Patents

Literature

106results about How to "Easy way to determine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

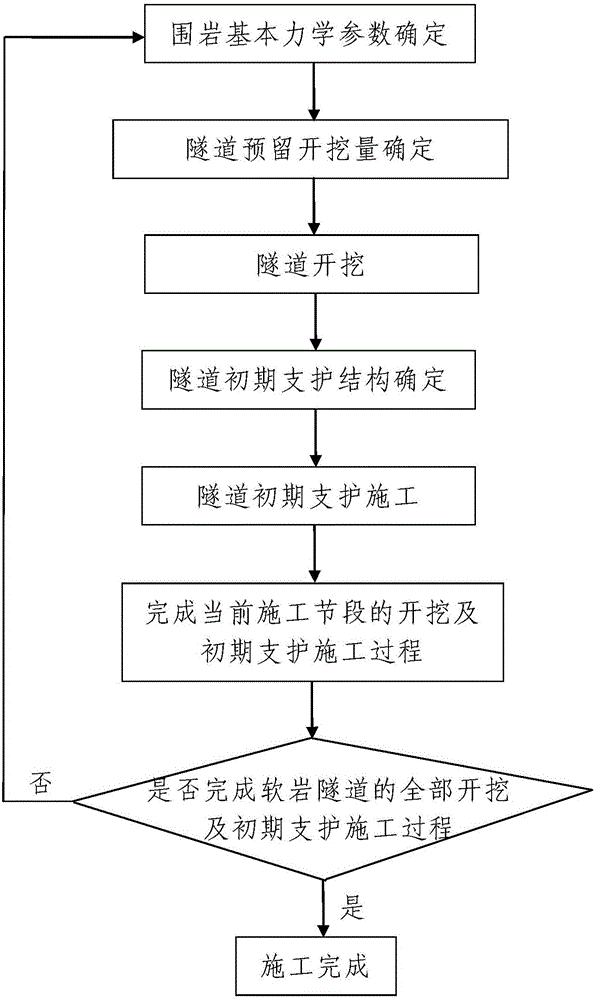

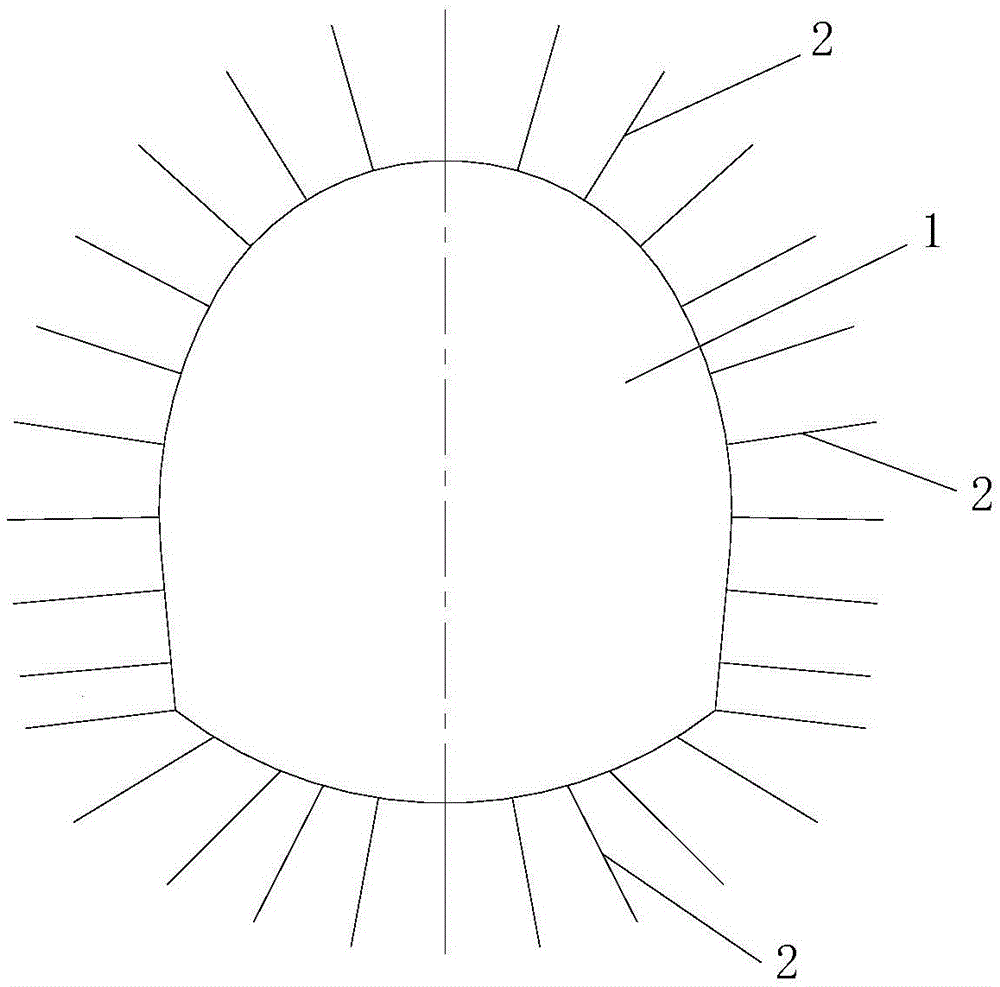

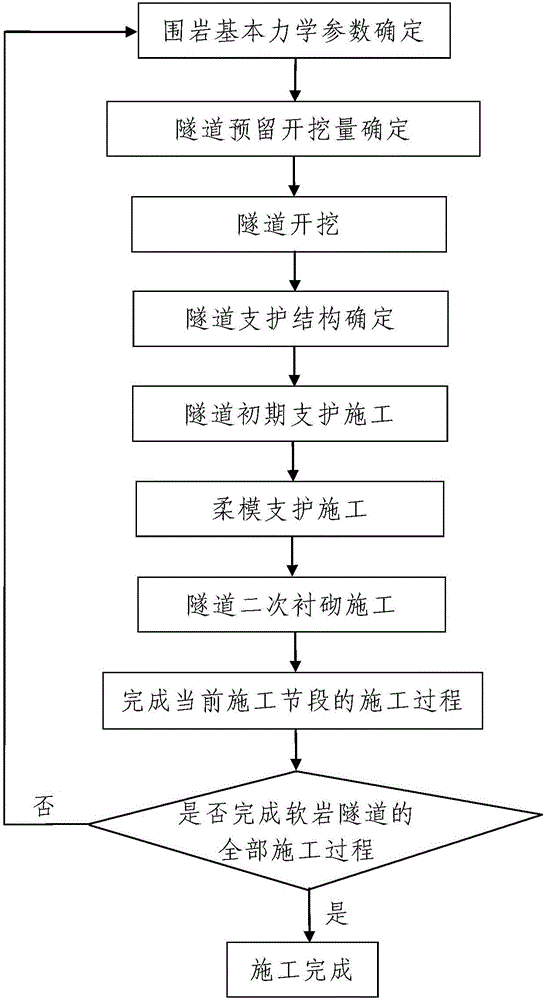

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

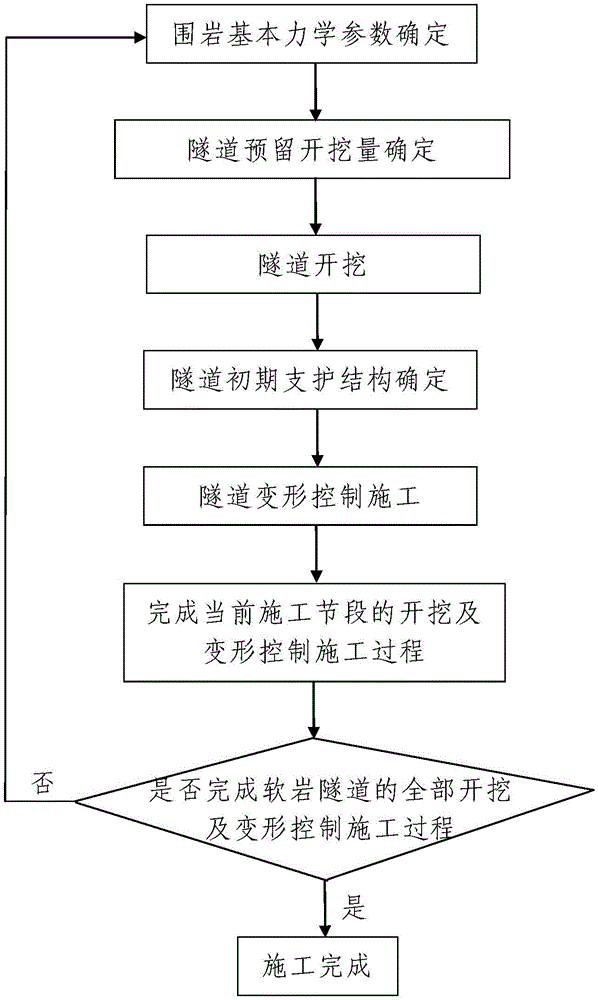

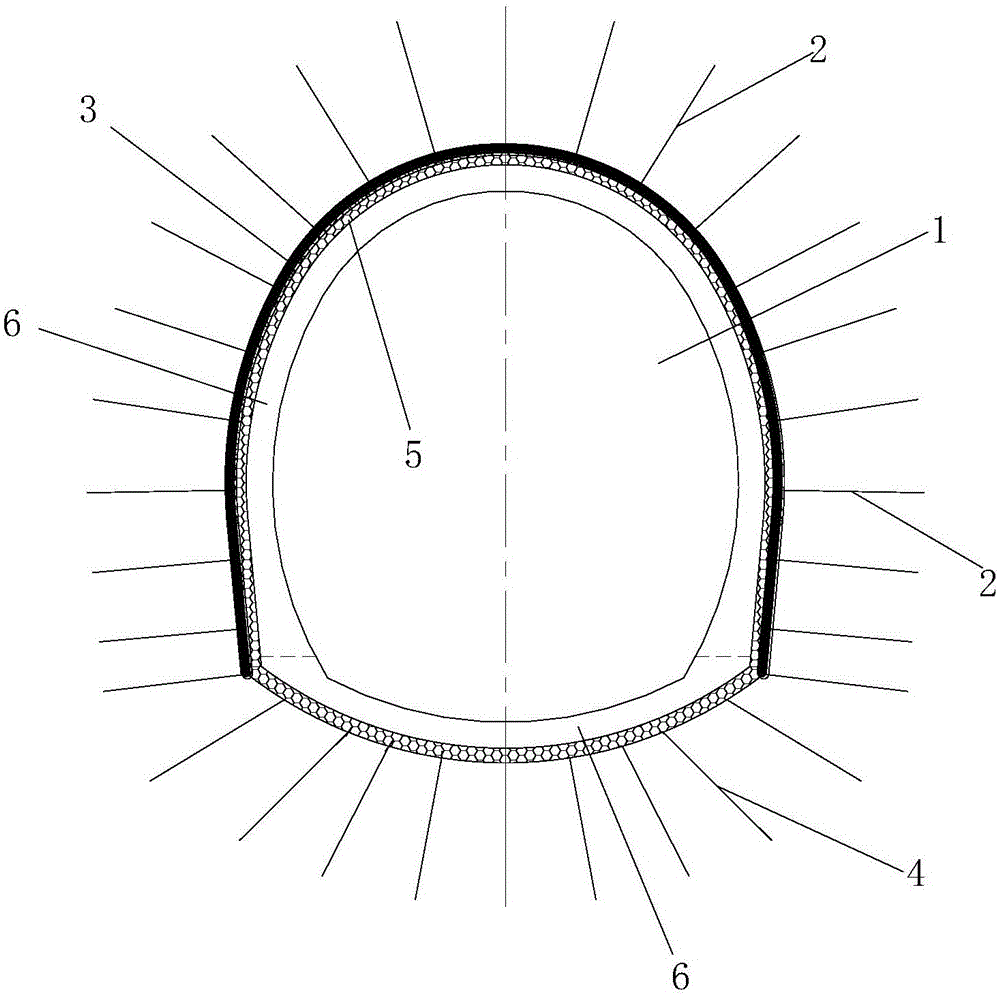

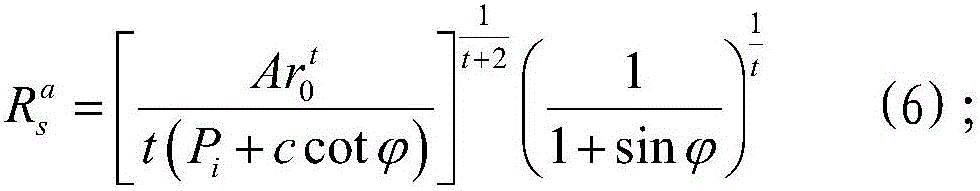

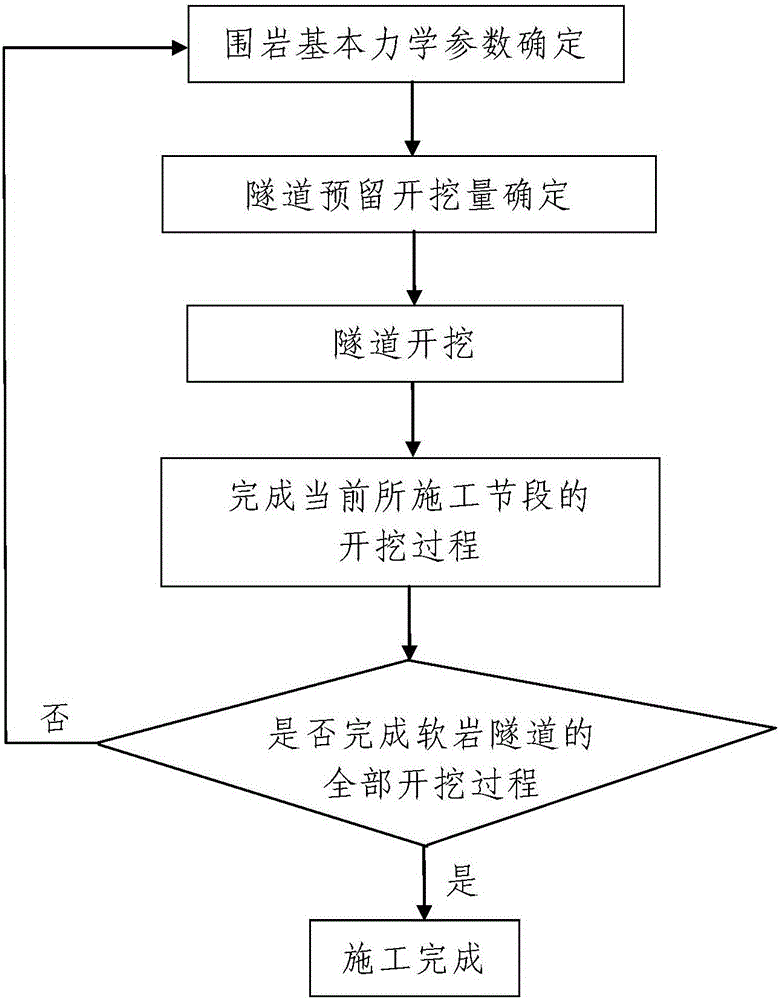

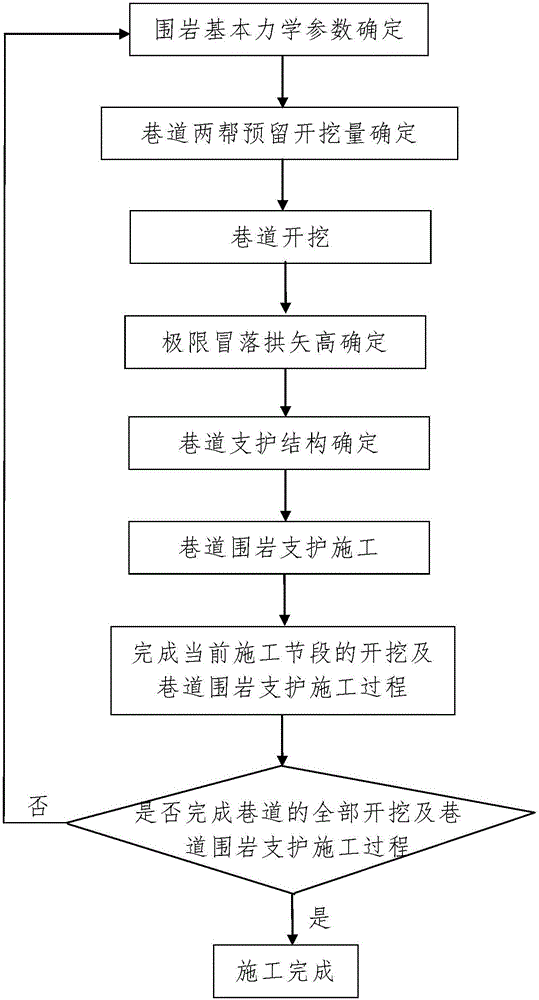

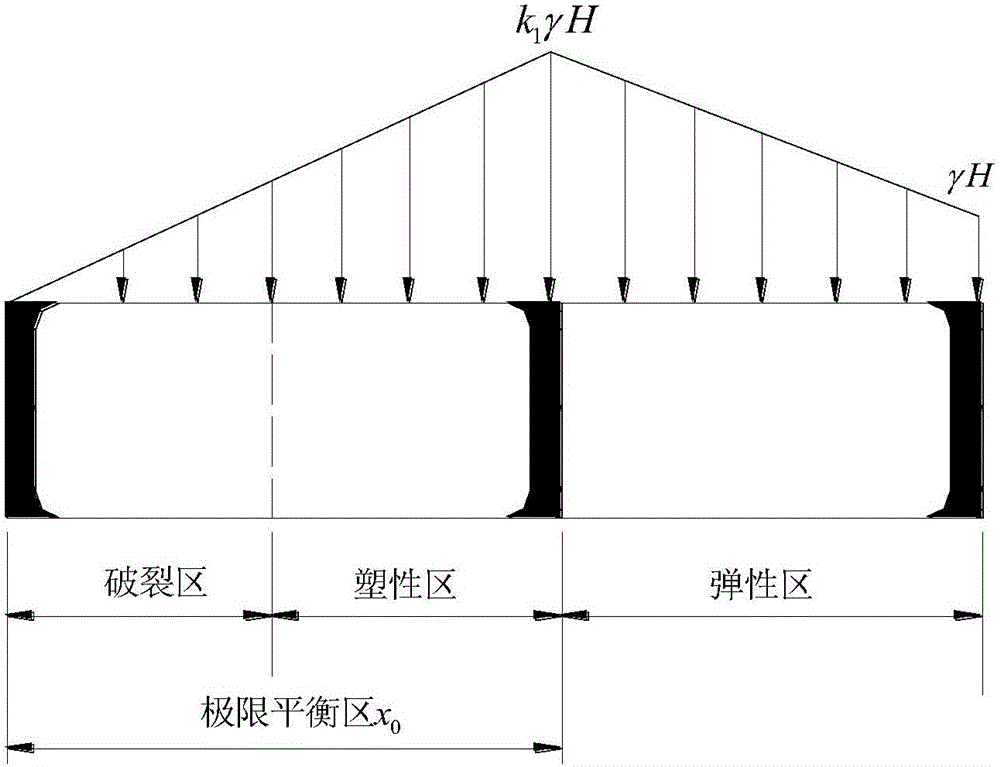

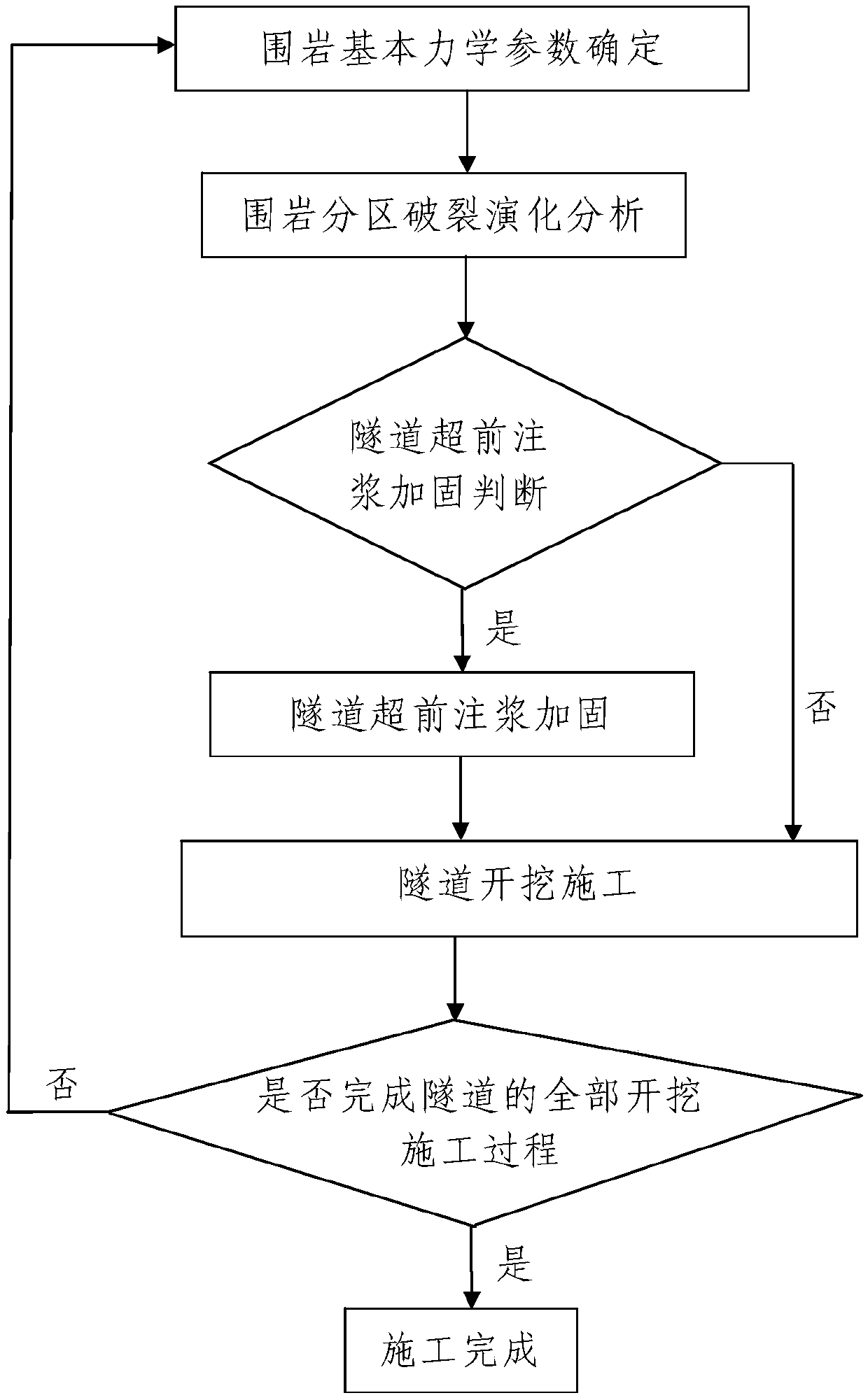

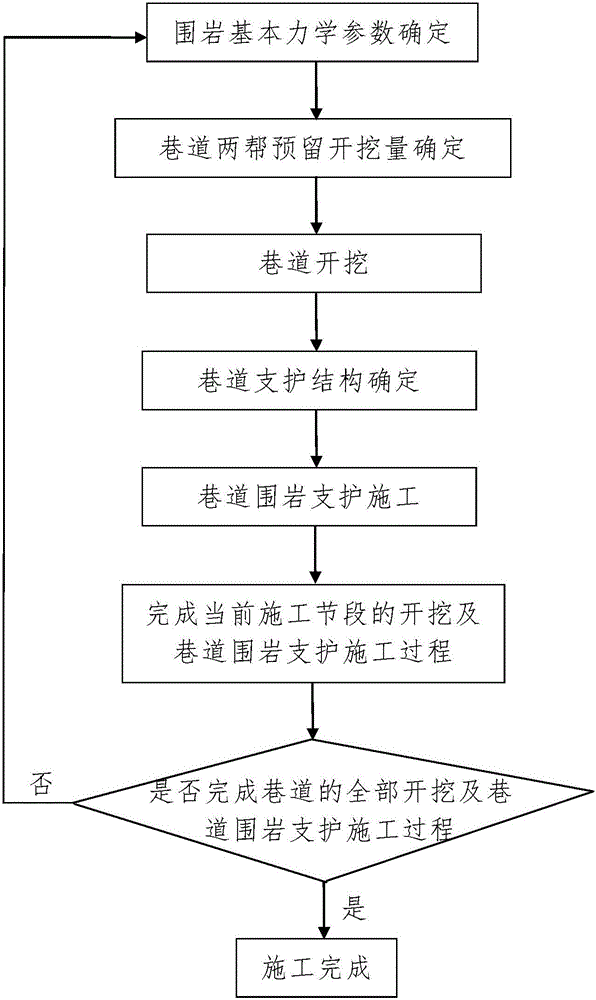

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

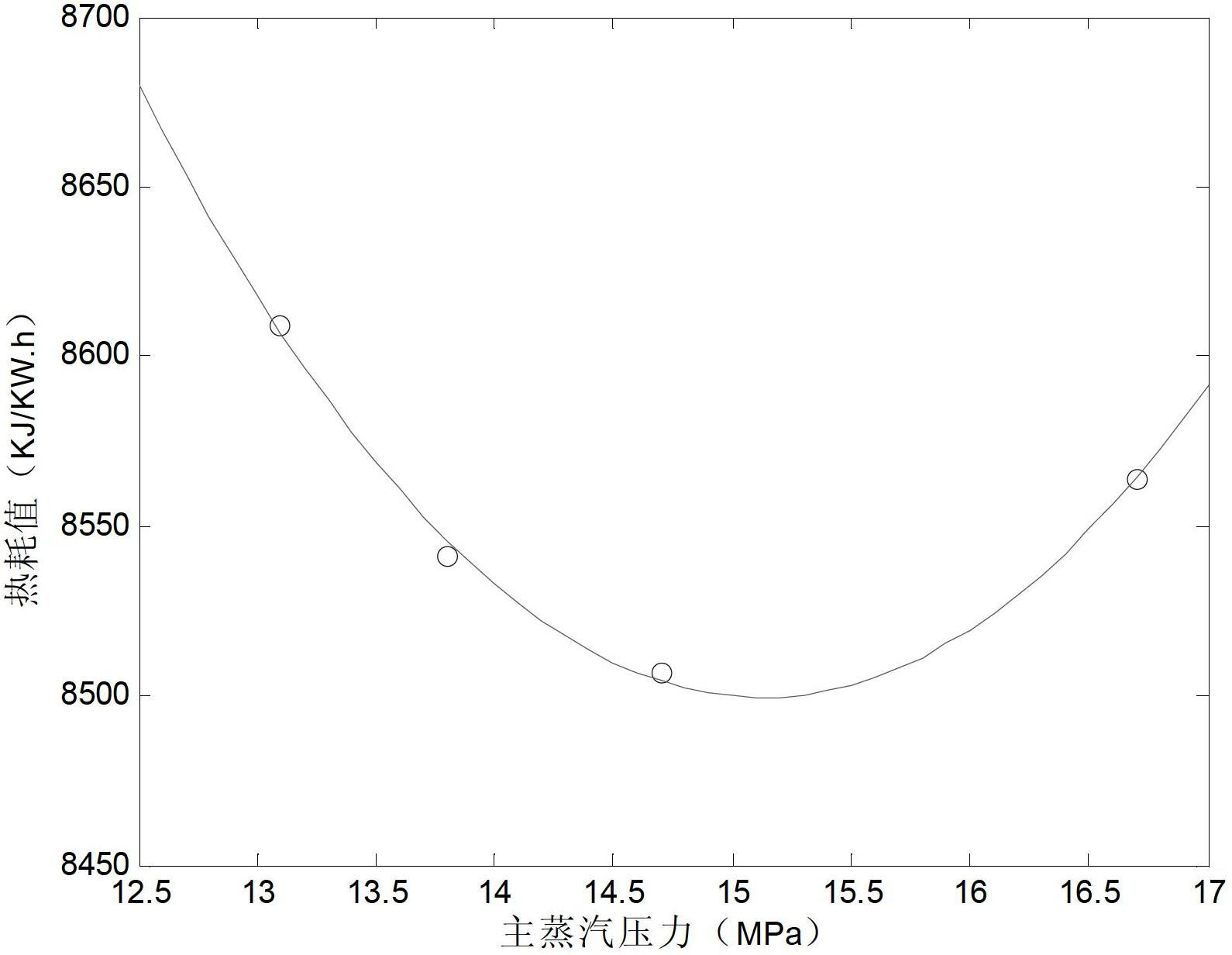

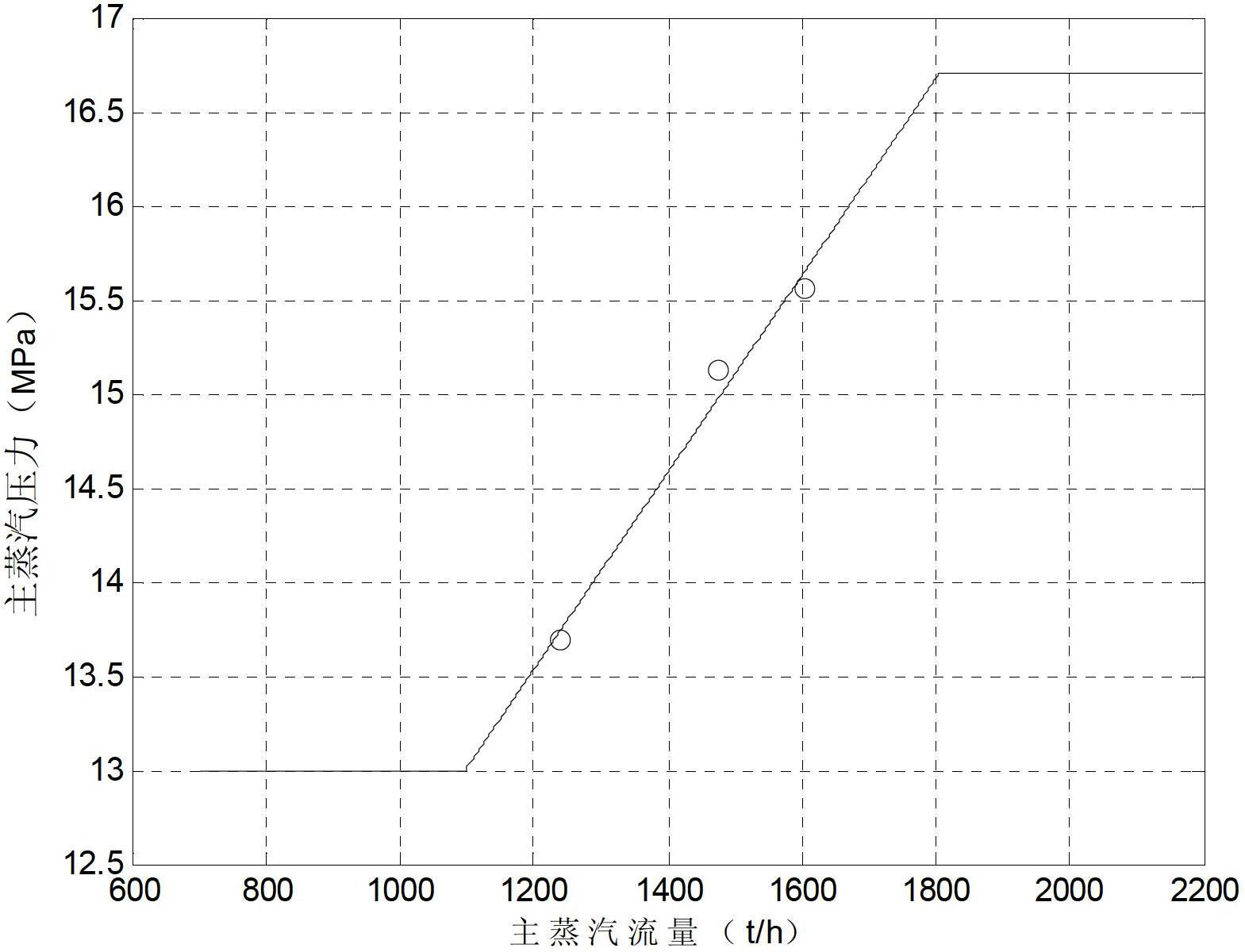

Acquisition method of sliding pressure curve of steam turbine by using main steam flow as scheduling variable

ActiveCN102661176AMeet operational needsEasy way to determineMachines/enginesEngine componentsPressure curveSteam pressure

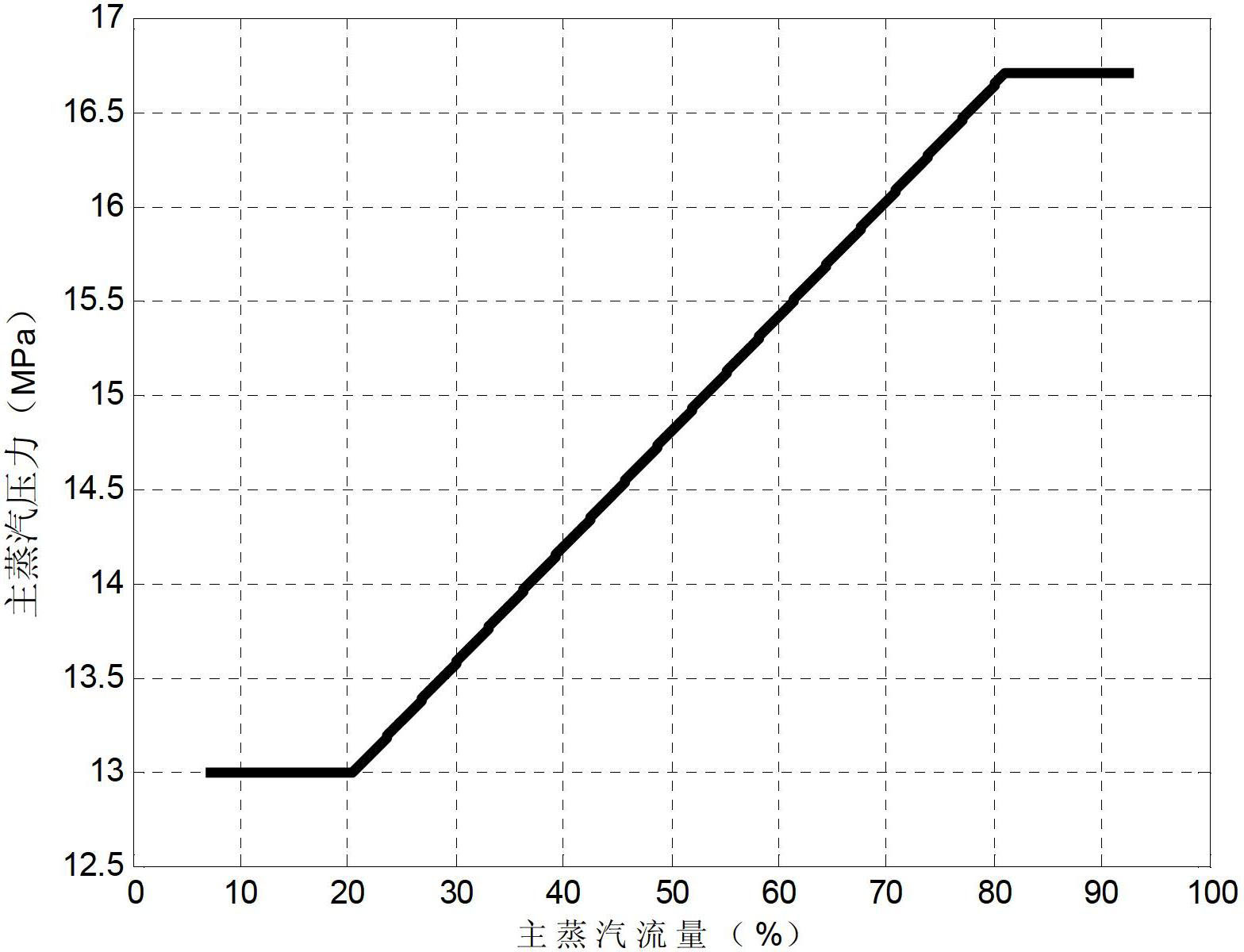

The invention provides an acquisition method of a sliding pressure curve of a steam turbine by using a main steam flow as a scheduling variable, relates to a determining method of a sliding pressure curve, and aims at solving the problem that the heat supply steam extraction capacity variation and back pressure variation operation status cannot be fulfilled by one sliding pressure curve. The method comprises the following steps: selecting M main steam flows according to the type of a heat supply steam extraction unit, wherein M is an integer of greater than 2, and each main steam flow is respectively subjected to the following steps: N different main steam pressure values of the heat supply steam extraction machine are selected with the main steam flow being the selected main steam flow, and N is an integer of greater than 4; calculating heat consumption values of the heat supply steam extraction unit; performing curve fitting on the N main steam pressure values and corresponding heat consumption values