon materials are subject to a great amount of stripping processes in a short time through the shearing and impacting functions of the solid particles on the carbon materials, and thereby the method obviously improves the stripping efficiency, has low cost and is suitable for the industrial and large-batch production of the graphene or the graphene oxide.

Owner:HARBIN INST OF TECH

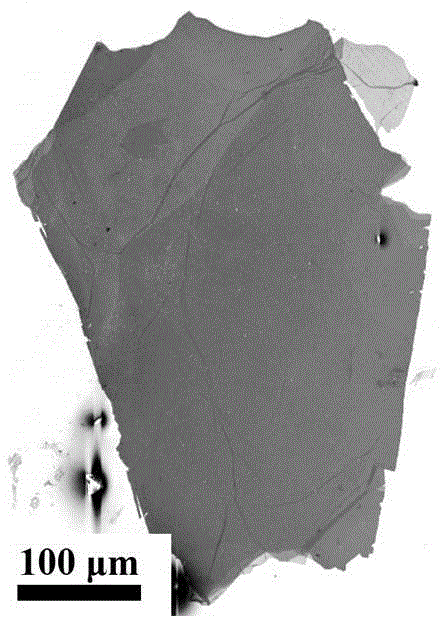

Preparation method of large-size graphene oxide or graphene

ActiveCN105293476ASmall sizeQuality improvementMaterial nanotechnologySingle layer grapheneHigh energyReducing agent

The invention discloses a preparation method of large-size graphene oxide or graphene. The preparation method mainly utilizes graphite as a raw material and comprises that 1, under the action of an intercalator and an expanding agent, graphite fully releases interlayer spaces so that interlayer interaction is reduced and a graphene aggregate is obtained, 2, the graphene aggregate is oxidized by an oxidizing agent, and then the oxidized graphene aggregate is peeled in water under gentle mechanical action so that a large area of a dispersion liquid of graphene oxide is obtained, and 3, the peeled graphene oxide is reduced by a reducer or heat treatment so that high conductivity graphene is obtained. The preparation method utilizes cheap raw materials, has a simple process, can be controlled easily, realizes fast and high efficiency solid-liquid separation, is convenient for industrial large scale production, prevents graphene crystal structure destroy caused by high energy supersonic wave, high speed shearing or fluid crushing. The obtained graphene has a large size and high conductivity and can be popularized and used in fields of high efficiency heat management, flexible display, energy conversion and storage.

Owner:FUDAN UNIV

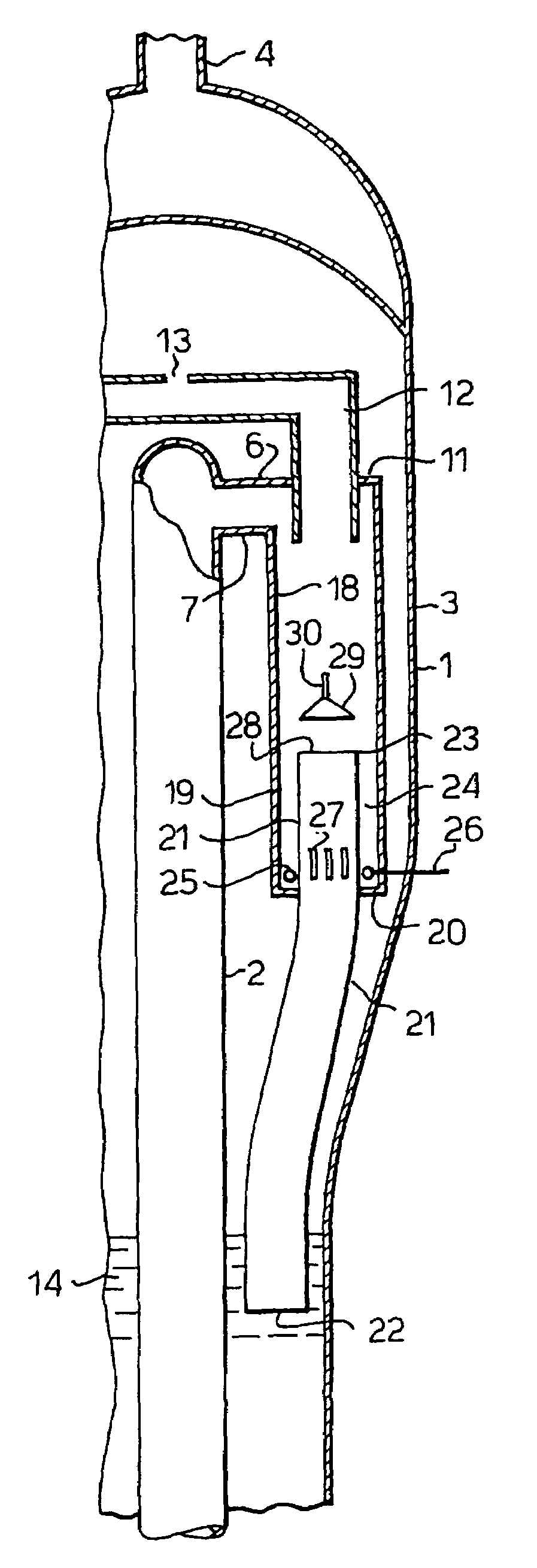

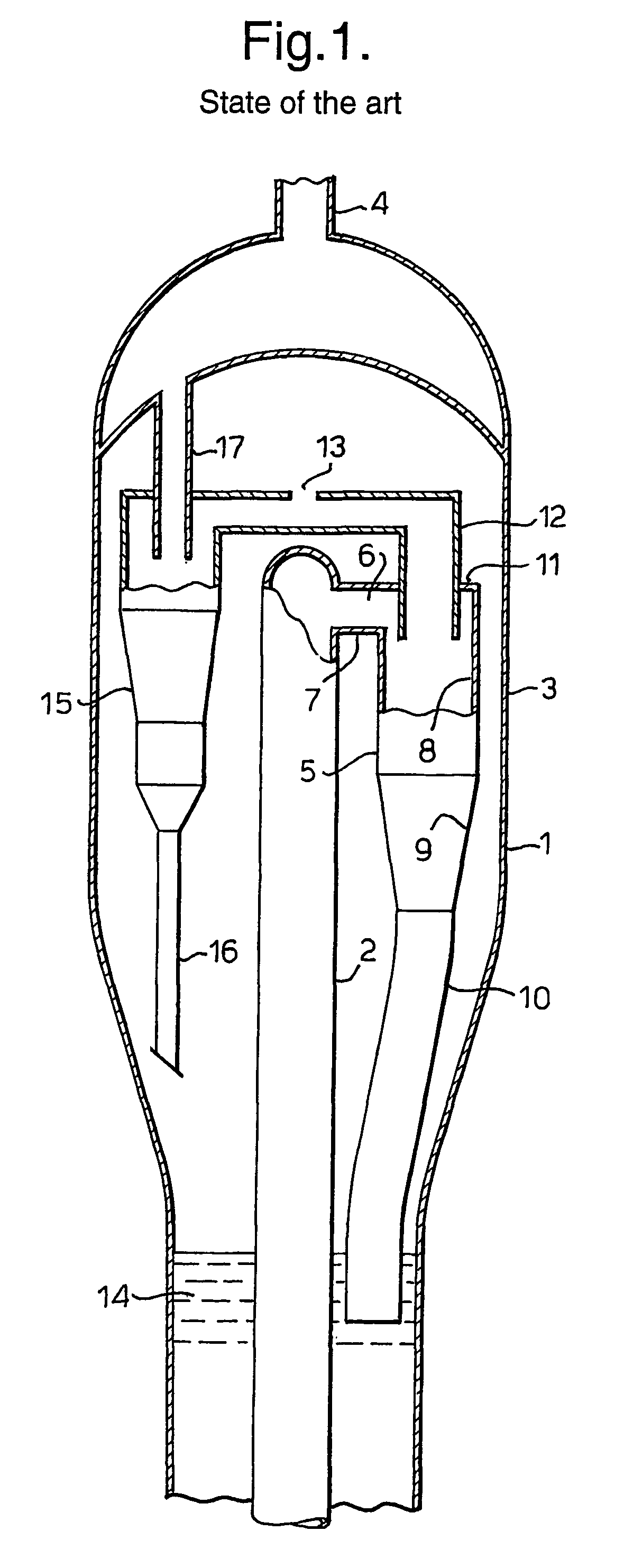

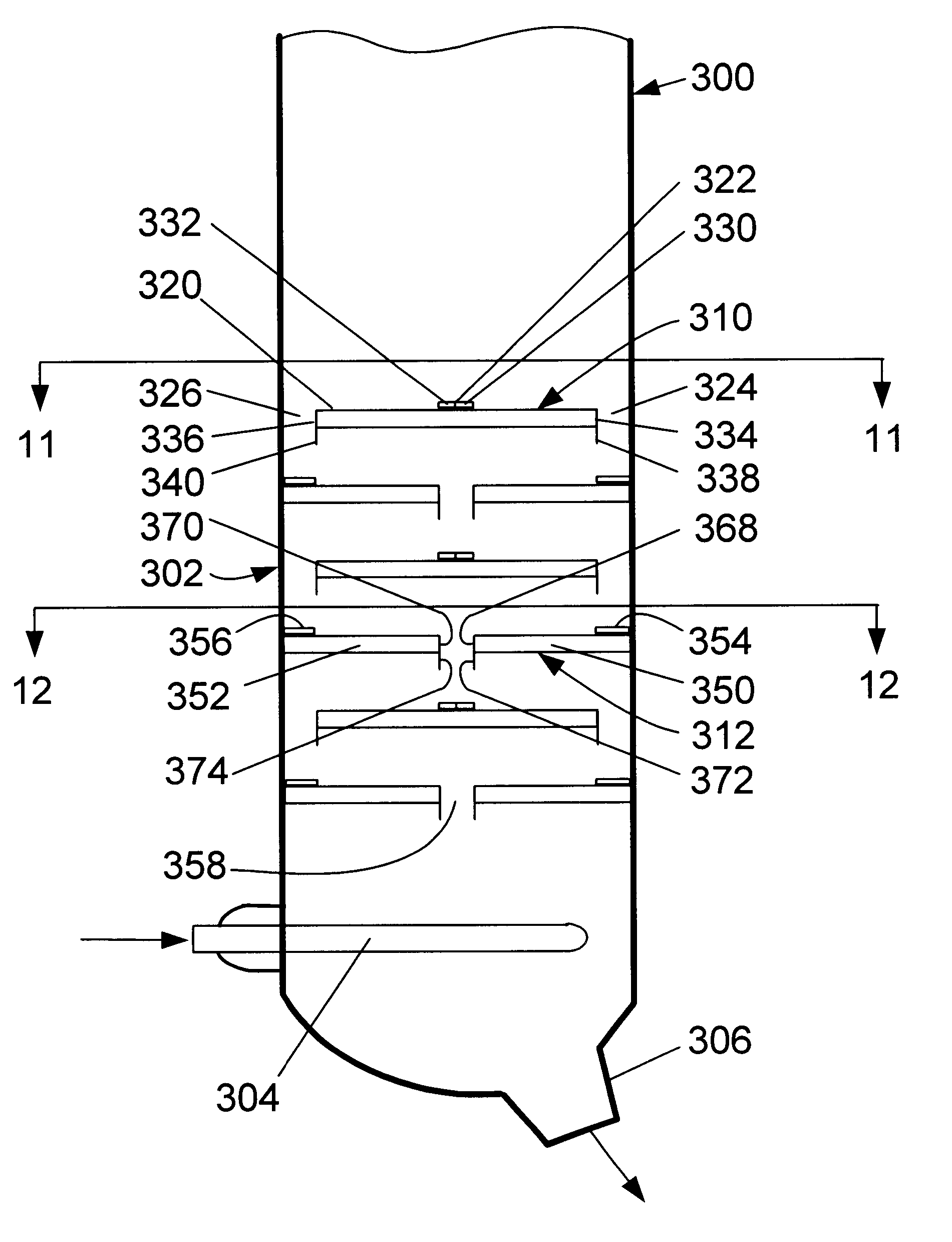

Cyclone separator

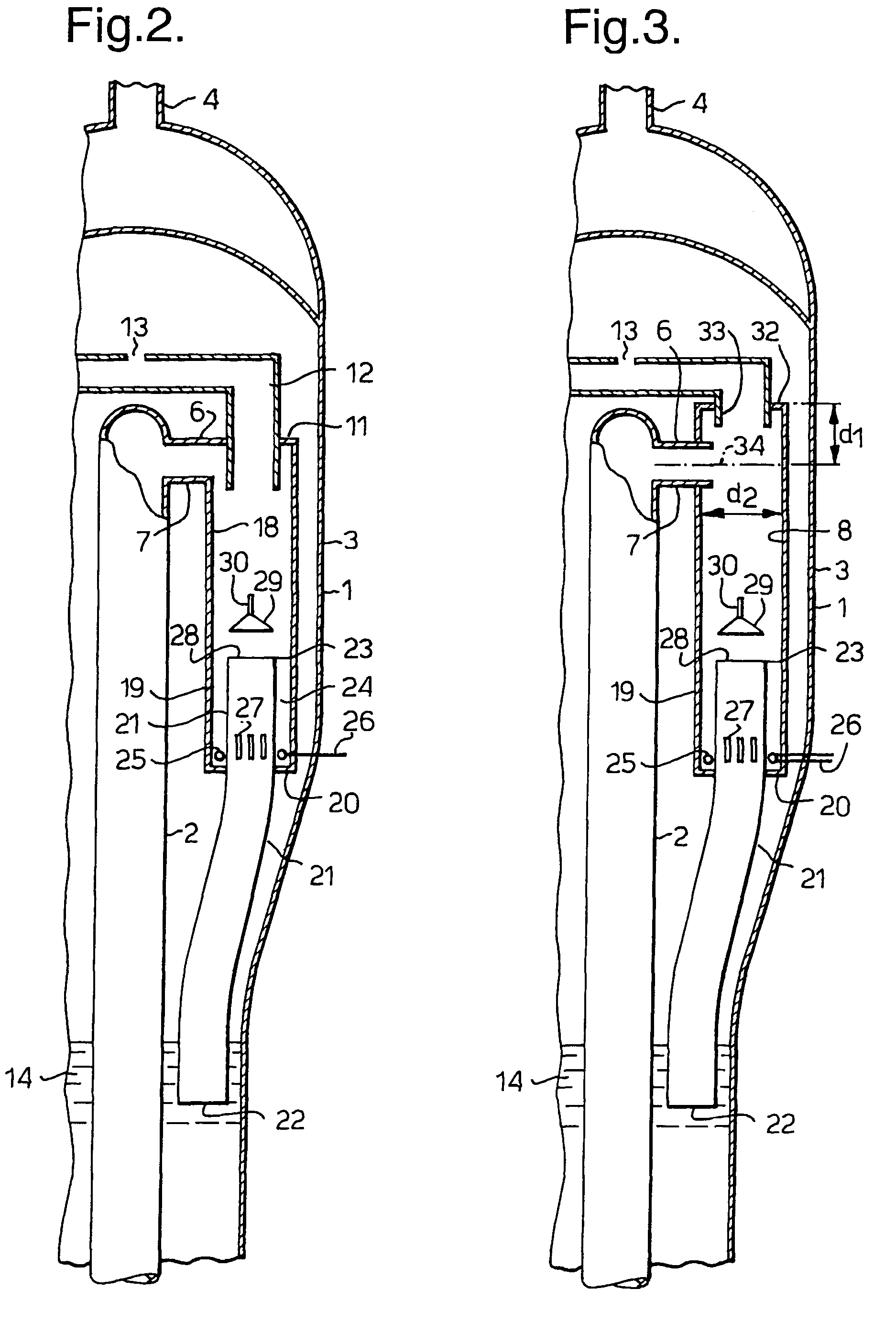

InactiveUS7160518B2Improve stripping efficiencyCatalytic crackingReversed direction vortexCycloneEngineering

A cyclone separator provided with an inlet for receiving gas and solid particles, + a gas outlet at its upper end and a lower tubular part, wherein the lower tubular part is provided with a closed lower end, through which closed lower end a substantially vertical particle withdrawal conduit extends from a position below the closed lower end to a position in the tubular part and below the inlet for receiving gas and solid particles, said conduit being provided with openings to withdraw solid particles from the cyclone separator and wherein said conduit has a smaller cross-sectional area than the lower tubular part, thereby defining a space between conduit and inner wall of the lower tubular part, wherein in the lower part of said space main means to add a primaxy fluidizing medium are present.

