Patents

Literature

95 results about "Forming limit diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

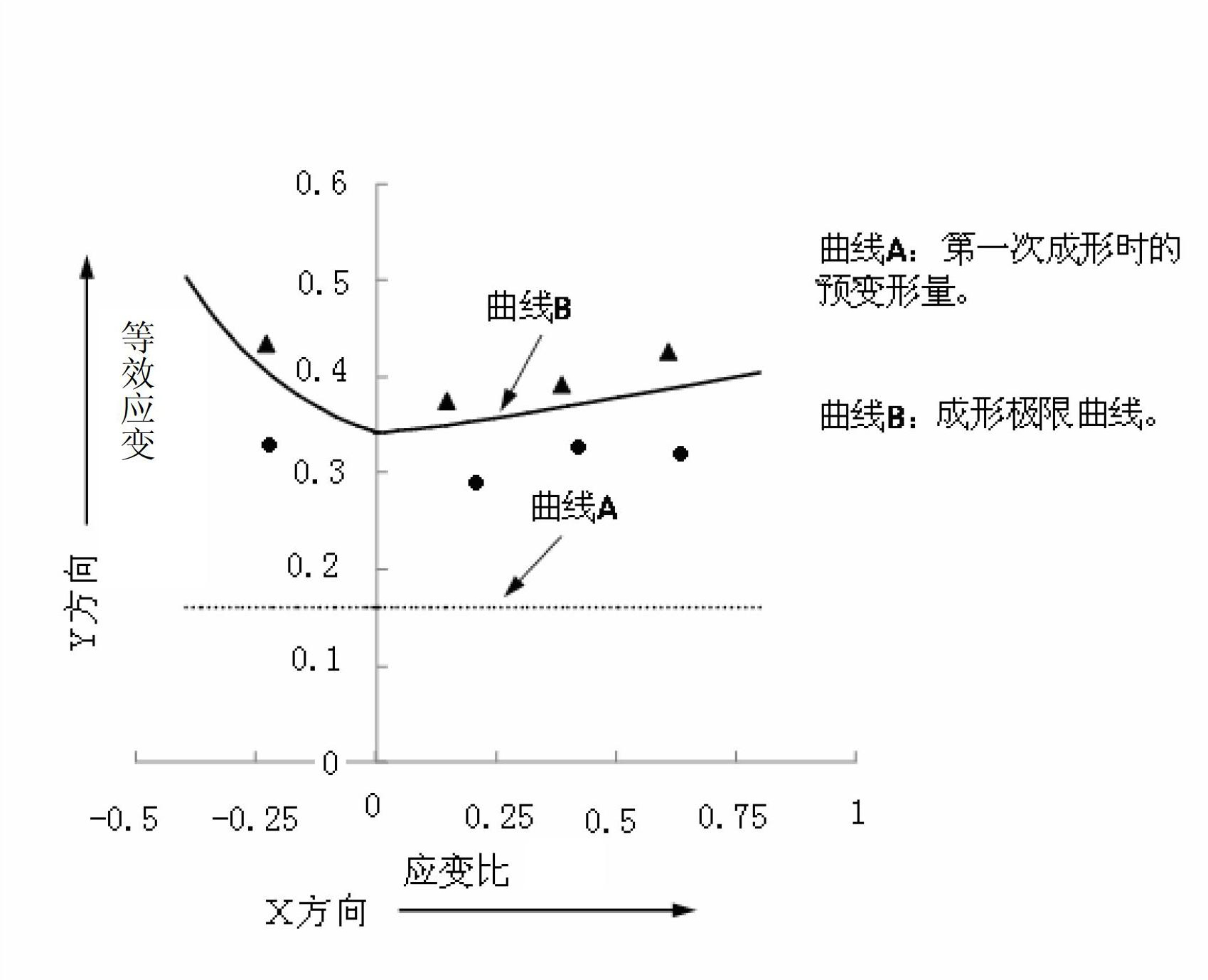

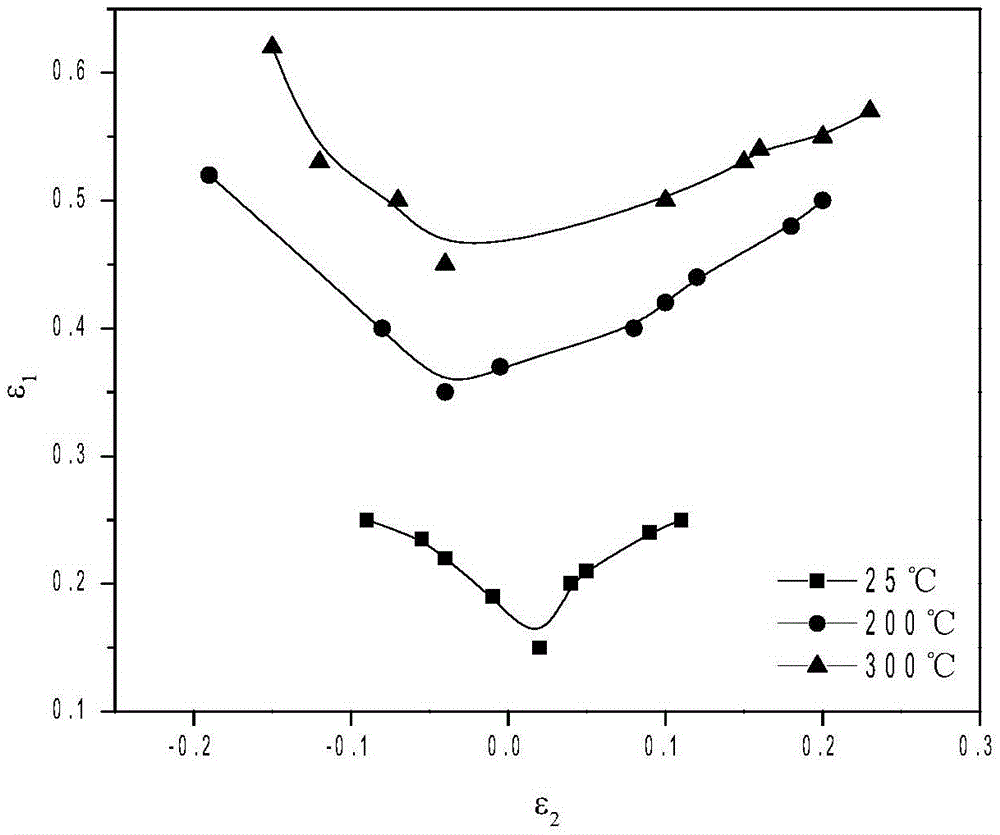

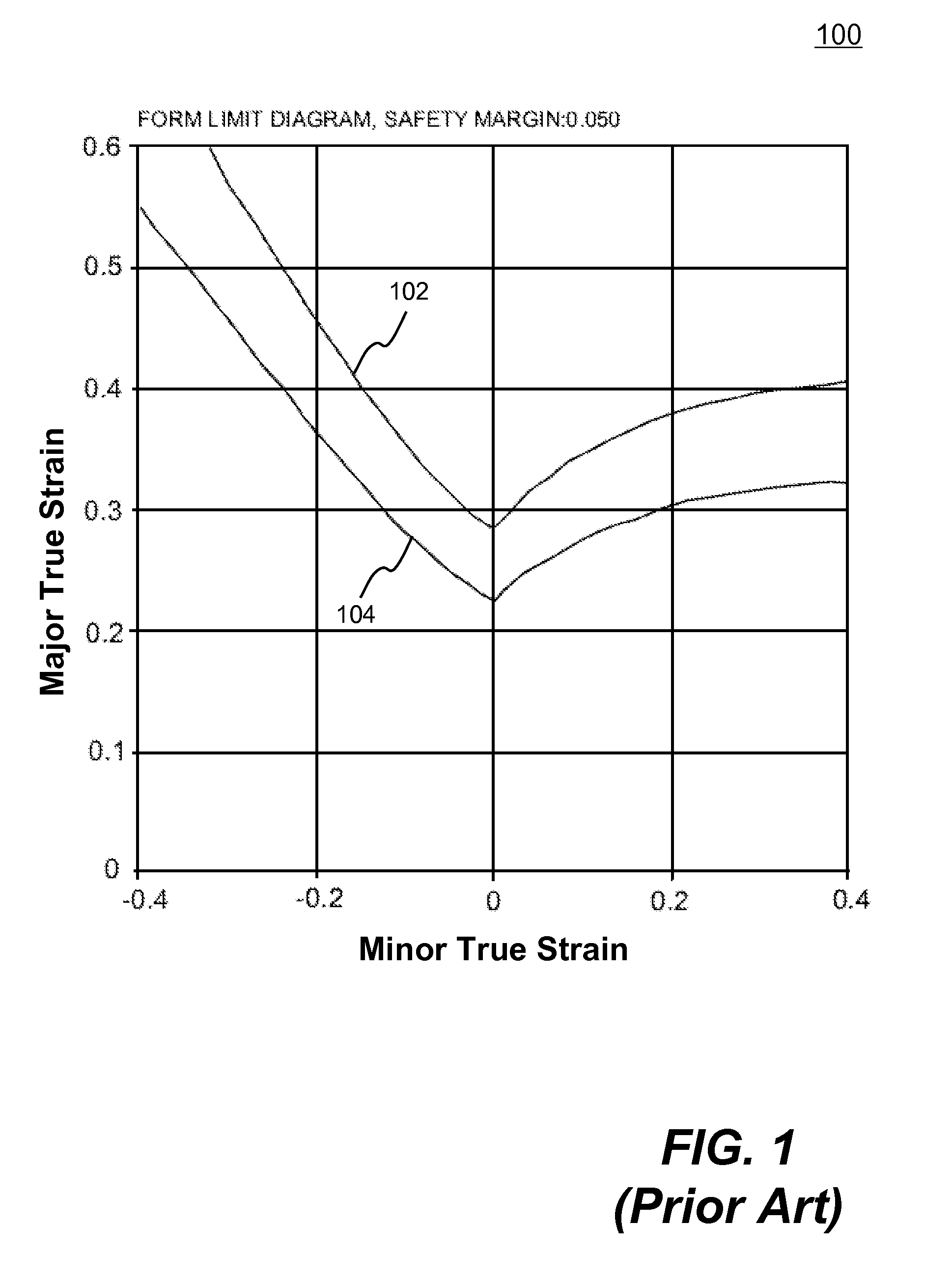

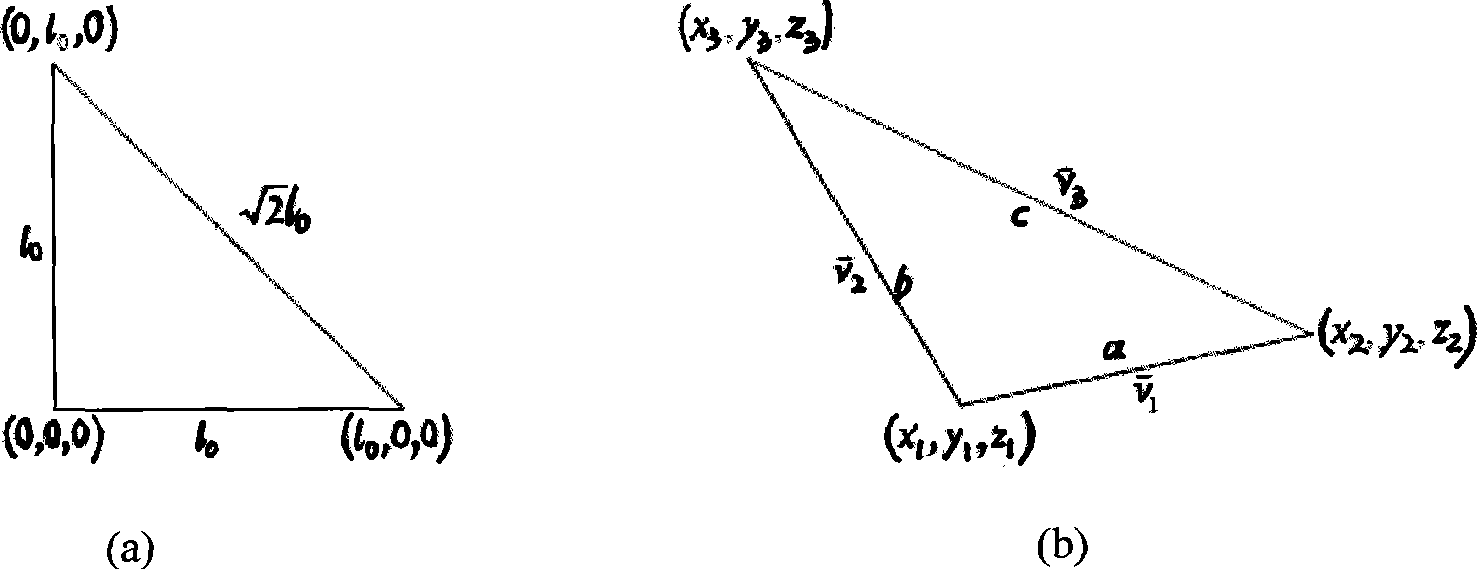

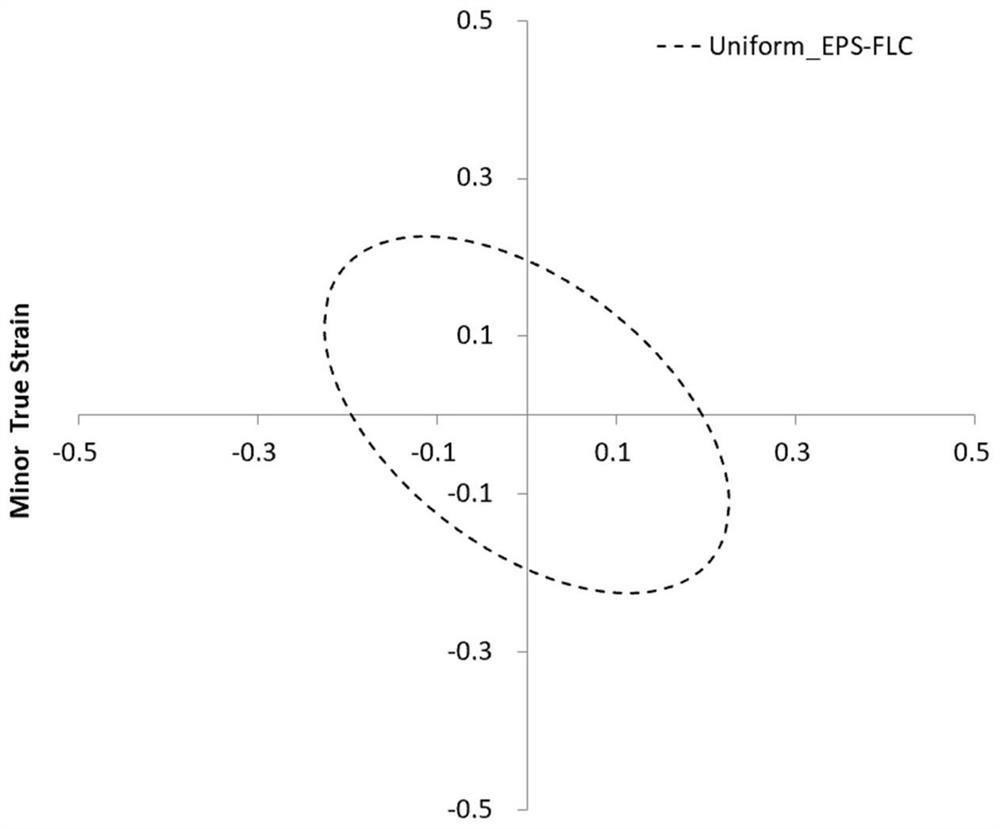

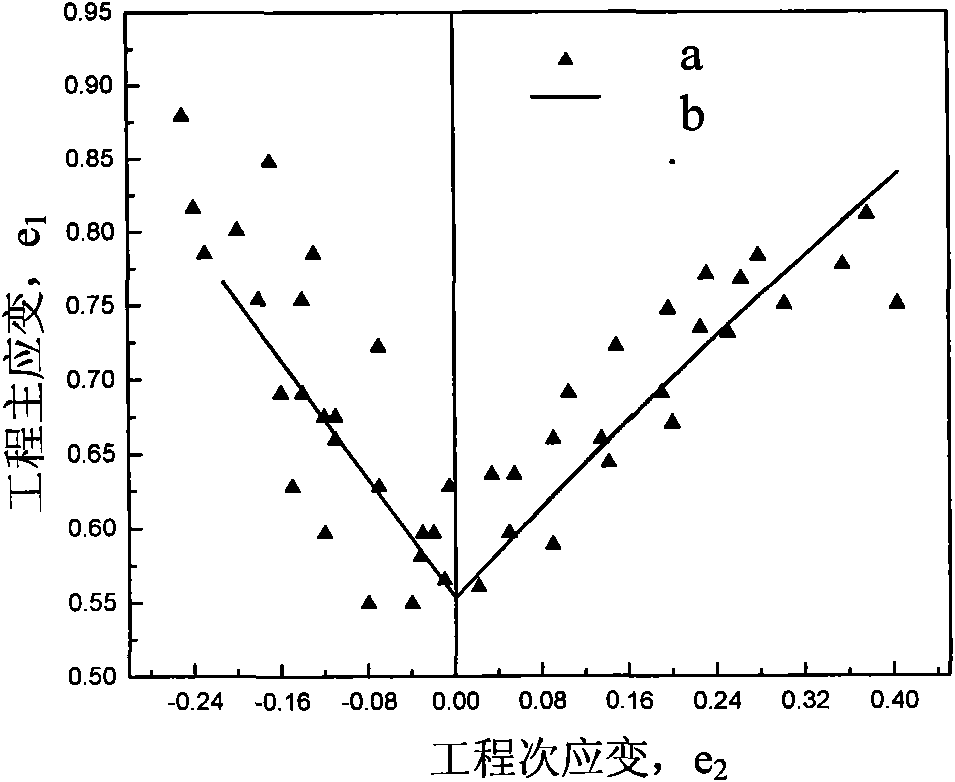

A forming limit diagram, also known as a forming limit curve, is used in sheet metal forming for predicting forming behavior of sheet metal. The diagram attempts to provide a graphical description of material failure tests, such as a punched dome test.

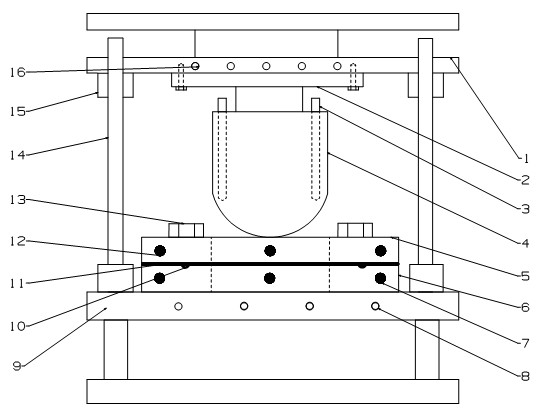

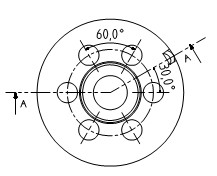

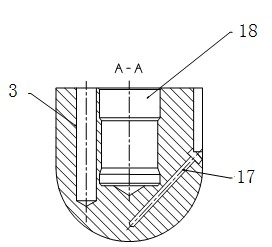

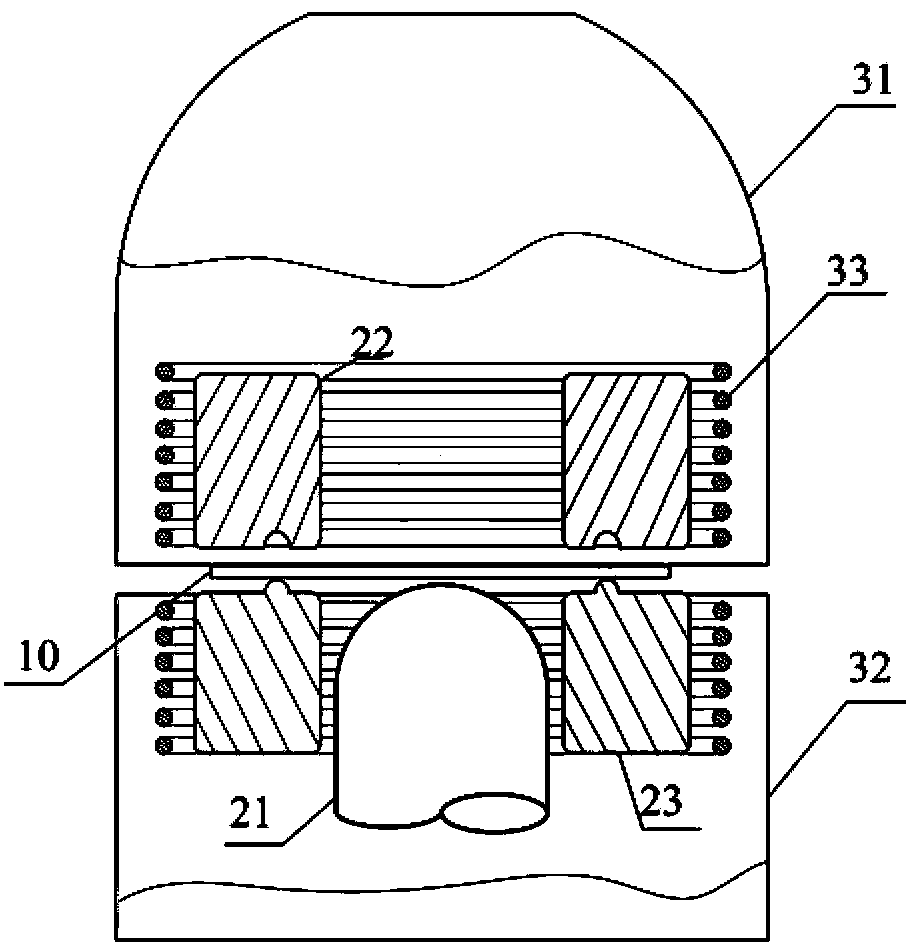

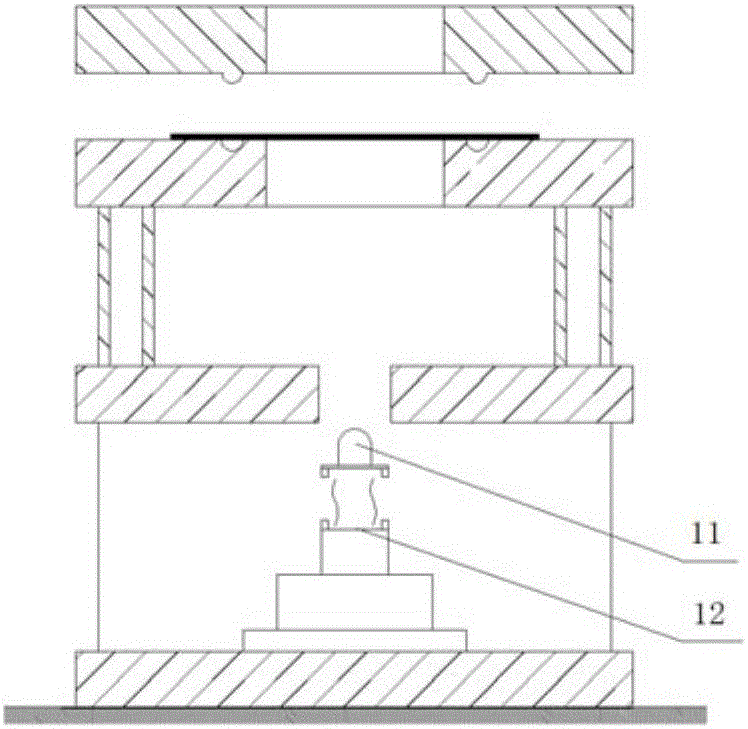

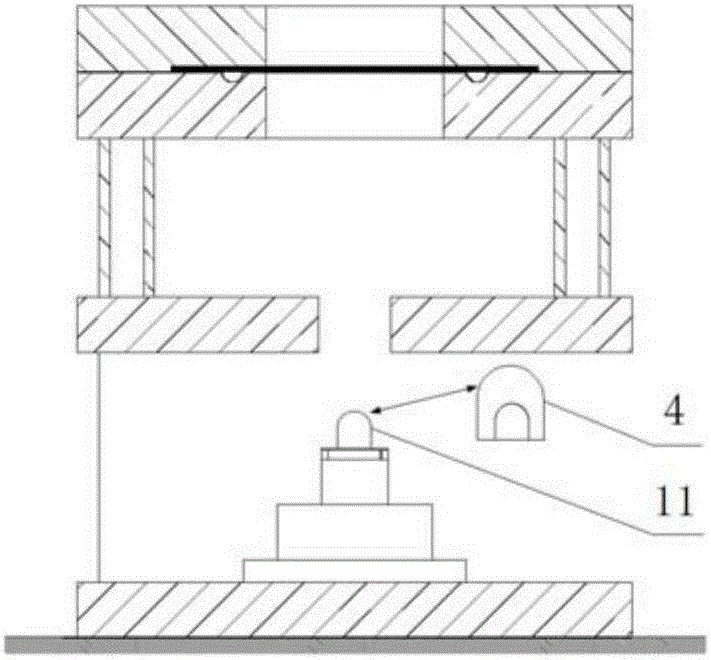

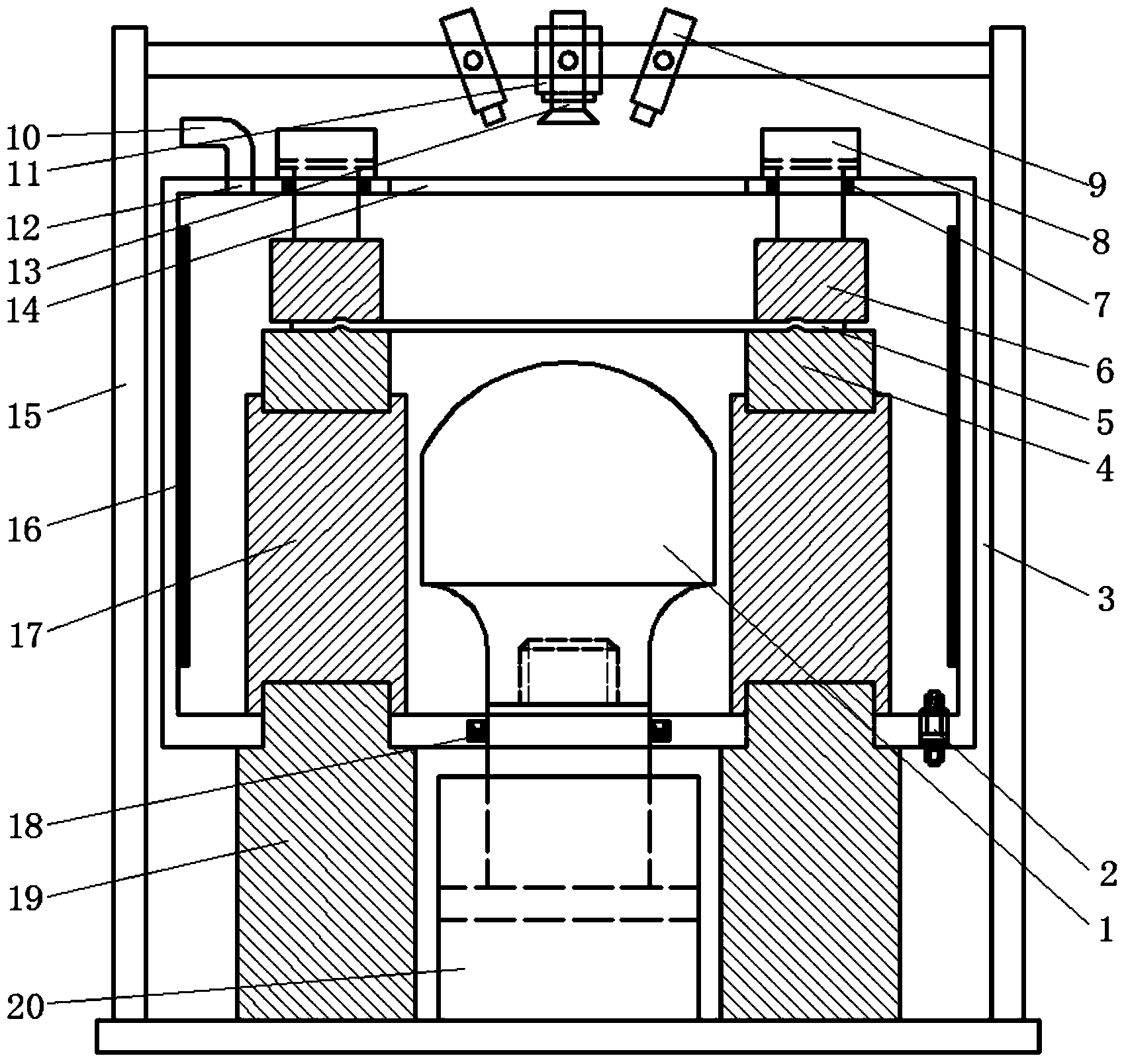

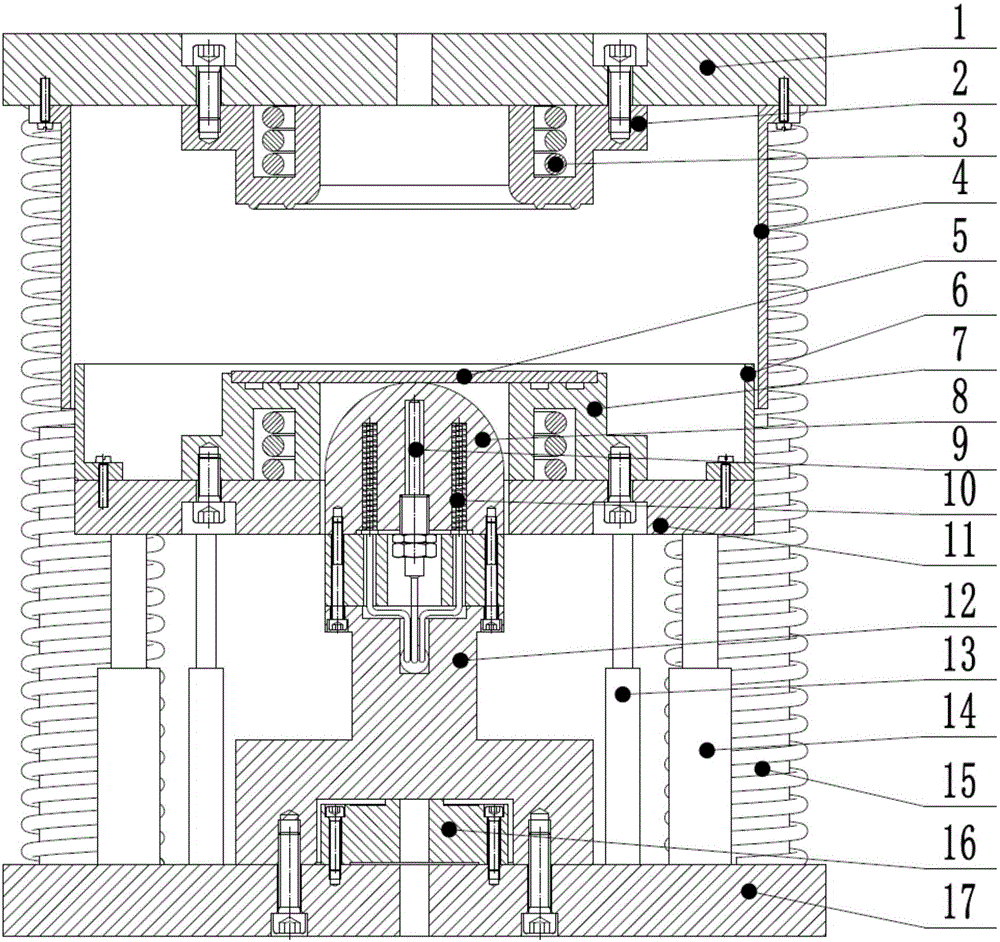

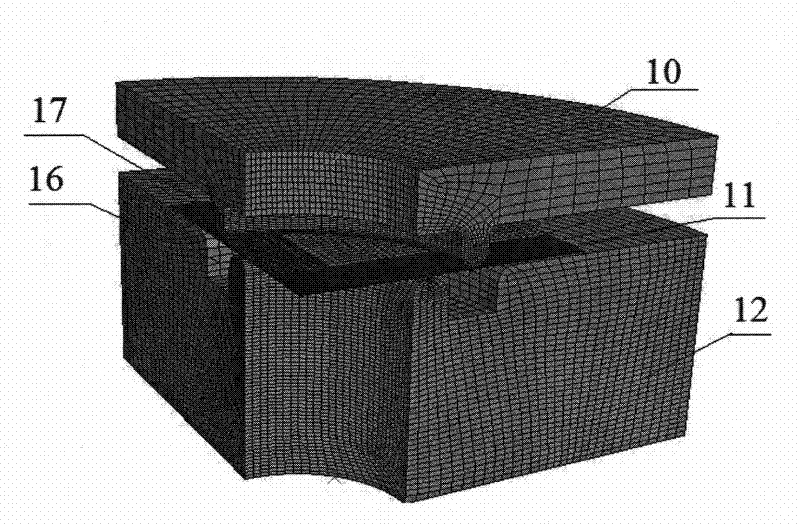

Testing device and testing method for establishing high-temperature formed limit diagram of ultrahigh-strength boron steel plate

