Film winding core, and wound film body using same

一种薄膜卷绕、卷芯的技术,应用在薄膜卷绕用卷芯,薄膜卷绕体领域,能够解决薄膜应变、妨碍薄膜放卷等问题,达到降低生产不良、成品率和薄膜的利用率改善、防止弯曲或松弛的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

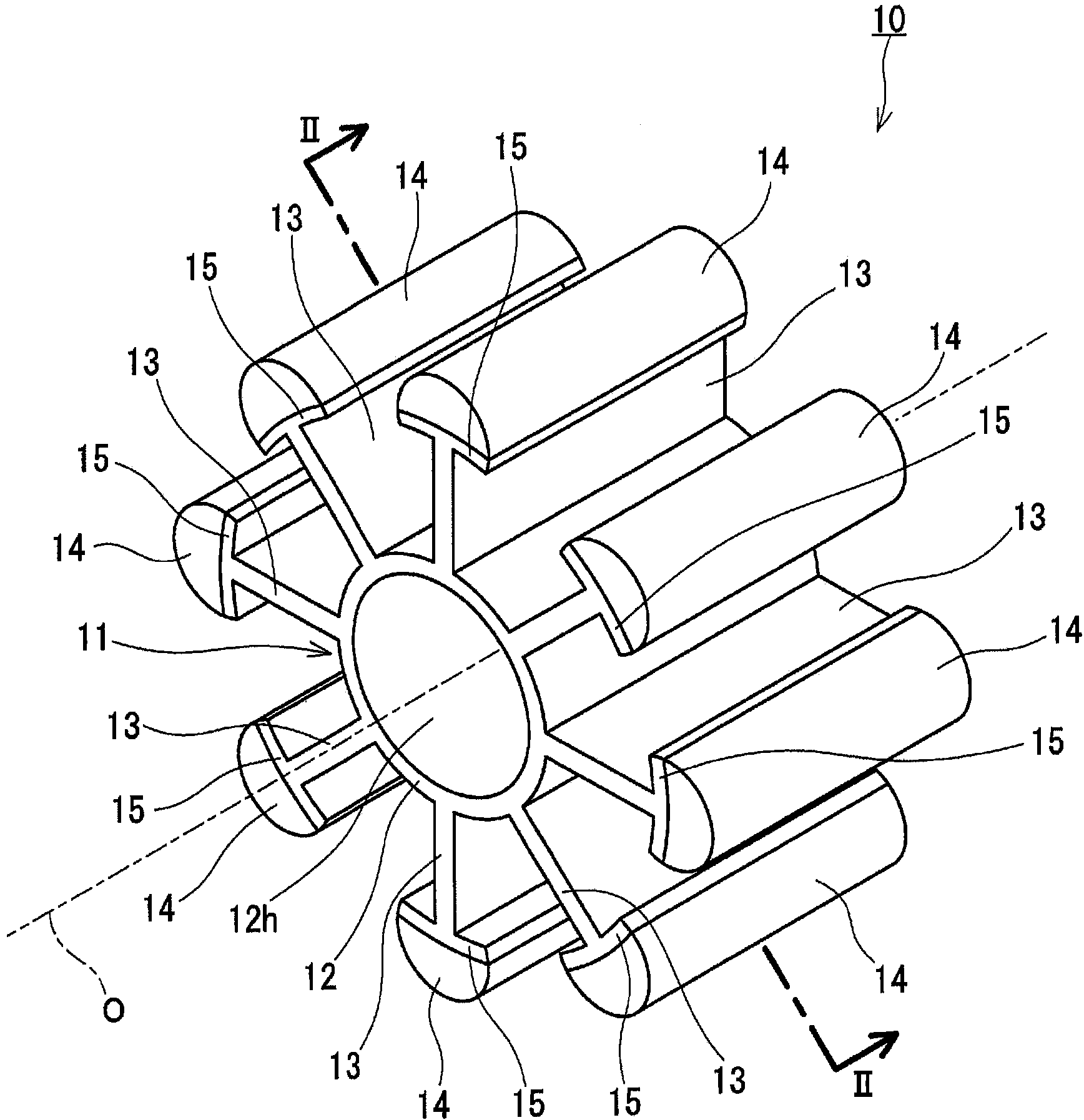

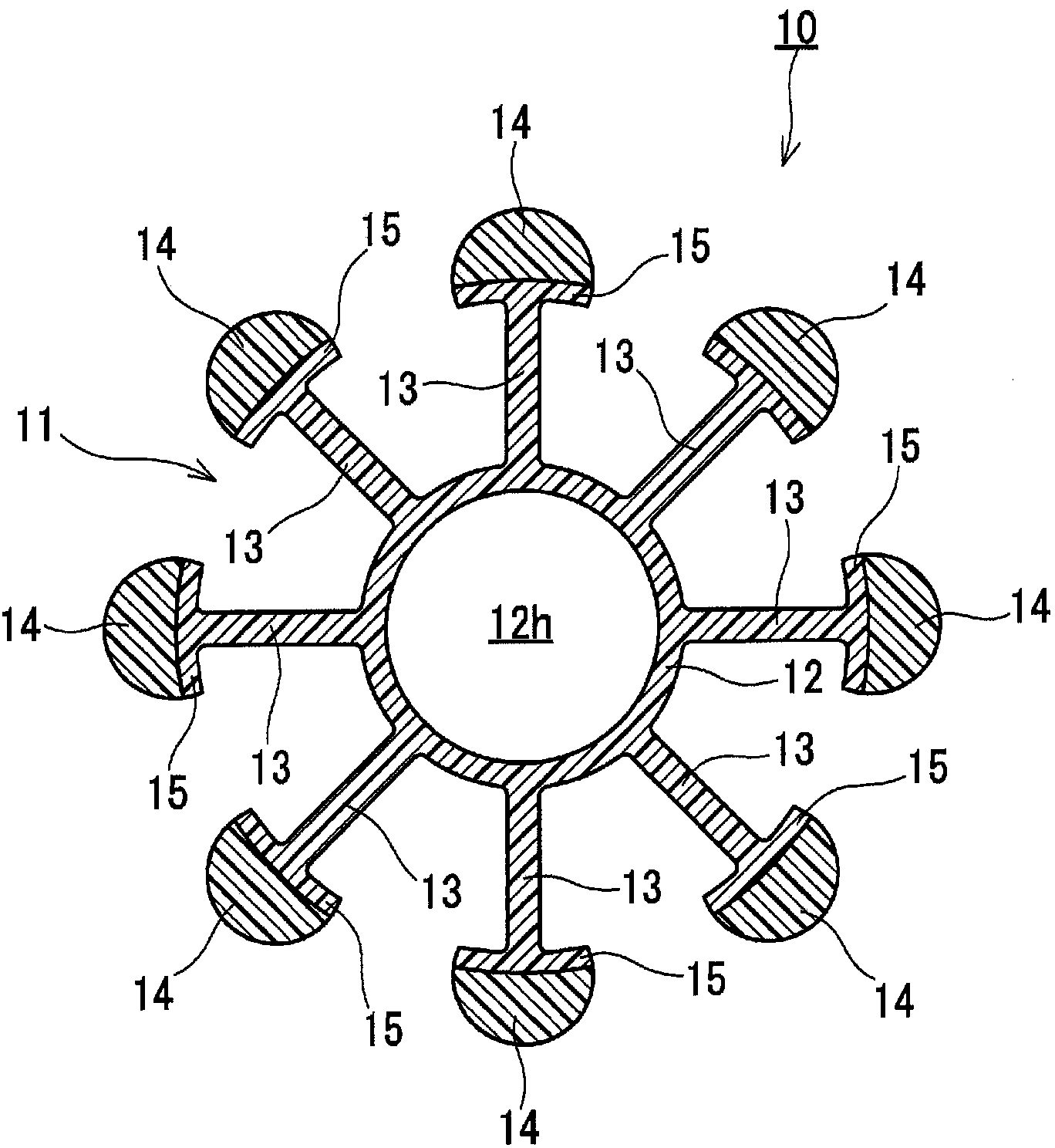

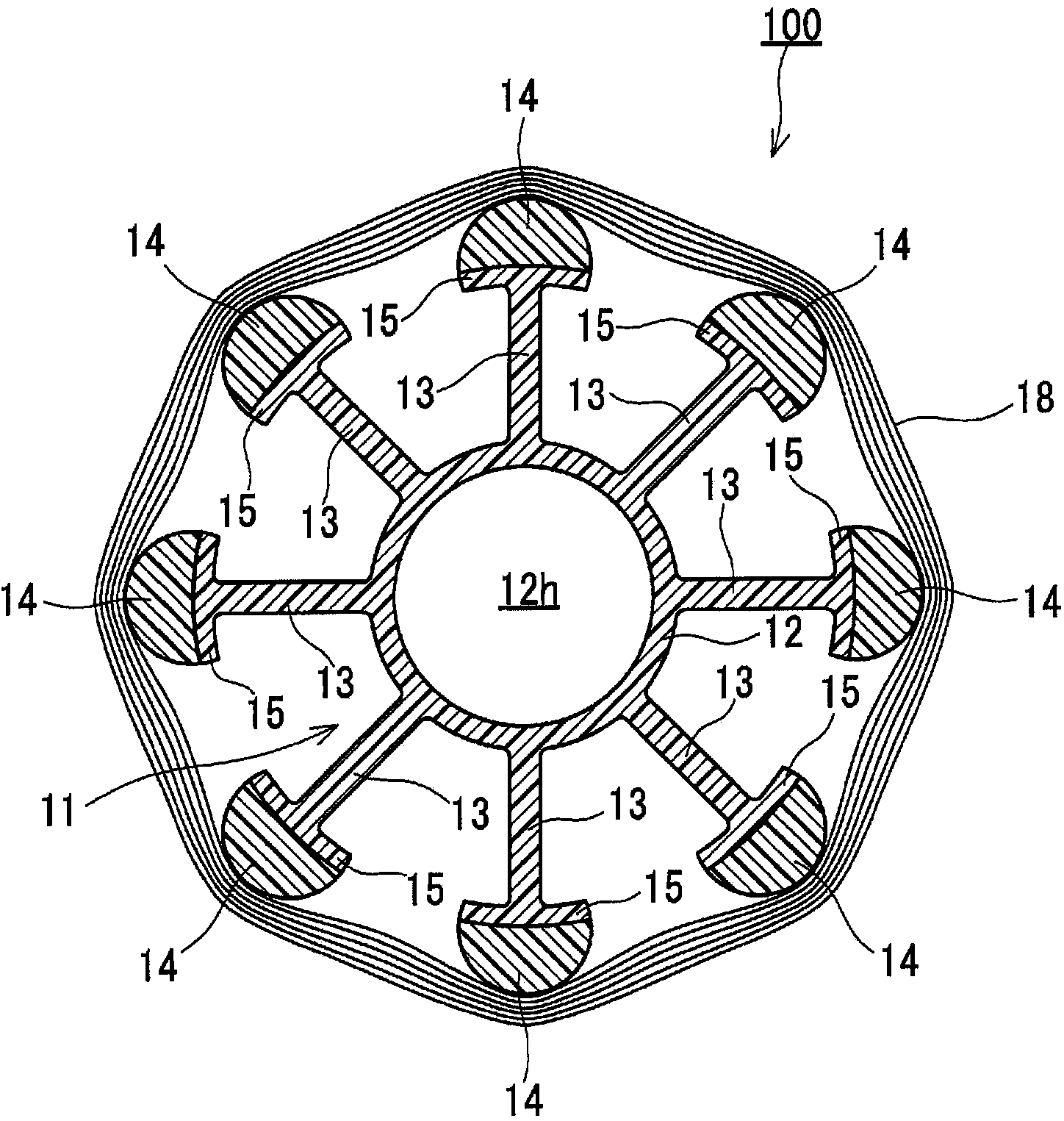

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Hereinafter, in this specification, the core for film winding is simply referred to as "core".

[0033] Such as figure 1 with figure 2 As shown, the core 10 is composed of a core body 11 and a plurality of film supporting parts 14 mounted on the core body 11 . The core main body 11 is composed of a bearing portion 12 having a bearing hole 12h, a plurality of blade portions 13 and a plurality of rim portions 15 . Such as image 3 As shown, the film roll body 100 includes a core 10 and a long film 18 wound on the core 10 . The winding core 10 can be rotated around the rotation axis O passing through the bearing hole 12h.

[0034] The bearing portion 12 is a portion into which a shaft (not shown) used to rotate the winding core 10 can be inserted, and has a cylindrical shape. The cross-sectional shape of the bearing portion 12 is not particularly limited, and may be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com