Patents

Literature

125results about How to "The construction process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

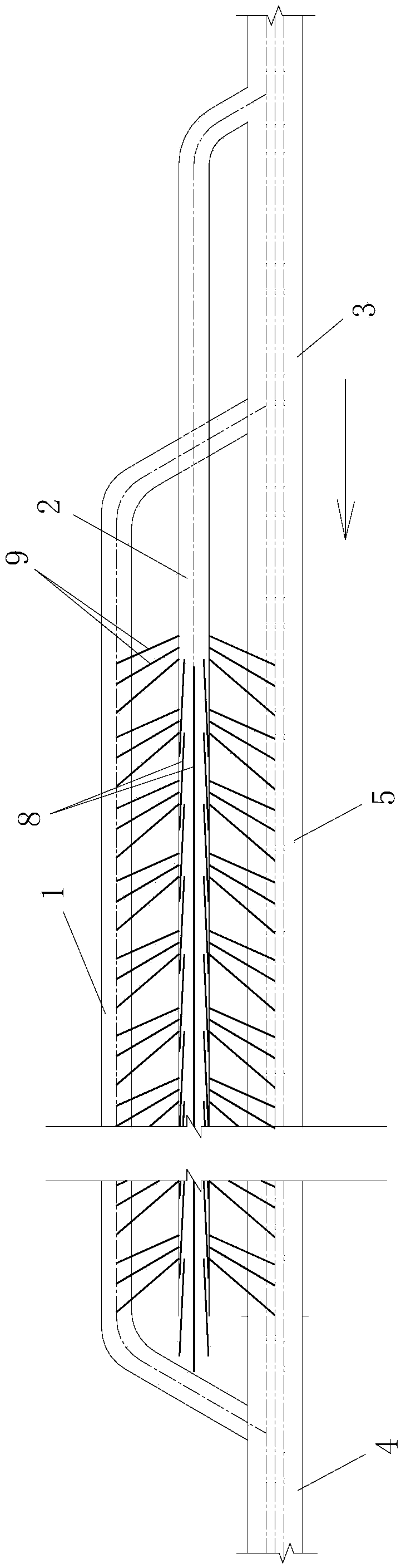

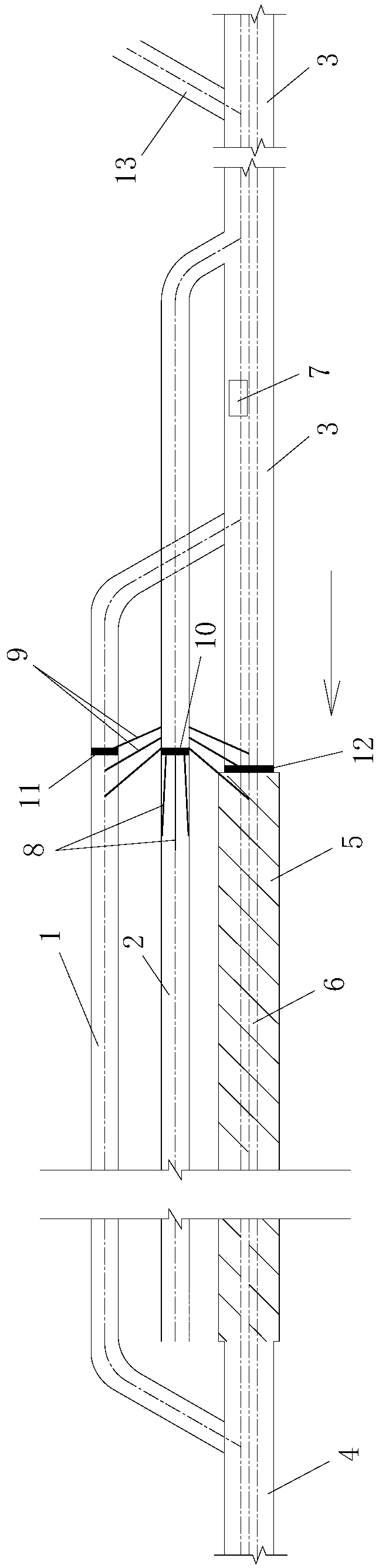

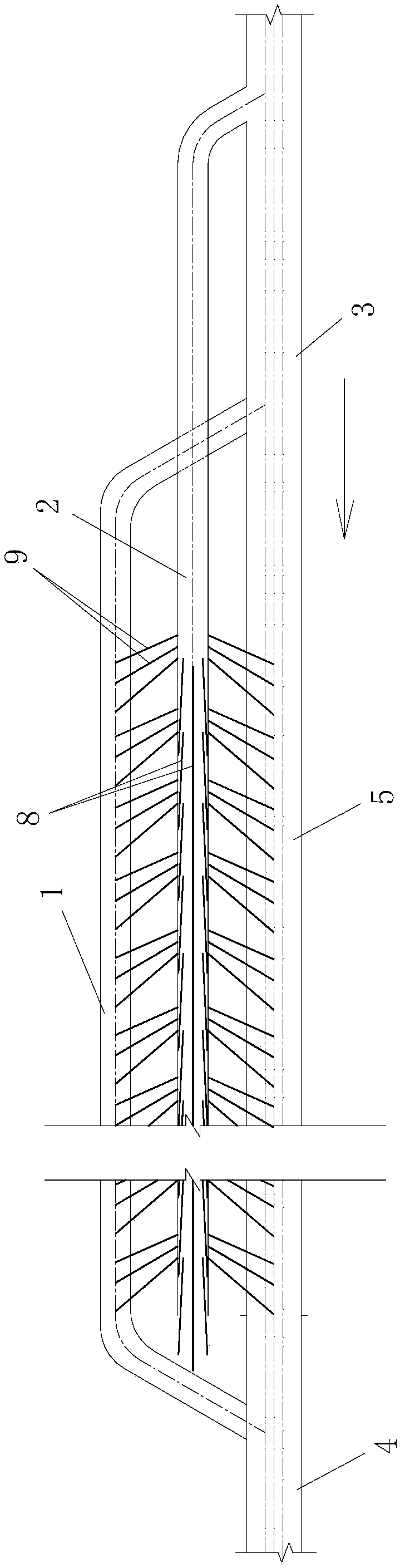

Bidirectional helix extruding-enlarging pile construction method and bidirectional helix closed extruding-enlarging aiguille

ActiveCN101012649AIncrease resistanceImprove bearing capacityDrill bitsBulkheads/pilesConcrete pumpEnergy consumption

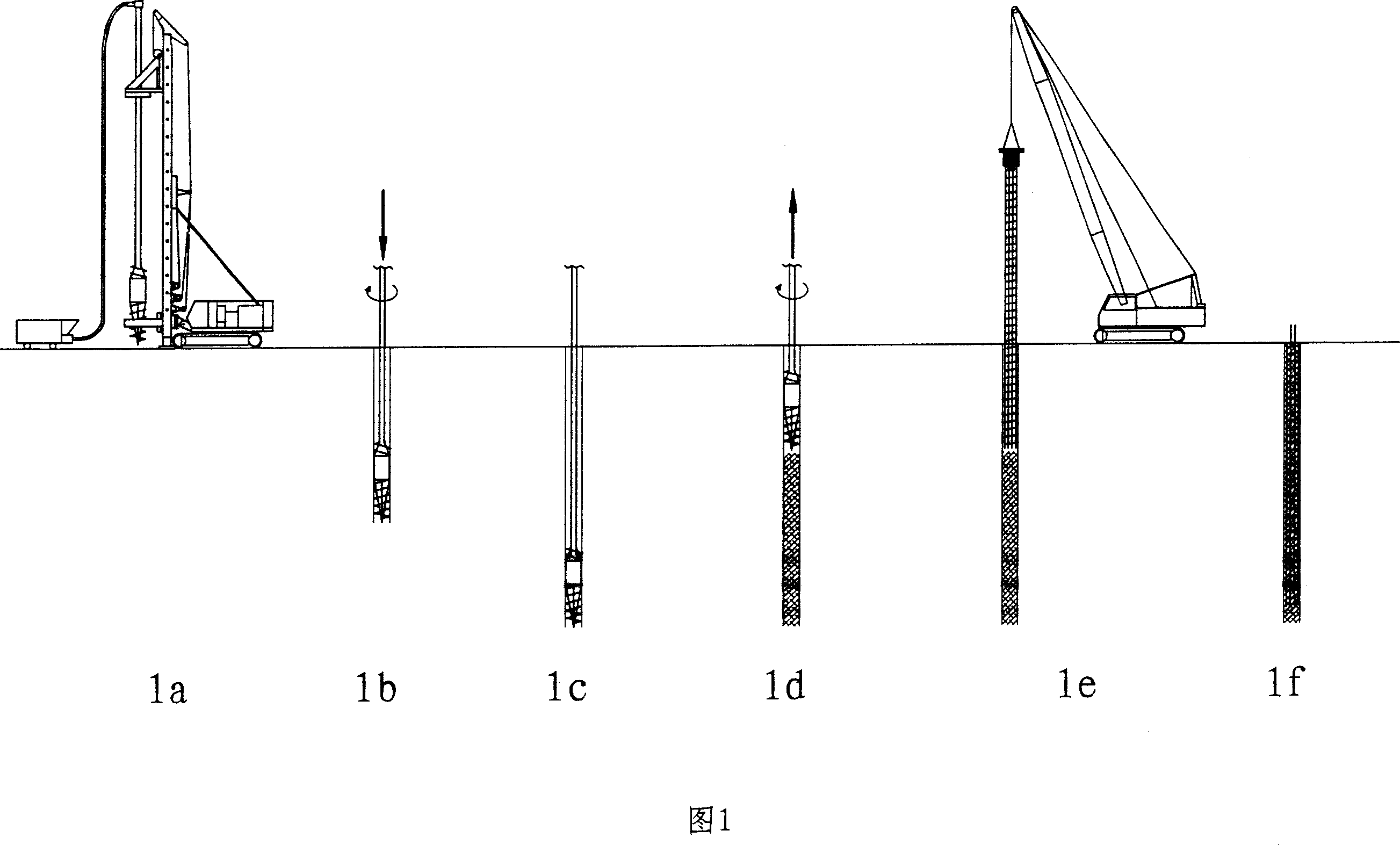

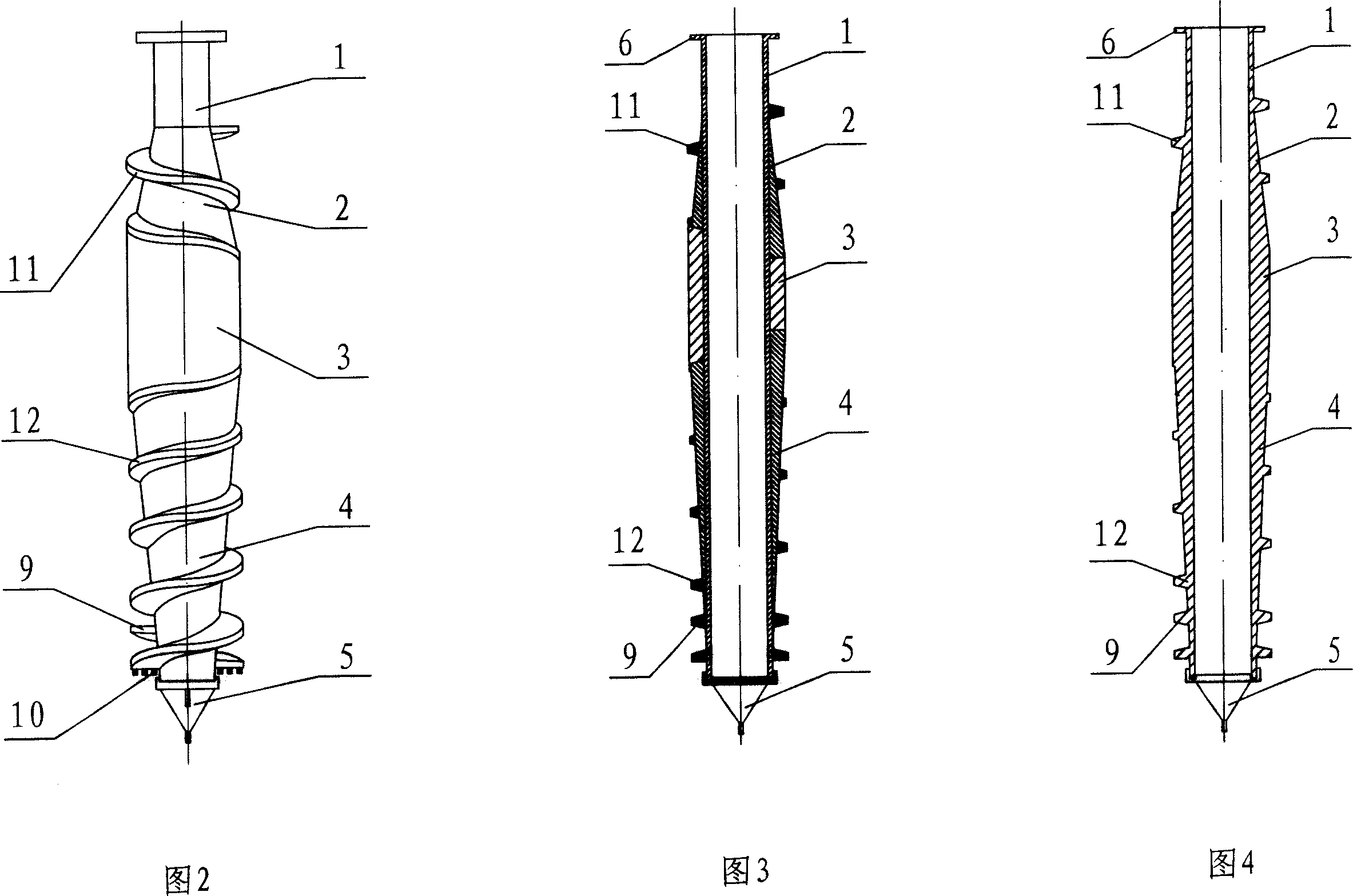

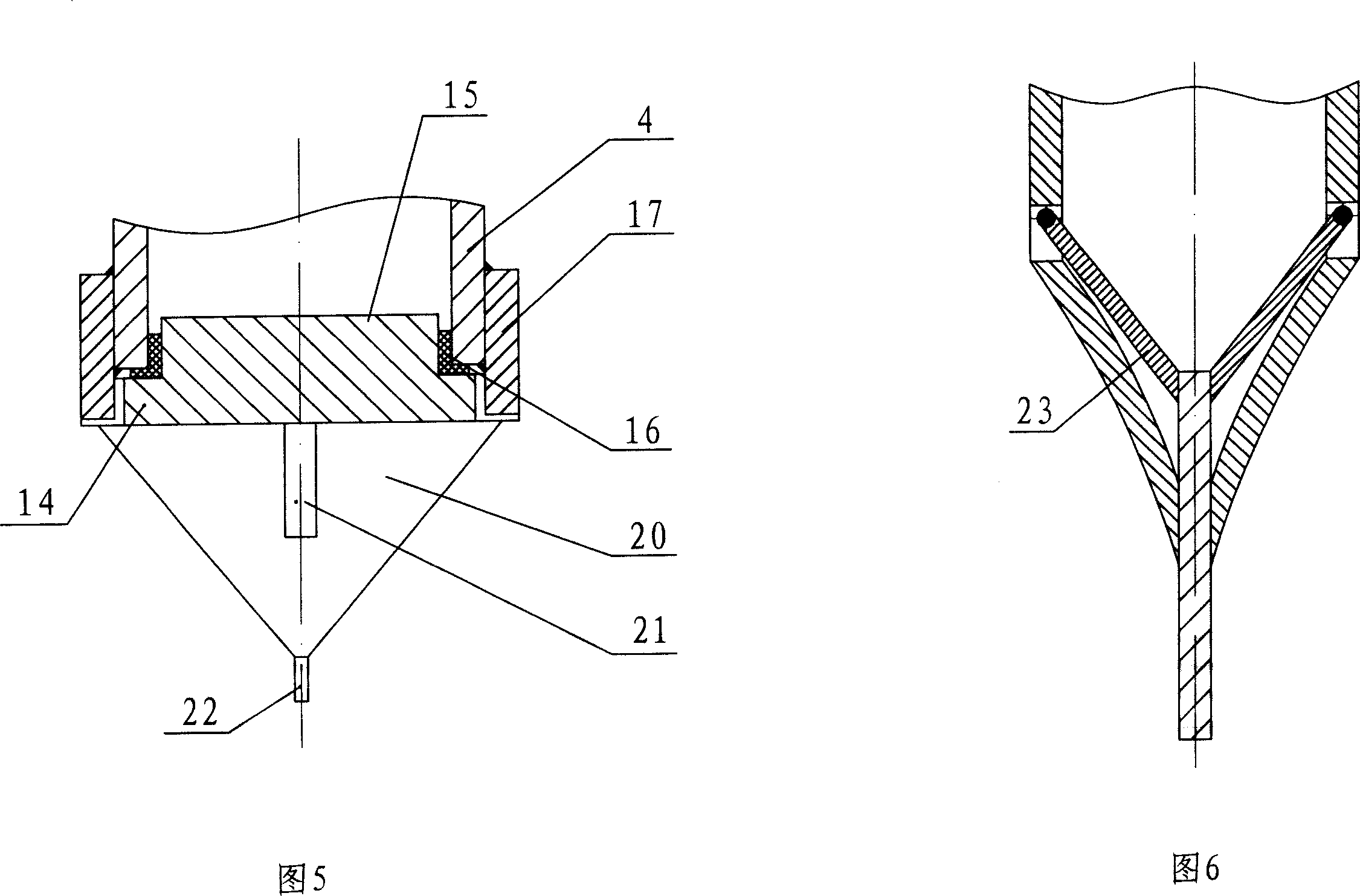

The invention relates to a construction method for bidirectional spiral expand pile and the bidirectional spiral closed expand bit. The construction method comprises drilling and expanding bore by the bidirectional spiral closed expand bit; pushing soil, which is obtained in drilling and expanding bore downwards, into the side wall of pile bore; the bidirectional spiral closed expand bit rotating upwards to drill and expand the bore again; pushing soil, which is obtained in drilling, expanding and lifting upwards, into the side wall of pile bore; starting the concrete pump to press the pile material into the pile bore while the bit is lifted. The bidirectional spiral closed expand bit comprises a connecting bar. At the lower of the connecting bar spiral expand body, closed expand body and dynamic sealing expand body are assembled on the connecting bar in the same axial line in turn from the bottom to the top or they are machined on the connecting bar together. The invention is provided with high loading capacity, small sedimentation quantity, better quality, low cost and smaller energy consumption so on.