thereof according to a least square method to determine an optimal main steam pressure value; and performing linear fitting on the acquired M main steam flows and the corresponding optimal main steam pressure data thereof to acquire a final sliding pressure operation curve. The acquisition method is used for determining the sliding pressure curve of the steam turbine.

Owner:NANJING POWER HORIZON INFORMATION TECH CO LTD

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

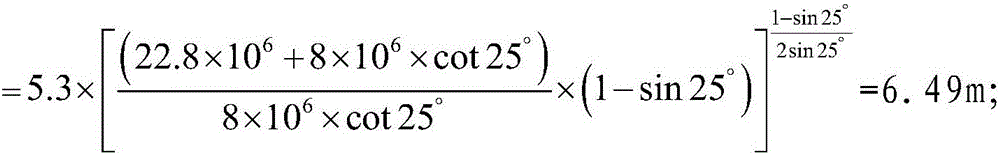

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

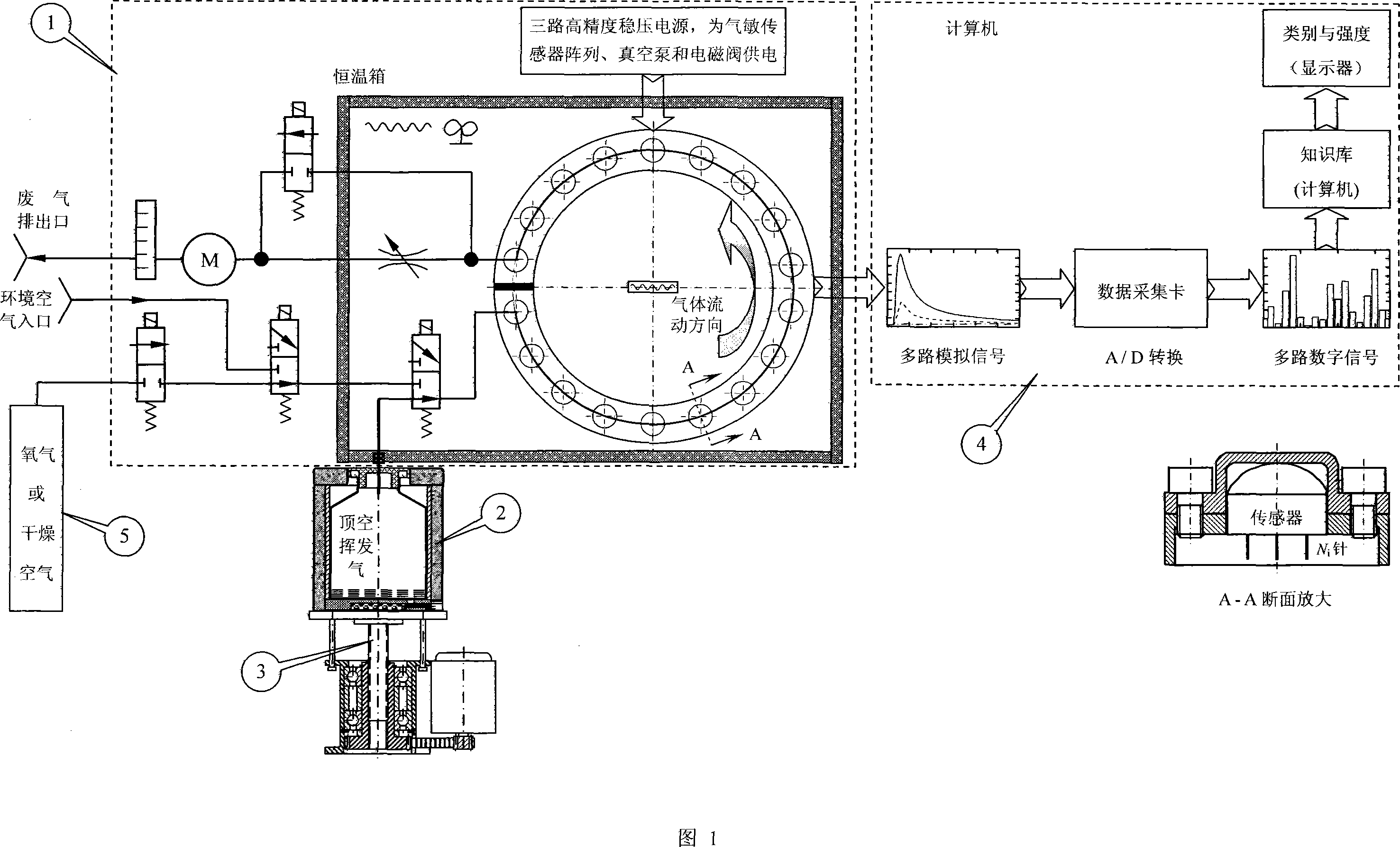

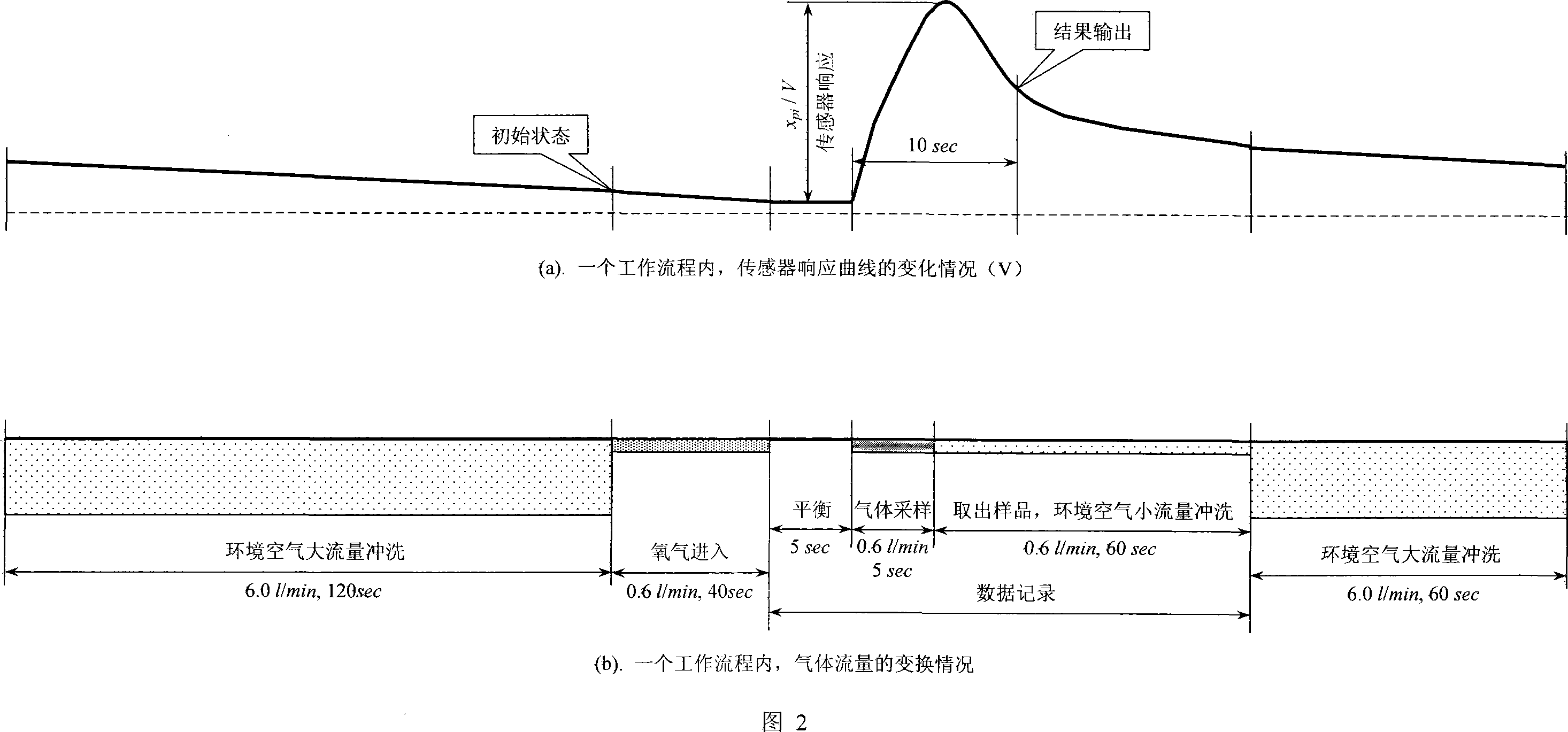

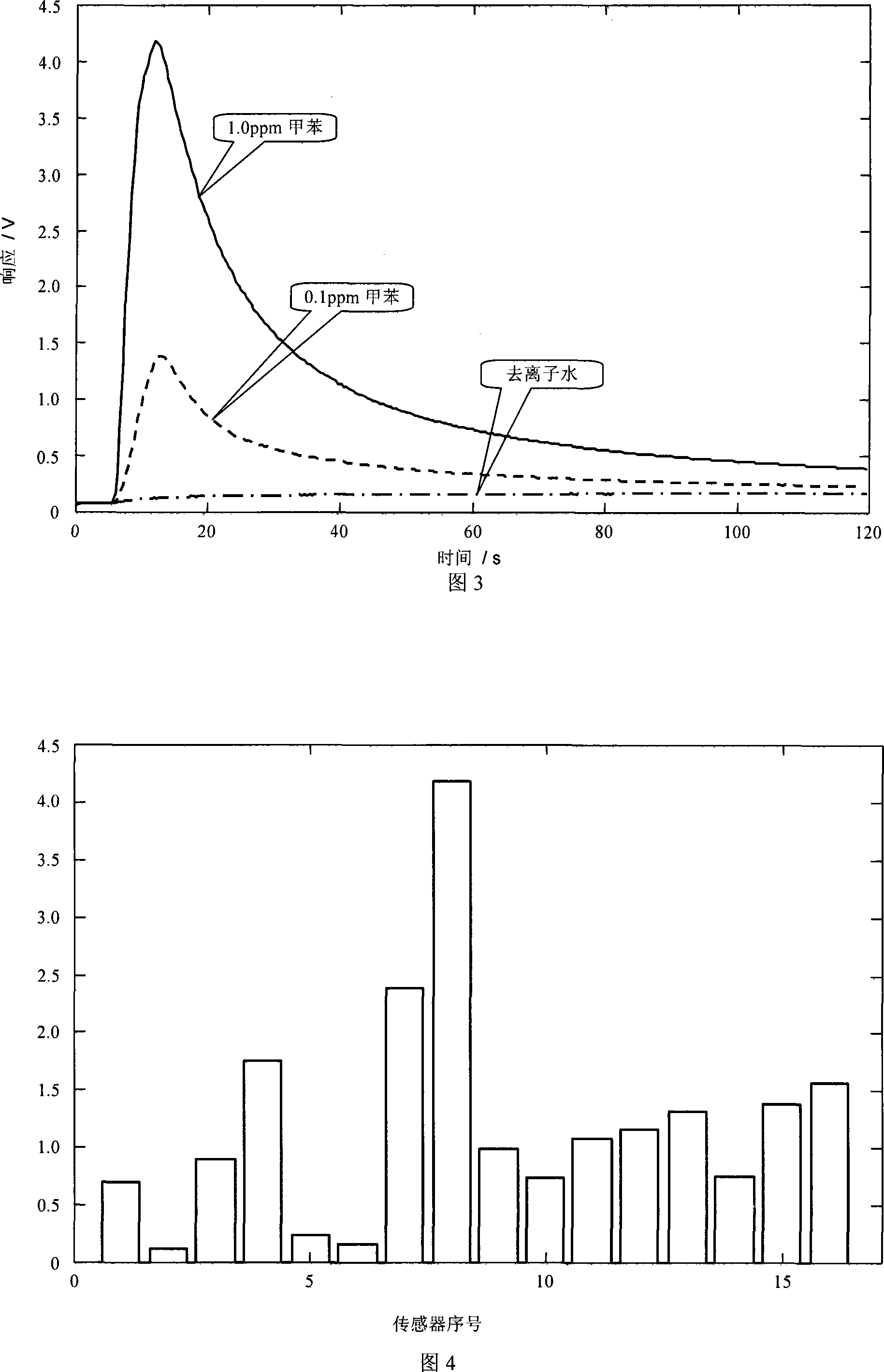

Parallel-tandem mode identification method and its uses in machine scent

InactiveCN101101299AFast learningSimple structureBiological neural network modelsMaterial analysisAlgorithmApposition

A discriminating method of parallel series patter and its application in the machinery smell, the characteristics is that regarding the big scale smell sorts and intension confirm problem as assortment problem, and then regarding as approximation problem, giving settling respectively for the mode which is made up of classifier layer and function approximation mode layer. It includes the four implementation steps: (1) n pieces one output neural net of classifier layer takes charge of ensuring the types of n kinds of smell, one to one correspondence. The training subset of a network is made up of all representative smell samples and the part apposition smell samples. (2) n pieces one output neural net of function approximation mode layer takes charge of ensuring the intensity of n kinds of smell, one to one correspondence. The training subset of a network is made up of all representative smell samples. (3) The suppositional balance of imbalance training subset. (4) n+1 pieces one output neural net puts up decision. By using the invention, the machinery olfactometer can solve the simultaneous estimation problem of thousands upon thousands smell types and intensity.

