Patents

Literature

103results about How to "Improve residual problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

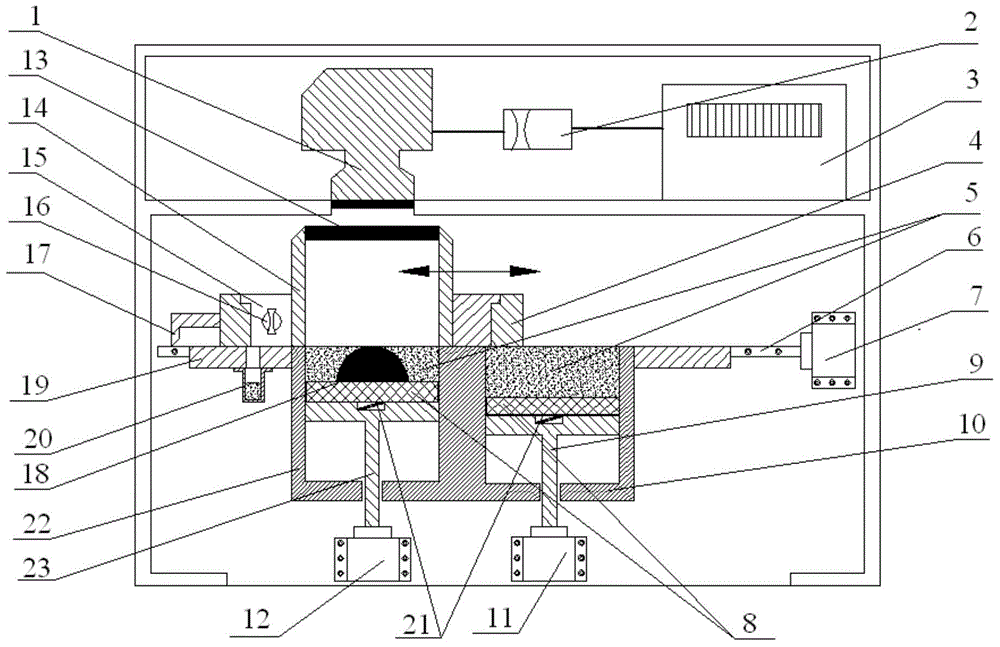

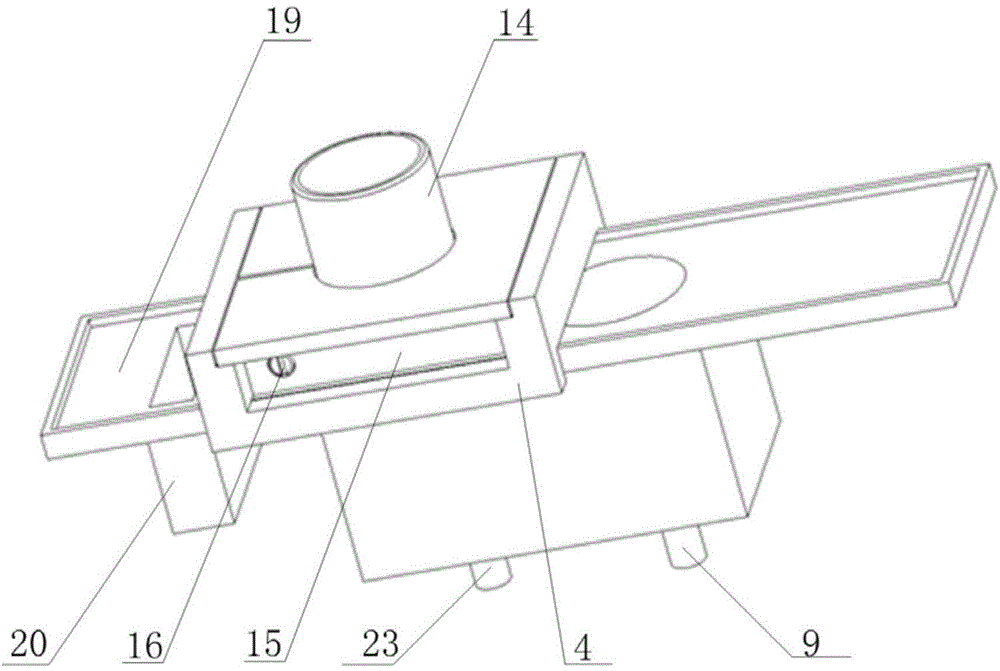

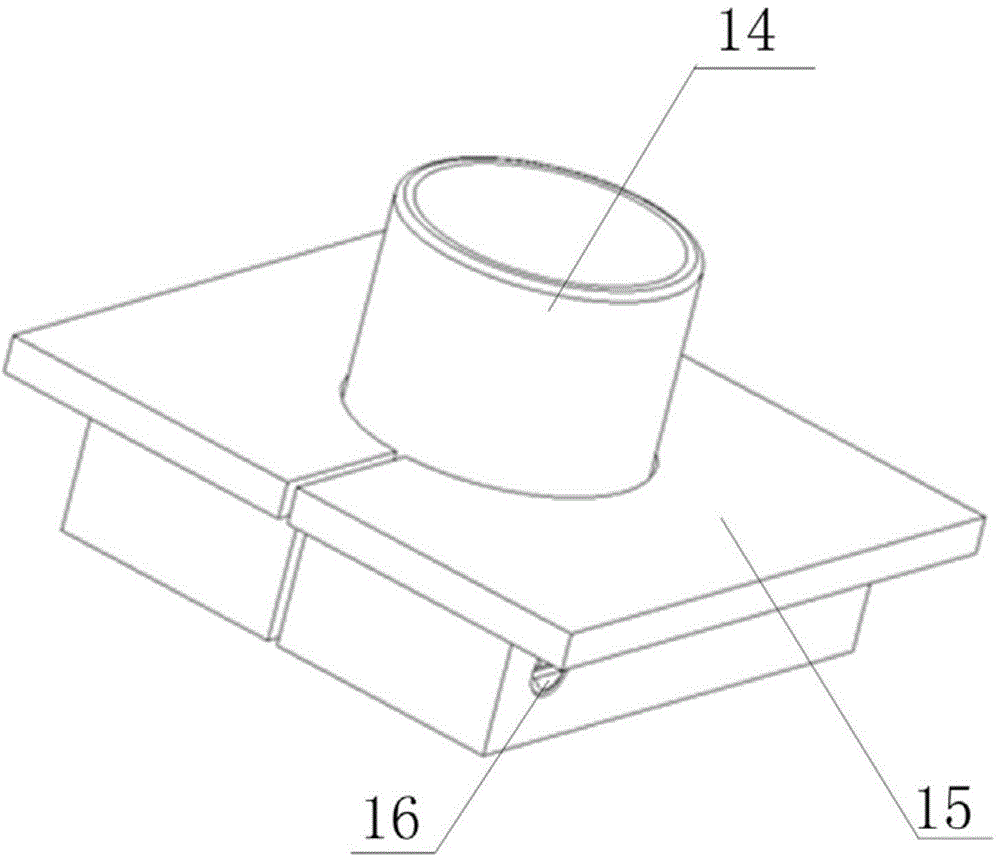

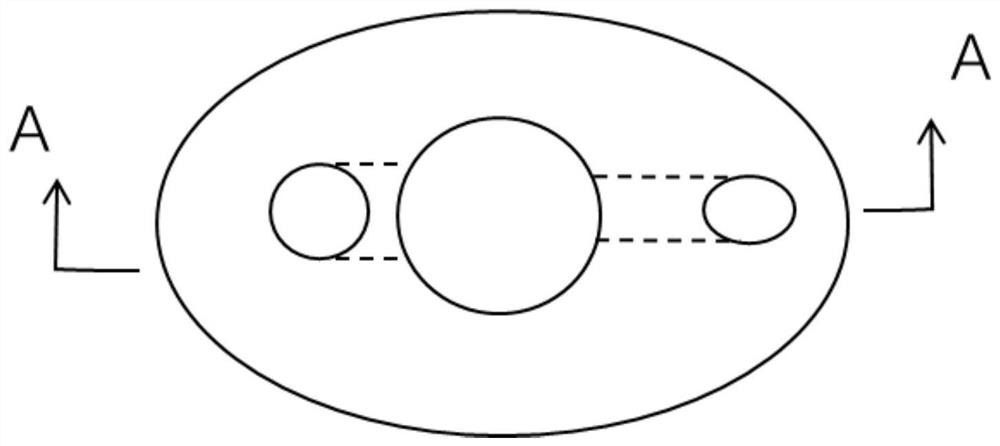

Dual-cylinder tabletop-type selective laser melting molding equipment and dual-cylinder tabletop-type selective laser melting molding method

The invention discloses dual-cylinder tabletop-type selective laser melting molding equipment and a dual-cylinder tabletop-type selective laser melting molding method. The dual-cylinder tabletop-type selective laser melting molding equipment comprises a sealed molding chamber, an optical transmission system, a powder spreading device, a molding cylinder and a powder cylinder, wherein a molding platform is arranged on the upper part of the molding cylinder and the powder cylinder; a movable platform is arranged above the molding platform; the molding platform serves as a guide rail of the movable platform, so that the movable platform can move left and right on the molding platform; the molding platform is provided with a powder spreading device and a powder acquiring system; the powder acquiring system comprises a powder acquiring base platform and a powder acquiring barrel, the powder acquiring barrel is arranged on the upper part of the powder acquiring base platform. Aiming at key points of a direct precious metal molding system, namely powder recovering and clearing, the dual-cylinder tabletop-type selective laser melting molding equipment is provided with the powder acquiring structure which can be completely taken out easily, and no powder is remained on the inner corners of the molding cylinder / powder cylinder, so that material wastes in a molding process are reduced, and the dual-cylinder tabletop-type selective laser melting molding equipment can be applied to direct molding of individual parts made of precious metals such as gold, silver and platinum in the bijouterie industry.

Owner:GUANGZHOU LEIJIA TECH CO LTD

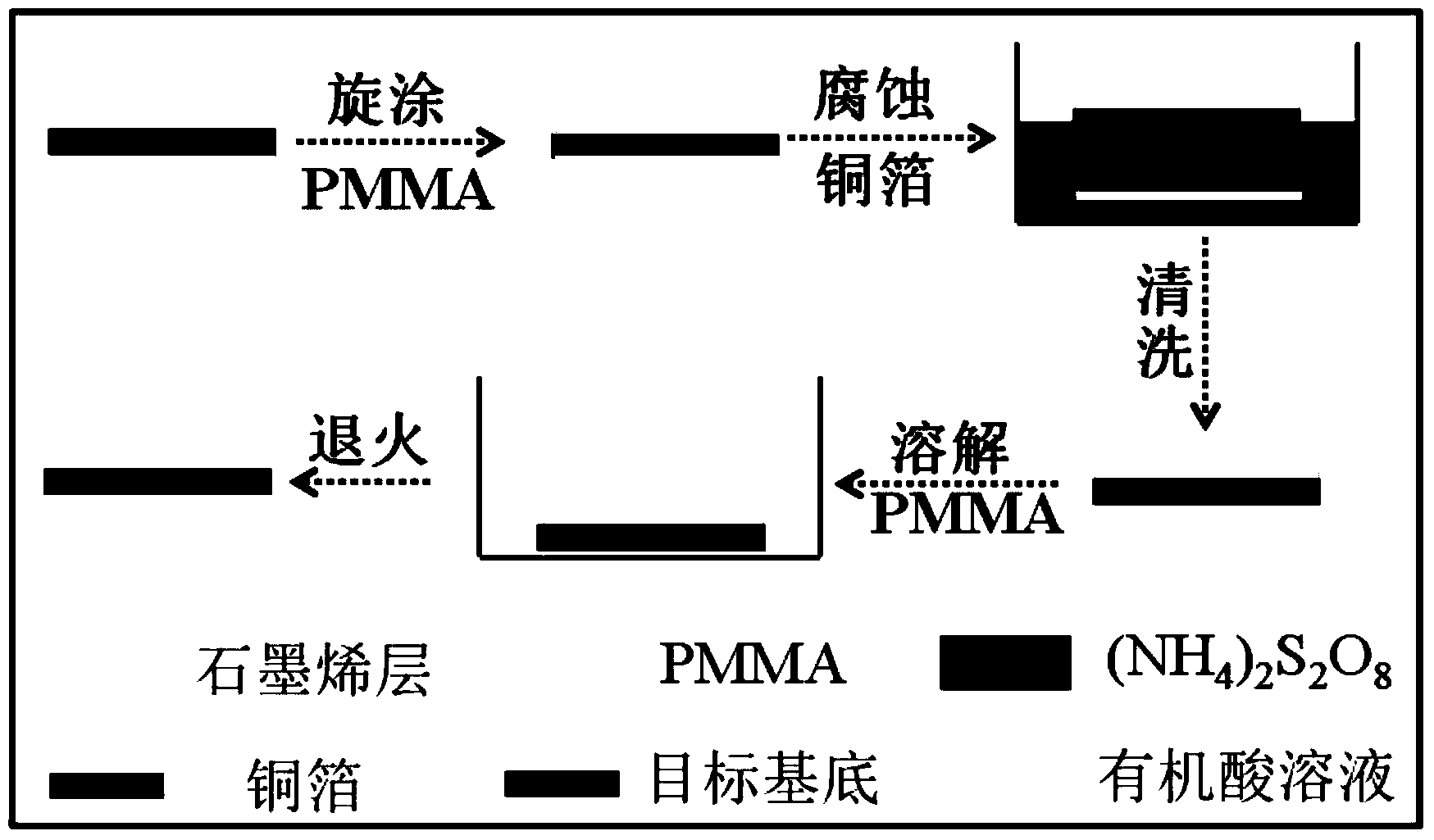

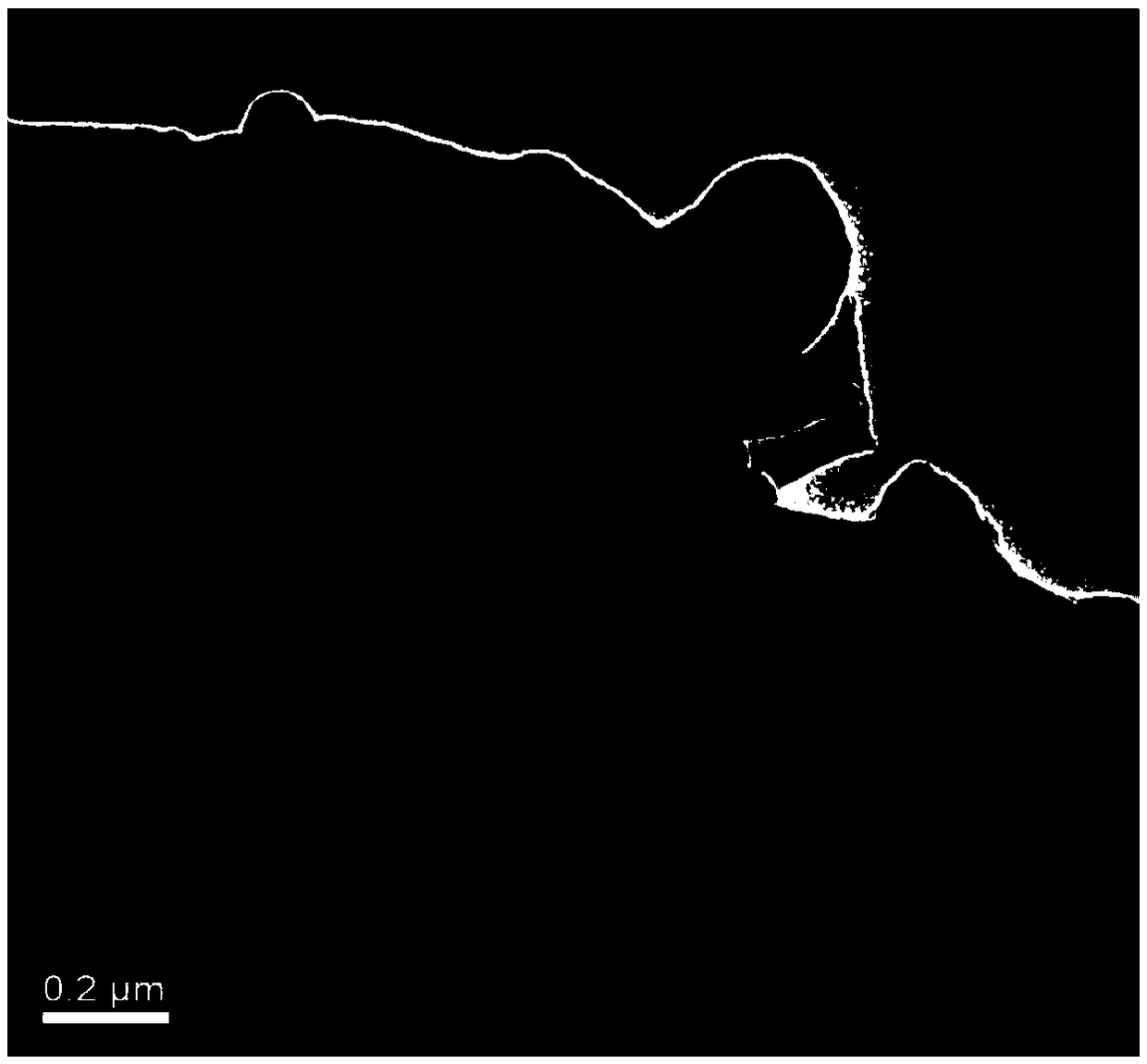

Method for transferring graphene with atomic cleanness

InactiveCN103449418APromote degradationImprove solubilityCarbon compoundsPolymethyl methacrylateSolvent

The invention discloses a method for efficiently transferring CVD (Chemical Vapor Deposition) graphene and acquiring atomically clean surfaces. The method comprises the following steps: spin-coating a layer of PMMA (polymethyl methacrylate) solution on the surface of a graphene / metal substrate, removing the metal substrate through corrosion of an (NH4)2S2O8 solution after being cured, cleaning graphene / PMMA, fishing out through a target substrate and then drying, then dissolving the PMMA layer through an organic acid solvent, and finally further removing the residual PMMA on the surface of the graphene through a high-temperature annealing manner, thus acquiring the atomically clean graphene surfaces. The graphene surface is large in area, complete in structure and little in defects and residual PMMA. According to the method, the residual PMMA is little, and the atomically clean surfaces can be more easily acquired. The graphene acquired through adopting the method is applicable to constructing electronic devices such as a field effect transistor, a light-emitting diode and a transparent electrode, and also can be used for theoretical research of surface interfaces.

