Patents

Literature

1331results about "Protective construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

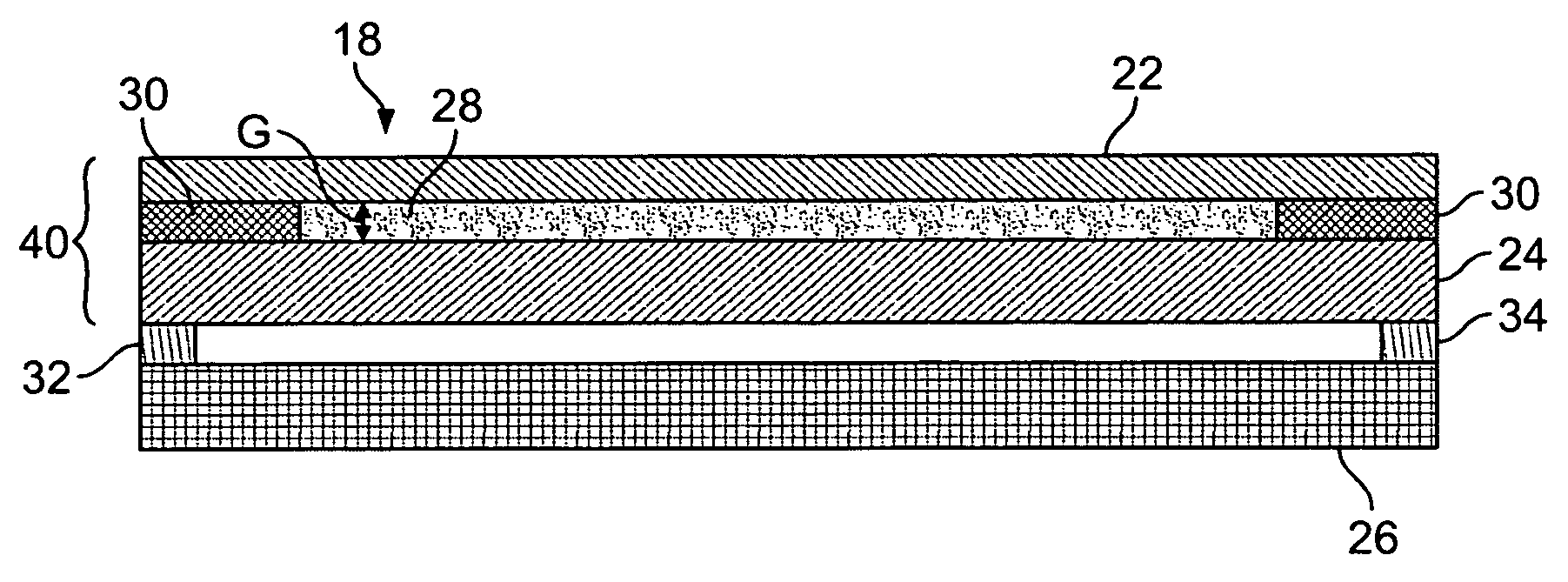

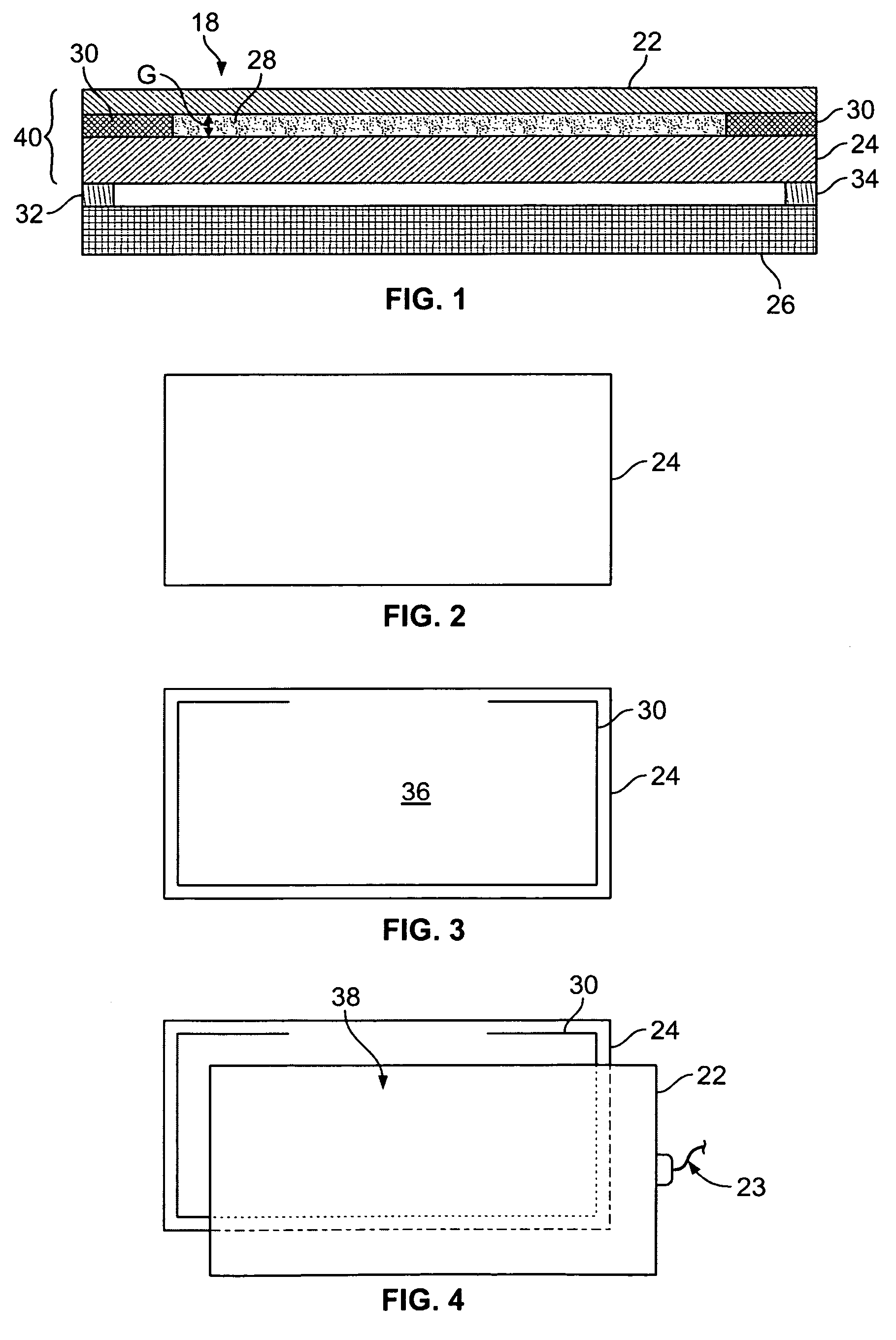

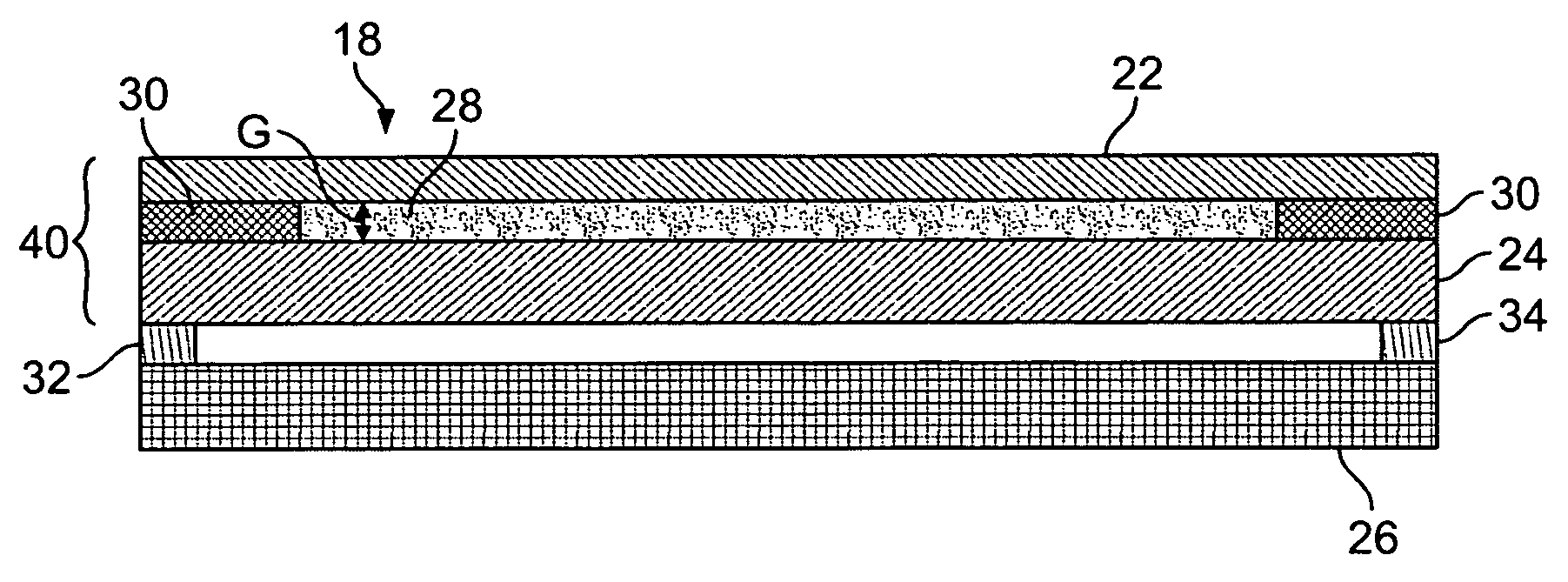

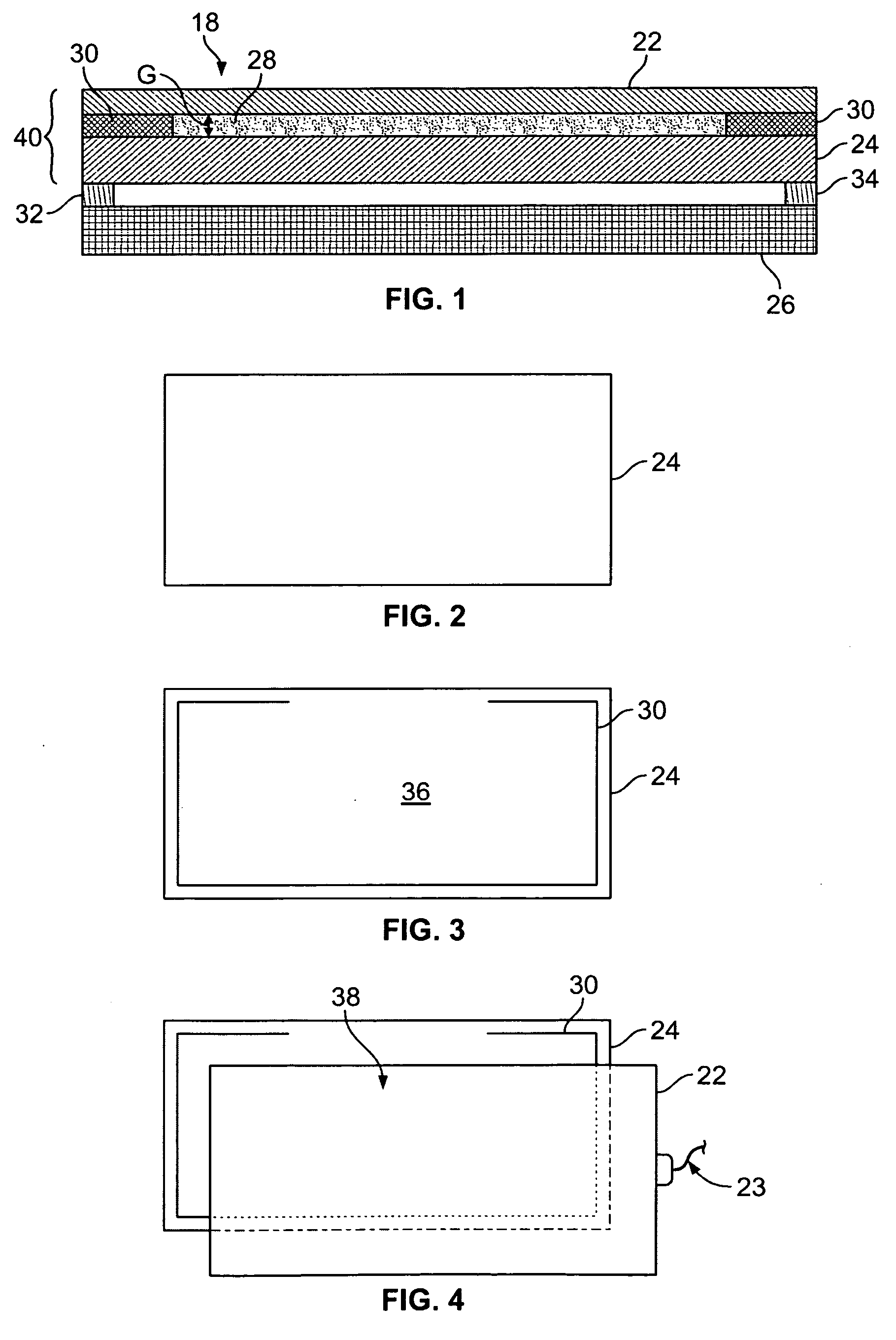

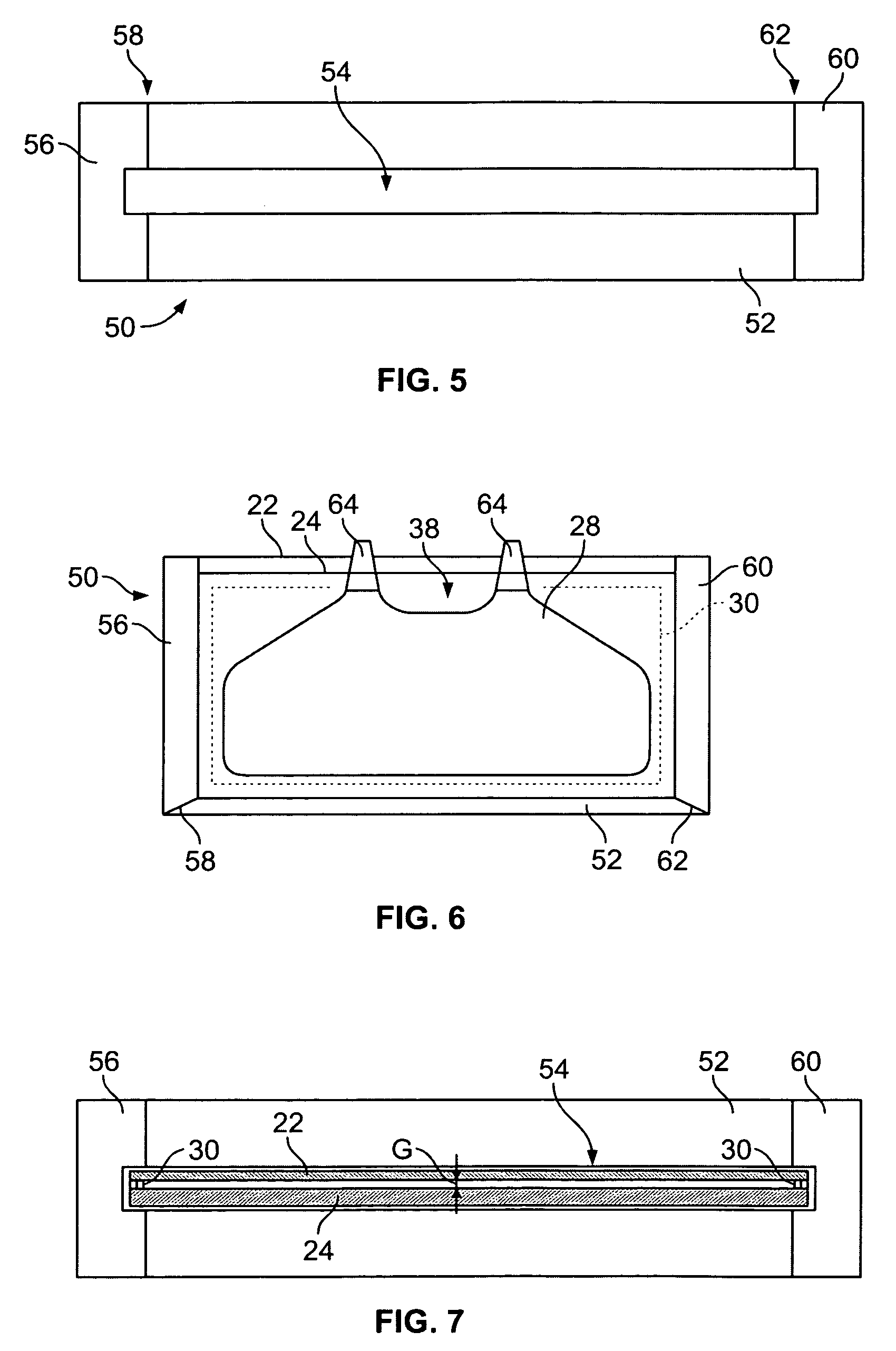

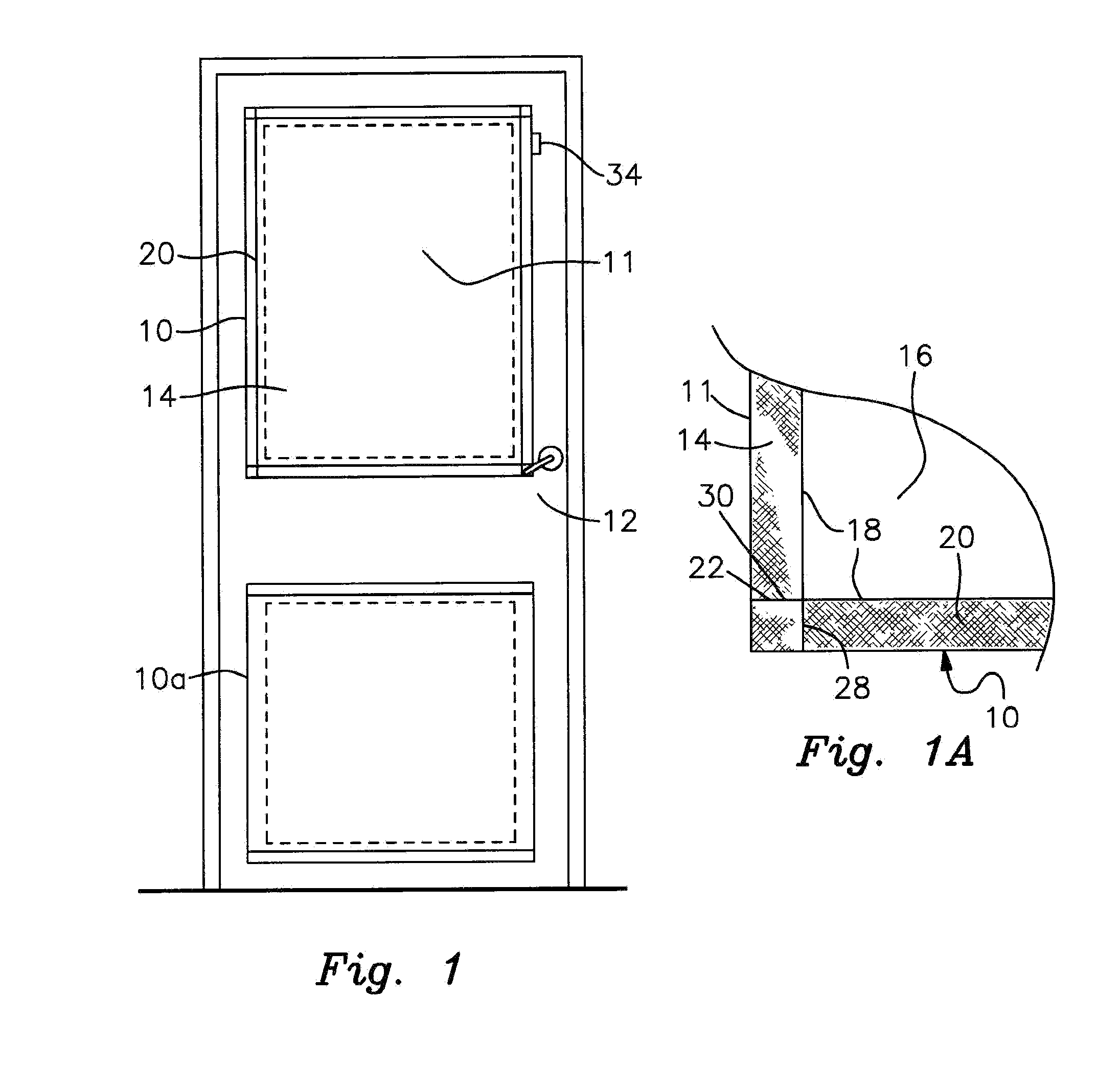

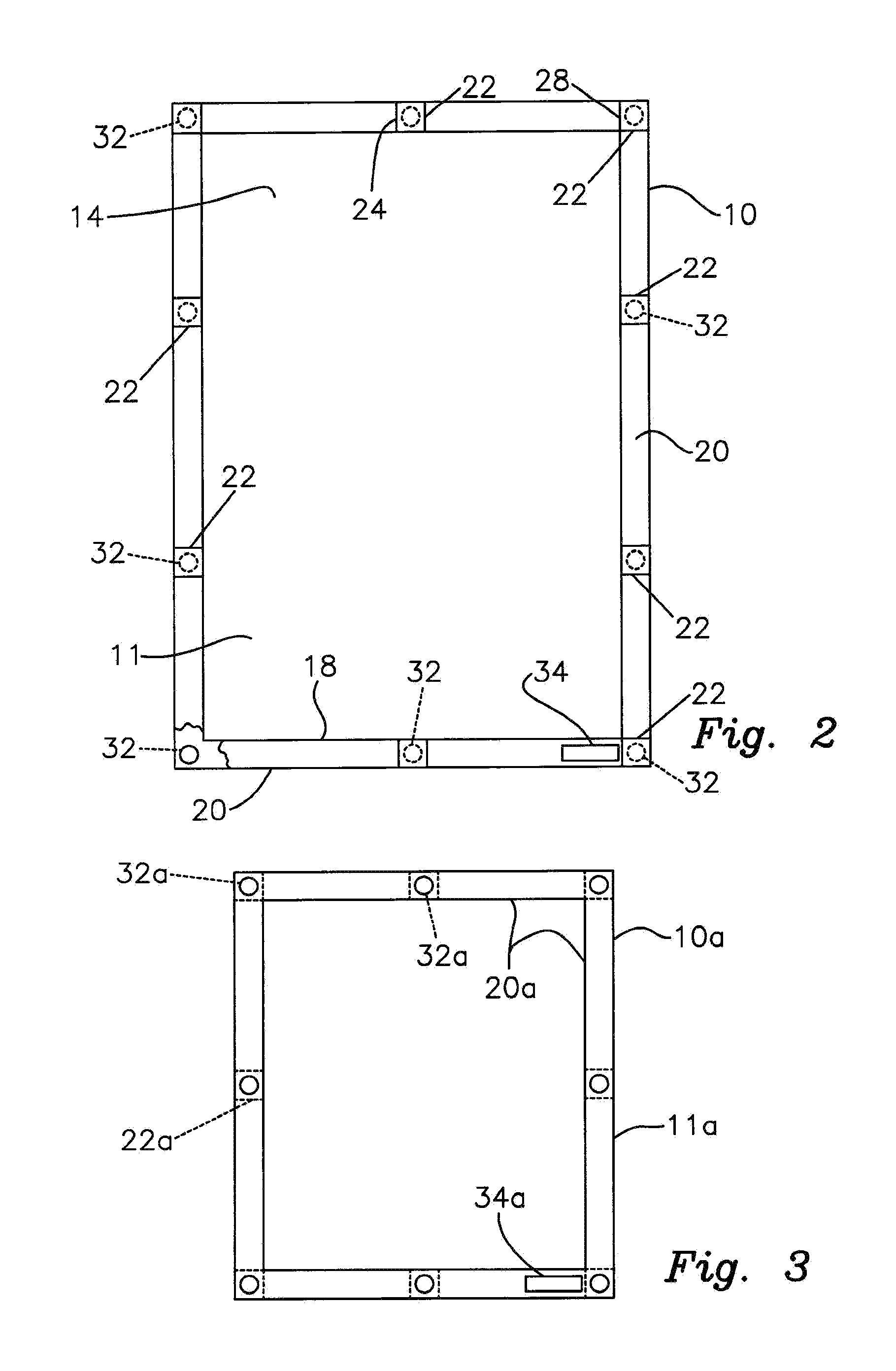

Video display and touchscreen assembly, system and method

A touch screen assembly for use with a display, such as a flat panel display. The touch screen assembly includes a transparent panel, preferably in the form of a panel of tempered glass adhered to a touch screen panel. Consoles having touch screen assemblies are also disclosed.

Owner:WELLS GARDNER TECH INC

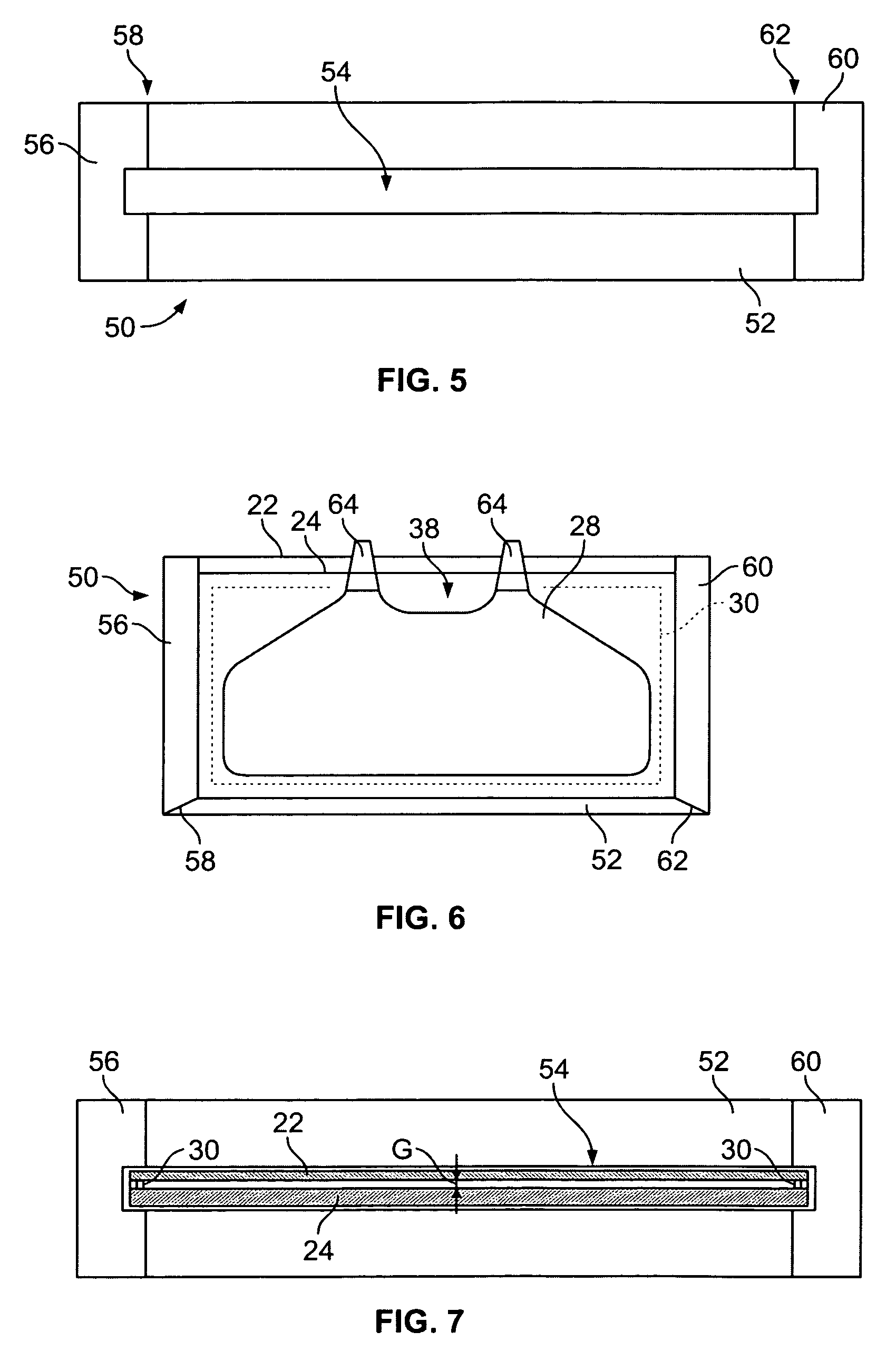

Coupling systems and methods for marine barriers

A marine barrier system comprising first and second barrier sections and a coupler system. The first and second barrier sections comprise first and second main flotation members, respectively, and each main flotation member contains buoyant material. The coupler system is arranged at the juncture of the first and second barrier sections. The coupler system is arranged such that the first and second main flotation members may be placed in a storage configuration and in a deployed configuration. In the storage configuration, the first and second main flotation members are arranged in a parallel, side by side arrangement. In the deployed configuration, the first and second main flotation members are arranged end to end to define a barrier line in a body of water across which movement is limited.

Owner:SPINK RICHARD

Safety barrier with illuminating components

InactiveUS6969185B1Restrains entryEasy to transportLighting support devicesRoad vehicles traffic controlRoad traffic controlFiber

A safety net that includes at least one illuminating element. The safety net is intended to be stored in a rolled-up fashion (similar to a roll-up window shade) in the trunk of a vehicle. When illuminated, the safety net provides a completely new and unique means of alerting oncoming traffic to a road hazard or other situation requiring traffic control. The safety net provides a warning means that will not be knocked over by the wind, as wind blows freely through the voids of the net. In addition, the safety net screens the scene from the view of those in oncoming traffic. The device may include a solid state controller that provides a variety of patterns or symbols to further enhance the visual safety features of the device. This can be accomplished by placing fiber optic strands in the net voids, or within the side illuminating fiber optic conduit itself. The device may also include metal cables to form a physical barrier.

