Patents

Literature

280results about How to "Constant thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implantable medical devices

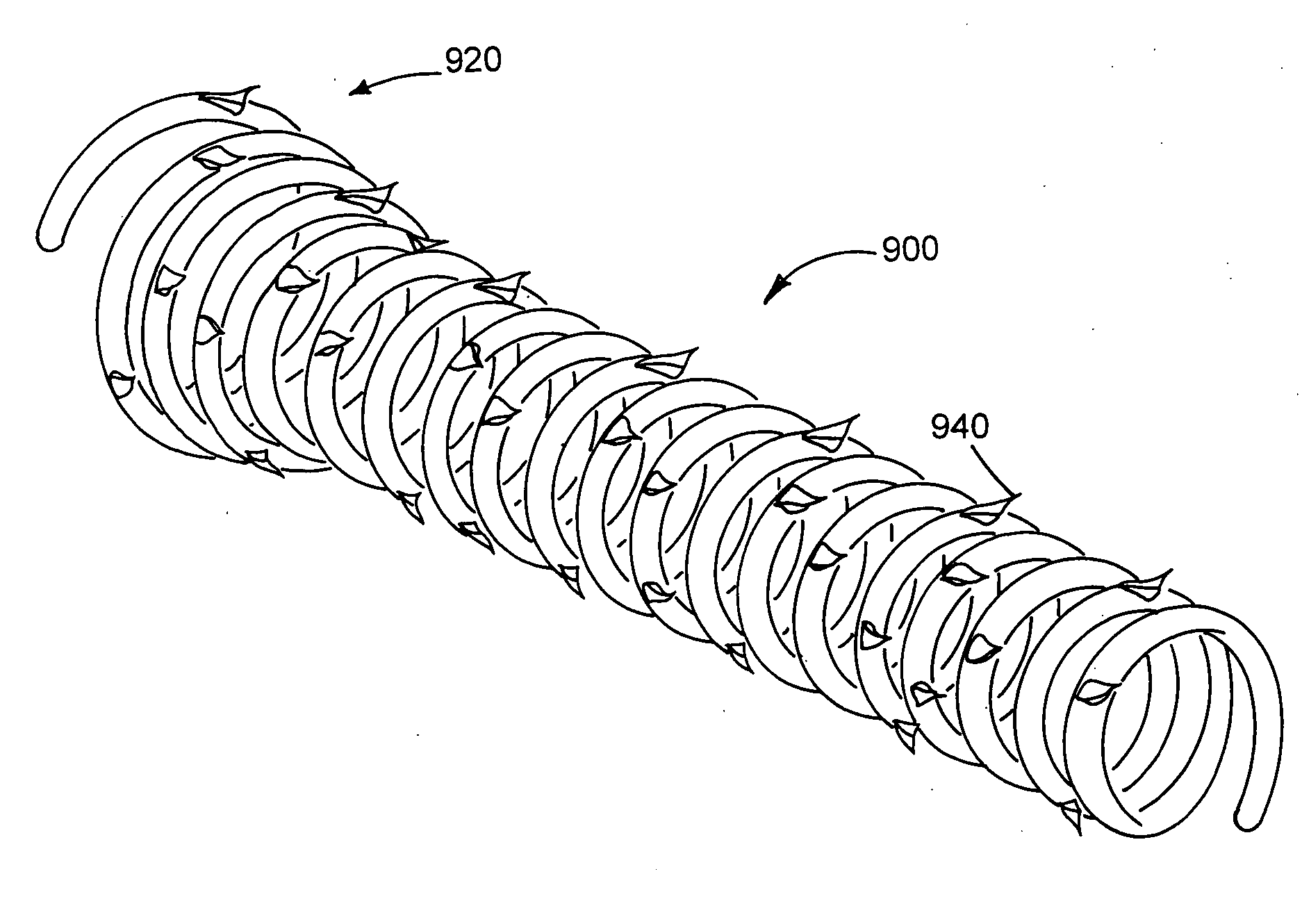

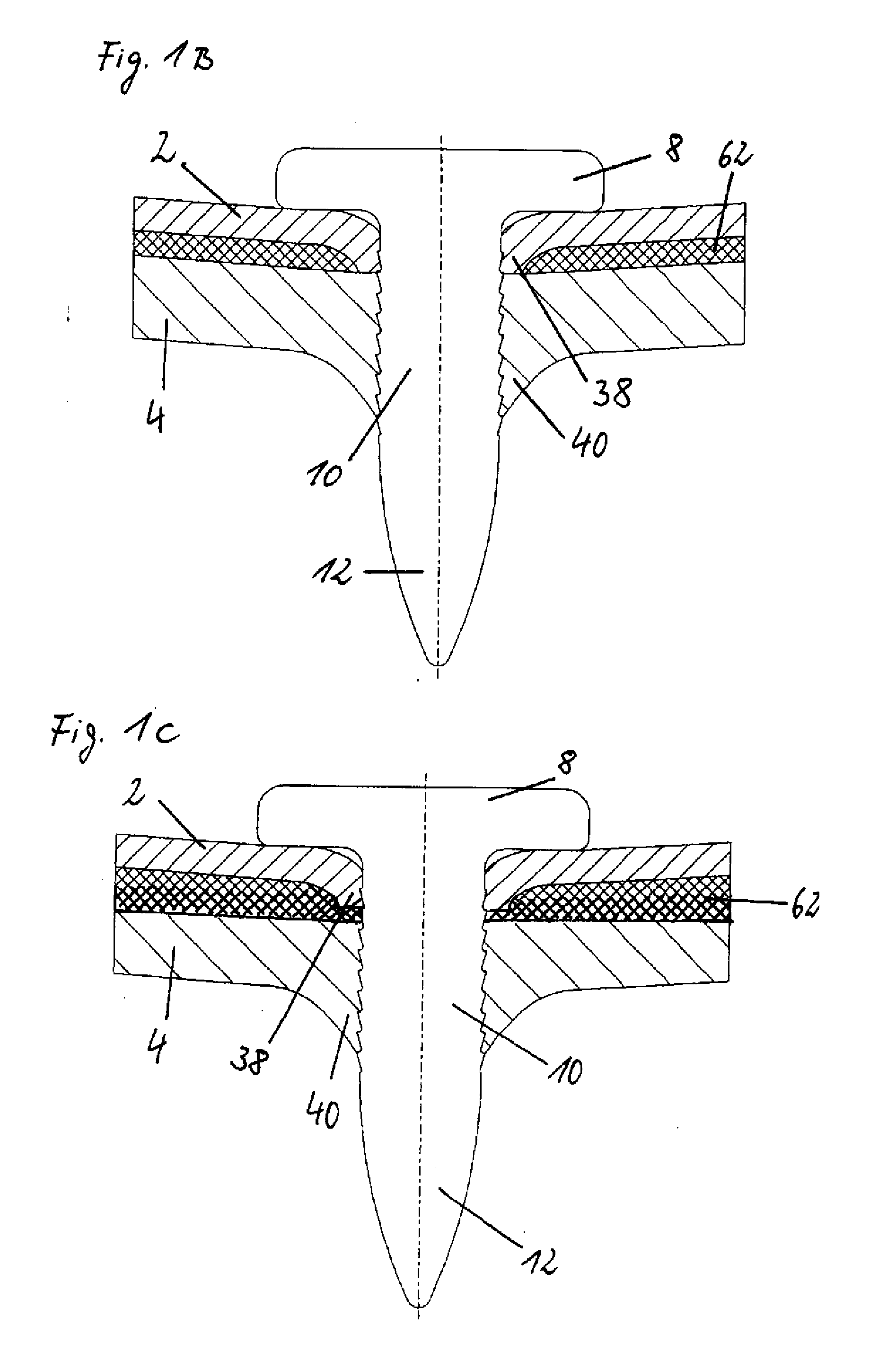

InactiveUS20050010275A1Improve abilitiesIncrease resistanceStentsWound drainsInsertion stentBalloon catheter

A medical device includes a balloon catheter having an expandable member, e.g., an inflatable balloon, at its distal end and a stent or other endoprosthesis. The stent is, for example, an apertured tubular member formed of a polymer and is assembled about the balloon. The stent has an initial diameter for delivery into the body and can be expanded to a larger diameter by inflating the balloon.

Owner:UNIV OF CONNECTICUT +2

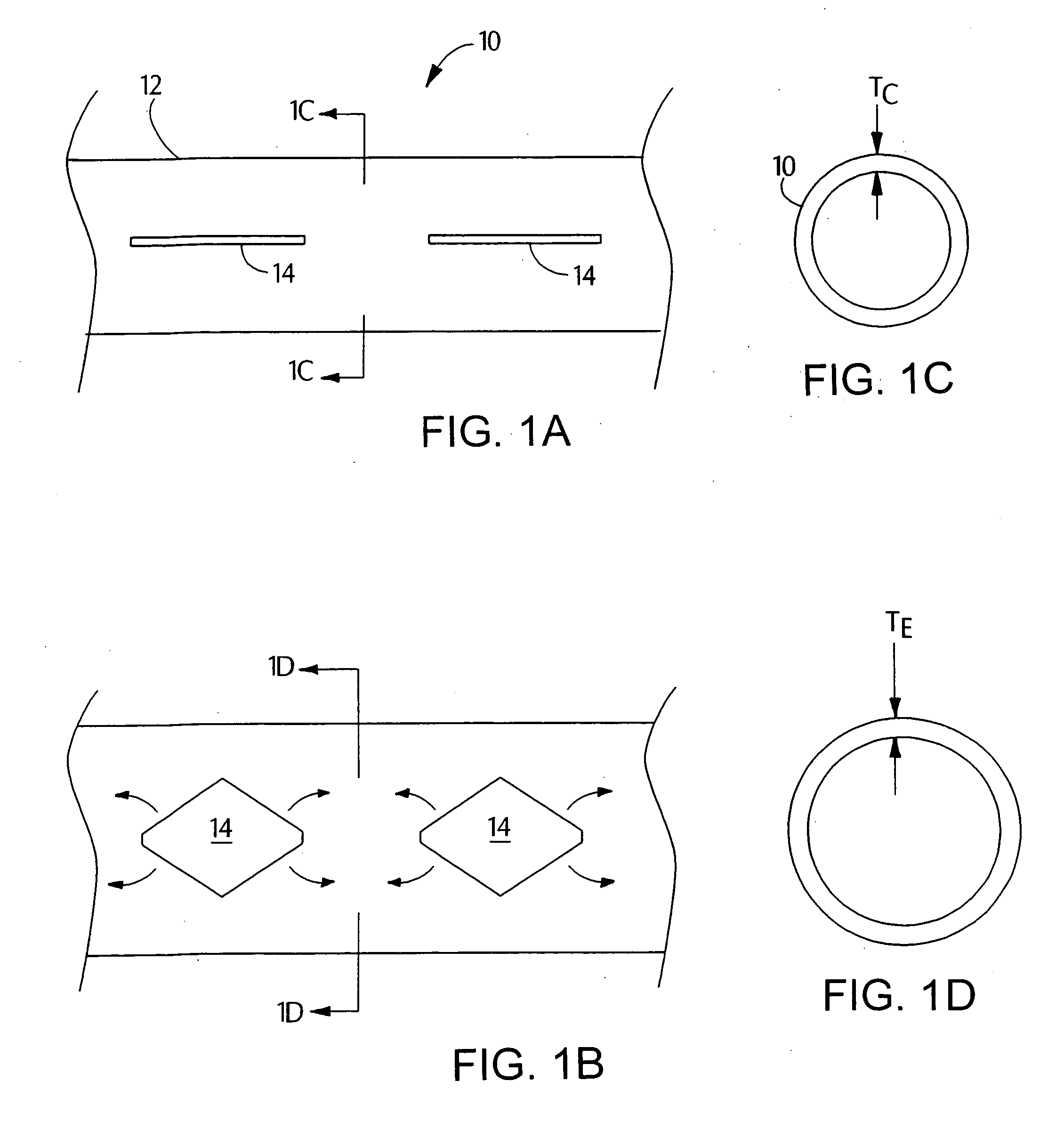

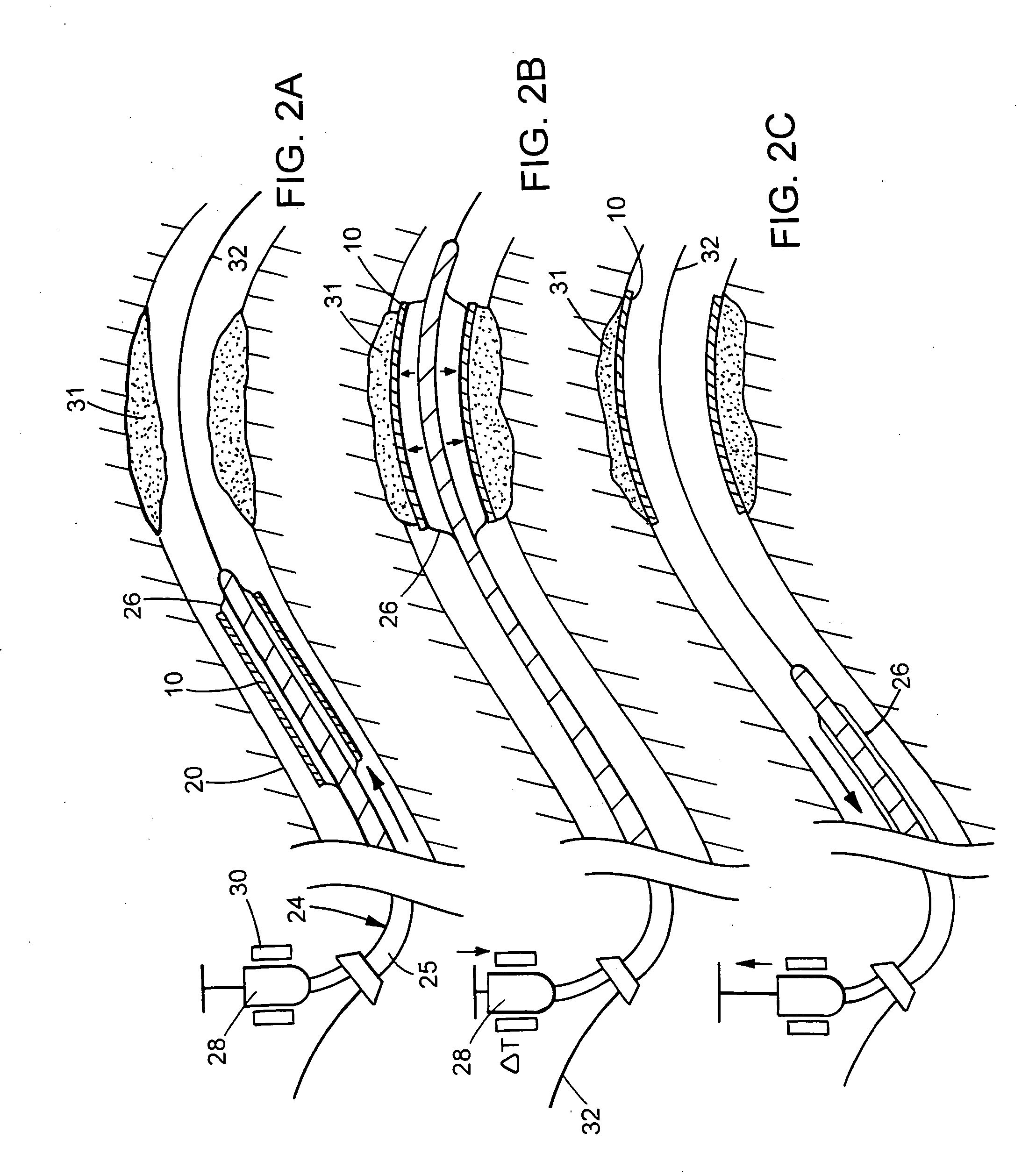

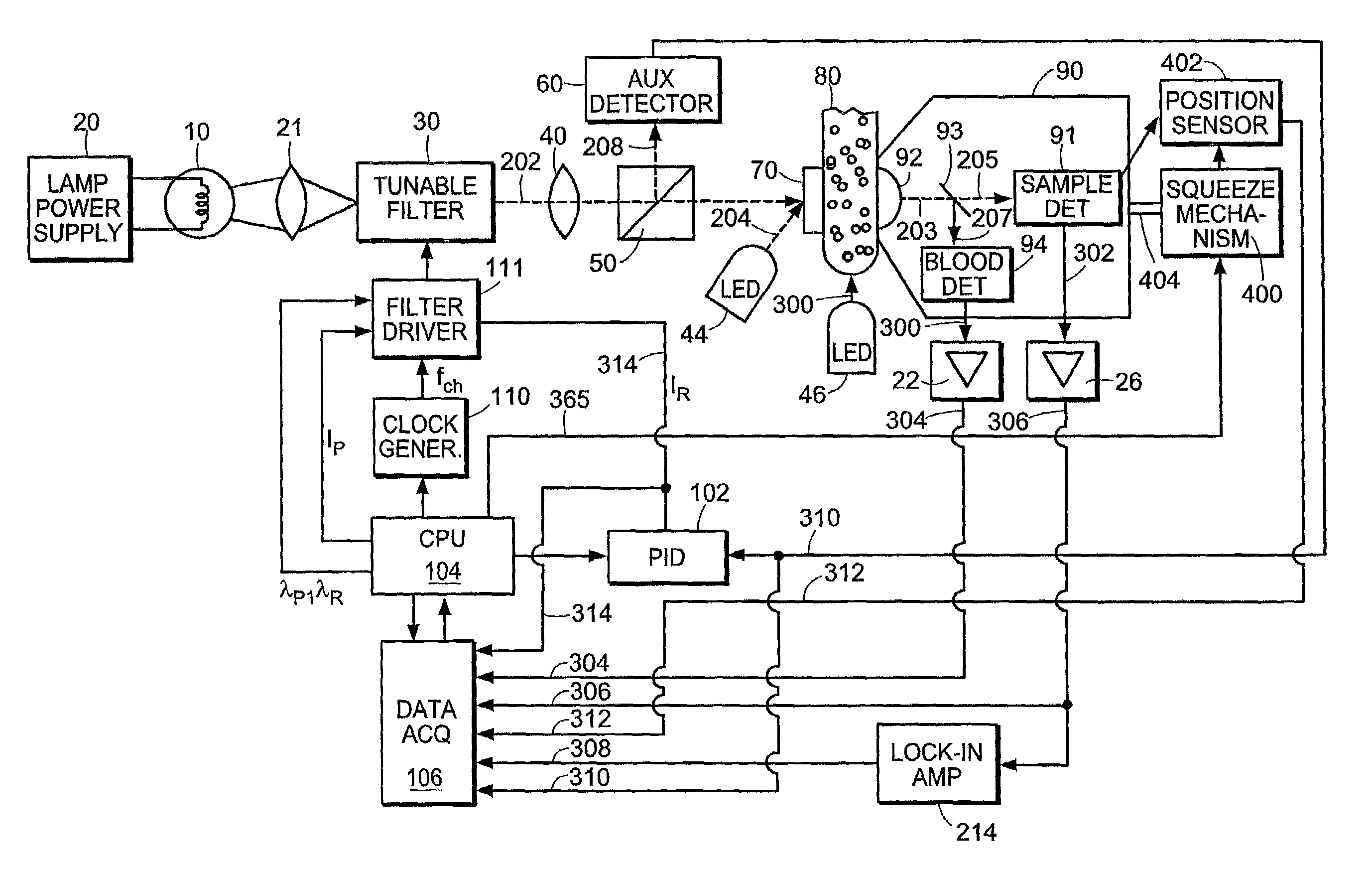

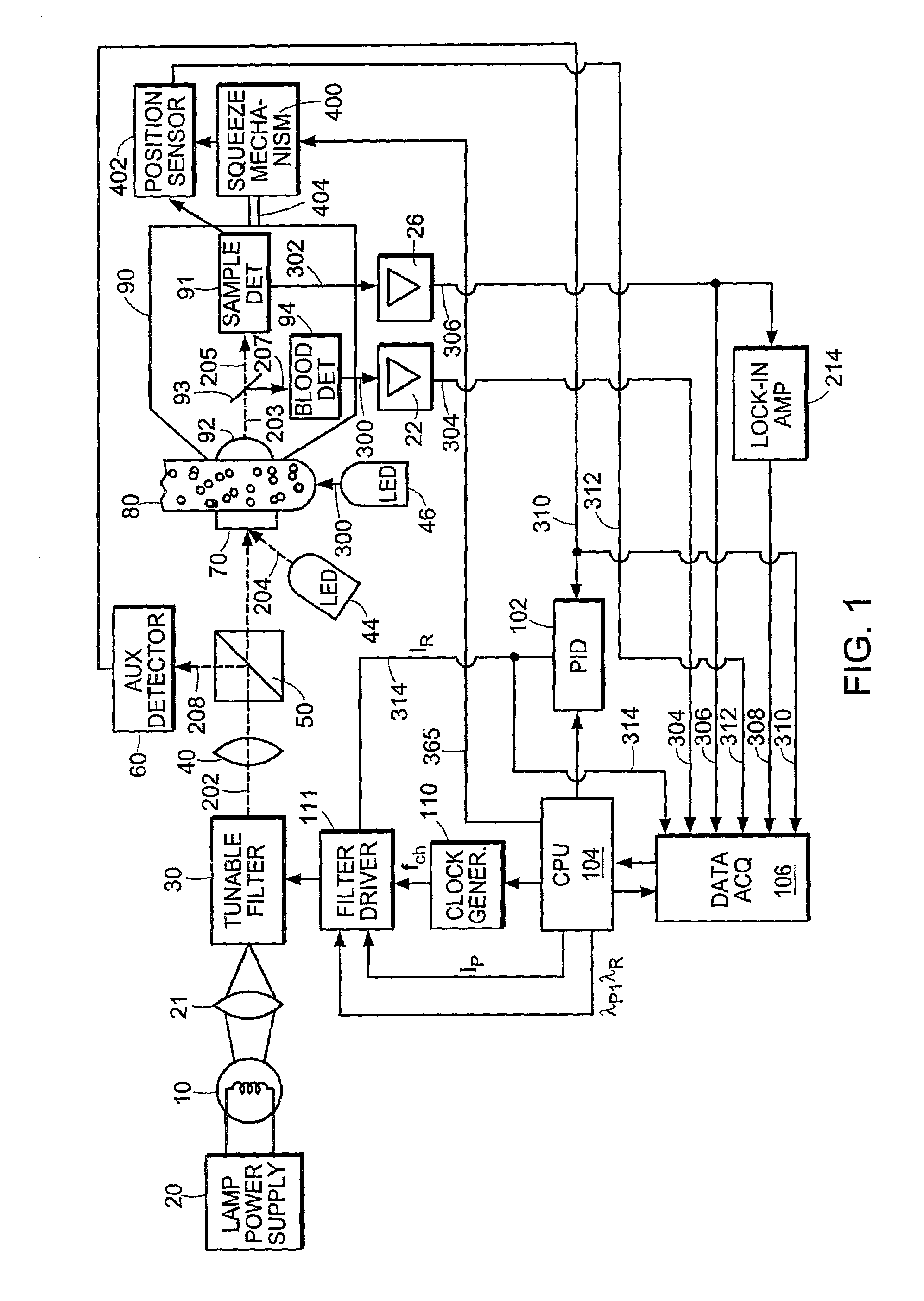

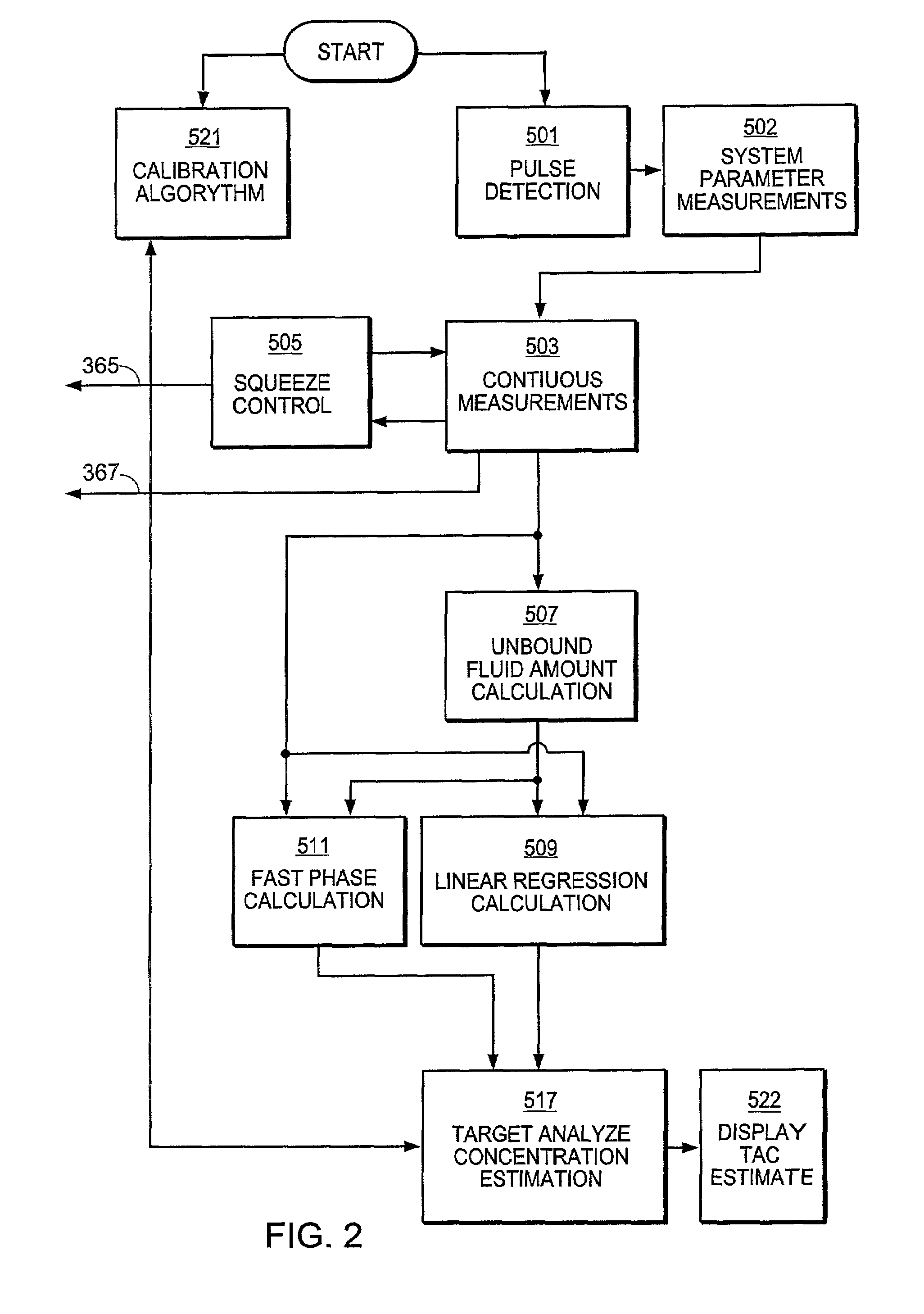

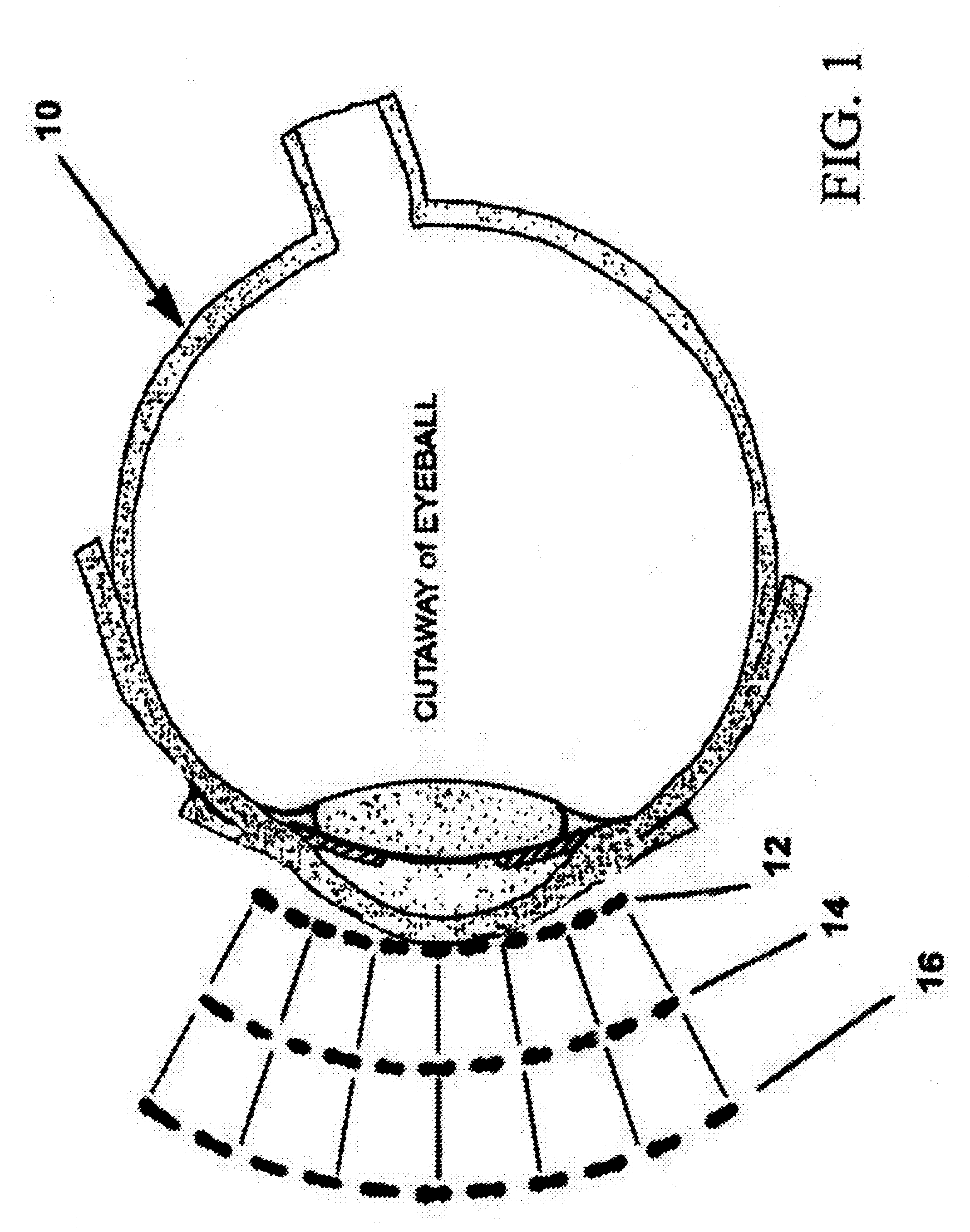

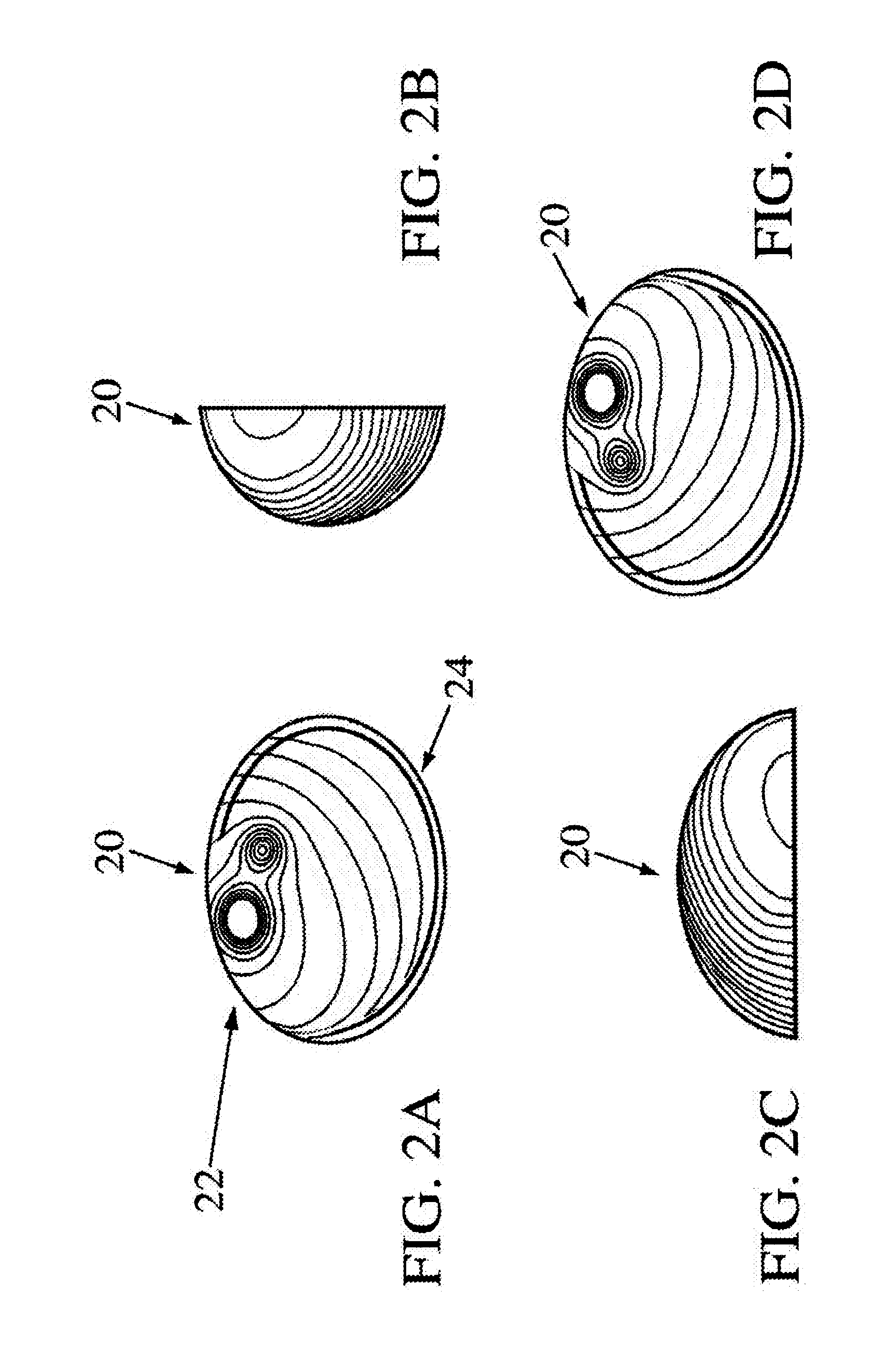

Non-invasive substance concentration measurement using and optical bridge

InactiveUS7003337B2Vary thicknessHigh target accuracyScattering properties measurementsDiagnostic recording/measuringPhysicsNon invasive

An improved method for non-invasively measuring a concentration of a target analyte dissolved in a fluid flowing through a sample is presented. It includes directing a probe beam of electromagnetic radiation, consisting of time multiplexed components of different wavelengths, through the sample and measuring the difference of the absorption of the radiation at at least one wavelength pair at different sample states. During sample state changes, the amount of fluid containing the target analyte within the sample is changing, which varies the total amount of target analyte in the sample, as well as the absorption properties of the sample. The sample states are produced, for instance, by compressing and uncompressing the tissue sample. The accuracy of the presented method is enhanced by including continuous estimation of the amount of the fluid containing the target analyte within the sample, and measurement of the variations of the absorption at a wavelength at which the target analyte absorbs significantly. The method is particularly useful in measuring the concentration of a target analyte, such as glucose, in tissue containing blood. An apparatus for performing this method also is disclosed.

Owner:GROVE INSTR

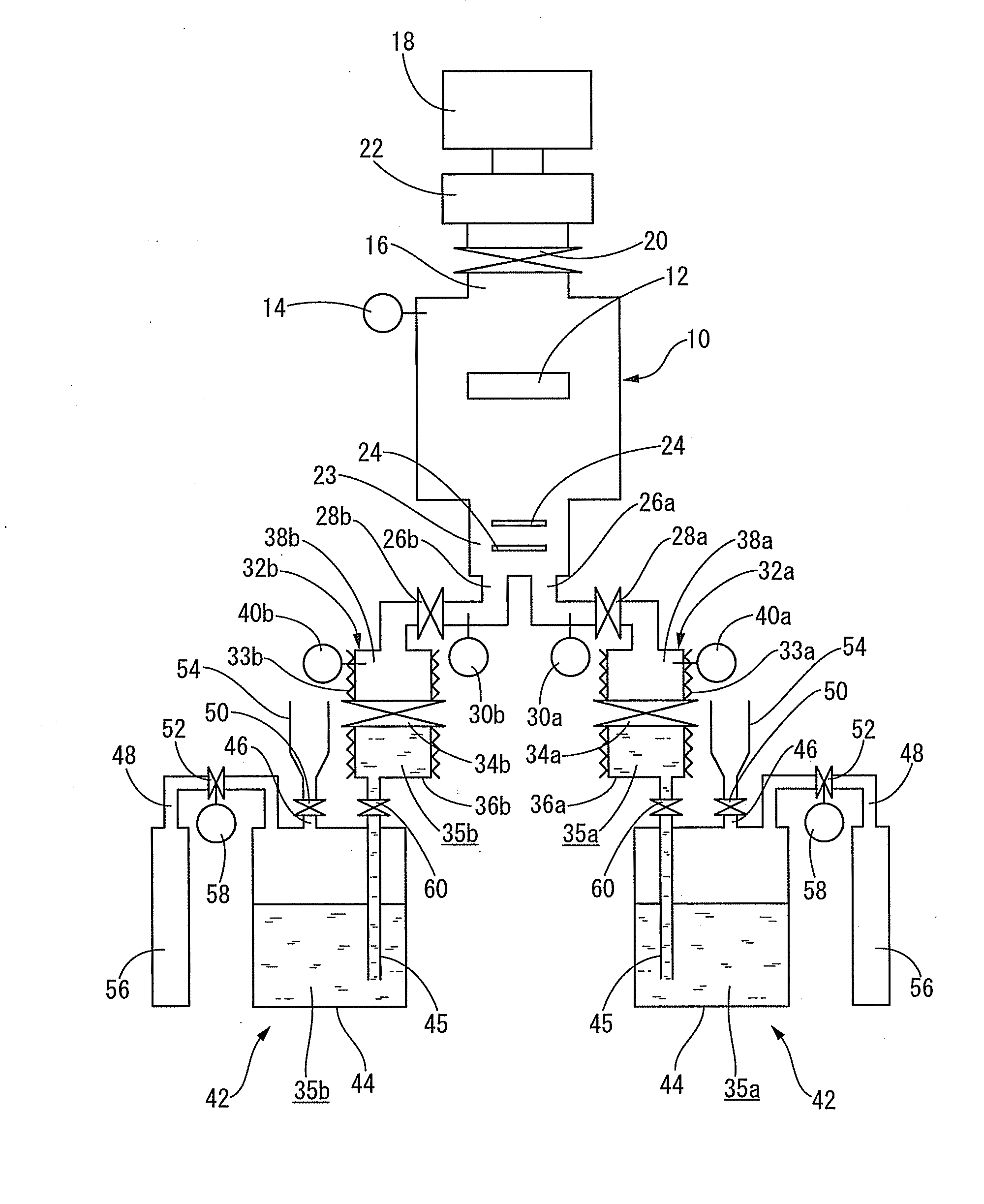

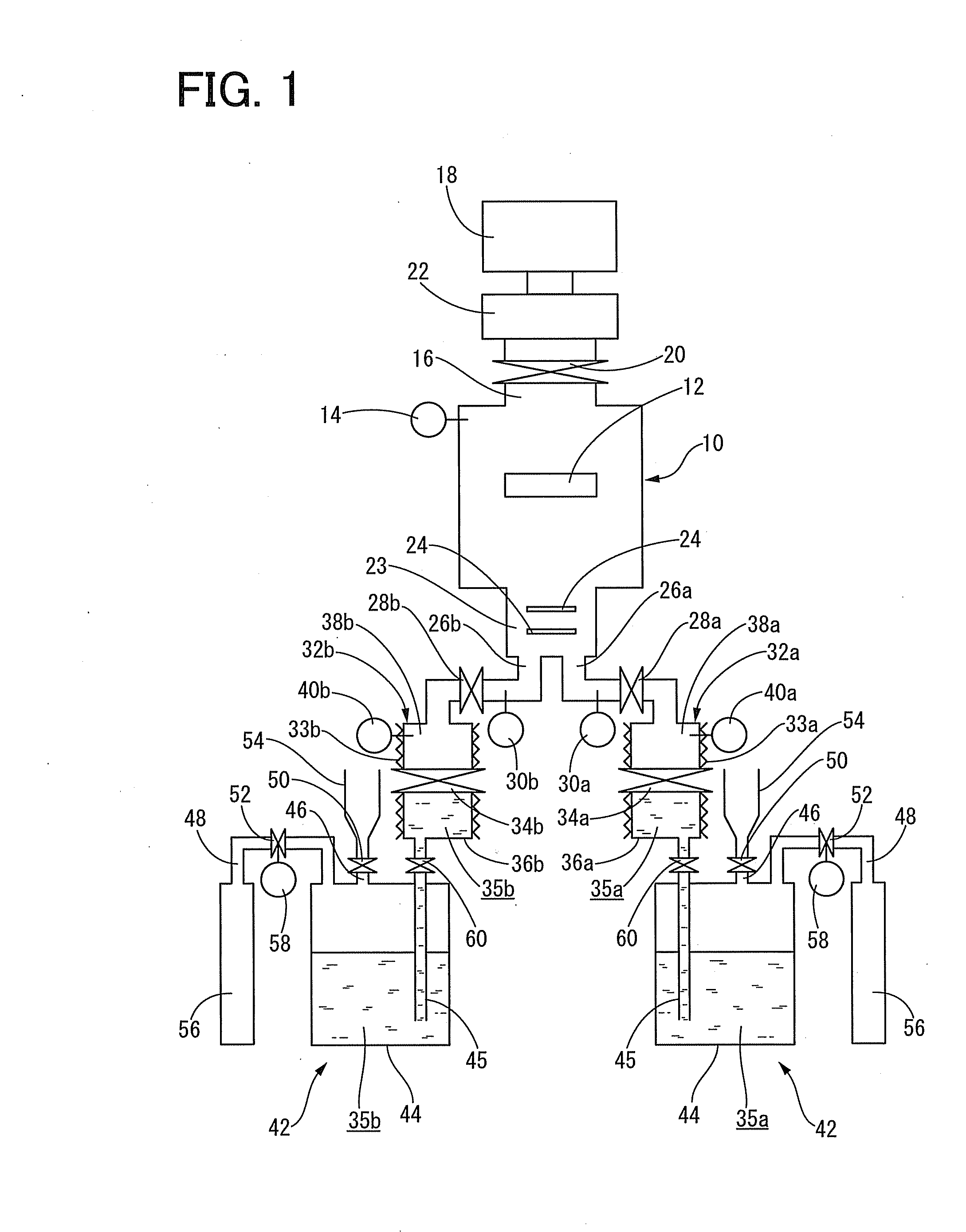

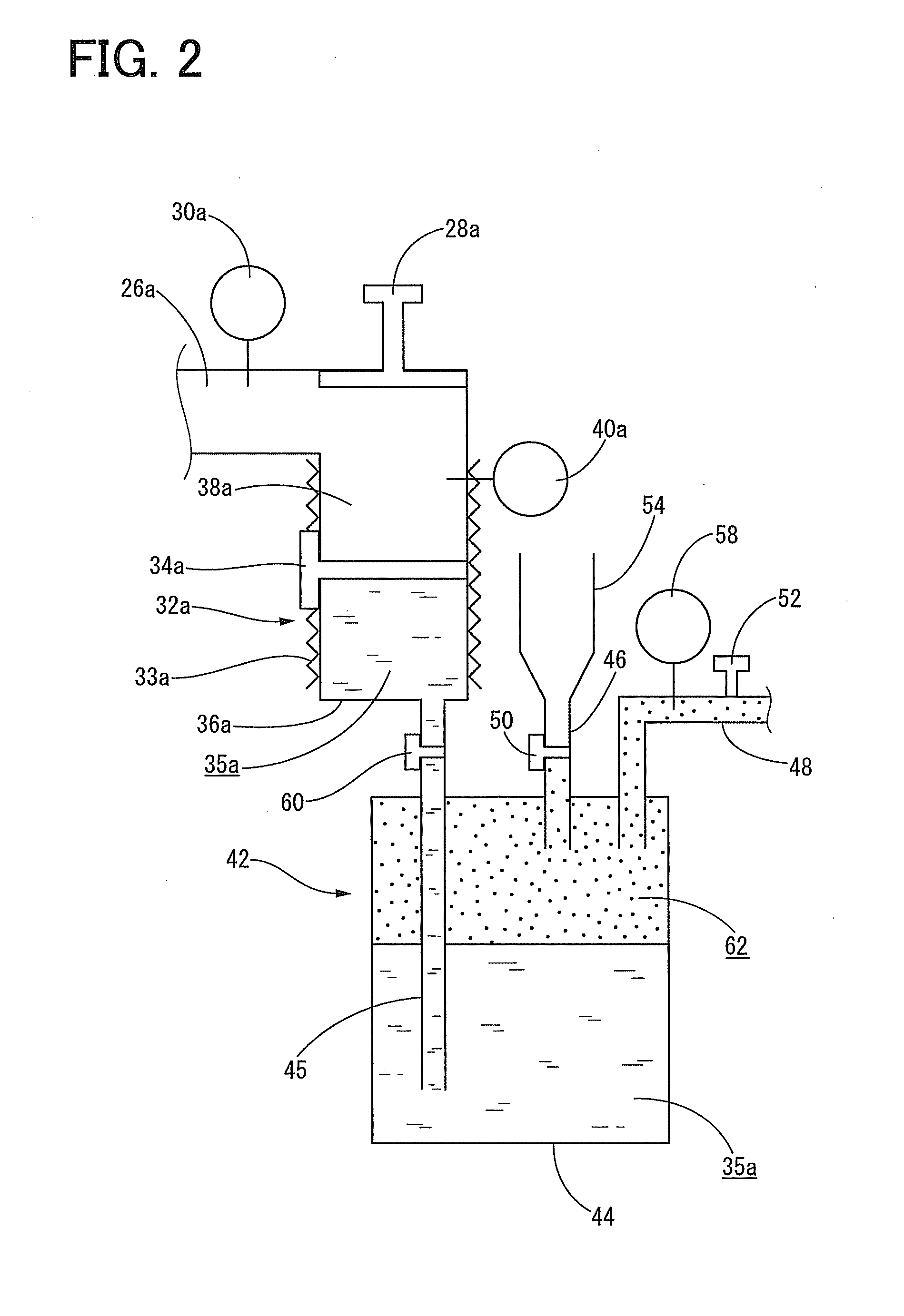

Method of forming organic polymer thin film and an apparatus for forming the organic polymer thin film

ActiveUS20110091650A1Small pressureHigh film formation efficiencyVacuum evaporation coatingSputtering coatingPolymer thin filmsOptoelectronics

A technique for forming an organic polymer thin film on a surface of a substrate with high film formation efficiency and excellent reproducibility and stability is provided. When a vacuum deposition polymerization for forming an organic polymer thin film is performed on a surface of a substrate 12 repeatedly, in which a plurality of kinds of monomers evaporated in a plurality of evaporation source containers 32a, 32b in vacuum state are introduced into a deposition chamber 10 in a vacuum state and polymerized on a surface of the substrate 12 arranged in the deposition chamber 10, each of the monomers in a liquid form is present in the evaporation source containers 32a, 32b in a constant amount every time, at the beginning of the evaporation operation of monomers.