Owner:INST OF CHEM CHINESE ACAD OF SCI

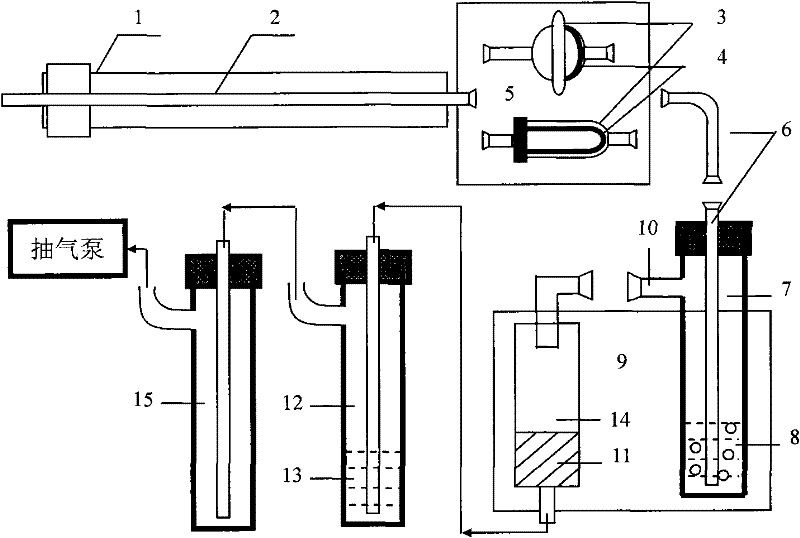

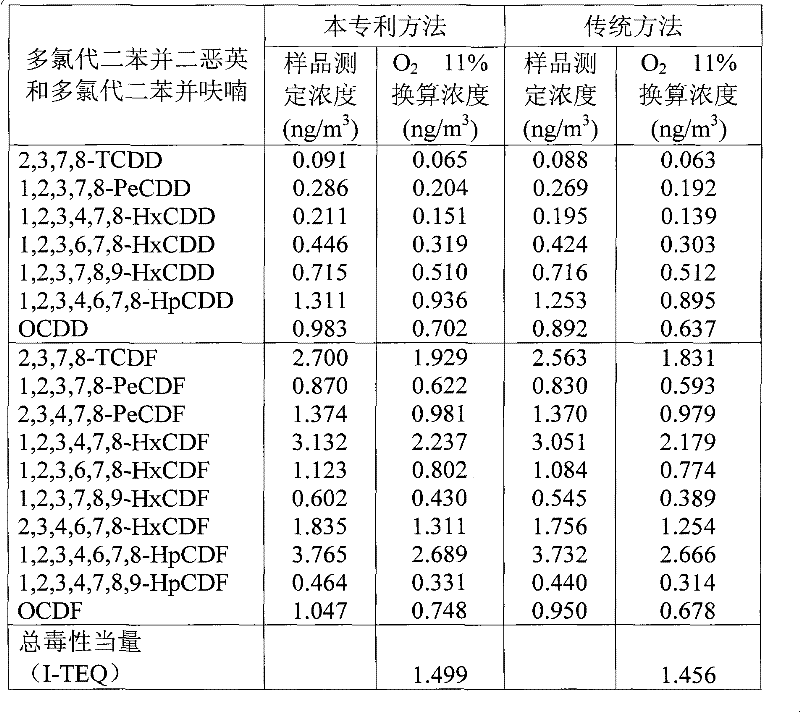

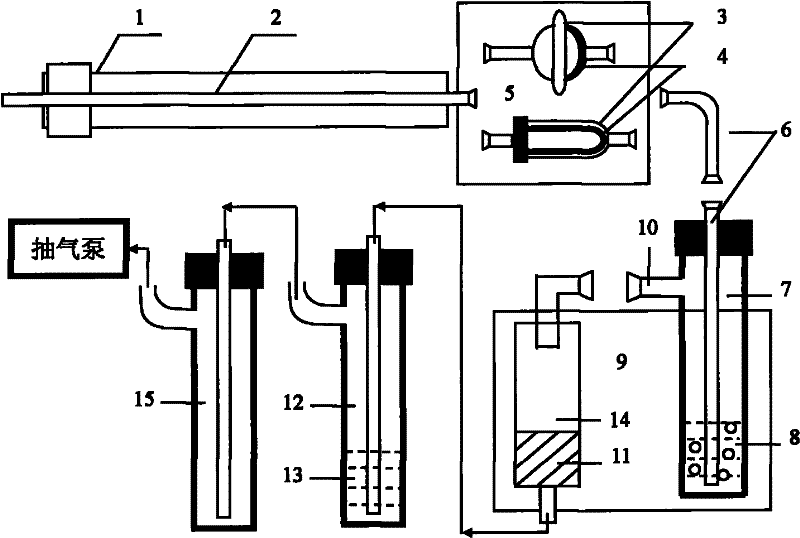

Trapping device for sampling dioxin in flue gas and application thereof

InactiveCN102455258AGuaranteed capture efficiencyImprove residual problemsWithdrawing sample devicesPreparing sample for investigationGlass fiberFlue gas

The invention provides a trapping device for sampling dioxin in flue gas and application thereof. The trapping device is characterized in that a smoke dust trapping unit consists of a glass fiber filter cartridge or filter film, a flue gas cooling unit consists of a through-type water cooling condenser, and a flue gas trapping unit consists of XAD2 resin. The trapping device and method for sampling dioxin in flue gas, relating to the invention, are also applicable to the collecting of other semivolatile organic pollutants in flue gas. The trapping device has the characteristics that a condensing device in a device for collecting dioxin in flue gas is improved, and the trapping efficiency of the process of collecting dioxin in flue gas can be enhanced, residuals of a sampler can be reduced, and accuracy of sampling and environmental monitoring can be improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

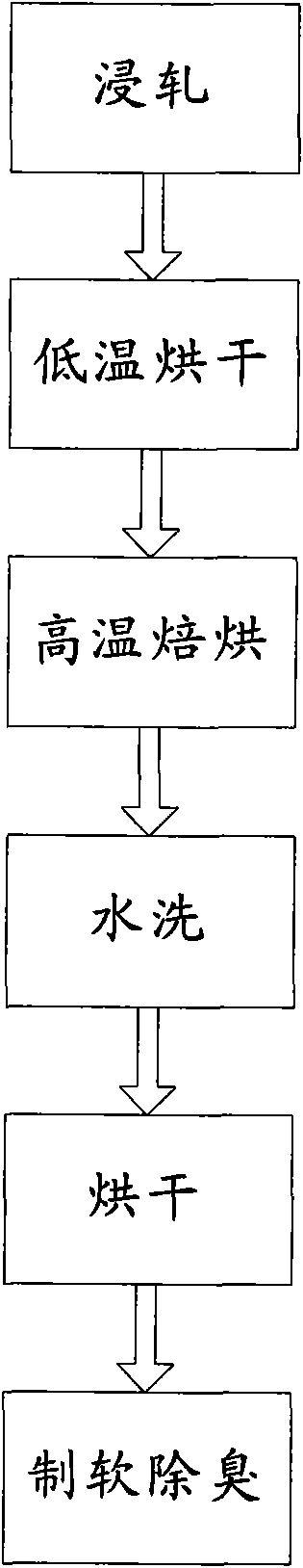

Environmentally-friendly and long-lasting fire-retarding treatment method for all-cotton knitted fabrics

The invention discloses an environmentally-friendly and long-lasting fire-retarding treatment method for all-cotton knitted fabrics, which adopts a processing flow comprising padding, low-temperature drying, high-temperature drying, washing with water, drying and softening and deodorizing. In the invention, an Aflammit KWB fire retardant is used, processing is performed on the conventional dyeing and finishing equipment, and the products have higher fire-retarding performance due to the combination of the fire retardant and cotton fibers by covalent bonds and offer a soft handfeel and are more in accordance with an environment protection requirement. The products produced by the process offer a soft handfeel, the fire-retarding effect after 50 times of washing with water reaches American CFR1615 standards, the formaldehyde content is lower than 20ppm, the products are more environmentally-friendly and have no irritating smell.

Owner:常熟新锦江印染有限公司

Preparation technology of low solubility residual water setose thistle extract and its preparation technology

A process for preparing the high-solubility general flavone of milk thistle from its seeds includes such steps as squeezing oil to obtain cake, pulverizing, extracting in ethanol or acetone twice, collecting extract, depositing, supercritical CO2 extracting of deposit, and baking.

Owner:陕西赛德高科生物股份有限公司

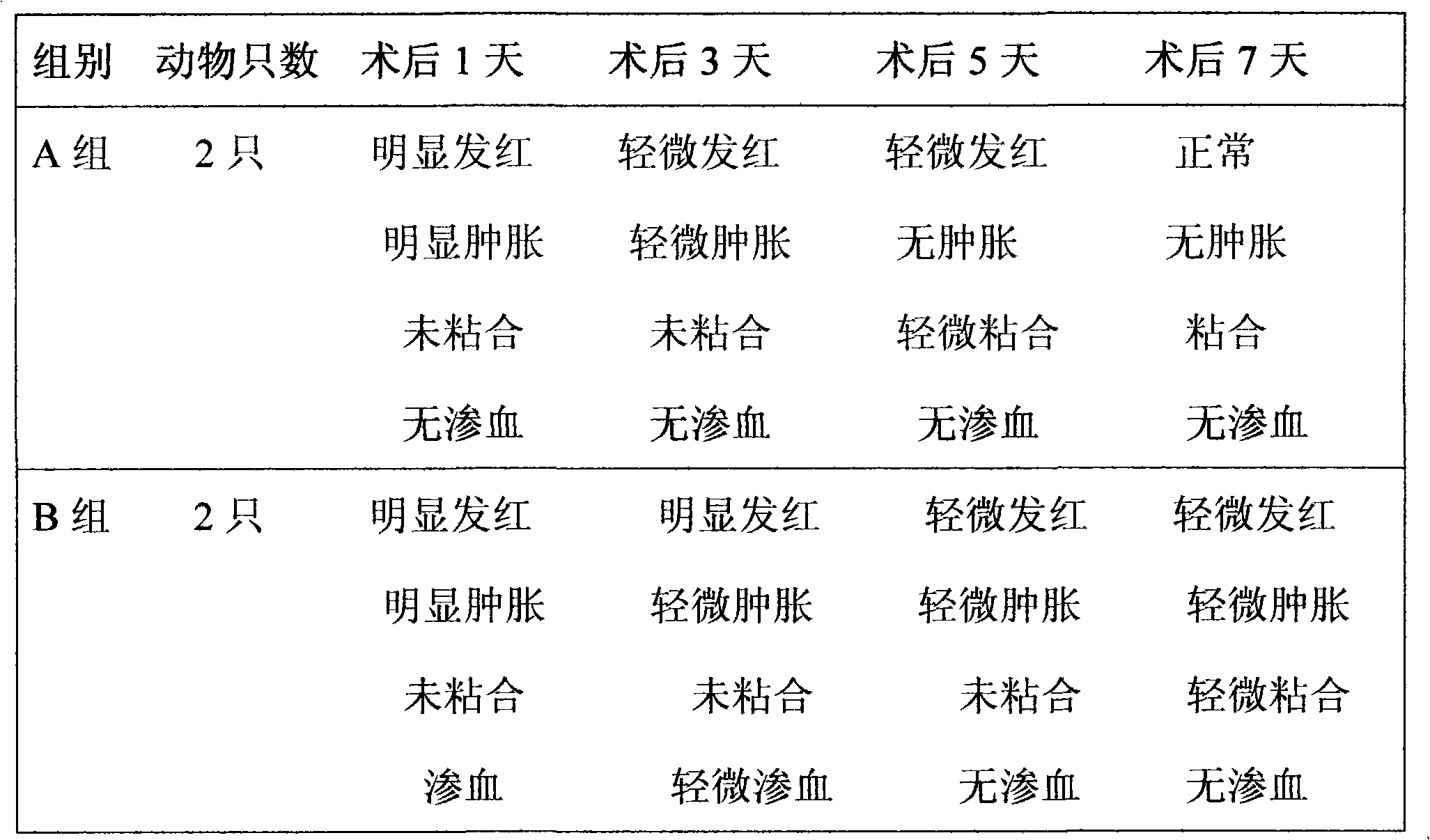

Chitosan collagen gel and application thereof

InactiveCN102108211AKeep a humid environmentPromote healingAbsorbent padsBandagesChronic woundWater soluble

The invention relates to a chitosan collagen gel and an application thereof, and the gel comprises 1-15% of chitosan, 1-20% of collagen, 0.1-1% of gel matrix and water, wherein the chitosan is water-soluble chitosan with the molecular weight of 1500 Daltons-0.4 million Daltons, the molecular weight of the collagen is 5000 Daltons-3 million Daltons; and the gel matrix is selected from one or two of carbomer, polyethylene type and cellulose derivatives. The chitosan collagen gel is applied in hemostasis of acute and chronic wounds, absorption of seepage, autolytic debridement, protection of exposed nerve endings and pain relief, and can be simultaneously used for keeping moist environment of the wounds, accelerating the healing of the wounds and inhibiting scar formation.

Owner:沈阳圣兴生物科技有限公司

Feed for common carp

InactiveCN106306571AMeet growth needsImprove digestion utilizationFood processingClimate change adaptationMultivitaminFishery

The invention relates to the technical field of aquaculture, in particular to a feed for common carp, made from 80% of base feed, 12% of a Chinese herbal additive and 8% of a growth promoter; the base feed is made from rice bran, rapeseed dregs, shrimp meal, soybean protein powder, and distillers' grains; the Chinese herbal additive is made from Herba Houttuyniae, Herba Taraxaci, Radix Bupleuri, Radix Isatidis, Folium Ginkgo, Poria, Radix Ophiopogonis, Bulbus Fritillariae, Fructus Crataegi, Radix Stemonae, Radix Paeoniae Alba, Radix Salviae Miltiorrhizae, Radix Polygalae and the like. The feed for common carp has complete and balanced nutrition, can fully meet the growth need of common carp and provides improved quality of common carp. The Chinese herbal additive can provide improved feed nutrition structure and enhanced immunity, can prevent and treat various fish diseases, can provide reduced incidence rate and mortality of common carp without using any antibiotic medicine; the growth promoter can provide increased digestive and utilization rate of the feed and promote the growth of common carp.

Owner:西双版纳颜轩农业科技有限公司

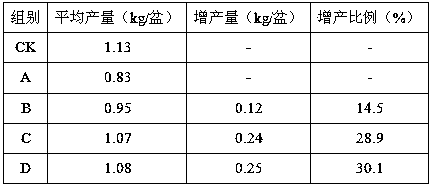

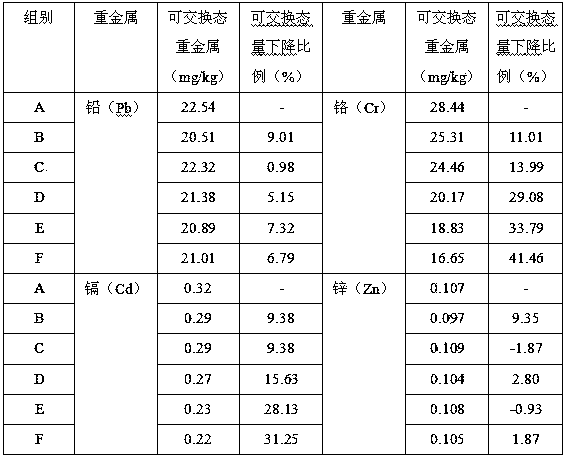

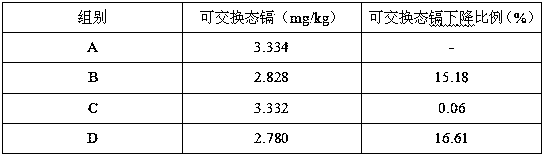

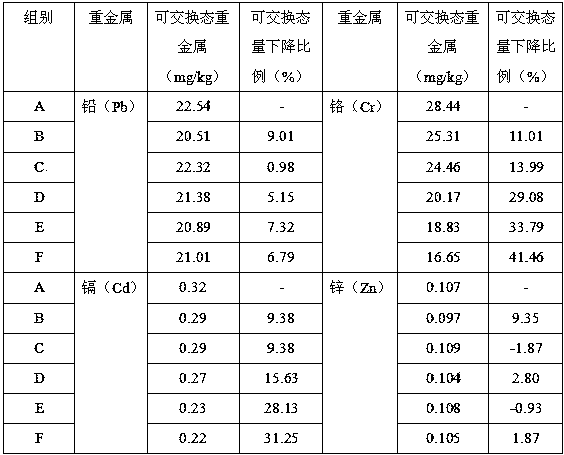

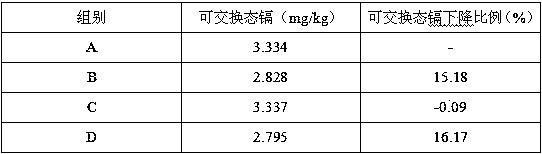

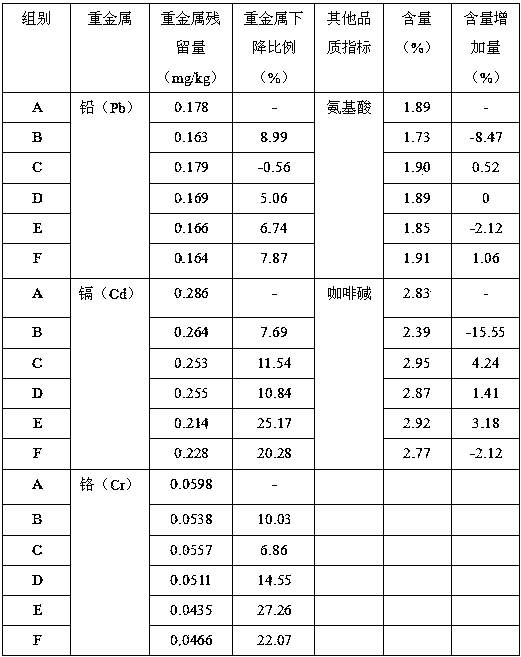

Soil heavy metal repairing agent and application thereof to jointly contaminated soil

InactiveCN104119925AReduce manufacturing costRepair pollutionAgriculture tools and machinesOrganic fertilisersPollution soilSoil heavy metals

The invention provides an application of a repairing composition used in heavy metal contamination of soil. The composition comprises lentinan and chitosan and can be used for increasing the yields of plants such as peppers and the like on the heavy metal jointly contaminated soil. Besides, the invention also provides a preparation and the like based on the composition.

