Composite article made with unidirectional fibre reinforced tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

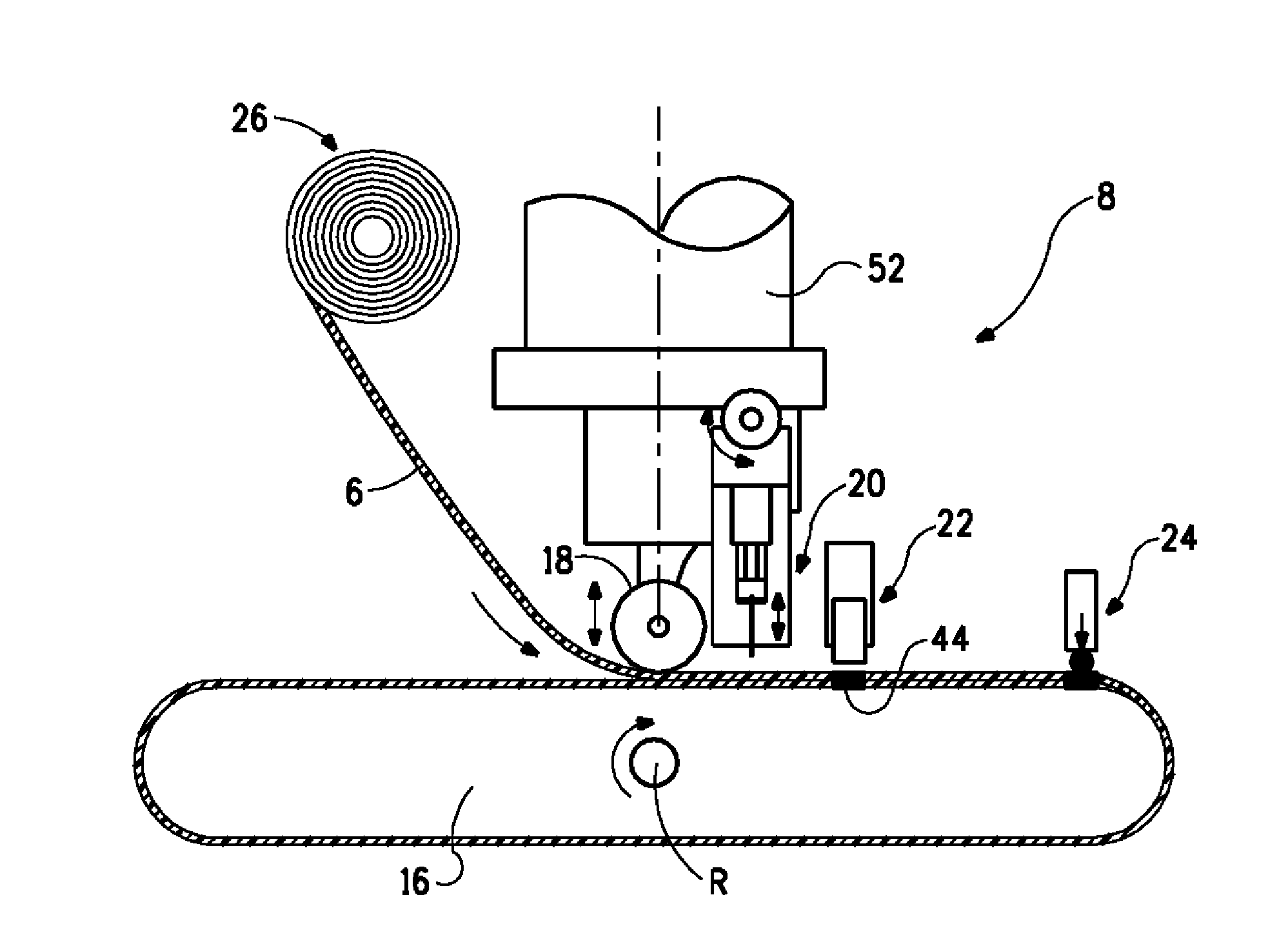

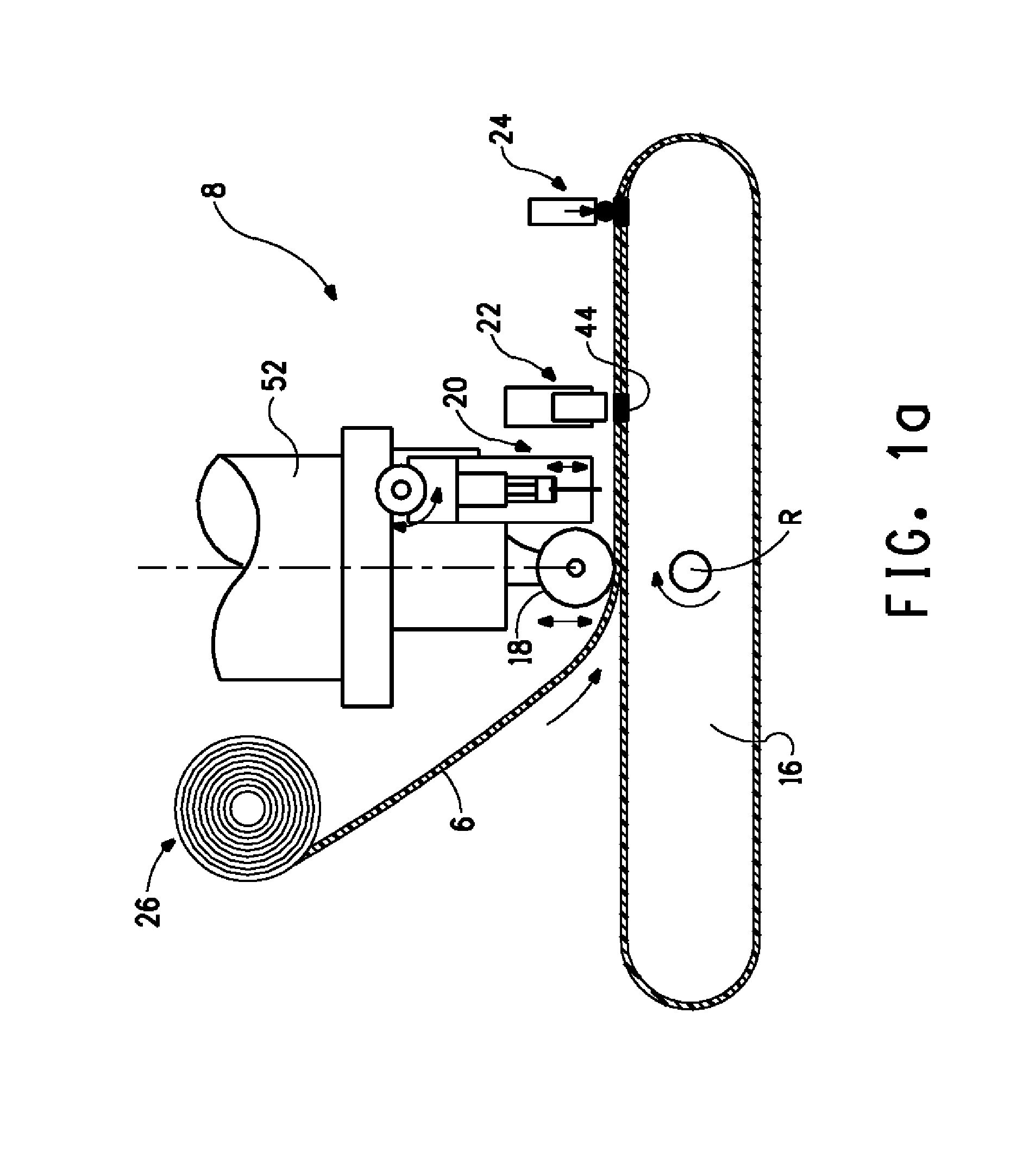

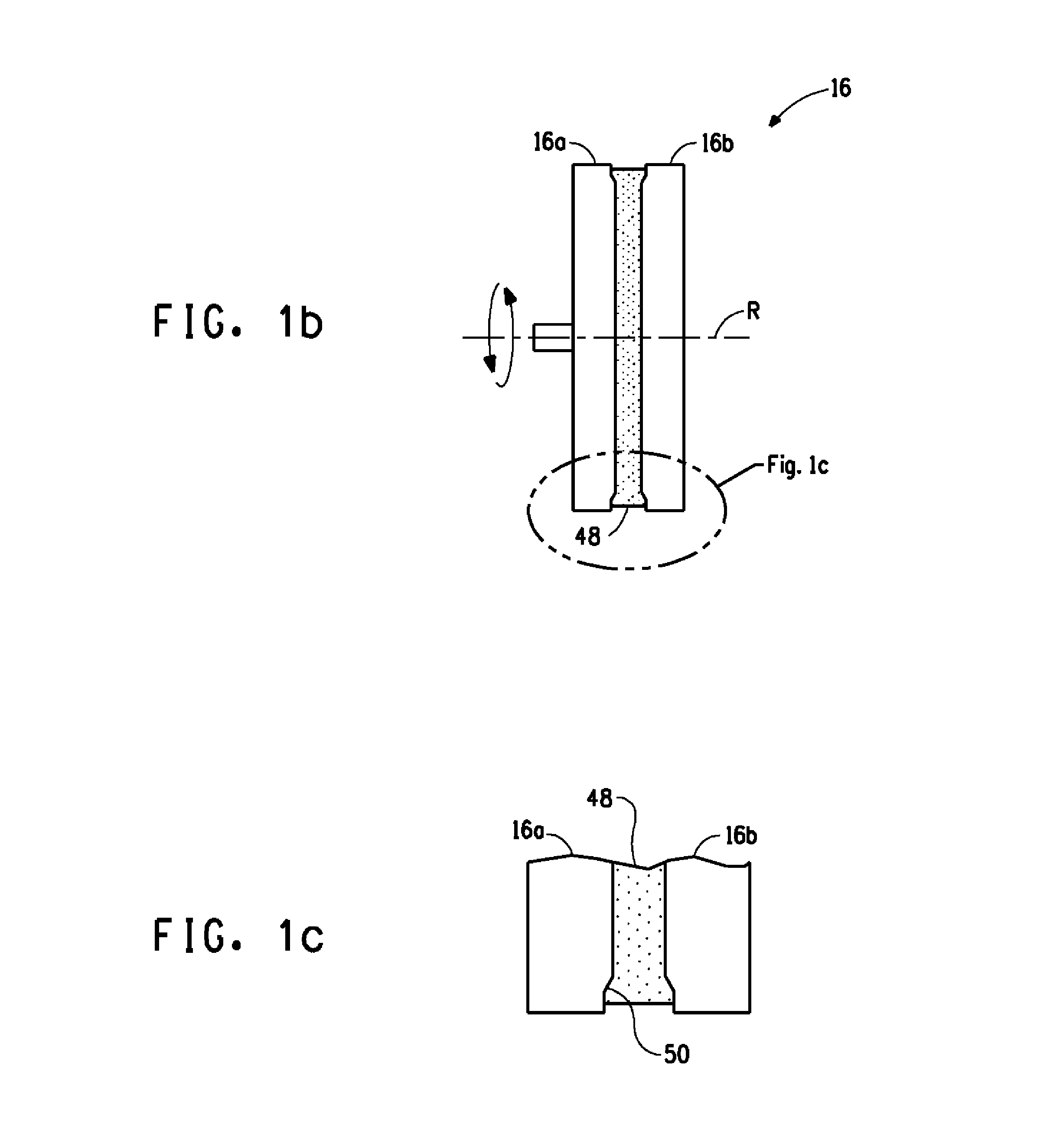

[0052]Referring to FIGS. 8a to 8c, an example of a composite article 4 is shown, the article in this example representing a vehicle suspension arm or control rod. The article comprises a consolidated fibre reinforced part 37 forming a closed loop, an overmolding 42 and optionally one or more inserts 40. The consolidated fibre reinforced part 37 is made from a wound unidirectional tape preform 38 made using a process according to embodiments of the invention that are described further on. Composite articles according to the invention may be formed uniquely from unidirectional tape, or from a unidirectional tape combined with inserts, overmolding, and other elements mounted to or around the wound UD tape preform. In the illustrated example of FIGS. 8a to 8c, the overmolding 42 may for example be an injected polymer, and the one or more inserts could be made of various materials, for example an insert made of a metal, composite material, or of a ceramic, depending on the application an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com