Owner:ADAIR DARRYL

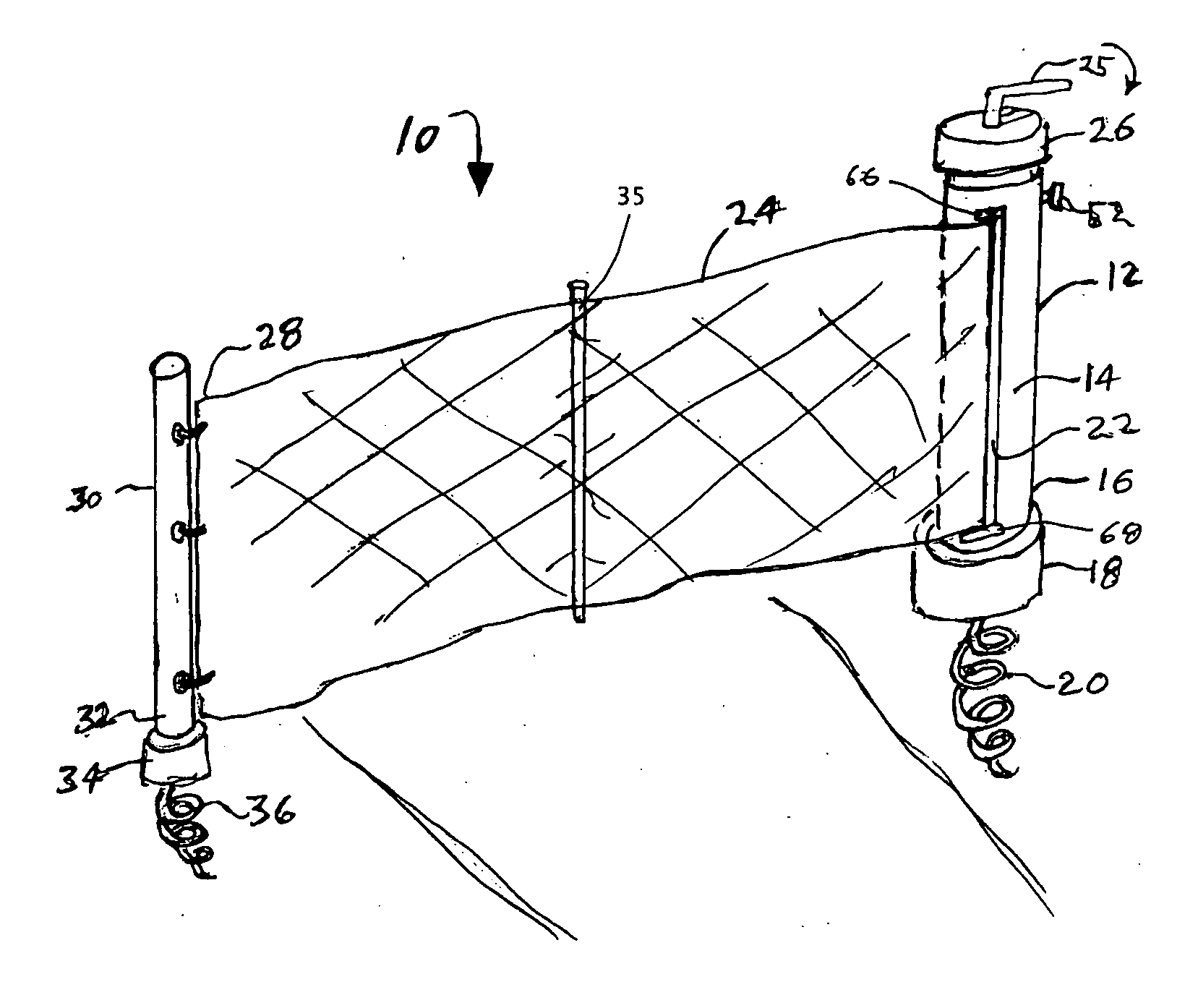

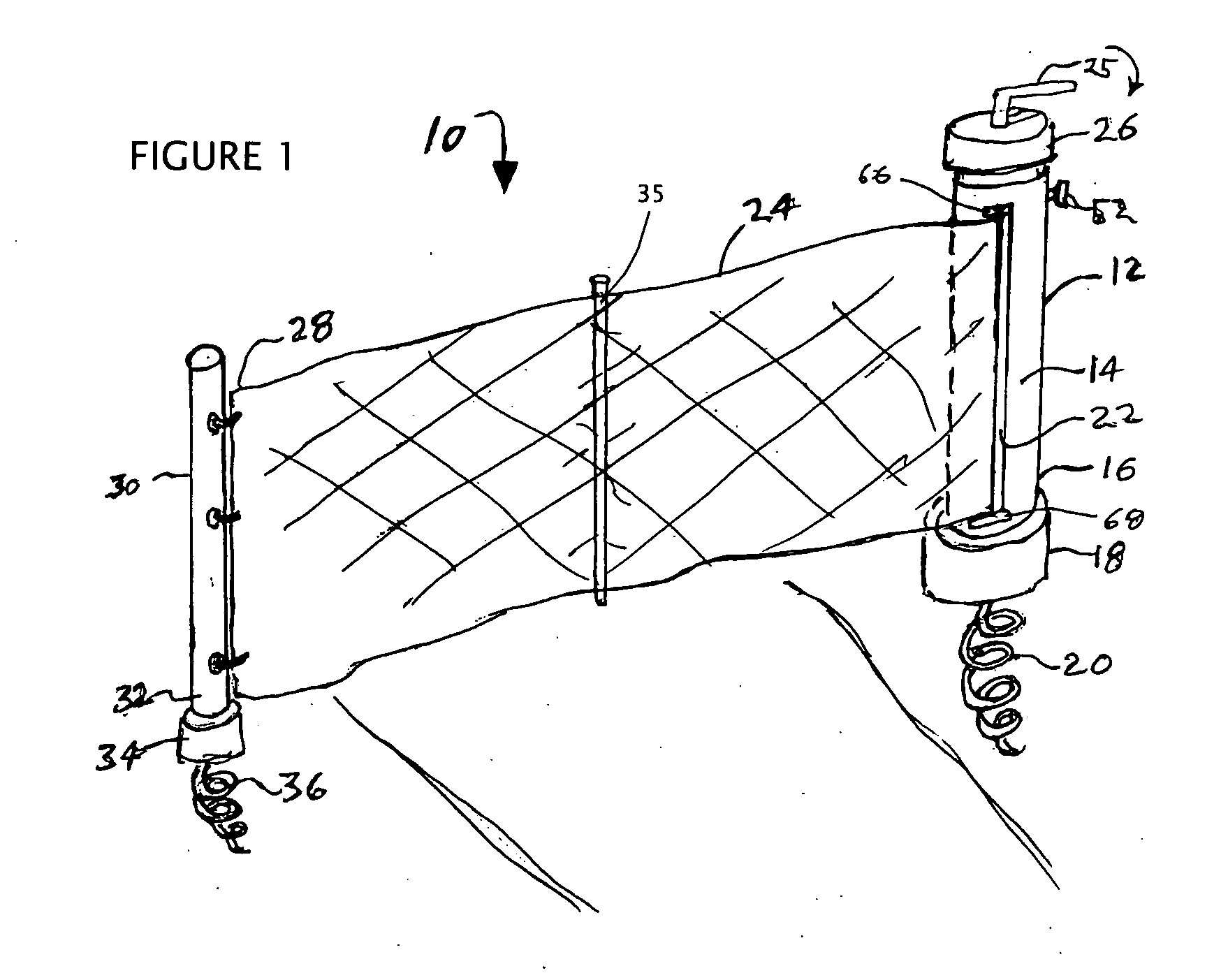

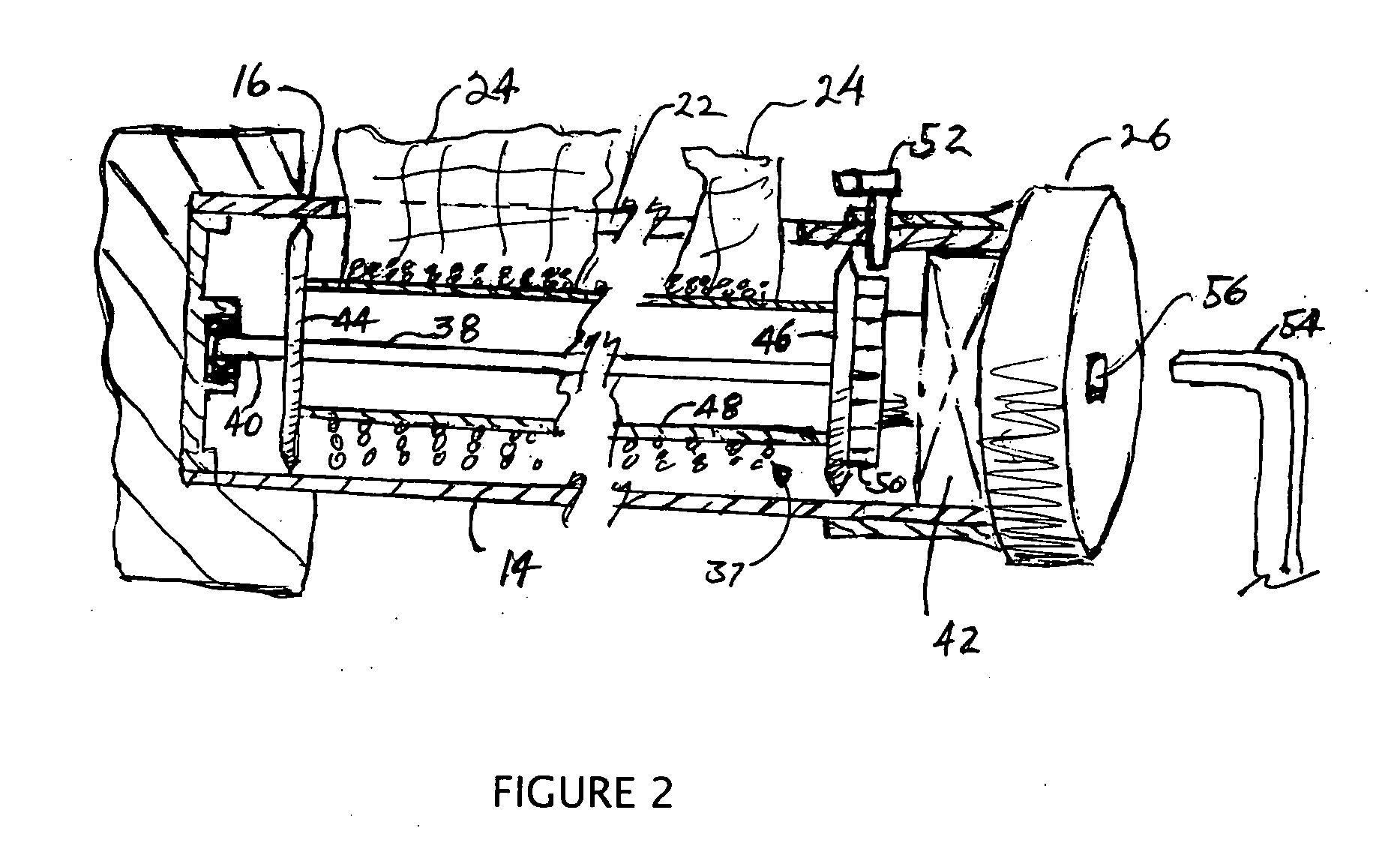

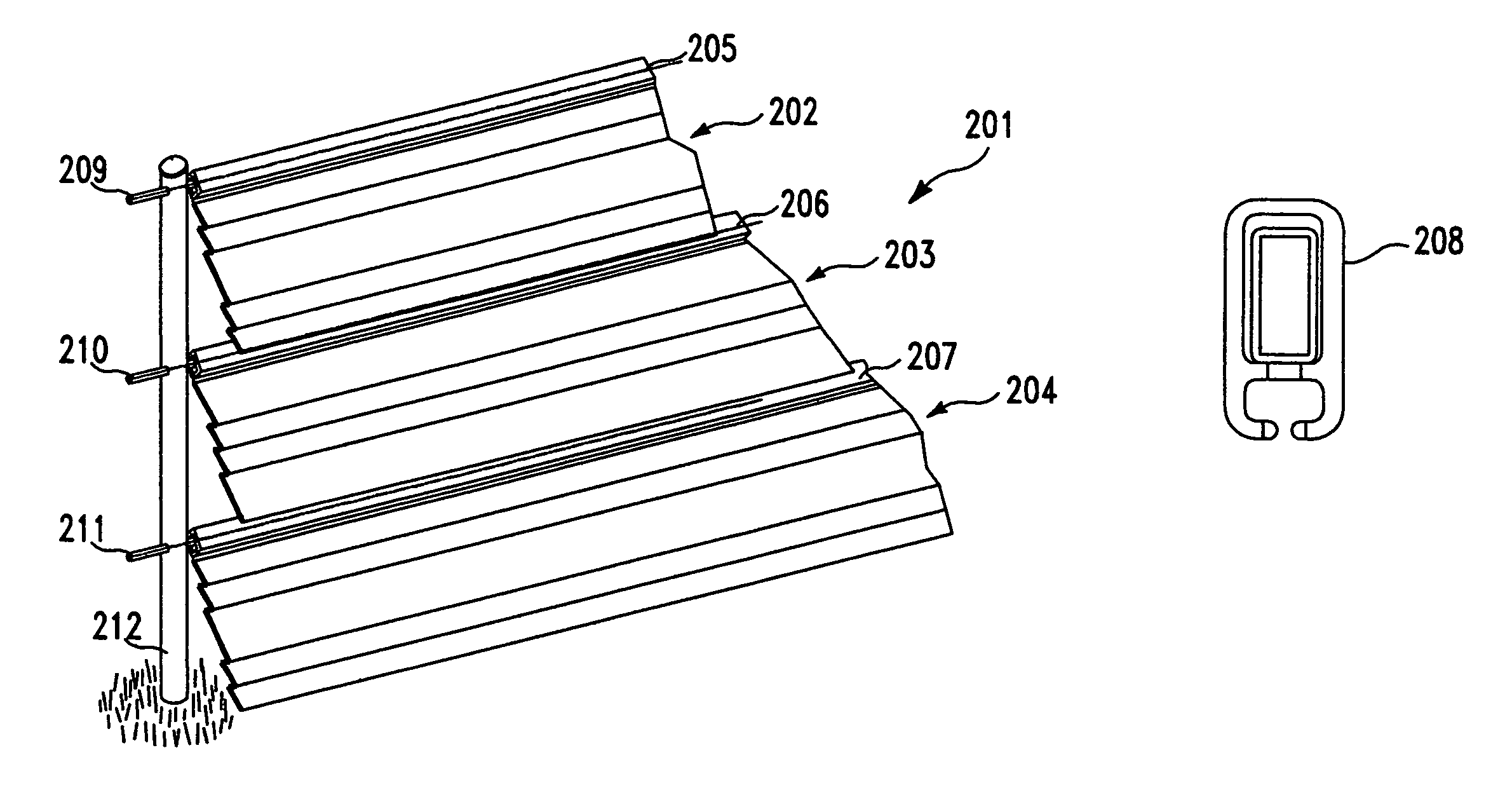

Portable safety barrier

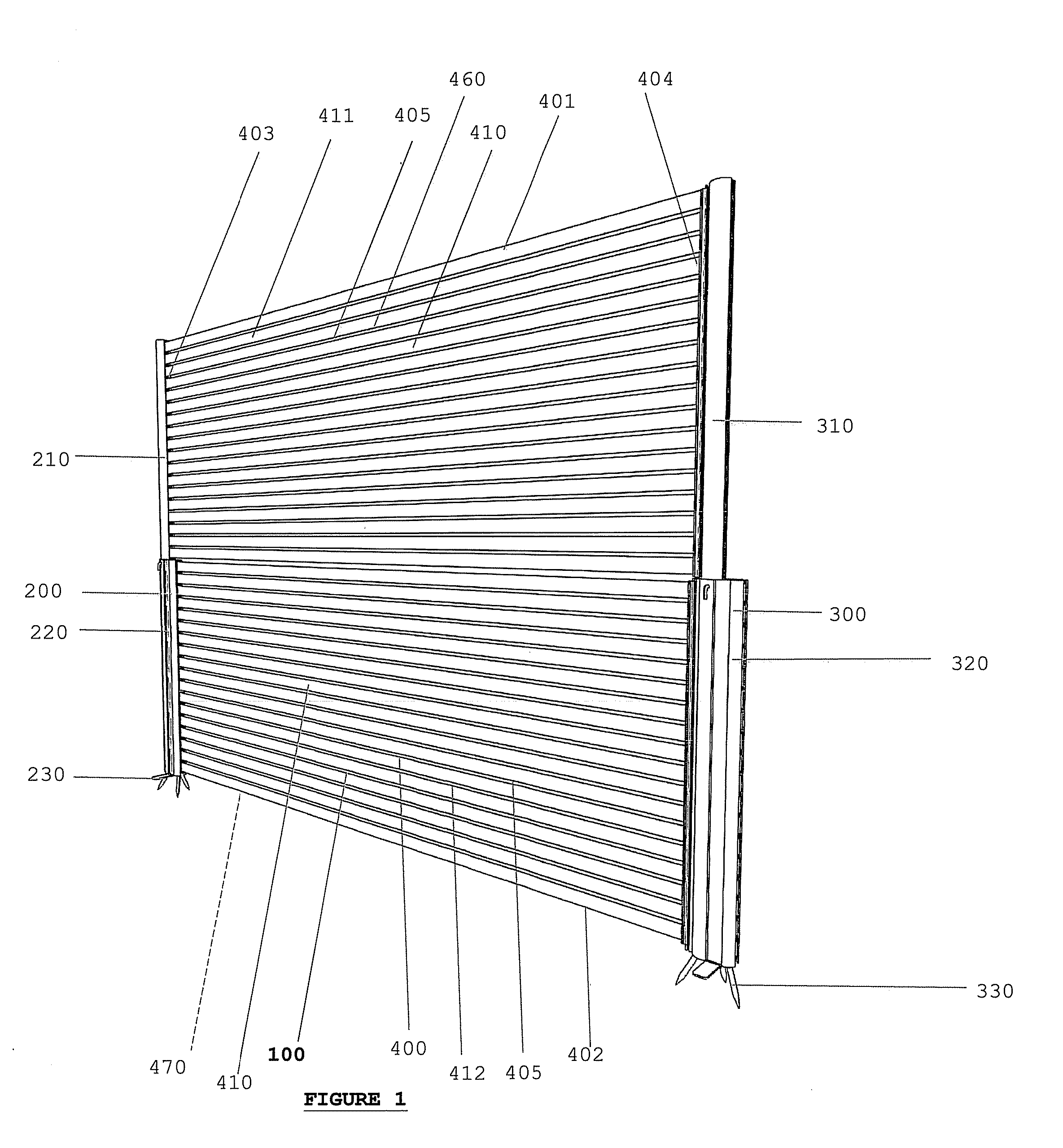

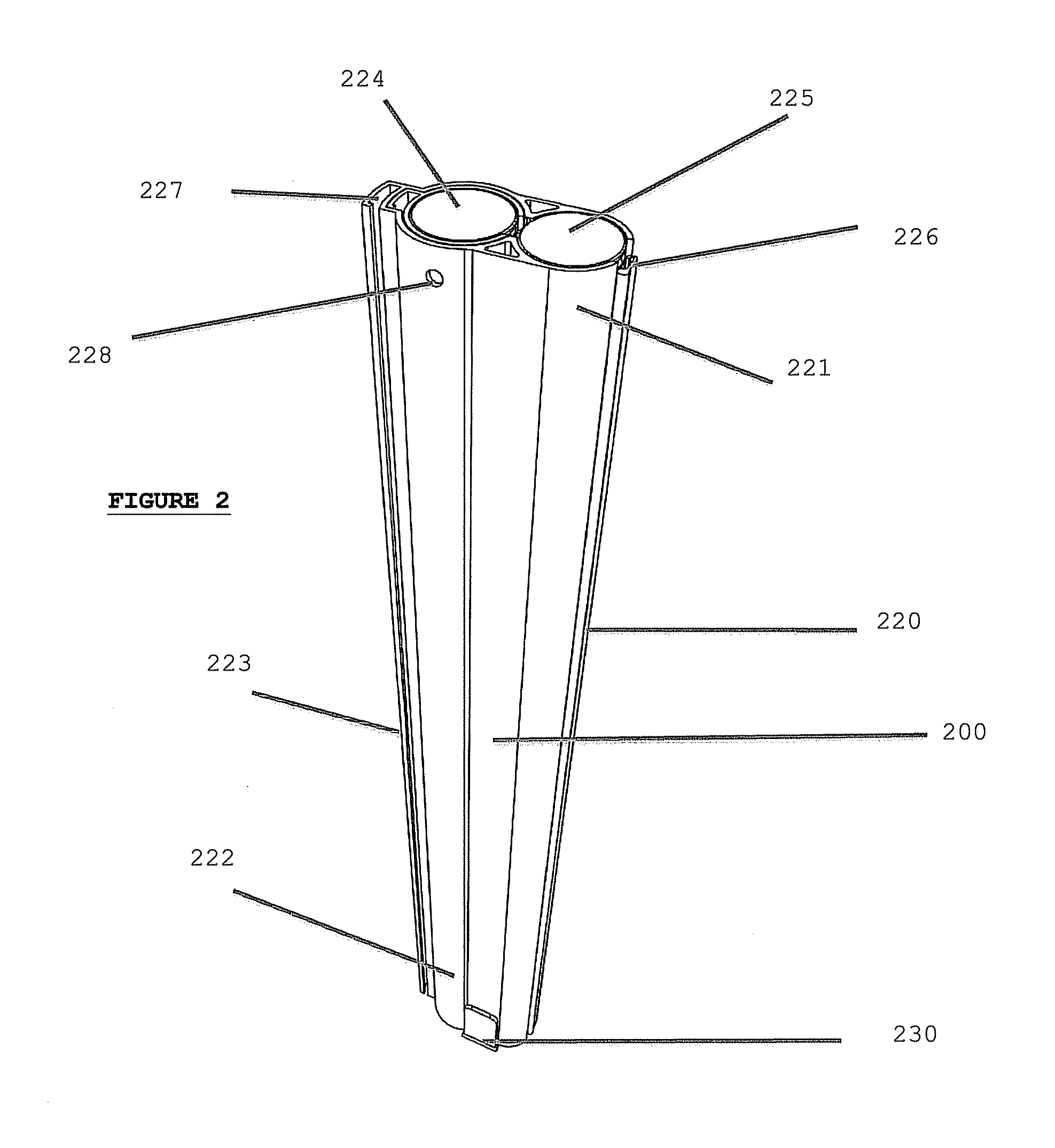

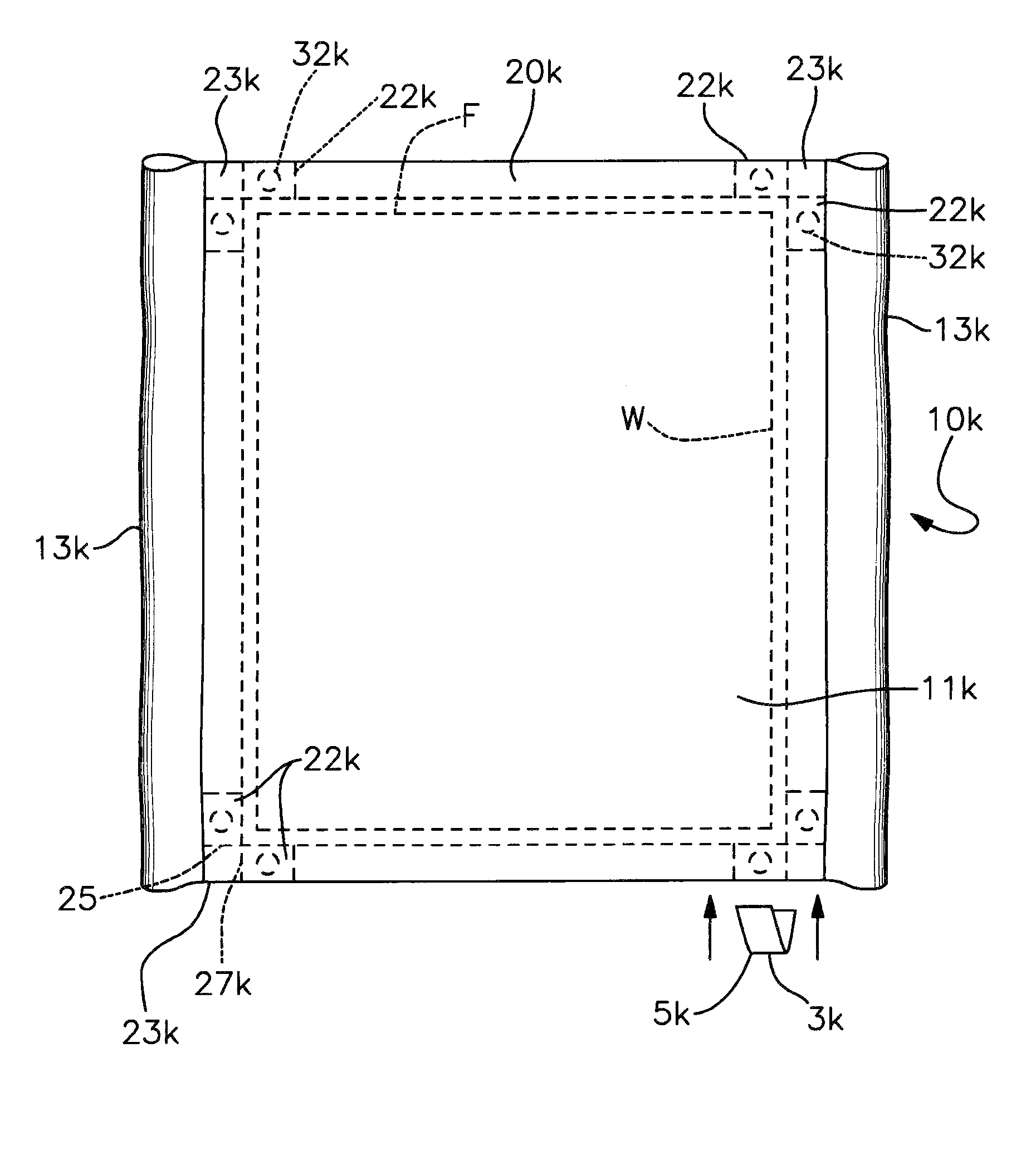

InactiveUS20070176158A1Facilitate manual rewindingEasy to rewindProtective constructionTraffic restrictionsEngineeringGear train

A portable safety barrier that can be set up across a drive way or other path to provide a visible and physical indication of a safe zone boundary particularly for children. Netting attached to a core or reel disposed in a housing forms the barrier. The netting is free to deploy from the housing for attachment to a remote post; both the housing and post including an auger for anchoring the housing and post to ground. The housing has a rewind system to reel in the netting which includes a gear train for mechanical advantage. The rewind system operates manually and with out a bias assist. A selectively operated stop cooperates with the rewind system to tighten the netting after deployment and keeps the netting taut.

Owner:ROBINSON JEFFERY A

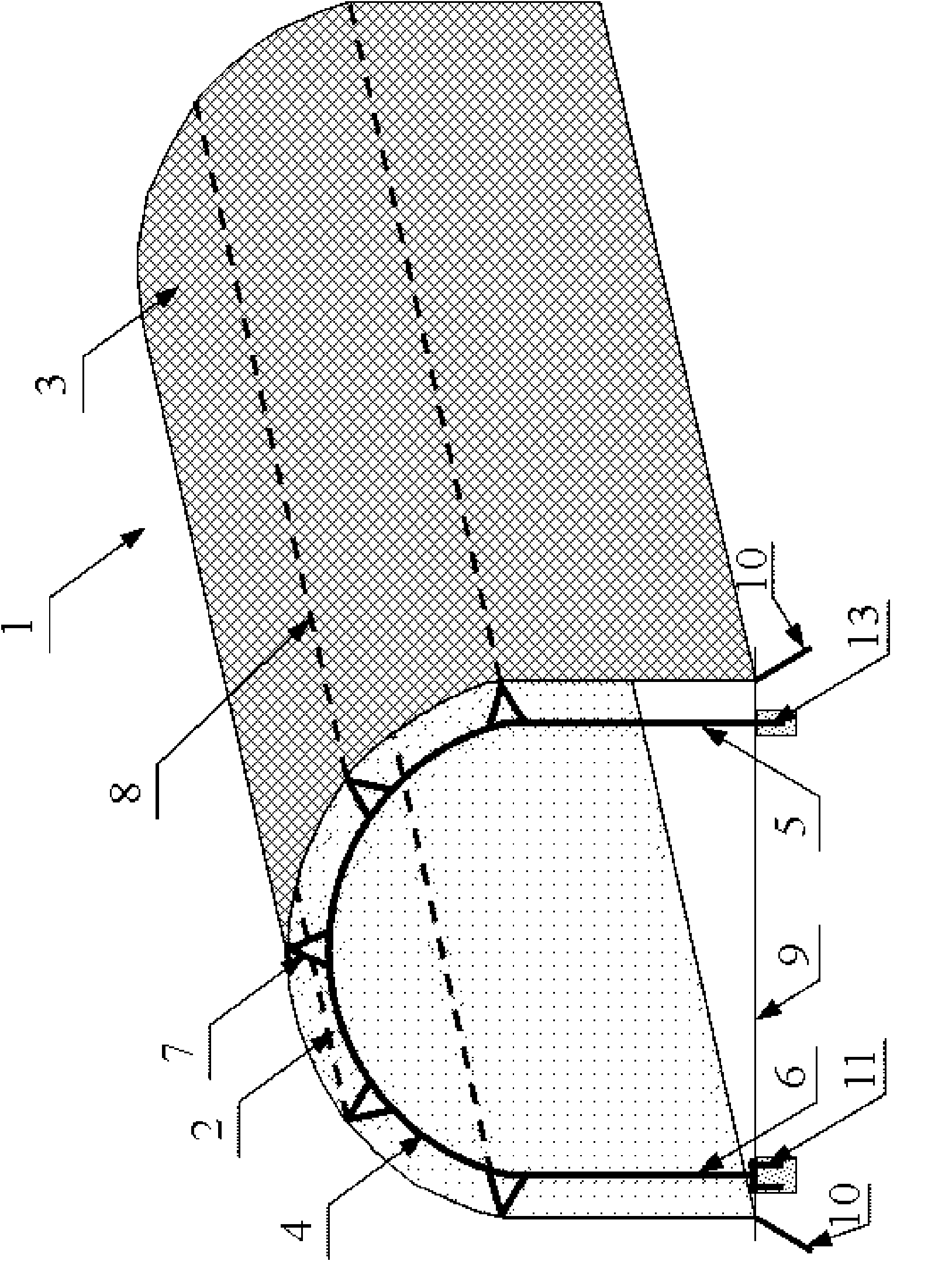

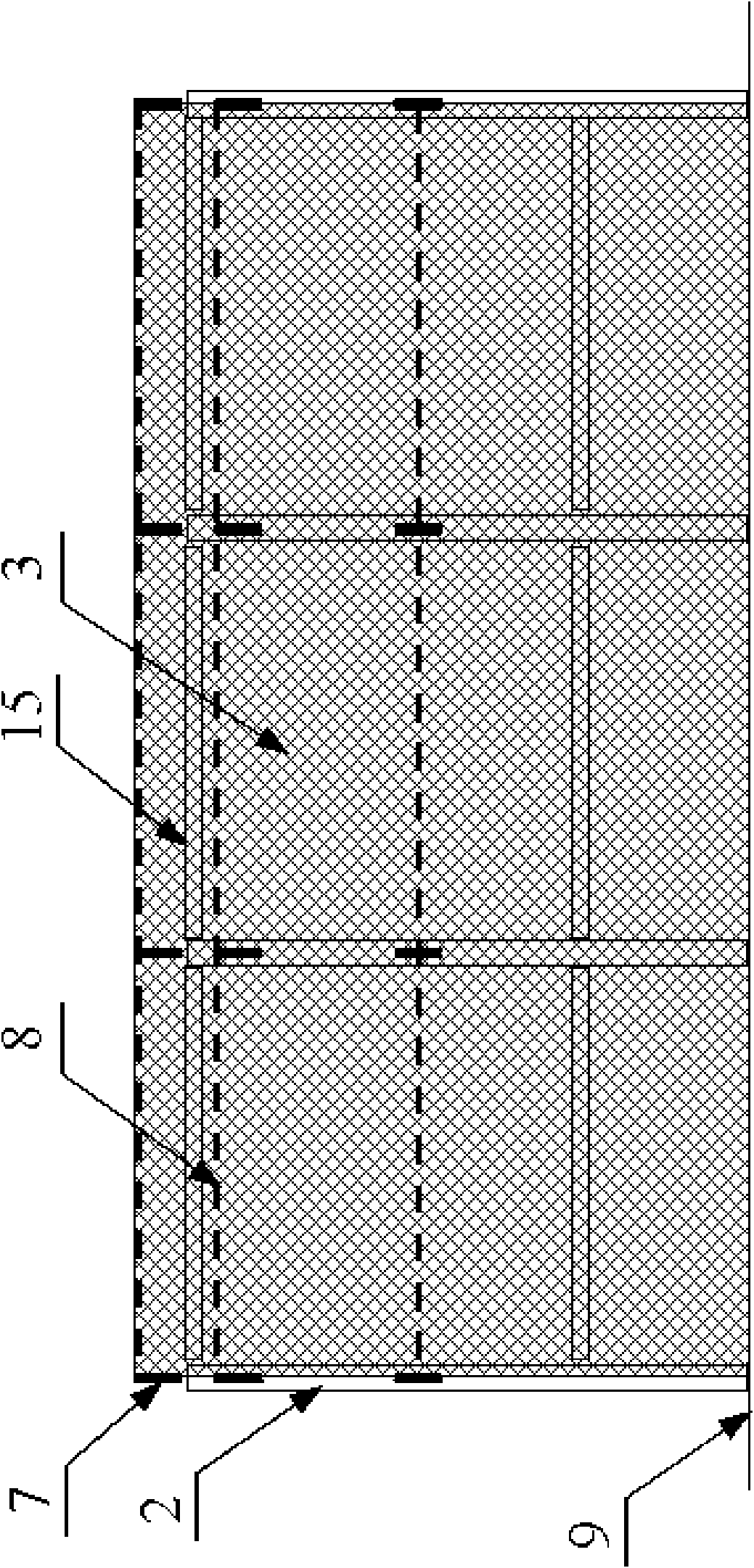

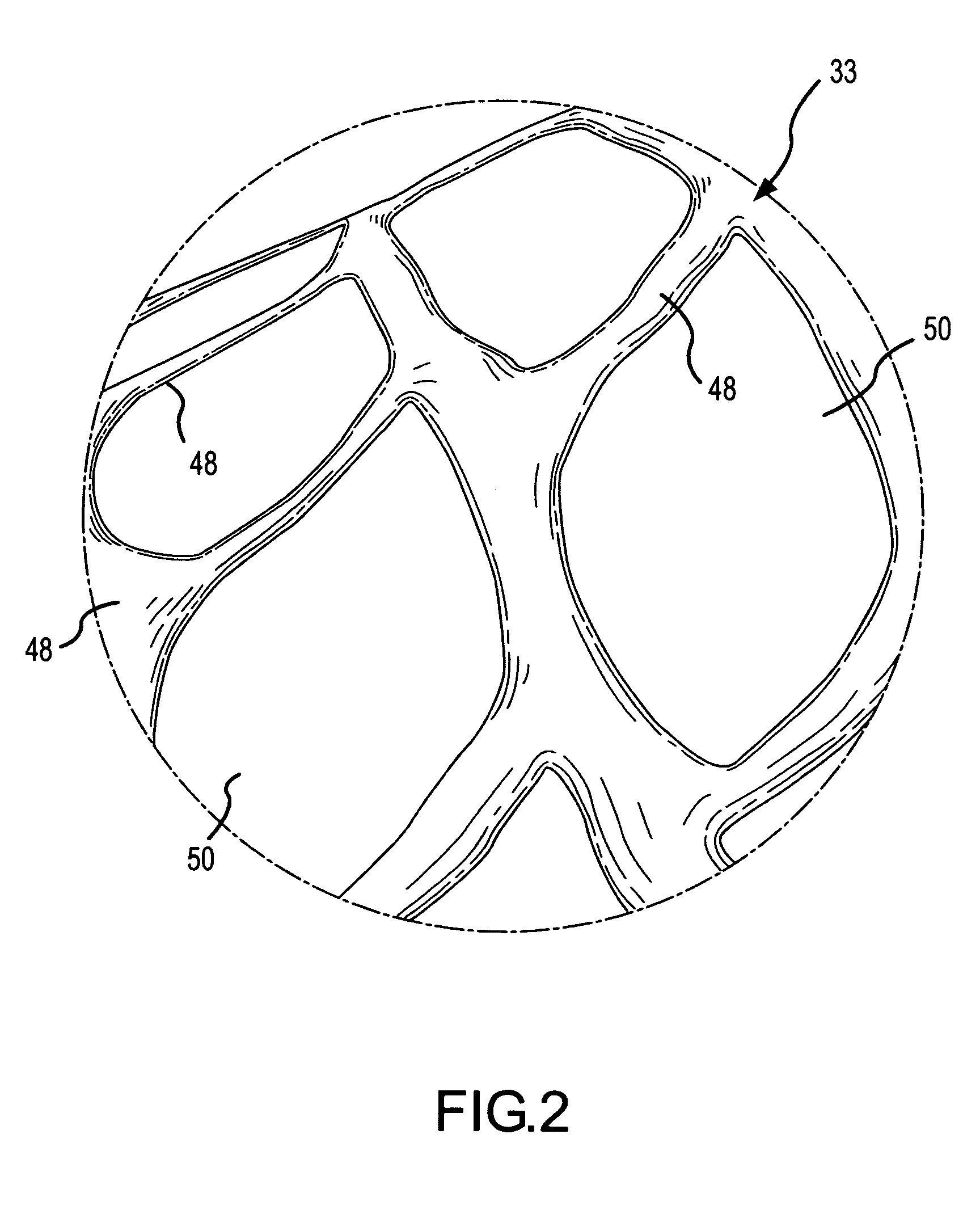

Flexible protective shed-tunnel and method for designing same

InactiveCN102493328AImprove flexibilitySimple structureProtective constructionBridge structural detailsBridge deckDesign methods

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

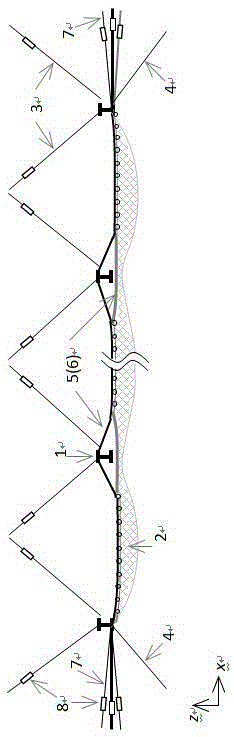

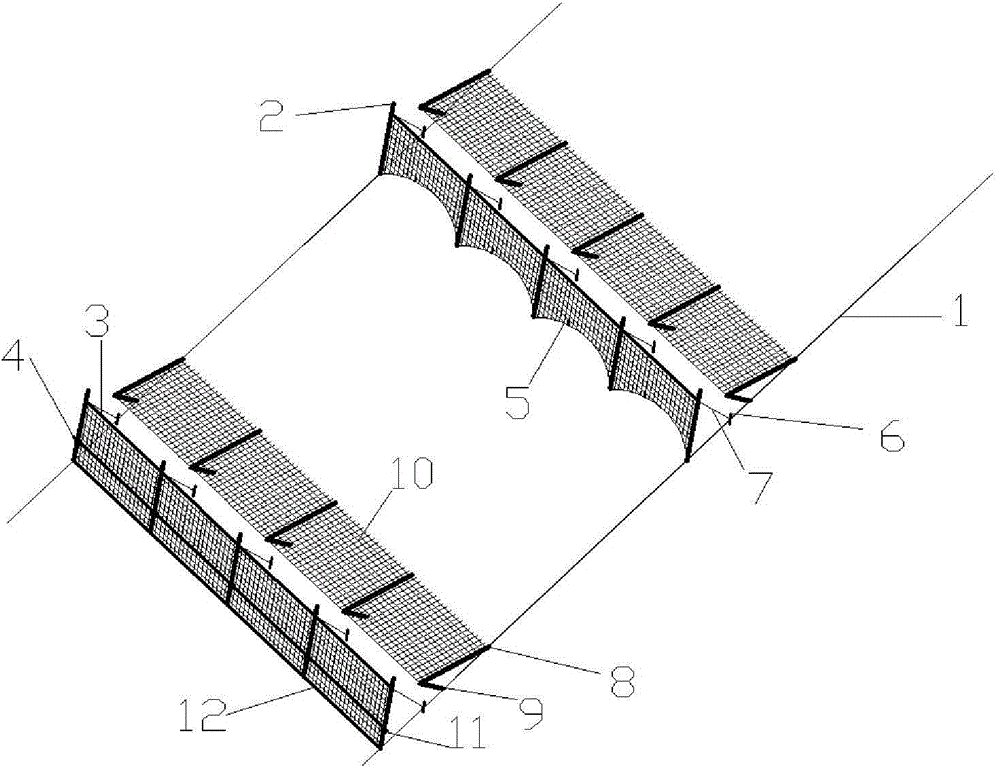

Rockfall prevention driven flexible protective net system designing method based on energy matching principle

ActiveCN105256731AClarify the design processOperableProtective constructionModel selectionEngineering

The invention discloses a rockfall prevention driven flexible protective net system designing method based on the energy matching principle. The rockfall prevention driven flexible protective net system designing method comprises the steps that 1, the energy consumption rate matching principle of components of a driven flexible protective net structure is established; 2, preliminary model selection and arrangement are performed on the components of the driven flexible protective net structure; 3, an explicit dynamics computation model capable of considering features such as the initial perpendicularity, large sliding of a supporting rope, large rotation of a supporting column and large deformation of an interception net is built through a finite element computing method; 4, impact loading is performed on the computation model, and dynamics response of the structure under the impact effect is analyzed; 5, structural design of the driven flexible protective net is performed. According to the method, the design principle of energy matching is adopted, both the force balance and the energy balance are considered, and the design is more scientific and reasonable; the component strength, stability, deformation and the like are used as design verification control indexes, and both the component design bearing capacity safety storage and the applicability of the protective net structural overall interception effect are considered.