Owner:EAST CHINA UNIV OF SCI & TECH

Soft rock tunnel excavation method based on anchor bolt stress

InactiveCN106499398AThe method steps are simpleEasy to implementTunnelsAnchoring boltsRock tunnelRock bolt

The invention discloses a soft rock tunnel excavation method based on anchor bolt stress and the soft rock tunnel is excavated by a plurality of sections in a longitudinally direction of the tunnel from rear to front. The method for excavating any section of the soft rock tunnel comprises the following steps: first, determing the basic mechanical parameters of surrounding rock; second, determing the reserved excavation capacity of tunnels: determing the capacity of reserved excavation of the current construction section according to a theoretical value S of the soft rock tunnel inward displacement after the completion of supporting, the S is the sum of plastic displacement of surrounding rock in soft rock tunnel and displacement after shaping deformation of surrounding rock in soft rock tunnel; third, the tunnel is excavated; fourth, the next section is excavated; fifth, repeating step fourth until the full excavation of the soft rock tunnel is completed. The soft rock tunnel excavation method has the advantages of simple steps, reasonable design and convenient implementation, and has good effect. The excavation capacity is determined according to the deformation of the surrounding rock of the soft rock tunnel, which can solve the problem of the reserve deformation of the soft rock tunnel, avoid the problem of soft rock tunnel repair work and cost less.

Owner:XIAN UNIV OF SCI & TECH

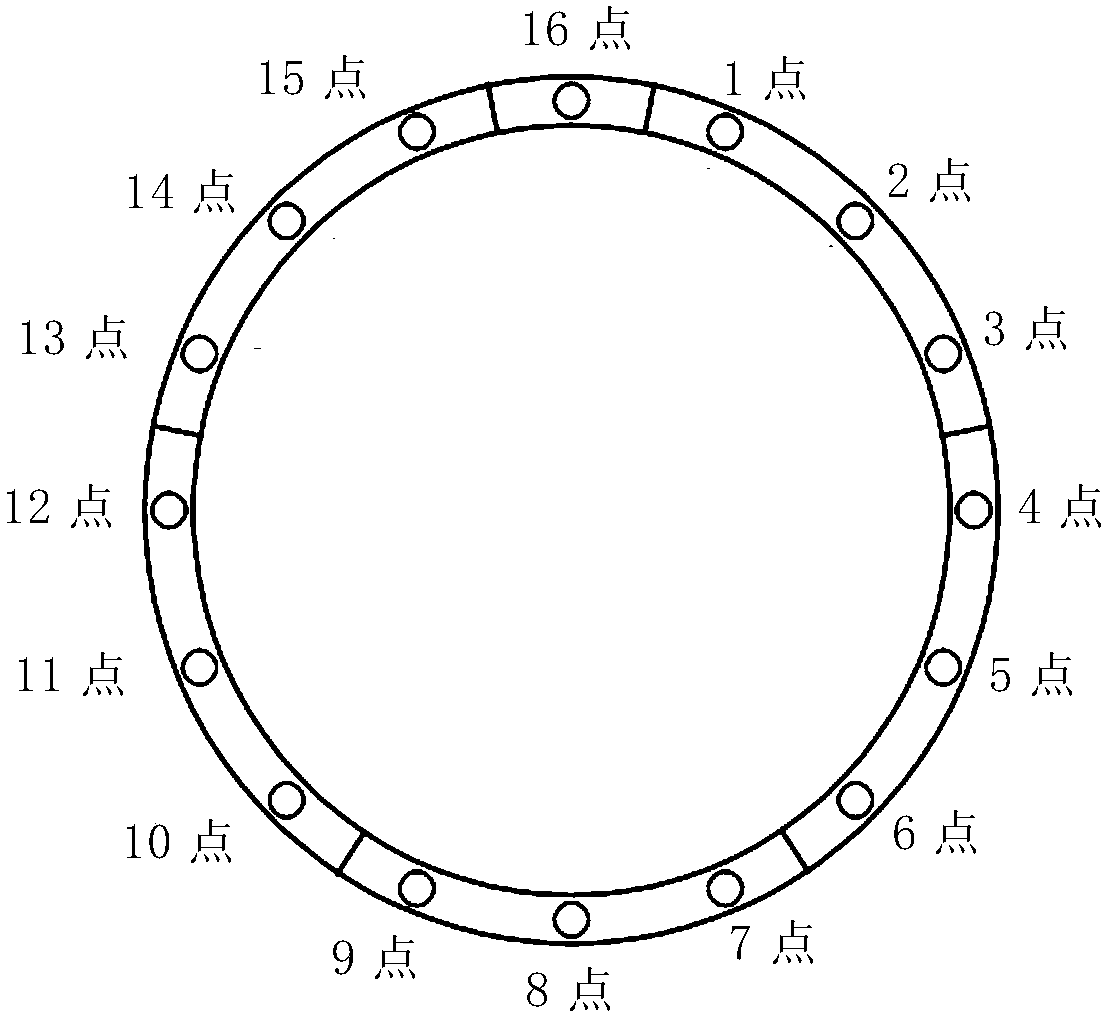

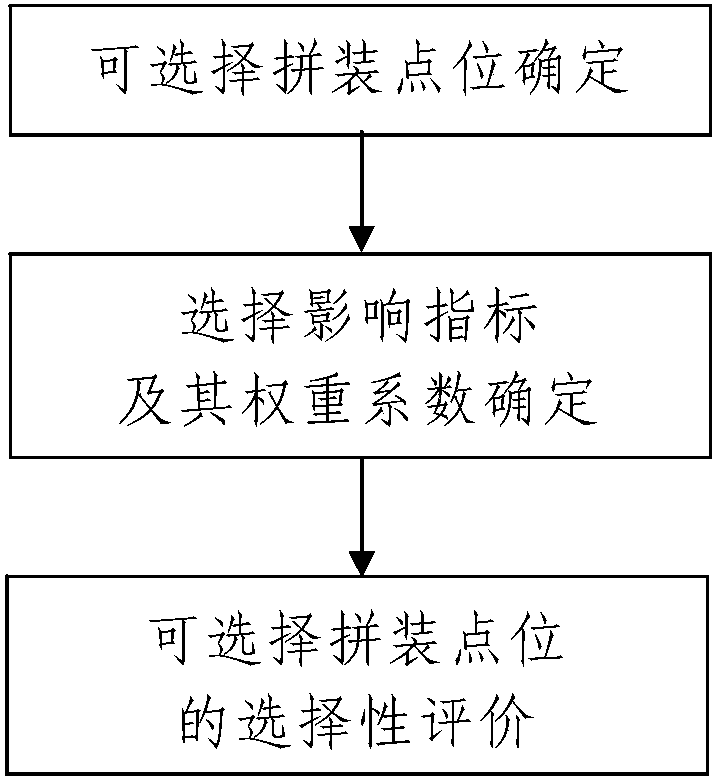

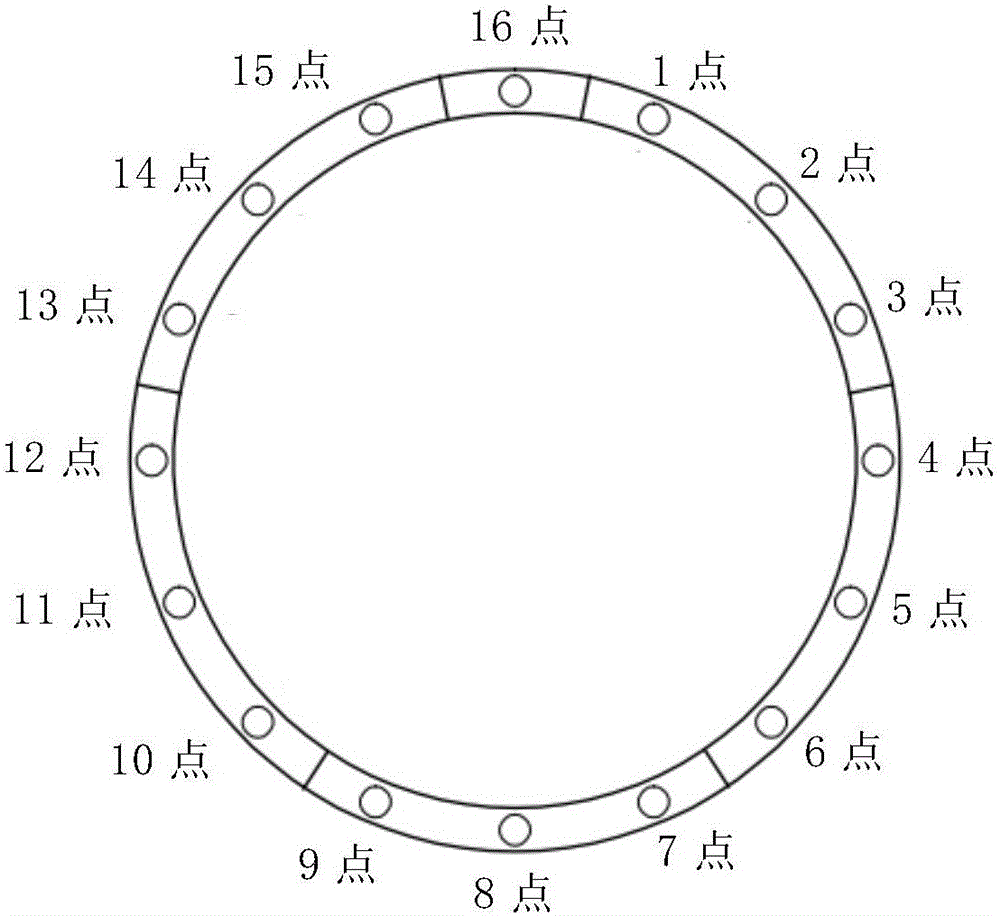

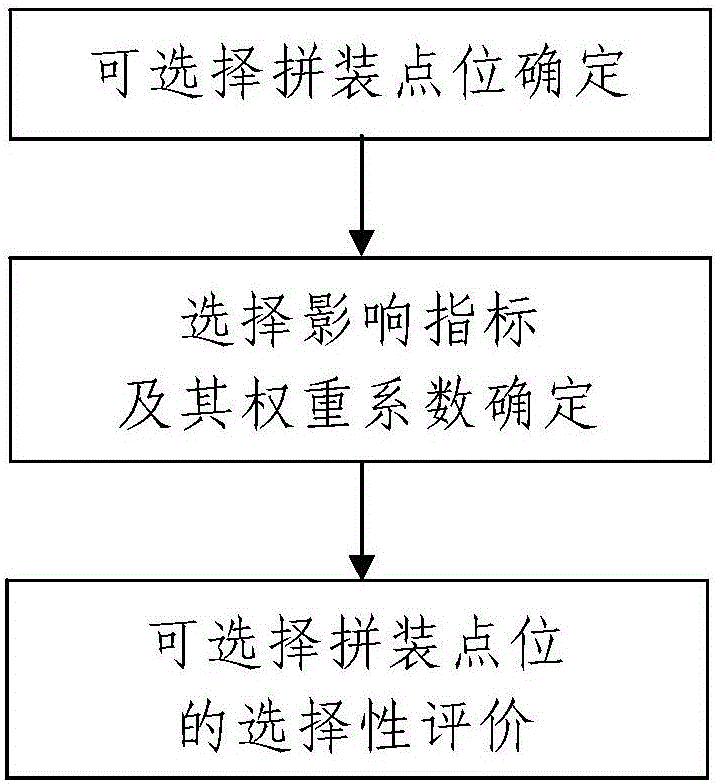

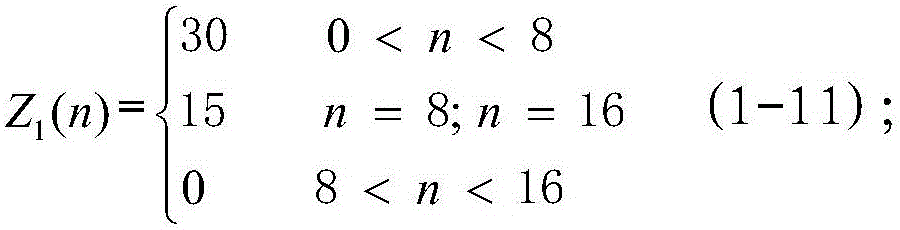

Shield general segment assembling point location determining method

ActiveCN107725067AThe method steps are simpleLow input costUnderground chambersResourcesWeight coefficientEngineering

The invention discloses a metro shield construction general segment assembling point location determining method. A shield tunneling machine is used for conducting shield tunneling construction on a construction tunnel along a tunnel central axis from back to front. After the shield tunneling construction is completed for one link, shield segment assembling construction is carried out. Before anylink of shield segment assembling construction is performed, first of all, segment assembling point locations of current shield segments are determined. Processes include the following steps that firstly, selectable assembling point locations are determined; secondly, selection influence indexes and weight coefficients of the selection influence indexes are determined, and the three selection influence indexes and the weight coefficients of the three selection influence indexes influencing segment assembling point location selection are determined separately; thirdly, the selectable assemblingpoint locations are selectively evaluated, wherein according to a weight coefficient method, the selection of all the selectable assembling point locations is evaluated separately, and the segment assembling point locations of the current shield segments are determined. The shield general segment assembling point location determining method is simple in step reasonable in design, convenient to achieve, good in using effect and capable of conveniently, fast and precisely determining the assembling point locations of the general segments.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

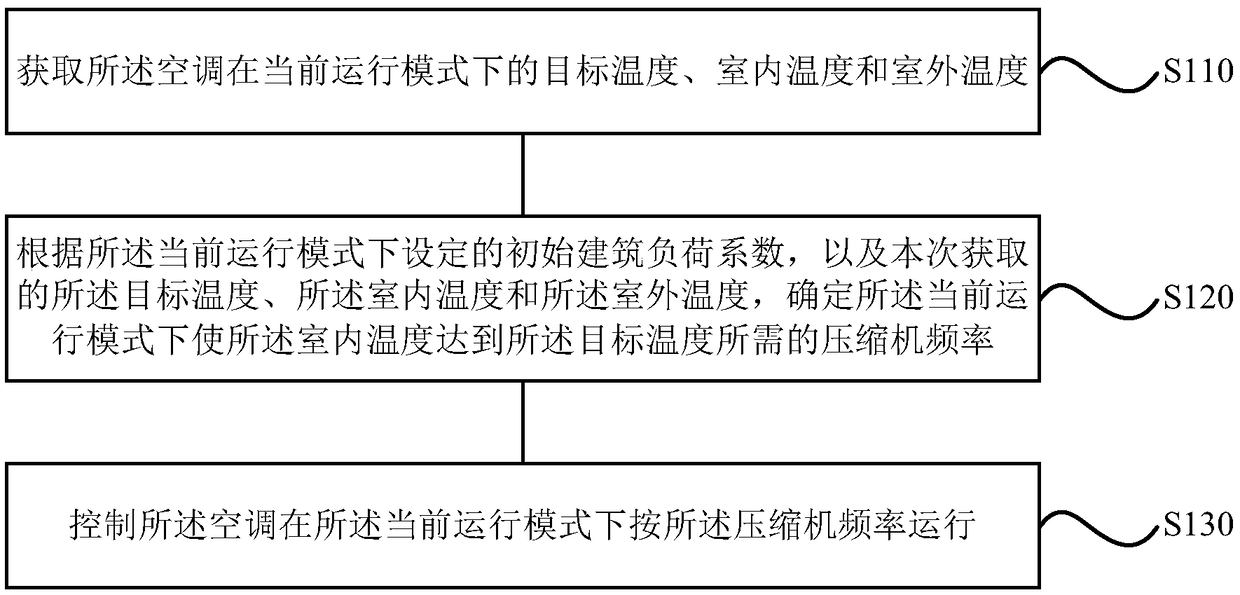

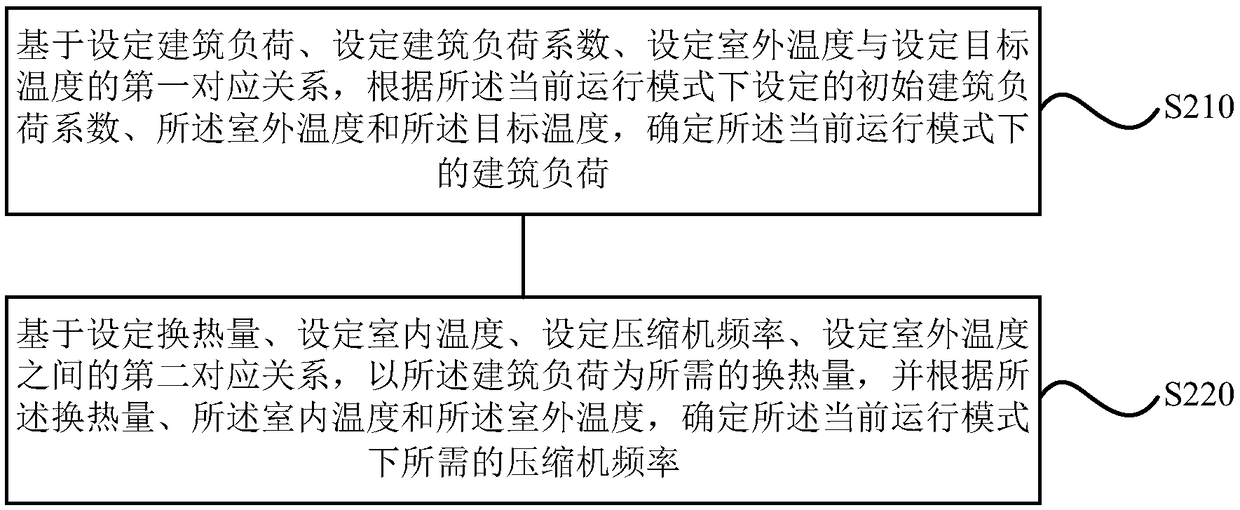

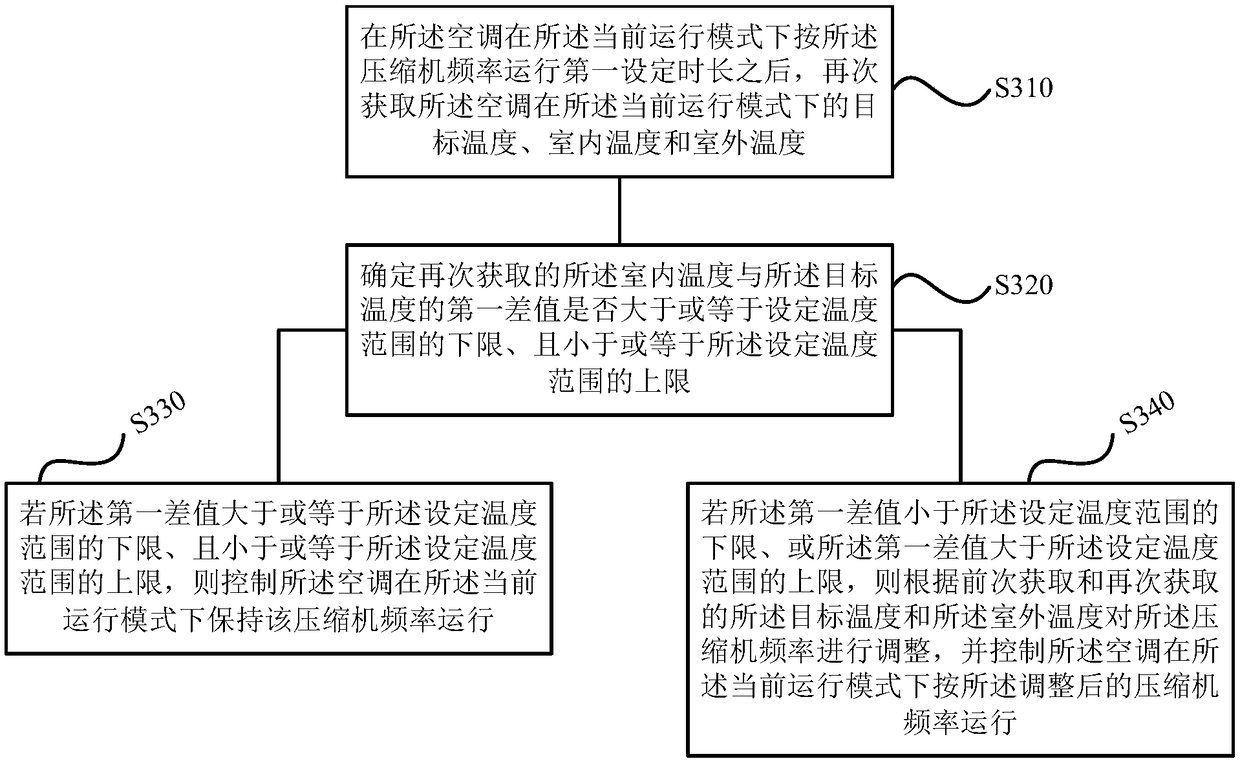

Air conditioner control method and device, storing medium and air conditioner

ActiveCN109210676AFast adjustmentImprove experienceMechanical apparatusSpace heating and ventilation safety systemsPower conditionerRoom temperature