Owner:KOJIMA PRESS IND CO LTD +1

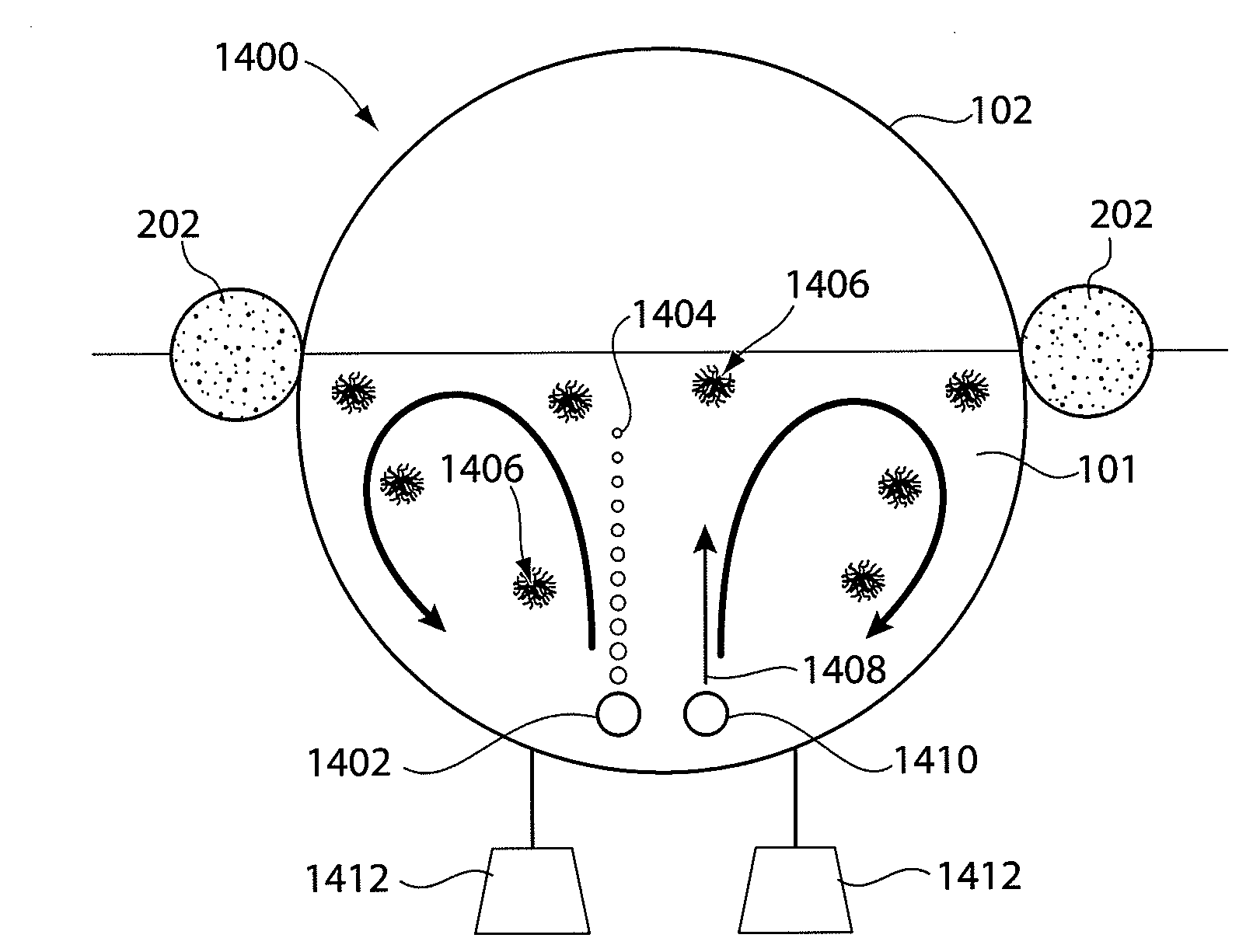

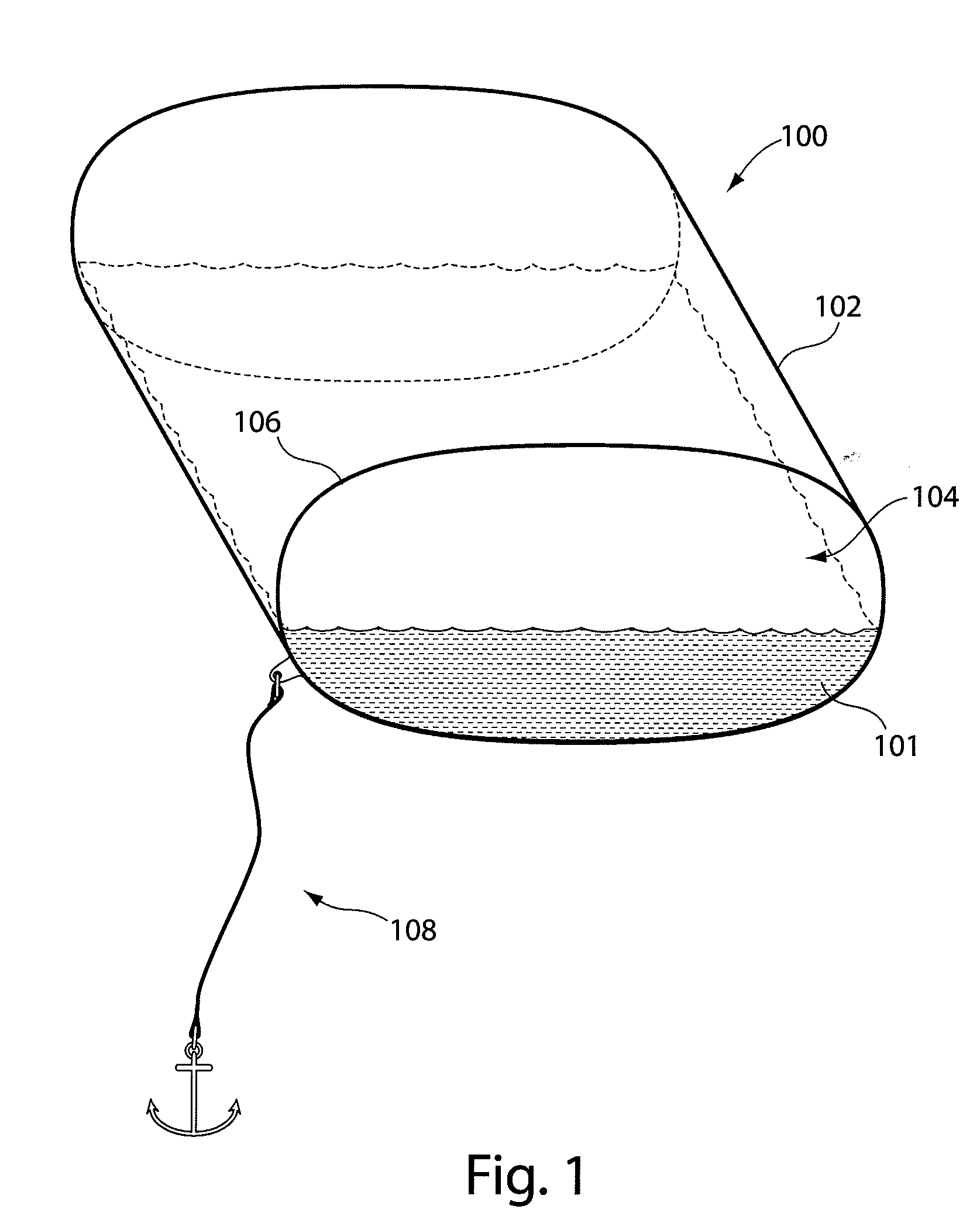

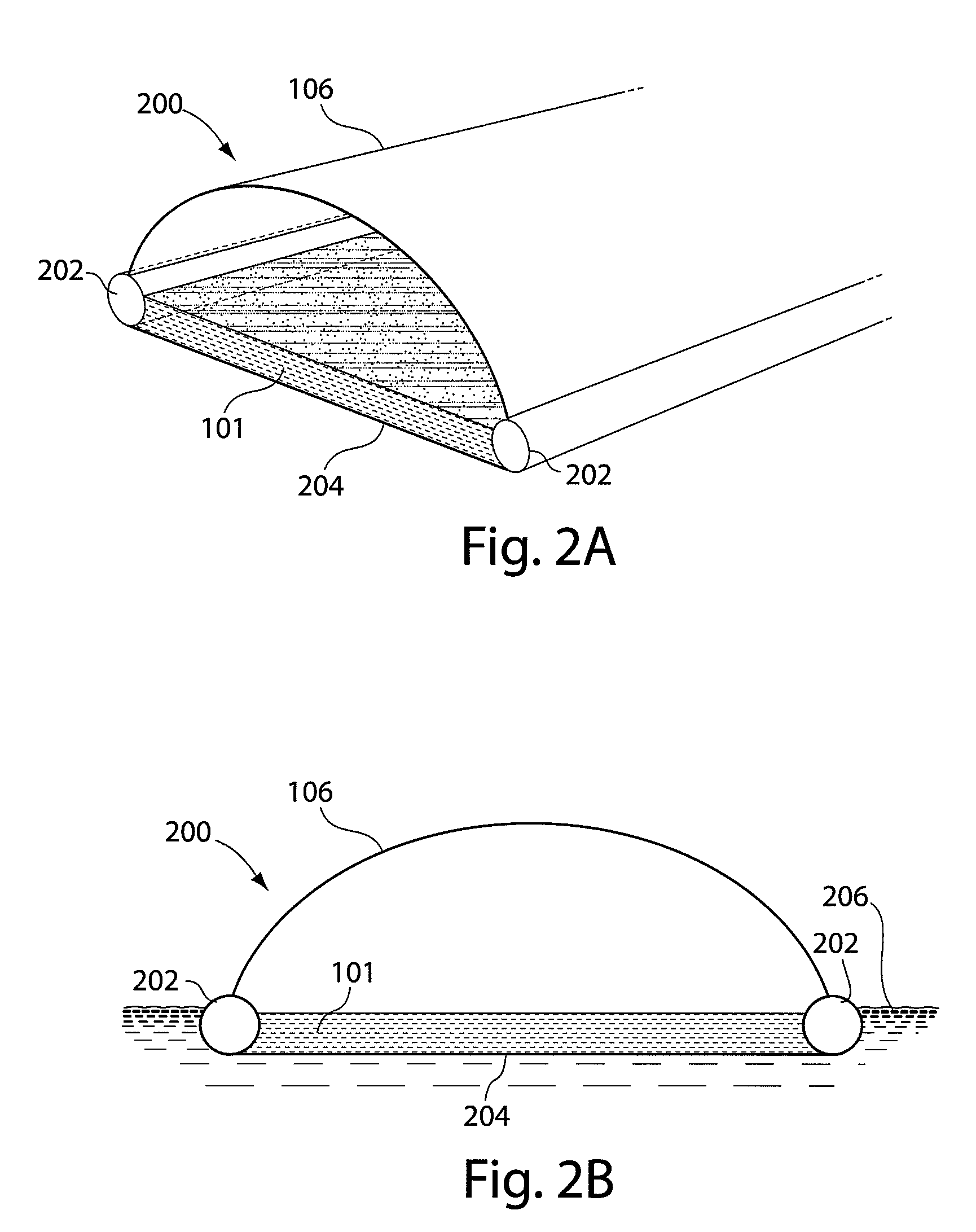

Photobioreactor systems positioned on bodies of water

InactiveUS20090130706A1Maintain depthConstant thicknessBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

Certain embodiments and aspects of the present invention relate to a photobioreactor including photobioreactor units through which a liquid medium stream and a gas stream flow. The photobioreactor units are floated on a body of water such as a pond or a lake. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, the photobioreactor units are formed of flexible, deformable material and are configured to provide a substantially constant thickness of liquid medium. In certain embodiments, a barrier between the photobioreactor unit and the body of water upon which the unit is floated facilitates thermal communication between the liquid medium and the body of water.

Owner:THE TRON GRP

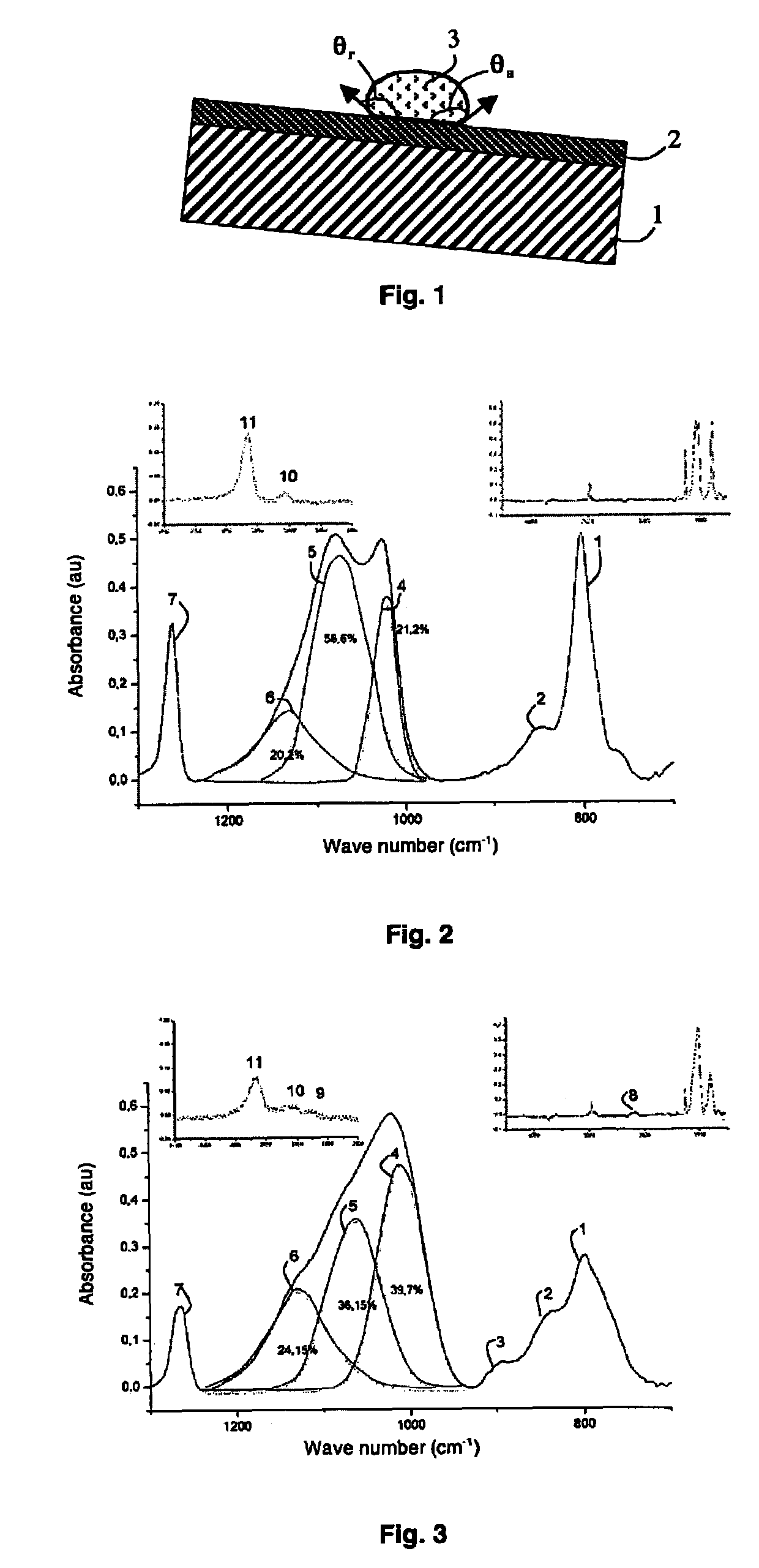

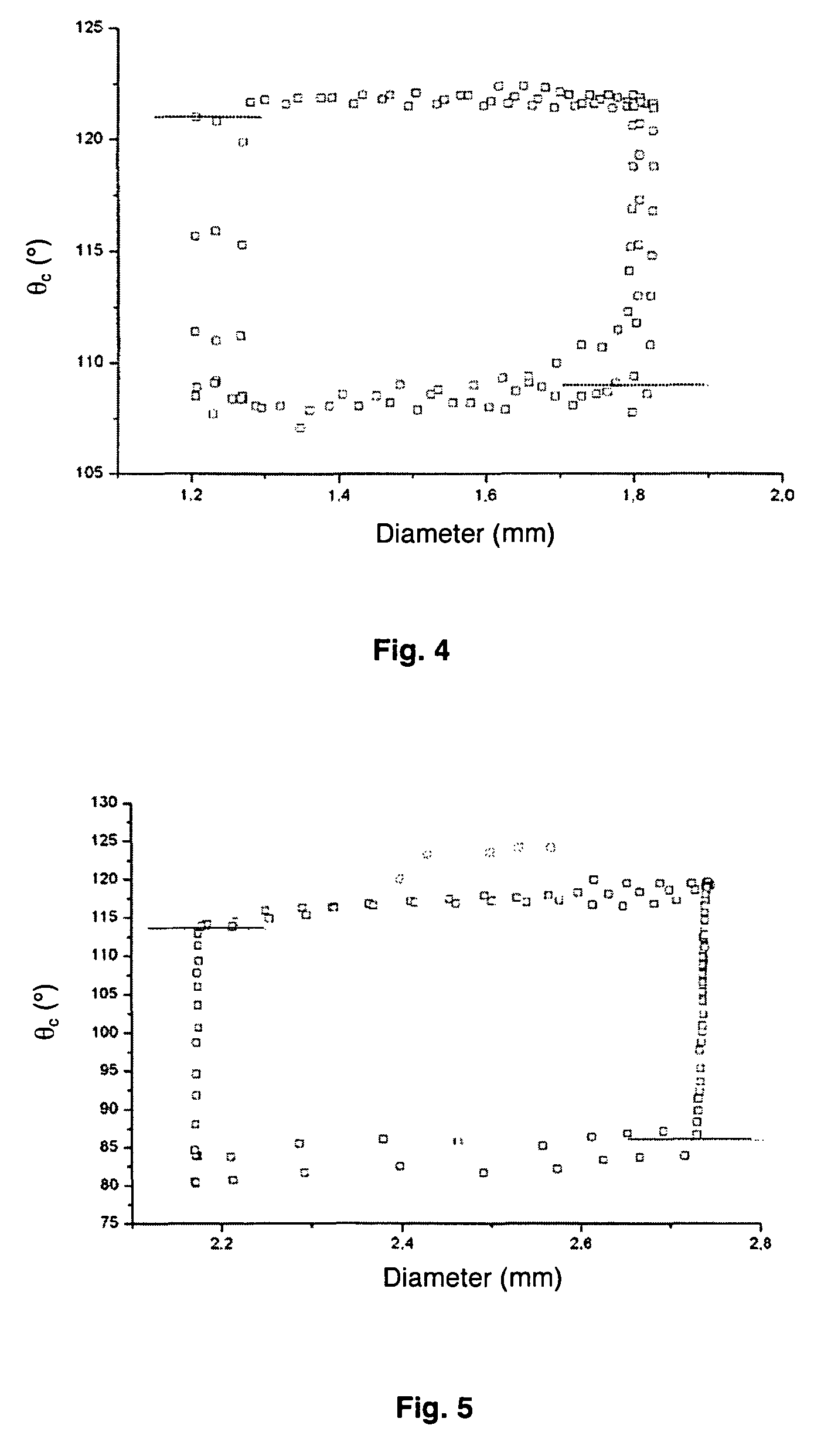

Hydrophobic Surface Coating With Low Wetting Hysteresis, Method for Depositing Same, Microcomponent and Use

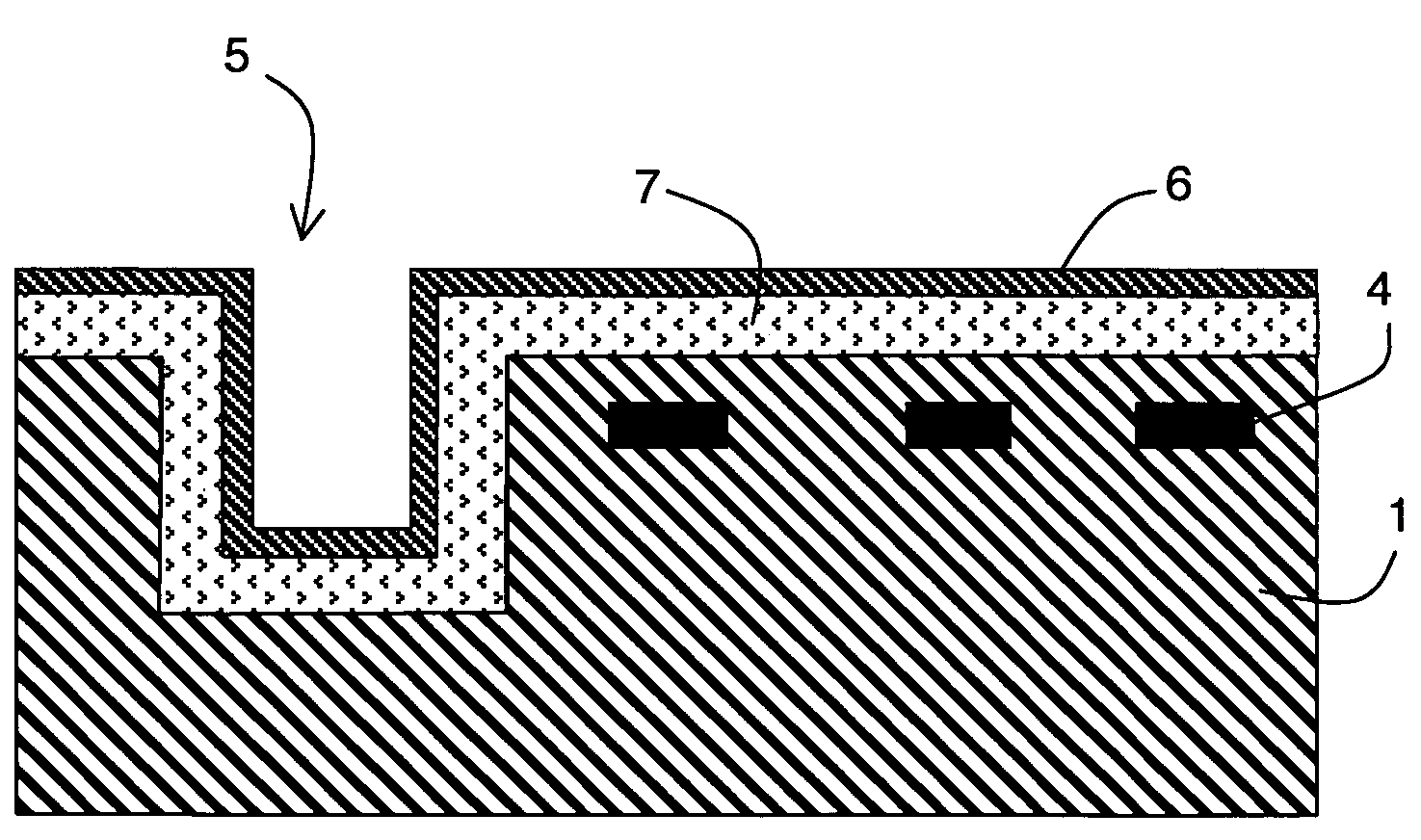

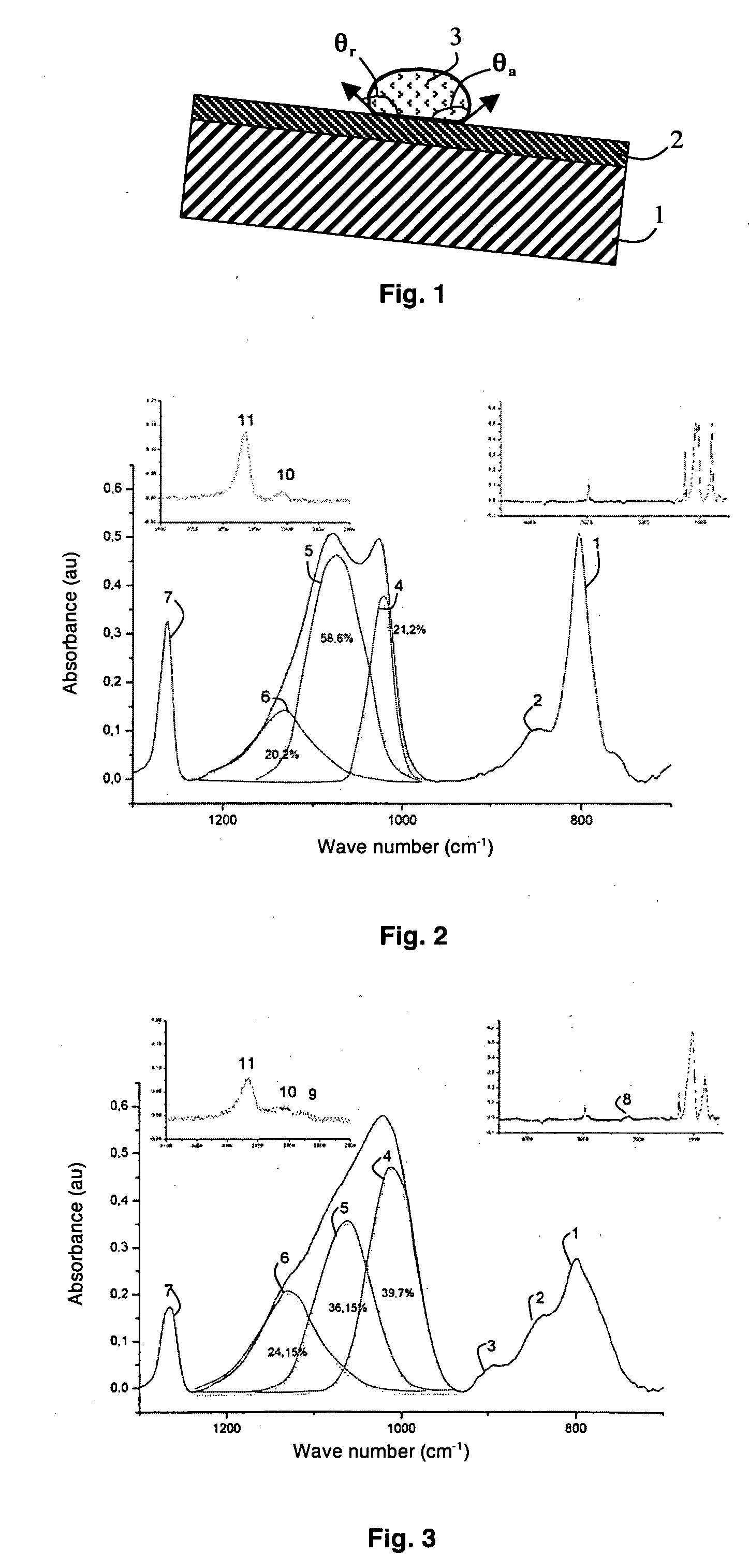

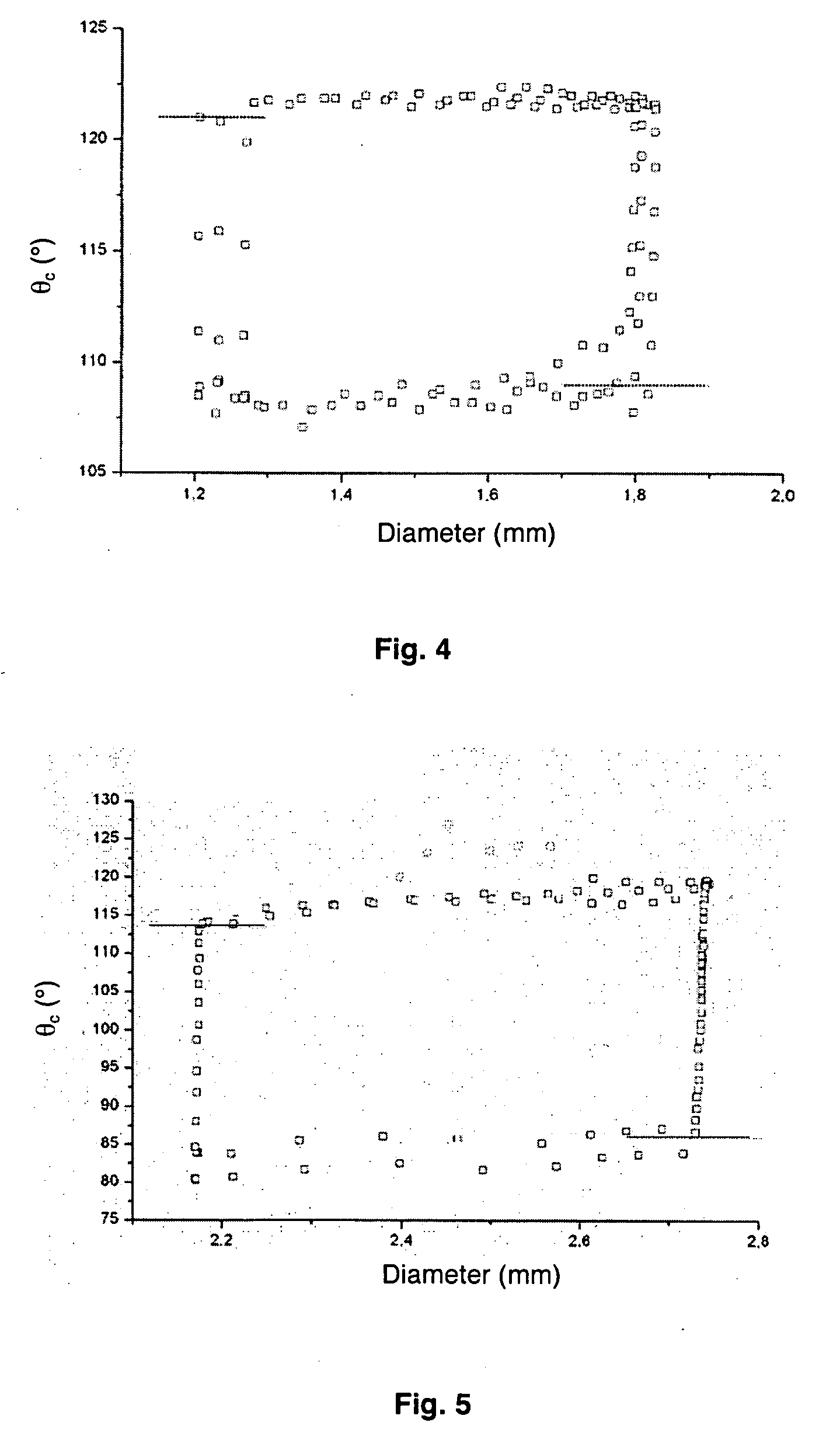

ActiveUS20090142564A1Improve hydrophobicityHigh dielectric constantGroup 4/14 element organic compoundsSynthetic resin layered productsHysteresisDielectric

A hydrophobic surface coating, preferably obtained by chemical vapor deposition, comprises at least an upper thin layer formed by a compound selected from the group consisting of SiCxOy:H with x comprised between 1.4 and 2 and y comprised between 0.8 and 1.4 and SiCx′Ny′:H with x′ comprised between 1.2 and 1.4 and y′ comprised between 0.6 and 0.8, so as to obtain a free surface with a low wetting hysteresis. Such a hydrophobic surface coating can be arranged on the free surface of a microcomponent comprising at least one substrate provided with, an electrode array and particularly suitable for moving drops of liquid by electrowetting on dielectric.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

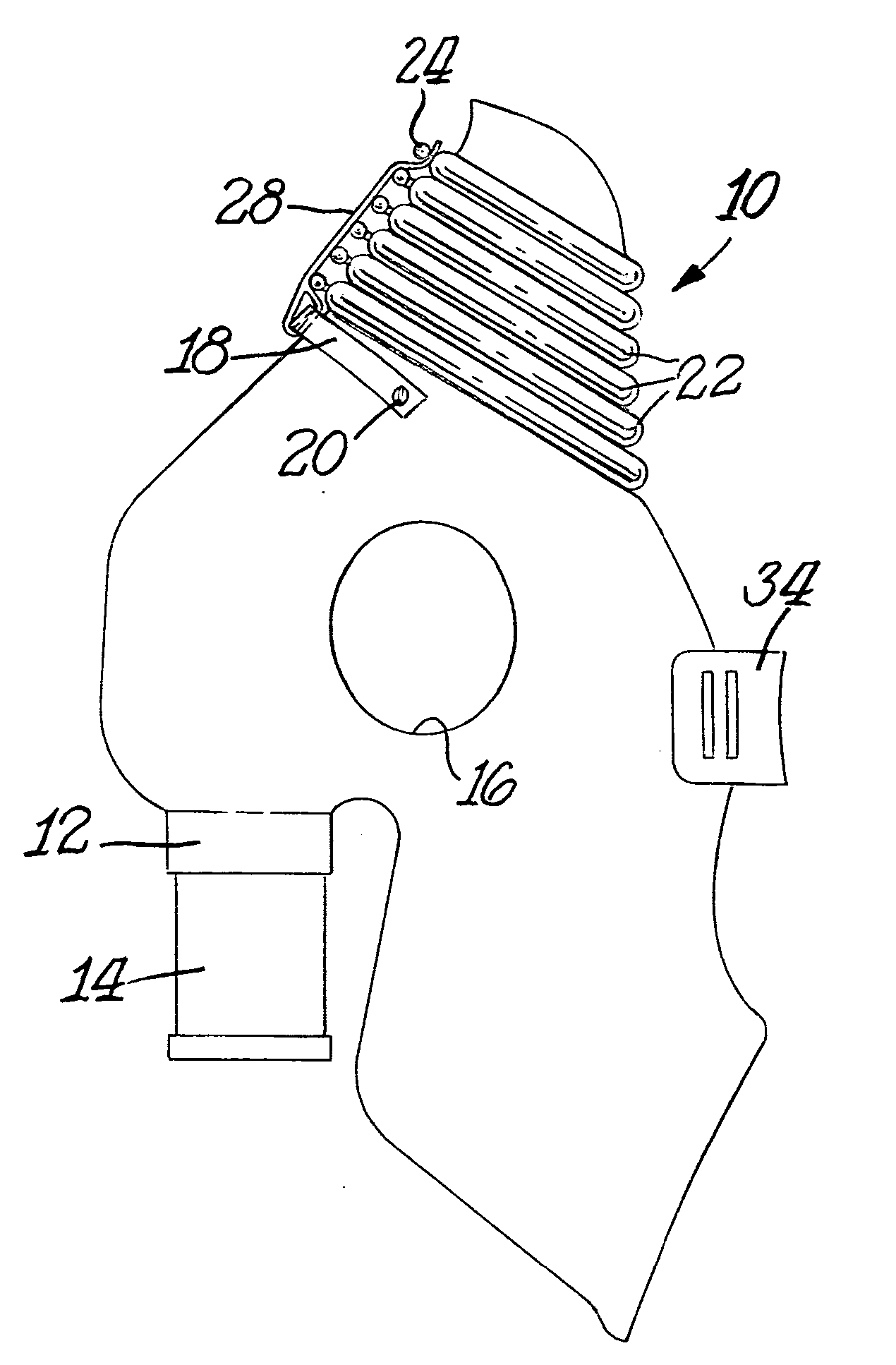

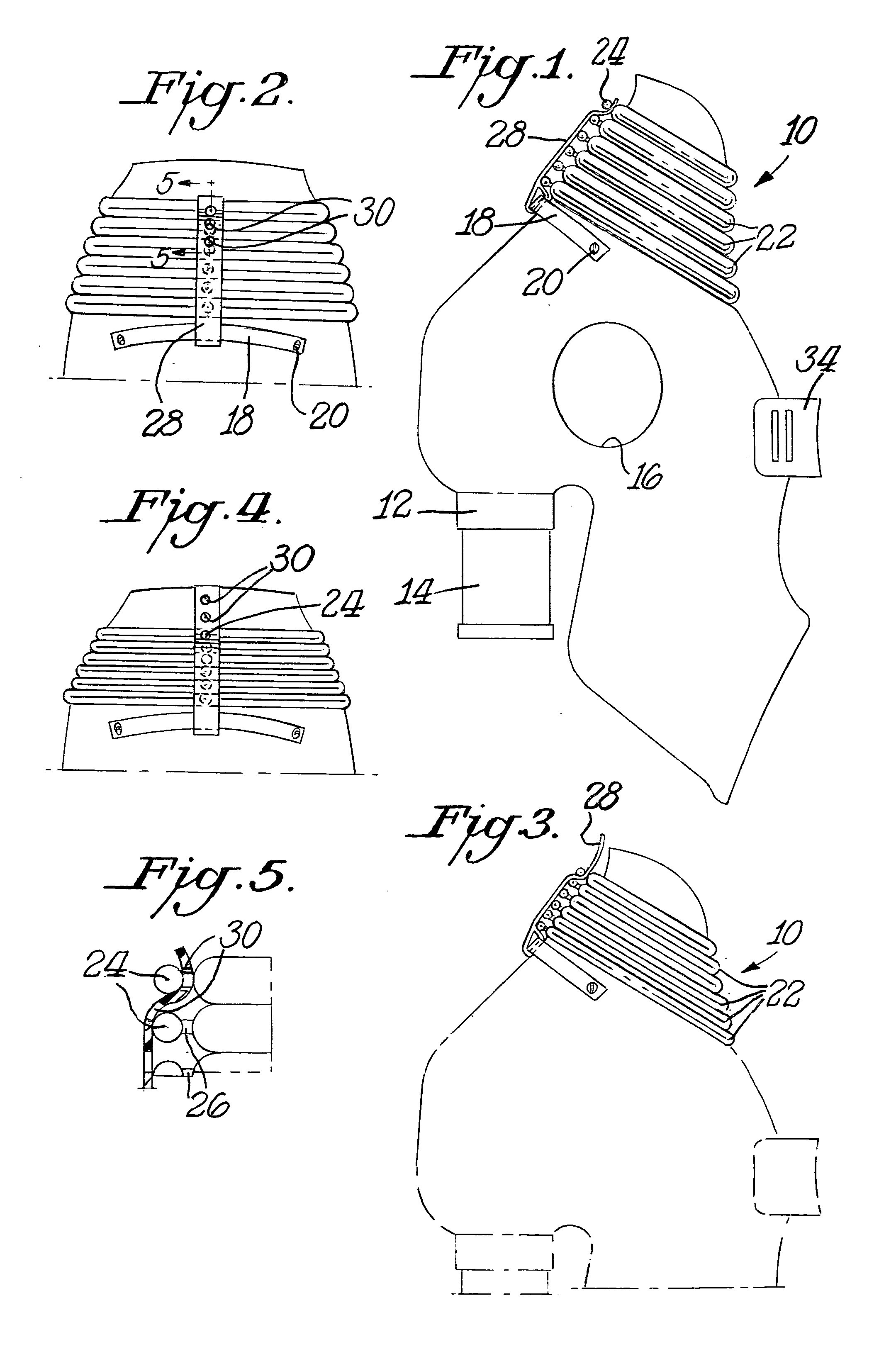

Respiratory mask

InactiveUS20060219246A1Adjustable in lengthConstant thicknessBreathing filtersRespiratory masksRespiratory maskIntensive care medicine

A respiratory mask is reduced in size to better fit patients with smaller faces by folding accordion folds of the mask. An adjustment member allows for selective folding of the accordion folds, thereby determining the size of the mask. The respiratory mask can thus be adjusted to fit both larger and smaller persons.