Owner:SICHUAN OST SLOPE PROTECTION ENG

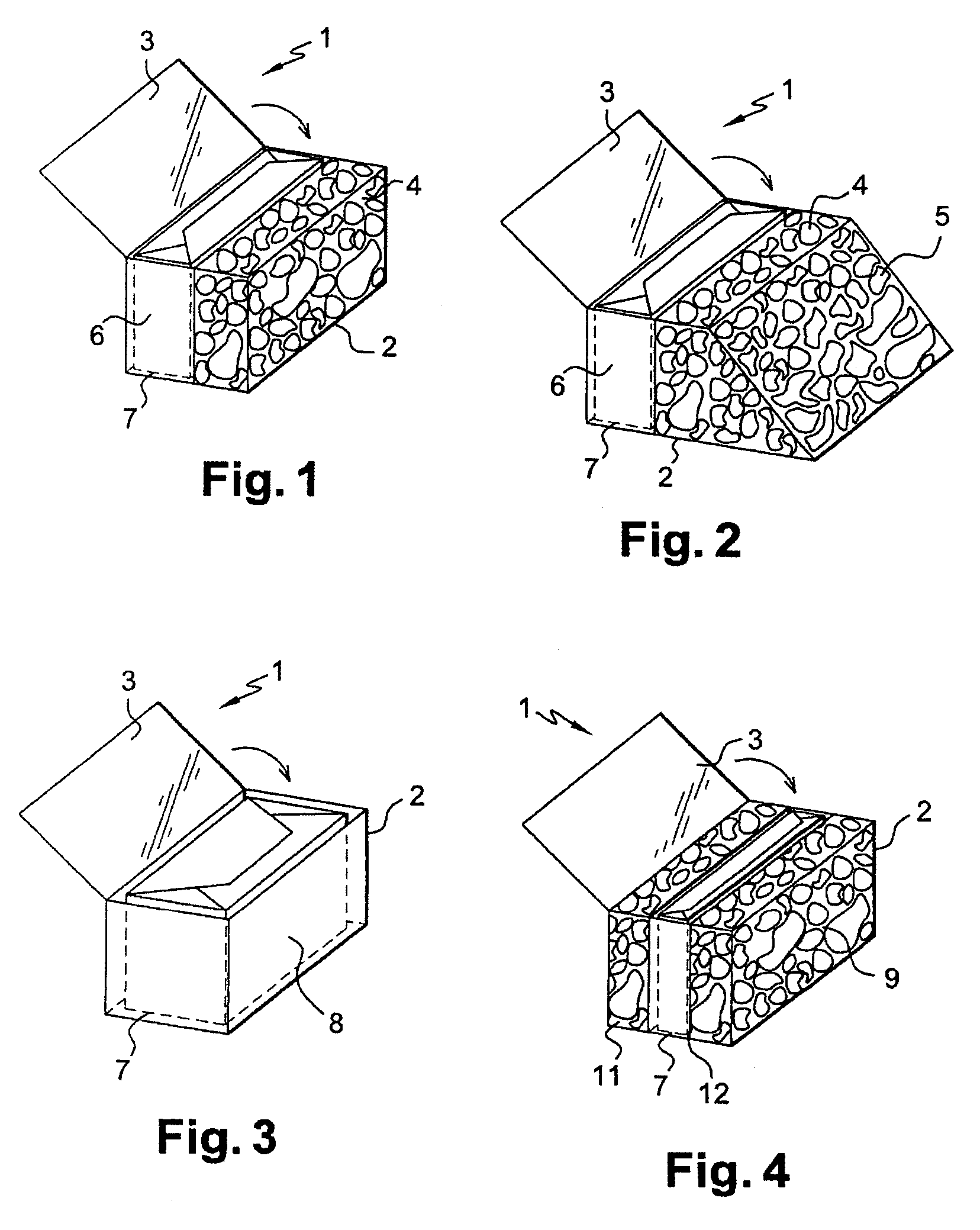

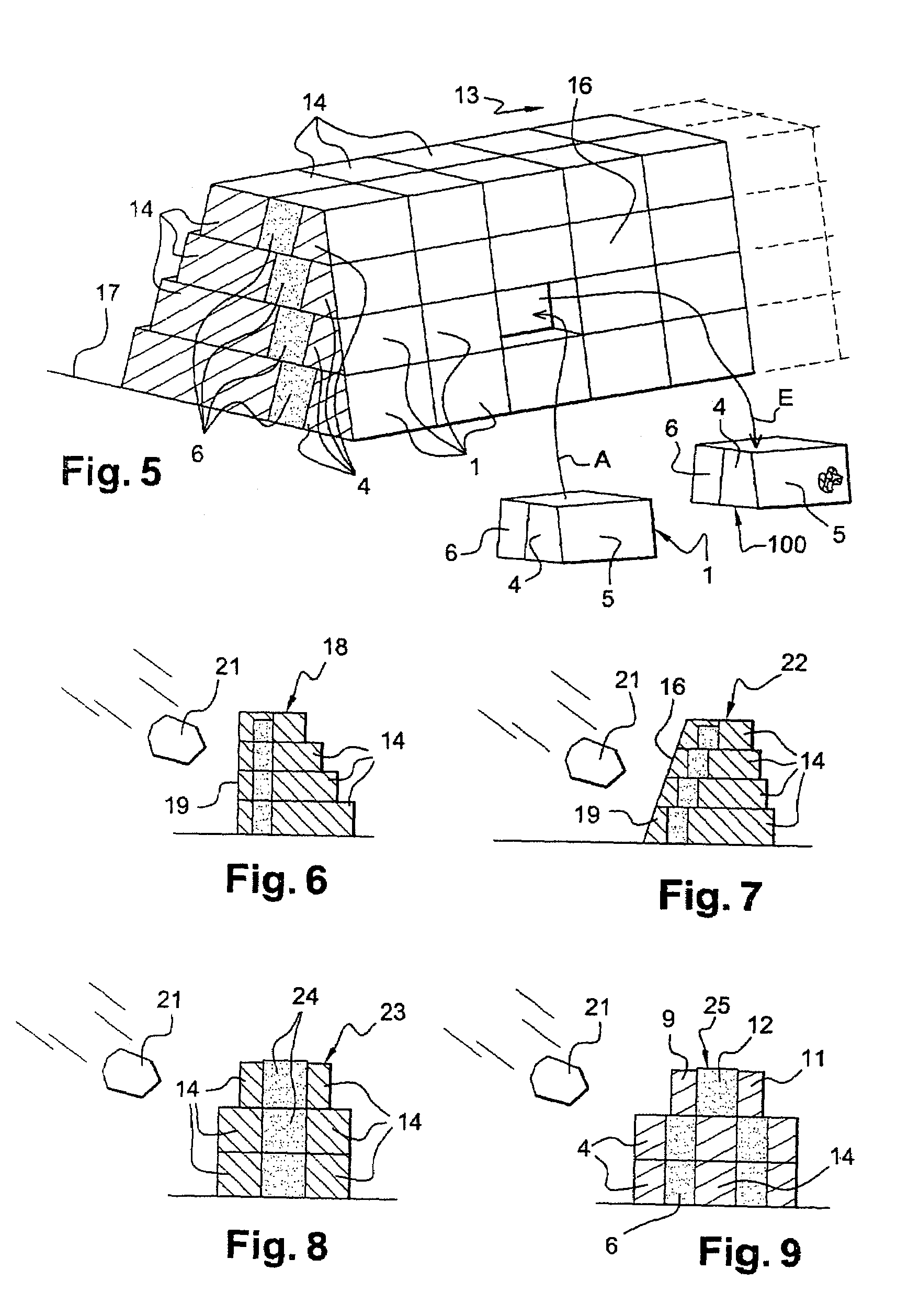

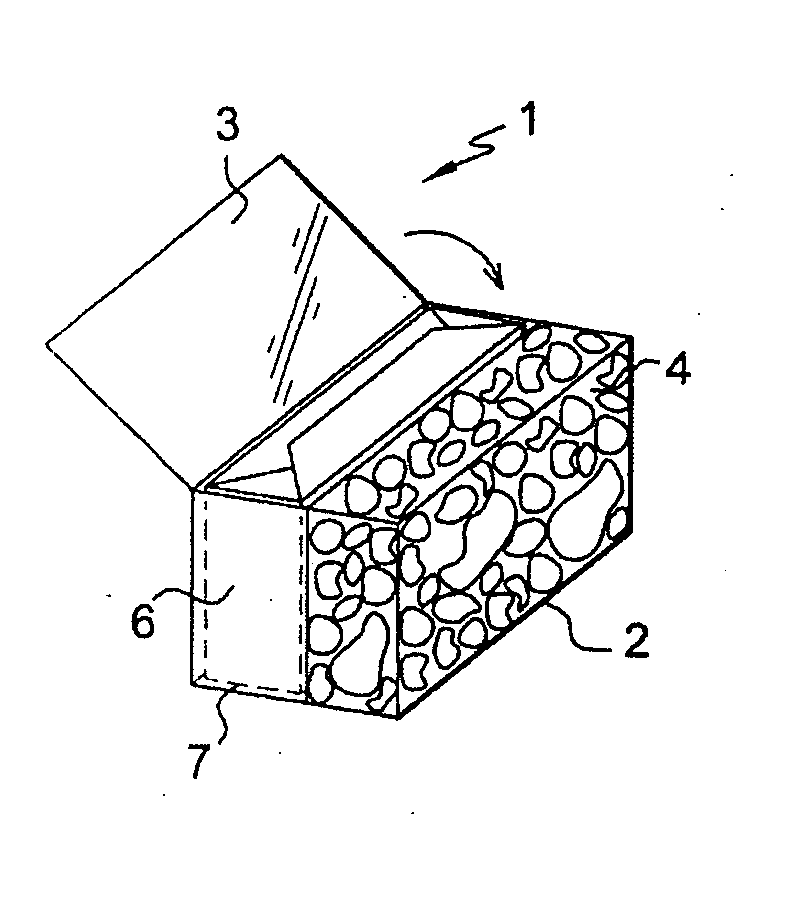

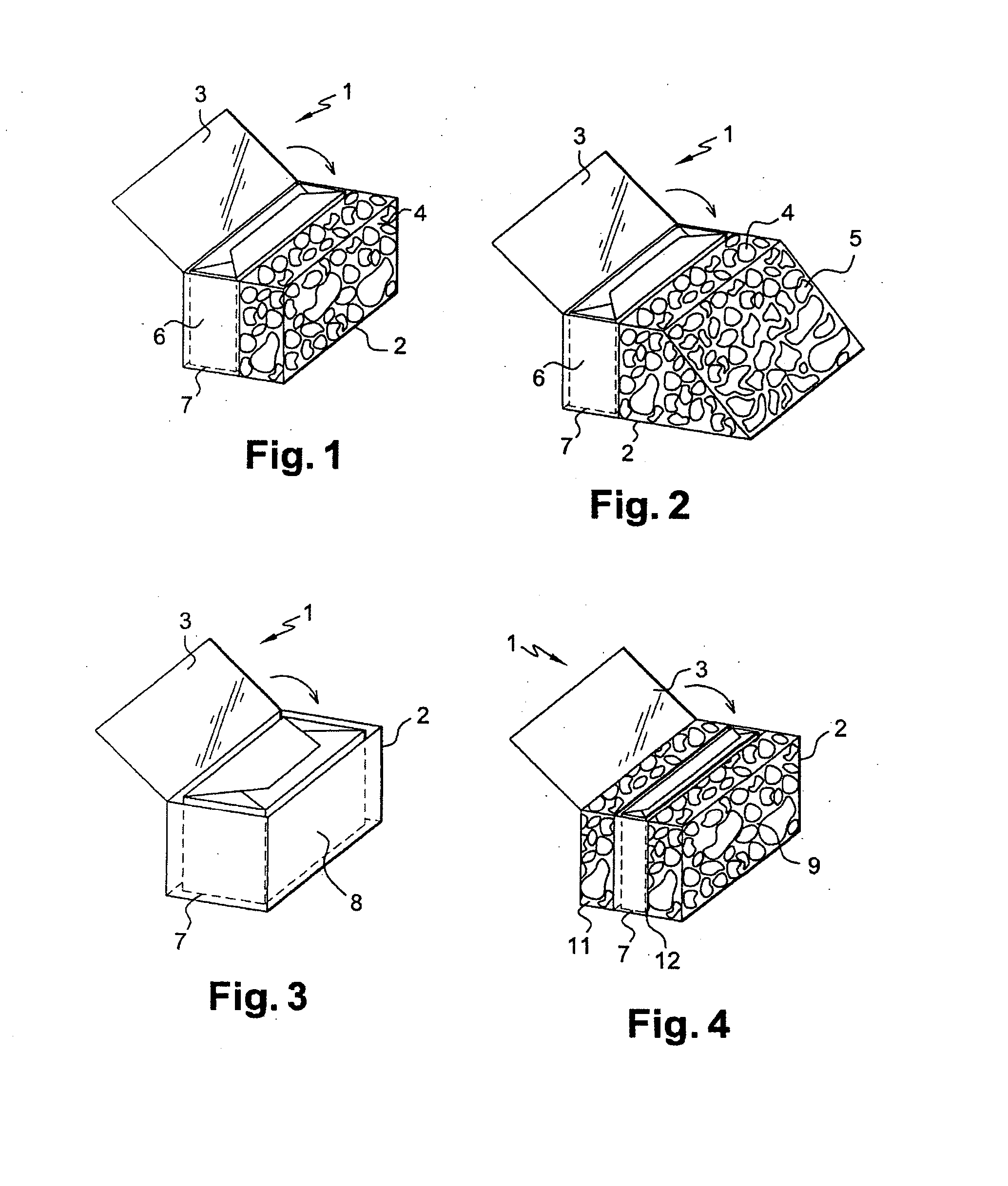

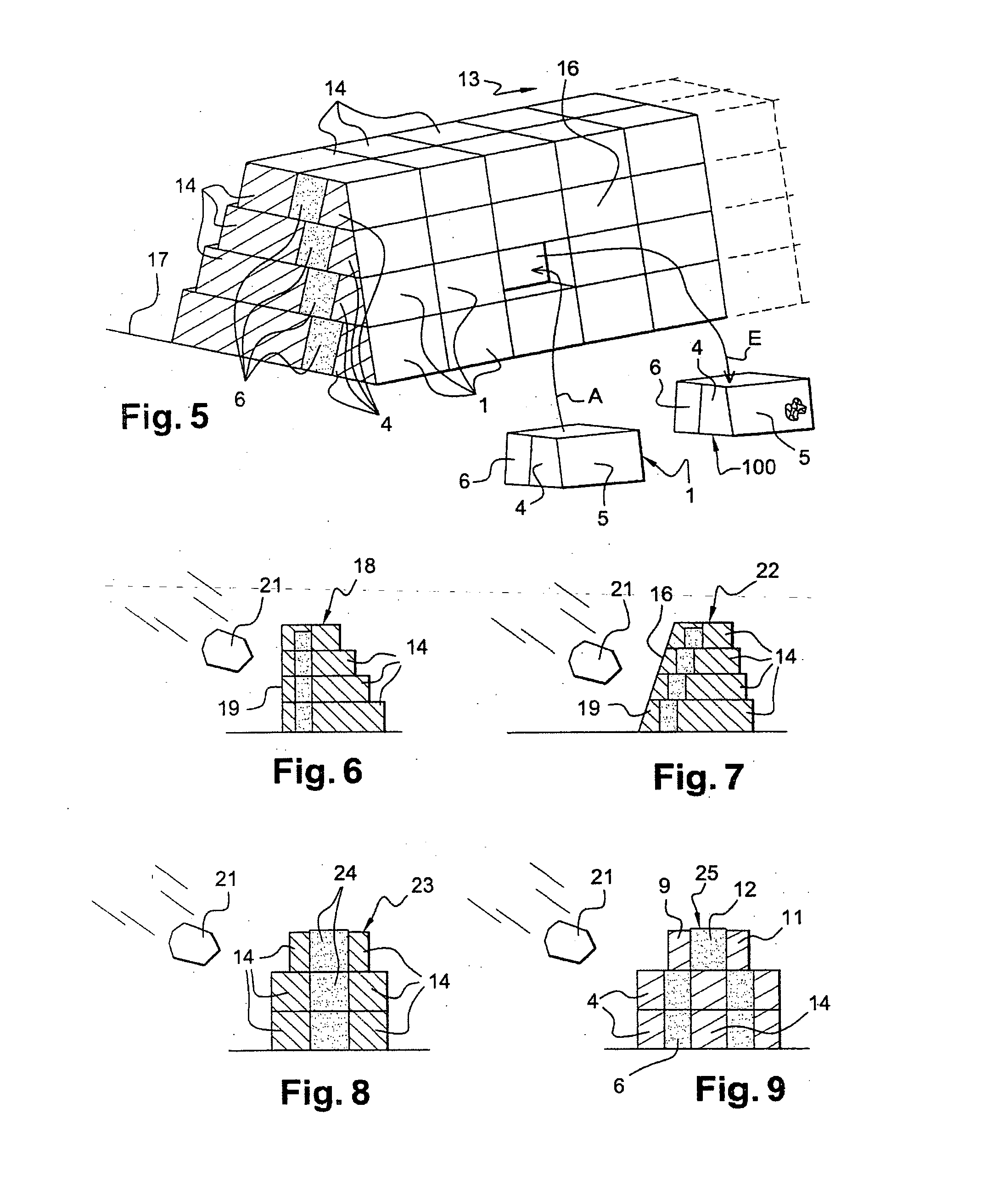

Civil engineering structure, individual construction element and method for reinforcing such a structure

InactiveUS7425107B2Artificial islandsProtective constructionEngineering structuresElastic plastic deformation

A civil engineering structure, intended for ensuring protection against impacts of moveable masses, has a face exposed to the impacts of moveable masses. The structure includes, in the region of the face exposed to the impacts of moveable masses, a set of individual construction elements secured to one another and filled completely or partially with at least one material having a capacity for being deformed elastoplastically, the individual construction elements liable to be damaged by impacts of moveable masses being capable of being replaced individually by similar individual construction elements.

Owner:FRANCE GABION ZONE IND

Multi-purpose anti-glare divider using modular approach

InactiveUS6962461B2Improve efficiencyReduce pressureProtective constructionPasturing equipmentModularityEngineering

A multi-purpose anti-glare divider system for minimizing glare from oncoming traffic on a two-way road. The anti-glare divider system includes at least one light blocking module arranged and constructed to minimize glare from oncoming traffic. An electrical generating system is associated with the light blocking module for generating electrical energy for use by an auxiliary device. A mounting system supports the light blocking module in a desired position relative to the road.

Owner:CHOI BAEK SUNG +1

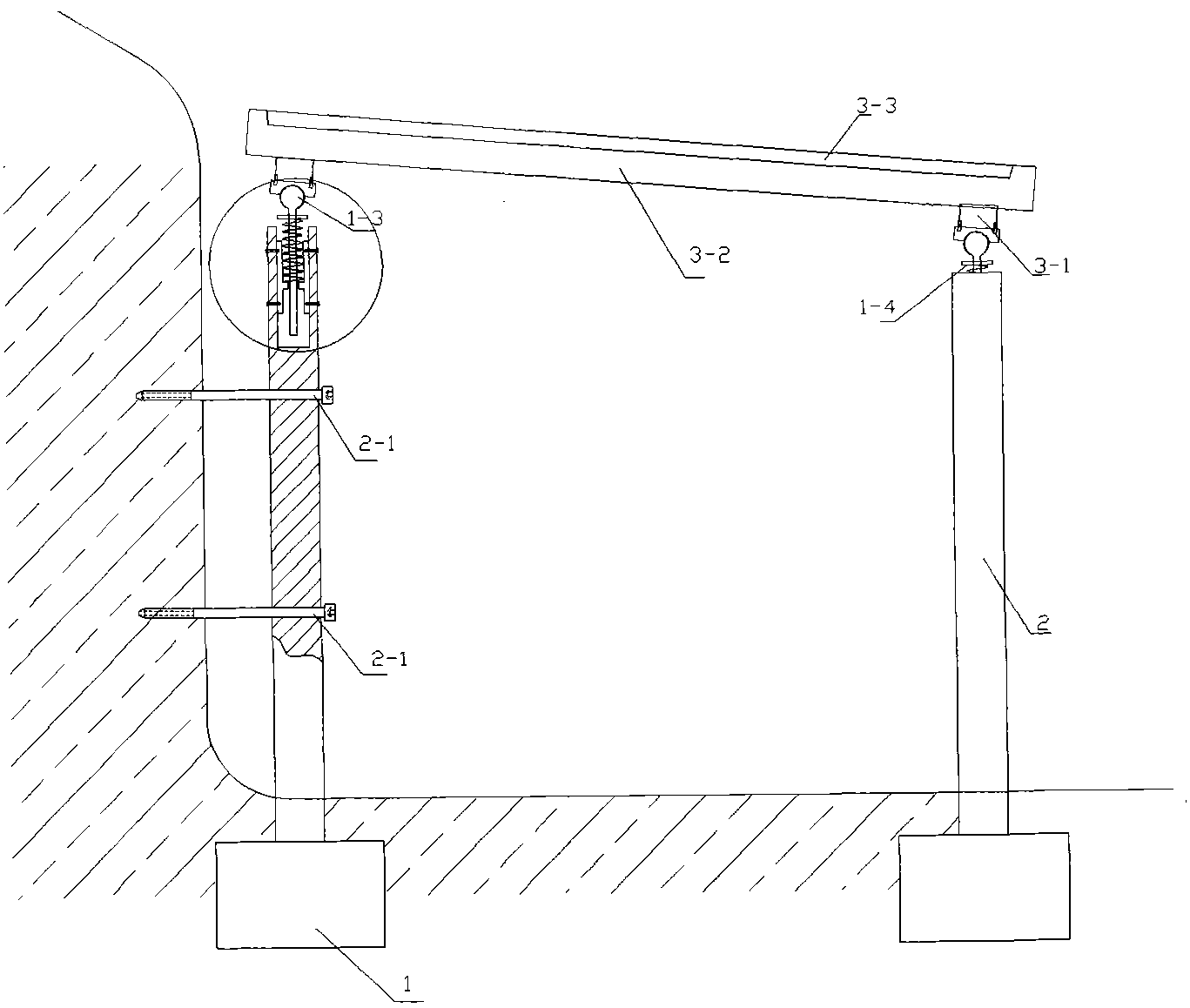

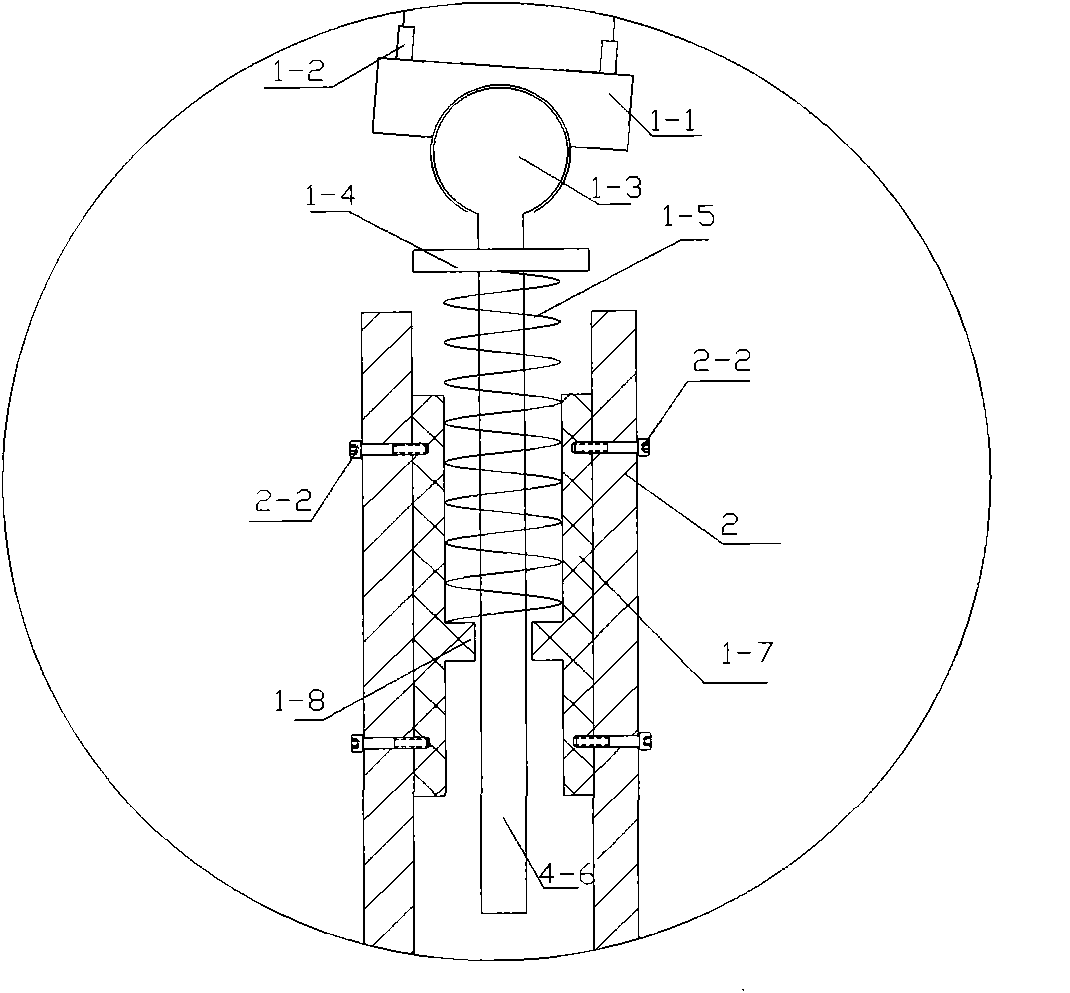

Energy-dissipating hangar tunnel and energy-dissipating supporting base thereof

InactiveCN101967802AImprove affordabilitySimple structureProtective constructionBuilding constructionsHangarSteel plates

The invention discloses an energy-dissipating hangar tunnel and an energy-dissipating supporting base thereof. The energy-dissipating supporting base comprises a spring guide rod, wherein the spring guide rod is sleeved in the spring; a protective shed is supported by the upper end of the spring guide rod; the lower end of the spring guide rod passes through a load-transferring steel plate; the upper end of the spring is fixed on the bottom surface of a load-transferring bracket; the lower end of the spring is supported on the load-transferring bracket; and the load-transferring steel plate is fixed on a support. The energy-dissipating hangar tunnel and the energy-dissipating supporting base thereof have the innovative points that: the energy-dissipating supporting base is simple in structure, low in cost, light in weight, high in rigidity and high in buffer capacity when impacted violently; and the energy-dissipating supporting base is suitable for performing energy dissipation on facilities easily subjected to violent impact, such as the hangar tunnel and the like.

Owner:陈洪凯 +2

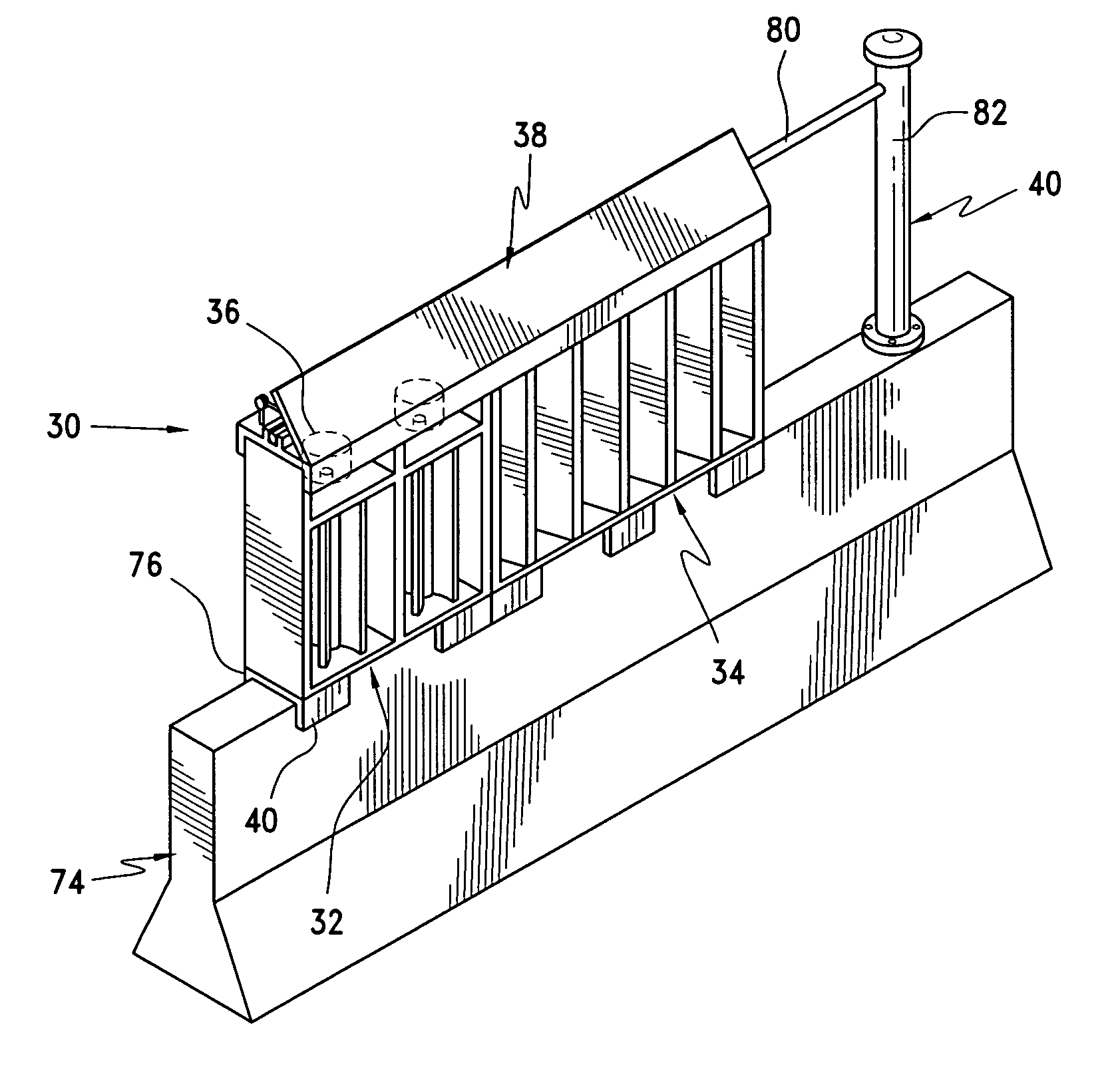

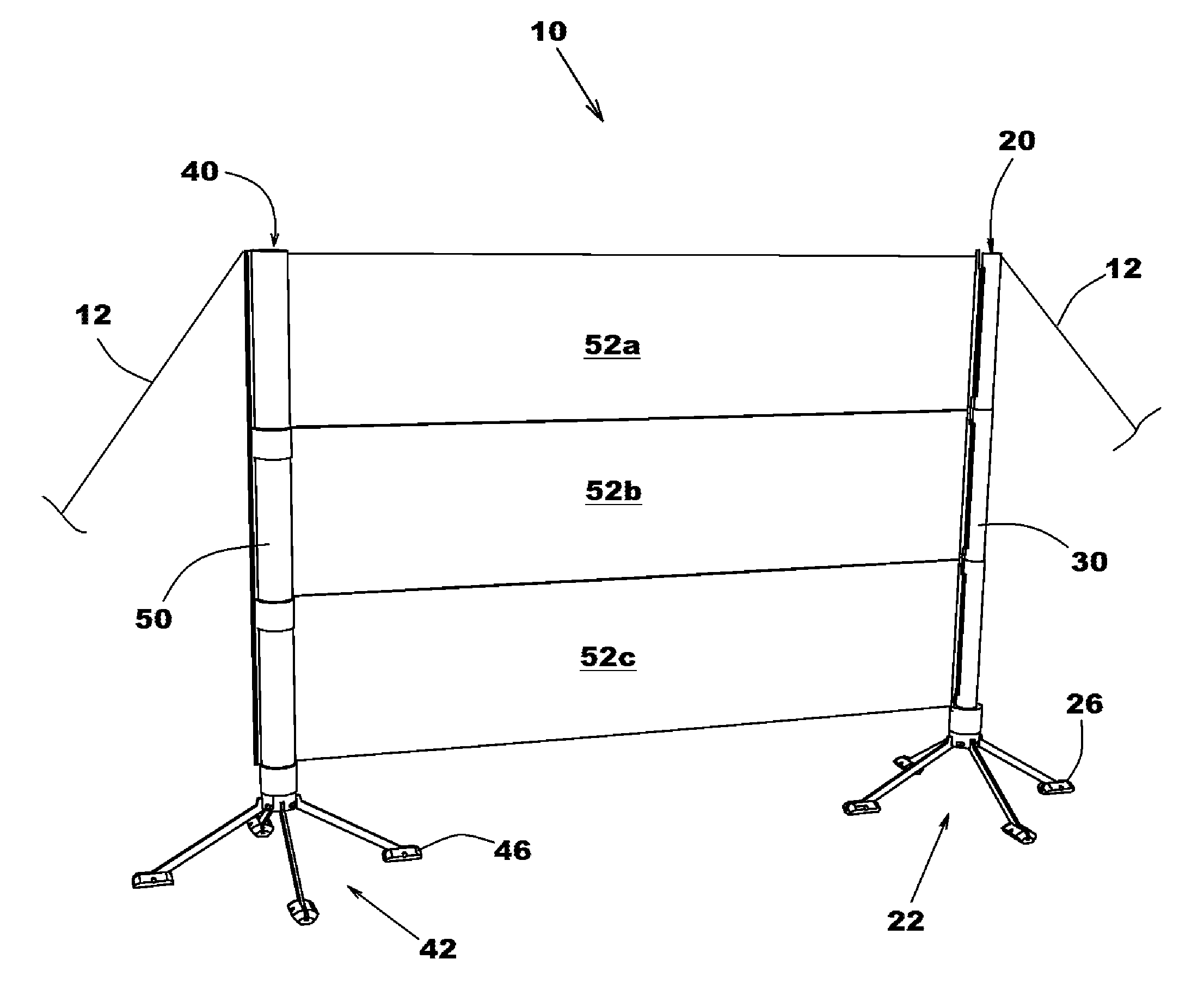

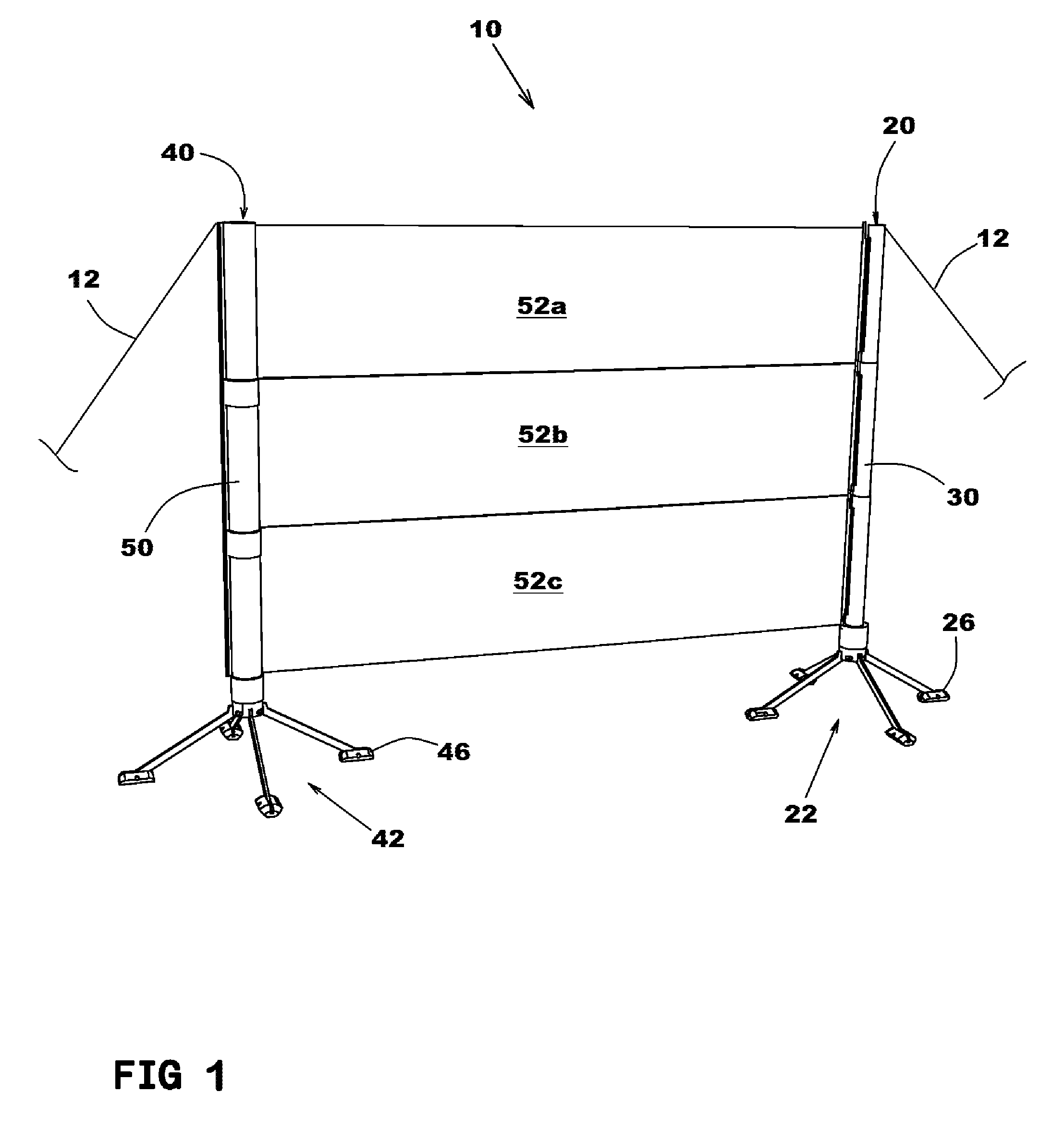

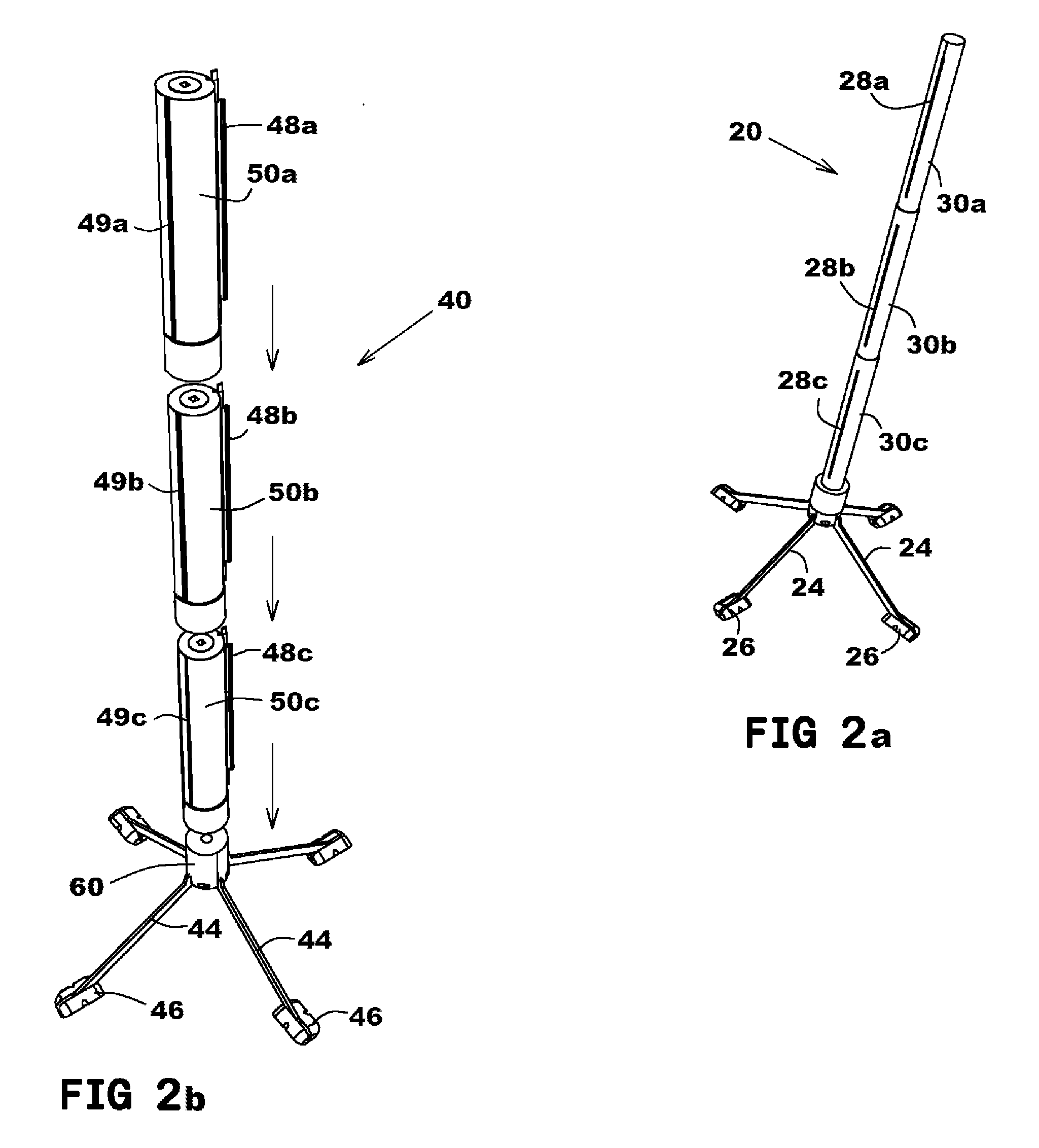

Portable scene isolator

InactiveUS20100288450A1Compact storageImprove stabilityScreensProtective constructionEngineeringMechanical engineering

In one aspect, the present invention is directed to a septum apparatus (10), for concealing a site from passersby, the apparatus comprising: a first pole (40), comprising a plurality of segments (50), each storing a folded sheet (52); a second pole (20), comprising means for connecting thereto the end of each sheet (28), the second pole being foldable or telescopic, thereby providing a compact structure; each of the poles comprises a stand (42, 22), for retaining the pole thereof (40, 20 correspondingly) upright; and each pole (40, 20) comprises fixing means (12 or 46, 26), for fixing the pole thereof to the ground; thereby providing a septum compact in storage, simple in mounting and dismounting. The apparatus may further comprise a case (80), for storing therein the parts thereof.

