Organochlorosilane hydrolysis and hydrochloric acid refining system and method

An organochlorosilane and refining system technology, applied in chemical instruments and methods, inorganic chemistry, chlorine/hydrogen chloride, etc., can solve problems such as shortening the start-up cycle, reducing the yield of siloxane, and affecting the synthesis process of methyl chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

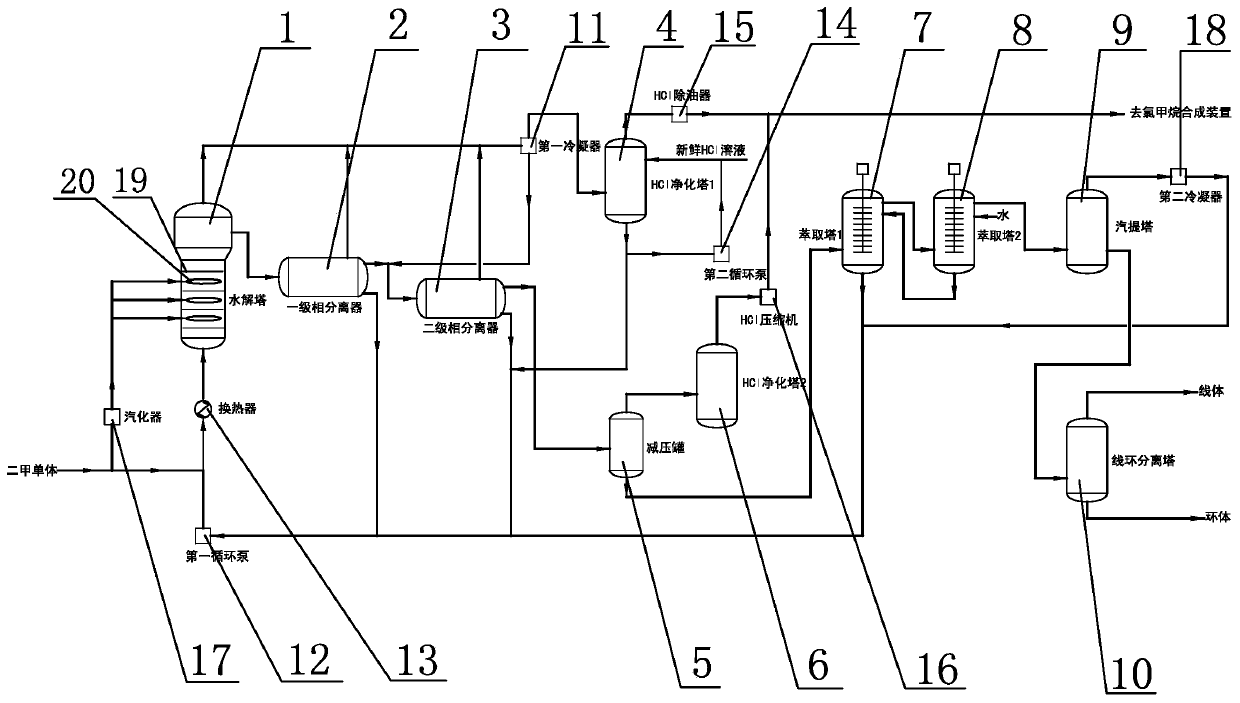

[0033] An organochlorosilane hydrolysis and hydrochloric acid refining system, such as figure 1 As shown, it includes a hydrolysis tower 1, a primary phase separator 2, a secondary phase separator 3, a first hydrochloric acid purification tower 4, a decompression tank 5, a second hydrochloric acid purification tower 6, a first extraction tower 7, and a second extraction tower. Tower 8, stripper 99 and wire-loop separation tower 10, the side of hydrolysis tower 1 is provided with multi-section feed inlet, the upper oil phase outlet of hydrolysis tower 1 is connected with the feed inlet of primary phase separator 2, and the first stage The oil phase outlet of the phase separator 2 is connected with the feed port of the secondary phase separator 3, the top gas phase outlet of the hydrolysis tower 1, the gas phase outlet of the primary phase separator 2 and the gas phase outlet of the secondary phase separator 3 are respectively connected The first condenser 11, the top gas phase ...

specific Embodiment 2

[0036] A method for organochlorosilane hydrolysis and hydrochloric acid refining, comprising the following steps:

[0037] (1) After the pressurized liquid phase dimethyl dichlorosilane of 0-0.5MPaG is vaporized by the vaporizer 17 or the liquid phase dimethyl dichlorosilane is heated by the heat exchanger 13, it is sent into the hydrolysis tower 1 in sections Carry out the hydrolysis reaction, control the reaction temperature in the hydrolysis tower 1 to 20-60°C, and control the pressure to 0-0.5MPaG, send the gas phase obtained from the reaction to the first condenser 11, and send the oil phase obtained from the reaction to the primary phase separator 2; Dimethyldichlorosilane in the hydrolysis tower 1 adopts gas-phase multi-stage feeding, and the feeding amount of each section of dimethyldichlorosilane is 40-90%, 40-5% and 20-5%;

[0038] (2) Control the pressure of the primary phase separator 2 to the same pressure as that of the hydrolysis tower 1 for three-phase separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com