Patents

Literature

90results about How to "High strength to weight ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

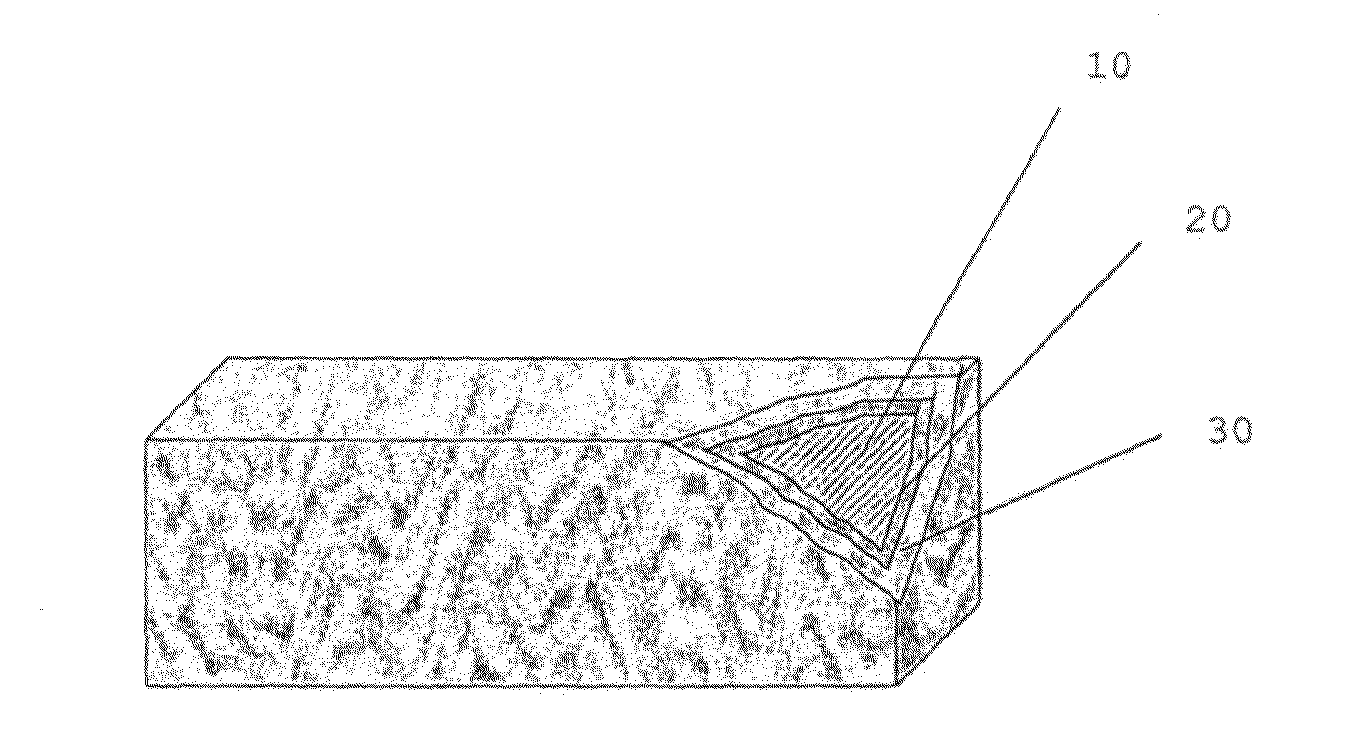

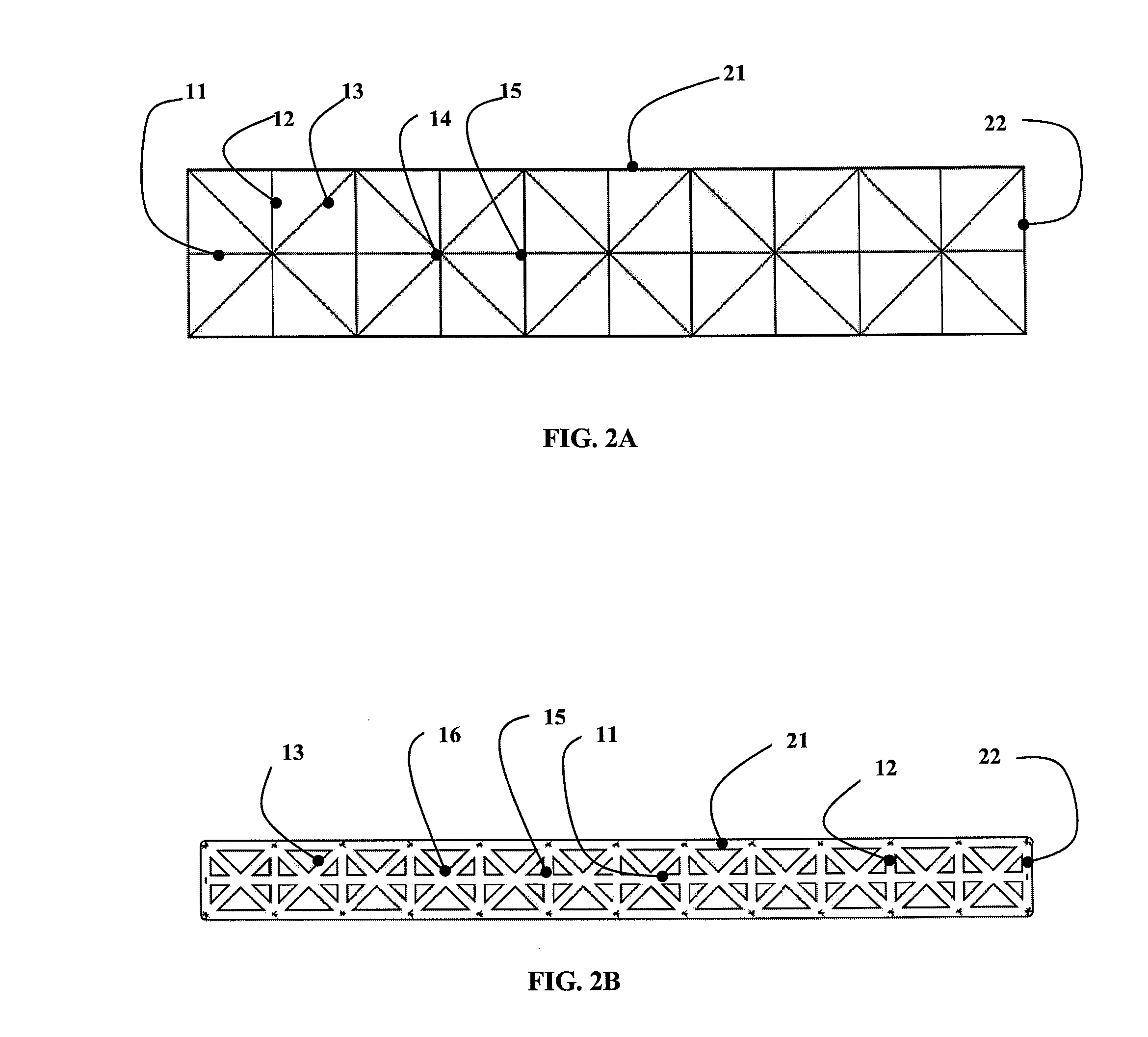

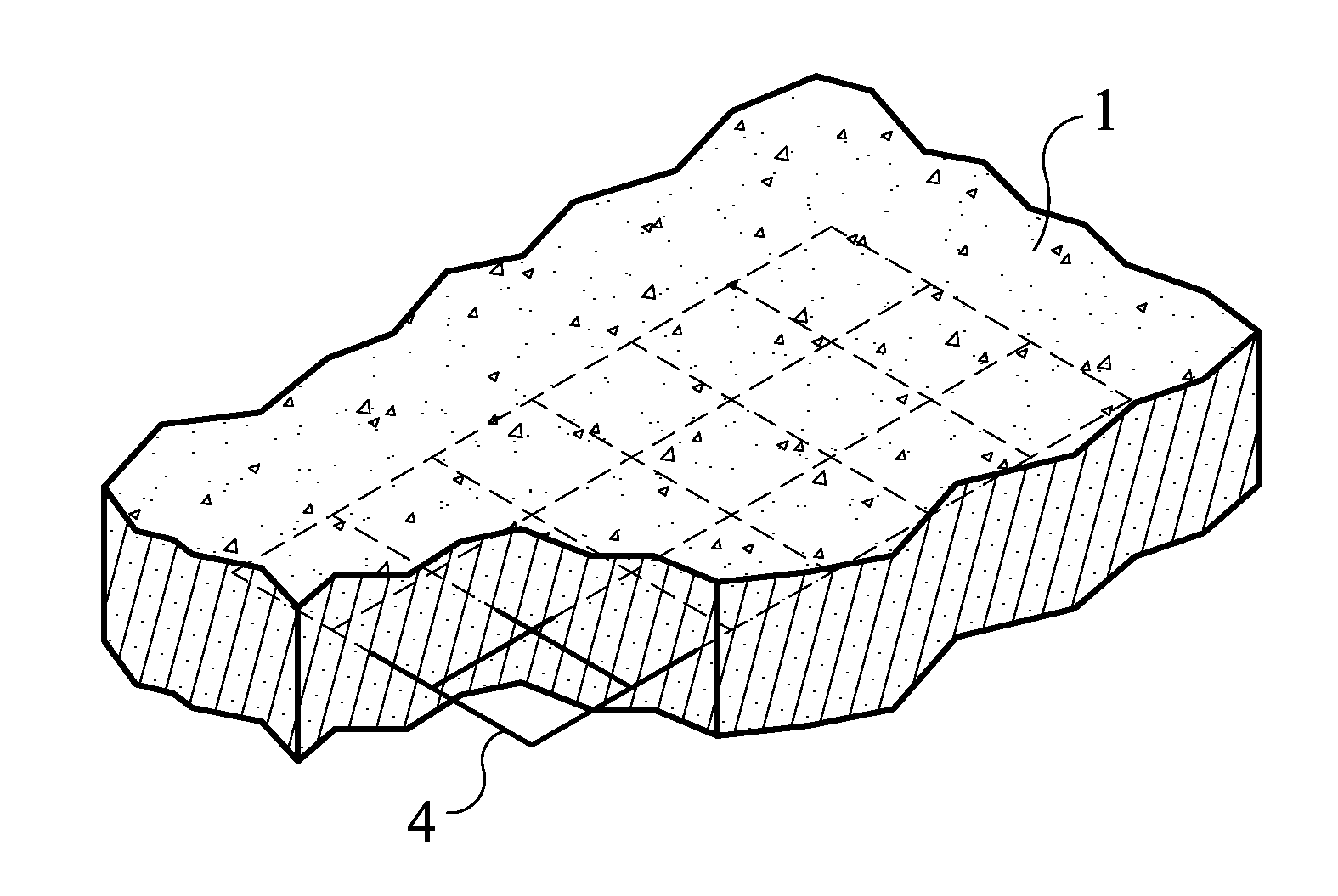

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

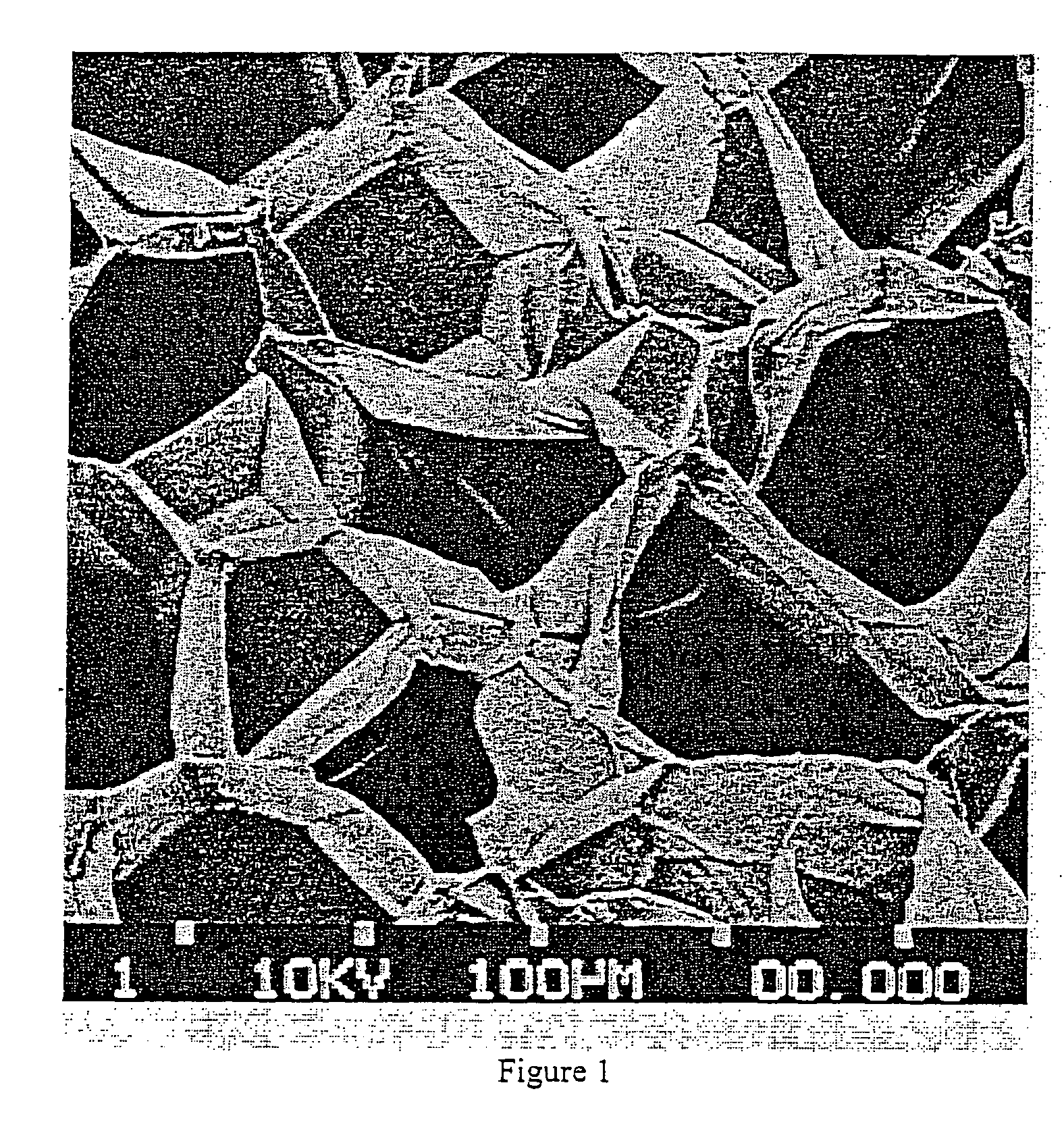

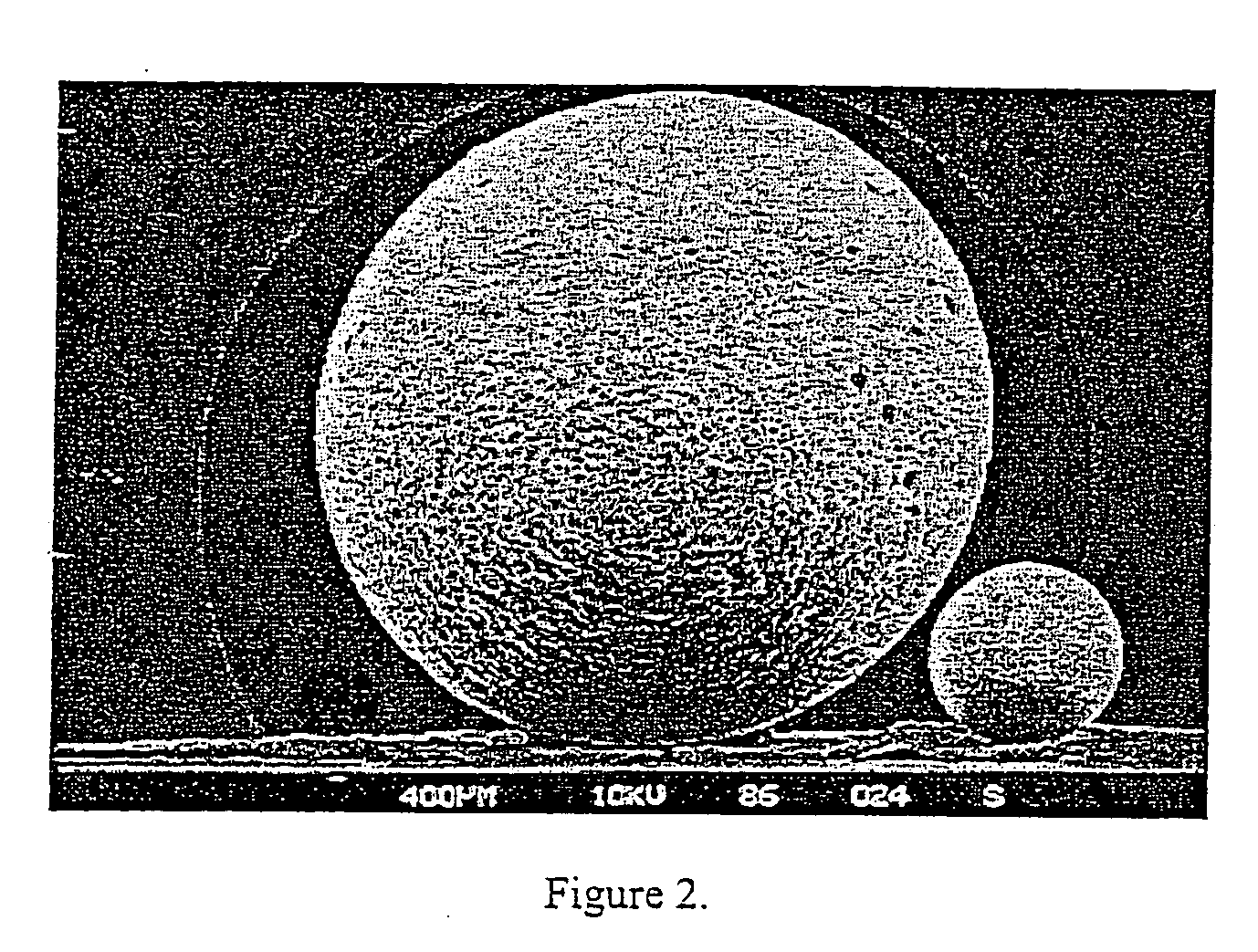

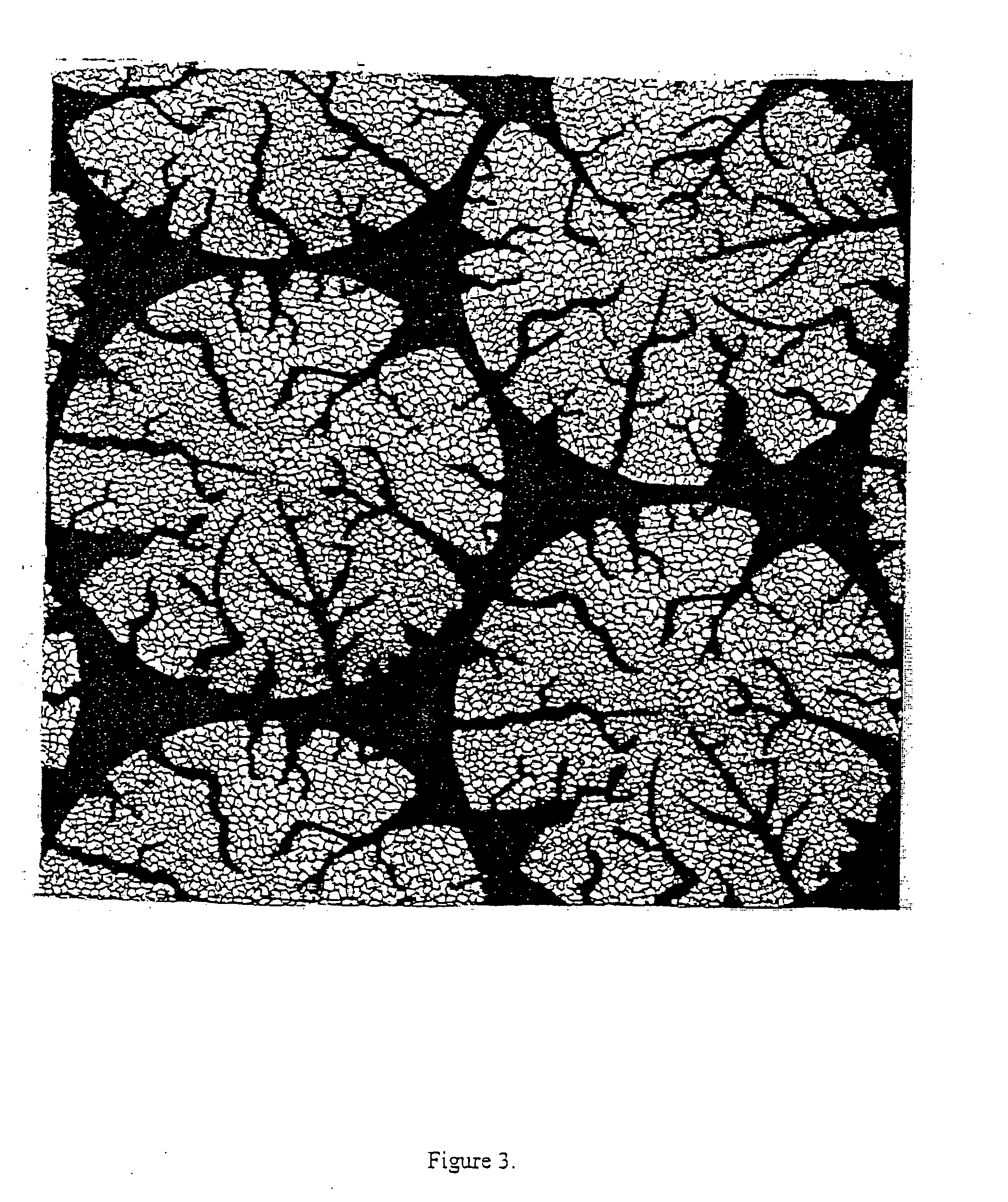

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

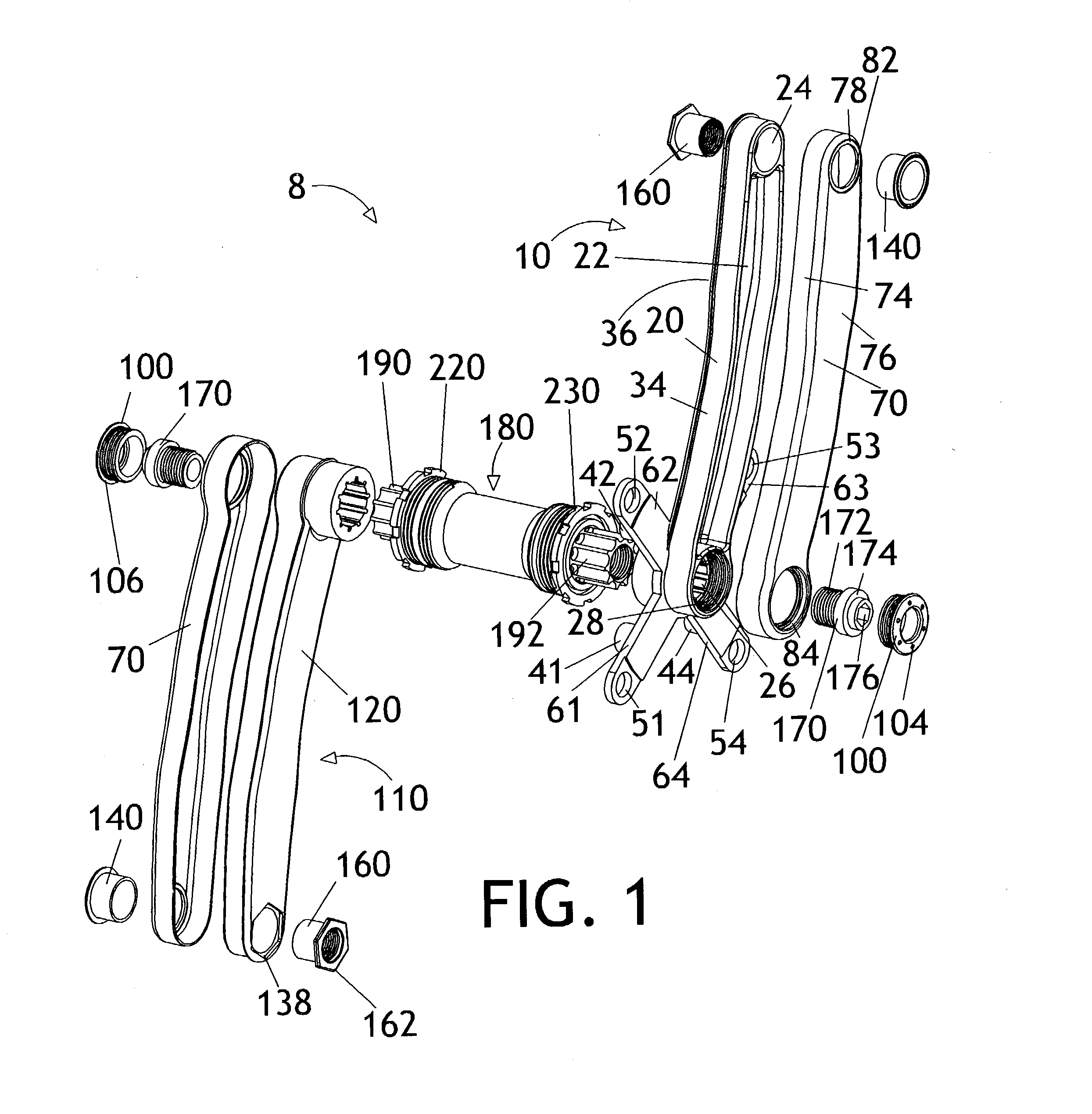

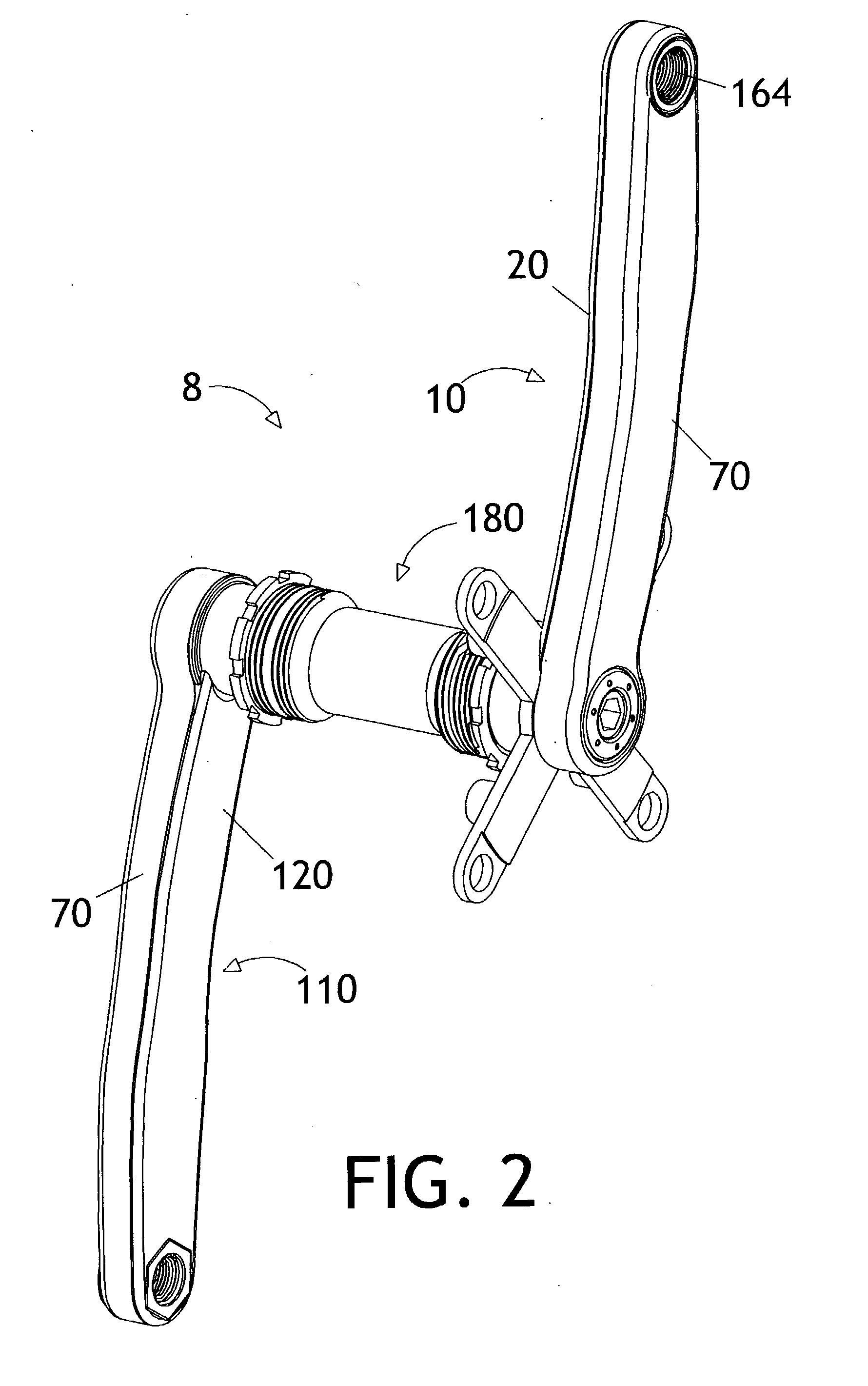

Bicycle crank arm

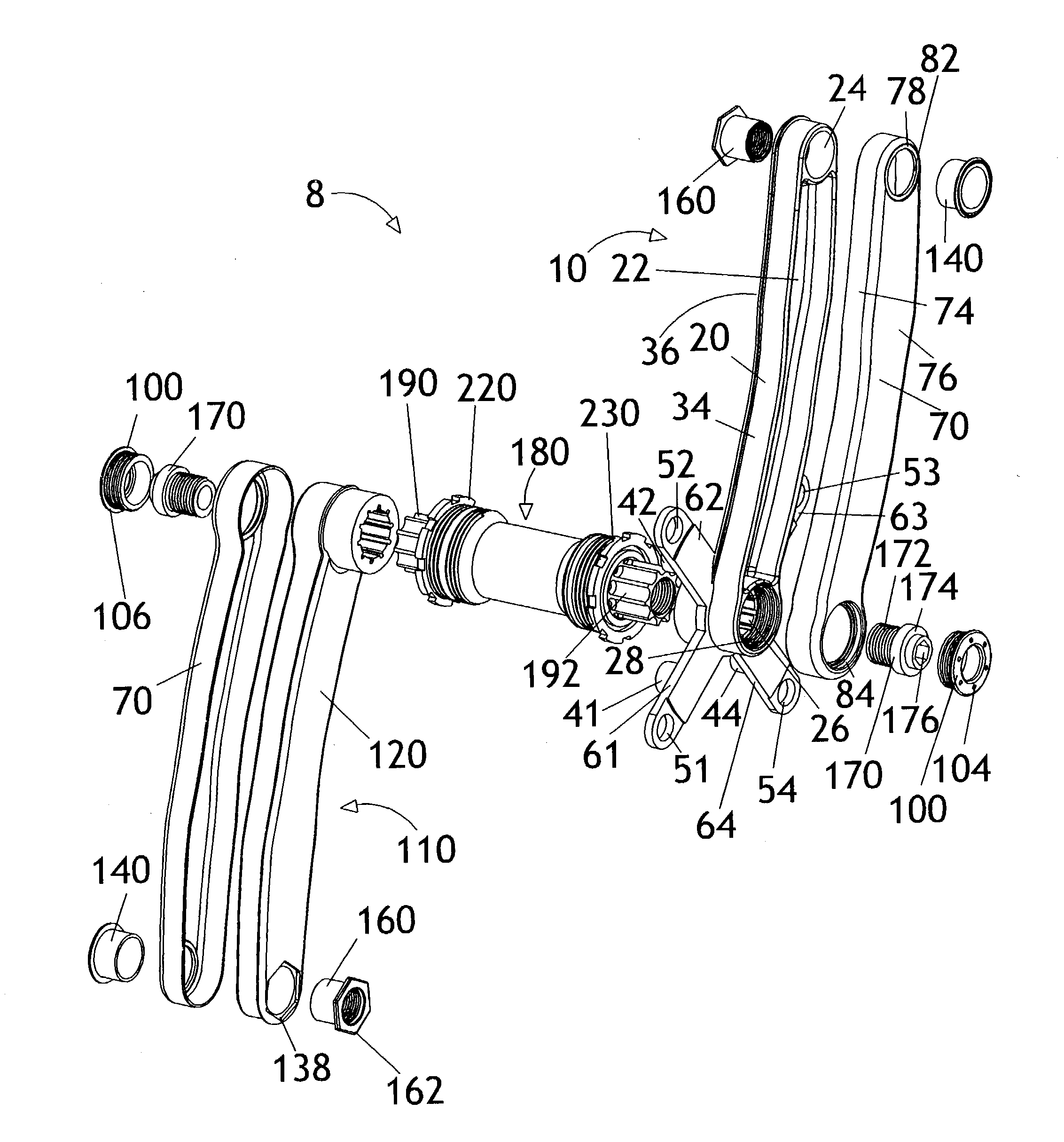

InactiveUS20040200314A1High strength to weight ratioSimple and inexpensiveControlling membersMechanical apparatusDie castingEngineering

A hollow bicycle crank arm has a central tubular portion to reduce weight and two mounting-boss portions for mounting a crank spindle and pedal during use. A crank arm base is forged or cast with a relatively thin back and sides, preferably out of aluminum or magnesium. The crank arm base has a generally C-shaped cross section. An arm cover has a top and sides and is made from stamped steel or titanium. The cover is placed over the open crank arm base to enclose a significant hollow section. The stamped arm cover does not require any threading or welding. It can be made using a very inexpensive stamping process. The crank arm can be made using relatively inexpensive traditional manufacturing processes such as die casting or forging.

