Patents

Literature

732results about How to "Avoid conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

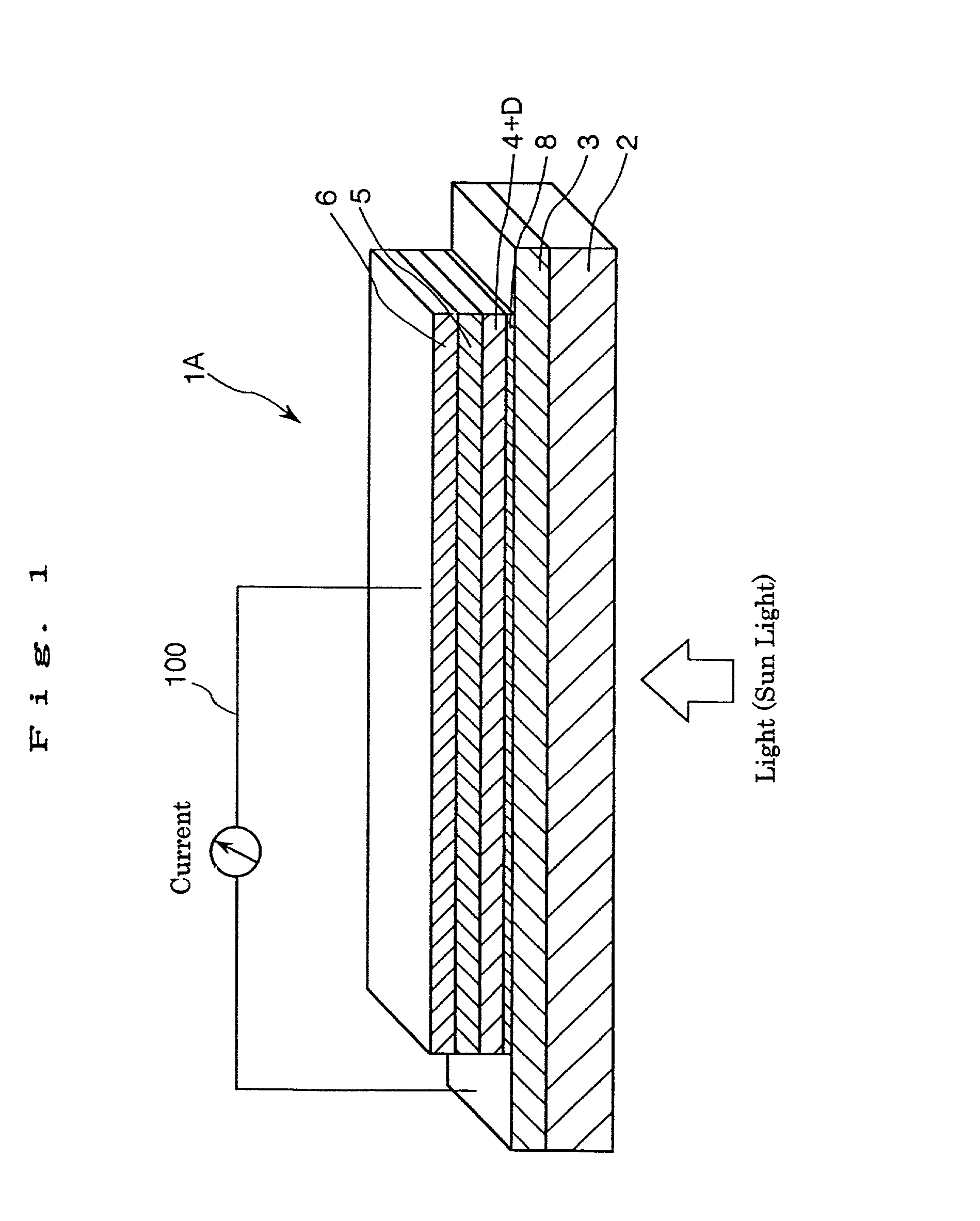

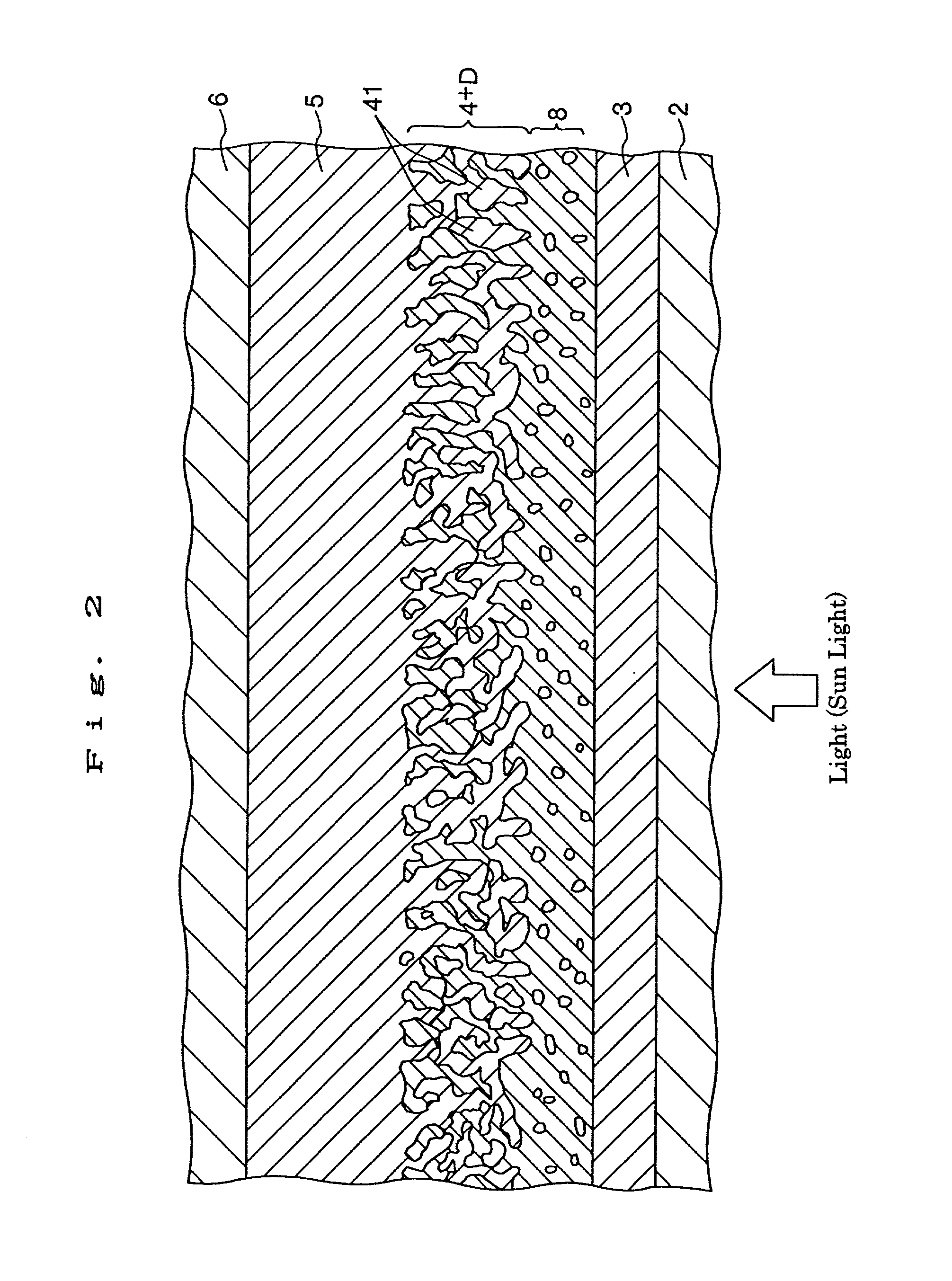

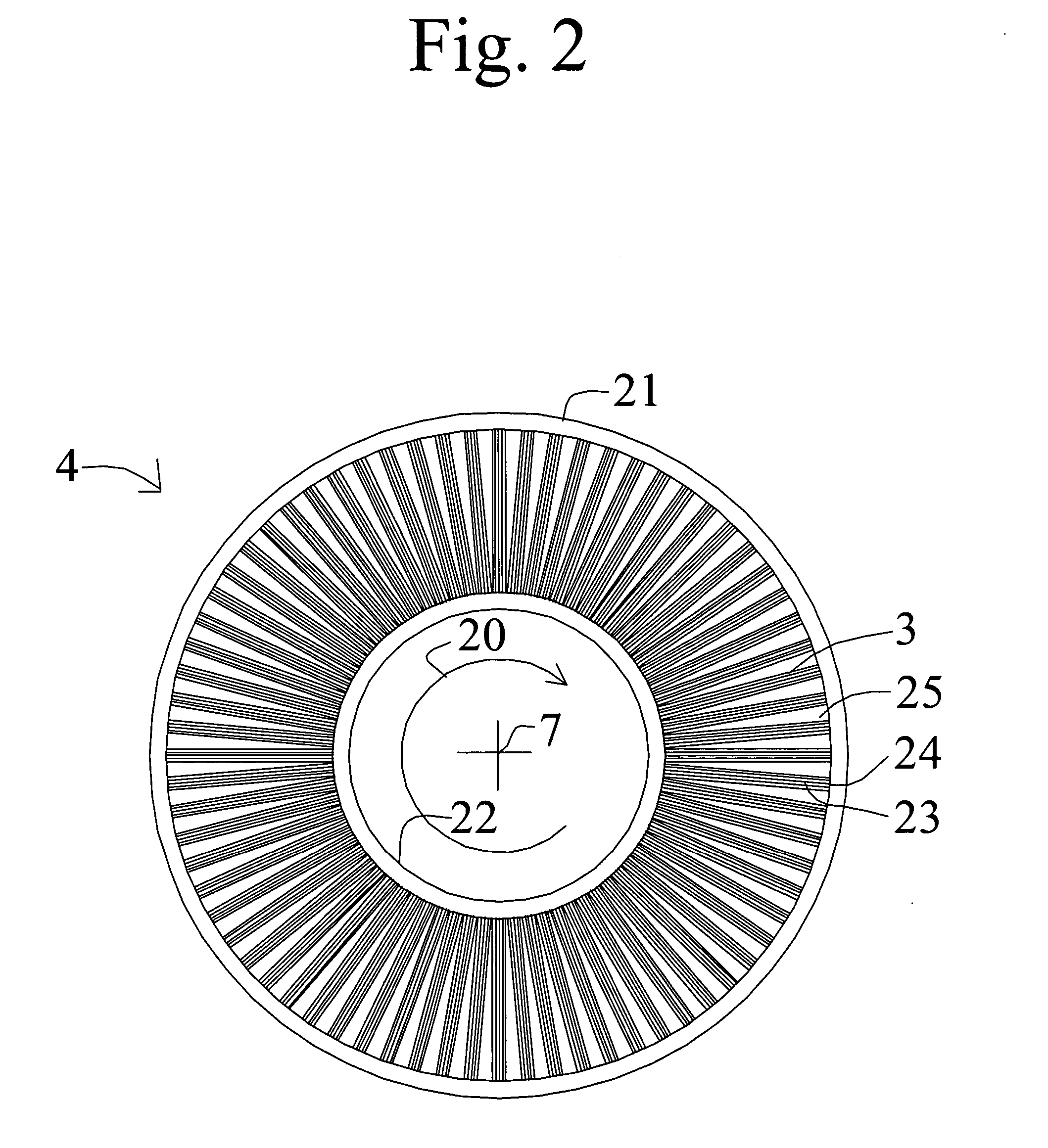

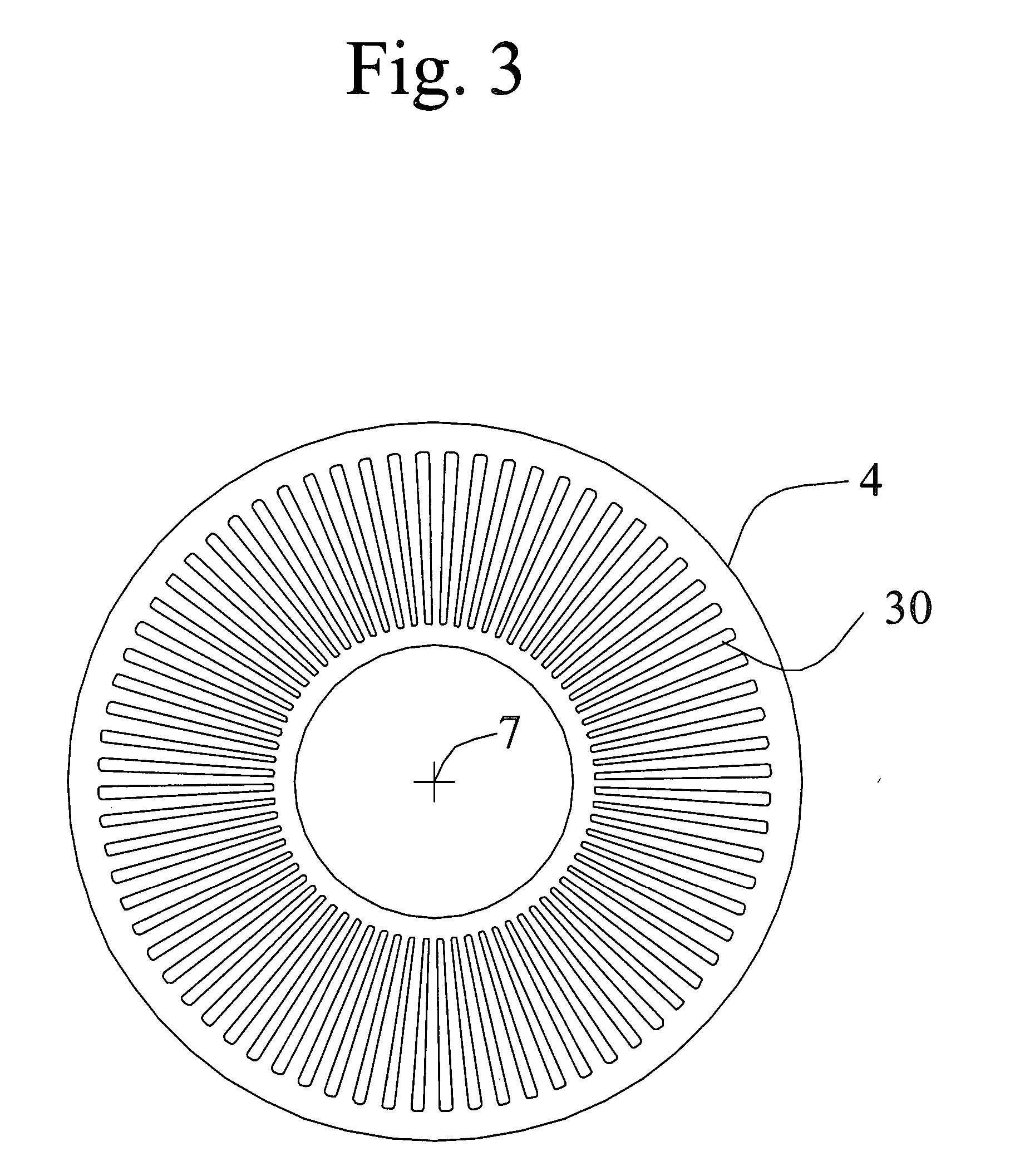

Photoelectric conversion element

InactiveUS6683244B2Improve photoelectric conversion efficiencyPrevent and suppressLight-sensitive devicesDeferred-action cellsPorosityPhotoelectric conversion

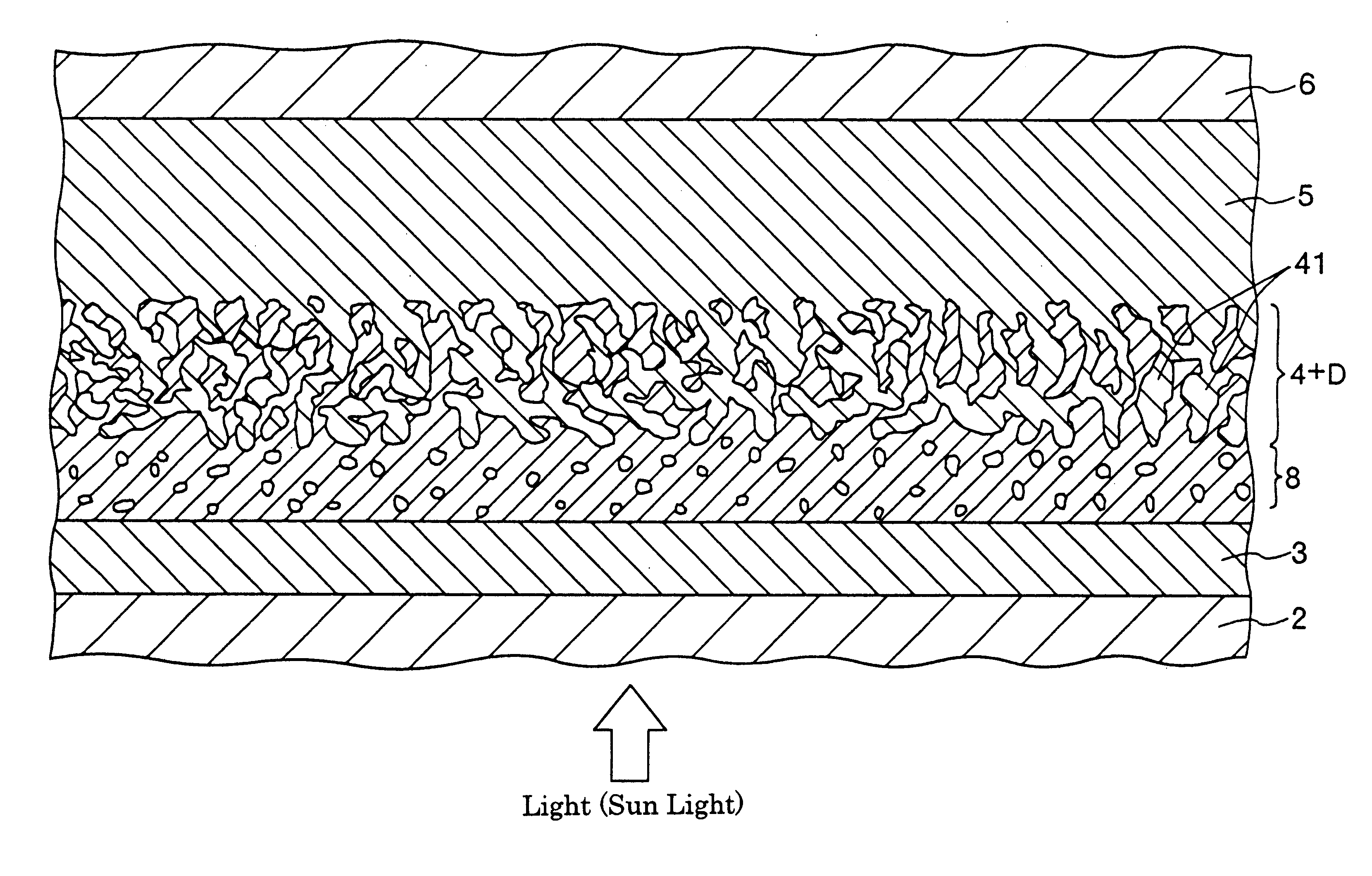

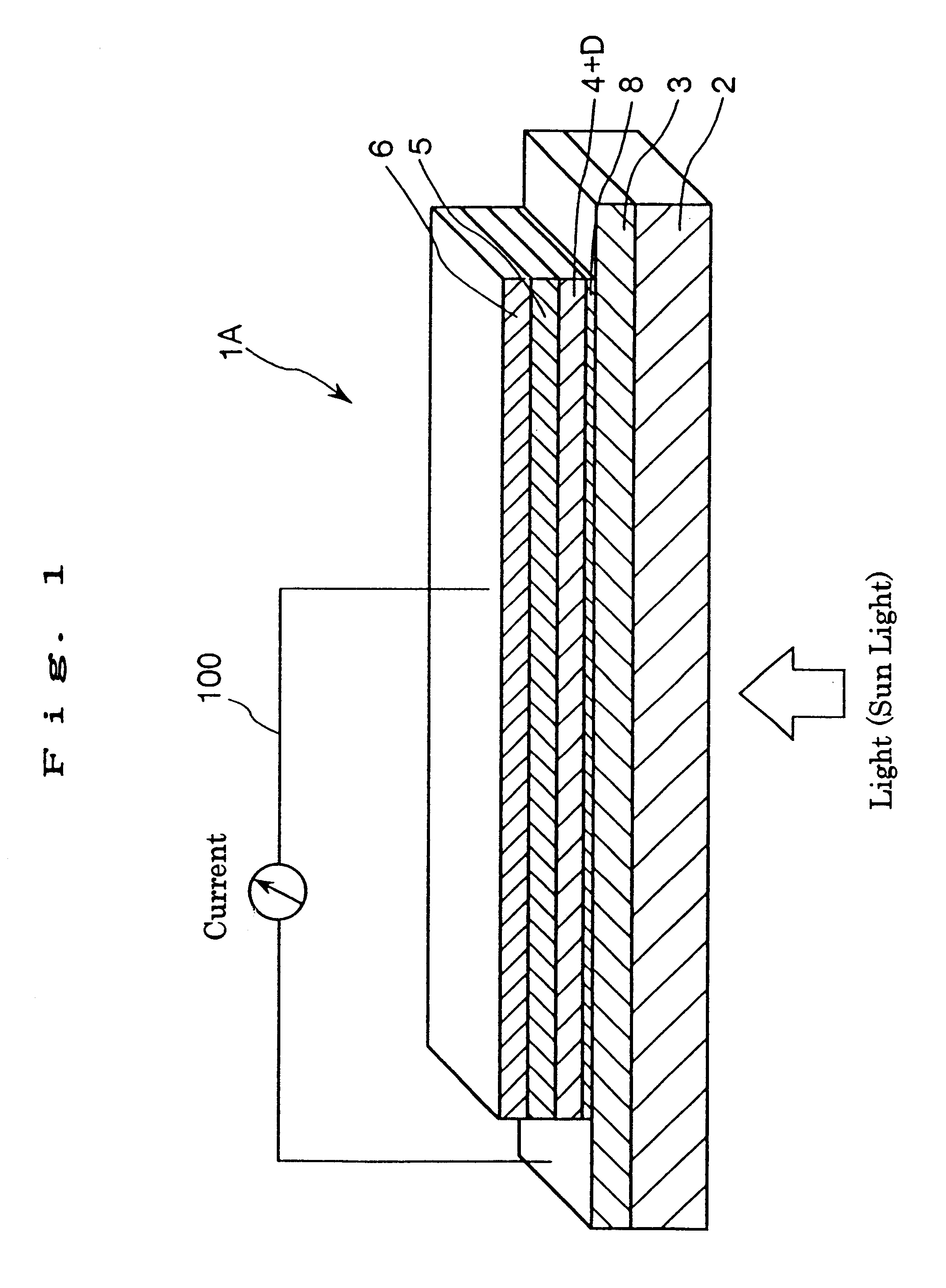

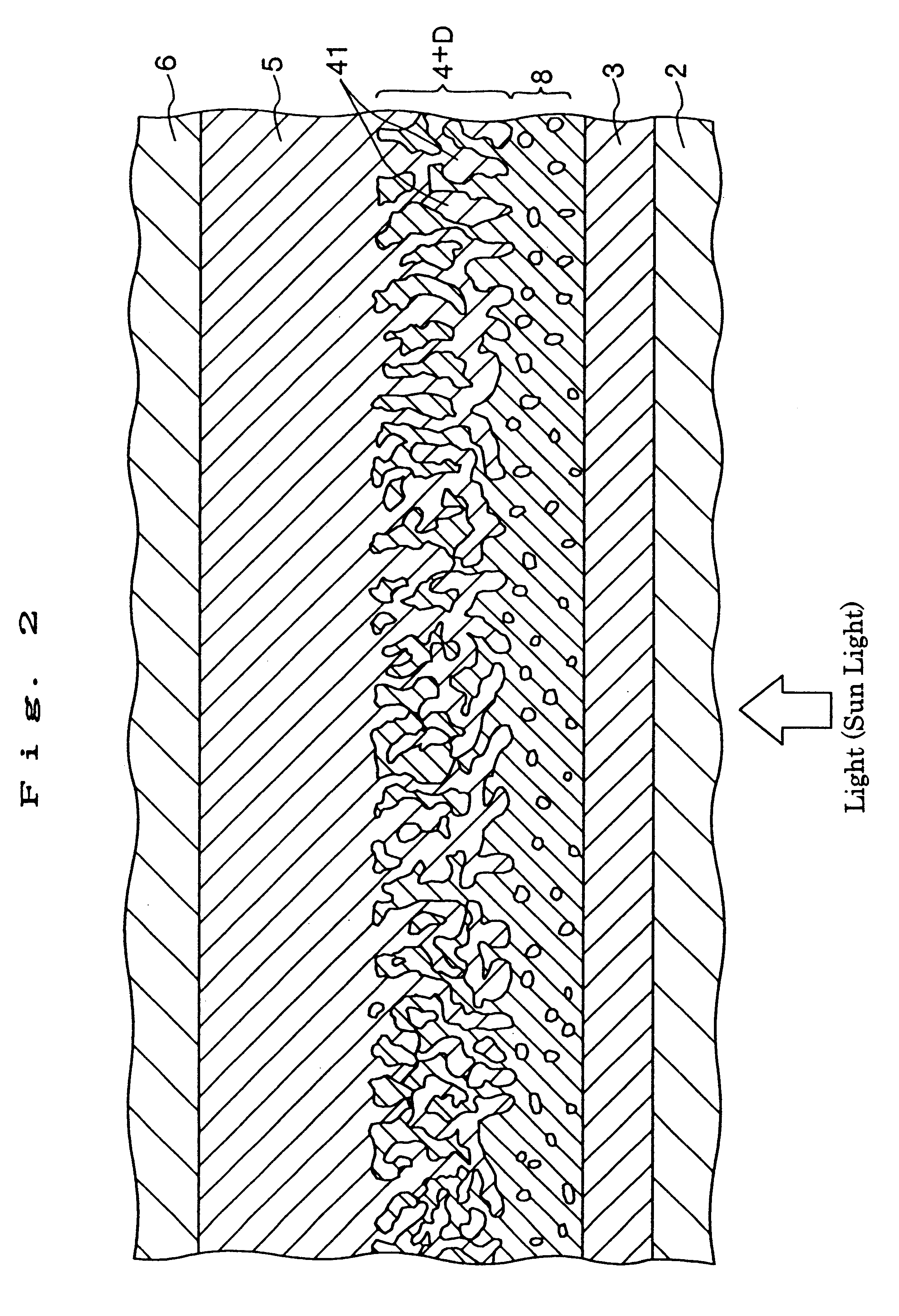

A solar cell including a first electrode, a second electrode arranged opposite to the first electrode, an electron transport layer arranged between the first electrode and the second electrode, a dye layer D which is in contact with the electron transport layer, a hole transport layer arranged between the electron transport layer and the second electrode and being in contact with the dye layer D, and a barrier layer, and these elements are provided on a substrate. The barrier layer prevents or suppresses short-circuit between the first electrode and the hole transport layer. The porosity of the barrier layer is made smaller than that of the electron transport layer. The barrier layer is formed into a film-like shape and arranged between the first electrode and the electron transport layer. The solar cell can accomplish excellent photoelectric conversion efficiency by the provision of such a barrier layer.

