Patents

Literature

52results about How to "Little traffic disturbance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

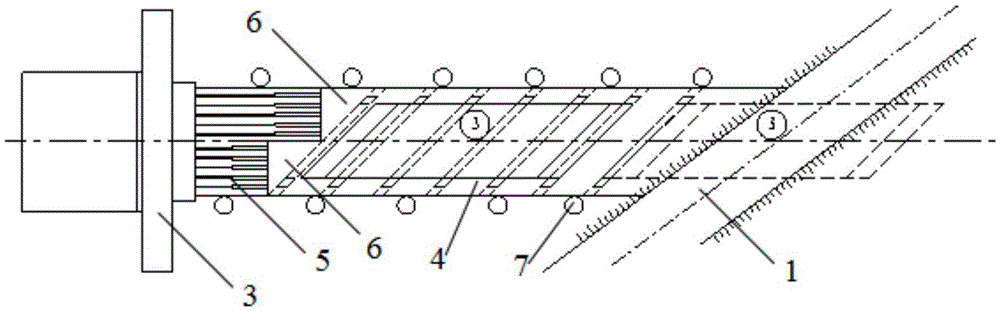

Small-bore long distance curved pipe jacking method

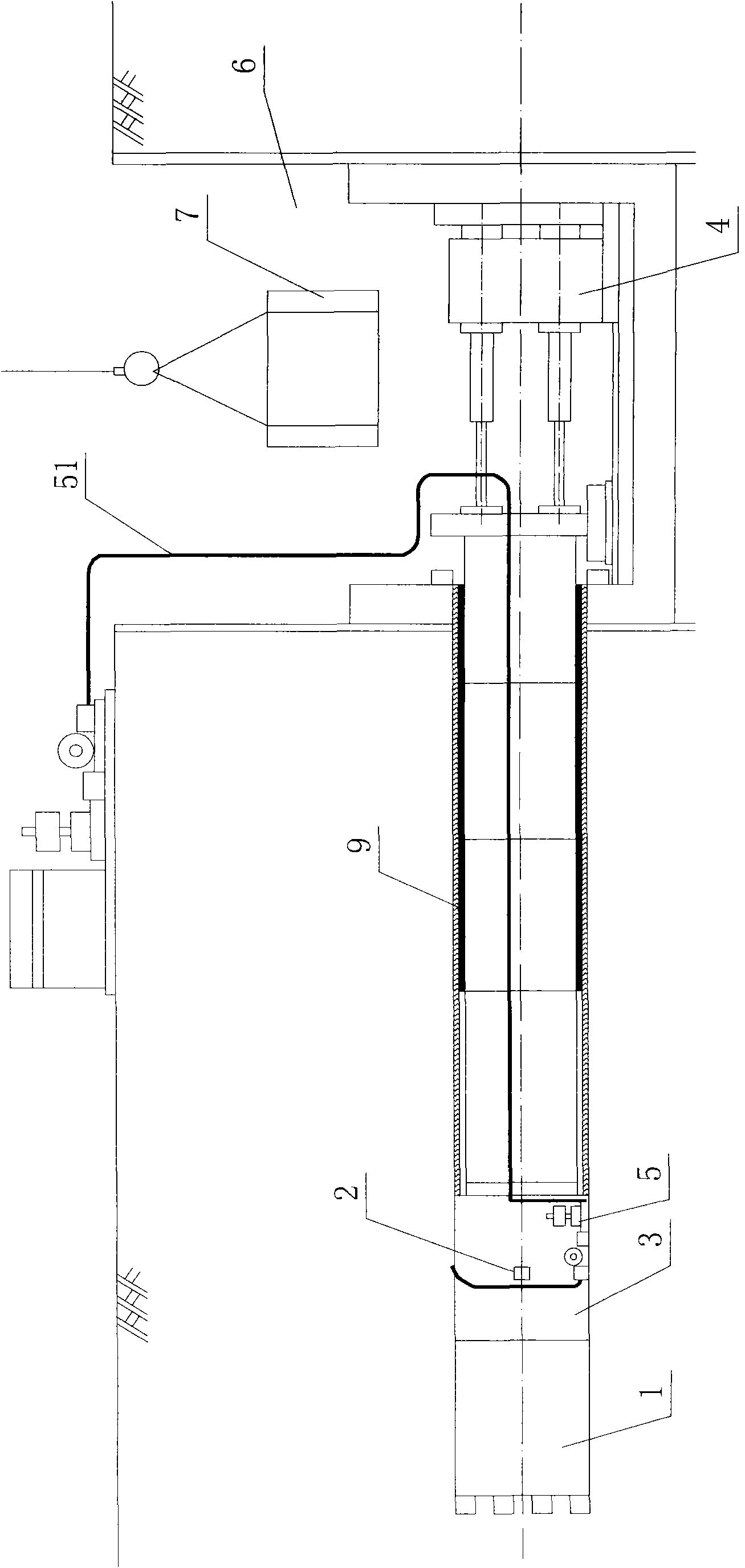

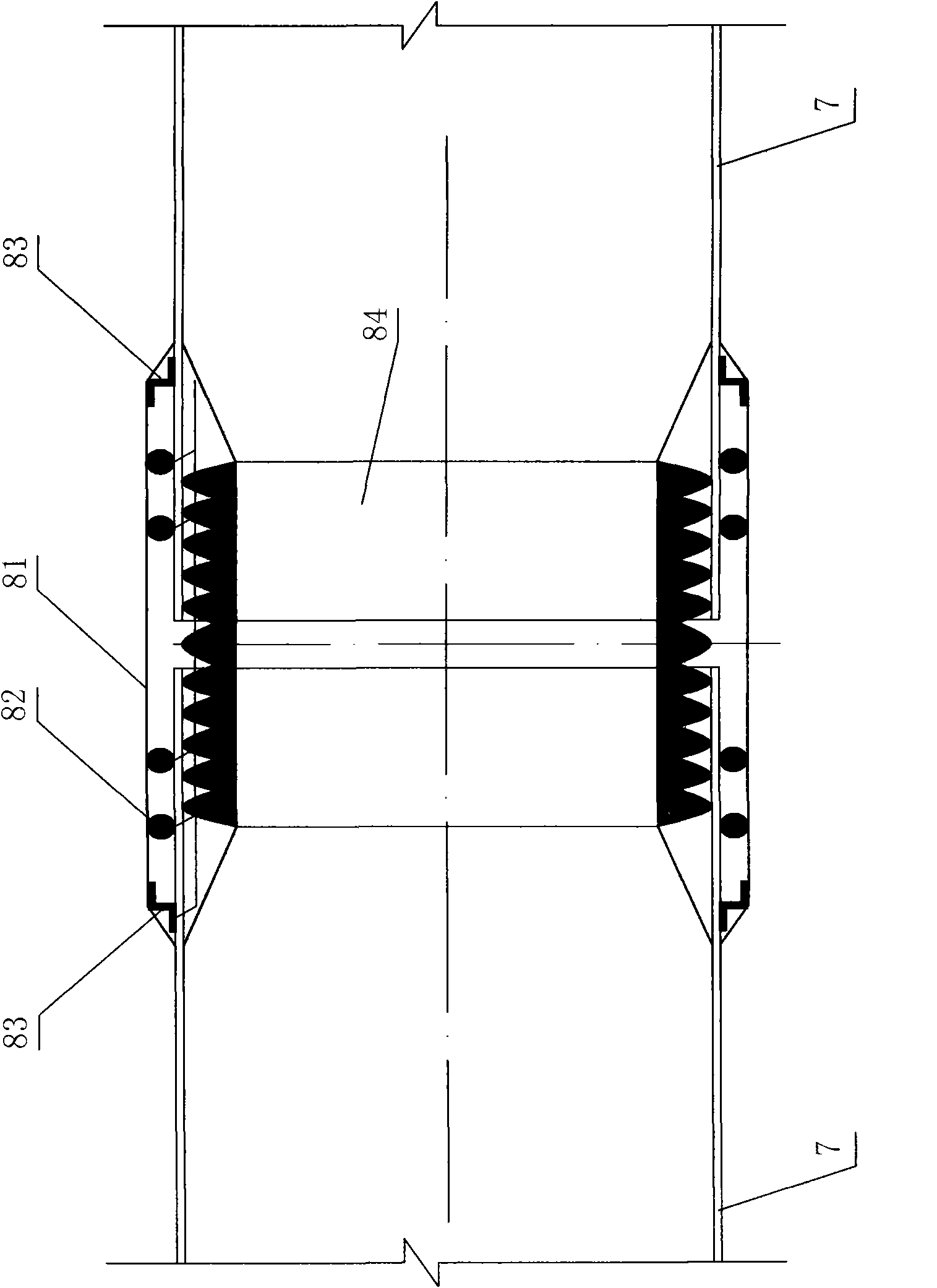

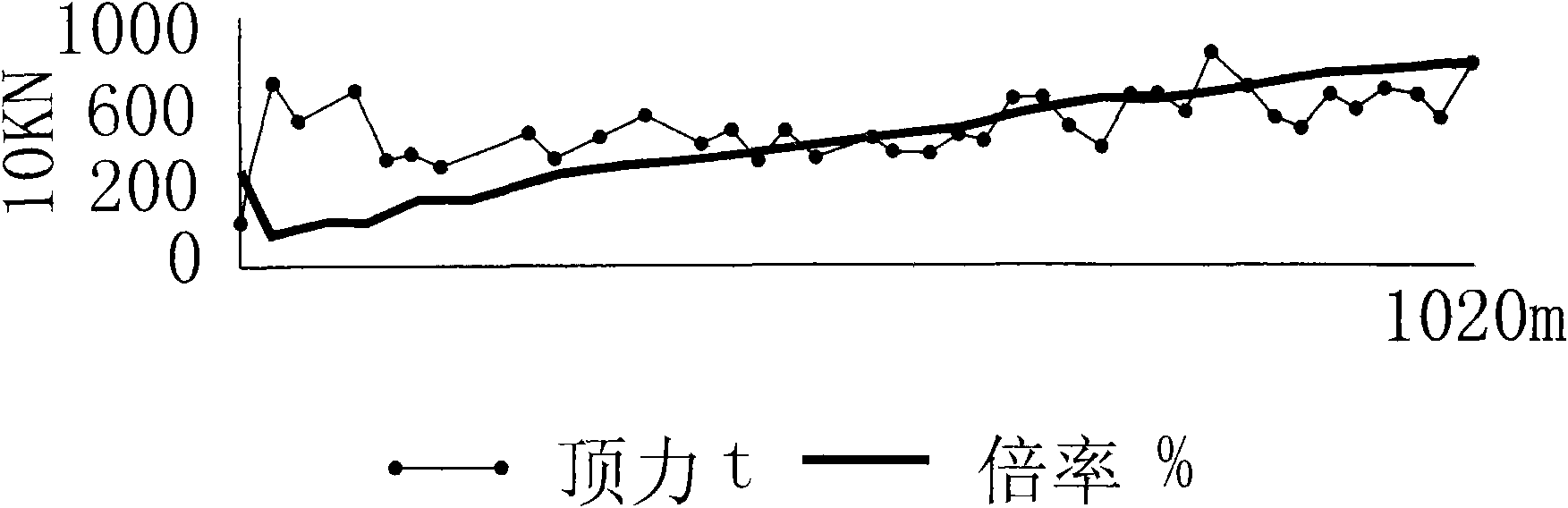

The present invention discloses a small-bore long distance curved pipe jacking method, belonging to the technical field of architectural construction, and comprising the following steps: constructing a working well; mounting construction equipment; leading in a measuring axis and a benchmark; taking the jacking tubes in position; jacking; grouting; constructing pipelines in the working well; and finishing the cleaning; the construction equipment comprises a development machine, a curved guide machine with an automatic measurement system, a jack and a pump cylinder, wherein the curved guide machine is connected to a back end of the development machine; the jack is mounted in the working well; the pump cylinder is mounted in a duct of the curved guide machine; the pump cylinder is used for conveying thixotropic mud to between an outer wall of the jacking tube and a soil body via a slip casting tube; during the jacking procedure, the adjacent jacking tubes are connected by a pipe joint sleeve. The method of the present invention enables the prior impossible small-bore long distance quick turn construction to be possible; the economic benefit is good, and construction precision is high; the environment problems like traffic obstruction and the like are solved successfully.

Owner:大有环境有限公司

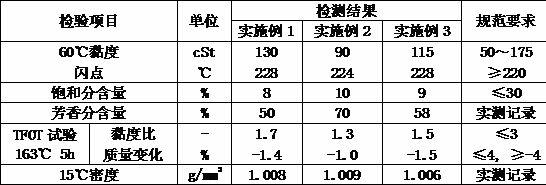

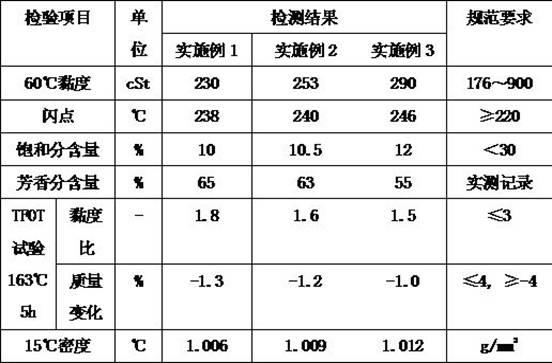

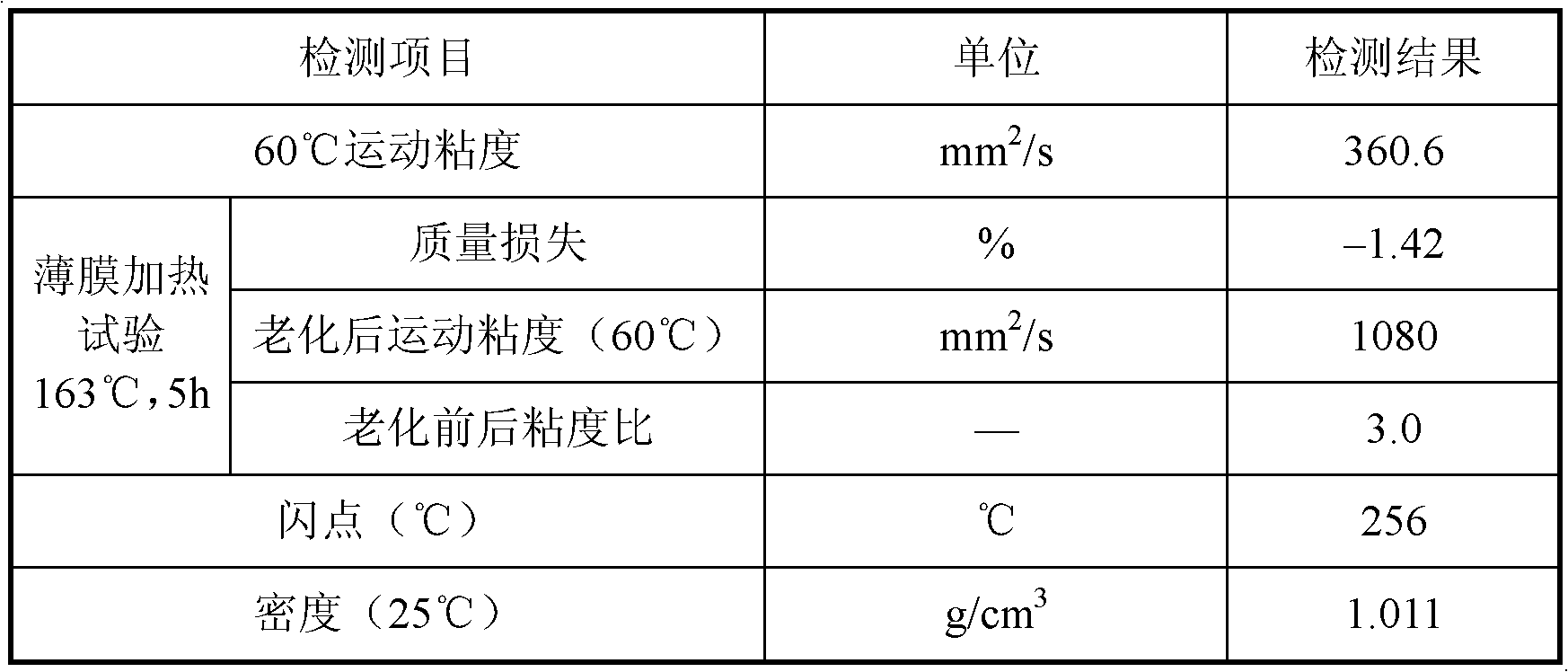

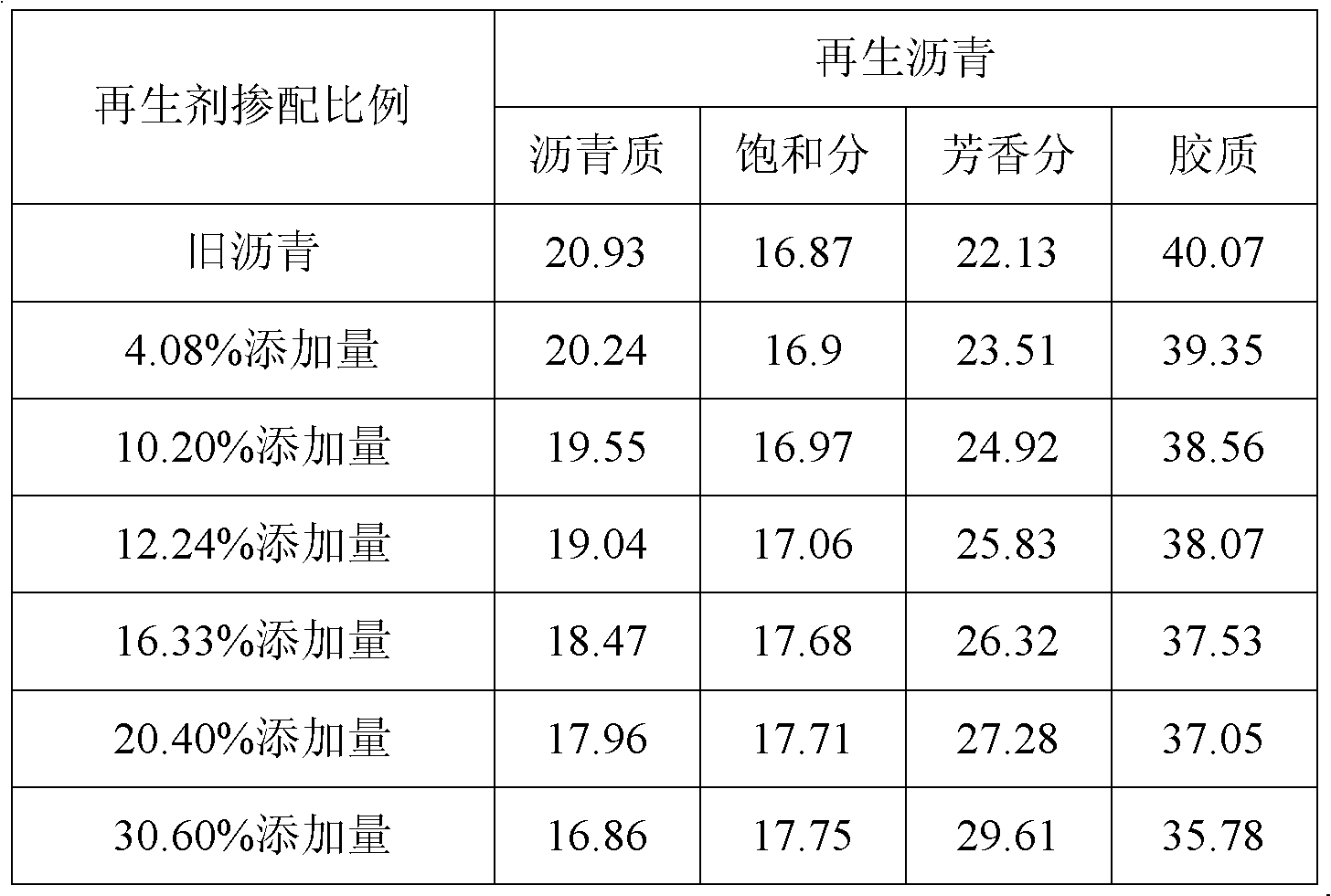

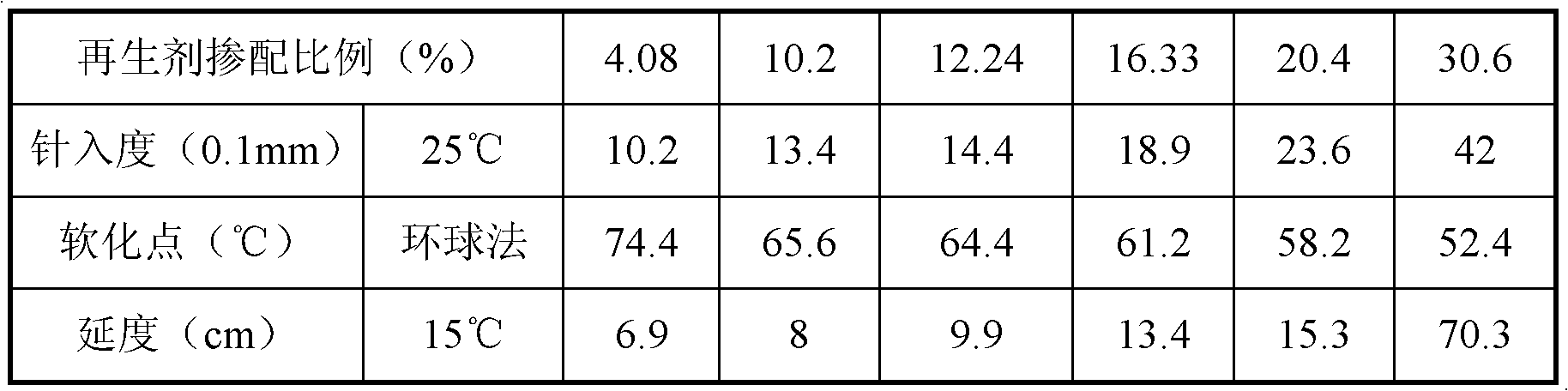

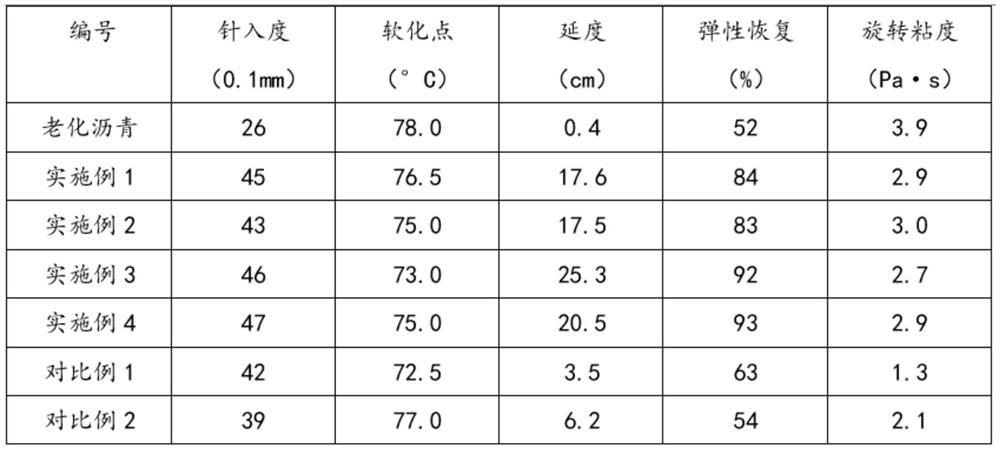

Asphalt recycling agent for hot recycling of asphalt on asphalt road surface

The invention discloses an asphalt recycling agent for hot recycling of asphalt on an asphalt road surface. The recycling agent comprises the following components by weight: 19-70% of an aromatic oil, 20-60% of heavy oil, 5-30% of liquid petroleum resin and 0.2-1% of a stabilizer. The invention also provides a preparation process of the asphalt recycling agent and a method for preparing recycled asphalt by use of the asphalt recycling agent. The recycling agent disclosed by the invention is good in recycling effect, easy for raw materials purchase, stable in quality, low in equipment investment, simple in processing steps, short in processing time of finished products, good in storage stability, stable in physicochemical property, and convenient for on-site operation, and is suitable for on-site hot recycling construction as a special recycling agent.

