Patents

Literature

227results about How to "Increase span" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

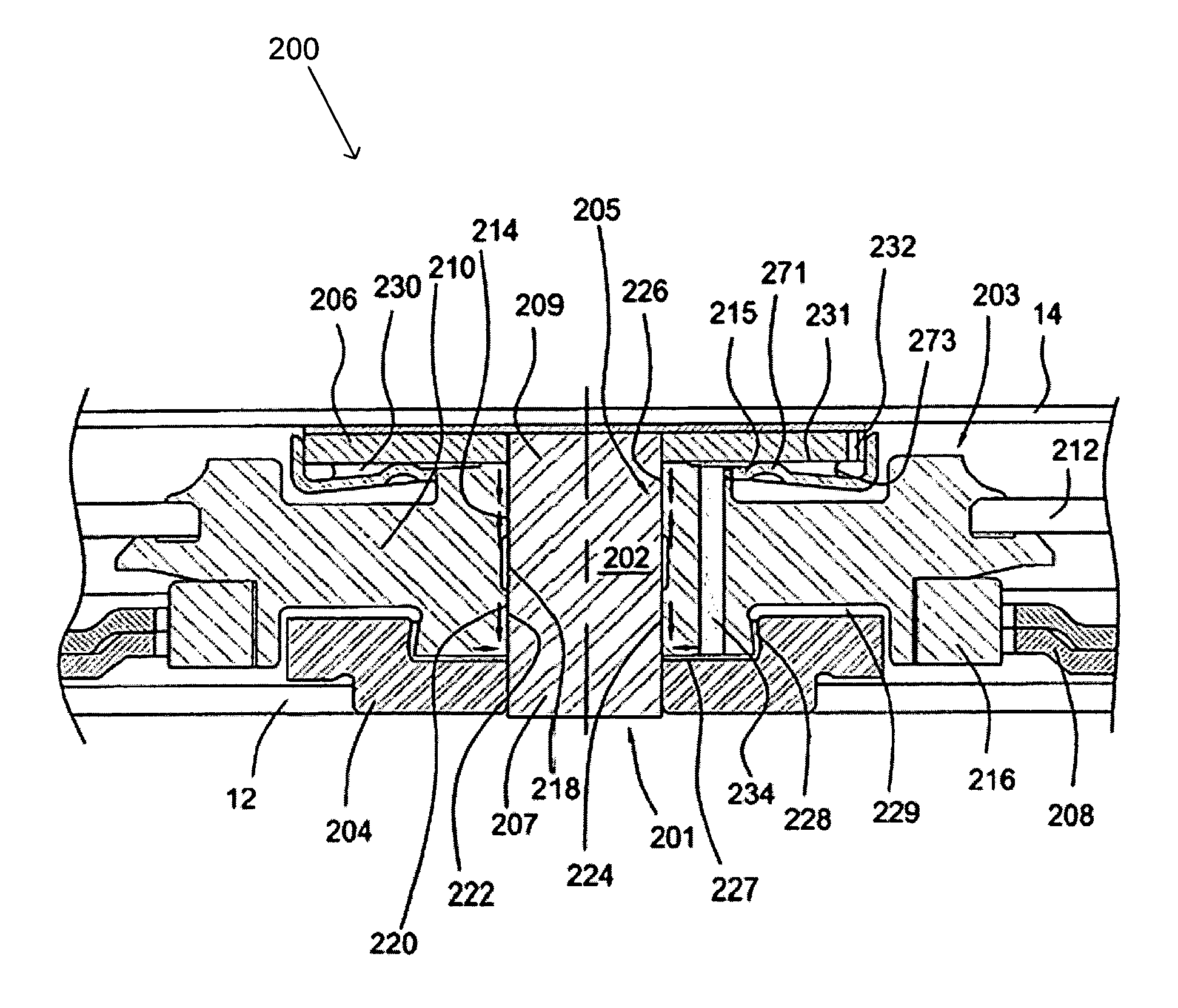

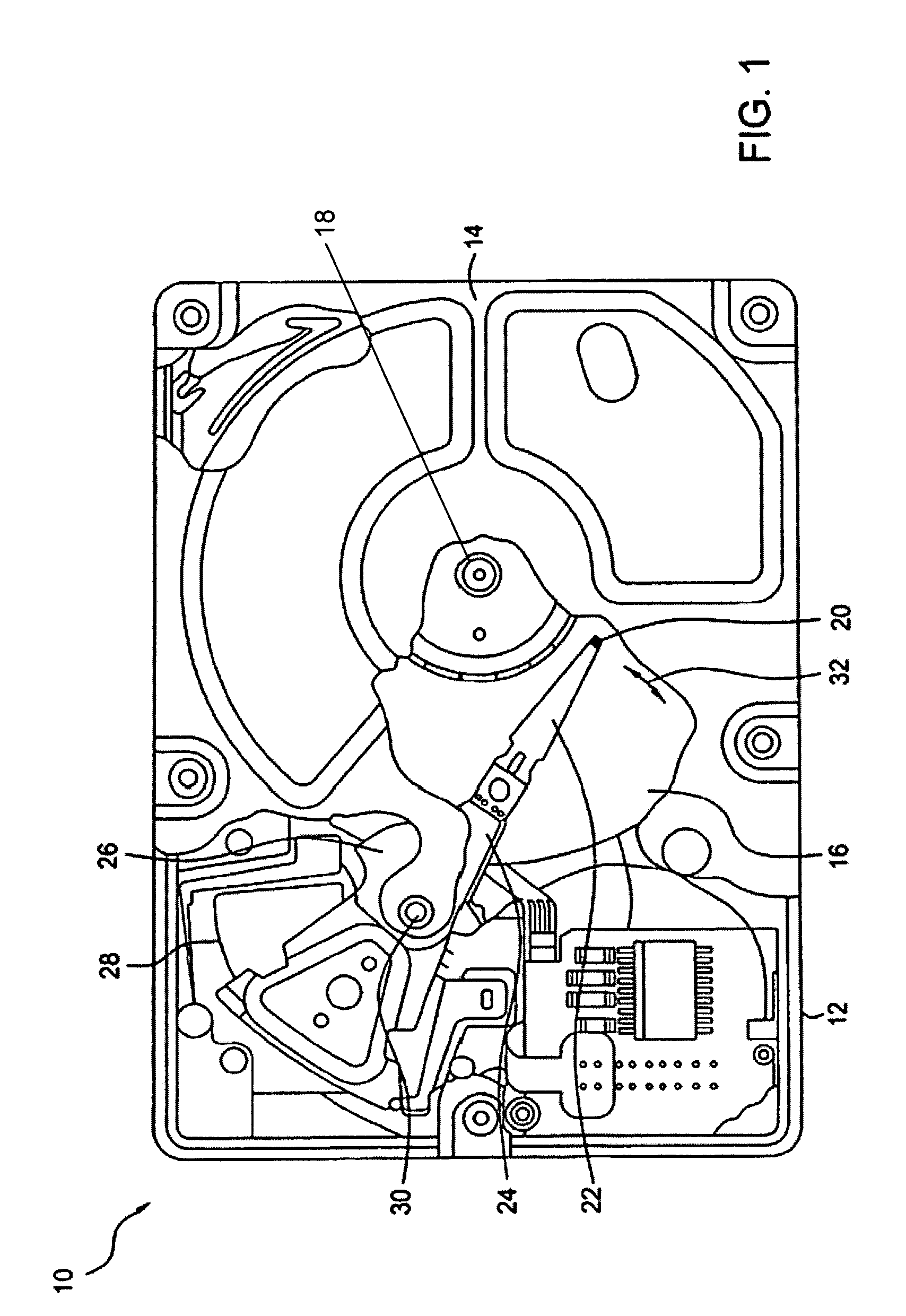

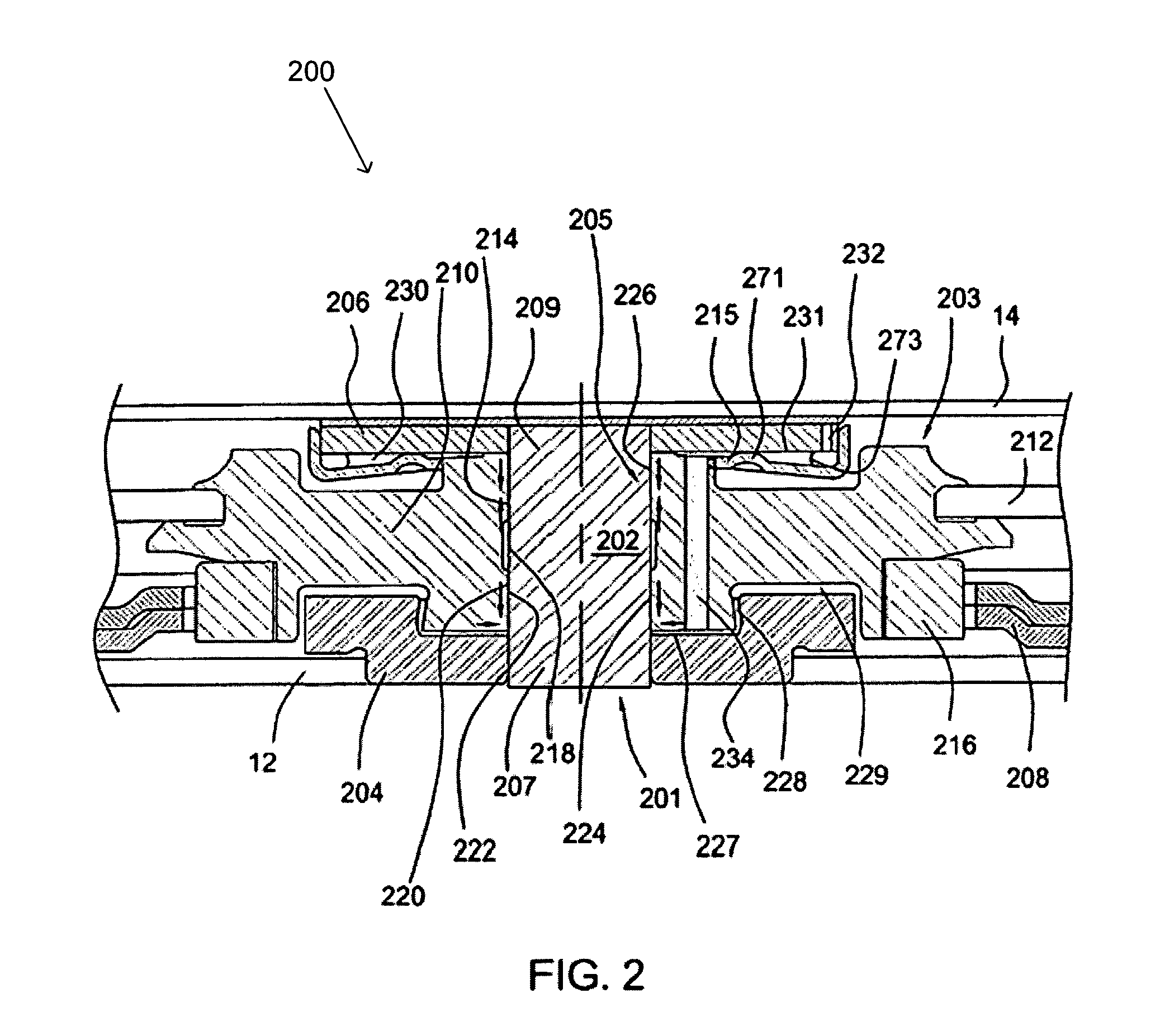

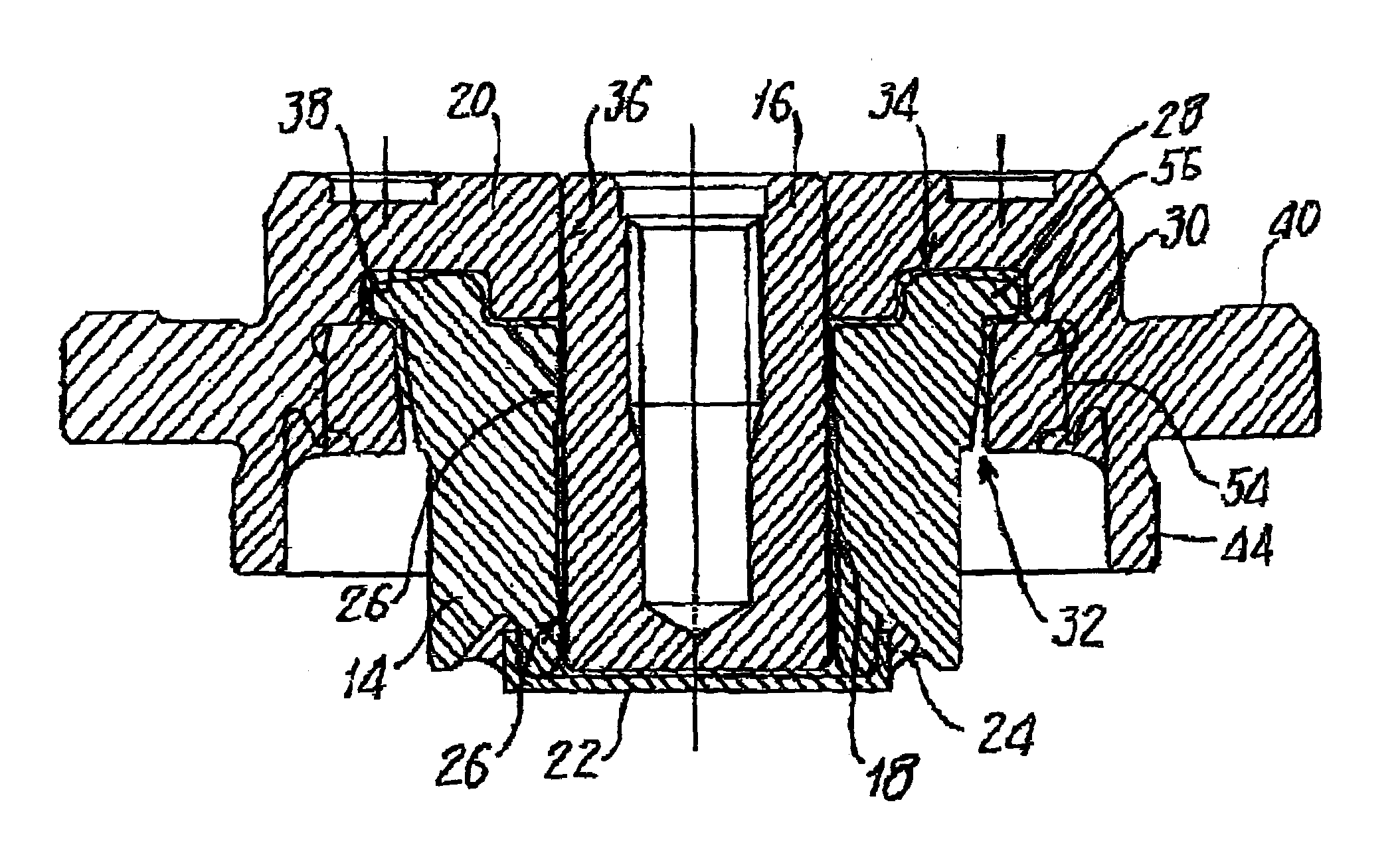

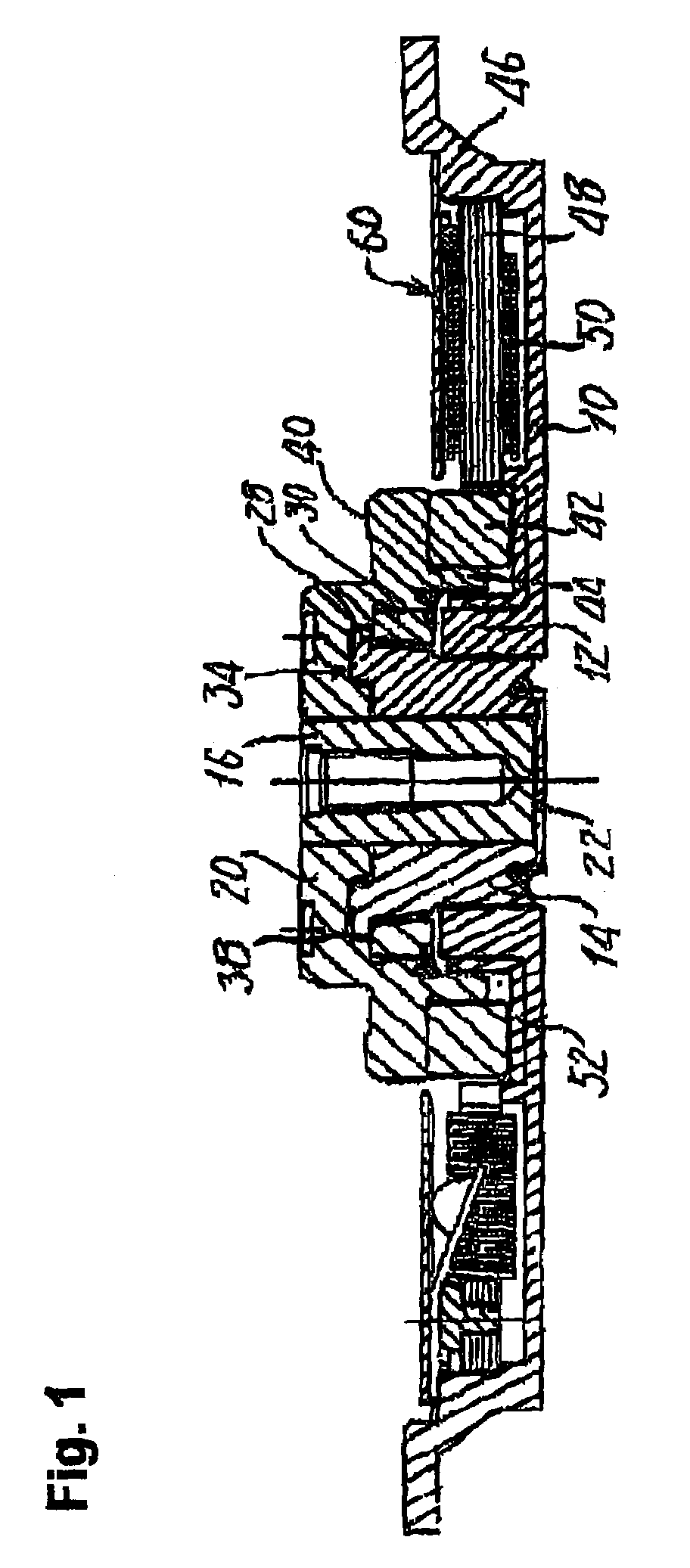

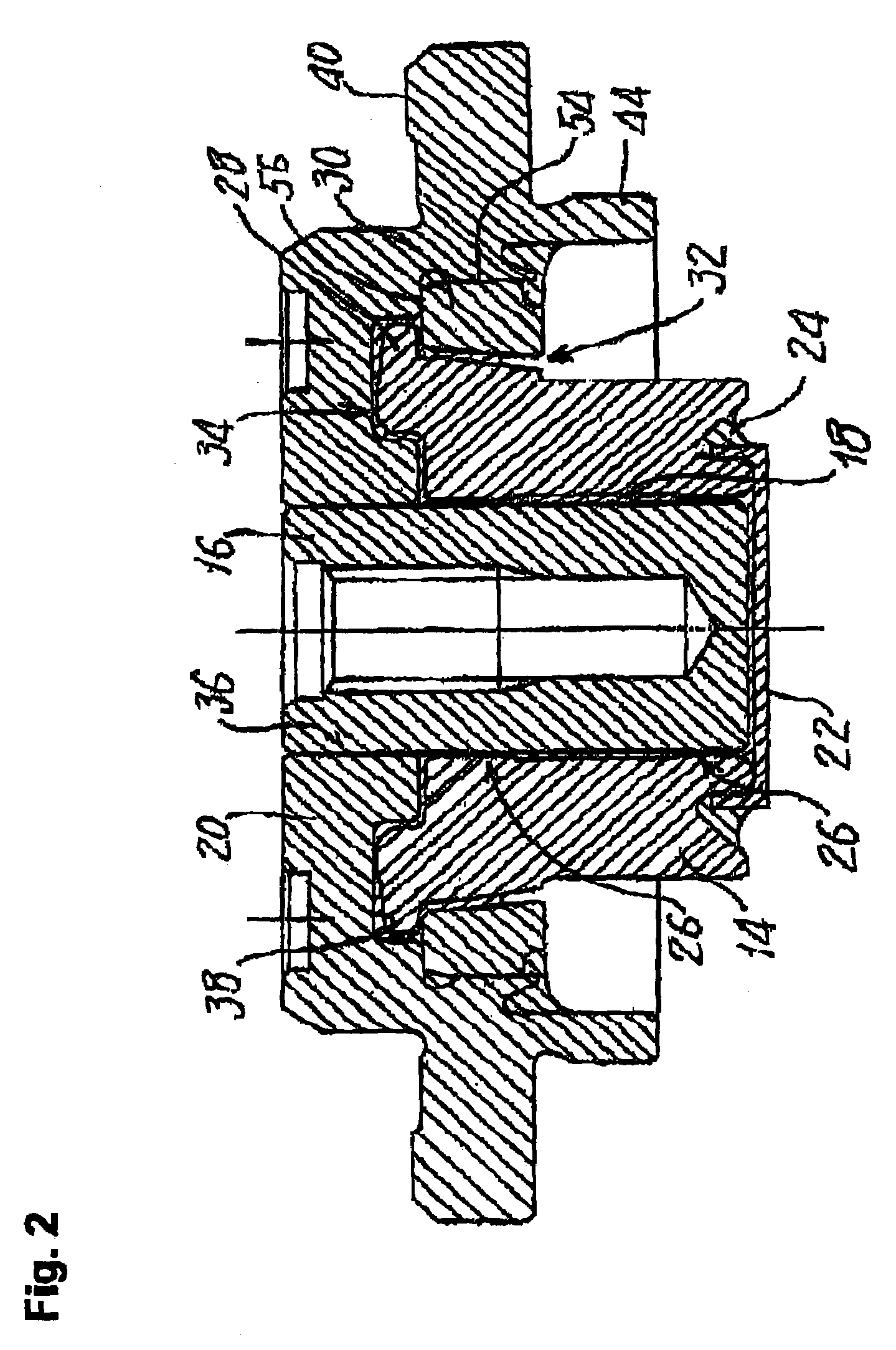

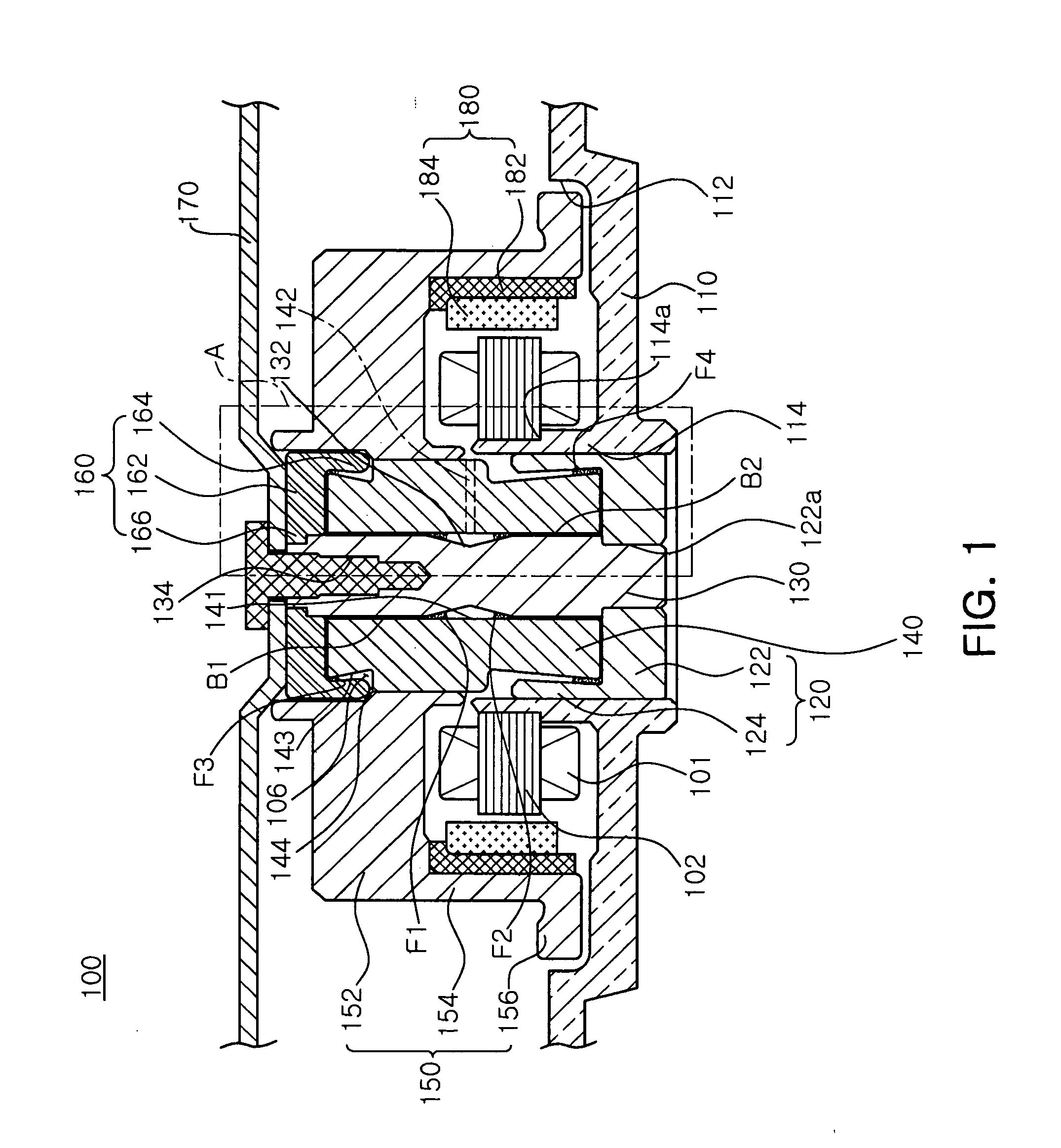

Low profile fluid dynamic bearing motor having increased journal span

InactiveUS6991376B2Reduce dependenceIncrease stiffnessBearing assemblyShaftsEngineeringElectric motor

Owner:SEAGATE TECH LLC

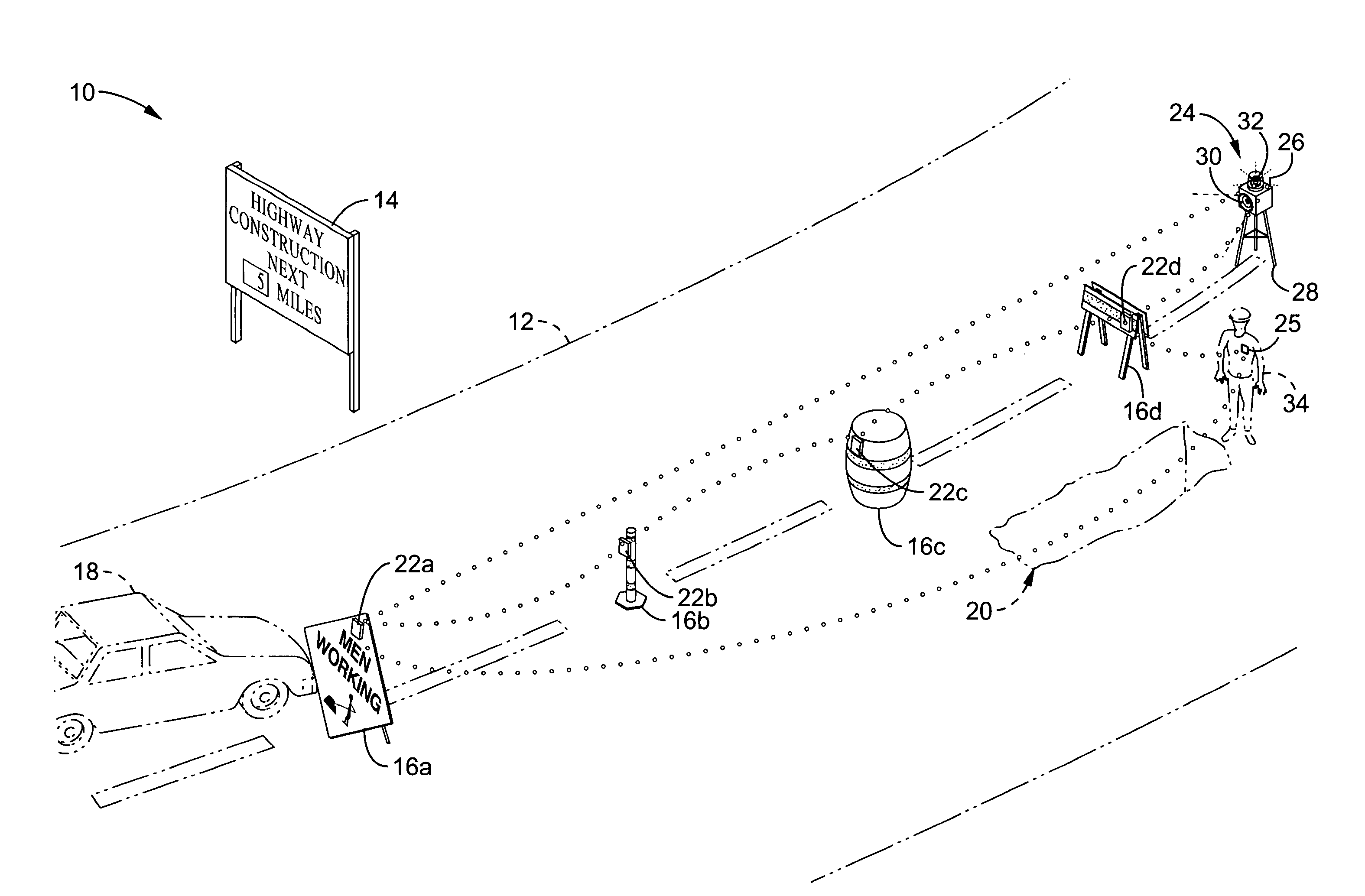

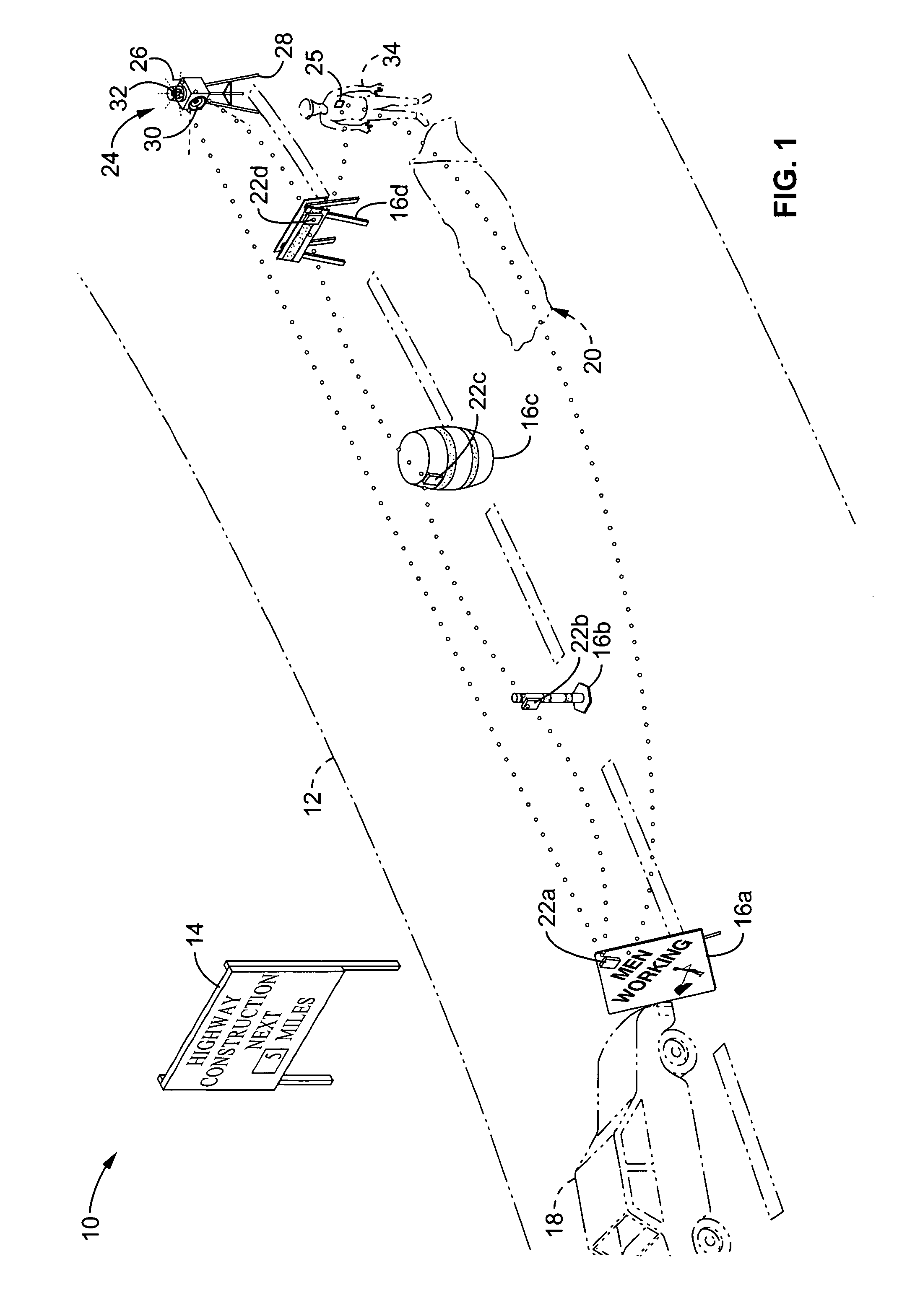

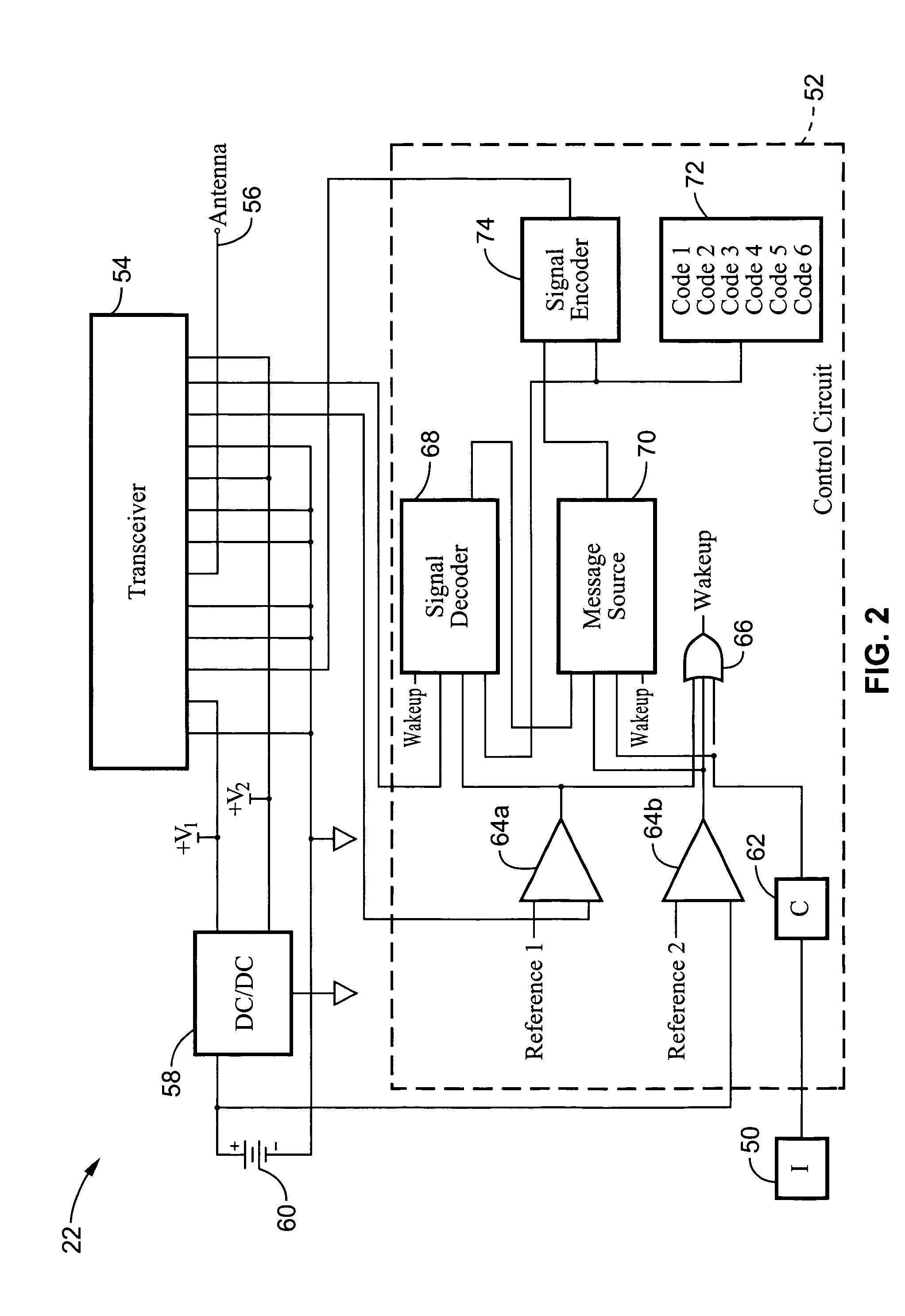

Roadway incursion alert system

InactiveUS7230546B1Increase rangeIncrease spanPortable emergency signal deviceDetection of traffic movementEngineeringBiological activation

An apparatus and method for generating incursion alerts in response to incursion events detected by incursion detector units, attached to safety icons such as traffic cones and signage. The incursion detector units are activated by automatic activation sensors and remain activated for a period of time. Alerts are generated in response to impacts detected at the safety icons by an incursion detector and transmitted to one or more incursion receiver units which annunciate the alert with audio, lights, or tactile output to warn personnel of possibly impending danger. Alert signals are preferably repeated by other incursion detectors wherein the distance and conditions over which the alert signals may be communicated is extended. A validation circuit and tilt sensor filter out not incursion events such as wind tipping. The incursion detectors may generate area alerts, or personal alerts and can transmit operational status and alerts to discrete groups of receivers.