Owner:SEIKO EPSON CORP

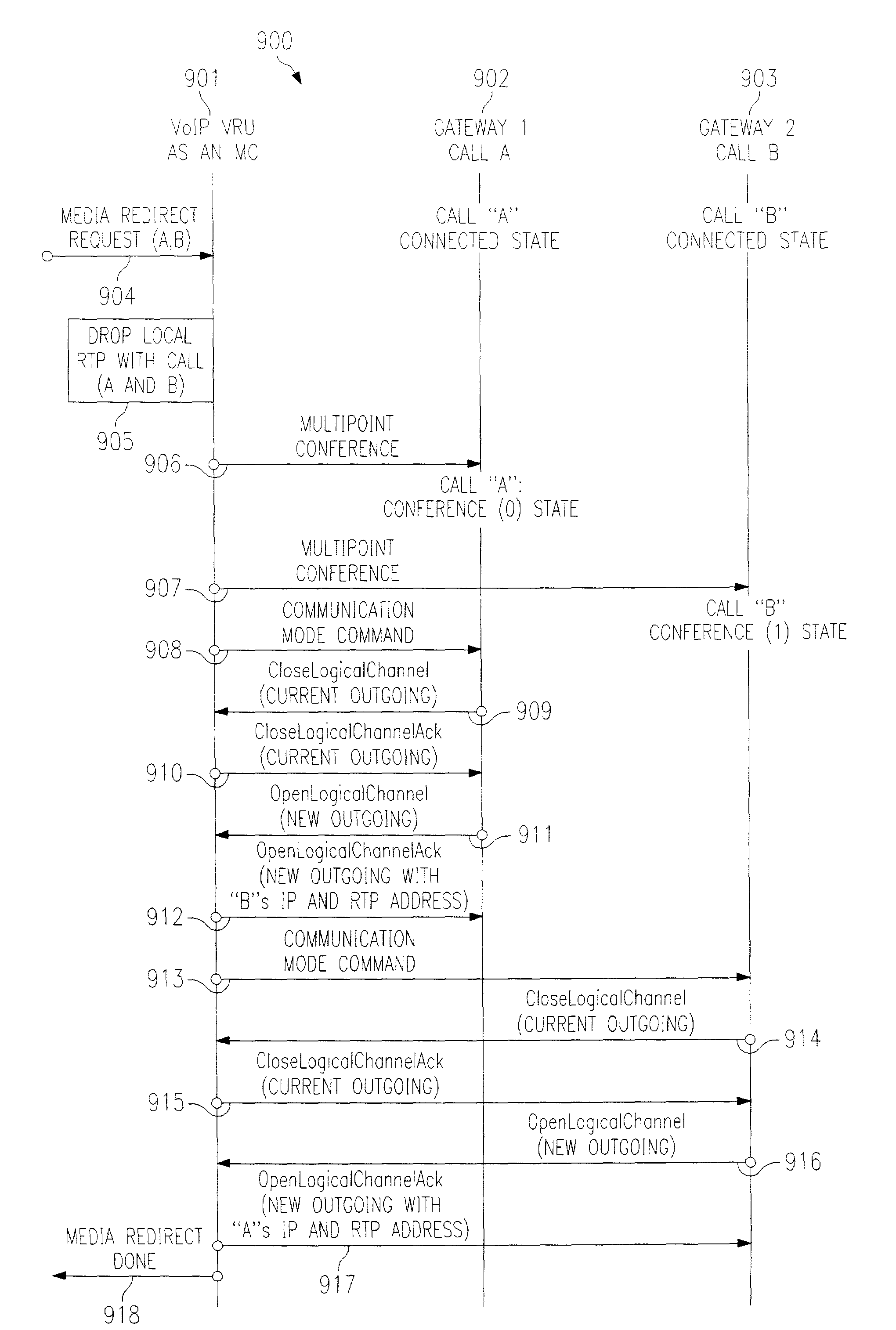

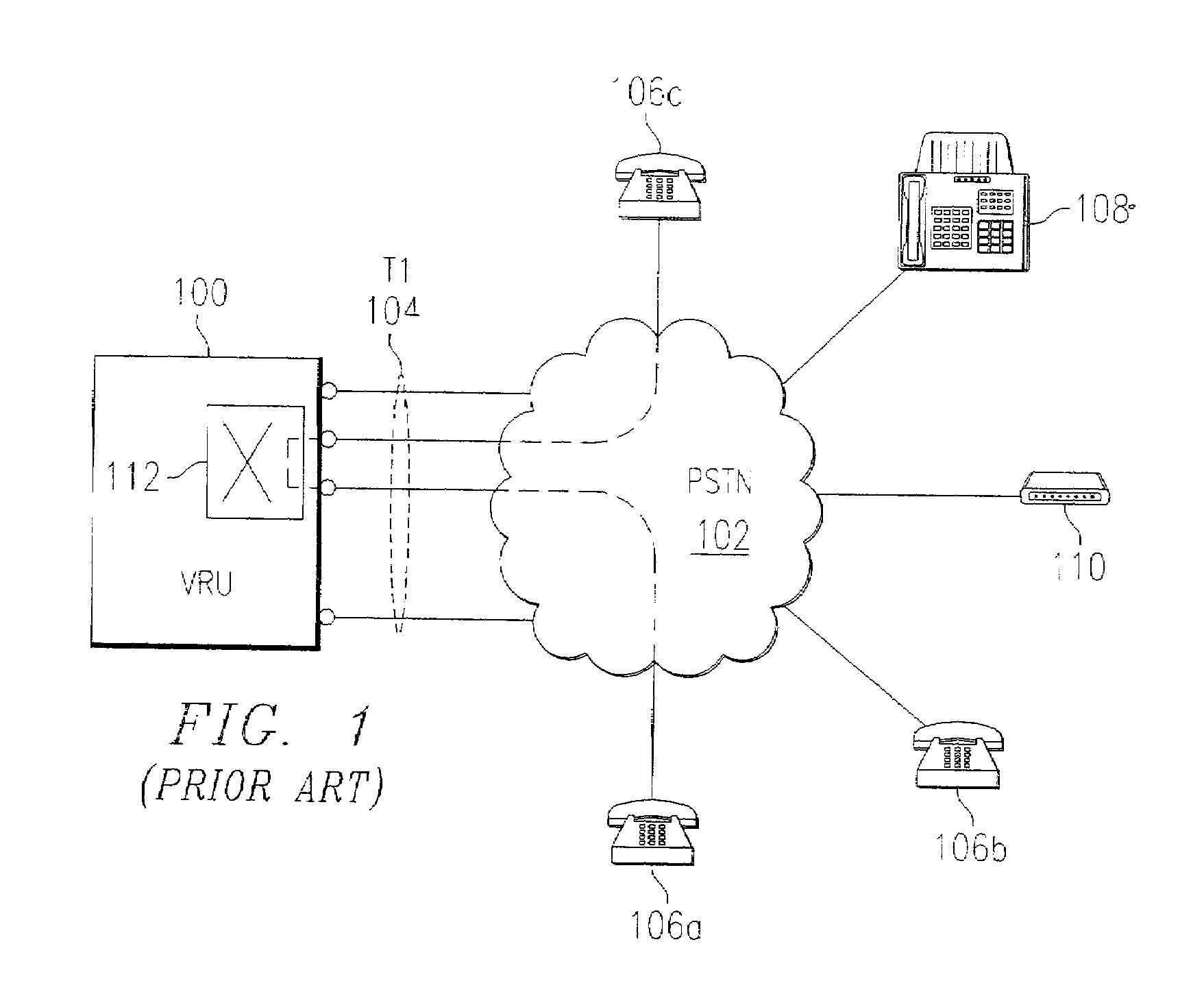

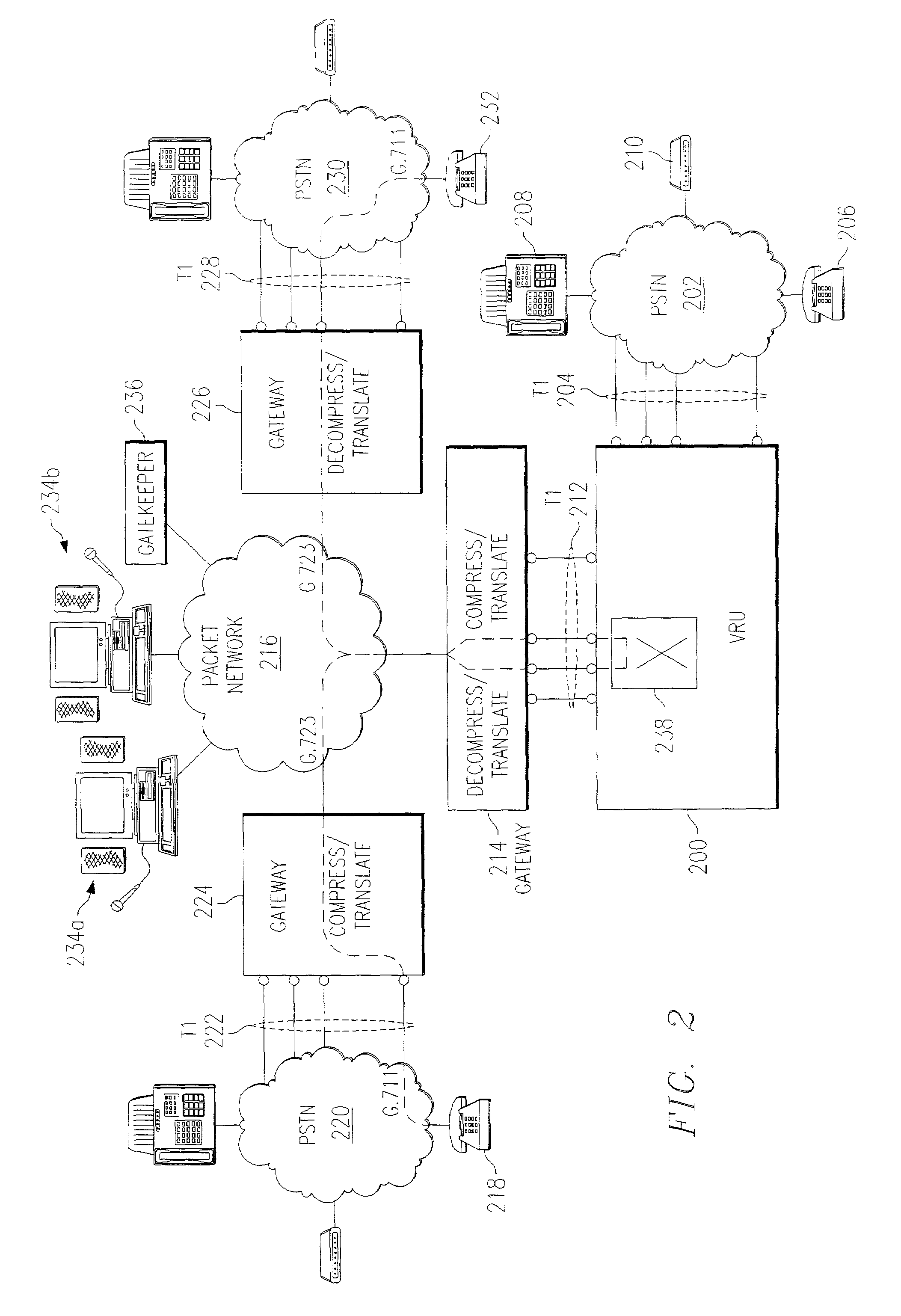

Cooperative media applications using packet network media redirection

InactiveUS7035252B2Good serviceAvoid conversionMultiplex system selection arrangementsSpecial service for subscribersNetworking protocolPacket generator

Owner:INTERVOICE PARTNERSHIP

Stent device and method

Owner:BOSTON SCI SCIMED INC

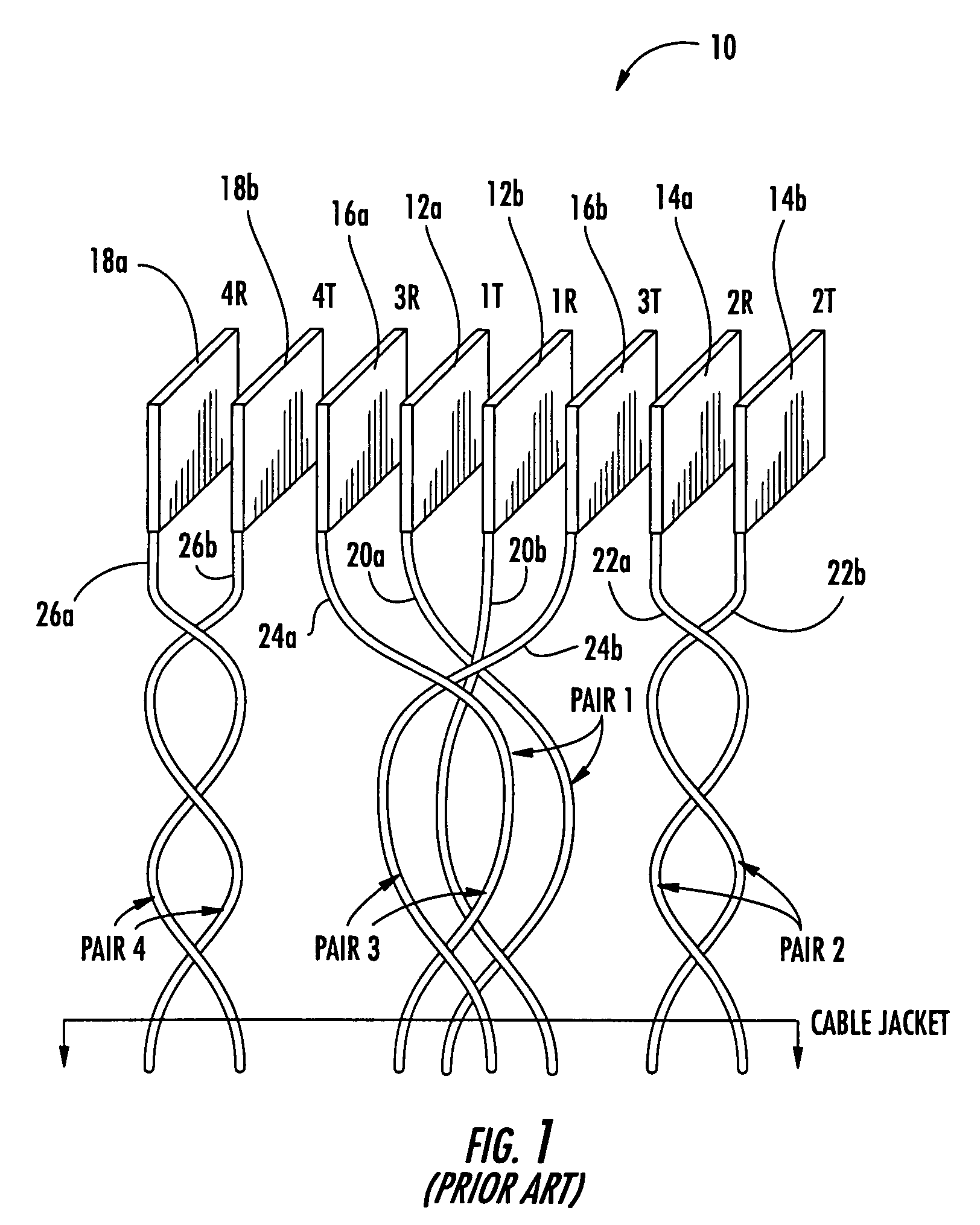

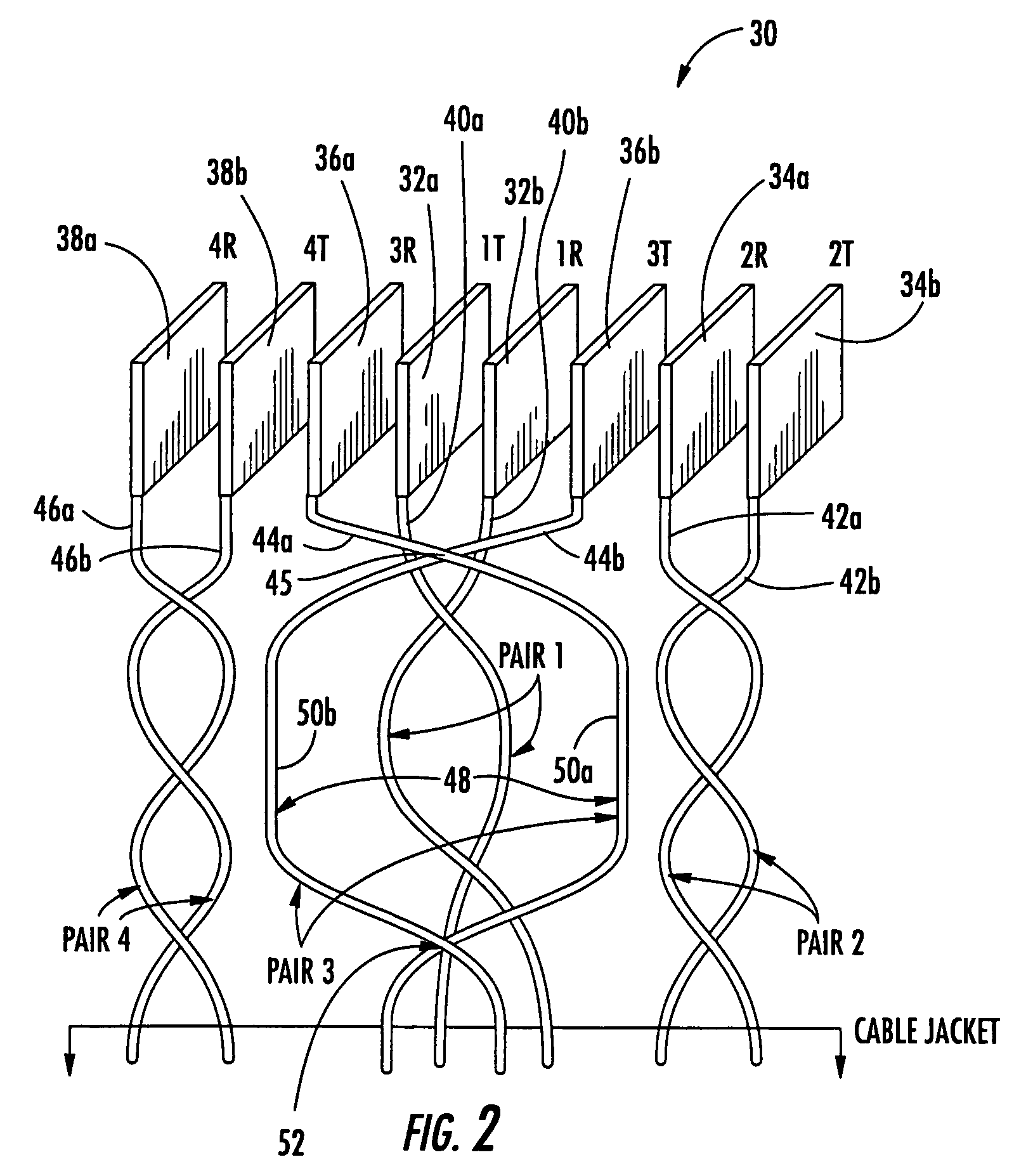

Communication plug with balanced wiring to reduce differential to common mode crosstalk

ActiveUS7220149B2Trend downImprove alien NEXT performanceCoupling device detailsTwo-part coupling devicesTelecommunicationsElectrical conductor

Owner:COMMSCOPE INC

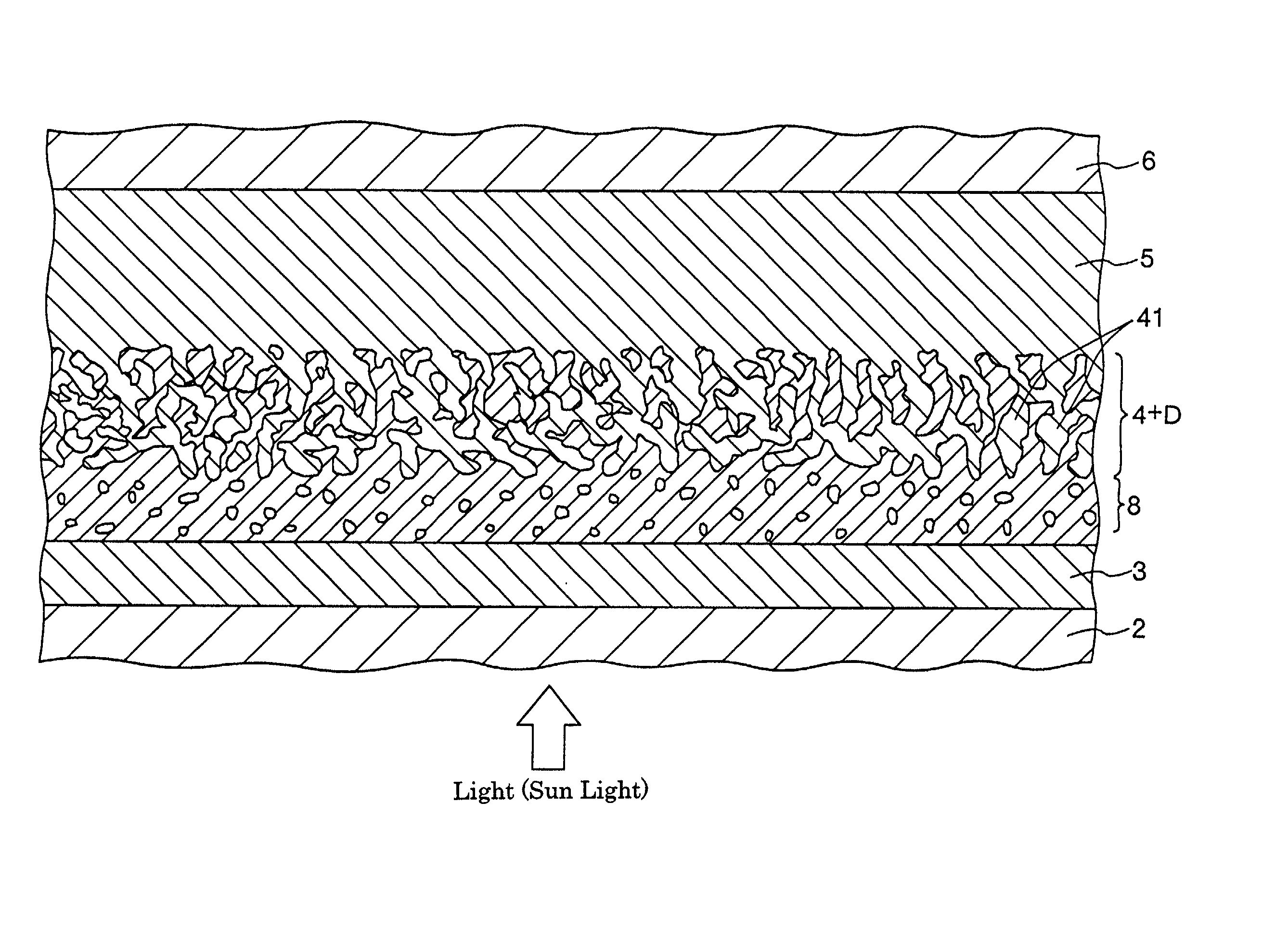

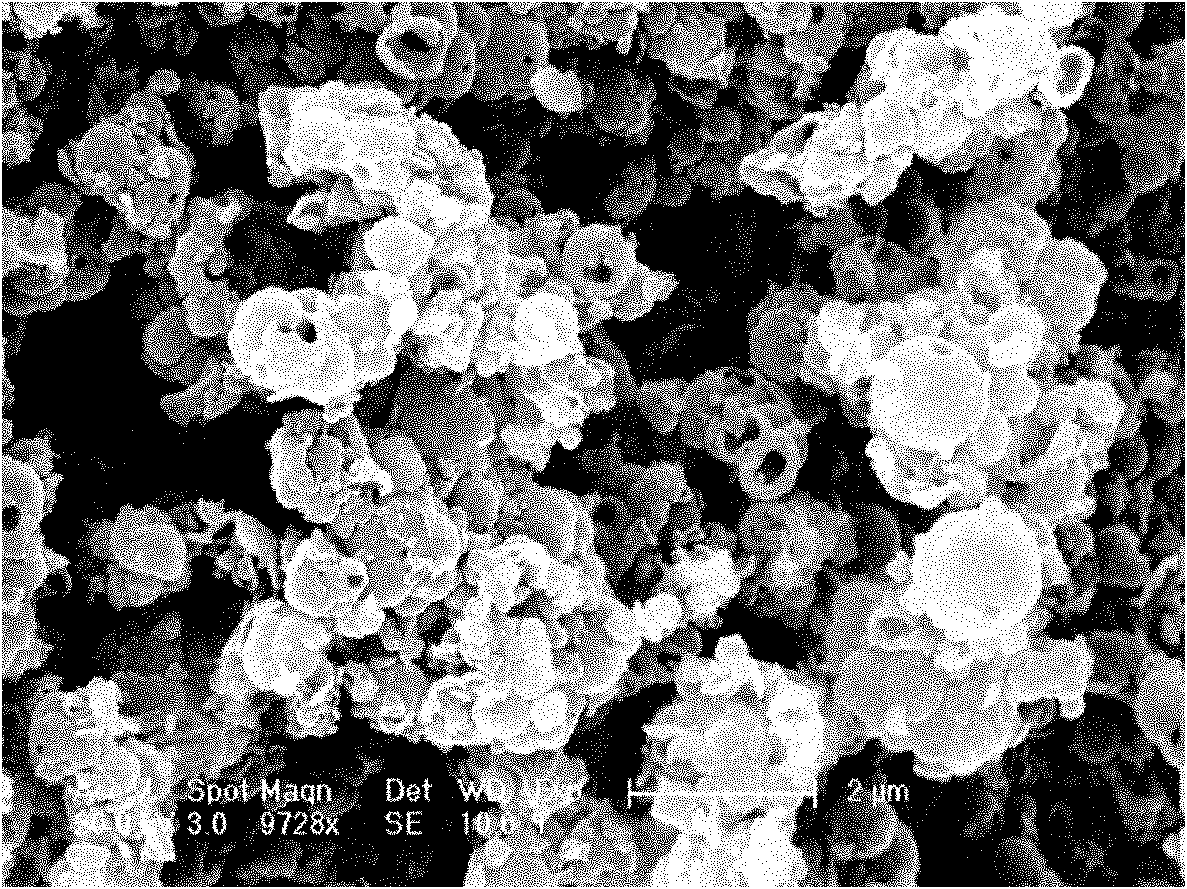

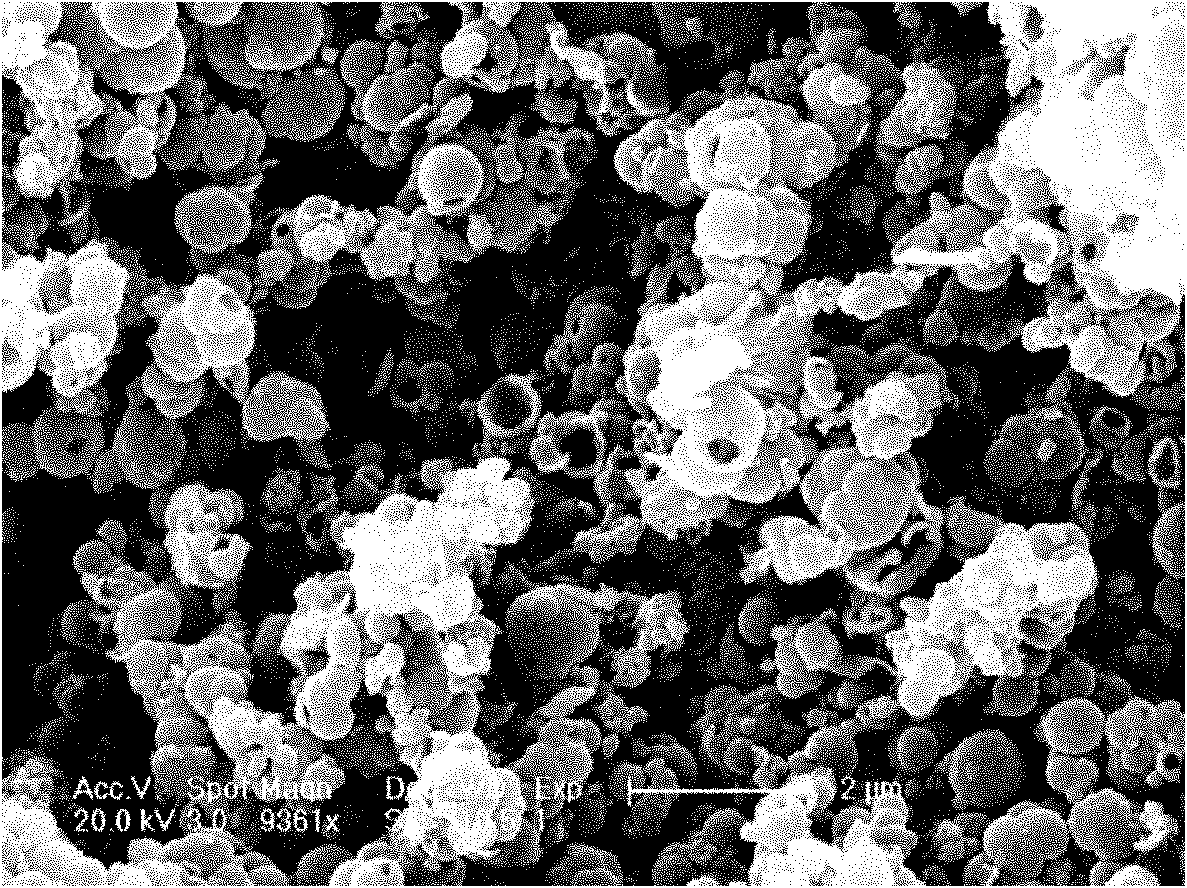

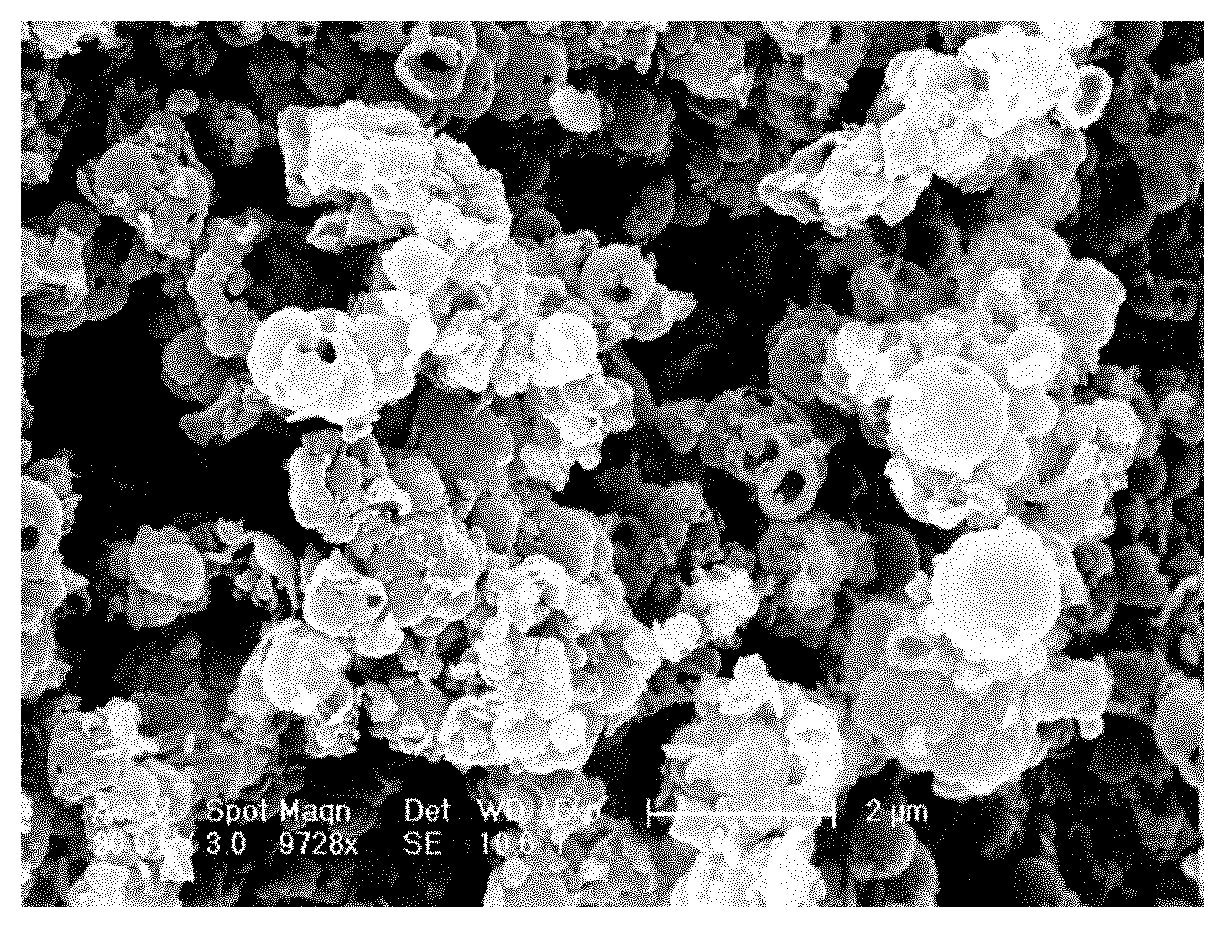

Photoelectric conversion element

InactiveUS20020108649A1Improve photoelectric conversion efficiencyPrevent and suppressLight-sensitive devicesSolid-state devicesPorosityTransport layer

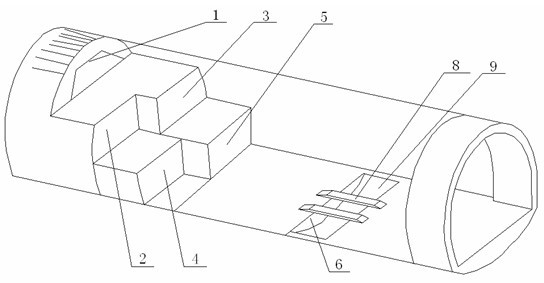

A solid type dye-sensitized photoelectric conversion element which is excellent in photoelectric conversion efficiency and which can be manufactured at a low cost is disclosed. The photoelectric conversion element can be applied to a so-called wet type solar cell which does not use any electrolyte. The solar cell comprises a first electrode 3, a second electrode 6 arranged opposite to the first electrode 3, an electron transport layer 4 arranged between the first electrode 3 and the second electrode 6, a dye layer D which is in contact with the electron transport layer 4, a hole transport layer 5 arranged between the electron transport layer 4 and the second electrode 6 and being in contact with the dye layer D, and a barrier layer 8, and these elements are provided on a substrate 2. The barrier layer 8 constitutes short-circuit preventing or suppressing means for preventing or suppressing short-circuit between the first electrode 3 and the hole transport layer 5. The porosity of the barrier layer is made smaller than that of the electron transport layer 4. The barrier layer is formed into a film-like shape and arranged between the fist electrode 4 and the electron transport layer 4. The solar cell can accomplish excellent photoelectric conversion efficiency by the provision of such a barrier layer 8.

