Patents

Literature

337results about How to "Improve polishing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

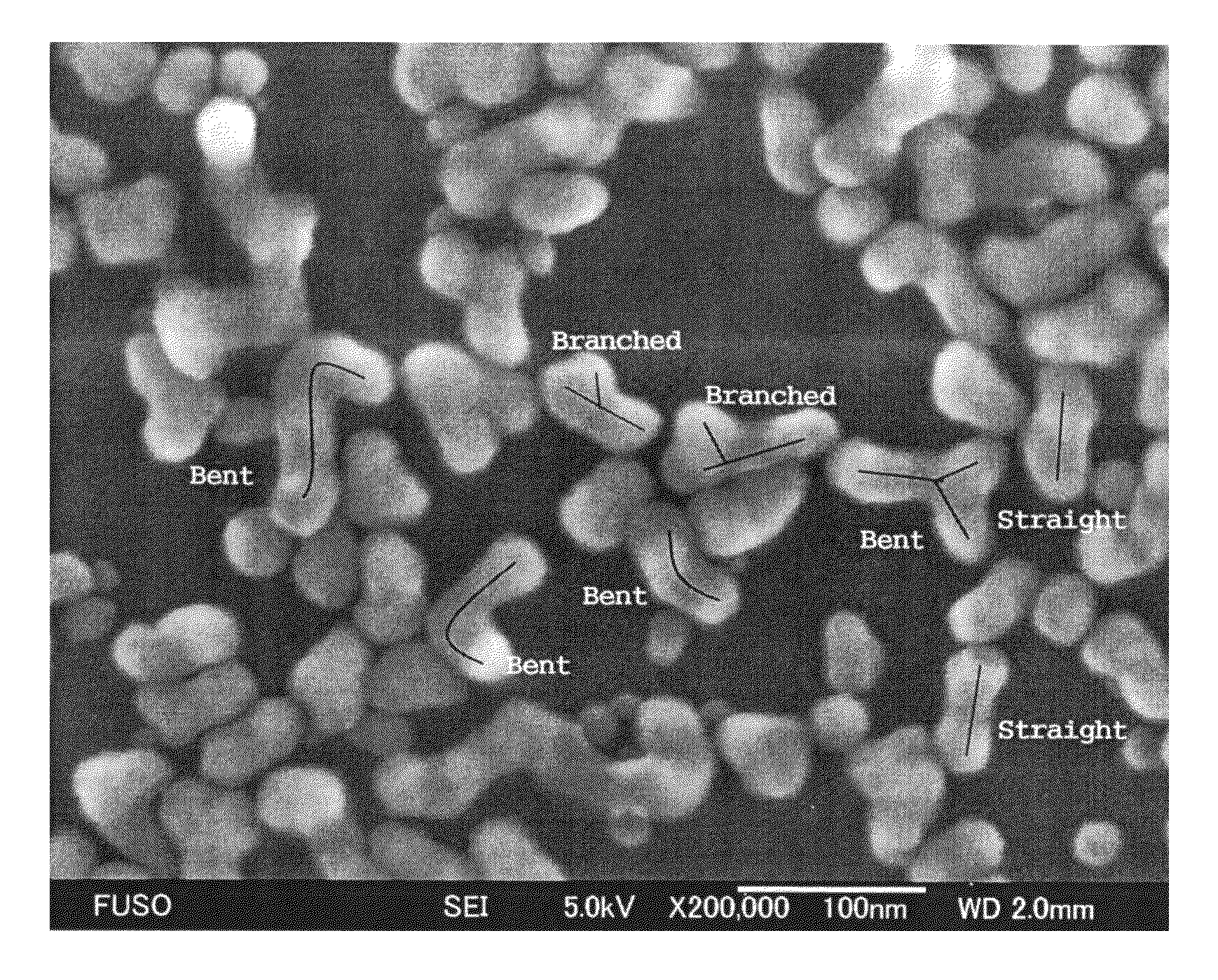

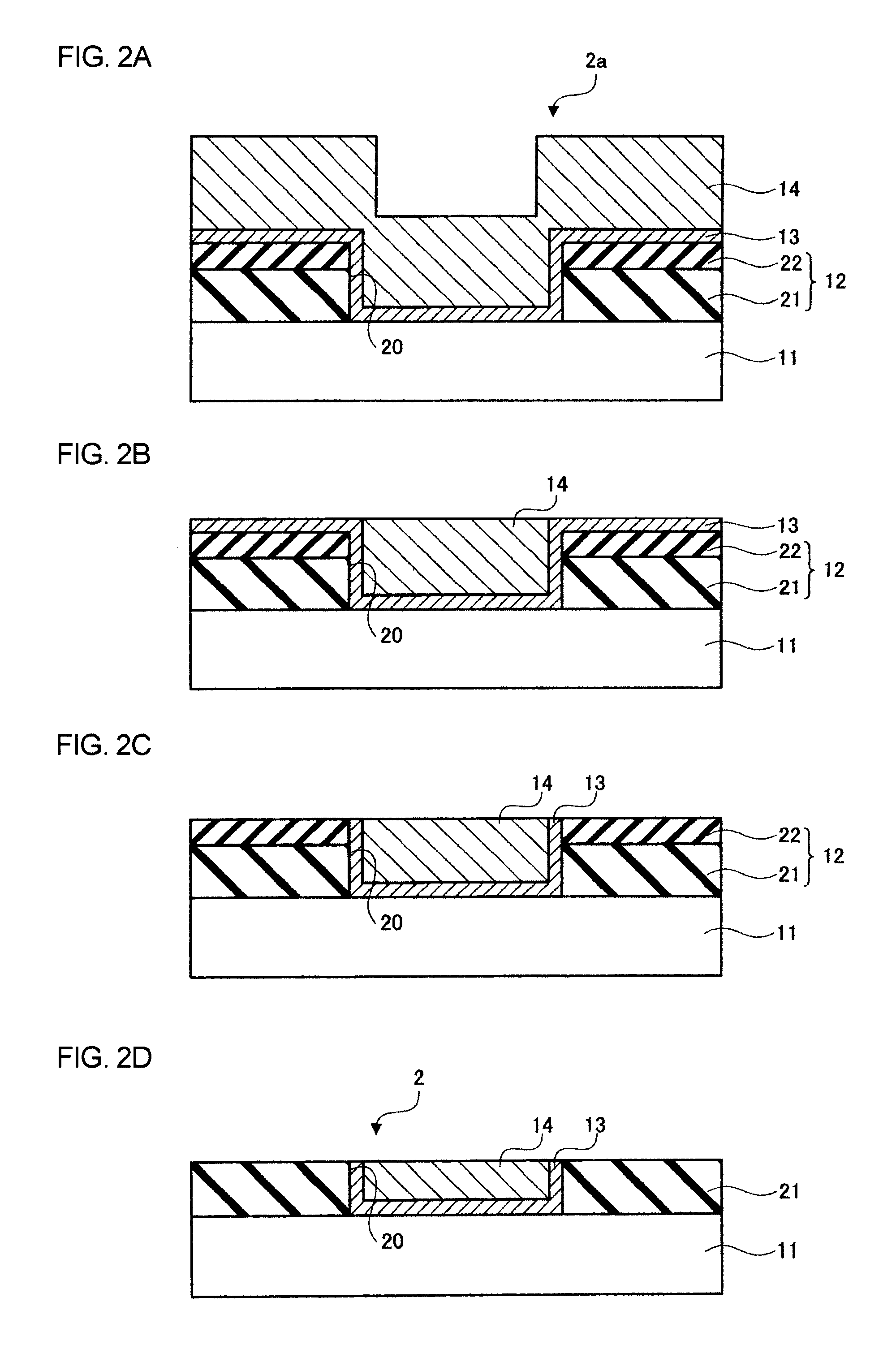

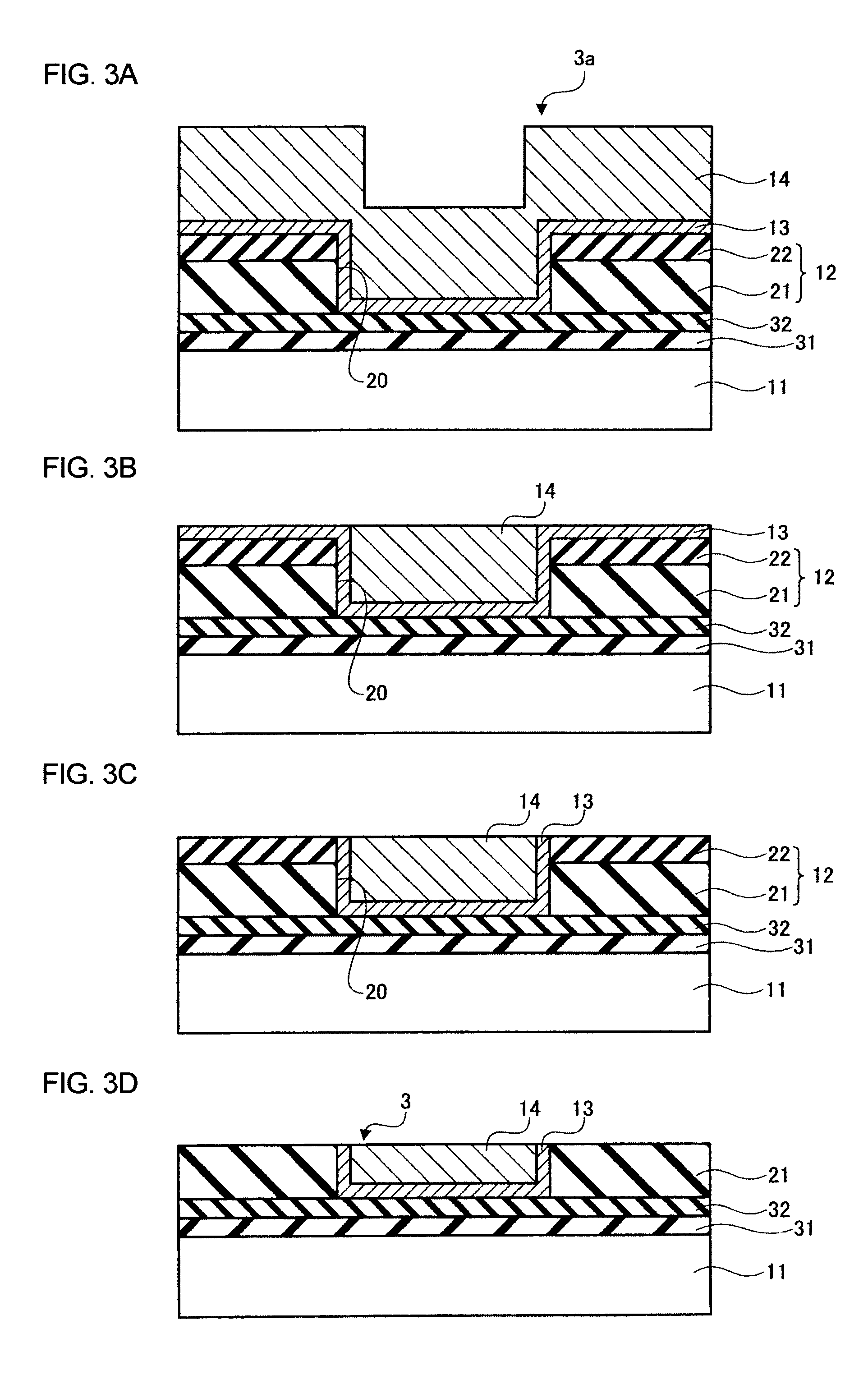

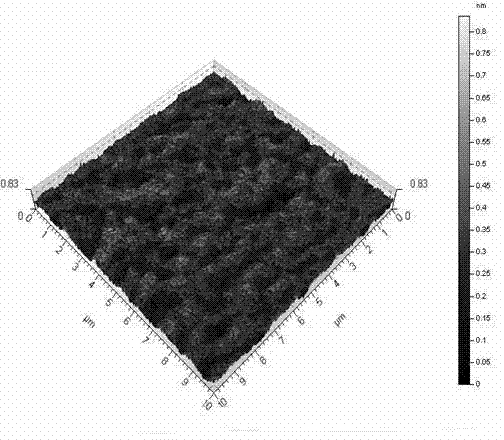

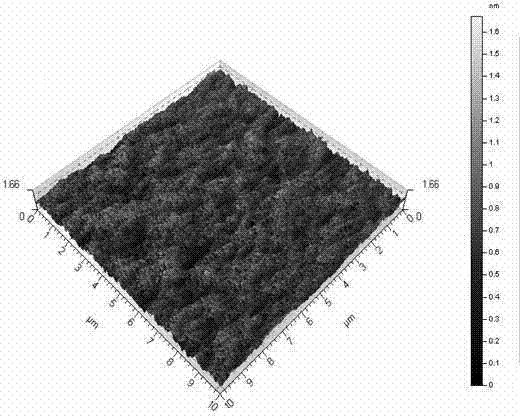

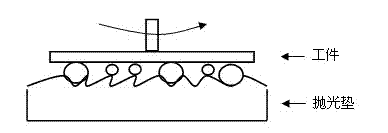

Colloidal silica containing silica secondary particles having bent structure and/or branched structure, and method for producing same

ActiveUS8529787B2Improve polishing rateLarge aspect ratioSilicaOther chemical processesColloidal silicaColloid

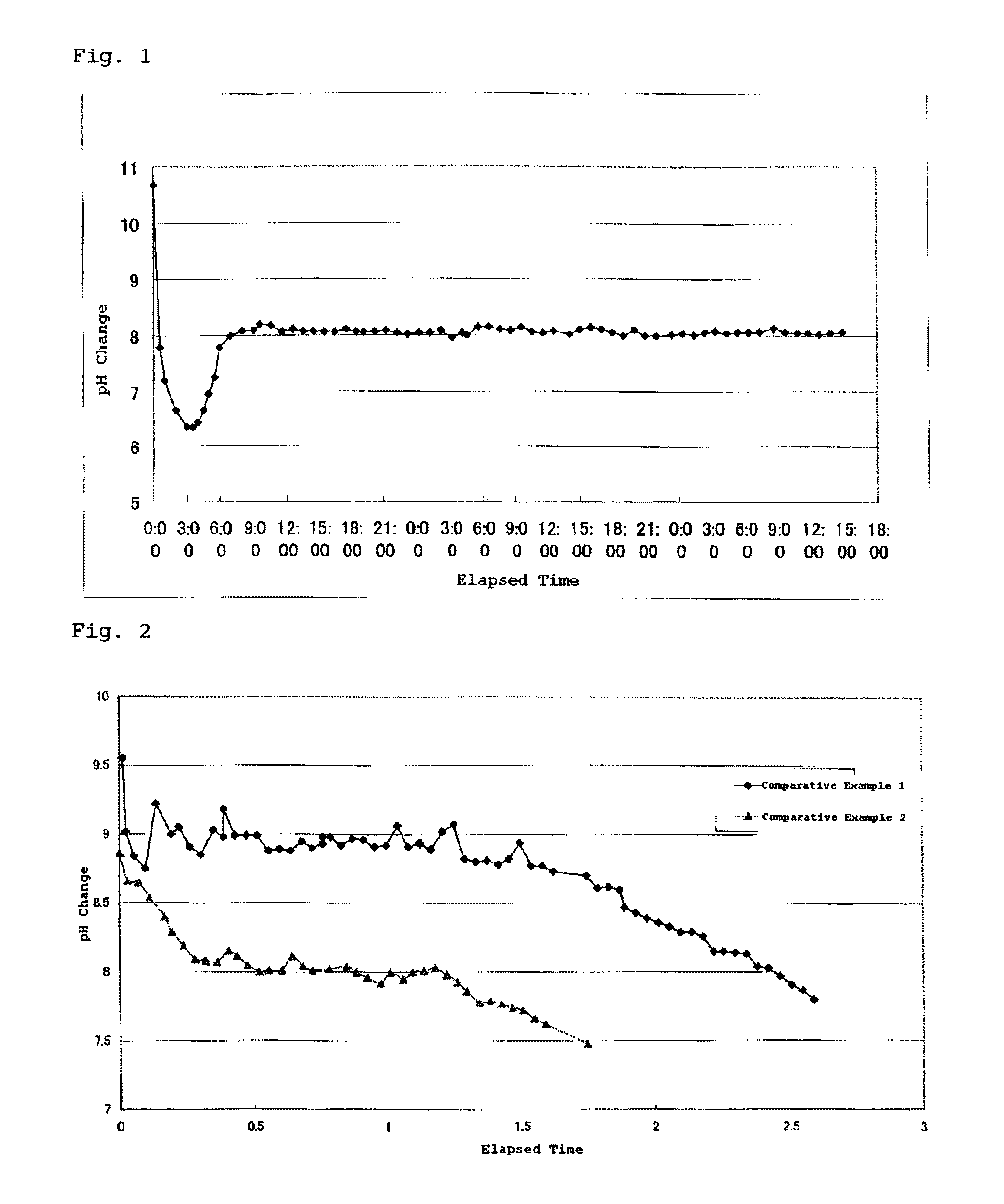

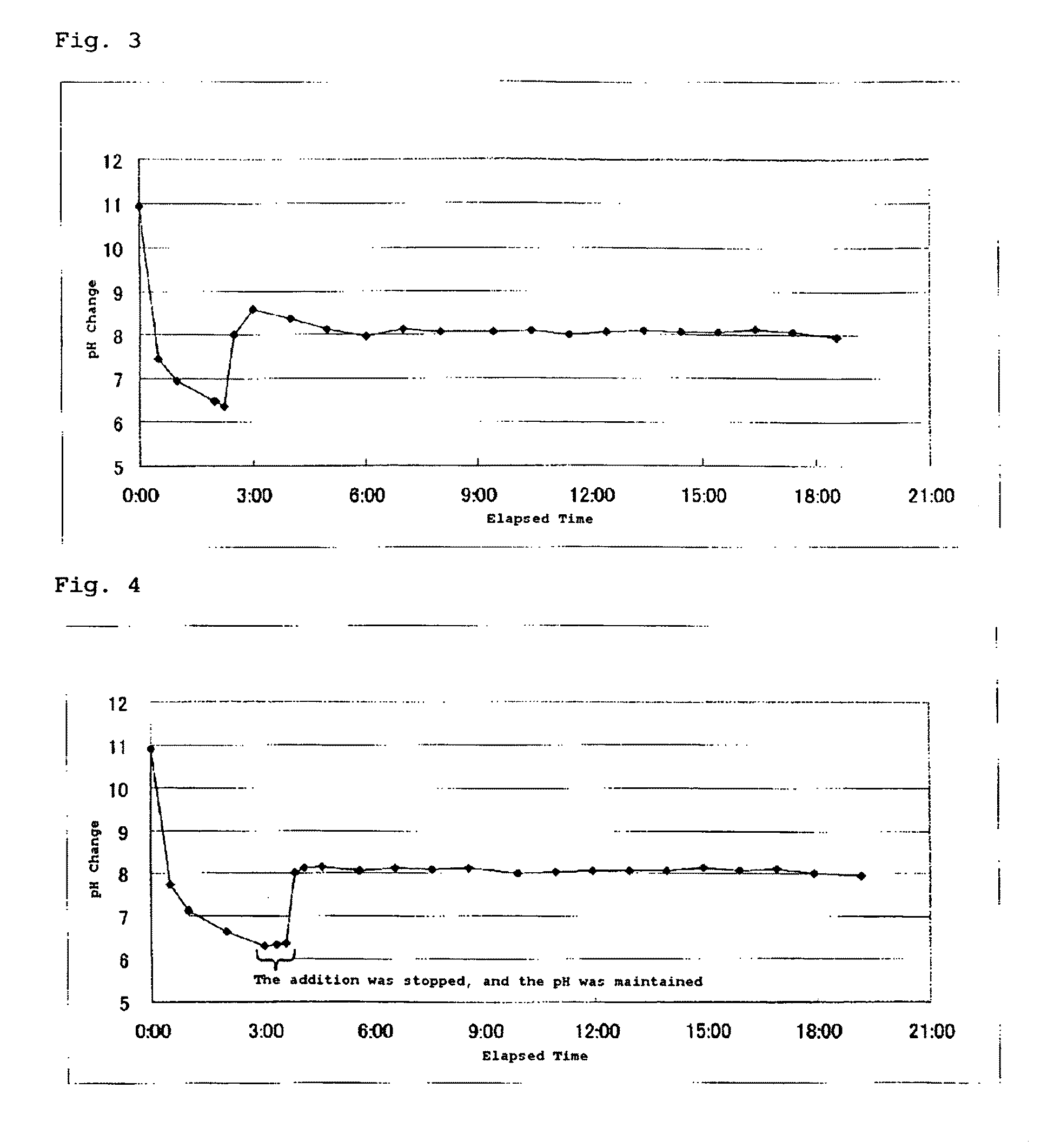

This invention provides a dense, high-purity colloidal silica containing silica secondary particles having a branched and / or bent structure, and a production method thereof. Specifically, this invention provides a method for producing a colloidal silica, comprising the steps of 1) preparing a mother liquid containing an alkali catalyst and water, and having a pH of 9 to 12; and 2) adding a hydrolysis liquid obtained by hydrolysis of an alkyl silicate to the mother liquid, wherein the step of adding the hydrolysis liquid to the mother liquid sequentially comprises A) step 1 of adding the hydrolysis liquid until the pH of the resulting liquid mixture becomes less than 7; B) step 2 of adding an aqueous alkali solution until the pH of the liquid mixture becomes 7 or more; and C) step 3 of adding the hydrolysis liquid while maintaining the pH of the liquid mixture at 7 or more, and a colloidal silica containing silica secondary particles having a branched and / or bent structure, obtained by this method.