Owner:DENNIS CARNELL K

Hydrophobic surface coating with low wetting hysteresis, method for depositing same, microcomponent and use

ActiveUS7989056B2Low wetting hysteresisImprove hydrophobicityGroup 4/14 element organic compoundsSynthetic resin layered productsHysteresisDielectric

A hydrophobic surface coating, preferably obtained by chemical vapor deposition, comprises at least an upper thin layer formed by a compound selected from the group consisting of SiCxOy:H with x comprised between 1.4 and 2 and y comprised between 0.8 and 1.4 and SiCx′Ny′:H with x′ comprised between 1.2 and 1.4 and y′ comprised between 0.6 and 0.8, so as to obtain a free surface with a low wetting hysteresis. Such a hydrophobic surface coating can be arranged on the free surface of a microcomponent comprising at least one substrate provided with, an electrode array and particularly suitable for moving drops of liquid by electrowetting on dielectric.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

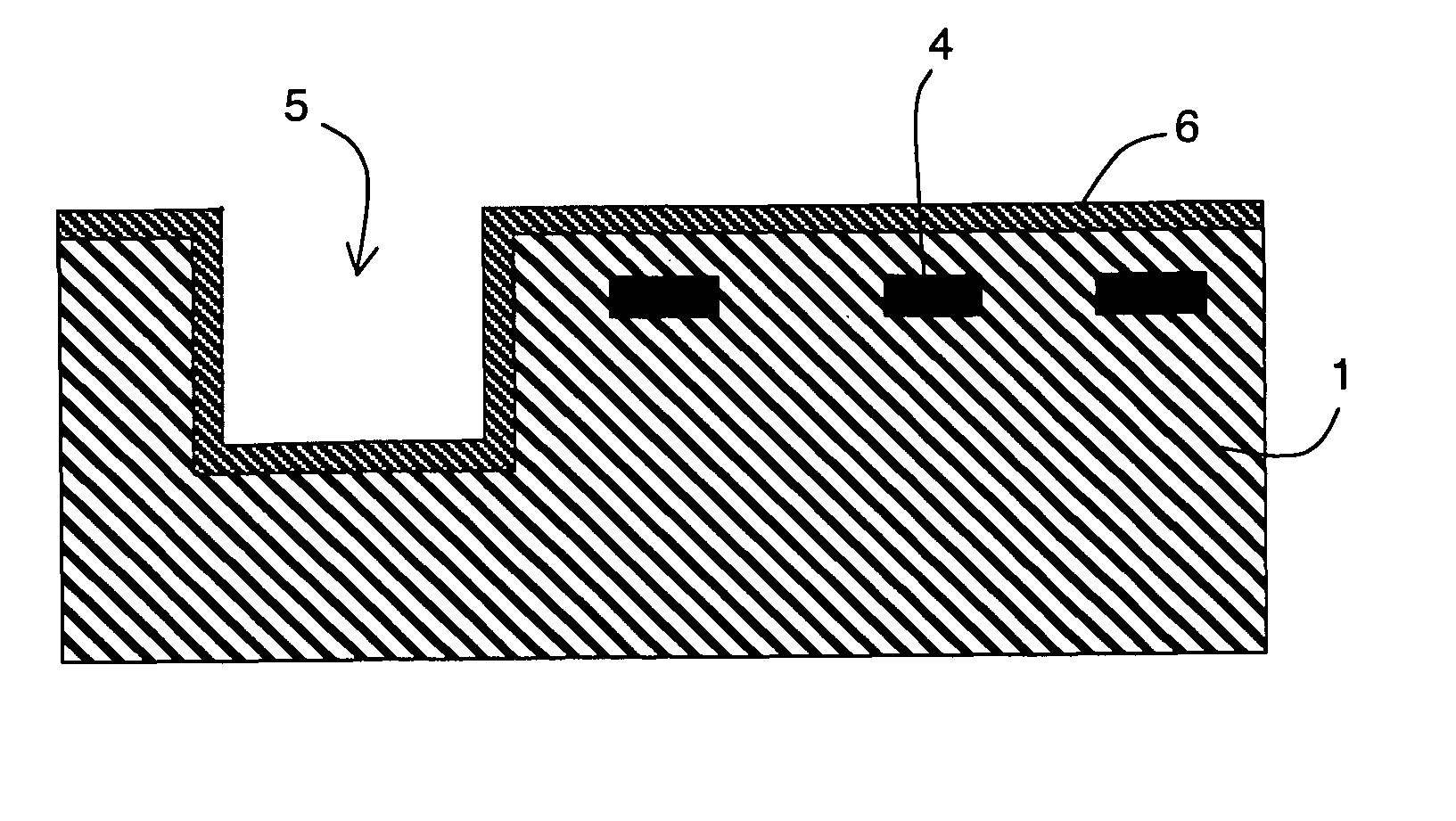

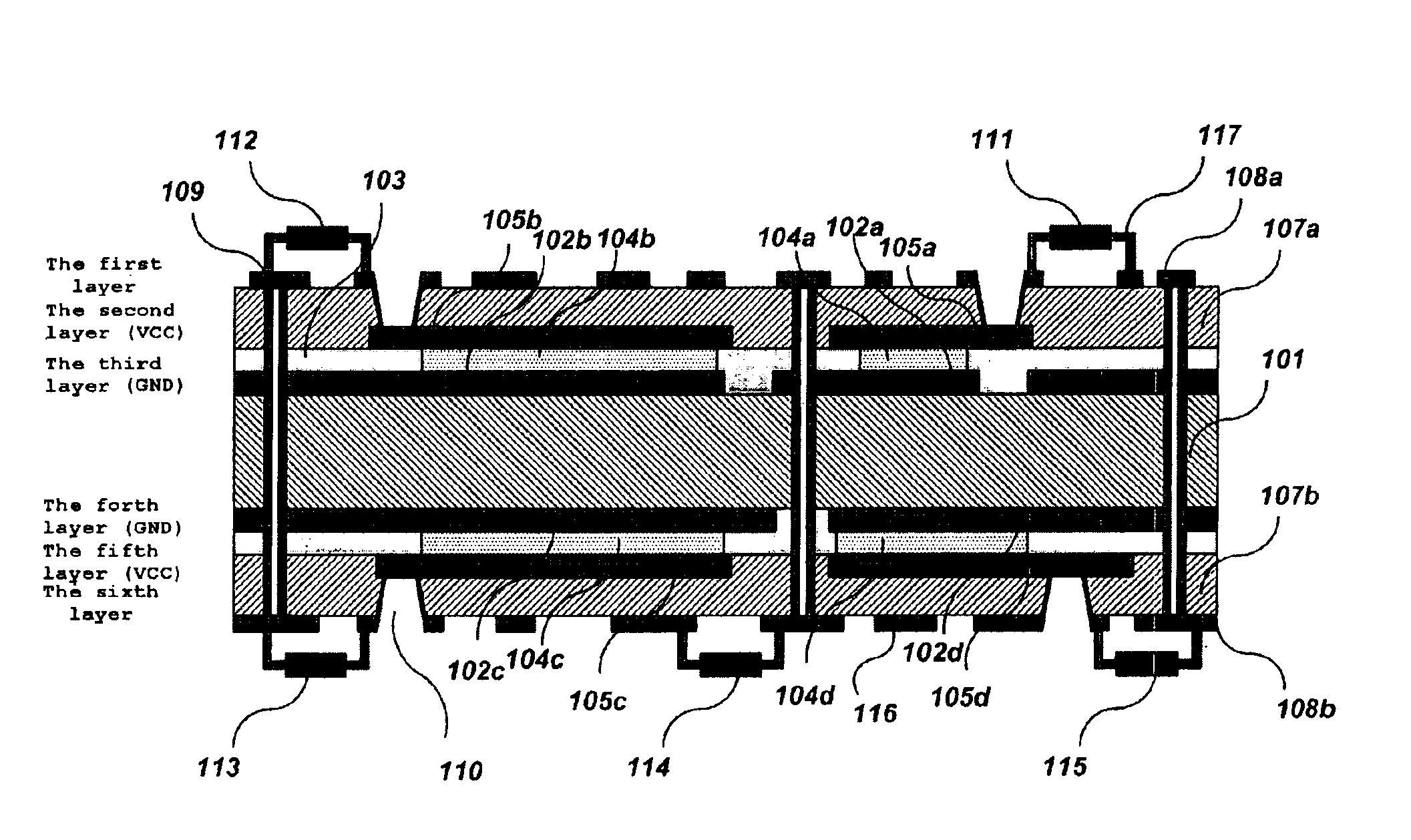

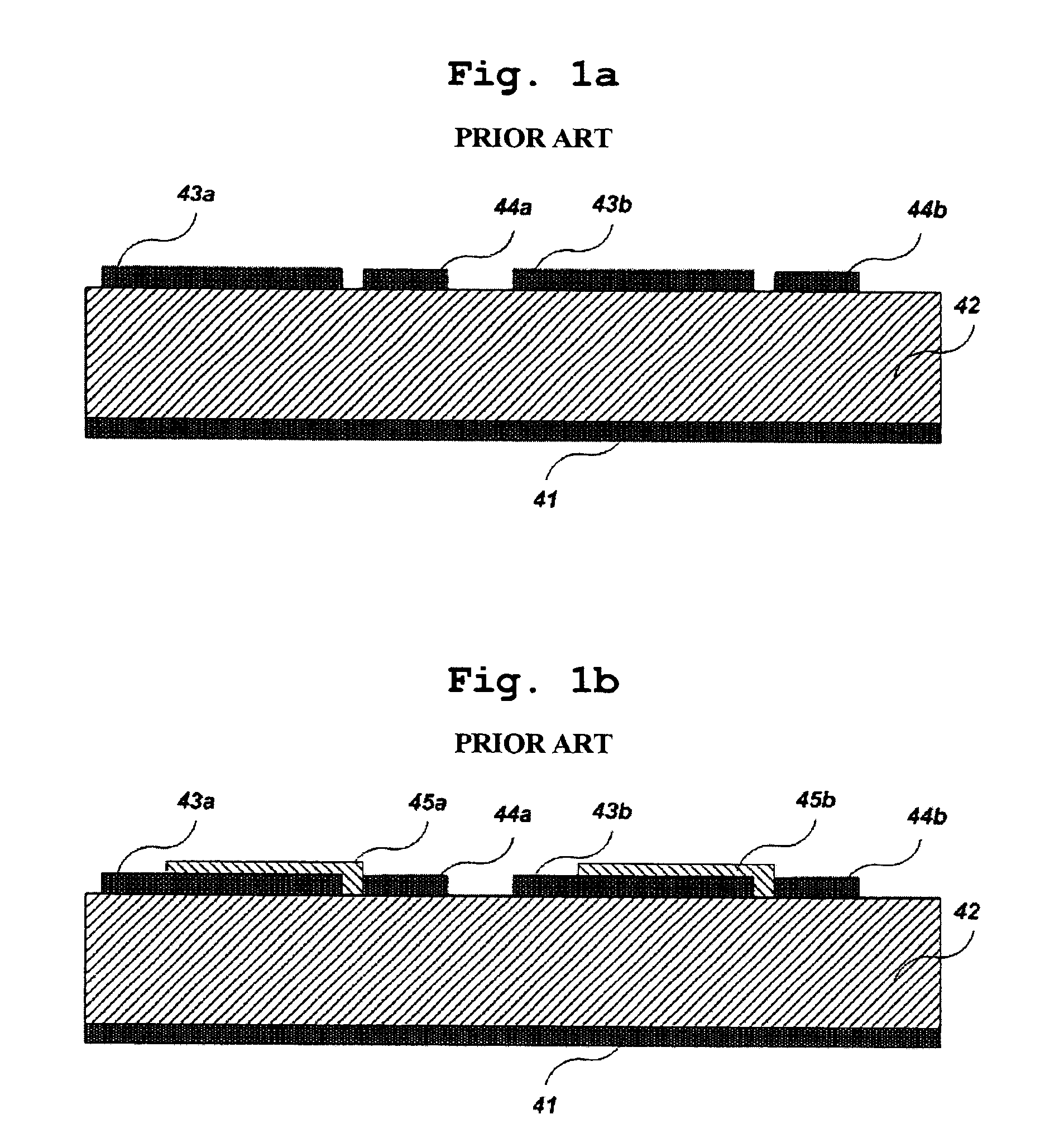

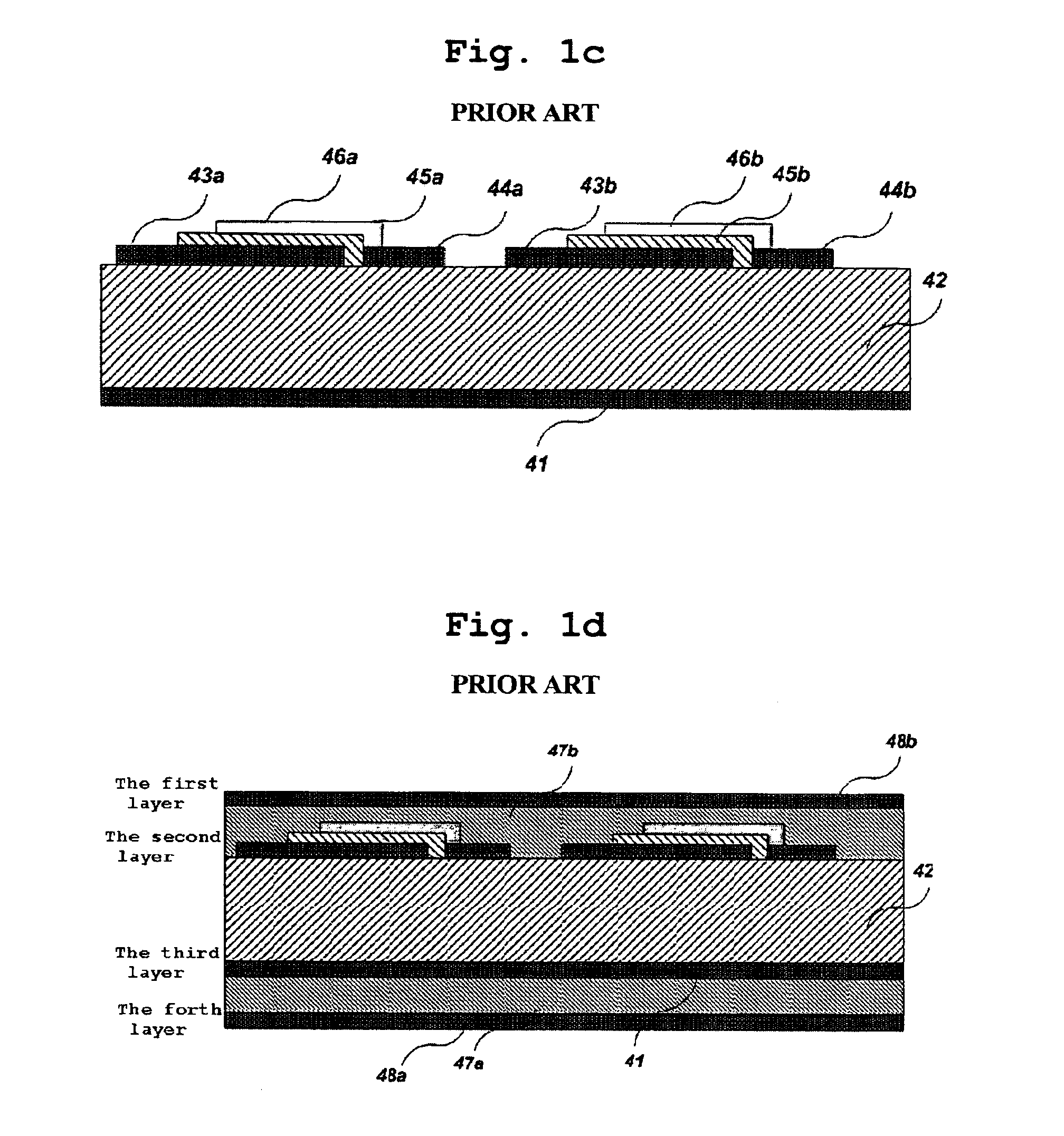

Printed circuit board with embedded capacitors therein, and process for manufacturing the same

InactiveUS6910266B2High capacitance valueIncrease capacitancePrinted circuit assemblingLine/current collector detailsCopper foilCopper plating

Disclosed herein are a printed circuit board with embedded capacitors therein and a process for manufacturing the printed circuit board. The embedded capacitors are formed by applying a photosensitive insulating resin to a printed circuit board inner layer, and applying a high dielectric polymer capacitor paste thereto. The process for manufacturing a printed circuit board with embedded capacitors therein comprises the steps of: i) laminating photoresist dry films to a copper clad FR-4, exposing to light and developing the dry films, and etching copper foils of the copper clad FR-4 to form bottom electrodes for forming capacitors; ii) applying a photosensitive insulating resin to the surfaces of the bottom electrodes, and exposing to light and developing to etch the photosensitive insulating resin; iii) applying a capacitor paste to the etched regions and curing the capacitor paste; iv) plating the upper regions of the cured capacitor paste and the photosensitive insulating resin using an electroless copper plating process to form copper foil layers for top electrodes; v) laminating photosensitive dry films to the copper foil layers for top electrodes, and exposing to light and developing the photosensitive dry films to etch regions of the dry films except for the copper foil layers where the top electrodes are to be formed; and vi) etching the regions of the dry films except for the copper foil layers where the top electrodes are to be formed, and the dry films formed on the top electrodes are removed so that the capacitor paste is discretely positioned between the top electrodes and the bottom electrodes to form discrete capacitors.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

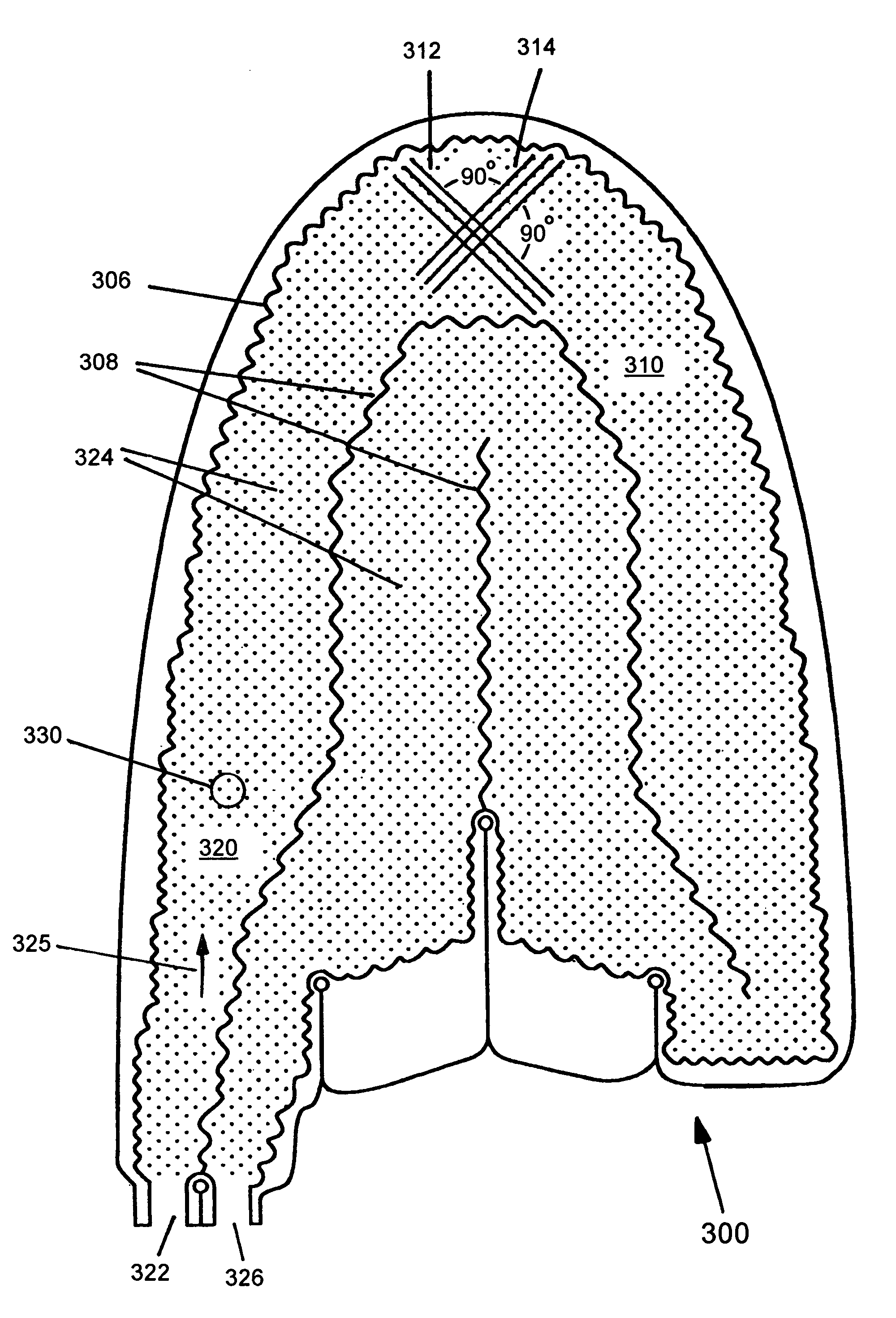

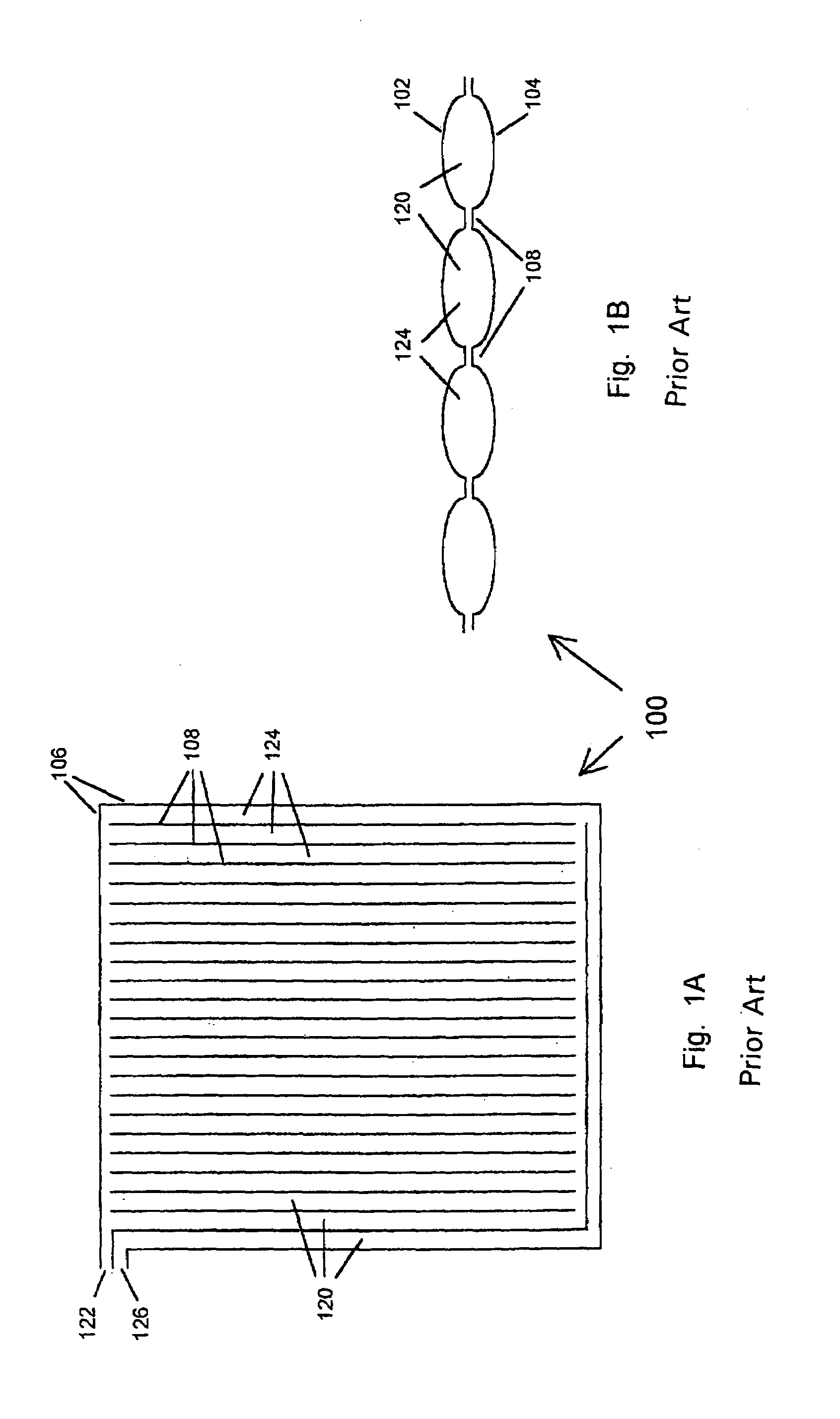

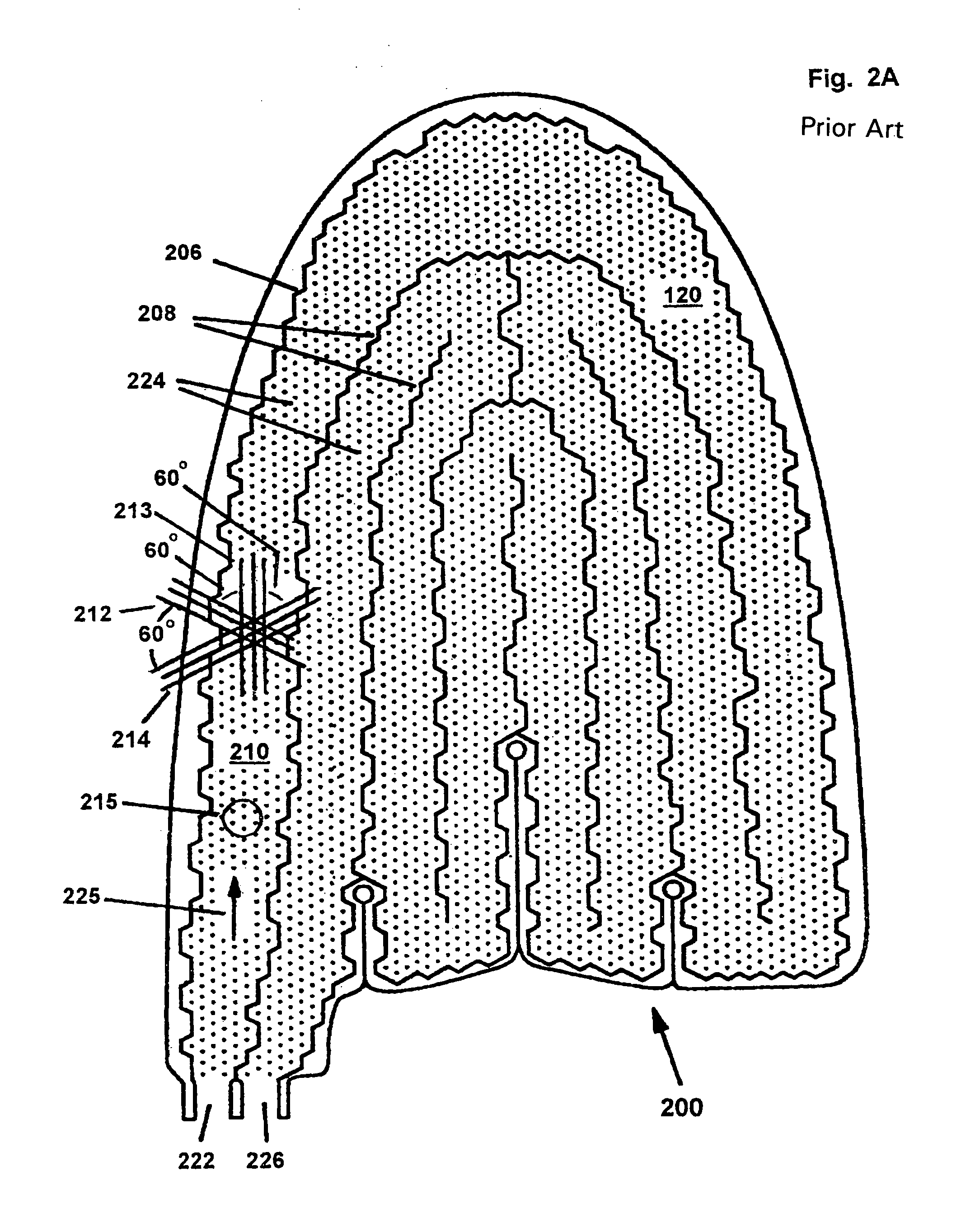

Compliant heat exchange panel

InactiveUS7198093B1Uniform temperatureComplex shapeMetal-working apparatusTherapeutic coolingDot matrixVia fence

A heat exchange panel for use in an active heat exchange system. The heat exchange panel includes first and second layers having seals between the layers at a common border, at fences, and at dots of a dot matrix. The dot matrix is organized into first parallel lines and second parallel lines where the first and second parallel line cross at a 90° angle. The seals at the border and the fences are rippled with smooth ripples.

Owner:AVENT INC

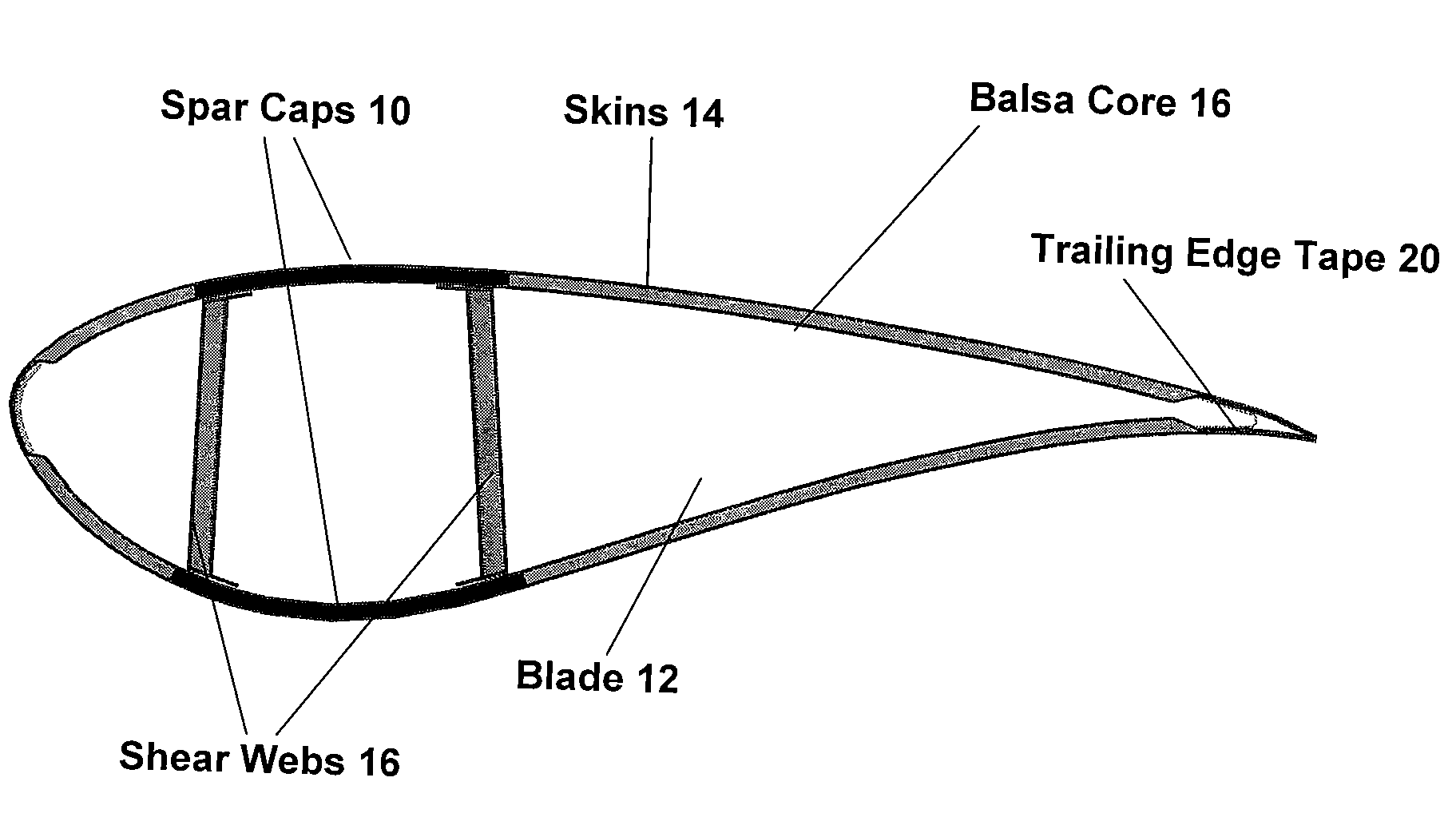

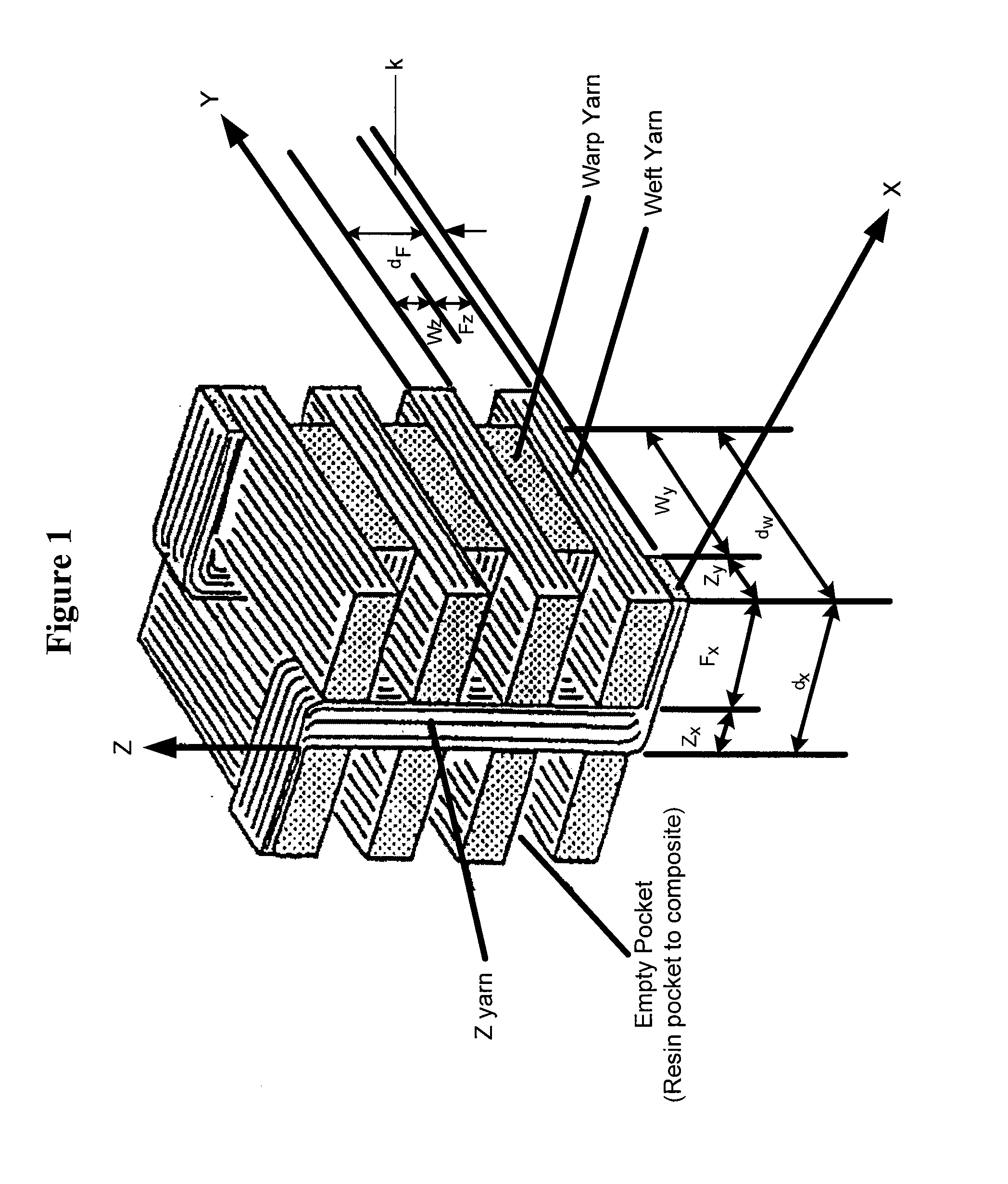

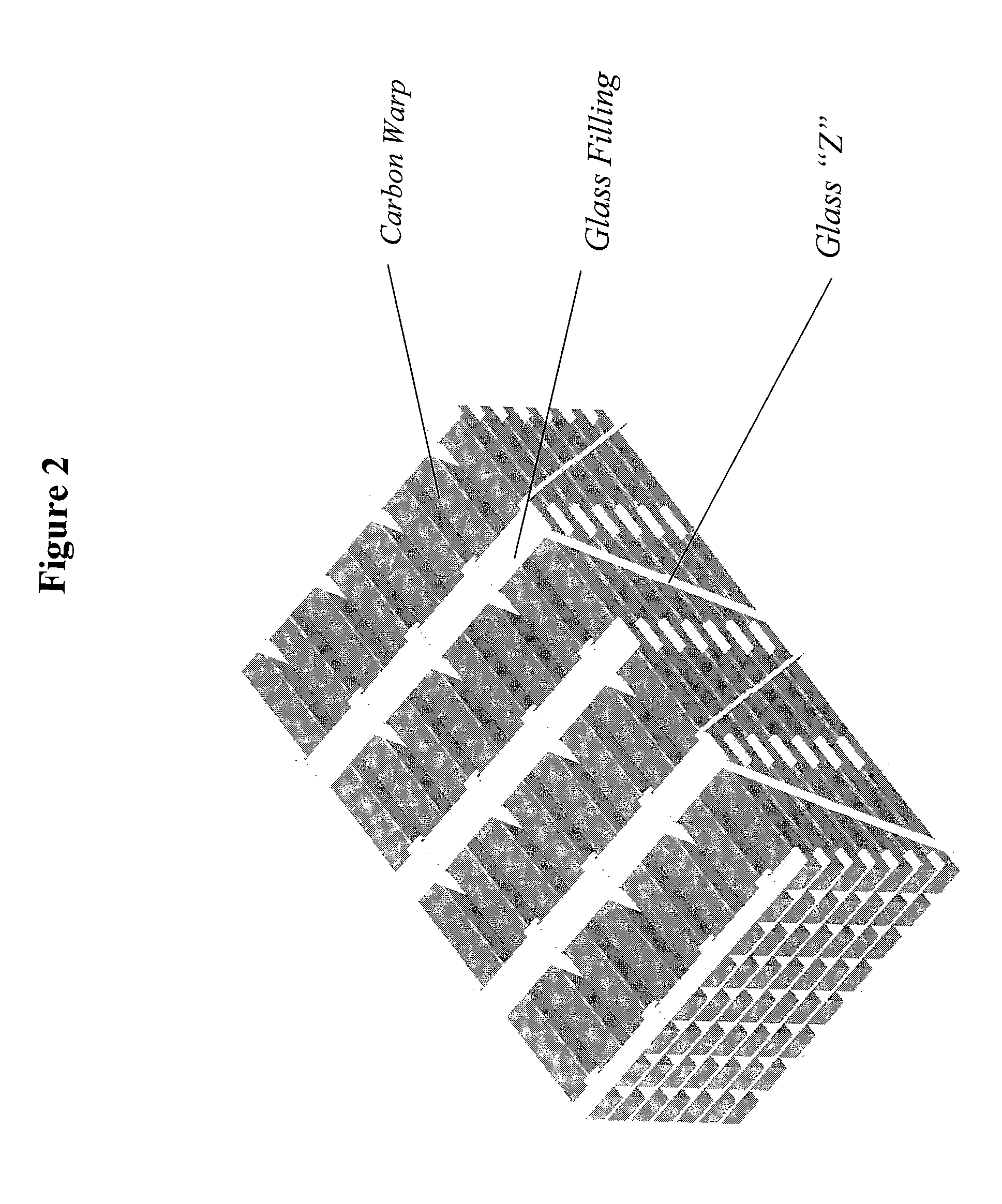

Wind blade spar cap and method of making

InactiveUS20070189902A1Constant thicknessReduce weightRotary propellersFinal product manufactureDecrease weightEngineering

