Patents

Literature

205results about How to "Remove tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

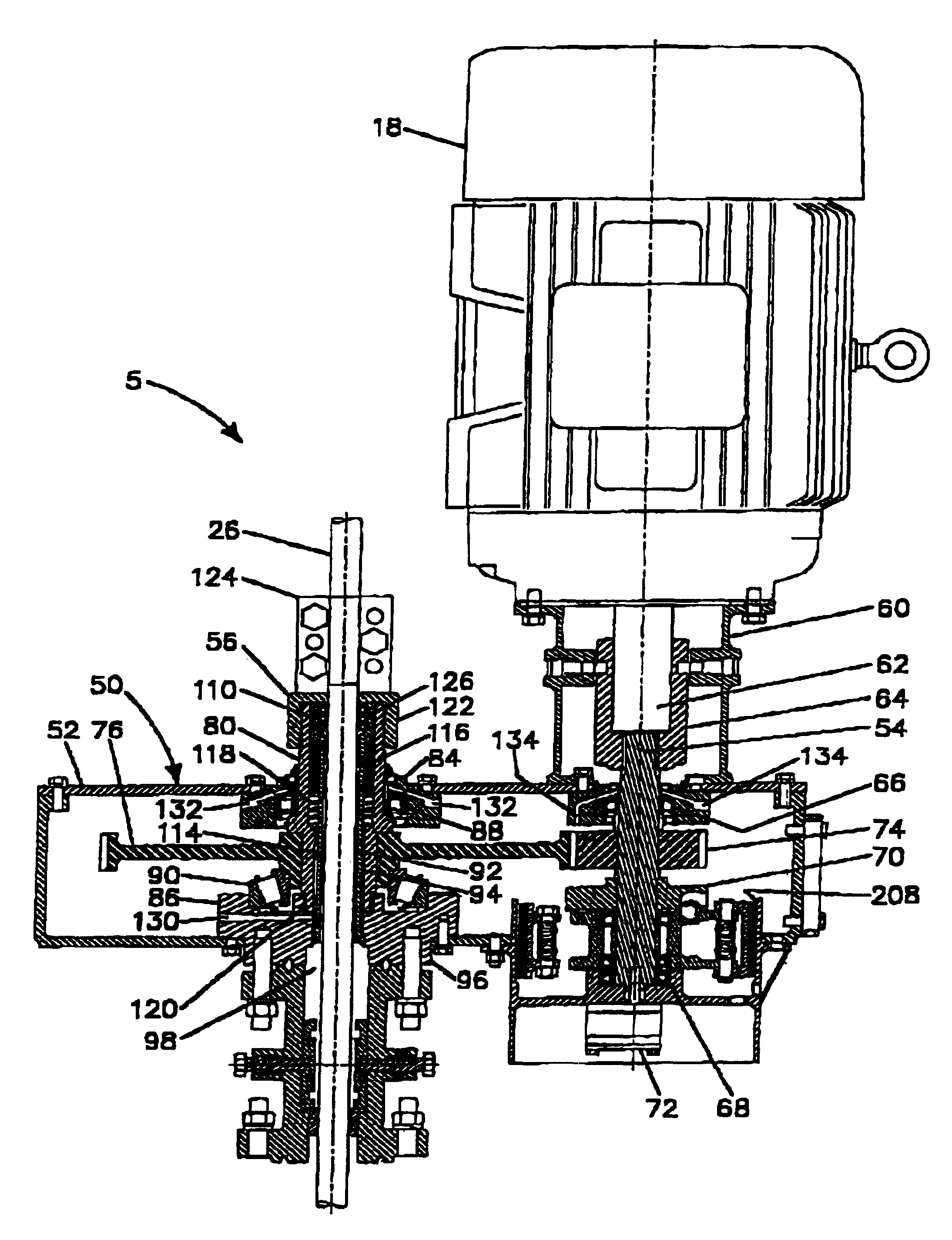

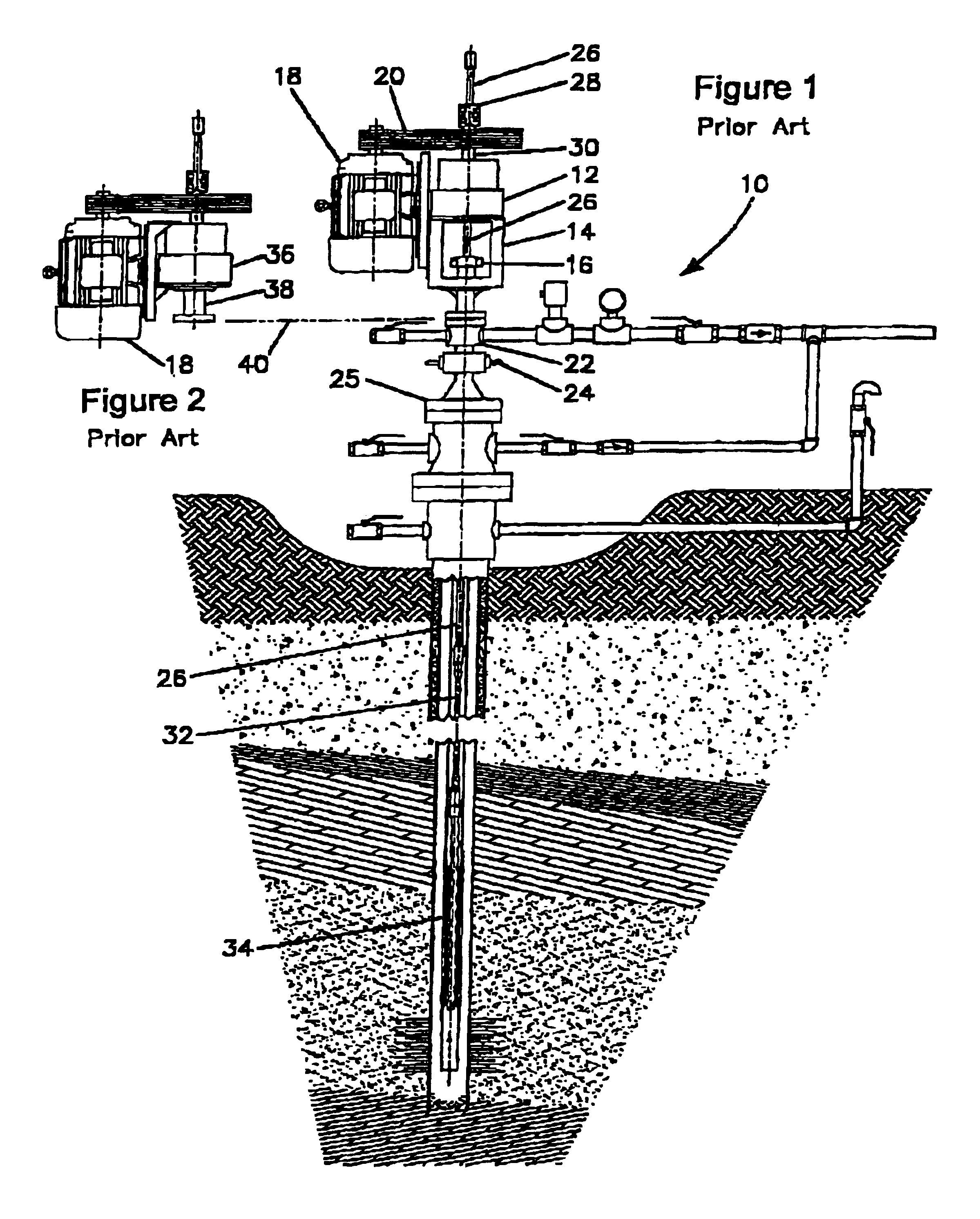

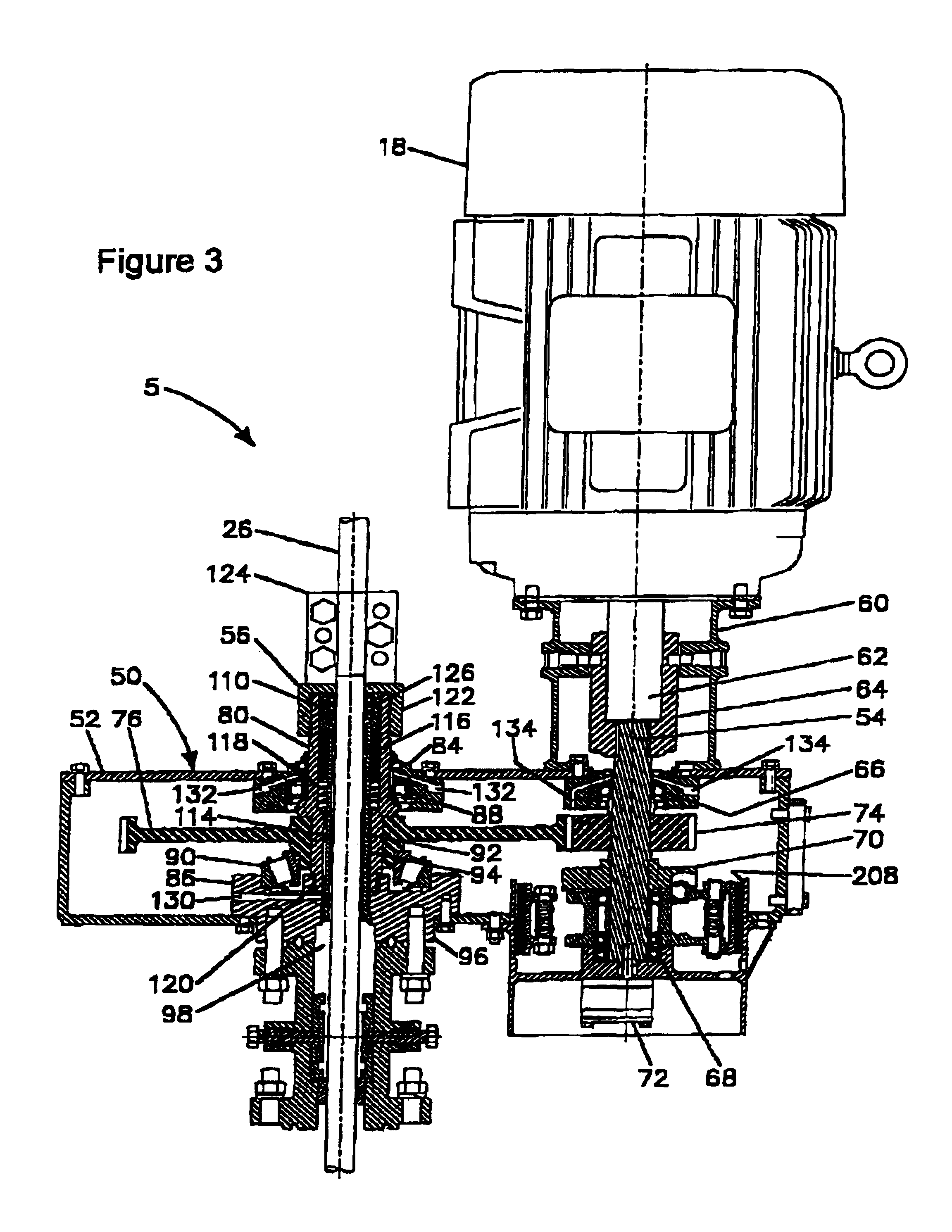

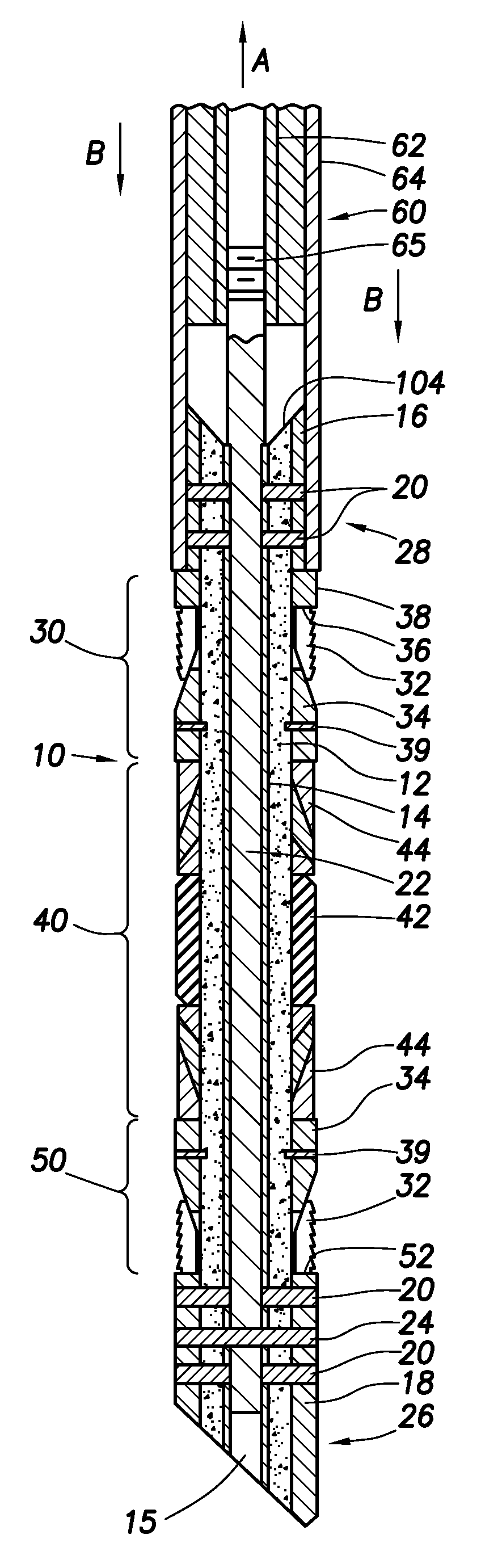

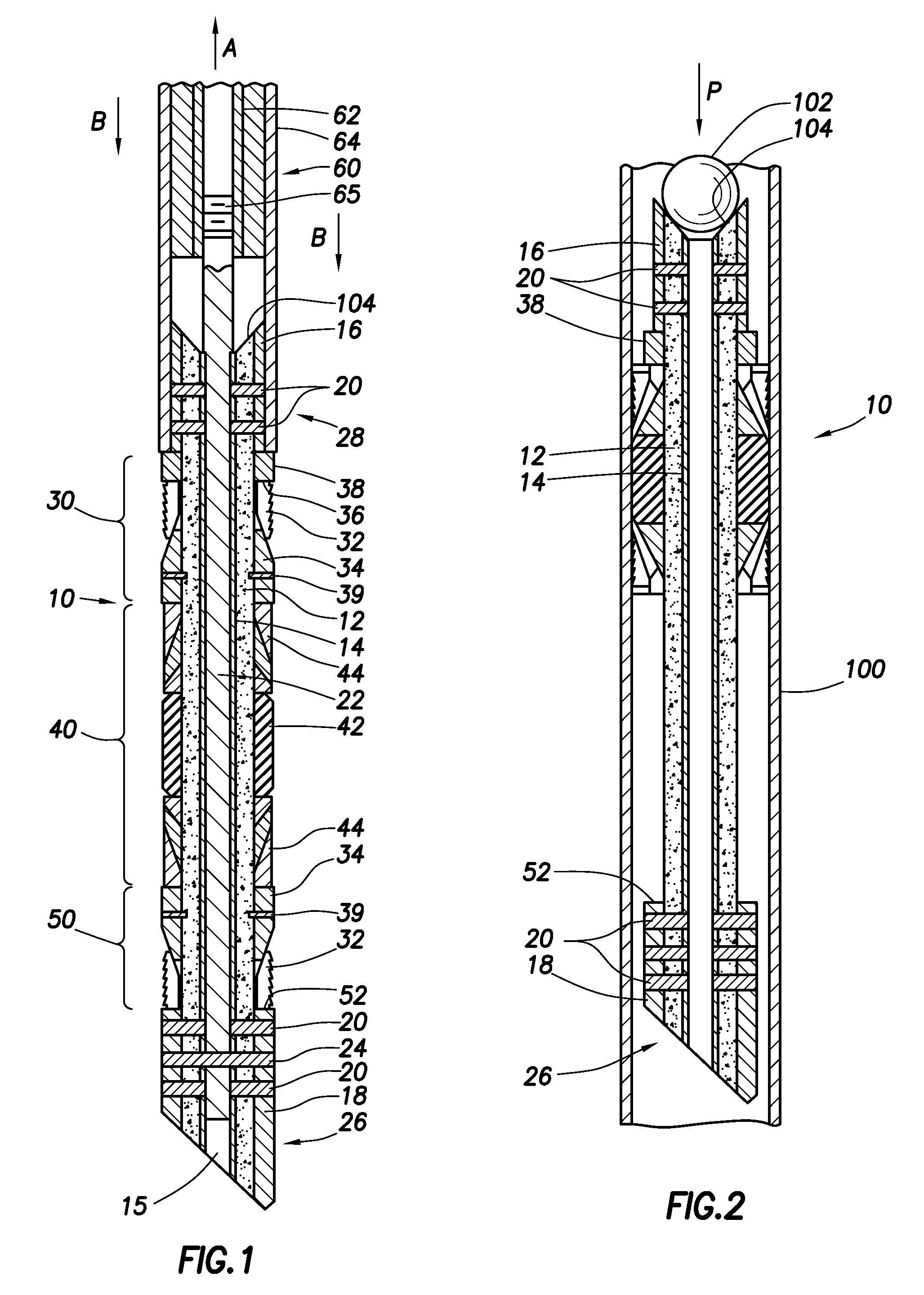

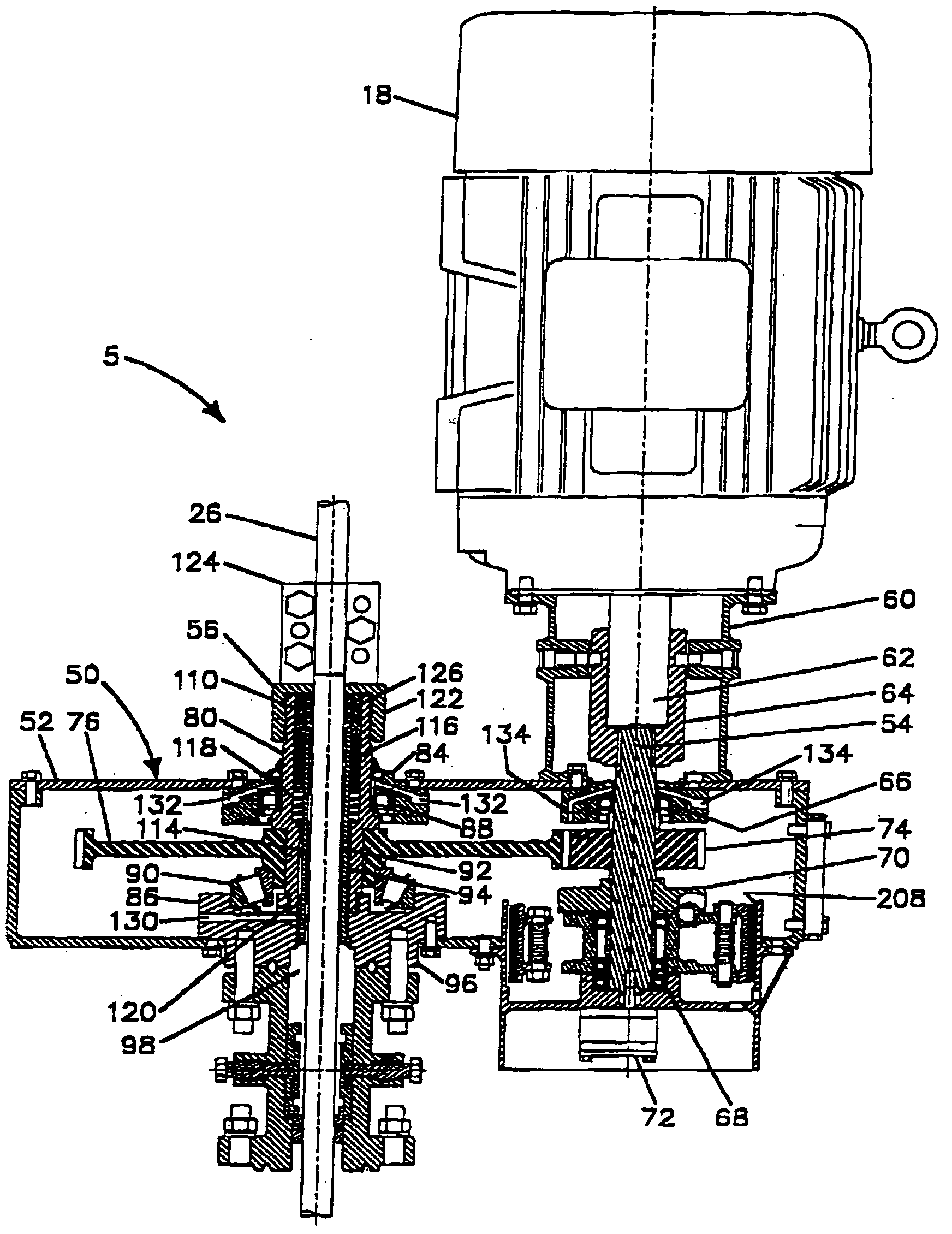

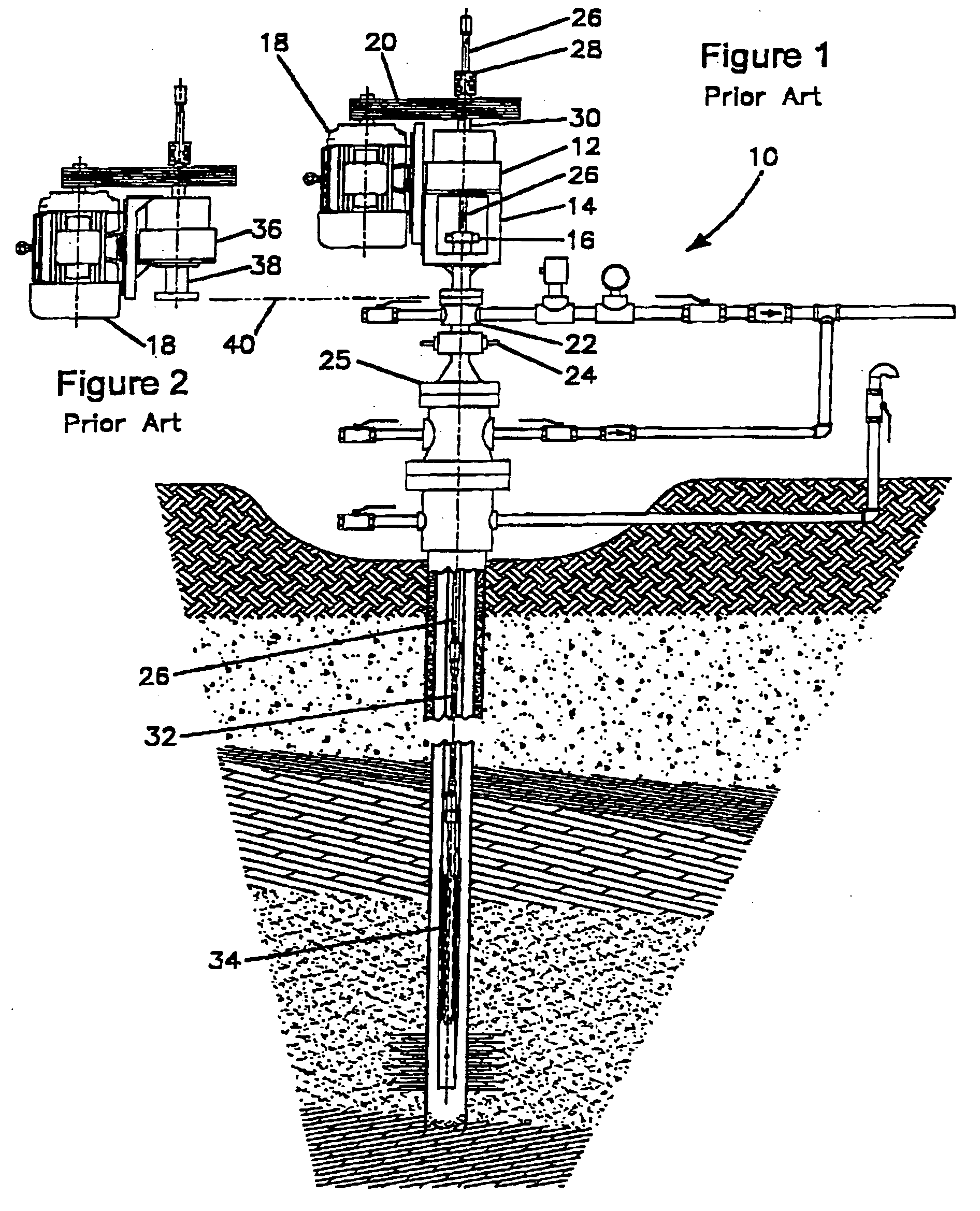

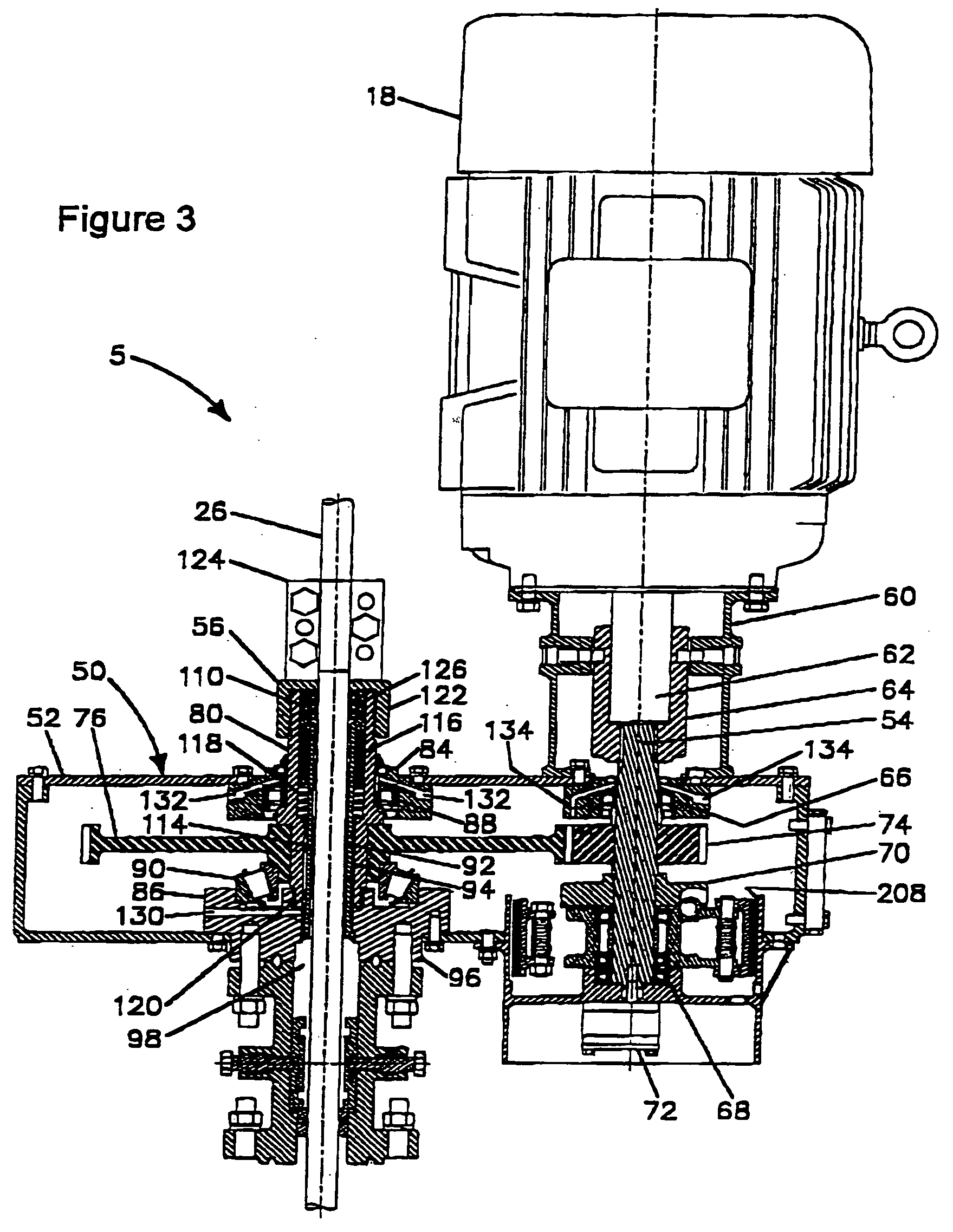

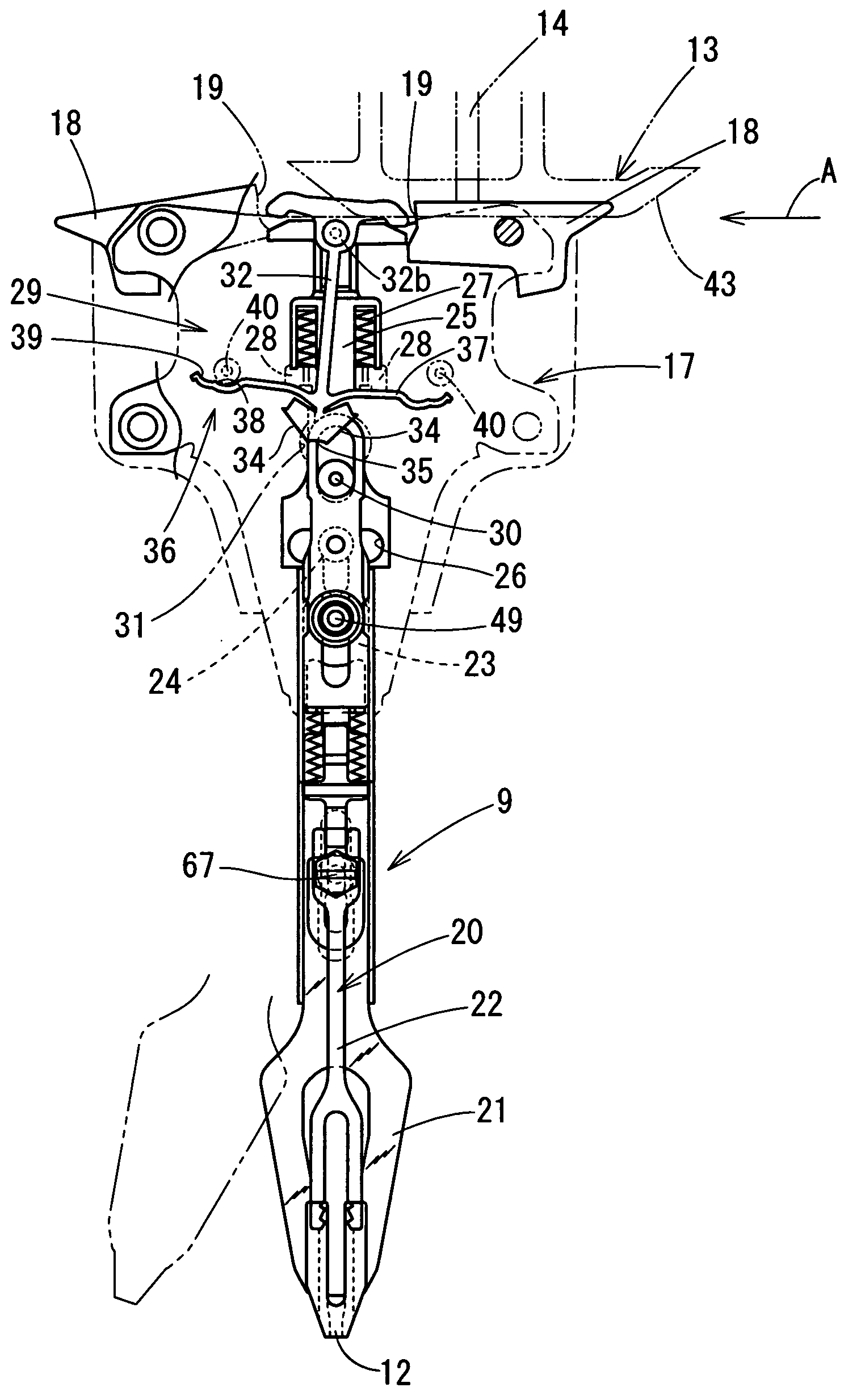

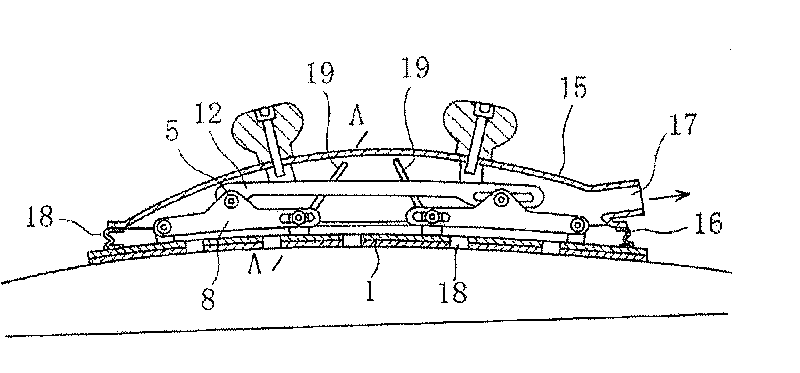

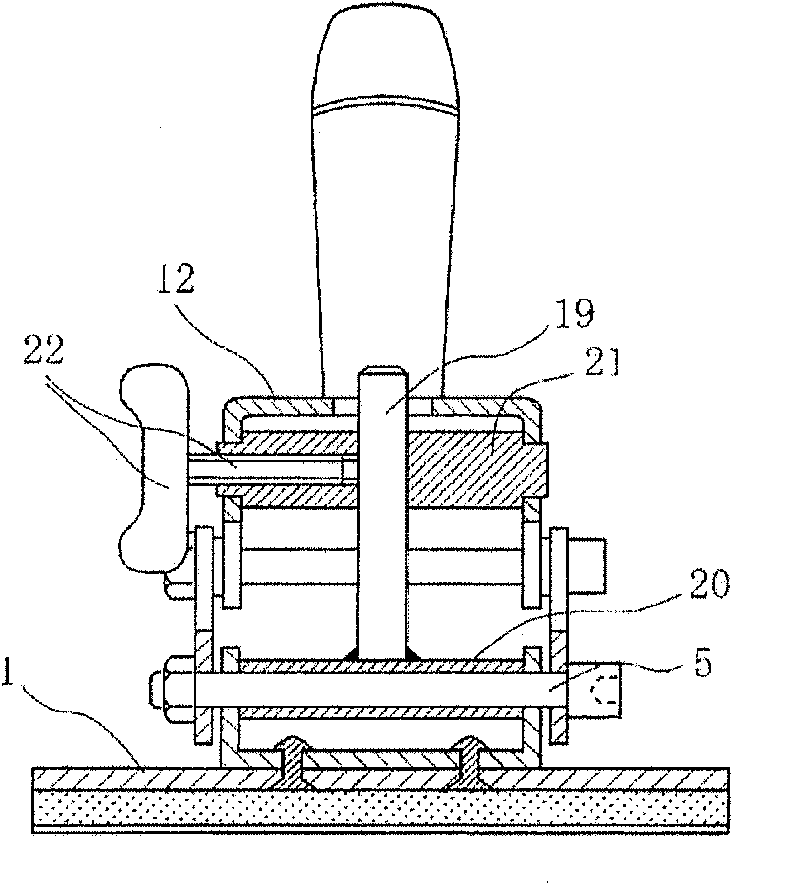

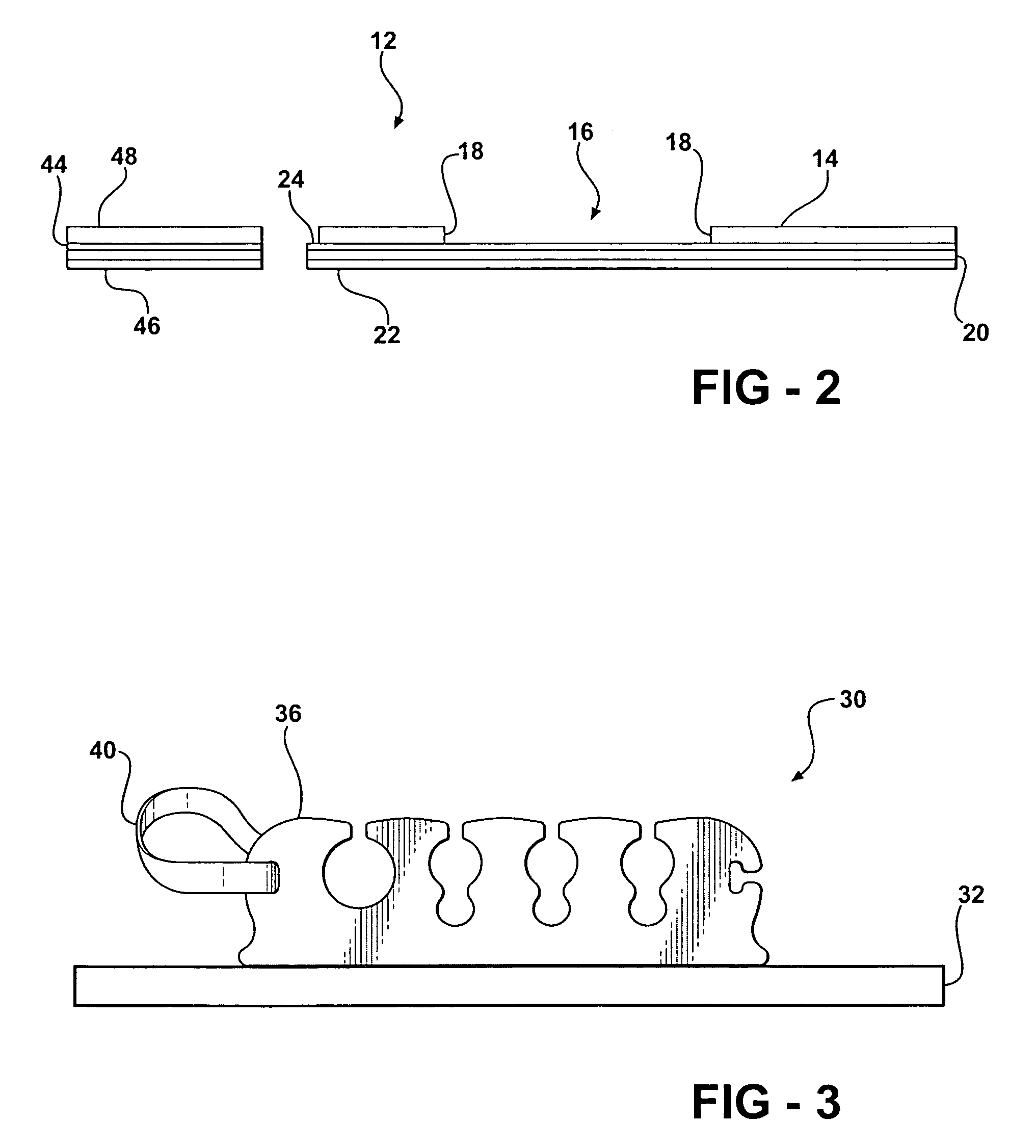

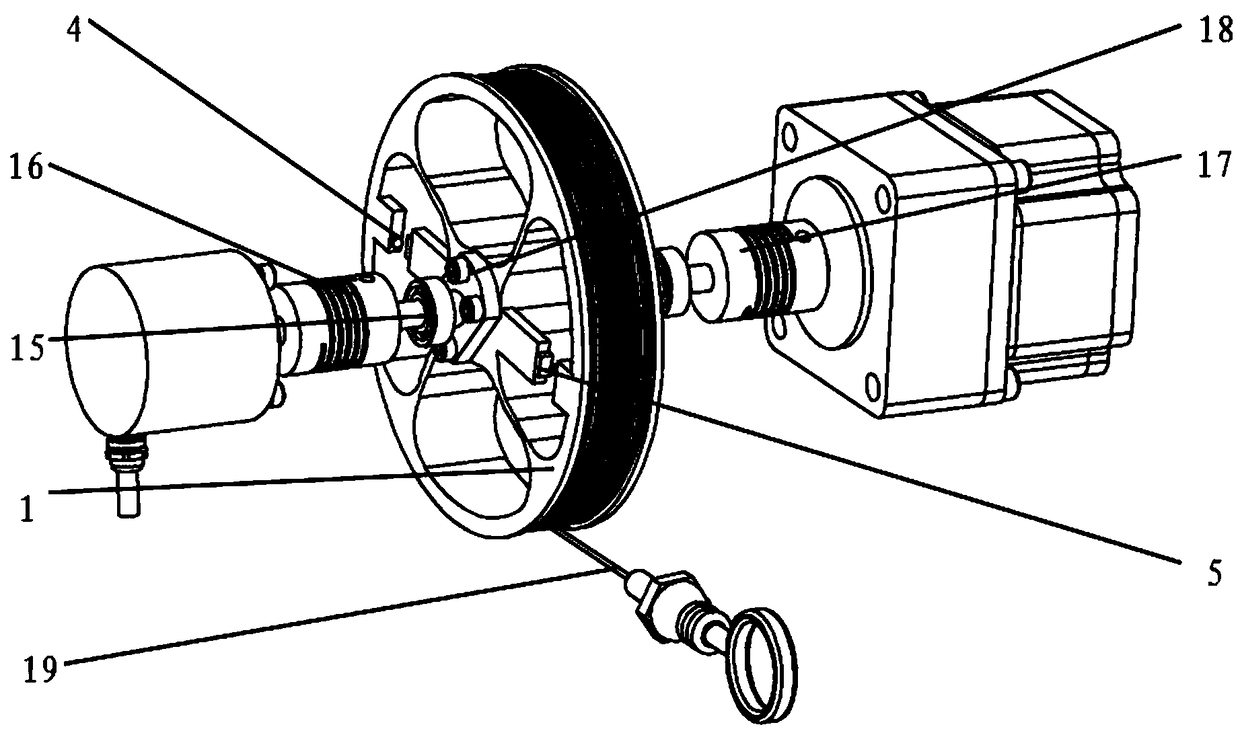

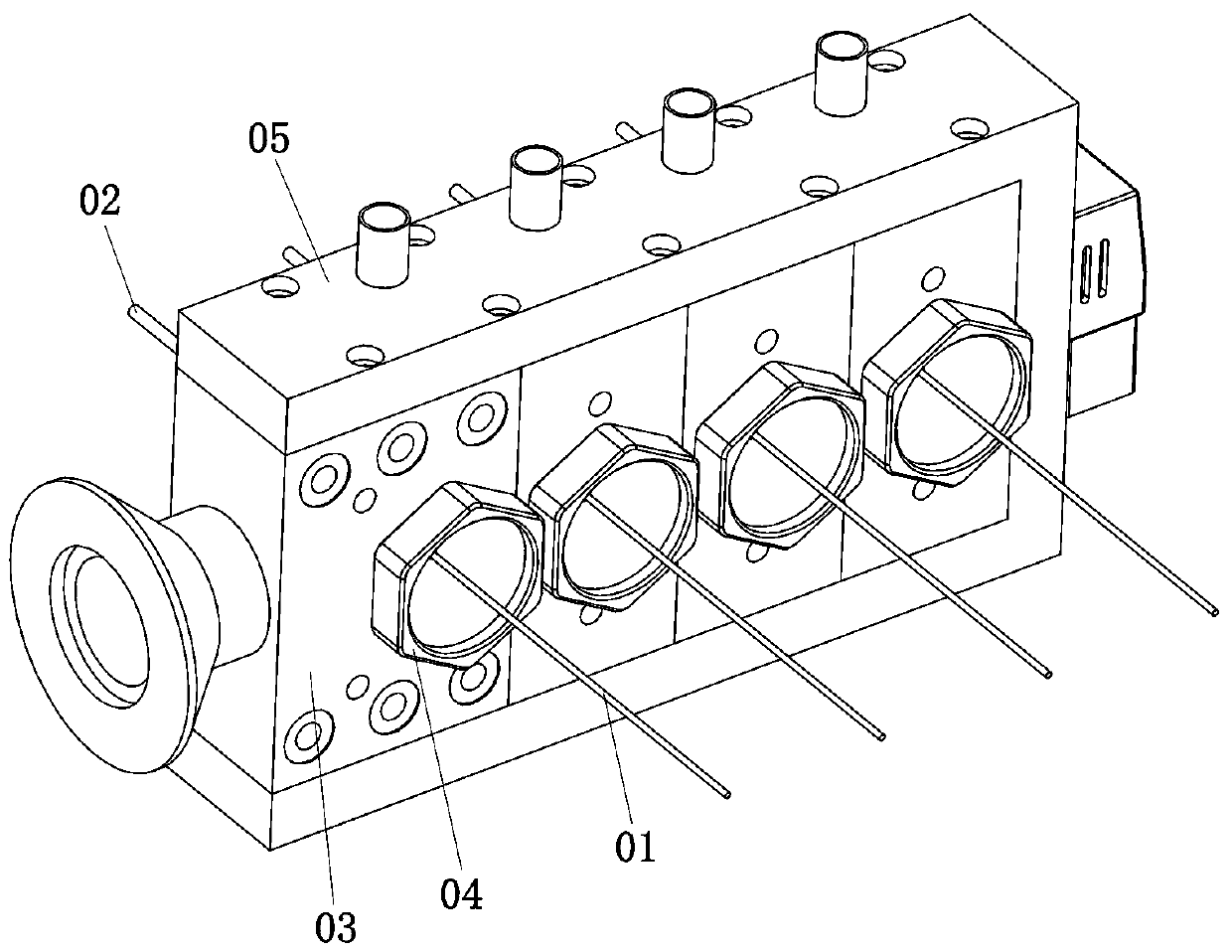

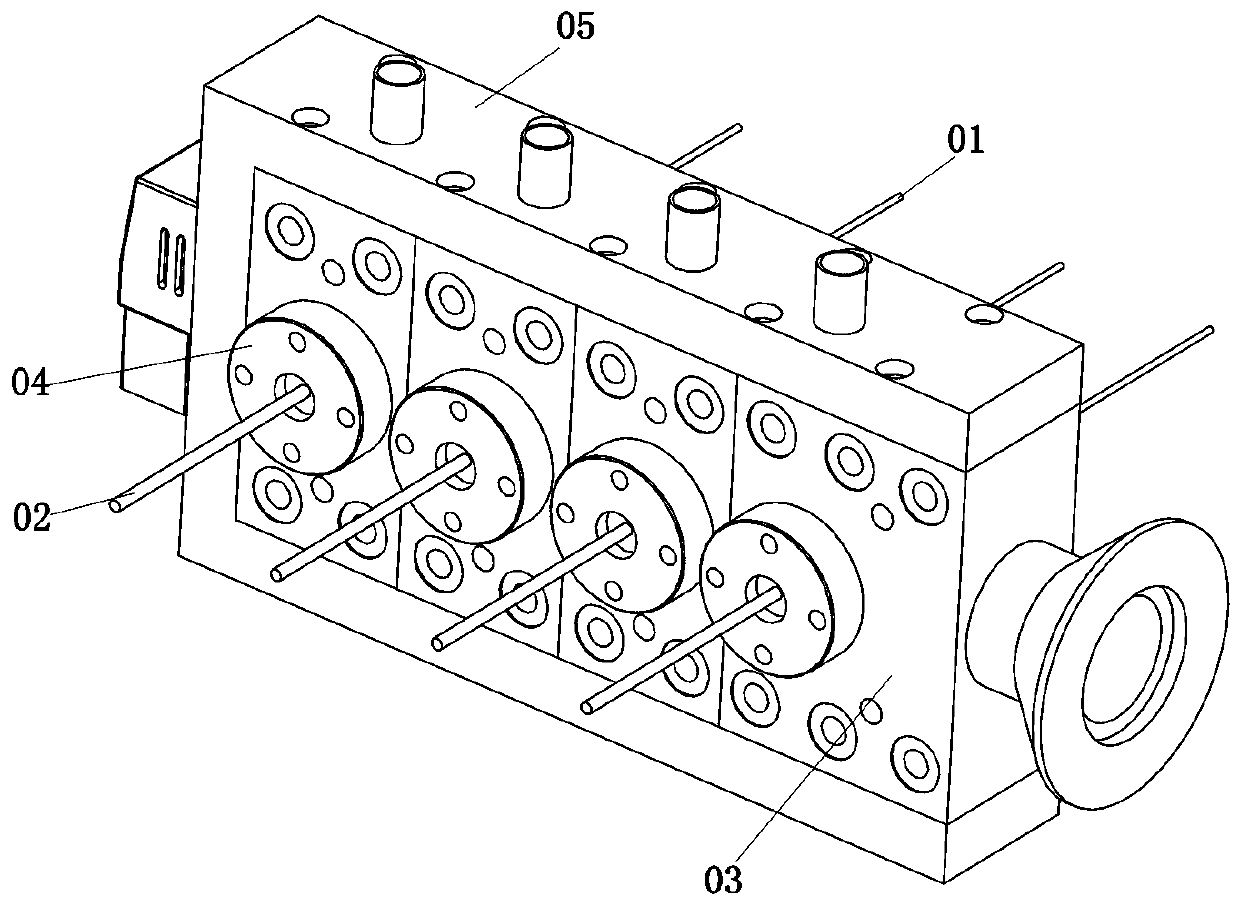

Pump drive head with stuffing box

InactiveUS6843313B2Eliminating belt tensioningEliminate replacementDrilling rodsFluid removalGear driveEngineering

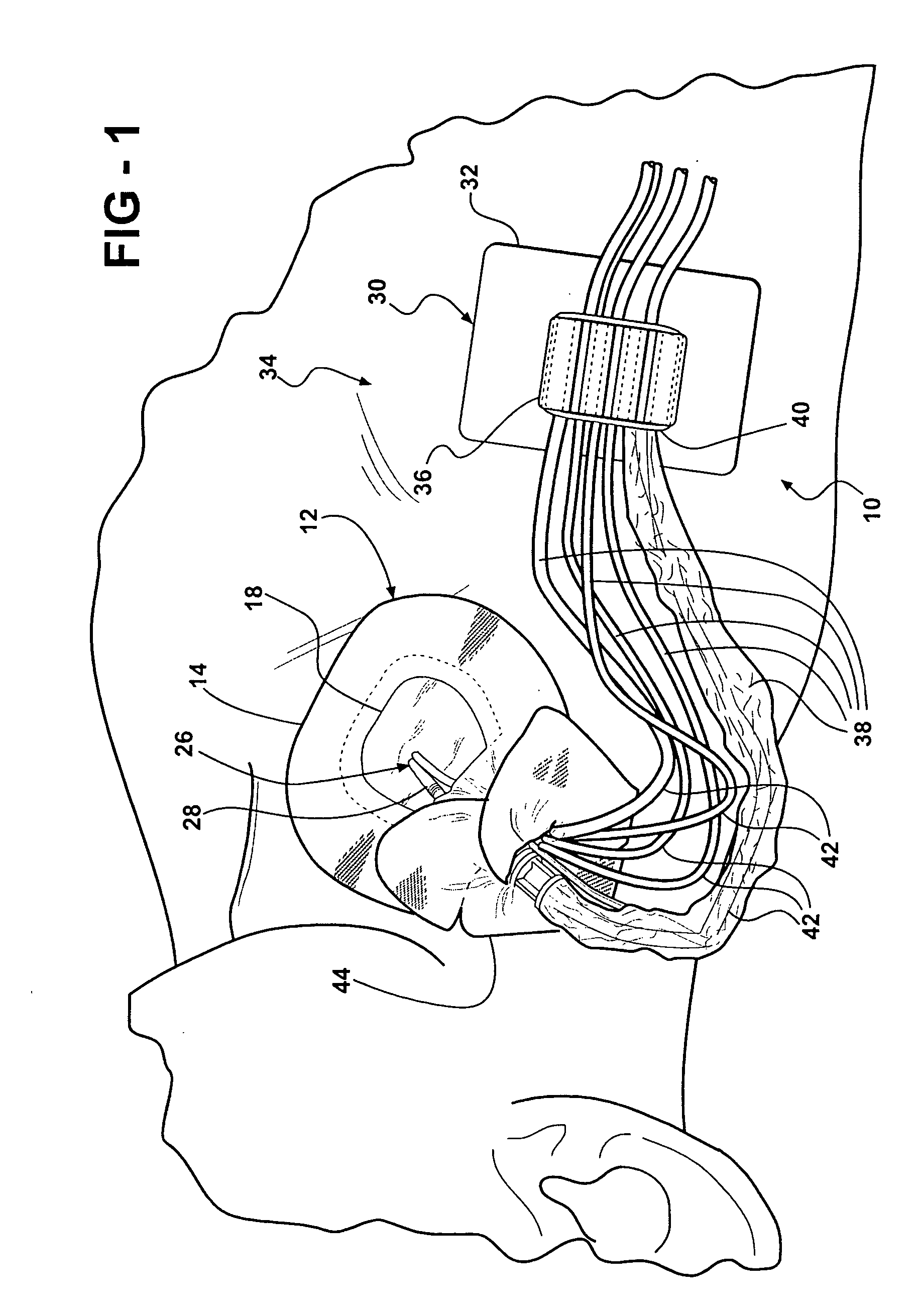

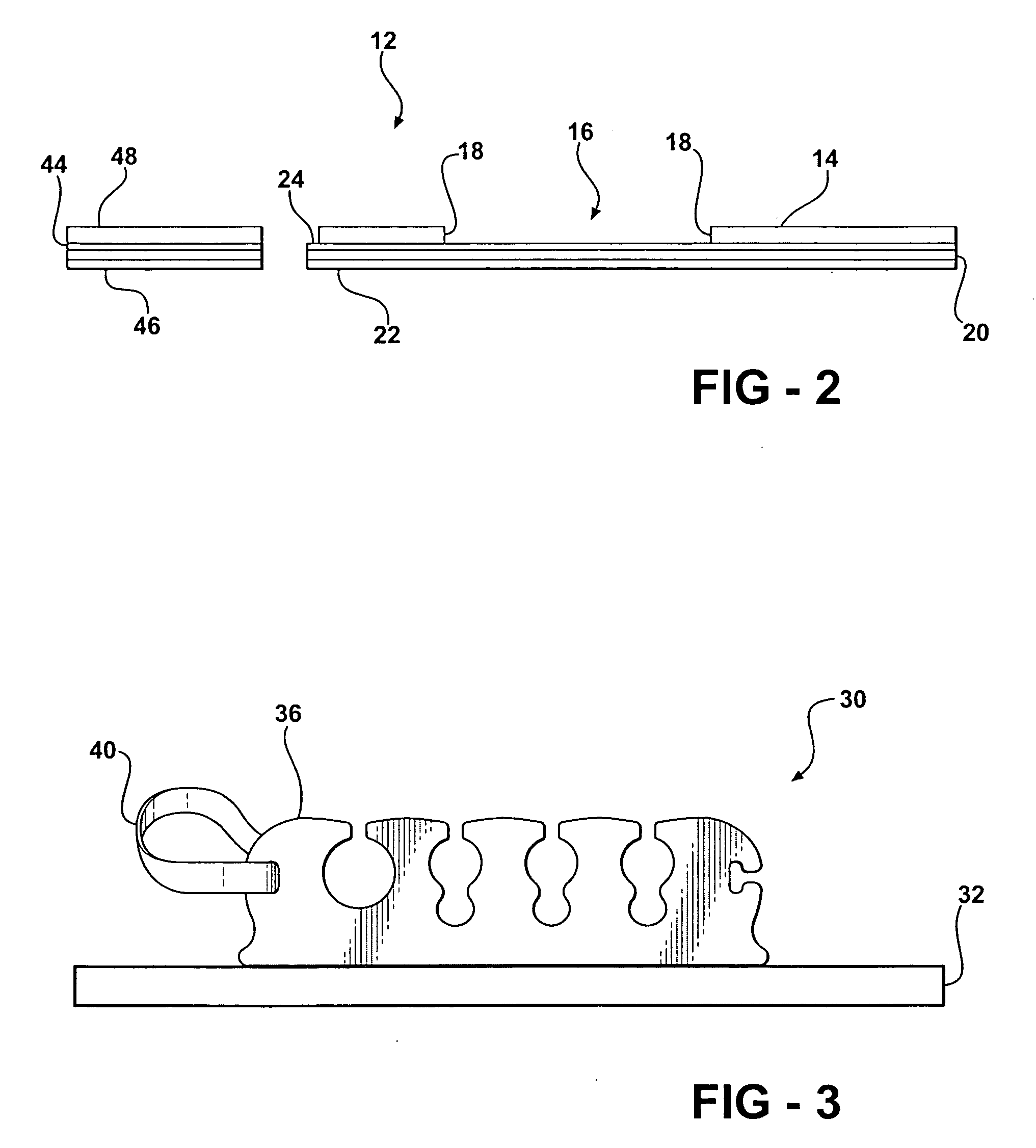

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

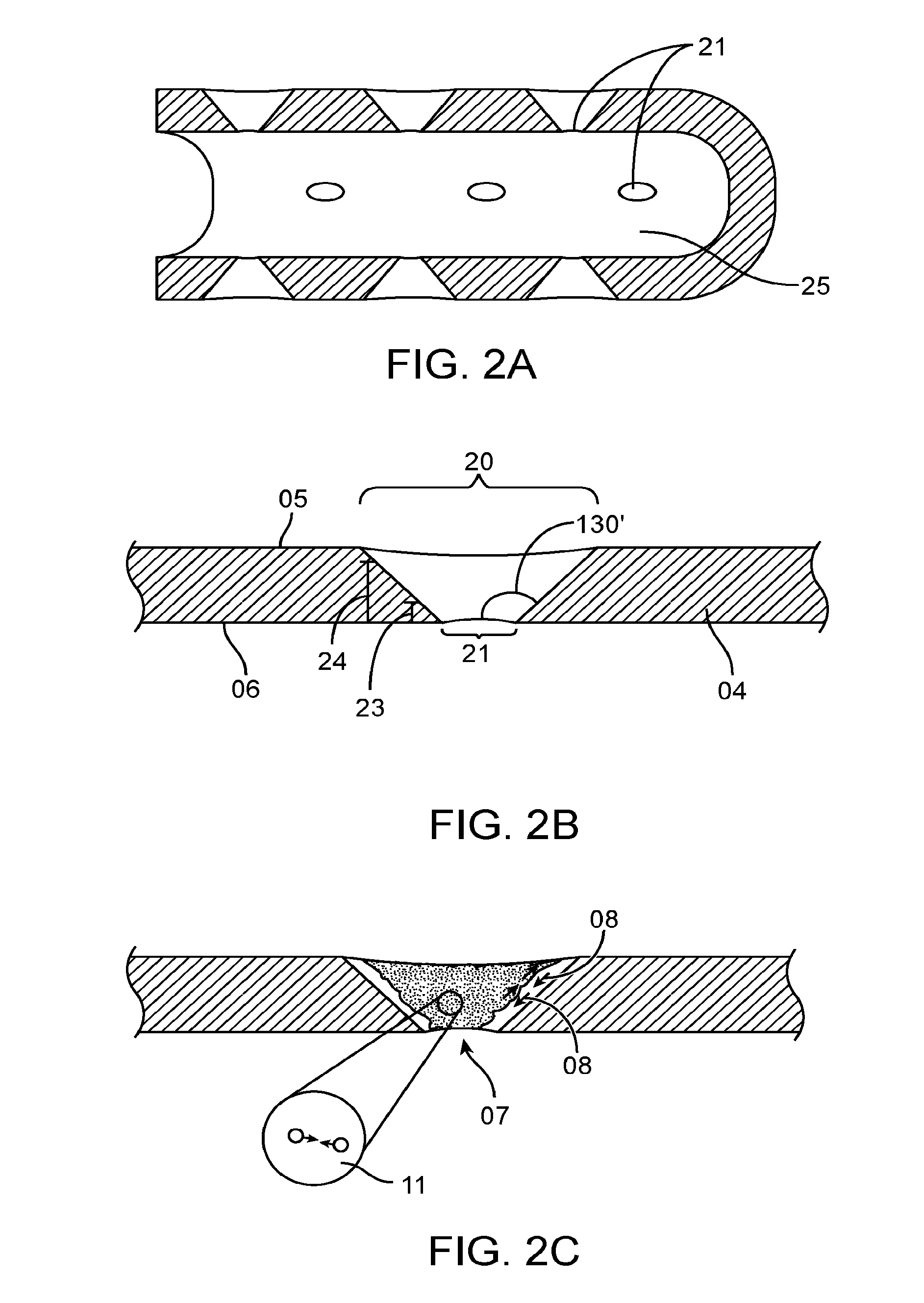

Wellbore plug and method

InactiveUS20130008671A1Remove tensionReduce tensionFluid removalSealing/packingEngineeringMechanical engineering

Disclosed is a wellbore plug having a design that allows the mandrel of the plug to be made of concrete or other easy-to-drill materials. Disclosed is a wellbore plug assembly with slip and packing assemblies configured to hold the plug in place during setting and use without tensioning the mandrel, thereby allowing the mandrel to be made from easily drillable material, such as concrete.

Owner:BOOTH JOHN F

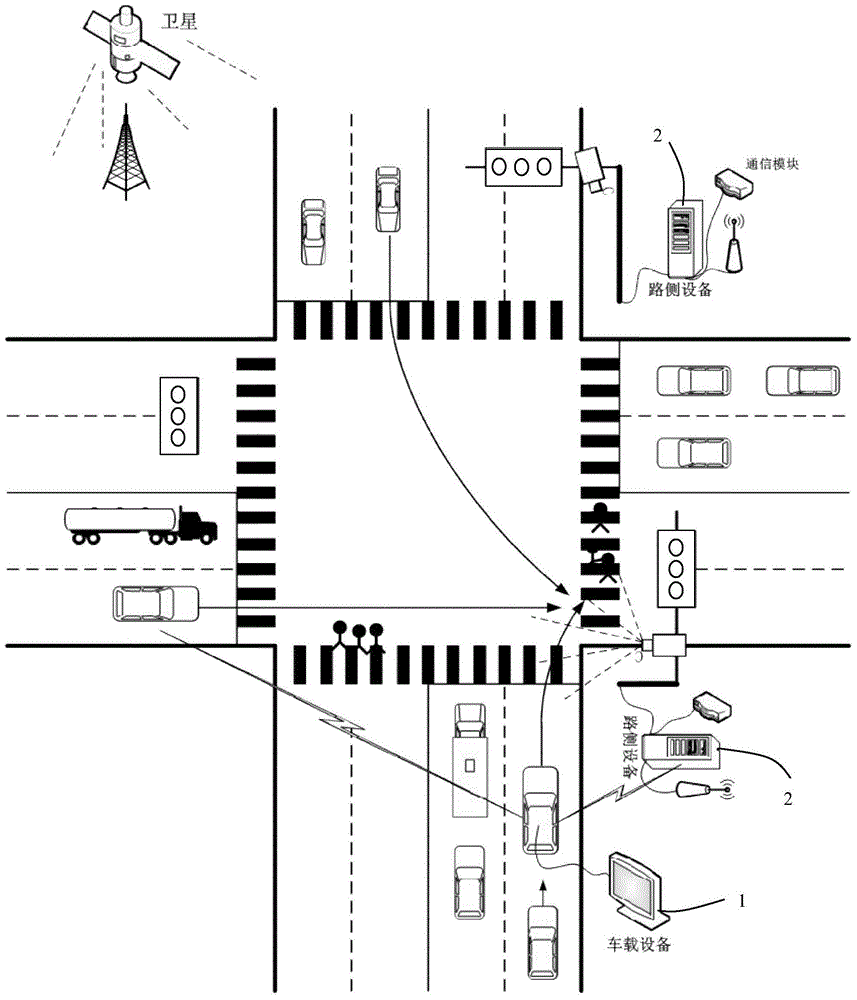

