Method for transferring graphene with atomic cleanness

A transfer method, graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of reducing PMMA residues, retaining initial properties, and improving residue problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

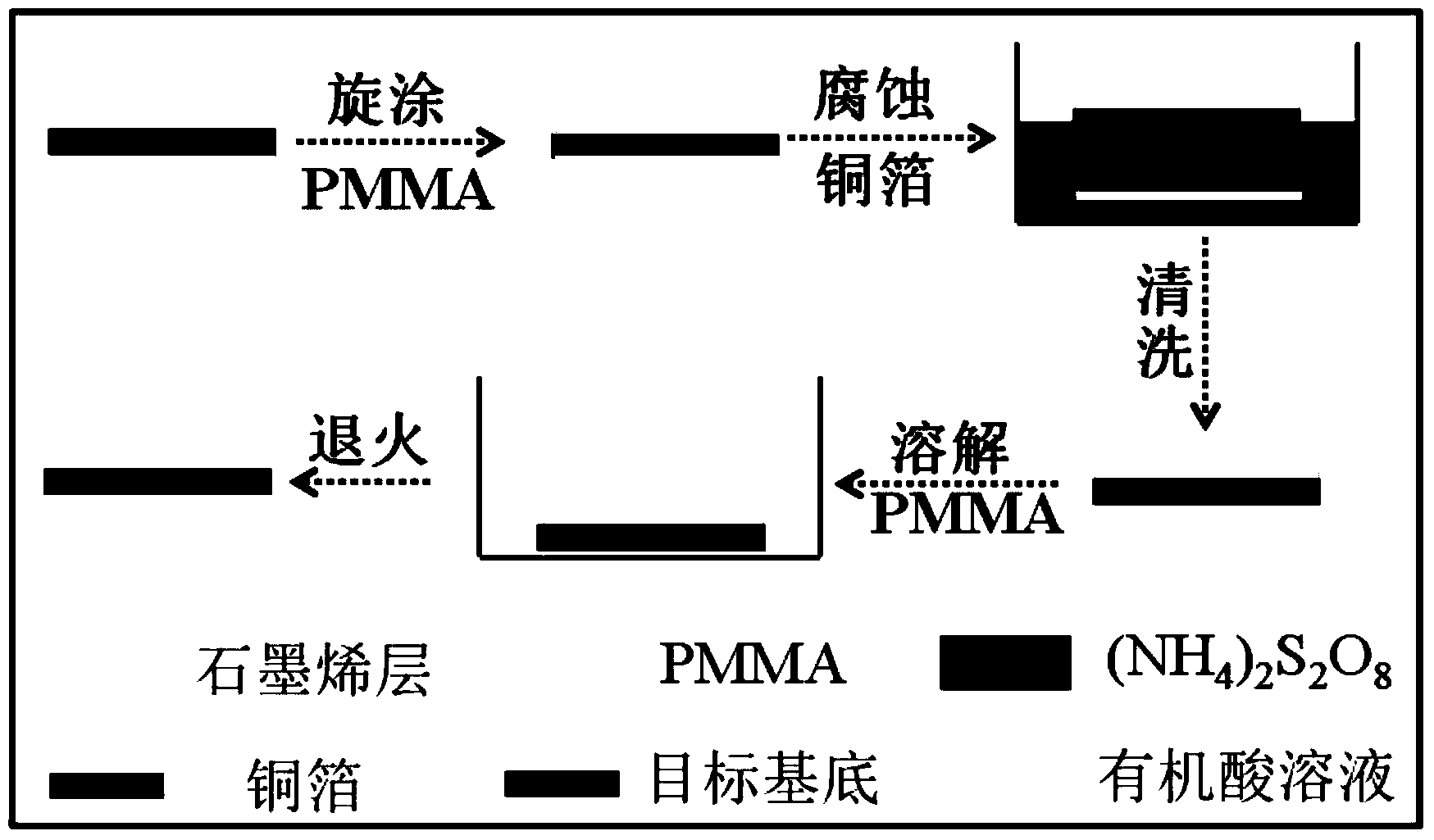

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1, CVD graphene is transferred to SiO with acetic acid as organic acid solution 2 Substrate surface

[0069] The preparation steps are as follows:

[0070] (1) Spin-coat a layer of PMMA solution (960PMMA A4, MicroChem) on the surface of copper foil with graphene (for the specific preparation method, refer to Nanotechnology,.2012, 23, 0957-4484.), and the spin-coating speed is 3000rpm. After the spin coating, the copper foil coated with PMMA was placed on a heating plate at 180°C for heating and curing.

[0071] (2) The sample PMMA faces up and floats at 0.1mol / L (NH 4 ) 2 S 2 o 8 The surface of the solution was corroded for 3 hours. After the copper foil is fully dissolved, transfer it to clean water and soak for 60 minutes.

[0072] (3) After cleaning the residual ions on the graphene surface, select a piece of clean SiO 2 The substrate scoops up thin layers of graphene and PMMA. Transfer the sample to the heating table and heat at 180°C for 1h to m...

Embodiment 2

[0077] Embodiment 2, CVD graphene is transferred mica substrate surface with acetic acid as organic acid solution

[0078] Use organic acid as a solvent to transfer CVD graphene to the surface of mica substrate, except that the target substrate is made of SiO in step (3). 2 Except changing to mica, all the other operations are the same as in Example 1.

Embodiment 3

[0079] Embodiment 3, using the graphene obtained in Embodiment 2 as a substrate, constructing a self-assembled layer of 8-octyloxyphthalocyanine copper molecules on its surface.

[0080] Taking the graphene obtained in embodiment 2 as the substrate, the concentration of dripping on its surface is about 10 -5 mol / L toluene solution of 8-octyloxycopper phthalocyanine, after the solvent evaporates, a self-assembled layer of 8-octyloxycopper phthalocyanine on the graphene surface can be obtained.

[0081] Compared image 3 with Figure 4 It can be found that although the conventional solvent acetone can dissolve most of the PMMA coating, the residue of partially overpolymerized PMMA is still very serious. Using acetic acid as a solvent can greatly improve the problem of PMMA residue on the graphene surface. In the atomic force microscope scanning image, the PMMA residue on the graphene surface treated with organic acid as solvent is significantly less than the graphene surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com