Polishing head, edge controlling loop thereof as well as method for increasing velocity of crystal edge polishing

A technology of edge control and polishing rate, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of limited crystal edge polishing rate and crystal edge residue, so as to improve crystal edge residue and improve polishing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

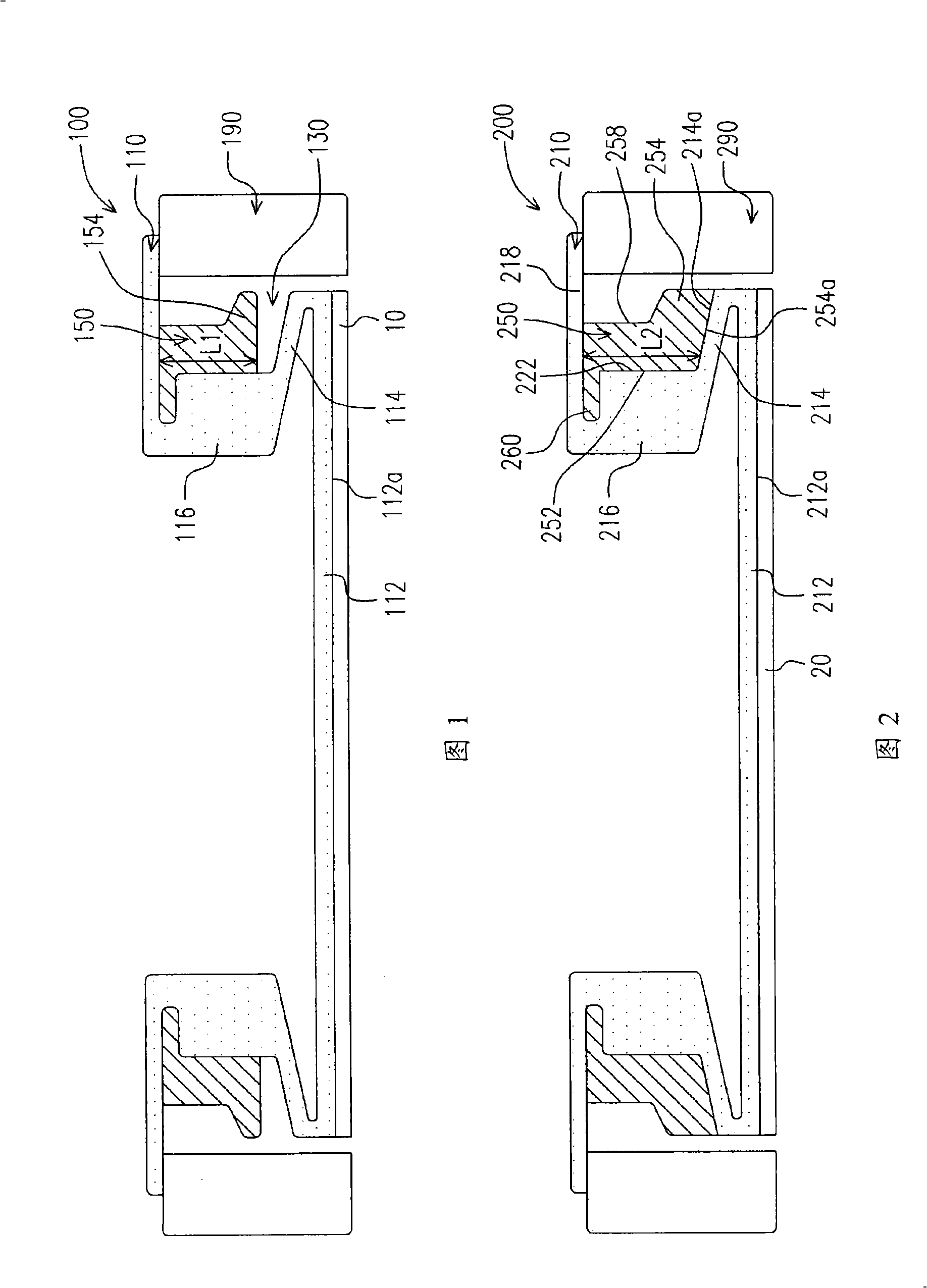

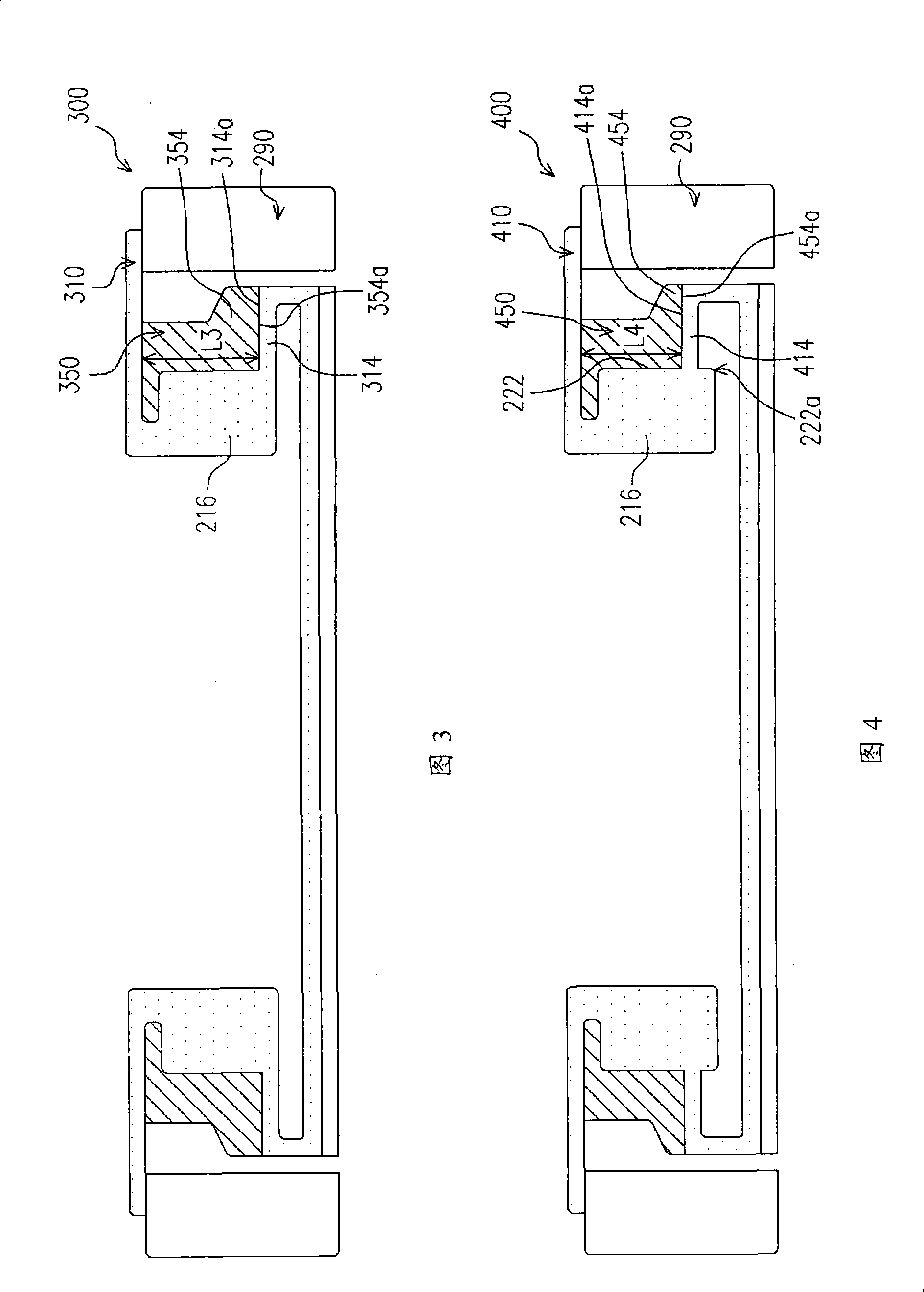

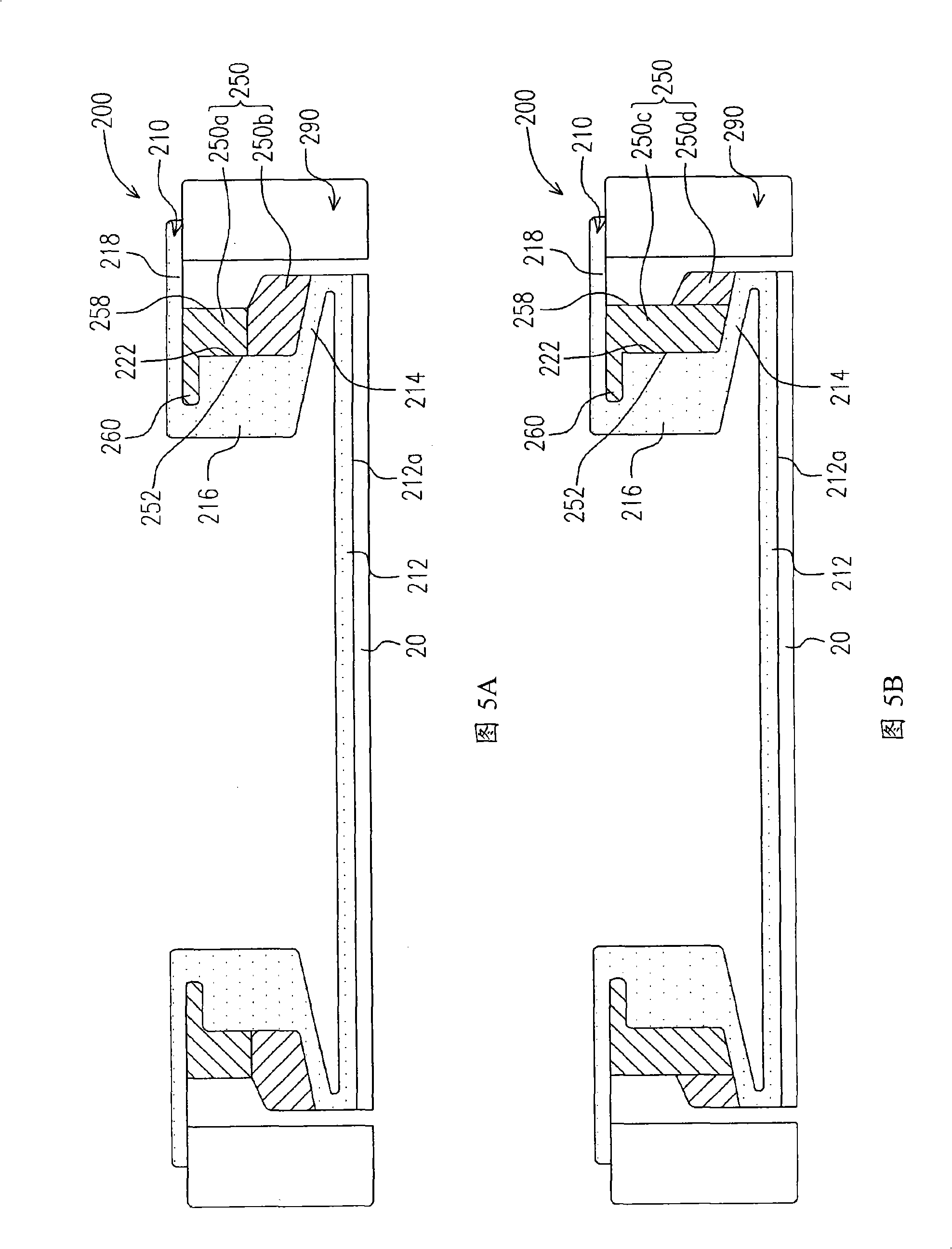

[0084] The inventor found that the key to the insufficient polishing rate of the crystal edge of the prior art shown in Figure 1 and the inability of US 6,979,250 and US 6,776,694 to effectively solve the insufficient polishing rate of the crystal edge is that the bottom surface of the edge control ring and the lip of the flexible film The outer surfaces of the parts have gaps between each other when they are not yet inflated. When the flexible film is inflated, there is a gap between the lip and the contact bottom surface of the edge control ring, so it will be lifted upwards, so that the load provided to the edge is reduced or eliminated, resulting in insufficient polishing rate for edge polishing.

[0085] The present invention proposes several methods that can increase the crystal edge load for this discovery, which mainly makes the contact bottom surface of the edge control ring of the polishing head and the outer surface of the lip of the flexible film contact each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com