Patents

Literature

204results about How to "Achieve the purpose of reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

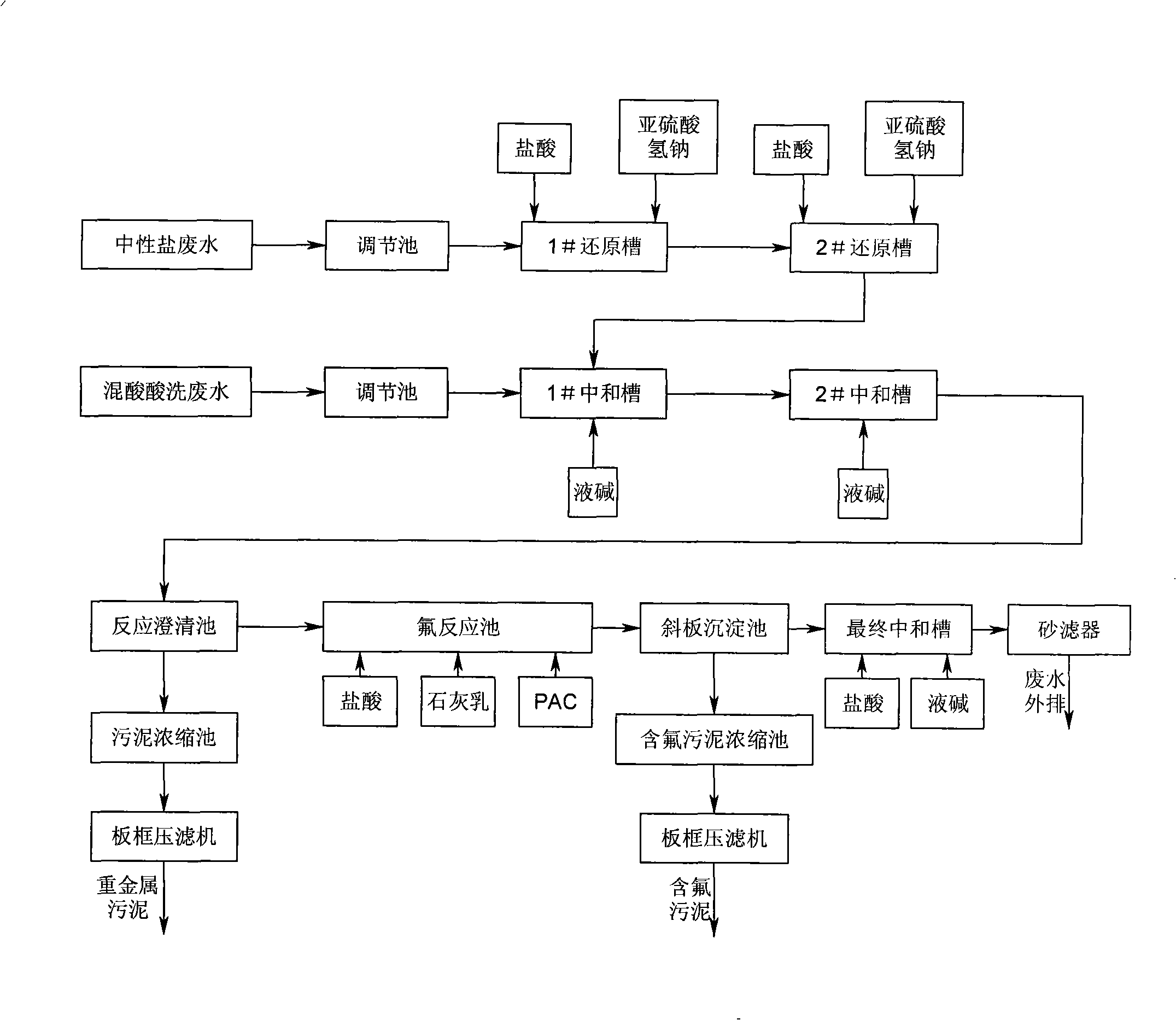

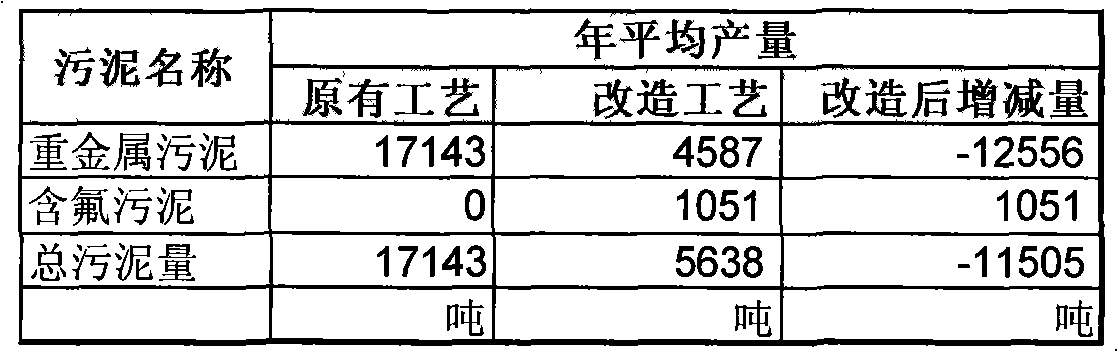

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

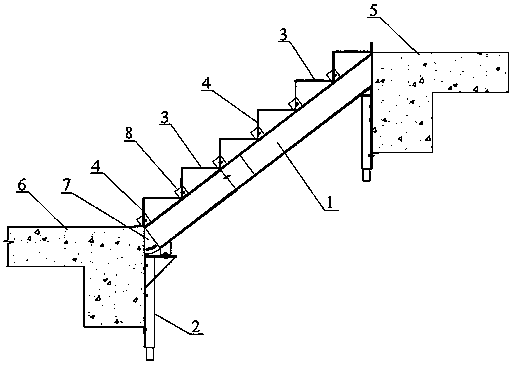

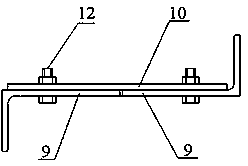

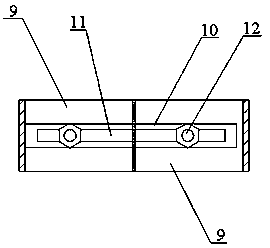

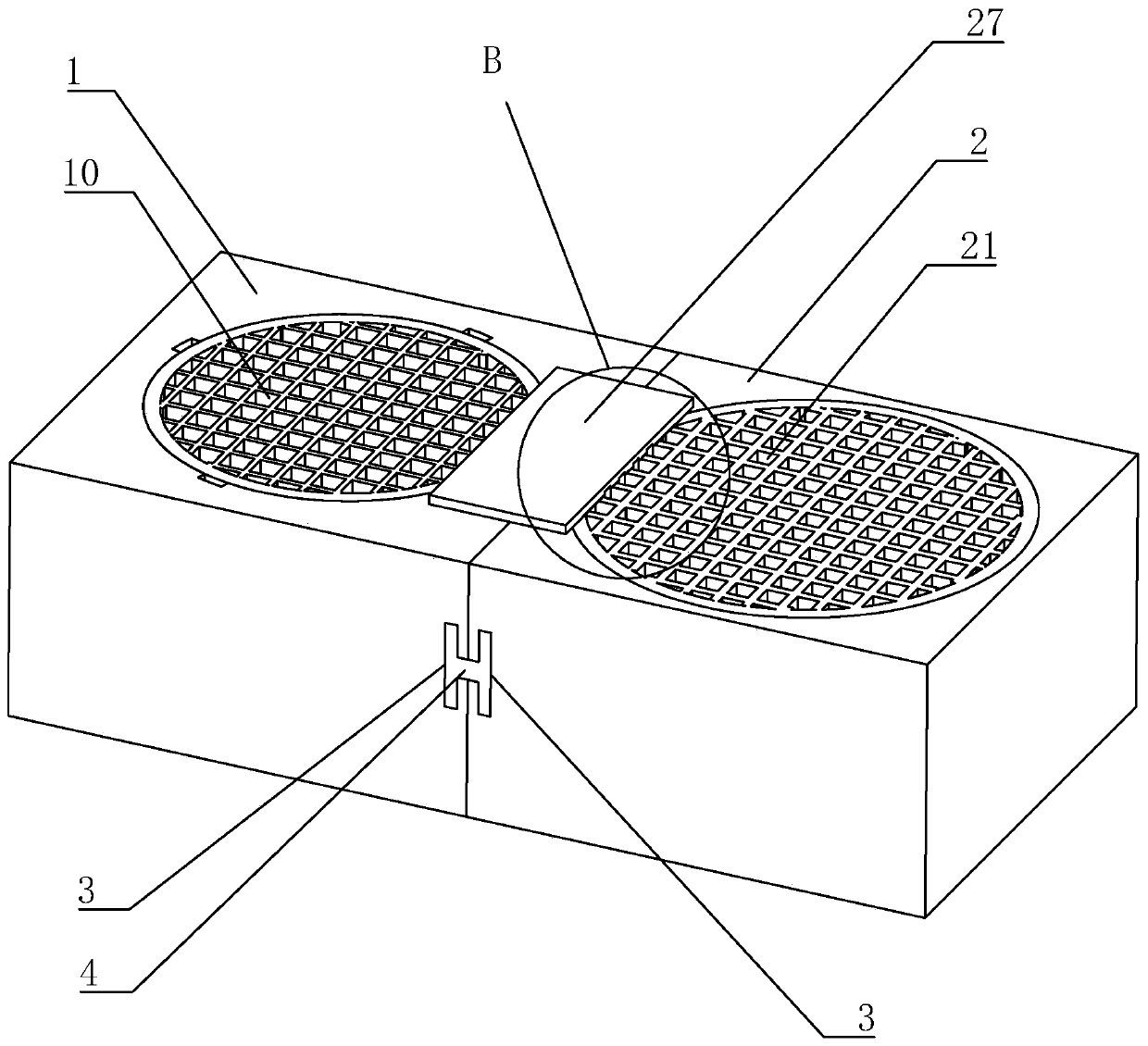

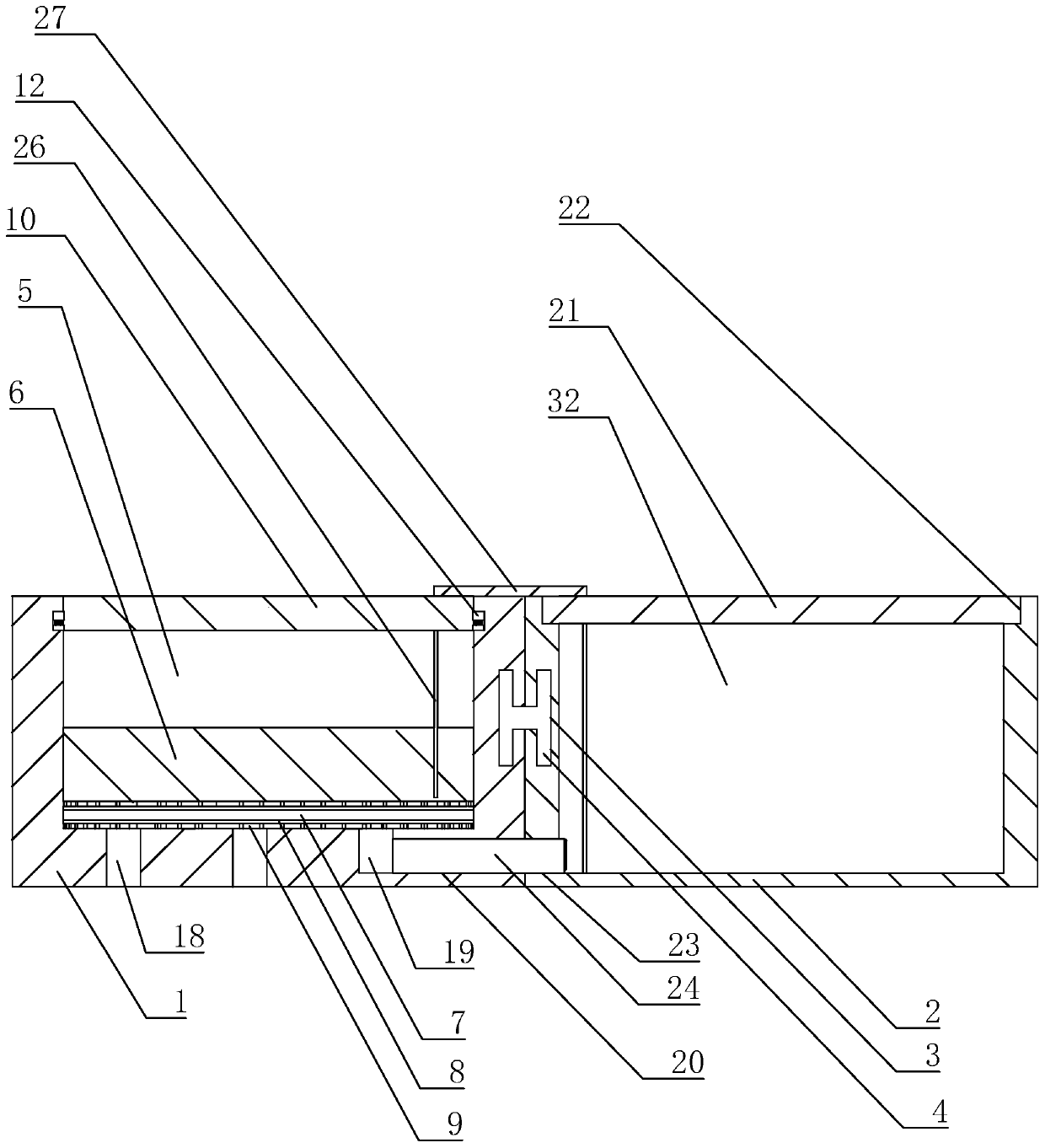

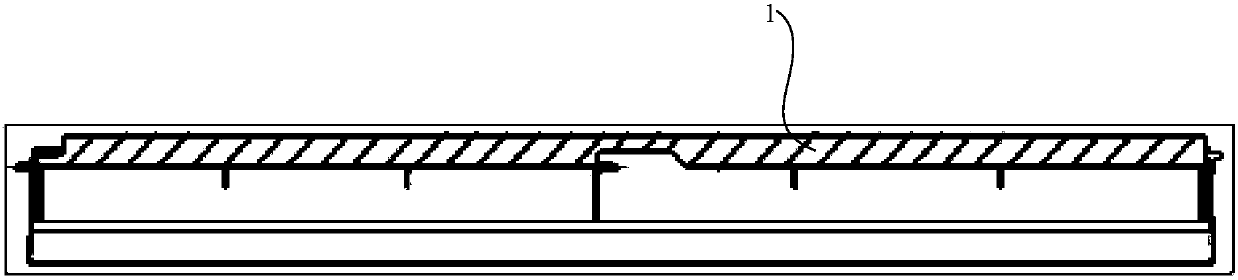

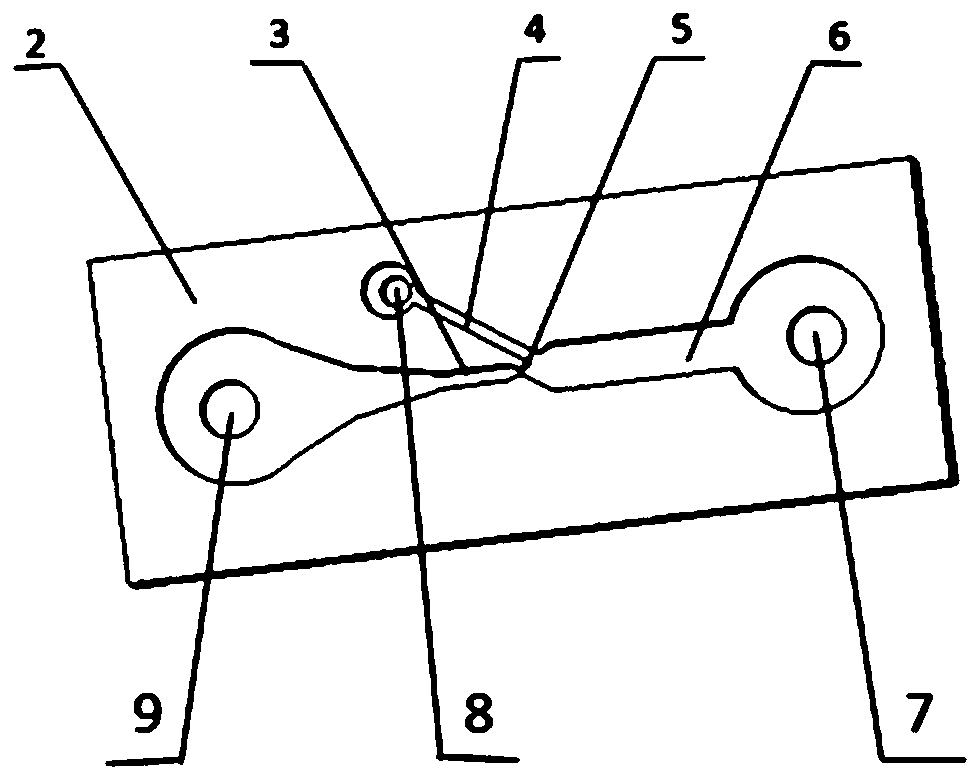

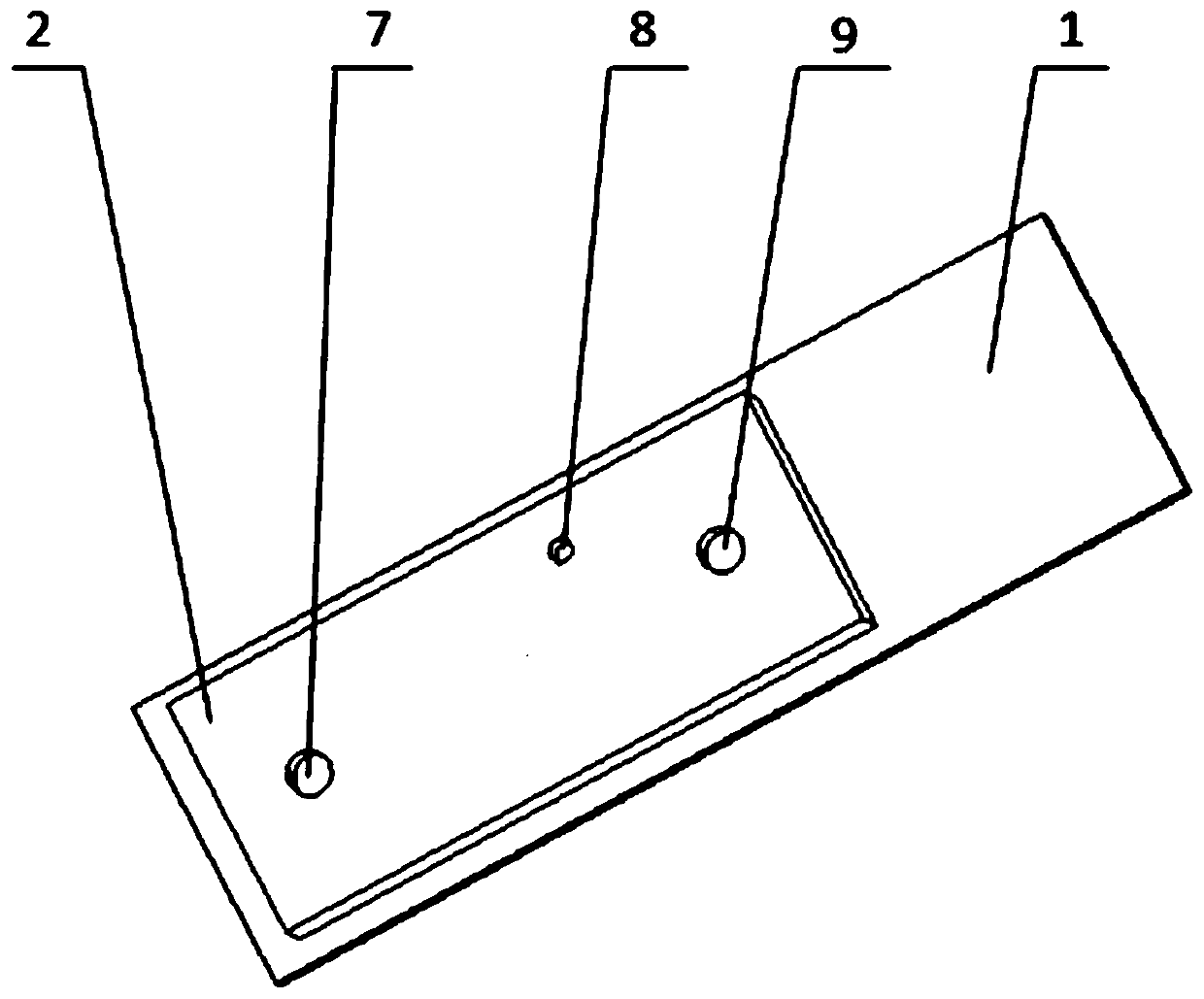

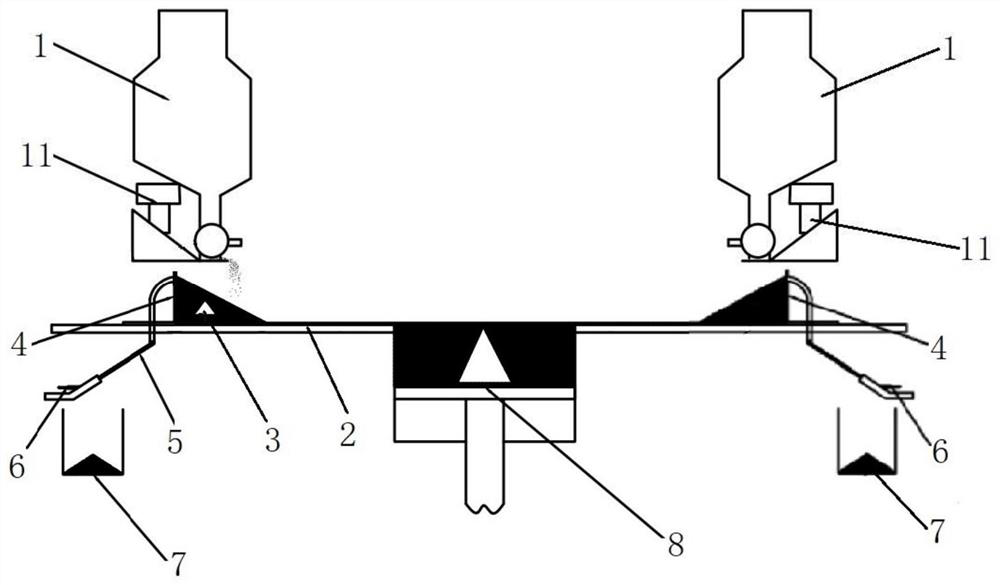

Adjustable type universal stair formwork

ActiveCN104060825AAchieve the purpose of reuseForms/shuttering/falseworksClassical mechanicsMechanical engineering