Owner:BRUCK NAFTALI +1

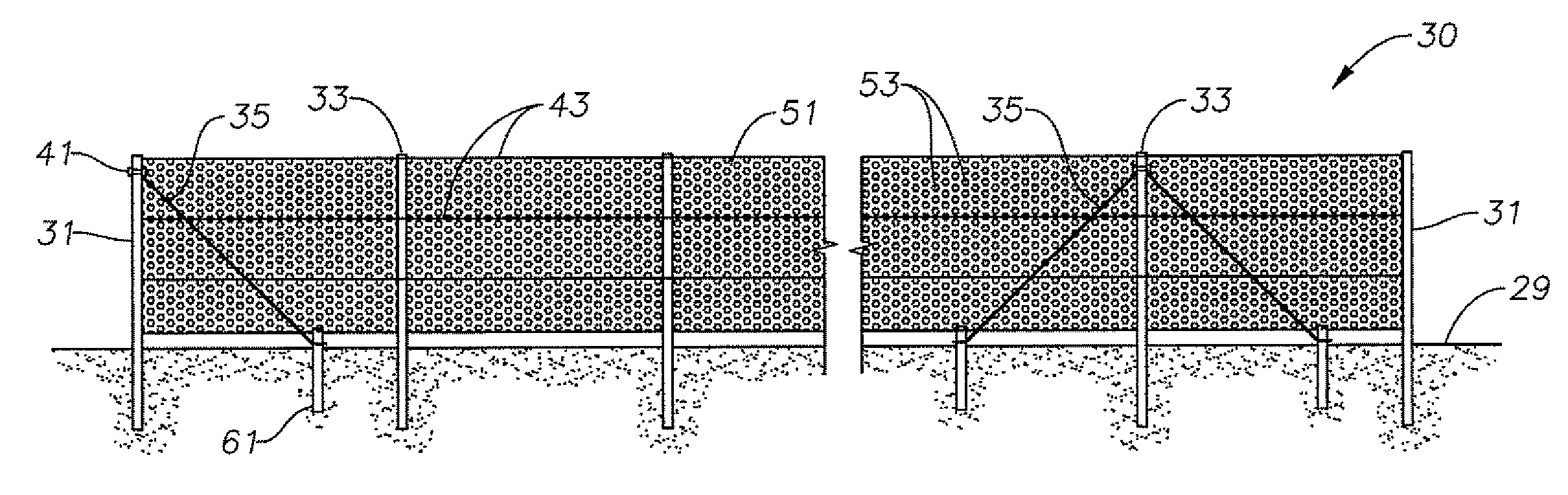

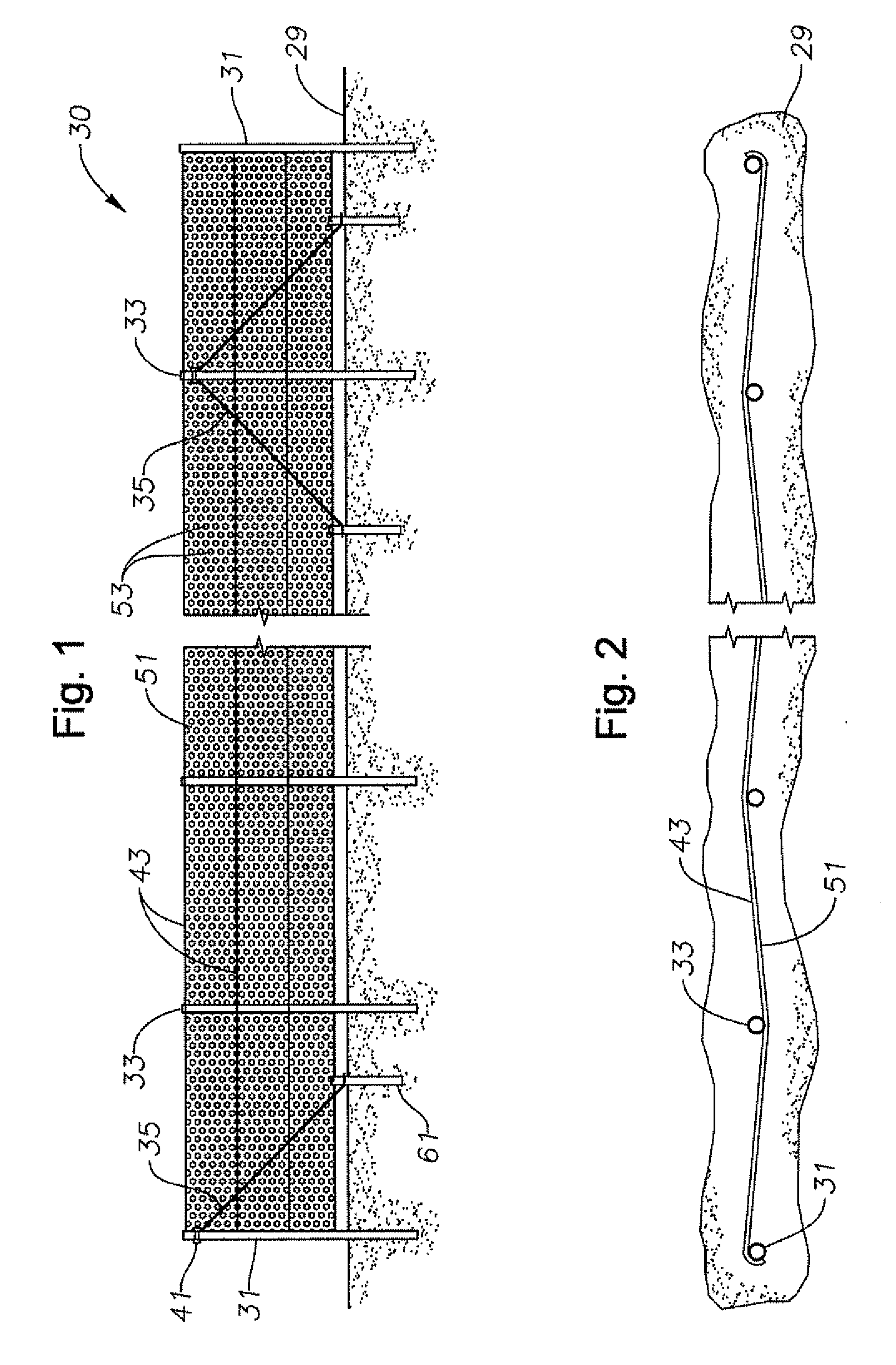

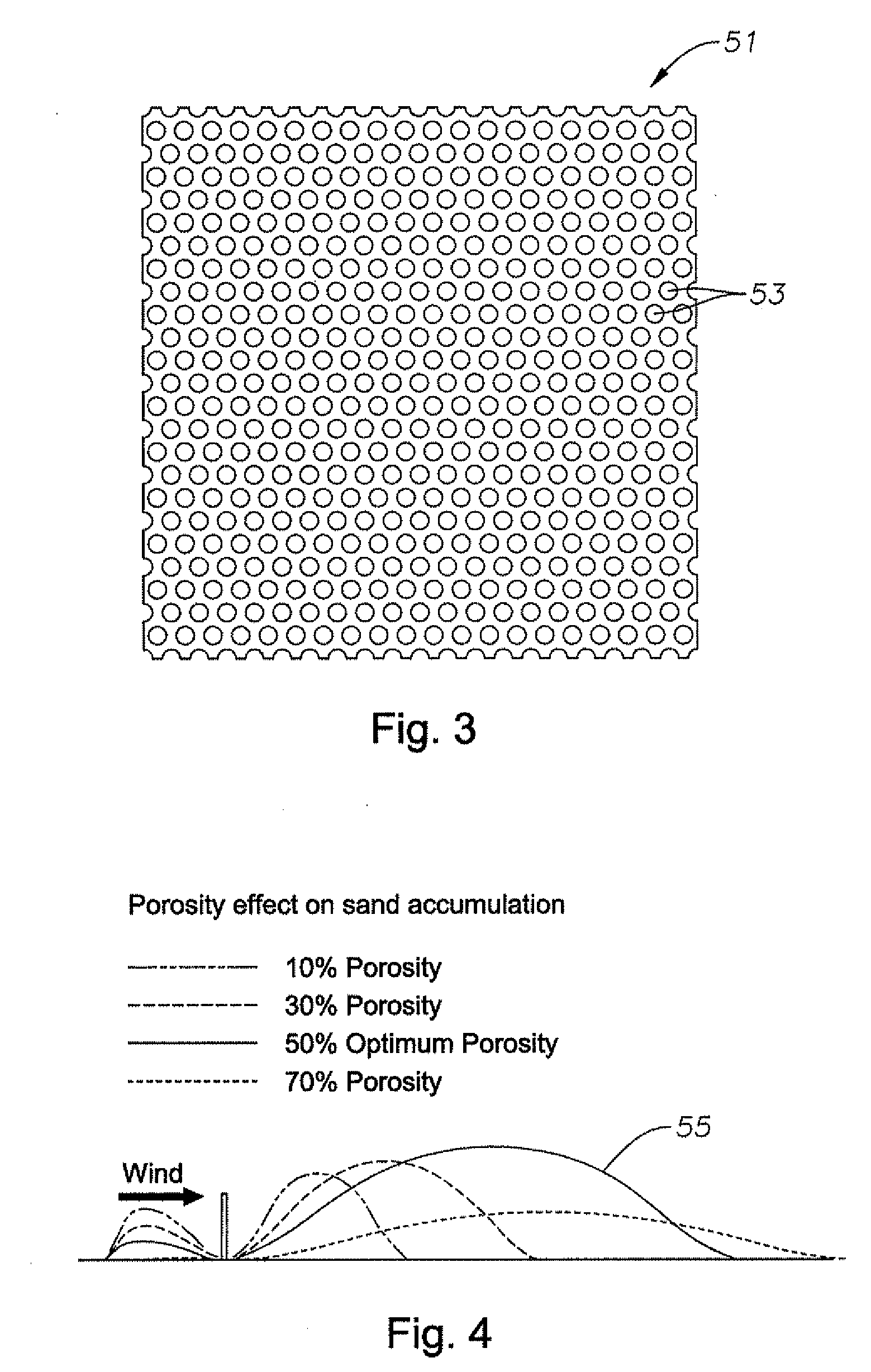

Geogrid sand fence

An apparatus comprising a geogrid sand fence for depositing matter moved by wind currents including a stand fence and related methods are provided. A geogrid sand fence for the control of sand or other particulate matter movement can include support members carrying a fencing material. The fencing material can include a High Density Polyethylene geogrid mesh material having apertures distributed to provide a 50% porosity to maximize sand deposit volume. The geogrid mesh material has sufficient structural weight to be employed with a height of approximately 2 meters, which can be adjusted to maintain maximum effectiveness.

Owner:SAUDI ARABIAN OIL CO

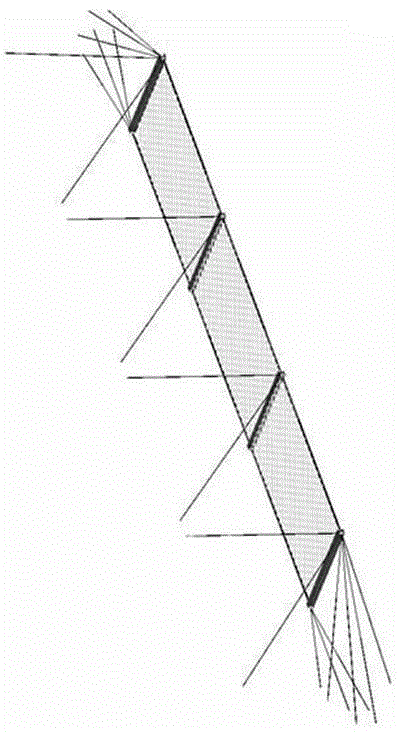

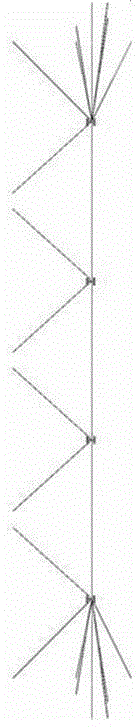

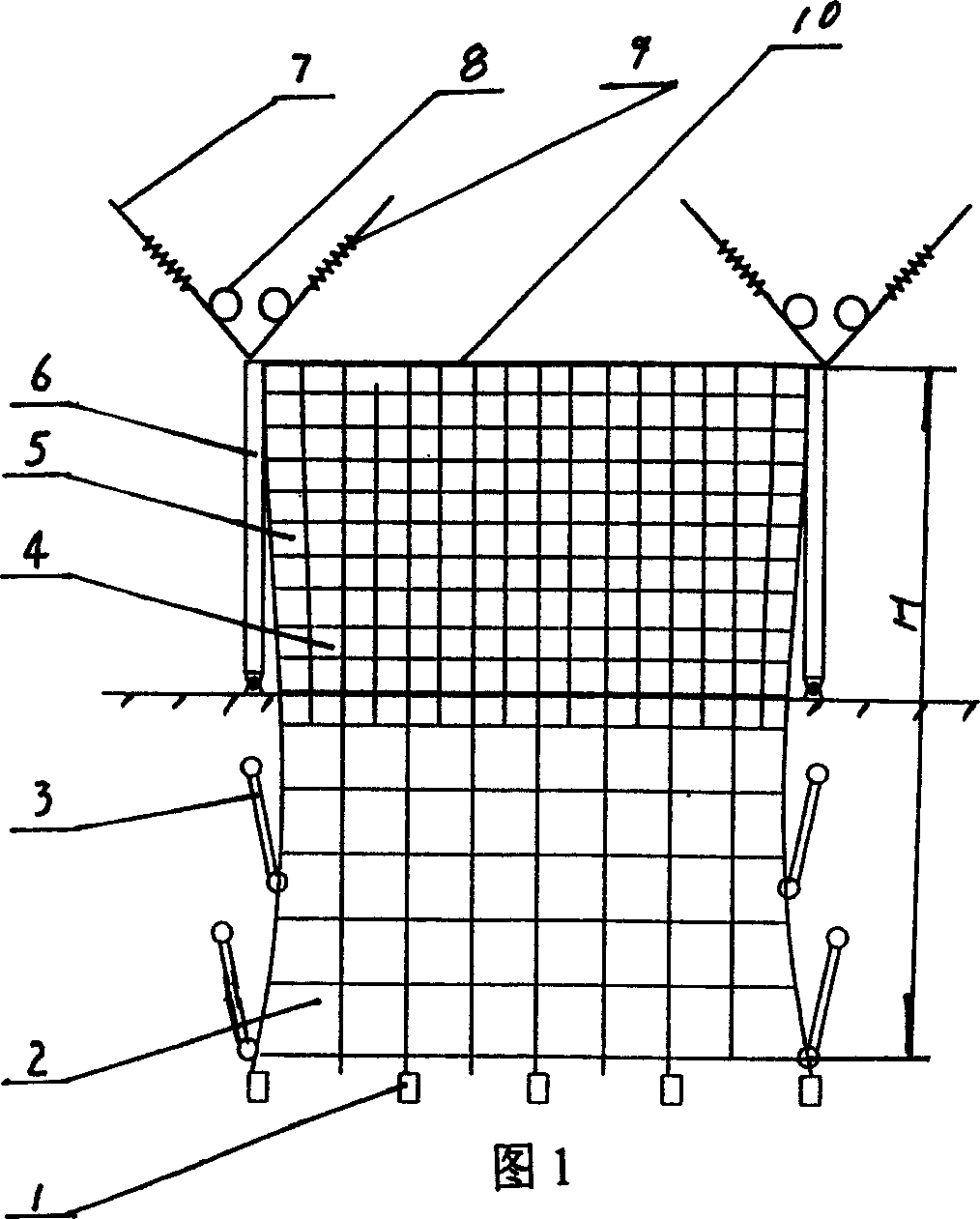

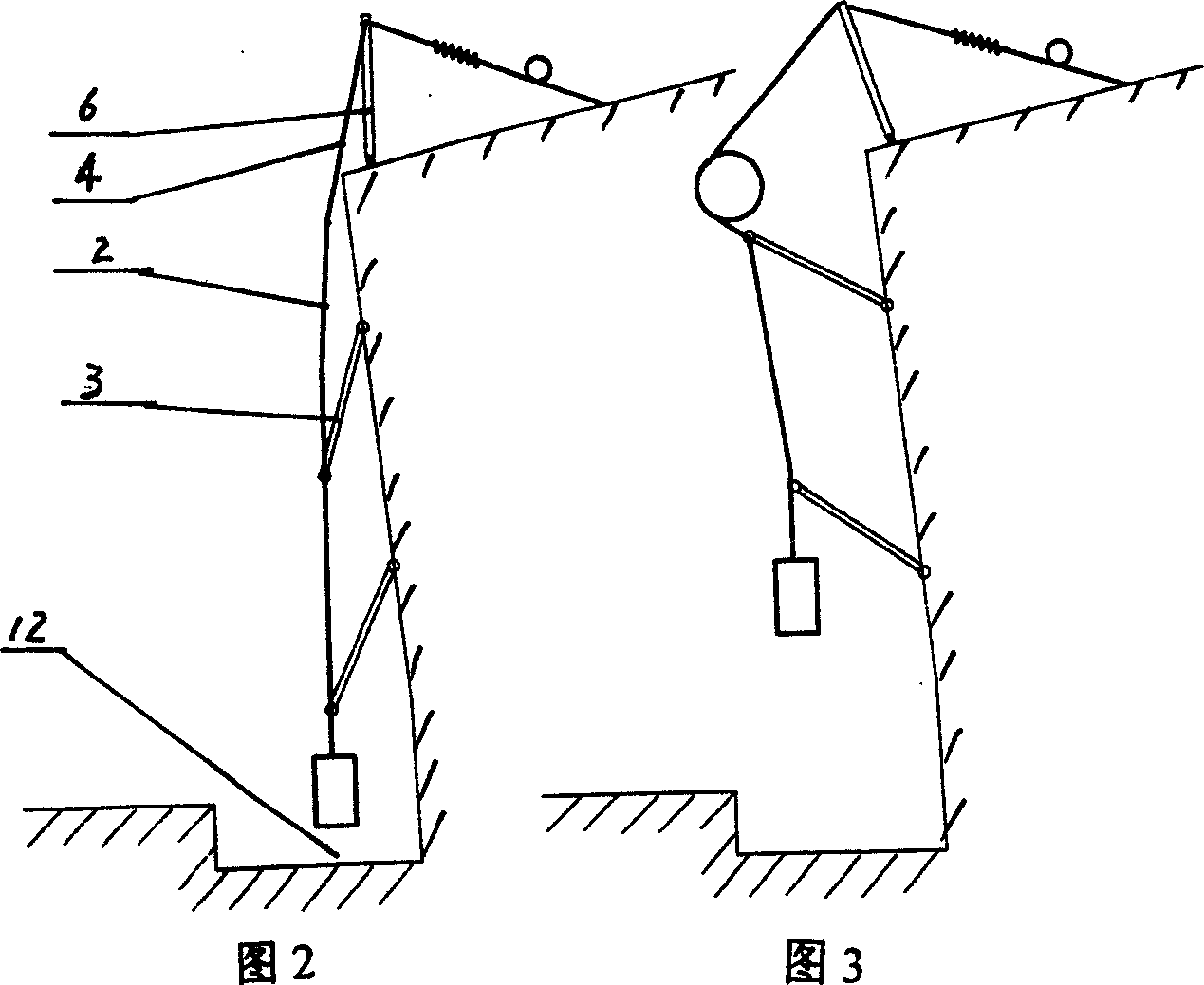

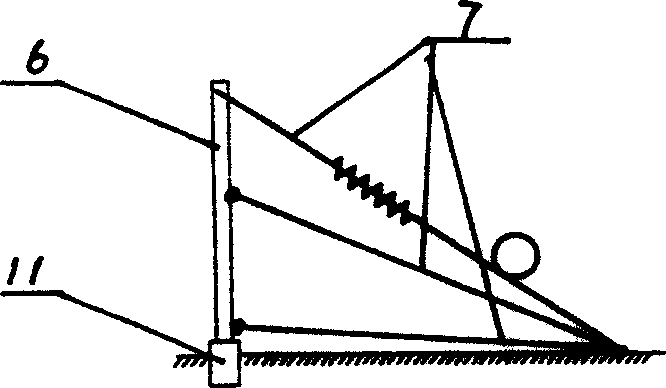

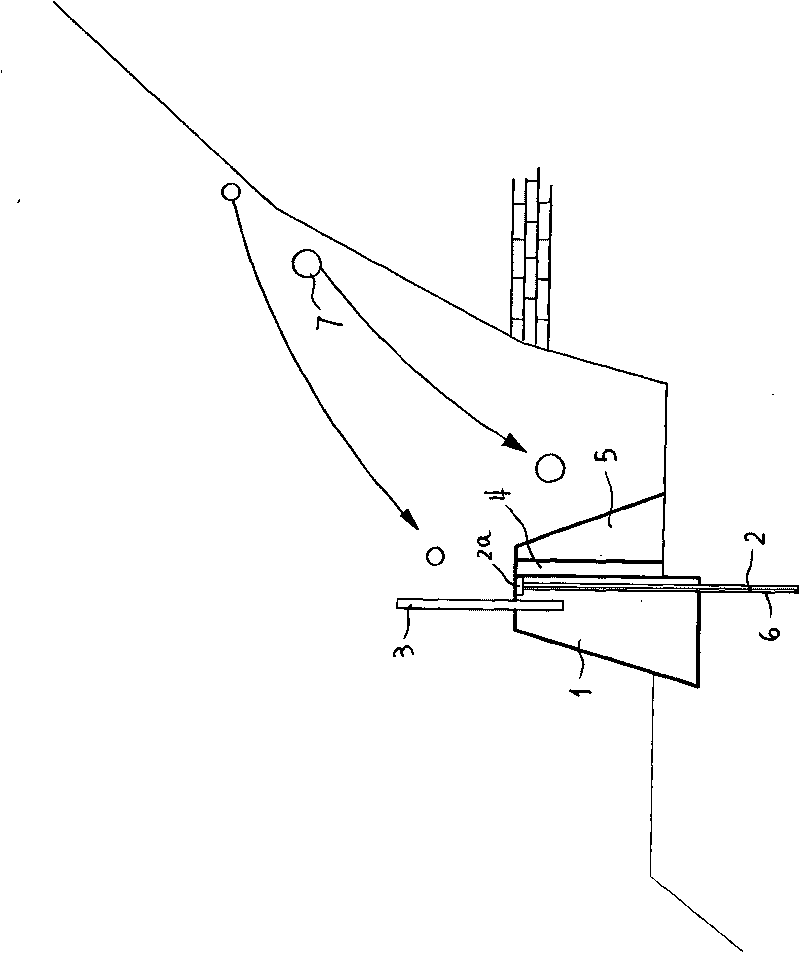

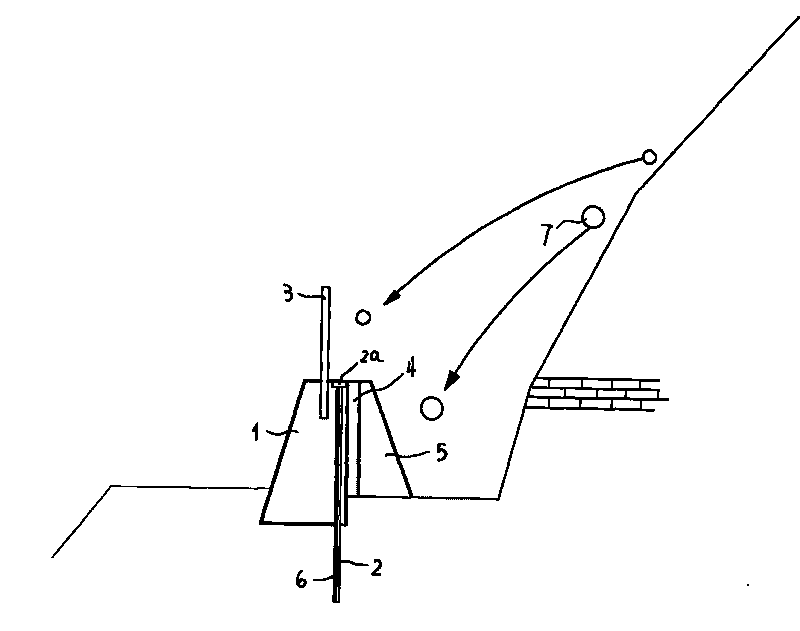

Rock-fall proof method and pulled guiding rock-fall proof flexible mesh

The present invention is rockfall preventing method and flexible rockfall guiding and preventing net. The flexible rockfall guiding and preventing net with width greater than the protected section and sufficient height for stopping rockfall and guiding the rockfall to safety position is suspended with uprights in the protected area. The net has the upper edge suspended to the uprights and the lower end opening drawn to the massif to guide the rockfall to required position. The net has parts capable of moving with the shock of rockfall to produce corresponding deformation, and has position limiters set on its two sides. The present invention may be used widely for various kinds of rockfall preventing engineering for montanic railway, highway and building.

