Energy-dissipating hangar tunnel and energy-dissipating supporting base thereof

An energy dissipation and shed tunnel technology, applied in the field of shed tunnels, can solve the problems of increasing the impact resistance of shed tunnels, increasing the construction cost of shed tunnels, and difficult construction of shed tunnels, and achieving the effects of light weight, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

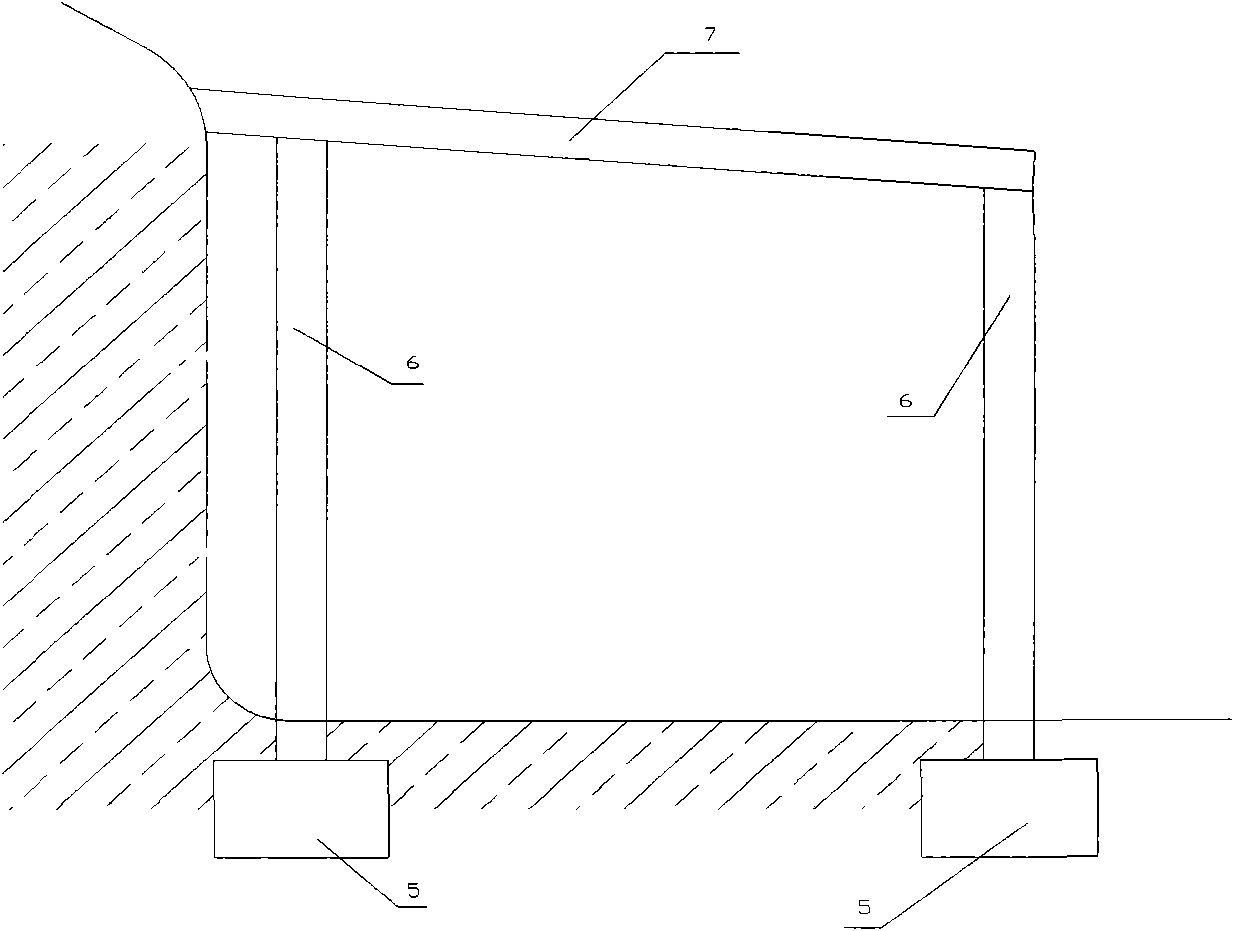

[0012] Embodiment 1 The structure of the energy-dissipating shed

[0013] attached figure 2 The cross-sectional schematic diagram of the energy dissipation shed hole, as can be seen from the figure, the energy dissipation shed hole includes pile foundations, pillars and protective sheds, and an energy dissipation support is arranged between the pillars and the protective shed. The setting of the energy-dissipating support enables the huge energy of dangerous rocks and falling rocks to be absorbed by the energy-dissipating support, which reduces the impact on the pillars and pile foundations, and improves the impact resistance of the pillars and pile foundations.

