Patents

Literature

999results about How to "Avoid slack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

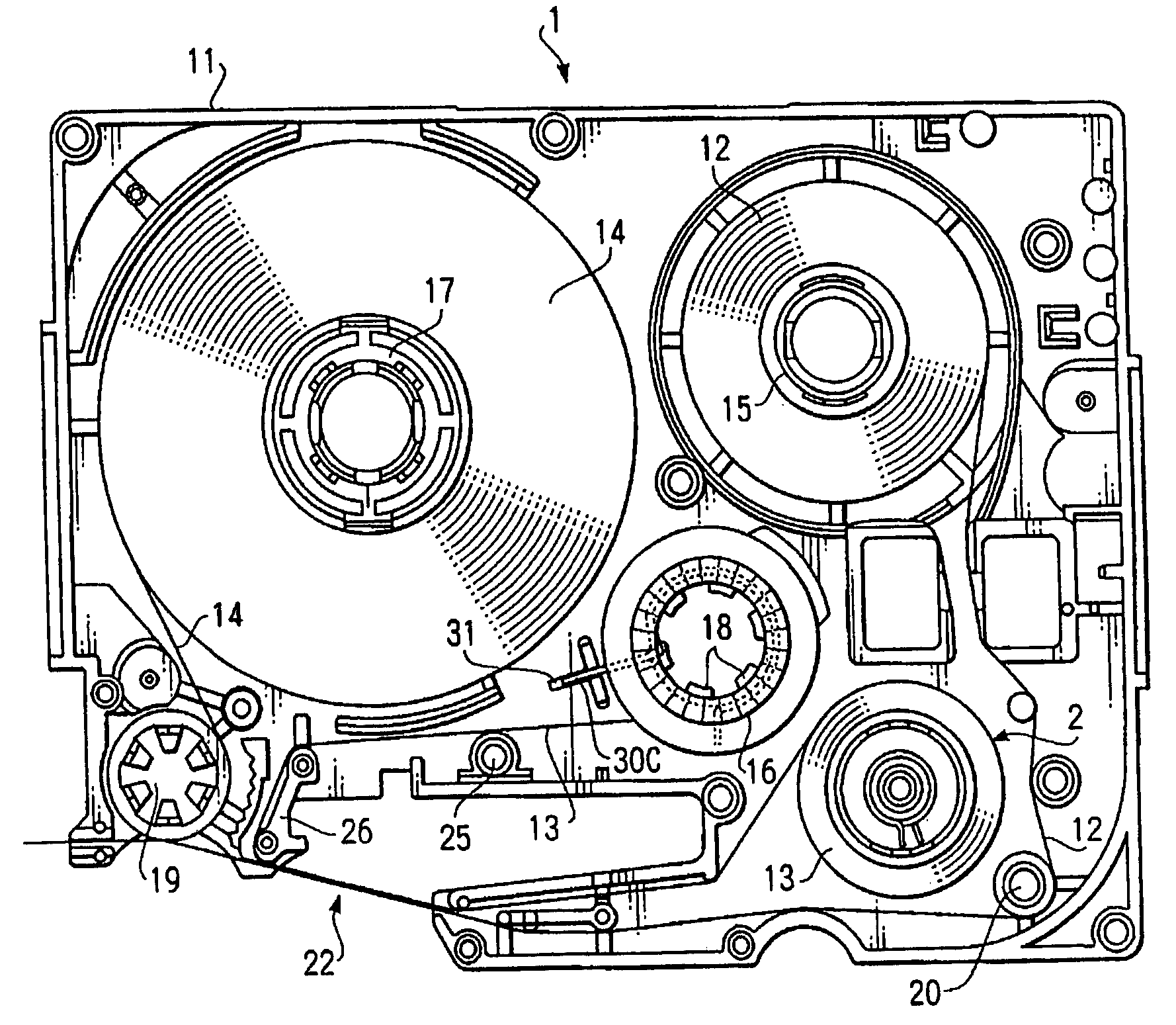

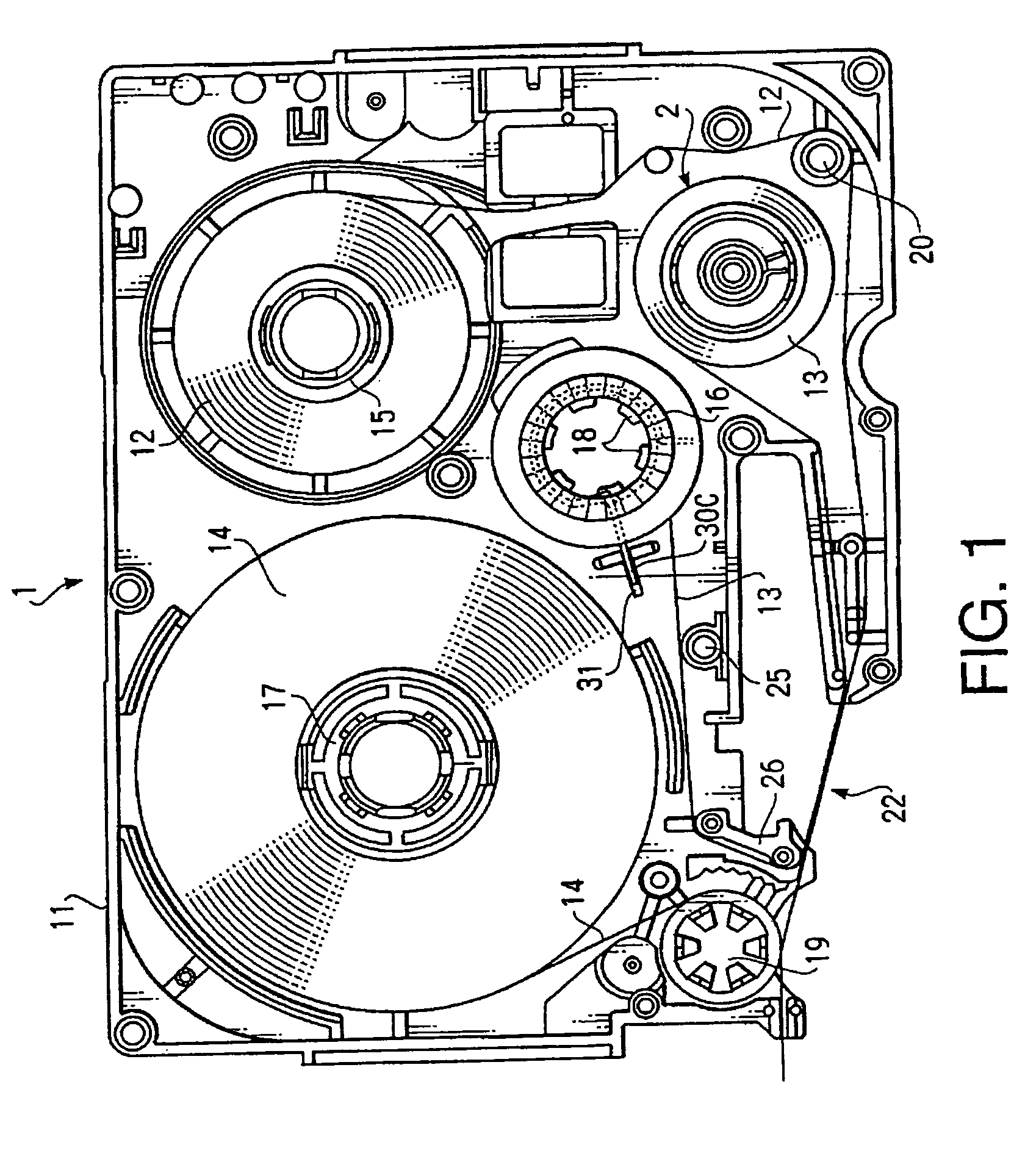

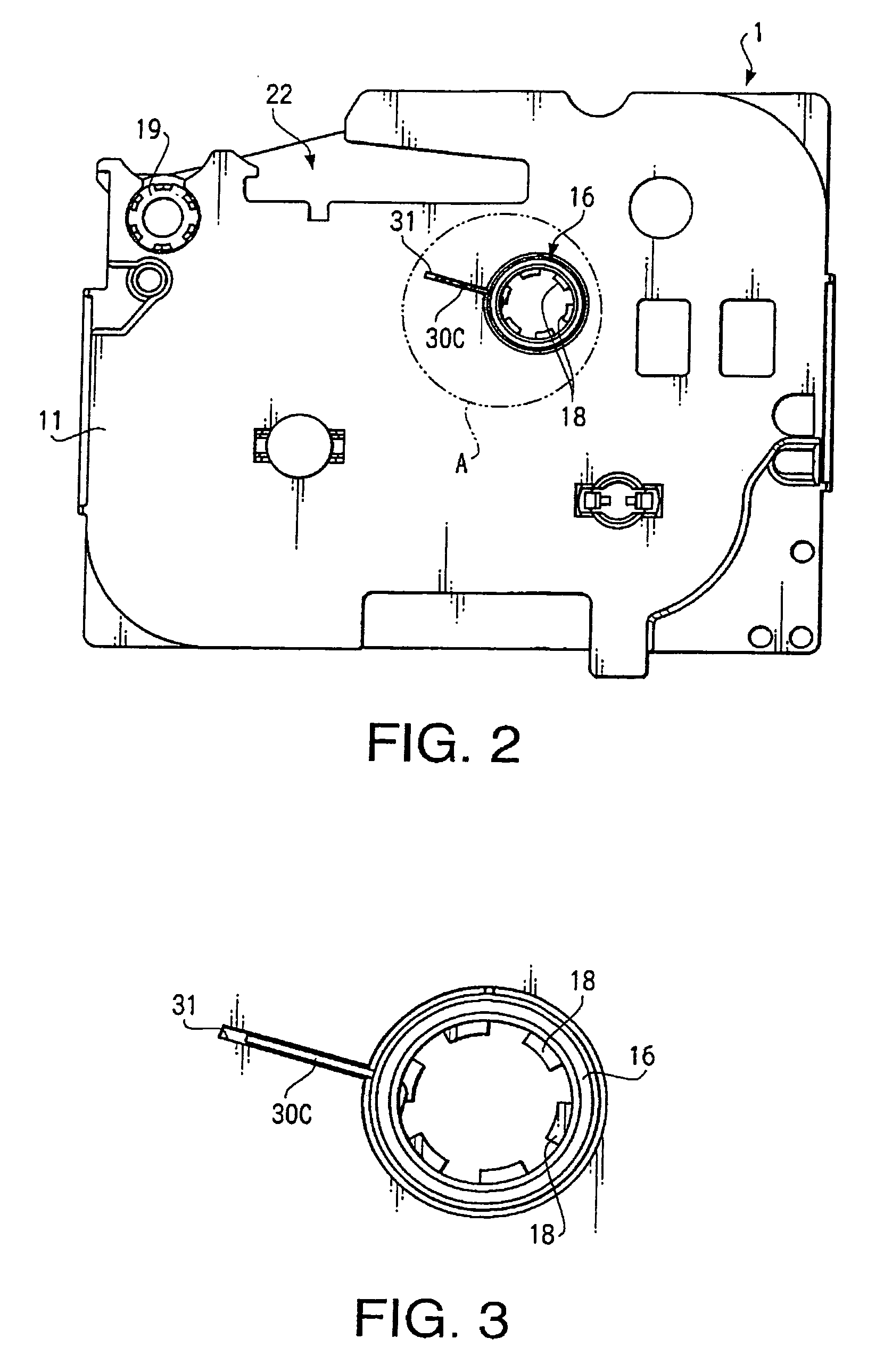

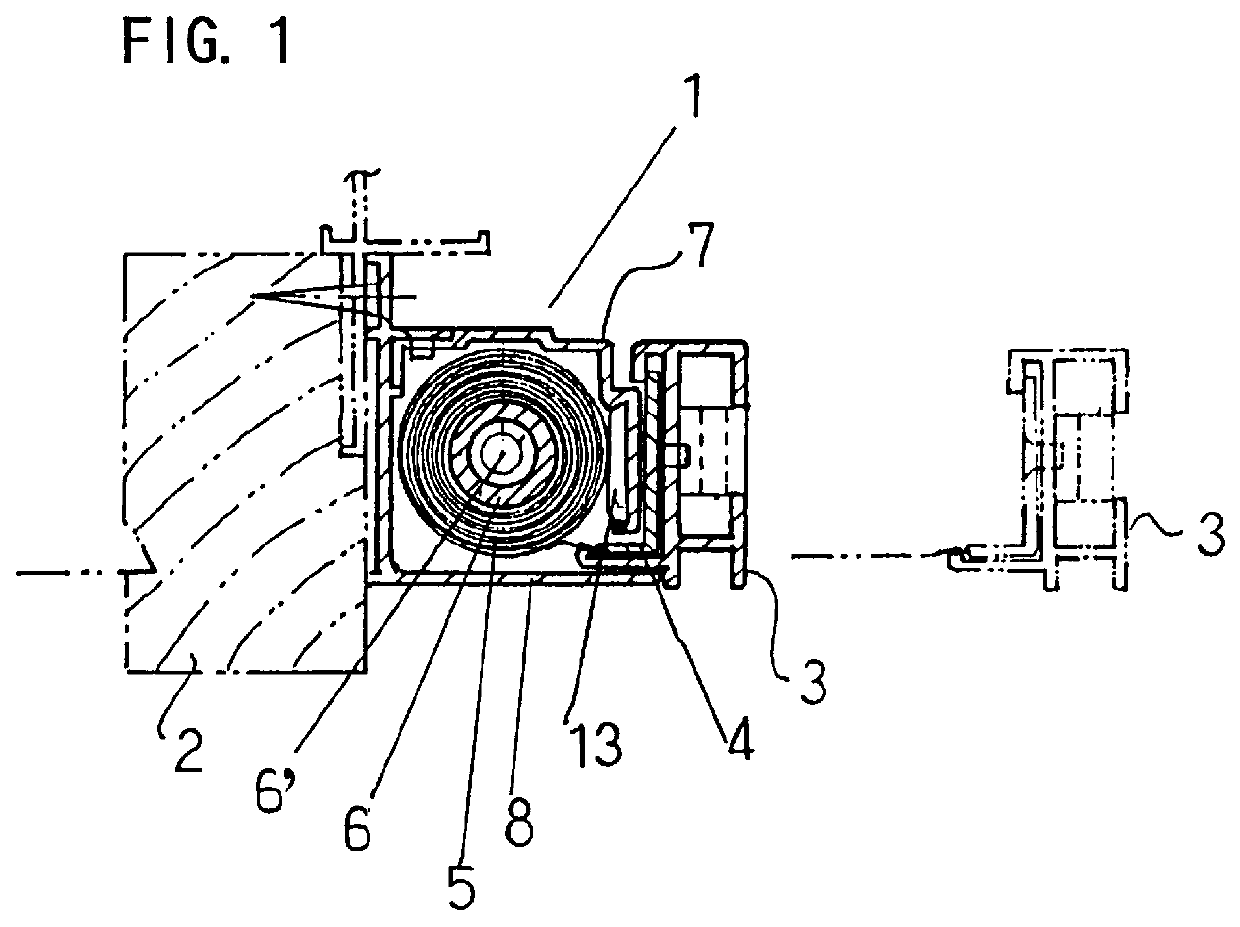

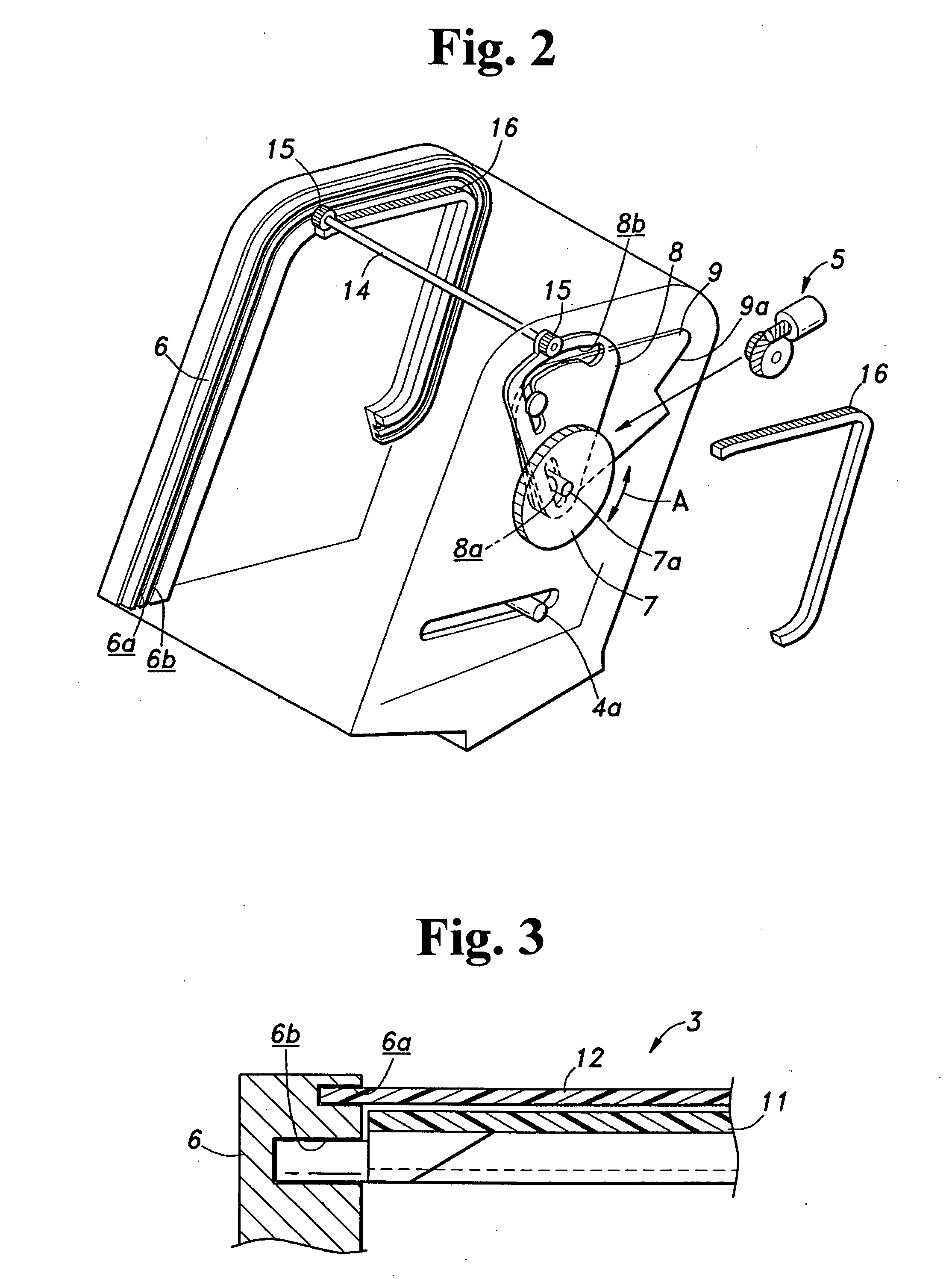

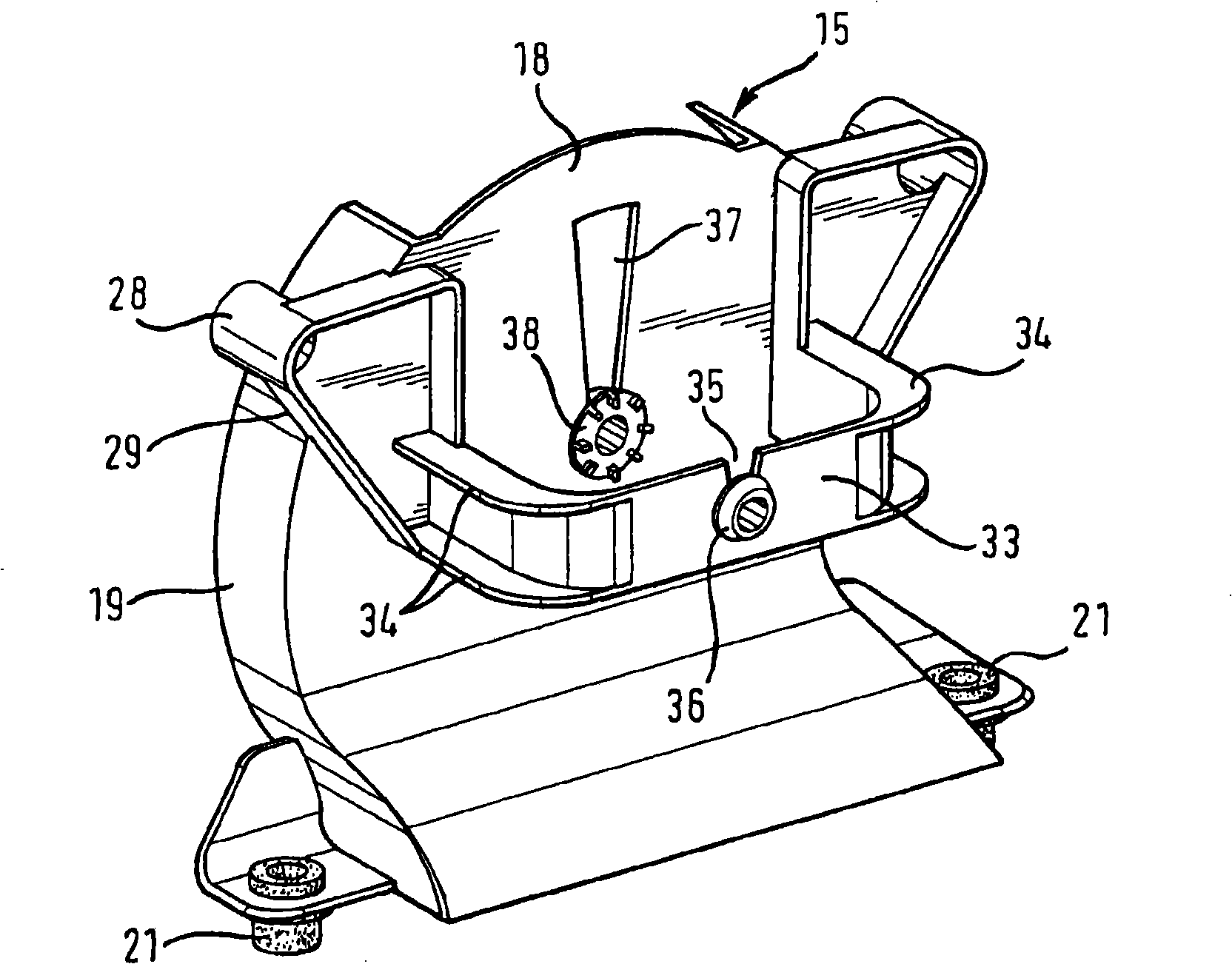

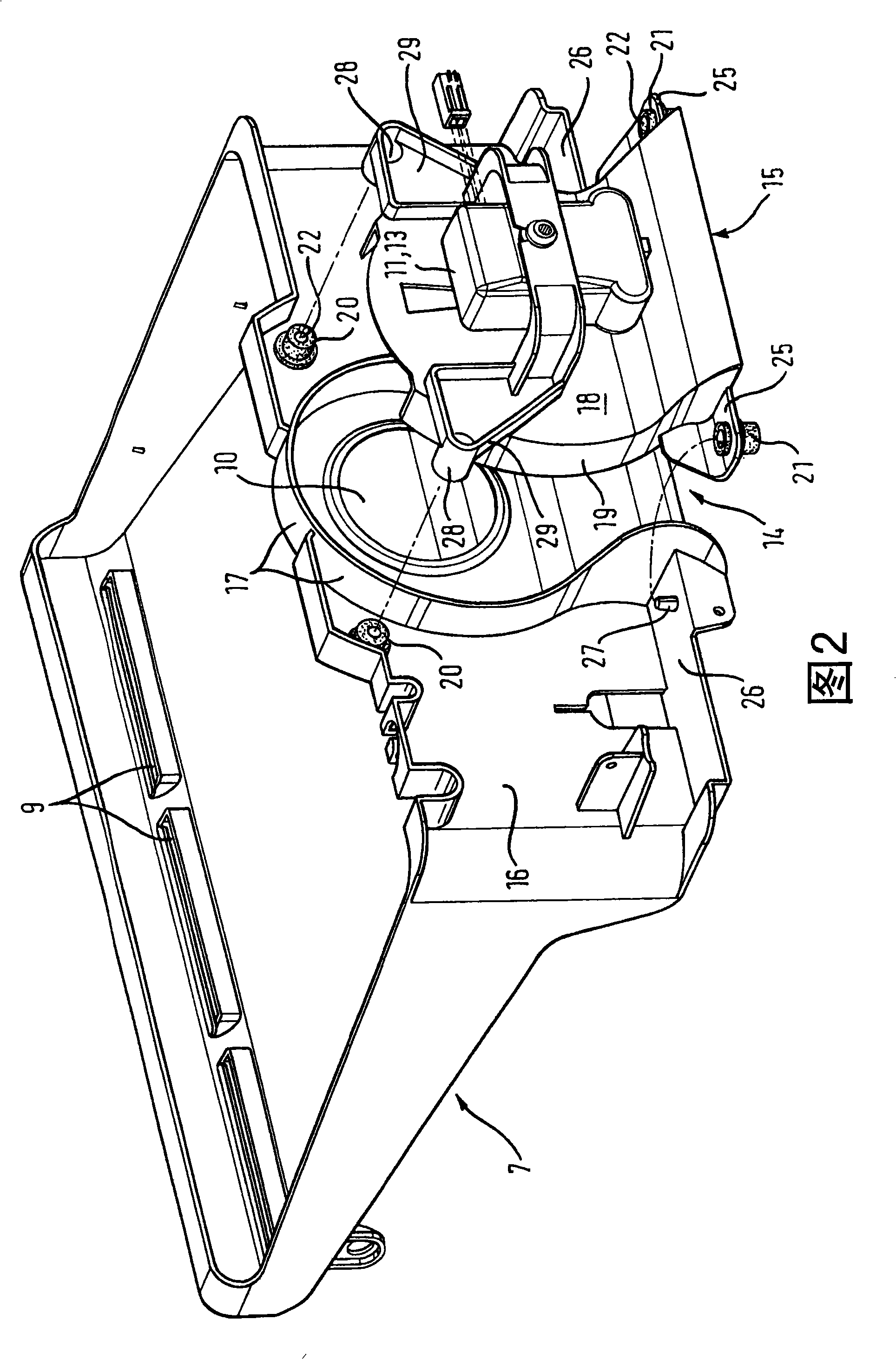

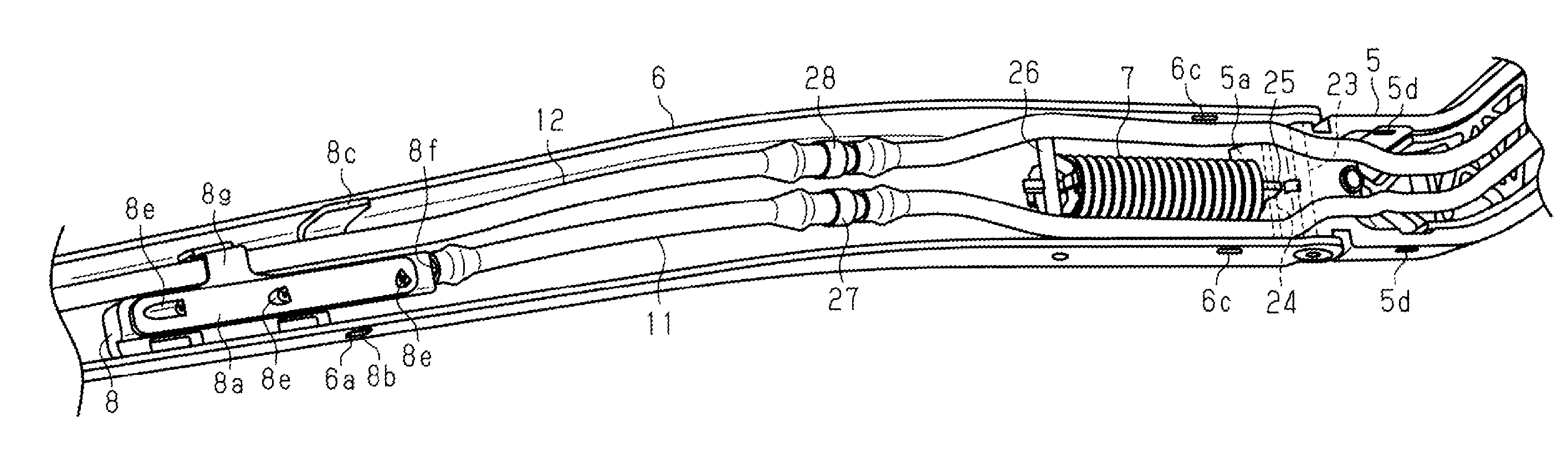

Ribbon cassette with ink ribbon slack prevention mechanism

ActiveUS7128483B2Smooth take-upPrevents slack in the ink ribbon from occurringInk ribbon cartridgesInk ribbonsEngineeringMechanical engineering

Owner:BROTHER KOGYO KK

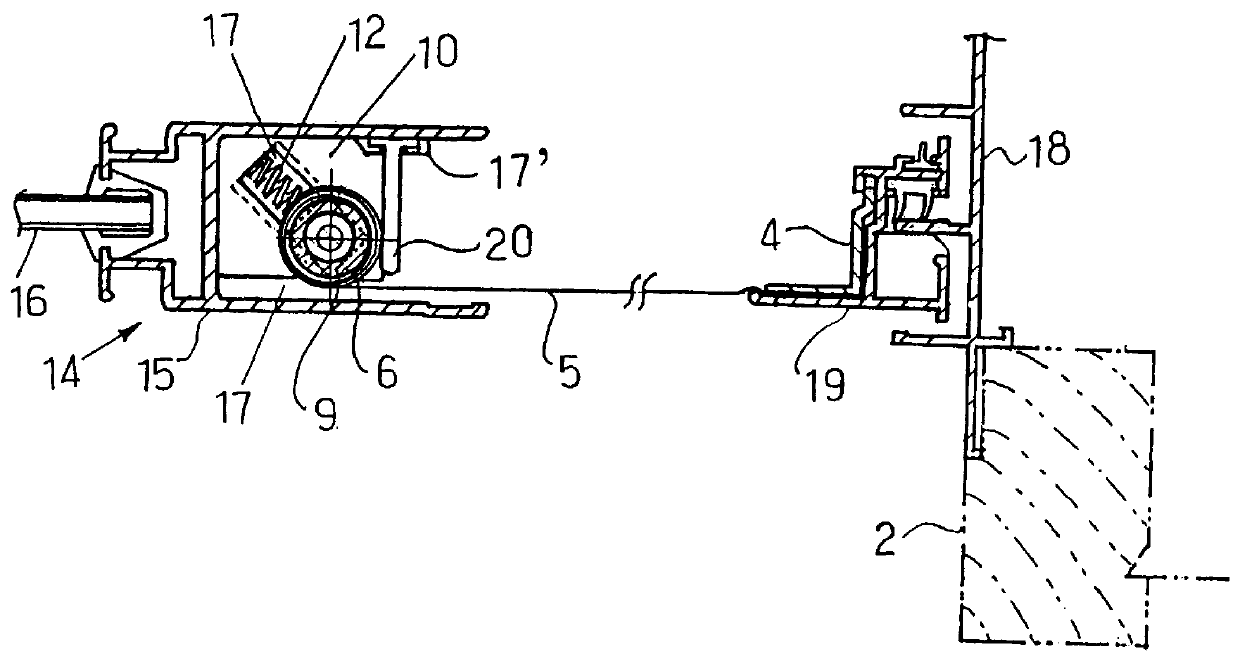

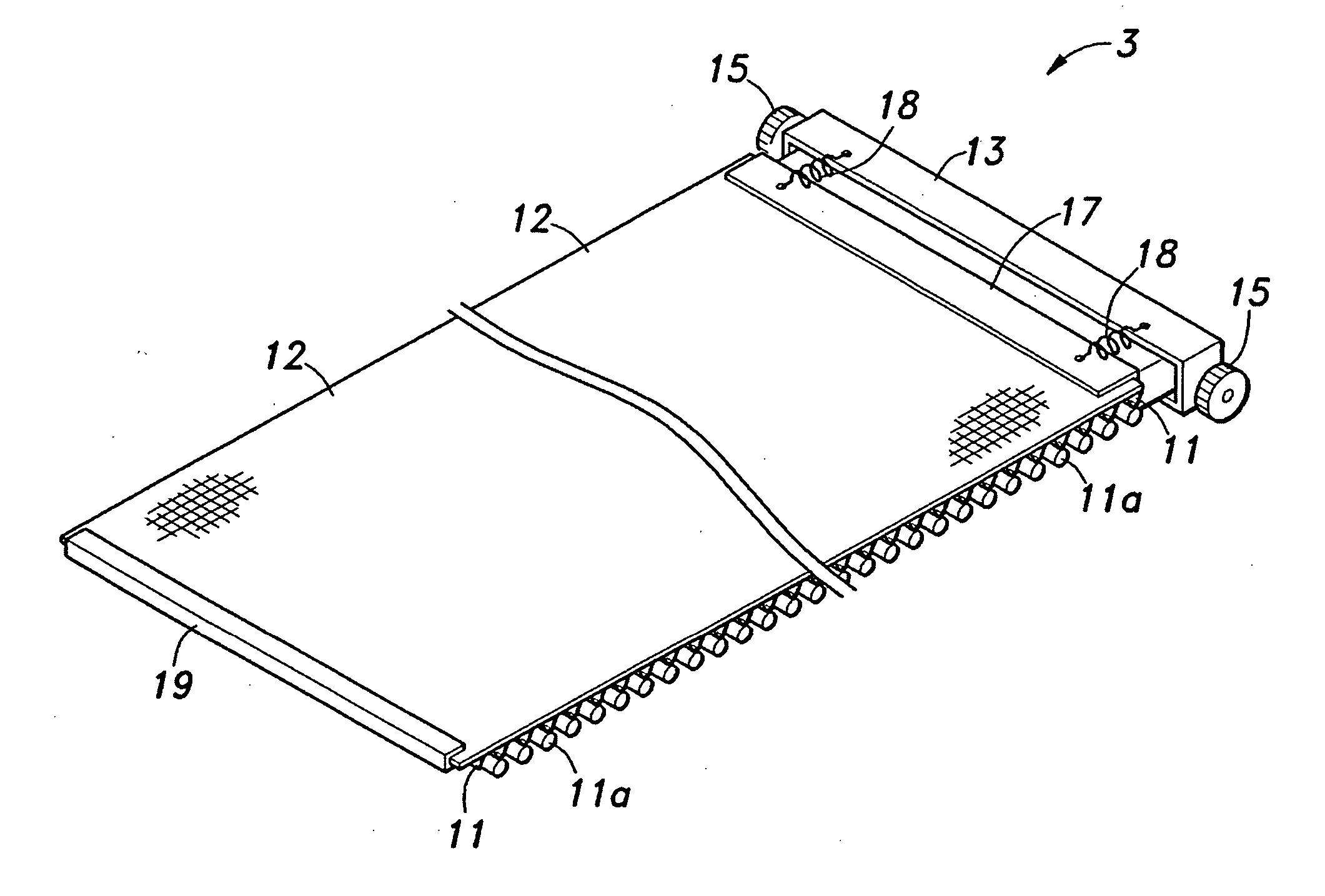

Rolling screen

A rolling screen comprises a screen case, a take-up shaft arranged rotatably about a central axis thereof within the screen case, and a screen wound on said take-up shaft so that the screen can be wound out of said screen case. The take-up shaft is normally biased in a screen-winding direction by a torsion spring. An outer peripheral surface of the screen wound on the take-up shaft is always maintained in contact with an inner wall of the screen case, said inner wall being located in a direction of winding-out of the screen, by pulling force applied to the screen upon extension of the screen or resilient force of a pressing spring when the screen is wound out or wound in.