Owner:LOGIC SYST

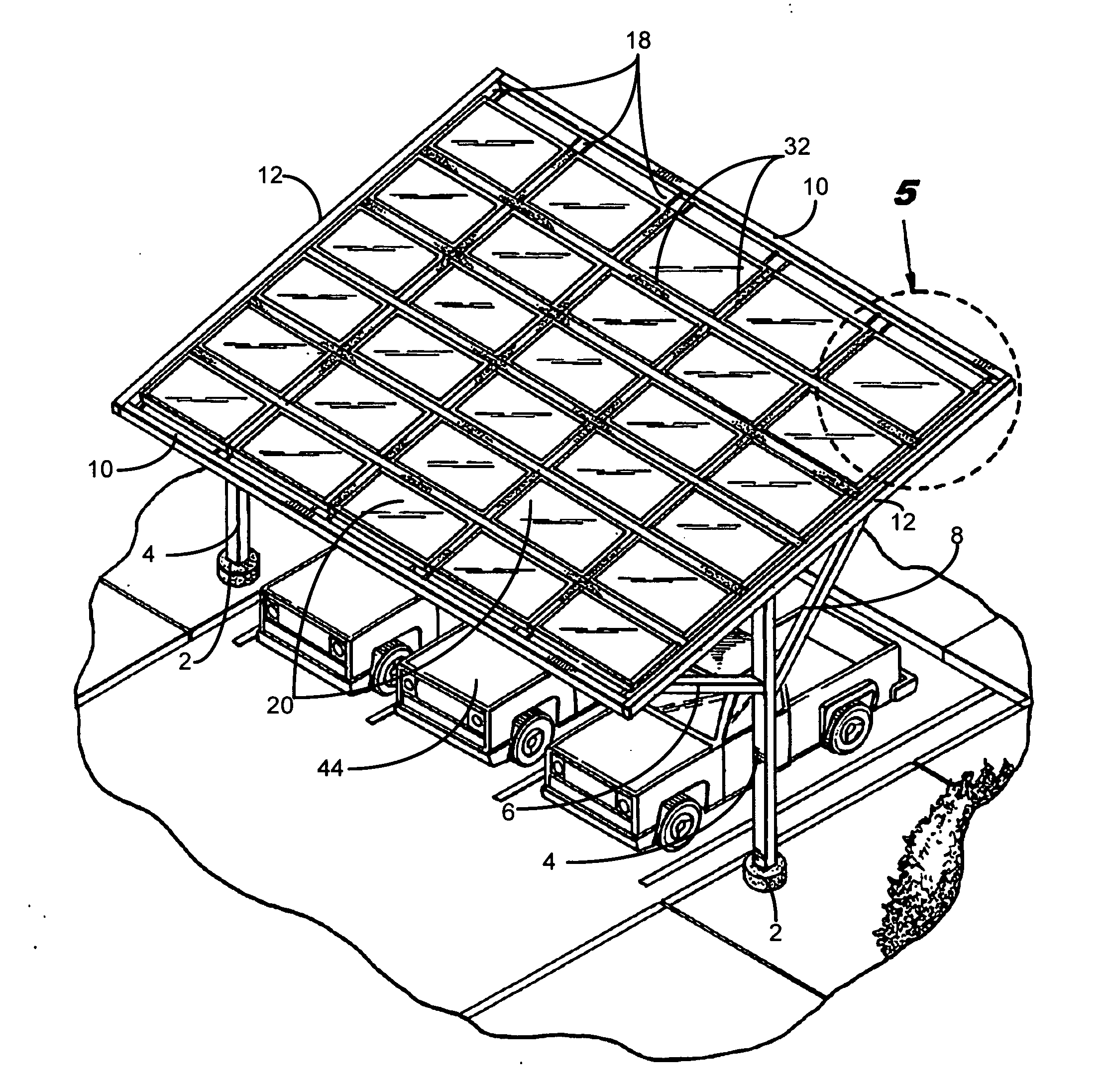

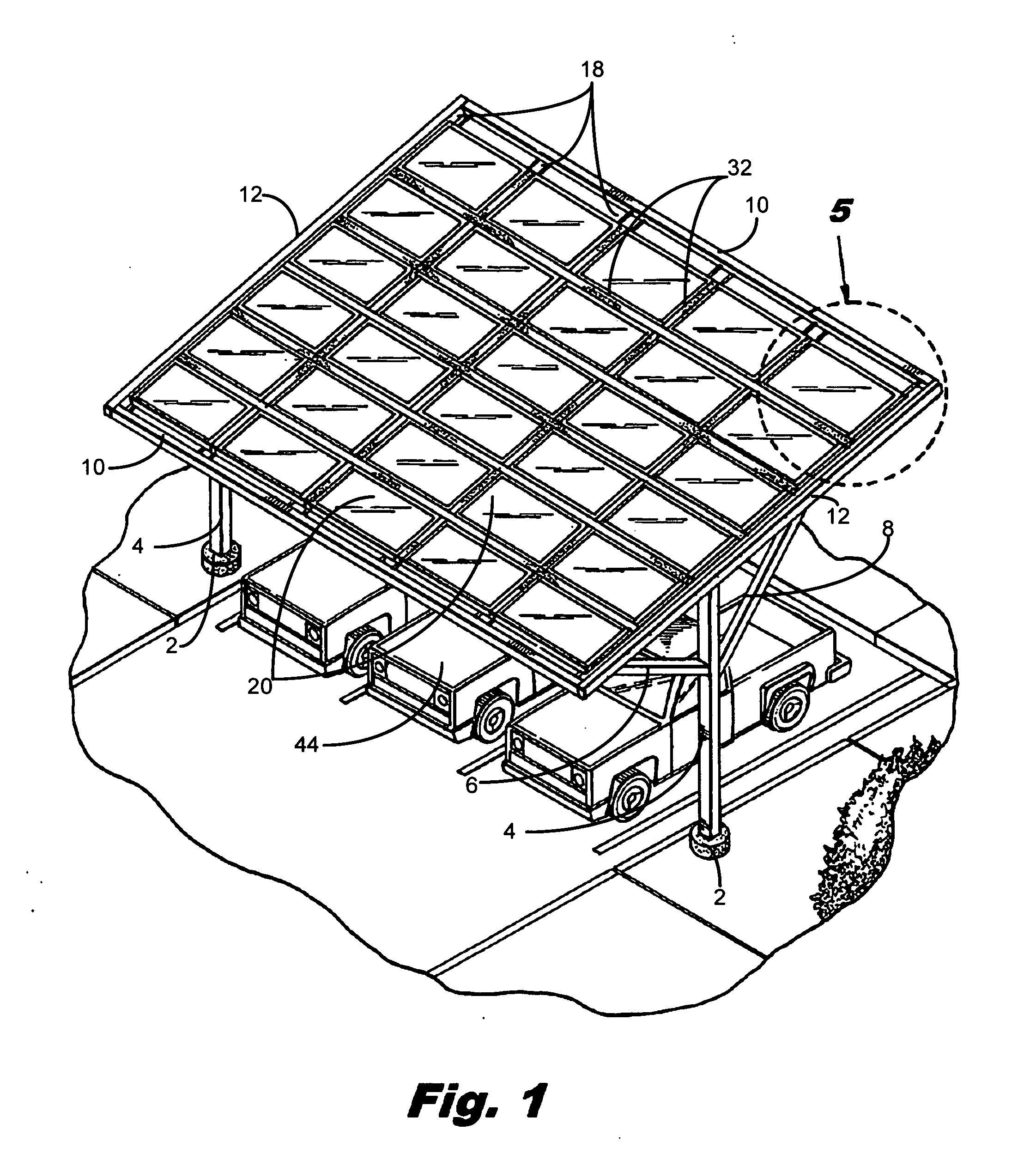

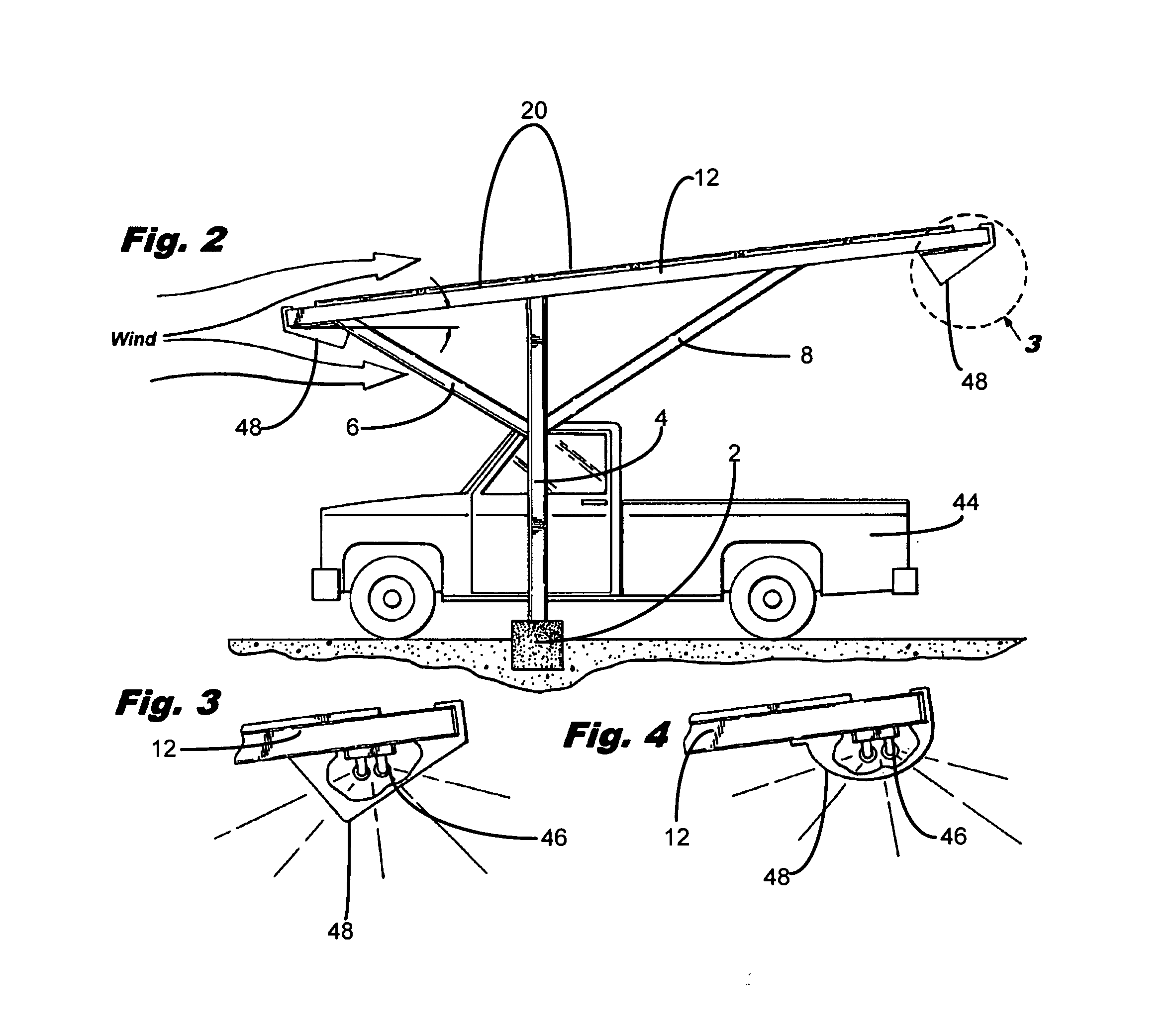

Cabled matrix for cantilevered photovoltaic solar panel arrays, apparatus and deployment systems

InactiveUS20110290305A1High strength-to-weight ratioProlong lifePhotovoltaic supportsSolar heating energyDistal portionCoupling

A cable reinforced matrix to support a solar panel array comprising array bracing beams which define a perimeter including longitudinal array bracing beams and latitudinal array bracing beams with coupling apertures at various points along the latitudinal array bracing beams; cable couplings at opposite points along the latitudinal array bracing beams; cabling traversing the latitudinal array bracing beams; solar panels atop the cabling; longitudinal I-beams; latitudinal I-beams; interpanel I-beam(s); grommets along the cabling; grommet clips; grommet clip fasteners; panel fasteners; columns at either end of the longitudinal array bracing beams; a first cantilever support post extending from the column to the distal portion of the longitudinal array bracing beam; a second cantilever support post extending from the column to the proximal portion of the longitudinal array bracing beam; a footing at the bottom of each column; and dampening / stabilizing element(s) to mitigate vibration and uplift.

Owner:HOFFMANN STEVE +2

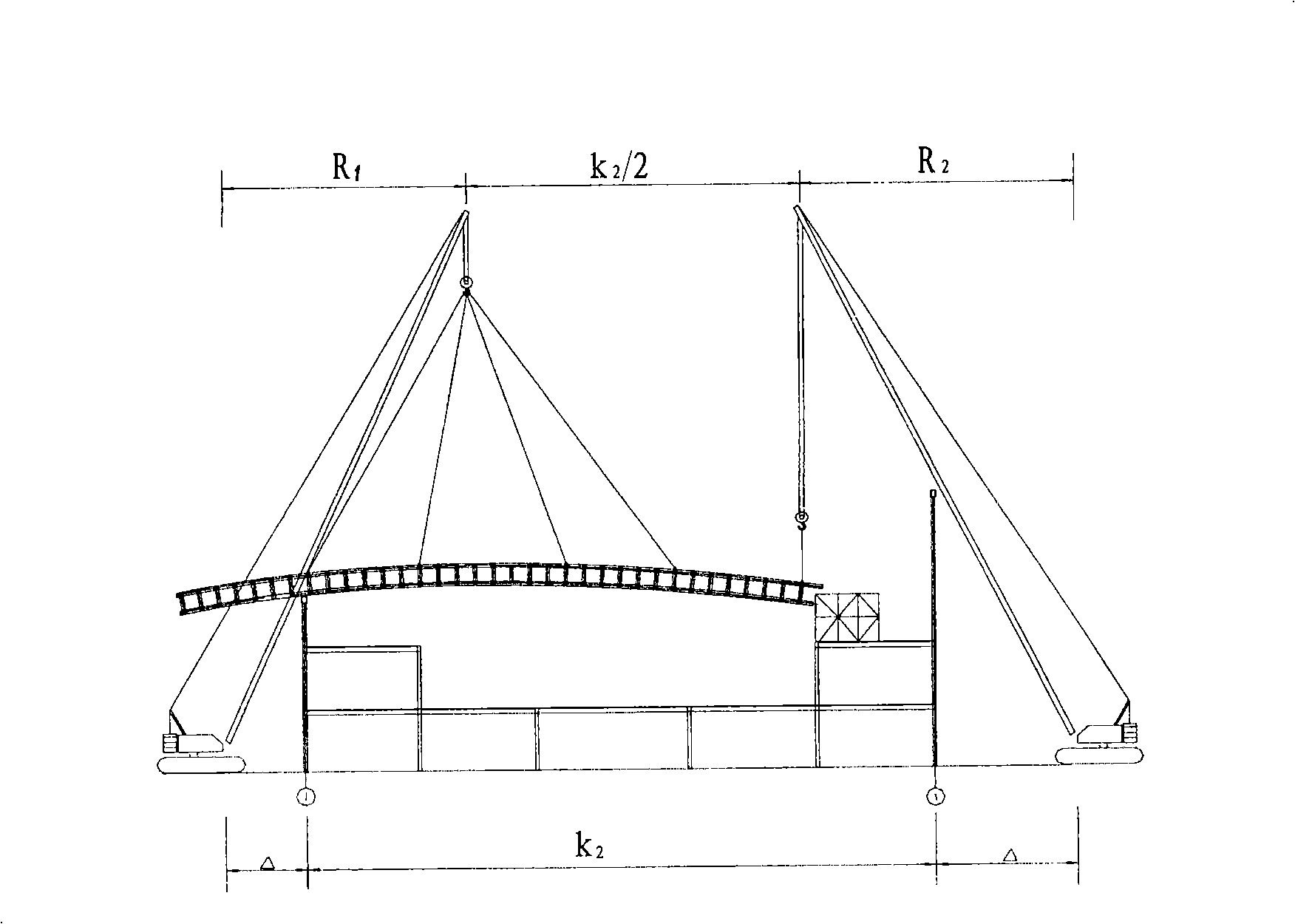

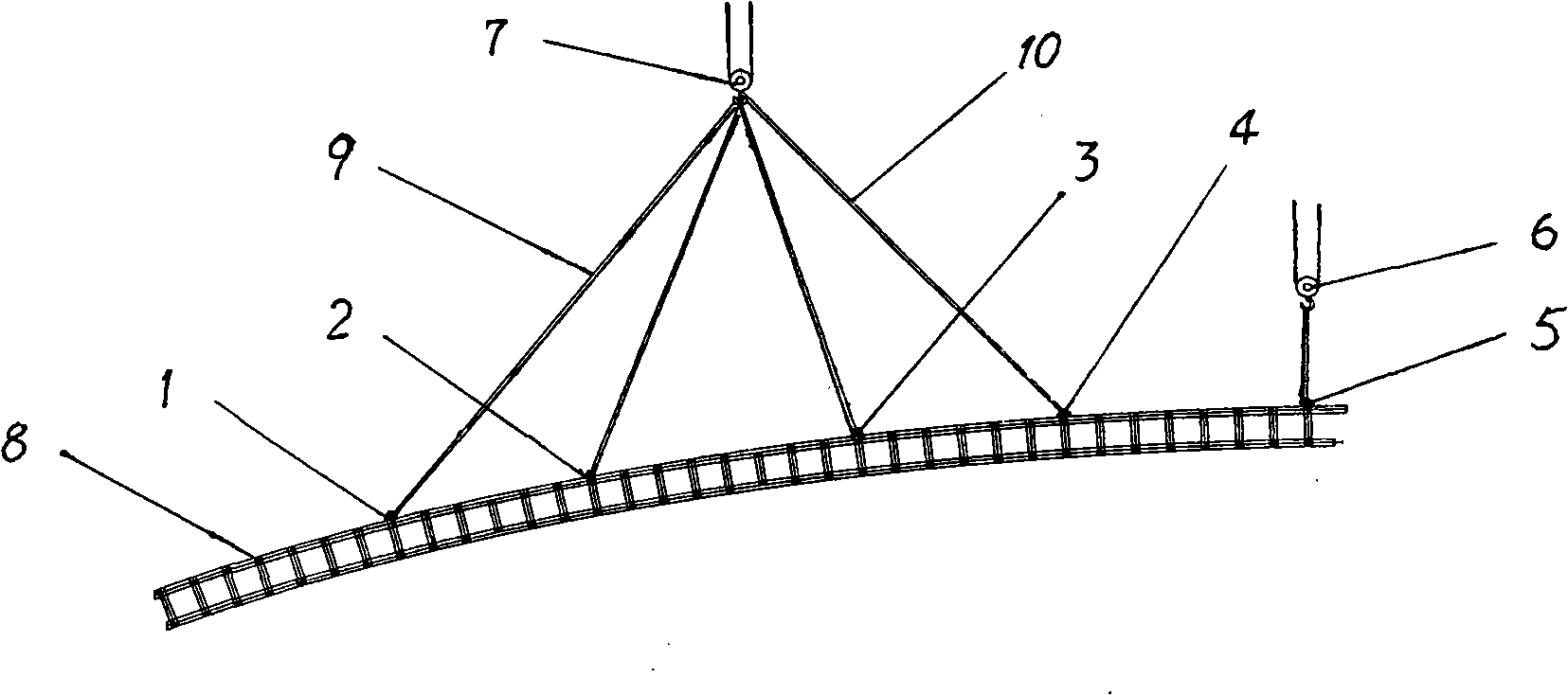

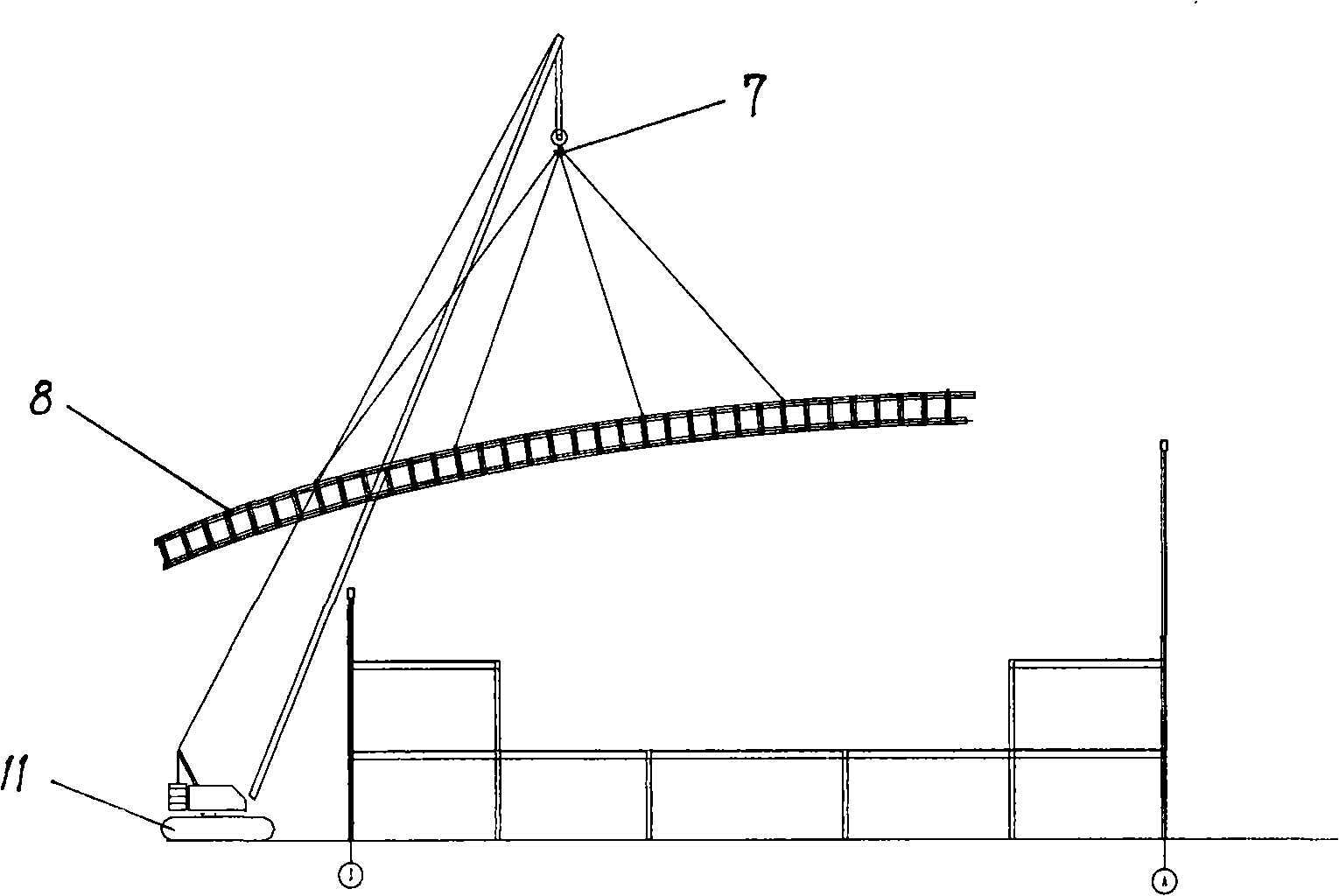

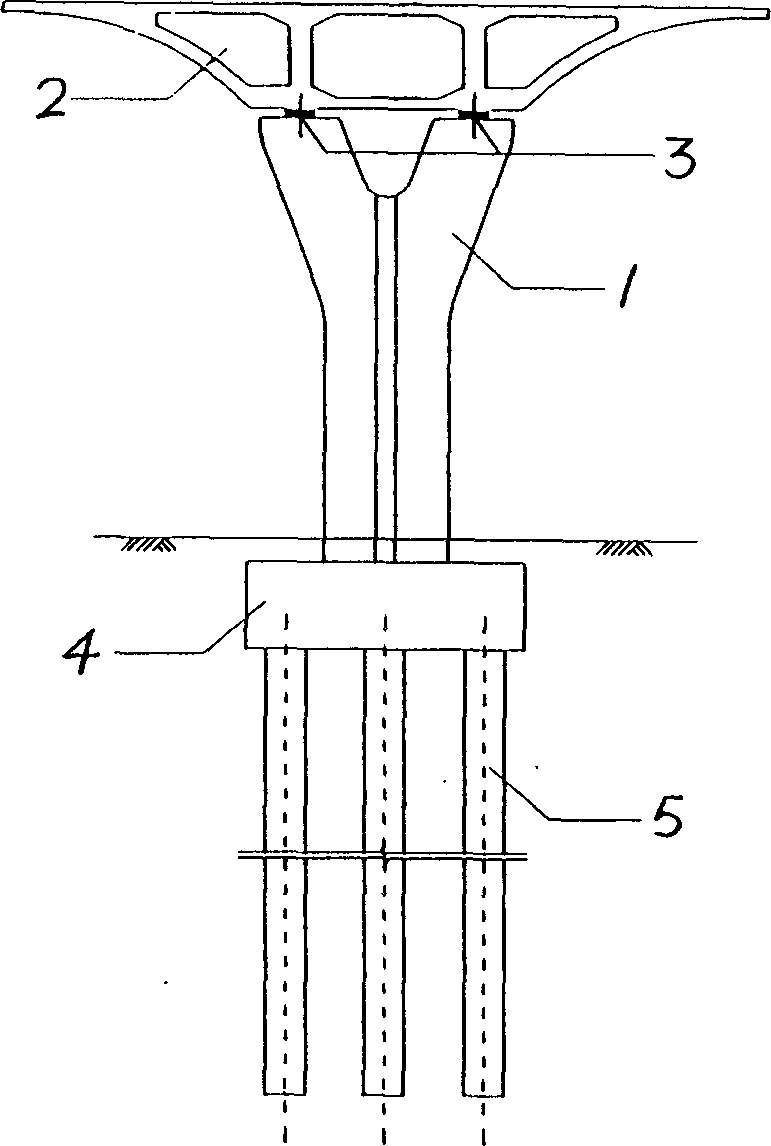

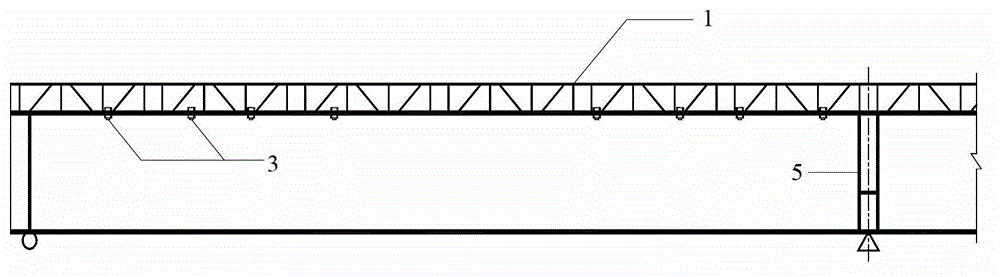

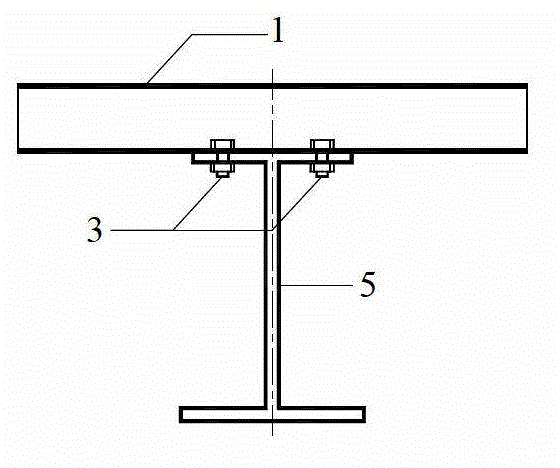

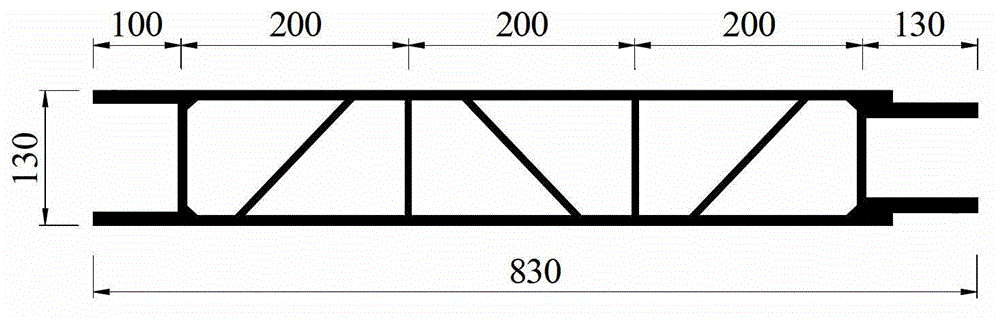

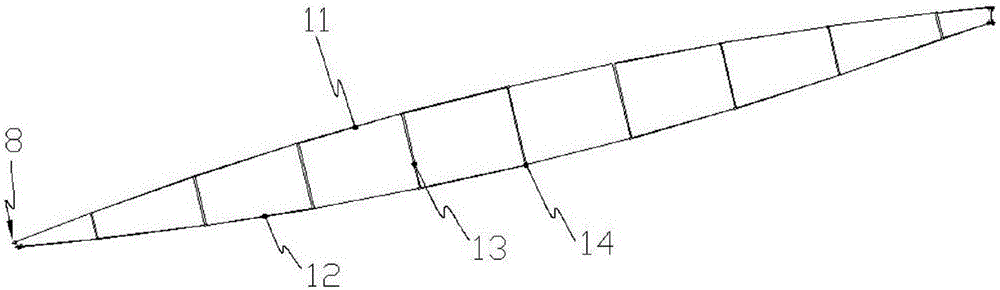

Construction method for hanging wide span arcuated open-web beam

InactiveCN101324146ASolve lifting problemsIncrease spanBuilding material handlingSpandrelStructural component

The invention relates to a large-span arc laced beam hoisting construction method used for constructing an ellipsoid roof. The method comprises the steps that a main crane hoists in a stand-alone way at one side beyond the span and delivers the laced beam to be within the span, one end of the laced beam is hoisted by an assistant crane beyond the span at the other side of a building, and dual-machine lifting and hoisting is formed by hoisting point shifting on the laced beam so as to jointly hoist and position the laced beam. The invention is a brand new dual-machine delivering lifting and hoisting construction method, and solves the hoisting problem of the large-span steel structure laced beam under special conditions that a construction field can not be provided within the span of the building, the dual-machine lifting and hoisting can not be carried out due to the obstruction of the running line of the cranes at the two sides of the building, and a gliding method can not be used for hoisting, etc., and the span of a hoisting structural component can be greatly improved, thus improving construction safety, guaranteeing construction quality and shortening construction period.