InactiveCN102156080ARigid enoughGuaranteed reliabilityInvestigating material ductilityForming limit diagramSheet steel

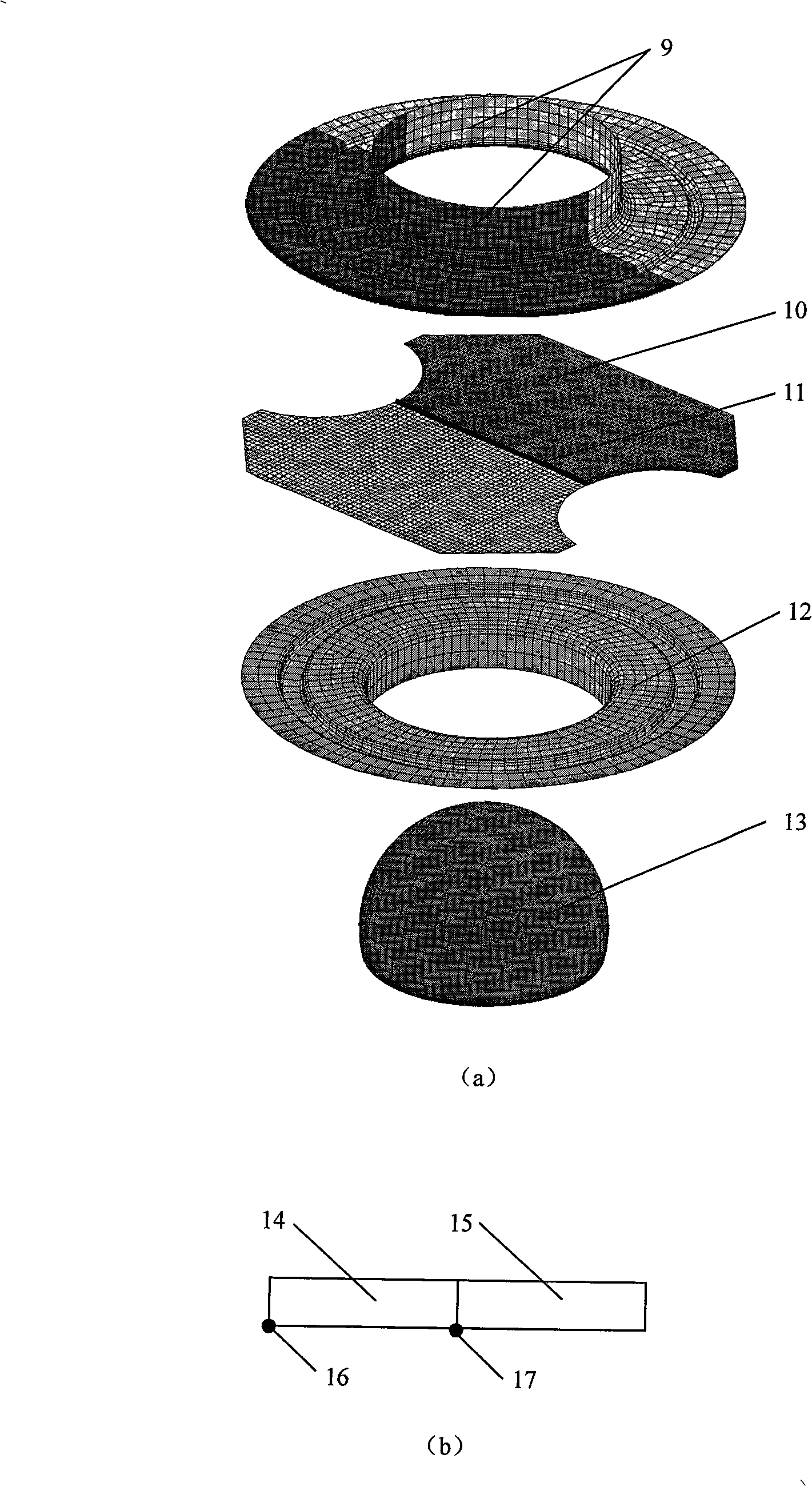

The invention relates to a testing device for establishing a high-temperature formed limit diagram of an ultrahigh-strength boron steel plate. The testing device comprises an upper die frame and a lower die frame, wherein the lower die frame is provided with a plurality of guide posts, the upper die frame is sleeved on the guide posts, the lower surface of the upper die frame is provided with a male die device, and the lower die frame is provided with a blank holder and a female die which correspond to the position of the male die device and are stacked up and down and fixed together through a connector; the upper die frame and the lower die frame are provided with a cooling water passage respectively; heaters are arranged in a male die, the female die and the blank holder; and a temperature probe is arranged at the inner end of the male die. Meanwhile, the invention also discloses a testing method using the device. By combining the high-temperature expansion test requirement of the ultrahigh-strength steel plate, the formed limit diagram of the ultrahigh-strength steel plate at a certain specific high temperature is obtained by thermal forming limit test. The device and the method have significance for researching the forming performance of the ultrahigh-strength boron steel plate for an automobile, and can promote the popularization and application of ultrahigh-strength boron steel in the field of automobiles.

Owner:SHANDONG JIANZHU UNIV

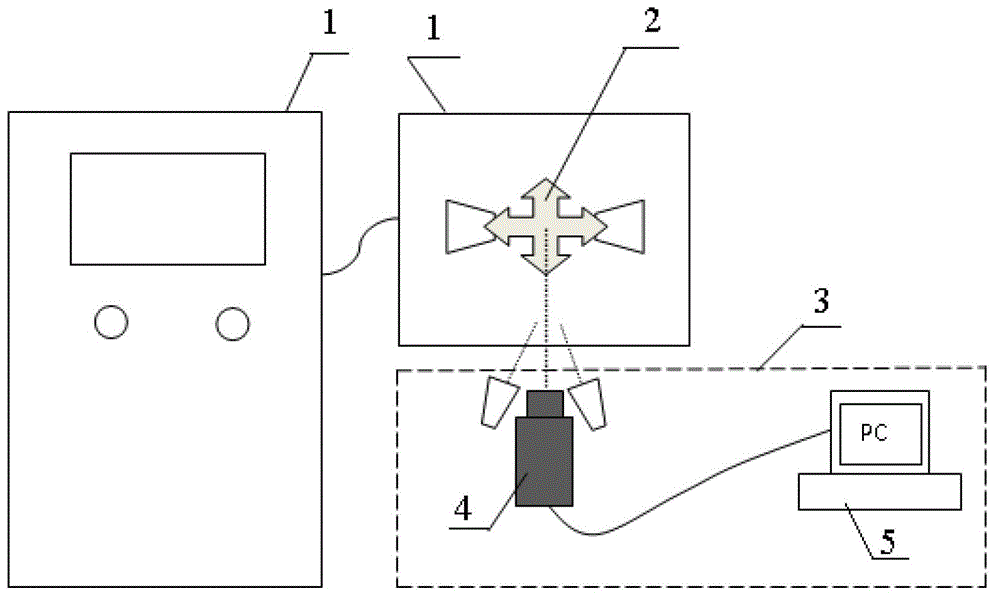

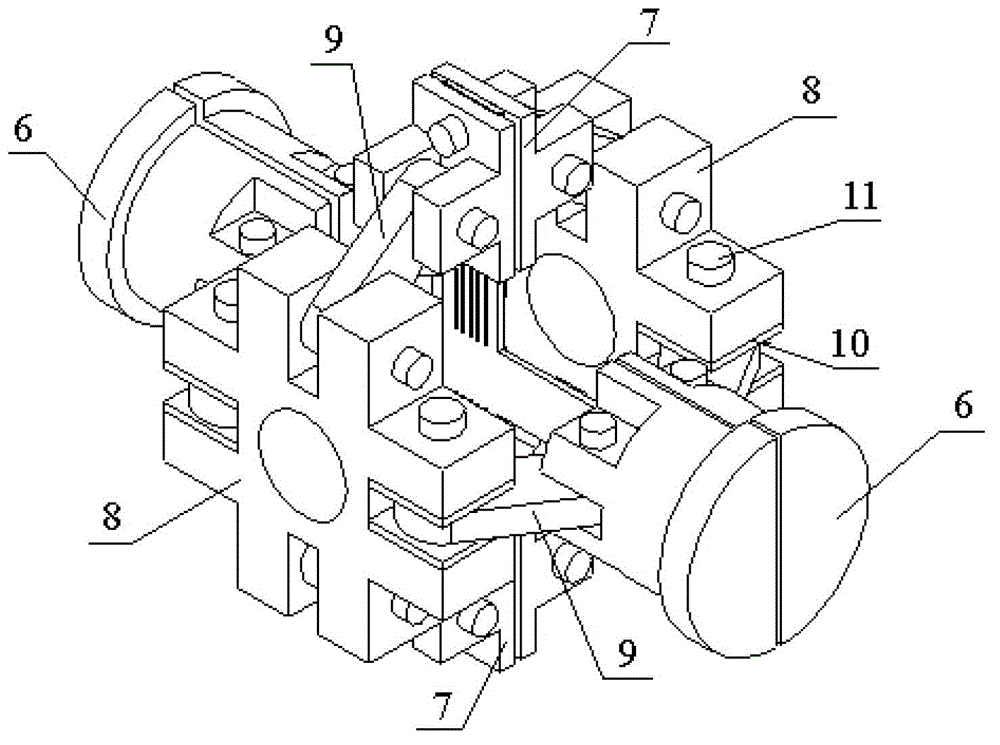

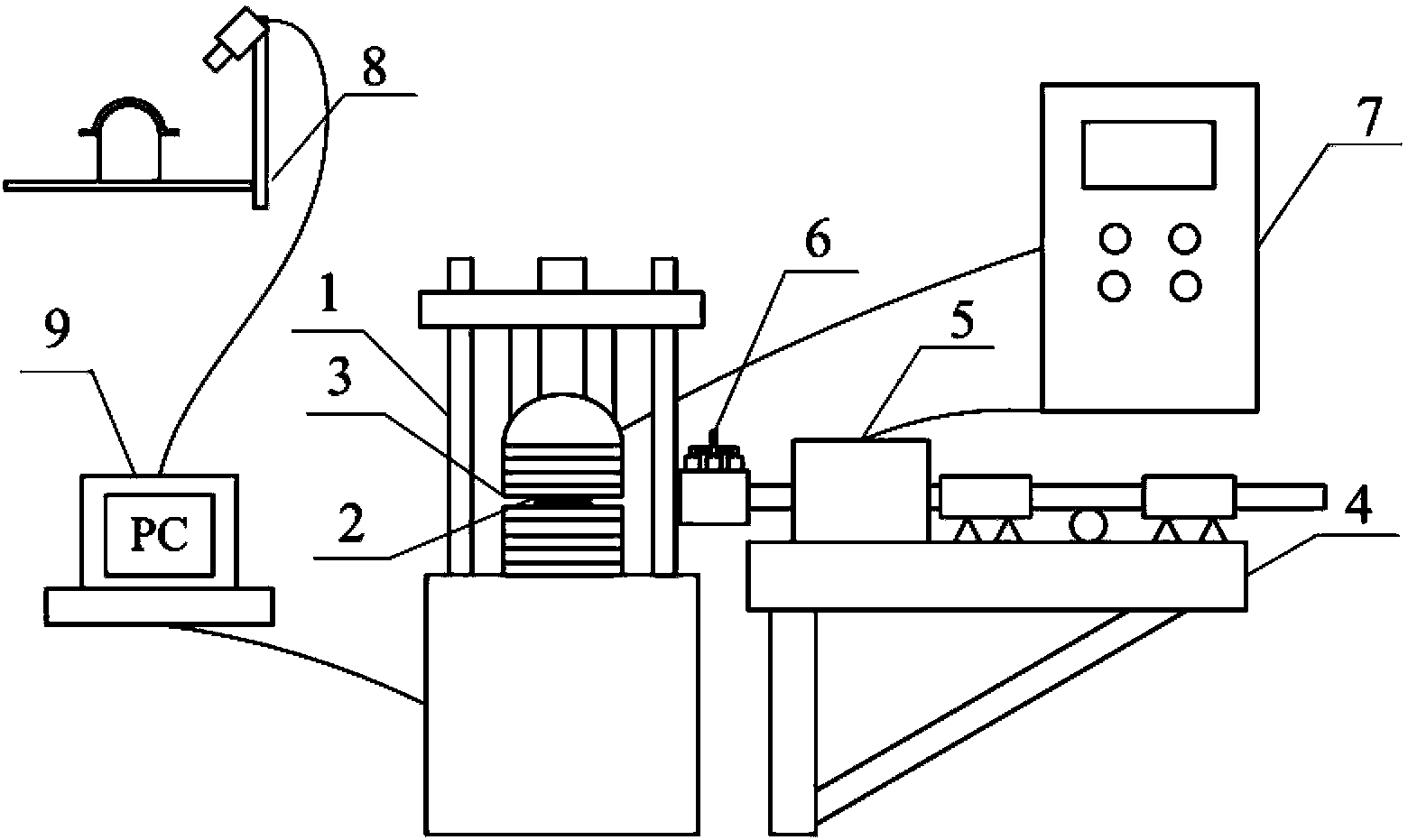

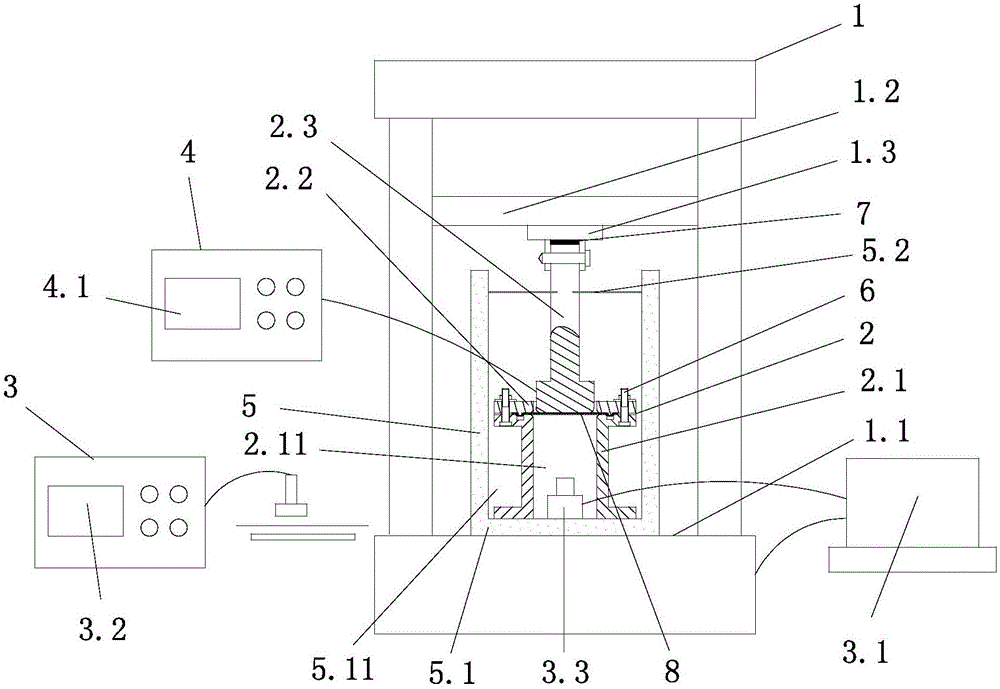

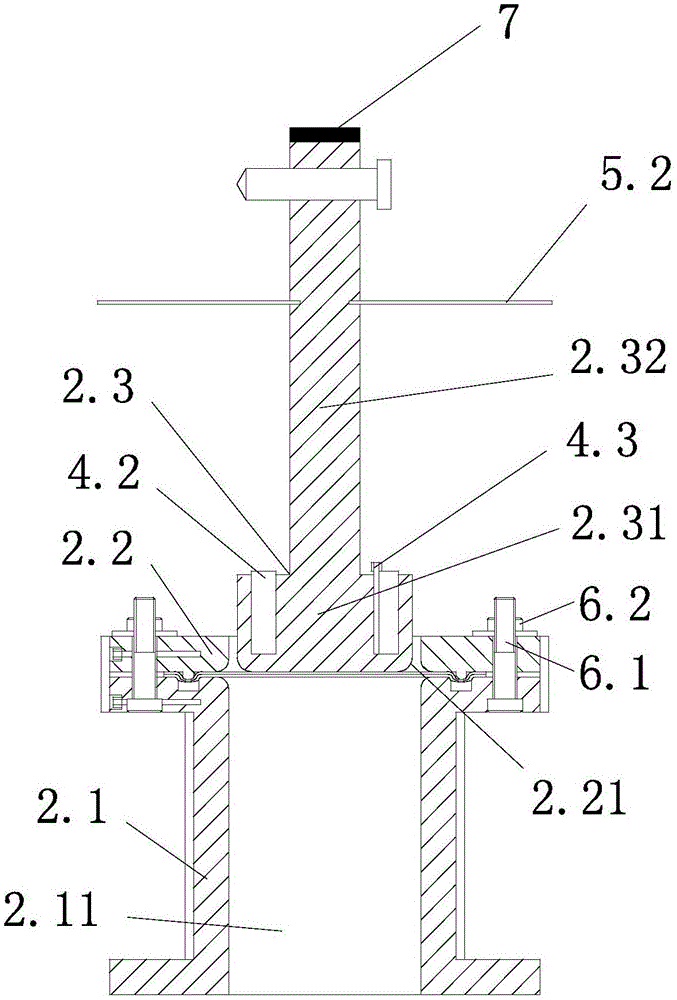

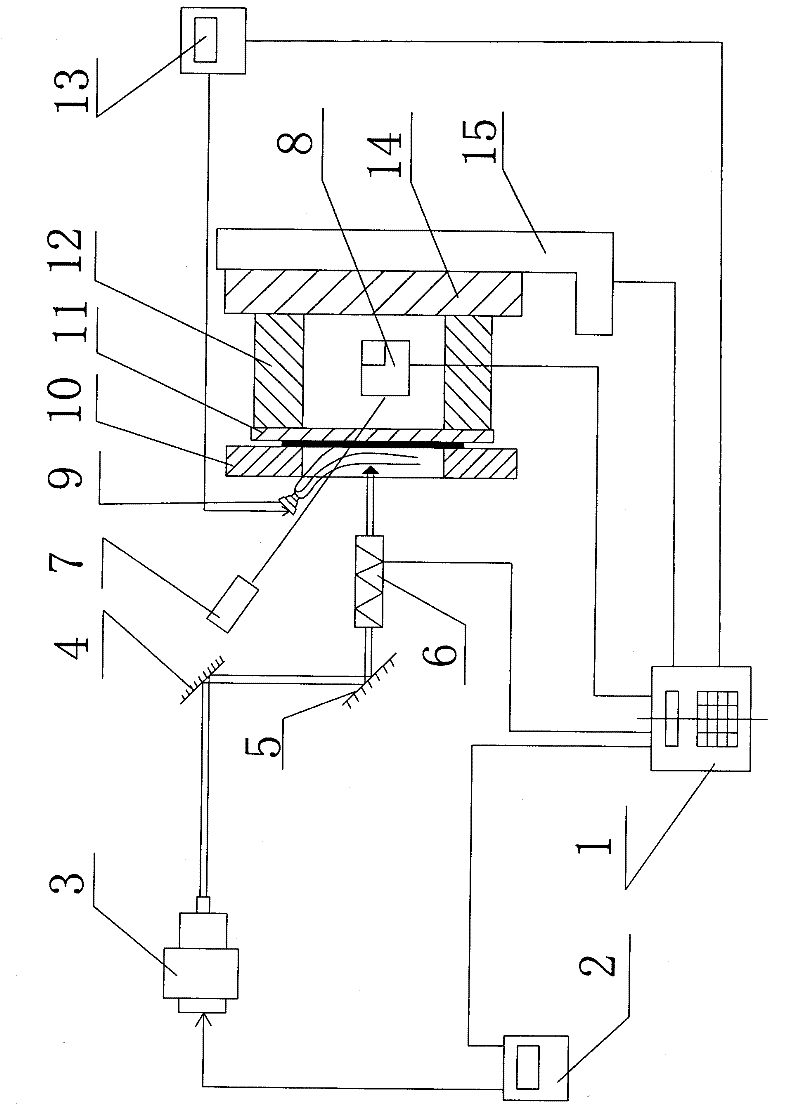

Testing system and method of plate high temperature forming limit diagram

ActiveCN102749253APrecise temperature controlFrictionlessInvestigating material ductilityForming limit diagramSimulation testing

The invention discloses a testing system of a plate high temperature forming limit diagram. The testing system comprises a biaxial drawing device, a material heat / force simulation testing device and a measurement analysis device, wherein the biaxial drawing device is used for carrying out drawing deformation on a sample after the sample is heated by the material heat / force simulation testing device; the measurement analysis device is used for obtaining sample deformation data and analyzing and calculating the sample transformation data so as to obtain the plate forming limit diagram. According to the testing method of the plate high temperature forming limit diagram, by designing the biaxial drawing device and corresponding samples at different strain states, the temperature and the strain velocity of a sample transformation area can be controlled accurately by using the material heat / force simulation testing device; and moreover the deformation area is free from friction during the drawing process; the operation is simple; the forming limit diagrams under different temperatures and strain velocities of a plate can be obtained; and important references are provided for process design and mold design in the plate tepidity forming technology.

Owner:SHOUGANG CORPORATION

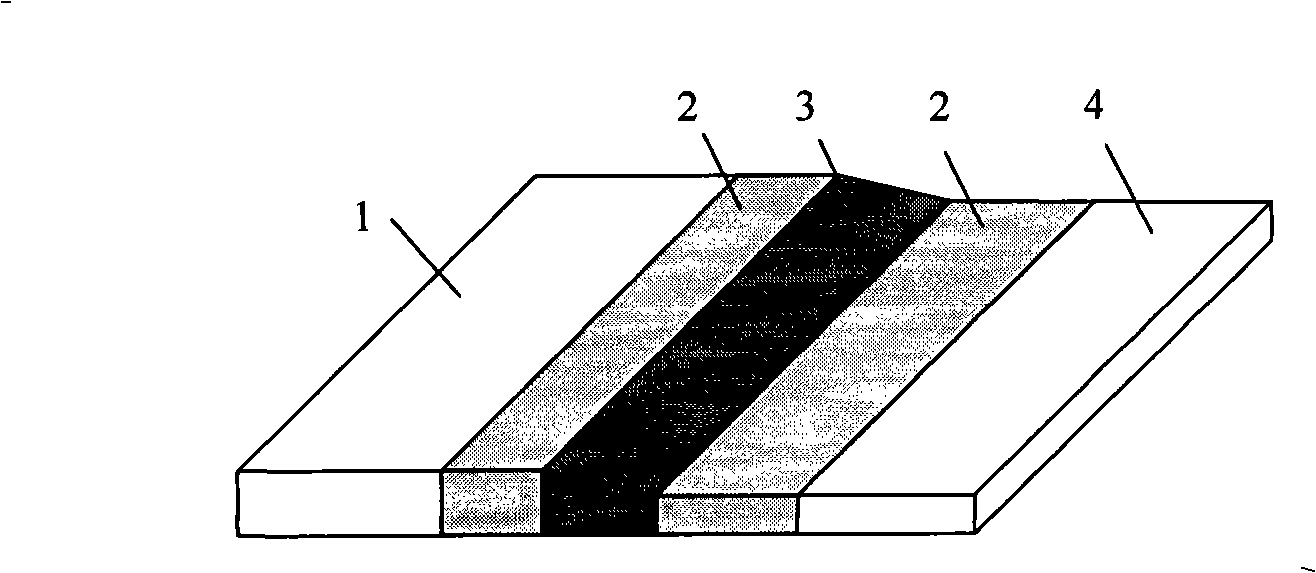

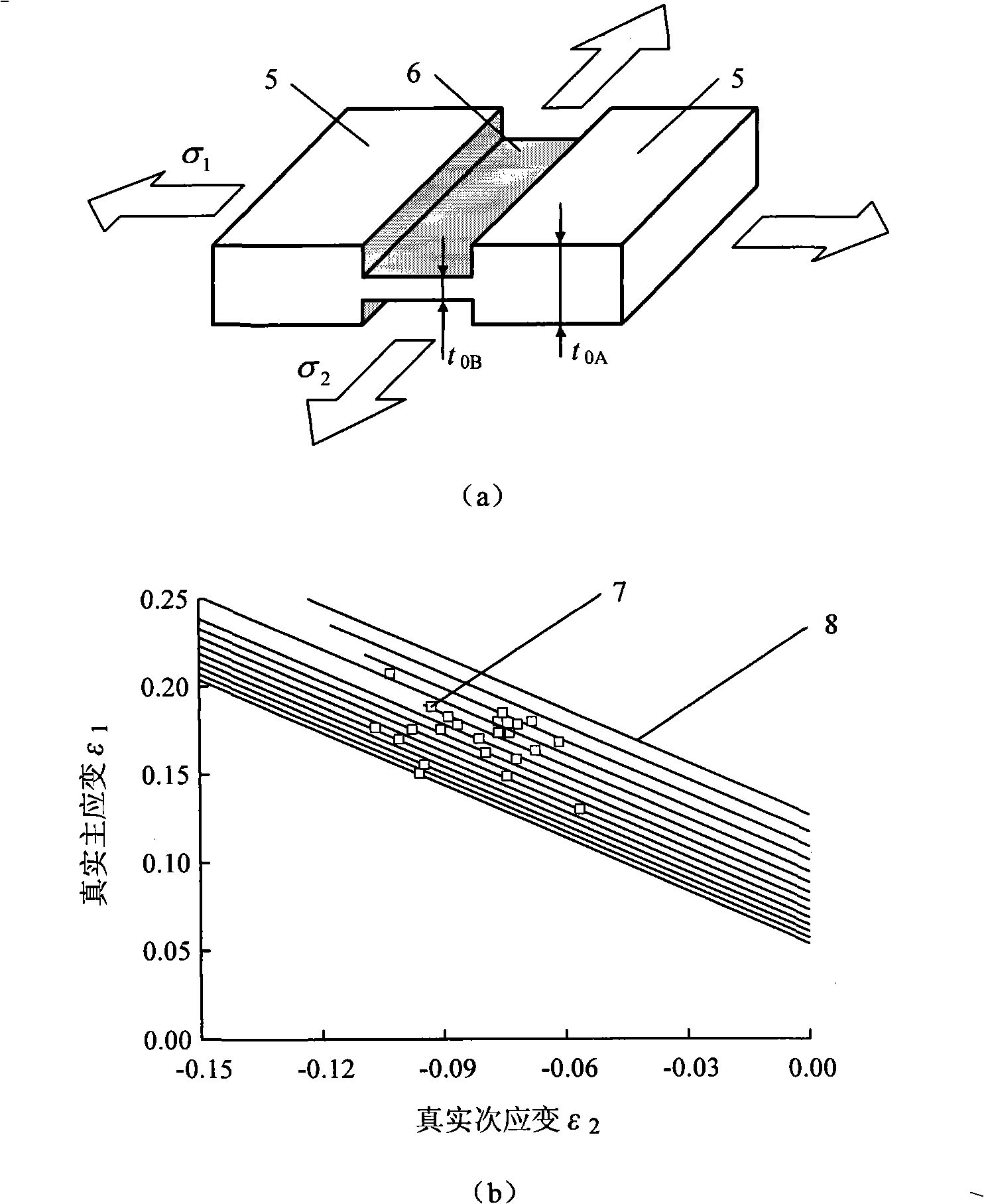

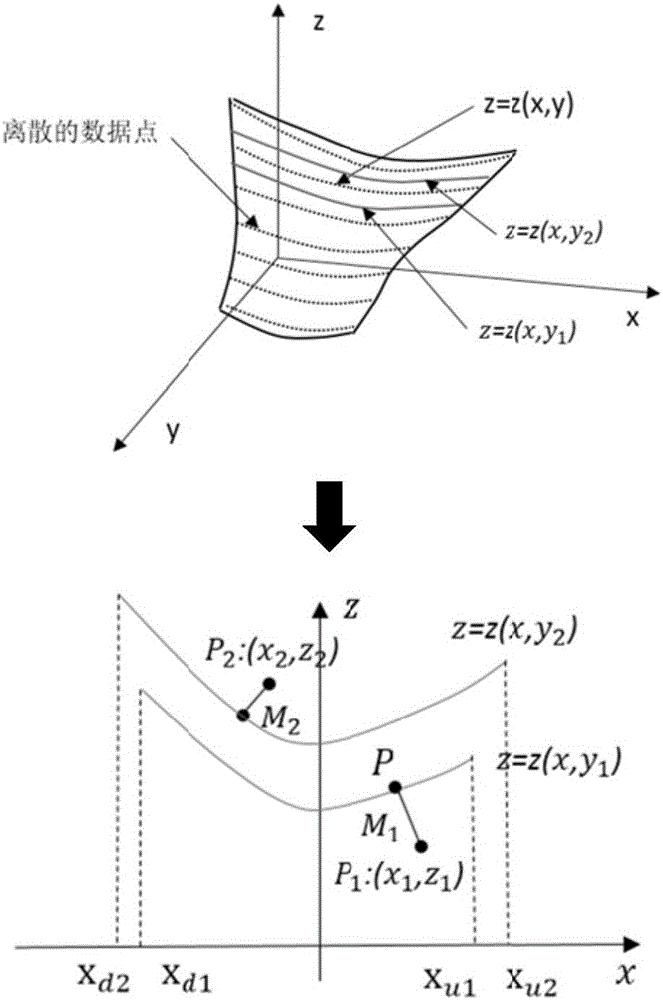

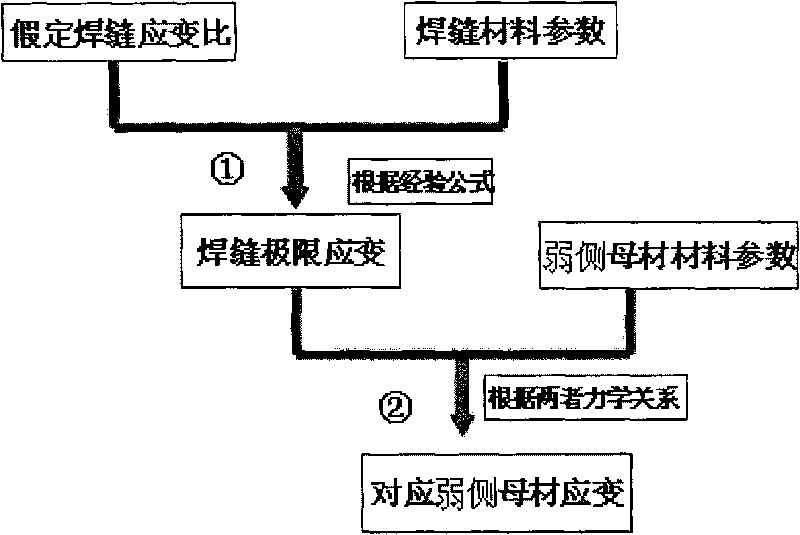

Method for establishing and using difference thick laser assembly solder plate forming limit picture