Owner:YINGDA HEAT REGENERATION

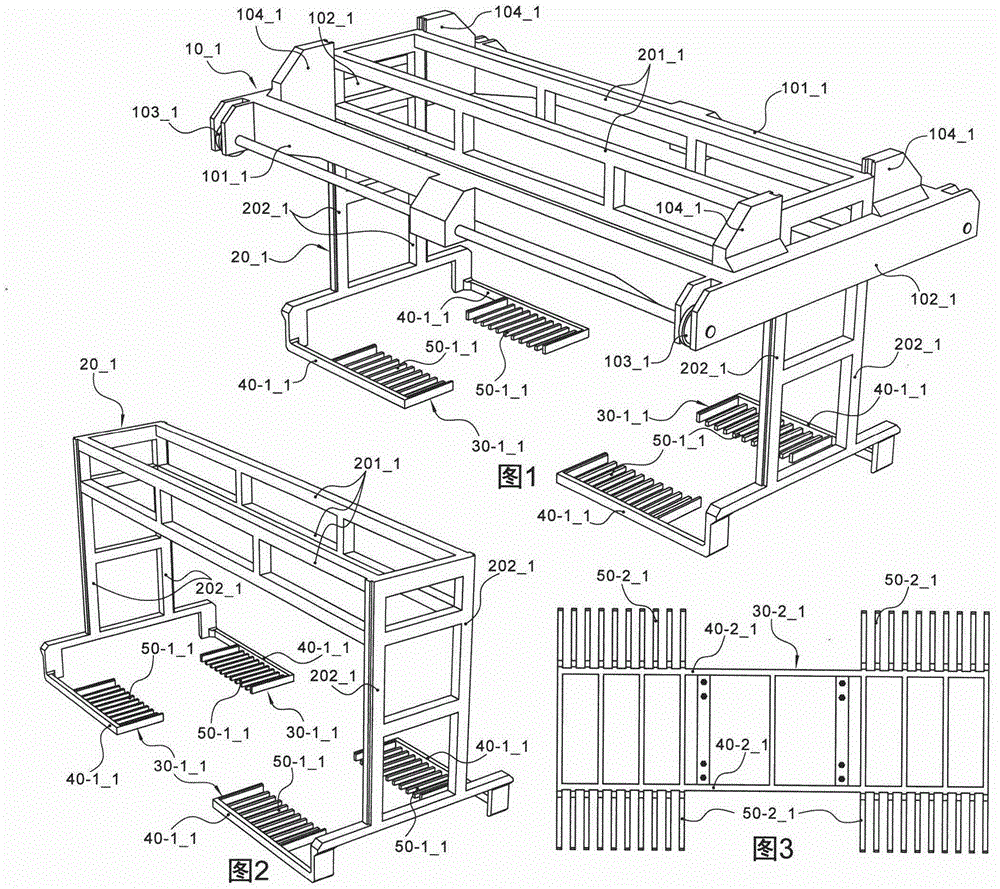

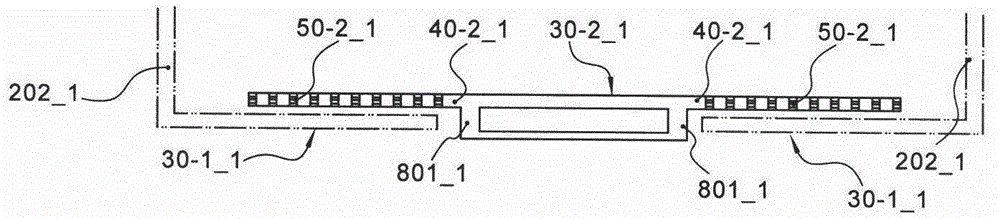

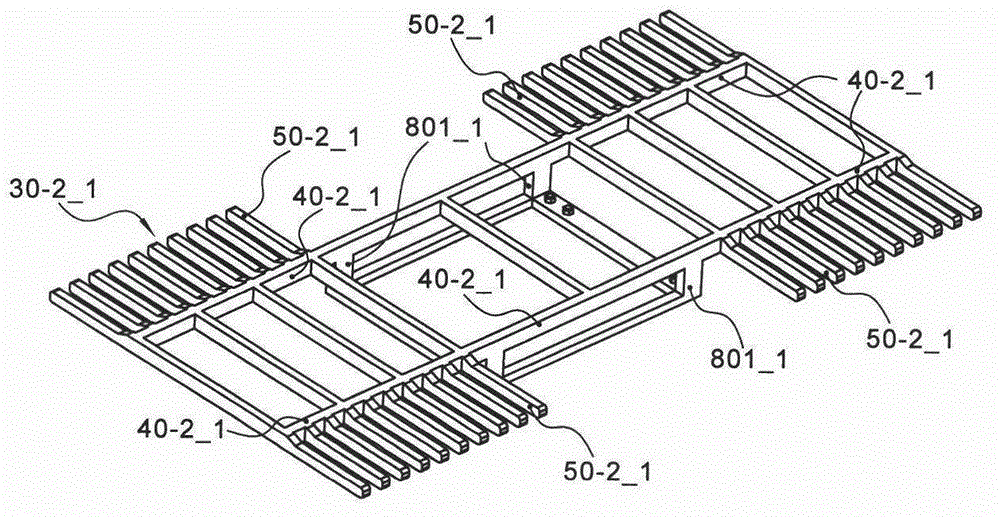

Parking device with comb teeth for supporting, storing and withdrawing vehicle

The invention provides a vehicle carrying scheme that lifting racks are used for lifting a vehicle above a vehicle top so as to perform leap-type translation in order to solve the problems that existing parking devices with the comb teeth for supporting, storing and withdrawing the vehicle are low in using ratio of the ground, inflexible in application, poor in storing and withdrawing efficiency and the like. Besides, by means of mutually communicated storing and withdrawing rack channels which are distributed below all comb-shaped parking racks of a parking queue, comb-shaped storing and withdrawing racks of carriers can directly and rapidly move and operate between each comb-shaped parking rack and vehicle storing and withdrawing port, the process of lifting and putting the road vehicle to a garage can be simply finished by the aid of comb-shaped lifting racks which are arranged at positions of the vehicle storing and withdrawing ports, a system is effectively simplified, and the efficiency is increased.

Owner:于君

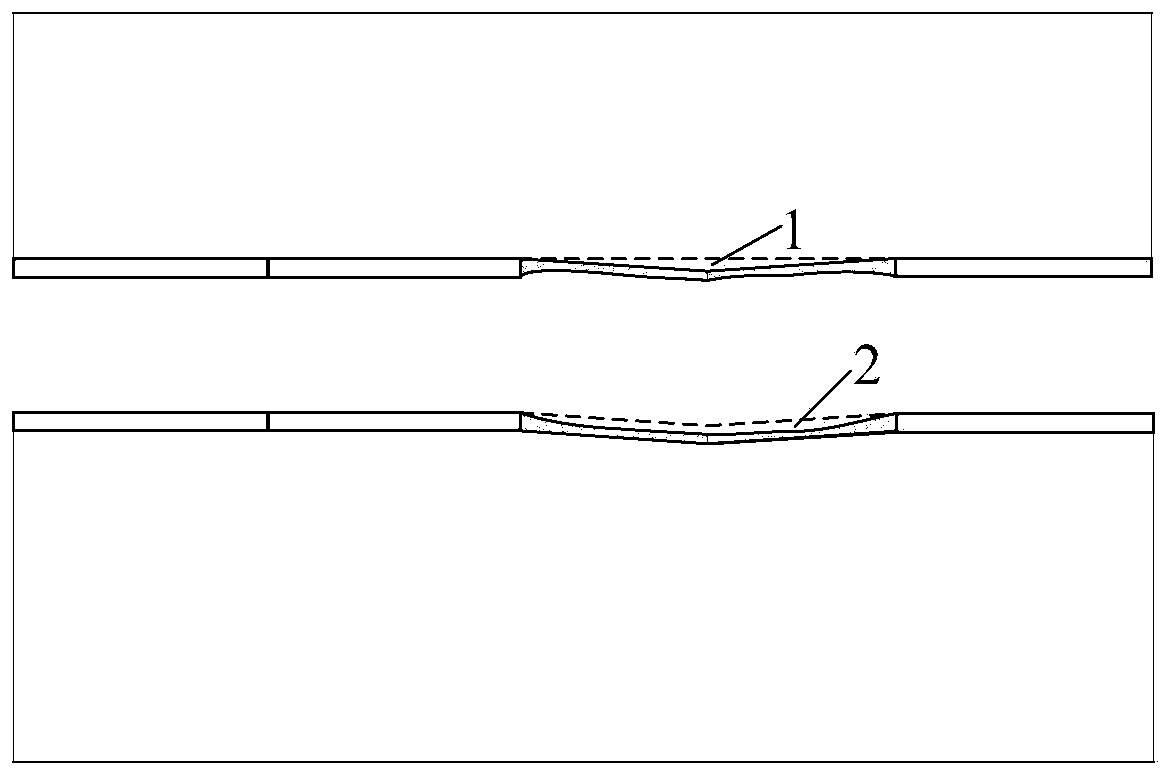

Compensation method for roadbed settlement

InactiveCN102322008AShort construction timeLittle traffic disturbanceRoadwaysArchitectural engineeringRoad surface

The invention provides a compensation method for roadbed settlement, which comprises the steps that: when in a roadbed construction process, on a road section which can easily settle and deform after being open to traffic, when a roadbed is filled to a height which is 30cm to 200cm from the top surface, retaining walls are built on both sides of the roadbed; bagged lime is uniformly paved on the inner sides of the retaining walls within the full-width range of the roadbed on different layers; a rubber pipe is pre-reserved on each lime bag to the outer side of the roadbed as a water injection channel in a later period; the bottom surfaces of the retaining walls are 20cm to 100cm lower than the bottom surfaces which are paved from the bagged lime, and the top surfaces of the retaining wallsare in alignment with the top surface of the roadbed; and when the roadbed settles, the water is injected into the lime bags through the pre-reserved rubber pipe, the lime absorbs the water, swells and jacks a road surface structure up. The compensation method for roadbed settlement completes the water injection on the outer side of the roadbed, has a short construction time, does not interrupt the traffic during the construction process and has little interference to the traffic; and the construction is not restricted by the weather and the environment, the settlement can be handled at any time when being found, and the construction process is controllable.

Owner:广东大象交通科技有限公司

SBR (styrene butadiene rubber) modified recycling agent for aged asphalt road surface in alpine regions, and preparation method and usage of the recycling agent

ActiveCN102604401AImprove ductilityImprove crack resistanceRoads maintainenceBuilding insulationsCrack resistanceRoad surface

The invention discloses an SBR (styrene butadiene rubber) modified recycling agent for an aged asphalt road surface in alpine regions, which comprises the following components by mass: 9.95-30% of SBR, 15-60% of 90A asphalt, 30-70% of extract oil, and 0.05-0.2% of a crosslinker. The invention also discloses a preparation method of the SBR modified recycling agent and a method for preparing recycled asphalt by use of the SBR modified recycling agent. The SBR modified recycling agent provided by the invention significantly improves the ductility of the aged asphalt, the recycled asphalt becomes pliable, the crack resistance of the road surface is remarkably improved, and the recycling agent is suitable for recycling of the aged asphalt road surface in alpine regions. For upgrading and processing of asphalt, generally only addition of the SBR modified recycling agent provided by the invention is needed, the processing technology is simple and the quality is easy to control. The SBR modified recycling agent has a good effect at a low temperature, raw materials are stable in quality and easy to purchase, storage stability are good, the physicochemical properties are stable, on-site operation are convenient, and the SBR modified recycling agent is suitable for on-site hot recycling construction as a special recycling agent in alpine regions and for factory processing for upgrading of asphalt.

Owner:YINGDA HEAT REGENERATION

Plain asphalt reclaiming agent and preparation method and application thereof

InactiveCN101845227ARaw materials are easy to getLow preparation equipment requirementsBuilding insulationsPlasticizerBituminous materials

The invention belongs to the field of a composite containing an asphalt material and a preparation method and application thereof, in particular to a plain asphalt reclaiming agent and preparation and application thereof. The plain asphalt reclaiming agent is prepared from the following components: 23-35 parts of matrix asphalt, 60-75 parts of reclaimed oil, 3-5 parts of plasticizer and 0-5 parts of high temperature stabilizer, and is obtained by heating, mixing and stirring the materials. The preparation method comprises the following steps: heating the matrix asphalt at 115-135DEG C; heating and evenly stirring the reclaimed oil, plasticizer and high temperature stabilizer at 115-135 DEG C to obtain a mixture; and finally, stirring the matrix asphalt and the mixture at 115-135 DEG C and cooling to obtain the plain asphalt reclaiming agent. The application is as follows: taking aging asphalt and heating at 110-135 DEG C, adding the plain asphalt reclaiming agent, wherein the additive amount thereof is more than 30% of that of the aging asphalt; and stirring the mixture at 100-110 DEG C to obtain the reclaimed asphalt. The invention has the advantages of low cost and good reclaiming effect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

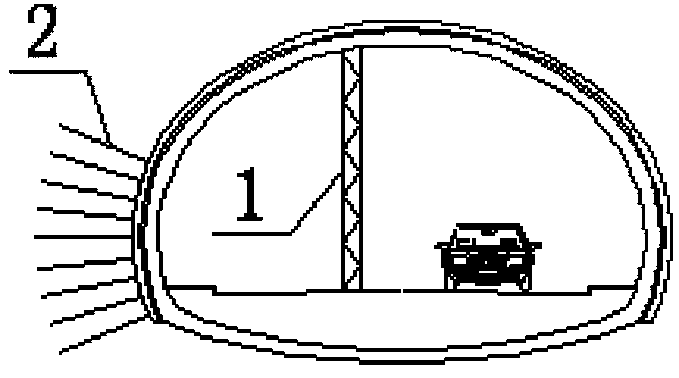

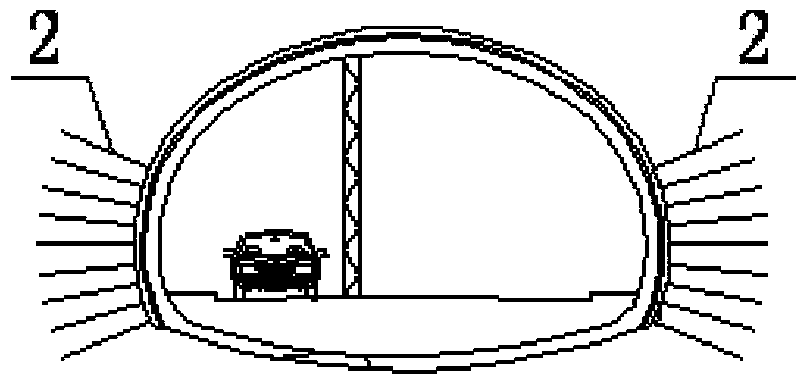

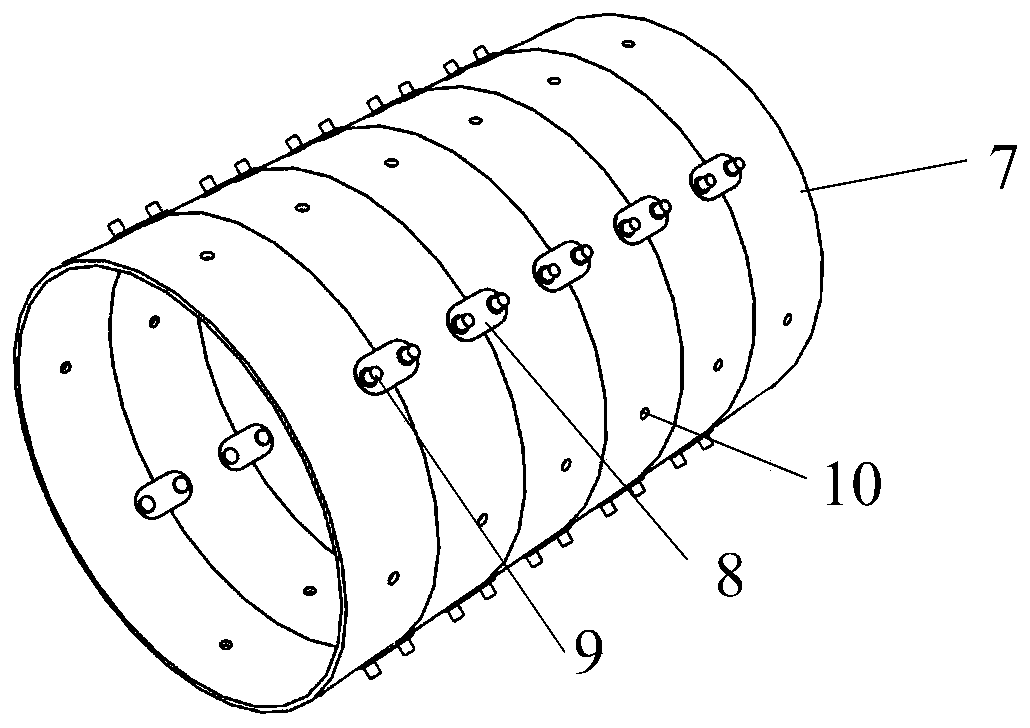

Existing tunnel down-digging extension construction method without traffic interruption

The invention discloses an existing tunnel down-digging extension construction method without traffic interruption, which is mainly alternately implemented on the left side and the right side in an existing tunnel hole. The existing tunnel down-digging extension construction method without traffic interruption comprises the following steps: firstly, establishing a partition fence (1), and adding anchor rods (2) on a haunch and an arch springing; then, carrying out down-digging extension, adding a waterproof layer till the lateral drain on the bottom of an extension tunnel on the inner side of the secondary lining of the existing tunnel, and adding a third lining (7); finally, pouring a vertical wall (9) and a reinforced concrete road slab (10), removing the partition fence (1) in the hole, and restoring the normal traffic. The construction method is scientific, reasonable, safe and reliable, the safety problem of the existing tunnel structure in the construction process is effectively solved, the integrity of the tunnel structure is guaranteed, and the traffic interference caused by the extension construction is reduced.