Owner:TOMITA KATSUAKI

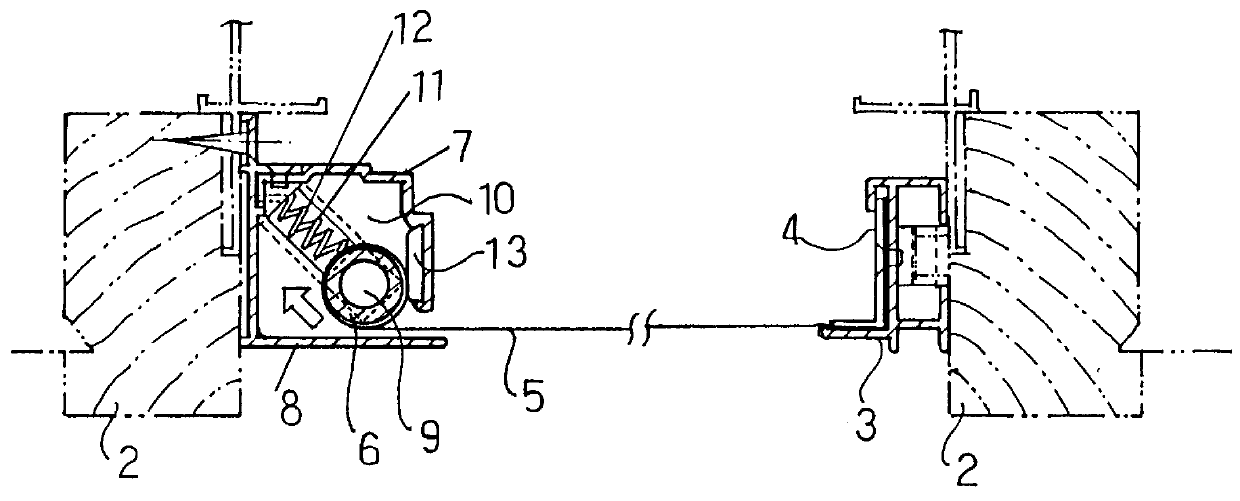

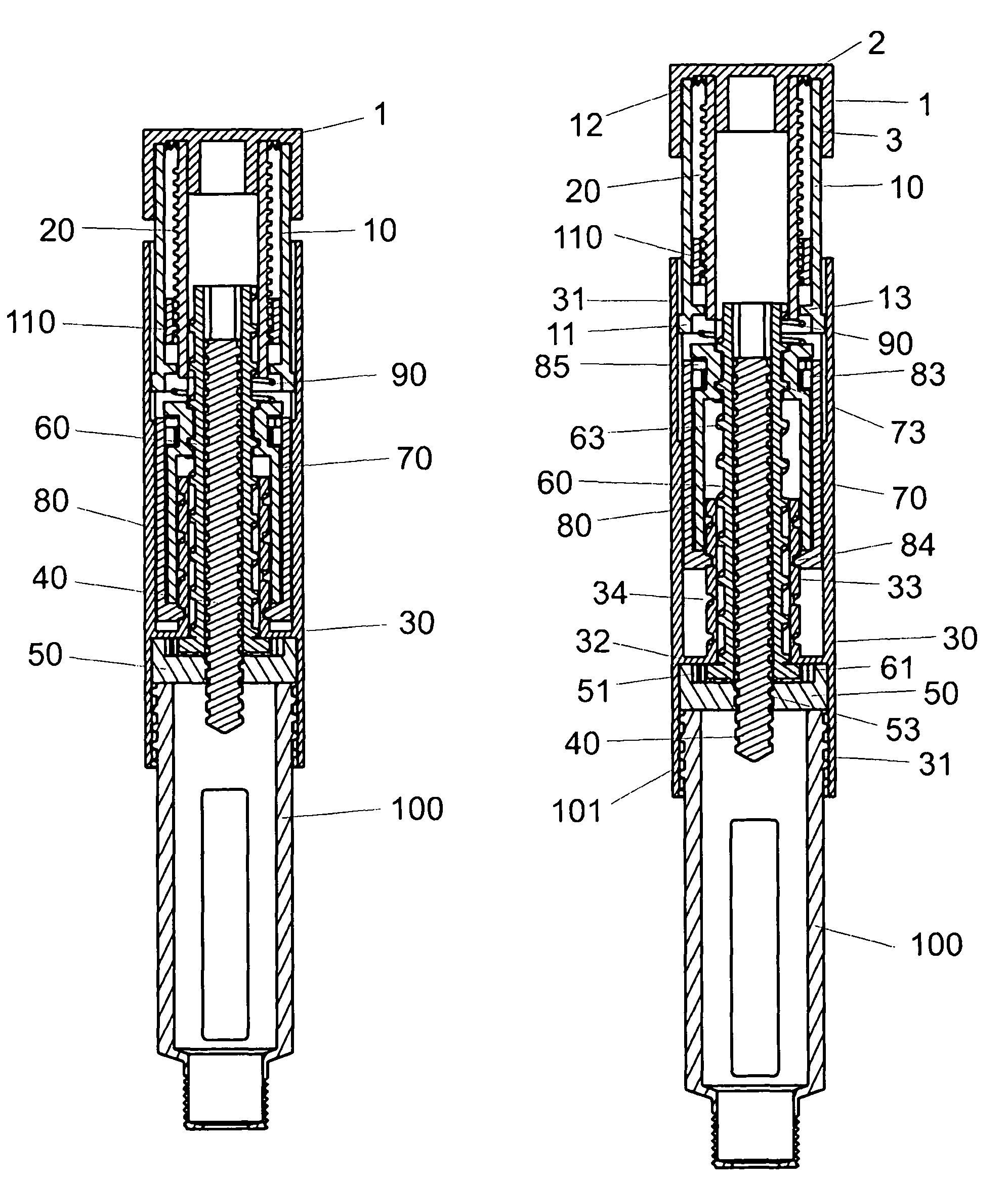

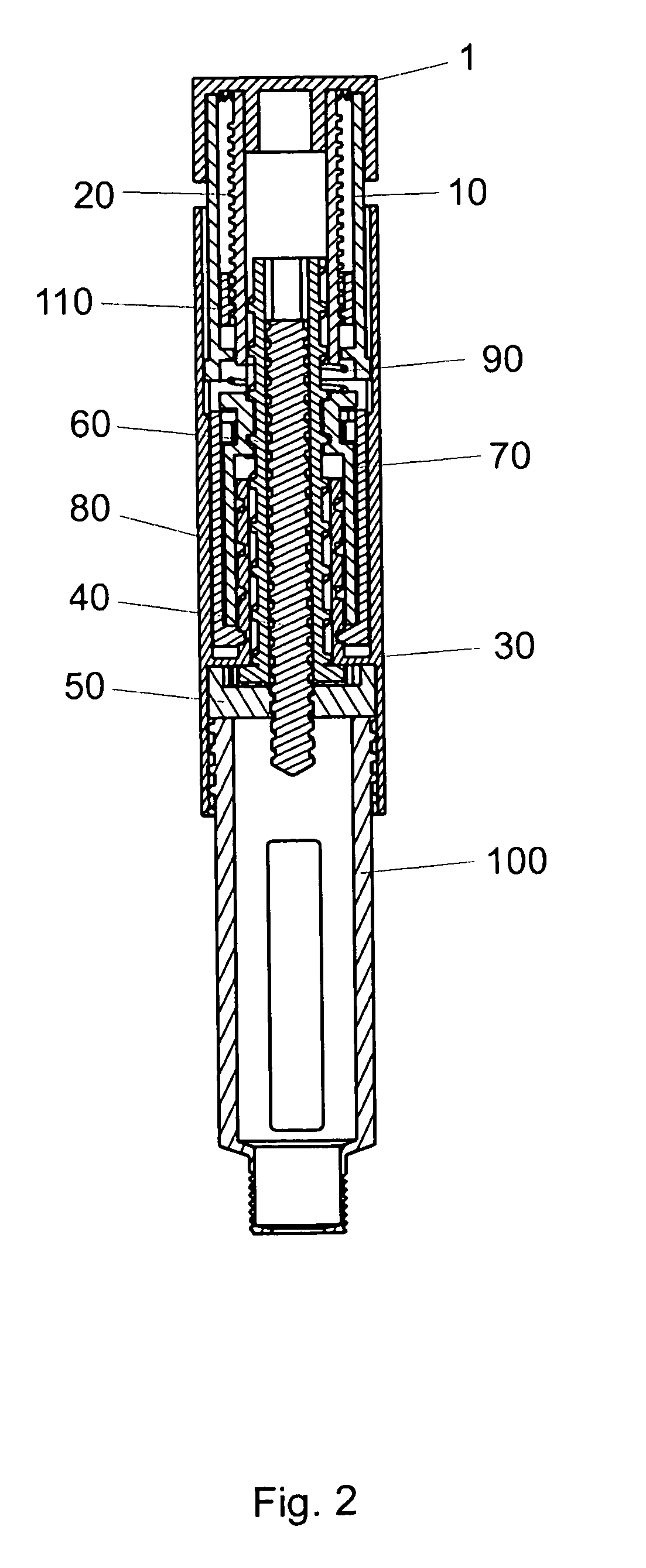

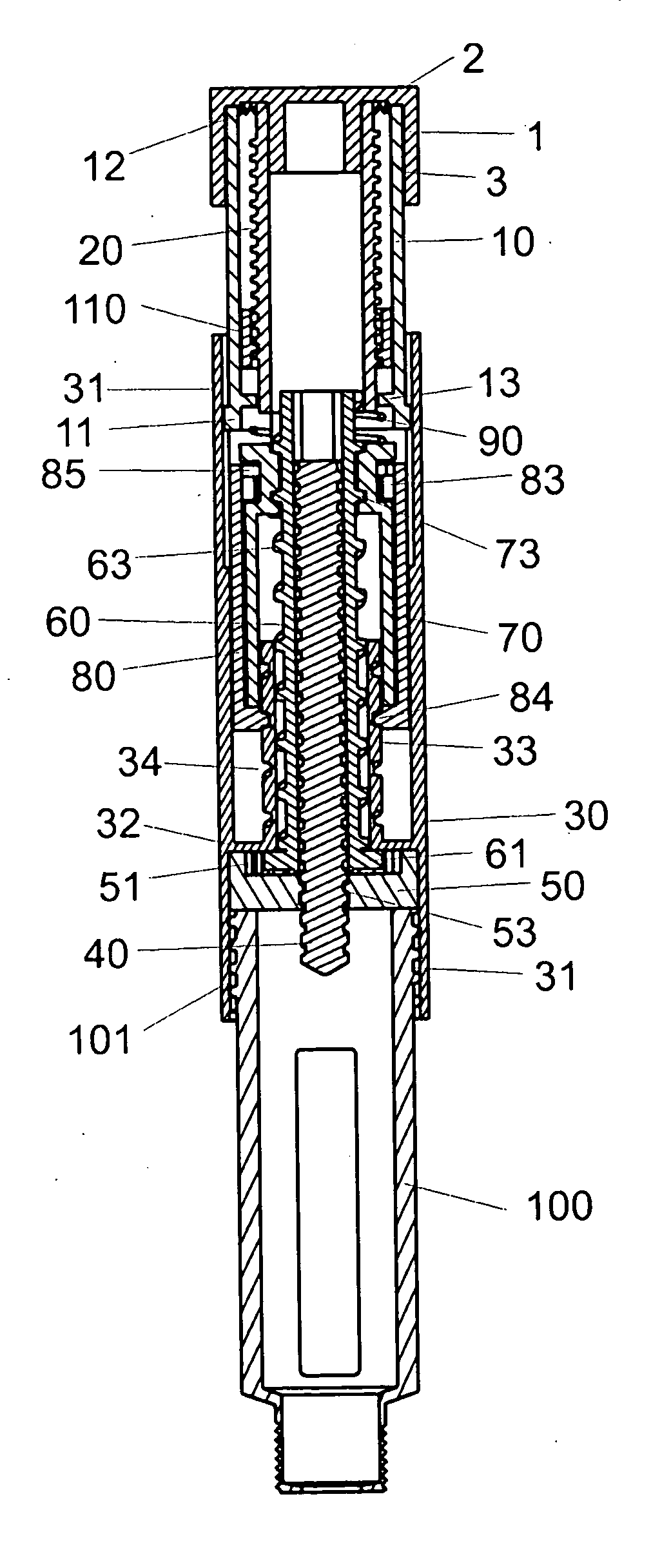

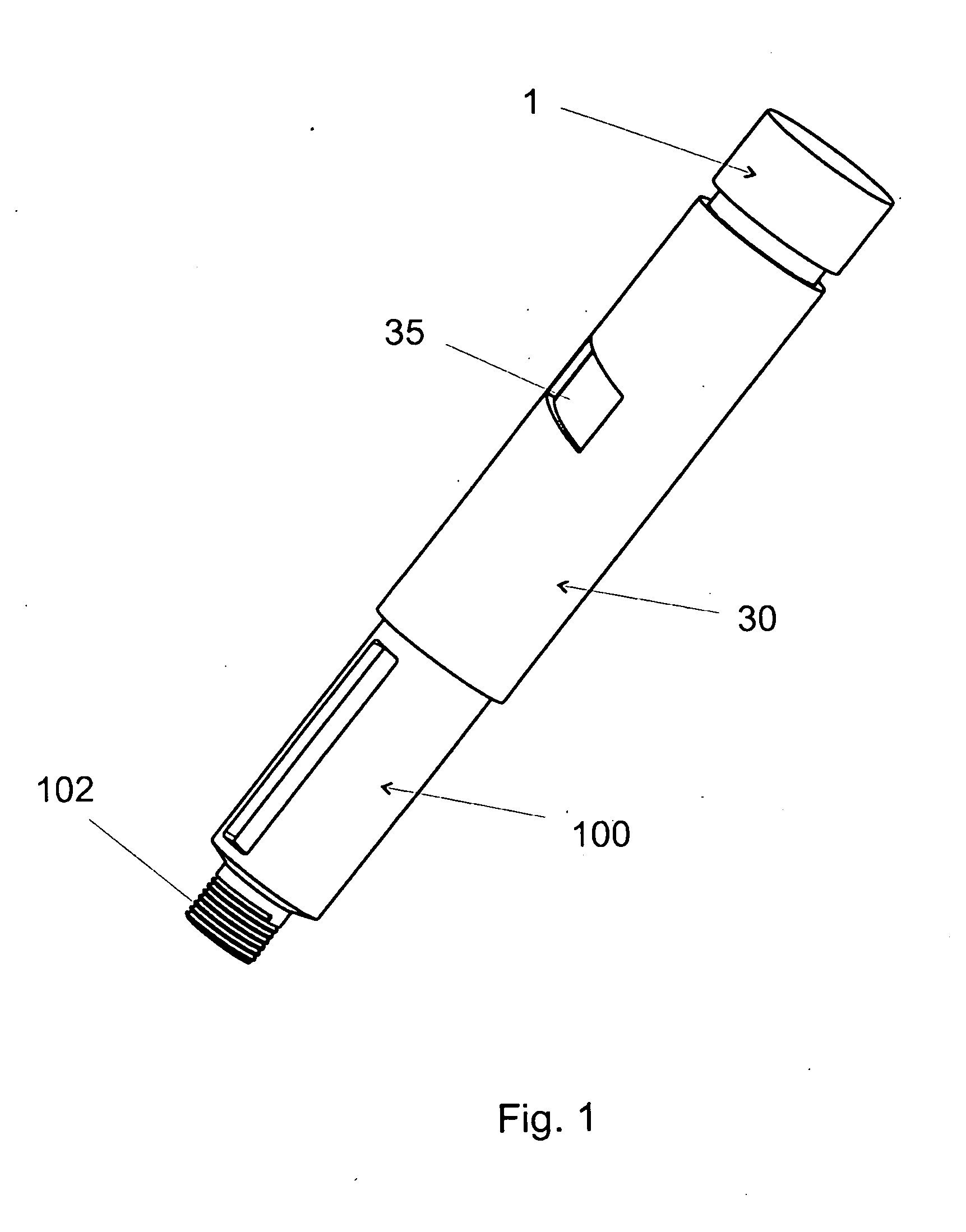

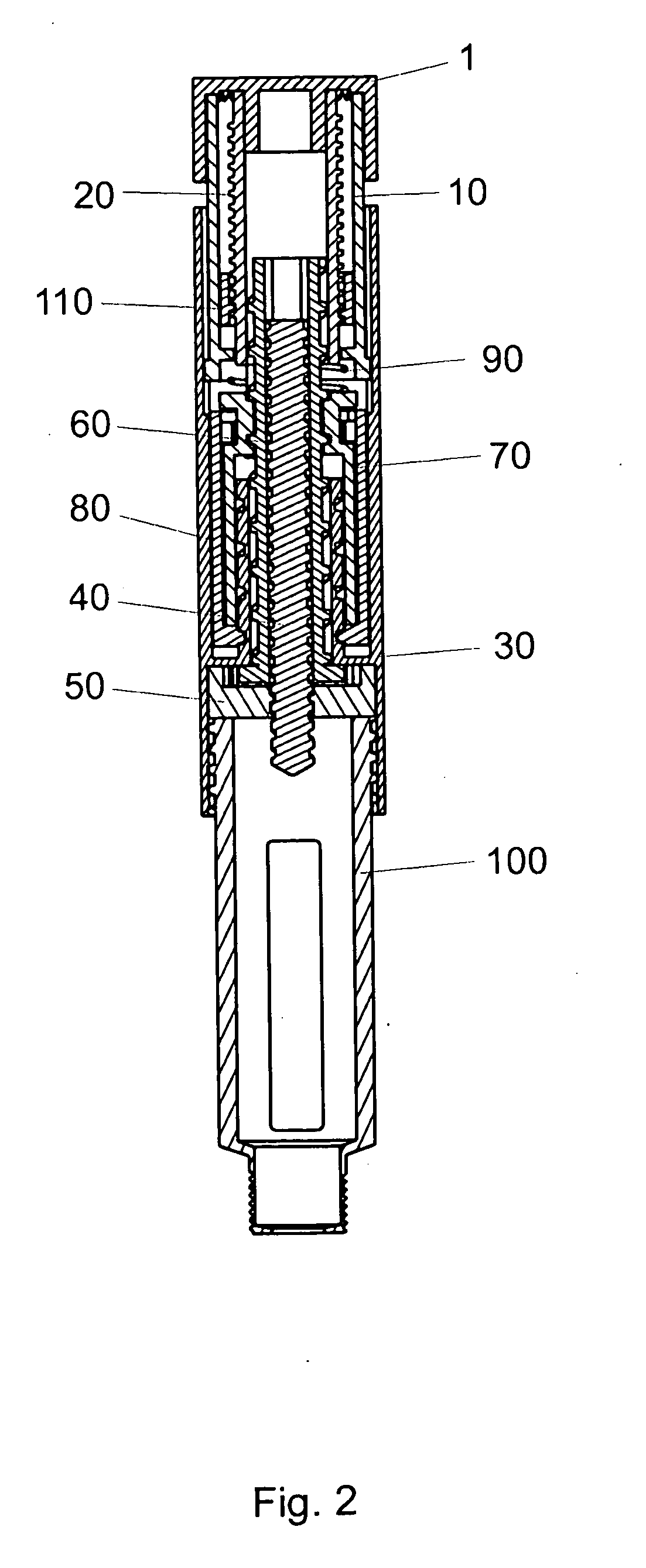

Injection device for apportioning set doses

ActiveUS8608709B2Accurate displayEliminate disadvantagesAmpoule syringesInfusion needlesInjection deviceBiomedical engineering

The invention concerns an injection device for apportioning set doses of a drug from a reservoir to a subject. The injection device comprises a dose setting member (20, 70) which is screwed out from the housing (30) to set a dose and pushed axially back to the housing (30) in order to expel the set dose. A scale drum (80) is axially and inrotatable coupled to the dose setting member (20, 70) such that the scale drum (80) is rotated up a thread (34) when the dose setting member (20, 70) is rotated to set a dose. When the dose setting member (20, 70) is pushed axially back to its initial position to inject the set dose, the scale drum (80) is released from its inrotatable connection in order to allow the scale drum (80) to rotate down the thread (34) and back to its zero position.

Owner:NOVO NORDISK AS

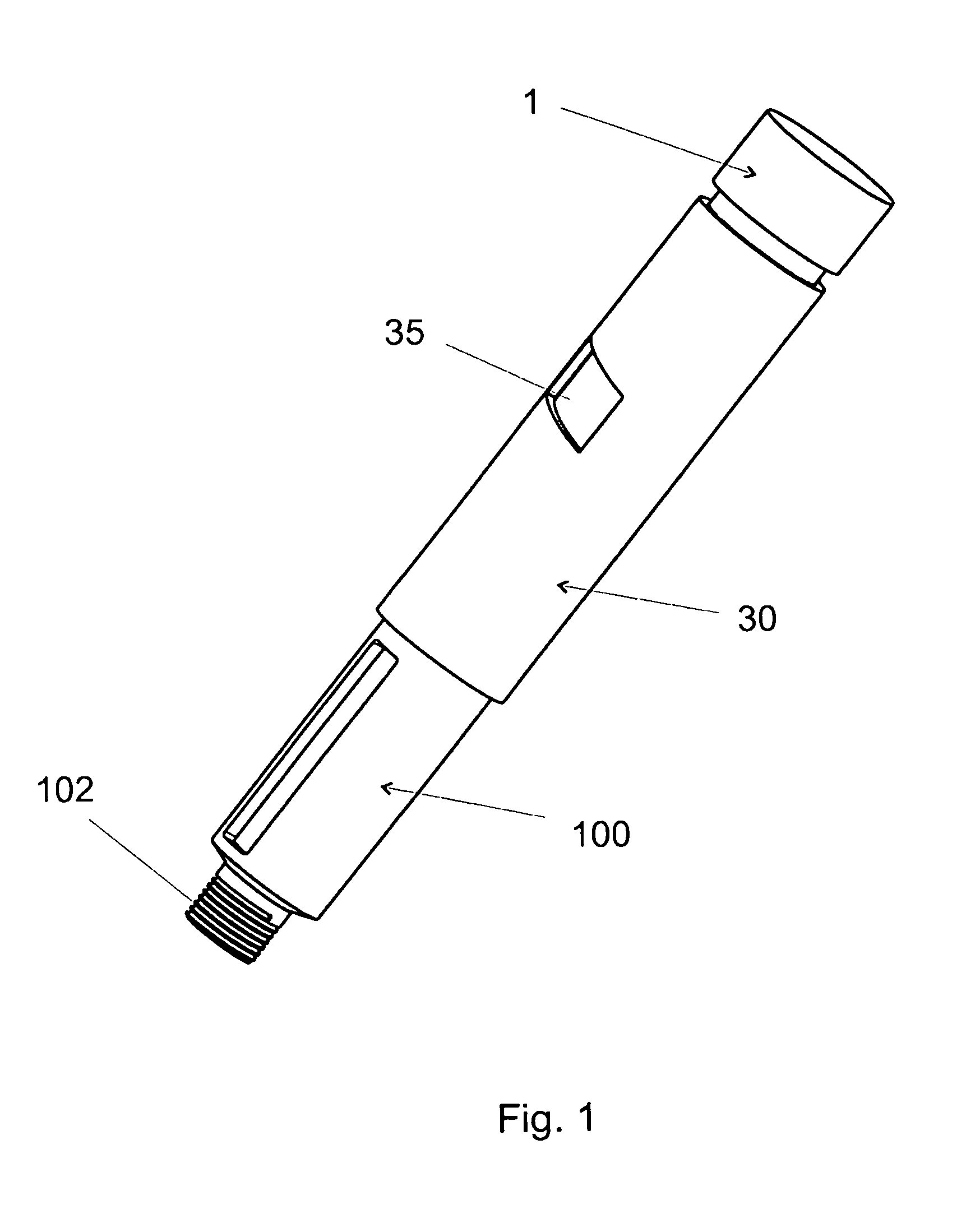

Injection device

ActiveUS20090299297A1Accurate displayEliminate disadvantagesAmpoule syringesInfusion needlesPharmaceutical drugEngineering

