Method for determination of forming limit curve of sheet metal

A technology of forming limit curve and metal sheet, which is applied in the field of determining the plastic forming performance index of metal sheet - the determination of forming limit curve, which can solve the problems of difficult to see the grid, electrochemical corrosion grid wear, measurement difficulty, etc. The determination method is simple and feasible, the cost is low, and the error is small.

Inactive Publication Date: 2013-12-04

SHANGHAI UNIV OF ENG SCI

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] 3. After the stamping deformation of the metal sheet, due to the contact and extrusion between the metal sheet and the punch and die during the forming process, the electrochemical corrosion mesh at the part with a large amount of deformation is often worn, making it difficult to see the worn mesh. , calculate ε 1 , ε 2 There are certain difficulties, which relatively increase the error and difficulty of drawing the FLC curve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

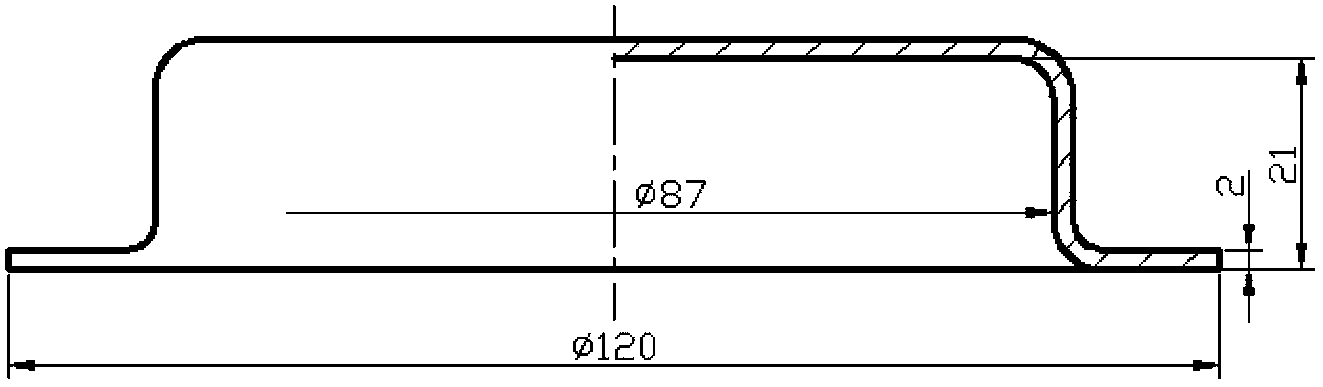

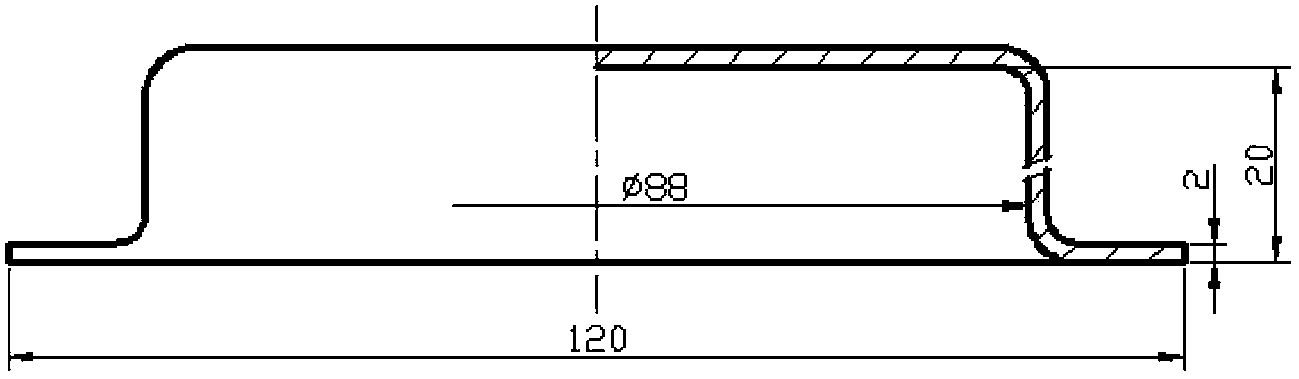

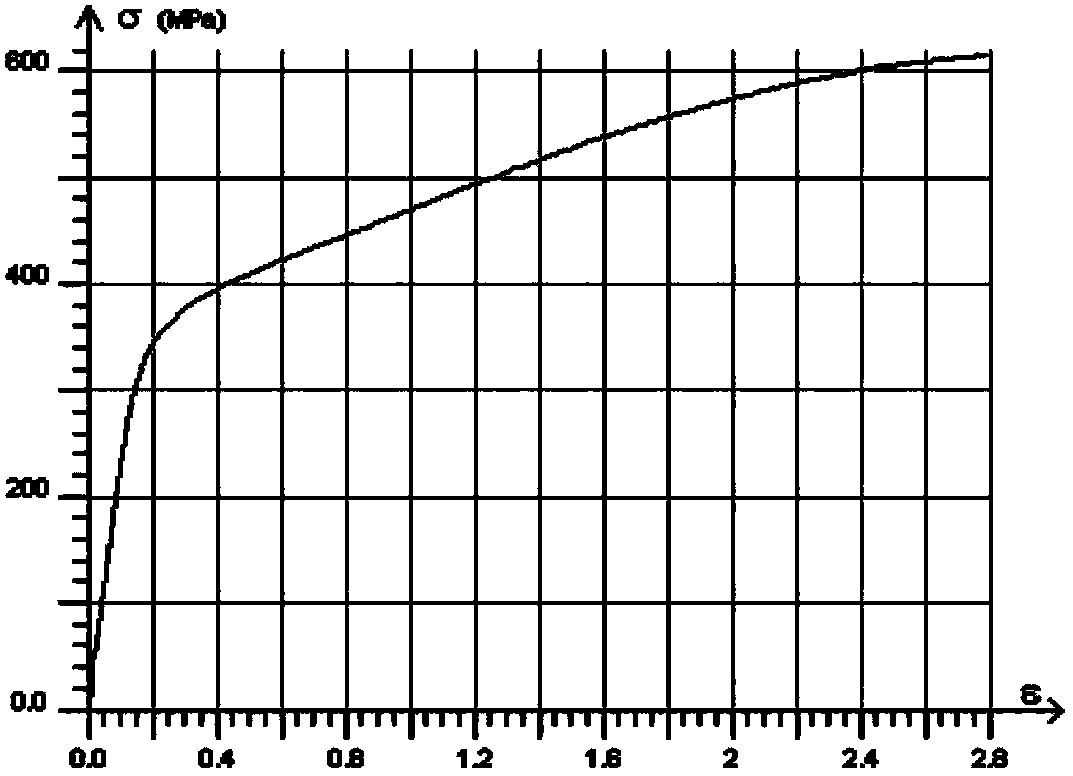

[0029] In this embodiment, the determination of the forming limit curve of a dual-phase steel for high-strength testing includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for determination of a forming limit curve of sheet metal. A piece of stamping shaping CAE simulation analysis software DYNAFORM is used for simulation of stamping forming of a piece of sheet metal to be detected, thereby determining a FLD 0 value in a shaping limit graph; and the forming limit curve of the sheet metal to be detected is calculated out though the Keeler formula. Compared with the prior art, the method for determination of the forming limit curve of sheet metal provided by the invention is simple, feasible and has low cost and small error.

Description

technical field [0001] The invention relates to a method for determining the plastic forming performance index of a metal plate—the forming limit curve. Background technique [0002] The basic mechanical performance index of sheet metal can only make a qualitative and comprehensive half evaluation of sheet metal formability. For the forming of parts with complex shapes, the actual deformation of each part of the blank cannot be fully described and measured with the basic mechanical performance indicators. The forming limit curve (Forming Limit Curves - abbreviated as FLC) focuses on each deformation part of the complex part, and it is the local instability limit strain principal strainε of the sheet metal under different strain paths 1 and secondary strain ε 2 composed of striped curves. FLD (Forming Limit Diagram - abbreviated as FLD, which has the same physical meaning as FLC) comprehensively and intuitively reflects the formability of sheet metal under different strain...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/28

Inventor 苏钰程光牛景弘王一伟王娟

Owner SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com