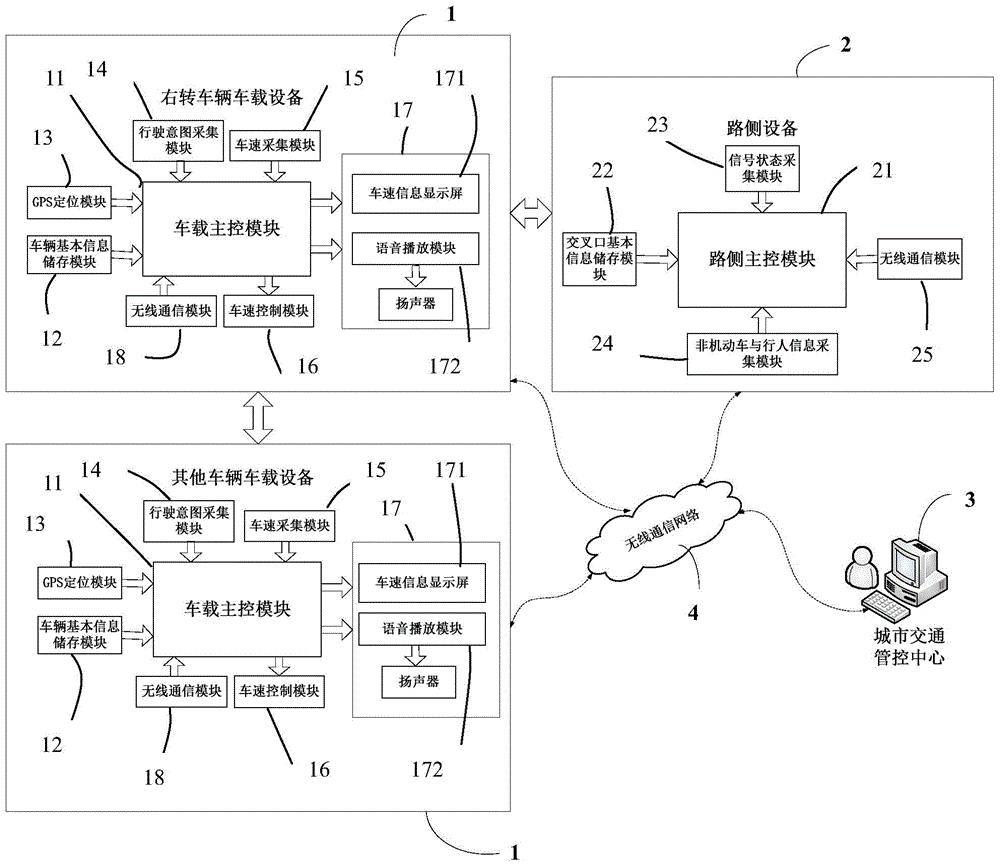

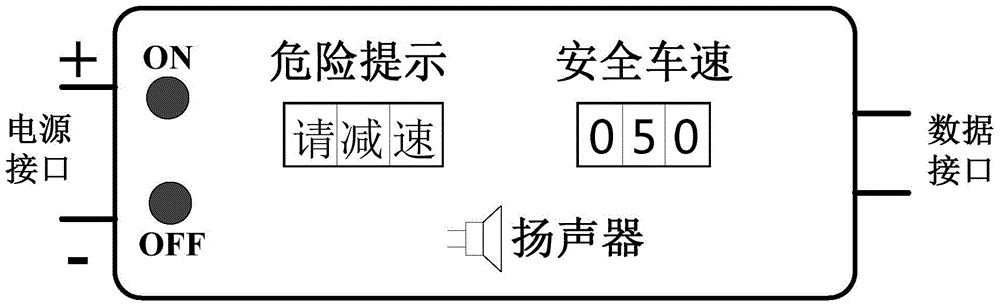

Cooperative vehicle infrastructure system-based intersection vehicle right turning guidance system and guidance method thereof

InactiveCN104916152AEasy to solveRealize information exchangeRoad vehicles traffic controlGuidance systemDriver/operator

The invention relates to a cooperative vehicle infrastructure system-based intersection vehicle right turning guidance system and a guidance method thereof. The guidance system includes a road-side device, a monitoring center and at least one vehicle-mounted device. When a vehicle entering an intersection communication range of the road-side device, a vehicle-mounted main control module performs analysis and judgment according to the static information of the vehicle, vehicle operating location information, vehicle driving direction, vehicle speed and traffic status information of an intersection where the vehicle is located; if judging that conflict between a motor vehicle and a non-motor vehicle or conflict between motor vehicles will occur in the future, the vehicle-mounted main control module analyzes safe vehicle speed required by right turning and transmits the safe vehicle speed to a prompt module and a vehicle speed control module; a driver will be prompted with the safe vehicle speed required by right turning through the prompt module; and the vehicle-mounted main control module monitors whether the vehicle drives at the safe vehicle speed; and if the vehicle-mounted main control module monitors that the vehicle does not drive at the safe vehicle speed, the vehicle speed control module will automatically control the speed of the vehicle.