Owner:SEIKO EPSON CORP

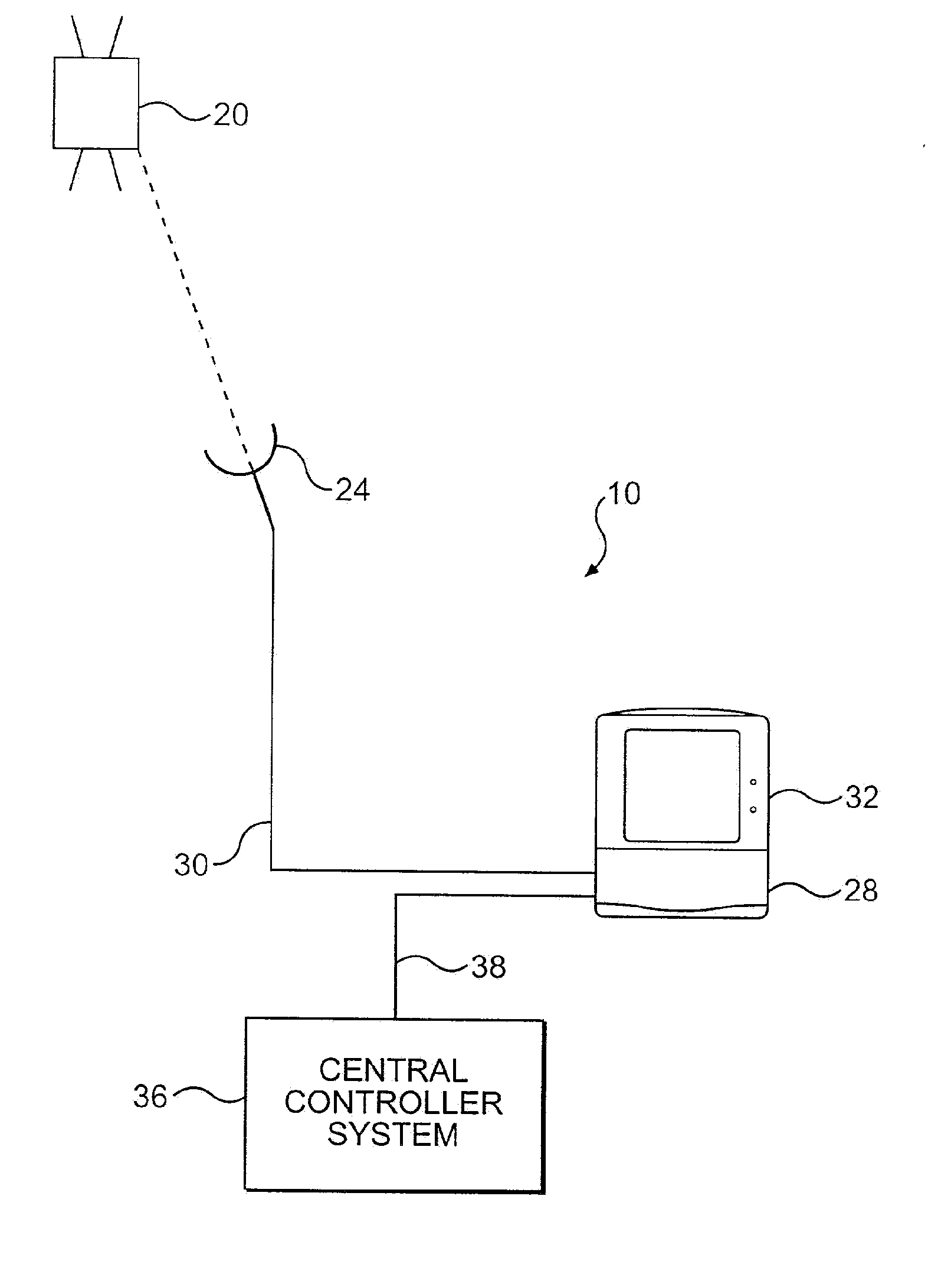

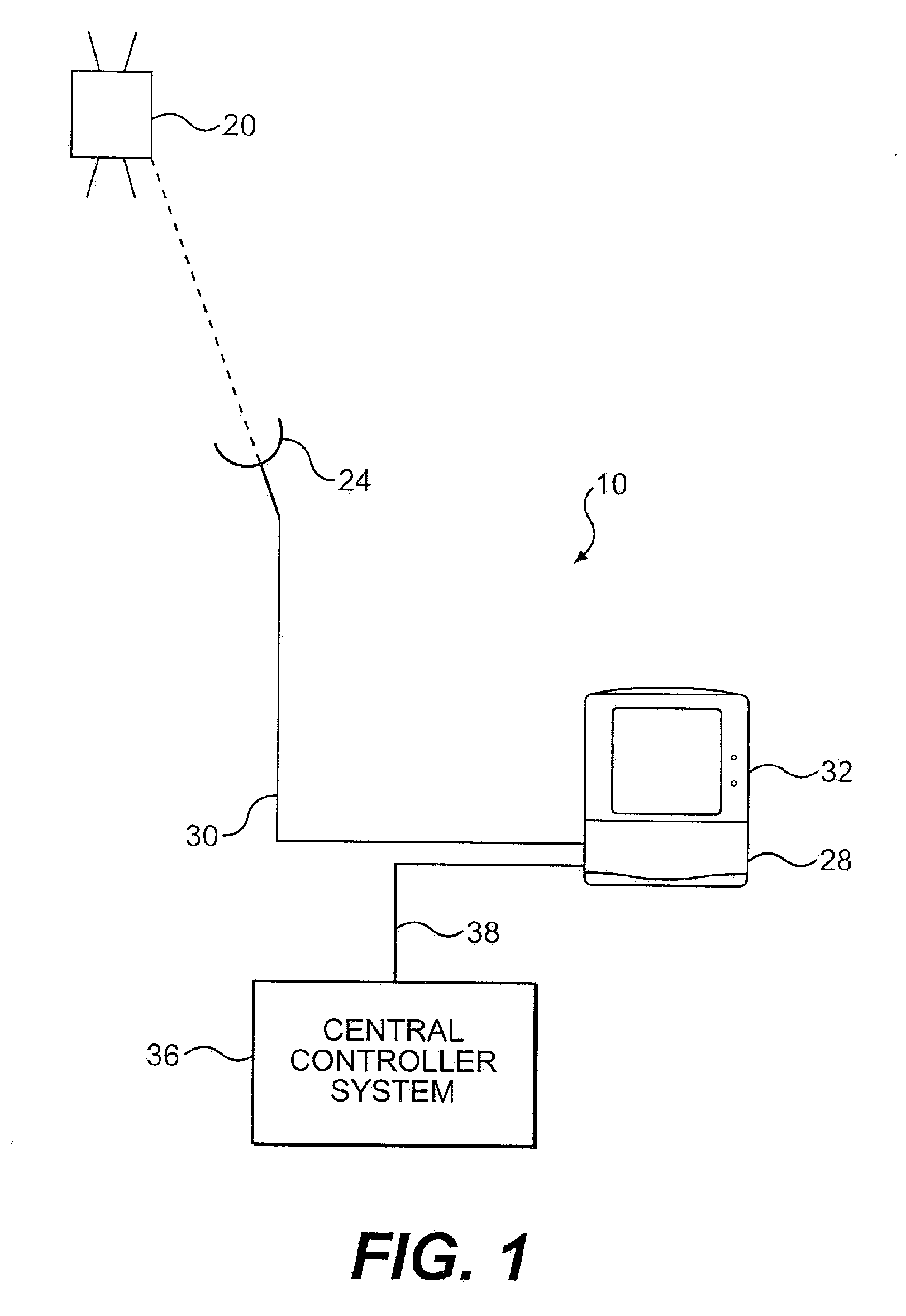

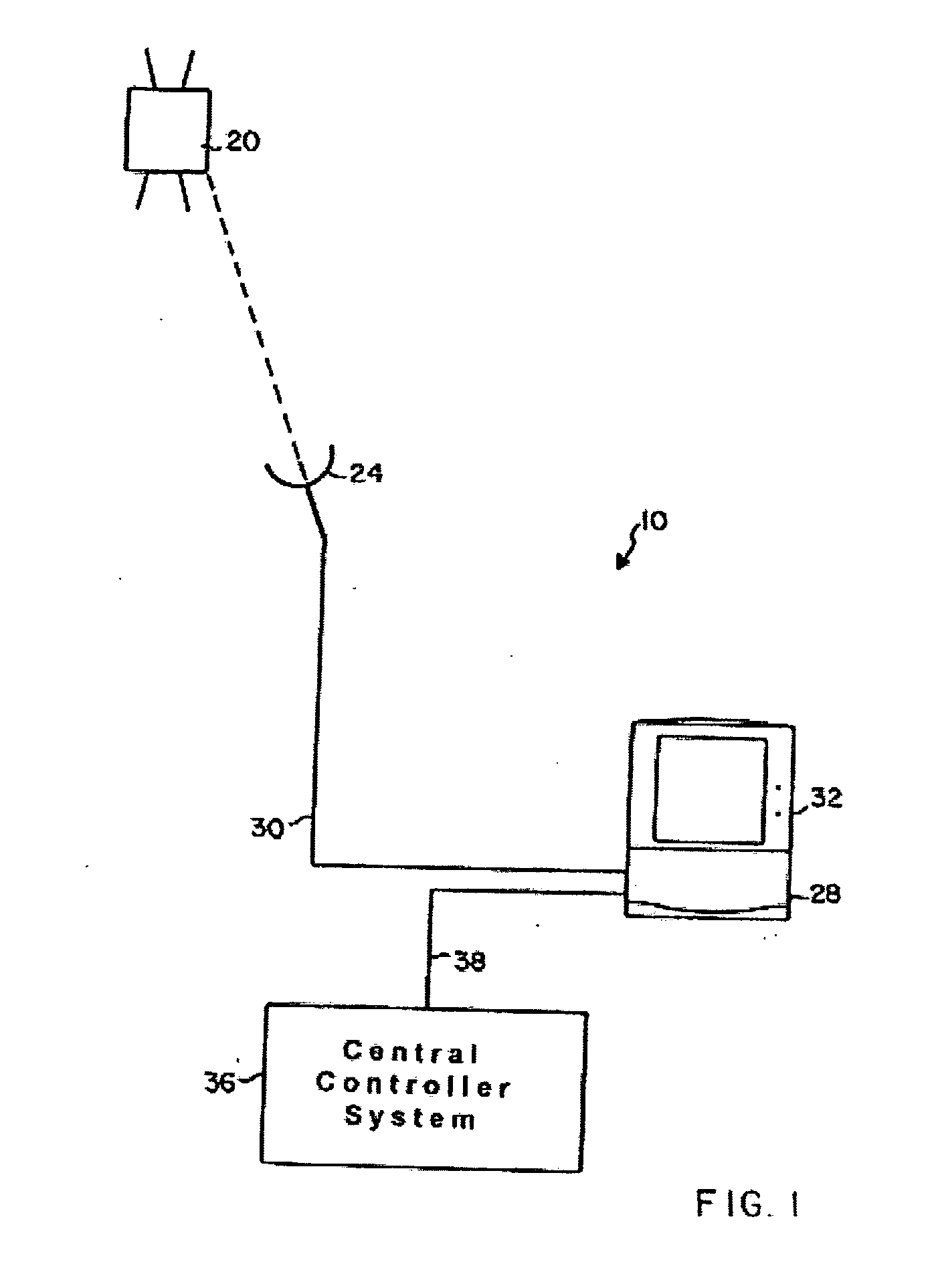

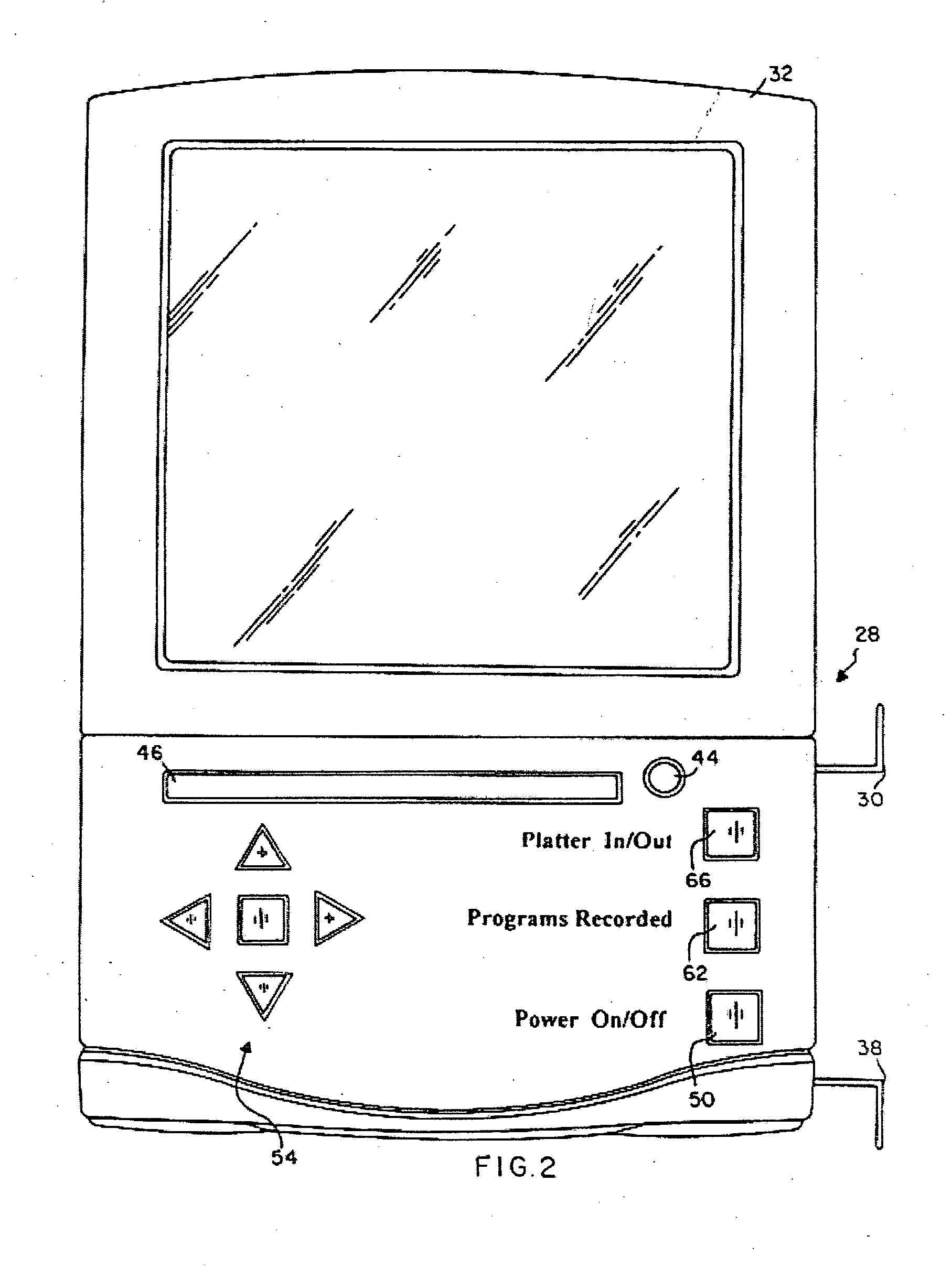

Video distribution system

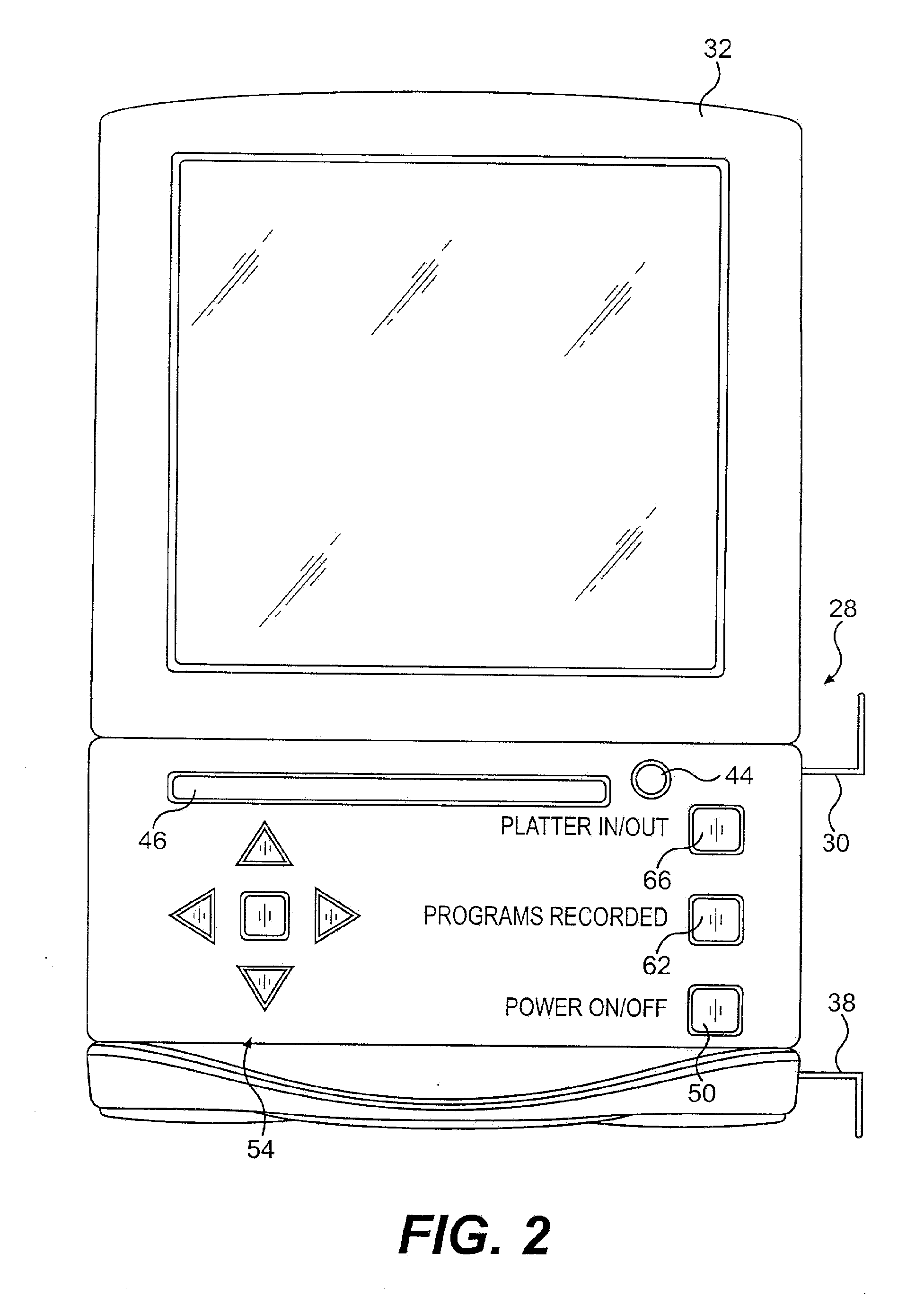

InactiveUS20070234391A1Avoid conversionAvoid duplicationTelevision system detailsRecord information storageDistribution systemSubject matter

The disclosed subject matter relates to video distribution systems and, more particularly, to a system that blanket transmits video / audio content such as movies (for example, via satellite downlink transmission) to each customer's recording, storage and playback system. Customers may preselect from a list of available movies or other content in advance using an interactive screen selector, and pay for the video / audio content that is actually viewed.

Owner:OCHOA OPTICS

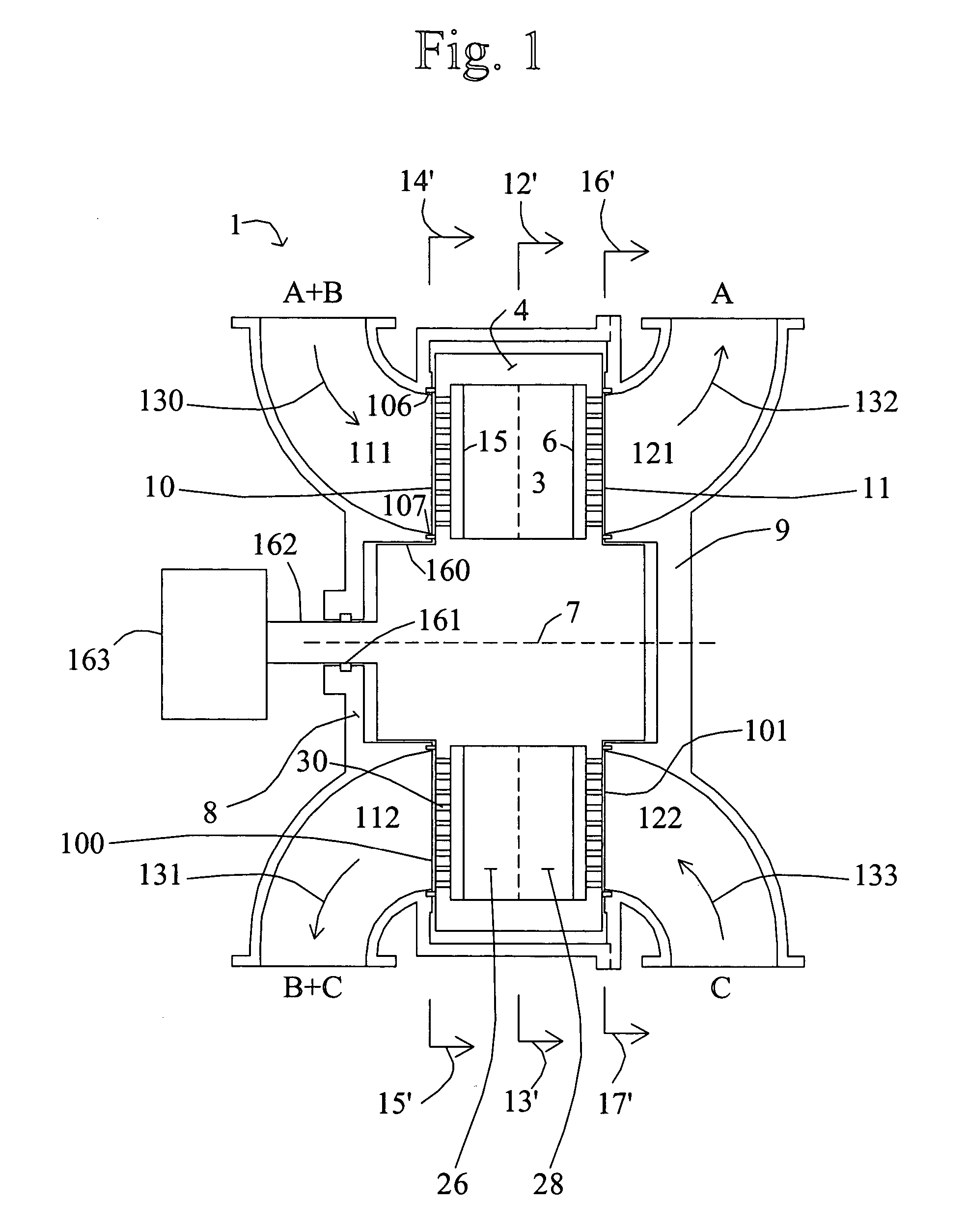

Hydrogen recycle for high temperature fuel cells

InactiveUS20040197612A1Improve efficiencyImprove sustainabilityGas treatmentRegenerative fuel cellsOxygenContamination

High temperature fuel cell electrical generation systems are provided that are adapted to enable selective generation of electrical power, and / or hydrogen fuel, and / or useable heat, allowing flexible operation of the generation system. In such embodiments, the high temperature fuel cell may be either a MCFC or a SOFC. The disclosed systems relate to high temperature fuel cells exploiting gas separation devices in which a first gas mixture is to be separated so that a first product of the separation is enriched in a first component, while a second component is mixed with a displacement purge stream to form a second gas mixture, with provision to prevent cross contamination of purge gas components into the first product stream. The process may be applied to hydrogen (component A) enrichment from syngas mixtures such as fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere or for recycle to the fuel cell cathode in the case of molten carbonate fuel cells, by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:QUSIR TECH

