Roadside support method of short-distance coal seam roadway

A short-distance, roadway side technology, applied in the direction of earthwork drilling, installation of bolts, instruments, etc., can solve problems such as unsuitable mining roadways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

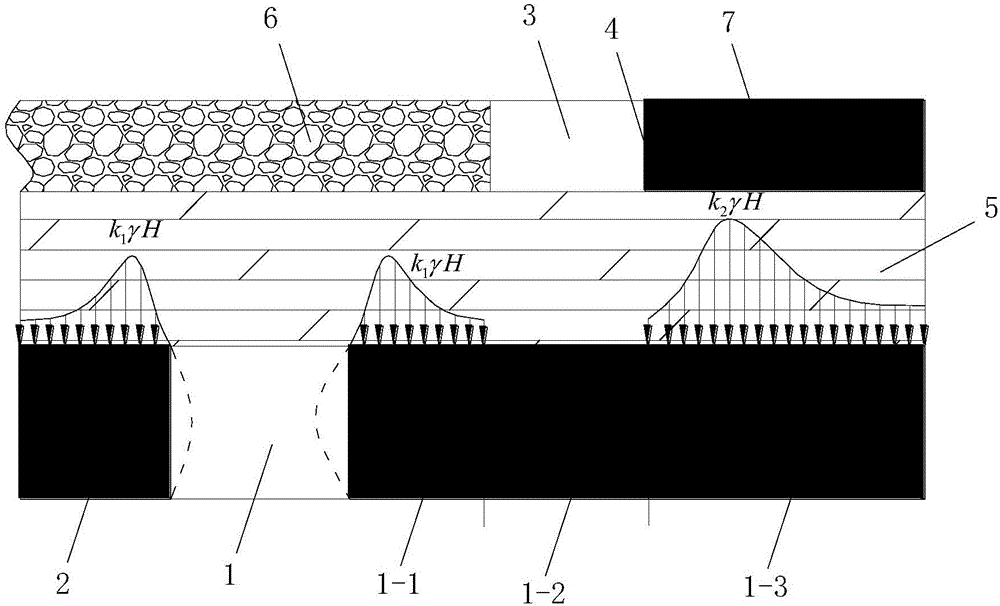

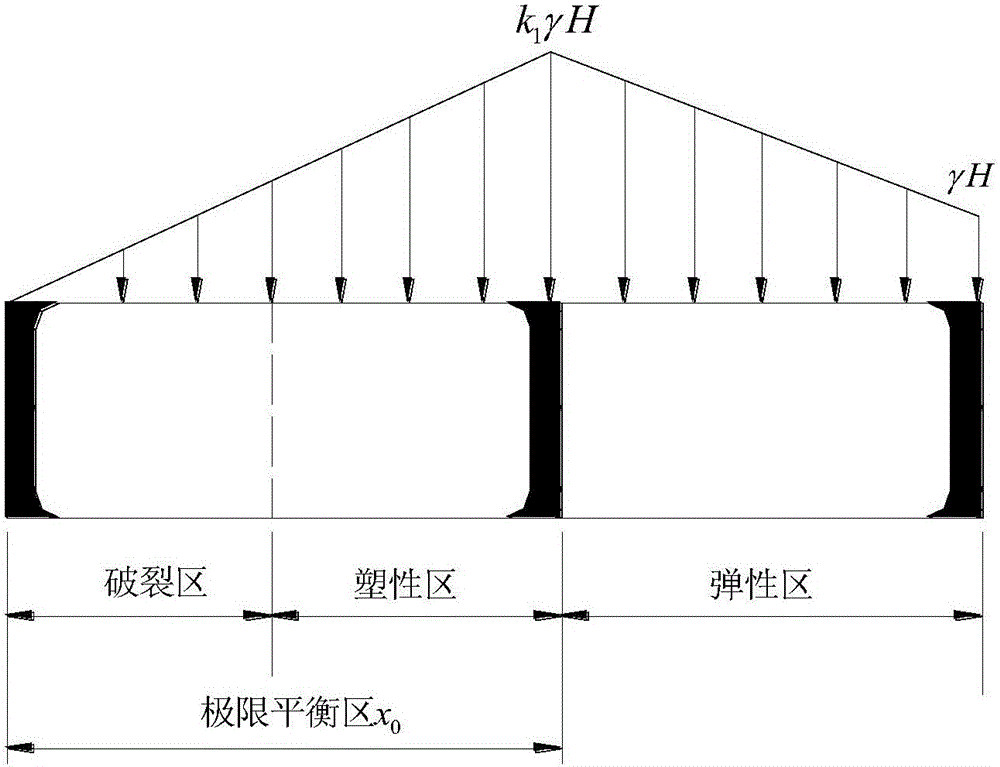

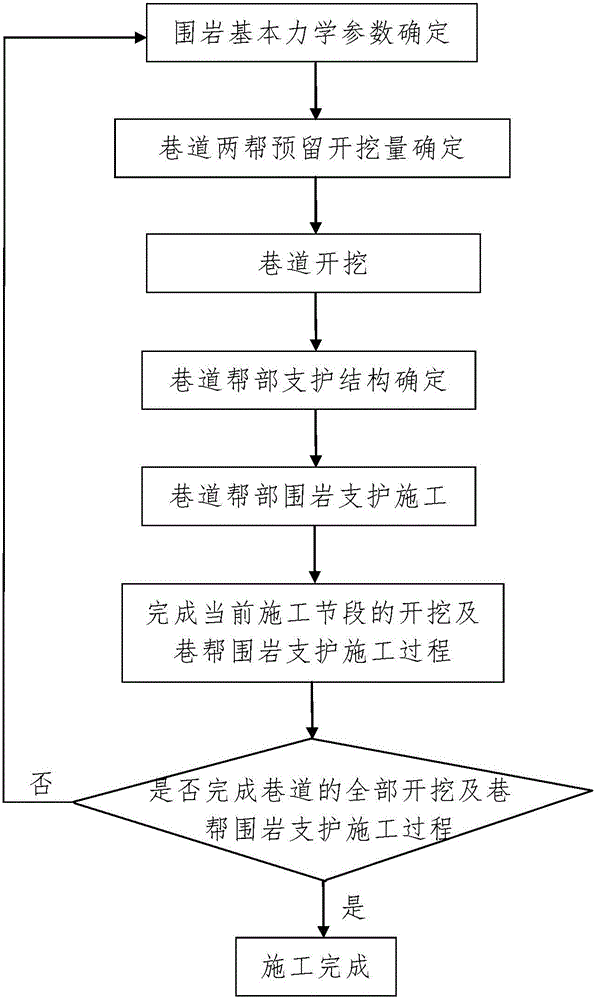

[0053] Such as image 3 A roadside support method for a short-distance coal seam roadway is shown, and the short-distance coal seam roadway 1 is excavated and roadside surrounding rock support construction is carried out in multiple segments along the longitudinal extension direction of the roadway from the back to the front; The cross-section of the short-distance coal seam roadway 1 is rectangular and it is a roadway mined in the lower coal seam 2, and the short-distance coal seam roadway 1 is located under the side of the upper coal seam roadway 3, and the upper coal seam roadway 3 is in the upper coal seam 4 In the roadway mined inside, the upper coal seam 4 is located above the lower coal seam 2, and the upper coal seam 4 and the lower coal seam 2 are separated by an interlayer 5; the short-distance coal seam roadway 1 and the upper coal seam roadway 3 are arranged in parallel; One side of the upper coal seam roadway 3 is a goaf 6 and the other side is a reserved protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com