Owner:CHANGAN UNIV +1

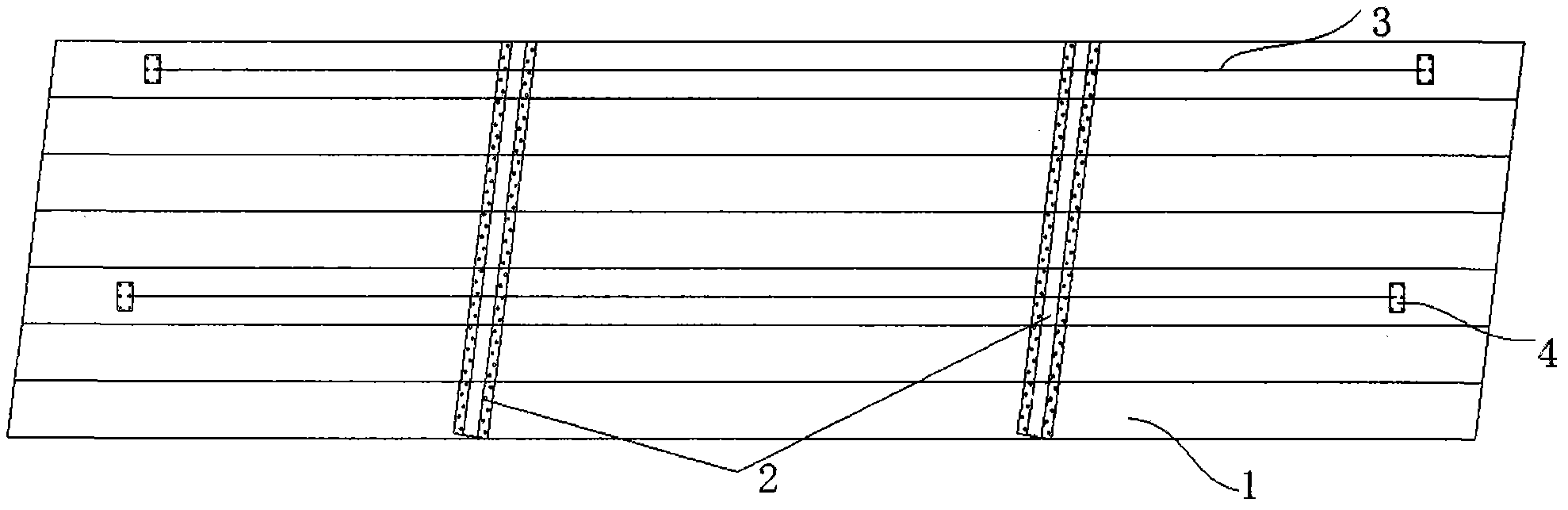

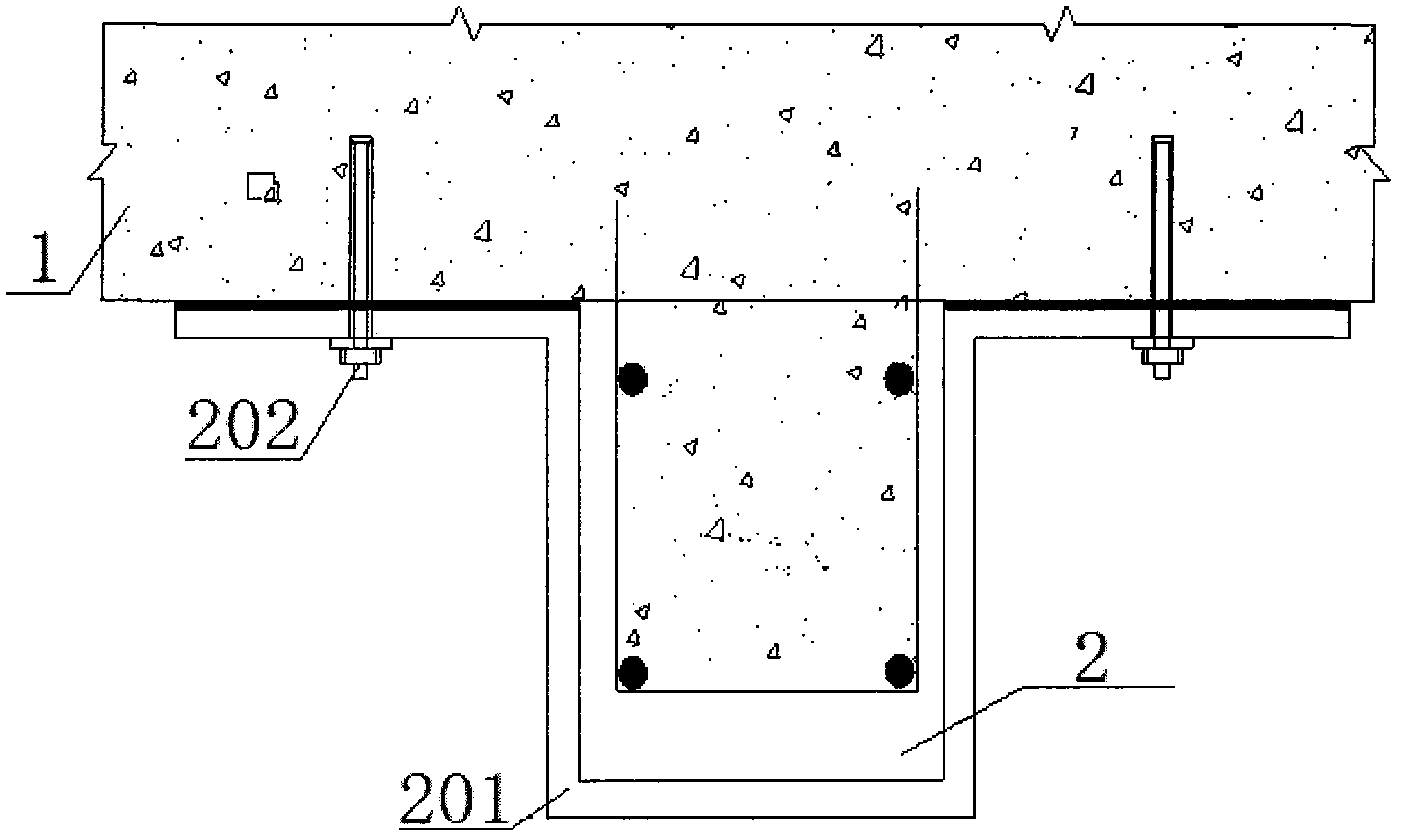

Reinforcement method for single beam bearing of bridge and construction method thereof

InactiveCN104328747AImprove lateral forceEasy constructionBridge erection/assemblyBridge strengtheningRebarPre stressing

The invention relates to a reinforcement method for single beam bearing of a bridge and a construction method thereof, and provides an anchor riveted steel concrete cross beam which is provided with longitudinal pre-stressed reinforcements to serve as elastic support so as to achieve the purposes of increasing the integrity of a hollow slab, improving load lateral distribution and improving the integral bearing capacity of the bridge. The other purpose of the invention is to provide a reinforcement construction method for single beam bearing of the bridge. The method comprises the following steps: 1, transversely lofting and positioning; 2, matting on the surface and perforating; 3, cleaning holes and embedding reinforcements and anchor screws in the holes; 4, arranging U-shaped steel at the locating position through anchor riveting; 5, pouring concrete into the U-shaped steel. The method has the technical effects that certain rigidity is achieved by additionally arranging the cross beams and the purpose of improving the lateral stress is achieved. Active reinforcement can be achieved and the elastic support is also equivalently added by tensioning the longitudinal pre-stressed reinforcements; the under-bridge construction causes less interference to traffic, and the construction is convenient.

Owner:金辉

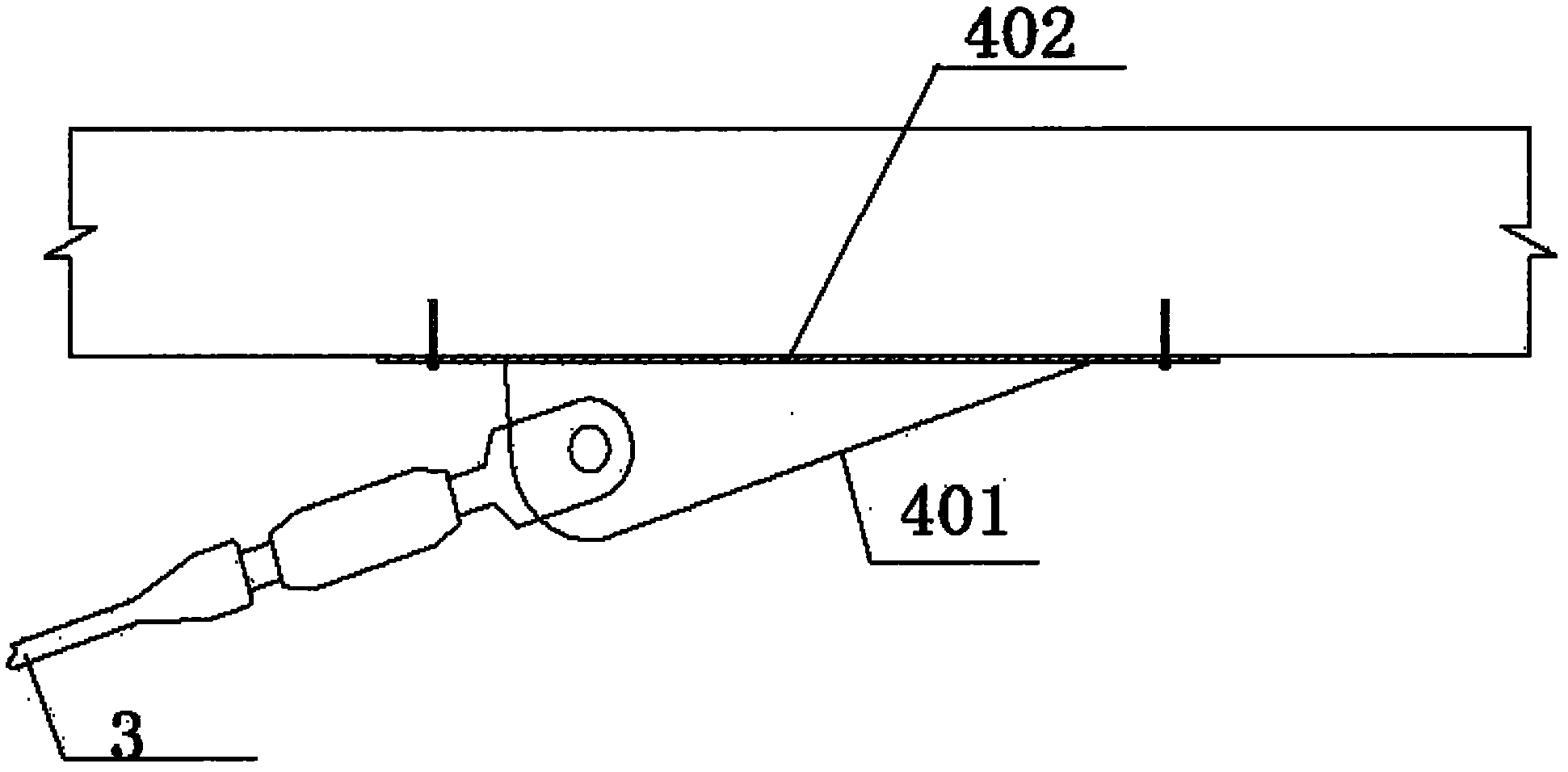

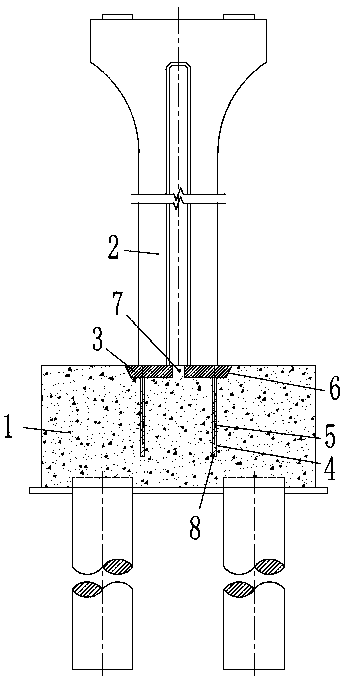

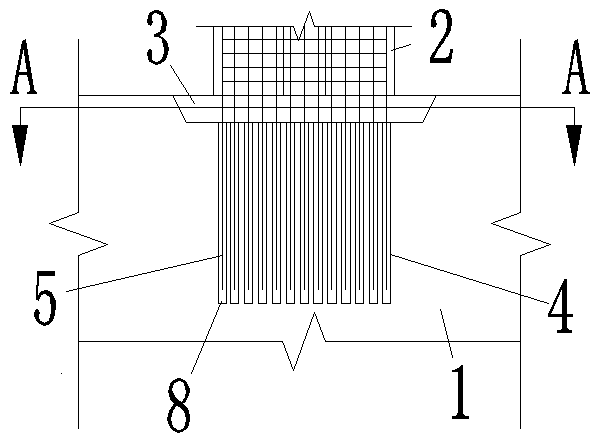

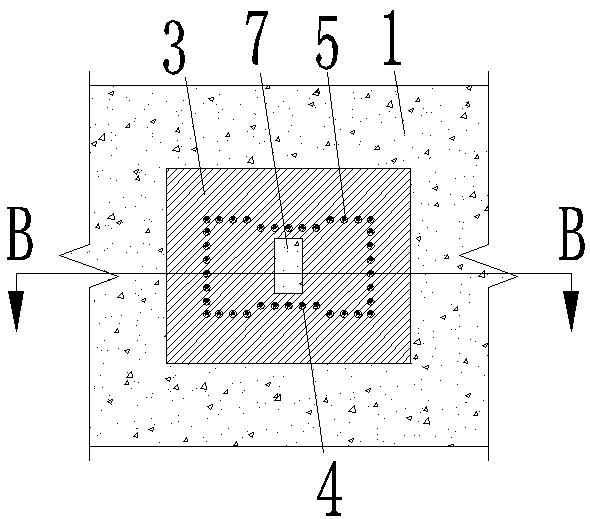

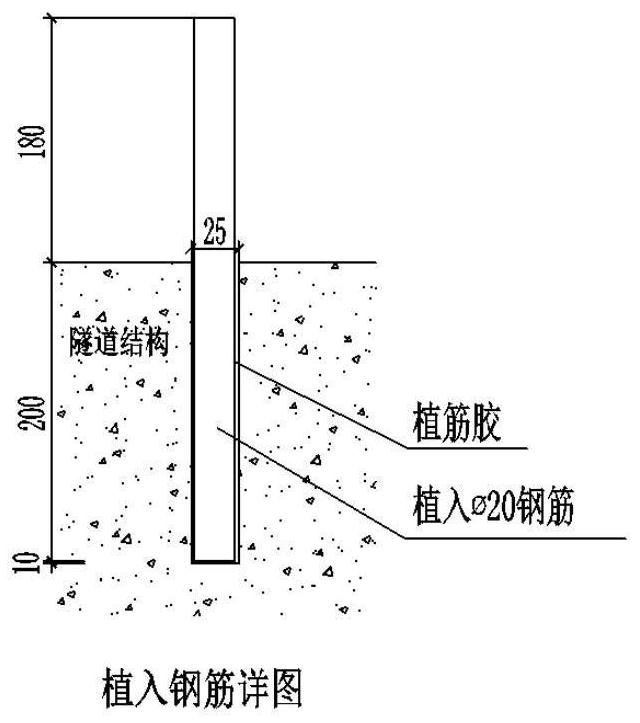

Prefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes and construction method thereof

PendingCN110205921ASimple structureOn-site construction is fast and safeBridge structural detailsFoundation engineeringRebarColumn structure

The invention relates to a prefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes. The prefabricated assembled pier column structure comprises a bearingplatform, wherein a groove is formed in the upper surface of the bearing platform, a supporting column used for supporting the bottom surface of the pier column is arranged inside the groove, a plurality of corrugated pipes are vertically embedded in the periphery of the supporting column inside the groove, a plurality of main steel bars at the bottom of the pier column are in one-to-one correspondence with the corrugated pipes and are inserted into the corrugated pipes, inner filling layers are arranged inside the corrugated pipes, and concrete filling layers are poured inside the groove. Theprefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes is simple.

Owner:FUZHOU UNIV

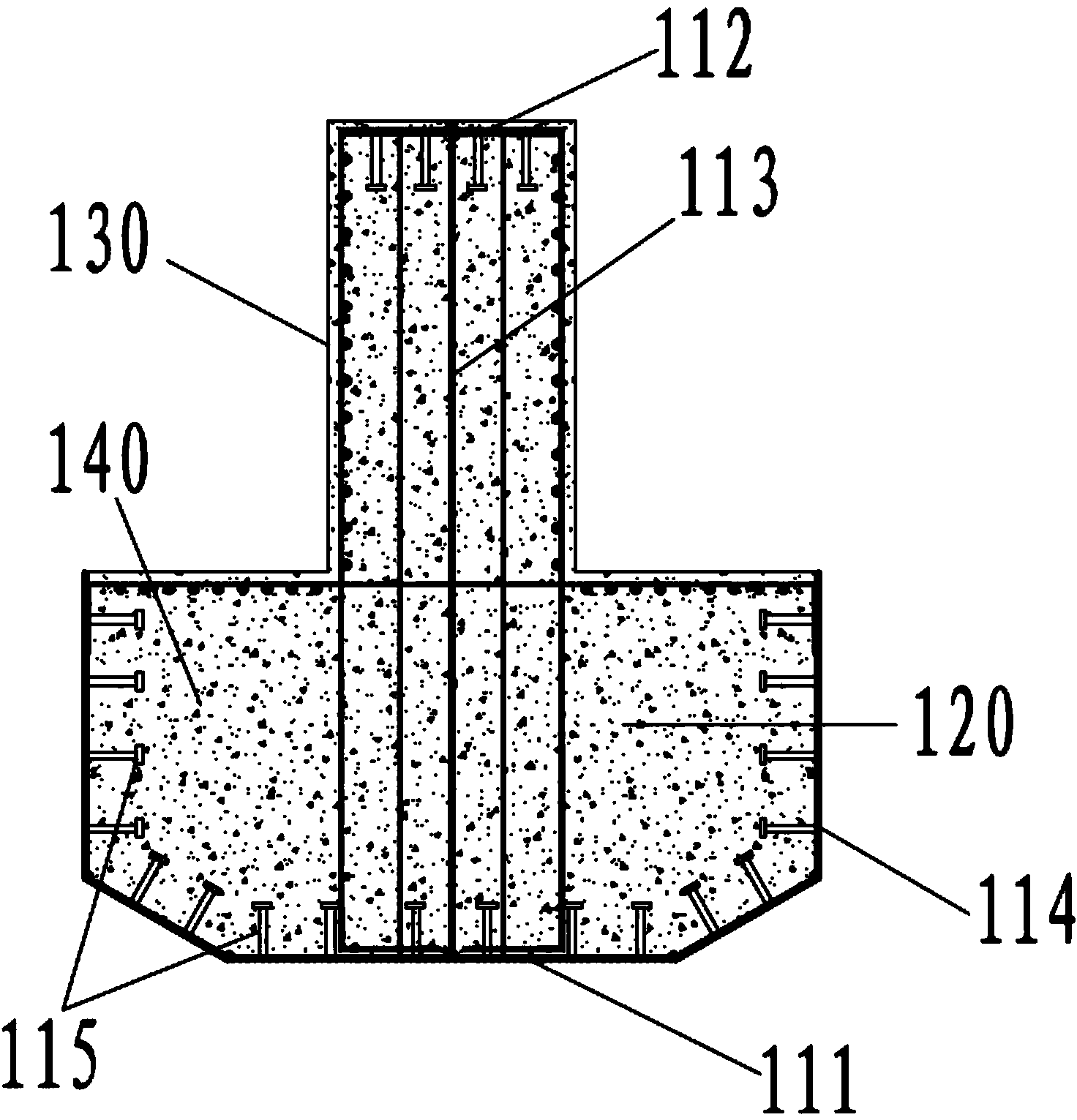

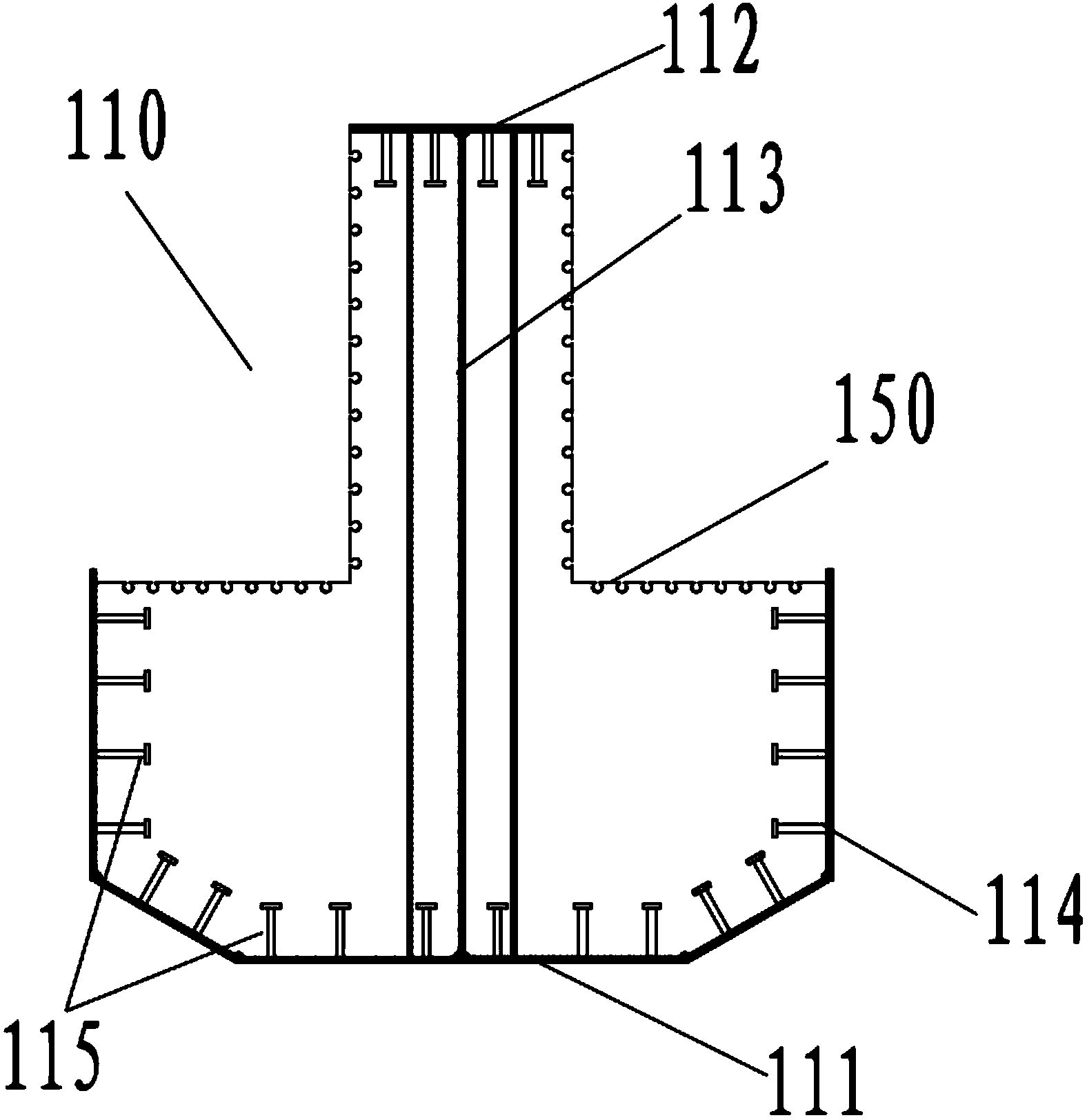

Cast-in-situ inverted-T-shaped bent cap and pier and pier construction process

ActiveCN103452039AImprove structural performanceIncrease stiffnessBridge structural detailsBridge erection/assemblyRebarInverted t