Owner:昆明铁路局科学技术研究所

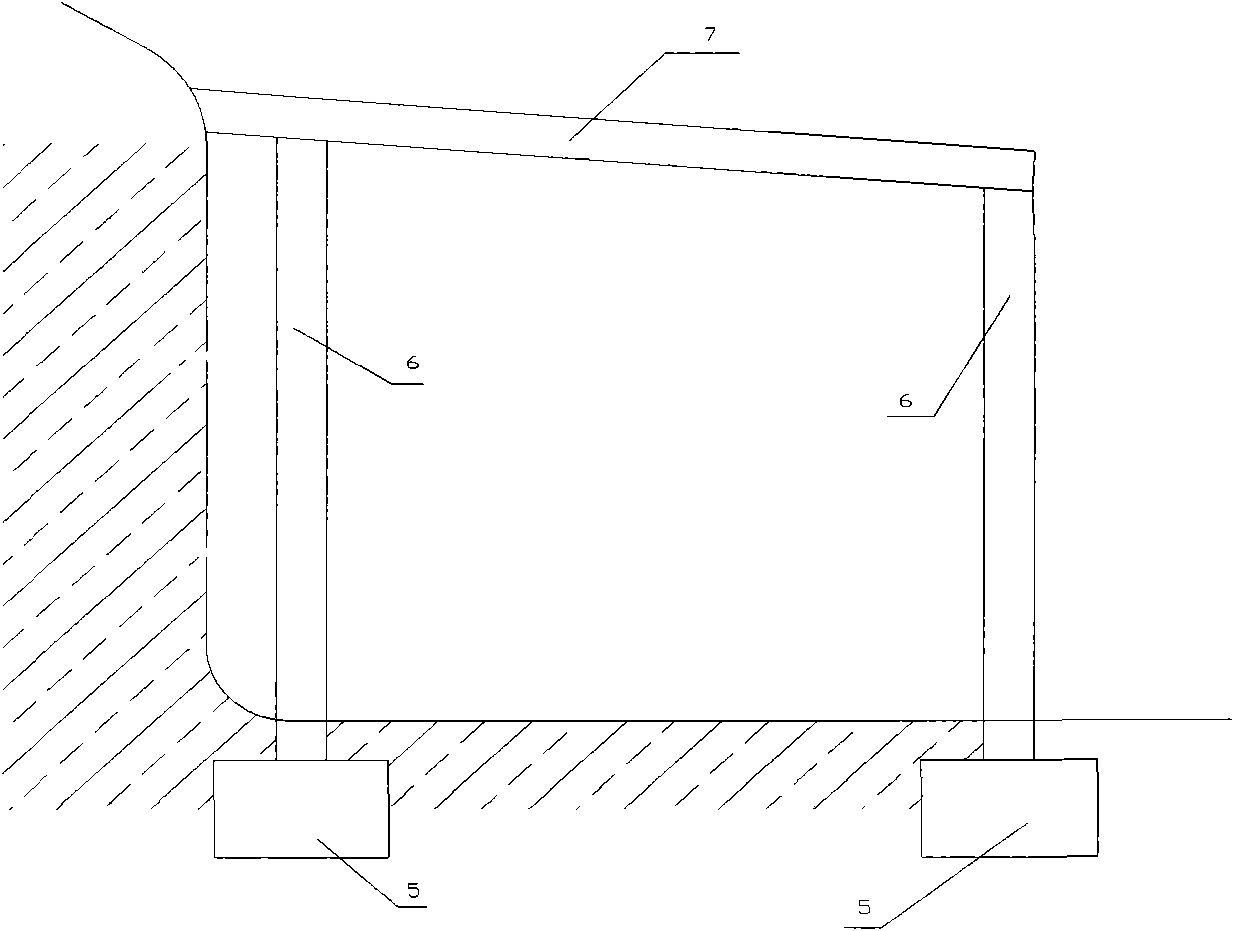

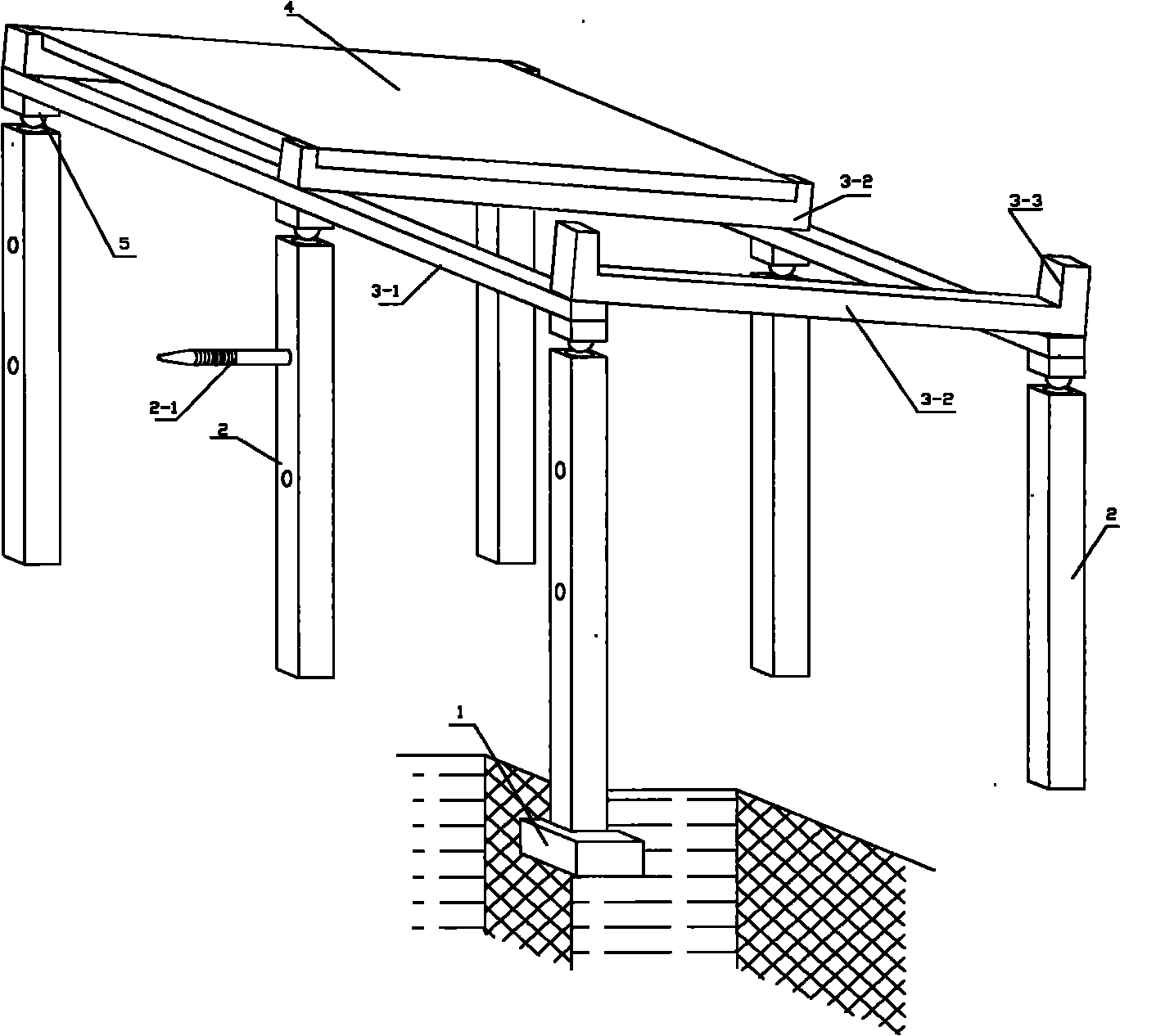

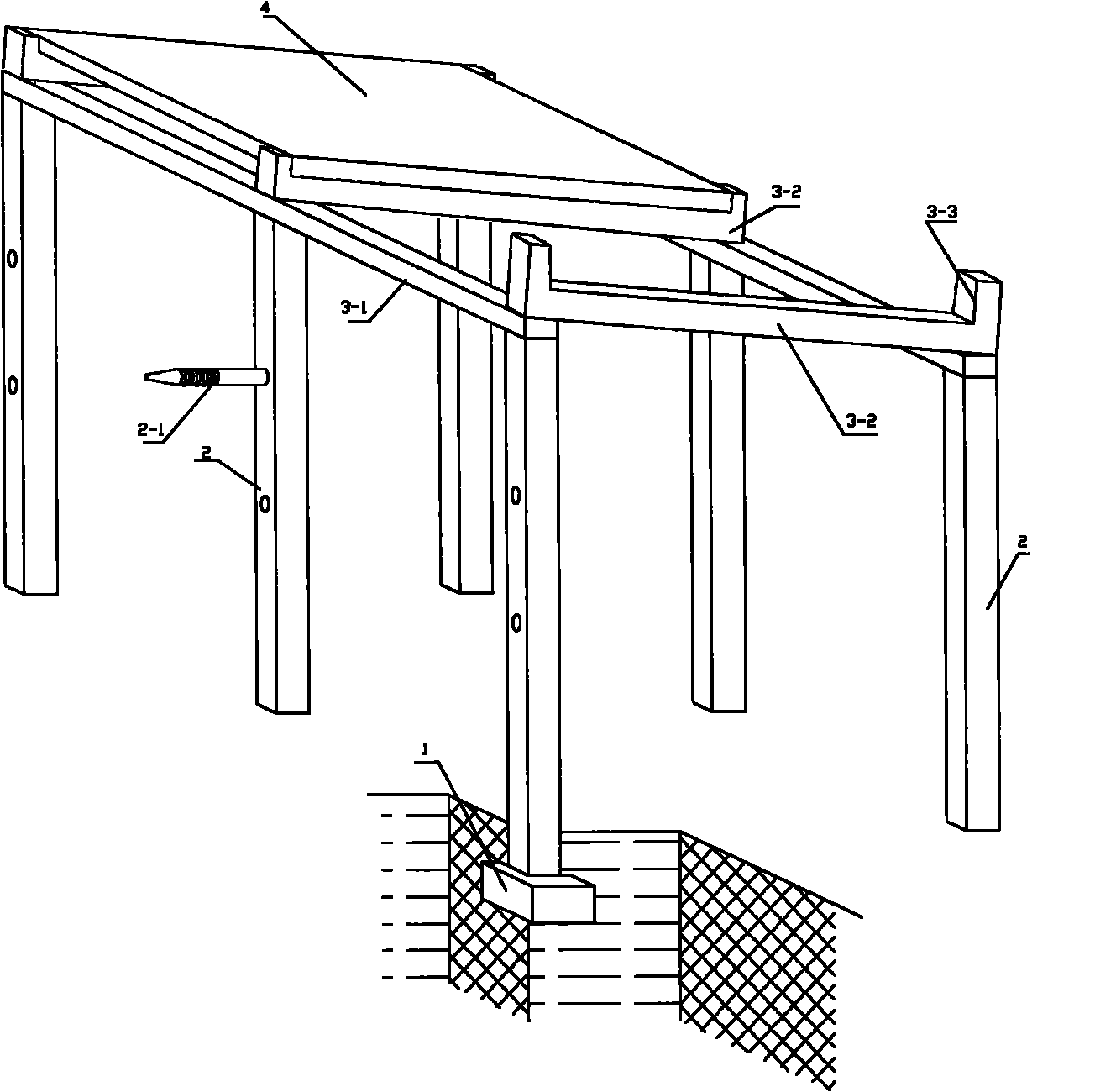

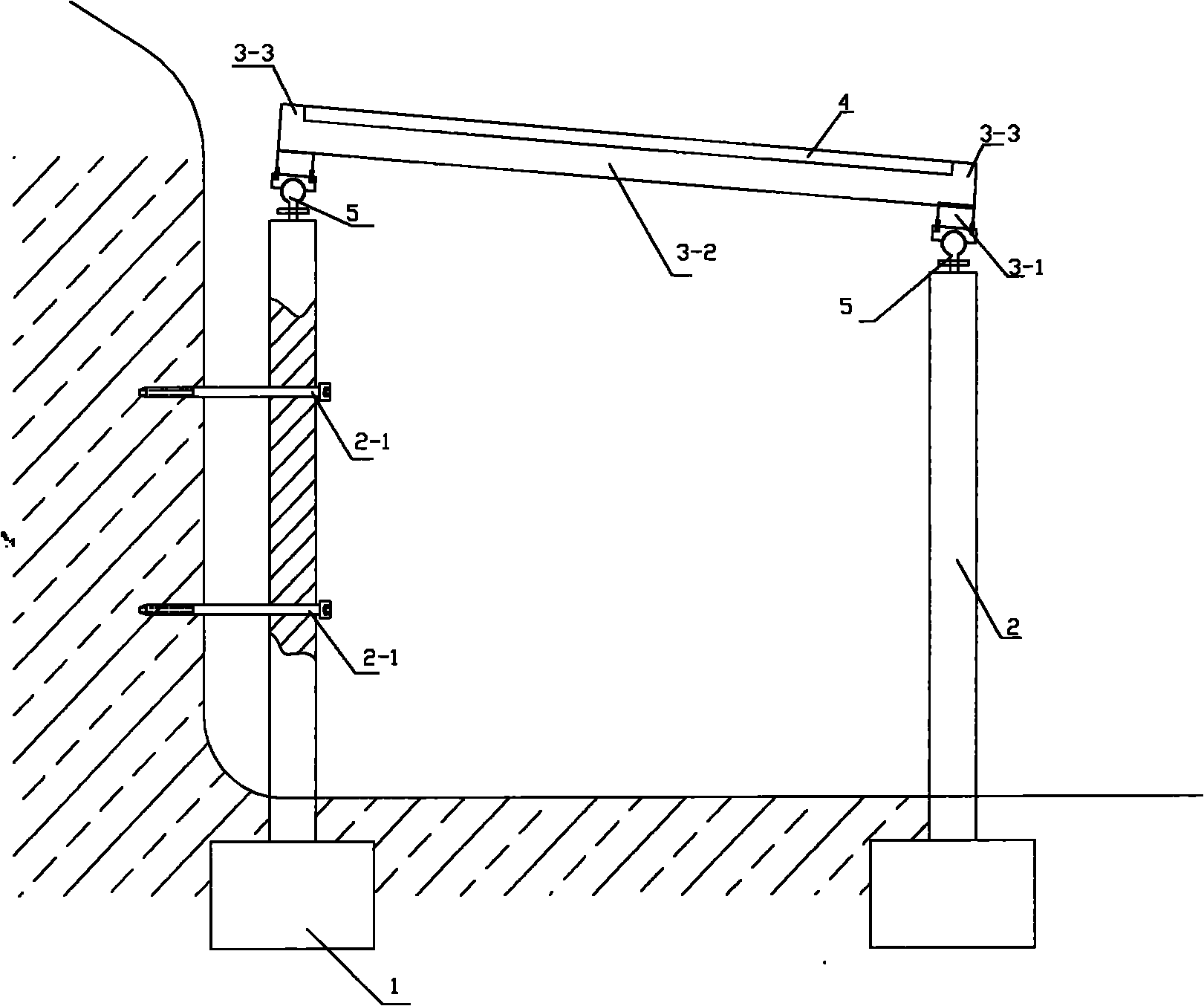

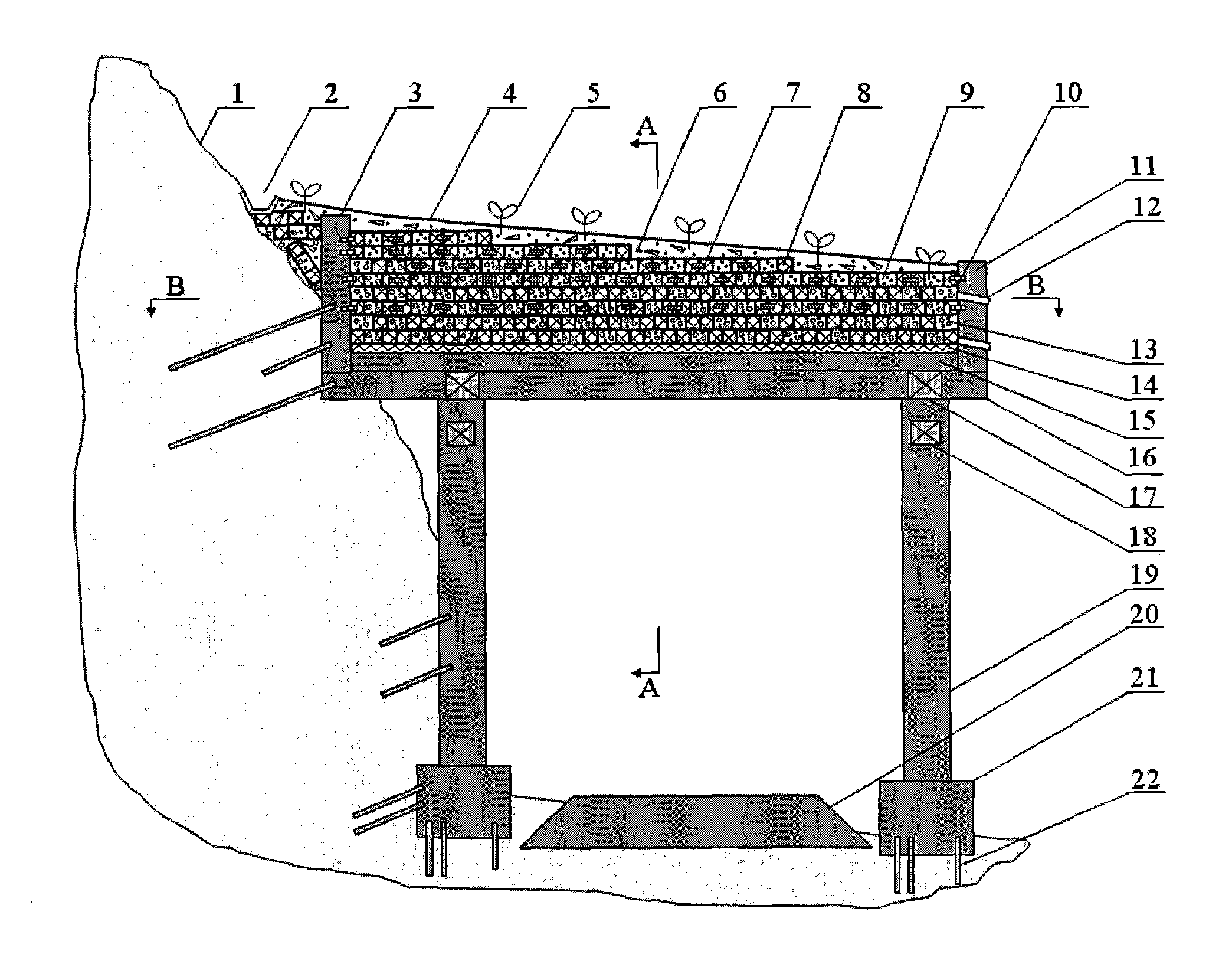

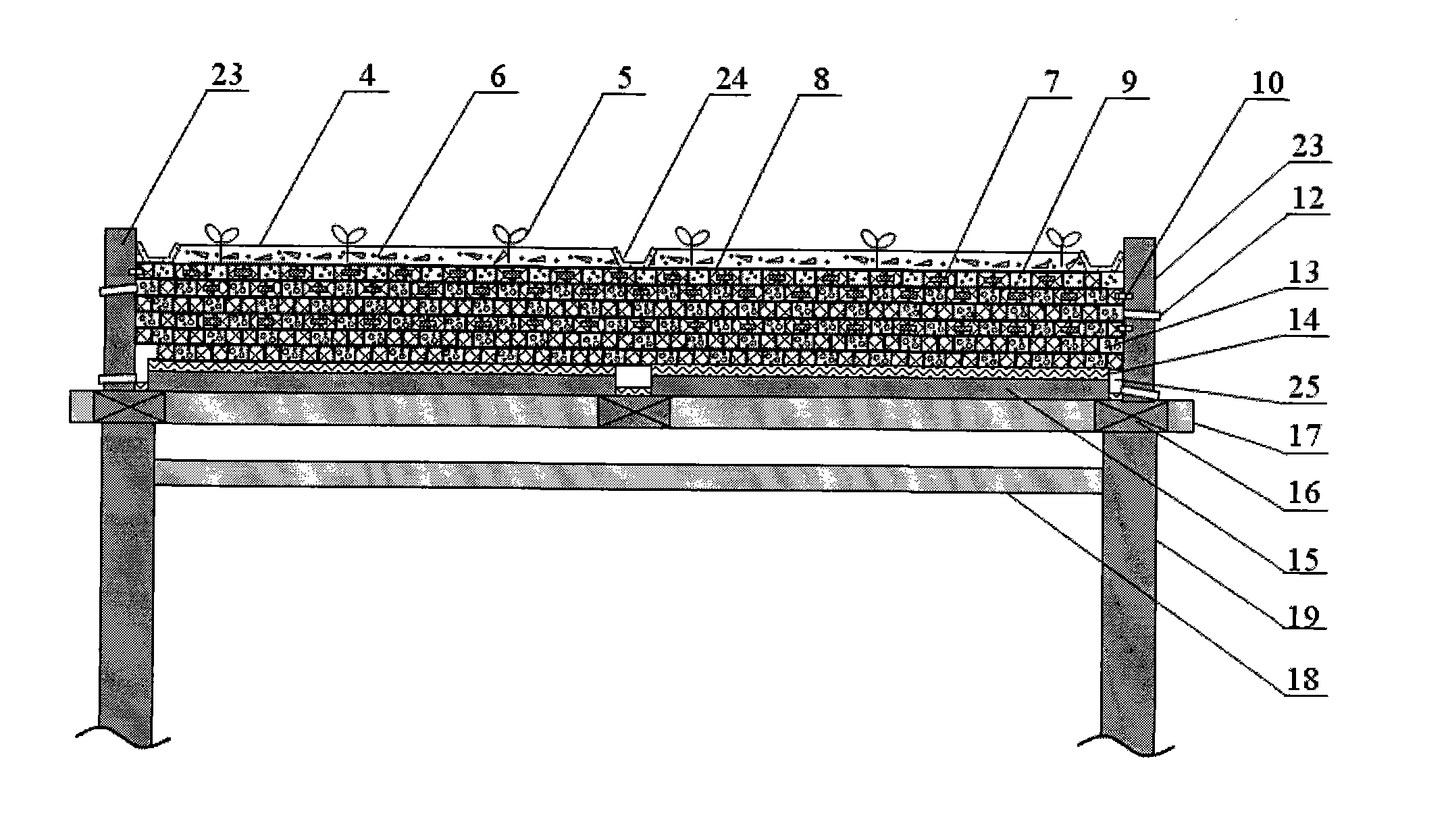

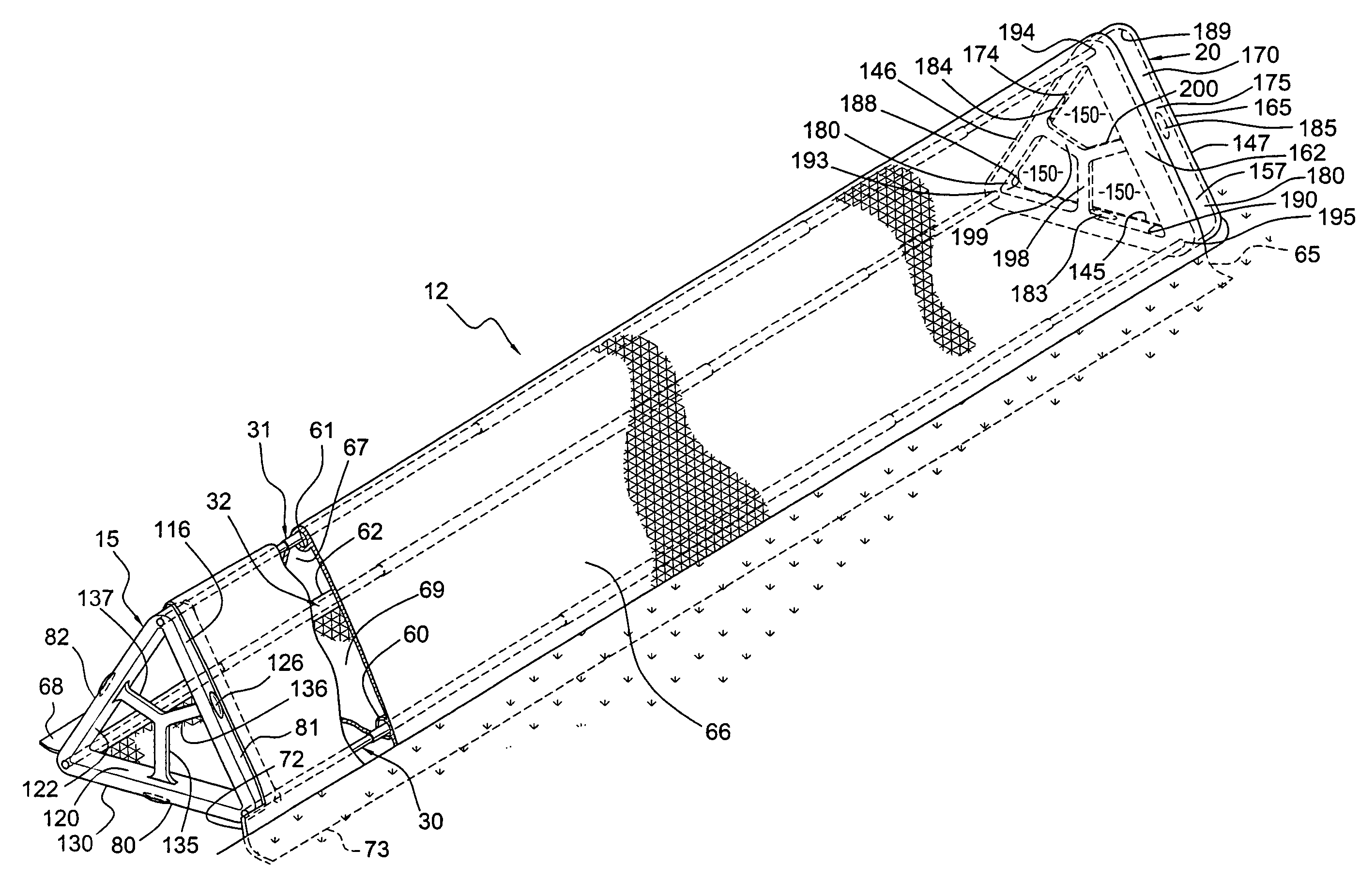

Combined rock fall shed tunnel and installation method thereof

The invention discloses a combined rock fall shed tunnel and an installation method thereof. The shed tunnel is formed by combining a cast-in-situ pile foundation arranged below a pavement with prefabricated parts, wherein the prefabricated parts comprise a pile foundation arranged below the pavement, a support pillar arranged above the pile foundation, a support beam arranged above the support pillar, and a protection plate arranged above the support beam. The invention has the advantages that: the shed tunnel has a simple structure, low cost, light weight and good protection effect; and more importantly, the parts are made of prefabricated materials, so during use, the shed tunnel can be quickly transported to a construction site by a vehicle or manually, is installed in a combined mode, has high installation speed and can meet the requirement of emergently erecting the shed tunnel to ensure traffic under critical conditions such as continuous mountain landslide and the like caused by earthquake.

Owner:陈洪凯 +2

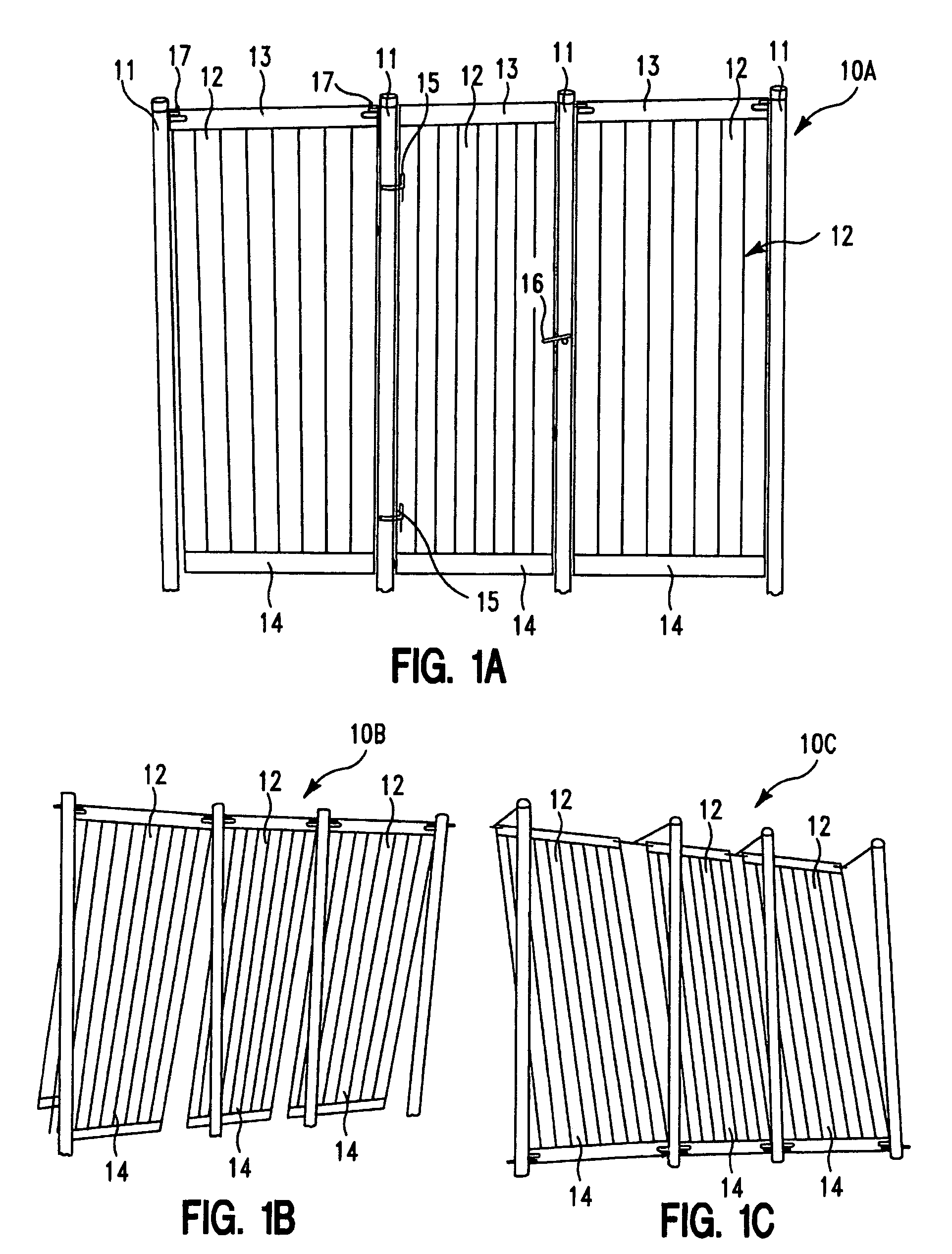

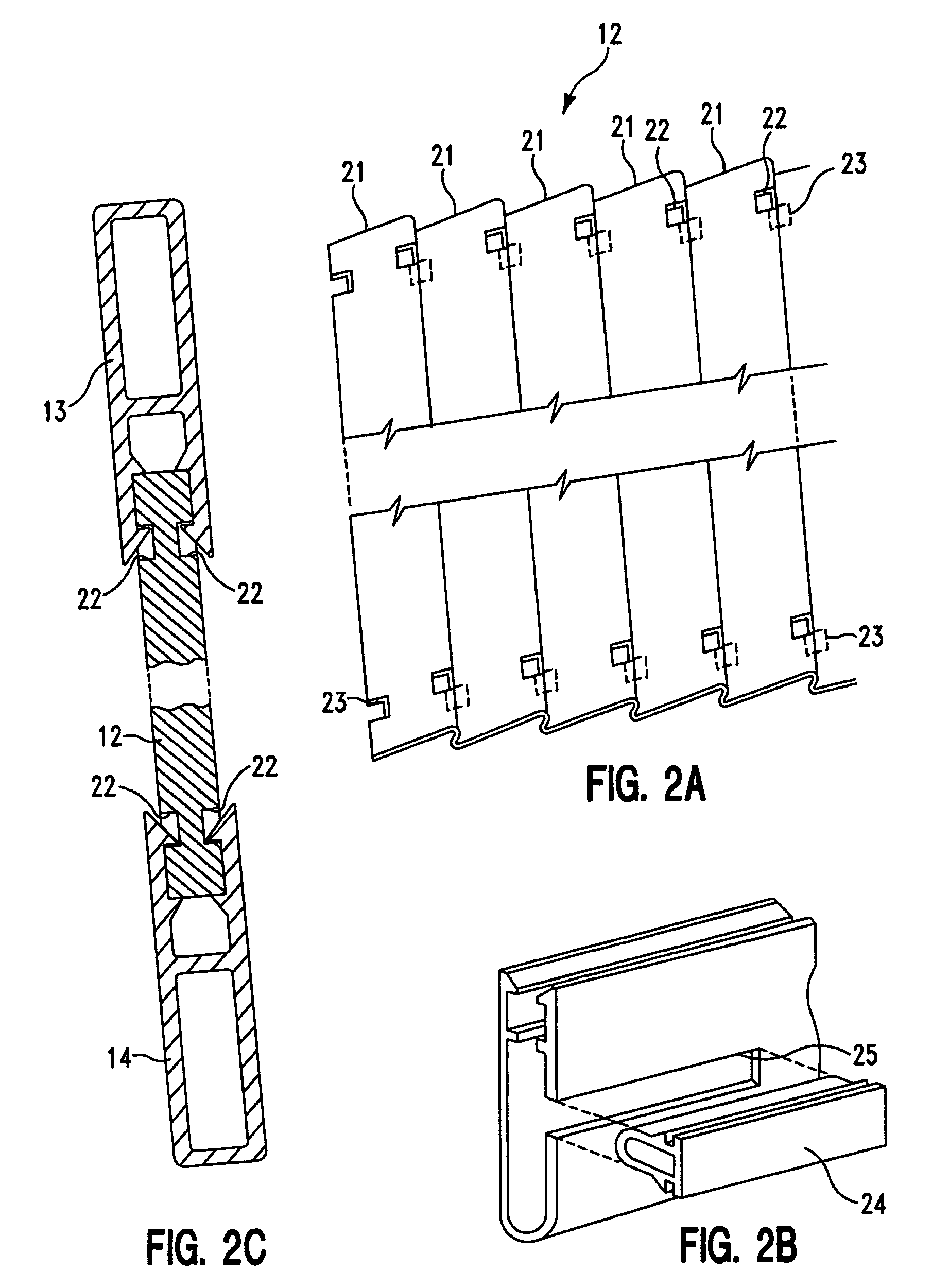

Flexible fence assembly

InactiveUS7857291B2Easy to installEasy to removeProtective constructionFencingVertical edgeVia fence

A fence assembly is made up of a plurality of fence sections. Each section is made up of panels with top, bottom and side edges and front and rear surfaces. Slots are spaced from and milled into the panels along one of the sets of edges. A pair of trim extends over and covers the set edges and each trim has projections that snap or slide into the front and rear slots. Alternatively the edges of the panel may be beaded and slid over the slotted side of the trim. The fence sections are coupled pivotably to fence posts such that the panels may pivot, under force of wind, about either their top or bottom end. The panels are restored to generally vertical position by the force of gravity. A counterweight within the fence post linked to the panels can be used to restore panels to their vertical position. In an alternate embodiment, the brackets coupling the panels to the fence posts may slide along the fence posts and the panels bow in response to high winds. The fence panels may include resilient strips along their vertical edges.

Owner:DOMBROSKI EDWARD L

Method for manufacturing cushion pad layer of rock protective shed by utilizing waste tyres

InactiveCN101982612ATo achieve the purpose of disaster prevention and mitigationImprove water and soil conservation effectProtective constructionChipsealWaste rubber

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Civil engineering structure, individual construction element and method for reinforcing such a structure

A civil engineering structure, intended for ensuring protection against impacts of moveable masses, has a face exposed to the impacts of moveable masses. The structure includes, in the region of the face exposed to the impacts of moveable masses, a set of individual construction elements secured to one another and filled completely or partially with at least one material having a capacity for being deformed elastoplastically, the individual construction elements liable to be damaged by impacts of moveable masses being capable of being replaced individually by similar individual construction elements.