Owner:SHELL OIL CO

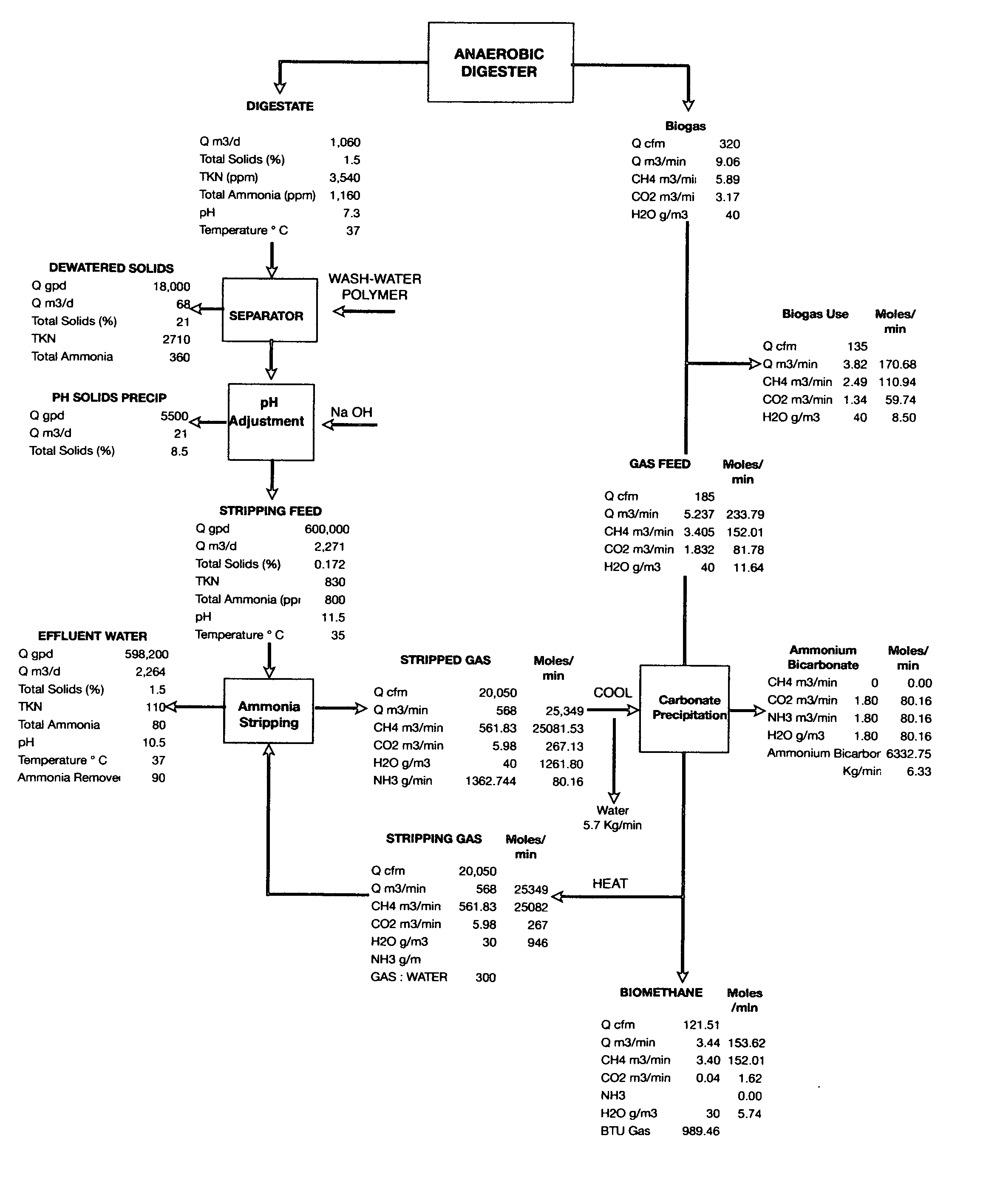

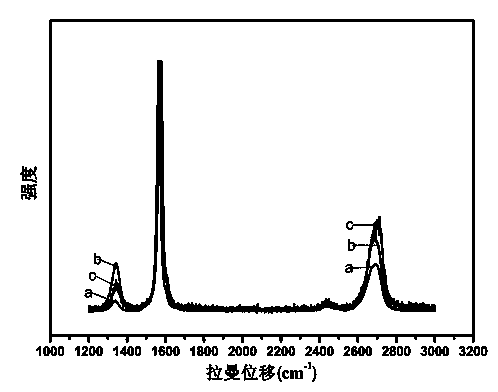

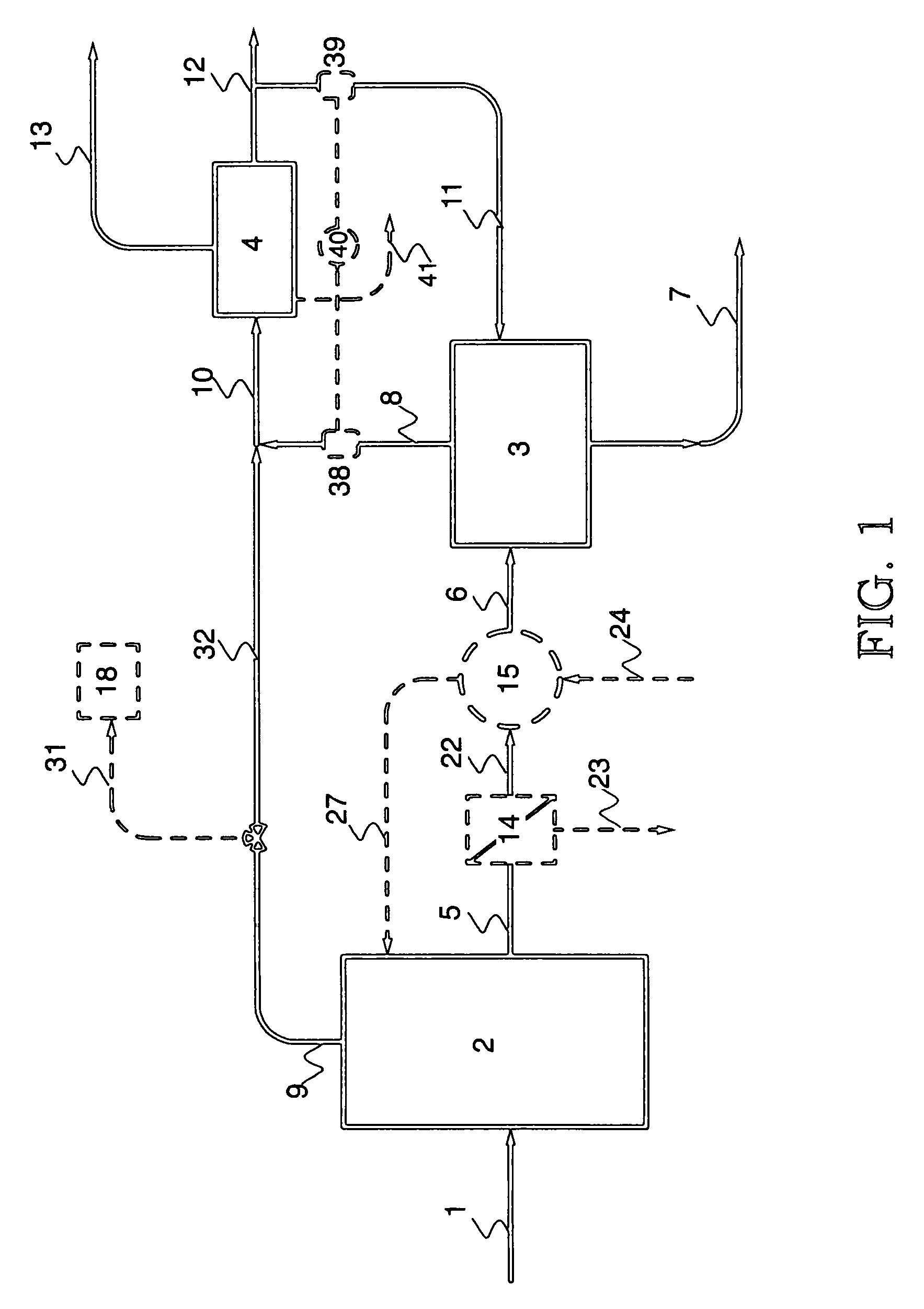

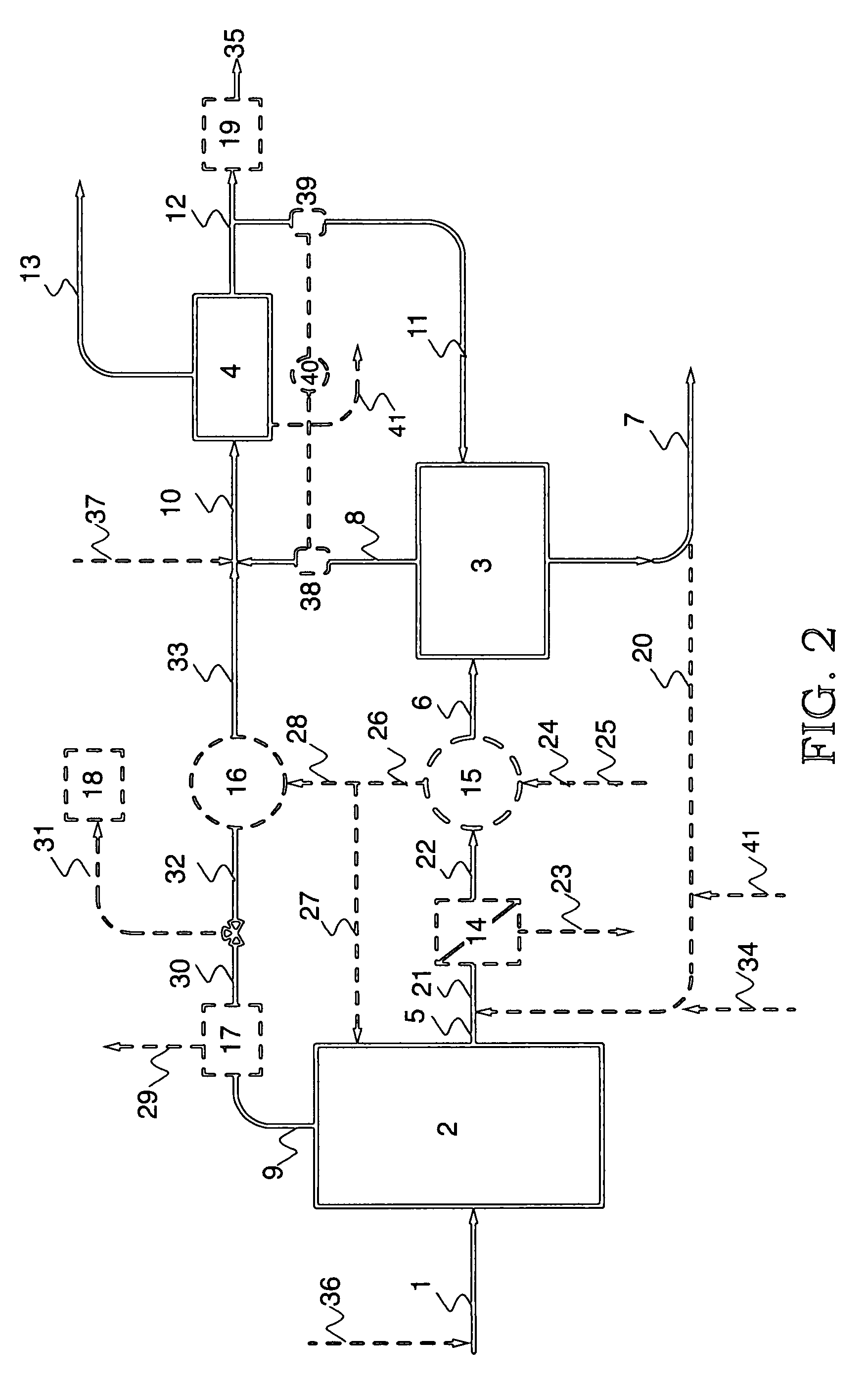

Removal of ammonia from fermentation effluent and sequestration as ammonium bicarbonate and/or carbonate

InactiveUS20080302722A1High economic valueGood economic valueGas treatmentCyanogen compoundsSodium bicarbonateSlurry

A method for the removal and sequestration of ammonia nitrogen from anaerobic fermentation effluent while producing a higher BTU biogas. The method includes the steps of removing the slurry from the digester, stripping the ammonia from the slurry or portion thereof with a high BTU biogas, blending the stripped ammonia with the digesters biogas to remove the carbon dioxide and precipitate ammonium bicarbonate / carbonate as a solid while producing a high Btu biogas, a portion of which is used to strip the ammonia and CO2 from the slurry. The process removes ammonia nitrogen from the digester effluent while producing a high Btu biogas and a solid ammonium bicarbonate / carbonate product. Ammonia stripping is accomplished with a recycled stripping gas deficient in CO2 and ammonia that is capable of removing the CO2 and ammonia from solution by virtue of the lower partial pressures of CO2 and ammonia in the stripping unit.

Owner:COYNE BRIAN J

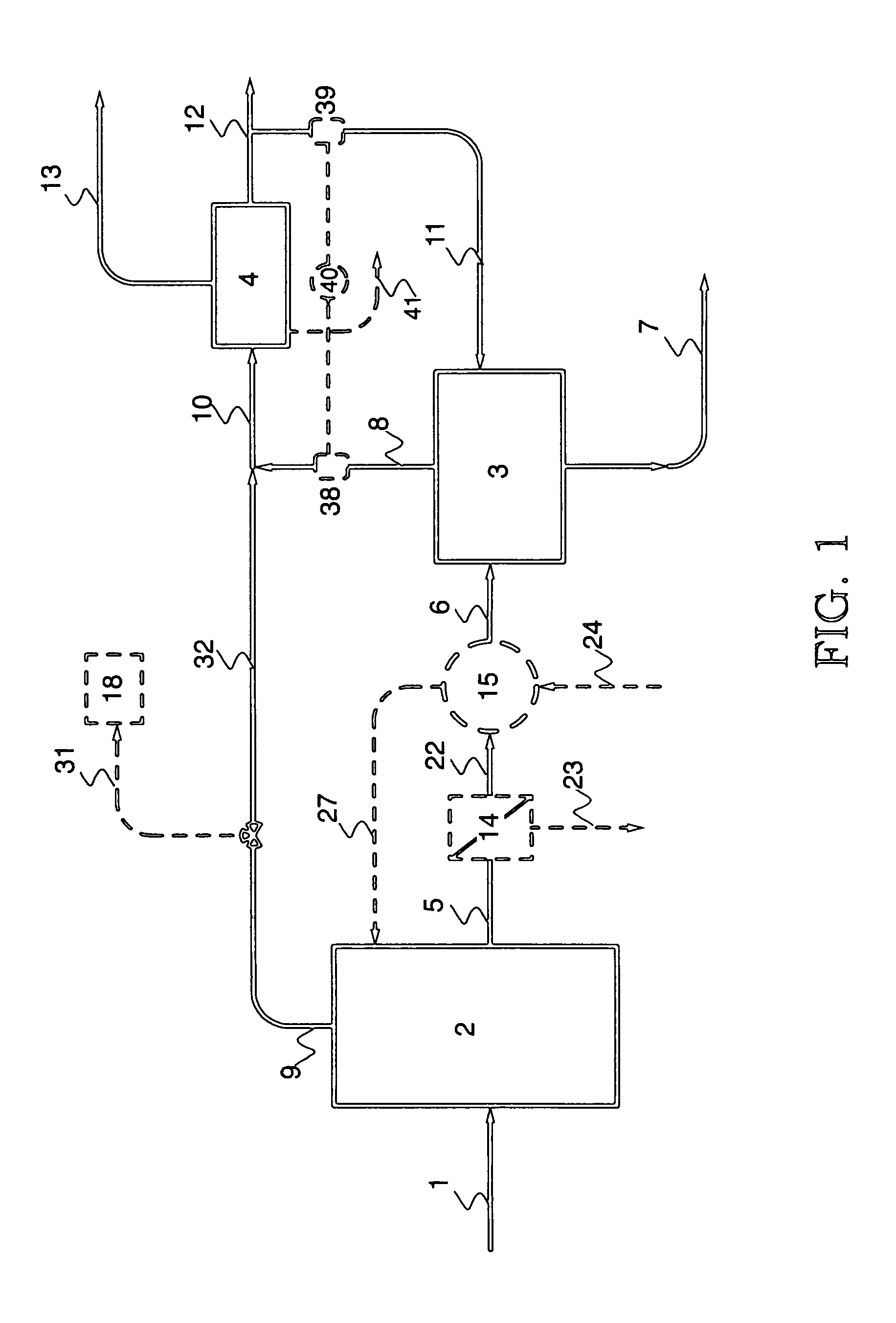

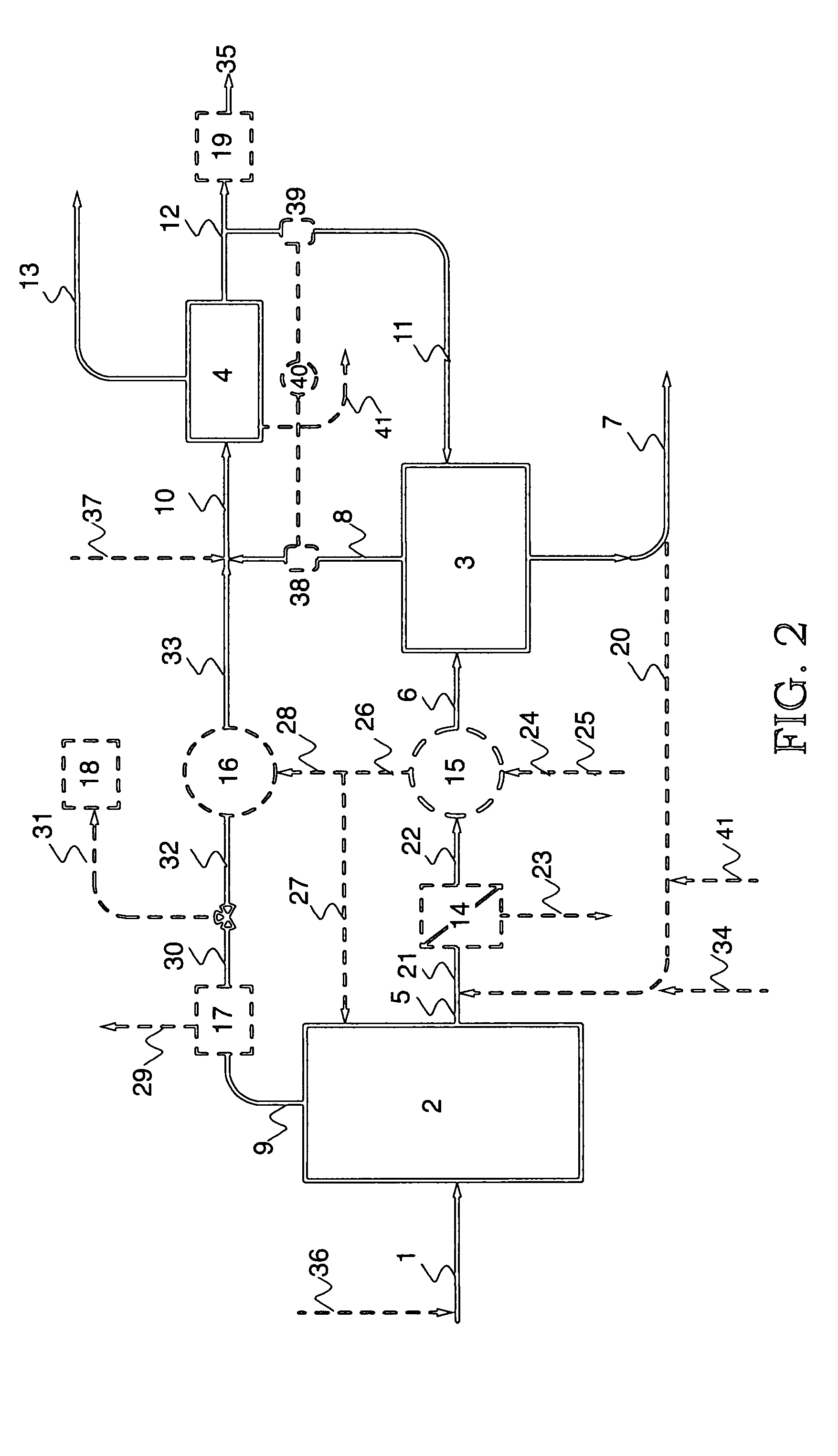

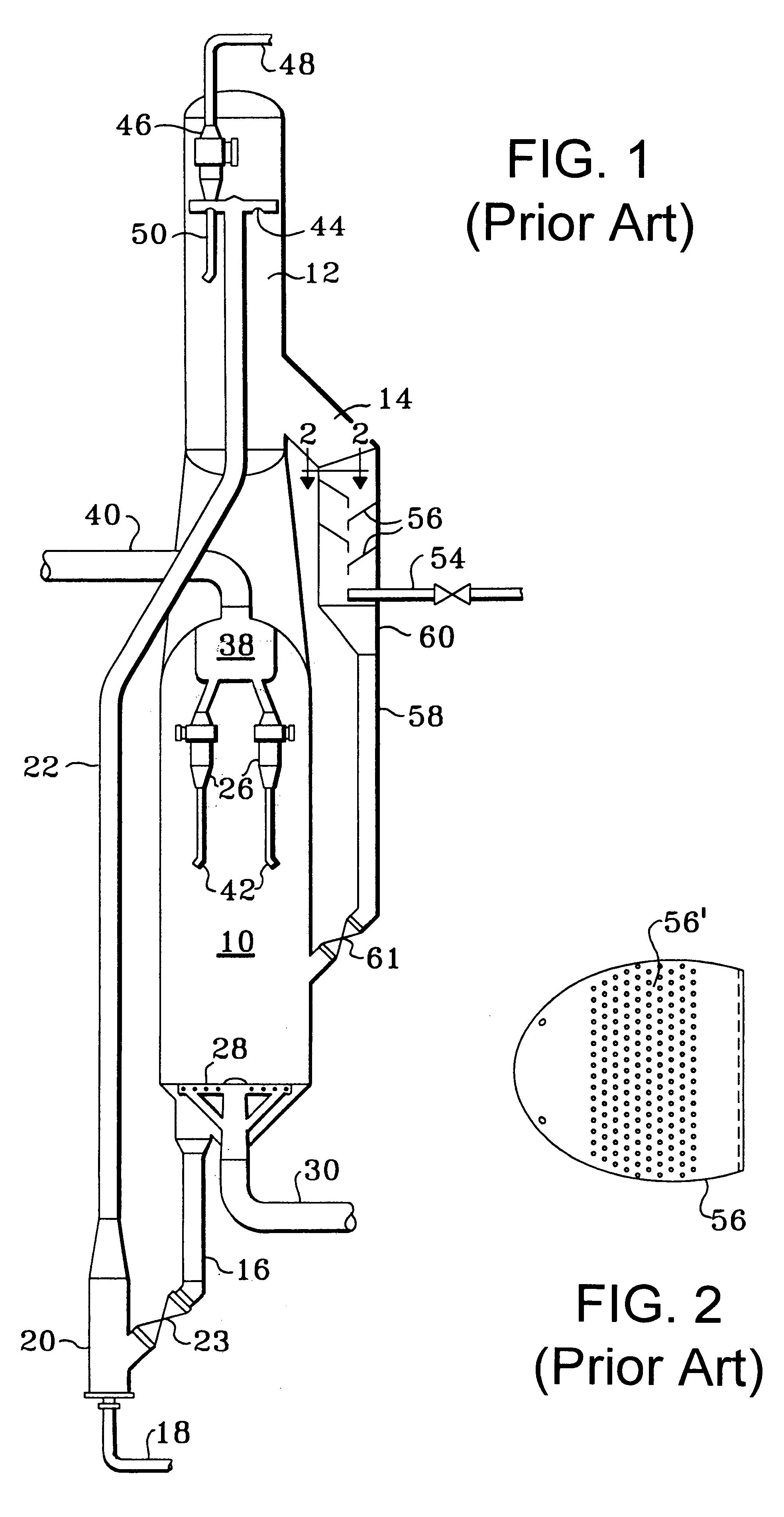

Stripping process with horizontal baffles

InactiveUS6680030B2Improve stripping efficiencyReduce utilizationCatalytic crackingLiquid degasificationEngineeringMechanical engineering

