Road roadbed material containing municipal sludge residues

A technology of municipal sludge and roadbed materials, applied in the field of road engineering materials, can solve problems such as high cost and unfriendly source environment, achieve high compressive strength, reduce road construction budget, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The municipal sludge sludge cake is firstly manually removed from solid impurities, dried in an oven at 105°C to constant weight, taken out, crushed and sieved to obtain pretreated municipal sludge, and then placed in an inert gas atmosphere at 900°C Municipal sludge residue was obtained after pyrolysis for 1 hour.

[0027] Select 50 kg of medium-sized municipal sludge particle residues and 10 kg of quicklime, add them to a mixer, and add 12.5 kg of water, and stir to obtain a road subgrade material containing municipal sludge.

[0028] It is measured that the loss on ignition of the municipal sludge residue is 6.5% to 7.5%, and the road subgrade material obtained in this embodiment does not contain microorganisms such as pathogenic bacteria, and the heavy metal content meets the "Soil Environmental Quality Standard (GB15618-1995)" Grade III or above is required.

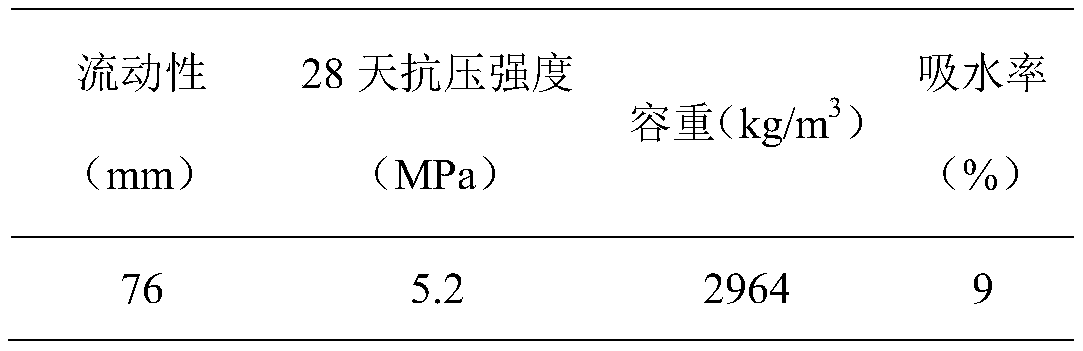

Embodiment 2

[0030] After the municipal sludge sludge cake is manually removed from solid impurities, it is dried in an oven at 105°C to a constant weight, taken out, crushed and sieved to obtain pretreated municipal sludge, and then placed in an inert gas atmosphere at 300°C Municipal sludge residue was obtained after pyrolysis for 4 hours.

[0031] Select 60 kg of medium-sized municipal sludge particle residue, 24 kg of sand, 6.4 kg of quicklime, 20 kg of cement and add 40 kg of water into the mixer, and mix well to obtain a road subgrade material containing municipal sludge. The sand is medium-coarse sand, and the cement is slag cement grade 32.5.

[0032] It is measured that the loss on ignition of the municipal sludge residue is 6.5% to 7.5%, and the road subgrade material obtained in this embodiment does not contain microorganisms such as pathogenic bacteria, and the heavy metal content meets the "Soil Environmental Quality Standard (GB15618-1995)" Grade III or above is required.

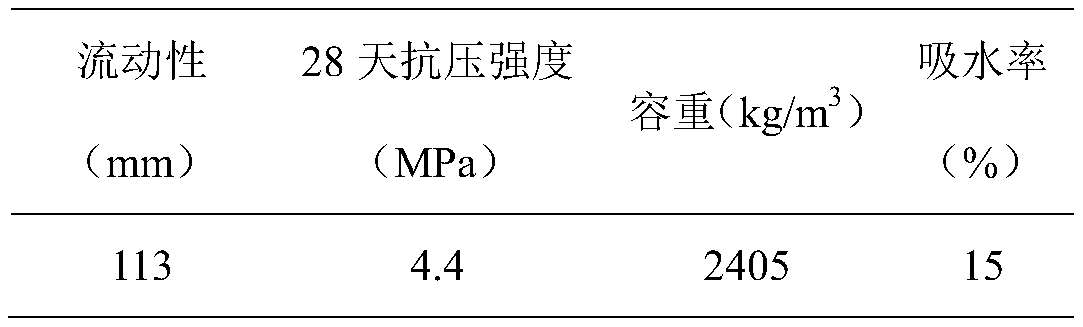

Embodiment 3

[0034] After the municipal sludge sludge cake is manually removed from solid impurities, it is dried in an oven at 105°C to a constant weight, taken out, crushed and sieved to obtain pretreated municipal sludge, and then heated at 600°C under an inert gas atmosphere. After pyrolysis for 2 hours, municipal sludge residue was obtained.

[0035] Select 50 kg of medium-sized municipal sludge particle residue, 20 kg of sand, 10 kg of quicklime, and 10 kg of cement and add them to the mixer, and add 30 kg of water, and mix well to obtain a road subgrade material containing municipal sludge. The sand is medium-coarse sand, and the cement is slag cement grade 32.5.

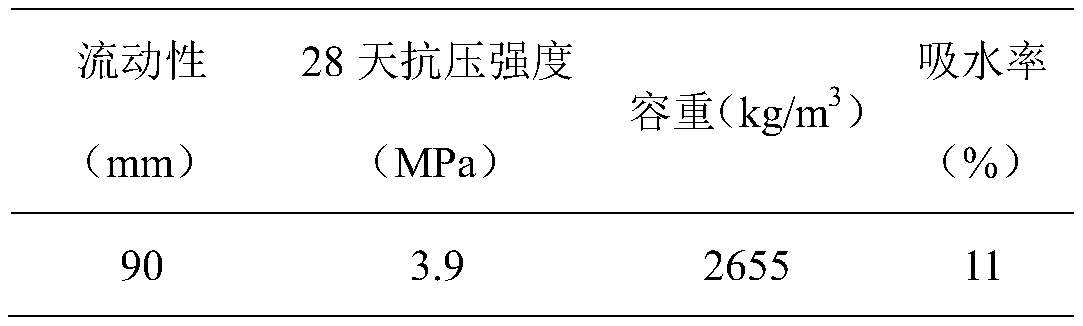

[0036] The obtained road subgrade materials were tested for performance, and the test results are shown in Table 1.

[0037] Table 1

[0038]

[0039] It is measured that the loss on ignition of the municipal sludge residue is 6.5% to 7.5%, and the road subgrade material obtained in this embodiment does not contain m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com