Embodiment 2

[0014] Embodiment 2 Structure of Energy Dissipating Support

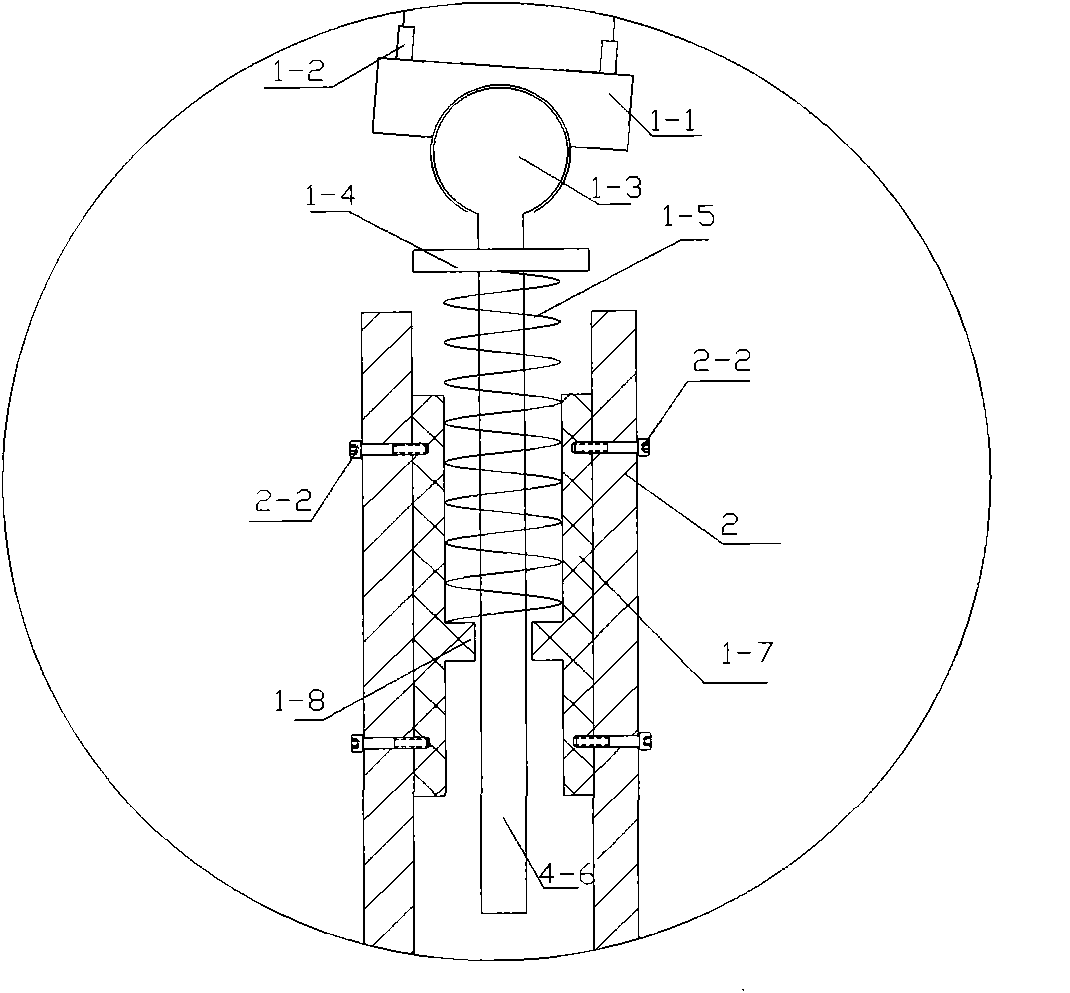

[0015] attached image 3 Schematic diagram of the structure of the energy dissipation support. It can be seen from the figure that the structure of the energy dissipation support from top to bottom is: rotating top plate connecting plate 1-1, connecting bolt 1-2, steel ball tenon 1-3, spring 1-4, The load transfer bracket 1-5, the spring guide rod 1-6 and the load transfer steel plate 1-7; the load transfer steel plate 1-7 is a cylindrical structure with an annular positioning ring 1-8 inside.

[0016] Among them, the load-transmitting steel plate 1-7 is fixed on the inner side of the pillar 2 by the bolt 2-2, and the spring guide rod 1-6 passes through the middle section of the load-transmitting steel plate 1-7 and is defined as the ring 1-8 along the middle of the load-transmitting steel plate 1-7. The axis moves up and down, the spring guide rod 1-6 is covered with a spring 1-4, the lower end of the spring 1-4 i...