Owner:CHENGDU NEWSUN CROPSCI

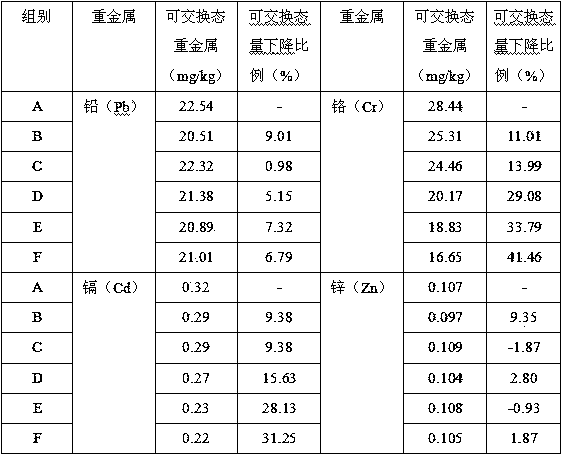

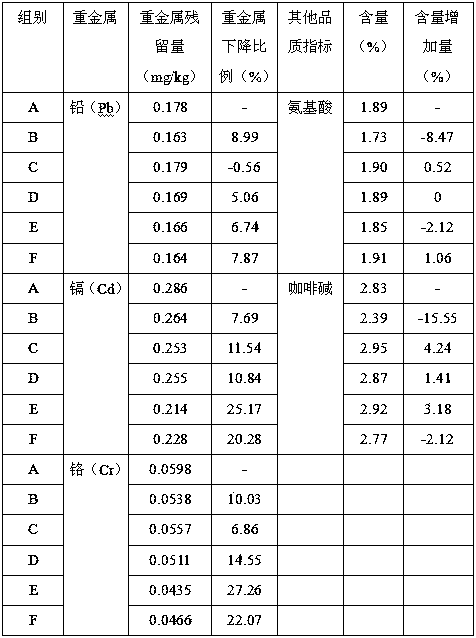

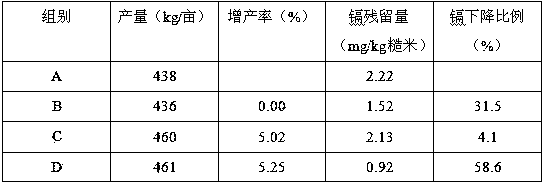

Combined application of zinc-selenium agricultural preparation and soil heavy metal repairing agent

ActiveCN104117534AImprove qualityResidue reductionContaminated soil reclamationLowering plantsSoil heavy metals

The invention provides combined application of an agricultural preparation containing zinc-selenium and a soil heavy metal repairing agent. The soil heavy metal repairing agent comprises lentinan and chitosan. With the combined application, the effect of the soil heavy metal repairing agent is enhanced while the plane yield is improved, and the content of heavy metal, such as cadmium, in plants (especially in plant seeds) is obviously reduced.

Owner:CHENGDU NEWSUN CROPSCI

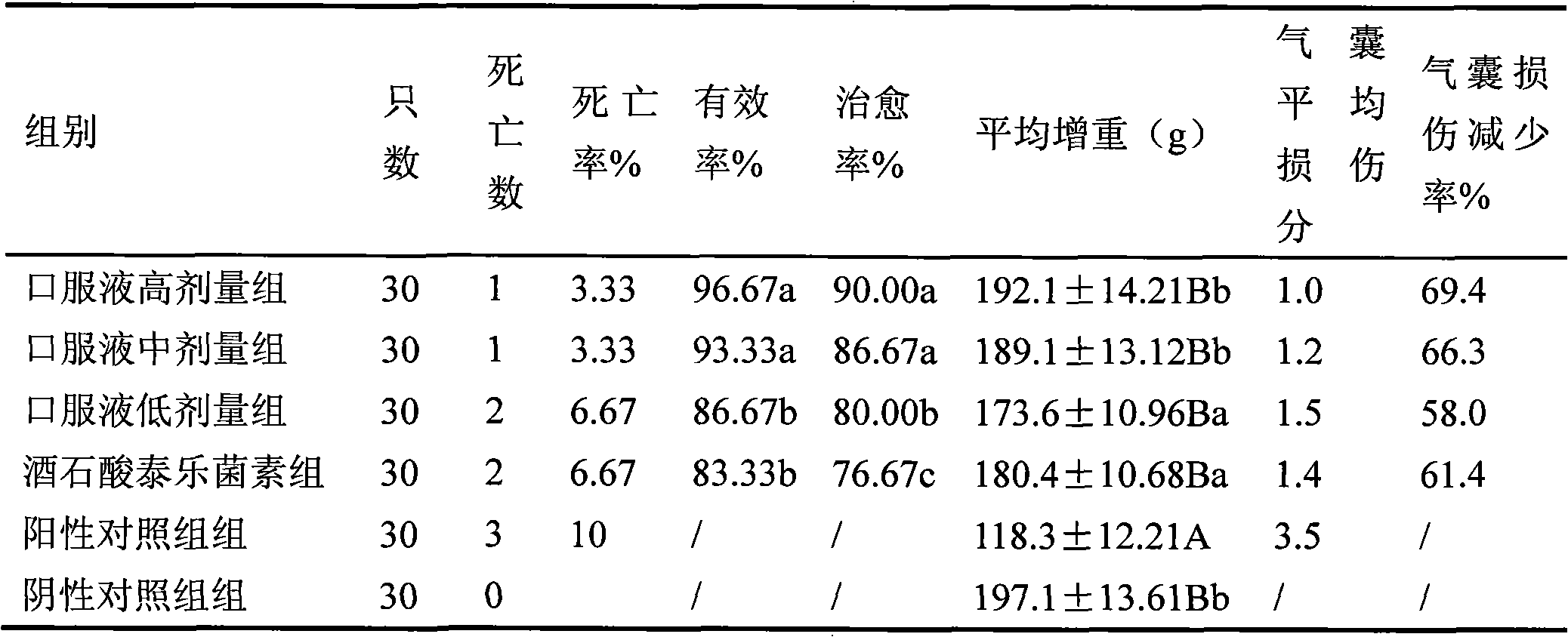

Traditional Chinese medicine oral liquid for treating mycoplasma gallisepticum infection

InactiveCN101897800AHigh cure rateLower resistanceAntibacterial agentsAluminium/calcium/magnesium active ingredientsCure rateForsythia suspensa

The invention discloses a traditional Chinese medicine oral liquid for treating mycoplasma gallisepticum infection. The traditional Chinese medicine is prepared by the following effective raw materials by parts by weight: 38-62 parts of ephedra, 38-62 parts of almond, 115-165 parts of gypsum, 38-62 parts of fructus forsythiae, 38-62 parts of isatis root, 22-38 parts of loguat leaf, 22-38 parts of tenuifolia, 22-38 parts of divaricate saposhnikovia root, 22-38 parts of houttuynia cordata and 38-62 parts of liquorice. The traditional Chinese medicine has better preventing and treating effects on mycoplasma gallisepticum infection and has the characteristics of less residue, low toxicity, high cure rate and difficult tolerance production, thus meeting the industrial requirement of green cultivation initiated by the modern society and having wide development prospect.

Owner:HEBEI AGRICULTURAL UNIV.

Production technique of green trichoderma by using mushroom slag fermentation

InactiveCN101063088AImprove survival and reproduction abilityResidue reductionFungiMicroorganism based processesDiseasePesticide residue

The invention discloses a preparing method of bacterial agent in agricultural applied microbiology technical domain, which comprises the following steps: choosing mushroom slag as raw material; adopting liquid and solid two-phase method to produce bacterial agent. This invention possesses cheap cost and simple craft, which can be used to prevent and cure soil-borne disease widely.

Owner:텐진인스티튜트오브플랜트프로텍션

Piglet feed

InactiveCN105248916AImprove palatabilityIncrease profitFood processingAnimal feeding stuffHouttuyniaGinkgo biloba

The invention discloses piglet feed. The piglet feed is prepared from traditional Chinese medicine raw materials: green tangerine peels, hawthorn fruits, motherwort herb, houttuynia cordata, officinal magnolia barks, honeysuckles, Indian buead, plantain herb, Danshen roots, astragalus membranaceus, sweet wormwood, villous amomum fruits, medicated leaven, ginkgo leaves, codonopsis pilosula, herb of shorthorned epimedium and honeysuckle vines. The piglet feed is prepared by the following steps: crushing the raw materials, fermenting and drying to prepare a premix, and adding the raw materials into basic feed at a ratio.

Owner:段仲达

Combined application of selenium-containing agricultural preparation and soil heavy metal remediation agent

ActiveCN104117533AImprove qualityResidue reductionContaminated soil reclamationLowering plantsSoil heavy metals

The invention provides a combined application of a selenium-containing agricultural preparation and a soil heavy metal remediation agent. According to the combined application of the soil heavy metal remediation agent, the soil heavy metal remediation agent comprises lentinan and chitosan. Through the combined application, the effect of the soil heavy metal remediation agent can also be enhanced, so that the content of heavy metal, such as cadmium in plants (especially plant seeds), can be remarkably reduced.

Owner:CHENGDU NEWSUN CROPSCI

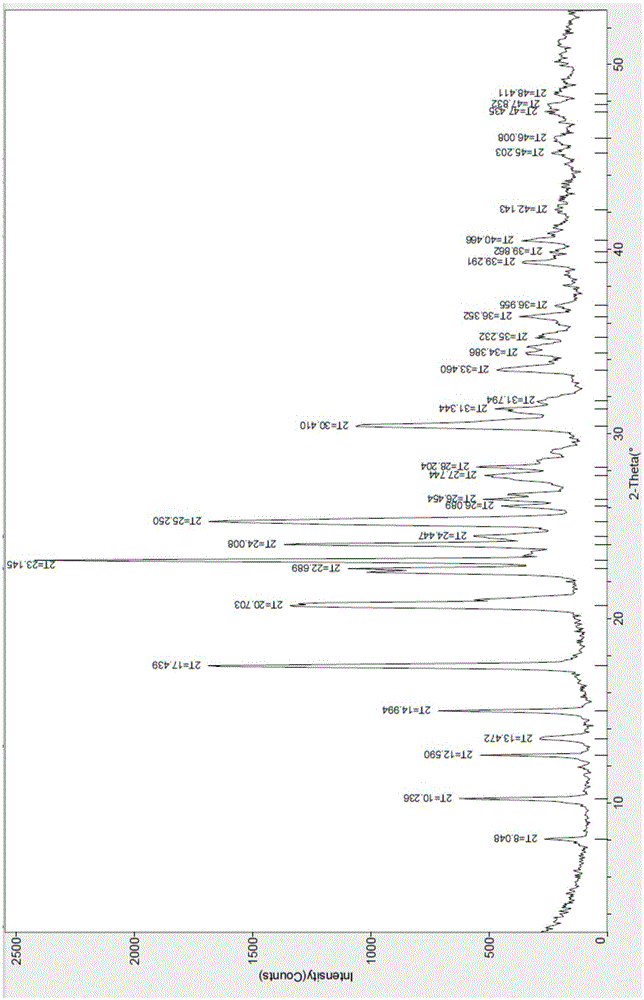

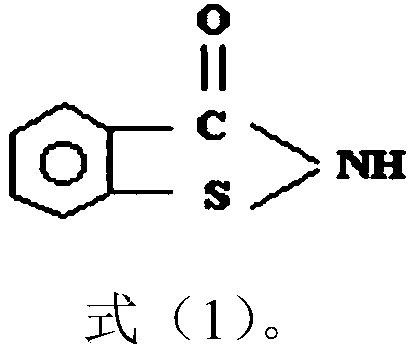

Hydrobromide of benzodiazepine derivative and multiple crystal forms thereof, and preparation method for multiple crystal forms

The invention discloses hydrobromide of benzodiazepine derivative and multiple crystal forms thereof, and a preparation method for the multiple crystal forms. The preparation method comprises the following steps: heating and dissolving hydrobromide of the crystal form or amorphous form of a compound as shown in a formula (I) which is defined in the specification or the compound as shown in the formula (I) and a hydrobromic acid solution in a crystallization solvent; carrying out cooling and crystallization; and then carrying out washing and drying so as to prepare hydrobromide of the compound as shown in the formula (I) or the crystal forms thereof. The prepared hydrobromide of the compound as shown in the formula (I) has good stability, high purity and no toxicity and can be better applied to clinical treatment.