Owner:GREE ELECTRIC APPLIANCES INC

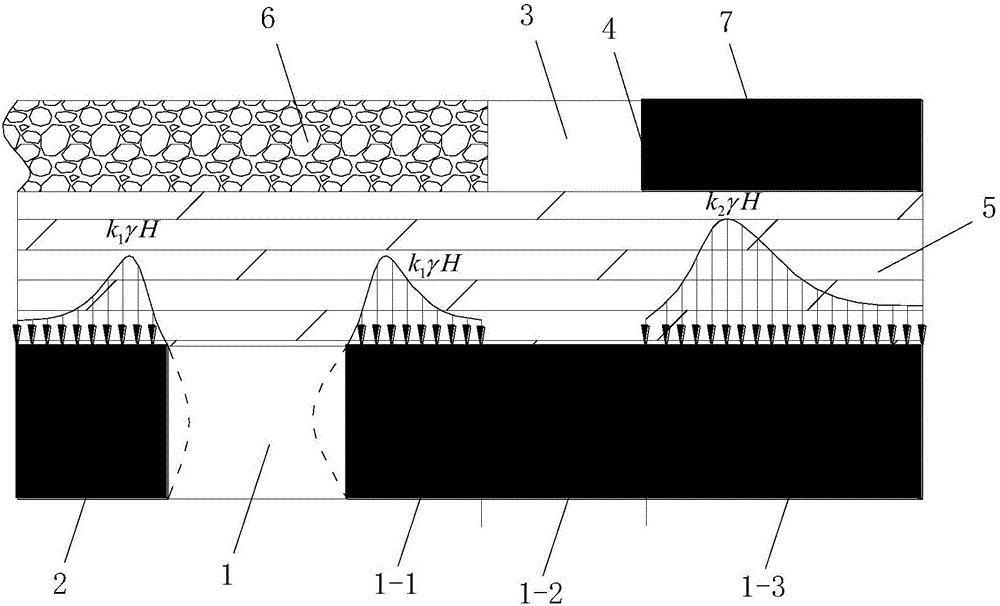

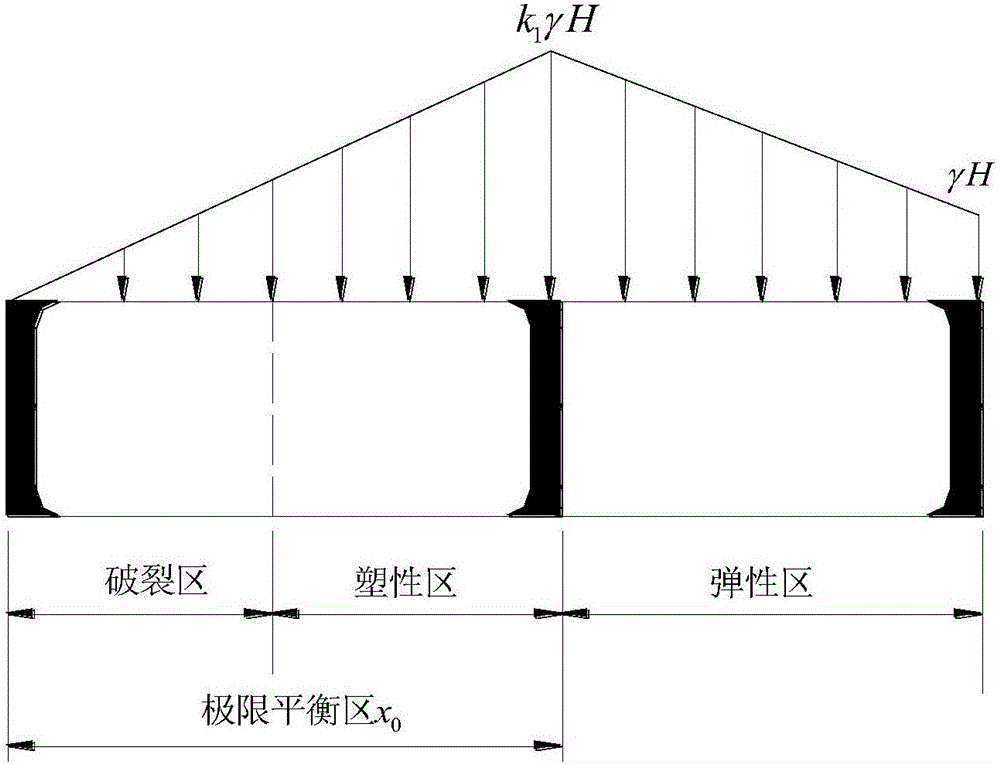

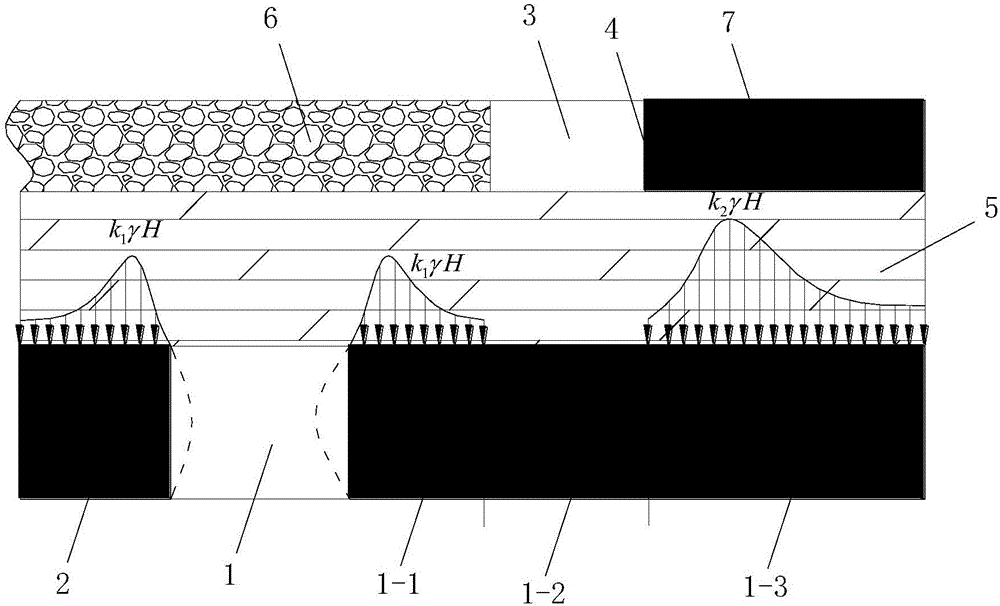

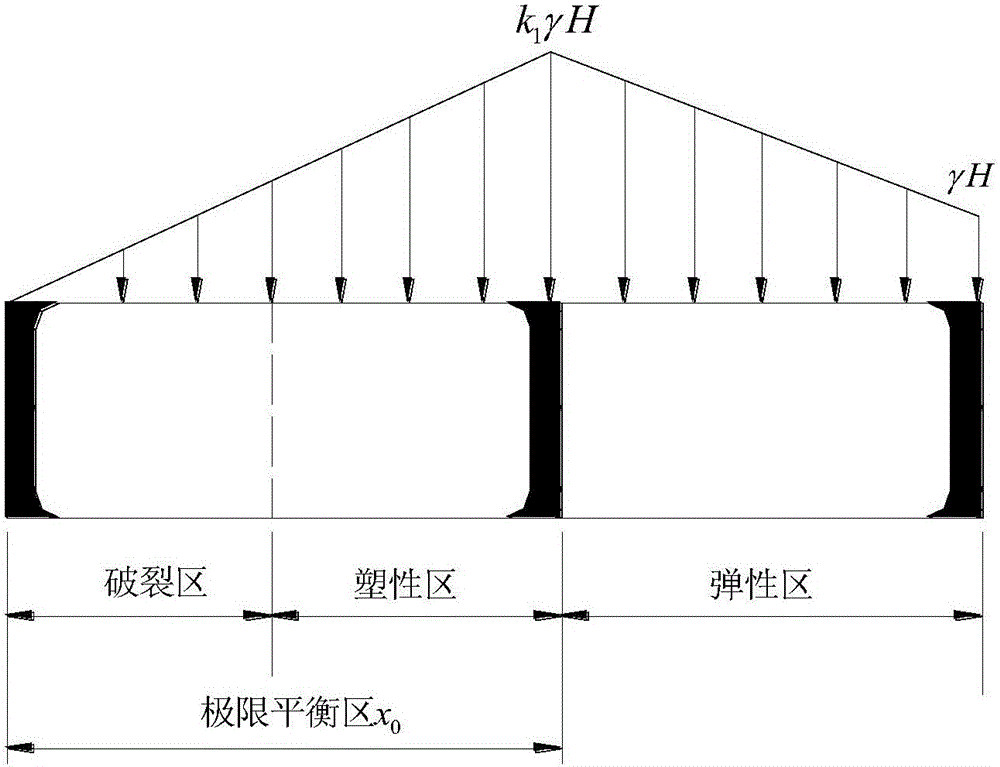

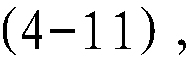

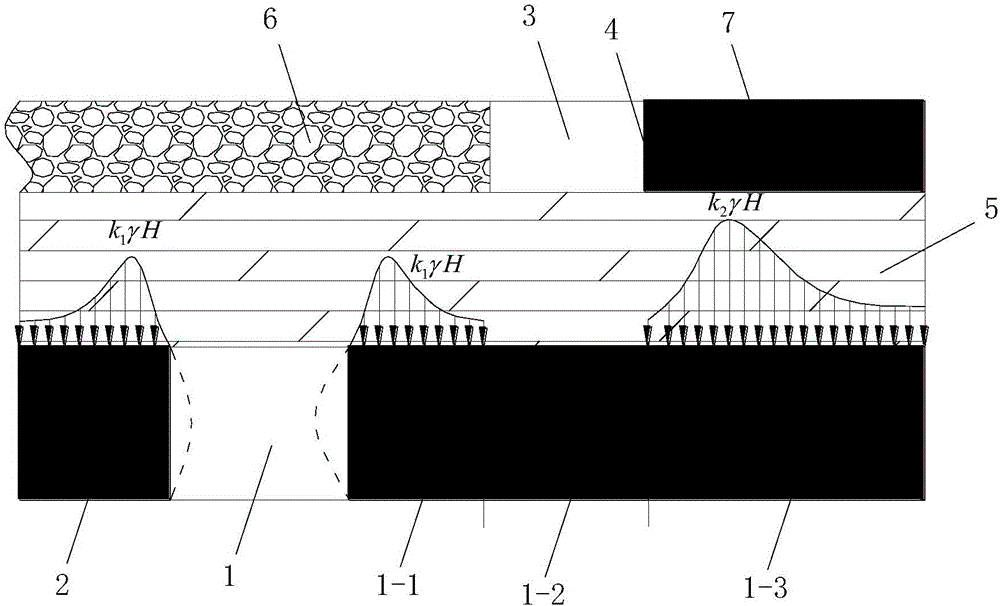

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

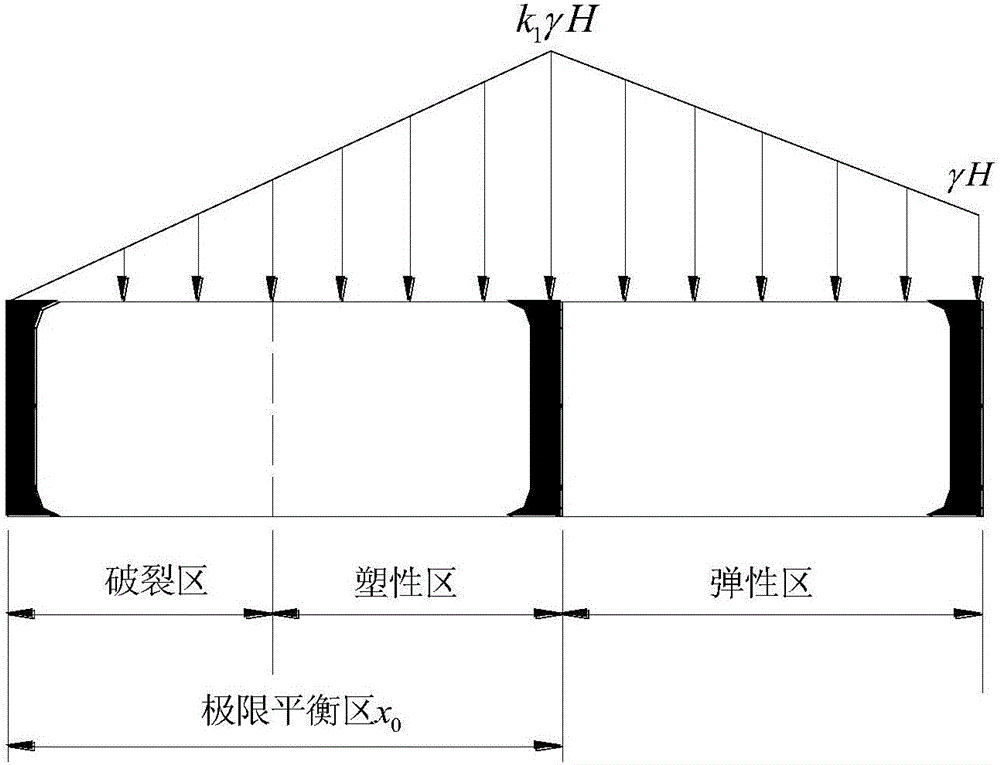

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

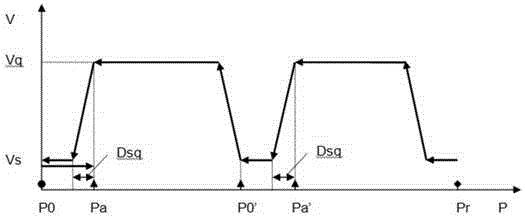

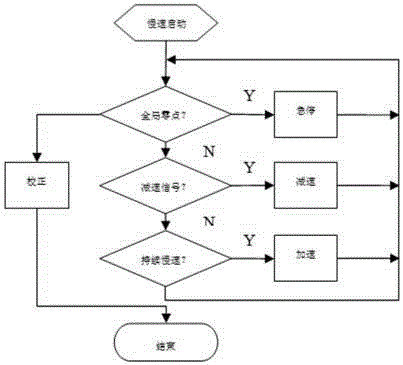

Self-check zero returning method for stepping motor motion system

ActiveCN106788010AFast and reliable self-test return to zeroFast and reliable self-checking and zeroing processDynamo-electric converter controlEngineeringMotion system

The invention provides a self-check zero returning method for a stepping motor motion system. According to the method, a stepping motor starts at any zero returning initial position Pr, through slow-speed and rapid-speed combination and switching, the stepping motor moves in only one direction, a global zero point P0 is found out, after the global zero point P0 is found out, correction to an actual zero point Pa is carried out, and a self-check zero returning method is accomplished. The self-check zero returning method is advantaged in that the time of a self-check zero returning process, bumping and debugging of the stepping motor motion system can be reduced, rapid and reliable self-check zero returning of the stepping motor motion system can be realized, the self-check zero returning process is rapid and reliable, noise generated in the self-check zero returning process can be effectively reduced, moreover, a debugging process and a debugging program can be further simplified, and diagnosis of possible faults of hardware and the structure of the stepping motor can be facilitated.

Owner:HUNAN MINGHE OPTO TECH

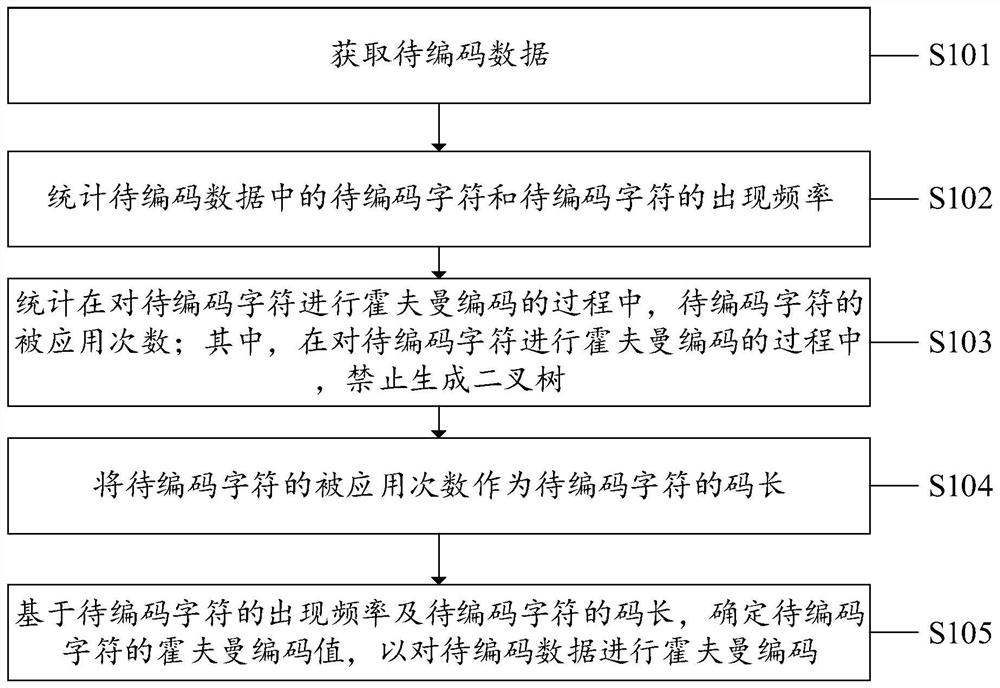

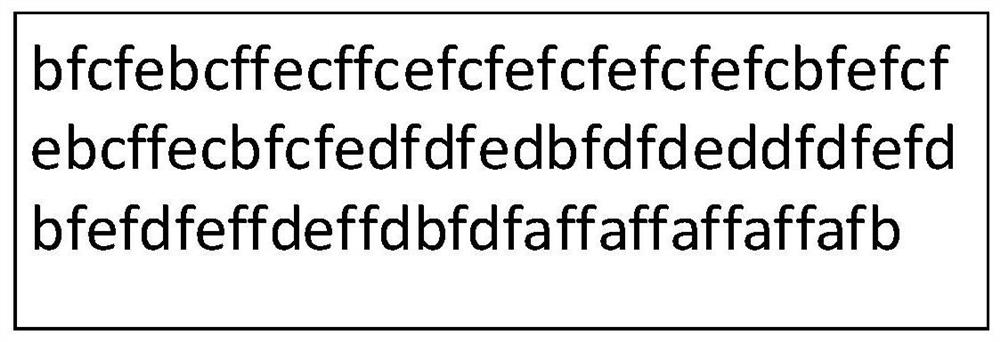

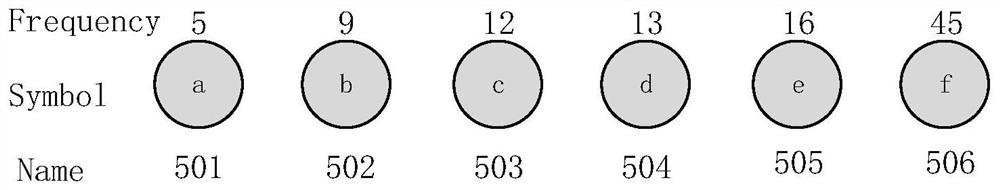

Huffman coding method, system and equipment

The invention discloses a Huffman coding method, system and equipment. The Huffman coding method comprises the steps of: acquiring to-be-coded data; counting to-be-coded characters in the to-be-codeddata and the occurrence frequency of the to-be-coded characters; counting the applied times of the to-be-coded characters in the process of performing Huffman coding on the to-be-coded characters; taking the applied times of the to-be-coded characters as a code length of the to-be-coded characters; and determining a Huffman coding value of the to-be-coded characters based on the occurrence frequency of the to-be-coded characters and the code length of the to-be-coded characters, so as to perform Huffman coding on the to-be-coded data, wherein a binary tree is forbidden to be generated in the process of carrying out Huffman coding on the to-be-coded characters. According to the Huffman coding method, a binary tree does not need to be generated, and memory consumption caused by storage of the binary tree is avoided; only the applied times of the to-be-coded characters need to be recorded, the recorded content is simple and few, and software and hardware implementation is facilitated; inaddition, the efficiency of Huffman coding can be improved, and the limitation is low.

Owner:山东云海国创云计算装备产业创新中心有限公司

Method for determining duct piece splicing point position of universal ring for subway shield construction

ActiveCN105673041AThe method steps are simpleLow input costData processing applicationsUnderground chambersWeight coefficientEngineering

The invention discloses a method for determining a duct piece splicing point position of a universal ring for subway shield construction. The method comprises the following steps: performing shield tunneling construction on a constructed tunnel from back to front along the central axis of the tunnel by adopting a shield tunneling machine; after a ring of the shield tunneling construction is completed, performing shield duct piece splicing construction; before any ring of shield duct piece splicing construction, determining the duct piece splicing point position of shield duct pieces of the current ring first, wherein the method for determining the duct piece splicing point position comprises the following processes: firstly, determining selectable splicing point positions; secondly, determining selection influence indexes and weight coefficients thereof: respectively determining the three selection influence indexes which influence the selection of the duct piece splicing position point and the weight coefficients thereof; thirdly, performing selectivity evaluation on the selectable splicing position points: respectively evaluating the selectivity of each selectable splicing position point according to a weight coefficient method, and determining the duct piece splicing point position of the current shield duct piece. The method disclosed by the invention is simple in step, reasonable in design, convenient to implement and good in using effect, and can determine the splicing point position of the duct pieces of the universal ring easily, conveniently and accurately.

Owner:CHINA RAILWAY FIRST GRP CO LTD

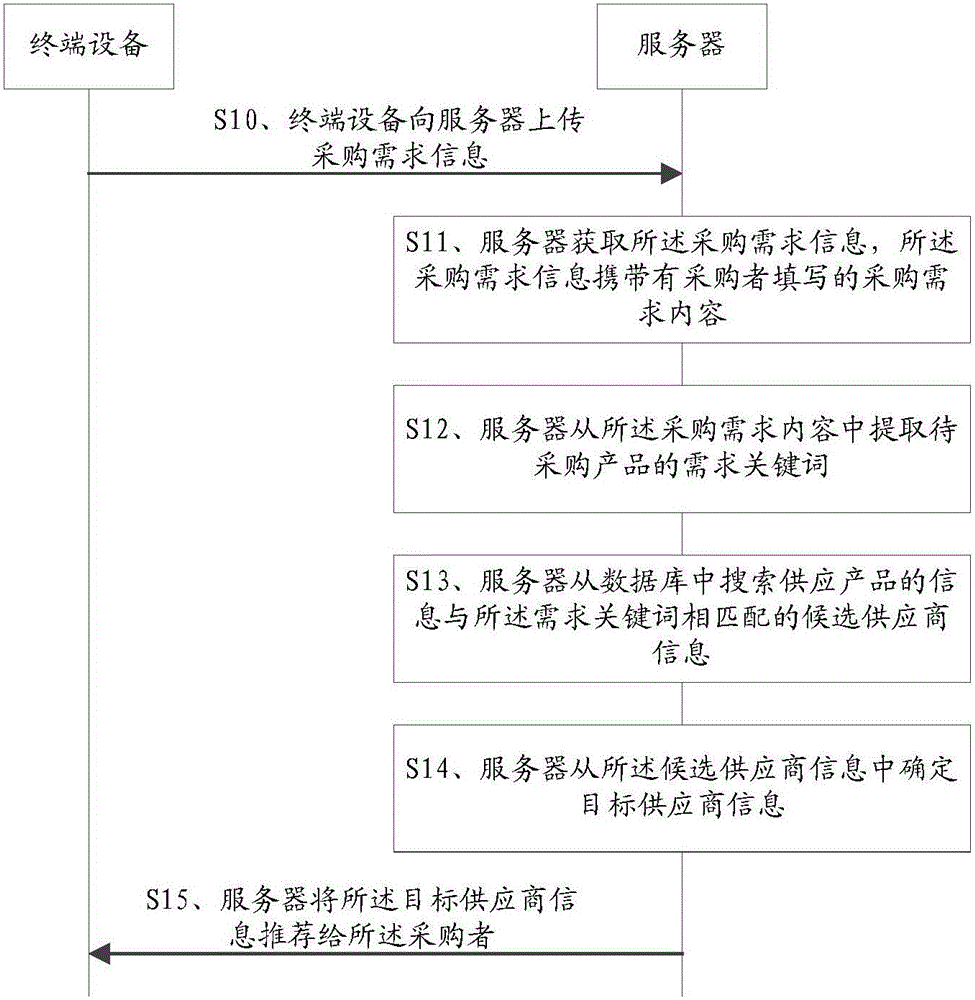

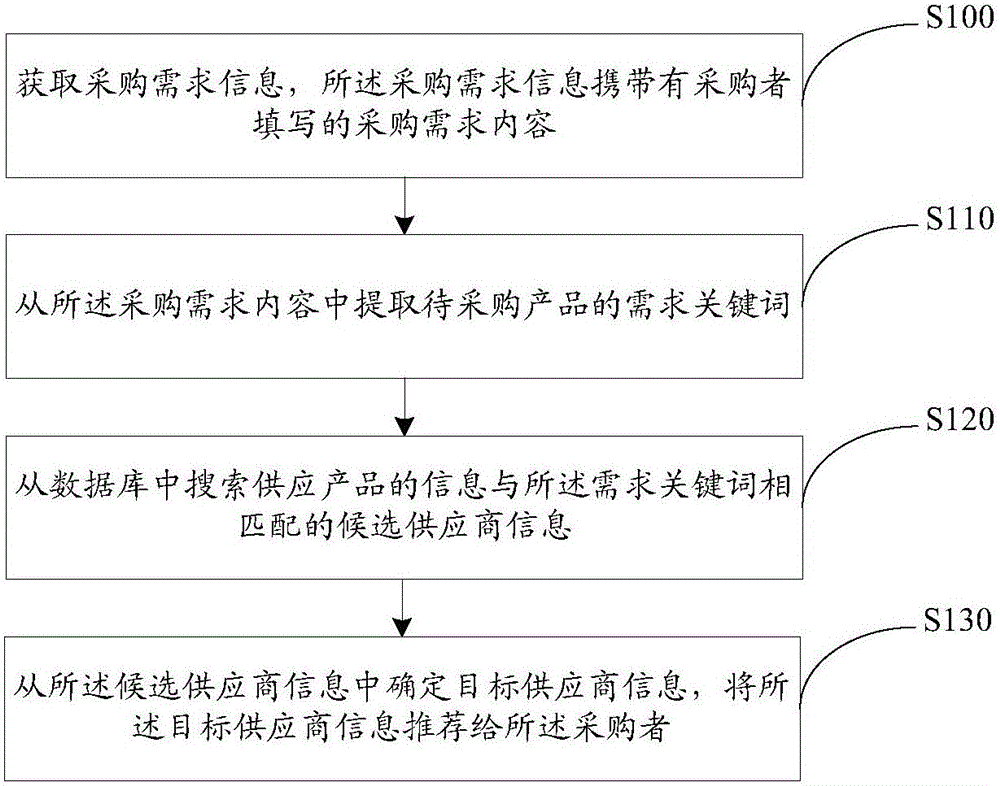

Purchasing method, server and terminal equipment

InactiveCN105956896AEasy way to determineDetermine the exact wayBuying/selling/leasing transactionsPurchasing processTerminal equipment

An embodiment of the invention provides a purchasing method, a server and terminal equipment. The purchasing method comprises the steps of acquiring purchasing requirement information which comprises a purchasing requirement content that is filled by a purchaser; extracting requirement key words of a to-be-purchased product from the purchasing requirement content; searching information of the supplied product and candidate supplier information which matches the requirement key words from a database; determining target supplier information from the candidate supplier information, and recommending the target supplier information to the purchaser. The purchasing method, the server and the terminal equipment is suitable for the scene with relatively complicated purchasing requirement of the purchaser. Furthermore relatively convenient determining manner and relatively accurate determining result of the supplier in the purchasing process are realized.