Embodiment 3

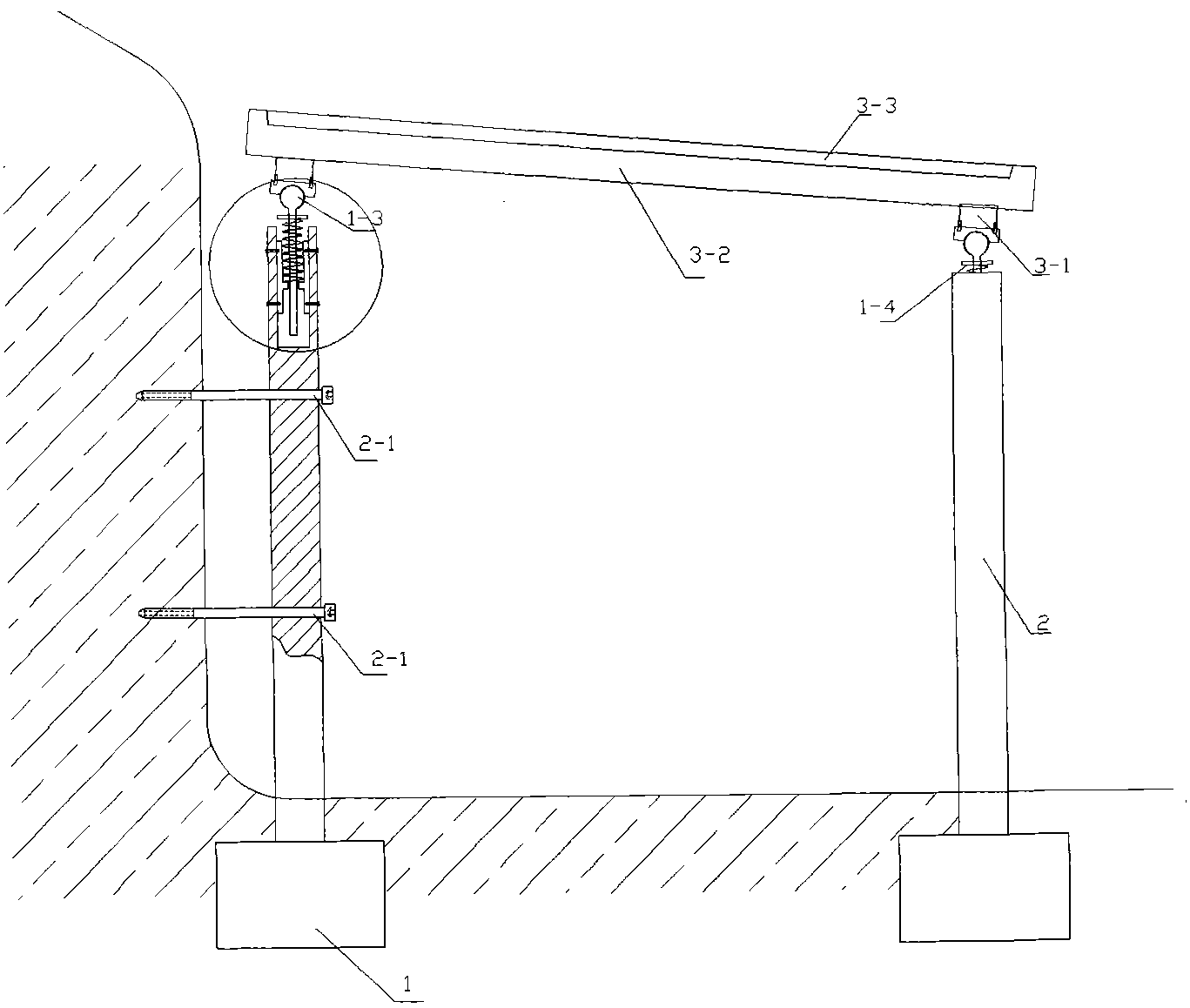

[0019] Embodiment 3 Installation of energy dissipation shed hole and its energy dissipation support

[0020] attached Figure 4 The three-dimensional schematic diagram of the installation of the energy-dissipating shed and the energy-dissipating support. It can be seen from the figure that the installation of the energy-dissipating shed and its energy-dissipating support includes the following steps: measure the terrain, determine the position of the pile foundation on both sides of the road along the road extension direction, Excavate the foundation and pour the pile foundation 1 on site or fill the prefabricated pile foundation 1 .

[0021] Install prefabricated columns 2 or cast-in-place columns 2 on the pile foundation, the height of a row of columns 2 near the mountain side is higher than that of the row of columns 2 on the other side, and reserve anchor rods on the row of columns 2 near the mountain side 2-1 guide hole; through the anchor rod guide hole 2-3 reserved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com