Owner:CRANK BROS INC

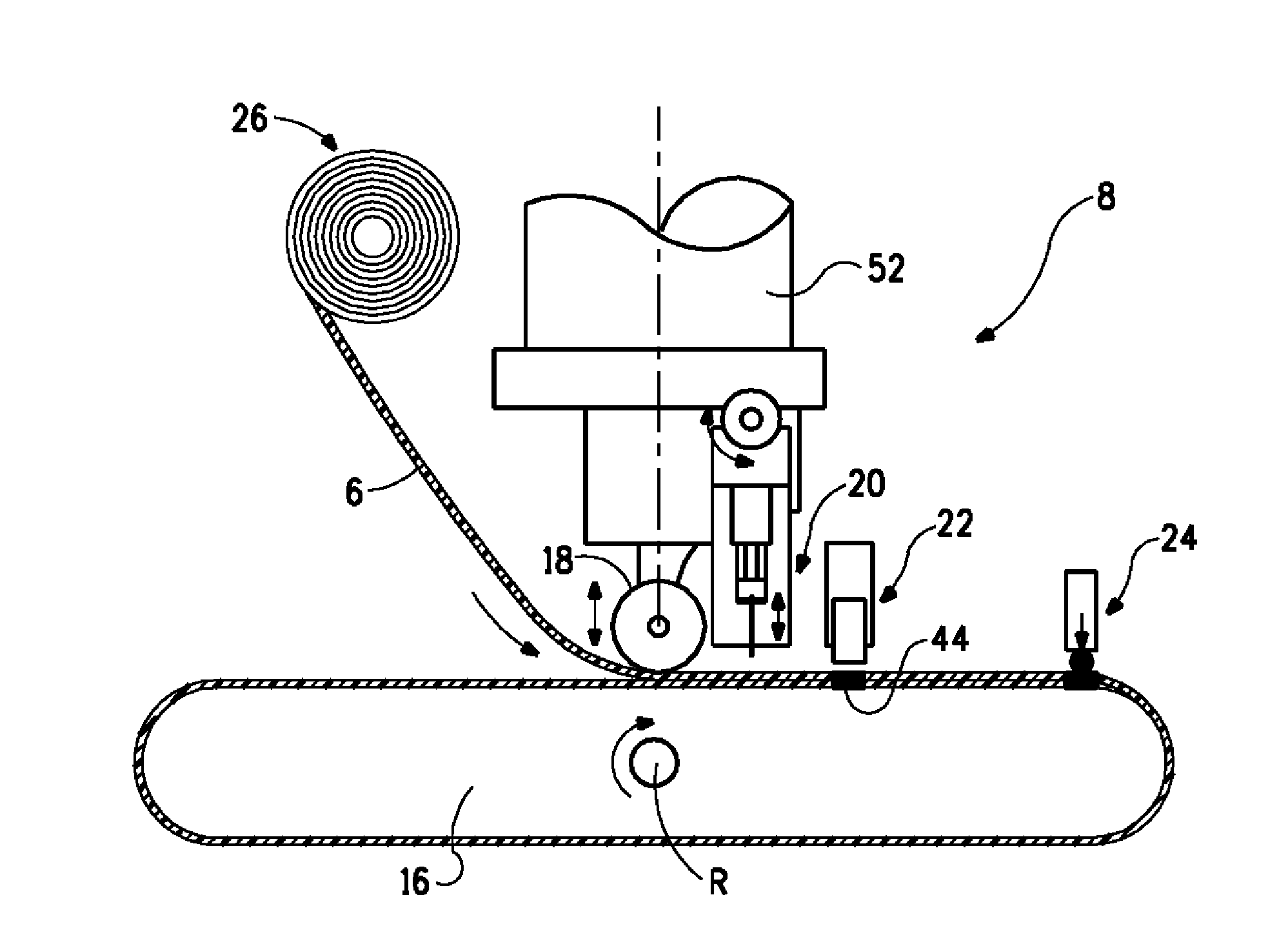

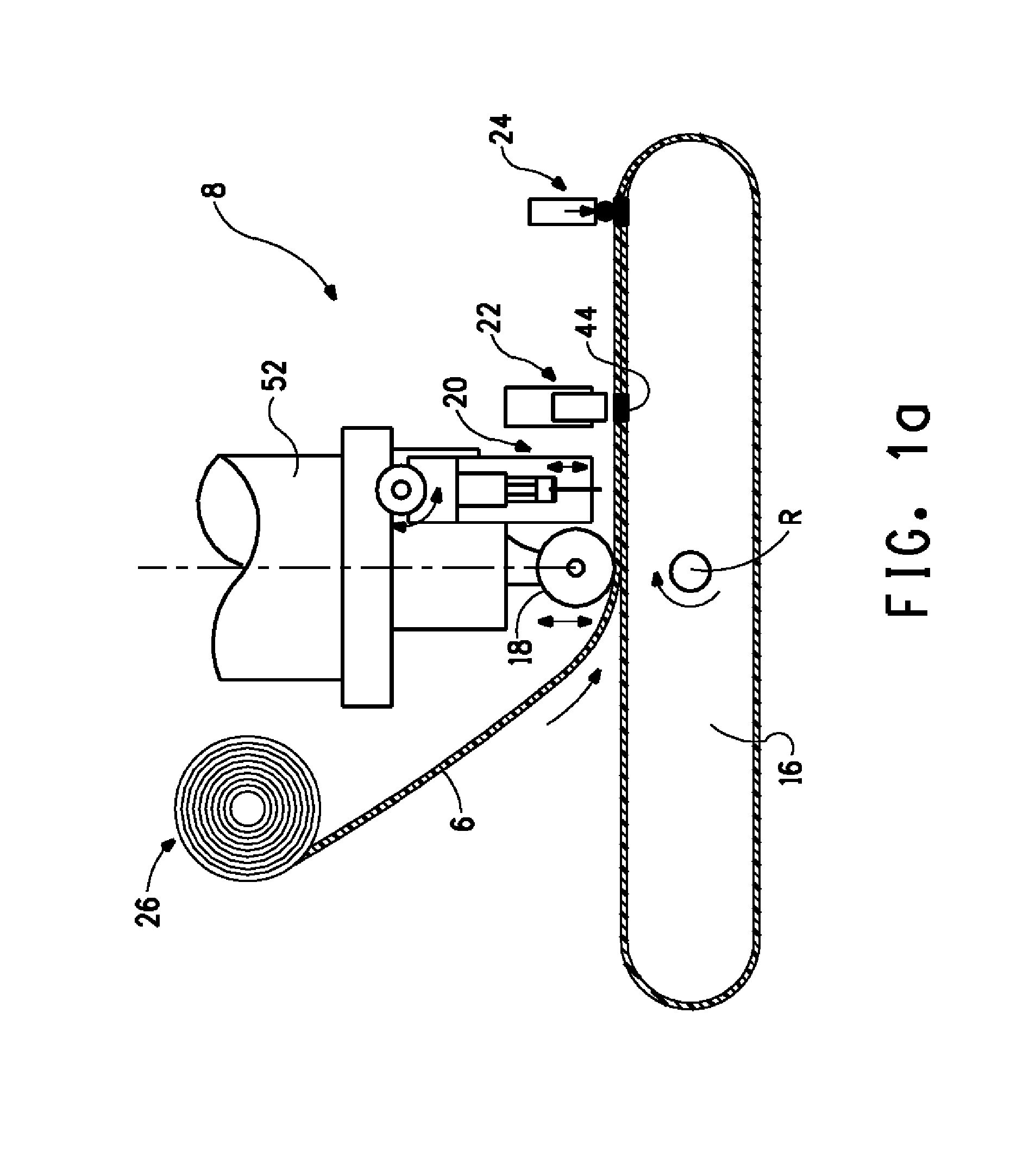

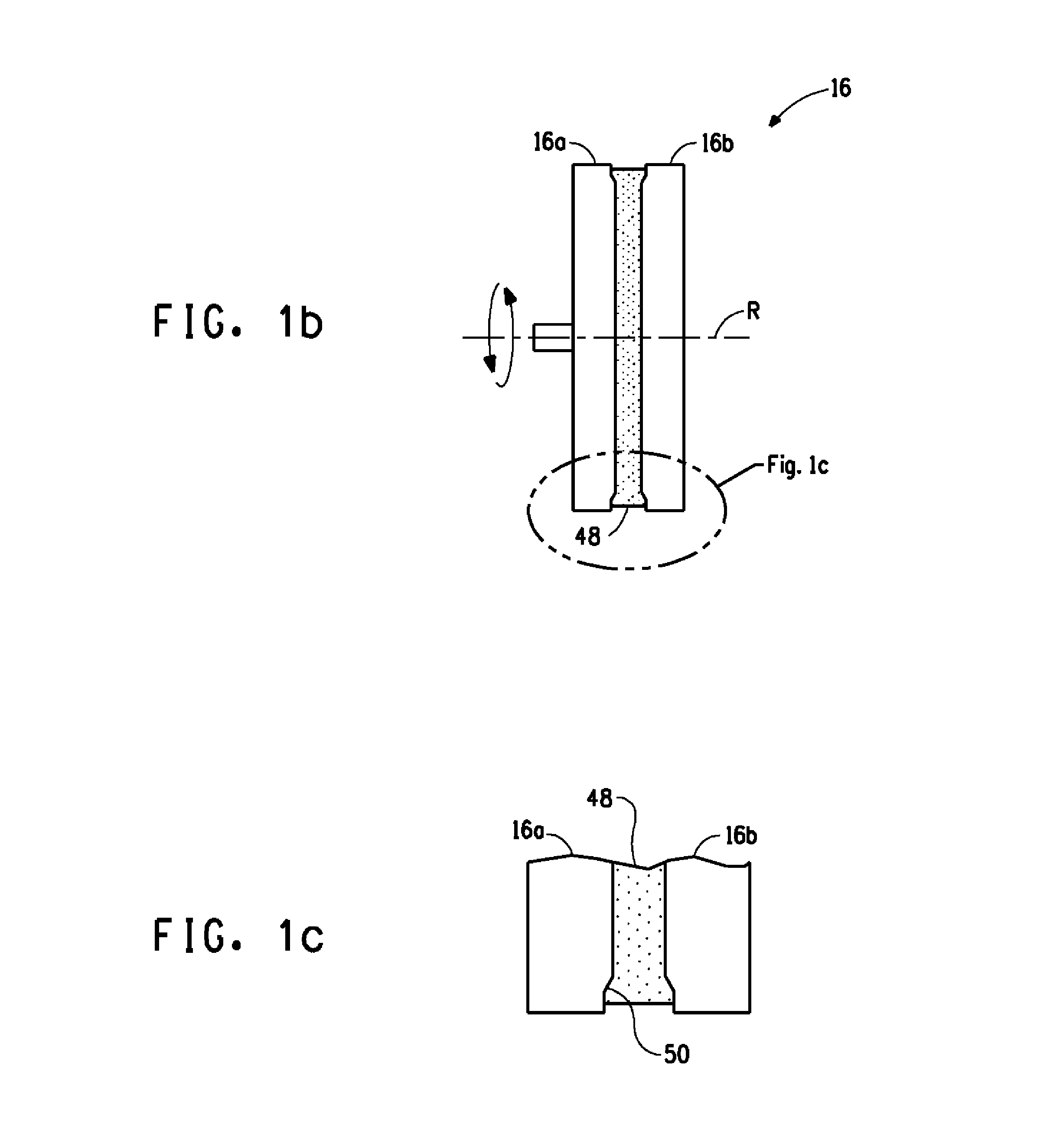

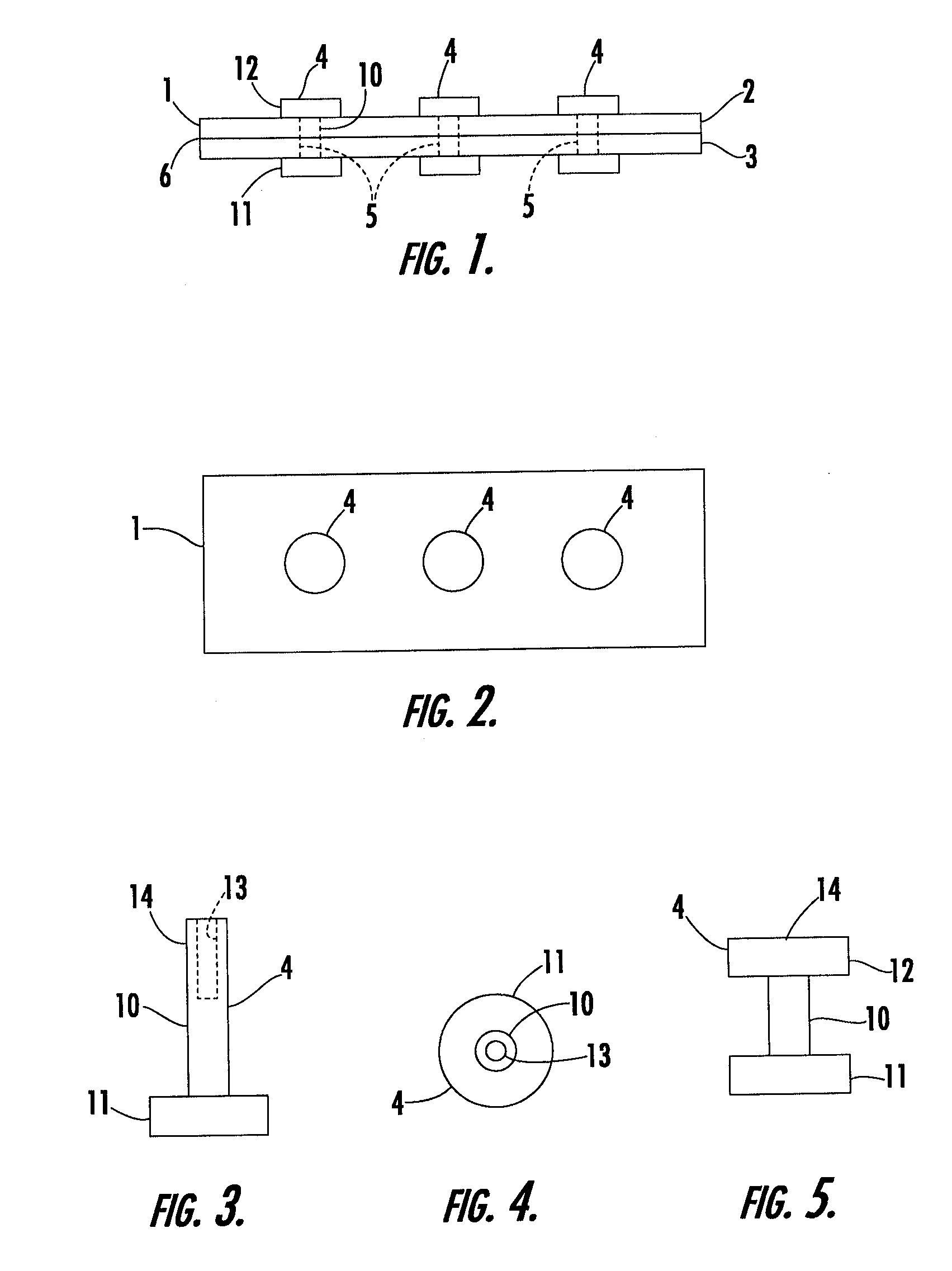

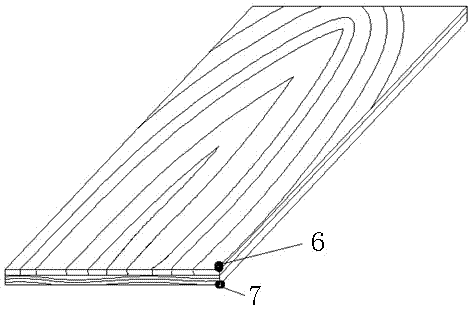

Composite article made with unidirectional fibre reinforced tape

InactiveUS20130149491A1High loadIncrease loadConnecting rodsLaminationFibre reinforcementClosed loop

Disclosed is a method of forming an article from a unidirectional (UD) tape comprising a continuous unidirectional fibre impregnated with polymer resin. The method includes winding a continuous section of cold UD tape to form a closed loop preform (38) comprising a plurality of stacked layers while discretely welding and consolidating the wound preform by heating and applying pressure.

Owner:EI DU PONT DE NEMOURS & CO

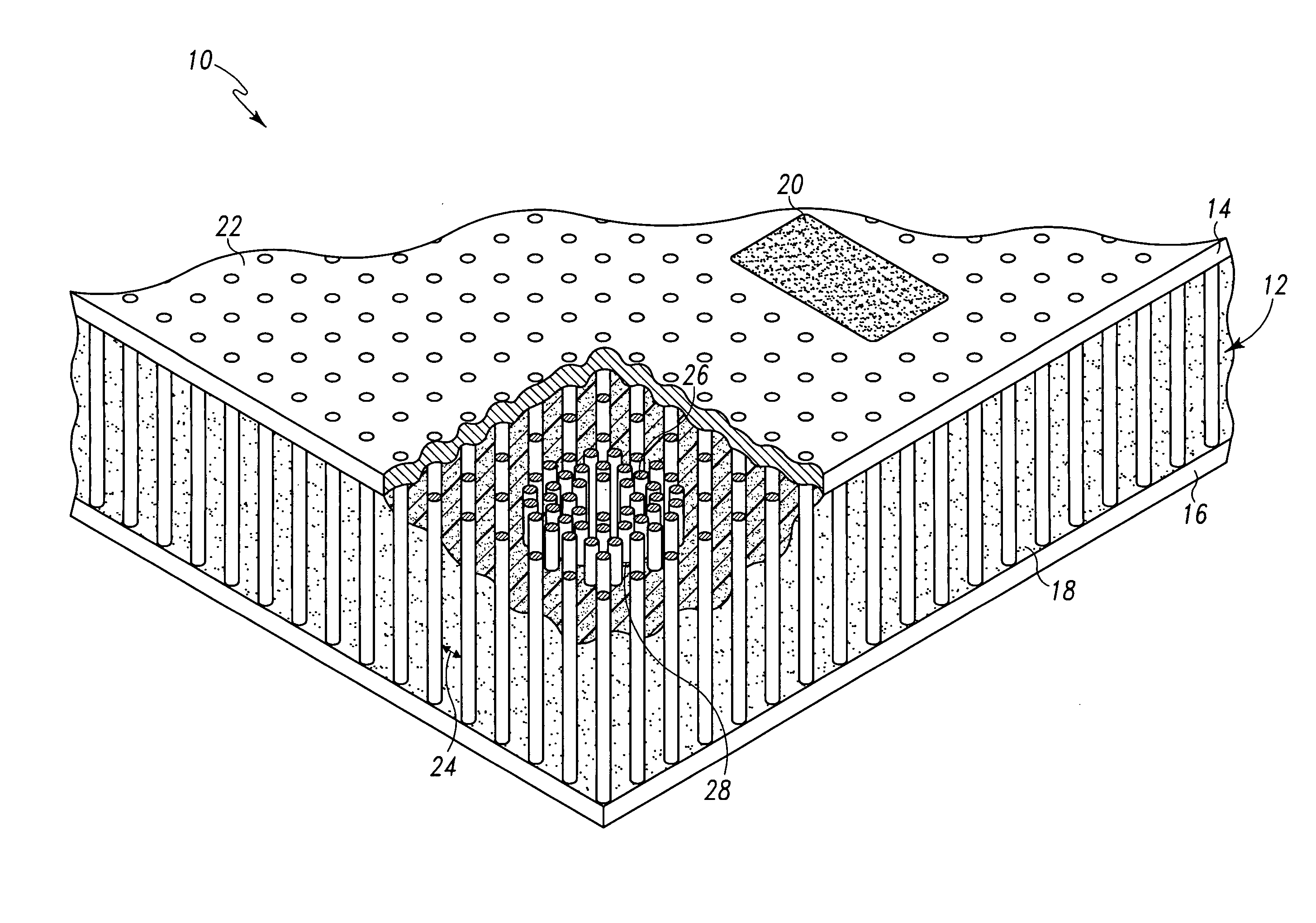

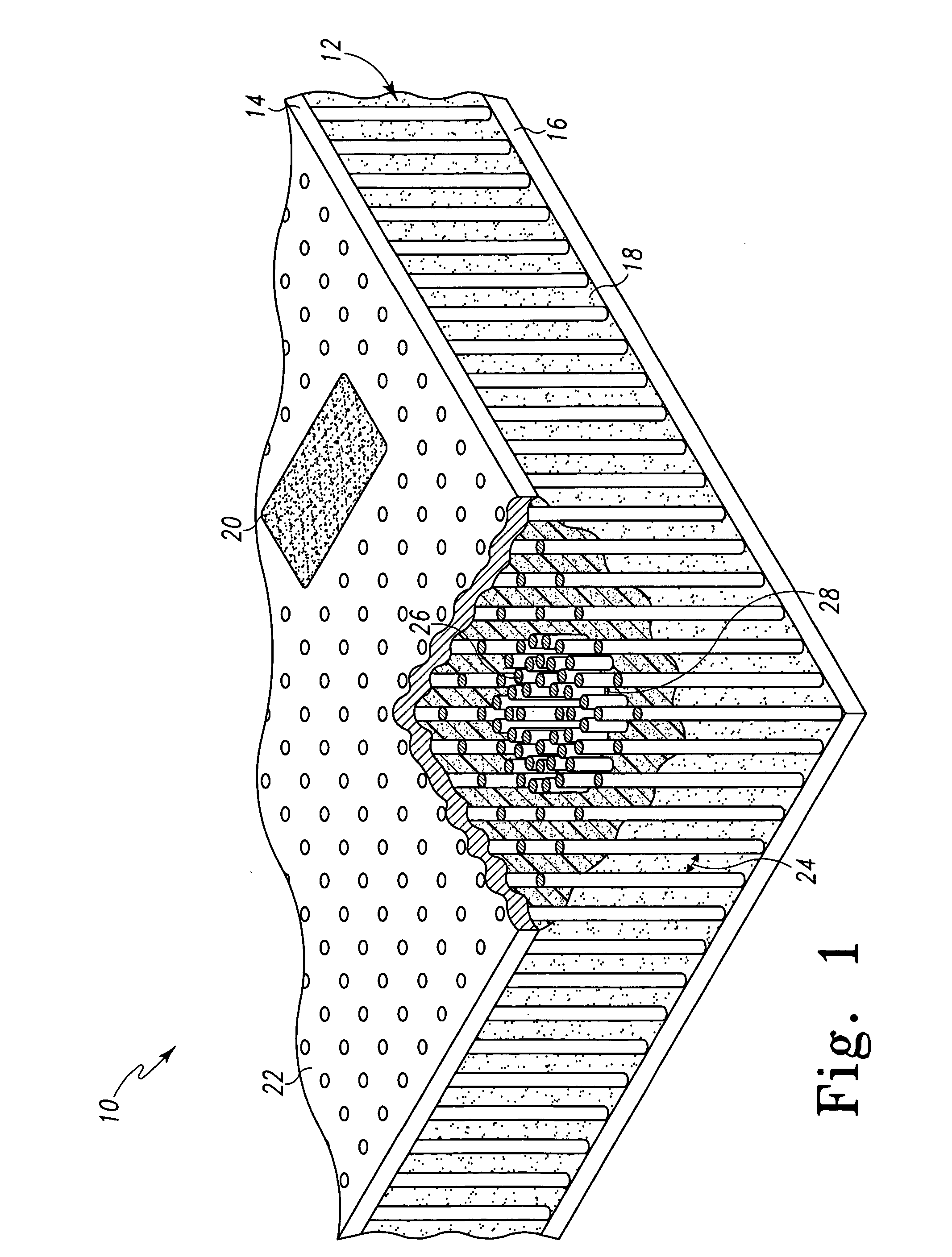

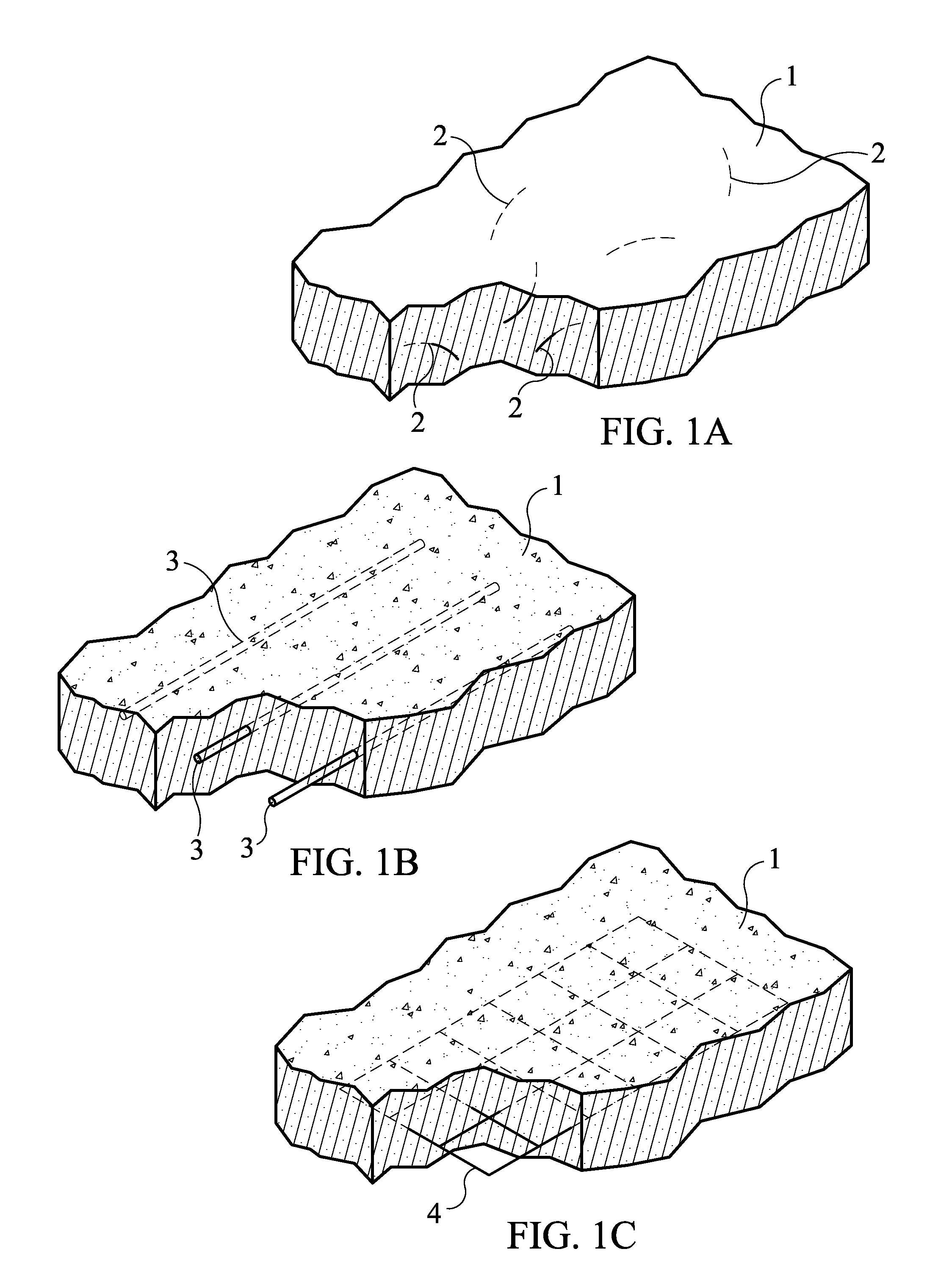

Composite structure with non-uniform density and associated method

InactiveUS20060121244A1High strength-to-weight ratioStiffness is easyBuilding componentsConstructions elementsFiberEngineering

A composite structure comprises a plurality of fiber insertions spaced relative to one another such that the fiber insertion density is non-uniform. An associated method is disclosed.

Owner:MARTIN MARIETTA MATERIALS

Beam incorporating aluminum extrusion and long-fiber reinforced plastic

InactiveUS20160159300A1Optimize locationReduce stressLaminationLamination apparatusCarbon fibersIn vehicle

A hybrid impact beam, suitable for use as a reinforced impact beam in vehicle bumpers, includes an extruded aluminum section, a fiber reinforced polymeric (FRP) section, and a structural adhesive bonding them together. The components are arranged so that during an impact, the aluminum section experiences compression and receives the direct impact, the FRP section experiences tension, and the adhesive experiences minimal stress by being on a neutral plane of the beam's bending moment. The extruded aluminum beam is preferably extruded as an open section, but becomes a closed section when the polymeric section is attached. The FRP section is preferably a continuous carbon fiber reinforced polymeric section, although different reinforcements can be used. A related method includes bonding an extruded aluminum and fiber-reinforced polymeric section together to form a closed bumper impact beam.

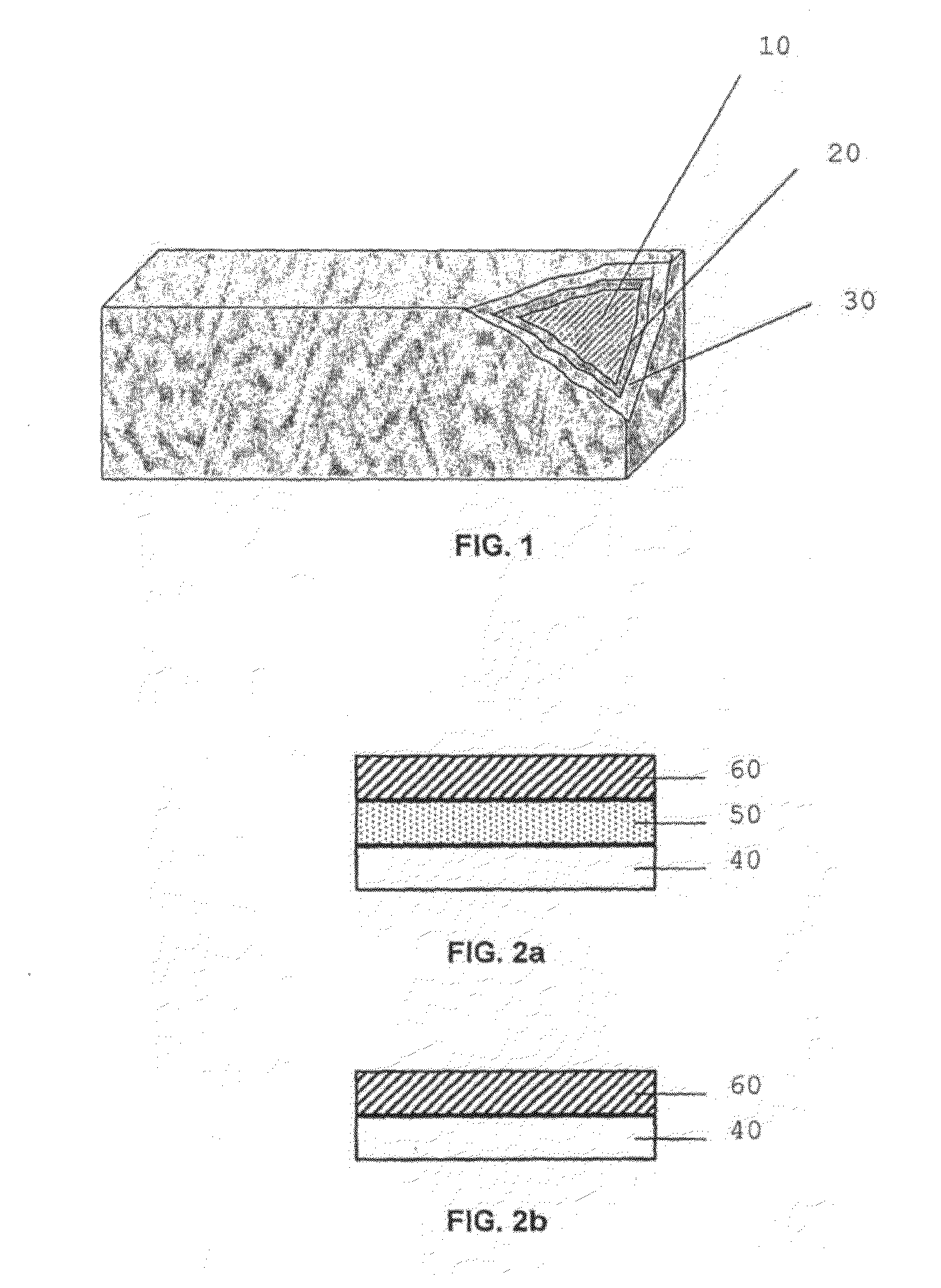

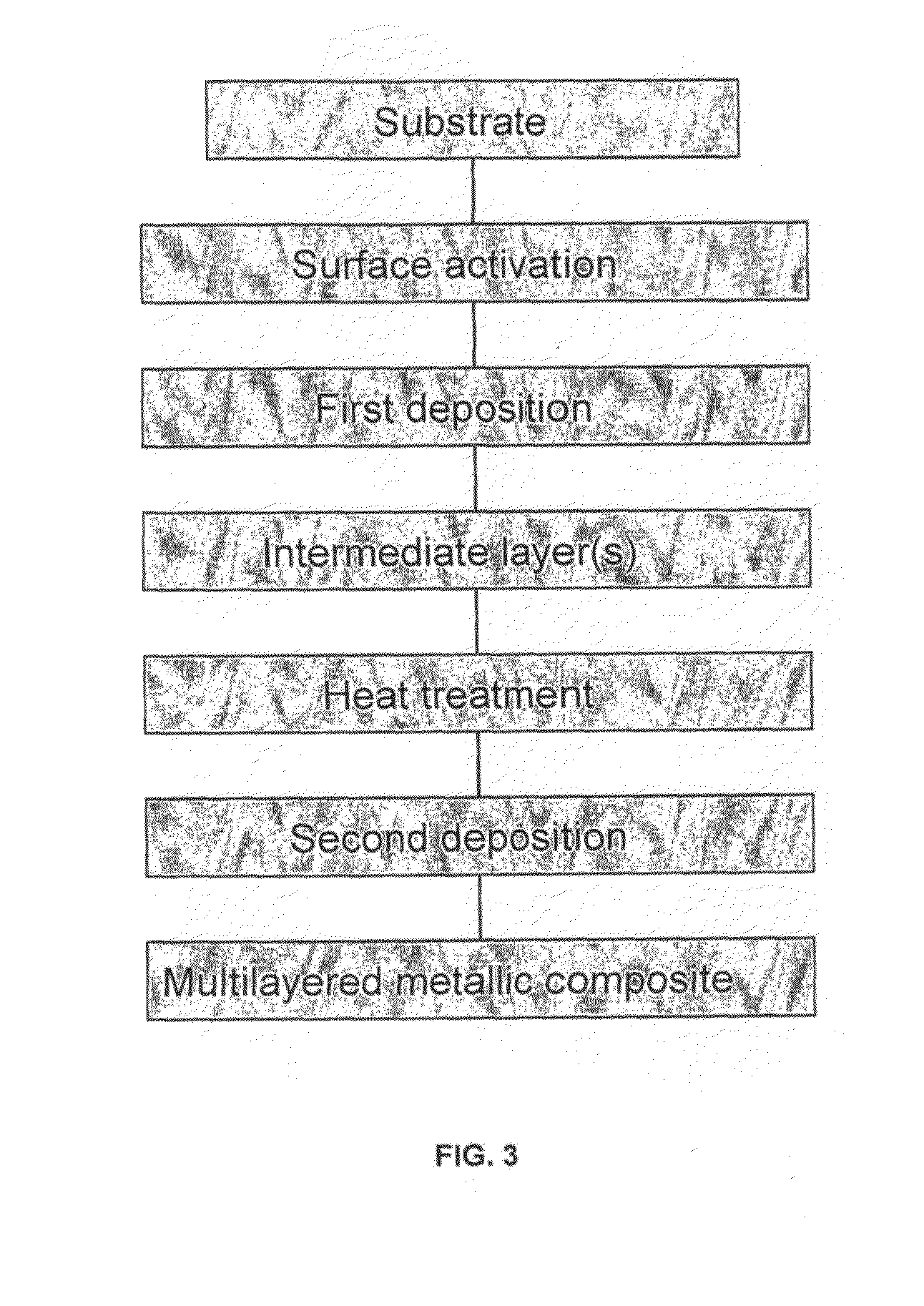

Composite metallic materials, uses thereof and process for making same

InactiveUS20100261034A1High strengthHigh strength-to-weight ratioHybrid capacitor electrodesDecorative surface effectsLow densityBiological materials

A lightweight, high strength and corrosion resistant composite metallic material is disclosed herein. The composite metallic material typically comprises a high-to-weight ratio, low density core material; and a corrosion resistant protective refractory metal layer. The method for making the composite metallic material comprises the steps of surface activating the core material and forming a refractory metal on the surface of the surface activated core material by physical, chemical or electrochemical processes. Such a composite material is suitable for making biomaterials, corrosion resistant equipment and industrial electrodes.

