Wellbore plug and method

a wellbore and plug technology, applied in the direction of wellbore/well accessories, fluid removal, sealing/packing, etc., can solve the problems of substantially higher setting force, inducing tension and compressive stresses in the mandrel, and affecting the operation of the plug, so as to achieve the effect of eliminating tension stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

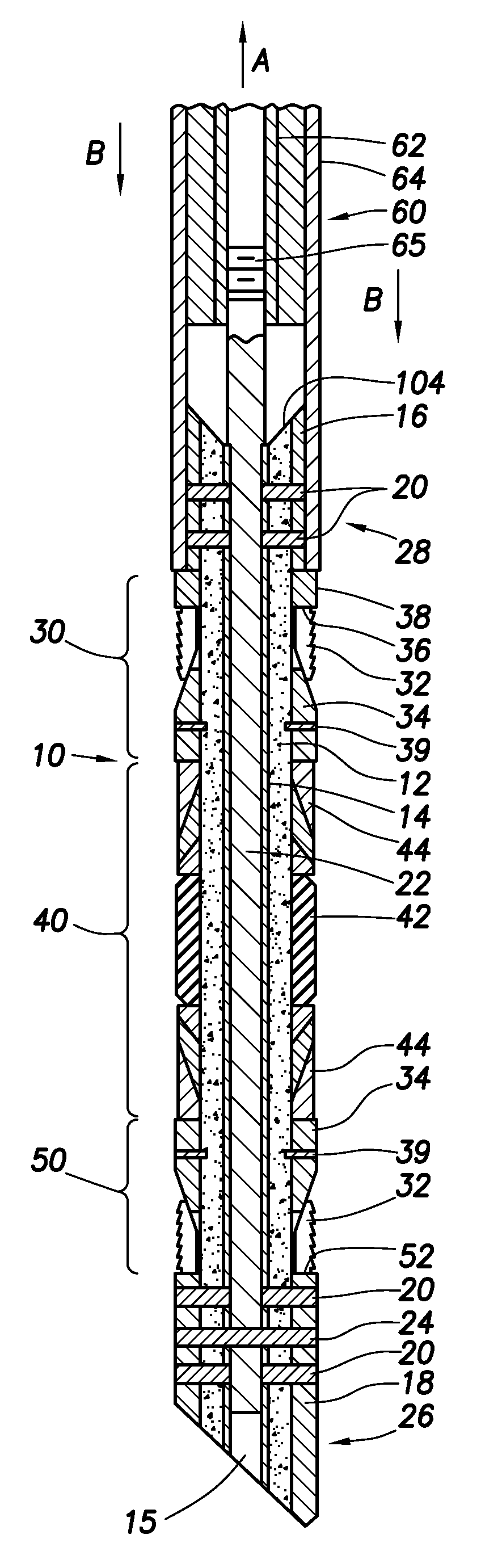

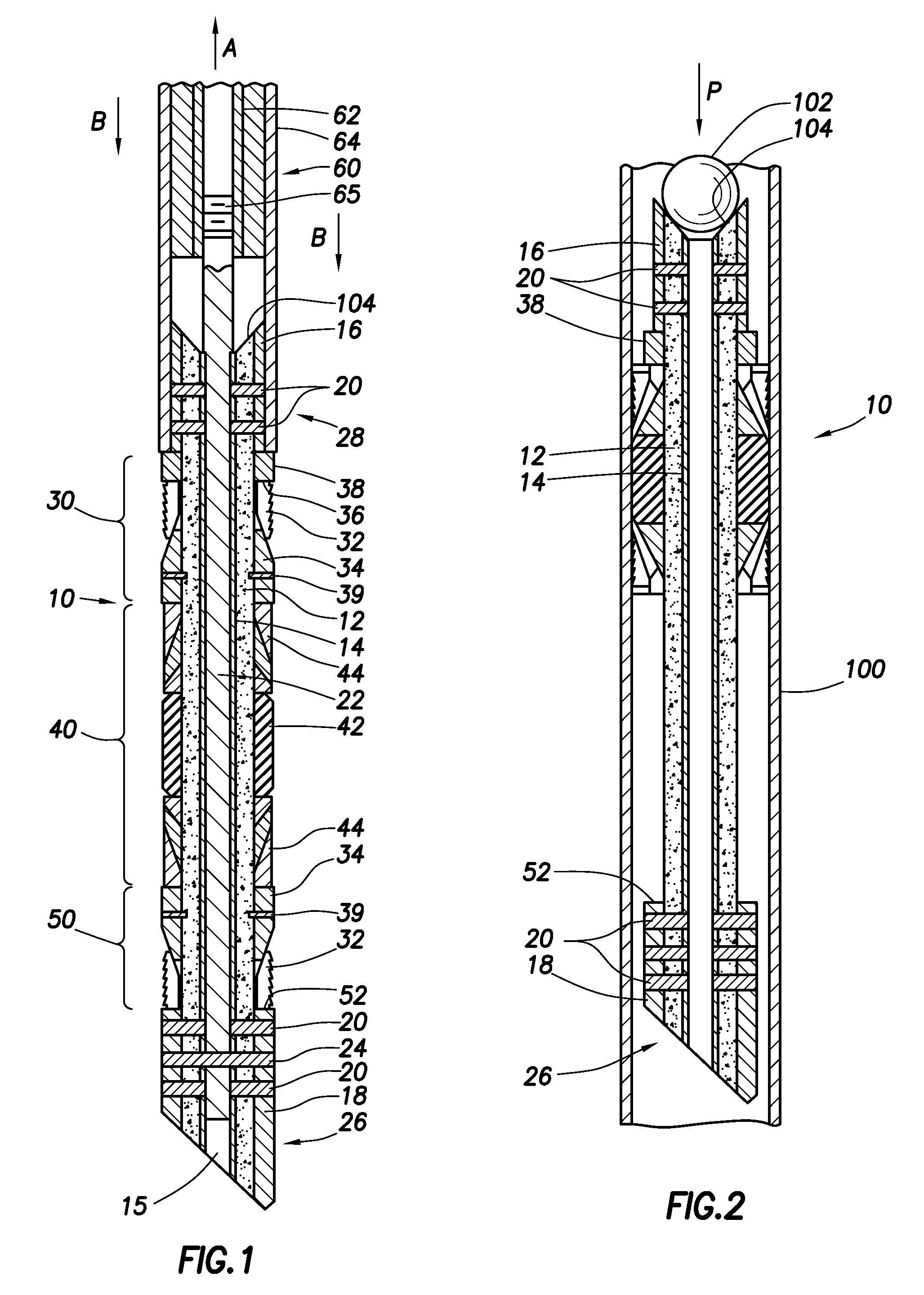

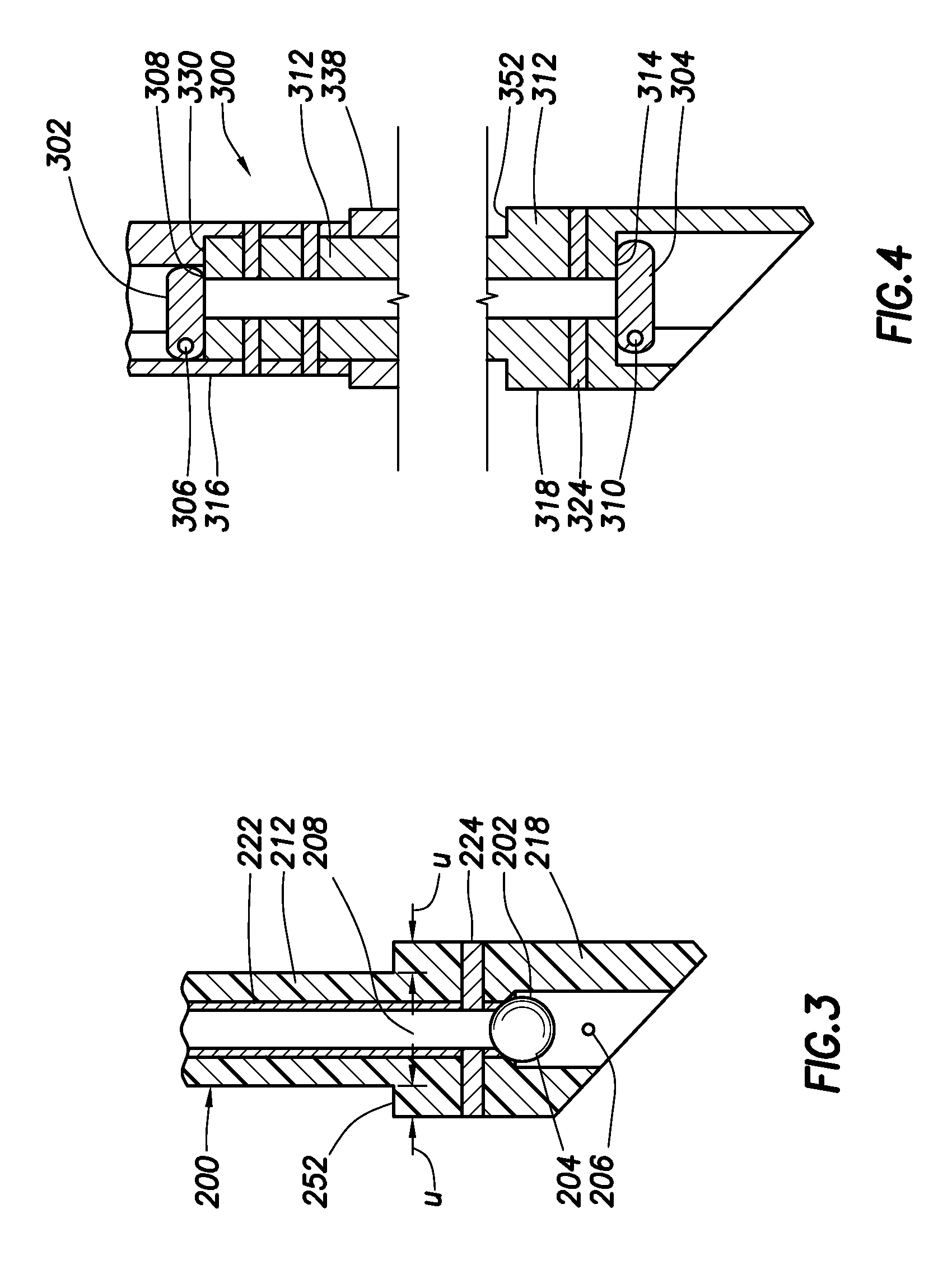

[0023]Referring now to the drawings wherein like reference characters designate like or corresponding parts throughout the several views, there is shown in FIG. 1 an embodiment of an improved double-slip type wellbore plug assembly 10 according to the present inventions. The plug embodiment selected for use in describing the present inventions comprises what is known in the industry as a frac plug. As will be described in detail, the frac plug, once set in the wellbore, permits hydrocarbon production flow along the wellbore upward through the plug, while preventing frac fluids pumped into the well to flow in a downward or downhole direction. For purposes of description, plug assembly 10 is illustrated in the figures with the upper end of the plug 28 orientated toward the top of the drawing page and lower end of the plug 26 toward the bottom of the page. It is to be understood that the embodiment selected for use as an example is not intended to limit the inventions to the selected c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com