Owner:FUSO CHEM

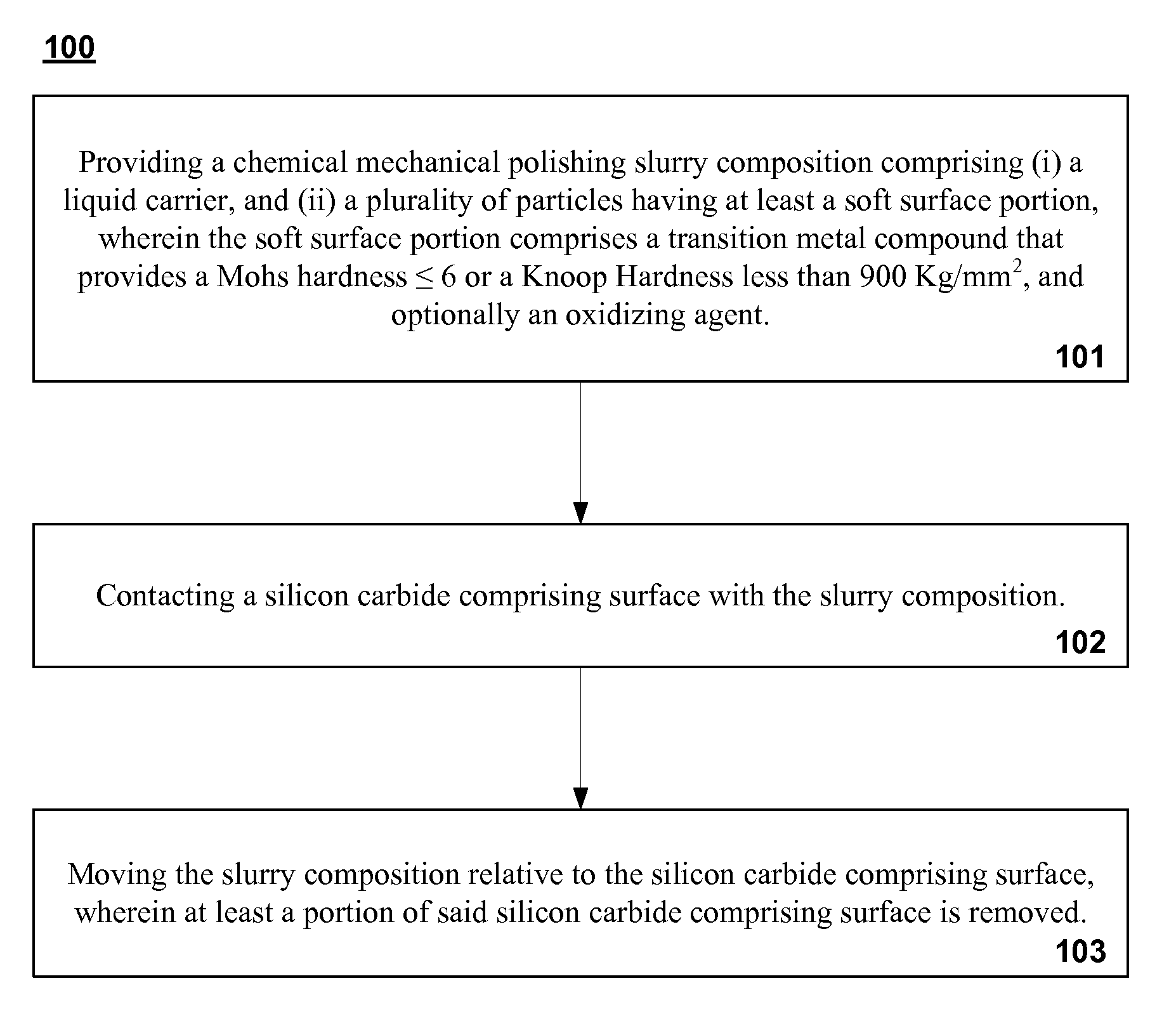

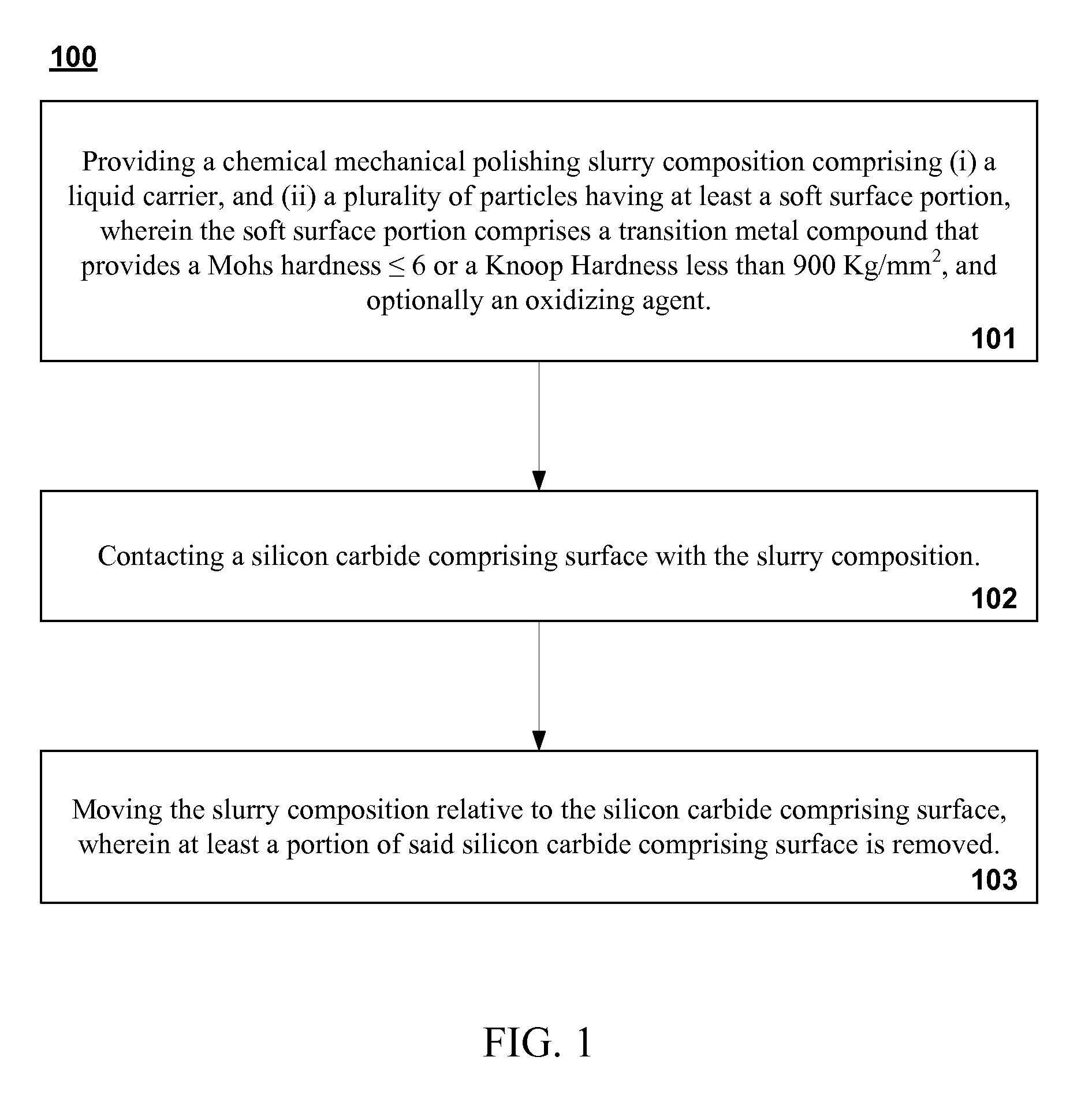

Chemical mechanical polishing of silicon carbide comprising surfaces

ActiveUS20100258528A1High polishing rateReduce sub-surface damageOther chemical processesDecorative surface effectsMohs scale of mineral hardnessSlurry

Slurry compositions and chemically activated CMP methods for polishing a substrate having a silicon carbide surface using such slurries. In such methods, the silicon carbide surface is contacted with a CMP slurry composition that comprises i) a liquid carrier and ii) a plurality of particles having at least a soft surface portion, wherein the soft surface portion includes a transition metal compound that provides a Mohs hardness ≦6, and optionally iii) an oxidizing agent. The oxidizing agent can include a transition metal. The slurry is moved relative to the silicon carbide comprising surface, wherein at least a portion of eth silicon carbide surface is removed.

Owner:ENTEGRIS INC +1

Polishing composition

InactiveUS20050208883A1Reduce scratchesImprove polishing ratePigmenting treatmentOther chemical processesZeta potentialSilica particle

The present invention relates to a polishing composition containing an aqueous medium and silica particles, wherein the silica particles in the polishing composition has a zeta potential of from −15 to 40 mV; a method for manufacturing a substrate including the step of polishing a substrate to be polished with a polishing composition containing an aqueous medium and silica particles, wherein the silica particles in the polishing composition has a zeta potential of from −15 to 40 mV; and a method for reducing scratches on a substrate to be polished with a polishing composition containing an aqueous medium and silica particles, including the step of adjusting a zeta potential of silica particles in the polishing composition to −15 to 40 mV. The polishing composition can be favorably used in polishing the substrate for precision parts, including substrates for magnetic recording media such as magnetic discs, optical discs and opto-magnetic discs; photomask substrates; optical lenses; optical mirrors; optical prisms; semiconductor substrates; and the like.