Owner:UOP LLC

Microwave method for peeling laminar inorganic material quickly

The invention relates to a method for peeling a laminar inorganic material quickly. The method comprises the following steps of: firstly, preparing laminar inorganic intercalating composite of the laminar inorganic material; secondly, decomposing or evaporating the inter-laminar organic material of the organic intercalating composite solid of the laminar inorganic material in a short time in the presence of microwaves and allowing the inter-laminar organic material to escape from the space between the layers of the laminar inorganic material so as to quickly peal the laminar inorganic material; and finally, performing separation, washing, drying and grinding to obtain the products. The method not only can peal the laminar inorganic material in a short time but also keep a good crystal structure of the laminar inorganic material, so the application of the laminar inorganic material is substantially widened and the use value thereof is multiplied.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing graphene through liquid-phase stripping method

The invention discloses a method for preparing graphene through a liquid-phase stripping method. The preparation method comprises the following steps: S1, performing expanding treatment on a graphite raw material through an expanding method; S2, dispersing the expanded graphite into an aqueous solution containing a surfactant to obtain a mixture, performing ultrasonic treatment on the mixture, centrifuging the mixture, and drying the mixture for later use; S3, adding the dried graphite into an organic solvent, a mixed solution of an organic solvent and a surfactant or a mixed solution of an organic solvent and substances with surface energy similar to that of the graphene, performing ultrasonic treatment and suction filtration, drying, and repeating the step S3 for 1-10 times, thereby obtaining graphene. Compared with the prior art, the method disclosed by the invention can be used for greatly shortening the ultrasonic treatment time, improving the stripping efficiency and obtaining high-quality graphene under low-power ultrasonic treatment.

Owner:SHENZHEN MINDKING TECH

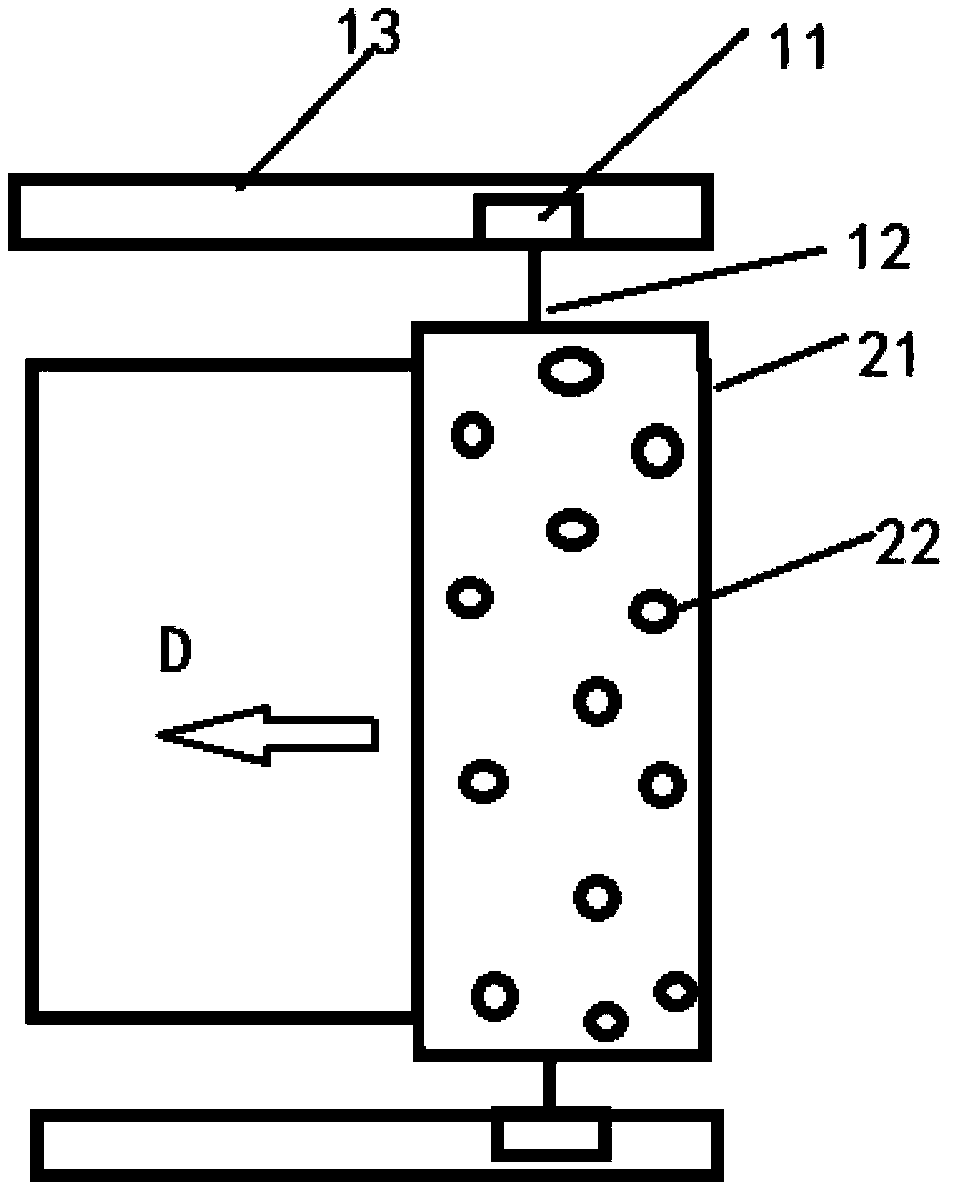

Peeling apparatus and peeling method

InactiveCN104347449AImprove stripping efficiencyLow costLamination ancillary operationsLaminationWire cutterMoving parts

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

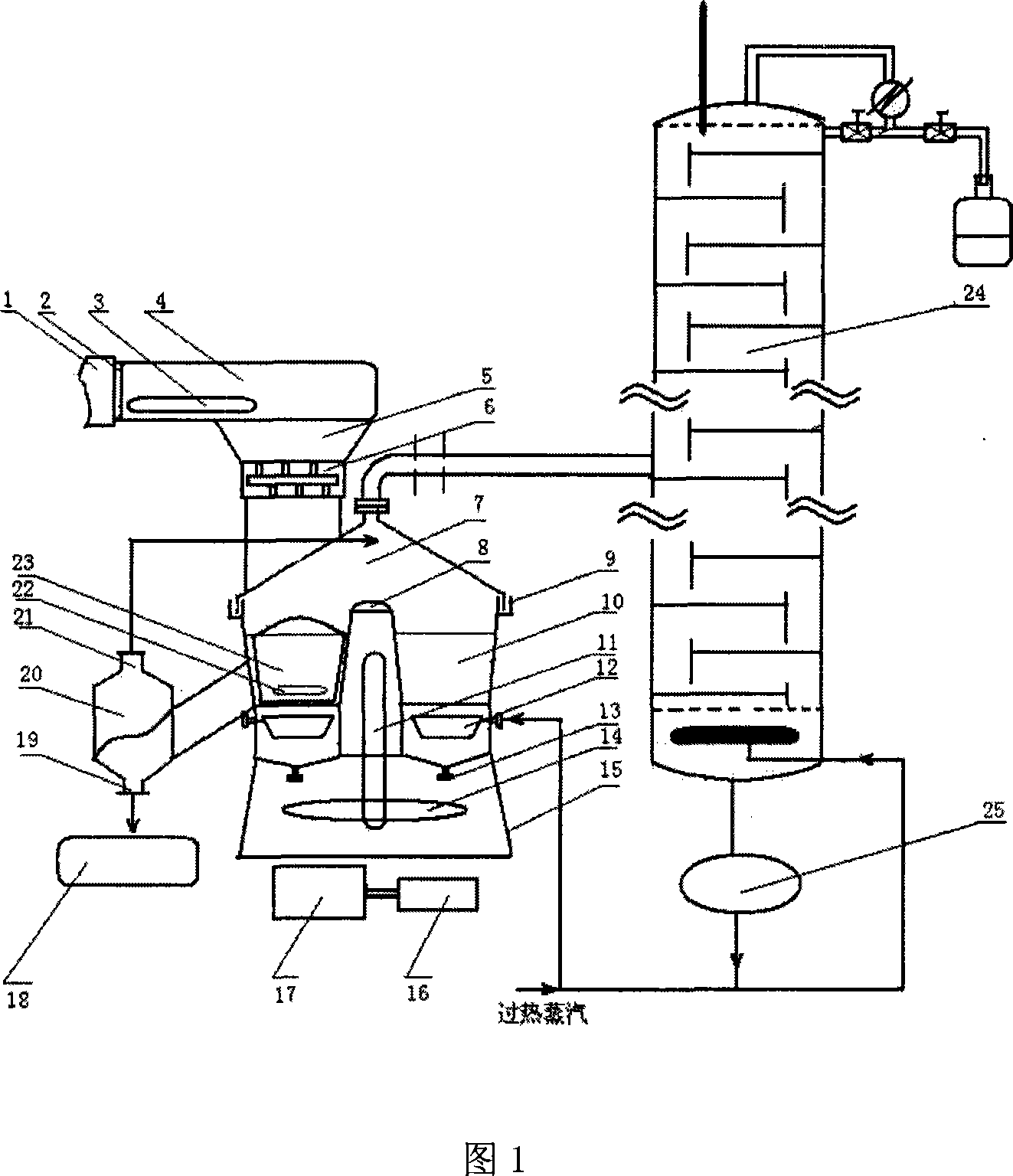

Method and system for continuously separating ethanol and utilizing residual heat based on solid-state fermentation material

InactiveCN101235391AReduce labor intensityMeet the needs of modern large-scale industrial productionBiofuelsEnergy inputDistillationSeparation technology

The invention relates to a method and a system for continuously separating alcohol and utilizing residual heat on the basis of solid state fermentation material, which belongs to the technical field of biomass fuel alcohol. The method mainly comprises the following steps: tight-line pumping, feeding into tower, distributing, stripping alcohol, discharging residue, utilizing residual heat and the like. The system achieves residual heat reutilization through the following two approaches which comprises firstly, looping back residual liquid to outer cylinder clamp ferrules of a closed ring groove rotating disc stripping tower, heating up material and closed tunnel outer clamp ferrules preheating fermentation material, secondly, complementing solid state distillation steam consumption through electrically heating. The alcohol-residue continuous separation technique and closed ring groove rotating disc alcohol stripping tower which are proposed by the invention are suitable for stripping alcohol in solid state fermentation products of sugar or starch such as sweet sorghum stalks and the like, which achieves a goal of automatically feeding and discharging, and continuously separating alcohol and residue, and the method of the invention effectively utilizes reactor residual liquid hidden heat, which complements partial steam gas, and achieves the superiorities of high net energy ratio of solid state fermentation path sweet sorghum alcohol and low environmental load.

Owner:TSINGHUA UNIV

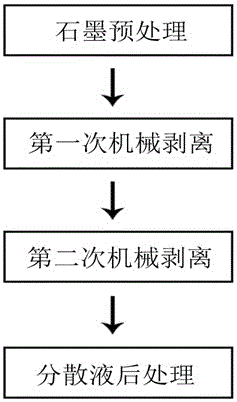

Method for preparing graphene micro-sheet dispersion on grade by mechanical stripping

The invention discloses a method for preparing graphene micro-sheet dispersion on grade by mechanical stripping; in the method, two different mechanical stripping apparatuses are combined; the method comprises the steps of first, stripping raw graphite and an expanding aid through the effects such as high-speed rotation incurred extrusion, high impact, and weightless expansion to obtain primary finished graphene; mixing the crude product with a dispersant, generating relative motion by high-speed rotation, and generating comprehensive effects in leak slits, such as high-speed shear, friction, centrifugal extrusion, and liquid flow collision to further mix the crude finished graphene and the dispersant so that fine and uniform graphene dispersion is formed. The method can provide improved mechanical stripping efficiency and reduced waste of material, is free of environmental pollution and is suitable for large-scale continuous production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

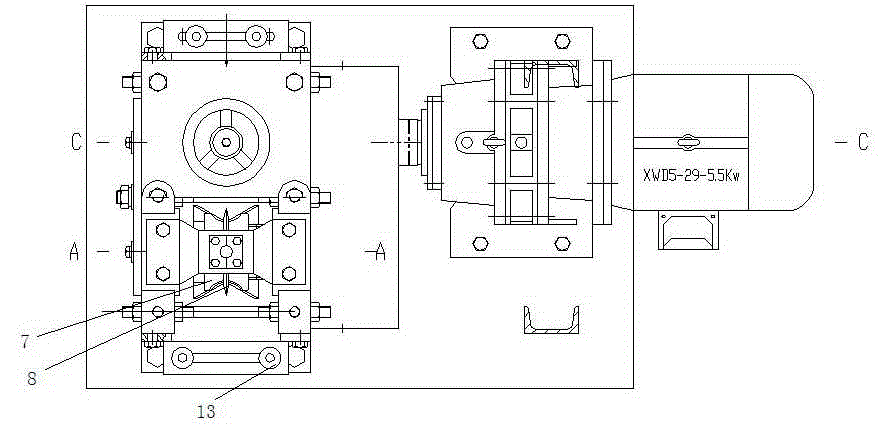

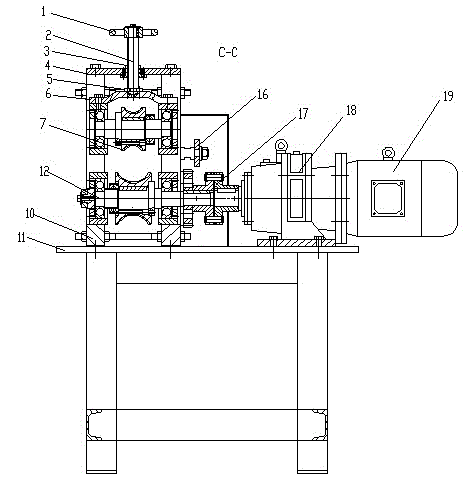

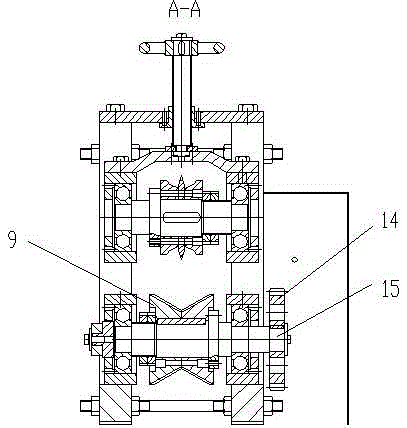

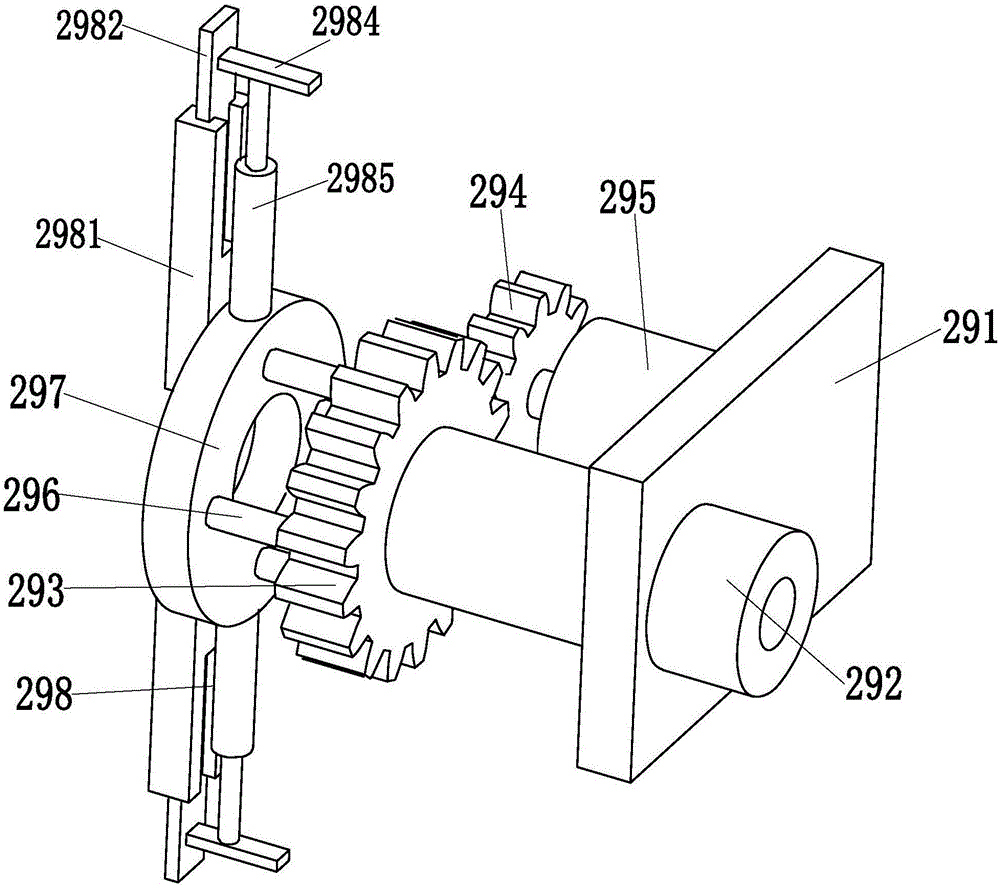

Wire-stripping machine for medium-high voltage cable

InactiveCN102946073AEasy to reuseAchieve the purpose of reuseApparatus for removing/armouring cablesTransmitted powerCoupling

A wire-stripping machine for a medium-high voltage cable comprises a frame, a speed reducer, a motor, a coupler, a gear, a bearing block, a bearing saddle, pressing wheels, blades, clamping devices and a frame cover plate. Two groups of pressing wheels are arranged on the frame side by side, each group of pressing wheels includes an upper pressing wheel and a lower pressing wheel which are oppositely mounted, a space for penetrating the cable is reserved between each upper pressing wheel and the corresponding lower pressing wheel, the working surface of each upper pressing wheel is semicircular, the working surface of each lower pressing wheel is umbrella-shaped, the blades are clamped in the middles of the working surfaces of the upper pressing wheels in the wire outlet direction, one clamping device is arranged above each group of pressing wheels, one of the lower pressing wheels of the two groups of pressing wheels is mounted on a driving shaft, the other one of the lower pressing wheels of the two groups of pressing wheels is mounted on a driven shaft, the driving shaft is connected with the speed reducer and the motor through the coupler, the gear is mounted on the driving shaft and transmits power to a transmission gear through an intermediate gear, and the transmission gear is mounted on the driven shaft and drives the other lower pressing wheel. By the aid of the wire-stripping machine, a wire insulating layer can be automatically separated from metal, wire-stripping efficiency is improved, labor cost is saved, and loss is furthest reduced.