Owner:FRANCE GABION ZONE IND

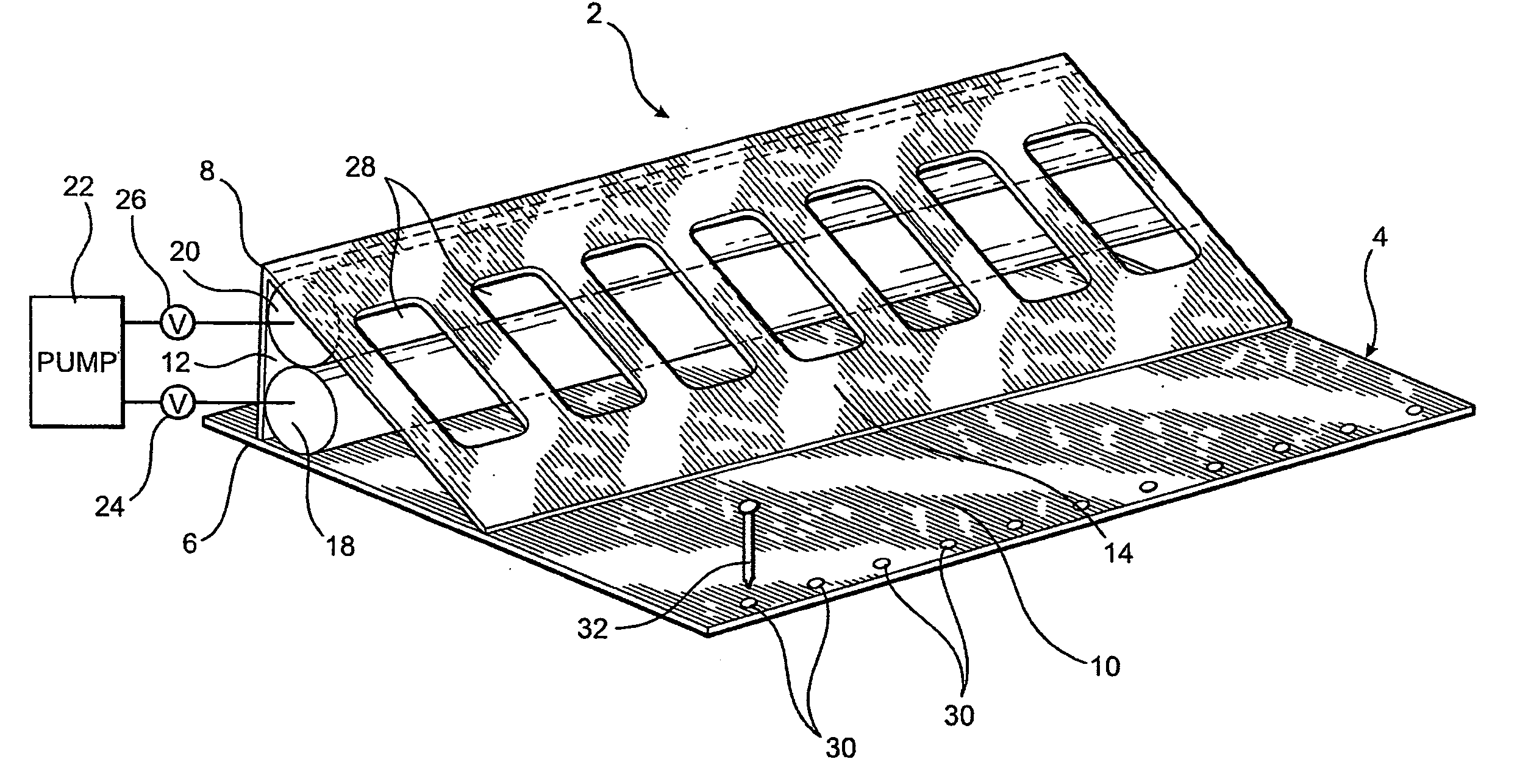

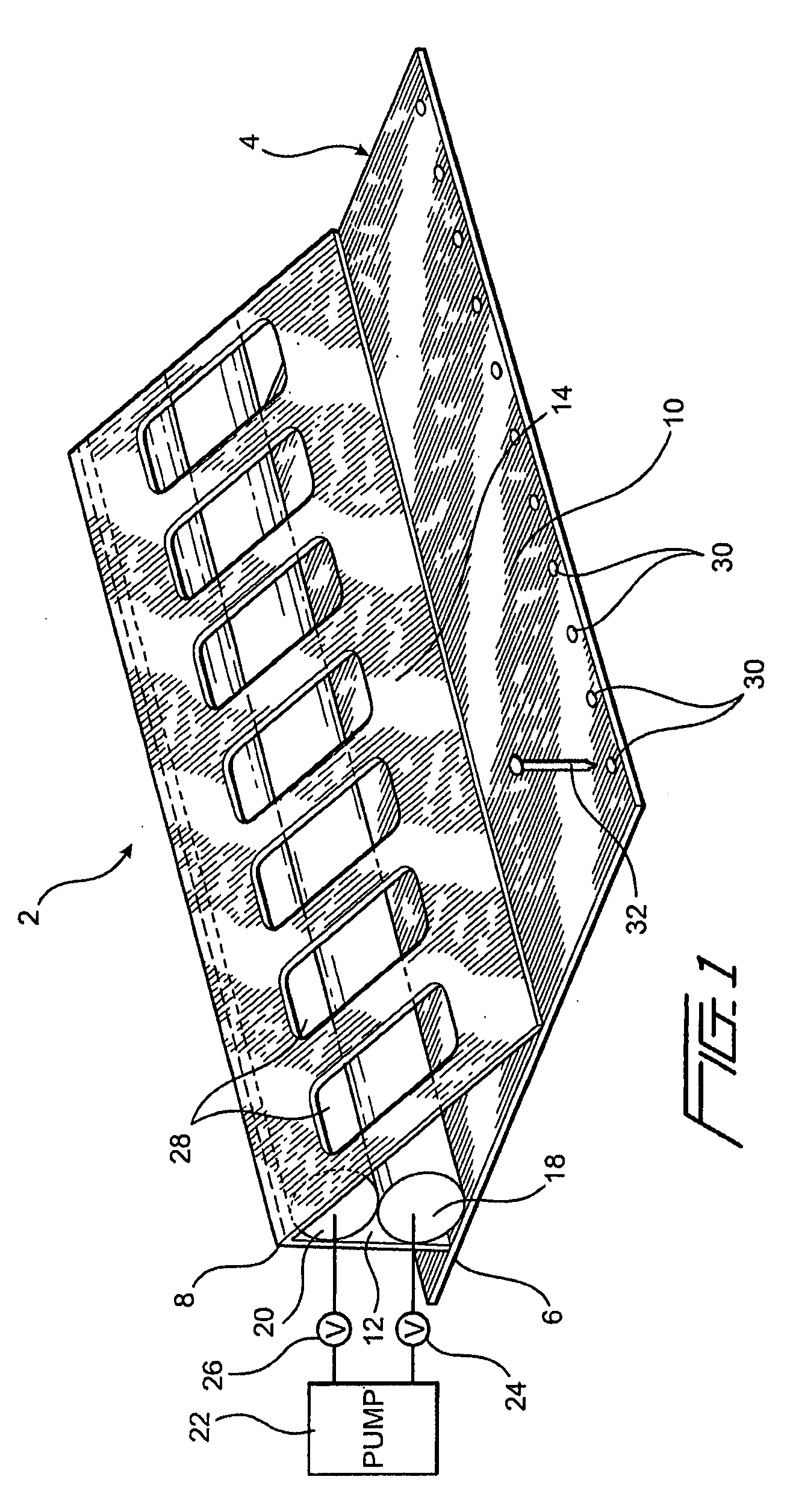

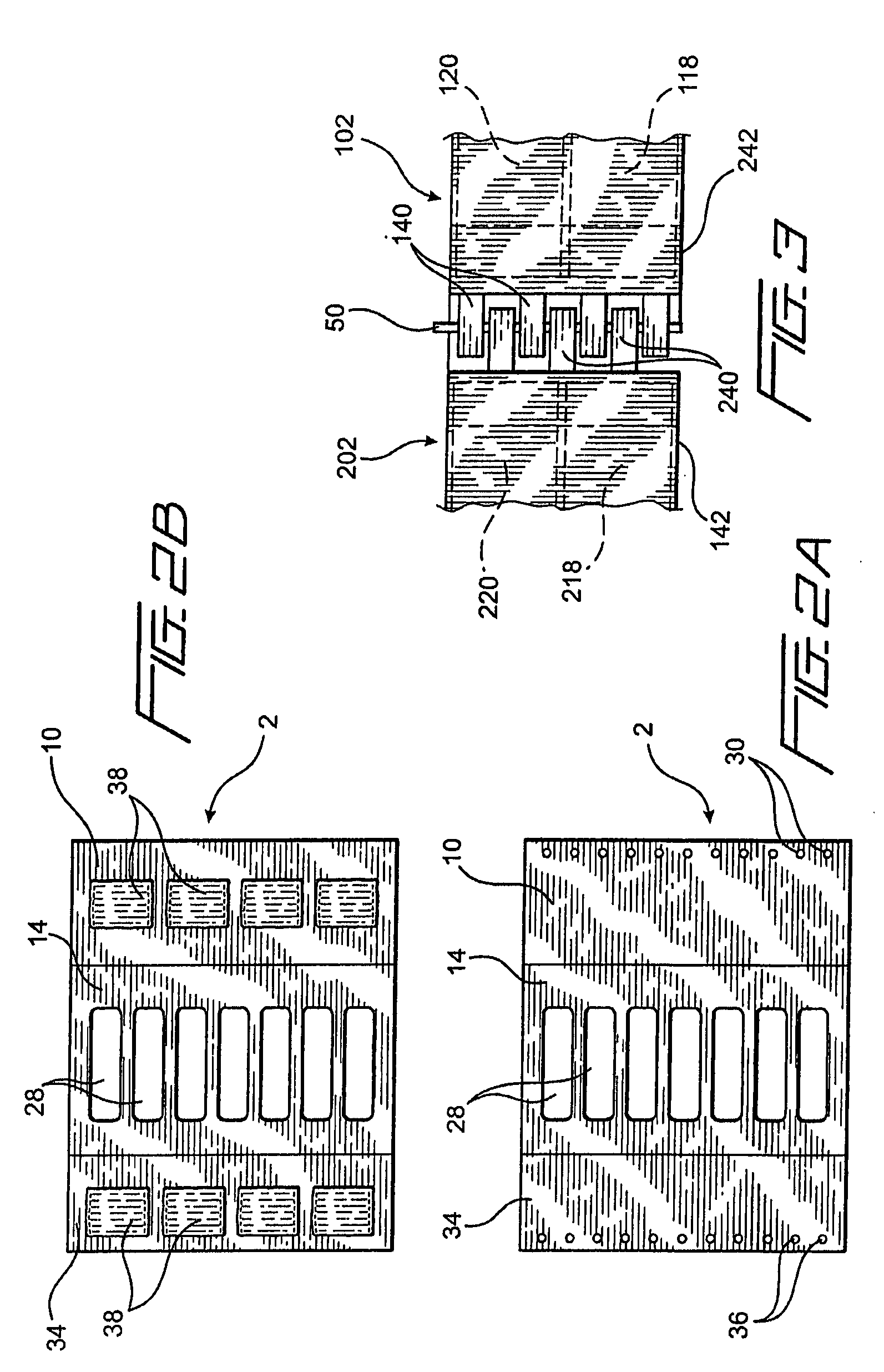

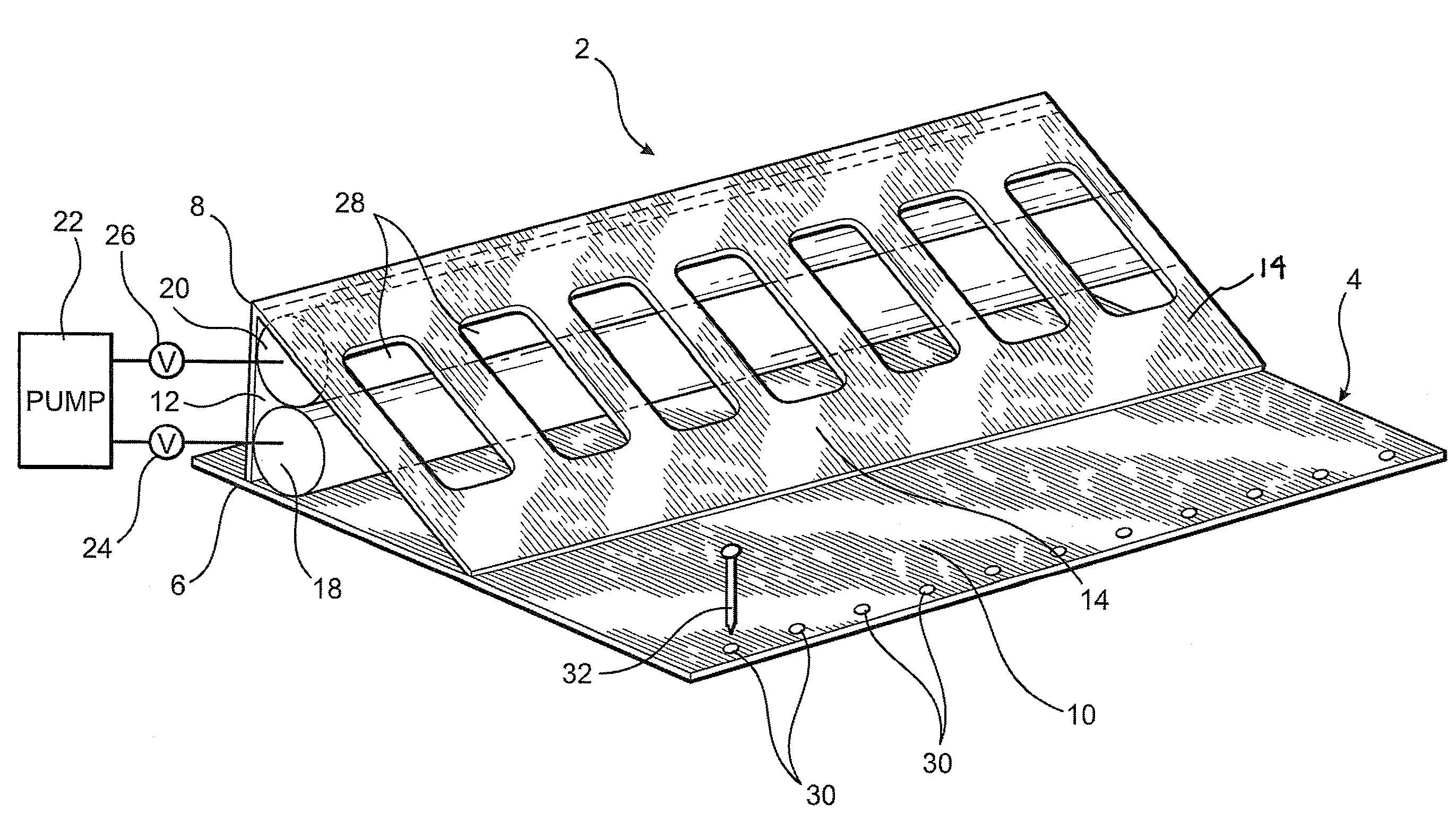

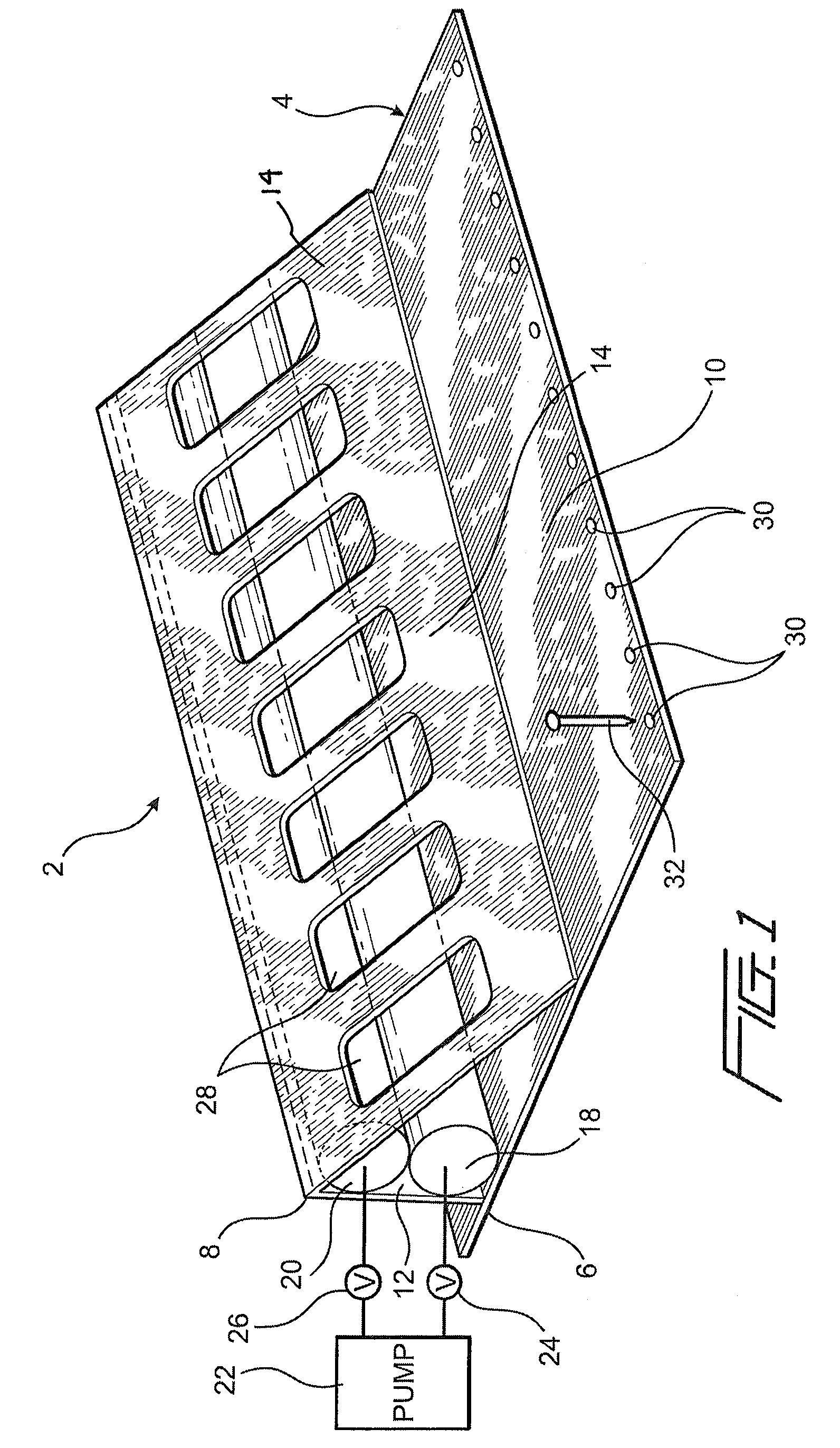

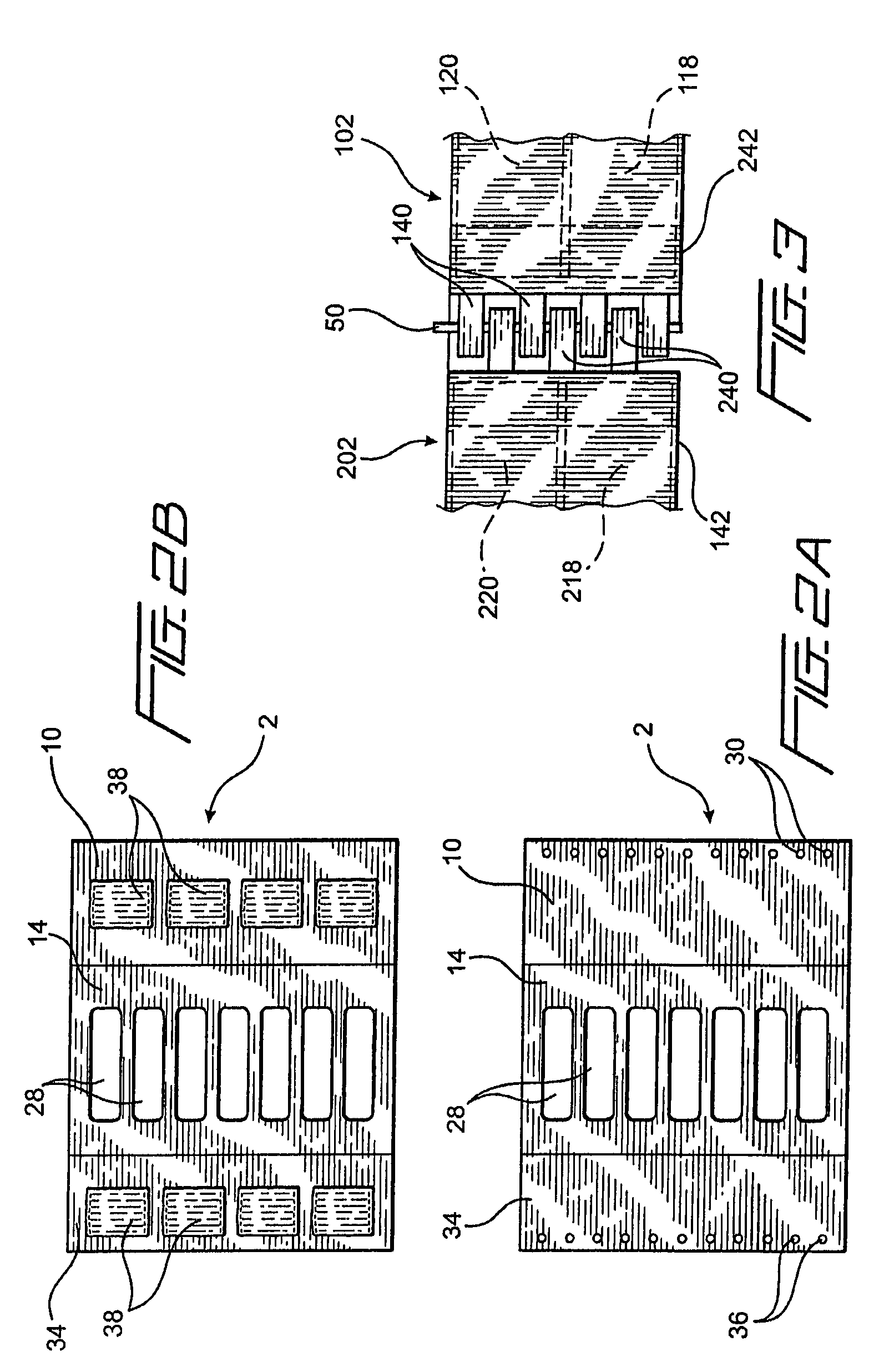

Flood Wall

A portable, inflatable flood wall is characterized by a sheet of synthetic plastic material which is folded back on itself to define a chamber between bottom, rear and front portions of the sheet and within which at least one inflatable bladder is secured. When the bladder is inflated, the rear portion of the sheet is erected to a vertical position which prevents water from passing beyond the sheet. The front portion preferably contains a plurality of openings to allow water to enter the chamber. The weight of the water on the bottom portion of the sheet serves to hold the wall in place. A plurality of such walls may be connected in end-to-end relation to construct a wall of a desired length.

Owner:SALEMIE BERNARD

Novel energy consumption damping stone blocking structure

InactiveCN101736707AReduce the amount of masonryIncreased resistance to overturning momentProtective constructionStone wallEngineering

The invention relates to a novel energy consumption damping stone blocking structure which belongs to structures for preventing and controlling stone rolling disasters. The structure comprises a stone blocking wall which is a flag concrete stone blocking wall; the top of the stone blocking wall is preembedded with a steel rail fence; a prestress anchor cable is arranged in the stone blocking wall, and the front slope surface of the stone blocking wall is sequentially provided with a foam plastic layer and a gravel filling layer which are arranged for playing the buffering function. The invention has the characteristics of light weight, economy, safety and simple construction.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Flood wall

A portable, inflatable flood wall is characterized by a sheet of synthetic plastic material which is folded back on itself to define a chamber between bottom, rear and front portions of the sheet and within which at least one inflatable bladder is secured. When the bladder is inflated, the rear portion of the sheet is erected to a vertical position which prevents water from passing beyond the sheet. The front portion preferably contains a plurality of openings to allow water to enter the chamber. The weight of the water on the bottom portion of the sheet serves to hold the wall in place. A plurality of such walls may be connected in end-to-end relation to construct a wall of a desired length.

Owner:SALEMIE BERNARD

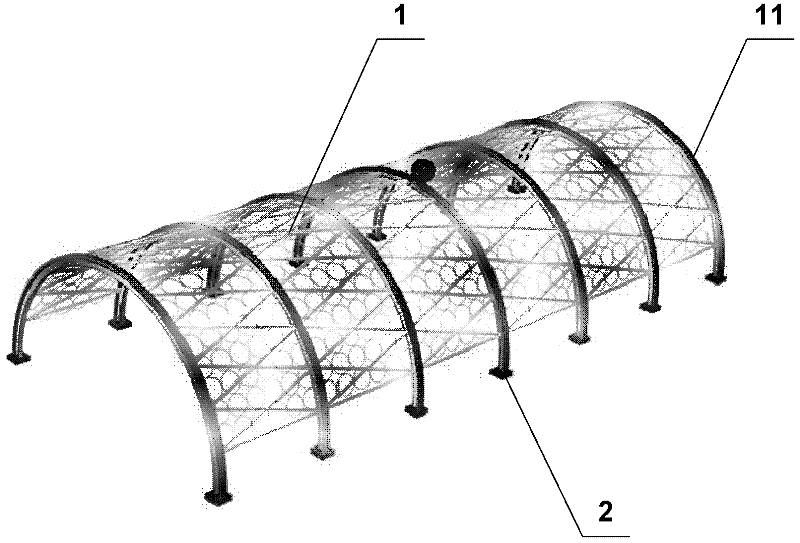

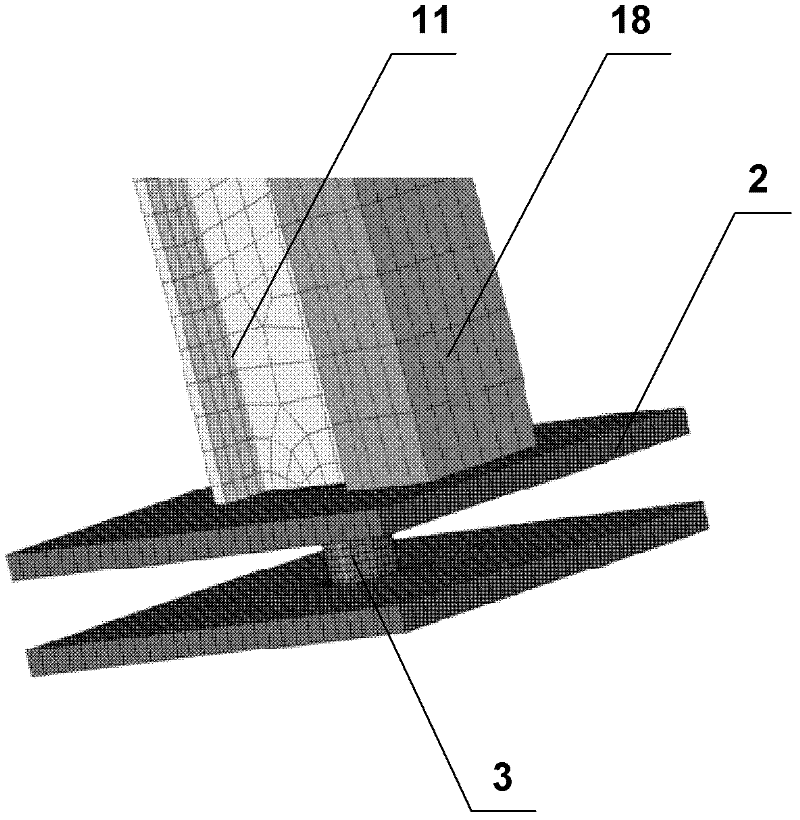

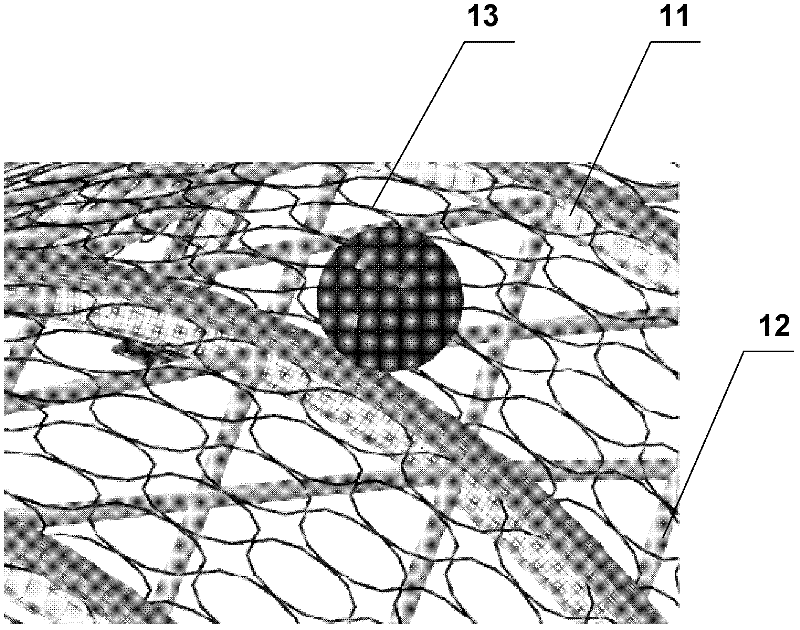

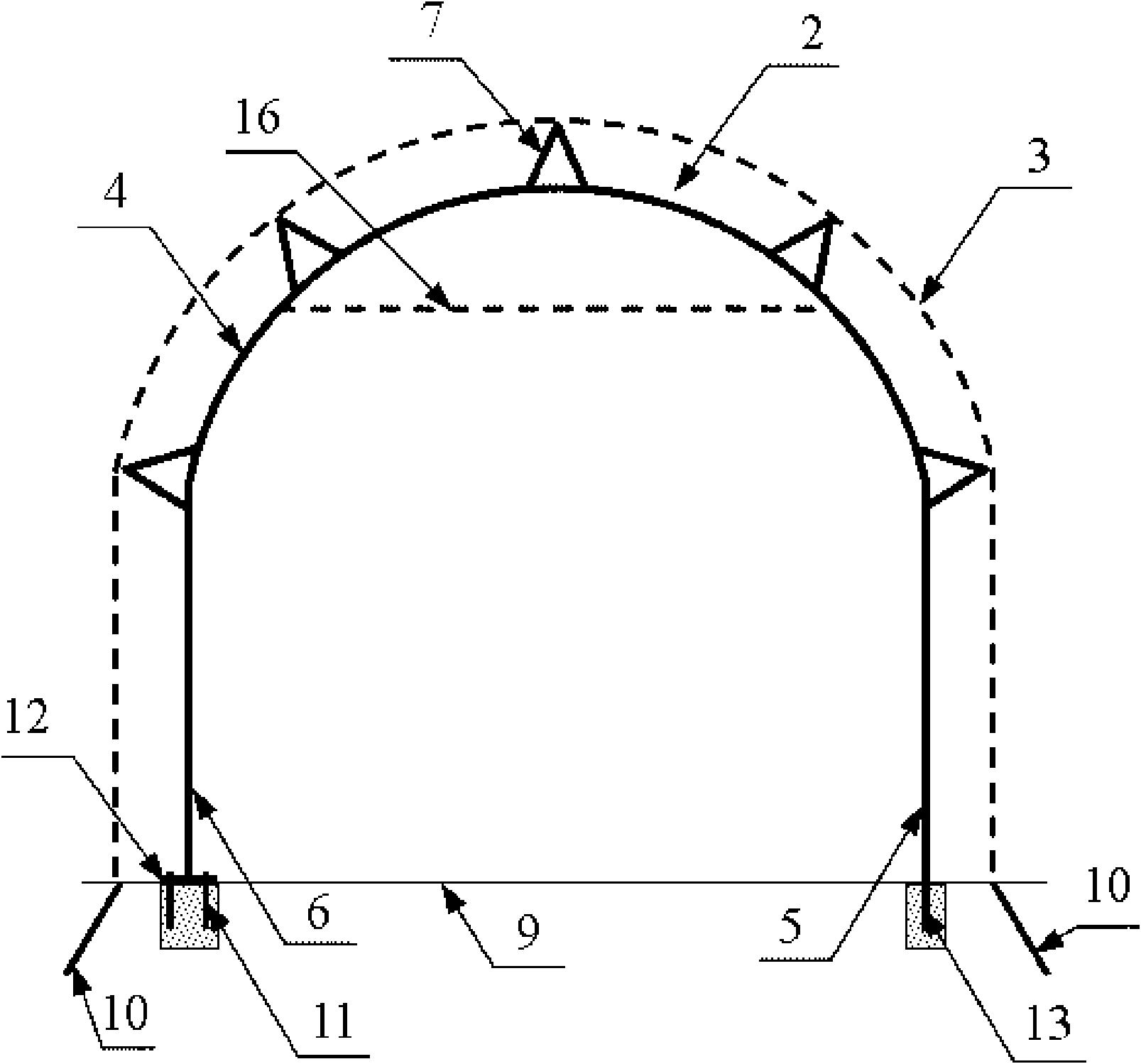

Flexible hangar tunnel used for isolating and protecting flying rocks or falling rocks

The invention discloses a flexible hangar tunnel used for isolating and protecting flying rocks or falling rocks and being capable of reducing construction difficulty, which consists of at least two steel structure arches arranged at intervals along the axis and at least one layer of metal net hung and connected on the steel structure arches, wherein the steel structure arches are fixed on the foundation; and the metal net is positioned outside the steel structure arches and connected with the foundation. Under the condition of meeting the same protection requirement, compared with the existing hangar tunnel of reinforced concrete structure, the size, weight and land occupying of the hangar tunnel are greatly reduced, and the fixing strength requirement between the structure and the ground is reduced, thus reducing the size requirement of the structure foundation, reducing the excavated volume and appendant damages thereof, reducing the damage to the environment, and having good permeability and no need of considering lighting and ventilation in the tunnel. The flexible hanger tunnel is especially applicable for isolating moving objects such as hillside falling rocks or blasting flying rocks.