InactiveCN101354731ATruly reflect the failure characteristicsAccurately obtain the ultimate strain valueSpecial data processing applicationsForming limit diagramMaterials science

The invention relates to a method for establishing and using failure criteria for a laser tailor-welded blank with different thicknesses. The method is mainly used for judging the necking or the fracture of the laser tailor-welded blank with different thicknesses and for estimating the forming performance. The method for establishing a forming limit diagram of the laser tailor-welded blank with different thicknesses comprises the following steps: the tailor-welded blank forming limit diagram is formed by combining a welding area material, and a forming limit curve of the thin tailor-welded lateral mother plate; and the forming limit curve of the tailor-welded material adopts the M-K theory and is obtained by calculating performance parameters by combining the tail-welded area material. The method for using the forming limit diagram of the laser tailor-welded blank with differential thicknesses comprises the following steps: the strain value of the danger part of the part of the tailor-welded blank is measured and is divided into the strains of the welding area and the thin lateral mother plate; the measured strain is compared with the welding area corresponding to the strain, and the forming limit curve of the thin tailor-welded lateral mother plate, and whether the part of the tailor-welded plate loses effectiveness is judged. The method for establishing and using the failure criteria for the laser tailor-welded blank with different thicknesses accurately establishes the forming limit diagram, predicts successfully the failure of the tailor-welded plate, and effectively estimates the forming performance.

Owner:JIANGSU UNIV

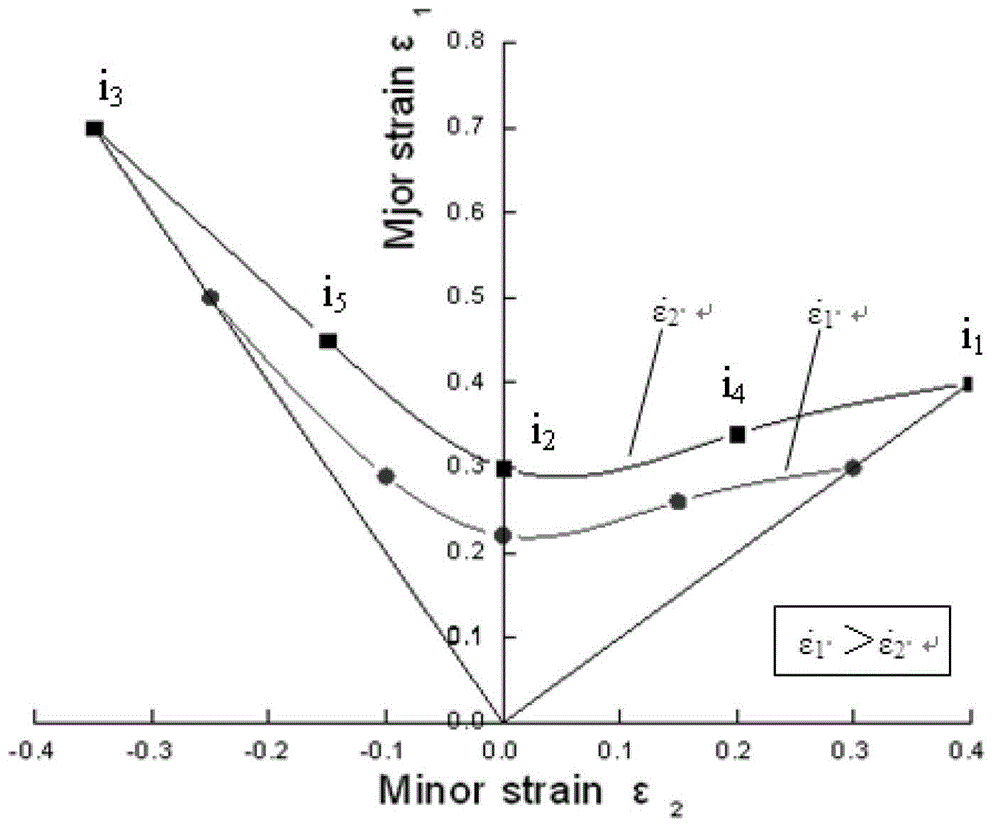

Method and system for numerically simulating and predicting necking failure in sheet metal forming

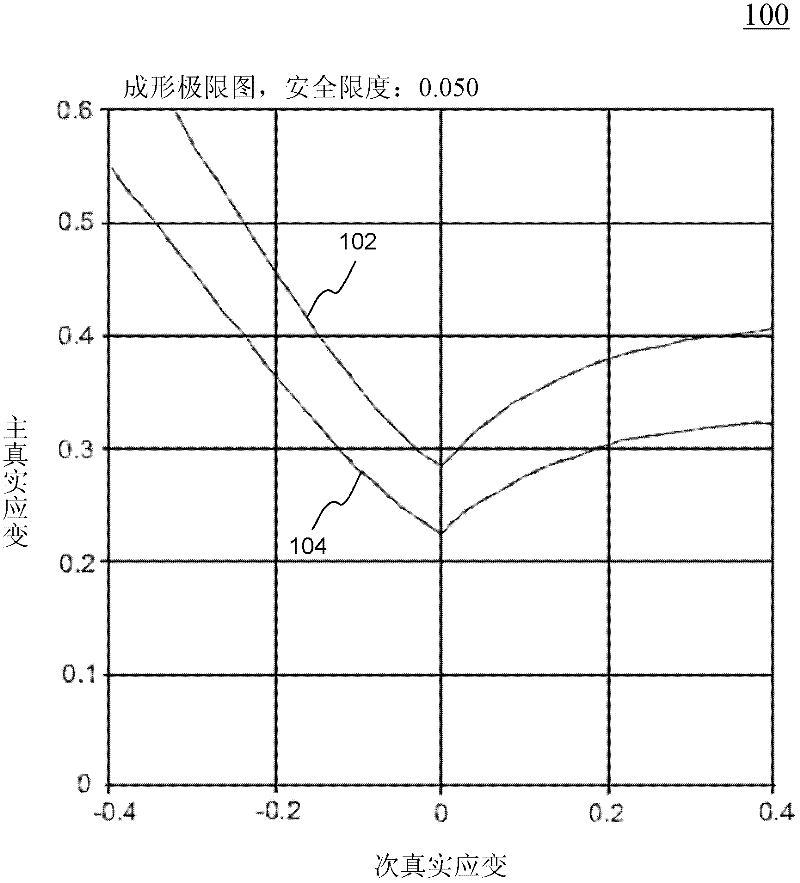

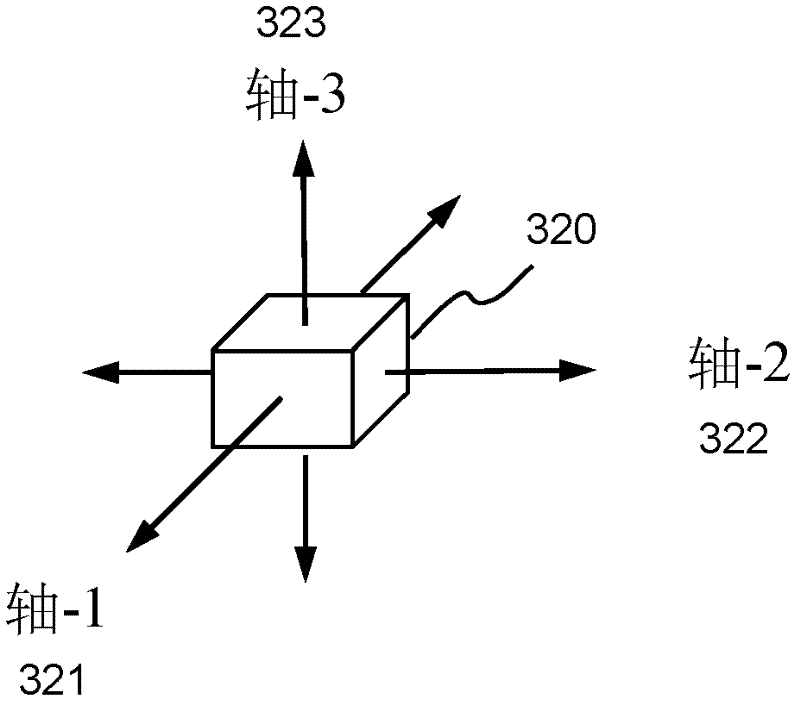

InactiveCN102262688AEasy to useEasy to observeDesign optimisation/simulationAerodynamics improvementForming limit diagramElement analysis

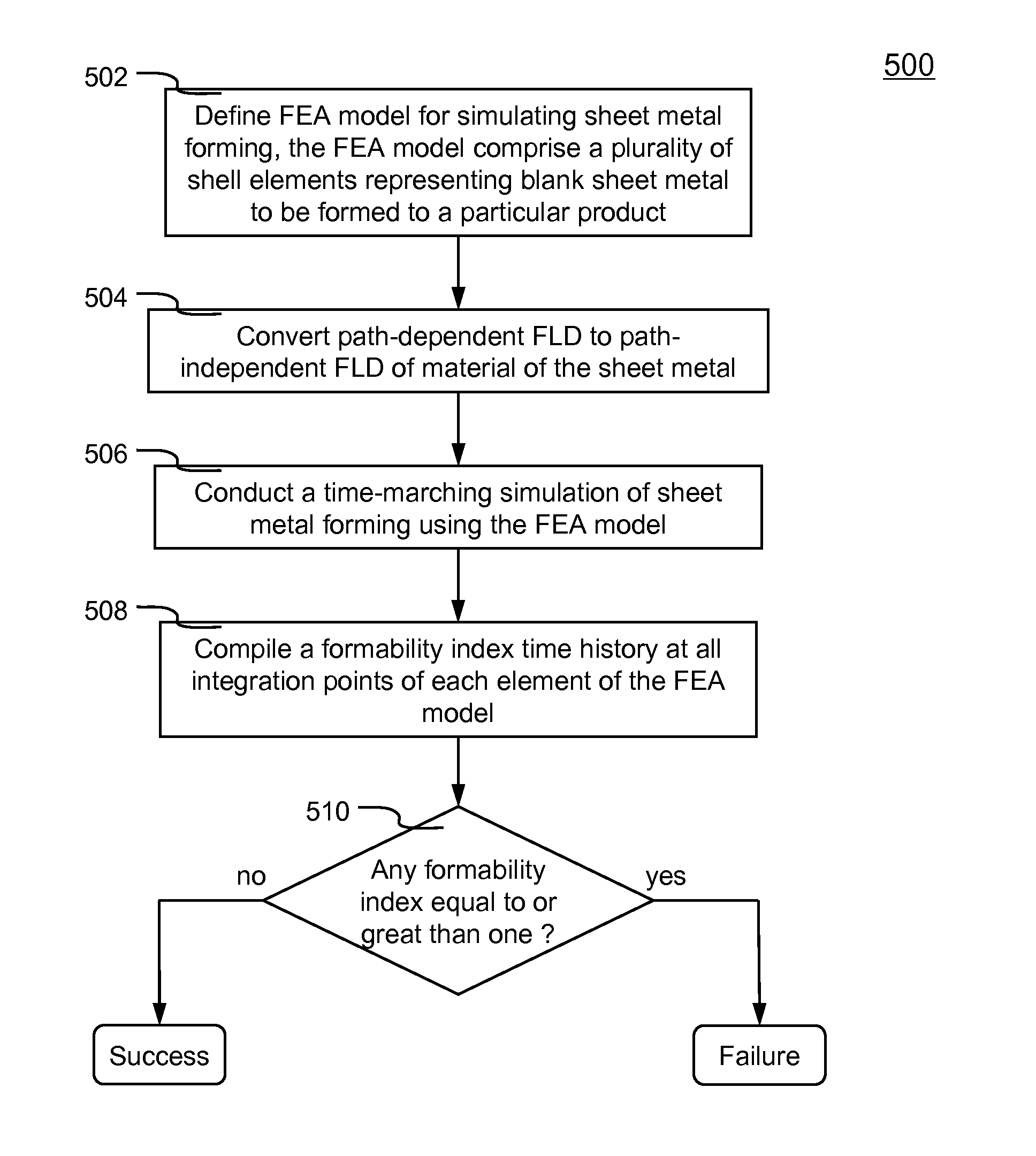

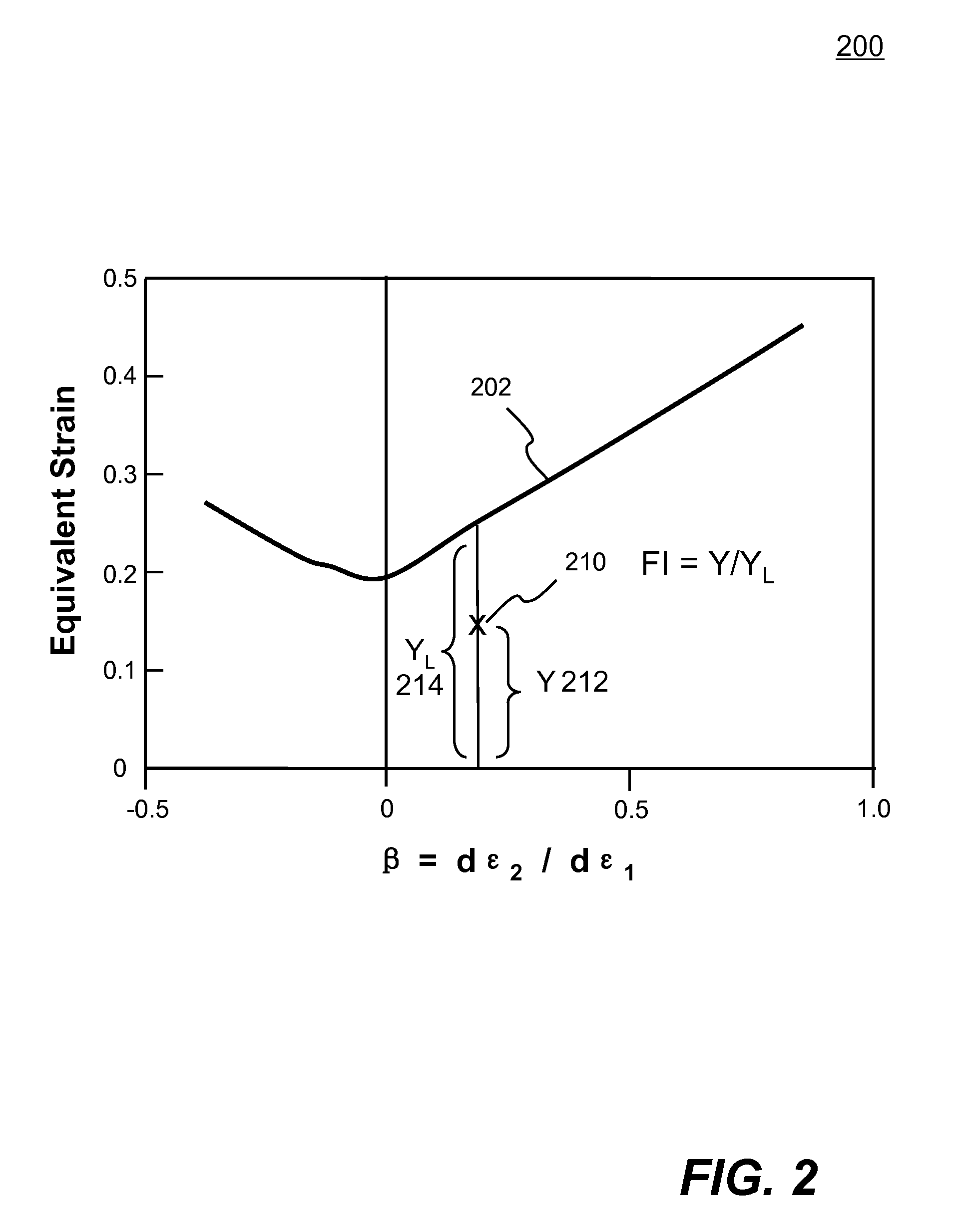

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

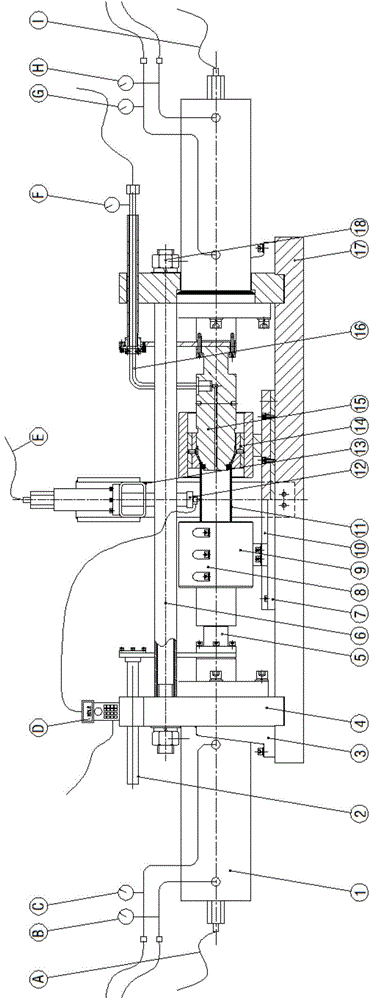

Method for acquiring metal temperature forming limit diagram (TFLD) and testing device therefor

InactiveCN103398909AThe test results are accurate and validEven heating speedInvestigating material ductilityForming limit diagramAlloy

The invention discloses a method for acquiring a metal temperature forming limit diagram (TFLD). The method is characterized by comprising acquiring a TFLD of a high-strength steel plate thermal-forming process, and acquiring a TFLD of a lightweight alloy warm-forming process. The invention also discloses a test device of a TFLD. The test device is characterized by comprising a hydraulic tester, a mold, a mold heating furnace, an automatic feeding mechanism, a plate heating furnace, a plate fast-cooling device, a heating control system and a strain measurement analysis device. The method and the test device guarantee mold heating uniformity, do not change a plate forming temperature, satisfy temperature forming requirements, acquire the TFLD comprising the all-range isothermal or non-isothermal forming limit diagram in a test temperature range, have the advantages of simple operation, high automation degree and high work efficiency, and satisfy practical temperature forming process requirements.

Owner:DALIAN UNIV OF TECH

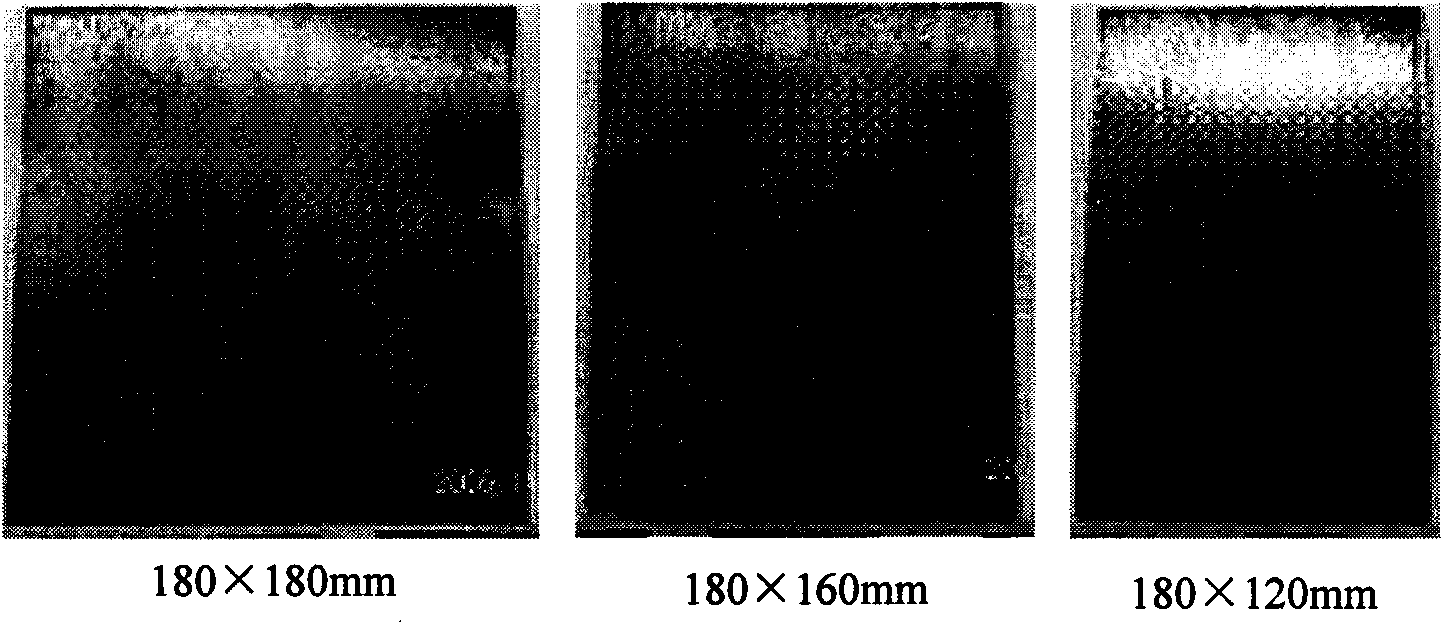

Test device and method for acquiring forming limit diagrams under complicated loading condition

ActiveCN106092778ASolve aging problemsShorten test timeInvestigating material ductilityForming limit diagramBatch processing

The invention discloses a test device and method for acquiring forming limit diagrams under the complicated loading condition and belongs to the technical field of forming processing of metal plates. The test device is formed by refitting a specially made male die on the premise that a multifunctional plate forming machine is included originally, and other devices and molds are original equipment; the specially made male die comprises a small male die and a large male die, a hoop interface is arranged at the lower end of the small male die and used for butt joint with a hydraulic ejection rod, and a cavity capable of being in sleeving connection with the small male die is formed in the large male die. By means of the provided test device and method, complicated loading can be further realized, corresponding predeformation on plates is not required before bulging, and the ageing problem and the relatively complicated test process are avoided. The plates in the same size are adopted, plates in various sizes are not required to be processed, batch processing can be performed, the test time is saved, and the test period is shortened.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