Owner:CHONGQING TAISHAN CABLE

Equipment for recycling waste electric communication cables

InactiveCN108565075AEasy to reuseEasy to cutBasic electric elementsElectronic waste recyclingMechanical engineeringElectric power

The invention provides equipment for recycling waste electric communication cables. The equipment comprises a cleaning device, a drying device, a cutting device, a striping device and a collection device, wherein the cleaning device comprises a cleaning slot and a plurality of lead wheels; the drying device comprises a support plate, an upper drying mechanism and a lower drying mechanism; the cutting device comprises a cutting board, a lead mechanism and a cutting mechanism; the cutting mechanism comprises an upper cutting assembly and a lower cutting assembly; the upper cutting assembly comprises an upper cutting air cylinder, an upper cutter and an upper fixing block; the lower cutting assembly comprises a lower cutting air cylinder, a lower cutter and a lower fixing block; the stripingdevice comprises a base, a telescopic rod, two wire separating rods, a positioning ring and a wire separating ring, the positioning ring is arranged at the top end of the telescopic rod, and the wireseparating ring is arranged at the top end of the wire separating rod; and the collection device comprises two parallel fixing plates and rotating shafts mounted on the two fixing plates. According tothe equipment, the striped leads and insulation protecting sleeves are collected, so that the labor is greatly saved, and the striping efficiency is improved.

Owner:XUCHANG YONGXIN ELECTRIC

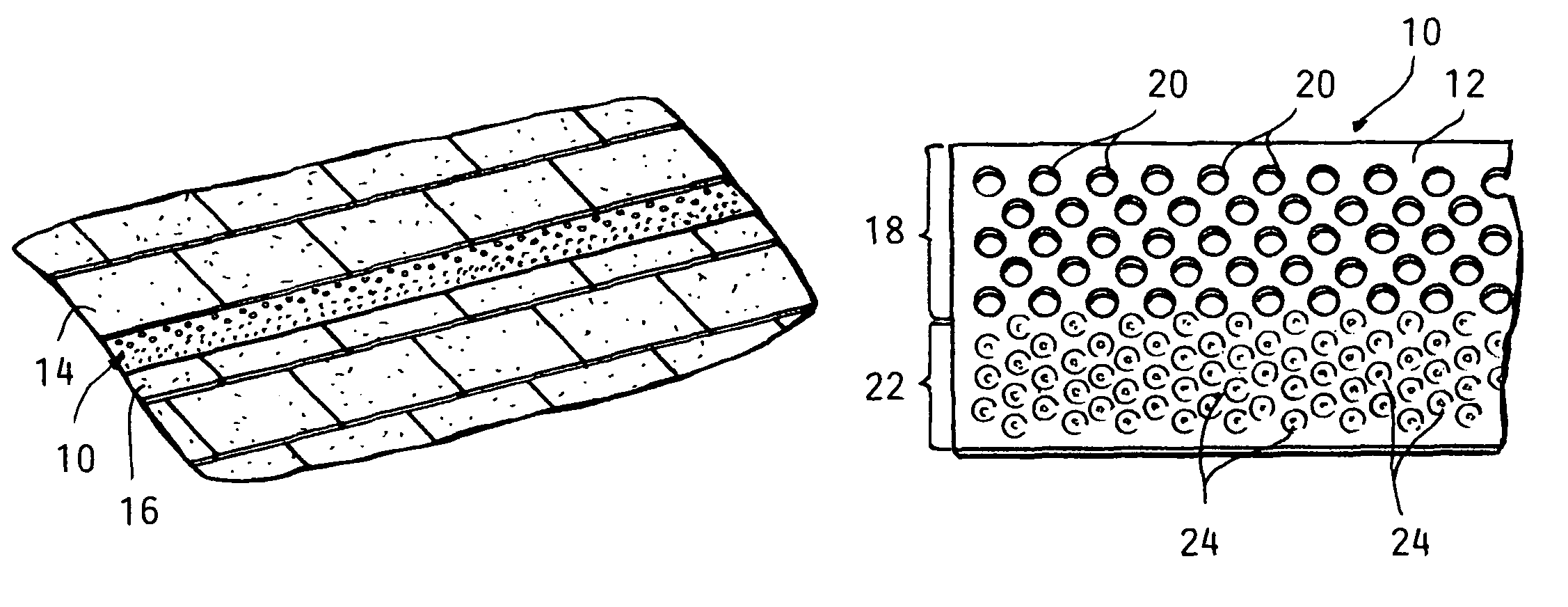

Method and roofing strip for retarding moss, fungi, and algae growth on roofs

ActiveUS7788870B1Maximize releaseFacilitated releaseRoof covering using slabs/sheetsBuilding roofsEngineeringDew

A method for inhibiting growths on shingled roofs, one or more of the strips installed along shingle courses. The strips are preferably formed of copper and have an upper portion formed with a pattern of through holes along the length of the strip and pattern of dimples extending along a lower portion of the length of the strips to increase the duration and extent of contact of rain or dew with the copper metal to increase the release of cupric ions effective in inhibiting growths on the roof.

Owner:SPENCER DAVID

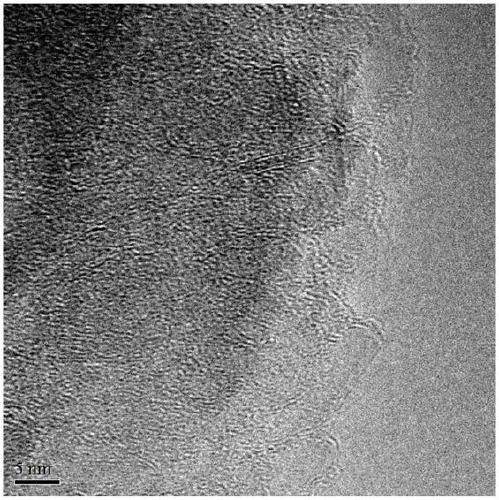

Electrochemical preparation method of graphene

InactiveCN103451670AHigh stripping efficiency and yieldReduce defectsElectrolysis componentsCvd grapheneDimethyl formamide

The invention provides an electrochemical preparation method of a graphene material. The preparation method comprises the following steps: using graphite electrodes as negative and positive electrodes respectively and one or more of 1-butyl-3-methylimidazolium dihydrogenphosphate, N-methyl pyrrolidone hydrosulfate, N-methyl pyrrolidone dihydrogenphosphate and 1-methylimidazolium hydrosulfate as an electrolyte, applying voltage of 3.1-6.0V, and obtaining highly expanded graphite at the negative and positive electrodes respectively; then adding the corresponding electrolyte to the expanded graphite according to (100:1)-(30:1), grinding for 3-6 hours, then transferring the expanded graphite to acetone and dimethyl formamide mixed liquor, carrying out centrifugation at 13000rpm, transferring the precipitate to dimethyl formamide, and carrying out centrifugation at 2000-10000rpm, thus obtaining a supernatant, namely a stable graphene solution, wherein the volume ratio of acetone to dimethyl formamide is (1.1:1)-(3:1). The preparation method has the beneficial effects that the preparation process of the graphene material produced by the preparation method is mild and simple and has a defect cure phenomenon, and the product graphene has few defects and high quality.

Owner:CENT SOUTH UNIV

Removal of ammonia from fermentation effluent and sequestration as ammonium bicarbonate and/or carbonate

InactiveUS7811455B2High economic valueReduce fossil fuel consumptionGas treatmentCyanogen compoundsSodium bicarbonateSlurry

A method for the removal and sequestration of ammonia nitrogen from anaerobic fermentation effluent while producing a higher BTU biogas. The method includes the steps of removing the slurry from the digester, stripping the ammonia from the slurry or portion thereof with a high BTU biogas, blending the stripped ammonia with the digesters biogas to remove the carbon dioxide and precipitate ammonium bicarbonate / carbonate as a solid while producing a high Btu biogas, a portion of which is used to strip the ammonia and CO2 from the slurry. The process removes ammonia nitrogen from the digester effluent while producing a high Btu biogas and a solid ammonium bicarbonate / carbonate product. Ammonia stripping is accomplished with a recycled stripping gas deficient in CO2 and ammonia that is capable of removing the CO2 and ammonia from solution by virtue of the lower partial pressures of CO2 and ammonia in the stripping unit.

Owner:COYNE BRIAN J

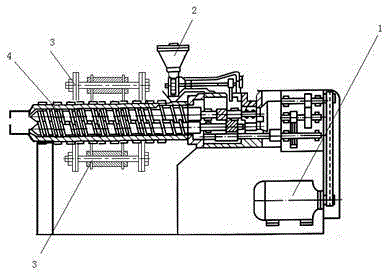

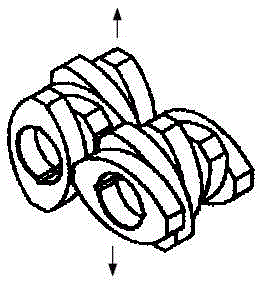

Method for preparing graphene through composite shear stress stripping of vibrating screw extruder

The invention provides a method for preparing graphene through composite shear stress stripping of a vibrating screw extruder, and belongs to the field of graphene materials. According to the method, an electromagnetic, ultrasonic and longitudinal mechanical vibration tensile force field is introduced into the extruder rotating at high speed, the vibration tensile force field periodically changes along with the time to enable the graphite interface to be tensioned, graphite becomes loosened under the action of a stripping agent, the graphite generates powerful shearing stripping through contact interfaces of meshing blocks of the extruder in a tensioned state, thinner graphene with the narrower thickness distribution range is obtained, and then rapid and efficient high-quality graphene preparation under the high-shearing action is achieved. The method has the advantages that the production cost of the high-quality graphene is significantly lowered, the preparation process is green and environmentally friendly, no exhaust gas or waste liquid or waste residue is generated, and scale production of the graphene is promoted.