The invention concerns an injection device for apportioning set doses of a drug from a reservoir to a subject. The injection device comprises a dose setting member (20, 70) which is screwed out from the housing (30) to set a dose and pushed axially back to the housing (30) in order to expel the set dose. A scale drum (80) is axially and inrotatable coupled to the dose setting member (20, 70) such that the scale drum (80) is rotated up a thread (34) when the dose setting member (20, 70) is rotated to set a dose. When the dose setting member (20, 70) is pushed axially back to its initial position to inject the set dose, the scale drum (80) is released from its inrotatable connection in order to allow the scale drum (80) to rotate down the thread (34) and back to its zero position.

Owner:NOVO NORDISK AS

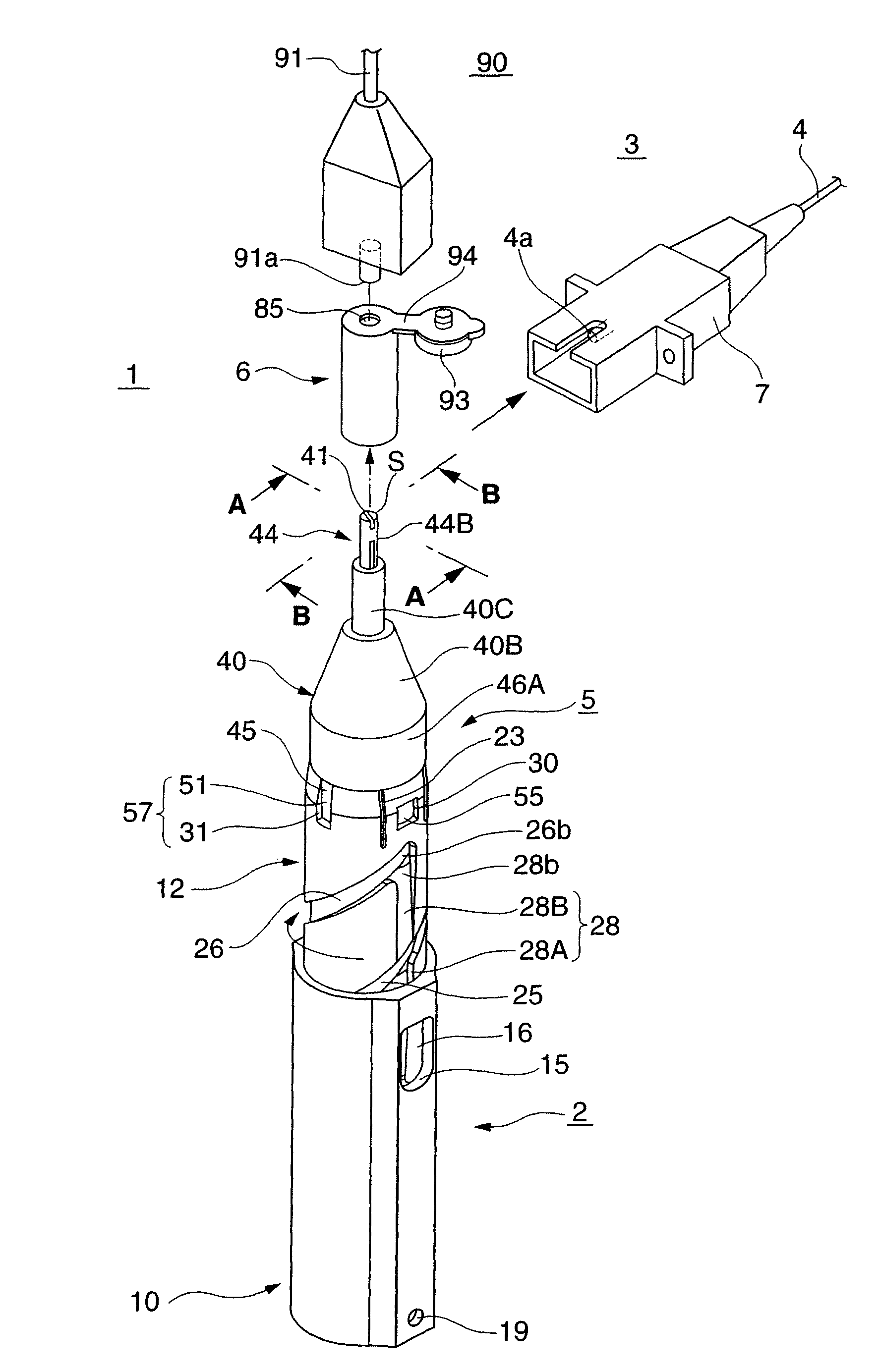

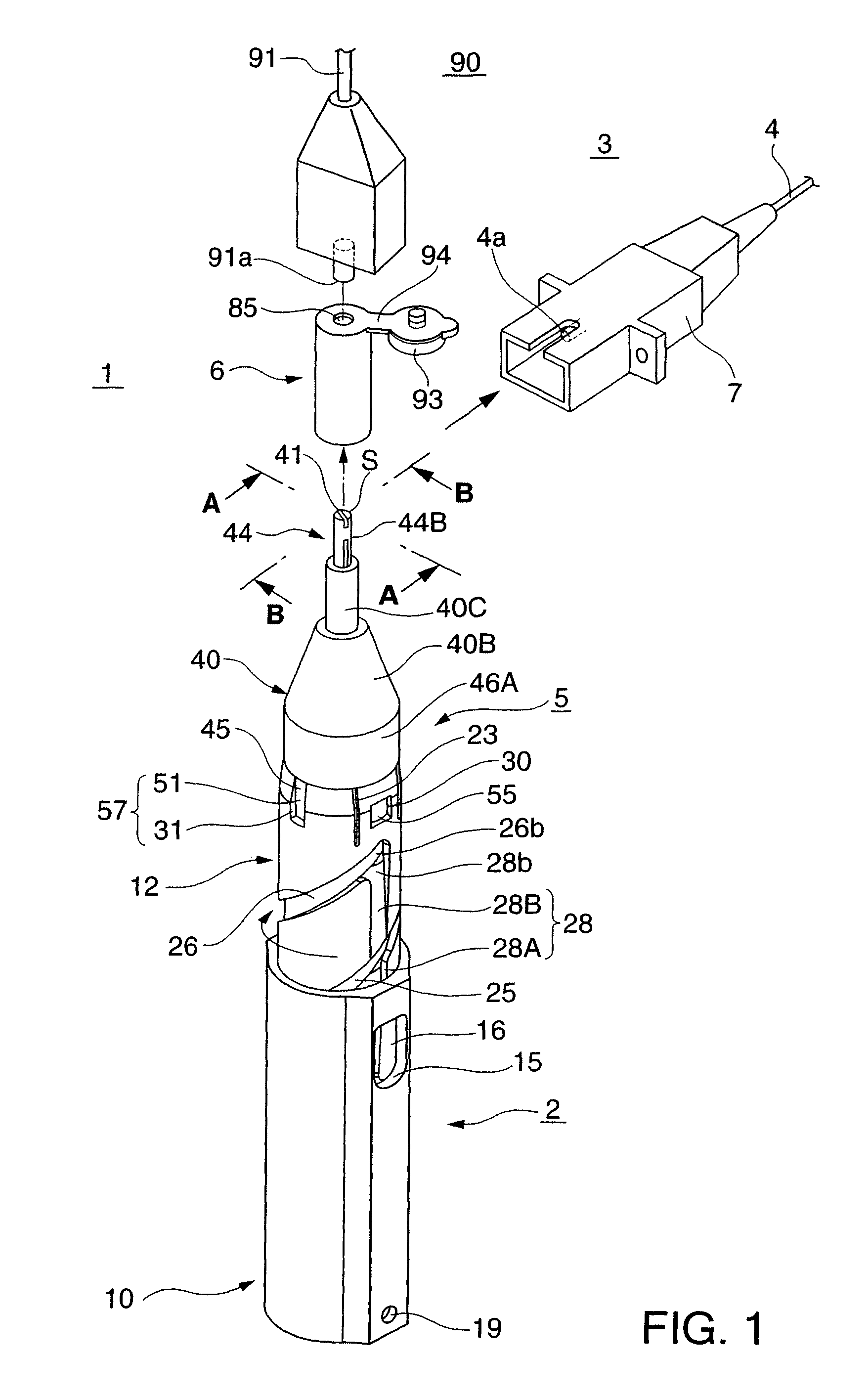

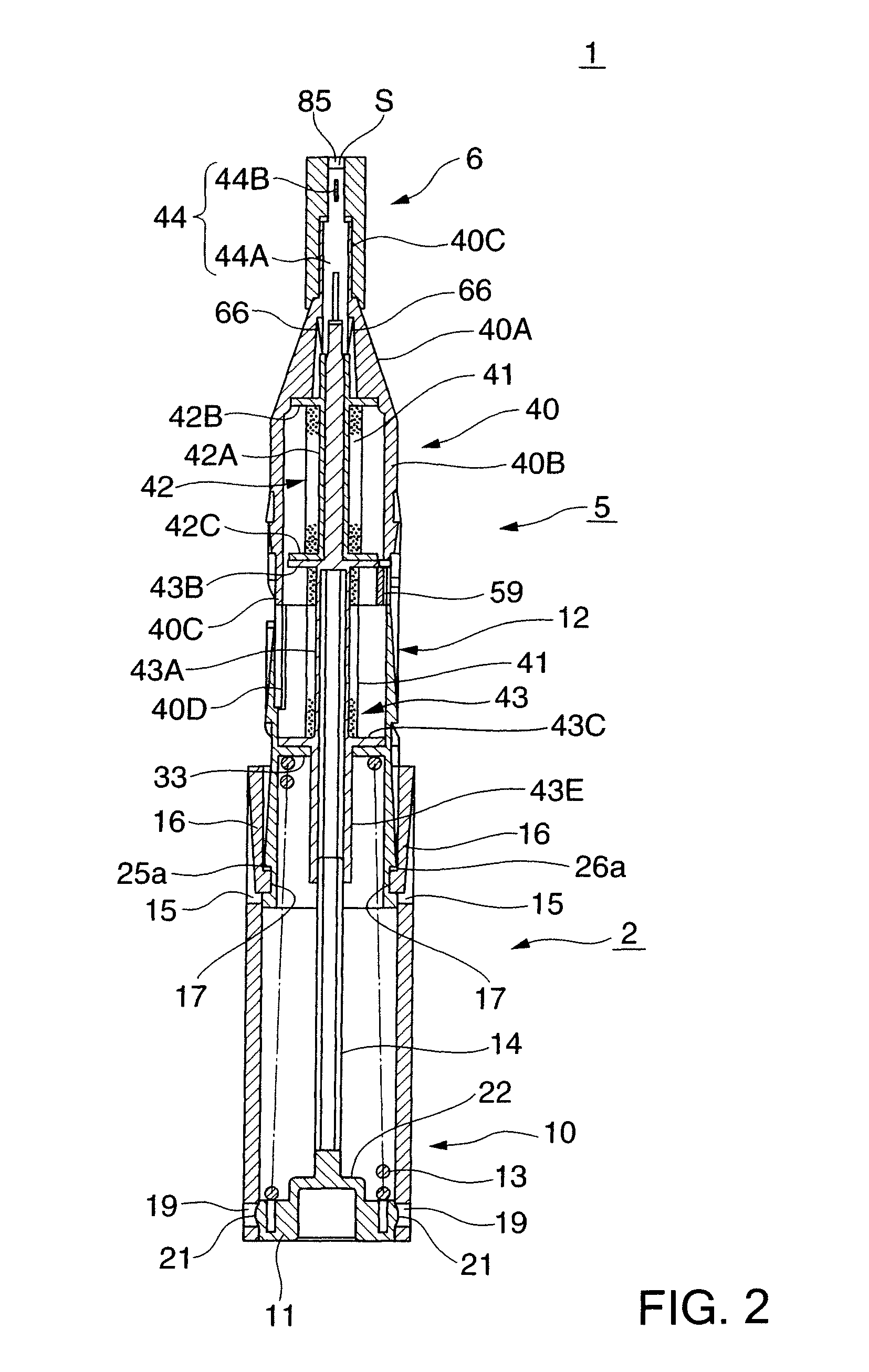

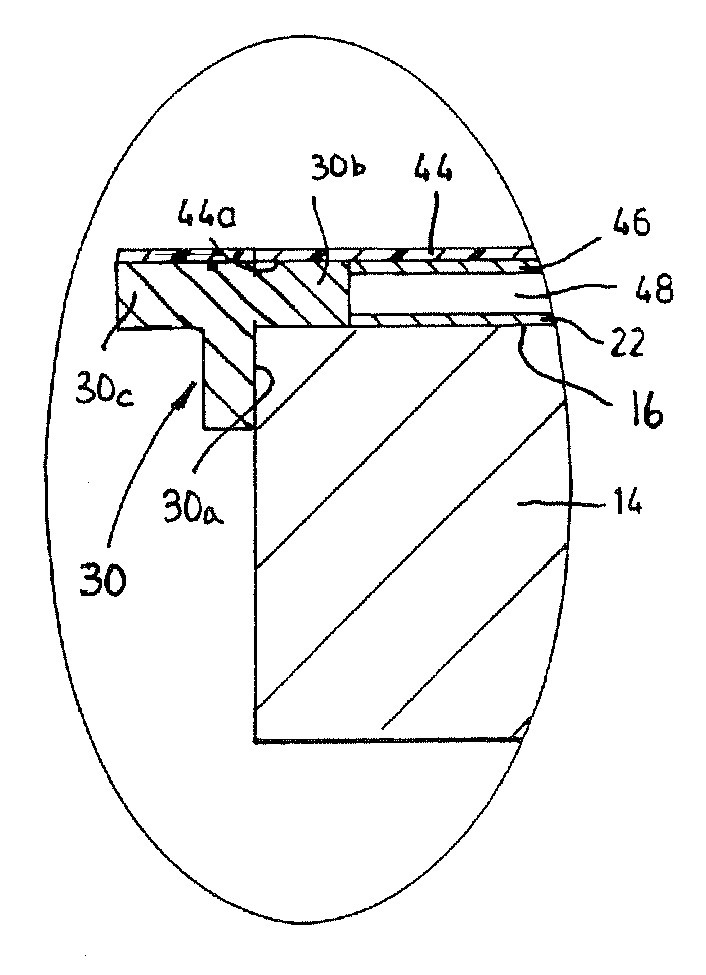

Optical connector cleaning tool

ActiveUS8402587B2Easy to carrySimple structureLiquid processingReconditioning/cleaning record carriersMechanical engineeringHelix

An optical connector cleaning tool includes a holder, cleaner, and cap. The holder includes, a cylindrical slider, a cylindrical body which is rotatable and movable in the axial direction with respect to the slider, and a slider return spring which biases the body forward to return the slider to the initial position. The slider has a pair of elastic pieces having guide projections. In the outer circumferential surface of the body, spiral grooves with which the guide projections engage are formed within the angular range of 360°. When the slider moves forward, the body rotates by the cam action of the guide projections and spiral grooves. The cleaner includes, a cleaning thread accommodated in a rotary pod, a supply reel, a take-up reel, and a cleaning pin, and is connected to the body.