Owner:CARDARELLI FRANCOIS

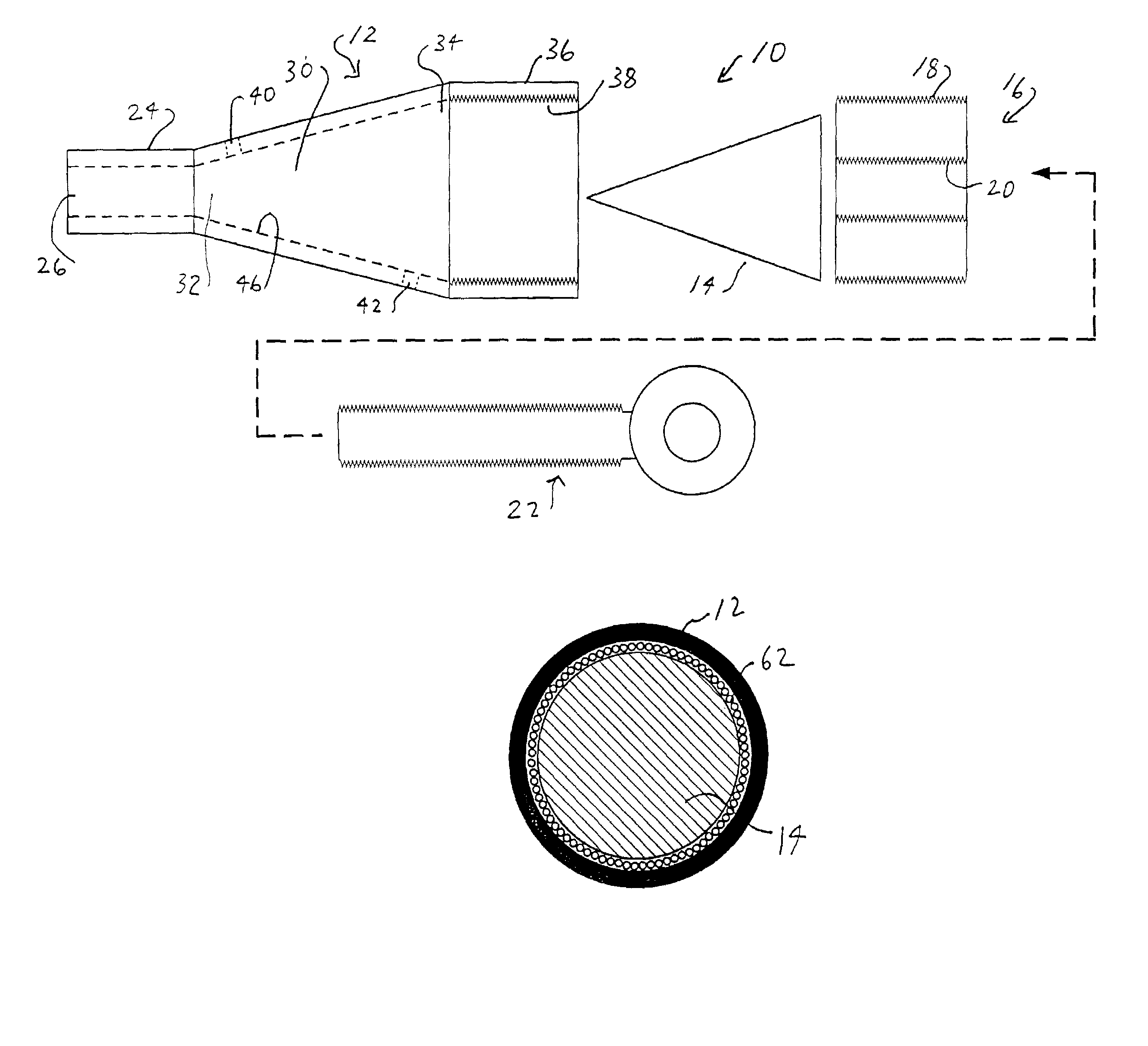

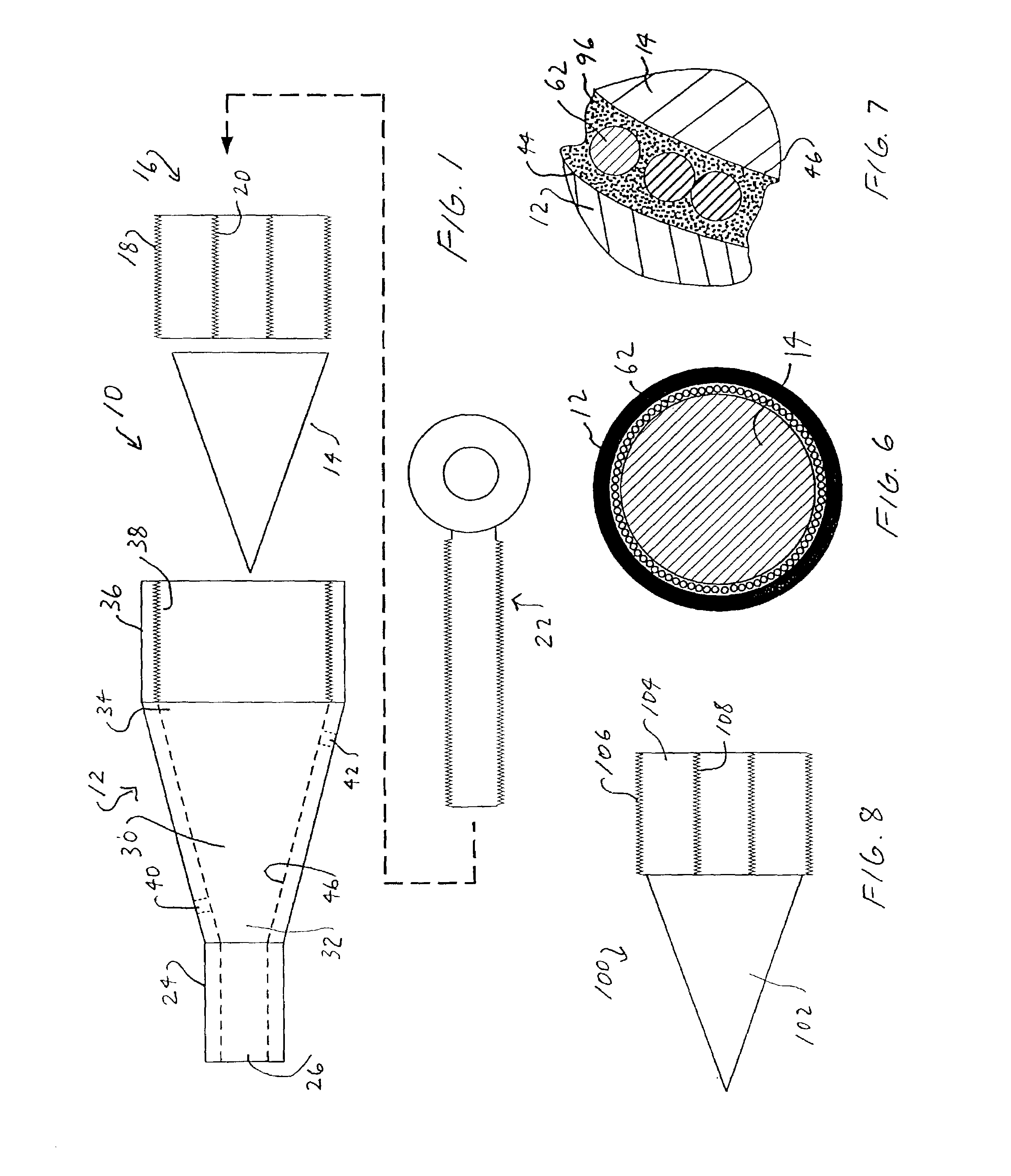

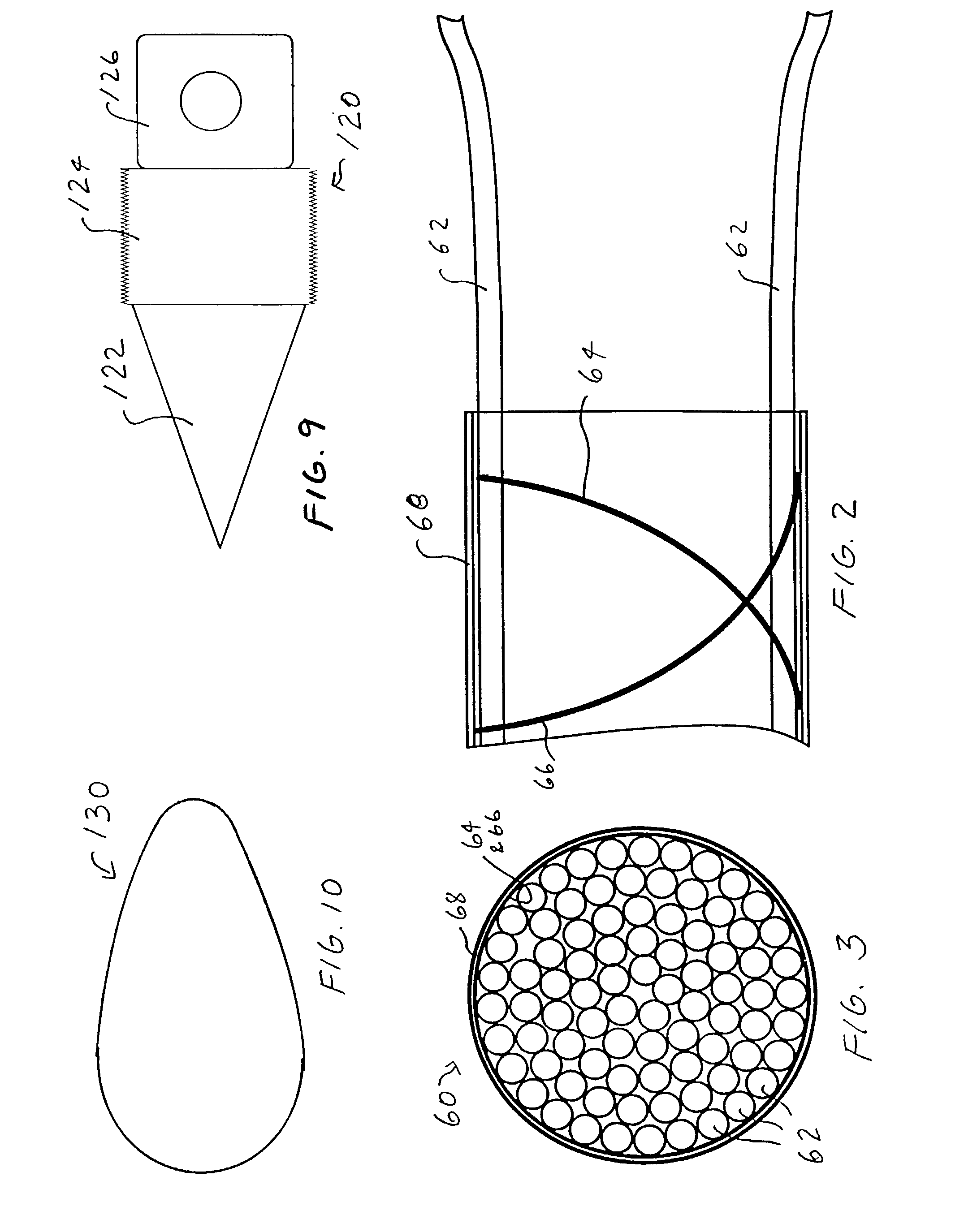

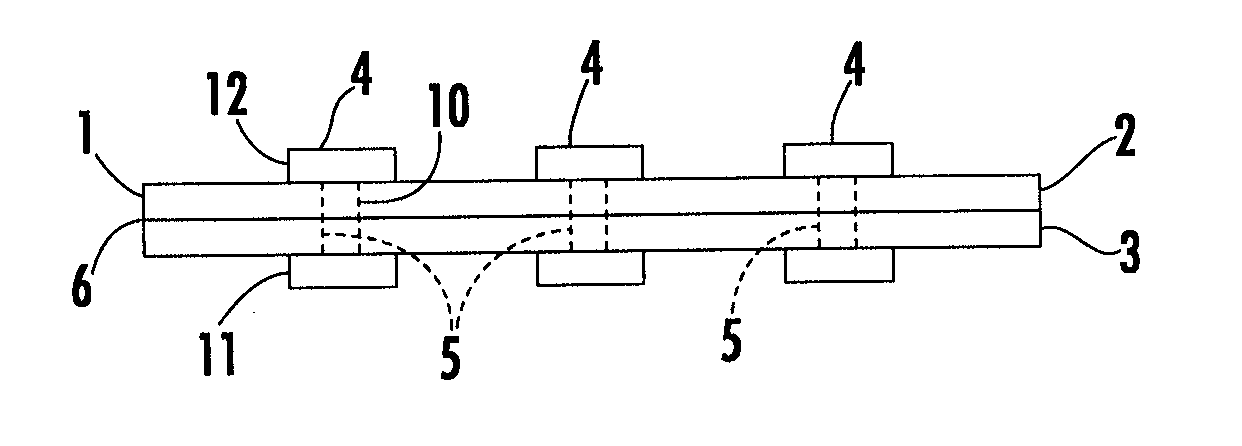

Composite tensioning members and method for manufacturing same

InactiveUS7137617B2Reduce weightHigh strength to weight ratioSnap fastenersWire toolsTension memberInternal cavity

A composite tension member. The composite tension member is assembled from a number of composite rods, each having two ends. A wedge plug is formed around the ends of the composite rods. The wedge plugs are inserted into termination fitting having a termination fitting body with an aperture at a proximal end for receipt of the bundle of composite rods and having an internal cavity that flares outwardly from a proximal end to a distal end to closely receive the wedge plug with the composite rods imbedded therein. A closeout nut is used to retain the wedge plug in the termination fitting body. The invention further provides method of manufacturing composite tension members.