Owner:ZHEJIANG ZHONGYANG SCREW MFG

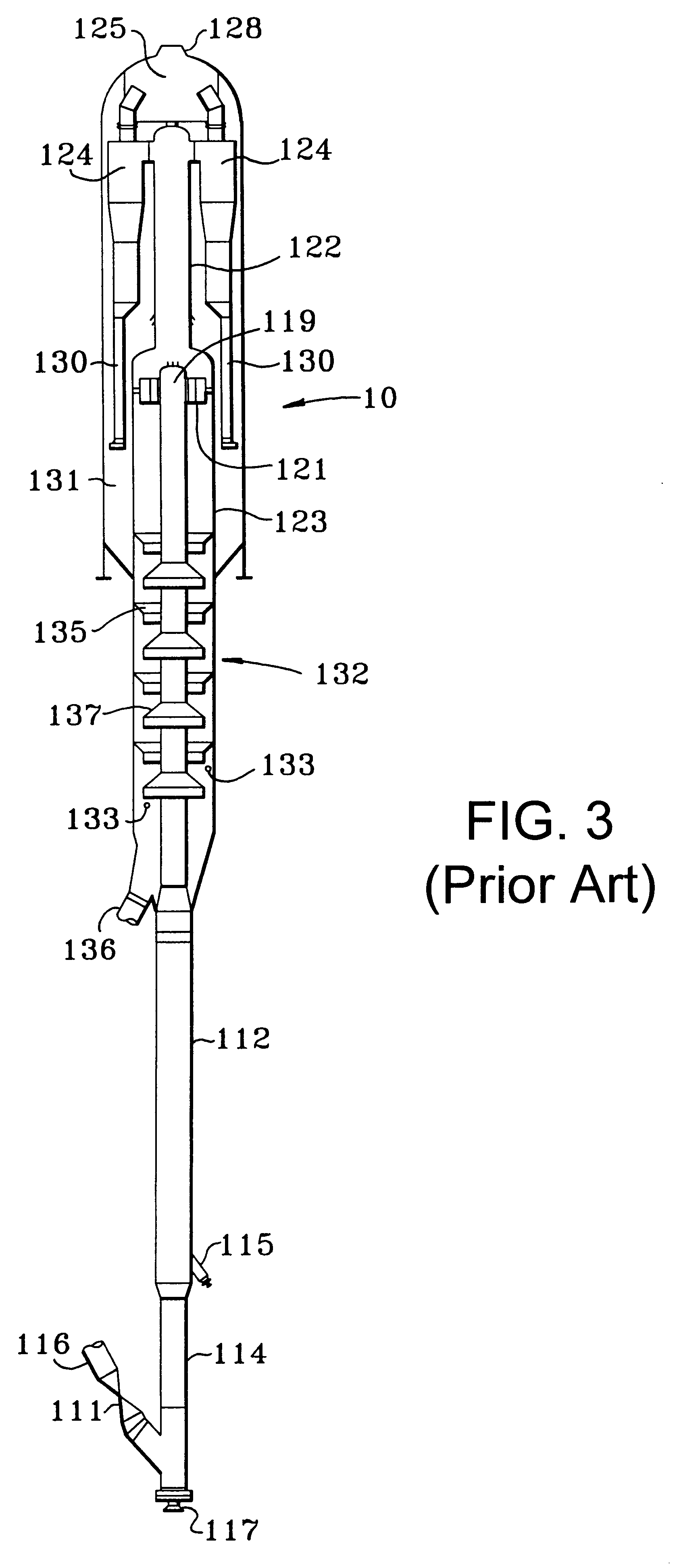

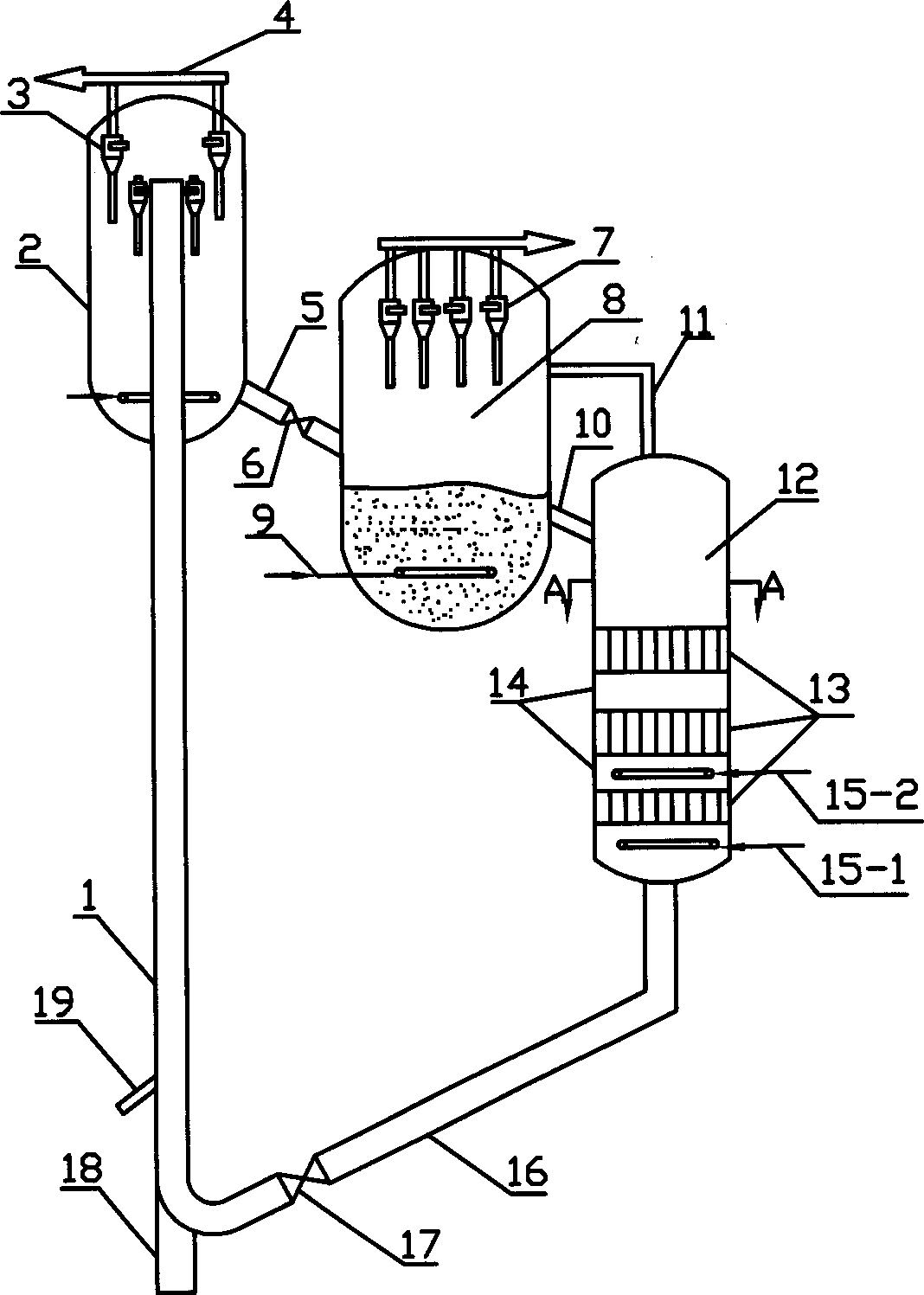

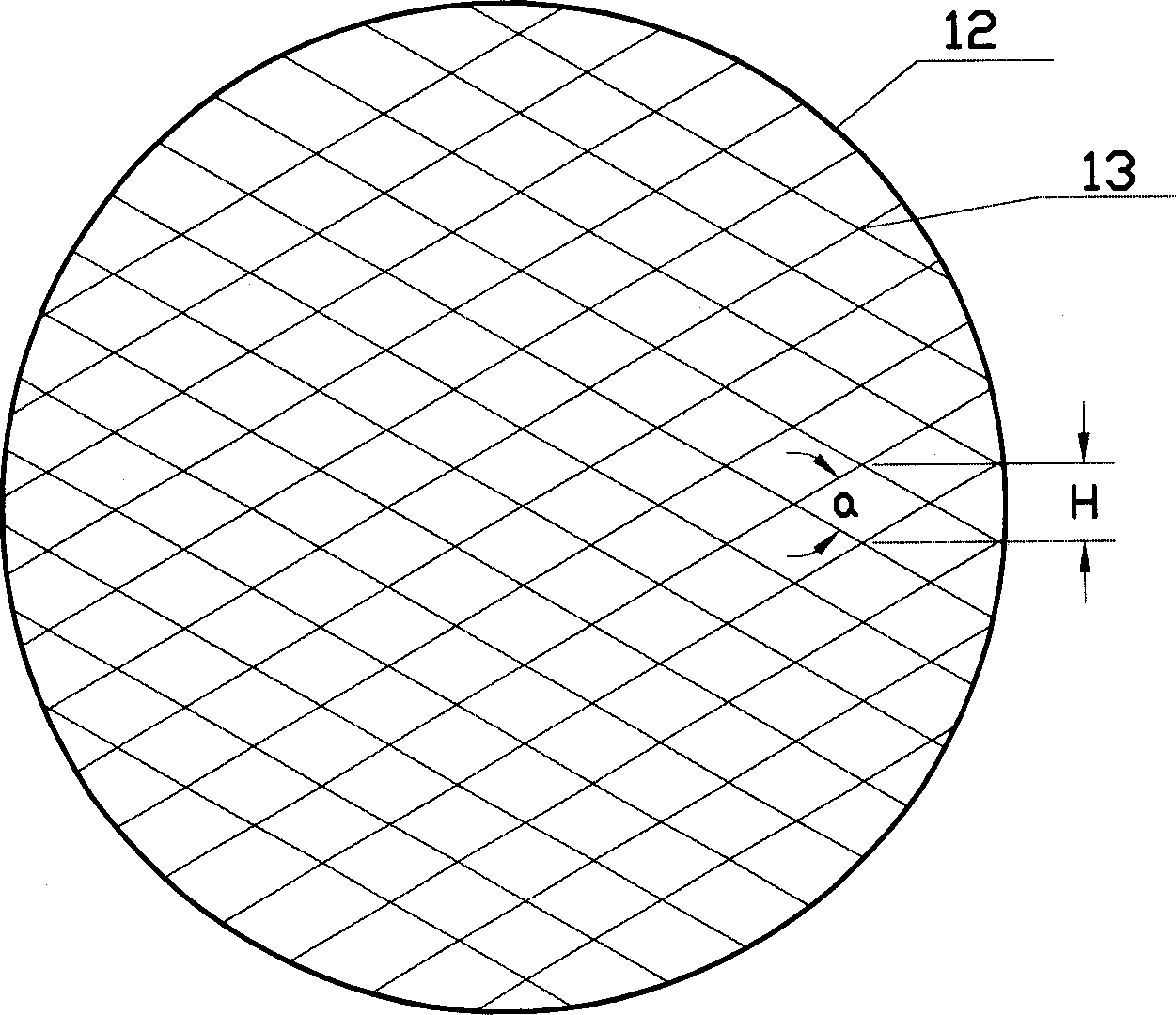

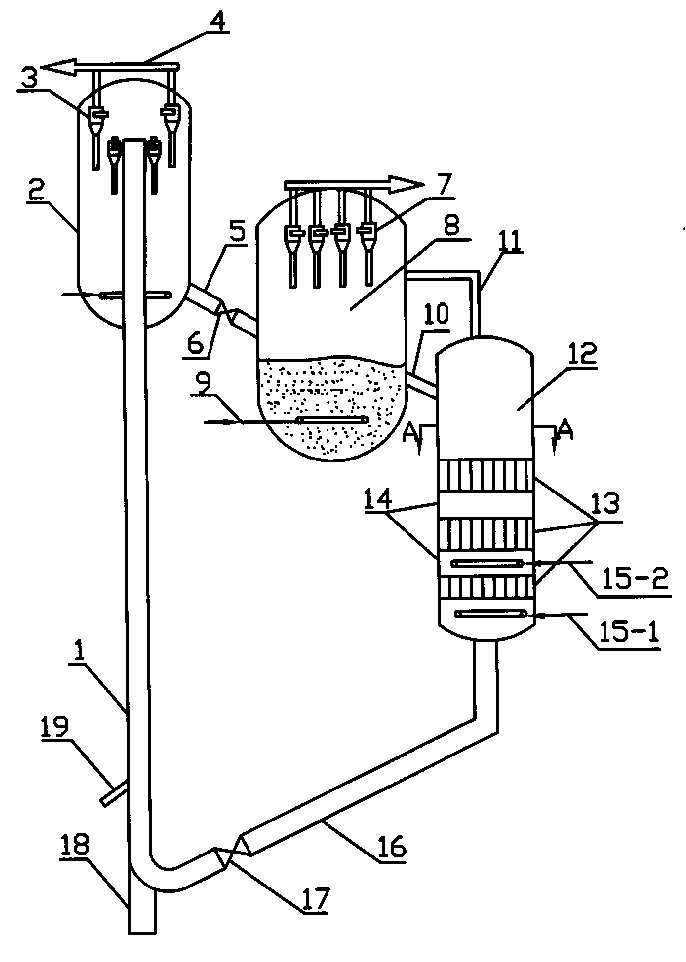

Stripping method and equipment for hydrocarbon catalytic converting catalyst

InactiveCN1335356AImprove uniformityPromote random contactCatalytic naphtha reformingCatalytic transformationEngineering

The present invention provides one method of raising the efficiency of stripping hydrocarbon converting catalyst and its equipment. According to the present invention, catalyst particle and strippingfluid are made to counterflow through one stripper with at least two layers of stuffing. The stuffing in the stuffing layers is crossed into diamond shaped grid plate parallel to the axis of the stripper. The stripper of the present invention has high efficiency. The present invention is especially suitable for catalytic conversion process of preparing olefin, the smoke impurity content in the regenerating agent is less than 0.05 vol%, and the stripper can be reduced in volume and equipment investment obviously.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

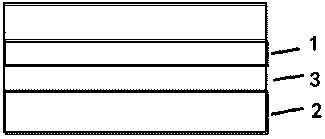

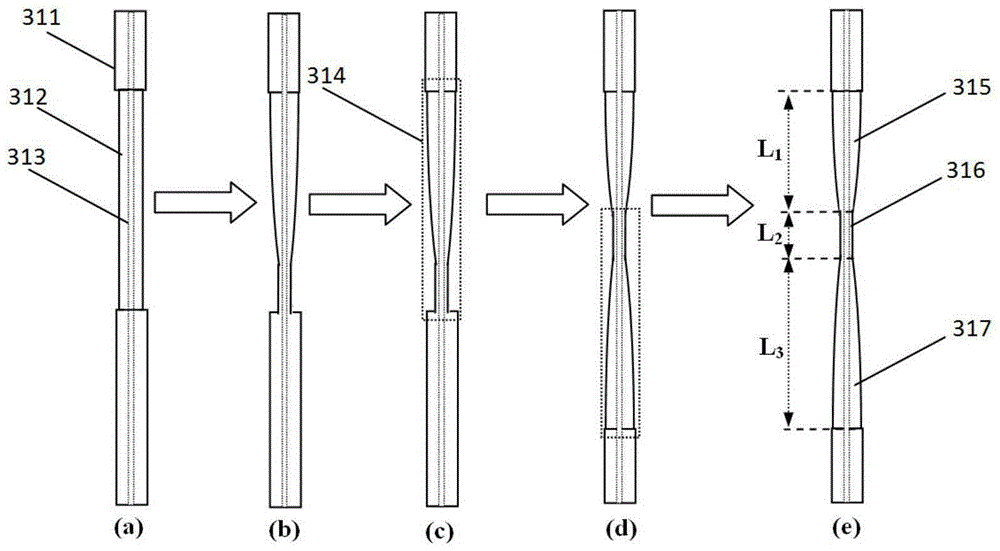

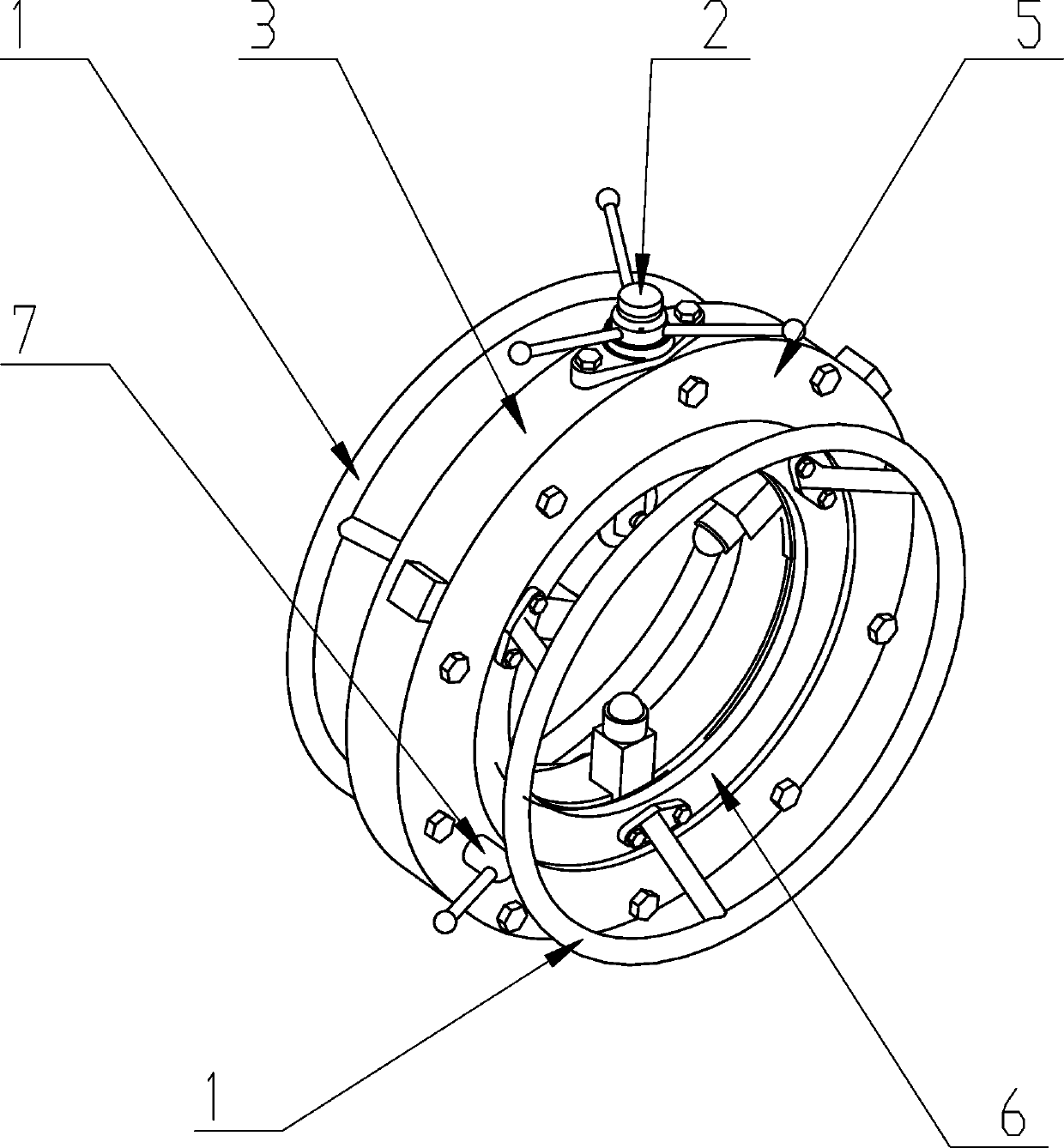

High-power double-clad optical fiber cladding light stripper device and manufacturing method

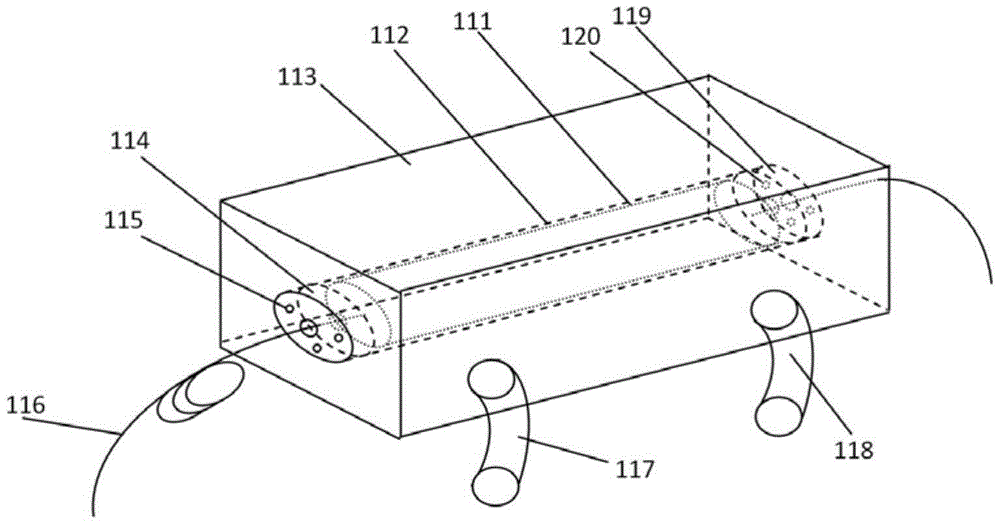

The invention provides a high-power double-clad optical fiber cladding light stripper device and a manufacturing method. The light stripper device comprises double-clad optical fibers (116), an optical module (111), a fixing material (113) and water-cooled tubes (117 and 118). The double-clad optical fibers (116) penetrate through the optical module (111) and the fixing material (113). The optical module (111) is arranged in the fixing material (113). The water-cooled tube (117) is installed on the lower portion of the fixing material (113). The optical module (111) is of a three-layer waveguide structure. A heat dissipating material is adopted as the fixing material (113). According to the device, double-clad optical fiber inner cladding is corroded to form an opposite conical structure, and placed into the waveguide structure manufactured with semi-hollow cylinders and semi-solid cylinders made of a transparent material so as to leak light, the light leaked by the inner cladding is leaked uniformly in the length direction of the optical fibers, power density of the light and heat is reduced, and the situation that because light leakage is excessively concentrated, optical gel is burned out can be avoided.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

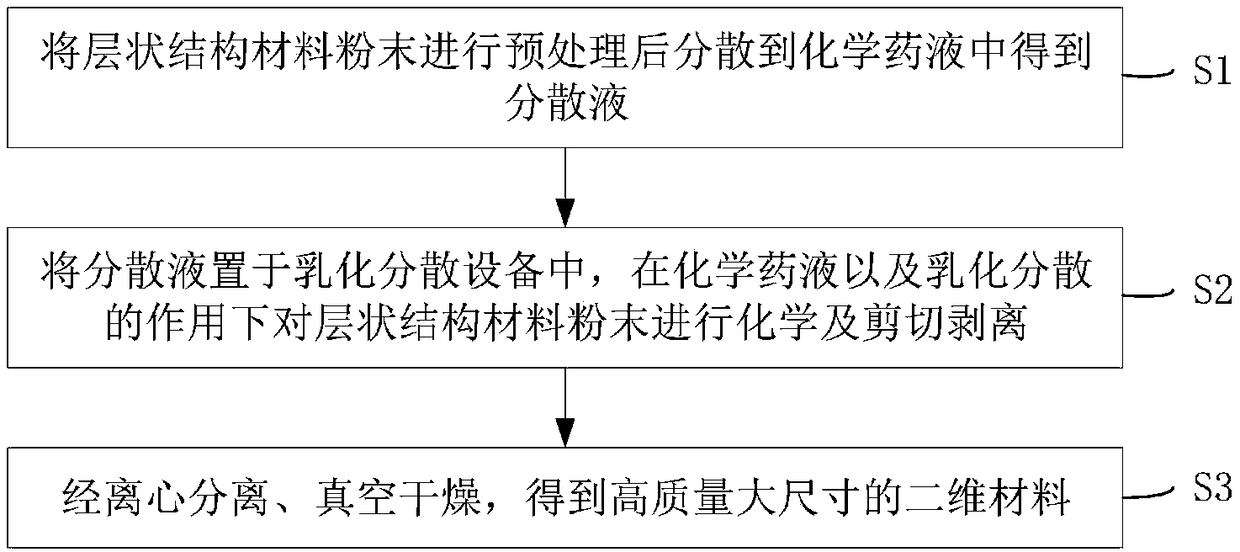

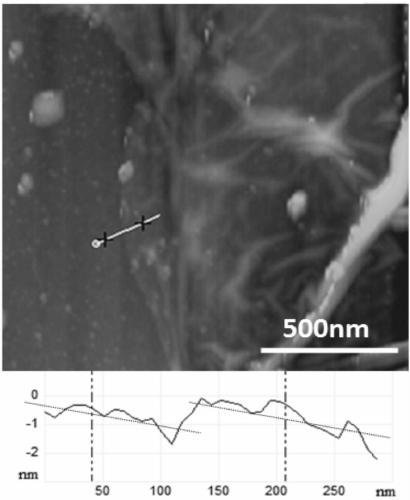

High-quality and large-size two-dimensional material and preparation method thereof

ActiveCN108793140AIncrease tangential speedImprove stripping efficiencyNitrogen compoundsTitanium carbidePre treatmentLarge size

The invention discloses a high-quality and large-size two-dimensional material and a preparation method thereof. The preparation method of the high-quality and large-size two-dimensional material comprises the following steps: S1, after pre-treating lamellar structure material powder, dispersing in chemical drug liquid, so as to obtain a dispersion solution; S2, putting the dispersion solution into emulsifying and dispersing equipment, and carrying out chemical and shearing peeling on the lamellar structure material powder under the action of the chemical drug liquid and emulsification and dispersion; S3, carrying out centrifugal separation and vacuum drying to obtain the high-quality and large-size two-dimensional material. The high-quality and large-size two-dimensional material and thepreparation method thereof, provided by the invention, have the advantages of simplicity and rapidness, high peeling efficiency and capability of realizing continuous scale production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for preparing two-dimensional inorganic nanomaterial by mechanical force intercalation stripping

InactiveCN109250693AImprove stripping efficiencyShort manufacturing timeRare earth metal oxides/hydroxidesNitrogen compoundsHigh energyCrystal structure

The invention relates to the technical field of inorganic nanomaterial preparation, and in particular, relates to a method for preparing a two-dimensional inorganic flaky nanomaterial by mechanical force intercalation stripping of a three-dimensional inorganic layered crystal material. With mixed metal halide as an intercalation and stripping medium, the purified layered inorganic crystal materialand the intercalation and stripping medium are subjected to solid-phase high-energy ball milling treatment together, mixed powder after ball milling treatment is washed with water to remove the intercalation and stripping medium, the three-dimensional layered material can be highly efficiently made into the corresponding two-dimensional flaky material. The method has universality for stripping ofthe inorganic non-metallic layered crystal material, has the advantages of simple preparation process, short production cycle, and high yield of the two-dimensional material, does not affect a crystal structure of the two-dimensional material, and the intercalation and stripping medium can be reused without causing environmental pollution.

Owner:深圳烯材科技有限公司

Process for extracting rare earth element by non-saponifiable phosphorous mixing extractant

ActiveCN1804063AImprove stripping efficiencyReduce acid consumptionProcess efficiency improvementRare-earth elementMaterial consumption

The extraction and separation method for rare-earth element comprises: with rare-earth solution contained a plurality of rare-earth elements as material, preparing mixed extractant with the non-saponifiable P204 and one or two from P507, P229, P350, TBP, C272, C301, C302 and HEOPPA; in the mixed solution with rare-earth sulfate solution, or rare-earth sulfate and rare-earth chloride solution and rare-earth nitrate solution, extracting and separating rare-earth elements. This invention eliminates saponification to overcome pollution, reduces acidity to improve rare-earth concentration, and decreases the main material consumption more than 30% compared with the technique with NH4HCO3 and P507.