Owner:HEBEI CONSTR GRP

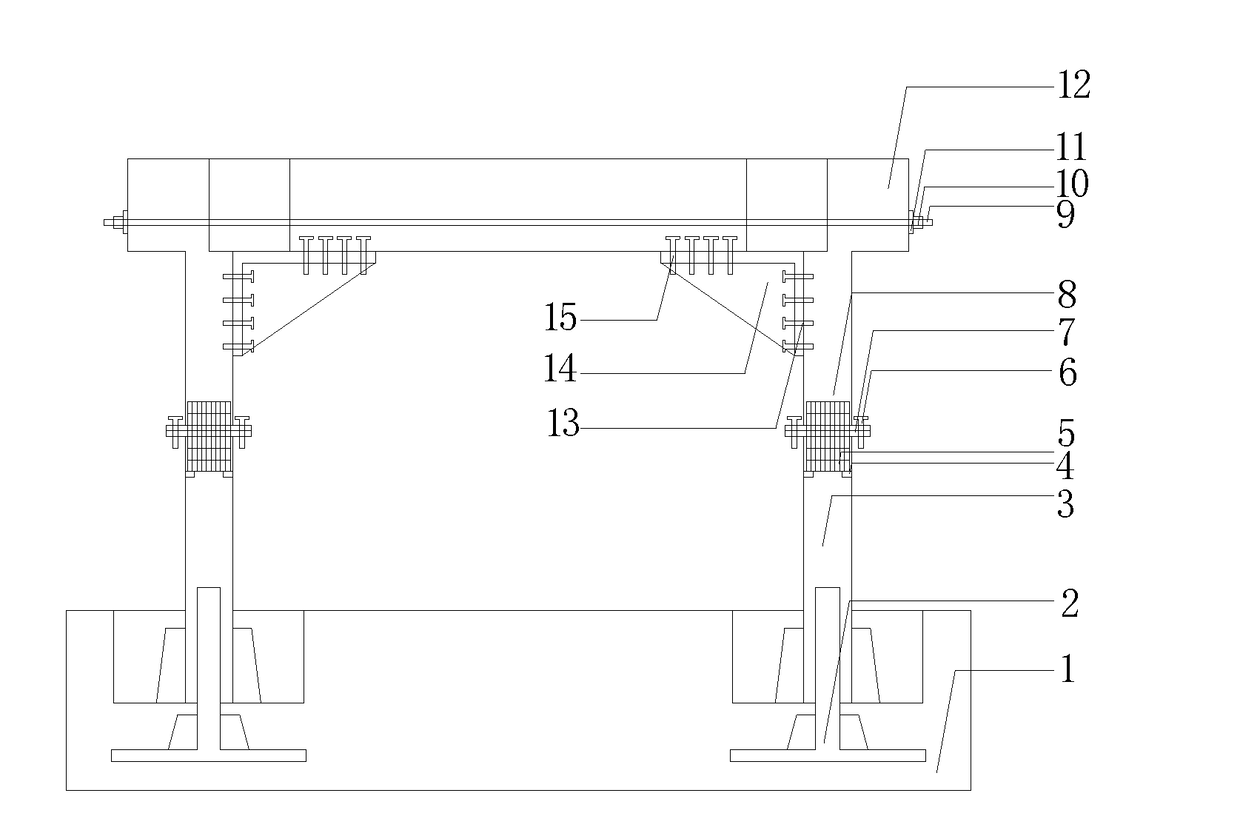

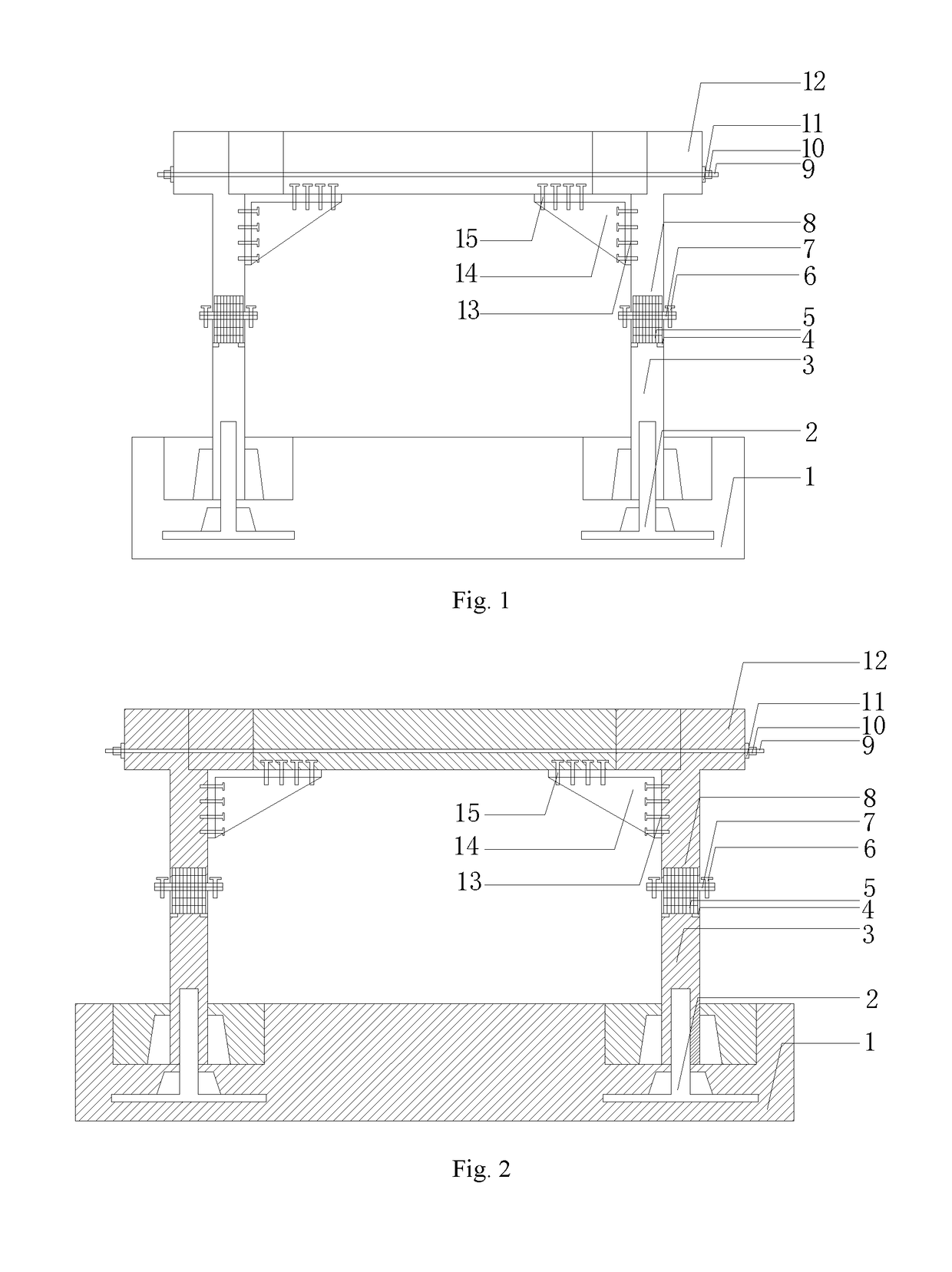

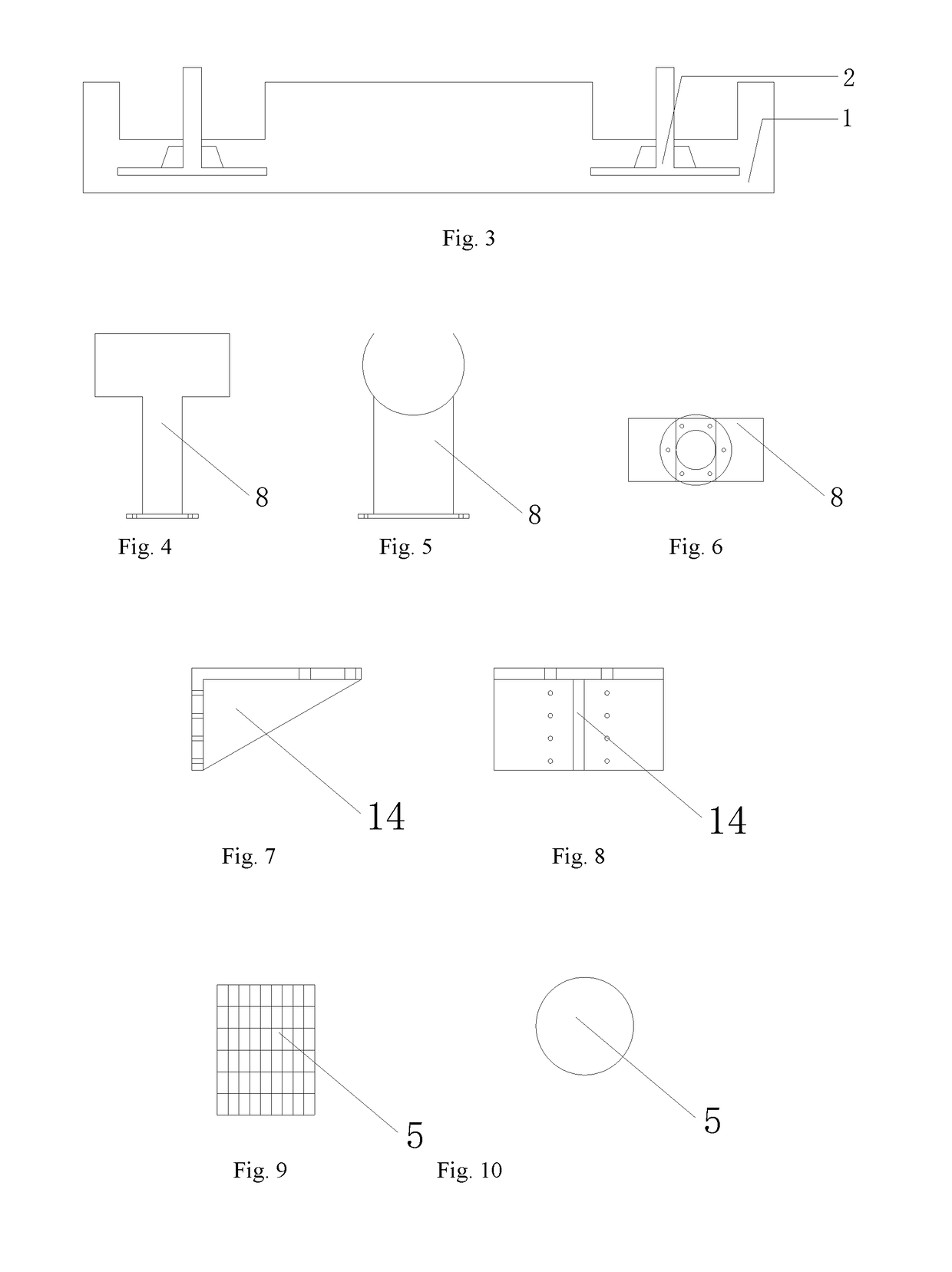

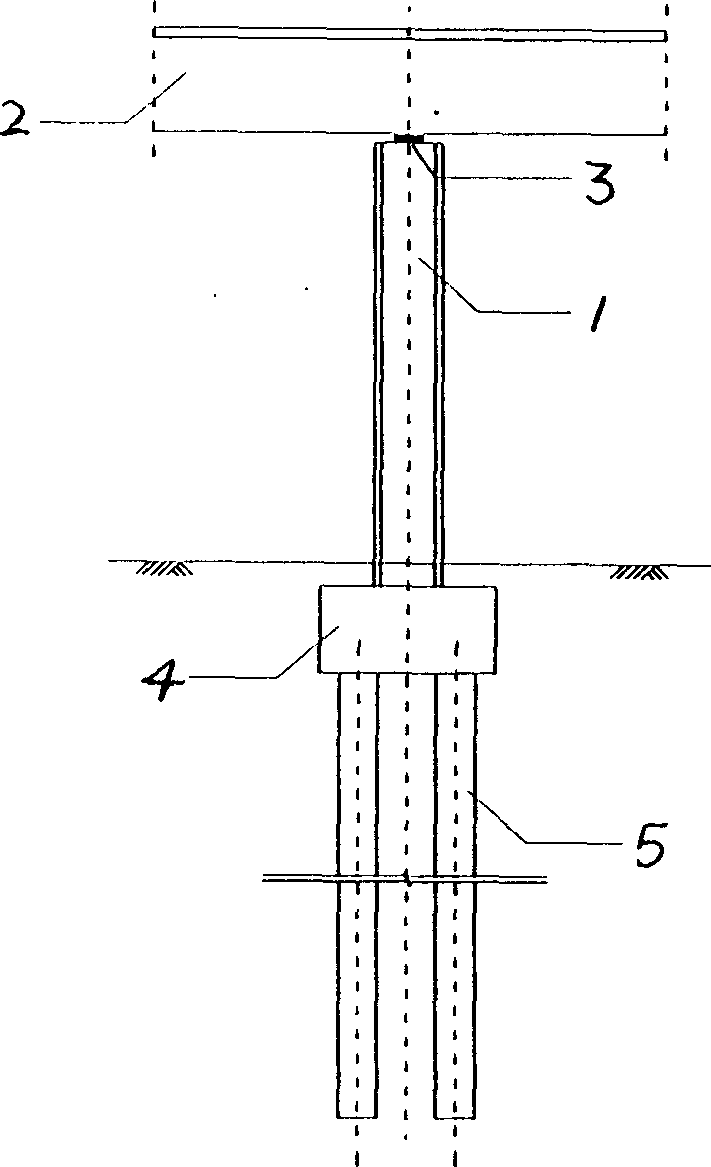

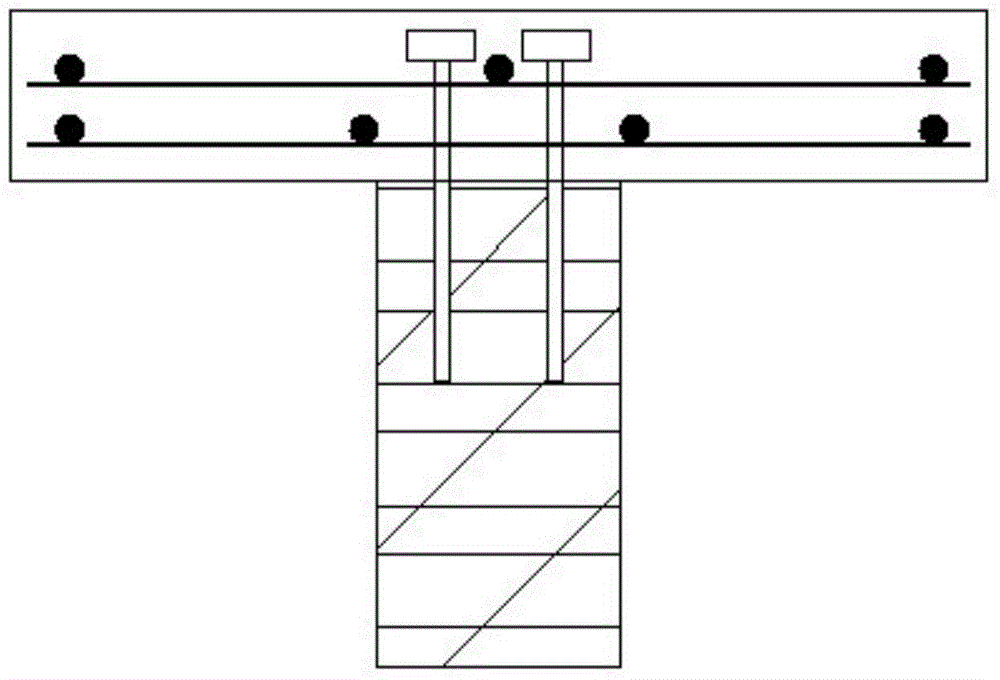

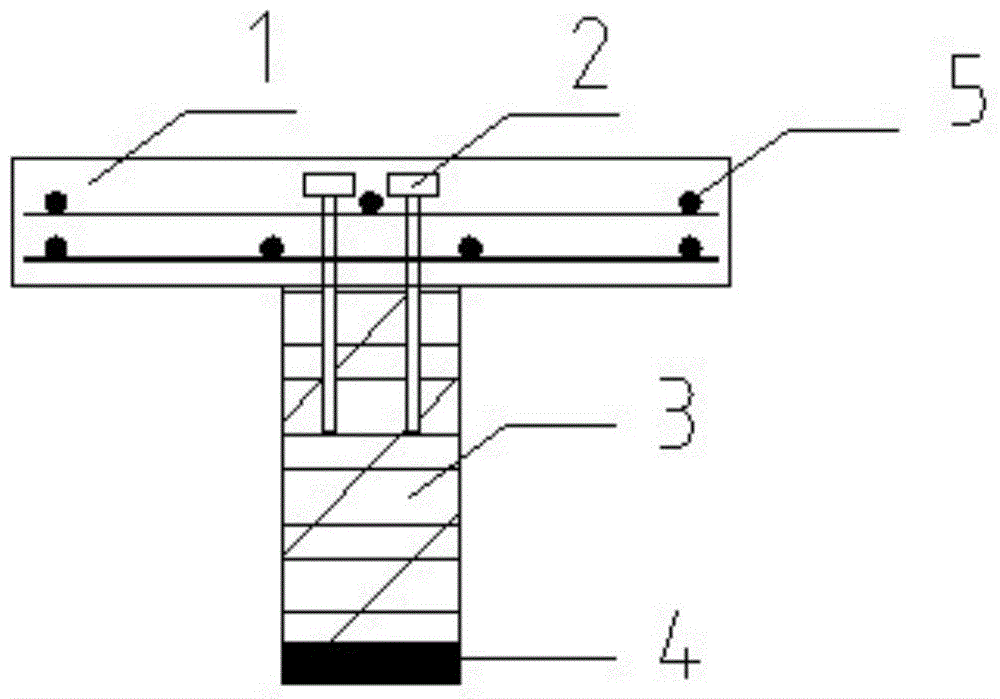

Assembled type pier column member with steel-concrete composite structure

InactiveUS20170356144A1Improve construction progressReasonable and convenient to constructBridge structural detailsBridge erection/assemblyPile capPre stress

A segment-assembled type pier column member with a steel-concrete composite structure includes a reinforcement tube embedded in a pile cap, wherein the reinforcement tube is connected with a bottom of a lower segment of a hollow steel tube pier and is poured with concrete, and pier columns in upper and lower segments are reinforced by means of segment connecting and being embedded with local reinforcing meshes. A steel cross beam is connected with an upper segment of the hollow steel tube pier in an assembled way. A pre-stressed tensioning duct is reserved between the steel cross beam and the pier column in the upper segment.

Owner:HOHAI UNIV

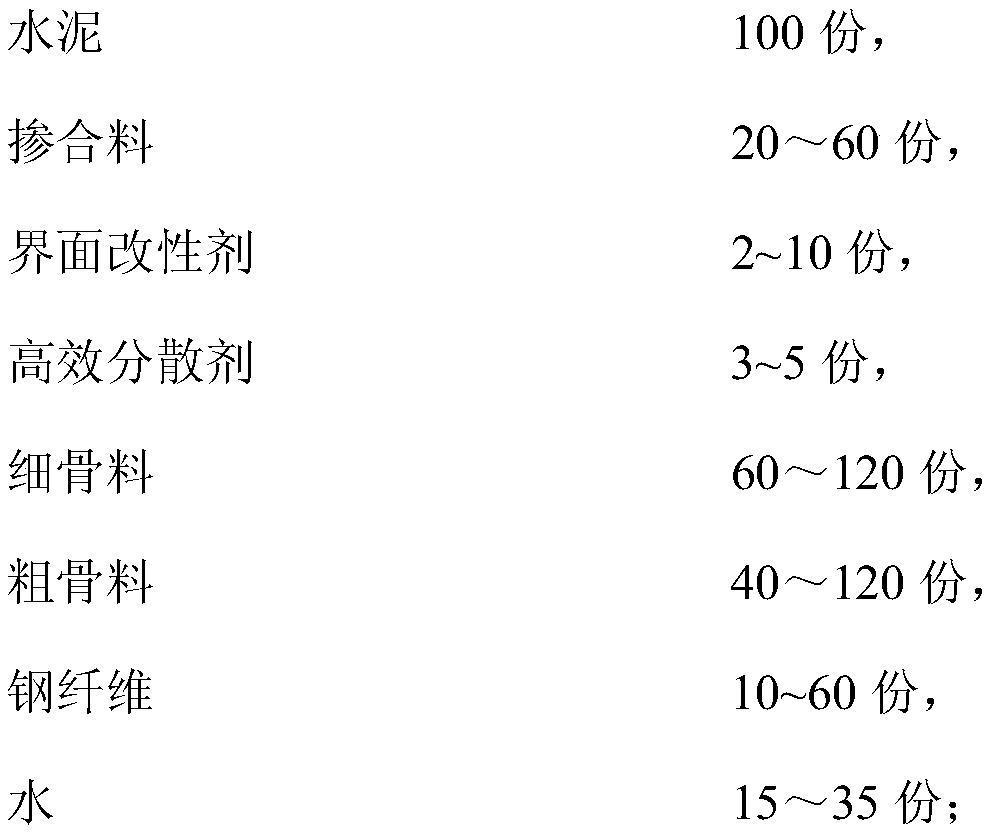

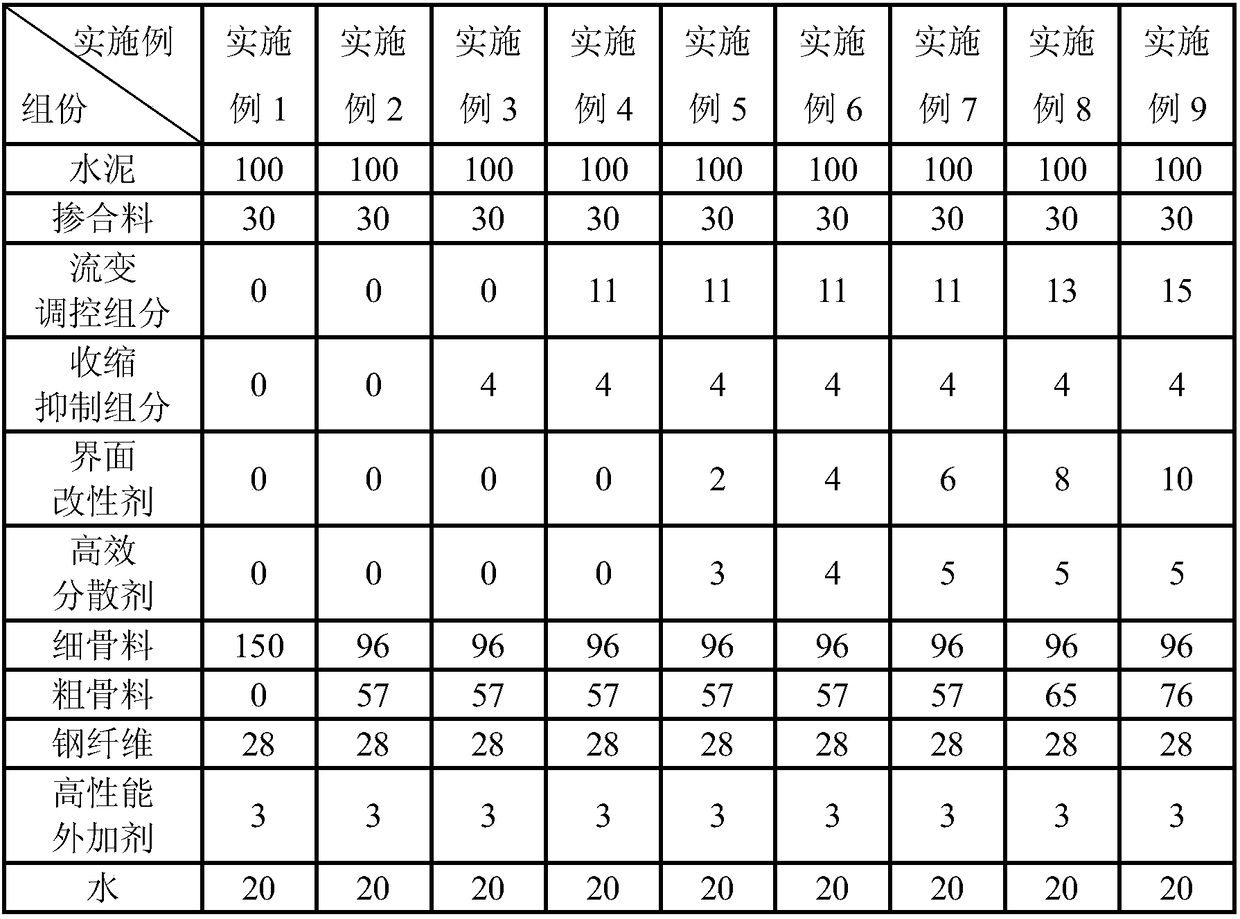

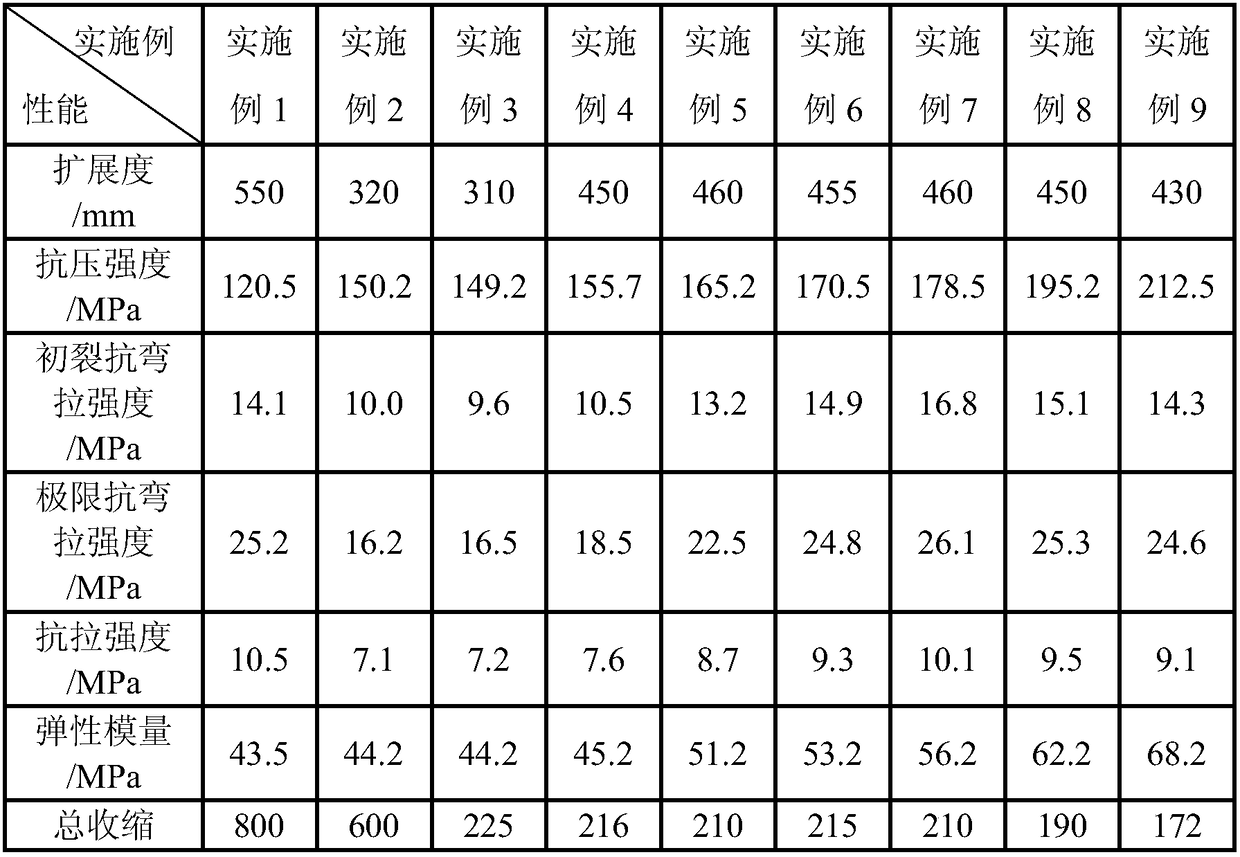

Bridge coarse aggregate active powder concrete and preparation method thereof

The invention discloses bridge coarse aggregate active powder concrete and a preparation method thereof. The coarse aggregate active powder concrete comprises, by weight, 100 parts of cement, 20-60 parts of blending materials, 2-10 parts of interface modifying agents, 60-120 parts of fine aggregates, 40-120 parts of coarse aggregates, 10-60 parts of fibers and 15-30 parts of water. Under conventional curing processes such as natural conditions, the coarse aggregate active powder concrete has super-high compressive strength, bending tensile strength and tensile strength and bonding strength andlow contraction performance and further has high elasticity modulus, anti-fatigue performance and durable performance and excellent construction performance, dead weight and shrinkage and creep influence of a bridge can be reduced, and the span, the structural stiffness and the bearing capacity of the bridge can be remarkably improved, and the service life of the bridge is prolonged.

Owner:南京市公共工程建设中心 +3

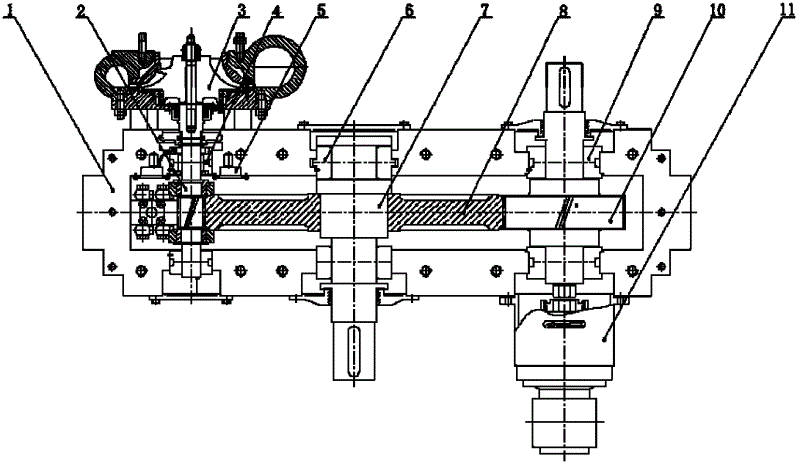

Fast rail-exchanging vehicle for jointless track and rail-exchanging method

InactiveCN101718066AReduce forcePrevent falling offRailway track constructionBogieFront and back ends

The invention relates to a fast rail-exchanging vehicle for a jointless track and a rail-exchanging method. The front and back ends of a travel mechanism of a fast rail-exchanging vehicle for a railway are provided with a guardrail recovering device; a crosstie-pressing device, a steel rail retraction device for clamping and moving a new steel rail and an old steel rail, a steel rail clincher and an operating position are arranged at intervals below the vehicle body between two bogies of the travel mechanism, the operating position is arranged according to the need; and the crosstie-pressing device and the steel rail clincher are arranged respectively close to the bogies at the two ends; and the vehicle can perform the marshalling operation together with the auxiliary vehicles, such as a fastener recovered vehicle, and the like. When the fast rail-exchanging vehicle for the railway is adopted for construction, the operation is divided into two parts of the old steel rail retraction operation and the new steel rail retraction operation which are synchronously carried out. The vehicle can reach the rail-exchanging speed of more than 2km / h, can be applied to the fast rail-exchanging need of the jointless track, complete the rail exchanging within 50 meters and is suitable for the construction needs of the section with less curve radius. The invention has the advantages of safety and high degree of automation.