Owner:AIRLOG ACQUISITION CORP

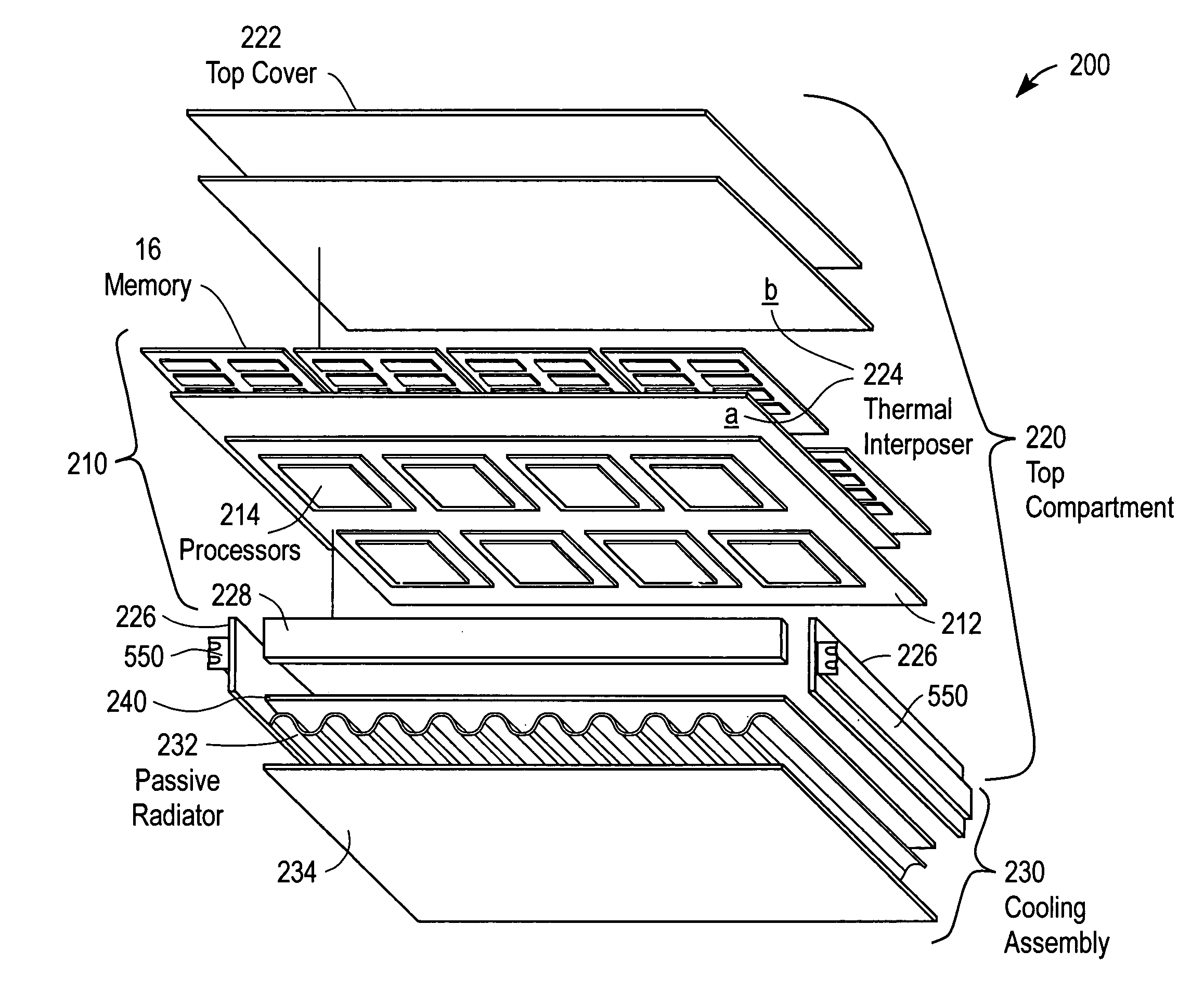

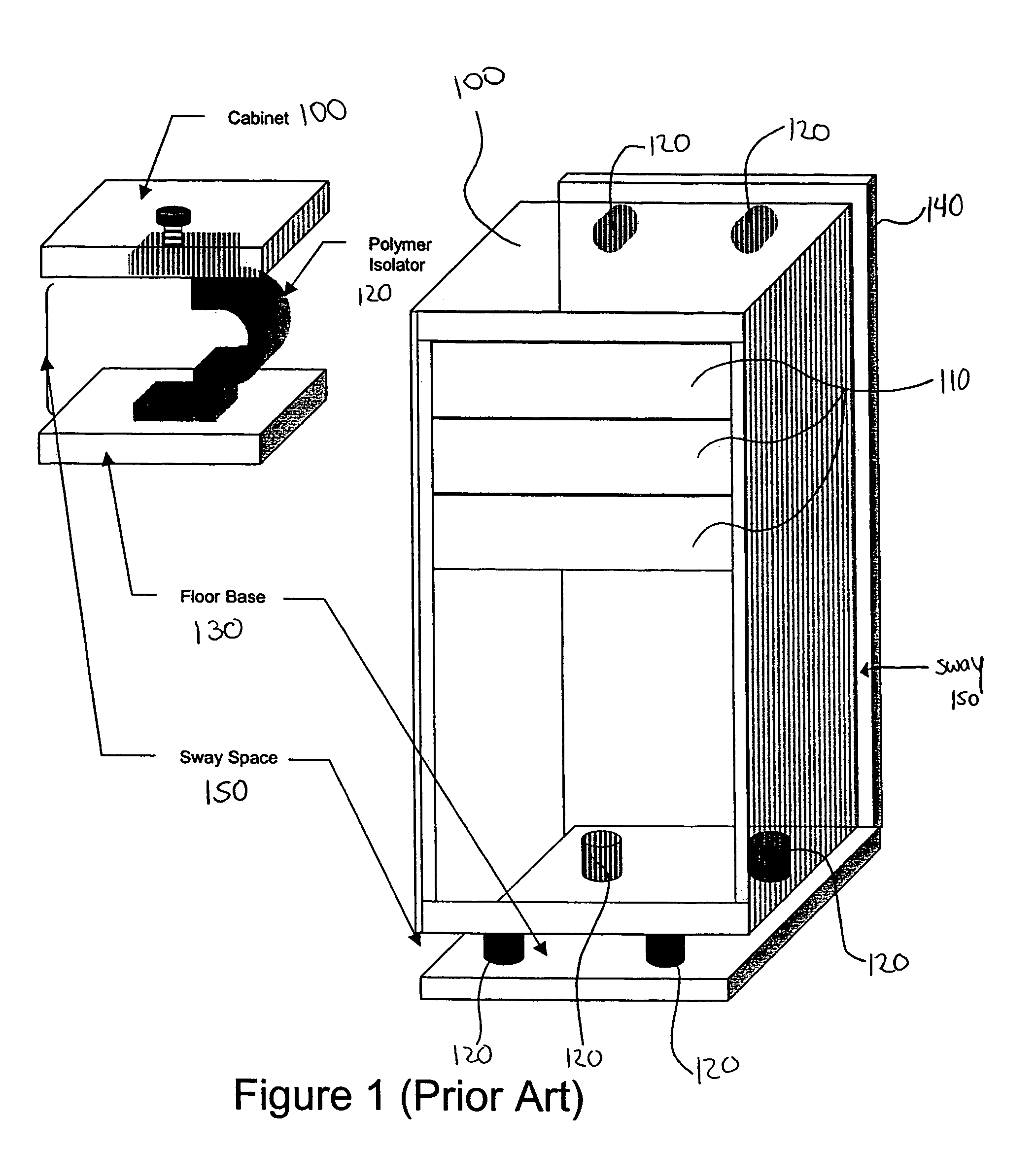

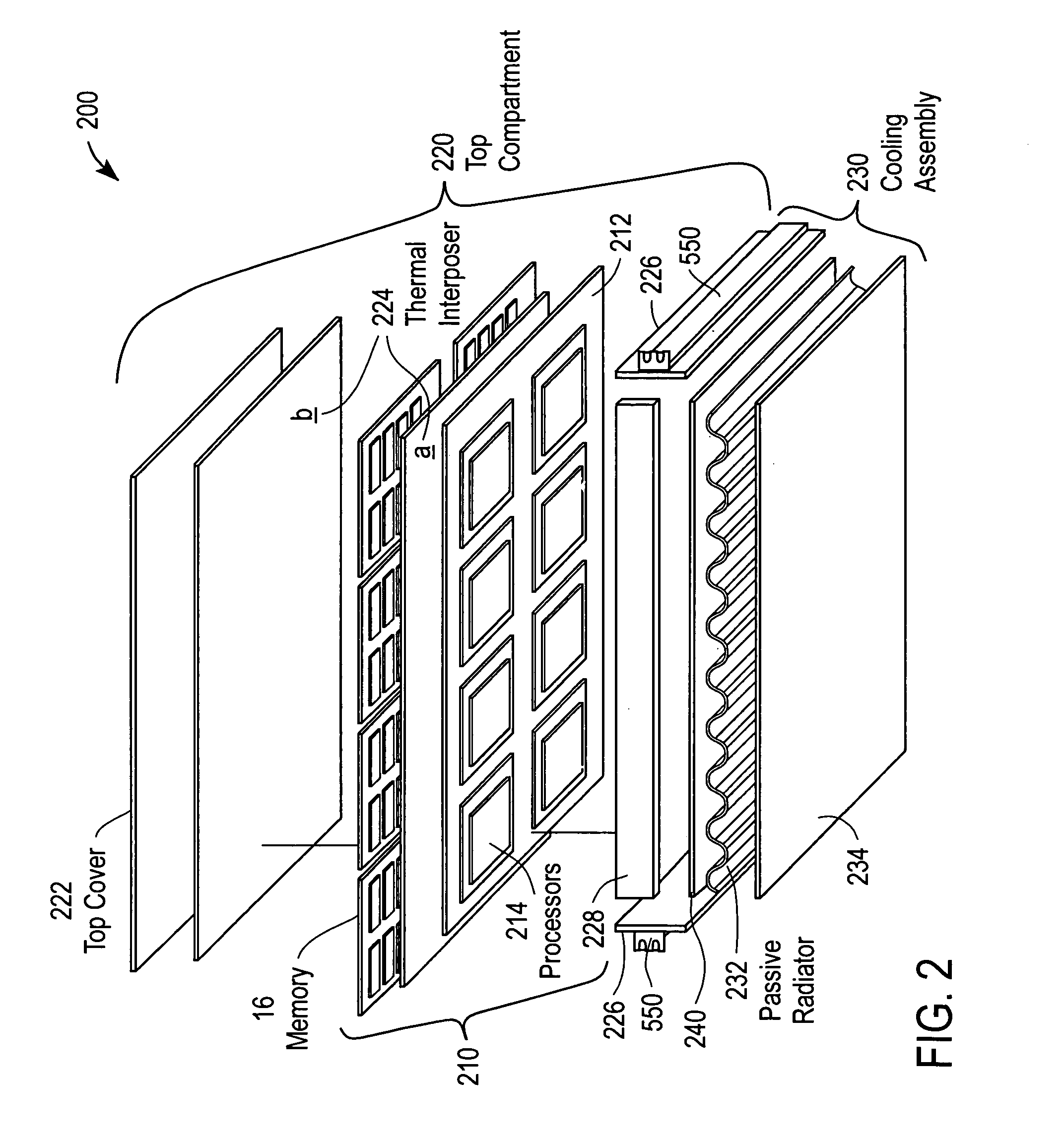

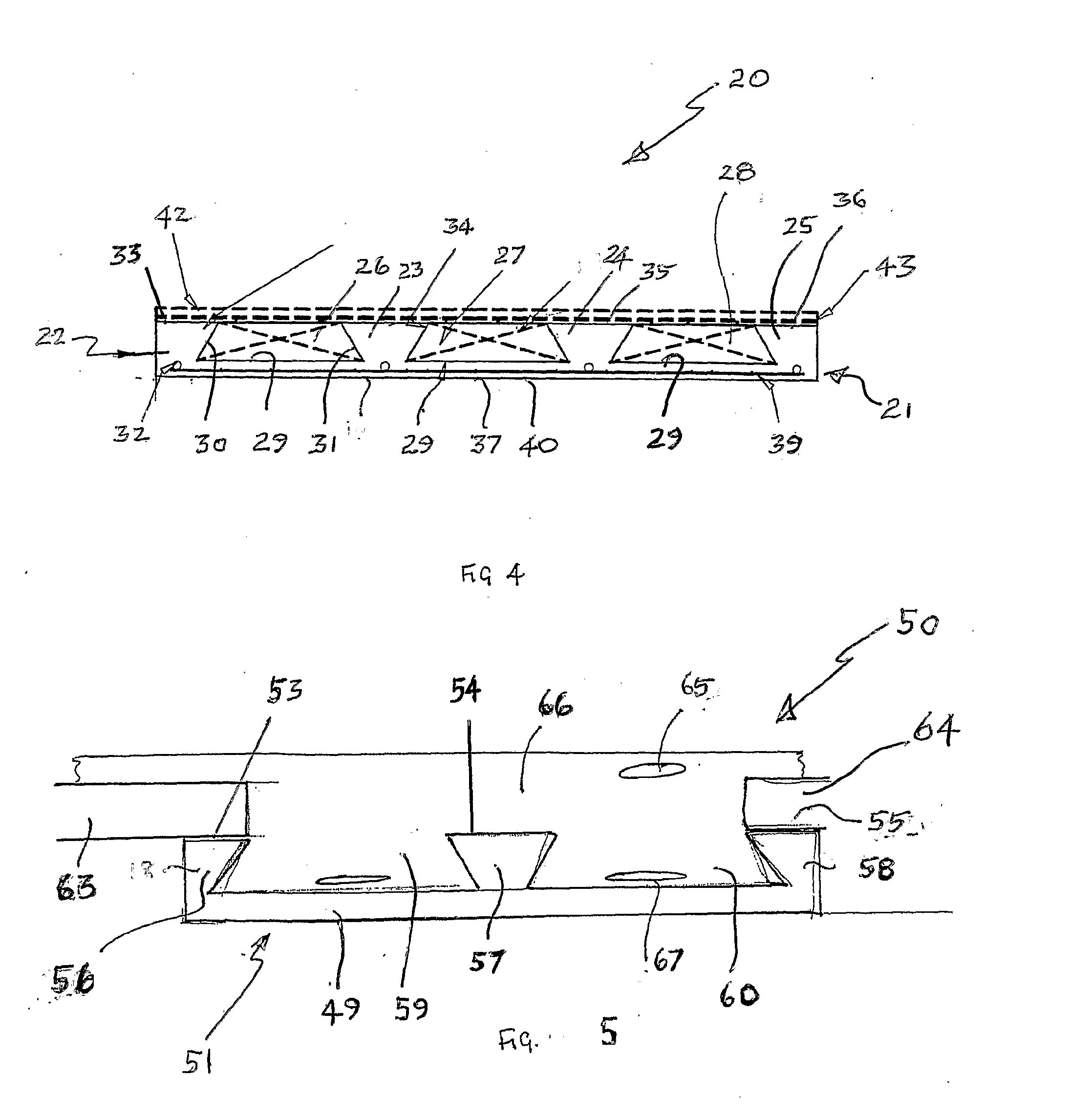

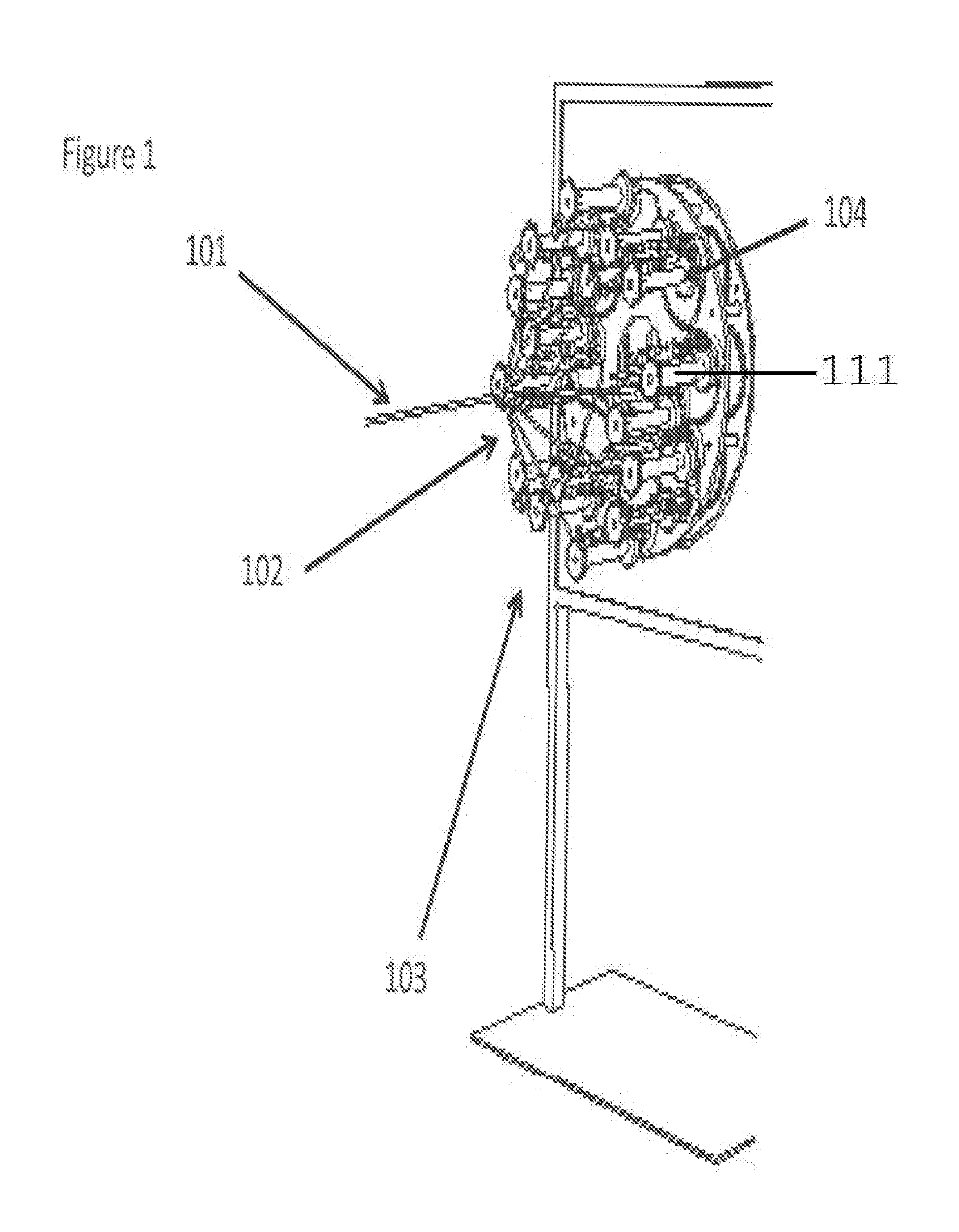

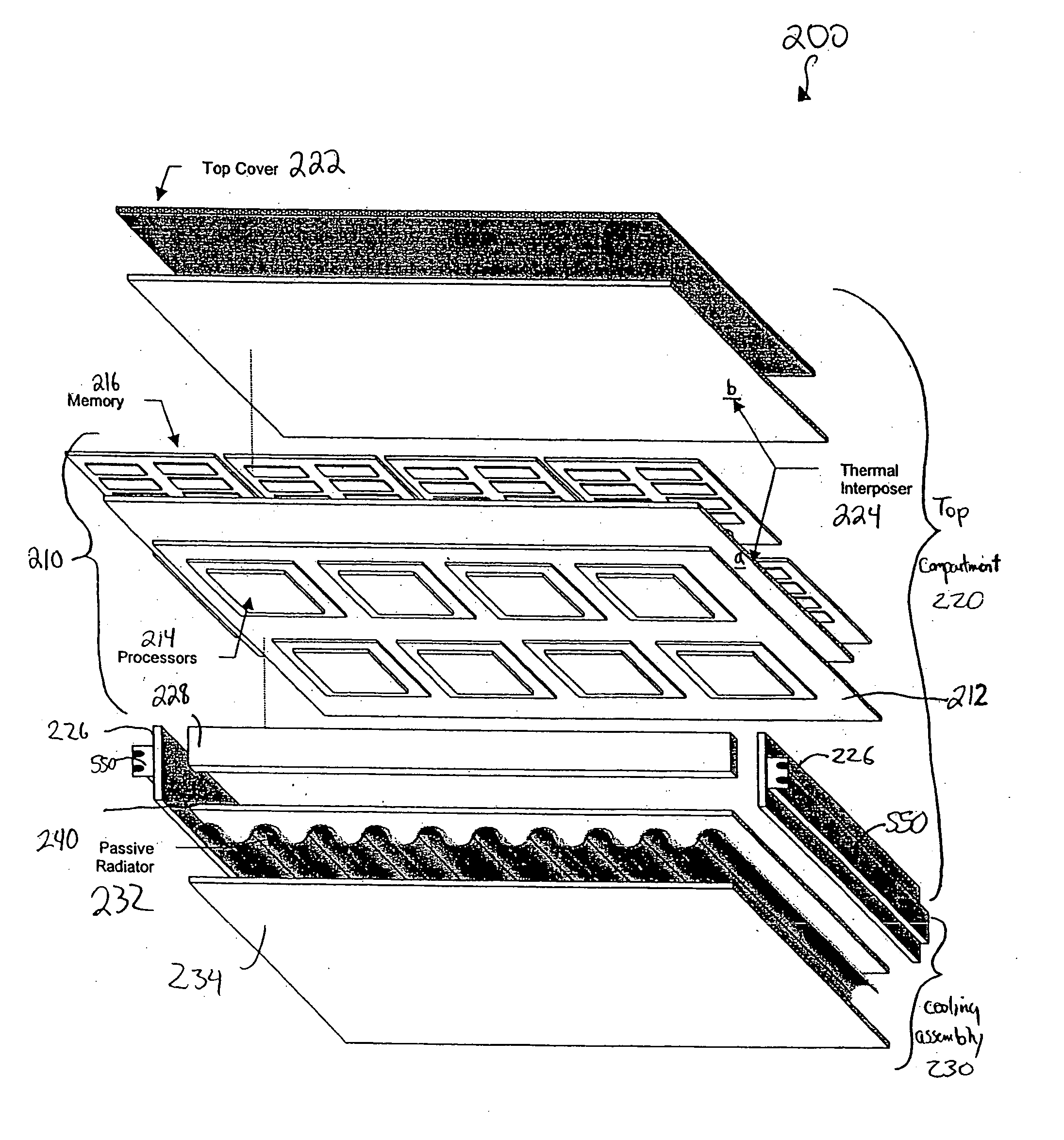

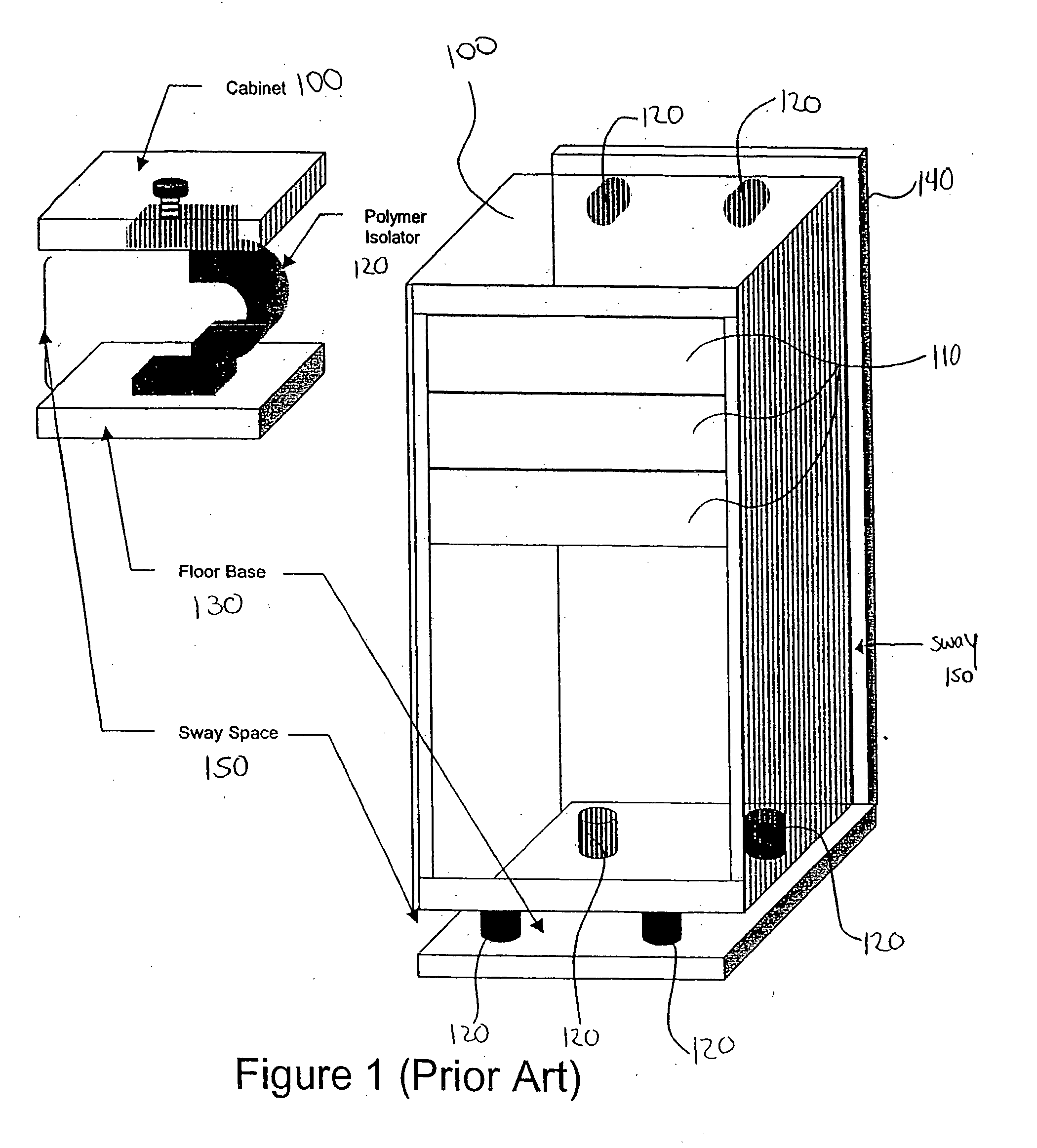

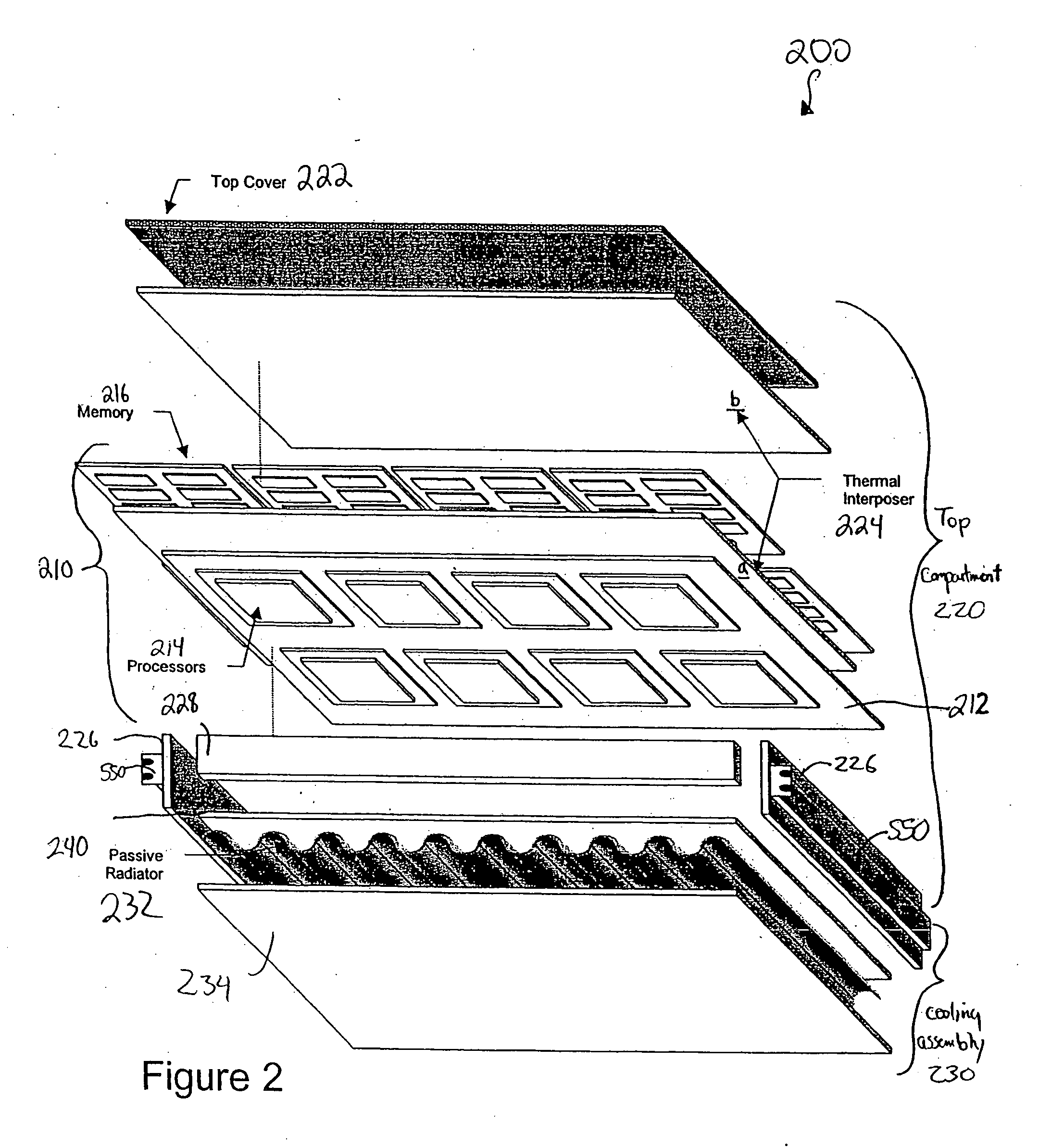

Ruggedized electronics enclosure

InactiveUS6944022B1Overcomes limitation and disadvantageHigh strength to weight ratioPrinted circuit board receptaclesModifications by conduction heat transferPassive radiatorEngineering

The present invention relates to a ruggedized enclosure for housing and protecting electronic circuits. The enclosure utilizes a top compartment for housing the circuit and a cooling assembly rigidly coupled to the top compartment. The cooling assembly utilizes a passive radiator to for a rigid truss plate structure. The truss plate structure rigidifies the enclosure helping to protect the enclosure and circuit from destructive shock events and destructive vibration events. The cooling assembly further provides an efficient heat exchange for removing heat from the electronic circuit. A method for protecting an electronic circuit utilizing a rigid truss plate structure is also provided.

Owner:MERCURY SYST TRUSTED MISSION SOLUTIONS INC

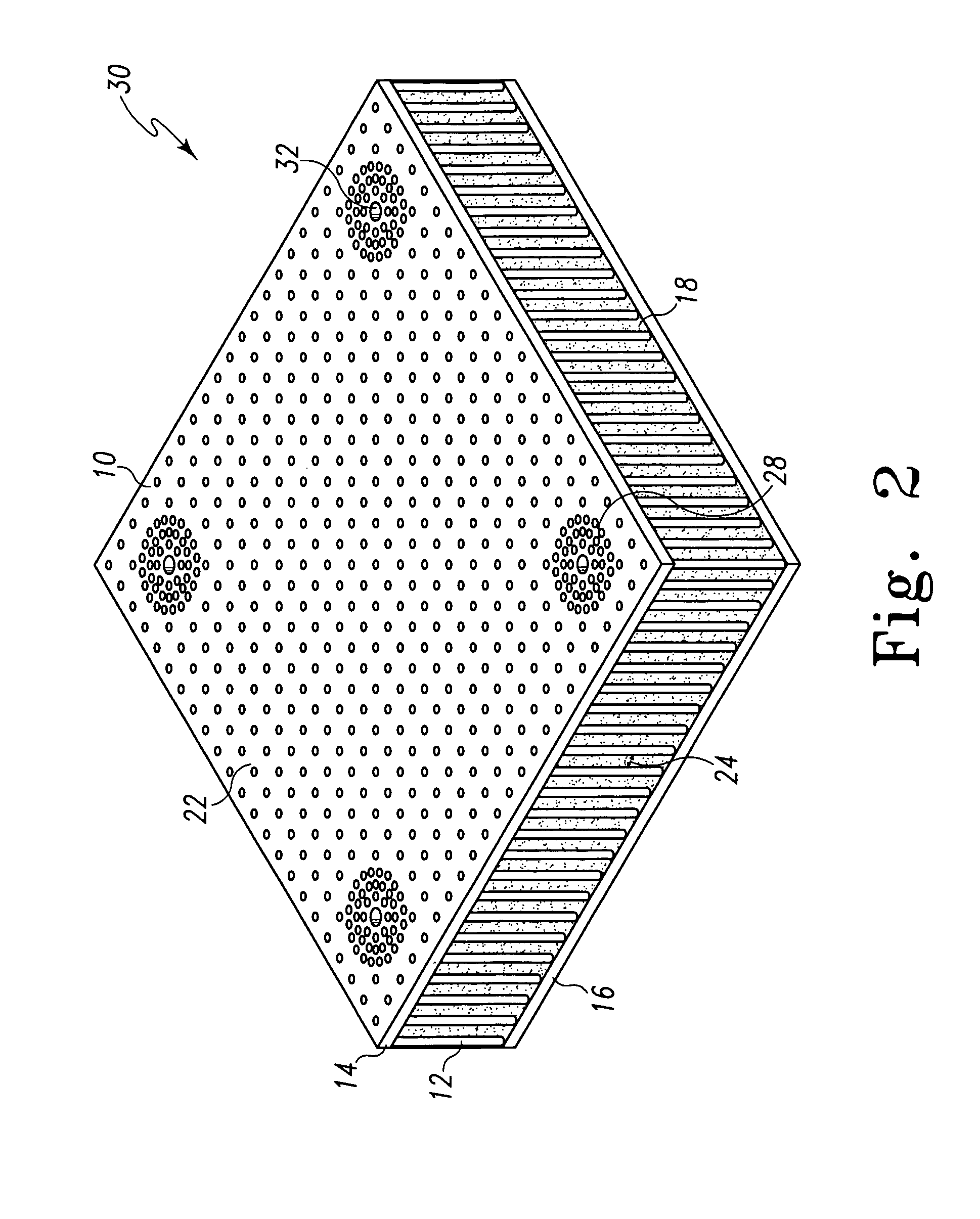

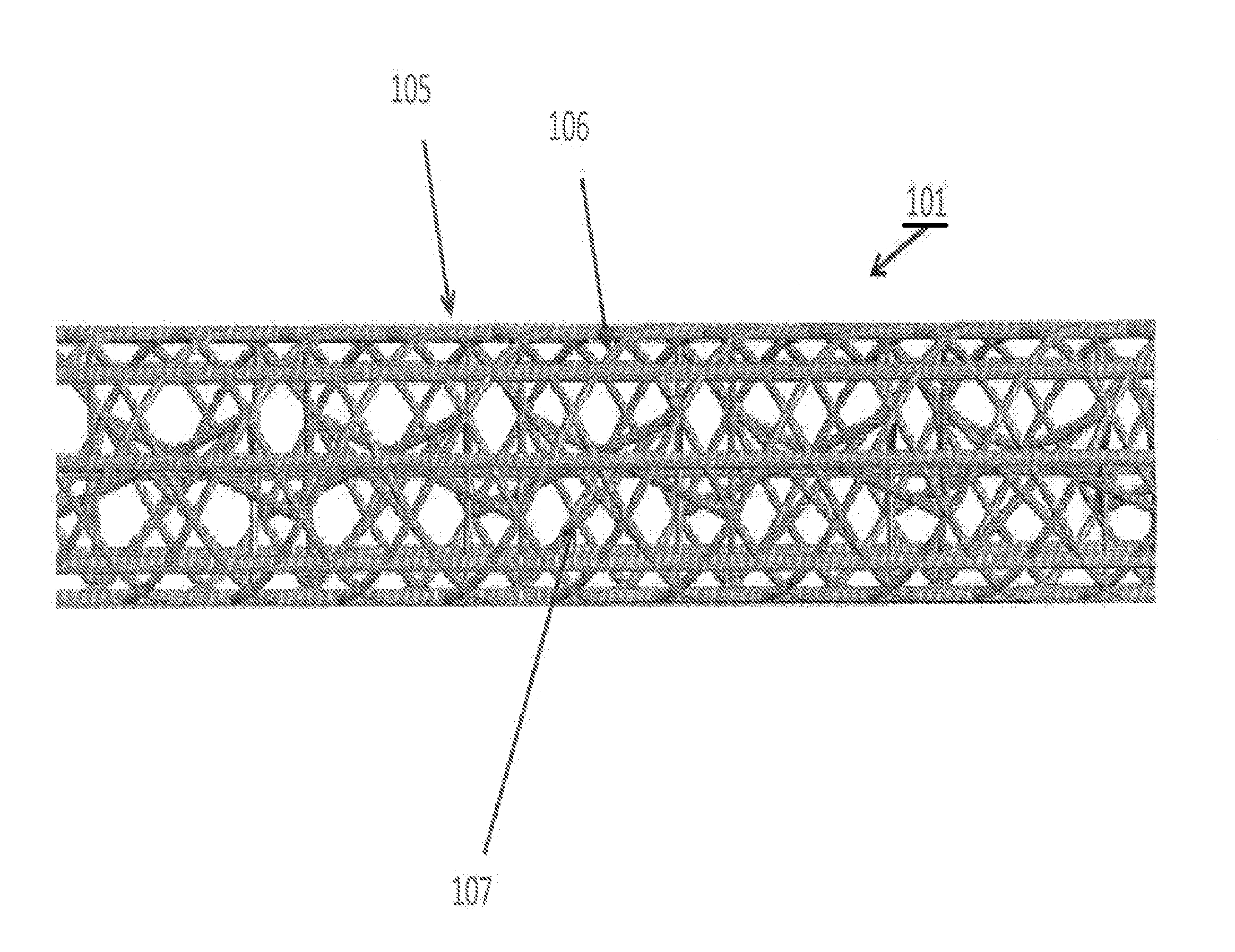

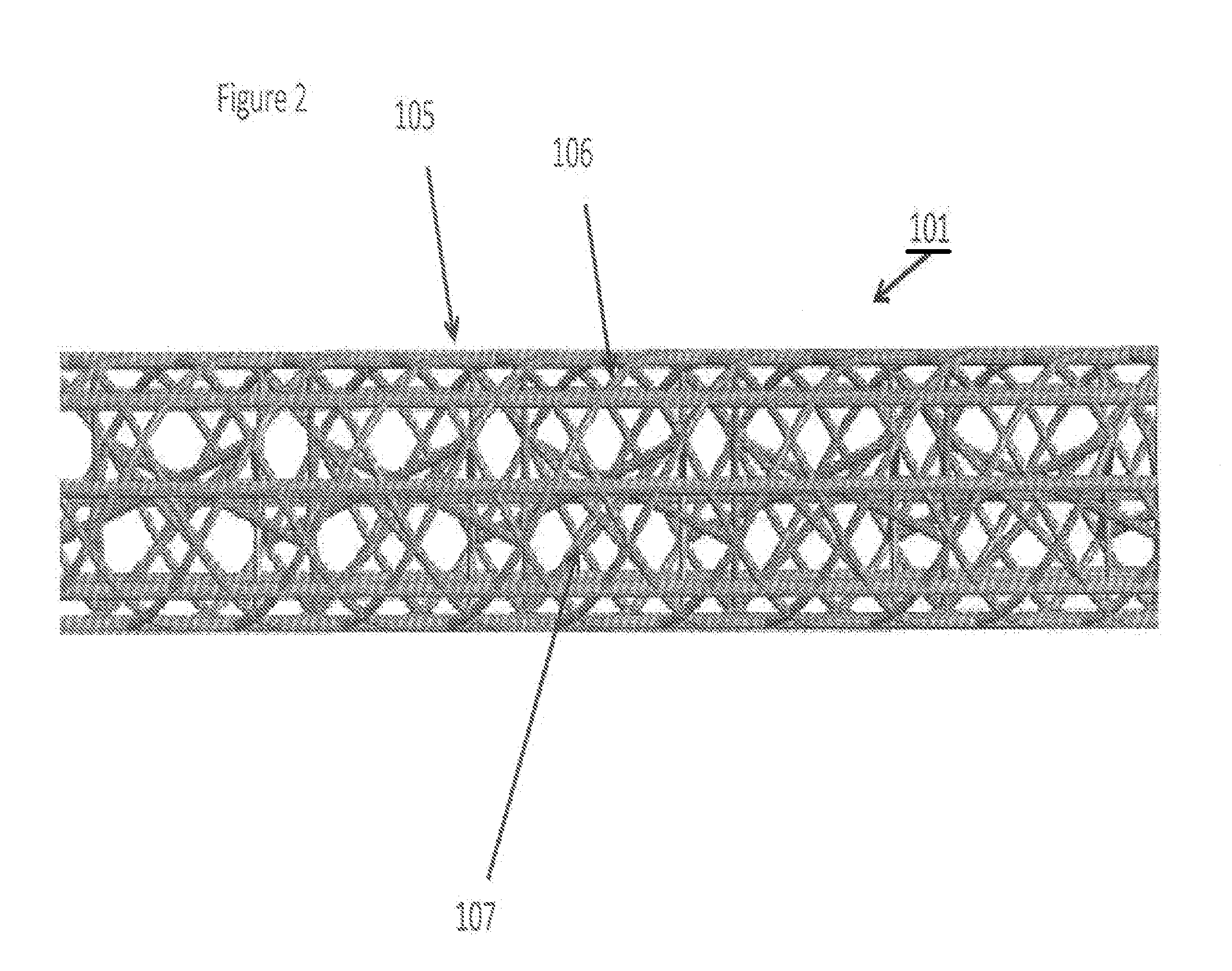

Minimal weight composites using open structure

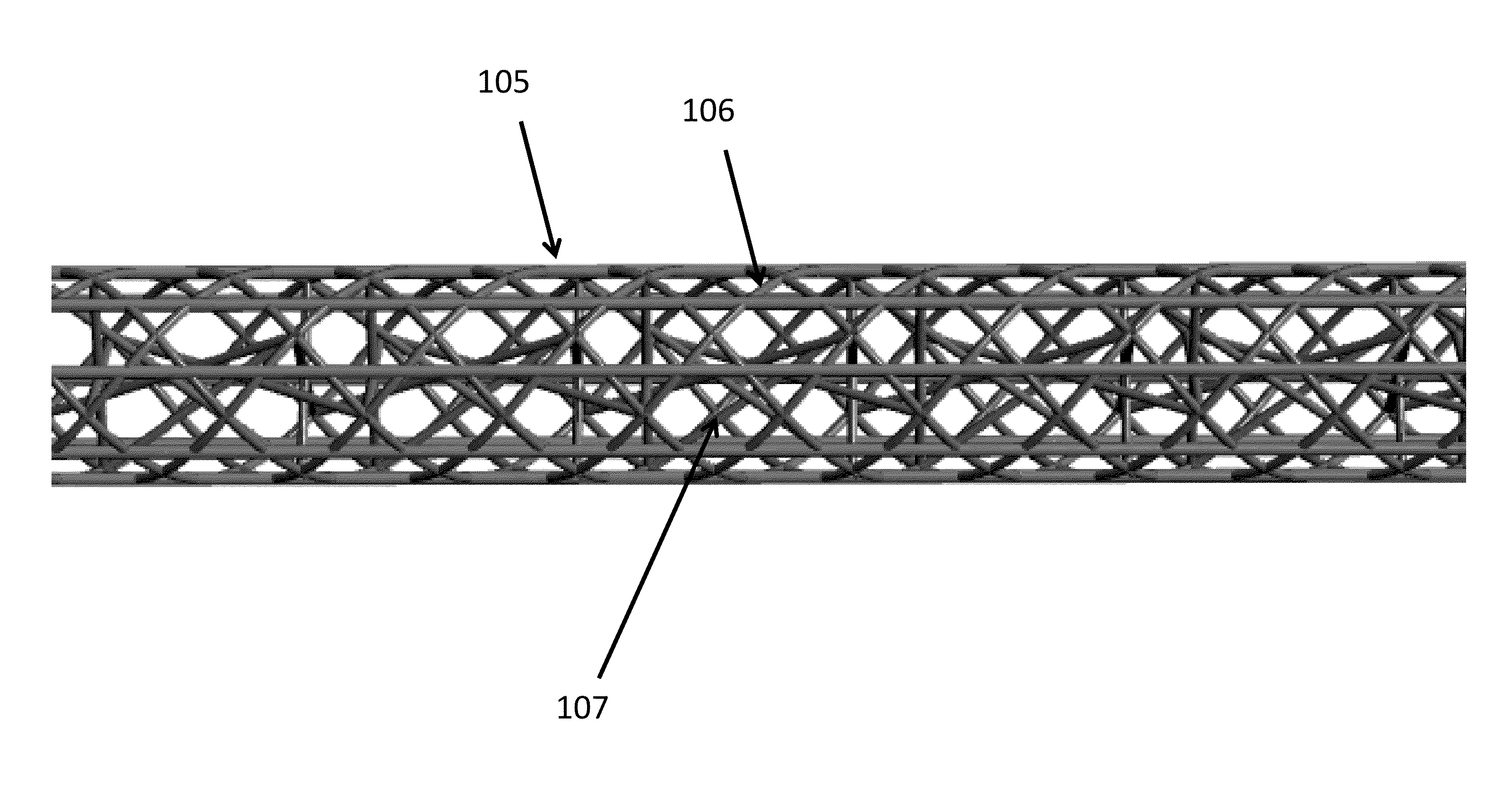

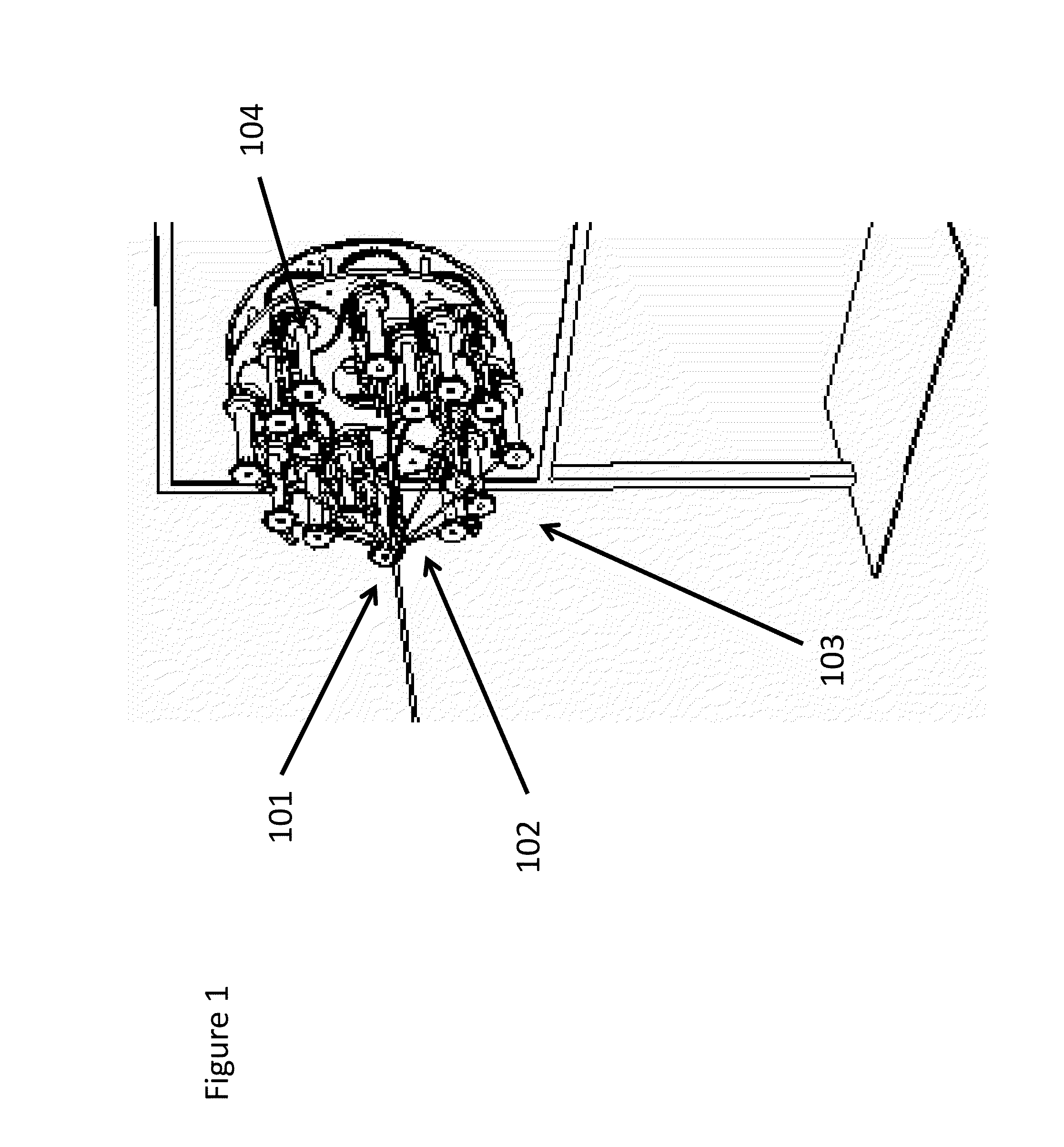

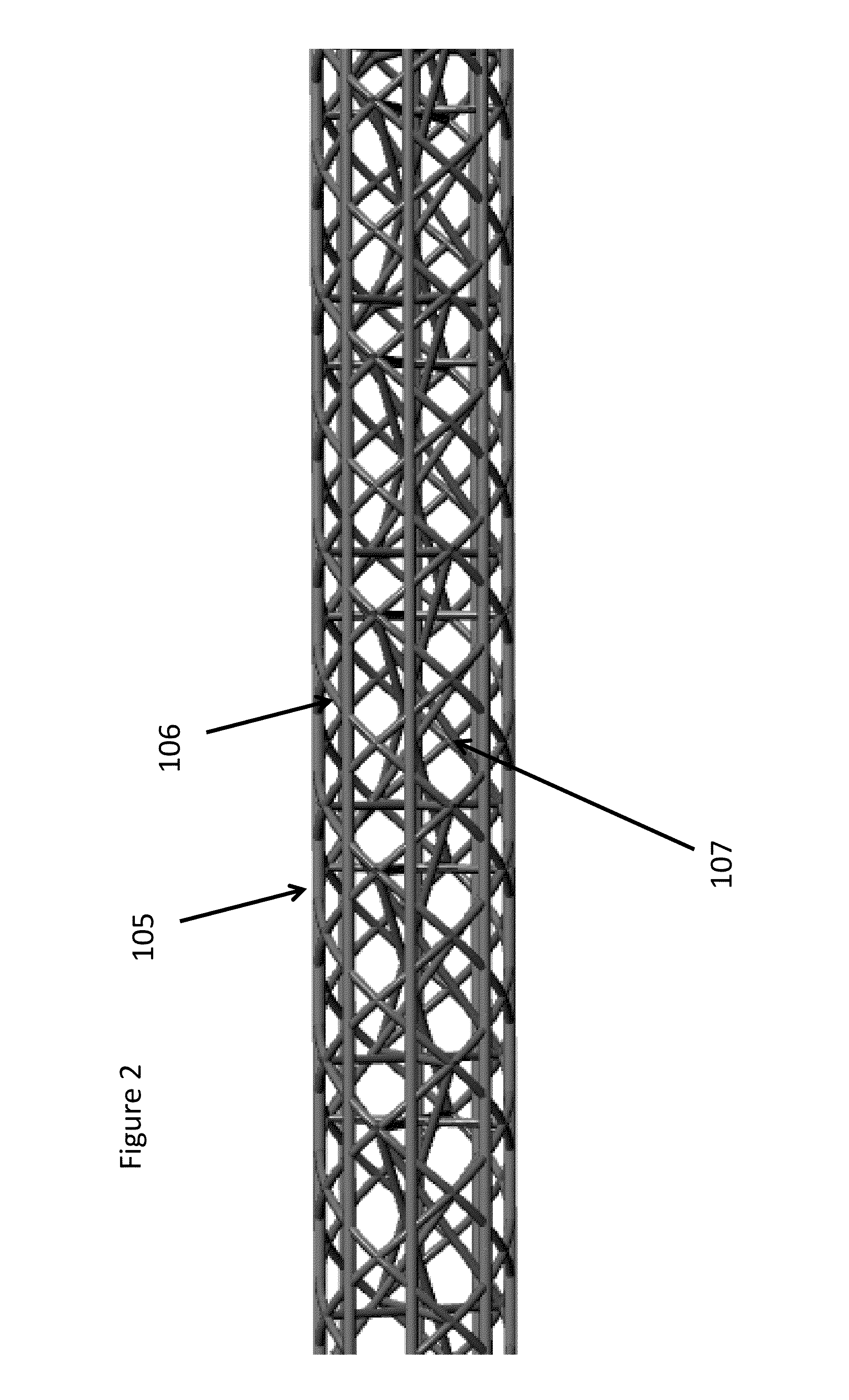

ActiveUS20130291476A1Simple processFast manufacturing processMetal-working apparatusGirdersOpen structureYarn