Owner:3TEX

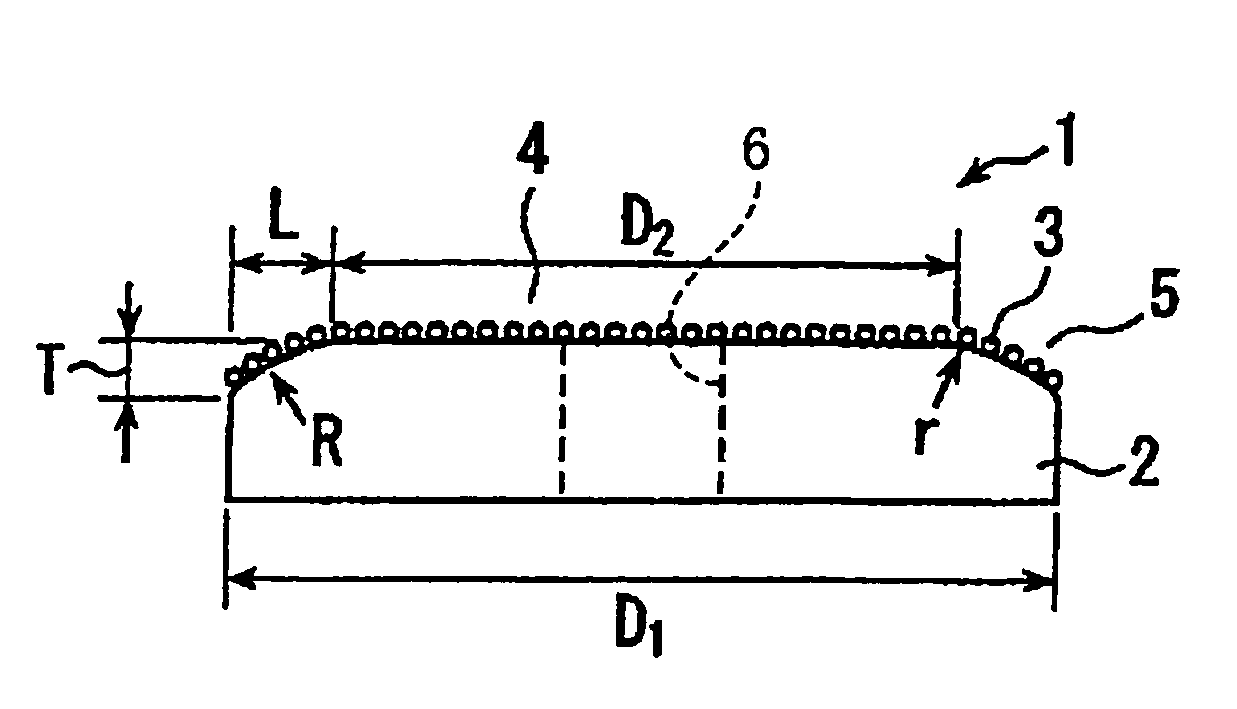

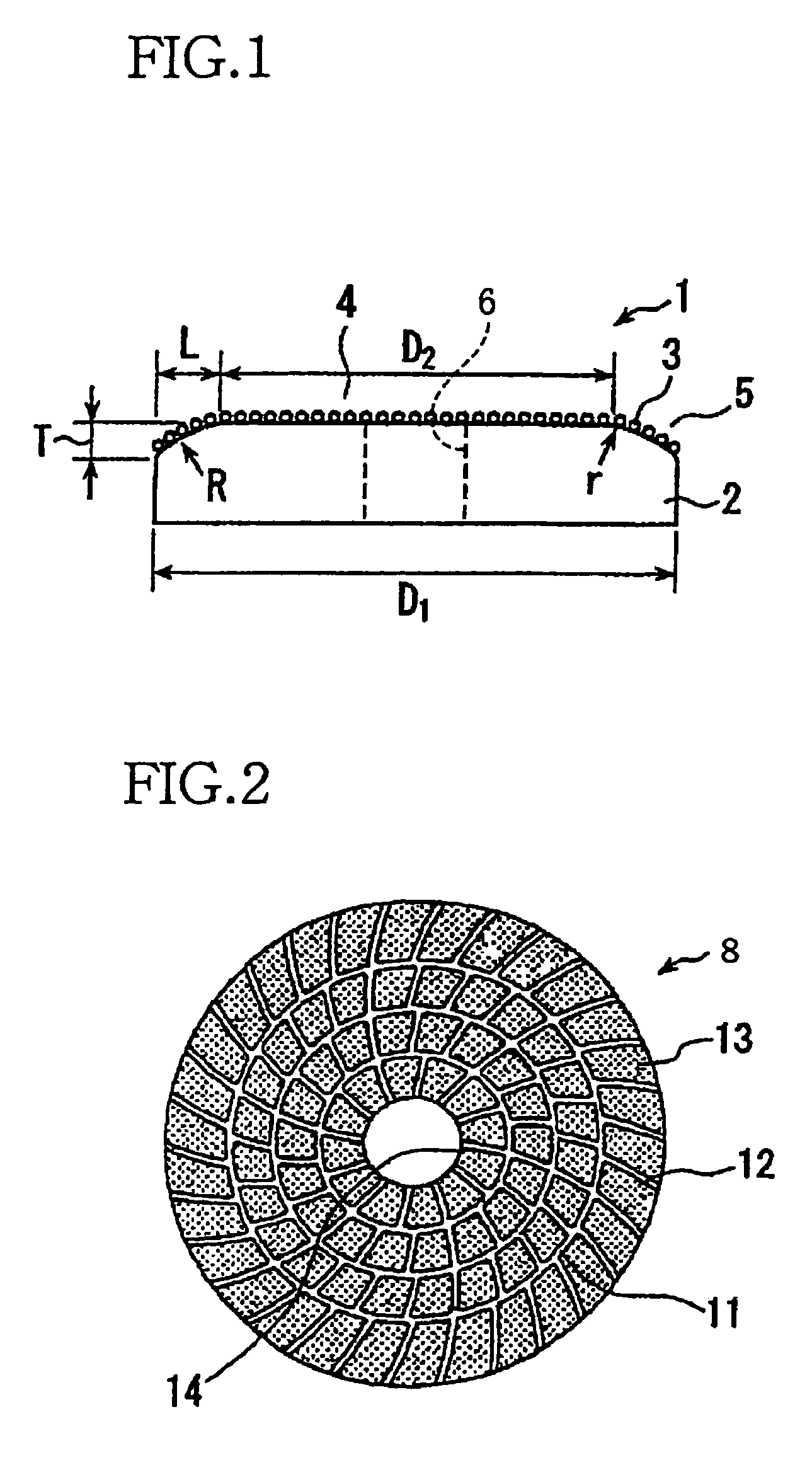

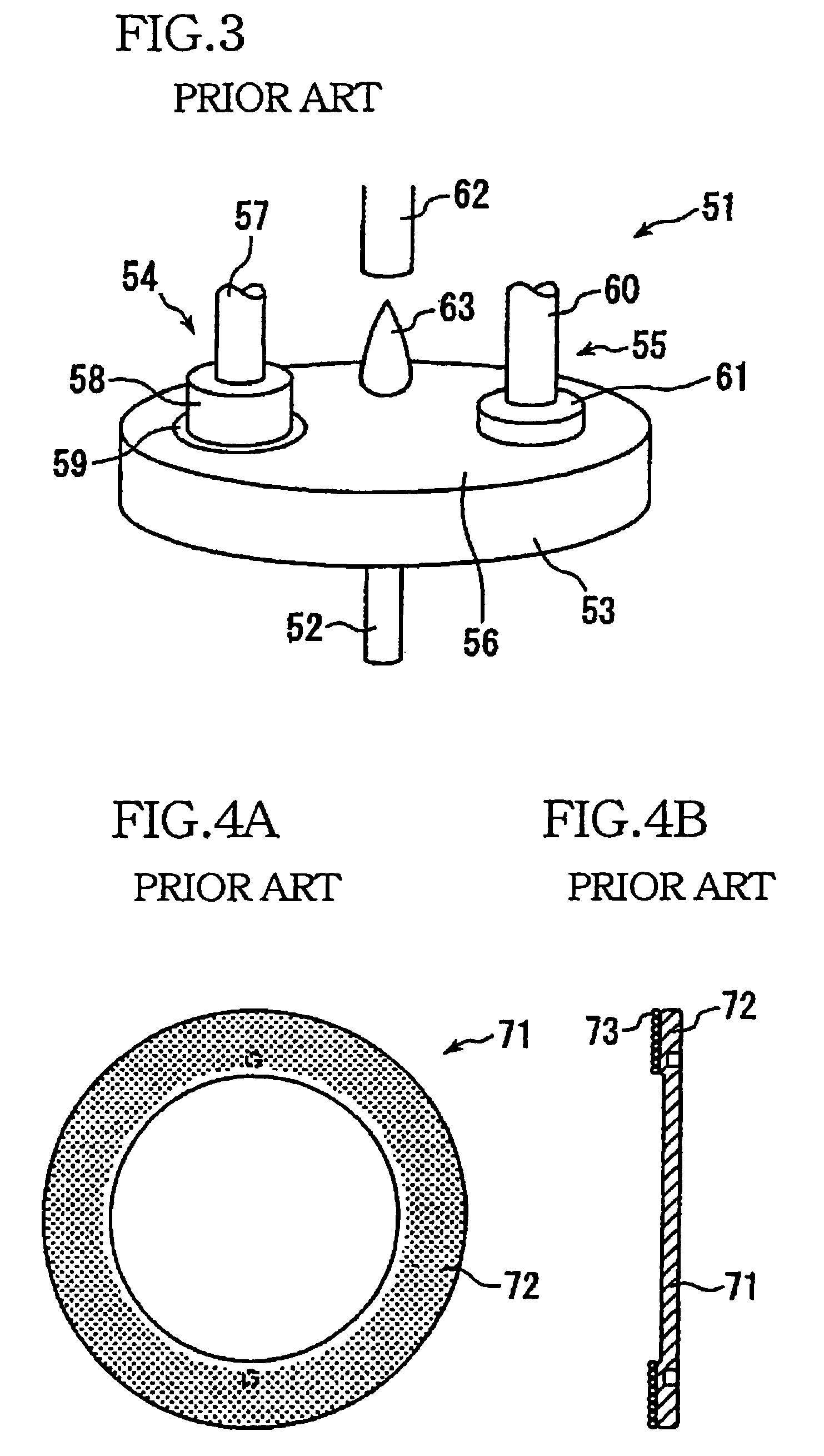

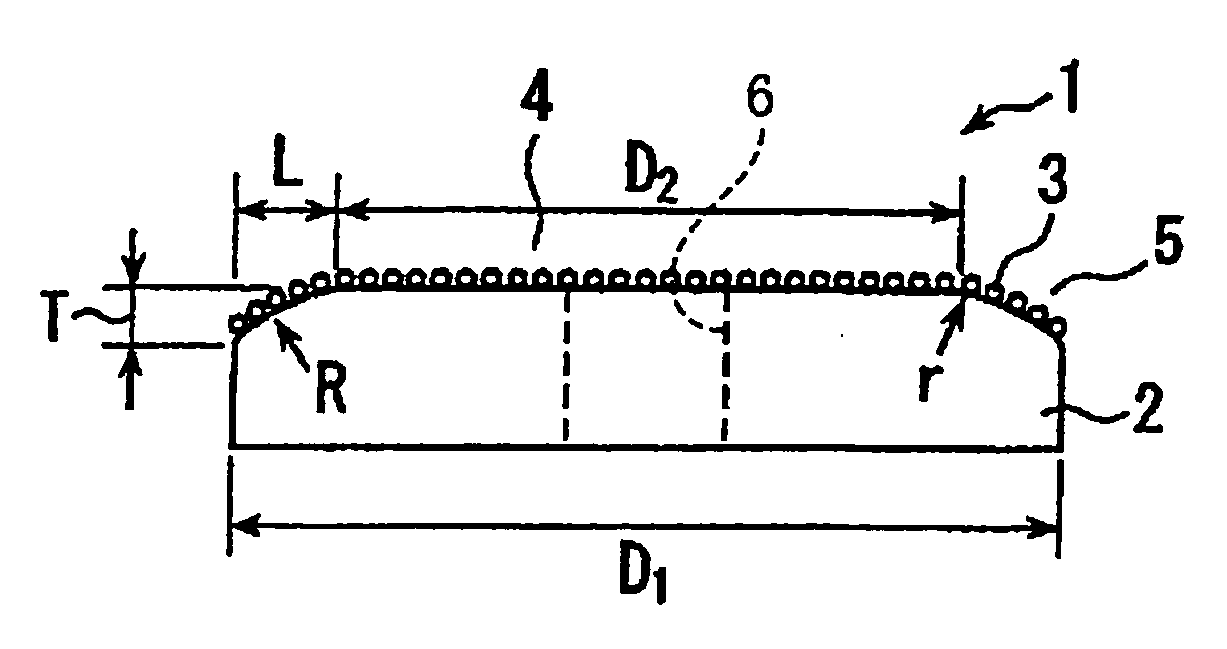

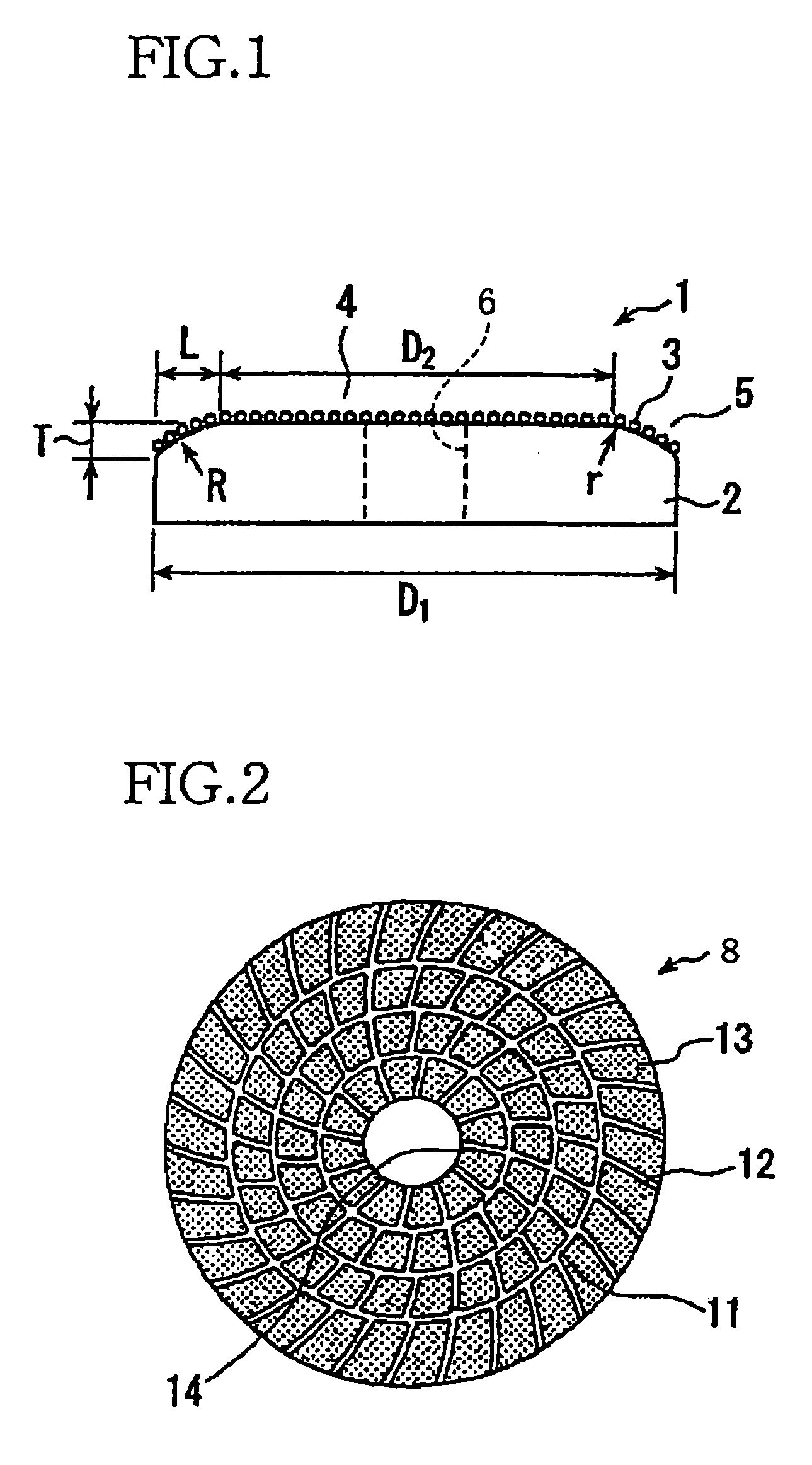

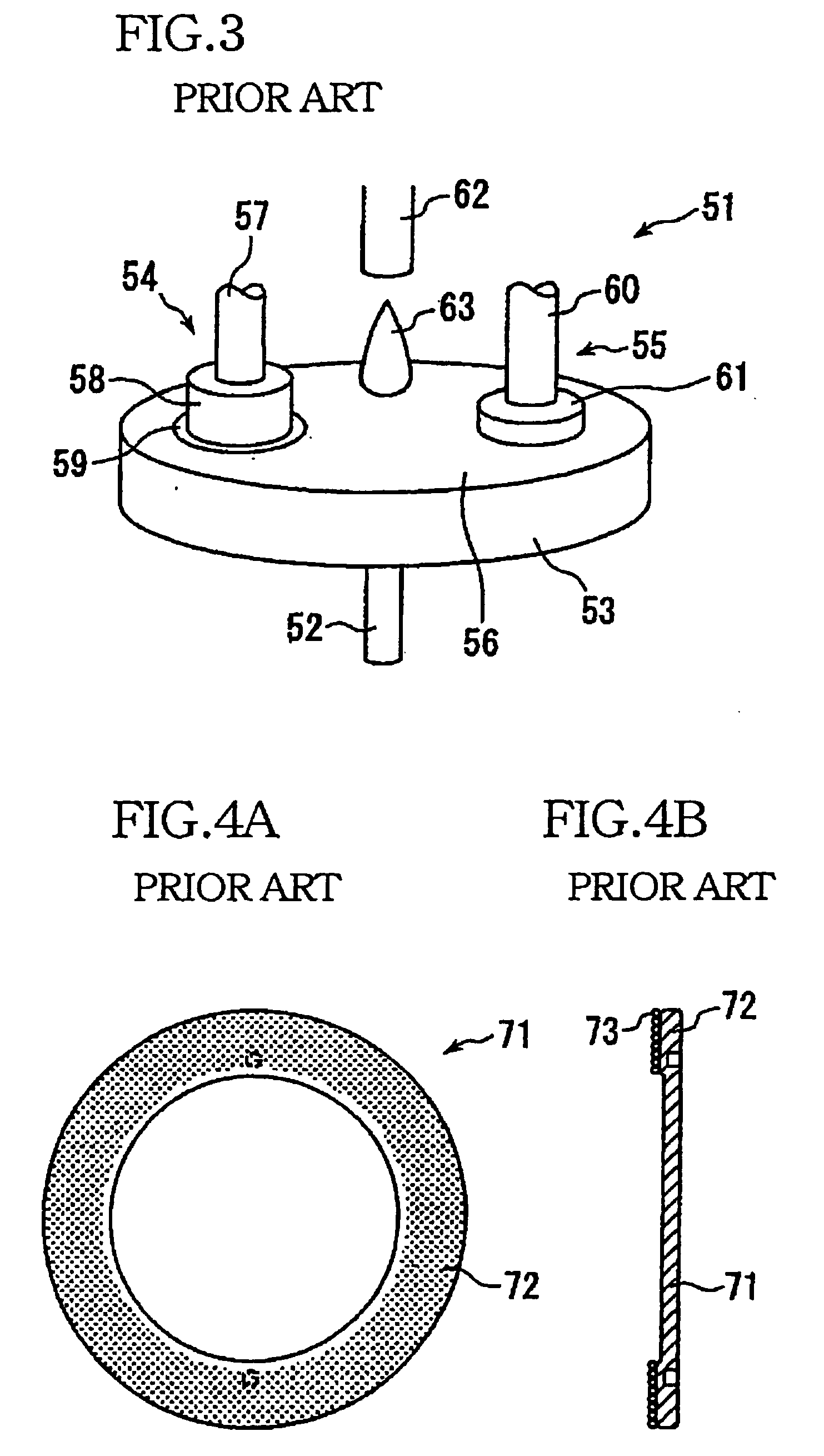

CMP pad conditioner having working surface inclined in radially outer portion

ActiveUS7021995B2Avoiding considerable damageExtended service lifeRevolution surface grinding machinesGrinding drivesMechanical engineeringEngineering

A CMP pad conditioner including: (a) a disk-shaped substrate having a working surface which is provided by one of its axially opposite end surfaces and which is to be brought into contact with the CMP pad; and (b) abrasive grains which are fixed to the working surface. The substrate includes a radially inner portion and a radially outer portion which is located radially outwardly of the radially inner portion. The working surface in the radially outer portion is inclined with respect to the working surface in the radially inner portion, such that a thickness of the radially outer portion as measured in an axial direction of the substrate is reduced as viewed in a direction away from an axis of the substrate toward a periphery of the substrate. A ratio of an outside diameter of the radially inner portion to an outside diameter of the substrate is 60–85%.

Owner:NORITAKE CO LTD +1

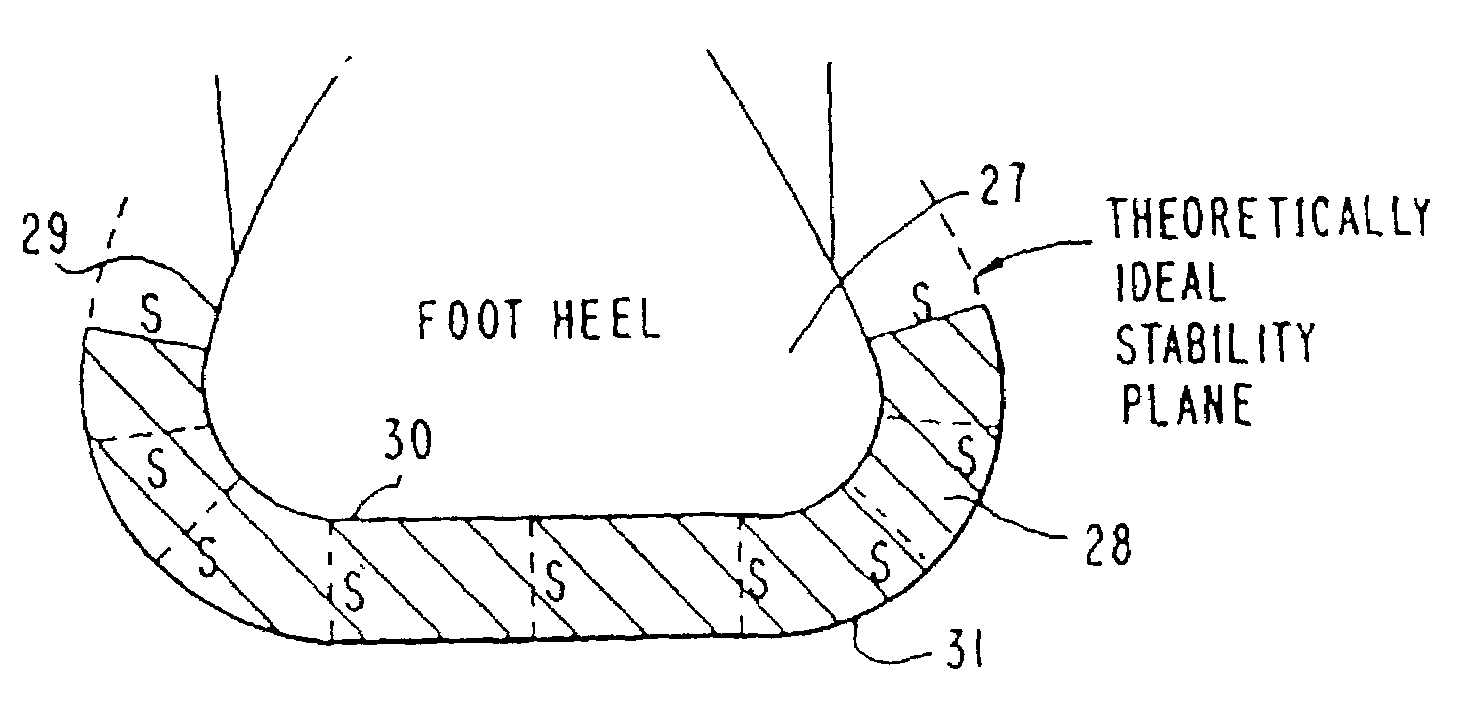

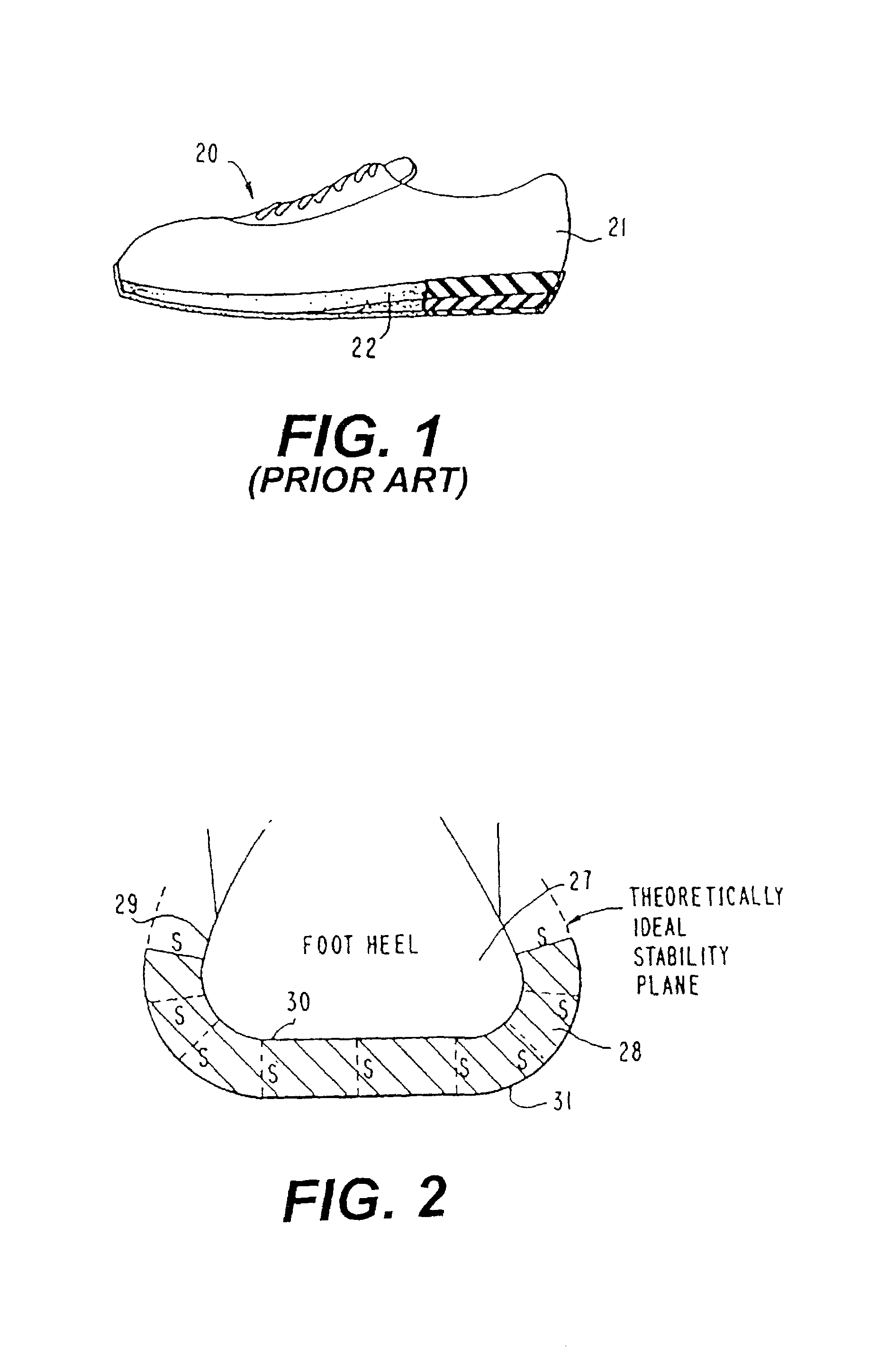

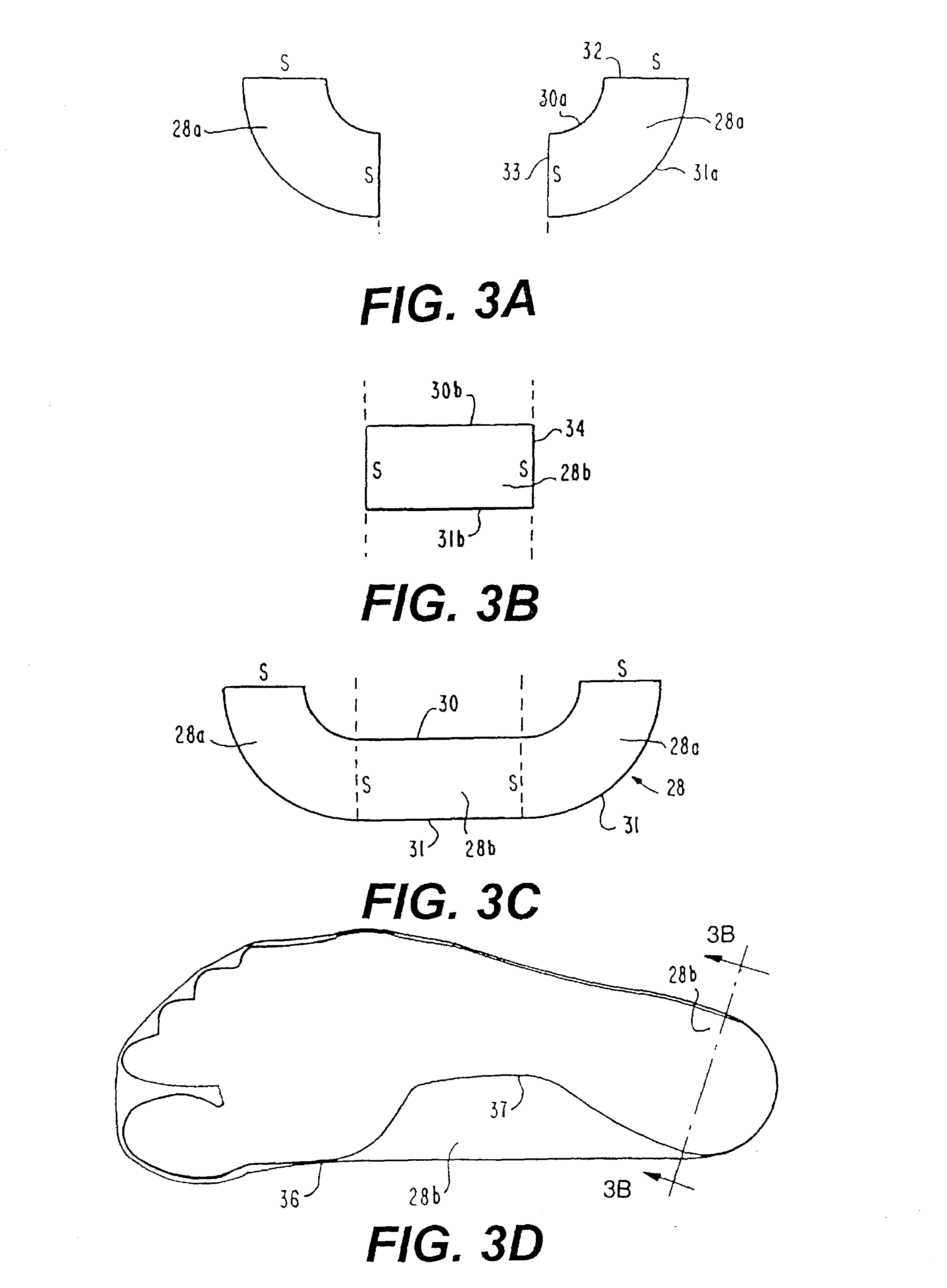

Shoe sole with rounded inner and outer side surfaces

An athletic shoe sole for a shoe has side portions with concavely rounded inner and outer surfaces, as viewed in at least a heel area and a midtarsal area of the shoe sole. The rounded surfaces increasing at least one of lateral and medial stability of the sole. The concavely rounded portion of the sole outer surface located at the heel area extends substantially continuously through a sidemost part of the sole side. The rounded portion of the sole outer surface located at the midtarsal area extends up the sole side to at least a level corresponding to a lowest point of the sole inner surface. A midsole component of the shoe sole extends into the sidemost section of the sole side and also extends up the sole side to above a level corresponding to a lowest point of the sole inner surface. The concavely rounded portions of the sole midtarsal area are located at least at the sole lateral side. The sole outer surface of at least part of the midtarsal area is substantially convexly rounded, as viewed in a shoe sole sagittal plane.

Owner:ANATOMIC RES

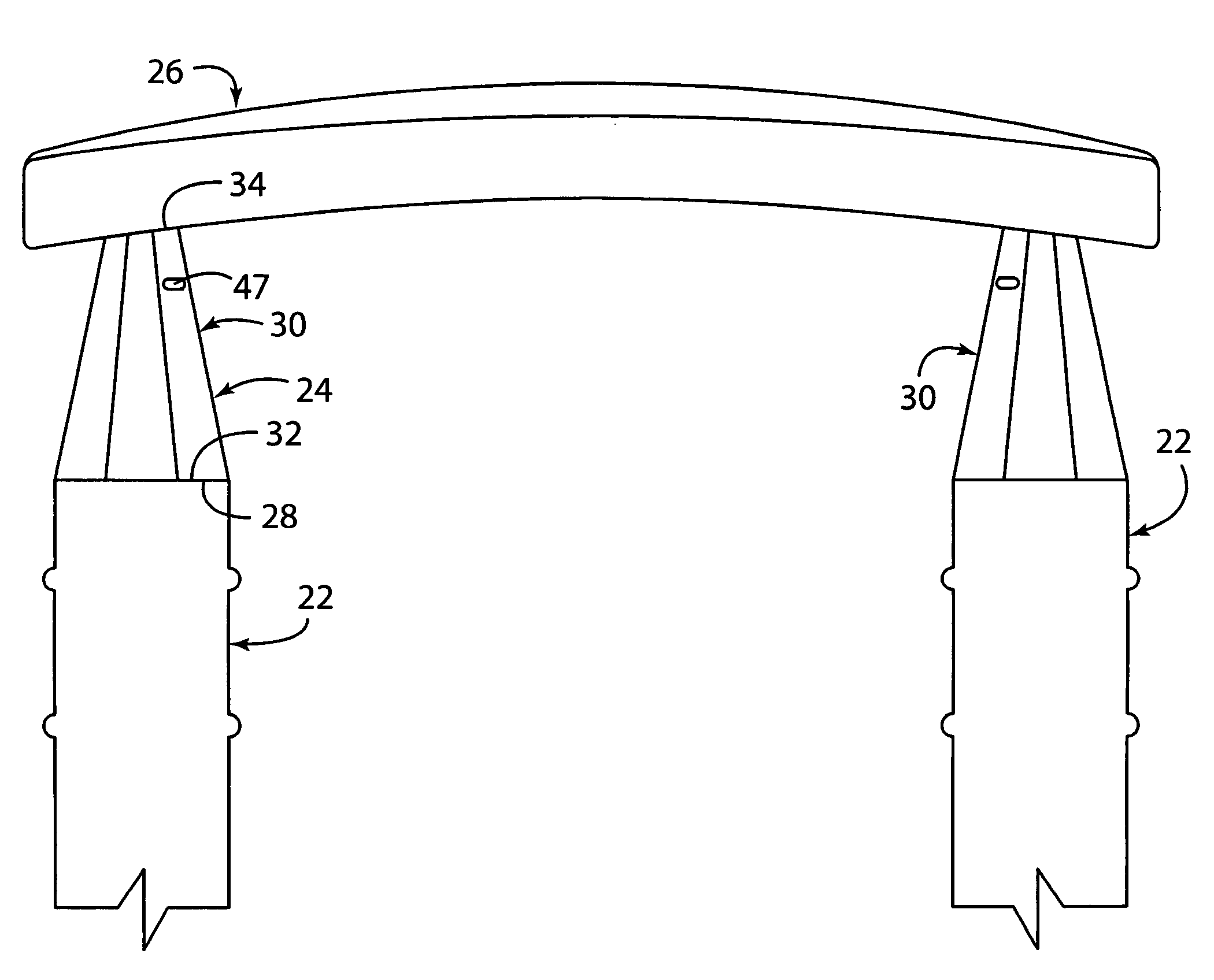

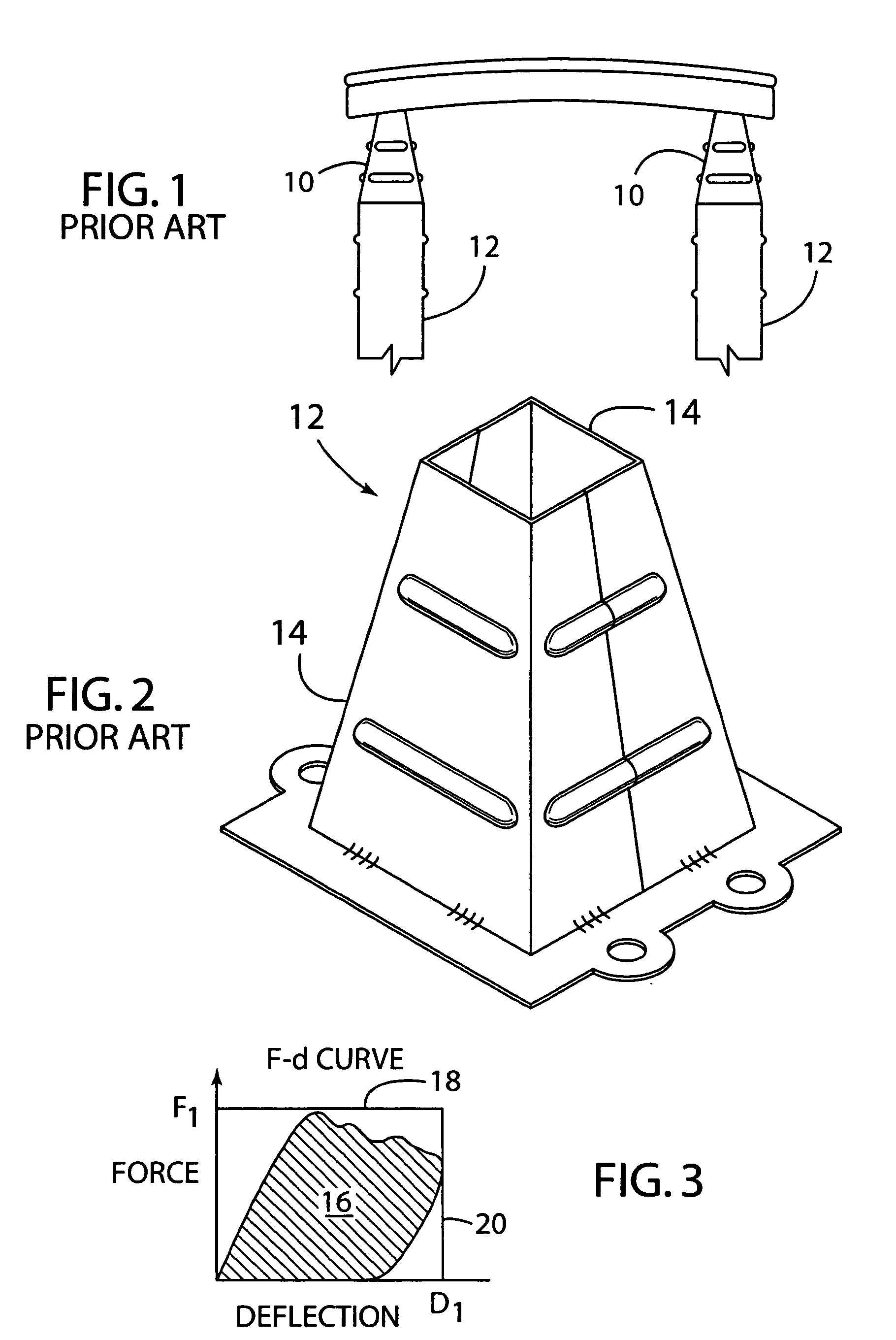

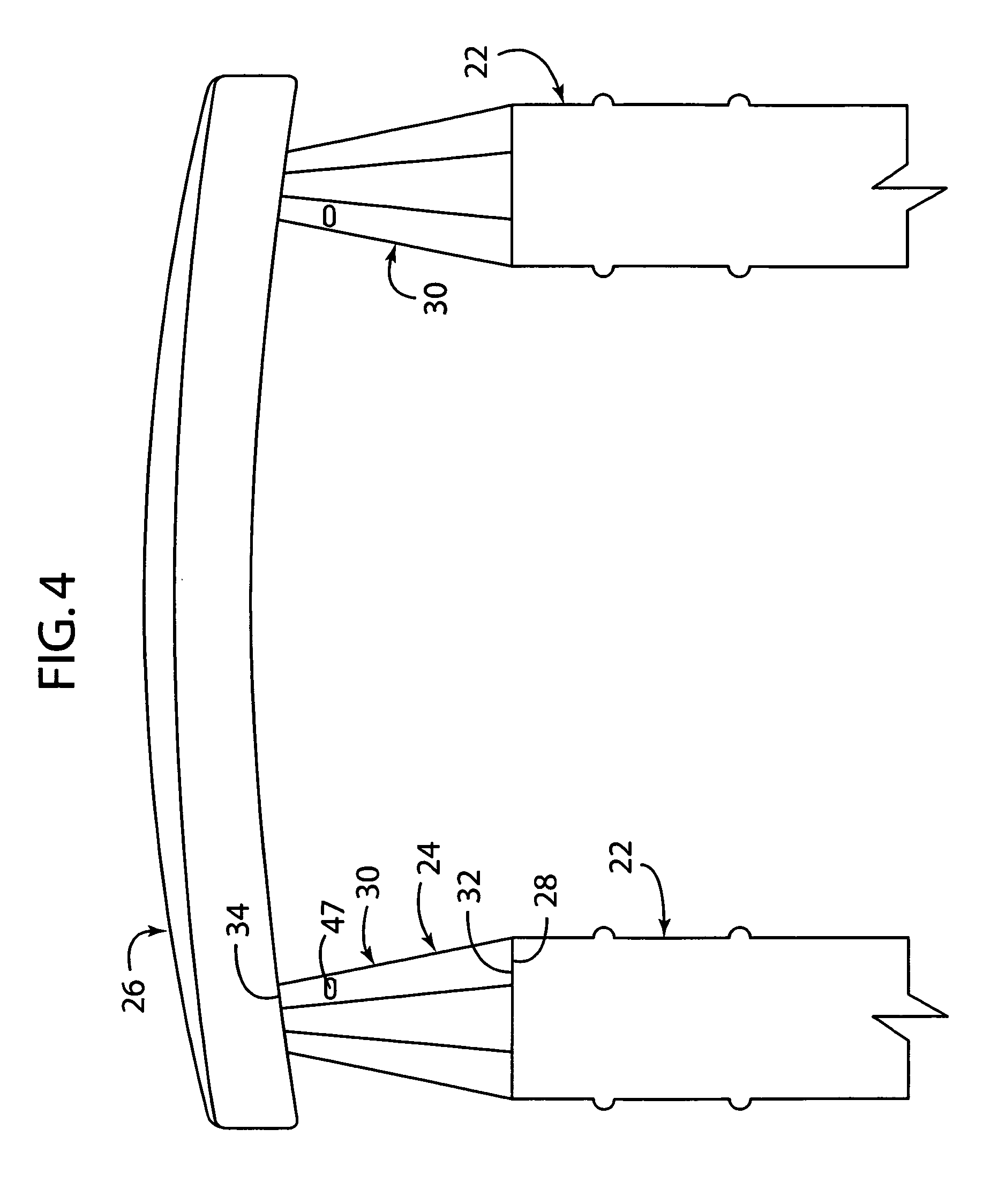

Crushable structure manufactured from mechanical expansion

A crush member for a vehicle having frame rails comprising a tube having a first end configured to be connected to the frame rails of the vehicle and a second end configured to be connected to a bumper. The tube has a constant thickness from the first end to the second end. The tube further has a taper along a axial direction from the first end to the second end, the tube having a larger cross section at the first end and a smaller cross section at the second end. The tube is configured to crush to absorb impact energy upon an axial or near axial load.