Owner:NTT ADVANCED TECH

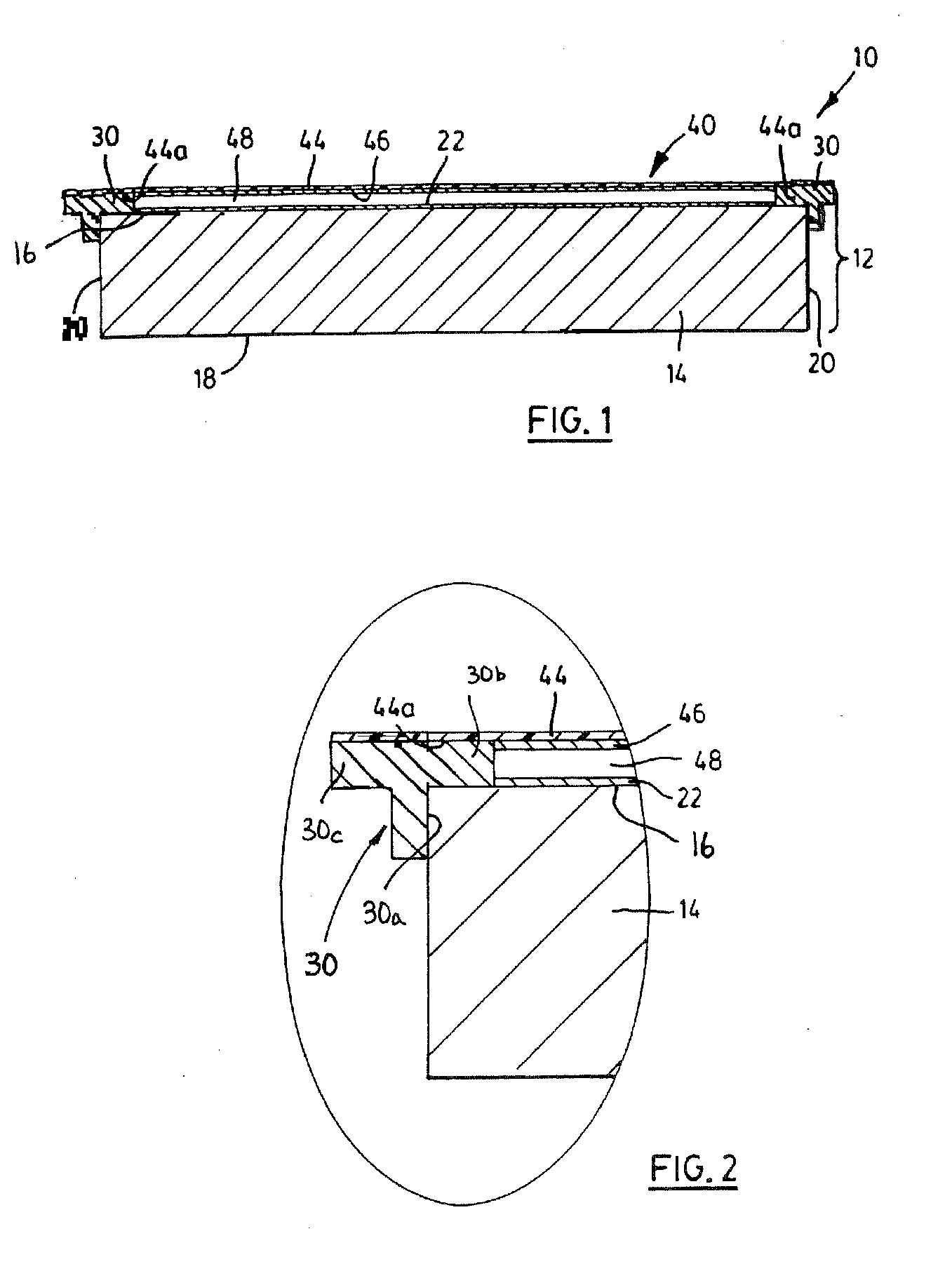

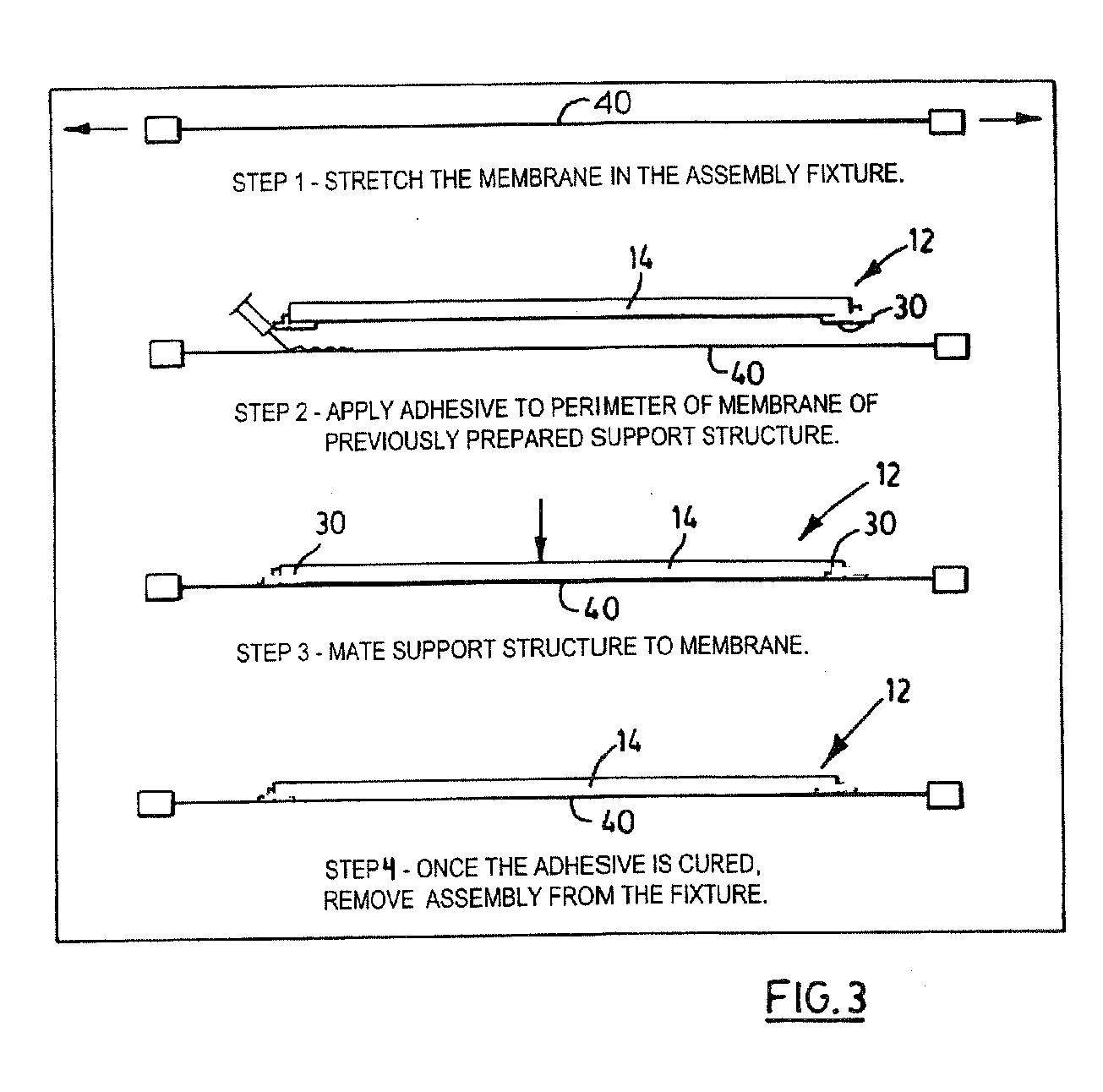

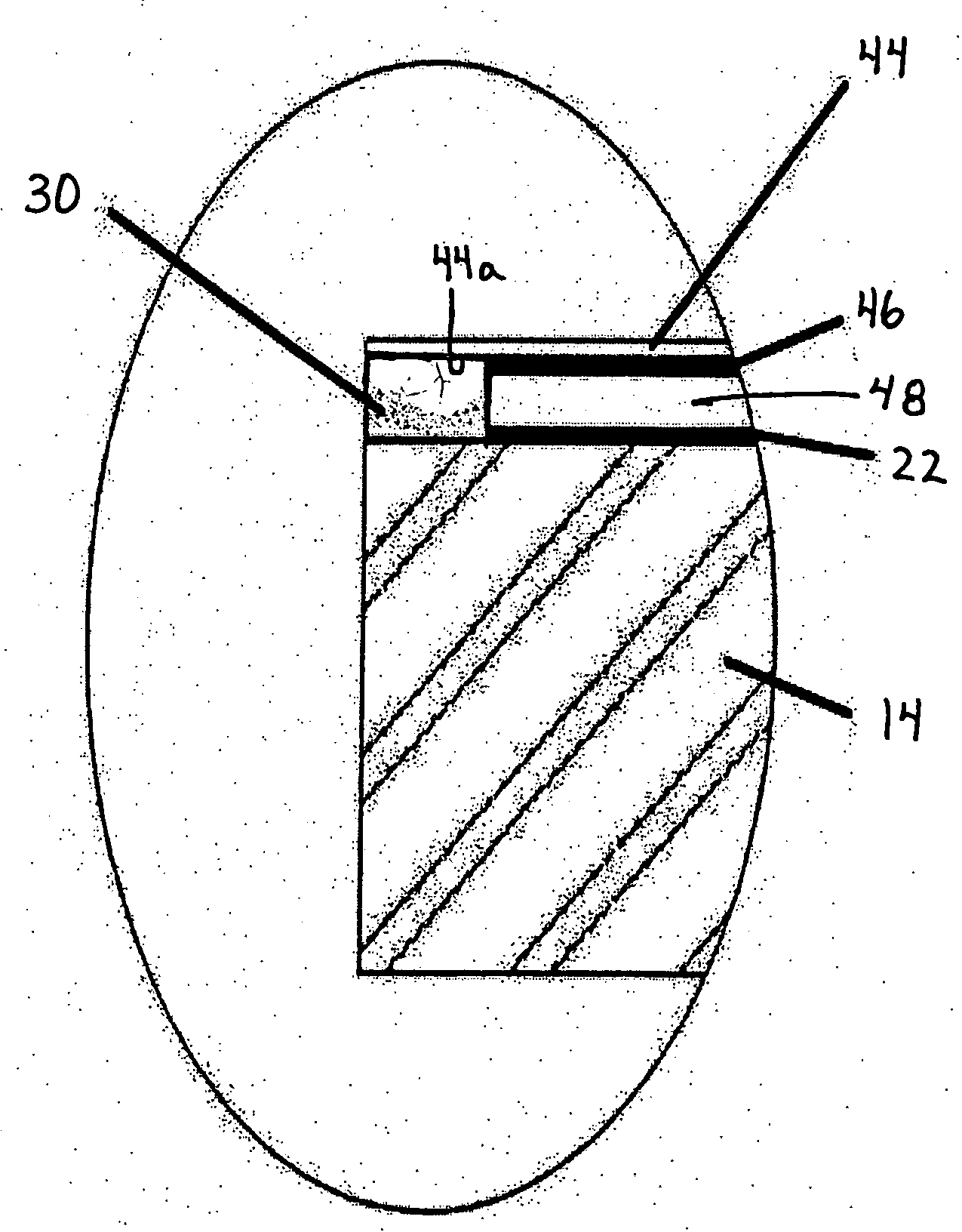

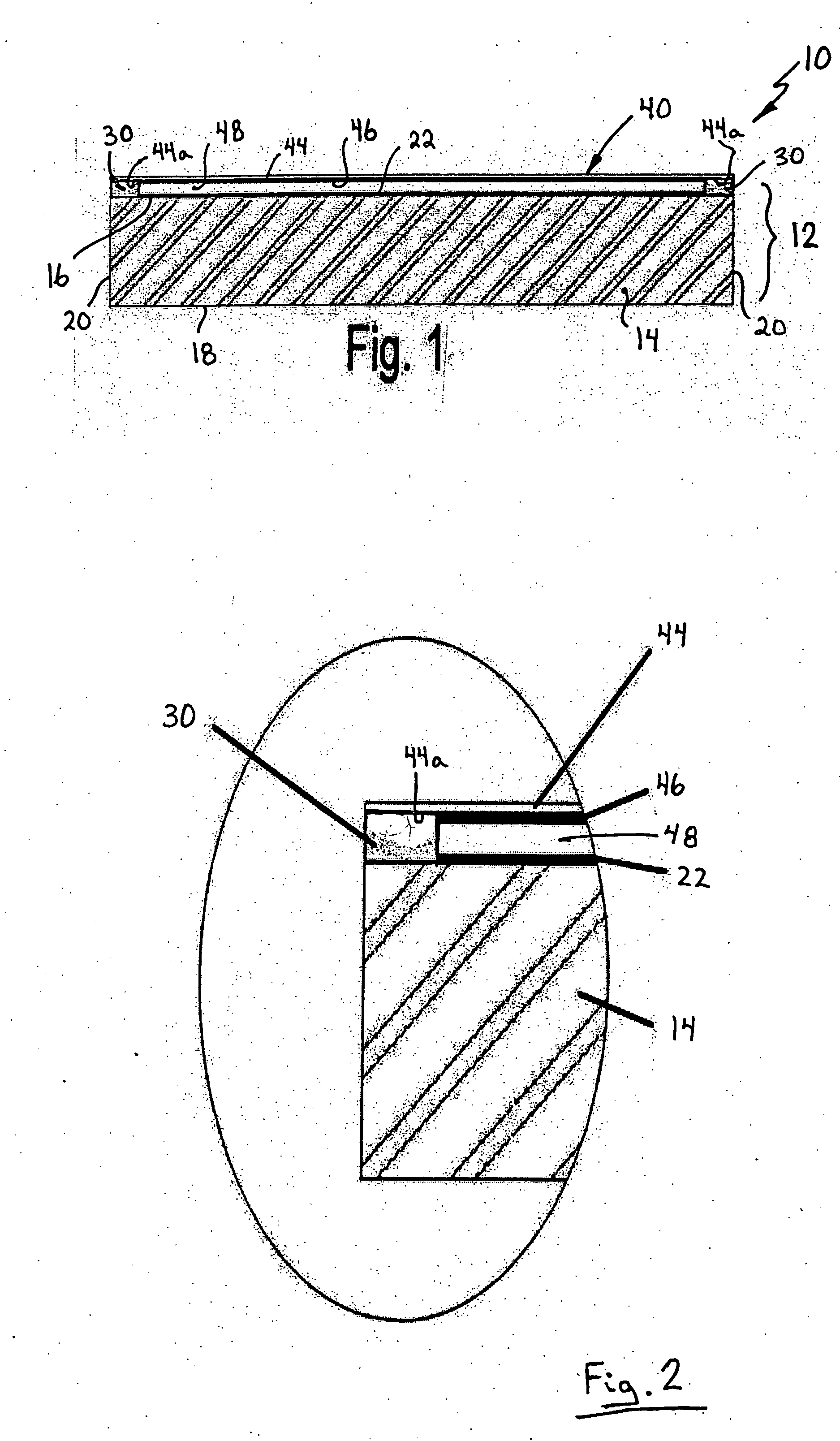

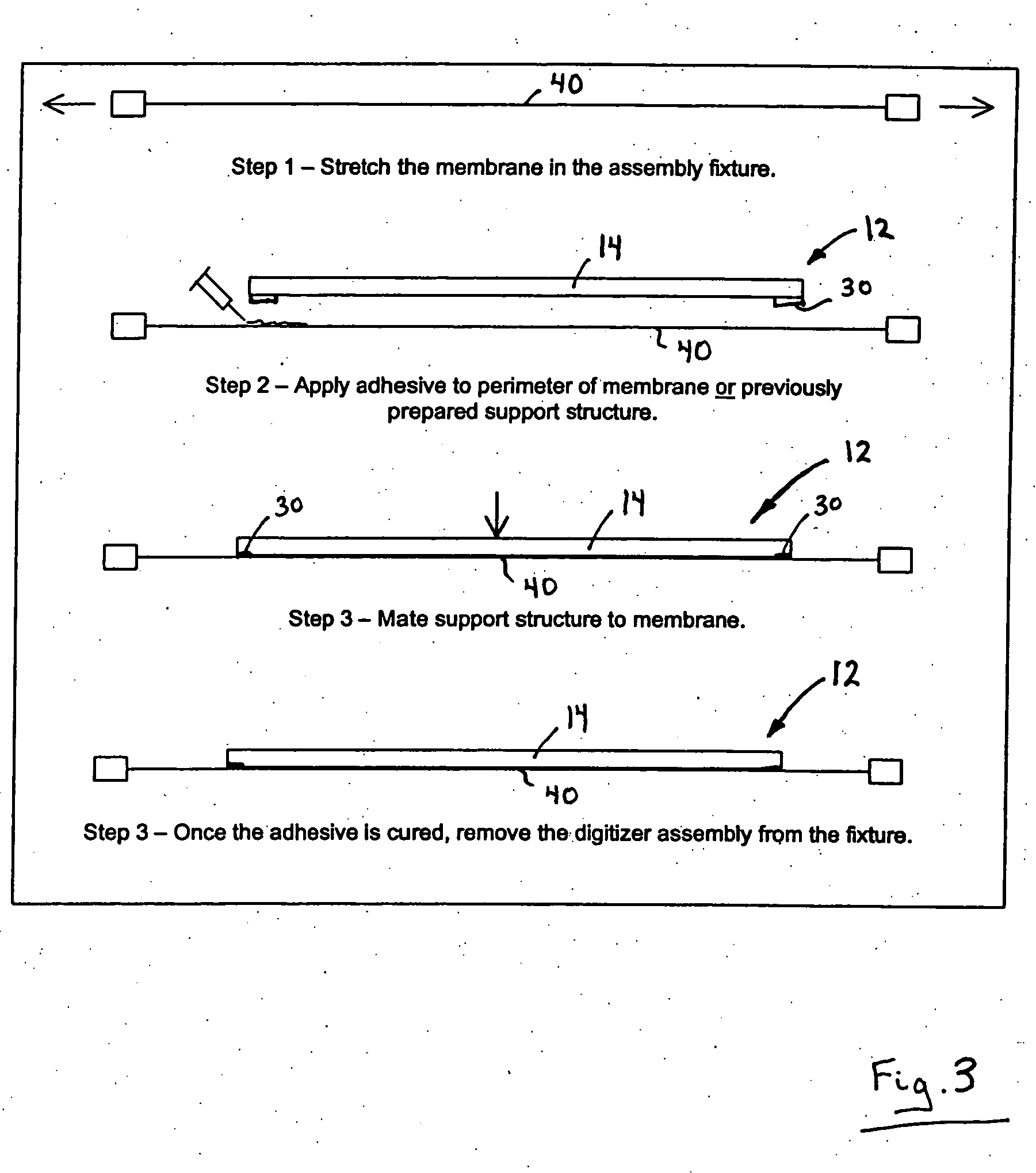

Tensioned touch panel and method of making same

ActiveUS20080083602A1Reducing manufacturing and labour costUniform tensionContact materialsLine/current collector detailsTouchscreenTouch panel

A tensioned touch panel includes a support structure having a substrate with a generally planer conductive surface disposed thereon and an insulating spacer generally about the periphery of the substrate. A pretensioned conductive member overlies the support structure. The spacer separates the conductive membrane and the conductive surface thereby to define an air gap therebetween. A conductive membrane is secured to the support structure under sufficient tension to inhibit slack from developing in the conductive membrane as a result of changes in environmental conditions. A method of assembling a tensioned touch panel is also provided.

Owner:SMART TECH INC (CA)

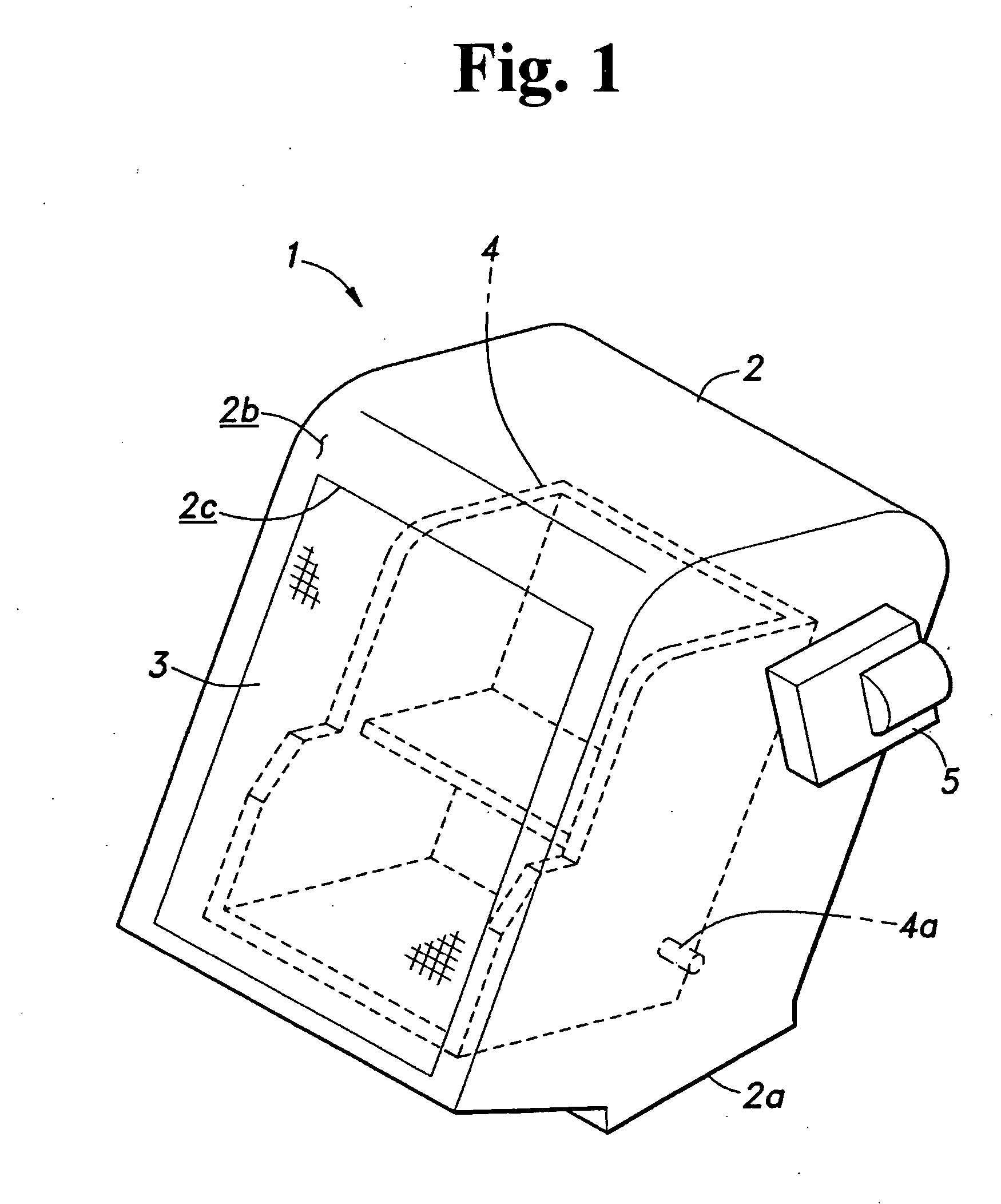

Door unit

InactiveUS20060037713A1Avoid noiseImprove design flexibilityPassenger spaceSunshadesSheet materialEngineering

A door unit for selectively opening and closing an opening in an object includes a door having a bendable slatted door body and a flexible sheet member positioned over the door body. Guide grooves in the object slidably guide at least the door body, and the respective ends of the door body and the sheet member are connected on one end in the sliding direction. By setting an appropriate spacing between the guide grooves, the generation of noise that would otherwise be caused by the door body and the sheet member rubbing against each other when they are opened or closed, is avoided. The use of the separate sheet member also significantly increases the options for the material to be employed for the design surface of the door unit.