Owner:CHENGDU BRILLIANT PHARMA CO LTD

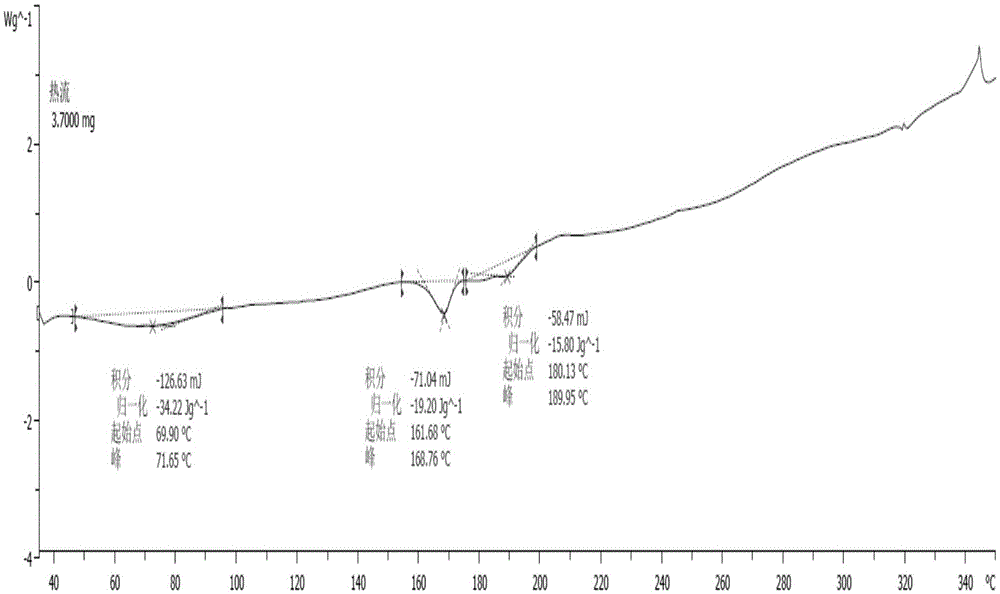

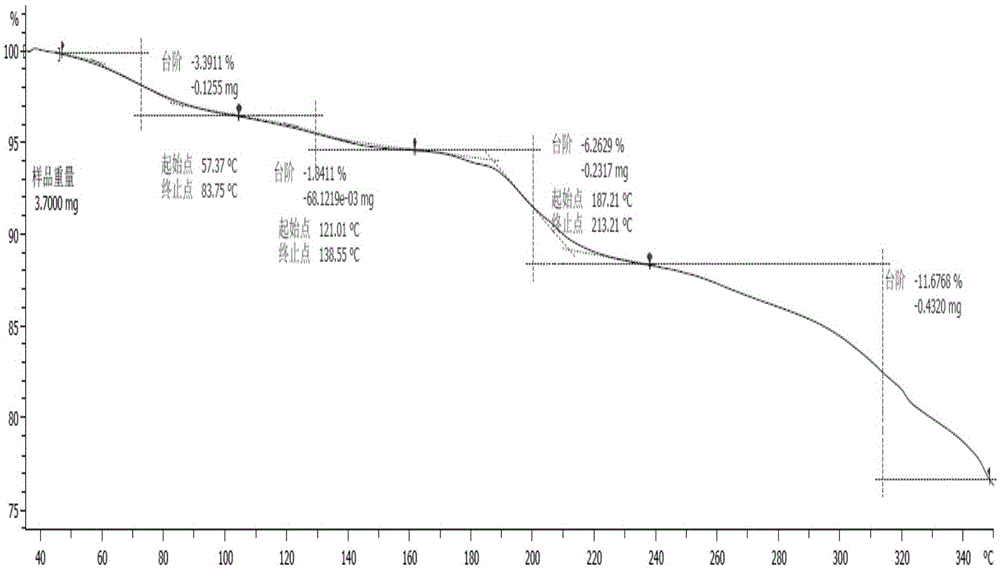

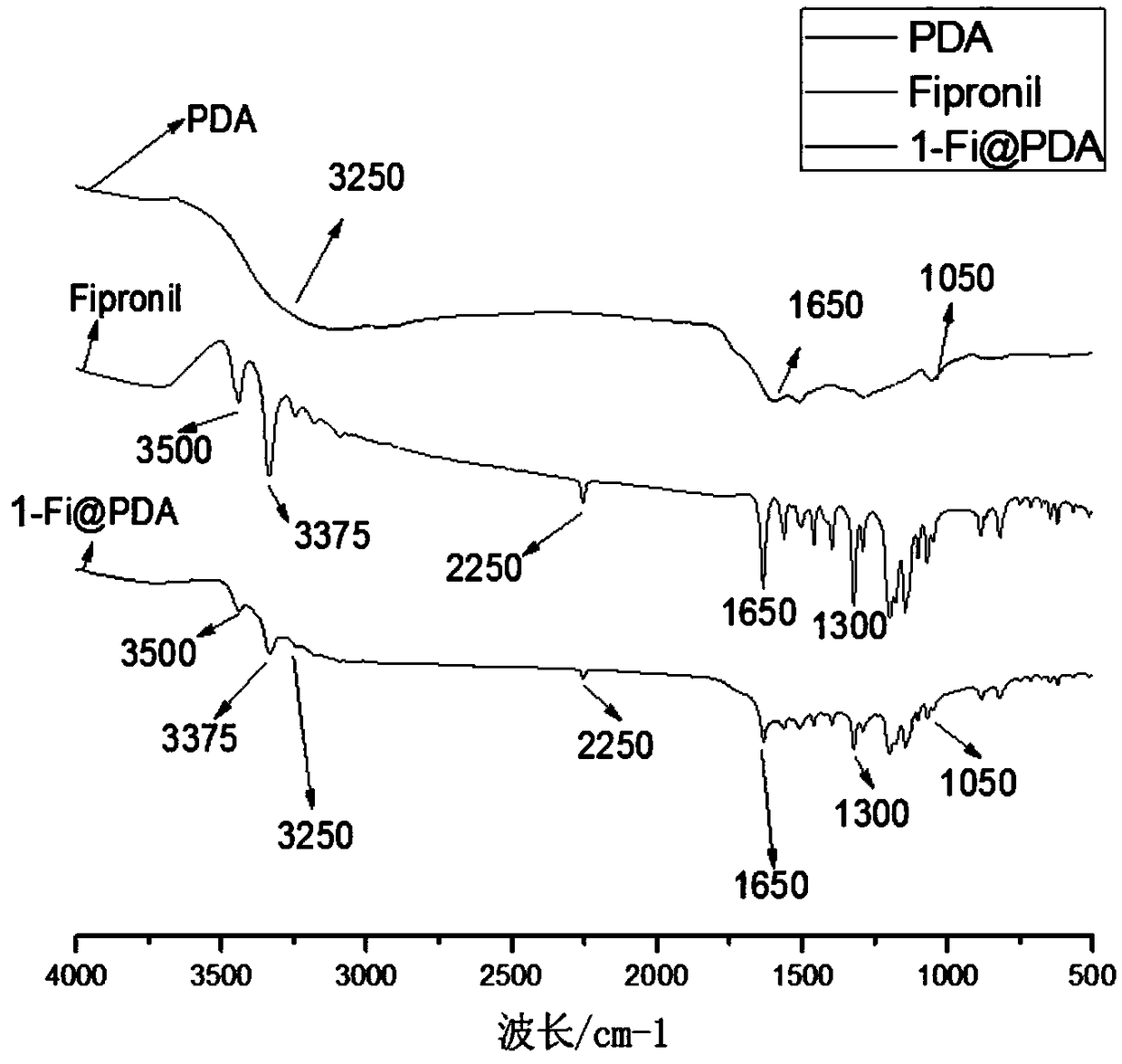

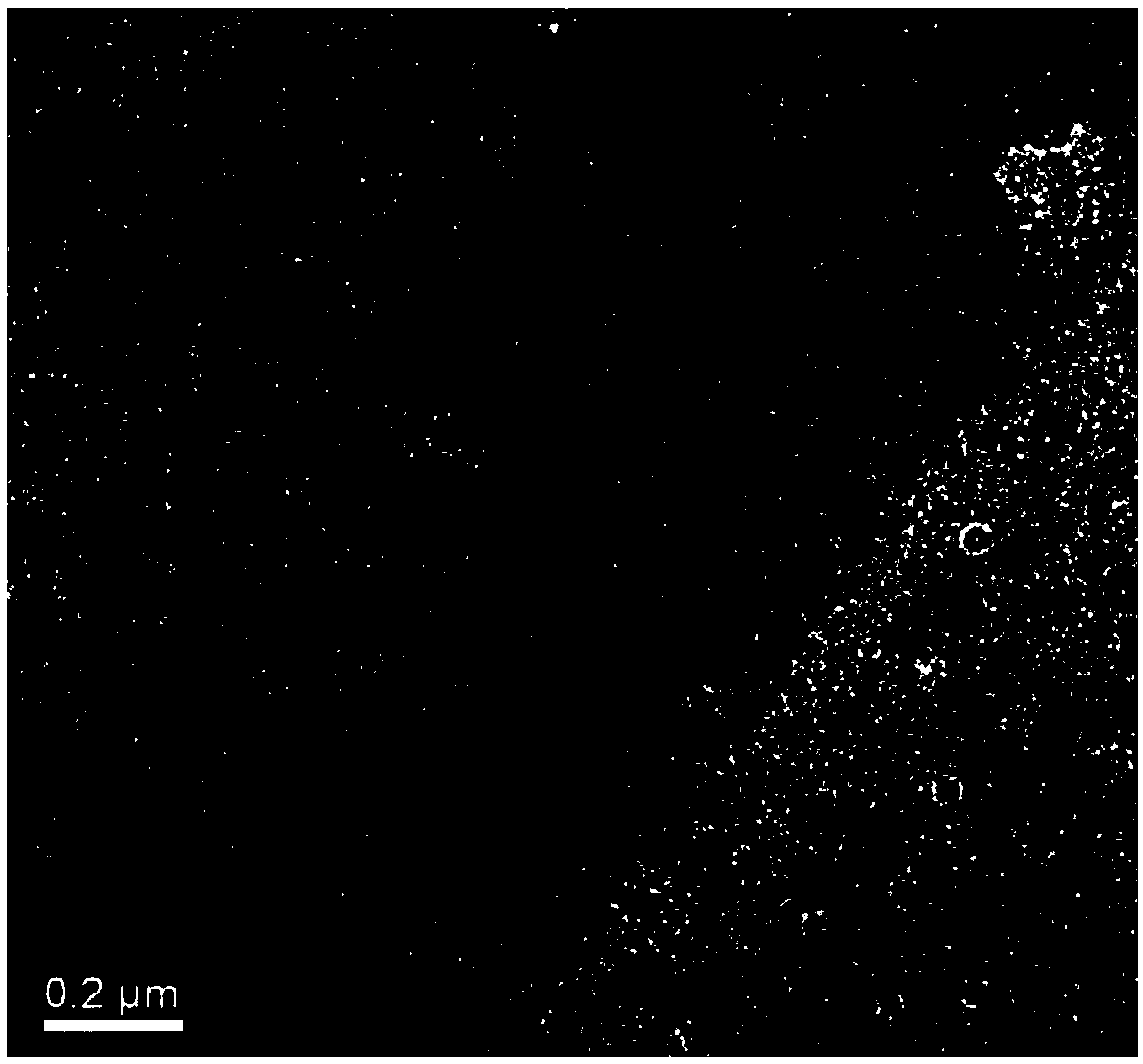

Polydopamine pesticide microcapsule and preparation method thereof

ActiveCN109287646AImprove hydrophilicityImprove adhesionBiocideAnimal repellantsLoss rateDecomposition

The invention discloses a polydopamine pesticide microcapsule and a preparation method thereof. The polydopamine pesticide microcapsule comprises a capsule core and a coating layer covering the capsule core, the capsule core is a phenylpyrazole pesticide, and the coating layer is polydopamine. The method uses polydopamine as the coating layer to microencapsulate the phenylpyrazole pesticide, and polydopamine has good reflection and absorption properties to ultraviolet rays, and also has excellent hydrophilicity and adhesion performance, thus, the photodegradation rate and the ultraviolet decomposition rate of the phenylpyrazole pesticide can be effectively alleviated, the hydrophilicity of the phenylpyrazole pesticide can be improved, the dispersion property in water can be improved, and the adhesive properties of the phenylpyrazole pesticides can be greatly improved, when applied to soil and foliage, the pesticide can achieve better residue, reduces the loss rate, and has better effect in maintaining efficacy and reducing pollution.

Owner:ZHONGKAI UNIV OF AGRI & ENG

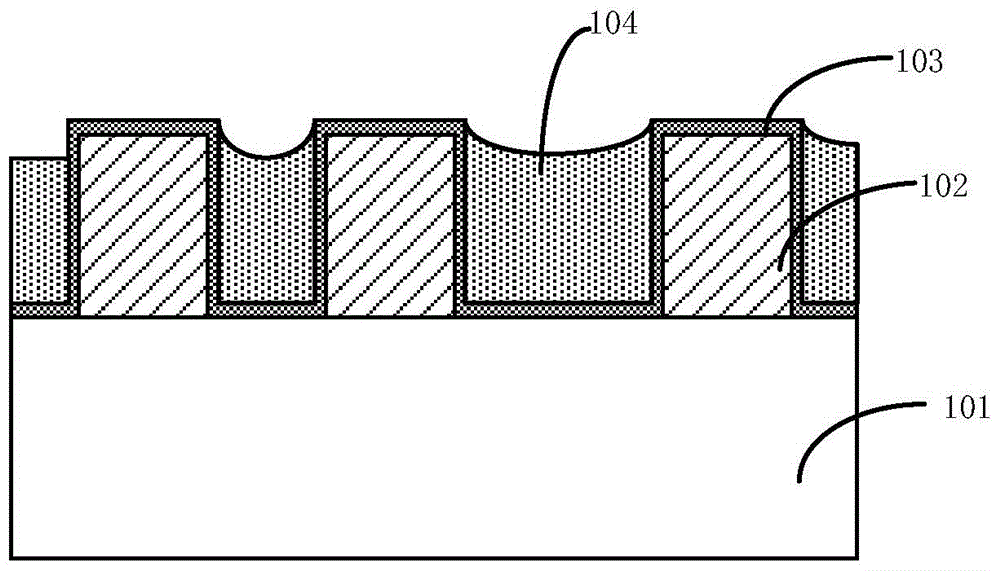

Semiconductor device, manufacturing method therefor, and electronic device

InactiveCN105448682AEasy to determineEasy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingEngineering

The invention relates to a semiconductor device, a manufacturing method therefor, and an electronic device. The method comprises the steps: providing a substrate, and forming a virtual grid, a gap wall layer and / or contact hole etching stop layer located on a side wall of the virtual grid, and an interlayer dielectric layer which covers the gap wall layer and / or contact hole etching stop layer; carrying out flattening from the interlayer dielectric layer to the virtual grid; carrying out the back etching of the gap wall layer and / or contact hole etching stop layer; removing the virtual grid and then forming a metal grid; and carrying out flattening from the metal grid to the gap wall layer and / or contact hole etching stop layer. The method is characterized in (1), improving the determination of a flattening end point signal of the metal grid, so as to improve the control of the height of the grid, and to improve the height uniformity of the metal grid; (2), improving a residue problem of the metal grid; (3), enlarging the technological window of the rear grid process of the metal grid.

Owner:SEMICON MFG INT (SHANGHAI) CORP

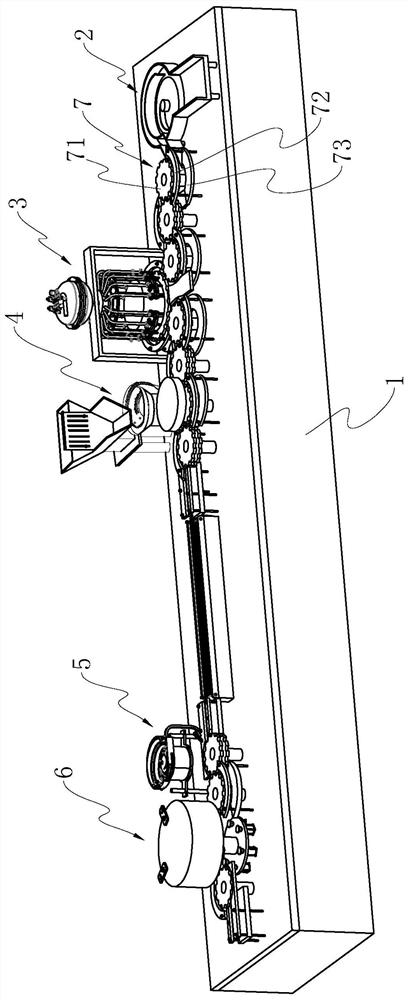

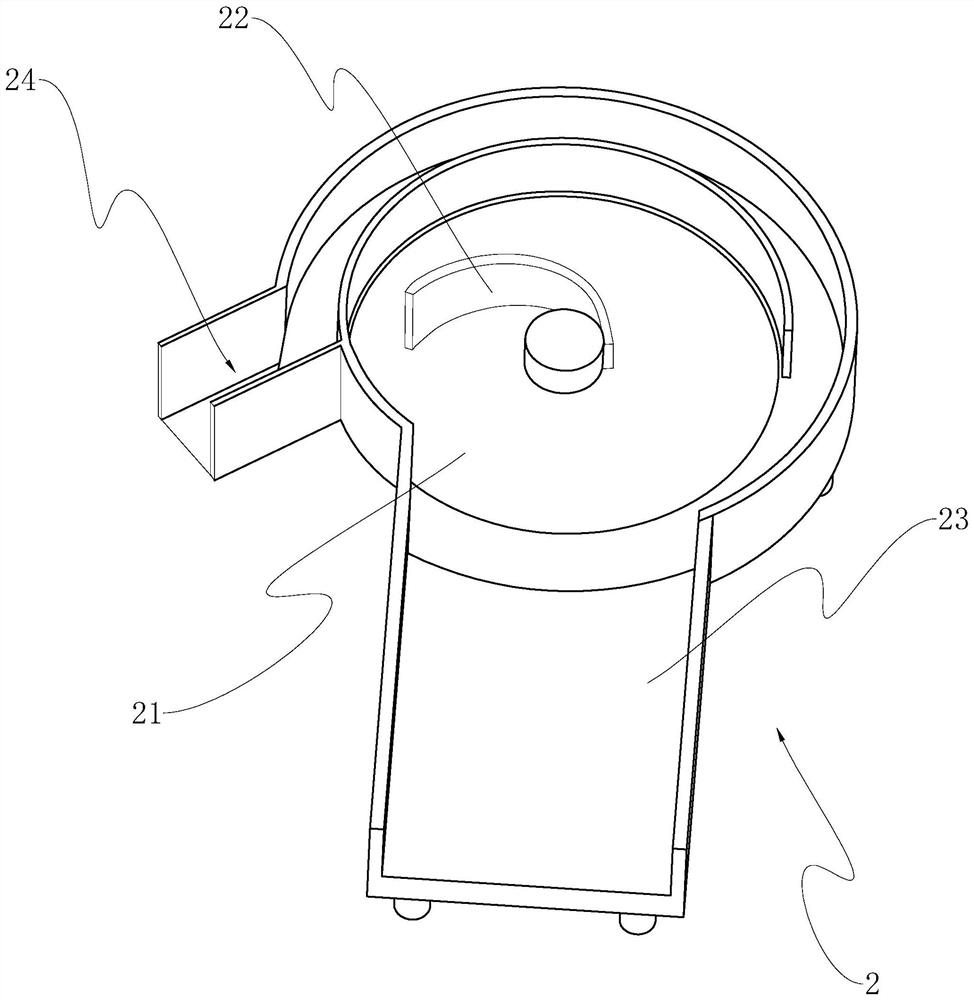

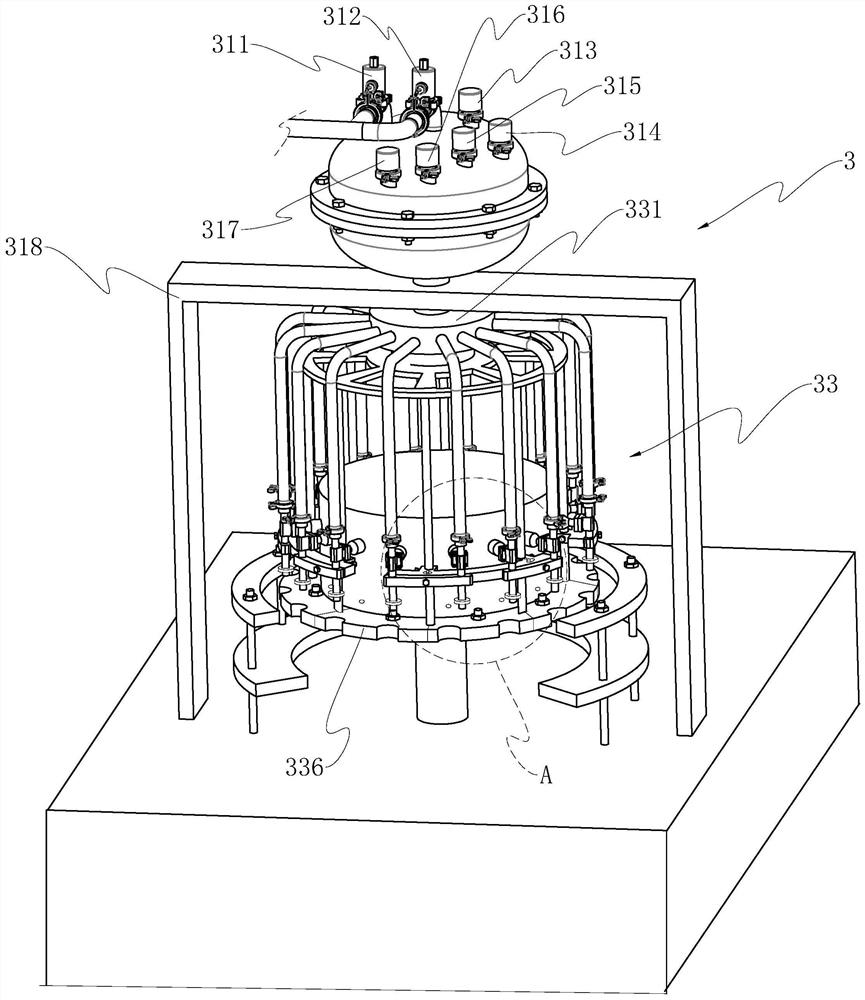

High-speed filling machine

ActiveCN113307208ARealize online cleaning and sterilization functionReduce process gap timeSafety device in filling machineryLiquid storage tankElectric machinery

The invention relates to a high-speed filling machine. The high-speed filling machine comprises a workbench and a filling machine body arranged on the workbench. The filling machine body comprises a liquid storage tank, a filling assembly arranged on a liquid outlet of the liquid storage tank, and a control host. The filling assembly comprises a multi-pass rotating connector arranged at the liquid outlet, filling pipes connected to the multi-pass rotating connector, filling needles arranged on the filling pipes, a filling control valve, a filling rotary disc assembly arranged below the filling needles and used for bottle body transferring, a rotating support arranged between the filling rotating disc assembly and the multi-pass rotating connector, and a driving motor driving the rotating support to rotate. The filling rotating disc assembly is provided with filling stations which are distributed in an annular array mode, the filling pipes and the filling stations are arranged in a one-to-one correspondence mode, and the filling needles are located over the filling stations. Filling photoelectric sensing assemblies corresponding to the filling stations are arranged on the rotating support and connected with the data end of the control host, and the filling control valve and the driving motor are controlled by the control host. The high-speed filling machine has the effect of improving the continuity of the high-speed filling production.