Owner:KAO CORP

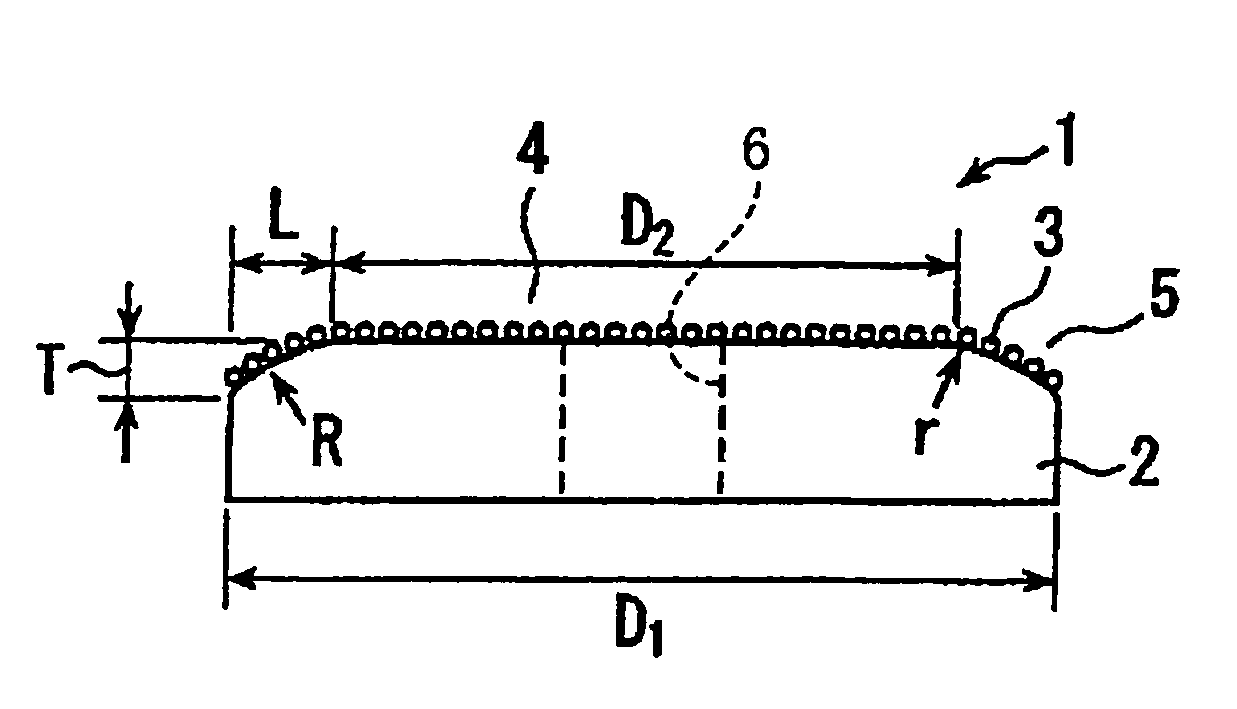

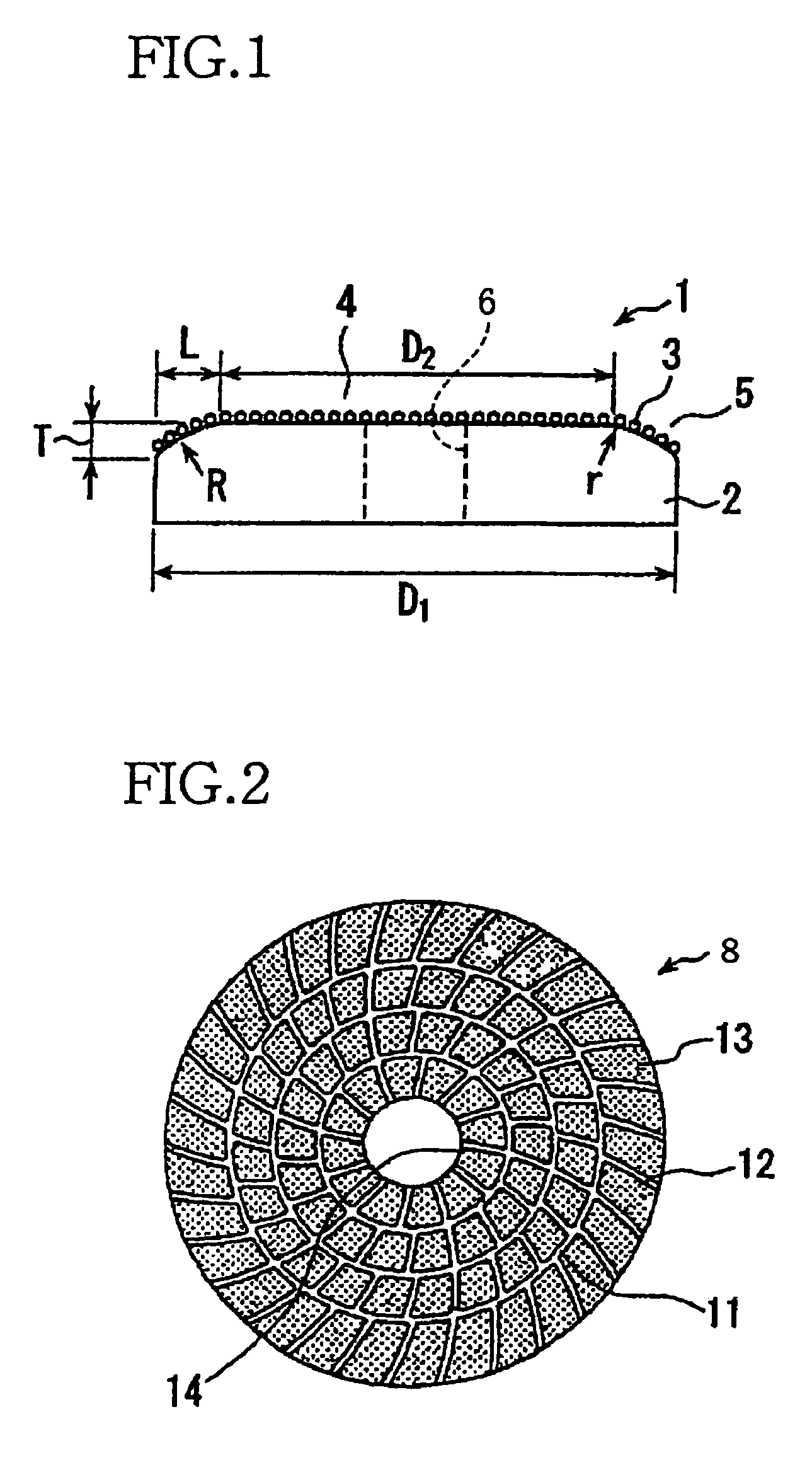

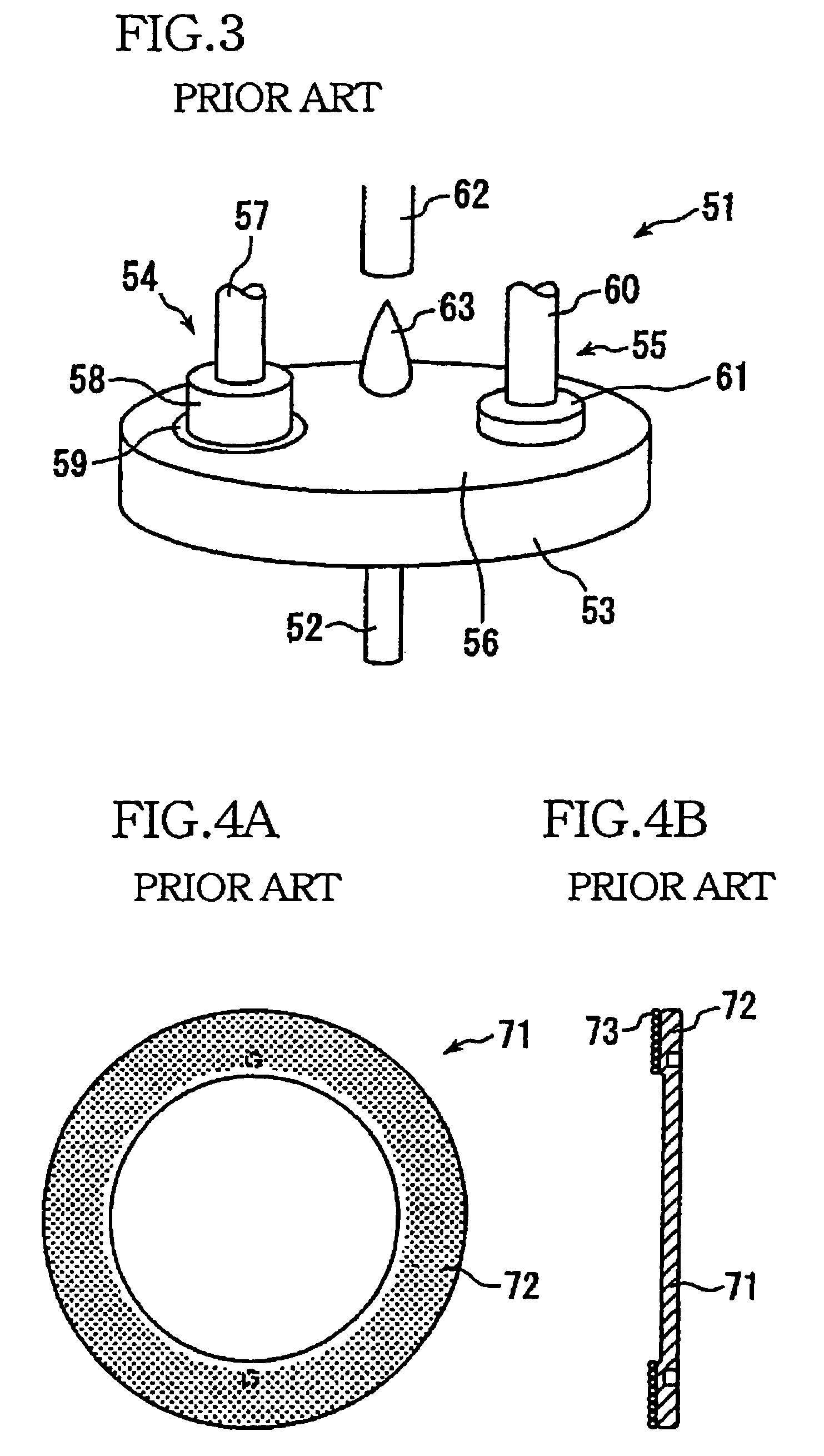

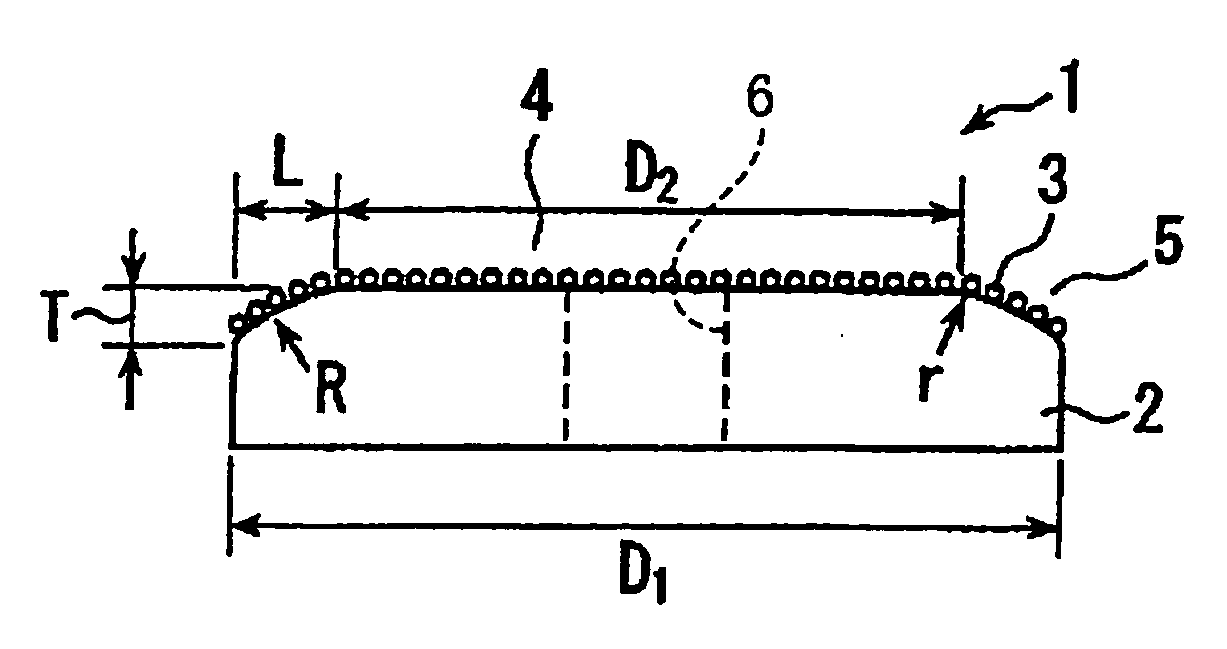

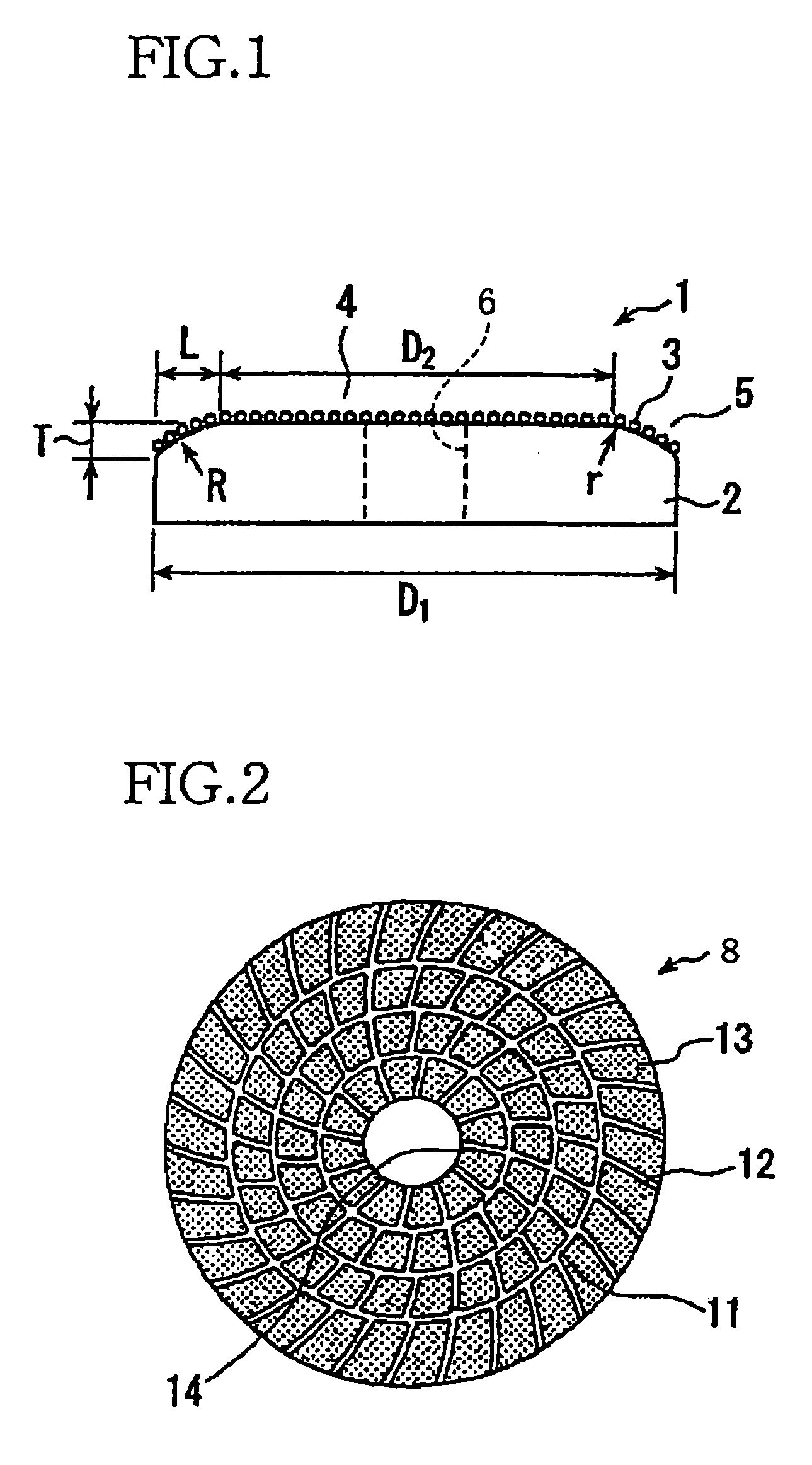

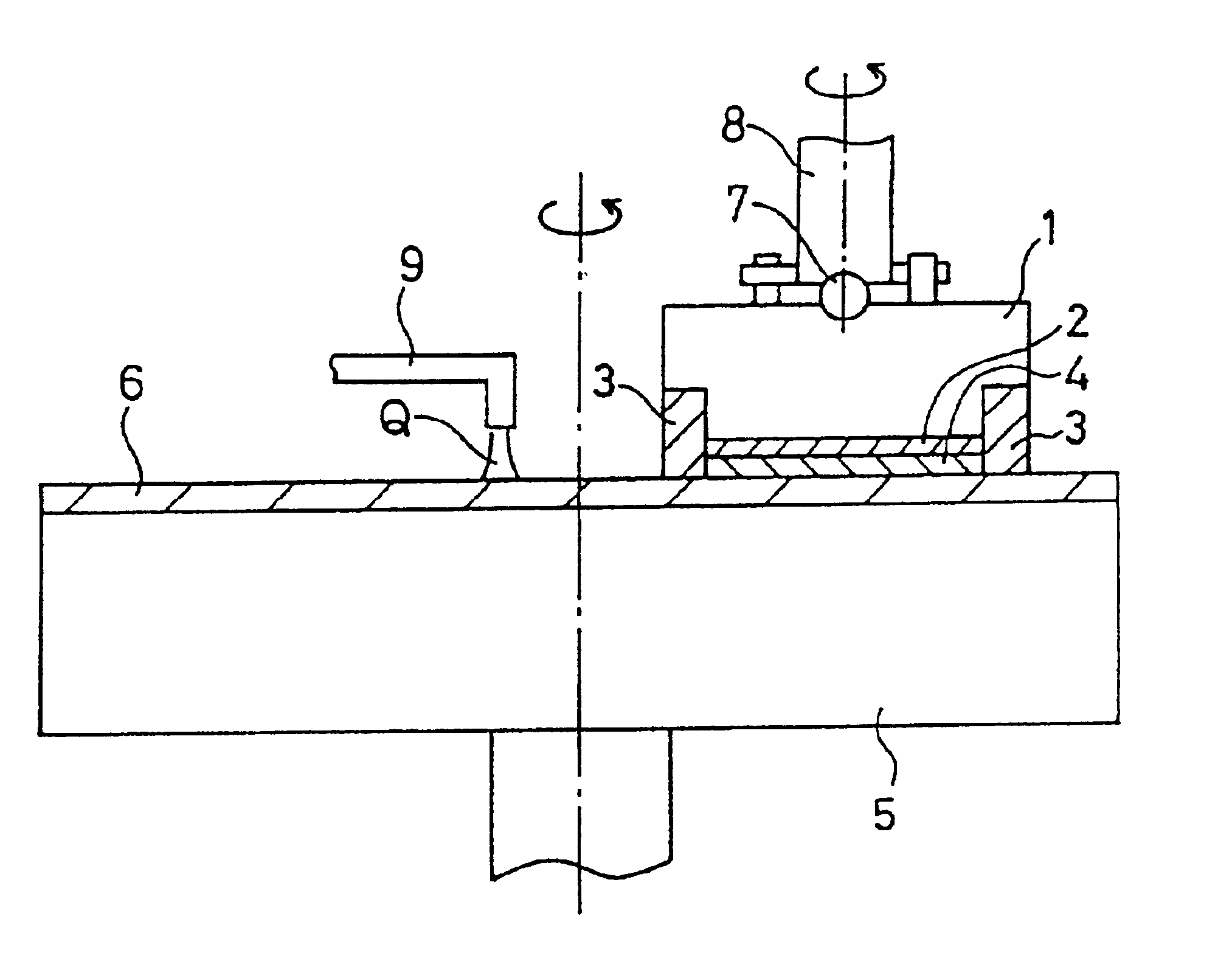

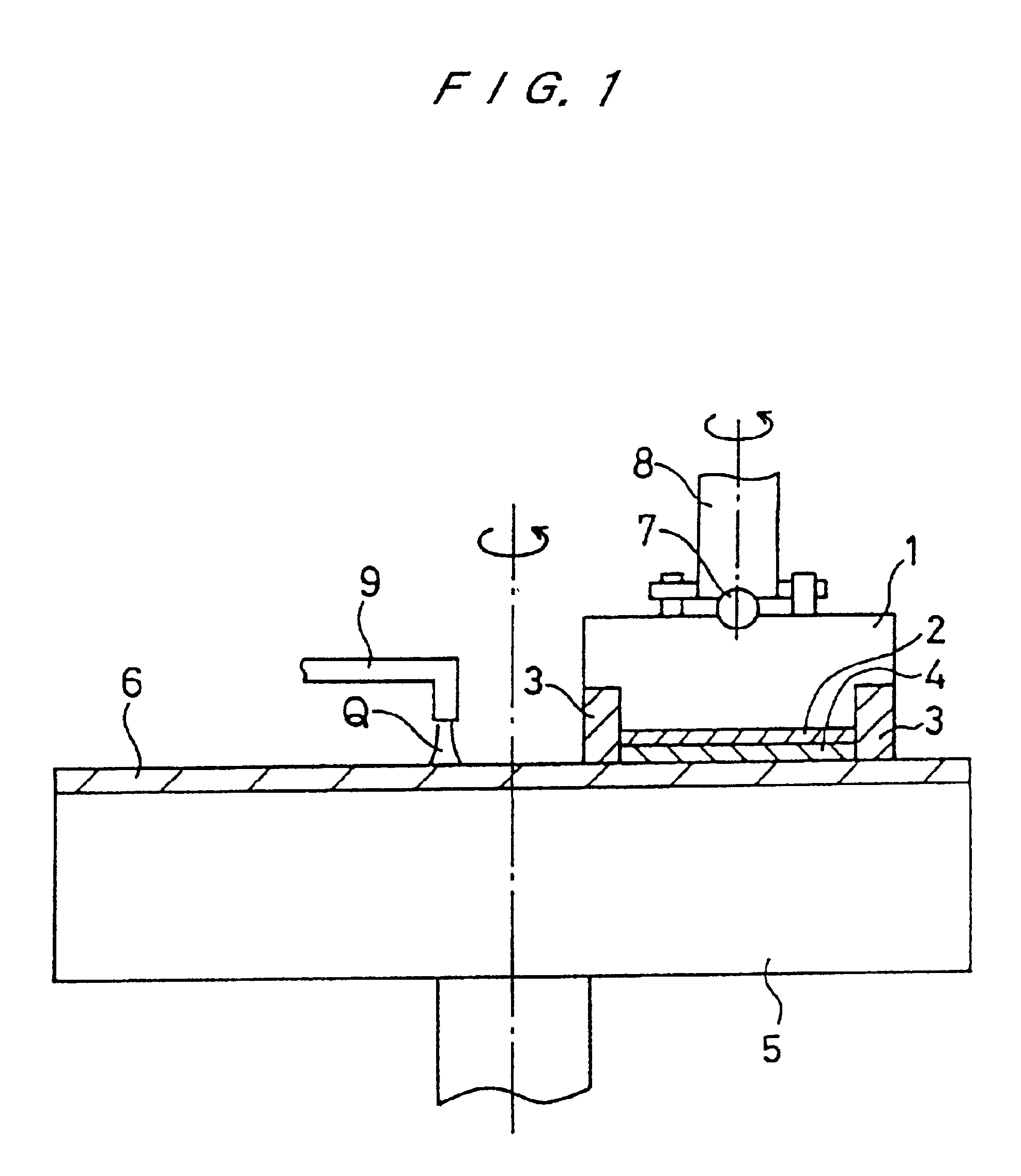

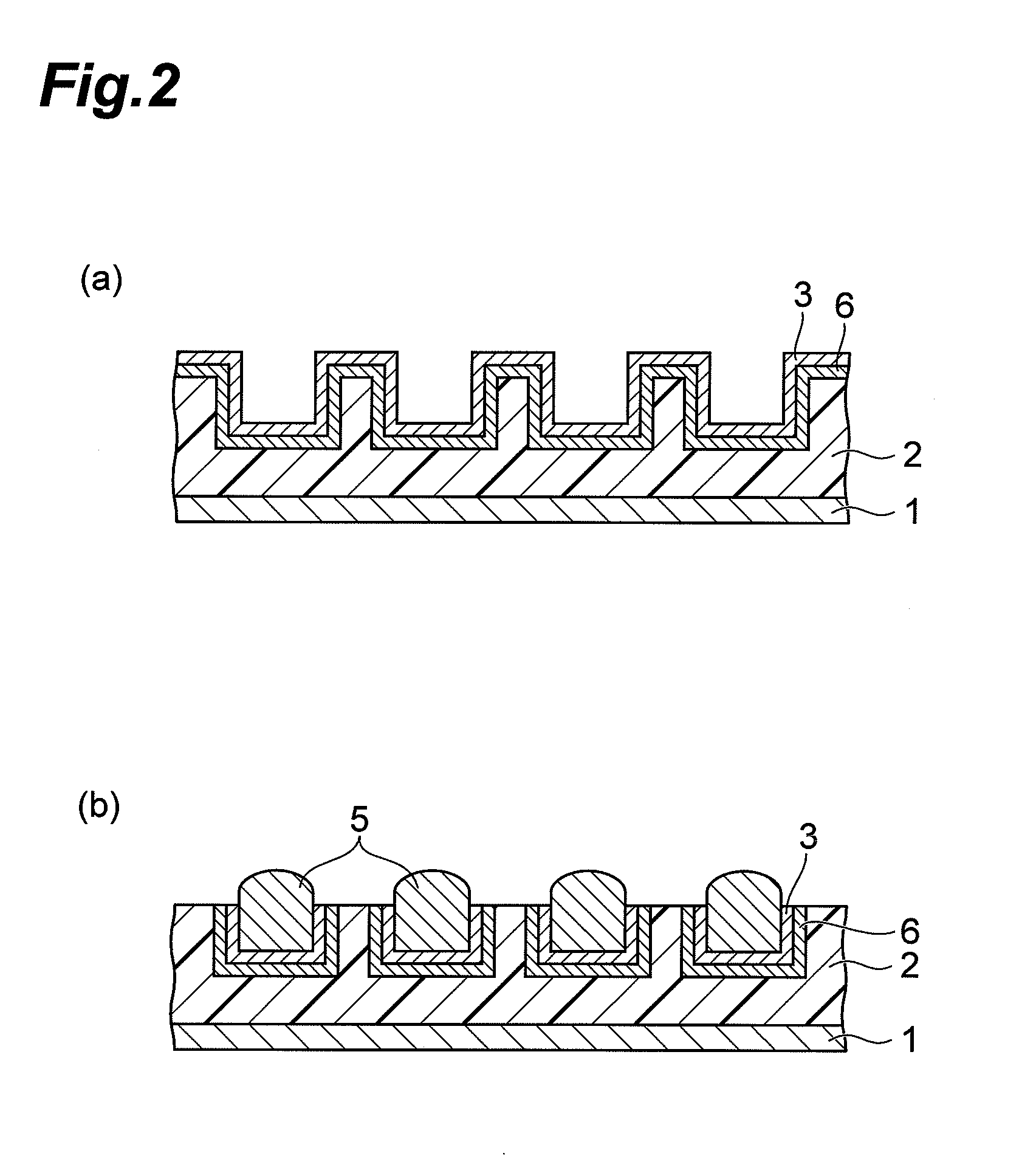

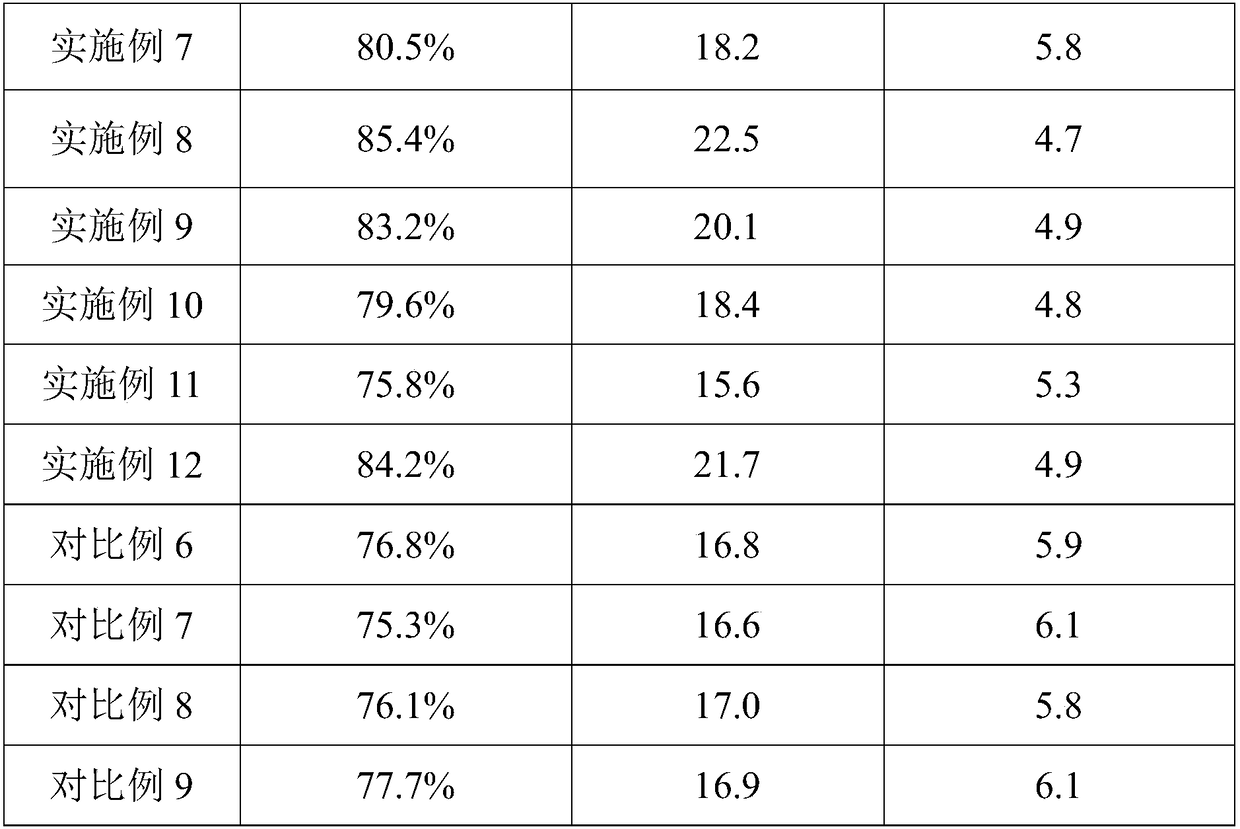

CMP pad conditioner having working surface inclined in radially outer portion

ActiveUS7021995B2Avoiding considerable damageExtended service lifeRevolution surface grinding machinesGrinding drivesMechanical engineeringEngineering

A CMP pad conditioner including: (a) a disk-shaped substrate having a working surface which is provided by one of its axially opposite end surfaces and which is to be brought into contact with the CMP pad; and (b) abrasive grains which are fixed to the working surface. The substrate includes a radially inner portion and a radially outer portion which is located radially outwardly of the radially inner portion. The working surface in the radially outer portion is inclined with respect to the working surface in the radially inner portion, such that a thickness of the radially outer portion as measured in an axial direction of the substrate is reduced as viewed in a direction away from an axis of the substrate toward a periphery of the substrate. A ratio of an outside diameter of the radially inner portion to an outside diameter of the substrate is 60–85%.

Owner:NORITAKE CO LTD +1

Chemico-mechanical polishing liquid and polishing method

InactiveCN101870851AHigh removal rateImprove metal surface qualityPolishing machinesPolishing compositions with abrasivesOxideSmall particle

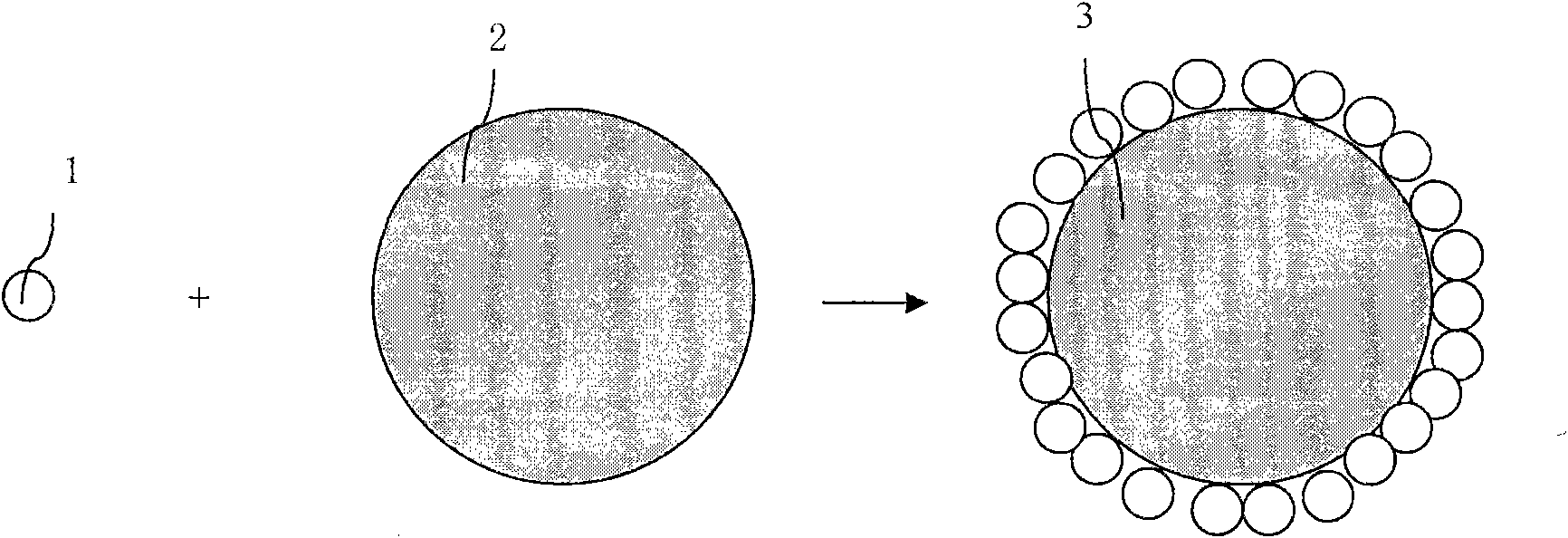

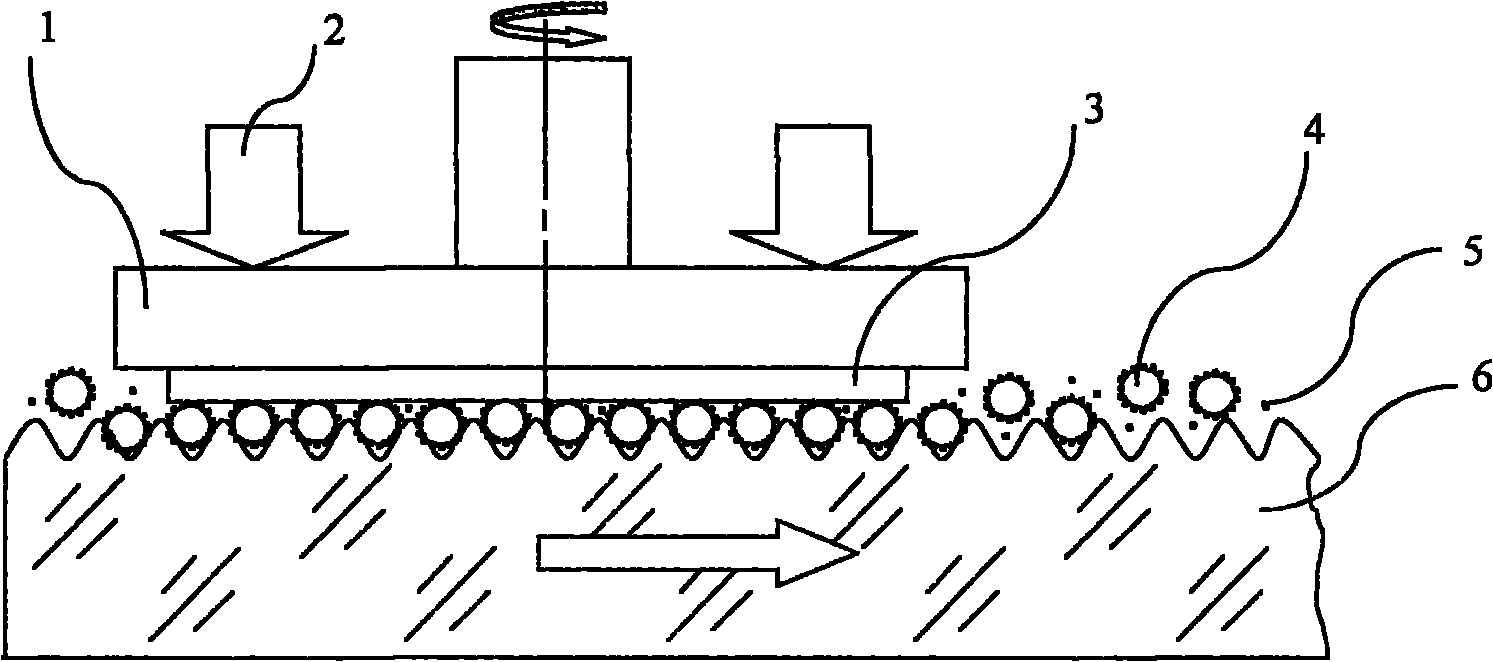

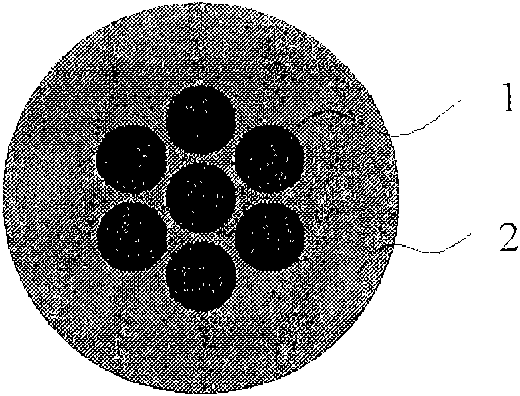

The invention discloses a chemico-mechanical polishing liquid, comprising a liquid. Composite abrasive particles are distributed in the liquid and are formed by attaching small particle diameter abrasive particles to the outside of big magnetic polymer particles, wherein the magnetic polymer particles are formed by polymer materials coating the magnetic materials. The invention also discloses a chemico-mechanical polishing method. By adopting the chemico-mechanical polishing liquid , the composite abrasive particles are kept on a soft polishing pad or the surface of a hard polisher by using an auxiliary magnetic field, and the polished surface of the polishing material is polished. When the chemico-mechanical polishing is carried out on materials, such as semiconductor substrates, oxides,metal, and the like, and a Cu / low-k medium during the processing of the semiconductor parts, the technical scheme can improve the polishing rate, control and reduce the collapsing edge of the polishing surface and improve the metal surface quality of a polishing workpiece.

Owner:ZHEJIANG UNIV OF TECH

Silane containing polishing composition for CMP

InactiveUS6646348B1High removal rateImprove polishing rateOther chemical processesSemiconductor/solid-state device detailsSilane compoundsSilanes

Polishing compositions comprising at least one soluble silane compound and at least one abrasive that are useful for polishing substrate surface features.

Owner:CABOT MICROELECTRONICS CORP

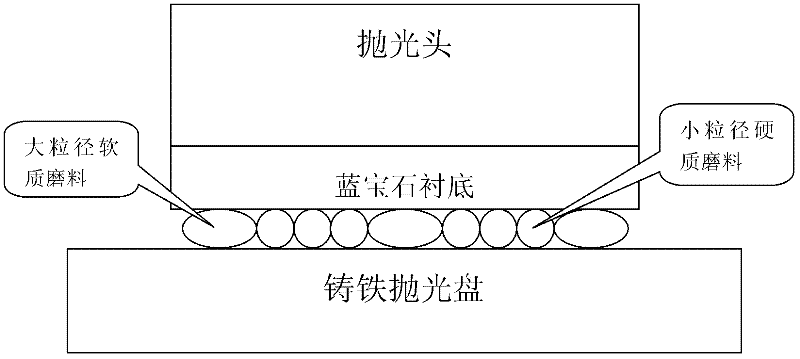

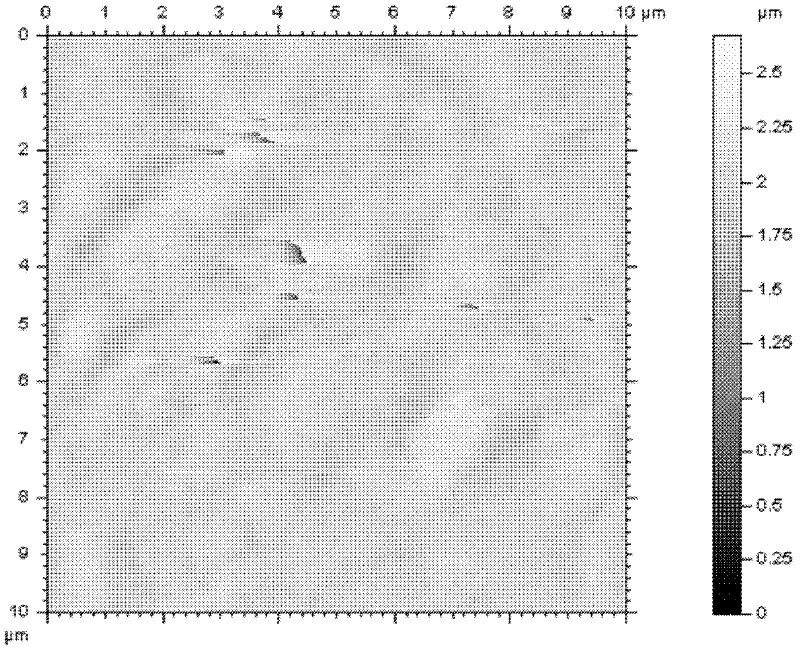

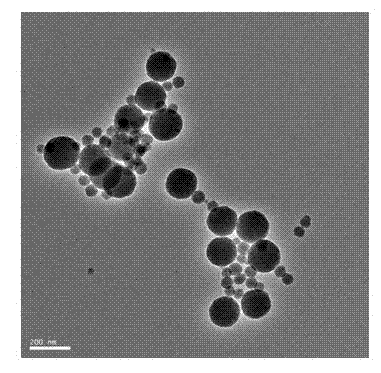

Thermochemistry mechanical polishing method of sapphire substrate material and polishing solution

InactiveCN102343547AImprove polishing rateGuaranteed uniformityLapping machinesPolishing compositions with abrasivesIonSurface-active agents

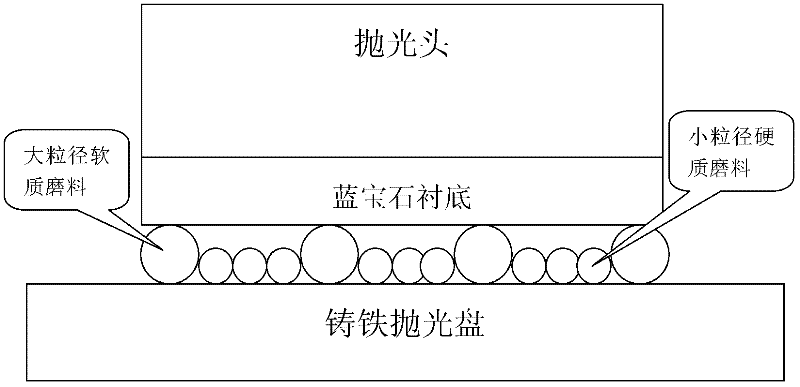

The invention relates to a thermochemistry mechanical polishing method of a sapphire substrate material; a polishing disk is heated in the polishing process; the temperature of the polishing disk is 30 DEG C-100 DEG C; a polishing solution adopted in the polishing method comprises a compound abrasive material, a pH compound conditioning agent, a surface active agent, a dispersing agent and deionized water, wherein the compound abrasive material is formed by mixing particles of a hard abrasive material and a soft abrasive material; the pH compound conditioning agent comprises organic strong base and organic weak base; and the pH value of the polishing solution is 8-13. The thermochemistry mechanical polishing method has the advantages: in the polishing process, the cast ion polishing disk is heated to promote a reaction rate between the polishing solution and the sapphire substrate material, thereby improving the polishing efficiency; problems such as surface scratch, subsurface cracks and the like can be avoided by using the compound abrasive material in the polishing solution so as to obtain surface characteristics of high quality and high evenness; meanwhile, the polishing efficiency is considered; and the polishing solution also has the advantages that the stability is high, equipment is not corroded, washing is easy and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