The invention discloses an adjustable type universal stair formwork. The adjustable type universal stair formwork comprises step surface formworks (3), step kickplate formworks (4) and a side edge formwork (1). A length adjusting structure is arranged on each step surface formwork (3). A height adjusting structure is arranged on each step kickplate formwork (4). A telescopic adjusting structure is arranged on the side edge formwork (1). A stair angle adjusting structure (7) is arranged at the bottom of the connection portion between the stair and a lower platform (6). A kickplate angle adjusting device (8) is arranged at the bottom of each step kickplate formwork (4). Each kickplate angle adjusting device (8) enables the corresponding step kickplate formwork (4) to be connected with the adjacent step surface formwork (3). By the adoption of the adjustable type universal stair formwork, the length, the height and the angle of the stair formwork can be adjusted, the universality is high, recycling can be achieved, the problems that steel and wood of an existing stair formwork are used disorderly, and efficiency is low can be solved, the progress of industrialization and standardization of constructional engineering is accelerated, and energy consumption and construction cost are reduced.

Owner:贵州建工集团第四建筑工程有限责任公司

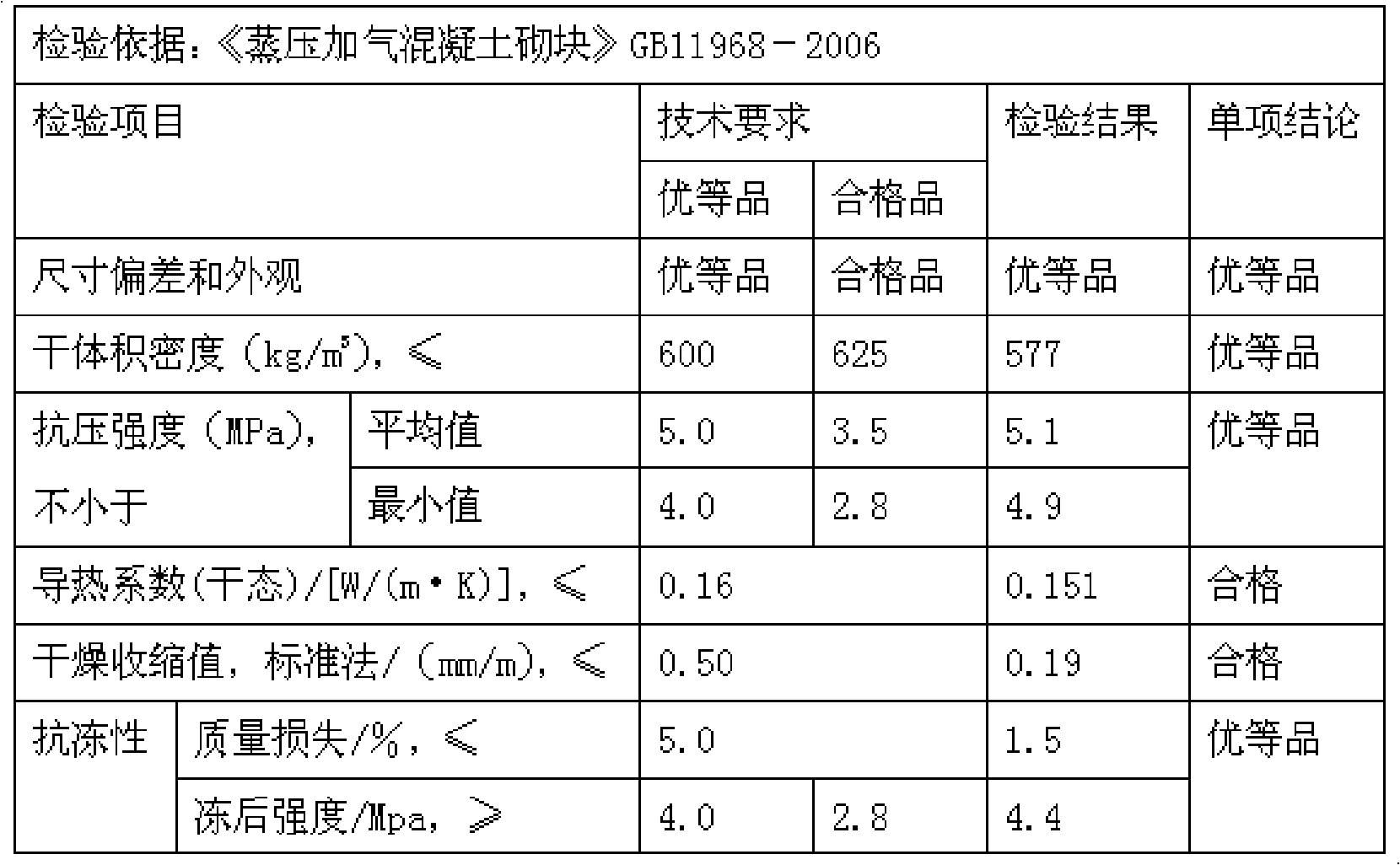

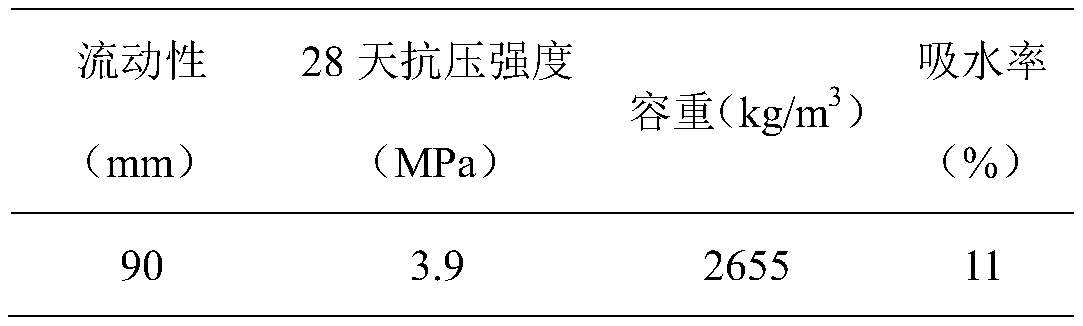

Phosphorous slag autoclave aerated concrete building block and preparation method thereof

ActiveCN101608484AAchieve the purpose of reuseTake advantage ofSolid waste managementCeramic shaping apparatusSlagGypsum

The invention discloses a phosphorous slag autoclave aerated concrete building block and a preparation method thereof. The phosphorous slag autoclave aerated concrete building block is prepared by adding water in phosphorous slag, silica sand, calcium lime, cement, gypsum and aluminium powder. Compared with the prior art, the method uses slag produced by phosphorus production as a main material for providing siliceous composition to produce the autoclave aerated concrete building block with light weight and insulation, can produce the autoclave aerated concrete building blocks with different levels according to different requirements, fully utilize the phosphorous slag waste, simultaneously also can reach or slightly excess the performances of the traditional similar building block and achieve the purpose of reusing the waste while reducing the production cost.

Owner:贵州源隆新型环保墙体建材有限公司 +1

Method for removing heavy metal in soil

InactiveCN102319725AEasy to handleGood effectContaminated soil reclamationPollution soilCombined use

The invention discloses a method for removing heavy metal in soil, and belongs to the field of polluted soil treatment. The method comprises the following steps: adjusting the water content of the soil to be treated to 8%-12%; uniformly adding a magnetic adsorption material into the soil with adjusted water content, wherein the adding amount of the magnetic adsorption material is 10-50 g per 1 kg of soil; regularly adjusting the water content of the soil after magnetic adsorption material addition, maintaining the water content of the soil to 8%-12%, regularly and uniformly stirring the soil; collecting the magnetic adsorption material in the soil treated by above procedures for a certain period in a manner of magnetic separation so as to complete the removal of heavy metal in the soil. The method has simple operations, can realize high-efficient low-cost treatment of heavy metal-polluted soil, and has the advantages of low energy consumption and environment protection; the method can be combined with common technology of phytoremediation of heavy metal-polluted soil, and has good popularization and application value.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

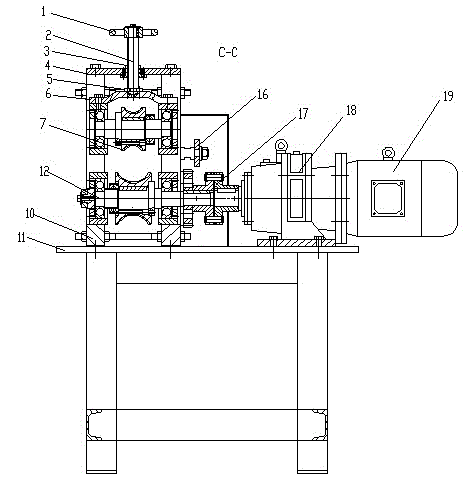

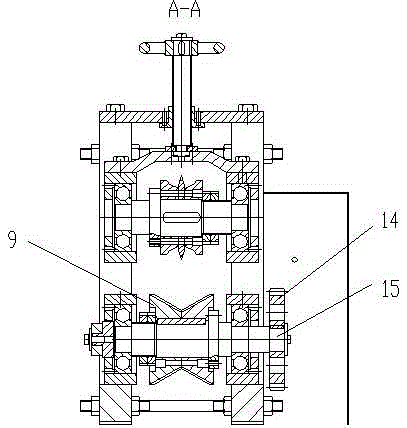

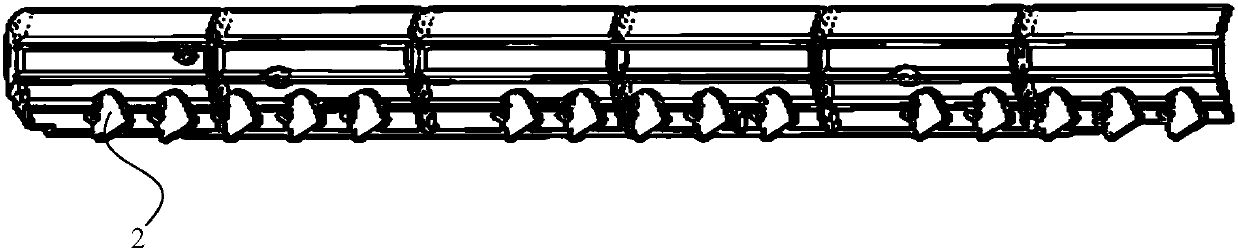

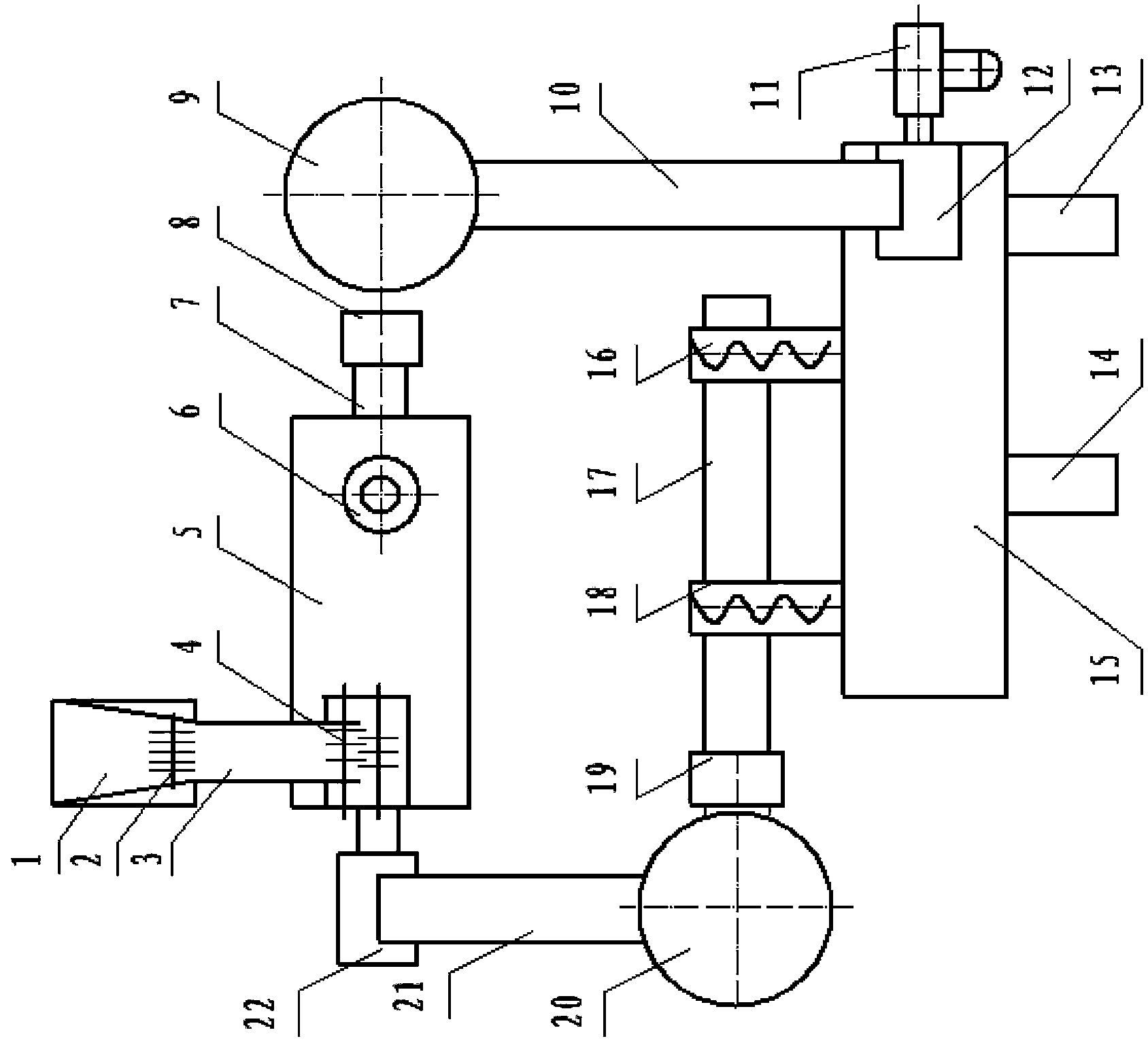

Wire-stripping machine for medium-high voltage cable

InactiveCN102946073AEasy to reuseAchieve the purpose of reuseApparatus for removing/armouring cablesTransmitted powerCoupling

A wire-stripping machine for a medium-high voltage cable comprises a frame, a speed reducer, a motor, a coupler, a gear, a bearing block, a bearing saddle, pressing wheels, blades, clamping devices and a frame cover plate. Two groups of pressing wheels are arranged on the frame side by side, each group of pressing wheels includes an upper pressing wheel and a lower pressing wheel which are oppositely mounted, a space for penetrating the cable is reserved between each upper pressing wheel and the corresponding lower pressing wheel, the working surface of each upper pressing wheel is semicircular, the working surface of each lower pressing wheel is umbrella-shaped, the blades are clamped in the middles of the working surfaces of the upper pressing wheels in the wire outlet direction, one clamping device is arranged above each group of pressing wheels, one of the lower pressing wheels of the two groups of pressing wheels is mounted on a driving shaft, the other one of the lower pressing wheels of the two groups of pressing wheels is mounted on a driven shaft, the driving shaft is connected with the speed reducer and the motor through the coupler, the gear is mounted on the driving shaft and transmits power to a transmission gear through an intermediate gear, and the transmission gear is mounted on the driven shaft and drives the other lower pressing wheel. By the aid of the wire-stripping machine, a wire insulating layer can be automatically separated from metal, wire-stripping efficiency is improved, labor cost is saved, and loss is furthest reduced.