Owner:株洲新通铁路装备有限公司

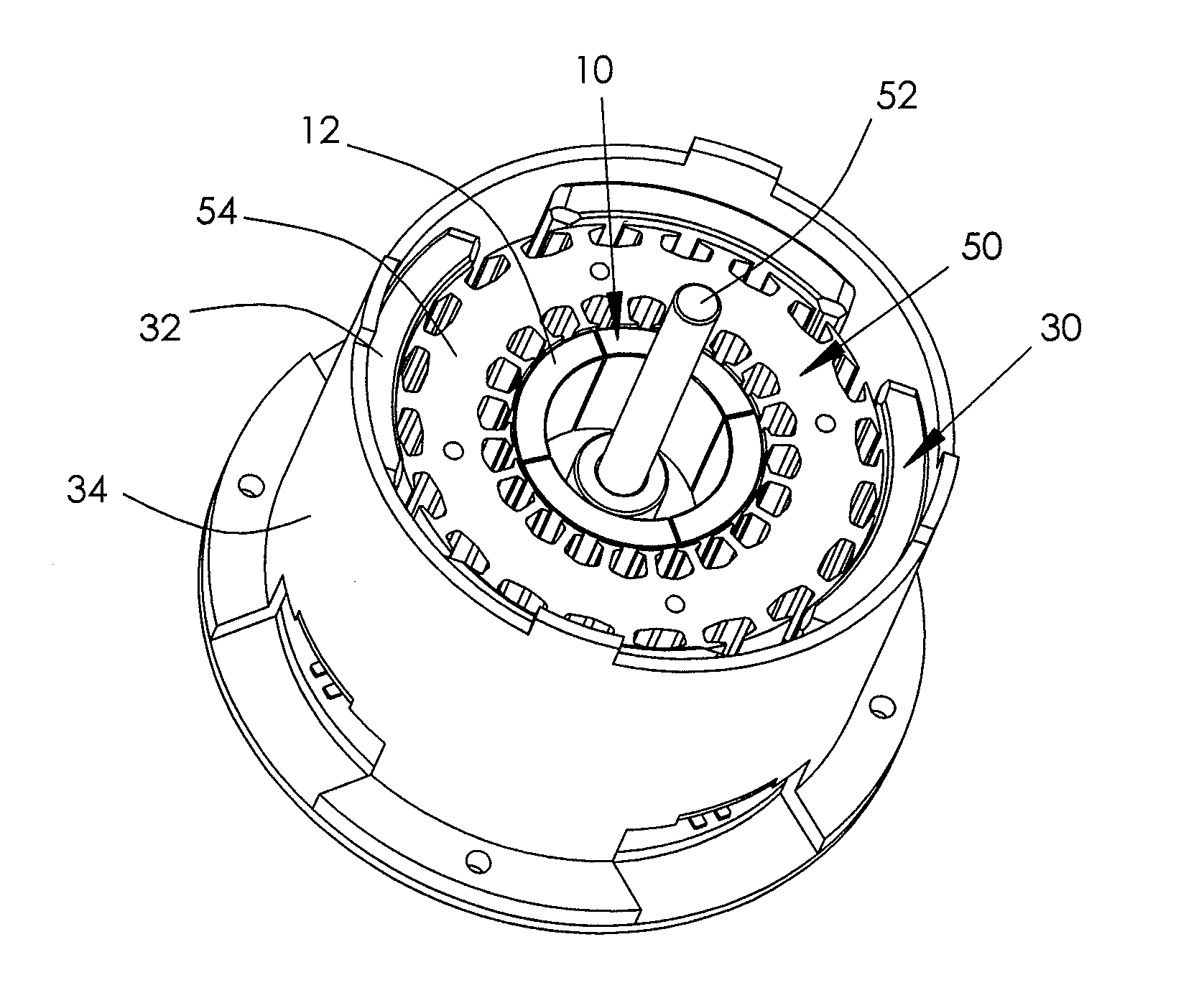

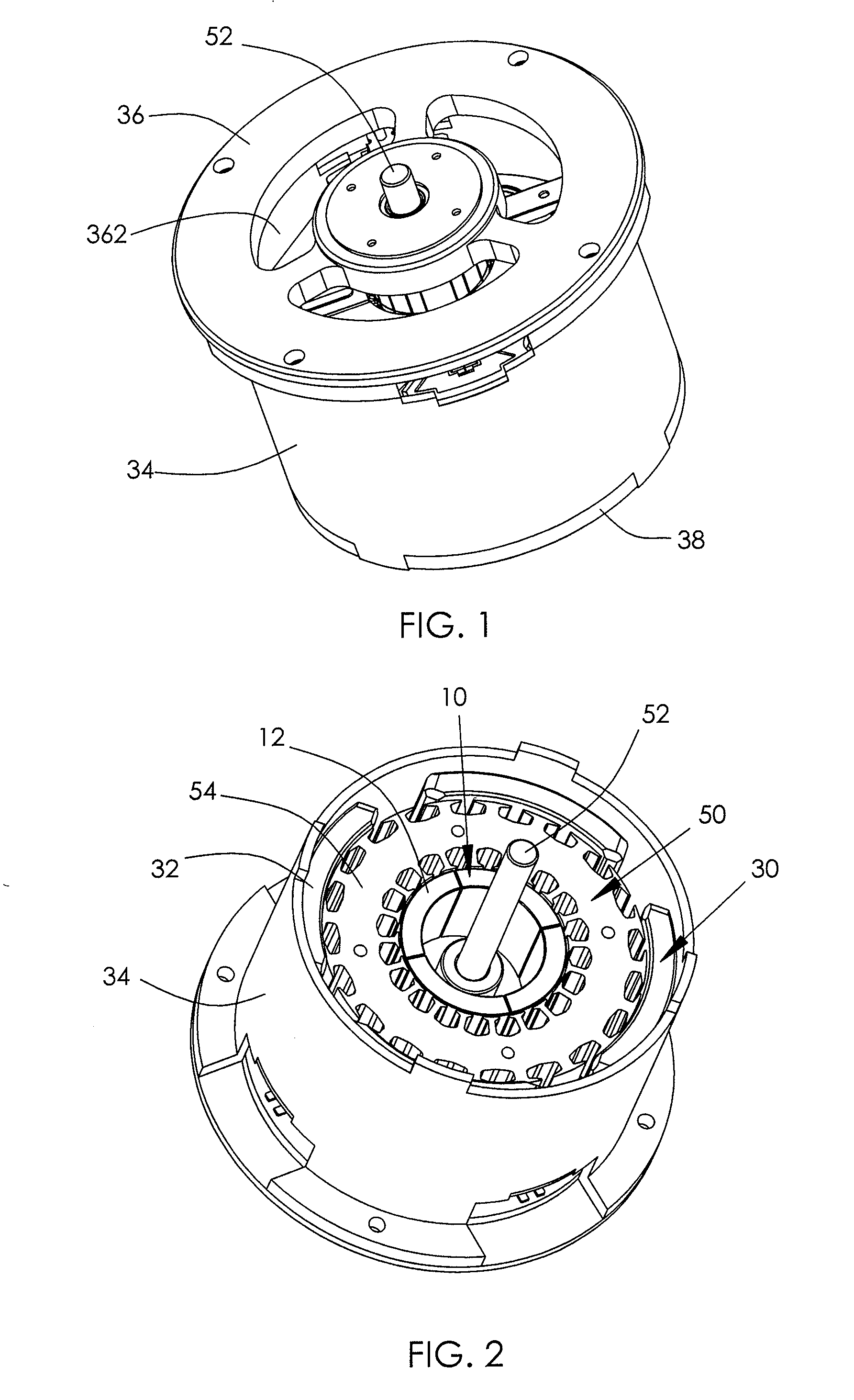

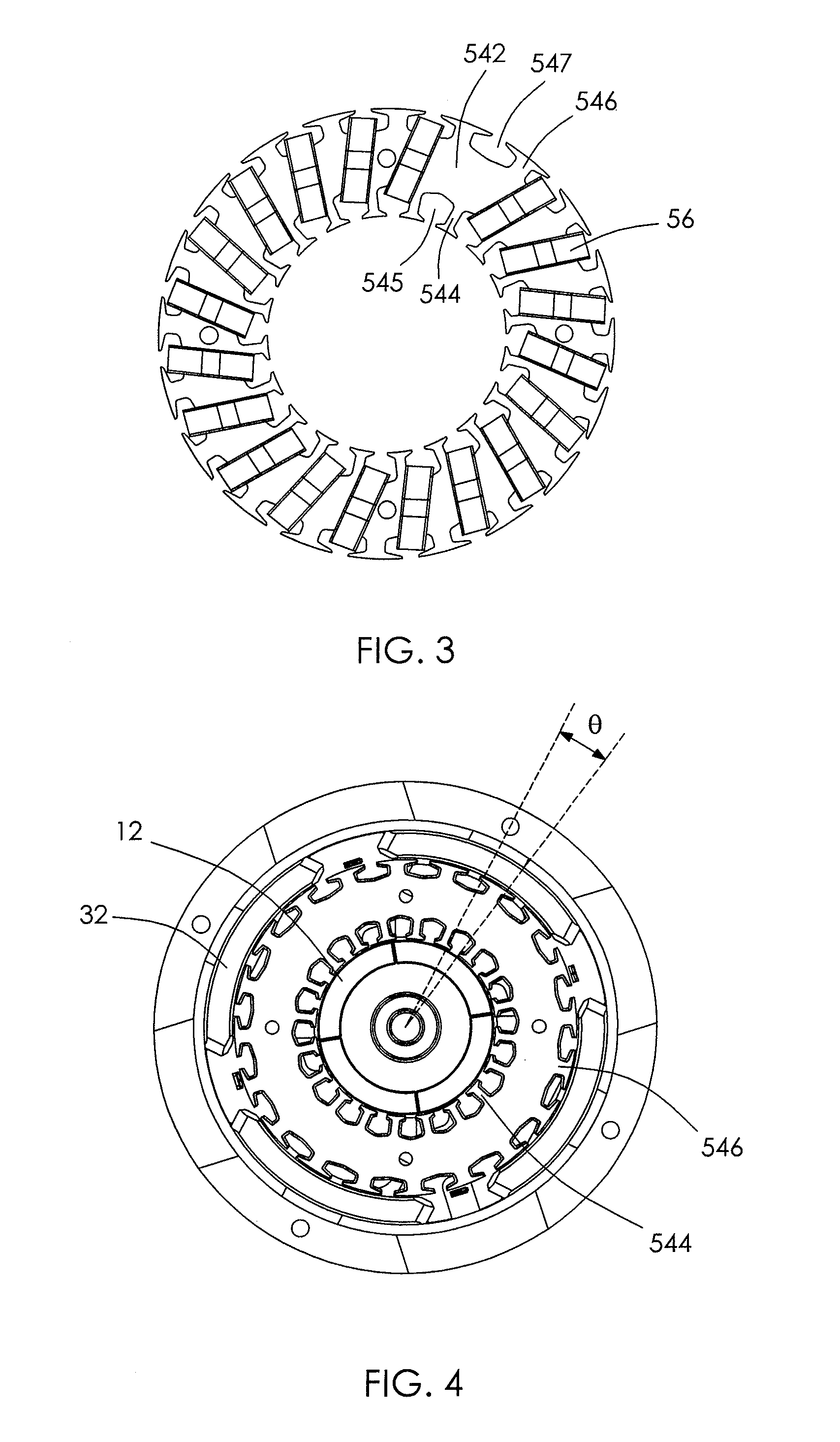

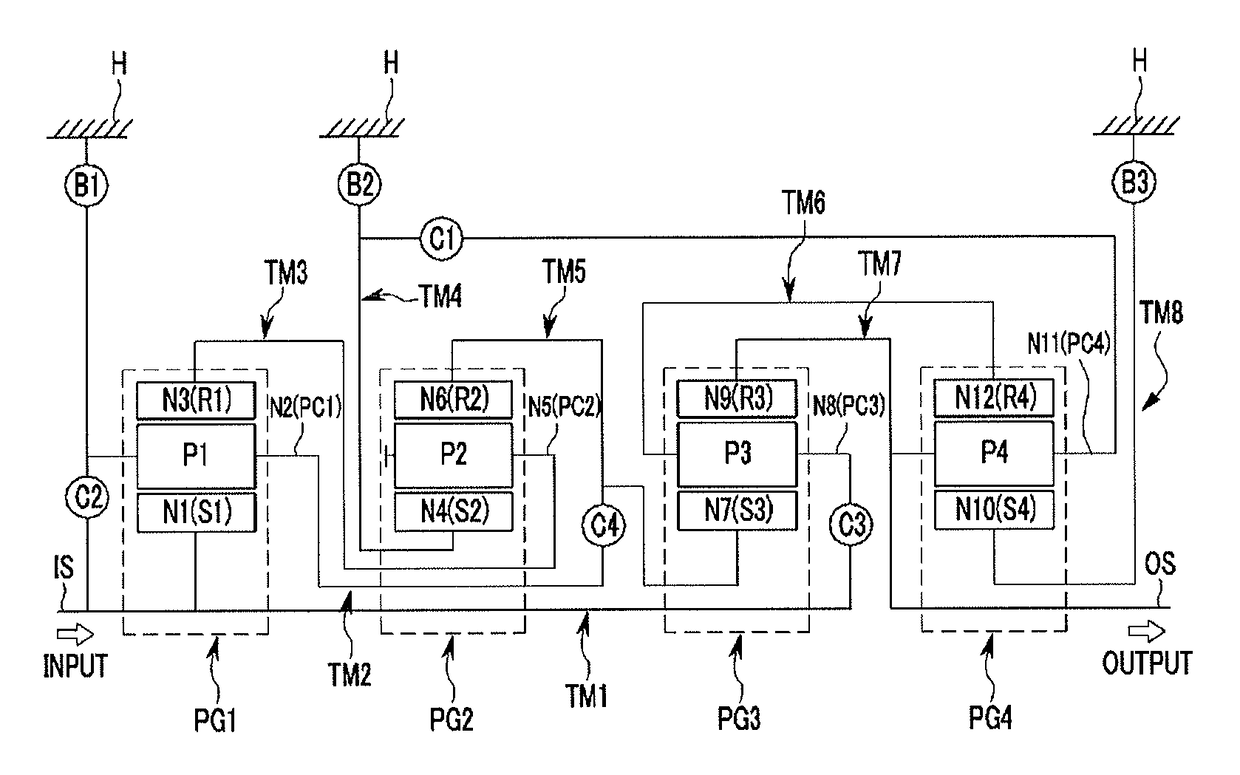

Electric motor

InactiveUS20120299405A1Reduce axial lengthIncrease usage ratioMagnetic circuit rotating partsDC commutatorStatorEngineering

An electric motor includes an inner stator including inner magnetic poles arranged circumferentially, an outer stator including outer magnets arranged circumferentially, and a rotor rotatably disposed between the inner and outer stators. The rotor includes a shaft, a rotor core fixed to the shaft and a winding wound on the rotor core. The rotor core includes a ring shaped yoke having a plurality of inner teeth extending inwardly and a plurality of outer teeth extending outwardly. The winding includes a plurality coils each including an inner side received in a corresponding inner slot formed between adjacent inner teeth and an outer side received in a corresponding outer slot formed between adjacent outer teeth.

Owner:JOHNSON ELECTRIC INTERNATIONAL AG

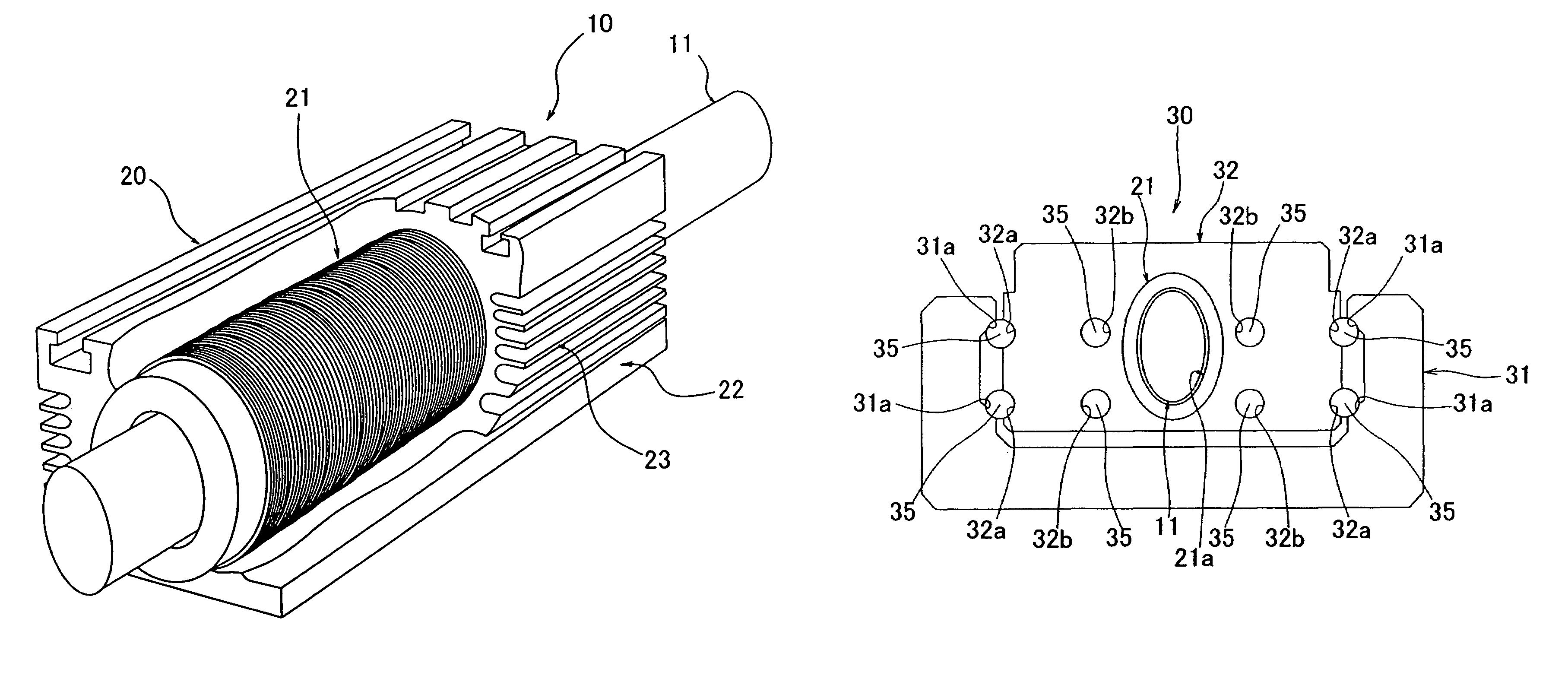

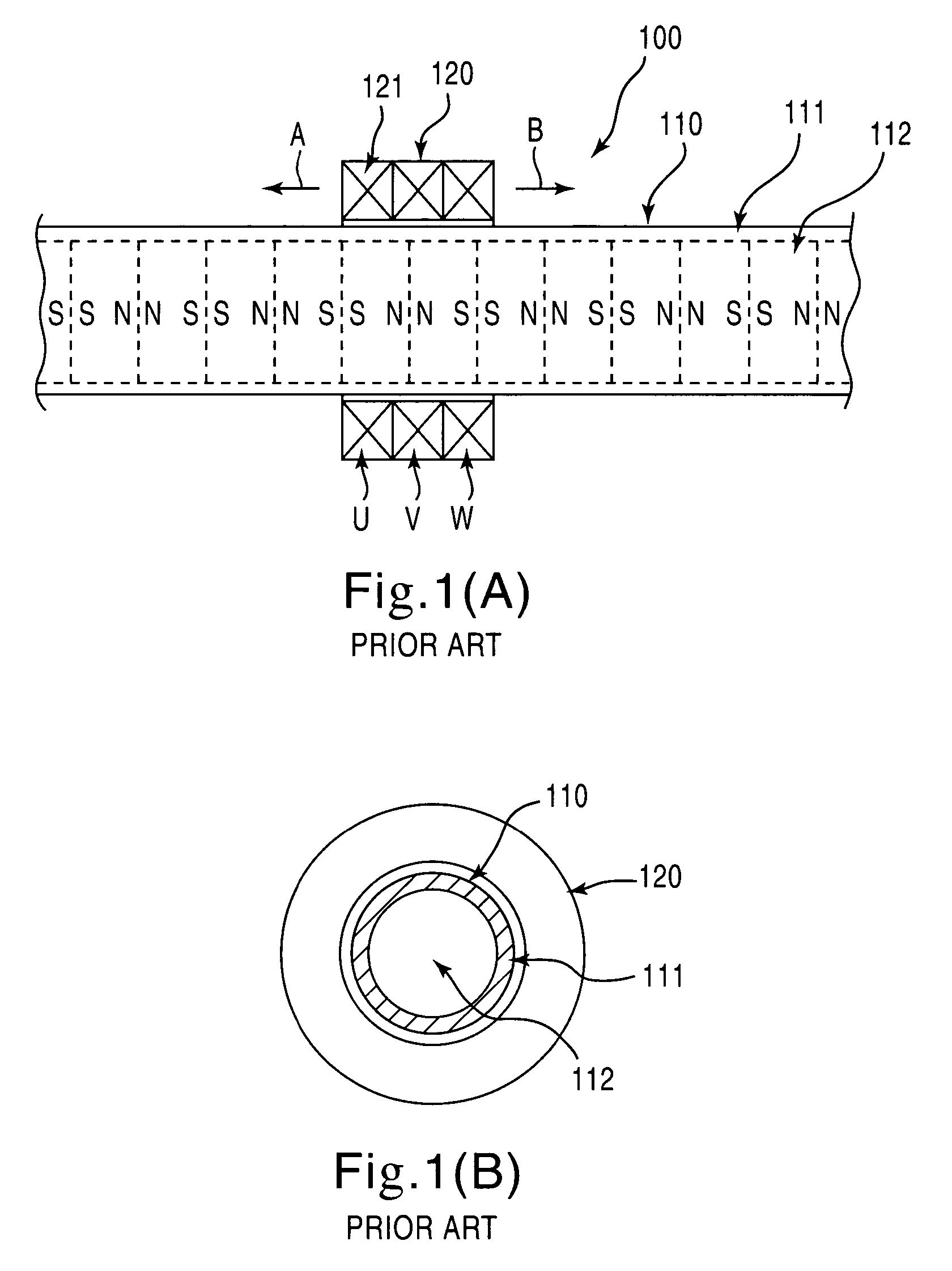

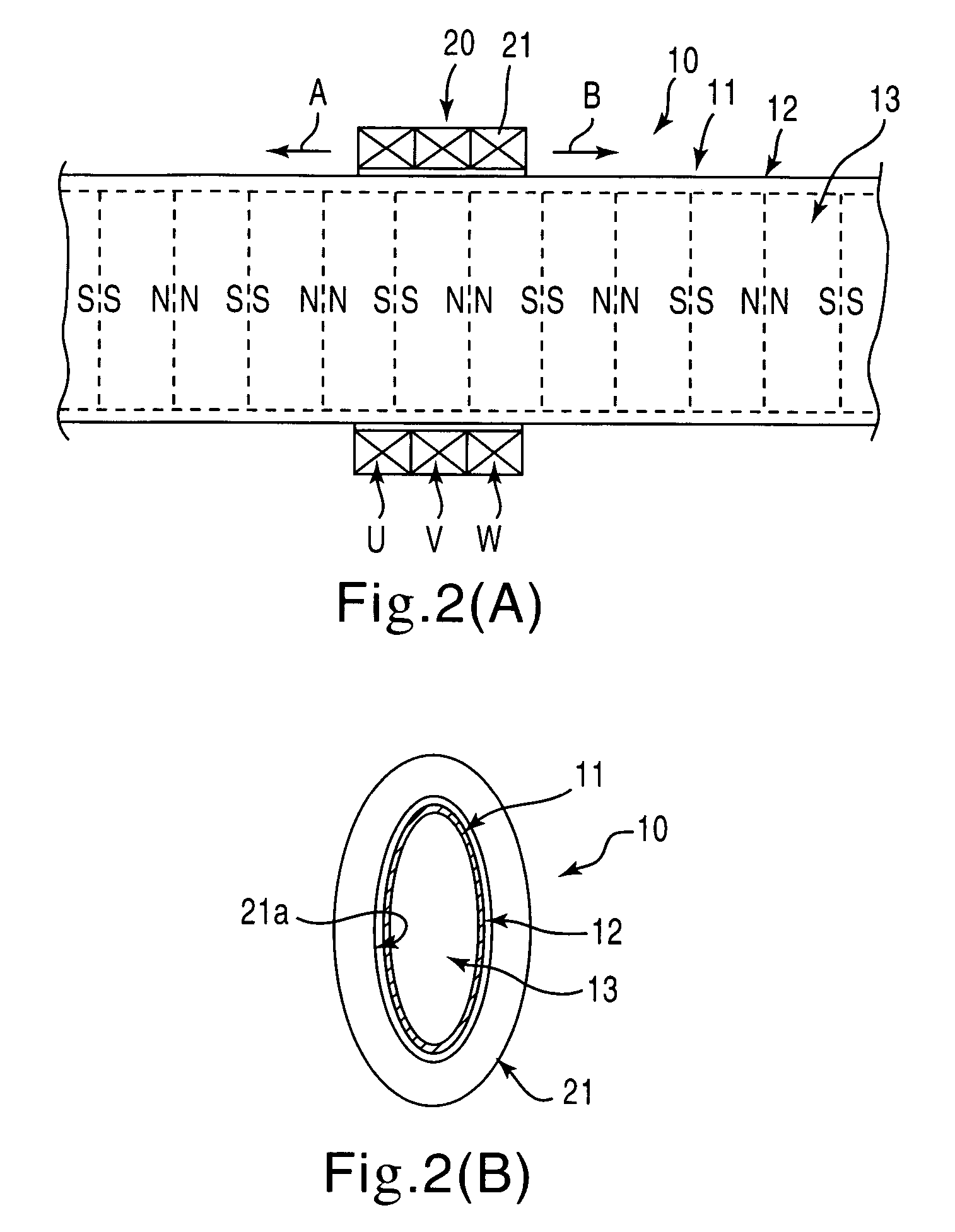

Linear motor and linear guiding apparatus

InactiveUS6977450B2Improve rigidityLarge thrustData processing applicationsFeeding apparatusEngineeringNon magnetic

A linear motor is provided that includes a rod-like member having a cylindrical body made of a non-magnetic material and a plurality of plate-like segment magnets accommodated in the cylindrical body such that they are stacked in a longitudinal axial direction of the cylindrical body and a coil member having a polyphase coil. The rod-like member is arranged to extend through a center bore of the coil member. The rod-like member of the linear motor comprises the cylindrical body having a substantially oval or substantially rectangular section and the plurality of segment magnets having a substantially oval or substantially rectangular plate shape that are accommodated in the cylindrical body and stacked in the axial direction of the cylindrical body. The section of the center bore of the coil member is substantially oval or substantially rectangular corresponding to the shape of the section of the rod-like member.

Owner:THK CO LTD

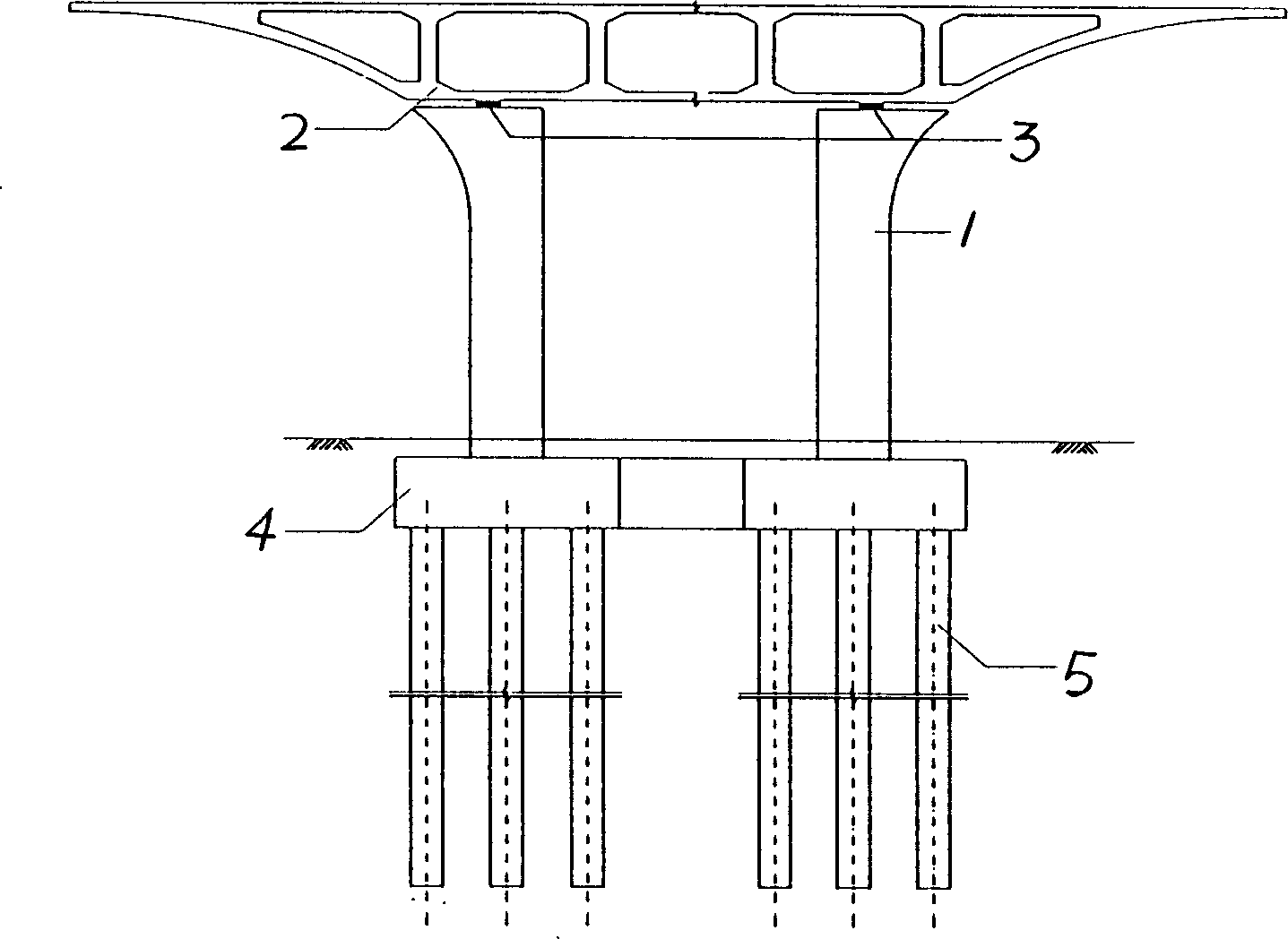

Bridge structure and construction method therefor

InactiveCN1635224AReasonable and coordinated structureThe structure is novel and beautifulBridge structural detailsBridge erection/assemblyCross bridgeBox girder

The invention discloses a bridge structure, mainly comprising: piers arranged on the bases, box girders arranged on the piers. It is characterized in that: the top box girder of the bridge is an arched single-box multi-chamber concrete box girder; the bottom pier cross bridge is arranged with an upward column; the top part of the column is a pier column of abducted curved or straight Y type, I I type and H type; the bottom part of the column is straight or abducted curve. The technical characteristics of the invention are: firstly, the structure of the bridge is harmonious, reasonable and the appearance is elegant; secondly, the bridge span is enlarged, and the arched box girder can be preformed or on-site casting according to the bridge width, span and situations of the construction site, by which the project time can be shortened and the effect to the traffic is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