Owner:SHAPE CORP

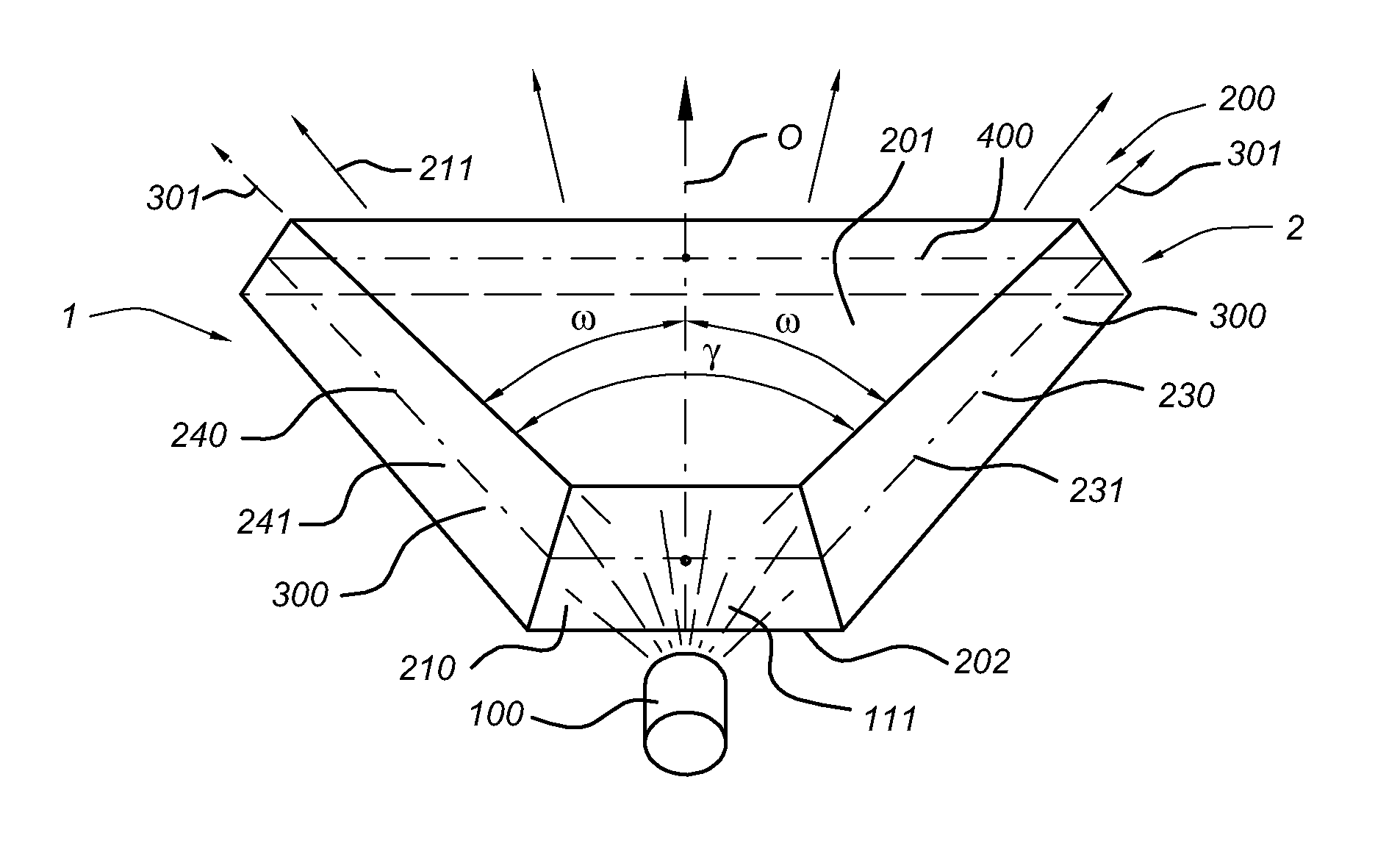

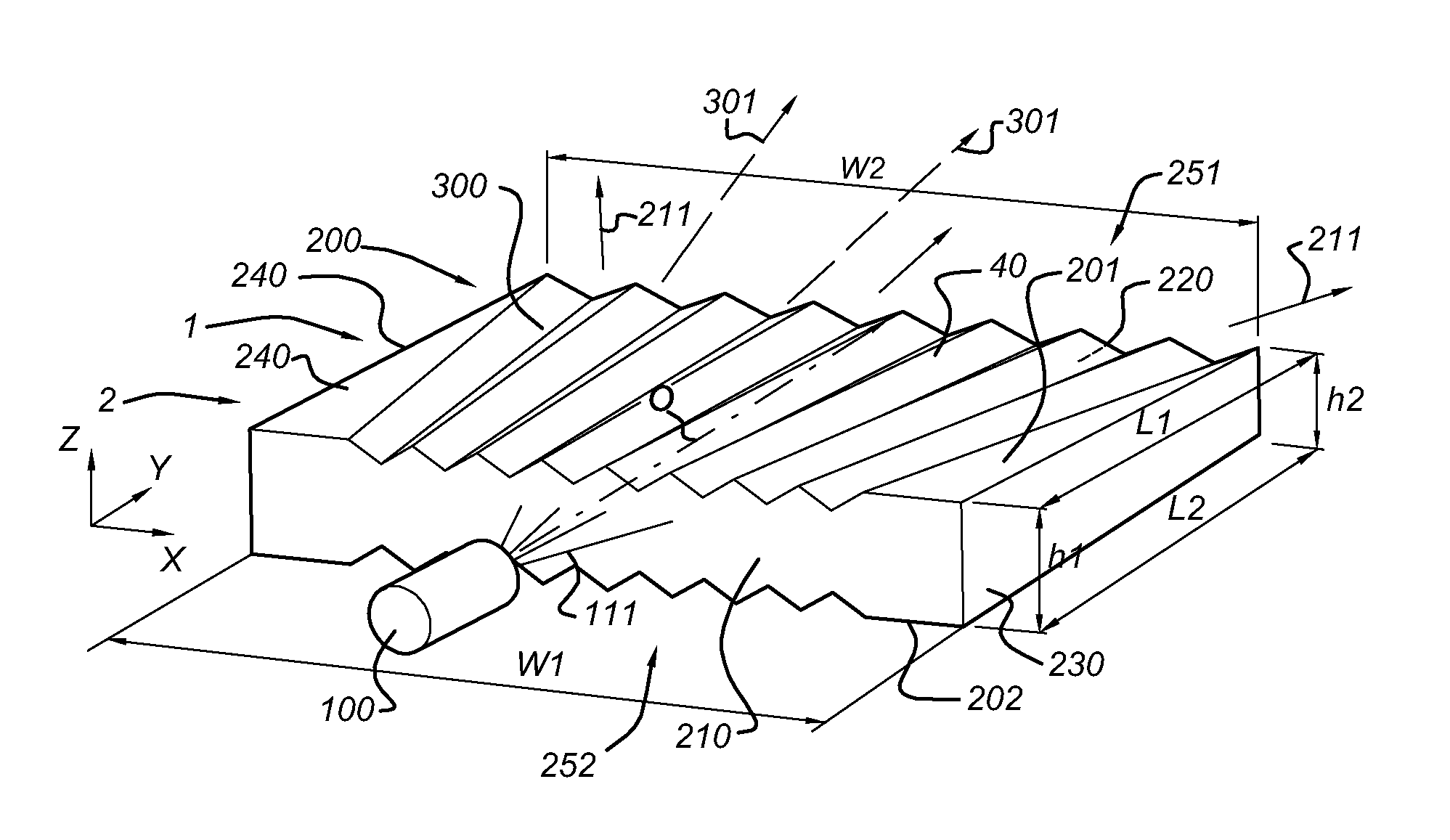

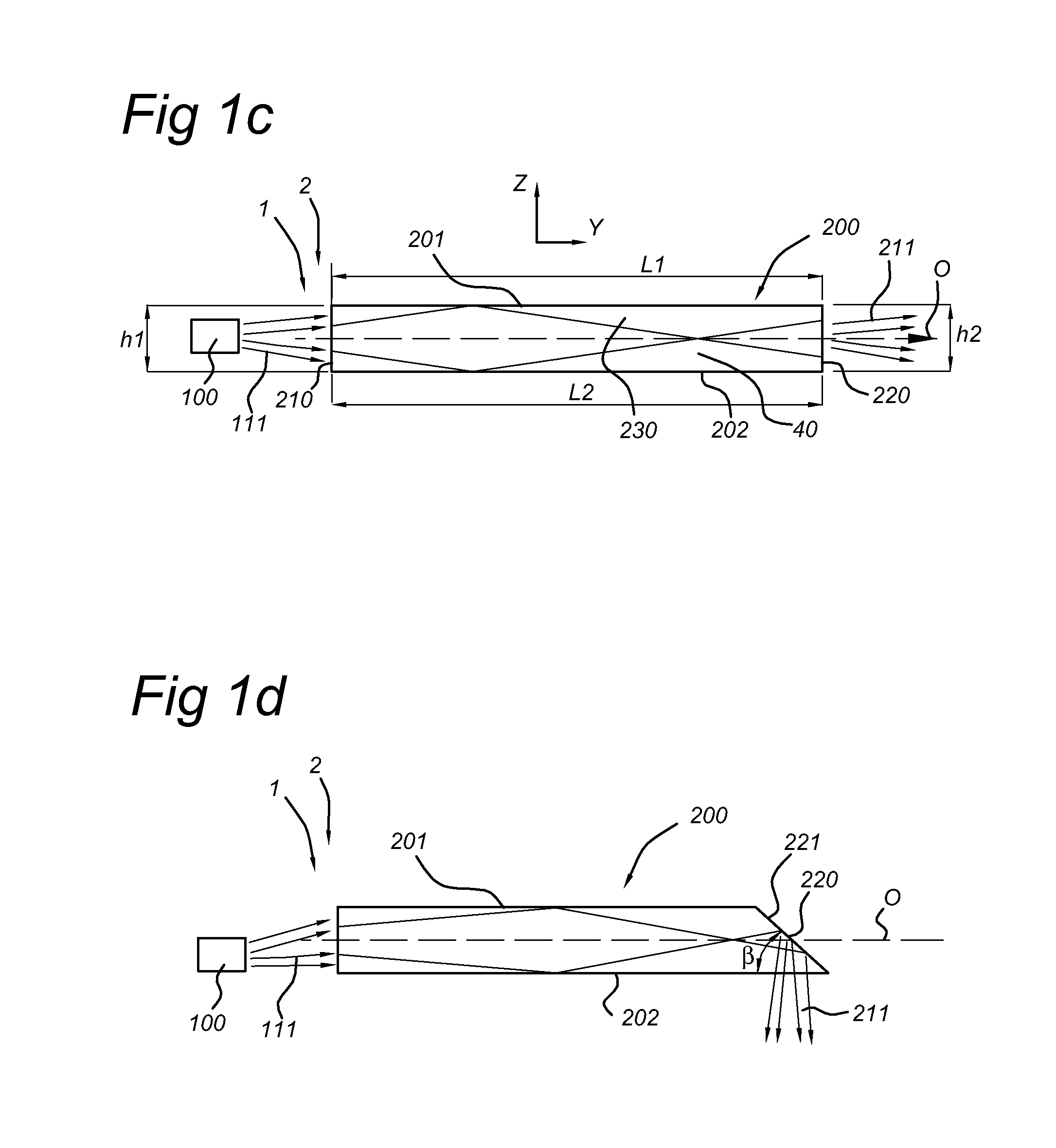

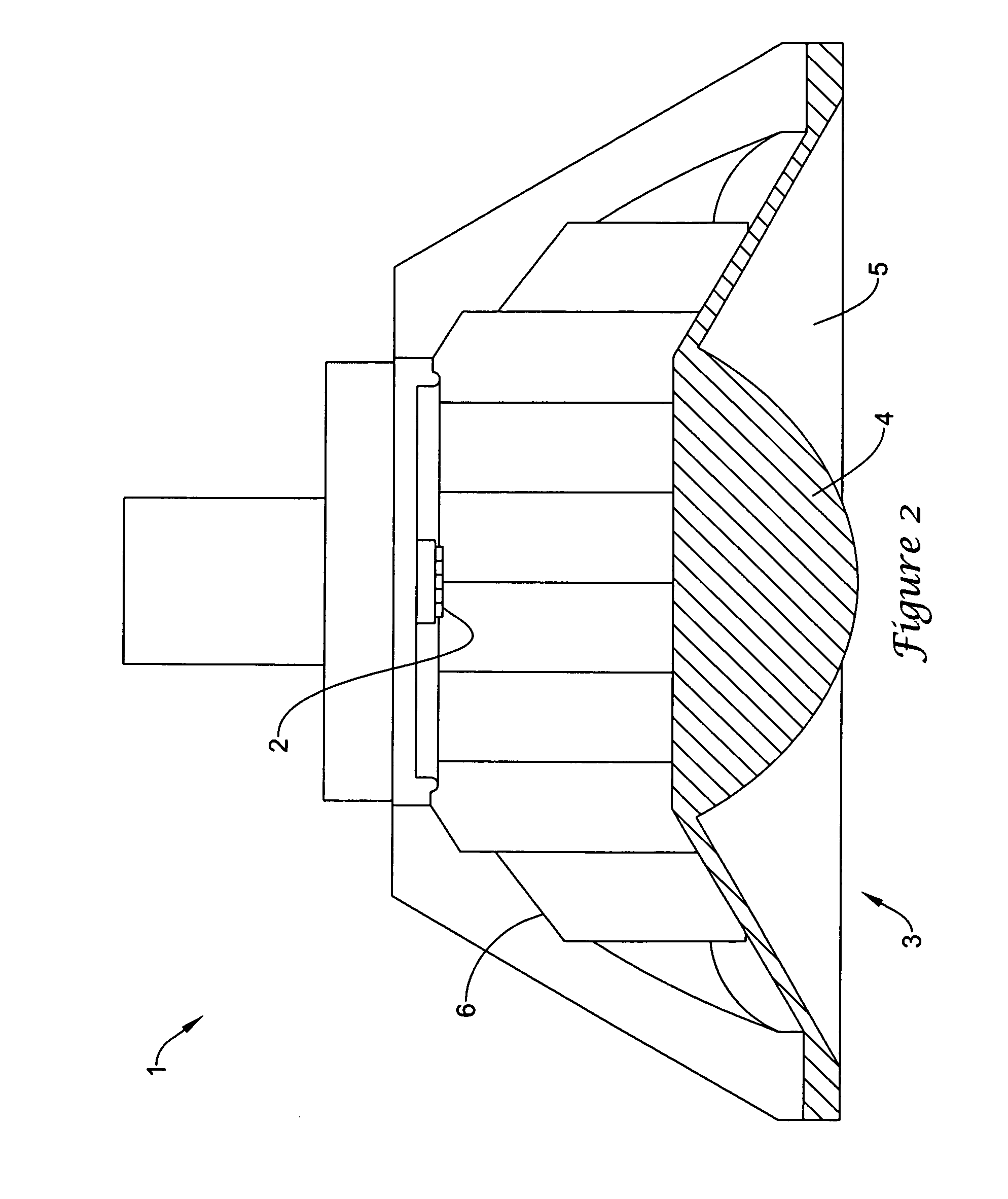

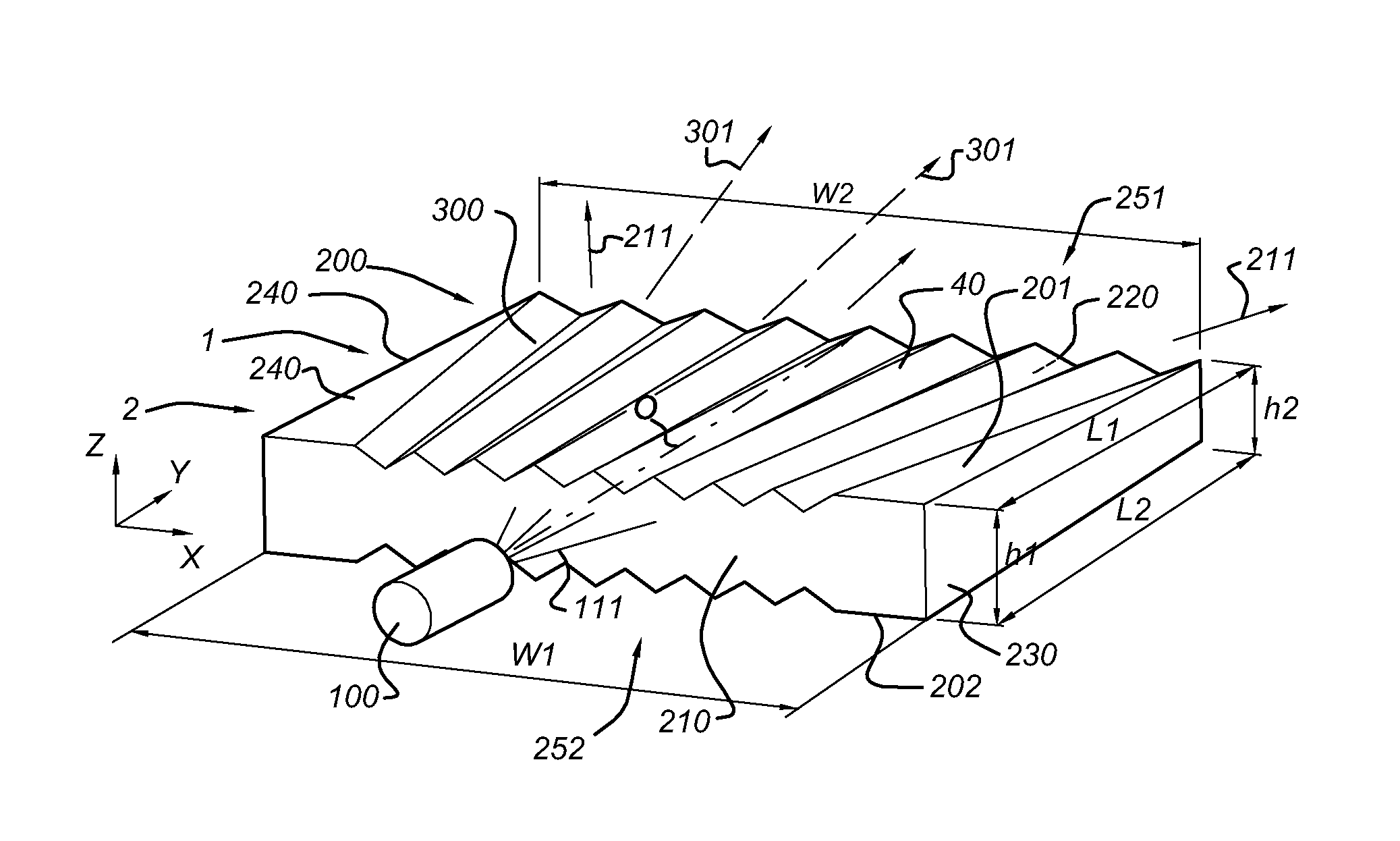

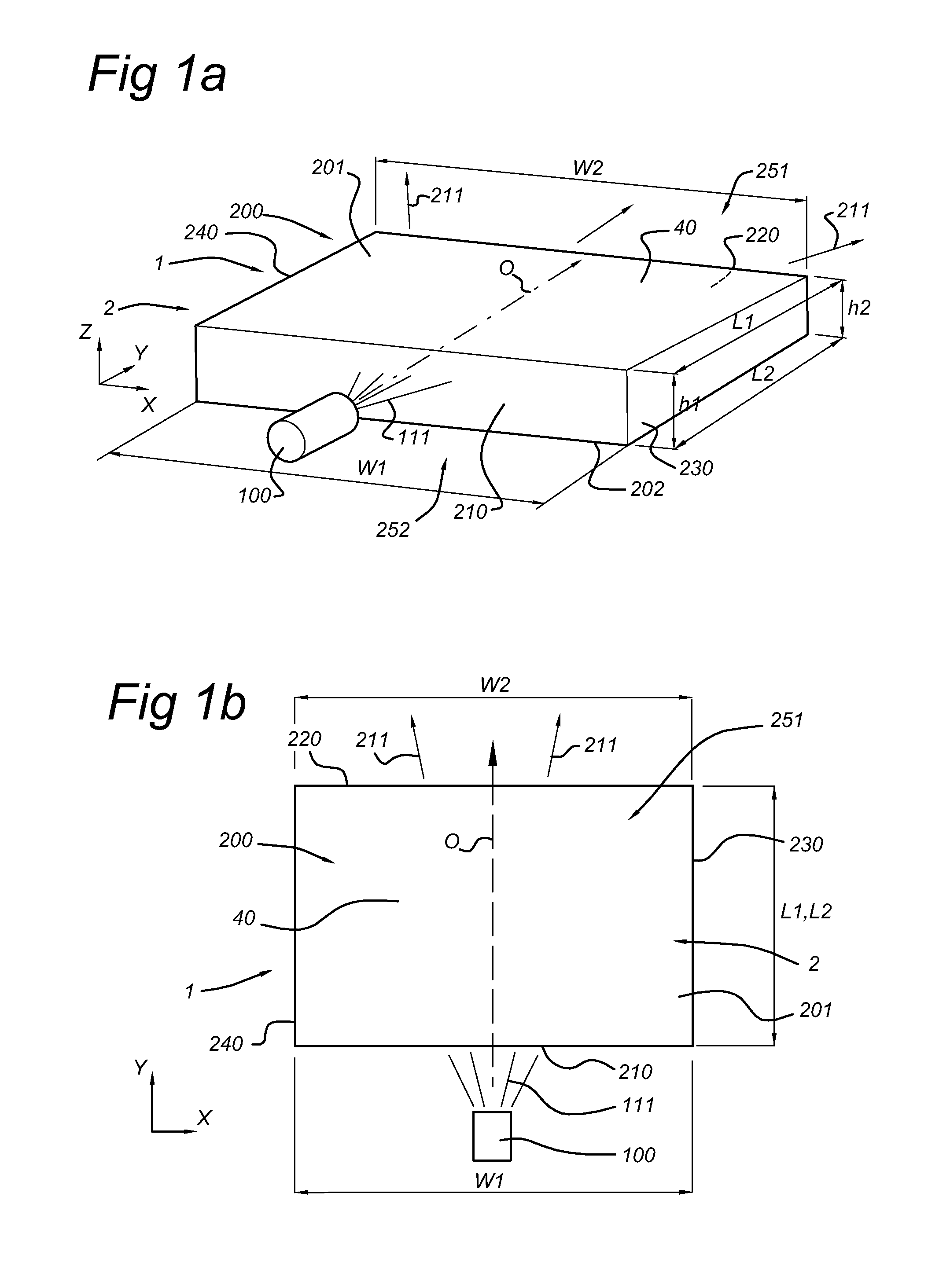

Illumination device comprising a collimator

ActiveUS8475010B2Easy to manufactureEasy to shapeNon-electric lightingPoint-like light sourceOptical axisOptoelectronics

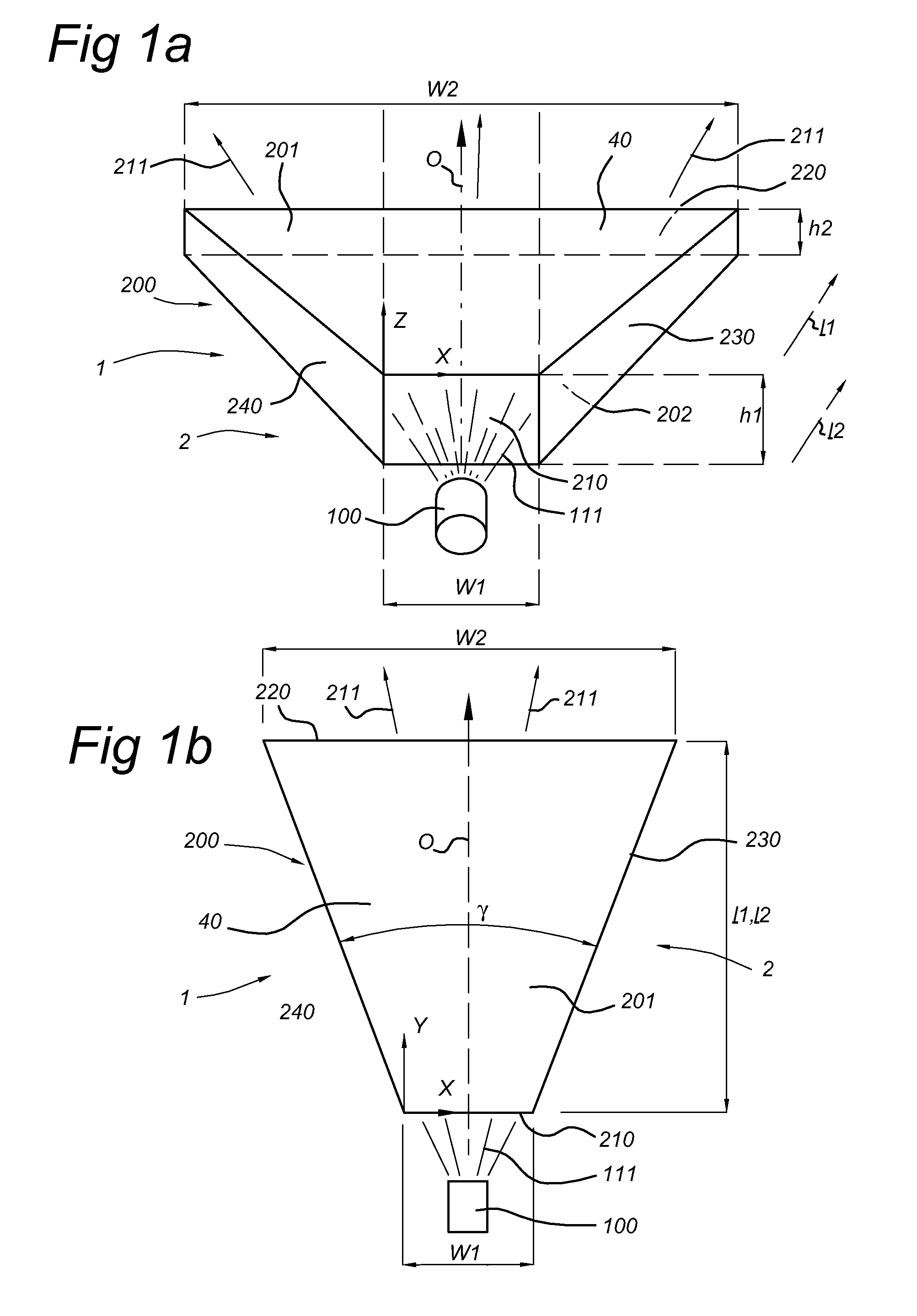

The invention provides an illumination device (1) comprising a lighting unit (2). The lighting unit (2) comprises a light source (100) and a substantially flat collimator (200), arranged to collimate light source light (111). The collimator (200) has an entrance window (210), an edge window (220), a top collimator surface (201), a bottom collimator surface (202), a first collimating side edge (230) and a second collimating side edge (240). The lighting unit has an optical axis (O). One or more of the top collimator surface (201), the bottom collimator surface (202), the first collimating side edge (230) and the second collimating side edge (240) comprise n*½ grooves (300), wherein n is a positive integer number, and wherein the grooves (300) independently have a longitudinal axis (301) having a groove direction angle (ω) with the optical axis (O) ≧0° and & and <90°.

Owner:SIGNIFY HLDG BV

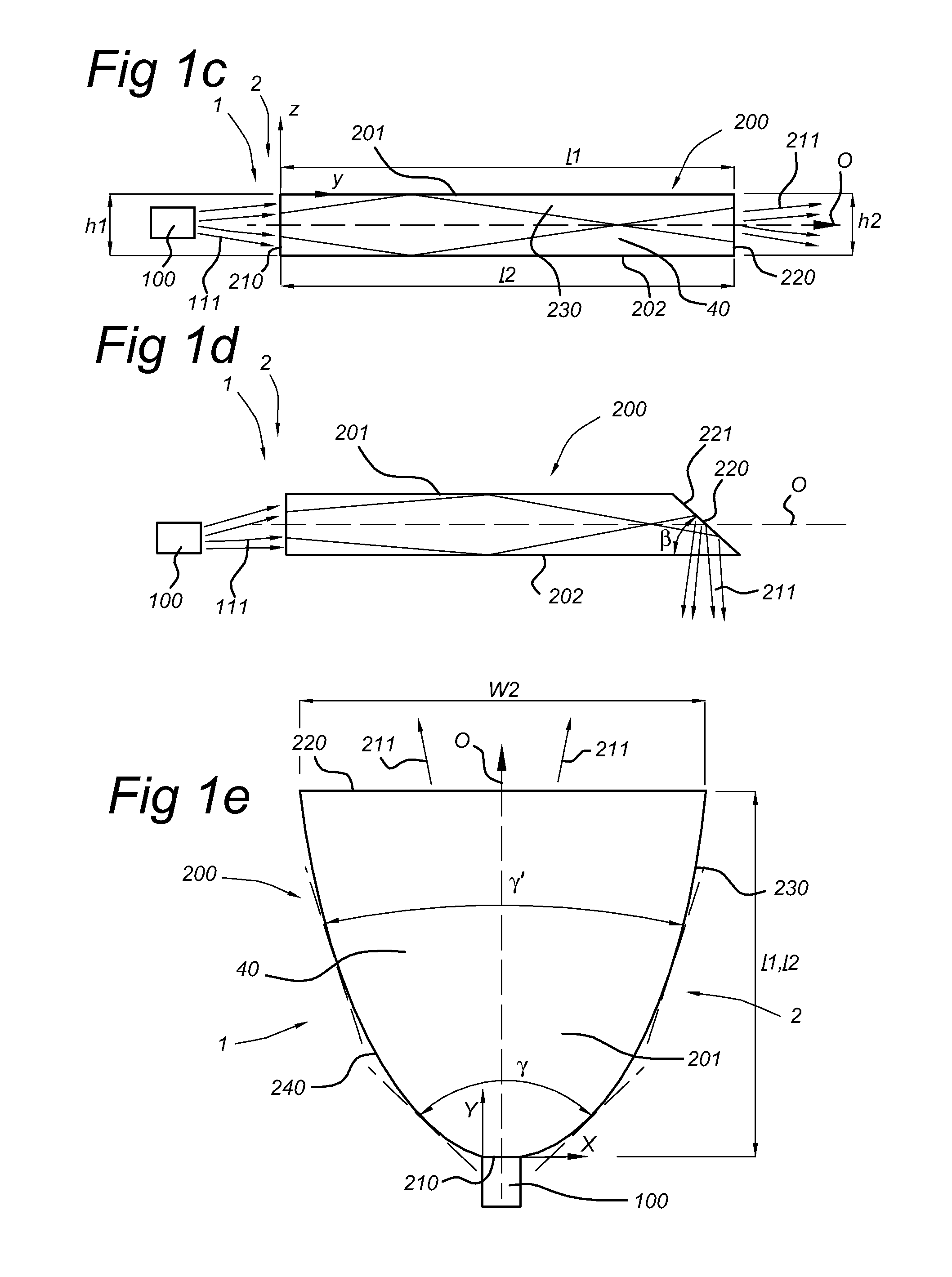

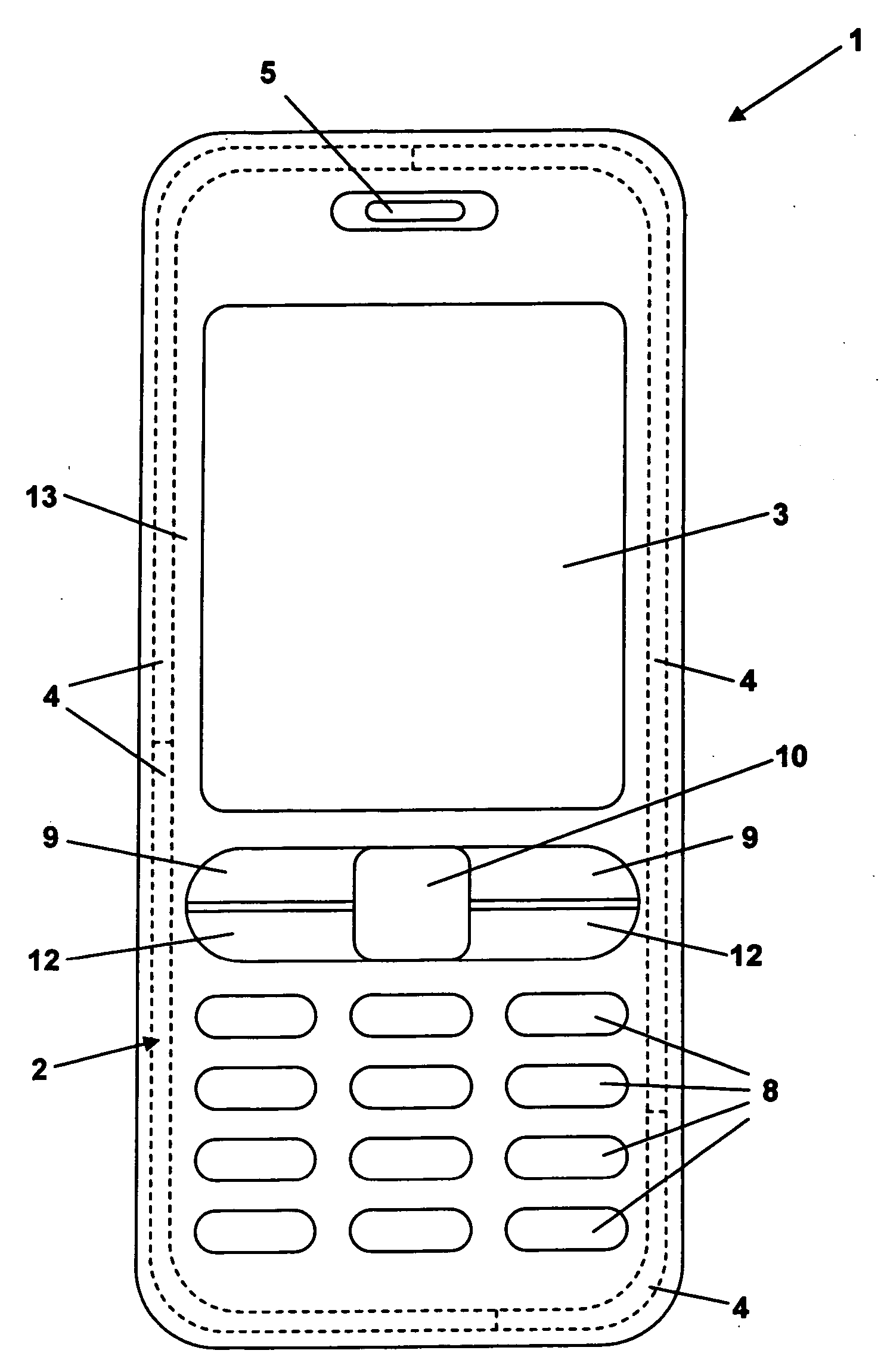

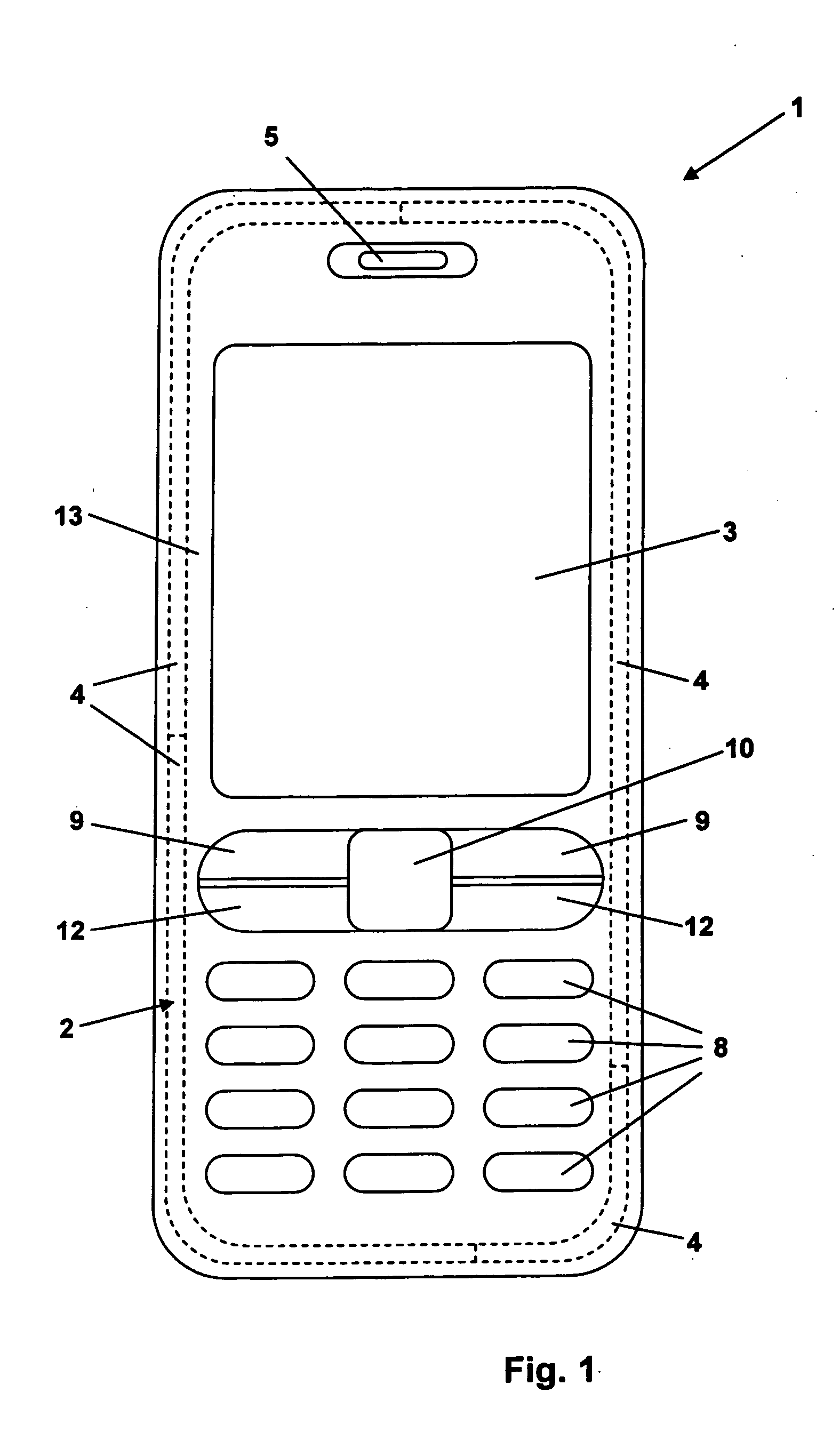

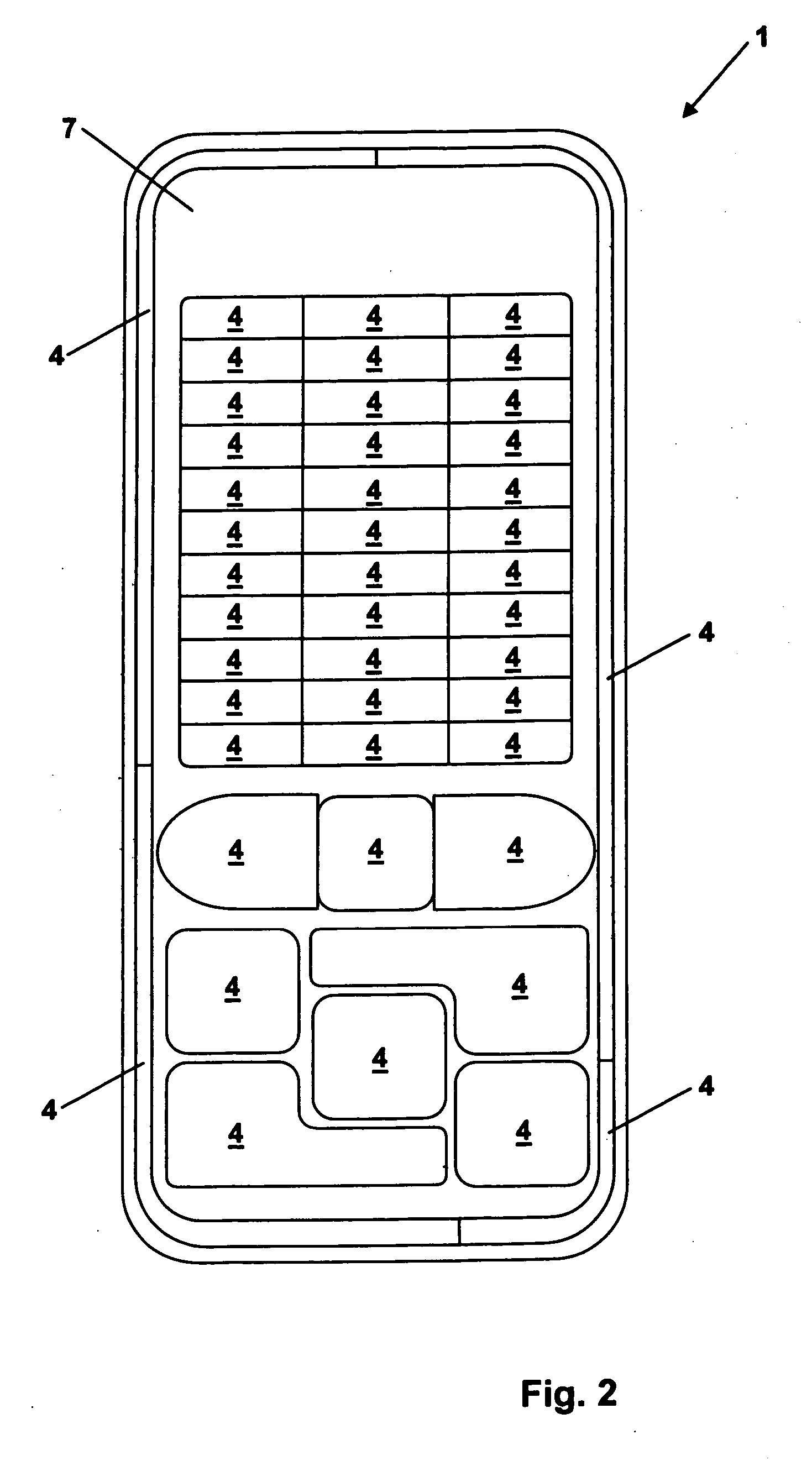

Electroluminescent lighting system

InactiveUS7246912B2Reduce decreaseFriendly constructionDischarge tube luminescnet screensStatic indicating devicesCapacitanceElectricity

Electroluminescent panels for use in battery operated devices include a driver circuit and a plurality of panel regions having a capacitance. Each panel region has a substitute capacitor with a capacitance substantially equal to the capacitance of the panel region concerned. The driver circuit switches between the panel region and the substitute capacitor, switching the panel region on and off. The capacitance of the load on the driver circuit does not change. The electroluminescent panels can have an elimination layer that eliminates noise produced by the emission layer in operation caused by changes in emission layer thickness. The elimination layer is added to the panel and operated in phase opposition to the emission layer. Changes in layer thickness occurring in operation in the emission layer are offset by changes in thickness in the elimination layer. Thus, the overall thickness of the panel is constant.