Owner:上海拓达机电设备有限公司

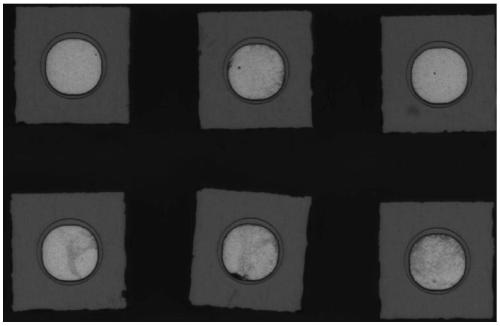

Treatment method for improving surface pollution of LED chip

ActiveCN111092011AImprove the phenomenon that is prone to oxidationQuick removalSemiconductor/solid-state device manufacturingSemiconductor devicesAcetic acidAlcohol

The invention relates to a treatment method for improving surface pollution of an LED chip and belongs to the technical field of the LED chip. The method comprises steps of (1) sequentially placing achip in absolute ethyl alcohol solution and the deionized water for cleaning and scrubbing; (2) sequentially placing the chip in acetic acid aqueous solution and the deionized water for cleaning and scrubbing; (3) cleaning the chip in mixed solution consisting of acid, the deionized water and fluoride, taking out the chip, and washing the chip in the deionized water; (4) placing the chip in a cleaning machine for high-pressure deionized water cleaning, and utilizing nitrogen for blow-drying; and (5) taking out the chip and placing the chip on a heating table for baking, and thoroughly removingthe water vapor. The method is advantaged in that the method is less in raw material consumption, simple in steps, simple and convenient to operate, low in processing cost, and capable of effectivelyremoving surface anomalies such as chip surface pollution, residual reagents, roughness and the like, and improves the chip quality and yield.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

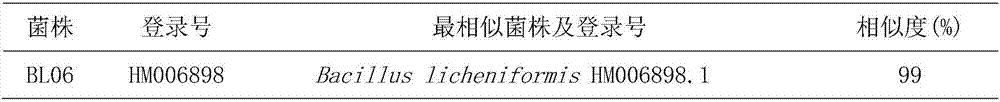

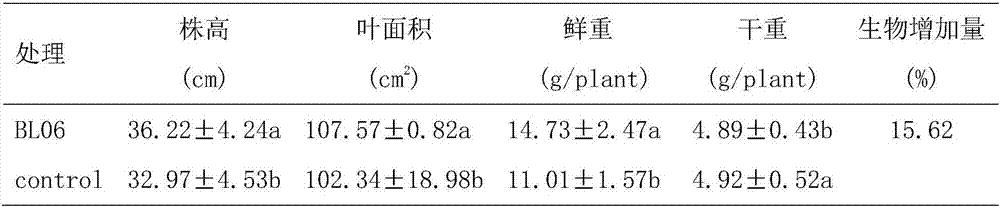

Bacillus licheniformis strain BL06 and application thereof

ActiveCN106929447AReduce dosageImprove residual problemsBiocidePlant growth regulatorsLaboratory cultureLichen

The invention discloses a Bacillus licheniformis strain BL06 and application thereof. The Bacillus licheniformis strain BL06 is preserved in China General Microbiological Culture Collection Center (CGMCC) on December 16, 2016, with a strain preservation number No.13462. The Bacillus licheniformis strain BL06 can be used for preparing biological preparations for controlling Brassica soft rot, and promoting plant growth.