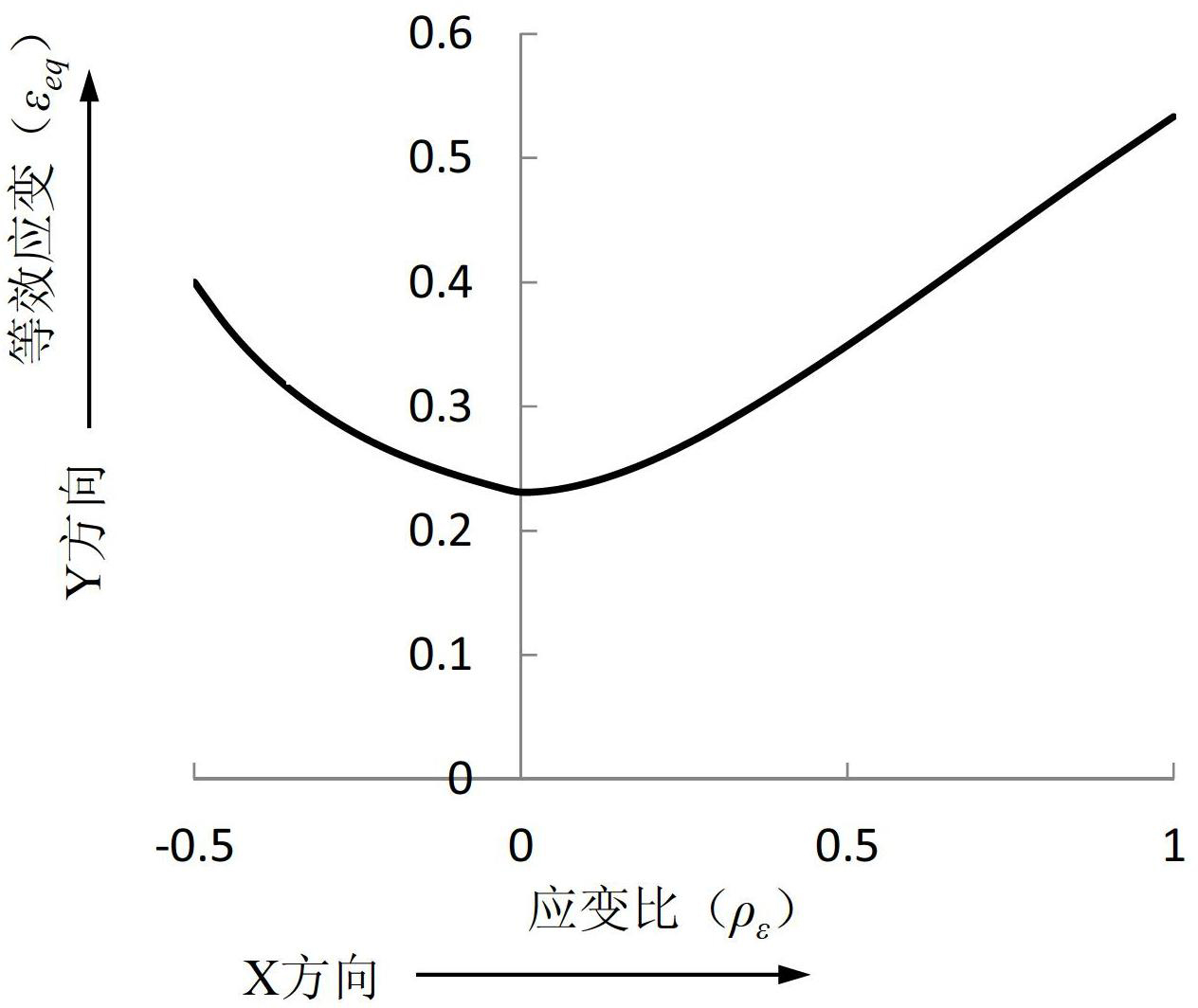

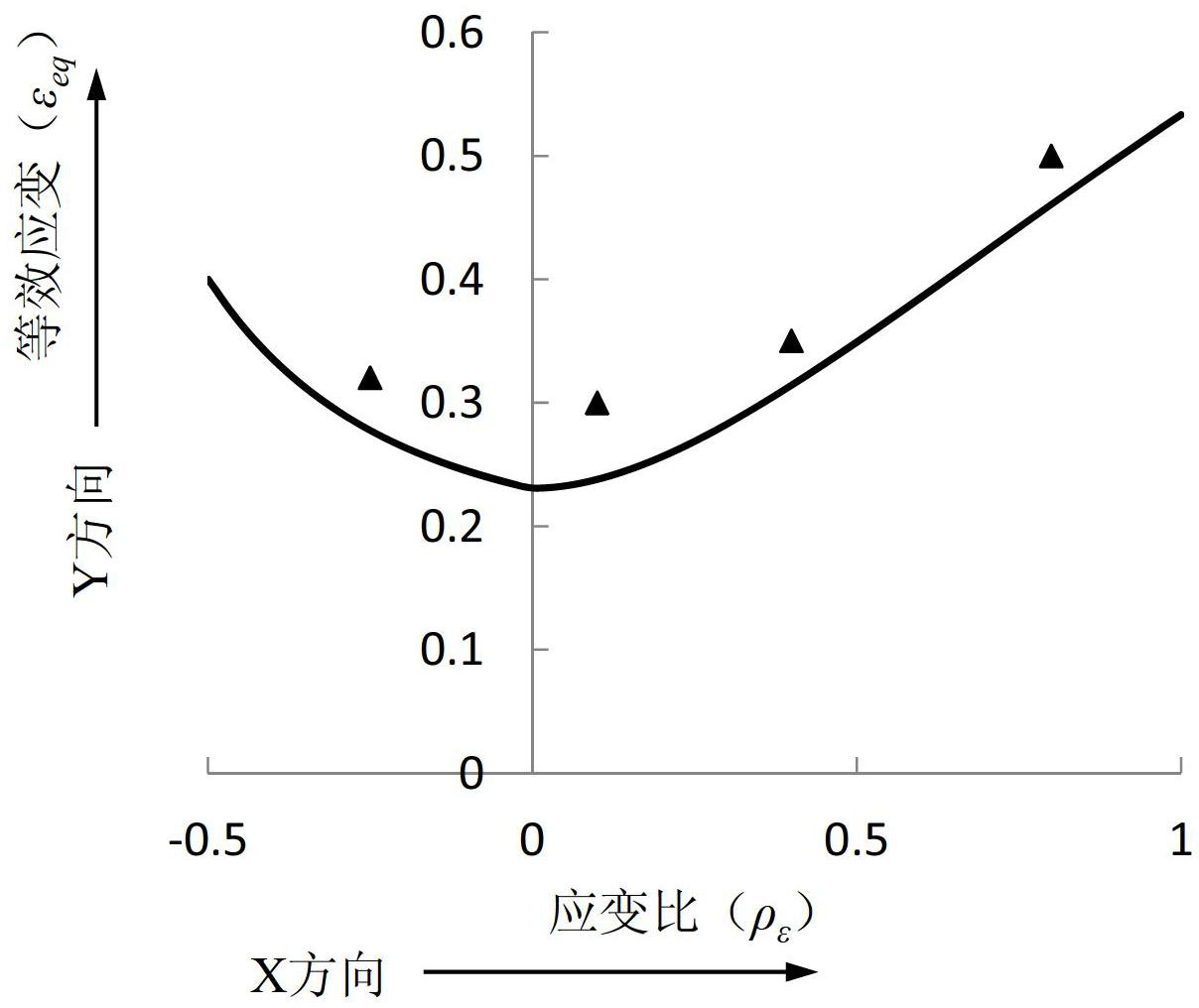

Method for establishing and using forming limit diagram of metal sheet material

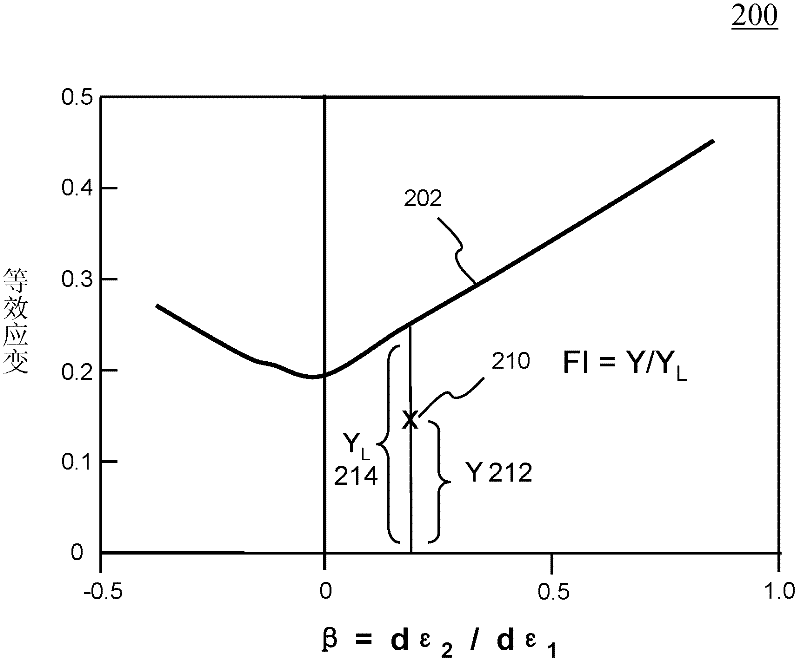

InactiveCN102661899AForming limit judgmentInvestigating material ductilityStored energyForming limit diagram

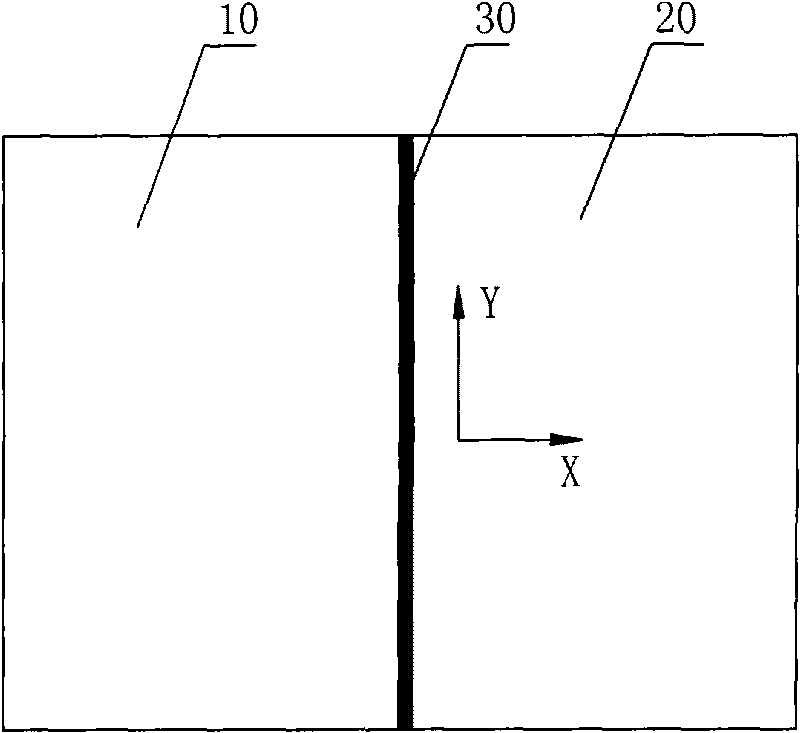

The invention discloses a method for establishing and using a forming limit diagram of a metal sheet material. The method comprises the following steps of: A, establishing an XY coordinate system, wherein an X coordinate represents a strain ratio and a Y coordinate represents an equivalent strain; B, setting different values of the strain ratio, and calculating corresponding main strain and secondary strain according to the different strain ratios; C, calculating limit equivalent strain values at the different strain ratios through a formula according to the main strain and the secondary strain obtained in the step B; and D, marking the limit equivalent strain value corresponding to each strain ratio, which is obtained in the step C, on the XY coordinate system, and connecting marked points to be a curve, namely the forming limit curve shown by the limit equivalent strain values, wherein the XY coordinate system and the forming limit curve form the forming limit diagram of the metal sheet material. According to the method disclosed by the invention, the equivalent strains are used as variable values. Each equivalent strain is the single variable value, so that the influences of deformation in a pre-forming process on deformation stored energy and a forming limit of a magnesium alloy sheet material after thermomechanical treatment can be reflected in a more direct manner.

Owner:TONGJI UNIV

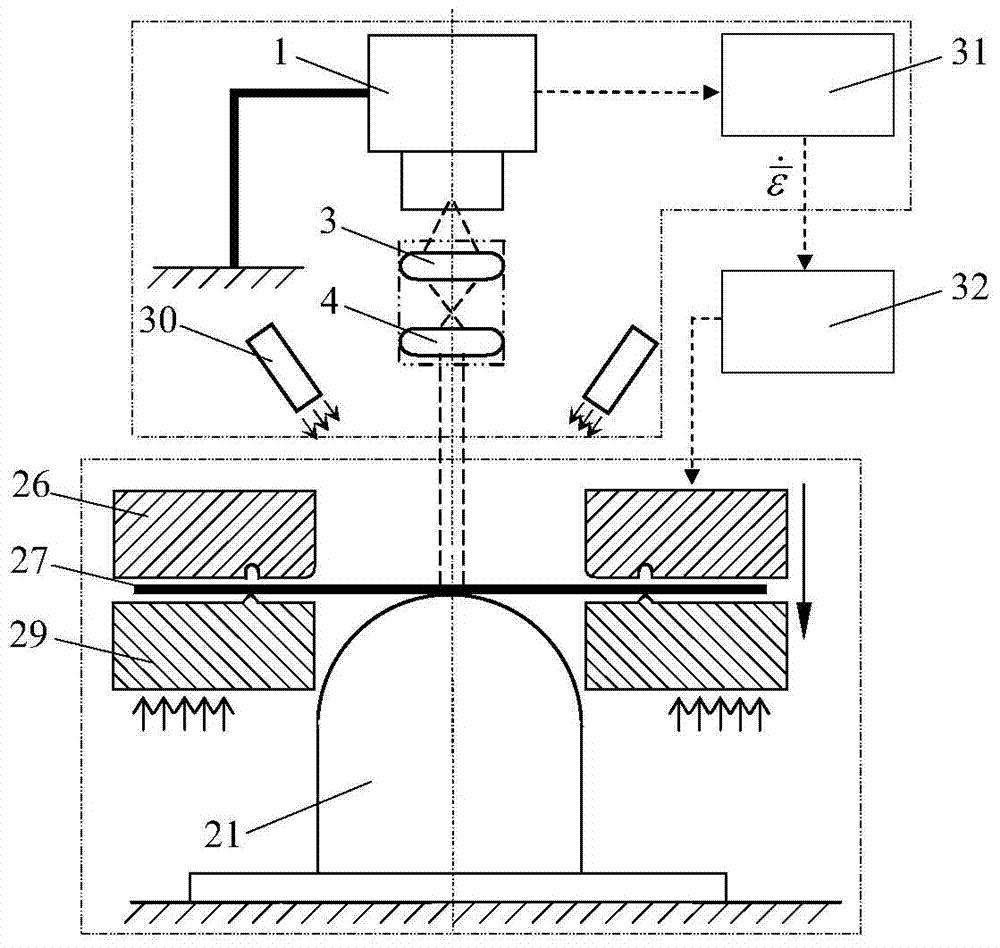

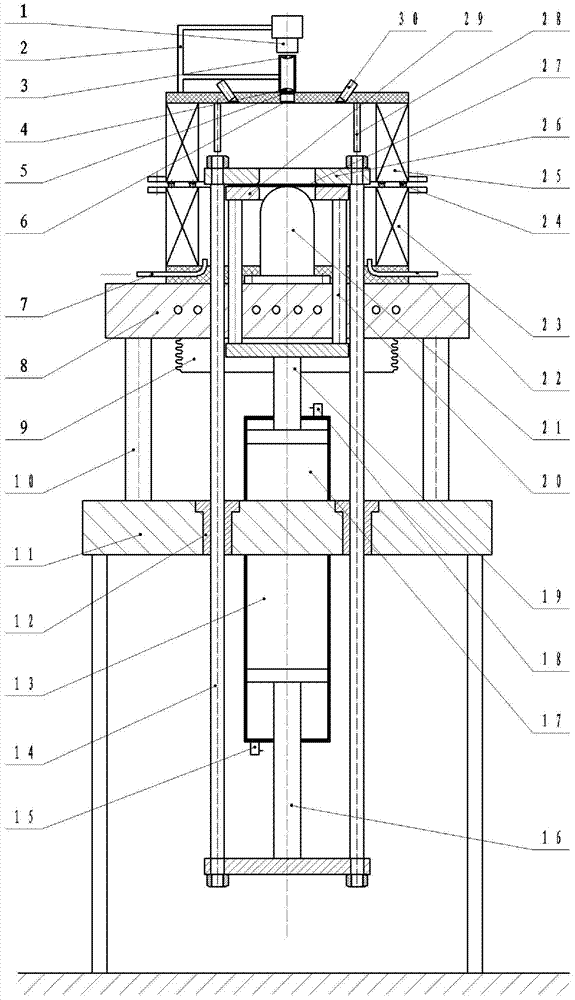

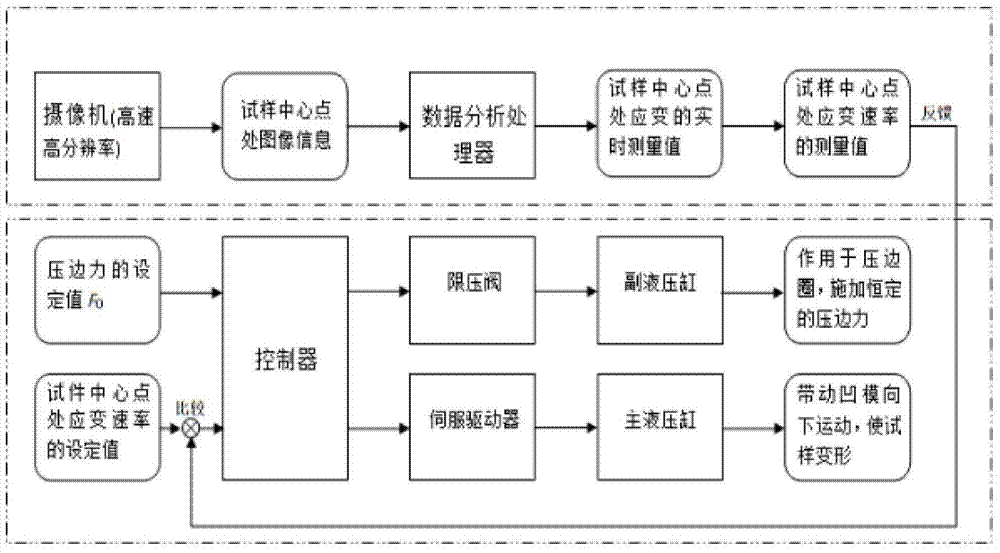

Testing device and testing method for forming limit diagram under high-temperature constant-strain rate condition

InactiveCN104729928AEliminate the strain rate factorStrain rate is easy to studyMaterial strength using tensile/compressive forcesForming limit diagramEngineering

The invention relates to a testing device and a testing method for a forming limit diagram under a high-temperature constant-strain rate condition. The device comprises a sample deformation pressure device, a real-time strain measurement device and a controller; based on a testing method for the forming limit diagram under the high-temperature constant-strain rate condition built by the testing device, the constancy of the strain rate of a sample in a central point is realized under the condition of constant forming temperature, and a forming limit diagram under the obtained slab isothermal condition contains a forming limit curve under a constant-strain rate condition in a certain strain rate range. The testing device and the testing method have the advantages of high control accuracy and accuracy in measurement, and are significant in theoretical research and practical application of light alloys and high-strength steel warm-hot forming.

Owner:JILIN UNIV

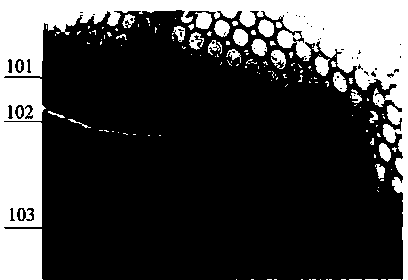

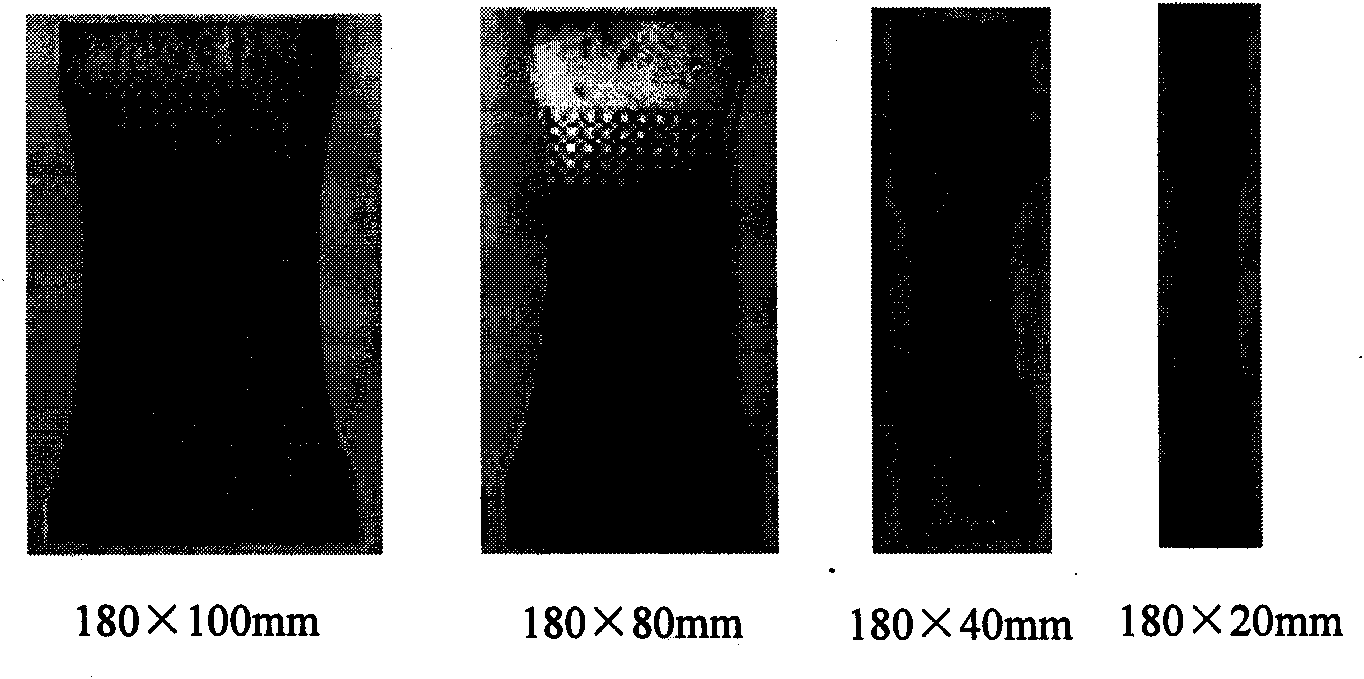

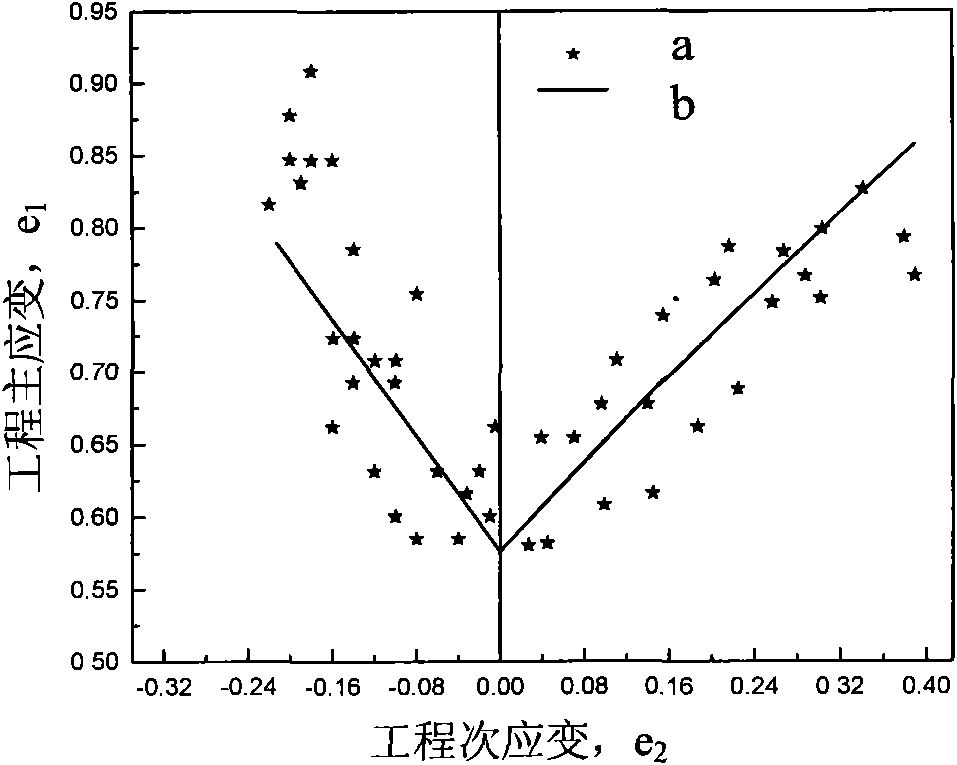

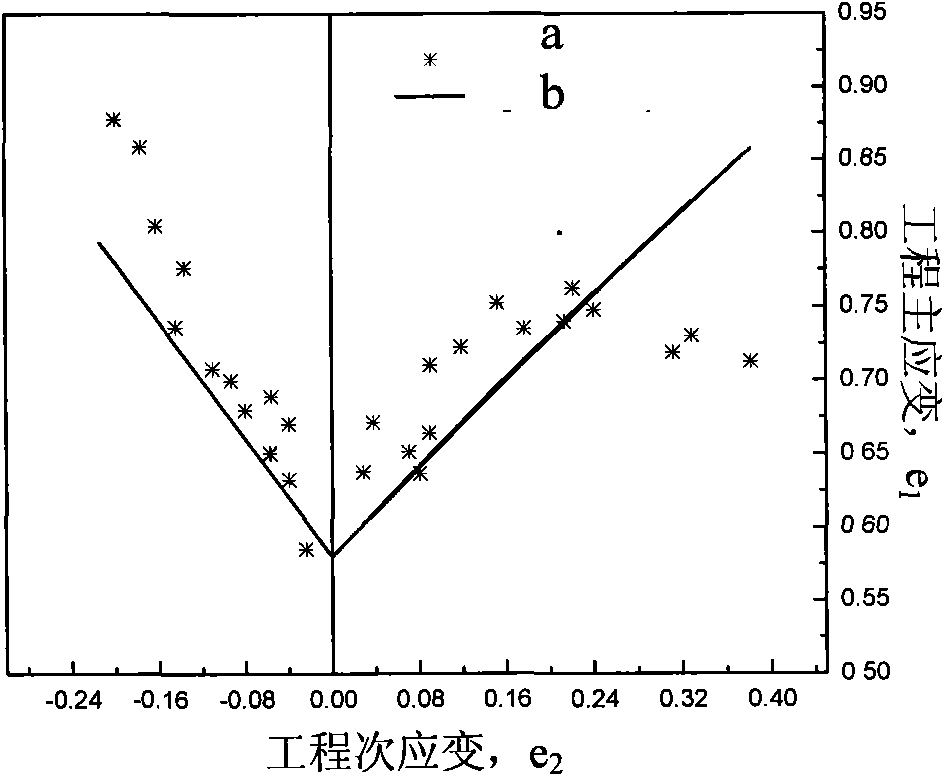

Experimental method for building forming limit diagram of transformation induced plasticity steel plate

The invention discloses an experimental method for building forming limit diagram of transformation induced plasticity steel plates, relating to the building method of forming limit diagrams. The method of the invention comprises the following steps: (1) a transformation induced plasticity steel plate is prepared into a sheet forming experiment sample; (2) the sample is cleaned, and is printed with grids; (3) a forming experiment device is started to punch the sample until the sample generates necking or cracking, then the experiment stops; (4) a critical region is shot; and (5) the long axis diameter and the short axis diameter of a critical grid circle are measured so as to calculate the principal strain and minor strain of a project, build a strain coordinate system and build the forming limit diagram of the transformation induced plasticity steel plate. The experimental method of the invention adopts standard experiment devices, thus the method can judge the shaping limit of the transformation induced plasticity steel plate, destruction position and shaping performance in the shaping process.

Owner:NORTHEASTERN UNIV LIAONING

Method for determination of forming limit curve of sheet metal

InactiveCN103424318AEasy way to determineLow costInvestigating material ductilityForming limit diagramEngineering

The invention relates to a method for determination of a forming limit curve of sheet metal. A piece of stamping shaping CAE simulation analysis software DYNAFORM is used for simulation of stamping forming of a piece of sheet metal to be detected, thereby determining a FLD 0 value in a shaping limit graph; and the forming limit curve of the sheet metal to be detected is calculated out though the Keeler formula. Compared with the prior art, the method for determination of the forming limit curve of sheet metal provided by the invention is simple, feasible and has low cost and small error.

Owner:SHANGHAI UNIV OF ENG SCI

Test device for acquiring plate thermoforming limit diagram

InactiveCN105067455AWill not cause ruptureOvercoming defects such as uneven forming resultsInvestigating material ductilityTemperature controlForming limit diagram

The invention provides a test device for acquiring a plate thermoforming limit diagram. The device includes a universal tester, a mould, a strain measurement analysis apparatus, a heating control apparatus and a heat insulation apparatus. The universal tester includes a middle beam and a force sensor connected to the middle beam. The heating control apparatus consists of a temperature control unit and a heating component and a temperature sensing component that are respectively connected to the temperature control unit. The mould comprises a female die base, a blank-holding die and a male die. The female die base and the blank-holding die are assembled through a blank holding force control apparatus to form a plate clamping part for clamping plates. The strain measurement analysis apparatus consists of a controller, a metal corrosion marking unit and a CCD image sensor. The test device provided by the invention has a simplified overall structure, through combination of the universal tester, the mould, the strain measurement analysis apparatus, the heating control apparatus and the heat insulation apparatus, realizes precise control of the plate blank holding process and stamping forming process, and accurately acquires the plate thermoforming limit diagram.