Owner:CHINA JINGYE ENG

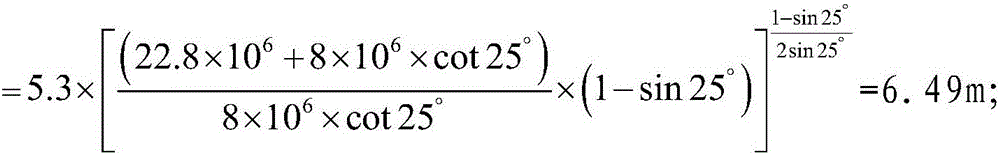

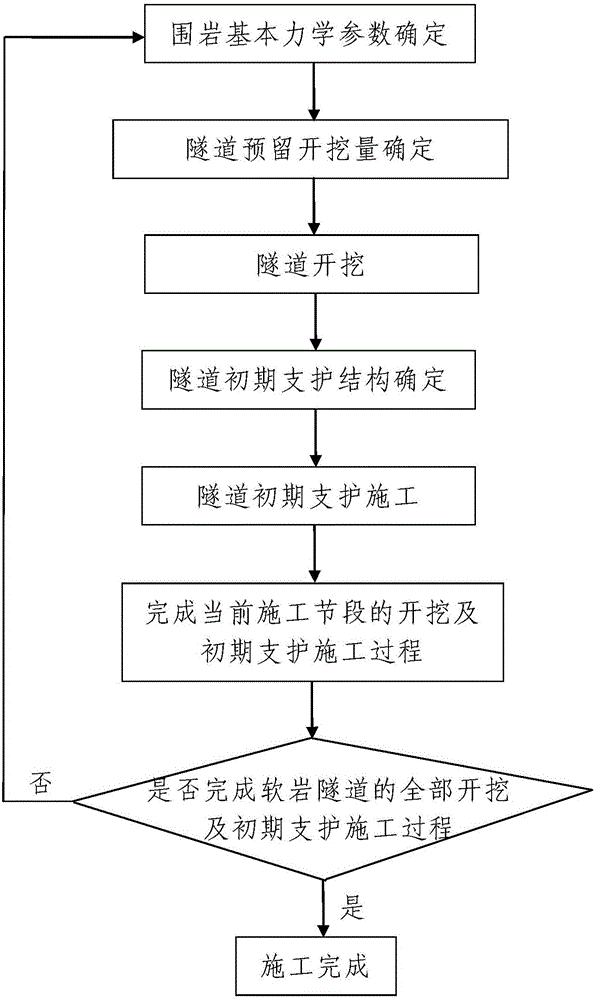

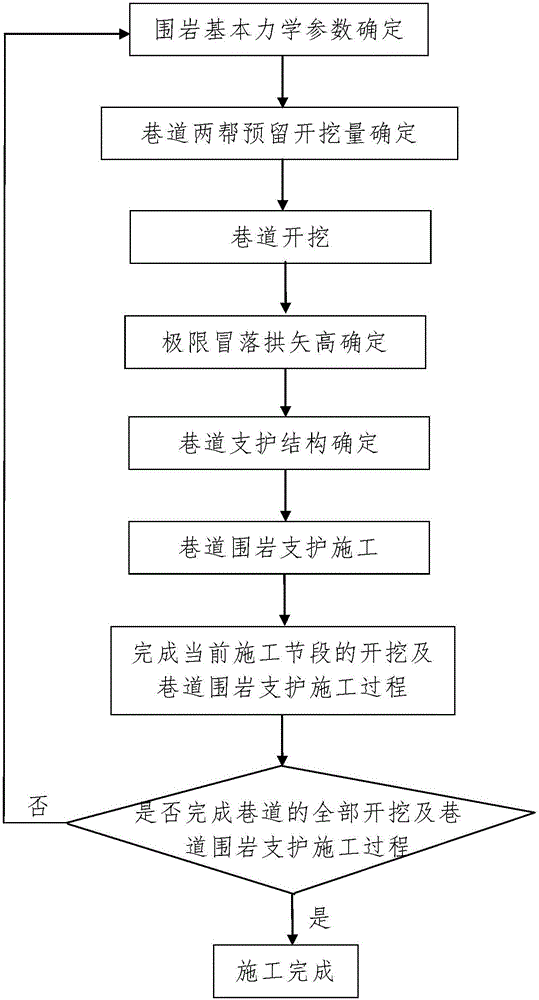

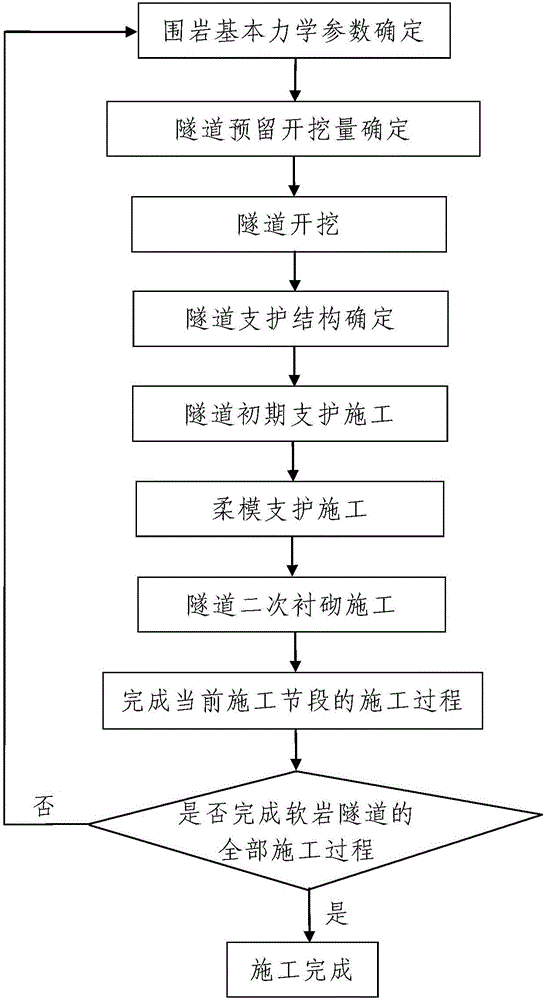

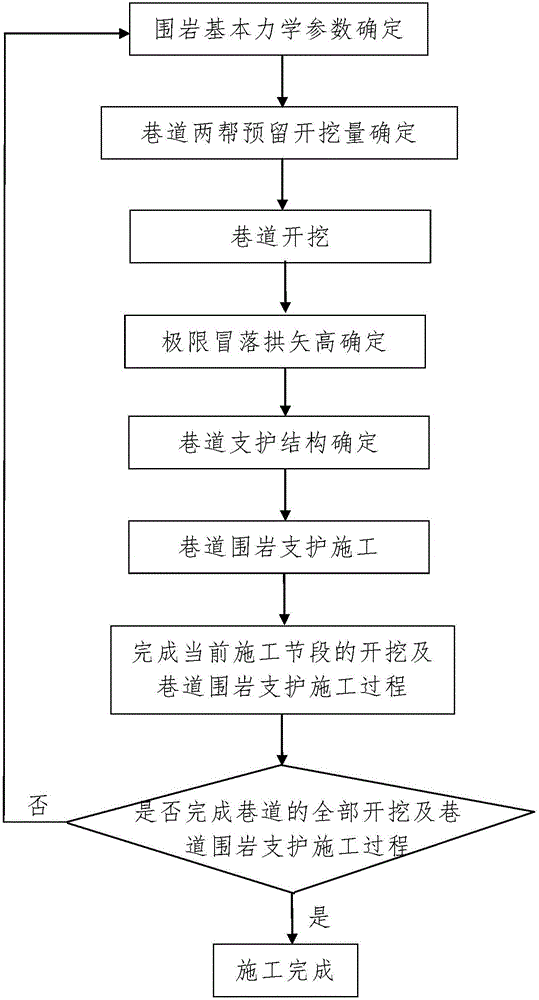

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

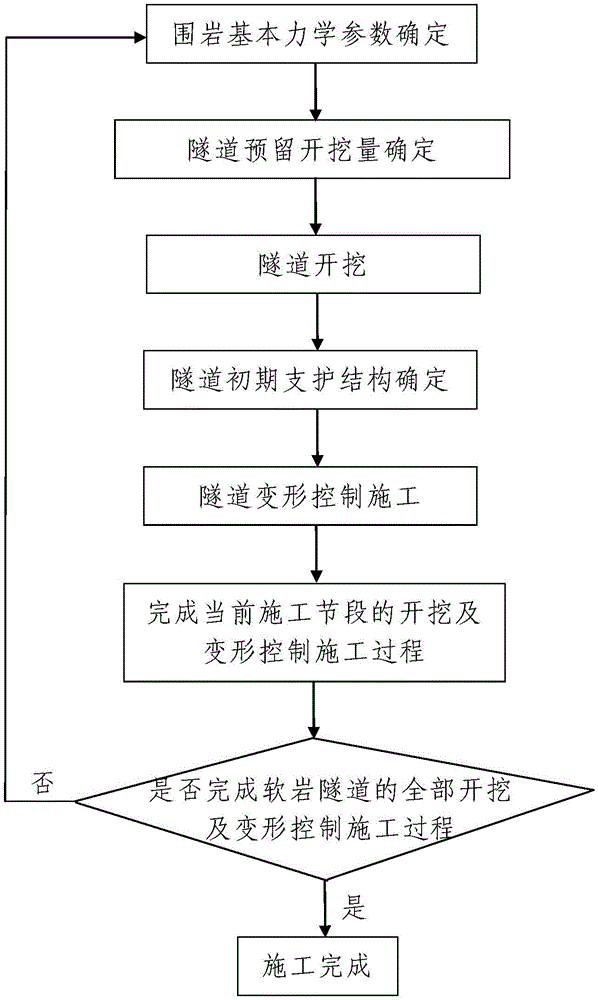

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

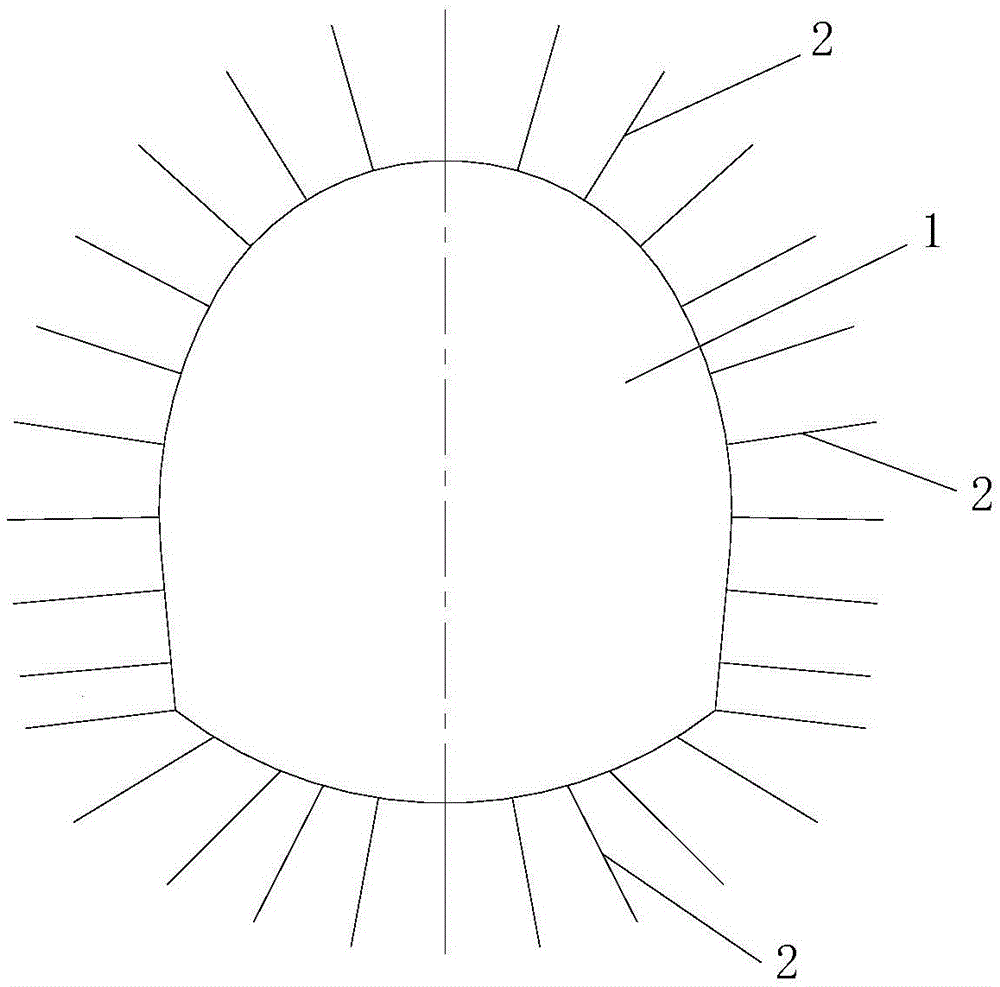

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

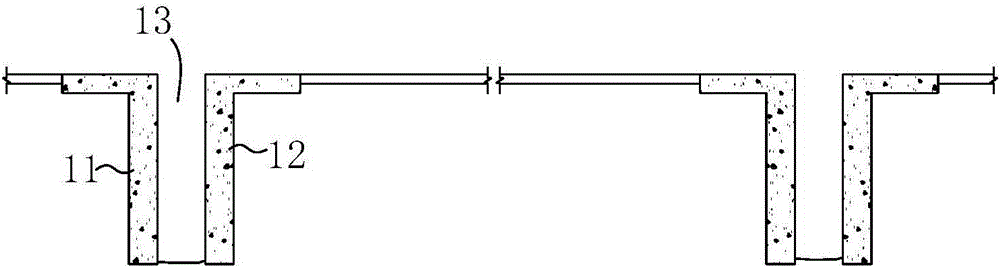

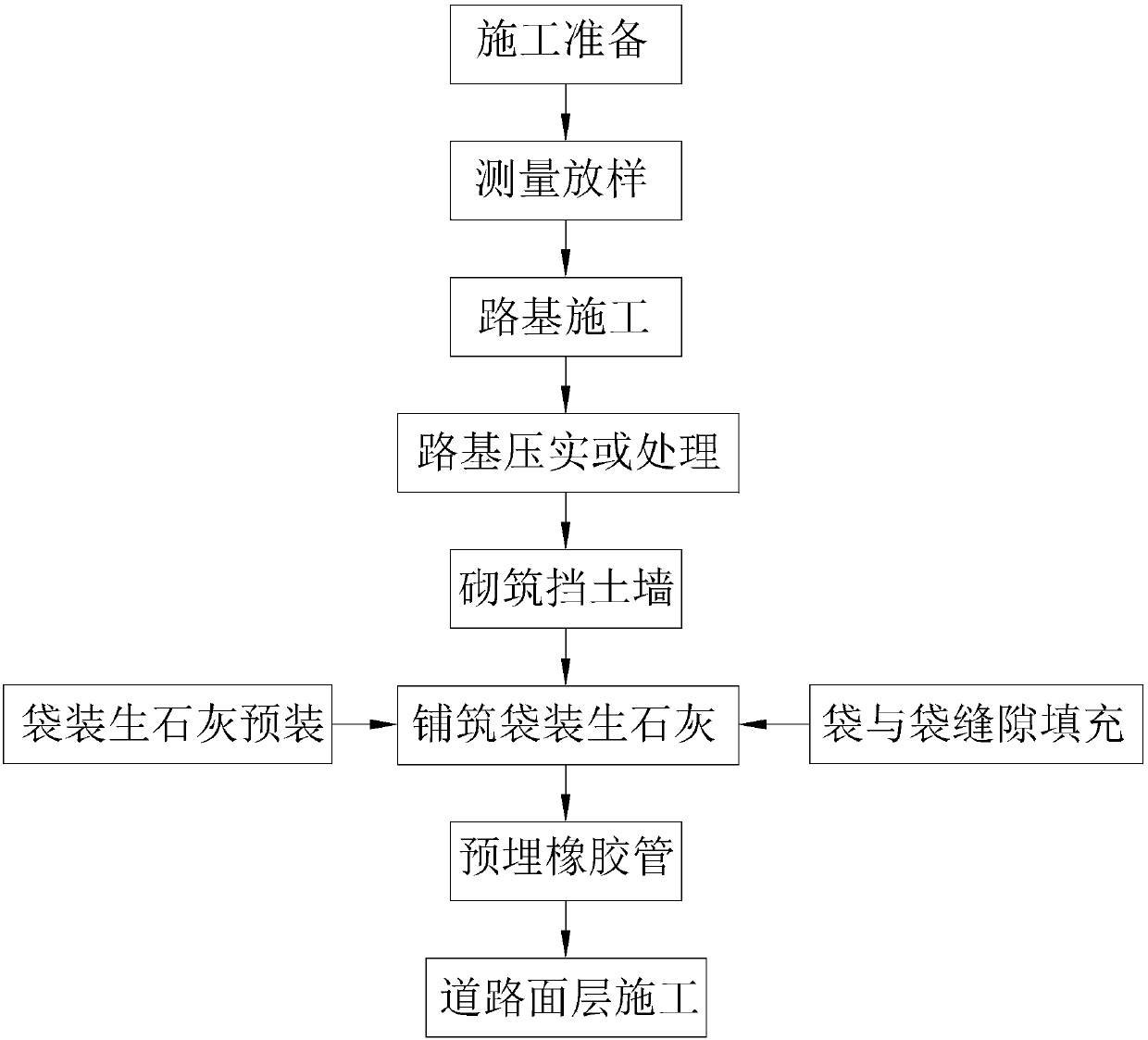

Compensation method for roadbed settlement

InactiveCN102322008AShort construction timeLittle traffic disturbanceRoadwaysArchitectural engineeringRoad surface

The invention provides a compensation method for roadbed settlement, which comprises the steps that: when in a roadbed construction process, on a road section which can easily settle and deform after being open to traffic, when a roadbed is filled to a height which is 30cm to 200cm from the top surface, retaining walls are built on both sides of the roadbed; bagged lime is uniformly paved on the inner sides of the retaining walls within the full-width range of the roadbed on different layers; a rubber pipe is pre-reserved on each lime bag to the outer side of the roadbed as a water injection channel in a later period; the bottom surfaces of the retaining walls are 20cm to 100cm lower than the bottom surfaces which are paved from the bagged lime, and the top surfaces of the retaining wallsare in alignment with the top surface of the roadbed; and when the roadbed settles, the water is injected into the lime bags through the pre-reserved rubber pipe, the lime absorbs the water, swells and jacks a road surface structure up. The compensation method for roadbed settlement completes the water injection on the outer side of the roadbed, has a short construction time, does not interrupt the traffic during the construction process and has little interference to the traffic; and the construction is not restricted by the weather and the environment, the settlement can be handled at any time when being found, and the construction process is controllable.

Owner:广东大象交通科技有限公司

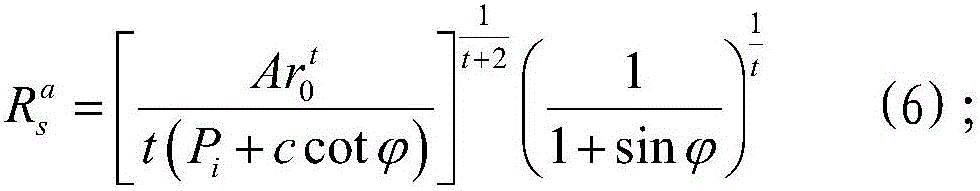

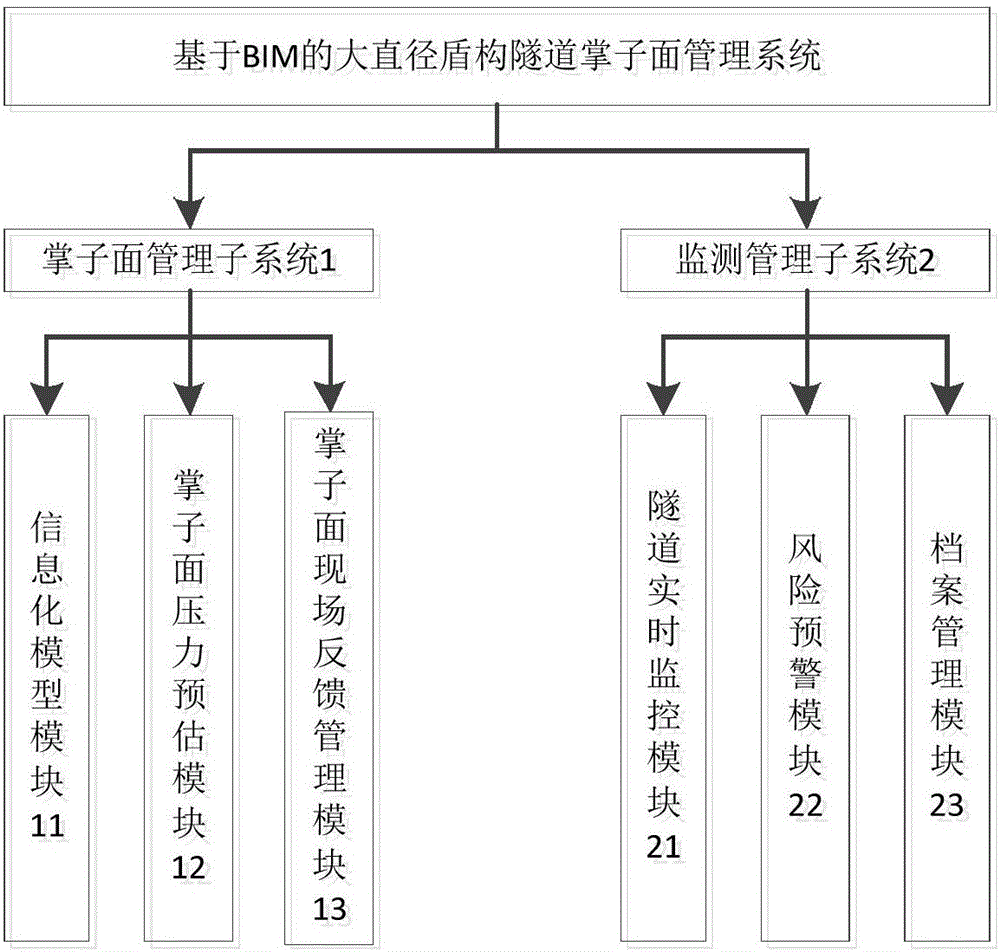

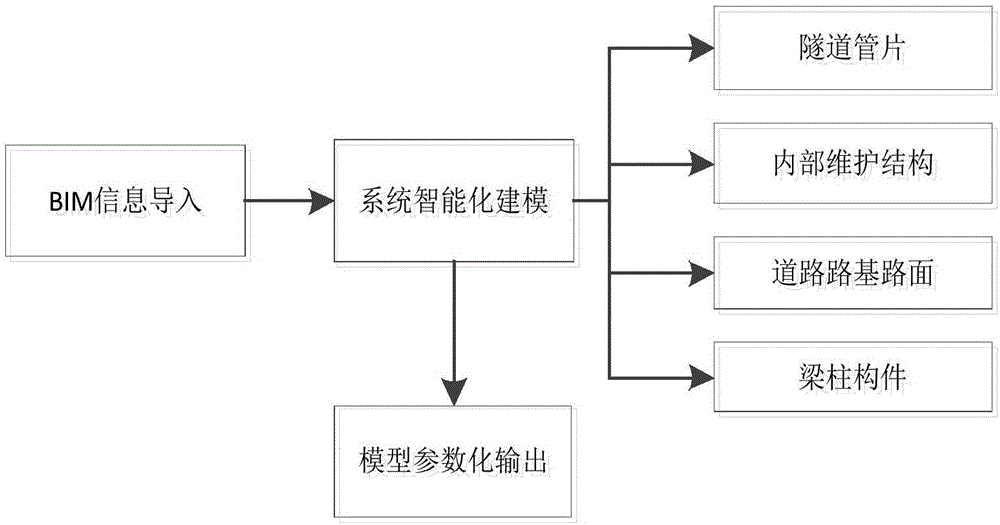

BIM (building information modeling)-based management system for tunnel face of large diameter shield tunnel

ActiveCN106761798APreset Pressure AdjustmentThe construction process is visibleTunnelsPaper documentManagement system

The invention relates to a BIM (building information modeling)-based management system for a tunnel face of a large diameter shield tunnel. The system comprises a tunnel face management subsystem which, according to project profile information, takes advantage of BIM technology to carry out informationalized modeling on the large diameter shield tunnel and conducts pre-estimation, setting and amendment on tunnel face pressure; a monitoring management subsystem, which carries out real-time monitoring and pre-warning on the construction of the large diameter shield tunnel, stores construction data, assesses engineering construction and management situation, and performs document management. Compared with the prior art, the management system combines classical tunnel face pressure pre-estimation theory with BIM technology, the pre-estimation and presetting of tunnel face pressure are completed before tunneling, and simultaneously, the preset pressure can be adjusted according to real-time monitoring results; and the stratum information, the tunnel face pressure information and surrounding environment deformation information are all integrated in a BIM model, and the visible and controllable whole construction process is realized.

Owner:TONGJI UNIV

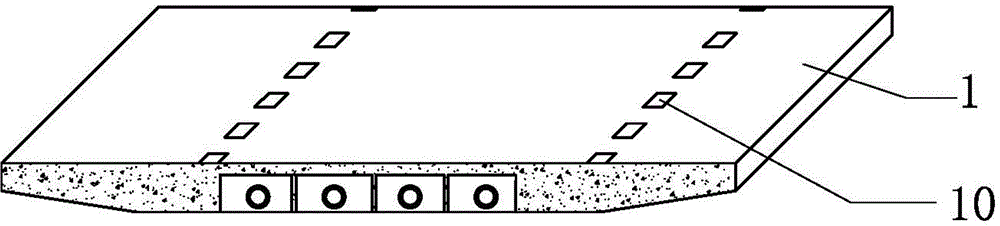

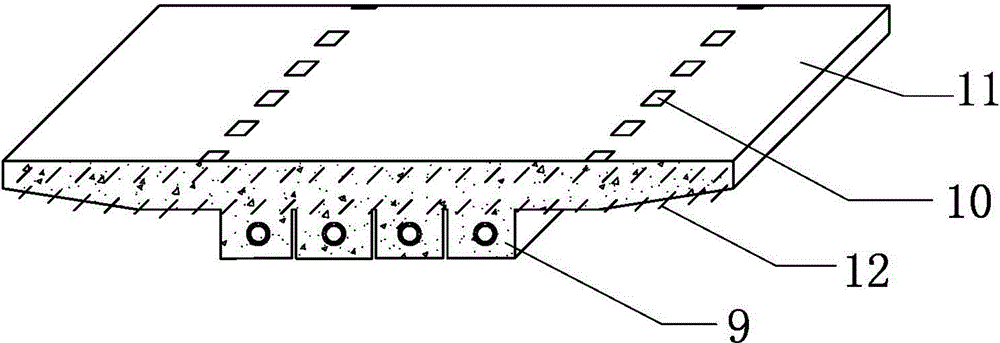

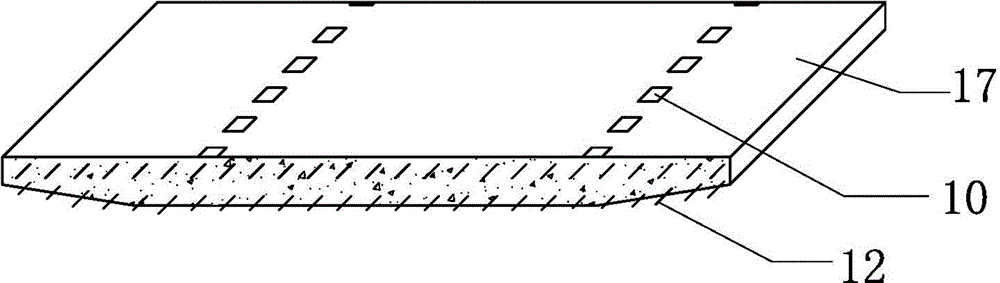

Steel-concrete combined continuous beam bridge deck as well as manufacturing method and application thereof

InactiveCN105926440AAvoid early crackingIncreased durabilityBridge structural detailsBridge erection/assemblyCrack resistancePre stress

The invention discloses an assembly type steel-concrete combined continuous beam bridge deck formed by exerting prestress to a concrete bridge deck in a hogging moment region. The deck comprises a hogging moment region concrete segmental plate, a hogging moment region concrete end plate and a sagging moment region segmental plate. The manufacturing method comprises the following steps of erecting of shuttering, pouring and curing; the deck is applied to the construction of a steel-concrete combined continuous beam bridge. Prestress is exerted to the inner part of the concrete bridge deck of the hogging moment region, but a tendon beam is not used, so that material consumption is reduced, the crack resistance and the bending resistance bearing capacity in the hogging moment region are effectively improved, and the condition that prestress beams rust is avoided; during construction of the steel-concrete combined continuous beam bridge, an assembled type prefabricated prestressed concrete deck is adopted, so that the factory degree is high, the quality of structural members is guaranteed, and the durability of a concrete bridge deck is improved. The assembly type steel-concrete combined continuous beam bridge deck disclosed by the invention is simple in method, convenient to construct, and high in quality, the construction period is greatly shortened, and the comprehensive economic benefits are improved.