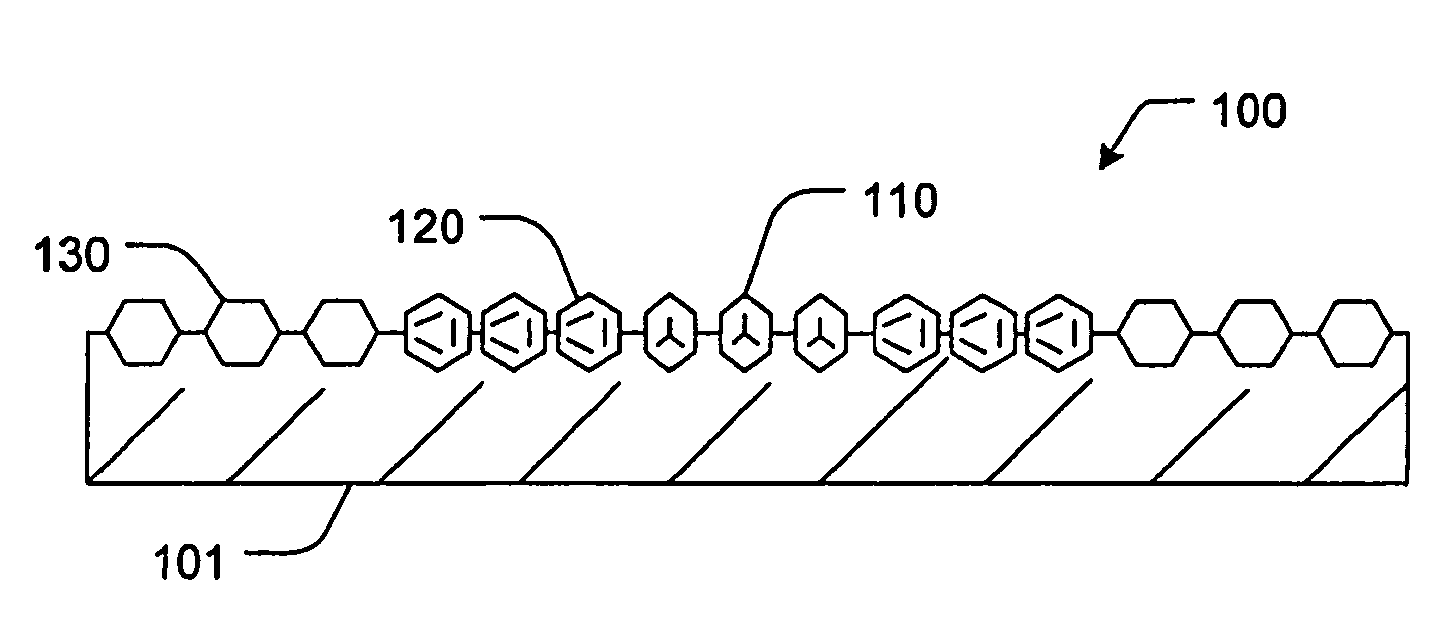

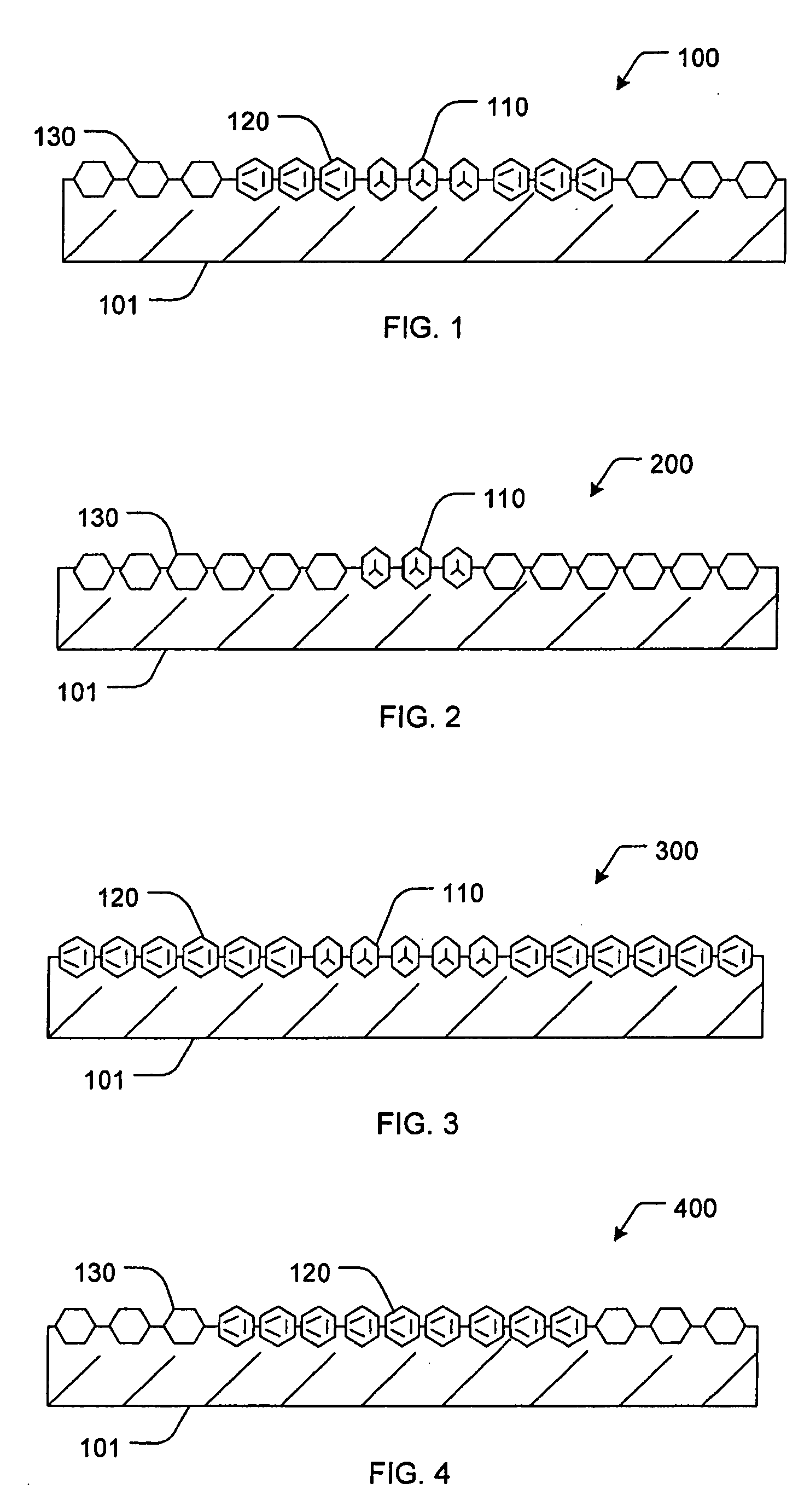

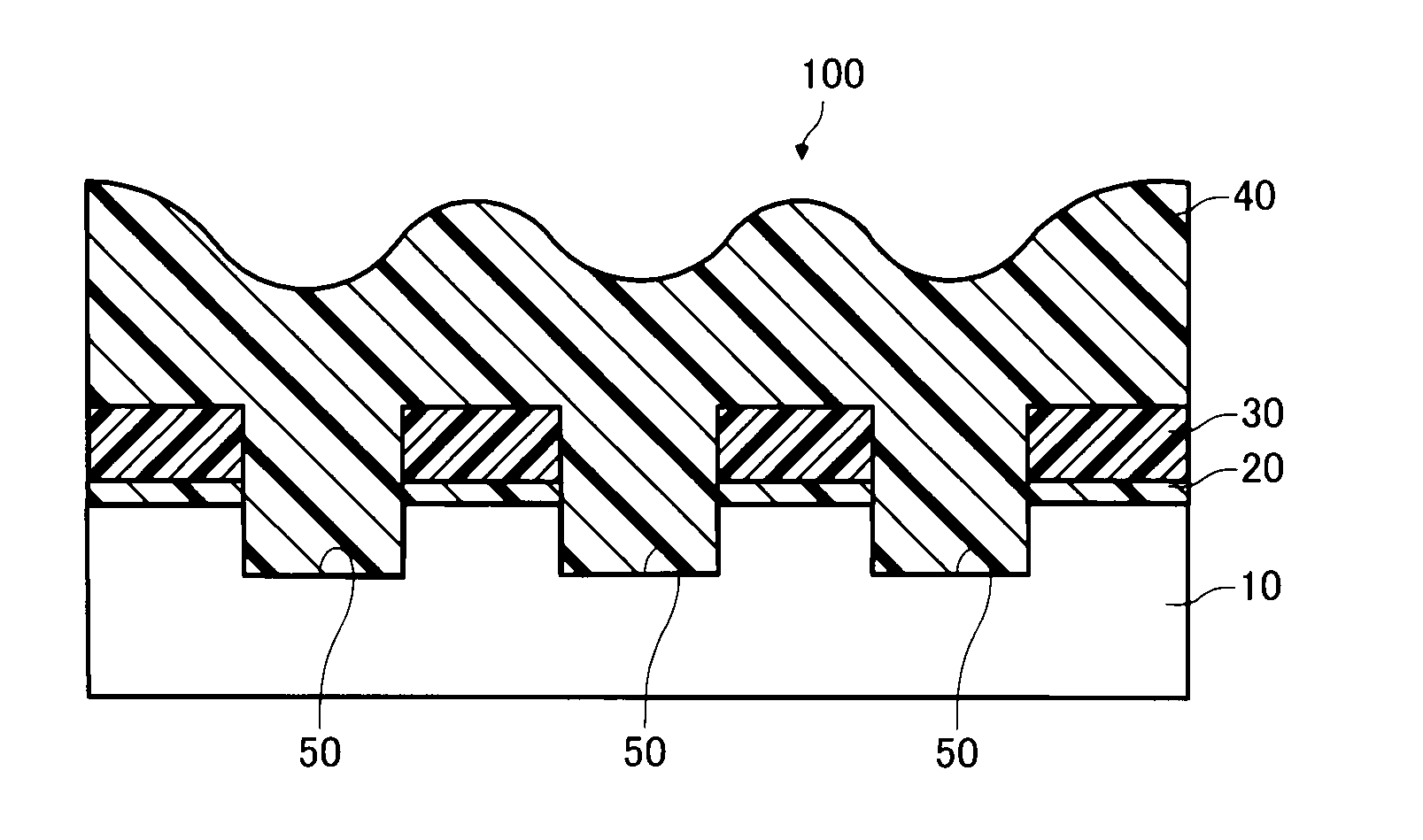

CMP pad dresser with oriented particles and associated methods

ActiveUS20060073774A1Optimize dressing rateOptimize dresser wearEdge grinding machinesGrinding drivesEmbedded system

Owner:KINIK

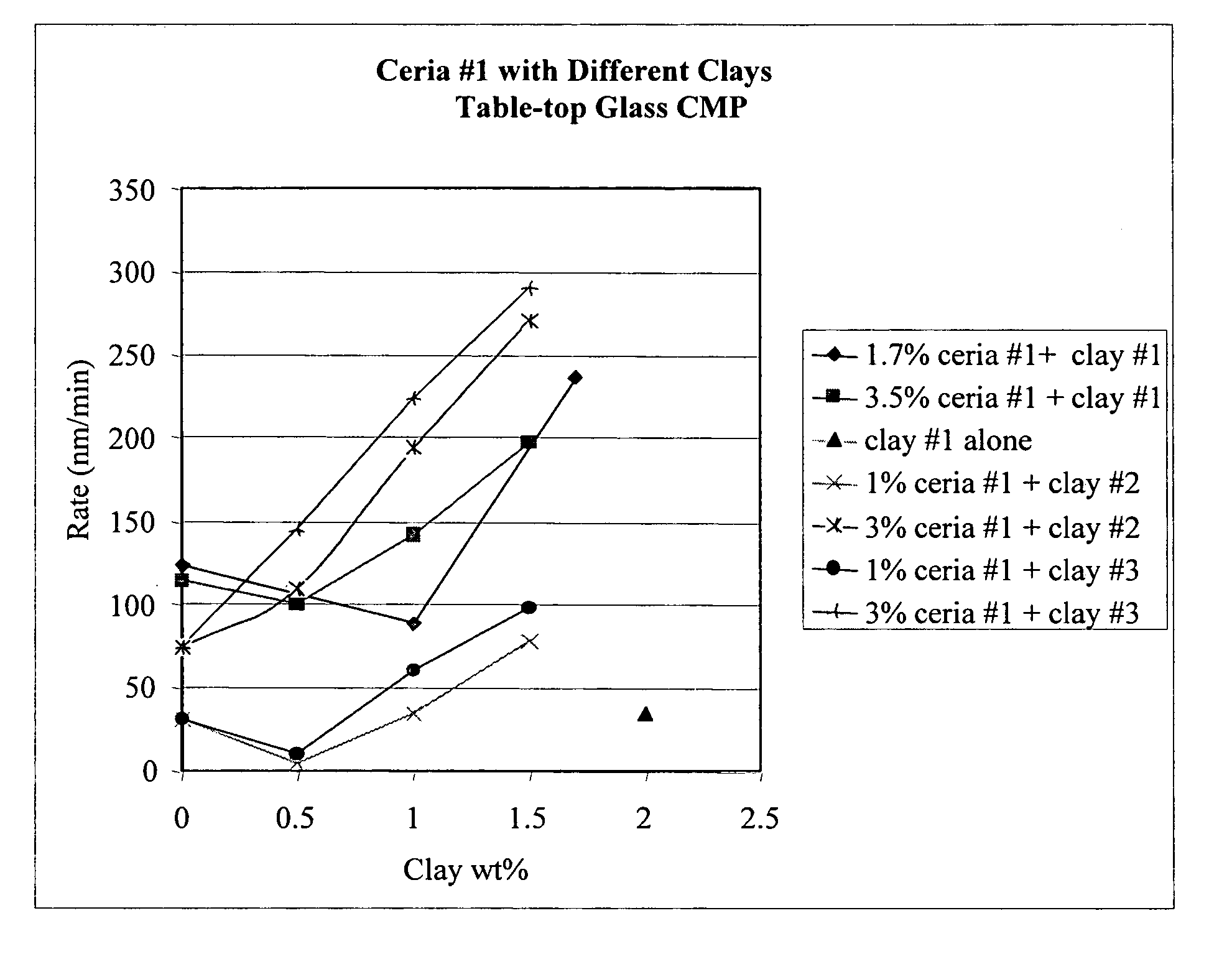

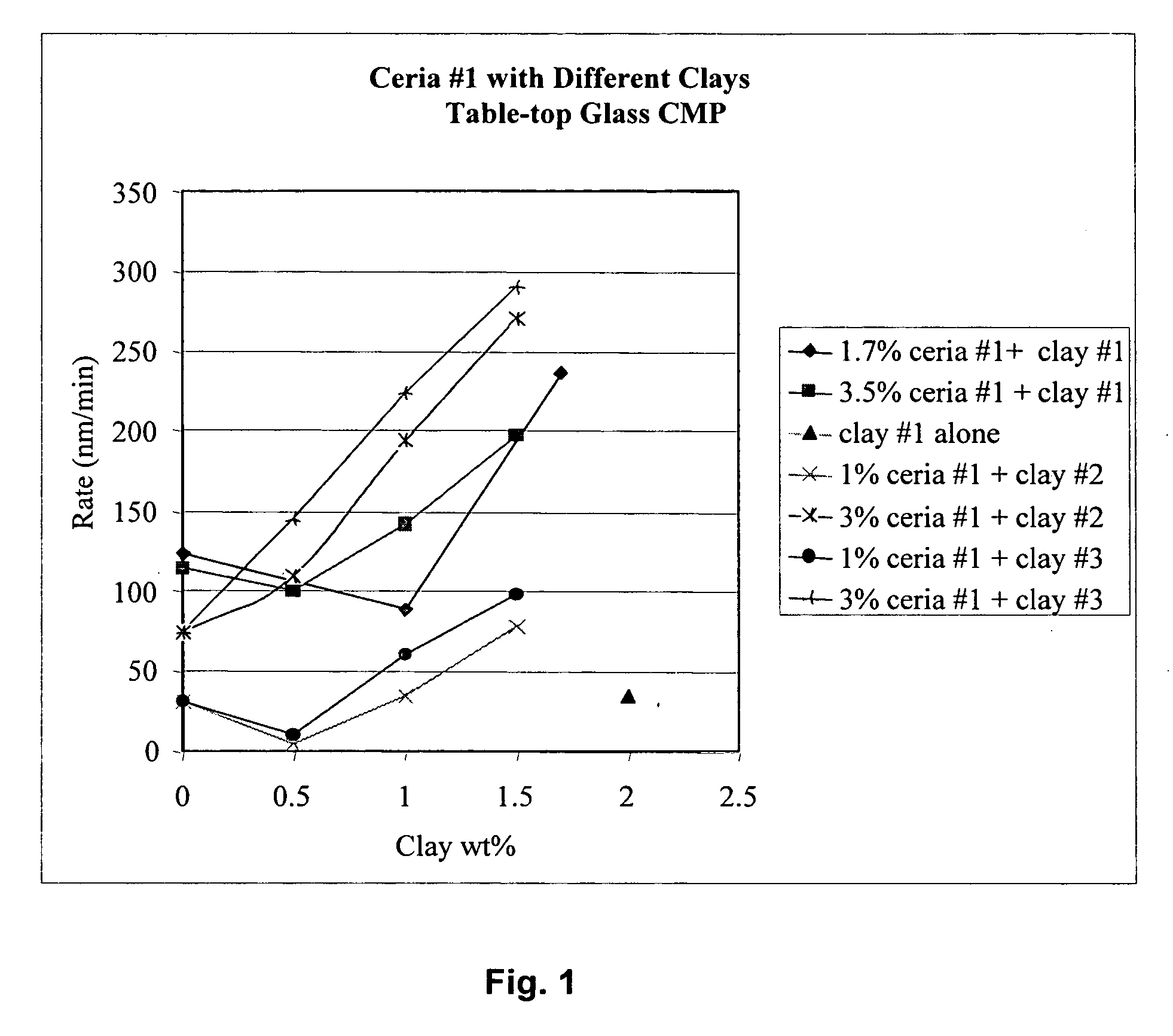

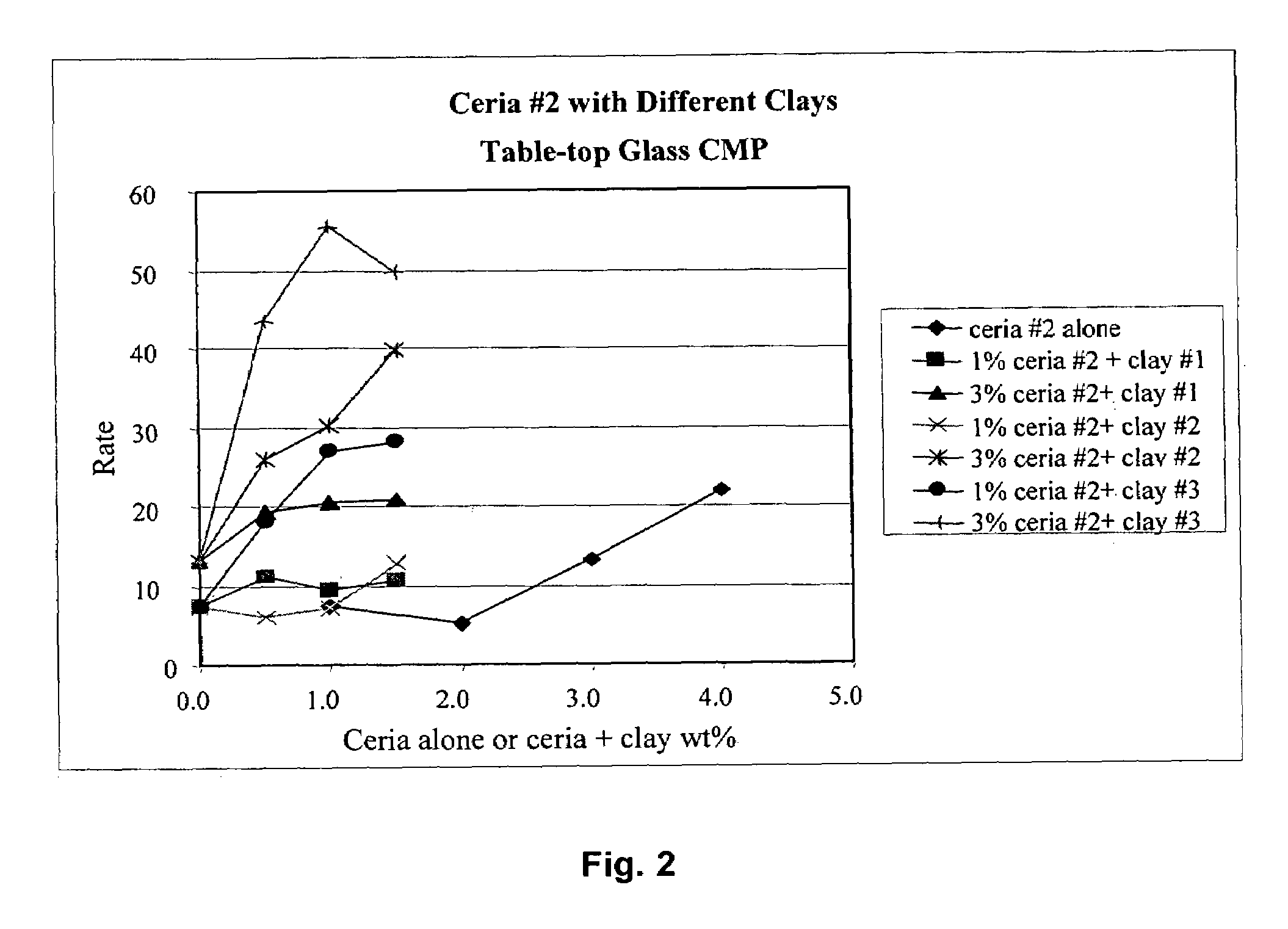

Chemical-mechanical polishing (CMP) slurry containing clay and CeO2 abrasive particles and method of planarizing surfaces

InactiveUS7112123B2Improve polishing ratePolishing machinesRevolution surface grinding machinesSlurryMaterials science

A composition for planarizing or polishing a surface comprising (a) a liquid carrier, and (b) solids comprising about 0.1 to about 10% by weight clay abrasive particles, and about 0.1% to about 50% by weight CeO2 particles, based on the total weight of solids in the composition, said clay and CeO2 abrasive particles having a particle size such that at least 90% of the particles (by number), when slurried in water, have a particle size in the range of about 10 nm to about 10 μm.

Owner:AMCOL INTERNATIONAL CORPORATION

CMP pad conditioner having working surface inclined in radially outer portion

ActiveUS20050215188A1Facilitates evacuationEfficient evacuationRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

A CMP pad conditioner including: (a) a disk-shaped substrate having a working surface which is provided by one of its axially opposite end surfaces and which is to be brought into contact with the CMP pad; and (b) abrasive grains which are fixed to the working surface. The substrate includes a radially inner portion and a radially outer portion which is located radially outwardly of the radially inner portion. The working surface in the radially outer portion is inclined with respect to the working surface in the radially inner portion, such that a thickness of the radially outer portion as measured in an axial direction of the substrate is reduced as viewed in a direction away from an axis of the substrate toward a periphery of the substrate. A ratio of an outside diameter of the radially inner portion to an outside diameter of the substrate is 60-85%.

Owner:NORITAKE CO LTD +1

Aluminum and aluminum alloy material polishing solution

The invention provides a polishing fluid for aluminum and aluminum alloy materials which includes grinding material, surface active agent, oxidizer, pH regulator, brightener and de-ionized water. The weight percentage of each component is as follows: 10 to 40 percent of grinding material, 0.01 to 0.6 percent of surface active agent, 0.5 to 10 percent of oxidizer, 1 to 6 percent of pH regulator, 1 to 15 percent of brightener and the rest is the de-ionized water; the pH value of the polishing fluid is 8 to 10; the polishing fluid can be used for the surface polishing process on the aluminum and aluminum alloy materials, can effectively reduce the surface scuffing of the aluminum alloy materials after being polished, reduce the surface coarseness of the aluminum alloy materials after being polished and improve the processing quality of the aluminum alloy materials; besides, the polishing fluid has the advantages of fastening the polishing speed, not corrupting the devices, having a high use property, and the like. The polishing fluid can also be used to stop the problems of generating alkaline fog and ammonia gas during the processing process and optimize the working environment.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Abrasive fluid compositions

InactiveUS6569216B1Improve polishing rateReduce surface roughnessPigmenting treatmentOther chemical processesFluid compositionChemistry

A polishing composition comprising a chelating compound or a salt thereof; a partially esterified product and / or partially etherified product of a polyhydric alcohol compound; and water; a polishing composition comprising water, an abrasive, an intermediate alumina, and a chelating compound or a salt thereof, wherein the content of the intermediate alumina is from 1 to 50 parts by weight, based on 100 parts by weight of the abrasive; and a polishing composition comprising water, an abrasive, an intermediate alumina, a chelating compound or a salt thereof, and a partially esterified product and / or partially etherified product of a polyhydric alcohol compound, wherein the content of the intermediate alumina is from 1 to 50 parts by weight, based on 100 parts by weight of the abrasive. By using the polishing composition, the polishing rate can be increased, and the surface roughness can be lowered, without causing defects such as scratches and pits on the surface of an object to be polished.