Owner:CENT SOUTH UNIV

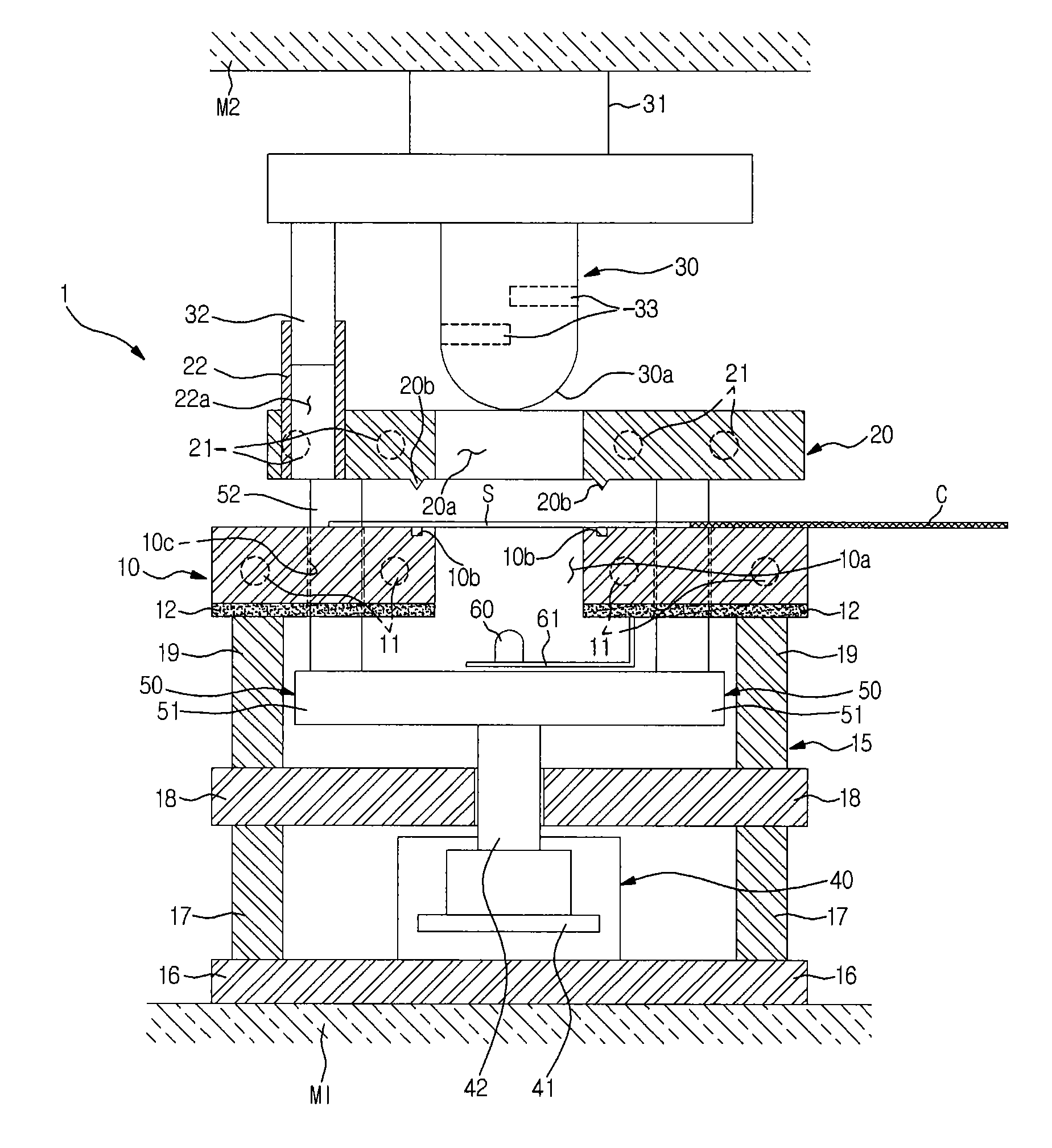

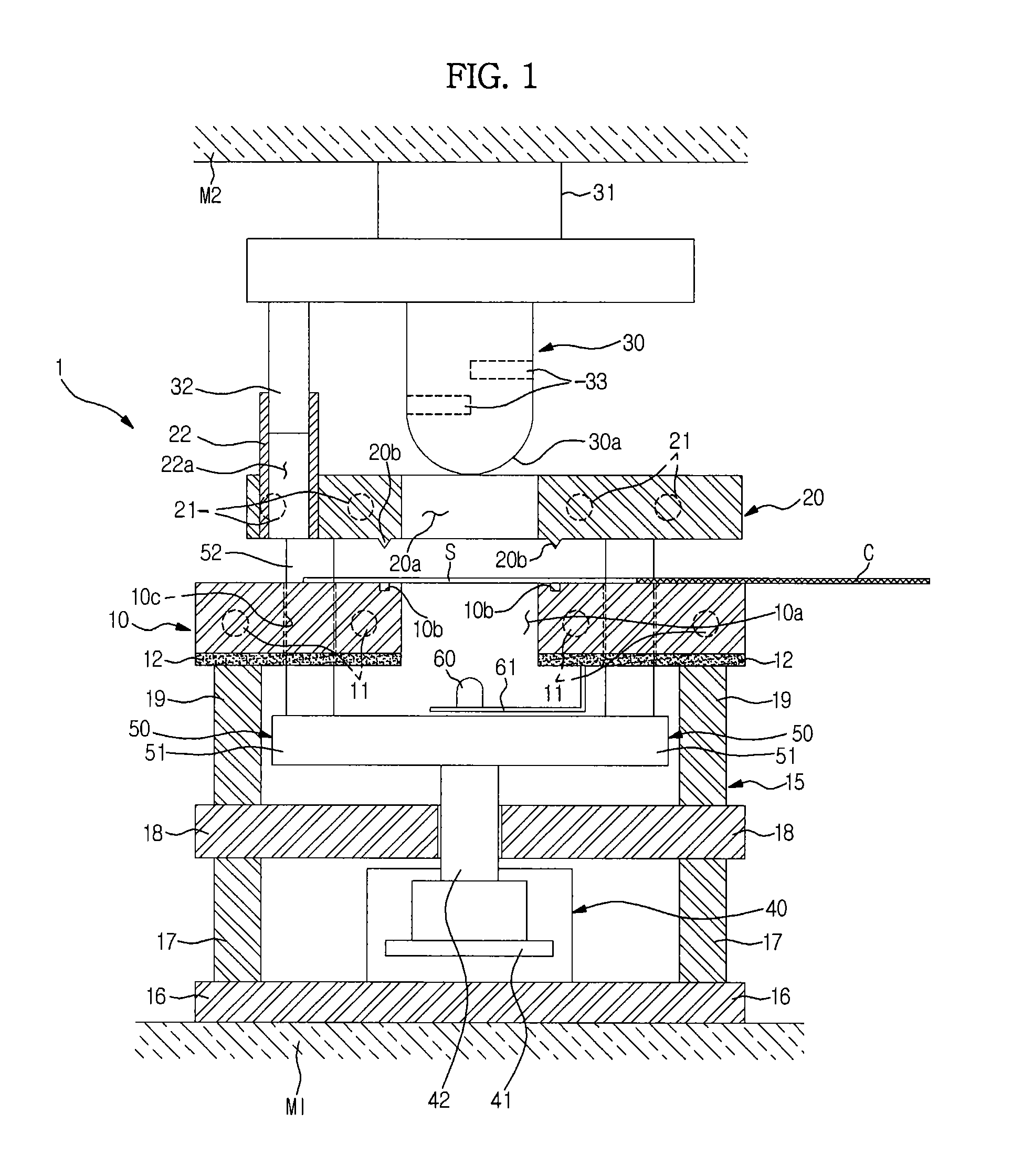

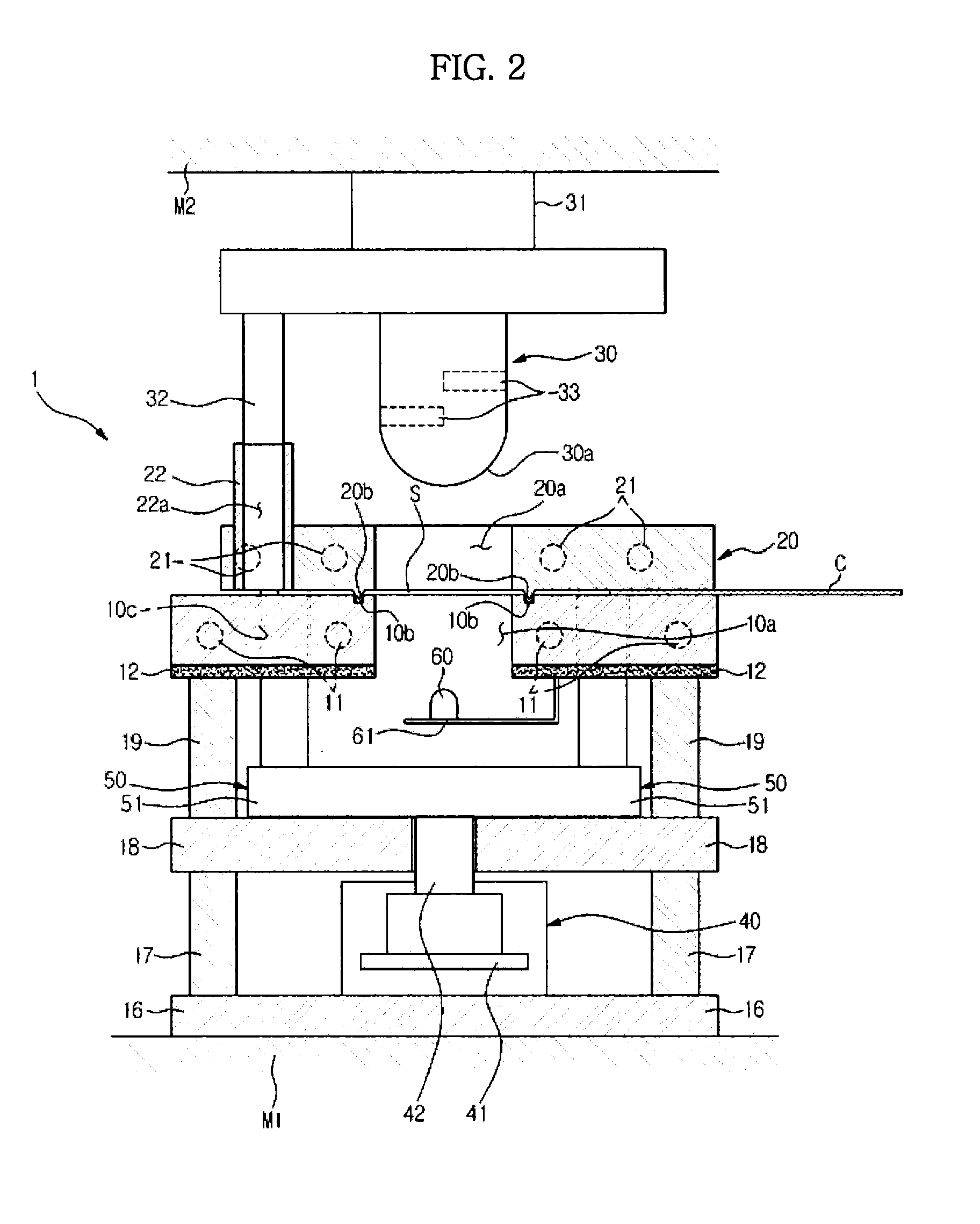

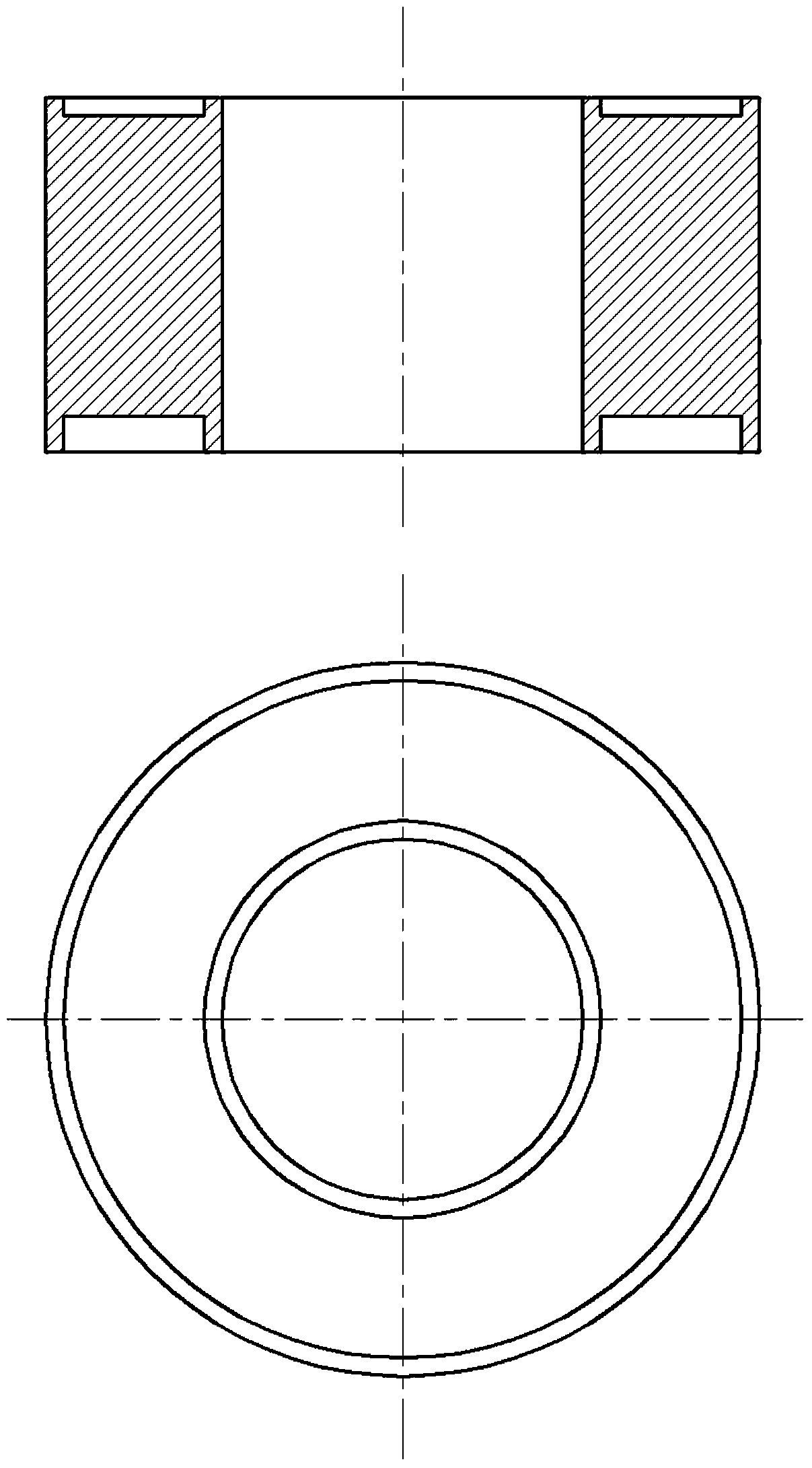

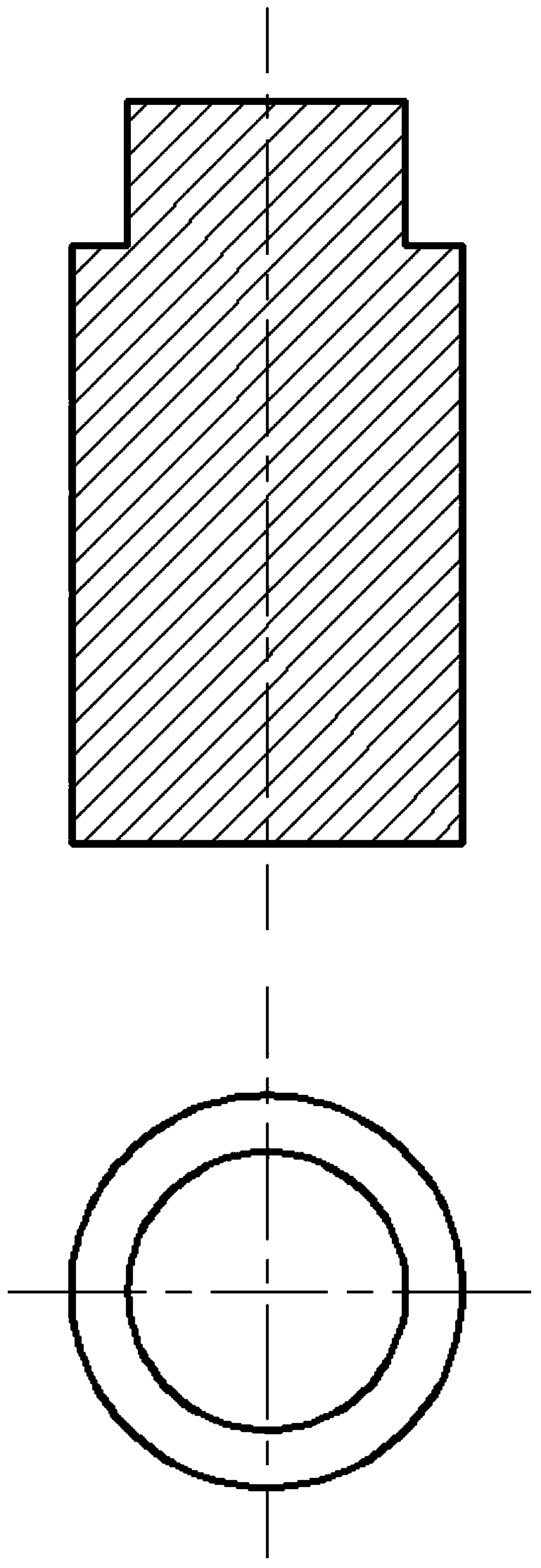

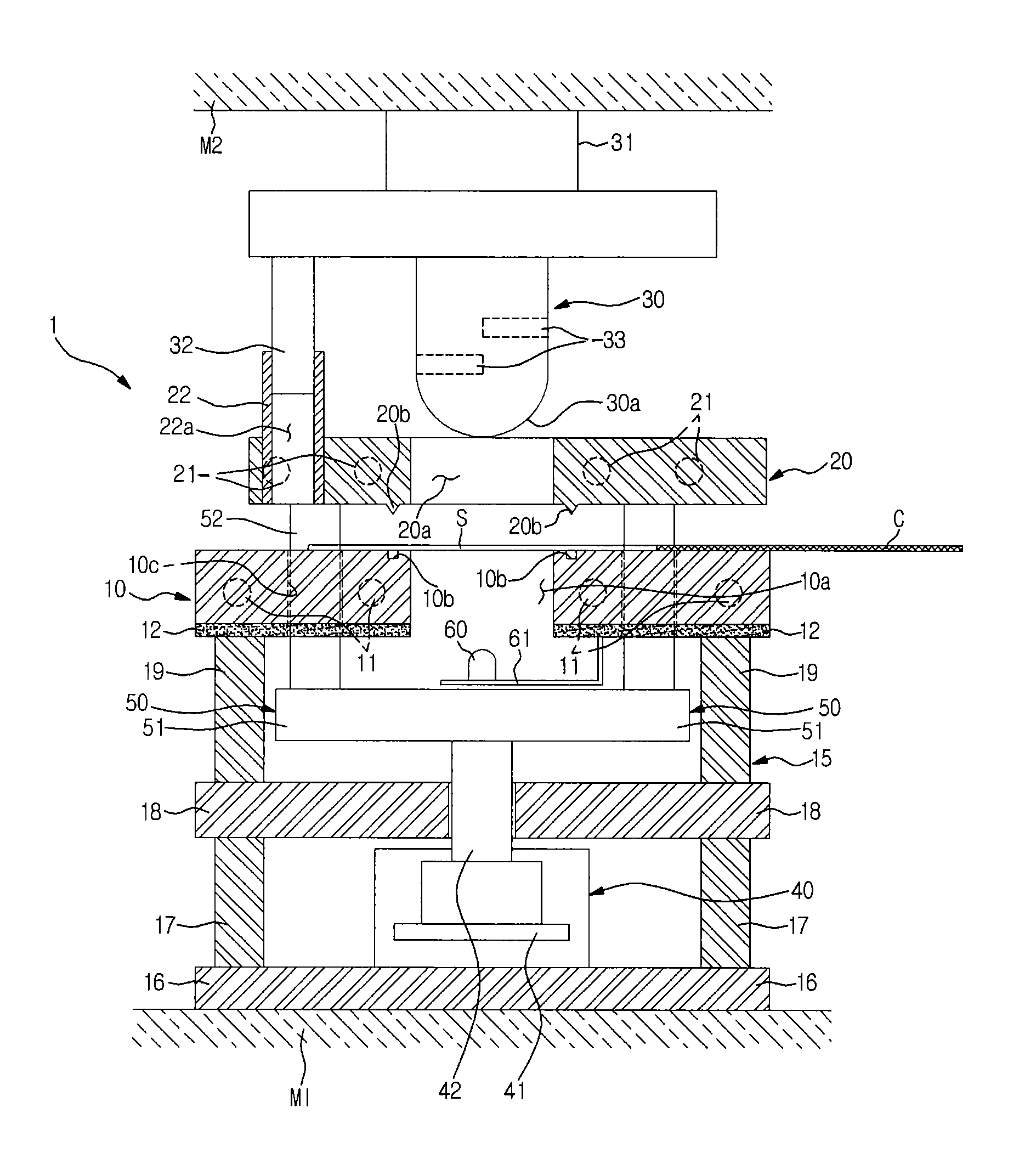

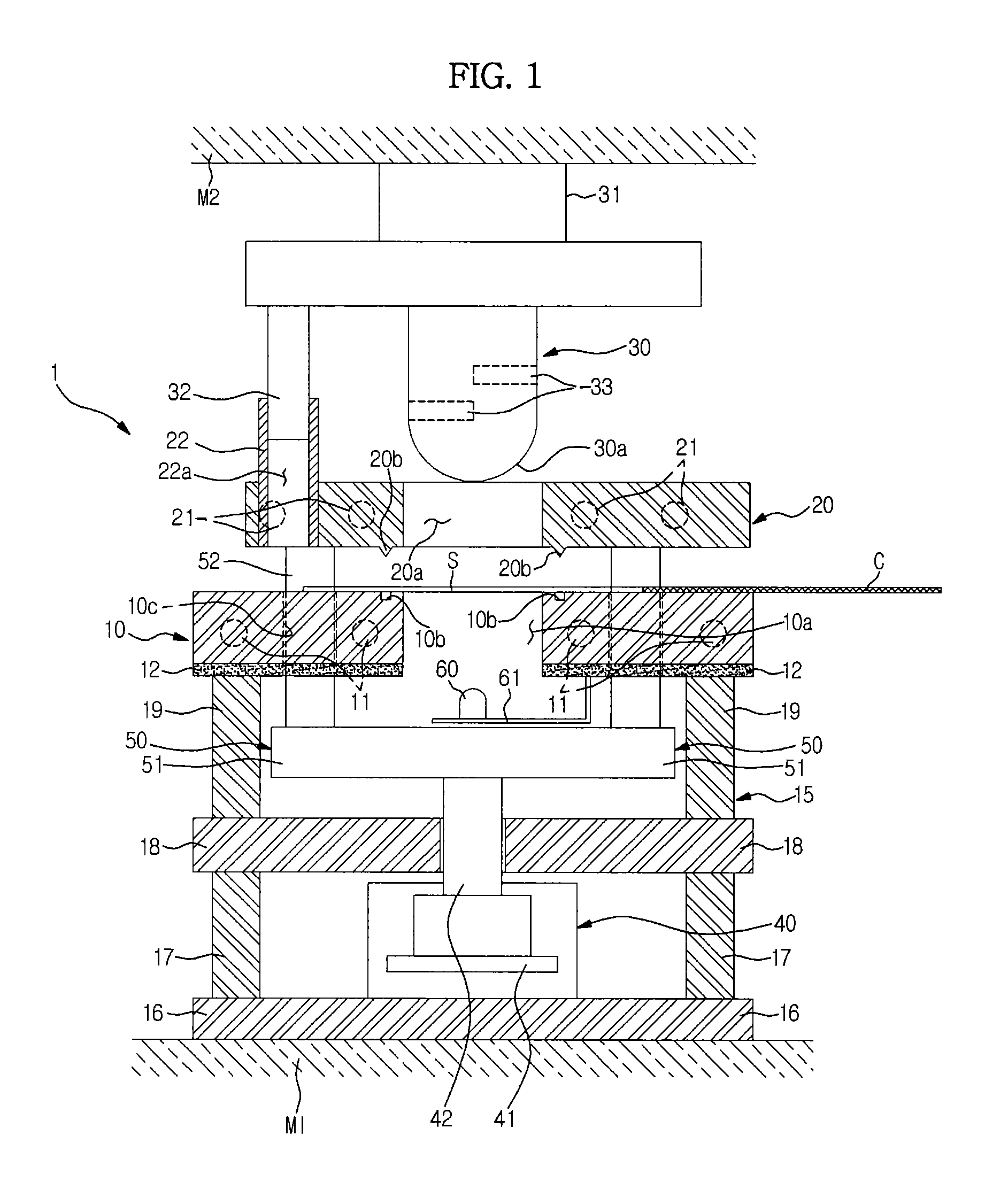

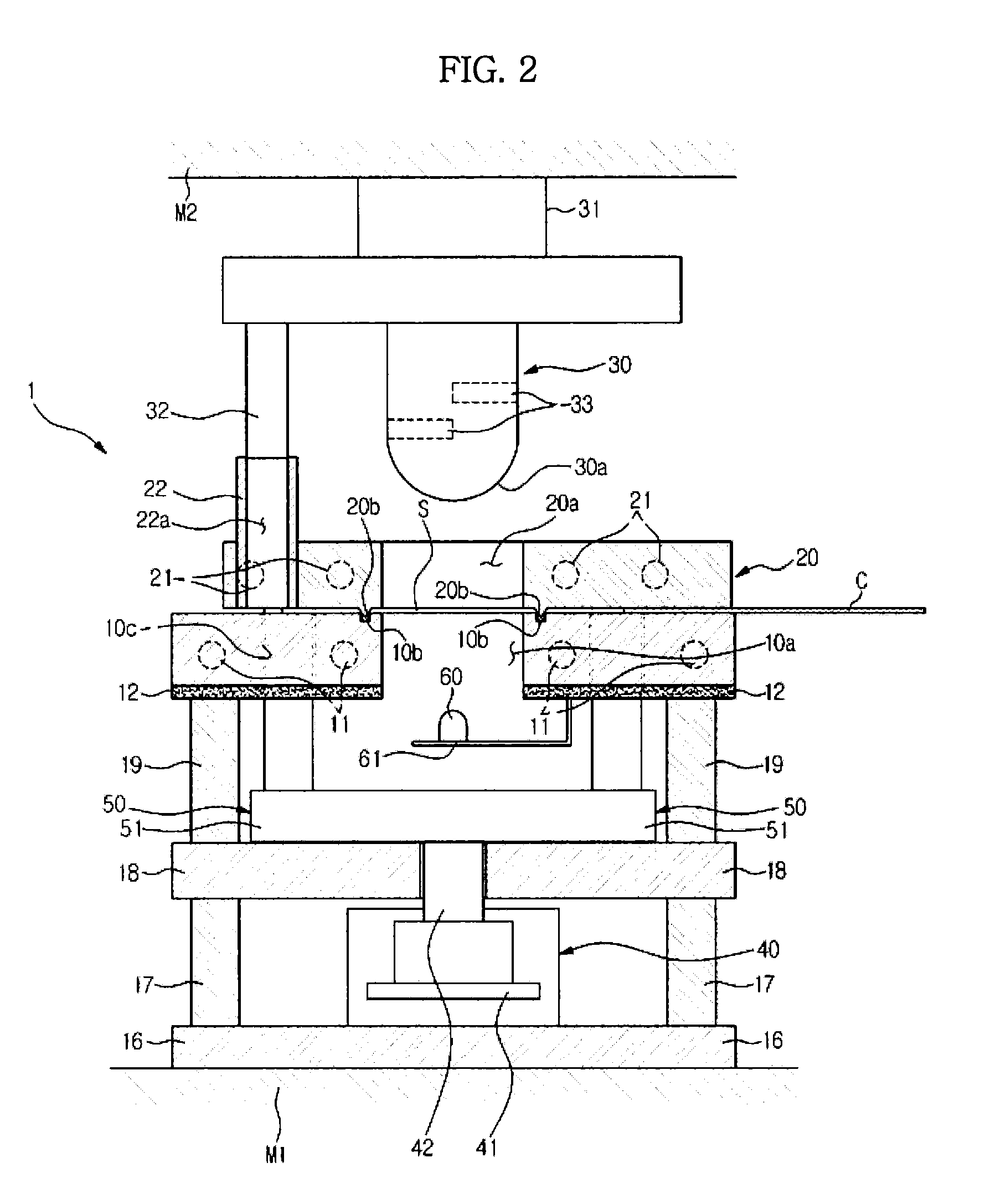

Tester apparatus for obtaining forming limit diagram

ActiveUS20130152706A1High precisionGeometric CADWithdrawing sample devicesForming limit diagramTester device

A tester apparatus capable of obtaining a forming limit diagram pertaining to a sample having a high degree of precision includes a fixing jig and a mobile jig installed at an upper side of the fixing jig so as to enable a vertical movement. The mobile jig may be configured to fix the sample in cooperation with the fixing jig, and a driving apparatus disposed at a lower side of the fixing jig may be configured to drive the vertical movement of the mobile jig. An interlocking apparatus provided in between the mobile jig and the driving apparatus may be configured to deliver a driving force of the driving apparatus to the mobile jig.

Owner:SAMSUNG ELECTRONICS CO LTD

Sheet Metal Forming Failure Prediction Using Numerical Simulations

InactiveUS20110295570A1Computation using non-denominational number representationDesign optimisation/simulationForming limit diagramElement analysis

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

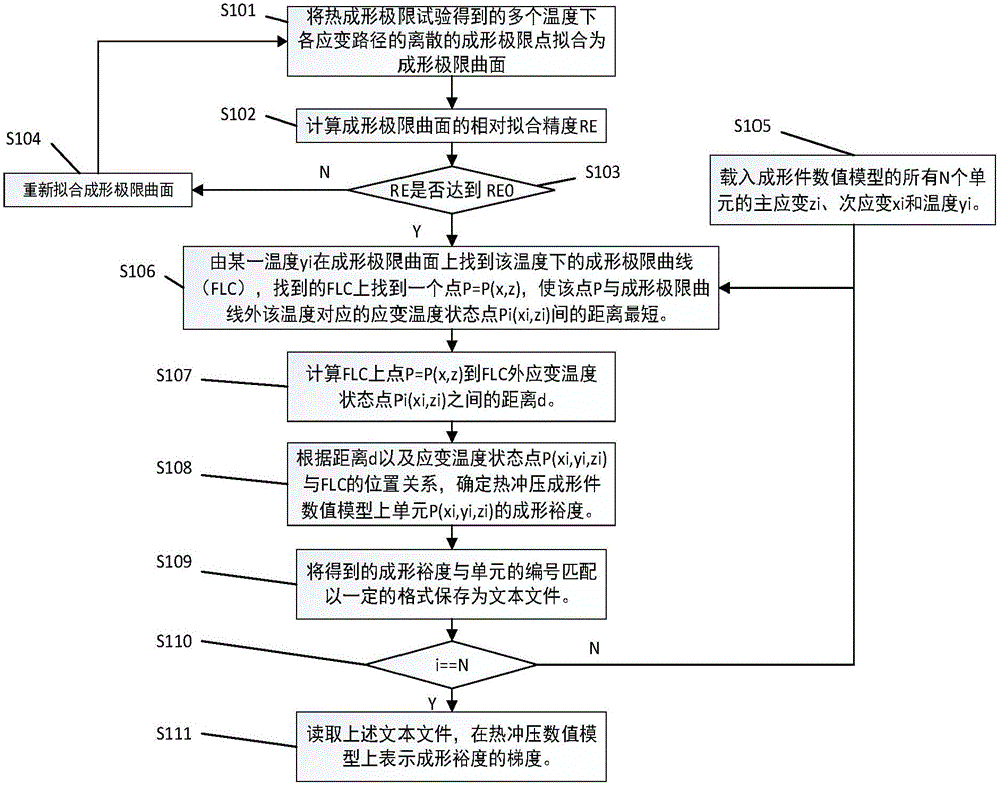

Evaluation method for hot stamping fracture property of automobile part

ActiveCN106018129AAccurately judge stamping performanceJudging stamping performanceMaterial strength using tensile/compressive forcesDesign optimisation/simulationHot stampingForming limit diagram

The invention relates to an evaluation method for the hot stamping fracture property of an automobile part. The evaluation method comprises the steps that the shortest distance between a strain-temperature state coordinate point of one unit on a numerical model subjected to finite element simulation and a forming limit curve at corresponding temperature is expressed as a forming margin, and the degree of the hot stamping part relative to a fracture limit is reflected by the forming margin. The forming margins of all the units on the numerical model subjected to finite element simulation are calculated, and distribution of the strain-temperature state points is expressed in a forming limit diagram through different colors according to the forming margin gradient; the forming margins are stored in a text document in a certain format, the text document containing the forming margin information is read by a stamping forming finite element simulation software postprocessing module, and the stamping property of the hot stamping part is directly reflected in the mode of a forming margin cloud diagram on the hot stamping part numerical model. According to the method, the stamping property of the hot stamping part can be more accurately judged.

