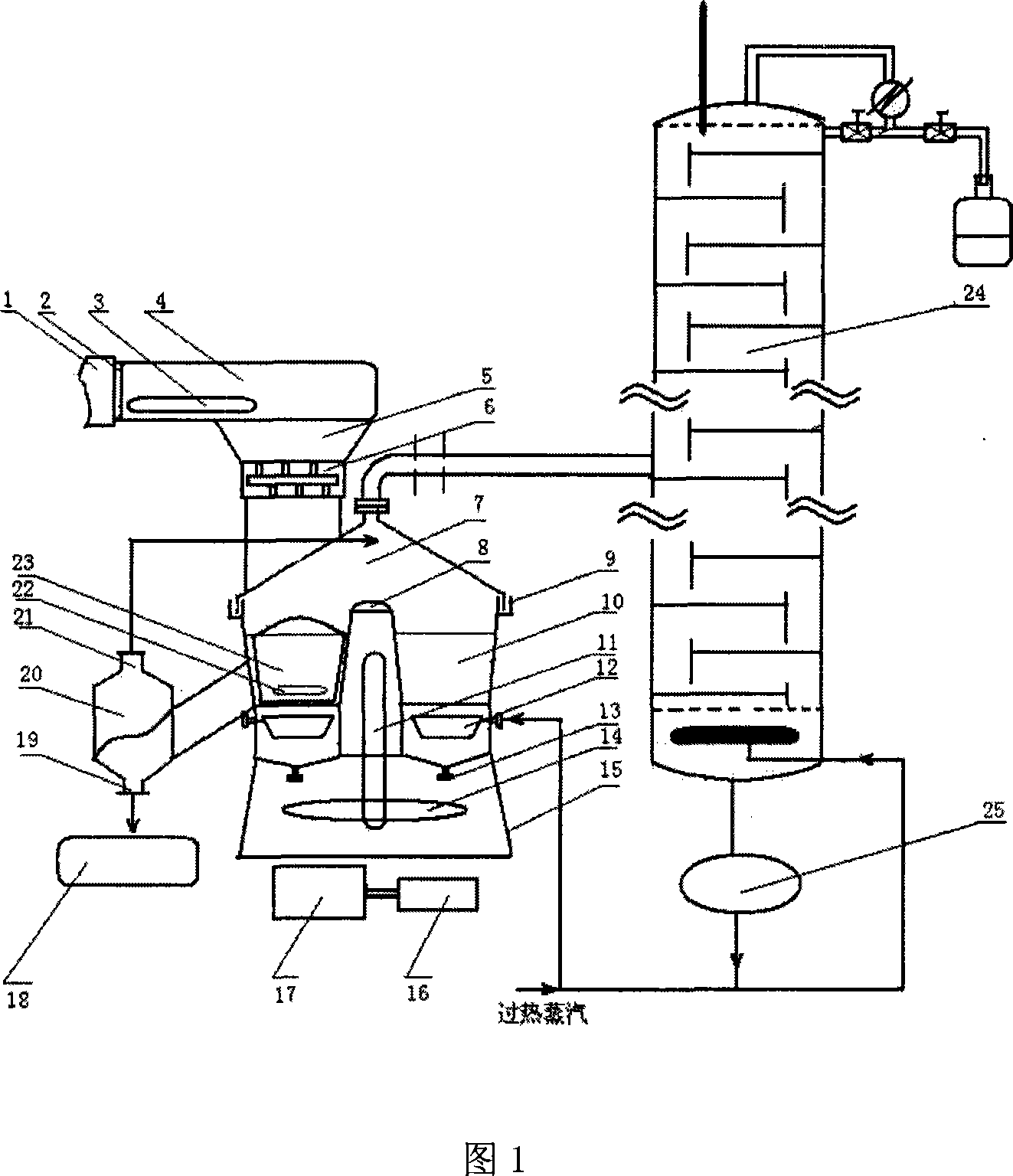

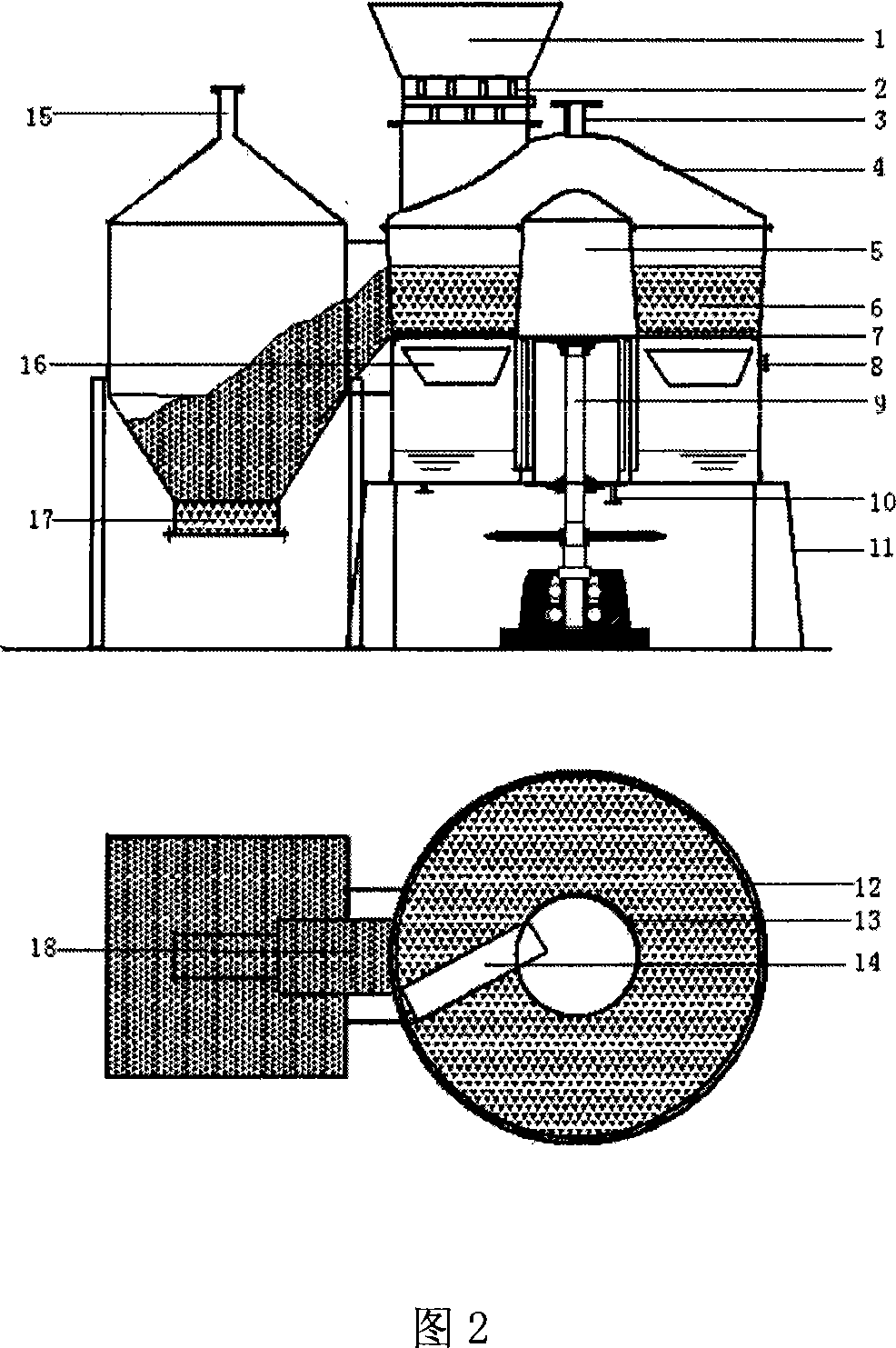

Method and system for continuously separating ethanol and utilizing residual heat based on solid-state fermentation material

A technology of solid-state fermentation and fermented materials, applied in the field of integration, can solve problems such as high production costs, unbearable processing costs, and unsuitability for annual continuous production, so as to ensure steady-state continuous operation of rectification and improve ethanol stripping Efficiency, to achieve the effect of mechanized treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] 1.1 tons of solid fermentation material containing 7% (v / v) ethanol is discharged to the conveyor belt through the sealed cabin, transported in the sealed tunnel, and enters the closed ring groove rotary disc stripper through the feed hopper and star distributor. Control the rotation speed of the rotating disc at 0.1~2rpm, and the speed is 3.5kg / cm 2 The superheated steam is used to separate ethanol, and 30-40% (v / v) ethanol vapor can be obtained, which is equivalent to 99.5% (w / w) ethanol 60.0kg, and the ethanol yield in the solid-state distillation process is 98.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com