Owner:CHONGQING TAISHAN CABLE

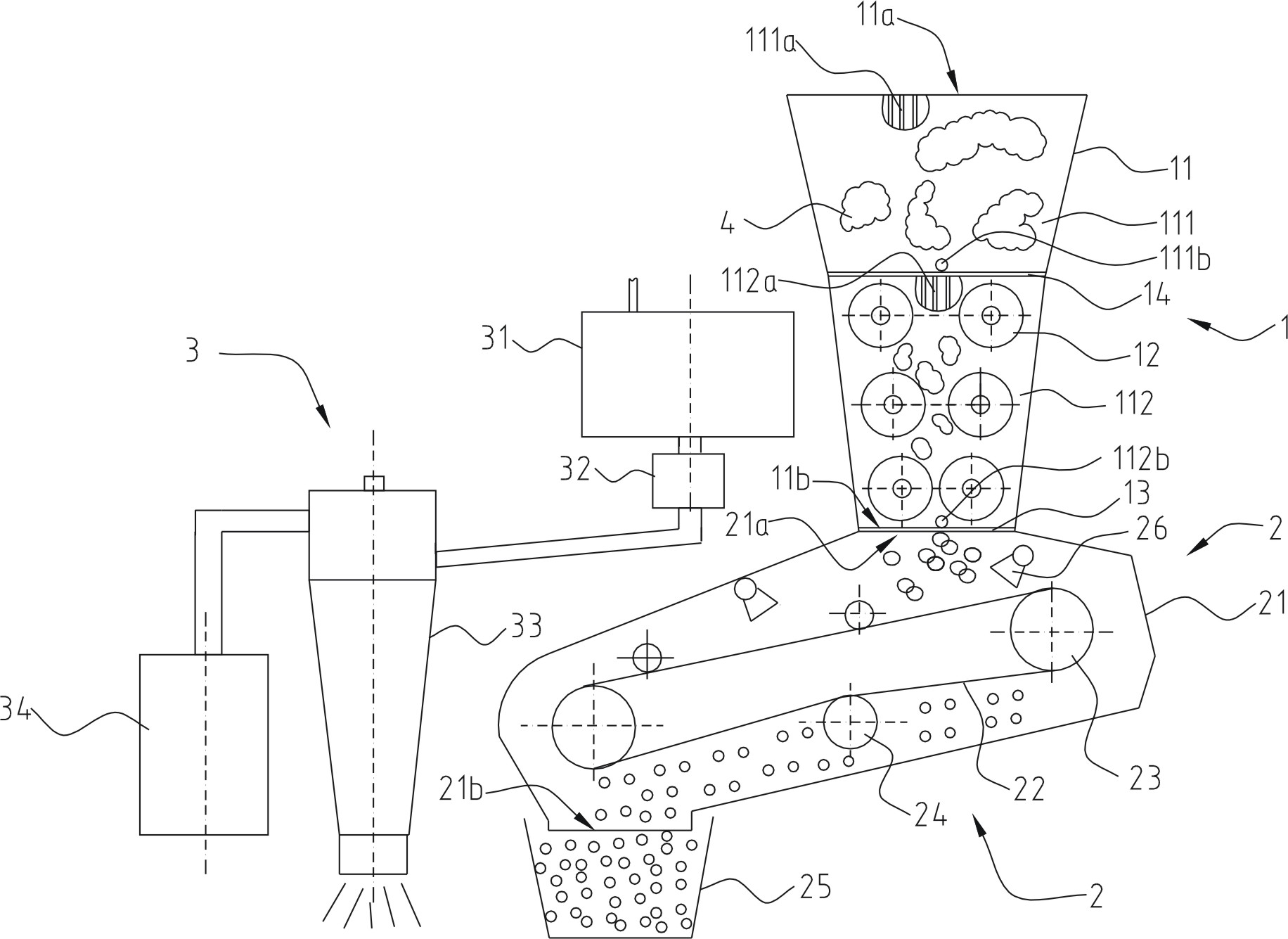

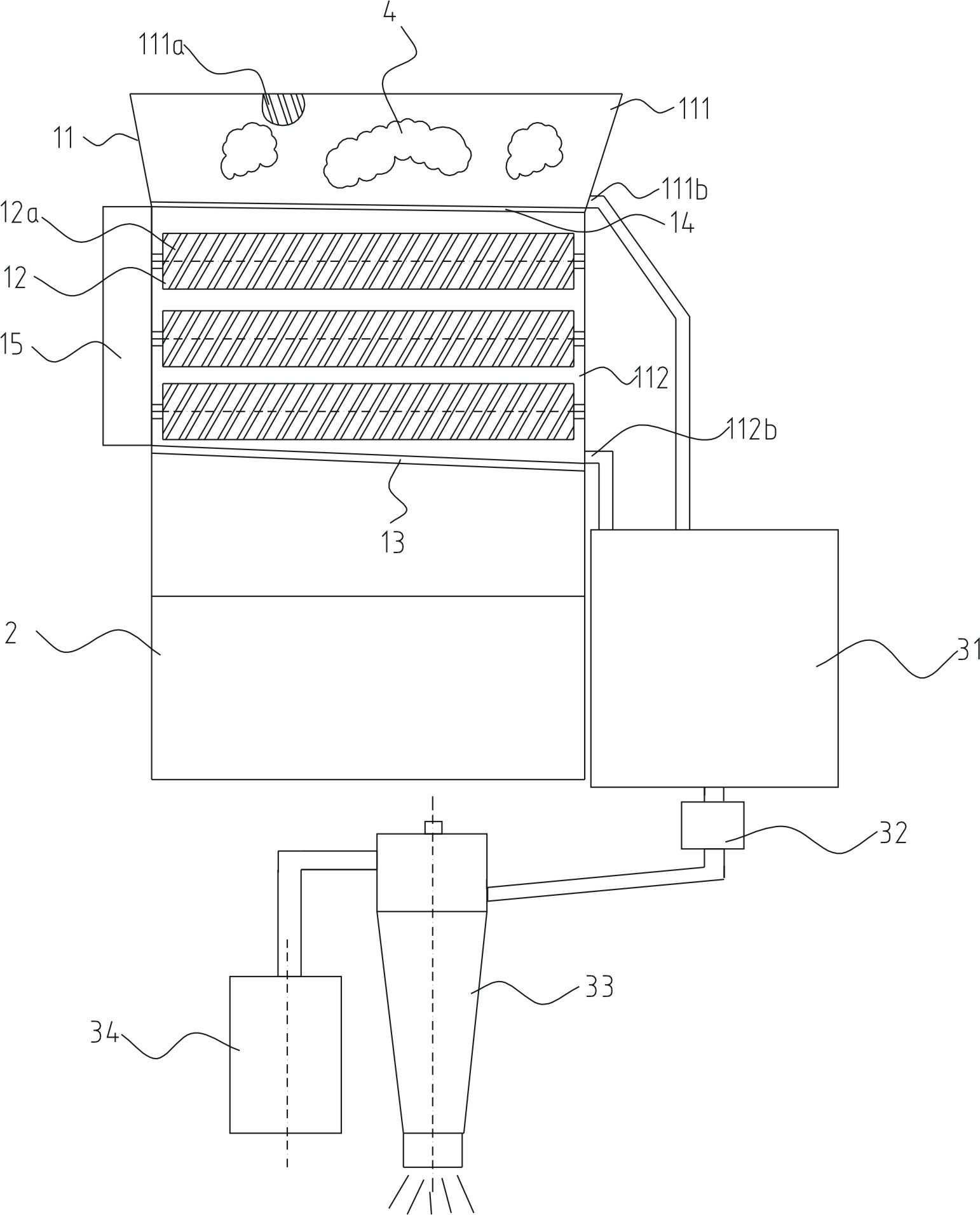

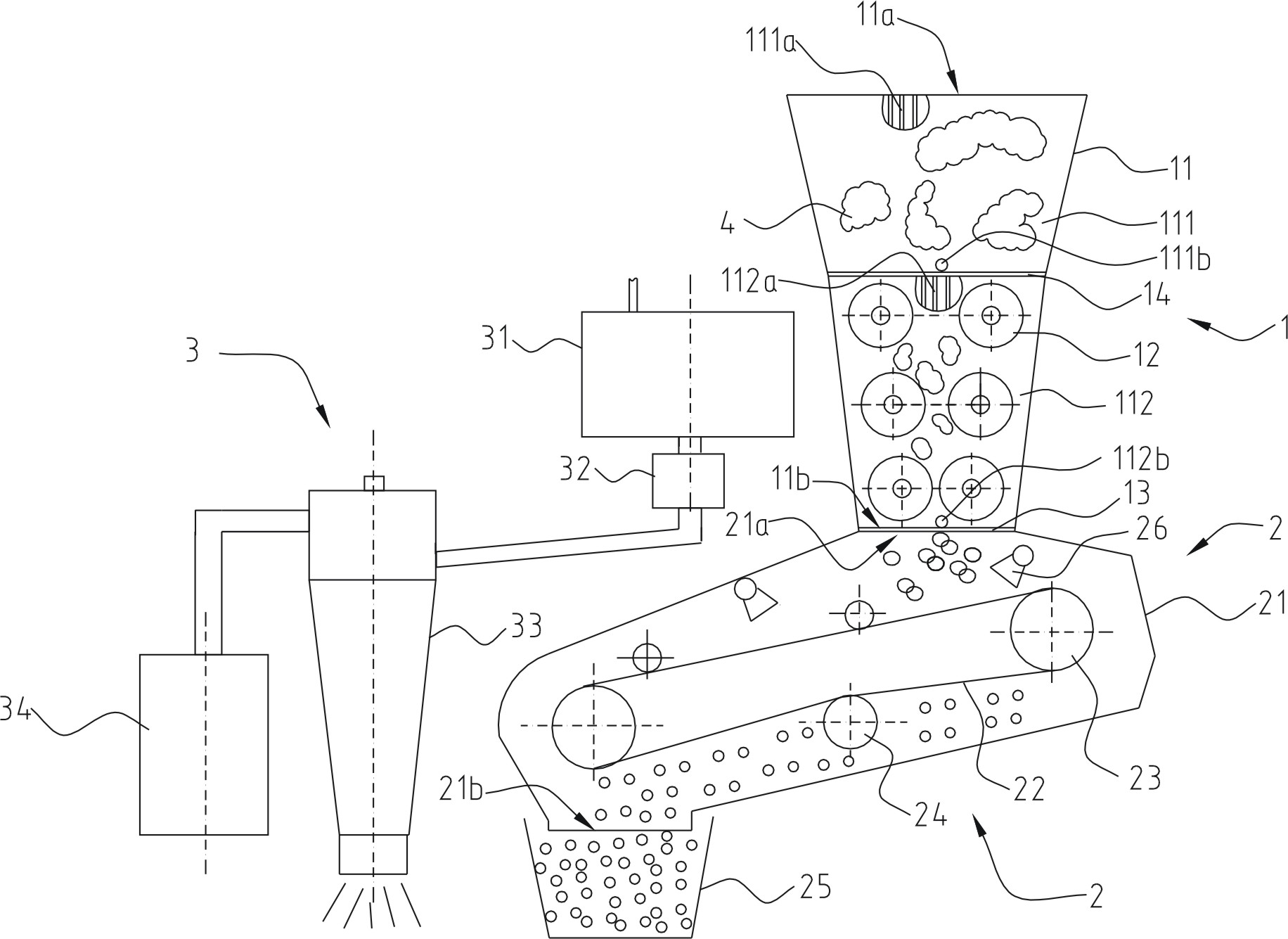

Processor for domestic garbage

ActiveCN102205344AEasy to useHigh shear forceDrying solid materials with heatSolid waste disposalLitterMechanical engineering

The invention discloses a processor for domestic garbage, which comprises a grinding device and a drying device, wherein the grinding device comprises a first shell, a grinding mechanism and a driving mechanism; the first shell is provided with a first feeding port and a first discharging port; the grinding mechanism is arranged in the shell between the first feeding port and the first discharging port; the grinding device further comprises a first baffle mechanism and a first liquid outlet; the first baffle mechanism is arranged at the first discharging port and is used for opening and closing the first discharging port; the first liquid outlet is arranged on the lower part of a side wall of the first shell; the grinding mechanism comprises 2-4 sets of rollers which are uprightly arranged; each set of rollers comprises two laterally arranged rollers with an clearance leaved therebetween; the clearance of each set of rollers is gradually diminished from top to bottom; raised teeth arearranged on circumference of each roller at intervals; and the driving mechanism is connected to each roller and is used for driving the two rollers of each set of rollers to rotate along opposite directions. The processor for domestic garbage provided by the invention can be used for processing hard and big garbage. The garbage after being processed can be regenerated and reused.

Owner:广州忻绿溢环保科技有限责任公司

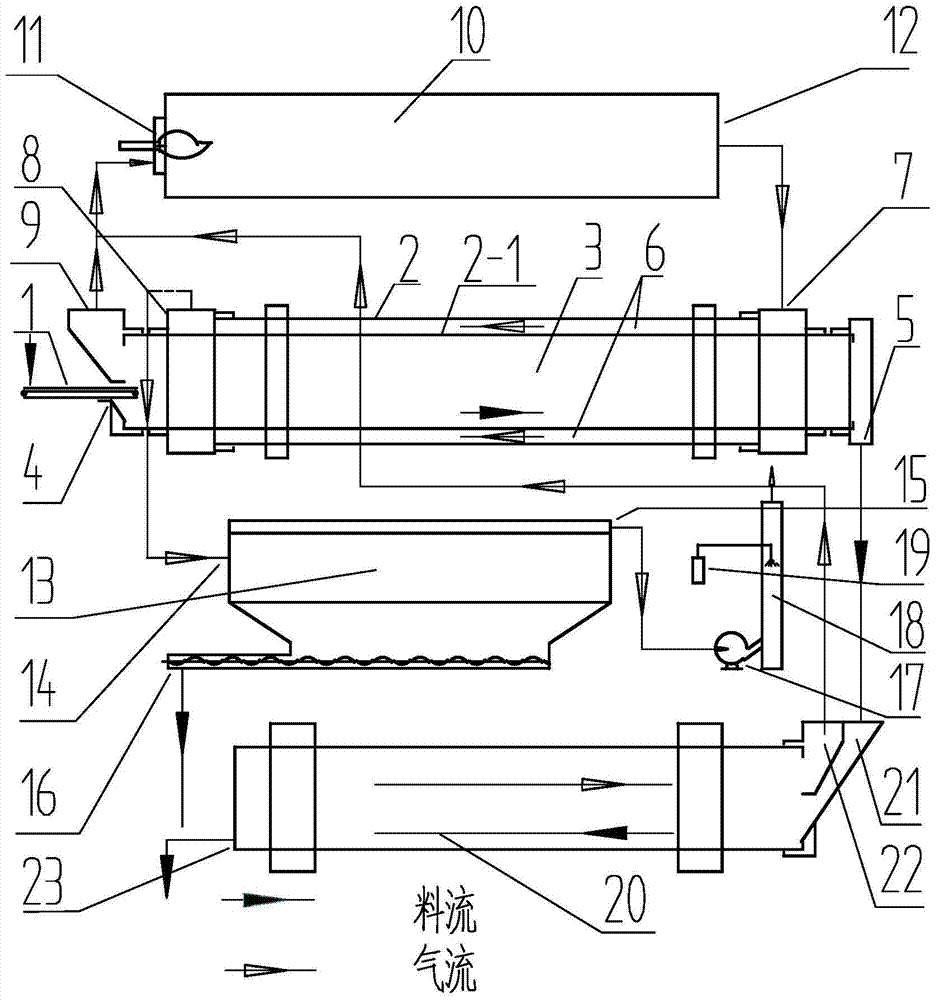

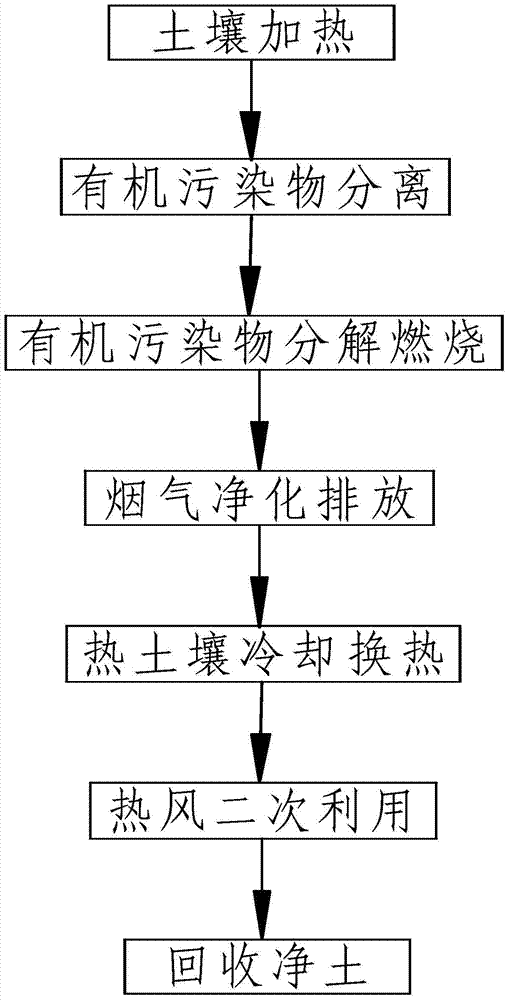

Organically-polluted soil remediation method

ActiveCN103495598AAchieve the purpose of repairPrevent leakageContaminated soil reclamationDesorptionEngineering

The invention discloses an organically-polluted soil remediation method which refers to a conveyer, a rotary kiln, a roasting furnace wall, a roasting chamber, a material inlet, a material outlet, a heating channel, a heating channel heat inlet, a heating channel heat outlet, a polluting gas outlet, a combustion furnace, a combustion furnace gas inlet, a combustion furnace heat outlet, a bag deduster, a bag deduster air inlet, a bag deduster smoke outlet, a soil particle outlet, an exhaust fan, a chimney, a deacidification device, a cooler, a cooler feed port, a cooler hot air outlet and a cooler discharge port. Since indirect heating desorption is adopted, hot air and soil are not in direct contact, energy consumption is low, desorption efficiency is high, and the soil can be thoroughly remedied; separated organic pollutants enter the combustion furnace to be completely combusted and decomposed by enriched oxygen, as a result, exhausted air quantity is small, secondary pollution is not caused, energy is saved, efficiency is improved, and investment is low.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