Owner:HUNAN UNIV

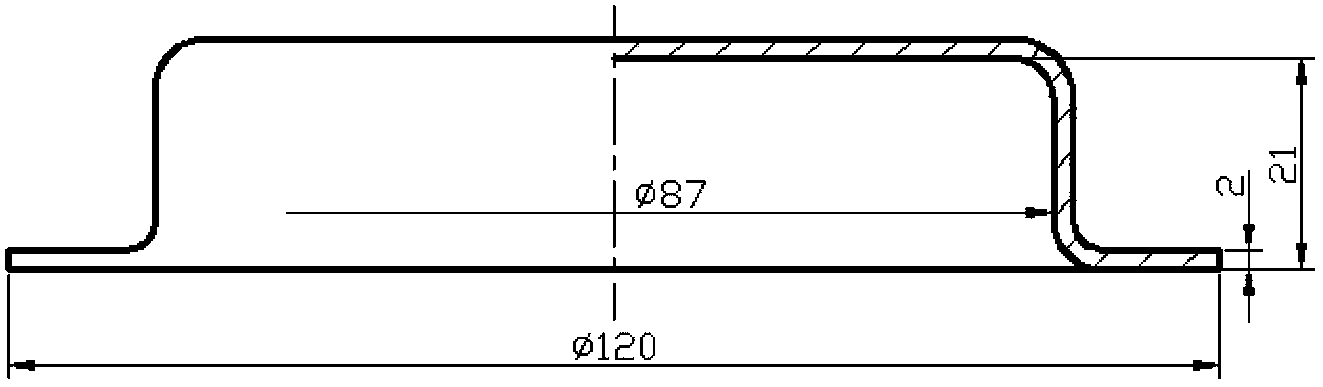

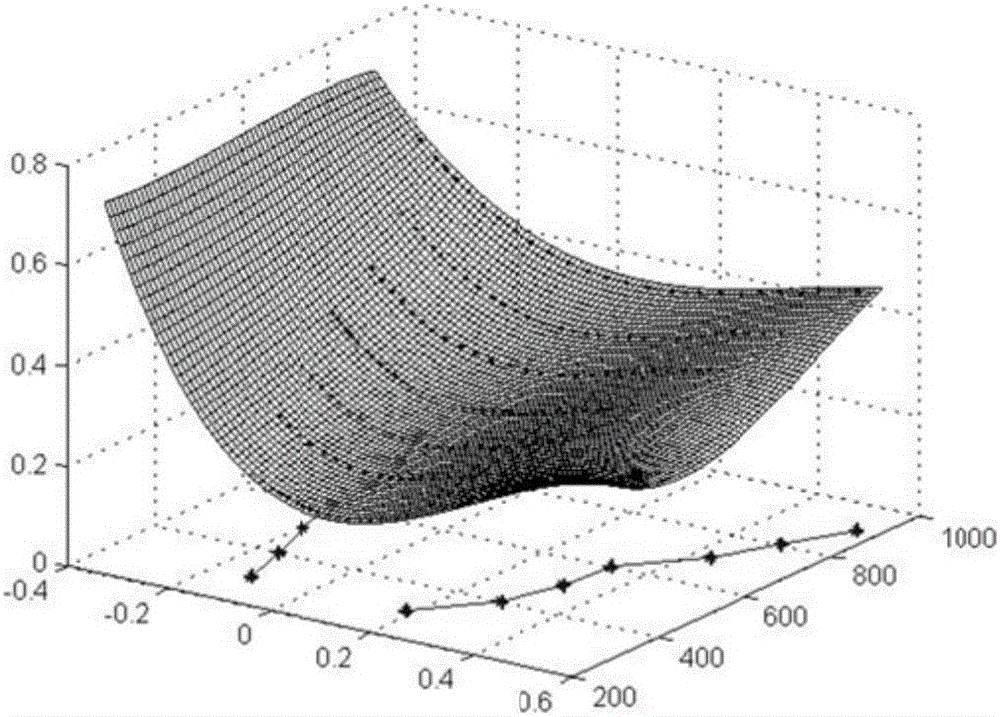

Establishment method of high-strength steel plate thermoforming limit diagram

InactiveCN103852382AExcellent thermoforming propertiesIntuitive and accurate judgmentMaterial strength using tensile/compressive forcesForming limit diagramMartensite transformation

The invention relates to an establishment method of a high-strength steel plate thermoforming limit diagram. The method is characterized by comprising the steps of A. heating the reagent up to 950 DEG C in a sealing box 3, and carrying out heat preservation for 5min so as to enable the reagent to be completely austenitized; after that, cooling the reagent to the temperature needed to be measured in the experiment; B. establishing the forming limit lines of a high-strength steel plate in a single-drawing state, a double-isometric drawing state, a plane strain state and an intermediate state at all temperature by an expanding model in the sealing box; C. for the forming limit lines at the temperature below 400 DEG C, cooling the reagent to the temperature needed to be measured in the experiment at the cooling speed higher than the critical cooling rate vk so as to generate martensite phase transformation, and calculating to obtain the result; D. connecting the forming limit lines at all the temperature into two curved surfaces in origin software by a difference value method, and defining the two curved surfaces as a three-dimensional forming limit surface. After the establishment method of the thermoforming limit diagram is adopted, the thermoforming performance of the high-strength steel plate can be judged, and the higher the forming limit surface is, the better the thermoforming performance of the high-strength steel plate is.

Owner:HUNAN UNIV

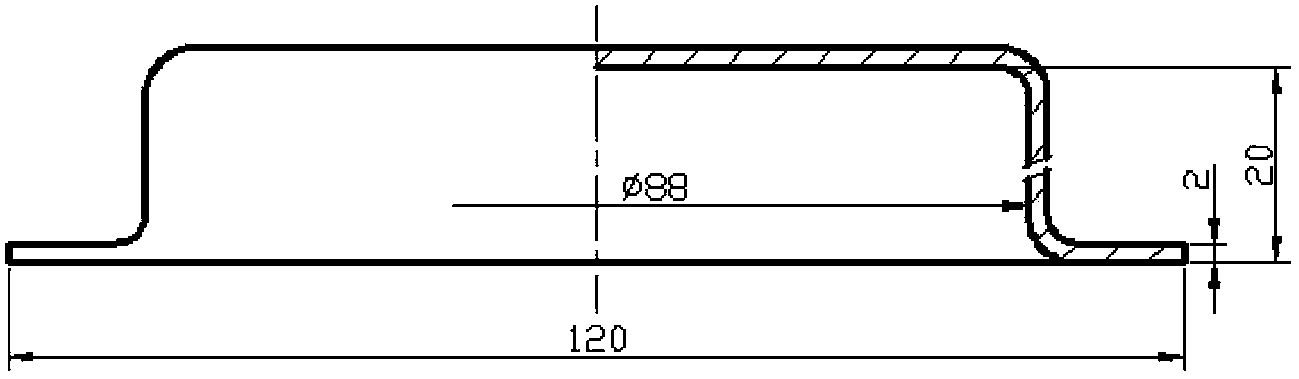

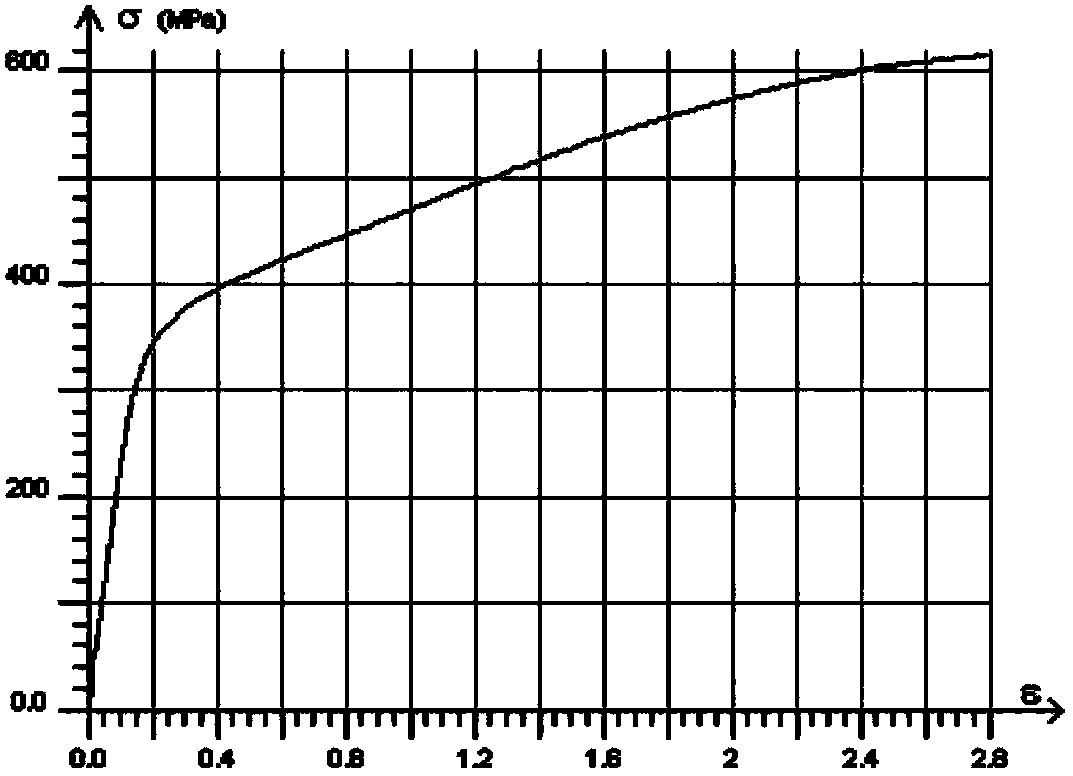

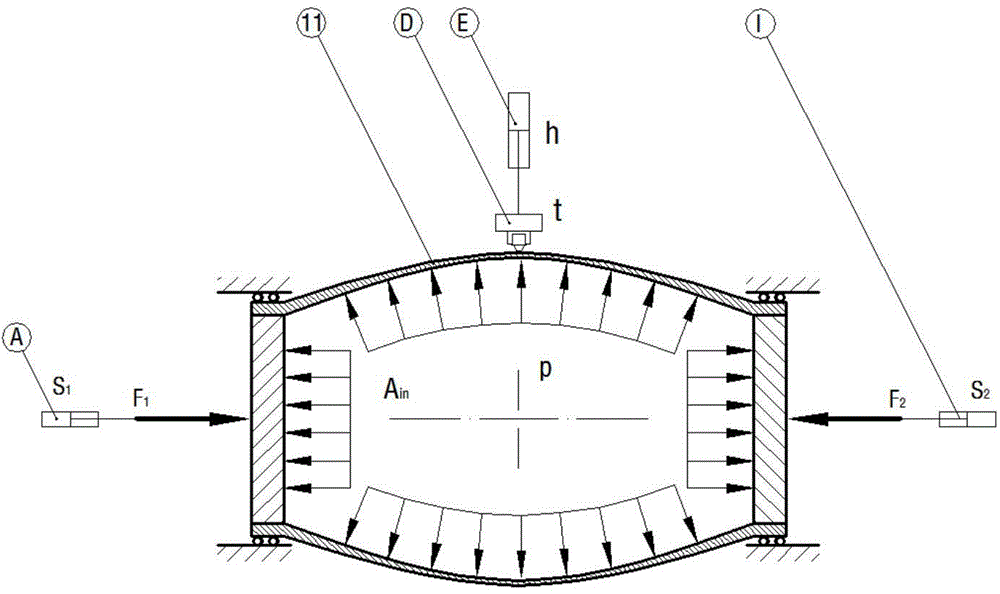

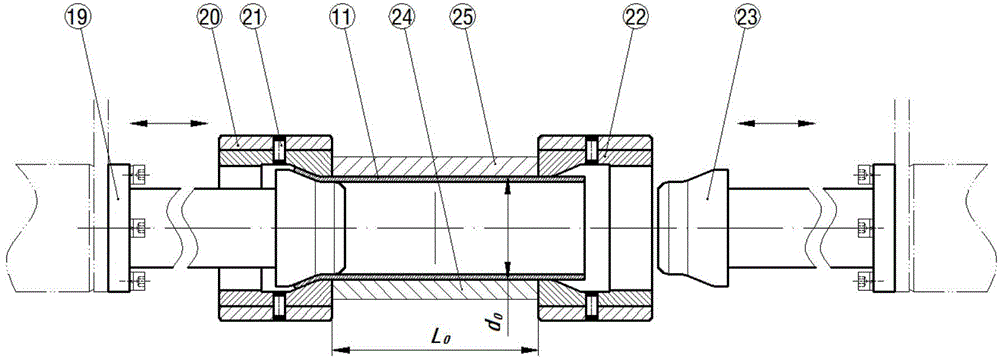

Pipe liquid filling bulging test method and device

InactiveCN104634665AMaterial strength using tensile/compressive forcesInternal pressureForming limit diagram

The invention discloses a pipe liquid filling bulging test method and device. The pipe liquid filling bulging test method comprises the following steps: restraining two ends of a test pipe, only releasing the freedom degree of axial movement of the test pipe, applying uniformly-increased hydraulic pressure p inside the test pipe, and synchronously applying equal force on the two ends of the pipe respectively until the pipe is broken; acquiring a real-time wall thickness t and a bulging height h of a highest point of the pipe in a bulging process; when the axial force can be used for rightly counteracting the acting force of internal pressure to the end surface of an inner cavity of the pipe, deducing an axial free bulging stress-strain curve and material parameters of the pipe by virtue of acquired bulging process data p, t and h according to a plastic theory. Pipe forming tests under different loading routes can be completed by applying different pulling force or pushing force at the two ends of the pipe so as to provide test data for the drawing of a pipe forming limit diagram. Embodiments show that a pipe bulging stress-strain curve and pipe stress-strain data with a relatively large strain range can be accurately acquired by using the method disclosed by the invention; and the test device and the pipe are convenient to disassemble and assemble repeatedly in expansion and bulging processes, and are good in implementation effect.

Owner:BEIHANG UNIV

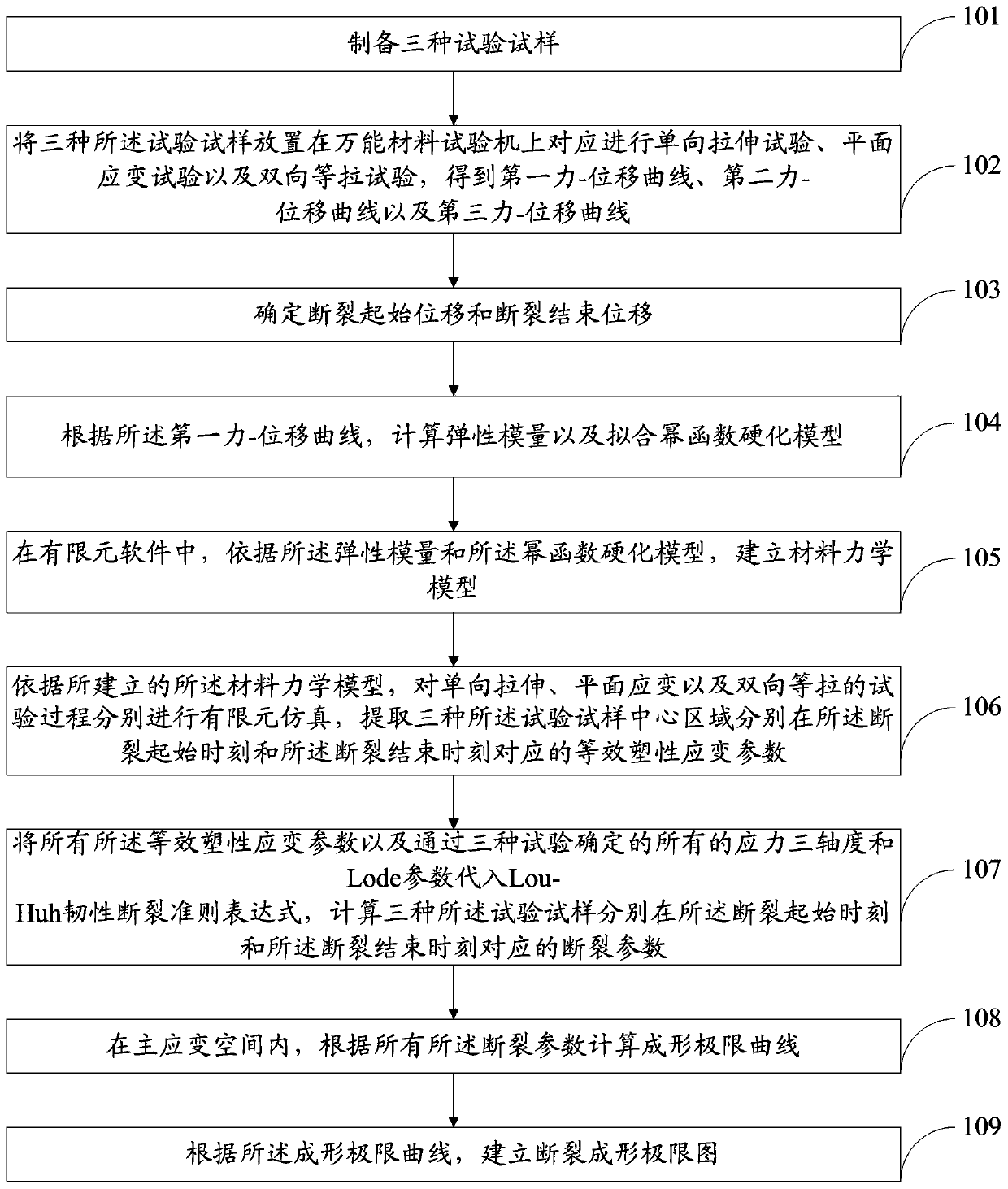

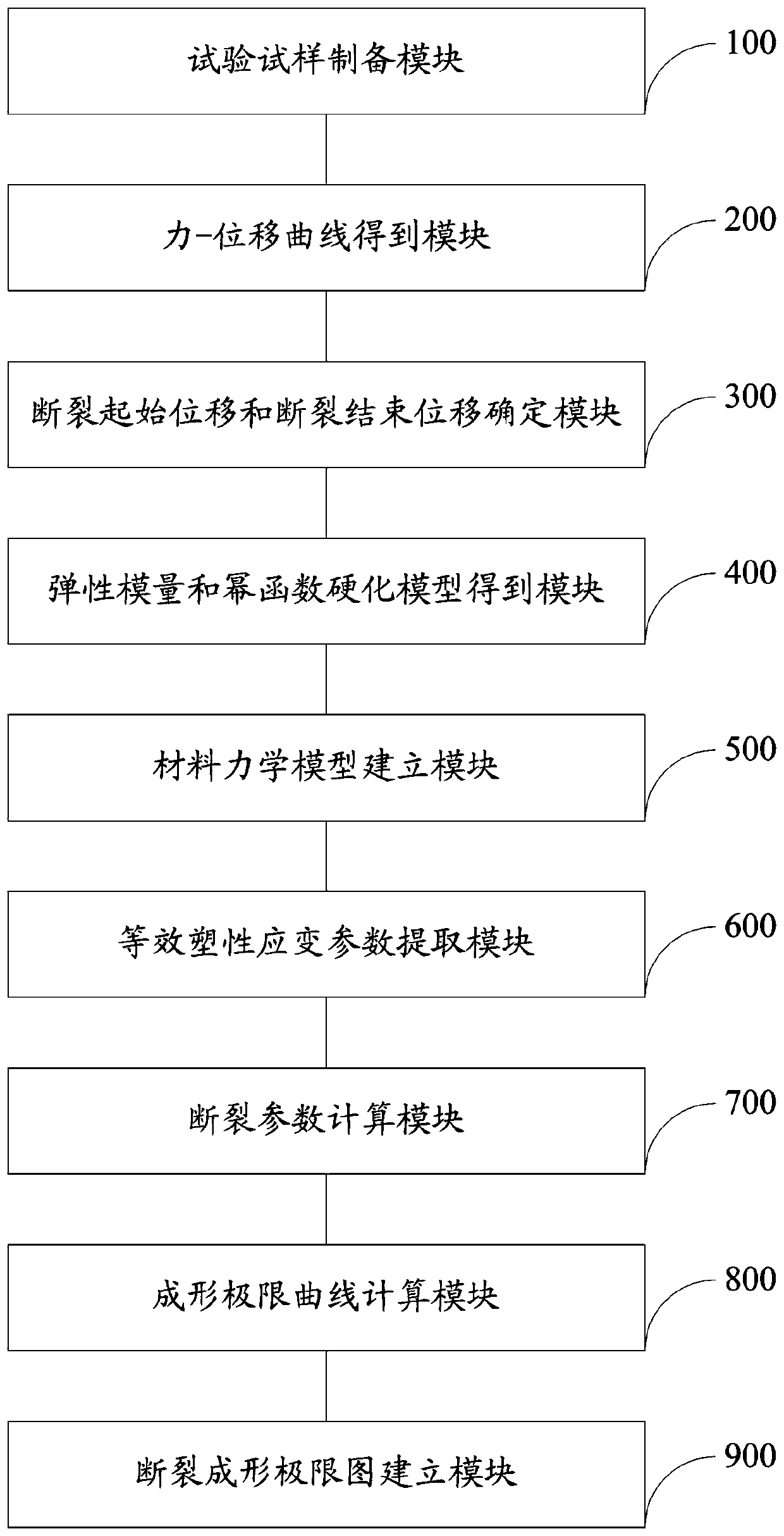

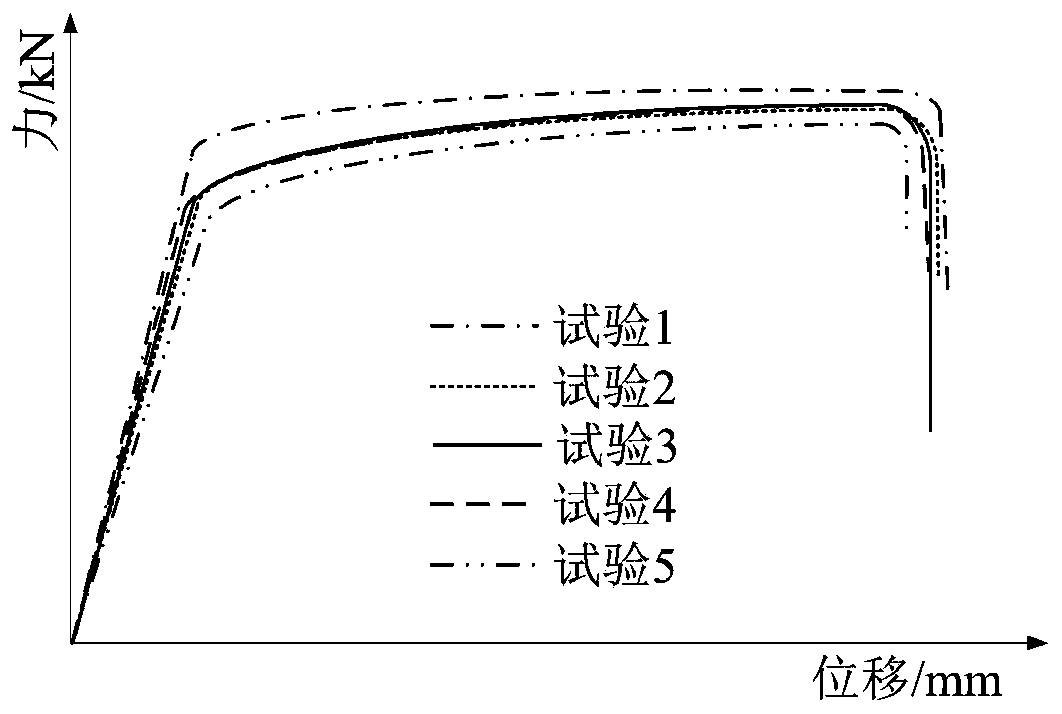

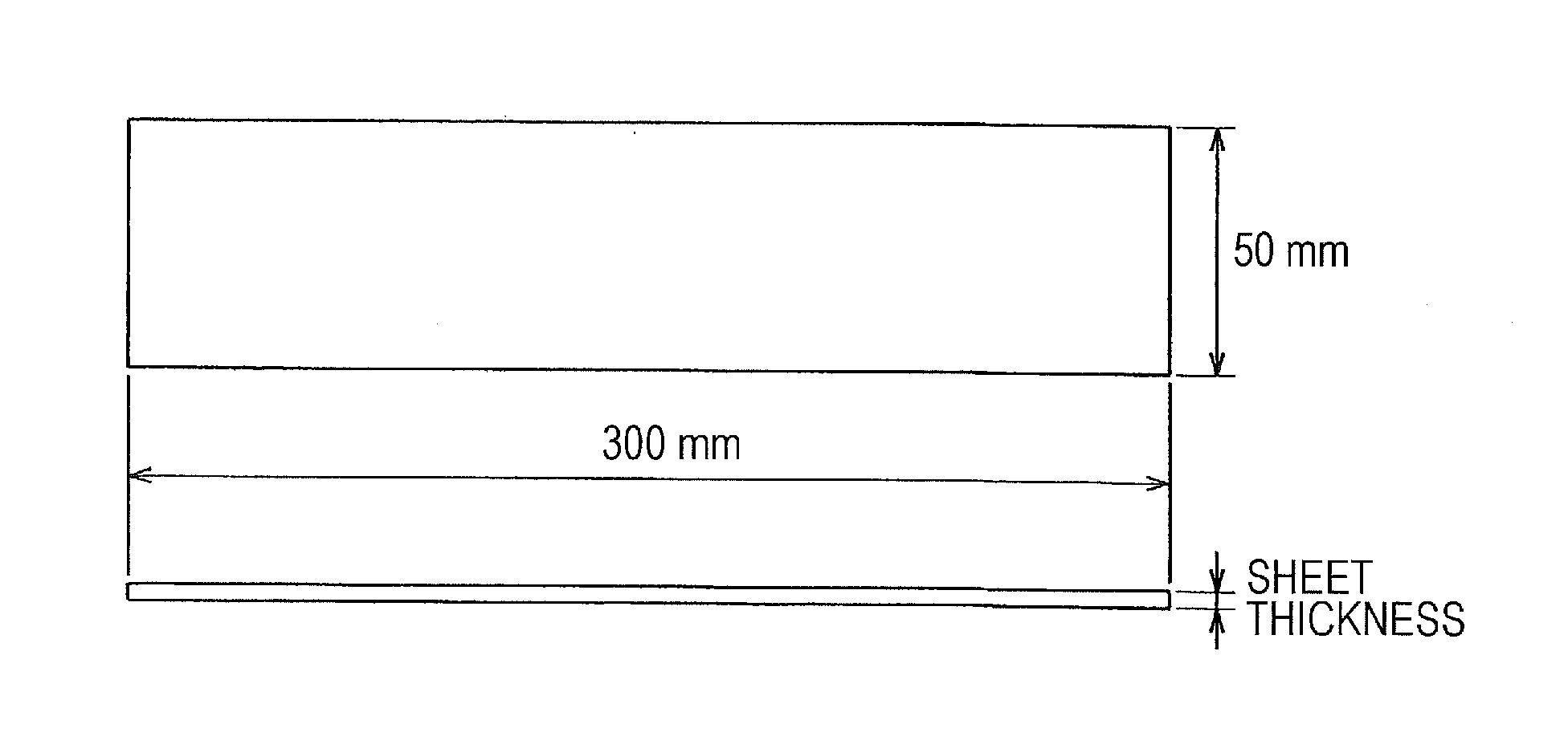

Method and system for establishing fracture forming limit diagram of high-strength aluminum alloy sheet

ActiveCN109870362AReliable theoretical applicabilityAvoid determination errorMaterial strength using tensile/compressive forcesForming limit diagramFracture zone

The invention discloses a method and a system for establishing a fracture forming limit diagram of a high-strength aluminum alloy sheet, and relates to the technical field of sheet forming limit determination. The method comprises the following steps of firstly, obtaining a fracture criterion related mechanical variable comprising fracture initial strain and fracture end strain through a combination scheme of a unidirectional tensile test, a plane strain test and a bidirectional equal-tension test in the stable stress states; secondly, determining two groups of fracture parameters according tothe mechanical variable and a Lou-Huh toughness fracture criterion; and finally, computing a forming limit curve according to the two groups of fracture parameters, and drawing a fracture forming limit diagram with a fracture zone, a dangerous zone and a safety zone. According to the method disclosed by the invention, the establishment of the forming limit diagram of the high-strength aluminum alloy sheet is realized through a simple and easily-implemented test means in combination with a novel theoretical method with stronger applicability, so that the complexity of the forming limit diagramobtained by testing is avoided, the inapplicability of a traditional theory to the high-strength aluminum alloy sheet is also solved, and typical problems existing in a realization process of the novel theoretical method are also effectively avoided.