Owner:SUZHOU UNIV

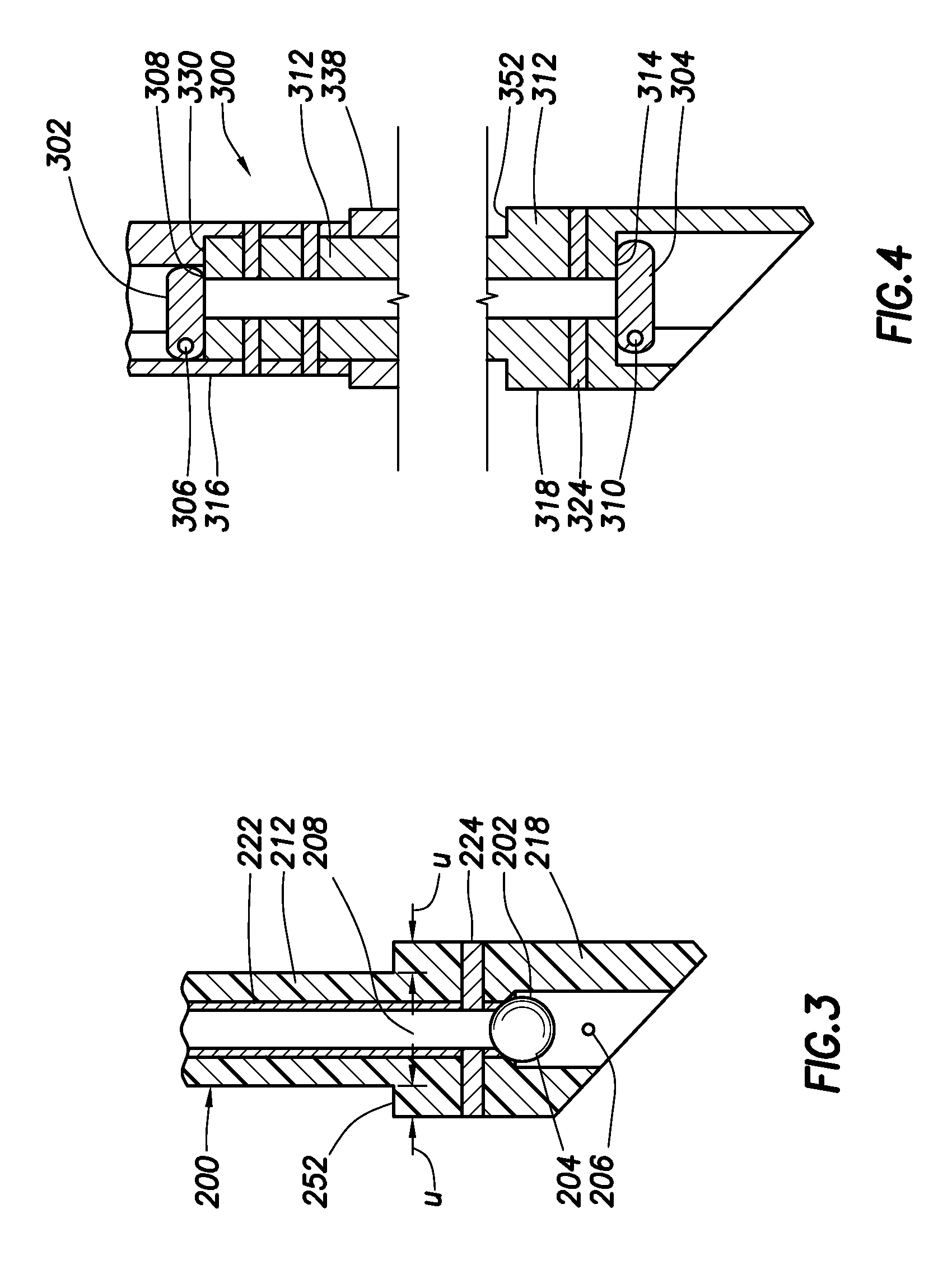

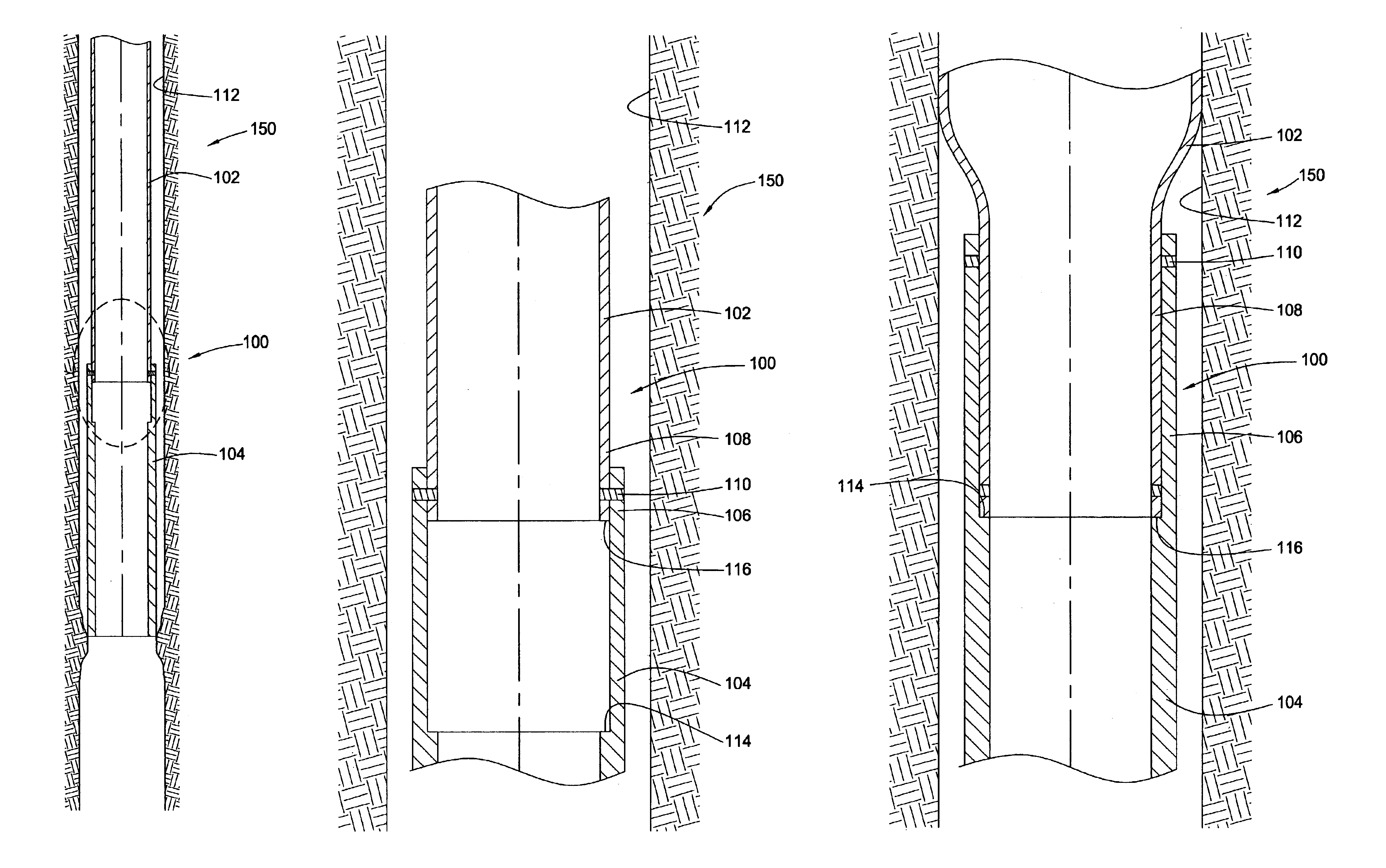

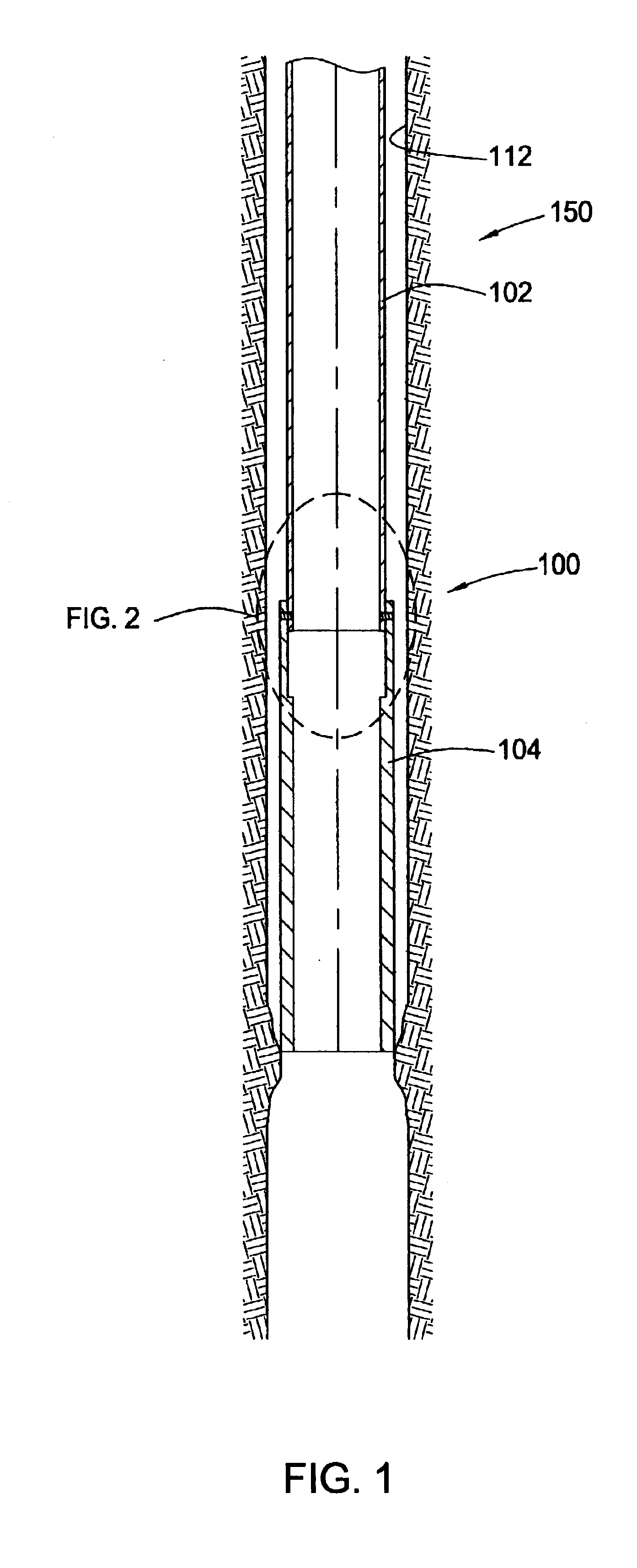

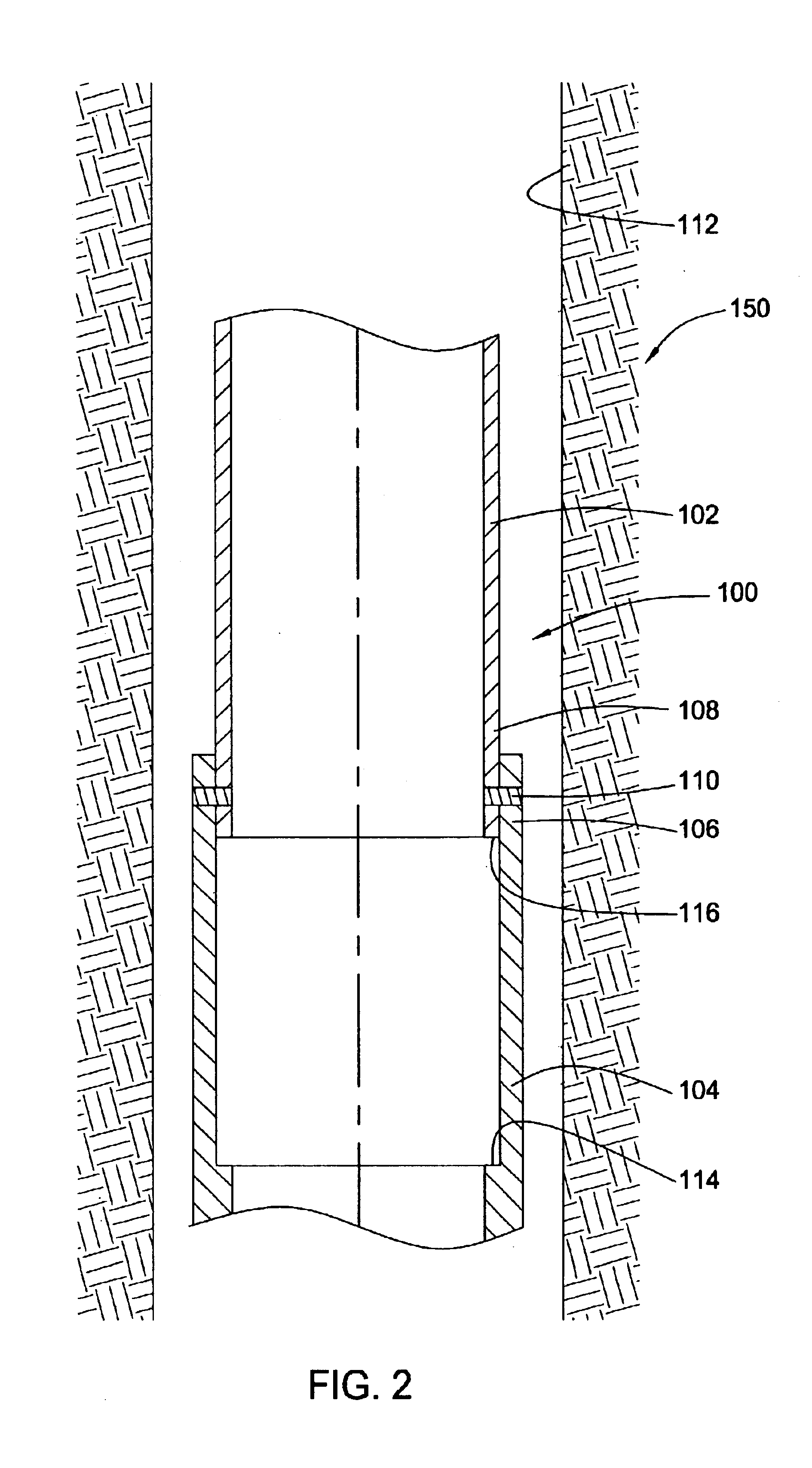

Joint for use with expandable tubulars

InactiveUS6920932B2Eliminate forceRemove tensionDrilling rodsFluid removalBiomedical engineeringWellbore

Embodiments of the present invention generally relate to a joint used with expandable sand screens and other expandable tubulars that permits elongation or contraction of the expandable tubulars during a tubular expansion operation within a wellbore. In one aspect, a connection assembly for use with expandable tubulars is provided. The connection assembly includes a first expandable tubular axially fixable at one end within a wellbore and a second expandable tubular axially fixable at one end within the wellbore. The second expandable tubular has an opposite end adapted to receive an opposite end of the first expandable tubular to provide a joint between the tubulars. The connection assembly further includes a releasable connection between the opposite ends of the tubulars for selectively permitting axial movement of the opposite ends relative to each other. In another aspect, a method for joining a first expandable tubular and a second expandable tubular is provided. Furthermore, a method for substantially eliminating tension or compression forces within an expandable tubular string positioned in a wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

Pump drive head with stuffing box

InactiveUS20050045323A1Eliminate replacementRemove tensionDrilling rodsFluid removalGear driveBraking system

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

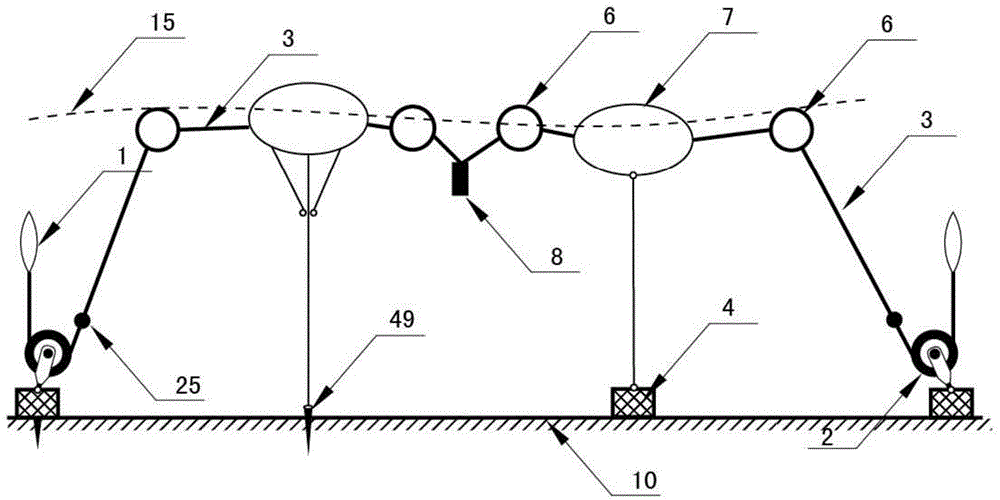

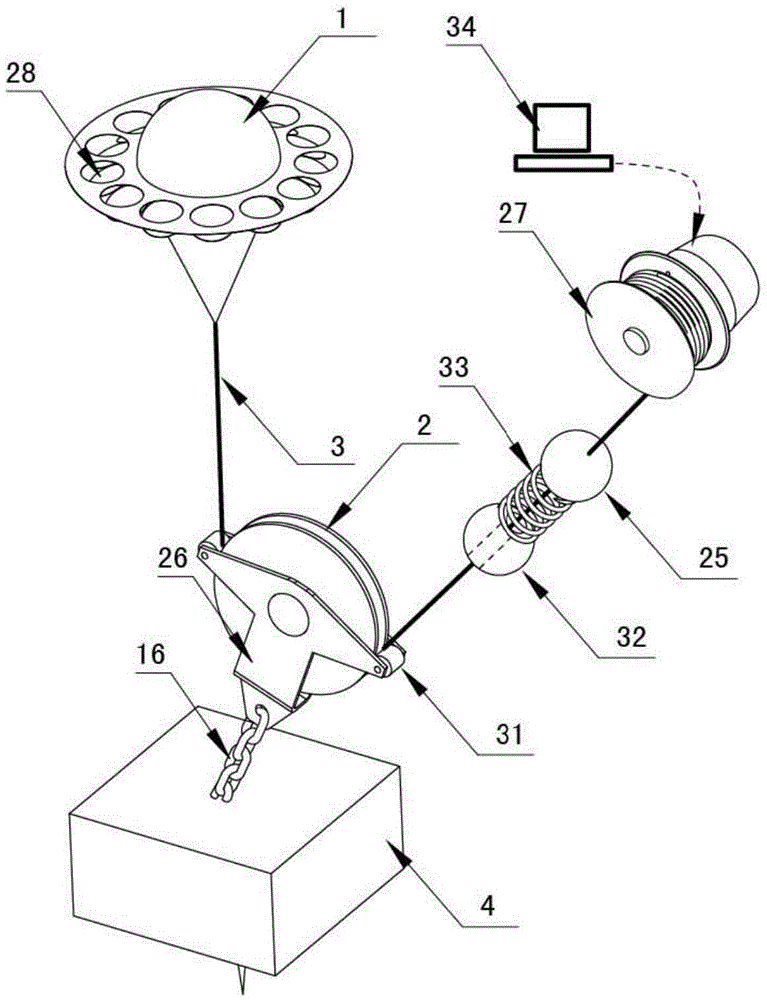

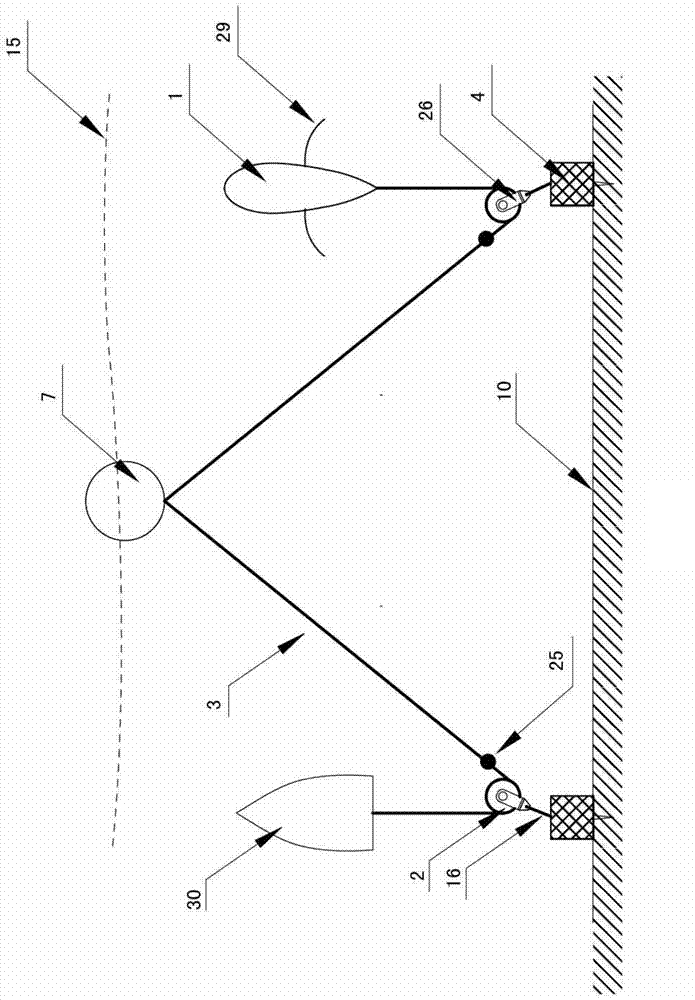

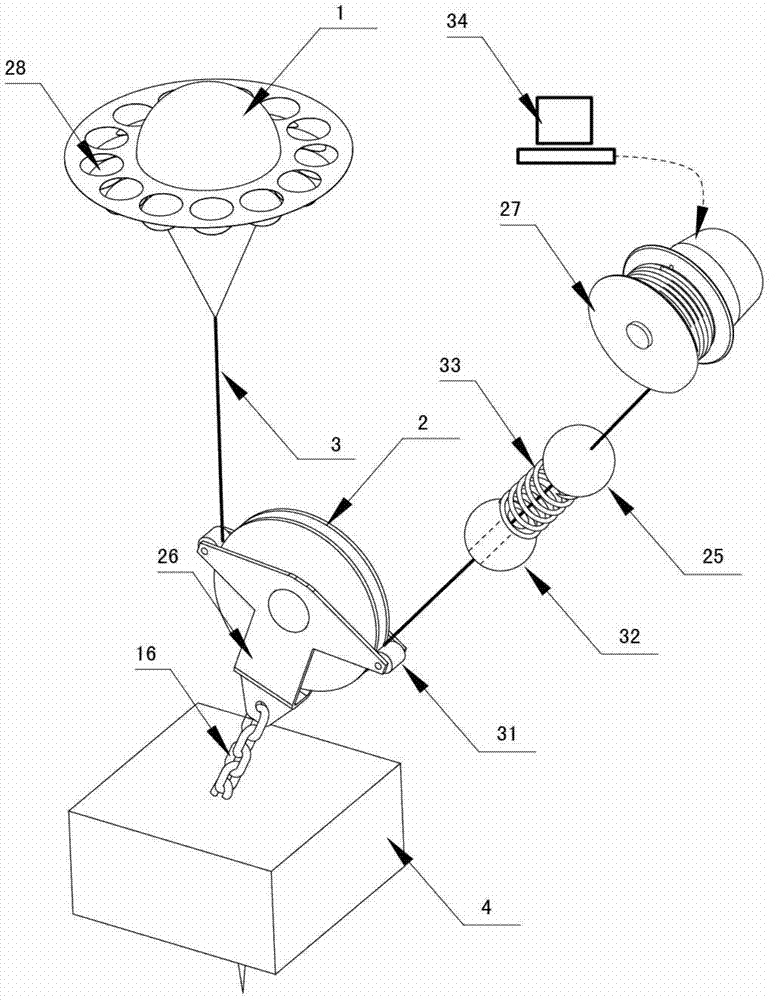

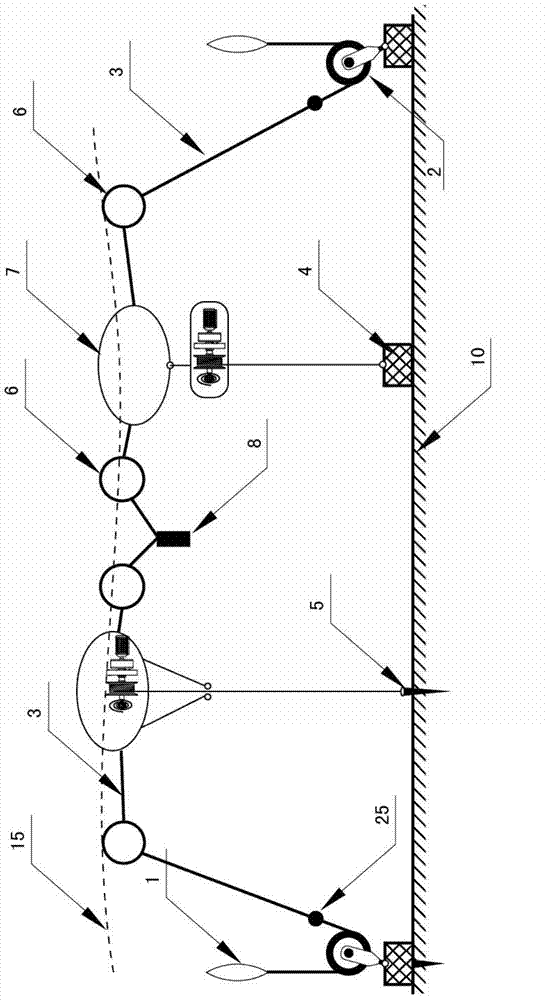

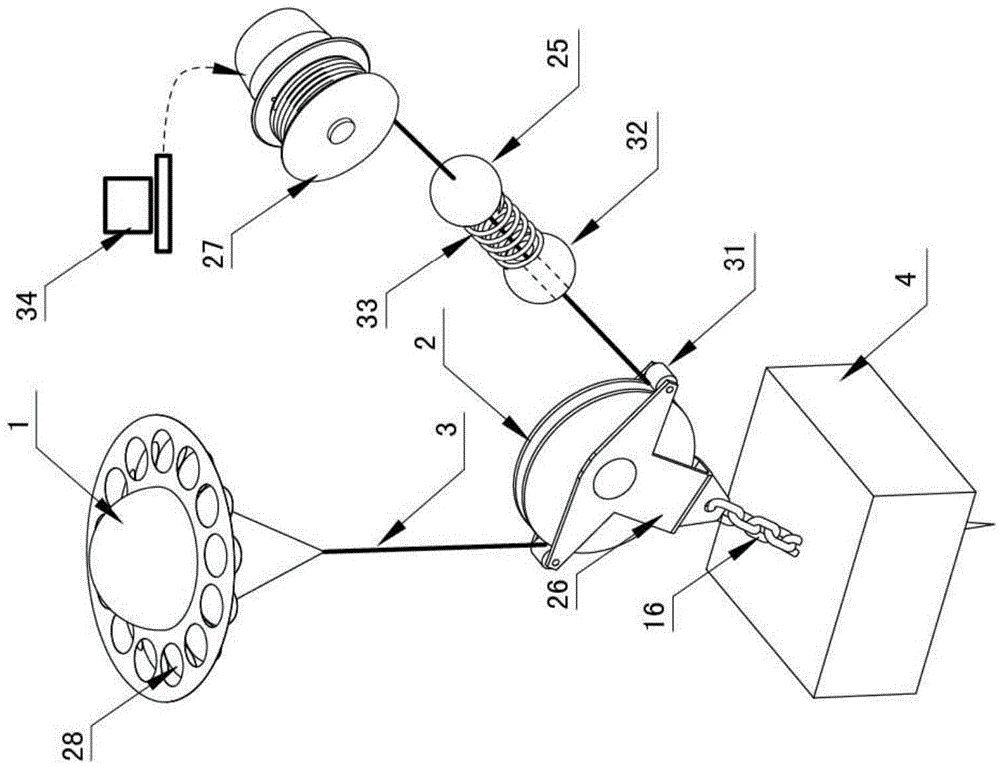

Submersible buoy pulley mooring system

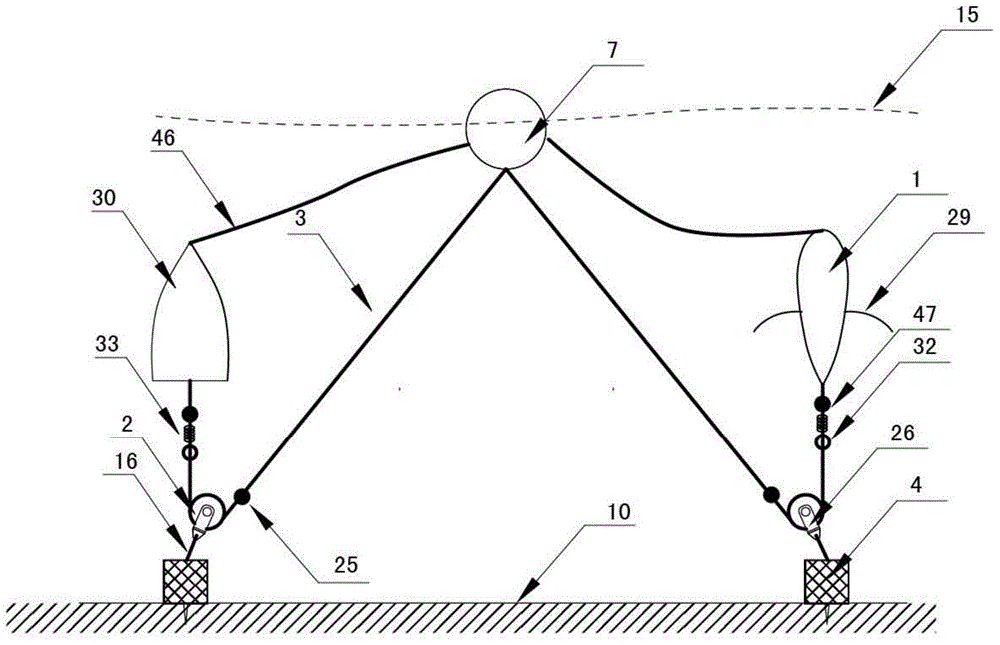

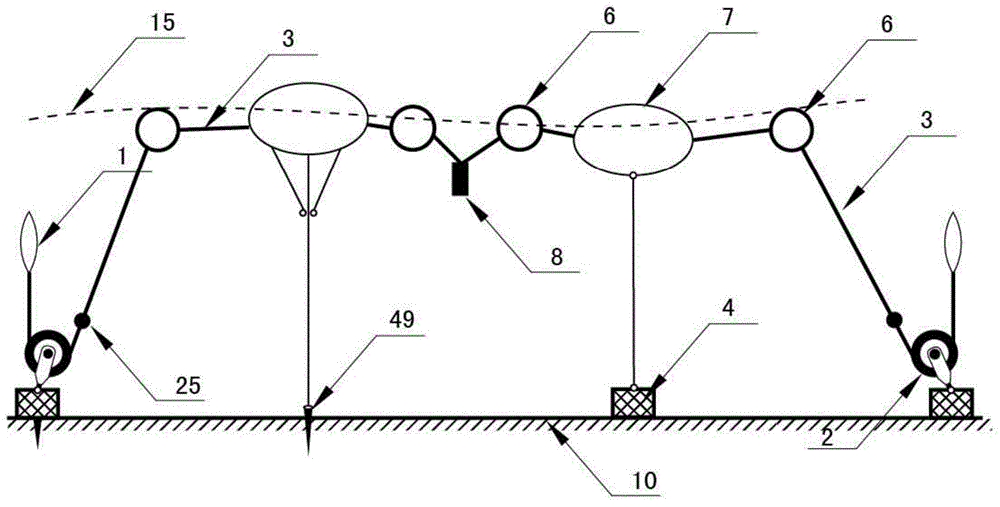

The invention provides a submersible buoy pulley mooring system and relates to a mooring system. The submersible buoy pulley mooring system mainly comprises submersible buoys, pulleys, anchor bases, ropes and rope knots. The anchor bases are provided with rope chains in a tying mode. The other end of each rope chain is tied to each fixed pulley support. Each pulley is wound with a rope. One end of each rope is tied to the corresponding submersible buoy. The other end of each rope is tied to a floating body required to be moored. The positions, between the pulleys and the moored floating body and close to the pulleys, of the ropes are provided with the rope knots in a tying mode. Combination of a plurality of submersible buoy pulley anchoring units distributed on the periphery tightly pull the central floating body required to be moored jointly. By means of the submersible buoy pulley mooring system, the problems of anchor chain breakage or anchor base slippage and the like generated due to the fact that the mooring constraining force is violently increased can be avoided, so that the storm resistance capacity can be provided, and the mooring cost is lowered.

