Method for determining thickness of wall of container for simulating explosion test in deepwater environment

An explosion test and determination method technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of difficult implementation of container wall thickness determination method, short positive pressure action time, and inability to obtain wall thickness, etc., so as to reduce subjective factors and simplify the determination method , the effect of meeting the actual bearing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

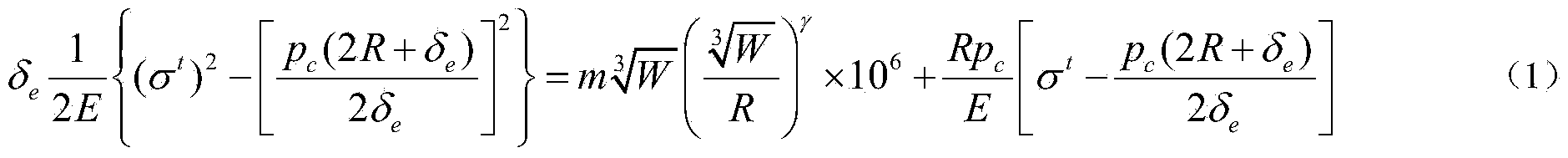

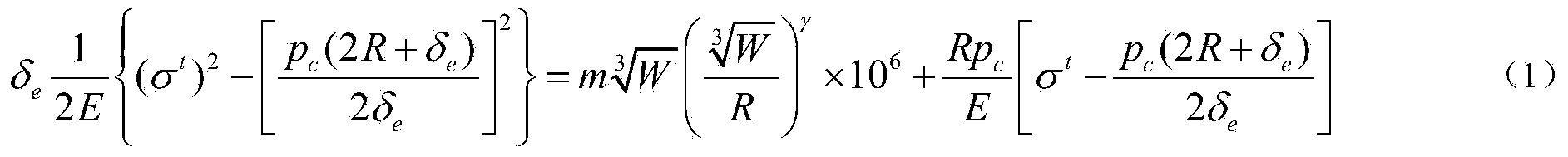

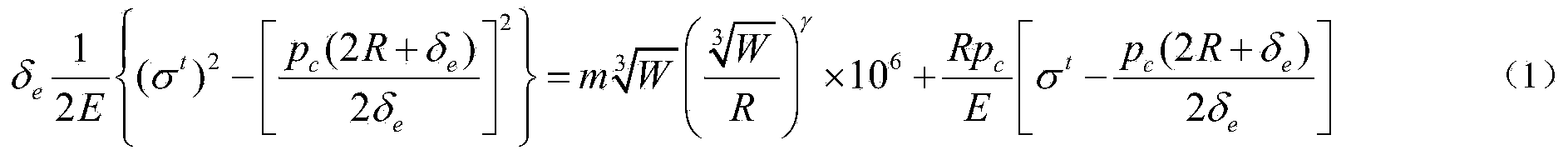

Image

Examples

Embodiment 1

[0061] A method for determining the wall thickness of a container used in a simulated deep-water environmental explosion test. Its specific steps are:

[0062] Step 1. Determine the technical parameters of the container (or container for short) used to simulate the explosion test in the deep water environment

[0063] ① Container structure: The container is an axisymmetric structure, that is, a cylindrical structure composed of a straight cylindrical section in the middle and standard elliptical heads at both ends;

[0064] ②Vessel size: the effective test space in the container cylinder, the specific size is Ф2000mm×3000mm (including the elliptical head part);

[0065] ③ Simulated water depth: the depth of water when the pressure that the object bears underwater is equal to the static pressure loaded after the container is filled with water. The simulated water depth in this embodiment is 200m, that is, the loaded hydrostatic pressure after the container is filled with water...

Embodiment 2

[0083] A method for determining the wall thickness of a container used in a simulated deep-water environmental explosion test. Its specific steps are:

[0084] Step 1. Determine the technical parameters of the container (or container for short) used to simulate the explosion test in the deep water environment

[0085] ①Container structure: The container is an axisymmetric structure, and the main body of the container is a spherical structure;

[0086] ② Container size: the effective test space in the container cylinder, with a diameter of 3000mm;

[0087] ③ Simulated water depth: the depth of water when the pressure that the object bears underwater is equal to the static pressure loaded after the container is filled with water. The simulated water depth in this embodiment is 300m, that is, the loaded hydrostatic pressure after the container is filled with water is 3MPa ;

[0088] ④ Allowable charge: on the premise that the container does not undergo plastic deformation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com