Owner:YANSHAN UNIV

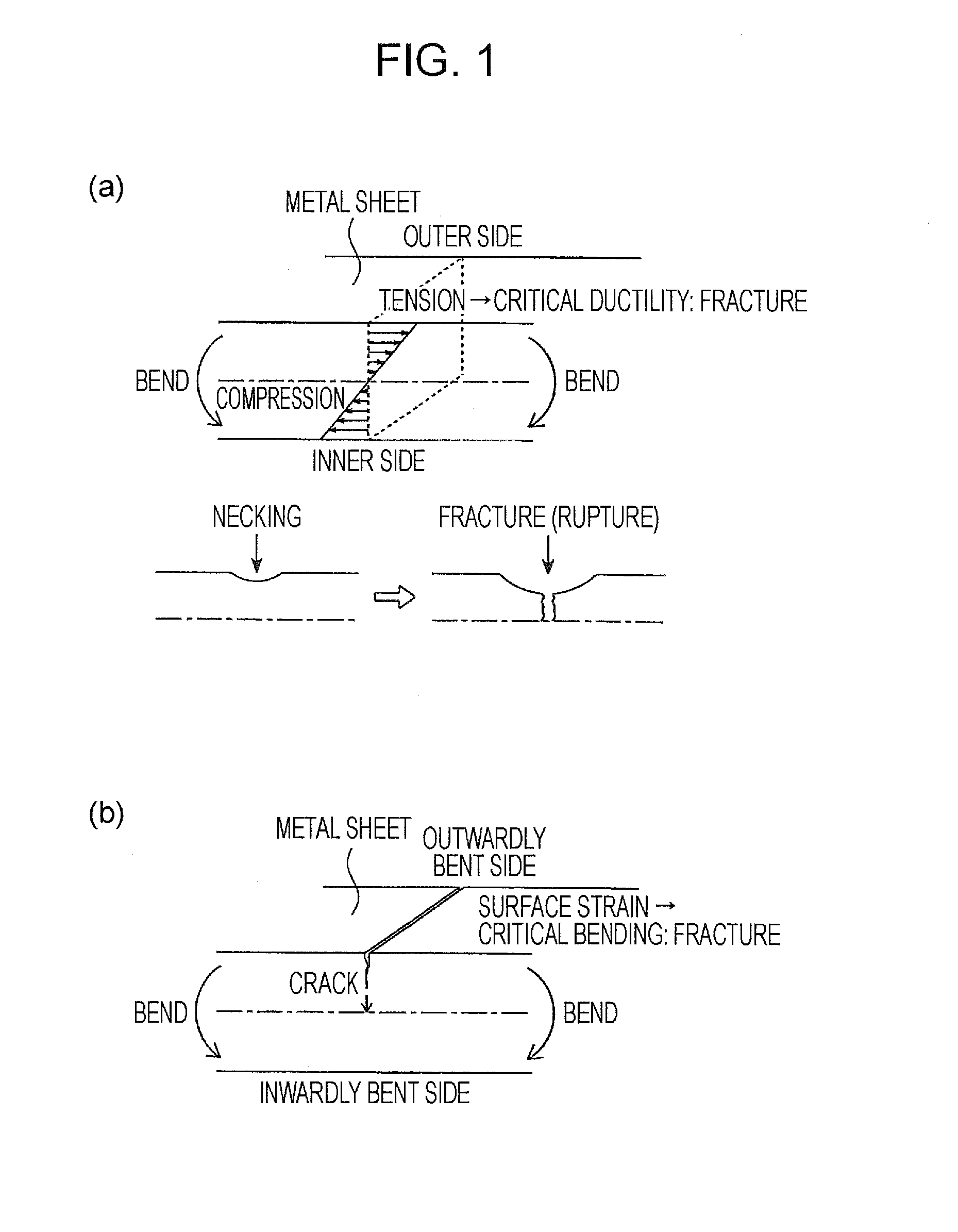

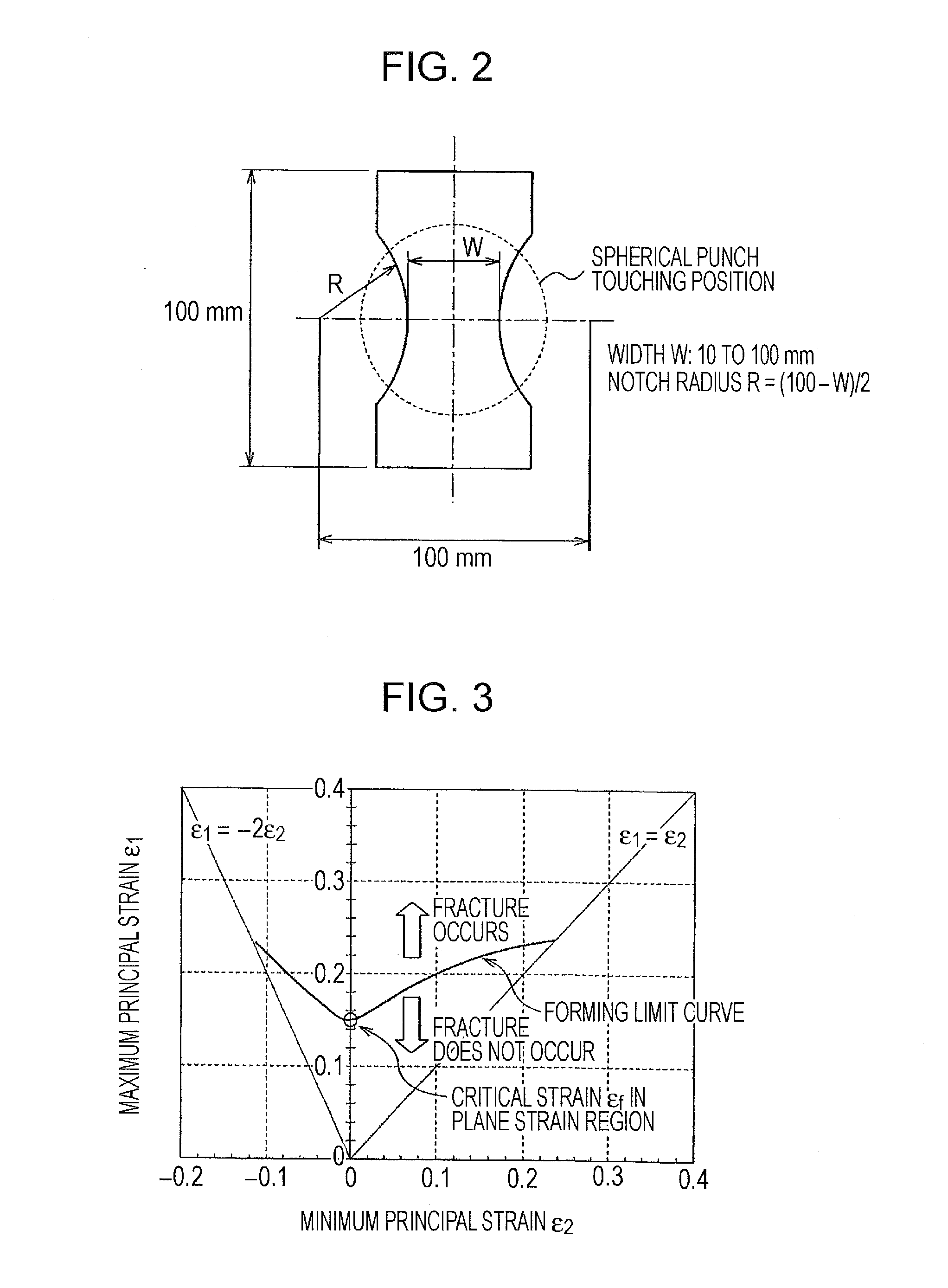

Press-forming mold designing method and press-forming mold

InactiveUS20150231682A1Stable press formingImproving press forming failure rateShaping toolsForging/hammering/pressing machinesForming limit diagramCritical surface

Owner:JFE STEEL CORP

Method for testing 3-chlorine-1, 2-propylene glycol and aliphatic ester content of 3-chlorine-1, 2-propylene glycol

The invention discloses a method for testing 3-chlorine-1, 2-propylene glycol. The method comprises the steps: (1) oxidizing the 3-chlorine-1, 2-propylene glycol in a water solution into chloroacetaldehyde; (2) performing derivatization to subject the chloroacetaldehyde and a derivatization reagent to a reaction to produce substances with fluorescent effects; and (3) using a high performance liquid chromatograph-forming limit diagram (HPLC-FLD) method to perform testing, and obtaining content of 3-chlorine-1, 2-propylene glycol. Compared with an existing gas chromatography-mass spectrometer (GC-MS) method, the method is simple in operation, equipment investment is greatly reduced, an expensive deuterated master standard is not needed, the using cost is greatly reduced, and barriers are cleared for addition of testing indexes of 3-chlorine-1, 2-propylene glycol for relative products. 3-chlorine-1, 2-propylene glycol aliphatic ester is converted into 3-chlorine-1, 2-propylene glycol by ester exchange so that the aliphatic ester content of 3-chlorine-1, 2-propylene glycol is tested.

Owner:湖北莱菔子科技有限公司

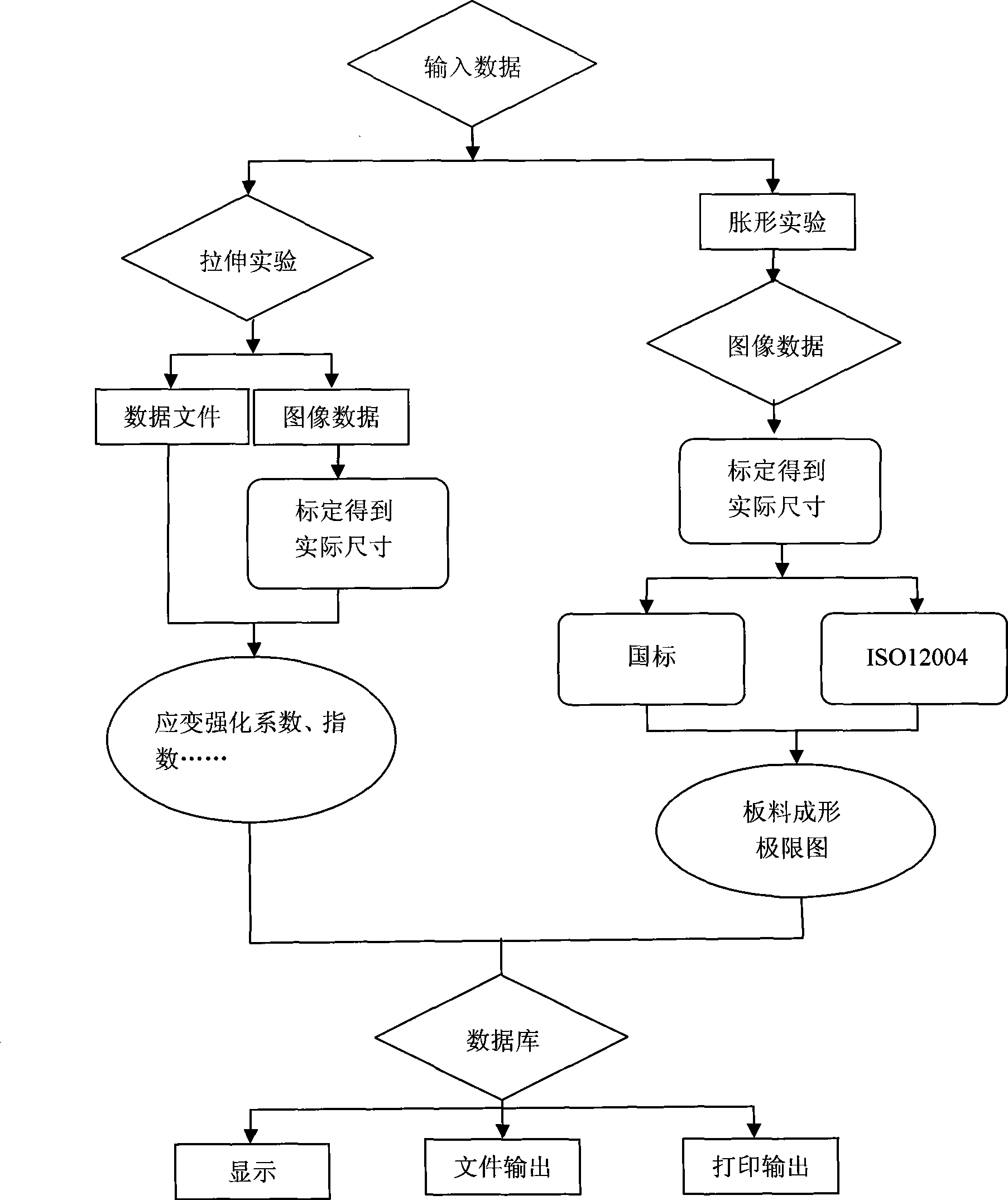

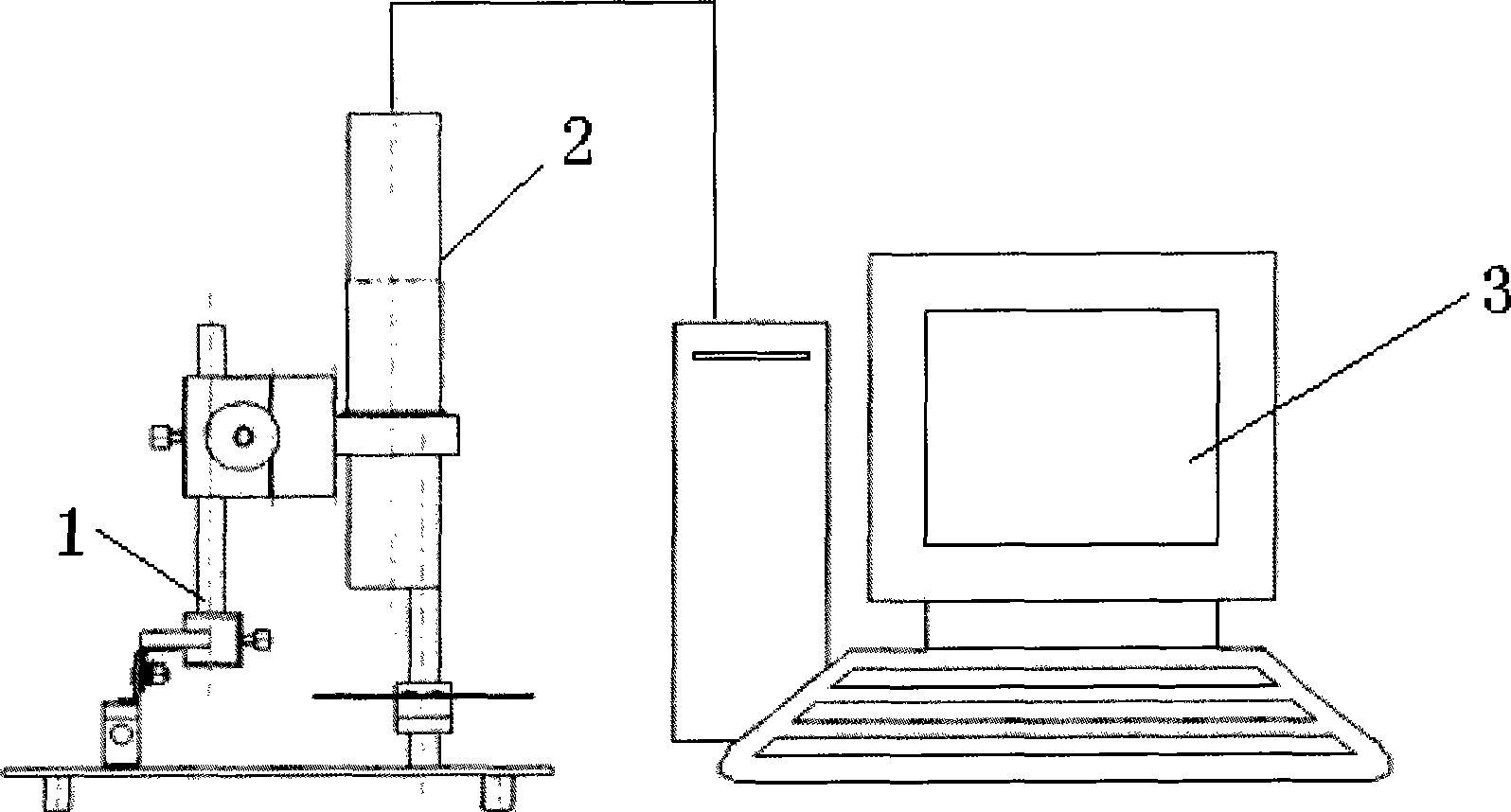

Method for measuring sheet metal deformation based on images

InactiveCN101520318APerfect data processingStrain Measurement ScienceUsing optical meansForming limit diagramData file

The invention discloses a method for measuring sheet metal deformation based on images, which adopts a multi-axis rotation and lifting structure, a CCD camera, an optical lens, and an image and data processing computer. The images of a sheet metal before and after deformation are shot and stored in the image and data processing computer to form data files; and a forming limit diagram and parameter information are acquired through a bulging test and a tension test respective to form standard data files. The method can store and analyze material performance in various aspects so as to screen spare sheet metals from various aspects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

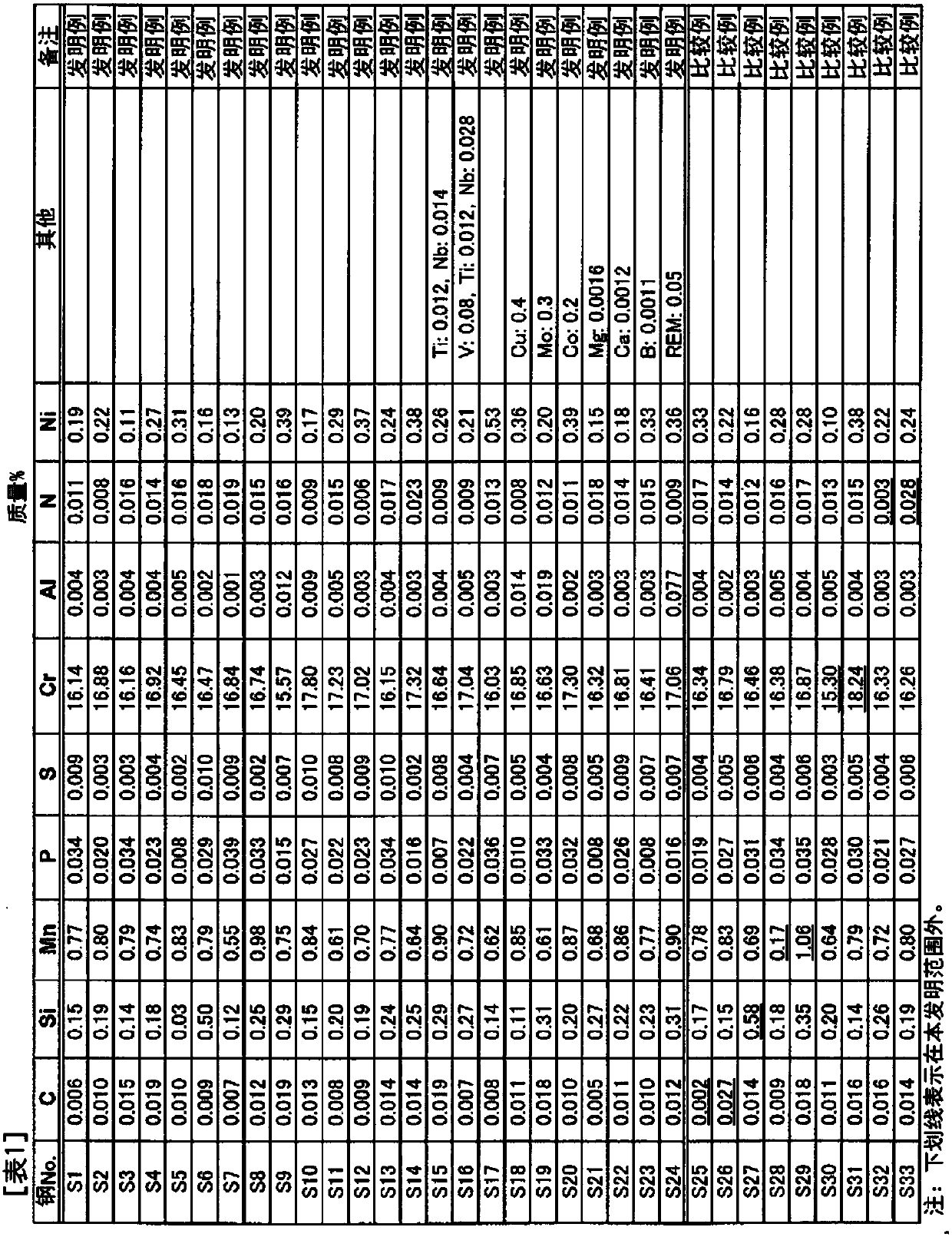

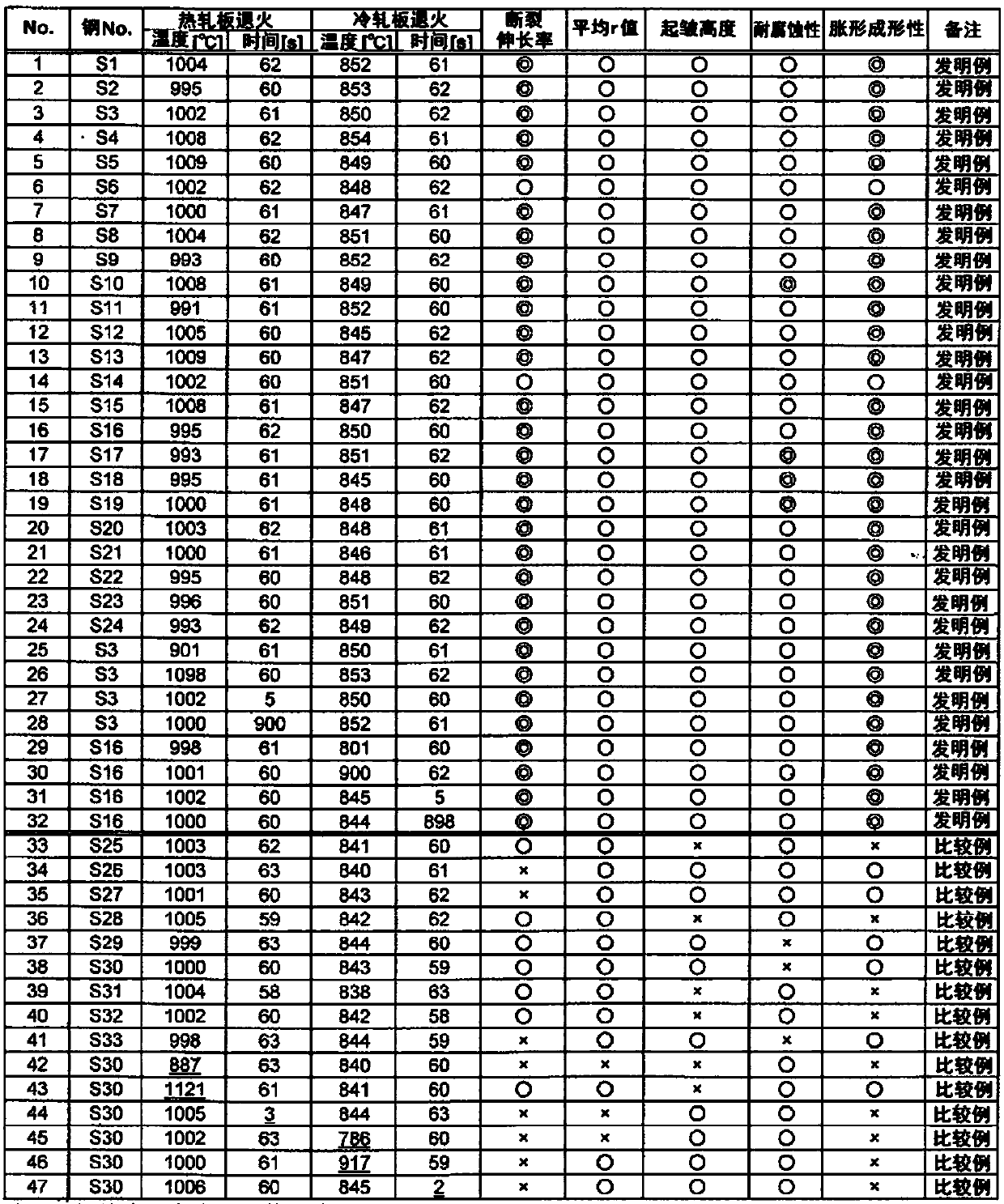

Ferritic stainless steel sheet and method for manufacturing same

ActiveCN107709592AFull corrosion resistanceGood formabilityFurnace typesHeat treatment furnacesForming limit diagramCorrosion

Provided are a ferritic stainless steel sheet having adequate corrosion resistance and excellent forming properties and ridging resistance, and a method for manufacturing the same. This ferritic stainless steel sheet contains, in terms of % by mass, 0.005-0.025% C, 0.02-0.50% Si, 0.55-1.00% Mn, 0.04% or less of P, 0.01% or less of S, 0.001-0.10% Al, 15.5-18.0% Cr, 0.1-1.0% Ni, and 0.005-0.025% N,the remainder comprising Fe and unavoidable impurities, the breaking elongation of the ferritic stainless steel sheet being 28% or greater, the average r value thereof being 0.75 or greater, and the minimum value of the maximum logarithmic strain of the forming limit based on a forming limit diagram (FLD) being 0.15 or greater.

Owner:JFE STEEL CORP

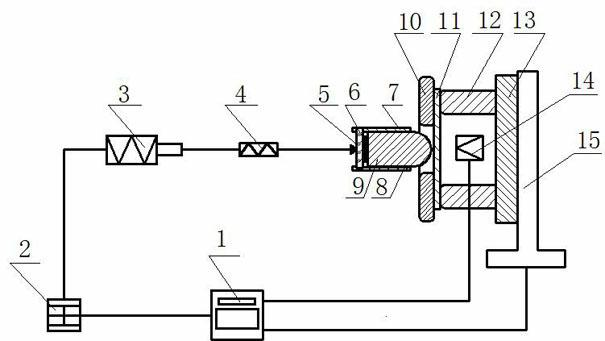

Laser-propelling-based method and laser-propelling-based device for producing sheet shock forming limit diagram

InactiveCN102513699AShort preparation timeLow costLaser beam welding apparatusForming limit diagramMomentum

The invention relates to a method and a device of forming a limit diagram in the technical field of laser shock sheet forming, in particular to a laser-propelling-based method and a laser-propelling-based device for producing a sheet shock forming limit diagram, which are mainly used for judging failure and deformation of sheets such as necking or cracking and for evaluating forming performance of the sheets. The method is characterized in that: a laser controller (2) controls a repeatable frequency pulse laser device (3) to transmit laser beam of a certain laser pulse width, a facular adjusting device adjusts the diameter of a facular, the laser beam acts on a bullet, the bullet produces momentum under the laser effect to act on different sheets with different widths, a bullet guide structure is changed along with different width of the sheets, the bullet guide structure guarantees an acting force and an acting direction of a shock force, so the sheets are uniform to deform; and by changing the length-to-width ratio of the sheets (11), different limit stress points under different stress ratios can be obtained so as to obtain the forming limit diagram of the sheets.

Owner:JIANGSU UNIV

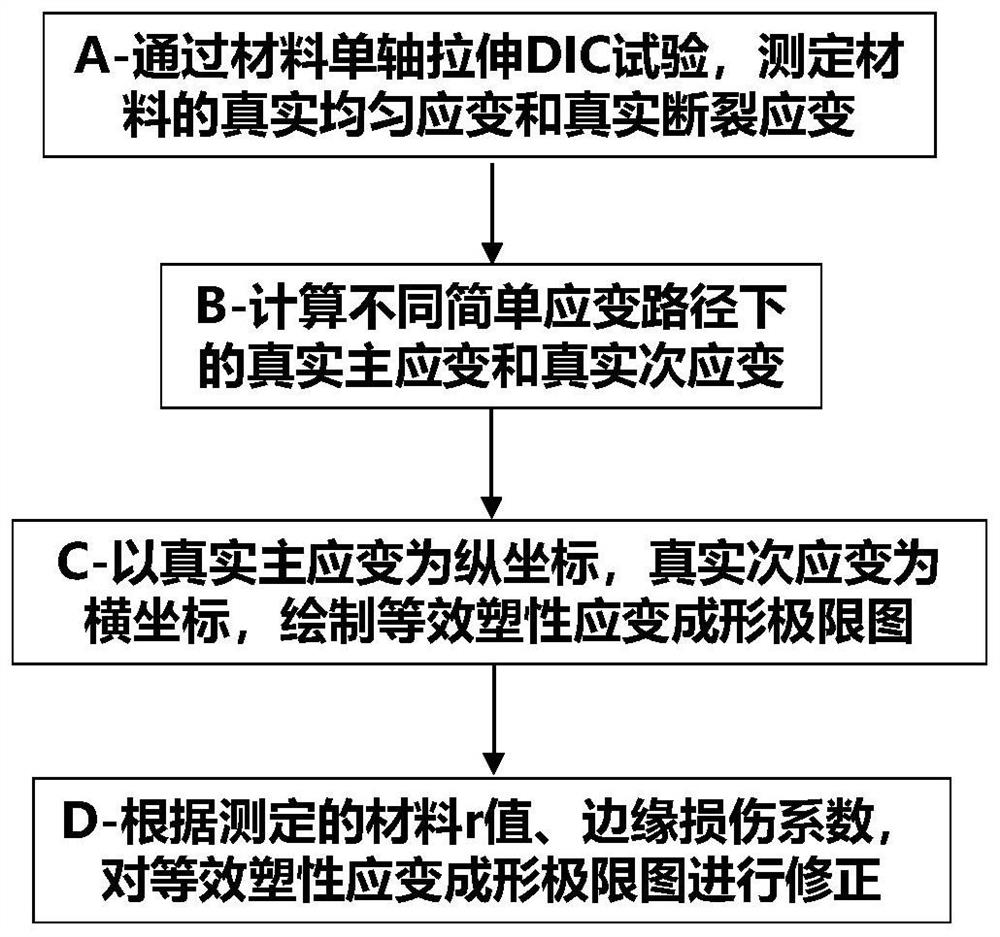

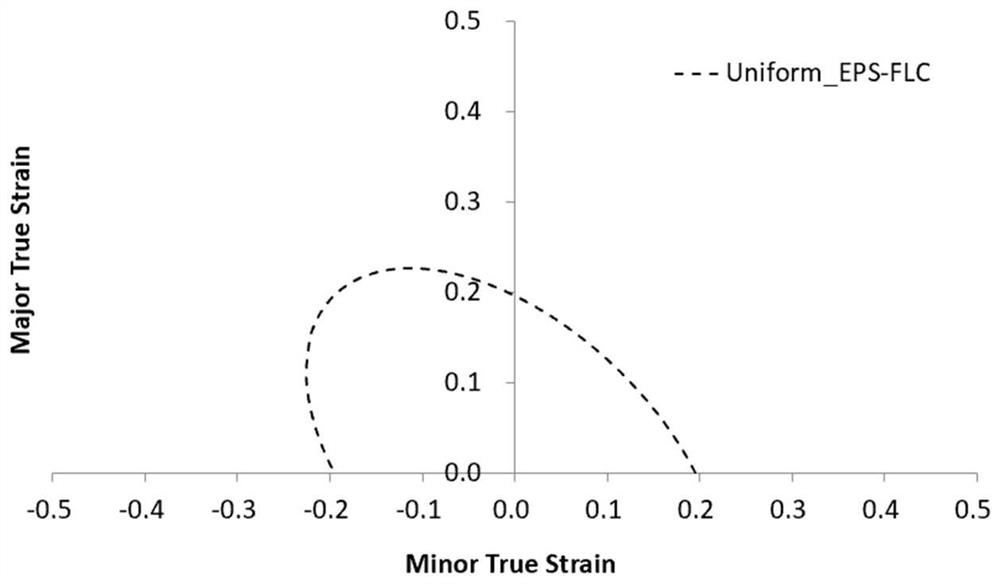

Test and calculation method for measuring equivalent plastic strain forming limit diagram

ActiveCN111896373AAccurate Technical TargetLow costSustainable transportationMaterial strength using tensile/compressive forcesForming limit diagramStructural engineering

The invention discloses a test and calculation method for measuring an equivalent plastic strain forming limit diagram. The method comprises the following steps: measuring real uniform strain and realbreaking strain of a material; calculating primary strain and secondary strain under different simple strain paths; and drawing and correcting an equivalent plastic strain forming limit diagram (EPS-FLD). Various defects in the prior art are overcome through theoretical innovation; a technical solution is provided for automobile steel under a new situation; meanwhile, the measurement of the uniform forming limit and the fracture forming limit of the material is integrated into a uniaxial tension DIC test; under the condition that no extra test is needed and a better technical target can be achieved, no extra test is needed, and precious manpower cost and equipment cost are saved, so that the method has important theoretical and engineering practice significance.