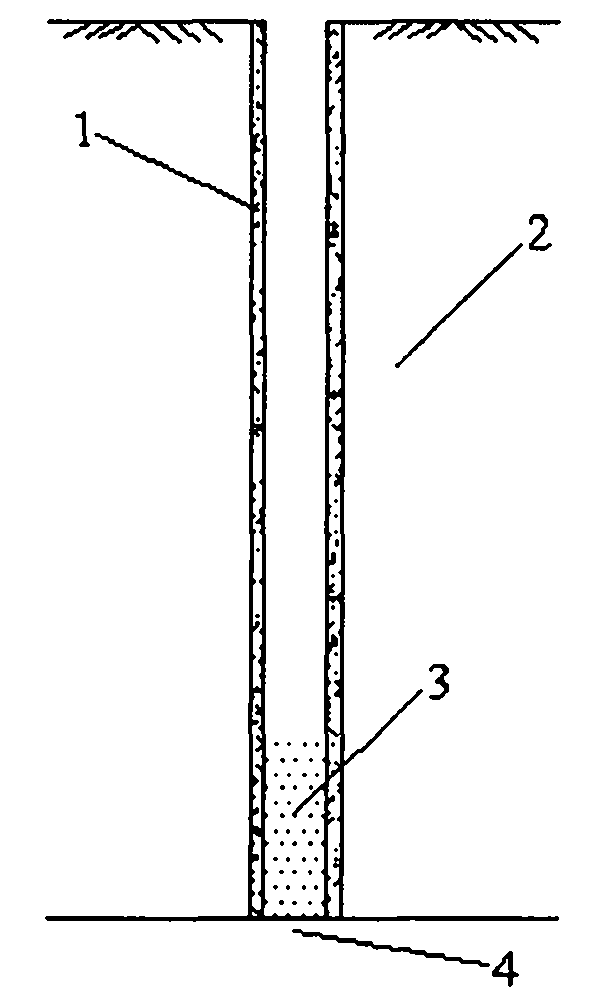

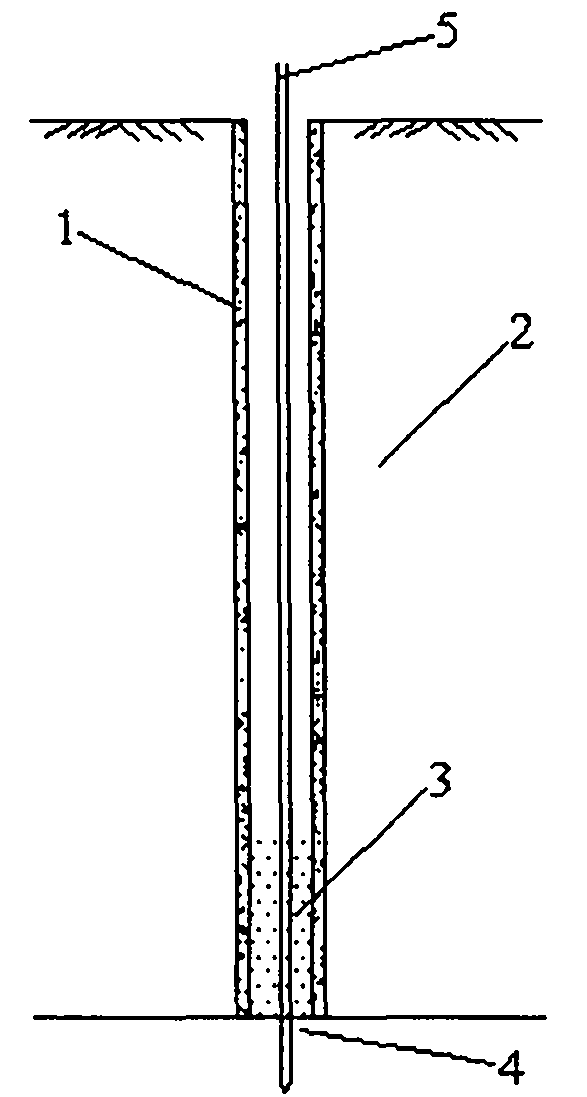

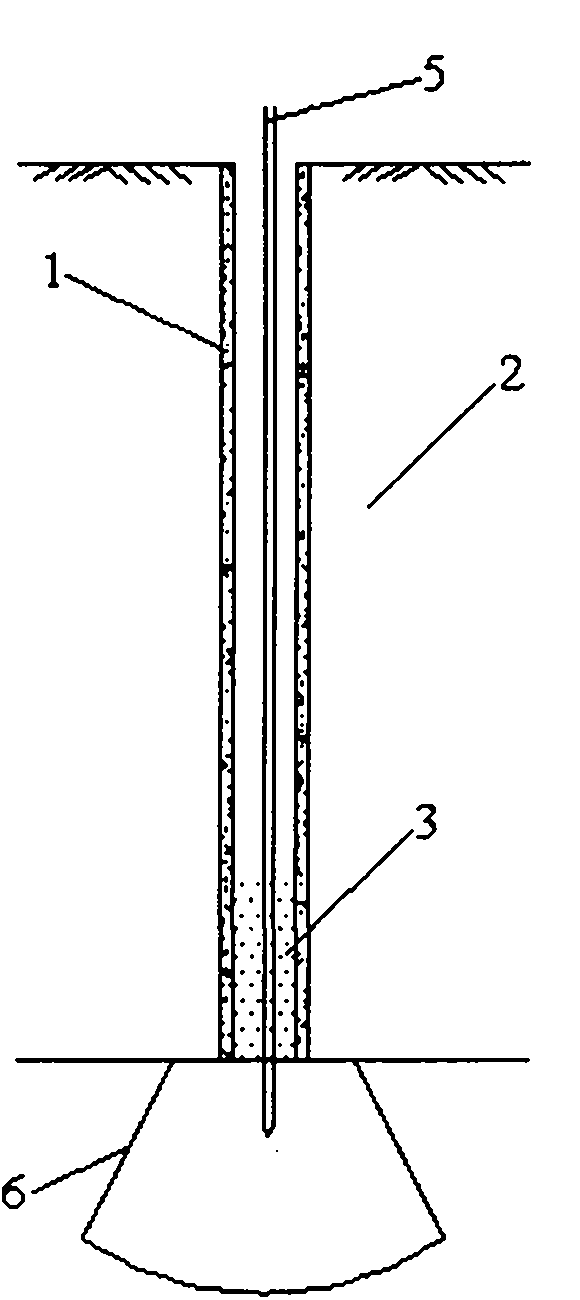

PHC pile-based multiple high jet pedestal pile construction method

The invention discloses a prestressed high-strength concrete (PHC) pile-based multiple high jet pedestal pile construction method, which comprises the following steps of: statically pressing a PHC pile to the designed depth of a soil layer, drilling to the depth below the bottom of the PHC pile through the hollow part of the PHC pile by a multiple high-pressure spiral jet drill rod, performing multiple tube construction at the bottom of the PHC pile to form an enlarged head cavity greater than the diameter of the PHC pile and in accordance with the design requirement, and then filling the enlarged head cavity to form an enlarged head. The method has obvious economic benefit; and compared with other pile types acquiring the same bearing capacity, the PHC pile-based multiple high jet pedestal pile has obvious economic advantage.

Owner:HENAN POLYTECHNIC UNIV

Method for recovery processing sulfur-containing mixed waste gas in production of viscose

InactiveCN103772250AAchieve the purpose of reuseEfficient use ofCarbon disulfideOrganic chemistrySocial benefitsExhaust fumes

The invention relates to a method for recovery processing sulfur-containing mixed waste gas in the production of viscose, which belongs to the technical field of the treatment of sulfur-containing waste gas in the production of viscose. The invention provides a novel technical route for the existing waste gas treatment situation of the viscose production enterprise, the sulfur-containing waste gas of low concentration is pretreated firstly, then the sulfur-containing waste gas is selectively absorbed by adopting the spraying absorption technology, then the absorption liquid is treated, and finally a product with high cost performance is obtained. The technical route is high in industrialization degree, the mixed waste gas consisting of low-concentration H2S, CS2, vast air and little solid waste in the production process of viscose industry can be effectively treated in time, certain economic benefit and social benefit also can be obtained, the technical feasibility and economical feasibility are good, and the sustainable development requirement of the society can be met.

Owner:YIBIN GRACE +2

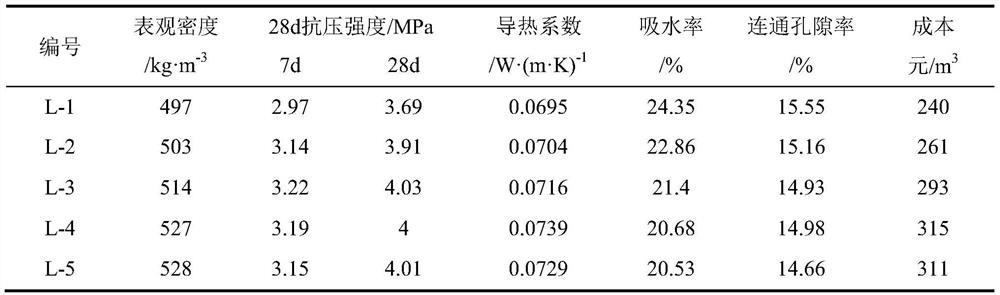

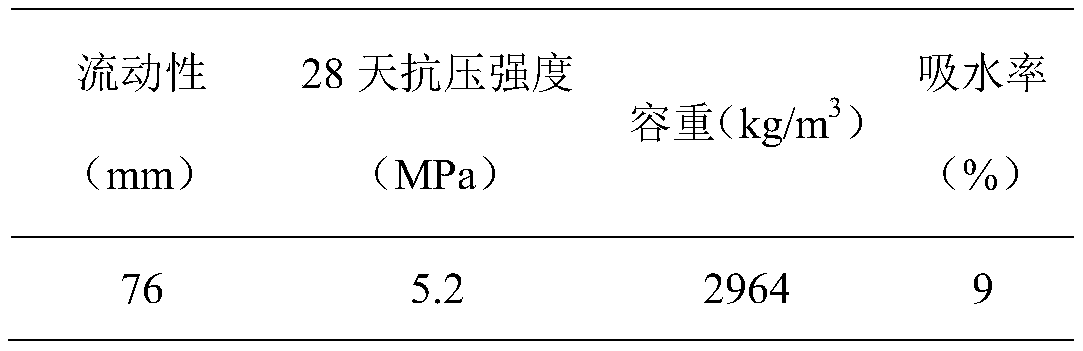

Non-autoclaved lightweight thermal insulation particle aerated concrete block and preparation method thereof

The invention discloses a non-autoclaved lightweight thermal insulation particle aerated concrete block and a preparation method thereof. The aerated concrete block comprises the following components:50 to 100 parts of cement, 0 to 37.5 parts of fly ash, 0 to 12.5 parts of superfine slag powder, 0 to 50 parts of light particles, 2 to 8 parts of a foaming agent, 0 to 5 parts of a coagulation accelerator, 0.025 to 0.175 part of a foam stabilizer, 0.2 to 1.4 parts of a water reducing agent, 0.1 to 0.7 part of a water repellent, 0 to 0.6 part of fibers and 30 to 60 parts of water. The aerated concrete block has the advantages of light weight, heat preservation and insulation, energy conservation, high strength, simple maintenance process and low cost, and solves the problems of non-ideal heatpreservation and insulation performance and complex maintenance process of the existing aerated concrete block.

Owner:CENT SOUTH UNIV +3

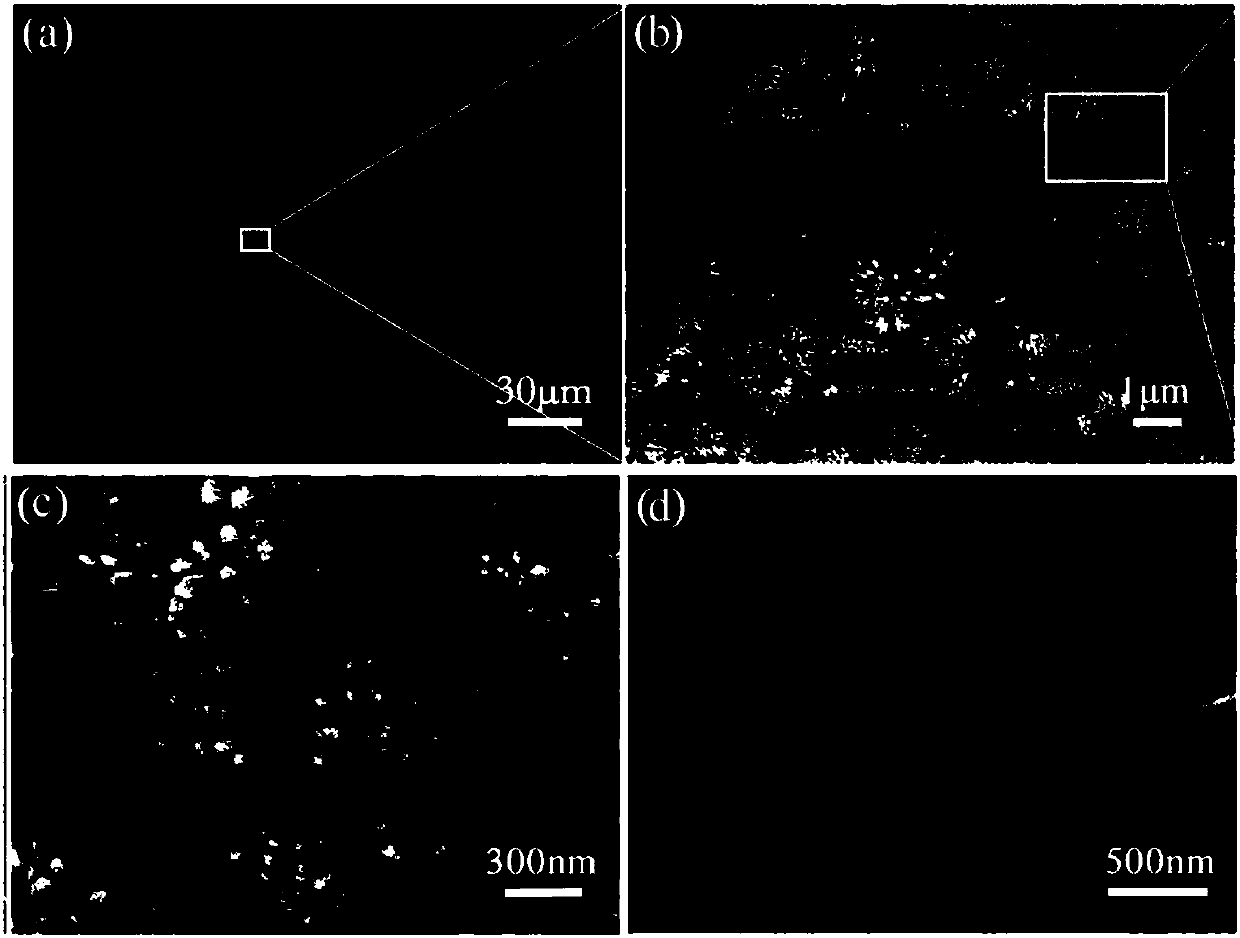

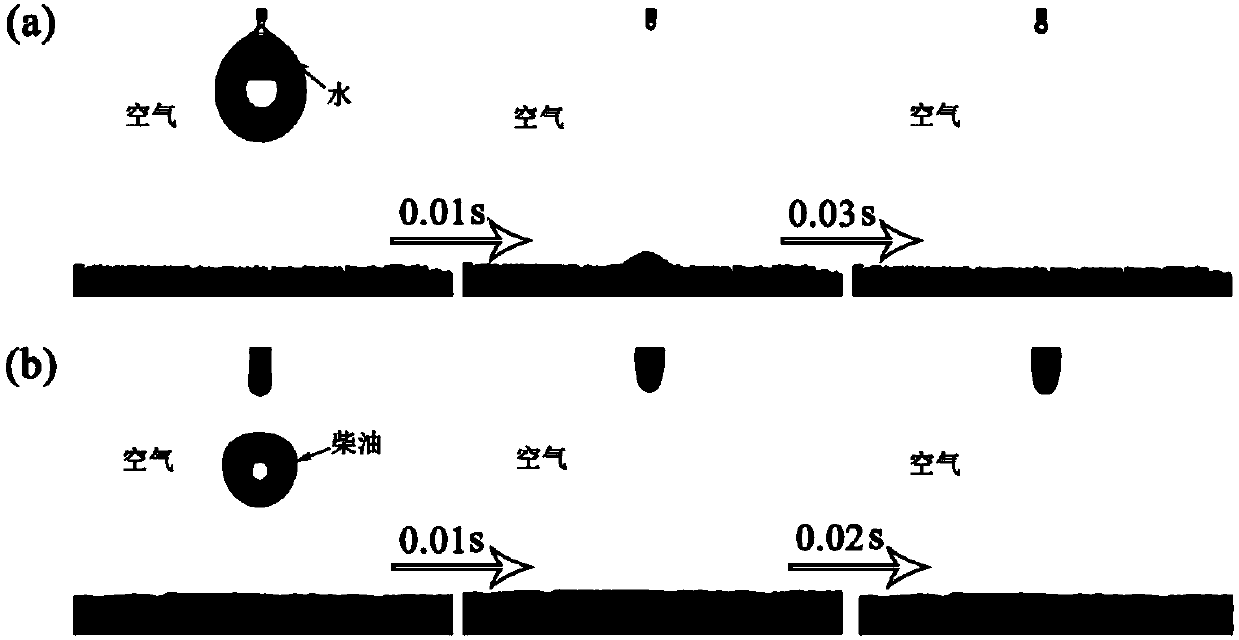

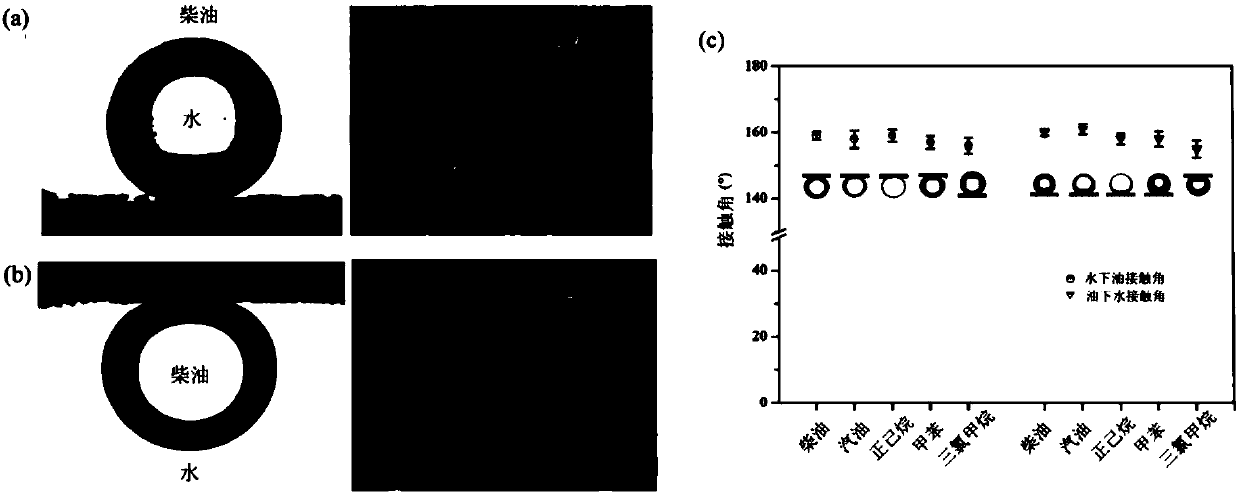

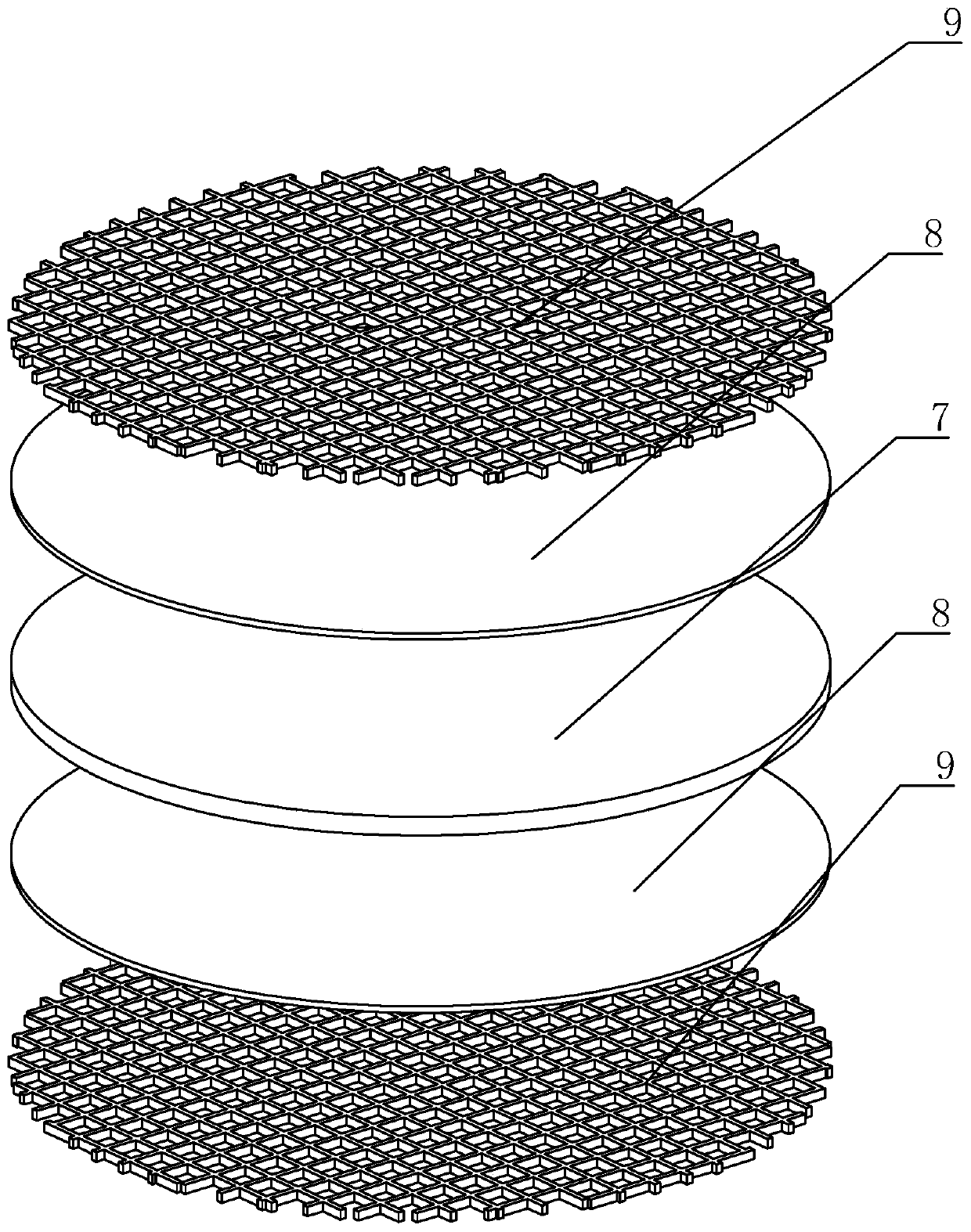

Device and method for preparing super-amphiphobic self-cleaning oil-water separation material

ActiveCN107596735ALow priceSimple preparation processLiquid separationChemical physicsSeparation technology

The invention relates to a device and a method for preparing a super-amphiphobic self-cleaning oil-water separation material, belongs to the fields of chemistry and chemical engineering, functional material and nanometer technology and in particular relates to a device with super-amphiphobic property and high separation rate. According to the device with the self-cleaning function, a main body part is an inverted T-shaped three-way pipe. Aiming at the defects existing in the conventional oil-water separation technology, titanium dioxide with a nanorod structure grows on the surface of a porousmetal substrate by a simple one-step hydrothermal deposition method, and multiple types of oil including diesel oil are respectively and simply wetted, so that the material has the super-amphiphobicproperty (super-hydrophobic in oil and super-oleophobic in water), and is applied to a special separation device so as to realize stable, continuous and high-efficiency oil-water separation. Moreover,the method is readily available in materials, simple in preparation and environmental-friendly, and the prepared material has the self-cleaning function and has very wide application prospects.