Owner:HUNAN CITY UNIV

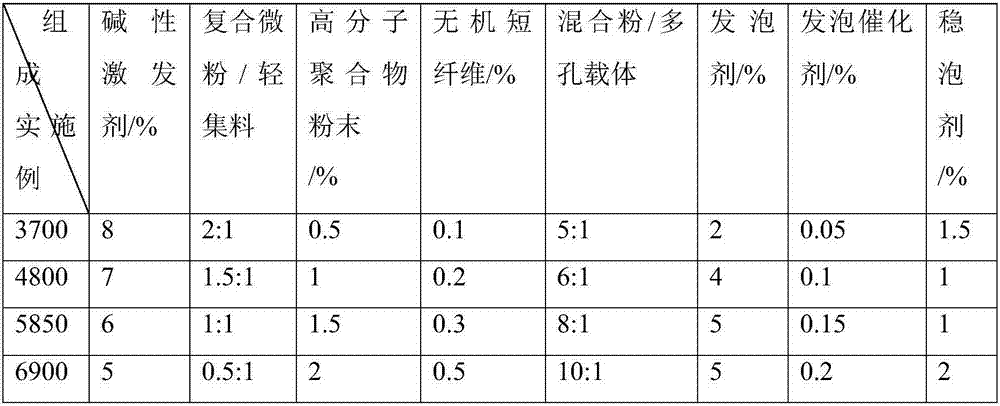

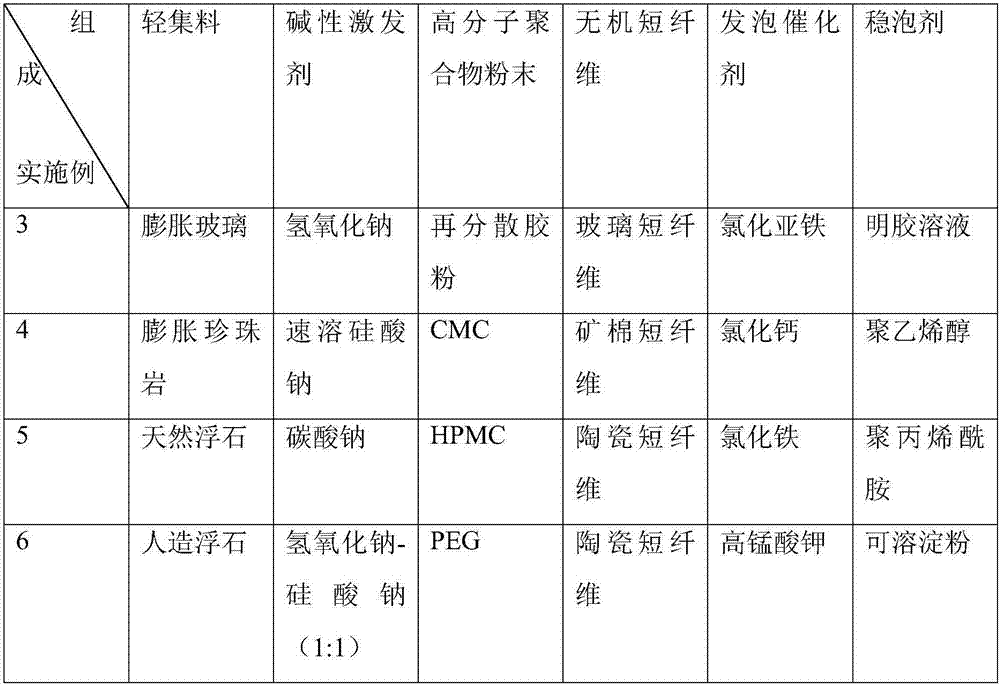

Geopolymer foamed light aggregate concrete and preparation method thereof

The invention discloses geopolymer foamed light aggregate concrete. The material is composed of slag-fly ash composite micro powder, an alkali activator, inorganic super-light aggregate, high-molecular polymer powder, inorganic staple fibers, a hydrogen peroxide chemical foaming agent, a foaming catalyst, an inorganic porous carrier and a foam stabilizer. The method for preparing the geopolymer foamed light aggregate concrete comprises the following steps: mixing and manufacturing various components according to a certain ratio. The problems that the strength of the conventional cement-based foam concrete material is greatly decreased when used for high-temperature insulation and foams and bubbles difficultly grow due to too fast setting of slag-based geopolymer foamed cement and the like can be effectively solved. Therefore, the durability of the foamed light aggregate geopolymer concrete layer is obviously improved, and the light aggregate concrete can be used for promoting energy-saving insulation of low-temperature and normal-pressure building envelopes, decreasing the dead weight of walls and reducing CO2 emission, contributes to improving ecological and economic benefits and is extremely convenient in construction. The construction cost and material cost can be greatly reduced.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

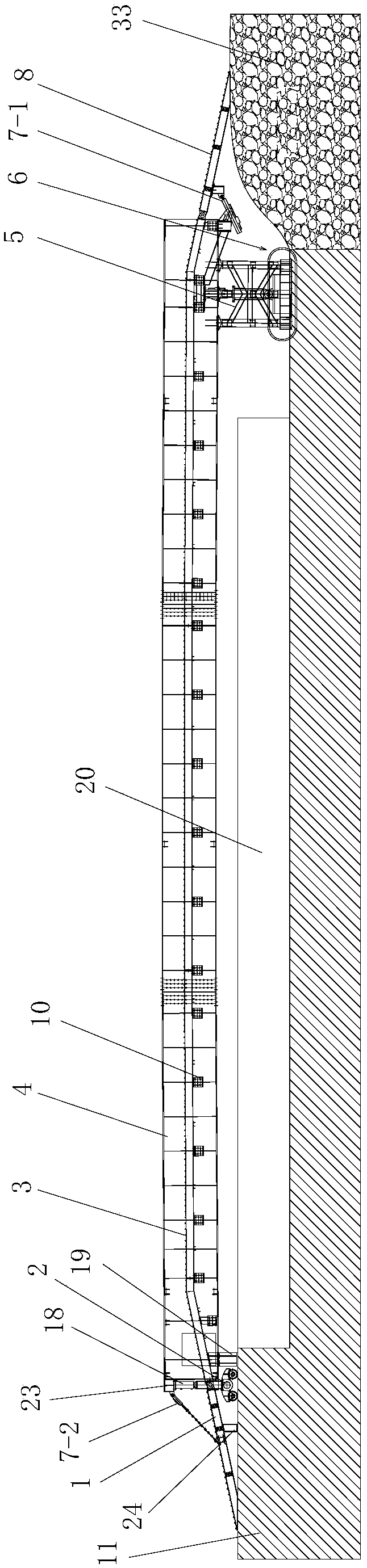

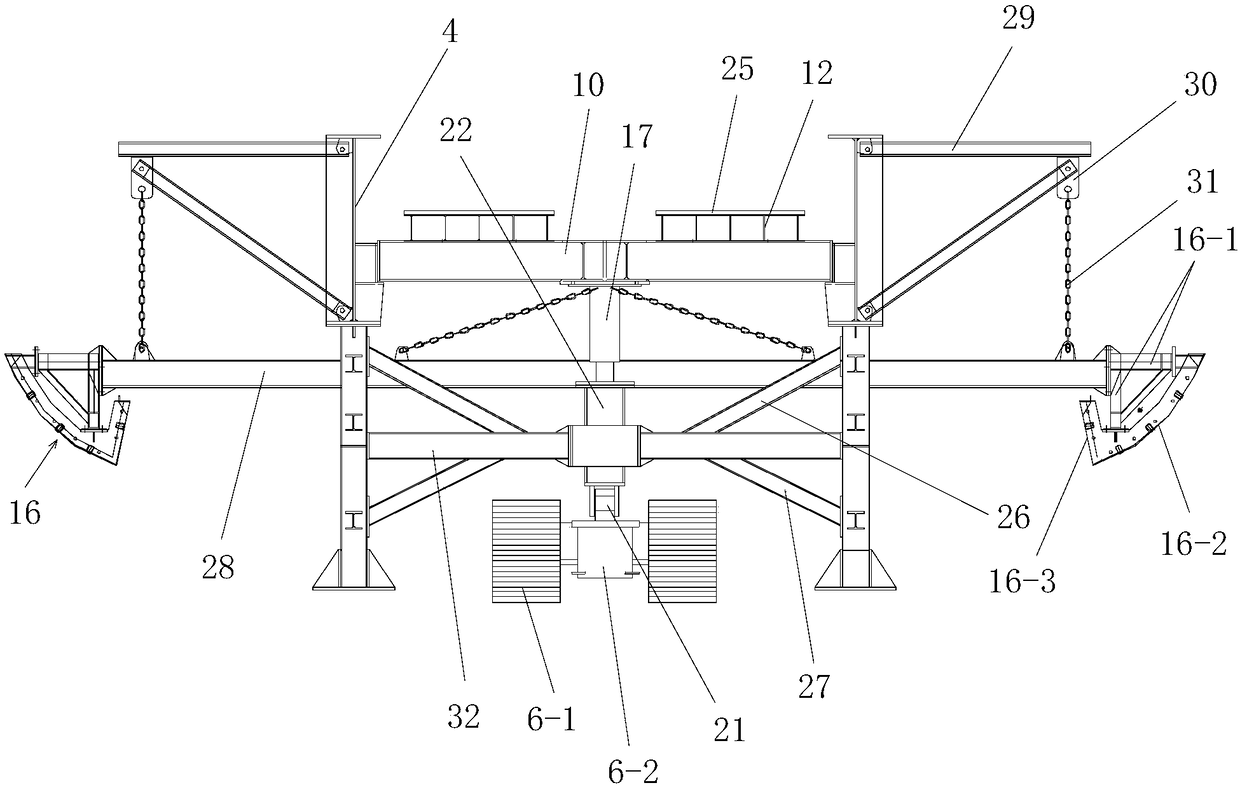

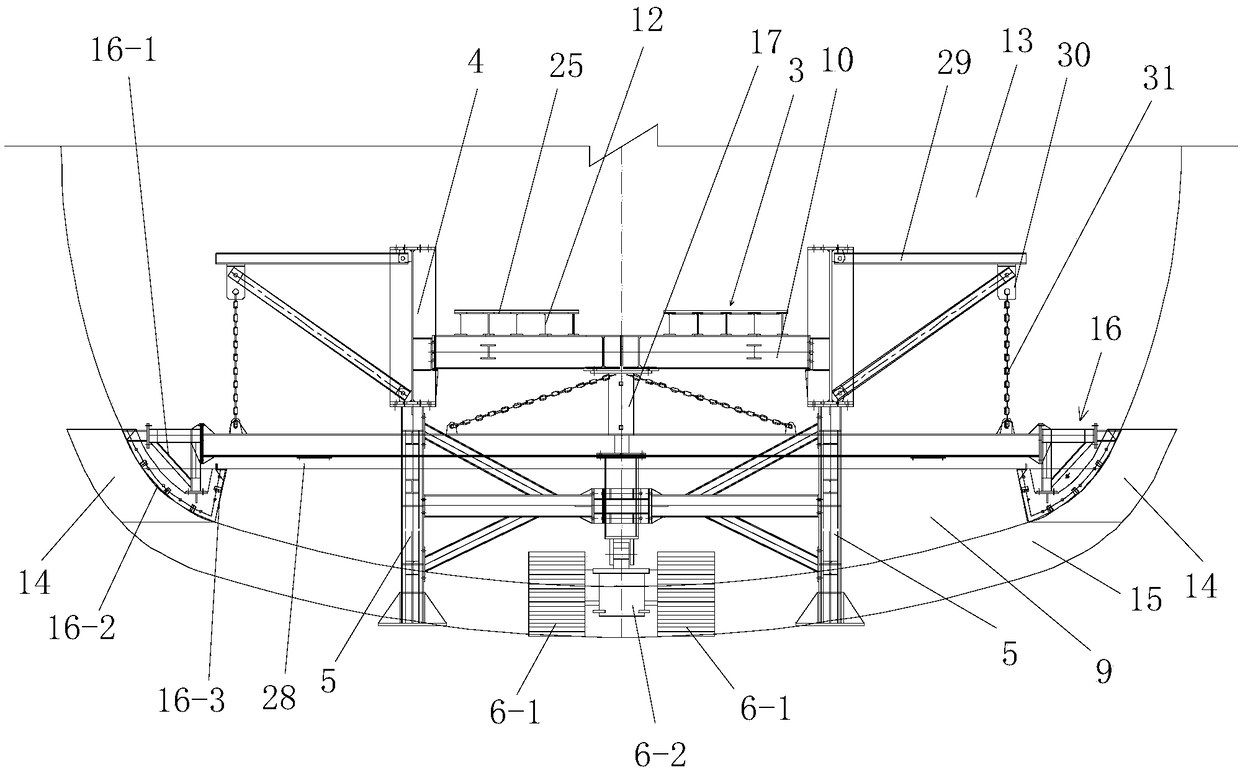

Full-hydraulic crawler-type self-propelled trestle and construction method thereof

ActiveCN109505630ASimple structureReasonable designUnderground chambersTravelling bridgesTunnel constructionBuilding construction

The invention discloses a full-hydraulic crawler-type self-propelled trestle and a construction method thereof. The trestle comprises a main bridge, a front approach bridge and a rear approach bridge,and further comprises two short-side walls symmetrically arranged at the left and right and an inverted arch backfill construction template, wherein the main bridge comprises two main beams symmetrically arranged at the left and right, a plurality of distributive girders and a bridge floor structure, and the short-side walls and the inverted arch backfill construction template comprise forming templates and template supporting frames; when a tunnel is constructed, the full-hydraulic crawler-type self-propelled trestle is used for constructing the tunnel bottom lining and inverted arch backfill layer of the constructed tunnel from back to front separately by multiple tunnel sections. The full-hydraulic crawler-type self-propelled trestle and the construction method thereof have the advantages that the design is reasonable, the construction is simple and convenient, the use effect is good, self-propelled stable walking can be performed in the tunnel by adopting a crawler-type walking mechanism, the synchronous construction of the tunnel inverted arch, short-side walls and inverted arch backfill can be achieved, tunnel digging and deslagging construction can be simultaneously performed, the tunnel construction efficiency can be greatly improved, the construction quality of the tunnel inverted arch, short-side walls and inverted arch backfill can be ensured, and the construction process is safe and reliable.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

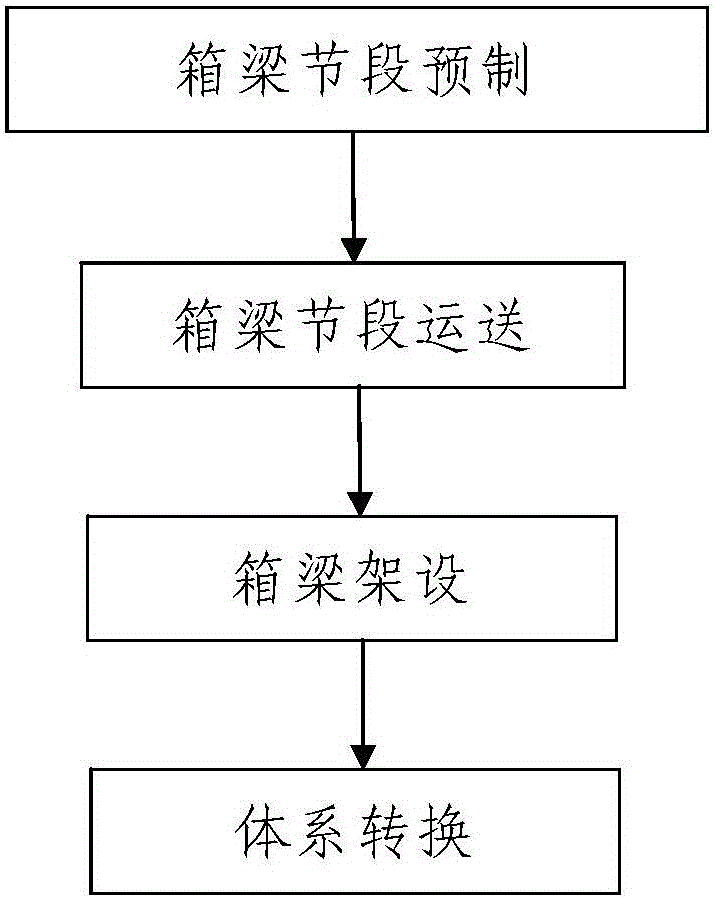

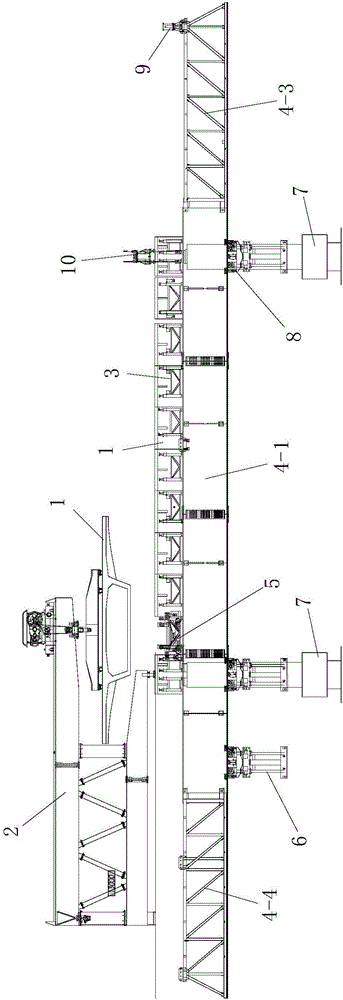

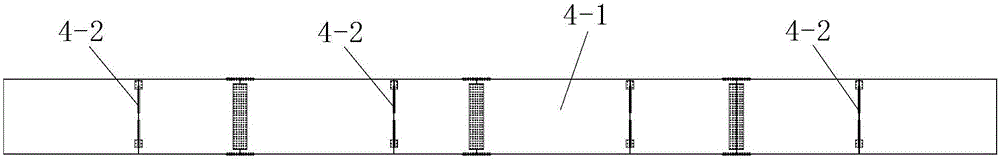

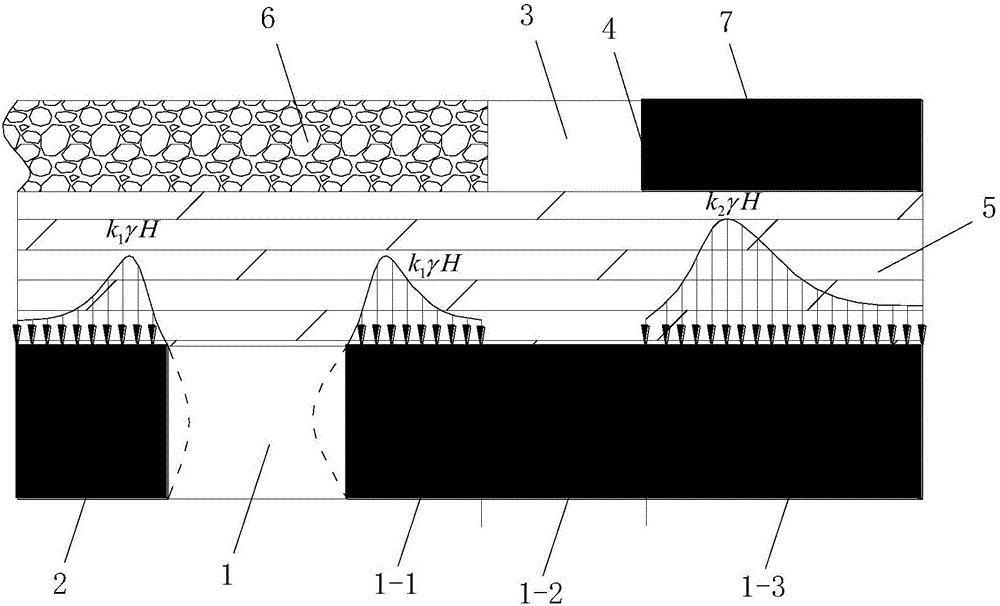

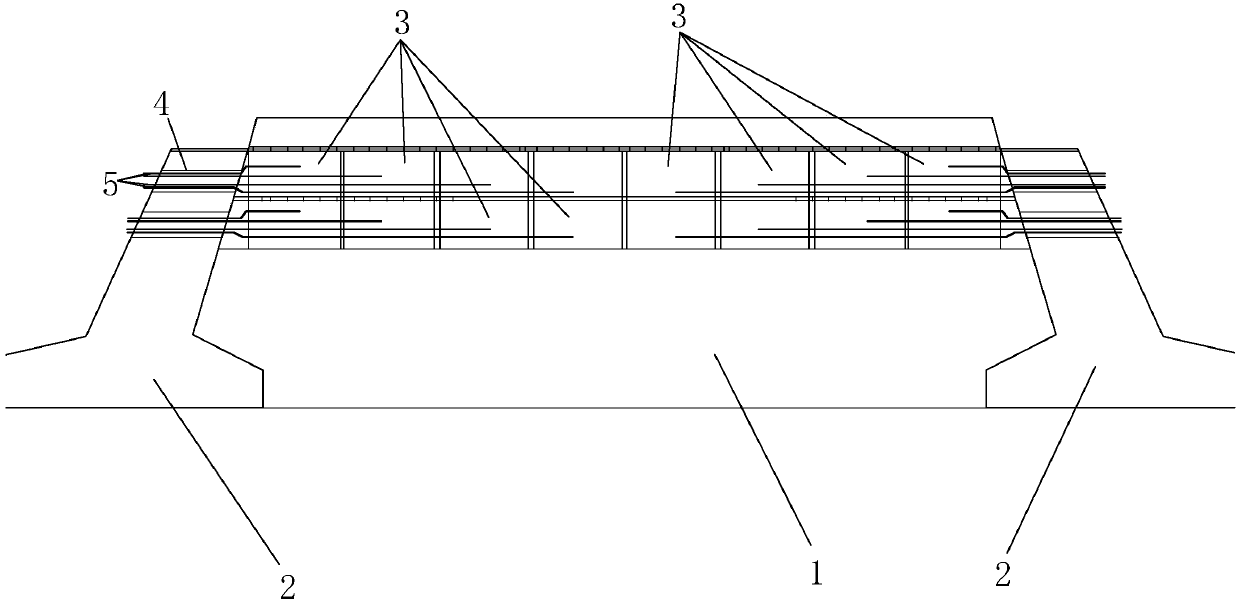

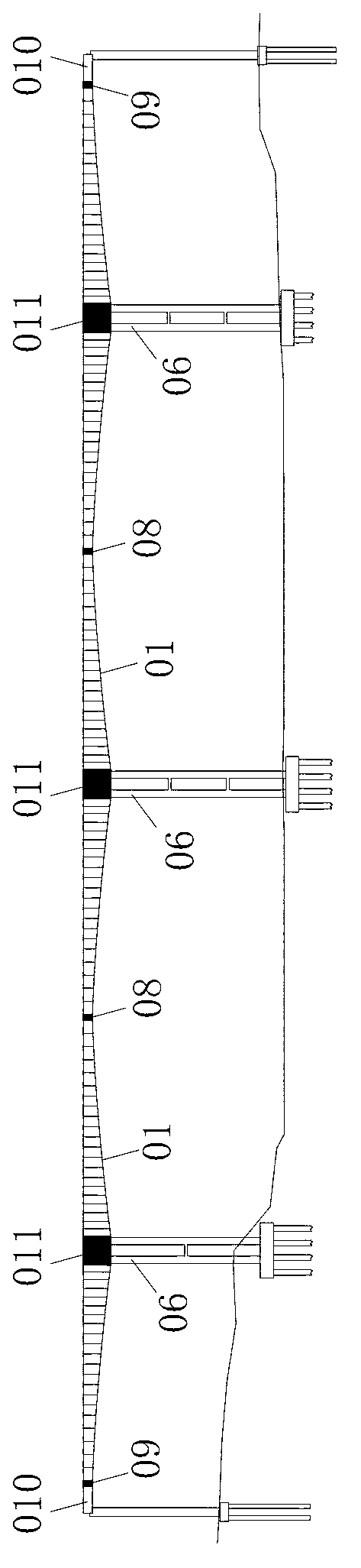

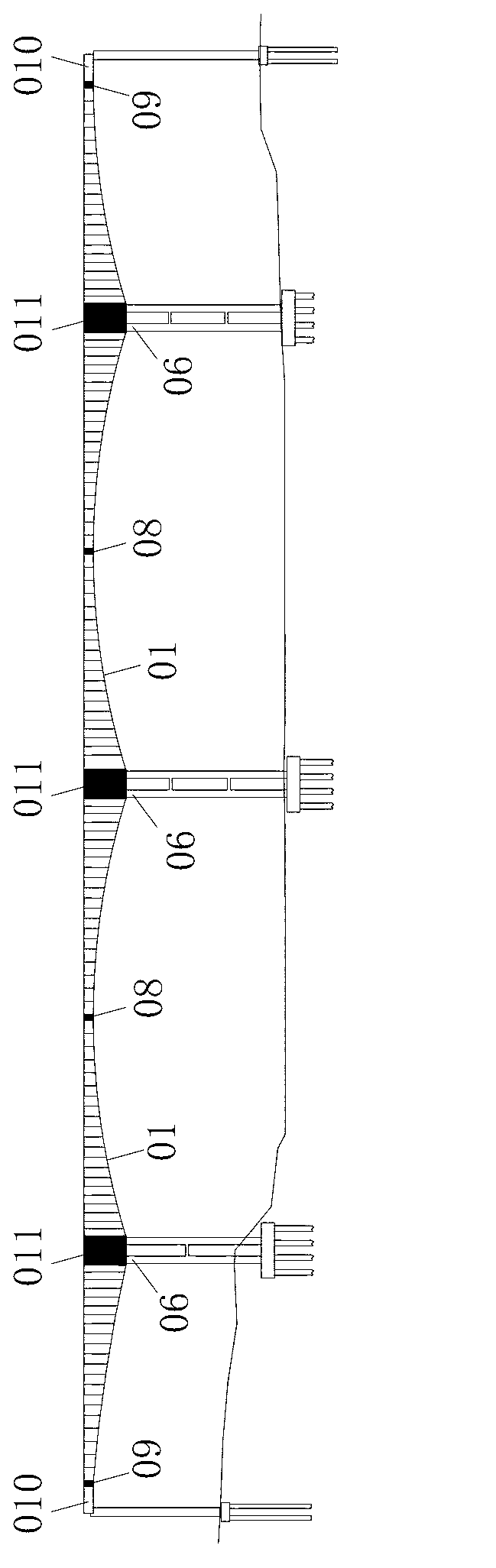

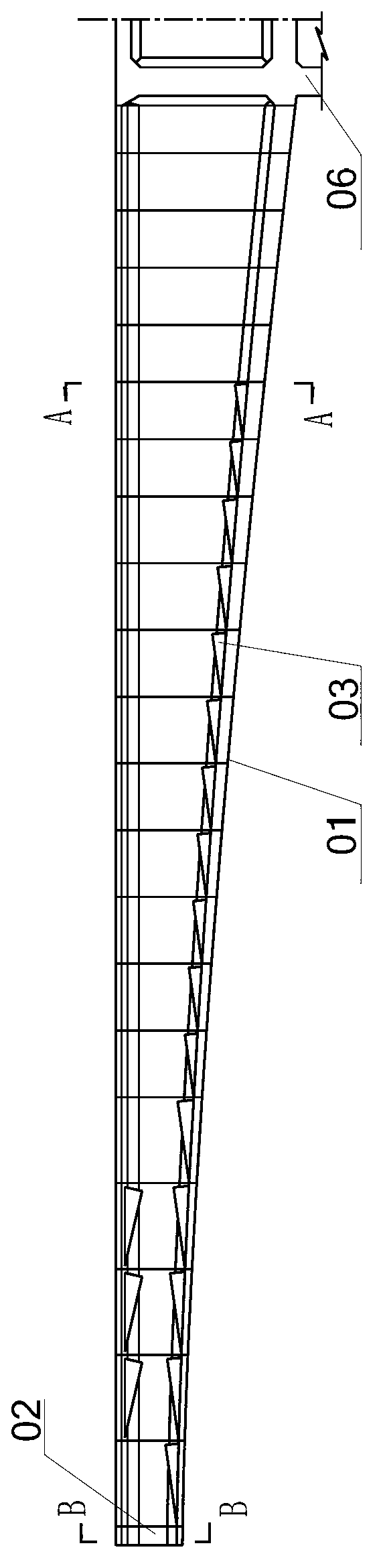

Segmental assembling box girder construction technology

ActiveCN105780660AThe construction process steps are simpleReasonable designBridge erection/assemblySupporting systemCantilever

The invention discloses a segmental assembling box girder construction technology. A constructed box girder is composed of multiple porous girders. Each porous girder is formed by assembling multiple box girder segments from back to front. When the constructed box girder is constructed, the process includes the following steps that firstly, the box girder segments are prefabricated, wherein all the box girder segments used for forming the constructed box girder are prefabricated in a prefabrication site in a concentrated manner; secondly, the box girder segments are transported, wherein all the box girder segments are transported to the erection position of the constructed box girder through a girder transport vehicle; thirdly, the box girder is erected, wherein the constructed box girder is erected and constructed through a descending bridge girder erection machine, and the descending bridge girder erection machine comprises a bottom horizontal supporting system, a main girder system, a longitudinal moving system, a cantilever crane, an assembling frame and an assembling vehicle; and fourthly, a system is converted, wherein the system is converted after the erection construction process is finished. By the adoption of the segmental assembling box girder construction technology, the technological step is simple, design is reasonable, construction is easy and convenient, a construction process is easy to control, a use effect is good, the segmental assembling box girder assembling process can be simply, conveniently and rapidly finished, and the construction quality is easy to guarantee.