Owner:NOKIA CORP

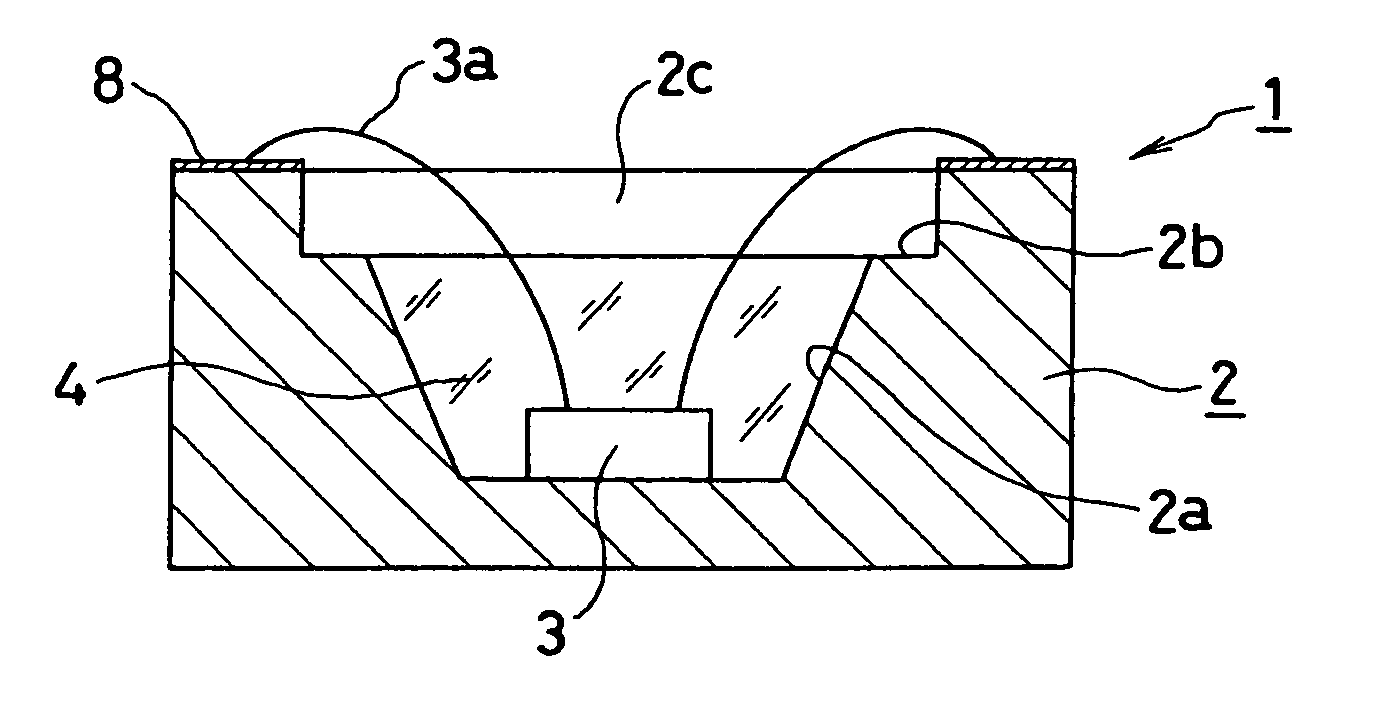

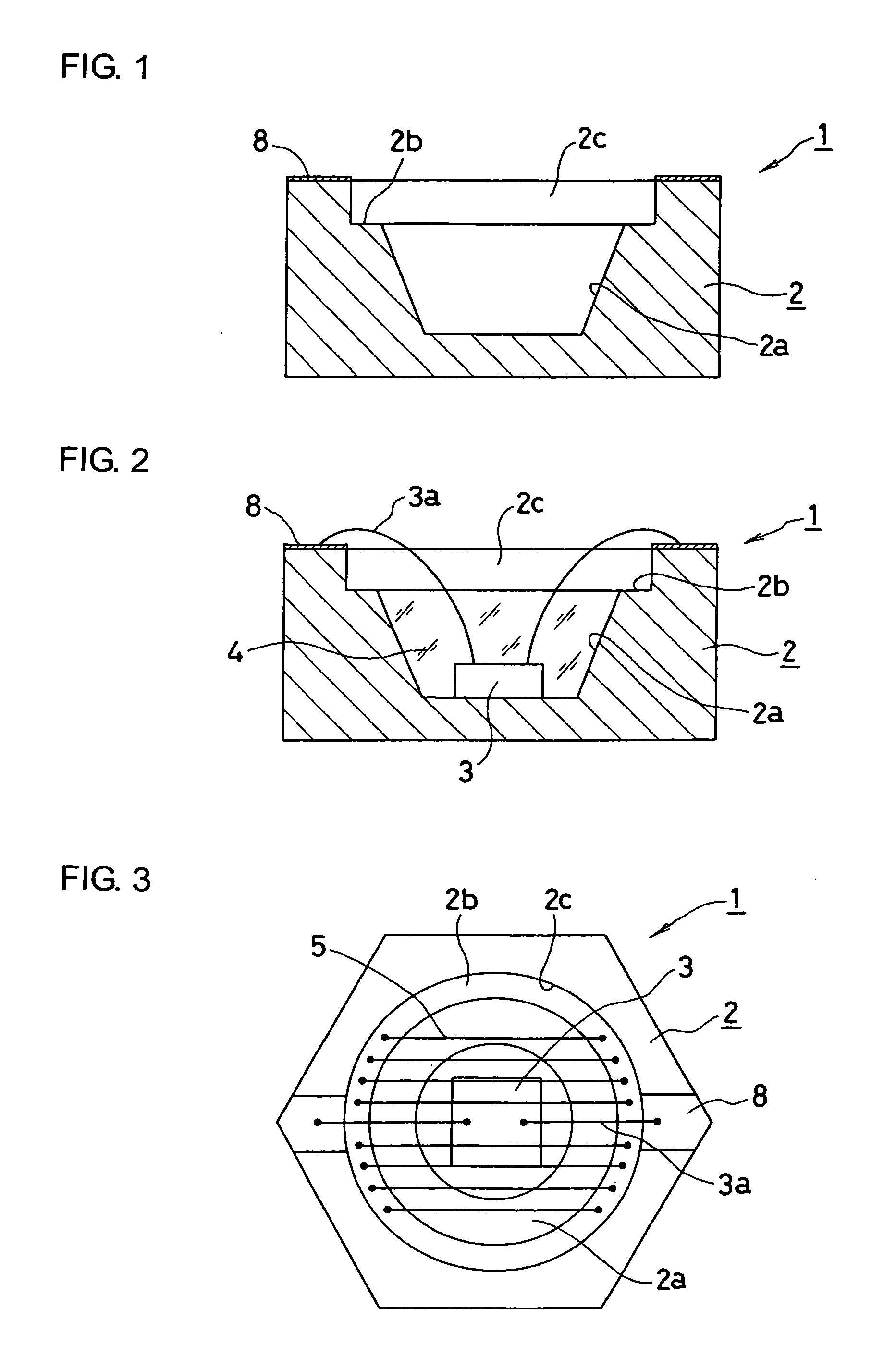

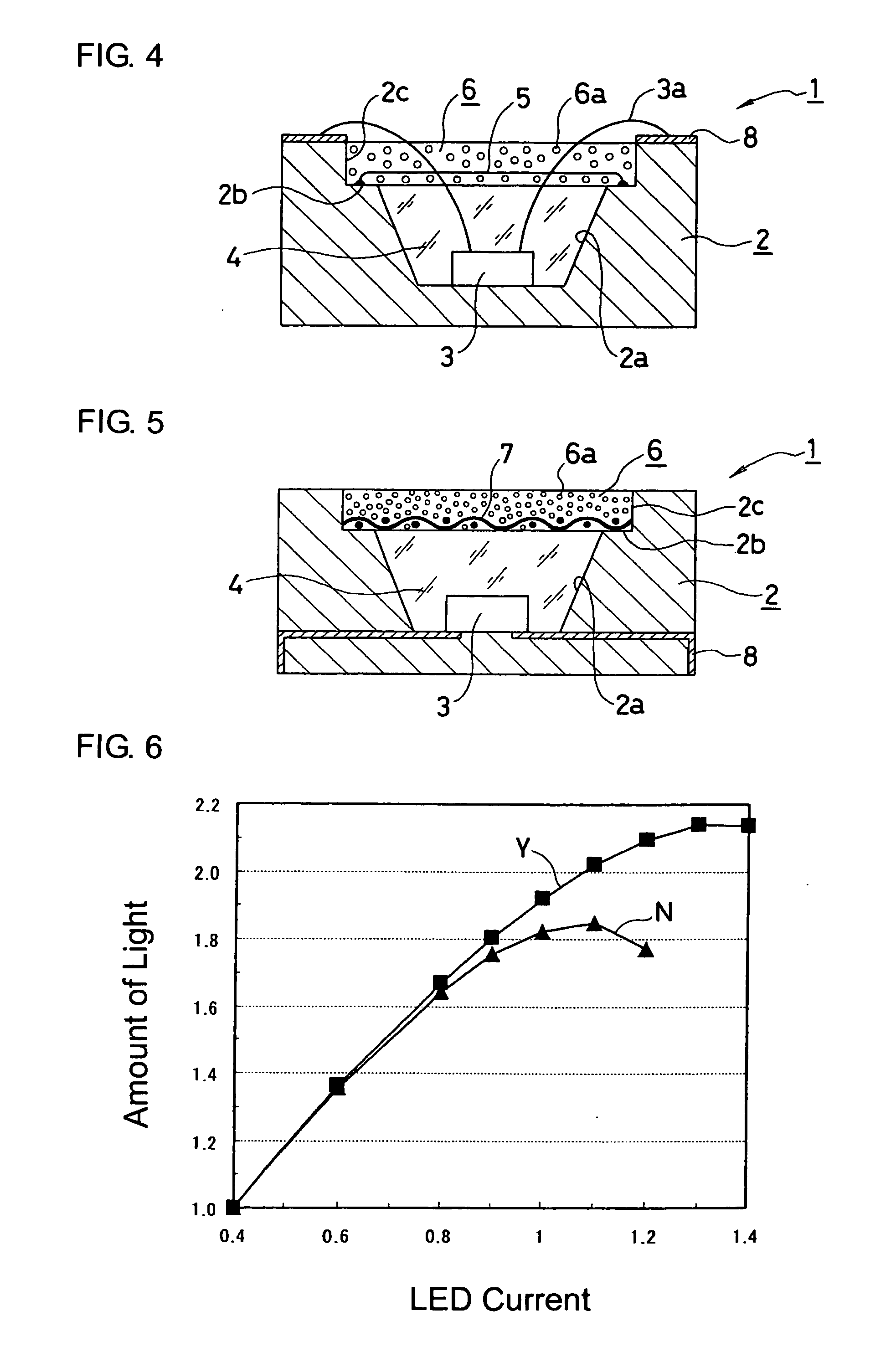

Semiconductor light emitting device and method of manufacturing the same

InactiveUS20050253153A1Low conversion efficiencyAvoid conversionSolid-state devicesSemiconductor devicesWavelength conversionLight emitting device

A semiconductor light emitting device can include a base having a cavity provided for housing an LED chip and a resin spacer therein. The resin spacer can be composed of at least two layers of spacers including a transparent resin spacer and a wavelength conversion spacer mixed with a fluorescent material and formed to have an almost constant thickness. The wavelength conversion spacer can include a metallic radiation mesh or radiation wire disposed therein.

Owner:STANLEY ELECTRIC CO LTD

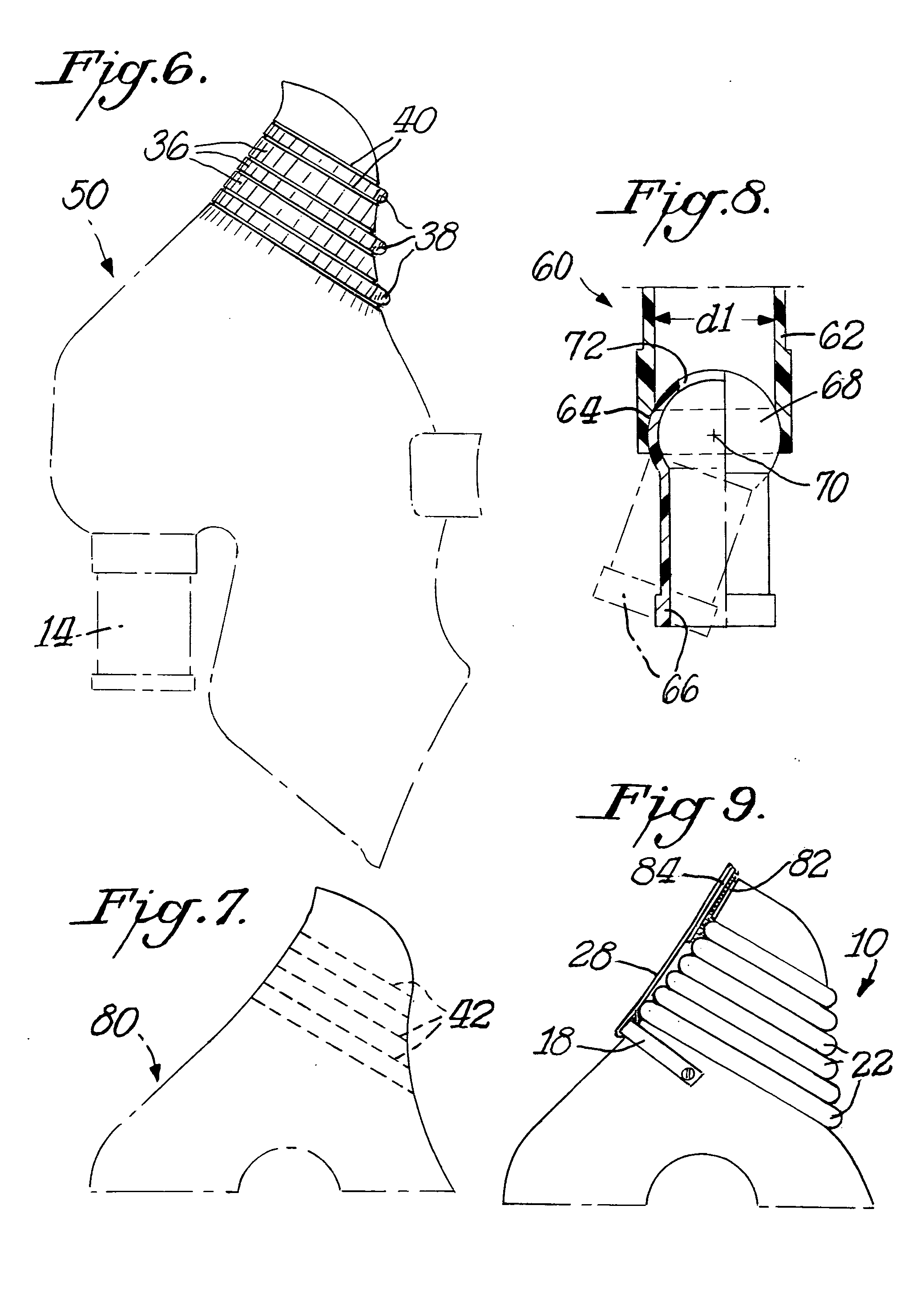

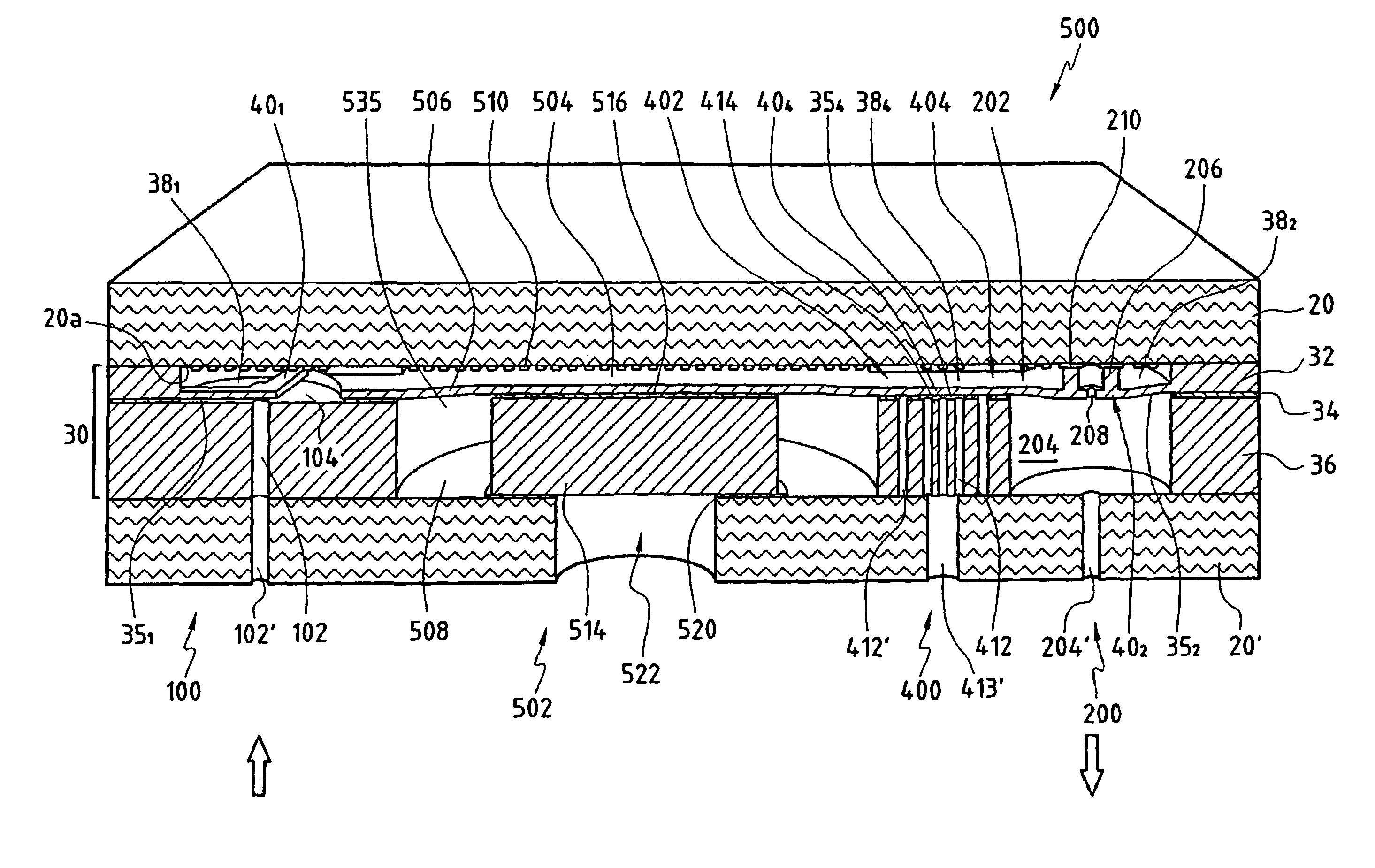

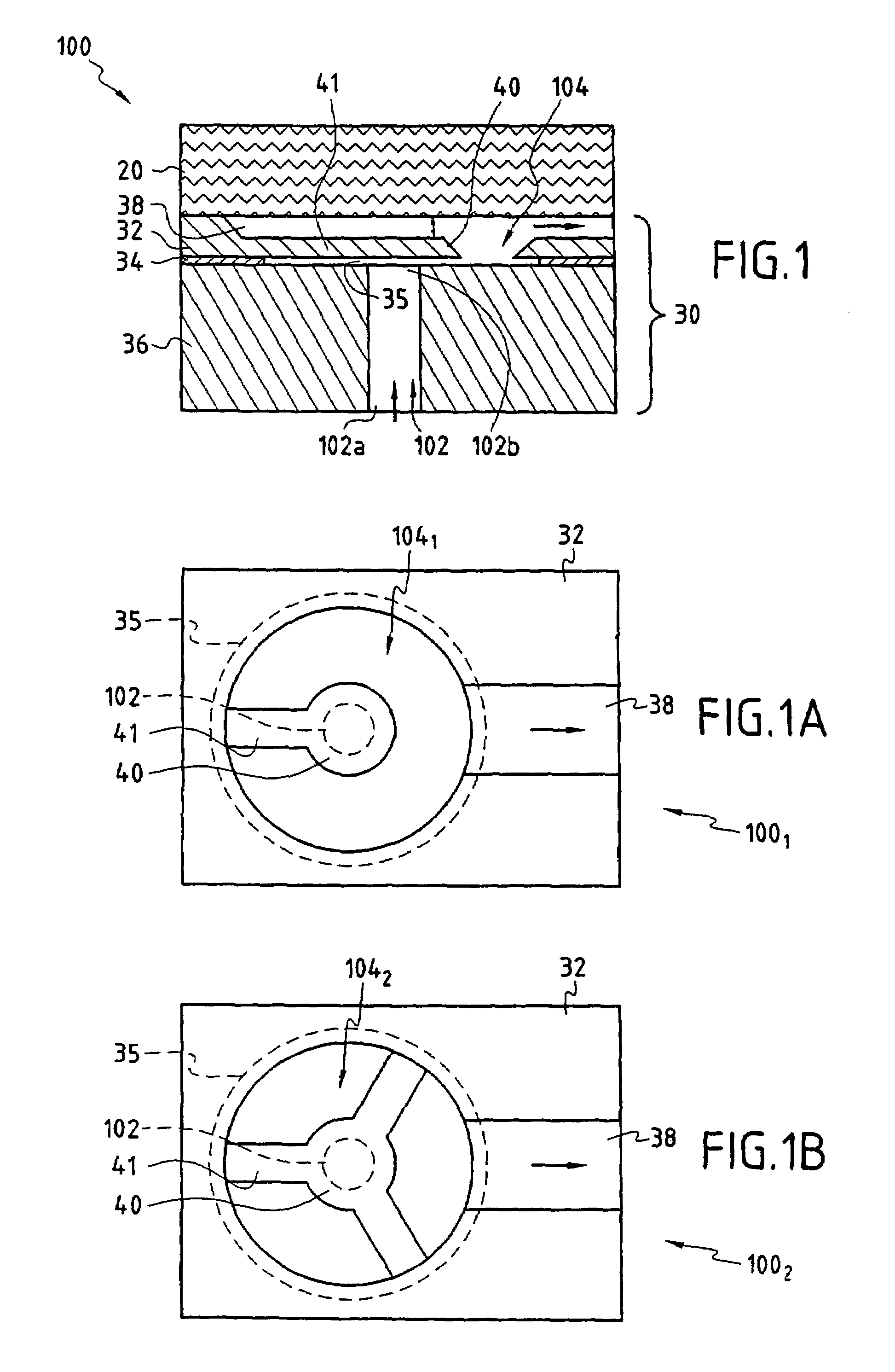

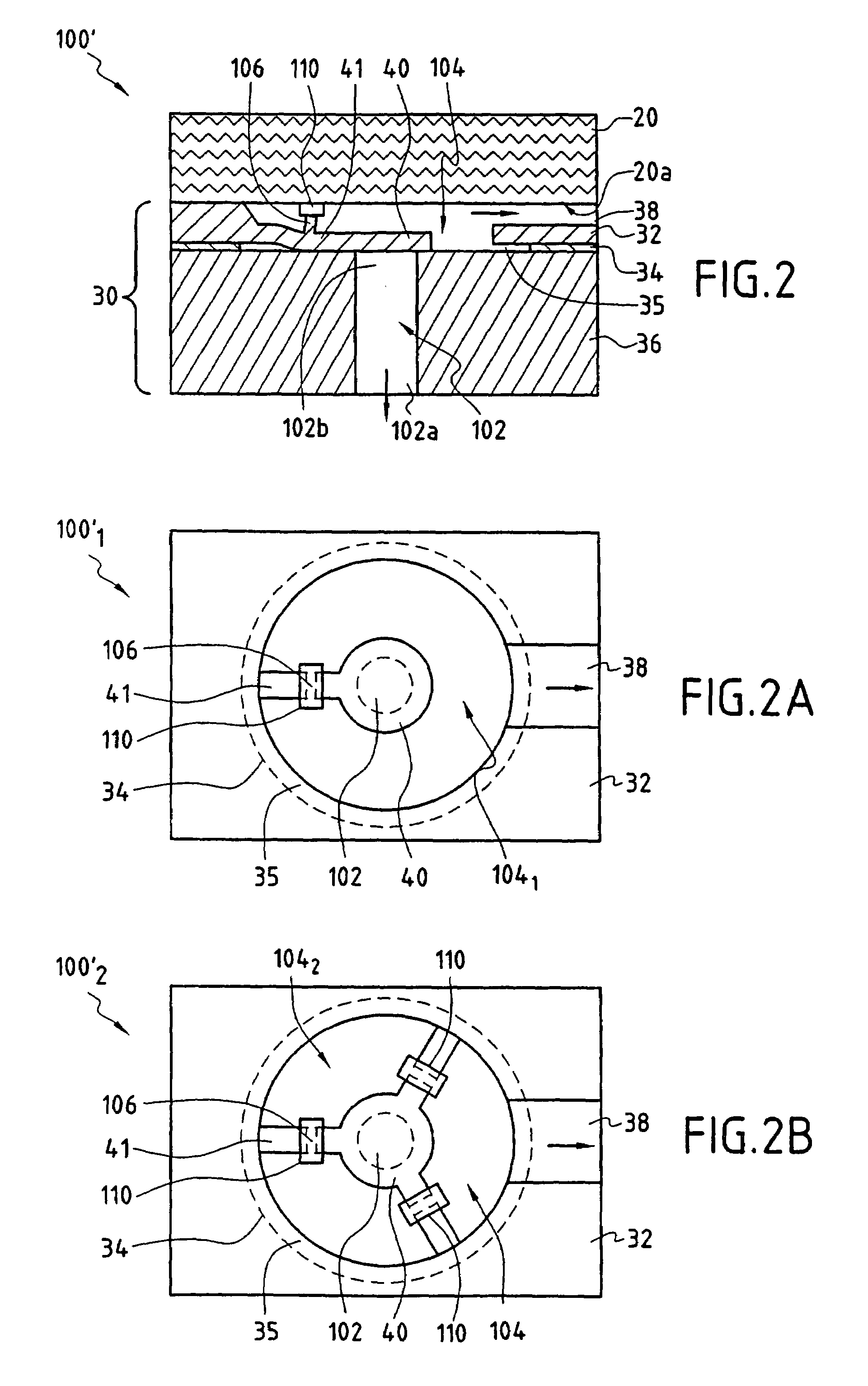

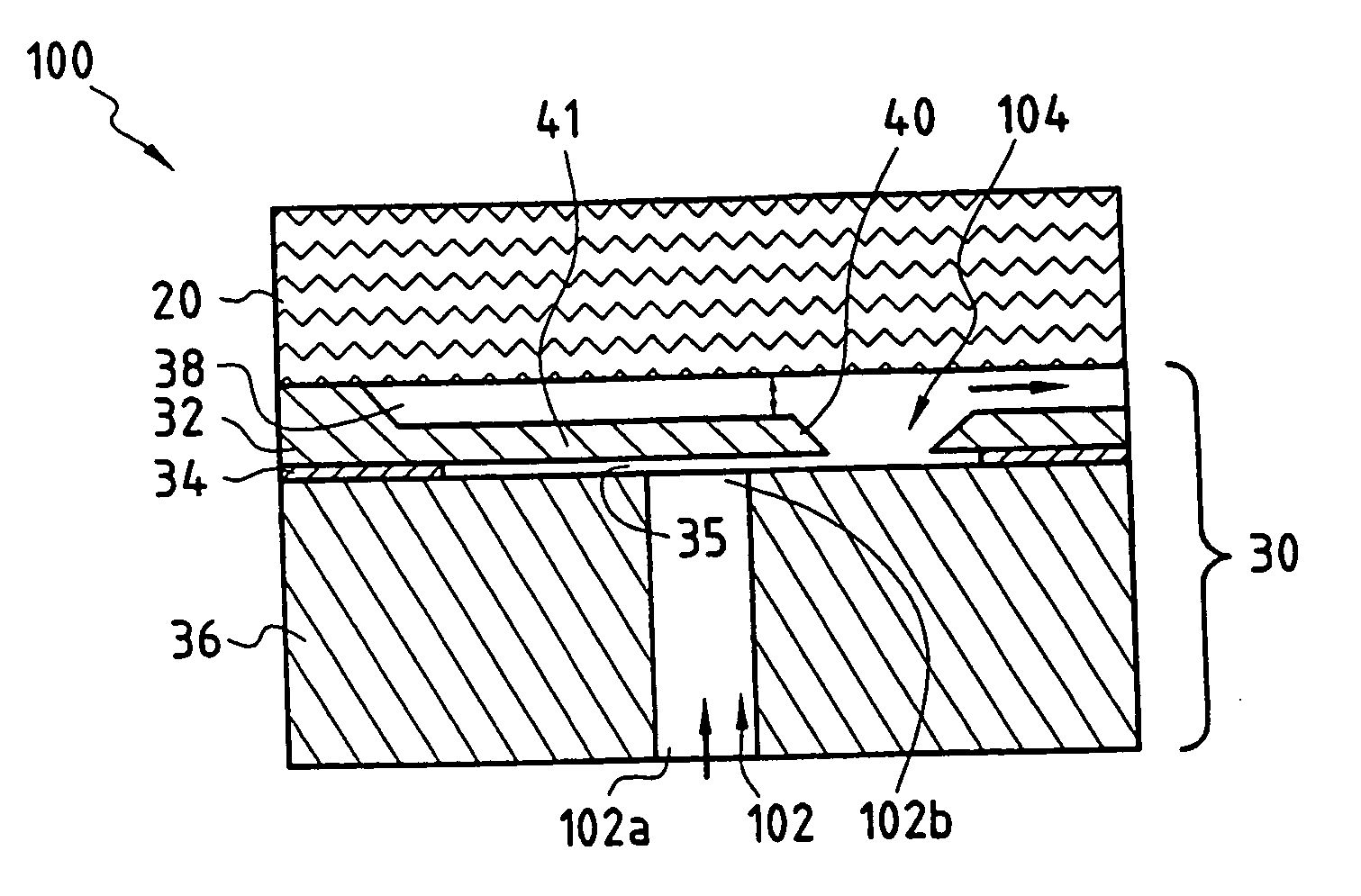

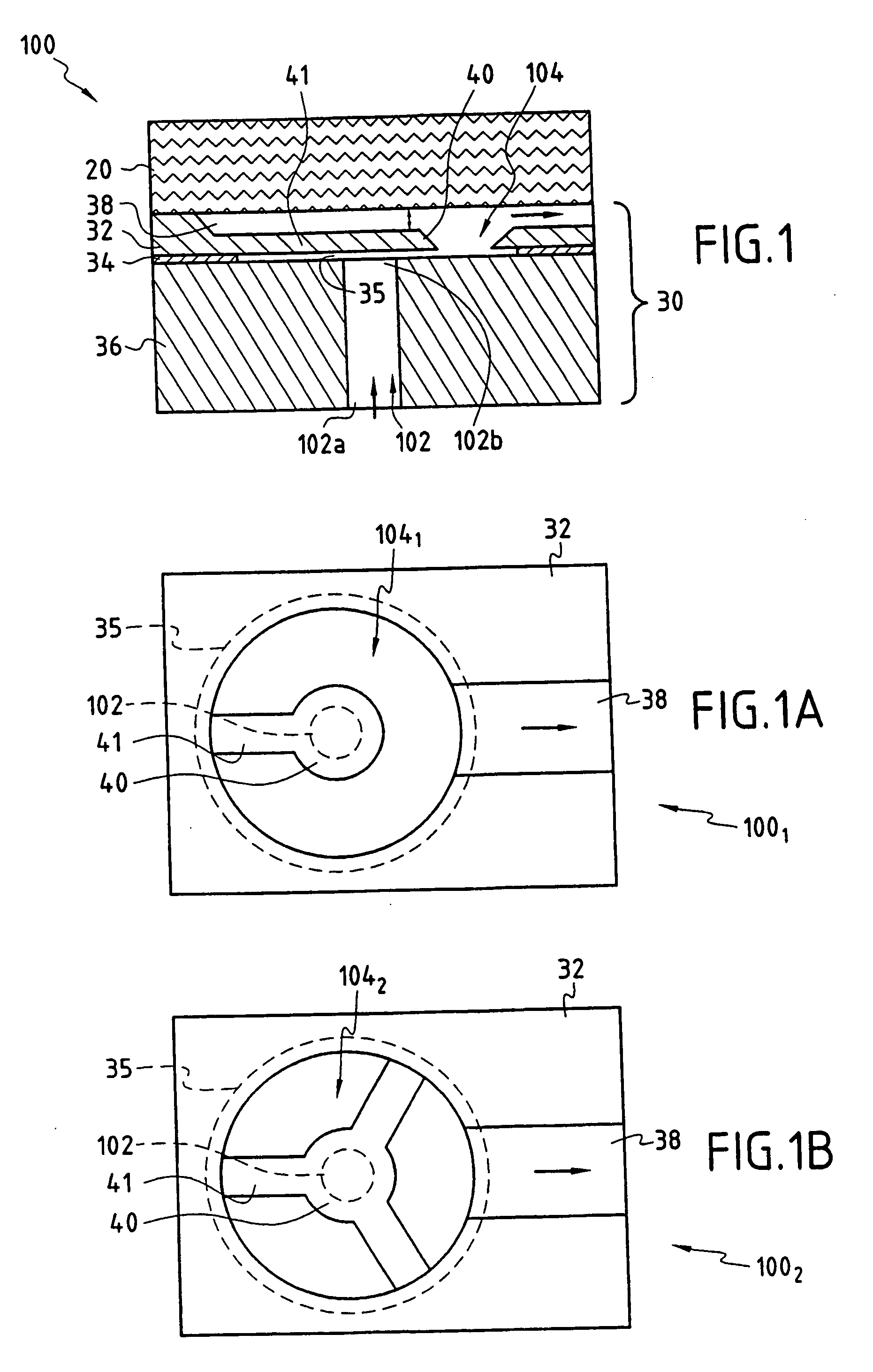

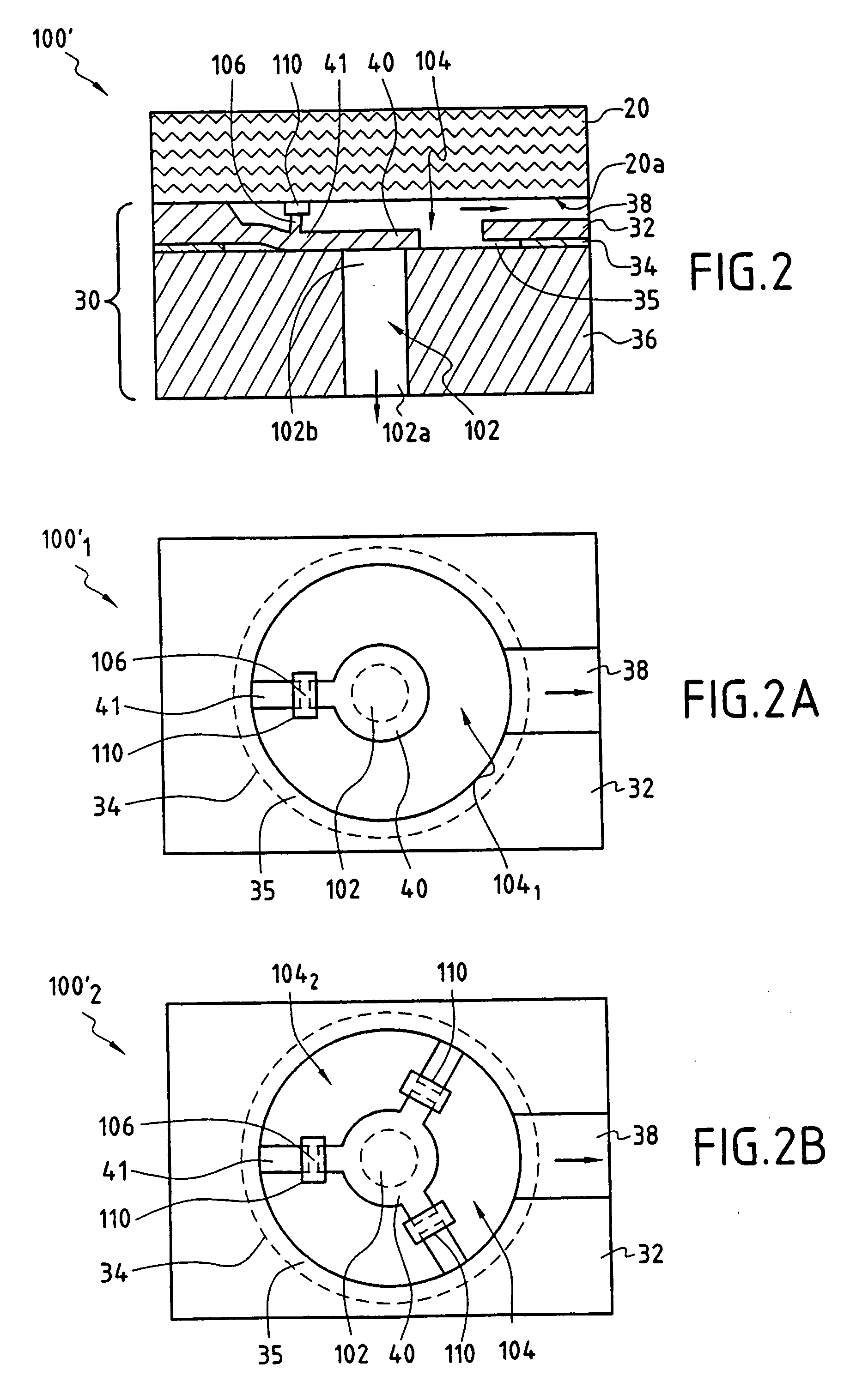

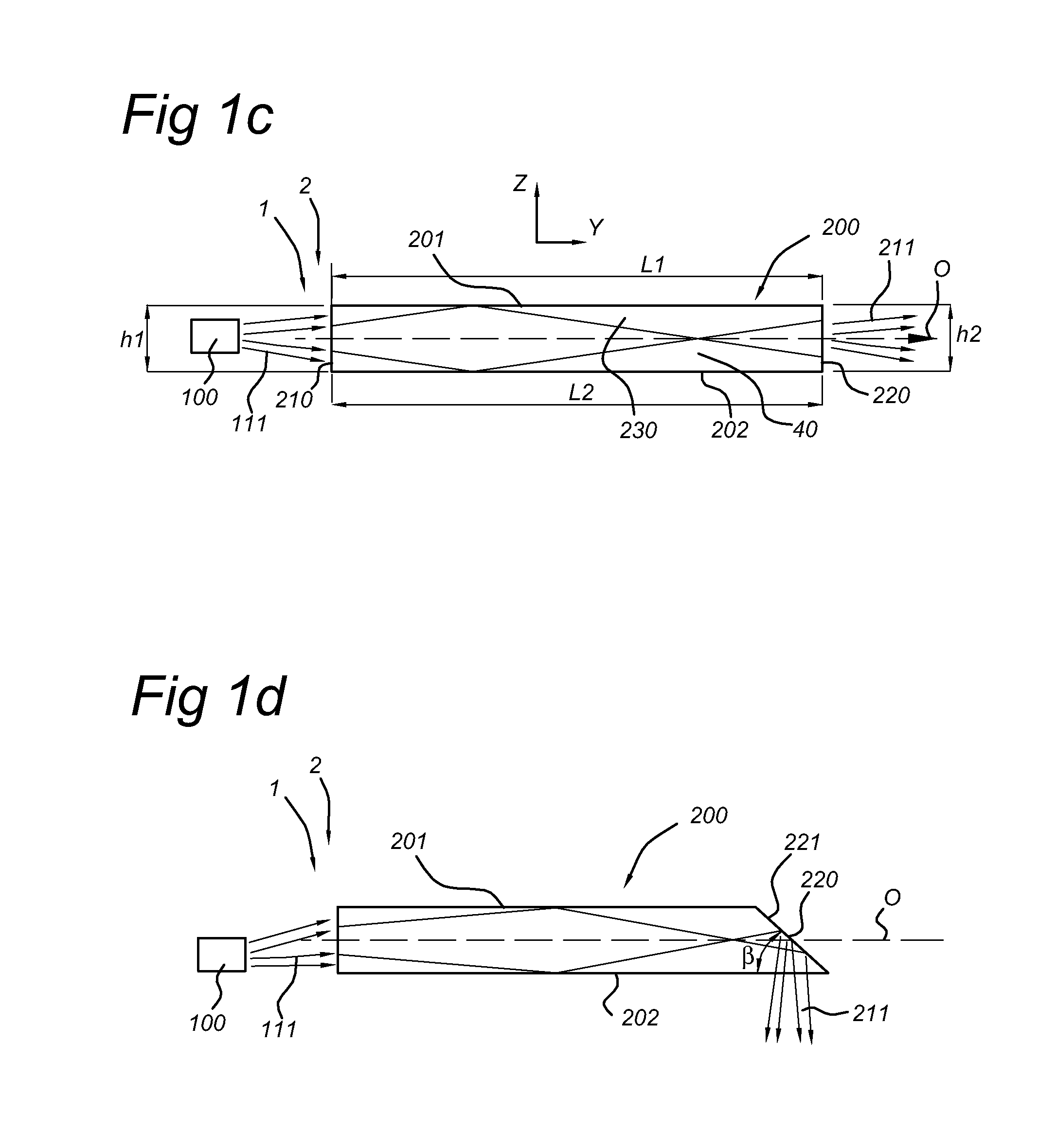

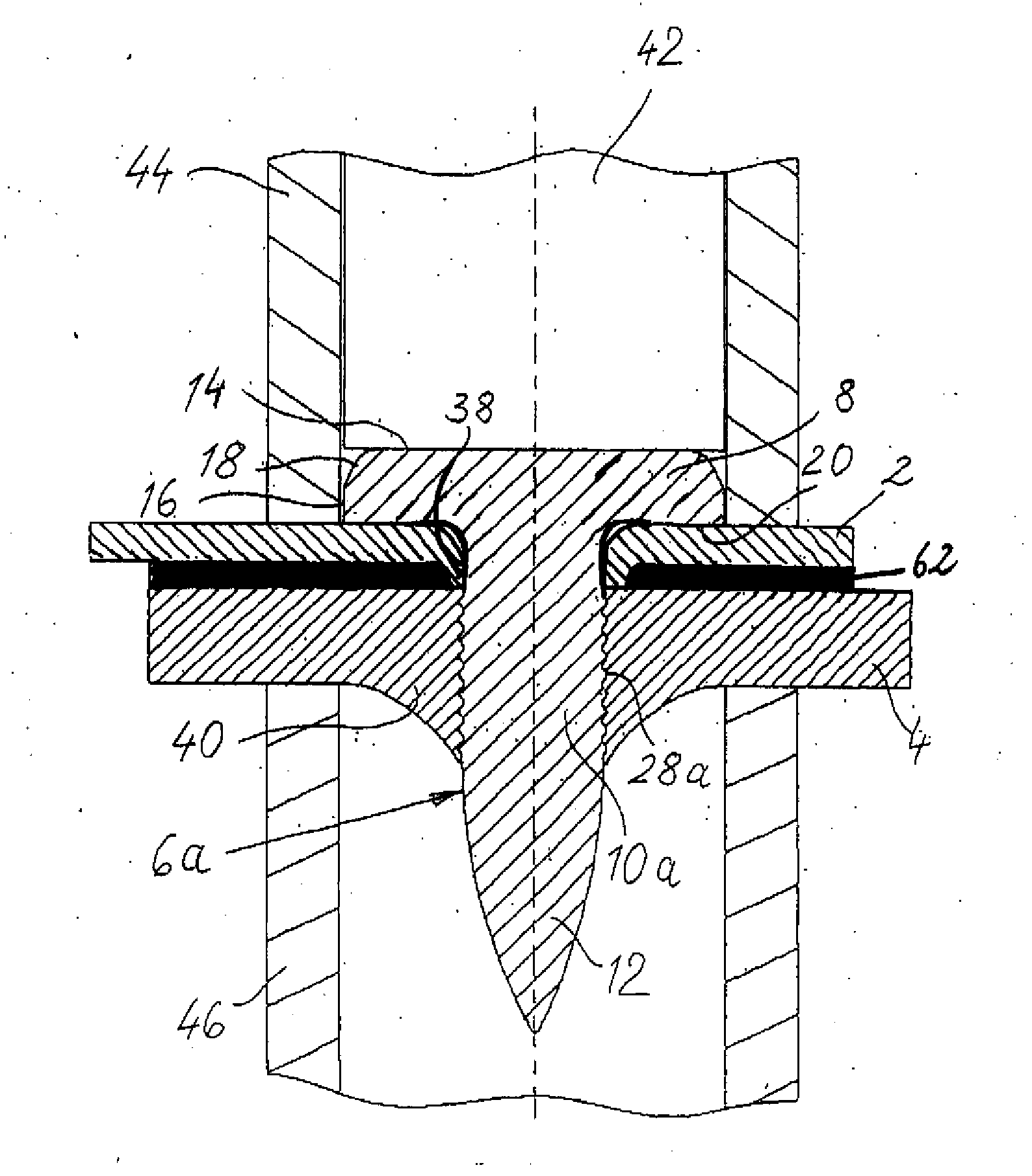

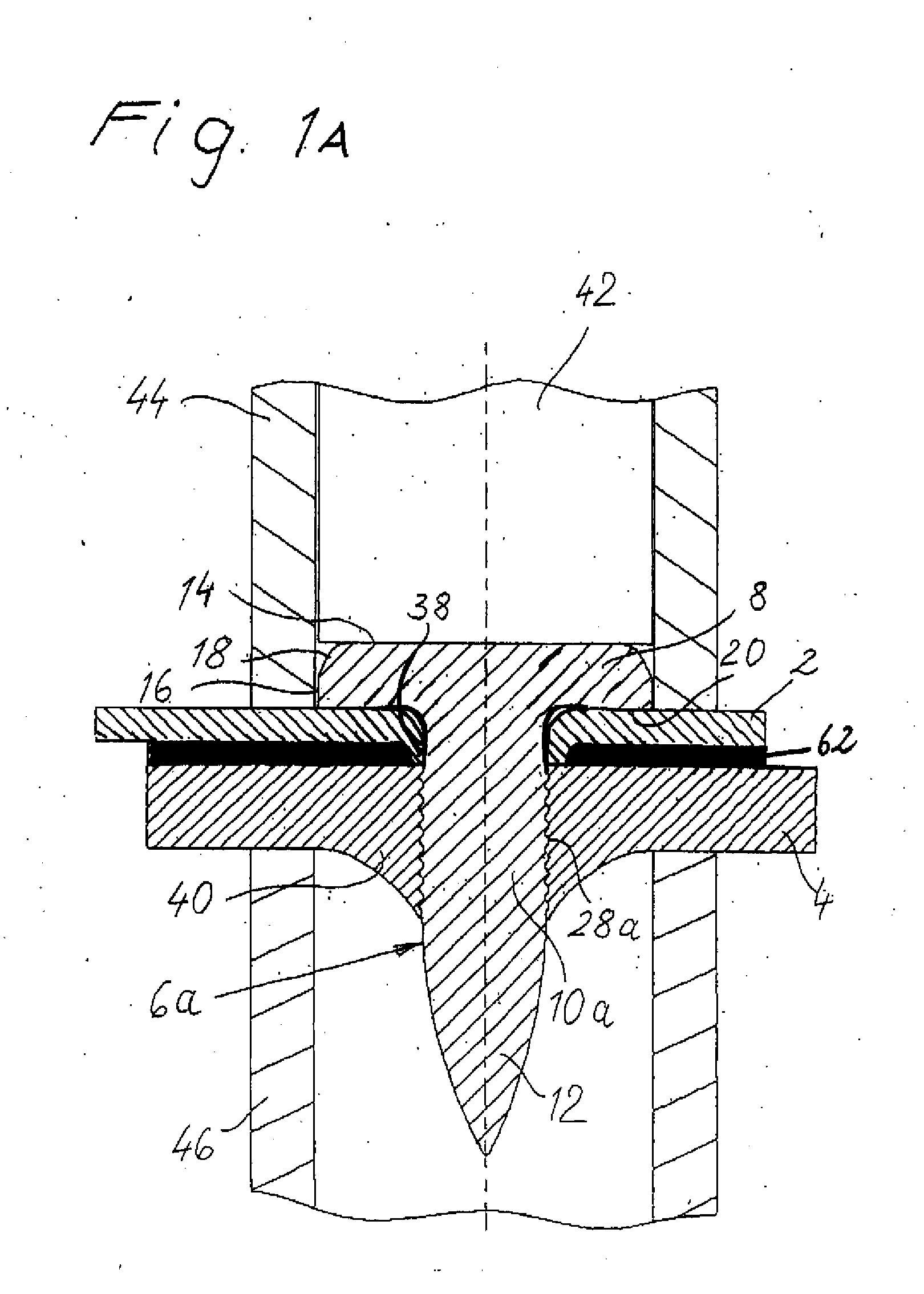

Micromachined fluidic device and method for making same

InactiveUS7311503B2Reliably madeMinimizing dead volumeFunctional valve typesFluid pressure measurement by electric/magnetic elementsEngineeringSilicon

The fluid-flow device (100) of the invention comprises a stack (30) covered by a closure wafer (20), said stack (30) comprising a support wafer (36), a layer of insulating material (34), and a silicon layer (32). The closure wafer (20) and / or said silicon layer (32) are machined so as to define a cavity (38) between said closure wafer (20) and said silicon layer (32), said support wafer (36) has at least one duct (102) passing right through it, said layer of insulating material (34) presenting at least one zone (35) that is entirely free of material placed at least in line with said duct (102) so as to co-operate with said cavity (38) to define a moving member (40) in said silicon layer (32), the moving member being suitable under the pressure of liquid in said cavity (38) for reversibly moving towards said support wafer (36) until contact is made between said moving member (40) and said support wafer (36).