Owner:KAO CORP

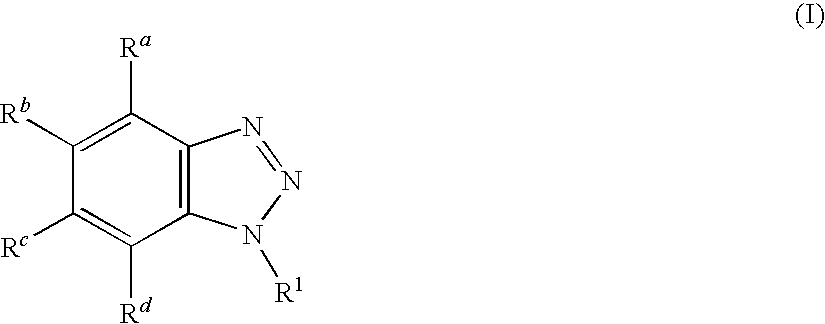

Aqueous dispersion for chemical mechanical polishng and chemical mechanical polishing method for semiconductor device

ActiveUS20100099260A1Improve polishing rateHigh rateOther chemical processesDecorative surface effectsColloidal silicaAmmonium compounds

A chemical mechanical polishing aqueous dispersion includes (A) colloidal silica having an average particle size calculated from the specific surface area determined by the BET method of 10 to 60 nm, (B) an organic acid having two or more carboxyl groups and one or more hydroxyl groups in one molecule, and (C) a quaternary ammonium compound shown by the following general formula (1),wherein R1 to R4 individually represent hydrocarbon groups, and M− represents an anion, the chemical mechanical polishing aqueous dispersion having a pH of 3 to 5.

Owner:JSR CORPORATIOON

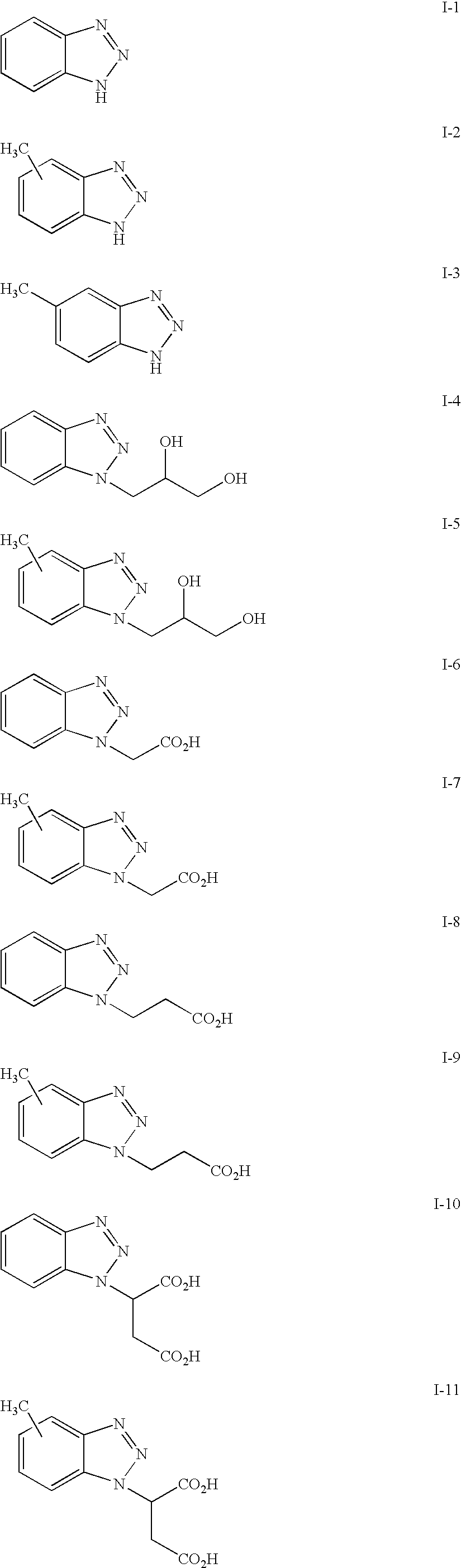

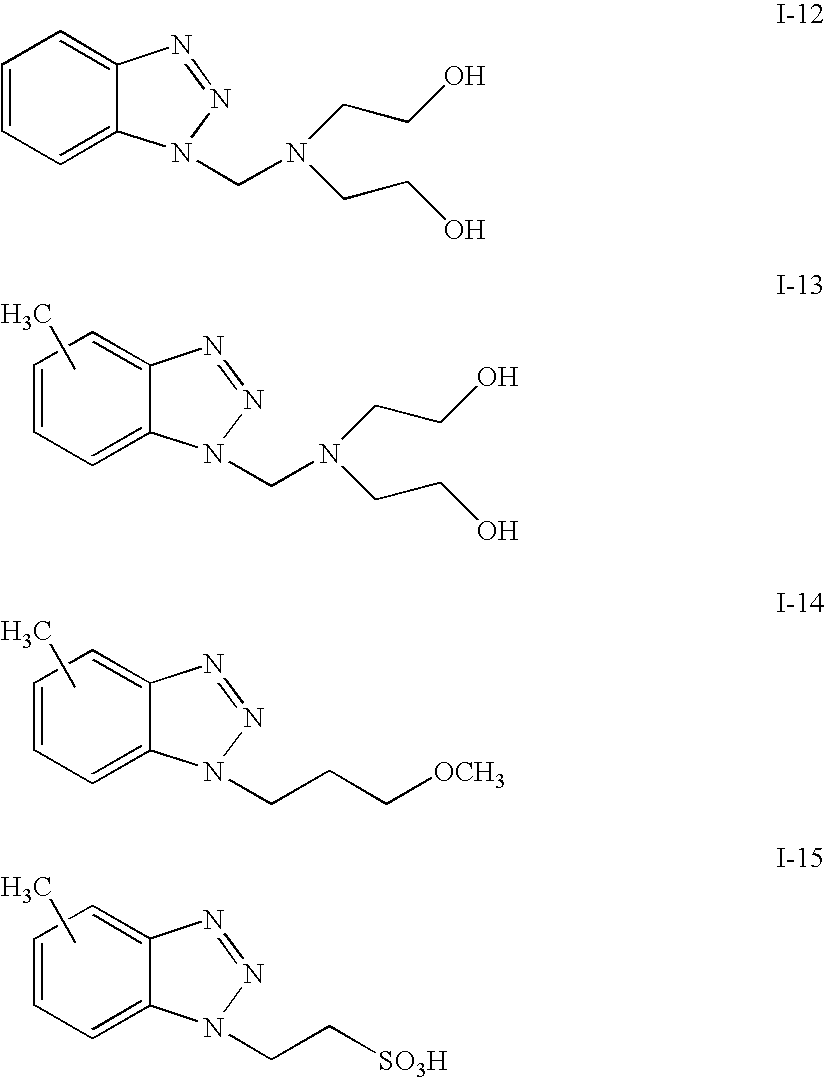

Polishing liquid for metal and polishing method using the same

ActiveUS20090239380A1Improve polishing rateGood planarityOther chemical processesNanoinformaticsColloidal silicaElectrical conductor

A liquid for polishing a metal is provided that is used for chemically and mechanically polishing a conductor film including copper or a copper alloy in production of a semiconductor device, and a polishing method using the metal-polishing liquid is also provided. The liquid includes: (a) colloidal silica particles having an average primary particle size of from 10 nm to 25 nm and an average secondary particle size of from 50 nm to 70 nm; (b) a metal anticorrosive agent; (c) at least one compound selected from the group consisting of a surfactant and a water-soluble polymer compound; (d) an oxidizing agent; and (e) an organic acid.

Owner:FUJIFILM CORP

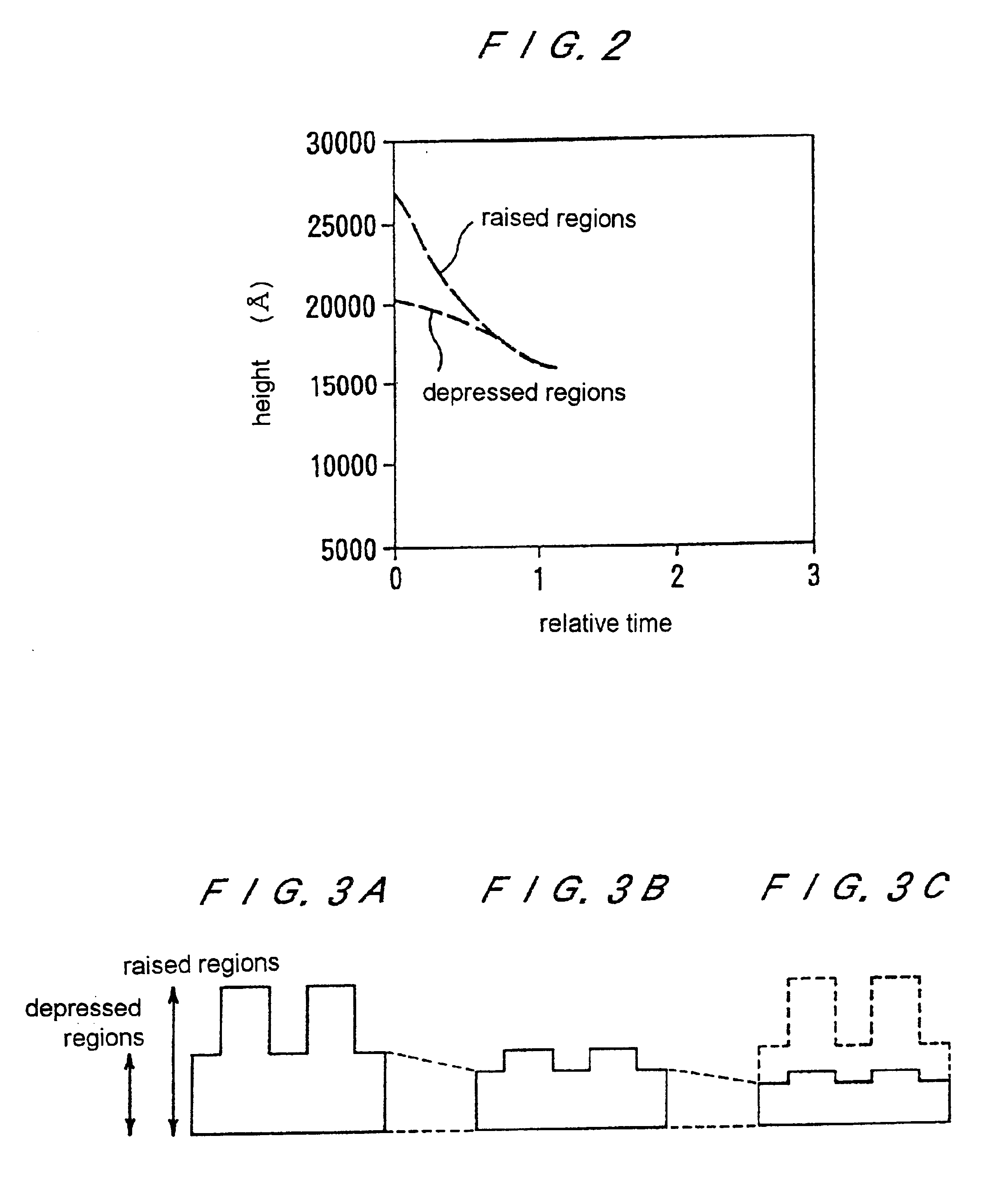

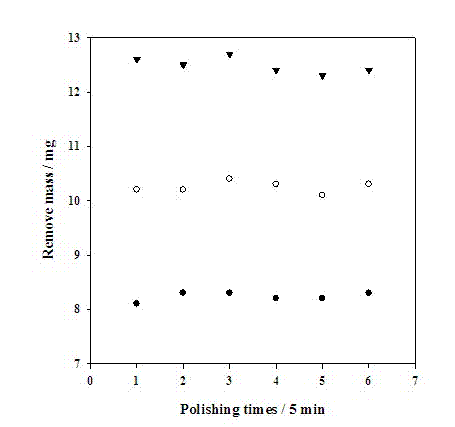

Polishing method using an abrading plate

InactiveUS6942548B2Stabilized polishing rateLow polishing ratePolishing machinesRevolution surface grinding machinesPorosityMicrometer

An abrading plate has a self-stopping capability such that when an object, such as a semiconductor wafer having a device structure that includes raised regions and depressed regions fabricated on the surface, is being polished, the raised regions are removed and polishing stops automatically. The abrading plate, to produce a flat and mirror polished surface on the an object, has abrasive particles having a chemical purity of not less than 90% and a particle size of not more than two micrometers, a binder material, and a given volume of porosity. A ratio of the abrasive particles and the binder material is not less than 1:0.5 by volume, and proportions of abrasive particles, a binder material and porosity are, respectively, not less than 10%, not more than 60% and 10-40% by volume. A surface is polished for a given duration with a liquid not containing abrasive particles so as to eliminate the raised regions and to obtain a flat surface. Additional surface removal is performed by supplying abrasive particles to the polishing interface to remove surface material uniformly from the entire surface.

Owner:EBARA CORP

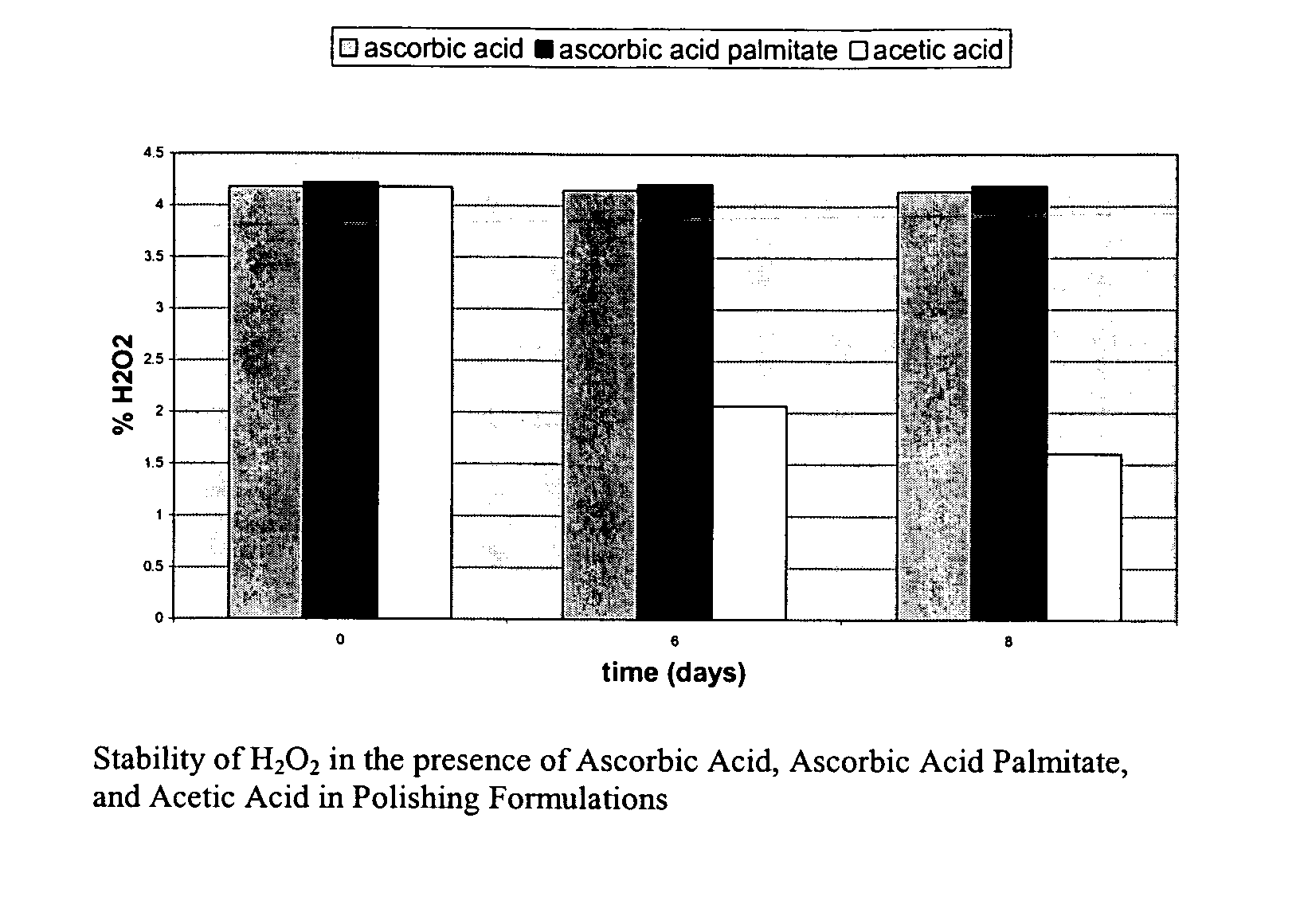

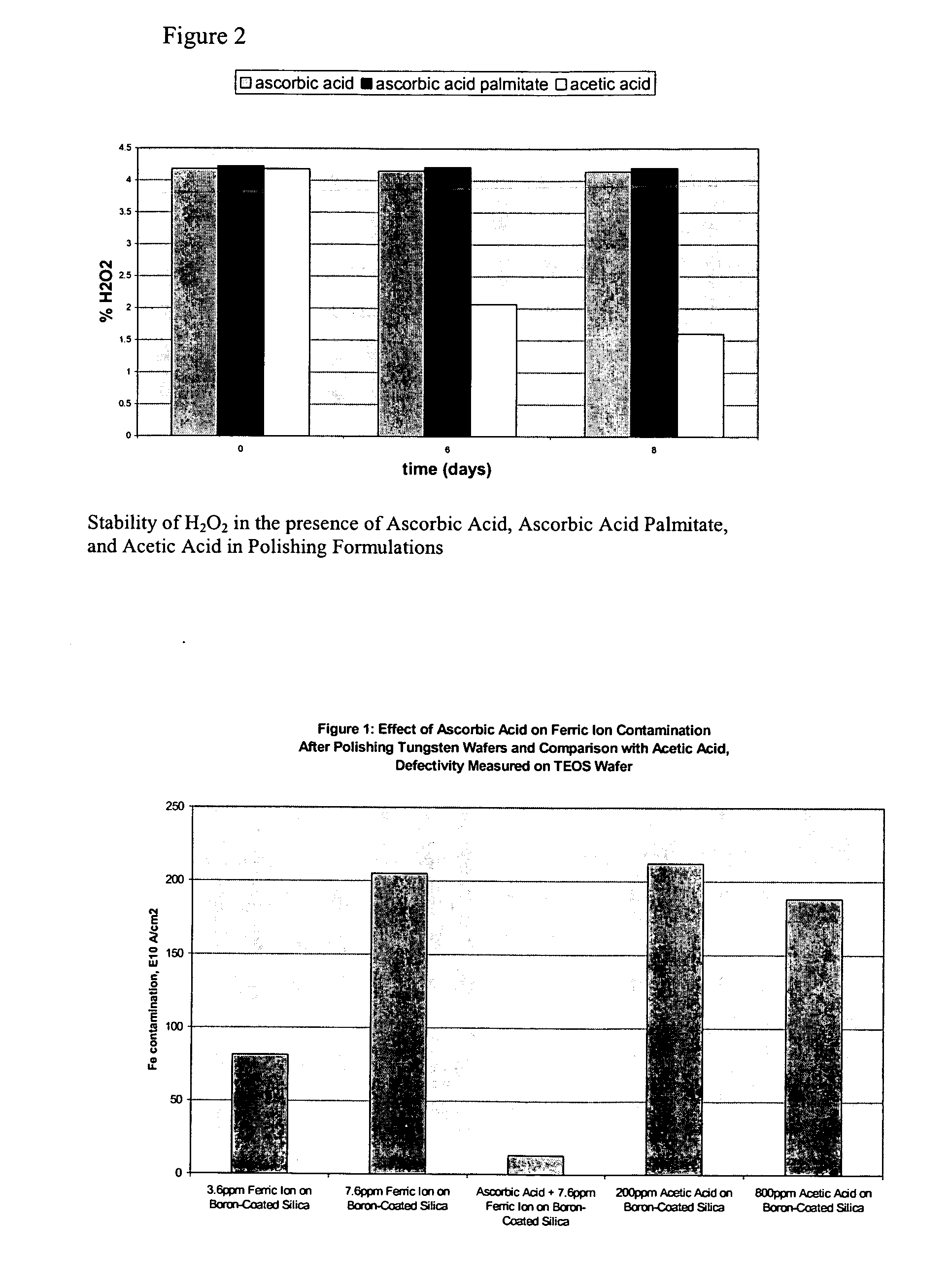

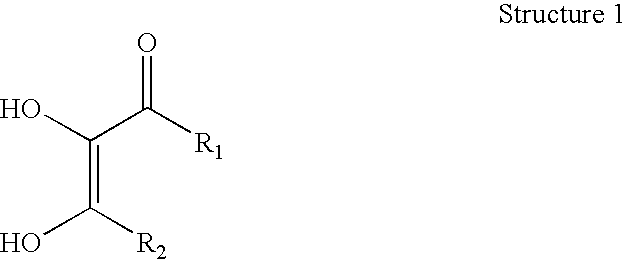

Dihydroxy enol compounds used in chemical mechanical polishing compositions having metal ion oxidizers

ActiveUS20060270235A1Improve polishing rateRemoval rateOther chemical processesDecorative surface effectsCompound (substance)Slurry

A chemical mechanical polishing composition contains 1) water, 2) optionally an abrasive material, 3) an oxidizer, preferably a per-type oxidizer, 4) a small amount of soluble metal-ion oxidizer / polishing accelerator, a metal-ion polishing accelerator bound to particles such as to abrasive particles, or both; and 5) at least one of the group selected from a) a small amount of a chelator, b) a small amount of a dihydroxy enolic compound, and c) a small amount of an organic accelerator. Ascorbic acid in an amount less than 800 ppm, preferably between about 100 ppm and 500 ppm, is the preferred dihydroxy enolic compound. The polishing compositions and processes are useful for substantially all metals and metallic compounds found in integrated circuits, but is particularly useful for tungsten. The present invention also pertains to surface-modified colloidal abrasive polishing compositions and associated methods of using these compositions, particularly for chemical mechanical planarization, wherein the slurry comprises low levels of chelating free radical quenchers, non-chelating free radical quenchers, or both.

Owner:VERSUM MATERIALS US LLC

Polishing medium for chemical-mechanical polishing, and method of polishing substrate member

InactiveUS20060037251A1Improve reliabilityReduce concentrationPigmenting treatmentOther chemical processesElectrical conductorFilm-forming agent

This invention provides a polishing medium for chemical-mechanical polishing, comprising an oxidizing agent for a conductor, a protective-film-forming agent for protecting a metal surface, an acid, and water; (1) the polishing medium having a pH of 3 or less, and the oxidizing agent being in a concentration of from 0.01 to 3% by weight, or (2) the polishing medium containing abrasive grains having an average particle diameter of 50 nm or less, and the abrasive grains having standard deviation of particle size distribution in a value of more than 5 nm.

Owner:HITACHI CHEM CO LTD

Aqueous dispersion for chemical mechanical polishing, chemical mechanical polishing method, and kit for preparing aqueous dispersion for chemical mechanical polishing

InactiveUS20090302266A1Appropriate viscosityGuaranteed normal transmissionOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidAqueous solubility

A chemical mechanical polishing aqueous dispersion comprises (A) abrasive grains, (B) an organic acid, (C) a water-soluble polymer, (D) an oxidizing agent, and (E) water, the water-soluble polymer (C) having a weight average molecular weight of 50,000 to 5,000,000.