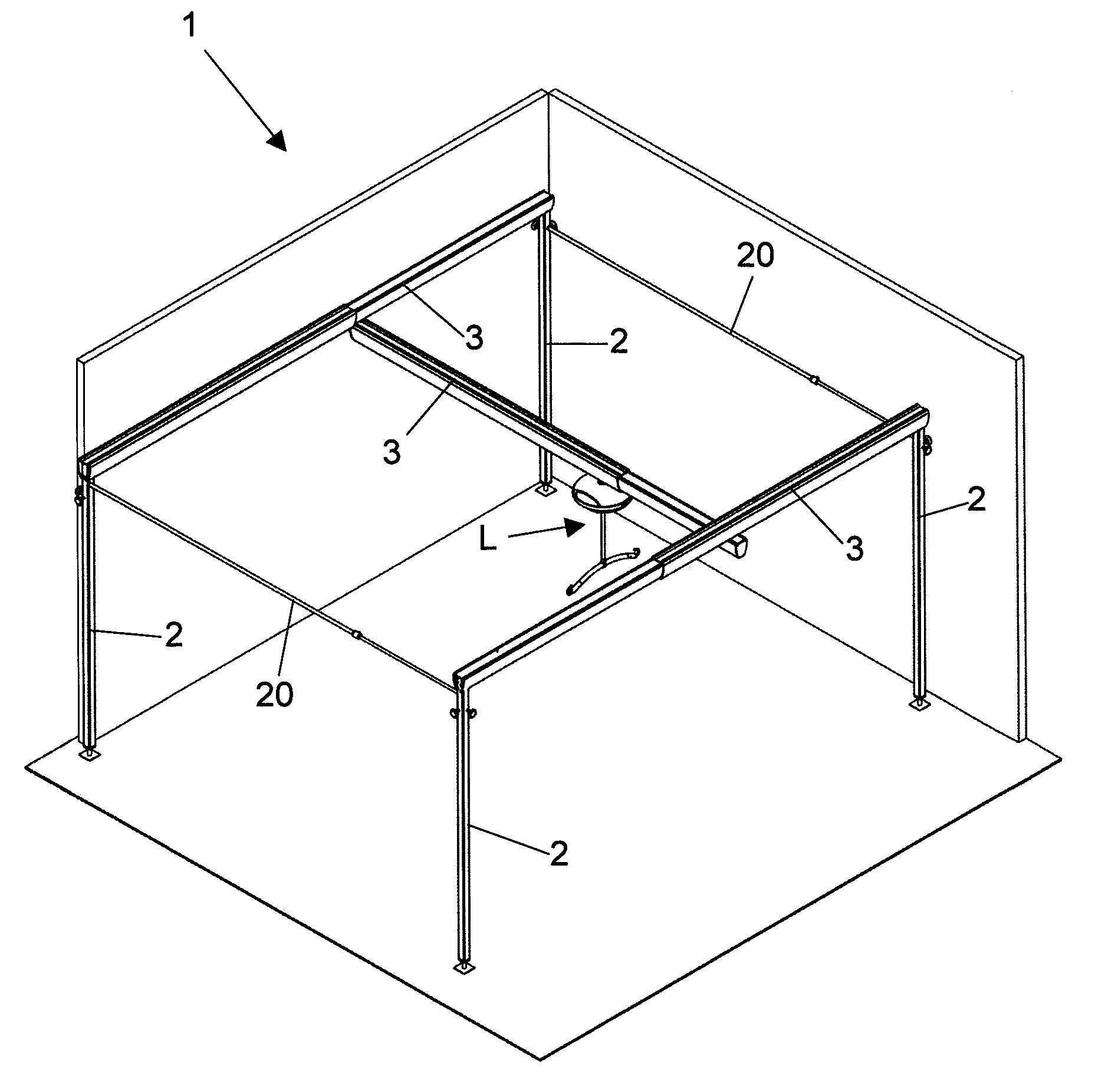

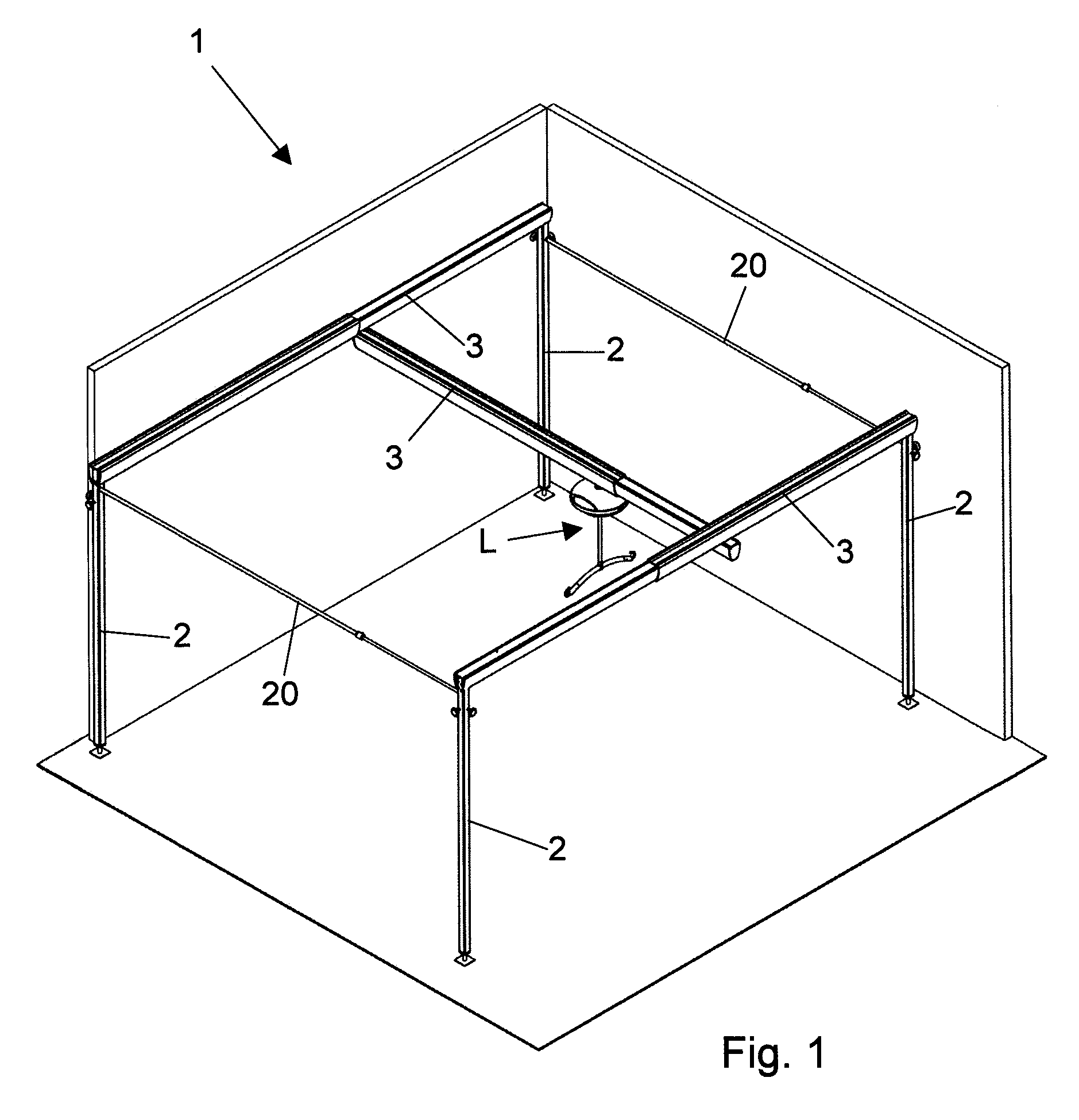

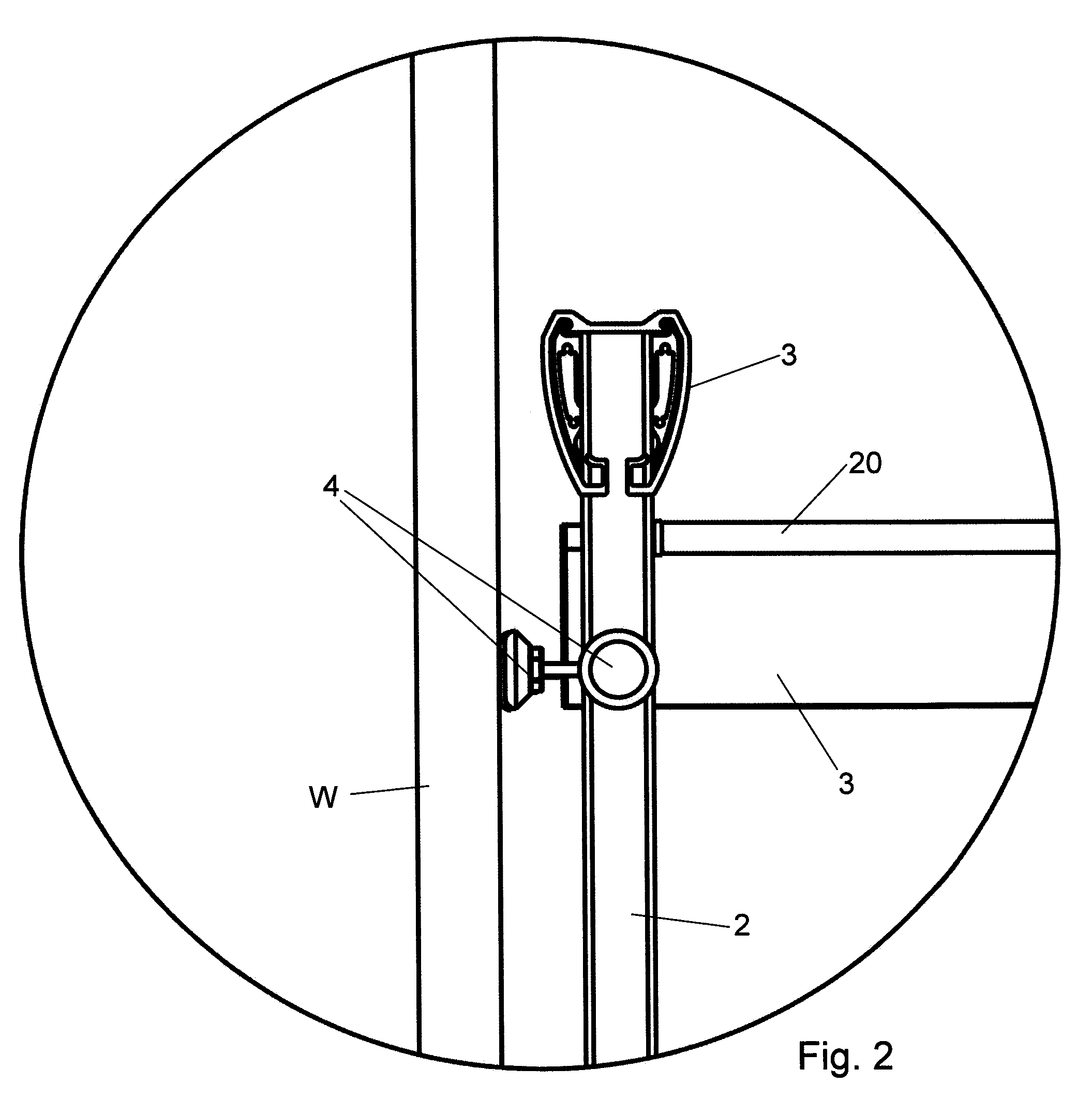

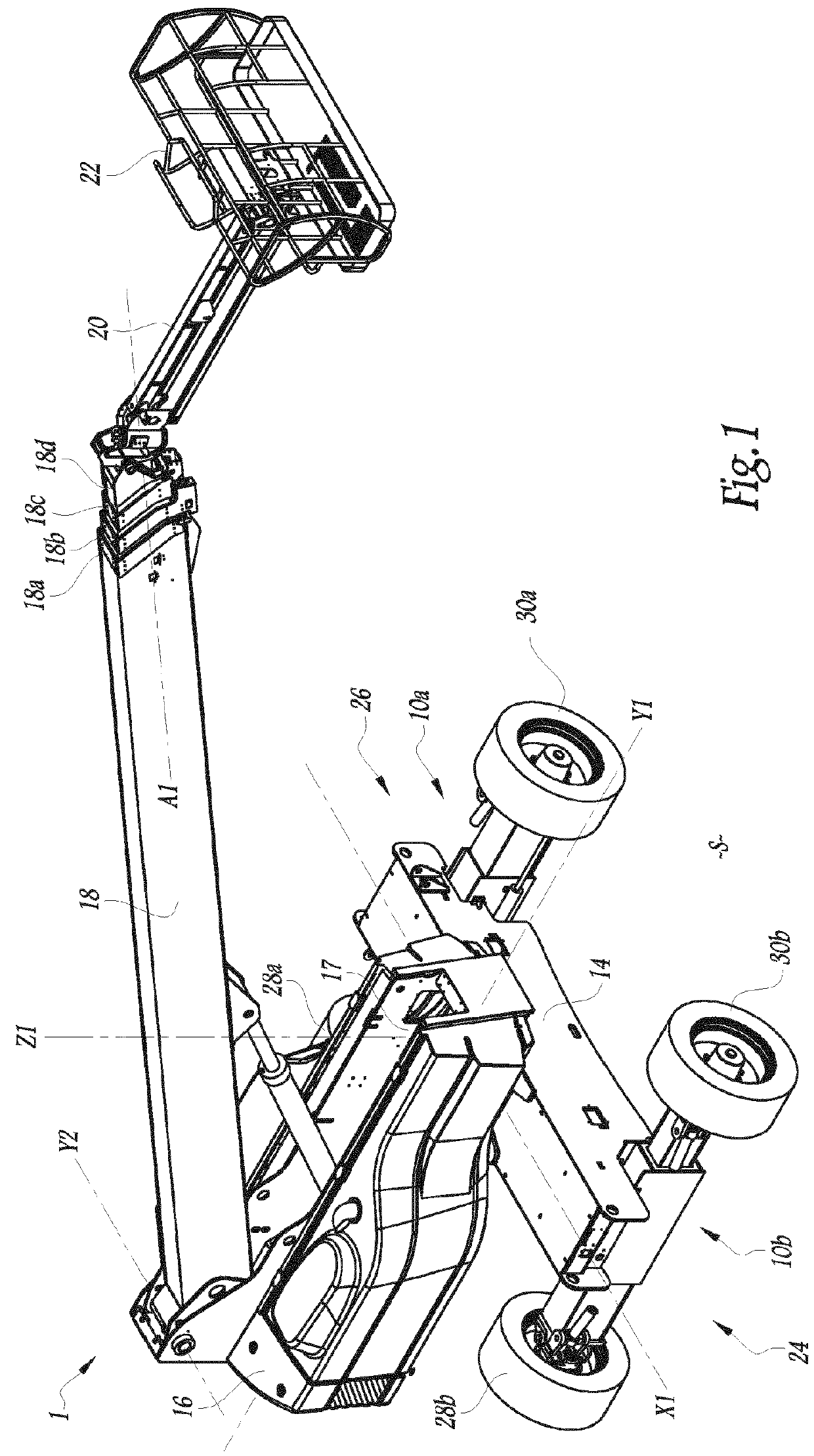

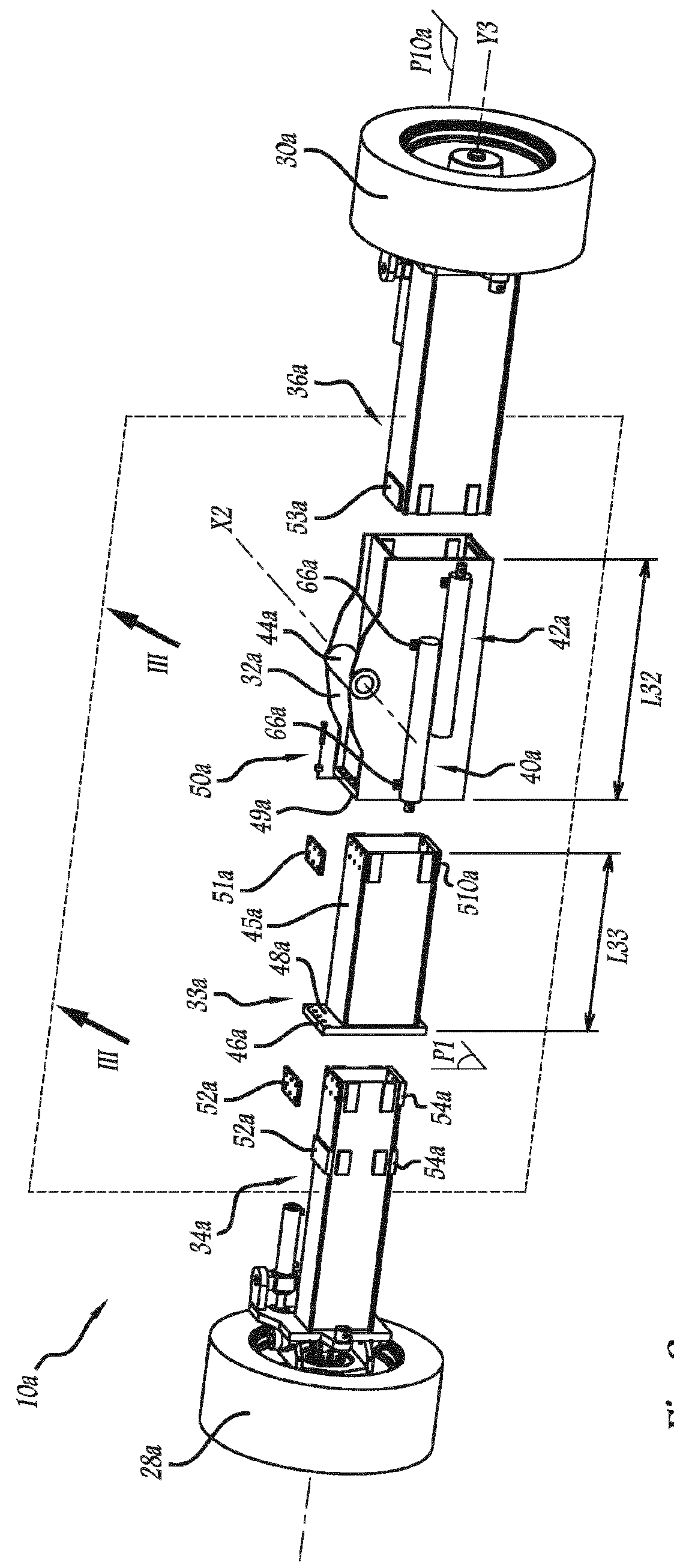

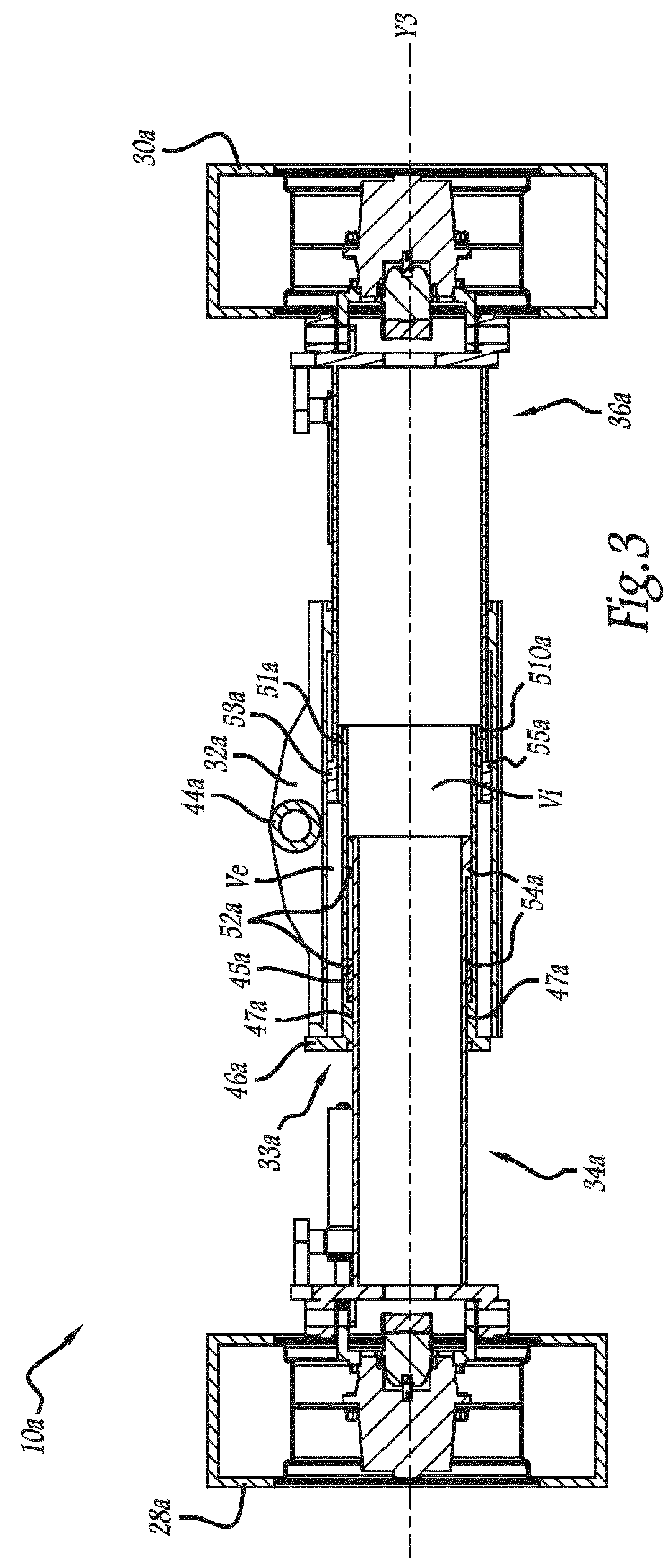

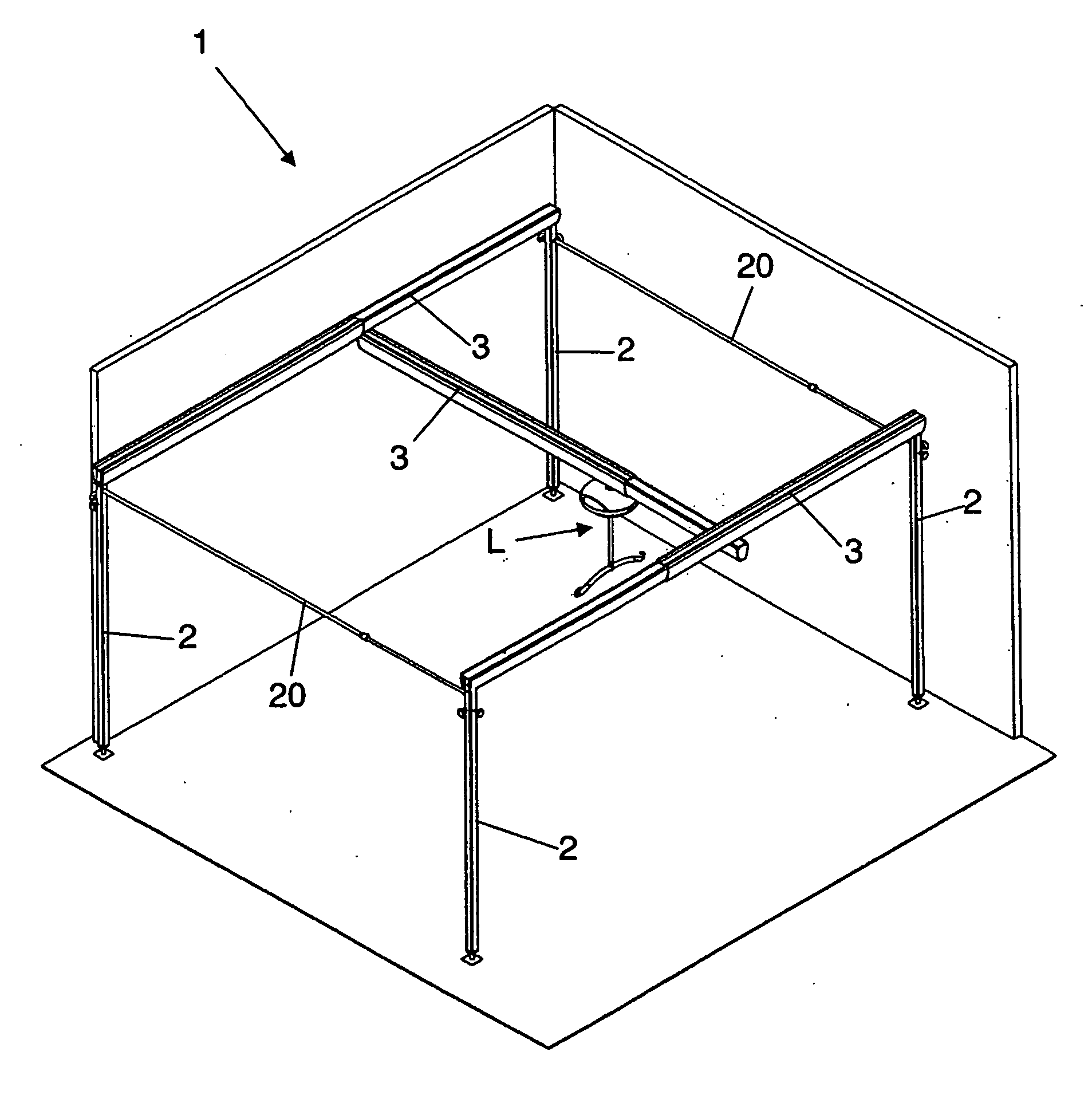

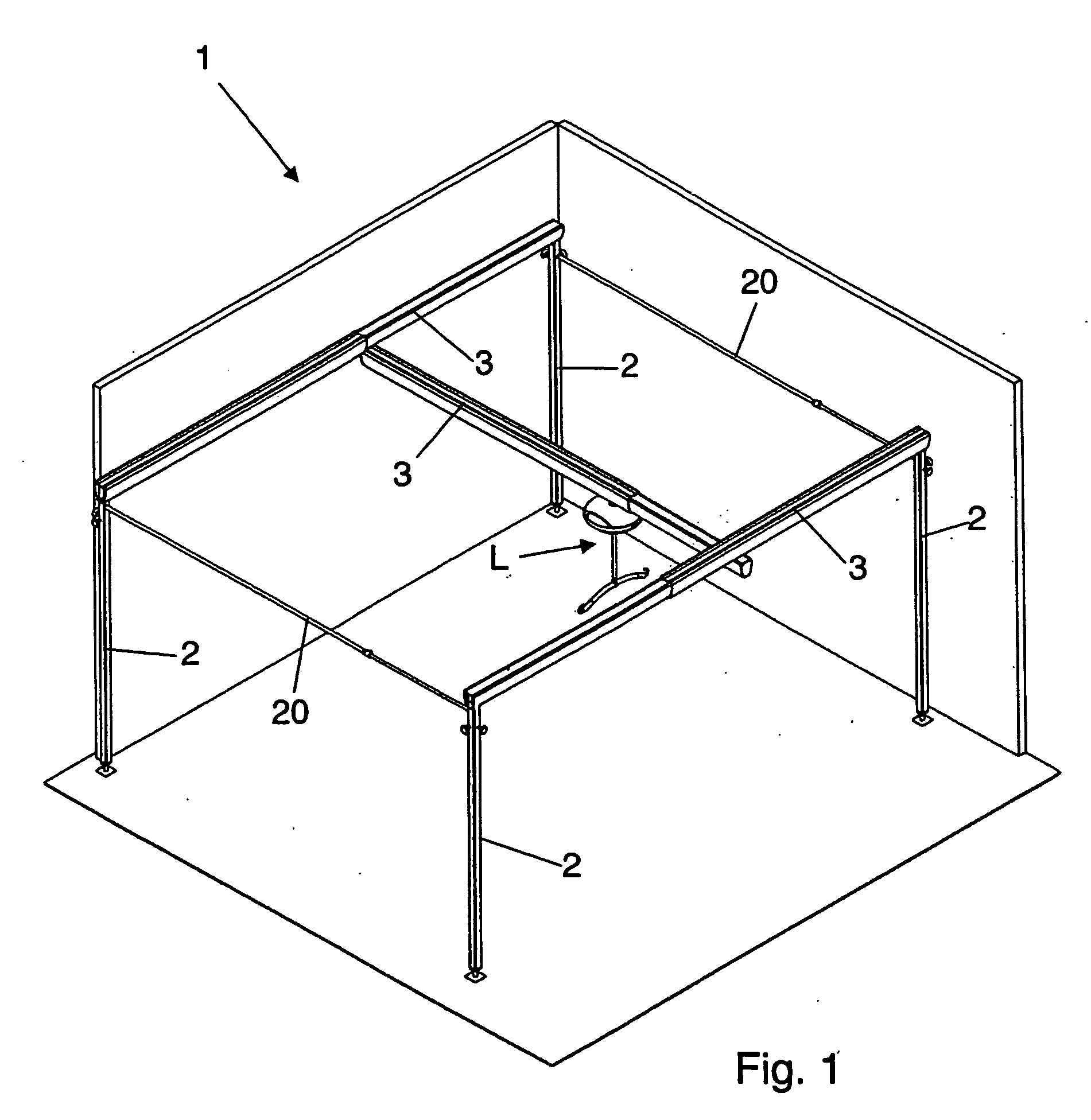

Telescopic Rail Carriage Assembly for Suspending a Patient Lift

InactiveUS20080271242A1Span of the telescopic rail can be increasedIncrease spanRailway tracksNursing bedsEngineeringCarriage

Owner:ERGOLET

Axle and vehicle comprising at least one such axle

An axle mounted on a vehicle chassis includes a central box section, a first support arm connected to a first wheel and slideably mounted inside the central box section, and a second support arm connected to a second wheel and capable of longitudinal translational movement inside the first support arm, a guiding box section fixed to the central box section, including a rectangular tube and defining an external annular volume included between the central box section and the tube, and an internal volume included inside the tube, the first support arm being housed inside the external annular volume and able to be guided by the guiding box section along a first longitudinal translational path, the second support arm being housed inside the internal volume and able to be guided by the guiding box section on a second longitudinal translational path. A vehicle equipped with such an axle is described.

Owner:HAULOTTE GROUP

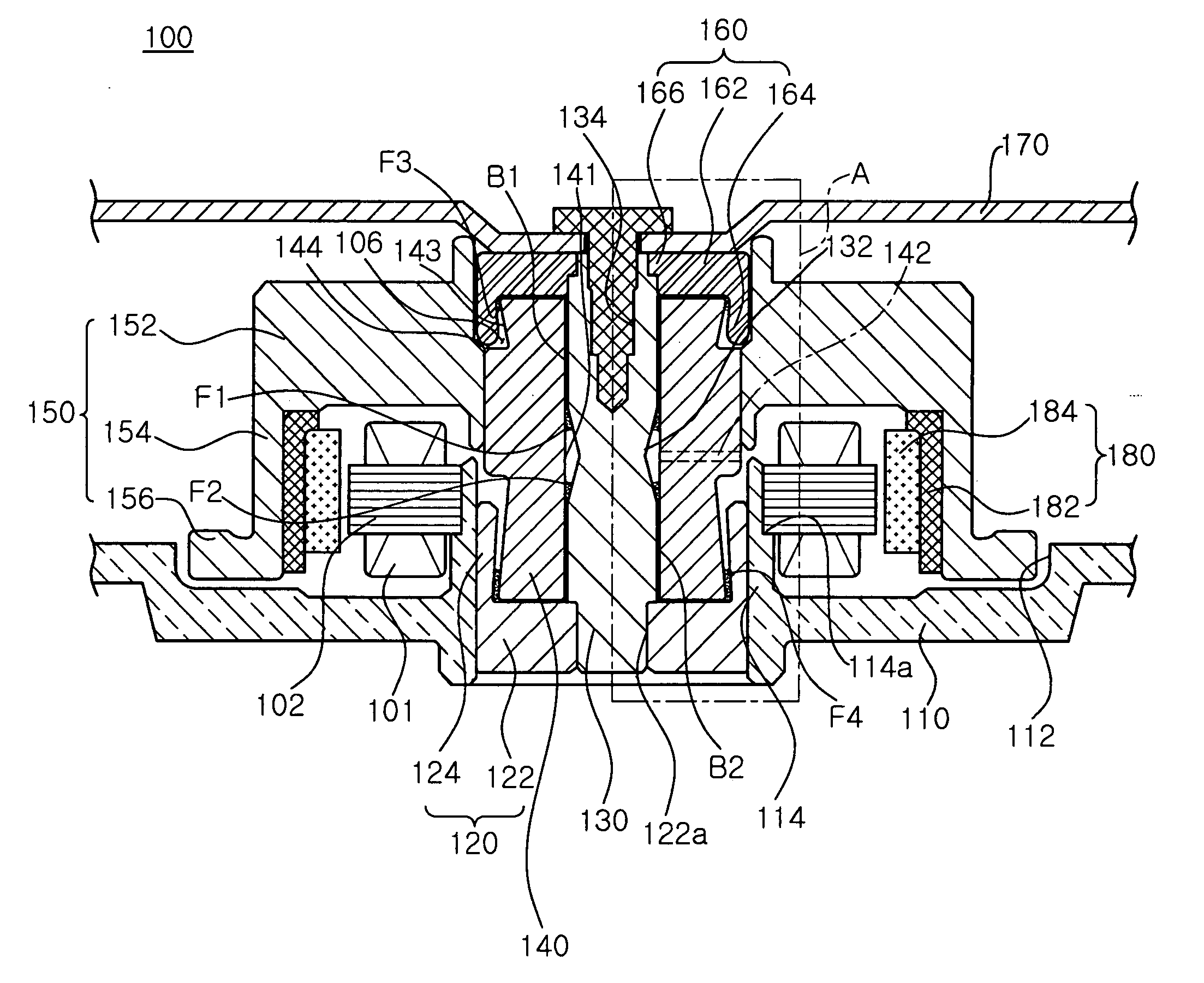

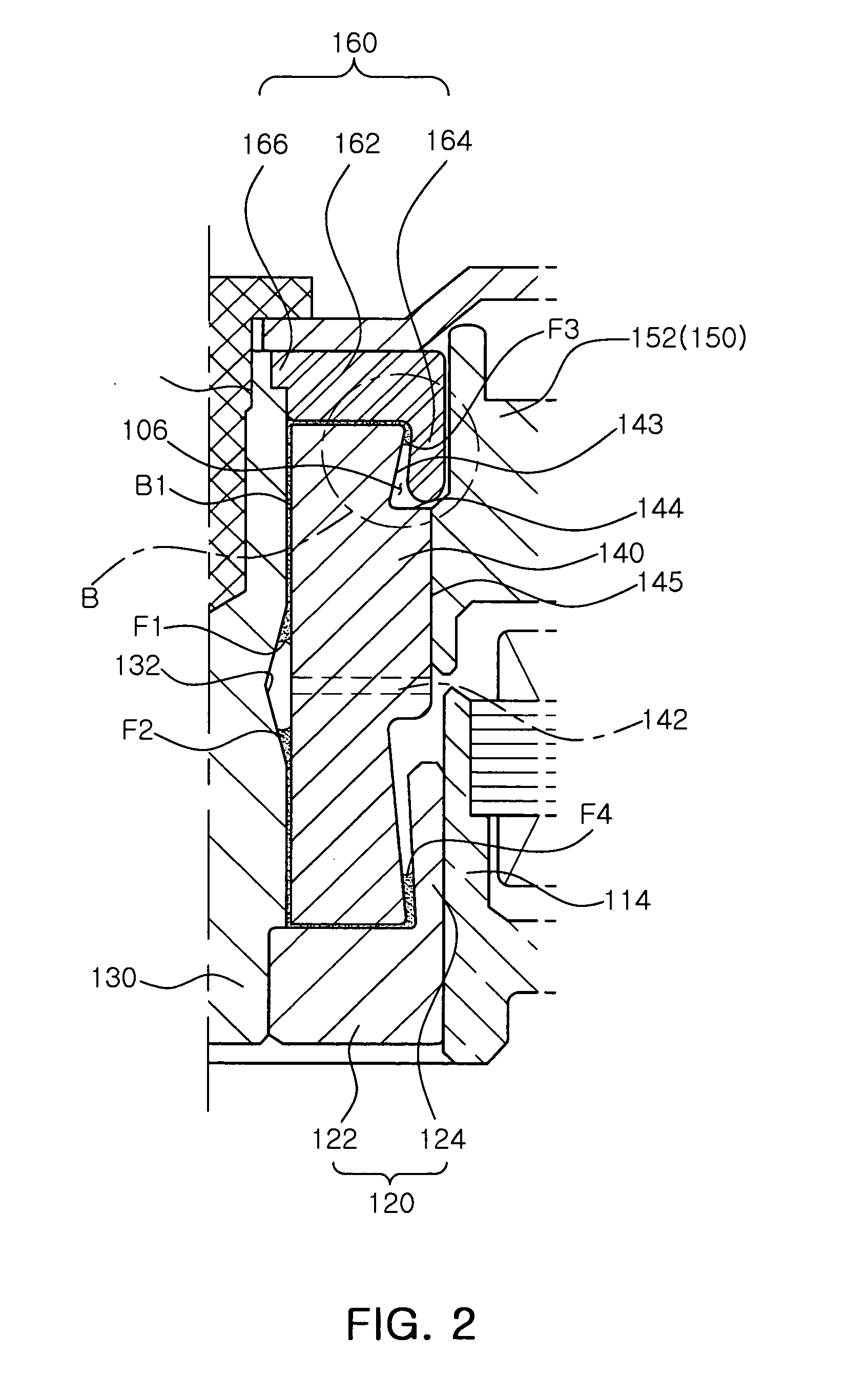

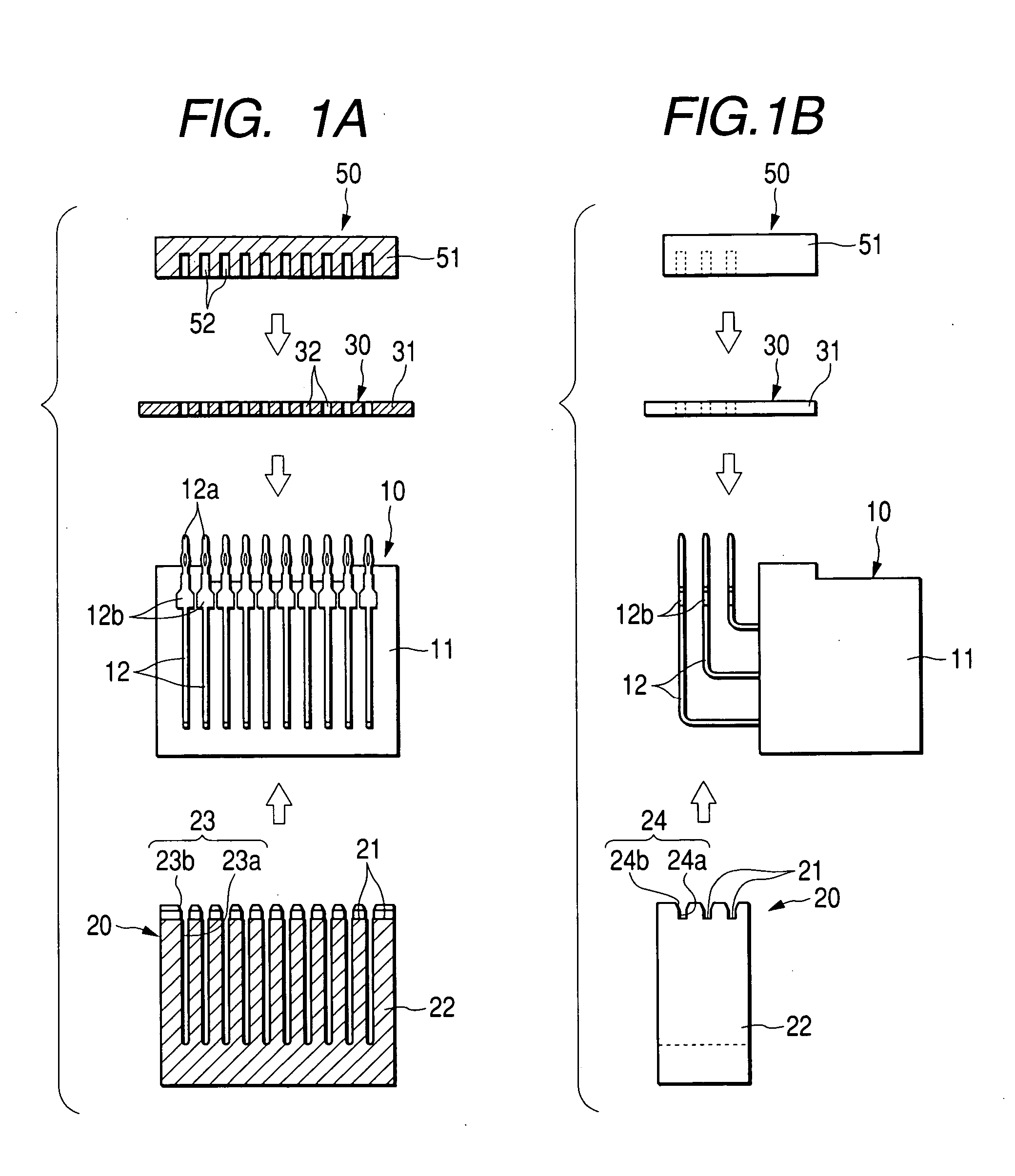

Motors with oil dynamic pressure bearing, oil dynamic pressure bearing devices and method for manufacturing the same

InactiveUS7059771B2Improve rigidityIncrease dynamic pressureShaftsBearing componentsEngineeringDynamic pressure

A motor with fluid dynamic pressure bearing is disclosed. The motor includes a dynamic pressure bearing member having a concave section that is concave in an axial direction, a rotary shaft that is rotatively supported by the dynamic pressure bearing, and a rotary member that is joined to the rotary shaft in one piece along a joint section between the rotary member and the rotary shaft, and rotatively driven by electromagnetic drive force, an expanded diameter section that is provided on the dynamic pressure bearing member. A fallout preventing member is provided on the rotary member, which overlaps the expanded diameter section of the dynamic pressure bearing member in the axial direction to prevent the rotary shaft from falling out of the dynamic pressure bearing member. The concave section of the rotary member opposes in the axial direction the expanded diameter section of the dynamic pressure bearing member, wherein the expanded diameter section is placed inside the concave section, and the joining section between the rotary member and the rotary shaft overlaps the expanded diameter section in the radial direction.