Owner:ZHENGZHOU XIZHI INFORMATION TECH

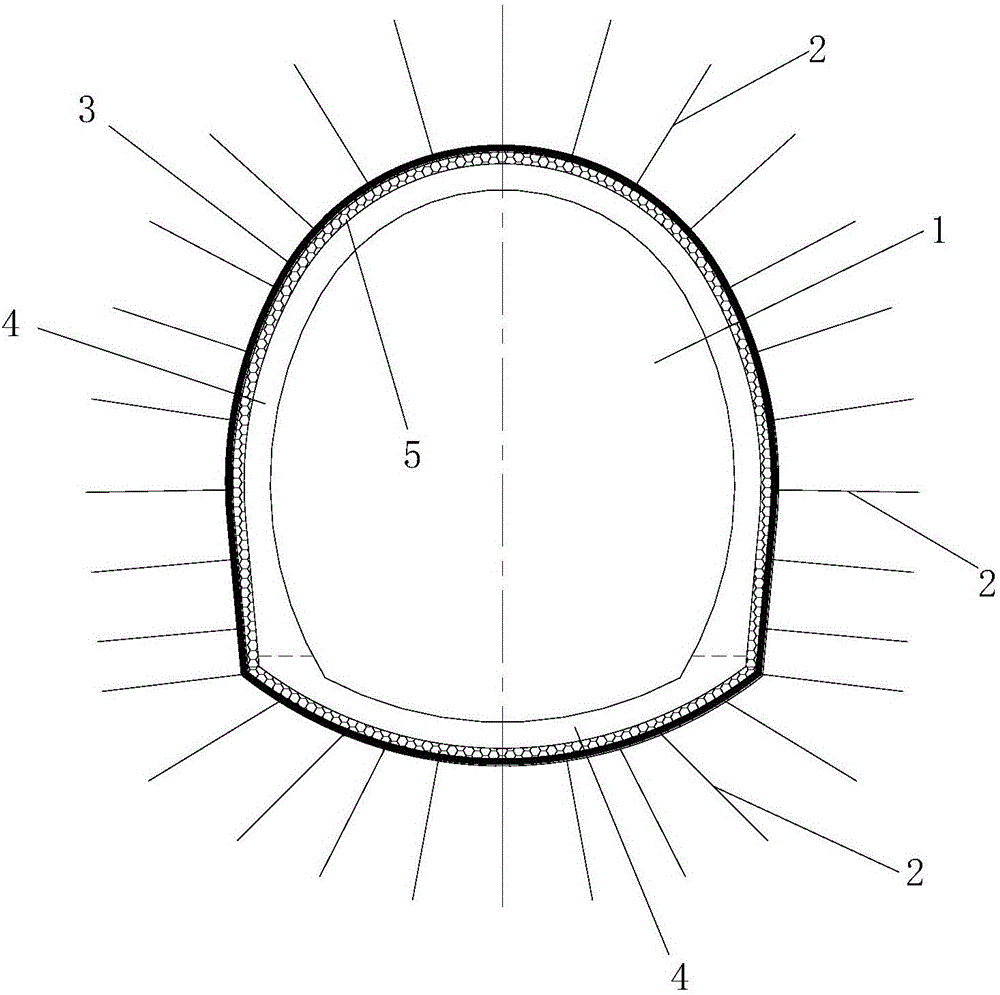

Soft rock tunnel construction method on the basis of flexible formwork support

InactiveCN106522978AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelStructural stability

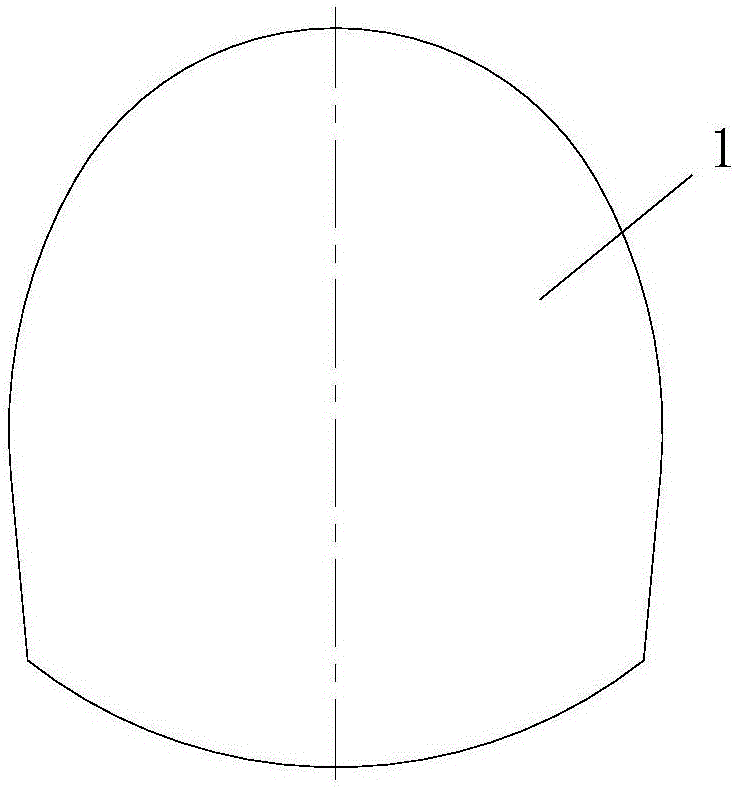

The invention discloses a soft rock tunnel construction method on the basis of flexible formwork support. A soft rock tunnel is divided into a plurality of segments from back to front to be subjected to construction. Construction of any one segment comprises the following steps that (1), basic mechanical parameters of surrounding rocks are defined; (2), the tunnel reserved excavating quantity is defined; (3), the tunnel begins to be excavated; (4), A tunnel support structure is defined: the tunnel support structure comprises a tunnel incipient support structure, a flexible formwork support structure and tunnel two-time linings; (5), tunnel incipient support is constructed; (6), the flexible formwork support is constructed; (7), the tunnel two-time linings are constructed; (8), a next segment is constructed; and (9), step (8) is repeated for many times until all the construction processes of the soft rock tunnel are completed. According to the soft rock tunnel construction method on the basis of the flexible formwork support, the method and the steps are easy, design is reasonable, achieving is convenient, and the using effect is good; and the reserved excavating quantity is defined according to deformation conditions of the surrounding rocks of the soft rock tunnel, the flexible formwork support structure is adopted to support full cross sections of the tunnel and subjected to coordination deformation with the tunnel incipient support structure, and thus structure stability of the tunnel two-time linings is guaranteed.

Owner:XIAN UNIV OF SCI & TECH

Roadside support method of short-distance coal seam roadway

InactiveCN105863700AThe method steps are simpleEasy to implementGeometric CADData processing applicationsSupporting systemShortest distance

The invention discloses a roadside support method of a short-distance coal seam roadway. The short distance coal seam roadway includes the steps of firstly, determining the basic mechanical parameters of surrounding rock; secondly, determining the excavation volume of two sides of the roadway; thirdly, excavating the roadway, to be more specific, excavating according to the excavation volume of the two sides of the roadway; fourthly, determining a roadside support structure which comprises a plurality of roadside support units and a plurality of grouting anchoring rods, wherein the roadside support units and the grouting anchoring rods are arranged in a staggered manner; fifthly, performing roadside surrounding rock support construction; sixthly, excavating the next section and performing roadside surrounding rock support construction; seventhly, repeating the sixth step until all the short-distance coal seam roadway is excavated and the roadside surrounding rock support construction is completed. The roadside support method has the advantages that the method is simple in steps, reasonable in design, convenient to implement and good in use effect, the reserved excavation volume of the two sides of the roadway is determined according to the surrounding rock deformation conditions of the short-distance lower coal seam roadway, and the grouting anchoring rods and the roadside support system are coordinated to achieve effective roadside support.

Owner:XIAN UNIV OF SCI & TECH

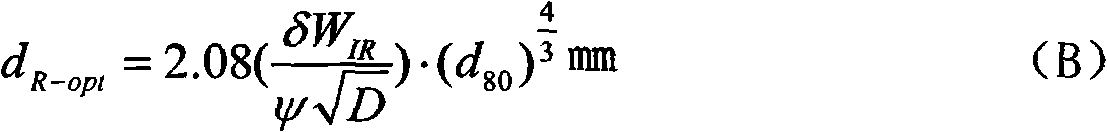

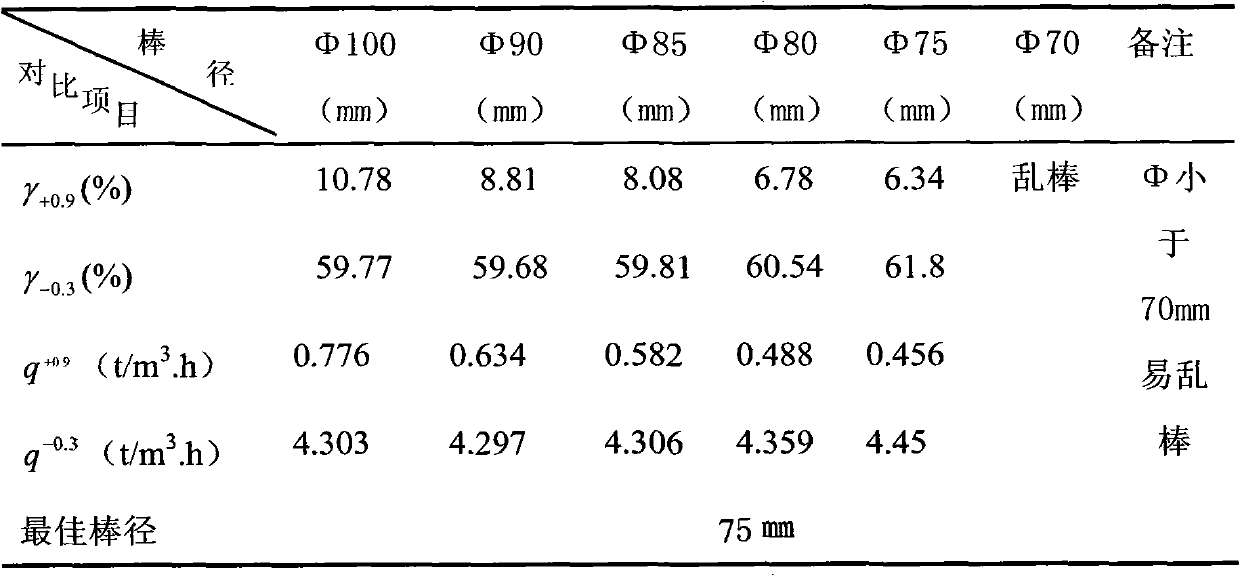

Method for determining rod diameter of rod mill

InactiveCN102172555AEasy way to determineAssays are lengthy and complexGrain treatmentsCompressive strengthBall diameter

The invention relates to a method for determining the rod diameter of a rod mill, belonging to the field of ore grinding and levigating technology. The method provided by the invention comprises the following concrete steps: (1) measuring the uniaxial compressive strength alpha of the ore to be milled, as a mechanical basis for determining the accurate rod diameter; (2) performing screen analysis of particle size for the feeding material of the rod mill, and determining the fraction d'f and average particle size for ensuring the screening rate of 95%; (3) converting the practical working conditions of the rod mill into the working conditions of a ball mill in the same conditions, and calculating the ball diameter in the conditions by using a half-theory formula of ball size (C.G.S system); (4) correcting the calculated ball diameter according to the breaking experience and ore milling characteristics of the steel rod, and calculating the required rod diameter through the formula D(R-opt)=(0.48-0.5)D'b; and (5) performing ore milling contrast test with the rod diameter greater than and less than D(R-opt), and determining the accurate rod diameter of the rod mill according to the ore milling result. Compared with the prior art, the method is simple and convenient, is accurate in calculation result, has low labor intensity of workers and shortens the test period.

Owner:YUNNAN UNIV

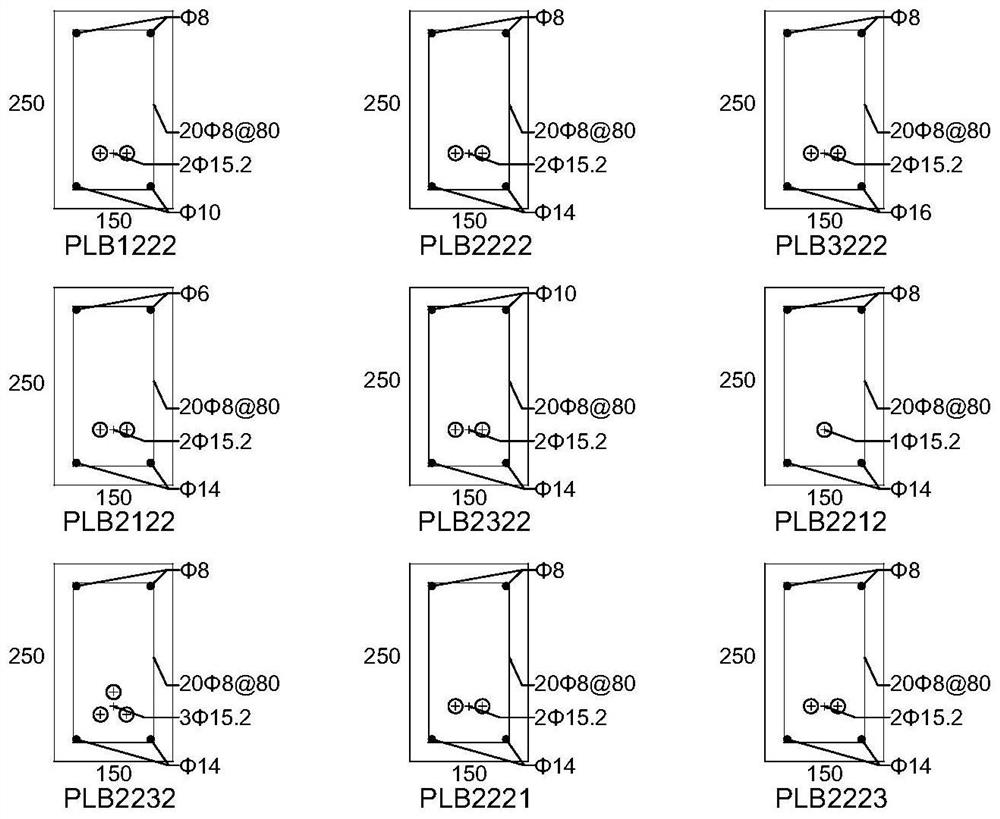

Design method for unbonded prestress and steel-concrete combined reinforcement of concrete box girder

ActiveCN106120574AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketPre stress

The invention discloses a design method for unbonded prestress and steel-concrete combined reinforcement of a concrete box girder. The design method comprises the following steps of I, determining a combined reinforcing structure: determining the unbonded prestress and steel plate-concrete combined structure of the box girder to be reinforced wherein the combined reinforcing structure comprises a steel jacket box formed by a base steel pate, two longitudinal side steel plates and two end part plugging steel plates, and a plurality of unbonded prestressed reinforcing bars are arranged in the steel jacket box; II, determining structural parameters for reinforcing the front box girder; and III, determining structural parameters of the combined reinforcing structure in the process comprising the following steps of initializing the parameters, calculating theoretical maximum thickness of the reinforcing steel plates, determining the thickness of the reinforcing steel plates and the thickness of concrete, and determining the height of the longitudinal side steel plates and the width of the base steel plate. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in using effect, the structural parameters of the combined reinforcing structure of a bridge can be simply, conveniently and quickly determined, and the designed combined reinforcing structure of the bridge is economical and practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

Method for controlling caving of roof of short distance coal bed roadway

InactiveCN105971630ASimple stepsEasy to implementUnderground chambersUnderground miningCoalEngineering

The invention discloses a method for controlling caving of a roof of a short distance coal bed roadway. The method comprises steps as follows: 1, determination of basic mechanical parameters of surrounding rock; 2, determination of reserved excavated volumes of two sides of a roadway; 3, excavation of the roadway; 4, determination of a roadway side part supporting structure: a roadway support structure comprises roadway support units and grouting anchor rods which are arranged in a staggered manner, and each roadway side part support unit comprises a roof support system and a roadway side part support system; 4, determination of the vector height of extreme caving arches; 5, determination of the roadway support structure; 6, support construction of roadway surrounding rock; 7, excavation of the next section and support construction of the roadway surrounding rock; 8, completion of the construction process of the short distance coal bed roadway after repeated implementation of the step 7. The method adopts simple steps and is reasonable in design, convenient to implement and good in use effect; the reserved excavated volumes of two sides of the roadway are determined according to the surrounding rock deformation condition of the short distance coal bed roadway respectively, and the roadway side parts and the roof are supported through matching of the grouting anchor rods and the roadway support units.

Owner:XIAN UNIV OF SCI & TECH

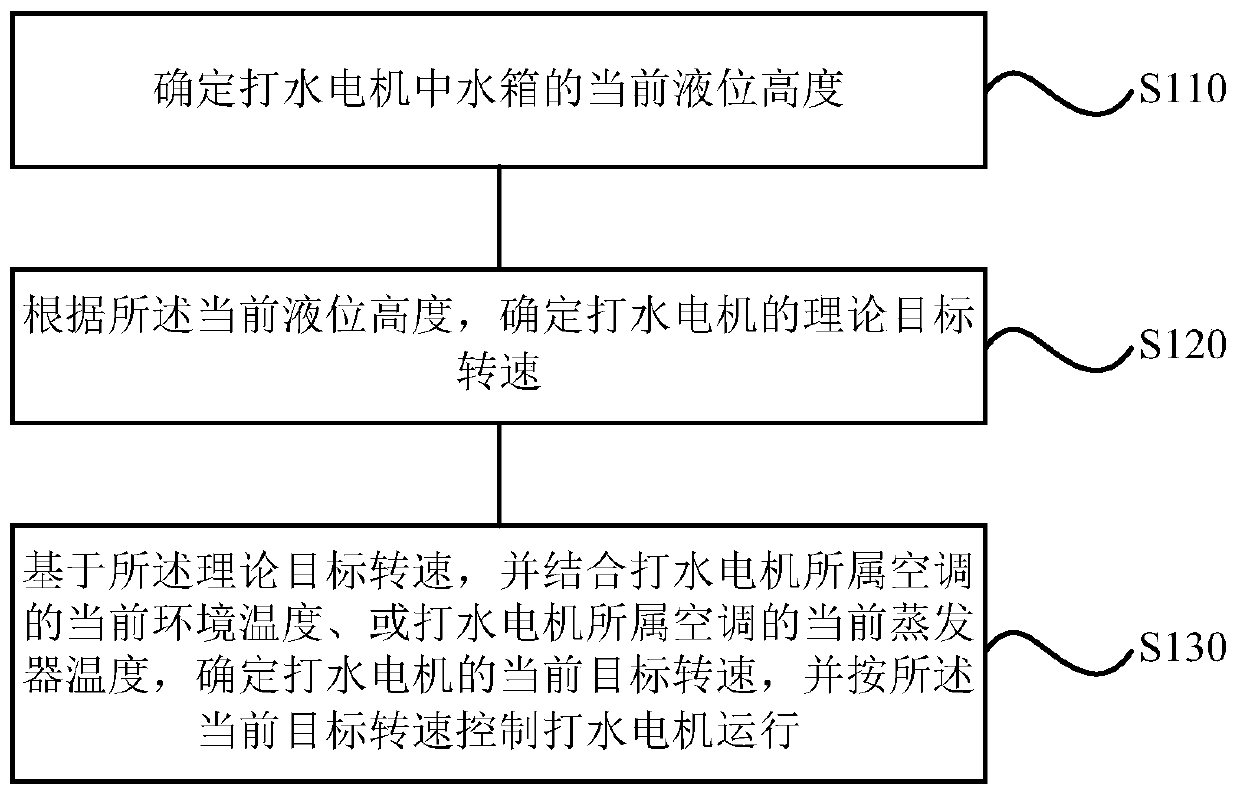

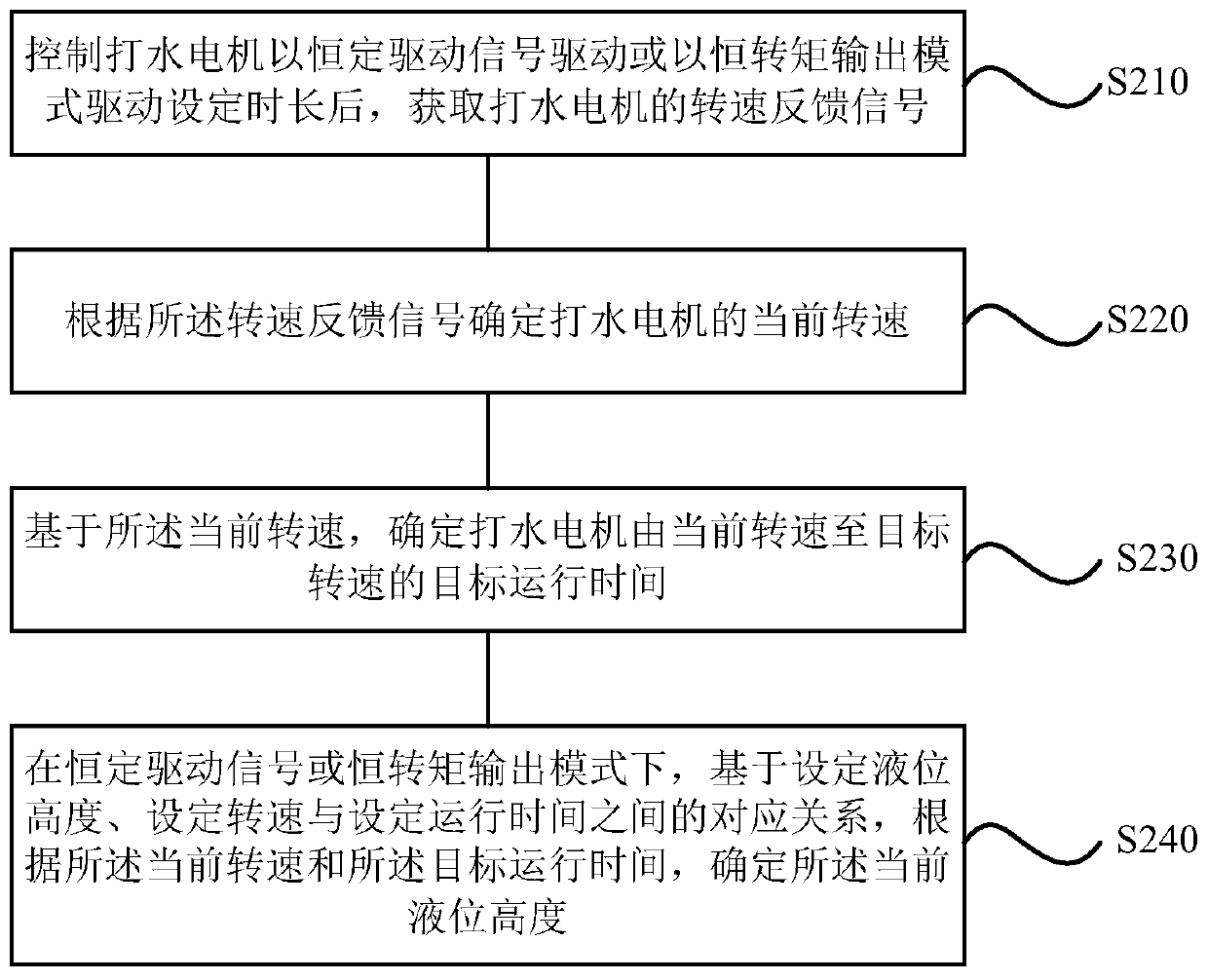

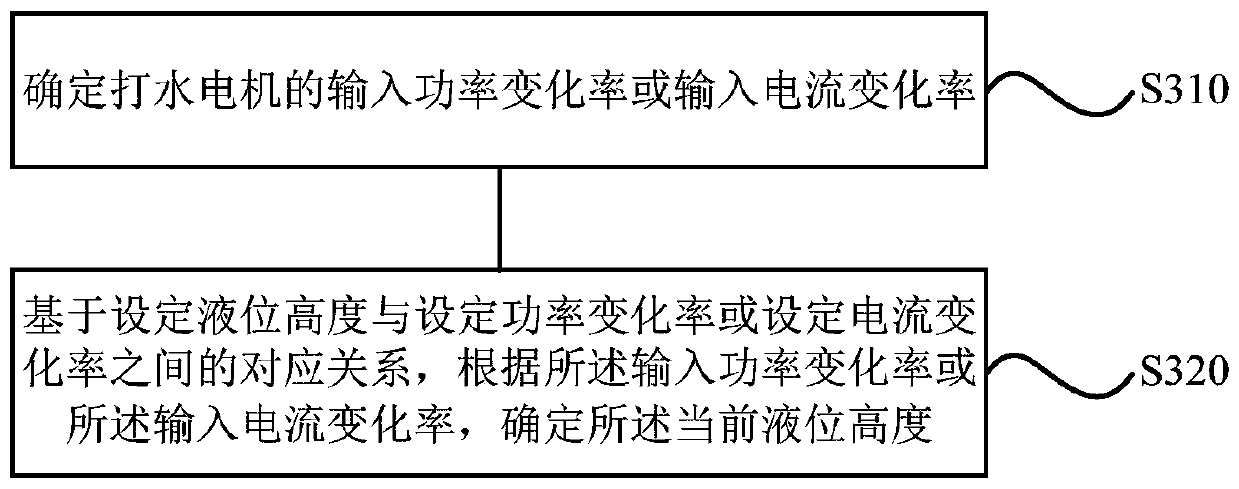

Rotating speed control method and device, storage medium and air conditioner

ActiveCN110296509AEasy way to determineMake sure the result is accurateMechanical apparatusEvaporatorEngineering

The invention discloses rotating speed control method and device, a storage medium and an air conditioner. The method comprises the following steps of determining a current liquid level height of a water tank in a water splashing motor; determining a theoretical target rotating speed of the water splashing motor according to the current liquid level height; and determining a current target rotating speed of the water splashing motor based on the theoretical target rotating speed and in combination with a current environment temperature or a current evaporator temperature of an air conditionerprovided with the water splashing, and controlling the operation of the water splashing motor according to the current target rotating speed. According to the scheme, the problem that the control precision of the water splashing motor is low can be solved, and the effect of improving the control precision of the water splashing motor is achieved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