Owner:CHINA RAILWAY FIRST GRP CO LTD

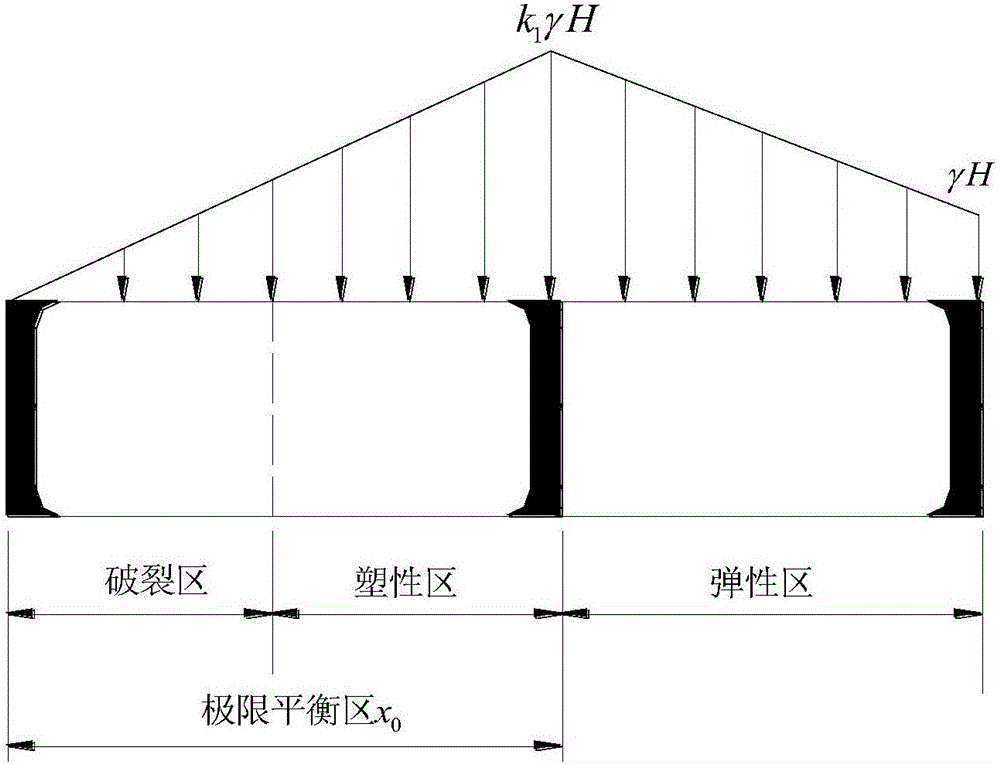

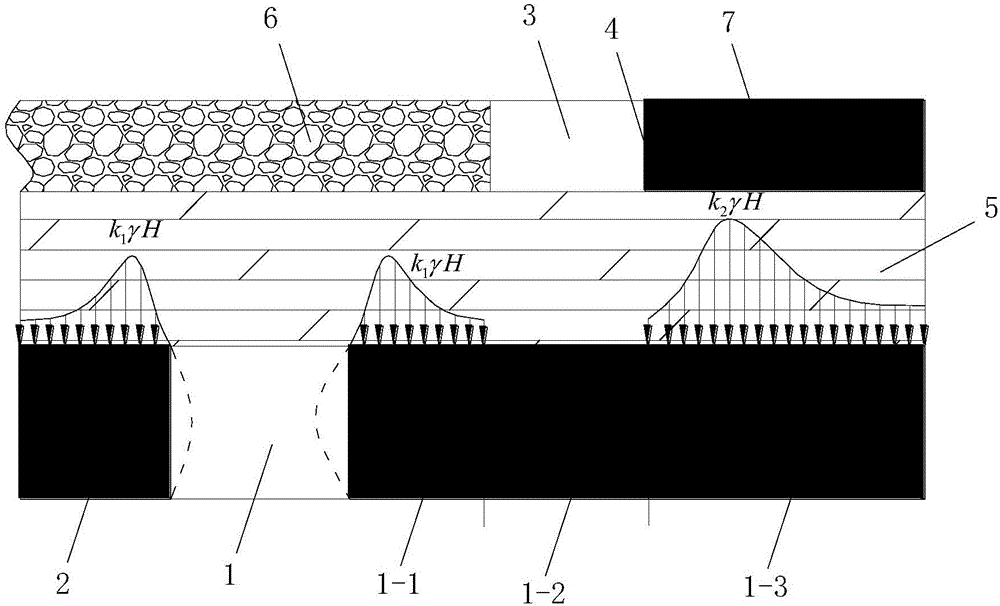

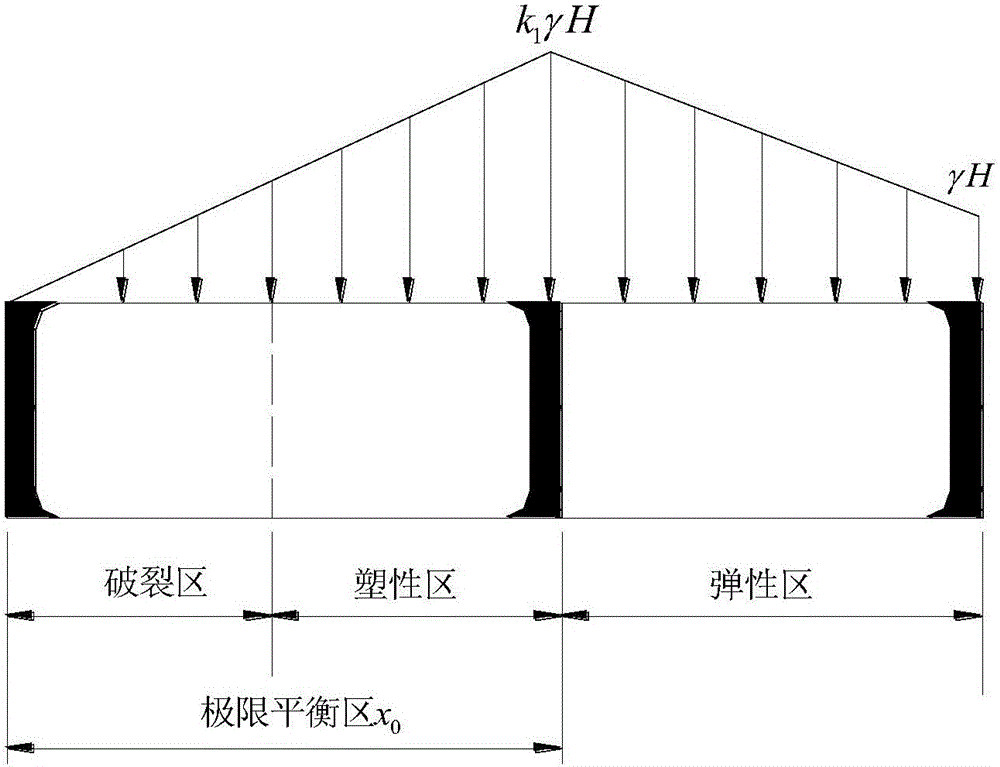

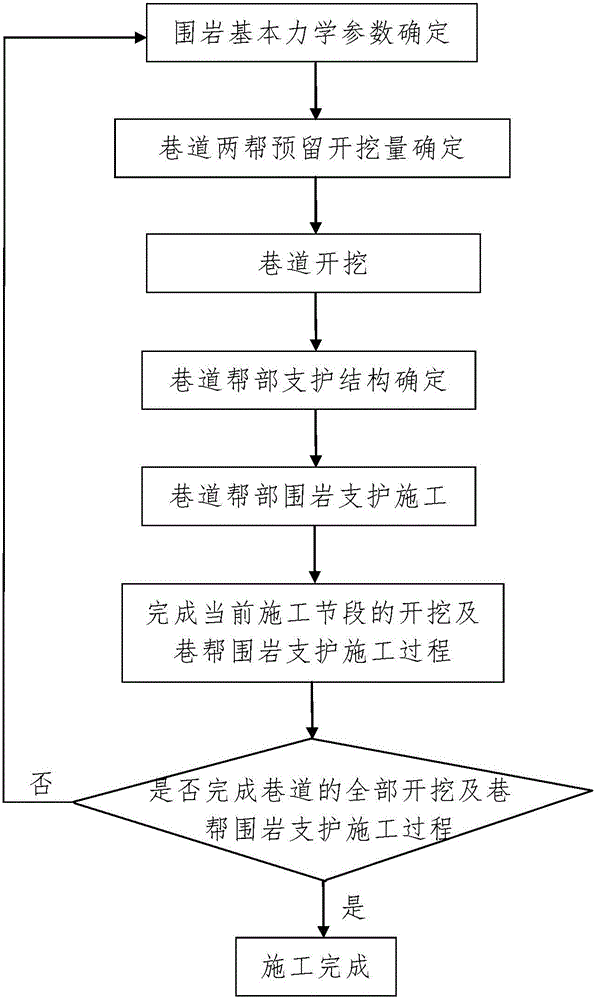

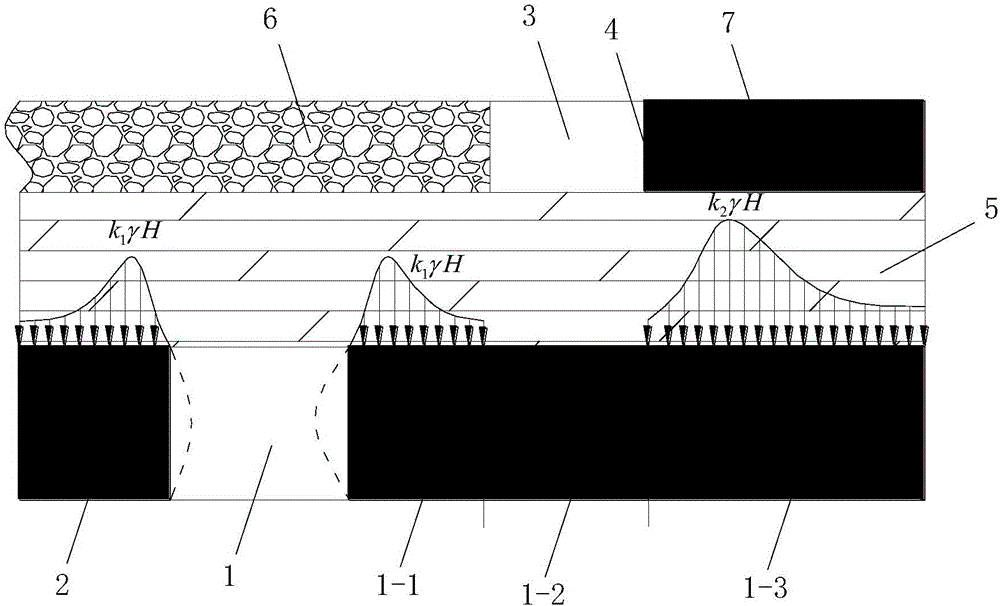

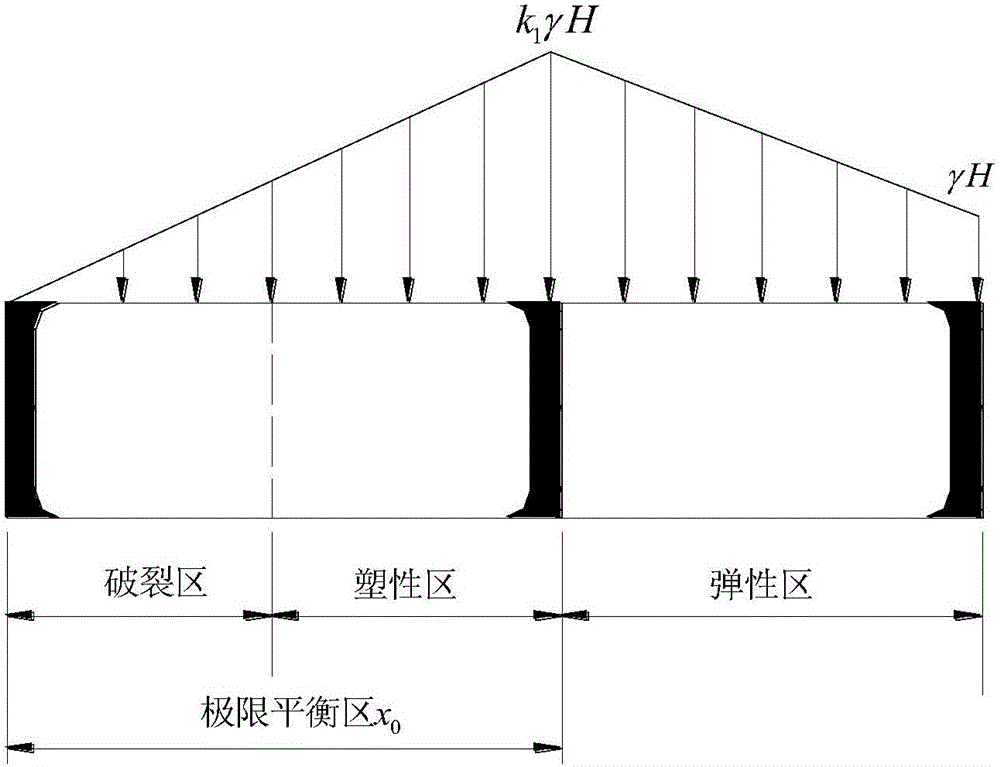

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

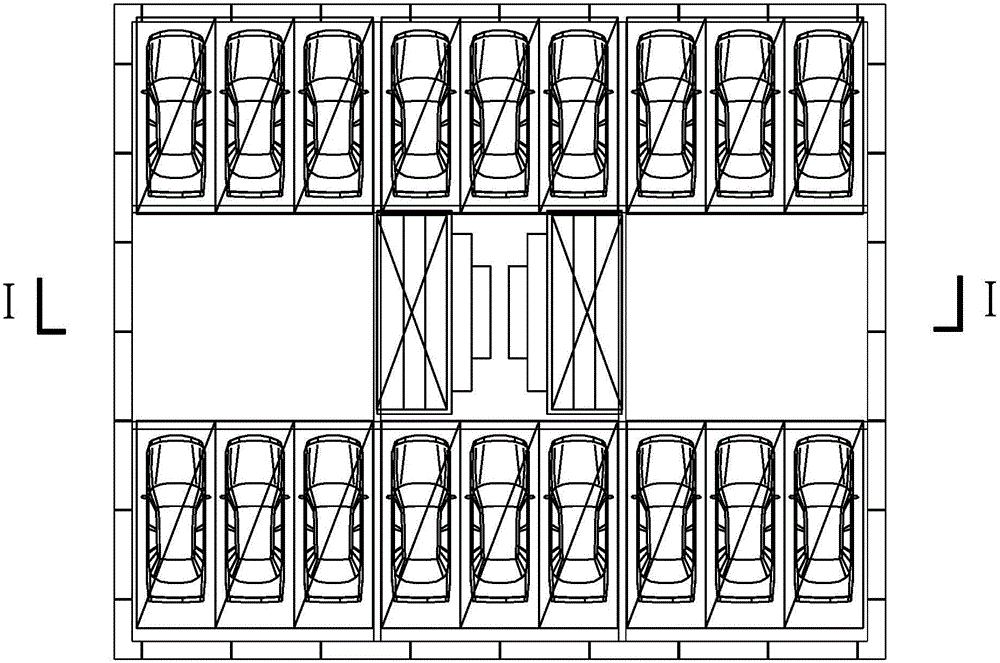

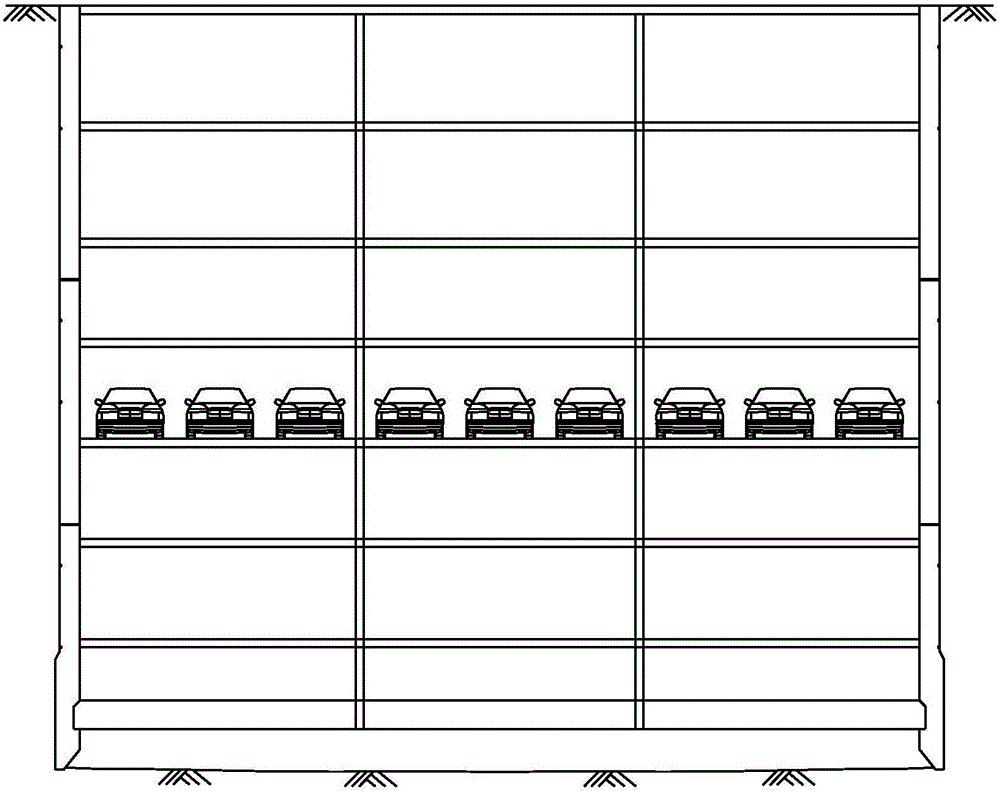

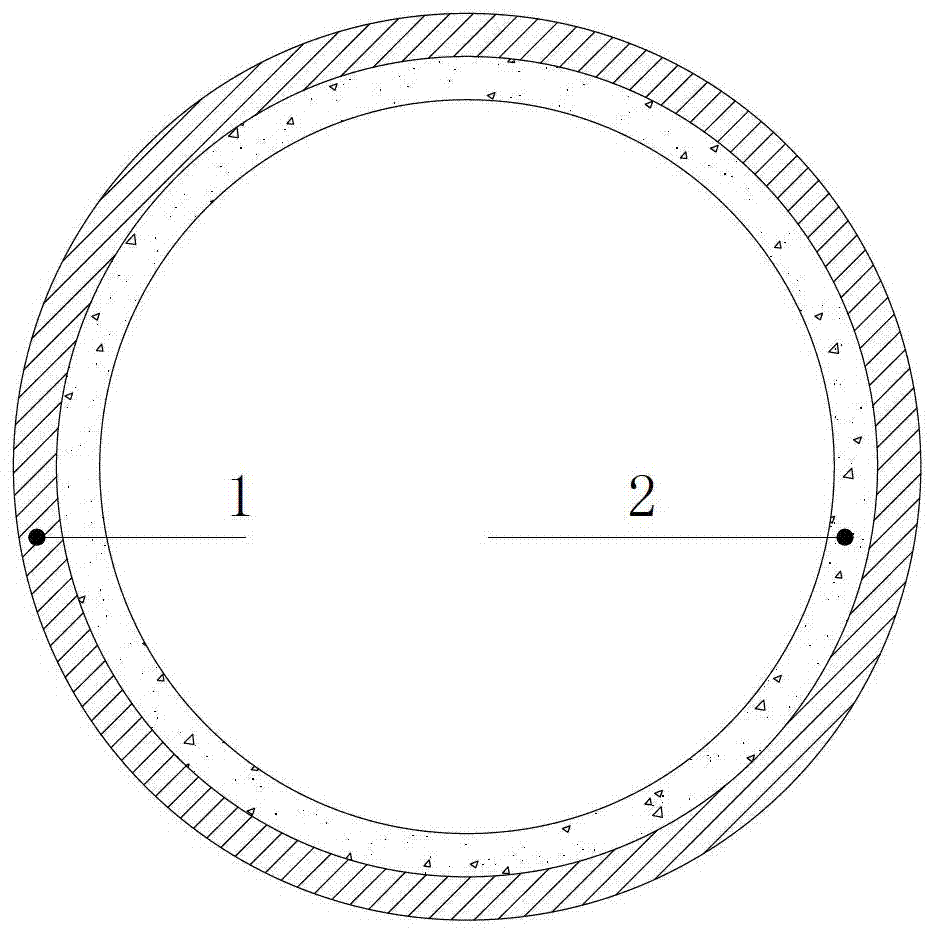

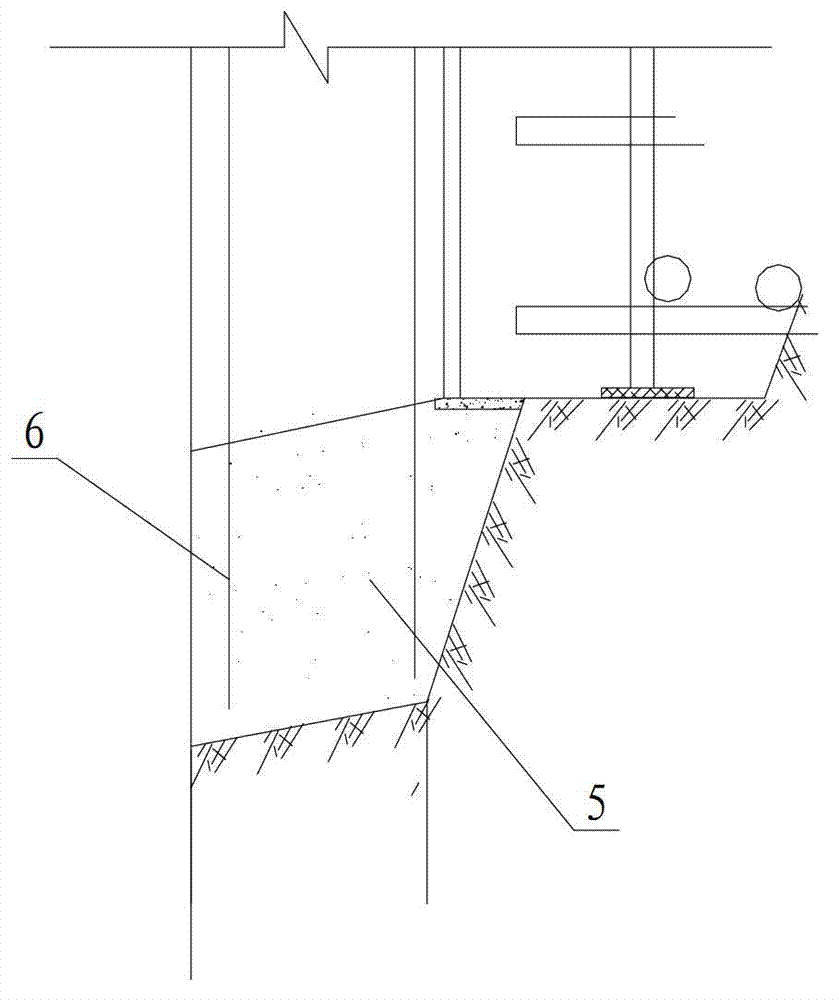

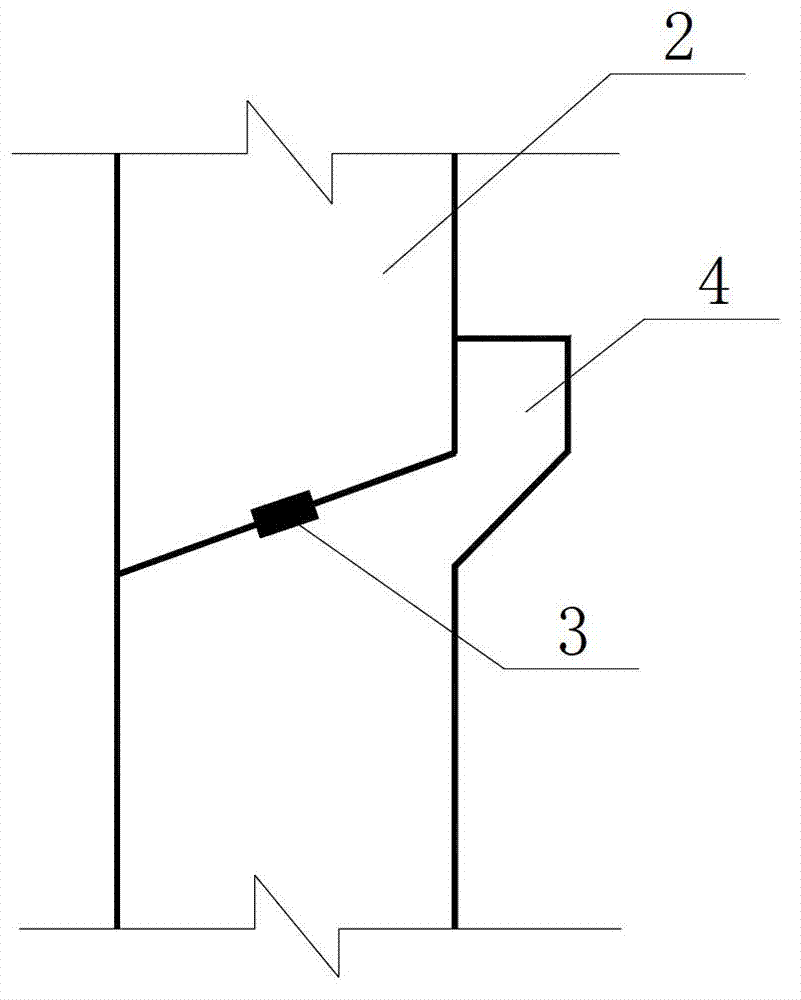

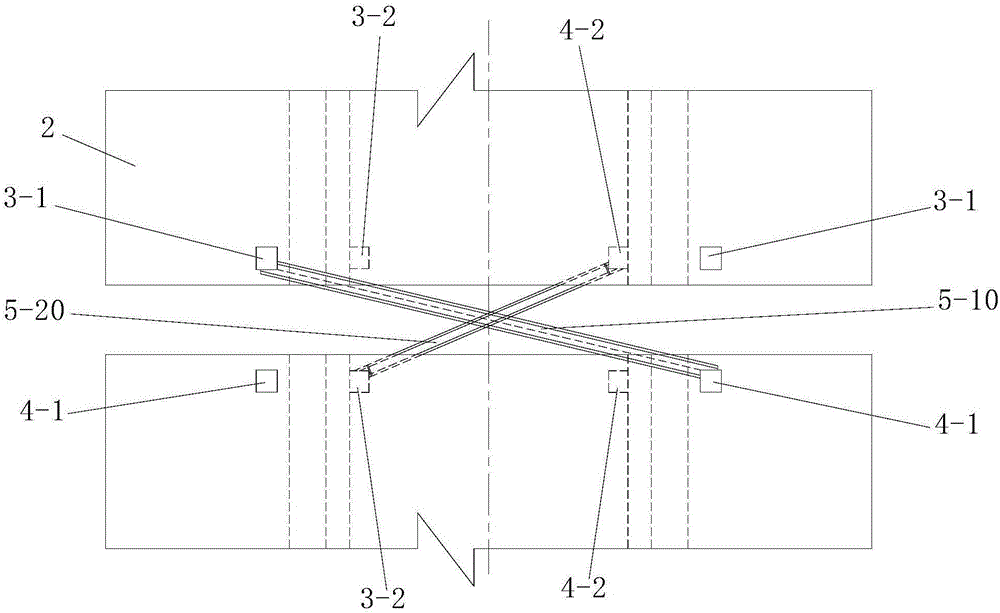

Building method for open caisson for underground garage

ActiveCN106013218AReduce construction costsBuild fastArtificial islandsUnderwater structuresPre stressBuilding process