The invention discloses a cast-in-situ inverted-T-shaped bent cap and a pier as well as a pier construction process. The cast-in-situ inverted-T-shaped bent cap comprises a rigid skeleton and a concrete structure, wherein the concrete structure is cast in the rigid skeleton; the rigid skeleton comprises a lower baffle plate, an upper baffle plate, a connecting plate and two side baffle plates, and the lower baffle plate, the upper baffle plate and the connecting plate are connected to form an I-shaped steel structure; the side baffle plates are respectively arranged at the two side edges of the lower baffle plate and extend upwards. The pier comprises a stand column and the cast-in-situ inverted-T-shaped bent cap, wherein the cast-in-situ inverted-T-shaped bent cap is arranged on the stand column. The pier construction process comprises the following steps: because the rigid skeleton is prefabricated, and the stand column is built, the rigid skeleton is lifted on the stand column, and the anchoring steel bar on the stand column is inserted into the rigid skeleton; the rigid skeleton is used as a concrete casting template to cast the concrete structure, and finally the pier is formed. The cast-in-situ inverted-T-shaped bent cap and the pier as well as the pier construction process have the advantages that the construction is convenient, no support or a few supports can be arranged, and the interference on ground traffic is smaller.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

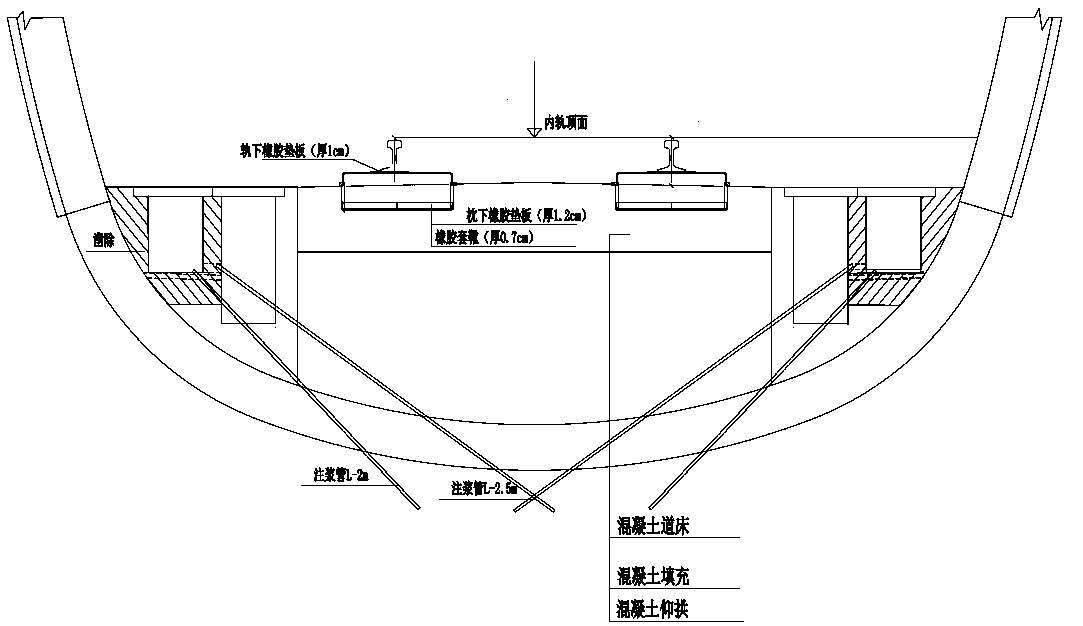

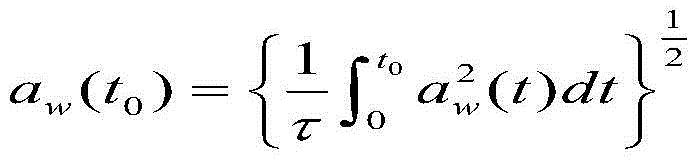

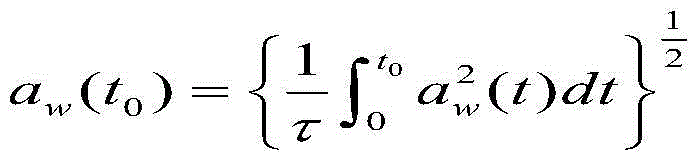

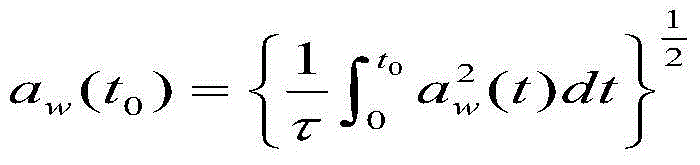

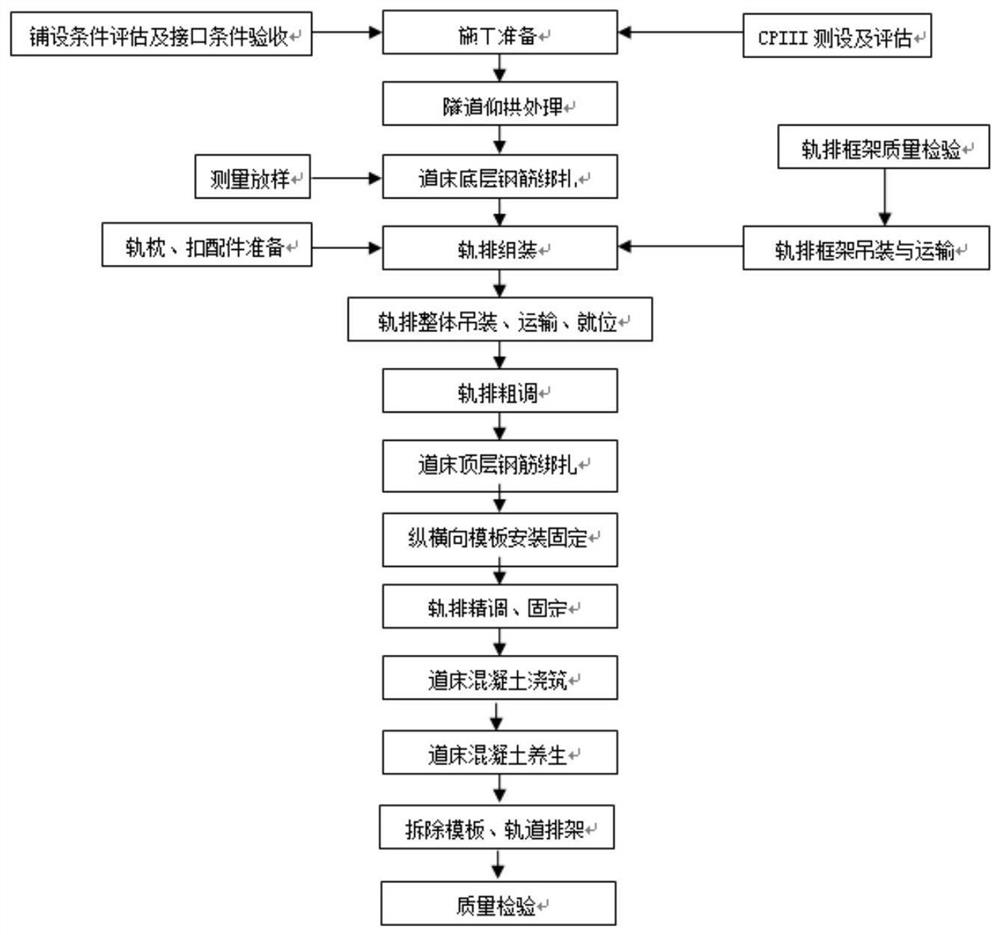

Regulating treatment method of railway tunnel integrated ballast bed subsidence

InactiveCN107858871AComprehensive constructionShort construction periodRailway tracksRailway tunnelBallast

The invention relates to a regulating treatment method of railway tunnel integrated ballast bed subsidence. Due to long-time service and utilization of a tunnel integrated ballast bed or based on original defects existing in the building process, an integrated ballast bed structure is likely to subside, and the subsidence degree and the subsidence development speed are increased year by year. A hole or a weak layer at the bottom of a tunnel inverted arch is filled and repaired in a grouting tamping mode, a subsiding supporting block is reset and treated in a heightening cushion adding mode ora lifting treatment mode, construction is overall, a ballast bed and a rail are both regulated and reset pertinently, a construction period is short, traveling disturbance is small, a treatment resultis obvious, and a reasonable and efficient regulating method is provided for tunnel running maintenance.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

On-site evaluation method and simulation evaluation method for road and bridge transition section flatness comfort

InactiveCN104568483AGood choiceLittle traffic disturbanceStructural/machines measurementData informationSimulation

The invention discloses an on-site evaluation method and a simulation evaluation method for road and bridge transition section flatness comfort. The on-site evaluation method adopts a data acquisition instrument which can acquire various data information such as time, test travel speed, acceleration data of each measurement point, the longitude and latitude of each test section, image data of test lanes and the like in real time in a test process; relatively complete data information facilitates data selection and provides theory data basis for follow-up pavement performance change of a test road. According to the simulation evaluation method, the motion law of an established whole-vehicle model is quite close to that of an actual vehicle, and the motion characteristics under excitation of road unevenness can be simulated better; the operational speed of a software model on a computer is higher than the speed of real-time operation by 3-6 times, the flatness of the test road can be evaluated rapidly, and the evaluation method has less outdoor work, is less affected by the outside, can save human and material resources effectively, omits a test instrument mounting process, is simpler and more convenient and requires shorter time.

Owner:CHANGAN UNIV

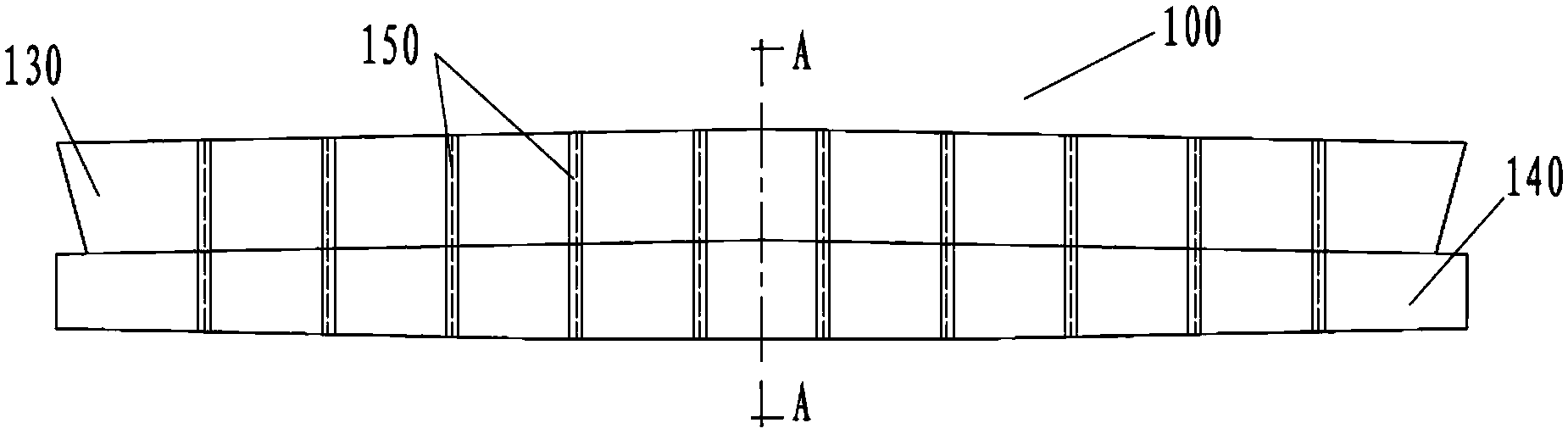

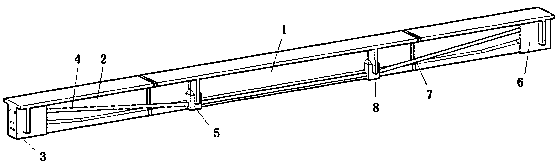

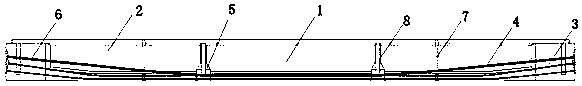

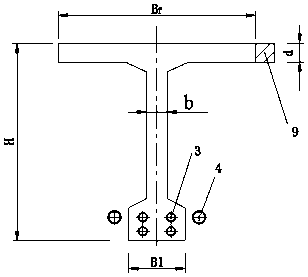

Segment-prefabricated T-beam bridge structure configured with internal and external prestressing tendons, and construction method for T-beam bridge structure

InactiveCN108842591ASmall sizeImprove transportation efficiencyBridge erection/assemblyBridge materialsT-beamPre stress

The invention discloses a segment-prefabricated T-beam bridge structure configured with internal and external prestressing tendons, and a construction method for the T-beam bridge structure. A T-beambridge is longitudinally divided into 3-5 segments along a bridge span; and the segments are prefabricated in a factory, transported to a location near a bridge site, and assembled and connected through internal and external mixed tendon allocation. A segment-prefabricated, assembled and simply supported T-beam comprises a central segment, beam end prefabricated segments, the internal prestressingtendons, the external prestressing tendons, cast-in-situ wet joints, diaphragm plates, external prestressing tendon steering blocks, and external prestressing tendon anchoring blocks, wherein the central segment and the beam end prefabricated segments of the T-beam are manufactured in the factory, transported to the bridge site and integrated through the cast-in-situ wet joints, and the internaland the external prestressing tendons are tensioned to complete assembly of a bridge span structure. The T-beam prefabrication and assembly technology provided by the invention is applicable to the bridge site without overall prefabrication conditions; segment prefabrication facilitates land transportation and achieves convenient hoisting; and the external prestressing tendons facilitate subsequent supplementary tensioning and overhauling, so that the comprehensive performance of the bridge is greatly improved.

Owner:SOUTHEAST UNIV

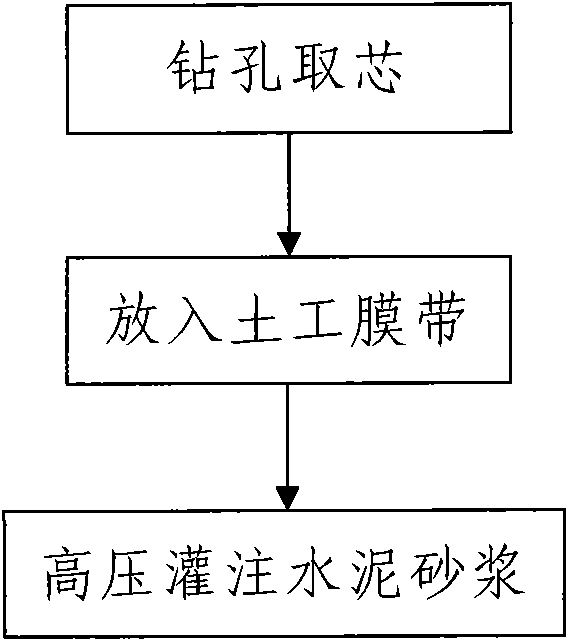

Roadbed longitudinal crack treatment method based on convex tenon type cement grouting geomembrane belt

InactiveCN102031742ASimple structureEasy to processRoadwaysSoil preservationGeomembraneTherapeutic effect

The invention discloses a roadbed longitudinal crack treatment method based on a convex tenon type cement grouting geomembrane belt based, which comprises the following steps of: (1) drilling for coring: drilling a plurality of rows of drill holes on the side slope of a treated roadbed with longitudinal cracks by using a coring machine; (2) geomembrane belt arrangment: putting prefabricated geomembrane belts into the drill holes one by one, wherein the geomembrane belts are round pipe-shaped geomembrane belts made from geomembranes, the diameters of the geomembrane belts are the same as that of the drill holes, and the side walls of each geomembrane belt is provided with a plurality of rows of round through holes; and (3) injecting cement mortar under high pressure: injecting prefabricated cement mortar into the geomembrane belts through a high-pressure grouting machine. The invention has the advantages of reasonable design, simple steps, high construction speed, good treatment effect and low investment cost and can effectively solves the practical problems of larger investment, longer traffic closing time, greater influence on service functions of roads, poor treatment effect, and the like of the traditional roadbed longitudinal crack treatment method for areas with frozen earth for many years.

Owner:CHANGAN UNIV

In-situ cold recycled foamed asphalt mixture and cold recycled pavement construction method

The invention discloses an in-situ cold recycled foamed asphalt mixture which comprises mineral aggregate, cement, foamed asphalt, fibers and mixing water, and the mineral aggregate comprises the following components in parts by weight: 30-40 parts of old pavement milling material with the particle size of less than 5mm, 20-25 parts of old pavement milling material with the particle size of 5mm-32mm, 10-15 parts of new stone with the particle size of less than 5mm and 6-10 parts of new stone with the particle size of 5mm-32mm; the using amount of the cement accounts for 23% of the mass of themineral aggregate, the using amount of the foamed asphalt accounts for 3-4% of the mass of the mineral aggregate, the using amount of the fibers accounts for 0.4-0.5% of the mass of the mineral aggregate, and the using amount of the mixing water accounts for 6-8% of the mass of the mineral aggregate; a pavement construction method using the foamed asphalt mixture in the scheme comprises the following steps: burdening, paving, rolling and curing. Compared with the prior art, the foamed asphalt mixture and the pavement construction method have the advantages that the constructed pavement is smooth, pavement surface layer diseases such as ruts, cracks, pits and pitted surfaces can be effectively eliminated, the gradation of an original pavement mixture can be improved, the road usability is improved, and the service life is prolonged.

Owner:安徽虹达道路桥梁工程有限公司

Compensation method for roadbed settlement

InactiveCN102322008BShort construction timeLittle traffic disturbanceRoadwaysArchitectural engineeringRoad surface

The invention provides a compensation method for roadbed settlement, which comprises the steps that: when in a roadbed construction process, on a road section which can easily settle and deform after being open to traffic, when a roadbed is filled to a height which is 30cm to 200cm from the top surface, retaining walls are built on both sides of the roadbed; bagged lime is uniformly paved on the inner sides of the retaining walls within the full-width range of the roadbed on different layers; a rubber pipe is pre-reserved on each lime bag to the outer side of the roadbed as a water injection channel in a later period; the bottom surfaces of the retaining walls are 20cm to 100cm lower than the bottom surfaces which are paved from the bagged lime, and the top surfaces of the retaining walls are in alignment with the top surface of the roadbed; and when the roadbed settles, the water is injected into the lime bags through the pre-reserved rubber pipe, the lime absorbs the water, swells and jacks a road surface structure up. The compensation method for roadbed settlement completes the water injection on the outer side of the roadbed, has a short construction time, does not interrupt the traffic during the construction process and has little interference to the traffic; and the construction is not restricted by the weather and the environment, the settlement can be handled at any time when being found, and the construction process is controllable.