Owner:NIFCO INC +1

Wireline System

A device and a method for seabed and water bottom drilling, core sampling and measuring, include a vertically movable and horizontally fixed cross beam, a winch fixed to the cross beam and having a rope wound thereon, a drill head disposed on the cross beam, a spindle having a bore formed therein and being driven by the drill head and an overshot having one end connected to the rope and another end passing through the bore in the spindle for attachment to and detachment from a drilling tool of a drillstring. The spindle, the rope and the drillstring together define a common centerline during attachment and detachment of the overshot to and from a drilling tool and during drilling. A lift rod connected between the rope and the overshot can be pulled into the bore in the spindle prior to commencing rotary drilling for sealing the top of the bore.

Owner:TGH US

Tensioned touch panel and method of making same

ActiveUS20050241929A1Lower manufacturing requirementsReduce labor costsContact materialsContact surface shape/structureTouchscreenTouch panel

A tensioned touch panel includes a support structure having a substrate with a generally planer conductive surface disposed thereon and an insulating spacer generally about the periphery of the substrate. A pretensioned conductive member overlies the support structure. The spacer separates the conductive membrane and the conductive surface thereby to define an air gap therebetween. A conductive membrane is secured to the support structure under sufficient tension to inhibit slack from developing in the conductive membrane as a result of changes in environmental conditions. A method of assembling a tensioned touch panel is also provided.

Owner:SMART TECH INC (CA)

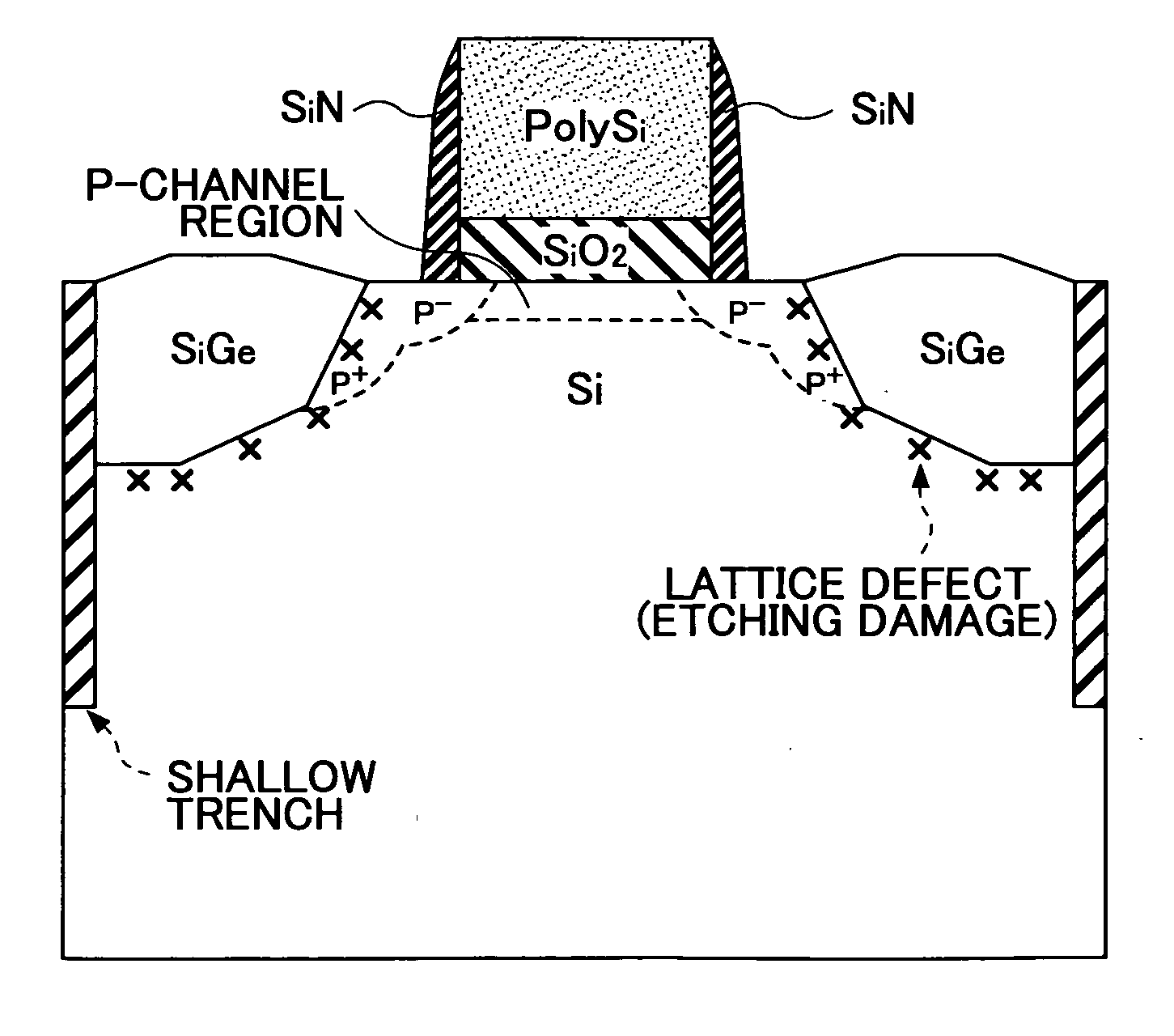

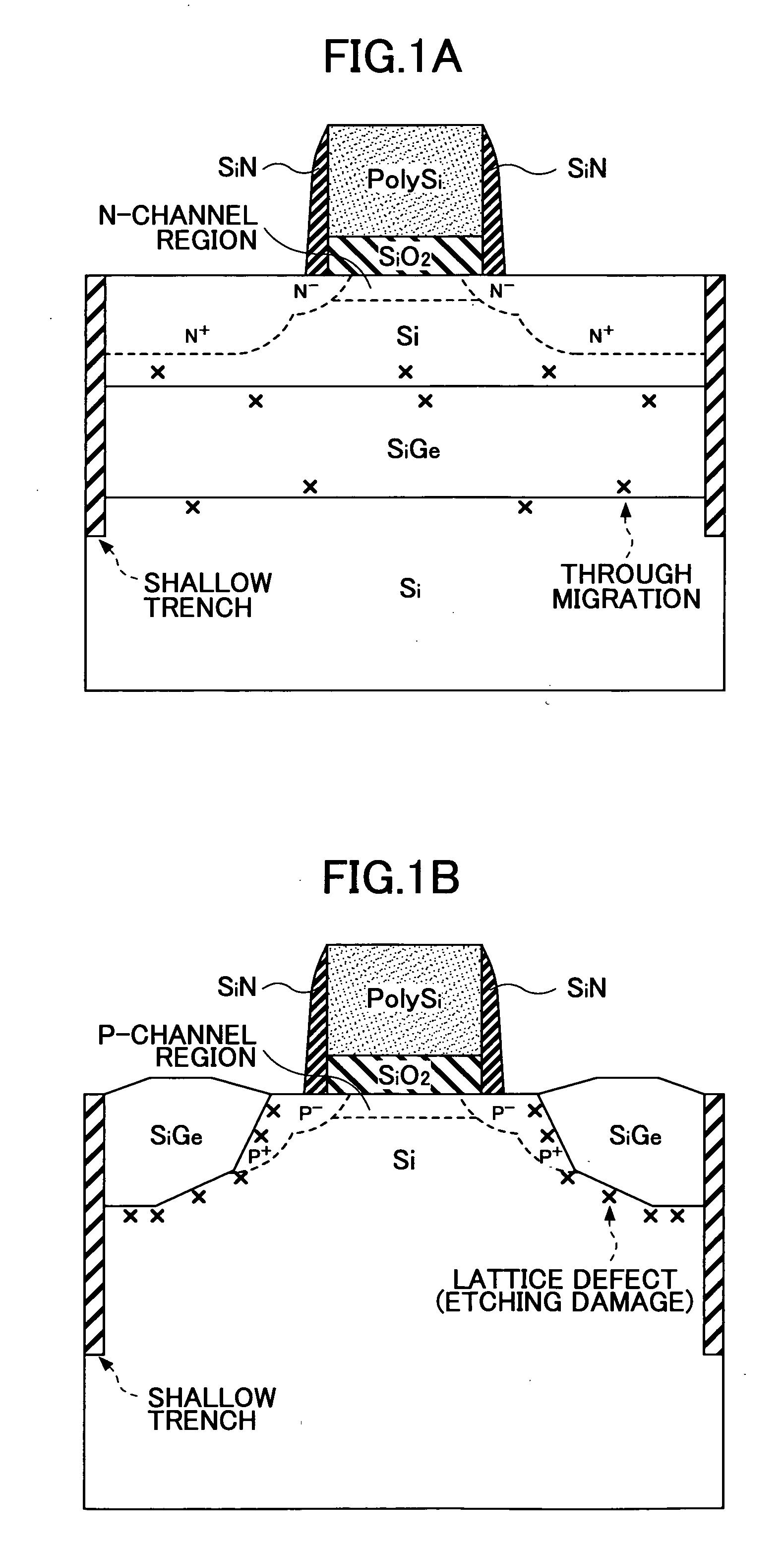

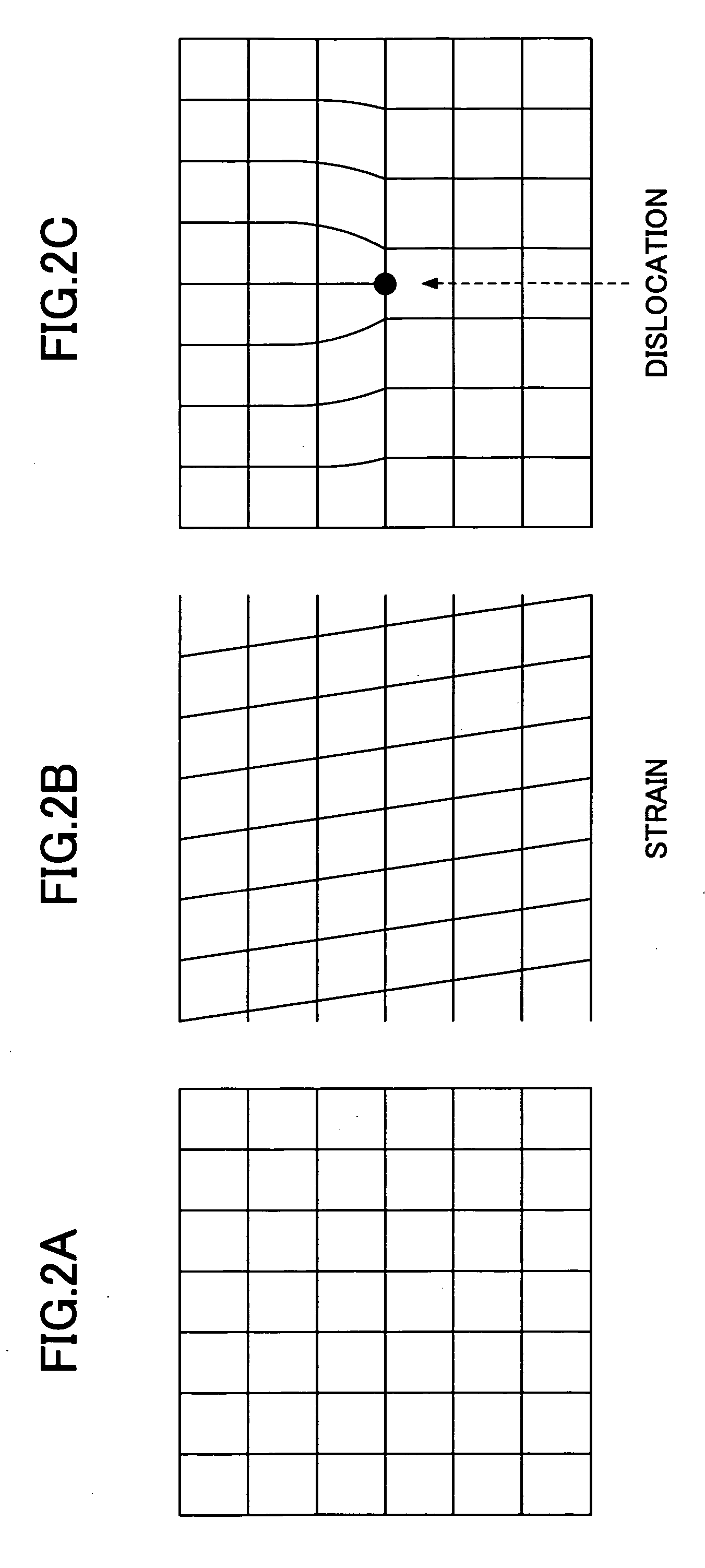

Semiconductor device and manufacturing method thereof

A semiconductor device includes a field effect transistor and a strain generating layer to apply a stress to a channel region of the field effect transistor. The strain generating layer contains at least one of oxygen and nitrogen of 1.0×1018 cm−3 to 5.0×1019 cm−3, or alternatively, the strain generating layer contains self-interstitial atoms and / or vacancies of 1.0×1018 cm−3 to 5.0×1019 cm−3. In the latter case, at least a portion of the self-interstitial atoms and / or the vacancies exist as a cluster.