The invention discloses a building method for an open caisson for an underground garage. The open caisson is composed of a well wall and a framework mounted in the well wall. The well wall is composed of N well cylinders stacked from top to bottom, wherein N is larger than or equal to 2 and smaller than or equal to 15. In the building process, firstly, prefabricated pipe pieces are assembled through concrete guide walls to form one well cylinder, and a part of the framework is built in each well cylinder; and after all the well cylinders are assembled, sinking is conducted, then the well cylinders are successively assembled and subjected to sinking till all the well cylinders and the framework are completed, and assembly and sinking of the open caisson are completed. According to the building method for the open caisson for the underground garage, the well wall of the open caisson is formed by assembling the pipe pieces, the pipe pieces are prefabricated, and standard manufacturing is facilitated; and when needed, the pipe pieces can be conveyed to the designated area for assembly of the open caisson, and it is avoided that when an open caisson is built through a cast-in-site manner, and the tedious processes such as prestress applying and concrete pouring are needed, so that concrete curing can be eliminated, construction efficiency is improved, and the engineering cost is lowered.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Construction method for compensating roadbed settlement by pre-burying expansion bags

InactiveCN107761495AIncrease gas productionImprove gas production efficiencyRoadwaysRoad surfaceRetaining wall

The invention relates to a treatment method for a road roadbed, in particular to a construction method for compensating roadbed settlement by pre-burying expansion bags. The construction method comprises the following steps: firstly, in a roadbed construction process, filling the roadbed at a road section which causes settlement deformation easily to a certain height; secondly, building retainingwalls on two sides of the roadbed; thirdly, paving a plurality of layers of bagged quick lime in the full width range of the roadbed on the inner sides of the retaining walls; fourthly, communicatingeach bag of the bagged quick lime to a rubber pipe on the outer side of the roadbed; fifthly, numbering and marking the rubber pipes, and sealing pipe openings after construction is completed; sixthly, injecting water into a quick lime layer when the roadbed settlement is treated, monitoring the elevation of the surface of the road in a water injecting process, and regulating water injecting speedand water injecting amount; finally, treating cracks which appear because of the settlement of a road surface. The invention aims to provide the construction method for compensating the roadbed settlement by pre-burying the expansion bags, which has the advantage that the roadbed settlement can be compensated timely in all weathers without affecting the traffic.

Owner:雨发建设集团有限公司

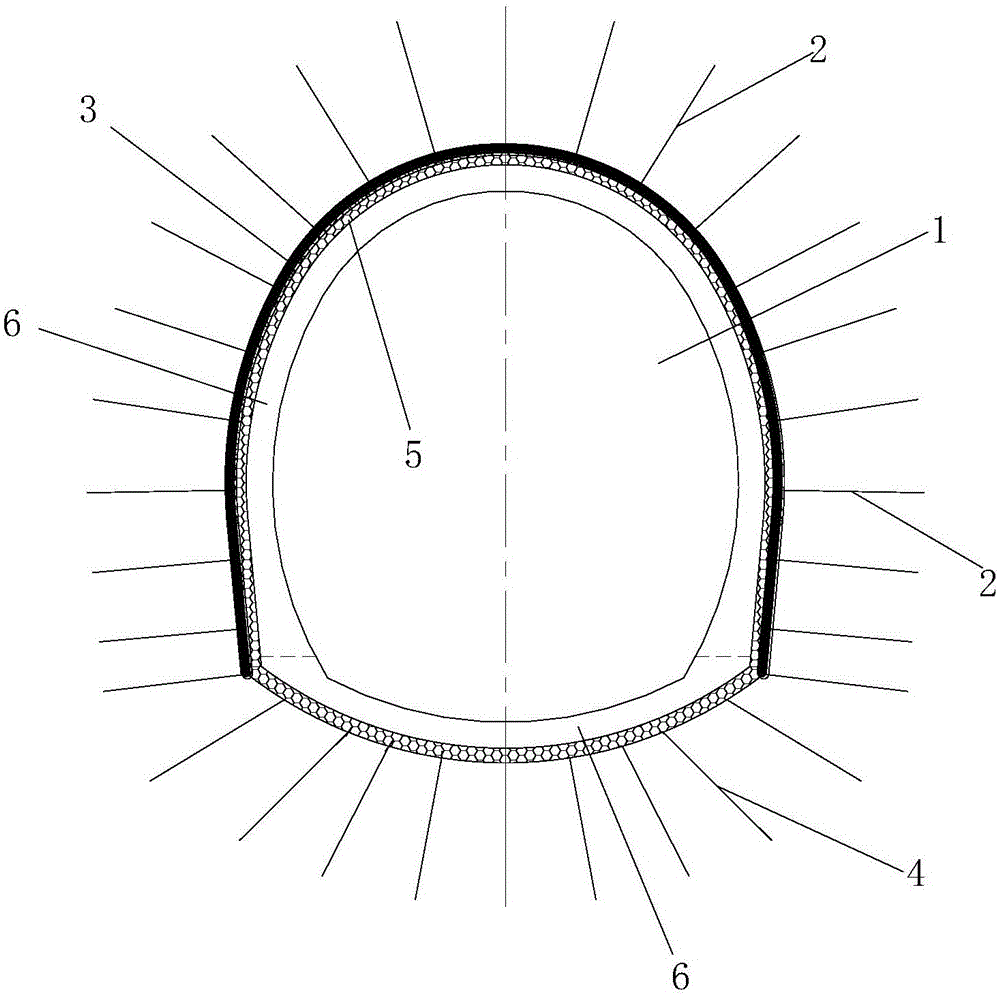

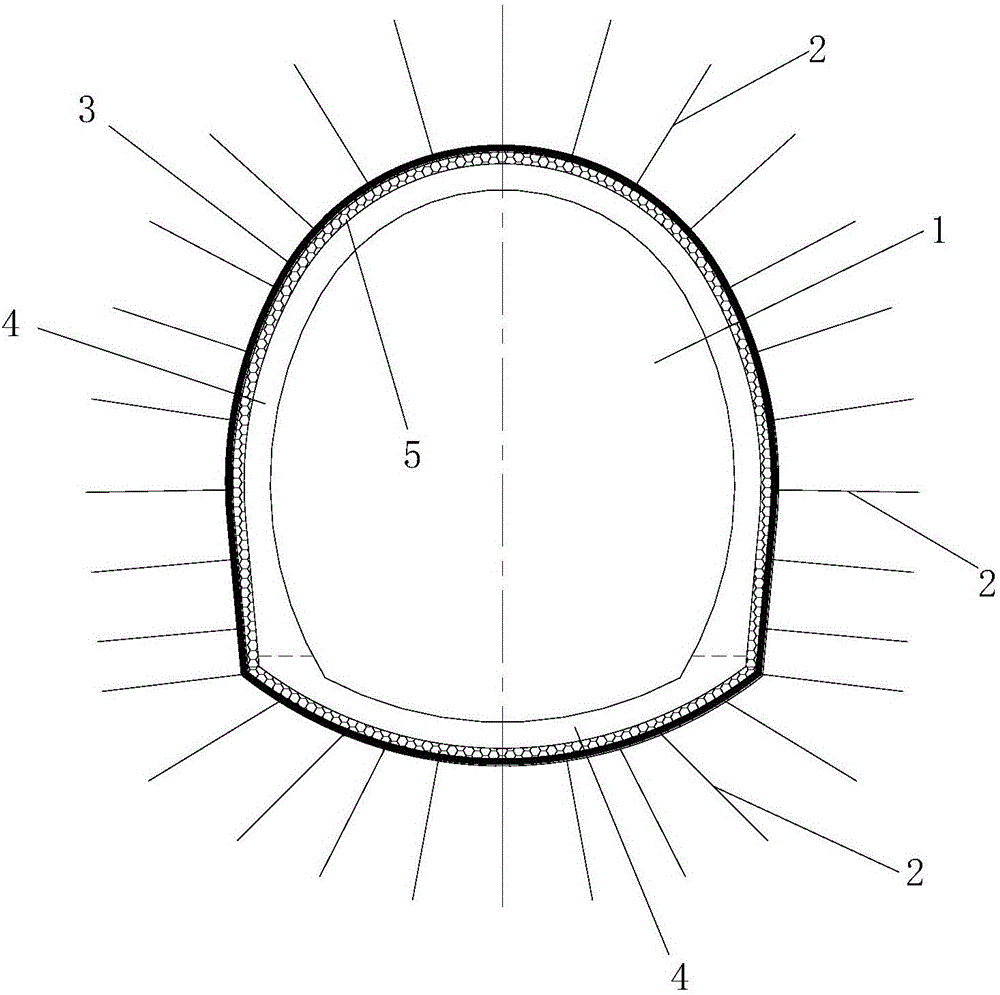

Soft rock tunnel construction method on the basis of flexible formwork support

InactiveCN106522978AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelStructural stability

The invention discloses a soft rock tunnel construction method on the basis of flexible formwork support. A soft rock tunnel is divided into a plurality of segments from back to front to be subjected to construction. Construction of any one segment comprises the following steps that (1), basic mechanical parameters of surrounding rocks are defined; (2), the tunnel reserved excavating quantity is defined; (3), the tunnel begins to be excavated; (4), A tunnel support structure is defined: the tunnel support structure comprises a tunnel incipient support structure, a flexible formwork support structure and tunnel two-time linings; (5), tunnel incipient support is constructed; (6), the flexible formwork support is constructed; (7), the tunnel two-time linings are constructed; (8), a next segment is constructed; and (9), step (8) is repeated for many times until all the construction processes of the soft rock tunnel are completed. According to the soft rock tunnel construction method on the basis of the flexible formwork support, the method and the steps are easy, design is reasonable, achieving is convenient, and the using effect is good; and the reserved excavating quantity is defined according to deformation conditions of the surrounding rocks of the soft rock tunnel, the flexible formwork support structure is adopted to support full cross sections of the tunnel and subjected to coordination deformation with the tunnel incipient support structure, and thus structure stability of the tunnel two-time linings is guaranteed.

Owner:XIAN UNIV OF SCI & TECH

Novel composite additive for solidifying material for dredged silt with high water content

The invention aims to solve the problems in the prior art that the river slit is usually dredged by the cutter-suction process, which results in that the initial water content of the soil body is extremely high and generally 2 to 10 times the liquid limit; in the commonly-used solidification process, only quicklime and cement are added to the silt, which results in that the strength of the solidified soil can not meet the design requirements or the addition amount is very large and the manufacturing cost is high. In order to solve the problems, the invention provides a composite additive which is the mixture of dredged silt with high water content, cement, quicklime and sodium polyacrylate. The composite additive can achieve the purpose of rapid solidification of the dredged silt with high water content, and can greatly improve the strength of the soil body. The composite additive comprises the following ingredients in percentage of the total weight of the solidified silt: 3 to 7 percent of cement, 7 to 15 percent of quicklime and 0.05 to 0.1 percent of sodium polyacrylate.

Owner:SOUTHEAST UNIV

Airbag type inner framework form traveler and primary tunnel supporting shotcrete construction method

ActiveCN105507927ASimple structureEasy to processMining devicesUnderground chambersShotcreteArchitectural engineering

The invention discloses an airbag type inner framework from traveler and a primary tunnel supporting shotcrete construction method. The form traveler comprises a movable supporting framed bent, an inflatable formwork located on the outer side of the movable supporting framed bent, and a retractable supporting device for supporting the inflatable formwork, and the retractable supporting device is installed on the movable supporting framed bent and located on the inner side of the inflatable formwork. The construction method includes the steps: firstly, forwarding the airbag type inner framework from traveler in place; secondly, performing primary tunnel supporting shotcrete construction; thirdly, performing primary tunnel supporting shotcrete construction on a next tunnel section; fourthly, repeating the third step for multiple times till the primary tunnel supporting shotcrete construction process of all the tunnel sections is finished. The airbag type inner framework from traveler is reasonable in design, simple to construct and good in using effect, resilience rate of primary tunnel supporting shotcrete is effectively controlled through an airbag type inner framework, construction efficiency is high, construction period is short, construction quality is high, and zero resilience rate of primary tunnel supporting shotcrete can be realized.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Roadside support method of short-distance coal seam roadway

InactiveCN105863700AThe method steps are simpleEasy to implementGeometric CADData processing applicationsSupporting systemShortest distance

The invention discloses a roadside support method of a short-distance coal seam roadway. The short distance coal seam roadway includes the steps of firstly, determining the basic mechanical parameters of surrounding rock; secondly, determining the excavation volume of two sides of the roadway; thirdly, excavating the roadway, to be more specific, excavating according to the excavation volume of the two sides of the roadway; fourthly, determining a roadside support structure which comprises a plurality of roadside support units and a plurality of grouting anchoring rods, wherein the roadside support units and the grouting anchoring rods are arranged in a staggered manner; fifthly, performing roadside surrounding rock support construction; sixthly, excavating the next section and performing roadside surrounding rock support construction; seventhly, repeating the sixth step until all the short-distance coal seam roadway is excavated and the roadside surrounding rock support construction is completed. The roadside support method has the advantages that the method is simple in steps, reasonable in design, convenient to implement and good in use effect, the reserved excavation volume of the two sides of the roadway is determined according to the surrounding rock deformation conditions of the short-distance lower coal seam roadway, and the grouting anchoring rods and the roadside support system are coordinated to achieve effective roadside support.

Owner:XIAN UNIV OF SCI & TECH

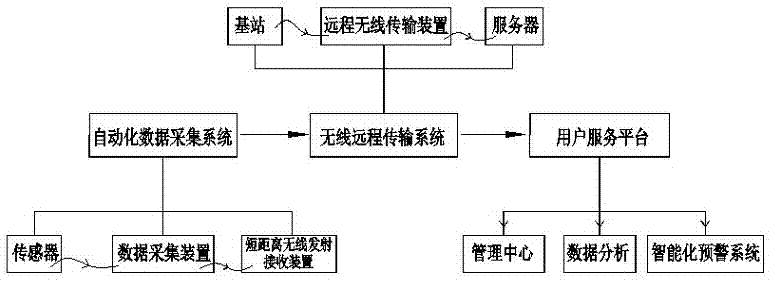

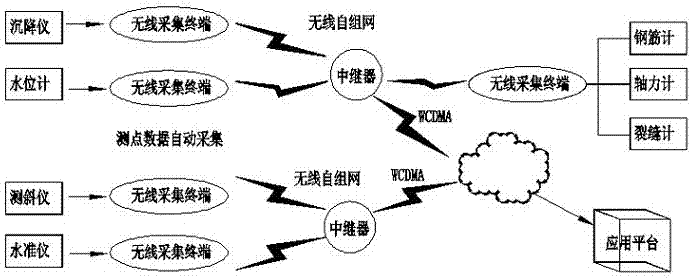

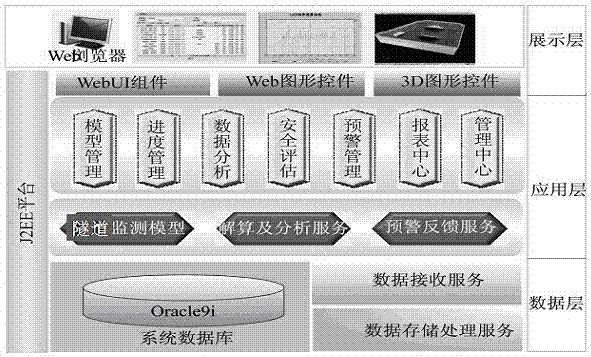

ZigBee-based tunnel automatic monitoring system and monitoring method thereof

InactiveCN107067690AReduce usageAvoid destructionTransmission systemsShort range wirelessTreatment system

The invention discloses a ZigBee-based tunnel automatic monitoring system and a monitoring method thereof. The system comprises an automatic data acquisition system, a wireless remote transmission system and a user service platform, wherein the automatic data acquisition system comprises a sensor, a data acquisition system and a short distance wireless transmitting and receiving device; the wireless remote transmission system comprises a base station, a remote wireless transmission device and a server; and the user service platform comprises treatment systems, such as a data analyzing and processing system, an intelligent early warning system and a management center. The monitoring system and monitoring method which are disclosed by the invention have the advantages that a wireless communication technology is adopted, fewer cables are used, damage caused by tunnel construction on the cables is avoided, a large-scale network is adopted for carrying out large-scale point distribution, and a tunnel structure can be monitored, early-warned and evaluated more detailedly and more accurately.