Owner:广东大象交通科技有限公司

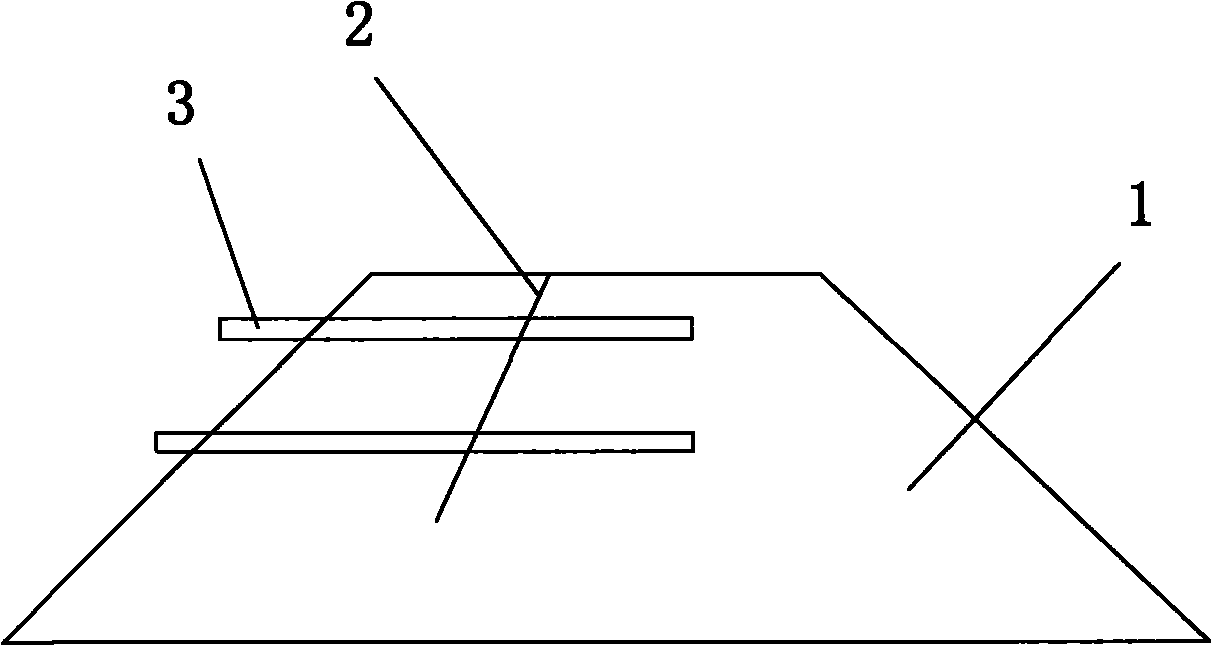

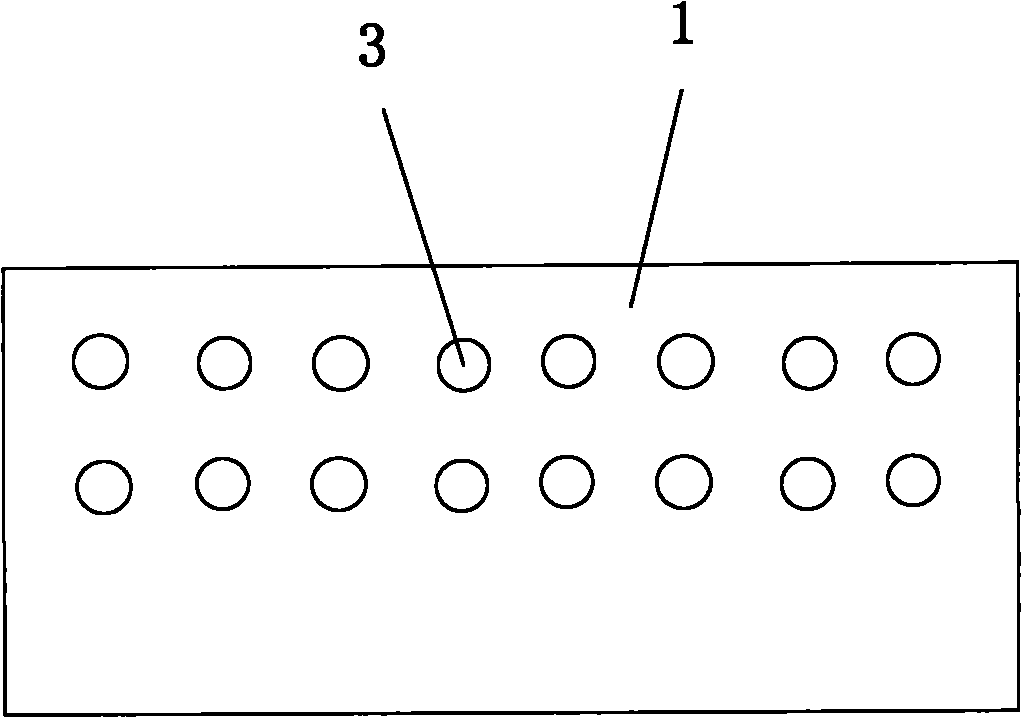

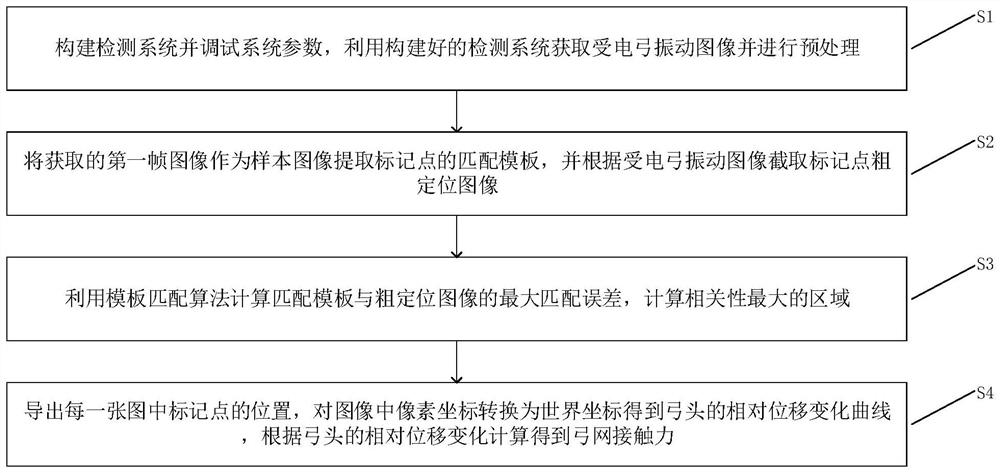

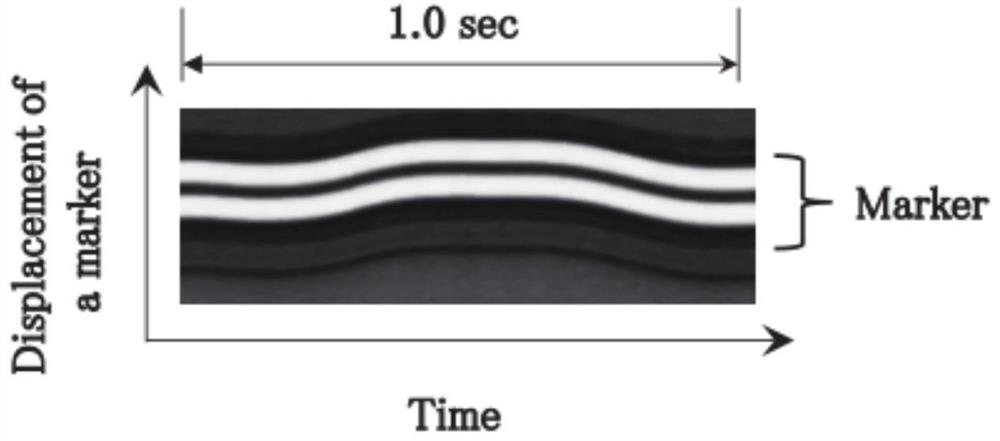

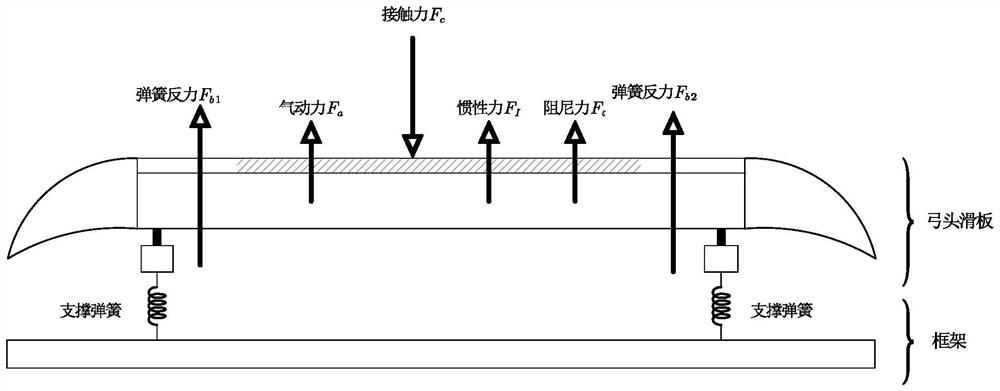

Non-contact pantograph-catenary contact force detection method based on image processing technology

PendingCN114140394AEasy to installGuaranteed dynamic performanceImage enhancementImage analysisImaging processingControl engineering

The invention discloses a non-contact pantograph-catenary contact force detection method based on an image processing technology, and compared with a traditional detection method, the method is simple in equipment installation, has the characteristics of real-time performance and non-contact performance, can avoid the transformation of a pantograph head during detection, and guarantees the original dynamic performance of the pantograph head. Meanwhile, more automation and intelligence are achieved, the detection flexibility is high, and the accuracy is high; moreover, the system is small in driving interference, and is suitable for long-distance and long-time continuous tracking detection under severe environment conditions. Through multiple groups of ground dynamic experiments, the effectiveness and accuracy of the method are verified, the detection precision after the inertia force and the damping force are corrected can greatly meet the detection precision of the pantograph-catenary contact force, the research on the pantograph-catenary contact force detection method in the non-contact measurement field at present is further enriched, and the detection accuracy of the pantograph-catenary contact force detection method is improved. And meanwhile, accurate contact force data can be provided for evaluation of pantograph-catenary current collection quality and real-time fault monitoring.

Owner:SOUTHWEST JIAOTONG UNIV +1

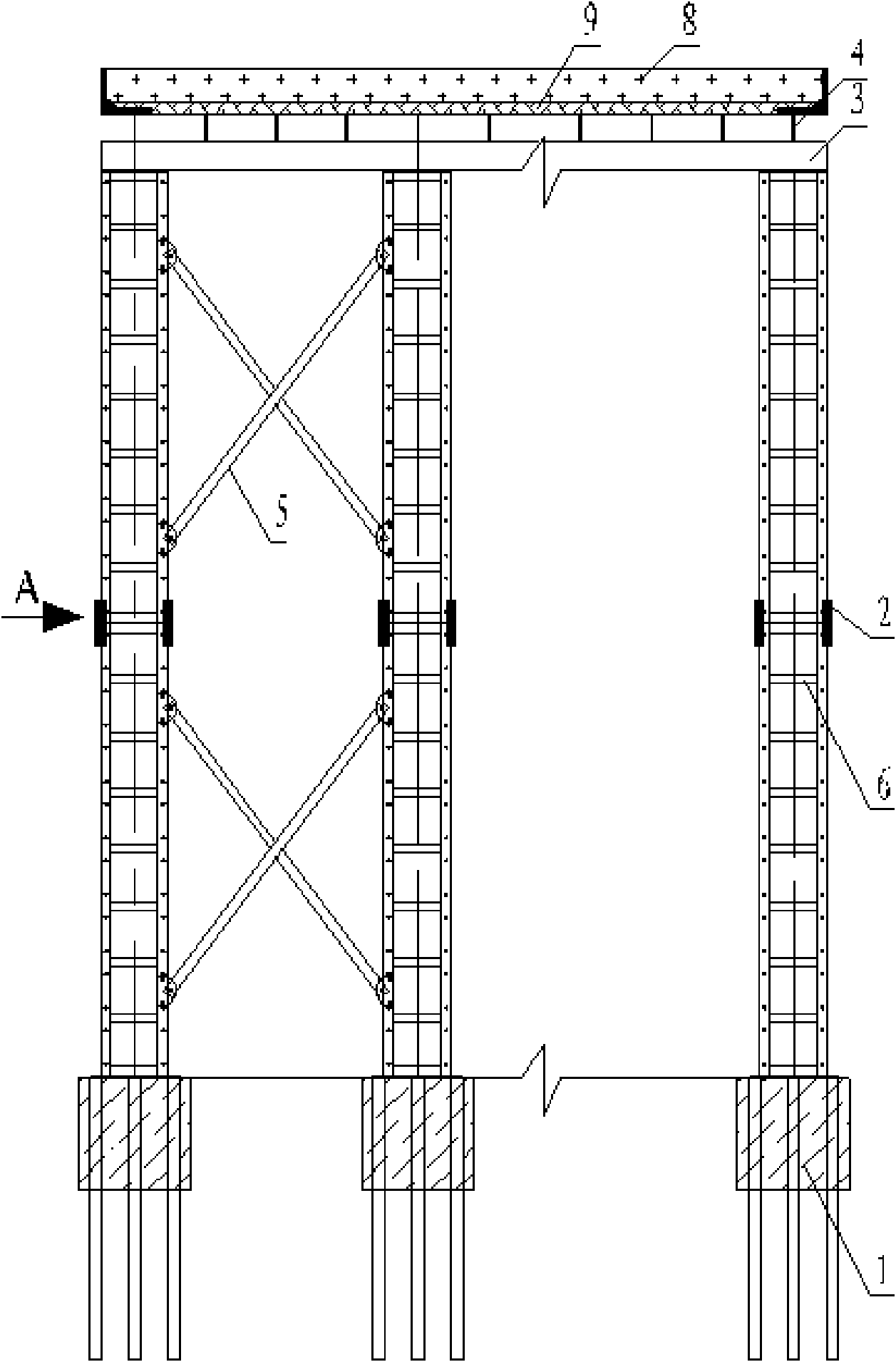

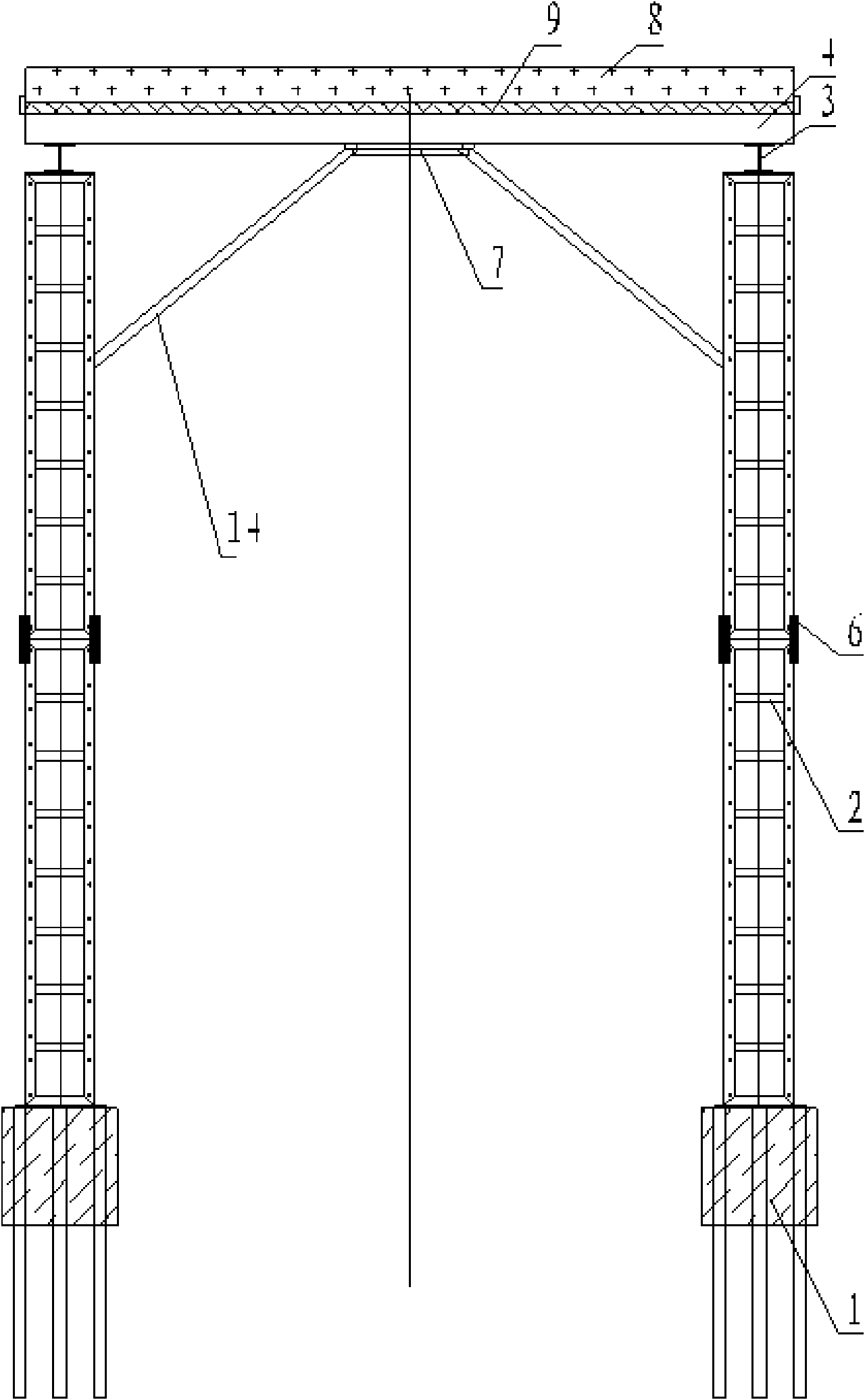

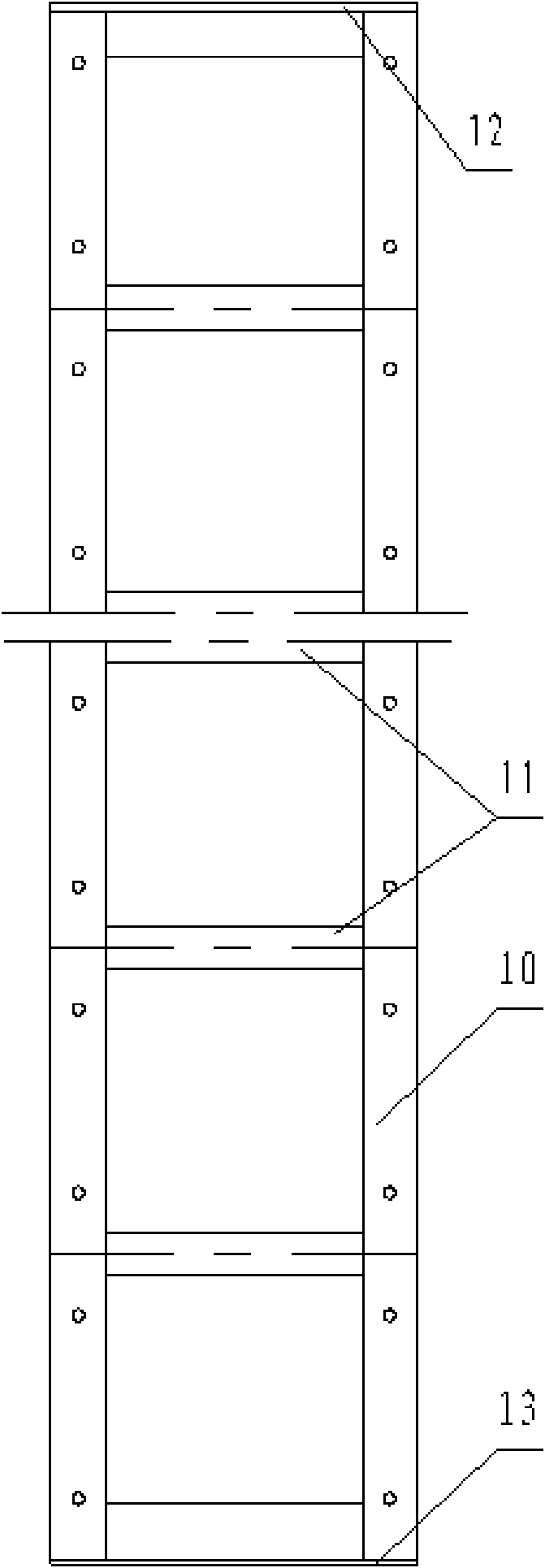

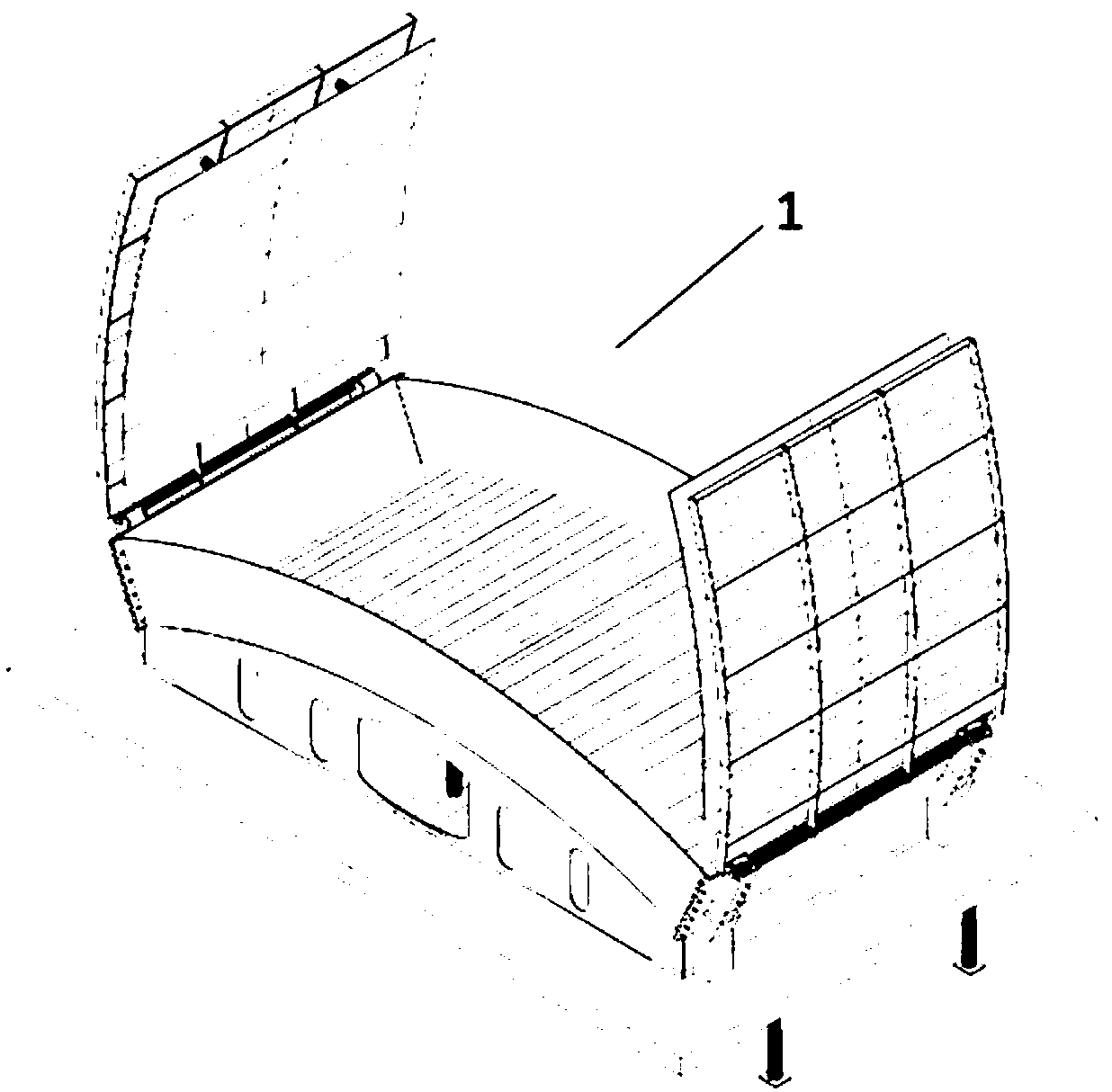

Steel structure hangar tunnel and installation method

InactiveCN101899816AImprove interchangeabilityVersatilityProtective constructionArchitectural engineeringStringer

The invention discloses a steel structure hangar tunnel and an installation method. The steel structure hangar tunnel comprises a base (1), wherein an upright post (2) is arranged on the base (1), a longitudinal beam (3) is arranged on the upright post (2), a crossbeam (4) is arranged on the longitudinal beam (3), and a wood board (9) and backfill soil (8) are laid on the crossbeam (4). The invention is designed into a steel structure mode according to the requirements of rigidity, strength and delimitation of a hangar tunnel by the traditional railroad line. The steel structure hangar tunnel is divided into a plurality of parts and assemblies by synthetically considering the characteristics of structural strength and transportation, and all the steel structure assemblies adopt factory production and have interchange ability and universality. The steel structure hangar tunnel is convenient to assemble and disassemble, is light and flexible, has quick construction progress and low interference with running vehicles and can be disassembled for recycling after dangerous cases are eliminated. Due to the adoption of the installation method, the hangar tunnel can be completely installed for 3-5 days in order to greatly reduce construction time.