Owner:FUJITSU LTD

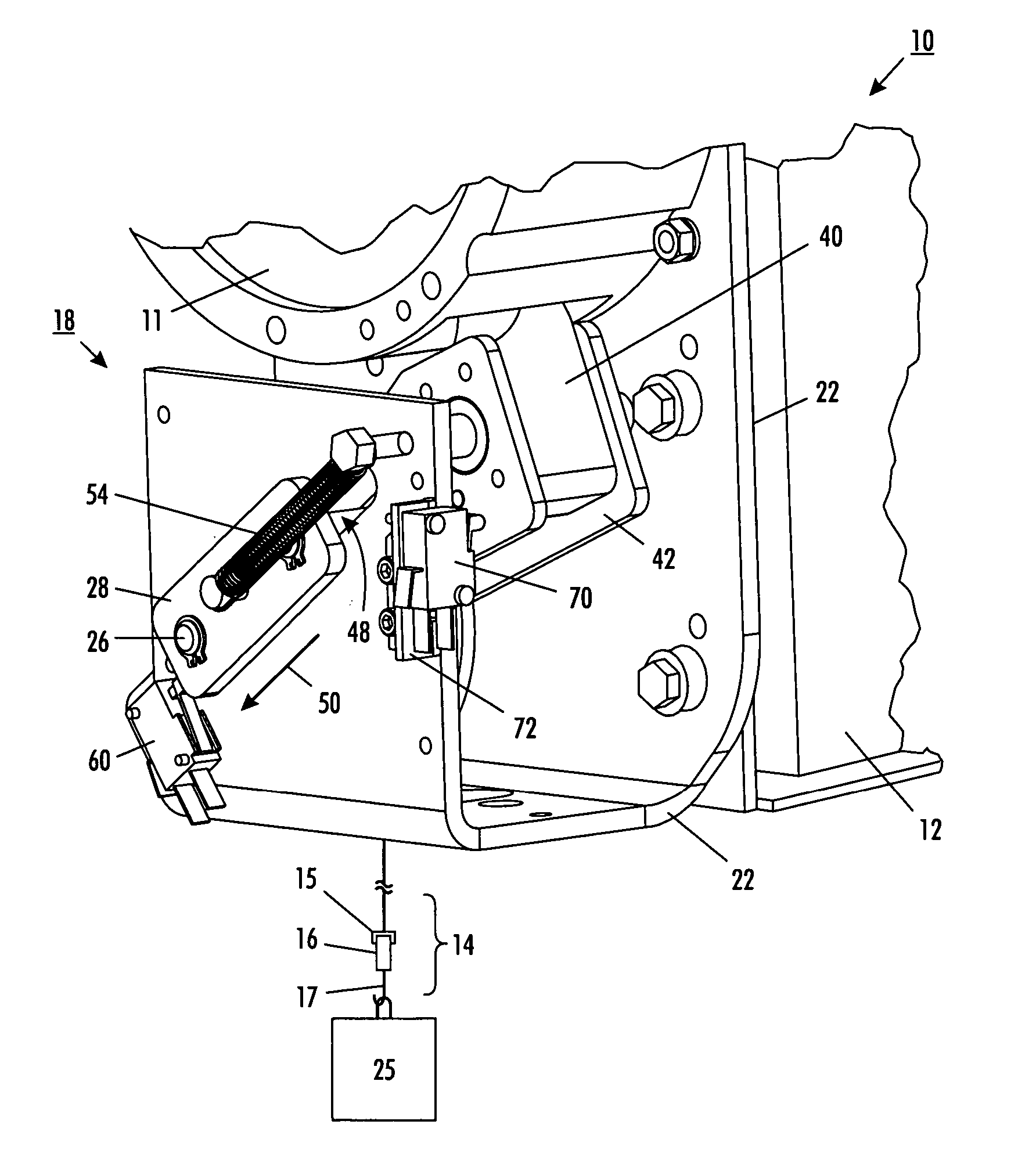

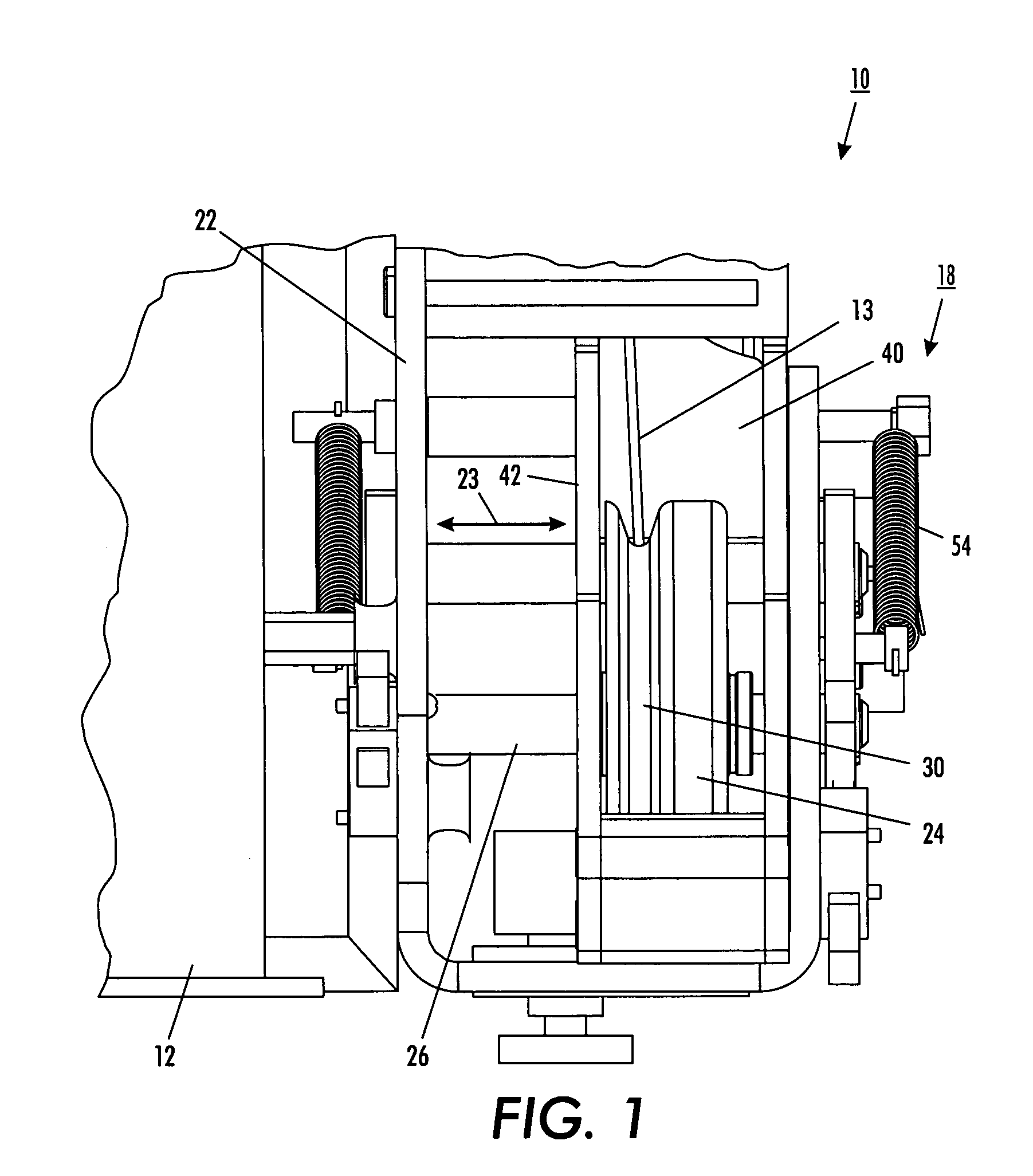

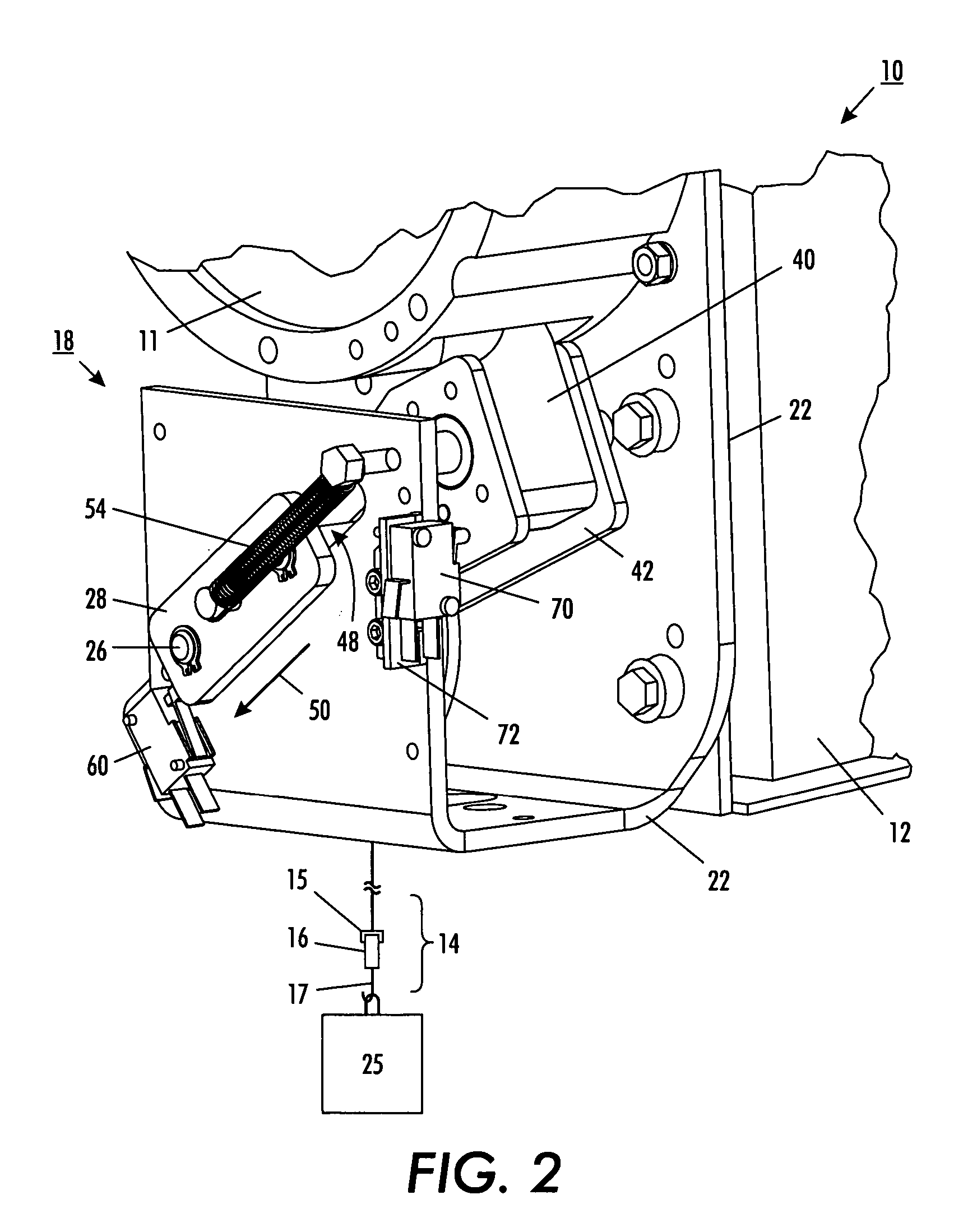

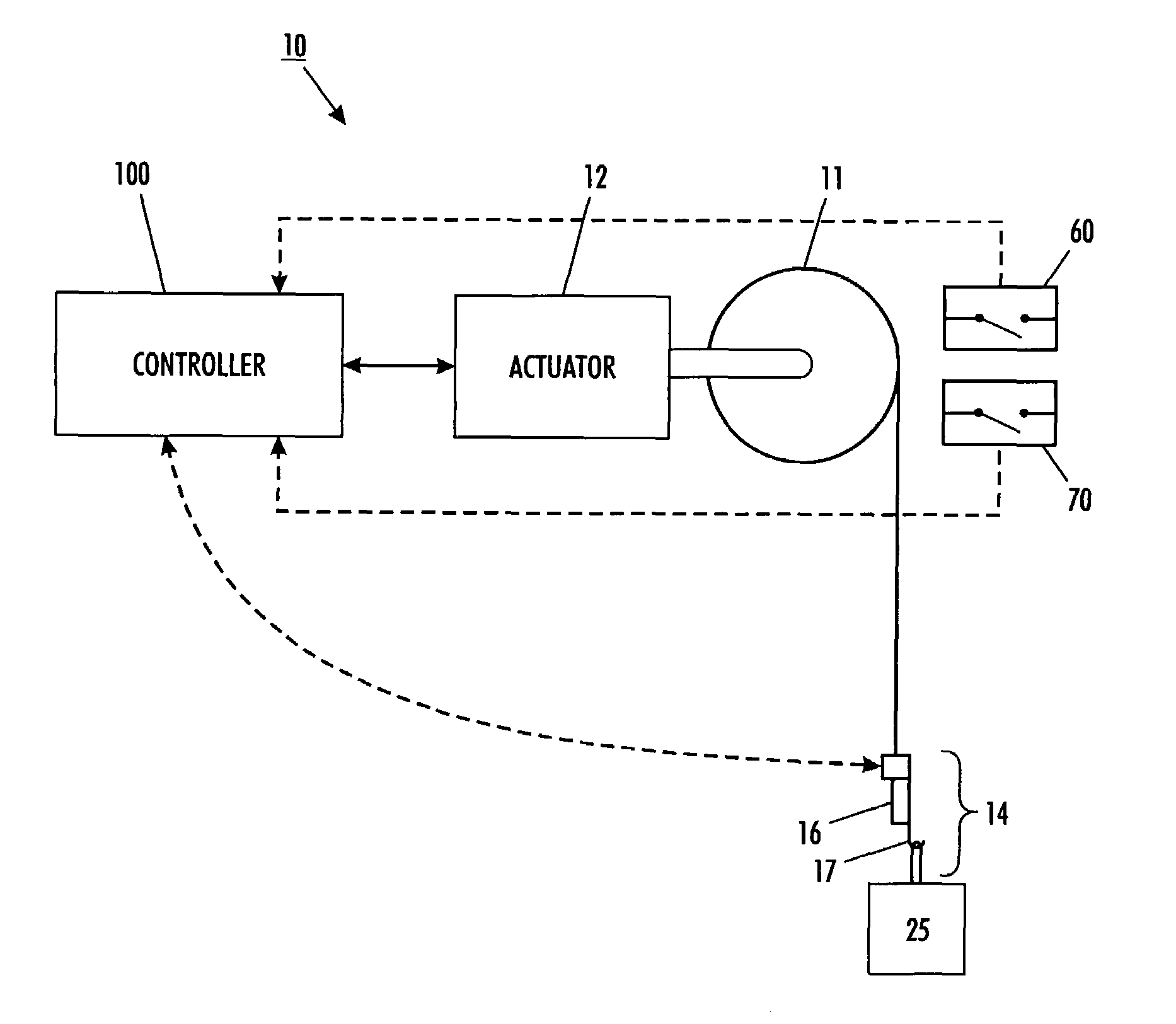

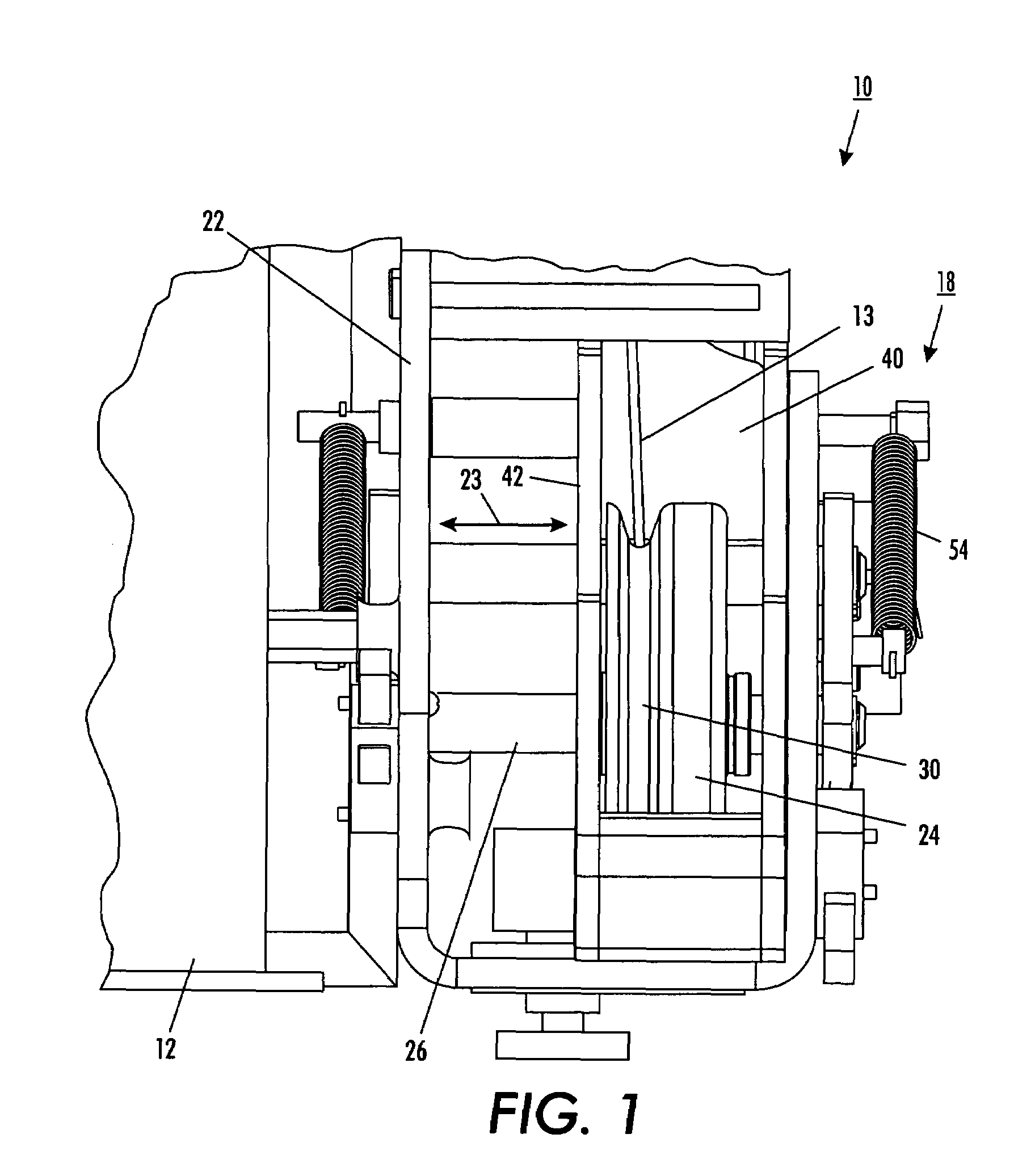

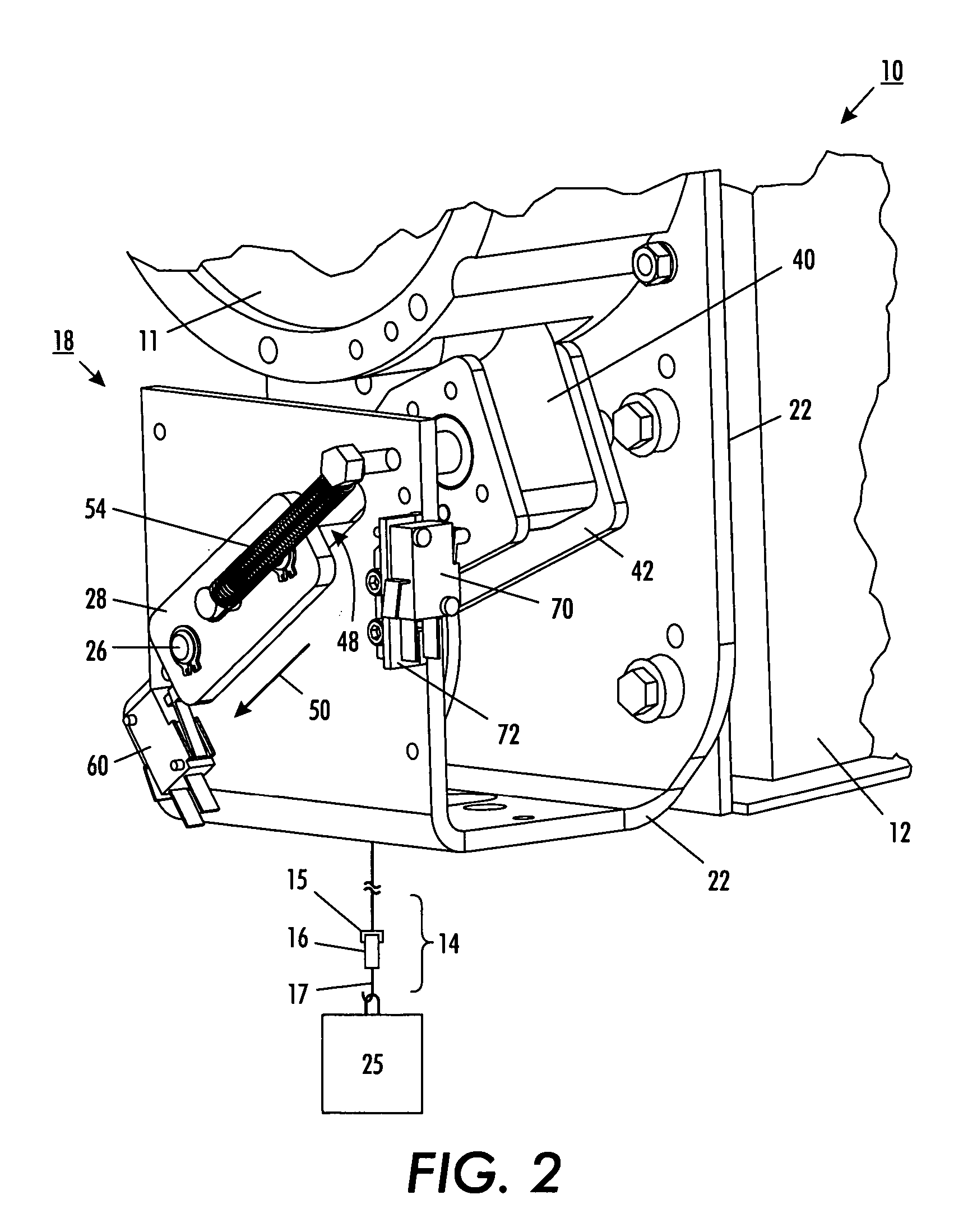

Cable slack and guide monitoring apparatus and method for a lift device

InactiveUS20050179020A1Improve performanceImprove securityFilament handlingPortable liftingElevator systemEngineering

The present invention is a method and apparatus for monitoring the condition of a cable in a human power amplifying lift system. The method and apparatus employ a cable slack sensor and a cable end sensor to override and prevent the lift from continuing to unwind the lift cable when slack or and end of travel limit has been reached.

Owner:GORBEL INC

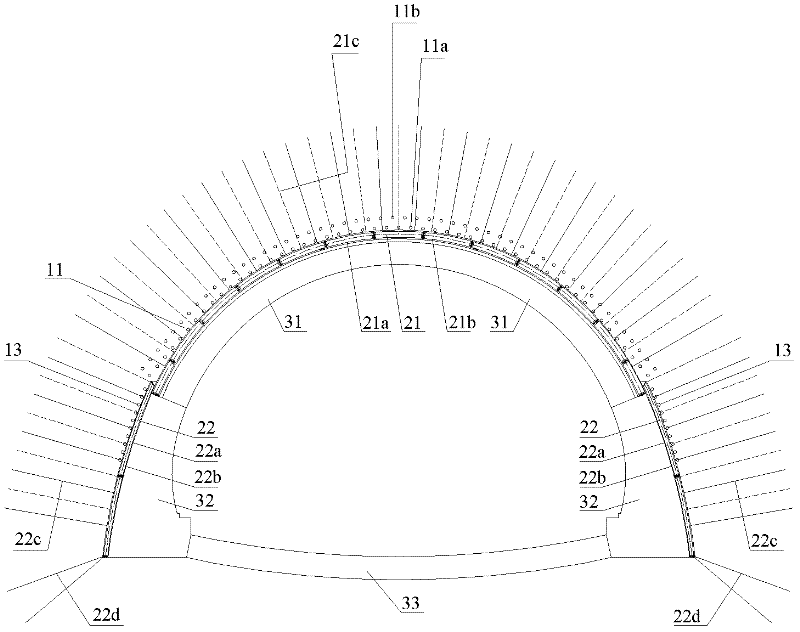

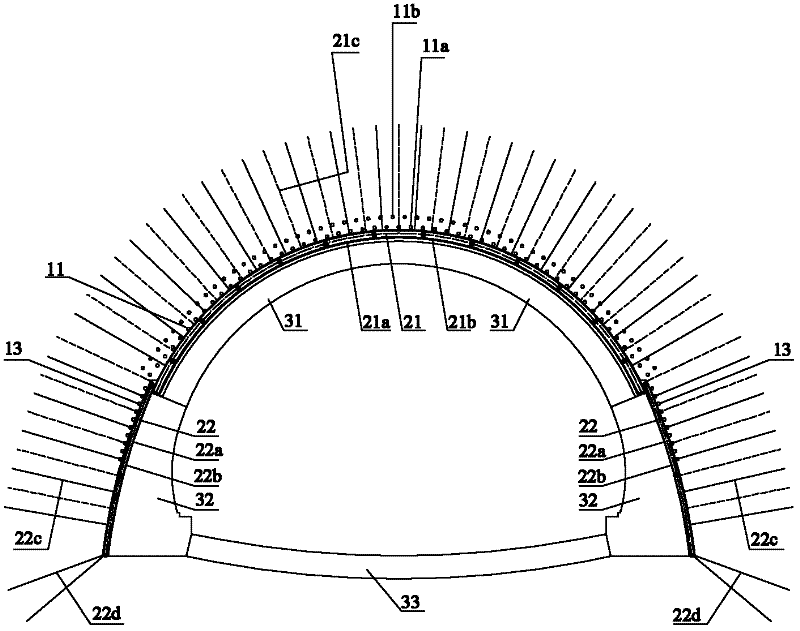

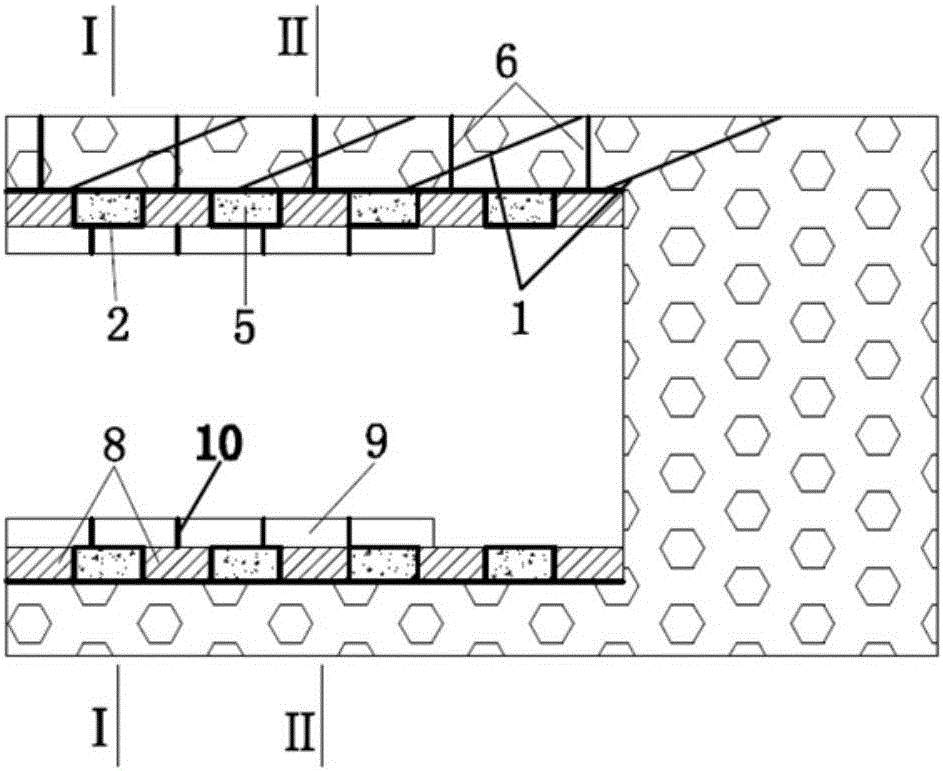

Composite liner structure of four-track large-span wall-foundation arched tunnel

InactiveCN102213099ASolve the problem of sinking deformationIncrease stiffnessUnderground chambersTunnel liningComposite linerSubsidence

The invention relates to a composite liner structure of a four-track large-span wall-foundation arched tunnel. According to the composite liner structure provided by the invention, subsidence of an arch crown of a four-track large-span tunnel can be effectively controlled, and crack of a liner, even a tunnel collapse accident caused by subsidence of an arch springing and deformation of the arch crown can be avoided so that the stability and the safety of tunnel construction and operation are ensured. The composite liner structure comprises a forepoling structure, a preliminary poling structure and a secondary liner structure which are arranged from inside to outside. The secondary liner structure comprises a secondary liner structure (31) at an arch part, wall-foundation structures (32) at two sides of a tunnel and an inverted arch; the forepoling structure comprises a forepoling structure (11) at the arch part and forepoling structures (12) on the side walls of a wall foundation; the preliminary poling structure comprises preliminary poling structures (21) at the arch part and preliminary poling structures (22) on the side walls of the wall foundation; and the lower ends of the preliminary poling structures (21) at the arch part and the secondary liner structure (31) at the arch part are respectively supported at the upper ends of the wall-foundation structures (32) at two sides of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