Owner:布鲁克(苏州)工程有限公司

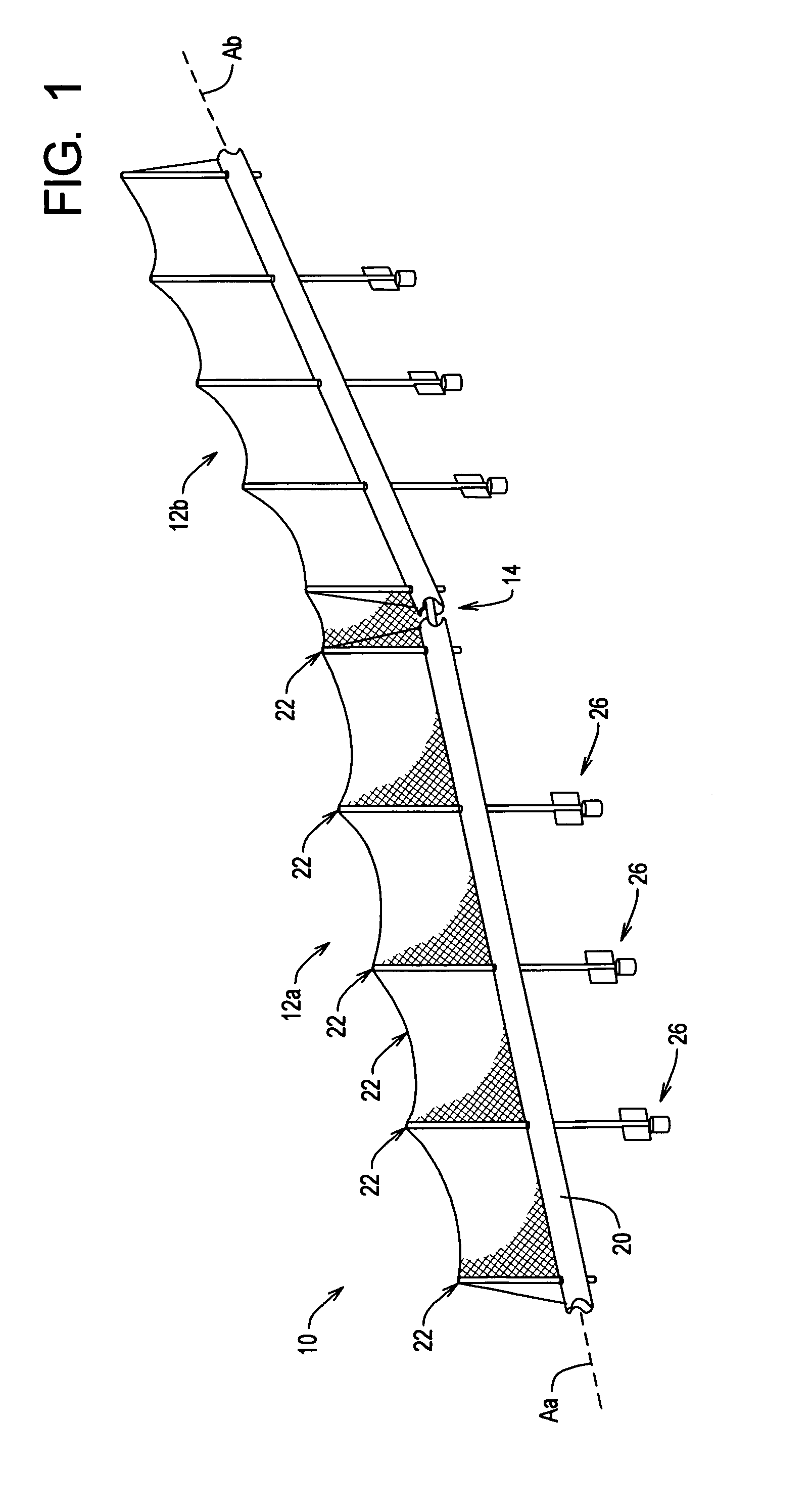

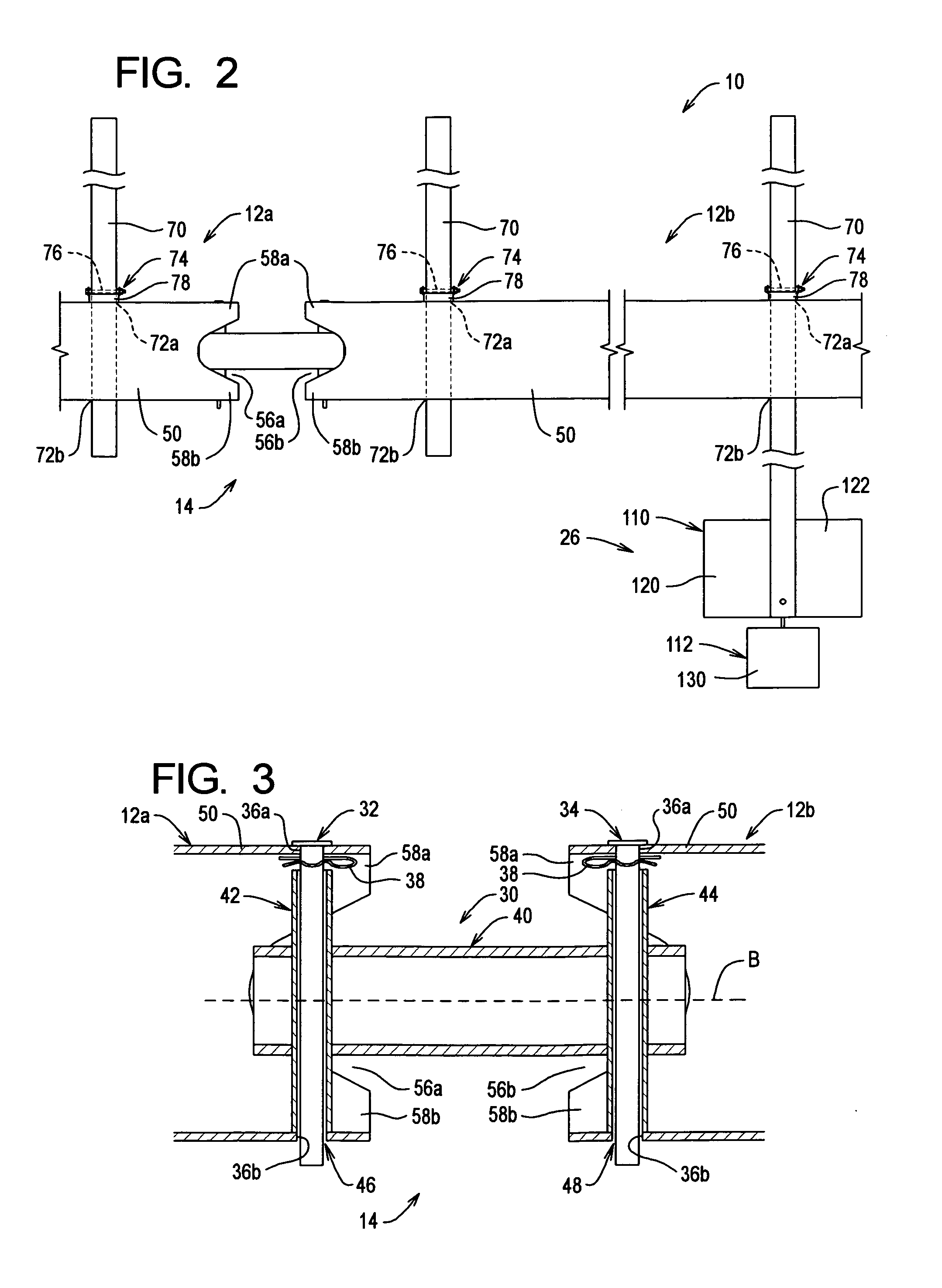

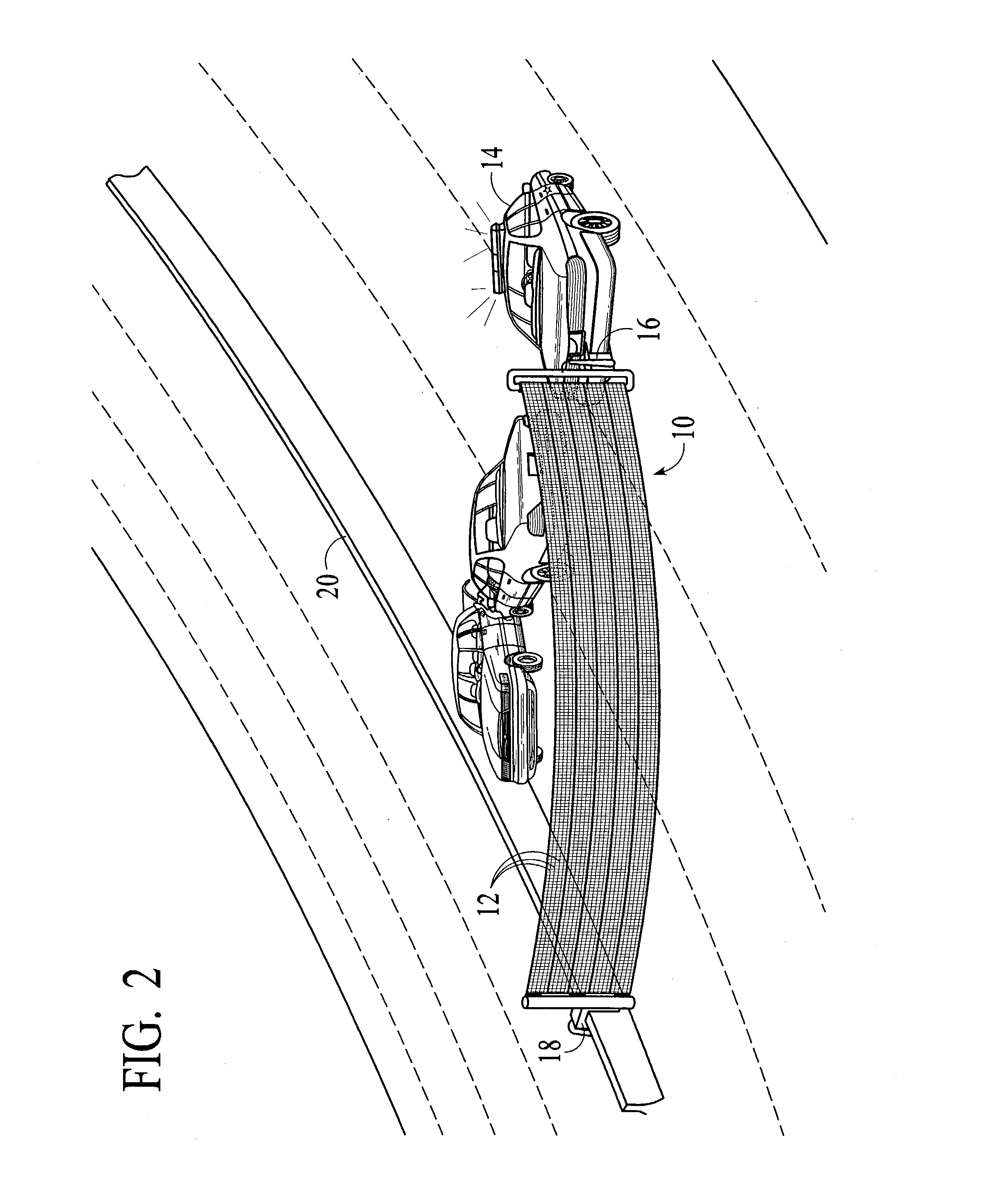

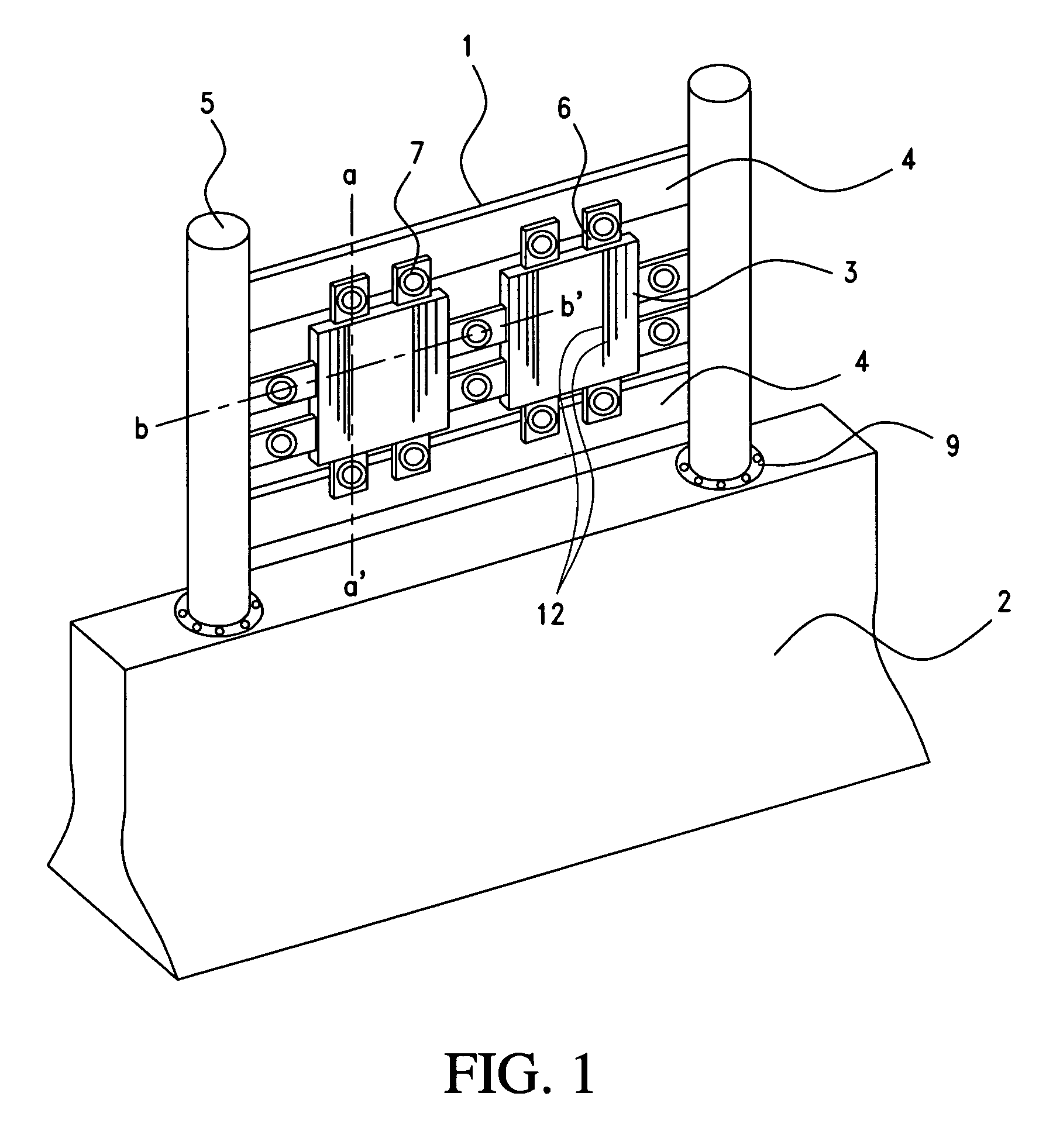

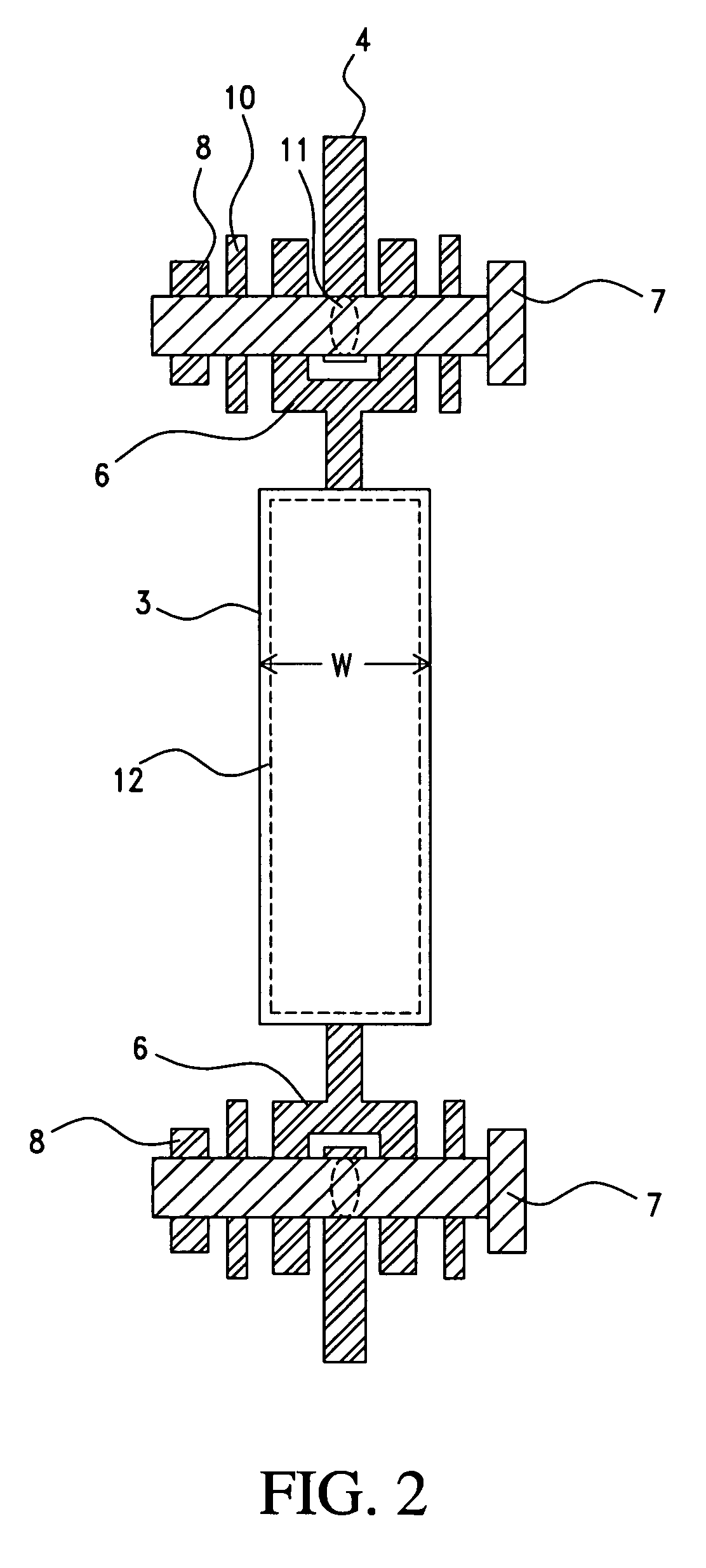

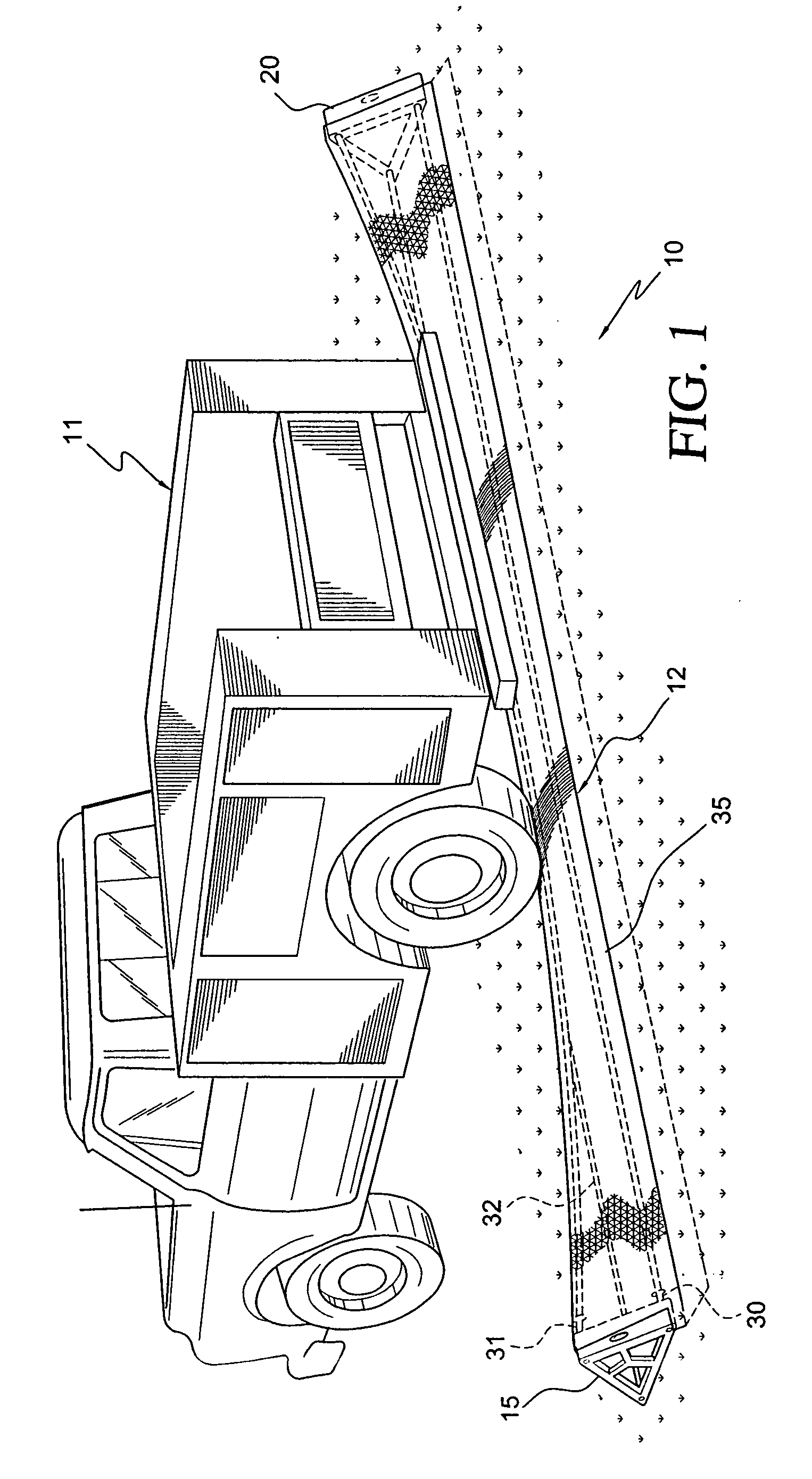

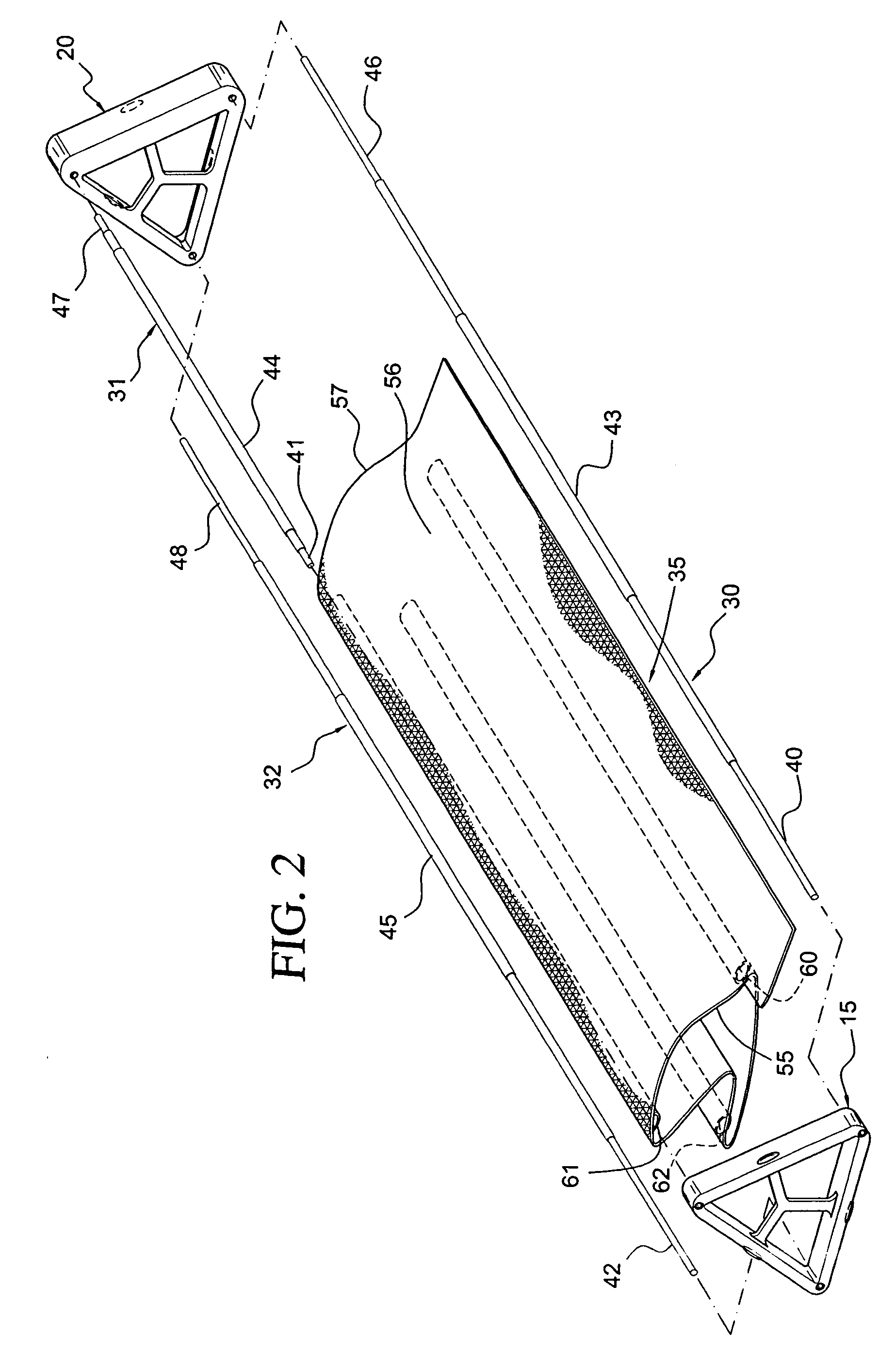

Silt fencing system

InactiveUS20090022552A1Easy to transportEasy to bendBarrages/weirsProtective constructionEngineeringTruck

A transportable and reusable silt fencing system for use at a construction site to prevent sediment and soil erosion comprises tension rods, a male section, a female section, and a fencing material having sleeve supports for the rods to slide in and support the fencing material. The tension rods are collapsible. The rods collapse when a truck drives over the fence, but re-assume their original form once the truck has passed. If a fence longer than the fencing section is required, additional fencing sections may be attached by connecting a male section of one fence section with the female section of another fence section.

Owner:BERENYI GARY

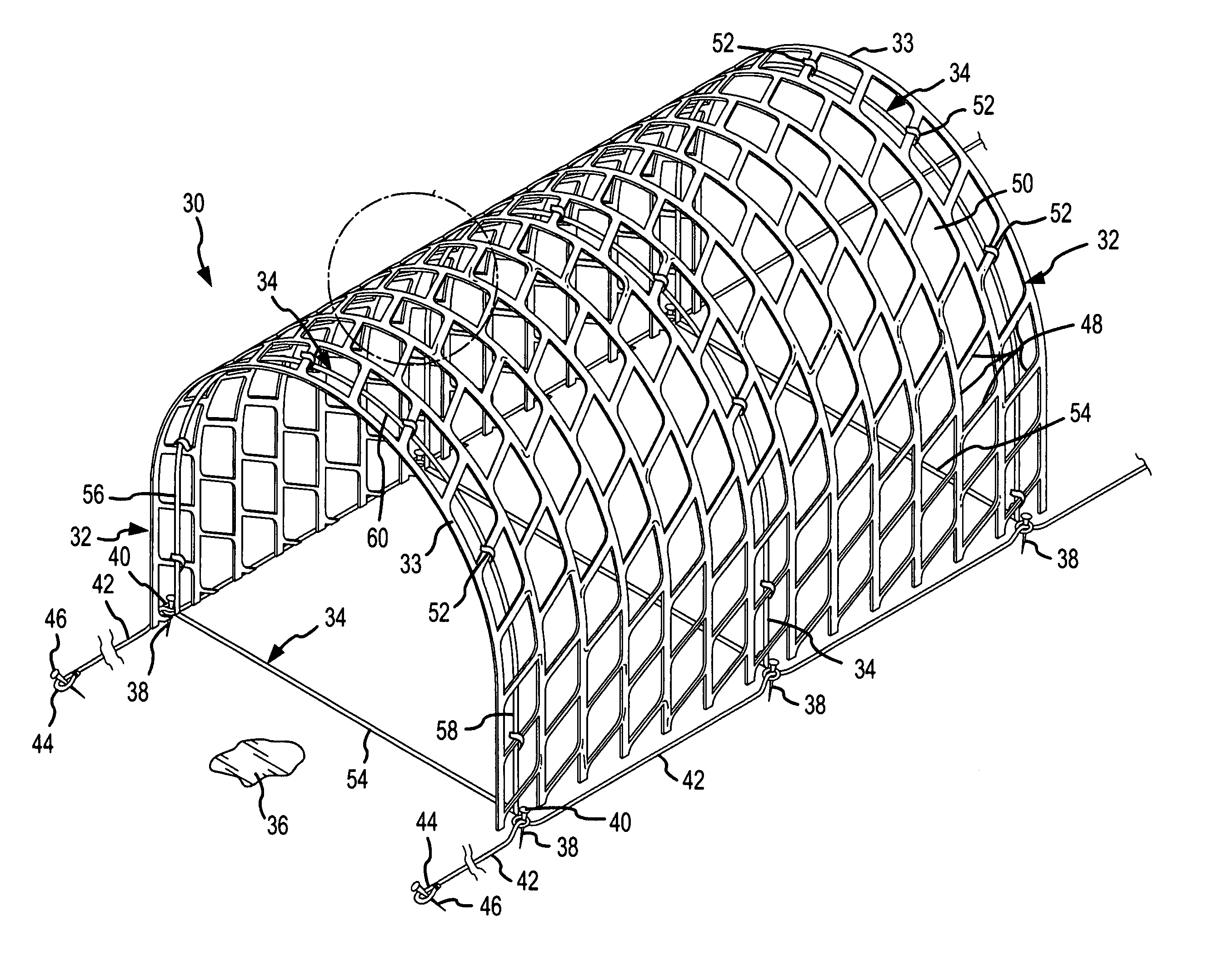

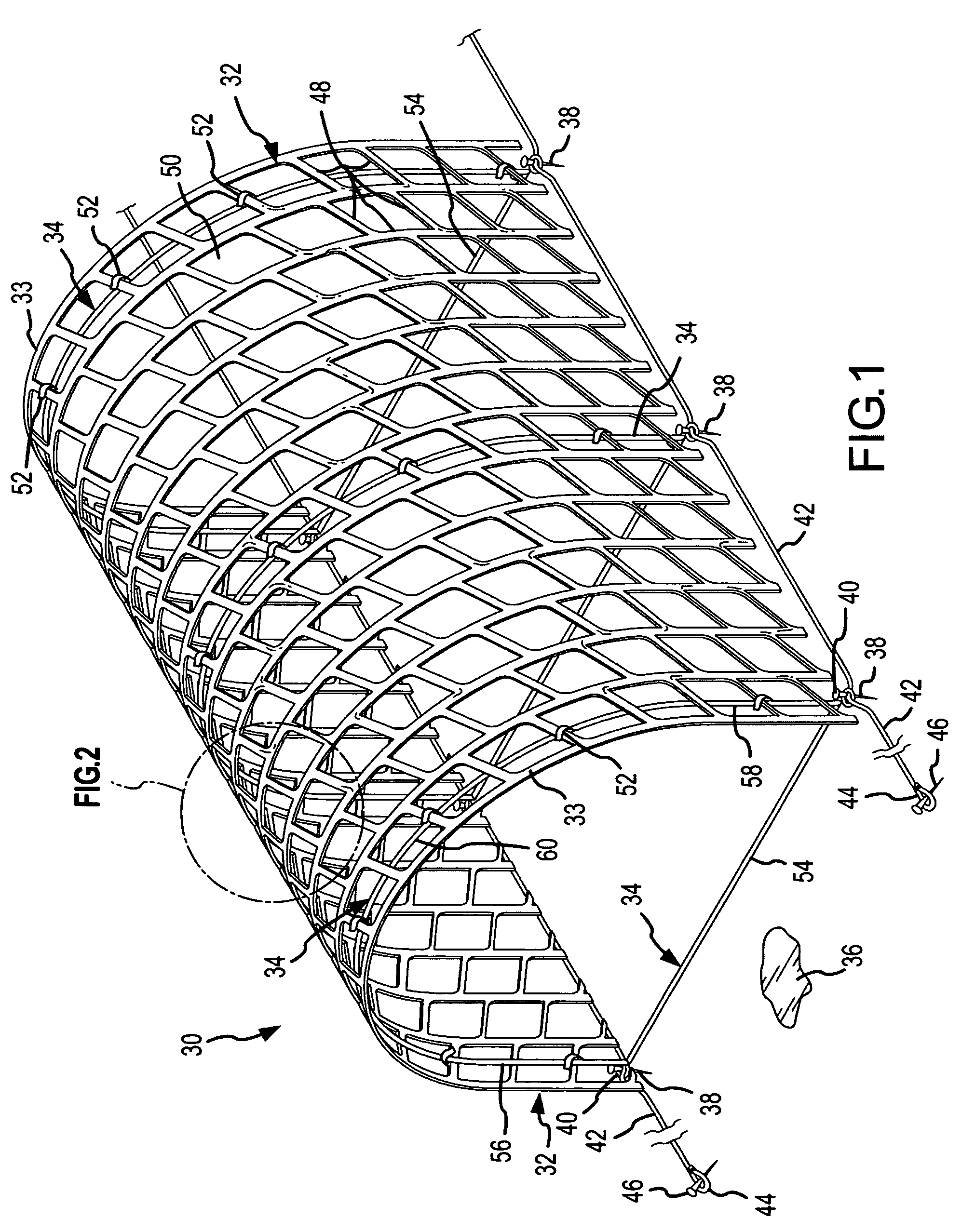

Porous tubular device and method for controlling windblown particle stabilization deposition and retention

InactiveUS6986624B1Easy to disassembleEasy to deployProtective constructionExcavationsAerodynamic dragDevice form

Owner:TABLER RONALD D

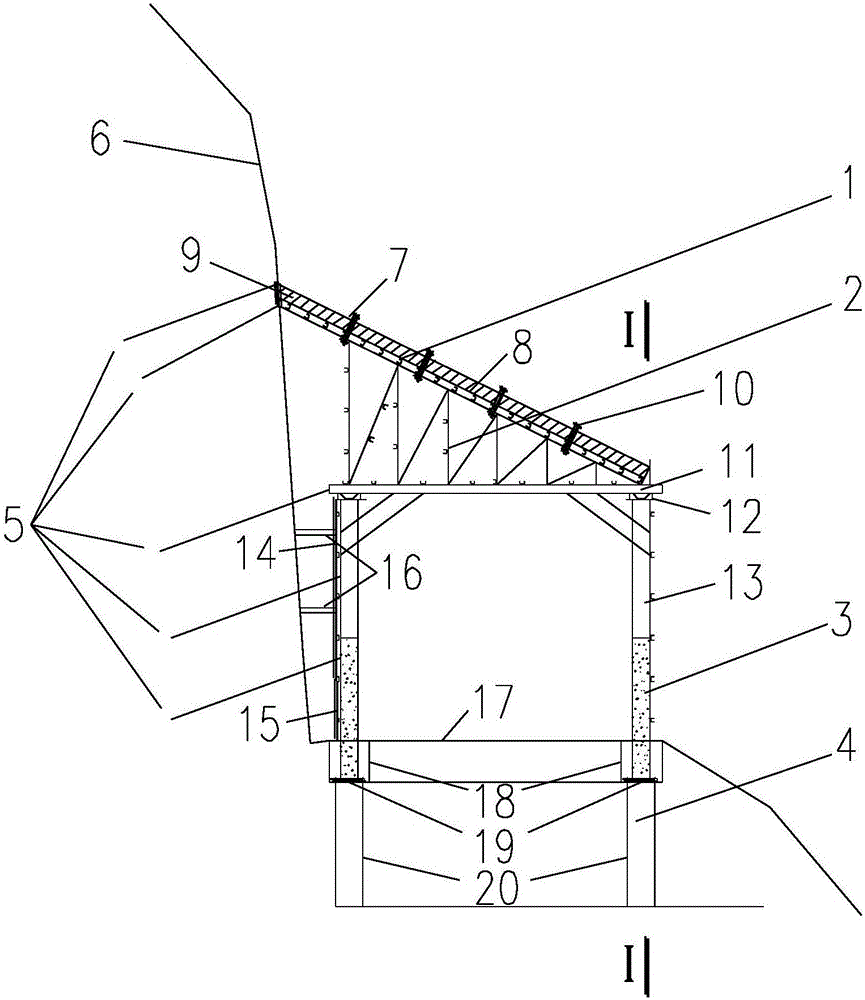

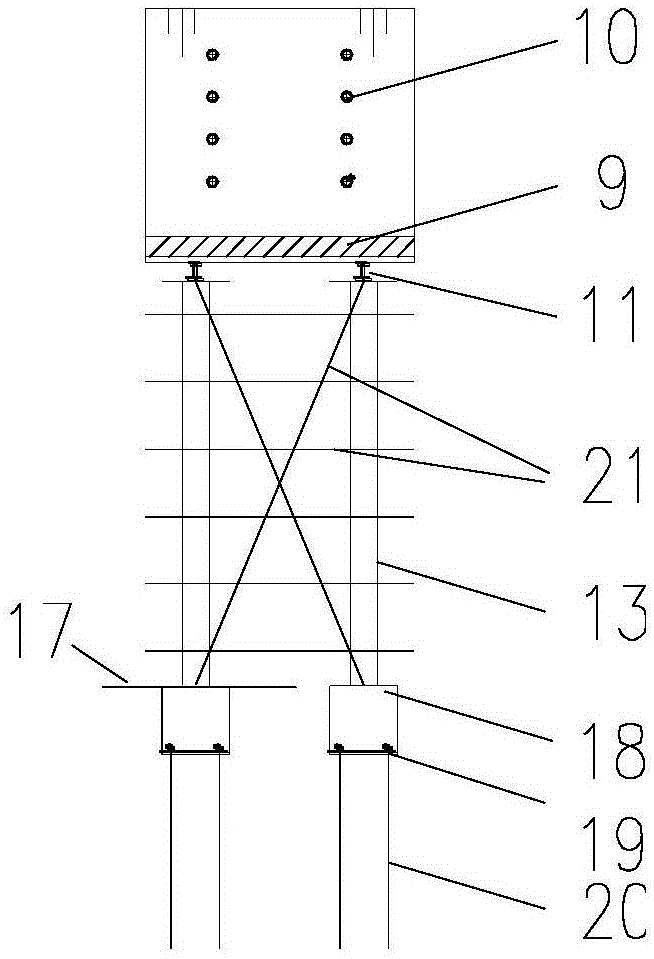

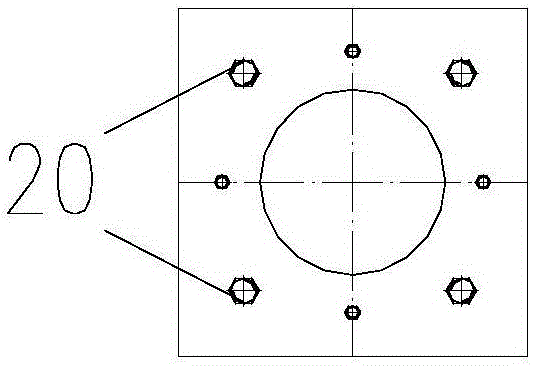

Combined energy dissipation shed frame structure for preventing rockfall of high and steep slope in earthquake region

InactiveCN106638340AImprove stabilityImprove seismic performanceProtective constructionSupporting systemPost disaster

The invention discloses a combined energy dissipation shed frame structure for preventing rock rolling-down hazards of a high and steep slope in highway construction, and belongs to the field of highway disaster prevention and control and post-disaster reconstruction engineering in an earthquake region. The combined energy dissipation shed frame structure is composed of a top surface anti-impact system tightly connected with an existing slope, a top surface supporting system composed of a three-dimensional steel frame system, a shed frame main structure composed of a cross beam and supporting steel tube stand columns on the two sides, a close-to-mountain side anchoring system for anchoring the top surface anti-impact system and the shed frame main structure, and a cast-in-place concrete bed formed by welding fixing pedestals to the bottoms of the steel tube stand columns and driving the fixing pedestals into a foundation through anchor rods. According to the combined energy dissipation shed frame structure, potential safety hazards caused by crag rockfall of a high and steep slope in an earthquake region to highway construction and vehicle driving are prevented, and the stability and seismic capacity of the shed frame structure are effectively improved. Compared with a traditional shed tunnel structure, the combined energy dissipation shed frame structure greatly shortens construction time and is beneficial to rapid traffic keeping and anti-disaster capacity improving.

Owner:DALIAN UNIV OF TECH

Video display and touchscreen assembly, system and method

A touch screen assembly for use with a display, such as, for example, a flat panel display. The touch screen assembly includes a transparent panel, preferably in the form of a panel of tempered glass adhered to a touch screen panel. Consoles having touch screen assemblies are also disclosed.

Owner:WELLS GARDNER TECH INC

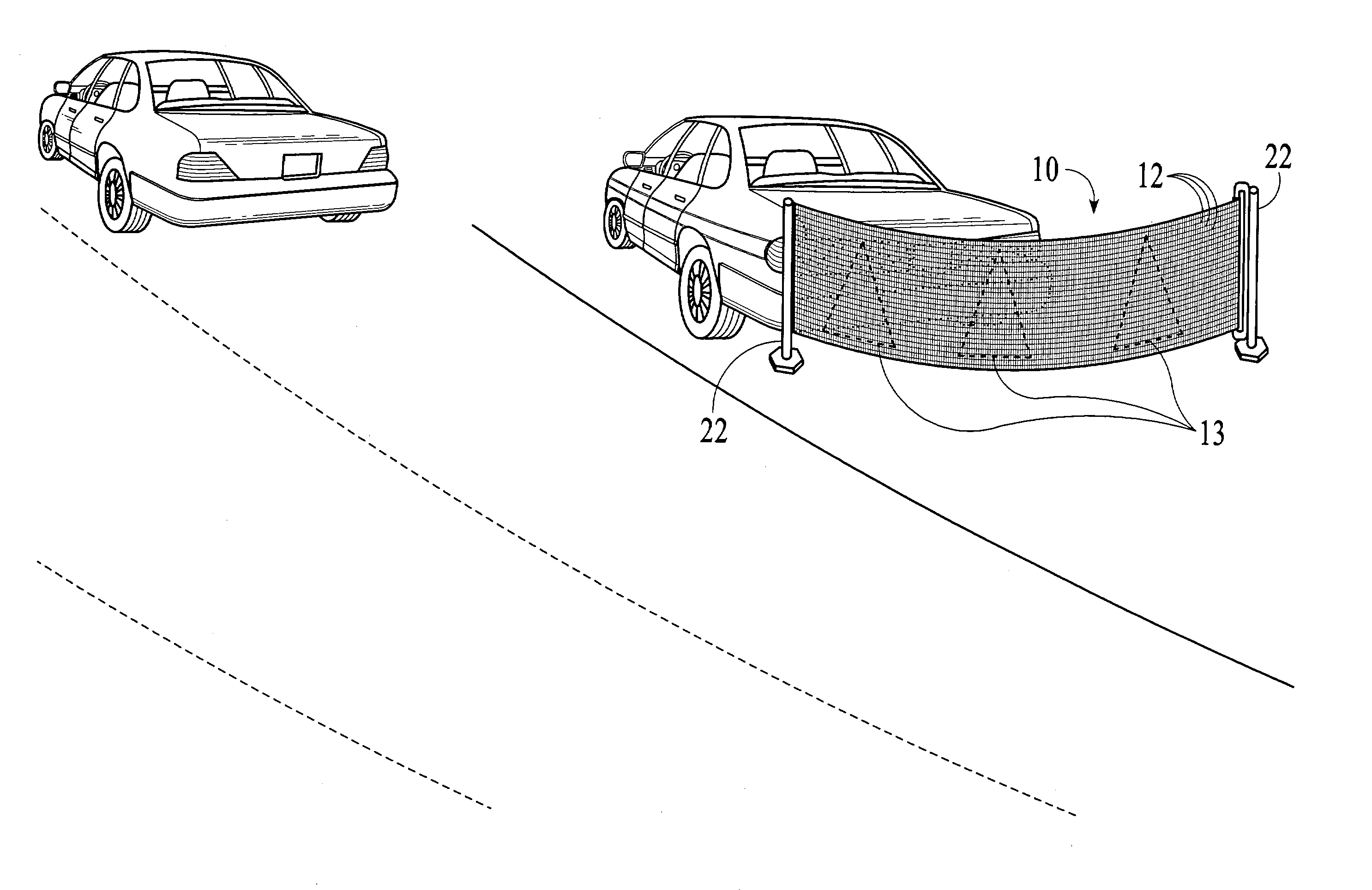

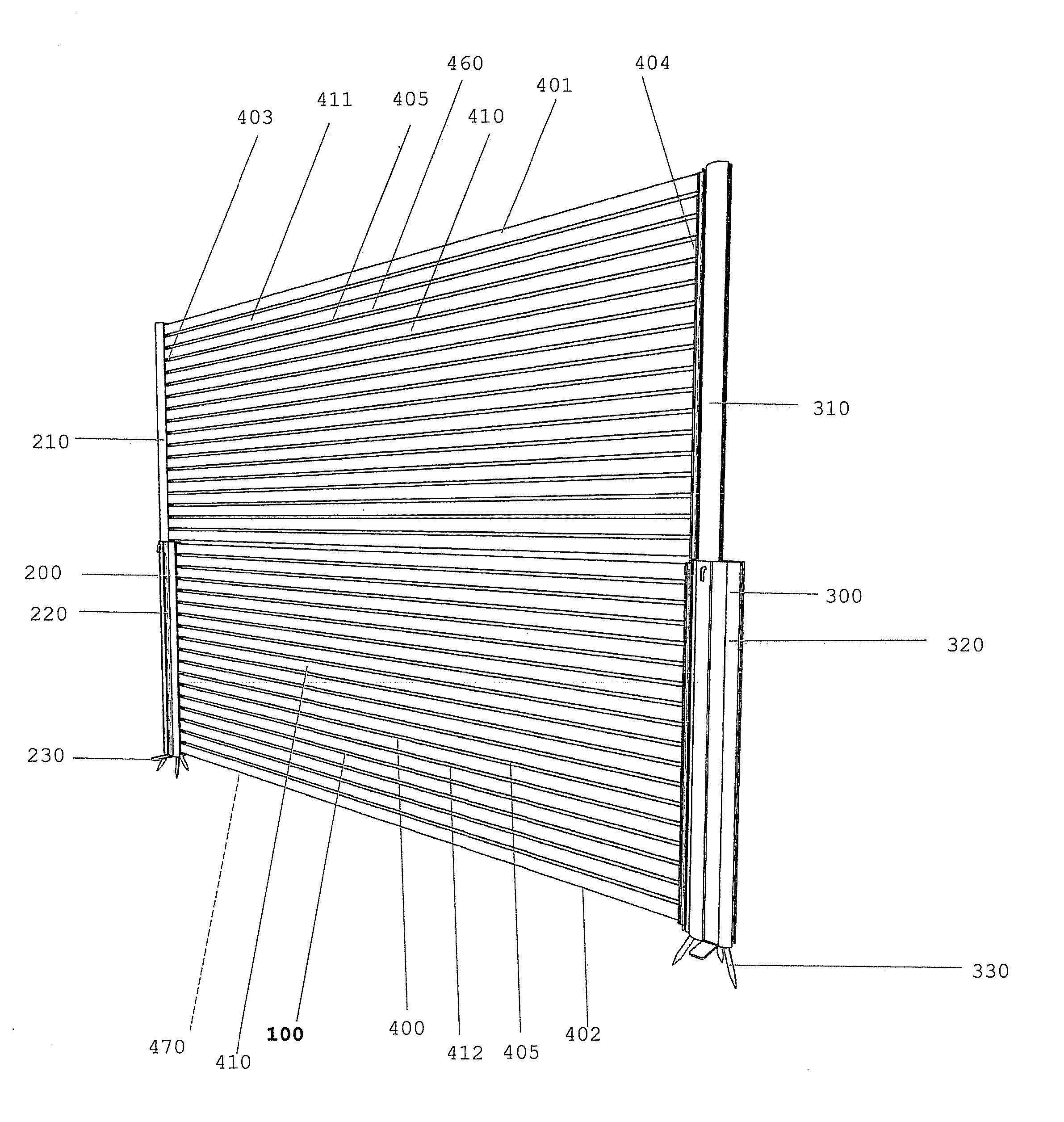

Portable Height Adjustable Barrier for Screening Off the Source of Traffic Congestion

InactiveUS20130048227A1Quickly and easily assembled on-siteCurrent is limitedScreensBurglar alarm by openingTraffic congestionEngineering

A portable barrier is provided to obstruct viewing the source of traffic congestion comprising a first vertical assembly, a second vertical assembly and a retractable screen. Each vertical assembly has a top portion, a middle portion, and a base stand. Each middle portion includes at least one tubular barrel capable of receiving the top portion and a female fastener. The retractable screen is drawn from (and may retract into) the first vertical assembly. This retractable screen has one or more partitions which include a plurality of parallel horizontal straps which all attach to a vertical fastener which engages the female fastener located on the second vertical assembly.