Owner:AUBURN UNIV

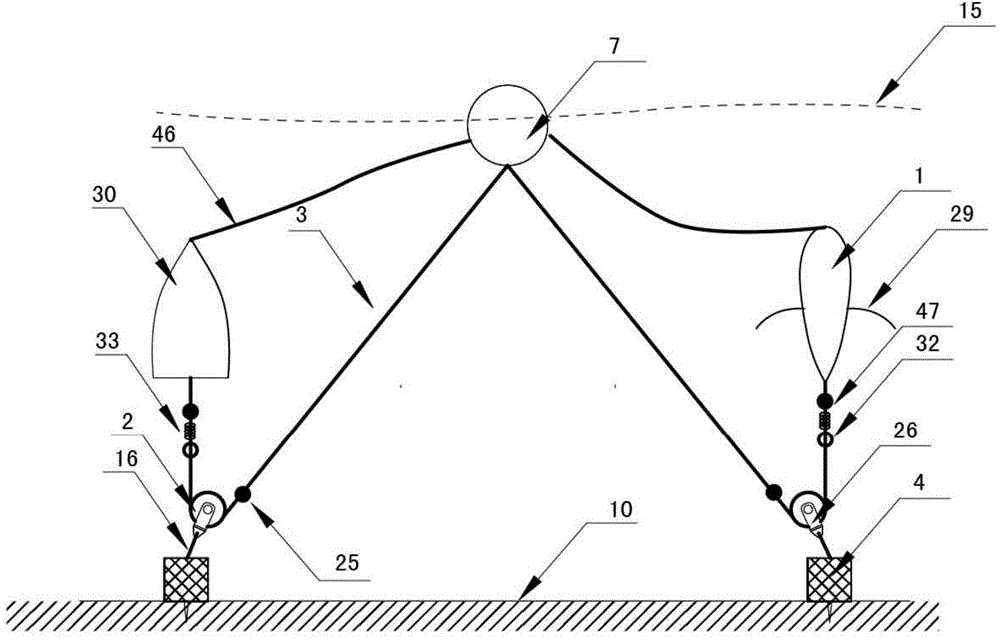

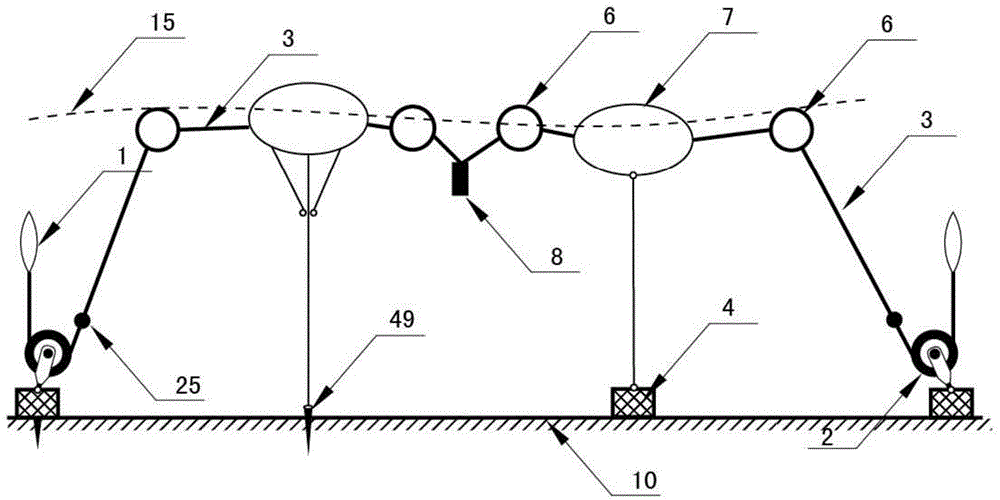

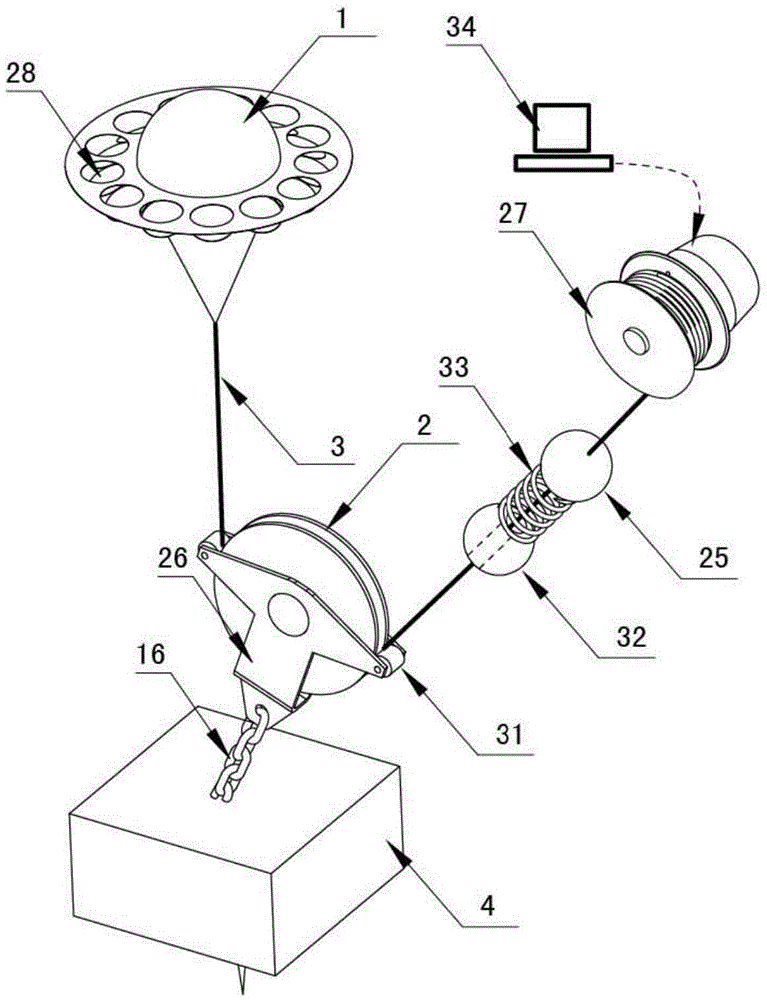

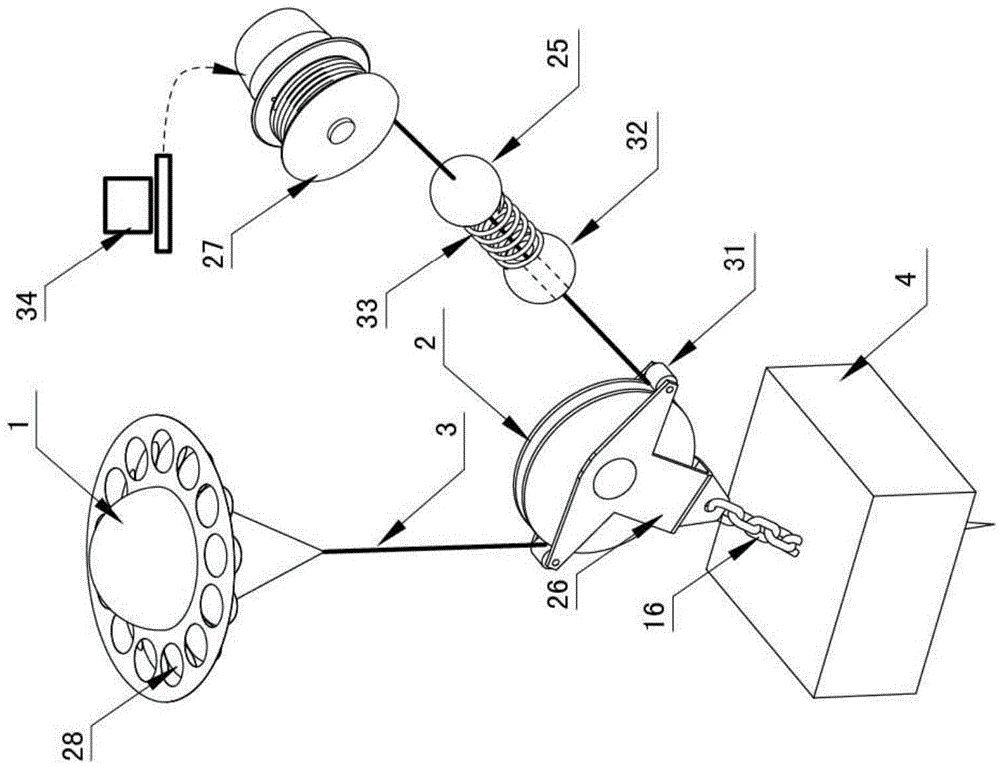

Submersible buoy pulley mooring system

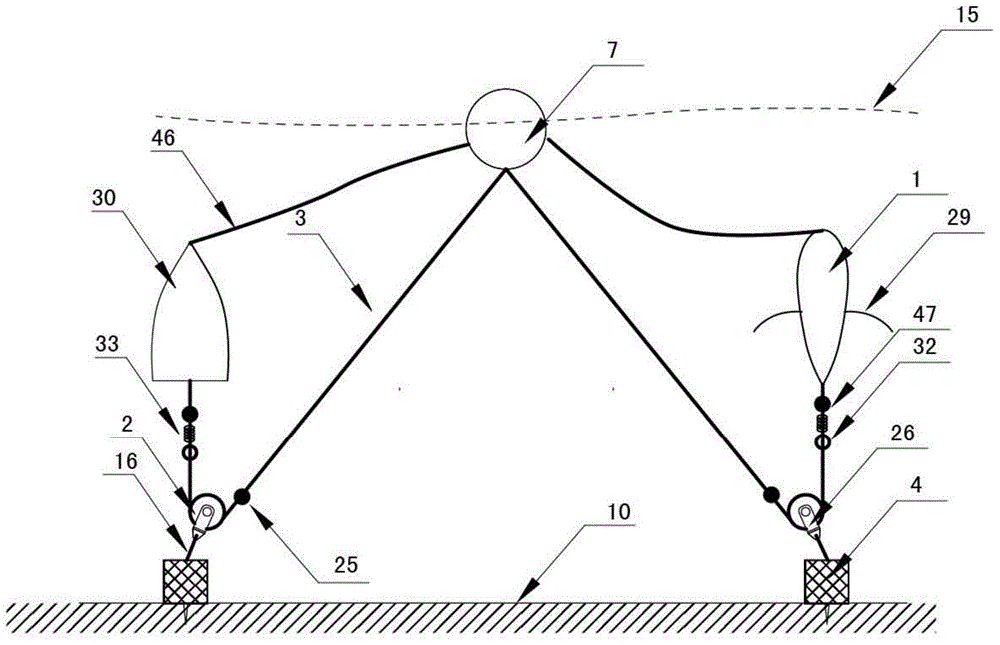

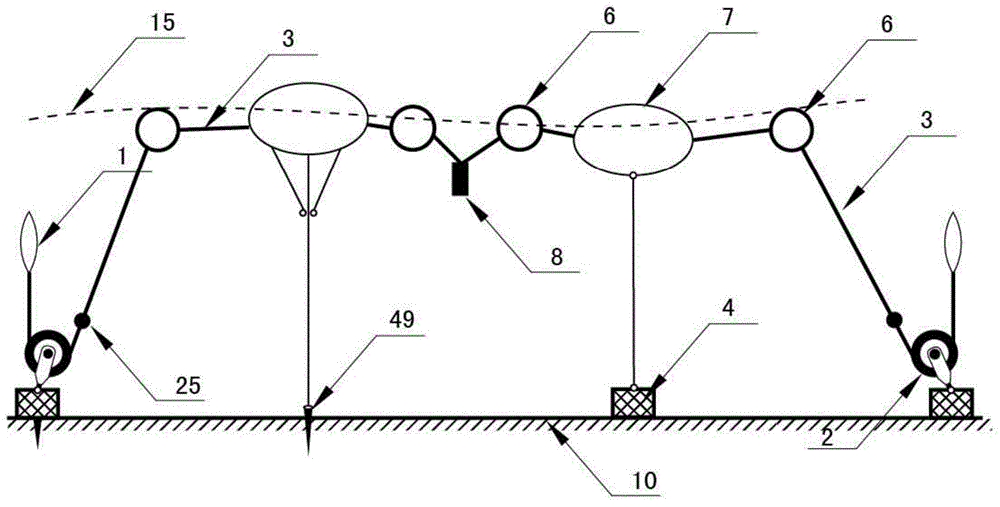

The invention provides a submersible buoy pulley mooring system and relates to a mooring system. The submersible buoy pulley mooring system mainly comprises submersible buoys, pulleys, anchor bases, ropes and rope knots. The anchor bases are provided with rope chains in a tying mode. The other end of each rope chain is tied to each fixed pulley support. Each pulley is wound with a rope. One end of each rope is tied to the corresponding submersible buoy. The other end of each rope is tied to a floating body required to be moored. The positions, between the pulleys and the moored floating body and close to the pulleys, of the ropes are provided with the rope knots in a tying mode. Combination of a plurality of submersible buoy pulley anchoring units distributed on the periphery tightly pull the central floating body required to be moored jointly. By means of the submersible buoy pulley mooring system, the problems of anchor chain breakage or anchor base slippage and the like generated due to the fact that the mooring constraining force is violently increased can be avoided, so that the storm resistance capacity can be provided, and the mooring cost is lowered.

Owner:曲言明

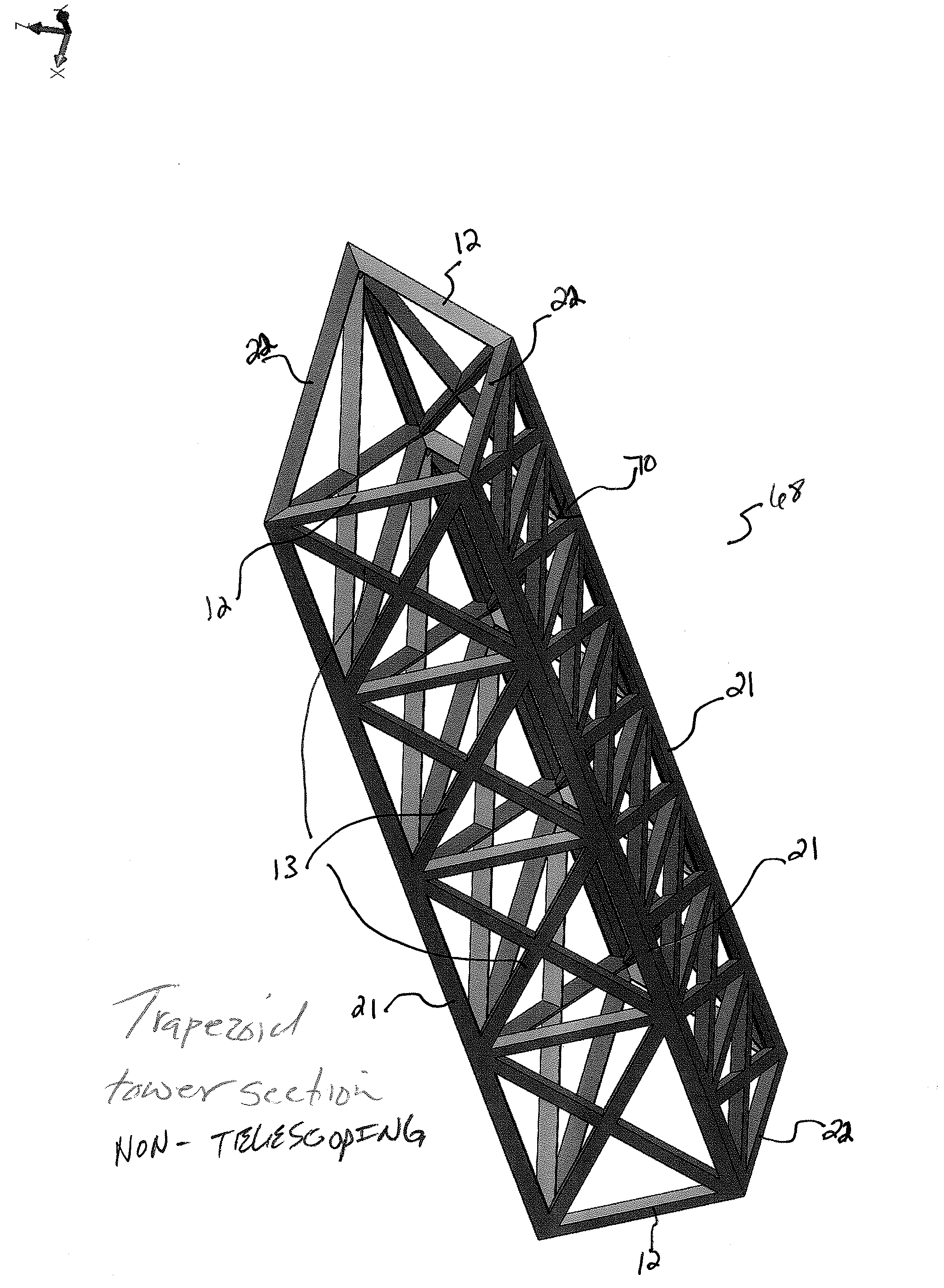

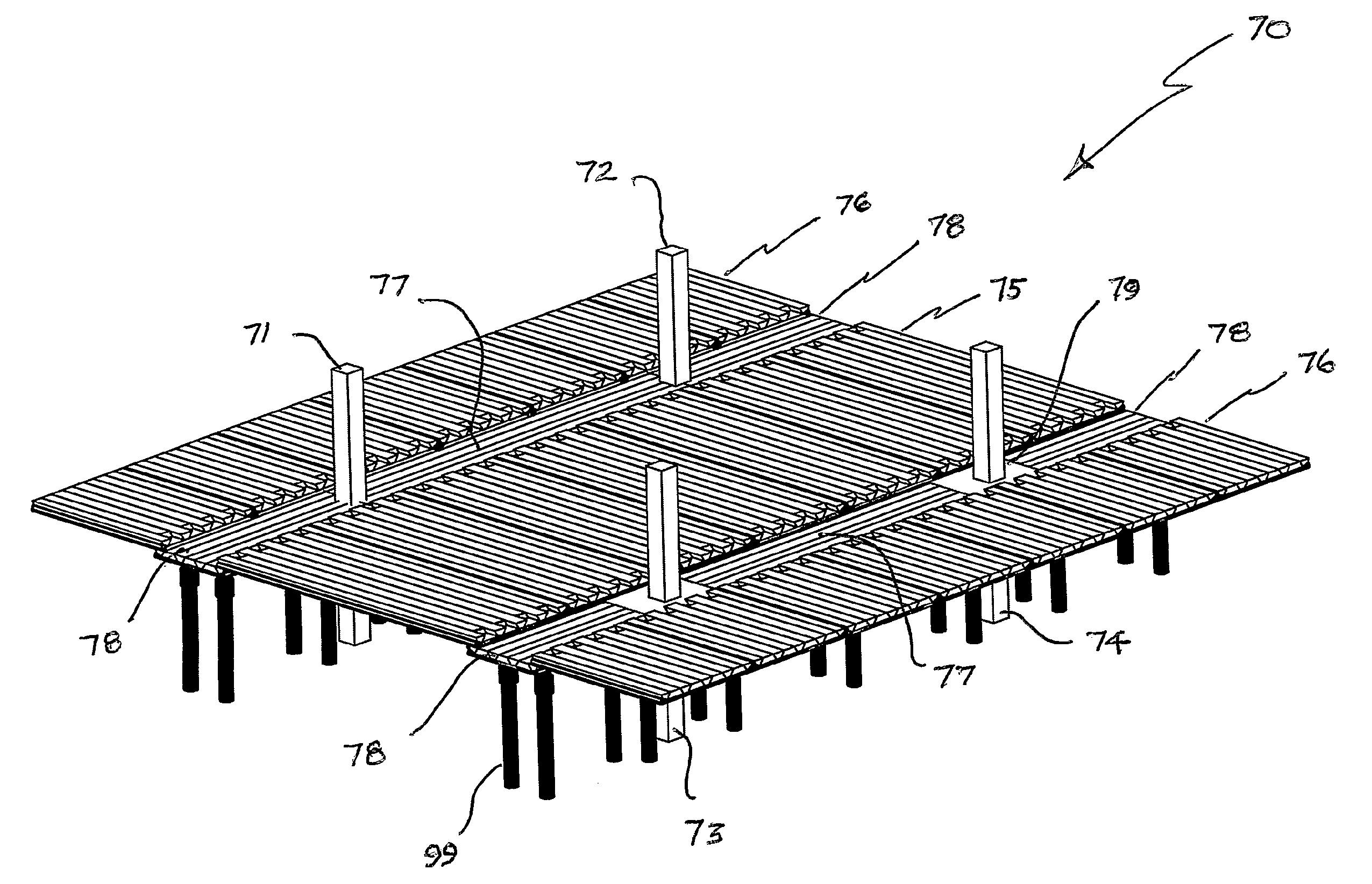

Composite open/spaced matrix composite support structures and methods of making and using thereof

InactiveUS20140182232A1Rapid deploymentLight weightPhotovoltaic supportsAntenna supports/mountingsEngineeringTower

A lattice support structure or tower comprising one or more open matrix composite strut members connecting a series of interlocking connectors to create a ridged support platform for telecommunications, surveillance, renewable energy, lighting and energy transmission applications. Embodiments of the invention are telescoping for ease of transport and erection. The erection and deployment can be achieved through means of automatic deployment or manual.

Owner:HOLT DREW RYAN

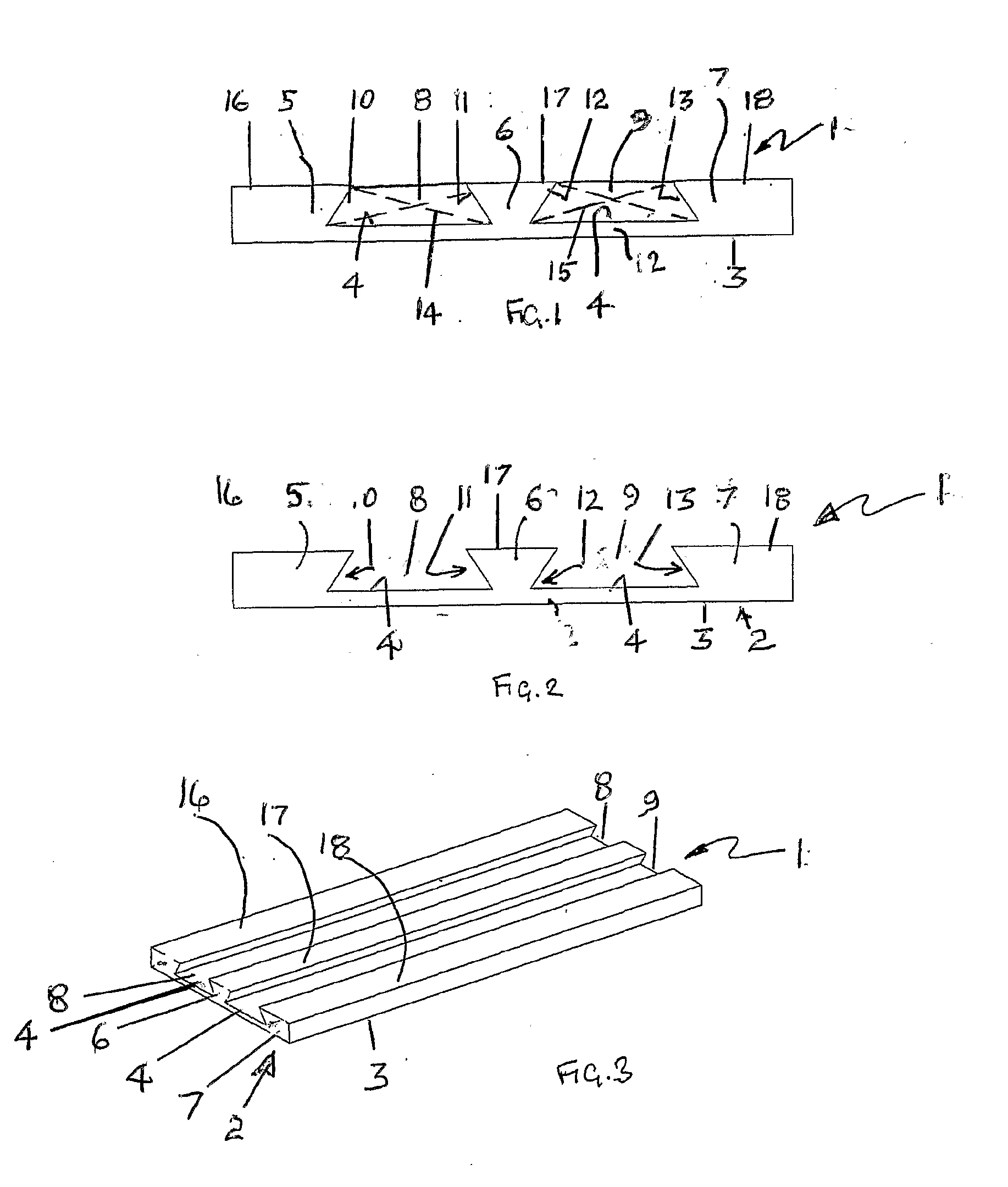

Structural element and methods of use thereof

InactiveUS20100024332A1Improve structural performanceHigh strength to weight ratioBuilding roofsConstruction materialMechanical engineeringVoid space

A pre-formed structural concrete element for use in the formation of a composite concrete floor of a building or the like, the element comprising: a generally planar base portion having opposing faces; a series of generally parallel spaced apart formations extending from one said faces of the base portion each defining along with an adjacent formation a void space therebetween and wherein the formations terminate in a plateau and have at least a narrow portion and a wide portion between the plateau and the one said faces of the base portion.