Owner:NIDEC CORP

Spindle motor

InactiveUS20130033137A1Improved rotational characteristicIncrease spanMagnetic circuit rotating partsShaftsEngineeringMechanical engineering

A spindle motor including: a lower thrust member fixedly coupled to a base member; a shaft fixedly coupled to at least one of the lower thrust member and the base member; a sleeve disposed on an upper portion of the lower thrust member and rotatably installed on the shaft; a rotor hub coupled to the sleeve to thereby rotate together with the sleeve; an upper thrust member fixedly coupled to an upper end portion of the shaft and forming a liquid-vapor interface together with the sleeve; and a cover member fixedly coupled to the shaft so as to be disposed on an upper portion of the upper thrust member, wherein the upper thrust member includes a stepped jaw part having a lower surface supported by an upper surface of the shaft and an upper surface pressed by the cover member, so as to increase coupling strength with the shaft.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Assembled-type aluminum alloy bridge deck slab-steel girder combined structure

InactiveCN102877411AReduce weightHigh specific strengthBridge structural detailsBridge materialsScrew jointParent material

The invention relates to a steel-aluminum alloy combined structure, and in particular discloses an assembled-type aluminum alloy bridge deck slab-steel girder combined structure and connecting mode. The combined structure comprises an assembled-type aluminum alloy bridge deck slab and a steel girder; the connecting mode comprises an aluminum alloy bridge deck slab-steel girder connecting structure (high-strength bolt connection) and aluminum alloy bridge deck slab connecting construction (a stainless steel screw joint), and the assembled-type connection prevents the reduction of the intensity of an aluminum alloy parent material due to welding. The aluminum alloy bridge deck slab-steel girder combined structure provided by the invention has the advantages that the structure is light in weight, durable, easy to machine, high in toughness, rapid to construct, free from maintenance and the like, can be widely applied to damaged bridge deck modification, bridge building, dangerous bridge modification, pedestrian bridge and emergency engineering, and generates favorable social and economic benefits.