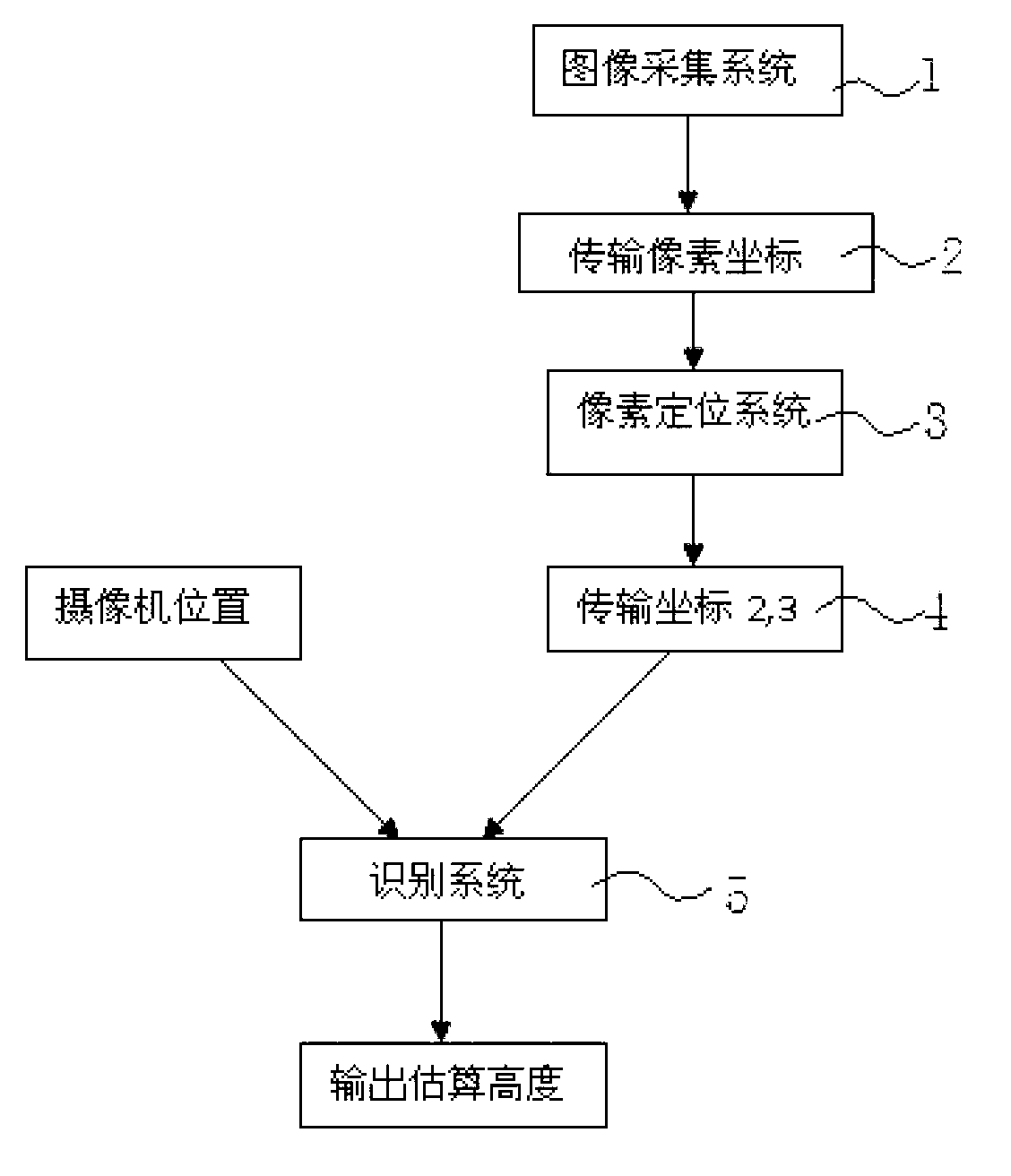

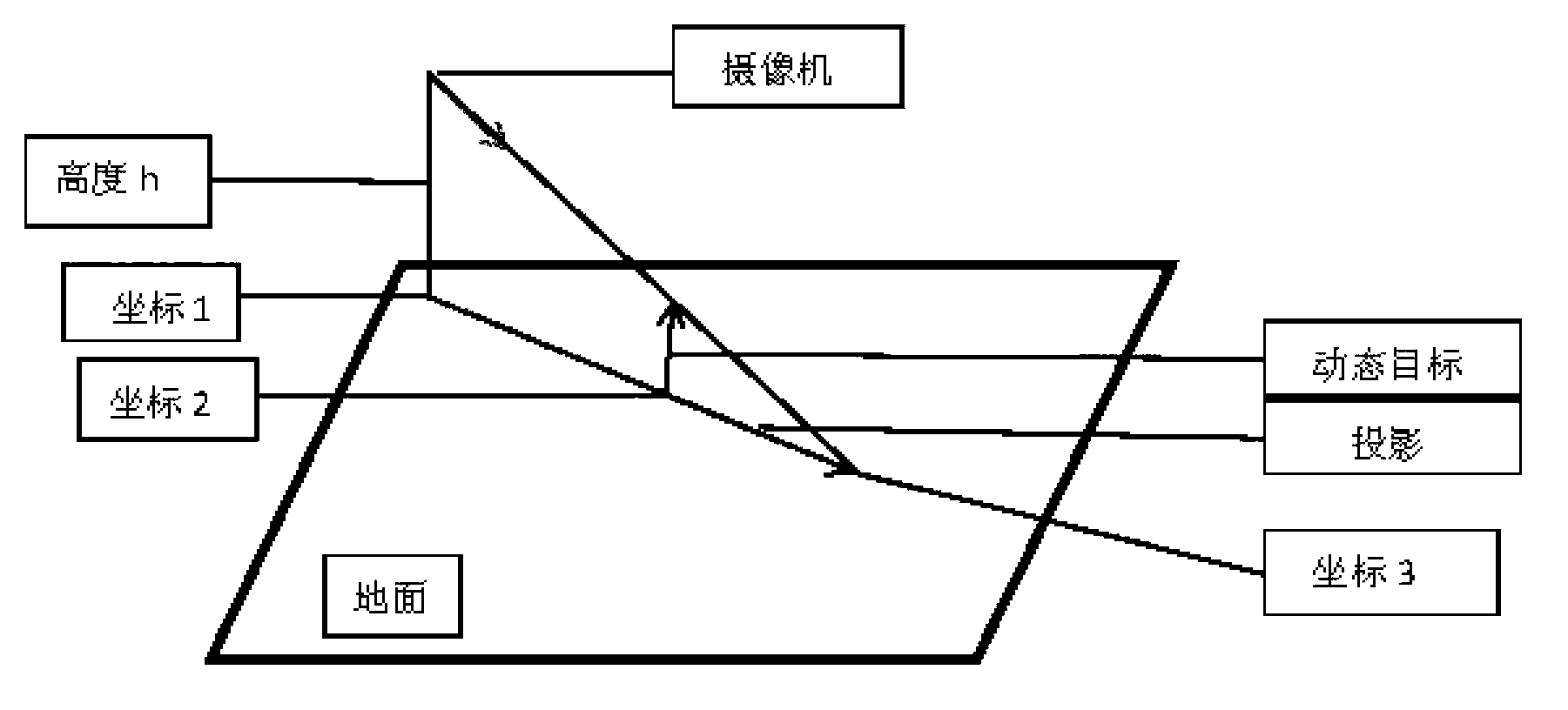

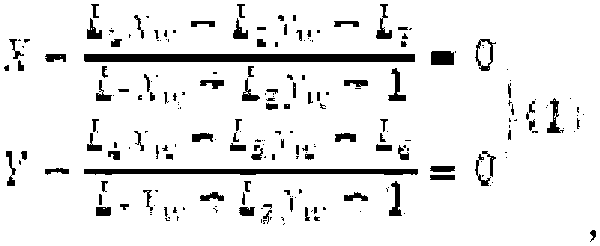

Determining method of moving target height under different projection angles

InactiveCN103258322AEasy way to determineMeet the application scenarios that do not require high precisionImage analysisProjection angleVideo camera

The invention discloses a determining method of a moving target height under different projection angles. The determining method comprises the following steps of obtaining position coordinates of a ground object in an image picture by using a real-time image collecting device which has the function of picture moving target capturing, according to the obtained position coordinate information, restoring a plurality of effective points on a pixel block to actual positions on the ground after projecting the ground object to the image picture, and at last, computing the actual height and position of a moving target according to the geometrical relationship between the ground object and a video camera under the projection of the video camera. The determining method is easy to implement, the characteristics of parameters of the video camera do not need to be considered, rough position restoration can be conducted on the points on the ground, and application scenarios which are not high in precision demands can be satisfied.

Owner:NANJING PENGYUAN ELECTRICAL

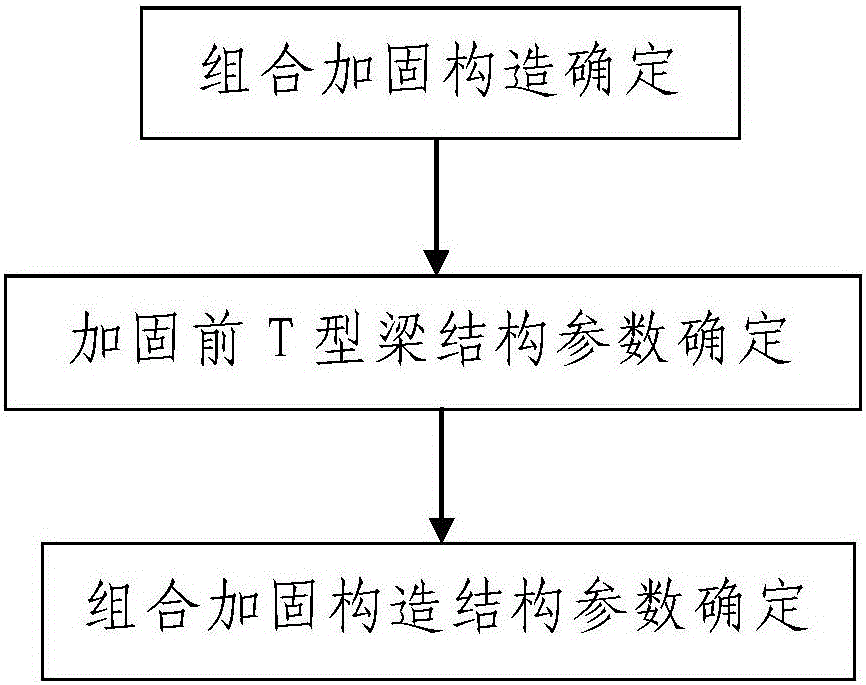

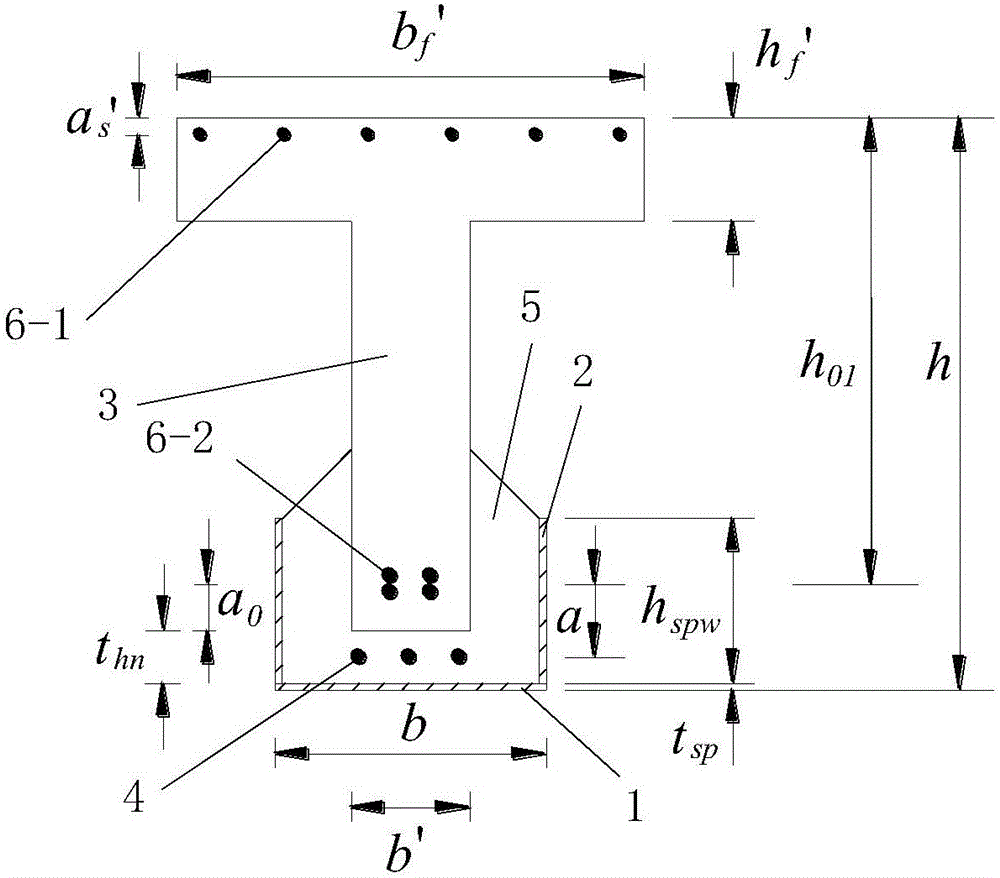

Unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams

ActiveCN105839551AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningRebarSteel plates

The invention discloses an unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams. The unbonded prestress and steel-concrete composite reinforcement design method includes steps of firstly, determining unbonded prestress and steel plate-concrete composite reinforcement structures for the reinforcement T-shaped beams; secondly, determining structural parameters of the T-shaped beams prior to reinforcement; thirdly, determining structural parameters of the composite reinforcement structures, to be more specific, initializing the parameters, computing the maximum theoretical thicknesses of reinforcement steel plates, determining the thicknesses of the reinforcement steel plates and the thickness of concrete and determining the heights of longitudinal side steel plates and the widths of bottom steel plates. Each composite reinforcement structure comprises the corresponding bottom steel plate, the two longitudinal side steel plates and a steel bushing case, each steel bushing case comprises two end blocking steel plates, and a plurality of unbonded prestress reinforcing steel bars are arranged in each steel bushing case. The unbonded prestress and steel-concrete composite reinforcement design method has the advantages that the steps are simple, the unbonded prestress and steel-concrete composite reinforcement design method is reasonable in design and convenient to implement, good service effects can be realized, the structural parameters of the bridge composite reinforcement structures can be easily, conveniently and quickly determined, the bridge composite reinforcement structures designed by the aid of the unbonded prestress and steel-concrete composite reinforcement design method are economical and practical, and good reinforcement effects can be realized by the bridge composite reinforcement structures.

Owner:XIAN HIGHWAY INST

Multi-pylon cable-stayed bridge supporting system with function of inhibiting longitudinal seismic response and working method

InactiveCN103422422AInhibition of longitudinal internal force responseIncreased longitudinal relative displacement responseCable-stayed bridgeBridge erection/assemblySupporting systemCable stayed

The invention discloses a multi-pylon cable-stayed bridge supporting system with a function of inhibiting longitudinal seismic response. The supporting system comprises a girder, bridge piers and pylons; both ends of the girder are connected to the bridge piers; the pylons are connected with the girder by stay cables; n pylons are provided; m pylons are respectively and longitudinally bound with the girder; the rest of n-m pylons has no longitudinal binding relation with the girder; the joint of each pylon without binding relation with the girder and the girder is provided with a first fluid damper; the joint of each bridge pier and the girder is provided with a second fluid damper; both the first fluid dampers and the second fluid dampers are longitudinally arranged; both n and m are integers; n is greater than or equal to 3; and n is greater than m and m is greater than 1. The supporting system has an excellent damping effect on longitudinal seismic response of the girder and the pylons of a multi-pylon cable-stayed bridge longitudinal part binding system, which is caused by the seismic action. Meanwhile, the invention also provides a working method of the supporting system. The working method is simple and has an excellent damping effect.

Owner:SOUTHEAST UNIV

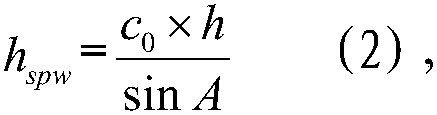

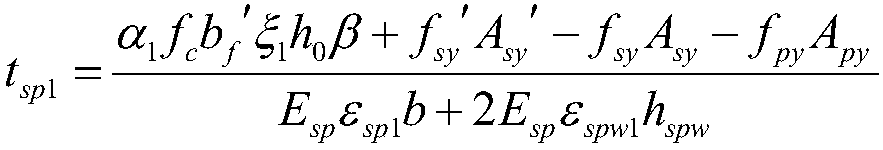

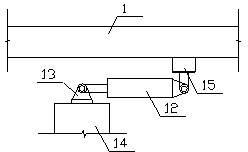

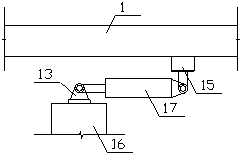

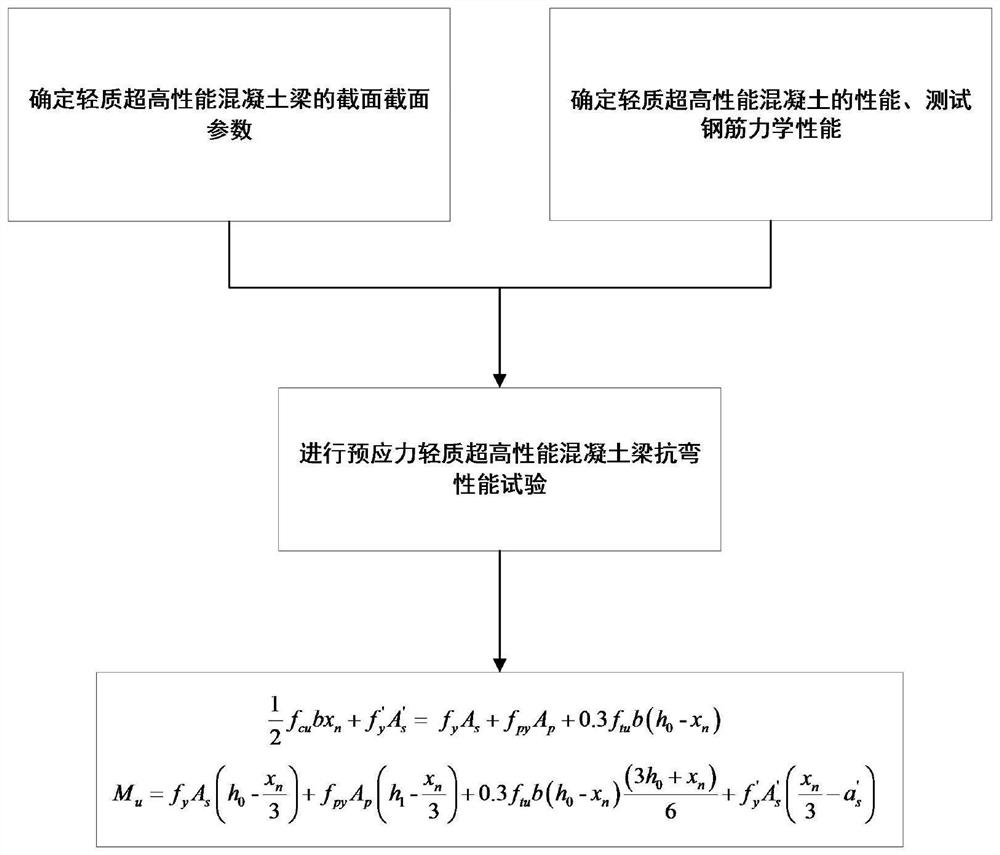

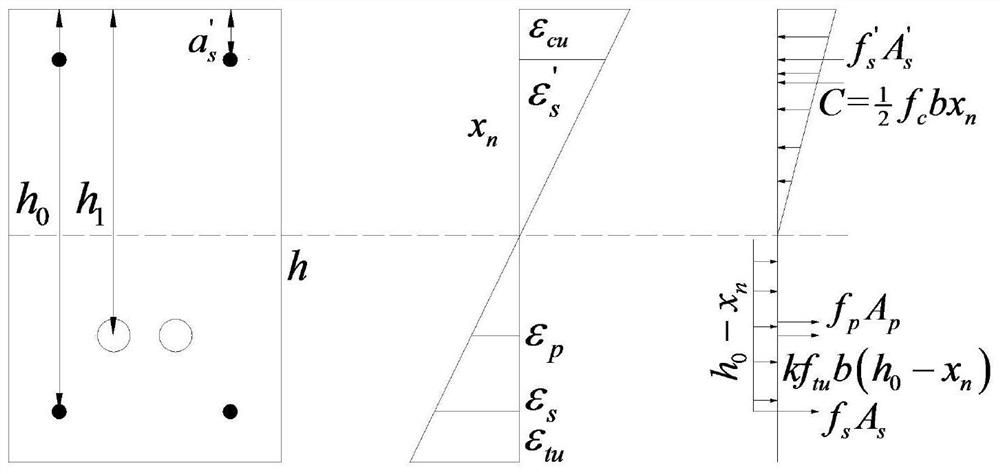

Method for determining flexural capacity of prestressed light ultra-high performance concrete beam

PendingCN113536418AEasy way to determinePractical engineering application value is greatGeometric CADDesign optimisation/simulationBridge engineeringPre stress

The invention belongs to the technical field of civil construction and transportation industry bridge engineering. The invention discloses a method for determining the flexural capacity of a prestressed light ultra-high performance concrete beam. The method is characterized by comprising the following steps: 1) determining basic parameters of the prestressed light ultra-high performance concrete beam; 2) determining the performance of the lightweight ultra-high performance concrete, and testing the mechanical properties of the reinforcing steel bar; (3) carrying out a bending test on the prestressed light ultra-high performance concrete beam to obtain a bending bearing capacity calculation formula of the prestressed light ultra-high performance concrete beam; and 4) substituting the corresponding data into a flexural capacity calculation formula of the prestressed light ultra-high performance concrete beam to determine the flexural capacity of the prestressed light ultra-high performance concrete beam. According to the method, the problem that an existing standard flexural capacity formula is not suitable for the prestressed light ultra-high performance concrete beam is solved, and theoretical and test basis is provided for application of LUHPC new materials in bridge engineering.