Owner:JSR CORPORATIOON

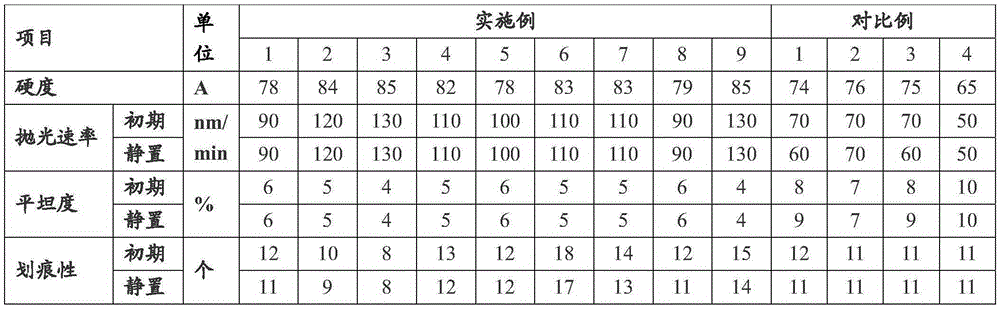

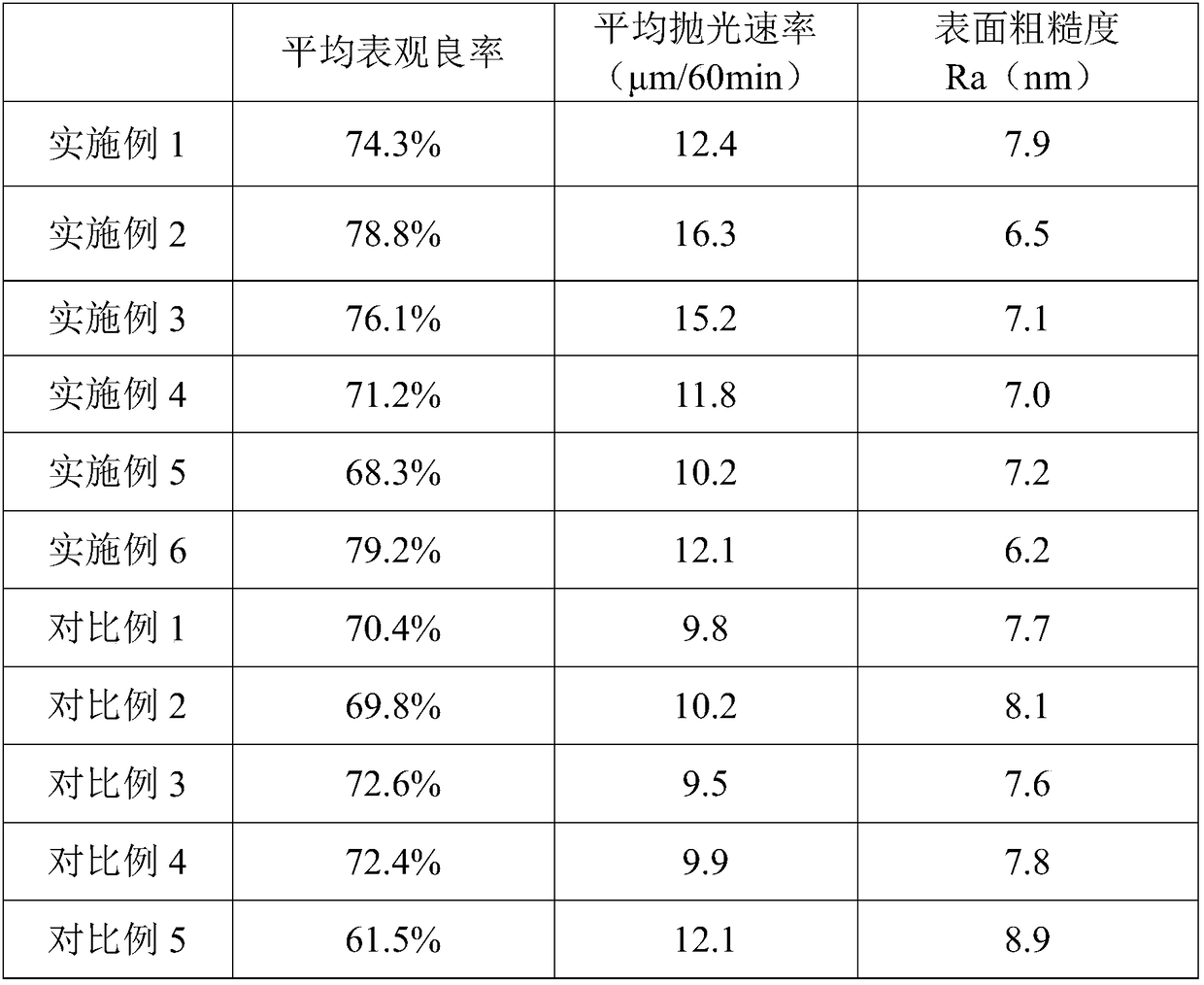

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

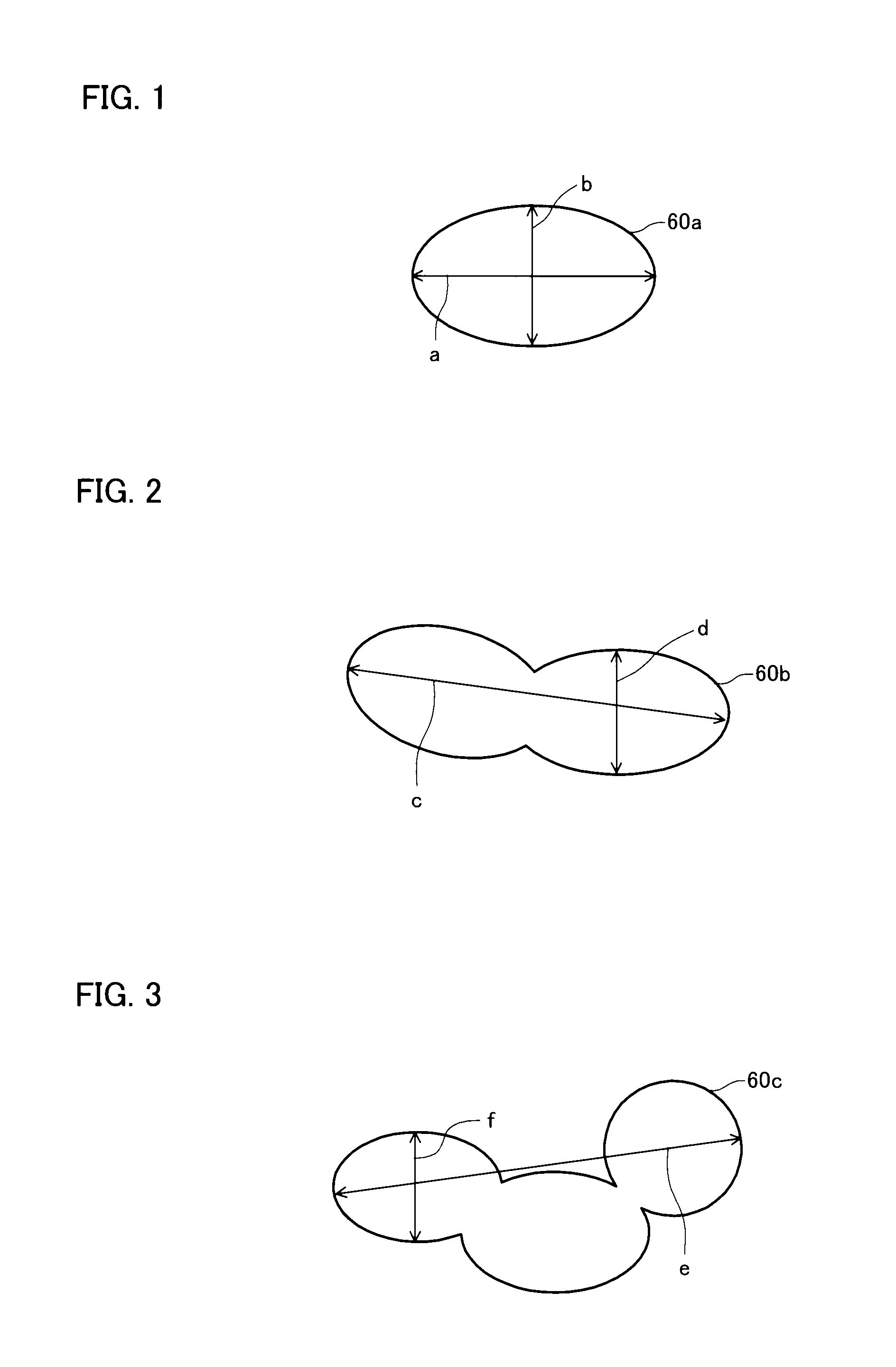

Preparation method of nonspherical nanometer-scale silica sol

InactiveCN102390837AImprove stabilityImprove polishing rateSilicaNanotechnologyCrystallographySilicic acid

The invention provides a preparation method of nonspherical nanometer-scale silica sol. The preparation method comprises the following steps of: with 2-5 percent of small-size nonspherical silica sol as seed crystals, dropwise adding a 5-40% mixed base solution, adjusting the pH value to 10, stirring and heating to 90-100 DEG C; and then dropwise adding active silicic acid to the system, maintaining a constant liquid level by adopting a heating concentration method, reacting for 10-40h and dropwise adding the mixed base solution to keep the pH value of the reaction system to 9-11 in the reaction peroid. The preparation method of the nonspherical nanometer-scale silica sol has the beneficial effects that: the nonspherical silica sol with grain size of 30-50nm is prepared by using the small-size nonspherical silica sol as the seed crystals, therefore the stability is good; the preparation method is suitable for chemically mechanical polishing and high polishing speed, and the polishing speed is accelerated by more than 10 percent compared with the polishing speed of the spherical silica sol with large size (130nm).

Owner:JIANGSU TIANHENG NANO SCI & TECH

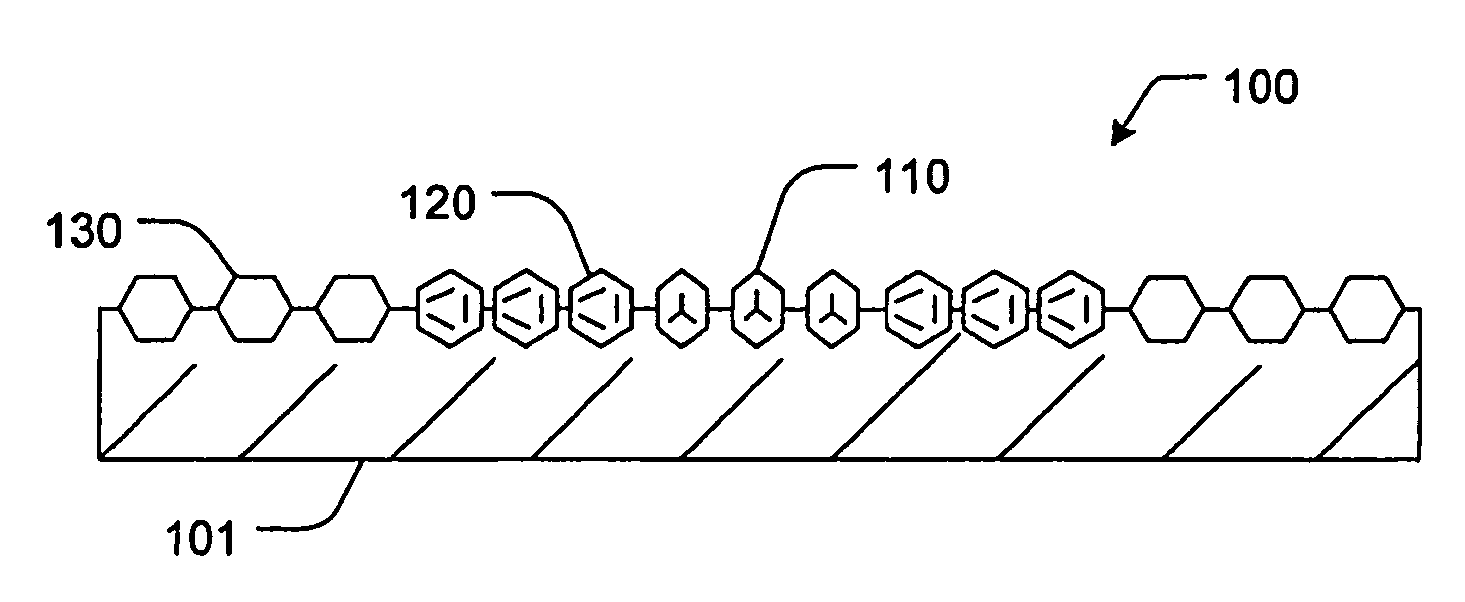

Composite polishing pad and preparation method thereof

ActiveCN105415168AReduce hair sheddingGood surface smoothnessGrinding devicesLapping toolsElastomerPolymer science

The invention discloses a preparation method of a composite polishing pad. The preparation method comprises the following steps that (1) non-woven fabric is preprocessed, specifically, (a) the non-woven fabric is put into a drying oven for flattening, (b) the flattened non-woven fabric is immersed into a glue solution and then is taken out after being infiltrated sufficiently, and a non-woven fabric substrate material is obtained; (2) a polymer solution is prepared, specifically, (I) a macromolecular elastomer is dissolved into a solvent, and a macromolecular elastomer solution is prepared; (II) polymer particles are added into the macromolecular elastomer solution, and the polymer solution is obtained; (3) the non-woven fabric is made into a pad, specifically, the non-woven fabric substrate material is infiltrated into the polymer solution and then is taken out after being infiltrated sufficiently, and unnecessary solutions on the surface of the non-woven fabric substrate material are scraped off; the non-woven fabric substrate material is immersed into coagulating bath for consolidation forming and then put into pure water for rinsing and finally dried to the constant weight, and an original polishing pad is obtained; and (4) the polishing pad is formed, specifically, after the surface of the original polishing pad is polished, cut and rubberized, and the finished polishing pad is obtained. By means of the preparation method, the composite polishing pad has a large polishing rate, and moreover the flatness of a polished object is good.