Owner:DEBIOTECH SA

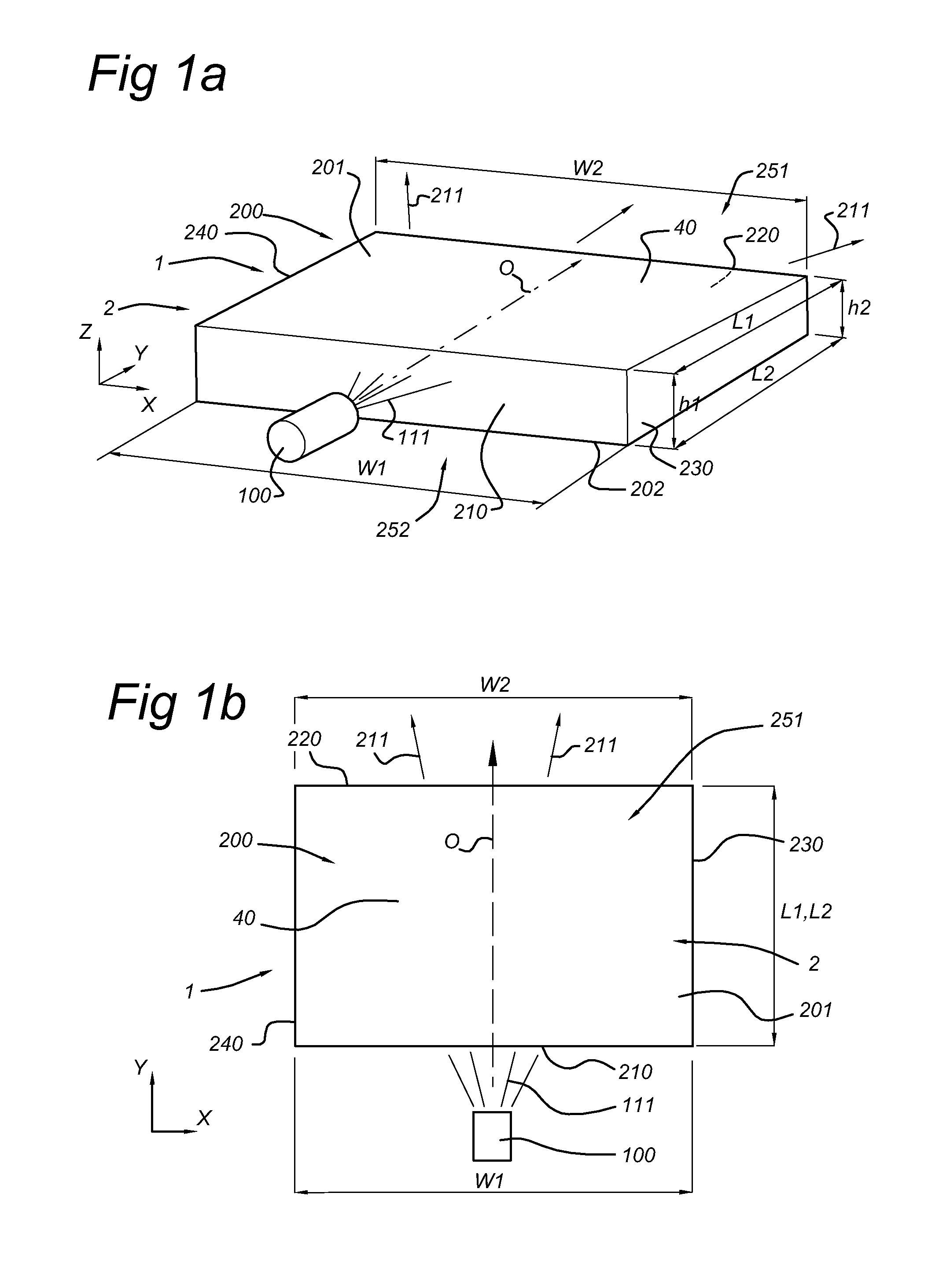

Illumination device comprising a light guide

ActiveUS20110096570A1Well mixedElegant appearanceMechanical apparatusLight guides for lighting systemsLight guideEffect light

The invention provides an illumination device (1) comprising a lighting unit (2). The lighting unit (2) comprises a light source (100) and a substantially flat light guide (200), arranged to collimate light source light (111). The light guide (200) has an entrance window (210), an edge window (220), a first light guide surface (201), a second light guide surface (202), a first side edge (230) and a second side edge (240). One or more of the first light guide surface (201) and the second light guide surface (202) comprise a plurality of grooves (300). In this way, latitudinal collimation is obtained.

Owner:SIGNIFY HLDG BV

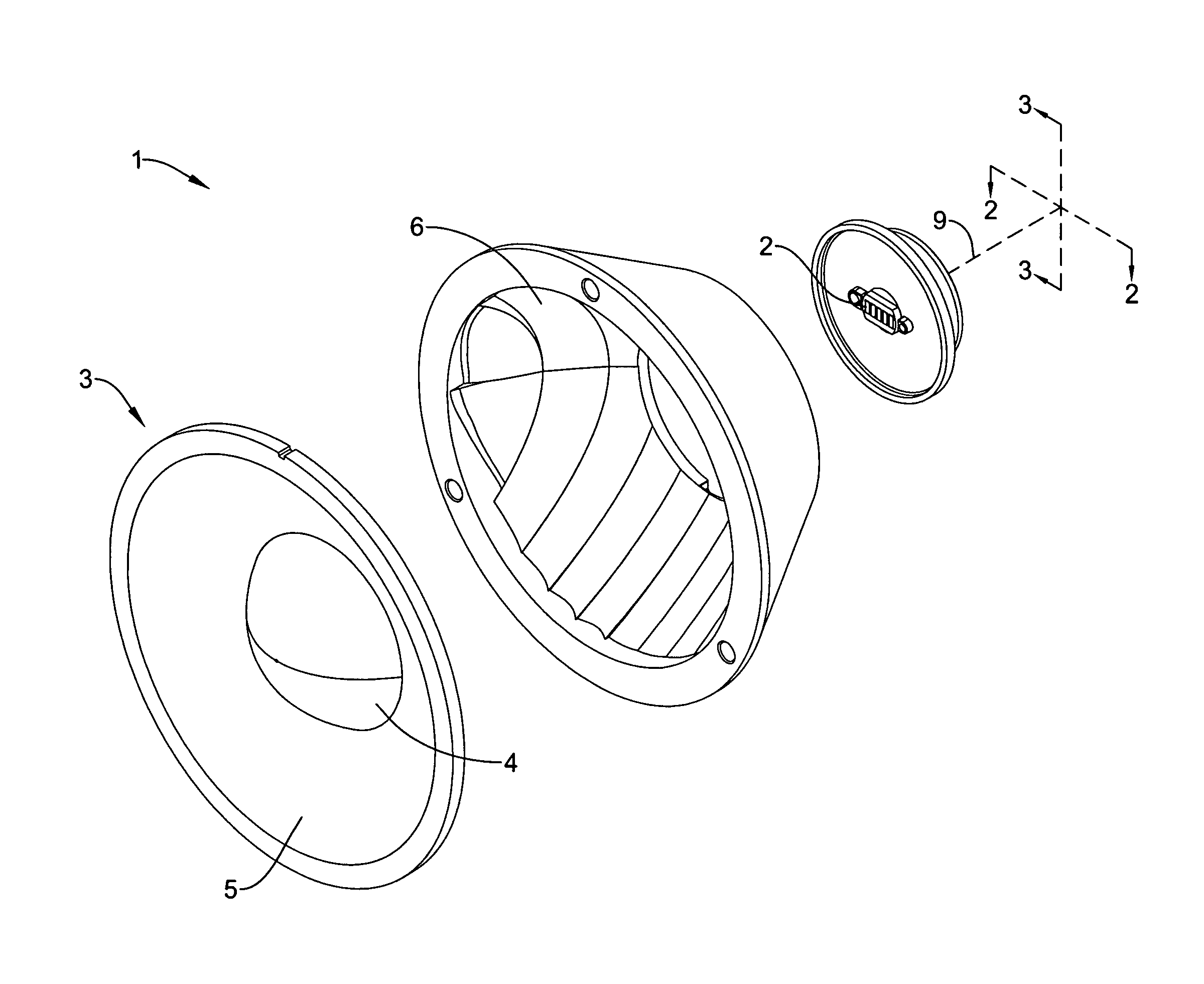

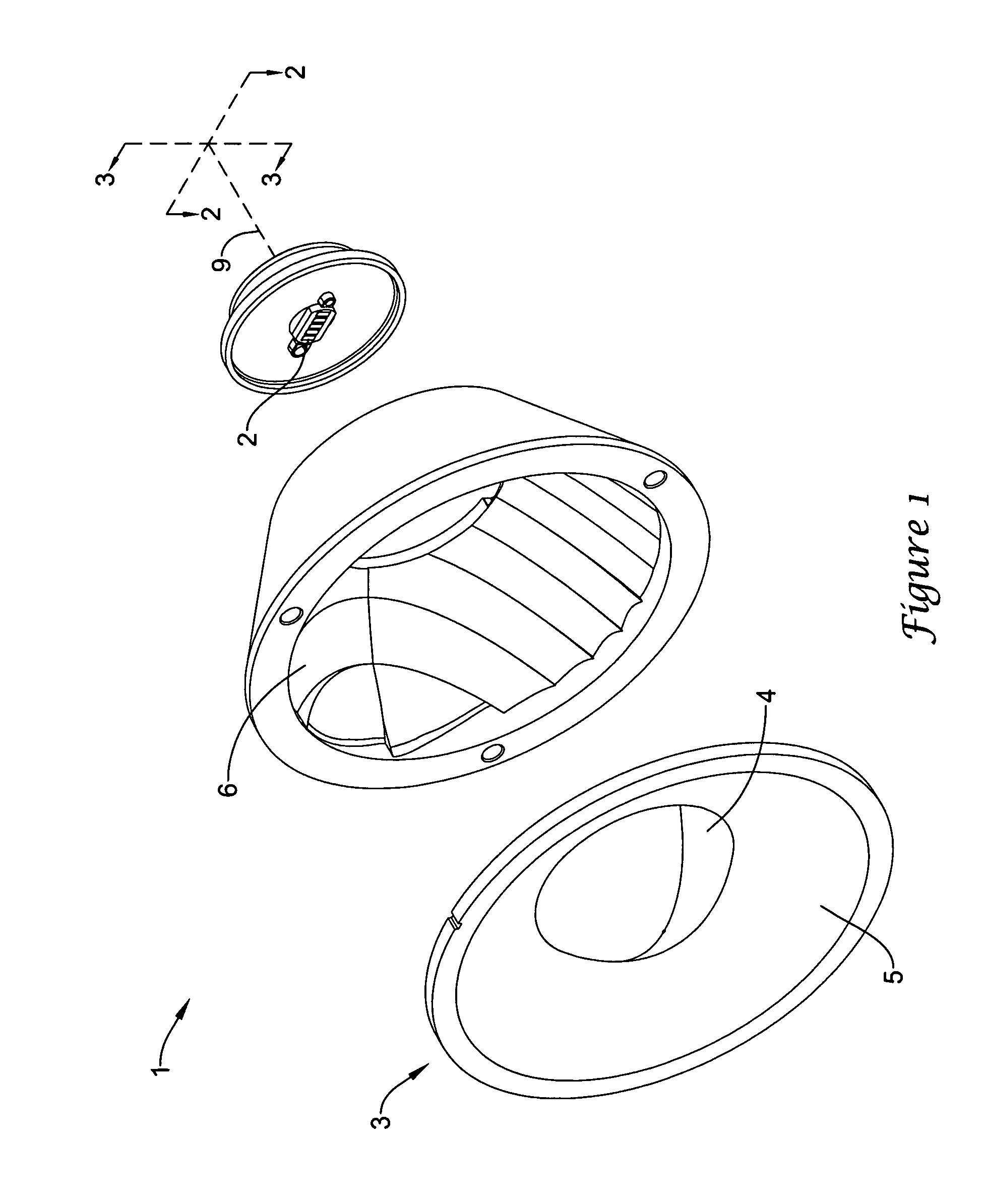

Combination optics light emitting diode landing light

ActiveUS20130094210A1Constant thicknessLighting support devicesPoint-like light sourceLight-emitting diodeAirplane

A light module (1) suitable for use as a landing light for an airplane is disclosed, using an elongated array (2) of light emitting diodes (LEDs) as the light source. Light from the LEDs is directed toward a transparent cover (3). The cover (3) may include a plano-convex lens (4) at its center for nominally collimating the light from the LEDs. The cover (3) may also include a generally featureless peripheral region laterally circumferentially surrounding the lens (4). A faceted reflecting surface (6) having a generally parabolic base curvature (8) may extend circumferentially around a longitudinal axis of the landing light from the LEDs to the cover (3). Light exiting the LEDs at a relatively high angle of exitance reflects off the faceted reflecting surface (6) and transmits through the generally featureless peripheral region of the cover (3).

Owner:OSRAM SYLVANIA INC

Micromachined fluidic device and method for making same

InactiveUS20060027523A1Minimizing dead volumeReliably madeFunctional valve typesFluid pressure measurement by electric/magnetic elementsEngineeringMachining

The fluid-flow device (100) of the invention comprises a stack (30) covered by a closure wafer (20), said stack (30) comprising a support wafer (36), a layer of insulating material (34), and a silicon layer (32). The closure wafer (20) and / or said silicon layer (32) are machined so as to define a cavity (38) between said closure wafer (20) and said silicon layer (32), said support wafer (36) has at least one duct (102) passing right through it, said layer of insulating material (34) presenting at least one zone (35) that is entirely free of material placed at least in line with said duct (102) so as to co-operate with said cavity (38) to define a moving member (40) in said silicon layer (32), the moving member being suitable under the pressure of liquid in said cavity (38) for reversibly moving towards said support wafer (36) until contact is made between said moving member (40) and said support wafer (36).

Owner:DEBIOTECH SA

CMP pad conditioner having working surface inclined in radially outer portion

ActiveUS20050215188A1Facilitates evacuationEfficient evacuationRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

A CMP pad conditioner including: (a) a disk-shaped substrate having a working surface which is provided by one of its axially opposite end surfaces and which is to be brought into contact with the CMP pad; and (b) abrasive grains which are fixed to the working surface. The substrate includes a radially inner portion and a radially outer portion which is located radially outwardly of the radially inner portion. The working surface in the radially outer portion is inclined with respect to the working surface in the radially inner portion, such that a thickness of the radially outer portion as measured in an axial direction of the substrate is reduced as viewed in a direction away from an axis of the substrate toward a periphery of the substrate. A ratio of an outside diameter of the radially inner portion to an outside diameter of the substrate is 60-85%.

Owner:NORITAKE CO LTD +1

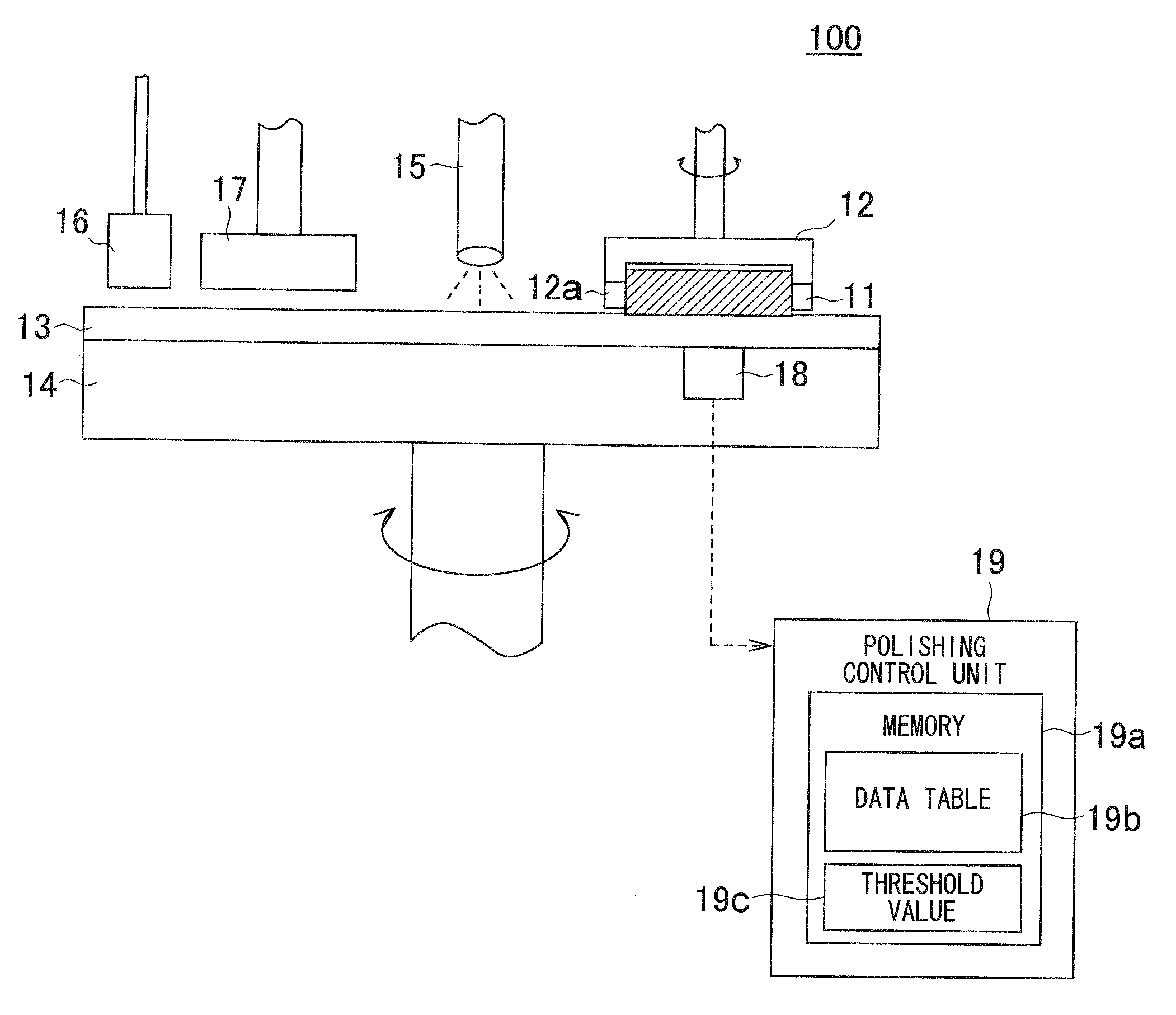

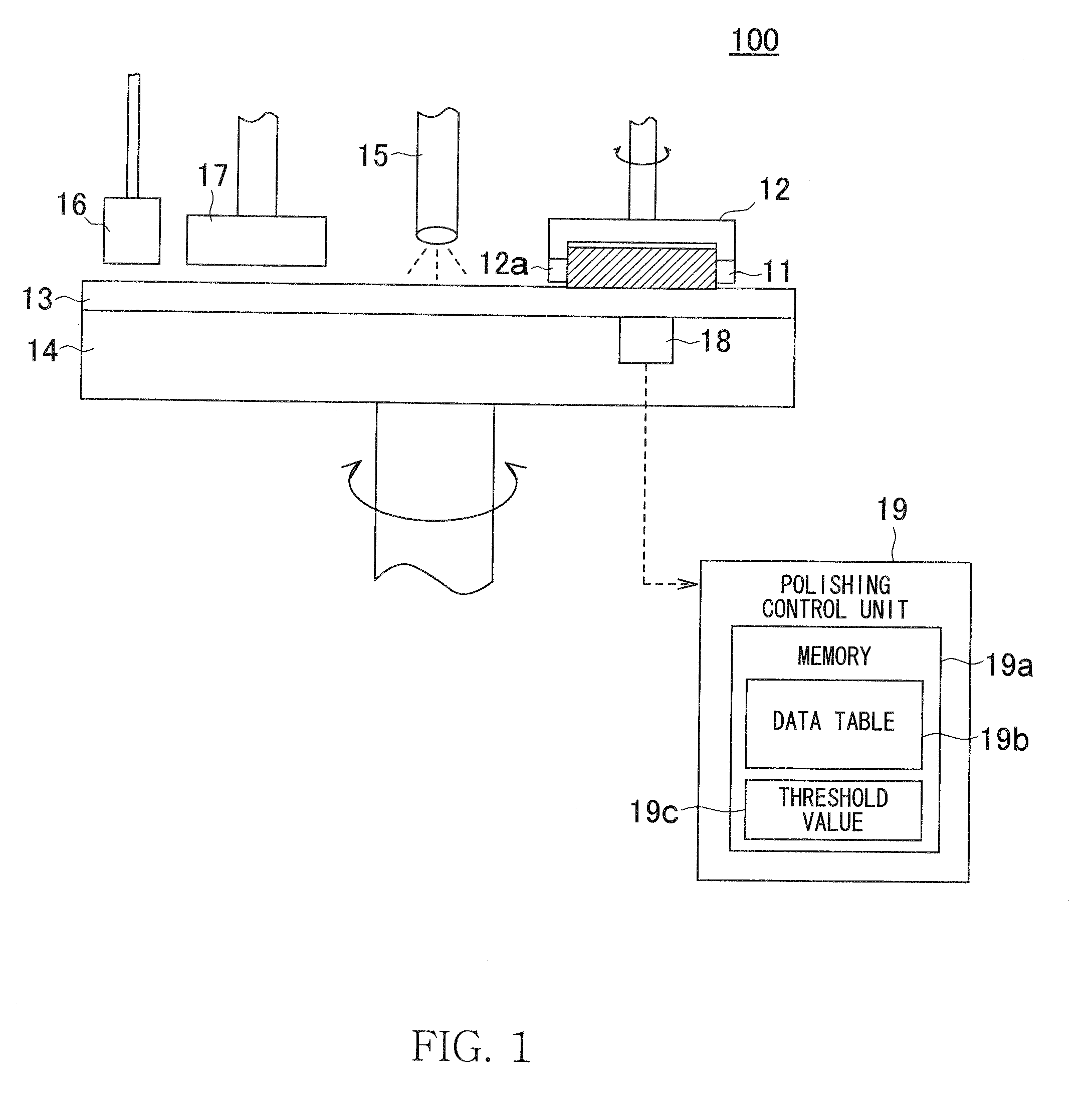

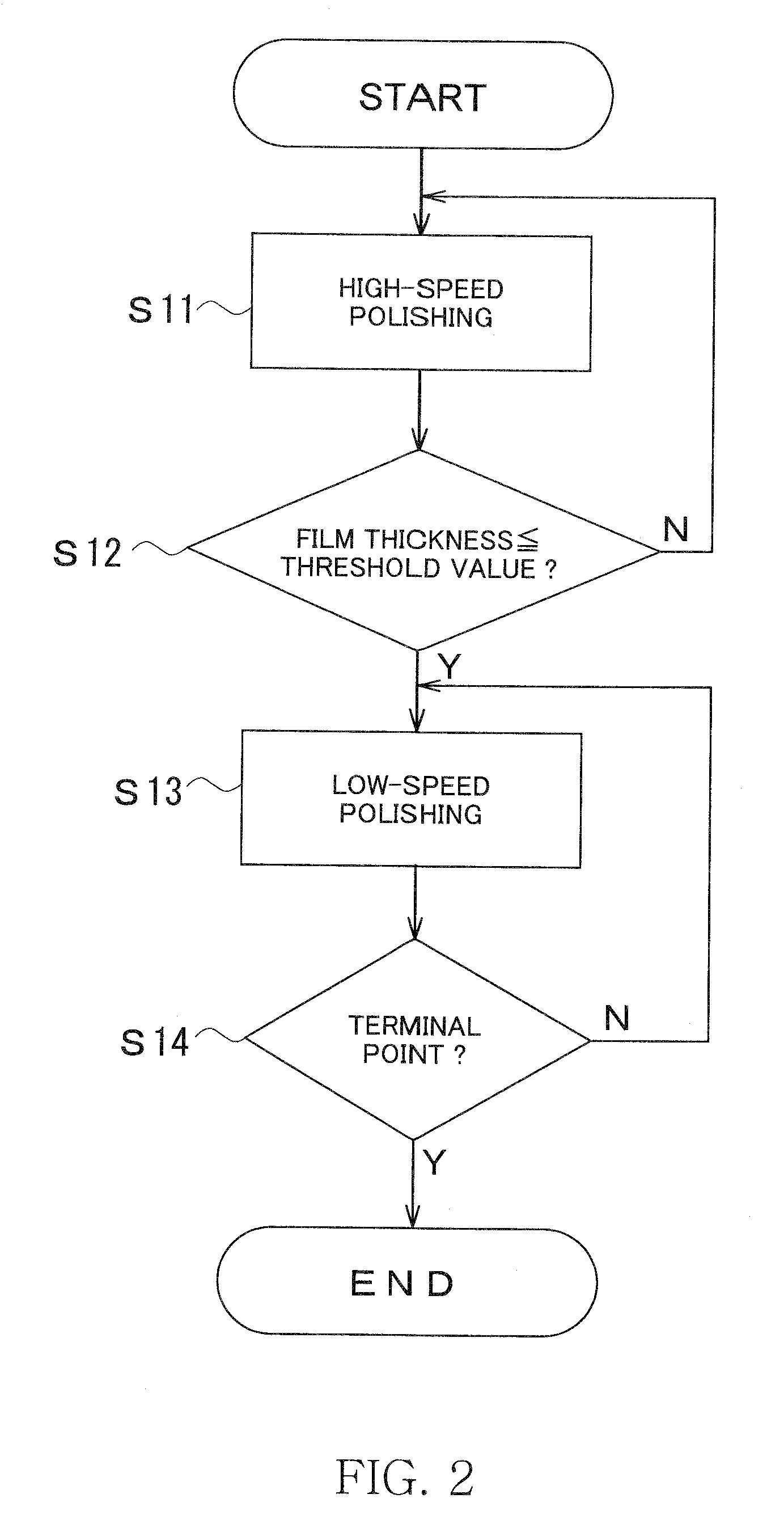

Cmp apparatus and method of polishing wafer using cmp

InactiveUS20090036024A1Improve throughputAccurate measurementPolishing machinesRevolution surface grinding machinesElectrical and Electronics engineering

A CMP apparatus is provided with a polishing pad, a film thickness sensor for measuring a thickness of a film being polished on a wafer via the polishing pad, a polishing pad thickness measuring unit for measuring the thickness of the polishing pad, a dresser for dressing the polishing pad, and a polishing control unit for switching polishing conditions in response to a fact that an output value from the film thickness sensor has exceeded a threshold value. The polishing control unit has a memory unit for storing a threshold value corresponding to the thickness of the polishing pad after dressing when the polishing pad is dressed.

Owner:PS4 LUXCO SARL

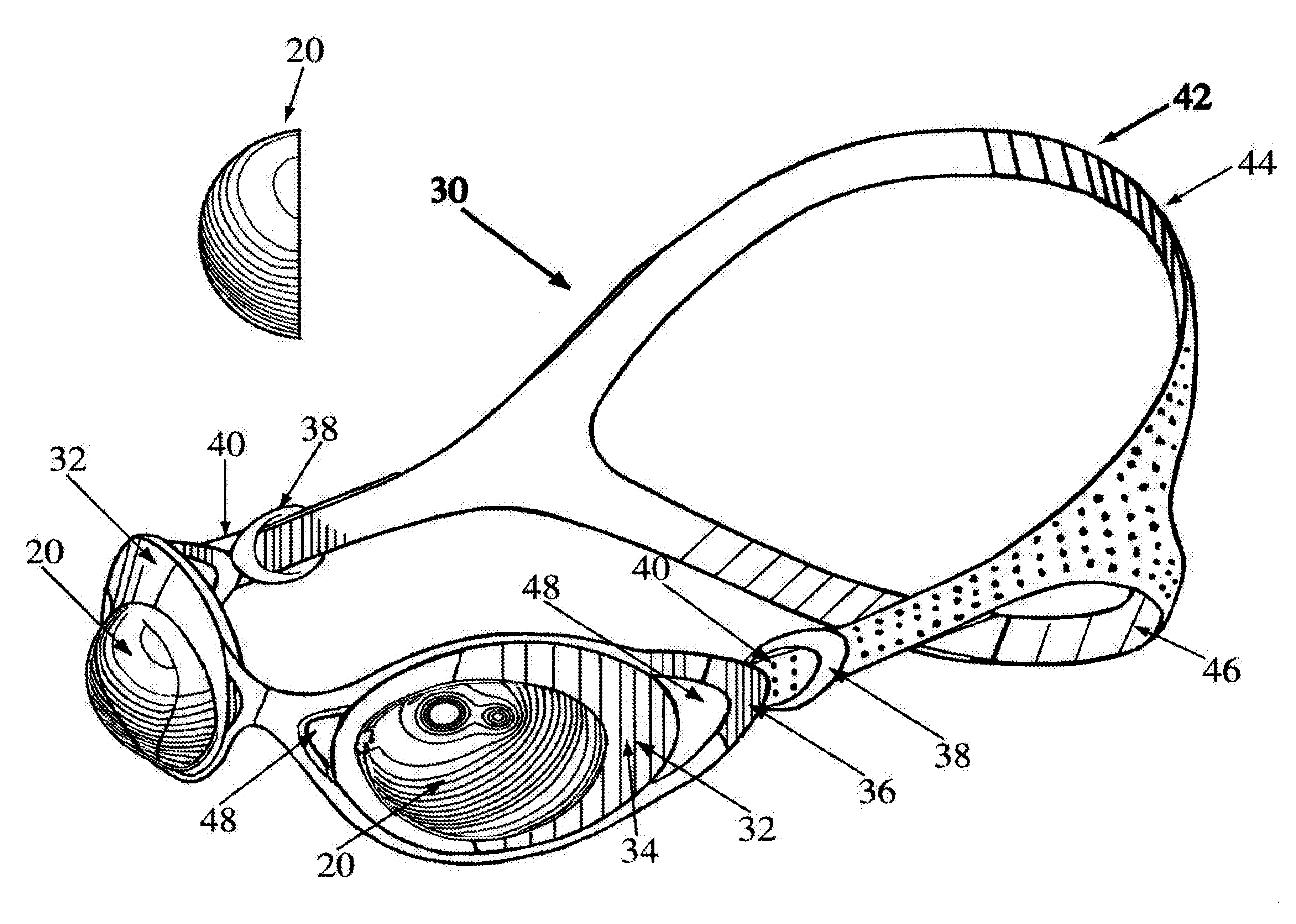

Toric-shaped lenses and goggle assembly

The present invention relates to toric-shaped see through lenses used in eyewear. The lenses have a substantially constant thickness and having base curve with a substantially constant radius of curvature of at least 15 mm and preferably in the range of 19-23 mm. The toric lenses may be supported in a frame formed of either rigid or flexible material and attached to a strap assembly adaptable to be worn by the user. Optionally, each of the lenses may be supported by a flanged member and ventilation passages preferably extending through the frame and / or the lenses to allow air to circulate around the lenses.

Owner:GREENHOUSE GROWN PRODS

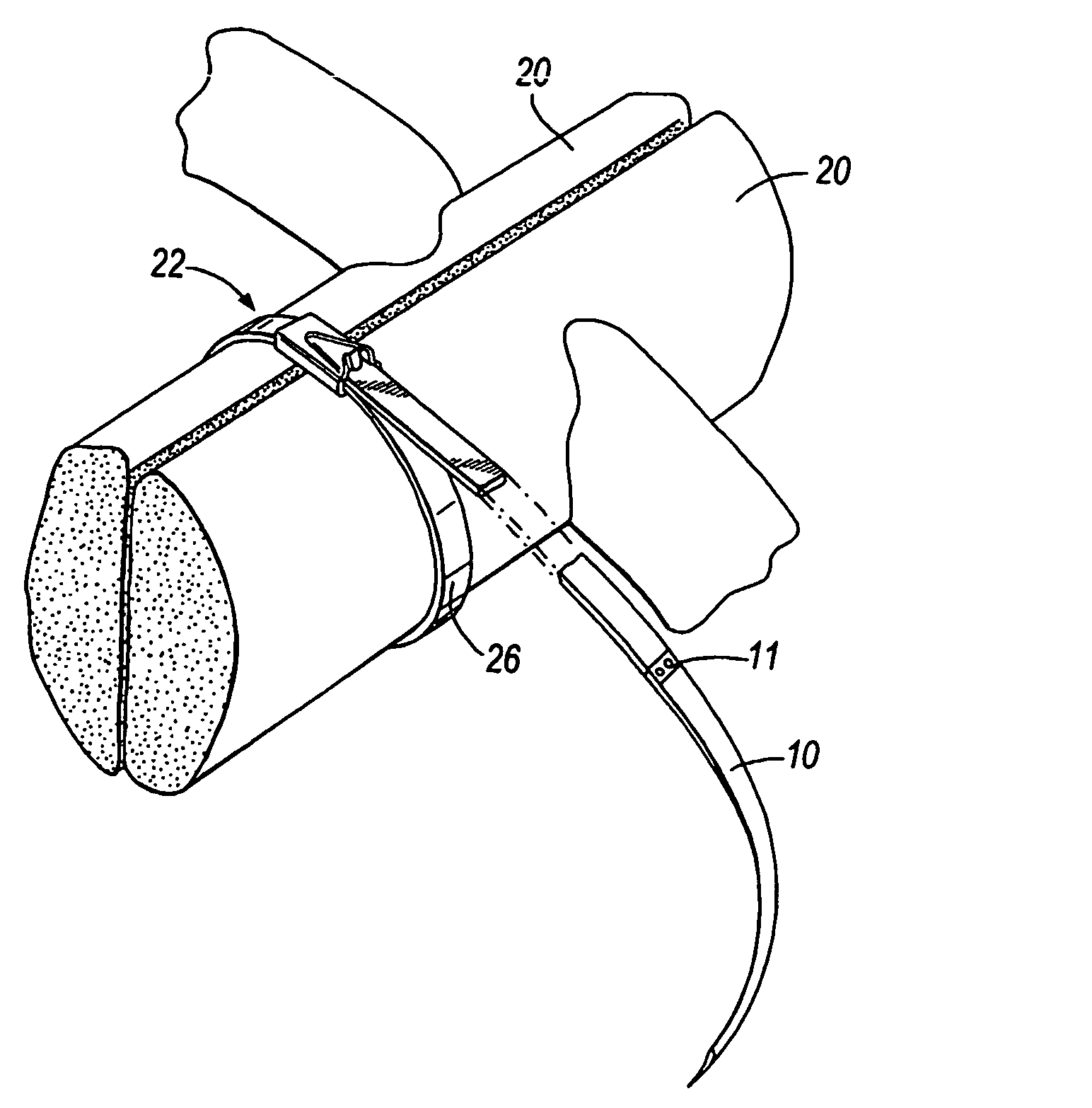

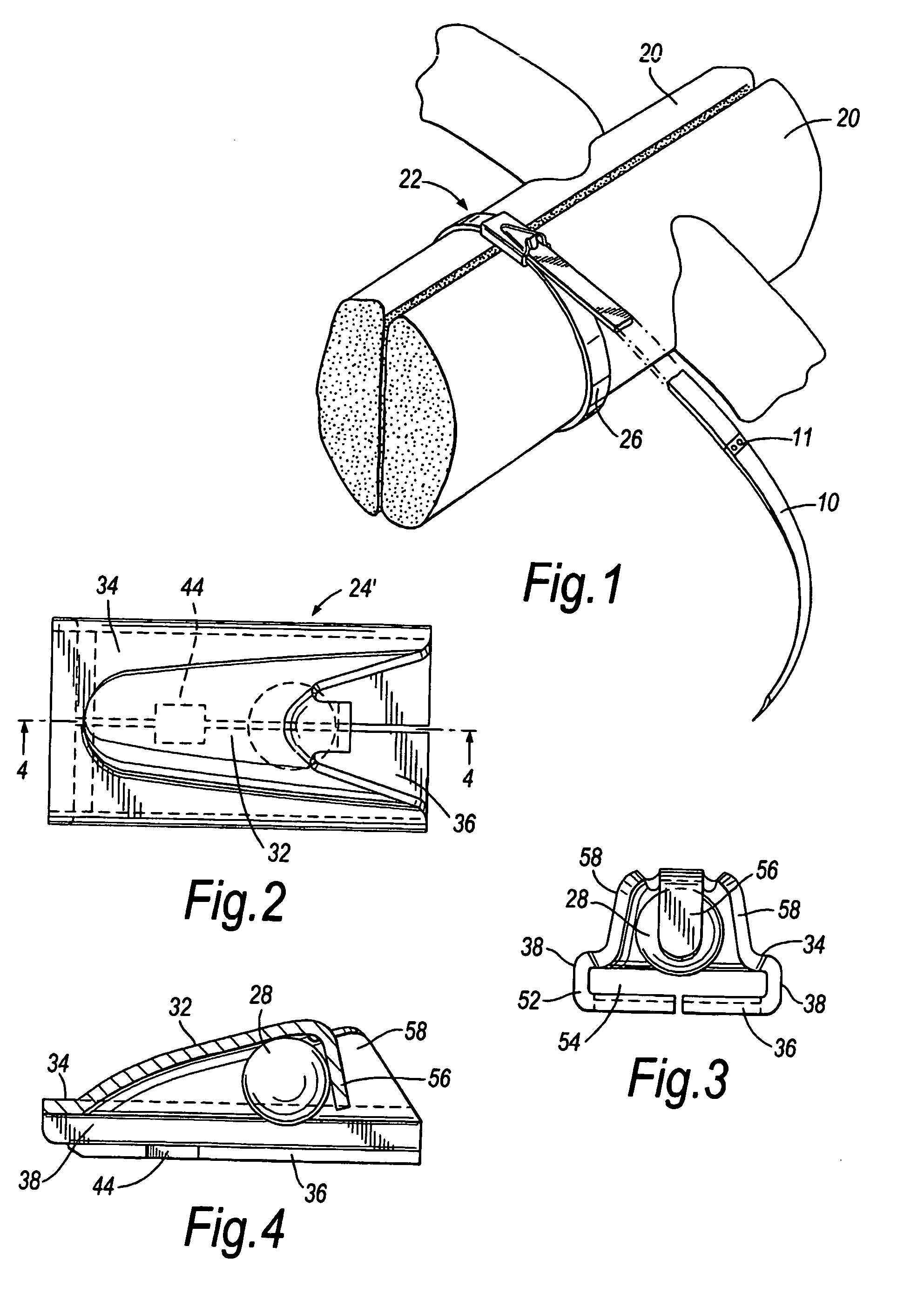

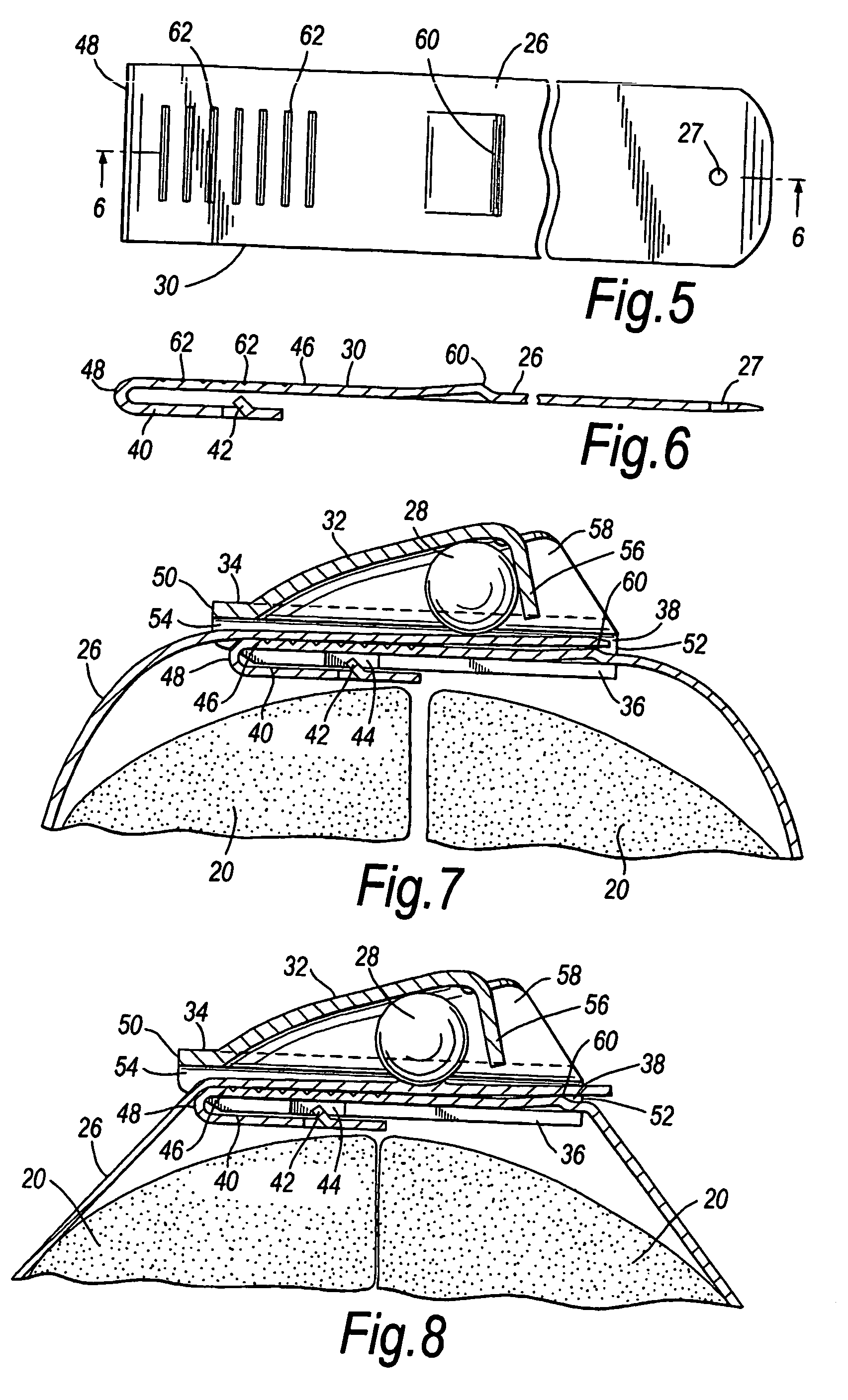

Suture band

InactiveUS20070055258A1Easy threadingPrevent movementSuture equipmentsInternal osteosythesisLocking mechanismEngineering

The present invention provides a suture band device comprising an elongated flexible band having first and second ends, a needle attached to the first end of the band, a buckle attached proximate the second end of the band for receiving and locking the band, characterised in the that buckle comprises a locking mechanism which enables the band to be locked at any point along its length.