Owner:VALAIRE TREVOR

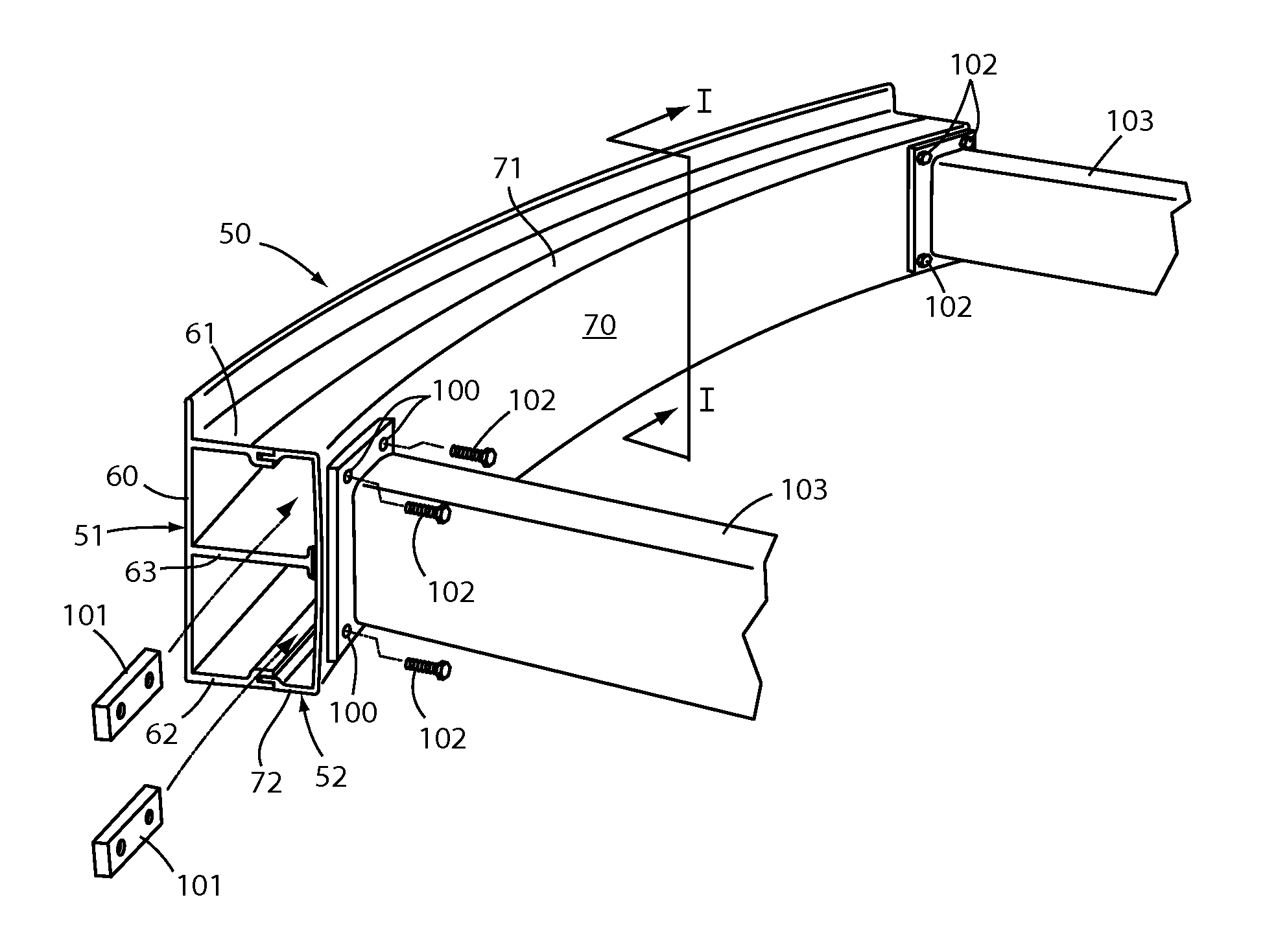

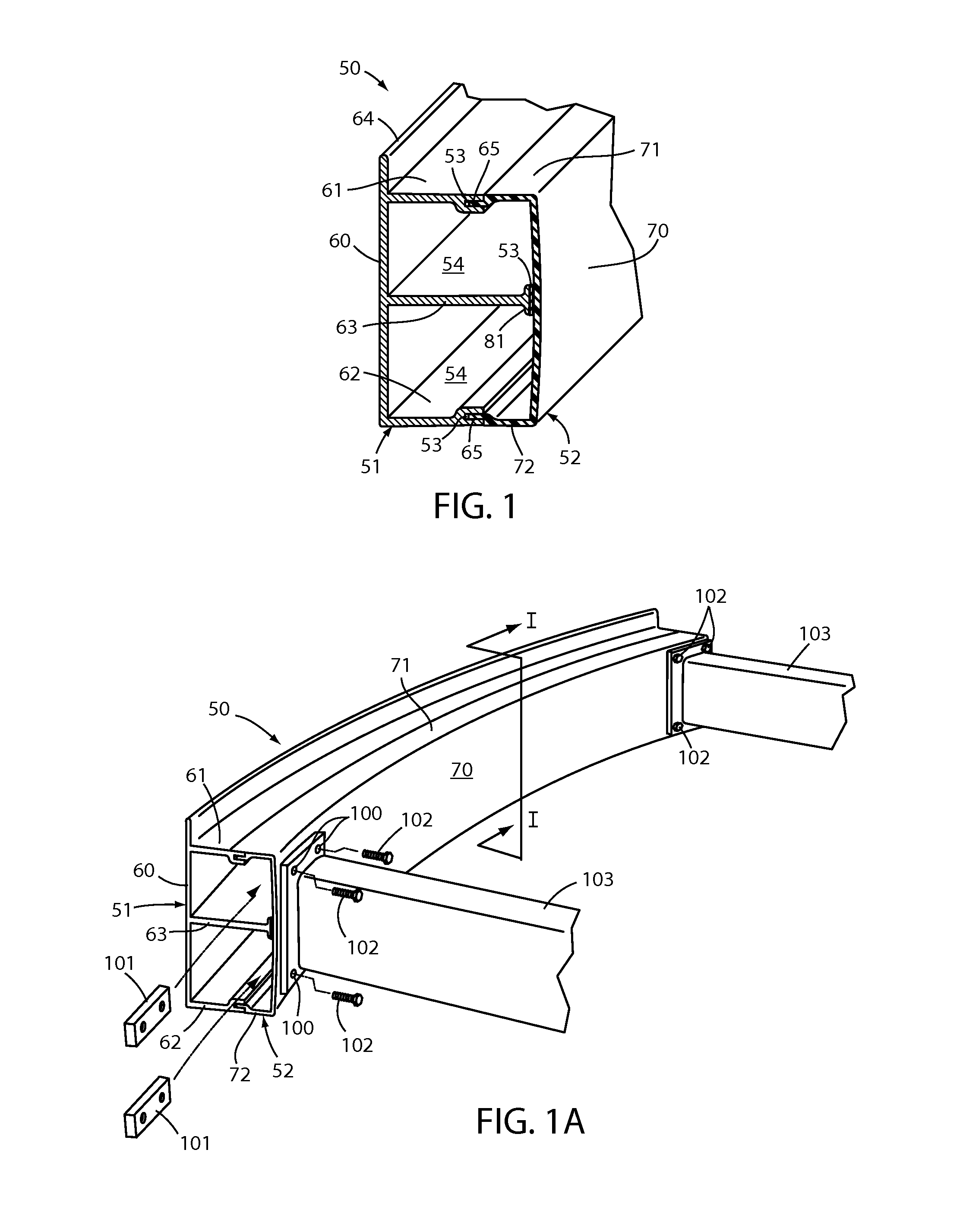

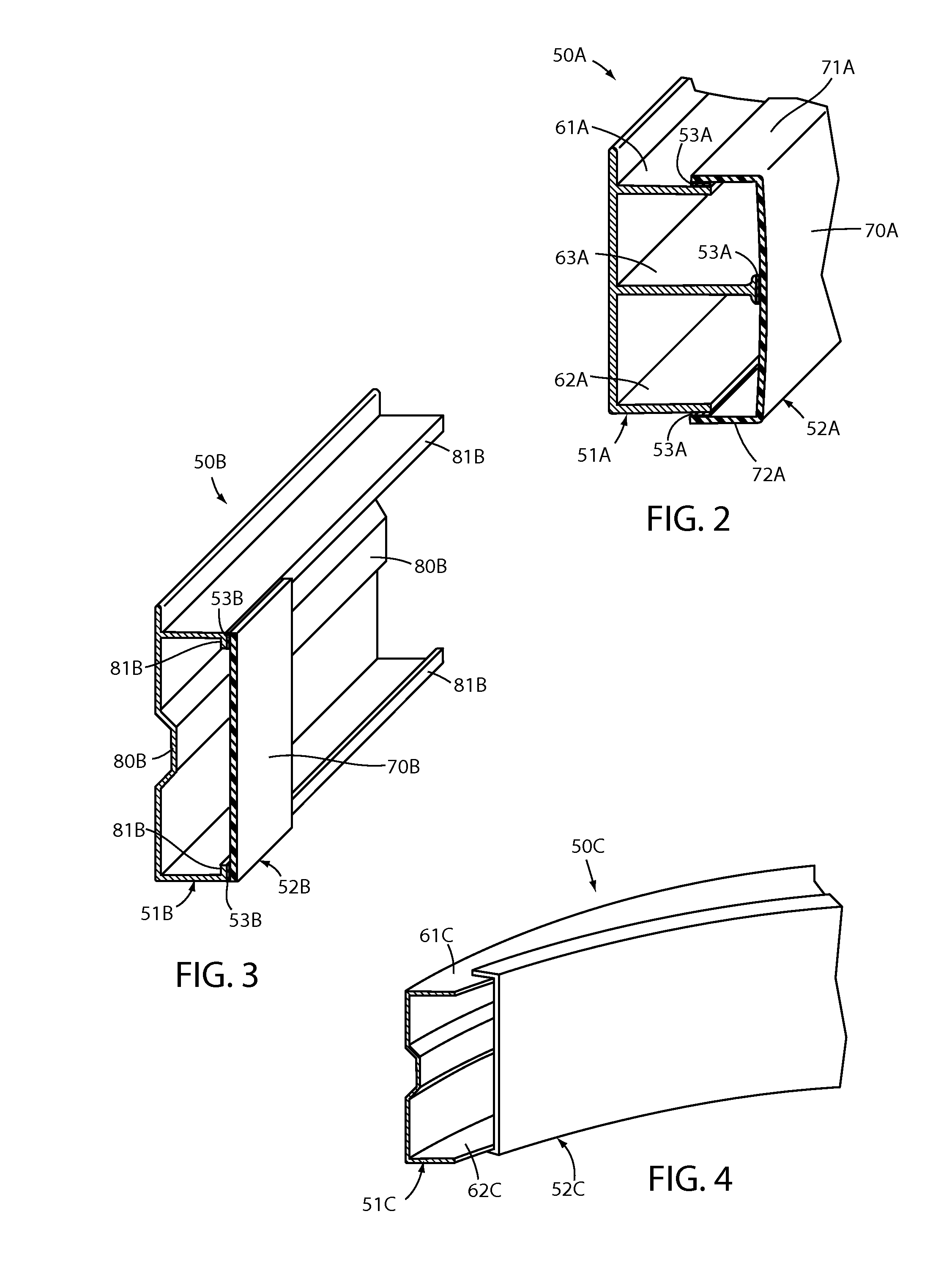

Minimal weight composites using open structure

ActiveUS20150056449A1High strength to weight ratioImprove joint strengthGirdersJoistsYarnPolymer science

Owner:AUBURN UNIV

Ruggedized electronics enclosure

InactiveUS20070177348A1Overcomes limitation and disadvantageHigh strength to weight ratioPrinted circuit board receptaclesModifications by conduction heat transferPassive radiatorEngineering

The present invention relates to a ruggedized enclosure for housing and protecting electronic circuits. The enclosure utilizes a top compartment for housing the circuit and a cooling assembly rigidly coupled to the top compartment. The cooling assembly utilizes a passive radiator to form a rigid truss plate structure. The truss plate structure rigidifies the enclosure helping to protect the enclosure and circuit from destructive shock events and destructive vibration events. The cooling assembly further provides an efficient heat exchange for removing heat from the electronic circuit. A method for protecting an electronic circuit utilizing a rigid truss plate structure is also provided.

Owner:KEHRET WILLIAM E +1

Low-density high-strength concrete and related methods

PendingUS20150251952A1Low densityHigh strength-to-weight ratioSolid waste managementControl apparatusHigh strength concreteGlass microsphere

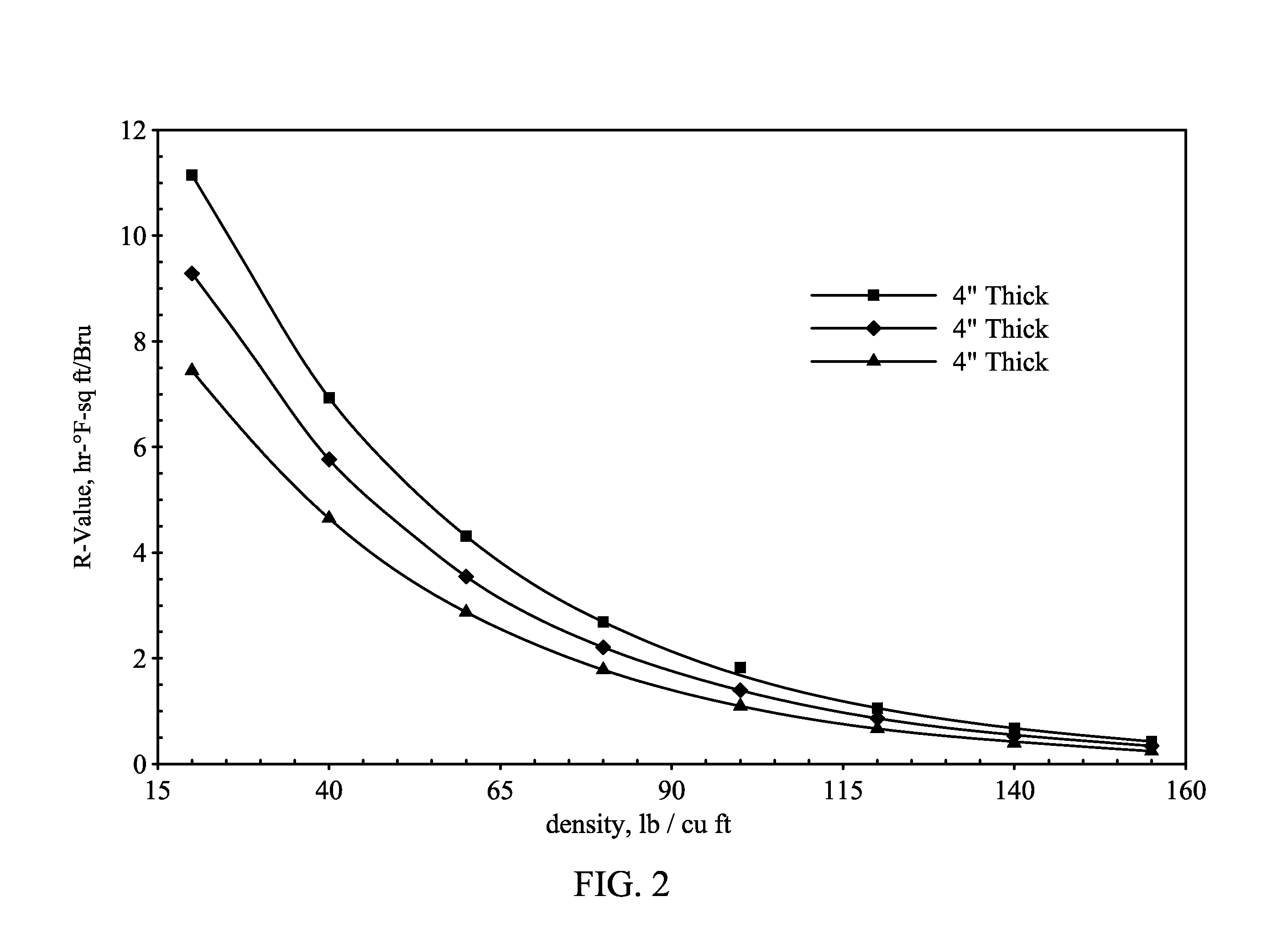

A low-density, high-strength concrete composition that is both self-compacting and lightweight, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at an oven-dried density as low as 40 lbs. / cu. ft. The concrete, at the density ordinarily found in structural lightweight concrete, has a higher strength and, at the strength ordinarily found in structural lightweight concrete, a lower density. Such strength-to-density ratios range approximately from above 30 cu. ft / sq. in. to above 110 cu. ft / sq. in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

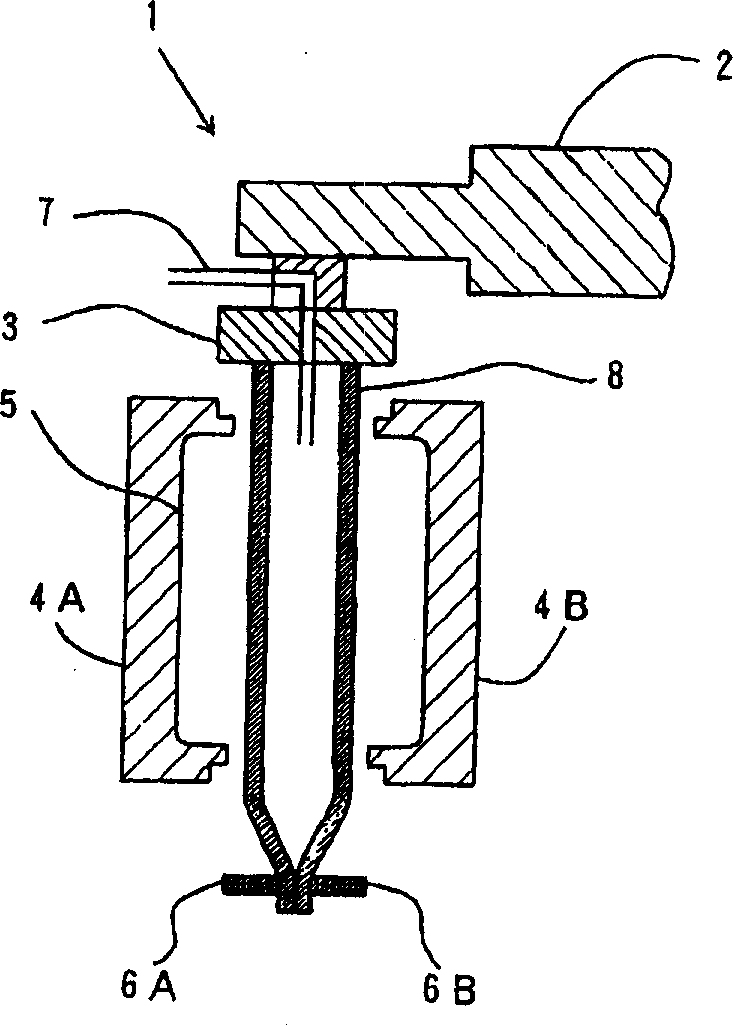

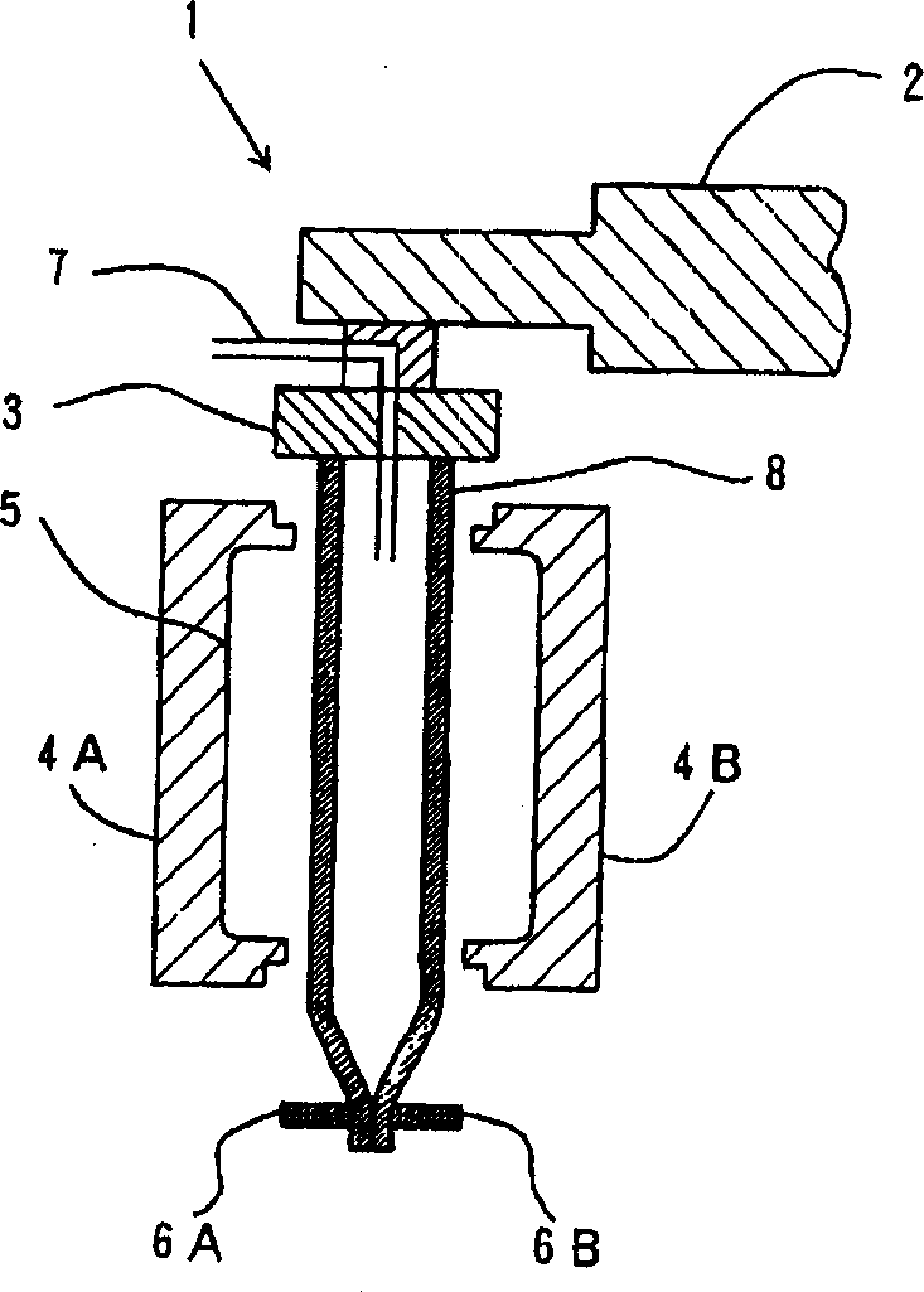

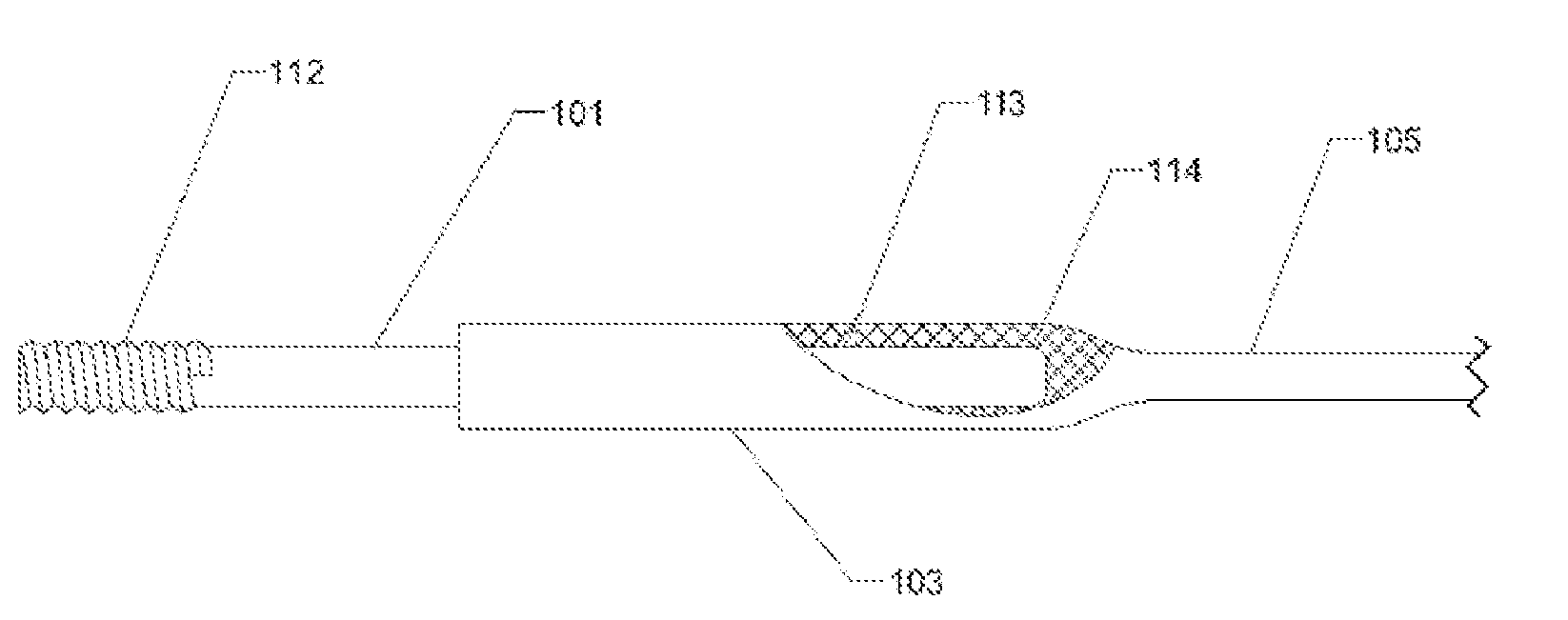

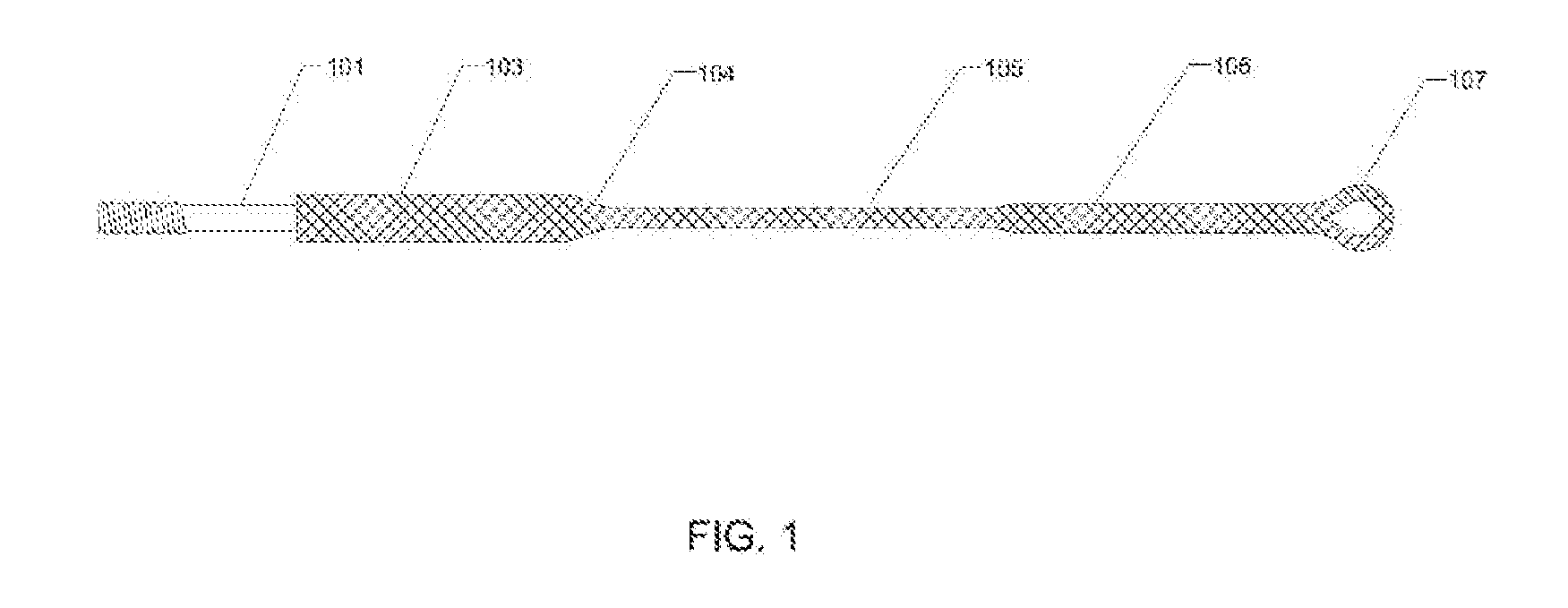

Pressure cylinder with composite piston rod and method for preparing a composite piston rod

InactiveCN101529101AHigh strength to weight ratioHigh strengthFluid-pressure actuatorsFiberEngineering

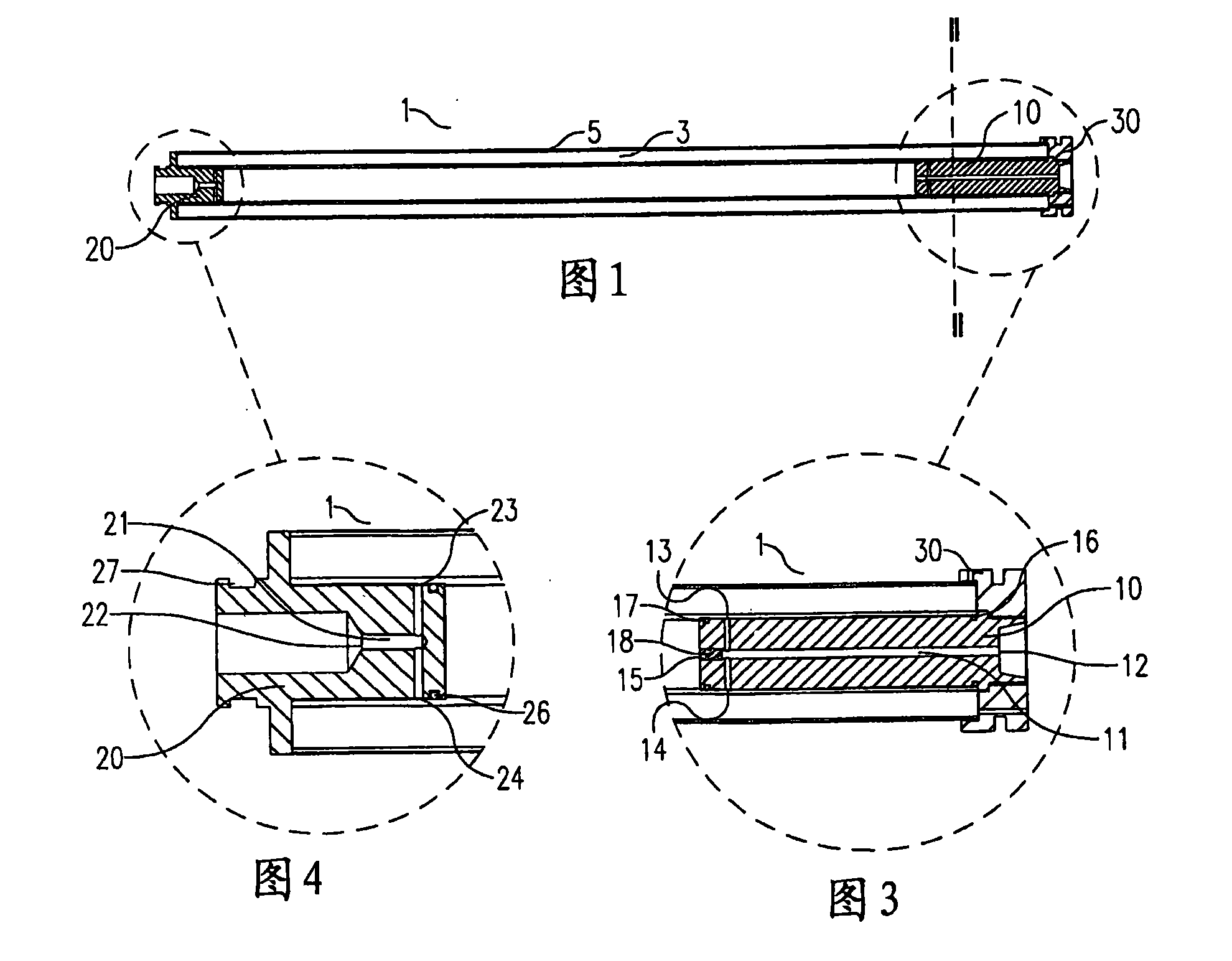

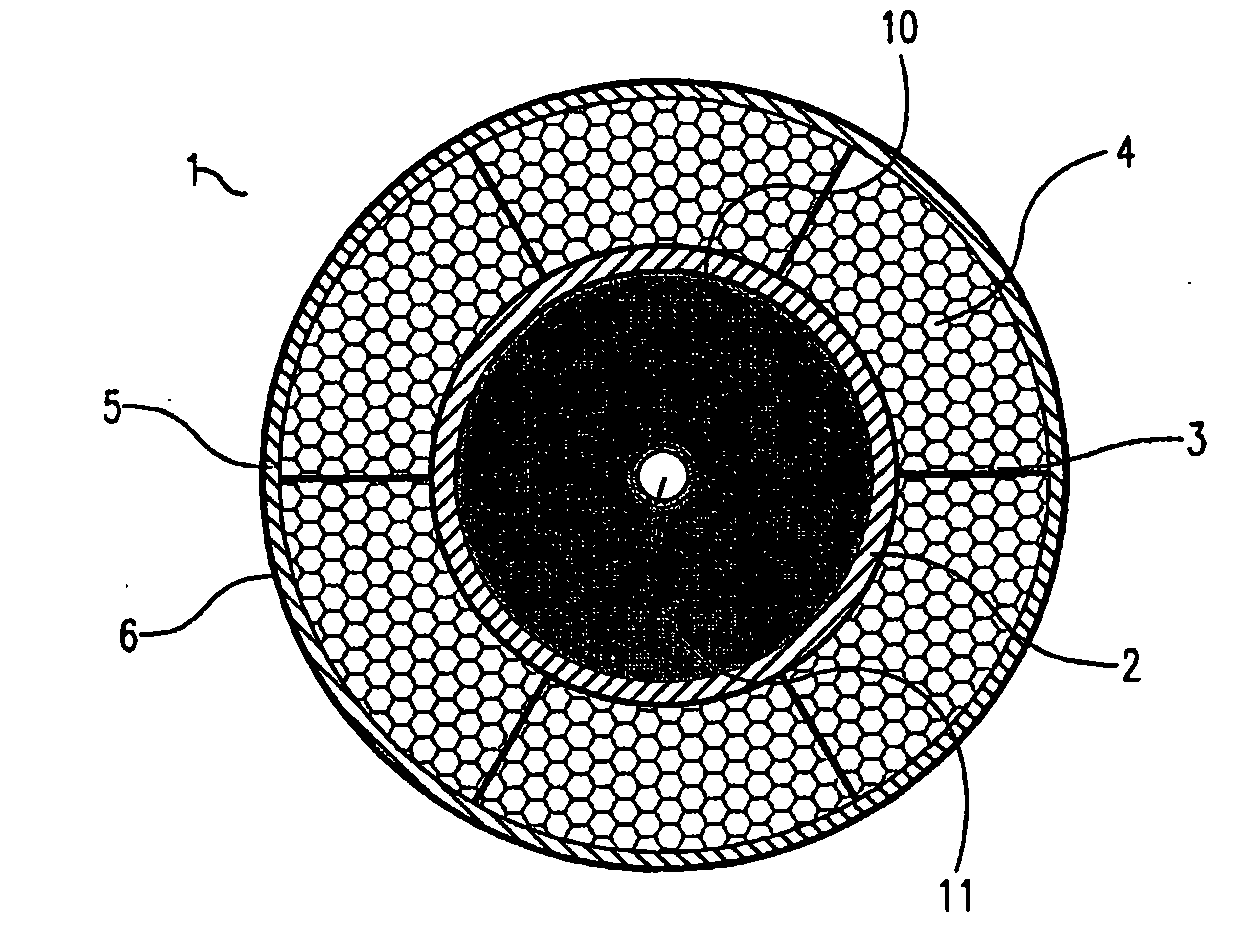

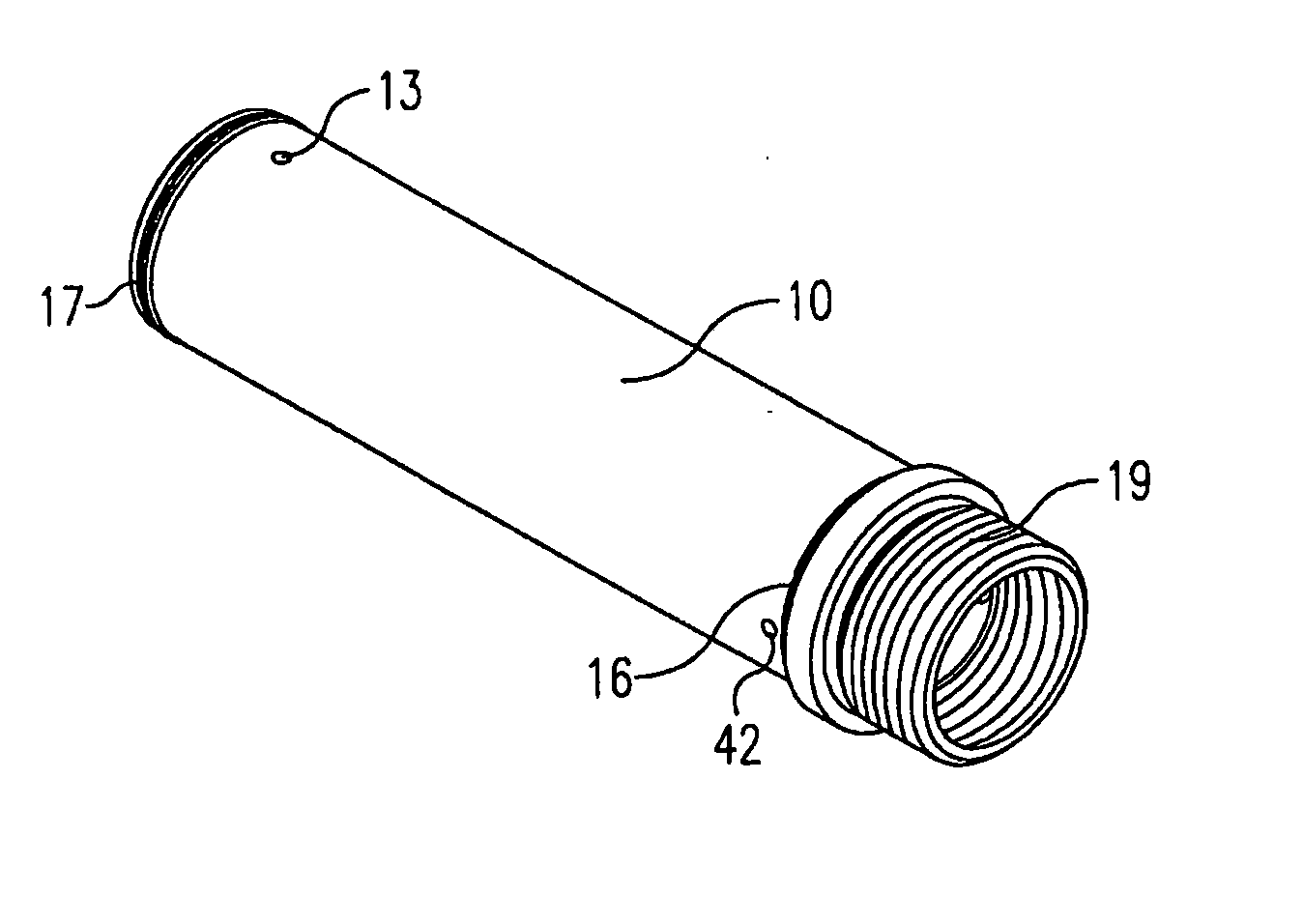

A pressure cylinder comprises a cylinder housing with a cylinder space in which a fitting piston is axially movable. A piston rod (1) of a composite material extends from the piston. The piston rod (1) comprises a layer of core material under a surrounding outer jacket (5). The layer of core material (3) is constructed from composite material fibres oriented parallel to a longitudinal axis of thepiston rod and straightened, and the outer jacket (5) is constructed from composite material fibres wound at an angle relative to the longitudinal axis. Thus provided is a pressure cylinder with a piston rod (1) of relatively light weight, which can withstand a relatively high pressure load. Less composite material is hereby required for the piston rod (1) while the strength remains the same.