Owner:WUHAN UNIV OF TECH

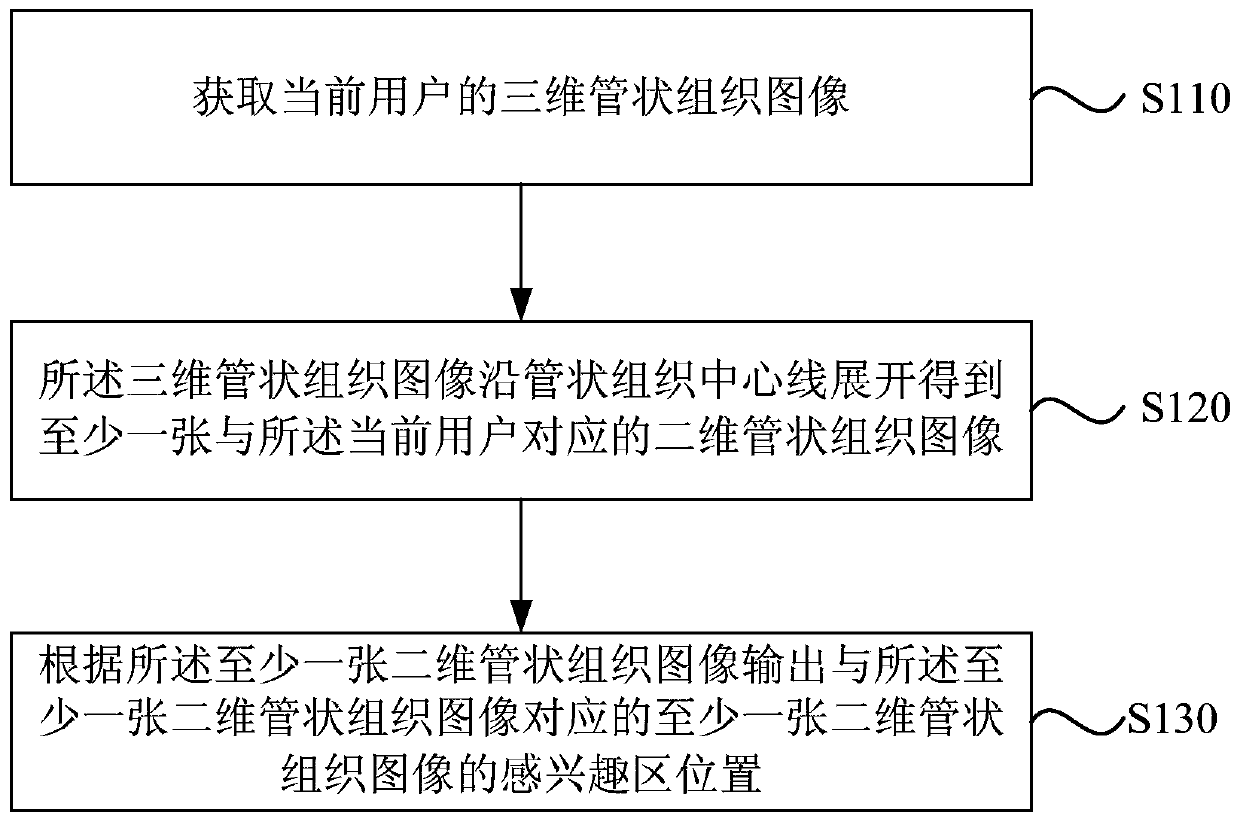

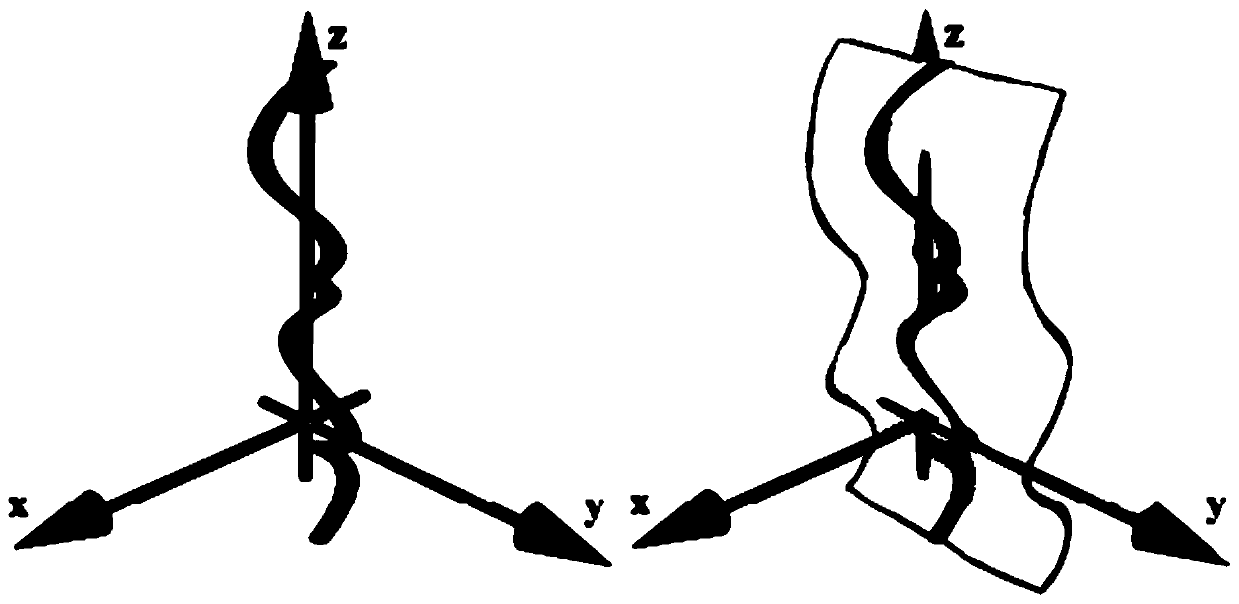

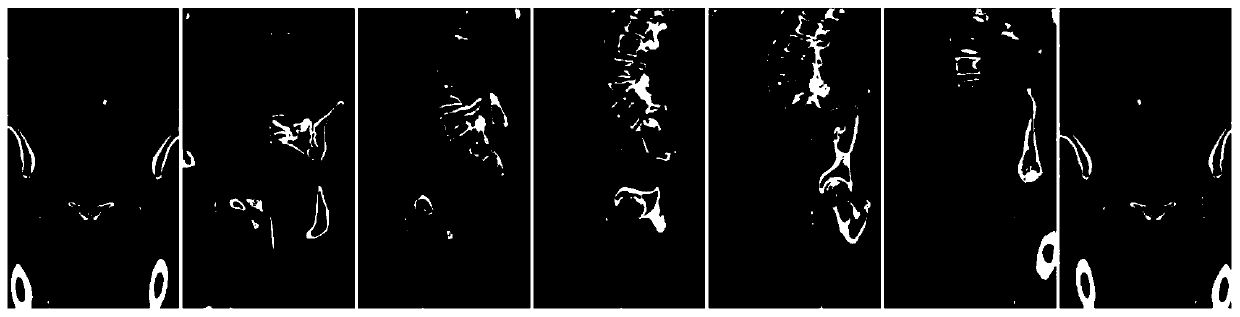

Method and device for determining tubular tissue region of interest, equipment and medium

ActiveCN110349143ASolutionTime-consuming and laborious to solveImage enhancementImage analysisMedicineRegion of interest

The embodiment of the invention discloses a method and a device for determining a tubular tissue region of interest, equipment and a medium. The method comprises the following steps: acquiring a three-dimensional tubular tissue image of a current user; wherein the three-dimensional tubular tissue image is expanded along a tubular tissue center line to obtain at least one two-dimensional tubular tissue image corresponding to the current user; and outputting a region of interest position of at least one two-dimensional tubular tissue image corresponding to the at least one two-dimensional tubular tissue image according to the at least one two-dimensional tubular tissue image. According to the embodiment of the invention, through obtaining a three-dimensional tubular tissue image of a currentuser, and after at least one two-dimensional tubular tissue image is obtained by expanding along the central line of the tubular tissue, the two-dimensional tubular tissue image is input into a pre-trained classifier to output the position of the region of interest of the corresponding two-dimensional tubular tissue image, so that the determination method of the region of interest of the tubulartissue is simpler, and the measurement and size evaluation of the region of interest of the tubular tissue are more accurate.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

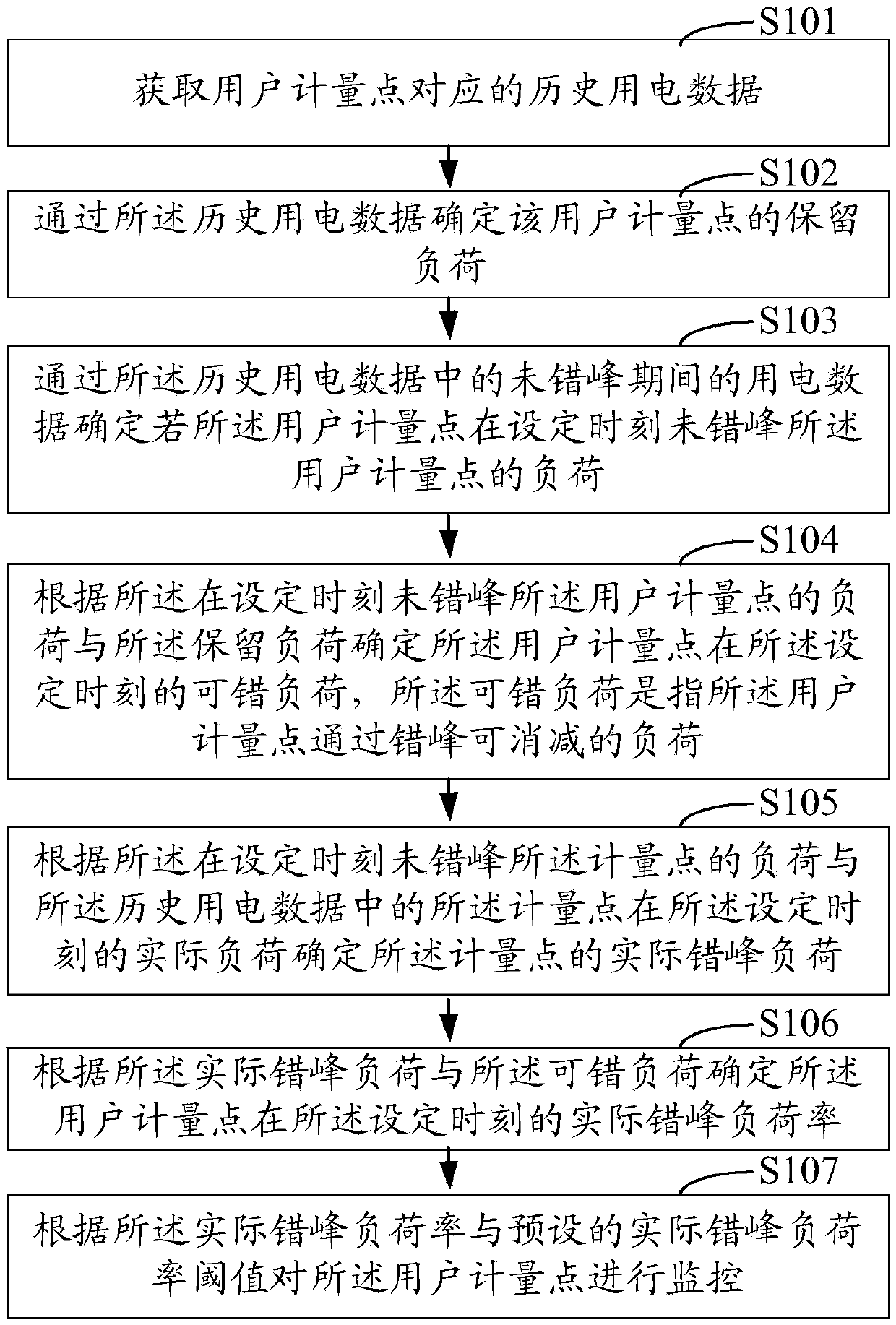

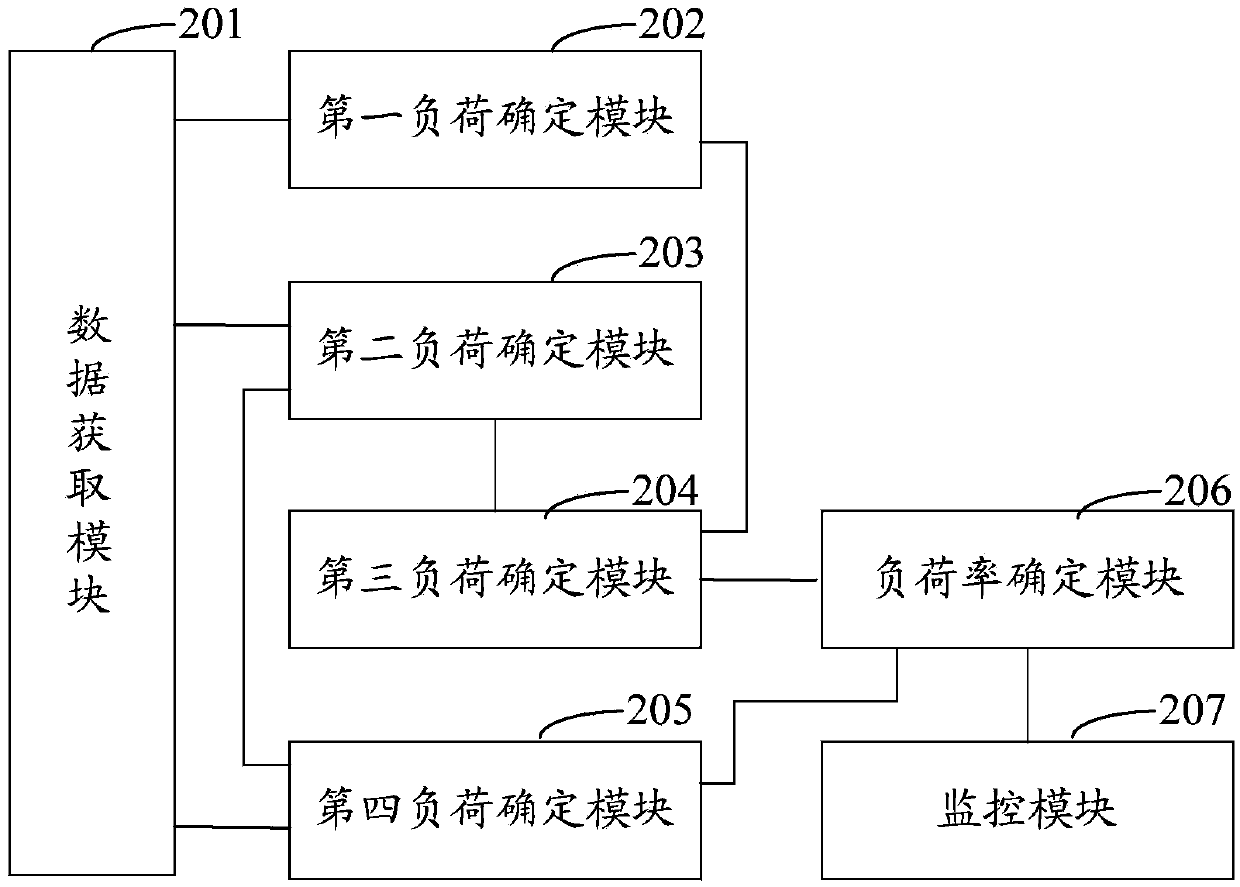

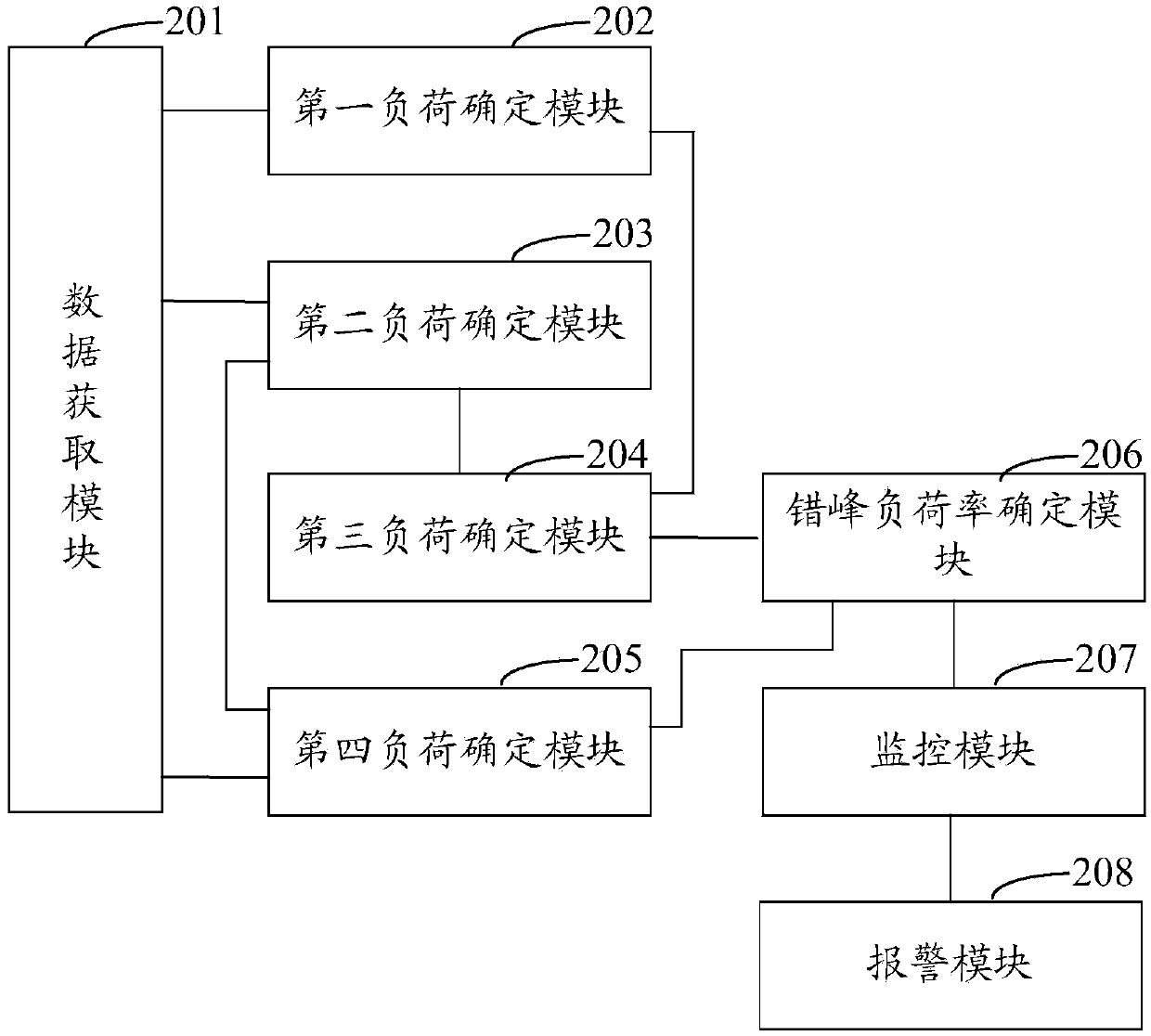

Off-peak monitoring method and system of orderly power utilization

ActiveCN103475000AAvoid misjudgmentSafe and stable operationPower network operation systems integrationAc network voltage adjustmentPeak loadReal-time computing

The invention discloses an off-peak monitoring method and an off-peak monitoring system of orderly power utilization. The method comprises the following steps: obtaining historical power data corresponding to a user metering point; determining reserved load of the user metering point through the historical power data; determining the load of the user metering point if the user metering point is not off-peak at the set moment through the power data during an on-peak period in the historical power data; determining off-peak load of the user metering point at the set moment according to the load of on-peak user metering point at set moment and the reserved load; determining actual off-peak load of the user metering point according to the load of the on-peak user metering point at the set moment and the actual load of the user metering point at the set moment; determining actual off-peak load rate of the user metering point at the set moment according to the actual off-peak load and the off-peak load; monitoring the user metering point according to the actual off-peak load rate and a preset threshold of the actual off-peak load rate, so that erroneous judgment on the off-peak execution condition in the off-peak monitoring process can be effectively avoided.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

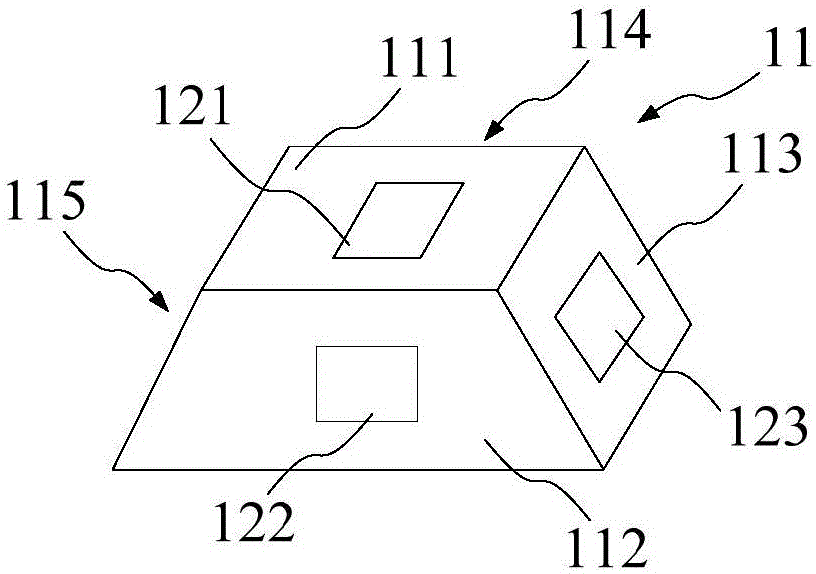

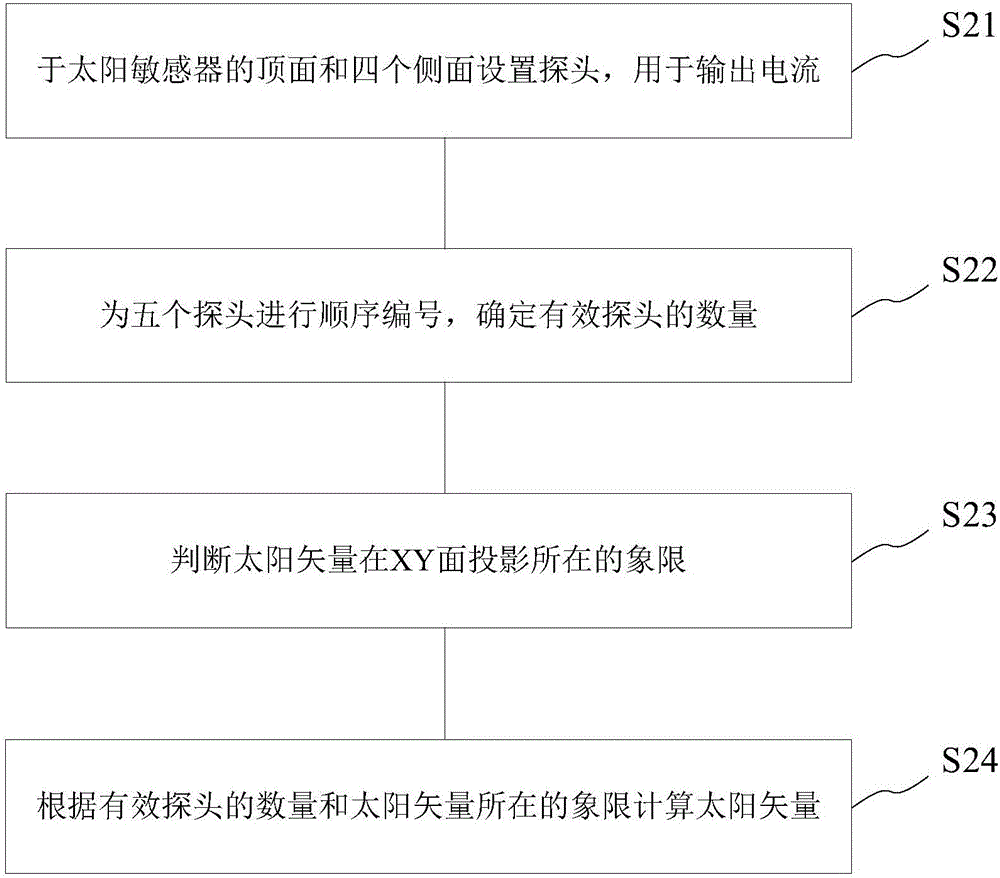

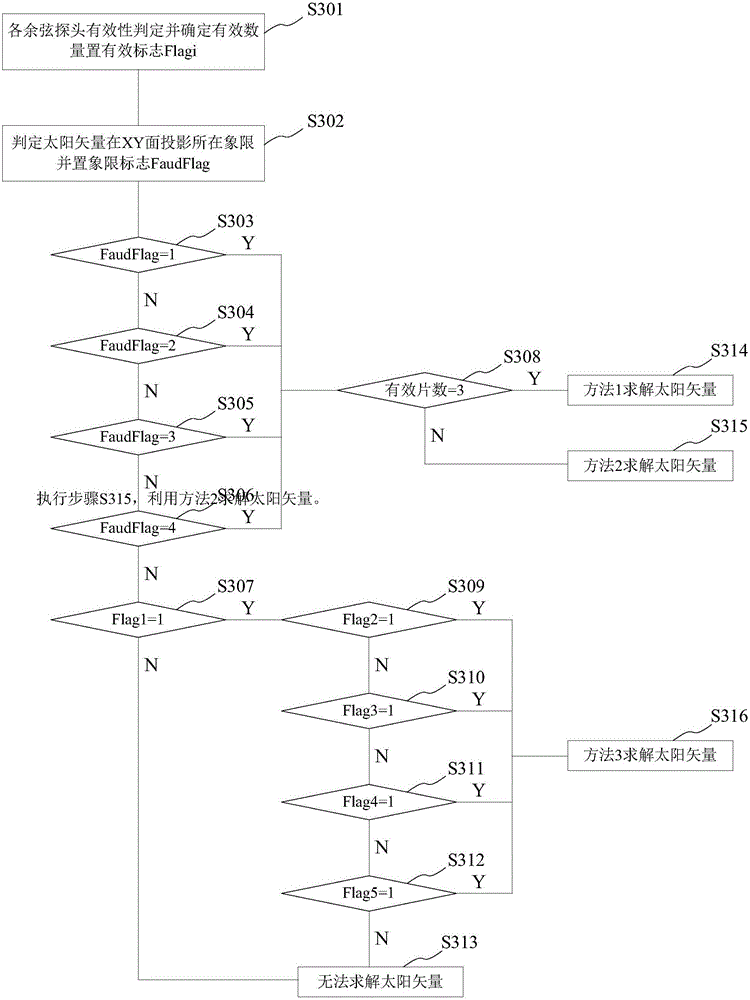

All-day ball view field sun sensor and determination method for sun vector thereof

ActiveCN105737822AAchieve coverageReduce volumeAngle measurementNavigation by astronomical meansEngineeringVector processor

The invention provides an all-day ball view field sun sensor and a determination method for a sun vector thereof.The sun sensor comprises a body structure, probes and a sun vector processor, wherein the body structure is in a rectangular pyramid shape and is provided with four side faces and a top face, the probes are arranged on the four side faces and the top face of the body structure and used for outputting current, and the sun vector processor is in communication connection with the probes and used for judging the number of the active probes and the quadrant where the projection of the sun vector in the XY plane and calculating the sun vector.According to the all-day ball view field sun sensor and the determination method for the sun vector thereof, on the condition that the requirement for the precision of the sun vector is met, the size can be decreased, the view field is increased, and coverage of an all-day 4 pi view field is achieved.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

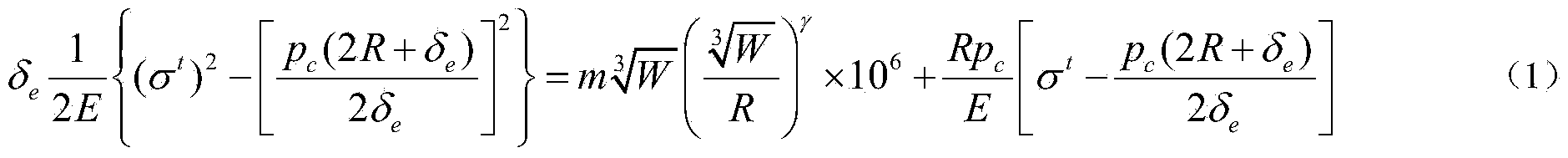

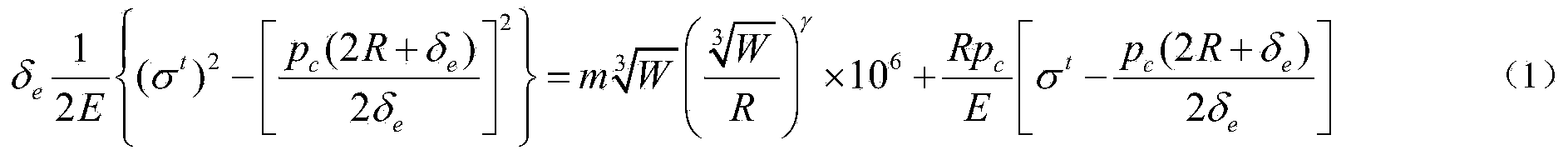

Method for determining thickness of wall of container for simulating explosion test in deepwater environment

ActiveCN103837117AReduce wall thicknessReduce processing costsMeasurement devicesEngineeringProcessing cost

The invention relates to a method for determining the thickness of the wall of a container for simulating an explosion test in a deepwater environment. According to the technical scheme, under the conditions that the constraint condition of the container (the container is called for short) for simulating the explosion test in the deepwater environment, the simulated water depth, the allowable powder charging amount, the container structure, the container size and the container materials are known, a model (please see the formula in the specification) for determining the thickness of the wall of the container for simulating the explosion test in the deepwater environment is built, and then the thickness delta e of the wall of the container is obtained according to the model for determining the thickness of the wall of the container. The method has the advantages of being capable of meeting actual bearing requirements and lowering processing cost, and being safe, reliable and convenient to use.