Owner:JILIN UNIV

Method and device for recovering molten blast furnace slag sensible heat

ActiveCN103484580ATake advantage ofIncrease temperatureBlast furnace detailsIncreasing energy efficiencyThermal energyCombustion

The invention belongs to the technical field of energy recovery, and particularly relates to a method and device for recovering molten blast furnace slag sensible heat. The process of the method sequentially includes the following steps that (1) blast furnace slag enters a segmented bottom blowing composite molten slag trough, compressed air is blown in from the bottom of the bottom blowing composite molten slag trough, and at the moment a heat accumulator is heated to be within the range from 1100 DEG C to 1250 DEG C; (2) molten slag of which the temperature is reduced to be within the range of 700 DEG C to 800 DEG C enters an old slag processing system through a connecting unit, and then follow-up processing is conducted on slag; (3) when slag stops being discharged from a blast furnace, air is still blown in from the bottom of the bottom blowing composite molten slag trough, and air is heated to be within the range from 800 DEG C to 900 DEG C when passing through the heat accumulator; (4) hot air is used for power generation after being dedusted, and then cooling water replaces heat for production. Compared with the prior art, the method and device have the advantages that through the improvement, heat can be efficiently recovered, the temperature of combustion air by a hot blast heater can be increased, the device and method can be also used for waste heat power generation, and then the purpose of energy reutilization is achieved.

Owner:鞍钢集团工程技术有限公司

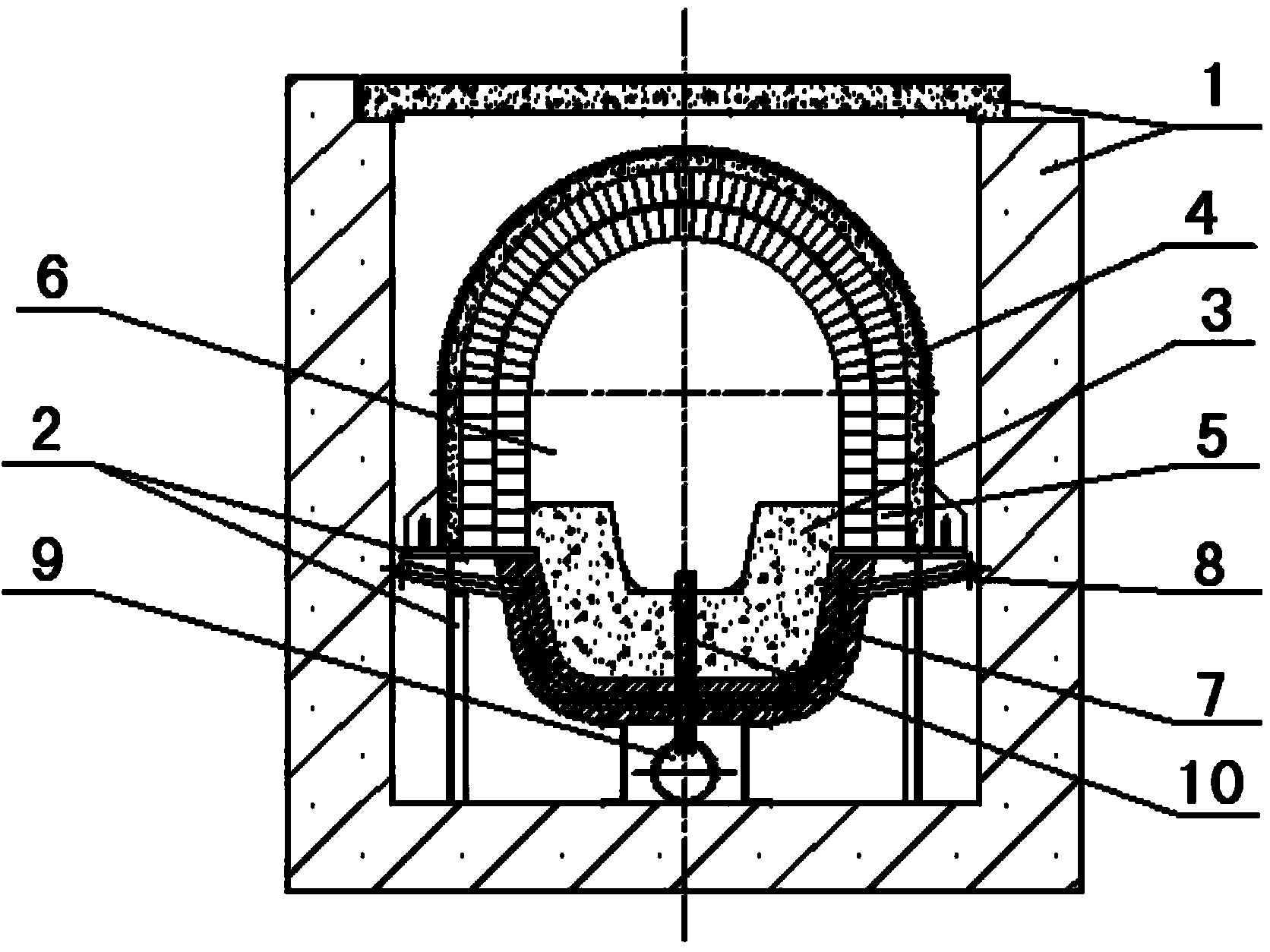

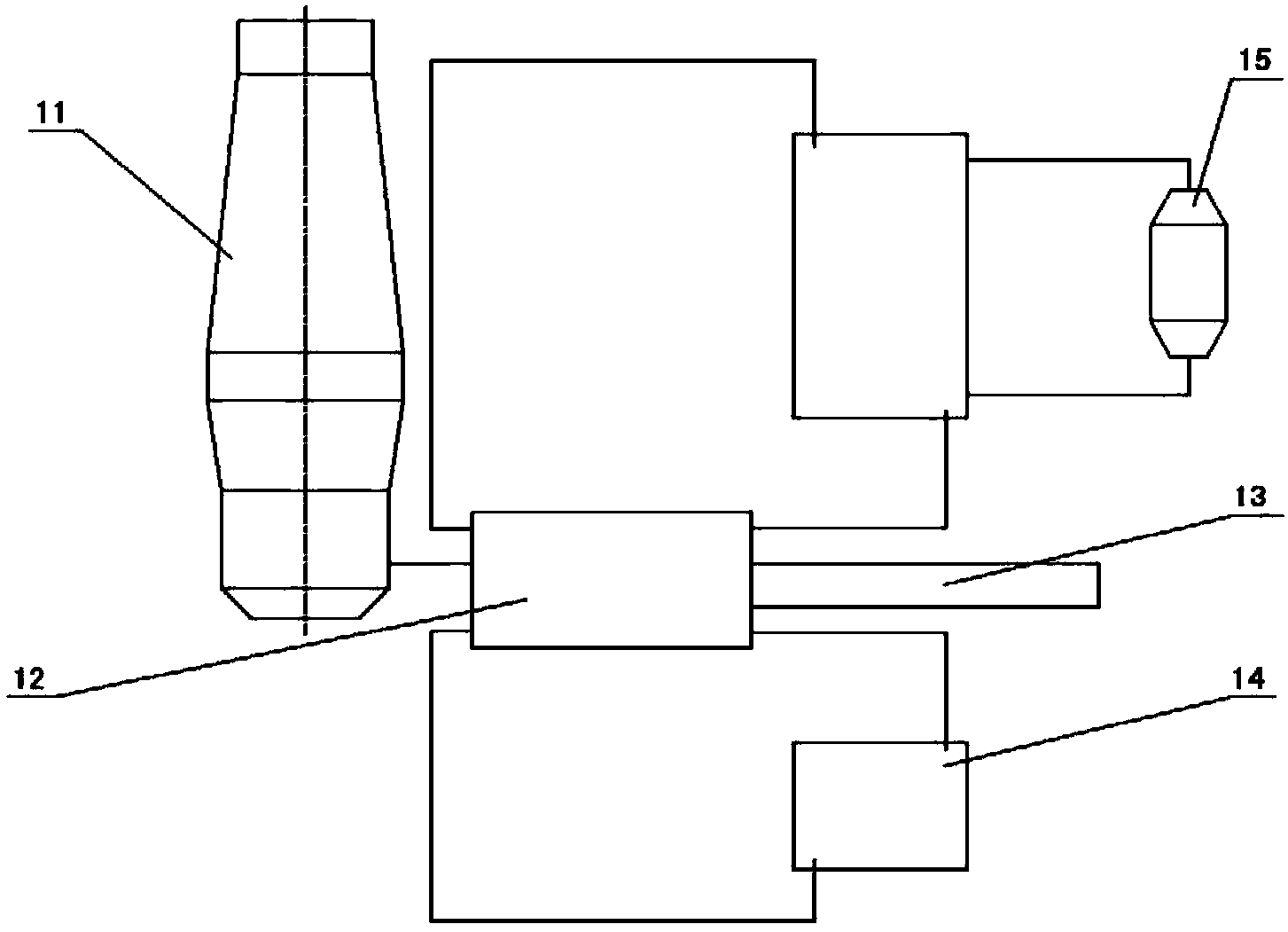

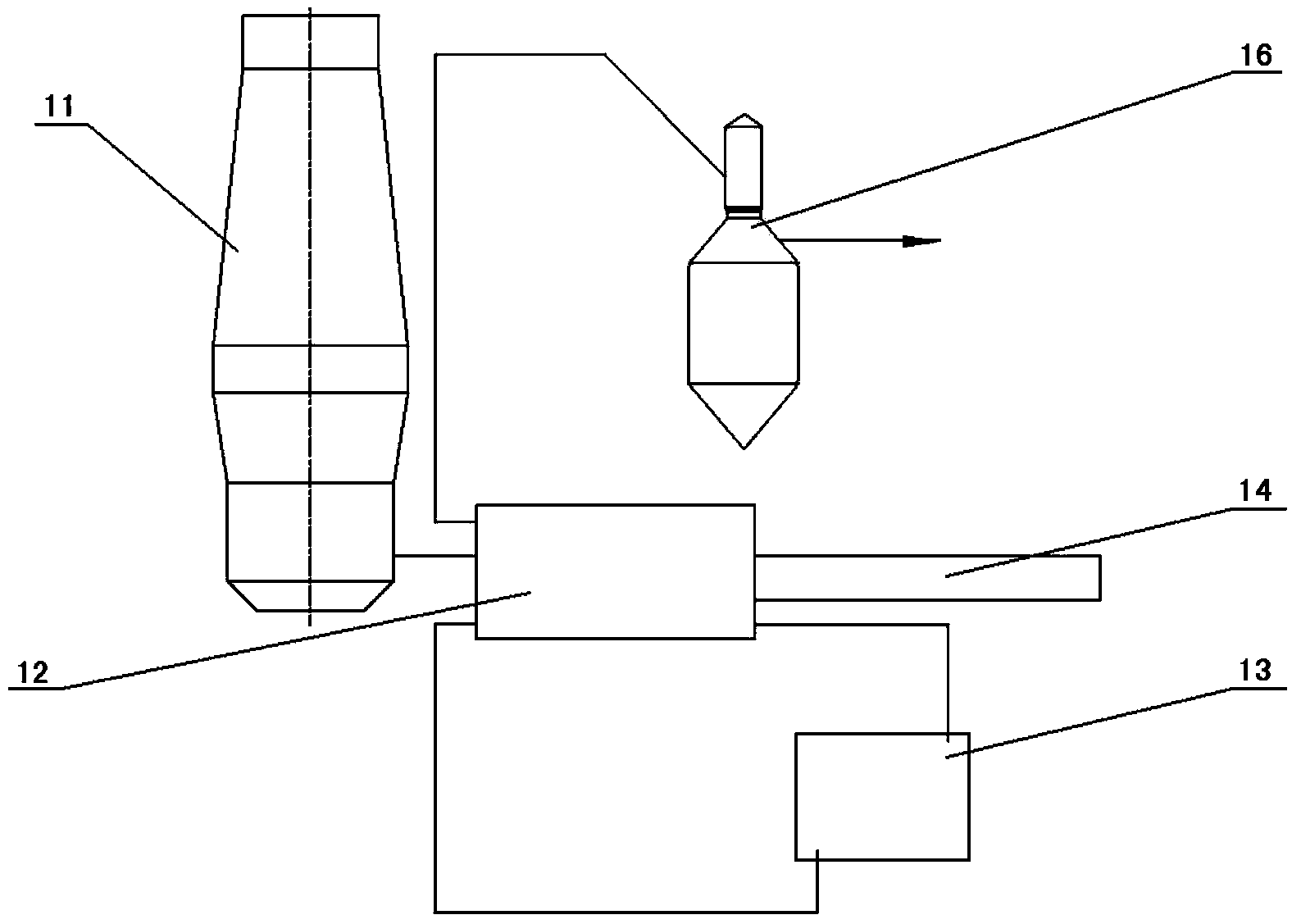

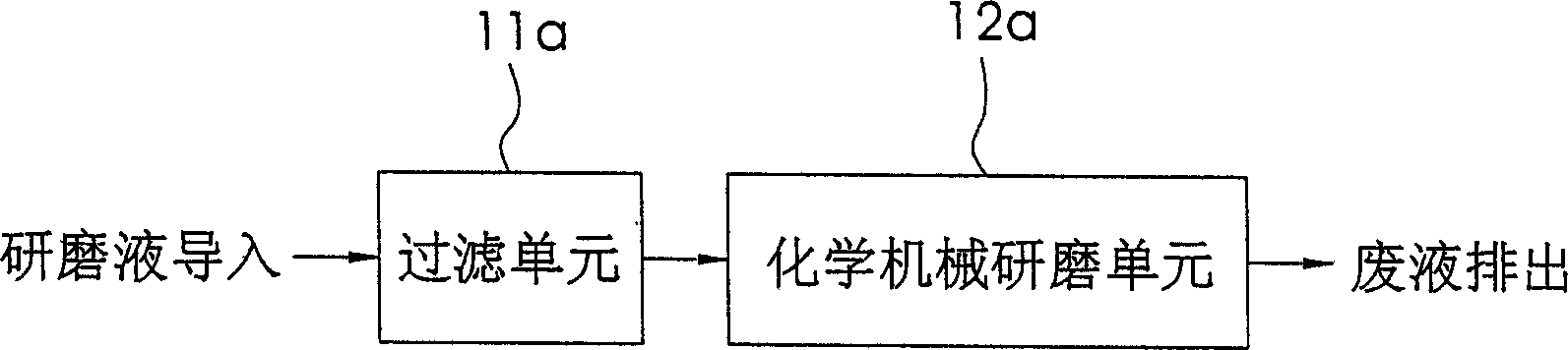

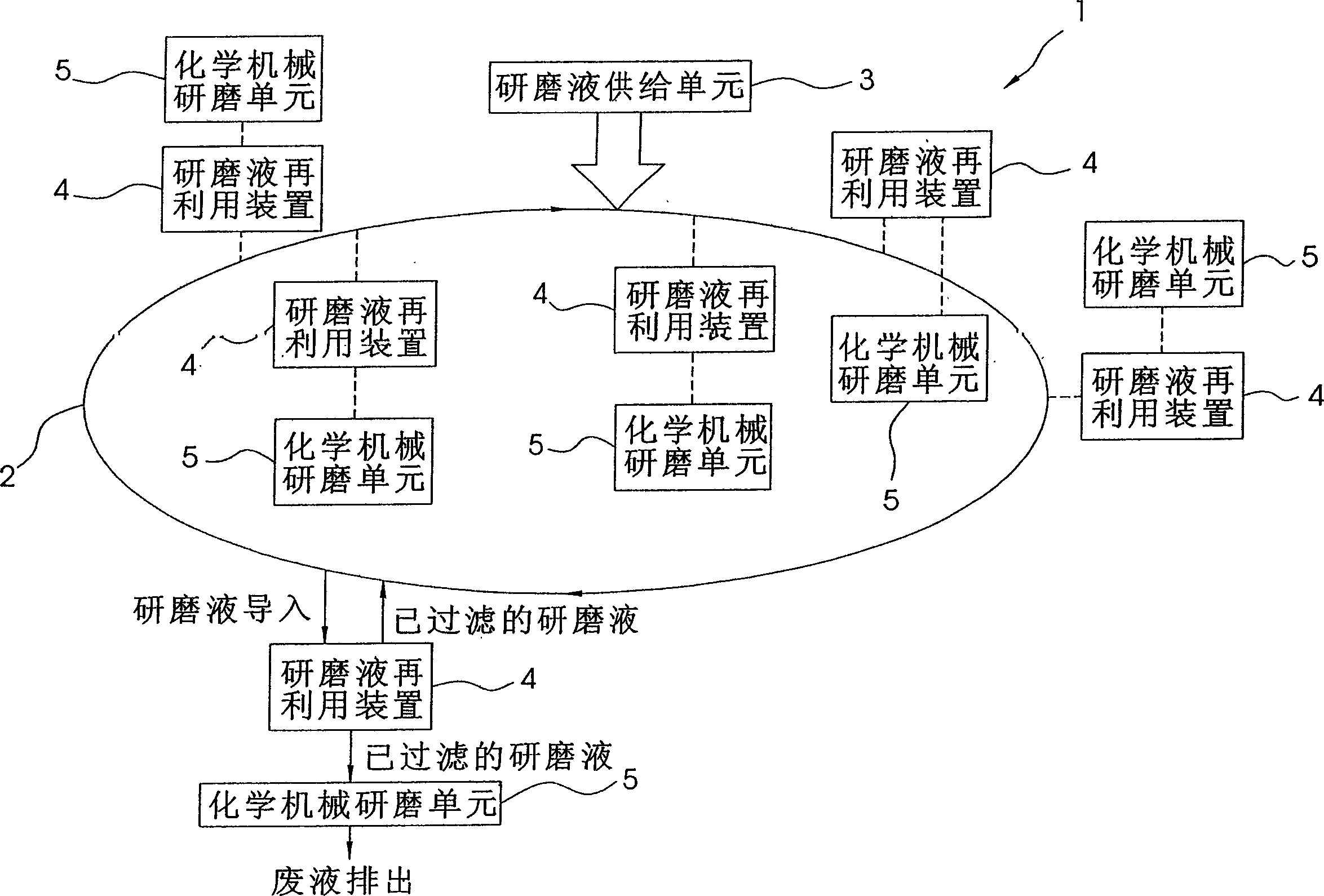

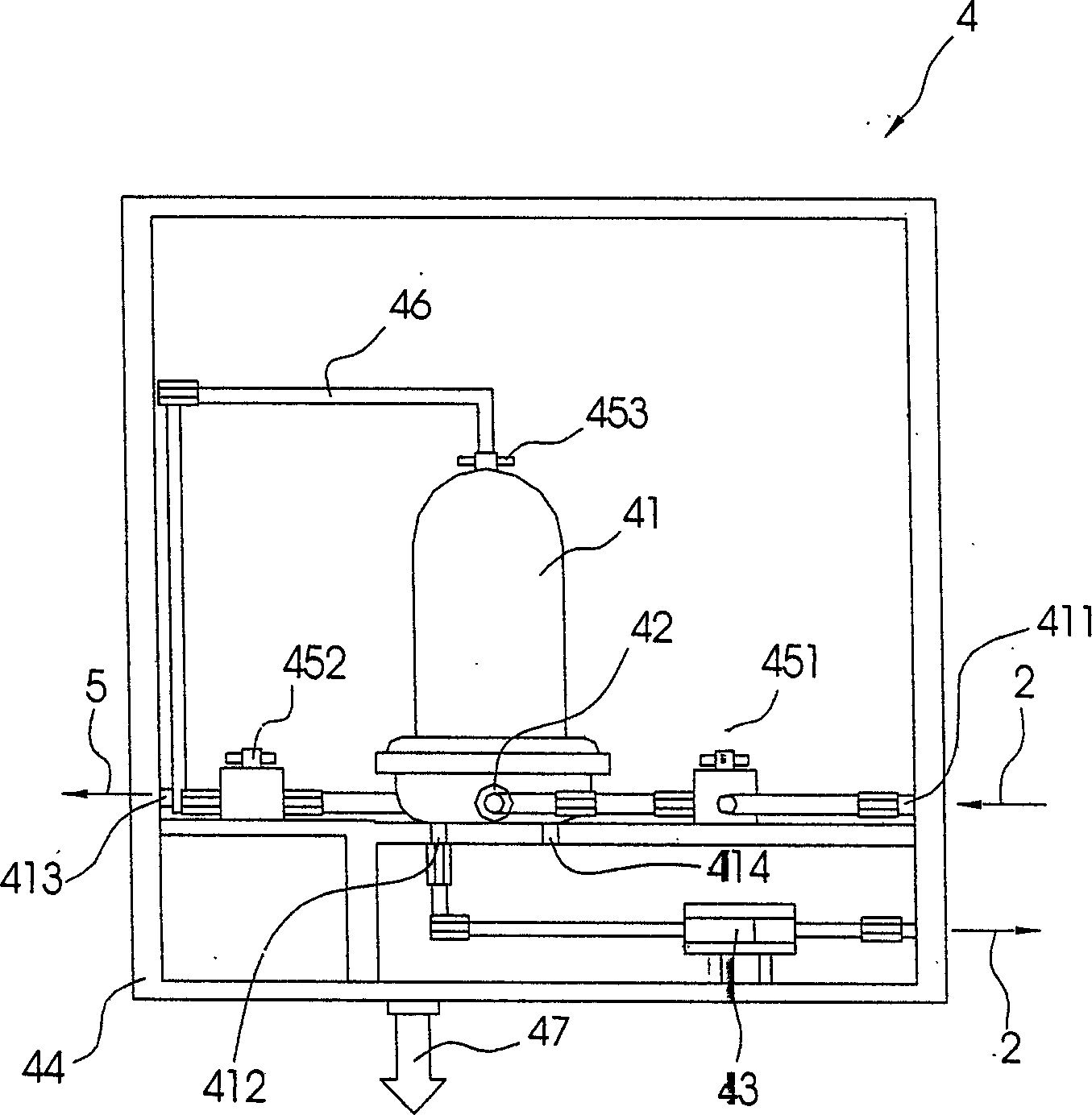

Grinding liquid reusing device and system thereof

InactiveCN1634682AAchieve the purpose of reuseTake advantage ofGrinding/polishing apparatusLiquid wasteEngineering