Owner:NANJING AGRICULTURAL UNIVERSITY

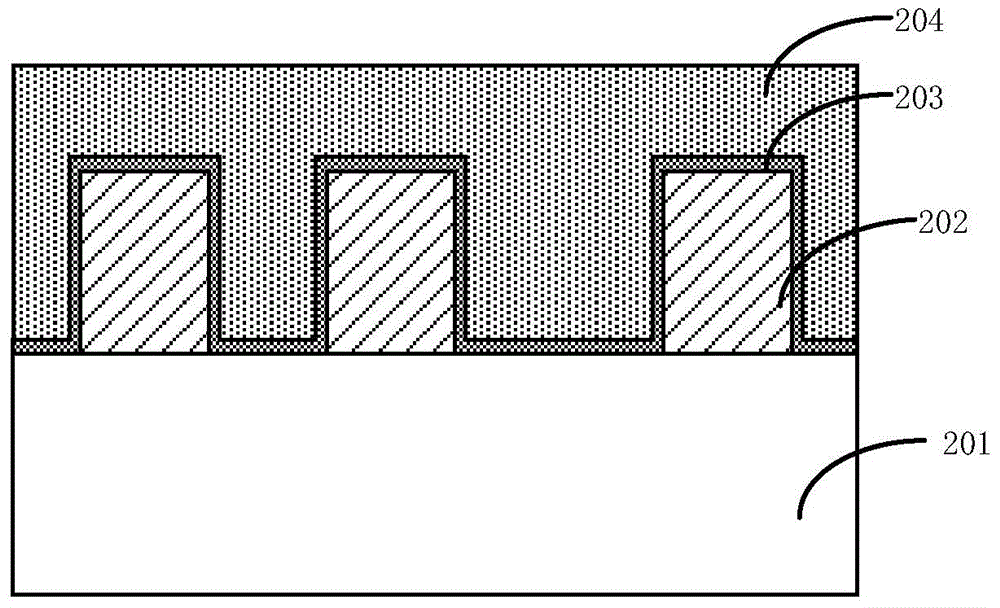

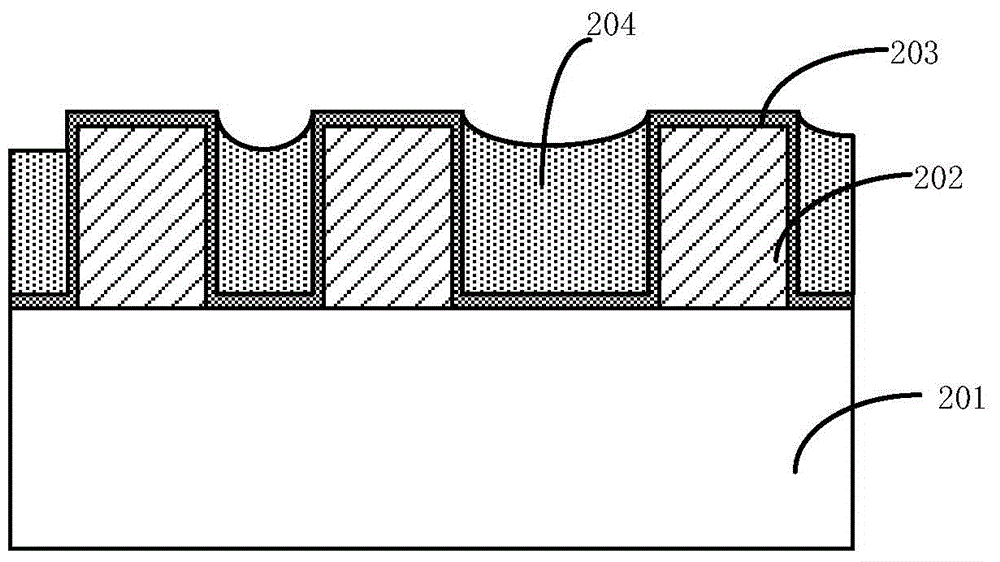

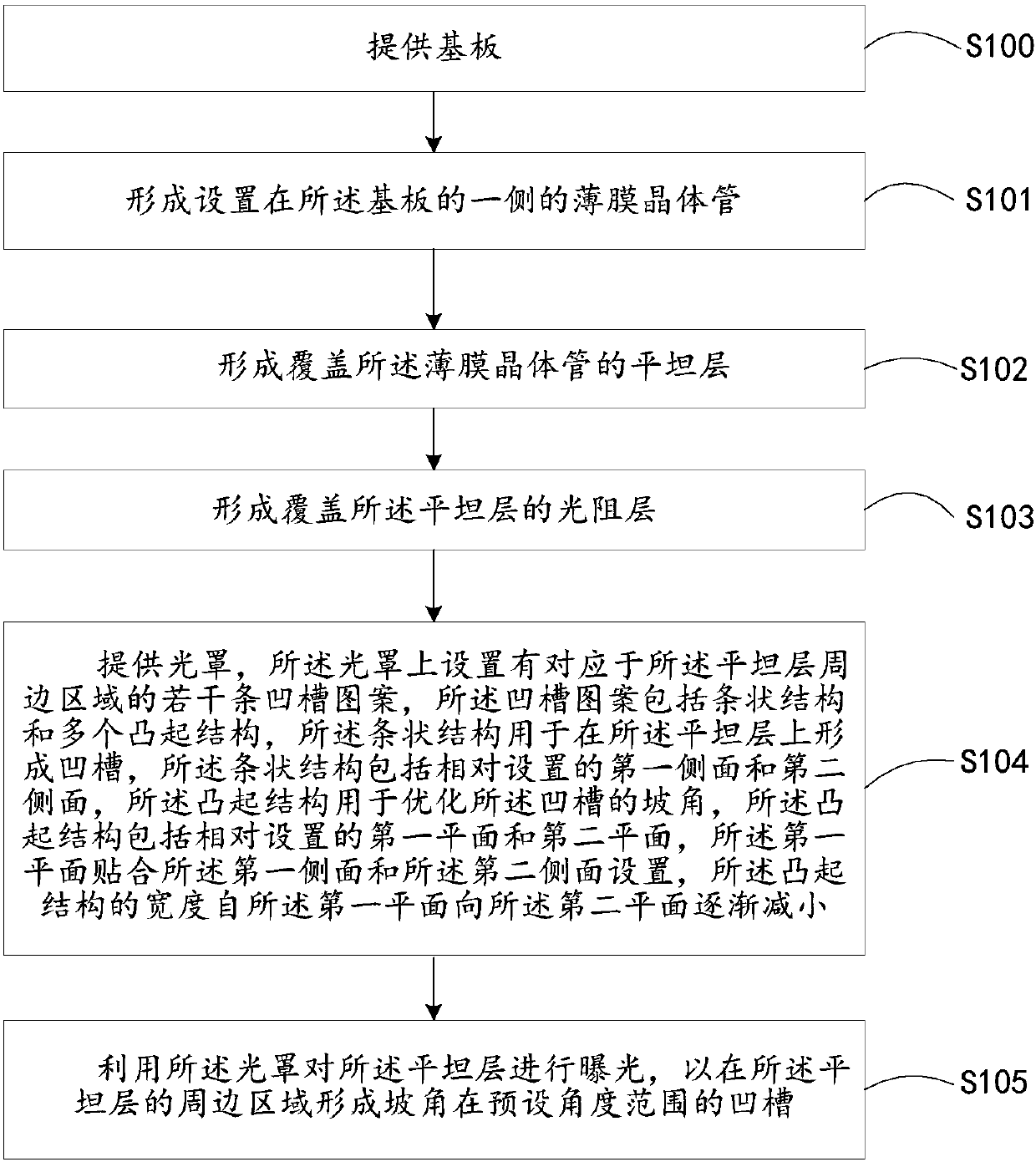

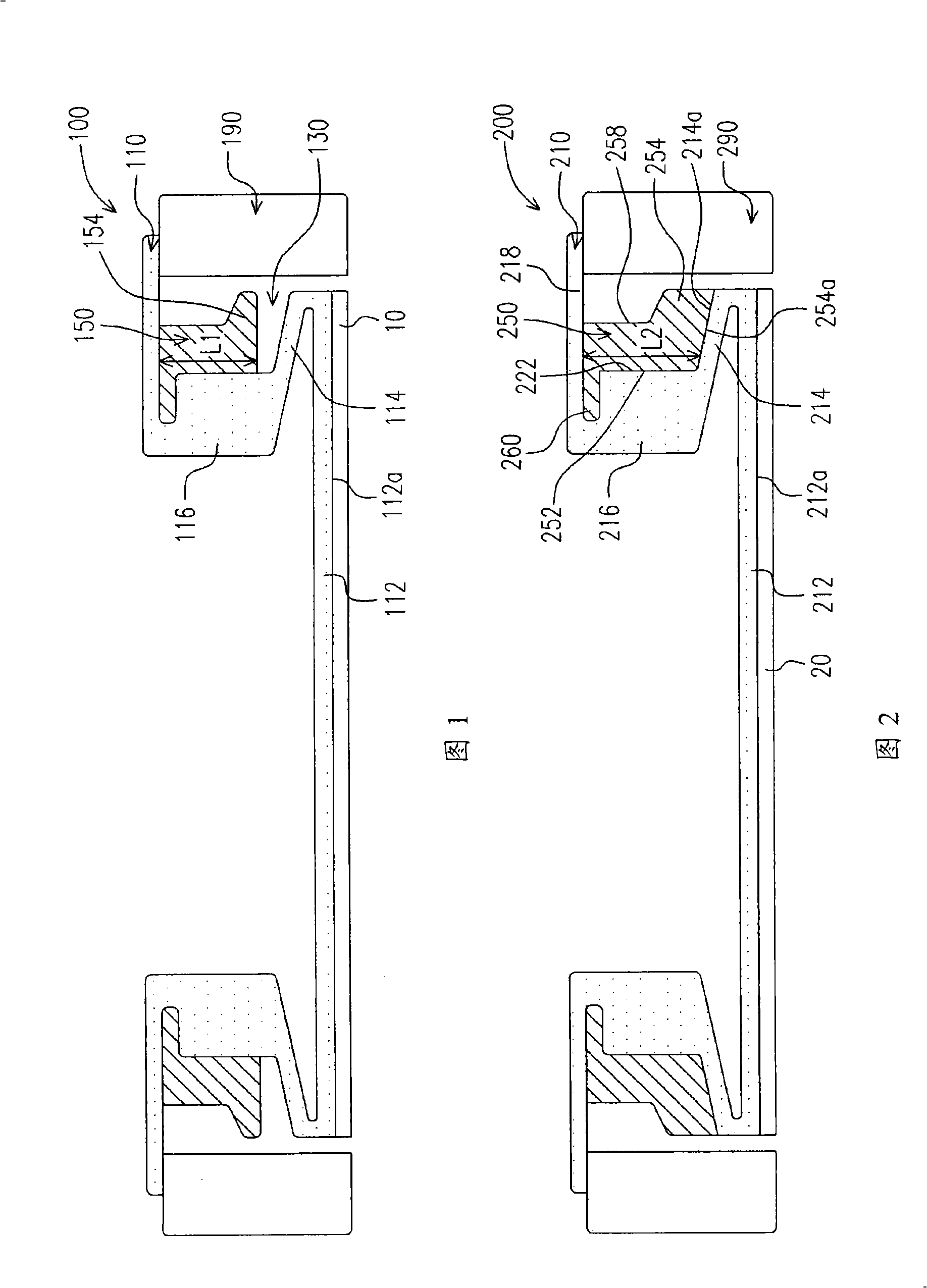

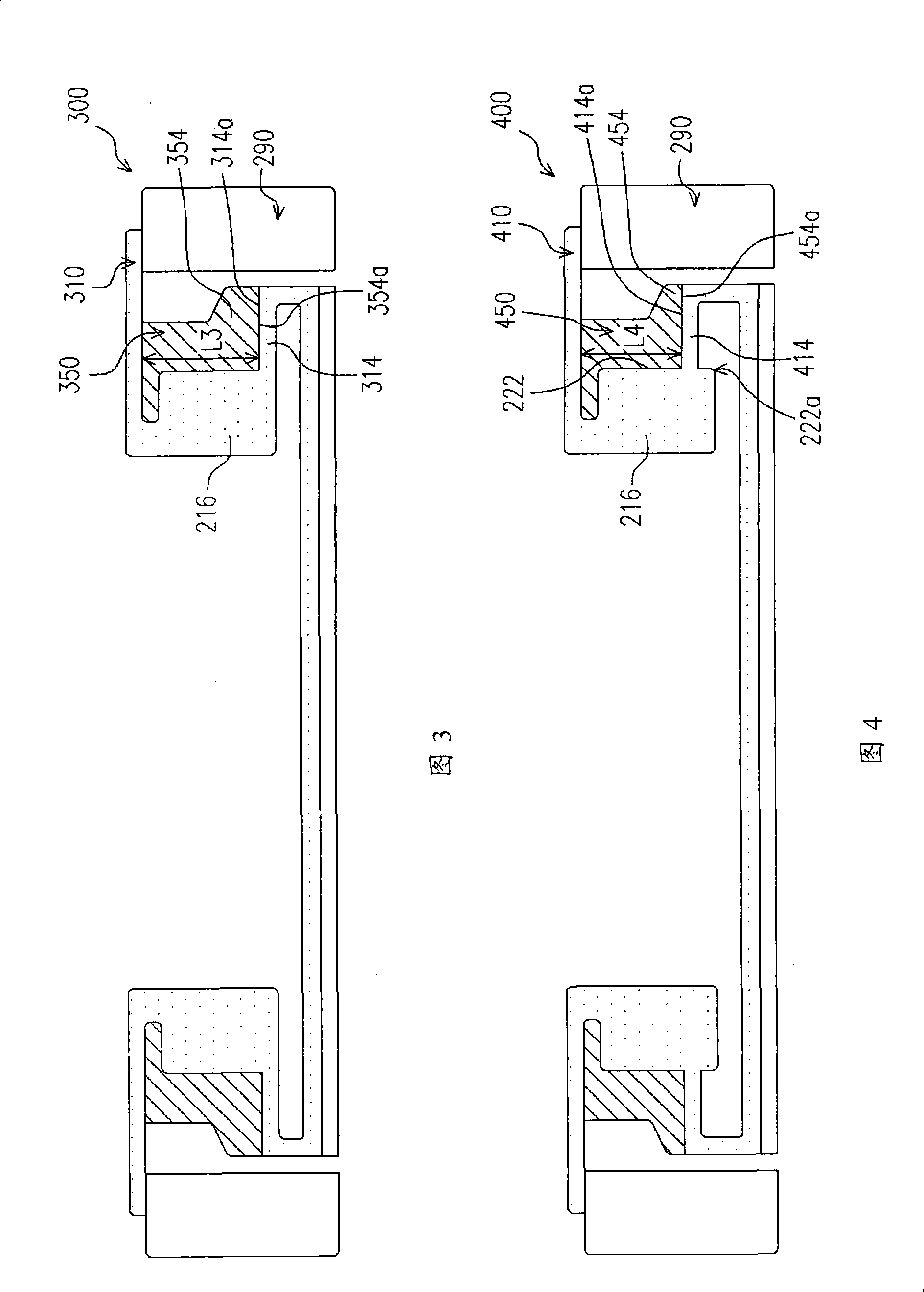

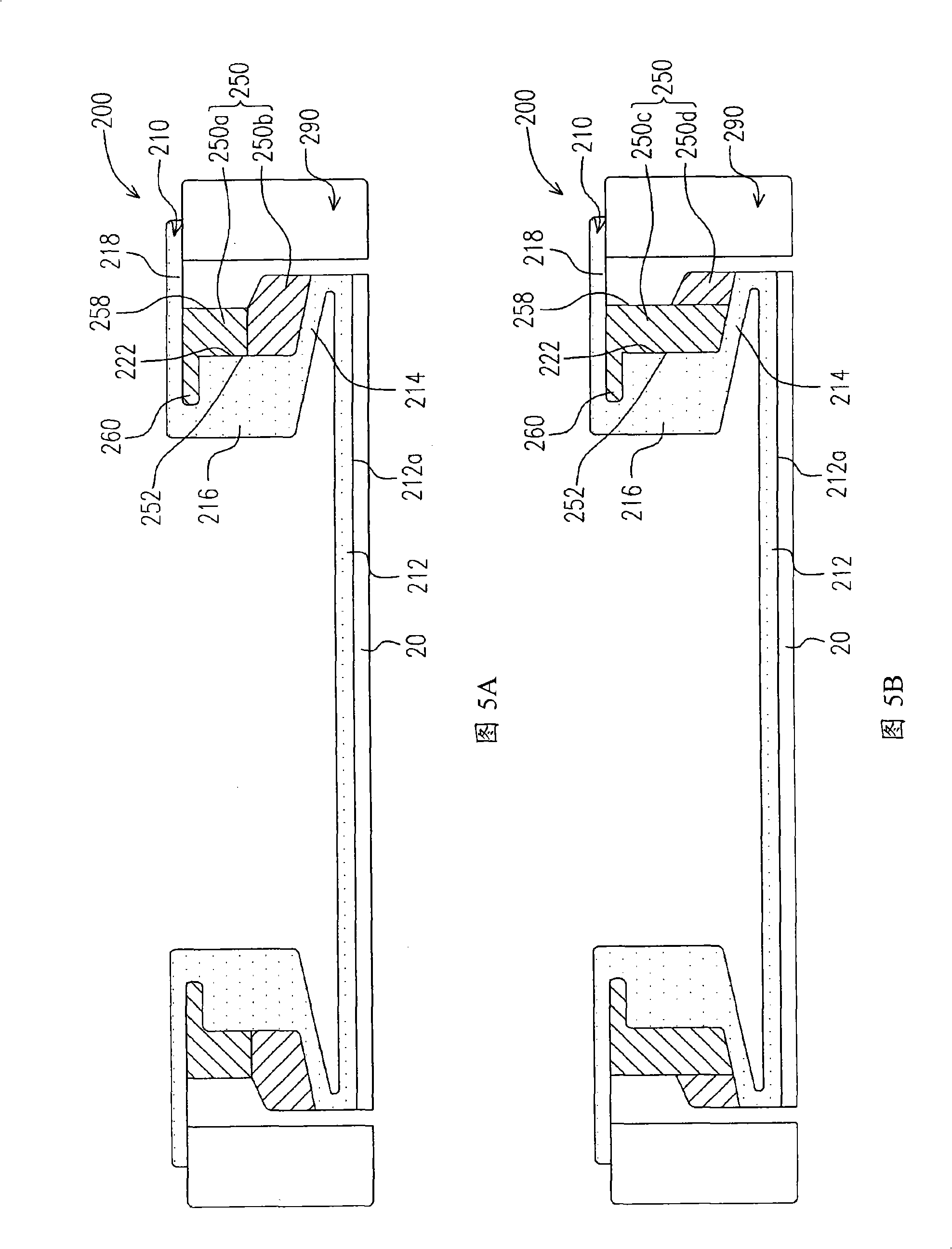

Manufacturing method of array substrate

InactiveCN107799473AIncrease exposureImprove residual problemsSemiconductor/solid-state device manufacturingNon-linear opticsSlope angleEngineering

The present invention provides a manufacturing method of an array substrate. The manufacturing method of the array substrate comprises the following steps: providing a substrate; forming a thin film transistor arranged on one side of the substrate; forming a flat layer covering the thin film transistor; forming a photoresist layer covering the flat layer; providing a light cover, wherein the lightcover is provided with a plurality of groove patterns corresponding to the peripheral area of the flat layer, the groove patterns comprises a strip-shaped structure and multiple protruding structures, the strip-shaped structure is used for forming grooves on the flat layer, the strip-shaped structure comprises a first side and a second side opposite to each other, the protruding structures are used for optimizing slope angles of the grooves, each protruding structure comprises a first plane and a second plane opposite to each other, the first planes are arranged on the first side and the second side, and the width of each protruding structure gradually decreases from the first plane to the second plane; exposing the flat layer by using the light cover to form the grooves on the peripheralarea of the flat layer, wherein the slope angles of the grooves are in the range of preset angles. The method can contribute to reducing the slope angles of the grooves on the flat layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

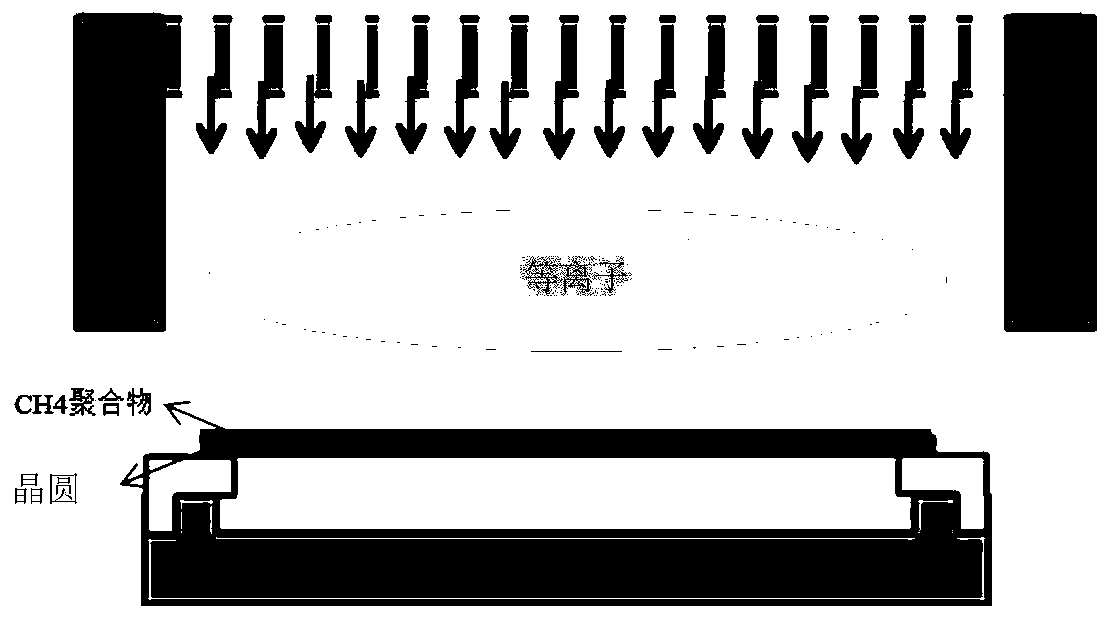

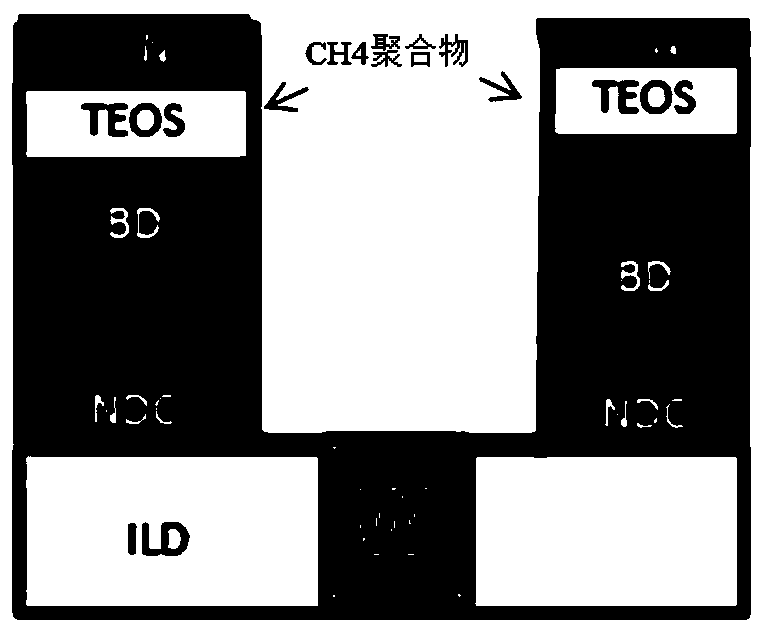

Method for improving residual microparticles on surface of wafer

PendingCN110400749AImprovement of micro particle residue on the wafer surfaceSolve particle attachmentElectric discharge tubesSemiconductor/solid-state device manufacturingSurface chargesPlasma reaction

The invention provides a method for improving residual microparticles on the surface of a wafer. The method comprises the following steps of firstly, providing a plasma reaction etching cavity and a wafer positioned in the plasma reaction etching cavity, arranging a semiconductor structure on the wafer, and ensuring that the semiconductor structure is in a process state that etching of a first layer of metal groove is finished; secondly, forming a polymer protective layer on the surface of the wafer; thirdly, introducing a plasma source into the plasma reaction etching cavity to remove chargeson the surface of the wafer; and finally, stopping introducing the plasma source, and standing the wafer. According to the invention, after the completion of the groove etching process on the first layer of metal groove, a protective layer is formed on the surface of the wafer by using a gas source for depositing a polymer in the subsequent process. After that, microparticles in the cavity are adsorbed and brought out of the etching cavity by using a macromolecular gas source assisted destaticizing process in the subsequent destaticizing process, so that particle attachments caused in the wafer decharging process are solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Refreshment pericarp duck meat sausage and making method thereof

InactiveCN105029484AAffect the tasteAffect colorFood ingredient functionsFood preparationBiotechnologyMonosodium glutamate

The invention discloses a refreshment pericarp duck meat sausage. The refreshment pericarp duck meat sausage is composed of, by weight, 100-110 parts of duck meat, 1-2 parts of fermented celery powder, 17-18 parts of pickled watermelon peel, 1.8-2 parts of rose hips, 1.5-2 parts of lychee seeds, 1.5-1.7 parts of rosemary and a proper amount of procyanidin, starch, ground pepper, monosodium glutamate, ground nutmeg, salt and water. According to the refreshment pericarp duck meat sausage, the fermented celery powder is used as a pickle agent so that the effect of synthesized sodium nitrite can be achieved, the fermented celery powder can be used as a natural pickle agent for replacing the synthesized sodium nitrite, and performance is good on the aspects of nitrite residue and oxidation resistance. The refreshment pericarp duck meat sausage is further added with traditional Chinese medicinal materials such as the rosemary and the lychee seeds, and thus the health-care effects of removing gaseous distention, improving memory, resisting fatigue, regulating qi are achieved. The duck meat sausage is moderate in degree of saltiness, savory and mellow when entering the mouth and long in aftertaste.