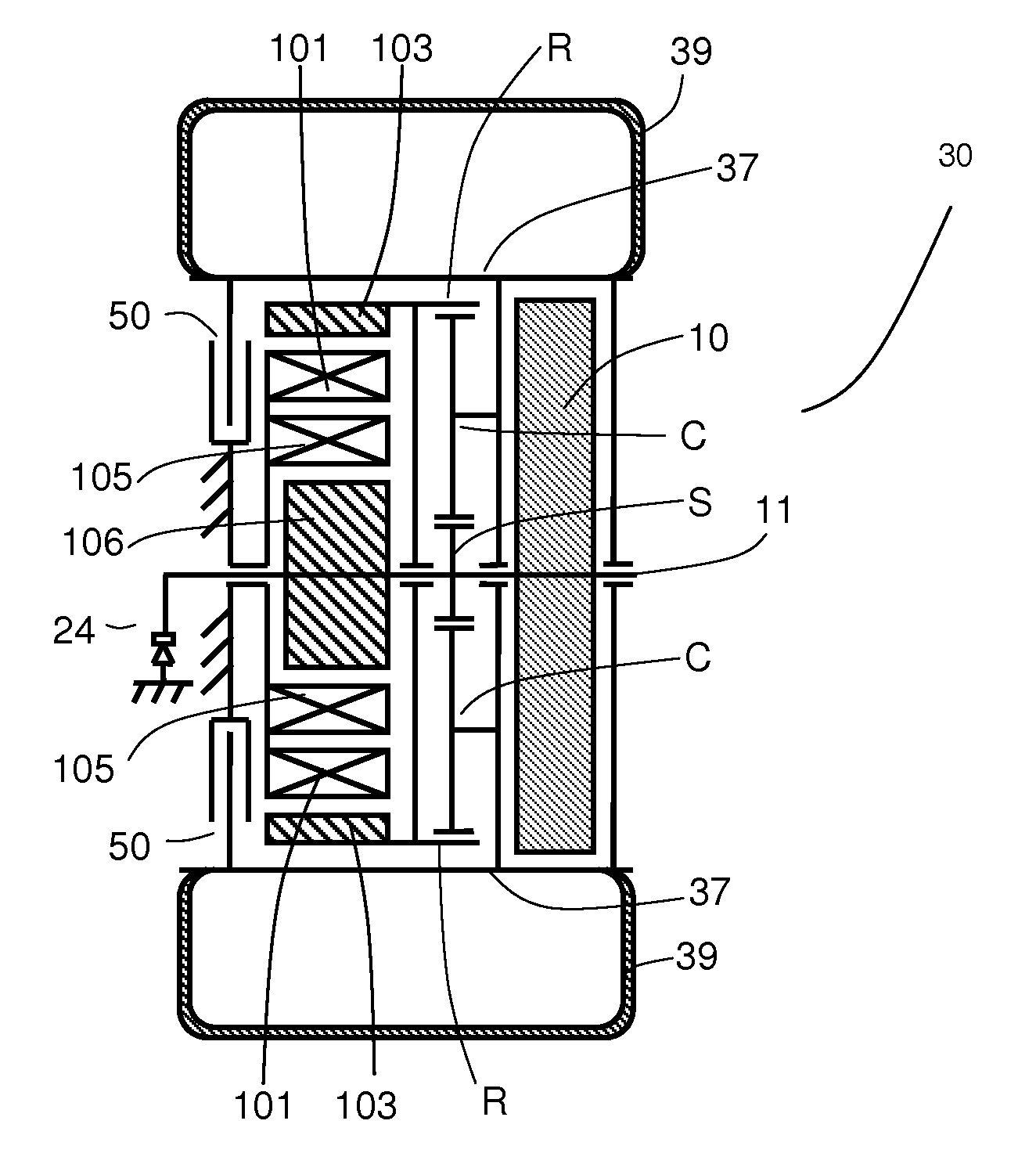

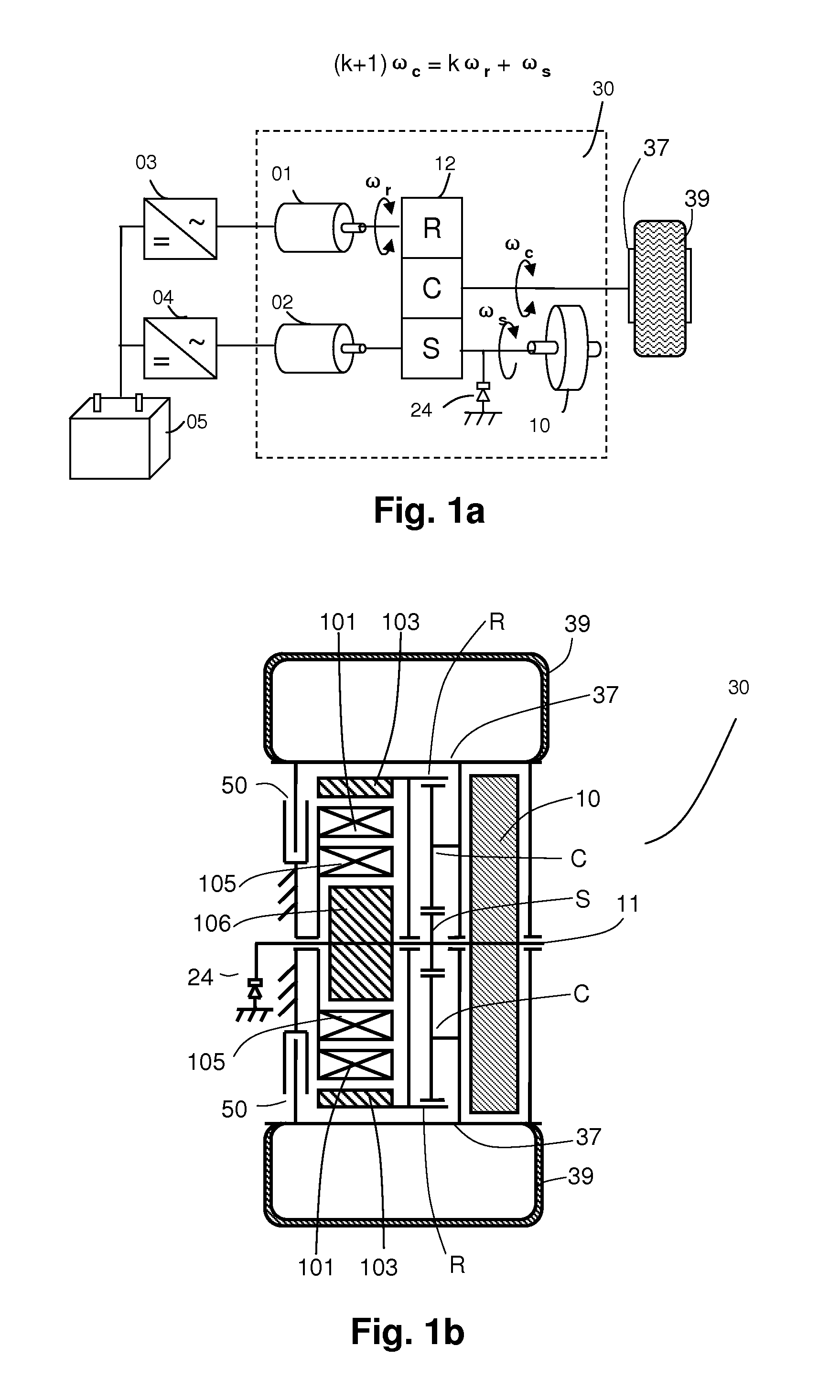

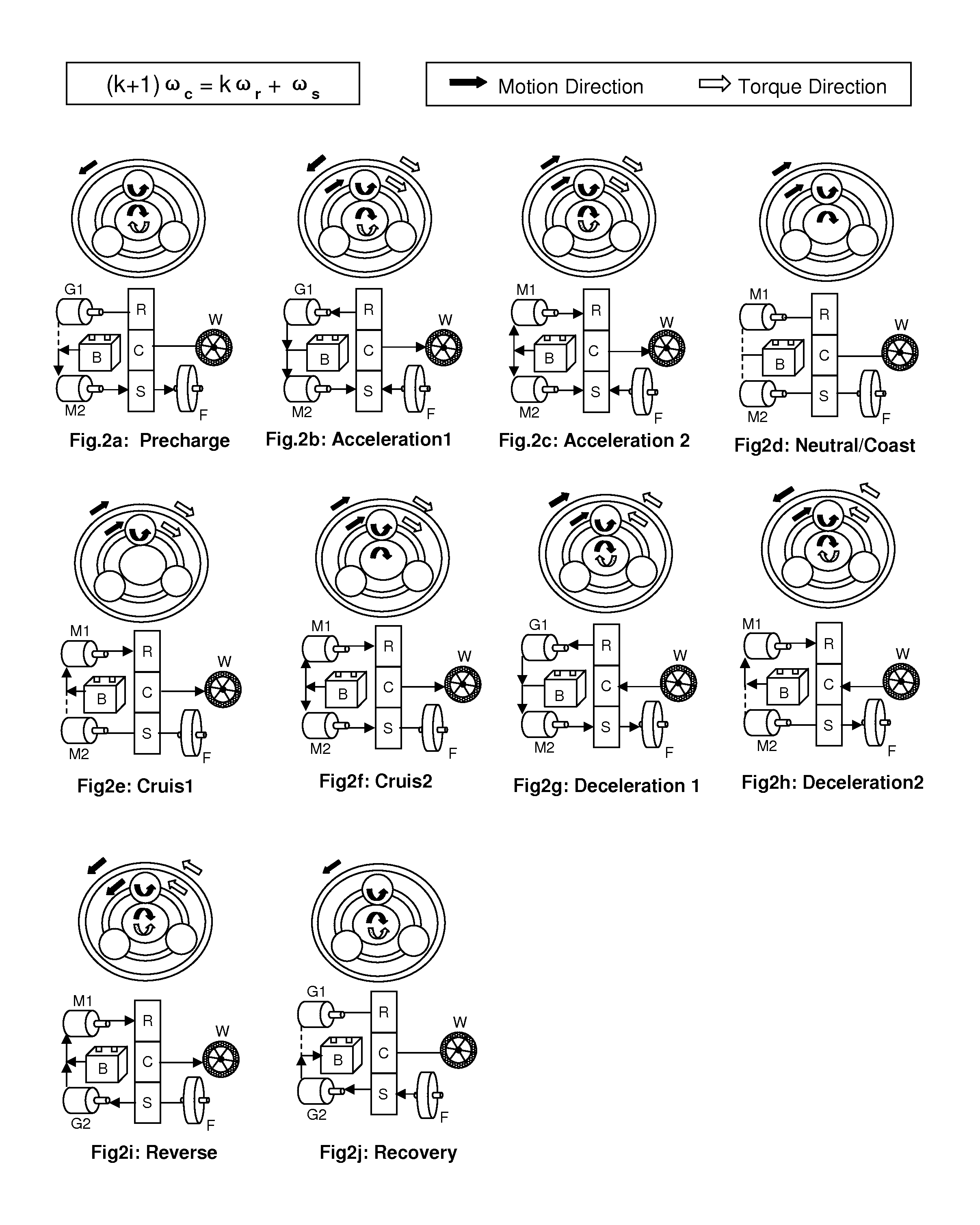

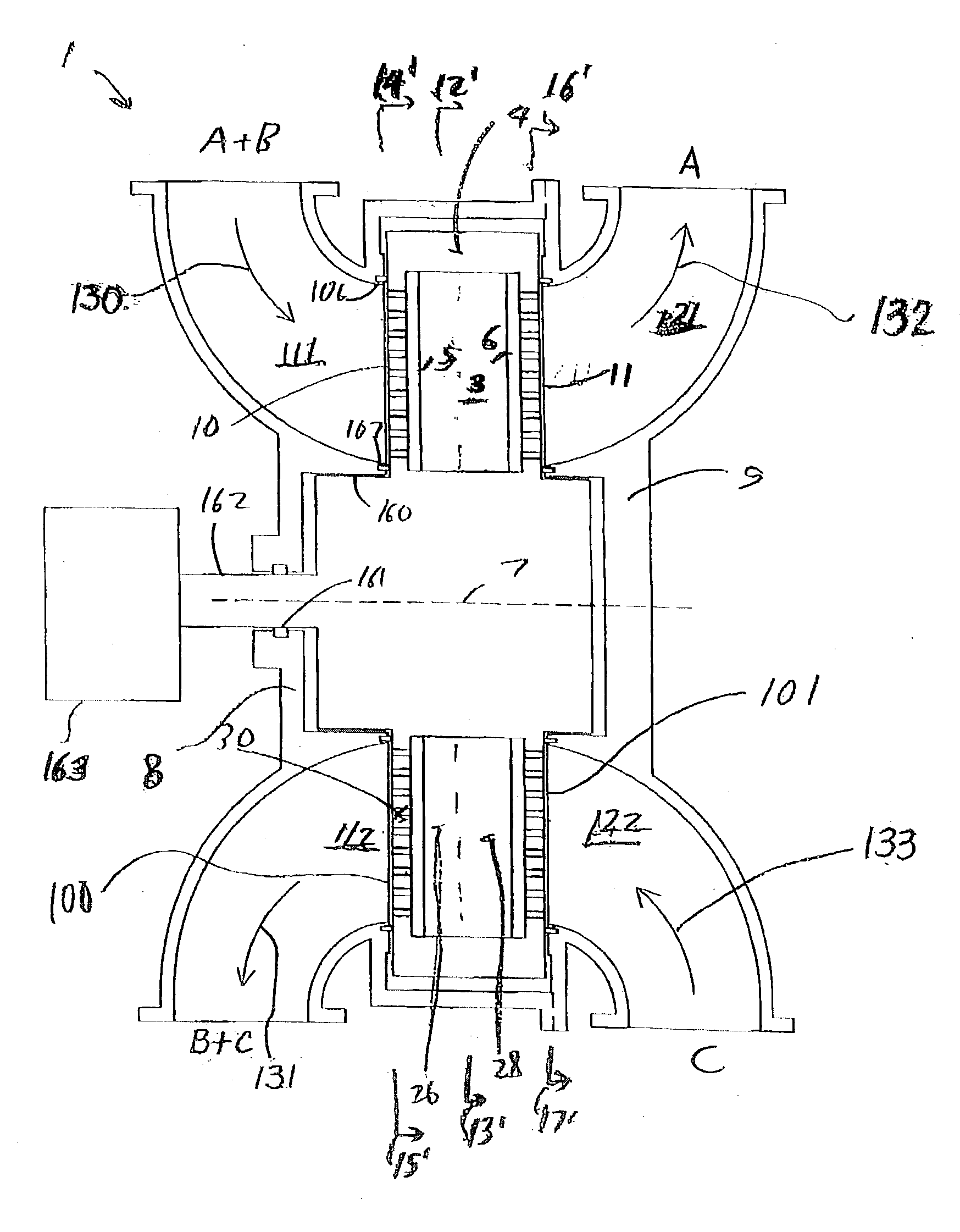

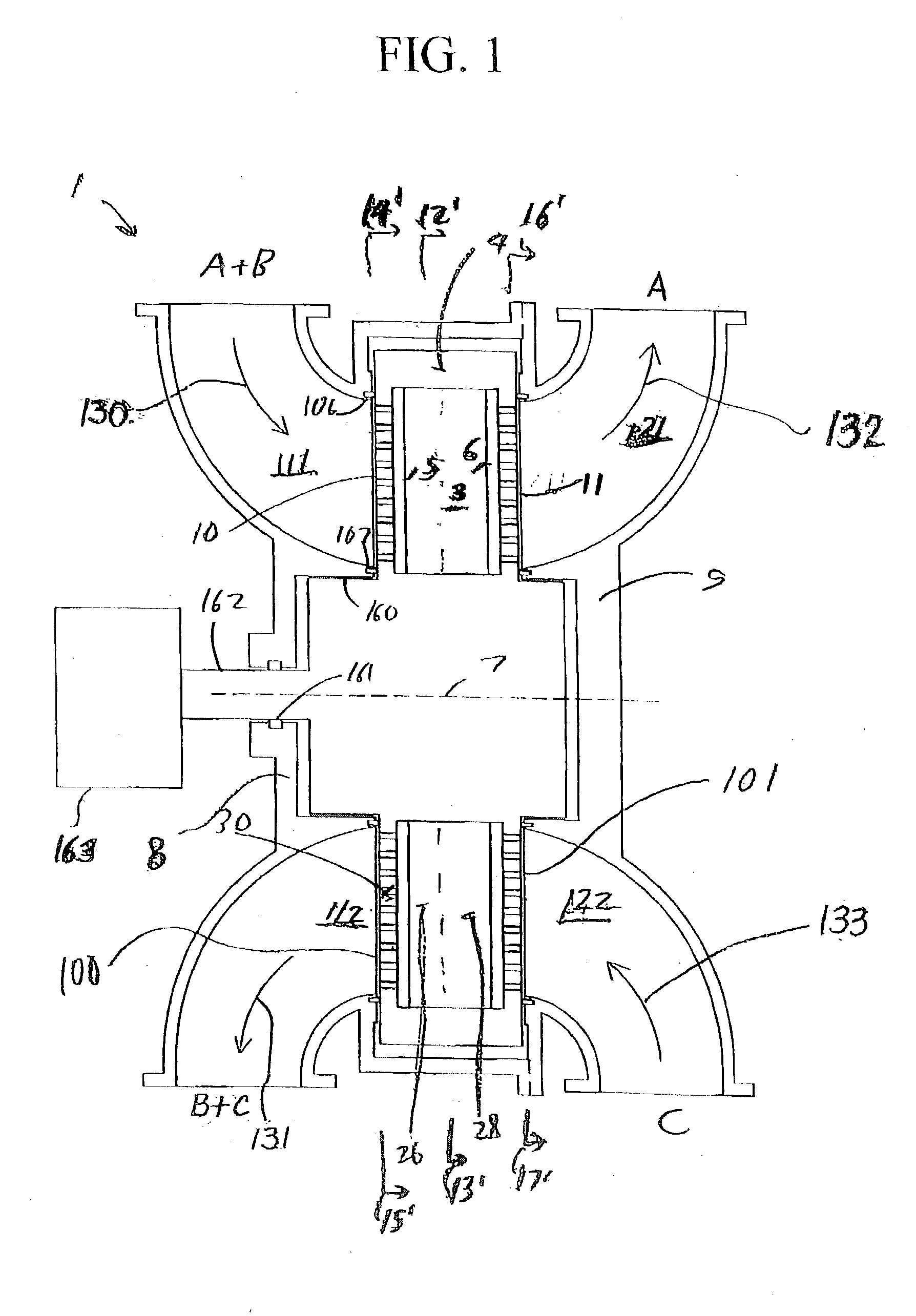

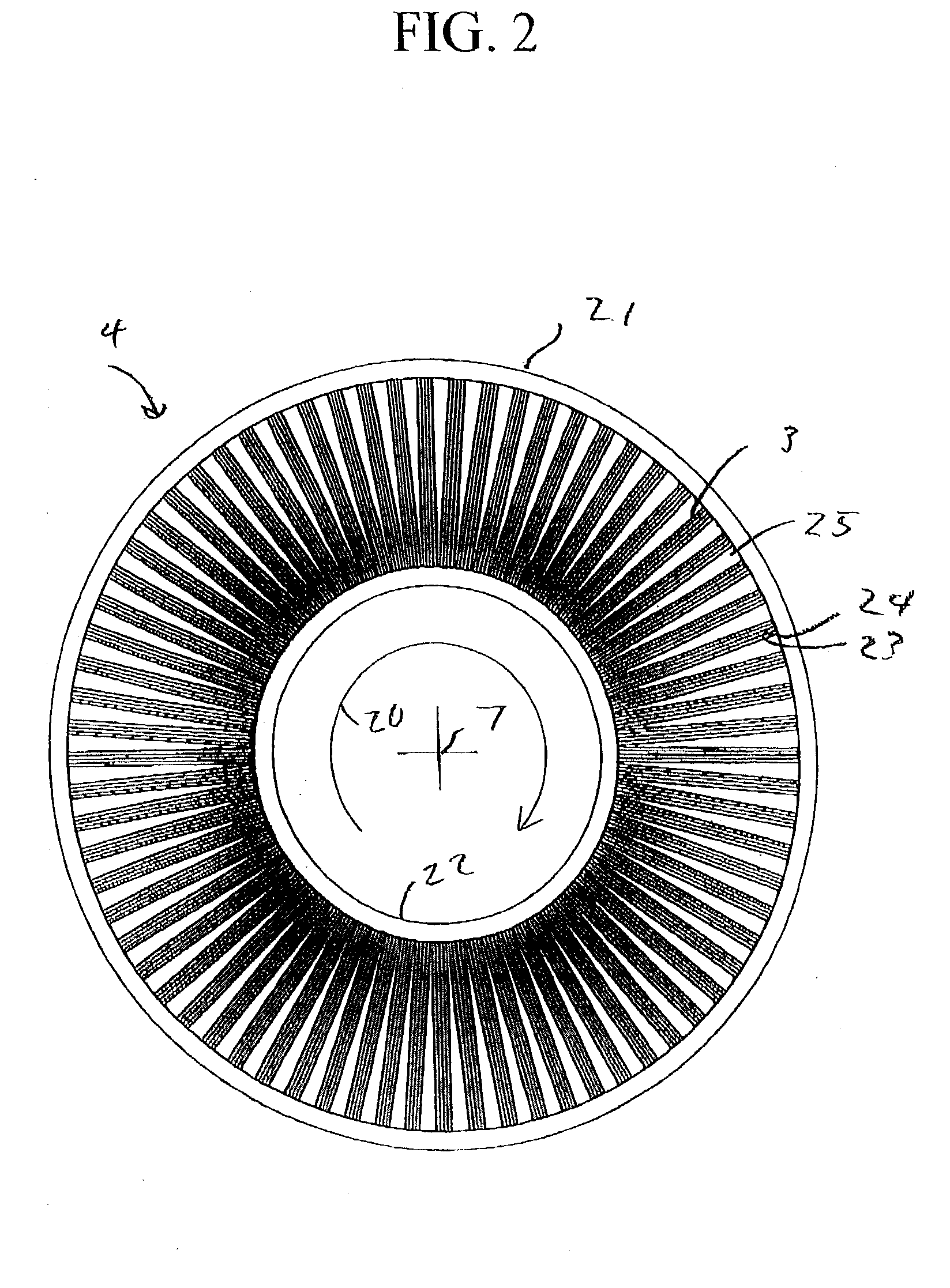

Wheel hub flywheel-motor kinetic hybrid system and method

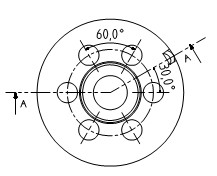

InactiveUS20120161497A1Emission reductionReduce energy lossPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsGear wheelEngineering

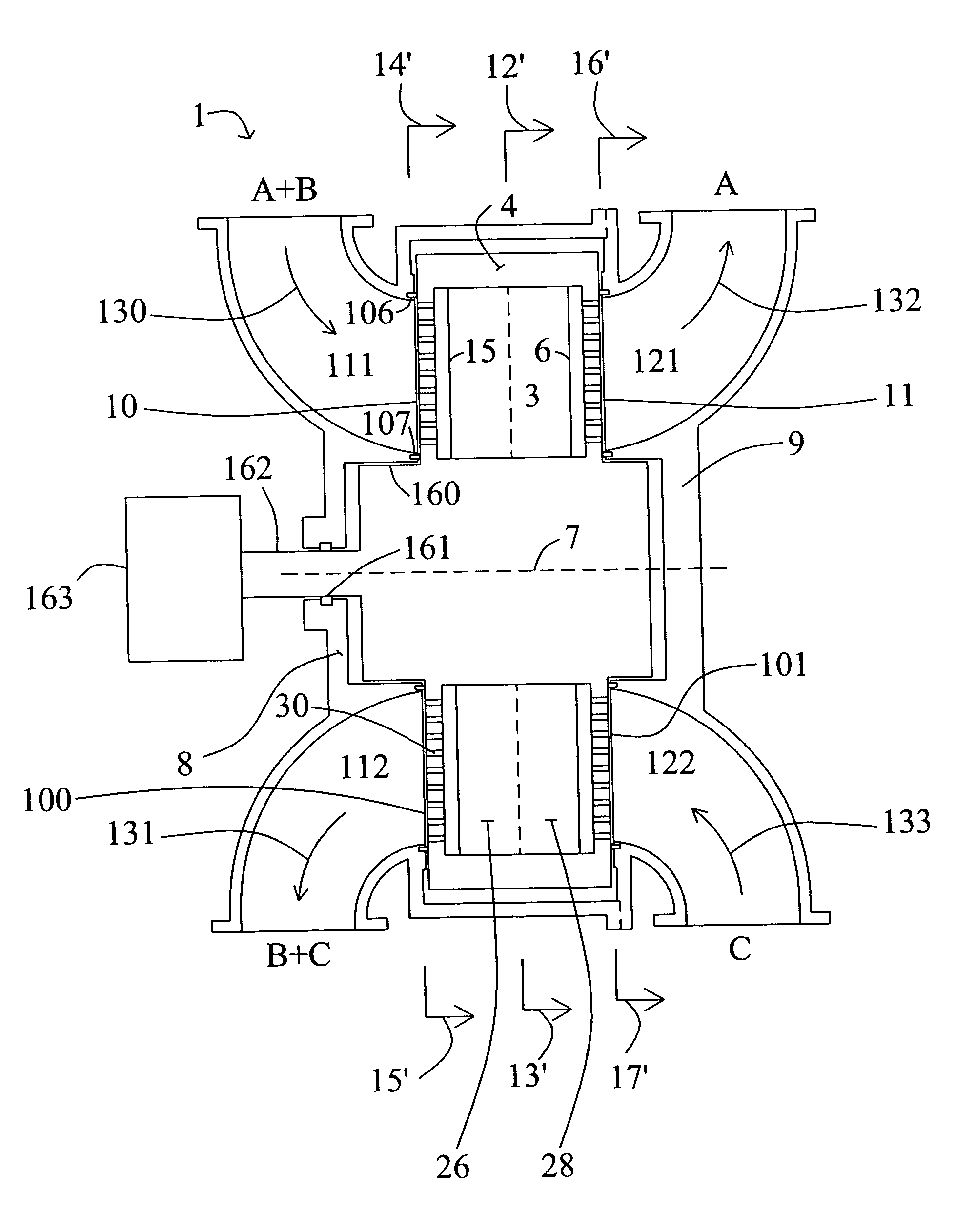

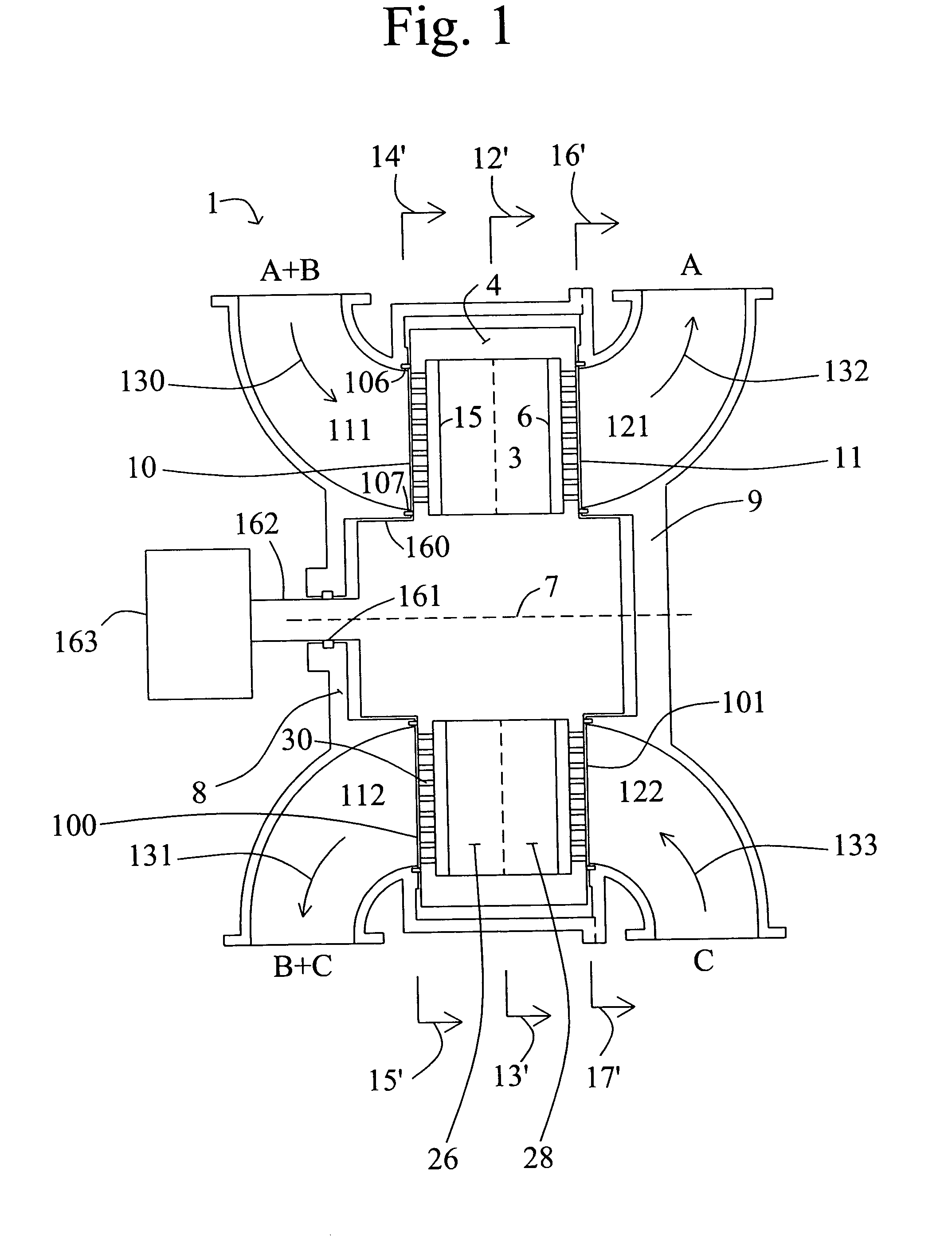

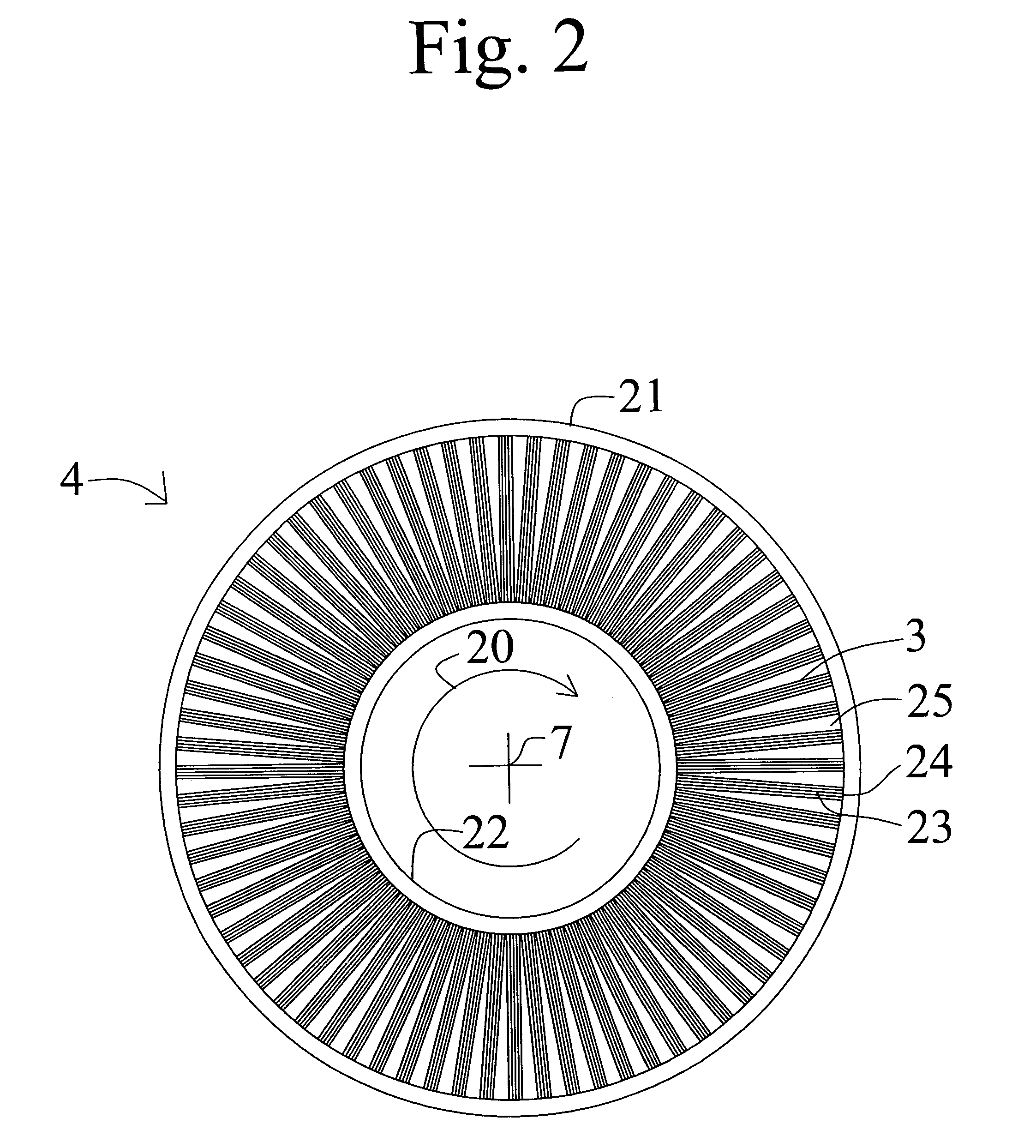

System and method for the combination of a flywheel and motor / generator inside a wheel hub for hybrid vehicle propulsion. The flywheel and motor / generator are connected by a planetary gear system, in which a first port is connected to the flywheel, a second port is connected to the wheel hub, and a third port is connected to a motor / generator. An additional motor / generator may be used at one of the first port and second port. The system may be used in an electric-kinetic hybrid mode, or in a fuel-kinetic hybrid mode, when used in a vehicle having an internal combustion engine as the prime mover. Efficiency of energy storage and release is significantly improved in comparison to prior art.