Owner:HUNAN UNIV

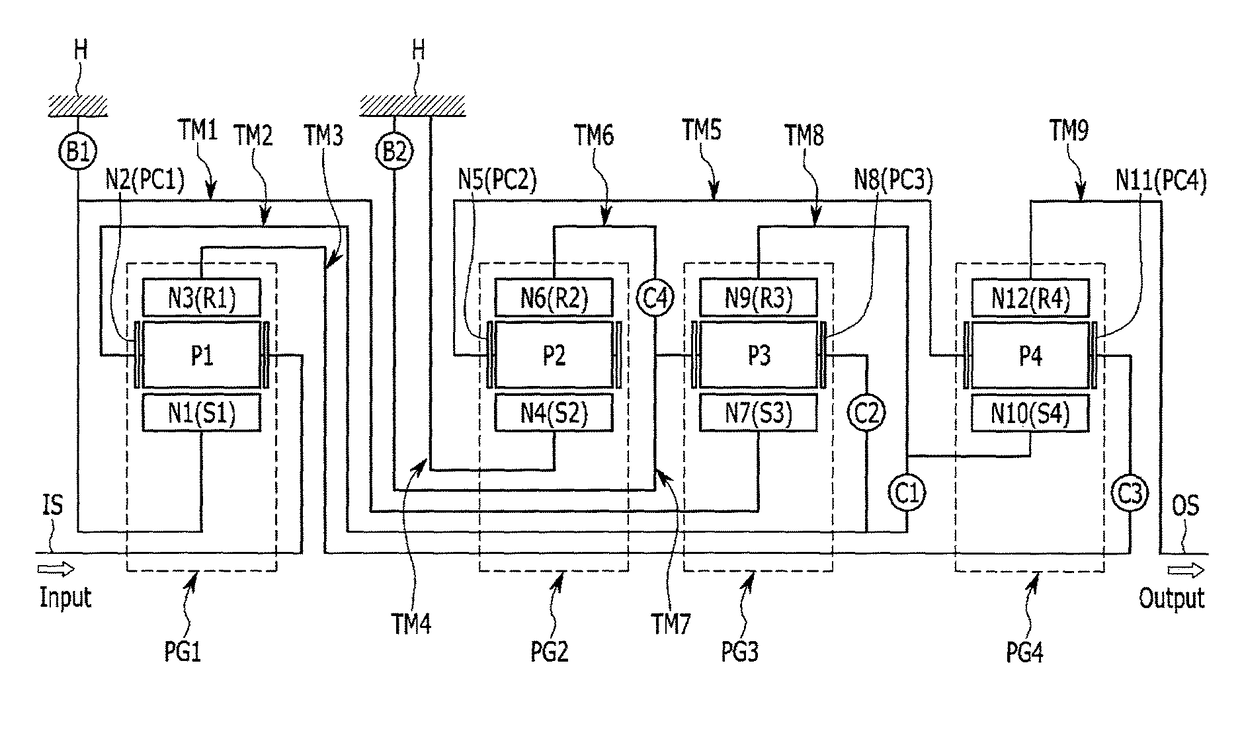

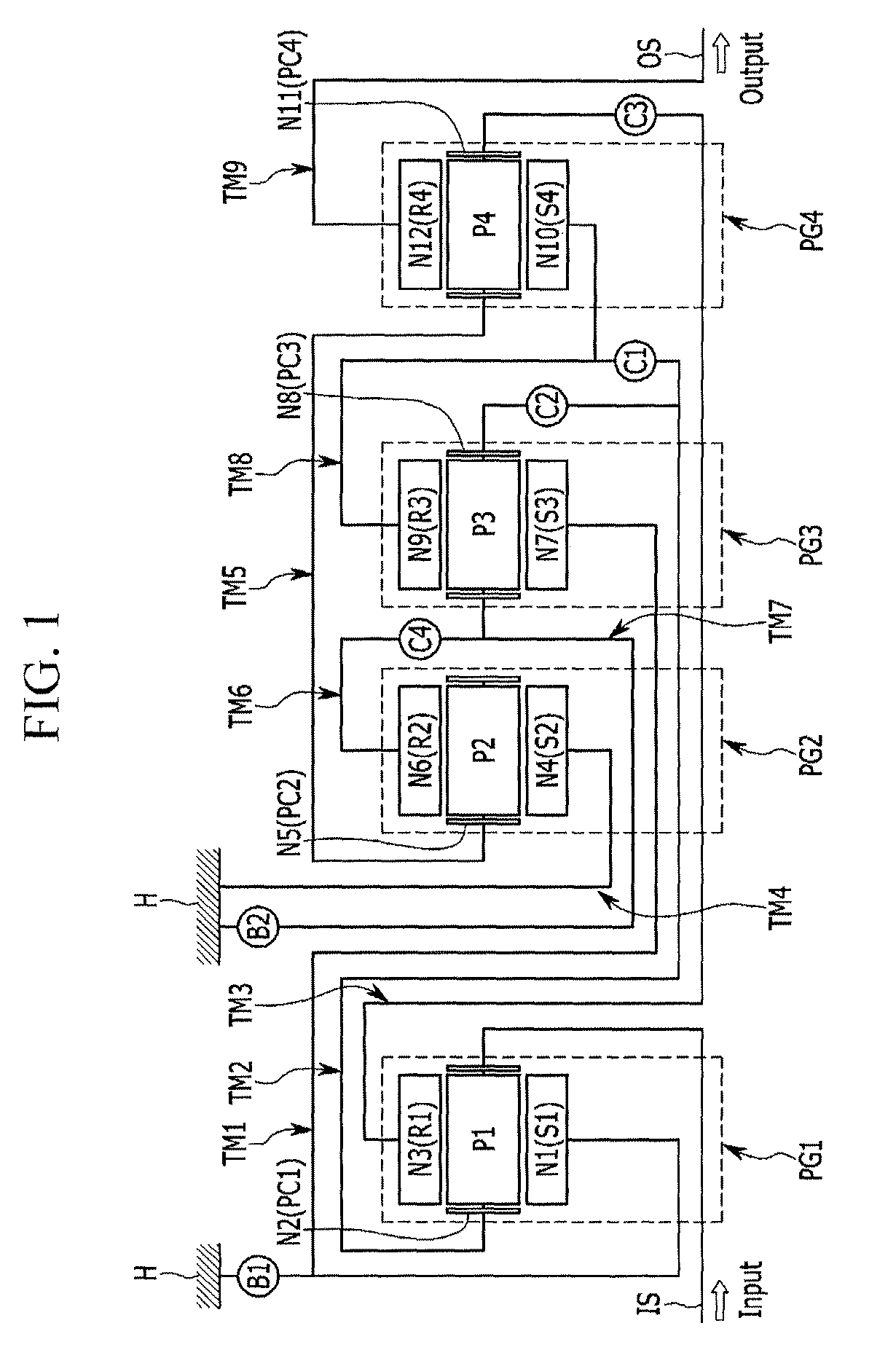

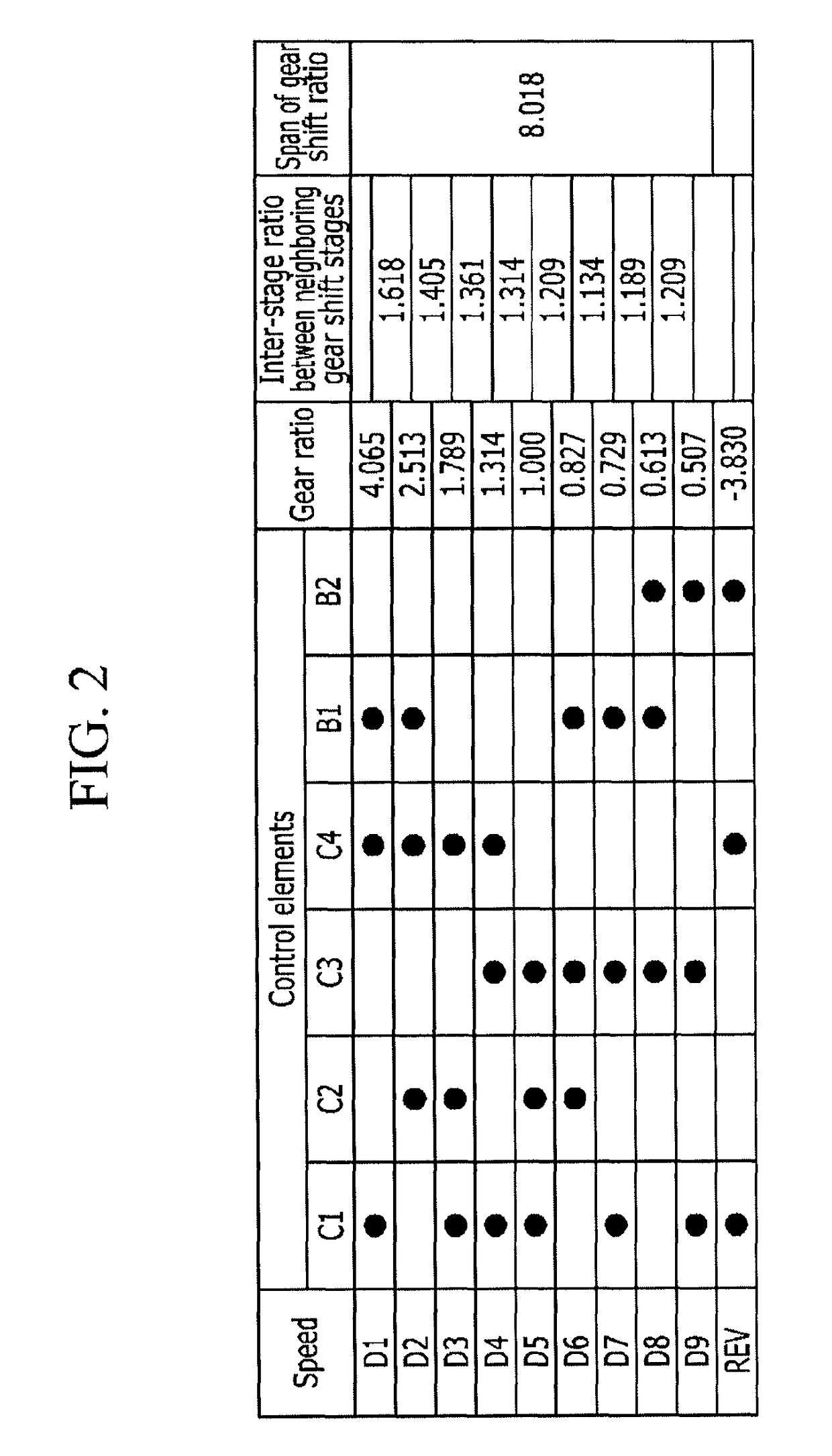

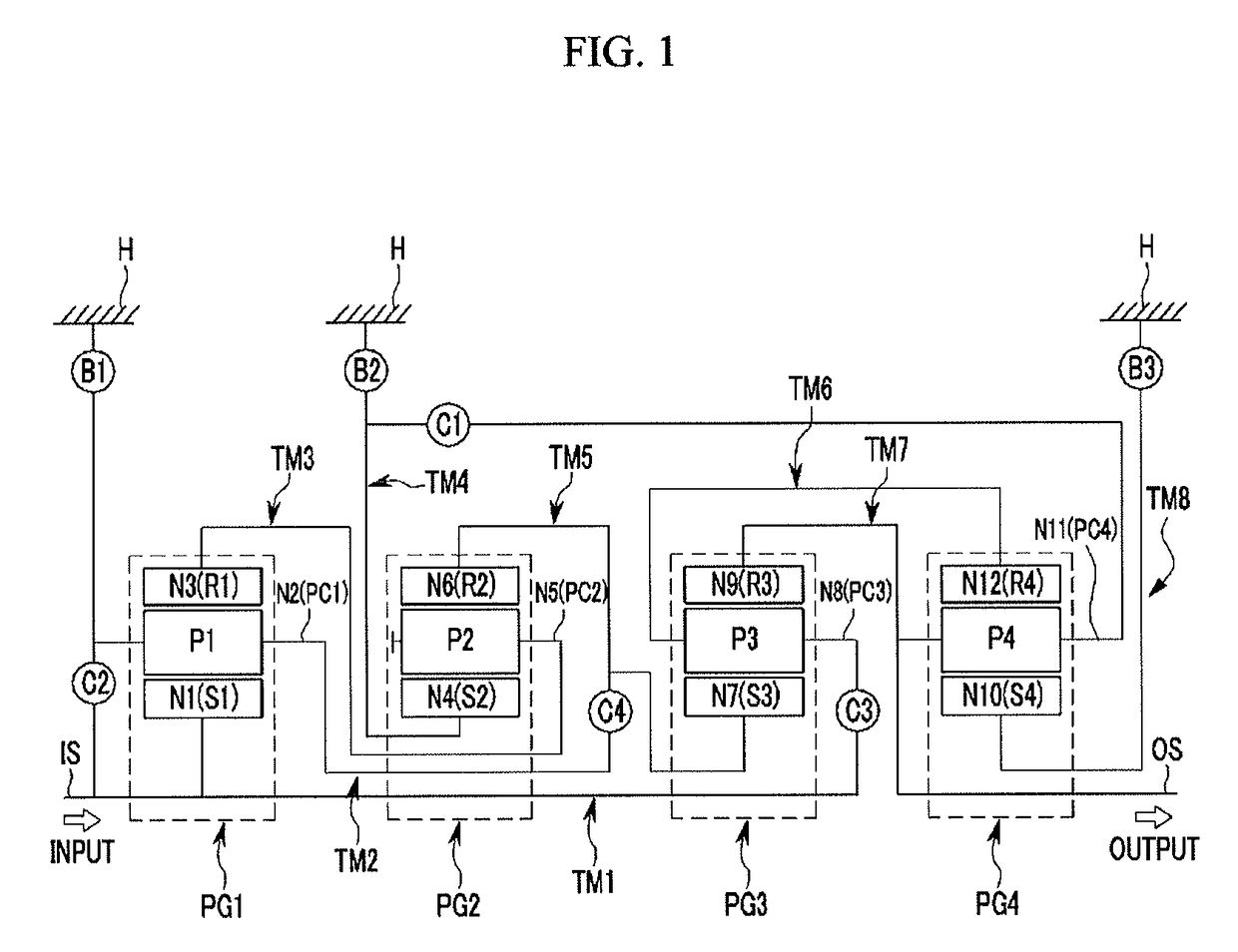

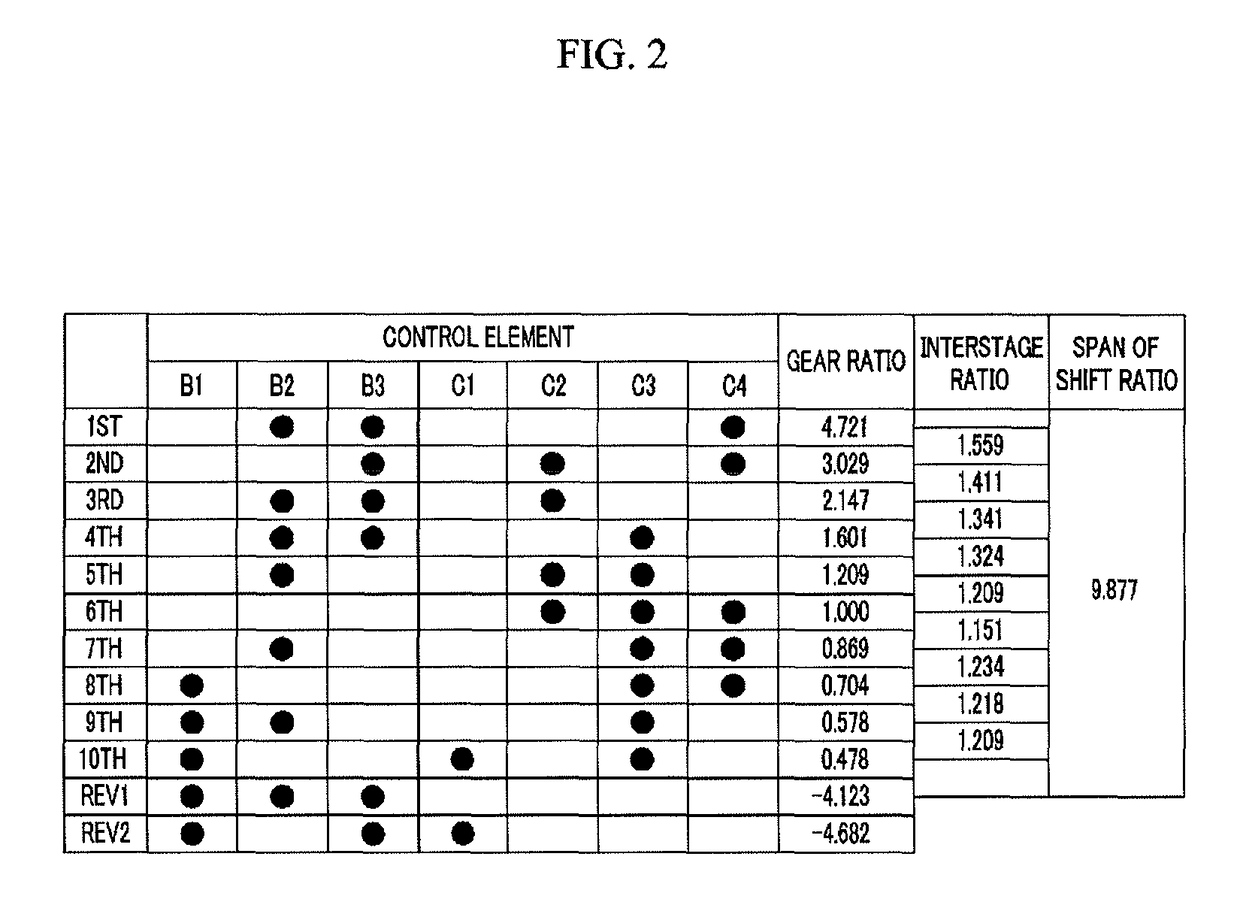

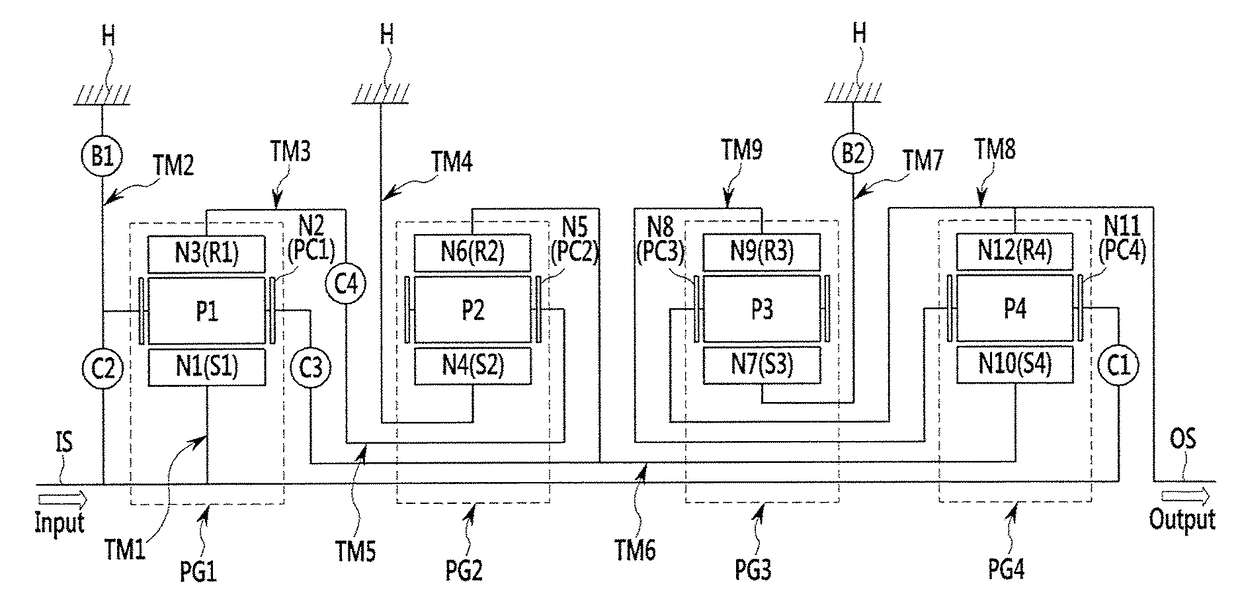

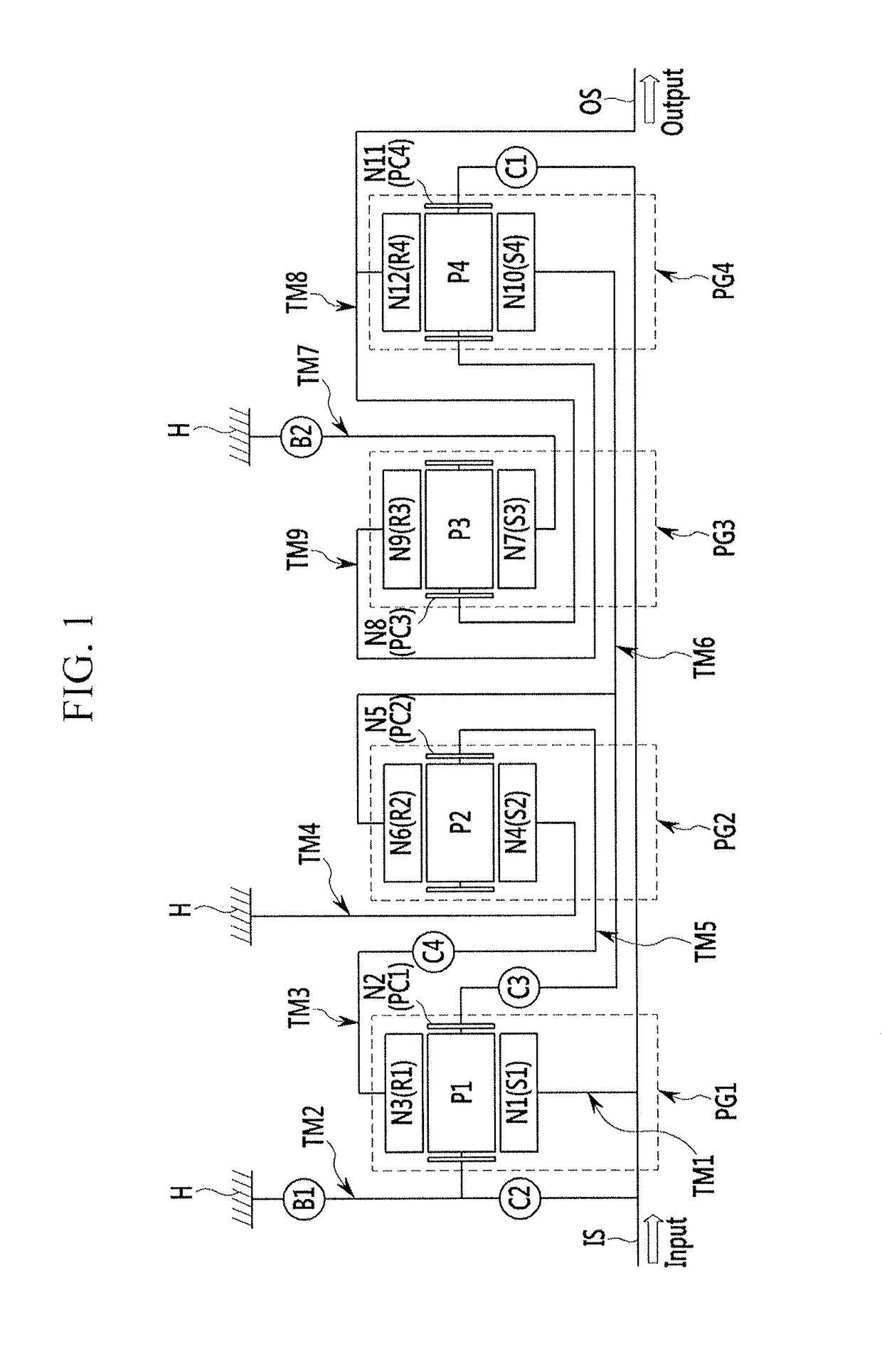

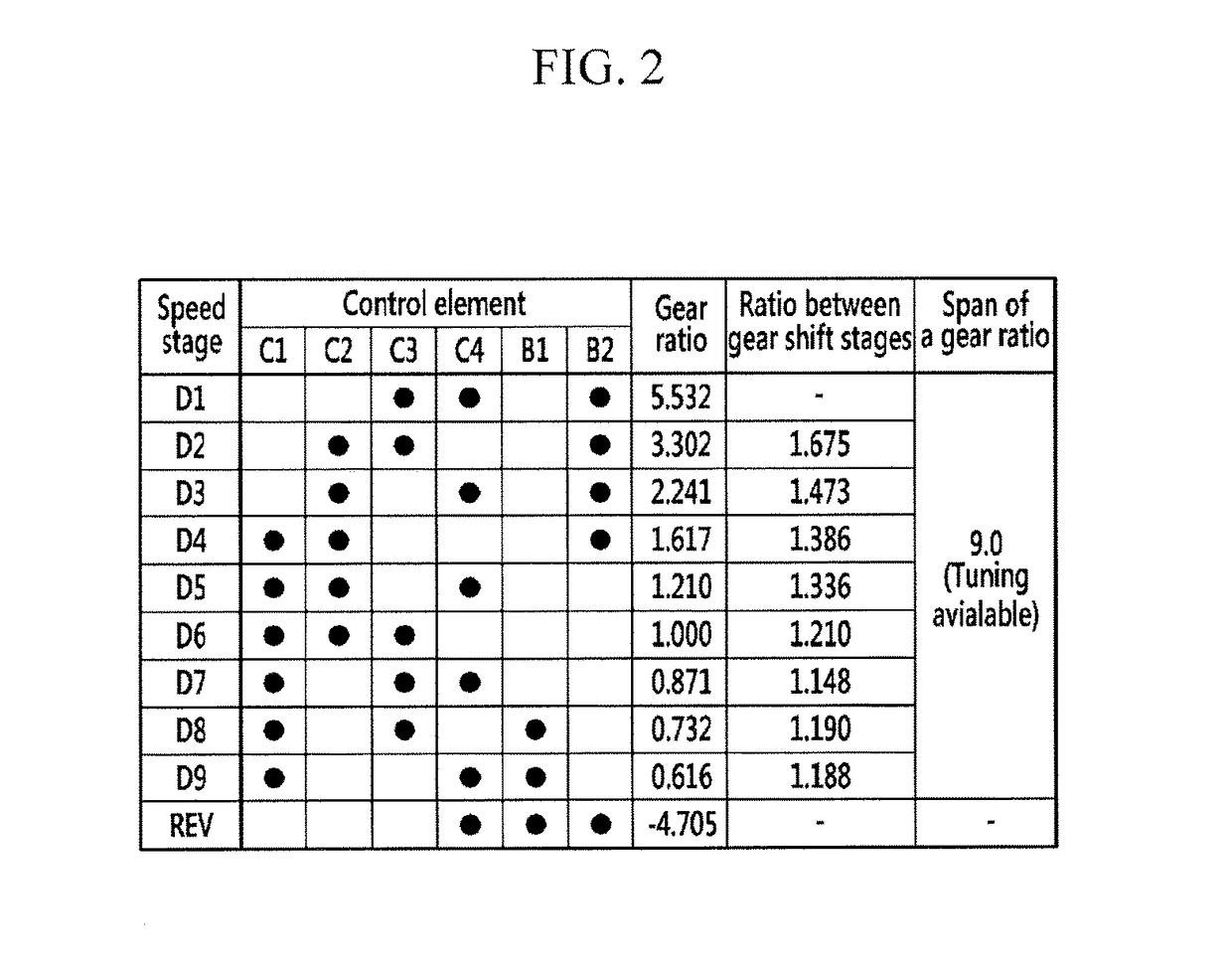

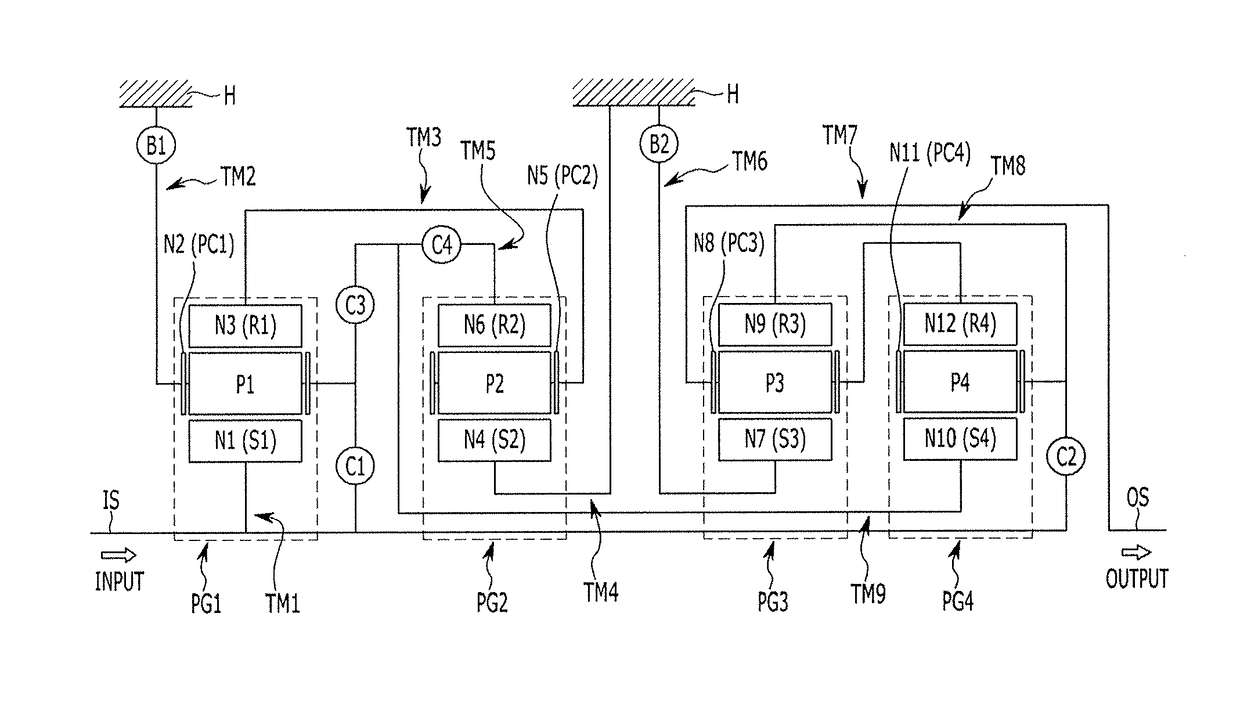

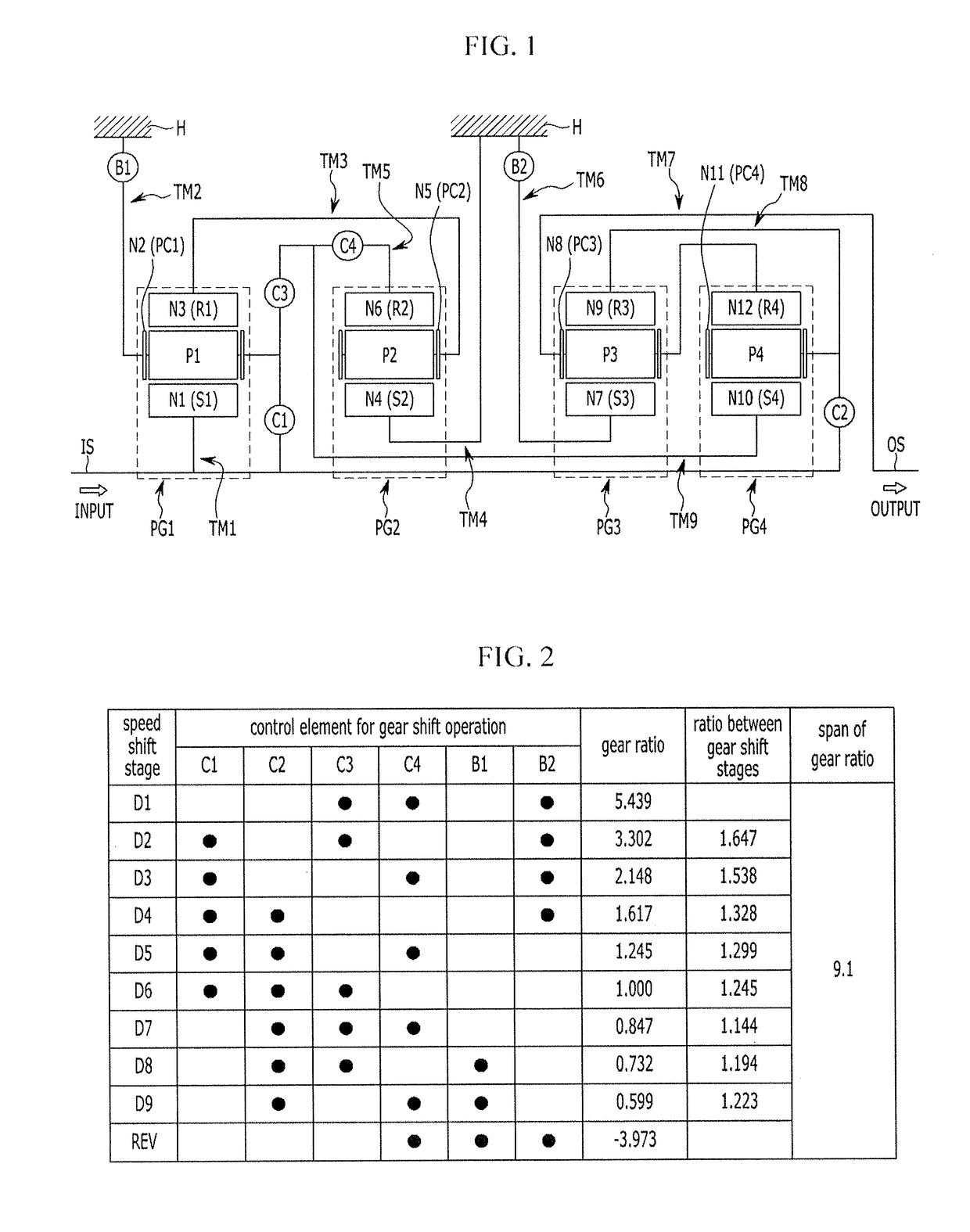

Planetary gear train of automatic transmission for vehicle

ActiveUS9822848B2Increase spanEnsuring linearityToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission may include: an input shaft; an output shaft; first to fourth planetary gear sets; and six control elements being disposed at a portion where one of the rotating element is selectively connected to another rotating element, or the rotating element is selectively connected to the transmission housing, wherein the input shaft is continuously connected to the second rotating element, the output shaft is continuously connected to the twelfth rotating element, the first rotating element is continuously connected to the seventh rotating element, the fourth rotating element is directly connected to the transmission housing, the fifth rotating element is continuously connected to the eleventh rotating element, and the ninth rotating element is continuously connected to the tenth rotating element.

Owner:HYUNDAI MOTOR CO LTD

Grapheme-nanomaterial-based conductive wire

ActiveCN103700440AReduce lossRaise the draw-to-weight ratioMaterial nanotechnologyNon-insulated conductorsFiberCarrying capacity

The invention provides a grapheme-nanomaterial-based conductive wire, belongs to the technical field of conductive wires for overhead transmission lines, and solves the problems that improvement on the conductivity of aluminum and copper and other conventional metal materials is limited and the transmission capacity of an overhead transmission line is limited. The grapheme-nanomaterial-based conductive wire comprises two structures as follows: 1, the grapheme-nanomaterial-based conductive wire comprises an inner layer and an outer layer, wherein the inner layer is formed by twisting monofilaments of steel or carbon fiber, nanotube monofilaments of a grapheme nanomaterial or composite monofilaments, and the outer layer is formed by twisting arc grapheme nanomaterial sheets; 2, the grapheme-nanomaterial-based conductive wire is formed by twisting circular linear nanotube monofilaments of the grapheme nanomaterial or the composite monofilaments, wherein the monofilament are tightly adhered to one another to form a regular tubular structure, circular cross sections of the composite monofilaments are made of a carbon fiber composite material, and the grapheme nanomaterial is filled into the circular cross sections. The grapheme-nanomaterial-based conductive wire can effectively reduce the line loss and improve the transmission power of the overhead transmission line, and has an allowable current-carrying capacity which is 10 times as that of an ordinary wire under the same external conditions.

Owner:CHINA ELECTRIC POWER RES INST +1

Planetary gear train of automatic transmission for vehicles

ActiveUS9651115B2Increase spanImprove efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for vehicles may include an input shaft receiving power of an engine, an output shaft outputting shifted power of the engine, a first planetary gear set including first, second, and third rotational elements, a second planetary gear set including fourth, fifth, and sixth rotational elements, a third planetary gear set including seventh, eighth, and ninth rotational elements, a fourth planetary gear set including tenth, eleventh, and twelfth rotational elements, and seven control elements disposed between the rotational elements and at positions at which the rotational elements and a transmission housing are selectively connected.

Owner:HYUNDAI MOTOR CO LTD

Telescopic rail and carriage assembly for suspending a patient lift

A telescopic rail and carriage assembly for suspending a patient lift. The carriage has a downward projection to which the patient lift is to be connected. The telescopic rail has an inner rail section and an outer rail section. The outer rail section is provided with first longitudinally extending interior support surfaces for supporting a lower set of wheels of the carriage. The inner rail section is provided with second longitudinally extending interior support surfaces for guiding and supporting an upper set of wheels of the carriage. In the extended state, the carriage is guided by the either the first or the second longitudinally extending support surfaces except where the first and second rail sections overlap. In the overlap, the wheels of the carriage are supported by both the first and second longitudinally extending interior support surfaces. A support structure for suspending a patient lift, having a telescopic rail provided with a carriage with means for attaching the patient lift thereto, a pair of upstanding pole components each provided with a stabilizing ground support. The opposite ends of the telescopic rail are connected to the upper ends of the upstanding pole components.

Owner:ERGOLET

Planetary gear train of automatic transmission for vehicles

ActiveUS9890834B2Ensuring linearityIncrease spanToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for vehicle may include an input shaft receiving power of an engine, an output shaft outputting shifted power of the engine, a first planetary gear set including a first rotation element, a second rotation element, and a third rotation element, a second planetary gear set including a fourth rotation element, a fifth rotation element, and a sixth rotation element, a third planetary gear set including a seventh rotation element, an eighth rotation element, and a ninth rotation element, a fourth planetary gear set including a tenth rotation element, an eleventh rotation element, and a twelfth rotation element, and six control elements disposed at positions selectively connecting the rotation elements to each other or at positions selectively connecting the rotation elements and a transmission housing.

Owner:HYUNDAI MOTOR CO LTD

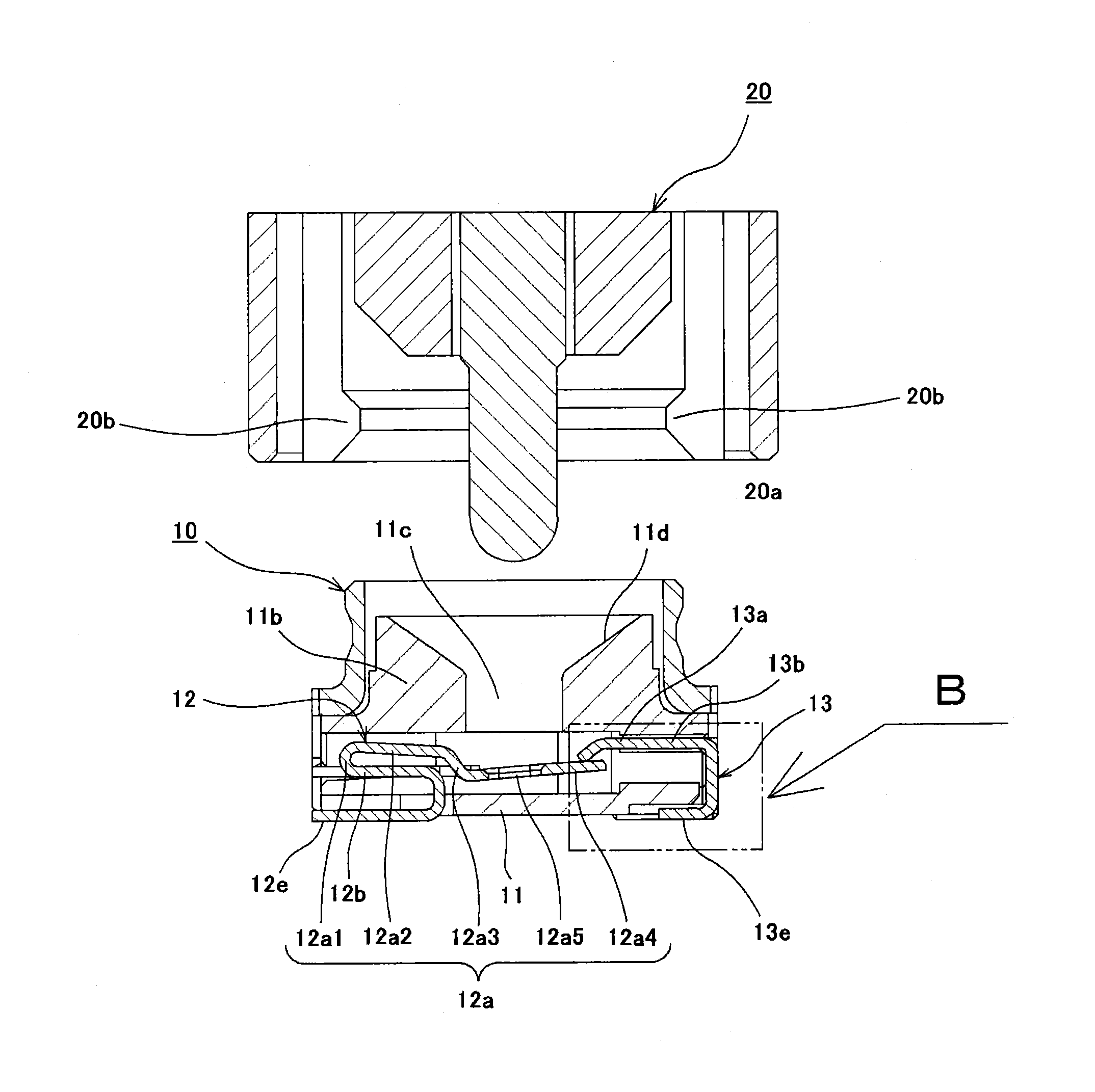

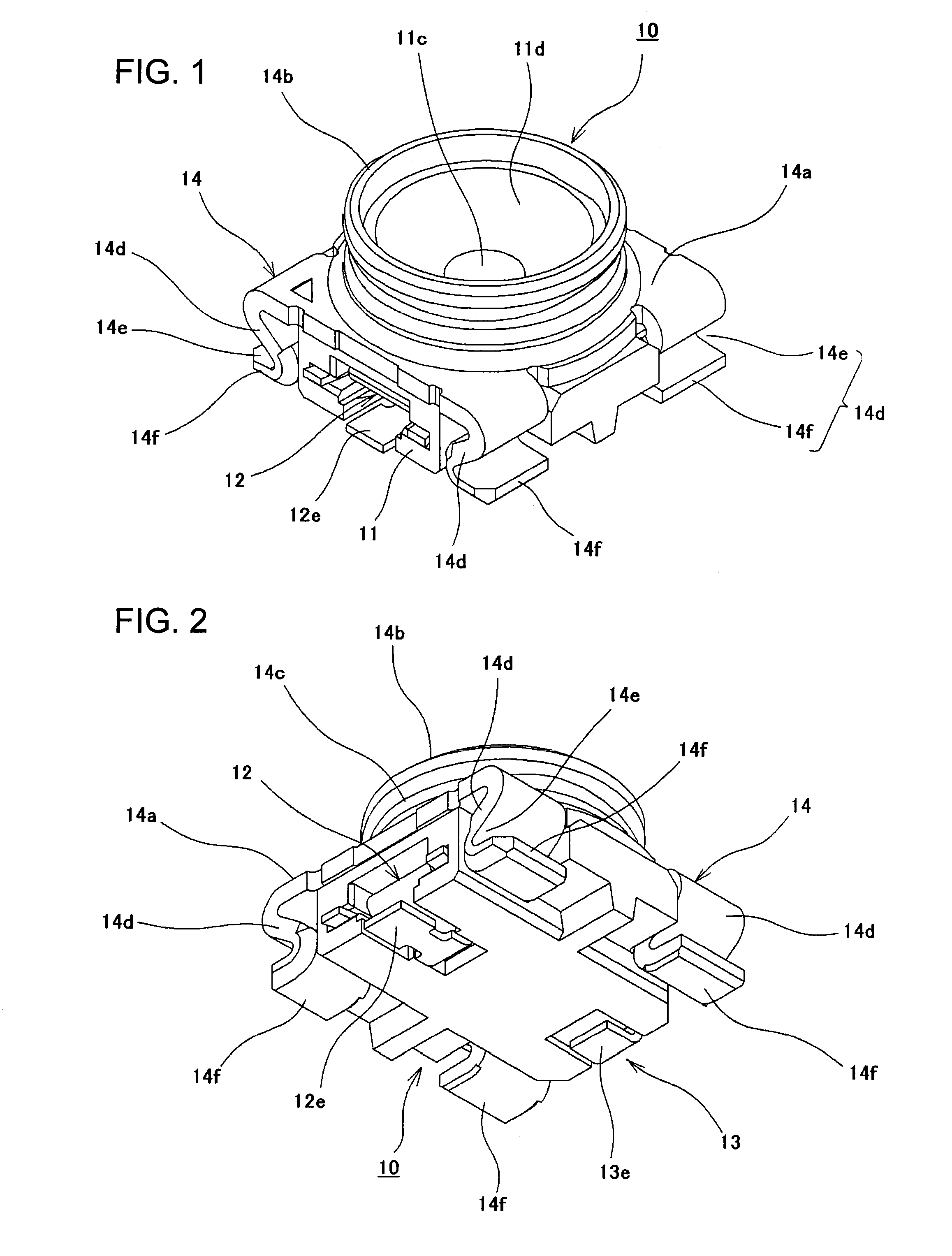

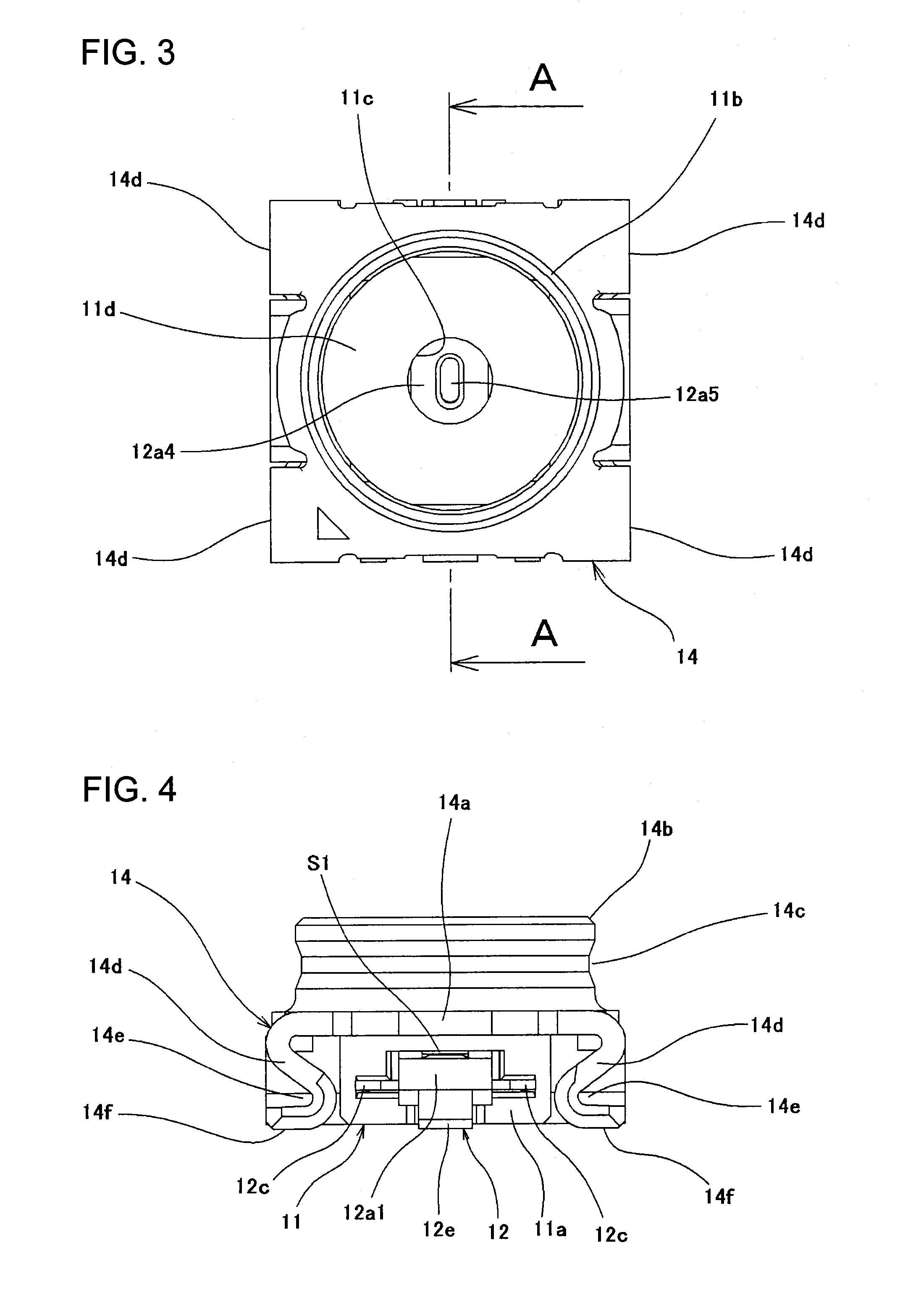

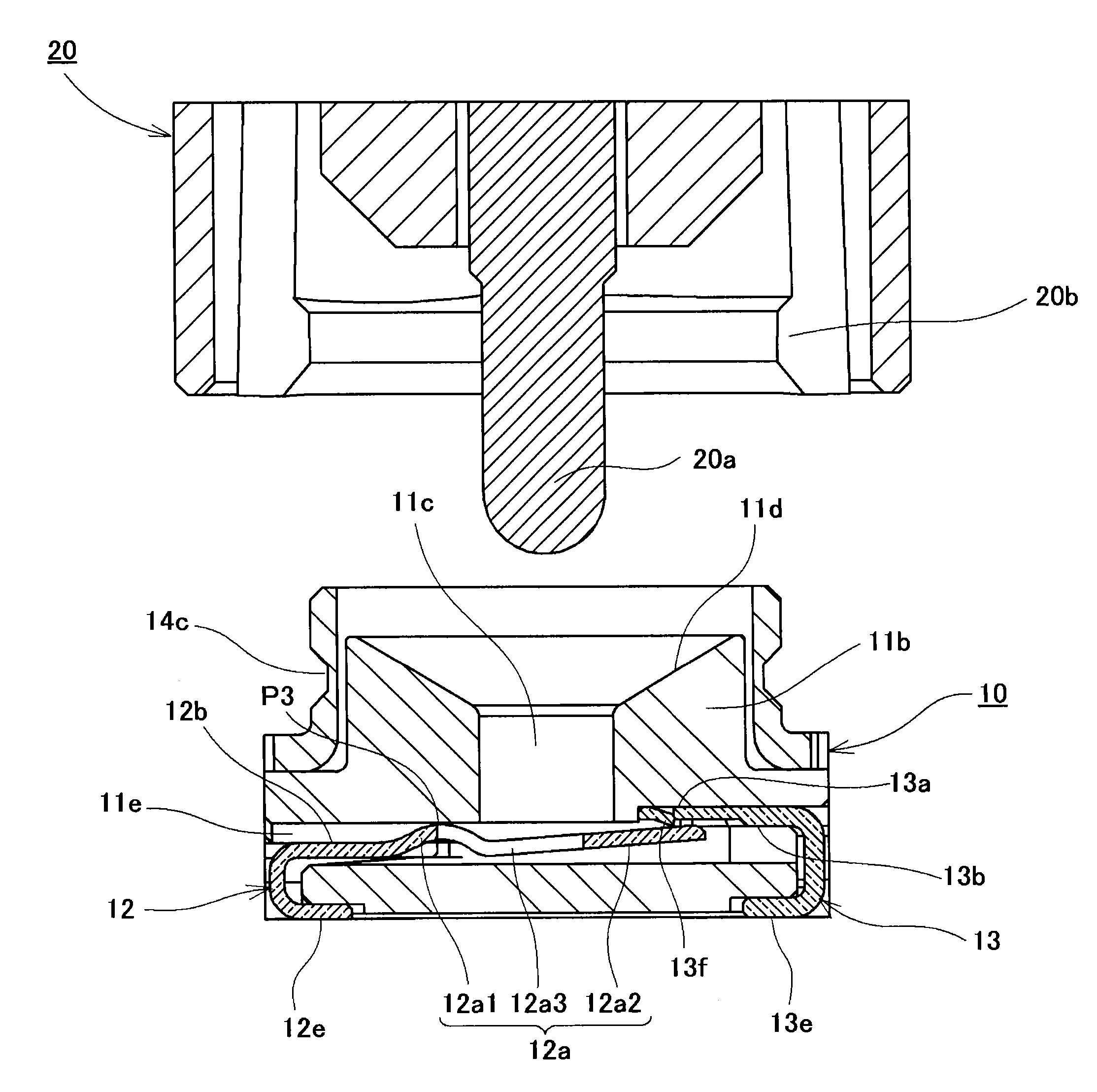

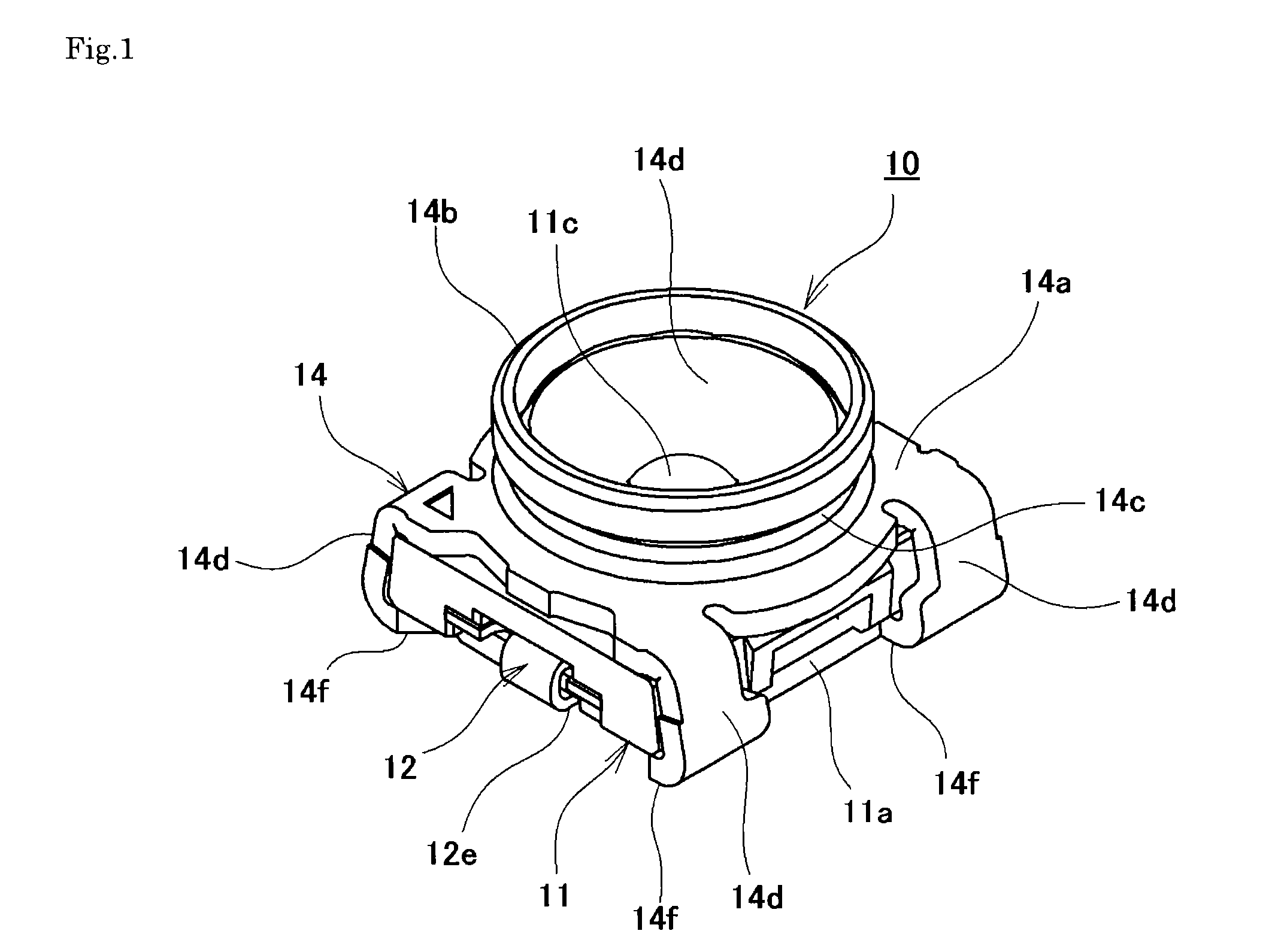

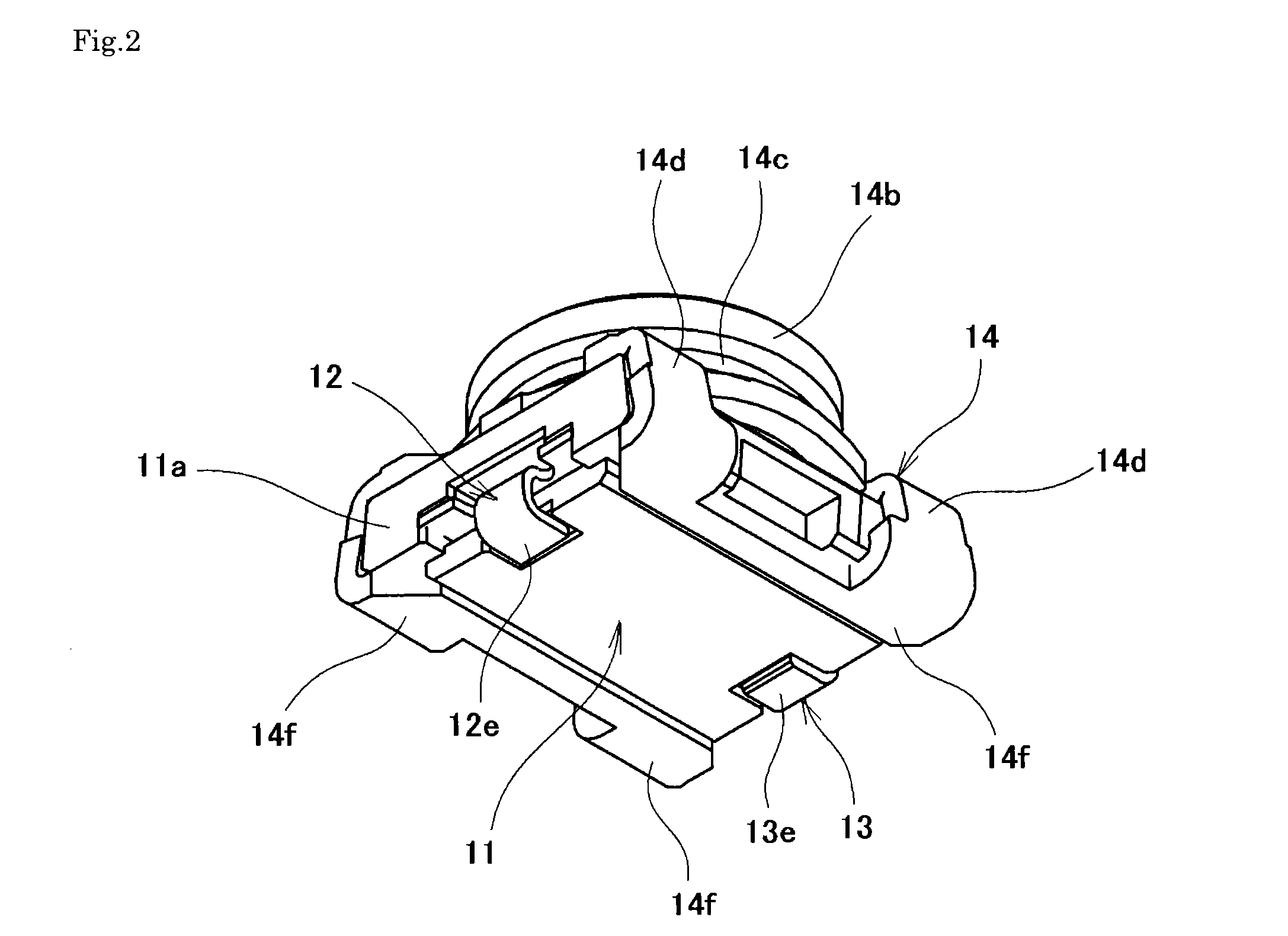

Switch-equipped coaxial connector

InactiveUS20130102173A1Improve performanceIncrease elasticityCoupling device detailsTwo-part coupling devicesElectricityElectrical connection

With a simple configuration, increase in size can be avoided, usage durability is improved, and occurrence of insufficient electrical connection caused by dust can be prevented well. A crank part is provided in at least one of both contacts including elastic beam-like members. Both of the contacts are provided with cut-away parts, which substantially increase the span lengths of the elastic beam-like members, and gaps between the contacts and an insulating housing which ensure flexibility of the elastic beam-like members to ensure flexibility and prevent permanent deformation of the contacts while enhancing elasticity of the contacts. Dust which has entered the interior thereof is moved along the crank part to ensure electrical conductivity well, which is an employed configuration.