Owner:全椒县福润禽业有限公司

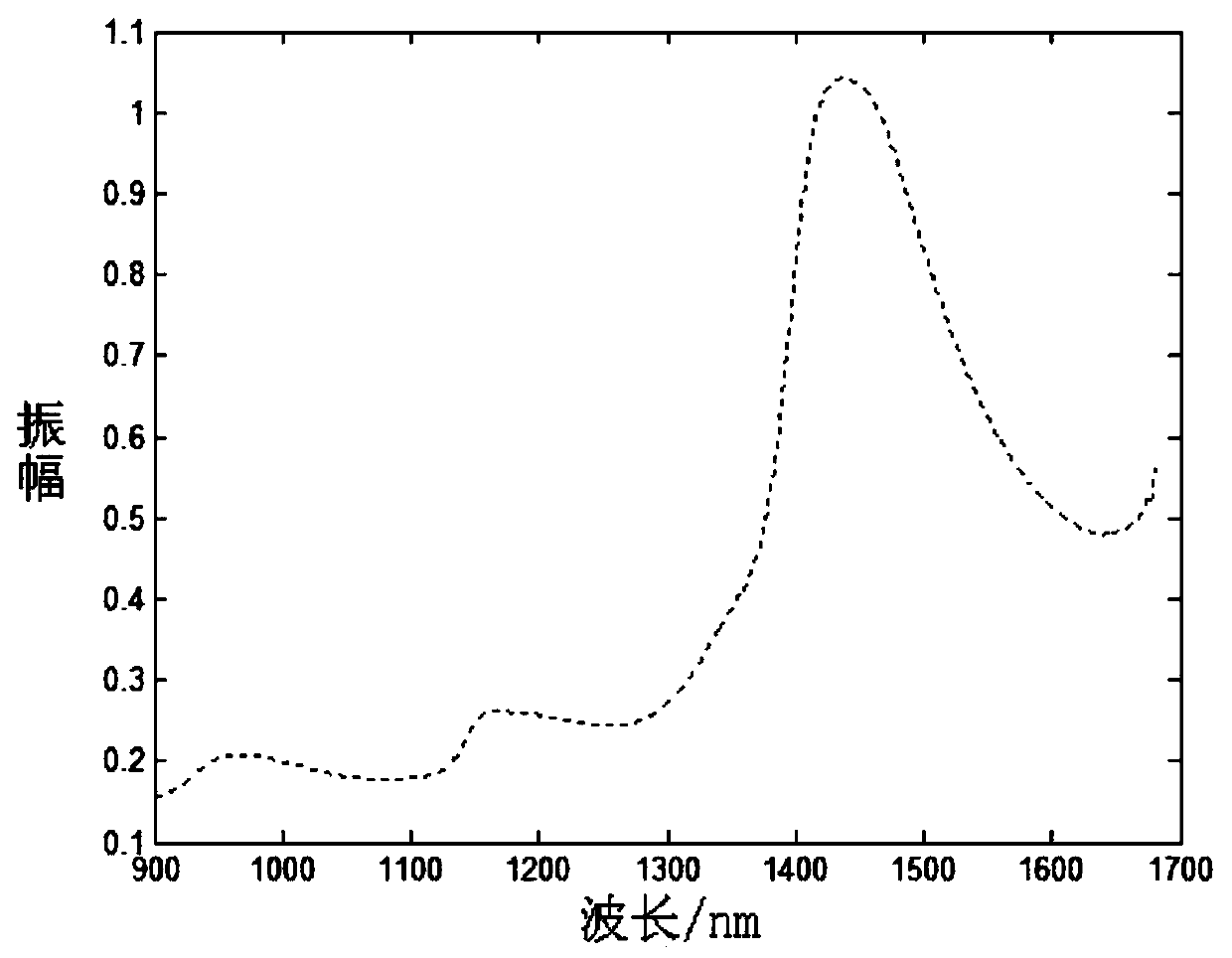

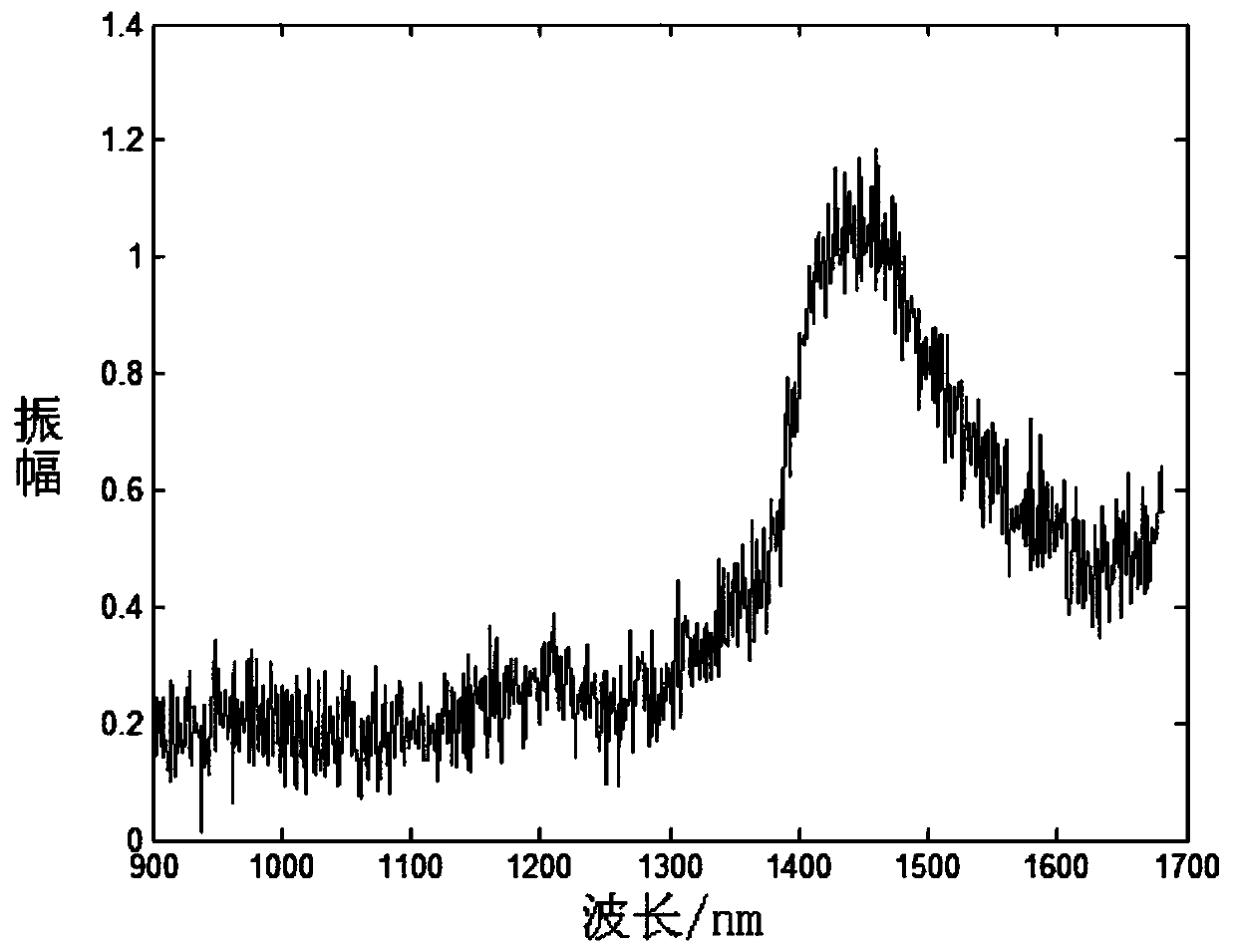

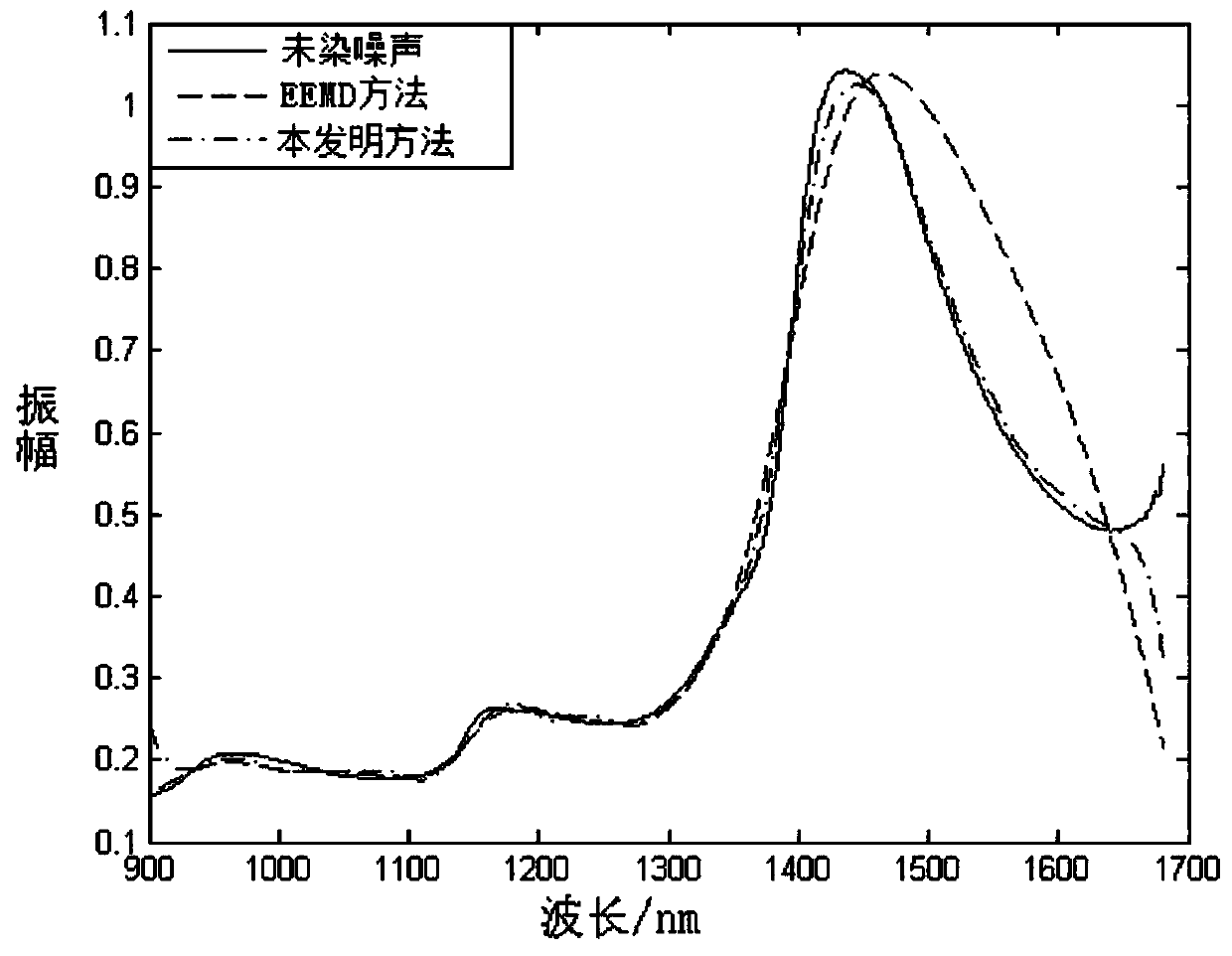

Near-infrared spectroscopy noise reduction method for pesticide residue detection

ActiveCN110208211ASolve the noiseSolve the problem of white noise introduced by EEMDMaterial analysis by optical meansPattern recognitionSignal-to-noise ratio (imaging)

The invention discloses a near-infrared spectroscopy noise reduction method for pesticide residue detection. The method comprises the following steps: 1, a near-infrared spectrum of a target is acquired; 2, an EEMD method is used to decompose signals of the near-infrared spectrum, and a plurality of IMF components are obtained; 3, a threshold is adaptively acquired based on the IMF components, andthe IMF components containing noise are selected; 4, an improved L2 regularization method is used to perform noise reduction processing on the selected noise-containing IMF components; and 5, the components after noise reduction and effective information components are reconstructed to acquire noise reduction signals. The problems that the near-infrared spectrum itself contains noise and white noise is introduced by the EEMD are solved, and the signal-to-noise ratio of the near-infrared spectrum and the recognition accuracy of the classification in the pesticide residue detection are improved.

Owner:NANJING FORESTRY UNIV

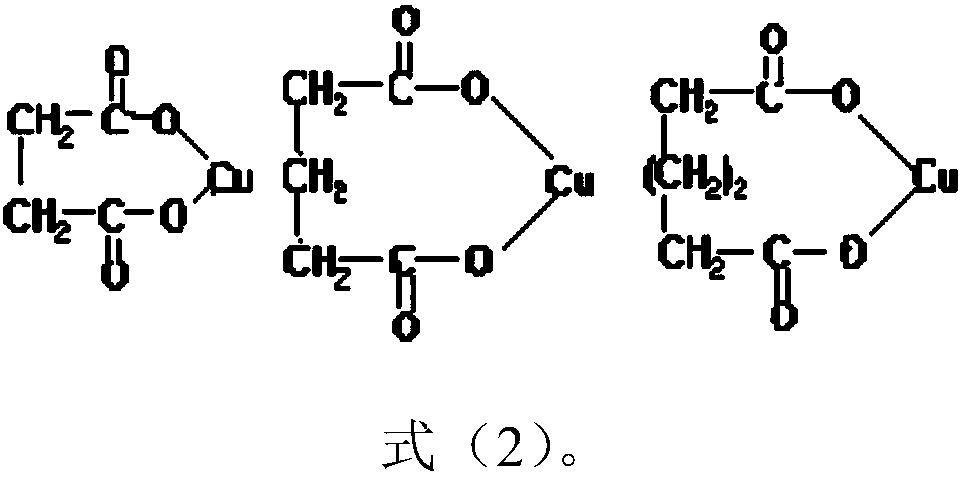

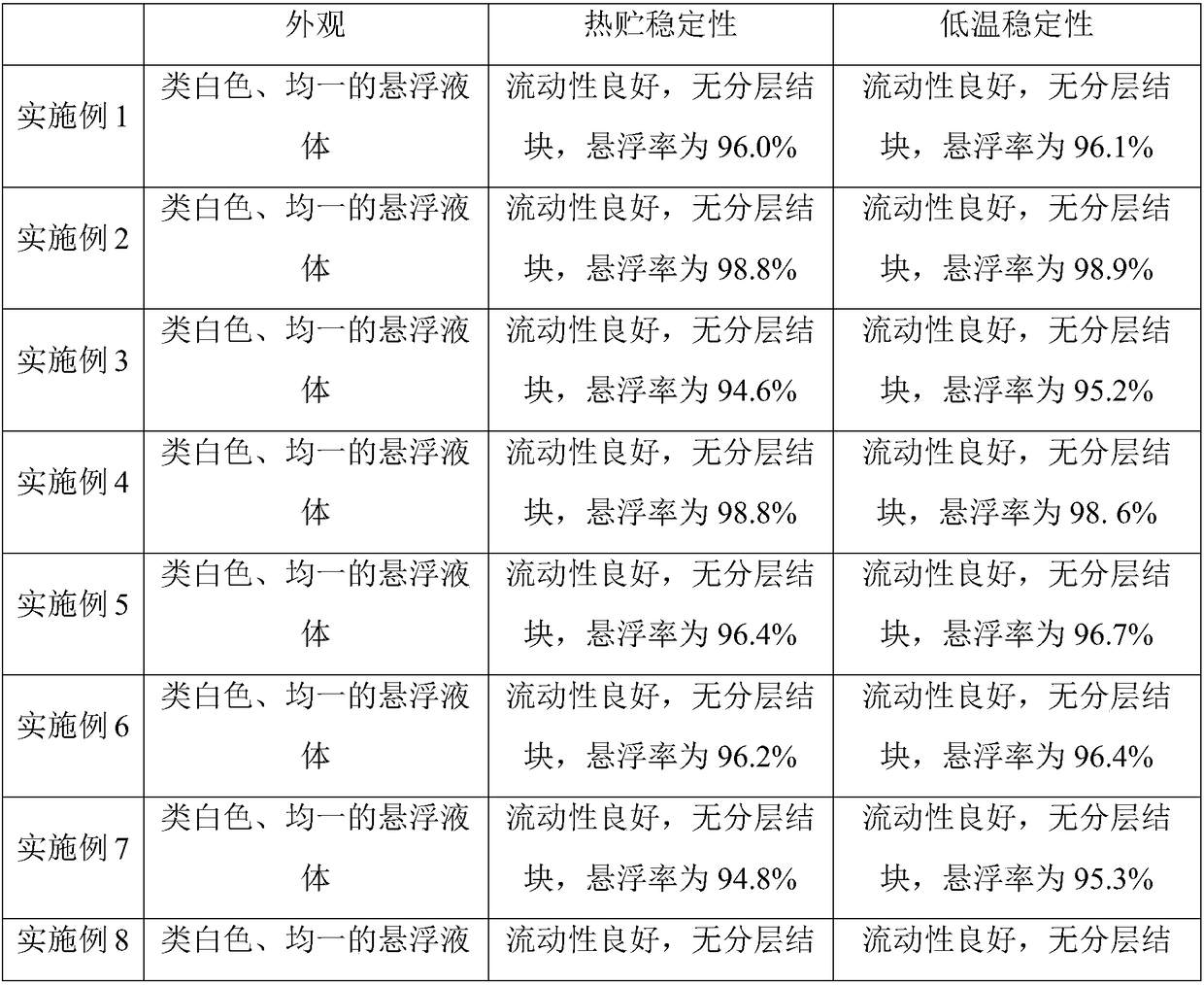

Benziothiazolinone and copper dicarboxylate-containing microcapsule suspension-suspending agent and preparation method thereof

InactiveCN108576017AGood storage stabilityImprove bioavailabilityBiocideFungicidesSuspending AgentsPolymer solution

The invention relates to a benziothiazolinone and copper dicarboxylate-containing microcapsule suspension-suspending agent and a preparation method thereof. The preparation method comprises the following steps: S1) uniformly mixing an oily capsule material-containing performed polymer solution and benziothiazolinone missible oil to obtain a first material; S2) mixing the first material and a buffer solution to obtain a second material, wherein a pH value of the second material is 5-7; S3) mixing the second material and an acidic solution to obtain a third material, wherein the pH value of thethird material is 3-5; S4) stirring the third material for 2-6 hours to obtain a fourth material; S5) mixing the fourth material, a first dispersant, a thickening agent and an antifreezing agent to obtain a benziothiazolinone microcapsule suspending agent; and S6) mixing the benziothiazolinone microcapsule suspending agent, a copper dicarboxylate suspending agent, and a second dispersant to obtainthe benziothiazolinone and copper dicarboxylate-containing microcapsule suspension-suspending agent. The benziothiazolinone and copper dicarboxylate-containing microcapsule suspension-suspending agent has the advantages of good stability and excellent drug effect.