Owner:曲言明

Method and apparatus for a clog resistant orifice

InactiveUS20150088090A1Minimize occurrenceReduce capacityMedical devicesCatheterEngineeringMedical device

Owner:HOSPI CORP

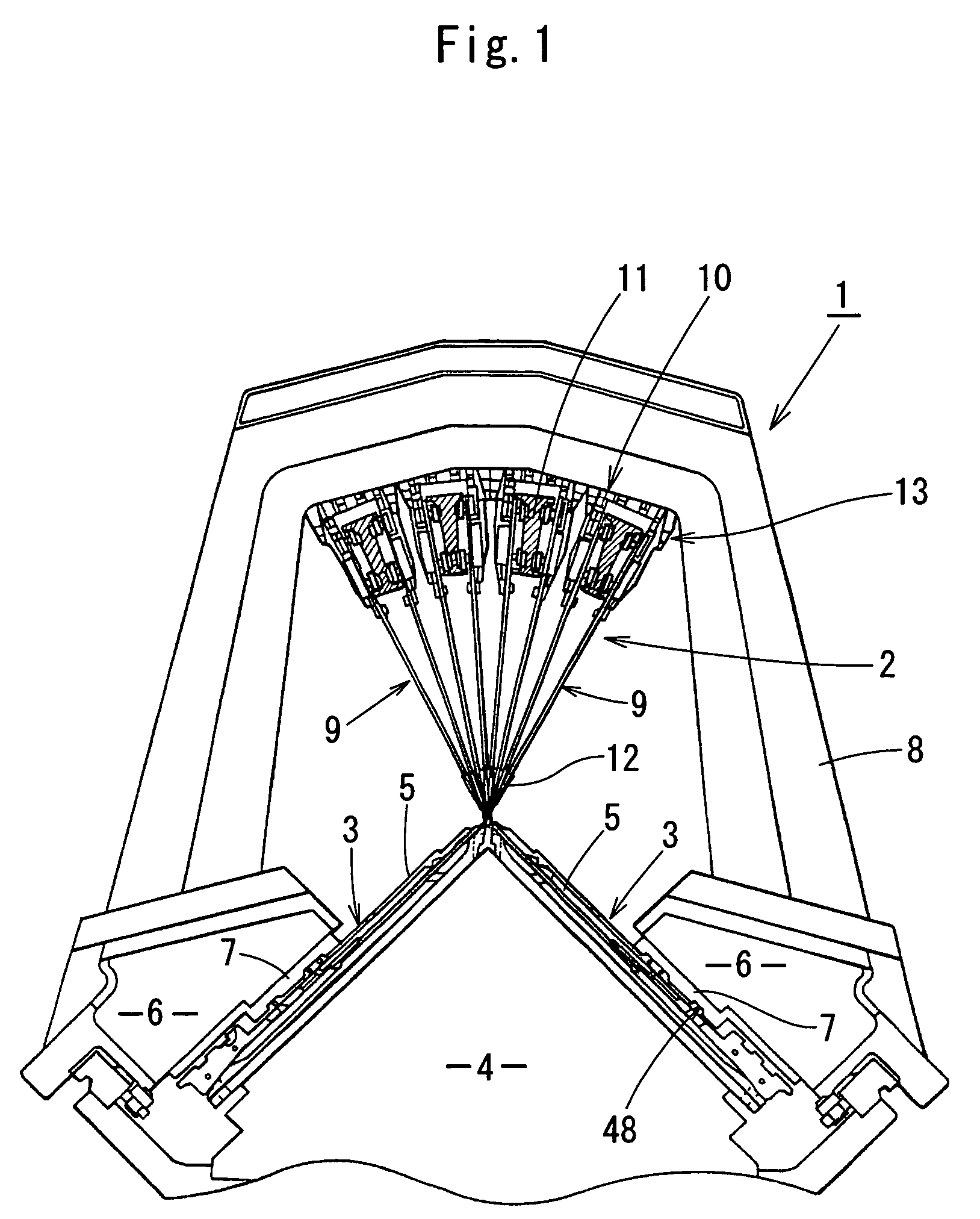

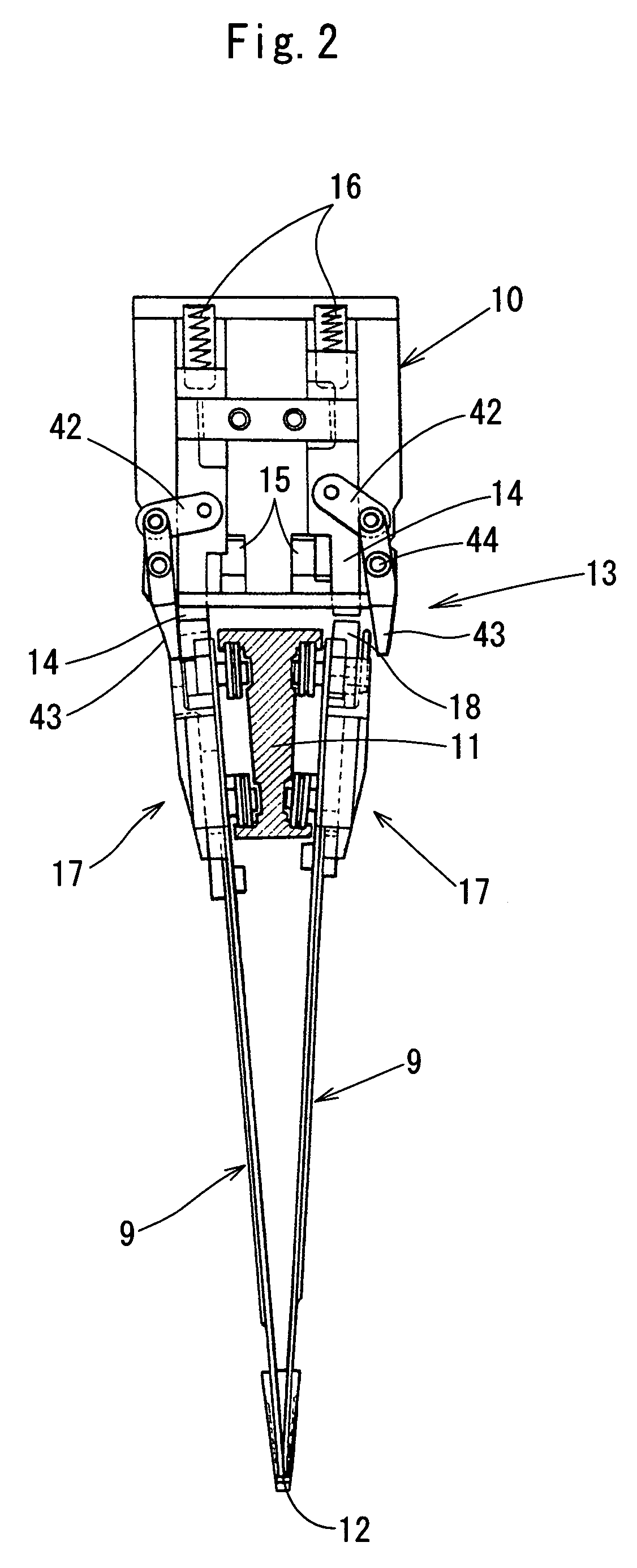

Yarn feeder of yarn feeding device for weft knitting machine

Owner:SHIMA SEIKI MFG LTD +1

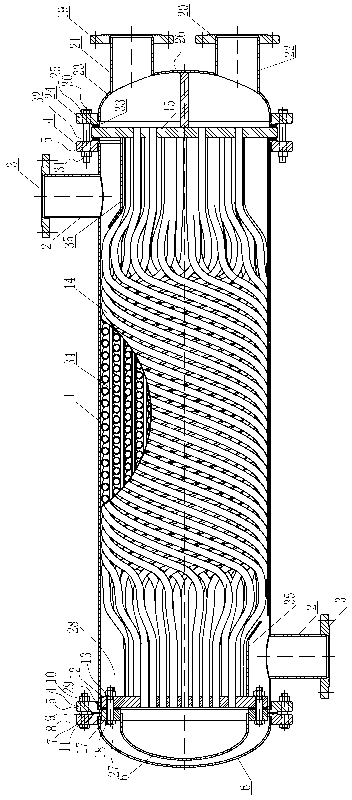

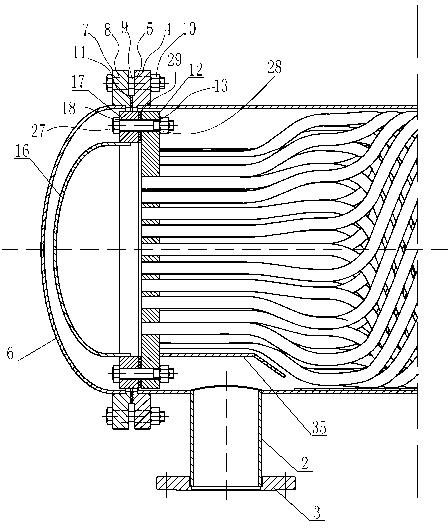

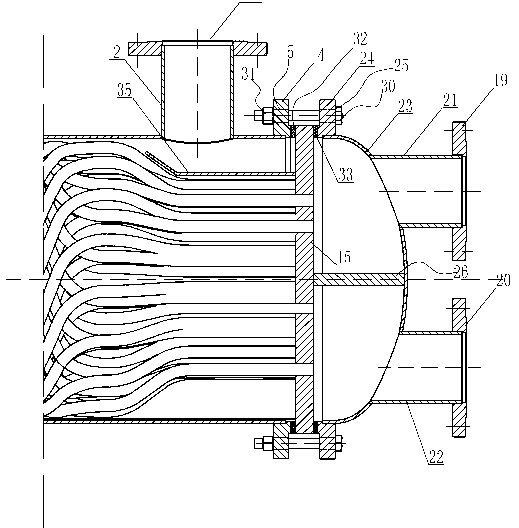

Spiral winding pipe floating heat exchanger

ActiveCN103344139AEasy maintenanceEasy to cleanHeat exchanger casingsStationary tubular conduit assembliesEngineeringMechanical engineering

The invention discloses a spiral winding pipe floating heat exchanger. The spiral winding pipe floating heat exchanger comprises a heat exchanger shell. A first shell end enclosure device and a second shell end enclosure device are arranged at the two ends of the heat exchanger shell respectively, and a heat exchanger core which can be drawn out of the heat exchanger shell is packaged in the heat exchanger shell; the second shell end enclosure device can be dismounted from the heat exchanger shell, therefore, the heat exchanger core and a channel end enclosure connected with the heat exchanger core can be drawn out of the heat exchanger shell, and heat exchange tubes can be maintained and cleaned conveniently. The spiral winding pipe floating heat exchanger is simple in structure and convenient to operate. A floating tube plate, a channel end enclosure flange and the channel end enclosure can move along with expansion caused by heat and contraction caused by cold of a tube bundle layer in the heat exchanger shell, and therefore pulling force and pushing force of the heat exchange tubes on the channel end enclosure and the second shell end enclosure device can be eliminated; the spiral tube bundle layer is beneficial to improving work stability of the heat exchanger, the structure enhances the turbulence effect greatly when fluid flows in the heat exchange tubes, and therefore heat exchange coefficients are improved.

Owner:HIMILE MECHANICAL MFG

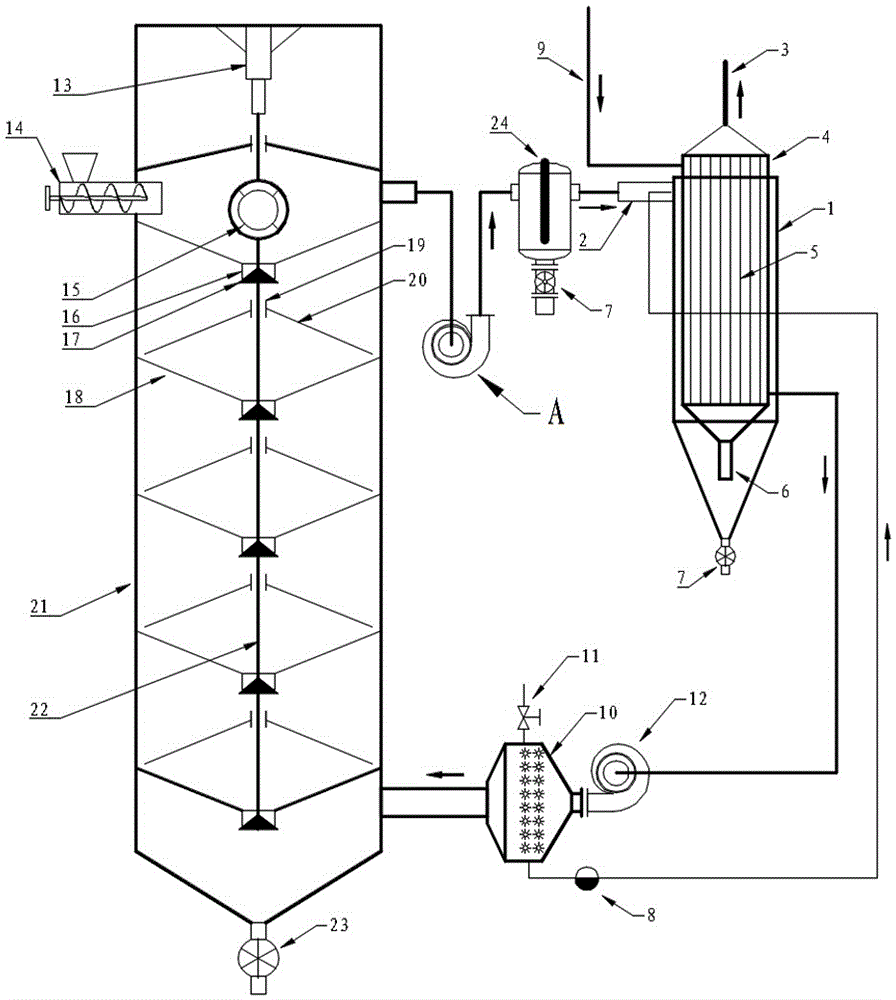

Hot air type penetration reverse flow fluidization drying machine with tail heat utilization and inertial dust collecting functions

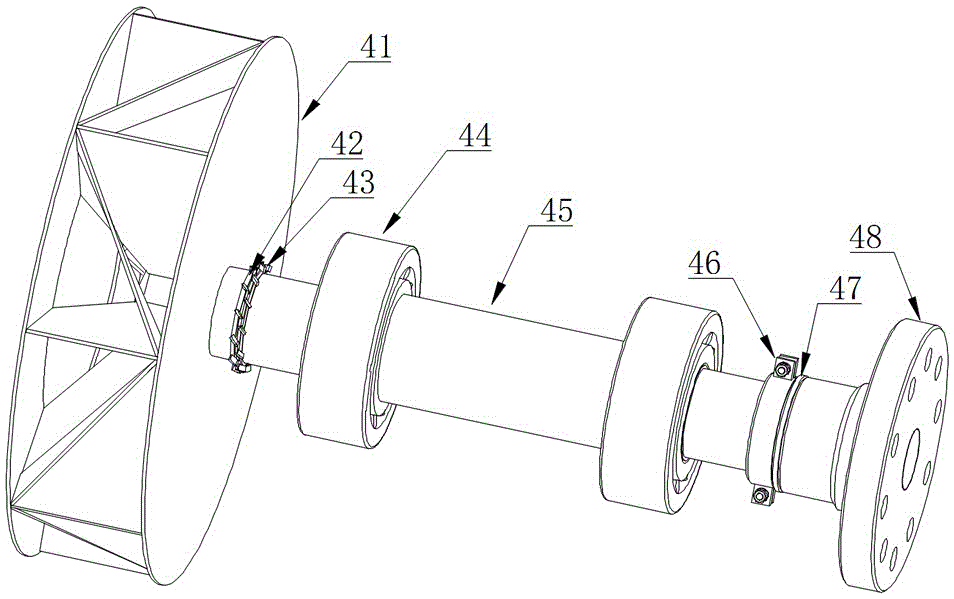

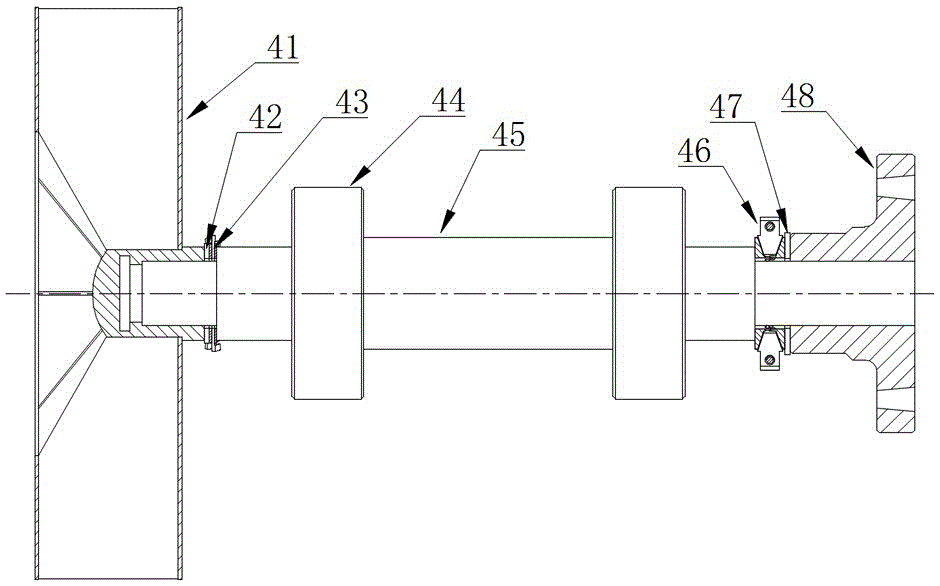

InactiveCN105783478AStrong extrusion rigidityEliminate fatigue fractureDrying solid materials with heatDrying gas arrangementsImpellerCyclone

The invention discloses a hot air type penetration reverse flow fluidization drying machine with tail heat utilization and inertial dust collecting functions. The upper portion of a drying tower is connected with an induced draft fan. The induced draft fan is connected with an efficient cyclone dedusting tail heat recovery device in a tangential manner through an inertial dust collecting device and then performs evacuation, wherein the efficient cyclone dedusting tail heat recovery device is formed by overlaying a tube bank type heat exchanger and a cyclone dust collector. The air inlet end of a shell pass of the tube bank type heat exchanger is communicated with atmosphere, and the air outlet end is connected with the lower portion of the drying tower through an air blower and a steam fin heater; and blades of an impeller of the induced draft fan are arranged to be in a radiation shape and are in radial and central symmetry with respect to an impeller shaft, the dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the hot air type penetration reverse flow fluidization drying machine, the drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly and assembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated simply when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the hot air type penetration reverse flow fluidization drying machine is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is particularly obvious.

Owner:罗军

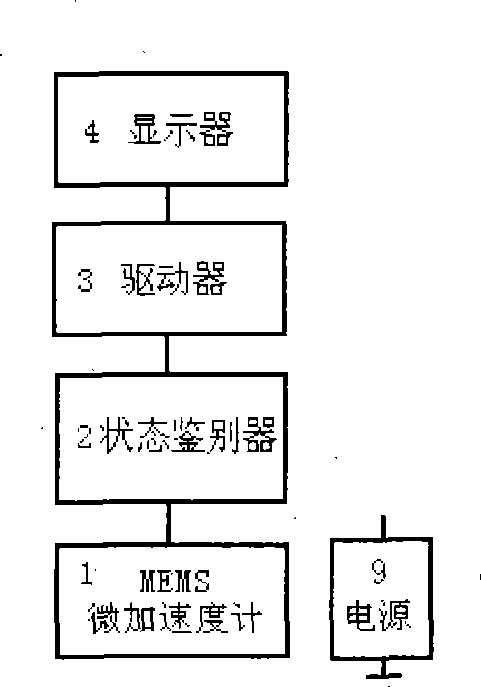

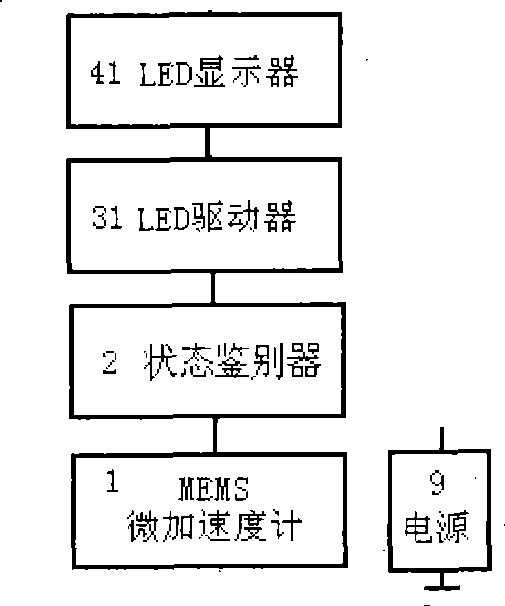

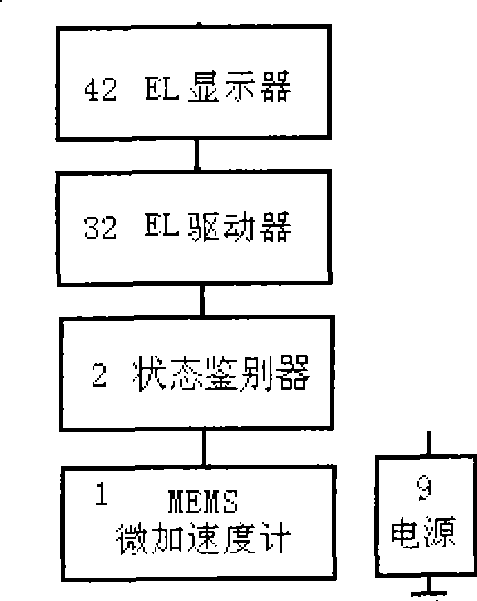

Dynamic state display apparatus of vehicle and display method

InactiveCN101428583AWide range of useReduce power consumptionOptical signalOptical signallingAutomatic controlSafe driving

The invention relates to a vehicle dynamic display device and a displaying method thereof. The vehicle dynamic display device comprises an MEMS microaccelerometer, a vehicle state discriminator, a driver, a LED display or an EL emitting diode. An accelerometer is adopted for detecting state; an automatic decision can be performed on states of collision, emergency brake, urgency speed reduction, general speed reduction and acceleration through the vehicle state discriminator; real-time display can be respectively performed according to the urgent degree ordering in various colors, graphics, characters or the combination thereof; hand operation is replaced by automatic control, and the two signals of Preparation-Break replace break signals, so that the difficulty of Emergency Brake Precaution is solved. Once a vehicle is in danger, all vehicles thereafter can synchronously put on the brakes as well as the front vehicle, and an early warning time of 0.8 second to 1 second can be gained, thereby effectively avoiding the phenomena of driving too close to the car in front and serially driving too close to the car in front. The comprehensive early warning mechanism overcomes a plurality of defects in the traditional signal lamp and creates the beginning of mutual communication among vehicles, knowing one and others and safe driving. The invention has the advantages of low cost, high cost performance and simple installation, and is suitable for high-level installation at the tail parts of various vehicles and the installation of rear boxes of motorcycles and mopeds.

Owner:龚立新

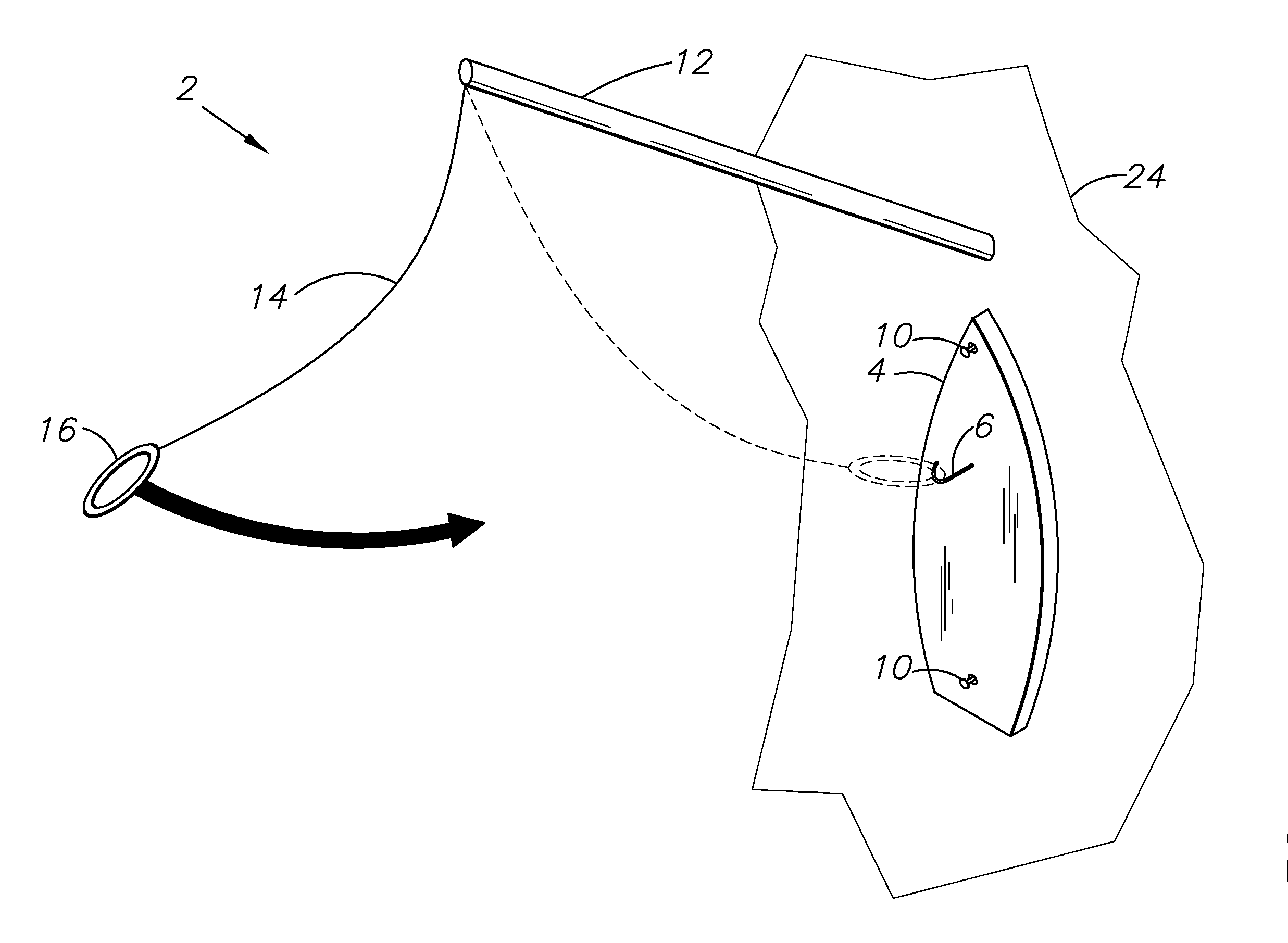

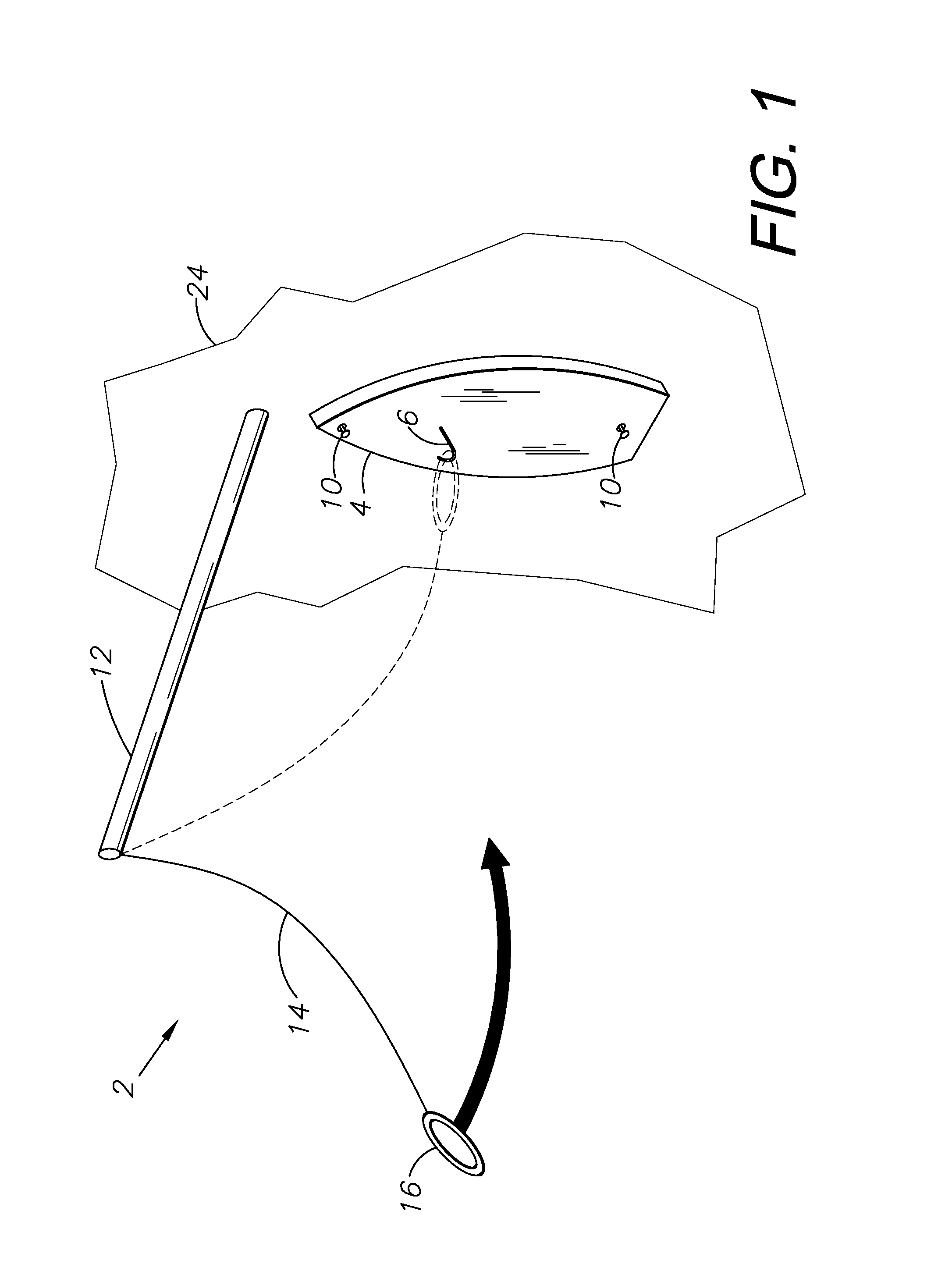

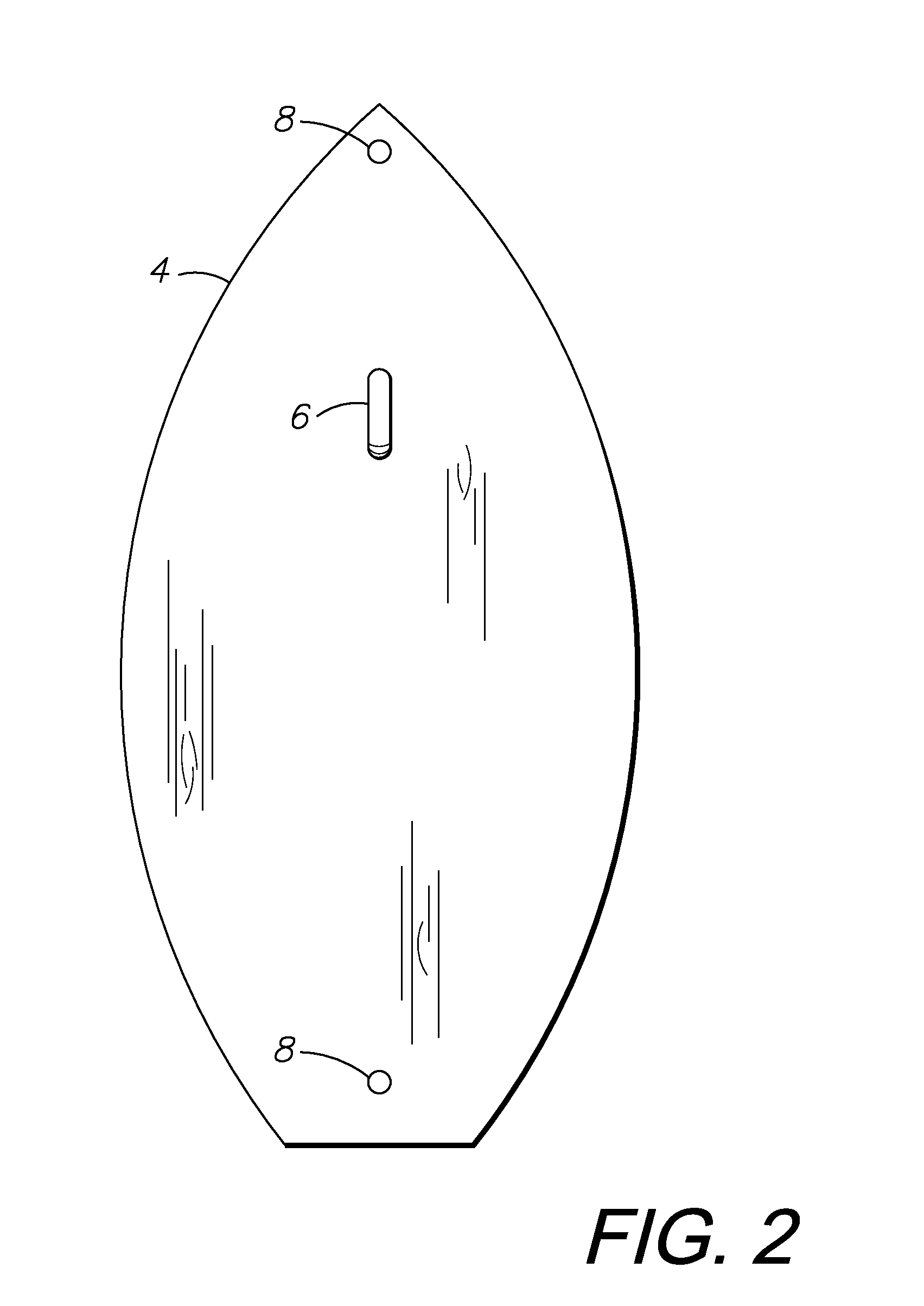

Ring toss game and system including pierced ring

InactiveUS20140049007A1Uniform gameplayRemoving of string tensionIndoor gamesBall sportsEngineeringGame play

A highly-portable and stylized ring toss game which includes a pierced ring. The piercing in the ring allows a string to be threaded directly through the ring, thereby removing the need to tie a string to the ring and removing the element of string tension from the game, thus allowing for more creative tricks and more uniform gameplay. The ring is suspended from the string a distance away from a backboard with a hook. The ring is tossed along a path toward the backboard with the intent of hooking the ring onto the hook. The ring may be spun or flipped to perform this feat in more dramatic fashion.