Owner:DAIICHI SEIKO CO LTD

Switch-equipped coaxial connector

InactiveUS8986043B2Simple configurationAvoid plastic deformationElectrically conductive connectionsCoupling device detailsElectricityCurve shape

Owner:DAIICHI SEIKO CO LTD

Planetary gear train of automatic transmission for vehicles

ActiveUS9958035B2Increase spanImprove efficiencyToothed gearingsGearing controlAutomatic transmissionGear wheel

Owner:HYUNDAI MOTOR CO LTD

Double-input high-speed gear transmission box used for steam turbine

ActiveCN102619961AReduce pitch circle speedReduce oil throwing power consumptionMachines/enginesEngine componentsLow speedEngineering

The invention discloses a double-input high-speed gear transmission box used for a steam turbine, and the double-input high-speed gear transmission box is used for a 1.5MW solar double-cylinder condensing steam turbine. The double-input high-speed gear transmission box comprises high-speed input shafts and low-speed input shafts, wherein the revolving speed of a high-speed input shaft I on a high-pressure end is 36000rpm (revolutions per minute); the revolving speed of a high-speed input shaft II on a low-pressure end is 7500rpm; the high-speed input shaft I is directly connected with a high-pressure impeller; the high-pressure impeller cantilever of the steam turbine is supported on the high-speed input shaft I; and the high-speed input shaft II is connected with the low-pressure cylinder of the steam turbine via a coupler. According to the double-input high-speed gear transmission box, the diameter of a gearwheel is drastically reduced, the oil slinging power consumption of the gearis lowered, and the gear box transmission efficiency is improved. A high-pressure impeller end supporting bearing and a box body are respectively provided with a cooling cavity so as to effectively reduce the influence of high-temperature steam on bearing alloy. The axial gap of a high-pressure spindle is not influenced by a low-pressure spindle so as to bring convenience for regulating the assembling gap and improving the performance of a high-pressure impeller. In addition to a solar thermal power generation system, the double-input high-speed gear transmission box also can be used for the fields of industrial waste heat power generation or combined heat and power, gas and steam combined power generation and the like.

Owner:JIN TONG LING TECH GRP CO LTD

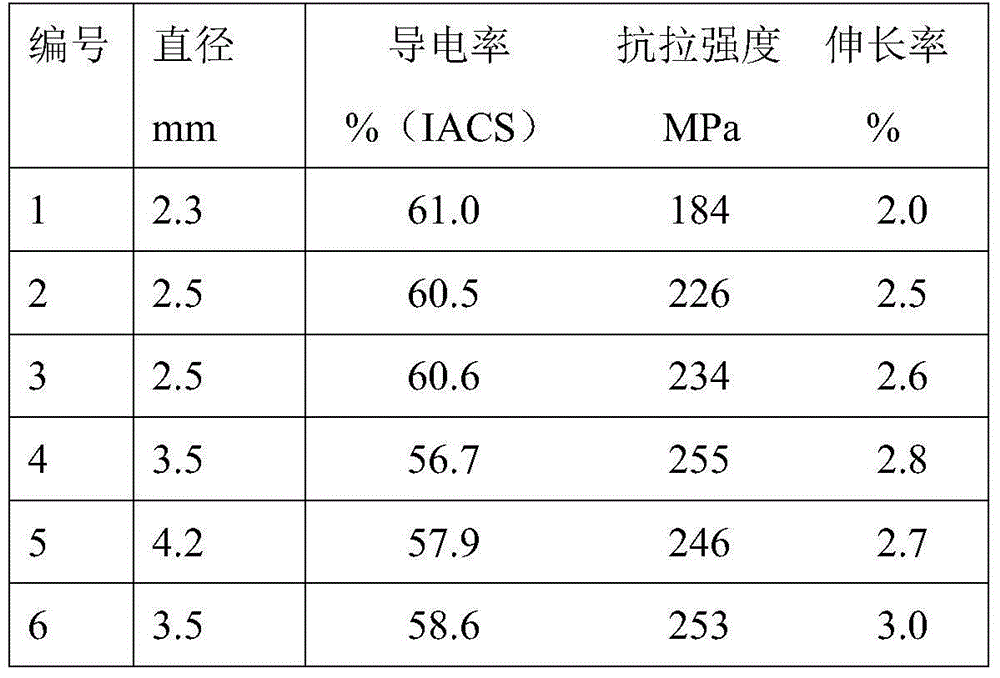

Non-heat treatment medium-strength aluminum alloy conductor material and preparation method thereof

InactiveCN104532067AHigh work hardening rateImprove conductivityMetal/alloy conductorsCable/conductor manufactureElectrical conductorRare earth

The invention relates to a non-heat treatment medium-strength aluminum alloy conductor material and a preparation method thereof, and belongs to the technical field of electrotechnical materials. The non-heat treatment medium-strength aluminum alloy conductor material comprises the following elements in percentage by weight: 0.35%-0.50% of iron, 0.10%-0.25% of copper, 0.01%-0.04% of magnesium, 0.001%-0.002% of boron, 0.02%-0.04% of rare earth (lanthanum or yttrium), impurity element silicon less than or equal to 0.11%, s(chromium+manganese+vanadium+titanium) less than or equal to 0.015%, less than or equal to 0.03% of each of other impurity elements and the balance of aluminum. The non-heat treatment medium-strength aluminum alloy conductor material disclosed by the invention can be used for enhancing the processing hardening rate of an aluminum alloy material to enhance the strength through an iron-containing second phase, copper and magnesium atom enrichment regions and dislocation interaction and enhancing the conductivity and elongation of an aluminum alloy through the matching of the iron, the copper, the magnesium, the rare earth lanthanum or yttrium and the boron. A medium-strength aluminum alloy wire manufactured by adopting the non-heat treatment medium-strength aluminum alloy conductor material can be used for solving the problem of continuous production bottleneck generated due to heat treatment, saving the power consumption and time consumption of heat treatment and reducing the cost and achieves the outstanding economic benefit.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

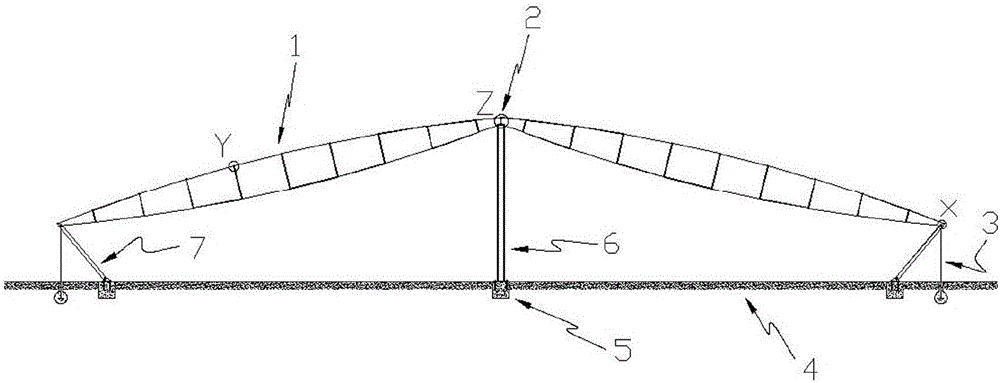

String structure, string beam and building

InactiveCN105863145AImprove support abilityIncrease spanBuilding roofsComposite structureEngineering

The invention discloses a string structure, a string beam and a building. According to the string structure, tensioned stay rope components are adopted as basic components. Stay ropes are building components frequently used at present, conventionally, the structure weight of the stay ropes is greatly reduced compared with that of rigid components used for rigid beams, certain supporting capability can be formed through tensioning, the supporting capability can be effectively improved in cooperation of the composite structure of upper string ropes and lower string ropes, and thus a light roof such as a thin film roof can be supported; by means of the structure, the influence of the self-gravity capability on the span is greatly relieved under the influence of the tensioning resisting capability of the stay ropes, and thus the span of the string beam can be relatively increased.

Owner:JINAN JIANGFUWAN AUTOMATION TECH

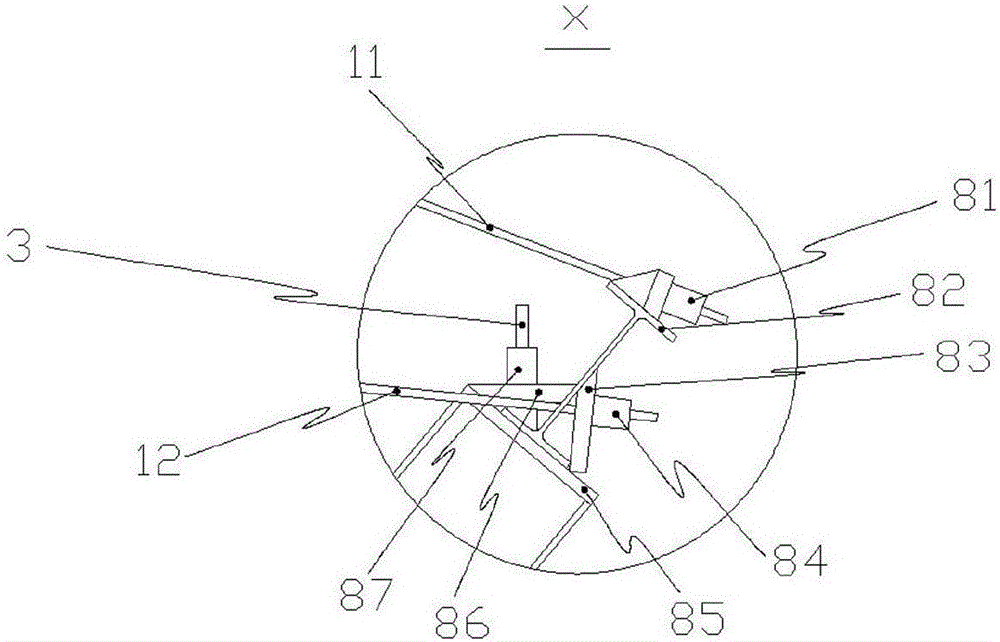

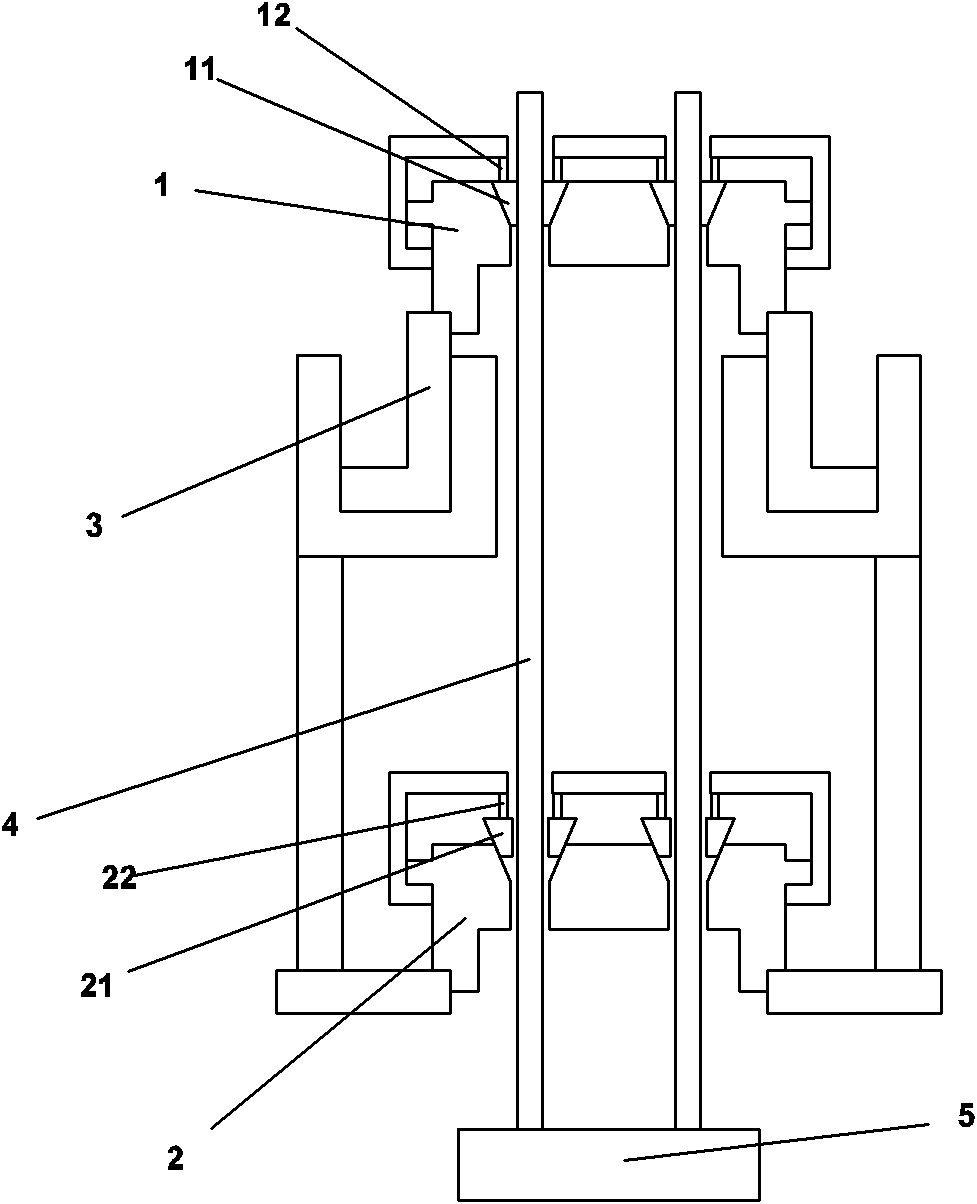

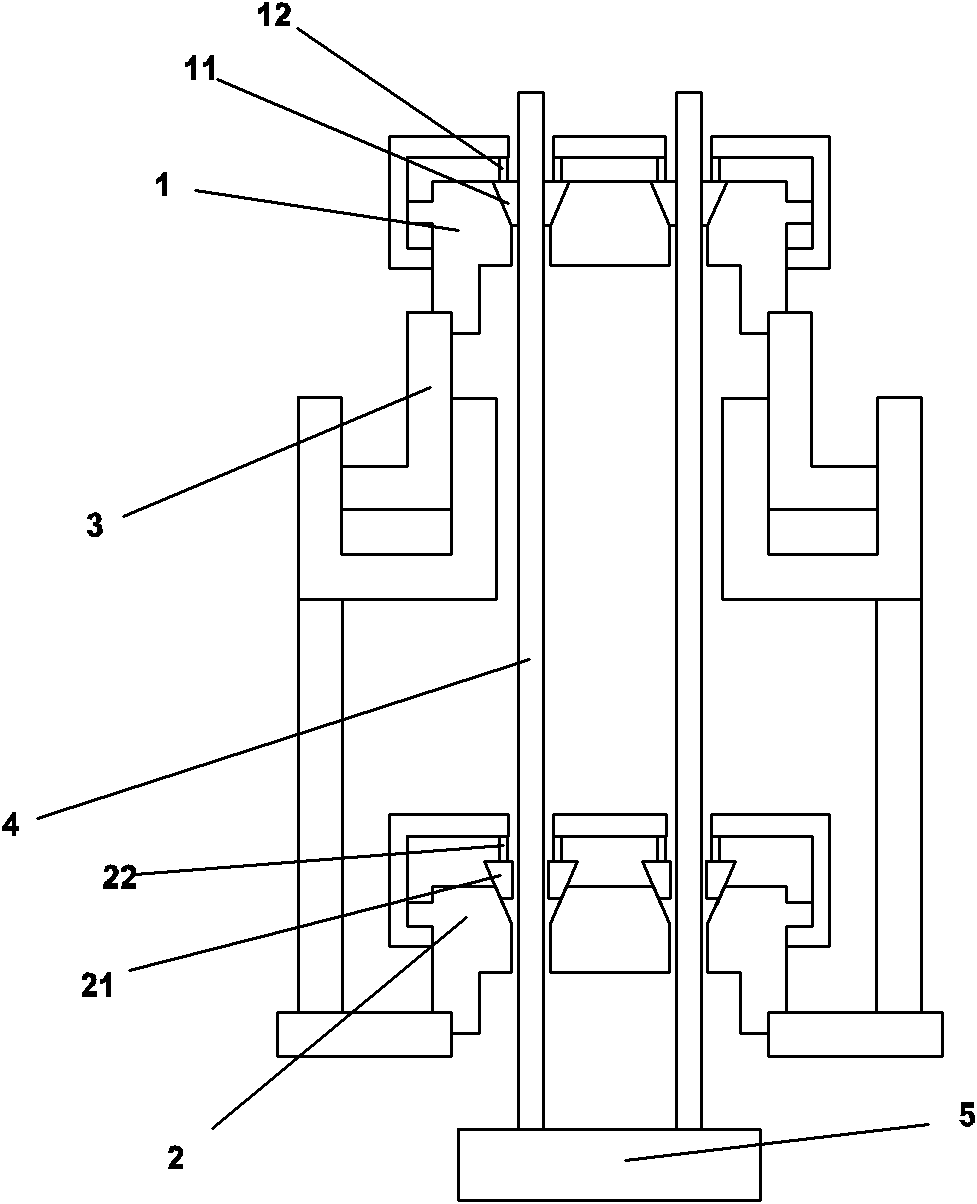

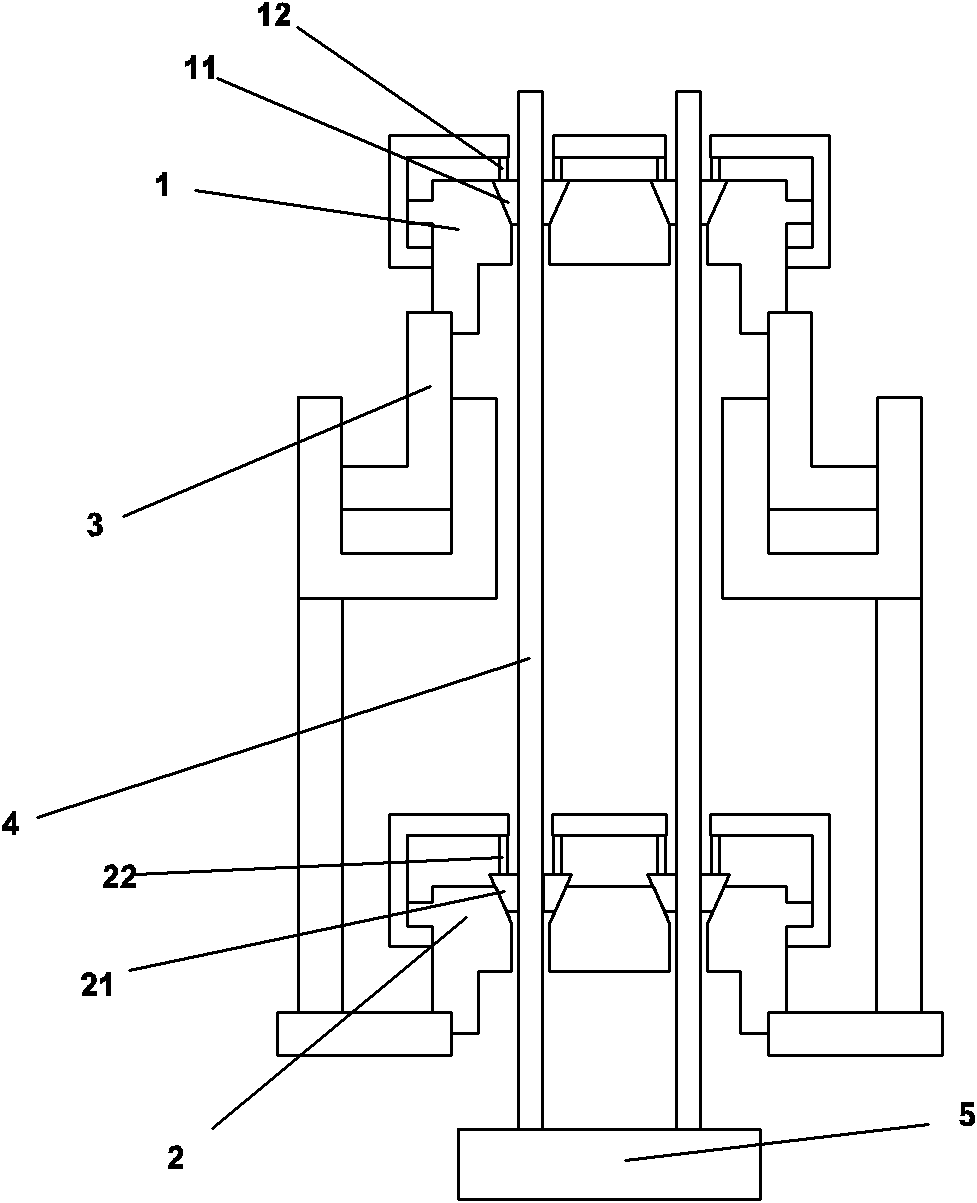

Hydraulic synchronous lifting hoisting technology and equipment for ultra-large members

The invention provides a hydraulic synchronous lifting hoisting technology and hydraulic synchronous lifting hoisting equipment for ultra-large members. The hydraulic synchronous lifting hoisting technology is characterized in that: the members are hoisted at the lower end of a steel strand; the steel strand passes through two upper wedge-shaped anchors and lower wedge-shaped anchors which are automatically locked downwards and are controlled to release and clamp by an upper anchor oil cylinder and a lower anchor oil cylinder, and a main oil cylinder controls the lifting of the upper wedge-shaped anchors; the upper wedge-shaped anchors and the lower wedge-shaped anchors clamp or release the steel strand alternately, and the main oil cylinder lifts or lowers the upper wedge-shaped anchors, so that the members ascend or descend; and the members are hoisted to the specified position by circulating the ascending or descending step alternately or continuously. According to the hydraulic synchronous lifting hoisting technology, lifting weight, span and areas are not limited, and lifting height and lifting amplitude are not limited; the lifting process is safe, and the members can be locked at any positions reliably for a long time in the lifting process; the equipment is small in volume, light in weight, high in carrying capacity, high in automaticity, conveniently and flexibly operated, high in safety and reliability, wide in application range and high in generality.

Owner:ELEPHANT KING HEAVY IND

Combined beam of FRP, wood and steel reinforced concrete

InactiveCN103603462AIncreased bending stiffnessImprove flexural strengthBuilding repairsGirdersEngineeringRebar

The invention discloses a combined beam of FRP, wood and steel reinforced concrete. The combined beam comprises steel reinforced concrete wing panels, shearing force connecting pieces, wood beams, FRP reinforcing members, FRP cloths, steel ribs and U-shaped stirrups, wherein the shearing force connecting pieces are disposed between the steel reinforced concrete wing panels and the wood beams; the FRP reinforcing members are disposed at the bottom of, in a cross section at the middle and lower part of and in the side surface of the wood beams; the bending zone of the combined beam is reinforced by transverse winding the FRP cloths; and the FRP reinforcing members in the bending shear zone of combined beam are anchored by using the U-shaped stirrups. The combined materials play the functions of their own and work cooperatively, so that cross sectional inertia of the wood-steel reinforced concrete combined beam is greatly increased; and strength and rigidity of original components are effectively increased. The combined beam has the advantages of light self-weight, good mechanical performances, low energy consumption and renewability, and can be widely applied in the fields of reinforcement of ancient architectures and modern wood structures.

Owner:NANJING UNIV OF TECH

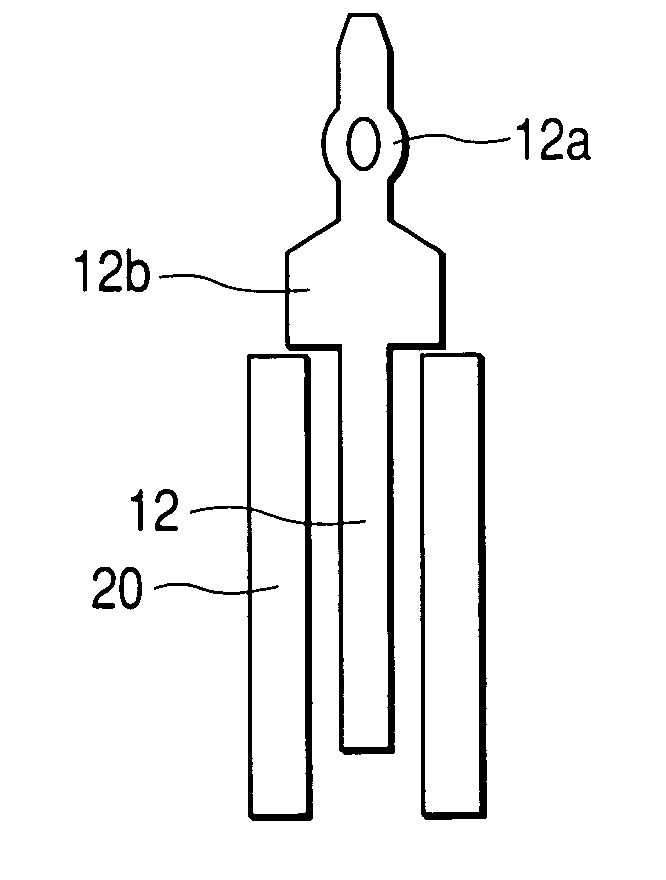

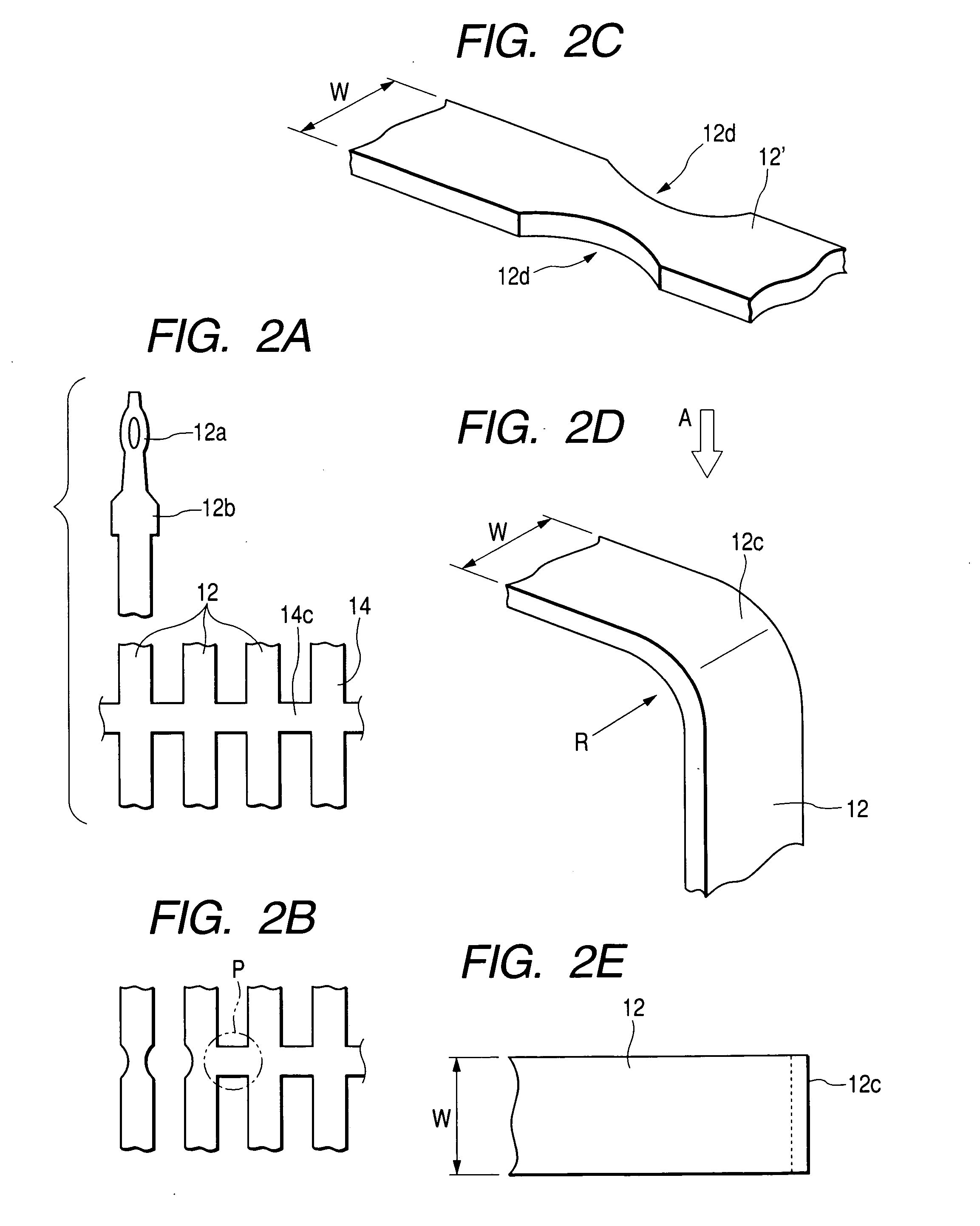

Connector terminal material, connector terminal, method for producing connector terminal and method for producing substrate with connector

InactiveUS20050014424A1Easy to set upIncrease productionContact member manufacturingElectrically conductive connectionsExtremity PartPrinted circuit board

A connector terminal material which extends in one direction and of which an intermediate specified part is bent is molded. The above-described specified part of the connector terminal material has notched parts formed at both sides in the terminal width direction and is made narrow thereat, and a flange part 12b is formed at this side of the tip end part. A connector terminal is produced by bending the specified part of the connector terminal material. While the connector terminal is being guided by a connector fixture which is narrower than the above-described flange part and has a wider deep groove than the other parts, the flange part is pressed by the press-fit surface of the end edge part of open end of the deep groove 23, whereby the tip end of the above-described connector terminal is press-fitted into the penetrating hole of the printed circuit board. Through the above-described processes, it is possible to produce a substrate with a connector.

Owner:AUTONETWORKS TECH LTD +2

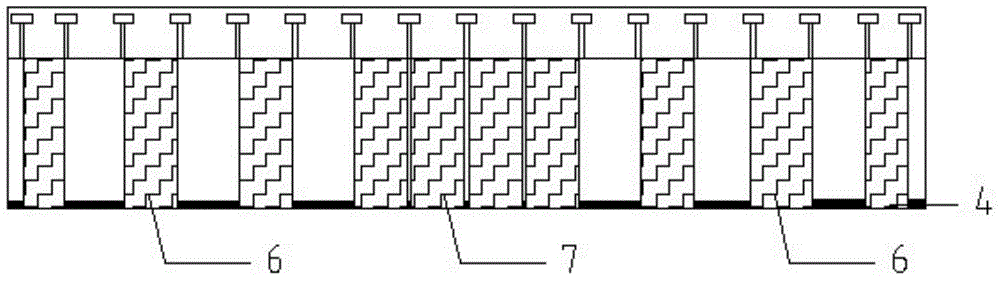

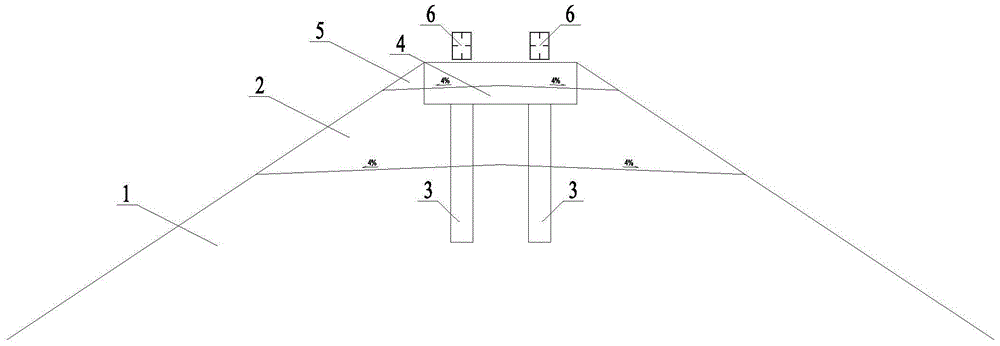

Straddle-type monorail bearing system and construction method thereof

The invention discloses a straddle-type monorail bearing system and a construction method thereof. The monorail bearing system comprises a roadbed body, a foundation bed bottom layer laid on the roadbed body, a foundation bed top layer laid on the foundation bed bottom layer, piles buried in the roadbed body and the foundation bed bottom layer, and a capping beam arranged at the top ends of the piles. Track beams are installed on the capping beam. The straddle-type monorail bearing system and the construction method thereof have the beneficial effects that the monorail bearing system combining the roadbed body and the piles is adopted, and the supporting function of the roadbed body among the piles is fully used so that the stress function of a roadbed structure can be improved; compared with existing overhead track beams, while the span of single-line track beams is enlarged, the usage amount of the overhead track beams, overhead structure bridge piers and base materials is effectively reduced; and the structure stress is improved, investment is reduced, and the monorail bearing system has remarkable social benefits and economic benefits.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com