Owner:河北赛丰生物科技有限公司

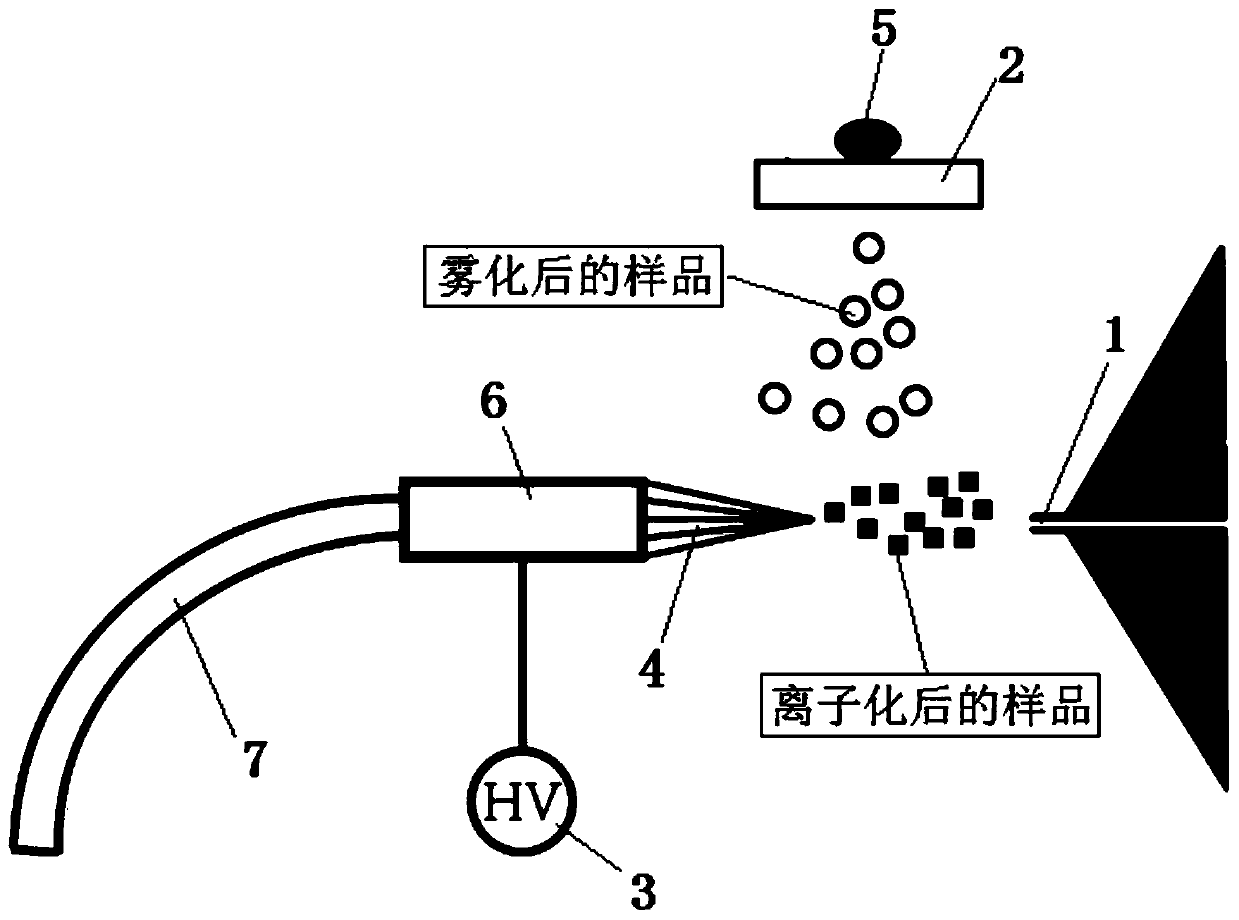

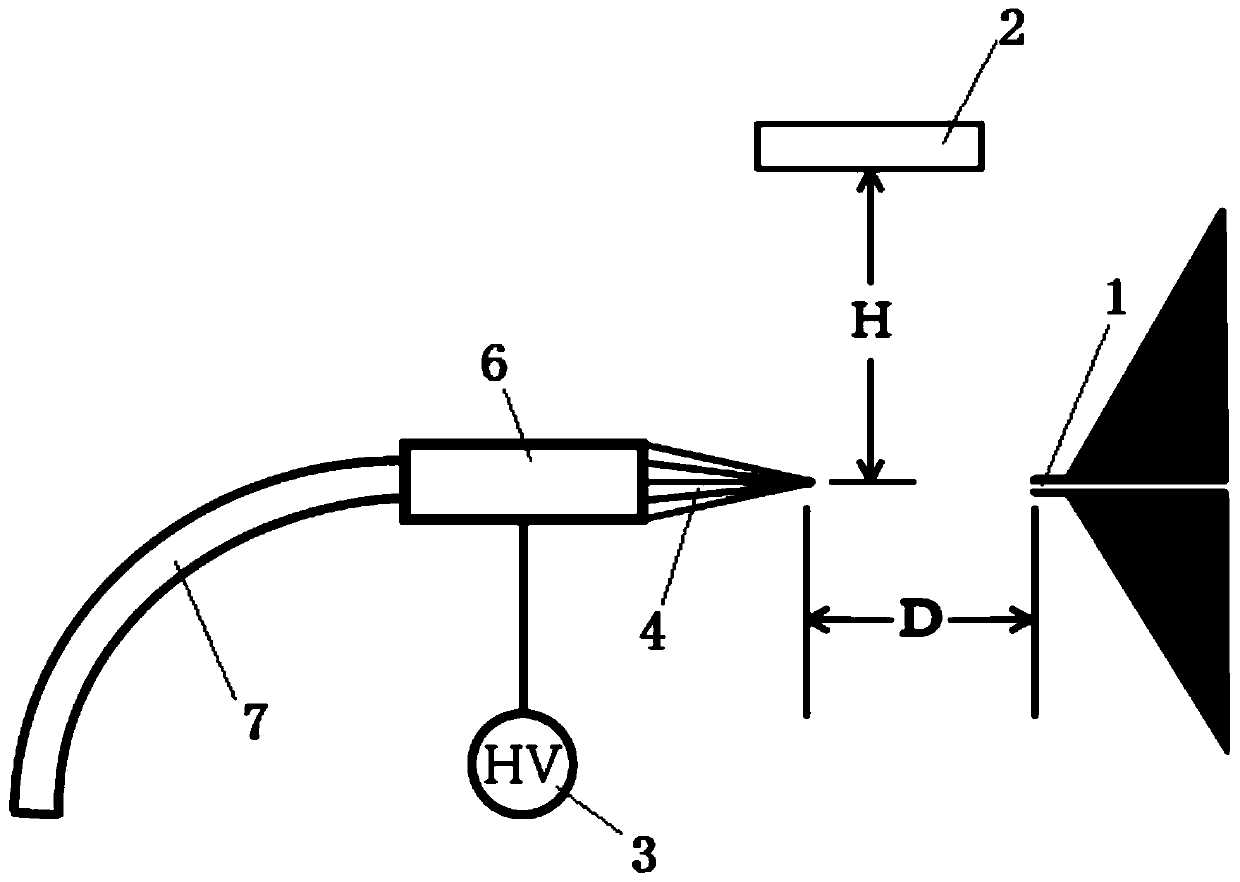

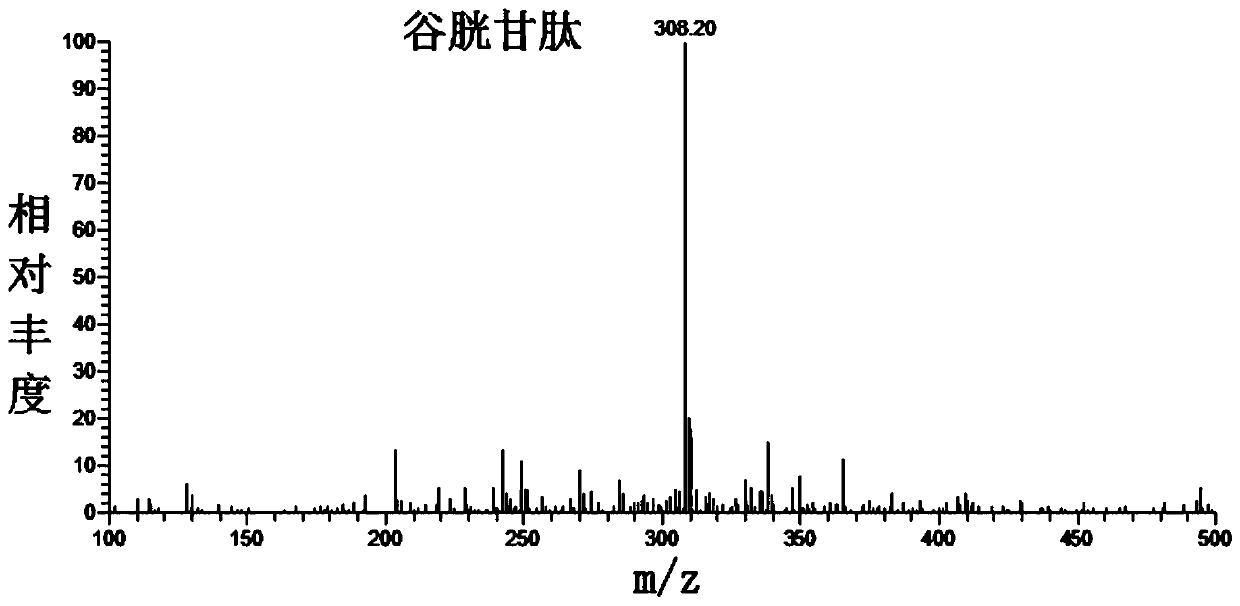

Ultrasonic extraction atomization auxiliary carbon fiber ionization device and method of using same to realize ionization

PendingCN110398532ALow selectivityImprove residual problemsPreparing sample for investigationMaterial analysis by electric/magnetic meansFiberCarbon fibers

The invention discloses an ultrasonic extraction atomization auxiliary carbon fiber ionization device and a method of using the same to realize ionization. The device includes a carbon fiber ion source and a mass spectrometry sample input channel. A sampling and ionization end of the carbon fiber ion source is located in front of a port of the mass spectrometry sample input channel. An ultrasonicextraction atomization device is arranged near the sampling and ionization end of the carbon fiber ion source. The method of using the ultrasonic extraction atomization auxiliary carbon fiber ionization device of the invention to realize ionization includes the operations of: placing a sample, which contains an extraction solvent, on the ultrasonic extraction atomization device, then sequentiallycarrying out extraction and atomization on the sample by the ultrasonic extraction atomization device, and then ionizing the atomized sample by the carbon fiber ion source. The ultrasonic extraction atomization auxiliary carbon fiber ionization device provided by the invention has good an ionization effect on peptide compounds, and can qualitatively and quantitatively analyze complex samples without the need for preprocessing the to-be-tested samples.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

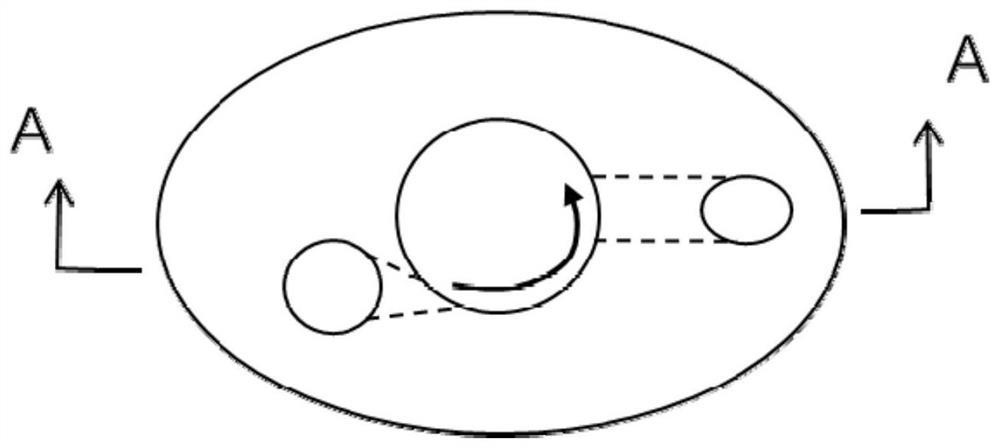

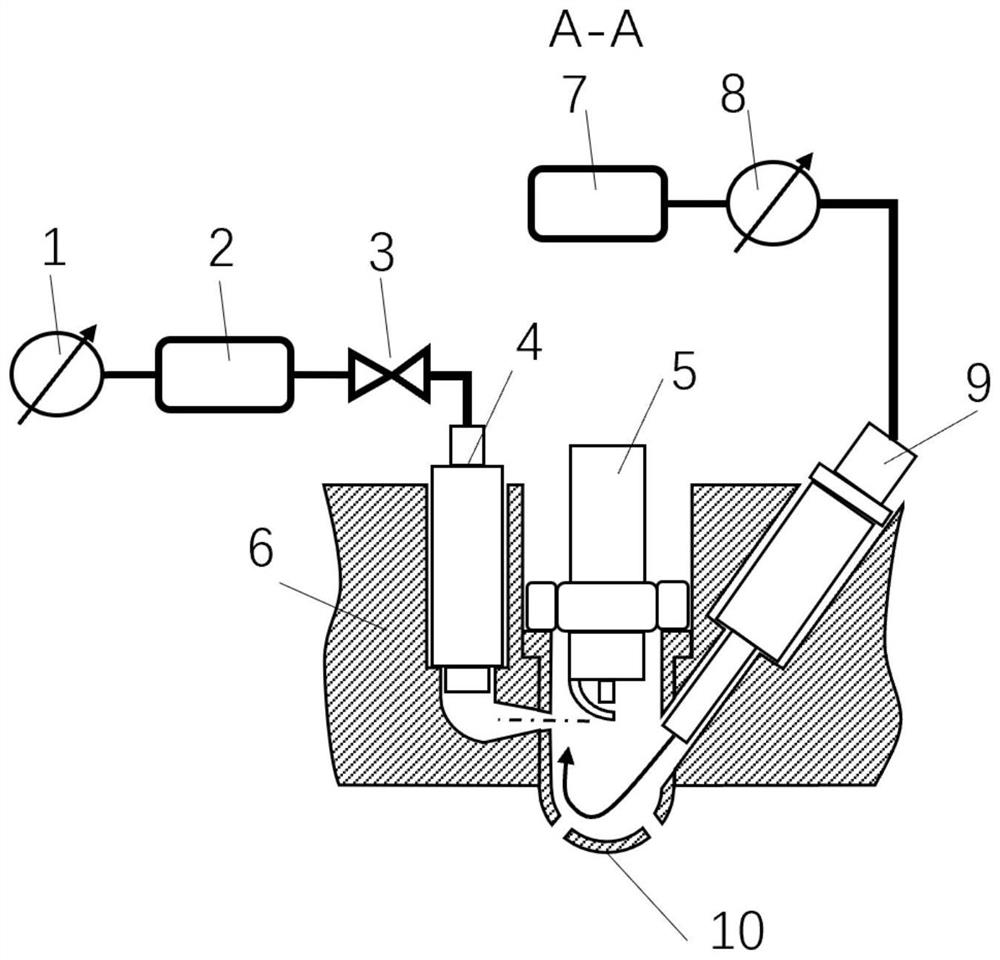

Fuel and air separation active control type ignition chamber system

ActiveCN113417733ARealize active scavengingImprove combustion stabilityInternal combustion piston enginesFuel injection apparatusSafety valveGas supply

The invention discloses a fuel and air separation active control type ignition chamber system, and relates to the technical field of combustion of internal combustion engines. The system comprises an air supply branch and a fuel supply branch which are arranged at the top of an ignition chamber; the ignition chamber is arranged on a cylinder cover or an ignition chamber adapter single body, the cylinder cover or the ignition chamber adapter single body is provided with a sparking plug, an air channel and a fuel channel, the sparking plug is arranged above the ignition chamber, the air channel and the fuel channel communicate with the ignition chamber, the air supply branch communicates with the air channel, and the fuel supply branch communicates with the fuel channel; pre-combustion air is directly supplied by an air pressure pump or supplied from a bypass arranged in the downstream position of a supercharger of an engine body, and air exchange of the ignition chamber is achieved through the pressure difference between the downstream position of the supercharger and the interior of the cylinder in the later stage of an exhaust stroke or the early stage of an intake stroke. After being stabilized by an air pressure accumulation chamber, the air is supplied to the air nozzle end through a one-way safety valve, active scavenging in the ignition chamber is achieved, and the composition of the mixed gas in the ignition chamber can be controlled in real time, so that the combustion stability and controllability are improved.

Owner:DALIAN UNIV OF TECH

Detection method for simultaneously measuring residue of tetracyclines (TCs) drugs in royal jelly

The invention relates to a detection method for simultaneously measuring the residue of tetracyclines (TCs) drugs in royal jelly, in particular to a detection method for simultaneously measuring the residue of 10 veterinary drugs including oxytetracycline, tetracycline, demethylchlortetracycline, chlorotetracycline, doxycycline, 4- epioxytetracycline, 4-epitetracycline, 4-epichlorotetracycline, minocycline and methacycline. The method comprises the following steps: precipitating protein by methanol; then, adjusting the PH value; further carrying out multi-stage purification; and simply and simultaneously measuring the residue of the TCs drugs by the liquid chromatography-mass spectrometry / mass spectrometer (LC-MS / MS). By carrying out the pre-treatment for one time, the invention can measure the residue of up to 10 TCs drugs in the royal jelly, wherein, the lower limits of detection (LLD) of the five TC antibiotics including oxytetracycline, tetracycline, demethylchlortetracycline, chlorotetracycline and doxycycline are 2.0 mug / kg; while the LLDs of the other veterinary drugs including 4- epioxytetracycline, 4-epitetracycline, 4-epichlorotetracycline, minocycline and methacycline are 10.0 mug / kg.

Owner:THE INSPECTION & QUARANTINE TECH CENT ZHEJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Polishing head, edge controlling loop thereof as well as method for increasing velocity of crystal edge polishing

InactiveCN101352843AHeavy loadImprove polishing ratePolishing machinesSemiconductor/solid-state device manufacturingMechanical engineeringCrystal

The invention discloses a polishing head which is suitable for the polishing process of chemical machines and comprises a fixed ring, a flexible film and an edge control ring; wherein, the fixed ring is used for fixing wafers; the flexible film comprises a lip part and a bottom part which are connected with each other; a bottom surface of the bottom part is attached to the wafers; the edge control ring comprises a bottom part which is provided with a contact bottom surface; the contact bottom surface and an external surface of the lip part of the flexible film are mutually attached when the flexible film is not aerated.

Owner:UNITED MICROELECTRONICS CORP

Preparation method of nano hydroxyapatite grafted polyhydroxybutyrate-hydroxyvalerate (PHBV)

ActiveCN105582577AGood biocompatibilityEasy reunionTissue regenerationProsthesisNano hydroxyapatiteAmmonia

The invention discloses a preparation method of nano hydroxyapatite grafted polyhydroxybutyrate-hydroxyvalerate (PHBV), which mainly comprises the following steps: (1) introducing amino groups on PHBV molecules by utilizing an ammonia plasma processing method; (2) processing PHBV after amination by utilizing glutaraldehyde so as to carry out hydroformylation on PHBV; (3) processing nano hydroxyapatite by utilizing a silane coupling agent so as to carry out amination on nano hydroxyapatite; and (4) reacting PHBV after hydroformylation and nano hydroxyapatite after amination to obtain PHBV grafted nano hydroxyapatite. The method disclosed by the invention effectively solves the problem that nano hydroxyapatite is easy to agglomerate in a PHBV substrate; meanwhile, the method is basically carried out at normal temperature and is mild in reaction condition, simple in preparation process, relatively high in preparation efficiency and wide in application prospect; Nano hydroxyapatite grafted PHBV prepared by the method disclosed by the invention has potential application in tissue engineering and bone defect repair.

Owner:HENAN INST OF ENG

Method for preparing animal feed additive from waste diatomite and application of animal feed additive

The invention relates to a method for preparing an animal feed additive from waste diatomite and application of the animal feed additive.The method includes: drying dewatered waste diatomite with solid content higher than wt20% and water content being wt70%-80% at 100-200 DEG C for 20-35h to control the water content below wt5%; using grinding equipment for grinding the dried diatomite into particles smaller than 100-mesh particles; adding according to a ratio of 1%-15% of the weight of feeds for livestock and poultry.Technical simplicity in production, sufficient raw material resources and low product cost are realized; the food safety problems caused by drug residues and drug resistance of pathogenic microorganisms can be effectively avoided, quality and output of livestock and poultry are improved, raising cost is reduced, absorption and appetite of animals can be promoted, and disease-resistant immunity is improved; the problems of environment pollution and residues caused by adoption of chemical insecticides in the breeding industry are effectively improved, and people's life quality is improved.

Owner:HENAN UNIV OF URBAN CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com