Owner:CANNOVA CARL S

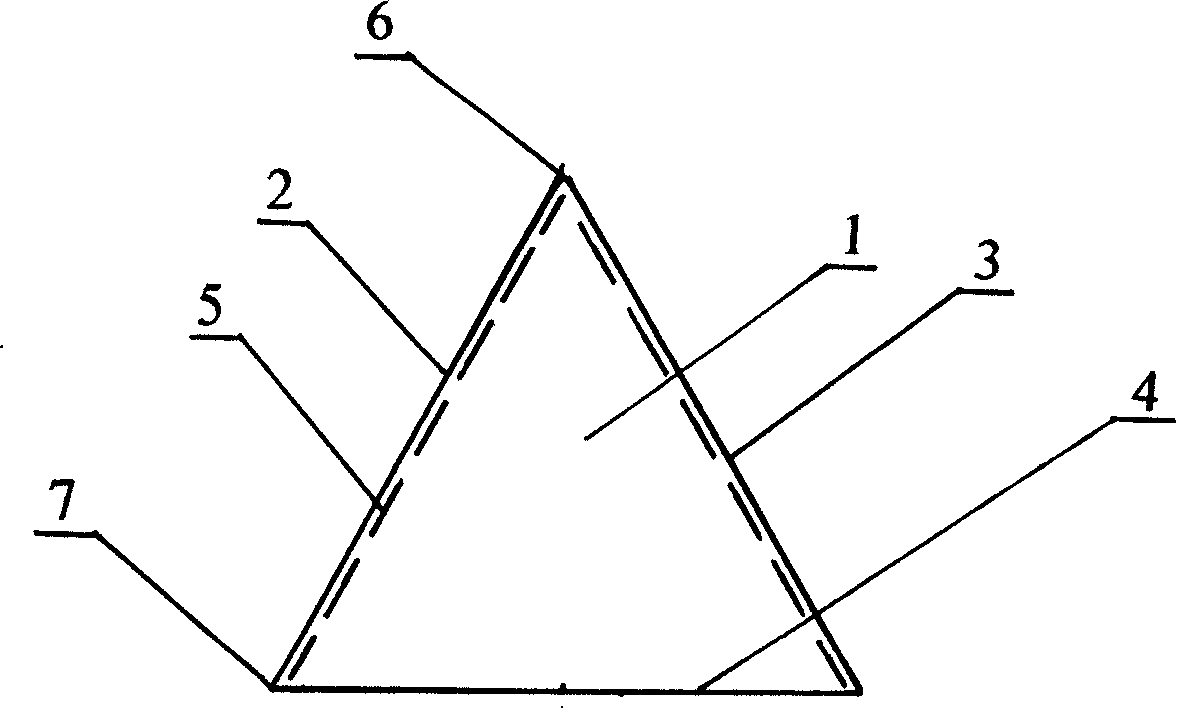

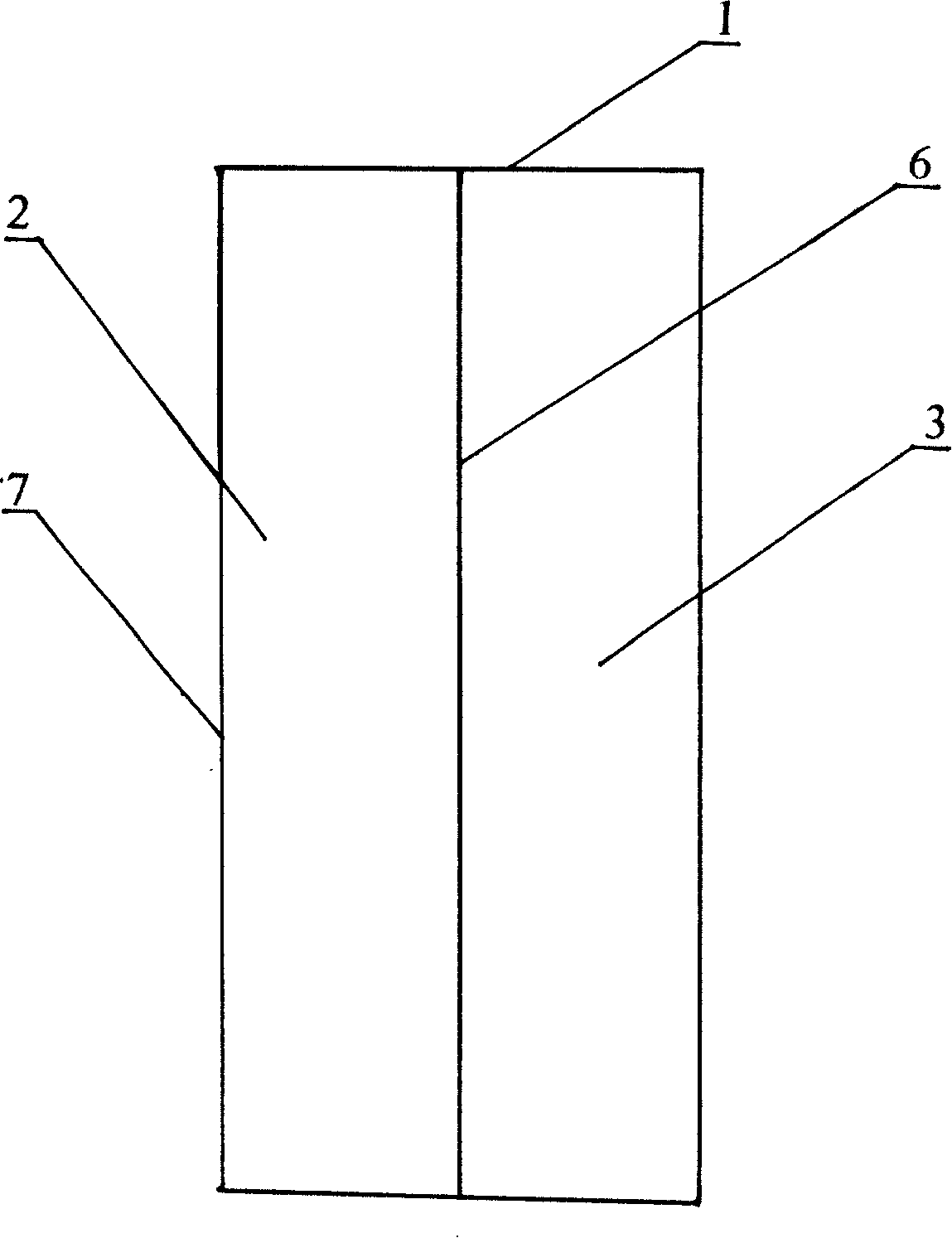

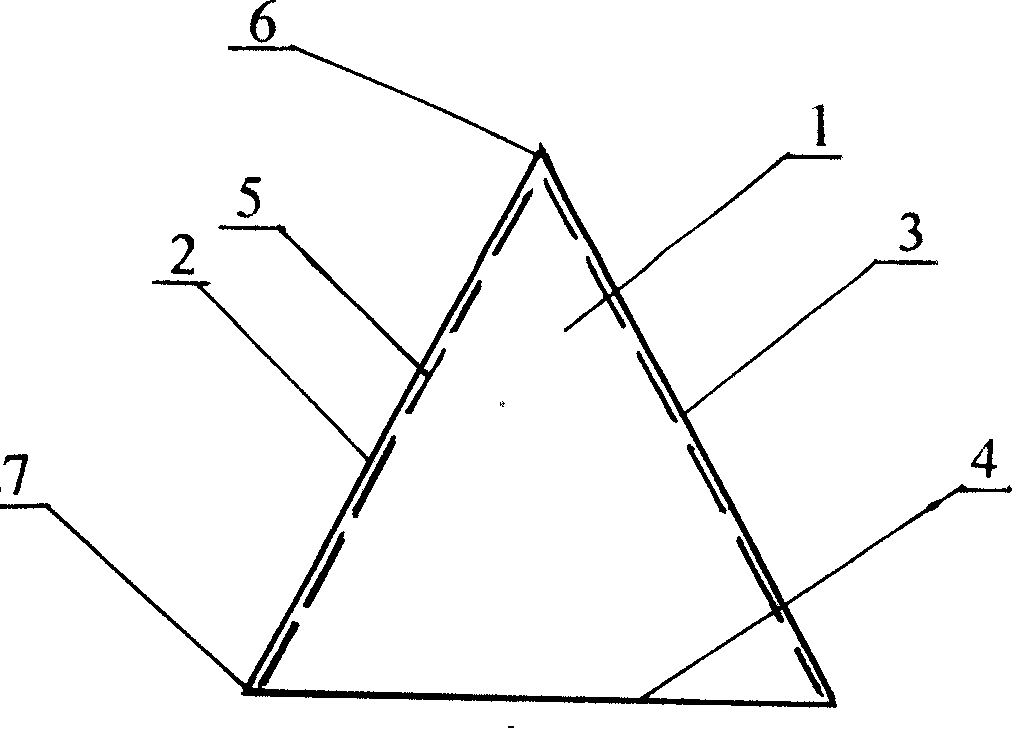

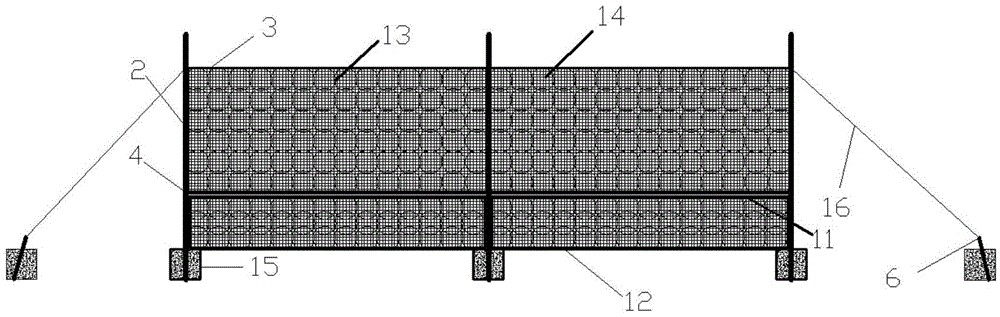

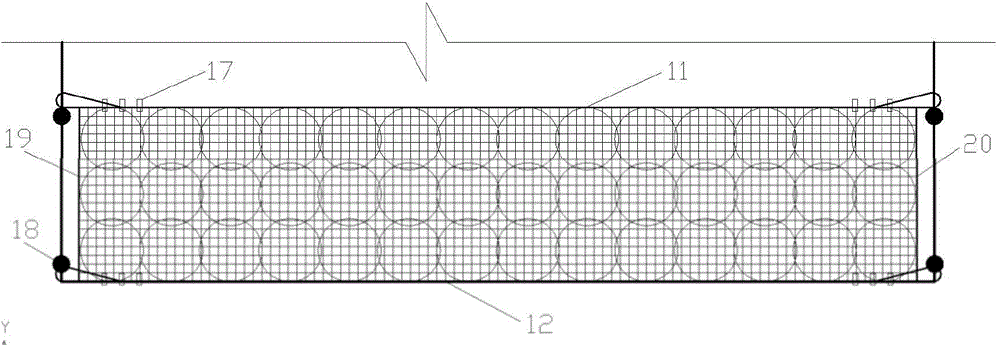

Tandem cylinder mould for manufacturing sand barrier, sediment storage dam, sand dyke and sand wall

The invented method provides a series mesh cage for constructing sand barriers, sediment storage dams, sand banks and sand walls, comprising a triangular cage body composed of a mesh cage front surface 2, a mesh cage rear surface 3, and a mesh case bottom surface 4, the inner of the front surface 2 and rear surface 3 of the mesh cage have earthwork cloth liners 5. The series mesh cage is used to construct sand barriers, sediment storage dams, sand banks and sand walls. Thereby sand in desert is used as building material for fathering desert. The invented mesh cage can be produced mechanically in large scale, and sand barriers, sediment storage dams, sand banks and sand walls made of mesh cages can be constructed mechanically.

Owner:娄成城

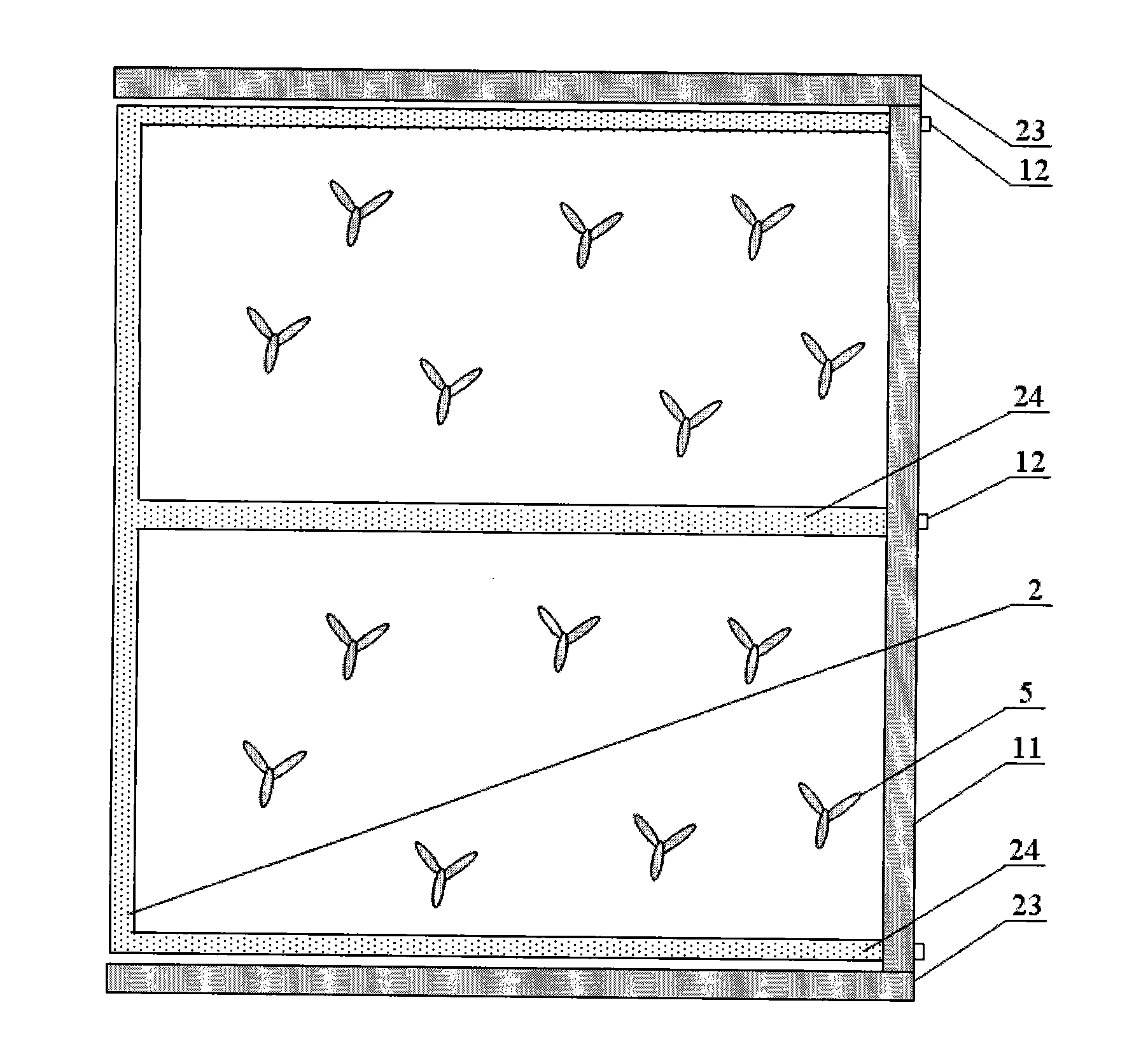

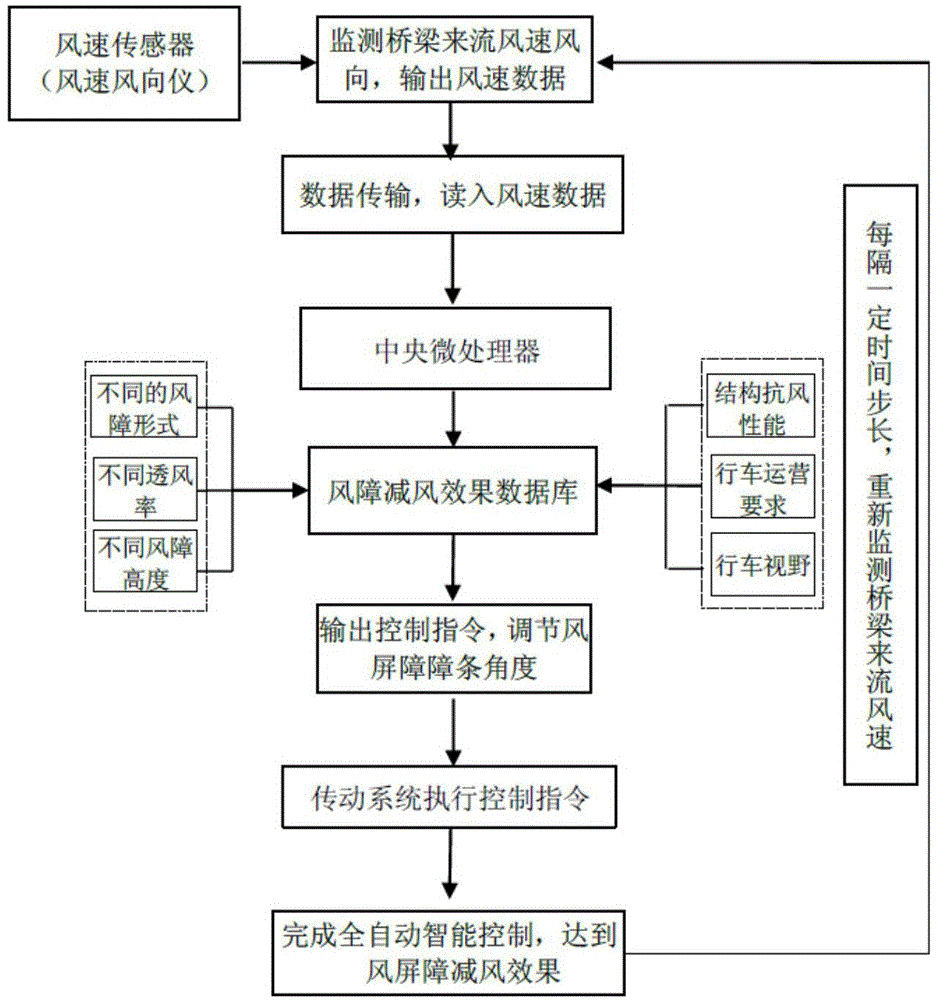

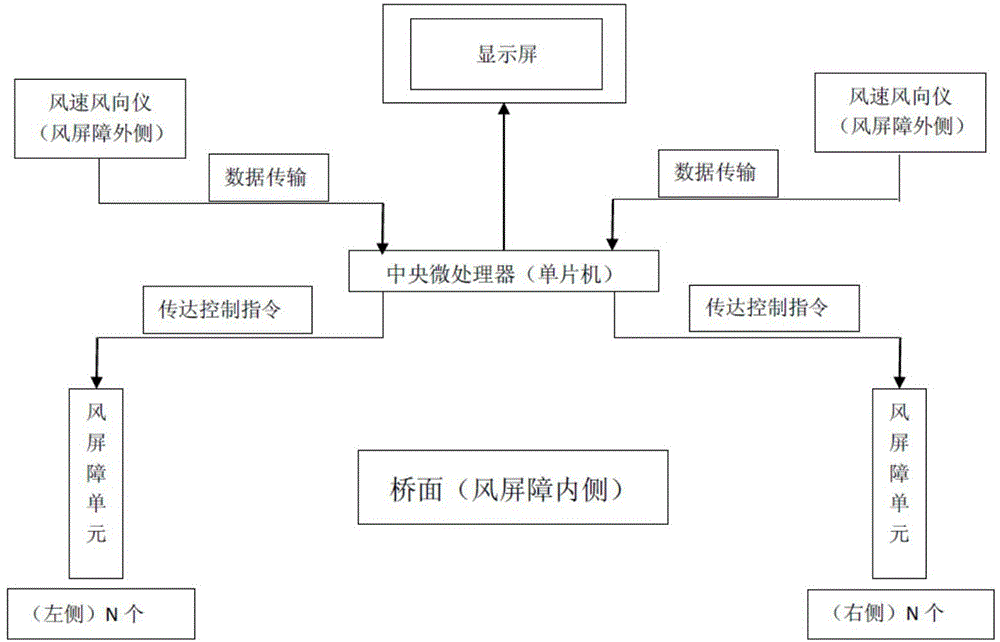

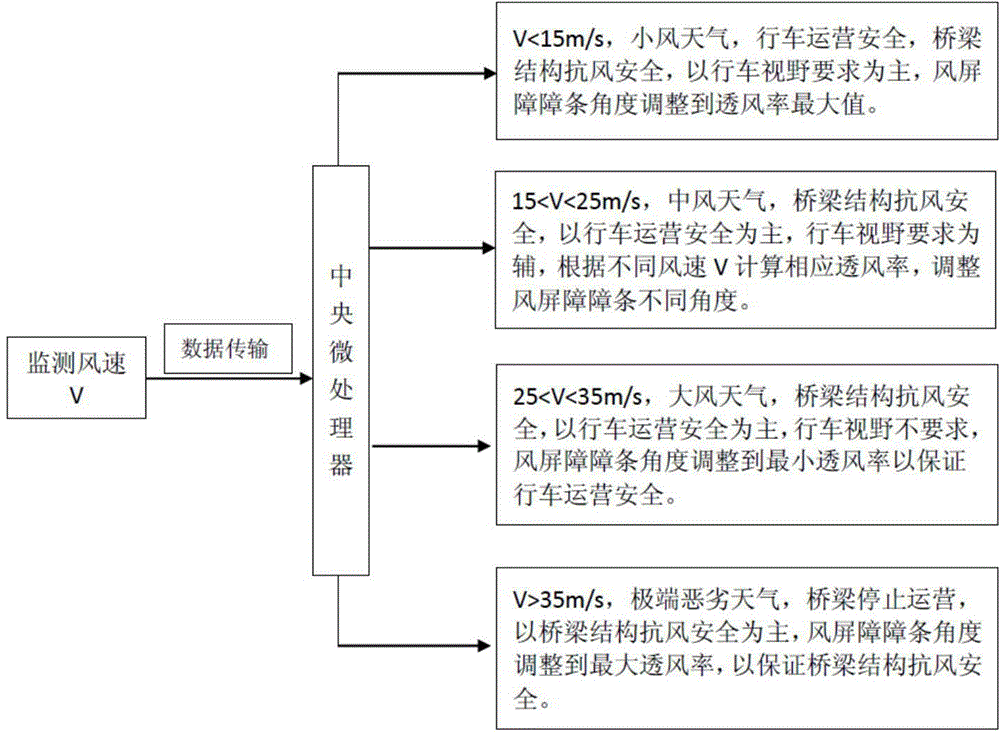

Bridge air barrier with full automatic intelligent control

ActiveCN104894987AGuaranteed wind safetyGuaranteed uptimeProtective constructionAutomatic controlControl system

The invention provides a bridge air barrier with full automatic intelligent control, comprising multiple automatically controlled air barrier units which are in linear arrangement along the bridge direction at the two sides of a bridge. Each air barrier unit comprises an air barrier structure system, an air barrier drive system and an air barrier control system. Each air barrier structure system comprises multiple air barrier strips capable of rotating along a rotary shaft. Each air barrier drive system comprises a drive gear, a drive chain, a drive main shaft and a drive motor; and the drive motor drives the air barrier strips to rotate around the rotary shaft. Each air barrier control system comprises an air speed sensor and a central microprocessor, wherein the air speed sensor is installed outside the bridge air barrier; the real-time air speed and direction data monitored by the air speed sensor are transmitted to the central microprocessor; and then the central microprocessor gives an instruction so that the air barrier strips rotate to the pointed angle; and the ventilation rate of the air barrier is automatically adjusted. The bridge air barrier with full automatic intelligent control can ensure the safety of driving under crosswind on the bridge, improve the wind-resistant performance of the bridge structure and meet the traveling vision requirement of passengers maximally.

Owner:SHANXI SHANGFENG TECH +1

Magnetically mounted privacy screen

ActiveUS9345357B1Secured quickly, conveniently and reliablyImprove privacyScreensProtective constructionEngineeringMagnet

A privacy screen includes a flexible panel having a hem formed peripherally about the panel. The hem includes a plurality of pockets. Each pocket accommodates a respective magnet. The magnets releasably adhere to a metallic door or frame surrounding a window or wall opening to be covered. This holds the panel over the window or wall opening to prevent viewing therethrough.

Owner:DAVILA JR GILBERTO

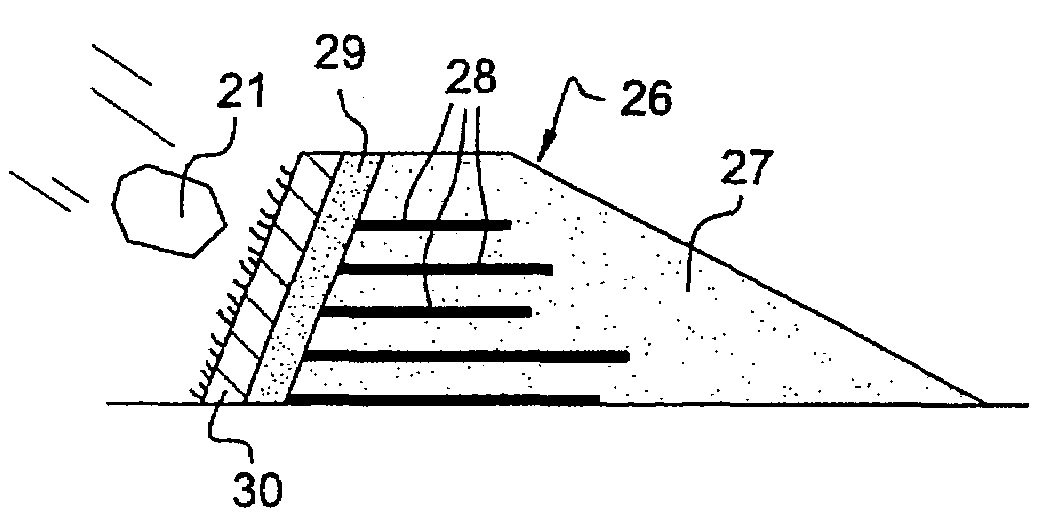

Side slope rockfall cushioning and protection system

The invention relates to a side slope rockfall cushioning and protection system. The side slope rockfall cushioning and protection system is formed by laminating a plurality of protection layers, and each protection layer is divided into two units, namely one passive protection unit and one energy-reducing buffer unit. The quantity of the protection layers is determined according to the oblique length of a side slope, a net distance between two adjacent protection layers is 20m to 25m, and a net distance between the passive protection unit and the energy-reducing buffer unit in the same protection layer is 8m to 10m. A first passive protection unit in the passive protection units consists of a steel-column supporting structure, a cat anchor structure, a continuous protection net and a detachable-type protection net; from the second protection layer, each passive protection unit consists of a steel-column supporting structure, a cat anchor structure and a continuous protection net; each energy-reducing buffer unit consists of a triangular supporting structure and high-elasticity meshes. By adopting the slope rockfall cushioning and protection system, the falling energy of the side slope rockfall can be reduced, the impact force of the rockfall for the protection net can be reduced, the accumulation problem of the rockfall in the system can be effectively solved, the consumption amount of materials is greatly reduced, and the engineering construction cost is reduced.

Owner:CHINA THREE GORGES UNIV

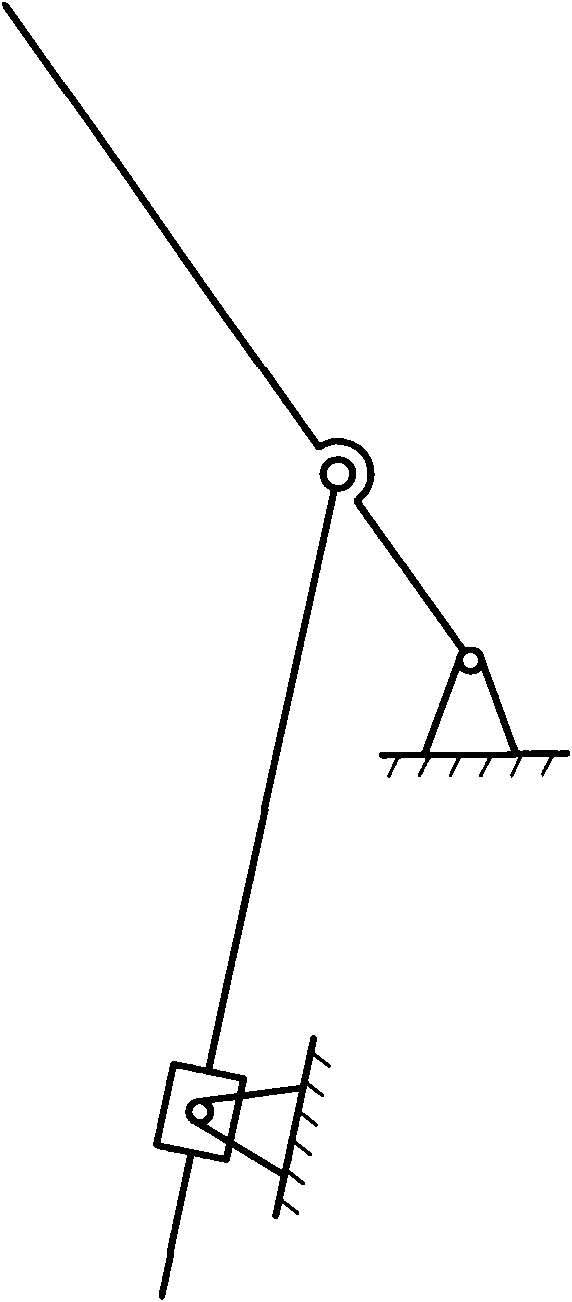

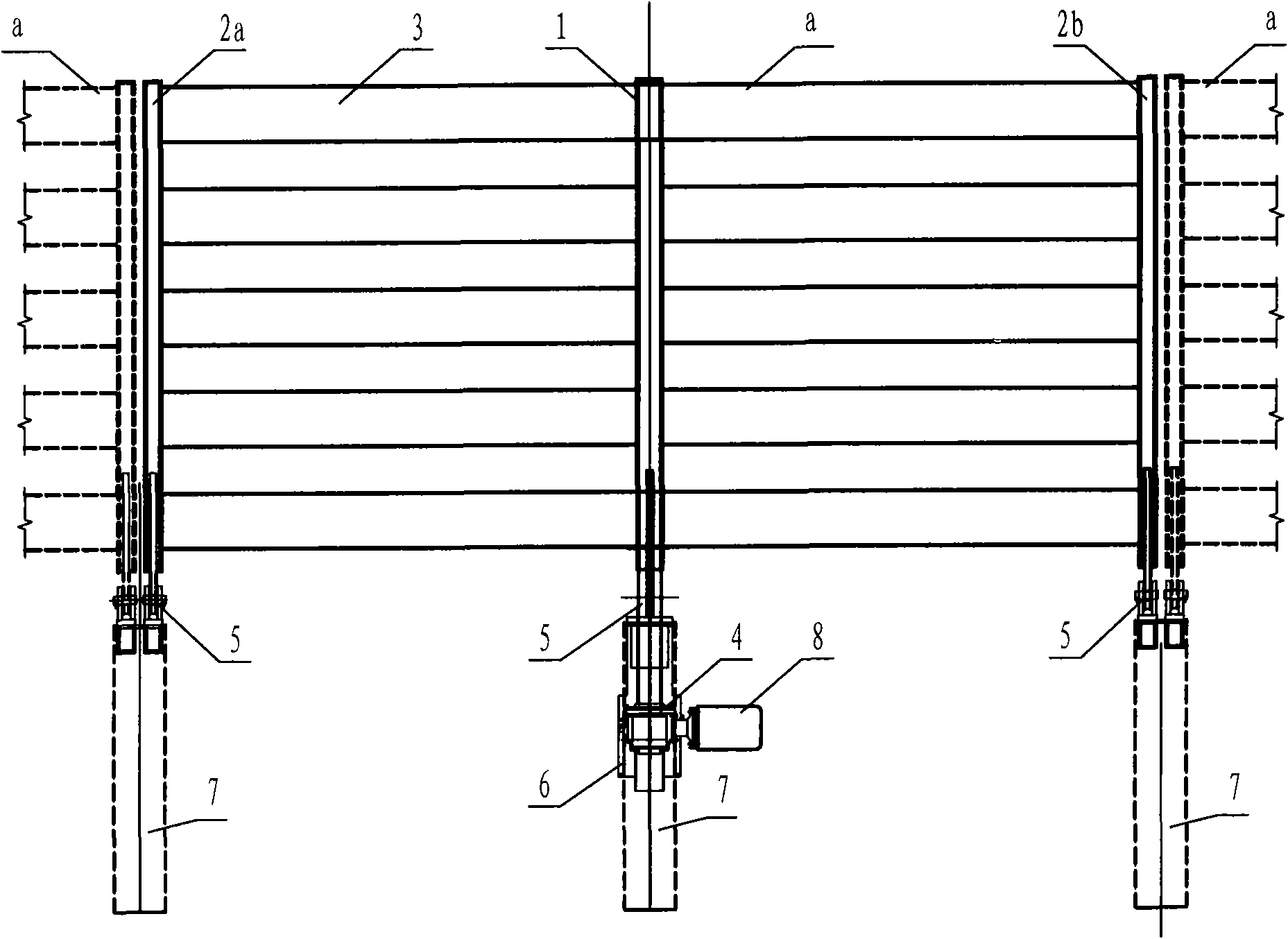

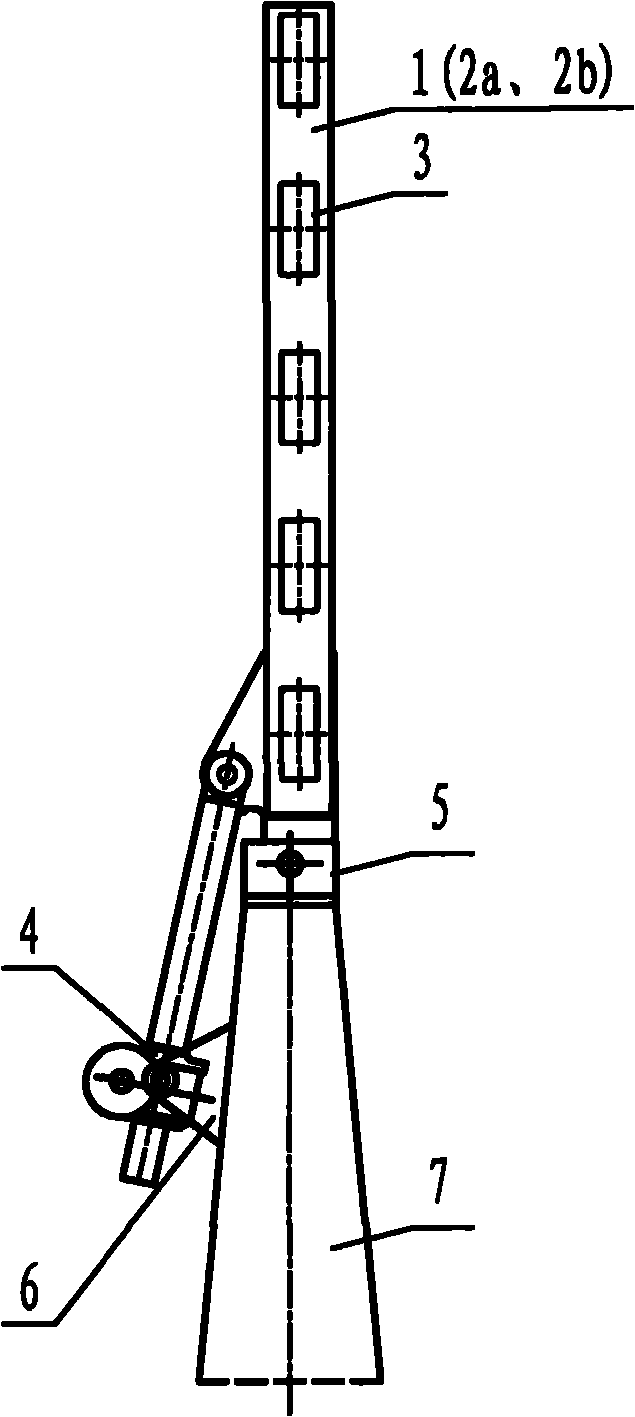

Movable windbreak for bridge

ActiveCN101864740AGood lookingClear actionProtective constructionBridge structural detailsWindbreakBridge deck

The invention discloses a movable windbreak for a bridge, and relates to a bridge technology. The movable windbreak comprises a plurality of movable windbreak units which are sequentially and linearly arranged along the bridge towards both sides of the bridge floor, wherein each movable windbreak unit comprises a movable windbreak face, a special driving mechanism, a bracket and a base. The movable windbreak for the bridge can effectively ensure the driving safety on the bridge under crosswind conditions, raise the ambient wind speed for driving on the bridge, effectively ensure the wind resistance safety of a major bridge structure after the windbreak is arranged, and effectively lower the cost of the major bridge structure in the aspect of wind resistance design.

Owner:CCCC HIGHWAY CONSULTANTS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com