Method and device for recovering molten blast furnace slag sensible heat

A technology of blast furnace slag and molten slag, which is applied in secondary energy recovery, iron and steel metallurgy energy saving and emission reduction fields, and can solve problems such as hot water and steam affecting production, inability to adapt to three seasons, and low utilization rate of slag heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

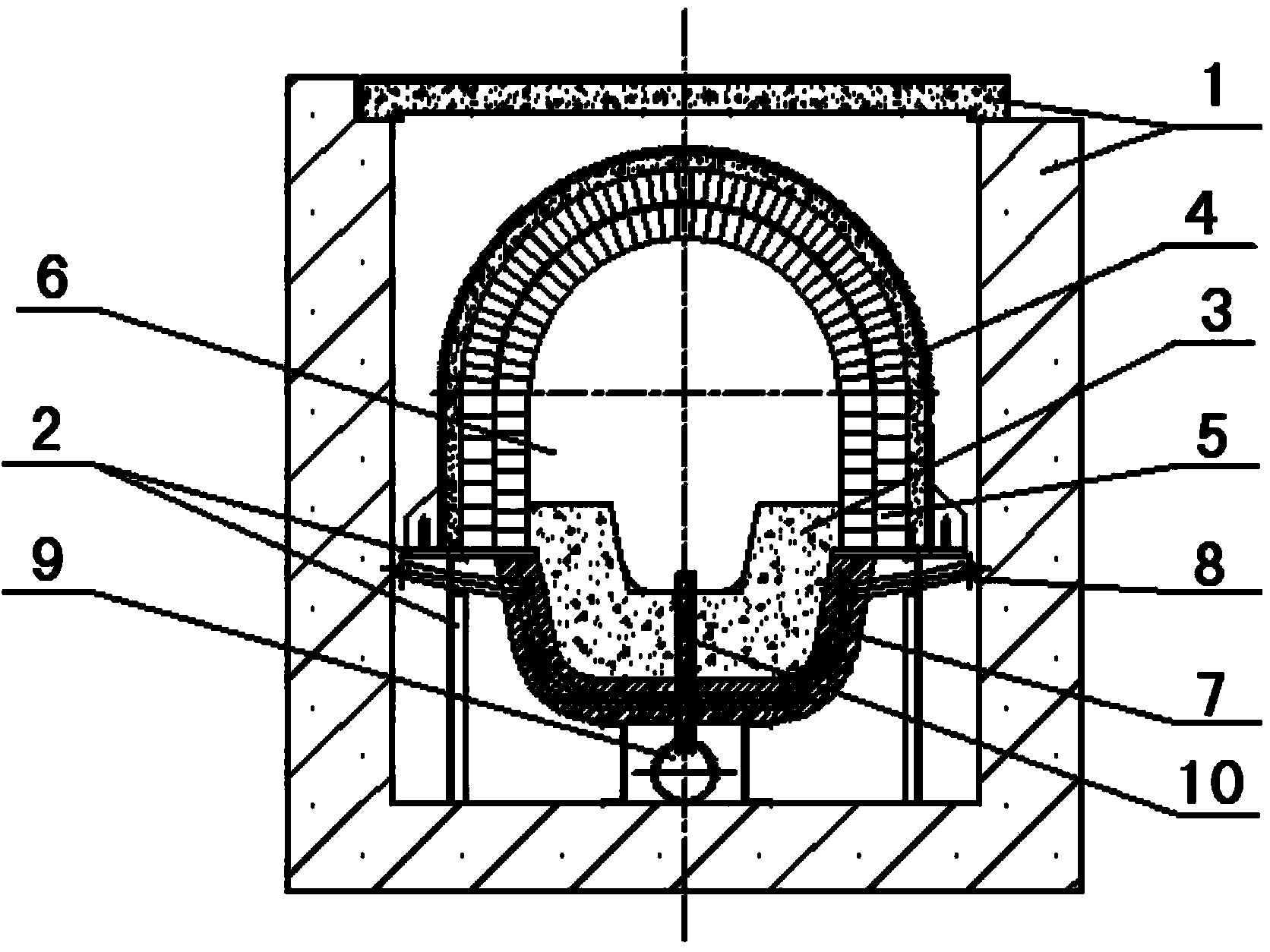

[0017] See figure 1 , is a structural schematic diagram of an embodiment of the bottom-blowing composite molten slag ditch of the present invention, including a cement outer slag ditch 1, a ditch body support 2, a ditch body 3 and a ditch cover 4, and the bottom of the cement outer slag ditch 1 is provided with a ditch body support 2, and the ditch The upper part of the body support 2 is provided with a ditch body 3 and a ditch cover 4 made of refractory materials, and the inner surface of the ditch cover 4 is provided with a heat storage masonry 5, and a slag flow channel 6 is formed between the ditch body 3 and the ditch cover 4 , the bottom of ditch body 3 is provided with copper stave 7, the copper stave 7 is provided with cooling water pipe 8, the bottom of copper stave 7 is provided with bottom blowing air pipe 9, and the bottom blowing air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com