Owner:ZUMRO

Multilayered structure and balloon including the same

InactiveUS20150336652A1High strengthHigh tensile strengthSynthetic resin layered productsDomestic containersNorborneneCyclo olefin polymer

Various embodiments of the present invention relate to a multilayered structure and balloon including the same. In various embodiments, the present invention provides a multilayered structure including at least one A layer (a) including a linear olefin polymer or copolymer, at least one B layer (b) including a cyclic olefin polymer or copolymer, and at least one A layer (c) including a linear olefin polymer or copolymer. The cyclic olefin polymer or copolymer of the at least one B layer is a polymer or copolymer of a substituted or unsubstituted norbornene.

Owner:VIAFLEX INC

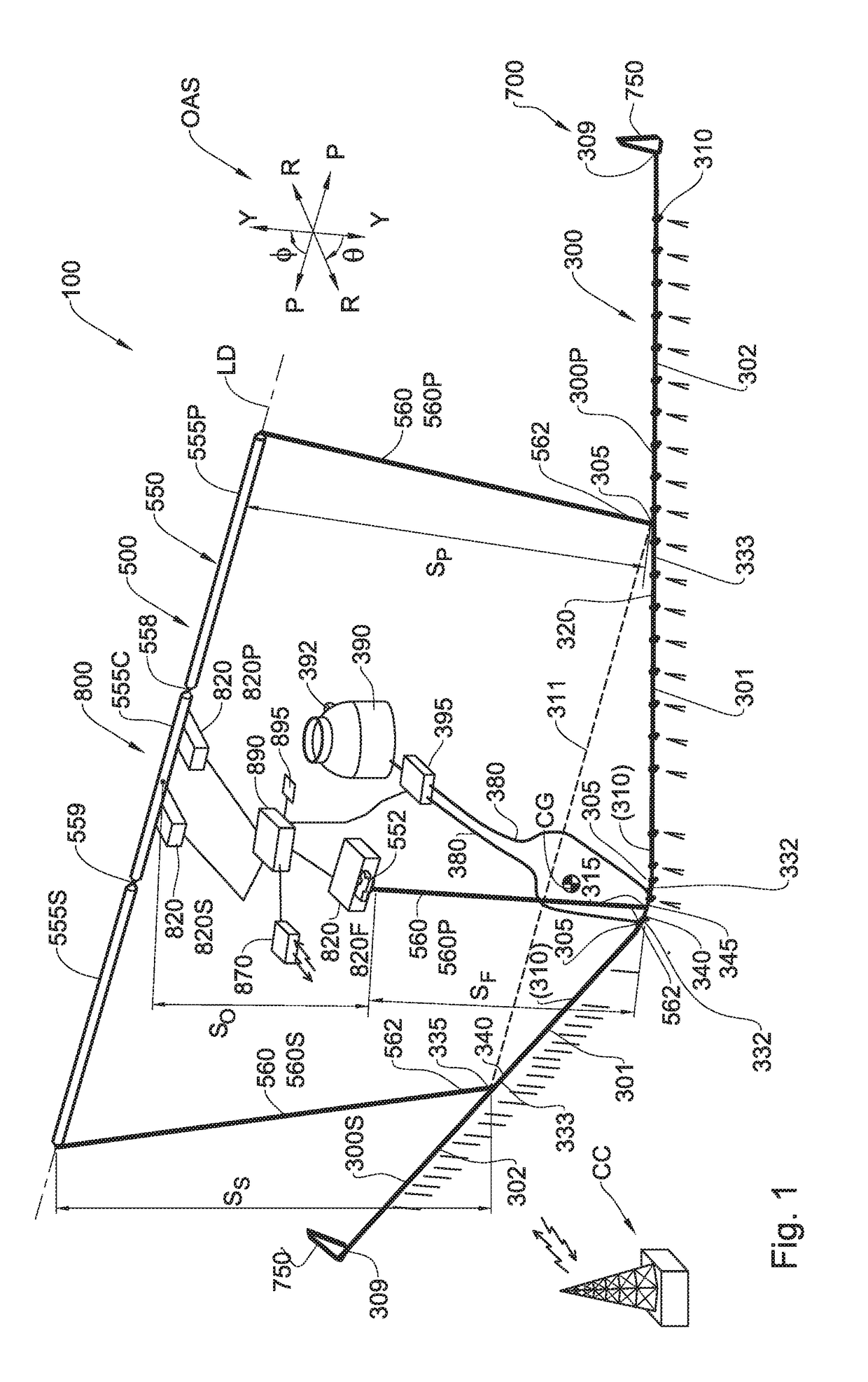

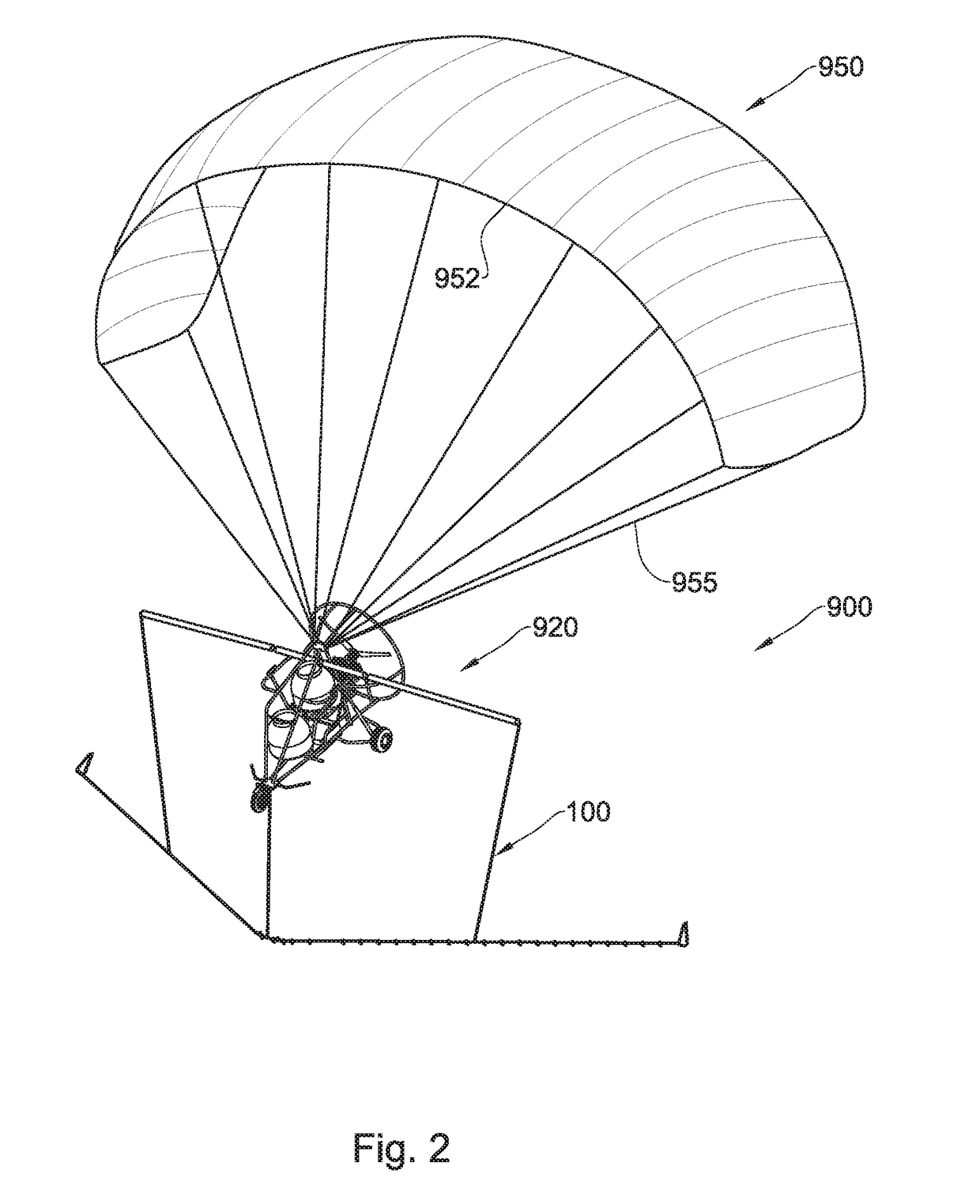

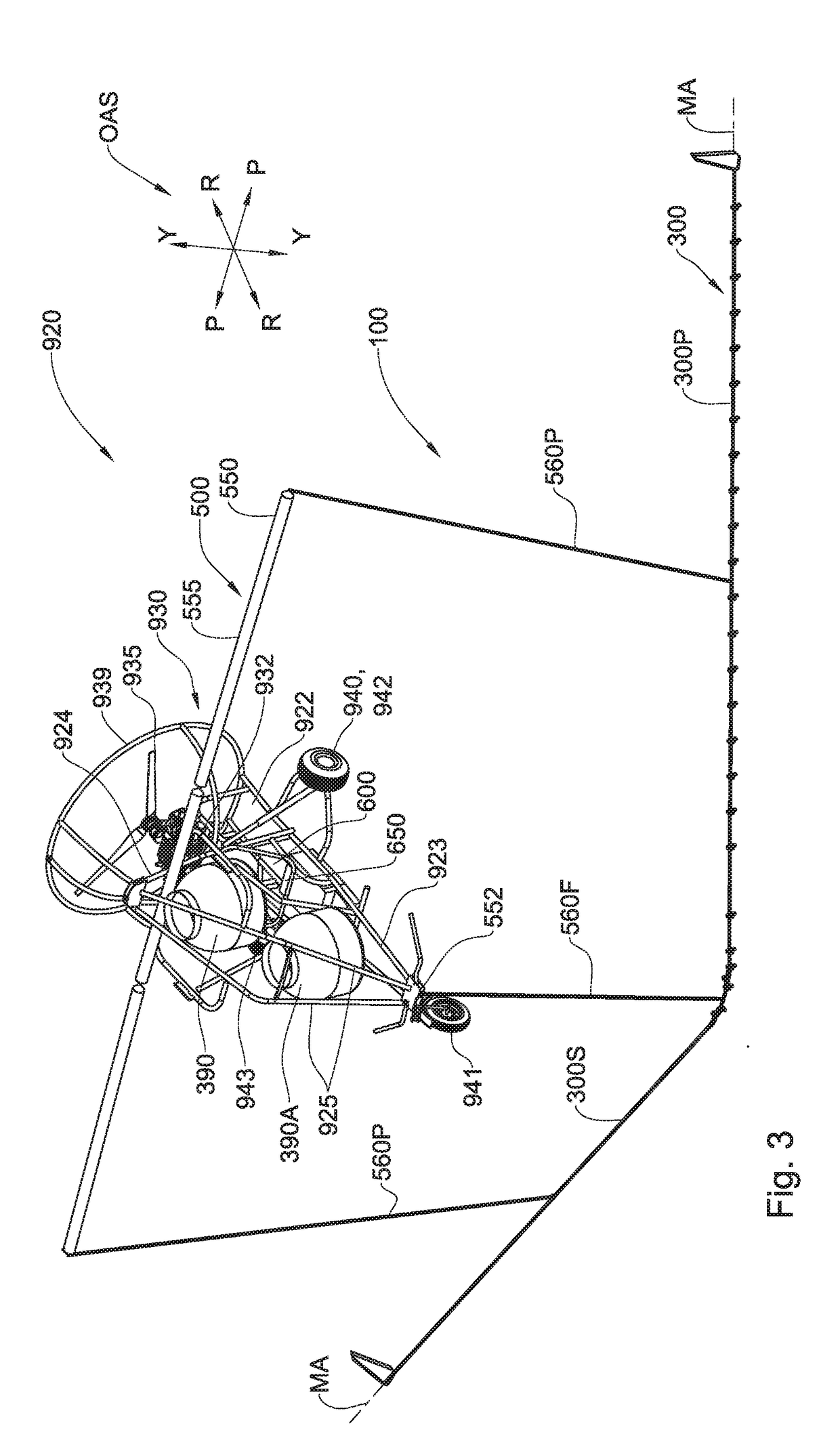

Aerial platforms for aerial spraying and methods for controlling the same

InactiveUS20190047694A1Low drag characteristicHigh strength to weight ratioAircraft componentsUnmanned aerial vehiclesSurface levelEngineering

There is provided an aerial platform comprising a spraying module, one or more actuators operatively coupled to the spraying module, at least a sensor for acquiring data indicative of altitude, wherein at least a controller is configured to control a position of the spraying module relatively to the aerial platform based on control signals generated during control cycles and applicable to the one or more actuators, the controlling comprising cyclically acquiring with said sensor data indicative of an altitude of a surface area in the flight path direction of the aerial platform, wherein said surface area is to be sprayed in a next control cycle, generating a control signal based on at least said acquired data, so as to maintain the altitude of the spraying module at a required distance of the altitude of the surface, and applying the generated control signal to the one or more actuators. There is also provided methods and systems for controlling a motion of the spraying module.

Owner:ISRAEL AEROSPACE IND

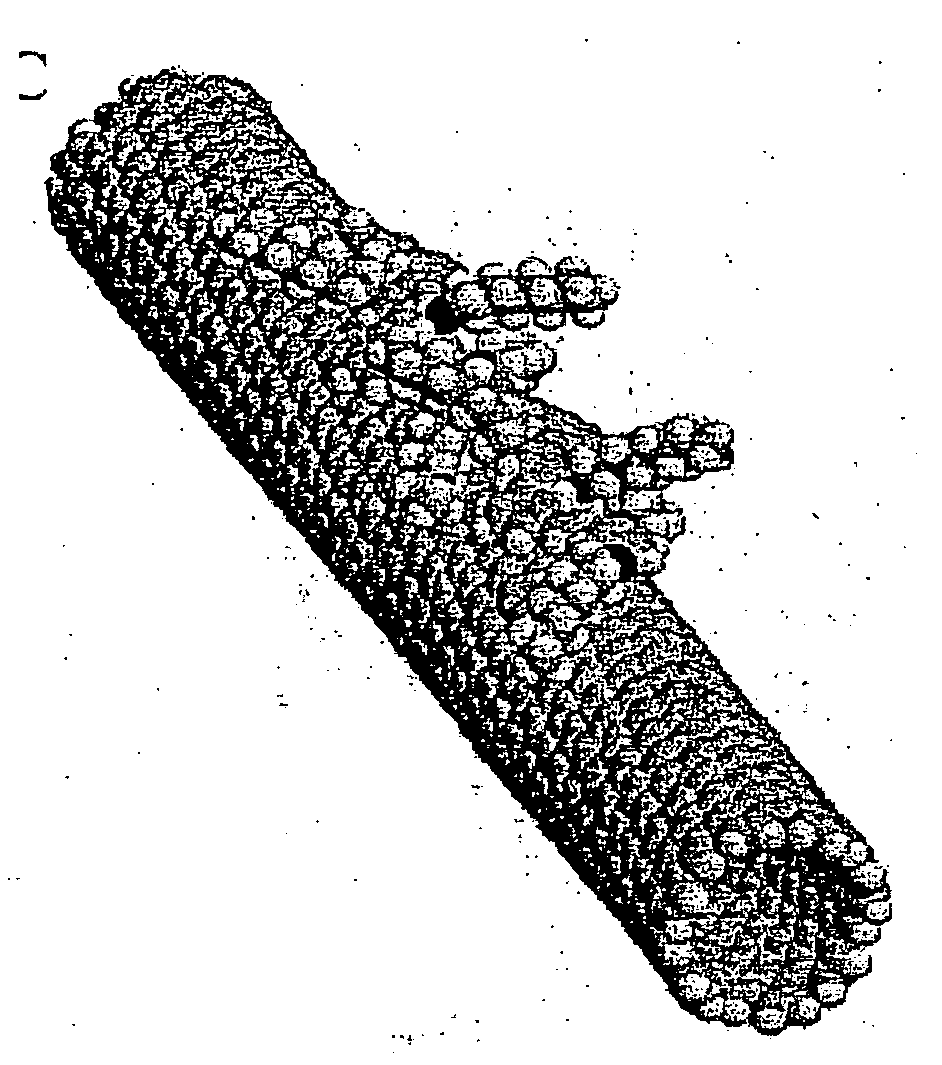

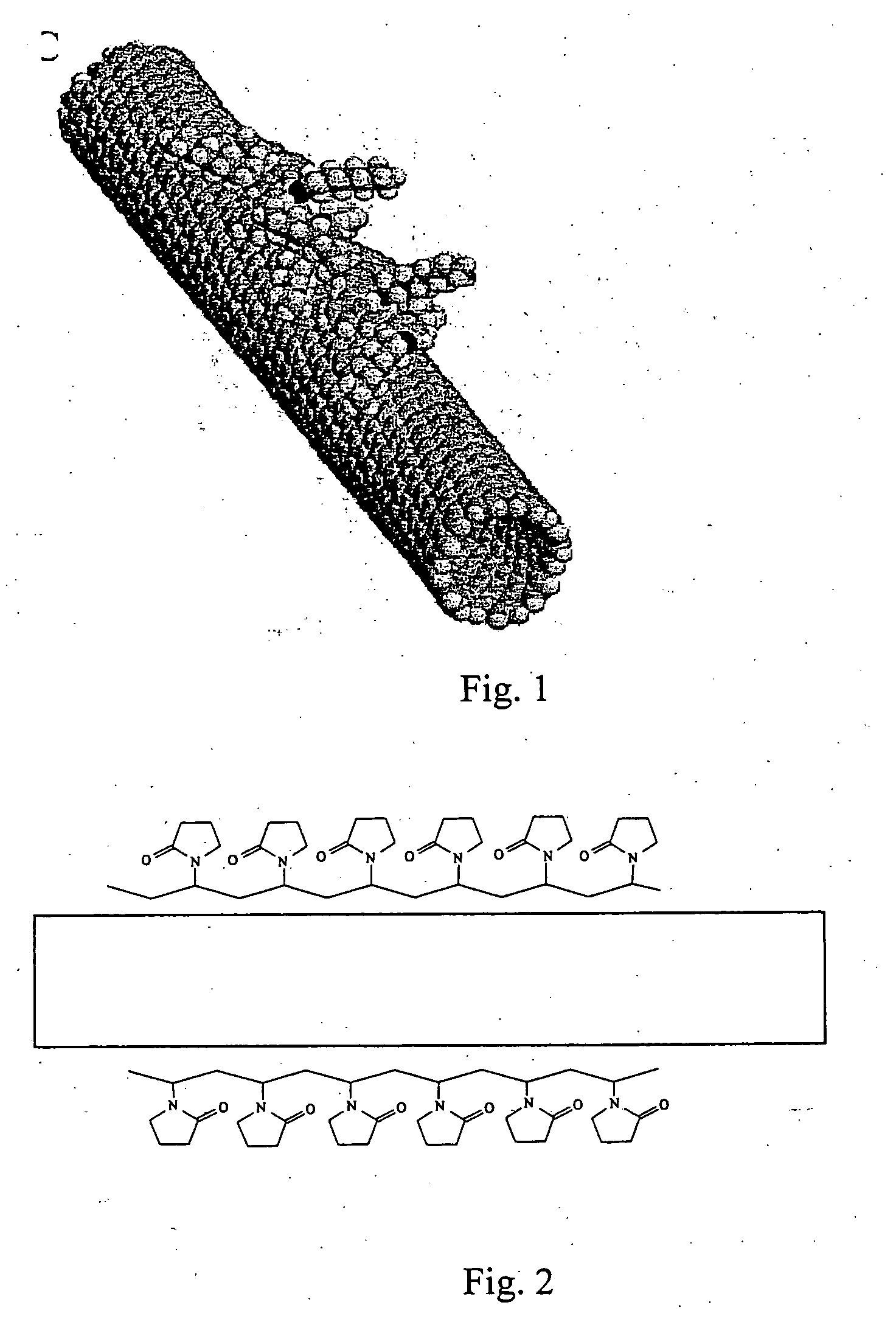

Product

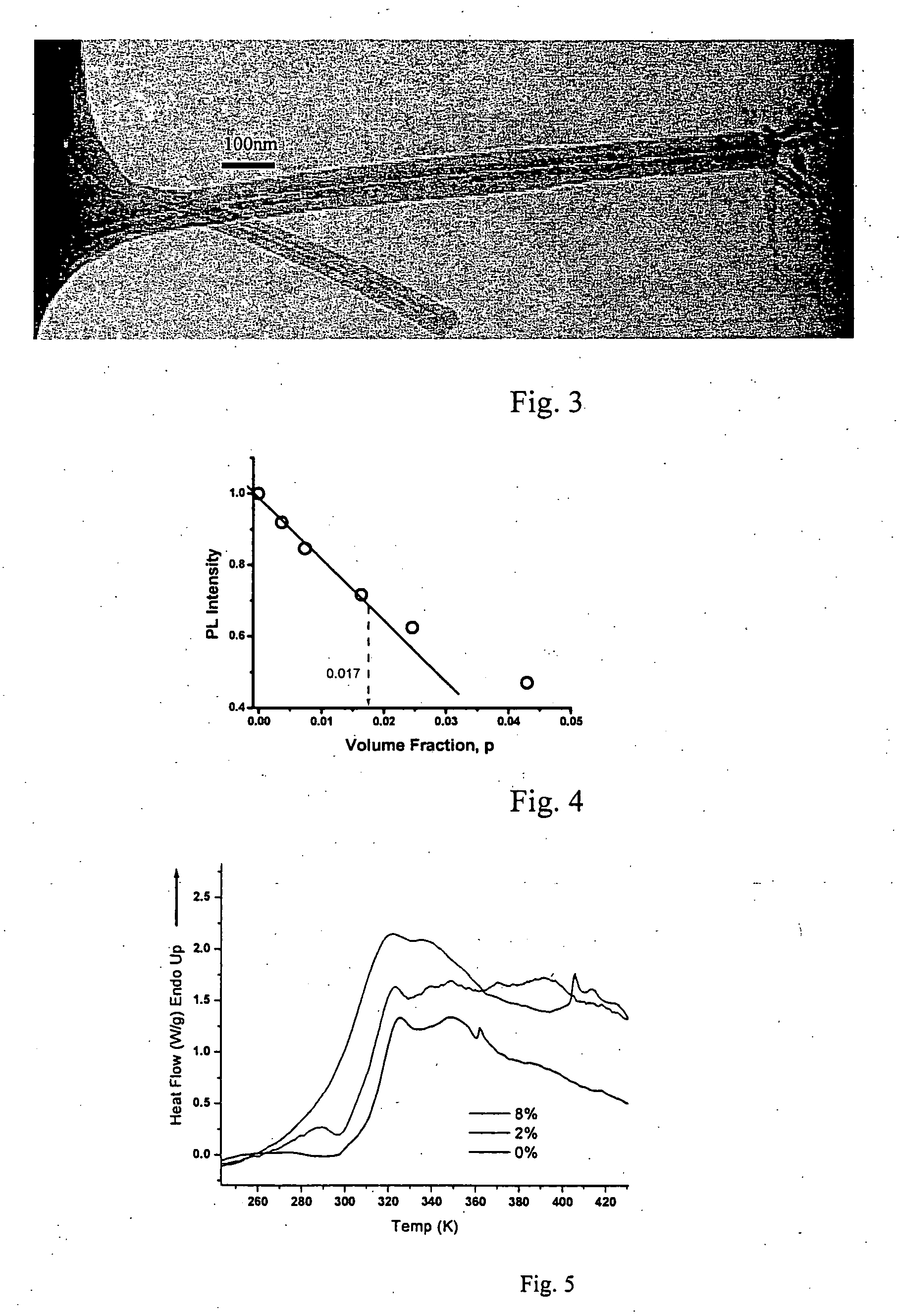

ActiveUS20100304136A1Lower ratioGood physical propertiesMaterial nanotechnologySynthetic resin layered productsNanotubePolymer

Owner:TRINITY COLLEGE DUBLIN

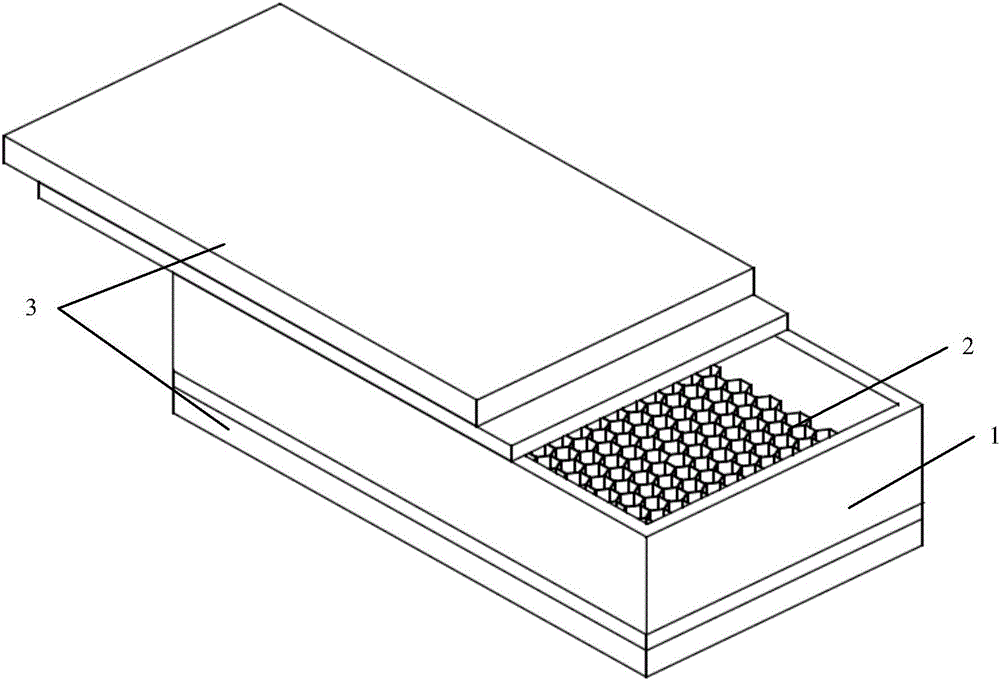

Honeycomb core board

ActiveCN103112202AHigh strength to weight ratioImprove fastnessLaminationLamination apparatusHoneycombPrism

The invention relates to a honeycomb core board used for replacing blockboards and the like, mainly aiming to solve the problems that present blockboards and the like have low strength and low weight ratios. The honeycomb core board comprises upper and lower panel layers and a honeycomb core layer and is characterized in that the upper and lower panel layers and the honeycomb core layer are prepared with polypropylene short fibers and jute fibers as raw materials; a preparation method of the honeycomb core board comprises the following steps of: preparing coiled materials or sheets from the polypropylene short fibers and the jute fibers in a weight ratio of 30-70%:70-30% by adopting an air laying method and preparing the upper and lower panel layers from the panels pressed at 180-200 DEG C; and putting the coiled materials or the sheets into a honeycomb core shaped die to be pressed at 180-200 DEG C to prepare the honeycomb core layer, adhering the upper and lower panel layers to the upper and lower surfaces of the honeycomb core layer and pressing the three layers to prepare the honeycomb core board; cylinders or prisms are arranged on a lower plate of the honeycomb core shaped die and under an upper plate; and the upper and lower panel layers can be also prepared from polymer boards, plywood or nonwovens and the like. The honeycomb core board has the advantages of high strength and high weight ratio.

Owner:辽宁艺朦织旺地毯有限公司

Method of manufacturing rivets having high strength and formability

InactiveUS20030218053A2Good molding effectReduced neckingRivetsWelding/cutting auxillary devicesHigh intensityMechanical property

Abstract of the Disclosure A rivet having improved formability is provided. The rivet has a shank having a head at one end. The shank and the head have a refined grain structure. The rivet is manufactured from the region of the workpiece having a refined grain structure by first forming a region having a refined grain structure in a workpiece and then forming the rivet. The refined grain structure results in improved mechanical properties, such as formability, strength, toughness, ductility, corrosion resistance, and fatigue resistance. The improved formability of the rivet reduces the formation and propagation of cracks during the manufacture and installation of the rivets.

Owner:THE BOEING CO

Aerogel honeycomb sandwich board

InactiveCN106499150AGood chemical stabilitySolution to short lifeCovering/liningsSynthetic resin layered productsSandwich boardThermal insulation

The invention relates to an aerogel honeycomb sandwich board. The aerogel honeycomb sandwich board is composed of an upper-layer panel (3), a lower-layer panel (3) and a middle aerogel honeycomb core body. The aerogel honeycomb sandwich board is resistant to fire and flames, achieves heat insulation, and is good in sound insulation performance, high in strength and resistant to compression; the aerogel honeycomb sandwich board is good in anti-impact performance, low in mass and environmentally friendly, and has good application prospects.

Owner:SUZHOU ZIAN METAL PROD

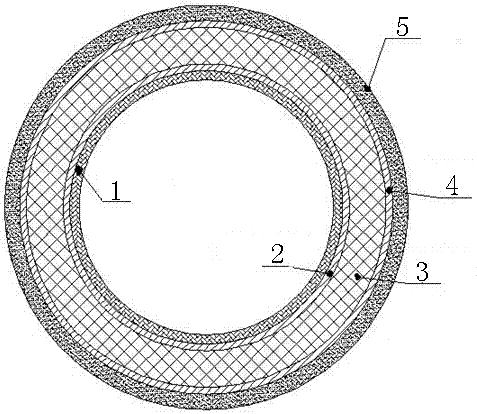

Wood-based composite pipe and preparation method thereof

ActiveCN104260422AAbundant resourcesIncrease stiffnessLamination ancillary operationsSynthetic resin layered productsPolymer scienceAdhesive

The invention discloses a wood-based composite pipe and a preparation method thereof. The pipe is composed of an inner lining layer, an inner interface adhesive layer, a wood-based strengthening layer, an outer interface adhesive layer, and an outer protective layer from inside to outside along the diameter direction; wherein the inner lining layer, the wood-based strengthening layer, and the outer protective layer are integrated into a solid pipe through adhesives. The preparation method comprises the following steps: (1) preparing the inner lining layer; (2) processing a wood-based strengthening material; (3) preparing the wood-based strengthening layer; (4) preparing the outer protective layer. The wood-based composite pipe has the following advantages: (1) the wood is obtained from artificial fast-growing woods and has the advantages of rich resources, low cost, large ratio of strength to weight, and high rigidity; (2) the pipe is prepared by winding dual composite plates with intercrossed fibers, and thus technical requirements in different application occasions can be met; (3) the pipe is heated and pressed during the winding process, the pipe is heated and winded at the same time, the winding and curing can be finished simultaneously, and the gluing quality and production efficiency are improved; (4) the milling slope of the dual composite plate, and the lap joint assembly are winded and integrated together after the gluing, and the pipe strength is high, the production efficiency is high, and the surface is smooth.