Owner:河南惠强新能源材料科技股份有限公司

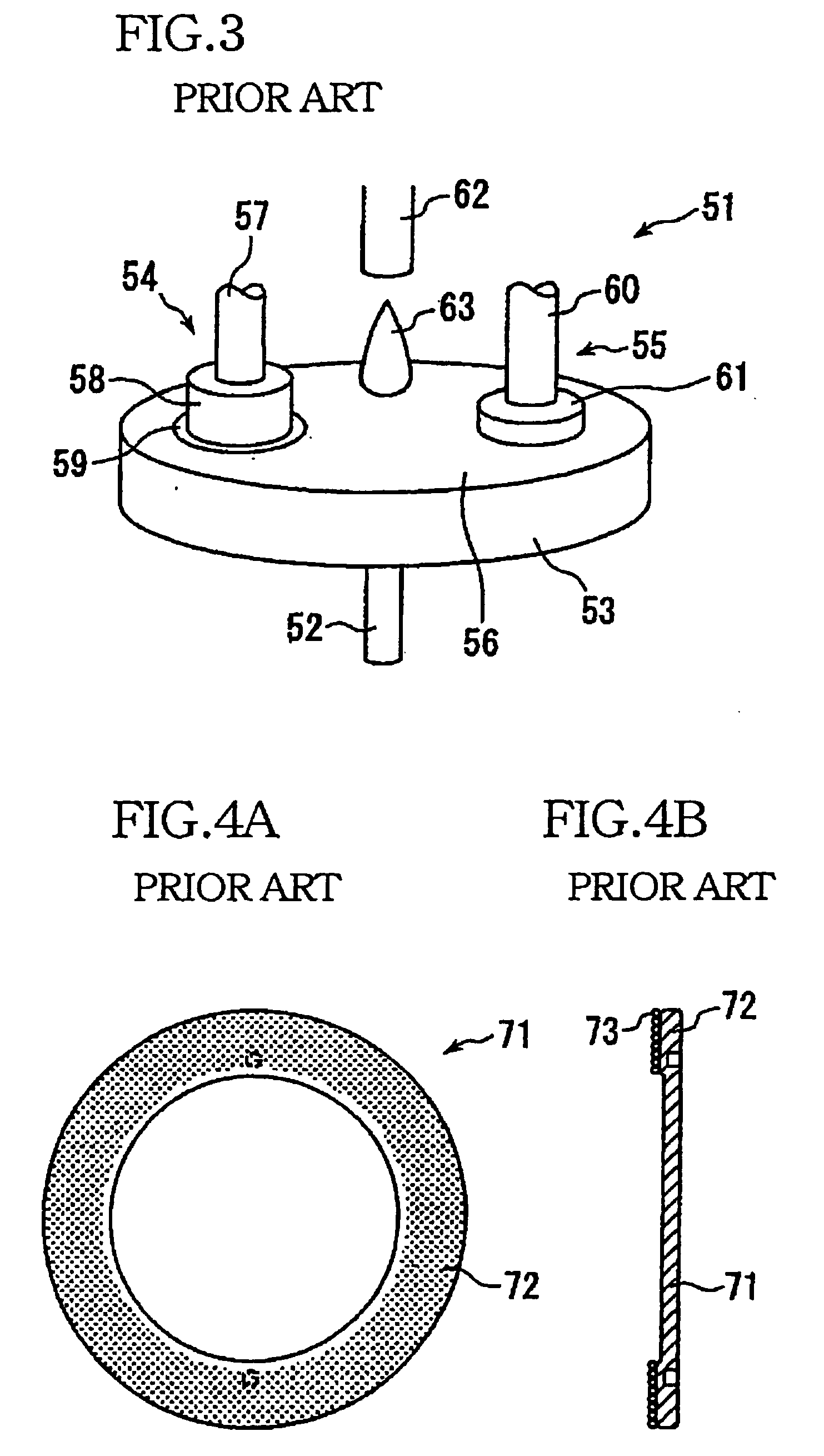

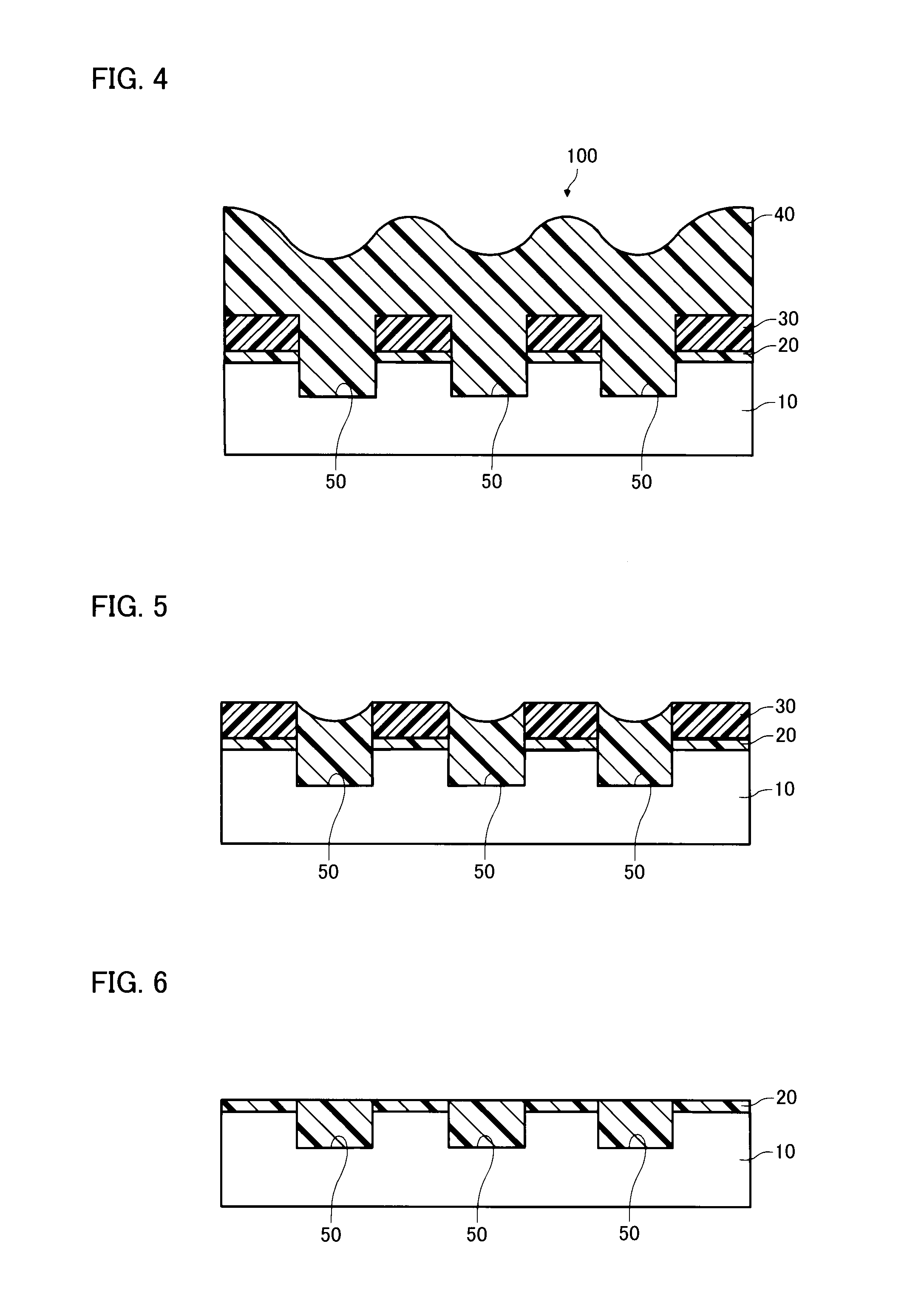

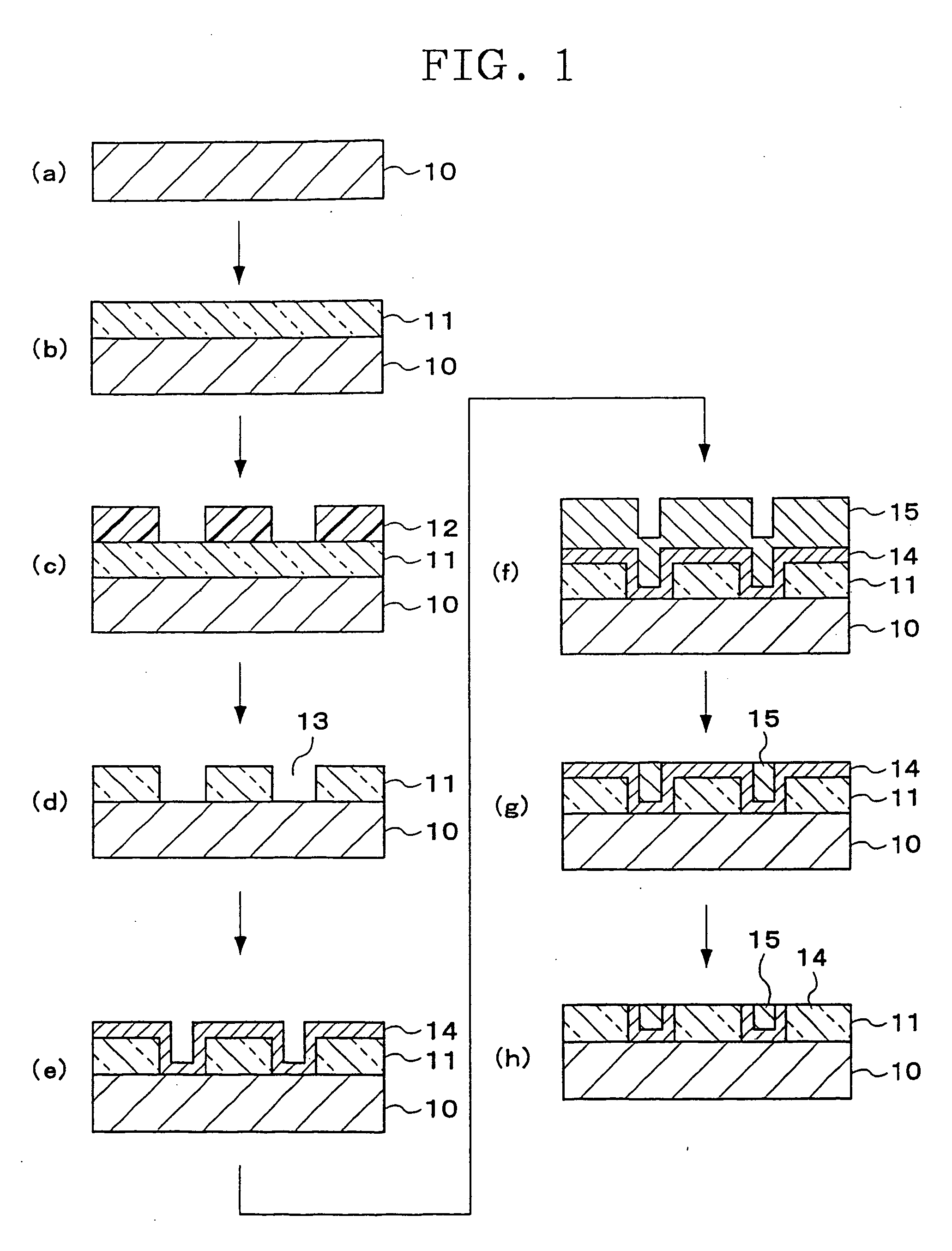

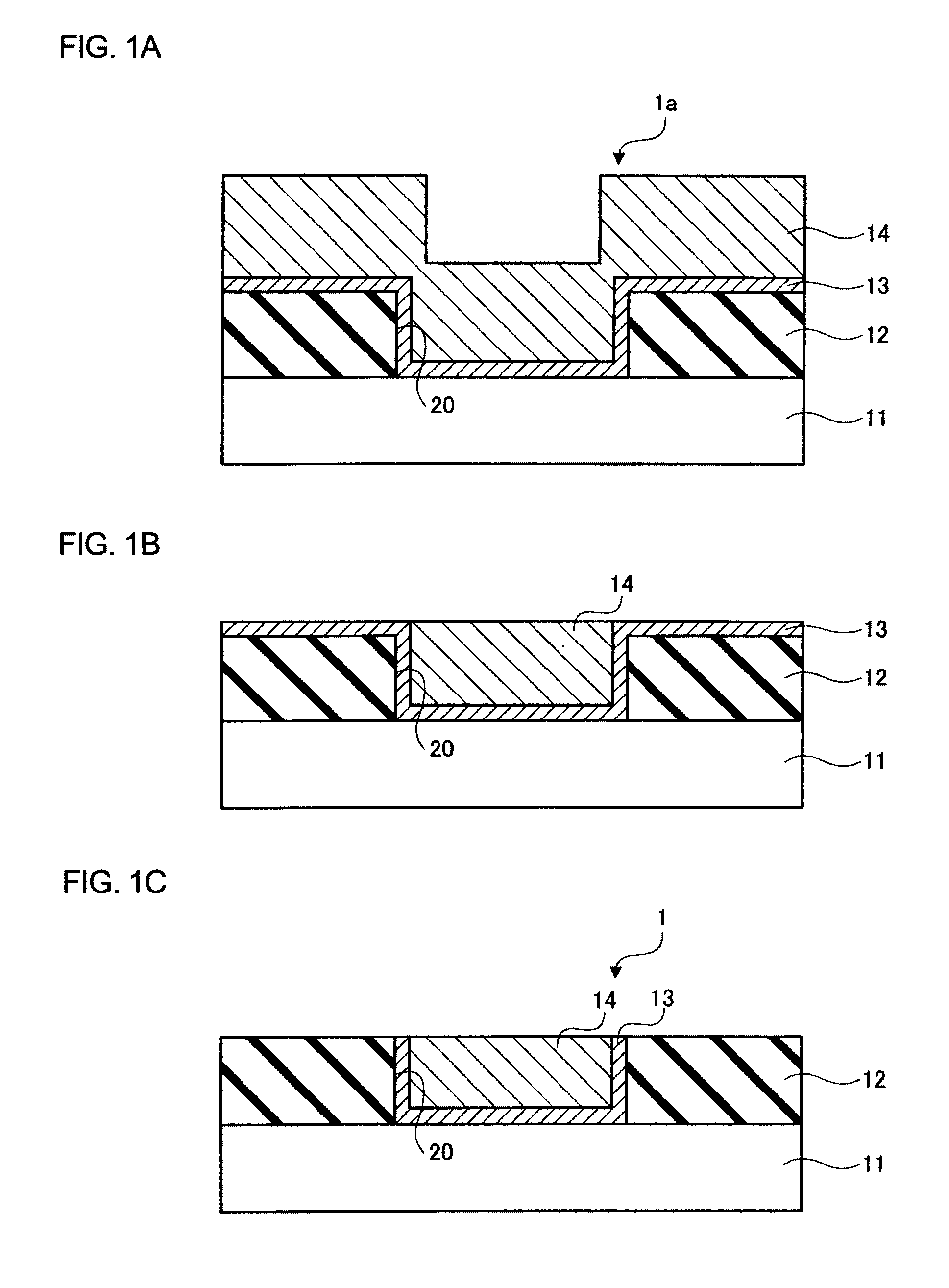

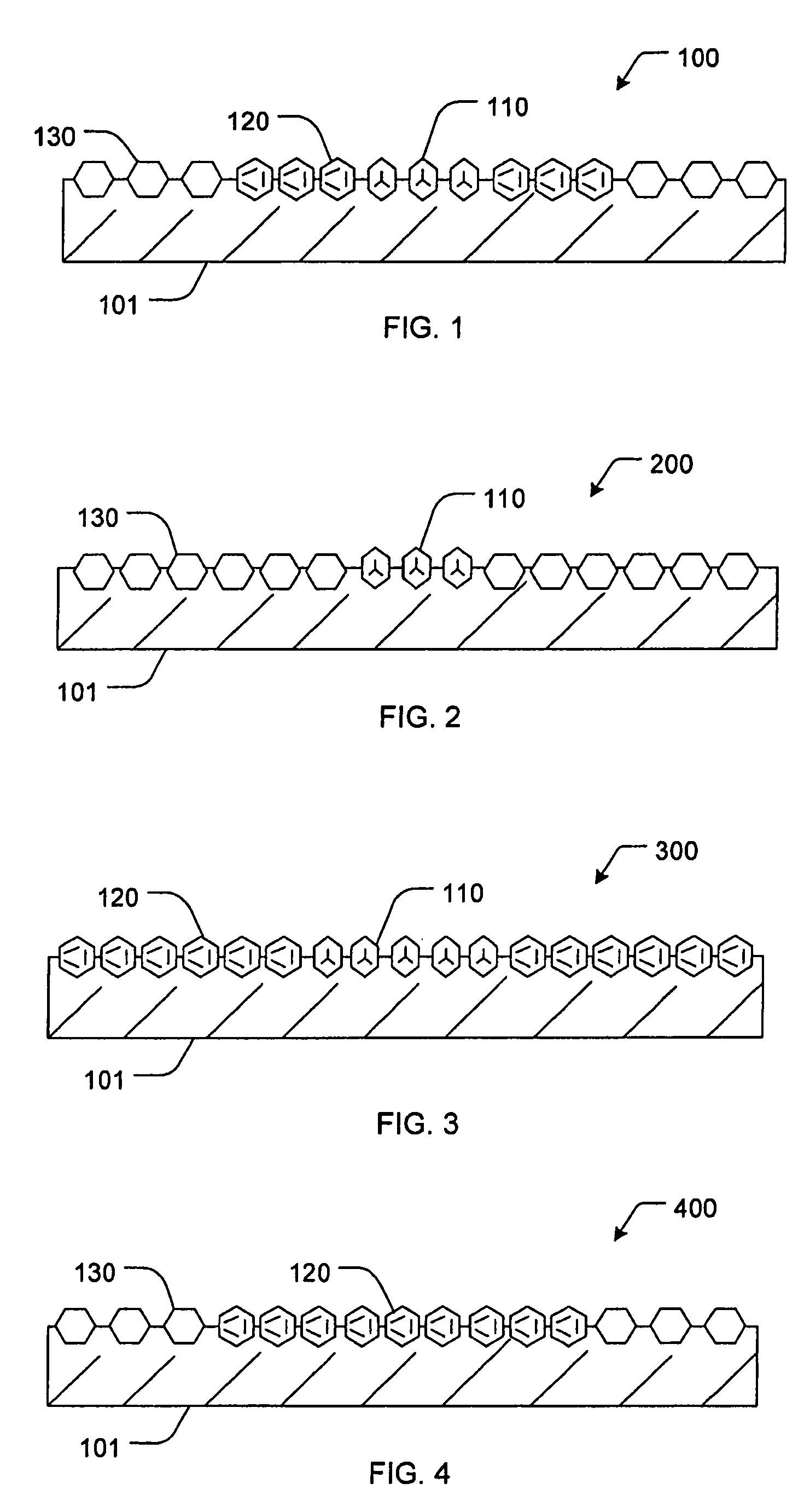

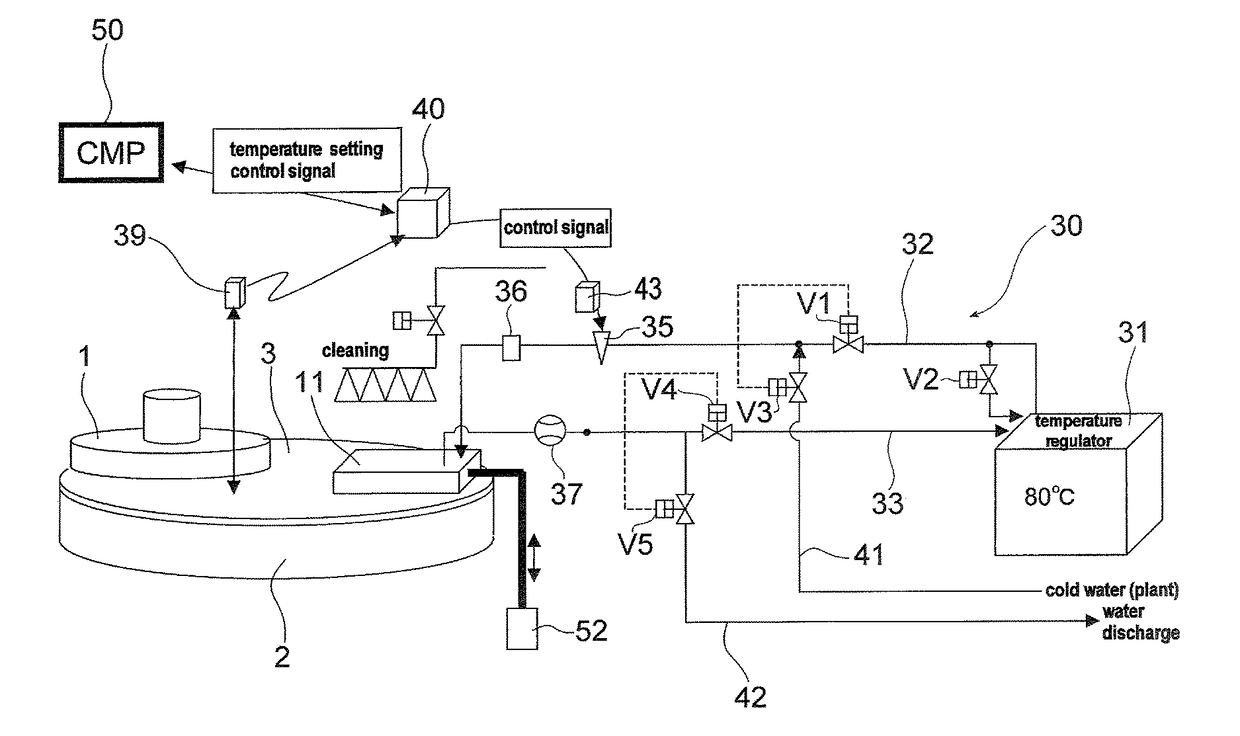

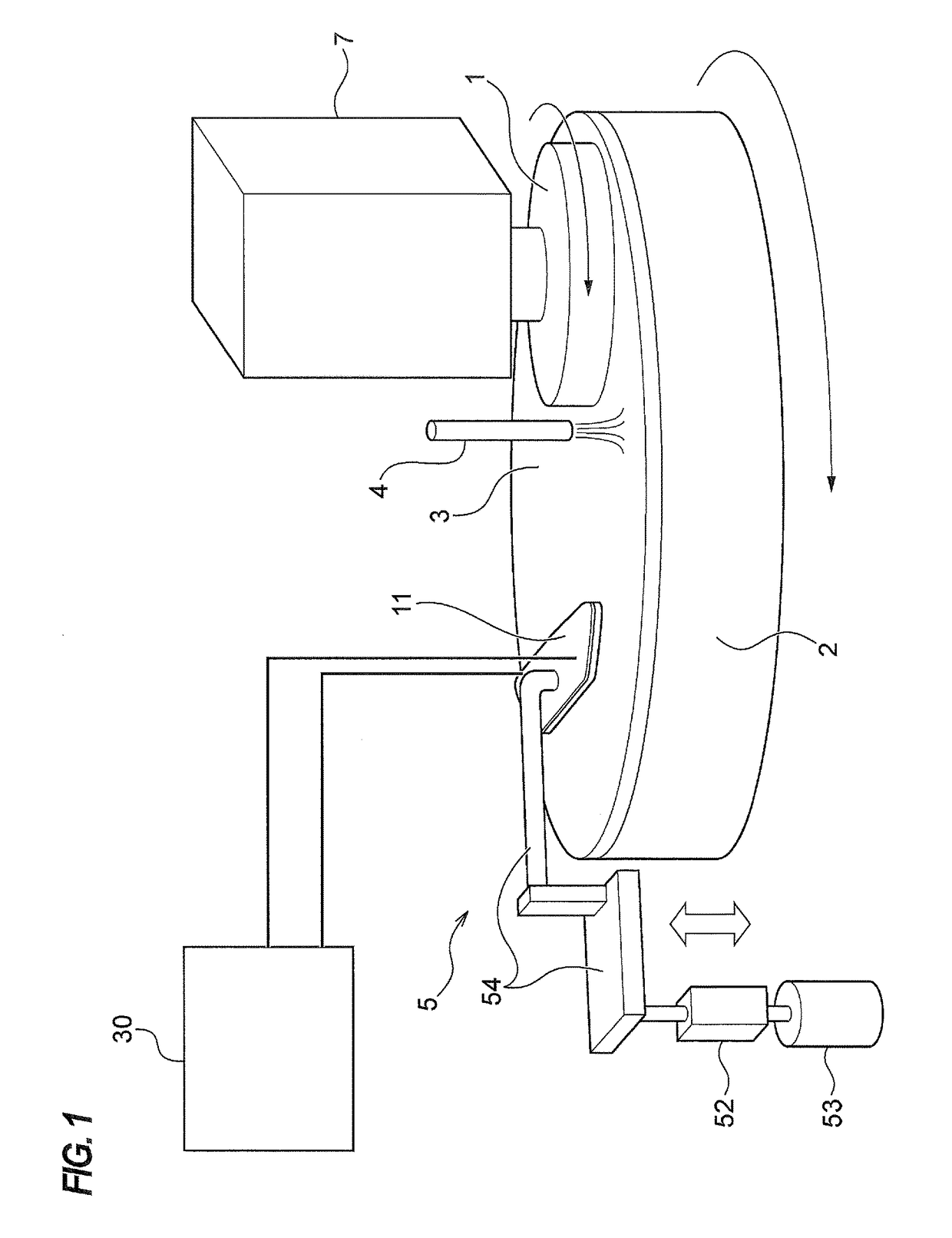

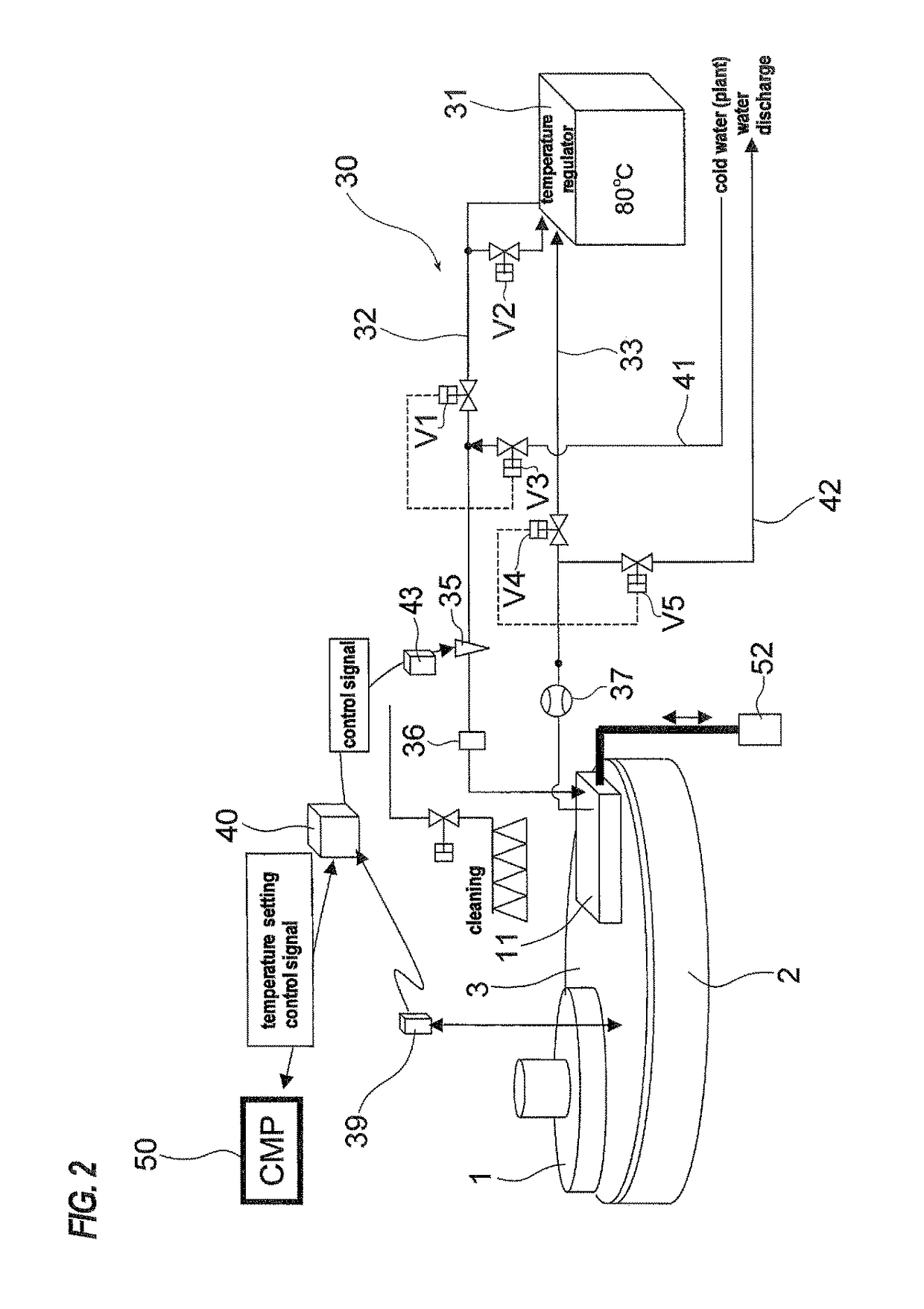

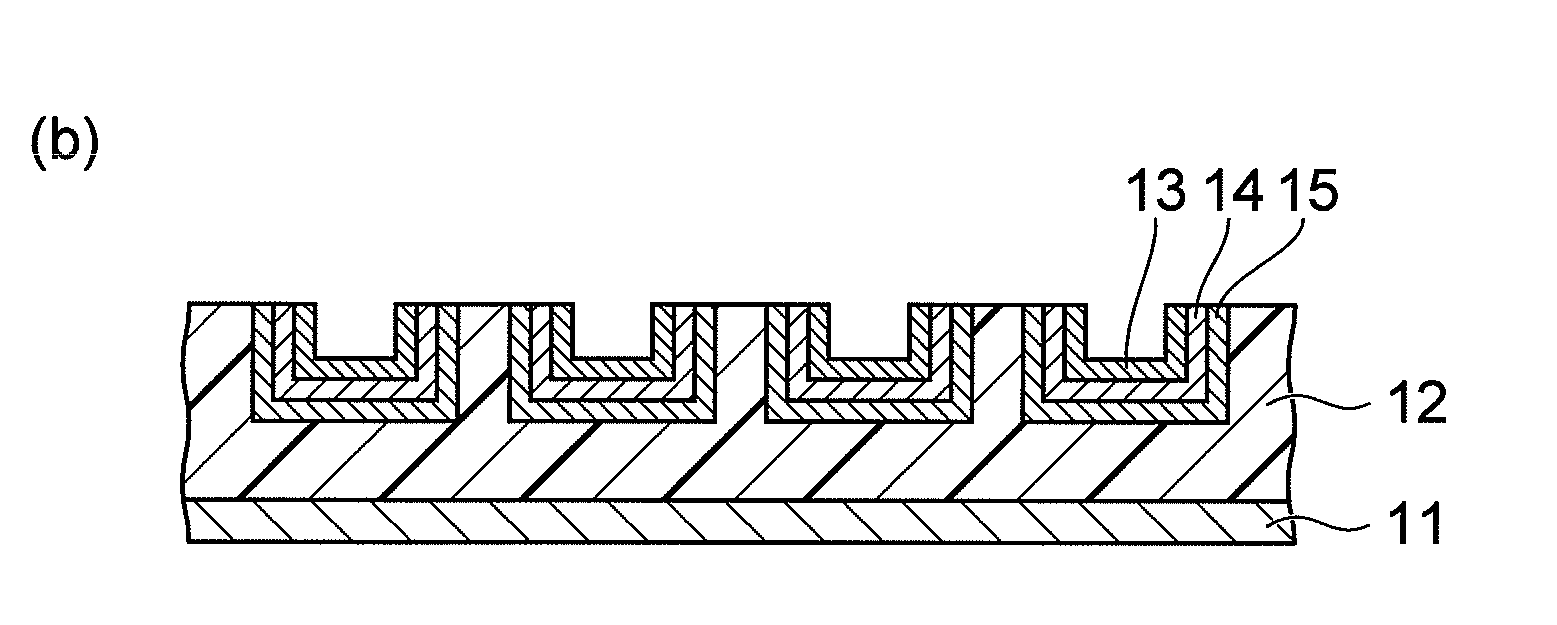

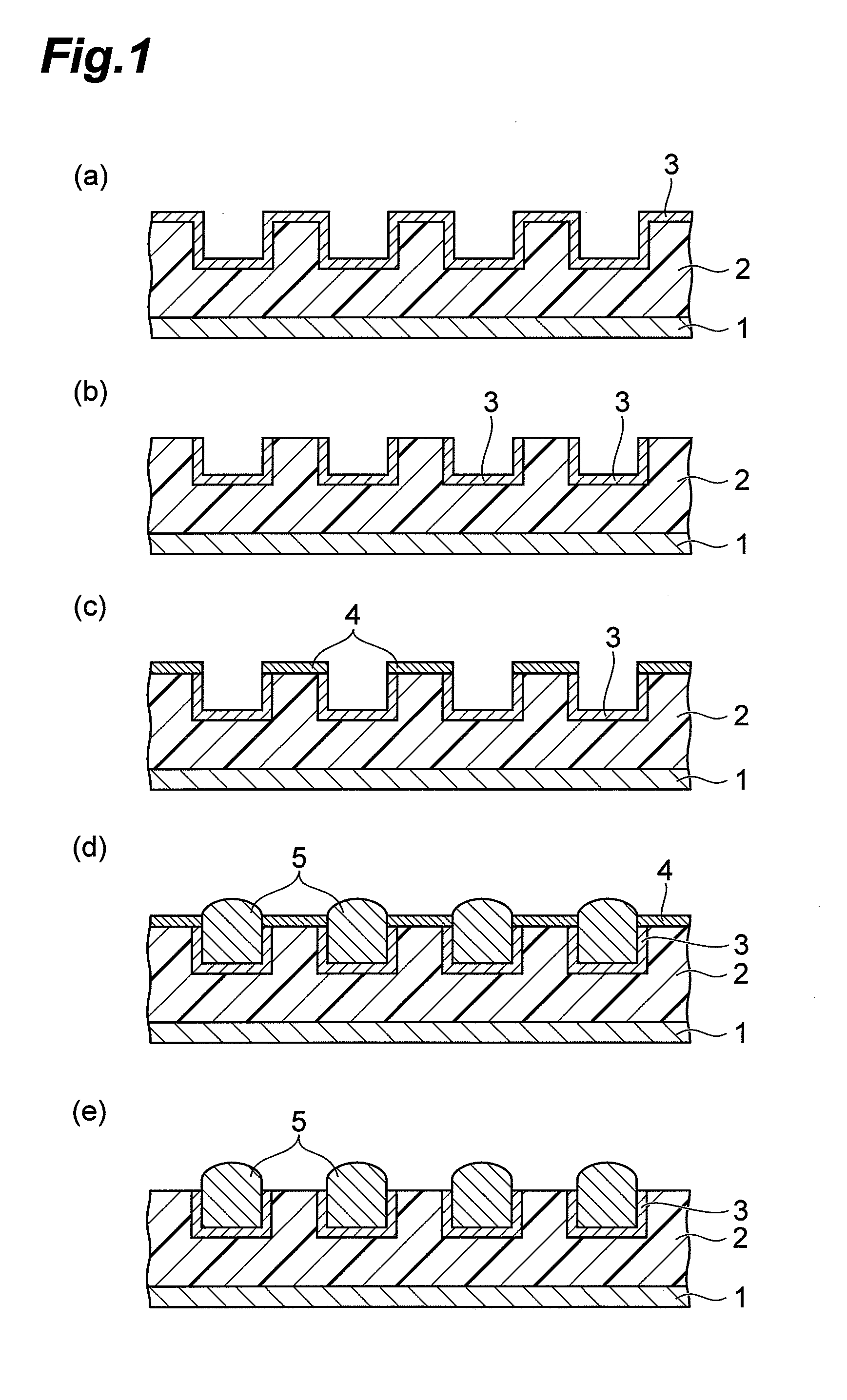

Polishing method and polishing apparatus

ActiveUS9782870B2Improve polishing rateSemiconductor/solid-state device manufacturingLapping machinesEngineering

A polishing method and a polishing apparatus which can increase a polishing rate and can control a polishing profile of a substrate being polished by adjusting a surface temperature of a polishing pad are disclosed. The polishing method for polishing a substrate by pressing the substrate against a polishing pad on a polishing table includes a pad temperature adjustment step of adjusting a surface temperature of the polishing pad, and a polishing step of polishing the substrate by pressing the substrate against the polishing pad having the adjusted surface temperature. In the pad temperature adjustment step, the surface temperature of a part of an area of the polishing pad, the area being to be brought in contact with the substrate, is adjusted during the polishing step so that the rate of temperature change of a temperature profile in a radial direction of the surface of the polishing pad becomes constant in the radial direction of the polishing pad.