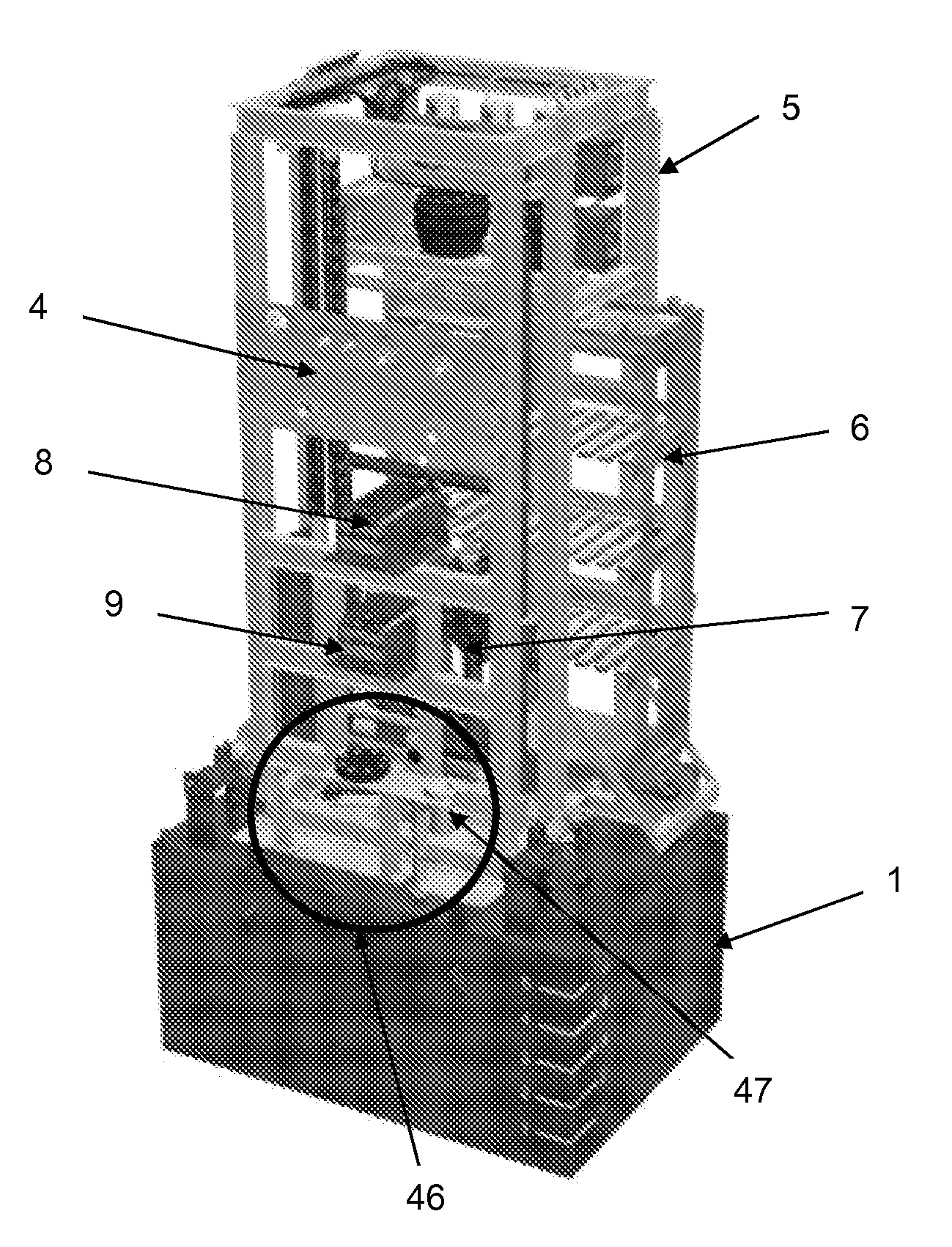

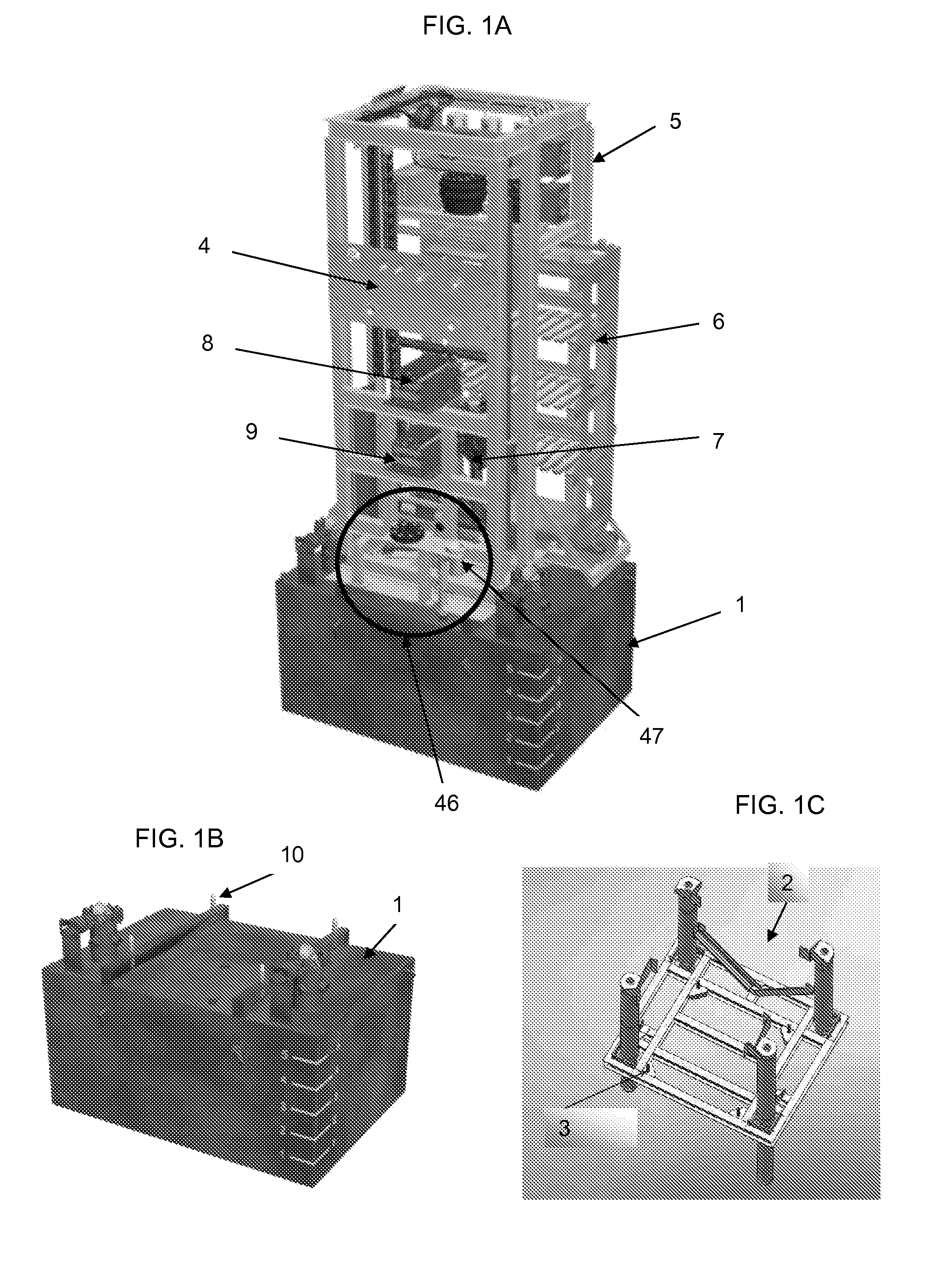

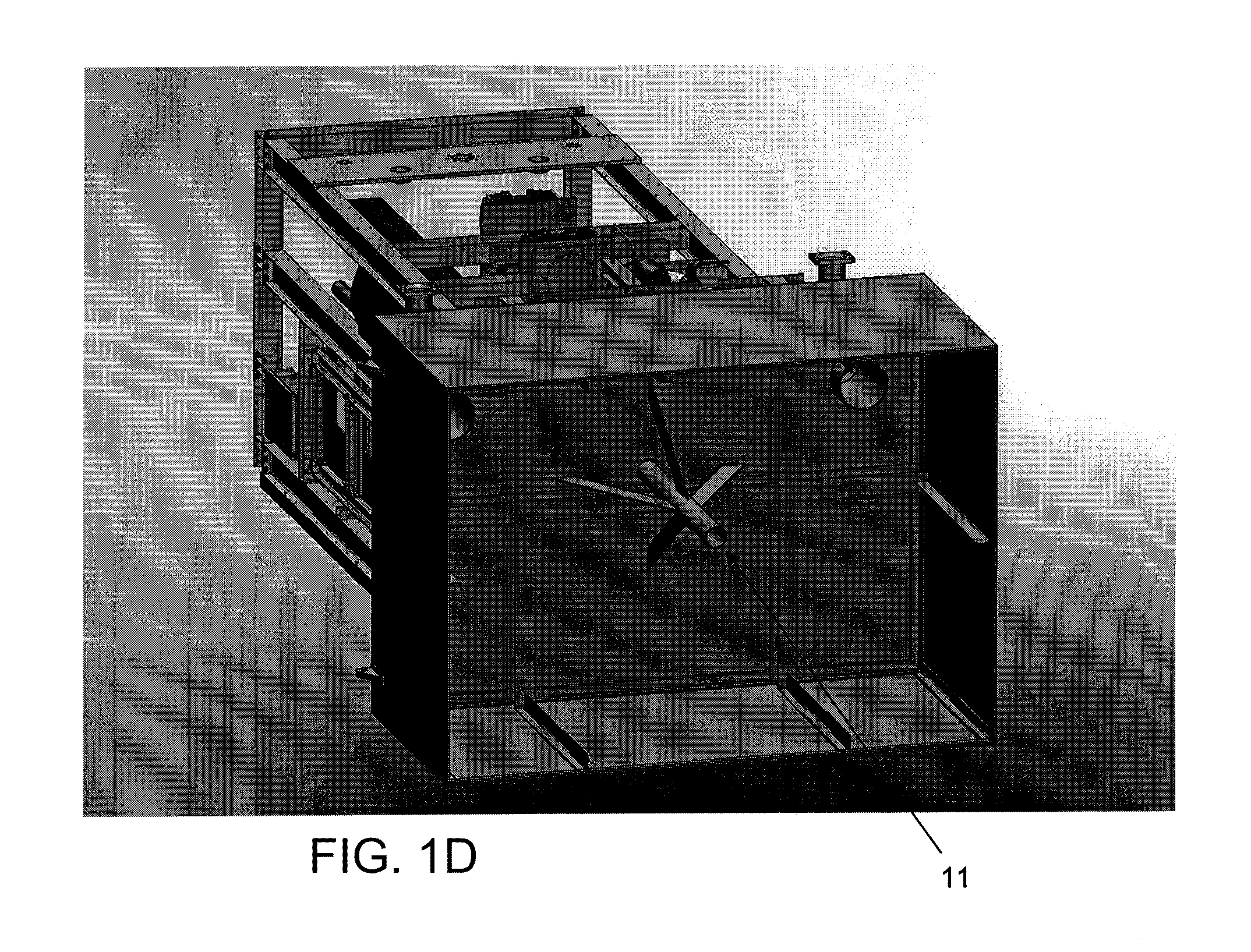

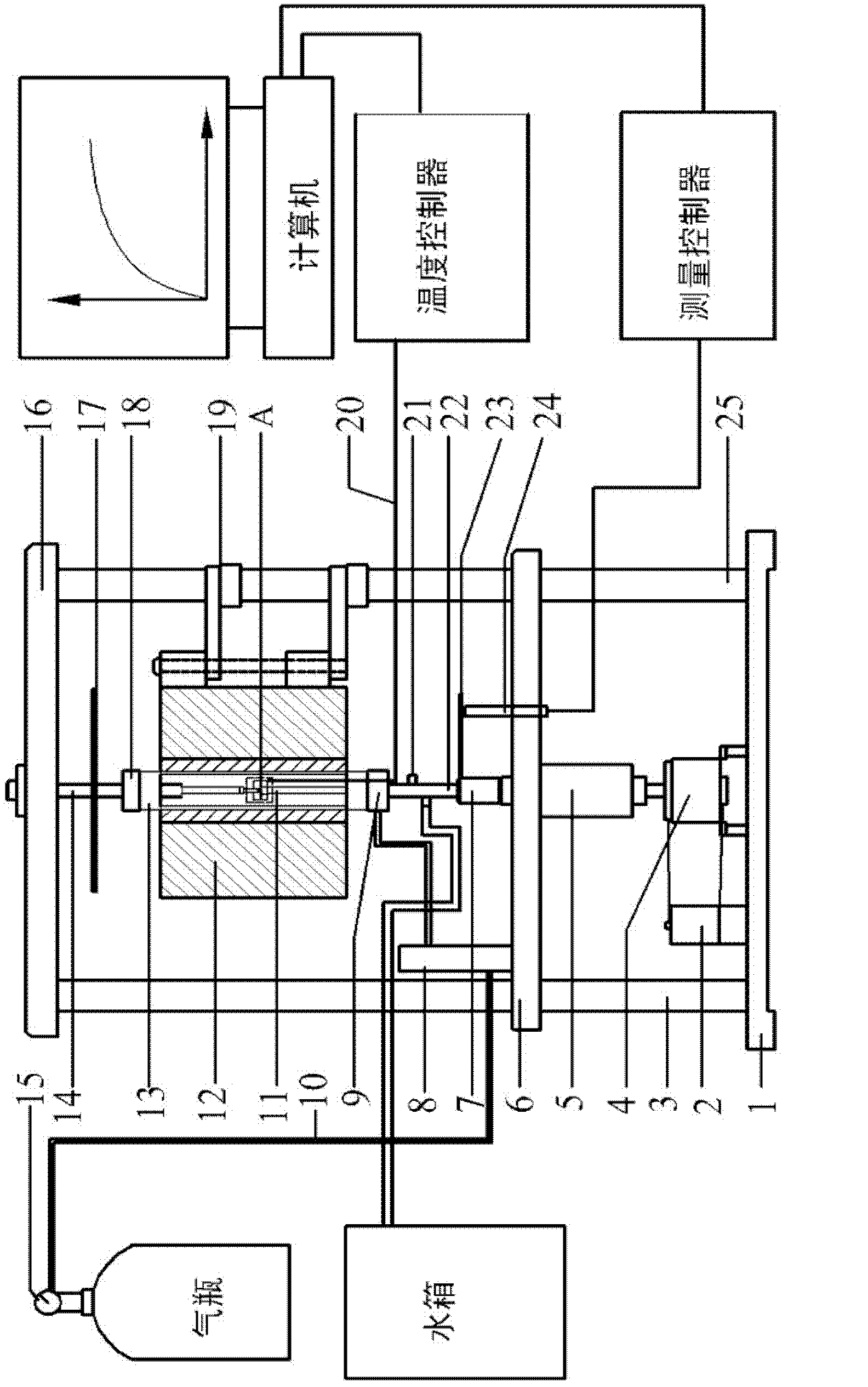

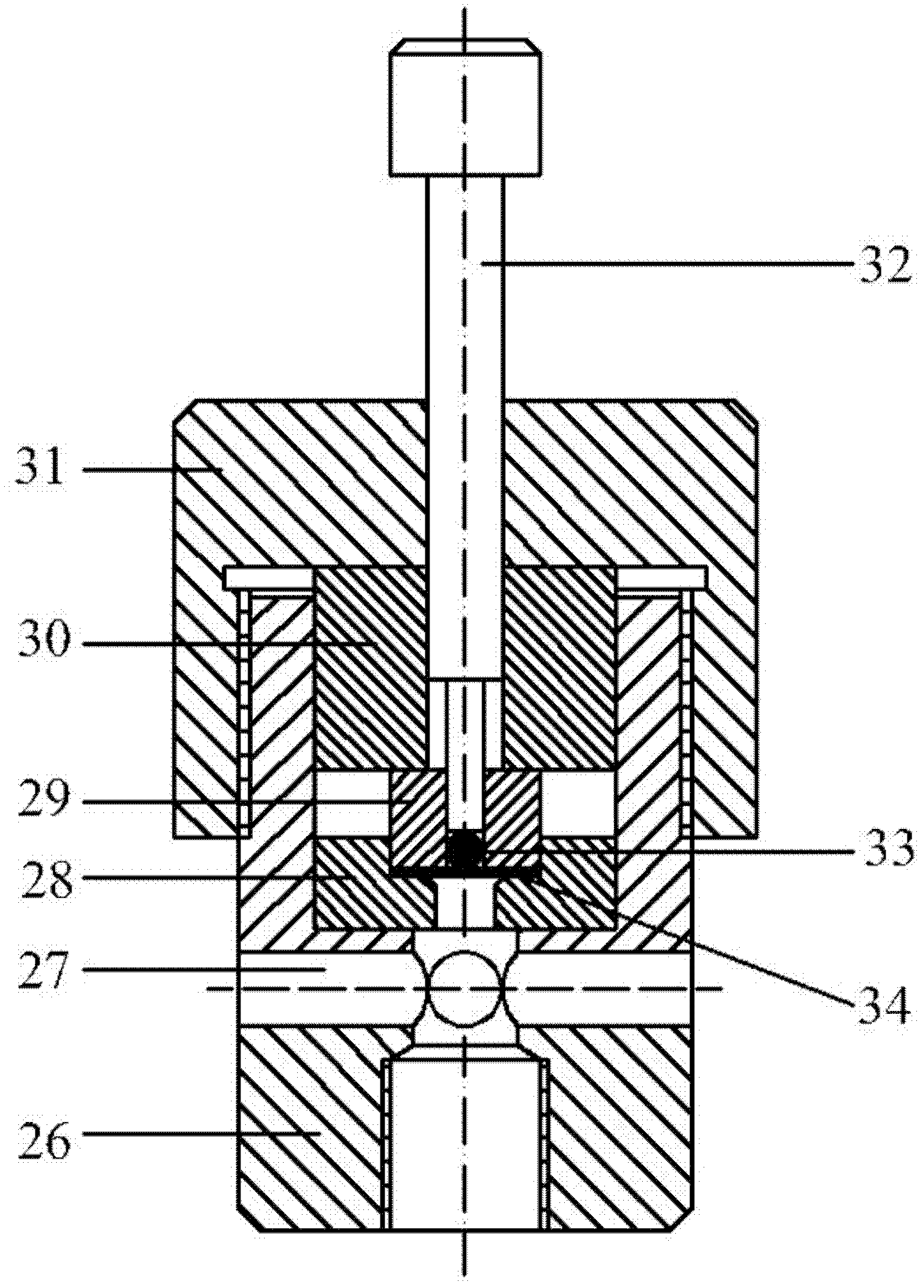

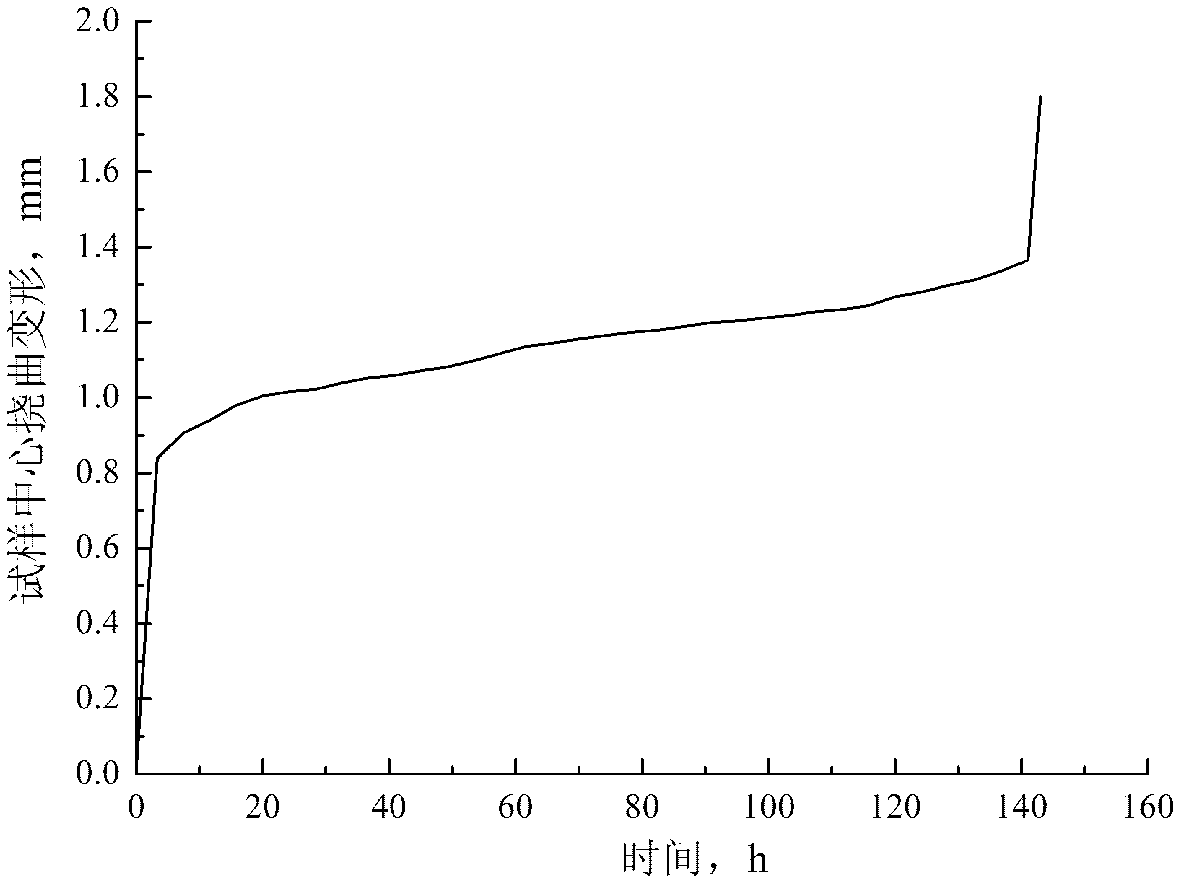

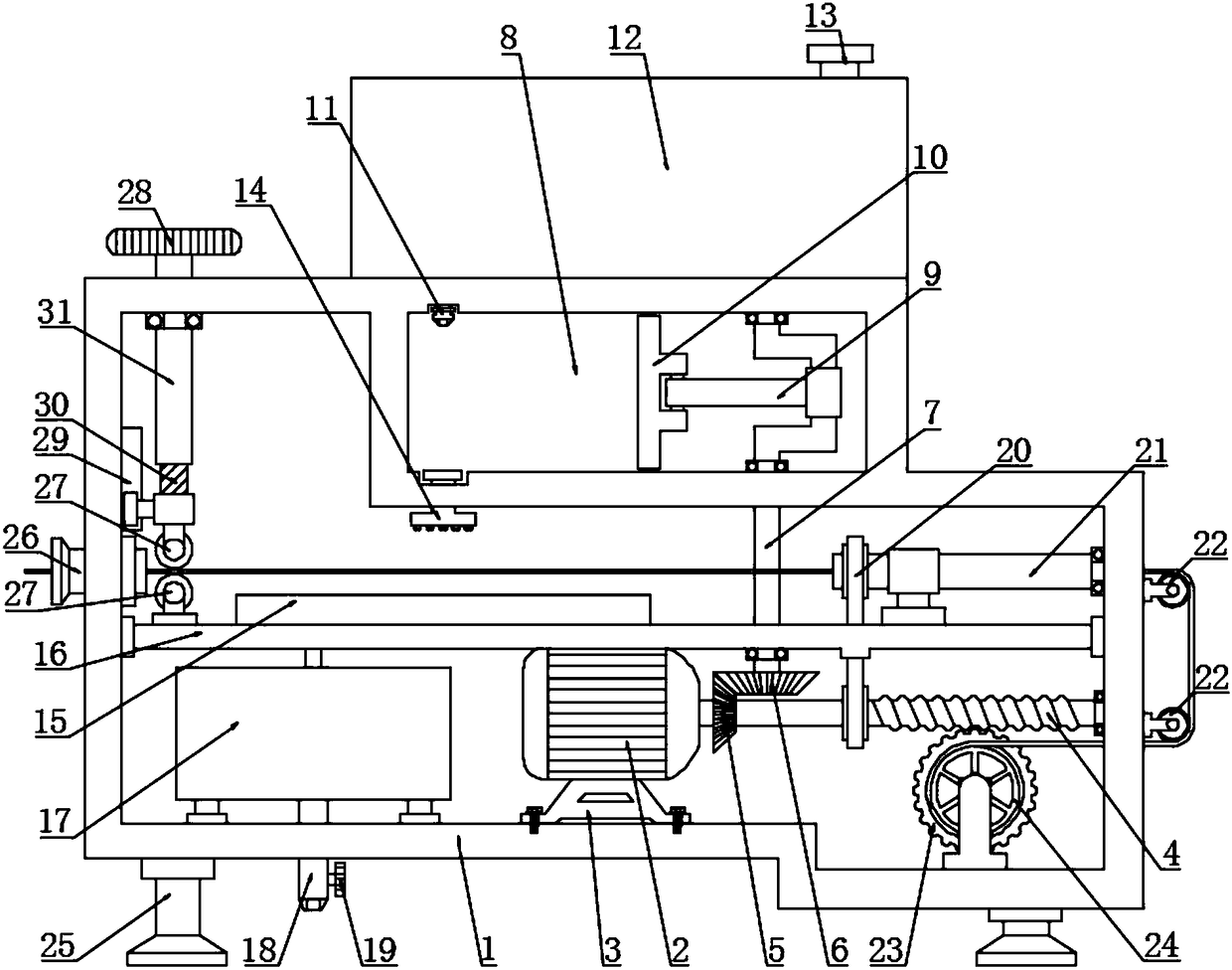

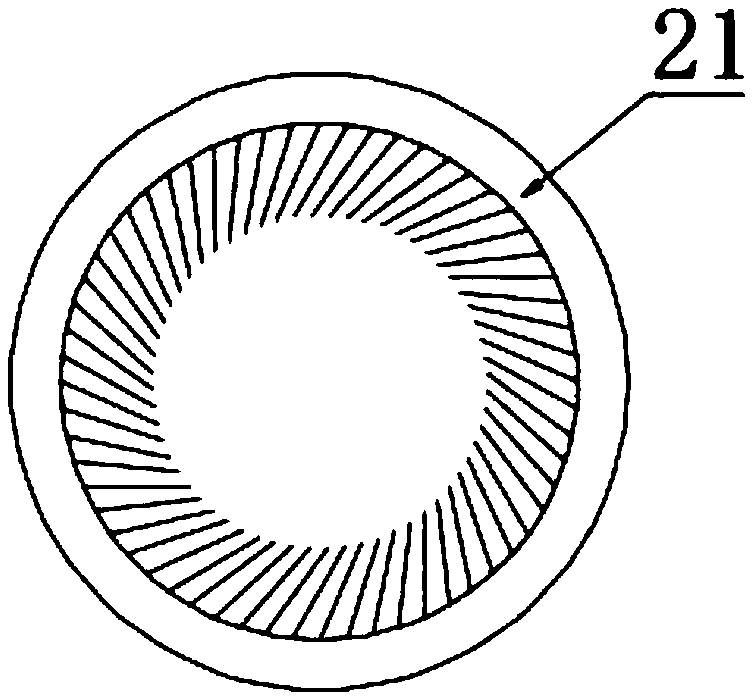

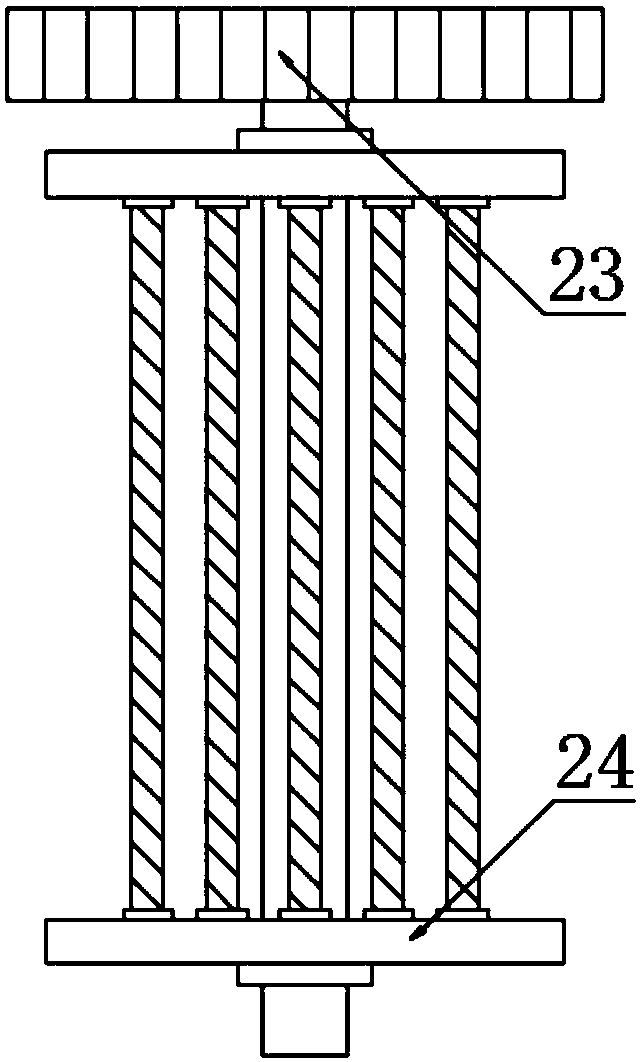

Subminiature minimal invasion high-temperature creep fatigue testing machine and application thereof

ActiveCN102621011AReduce the impactGuaranteed temperatureInvestigating material ductilityEngineeringProtection system

The invention discloses a subminiature minimal invasion high-temperature creep fatigue testing machine and the application thereof. The subminiature minimal invasion high-temperature creep fatigue testing machine mainly includes a driving system, a loading device, a constant temperature atmosphere furnace, a temperature control system, a high temperature gas protection system, a measurement control system and a water cooling system, wherein the loading manner of the machine is top vertical loading; a testing sample is positioned between an upper fixing platform and a lower fixing platform; and when loading is performed, a servo motor controls a lower loading rod to move upwards, a jumper bar is contacted with an upper loading rod, the lower end of the jumper bar is used for testing sample stamping through a pressure head. Aiming at an existing structure and a domain structure at a high temperature, the testing machine provided by the invention can be used for obtaining various high temperature performance of the material and estimating residual service life creep, safety operation state and the like of the high temperature structure, is convenient to operate, is uniform in testing temperature and high in testing precision, can be used for testing various high temperature performances such as high-temperature creep performance, high-temperature relaxation performance, high-temperature creep fatigue performance and high-temperature breaking toughness of the material.