This invention relates to a grinding recycle device and its system used in chemical and mechanic grinding process. The system comprises the following: grinding recycle pipes; at least one grinding liquid supply unit form the pipes; several grinding liquid recycle device connected to the grinding recycle pipes; several chemistry mechanic grinding units separately connected to the grinding liquid. The device comprises the recycled and filtered grind liquid recycle pump, waste liquid exhausted and drainage unit for waste gas.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

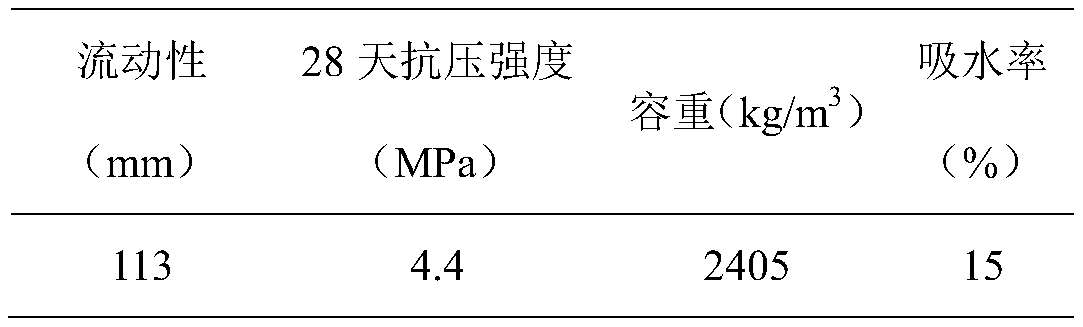

Anti-seismic wall material and method for preparing same

The invention discloses an anti-seismic wall material and a method for preparing the same. The anti-seismic wall material in a formula comprises, by weight, 5-30 parts of cement, 5-20 parts of lime, 50-70 parts of fly ash, 0.5-5 parts of gypsum, 5-25 parts of regenerated rubber powder and an appropriate amount of water. The method includes digesting the lime; weighing the components, pouring raw materials into a stirrer, stirring the raw materials under a dry condition for 2 minutes, then adding the appropriate amount of water into the stirrer and stirring the raw materials again for 3-5 minutes to obtain mixtures; pouring the stirred mixtures into brick molds or building block molds and vibrating and molding the stirred mixtures for 1-2 minutes; maintaining the mixtures for a day at the temperature of 20-30 DEG C under the condition of humidity higher than 50%, or delaying curing of the mixtures for 1 hour, then maintaining the mixtures in wet steam at the temperature of approximately 90 DEG C for 6-8 hours, and removing the mixtures from the molds to obtain bricks or building blocks; maintaining the bricks or the building blocks in high-temperature and high-pressure saturated steam at the temperature of 150-180 DEG C for 7-12 hours to obtain finished products. The anti-seismic wall material has the advantages of light weight, low elastic modulus, good elasticity, excellent toughness and ductility, high ratio of bending-compressive strength, heat insulation and the like.

Owner:YANCHENG INST OF TECH

Method for recovery treatment of sulfur-containing mixed waste gas in production of viscose fiber

InactiveCN103772251AAchieve the purpose of reuseEfficient use ofCarbon disulfideOrganic chemistryProcess engineeringViscose fiber

The invention relates to a method for recovery treatment of sulfur-containing mixed waste gas in production of viscose fiber, belonging to the technical field of treatment of the sulfur-containing waste gas in the production of the viscose fiber. According to the method provided by the invention, the sulfur-containing mixed waste gas in the production of the viscose fiber is treated through the steps of pretreatment, absorption, synthesis and the like and converted to thiourea to achieve the purpose of reutilizing the waste gas. The invention provides a method for producing thiourea by adopting the waste gas produced in the production process of a viscose fiber enterprise, a thiourea product with relatively high market values is obtained, the waste gas of the viscose fiber enterprise is effectively controlled, waste alkali and waste acid in the production process of the viscose fiber enterprise are simultaneously effectively utilized, then the viscose fiber enterprise can obtain certain economic benefits in the control process of the waste gas, and very high market popularization values are realized.

Owner:YIBIN GRACE +2

Greening combined walkway floor tile

ActiveCN111519494ASave waterLow costSewerage structuresSelf-acting watering devicesAgricultural engineeringBiology

The invention relates to the technical field of floor tiles and relates to a greening combined walkway floor tile. The floor tile comprises a first floor tile body; a planting groove is formed in thefirst floor tile body; drain holes are formed in the bottom of the planting groove; a filtering layer and a planting soil layer which is used for planting green plants are sequentially arranged in theplanting groove from bottom to top; the filtering layer comprises a sponge block, geotechnical cloth and a clamping net plate; the two sides of the sponge block are connected with the geotechnical cloth; the side, away from the sponge block, of the geotechnical cloth is connected with the clamping net plate; and a supporting grid used for shielding the groove opening of the planting groove is detachably connected to the first floor tile body. Accumulated water falling on the surface of the floor tile can be recycled, and water resources are saved.

Owner:无锡市锡山三建实业有限公司

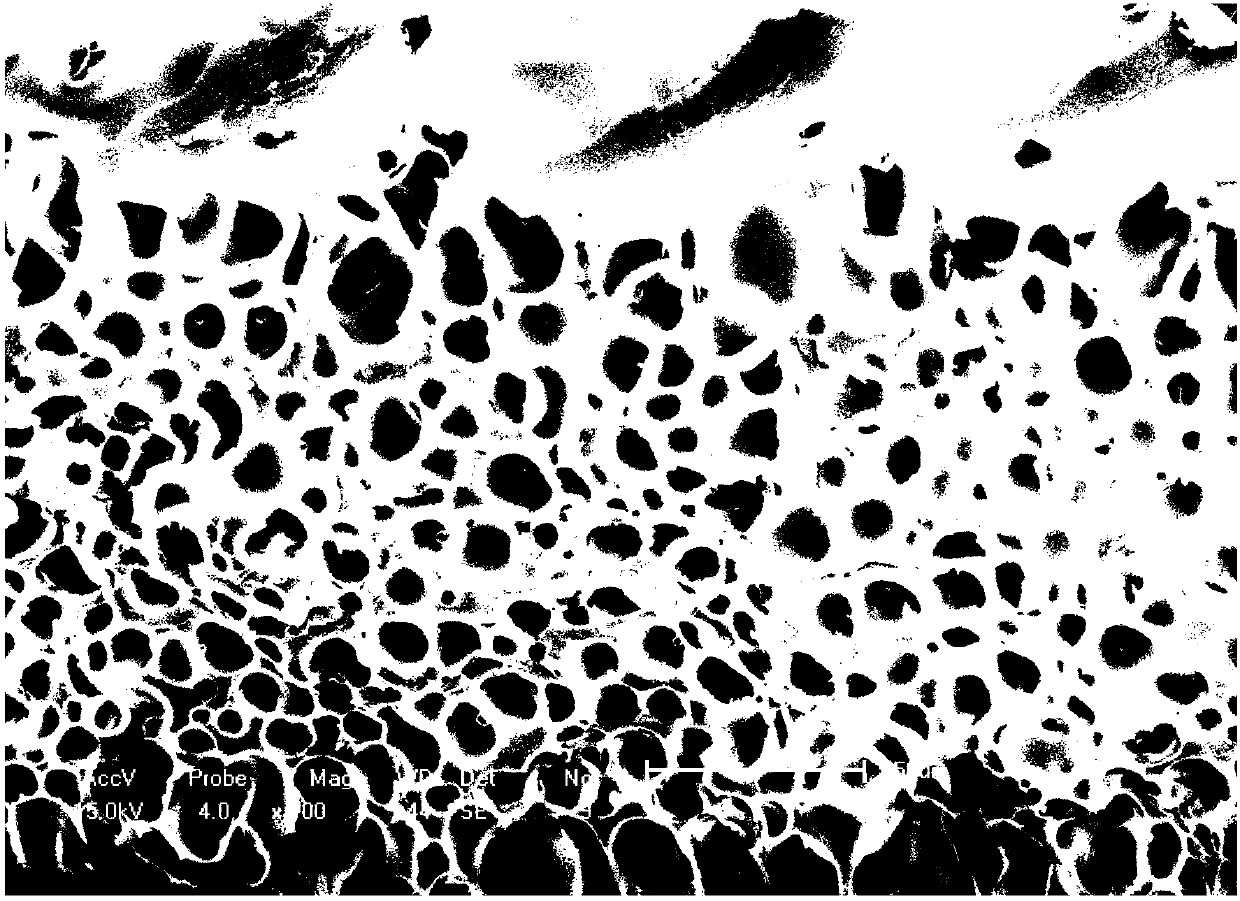

Anti-condensation material as well as preparation method and application thereof

InactiveCN108043367AImprove water absorptionImprove hydrophilicityOther chemical processesCondensate preventionPlastic filmBlow out

The invention relates to the technical field of anti-condensation and in particular to an anti-condensation material as well as a preparation method and application thereof. The anti-condensation material can be prepared as a matte plastic film, is attractive in appearance, is capable of replacing flocked cloth to adsorb condensate and is capable of increasing the volatilization speed of the condensate, the purpose of repeated use is achieved, condensate blowing out is reduced, problems of bacterial propagation caused by humidity increase and the like are avoided, and the user experience is improved. The anti-condensation material provided by the embodiment of the invention is a porous material made of a hydrophilic high polymer material. The embodiment of the invention is applied to air-conditioner condensate prevention.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

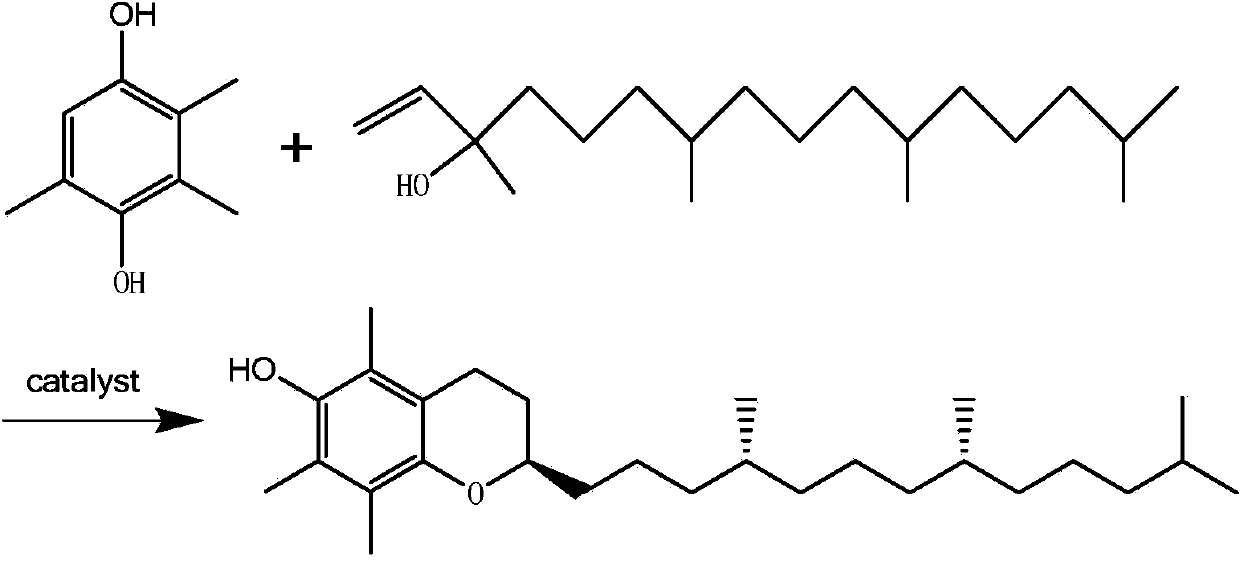

Preparation method of vitamin E acetate

InactiveCN103788052ASolve recycling difficultiesHigh yieldOrganic chemistryVitamin E AcetateHydrogen halide

The invention relates to a preparation method of vitamin E acetate. The preparation method comprises the following steps: by taking linear chain type organic amine, zinc halide and hydrogen halide as catalysts, reacting 2,3,5-trimethylhydroquinone with isophytol to generate tocopherol; and taking the tocopherol and acetic anhydride to have an esterification reaction to obtain the vitamin E acetate. The preparation method is simple in steps and moderate in conditions; the catalyst can be repeatedly utilized and few byproducts are generated; the purity and the yield of the product are higher than those of the product obtained by adopting the prior art and the preparation method is suitable for popularization.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

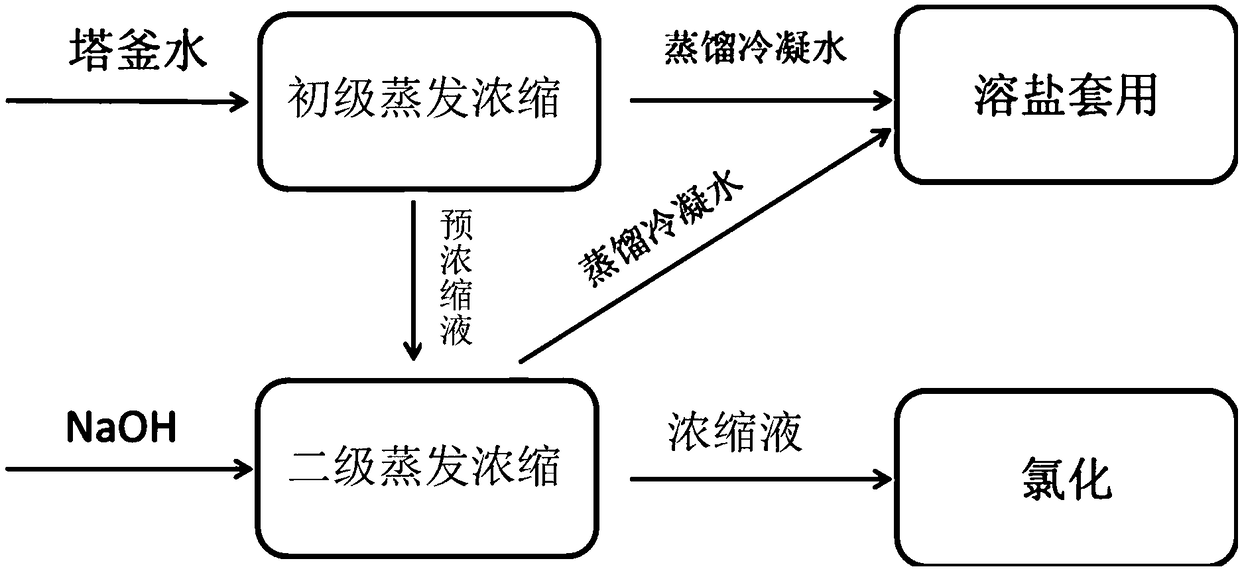

Treatment method of epoxy resin production waste water

InactiveCN109231637AAchieve the purpose of reuseWater treatment parameter controlPreparation by halogen introductionEpoxyAfter treatment

The invention relates to the field of epoxy resin production, and particularly relates to a treatment method of epoxy resin production waste water. The treatment method of the epoxy resin production waste water provided by the invention comprises the following steps: collecting epoxy resin production waste water after treatment of a stripping column in a column of the stripping column to obtain column water; performing primary concentration by evaporation on the column water to obtain pre-concentrated liquid; adjusting the pH value of the pre-concentrated liquid to be neutral, and then performing secondary concentration by evaporation to obtain concentrated liquid; and performing chlorination treatment on the concentrated liquid, and performing reduced pressure distillation to obtain dichlorohydrin, wherein the purity of the dichlorohydrin is 98.5-99.5wt%, and the chemical oxygen consumption of condensation water generated by primary concentration by evaporation and secondary concentration by evaporation is less than or equal to 1200mg / L. The treatment method provided the invention fully utilizes the materials in the epoxy resin production waste water, and achieves the purpose of recycling of waste, and the distilling condensation water obtained by concentration by evaporation treatment can achieve the standard of reuse water.