Owner:HE JING +1

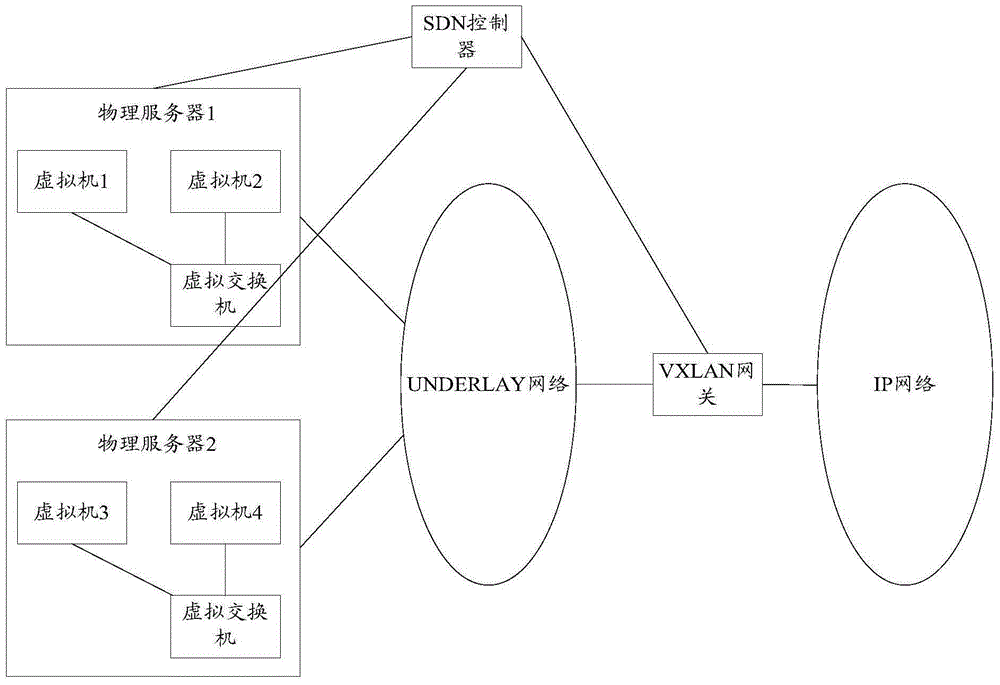

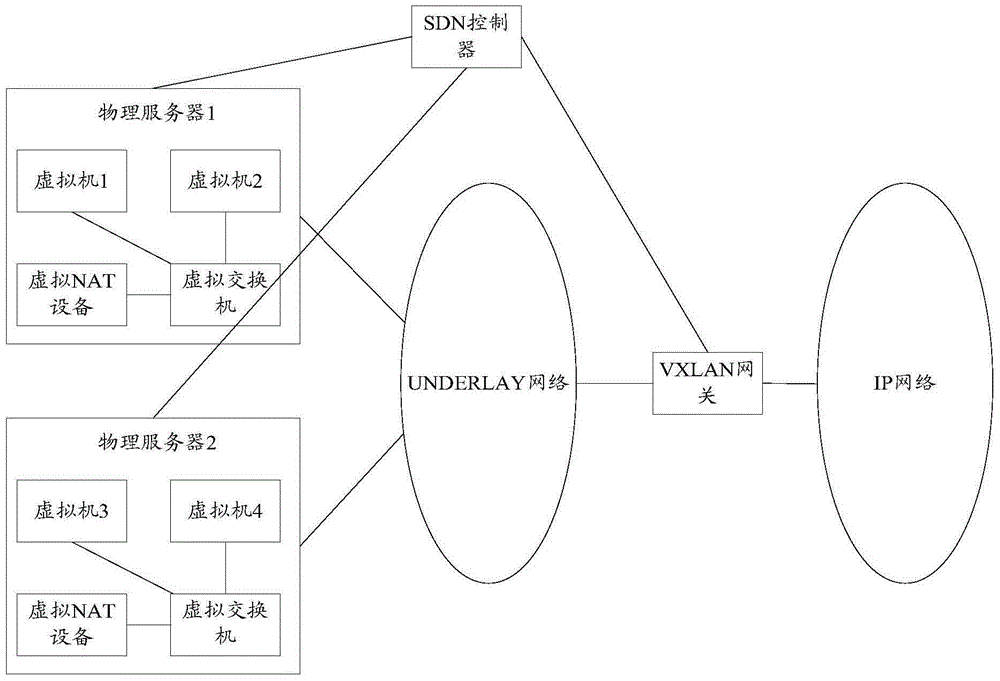

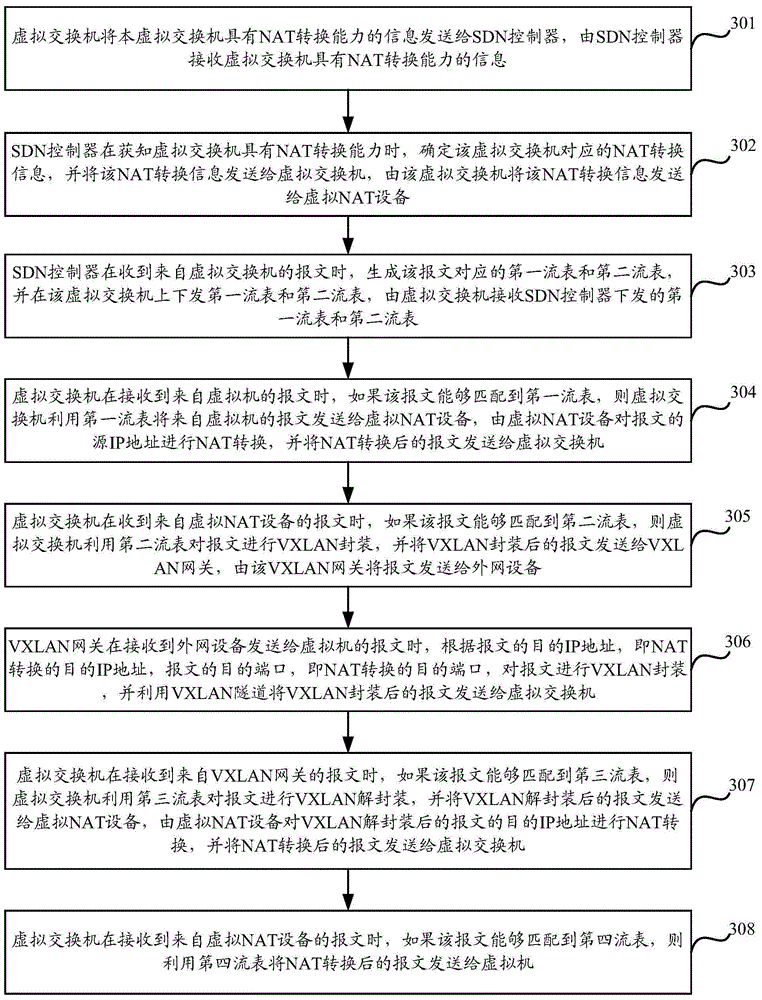

Method and device for transmitting message

ActiveCN104601432ANAT translation avoidanceAvoid conversionNetworks interconnectionComputer hardwareIp address

The invention discloses a method and a device for transmitting message. The method is as follows: a virtual switch receives the first flow stable and a second flow stable sent by the SDN controller; if the message is matched with the first flow table while the virtual switch receives the message from the virtual machine, the virtual switch sends the message to the virtual NAT device via the first flow table, the virtual NAT device does NAT conversion on the source IP address of the message and sends the conversion NAT message to the virtual switch; if the message is matched with the second flow table while the virtual switch receives the message from the virtual NAT device, the virtual switch uses the second flow table for executing VXLAN packaging operation on the message and sends the VXLAN packaged message to the VXLAN gateway. According to the embodiment, the NAT conversion is avoided to the message of the virtual machine by the VXLAN gateway, the CPU resource of the VXLAN gateway is saved and the processing performance of the VXLAN gateway is reduced.

Owner:NEW H3C TECH CO LTD

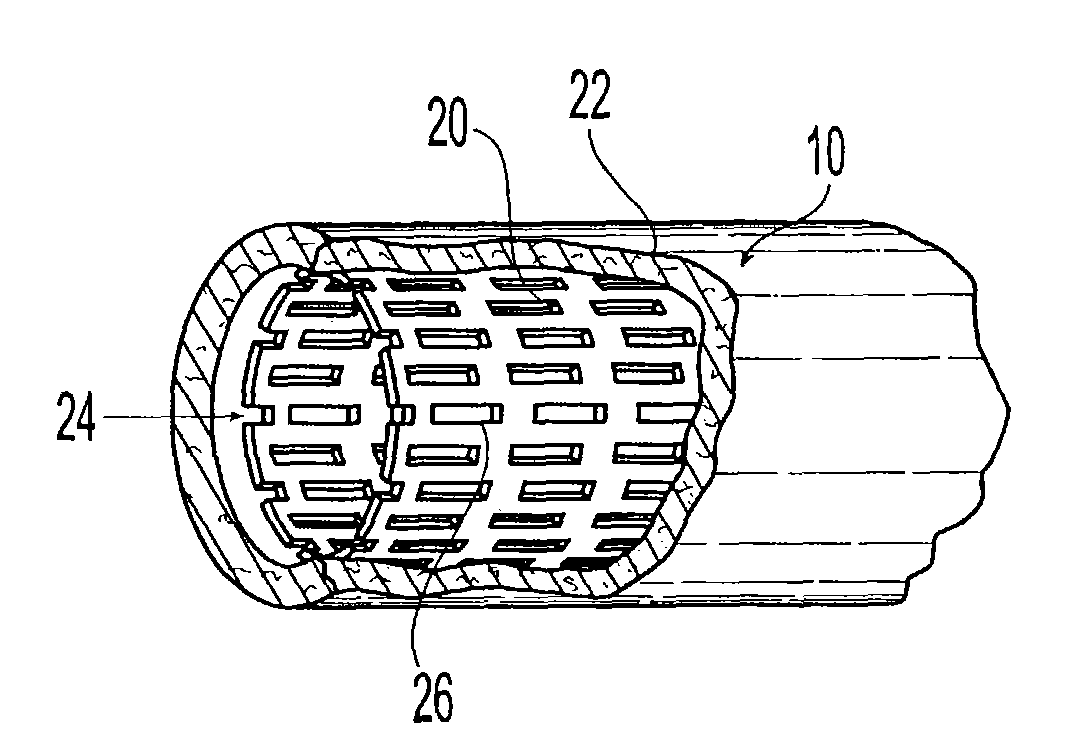

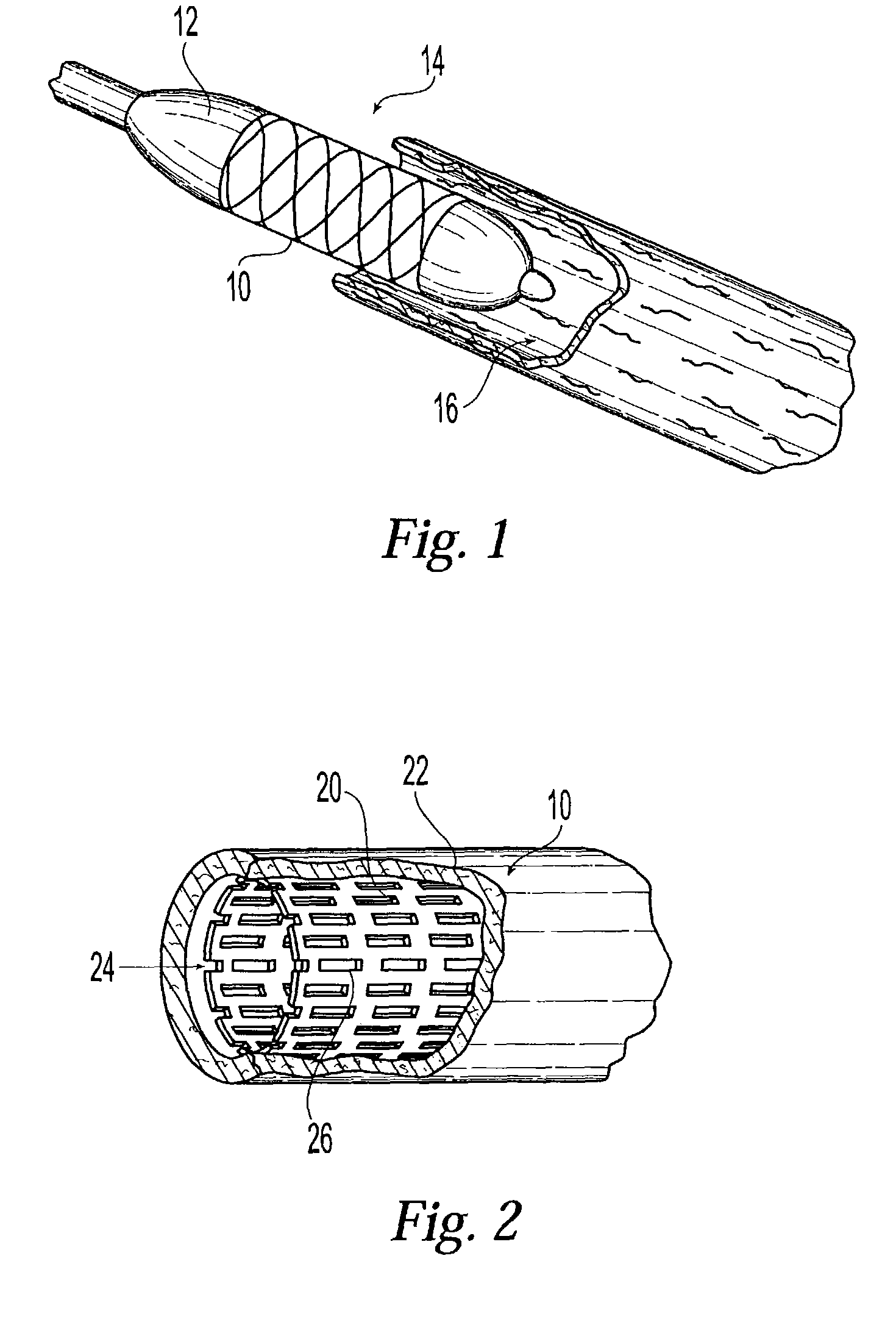

Carrier with solid fibrinogen and solid thrombin

InactiveUS7052713B2Safety and efficacyShorten hemostasis timePowder deliverySurgical adhesivesNatural sourceFiber

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and hemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm3, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin.The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibers. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, ε-aminocaproic acid or α2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

Hydrogen recycle for solid oxide fuel cell

InactiveUS20040005492A1High outputImprove voltage efficiencyDispersed particle separationFuel cell auxillariesContaminationRadiochemistry

The present disclosure relates to solid oxide fuel cells (SOFCs) exploiting gas separation devices in which a first gas mixture including components A (for example hydrogen) and B (for example carbon dioxide) is to be separated so that a first product of the separation is enriched in component A, while component B is mixed with a third gas component C (for example air, oxygen-enriched air or oxygen-depleted air) contained in a displacement purge stream to form a second gas mixture including components B and C, and with provision to prevent cross contamination of component C into the first product containing component A, or of component A into the second gas mixture containing component C. The invention may be applied to hydrogen (component A) enrichment from fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:AIR PROD & CHEM INC

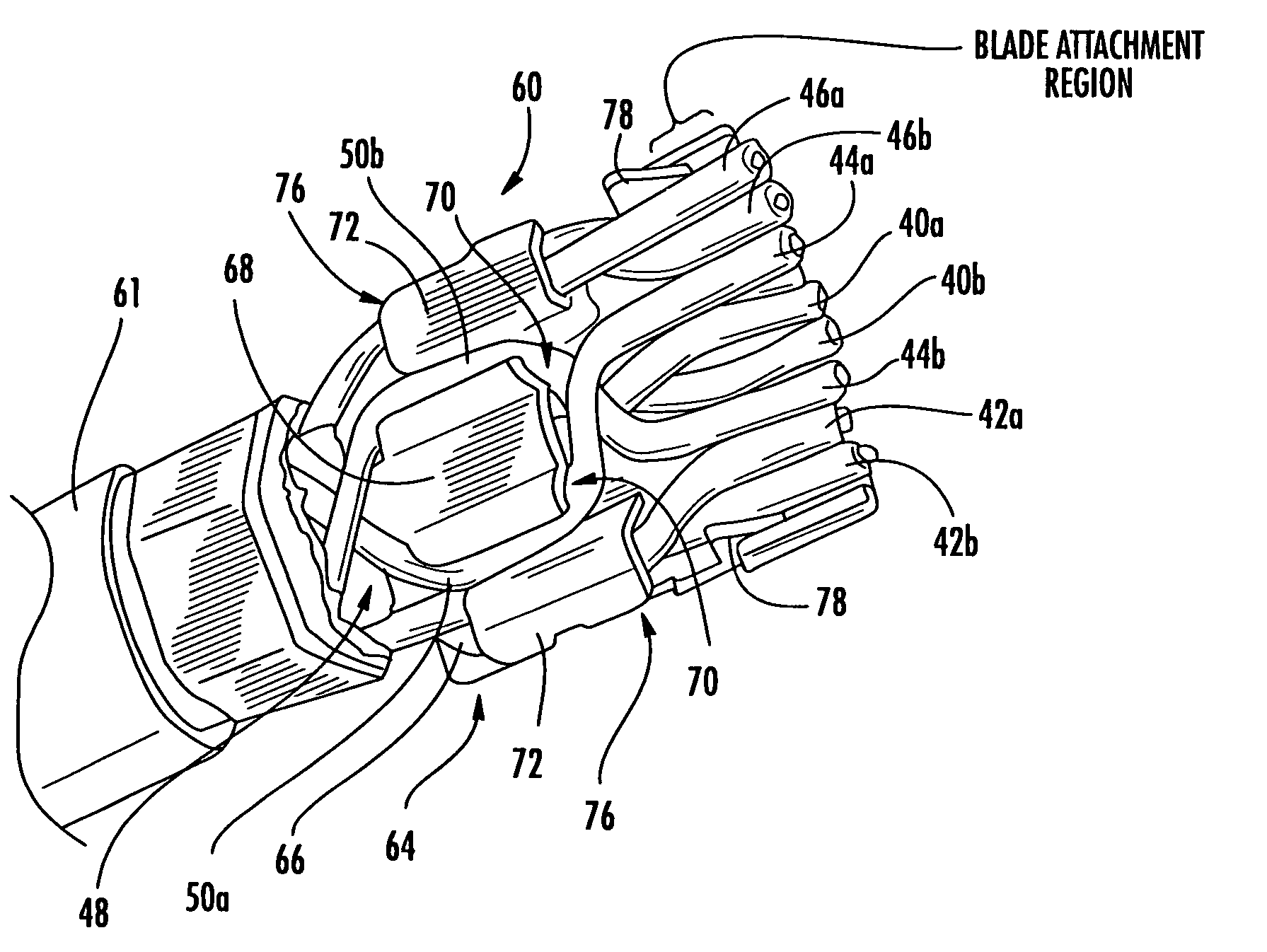

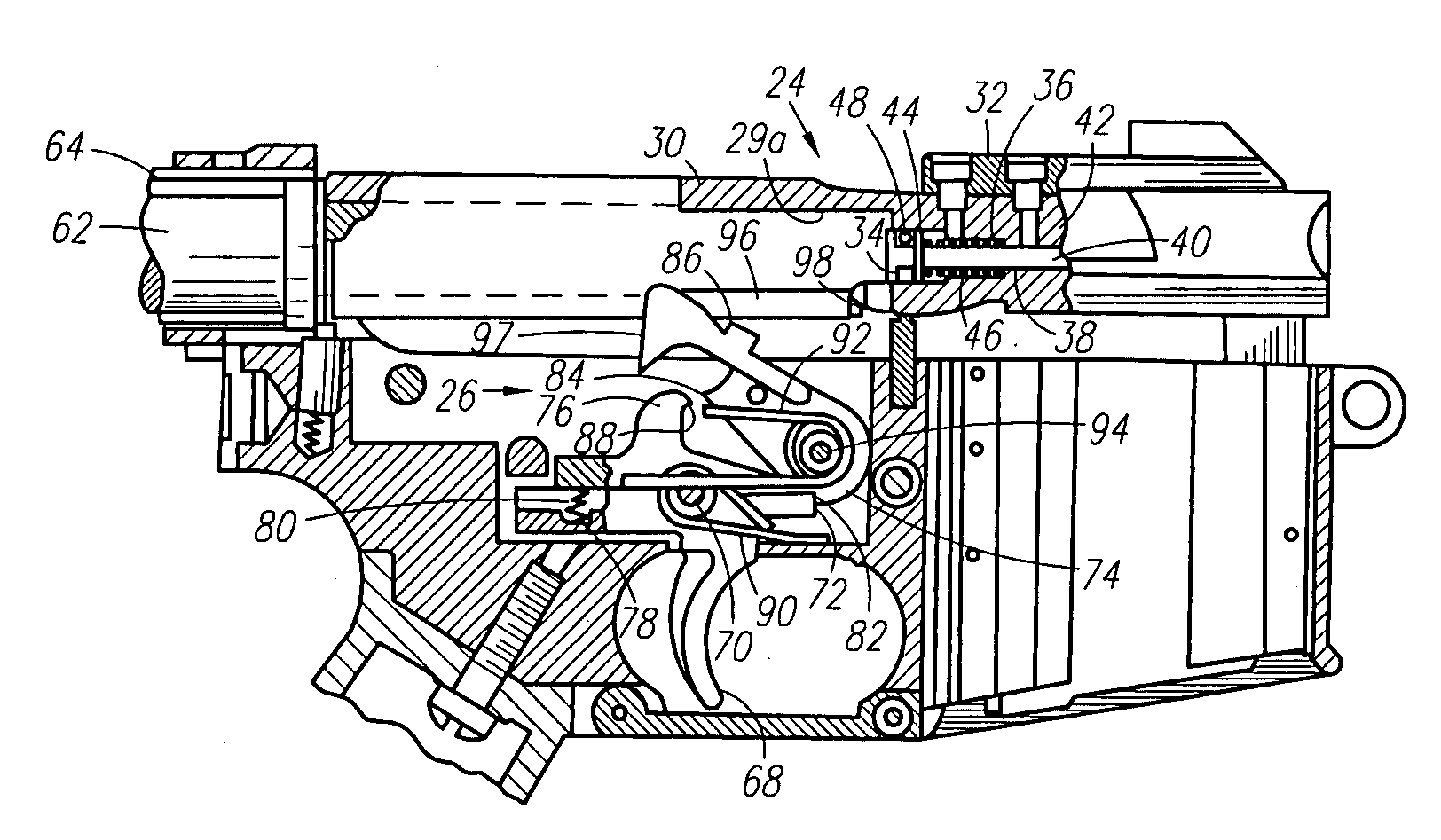

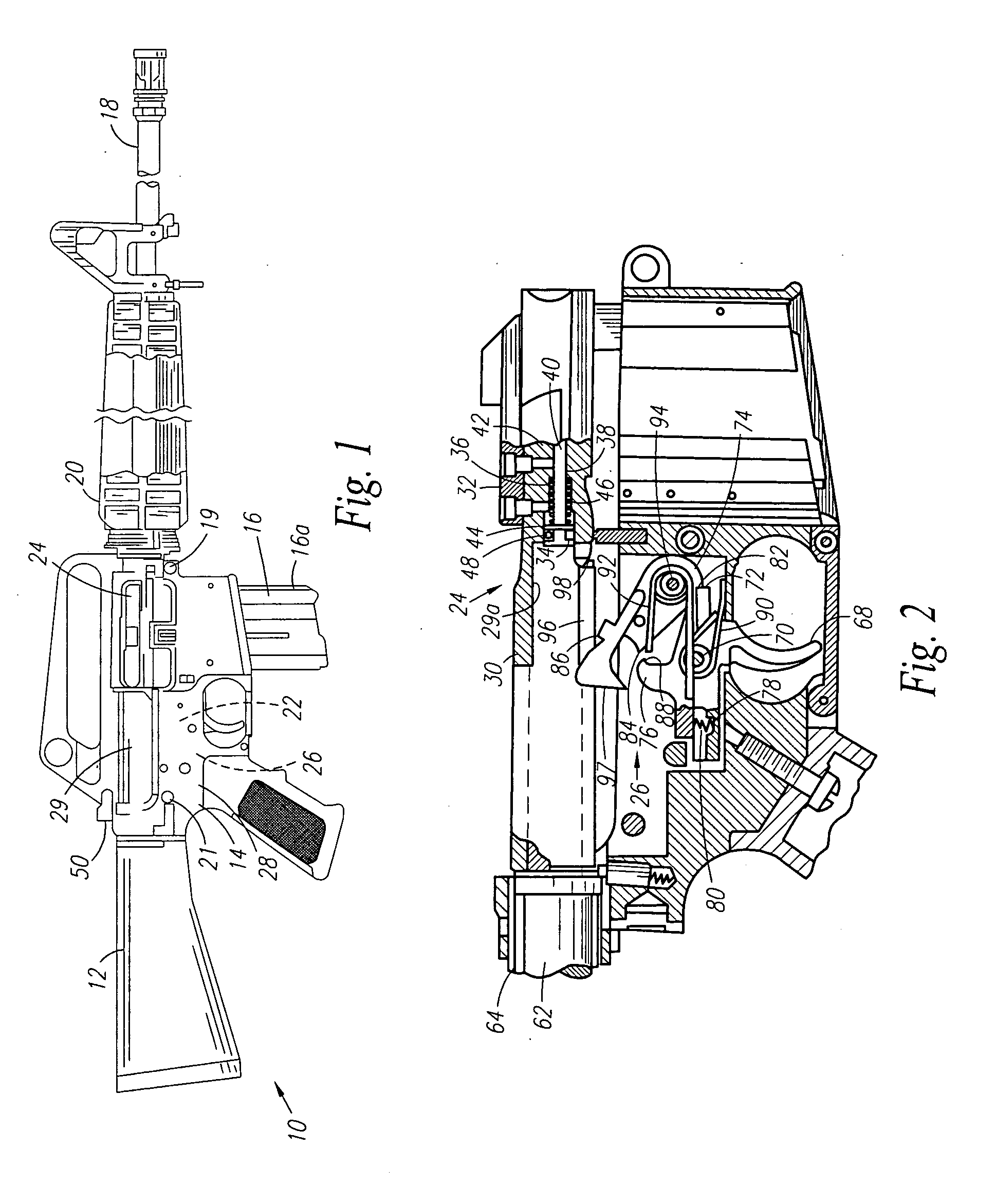

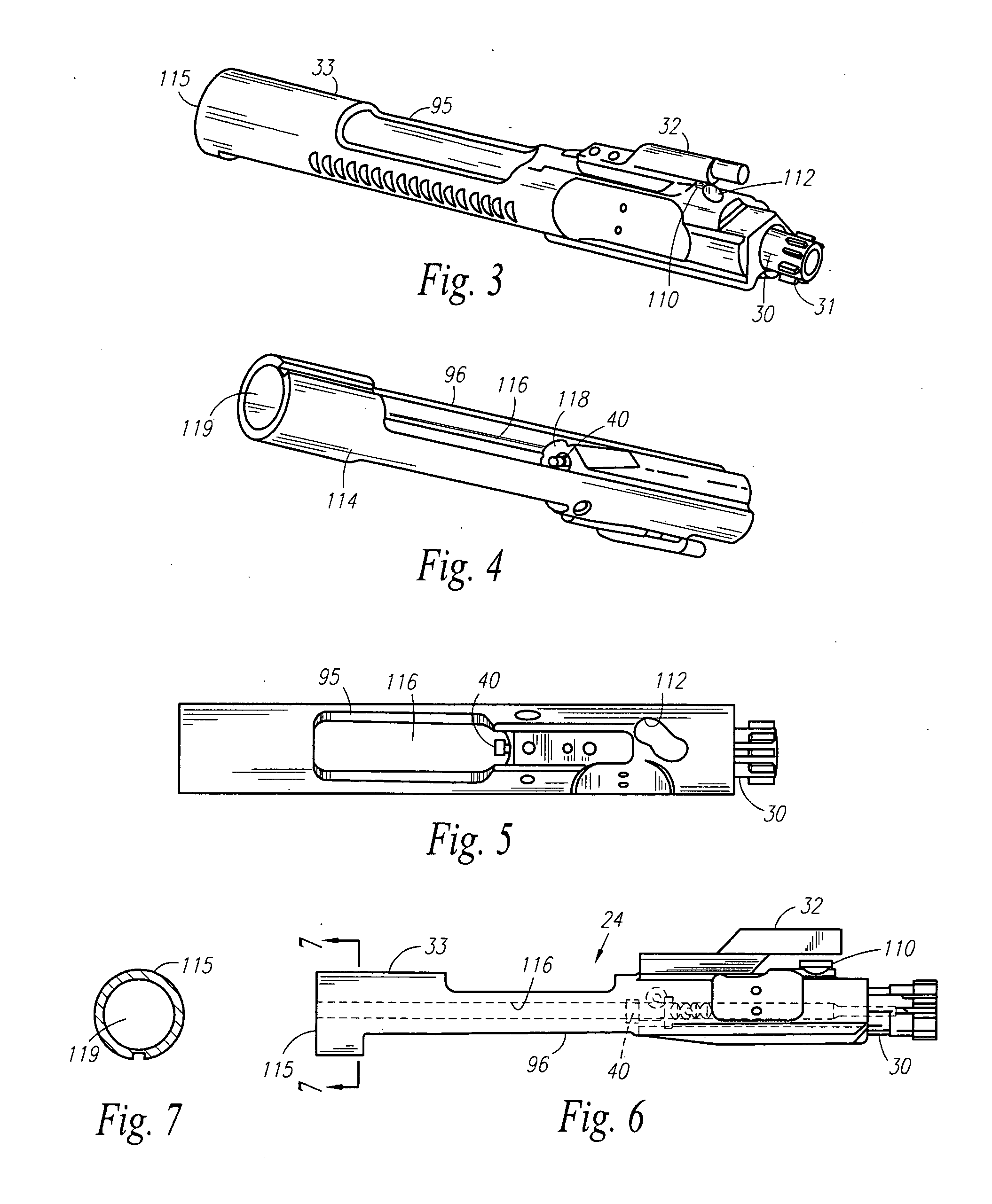

Device And Method For Converting And Preventing Conversion Of A Semi-Automatic Firearm To An Automatic Firearm

InactiveUS20090151213A1Avoid reciprocating motionAvoid conversionFiring/trigger mechanismsBreech mechanismsSemi automaticEngineering

A device and method is provided for easily and readily converting a semi-automatic firearm to a fully automatic firing firearm. An additional method is provided for preventing the conversion of a semi-automatic firearm to an automatic firing firearm.