Owner:HANSEN DORIS HJORTH

Electroluminescent lighting system

InactiveUS20050073829A1Reduce burnReduce decreaseDischarge tube luminescnet screensStatic indicating devicesCapacitanceDriver circuit

Electroluminescent panels for use in battery operated devices comprise a driver circuit and a plurality of panel regions having a capacitance. Each panel region has a substitute capacitor with a capacitance substantially equal to the capacitance of the panel region concerned. The driver circuit switches between the panel region and the substitute capacitor, switching the panel region on and off. The capacitance of the load on the driver circuit does not change. The electroluminescent panels can have an elimination layer that eliminates noise produced by the emission layer in operation caused by changes in emission layer thickness. The elimination layer is added to the panel and operated in phase opposition to the emission layer. Changes in layer thickness occurring in operation in the emission layer are offset by changes in thickness in the elimination layer. Thus, the overall thickness of the panel is constant.

Owner:NOKIA CORP

Illumination device comprising a light guide

ActiveUS8292467B2Easy to manufactureEasy to shapeOptical light guidesRefractorsLight guideEffect light

The invention provides an illumination device (1) comprising a lighting unit (2). The lighting unit (2) comprises a light source (100) and a substantially flat light guide (200), arranged to collimate light source light (111). The light guide (200) has an entrance window (210), an edge window (220), a first light guide surface (201), a second light guide surface (202), a first side edge (230) and a second side edge (240). One or more of the first light guide surface (201) and the second light guide surface (202) comprise a plurality of grooves (300). In this way, latitudinal collimation is obtained.

Owner:SIGNIFY HLDG BV

Method for Establishing a Nail Connection and a Nail for This Purpose

A method for establishing a nail connection between two components and a nail for this purpose are described. The nail 6 is driven through the non-preholed components in the joint area at a high speed such that the nail point completely penetrates both components and a material collar, which extends into an adhesive layer between the two components, is only formed in the to driving direction in the nail-head-side component.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

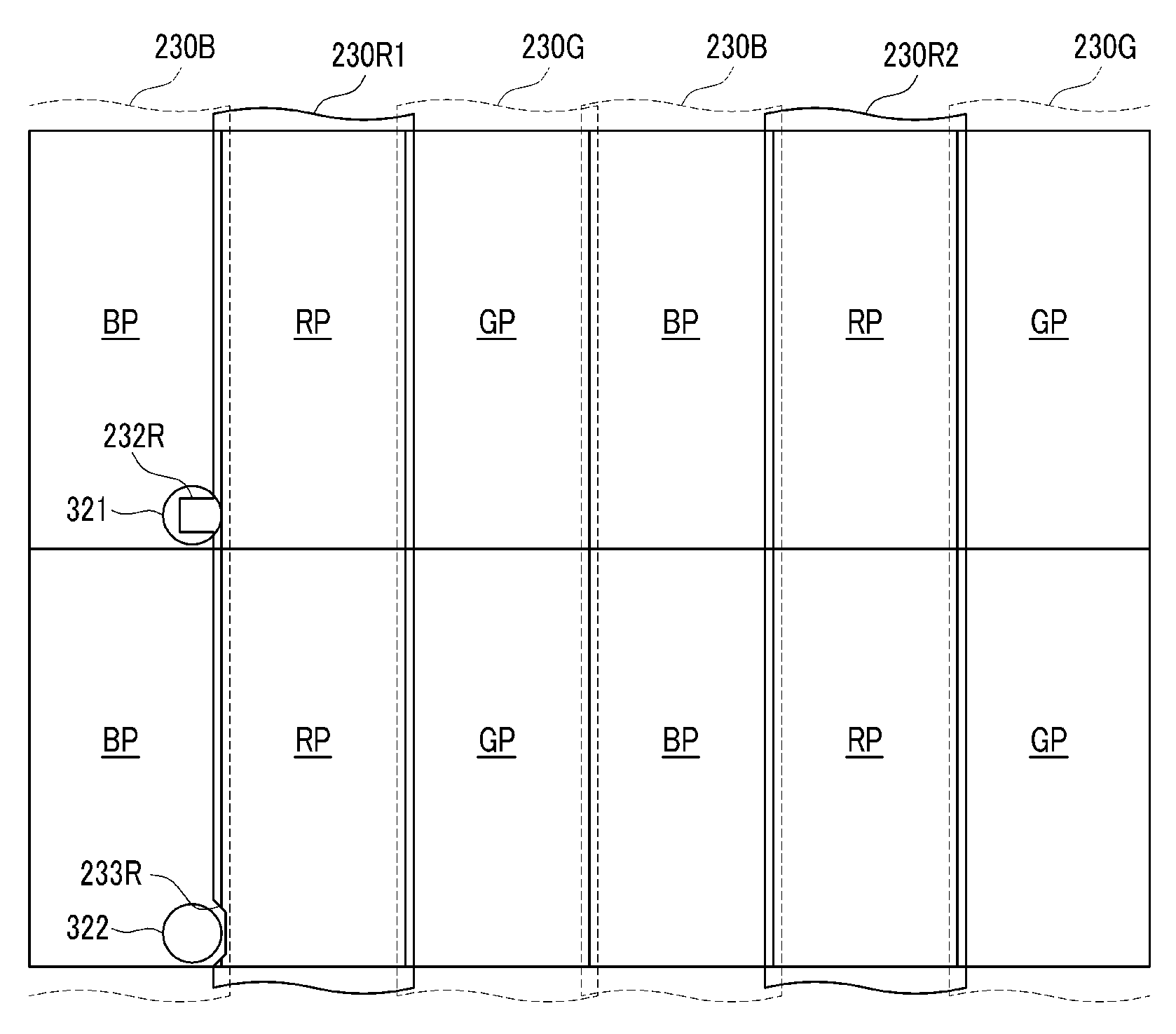

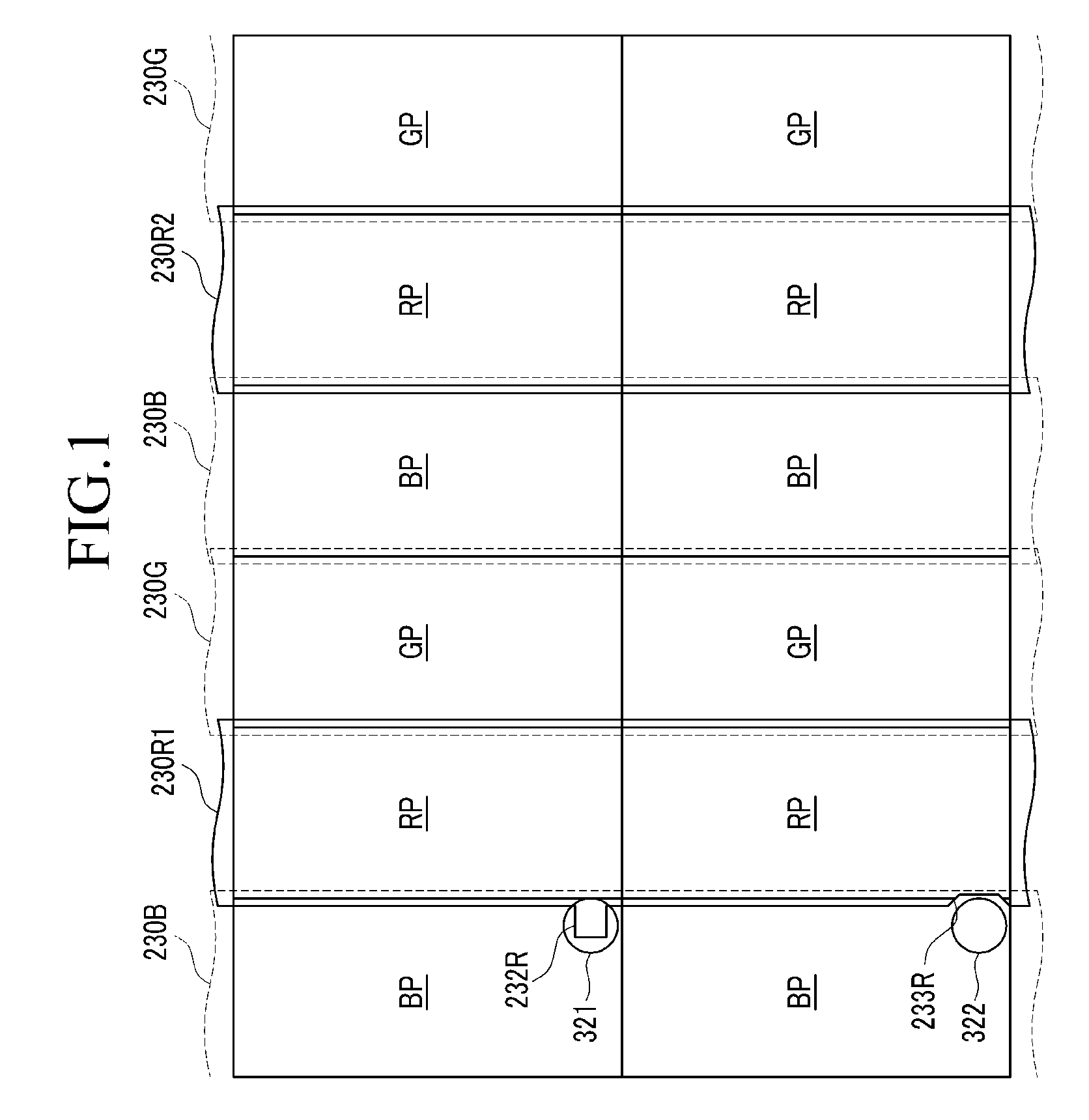

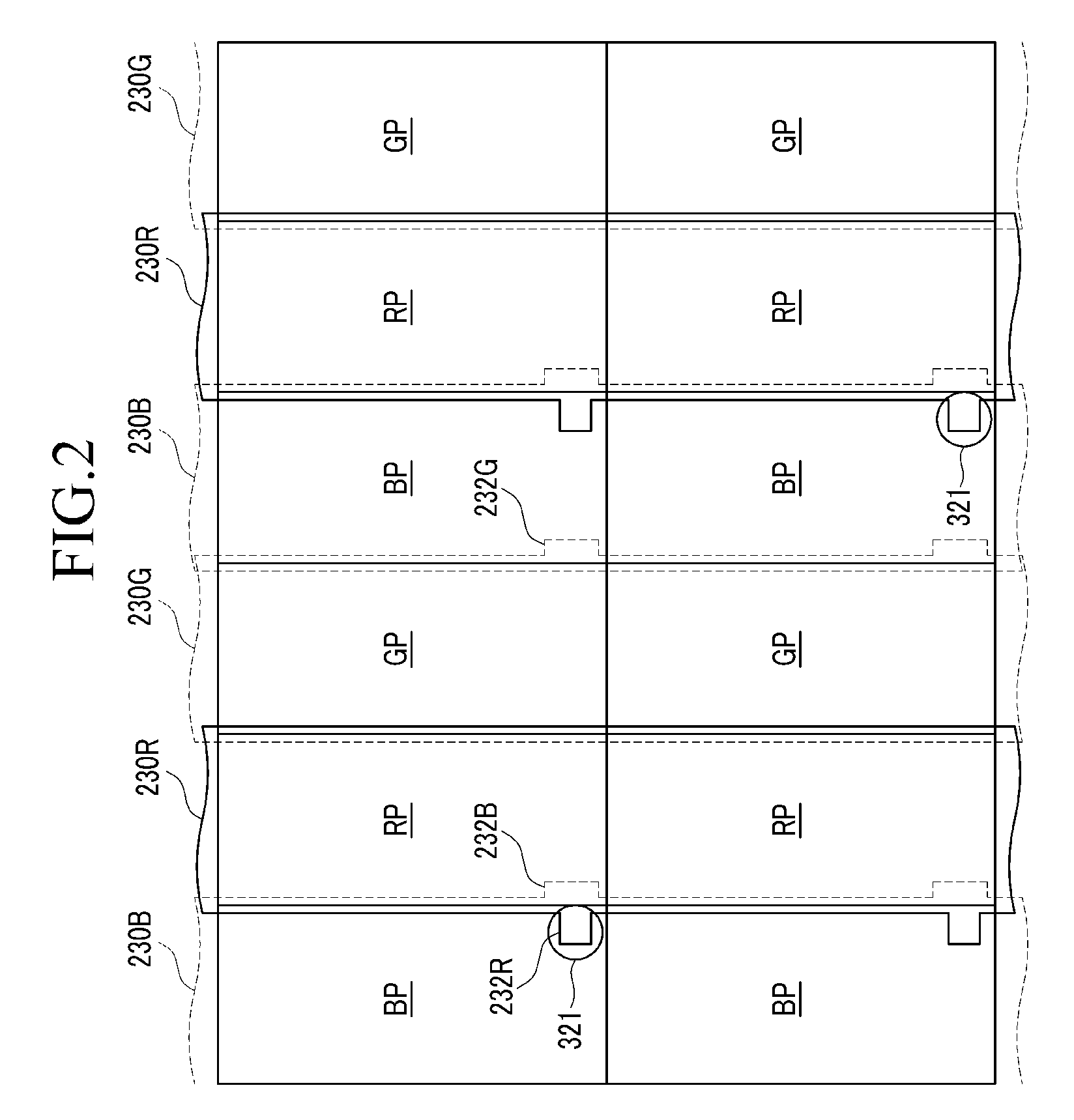

Liquid crystal display including color filters, and manufacturing method thereof

A liquid crystal display includes a first display panel including a first substrate, and first and second color filters disposed on the first substrate and adjacent to each other, a second display panel including a second substrate facing the first display panel and a first spacer disposed on the second substrate, and a liquid crystal layer disposed between the first and second display panels. The first color filter includes a first protrusion protruded toward and overlapped with the second color filter. The first spacer faces the first protrusion, and the first and second display panels contact each other at a location area of the first spacer.

Owner:SAMSUNG DISPLAY CO LTD

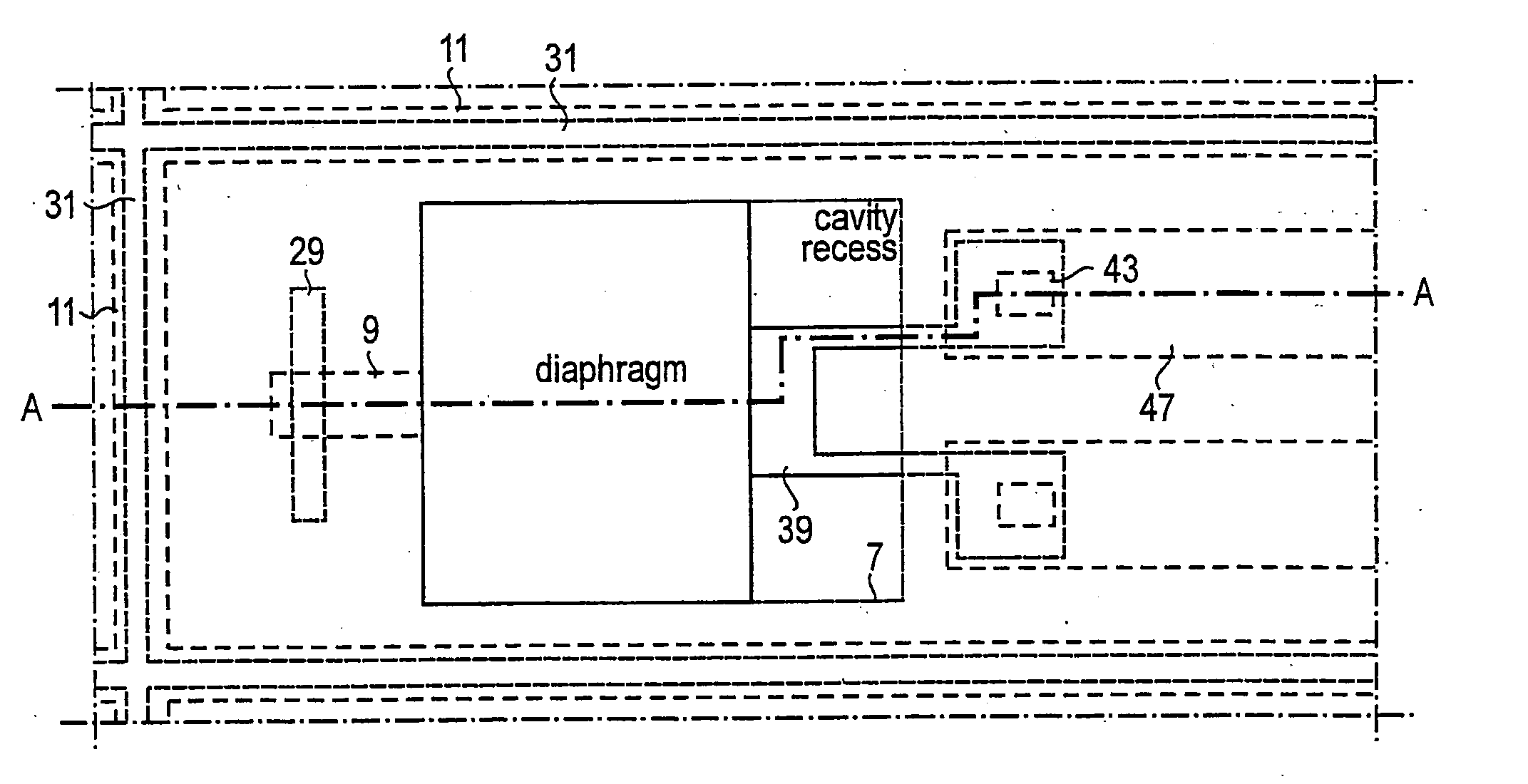

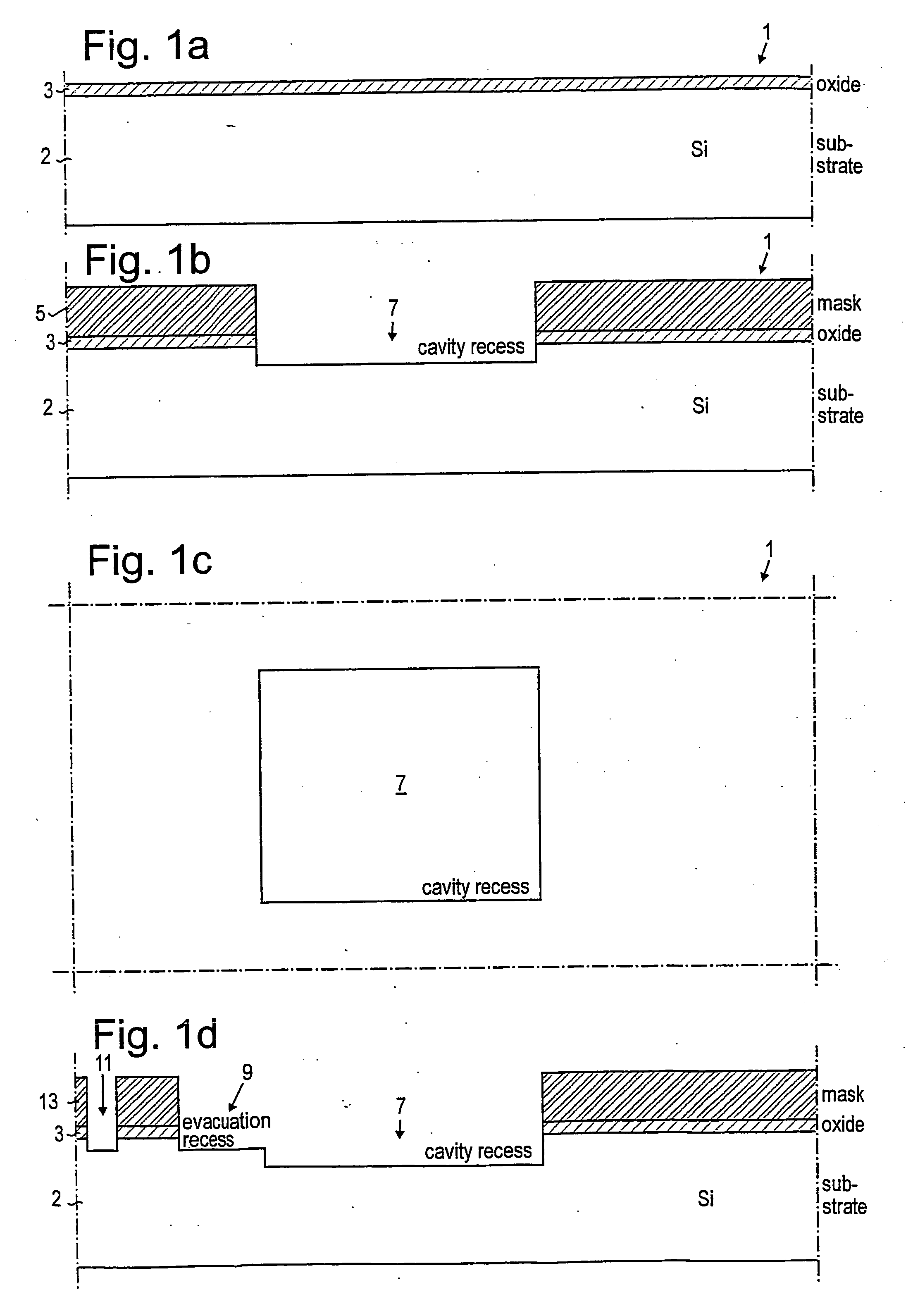

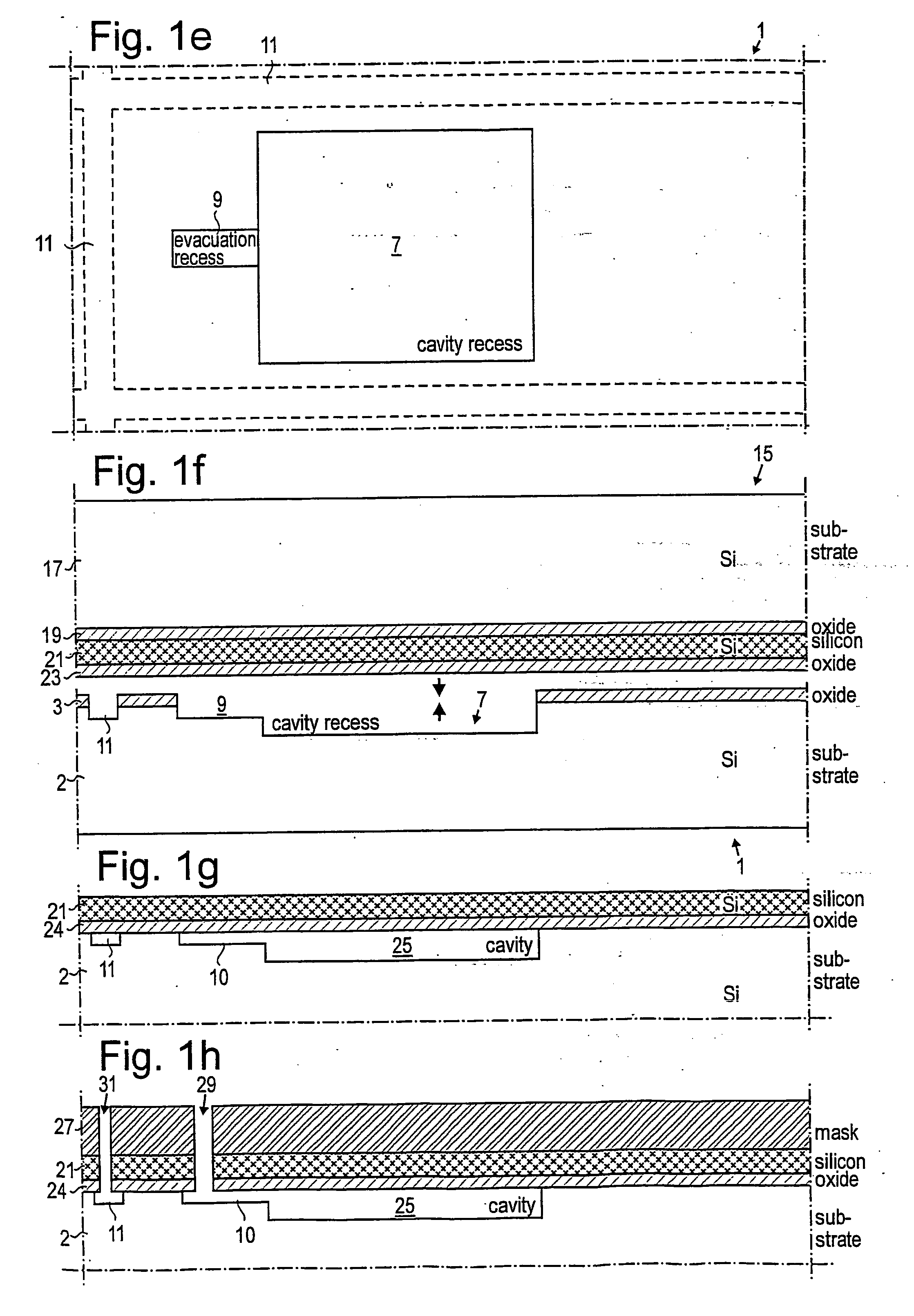

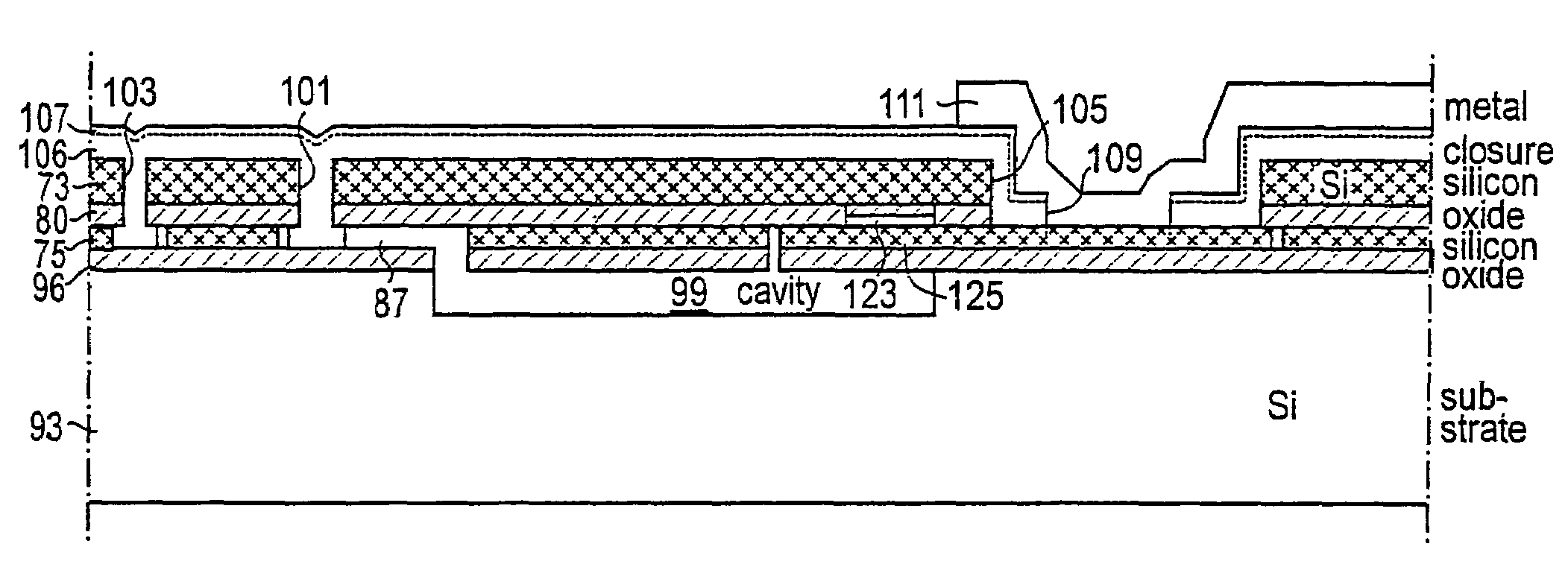

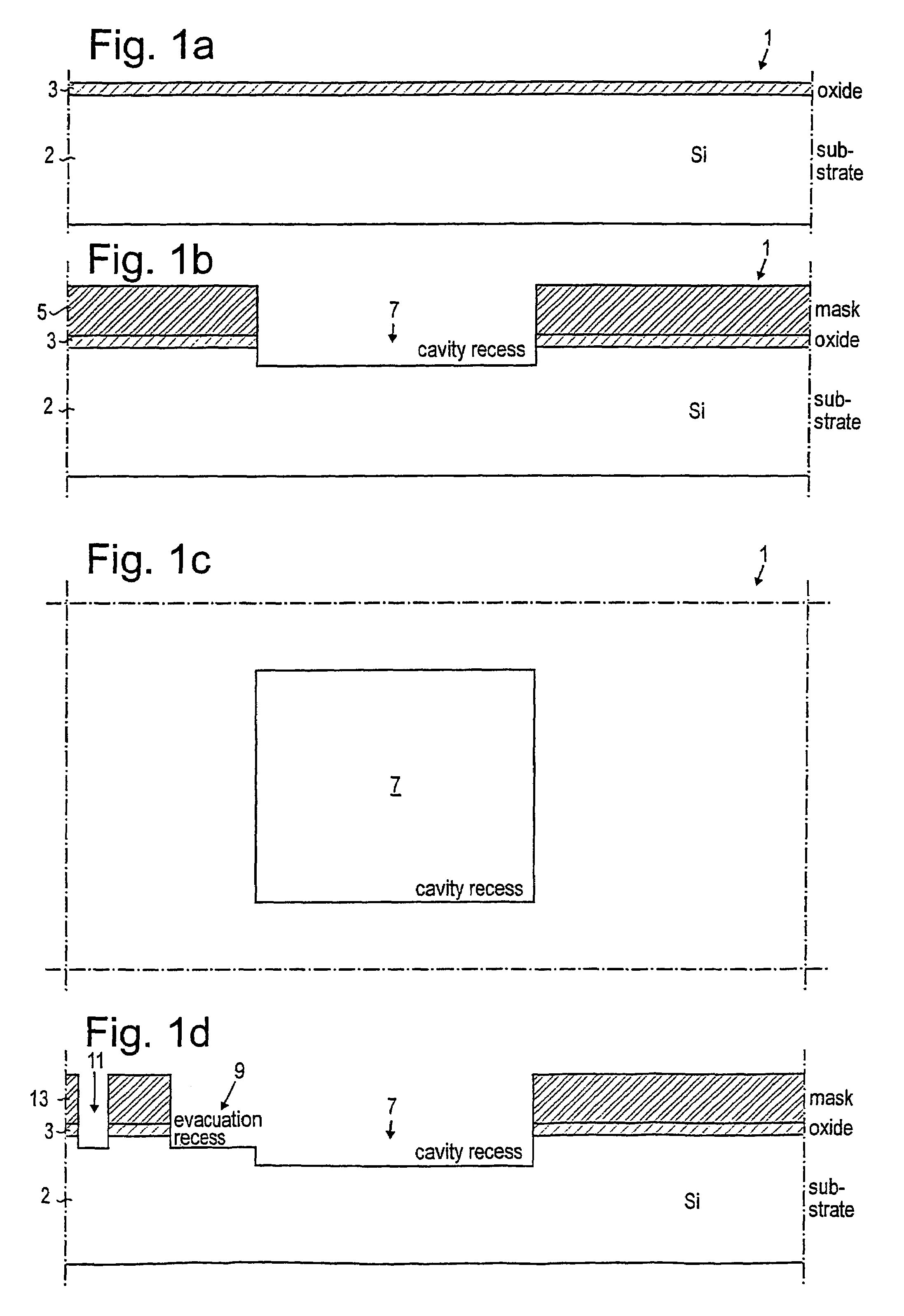

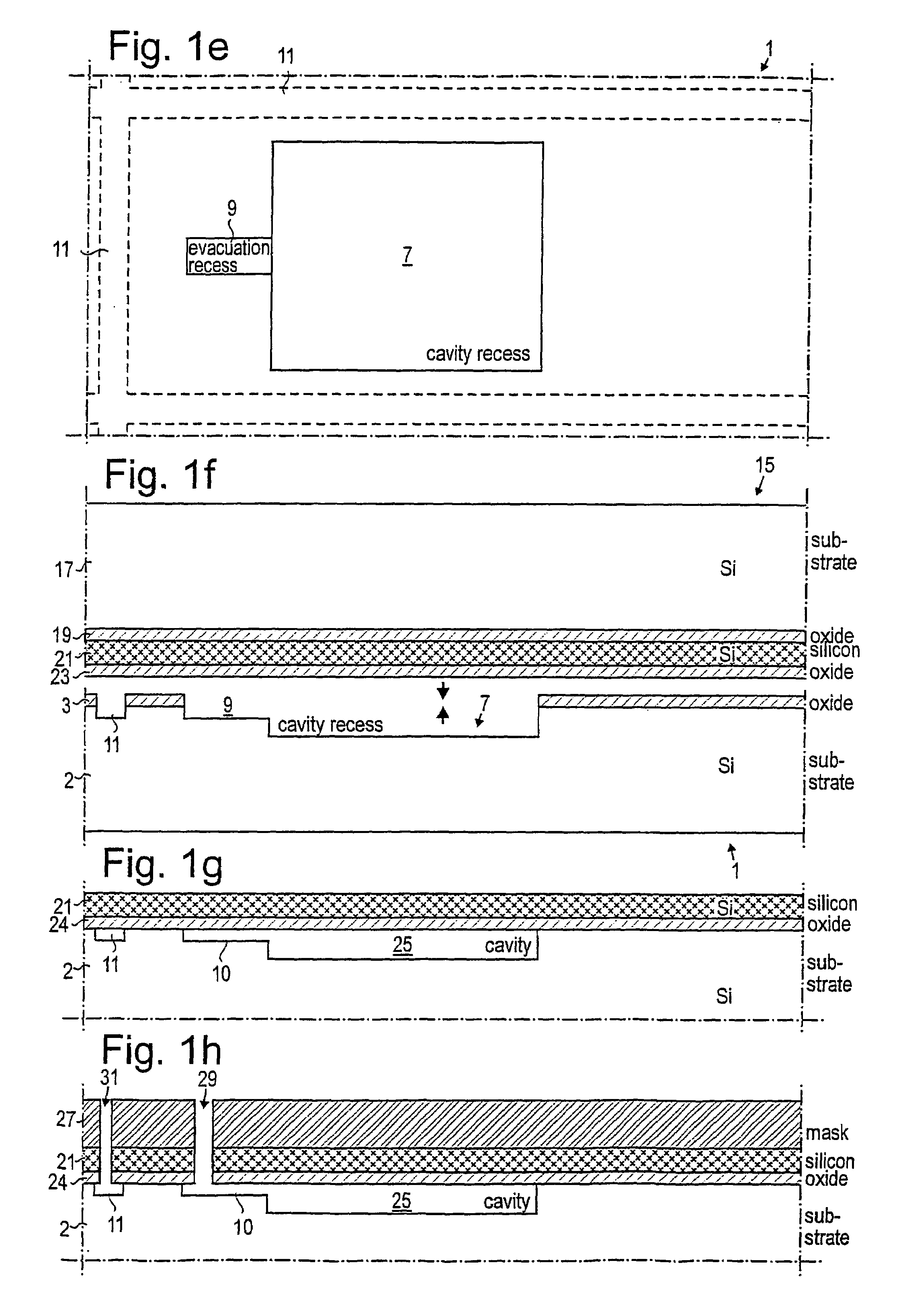

Pressure sensor

InactiveUS20060032039A1High yieldPrecise definitionWave amplification devicesElectronic circuit testingSingle crystalForce sensor

In manufacturing a pressure sensor a recess that will form part of the sensor cavity is formed in a lower silicon substrate. An SOI-wafer having a monocrystalline silicon layer on top of a substrate is bonded to the lower silicon substrate closing the recess and forming the cavity. The supporting substrate of the SOI-wafer is then etched away, the portion of the monocrystalline layer located above the recess forming the sensor diaphragm. The oxide layer of the SOI-wafer here acts as an “ideal” etch stop in the case where the substrate wafer is removed by dry (plasma) or wet etching using e.g. KOH. This is due to high etch selectivity between silicon and oxide for some etch processes and it results in a diaphragm having a very accurately defined and uniform thickness. The cavity is evacuated by forming a opening to the cavity and then sealing the cavity by closing the opening using LPCVD. Sensor paths for sensing the deflection of the diaphragm are applied on the outer or inner surface of the diaphragm. The monocrystalline diphragm gives the sensor a good long-term stability. Also the sensor path can be made of monocrystalline material, this giving the sensor even better good long-term characteristics. An increased sensitivity can be obtained by making active portions of the sensor paths freely extending, unsupported by other material of the pressure sensor, by suitable etching procedures.

Owner:SILEX MICROSYST

Pressure sensor

InactiveUS6973835B2High yieldPrecise definitionWave amplification devicesElectronic circuit testingSingle crystalPressure sensor

In manufacturing a pressure sensor a recess that will form part of the sensor cavity is formed in a lower silicon substrate. An SOI-wafer having a monocrystalline silicon layer on top of a substrate is bonded to the lower silicon substrate closing the recess and forming the cavity. The supporting substrate of the SOI-wafer is then etched away, the portion of the monocrystalline layer located above the recess forming the sensor diaphragm. The oxide layer of the SOI-wafer here acts as an “ideal” etch stop in the case where the substrate wafer is removed by dry (plasma) or wet etching using e.g. KOH. This is due to high etch selectivity between silicon and oxide for some etch processes and it results in a diaphragm having a very accurately defined and uniform thickness. The cavity is evacuated by forming a opening to the cavity and then sealing the cavity by closing the opening using LPCVD. Sensor paths for sensing the deflection of the diaphragm are applied on the outer or inner surface of the diaphragm. The monocrystalline diphragm gives the sensor a good long-term stability. Also the sensor path can be made of monocrystalline material, this giving the sensor even better good long-term characteristics. An increased sensitivity can be obtained by making active portions of the sensor paths freely extending, unsupported by other material of the pressure sensor, by suitable etching procedures.

Owner:SILEX MICROSYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com