Owner:JIANGSU KUMHO YANGNONG CHEM CO LTD

Road roadbed material containing municipal sludge residues

The invention discloses a road roadbed material containing municipal sludge residues. The road roadbed material comprises gel materials and auxiliary materials, wherein the gel materials comprise, inpercent by mass, 75-100% of the municipal sludge residues and 0-25% of cement, and the auxiliary materials comprise 0-30% of sand, 8-20% of lime and 25-50% of water based on the mass percentages of the components of the auxiliary materials in the total mass of the gel materials. The municipal sludge residues are prepared through the step of performing pyrolysis on pretreated municipal sludge in anitrogen atmosphere at 300-900 DEG C so that the municipal sludge residues are obtained. The prepared roadbed material can be applied to road construction, the road quality is improved, and meanwhilethe budget of road construction is reduced; and furthermore, a new way is provided for resource recycled utilization of an increasing amount of municipal sludge, so that waste recycled utilization isachieved, and the living environment is protected.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

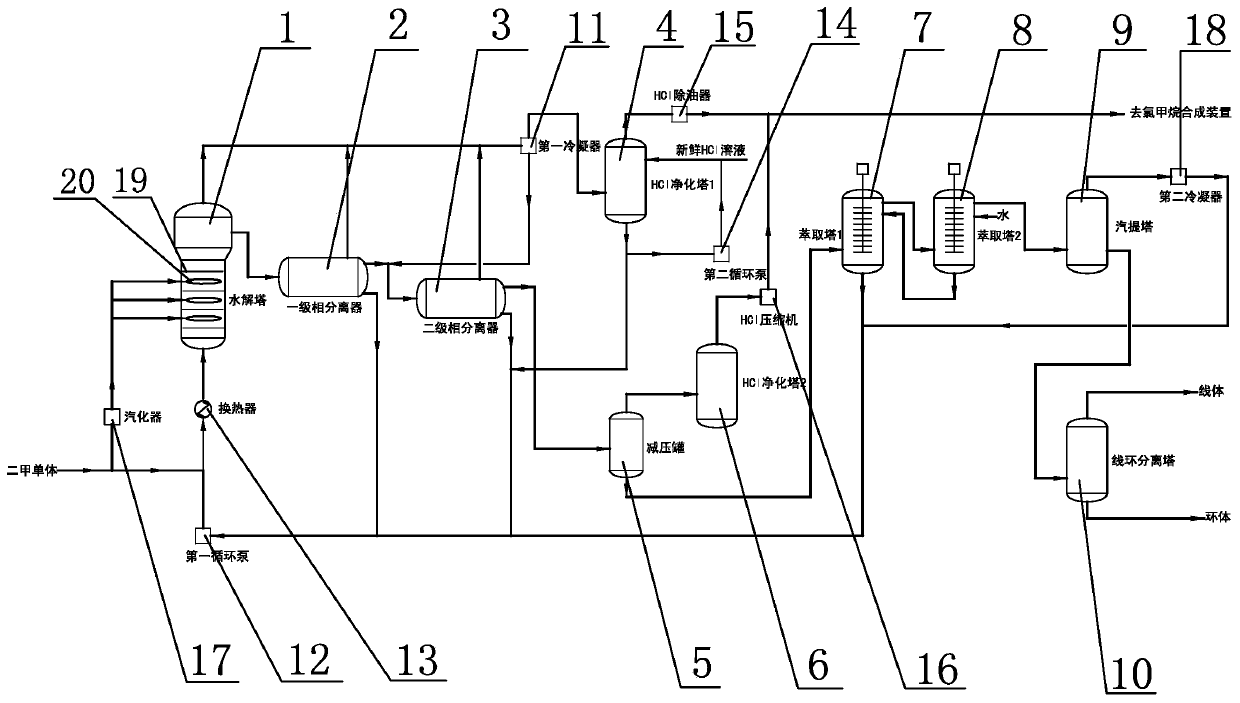

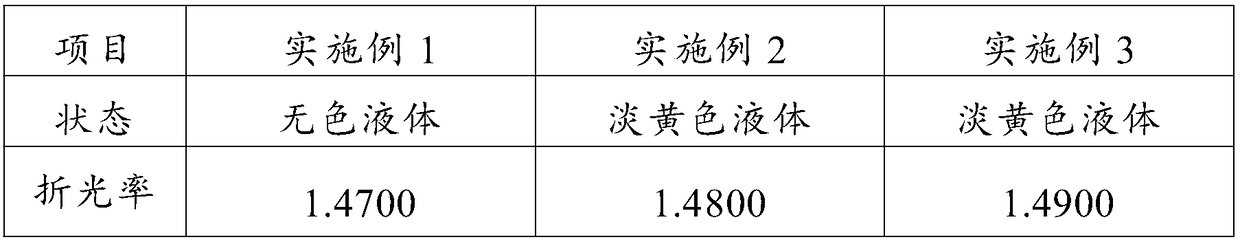

Organochlorosilane hydrolysis and hydrochloric acid refining system and method

ActiveCN110845734ARemove completelyInhibit aggregationChlorine/hydrogen-chloride purificationSpecific gas purification/separationPhysical chemistryHydrolysis

The invention discloses an organochlorosilane hydrolysis and hydrochloric acid refining system and a method. The organochlorosilane hydrolysis and hydrochloric acid refining system is characterized bycomprising a hydrolysis tower, a primary phase separator, a secondary phase separator, a first hydrochloric acid purification tower, a decompression tank, a second hydrochloric acid purification tower, a first extraction tower, a second extraction tower, a stripping tower and a line-loop separation tower; a plurality of sections of feeding holes are formed in the side part of the hydrolysis tower; an oil phase outlet at the upper end of the hydrolysis tower is connected with a feeding hole of the primary phase separator; an oil phase outlet of the primary phase separator is connected with a feeding hole of the secondary phase separator; a top gas phase outlet of the hydrolysis tower, a gas phase outlet of the primary phase separator and a gas phase outlet of the secondary phase separatorare respectively connected with a first condenser; a top gas phase outlet of the first condenser is connected with a lower end feeding hole of the first hydrochloric acid purification tower, the upperend of the first hydrochloric acid purification tower is provided with a fresh hydrochloric acid solution inlet, and the bottom of the first hydrochloric acid purification tower is provided with an oil phase outlet. The organochlorosilane hydrolysis and hydrochloric acid refining system has advantages of high reaction conversion rate and high product purity.

Owner:SEDIN NINGBO ENG

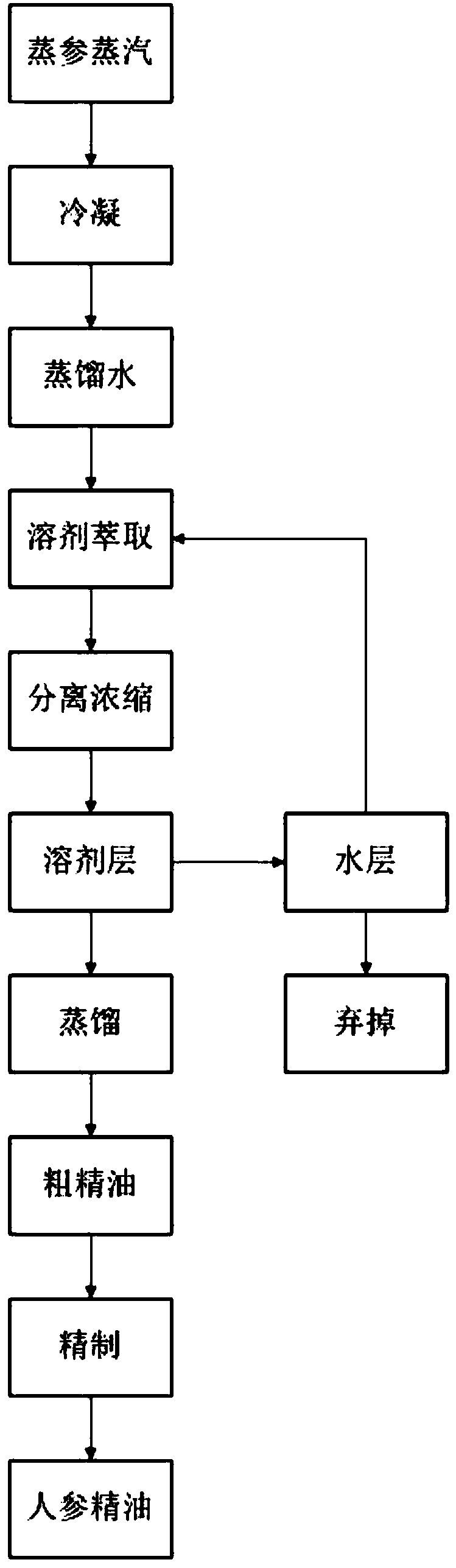

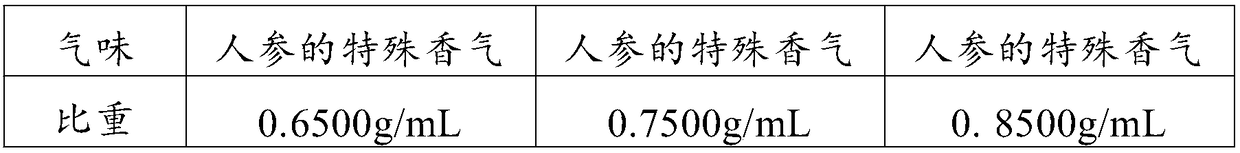

Method for extracting ginseng essential oil from ginseng processing wastes

PendingCN108424817AAchieve the purpose of reuseReduce processing costsEssential-oils/perfumesDistillationWater vapor

The invention discloses a method for extracting ginseng essential oil from ginseng processing wastes, and solves the technical problem that volatile oil in the red ginseng processing process is evaporated together with water vapor and discharged to cause great waste of resources, and belongs to the technical field of ginseng essential oil extraction. The method comprises the steps of steamed ginseng water collection, extraction, separation and concentration, distillation and refining, so that refined ginseng essential oil is obtained. According to the method, the byproduct of water vapor in the ginseng processing process is taken as an object, condensing equipment is used for collection, the extraction of ginseng volatile oil is carried out through the steps of solvent extraction, separation, distillation and the like, so that the purposes of changing waste maters into things of value and reducing the cost are reached, and the valuable resource is preferably utilized.

Owner:BAISHAN SCI & TECH INST

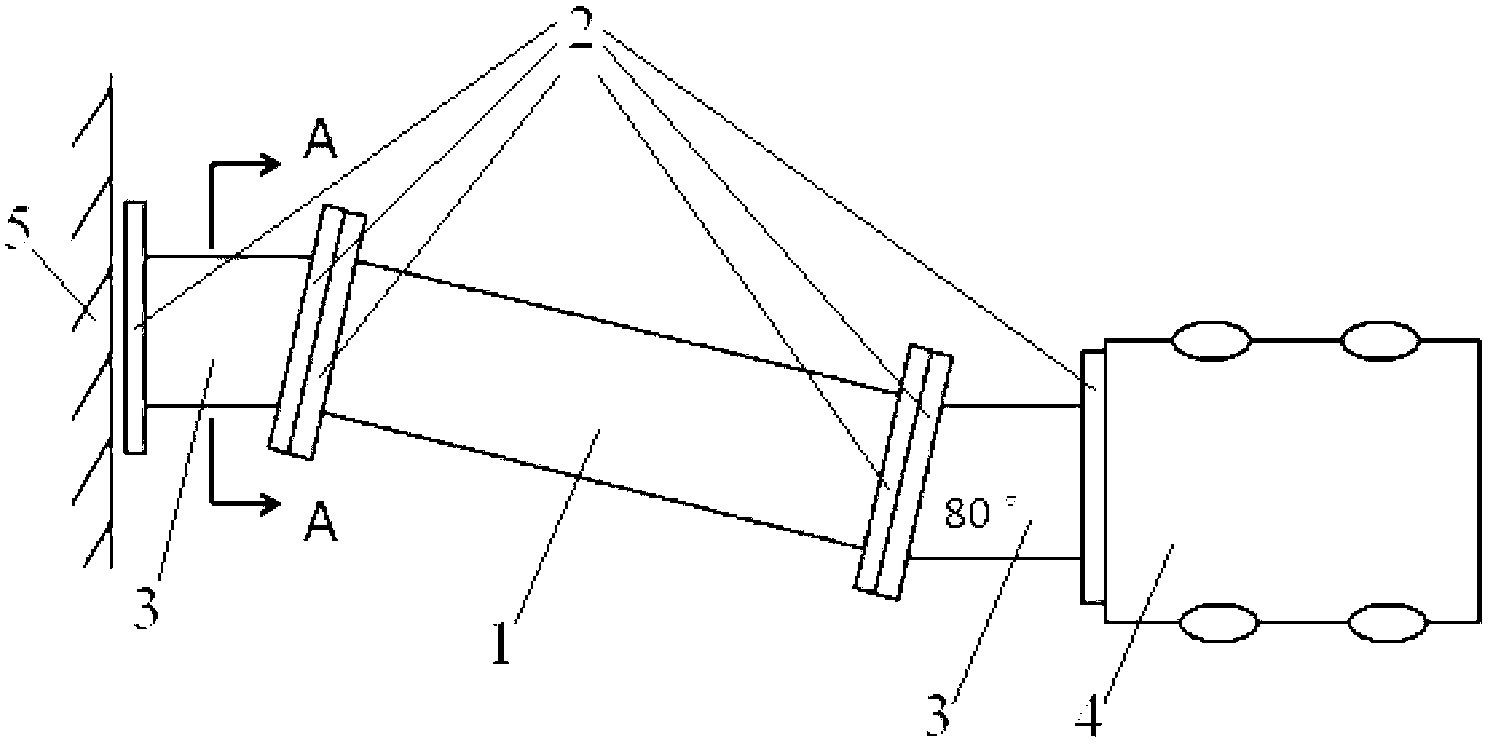

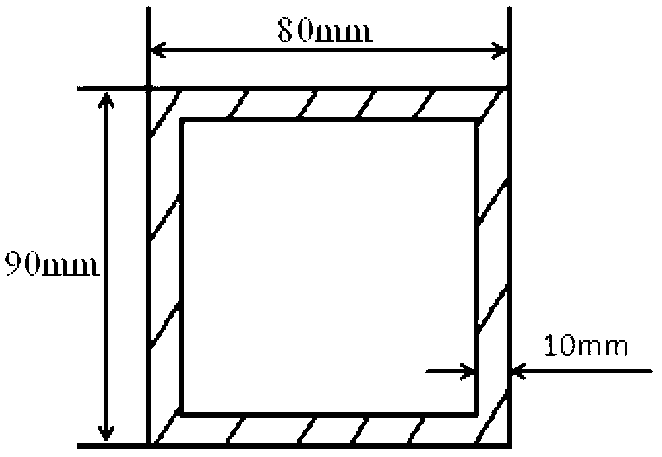

Stringer structure for frontal offset crash test and crash test method

ActiveCN103234727AIncrease wall thicknessIncrease wall thickness to increase its stiffnessVehicle testingShock testingIn vehicleCrash test

The invention discloses a stringer structure for a frontal offset crash test. The stringer is a square tube with a rectangular cross-section, two ends of the stringer are respectively in fastening connection with a stringer joint, the stringer joint connected with the end portion of the stringer through the end portion of the stringer joint is also a square tube with a rectangular cross-section, and a longitudinal centerline of the stringer joint and a longitudinal centerline of the stringer intersect and form an angle of less than 180 degrees. With the above technical scheme, the front end of the stringer is subjected to a bending moment during the test, and performance of the stringer in vehicle frontal offset crash is simulated, and thus, safety performance of the vehicle frontal offset crash is verified, the current test method of using a vehicle to do the frontal offset crash is replaced, test cost is reduced, test period is shortened, and the safety performance of the vehicle frontal offset crash can be predicted.

Owner:CHERY AUTOMOBILE CO LTD

A waste disposal system

InactiveCN104259171ADrying up toAchieve the purpose of reuseSolid waste disposalBiofuelsEnergy conservationWaste disposal

The invention relates to a waste disposal system and belongs to the field of waste disposal. Firstly, waste is sorted by a waste sorting part in the system, and then organic waste and combustible waste which are separated from the waste are reutilized as fuel energy for a drying part and a burning part in the system. The system can effectively dispose the waste and achieves objectives of drying, burning and sorting the waste and objectives of energy conservation and reutilization.

Owner:SUILING URBAN DOMESTIC RUBBISH DISPOSAL

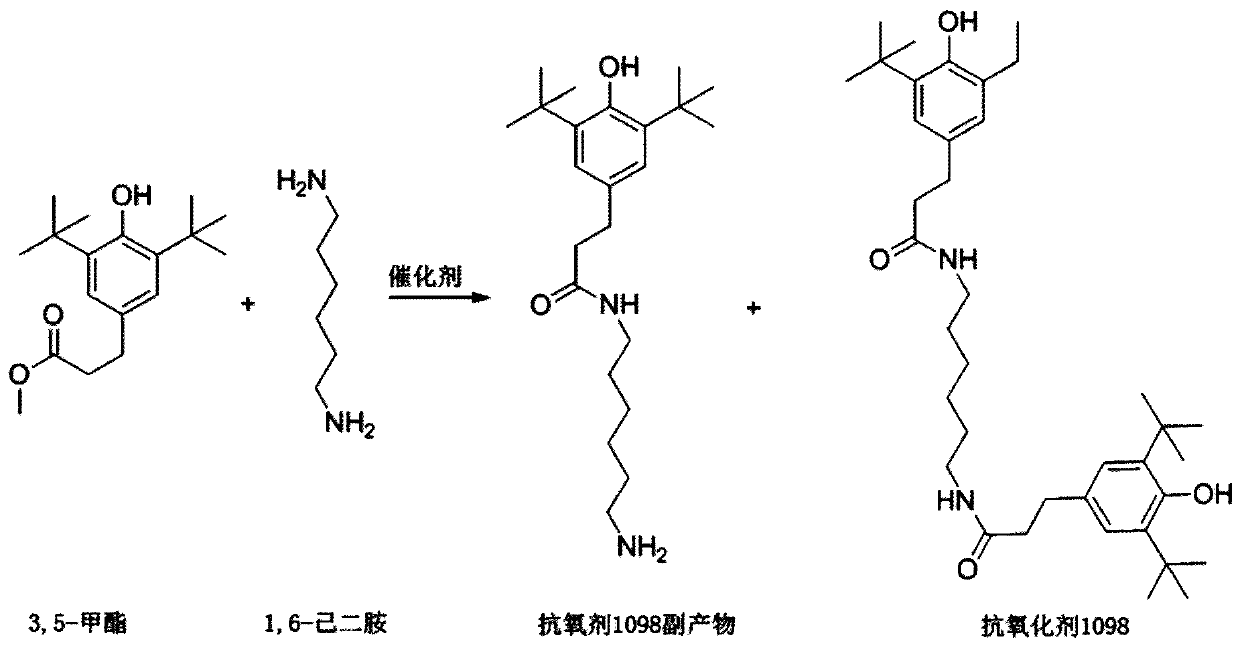

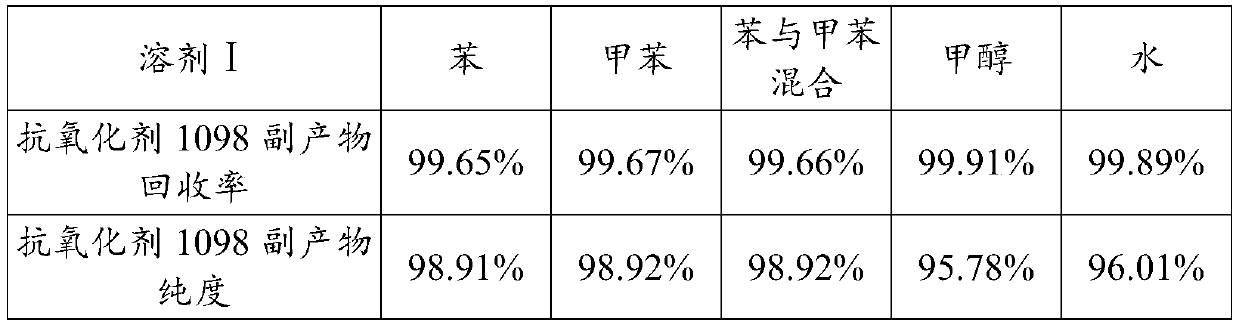

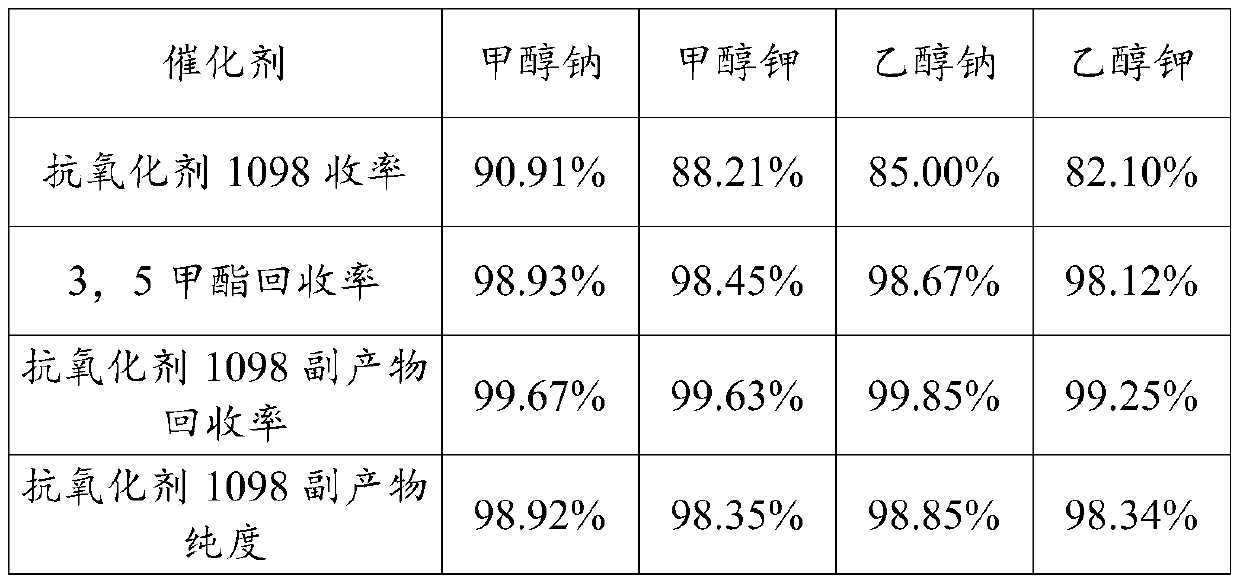

Method for recovering antioxidant 1098 by-product

ActiveCN110054570AReduce recycling costsControllableOrganic compound preparationCarboxylic acid amide separation/purificationRecovery methodAntioxidant

The invention discloses a method for recovering an antioxidant 1098 by-product. The method includes carrying out reduced pressure distillation treatment on a specific antioxidant 1098 mother liquor; and separating and recovering the antioxidant 1098 by-product and 3,5-methyl ester in the mother liquor by adopting a thermal filtration method to obtain the antioxidant 1098 by-product with higher purity. The recovery method has the advantages of tight connection, reasonable collocation, synergy, simplified and controllable recovery operation, high safety, high recovery rate of the antioxidant 1098 byproduct and 3,5-di-tert-butyl-4-hydroxyphenylpropionate, and realization of environmental benefits and economic benefits.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

Ecological water-permeable road pavement brick and preparation method thereof

InactiveCN107200531ASolve the problem that waste cannot be reusedGood water permeabilitySolid waste managementSingle unit pavingsSurface layerBrick

The invention provides an ecological water-permeable road pavement brick and a preparation method thereof, and relates to the technical field of production of road pavement bricks. The ecological water-permeable road pavement brick comprises a surface layer and a base layer, wherein the surface layer is prepared from the following raw materials in parts by weight: 20 to 30 parts of cement, 25 to 30 parts of sand, 5 to 10 parts of crushed stone, 4 to 6 parts of building waste residue coarse aggregate, 3 to 6 parts of volcanic ash, 6 to 10 parts of glass powder, 5 to 10 parts of fly ash, 3 to 10 parts of clay, 0.4 to 0.6 part of water reducing agent, 0.3 to 0.5 part of pigment powder, and 1 to 3 parts of water; the base layer is prepared from the following raw materials in parts by weight: 22 to 30 parts of cement, 18 to 32 parts of sand, 17 to 23 parts of crushed stone, and 2 to 3 parts of water. The preparation method comprises the following steps of (1) preparing of the materials of the surface layer; (2) preparing of the materials of the base layer; (3) forming, demolding, stacking and curing. The ecological water-permeable road pavement brick can solve the problems of failure to reutilize the wastes, poor water permeability, low compressive strength and poor abrasion-resistant property in the existing road pavement.