Owner:成都铁路局成都工务机械段贵阳劳动服务公司 +2

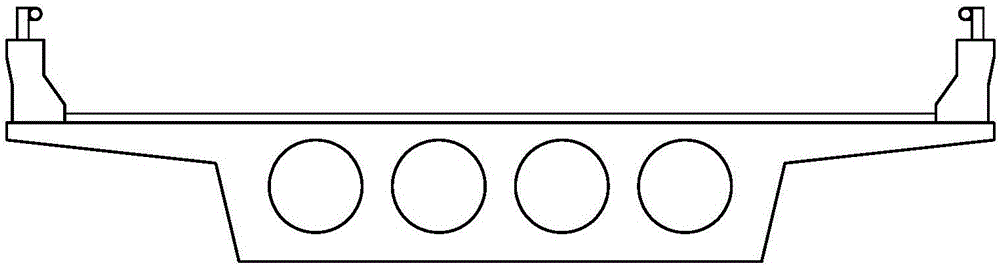

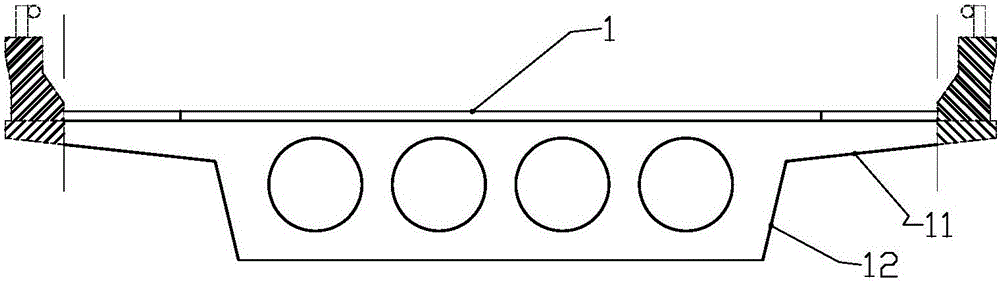

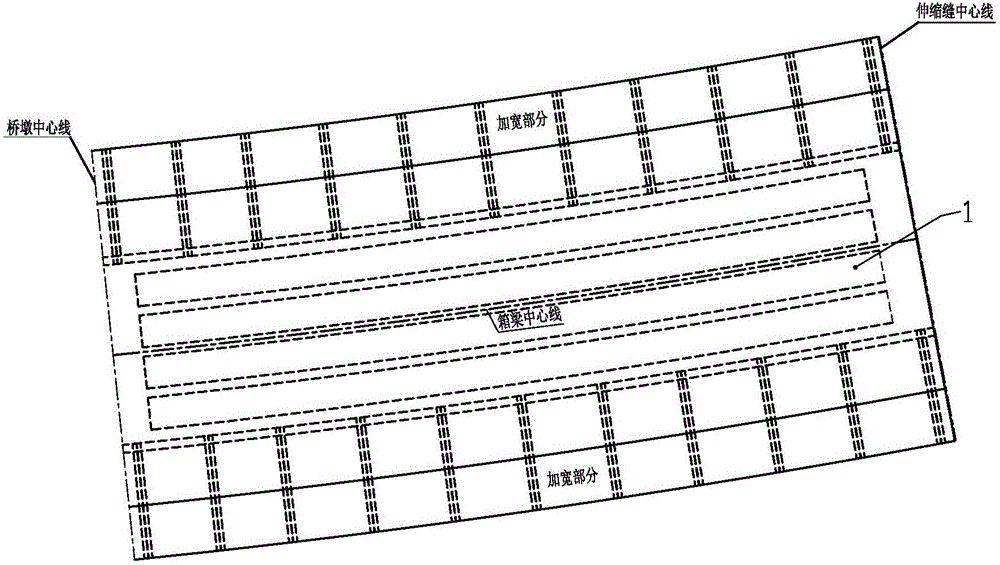

Steel cantilever combined bridge deck slab widening and reconstruction structure and construction method thereof

ActiveCN106436591ATake advantage ofThe second stage of the structure has less dead loadBridge structural detailsBridge erection/assemblyBridge deckEngineering

The invention discloses a steel cantilever combined bridge deck slab widening and reconstruction structure and a construction method thereof and aims at solving the problem existing in widening of a traditional box beam. The steel cantilever combined bridge deck slab widening and reconstruction structure comprises an original box beam and widening parts symmetrically arranged on two sides of the original box beam and is characterized in that each widening part comprises a steel cantilever, a steel bottom die, a steel guardrail and cast concrete, wherein the steel cantilever is a welding steel member of a triangular open web type structure, the steel cantilever is connected with the original box beam through an anchor bolt, and the steel bottom die is fixed to the steel cantilever, is provided with the cast concrete and form effective PBL key connection. The original box beam structure is fully utilized, and second phase dead load increase of the structure is small (only about 10% of an original structure), so that the lower portion and a foundation of an original bridge can be directly utilized, and the reconstruction project amount is remarkably decreased.