Owner:GRIREM ADVANCED MATERIALS CO LTD

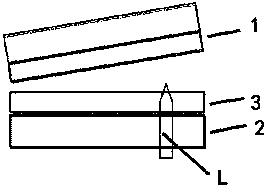

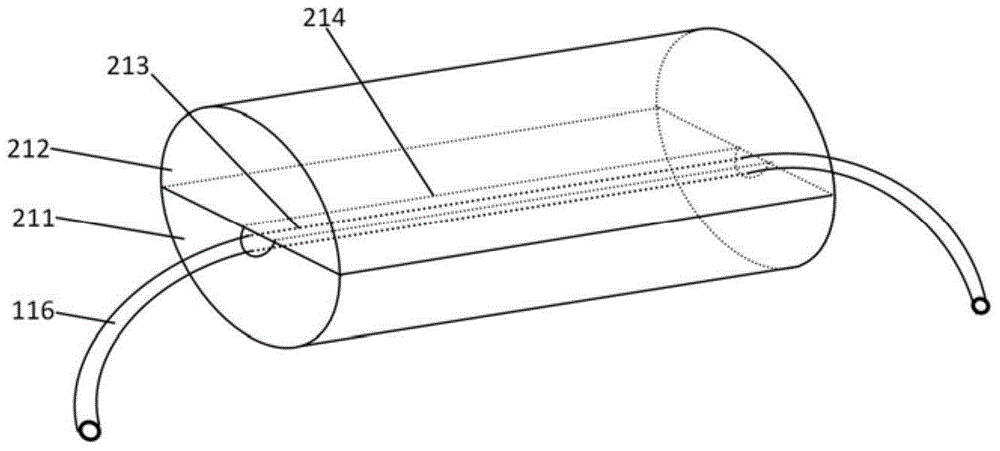

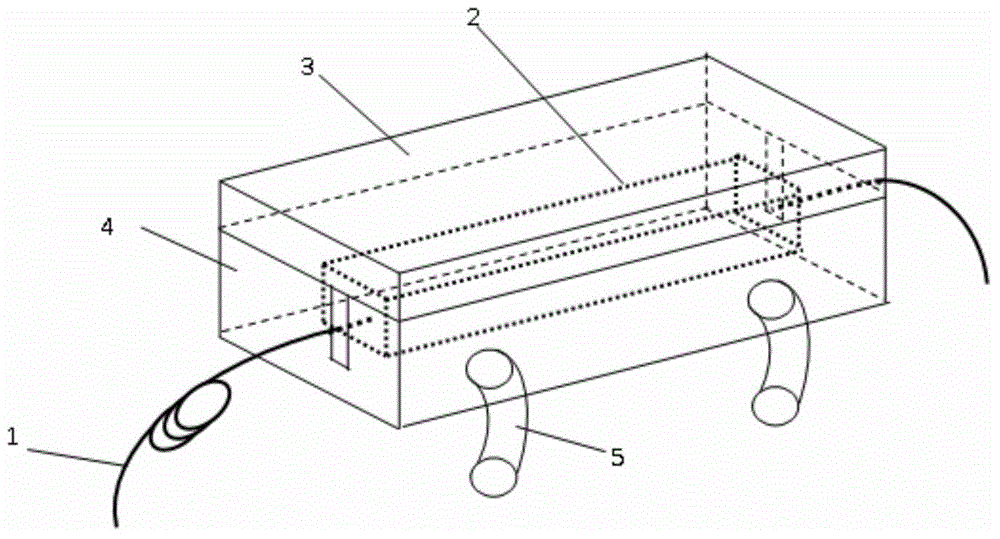

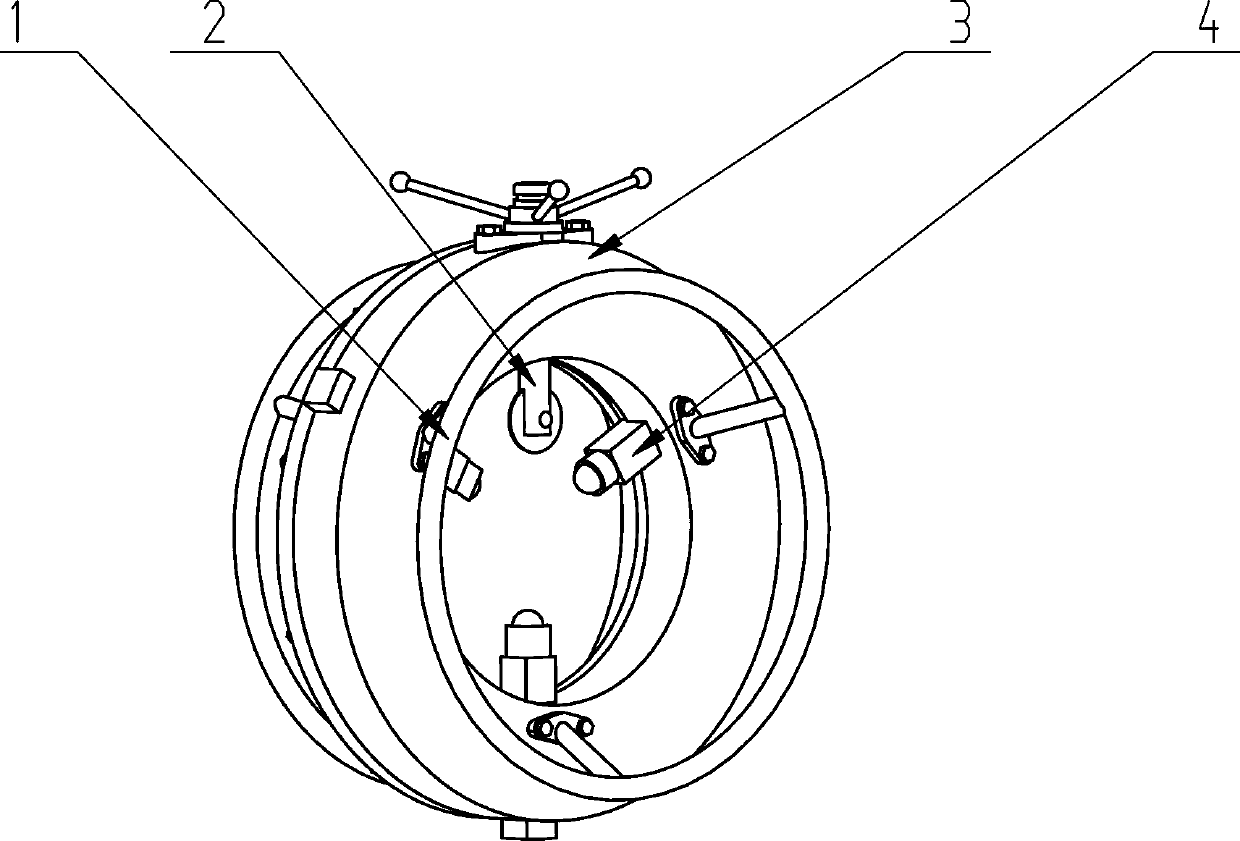

High-power optical fiber cladding power stripper device

ActiveCN104570213ALeak evenlyImprove stripping efficiencyOptical light guidesDouble-clad fiberOptical Module

The invention relates to a high-power optical fiber cladding power stripper device. The high-power optical fiber cladding power stripper device comprises a double-cladding optical fiber (1), an optical module (2), an upper cover plate (3), a water cooling base (4) and a water cooling tube (5); the double-cladding optical fiber (1) penetrates through the optical module (2) and the water cooling base (4), the optical module (2) is arranged in the water cooling base (4), the upper portion of the water cooling base (4) is packaged through the upper cover plate (3) made of materials with the good radiating performance, and the water cooling tube (5) is installed at the lower portion of the water cooling base (4). According to the high-power optical fiber cladding power stripper device, an inner cladding of the optical fiber is stripped to be in a step type and is coated with high-refraction-index optical gel with different refraction indexes, light leaked through the inner cladding is leaked in a relatively-even mode along the length of the optical fiber, a three-layer-optical-waveguide optical module structure is constructed, and the light leaked through the inner cladding can be guided out through optical waveguides. In addition, heat is taken away in time through circulation water, and a stripper is prevented from being excessively high in temperature.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

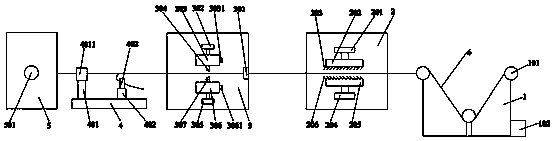

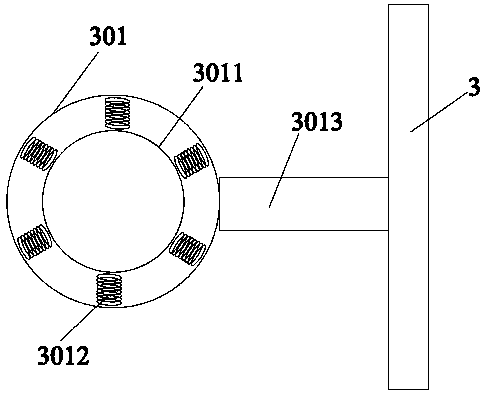

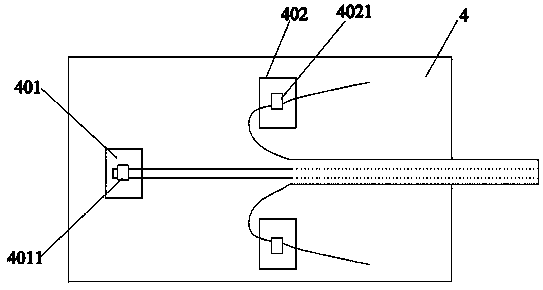

Vehicle wire harness girdling and peeling device

InactiveCN106229899AAchieve orientationNo guidance requiredApparatus for removing/armouring cablesCouplingEngineering

The invention relates to a vehicle wire harness girdling and peeling device which comprises a first support plate. Two moving lugs are respectively arranged on the side wall of the first support plate, and a movable screw is arranged between the two moving lugs through a bearing. A moving motor is arranged on the right end of the movable screw through a coupling, and the moving motor is arranged on a motor bracket. A moving block is arranged on the central section of the movable screw through threads, the upper and lower ends of the moving block are symmetrically provided with two moving slide bars, and the two moving slide bars are respectively mounted on two first linear slide rails. The two ends of each first linear slide rail is mounted on the side wall of the first support plate through screws. Four fixing posts are symmetrically welded on the side wall of the moving block, and a mounting plate is welded on the tail end of the four fixing posts. A wire peeling mechanism is arranged on the left side of the side wall of the mounting plate, and a girdling mechanism is arranged on the right side of the side wall of the mounting plate. Integrated processing function of automatically girdling and wire-peeling can be realized during vehicle wire harness processing.

Owner:YJH ELECTRICAL EQUIP

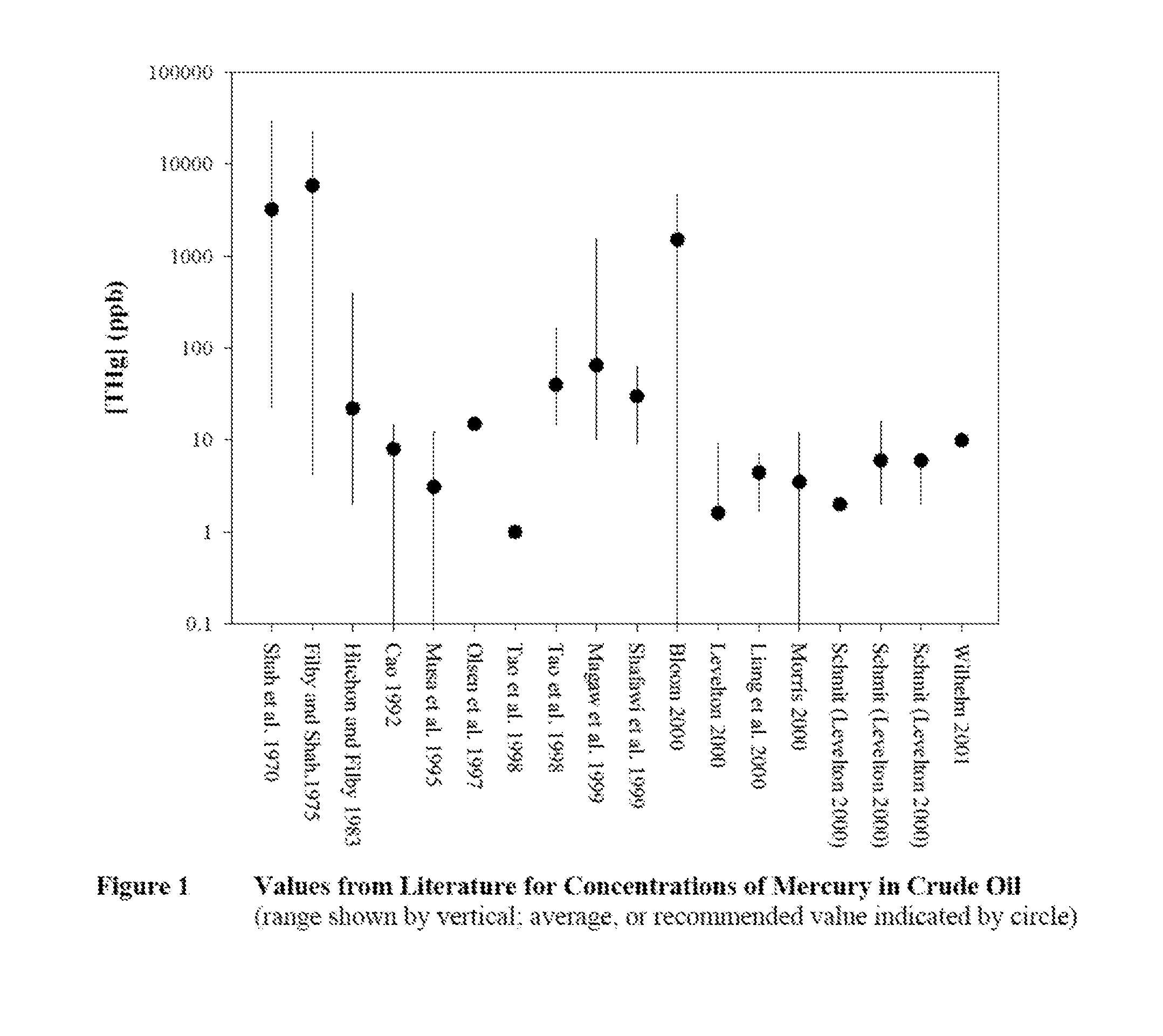

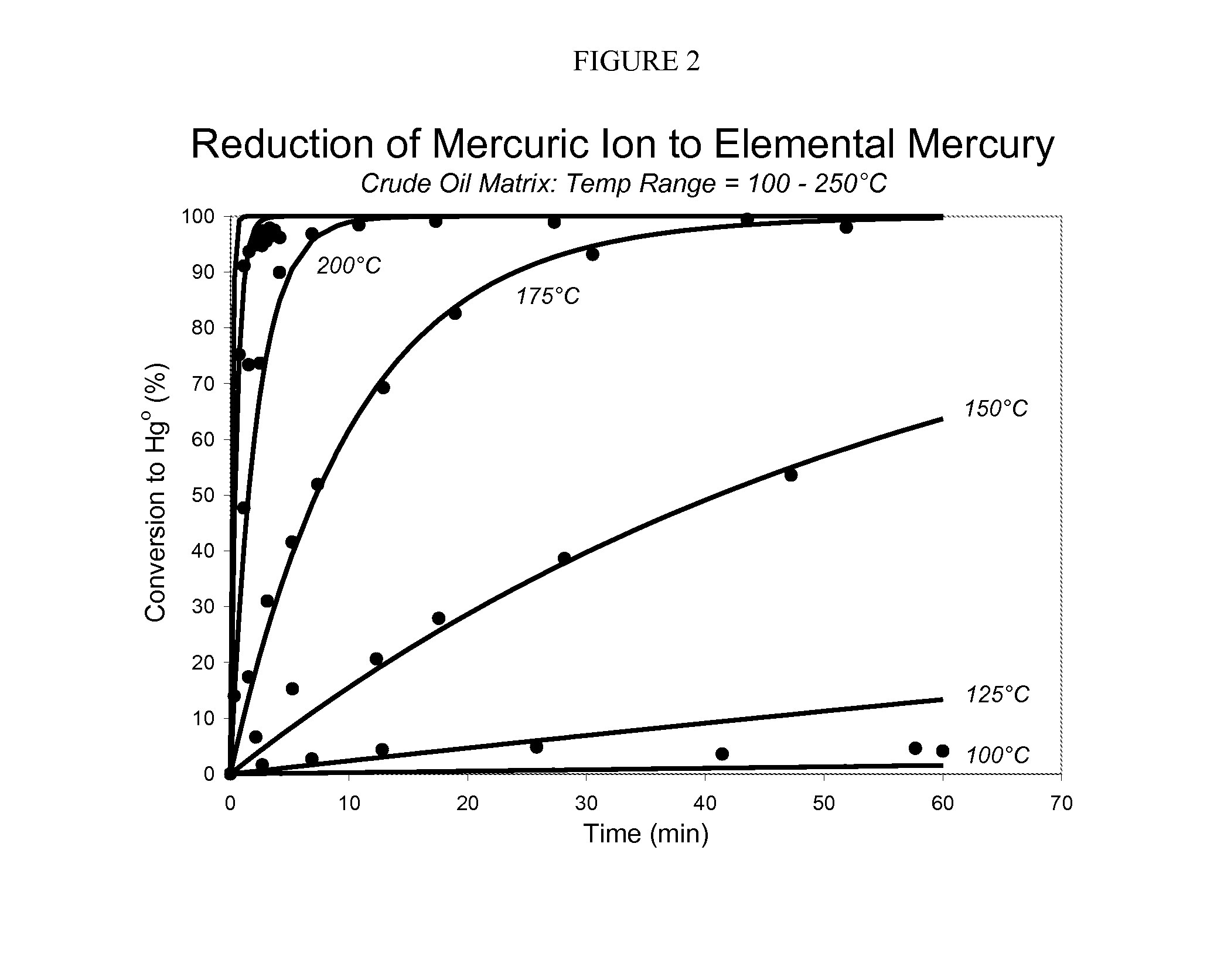

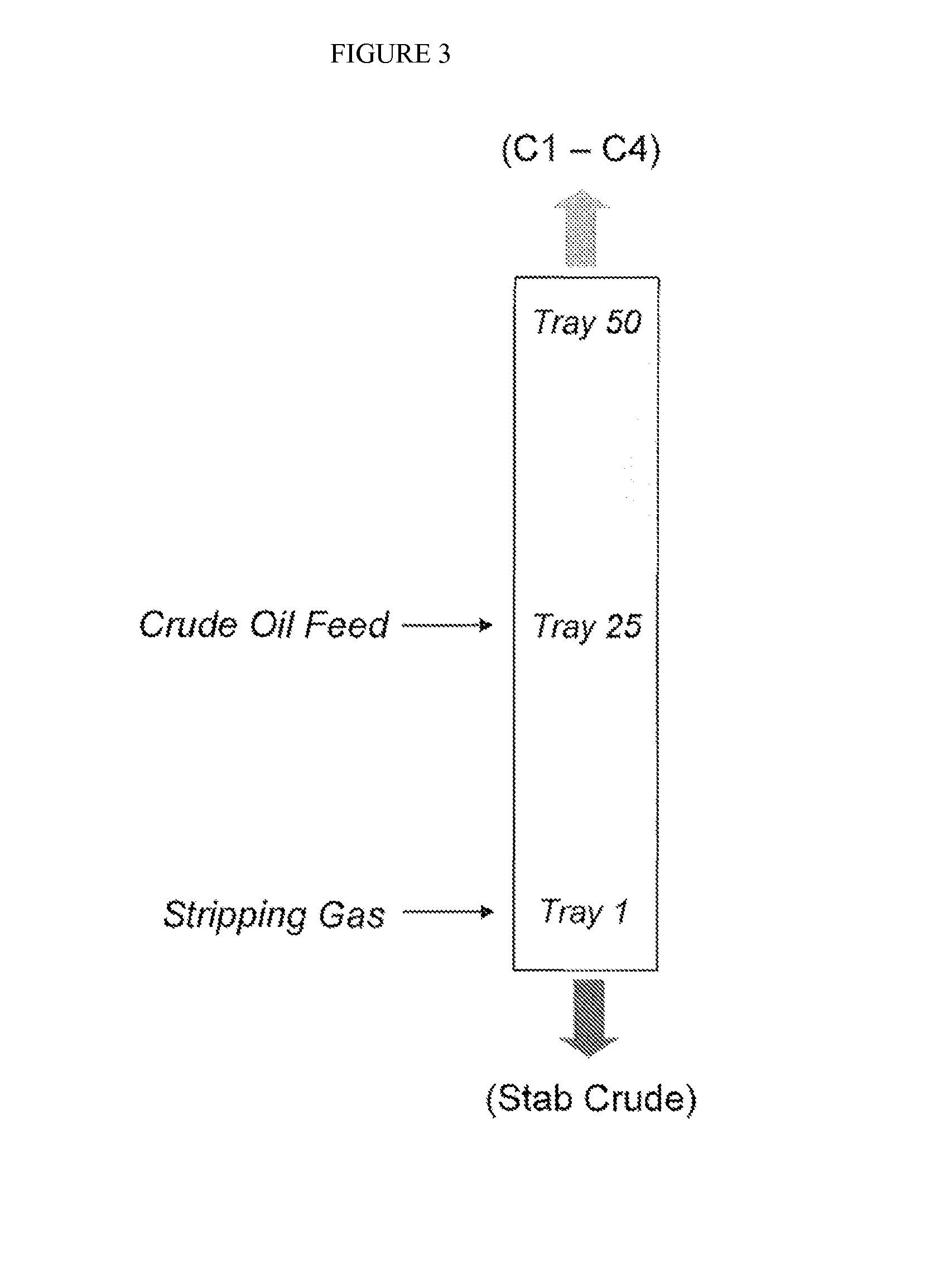

Removing mercury from crude oil using a stabilizer column

ActiveUS20150108040A1Enhance mercury stripping efficiencyImprove stripping efficiencyLiquid degasificationRefining by heating/coolingSufficient timeGas phase

Methods, systems and designs are provided for removing mercury from crudes. Crude oil is heated to a temperature above 100° C. in a stabilization column for a time sufficient to convert all of the forms of mercury in the oil into the elemental mercury form. The elemental mercury is then stripped from the crude oil by flashing, or preferably by gas stripping with a gas injected at the bottom of the column. Either process transfers the elemental mercury from the oil phase into the gas phase. Elemental mercury can then be removed from the gas phase by methods such as condensation, precipitation, or absorption either alone or in combination.