Owner:SUN YAT SEN UNIV

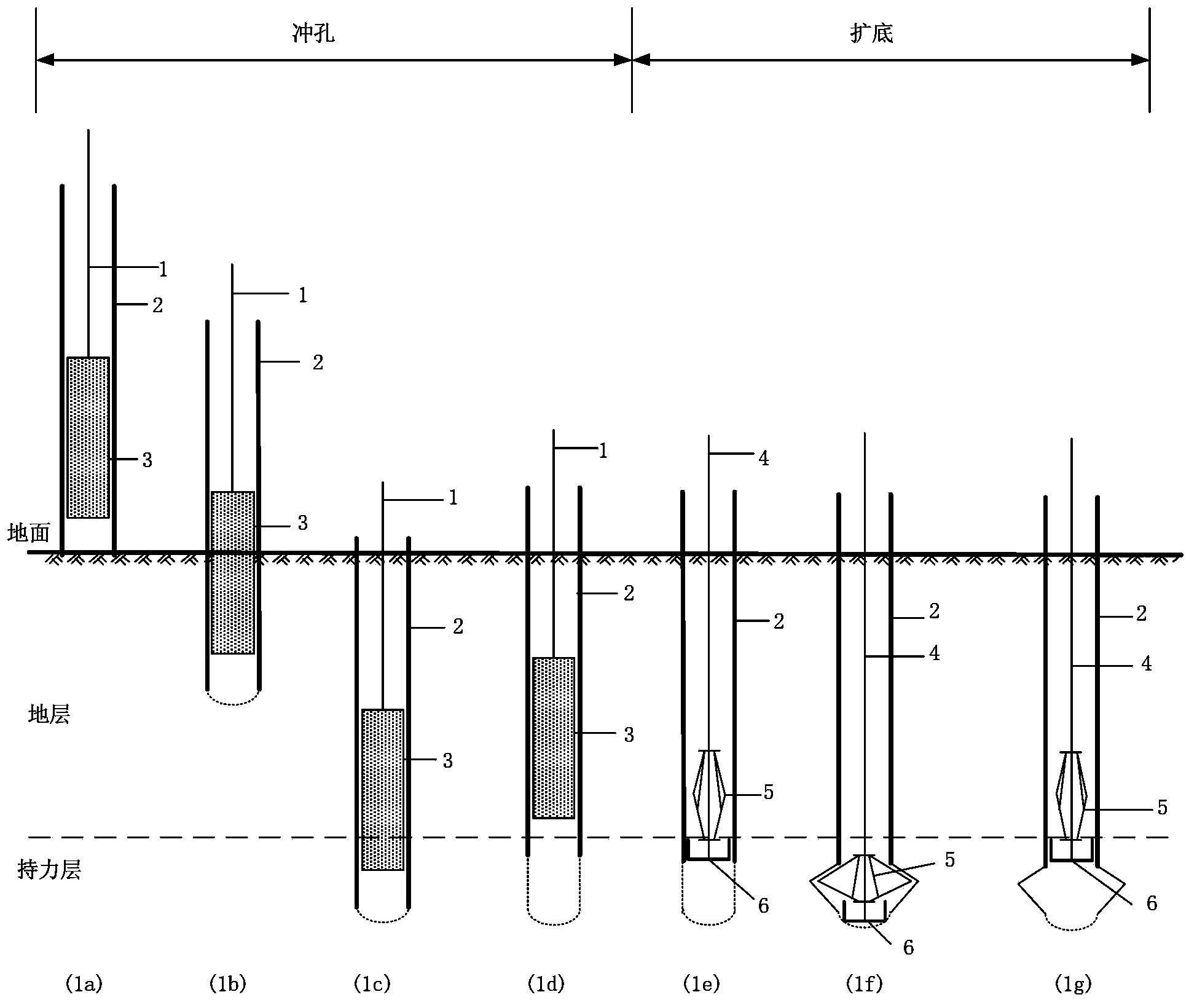

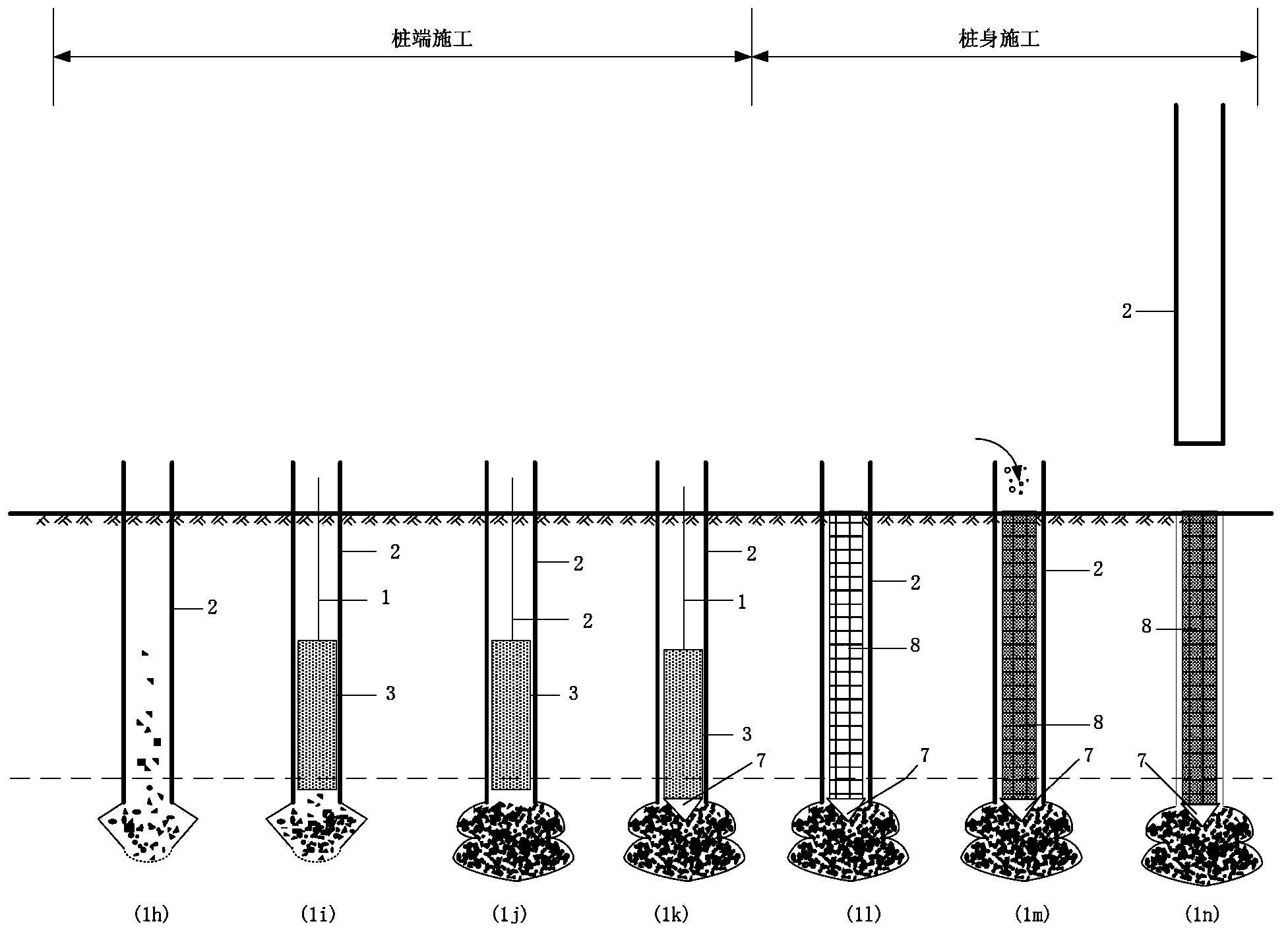

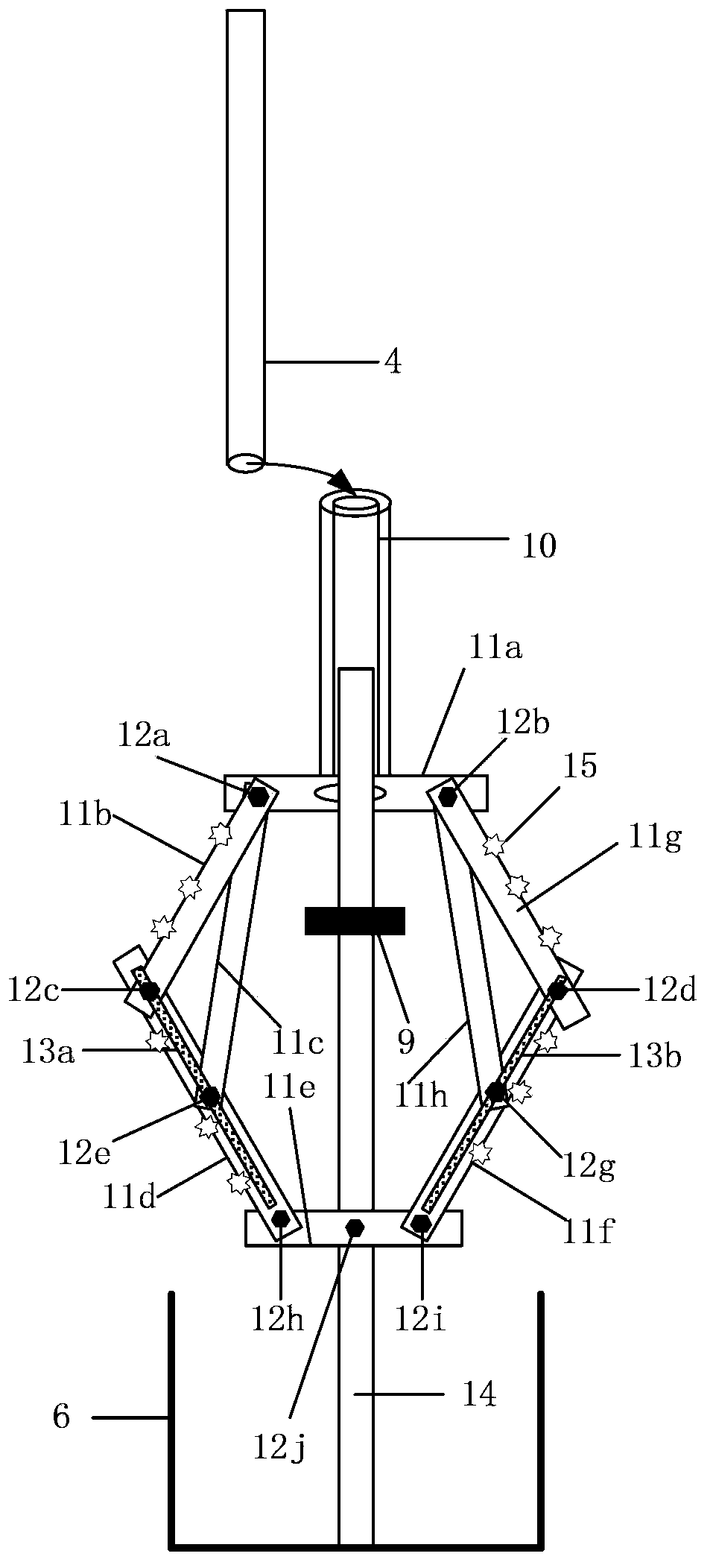

Construction method for cast-in-place pile through punching and base expanding and base expanding device

ActiveCN103410142AImprove bearing capacityReduce settlementBulkheads/pilesDrilling machines and methodsPunchingSlag

The invention discloses a construction method for a cast-in-place pile through punching and base expanding and a base expanding device. The method includes the steps of 1) punching which includes reserving the pile position and pressing a protection drum into soil by utilizing hydraulic pressure; 2) base expanding which includes connecting a drill rod and the base expanding device and placing the drill rod and the base expanding device into the protection drum; 3) pile end construction which includes pouring a hard bulk material into a hole, utilizing a heavy punch to conduct tamping repeatedly till the material is compacted and pressing a conical pile head into the pile end through the heavy punch; 4) pile body construction which includes that a connection pipe is connected with the drill rod through threads, the connection pipe is welded with a first rod piece, two ends of the first rod piece are connected with a second rod piece through bolts, the second rod piece is arranged in a guide groove through a bolt, the first rod piece is fixed on the second rod piece through a bolt, a baffle is arranged on the connection rod, the connection rod is connected with the bolts, and the connection rod is welded at the bottom of a slag clearing drum. The construction method is easy to implement, simple to operate, convenient to construct, reliable in piling quality, low in construction cost, high in bearing capability, simple in structure and convenient to use. Functions of a conventional base expanding device can be achieved, and the problem that a conventional base expanding drill bit can not effectively clear slag at the bottom of the pile is solved.

Owner:WUHAN ZHONGLI GEOTECHN ENG

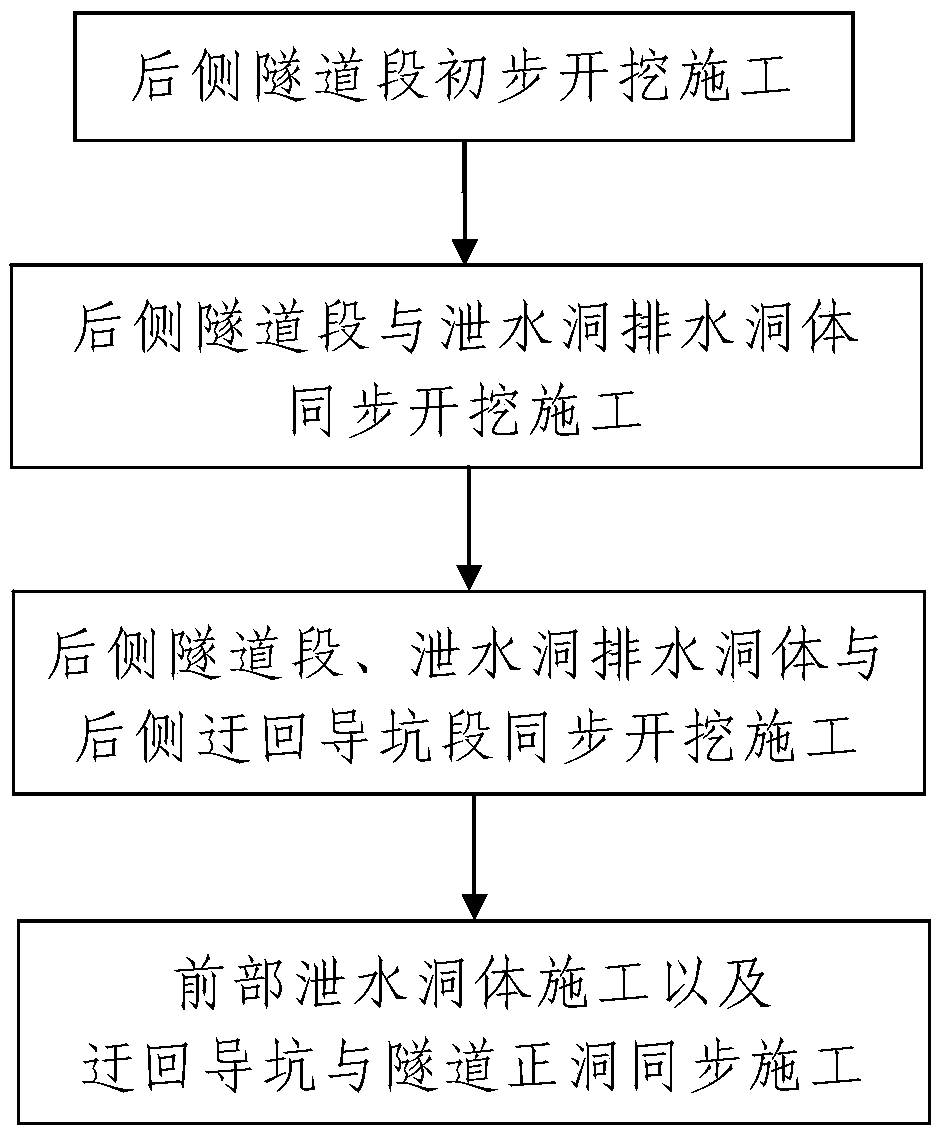

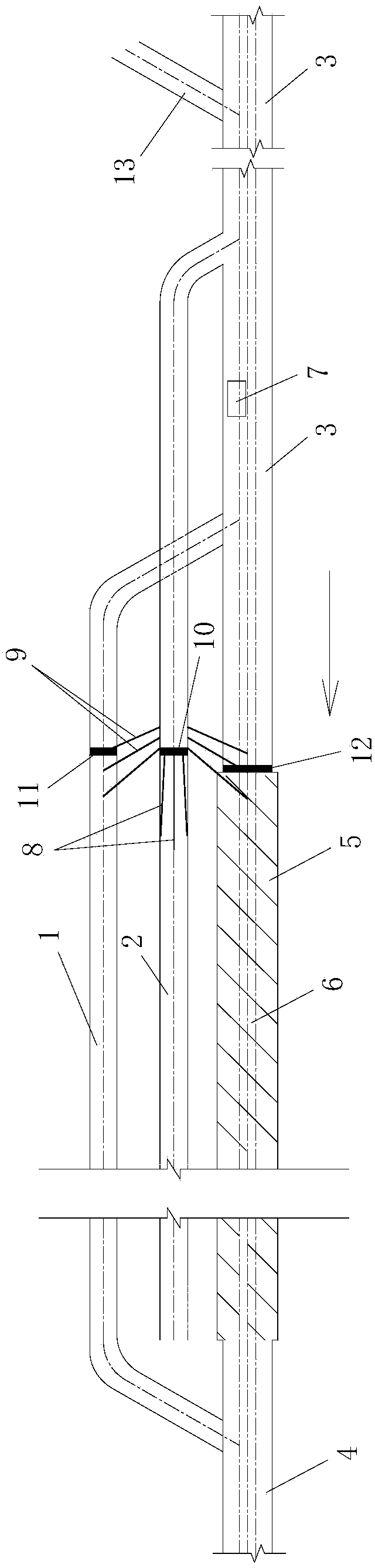

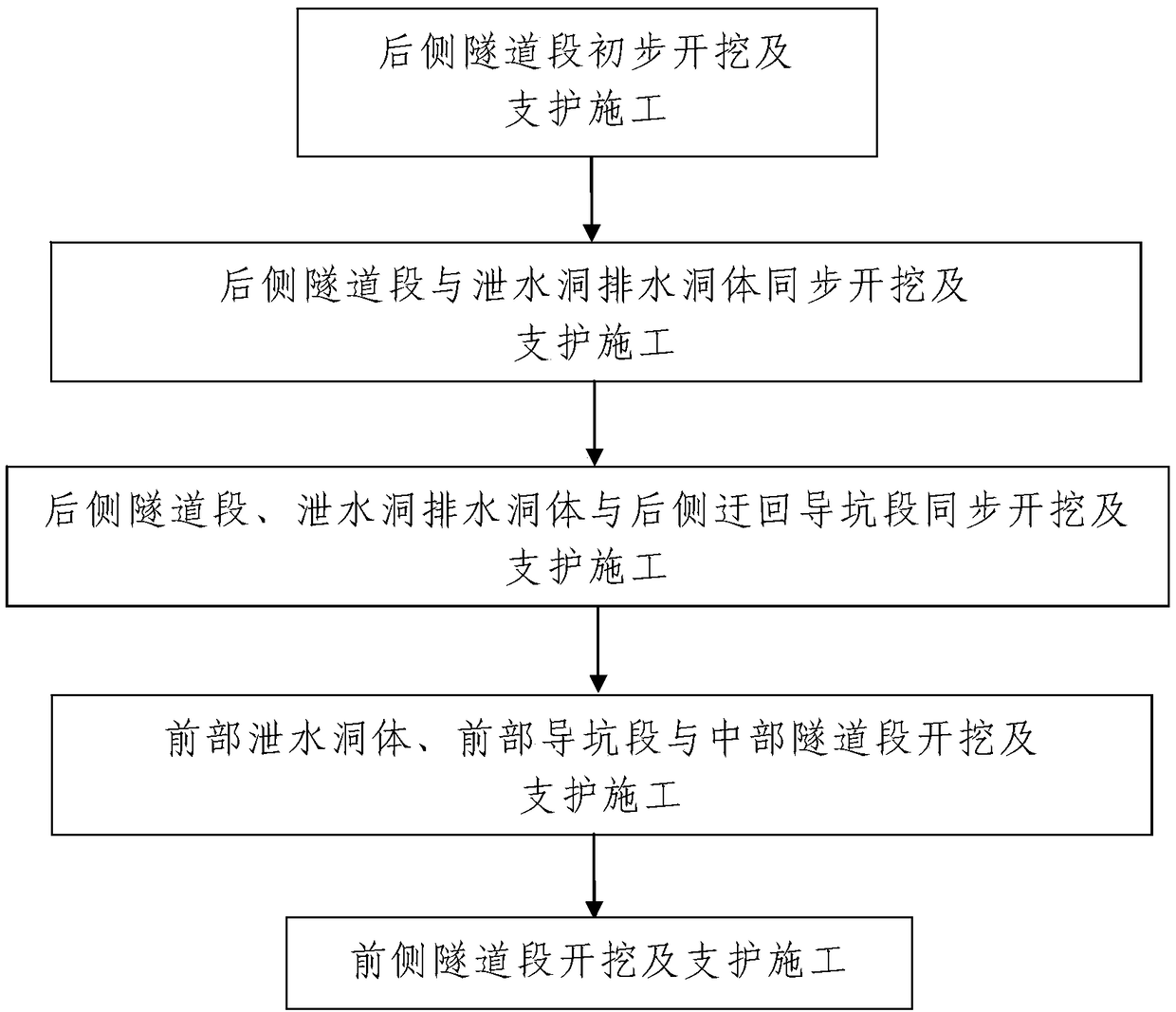

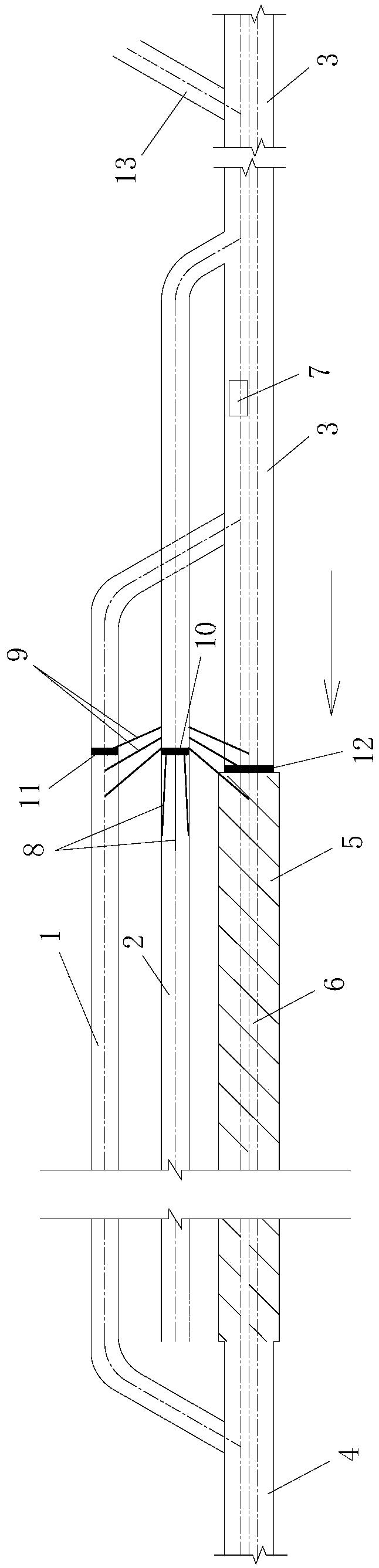

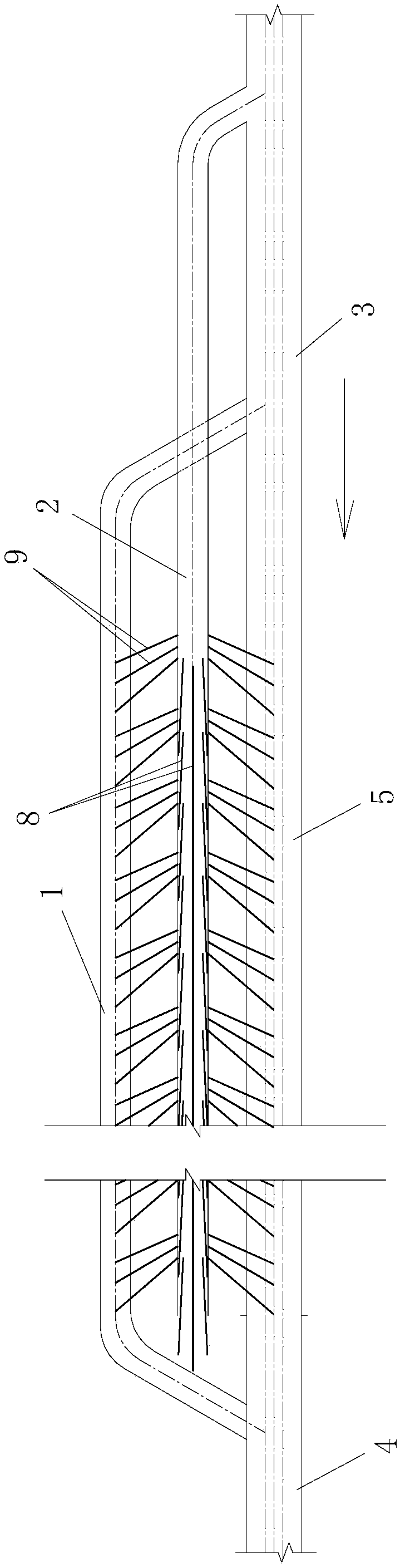

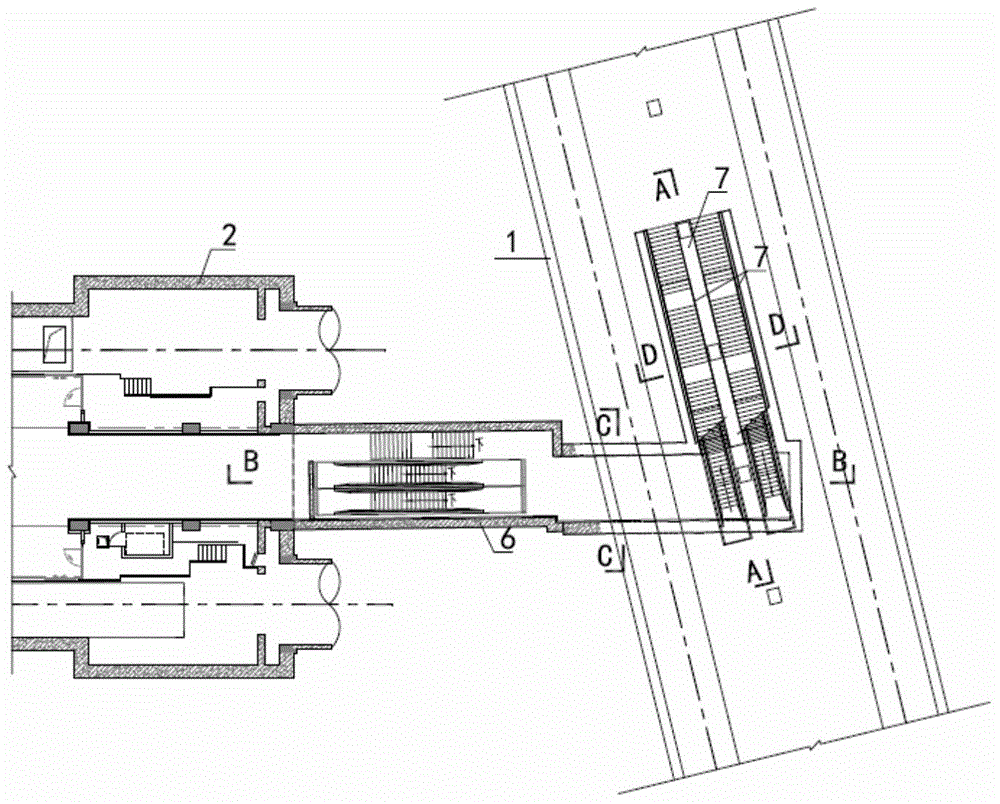

Drainage construction method for tunnel passing through clastic rock steeply inclined reverse thrust water-rich fault

ActiveCN109139104AThe method steps are simpleReasonable designDrainageTunnelsClastic rockWater pressure

The invention discloses a drainage construction method for a tunnel passing through a clastic rock steeply inclined reverse thrust water-rich fault. The drainage construction method is characterized in that a construction tunnel main cave is divided into a rear side tunnel section, a front side tunnel section and a middle portion tunnel section passing through the clastic rock steeply inclined reverse thrust water-rich fault, wherein a by-pass pilot tunnel and a drain cavern are formed in the same side of the construction tunnel main cave. When drainage construction is carried out in the construction tunnel main cave, the drainage construction method comprises the steps of: 1, carrying out preliminary excavation construction on the rear side tunnel section; 2, synchronously carrying out excavation construction on the rear side tunnel section and a drainage hole body of the drain cavern; 3, synchronously carrying out excavation construction on the rear side tunnel section, the drainagehole body of the drain cavern and a rear side by-pass pilot tunnel section; 4, and carrying out construction on the front portion drainage hole body, and synchronously carrying out construction on theby-pass pilot tunnel and the tunnel main cave. The drainage construction method provides a new construction working plane by means of the by-pass pilot tunnel, improves the working efficiency, provides the high-altitude drainage hole between the tunnel main cave and the by-pass pilot tunnel, can drain water embedded in the fault to the greatest extent, reduces water pressure in the fault in frontof a tunnel face, ensures safety construction of each tunnel face and can shorten the construction period.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Prestressed concrete variable-section box girder bridge with internal slant leg rigid frame, and construction method thereof

InactiveCN103290777AReduce flat bendReduce horizontal section hollowing ratioBridge erection/assemblyRigid framePre stress

The invention discloses a prestressed concrete variable-section box girder bridge with an internal slant leg rigid frame. The prestressed concrete variable-section box girder bridge with the internal slant leg rigid frame comprises a bottom slab box with box bottom slabs, box top slabs and box webs, top slabs and a pier. Middle webs and transverse partitions are disposed in a box girder. Upper bent anchor plates are arranged longitudinally along the box girder from the midspan to the pier. The slant leg rigid frame structure comprising internal longitudinal beams, internal upper slant legs and internal lower slant legs is disposed above the base slab box. The internal longitudinal beams are upwardly inclined or bent longitudinally along the box girder from the midspan to the pier. The internal longitudinal beams, the box bottom slabs and the upwardly bent anchor plates are all provided with upwardly bent bottom slab ropes. The invention further provides a construction method of the prestressed concrete variable-section box girder bridge with the internal slant leg rigid frame. The bridge and the construction method thereof have the advantages that layout of the bottom slab ropes is more reasonable, the upwardly bent bottom slab ropes provide upward radial force, and downward force generated by secondary dead load and partial vehicle load can be eliminated or reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Construction method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209397AThe method steps are simpleReasonable designUnderground chambersDrainageStructural safetyHigh angle

The invention discloses a construction method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. The method comprises the steps: 1, performing the preliminary excavationand the supporting construction of a rear tunnel segment; 2, performing the synchronous excavation and the supporting construction of the rear tunnel segment and a water drainage hole body of a waterdrainage hole; 3, performing the synchronous excavation and the supporting construction of the rear tunnel segment, the water drainage hole body of the water drainage hole and a rear detouring headingsegment; 4, performing the excavation and the supporting construction of a front water drainage hole body, a front heating segment and a central tunnel segment; 5, performing the excavation and the supporting construction of a front tunnel segment. According to the invention, the water on the upper wall of the fault is drained through a high-level water drainage hole between a tunnel front hole and a detouring heading pit, and the auxiliary water drainage is performed through the detouring heading pit, and the fault condition in front of the tunnel face of the front hole can be explored in advance, thereby guaranteeing the construction safety of each tunnel face. The method employs the three-step method for the excavation of the tunnel front hole, employs double preliminary supporting structures for the full-section supporting after excavation, can guarantee the safety of the tunnel structure later, and shortens the construction cycle.