Owner:合肥慧林建材有限公司

Micro fluidic chip capable of forming liquid state metal liquid drops, and preparation method thereof

ActiveCN110496657AEasy accessImprove insulation performanceLaboratory glasswaresLiquid stateLiquid metal

The invention relates to a micro fluidic chip capable of forming liquid state metal liquid drops. The micro fluidic chip capable of forming liquid state metal liquid drops comprises a substrate provided with a micro channel layer; the micro channel layer comprises a first micro channel, a second micro channel, a narrow opening, and a third micro channel; the first micro channel and the second micro channel are communicated through the narrow opening; the width of the first micro channel and the width of the second are much larger than the width of the narrow opening; the central axis of the first micro channel and the central axis of the second micro channel in the length direction are in a same straight line; the angle between the third micro channel and the first micro channel is controlled to be 30 DEG; the first micro channel, the second micro channel, and the third micro channel are respectively used for flowing of liquid state metal, generated liquid state metal drops, and a solution. The micro fluidic chip and the liquid state metal liquid drop generation method are simple and convenient in operation; the size of the generated liquid drops is convenient to control; and costis low.

Owner:SUZHOU UNIV

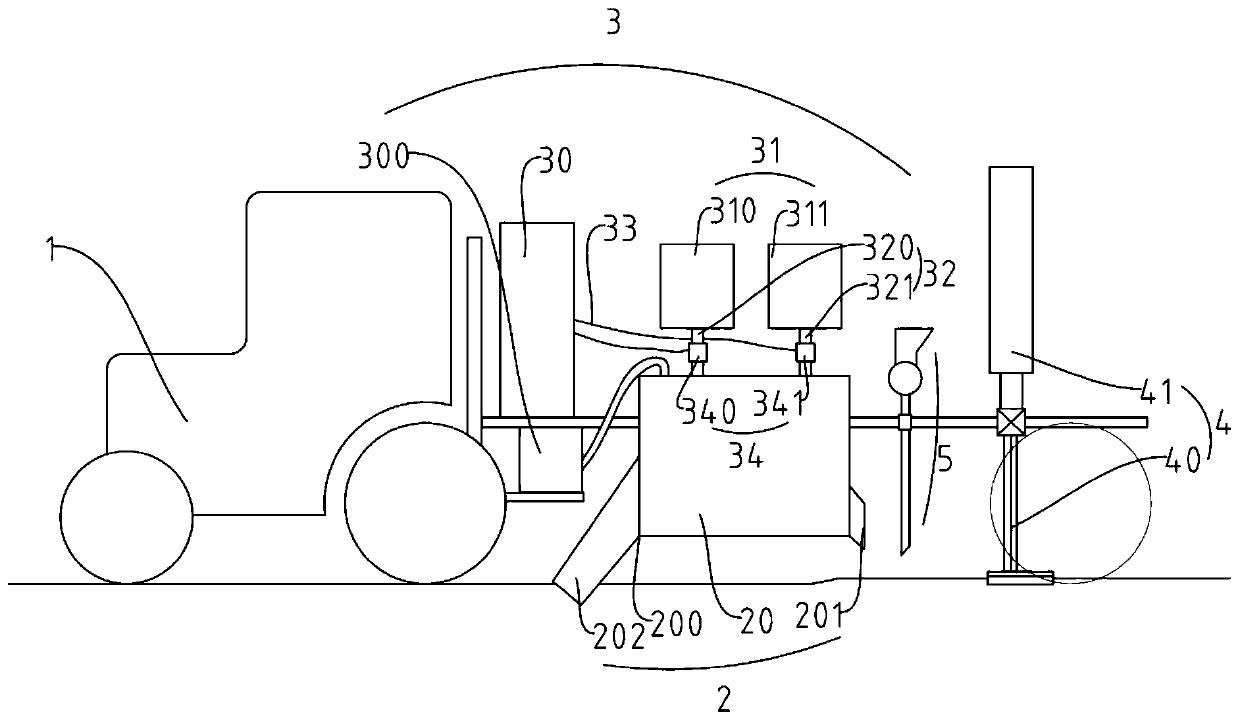

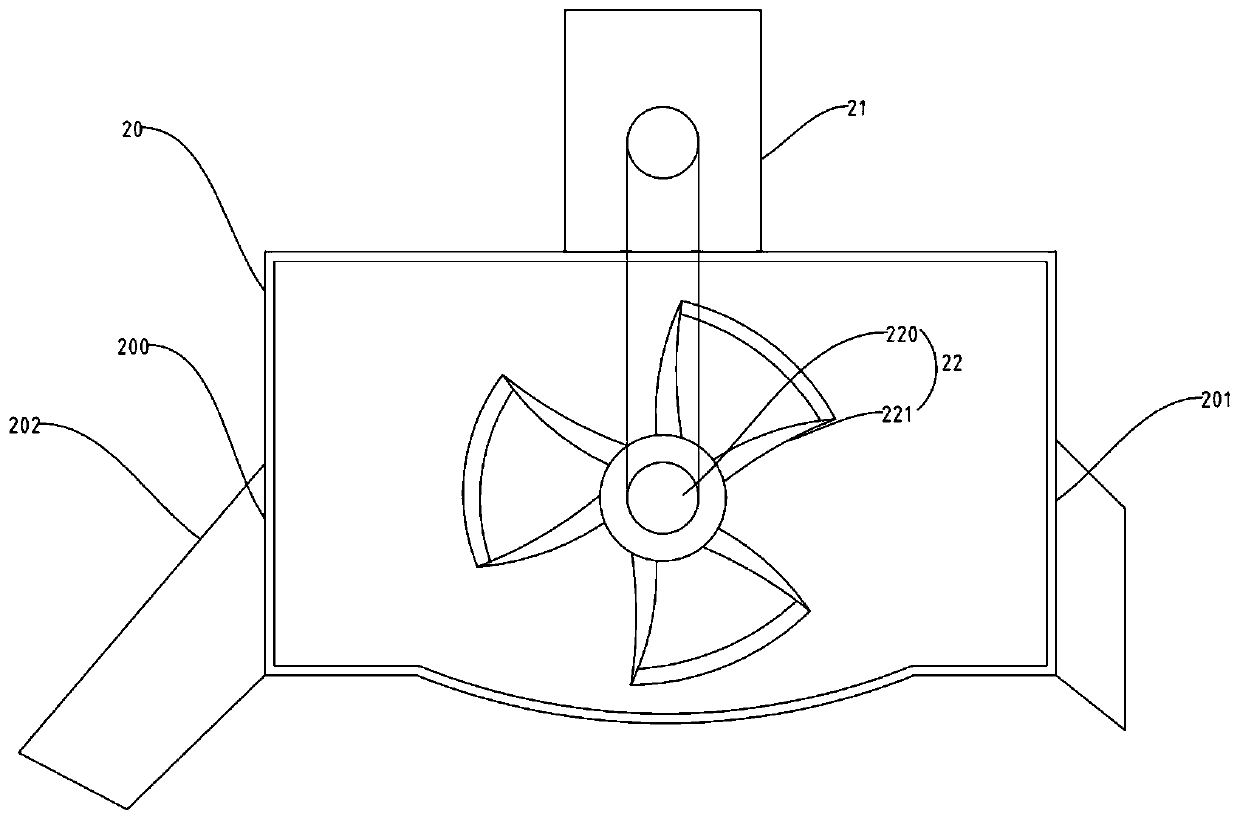

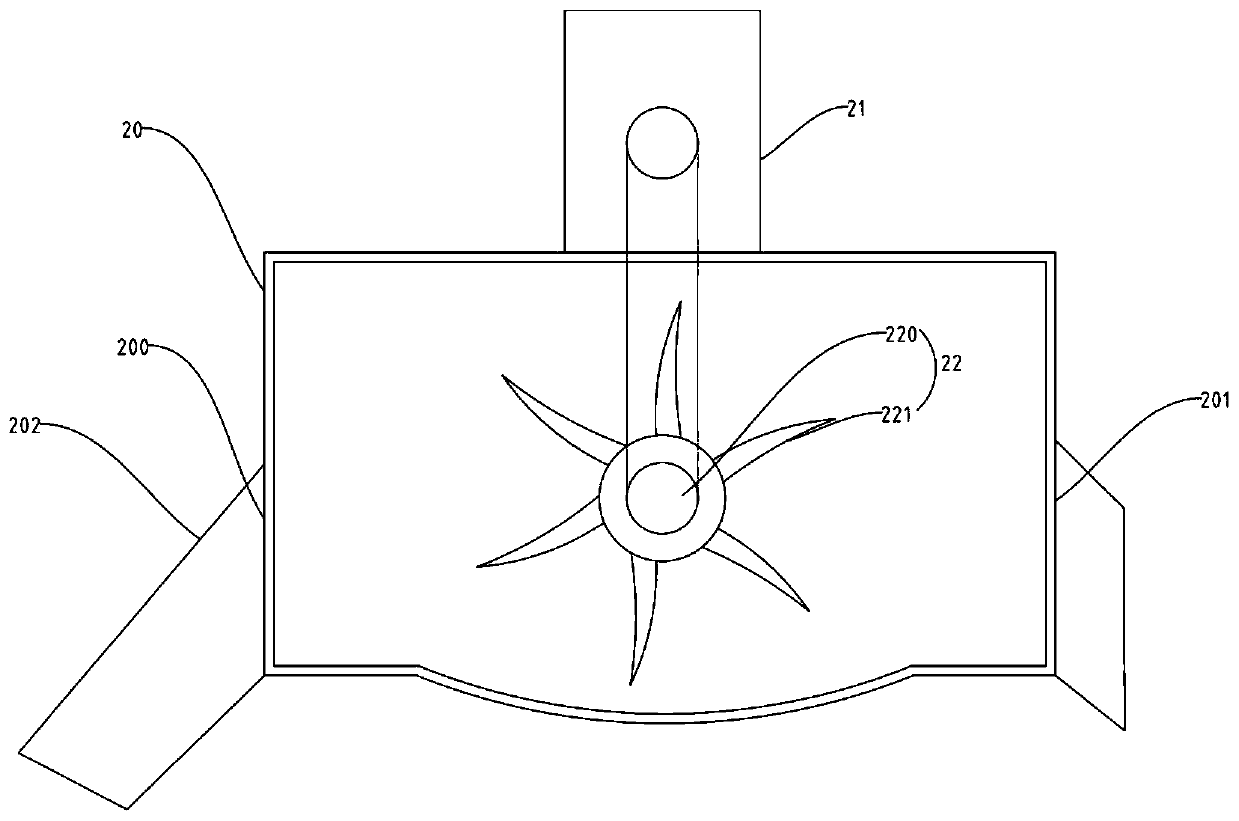

Soil improvement machine and soil improvement method

InactiveCN111557132ADosing is convenientImproved ease of operationSpadesSoil lifting machinesAgricultural engineeringBiology

The invention discloses a soil improvement machine. The soil improvement machine comprises a tractor, a deep ploughing device, a material applying device and a flattening device, wherein the deep ploughing device, the material applying device and the flattening device are fixedly arranged on the tractor and are sequentially arranged in the advancing direction of the tractor. The method comprises the following steps that: firstly, soil is turned up and enters a mixing box, and the soil is cut and raked step by step, so that soil blocks in the soil become small and loose, and chemical adding isfacilitated; chemical adding improvement is carried out on the soil while cutting and raking are carried out, and chemical adding comprises solid materials and liquid materials, so that the liquid adding requirements of different improvers can be met; and after the soil is cut, raked and mixed with added liquid, the soil is flattened by the flattening device, so that later soil fertilization and cultivation are facilitated. According to the soil improvement machine, the improvement operation of the soil is convenient, the improvement effect is good, all the procedures are automatically completed by the machine, the improvement working efficiency is high, and the soil improvement machine is suitable for large-range and large-area soil improvement work.

Owner:绍兴市米莉农业科技有限公司

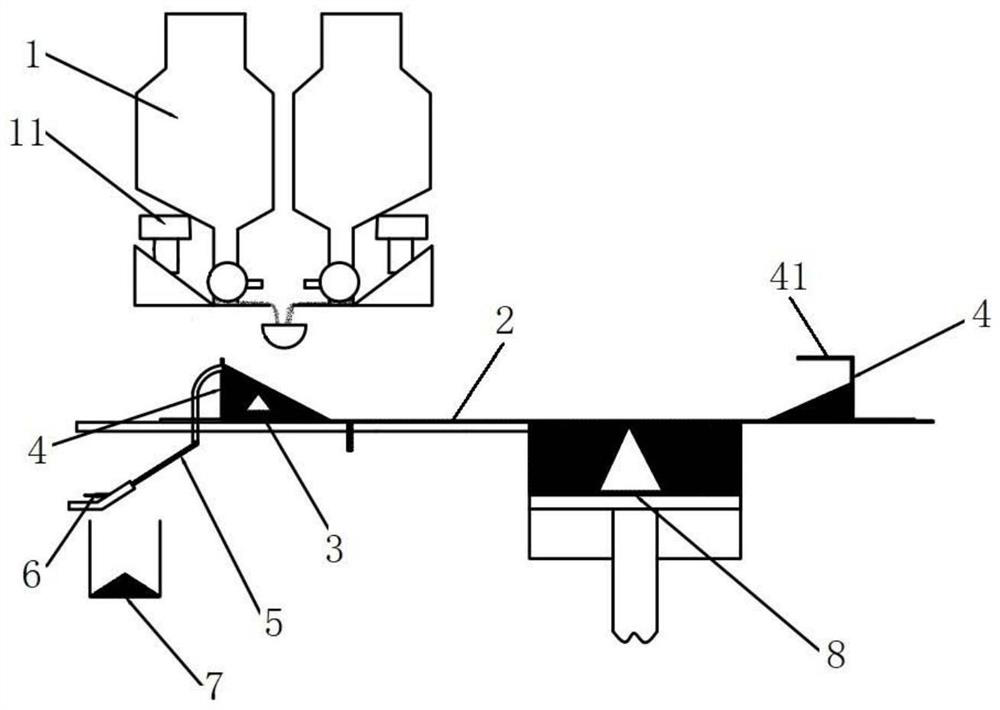

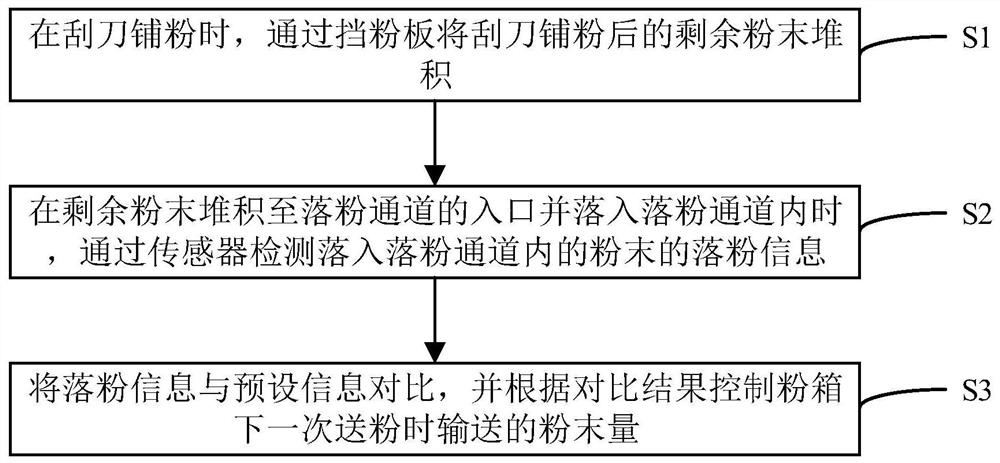

Additive manufacturing device and additive manufacturing method

InactiveCN111703071AAchieve the purpose of reuseIncrease profitAdditive manufacturing apparatus3D object support structuresProcess engineeringManufacturing engineering

The invention belongs to the technical field of additive manufacturing, and discloses an additive manufacturing device and an additive manufacturing method. The additive manufacturing device comprisespowder boxes, a powder laying platform arranged below the powder boxes, scrapers arranged on the powder laying platform, powder stopping plates arranged at the two sides of the powder laying platform, powder falling channels arranged at at least one powder stopping plate and sensors arranged at the powder falling channels. The powder stopping plates are configured to stack residual powder obtained after the scrapers conduct powder spreading; and the powder falling channels are configured to detect powder falling information of powder fallen into the powder falling channels to control the amount of powder conveyed when the powder boxes conduct powder feeding next time. According to the additive manufacturing device and the additive manufacturing method, the amount of powder conveyed next time by the powder boxes can be controlled to achieve the purpose of repeatedly utilizing the residual powder, the powder utilization rate is increased, and the powder in the powder boxes can be supplied for a long term for printing.

Owner:QUICKBEAM CO LTD

Method of recycling kitchen waste effluent

InactiveCN109734486AFavorable for direct absorptionPromotes rapid germinationBio-organic fraction processingBacteriaLiquid wasteAdditive ingredient

The invention discloses a method of recycling kitchen waste effluent and relates to the technical field of resource recycling. The method includes the steps of adjusting pH of waste effluent to 6-8, adding soybean cake powder and molasses, heating to 80 DEG C and above to obtain a pretreated fermentation liquor; lowering the temperature of the pretreated fermentation liquor to 32 DEG C and below,adding a Bacillus siamensis agent and a Staphylococcus carnosus agent into the pretreated fermentation liquor, carrying out ventilated aerobic fermentation, and applying a fermentation product as a liquid microbial fertilizer to agricultural planting. The method has the advantages that the whole process is free of fouling odor, the liquid microbial fertilizer meets the national standard of microbial fertilizers, contains massive free amino acids and polypeptide ingredients, is more helpful for direct absorption by crops, can promote quick germination of seeds and development of roots, allows crops to mature early, and has a significant biocontrol function.

Owner:陕西天仁雪农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com