Owner:WUHAN UNIV OF SCI & TECH

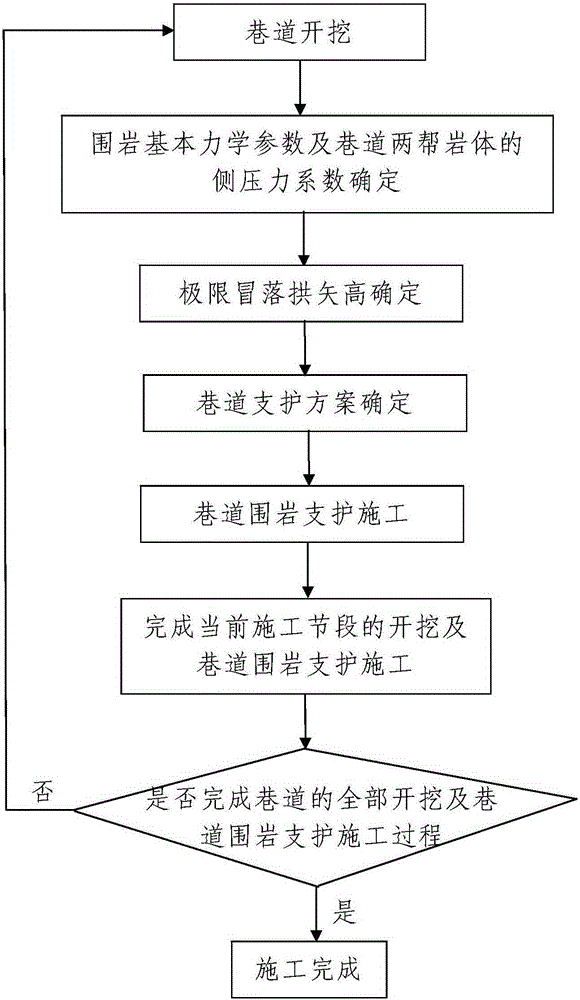

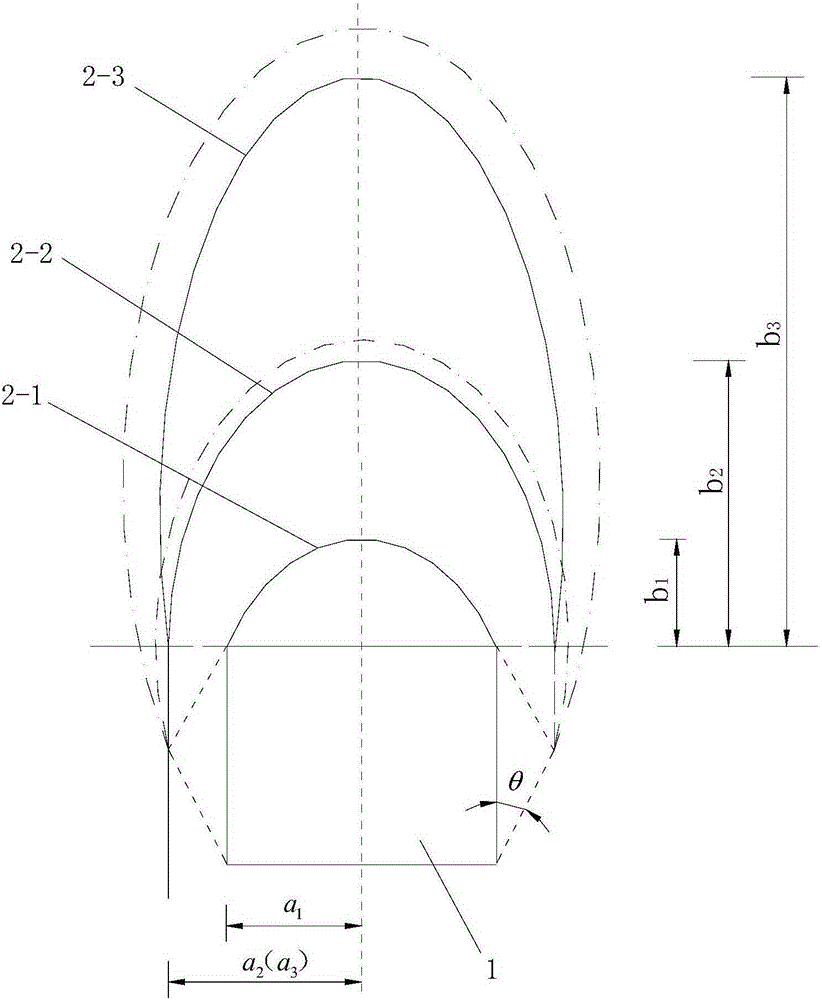

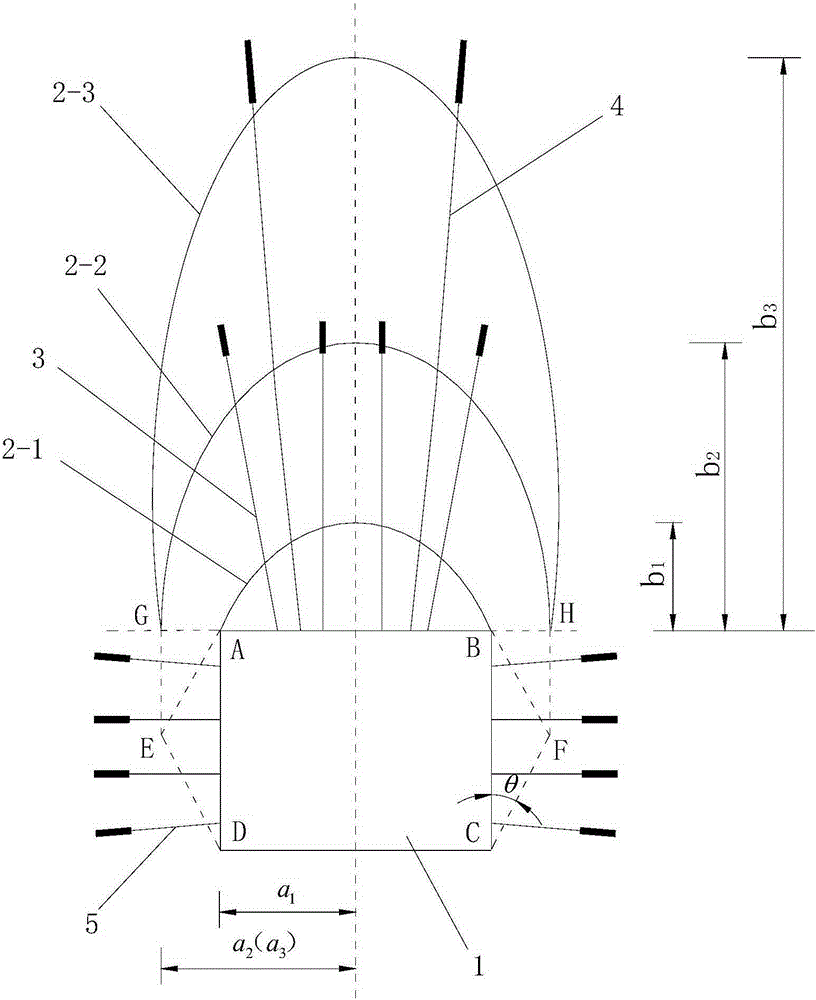

A mining roadway support method based on the determination of caving arch height

The invention discloses a recovery roadway supporting method based on determination of the rise of a caving arch. The method comprises the following steps: (1), excavating a roadway; (2), determining the basic mechanical parameters of surrounding rock and side pressure coefficient of rock masses at two sides of the roadway; (3), determining the rise of limit caving arches, namely determining the rise b2 of the first limit caving arch and the rise b3 of the second limit caving arch according to the determined side pressure coefficient lambda in combination with the basic mechanical parameters of surrounding rock; (4), determining a roadway supporting scheme, namely respectively determining a roadway top plate shallow supporting structure and a roadway top plate deep supporting structure according to b2 and b3; (5), supporting the surrounding rock of the roadway; (6), excavating the next section of roadway, and supporting the surrounding rock of the roadway; and (7), repeating the step (6) for many times till the rectangular roadway is completely excavated and the surrounding rock of the roadway is supported. The recovery roadway supporting method based on determination of the rise of the caving arch, which is disclosed by the invention, is simple in step, convenient to realize, good in use effect and low in construction cost; the top plate of the rectangular roadway can be effectively reinforced; repairing operation of the rectangular roadway is avoided.

Owner:XIAN UNIV OF SCI & TECH

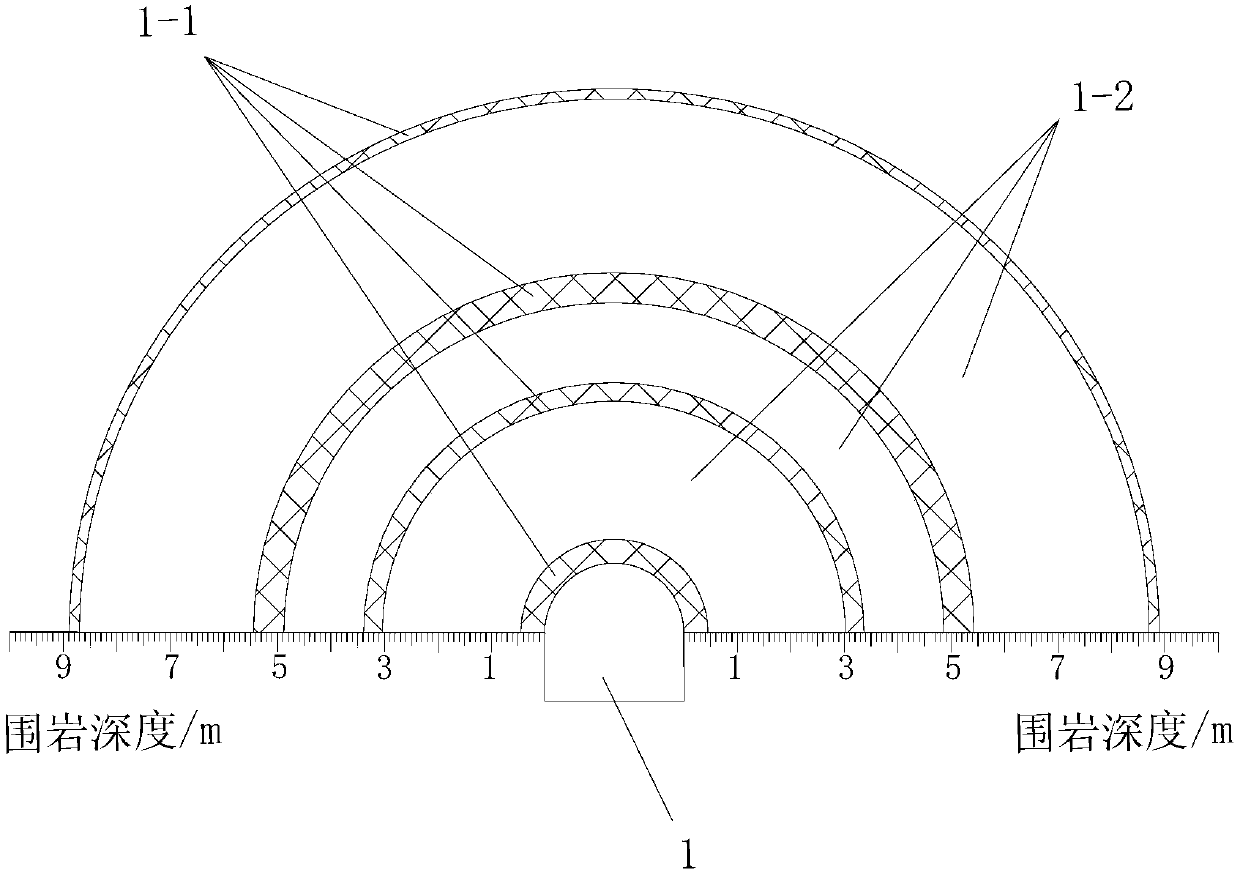

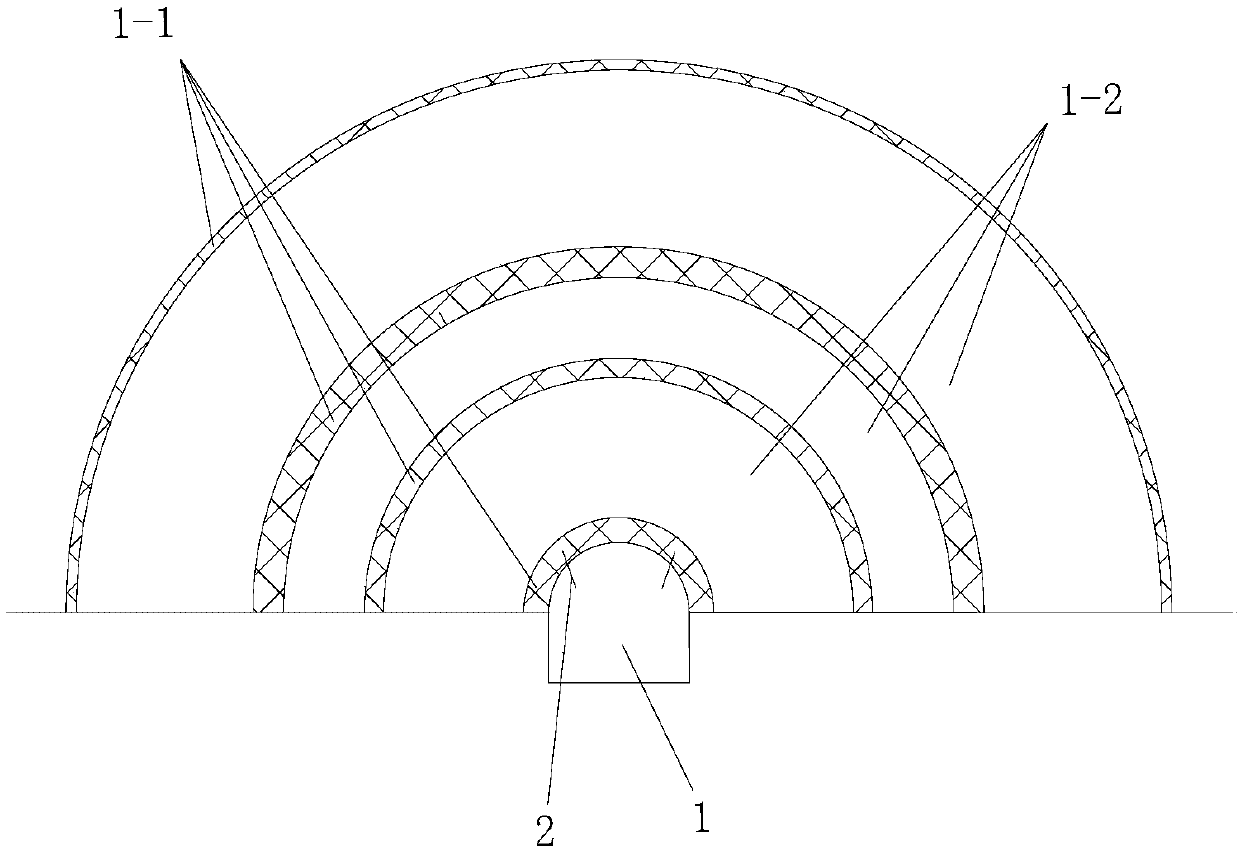

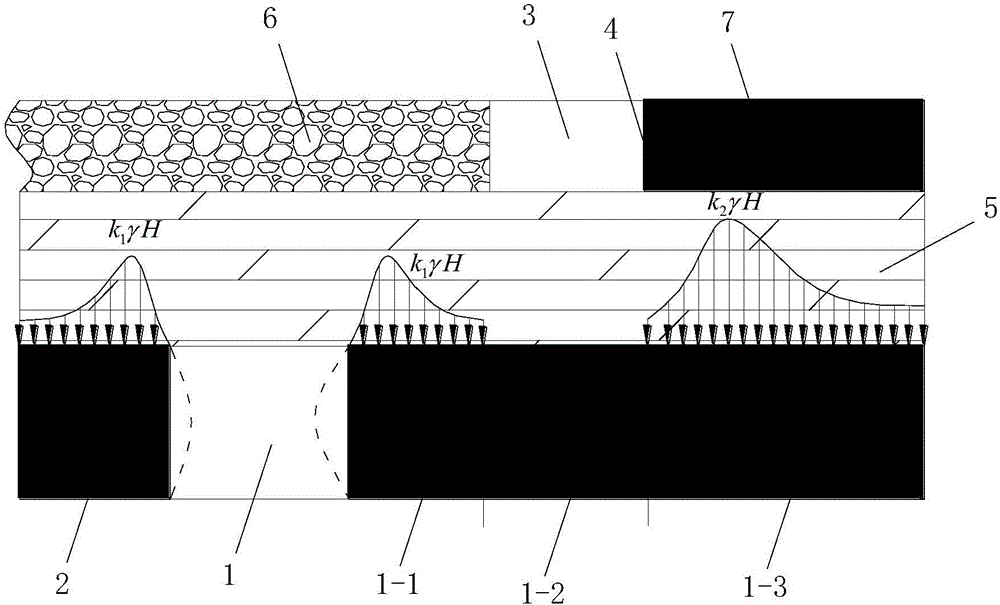

Tunnel excavation construction method based on zonal fracturing evolution analysis of surrounding rocks

ActiveCN108843329AThe method steps are simpleEasy to implementUnderground chambersTunnel liningEnvironmental geologyTunnel safety

Owner:SHANXI MEIJIA MINING EQUIP

Method for preventing and controlling floor heave disease of short-distance coal seam roadway

InactiveCN106202870ASimple stepsEasy to implementSpecial data processing applicationsInformaticsDiseaseSupporting system

The invention discloses a method for preventing and controlling a floor heave disease of a short-distance coal seam roadway. The method comprises the following steps of: 1, determining basic mechanical parameters of surrounding rocks; 2, determining excavated volumes reserved on two sides of the roadway; 3, excavating the roadway; 4, determining a roadway side support structure: the roadway support structure comprises a plurality of roadway support units and a plurality of grouting anchor rods, and the roadway side support units are staggered with the grouting anchor rods and respectively comprise a bottom plate support system and a roadway side support system; 5, constructing a roadway surrounding rock support; 6, excavating the next section and constructing the roadway surrounding rock support; and 7, repeating the step 6 until all the excavation of the short-distance coal seam roadway and the construction process of the roadway surrounding rock support are finished. The method disclosed by the invention is reasonable in design, convenient to realize and good in using effect; and the excavated volumes reserved on the two sides of the roadway are respectively determined according to the surrounding rock deformation condition of the short-distance lower coal seam roadway, and the grouting anchor rods and the roadway support units are matched to effectively support the roadway, so that the floor heave problem of the roadway can be effectively solved.

Owner:XIAN UNIV OF SCI & TECH

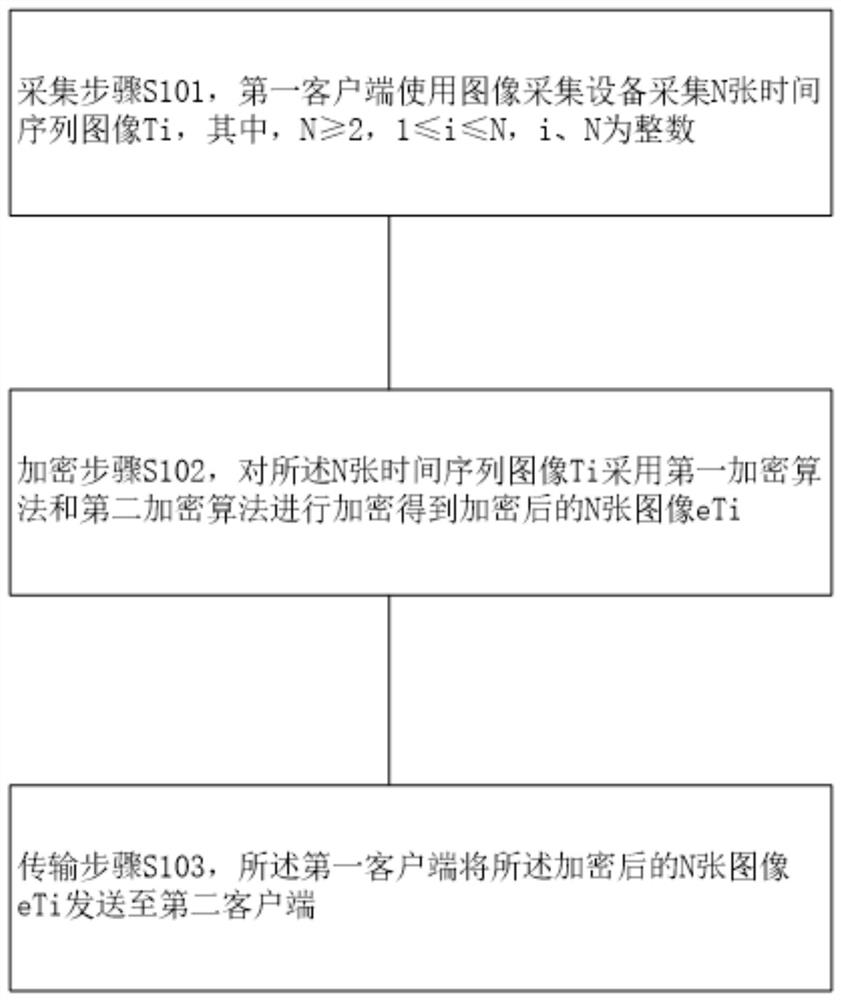

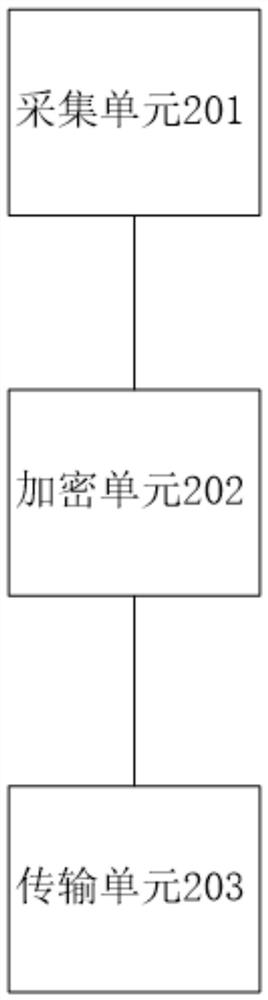

Image information security processing method and device

ActiveCN112699400AEnsure safetyImprove securityImage enhancementImage analysisEngineeringInformation security

The invention provides an image information security processing method and device, and the method comprises a collection step: enabling a first client to collect N time sequence images Ti through employing image collection equipment, and an encryption step: carrying out the encryption of the N time sequence images Ti through employing a first encryption algorithm and a second encryption algorithm, and obtaining N encrypted images eTi; and a transmission step: enabling the first client to send the encrypted N images eTi to a second client. According to the invention, each image is encrypted by adopting two encryption algorithms based on different characteristic values, and the two encryption algorithms consume different system resources, so that the key part of the image can be encrypted by using the encryption algorithm consuming more system resources, the common part of the image is encrypted by using an encryption algorithm consuming less system resources, and the computing resources of the terminal are saved while the image security is ensured.

Owner:齐丰科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com