Owner:CHINA RAILWAY 20 BUREAU GRP

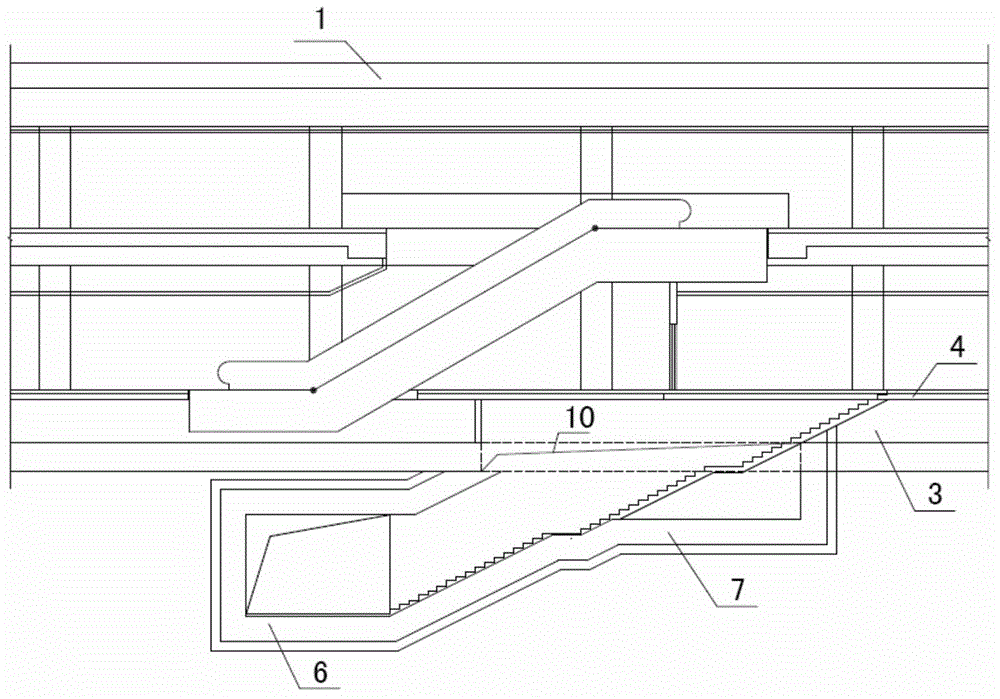

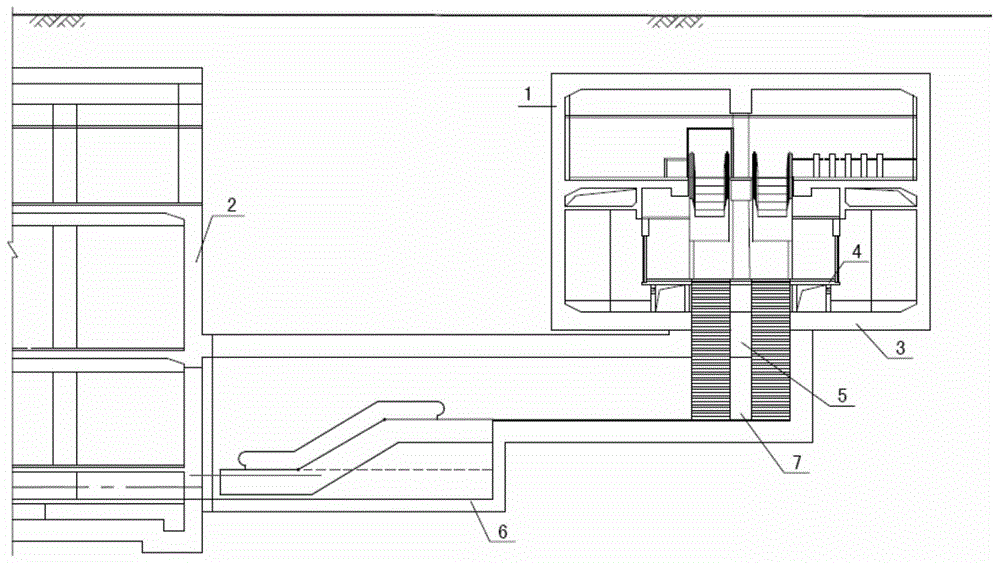

Construction method for implementing transfer between platform floor of existing subway station and platform floor of new subway station

ActiveCN104563158AShort transfer distanceLess transfer timeArtificial islandsExcavationsSubway stationRebar

The invention relates to a construction method for implementing transfer between a platform floor of the existing subway station and a platform floor of a new subway station. The construction method comprises the following steps of constructing the platform floor of the new subway station to a pedestrian path below a structural bottom plate of the existing subway station; reinforcing strata surrounding the pedestrian path; dividing a structural bottom plate longitudinal beam of a passageway which is arranged at a position of a table board of the existing subway station and is connected to the pedestrian path into a left portion and a right portion; respectively constructing the left portion and the right portion; correspondingly constructing surrounding rock of an excavation structure at a position of a structural bottom plate longitudinal beam on a side wall of a constructed pedestrian passage structure; breaking down a waterproof layer, a reinforcement cover, construction preliminary bracings and cross braces, a construction waterproof layer and assembling reinforcements on a structural bottom plate portion of a platform of the existing subway station; connecting a new structure and the existing structure by using embedded steel bars; pouring side walls and middle walls; constructing another structural bottom plate longitudinal beam to obtain a complete passageway structure; finishing construction of the passageway of the pedestrian path; and connecting the platform floor of the existing subway station to the platform floor of the new subway station. A construction process is safe, the practicability is high, and normal operation of the existing subway lines is not affected.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

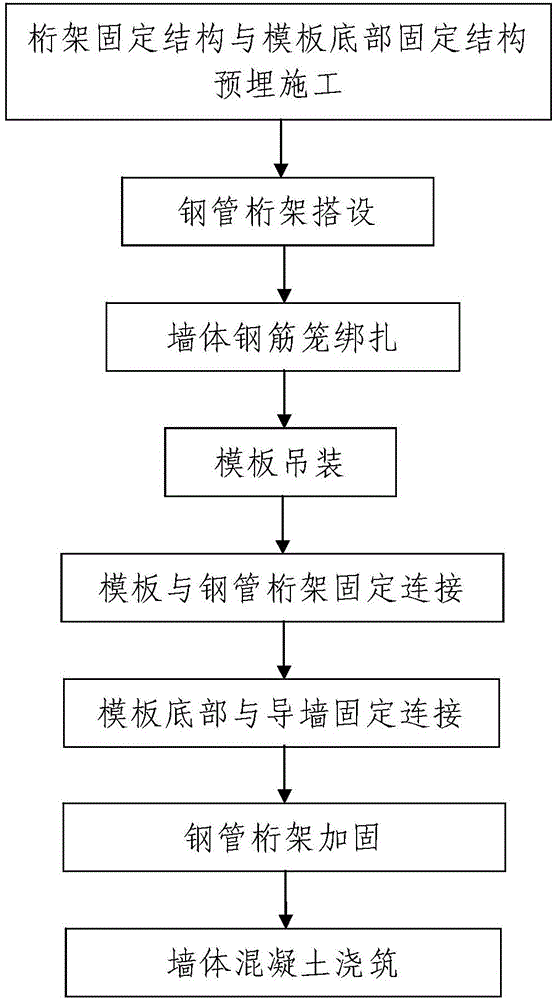

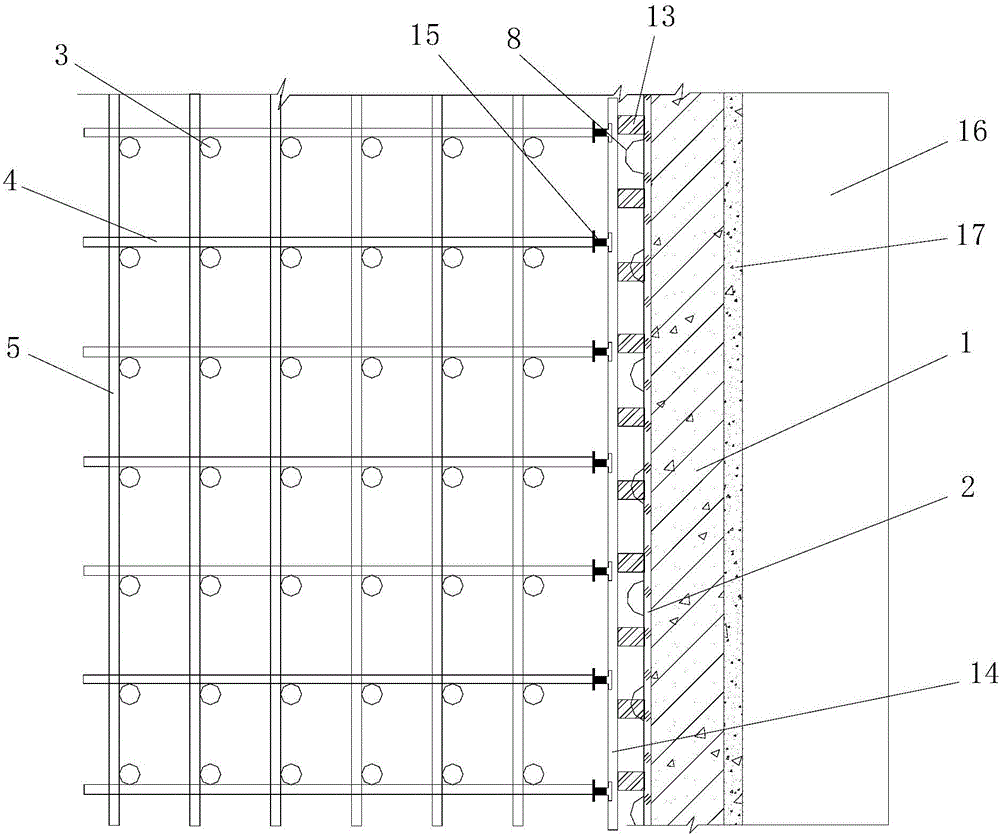

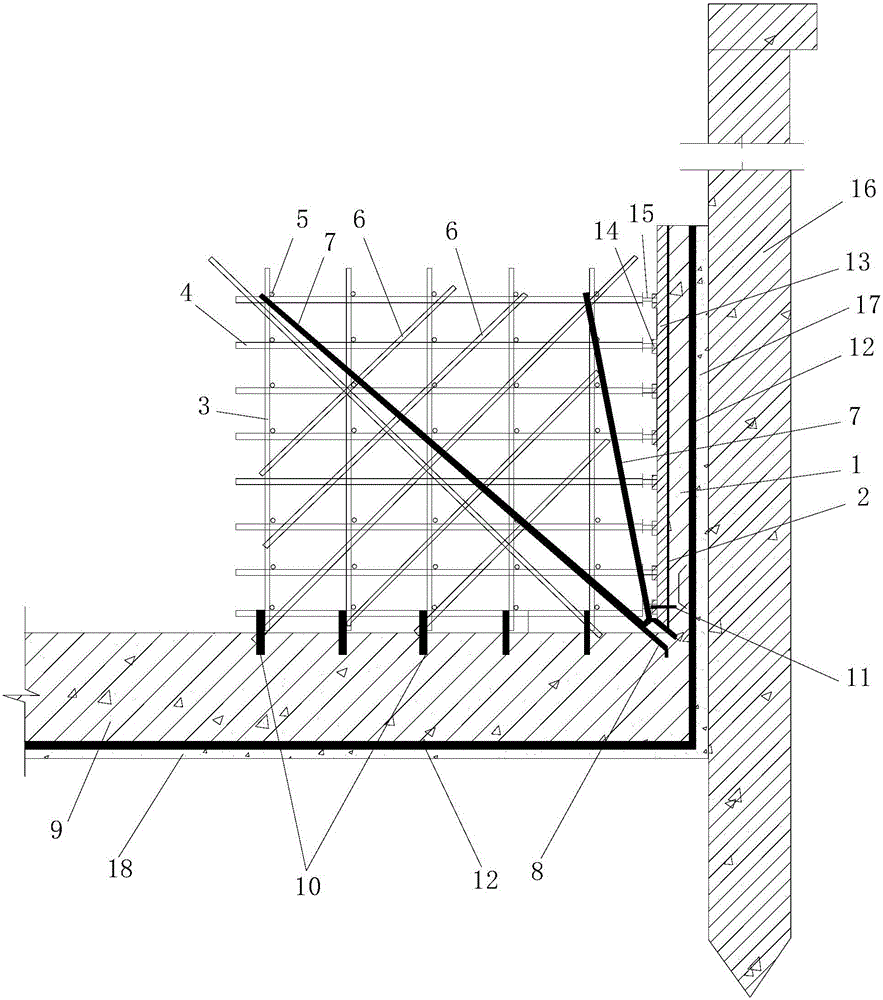

Unilateral formwork supporting construction method for basement exterior wall on basis of steel pipe truss

ActiveCN106245678AThe method steps are simpleEasy to implementArtificial islandsWallsSteel tubeBasement

The invention discloses a unilateral formwork supporting construction method for a basement exterior wall on the basis of a steel pipe truss. The method includes the steps of 1, carrying out embedment construction of a truss fixing structure and a formwork bottom fixing structure, specifically embedding the truss fixing structure for fixing the steel pipe truss into a supporting foundation and embedding the formwork bottom fixing structure for fixing a formwork into a guide wall; 2, erecting the steel pipe truss on the supporting foundation; 3, binding reinforcement cages of a wall body; 4, hoisting the formwork; 5, fixedly connecting the formwork to the steel pipe truss; 6, fixedly connecting the bottom of the formwork to the guide wall and specifically fixing the bottom of the formwork to the guide wall in a fastened mode through the formwork bottom fixing structure; 7 reinforcing the steel pipe truss; and 8, carrying out concrete pouring. The method has the advantages that the steps are simple, the design is reasonable, the construction is simple and convenient, and the use effect is good; and the steel pipe truss serves as a supporting structure, the truss fixing structure and the formwork bottom fixing structure realize the dual reinforcement effect, and therefore the unilateral formwork supporting effect of the basement exterior wall can be effectively improved.

Owner:陕西建总安装工程有限公司

Method for controlling caving of roof of short distance coal bed roadway

InactiveCN105971630ASimple stepsEasy to implementUnderground chambersUnderground miningCoalEngineering

The invention discloses a method for controlling caving of a roof of a short distance coal bed roadway. The method comprises steps as follows: 1, determination of basic mechanical parameters of surrounding rock; 2, determination of reserved excavated volumes of two sides of a roadway; 3, excavation of the roadway; 4, determination of a roadway side part supporting structure: a roadway support structure comprises roadway support units and grouting anchor rods which are arranged in a staggered manner, and each roadway side part support unit comprises a roof support system and a roadway side part support system; 4, determination of the vector height of extreme caving arches; 5, determination of the roadway support structure; 6, support construction of roadway surrounding rock; 7, excavation of the next section and support construction of the roadway surrounding rock; 8, completion of the construction process of the short distance coal bed roadway after repeated implementation of the step 7. The method adopts simple steps and is reasonable in design, convenient to implement and good in use effect; the reserved excavated volumes of two sides of the roadway are determined according to the surrounding rock deformation condition of the short distance coal bed roadway respectively, and the roadway side parts and the roof are supported through matching of the grouting anchor rods and the roadway support units.

Owner:XIAN UNIV OF SCI & TECH

Reverse construction method for pebble foundation swirling well

The invention discloses a reverse construction method for a pebble foundation swirling well. The construction method comprises the following steps: 1), measuring and positioning to determine the positions of a center, a well wall and a top beam of the swirling well; 2), excavating earthwork to form foundation pits of first section of well wall and the top beam; 3), binding top beam reinforcement and the first section of well wall reinforcement; 4), installing the top beam and an inner side mould board of the first section of well wall; casting concrete, so that the top beam and the first section of well wall form an integer; 5), forming a foundation pit of the second section of well wall; 6), binding second section of well wall reinforcement, connecting the upper end of a vertical reinforcement in the second section of the well wall reinforcement with a lower vertical preserved reinforcement of the first section of well wall reinforcement; 7), installing the inner side mould board of the second section of well wall, and casting the second section of well wall; 8), repeating the steps 5) to 7), until the construction for all well walls is completed; and 9), finishing the construction of a concrete structure inside the well. The reverse construction method is simple and easy, high in efficiency, convenient to control engineering quality, safe and reliable.

Owner:TIANJIN 20 CONSTR

Jacking system for closure section of continuous rigid frame bridge and jacking deviation rectifying method

The invention discloses a jacking system for a closure section of a continuous rigid frame bridge and a jacking deviation rectifying method. The jacking system is composed of a top plate jacking system and a bottom plate jacking system. The top plate jacking system comprises two sets of top plate embedded bases arranged at the ends of two cantilever beam sections of the continuous rigid frame bridge correspondingly, top plate rigid supporting structures supported between the two sets of top plate embedded bases and a top plate jacking mechanism. The bottom plate jacking system comprises two sets of bottom plate embedded bases arranged at the ends of the two cantilever beam sections correspondingly, bottom plate rigid supporting structures supported between the two sets of bottom plate embedded bases and a bottom plate jacking mechanism. The jacking deviation rectifying method comprises the steps of (1) measurement of position deviation of the cantilever beam sections, (2) adjustment of elevation deviation of the cantilever beam sections, (3) deviation rectifying adjustment and (4) longitudinal jacking. The jacking system is simple in structure, reasonable in design, easy and convenient to construct and good in using effect, the jacking deviation rectifying process of the cantilever beam sections on the two sides of the closure section can be completed easily, conveniently and rapidly, and the rectifying requirements of lateral deviation and reverse deviation of the cantilever beam sections can be met.

Owner:XIAN HIGHWAY INST

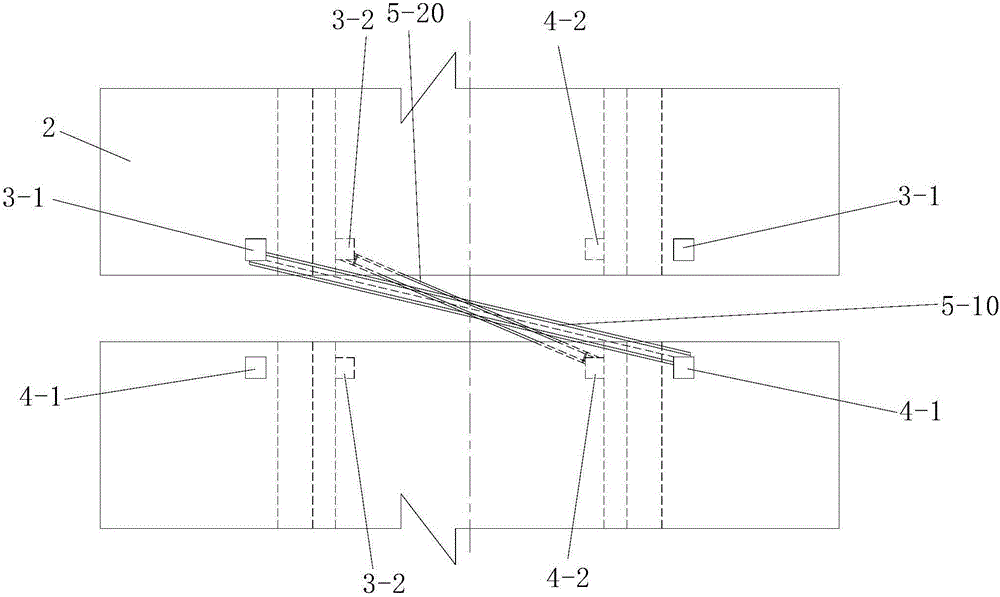

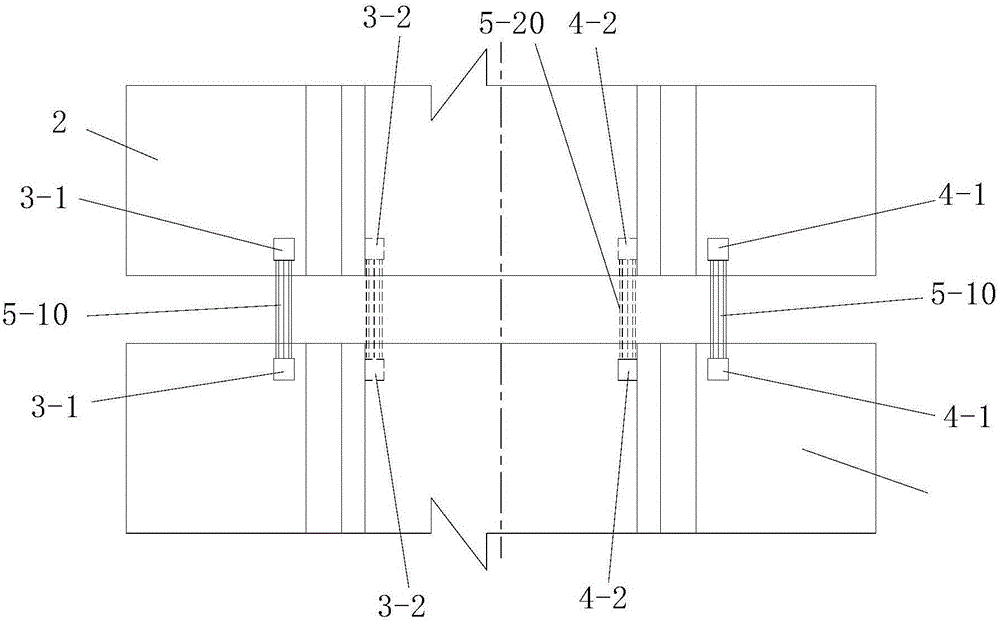

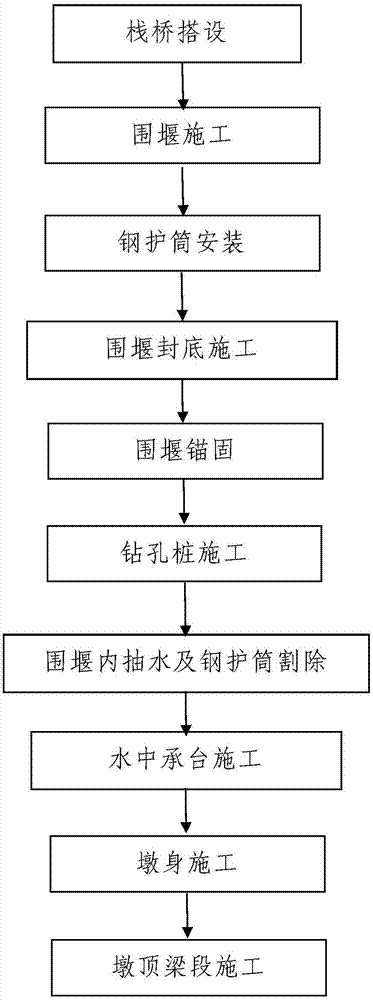

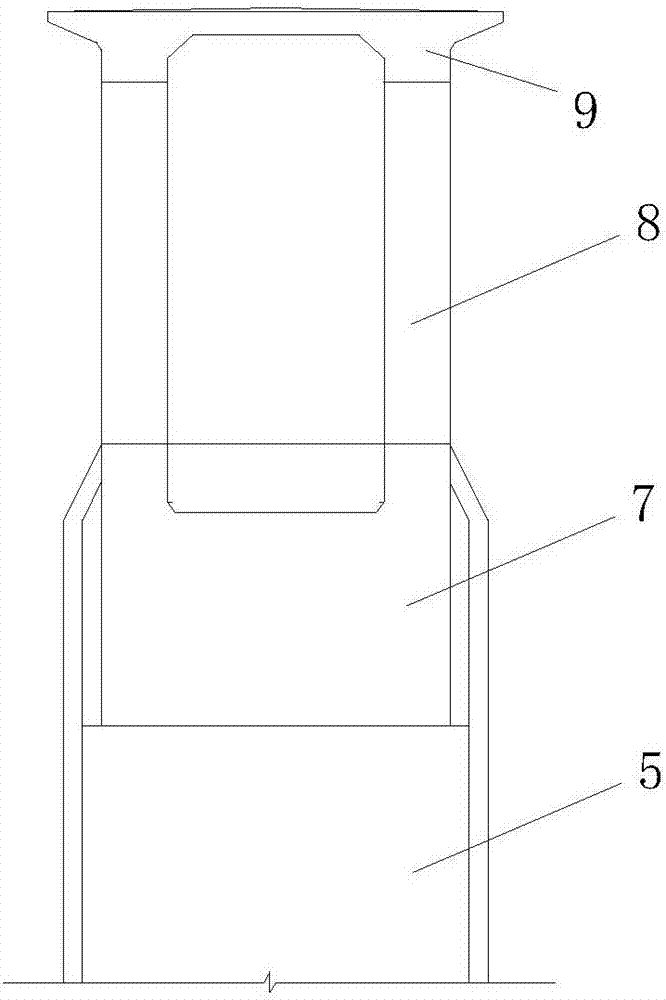

Construction method of in-water pier and pier top beam section of bare rock riverbed

ActiveCN108005094AThe method steps are simpleEasy constructionBridge structural detailsFoundation engineeringPre stressRiver bed

The invention discloses a construction method of an in-water pier and a pier top beam section of a bare rock riverbed. The construction method comprises the steps that first, a trestle is erected; second, a cofferdam is constructed; third, steel protective cylinders are mounted; fourth, cofferdam bottom-sealing construction is conducted; fifth, the cofferdam is anchored, specifically, the steel cofferdam is anchored through a prestressed anchoring device; sixth, bored piles are constructed; seventh, water in the cofferdam is pumped, and the steel protective cylinders are cut off; eighth, an in-water bearing platform is constructed; ninth, a pier body is constructed; and tenth, the pier top beam section is constructed. In the bored pile construction process in the sixth step, the in-water bearing platform construction process in the eighth step, the pier body construction process in the ninth step and the pier top beam section construction process in the tenth step, concrete pumping pipes are used for concrete conveying. The construction method is simple and convenient, the steel cofferdam and pile bodies of the bored piles are connected into a whole in a fastened mode through the prestressed anchoring device, thus the steel cofferdam is anchored on the pile bodies of the bored piles, the steel cofferdam can be effectively prevented from floating, the overturning-resistance safety factor of the steel cofferdam can be increased, and meanwhile long-distance concrete pumping can be easily and conveniently completed by using the trestle.