Owner:孟庆华

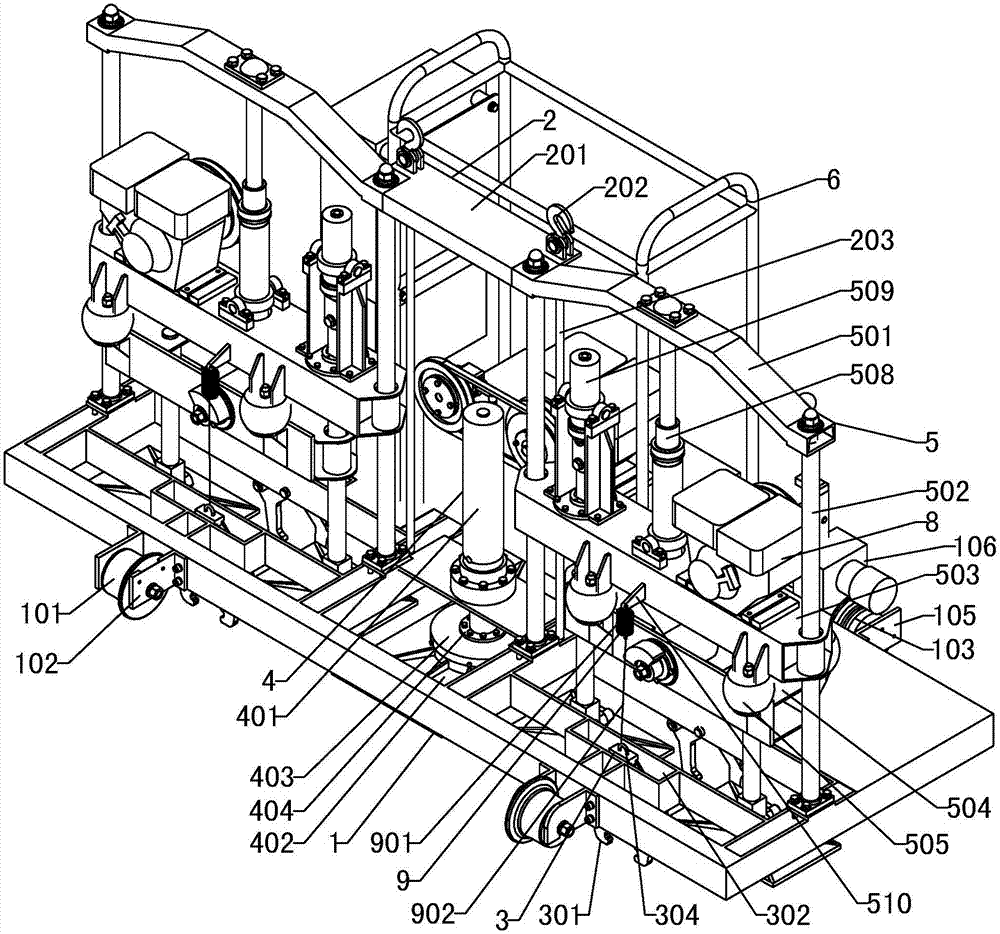

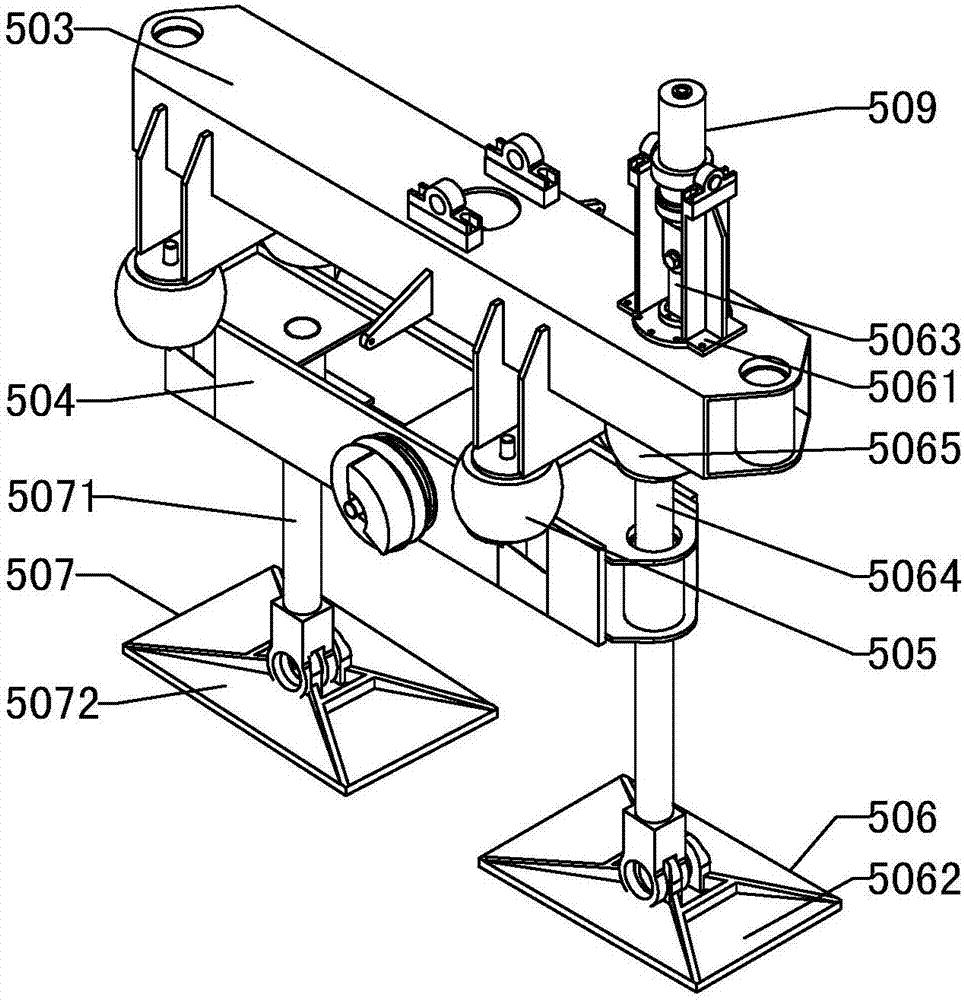

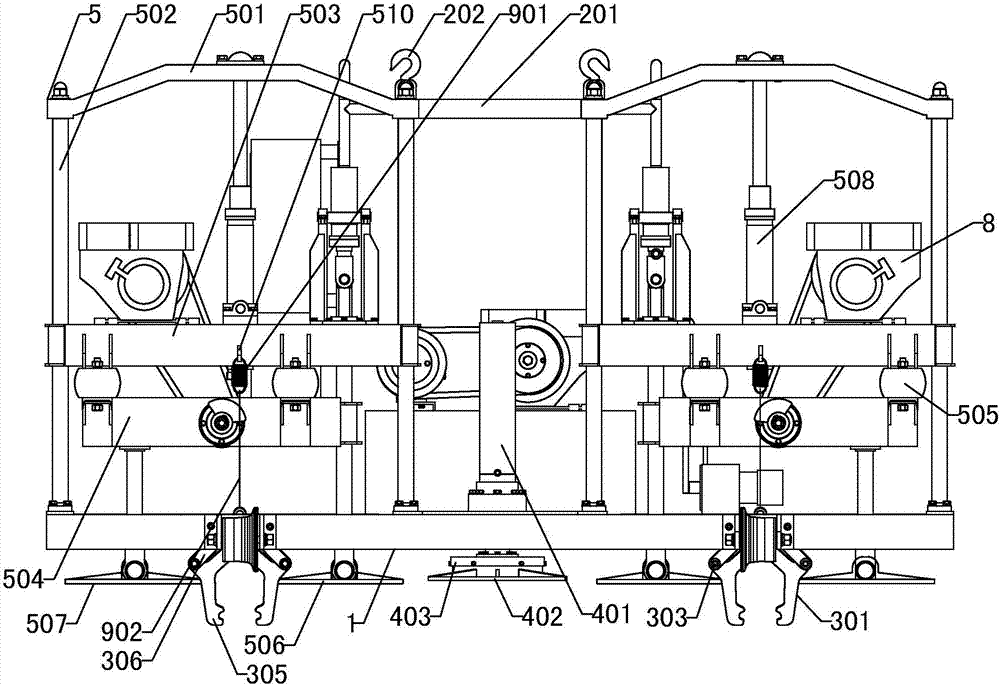

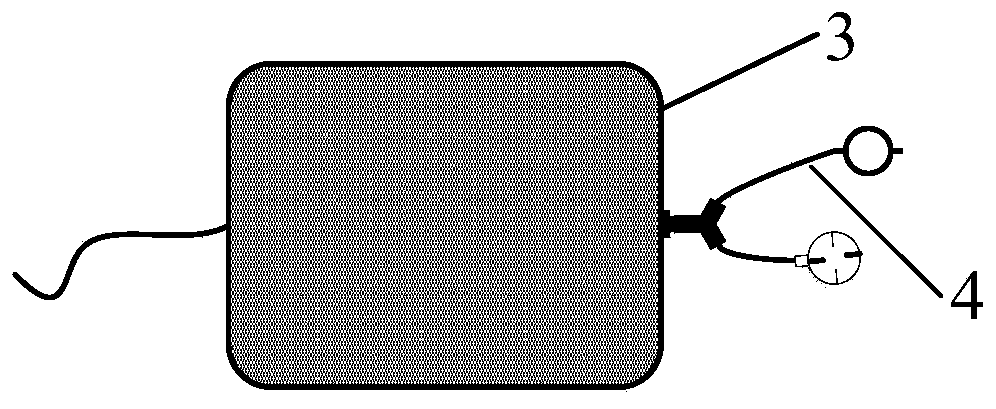

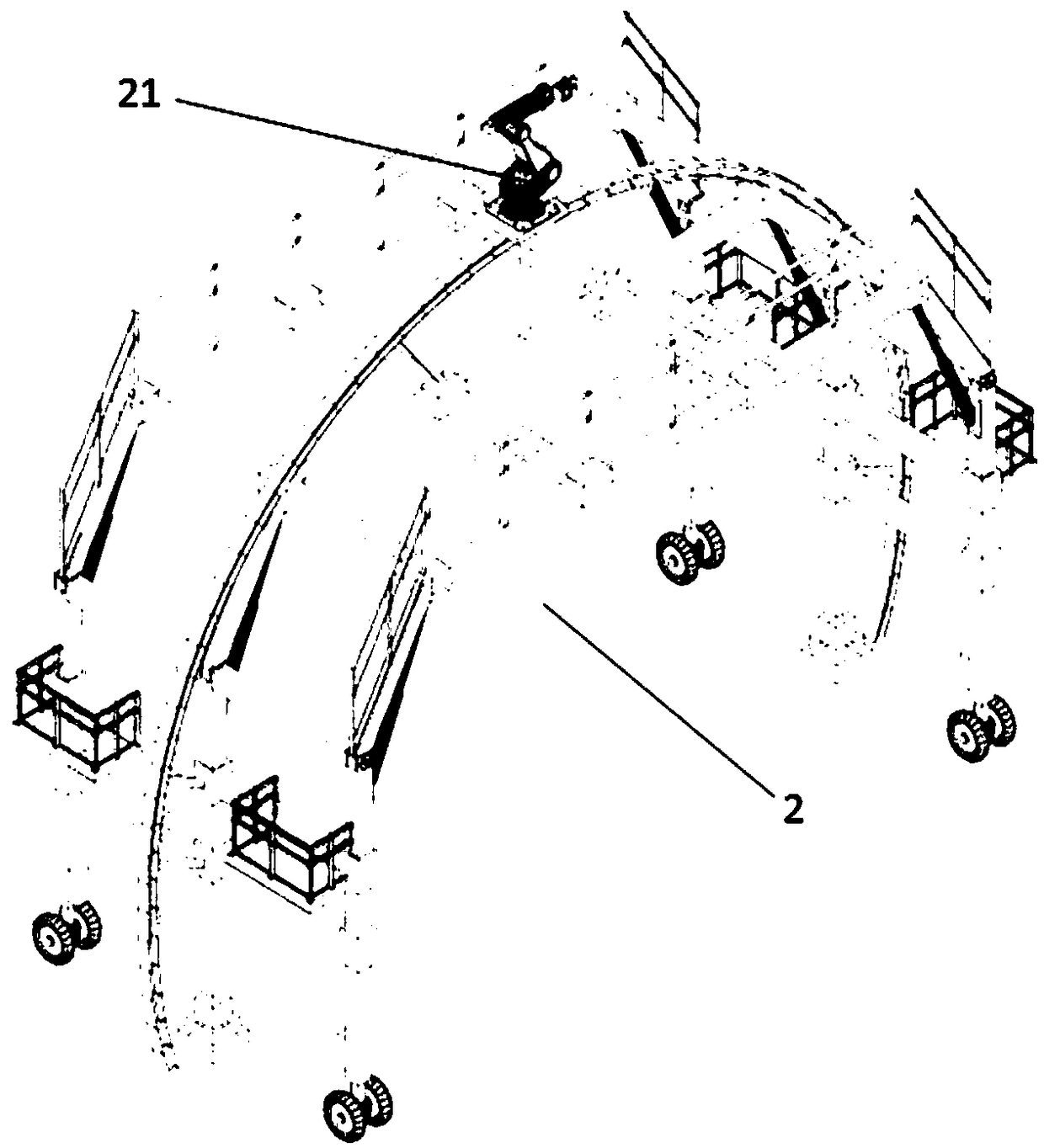

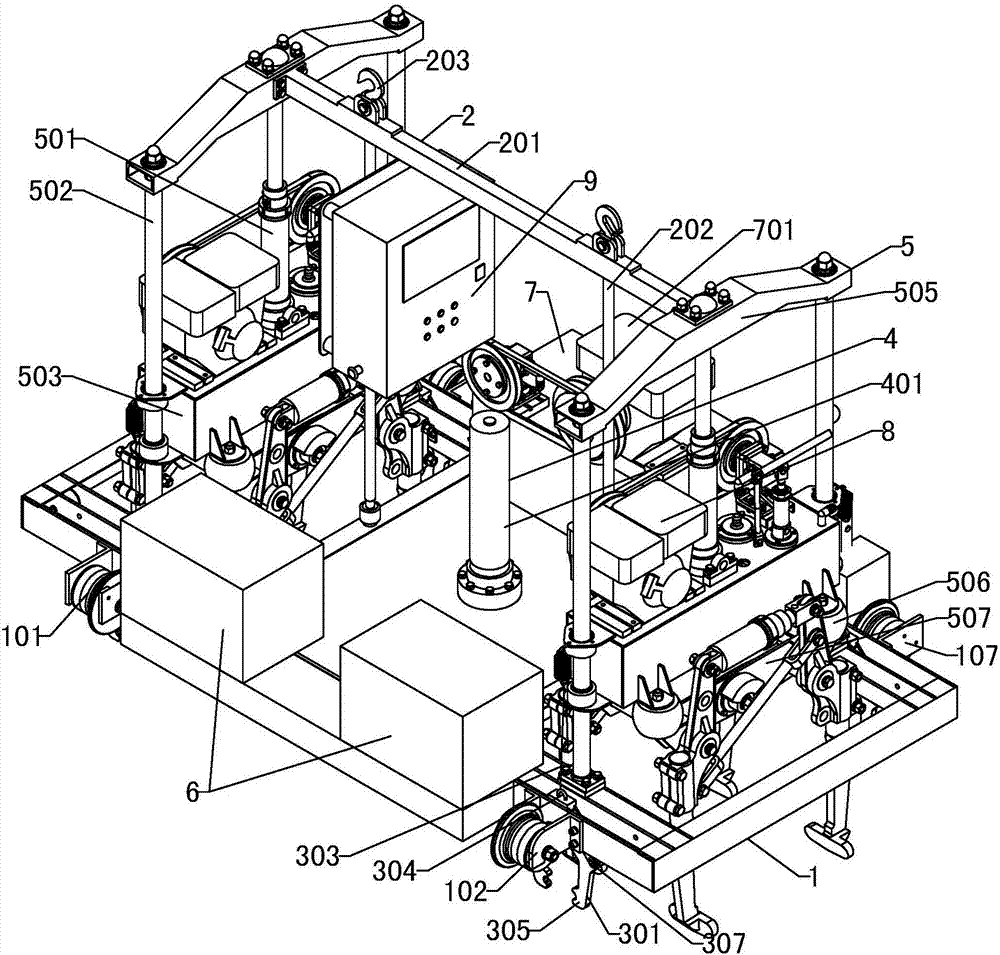

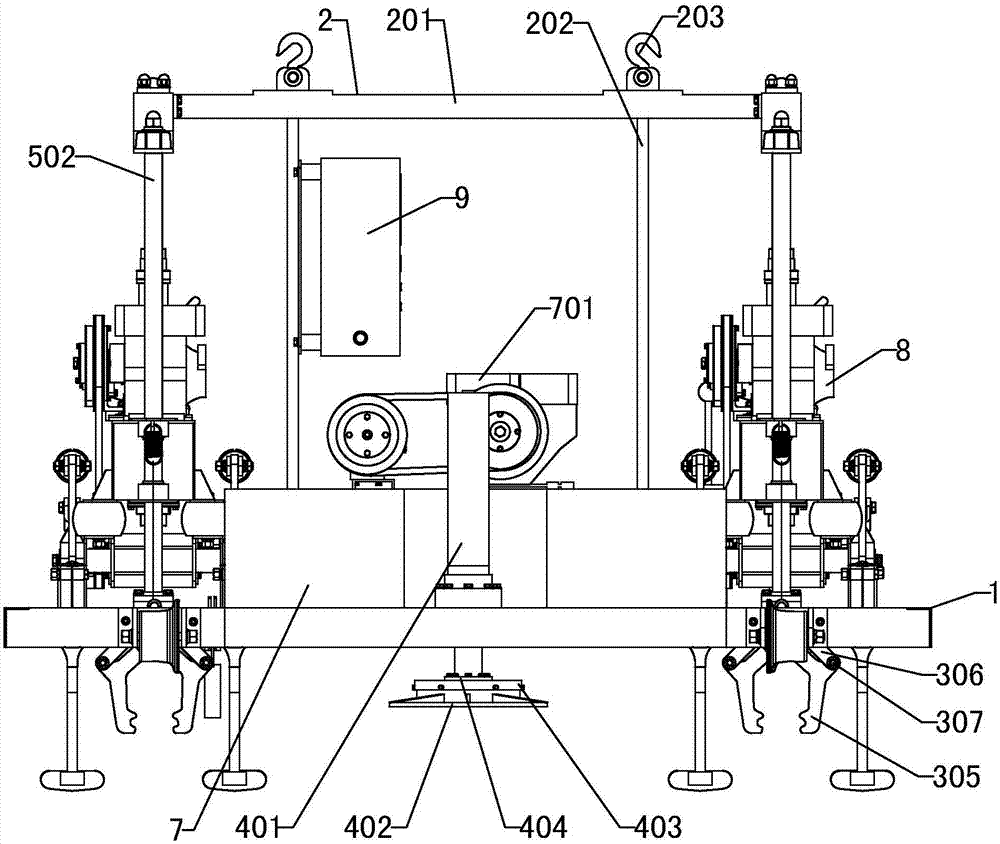

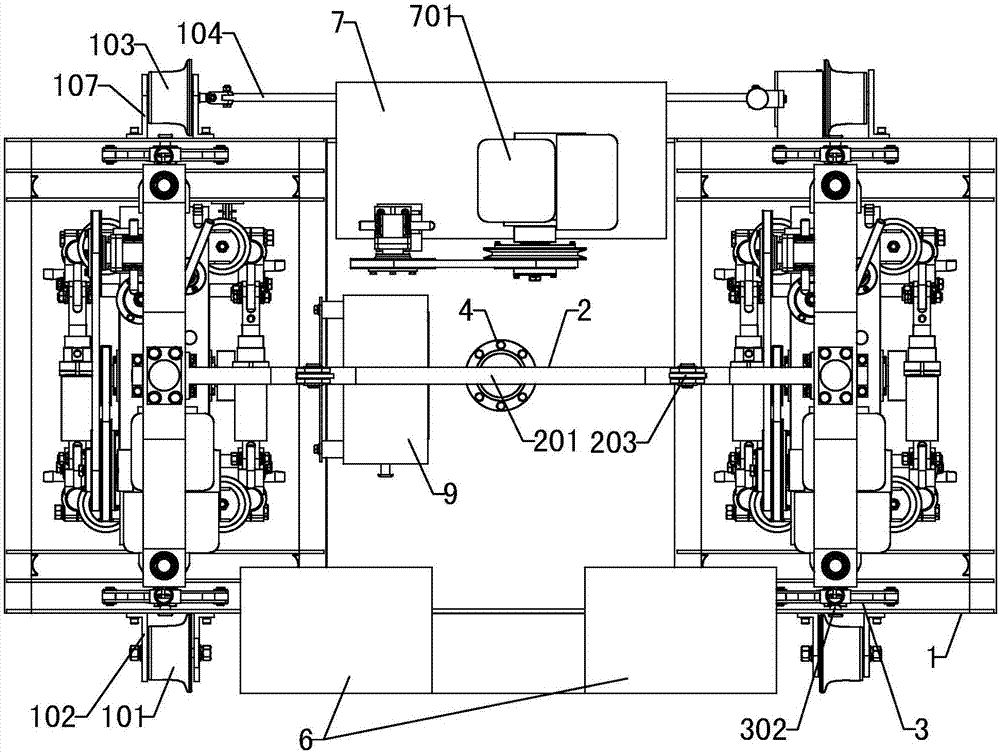

Small-sized automatic hydraulic railway line tamping car

The invention relates to a small-sized automatic hydraulic railway line tamping car, belonging to the field of railway line maintenance equipment. The small-sized automatic hydraulic railway line tamping car is characterized by comprising tamping mechanisms (5) and a travelling chassis (1), wherein travelling mechanisms are respectively arranged at the lower parts of the front side and the rear side along the travelling direction of the travelling chassis (1); the upper part of the travelling chassis (1) is divided into a front area and a rear area by taking the travelling direction as a benchmark; the two groups of tamping mechanisms (5) parallel to a railway line sleeper are respectively arranged at the left side and the right side of the front area; two groups of rail clamping mechanisms (3) are respectively arranged at the front side and the rear side of each group of tamping mechanism (5); a travelling down mechanism (4) capable of driving a whole machine to go up and down and rotate is arranged in the middle of the travelling chassis (1). The small-sized automatic hydraulic railway line tamping car is electromechanical integrated artificial intelligent equipment, and all operations such as transferring the equipment, automatically tamping and enabling the equipment to travel up and down can be realized by one person, so that not only is manpower greatly saved, but the working quality is also improved; the small-sized automatic hydraulic railway line tamping car has little interference to driving, and realizes the industrial upgrading of railway line turnout tamping operation from mechanization to automation.

Owner:淄博洁翔机电科技开发有限公司

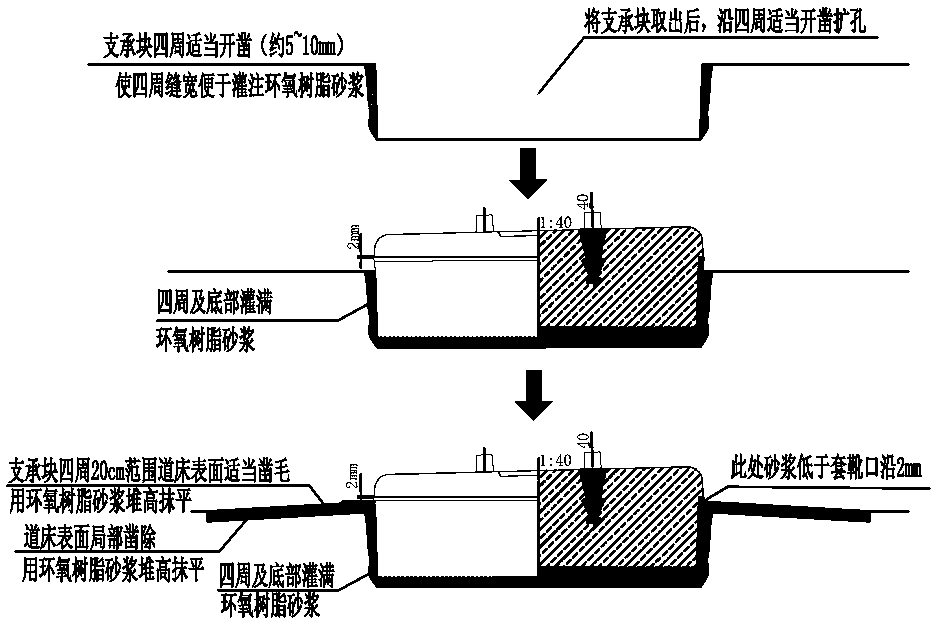

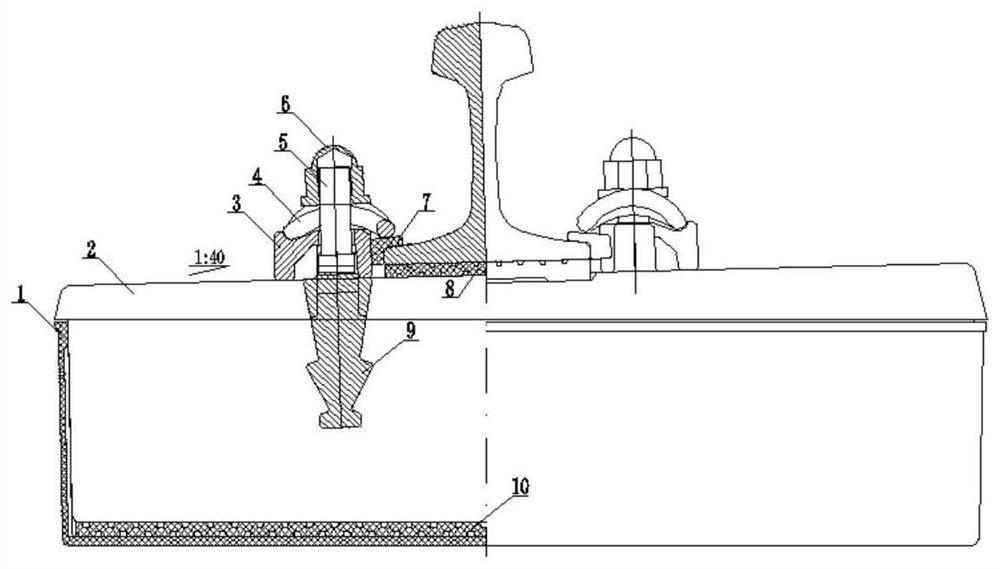

Tunnel boot sleeving method replaceable supporting block ballastless track construction method

InactiveCN111794018AReduce volumeLight in massBallastwayRail fastenersTrackwayArchitectural engineering

The invention discloses a tunnel boot sleeving method replaceable supporting block ballastless track construction method. The main construction process comprises the steps of pre-burying reinforcing steel bars in a base, roughening or chiseling the base, implanting connecting reinforcing steel bars, erecting a ballast bed lower-layer reinforcing mesh, assembling a track panel on site, erecting thetrack panel and roughly adjusting in place, erecting upper-layer longitudinal and transverse reinforcing steel bars, erecting a ballast bed template, finely adjusting and fixing the track panel, pouring ballast bed concrete and plastering, loosening fasteners after initial setting, curing concrete, dismounting and transferring the template. By means of the method, the technical problem in the prior art that a supporting block is difficult to replace is solved, and the replaceable supporting block is constructed through a boot sleeving method.

Owner:中铁九局集团第六工程有限公司 +1

Warm-mixing type asphalt hot-in-place recycling construction method

InactiveCN109653052AReduce environmental pollutionLittle traffic disturbanceIn situ pavingsClimate change adaptationEngineeringPitch blende

The invention discloses a warm-mixing type asphalt hot-in-place recycling construction method. The method includes steps: step 1) heating a to-be-treated pavement, wherein a heating temperature rangeis 125-195 DEG C; step 2) raking the to-be-treated pavement, wherein the to-be-treated pavement raking width is 10-20cm smaller than the to-be-treated pavement heating width of each side; step 3) spraying a recycling agent and a warm mixing agent, wherein consumption of the recycling agent is 7-15% of the weight of asphalt in a to-be-treated pavement loosened material, and consumption of the warmmixing agent is 10-15% of the weight of the recycling agent; step 4) stirring, to be more specific, mixing the to-be-treated pavement loosened material, the recycling agent and the warm mixing agent,adding a new asphalt mixture, and mixing to obtain a uniform recycled mixture; step 5) paving, to be more specific, paving the recycled mixture obtained in the step 4); step 6) rolling, to be more specific, sequentially adopting a double drum roller and a tire roller for combined rolling of the paved pavement.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

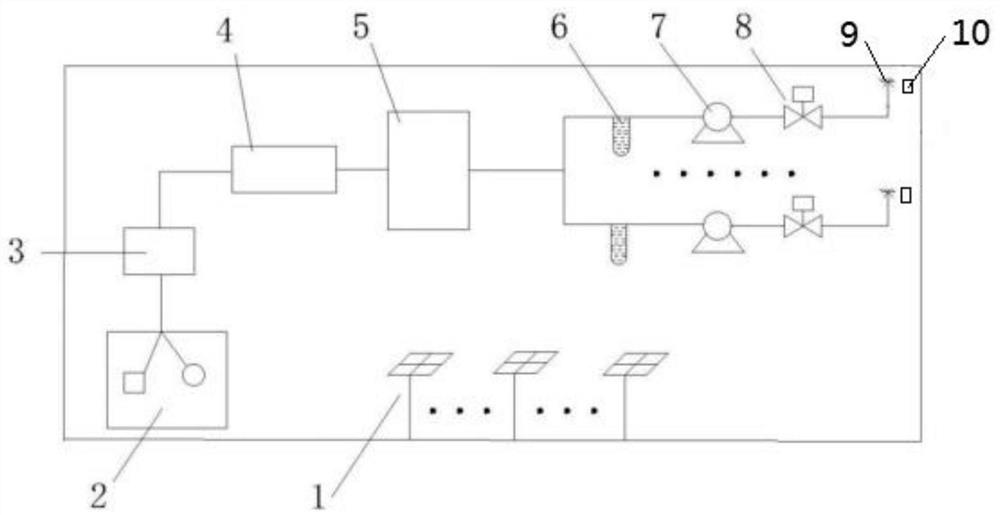

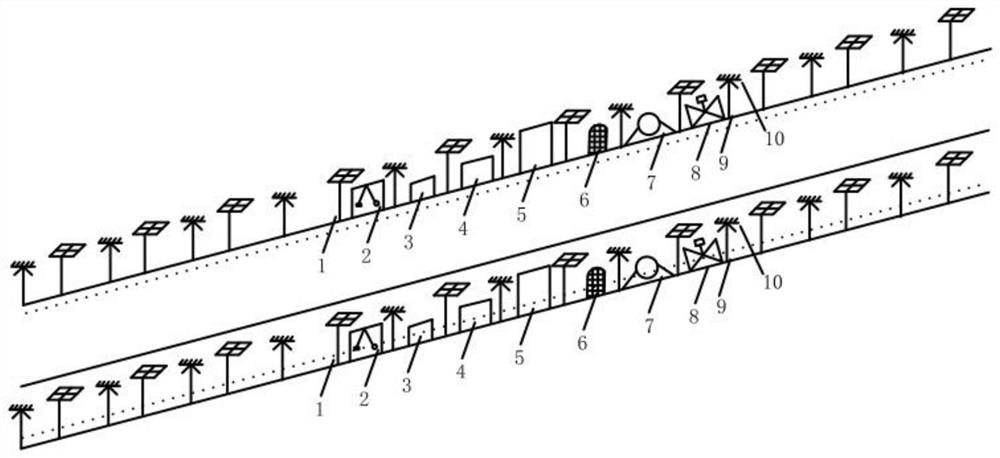

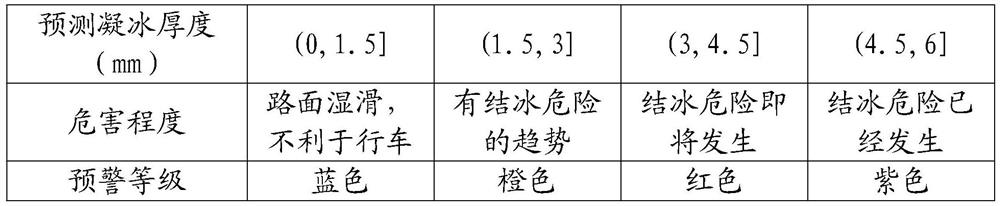

Road operation guarantee system and intelligent implementation method thereof

InactiveCN112012155ARealize multi-level early warningRealize automatic quantitative sprayingMeasurement devicesAlarmsLiquid storage tankRoad surface

The invention discloses a road operation guarantee system and an intelligent implementation method thereof. The guarantee system comprises a power generation module, a condensed ice information acquisition module, a condensed ice early warning module and a snow-melting agent spraying module. The power generation module comprises a solar panel, the condensed ice information acquisition module comprises a distributed sensor and a data processor, the condensed ice early warning module comprises an ice condensation danger level alarm, and the snow-melting agent spraying module comprises a liquid storage tank body, a filter, a centrifugal pump, an electromagnetic valve, a high-pressure spray head and an infrared sensor. The operation guarantee system has the advantages of being high in efficiency, economical, environmentally friendly, high in practicability, small in traffic interference and the like. The intelligent implementation method of the system is high in intelligent degree, real-time monitoring, multi-stage early warning, automatic triggering of the snow-melting agent and quantitative spraying of the snow-melting agent can be achieved, and the safety and smoothness of running of road infrastructures in ice and snow weather are guaranteed.

Owner:SOUTHEAST UNIV

Non-excavation overall repairing method for concrete drainage pipe containing various diseases

The invention discloses a non-excavation overall repairing method for a concrete drainage pipe containing various diseases. The non-excavation overall repairing method comprises the following steps that S1, a steel ring is precast according to the diseased pipe internal diameter, and grouting holes are reserved in the steel ring; S2, the steel ring is loaded at the diseased position in the pipe, so that the steel ring is tightly attached to the inner wall of the pipe to form a reinforcing ring; S3, the grouting holes of the proper quantity are selected according to the distributing situation of the subsidence disease, drilling is conducted on the subsidence position in the pipe, grouting pipes are inserted, grouting is conducted on the subsidence part slowly through a high polymer groutingsystem, close observation is conducted on the pipe lifting situation, and the grouting pipes are removed until the pipe is lifted to the desired level; and S4, a lining pipe is pulled into the pipe,so that the lining pipe is tightly attached to the steel ring and the pipe wall near the steel ring, curing is conducted on the lining pipe, and the lining pipe is tightly attached to the pipe wall and wraps the steel ring. By means of the non-excavation overall repairing method, a variety of pipe diseases such as subsidence, corrosion and cracking can be simultaneously repaired, and the problem of repair influences due to pipe cracking caused by direct grouting in the prior art is further solved.

Owner:南方工程检测修复技术研究院 +1

A Method for Quickly Pushing and Transversing the Whole Frame Bridge

ActiveCN104612056BReduce post-operation and maintenance workloadReduce the height of the structureBridge erection/assemblySlide plateEngineering

The invention discloses a quick pushing and transverse moving method for an integral frame bridge in existing rail way reconstruction, and a rail penetrates through the frame bridge. The method is characterized by comprising the steps that a sliding plate is constructed on one side of an existing rail way and a pushing back is constructed on the end of the sliding plate, the frame bridge is prefabricated on the sliding plate, and the top of a bottom plate of the frame bridge is roughly flush with the shoulder of the rail way; the pipe laying depth of pipelines on the two sides of a pushing and transverse moving area of the existing rail way is increased, and the pipe laying depth is larger than the bottom of the bottom plate of the frame bridge; a jack is installed at the back end of the frame bridge, lines and pathways of the existing rail way are dismantled, and the jack pushes and transversely moves the frame bridge; after the frame bridge is pushed and transversely moved to the position where an original rail way is removed, the lines and pathways of the existing rail way are restored in the normal position in the frame bridge. By the adoption of the form of the frame bridge, so the height of a bridge structure spanning the rail way is minimized, and a steel beam or a profiled-steel beam with the structure height in the same size is avoided; later operation and maintenance workloads of the rail way are lightened, and the requirements for safety, environment friendliness and energy conservation are satisfied.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

