Wire-stripping machine for medium-high voltage cable

A high-voltage cable and wire stripping machine technology, which is applied in the direction of dismantling/armored cable equipment, etc., can solve the problems of low efficiency, failure to meet production needs, waste of manpower, etc., achieve convenient maintenance and use, improve stripping efficiency, and save manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

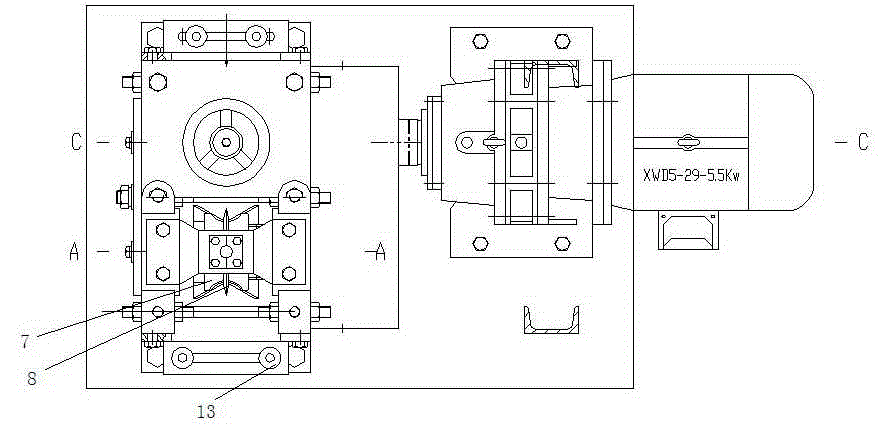

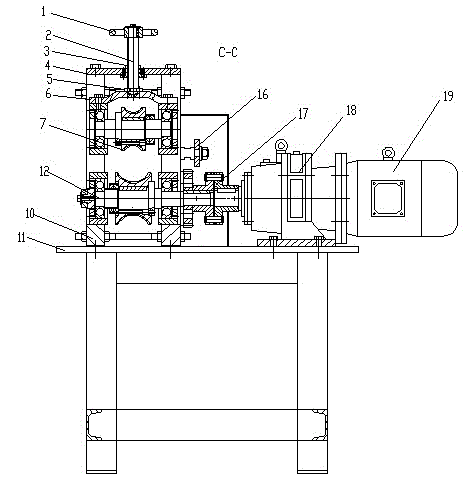

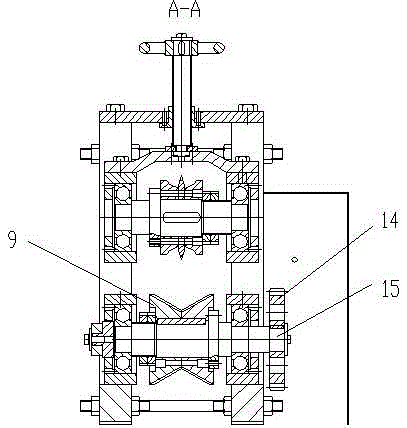

[0017] The structure of the machine is further described below in conjunction with the accompanying drawings:

[0018] see figure 1 , figure 2 , image 3 with Figure 4 , The medium and high voltage cable stripping machine includes a frame 11, a cycloidal pinwheel reducer 18, a motor 19, a coupling 17, a gear, a bearing seat, a bearing seat frame 10, a pressure wheel, a blade 8, a screw lifting mechanism, Lifting plate 6, frame cover plate 4, guide wheel 13 etc.

[0019] The bearing frame 10 is installed on the frame 11, and two groups of pressure rollers are arranged side by side in the bearing frame, and they are all installed on the bearing frame 10 by bearings and bearing blocks. Each group of pressure rollers has two upper and lower relative installations, and the space between them is the space for cables to pass through. The working surface of the upper pressure roller 7 in the direction of wire entry is a semicircle concave inward, and the working surface of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com