Owner:NO 1 ENG LIMITED OF CR20G

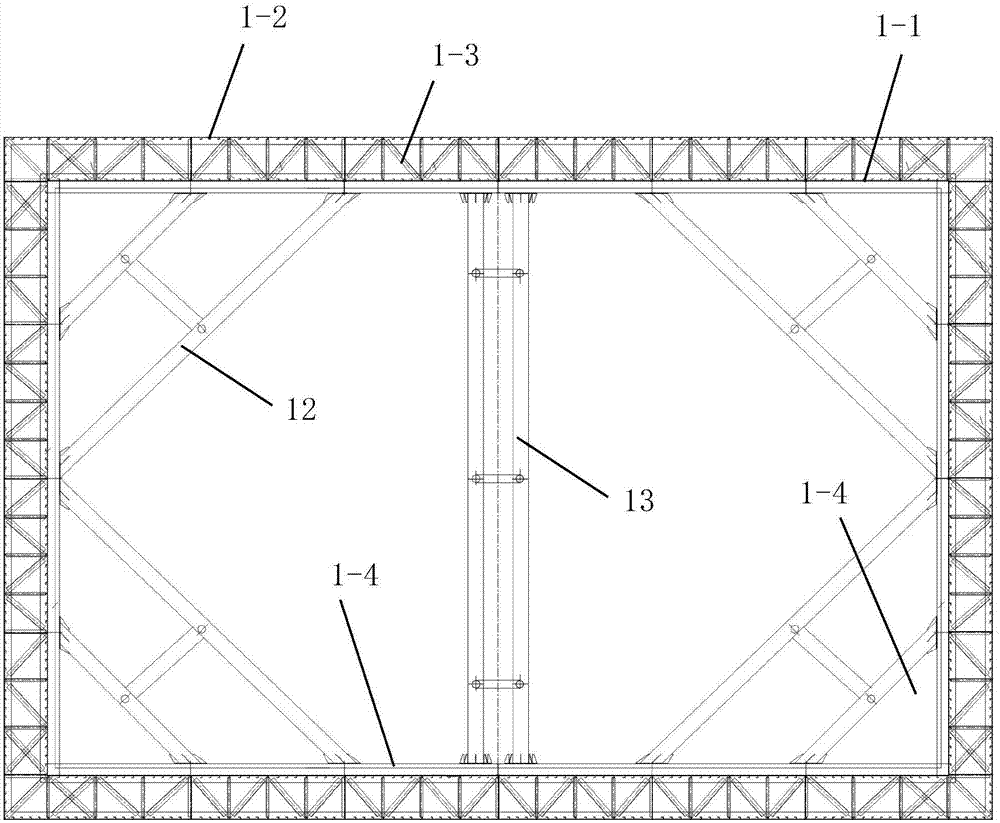

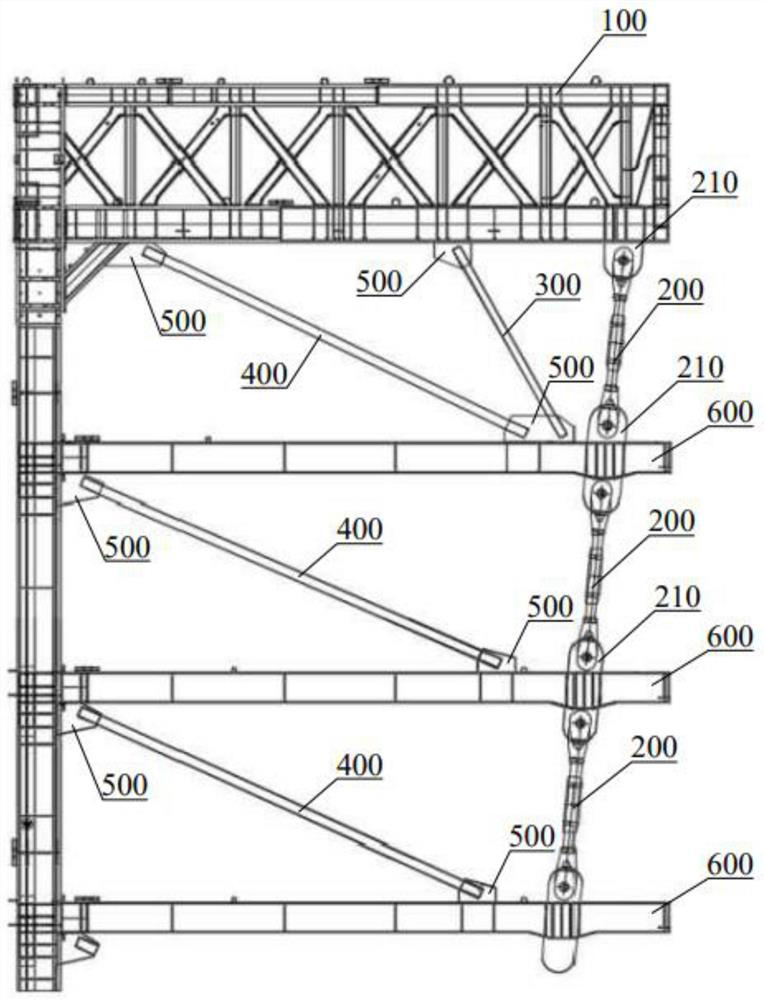

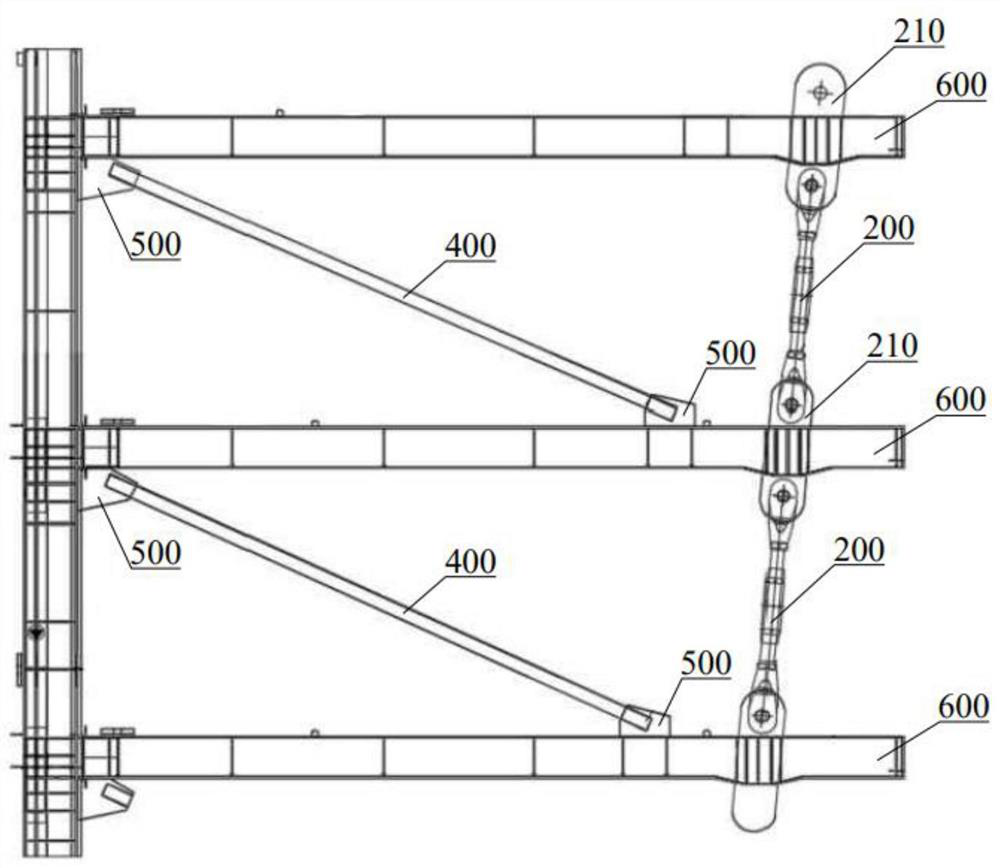

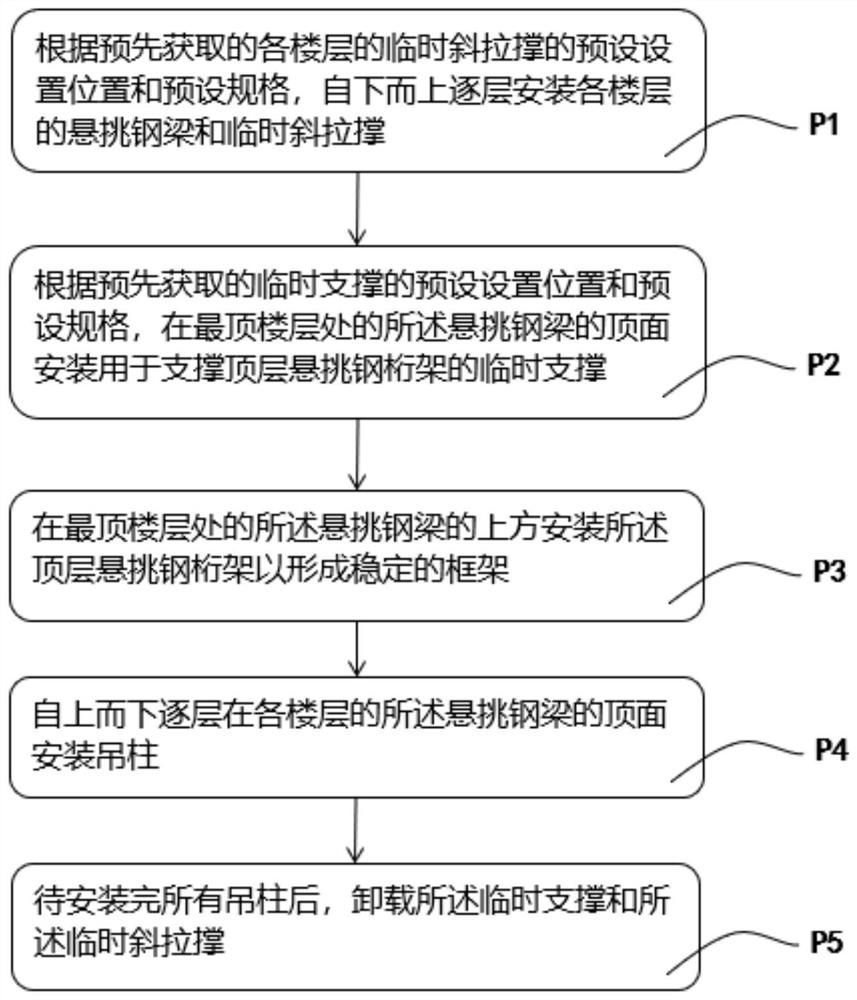

Construction method of suspension steel structure

ActiveCN112814395ASolve the installationGuaranteed stabilityBuilding material handlingArchitectural engineeringCantilever

The invention provides a construction method of a suspension steel structure. The construction method comprises the steps that according to the preset positions and preset specifications of temporary diagonal tension braces of all floors obtained in advance, cantilever steel beams and the temporary diagonal tension braces of all the floors are installed layer by layer from bottom to top; according to the preset positions and preset specifications of temporary supports obtained in advance, the temporary supports used for supporting a top-layer cantilever steel truss are installed on the top faces of the cantilever steel beams of the topmost floor; the top-layer cantilever steel truss is installed above the cantilever steel beams located on the topmost floor to form a stable frame; hanging columns are installed on the top faces of the cantilever steel beams of all the floors layer by layer from top to bottom; and after all the hanging columns are installed, the temporary supports and the temporary diagonal tension braces are unloaded. According to the construction method, the stress requirement of the hanging columns can be met, construction is safe and controllable, the construction quality and precision can meet the design requirement, the construction efficiency is improved, and the construction cost is reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP

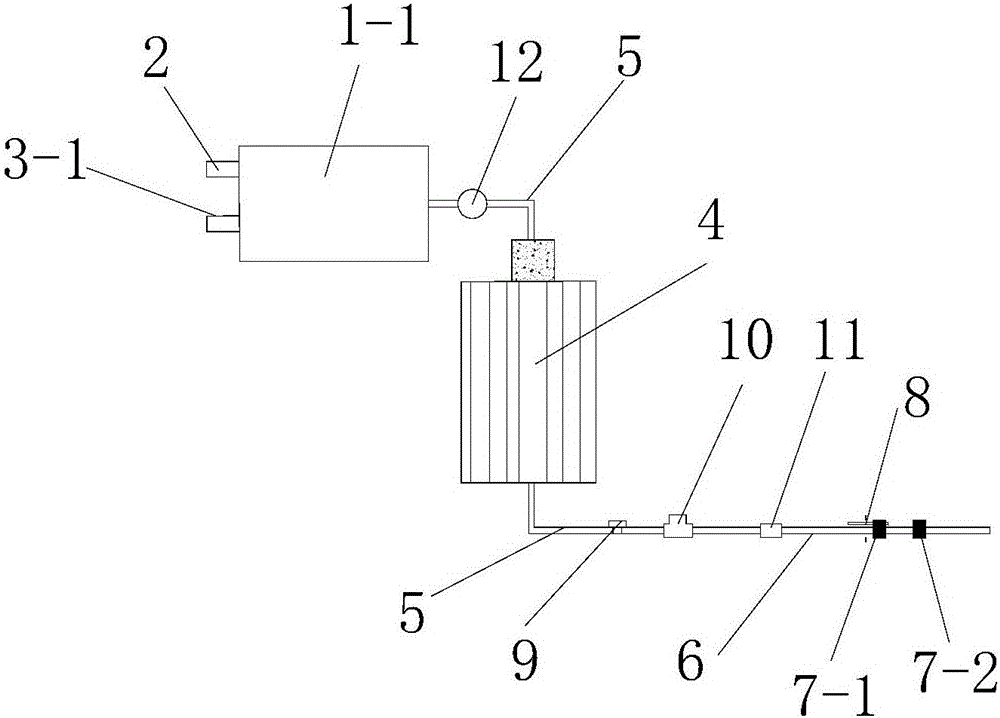

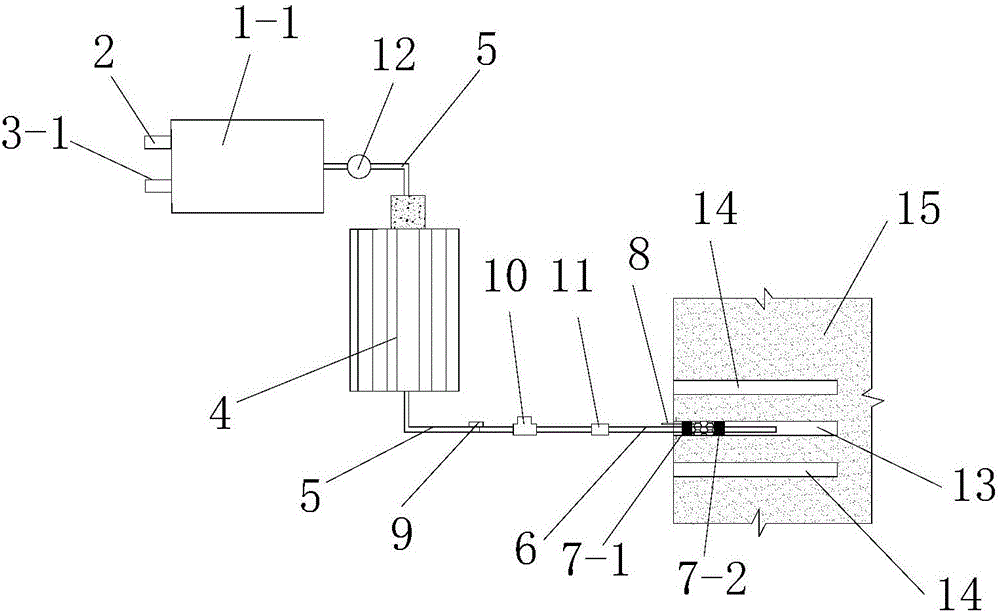

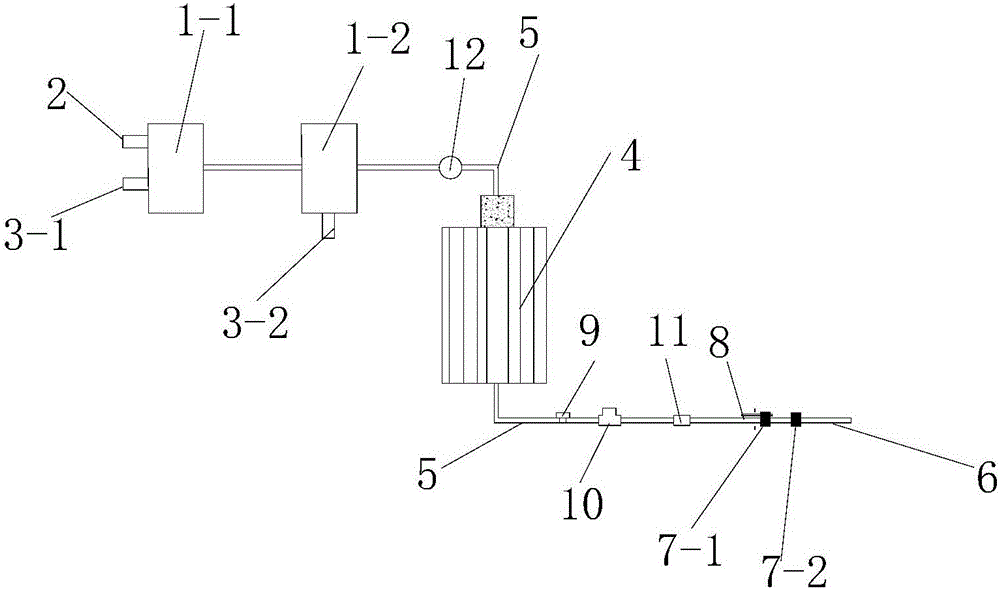

Active fracturing device for coal rock softening and coal rock fracturing construction process

The invention discloses an active fracturing device for coal rock softening and a coal rock fracturing construction process. The active fracturing device comprises a conveying mechanism and a fracturing mechanism communicated with the conveying mechanism, wherein the conveying mechanism comprises a pipeline and a supply unit, a power unit and an adjusting unit sequentially arranged on the pipeline, and the fracturing mechanism is arranged at the output end of the pipeline. The construction process comprises the steps of fracturing fluid preparation and drilling, pre-compression, hole sealing, fracturing and pressure relief. The active fracturing device is simple in structure and reasonable in design, a dustproof water fracturing fluid or supercritical CO2 active fracturing fluid serves as a fracturing fluid for a coal rock to be fractured, the input cost is low, a fracturing effect is good, fracturing energy can be continuously increased through gas-fluid two-phase circulating conversion of the fracturing fluid, a good fracturing effect is achieved, clay mineral expansion in the coal rock is effectively prevented, the damage of the fracturing fluid to a stratum is decreased, further the permeability of the coal rock to be fractured is further improved, and the construction process is easy to control.

Owner:库尔勒金川矿业有限公司 +1

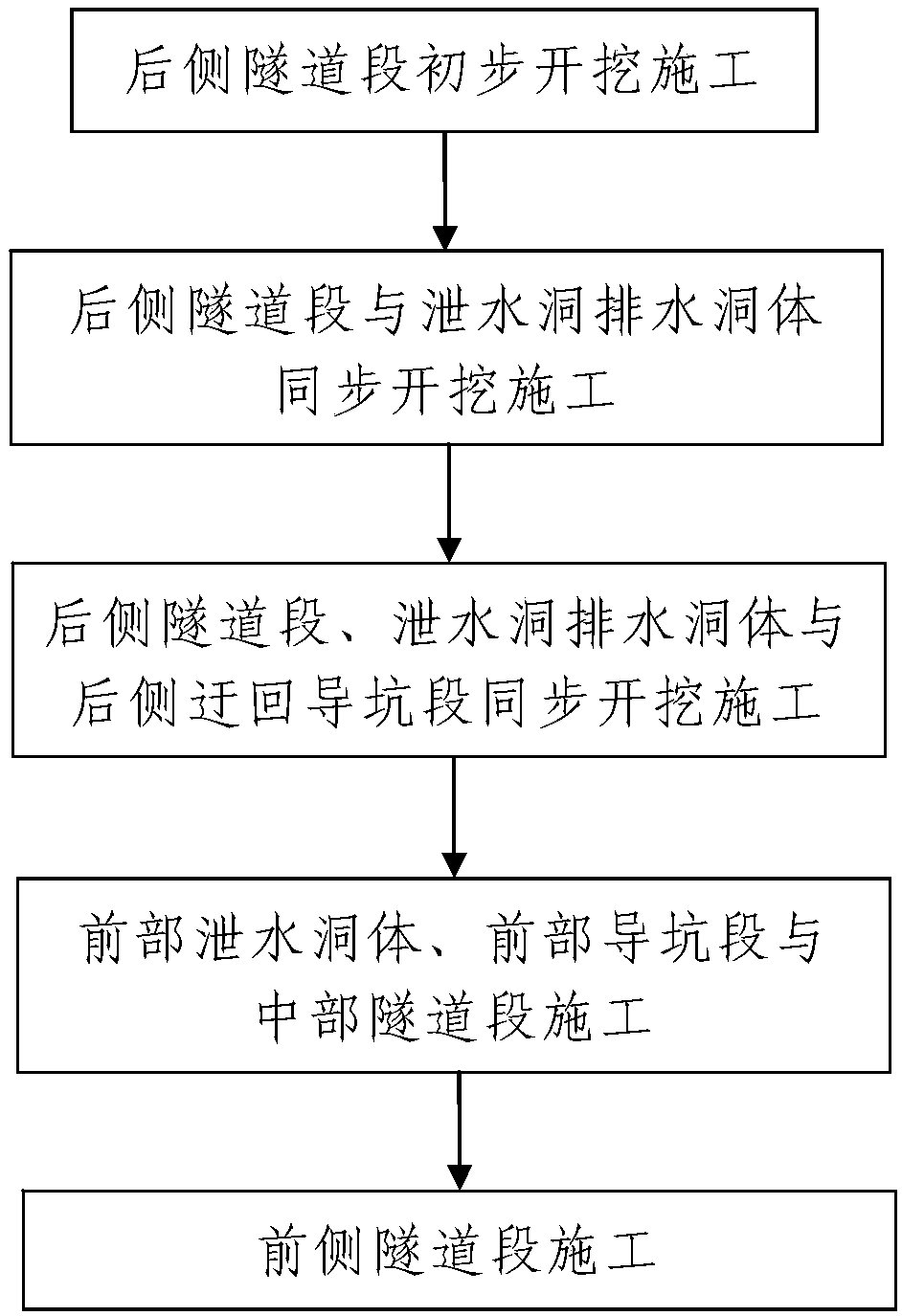

Crossing high-angle thrust water-rich sand-rich fault tunnel excavation and drainage construction method

ActiveCN109578007AThe method steps are simpleReasonable designUnderground chambersDrainageHigh angleWater pressure

The invention discloses a crossing high-angle thrust water-rich sand-rich fault tunnel excavation and drainage construction method. A tortuous pilot tunnel and a water release hole are formed in the same side of a front hole of a construction tunnel. The construction process includes the steps: first, preliminarily excavating and constructing a rear tunnel section; second, synchronously excavatingand constructing the rear tunnel section and a drainage hole body of the water release hole; third, synchronously excavating and constructing the rear tunnel section, the drainage hole body of the water release hole and a rear tortuous pilot tunnel section; fourth, constructing a front water release hole body, a front pilot tunnel section and a middle tunnel section; fifth, constructing a front tunnel section. The method is reasonable in design, simple and convenient in construction and good in use effect, water on an upper wall of a fault is drained by the high-level water release hole between the front hole of the tunnel and the tortuous pilot tunnel, drainage is assisted by the tortuous pilot tunnel excavated before the front hole of the tunnel, the front fault condition of a tunnel face of the front hole is verified in advance, the water in the fault can be maximally drained, water pressure in the front fault of the tunnel face is reduced, construction safety of each tunnel face can be ensured, and construction period is shortened.

Owner:CHINA RAILWAY 20 BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com