Owner:NANJING FORESTRY UNIV

Blow molding method and blow molded product

InactiveCN1315902AHigh strength to weight ratioImprove rigidityDomestic articlesPorosityBlow molding

A lightweight blow molded product which is high in strength per weight, rigidity and heat resistance, is excellent in sound-absorbing, heat-insulating and sound-insulating features, can be produced at low costs, and is useful for intake-system parts of an internal combustion engine; and a production method therefor. A blow molding method for a fiber-containing thermoplastic resin, wherein a parison formed of a thermoplastic resin having an inorganic fiber-containing, melt-expansibility is held between opposing molds, a gas is blown in for shaping, and then, as required, a gas pressure is reduced to expand the shaped product; and a blow molded product consisting of thermoplastic resin containing 15 to 70 wt.% of inorganic fibers having an average fiber length of 1 to 20 mm, and having a porosity of 10 to 90%.

Owner:PRIME POLYMER CO LTD

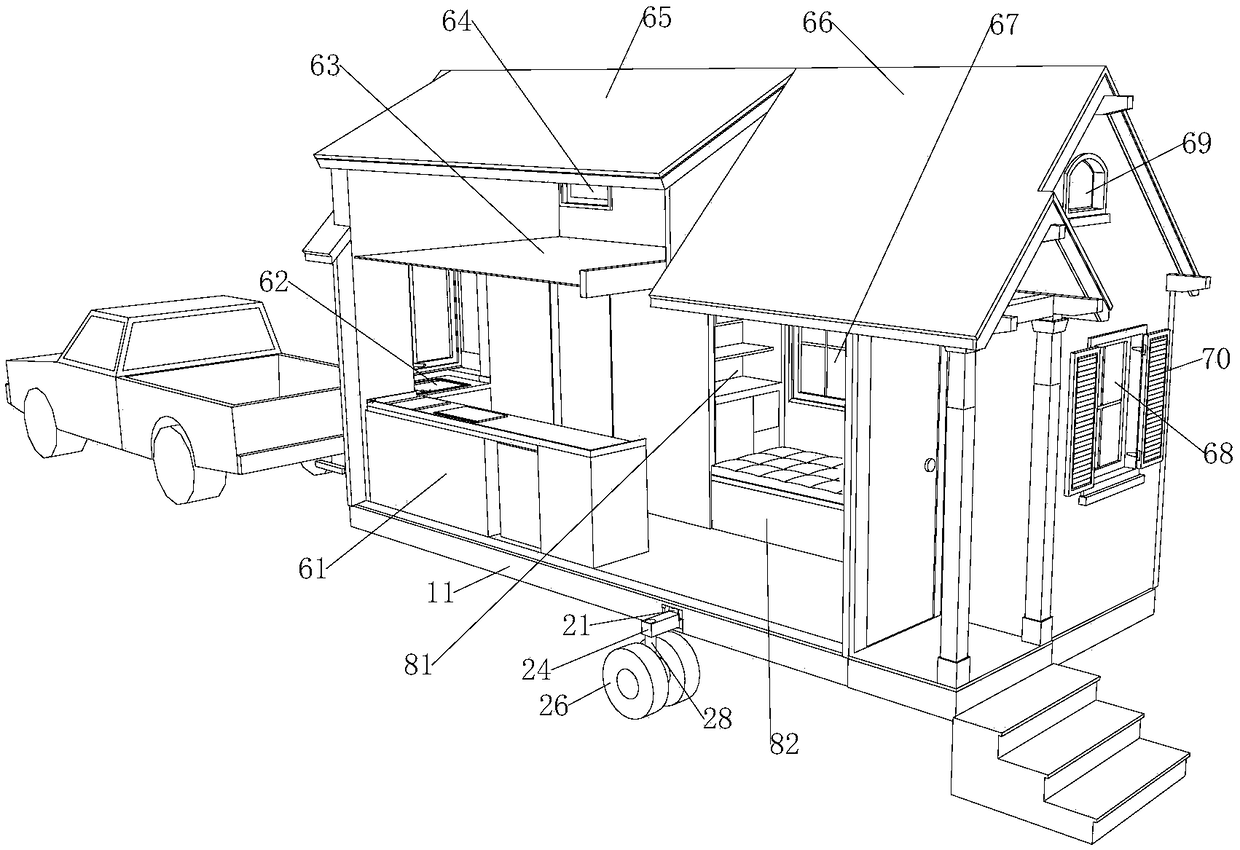

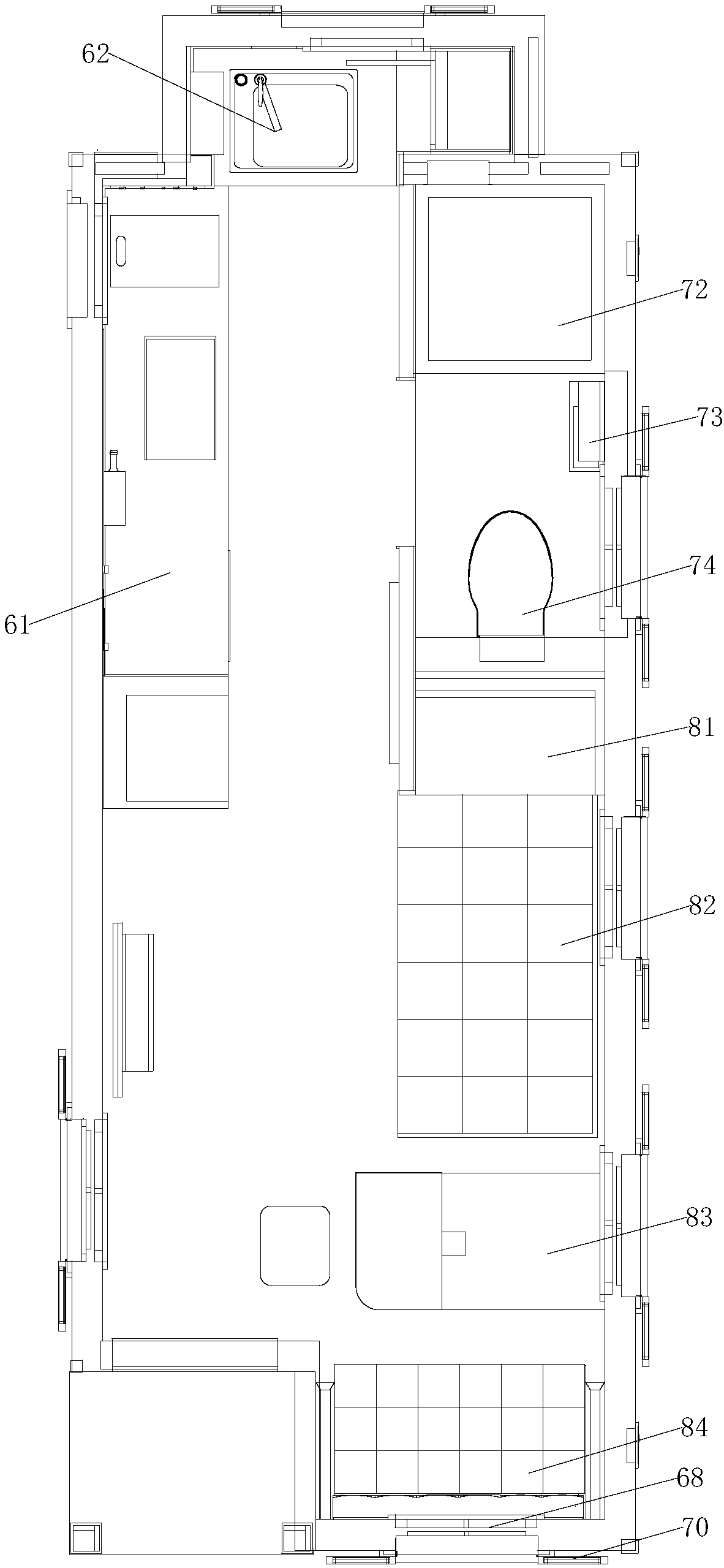

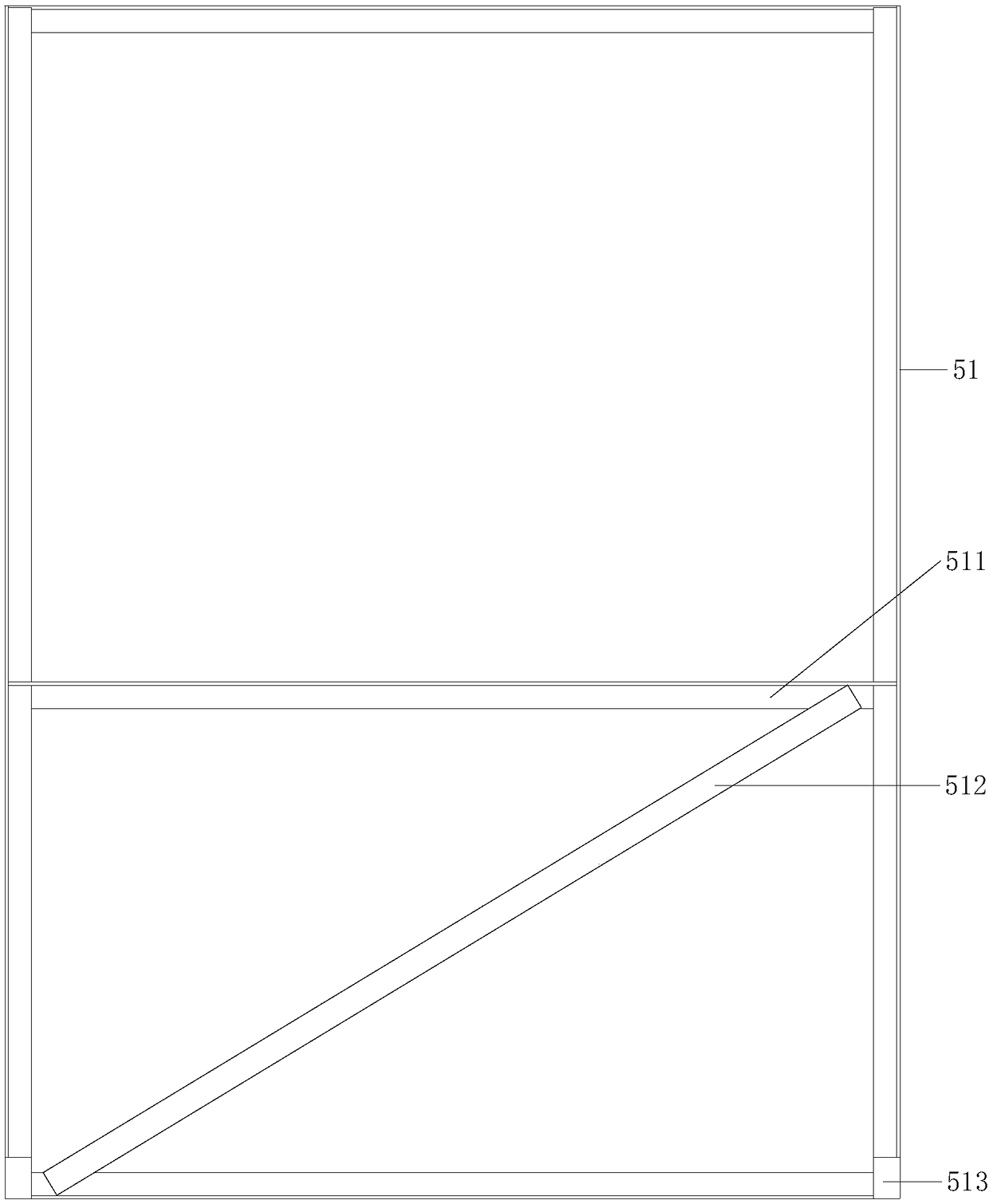

Modularized movable motor house or small temporary building

The invention relates to a motor house, in particular to a modularized movable motor house or a small temporary building. The modularized movable motor house or the small temporary building comprise an outer wall module, a chassis module, a furniture module, a toilet module and a kitchen module; the outer wall module is fixed to the chassis module and constitutes the wall body and roof of the motor house. The furniture module, the toilet module and the kitchen module are all located inside the motor house. The modularized movable motor house or the small temporary building is simple in structure, reasonable in layout, large in inner space, complete in domestic installation, comfortable to live, good in thermal insulation performance and lighting, high in strength and extensibility, convenient to transport, fast in assembly of the modularized structure and low in manufacturing cost.

Owner:黄浩哲

High-strength aluminum alloy rivet line and manufacturing method thereof

The invention discloses a high-strength aluminum alloy rivet line and a manufacturing method thereof. Compared with the prior art, the high-strength aluminum alloy rivet line according to the embodiment of the invention has the advantages that a plurality of elements are alloyed, an intermediate alloy is granulated and added as particles, the technologies of high-temperature rapid aluminum smelting, electromagnetic stirring and the like are utilized comprehensively, and sectional temperature control, directional freezing, continuously casting, cold rolling, repeated thermal treatment and drawing processes are adopted, so that a rivet line with high strength, high shearing strength, excellent plasticity and toughness and superior corrosion resistance can be manufactured, the riveting weight and cost can be lowered, and the safety performance of riveting is enhanced.

Owner:SHANDONG TAIYI METAL SCI & TECH

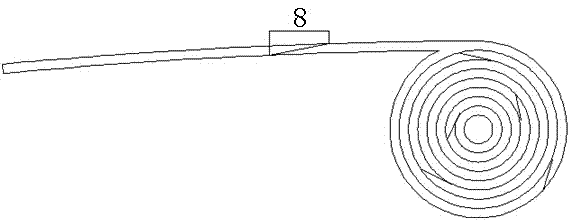

Novel carbon-fiber composite sucker rod

InactiveCN102086296AStrong fatigue resistanceImprove wear resistanceDrilling rodsDrilling casingsEpoxyFiber

A novel carbon-fibre composite sucker rod comprises carbon fiber and epoxy resin, and the novel carbon-fiber composite sucker rod is characterized in that glass fiber thermoplastic is added, and the novel carbon-fiber composite sucker rod is composed of the following components in wt%: 72% of carbon fiber, 1% of glass fiber thermoplastic, and 27% of epoxy resin glue liquid. The invention possesses strong tensile strength, strong anti-fatigue capability, high wear resistance, light weight, and a high ratio of intensity and weight, simultaneously, the production process is simplified, and production cost is reduced.

Owner:DANCHEN TECH DALIAN

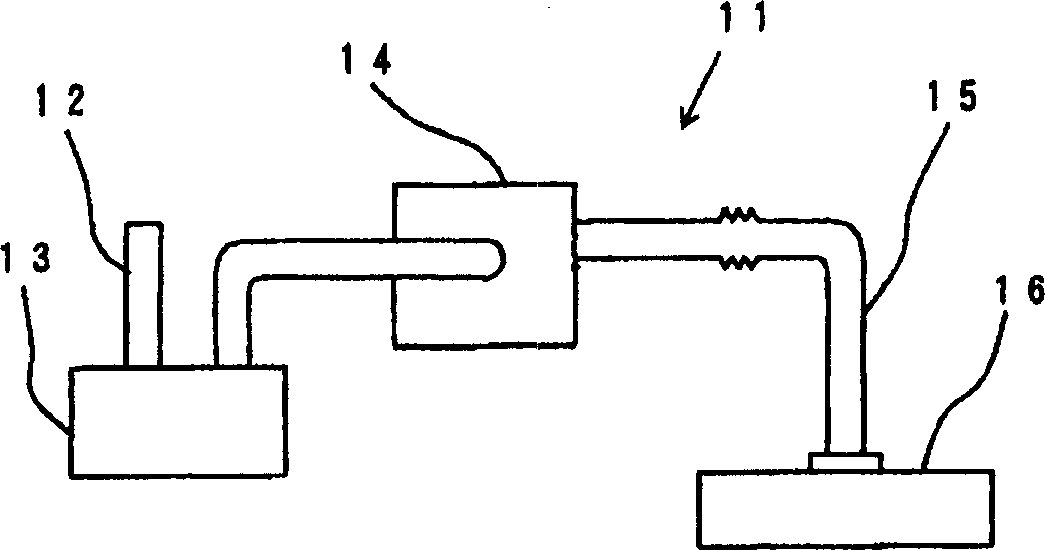

Mooring system with submerged buoys and pulleys

The invention discloses a mooring system with submerged buoys and pulleys. The mooring system comprises submerged buoys / counter weights, pulleys, anchor bases, ropes and rope knots, wherein a chain is tied to each anchor base, and the other end of the chain is tied to a bracket of the corresponding fixed pulley; each rope is wound around the corresponding pulley; one end of each rope is tied to the corresponding submerged buoy, and the other end of the rope is tied to a floating body which needs to be moored; each rope knot is tied to a position on the corresponding rope, between the corresponding pulley and the moored floating body / the anchor base, and close to the pulley. The central floating body which needs to be moored is jointly tightened by the combination of a plurality of anchoring units with submerged buoys / counter weights and pulleys, which are distributed at the periphery of the floating body. Through the adoption of the mooring system, the problems that anchor chains are fractured or the anchor bases slide away due to the rapid increase of mooring force are solved, so that the capability of resisting storms can be provided, and the mooring cost is reduced.

Owner:曲言明

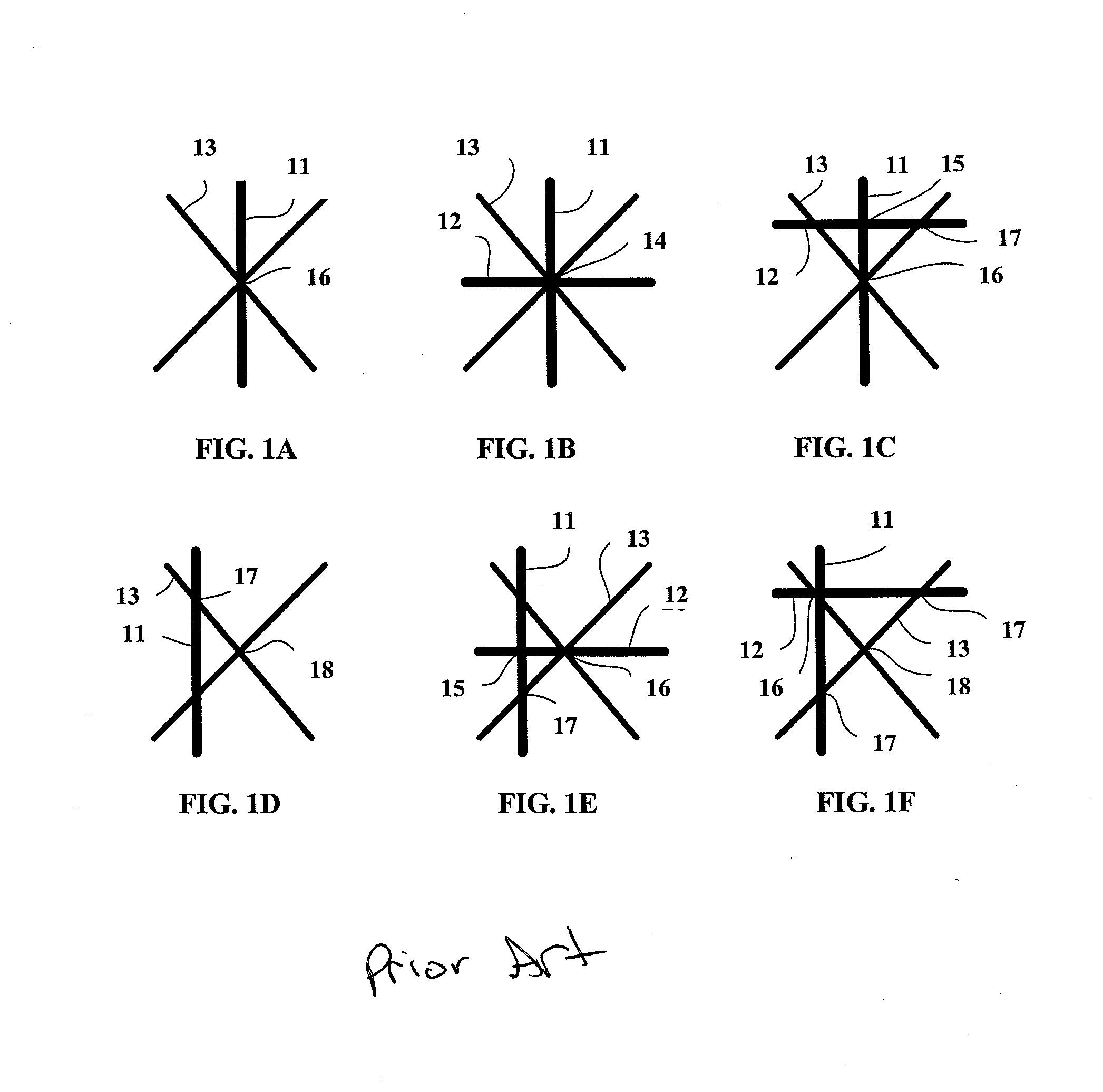

Spoke composed of braided fiber with hub and rim terminations

ActiveUS20160332481A1High strength-to-weight ratioEasilyNon-metallic wheel bodySpoked wheelsFiberCombined use

Owner:BERD L L C

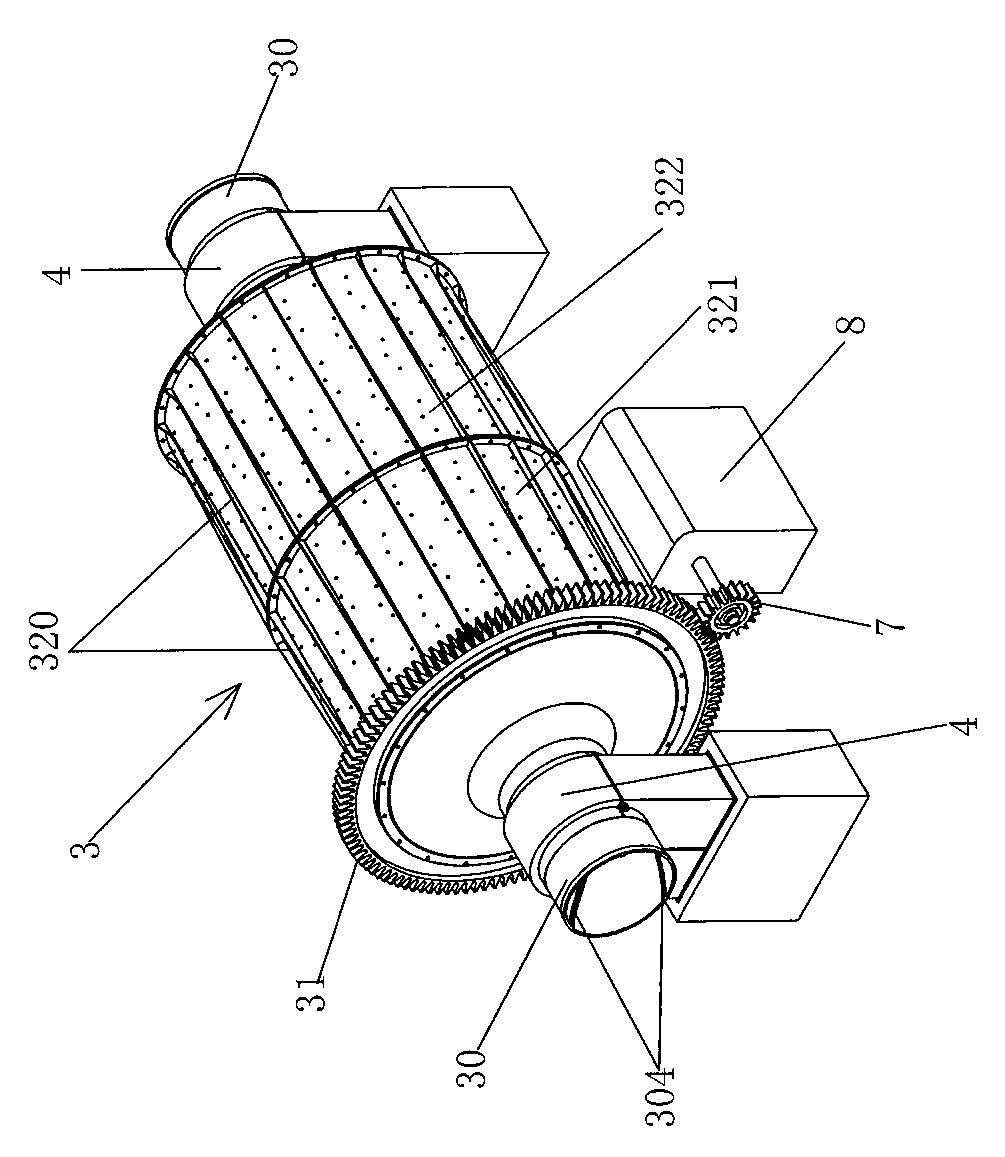

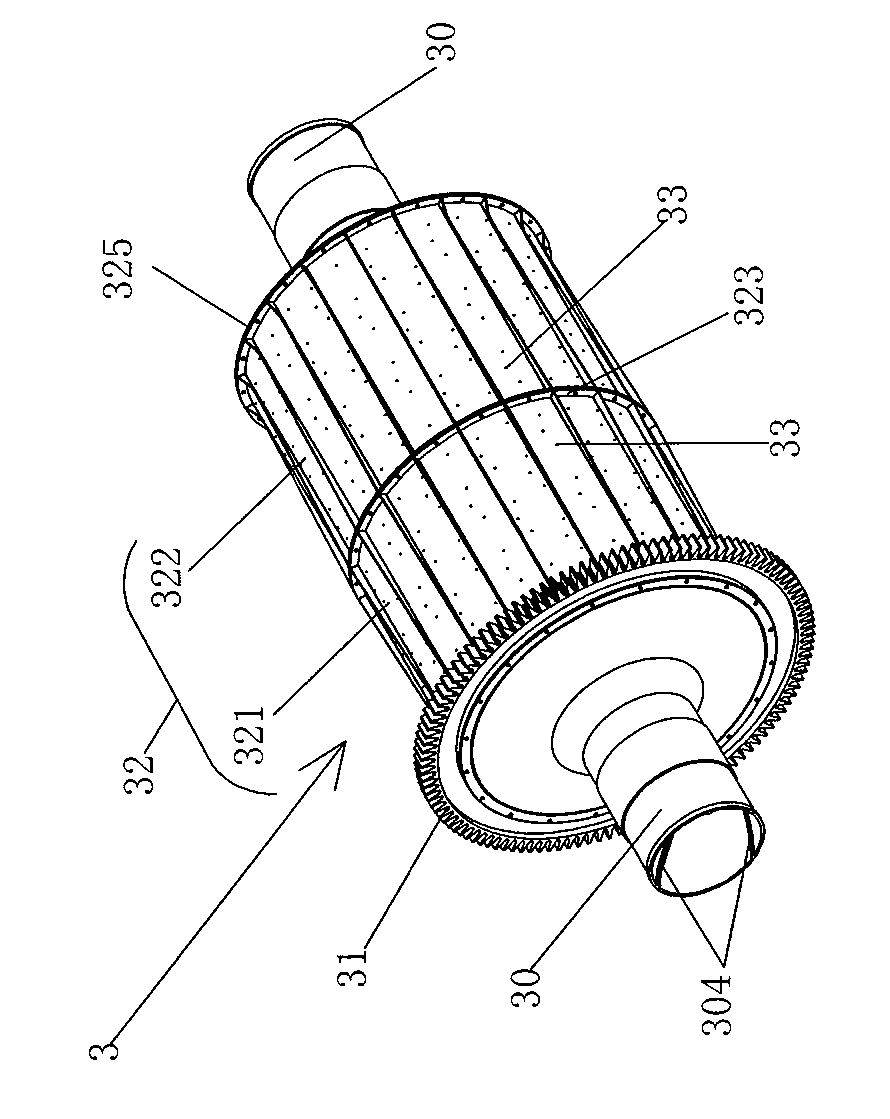

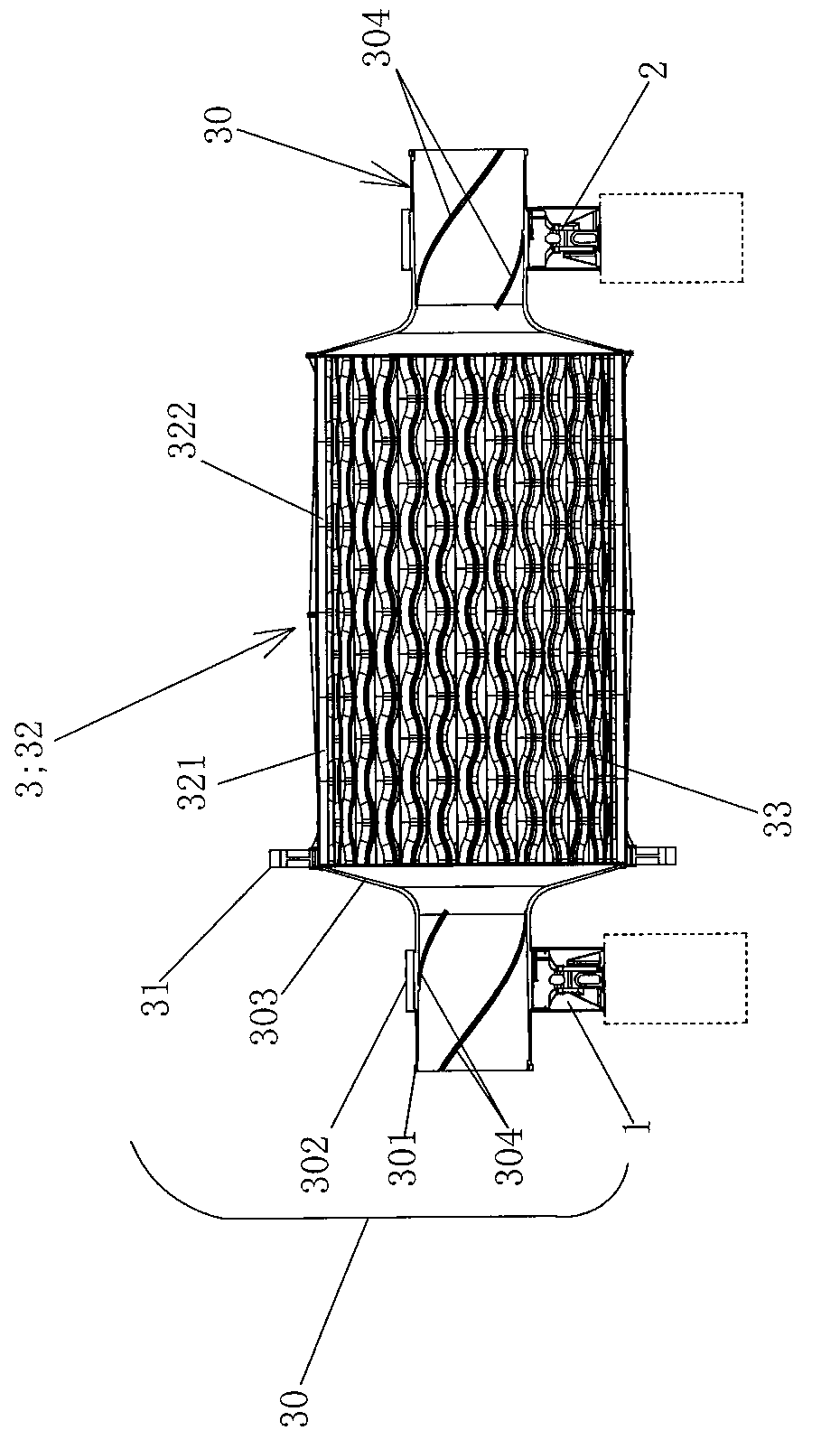

Novel energy-saving ball mill

InactiveCN103230818AImprove carrying capacityReduce energy consumptionBearing componentsGrain treatmentsWorking environmentEngineering

The invention discloses a novel energy-saving ball mill. The novel energy-saving ball mill consists of a first hydrostatic bearing, a second hydrostatic bearing, a rotator, hydrostatic bearing sealing covers, a local dust collector, a small gear and a transmission system; the shaft journals of hollow shafts at the two ends of the rotator are respectively placed on the first hydrostatic bearing and the second hydrostatic bearing and are covered by the two hydrostatic bearing sealing covers respectively; a large gear which is engaged with the small gear is arranged on the periphery of the rotator; high-pressure oil forms a lubricating oil film among the first hydrostatic bearing, the second hydrostatic bearing and the shaft journals of the hollow shafts of the rotator, so that the rotator can float, the completeness of the lubricating oil film can be guaranteed and the complete liquid lubrication can be realized; the bearing capacity of the bearings is large; when the rotator generates the small bending elastic deformation, bearing bodies of the first hydrostatic bearing and the second hydrostatic bearing rotate at a small angle relatively around respective first pin shafts, so that the thickness of the oil film is not changed basically; the grinding effect between a grinding medium and a mineral aggregate and among the mineral aggregates can be enhanced because of a corrugated liner plate in the rotator; and the sealing covers and the local dust collector can effectively prevent dust particles in the working environment of the ball mill from entering the working space of the hydrostatic bearings.

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com