Owner:MELLOW MILITIA

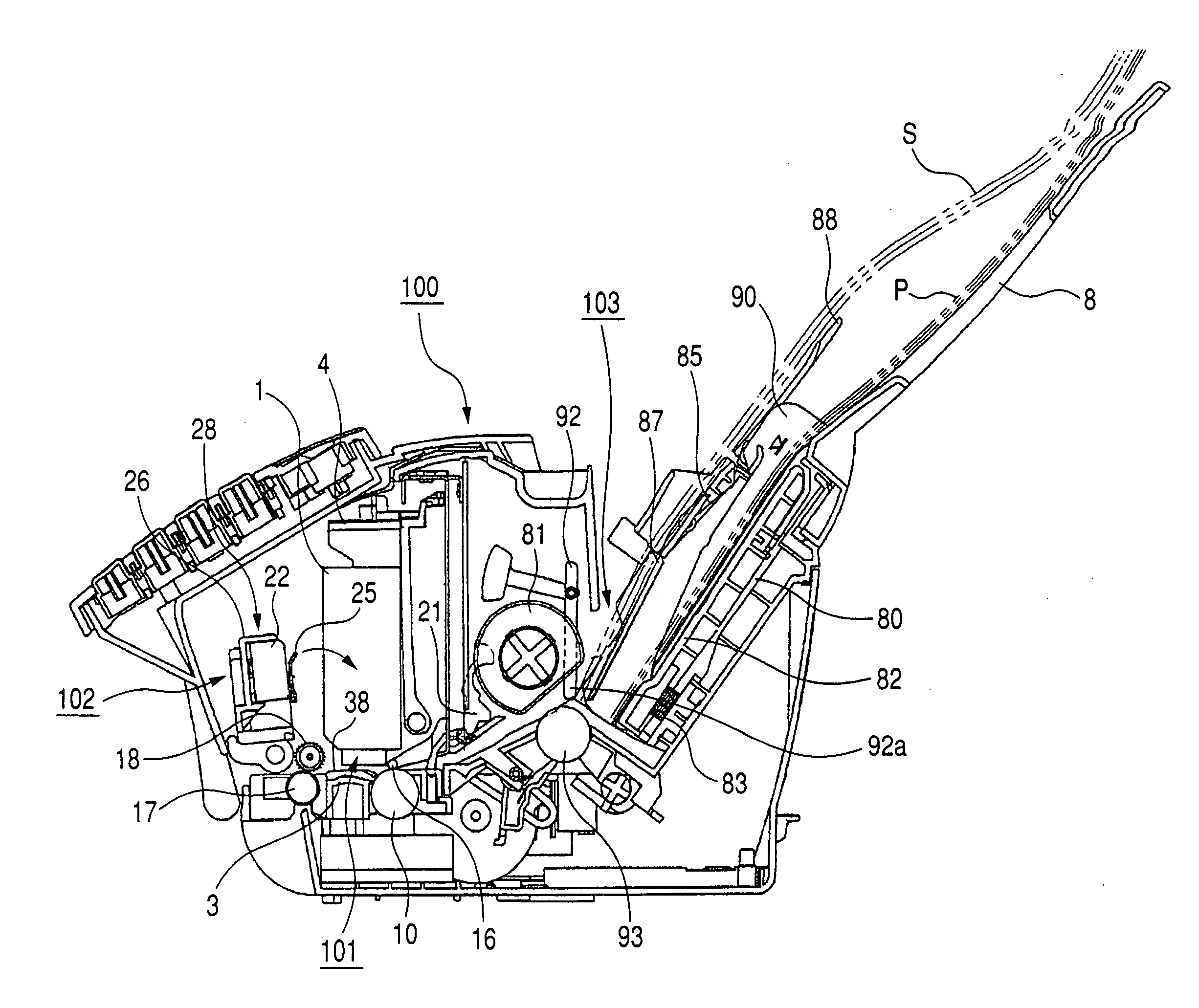

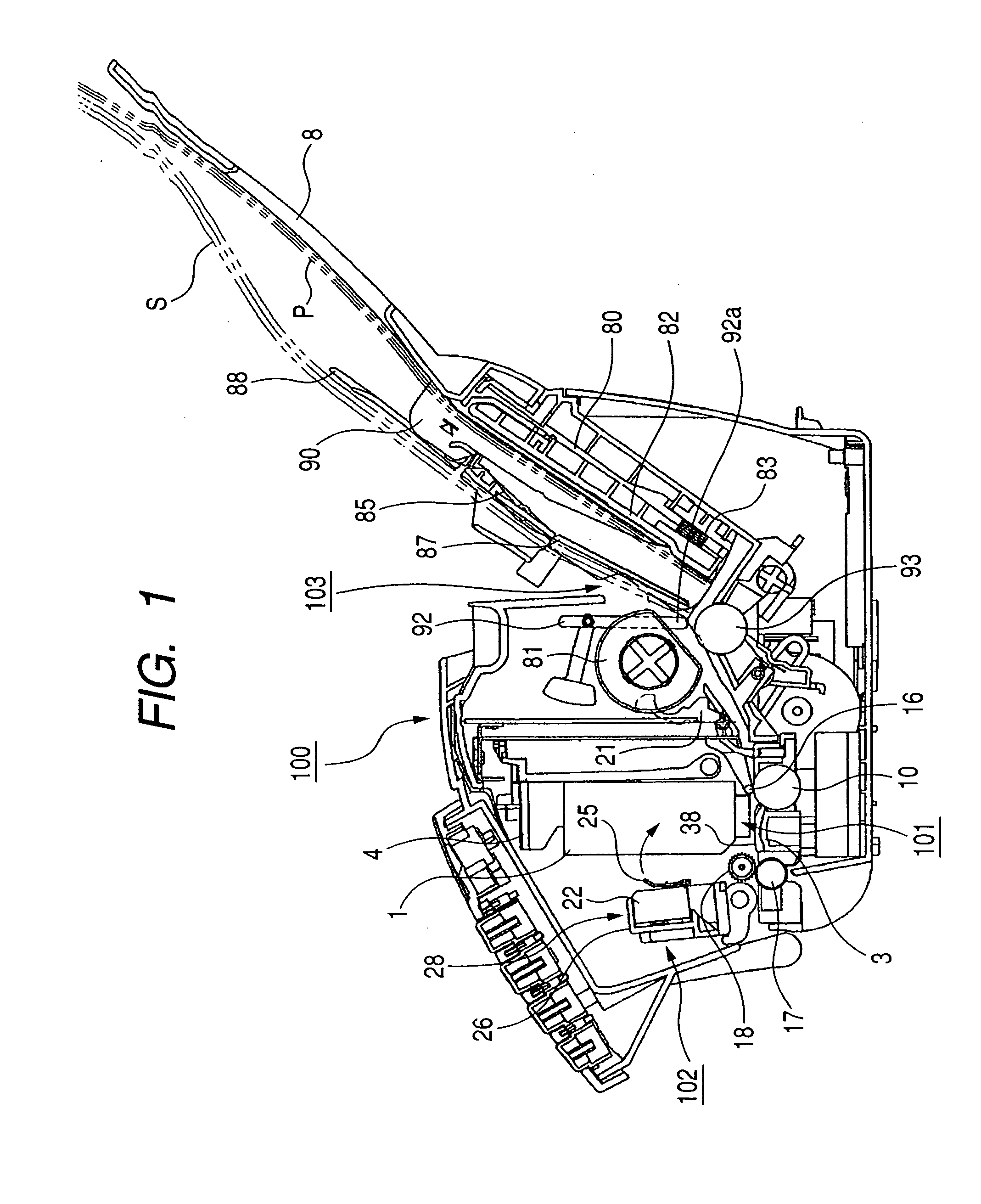

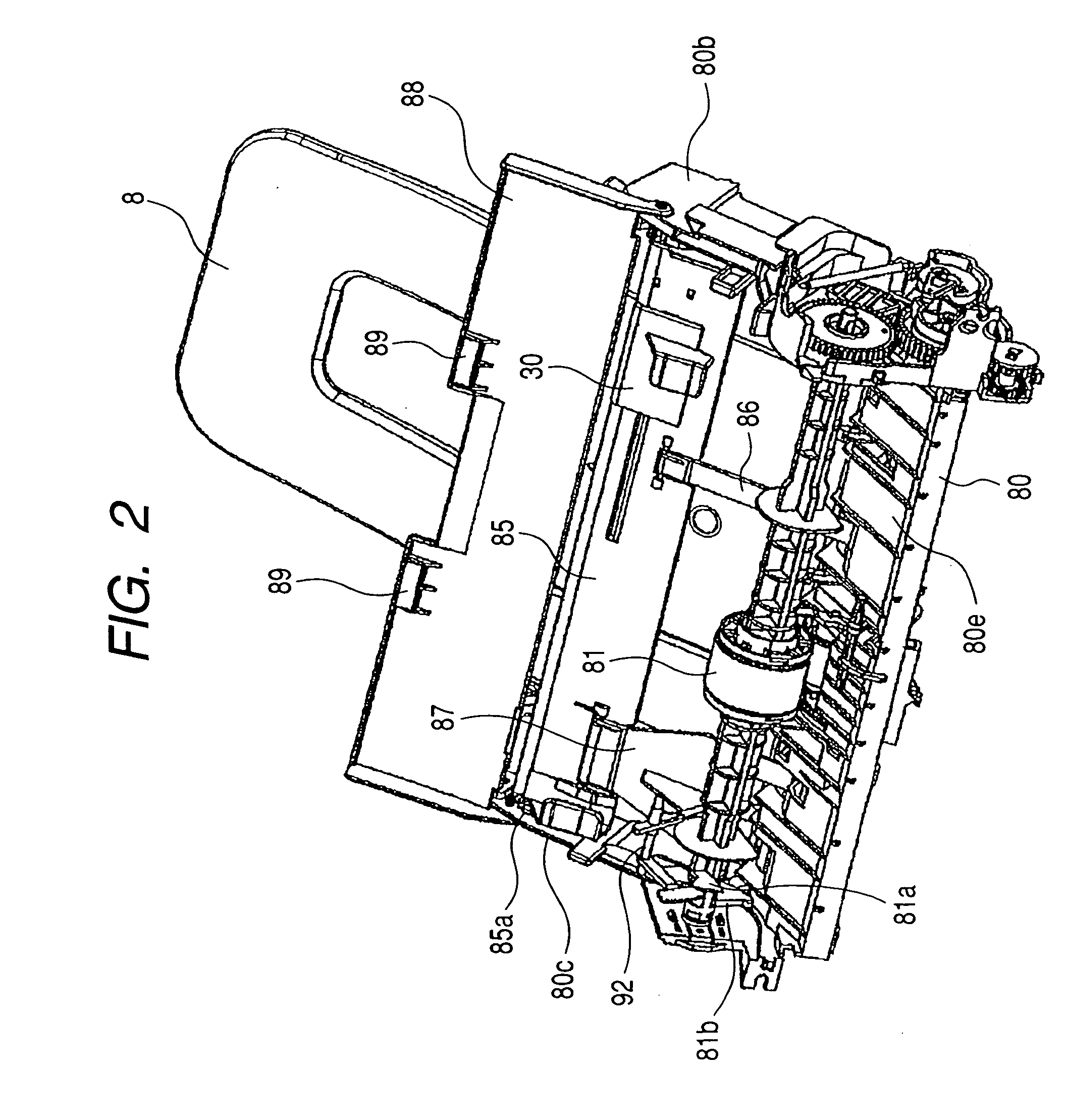

Image processing apparatus

InactiveUS20050286942A1Reduce cost of apparatusSmall sizeElectrographic process apparatusOther printing apparatusPaper documentDocument preparation

The typical configuration of an image processing apparatus includes a document stacking means on which documents are stacked, a recording medium stacking means on which recording medium are stacked, and a feeding roller for feeding documents or recording medium from the document stacking means or the recording medium stacking means. The feeding roller is located above the recording medium stacking means, and at least the lower end of the recording medium stacking means is movable in the direction approaching or moving away from the feeding roller. The document stacking means is attached above and substantially parallel to the recording medium stacking means, at a predetermined interval. Further, the document stacking means does not have a support portion at a location corresponding to the feeding roller, and is moved as the recording medium stacking means is moved.

Owner:CANON KK

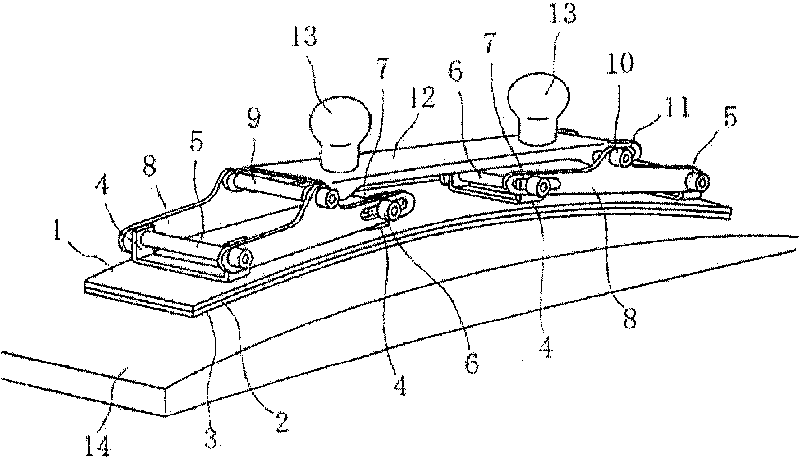

A sander used in particular for sanding of flat, concave, and convex surfaces and the method of its utilisation

InactiveCN101743096APrecisely form the curvatureFlexible constraintsPortable grinding machinesGrinding/polishing hand toolsTextileConcave surface

The sander for sanding particularly of the flat, concave and convex surfaces and the method of its usage is based on the fact, that the sanding tool (paper, linen or other carrier with sanding abrasive layer) is pressed onto the grinded surface by means of a flexible pressure plate able to copy the concave and convex surfaces with the possibility to set accurately the radius of this curve. The principle of the technical solution of the invention of the flexible pressure plate consists in the fact, that the pressure generated during the work onto the body, handle, or handles of the sander with mechanical drive is transferred onto this pressure plate at least at two points simultaneously or over at least one balance beam.

Owner:彼得·弗罗涅克

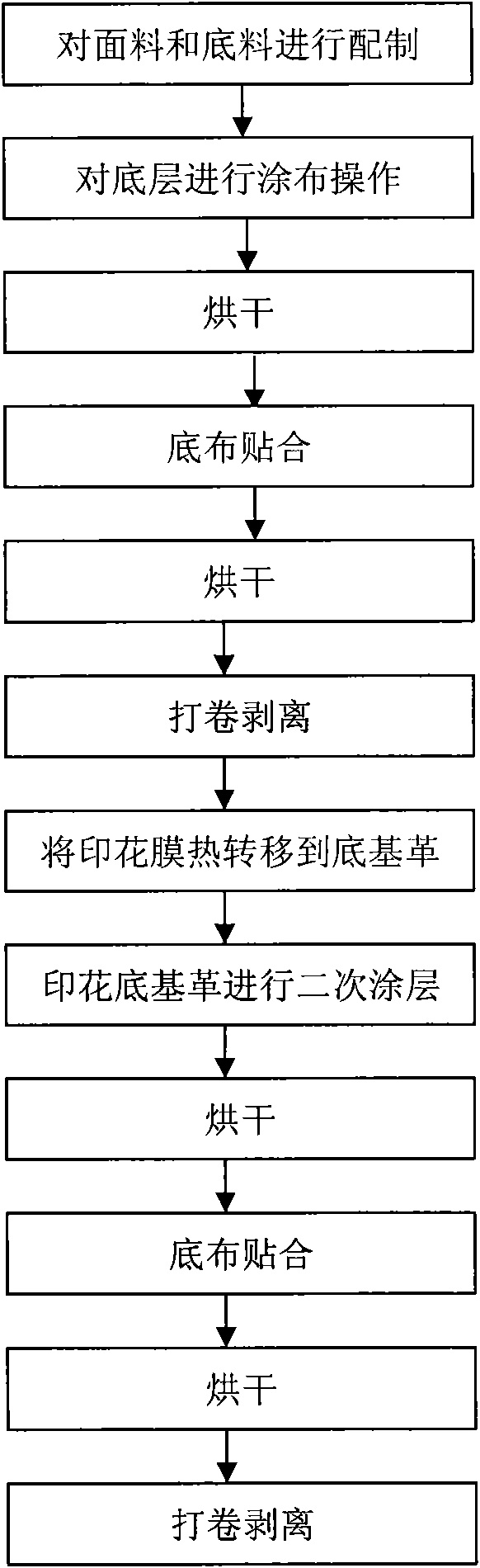

Novel PU printing waterproof and anti-crease fabric and preparation method thereof

InactiveCN101660277AImprove the three-dimensional effectRemove tensionSynthetic resin layered productsDyeing processDisperse dyeAlcohol

The invention discloses a novel PU printing waterproof and anti-crease new fabric, which comprises three layers: the first layer is PU surface layer mainly comprising PU polyurethane; the second layeris printing dyes; the third layer is a PU surface layer mainly comprising PU polyurethane. The printing dyes in the second layer are ink disperse dyes made of disperse dyes and water-soluble carrier,or ink disperse dyes made of the disperse dyes and alcohol-soluble carrier, or ink disperse dyes made of the disperse dyes and oil-soluble resin. The invention also discloses a method for preparing the novel PU printing waterproof and anti-crease fabric, comprising the following steps: firstly, preparing a shell fabric and a backing material; secondly, carrying out coating operation; thirdly, performing the backing lamination; fourthly, drying, rolling and stripping; fifthly, thermally transferring a printing film to base leather; and sixthly, performing the secondary coating on the printingbase leather. The novel PU printing waterproof, anti-crease fabric has advantages of terrific tensile strength and hydrostatic pressure, and is durable in use, fastness to washing, colorfast; and thepreparation method is easy to operate.

Owner:仪征新天地织物面料实业有限公司

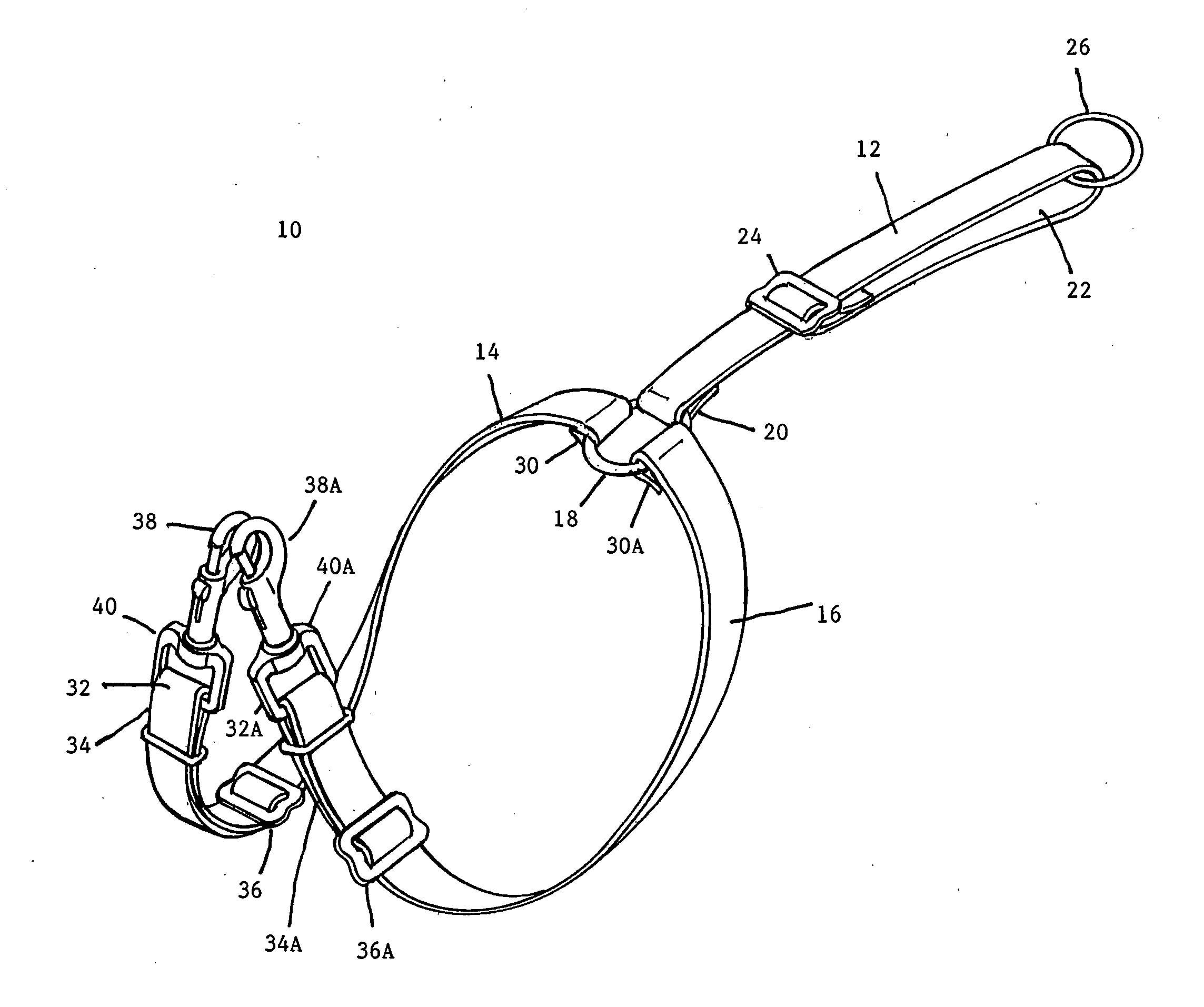

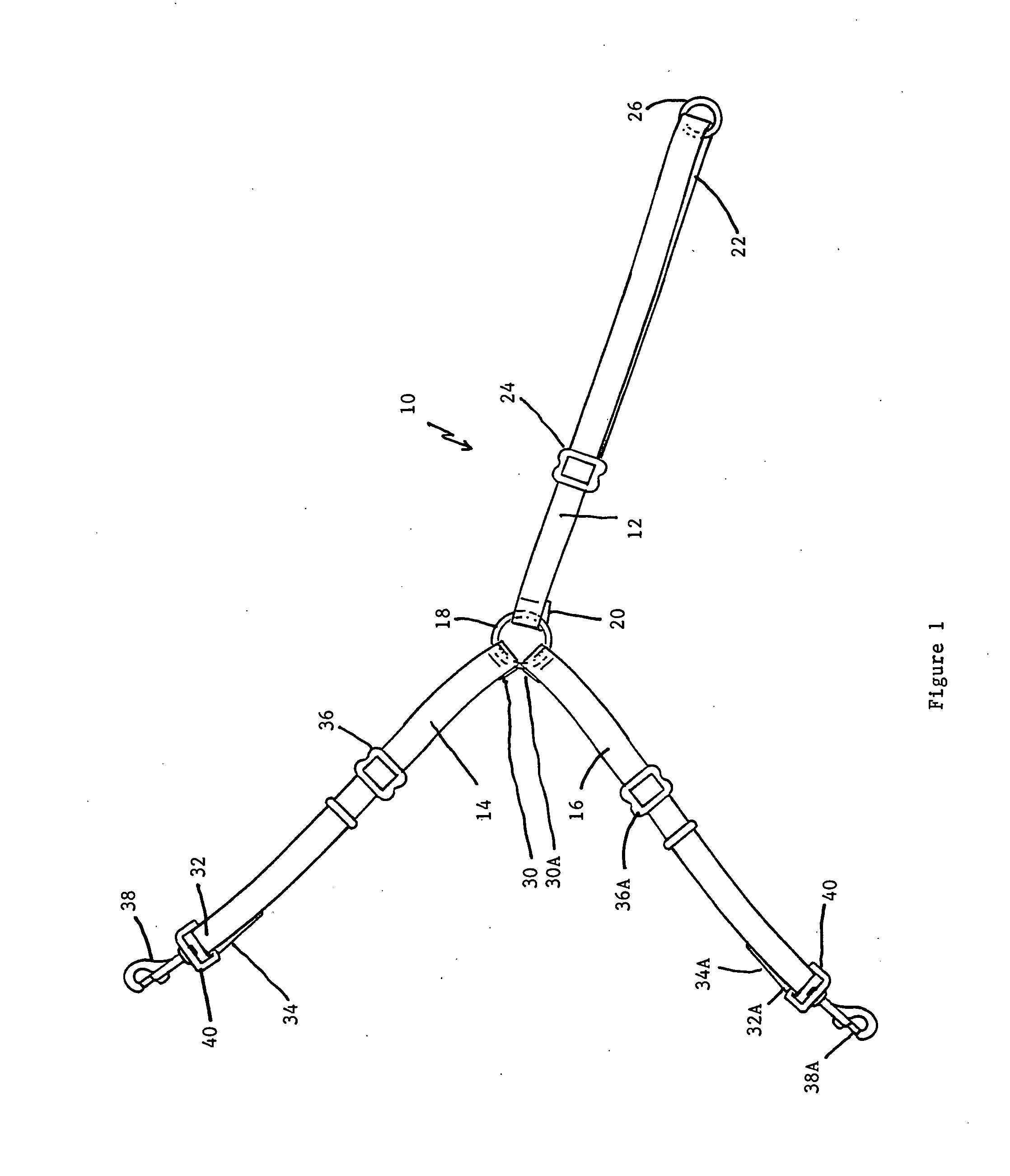

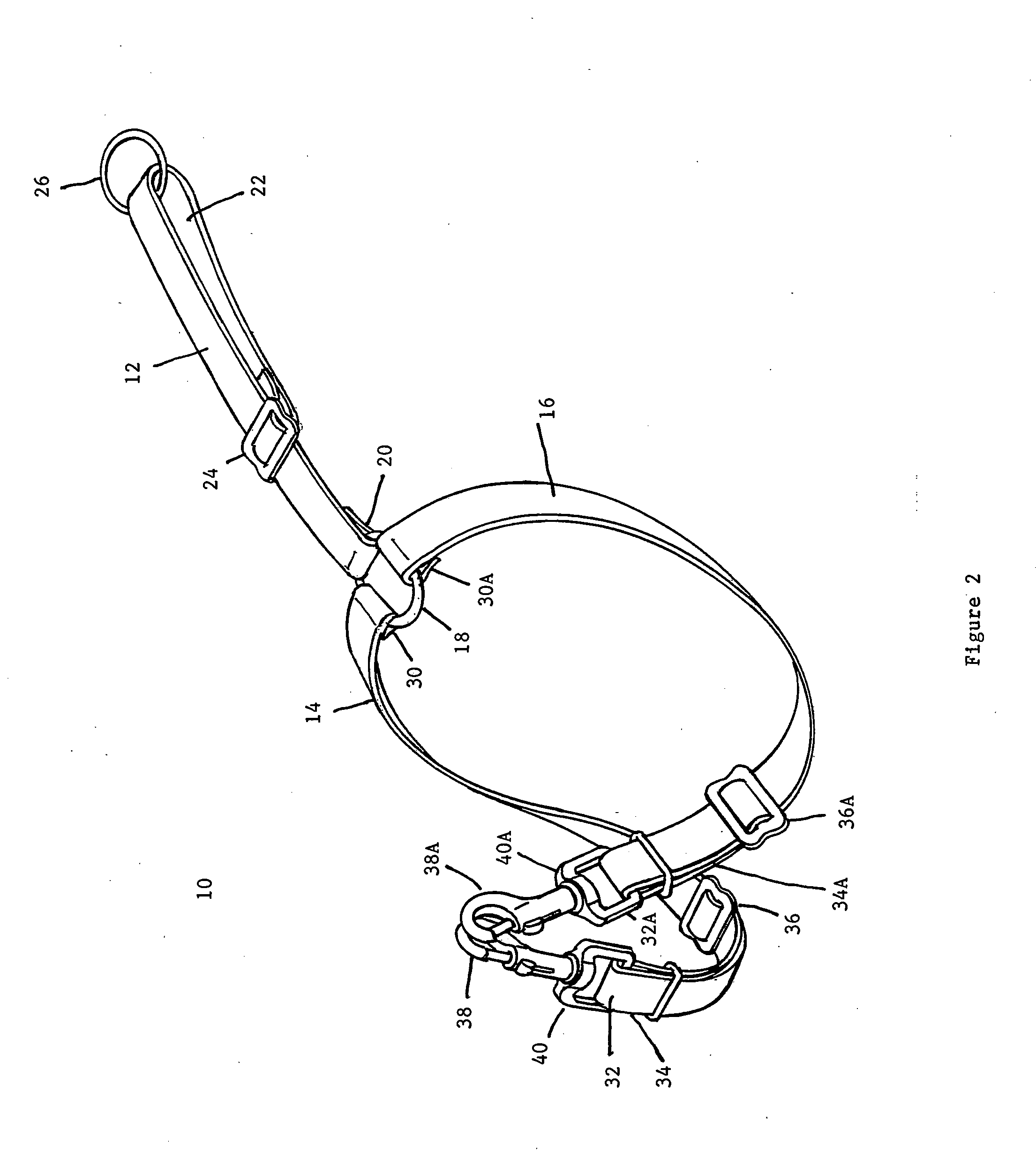

Dog harness

InactiveUS20150114311A1Eliminate pressureRemove tensionTaming and training devicesEngineeringCanis lupus familiaris

A dog harness comprising three flexible adjustable straps secured at a common midpoint, two adjustable flexible straps extending outwardly and under the forelegs of the dog and removably secured to a D-ring secured to the front of the collar of the dog underneath the dogs head, the third flexible adjustable strap having a D-ring secured to the end thereto for removable receipt of a leash, the harness controlling the pace and direction of the dog and also allowing the owner to control the head positioning of the dog without effecting a strain or choke to the dog's neck.