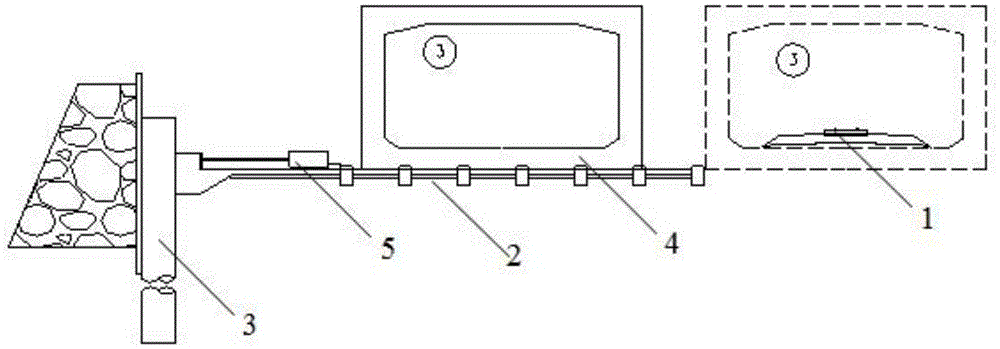

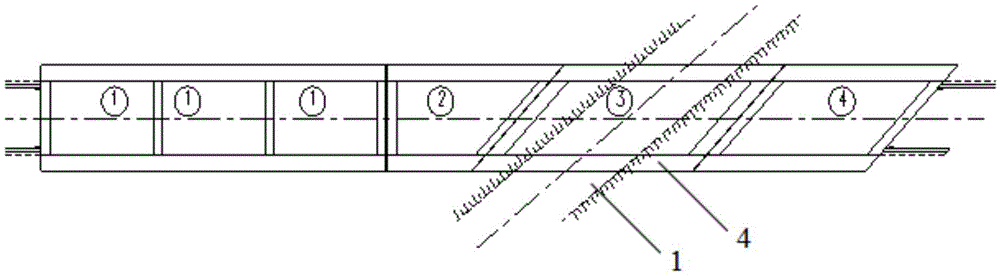

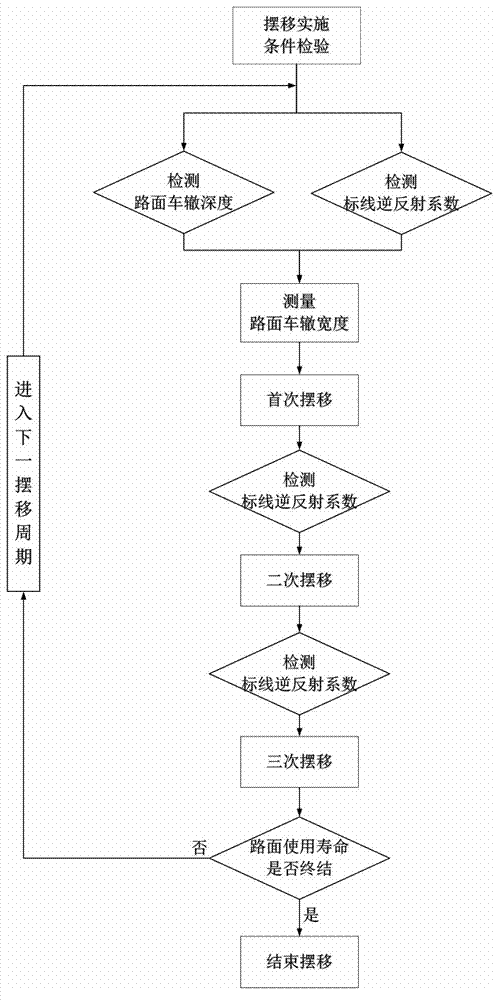

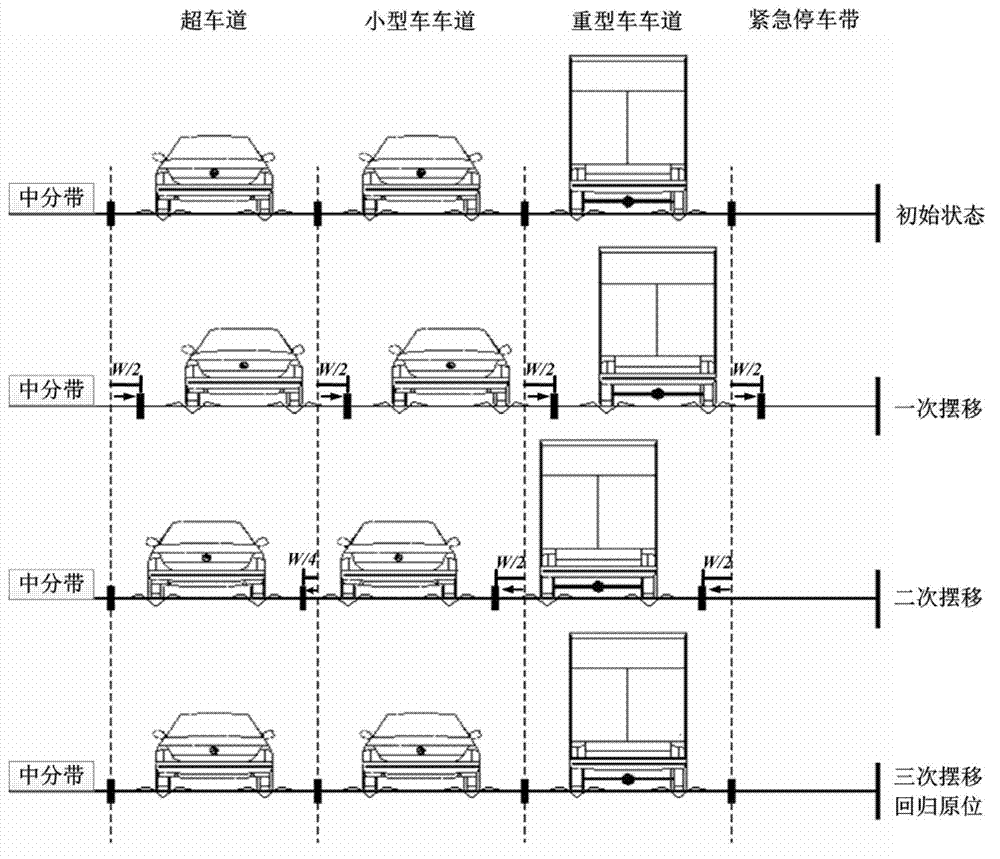

Bituminous pavement preventive maintenance method based on swinging lane markings

InactiveCN102776813ASimple methodShort construction periodTraffic signalsRoad signsDrive wheelPavement maintenance

The invention discloses a bituminous pavement preventive maintenance method based on swinging lane markings, which overcomes the shortcomings including long construction period and high construction cost of the existing roadway maintenance methods. The method is carried out from a traffic engineering perspective, swings construction partition positions of traffic lane markings at adequate time and amount, realizes guiding of re-distribution of driving wheel marks of vehicles, and further achieves the aims of improving road surface effective utilization, delaying development of road surface diseases and prolonging the service life of the road surface. The bituminous pavement preventive maintenance method based on swinging lane markings has the advantages of being low in cost, fast in construction speed, energy-conservation and environment-protection.

Owner:CHANGAN UNIV

Operating diseased tunnel fabricated treatment construction method

ActiveCN108798721AImprove targetingHigh degree of mechanizationUnderground chambersTunnel liningMedicineLine structure

The invention discloses an operating diseased tunnel fabricated treatment construction method applied to the field of tunnel engineering disease treatment. Based on a traditional fabricated lining structure construction working method, the characteristics of diverse types and different degrees of operating diseased tunnels and the requirements of tunnel operating for timeliness and safety are combined, the processes of disease treatment object identification, treatment range selecting, fabricated lining designing, lining segment production, matched machine and tool selection, determining of anon-site construction scheme and the like are combined, and thus the operating diseased tunnel fabricated lining structure treatment construction method is put forward. The disease treatment method has the advantages that the quality is reliable, rapidness and stability are achieved, adaptability is high, the accelerating working speed is high, the mechanical degree is high, and traffic interference is less.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Small full-automatic hydraulic tamping wagon

PendingCN107419624AEliminates tilting forcesSave human effortBallastwayTrack superstructureMachinePower apparatus

The invention provides a small full-automatic hydraulic tamping wagon, and belongs to the field of railway line maintenance equipment. The small full-automatic hydraulic tamping wagon is characterized in that the bottoms of tamping mechanisms (5) are installed on a travelling chassis (1), travelling mechanisms which drive the travelling chassis (1) to move are arranged on the lower portions of the two sides of the travelling chassis (1) in the travelling direction, and the two tamping mechanisms (5) are symmetrically installed on the left side and the right side of the travelling chassis (1) in the travelling direction. A plurality of rail clamping mechanisms (3) which are used for clamping steel rails are arranged on the two sides of the travelling chassis (1) in the travelling direction, a railway leaving mechanism (4) which drives a complete machine to ascend and descend and can achieve rotation of the complete machine is arranged in the middle of the travelling chassis (1), and power devices are arranged on the travelling chassis (1) and the two tamping mechanisms (5). By the adoption of the small full-automatic hydraulic tamping wagon, all operation such as equipment transfer, automatic tamping operation and railway coming and leaving operation of equipment can be achieved by a single worker, manpower is substantially saved, the working quality is improved, the interference on train travelling is low, and the industrial upgrade of the railway line turnout tamping operation from mechanization to automation is achieved.

Owner:淄博洁翔机电科技开发有限公司

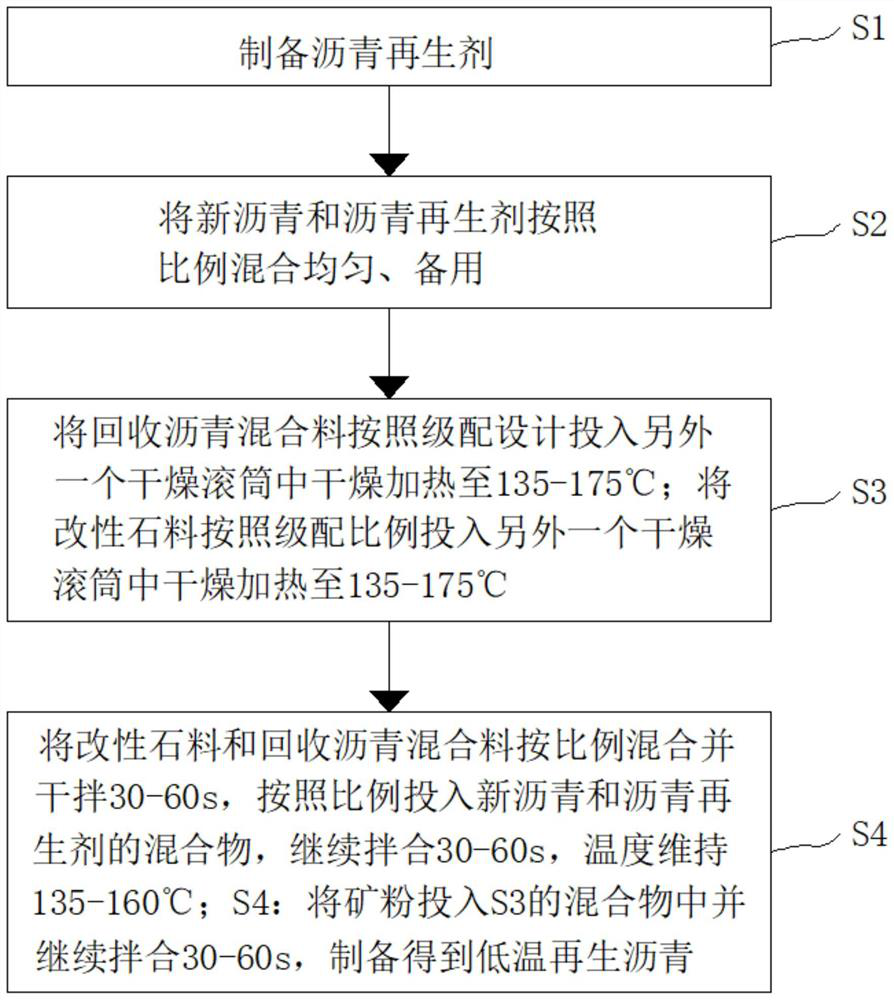

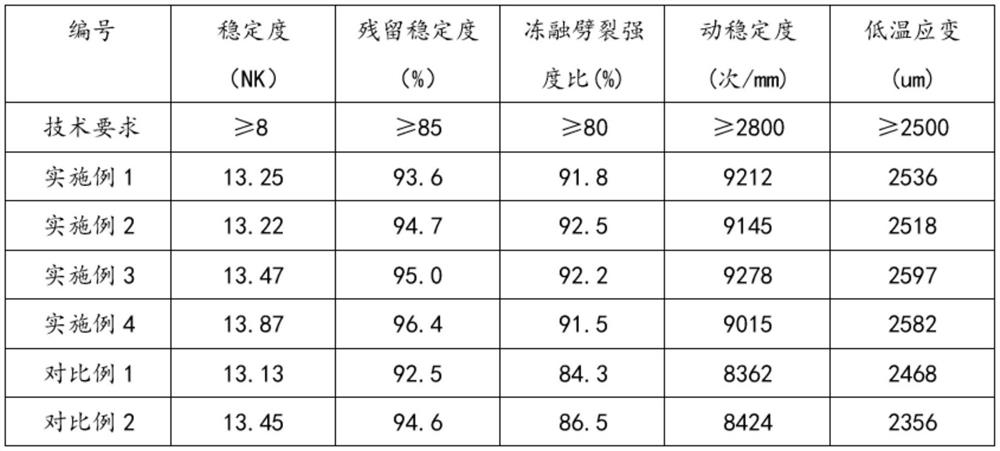

Preparation method of low-temperature recycled asphalt and mixture

PendingCN114853389AImprove ductilityImprove crack resistanceSolid waste managementPlasticizerRoad surface

The invention belongs to the technical field of recycled asphalt, and particularly relates to a low-temperature recycled asphalt and a preparation method of a mixture, the low-temperature recycled asphalt is prepared from the following raw materials in percentage by mass: 20-35% of modified stone, 60-80% of recycled asphalt mixture, 4-10% of new asphalt, 1-4% of mineral powder and 0.5-1% of asphalt regenerant; the asphalt regenerant is prepared from the following raw materials in percentage by mass: 10 to 25 percent of solution polymerized styrene-butadiene rubber, 20 to 60 percent of 90 # petroleum asphalt, 30 to 70 percent of aromatic oil, 0.05 to 0.5 percent of cross-linking agent, 0.05 to 2 percent of plasticizer, 0.05 to 1.5 percent of dispersing agent and 0.05 to 3 percent of stabilizer. The invention aims to enable the asphalt regenerant to be completely soluble with the aged asphalt, improve the low-temperature ductility of the asphalt, enhance the anti-freezing and anti-cracking capabilities of pavements in extremely cold regions and prolong the service life of the pavements.

Owner:遂宁天孜路新材料技术有限公司

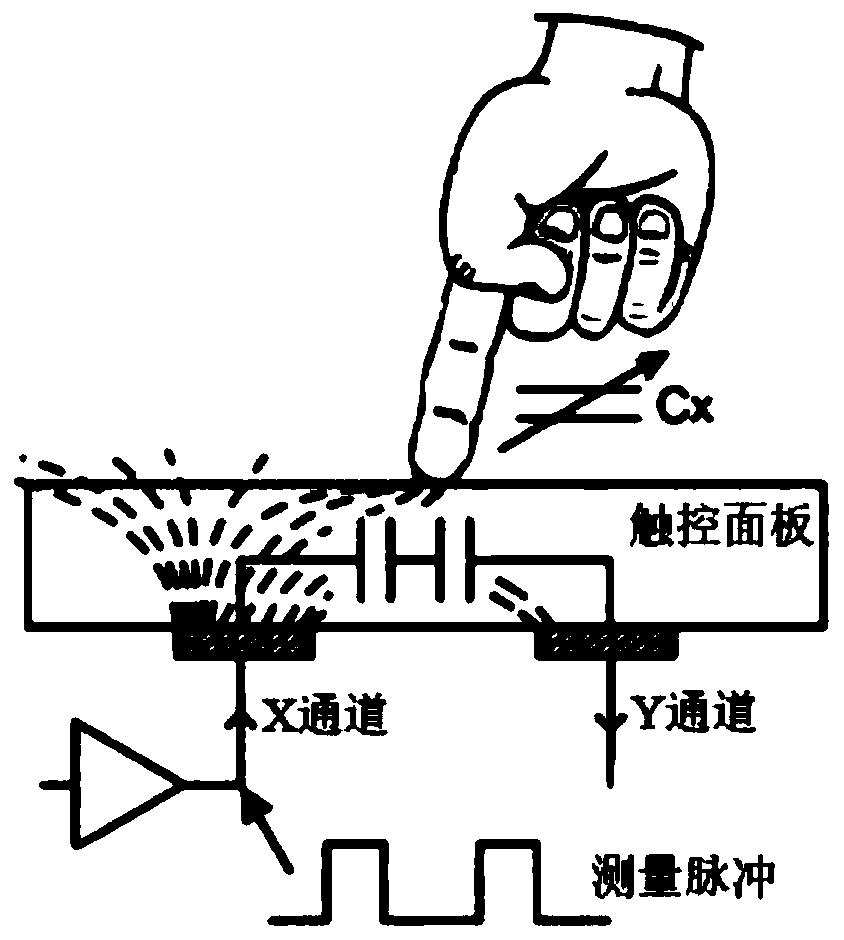

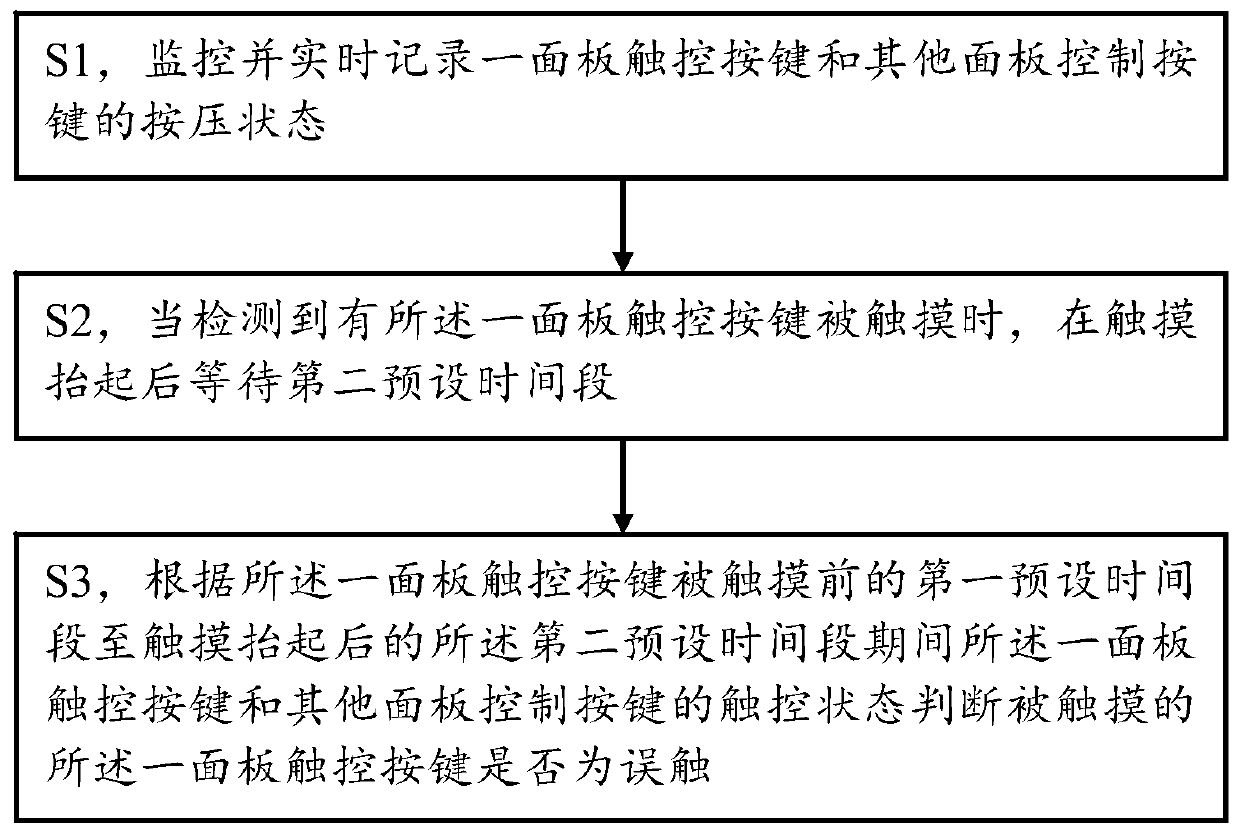

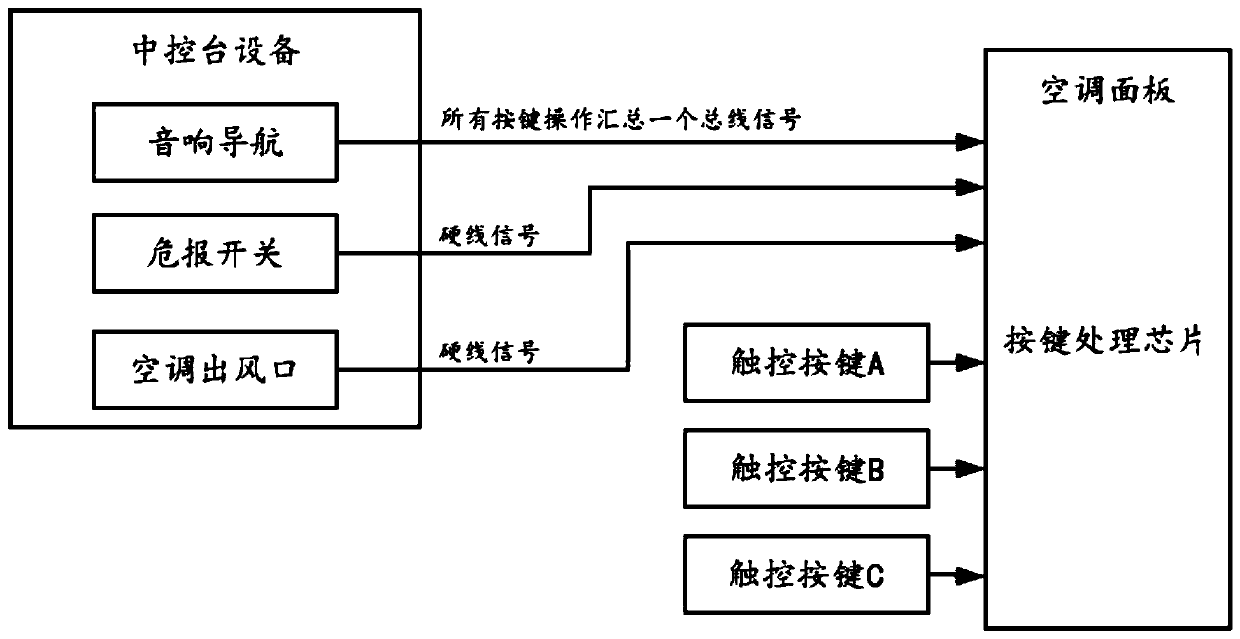

Mistaken touch prevention method of touch panel

ActiveCN110658950ASolve the problem of false touchImprove qualityAir-treating devicesVehicle heating/cooling devicesComputer hardwareTouchscreen

The invention provides a mistaken touch prevention method of a touch panel. The mistaken touch prevention method specifically comprises the following steps: S1, monitoring and recording pressing states of a panel touch key and other panel control keys in real time; s2, when it is detected that one panel touch key is touched, waiting for a second preset time period after touch lifting; and S3, judging whether the touched panel touch key is mistakenly touched or not according to the touch states of the panel touch key and other panel control keys in the period from the first preset time period before the panel touch key is touched to the second preset time period after the panel touch key is touched and lifted. The invention provides a mistaken touch prevention method of a touch panel, whichcan effectively solve the problem of mistaken touch of the touch air conditioner panel, does not influence the normal use of a user, not only can reduce the driving interference to a driver or a passenger caused by mistaken touch of a touch screen, but also can improve the quality of the touch air conditioner panel.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com