Owner:武汉上善仿真科技有限责任公司

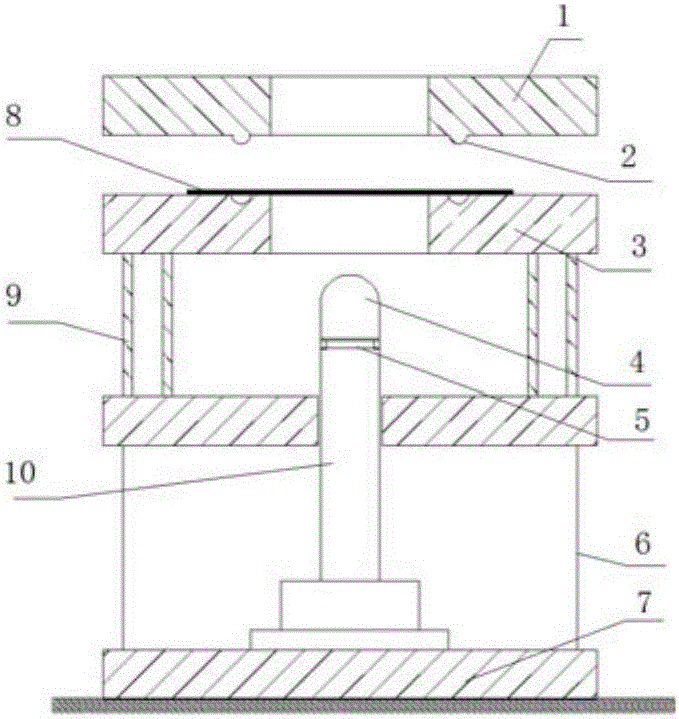

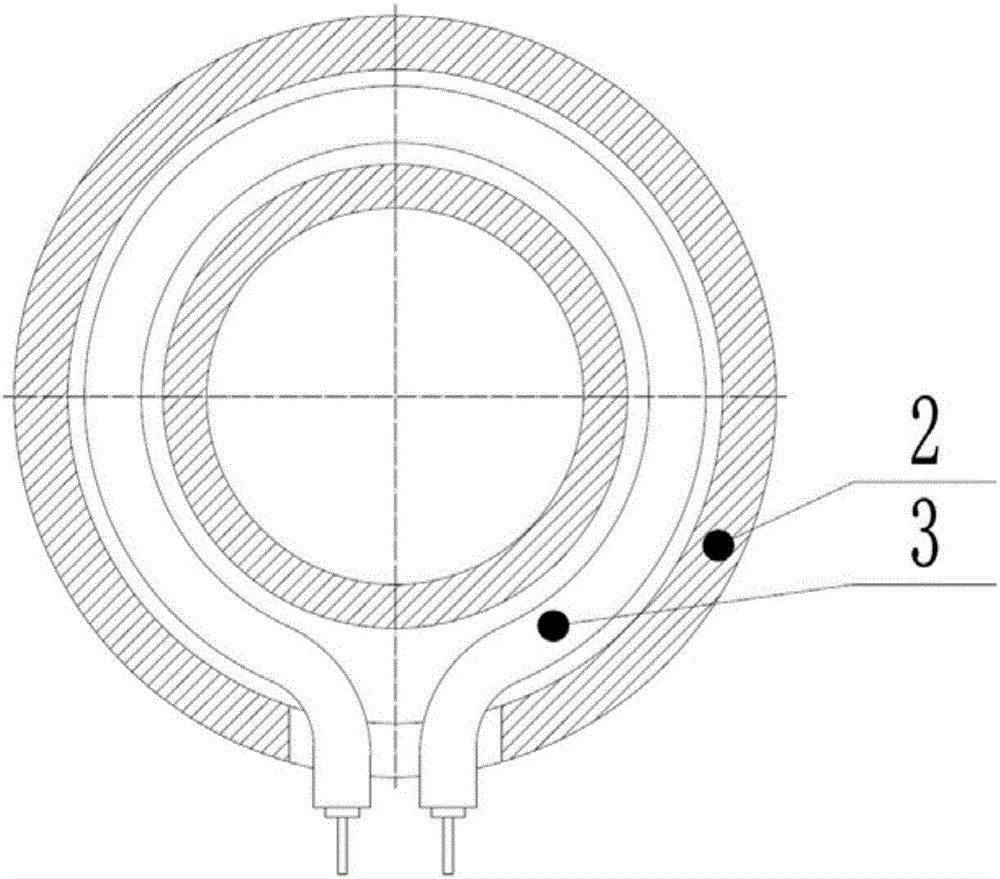

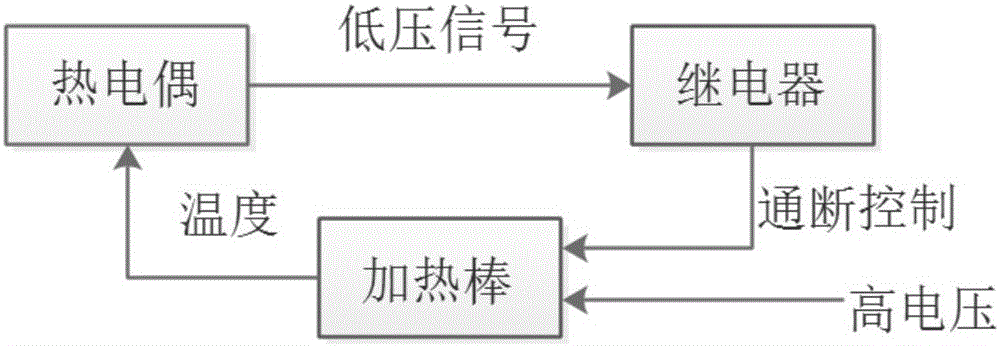

Thin plate high temperature forming limit testing device

ActiveCN106053259ACompact structurePrecise variable temperature testMaterial strength using single impulsive forceForming limit diagramThin slab

The invention discloses a thin plate high temperature forming limit testing device. The device comprises a press plate assembly, a concave mould assembly, a convex mould assembly, a guiding and supporting assembly, a heating assembly, and a sealing assembly. The press plate assembly is arranged on the upper side and lower side. The sealing assembly is arranged on the press plate assembly and the guiding and supporting assembly. The concave mould assembly is arranged in the sealing assembly. The convex mould assembly is arranged on the press plate assembly. The heating assembly is arranged in the concave mould assembly and the convex mould assembly. The provided thin plate high temperature forming limit testing device can be used to measure the forming limit pattern of a thin plate at different temperatures under different strain rates; a heating rod is arranged in the mould, thus the testing device has a compact structure; a thermocouple-relay control loop is adopted to realize precise varied temperature experiments; at the same time, an sealed environment filled with nitrogen is adopted to achieve the high temperature forming tests of metals that can be easily oxidized; and the external surface of moulds will not be destroyed due to built-in heating devices.

Owner:UNIV OF SCI & TECH BEIJING

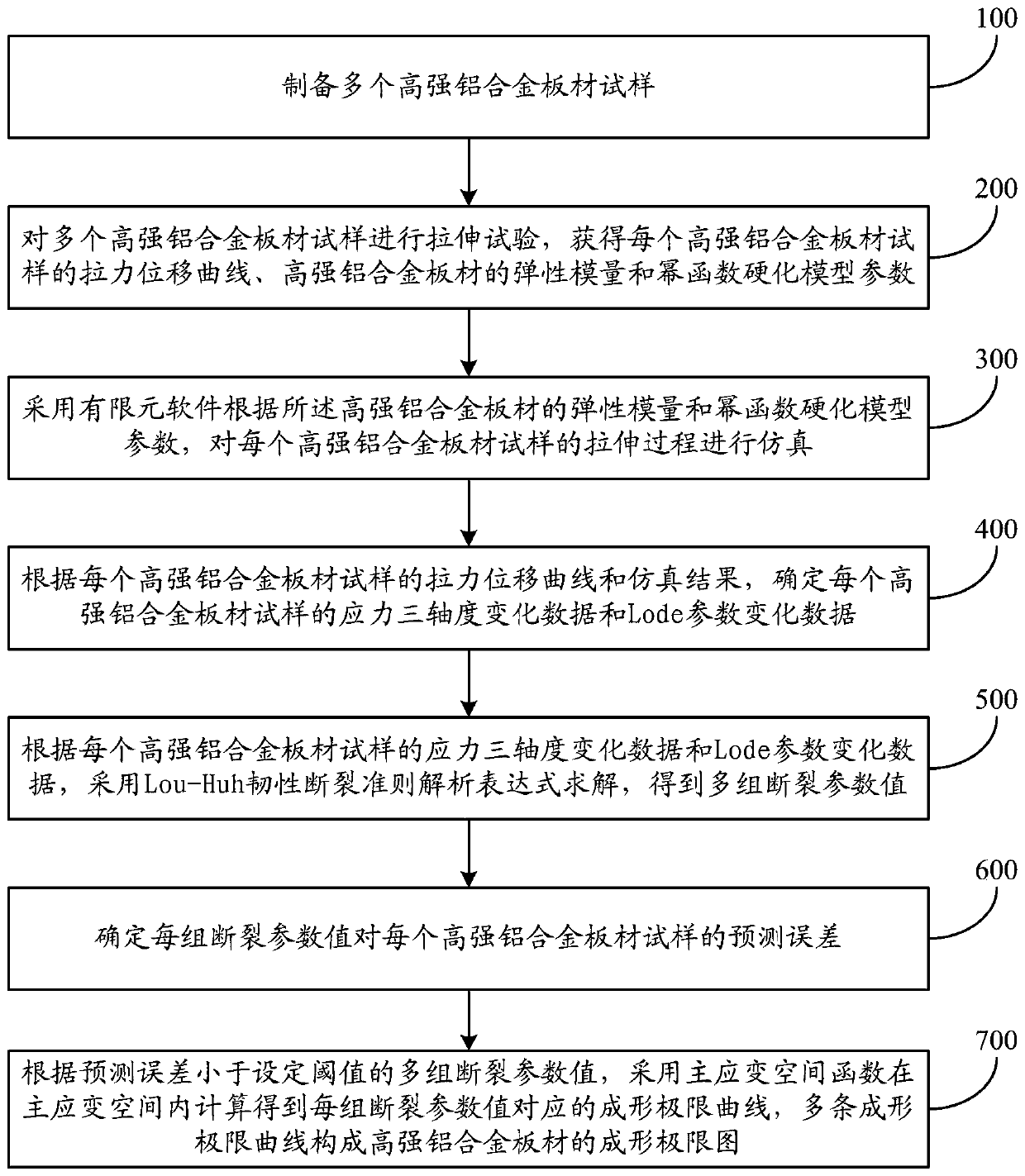

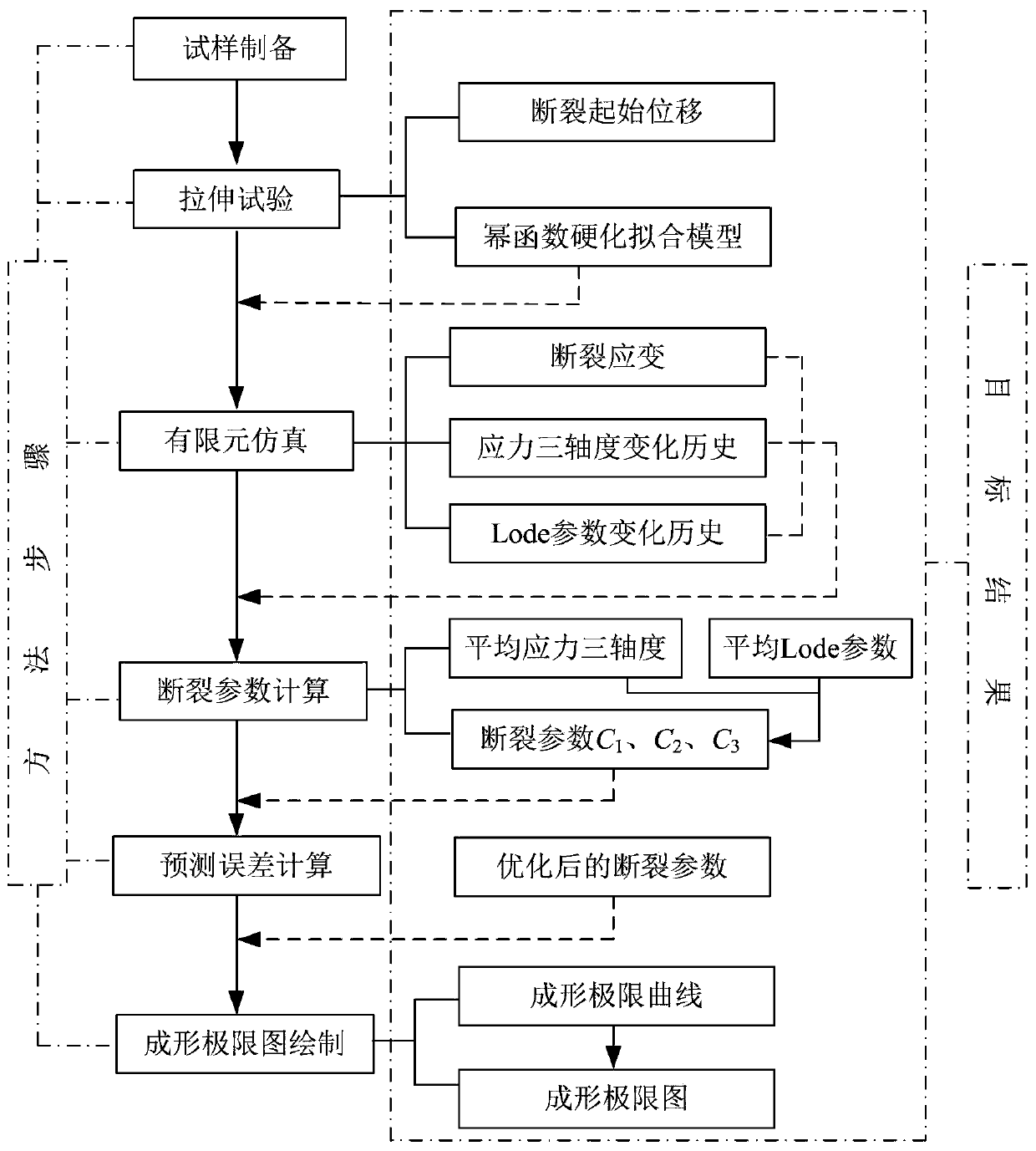

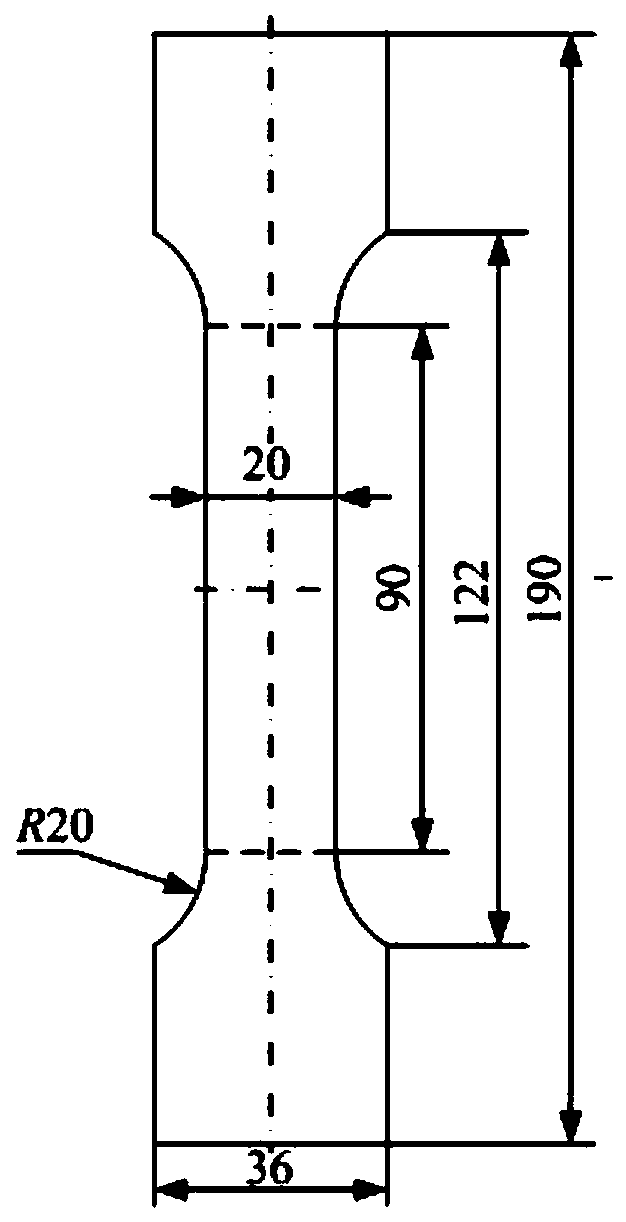

Method for determining forming limit of high-strength aluminum alloy sheet

ActiveCN109870357AAvoid printingAvoid the bulging test processMaterial strength using tensile/compressive forcesForming limit diagramModel parameters

The invention discloses a method for determining a forming limit of a high-strength aluminum alloy sheet. The method comprises the following steps of preparing a plurality of high-strength aluminum alloy sheet samples; carrying out a tensile test on the samples to obtain a tensile displacement curve of each sample, elastic modulus and power function hardening model parameters; carrying out simulation on a tensile process by adopting finite element software; determining stress triaxiality change data and Lode parameter change data of each sample according to the tensile displacement curve and asimulation result; solving by adopting an analytic expression of an Lou-Huh ductile fracture criterion in order to obtain a plurality of groups of fracture parameter values; determining a predictionerror of each group of fracture parameter values to each sample; and computing a forming limit diagram of the high-strength aluminum alloy sheet by adopting a principal strain space function in a principal strain space according to the plurality of groups of fracture parameter values of which the prediction error is smaller than a set threshold value. According to the method, on the basis of preferred selection, the ductile fracture criterion is applied to obtain the forming limit curves in order to form a fracture judgement ribbon area, and a judgement result is more reliable.

Owner:YANSHAN UNIV

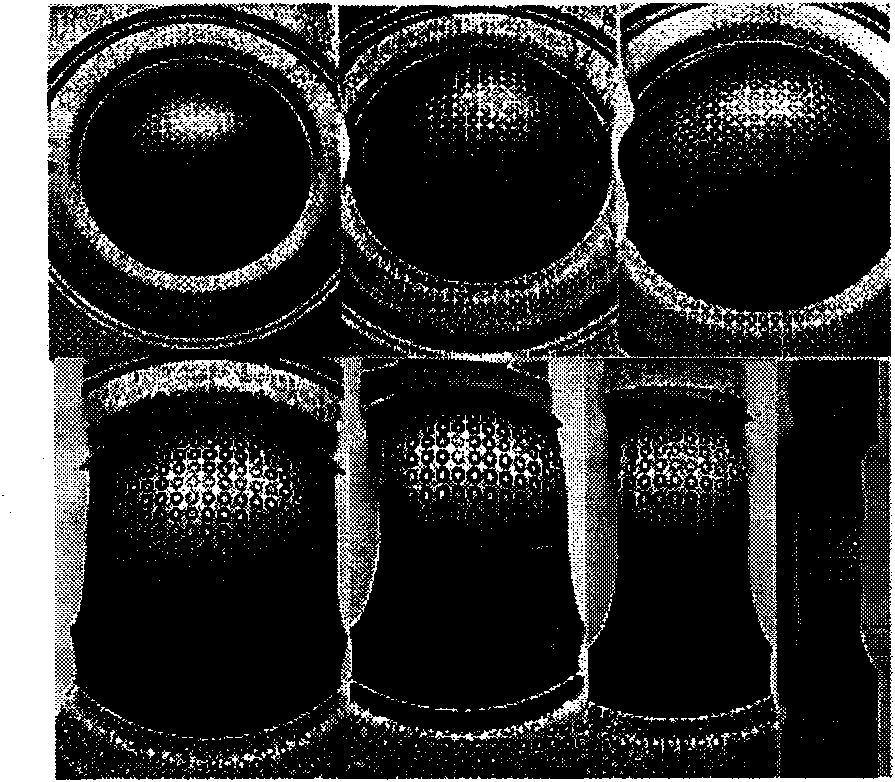

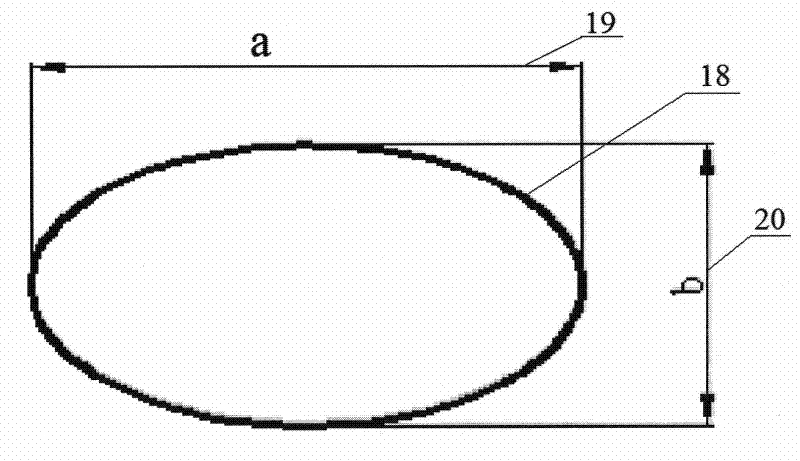

Manufacturing method of laser impact sheet forming limit diagram and data acquisition device

InactiveCN101745739AShort preparation timeLow costLaser beam welding apparatusForming limit diagramOptical power meter

The invention discloses a manufacturing method of a laser impact sheet limit diagram and a data acquisition device, the limit manufacturing comprises data acquisition and drawing sheet forming limit diagram, wherein, the data acquisition comprises (1) putting the sheet printed with fine circular grids at an oval concave module; (2) the center surface of the sheet is provided with vertical laser impact load, and an optical power meter is used as an instrument for detecting the sheet break, when a digital display of the optical power meter displays the continuous red light emitted by a red light, the laser impact is stopped, and the sheet is taken out from the oval concave module; (3) the grid which presents oval shape after deformation and is most near to the break point is selected from the sheet, an grid instrument is used to detect a long shaft value and a short shaft value of the oval grid and calculates and converts them to a first main strain value and a second main strain value; (4) the ovality of the oval concave module is changed, and the steps (1)-(3) are repeated, at least 5 groups of experimental data are obtained to draw the curve; the key point of the device lies in that an infrared lamp and the optical power meter are adopted to detect whether break occurs. The invention is simple, the experimental cost is low, and the laser impact forming limit diagrams of various sheets can be rapidly drawn.

Owner:JIANGSU UNIV

Experimental method for building forming limit diagram of transformation induced plasticity steel plate

InactiveCN101599094AEfficient evaluation of formabilityReduce testing workloadSpecial data processing applicationsForming limit diagramPunching

The invention discloses an experimental method for building forming limit diagram of transformation induced plasticity steel plates, relating to the building method of forming limit diagrams. The method of the invention comprises the following steps: (1) the thickness and the strain hardening index of the transformation induced plasticity steel plate are determined; (2) the limit strain value of the transformation induced plasticity steel plate under the condition of plane strain state is calculated; (3) a strain coordinate system is built, data is synthesized on the coordinate system so as to build the forming limit diagram of the transformation induced plasticity steel plate. The invention is an effective tool for solving the transformation induced plasticity steel plate material punching problem, can successfully predict transformation induced plasticity steel plate material invalidation, effectively estimates the forming performance and reduces the existing measuring workload for building a shaping limit diagram.

Owner:NORTHEASTERN UNIV

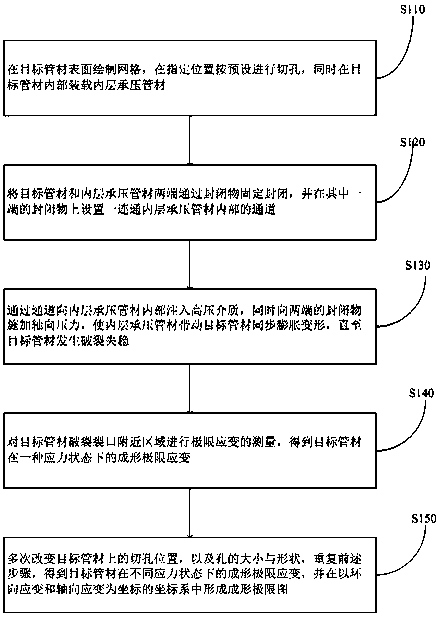

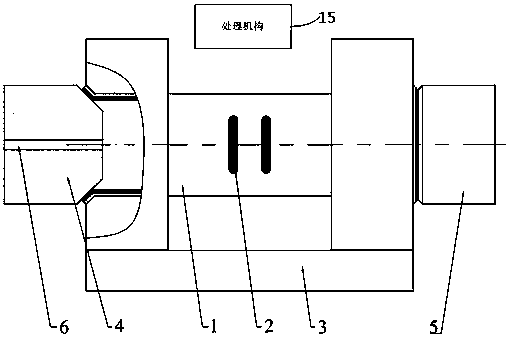

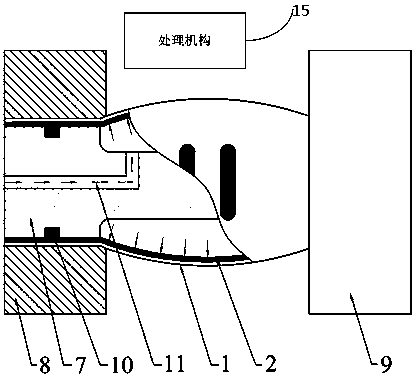

Method for establishing shaping limit graph of thin wall tubing and apparatus thereof

ActiveCN107941609AWill not be inaccurateSimple test methodMaterial strength using tensile/compressive forcesInternal pressureForming limit diagram

The invention discloses a method for establishing a shaping limit graph of a thin wall tubing and an apparatus thereof. The method is characterized in that symmetrical apertures are arranged on a surface of a target tubing, bulging is generated under effect of hydraulic pressure in a bearing tubing at an internal layer, by changing shapes, sizes and positions of the apertures, and shaping limit ofthe target tubing under all stress states in a scope from unidirectional stretching to bidirectional stretching can be obtained; under effect of hydraulic pressure in the bearing tubing at the internal layer, the target tubing and the bearing tubing at the internal layer are subjected to synchronous expansion, friction effect between two tubing is little, and an inaccurate result cannot be generated due to friction influence of the target tubing. Compared with a method for axially applying pressure or pulling force, the method of the invention is simple, closed loop servo control of the internal pressure and axial force are not required, the shapes, sizes and positions of the apertures are required to be designed in a reasonable mode, and the appropriate bearing tubing at the internal layer is selected as a support.

Owner:TAIYUAN UNIV OF TECH

Tester apparatus for obtaining forming limit diagram

A tester apparatus capable of obtaining a forming limit diagram pertaining to a sample having a high degree of precision includes a fixing jig and a mobile jig installed at an upper side of the fixing jig so as to enable a vertical movement. The mobile jig may be configured to fix the sample in cooperation with the fixing jig, and a driving apparatus disposed at a lower side of the fixing jig may be configured to drive the vertical movement of the mobile jig. An interlocking apparatus provided in between the mobile jig and the driving apparatus may be configured to deliver a driving force of the driving apparatus to the mobile jig.

Owner:SAMSUNG ELECTRONICS CO LTD

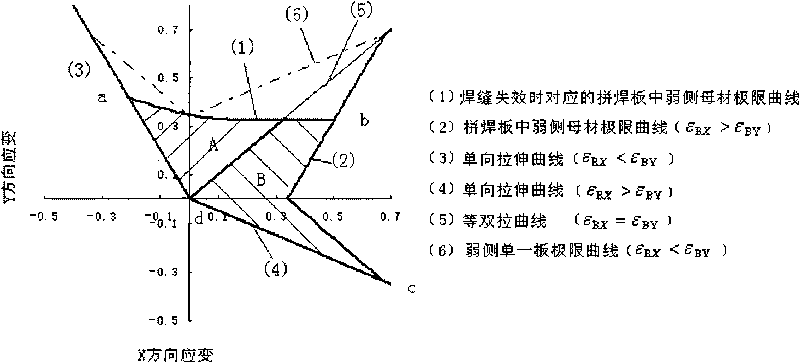

Method for establishing and using forming limit diagram of laser tailor-welded blank

InactiveCN101739489AIntuitive principal strain directionIntuitive Failure Form RelationshipsSpecial data processing applicationsLaser beam welding apparatusForming limit diagramWeld seam

The invention discloses a method for establishing a forming limit diagram of a laser tailor-welded blank. The method comprises the following steps: (A) establishing an XY coordinate system of which the X represents a direction perpendicular to the direction of a welding seam and the Y represents the direction parallel to the direction of the welding seam; (B) calculating an ultimate strain of a material in a welding zone by adopting an empirical formula and combining with performance parameters of the material, and then, based on stress strain relation of the material in the welding zone and weak side parent metal, calculating to obtain weak side parent metal FLC by combining with the performance parameters of the weak side parent metal when the material in the welding zone is invalid, namely, Y-direction strain is larger than X-direction strain; (C) calculating the weak side parent metal FLC when the weak side parent metal is invalid, namely, the Y-direction strain is smaller than the X-direction strain by adopting the empirical formula and combining with the performance parameters of the weak side parent metal; and (D) marking the weak side parent metal FLCs obtained in step (B)and step (C) into an XY direction strain coordinate system at the same time to establish the forming limit diagram of the laser tailor-welded blank. The method can establish the forming limit diagramof the laser tailor-welded blank suitable for engineering application to effectively evaluate forming limit of the tailor-welded blank.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com