Owner:CONOCOPHILLIPS CO

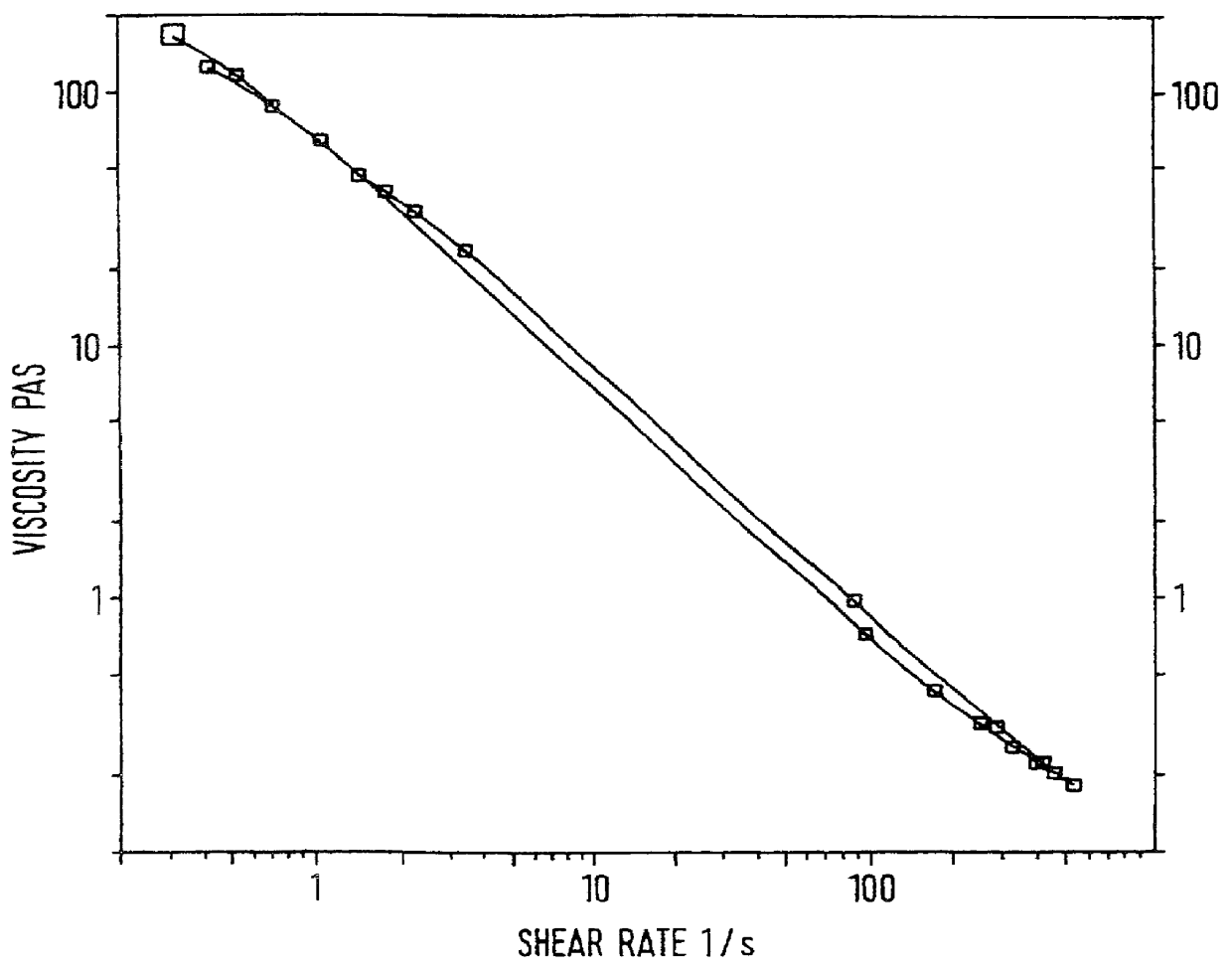

Aqueous composition for plasticizing paint prior to strip

InactiveUS6153573AHigh speedImprove stripping efficiencyOther chemical processesTransportation and packagingPolymer scienceOctanoic Acids

PCT No. PCT / GB96 / 03219 Sec. 371 Date Sep. 11, 1998 Sec. 102(e) Date Sep. 11, 1998 PCT Filed Dec. 23, 1996 PCT Pub. No. WO97 / 24409 PCT Pub. Date Jul. 10, 1997A predominantly aqueous composition for plasticising or softening paint, varnish and similar coatings prior to stripping the coating from a surface includes preferably a combination of the active agents triethylphosphate and a co-agent selected from dimethyl adipate, 1,2,3-propanetriol triacetate, tri-n-butyl citrate, n-octyl acetate, methyl octanoate and 2-ethyl-l-butanol, as an emulsified hydrophobic phase in which the actives are partitioned between the hydrophobic and aqueous phases. The emulsion is preferably stabilized using a non-ionic water-soluble block copolymer surfactant, being a copolymer of more than one alkaline oxide. The composition may be thickened using a rheology control agent. Synthetic smectic clays are particularly suitable. The composition is non-toxic and consists predominantly of water, and yet exhibits effective paint, varnish and lacquer plasticising / softening characteristics.

Owner:ECO SOLUTIONS

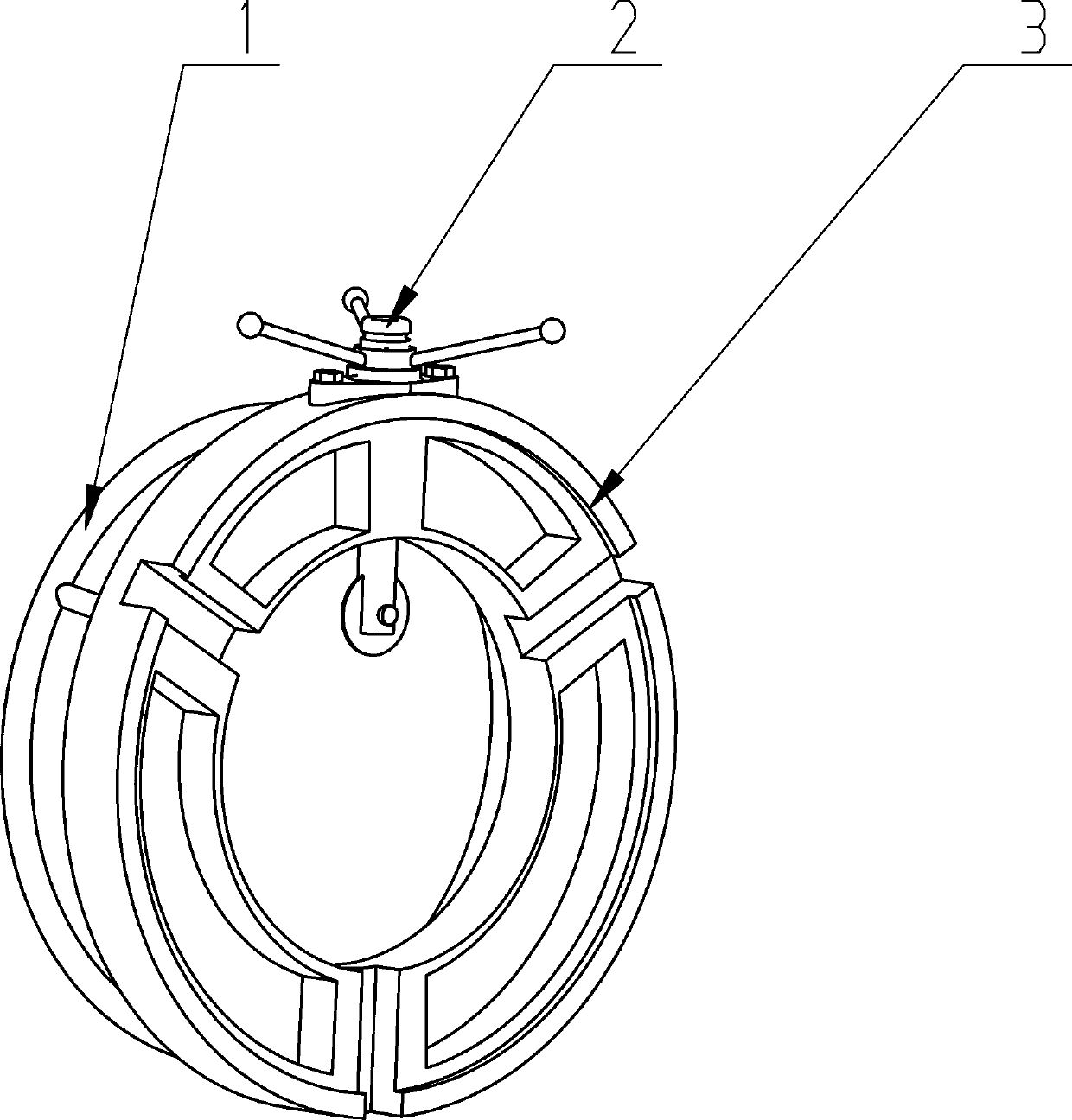

Multifunctional stripping tool for external insulation protection layer of high-voltage cable

ActiveCN111082369AEasy to operateLabor-saving operationApparatus for removing/armouring cablesInsulation layerStructural engineering

The invention discloses a multifunctional stripping tool for an outer insulating protective layer of a high-voltage cable. The multifunctional stripping tool is used for stripping the outer insulatingprotective layer of the high-voltage cable. The tool comprises a hand wheel assembly, a cutter assembly, a disc body, clamping jaw assemblies, a check ring, a wire disc and a locking handle. The handwheel assembly, the clamping jaw assemblies, the cutter assembly, the check ring and the wire disc are installed on the disc body, and the locking handle is installed on the check ring. The three clamping jaw assemblies have a self-centering function, and the cutter assembly can set the cutting thickness according to the thickness of a cut cable insulation layer. According to the high-voltage cable outer insulation stripping device, the high-voltage cable outer insulation can be stripped more conveniently, time and labor are saved, the stripping efficiency is improved, and hands are preventedfrom being scratched or the insulation layer of a cable core is prevented from being damaged due to insufficient experience of an operator.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +2

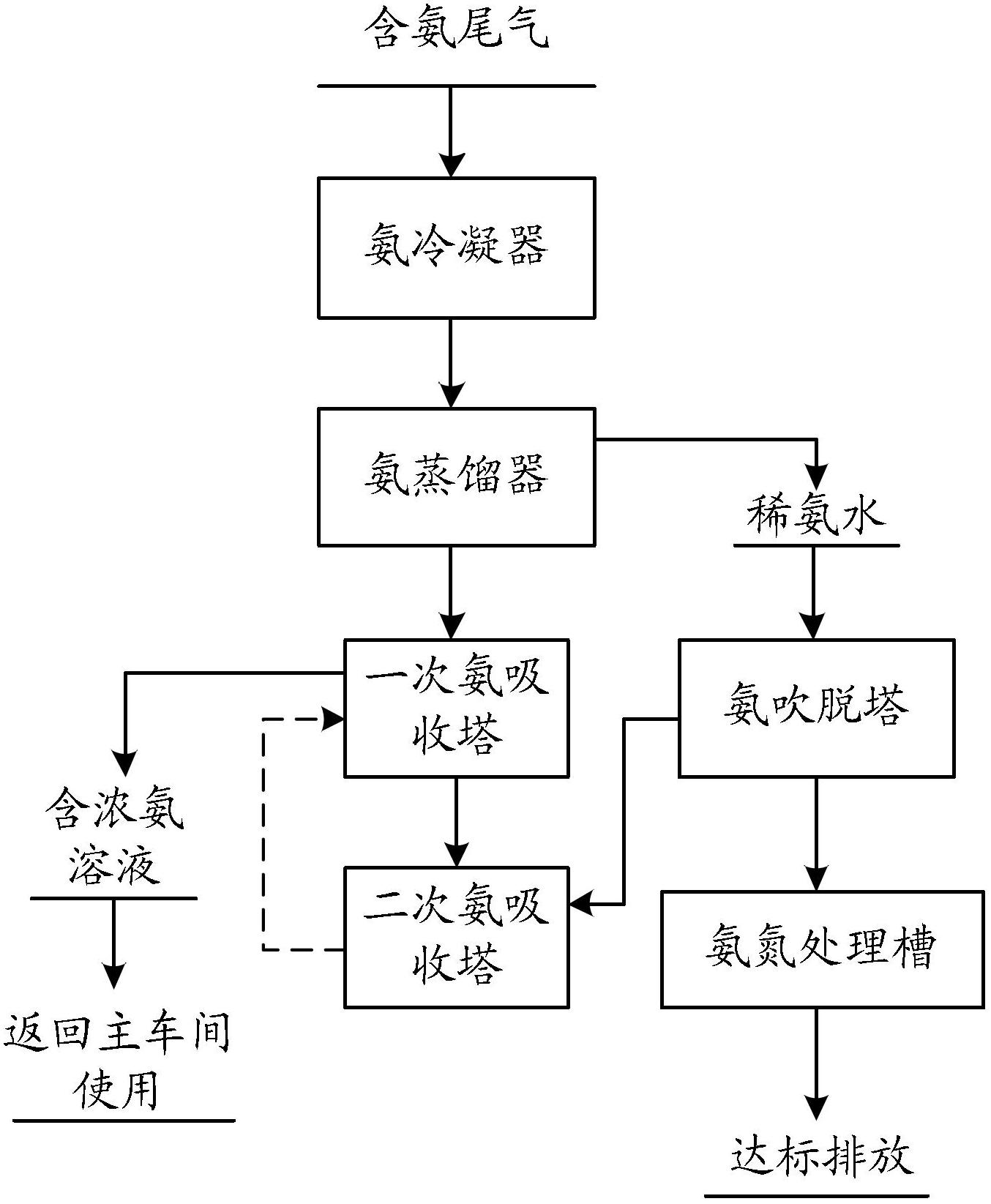

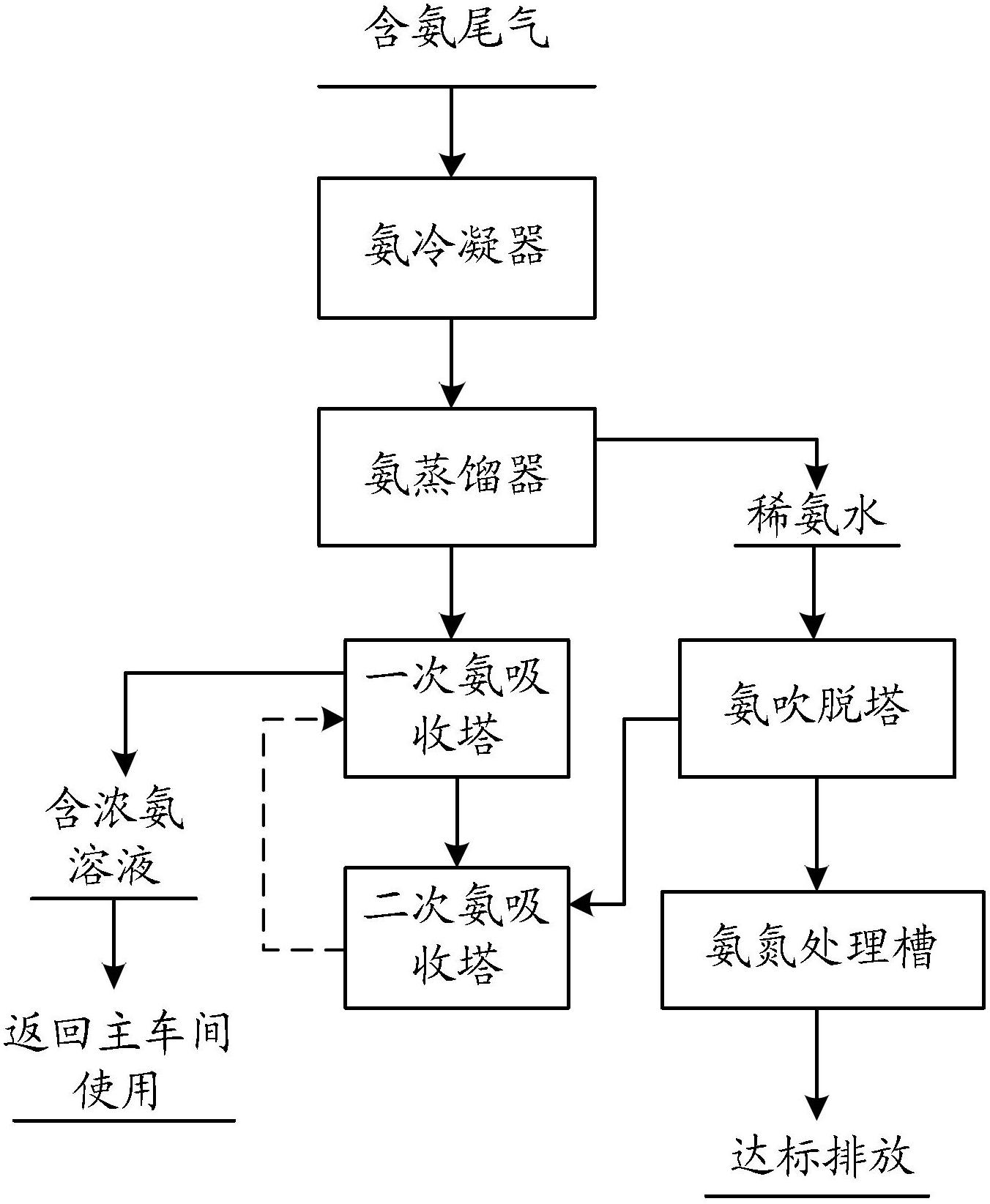

Ammonia tail gas recycling method and system

ActiveCN102688607AShort processSmall footprintDispersed particle separationVapor condensationRecovery methodChloride