Owner:BELL TIMOTHY L

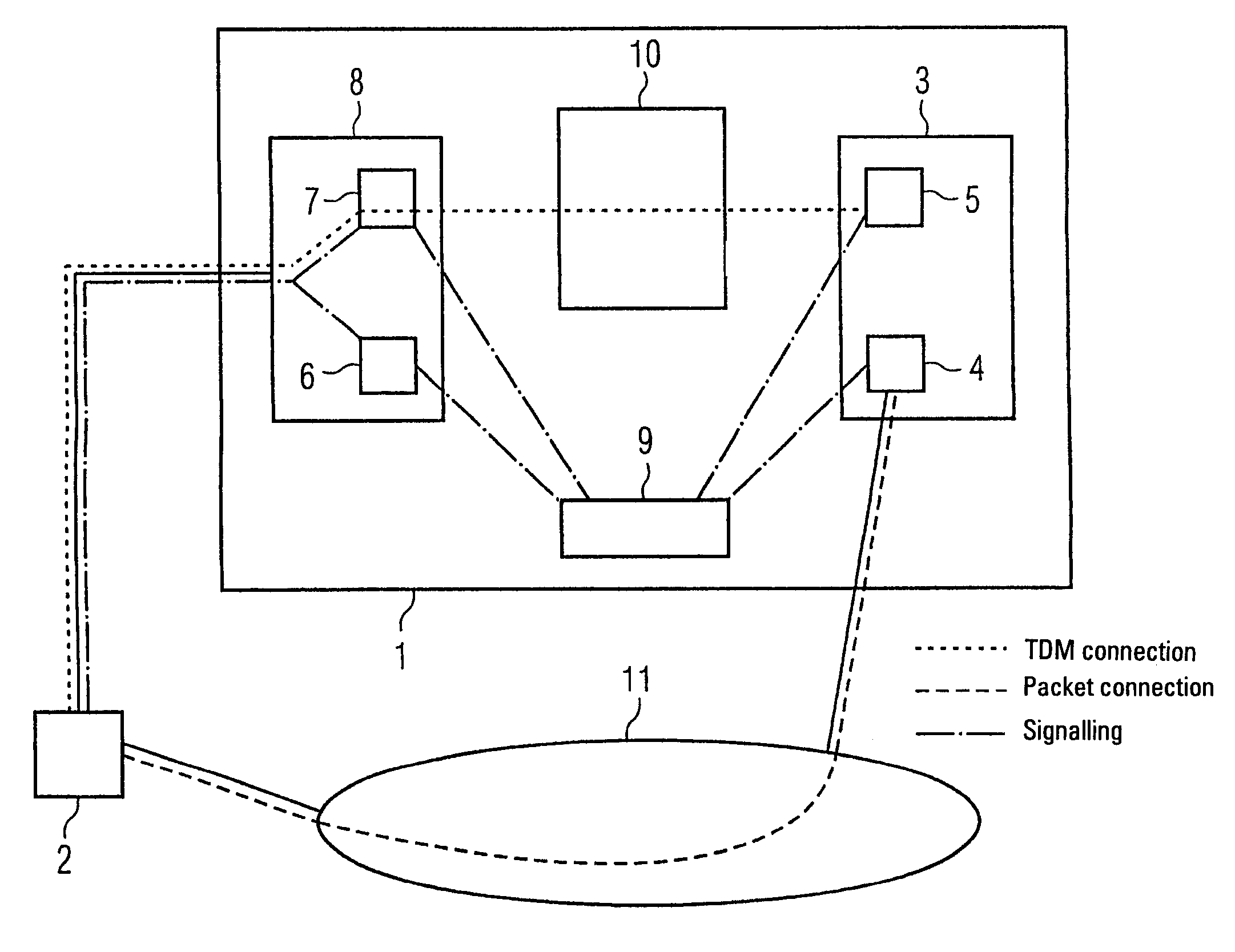

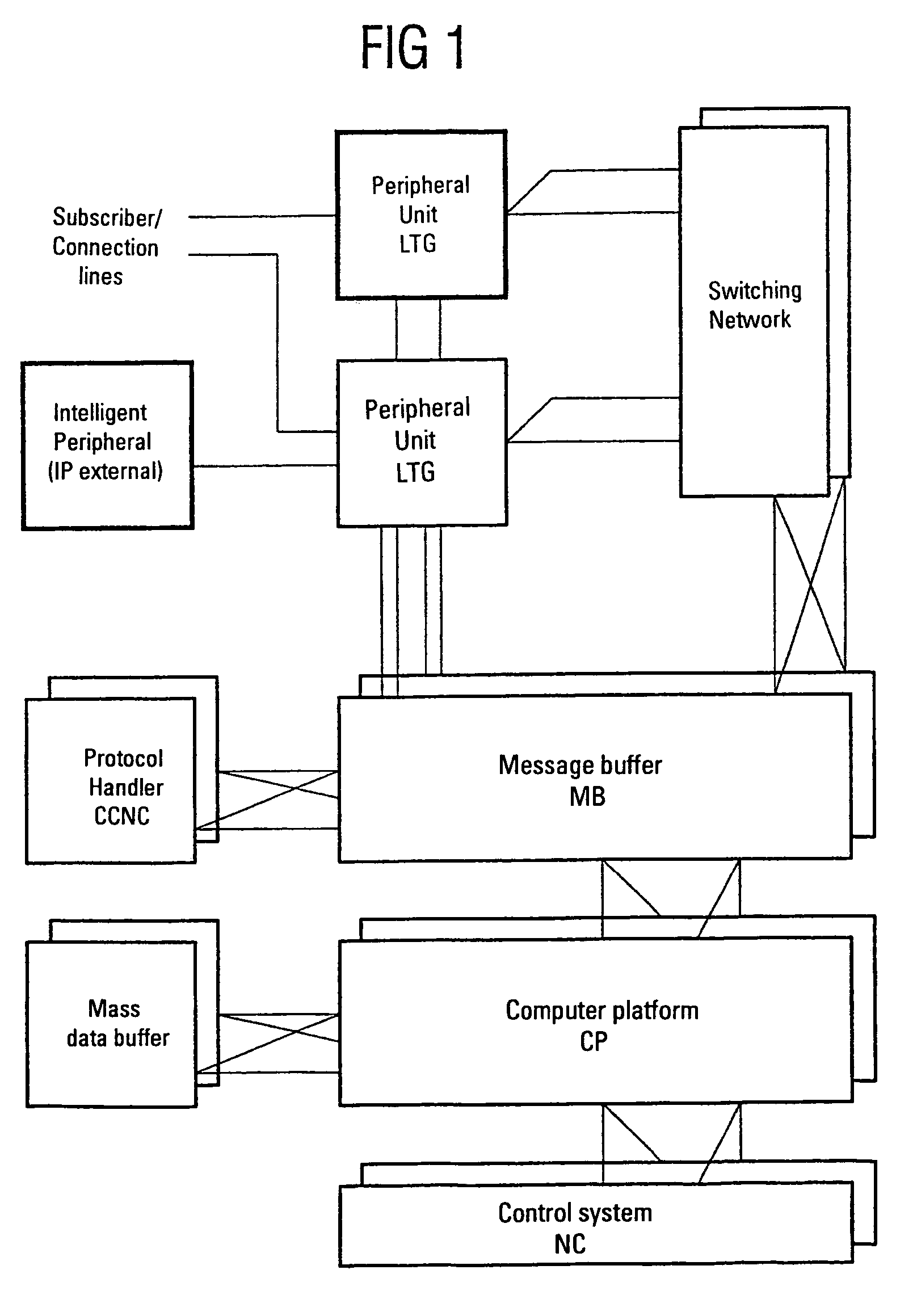

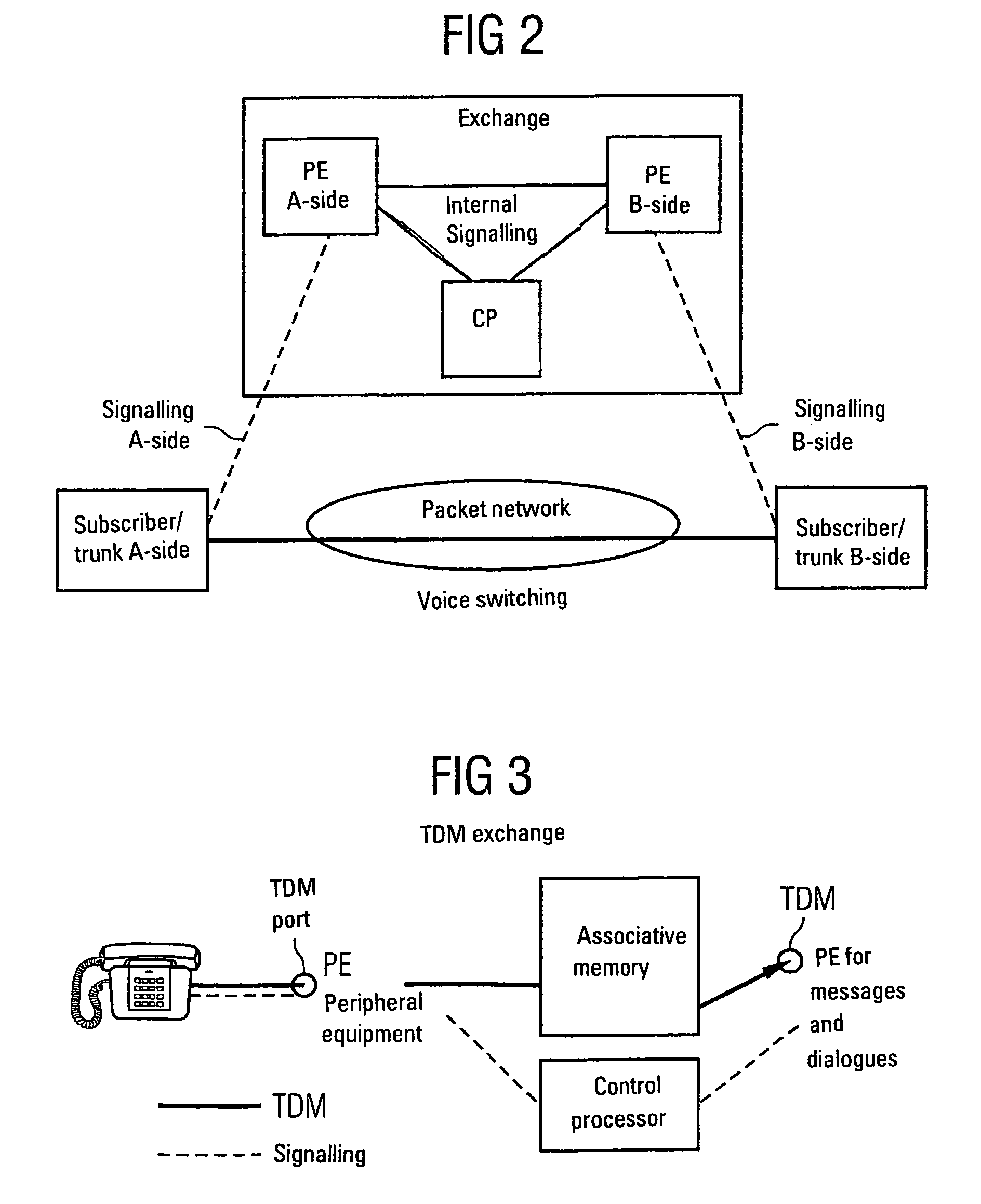

Arrangement for the provision of messages and dialogues in packet networks

InactiveUS7336650B2Minimal development costAvoid conversionData switching by path configurationAutomatic exchangesTelecommunications networkTelenet

The invention relates to an exchange for a telecommunication network, with a message / dialogue device, whereby said message / dialogue device, comprises one interface each for a packet-oriented data transmission network and a line-oriented data transmission network and a virtual port for controlling the message / dialogue device, by means of a connection running through the packet-oriented data transmission network, for the transmission of messages and / or dialogues to a user.

Owner:NOKIA SIEMENS NETWORKS GMBH & CO KG

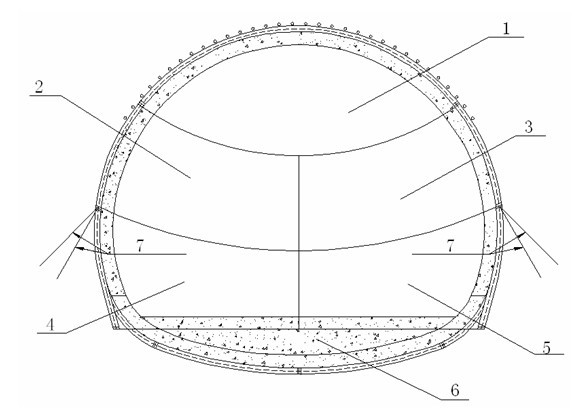

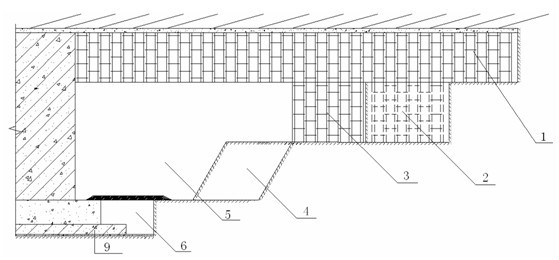

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075AMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

Hydrogen recycle for solid oxide fuel cell

InactiveUS7387849B2Improve efficiencyImprove sustainabilityDispersed particle separationFuel cell auxillariesContaminationRadiochemistry

The present disclosure relates to solid oxide fuel cells (SOFCs) exploiting gas separation devices in which a first gas mixture including components A (for example hydrogen) and B (for example carbon dioxide) is to be separated so that a first product of the separation is enriched in component A, while component B is mixed with a third gas component C (for example air, oxygen-enriched air or oxygen-depleted air) contained in a displacement purge stream to form a second gas mixture including components B and C, and with provision to prevent cross contamination of component C into the first product containing component A, or of component A into the second gas mixture containing component C. The invention may be applied to hydrogen (component A) enrichment from fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:AIR PROD & CHEM INC

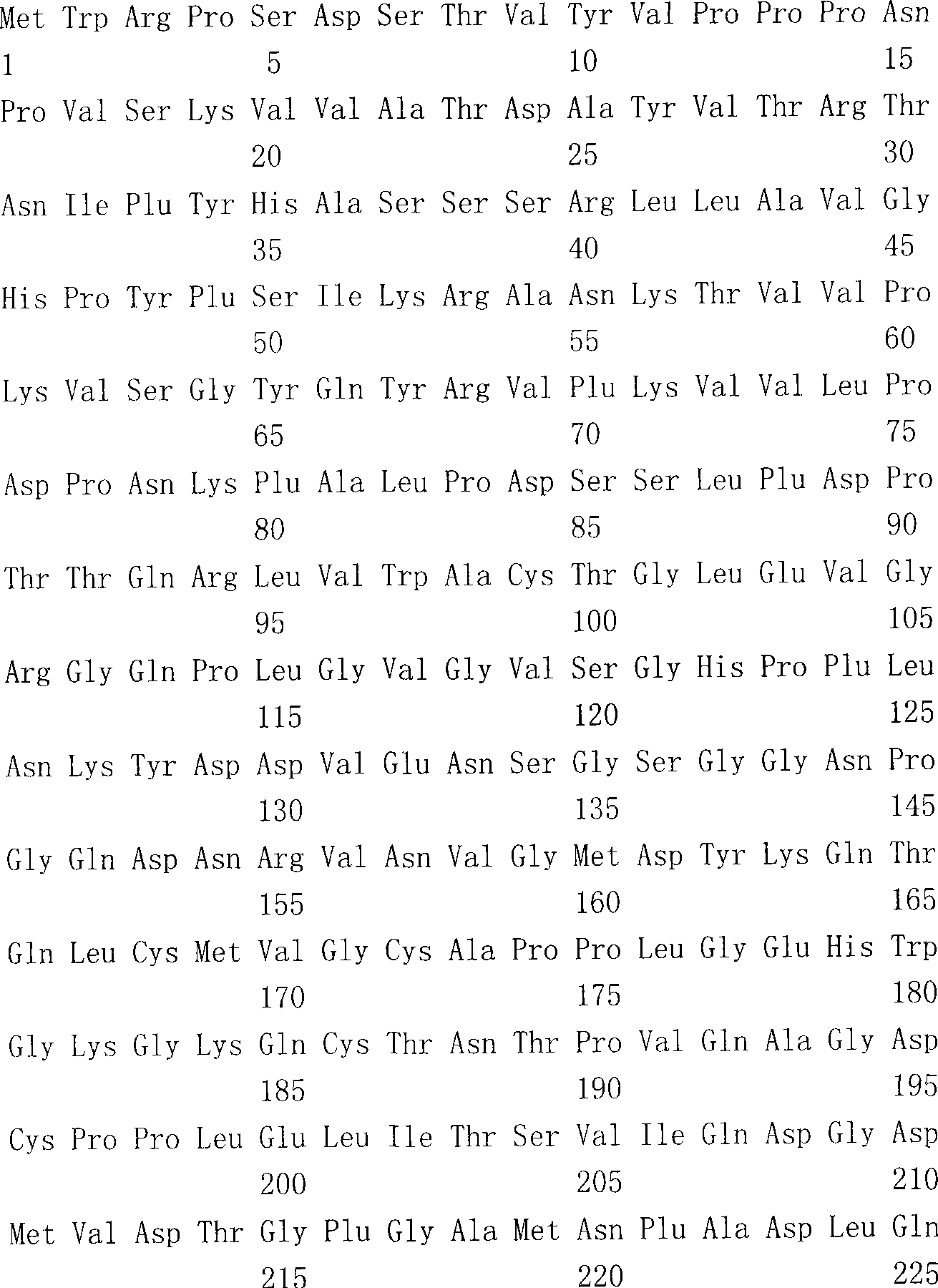

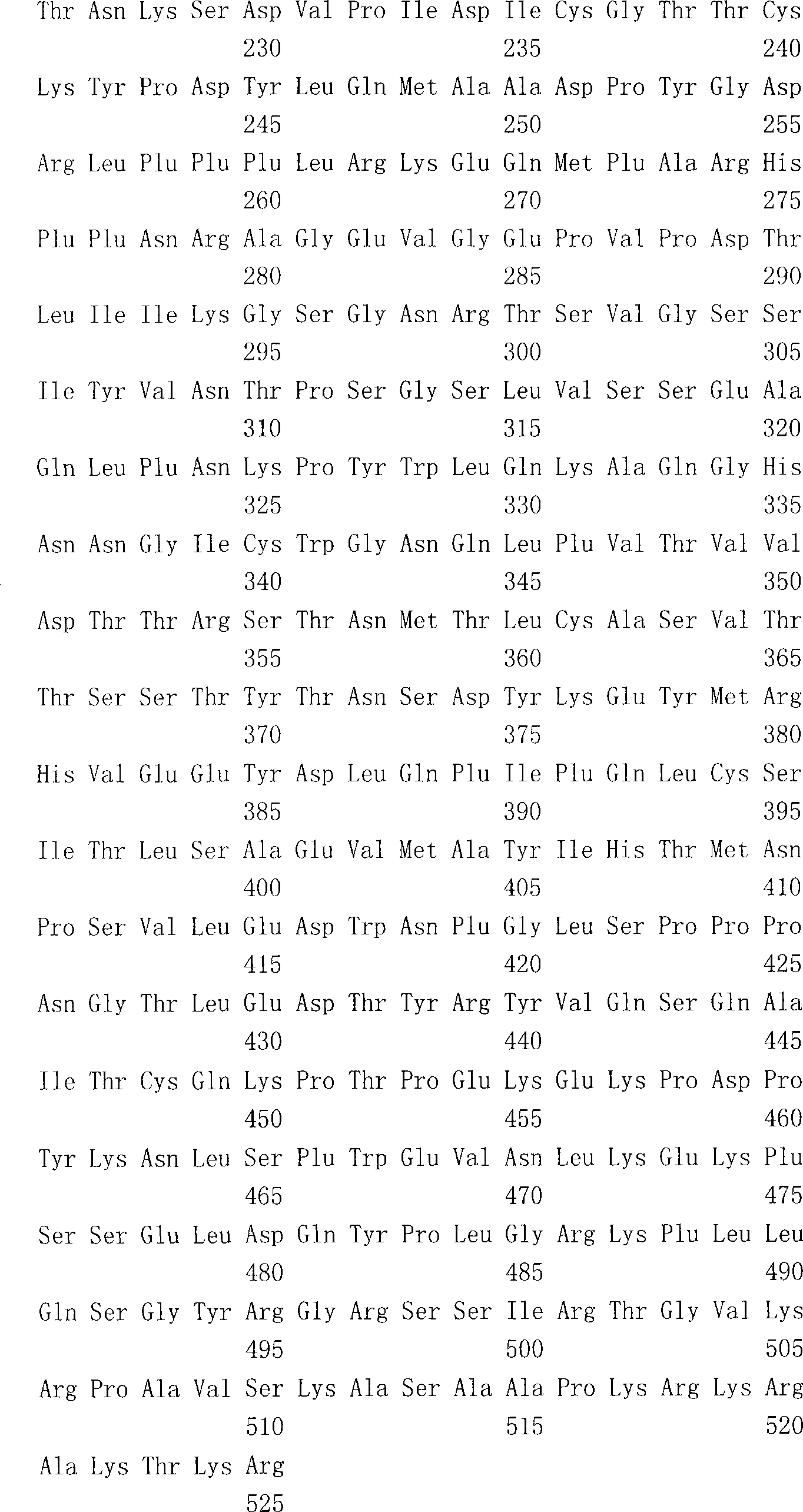

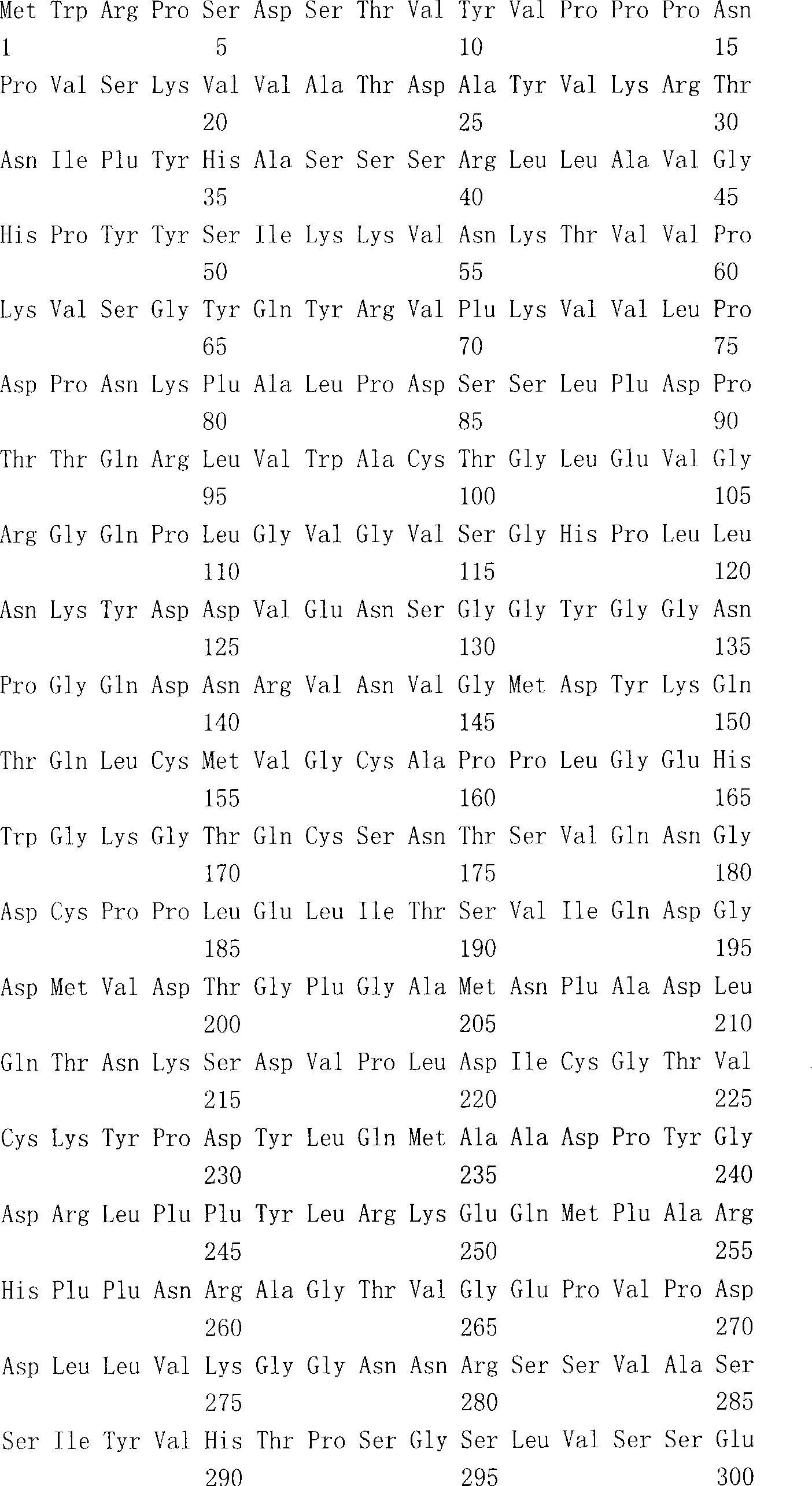

Human papilloma virus preventative vaccine, construction method and application

InactiveCN101518647AAvoid conversionAchieve broad-spectrum immune effectPeptide/protein ingredientsViral antigen ingredientsPolyvalent VaccineHuman papilloma virus

The invention provides a construction method of a human papilloma virus resistant HPV polyvalent vaccine and application thereof.

Owner:江阴艾托金生物技术有限公司

Class II active center hydrogenation catalyst start-up vulcanization method

ActiveCN102311766AImprove catalytic performanceMoisturize thoroughlyHydrotreatment operations starting-upHydrocarbon oil crackingHydrogenVulcanization

The invention discloses a class II active center hydrogenation catalyst start-up vulcanization method, which comprises the following steps: (1) taking class II active center hydrogenation catalyst before vulcanization; (2) filling the class II active center hydrogenation catalyst before vulcanization into a reactor at normal temperature and pressure, introducing nitrogen to replace air in a reaction system, then replacing the nitrogen with hydrogen and carrying out gas seal; (3) continuing to adjust the temperature of a bed layer of the reactor, and introducing vulcanized oil to moisten the catalysts; (4) cycling the vulcanized oil in a closed mode in the reaction system, gradually injecting vulcanizers into the vulcanized oil, and raising the temperature continuously to complete vulcanization; and (5) adjusting the bed layer to the reaction temperature after vulcanization, and switching raw oil. The catalyst start-up vulcanization method disclosed by the invention is conductive to forming more class II hydrogenation active centers for the catalysts, and is conductive to improving the use performance of the catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

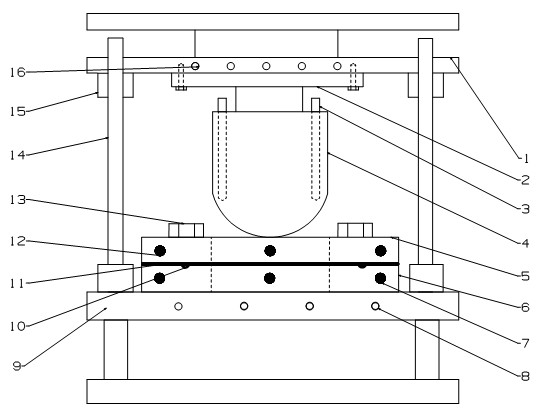

Testing device and testing method for establishing high-temperature formed limit diagram of ultrahigh-strength boron steel plate

InactiveCN102156080ARigid enoughGuaranteed reliabilityInvestigating material ductilityForming limit diagramSheet steel

The invention relates to a testing device for establishing a high-temperature formed limit diagram of an ultrahigh-strength boron steel plate. The testing device comprises an upper die frame and a lower die frame, wherein the lower die frame is provided with a plurality of guide posts, the upper die frame is sleeved on the guide posts, the lower surface of the upper die frame is provided with a male die device, and the lower die frame is provided with a blank holder and a female die which correspond to the position of the male die device and are stacked up and down and fixed together through a connector; the upper die frame and the lower die frame are provided with a cooling water passage respectively; heaters are arranged in a male die, the female die and the blank holder; and a temperature probe is arranged at the inner end of the male die. Meanwhile, the invention also discloses a testing method using the device. By combining the high-temperature expansion test requirement of the ultrahigh-strength steel plate, the formed limit diagram of the ultrahigh-strength steel plate at a certain specific high temperature is obtained by thermal forming limit test. The device and the method have significance for researching the forming performance of the ultrahigh-strength boron steel plate for an automobile, and can promote the popularization and application of ultrahigh-strength boron steel in the field of automobiles.

Owner:SHANDONG JIANZHU UNIV

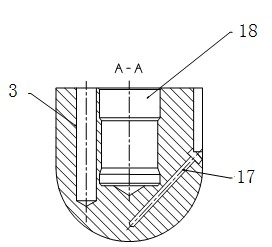

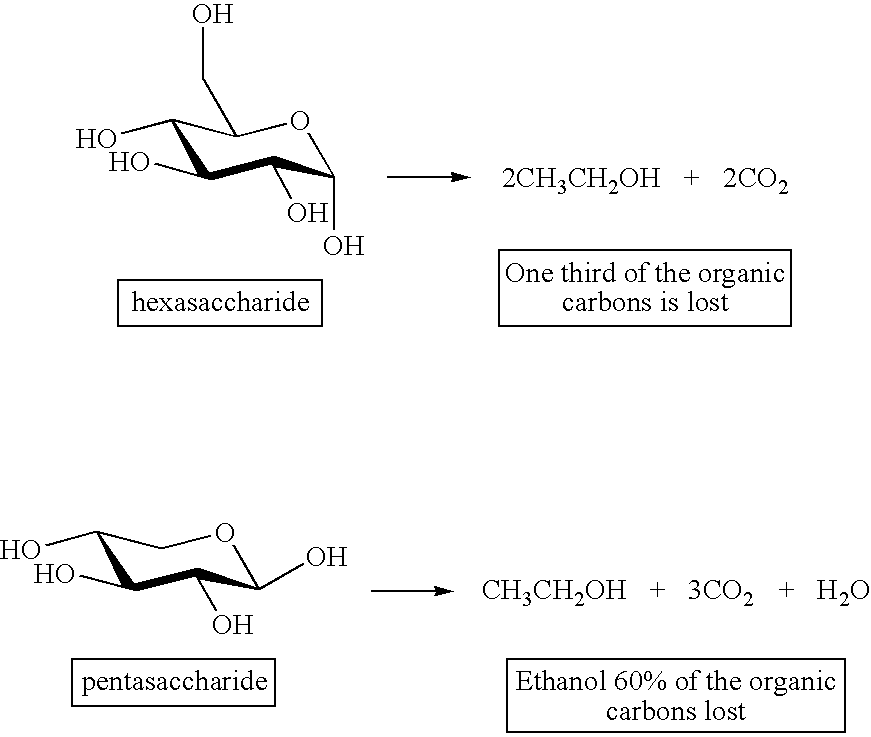

Process of producing liquid fuel from cellulosic biomass

InactiveUS20090326286A1Highly effectiveAvoid conversionCarbon compoundsCarboxylic acid esters preparationAlkaneCellulose

A liquid fuel production process from cellulosic biomass comprises the following steps: (1) providing a mixture of cellulose and water; (2) subjecting the obtained mixture to hydrolysis and catalytic hydrogenation under the presence of acid to obtain mono-sugar alcohol and optional solid material lignin, or subjecting the obtained mixture to hydrolysis to obtain monosaccharide; (3) esterifying the obtained mono-sugar with C2-C5 organic acid to obtain a liquid fuel II, or subjecting the obtained mono-sugar alcohol or monosaccharide to dehydration / hydrogenation to obtain an organic liquid fuel I consisting of alkanes. This process avoids the loss of organic carbon atoms during fermentation, and the sugar derived from cellulosic biomass can be converted to organic carbon in the liquid fuel. The lignin produced by the process can be used for preparing aromatics.