Owner:LYNCH WILLIAM

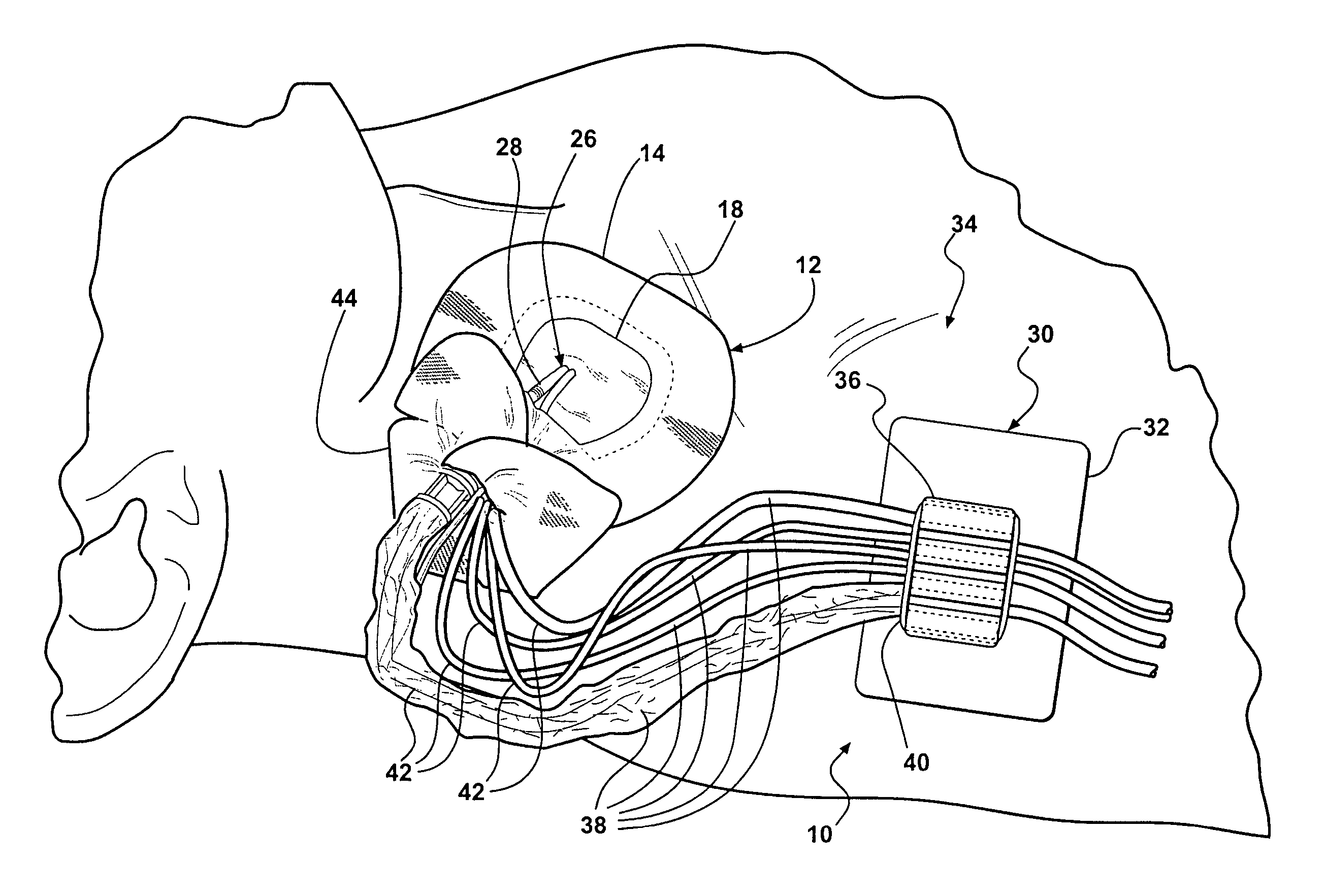

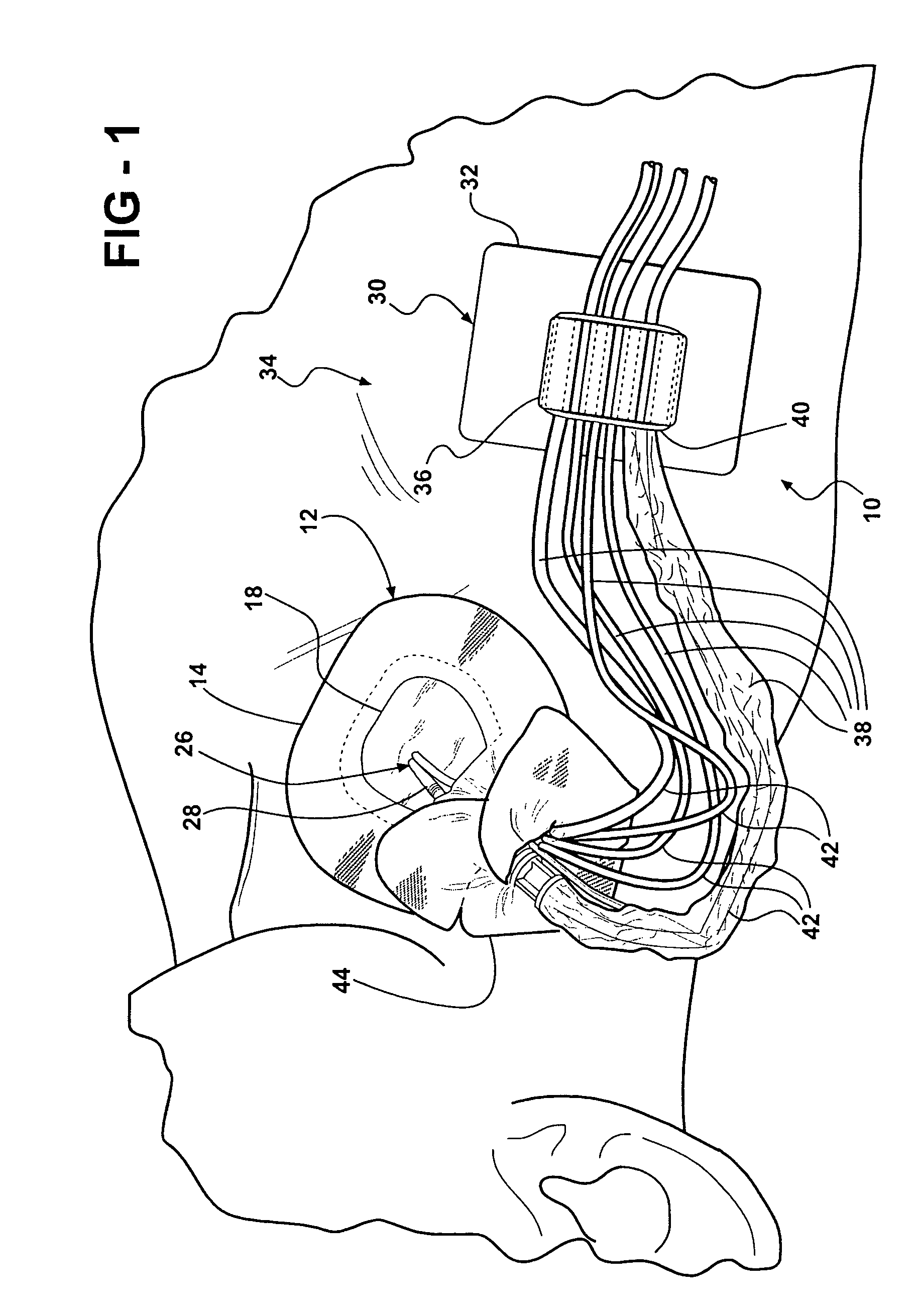

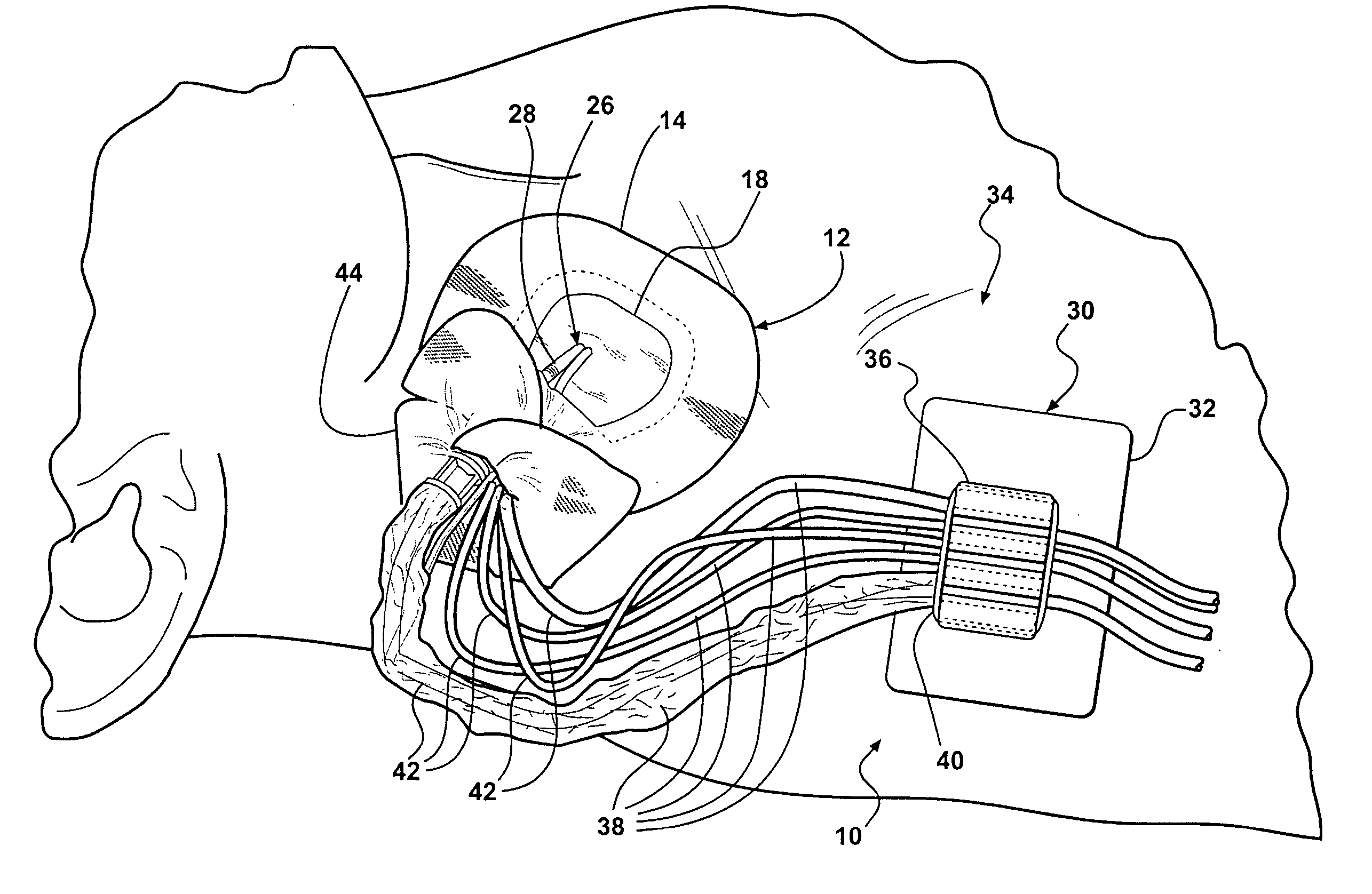

Jugular and subclavian access site dressing, anchoring system and method

ActiveUS7232427B2Eliminate twisting and tearing forceRule out the possibilityDiagnosticsRestraining devicesVeinPull force

A system adapted to tend a jugular or subclavian catheter and connecting tubing includes a jugular and subclavian access site dressing and a medical tubing anchor. The dressing is adapted to protect and cover a catheter access site and the catheter. The medical tubing anchor is spacedly disposed from the dressing. The connecting tubing connects with the catheter and the system allows for movement of the tubing without the tubing exerting a pulling force on the catheter.

Owner:TRI STATE HOSPITAL SUPPLY

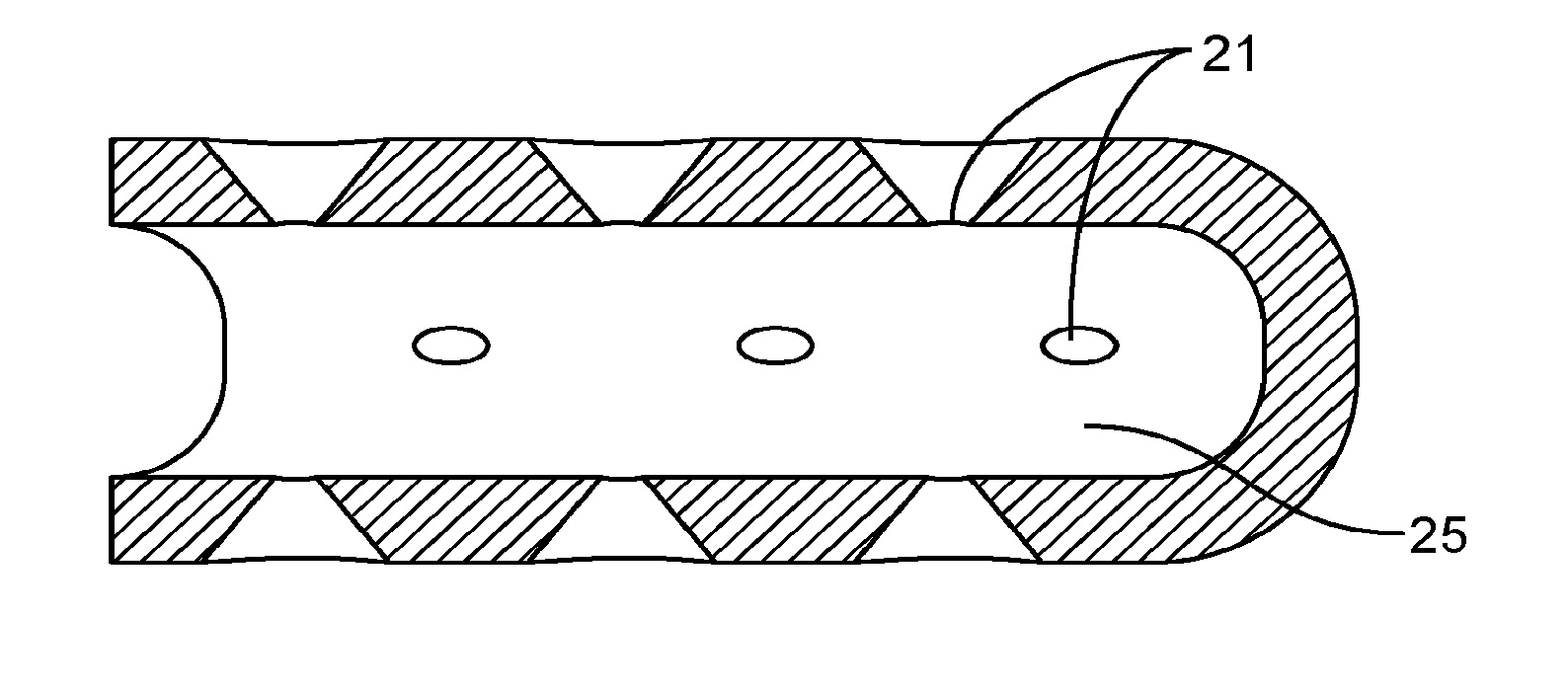

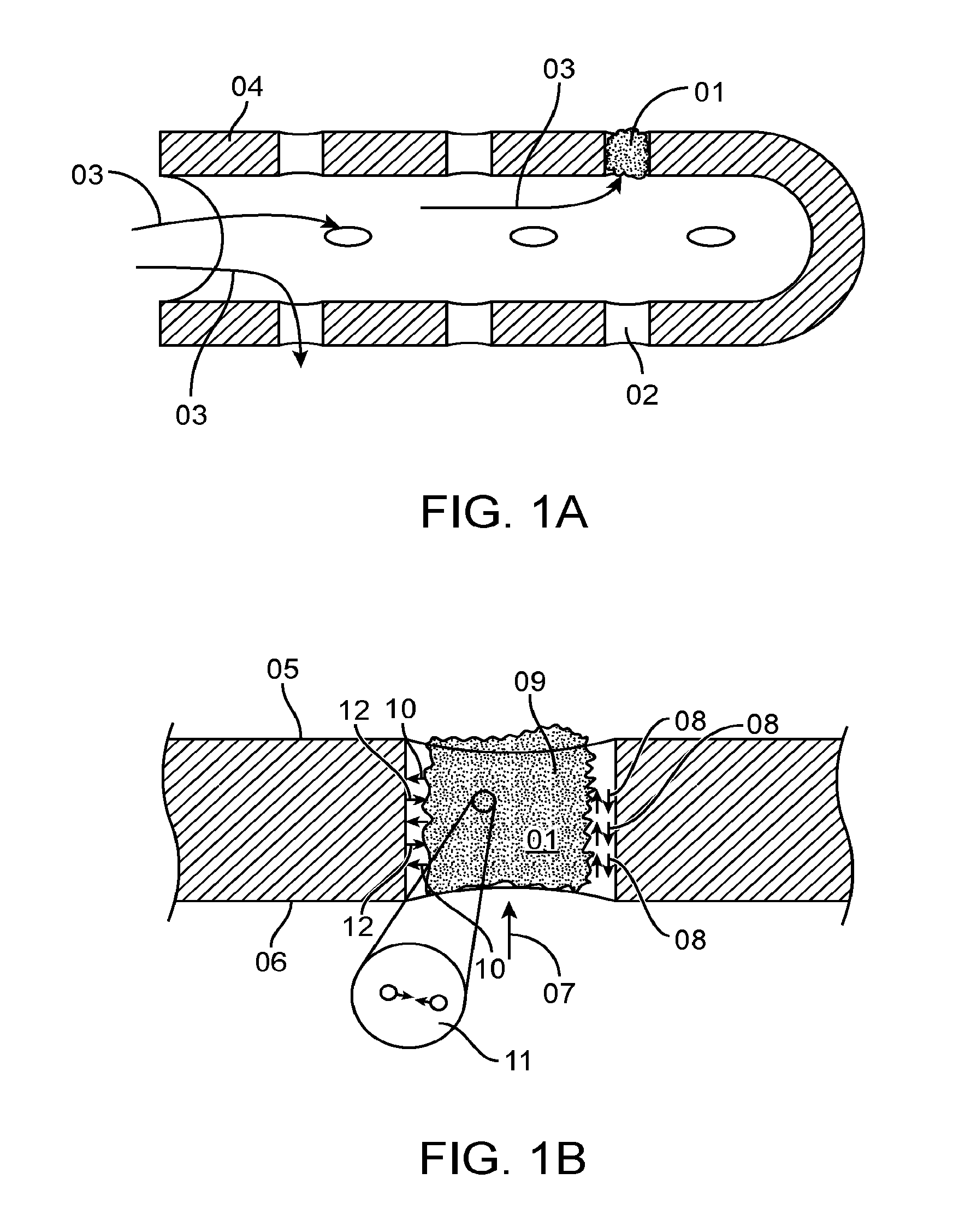

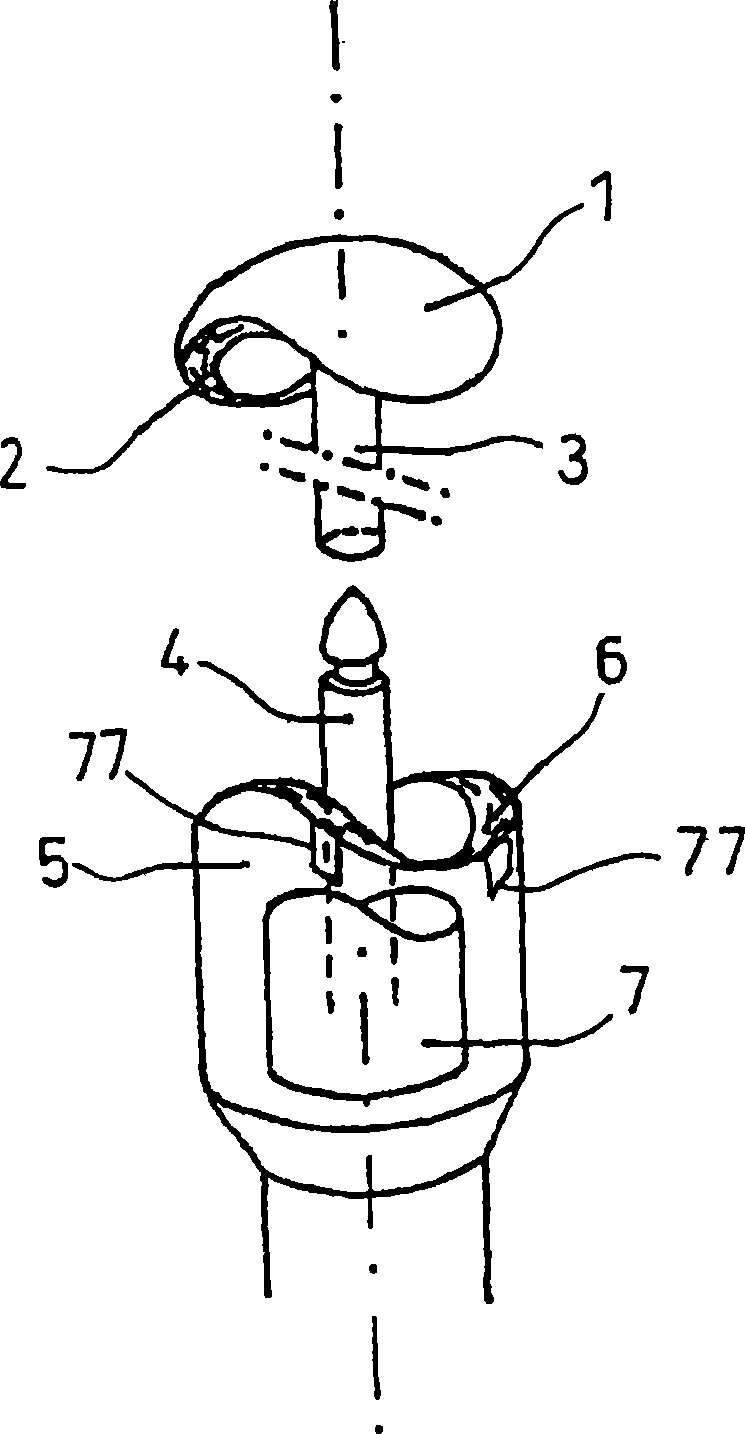

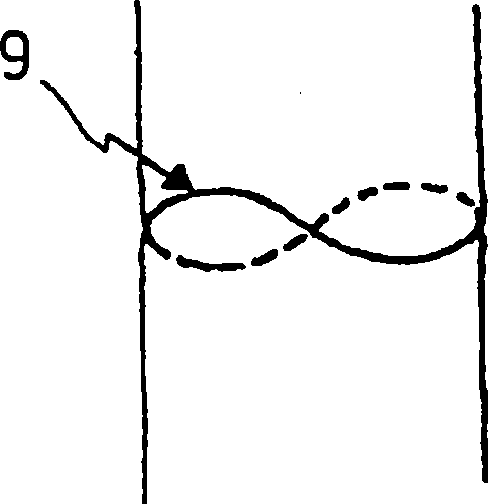

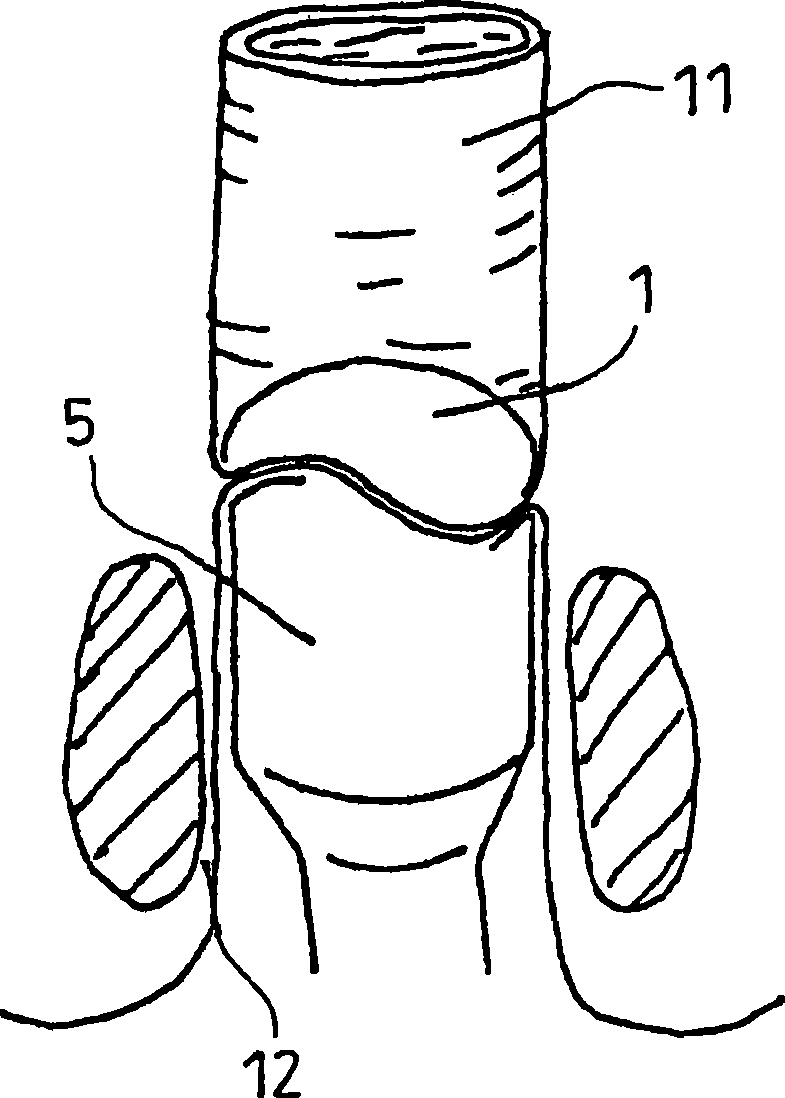

A surgical stapling instrument and a staple cartridge and staple for such an instrument

A surgical stapling instrument comprises a staple fastening assembly (1, 5; 24) including a cartridge device (5; 30) which comprises at least one row of staples (72, 77) and a generally wavy first tissue interface (34), and an anvil (1; 32) which is movable relative to the cartridge device (5; 30) and having a generally wavy second tissue interface (36) adapted to cooperate with the first tissue interface (34) of the cartridge device (5; 30) for clamping tissue therebetween and forming the ends (74) of the staples (72, 77) exiting from the cartridge device (5; 30), a staple driving device (60; 90) adapted to drive the staples (72, 77) out of the cartridge device (5; 30) towards the anvil (1; 32), wherein the staples comprise one or more non-symmetrical U-shaped staples (77) having two legs (78) with free pointed ends (74) facing toward the anvil (1; 32) and a transverse basis (79) connecting the legs (78), wherein said basis (79) is inclined with respect to the longitudinal direction (81) of the legs (78), such that the basis (79) has a length greater then its projection on a plane (80) perpendicular to the longitudinal direction (81) of the legs (78).

Owner:ETHICON ENDO SURGERY INC

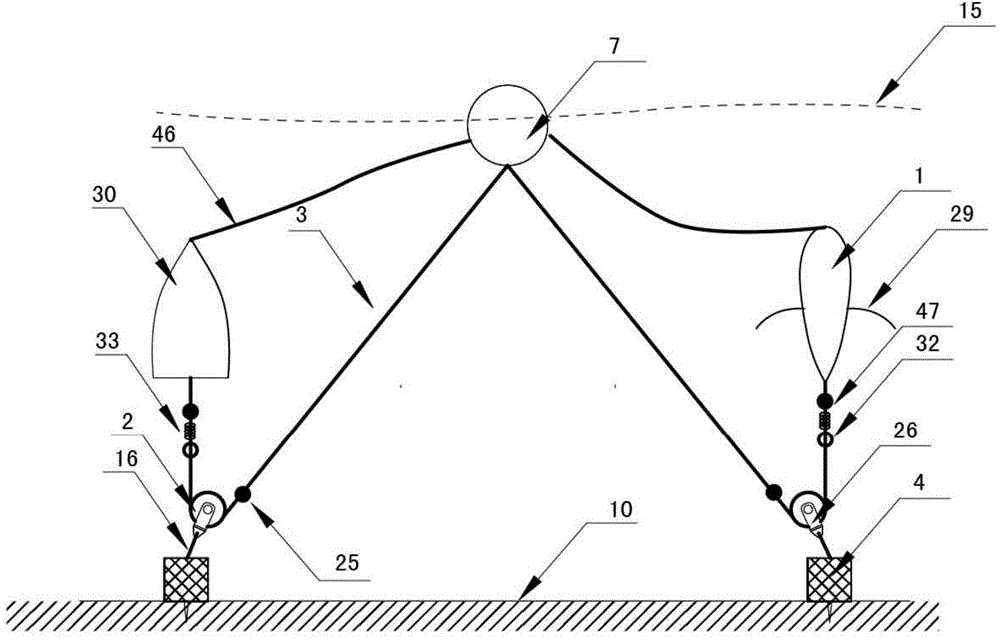

Mooring system with submerged buoys and pulleys

InactiveCN103708002ARemove tensionAvoid canceling each other outAnchoring arrangementsMooring systemBuoy

Owner:曲言明

Jugular and subclavian access site dressing, anchoring system and method

ActiveUS20050277888A1Eliminate twisting and tearing forceRule out the possibilityDiagnosticsRestraining devicesAccess sitePull force

A system adapted to tend a jugular or subclavian catheter and connecting tubing includes a jugular and subclavian access site dressing and a medical tubing anchor. The dressing is adapted to protect and cover a catheter access site and the catheter. The medical tubing anchor is spacedly disposed from the dressing. The connecting tubing connects with the catheter and the system allows for movement of the tubing without the tubing exerting a pulling force on the catheter.

Owner:TRI STATE HOSPITAL SUPPLY

Mooring system with submerged buoys and pulleys

The invention discloses a mooring system with submerged buoys and pulleys. The mooring system comprises submerged buoys / counter weights, pulleys, anchor bases, ropes and rope knots, wherein a chain is tied to each anchor base, and the other end of the chain is tied to a bracket of the corresponding fixed pulley; each rope is wound around the corresponding pulley; one end of each rope is tied to the corresponding submerged buoy, and the other end of the rope is tied to a floating body which needs to be moored; each rope knot is tied to a position on the corresponding rope, between the corresponding pulley and the moored floating body / the anchor base, and close to the pulley. The central floating body which needs to be moored is jointly tightened by the combination of a plurality of anchoring units with submerged buoys / counter weights and pulleys, which are distributed at the periphery of the floating body. Through the adoption of the mooring system, the problems that anchor chains are fractured or the anchor bases slide away due to the rapid increase of mooring force are solved, so that the capability of resisting storms can be provided, and the mooring cost is reduced.

Owner:曲言明

Method for longitudinally cutting side board of liquid crystal glass base plate

ActiveCN104310777AReduce tensionRemove tensionGlass severing apparatusGlass productionEngineeringFlywheel

The invention relates to a method for longitudinally cutting a side board of a liquid crystal glass base plate. The method comprises the steps of clamping the liquid crystal glass base plate by a tooling plate clamping claw, transporting to a longitudinal cutting station, clamping the liquid crystal glass base plate by a front leaning part and a rear leaning part of a longitudinal cutting machine, opening the tooling plate clamping claw, longitudinally cutting the side board of the liquid crystal glass base plate from top to bottom by knife flywheels at two sides of the longitudinal cutting machine, restarting the clamping claw to clamp the liquid crystal glass base plate after cutting, opening a sealing strip of the front leaning part of the longitudinal cutting machine, breaking off the glass base plate through suction cups at two sides of a cutting board strip of the rear leaning part of the longitudinal cutting machine, resetting the knife flywheels at two sides of the longitudinal cutting machine after the glass base plate is broken out, opening the suction cups at two sides of the cutting board strip of the rear leaning part of the longitudinal cutting machine, and transporting the broken liquid crystal glass base plate to the next station by a conveyer belt. The upward pulling force of the claw to the glass base plate is reduced and the glass base plate is prevented from breaking during cutting; and besides, only the sealing strip of the front leaning part is loosened during breaking off, so that the liquid crystal glass base plate is prevented from being scratched because of contacting with the longitudinal cutting machine during breaking off.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