The invention relates to an ammonia tail gas recycling method and system. The method comprises condensing tail gas containing ammonia so as to obtain dilute ammonia water and condensed ammonia tail gas; distilling the dilute ammonia water to obtain ammonia gas, water and distilled liquid; and subjecting the condensed ammonia tail gas and the ammonia gas to first spraying absorption by use of low-concentration ammonia chloride solution to obtain first spray ammonia nitrogen solution and first spray residual ammonia tail gas, wherein the ammonia nitrogen concentration in the ammonia nitrogen solution is not lower than 70g / L. With the inventive method, ammonia-containing tail gas can be effectively recycled.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

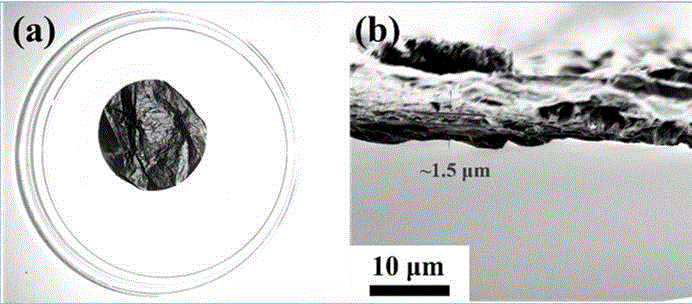

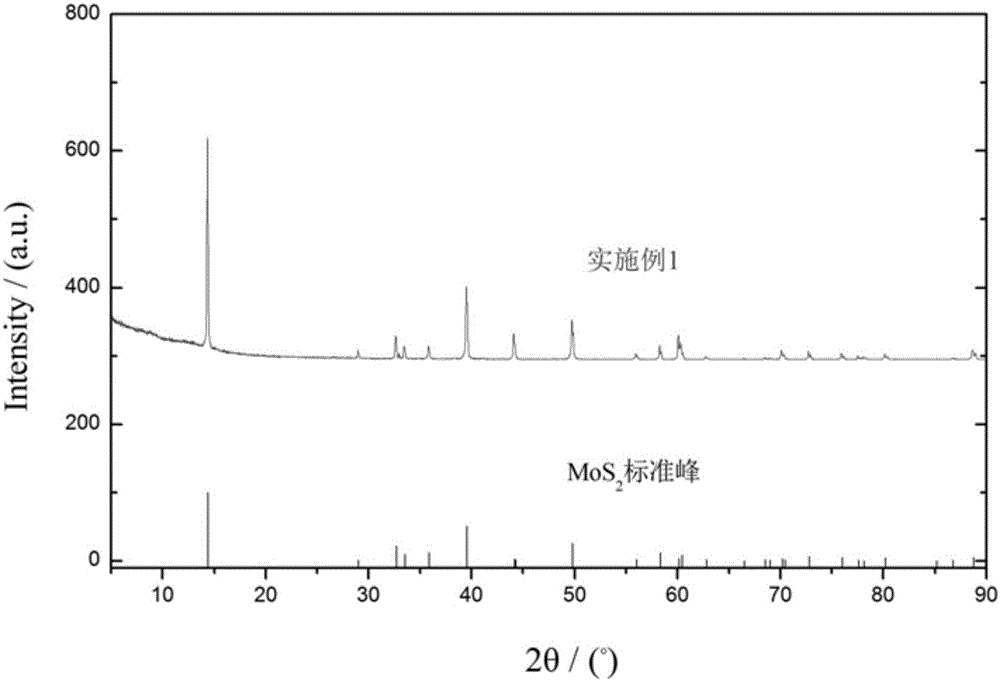

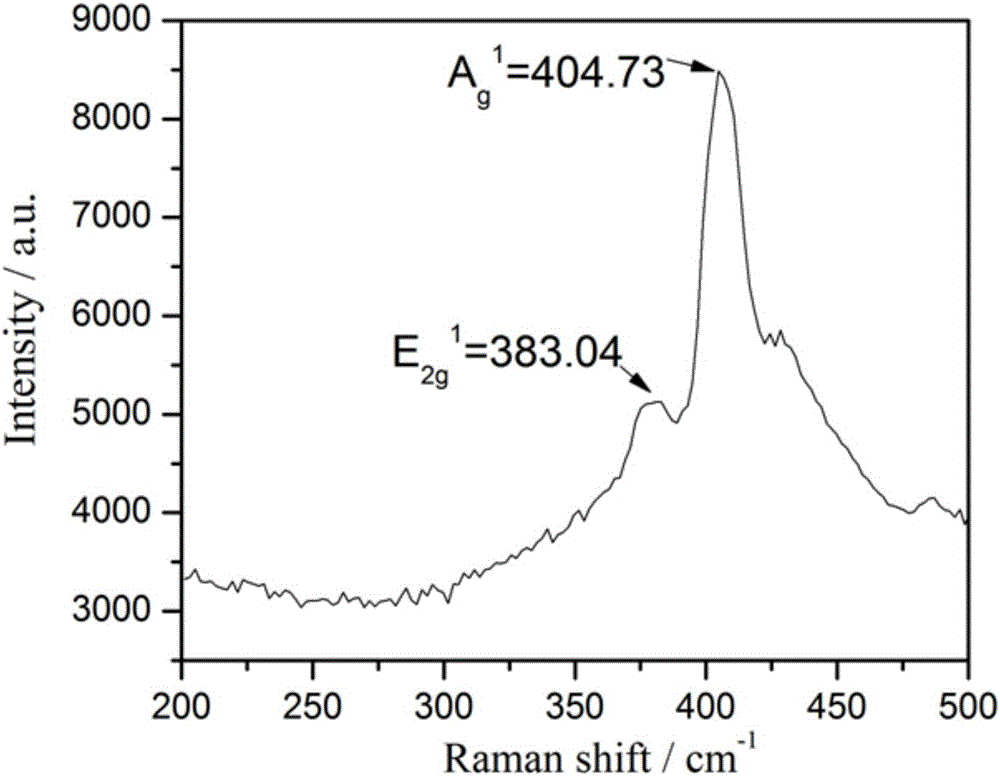

Preparing method of single-layer or few-layer molybdenum disulfide nanometer material

ActiveCN105668631AImprove stripping efficiencyIncrease productionMaterial nanotechnologyMolybdenum sulfidesIntercalation reactionMolybdenum disulfide

The invention provides a preparing method of a single-layer or few-layer molybdenum disulfide nanometer material. According to the method, molybdenum disulfide powder is added into a layering solution to be subjected to a layering reaction, so that mixed liquor is formed; then, an oxidizing agent is added into the mixed liquor to carry out the oxidation intercalation reaction, and a product is filtered and dried to obtain intercalation molybdenum disulfide powder; finally, an explosion agent is added to carry out the explosive reaction, after cooling is carried out to the room temperature, an explosive reaction product is taken out, so that the single-layer or few-layer molybdenum disulfide nanometer material is obtained. The single-layer or few-layer molybdenum disulfide nanometer material prepared through the method is high in stripping efficiency and large in yield; moreover, most stripped products are single-layer molybdenum disulfide with high carrier mobility, can be effectively applied to photoelectricity, a semi-conductor, a secondary battery, a sensor, a storage medium and other devices and has a wide application prospect. The method for preparing the single-layer or few-layer molybdenum disulfide nanometer material is easy to operate, a complex and tedious preparing method is not needed, and the method is suitable for industrialized production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

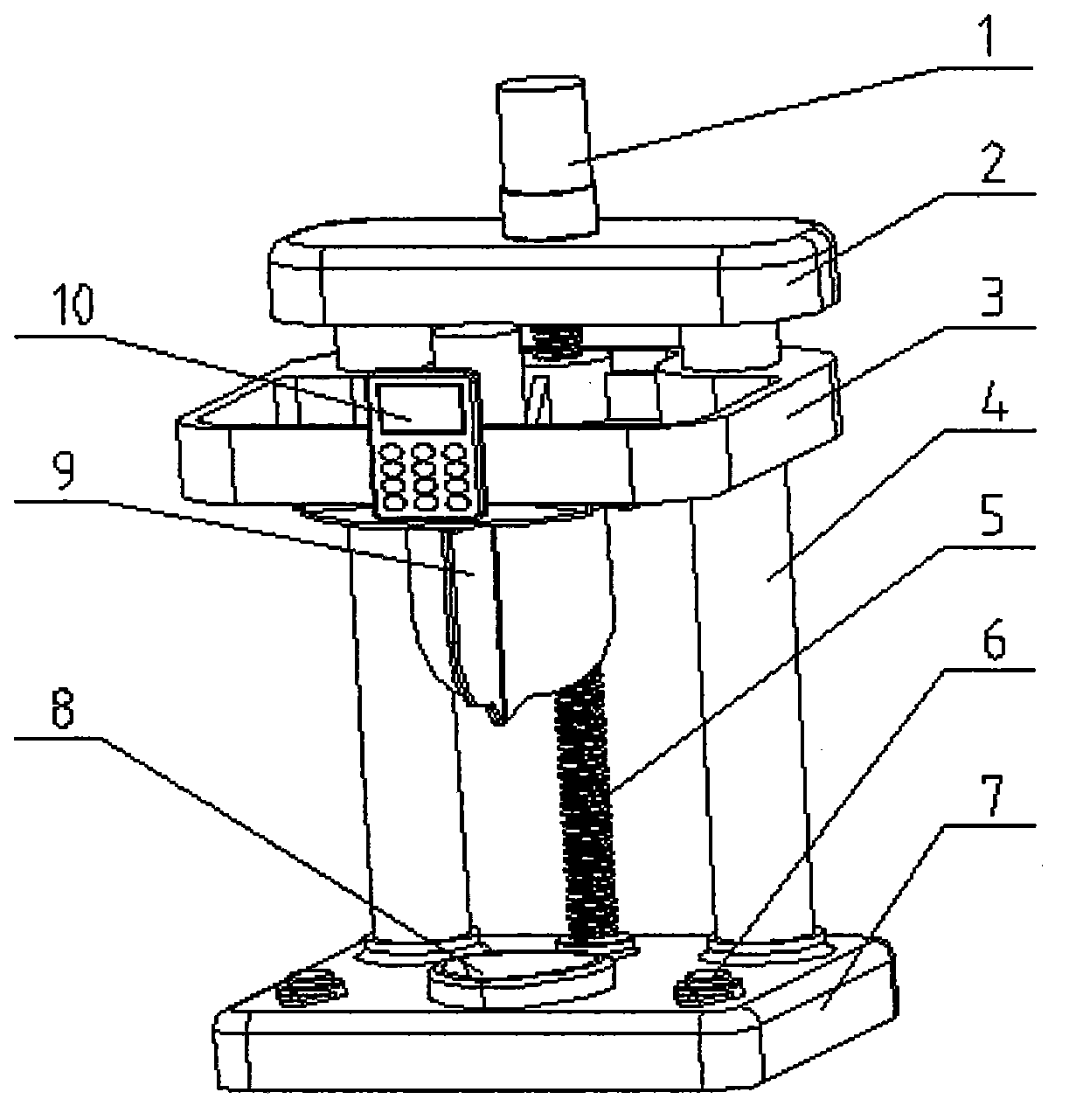

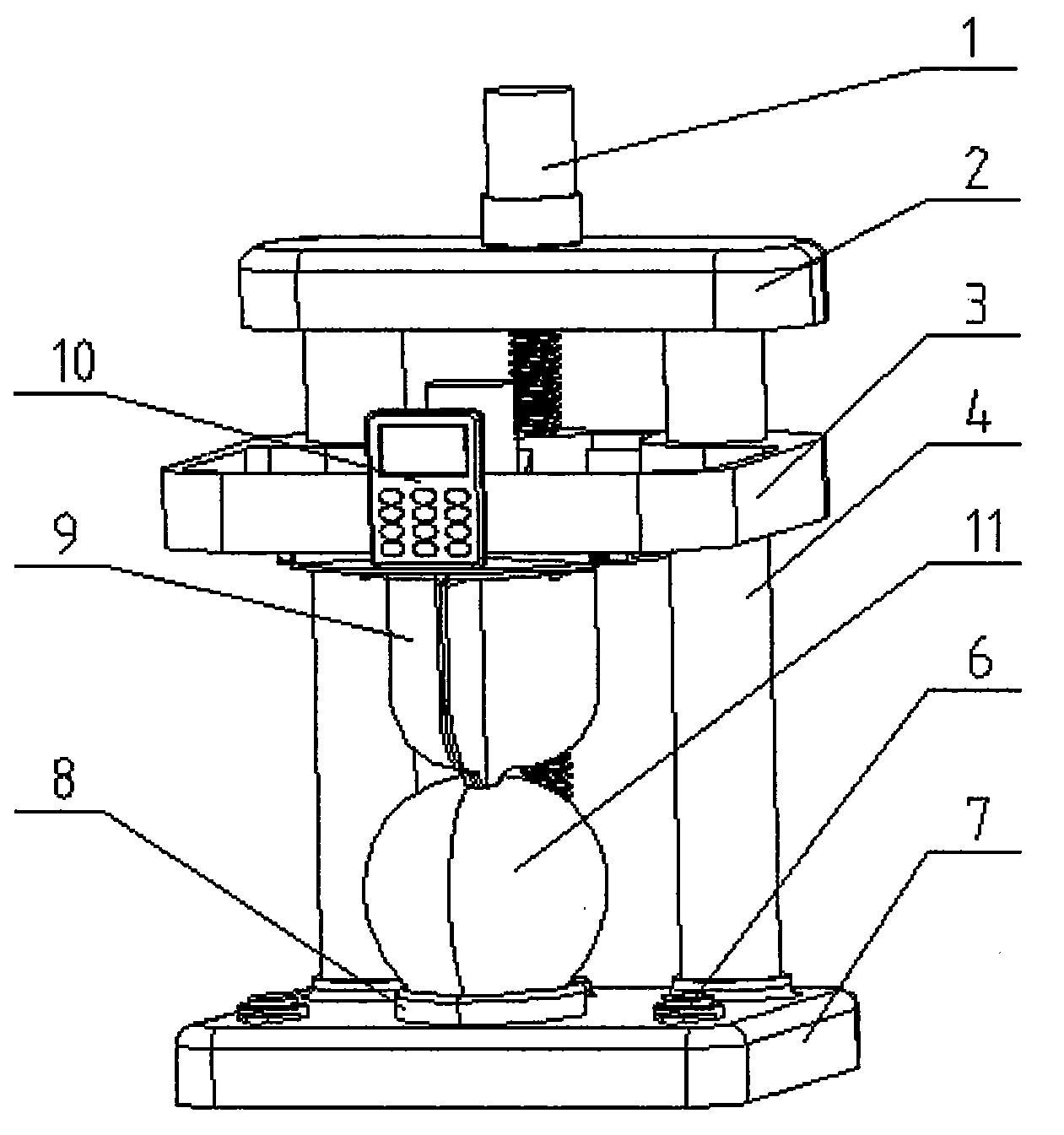

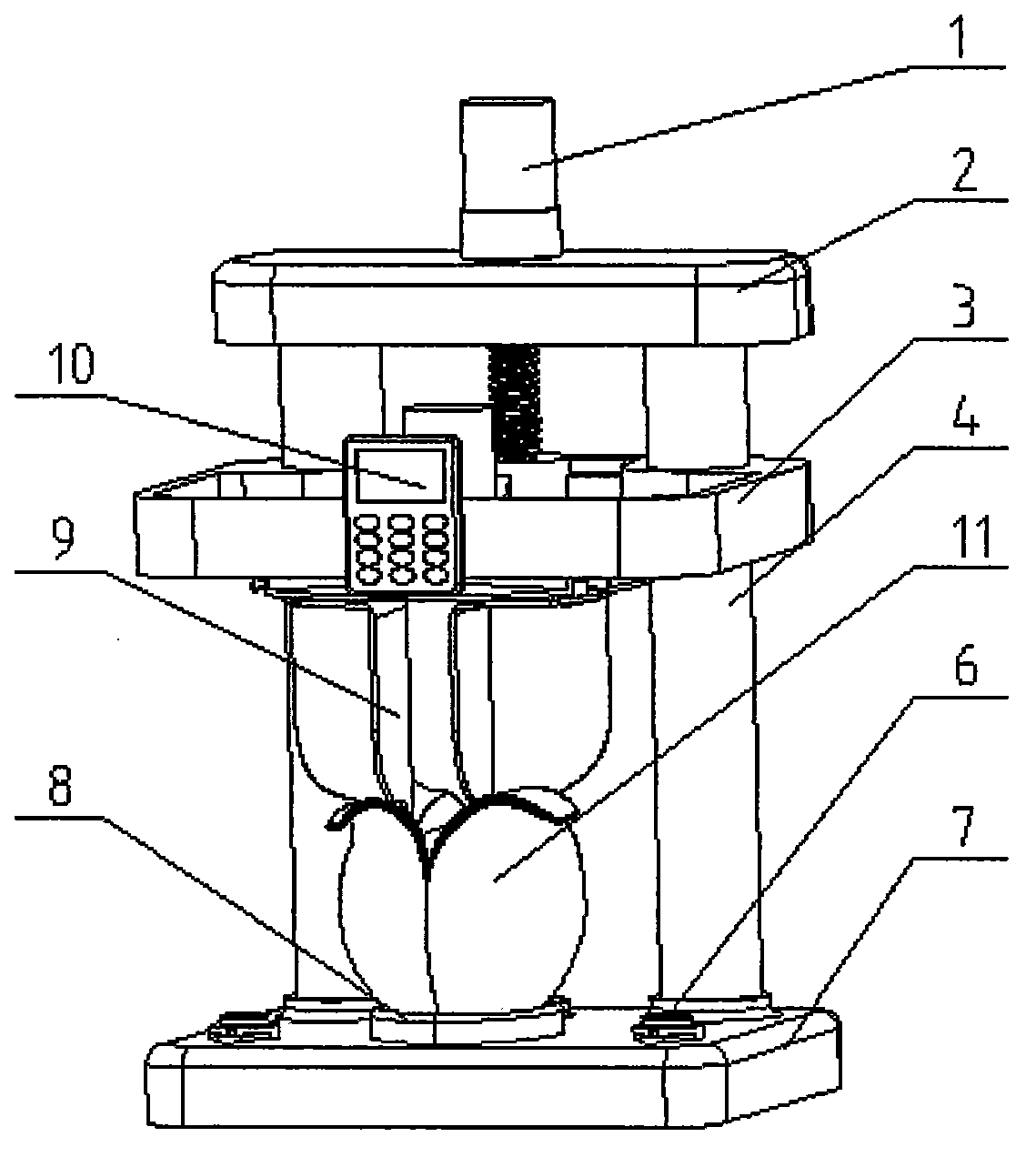

Coconut palm fiber peeling machine

InactiveCN104256859AImprove stripping efficiencyEasy to operateHuskingHullingPalm fiberMechanical engineering

The invention discloses a coconut palm fiber peeling machine. The coconut palm fiber peeling machine comprises a screw rod motor, a beam, a lifting platform, a stand pillar, a screw rod, press buttons, a bottom seat, a rubber seat, a turnover knife component and a controller, wherein the turnover knife component comprises a knife disk motor, a connection rod, a knife disk, a turnover knife, a rotator and a slide block. When a person uses the coconut palm fiber peeling machine to peel palm fibers of a coconut, the person only needs to right the coconut and place the coconut into the rubber seat, and simultaneously presses down the press buttons on two sides of the bottom seat, the palm fibers on the outer layer of the coconut can be peeled through united action of the lifting platform and the turnover knife component under control of the controller, and simultaneously the interior of the coconut can not be injured, and therefore the coconut palm fiber peeling machine is convenient to operate and greatly improves palm fiber peeling efficiency.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com