Owner:CHINA FUEL HUAIBEI BIOENERGY TECH DEV

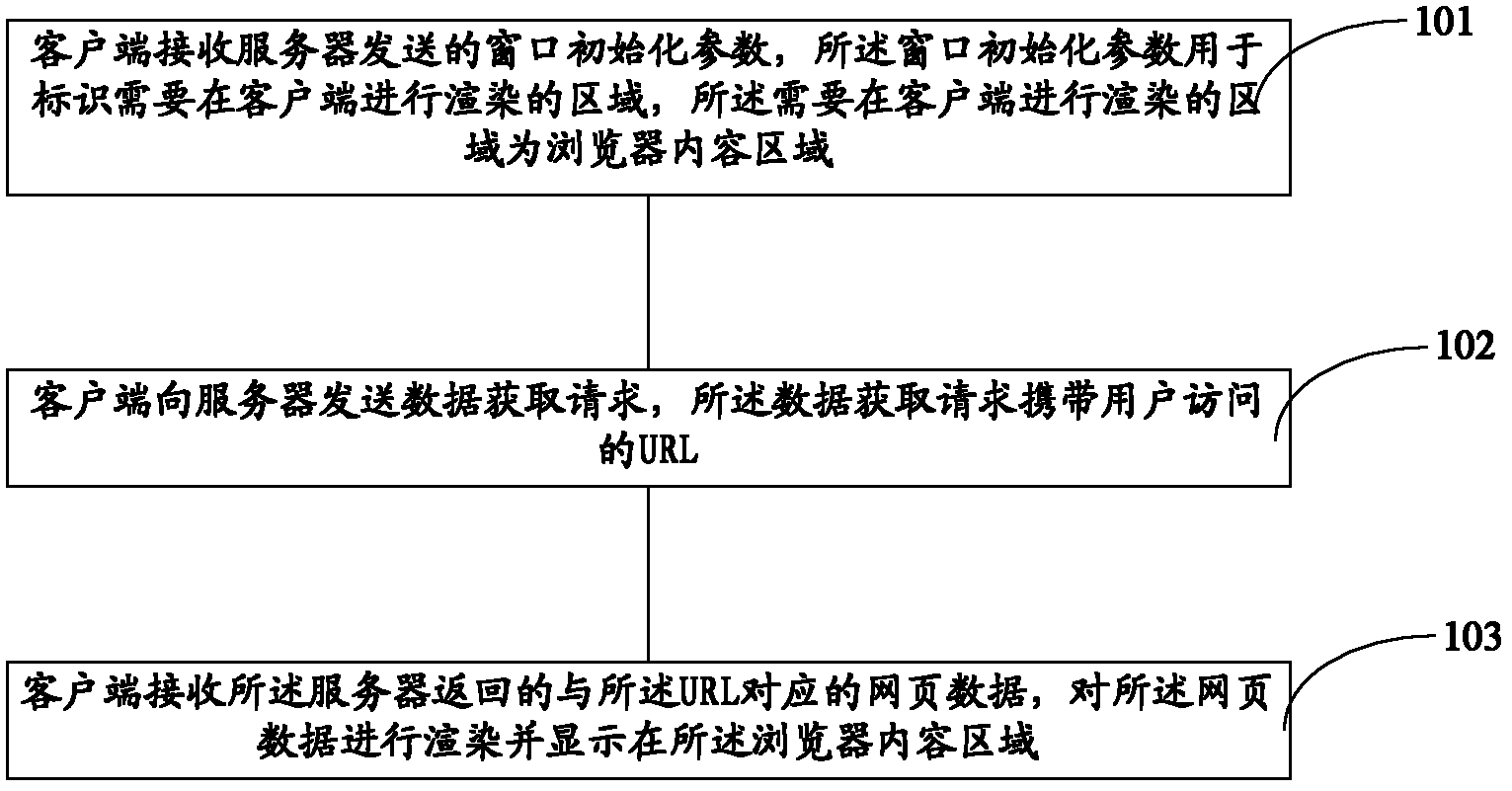

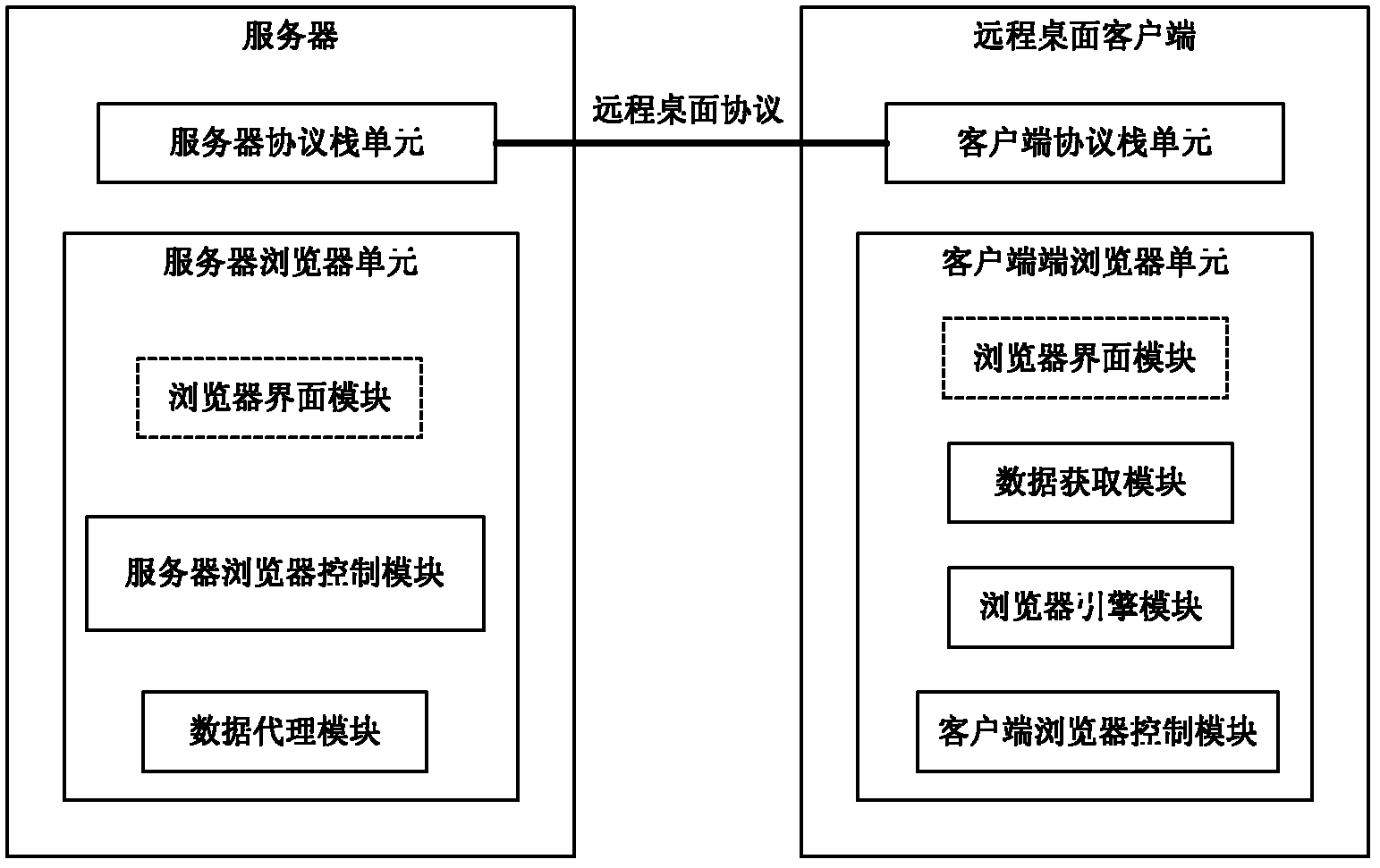

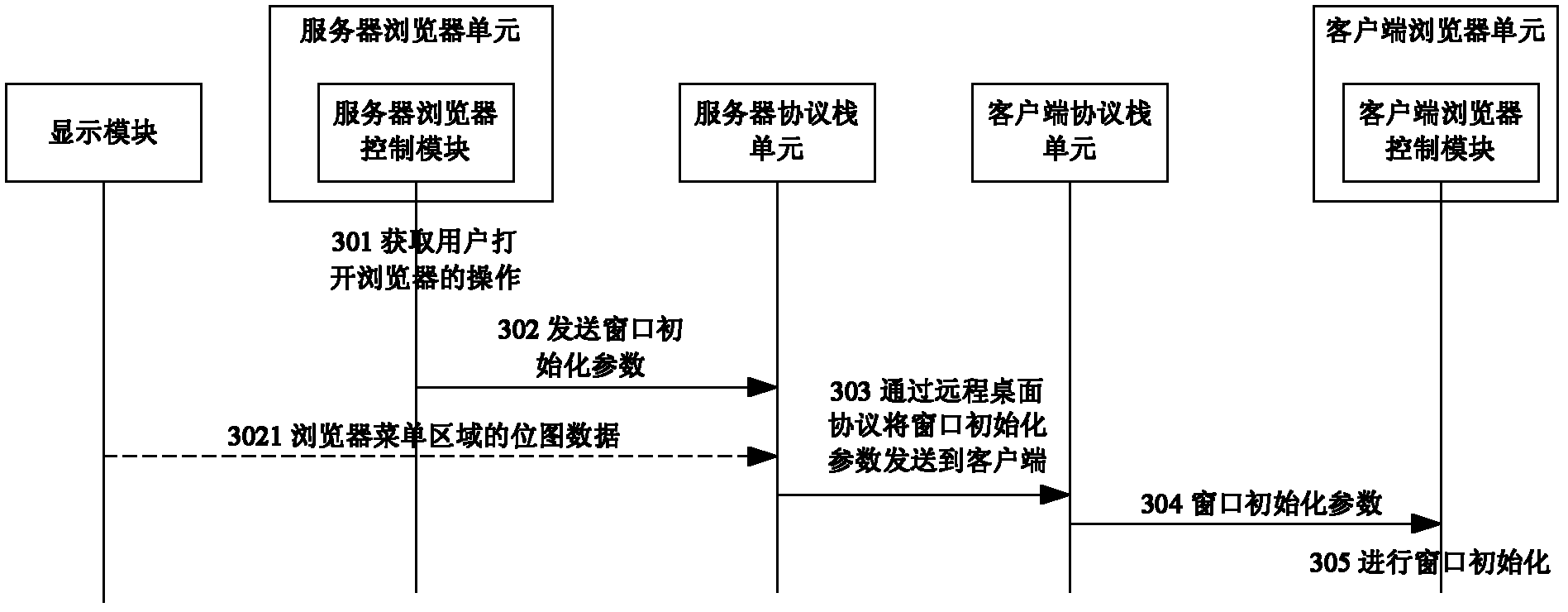

Method, apparatus and system for realizing web browsing in remote desk environment

ActiveCN102577327AAchieve renderingReduce resource consumptionWeb data retrievalTransmissionGraphicsResource consumption

Embodiments in the present invention provide a method, an apparatus and a system for realizing web browsing in remote desk environment, wherein a window initialization parameter sent by a server is received by a client, a browser content area needed to be rendered in the client is determined by the client according to the window initialization parameter, and website data corresponding to the URLs visited by users from the server is further acquired, rendered and displayed in the browser content area. Therefore, the rendering of browser content area in the client is rendered, conversion of video graphics and compression of bitmap data by the server is prevented, resource consumption of the server is reduced, and simultaneously the transmission of mass data between the server and the client is prevented and the bandwidth demand of data transmission is lowered.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

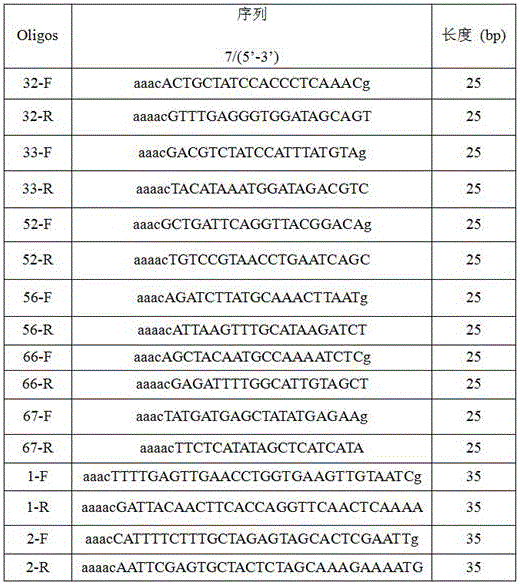

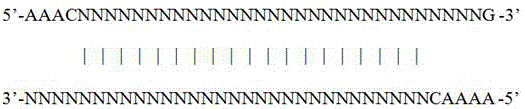

Method for eliminating mecA plasmids based on CRISPR/Cas9 technology

InactiveCN106167808AAvoid conversionEasy to operateNucleic acid vectorVector-based foreign material introductionBiotechnologyMethicillin resistance gene

The invention discloses a method for eliminating mecA plasmids based on CRISPR / Cas9 technology. The method comprises: selecting an MRSA strain to perform PCR amplification to a DNA sequence of a C terminal of mecA gene coding transpeptidase; carrying out gel extraction for mecA genes; connecting the mecA genes with a T-pMD19 (simple) carrier and preparing DH5[alpha] competent cells; electro-transforming the DH5[alpha] competent cells through the obtained T-pMD19-mecA plasmids; extracting the T-pMD19-mecA plasmids and performing sequencing and verification; performing double digestion treatment for the T-pMD19-mecA plasmids and performing gel extraction to the mecA genes; connecting pET-21a (+) plasmids with the mecA genes; designing and synthesizing oligos; constructing pCas9 :: mecA plasmids; electro-transforming the obtained pET-21a (+)-mecA plasmids into an escherichia coli expression strain BL21 (D3); and electro-transforming the pCas9 :: mecA plasmids and the pCas9 plasmids into BL21 (D3)+pET-21a(+)-mecA competent bacteria and BL21 (D3)+pET-21a(+) competent bacteria. The method is simple to operate and good in specificity, and can effectively block spread of mecA to eliminating the mecA strain.

Owner:ZHENGZHOU UNIV

Magnetic tape, magnetic tape cartridge, and magnetic tape apparatus

ActiveUS20200126589A1Deterioration in electromagnetic conversionIncrease recording capacityMagnetic materials for record carriersRecord information storageZeta potentialIonogram

The magnetic tape includes a non-magnetic support; a non-magnetic layer including a non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including a ferromagnetic powder and a binding agent on the non-magnetic layer, in which a total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, an isoelectric point of a surface zeta potential of the magnetic layer is equal to or greater than 5.5, the magnetic layer includes an oxide abrasive, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm.

Owner:FUJIFILM CORP

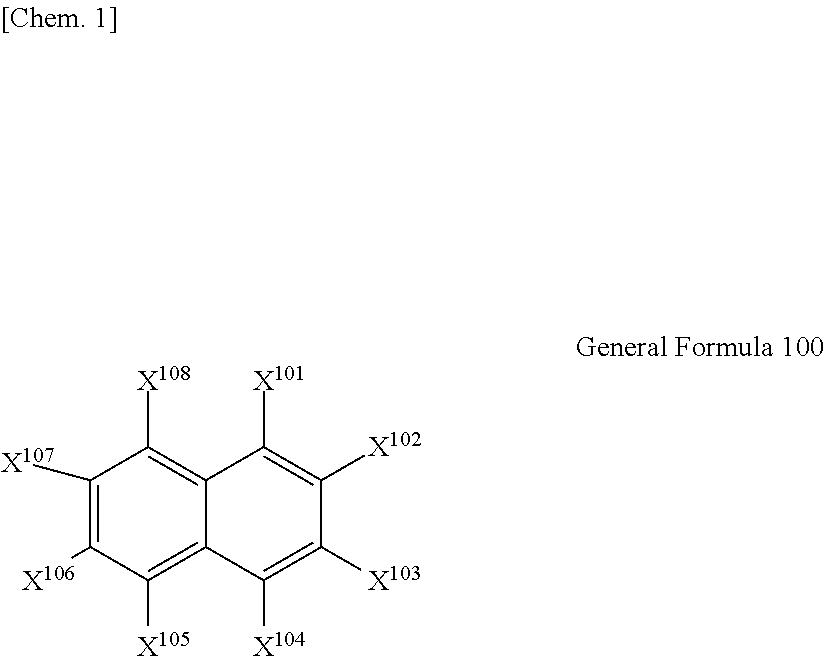

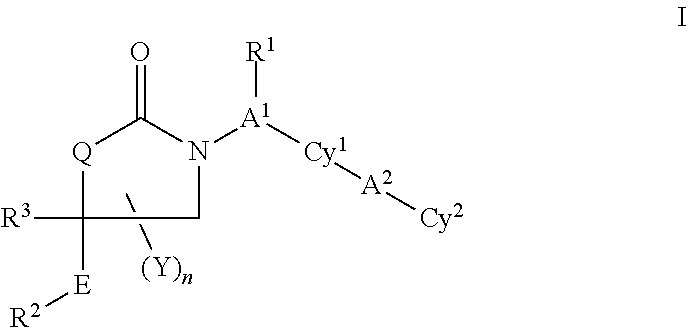

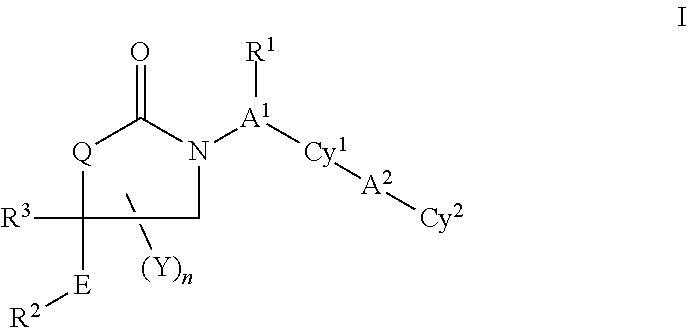

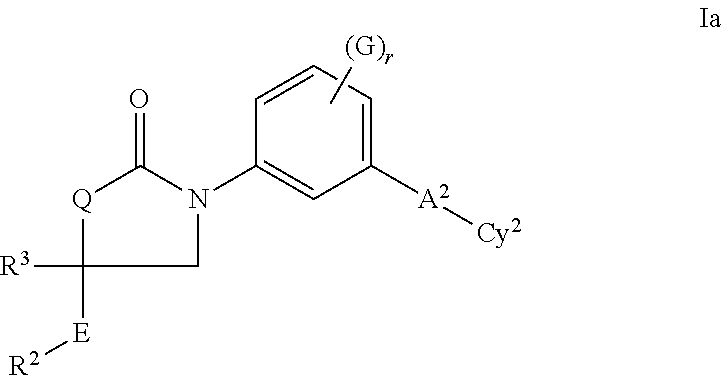

Inhibitors Of 11beta-Hydroxysteroid Dehydrogenase Type 1

InactiveUS20110105504A1Increase insulin sensitivityAvoid conversionAntibacterial agentsBiocide11beta hydroxysteroid dehydrogenaseDisease

This invention relates to novel compounds of the Formula (I) and pharmaceutically acceptable salts thereof, and pharmaceutical compositions thereof which are useful for the therapeutic treatment of diseases associated with the modulation or inhibition of 11β-HSD1 in mammals.

Owner:VITAE PHARMA INC

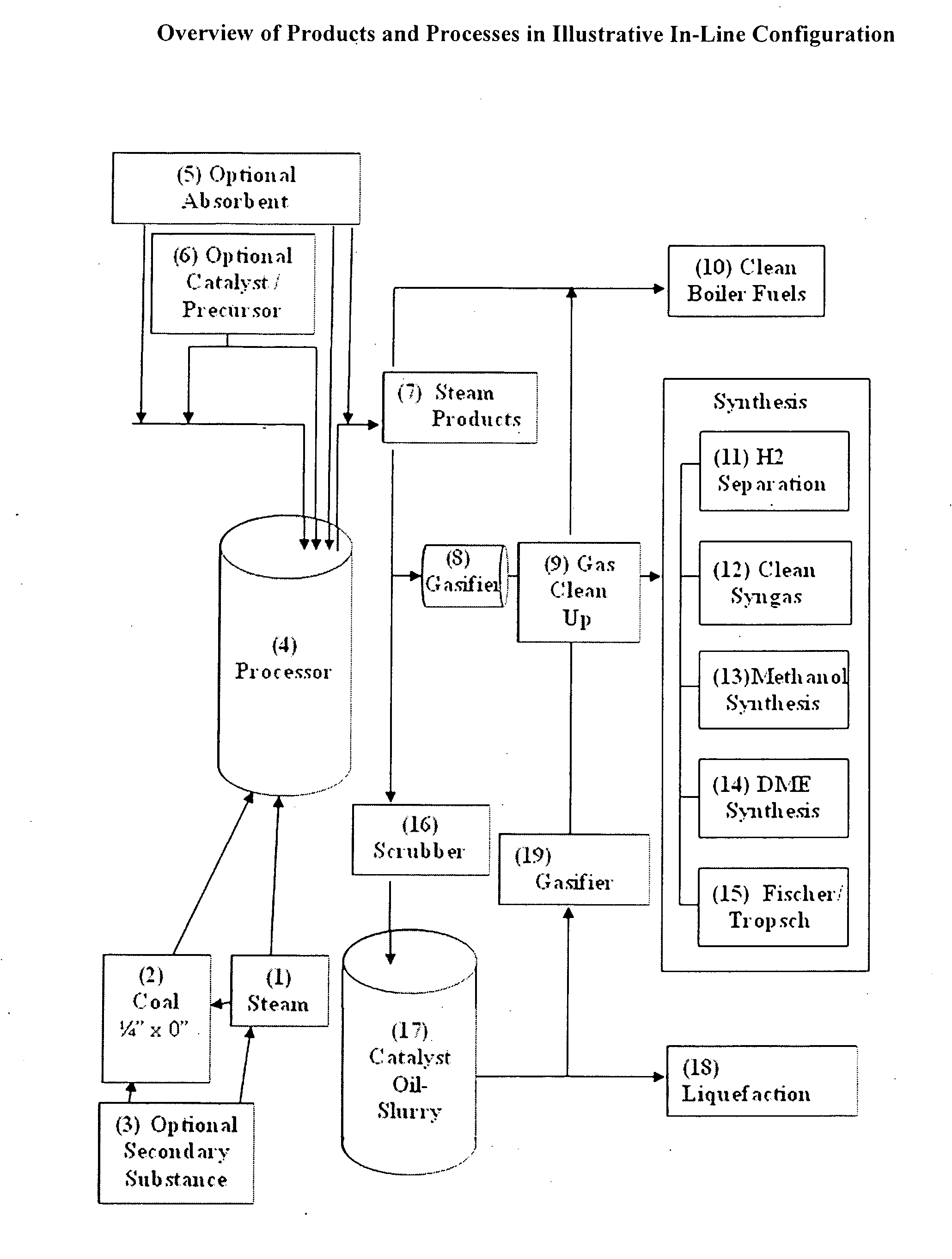

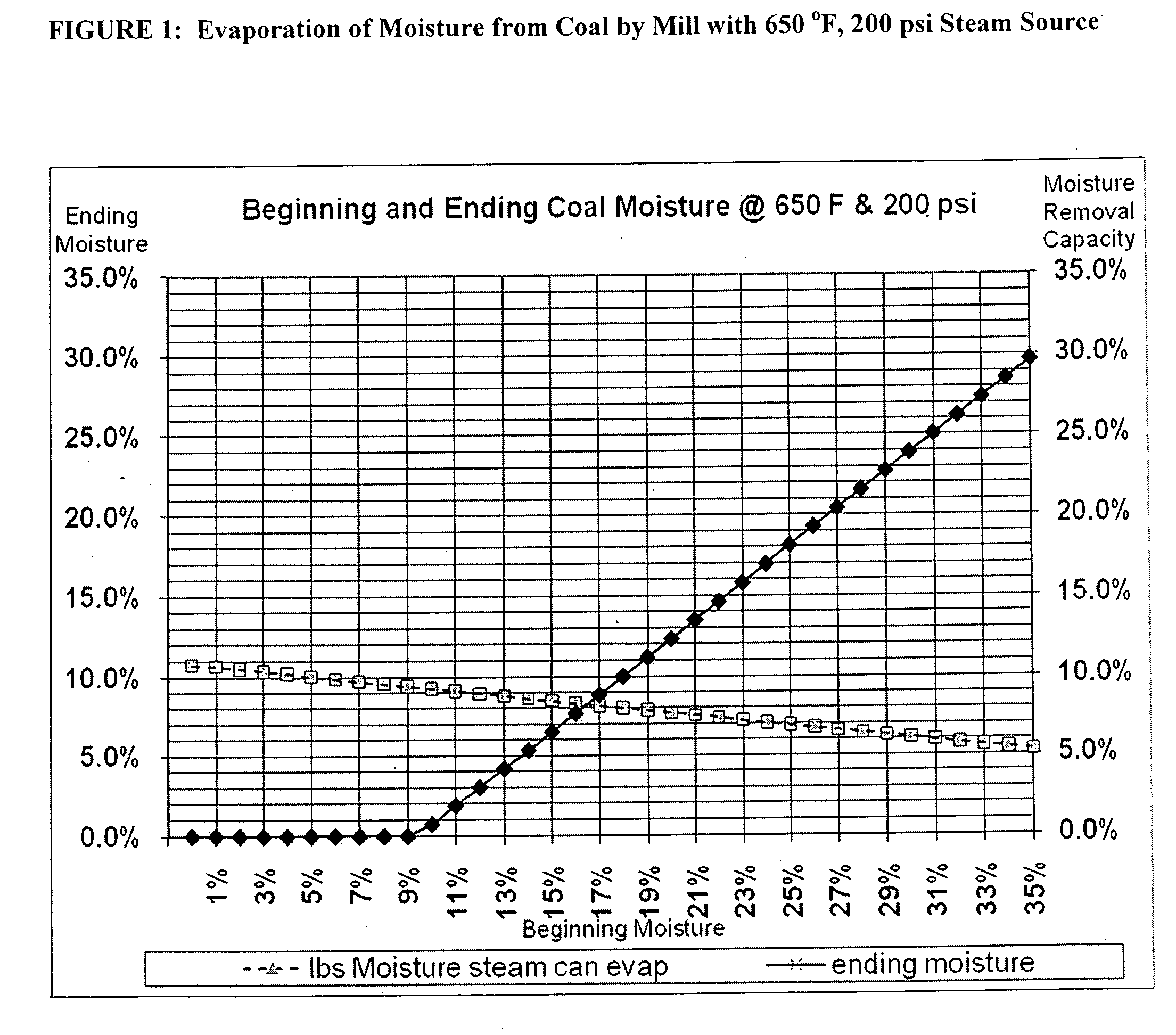

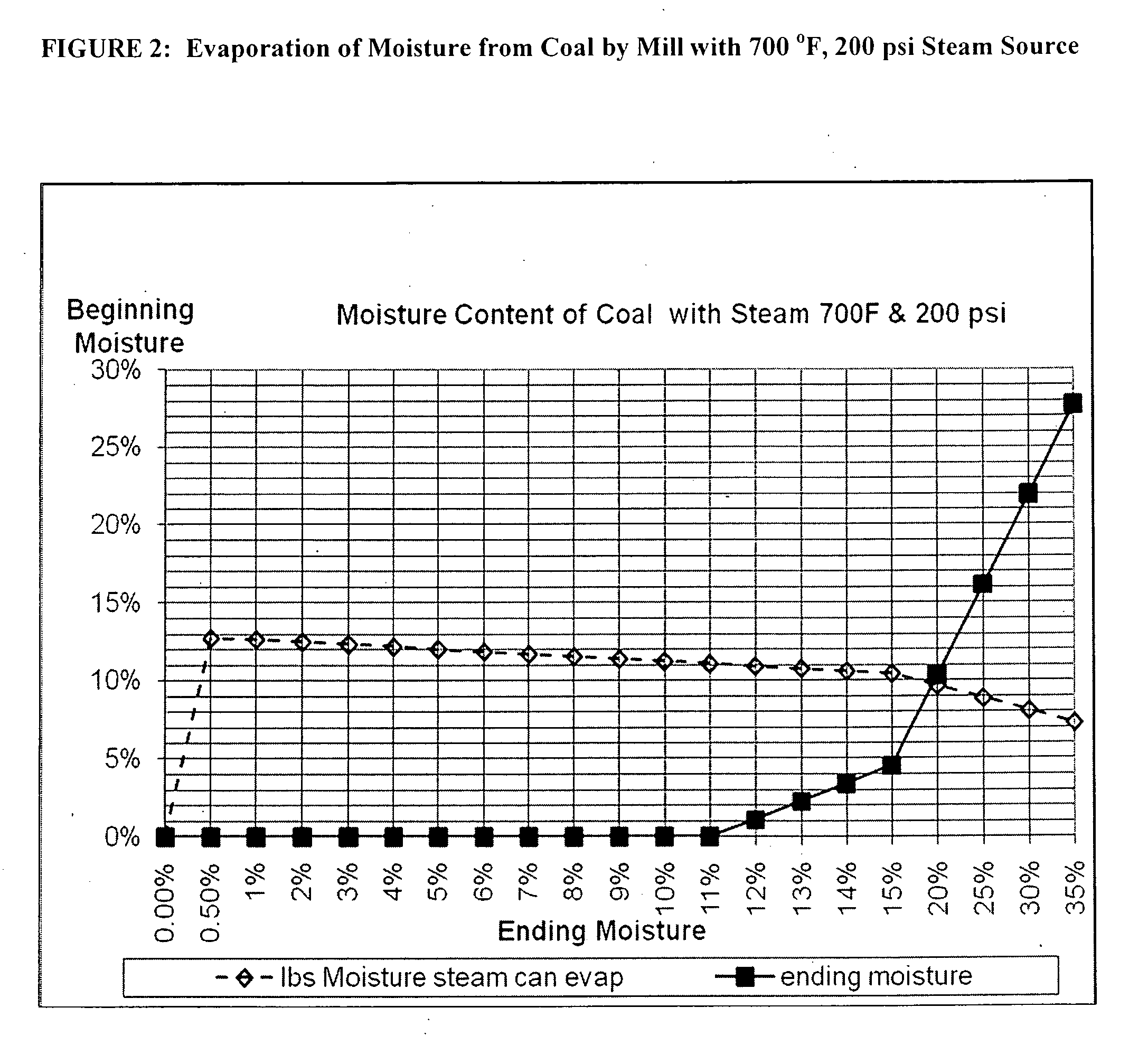

Processing device for improved utilization of fuel solids

InactiveUS20090199425A1Little wearRapid and uniform and fuel efficient gasificationDrying gas arrangementsWaste based fuelCombustionNitrogen oxides

The invention provides an apparatus for comminuting coal or other fuel solids in a shear field, and for optionally coating the solids with catalysts for combustion, liquefaction, and or gasification during the milling process. The apparatus further provides for control of water content in the solids may be controlled before, during and after the milling in order to obtain micronized solids with fine hydration layers. The output fuel solids of the apparatus can burn at low temperatures, avoiding emissions of nitrogen oxides, and they also have improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:HYDROCOAL TECH

Antiseptic wearable coat and coating method thereof

ActiveCN101191225ATo achieve the purpose of corrosion resistance and wear resistanceEasy to operateMetallic material coating processesRheniumThermal spraying

The invention discloses a corrosion and abrasion resistant coating and a coating method thereof, comprising: firstly, weight percentage of compositions of coating materials adopted is that: carbon: less than or equal to 0.5 percent; chromium: 16 to 26 percent; nickel: 3.5 to 9.5 percent; molybdenum: 1.0 to 4.0 percent; boron: 0.5 to 4.5 percent; silicon: 0.5 to 4.5 percent; copper: 1.0 to 4.0 percent; manganese: 0 to 2.0 percent; rare earth - rhenium: 0.01 to 1.5 percent; the residual is ferrum and inevitable impurities; secondly, pretreatment of the surface of a metallic matrix reaches technological demand; thirdly, thermal spraying is adopted on the matrix surface; a plurality of air cooling nozzles surrounding a spray gun which are in parallel with spraying flame velocity are arranged on the spray gun; travel rate of the spray gun is 150 to 400 millimeters per second; surface temperature of workpieces is controlled to be less than 150 DEG C; an amorphous stainless steel protective coating is formed on the matrix surface finally; fourthly, sundries on the coating surface are cleaned, and the coating is performed sealing treatment. The invention solves the protective problem of erosion-corrosion under the condition of acid humid environment and that Cl<-> ions and dust particles exist.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing hollow polyaniline microspheres

InactiveCN102153747AAvoid conversionLow costMicroballoon preparationMicrocapsule preparationMicrosphereAniline