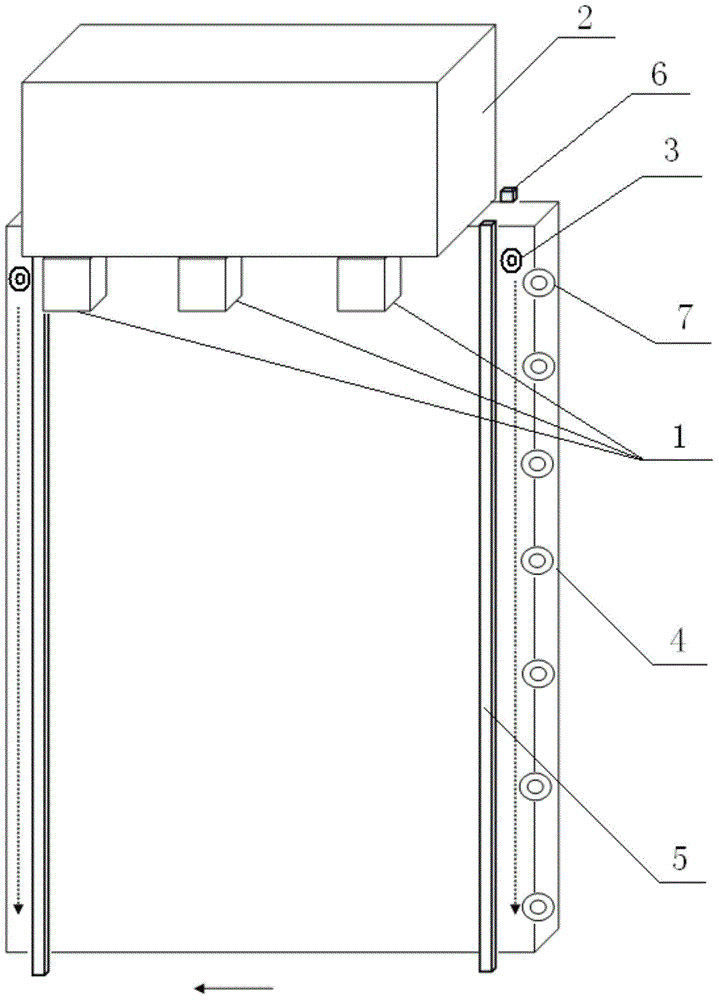

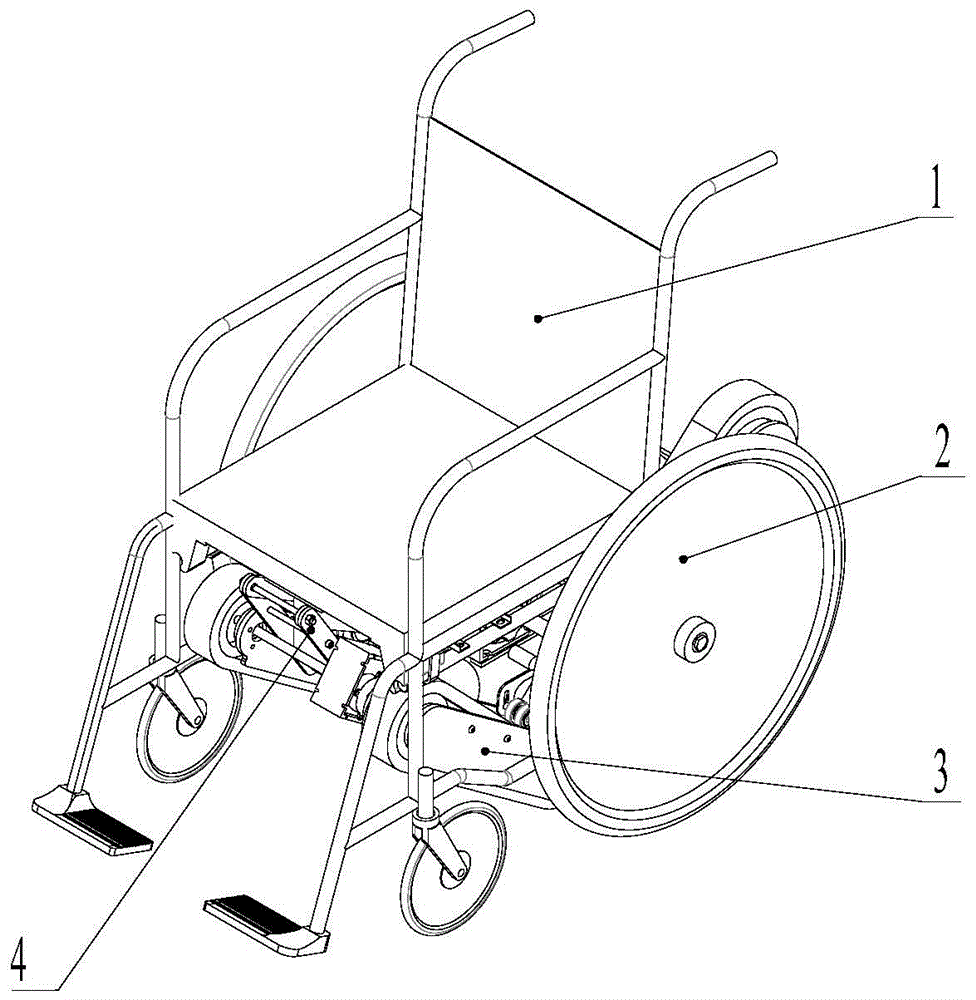

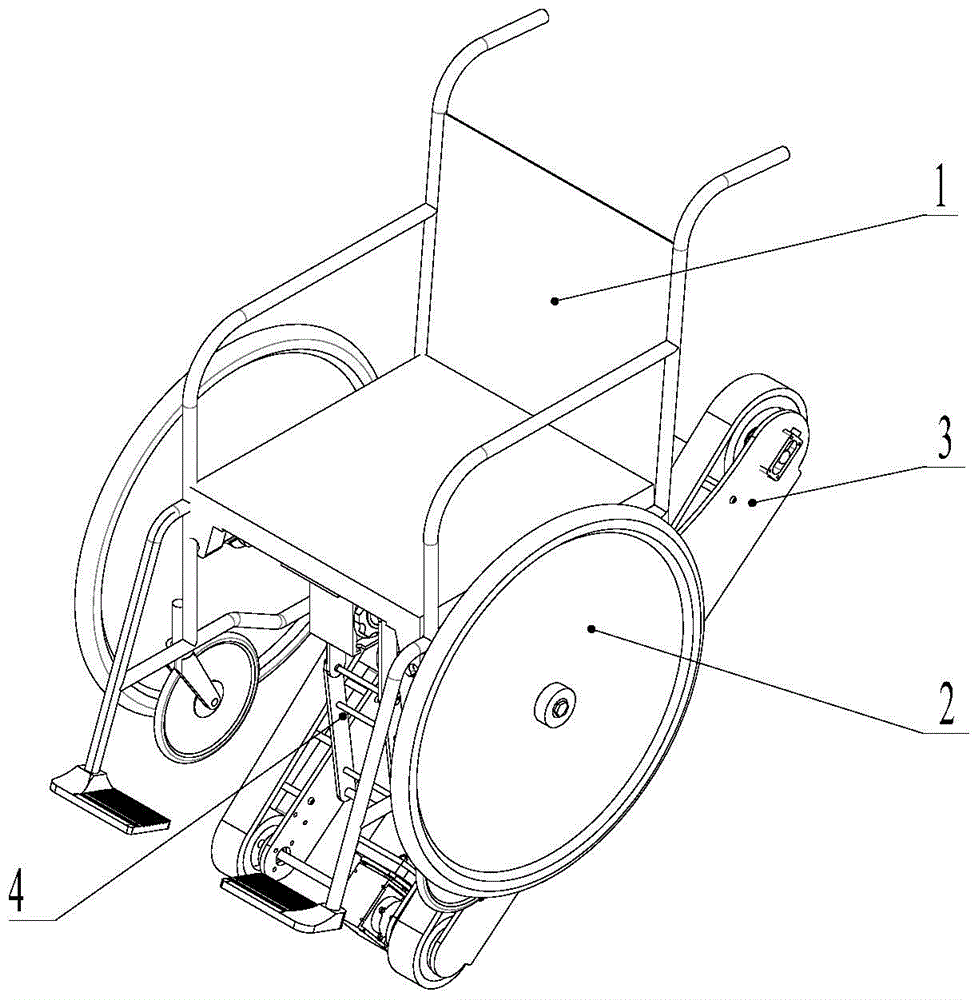

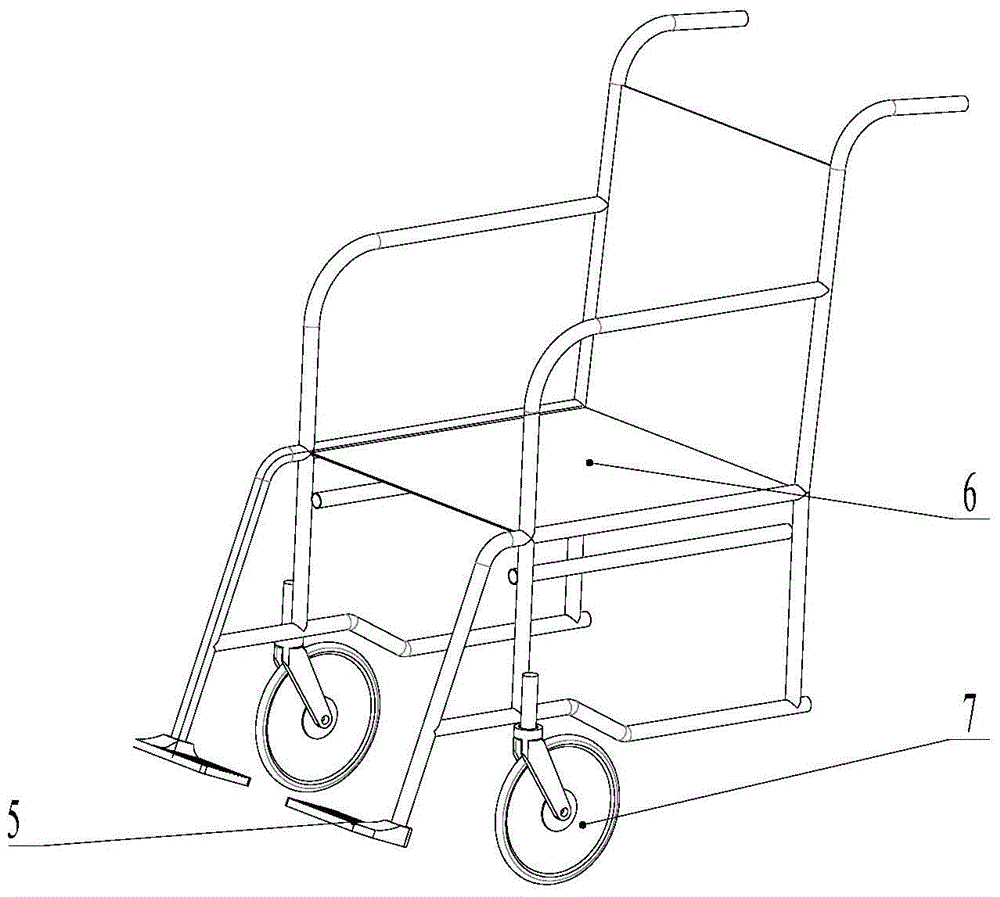

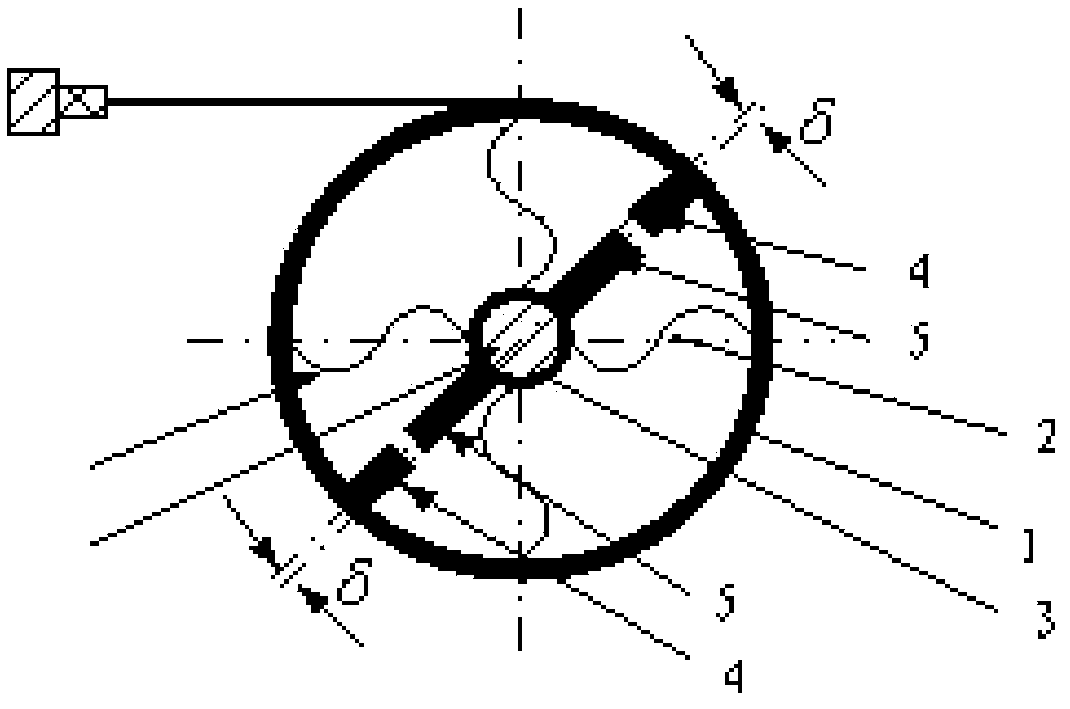

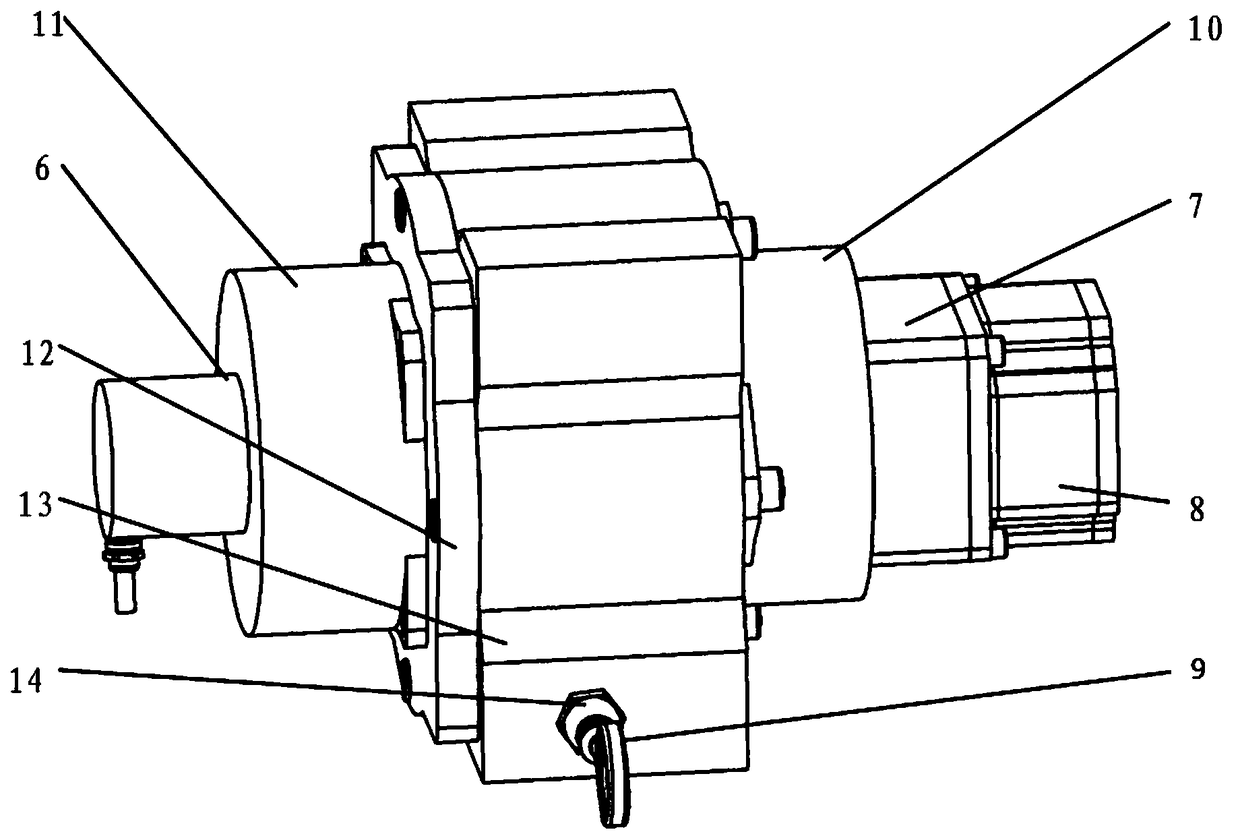

Double-section double-caterpillar-band stair climbing wheelchair based on travelling wheel swing and method for going upstairs and downstairs

InactiveCN105726232AEasy to use when going outFlexible walking on flat groundWheelchairs/patient conveyanceStairs climbedEngineering

The invention discloses a double-section double-caterpillar-band stair climbing wheelchair based on travelling wheel swing and a method for going upstairs and downstairs.The stair climbing wheelchair comprises a wheelchair body, two big traveling wheels, a caterpillar band stair climbing mechanism and a big wheel swing arm mechanism; the caterpillar band stair climbing mechanism comprises double caterpillar band mechanisms, and the caterpillar band mechanism at each side comprises a mechanism front segment, a mechanism rear segment and a rubber caterpillar band, wherein the mechanism front segment and the mechanism rear segment are hinged through a bearing axle into a whole mechanism for installing the rubber caterpillar band.After the caterpillar band stair climbing mechanism is folded on the flat ground, the outer sides of the caterpillar bands are supported by supporting bearings, the caterpillar bands are in a slightly slack state, which is beneficial for prolonging service life of the caterpillar bands, and the step that at ordinary times, when the caterpillar bands are not used for going upstairs and downstairs for a long time, a caterpillar band tensioning mechanism is adjusted repeatedly to remove tension force on the caterpillar bands is omitted.

Owner:SHANDONG UNIV OF SCI & TECH

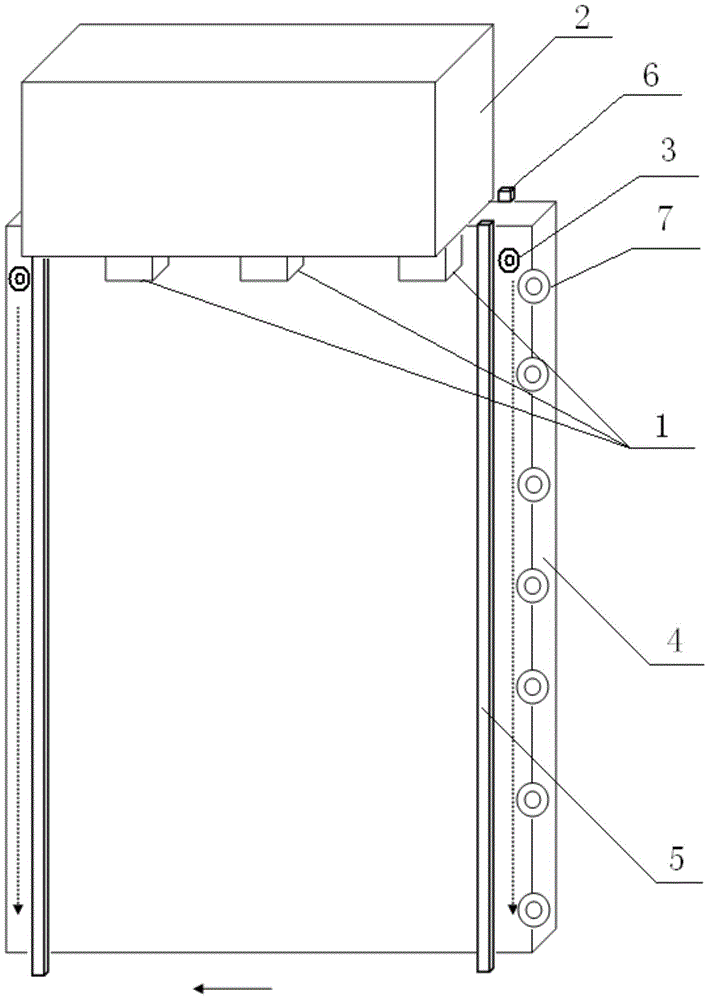

Force closed-loop large linear displacement sensor

The invention discloses a force closed-loop large linear displacement sensor. A wire rope is wound on a first flexible wheel, the centers of the first flexible wheel and a second flexible wheel are coincident, two light-emitting diodes are mounted on the inner side of the first flexible wheel, two photoresistors are mounted on the outer side of the second flexible wheel, two light-emitting diodesare on a straight line passing through the center of the circle, the two photoresistors are on the straight line passing through the center of the circle, the two straight lines are not coincident, aflexible spoke is located between the first flexible wheel and the second flexible wheel, the flexible spoke is S-shaped, when the wire rope is pulled, the flexible spoke is deformed, the positions ofthe photoresistors and the light-emitting diodes are relatively changed, one side of the second flexible wheel is connected to an encoder, the other side is connected to a speed reducer, and the other side of the speed reducer is connected to a stepping motor. The sensor can improve the accuracy of the displacement measurement and eliminate the limitation of the tension of a traditional open-looppulling line large displacement sensor and a measurement length.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

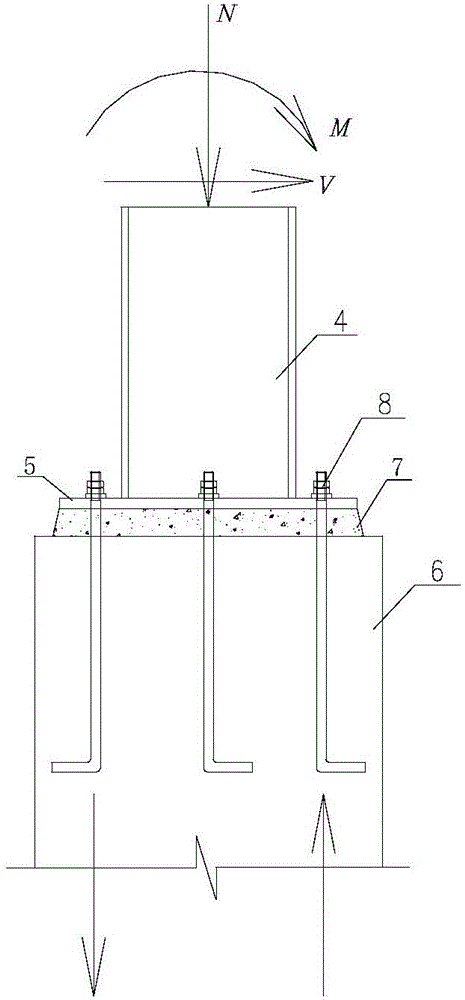

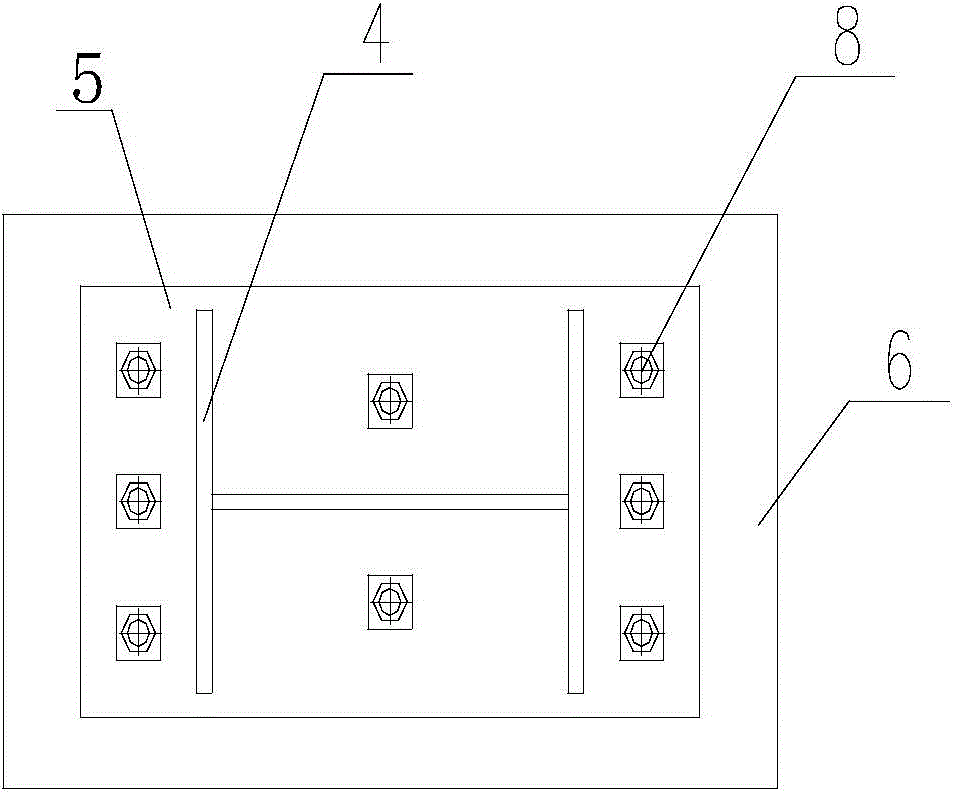

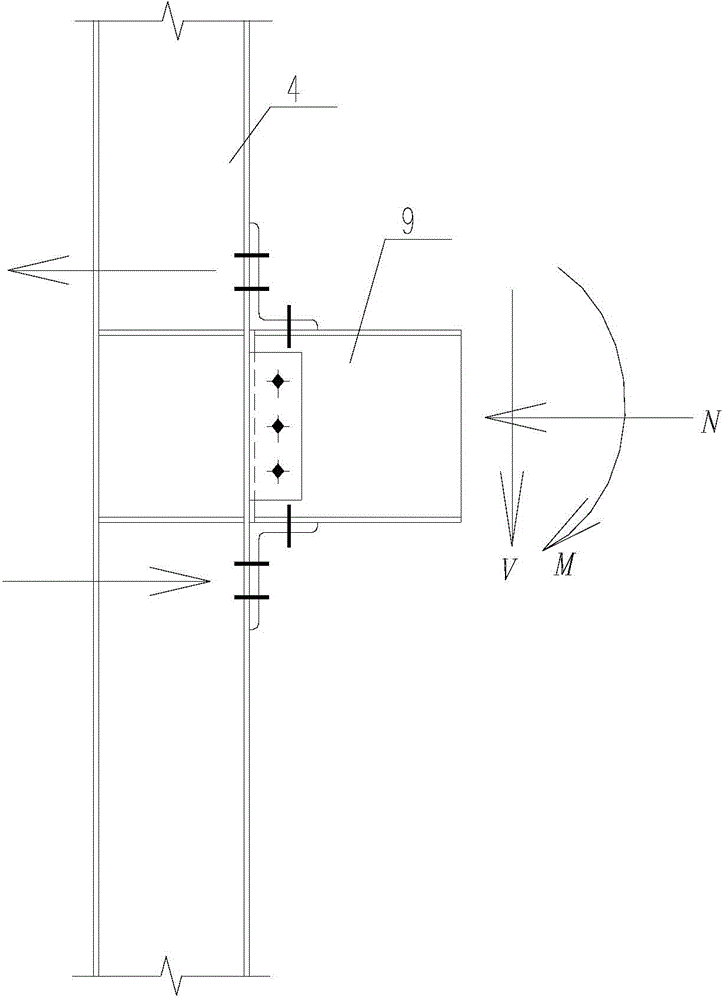

Connection device and connection method for preventing steel structure column foot from being tensioned

InactiveCN103603433AReduce dosageIncrease safety redundancyFoundation engineeringBuilding constructionsSteel columnsEngineering