Owner:EBARA CORP

Polishing composition

InactiveUS20070167116A1Improve polishing ratePigmenting treatmentOther chemical processesOptic lensPrism

The present invention relates to a polishing composition containing an aqueous medium and silica particles, wherein the silica particles in the polishing composition has a zeta potential of from −15 to 40 mV; a method for manufacturing a substrate including the step of polishing a substrate to be polished with a polishing composition containing an aqueous medium and silica particles, wherein the silica particles in the polishing composition has a zeta potential of from −15 to 40 mV; and a method for reducing scratches on a substrate to be polished with a polishing composition containing an aqueous medium and silica particles, including the step of adjusting a zeta potential of silica particles in the polishing composition to −15 to 40 mV. The polishing composition can be favorably used in polishing the substrate for precision parts, including substrates for magnetic recording media such as magnetic discs, optical discs and opto-magnetic discs; photomask substrates; optical lenses; optical mirrors; optical prisms; semiconductor substrates; and the like.

Owner:YOSHIDA HIROYUKI +3

CMP Fluid and Method for Polishing Palladium

ActiveUS20120100718A1Improve polishing rateStable polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic solventPhosphorus acid

The CMP polishing liquid for polishing palladium of this invention comprises an organic solvent, 1,2,4-triazole, a phosphorus acid compound, an oxidizing agent and an abrasive. The substrate polishing method is a method for polishing a substrate with a polishing cloth while supplying a CMP polishing liquid between the substrate and the polishing cloth, wherein the substrate is a substrate with a palladium layer on the side facing the polishing cloth, and the CMP polishing liquid is a CMP polishing liquid comprising an organic solvent, 1,2,4-triazole, a phosphorus acid compound, an oxidizing agent and an abrasive.

Owner:RESONAC CORP

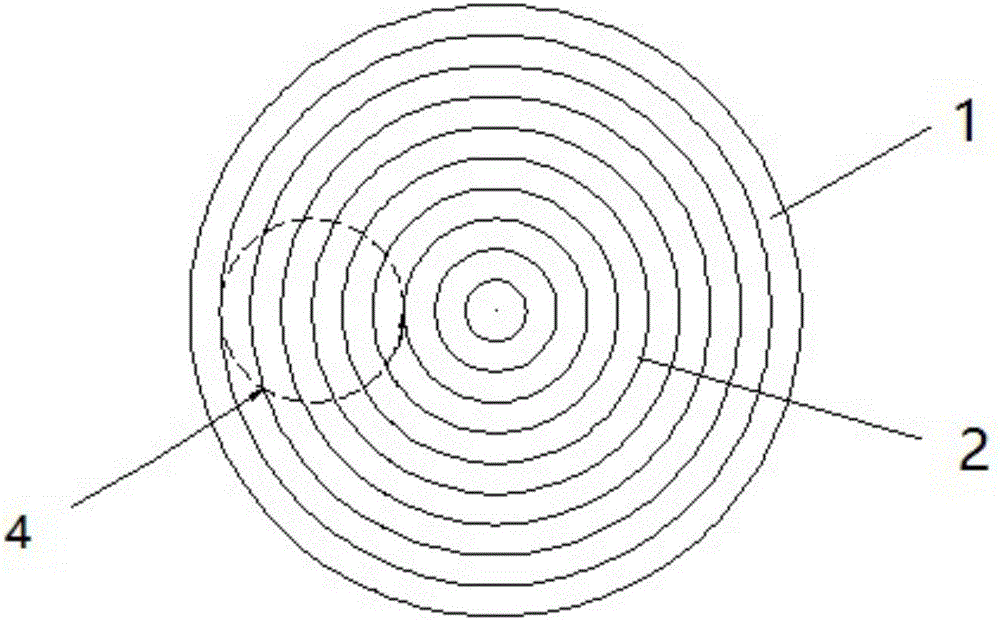

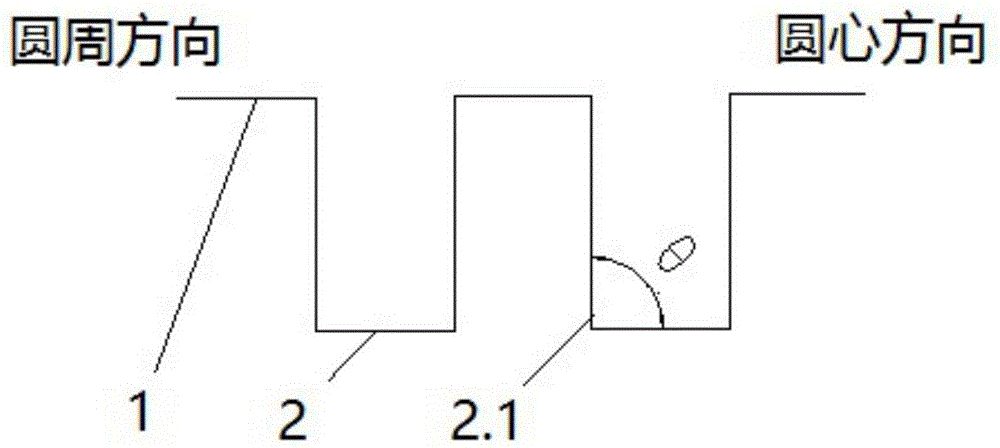

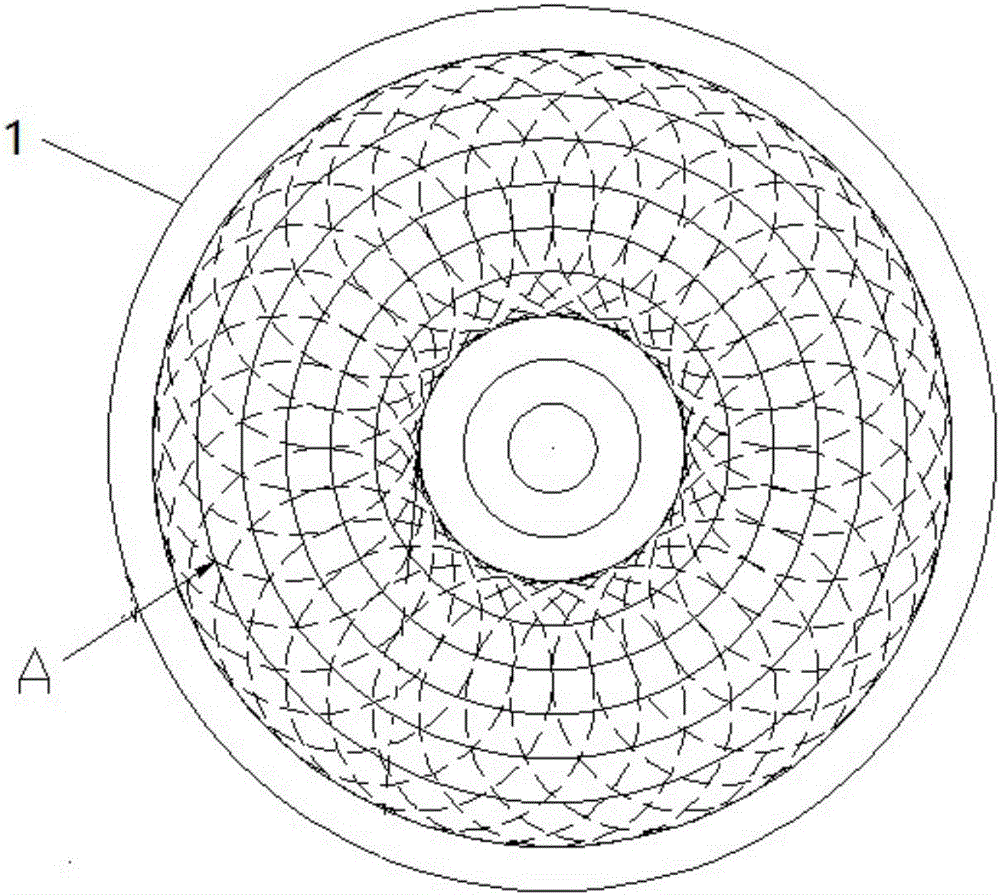

Polishing pad

The invention discloses a polishing pad for solving the problems of nonuniform distribution of polishing liquid and need of further improvement of the polishing speed and the leveling degree in a traditional polishing pad. The polishing pad at least comprises a circular polishing layer; a groove for flowing the polishing liquid is formed in the upper surface of the polishing layer; the groove consists of a peripheral groove and a radial groove; the peripheral groove is a peripheral geometric center symmetry pattern with the circle center of the polishing layer as center; the edges m of the pattern are not fewer than 3; and the radial groove is a straight line or / and a curve scattered from the peripheral direction along the circle center, and has an intersecting point with the peripheral groove. The polishing pad is simple in structure, can enable the polishing liquid to uniformly distribute and flow in a polishing area, keeps uniform concentration of reactants and products in the polishing liquid in the polishing area to the greatest extent, accelerates the polishing speed, and improves the wafer planar degree.

Owner:HUBEI DINGLONG CO LTD

Slurry composition for use in chemical mechanical polishing of metal wiring

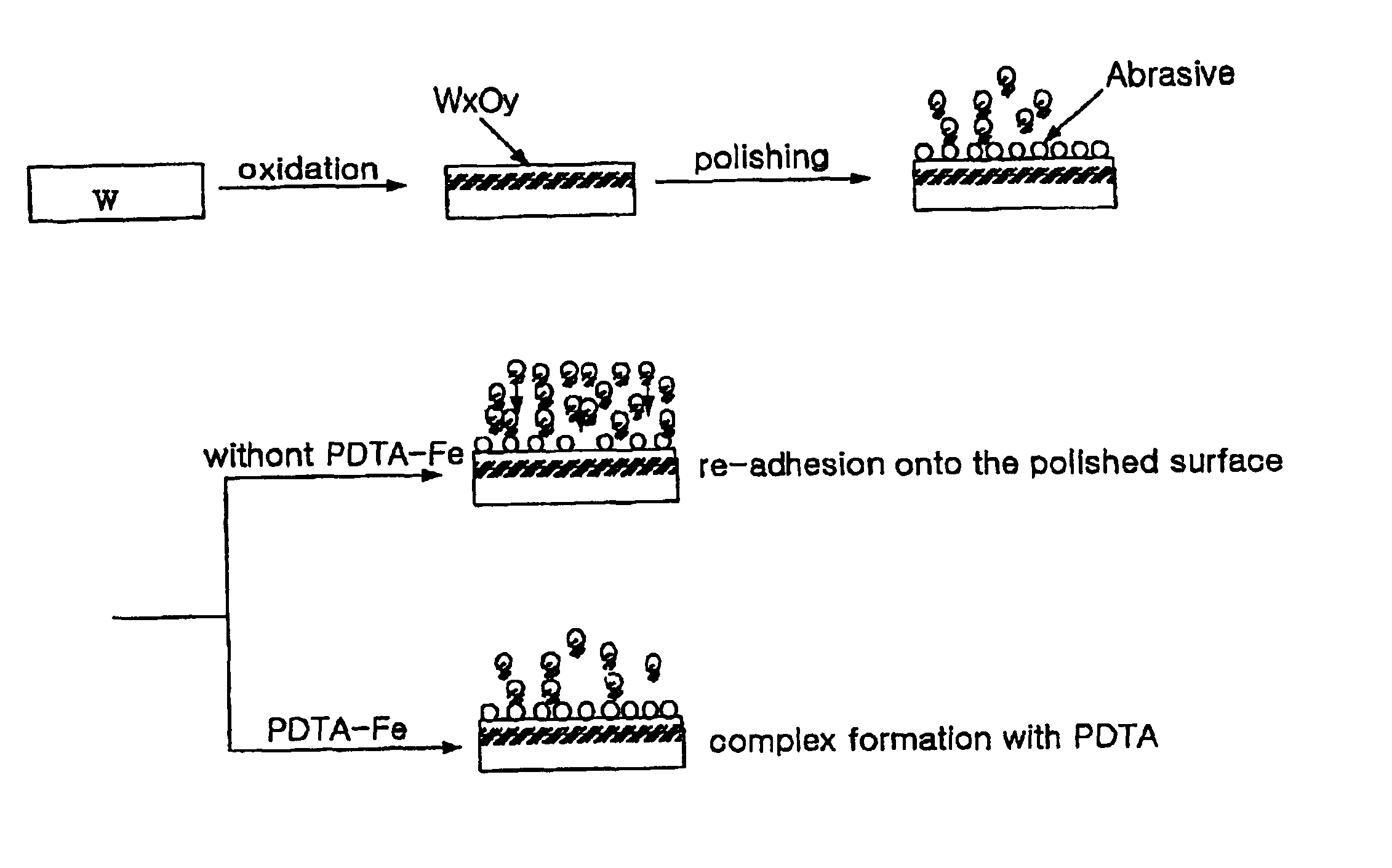

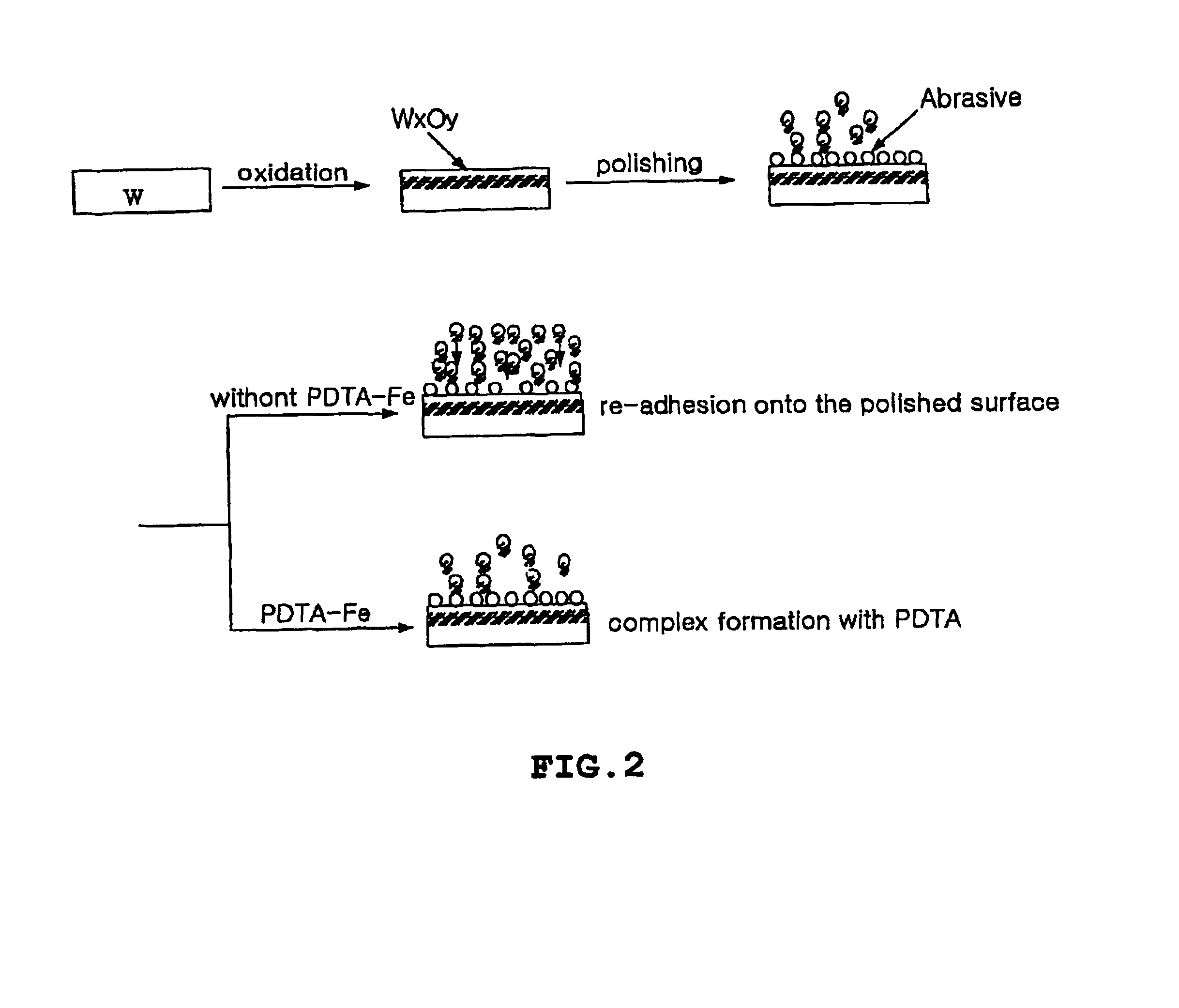

InactiveUS6930054B2Improve polishing rateGood dispersionOther chemical processesNon-surface-active detergent compositionsDispersion stabilityCarboxylic acid

Disclosed herein are slurry compositions for use in CMP(chemical mechanical polishing) process of metal wiring in manufacturing semiconductor devices, comprising a peroxide, an inorganic acid, a propylenediaminetetraacetate(PDTA)-metal complex, a carboxylic acid, a metal oxide powder, and de-ionized water, wherein the PDTA-metal complex plays a major role in improving overall polishing performance and reproducibility thereof by preventing abraded tungsten oxide from readhesion onto the polished surface, as well as in improving the dispersion stability of the slurry composition.

Owner:CHEIL IND INC +1

Polishing powder, polishing liquid for glass and preparation method thereof, glass and electronic product

InactiveCN108864948AHigh fluorine contentLow costTelephone set constructionsPolishing compositions with abrasivesMohs scale of mineral hardnessHardness

The invention discloses polishing powder, a polishing liquid for glass, and a preparation method thereof, glass and electronic products, relates to the technical field of glass polishing. The polishing powder is prepared from 50 to 60% of cerium oxide, 20 to 30% of lanthanum oxide and 10 to 20% of fluorine; D50 of the polishing powder is 1.0 to 1.6 mu m, D90 of the polishing powder is 2.4 to 2.6 mu m, the Moh's hardness is 7 to 8. The polishing liquid is prepared from 50 to 60% of the polishing powder, 0.5 to 1% of a suspension agent, 1 to 10% of a dispersing agent, 1 to 5% of a flatting agent, 1 to 5% of a grinding aid and the balance of water. By controlling the content, particle size distribution and hardness of the polishing powder, high cutting rate can be guaranteed and scratch can be reduced. In addition, through adding the suspension agent, the dispersing agent, the flatting agent and the grinding aid, the suspension, dispersion, leveling and uniformity properties of the polishing powder and the grinding efficiency are improved are improved, the polishing liquid has the advantages of excellent suspension and dispersion properties, high polishing rate and good surface quality.

Owner:LENS TECH CHANGSHA

Silica sol with double grain diameters and preparation method thereof

The invention provides a silica sol with double grain diameters. The silica sol comprises two grain diameter ranges, one grain diameter range is 50-100 nm, and the other grain diameter range is 150-200nm. The invention also provides a method for preparing the silica sol with the double grain diameters. The silica sol is prepared by using alkaline silica sol with uniform grain diameter, a size being 80nm and a specific gravity being 1.15-1.25 as a seed crystal. The preparation method of the silica sol with the double grain diameters is simple; and the prepared silica sol has long storage period and is suitable for chemical-mechanical polishing of metals, semiconductors, memory hard disk substrates, compound crystals, precise instruments and the like.

Owner:JIANGSU HAIXUN IND GROUP SHARE

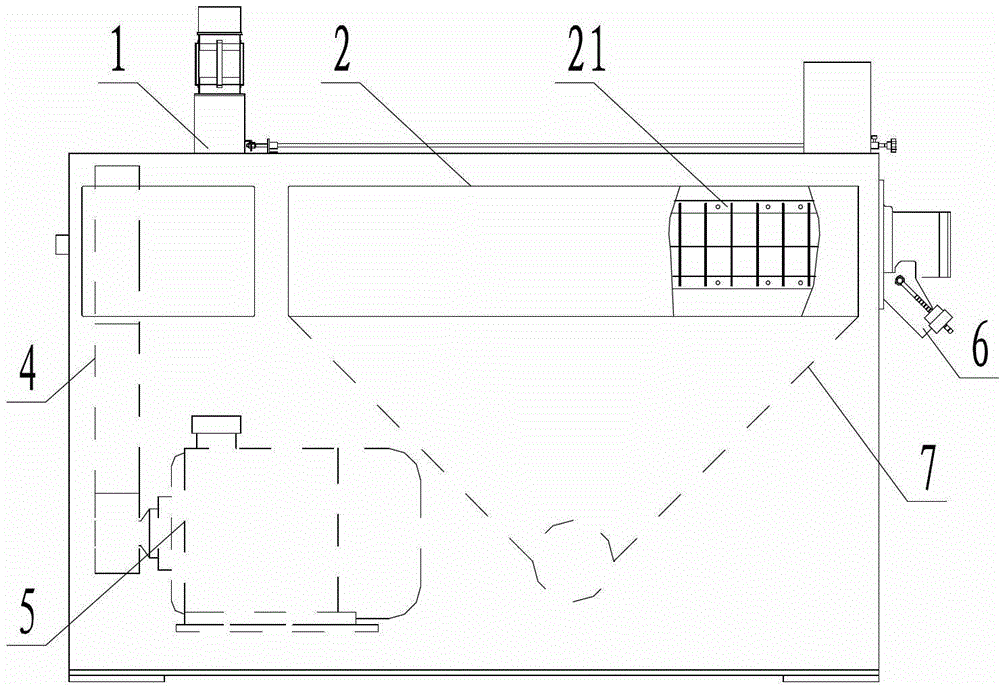

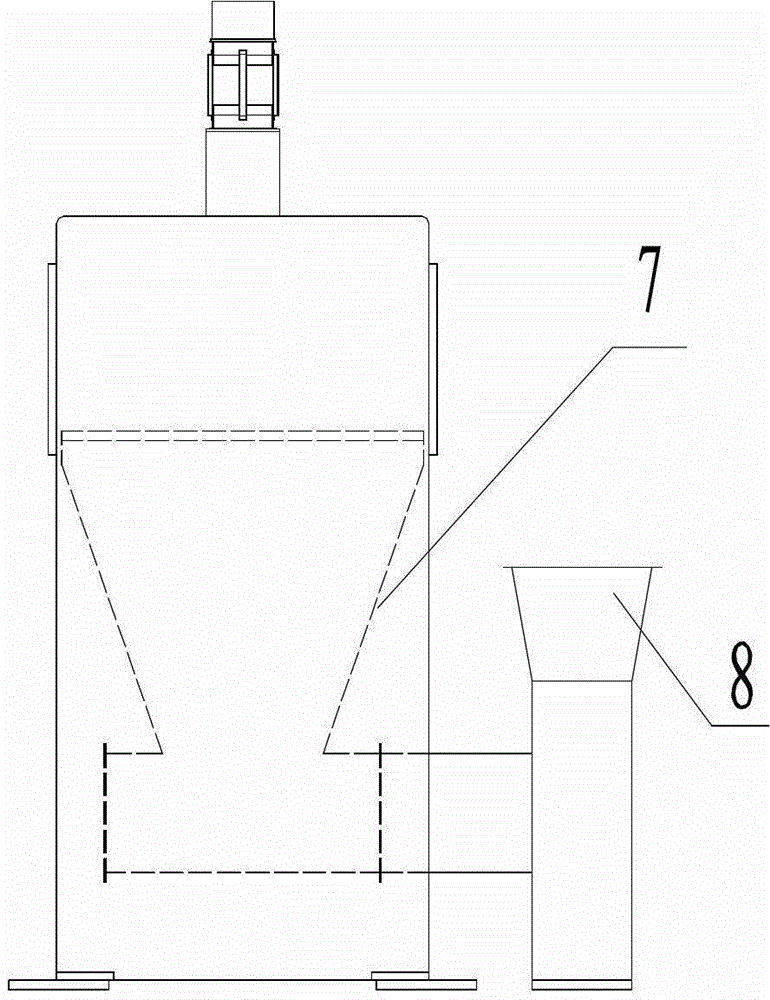

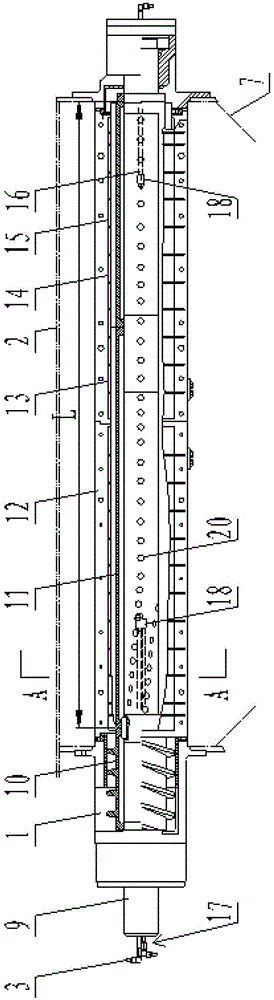

Rice polishing machine

ActiveCN103143409AImprove polishing rateImprove the finishGrain huskingGrain polishingSpray nozzleEngineering

The invention provides a rice polishing machine which comprises a fan (8); a backing strip (15) is fixedly arranged on a crossbeam (14); a feed opening (1) is fed into a first end above a thruster (10); a discharge port (6) is positioned on the tail end below a polishing chamber (21); spray nozzles (18) are connected onto the ends of a pressure air pipe (3) and a water injection pipe (26); the spray nozzles (18) penetrate through an upper crossbeam (14) and the backing strip (15) and are fed into the polishing chamber (21); and the length of a polishing roll (11) is 1000mm to 2000mm, and the outer diameter of the polishing roll (11) is 150mm to 190mm. The rice polishing machine overcomes the defects that an existing rice polishing machine has a non-uniform dampening method and small output and the rice is easily crushed, and has the advantages of uniform dampening method, low rice crushing rate and large output.

Owner:WUHAN KINHE FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com