The embodiment of the invention discloses a method for preparing hollow polyaniline microspheres, comprising the following steps: mixing aniline and an oxidant at the molar ratio of 1:(1.5-15) in a solvent for reaction, wherein the aniline can be potassium ferricyanide, sodium ferricyanide, iron phosphate or copper sulfate; and drying the products of reaction to obtain the hollow polyaniline microspheres. In the process of preparing the hollow polyaniline microspheres, spherical micelles are formed by the aniline in the solvent, and the cores of the spherical micelles are filled with aniline droplets. Because the oxidant adopted by the method has low oxidation-reduction potential, the oxidant can not generate acidic materials in the aniline polymerization process, the spherical micelle structure can be prevented from being changed to be in linear or sheet shape, and the hollow polyaniline microspheres can be finally obtained. The method does not require a dopant, is simple, ensures lower cost and can be used for preparing the hollow polyaniline microspheres.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

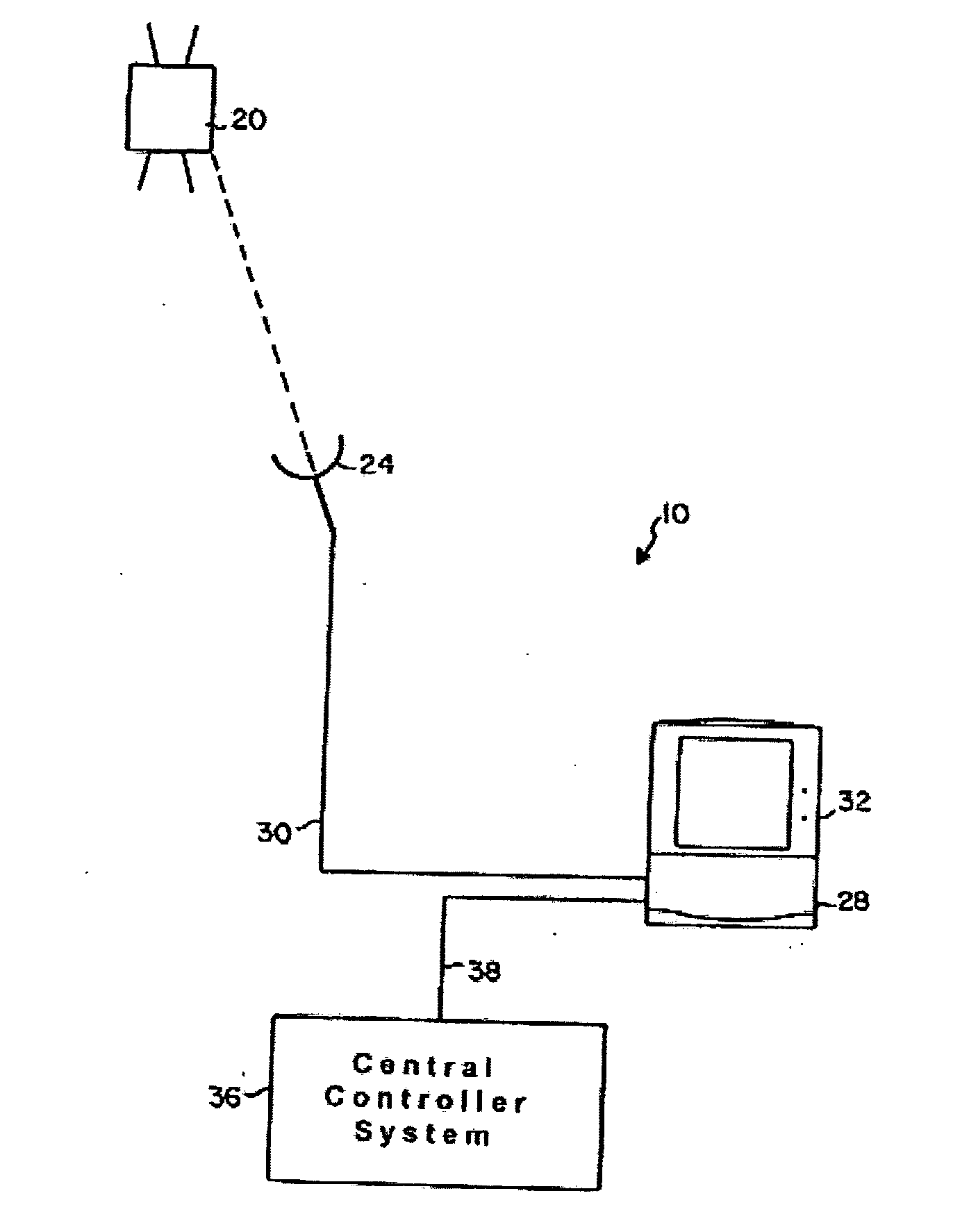

Video distribution system

InactiveUS20060195548A1Simplify controlAvoid conversionTelevision system detailsAnalogue secracy/subscription systemsDistribution systemSatellite downlink

The invention relates to video distribution systems and, more particularly, to a system that blanket transmits video / audio content such as movies (for example, via satellite downlink transmission) to each customer's recording, storage and playback system. Customers may preselect from a list of available movies or other content in advance using an interactive screen selector, and pay for the video / audio content that is actually viewed.

Owner:OCHOA OPTICS

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalyst

ActiveCN103773436AChange processLess investmentHydrotreatment operations starting-upHydrocarbon oil crackingNaphthaEngineering

The invention discloses a start-up method for an ex-situ prevulcanization secondary activity center hydrogenation catalyst. After resistance to air loss of a device is qualified, circulating hydrogen compressor working load is adjusted to 0-20% of a maximum load, the catalyst reacts at a low temperature to release heat; when the bed layer temperature rise to 60-150 DEG C, start-up activation oil is introduced, the circulating hydrogen compressor working load is adjusted to 60-100% of the maximum load for wetting of the catalyst; the start-up activation oil is cycled in a reaction system closed path, the catalyst bed temperature is risen to 180 to 230 DEG C by heat exchange; a proper amount of olefin-enriched naphtha is added into the start-up activation oil, the catalyst bed temperature is risen to 300-380 DEG C to complete start-up activation. The start-up method, in the premise of no influence on the use properties of the secondary activity center hydrogenation catalyst, can better use the catalyst characteristics, reduce the device energy consumption, and reduce the device investment cost, and the start-up process can be simplified.

Owner:CHINA PETROLEUM & CHEM CORP +1

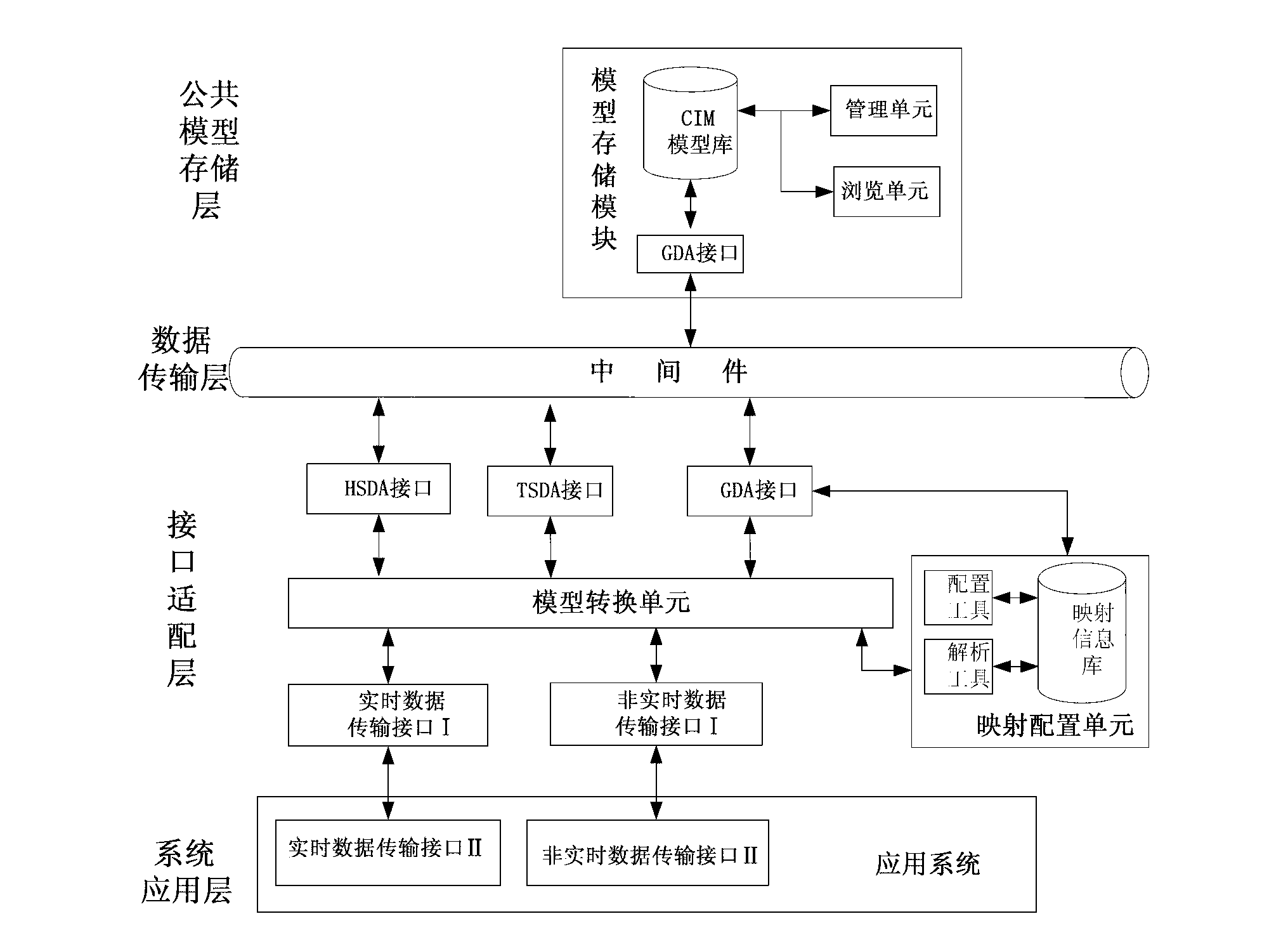

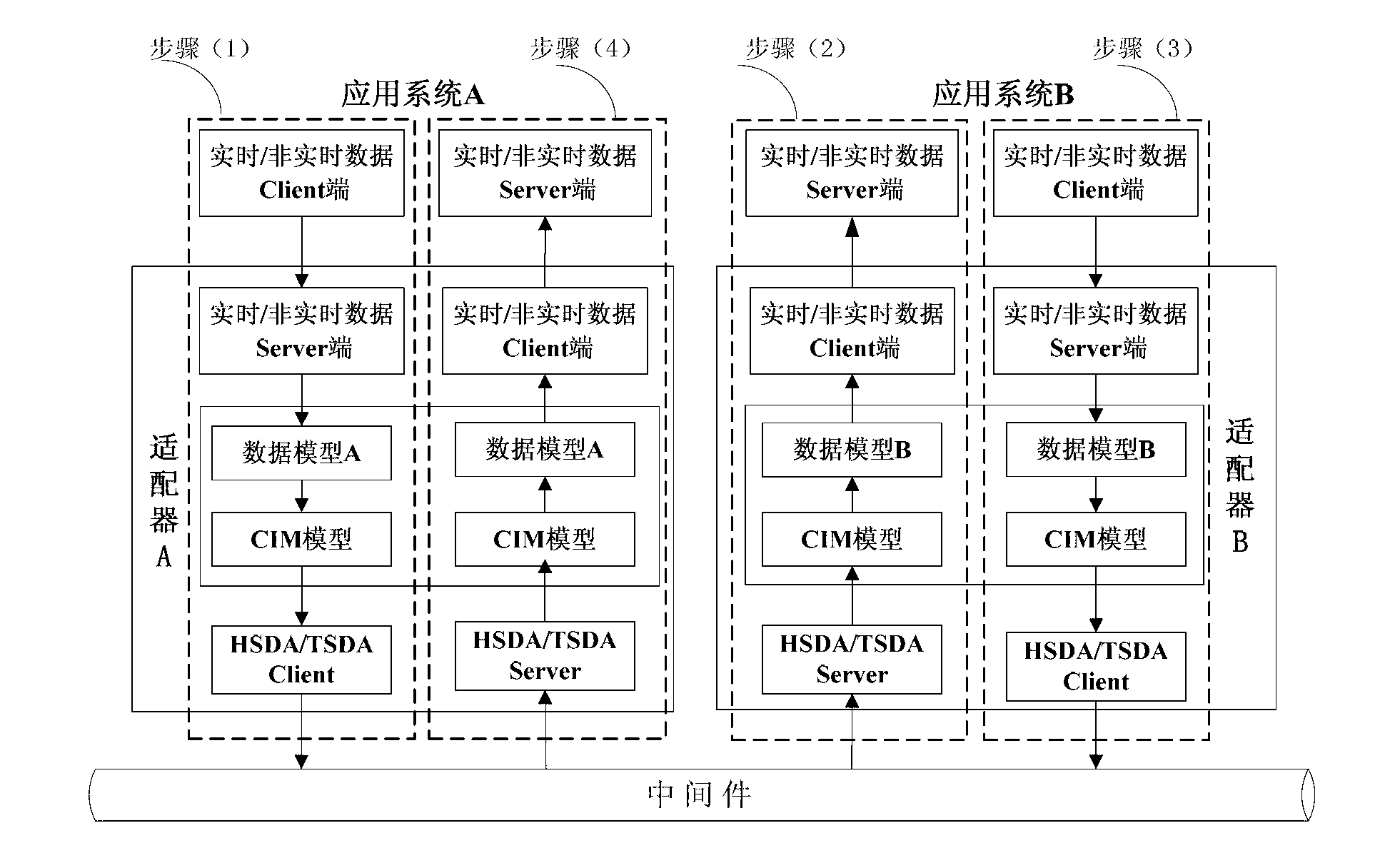

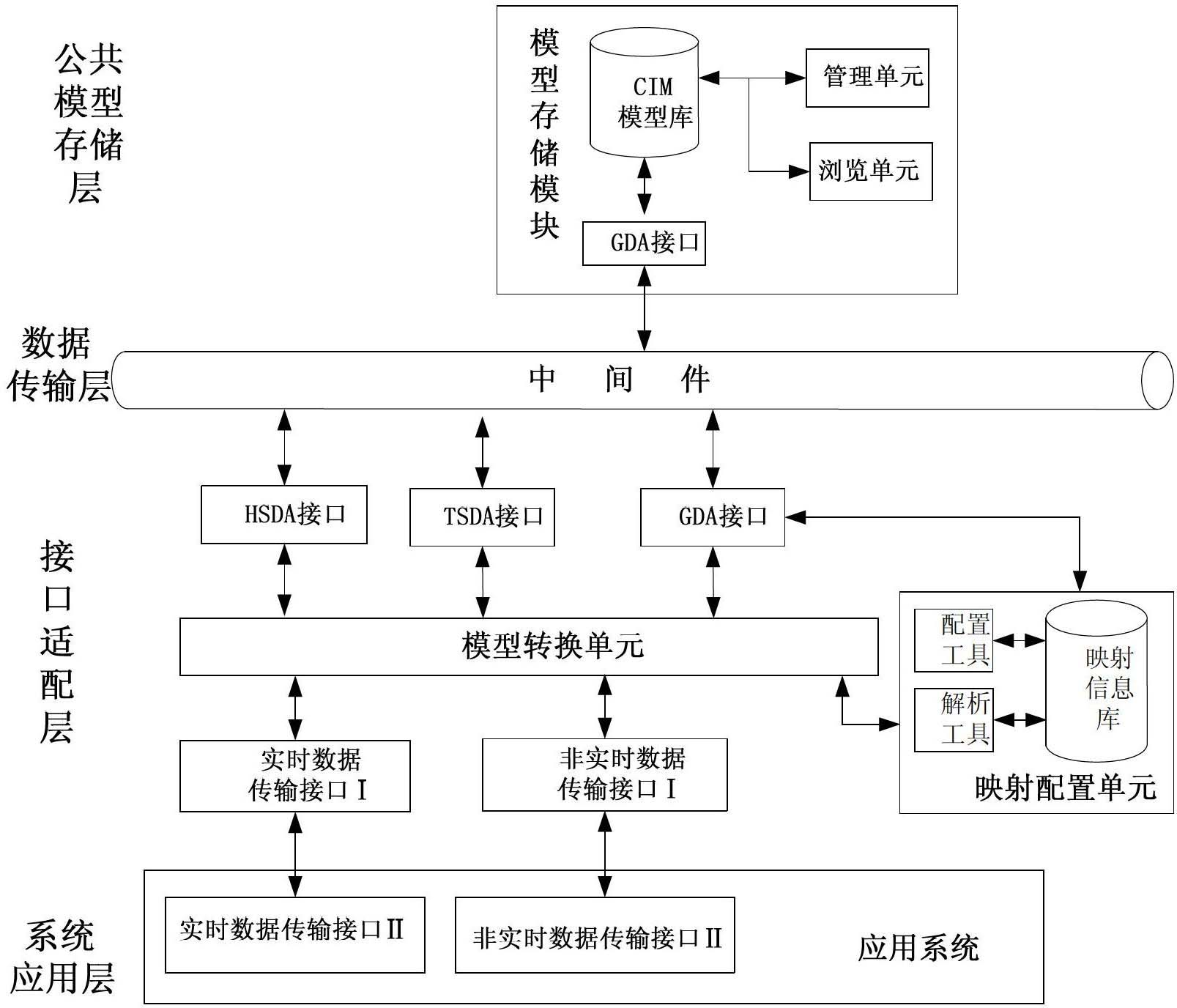

System integration interface adapter based on common information model (CIM)

ActiveCN102710435AStrong scalabilityReduce integration development costsElectric signal transmission systemsData switching networksData transmissionSystem information

The invention relates to a system integration interface adapter based on a common information model (CIM). The system integration interface adapter comprises a common model storage layer, a data transmission layer, an interface adaptation layer and a system application layer. The common model storage layer is used for storing common model information and providing application functions of model display, maintenance and management. The data transmission layer is used for providing data transmission channels and carrying out data transmission with the interface adaptation layer and the common model storage layer. The interface adaptation layer is used for completing bilateral switching of a data model and standard operation of an interface. The system application layer carries out data transmission with the interface adaptation layer. According to the system integration interface adapter, a CIM provided by the international electrotechnical commission (IEC) 61970 / 61968 standard is adopted and Chinese industrial standards (CIS) interface specifications are adopted as the basis of system information interaction, so that the system integration interface adapter accords with the development tendency of electrical power system information integration, is compatible with an application system built by power enterprises and put into operation, supports new system interface design standard proposed by the trade union, can meet integrating requirements of the existing application system, has wide applicability and perspectiveness, and has good market promotion and application value.

Owner:STATE GRID CORP OF CHINA +2

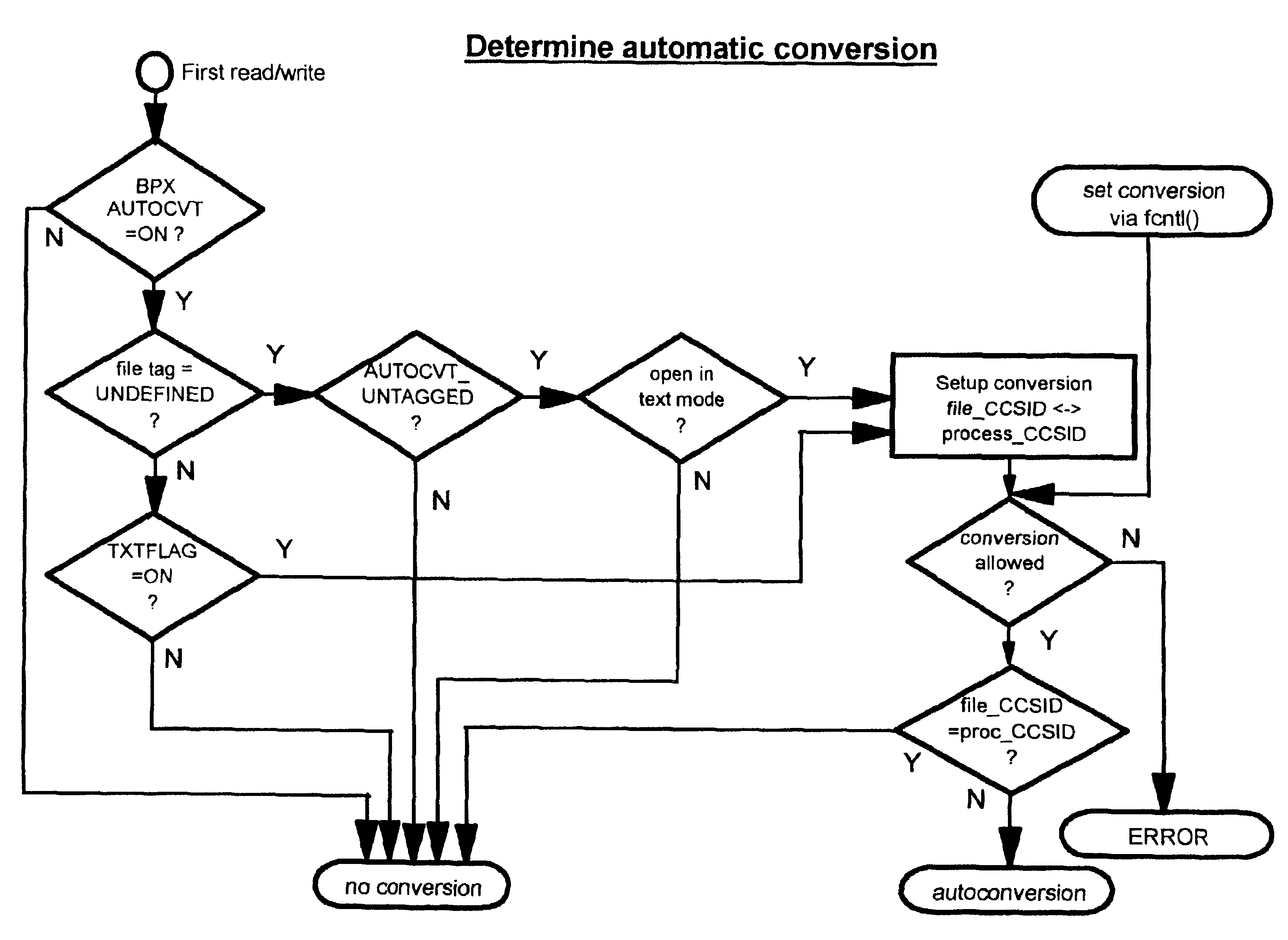

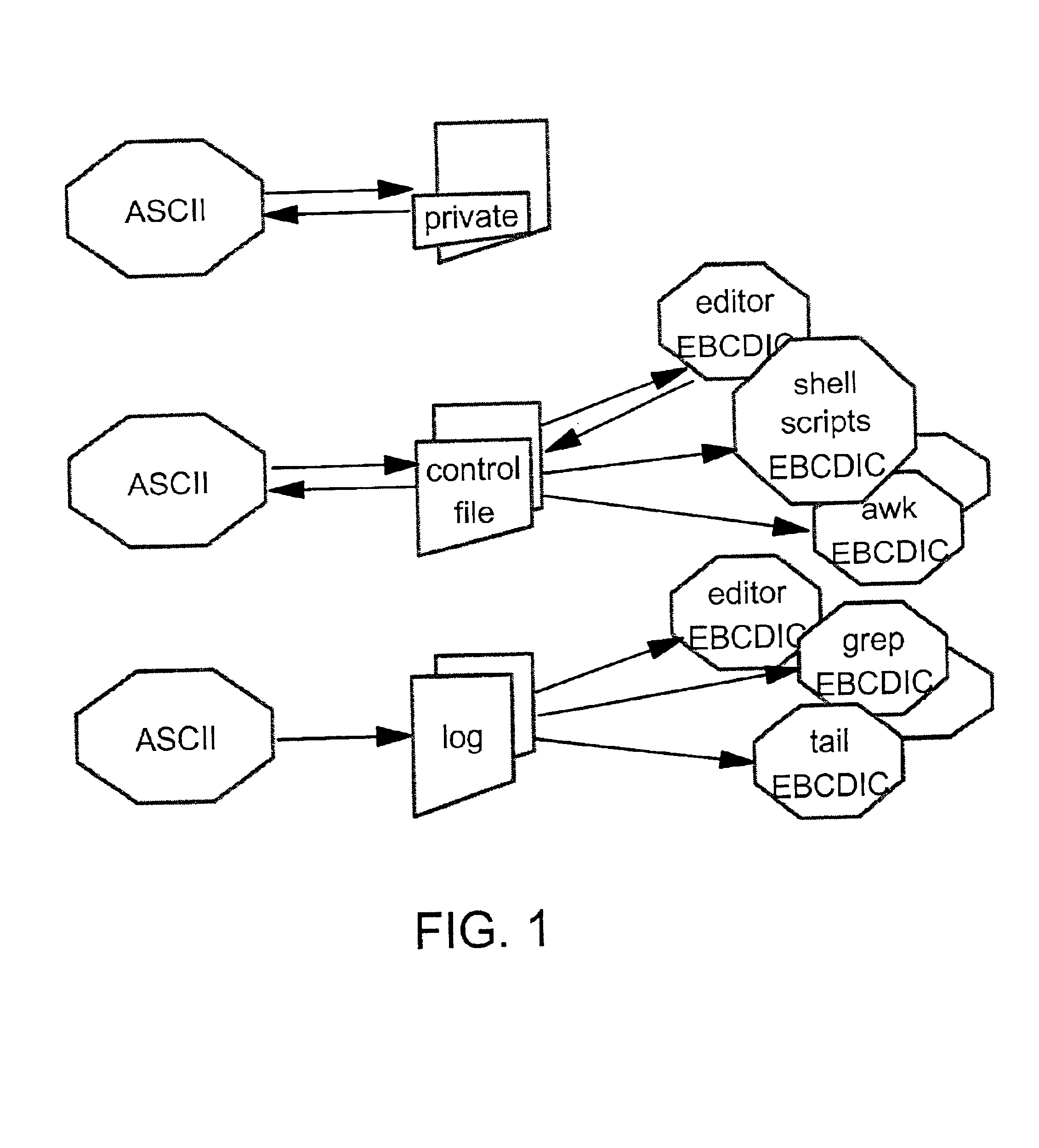

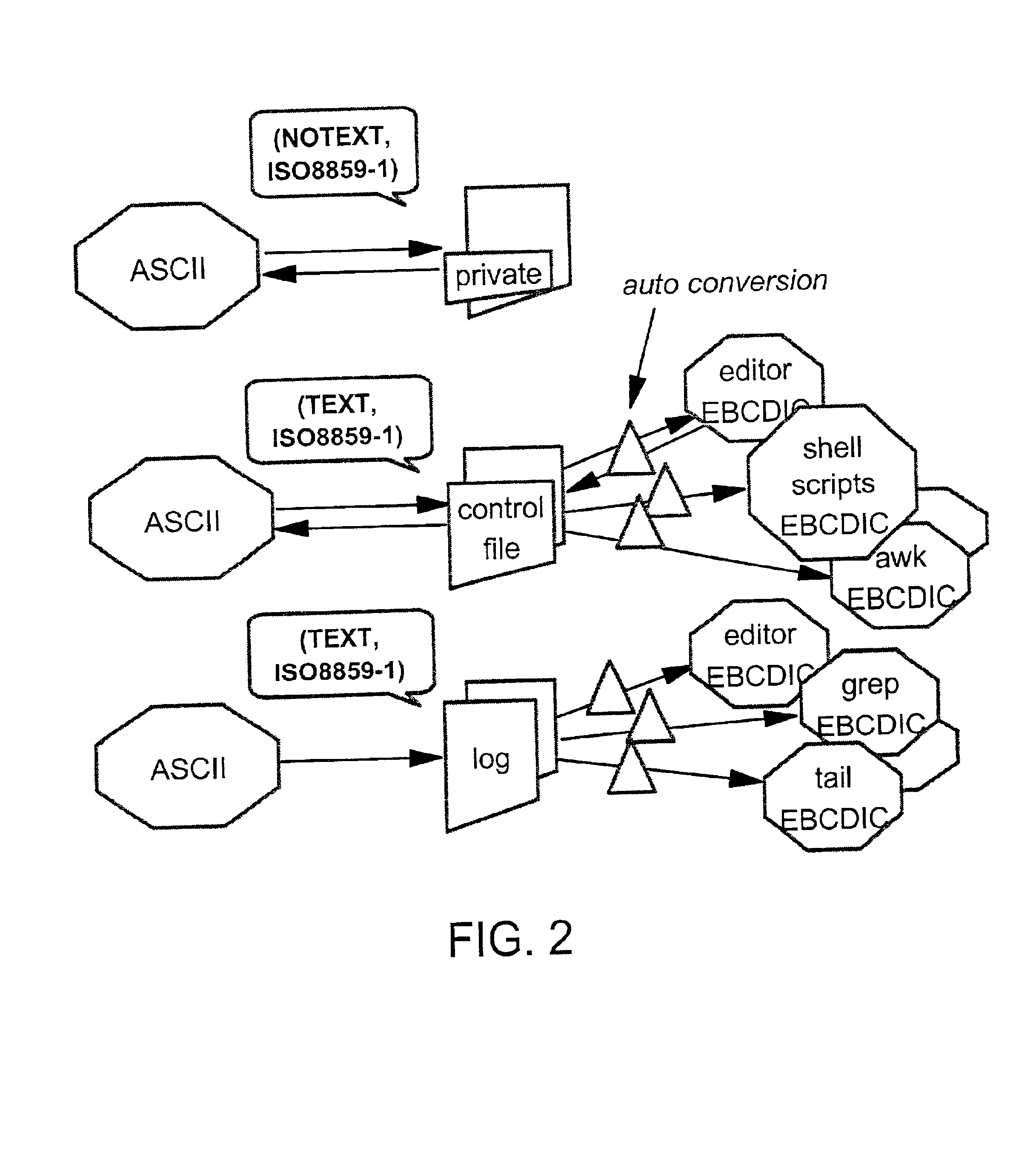

File tagging and automatic conversion of data or files

InactiveUS6910183B2Avoid conversionMetadata text retrievalData processing applicationsData conversionApplication software

The present invention provides facilities for tagging files or data with attribute information in the form of a file tag (TAGINFO) which contains an identifier for text information (TEXTFLAG) and an attribute (COSID) for identifying encoding schemes. TXTFLAG is an auto conversion flag. Furthermore, a runtime attribute (process CCSLD) is assigned to a process specifying the runtime encoding scheme. A conversion is done automatically by an auto conversion function if both CCSIDs allow a conversion. Files having no file tag are tagged with a virtual file tag by means of an automatic tagging (AUTOTAG) function using heuristic rules for determining whether the data or file contains text or binary information. Old applications must work with untagged files as before. Existing applications should be able to benefit from auto conversion and thereby to be enabled to process new, tagged files without code changes.

Owner:TREND MICRO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com