Owner:江苏祥珑石业有限公司

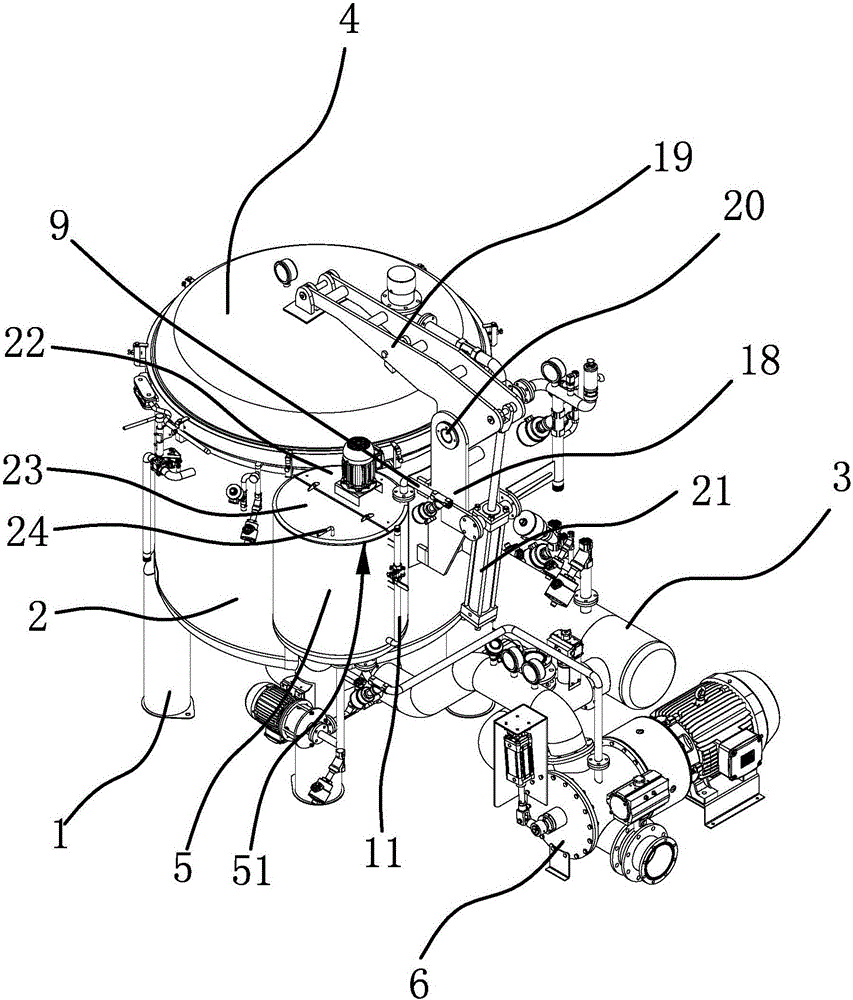

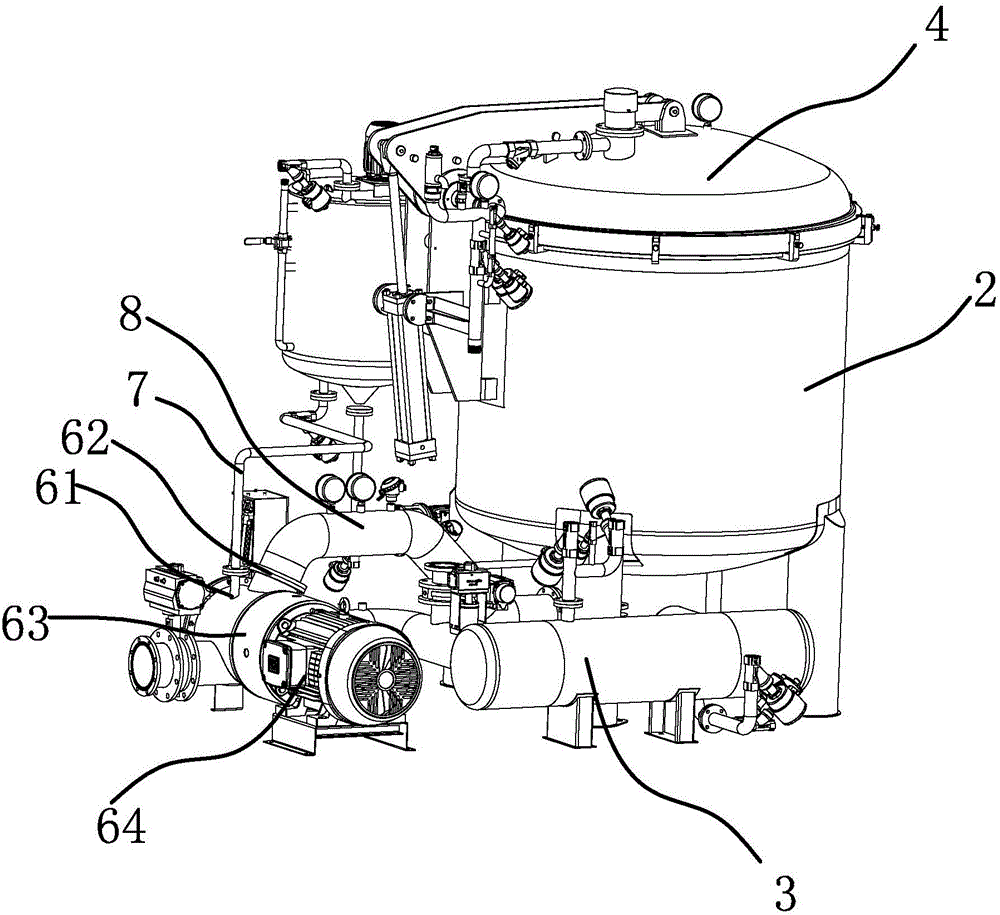

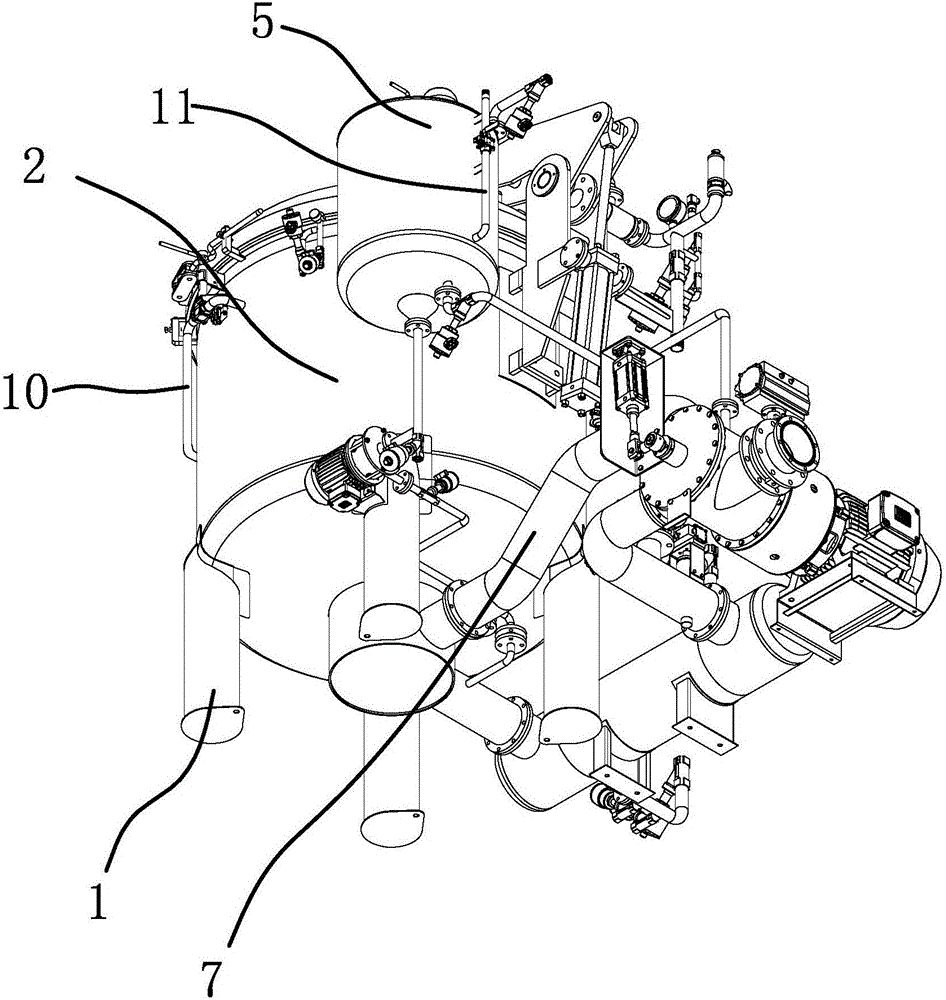

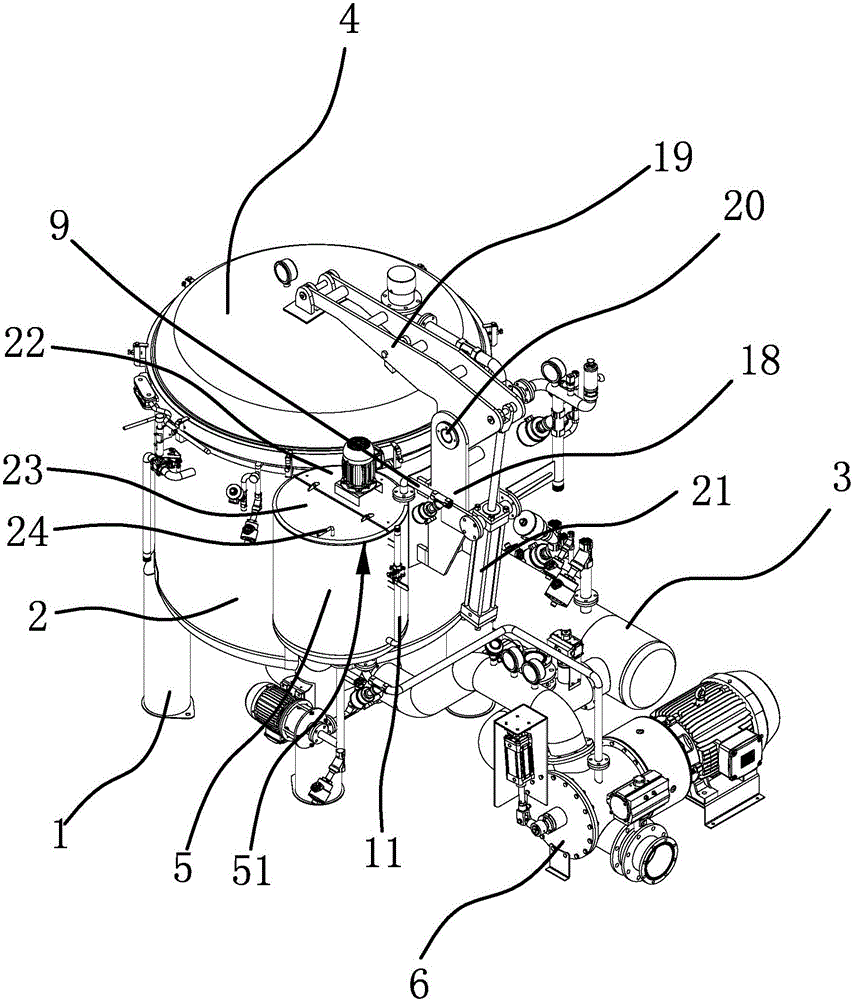

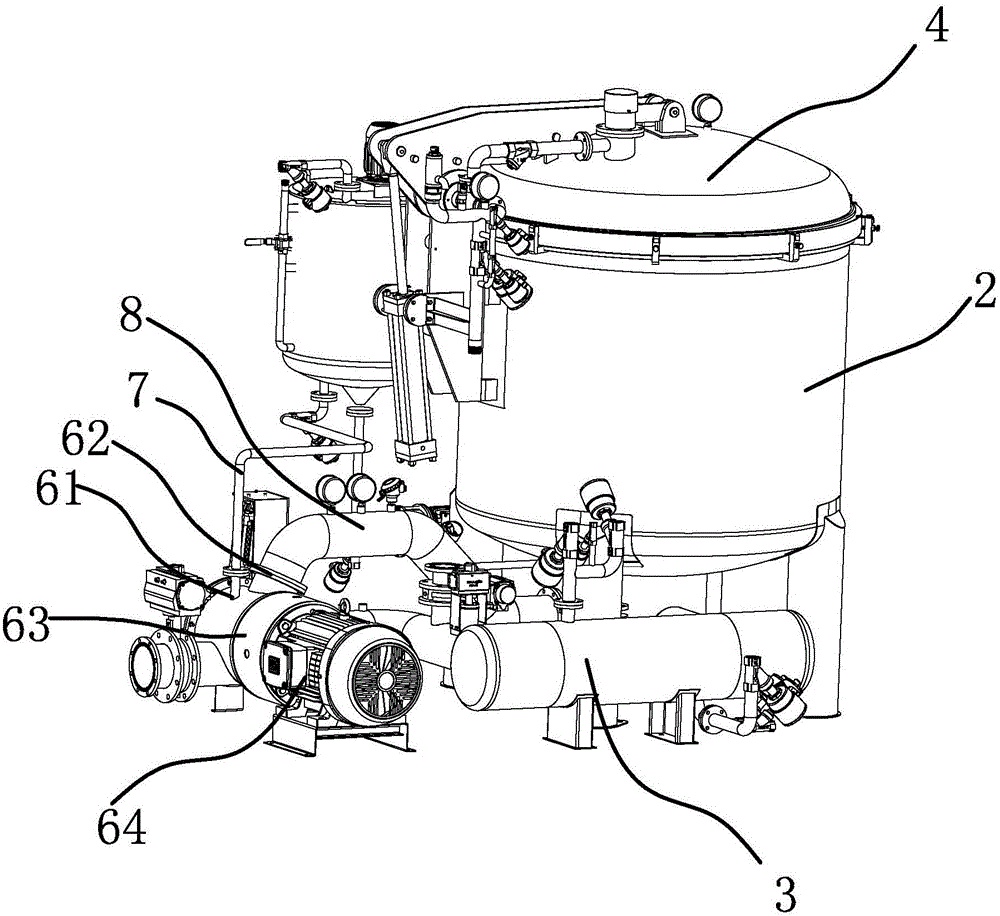

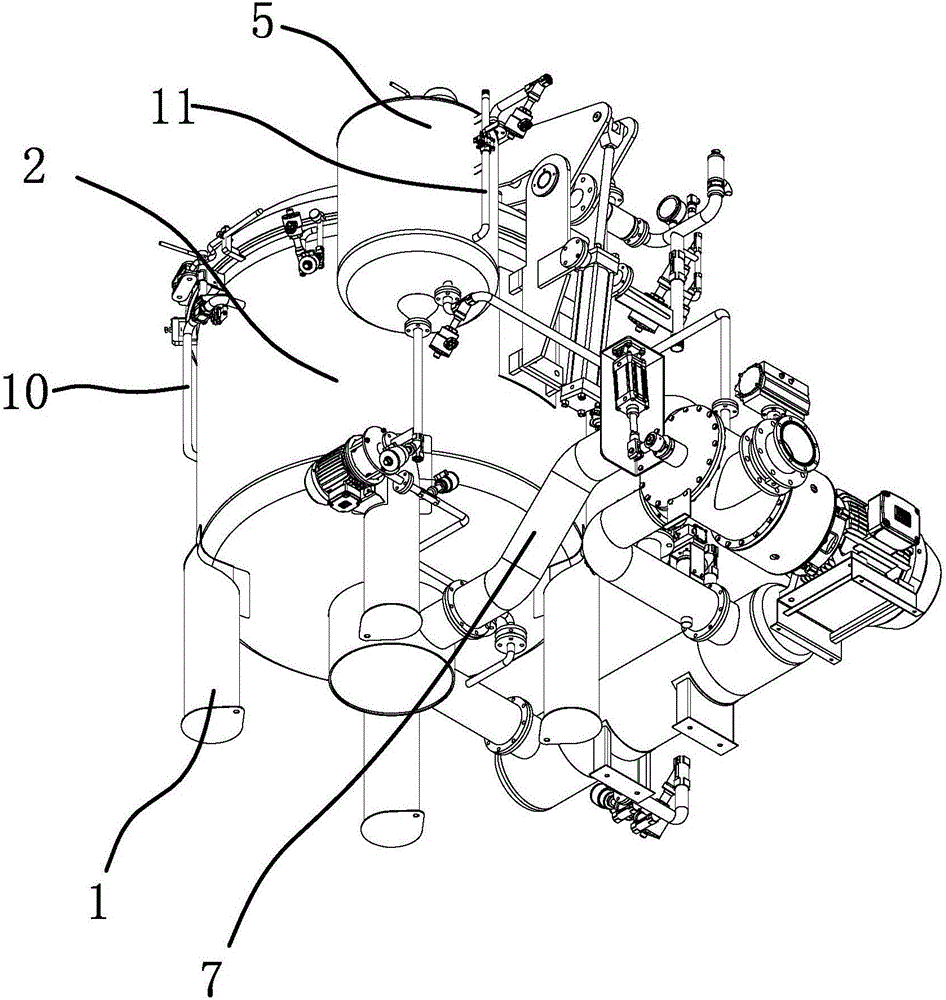

Yarn dyeing device and method

InactiveCN105839318AImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsDyeingYarn

The invention provides a yarn dyeing device, belongs to the technical field of equipment related to spinning, and solves the technical problems that an existing yarn dyeing device is low in efficiency, inconvenient to use, and the like. The yarn dyeing device comprises a frame, a dyeing barrel, an air compressor, a liquid preparing barrel and a filter, wherein the dyeing barrel is arranged on the frame, and the air compressor is communicated with a cavity in the dyeing barrel; the upper end of the dyeing barrel is provided with an openable barrel cover; the upper end of the liquid preparing barrel is provided with an opening, and the lower end of the liquid preparing barrel is connected with a first liquid pipe communicating the liquid preparing barrel and the dyeing barrel; the filter is respectively provided with an inlet and an outlet, the lower end of the dyeing barrel is connected with a second liquid pipe connected with the inlet of the filter, and the outlet of the filter is connected with a third liquid pipe communicating the filter and the liquid preparing barrel; the dyeing barrel is provided with a first liquid level meter capable of displaying the liquid level in the dyeing barrel; the liquid preparing barrel is provided with a second liquid level meter capable of displaying the liquid level in the liquid preparing barrel. By the dyeing device, efficiency is increased, and energy conservation and environment protection are achieved.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

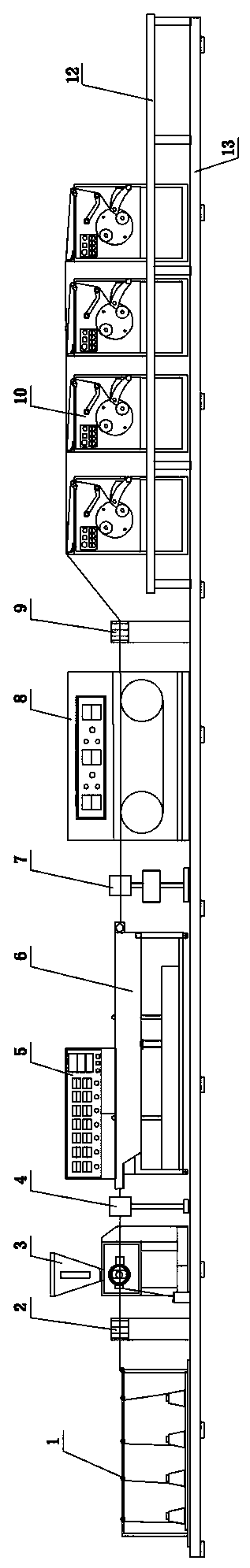

Plastic-covered silk thread production line

PendingCN109877000ARemove tensionQuality assuranceLiquid surface applicatorsCoatingsYarnProduction line

The invention discloses a plastic-covered silk thread production line. The plastic-covered silk thread production line comprises a yarn frame, thread guide frames, an extrusion unit, a diameter measurement instrument, a circular cooling water groove, a dryer, a traction machine, a take-up unit and a control cabinet; at least two rolls of silk threads to be covered are wound on the yarn frame, theextrusion unit is arranged on the rear side of the yarn frame in a spaced manner, when the silk threads penetrate through an extrusion film of an extruder, the plastic-covered silk thread is formed, the circular cooling water groove is arranged on the rear side of the extrusion unit in a spaced manner, a curing plastic layer of the plastic-covered silk thread is cooled, the dryer is arranged on the rear side of the circular cooling water groove in a spaced manner, and the dryer dries the plastic-covered silk thread; the traction machine is arranged on the rear side of the dryer in a spaced manner, and therefore, the plastic-covered silk thread is conveniently and backwards pulled out; the take-up unit is arranged on the rear side of the traction machine in a spaced manner, and is used forwinding finished product plastic-covered silk thread, the two thread guide frames are included, and the diameter measurement instrument is arranged on the rear side of the extrusion unit in a spaced manner, and is used for measuring the outer diameter of the plastic-covered silk thread. The production efficiency is greatly improved, the silk thread quality is effectively ensured, the production thread changing frequency is reduced, and production cost is reduced.

Owner:苟举才

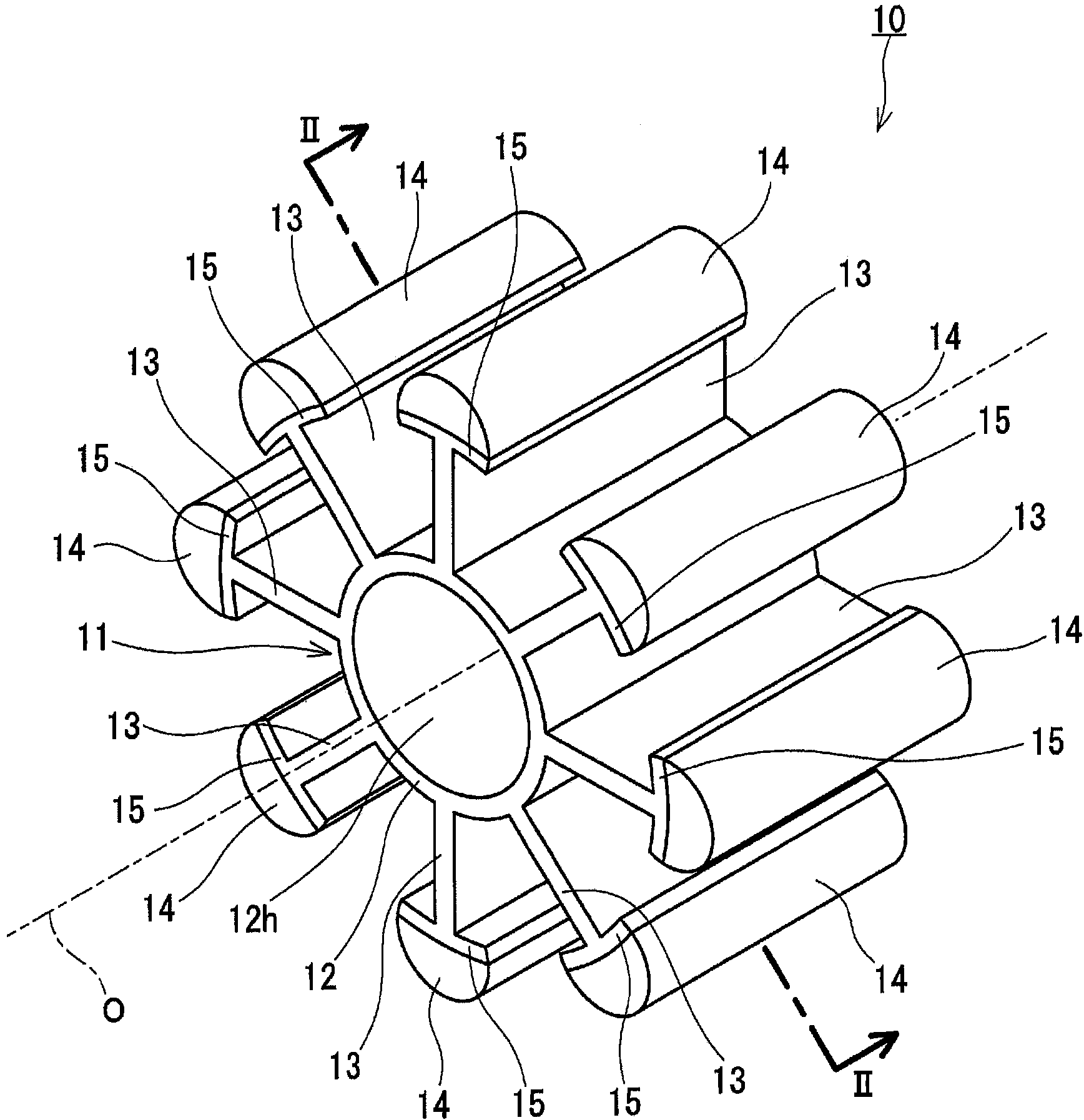

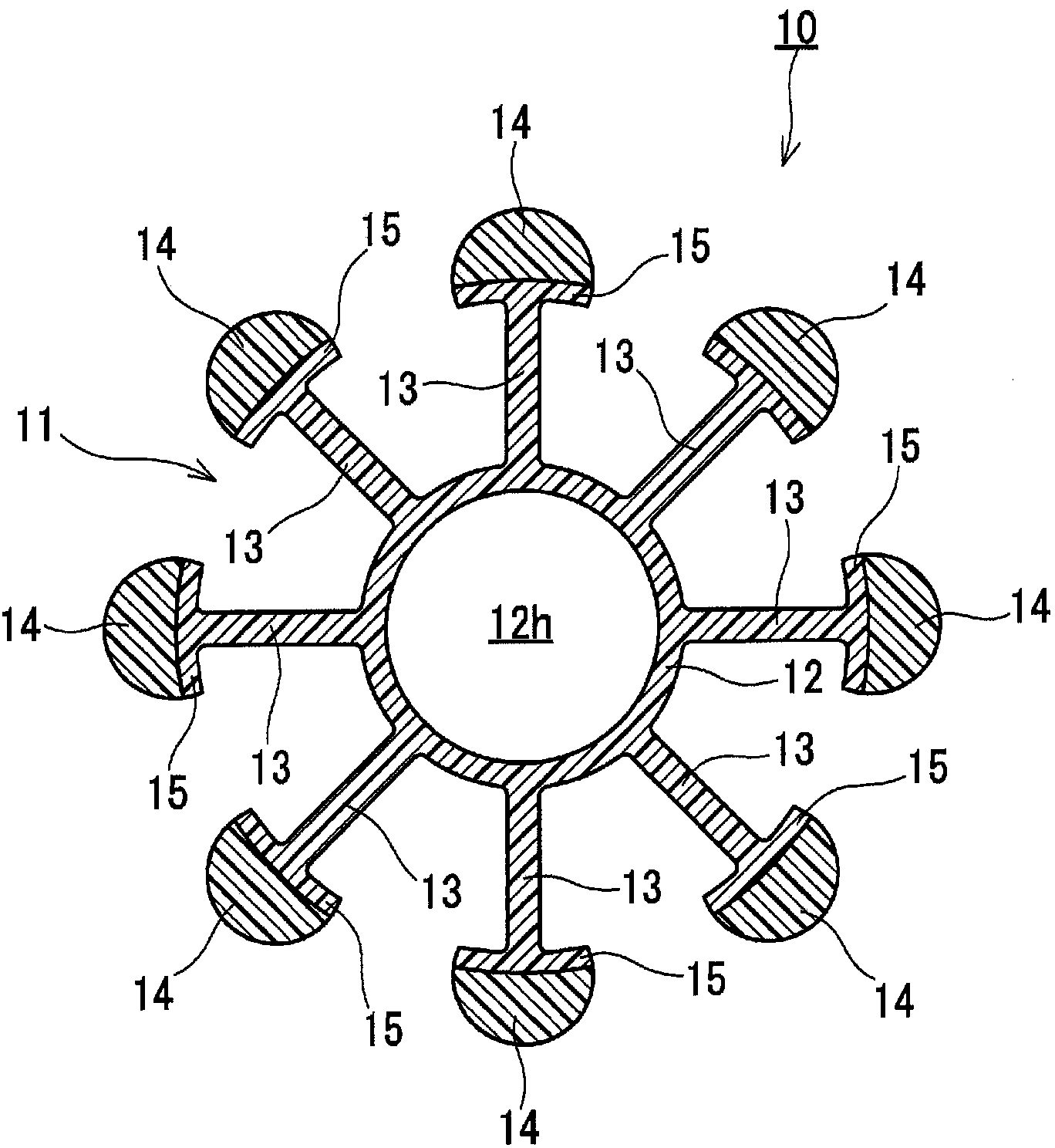

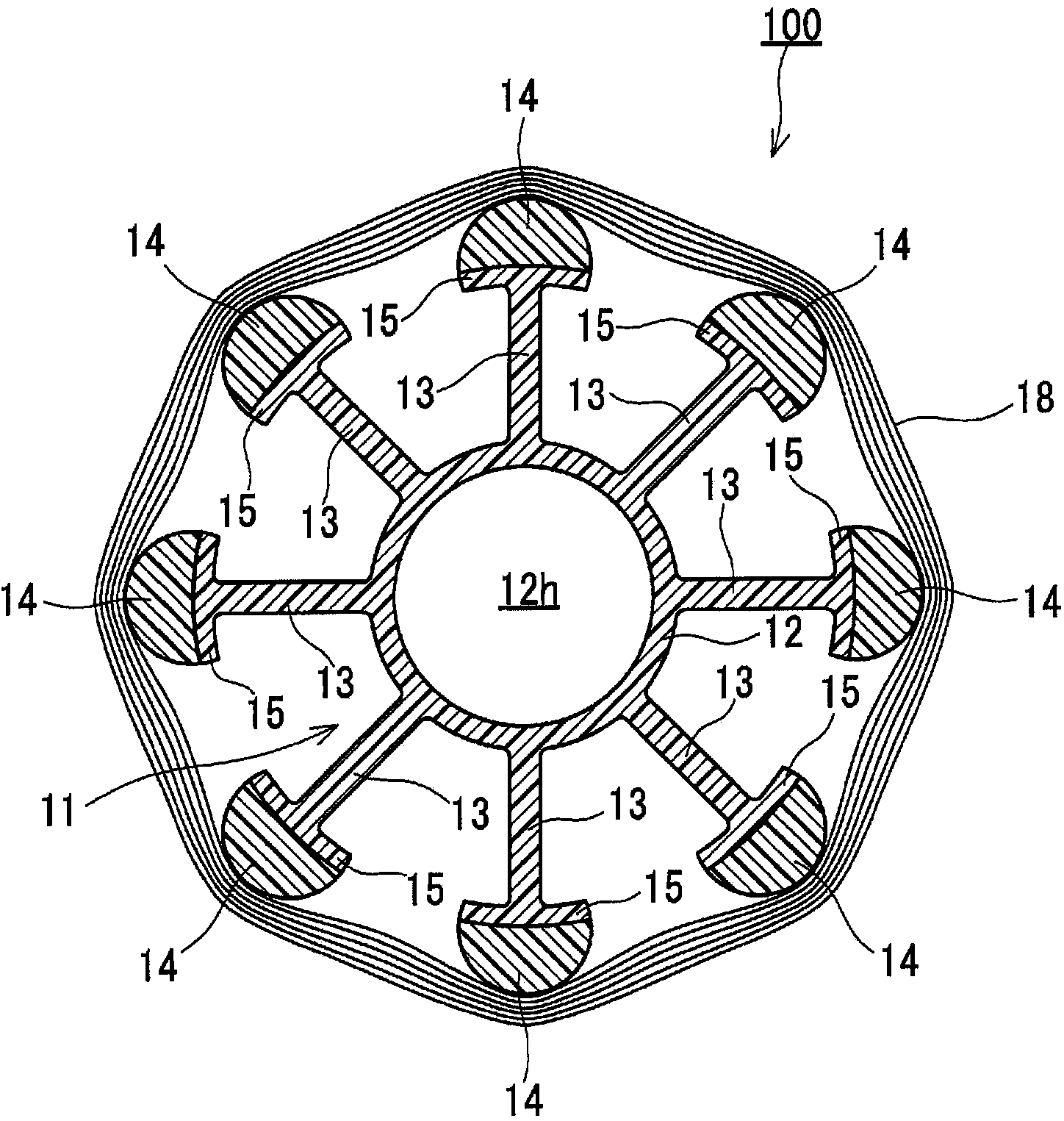

Film winding core, and wound film body using same

A film winding core (10) has: a cylindrical bearing portion (12); a plurality of blade portions (13) extending from the bearing portion (12) in the radial direction thereof; one or a plurality of rim portions (15, 15b, 15d) provided on the tips of the blade portions (13); and a plurality of film support portions (14) that are fixed to the rim portion (15, 15b, 15d) and that support a film (18). The support portions (14) comprise an elastic material such as sponge, rubber, or foam, and are in the shape of a semi-cylinder, a rectangular column, or a hollow semi-cylinder.

Owner:NITTO DENKO CORP

Yarn dyeing method

ActiveCN105821613AImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

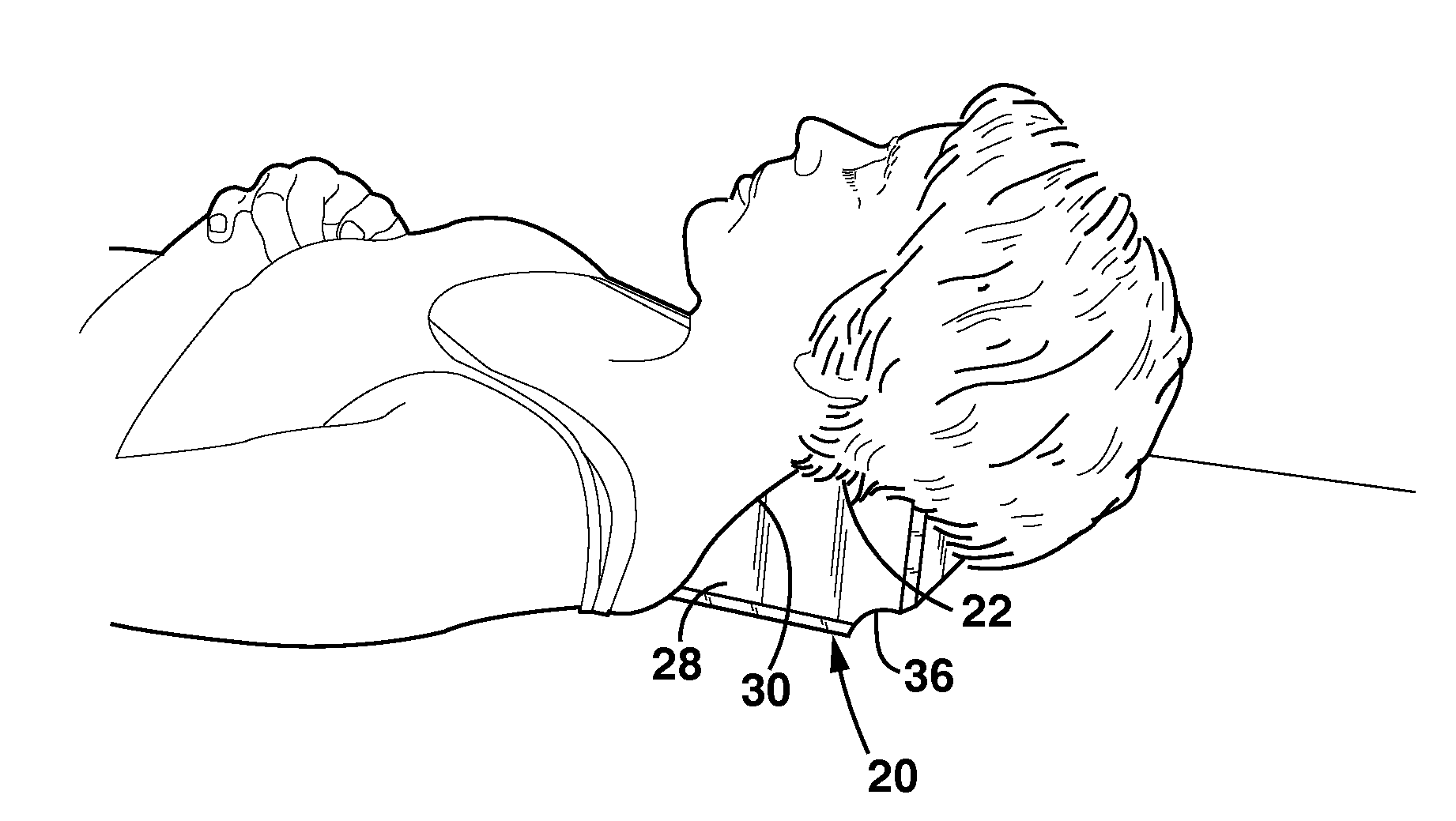

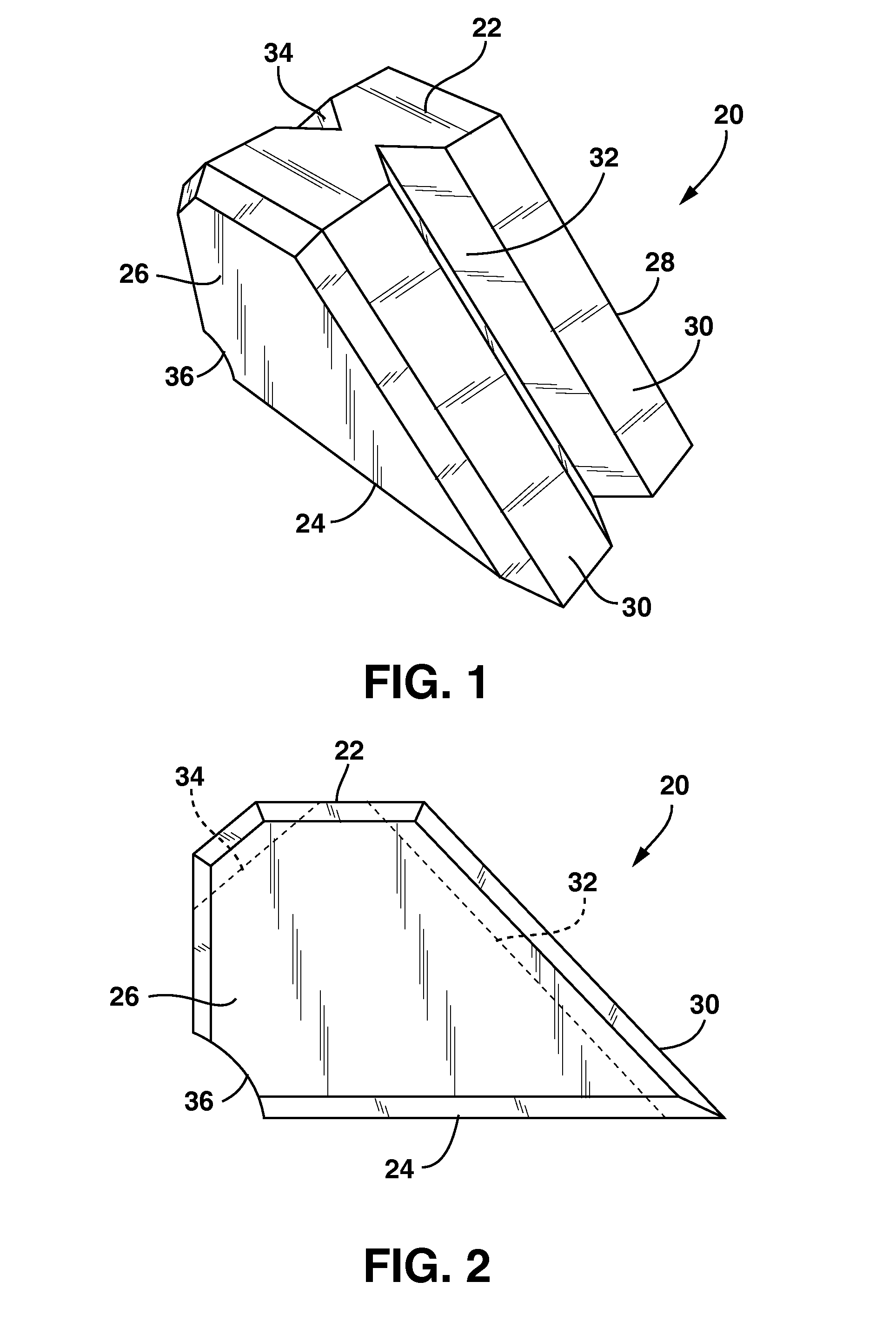

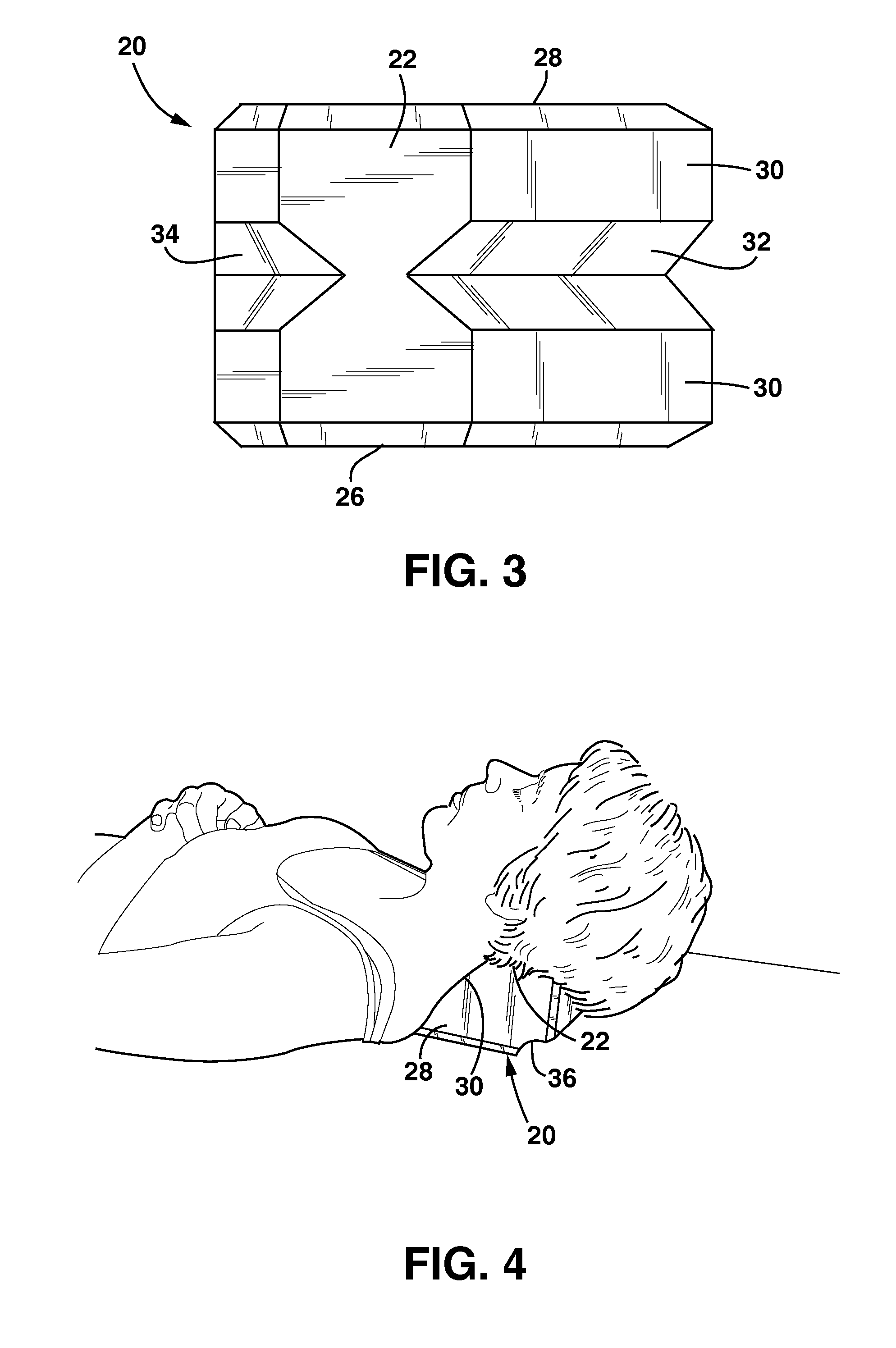

Decompression traction device and method

InactiveUS20100286729A1Enhance traction and decompressionEliminate stressChiropractic devicesNursing bedsEngineeringHead and neck

A device and method is disclosed for removing or otherwise ameliorating tension from the human body. The device having a body (20) a top or cusp (22) a bottom (24) and at least one inclined surface (30). Whereby a person lays on a flat surface supporting their head and neck on the body (20) for a period of time therewith decompressing tension from their body.

Owner:HAUGEN MATTHEW WILLIAM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com