Owner:TIANJIN UNIV

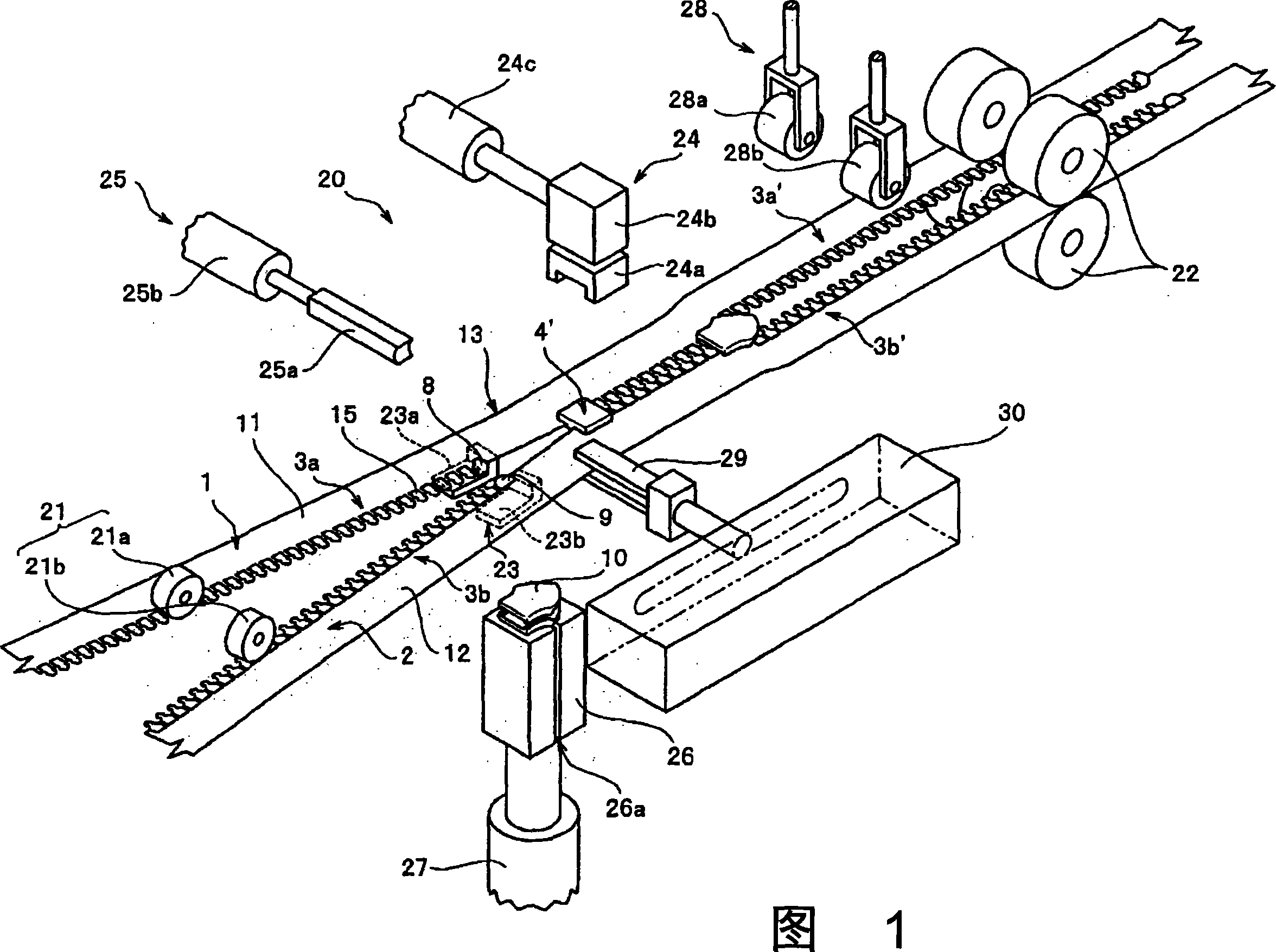

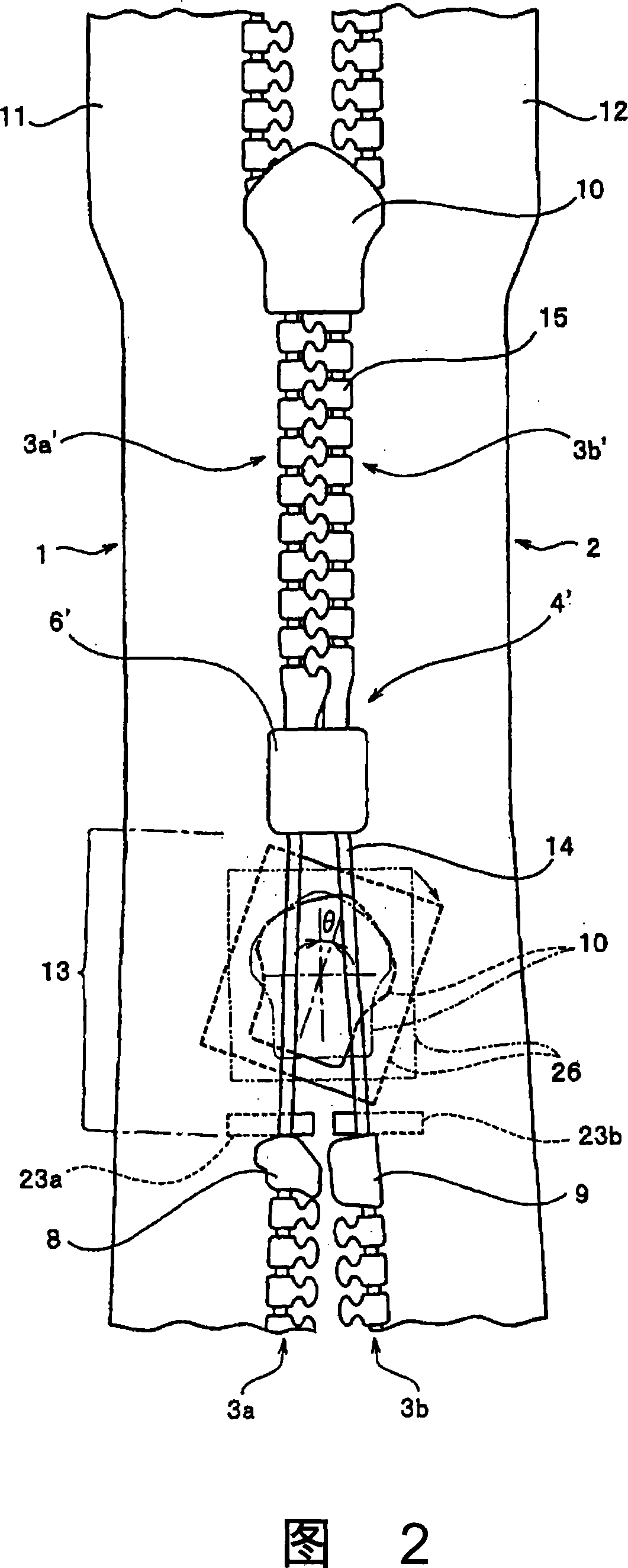

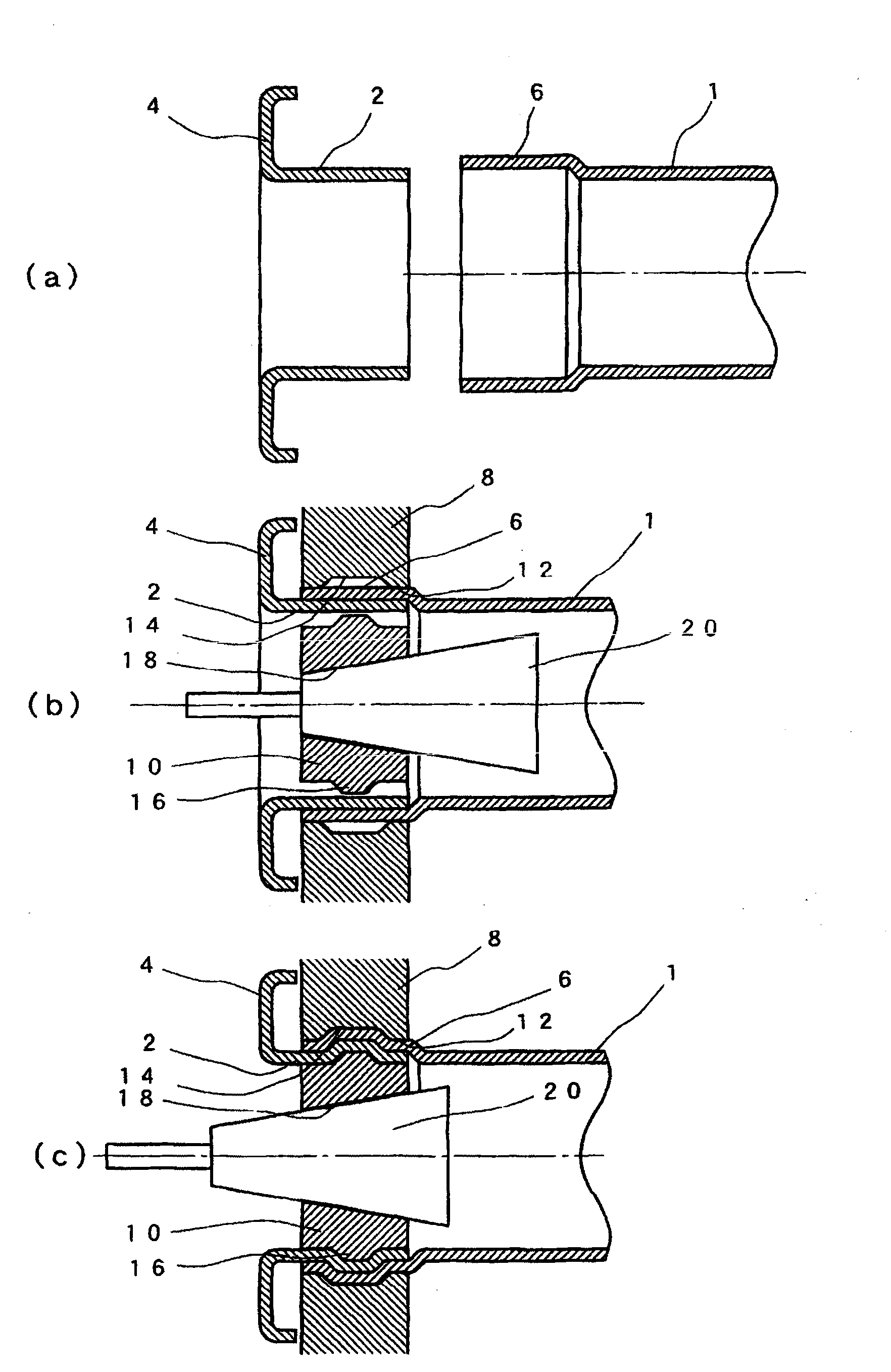

Fastener head covered method and fastener head covered device

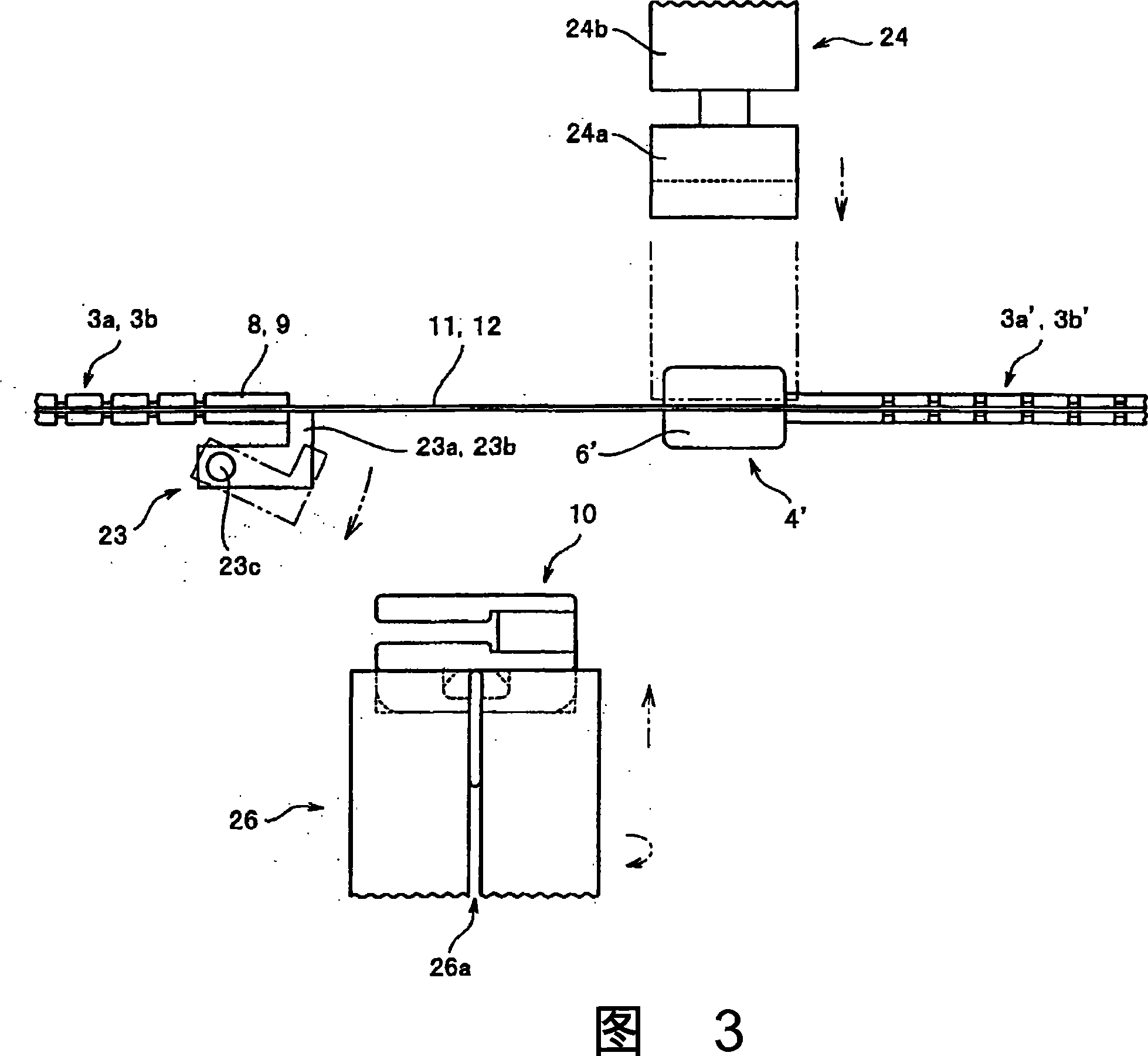

The present invention provides a method of setting a set of left-and-right slide fastener's vertical-line slider,making one end which is automatically set at the chain tooth line possess detachable bottom stop block,and making the other side of the slide fastener possess top stop block.Following the present invention the method of setting the slide fastener's slider is setting the slider(10) on the chain tooth lines(3a,3b) between the first and second vertical strip(1,2),includes: the first working procedure of orienting the direction of the chain tooth lines(3a,3b) to make the first and the second vertical line of the slide fastener(1,2) in a right-and-left curving state;the second woking procedure of moving the slider(10) to make the first vertical strip(1) located on the side of the slider(10) and make the second vertical strip(2) linking to the below wing board(18);the third woking procedure of jointing the first vertical strip(1) to the slider(10);the fourth working procedure of moving the first and the second vertical strip ahead to joint the box-shaped pin(5) to the slider(10);and the fifth working procedure of countermarching the inserted pin(7) when it has moved to the frontage of the slider(10) to make the slider(10) setting on the right-and-left chain tooth line.

Owner:YKK CORP

Cable slack and guide monitoring apparatus and method for a lift device

InactiveUS7222839B2Improve safety and performanceAvoid slackFilament handlingPortable liftingEngineeringHuman power

The present invention is a method and apparatus for monitoring the condition of a cable in a human power amplifying lift system. The method and apparatus employ a cable slack sensor and a cable end sensor to override and prevent the lift from continuing to unwind the lift cable when slack or and end of travel limit has been reached.

Owner:GORBEL INC

Mountable retractable screen unit

InactiveUS20060151123A1Well formedEliminate replacementShutters/ movable grillesCurtain suspension devicesWaste management

A self-contained, retractable screen unit that may be mounted to any railing system, fence or existing structure to provide additional safety and security.

Owner:CHANDLER CARLTON +1

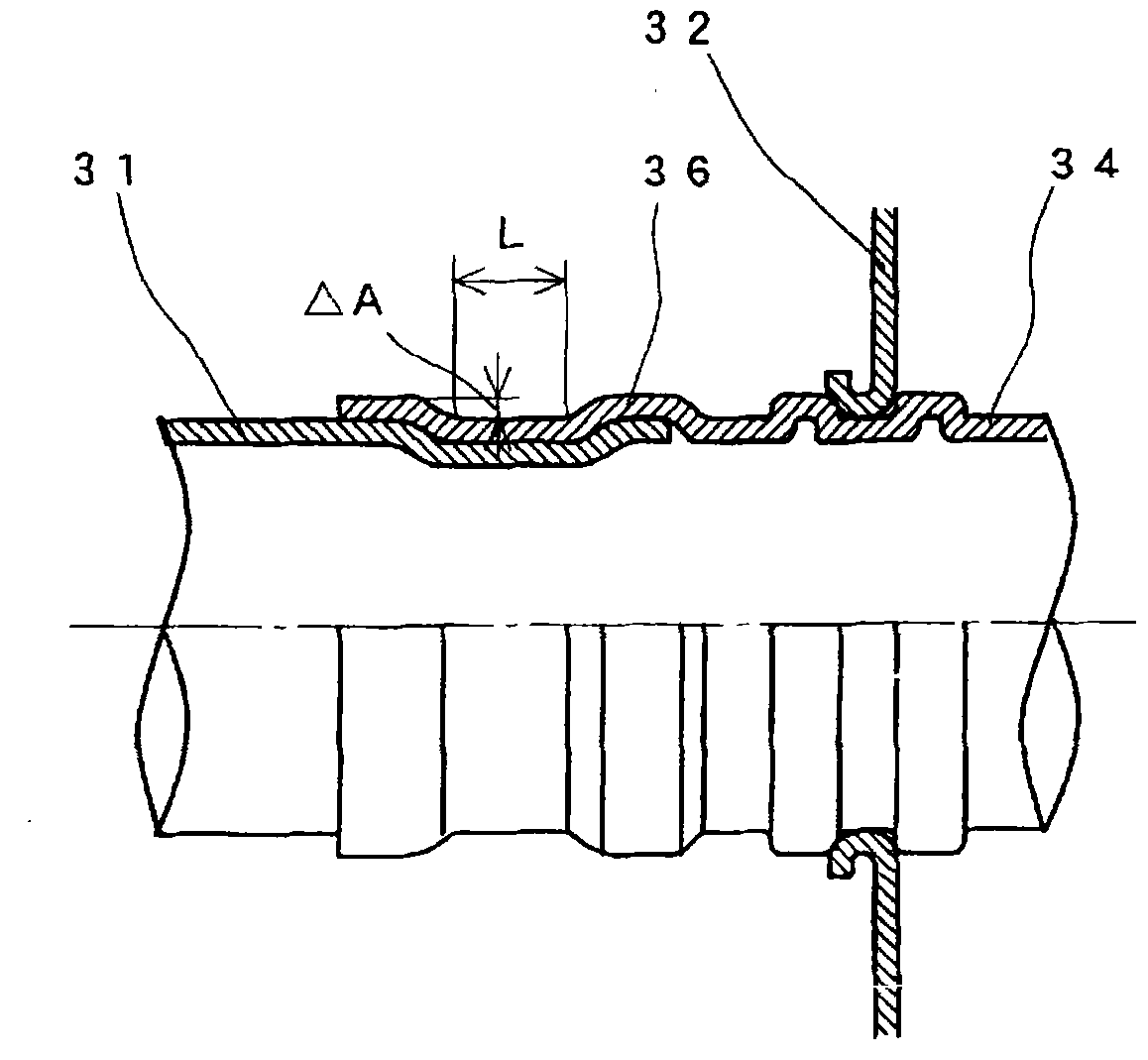

Exhaust pipe connection structure and exhaust pipe connection method

InactiveCN101779014AHigh shape accuracyPrevent looseningExhaust apparatusSilencing apparatusExternal combustion engineInternal combustion engine

An exhaust pipe connection structure for interconnecting a connection pipe and an exhaust pipe that are arranged in an exhaust system of an internal combustion engine. Either of the connection pipe and the exhaust pipe is inserted into the other, and the portion where the connection pipe and the exhaust pipe overlap each other is radially deformed for staking.

Owner:FUTABA IND CO LTD

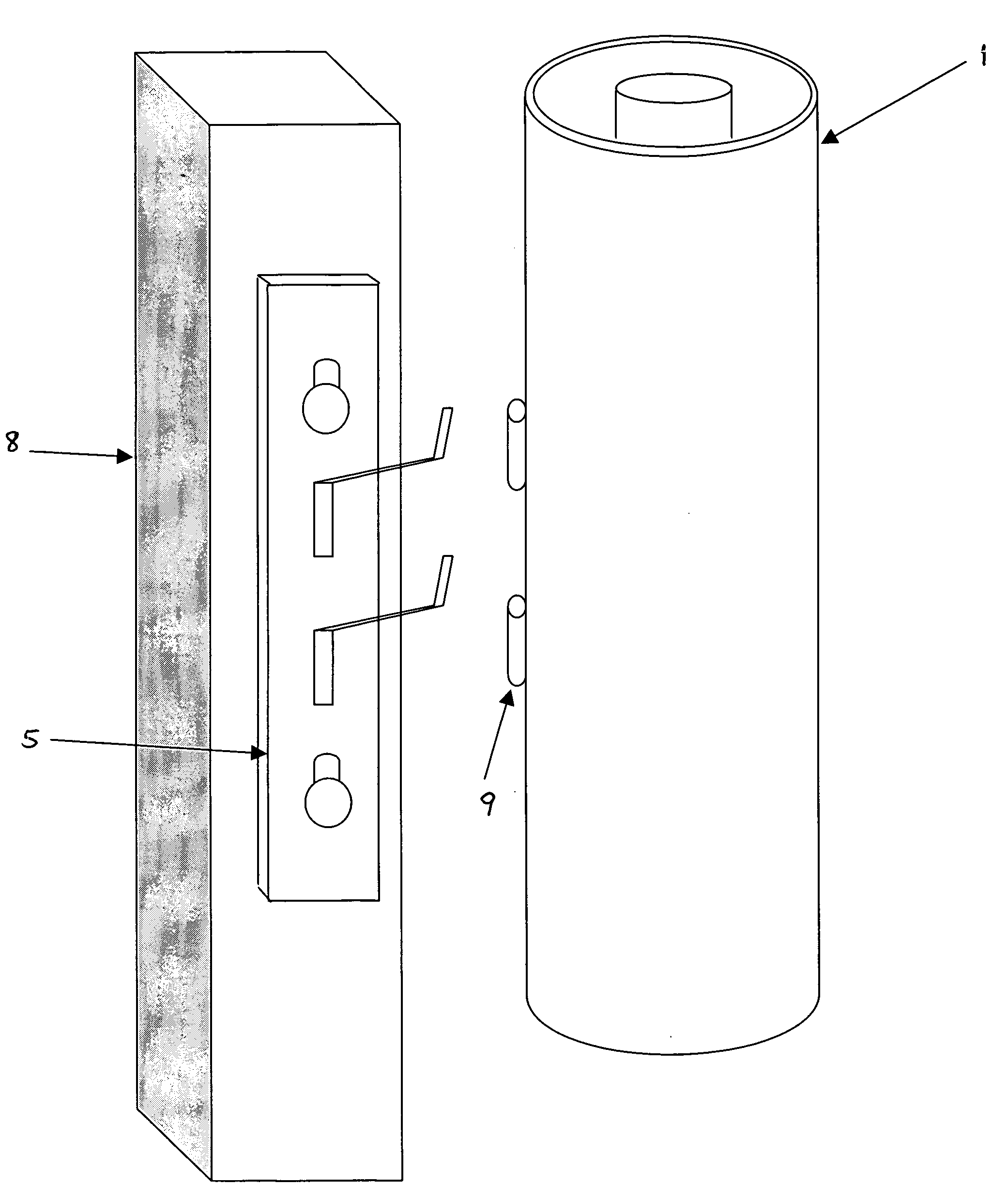

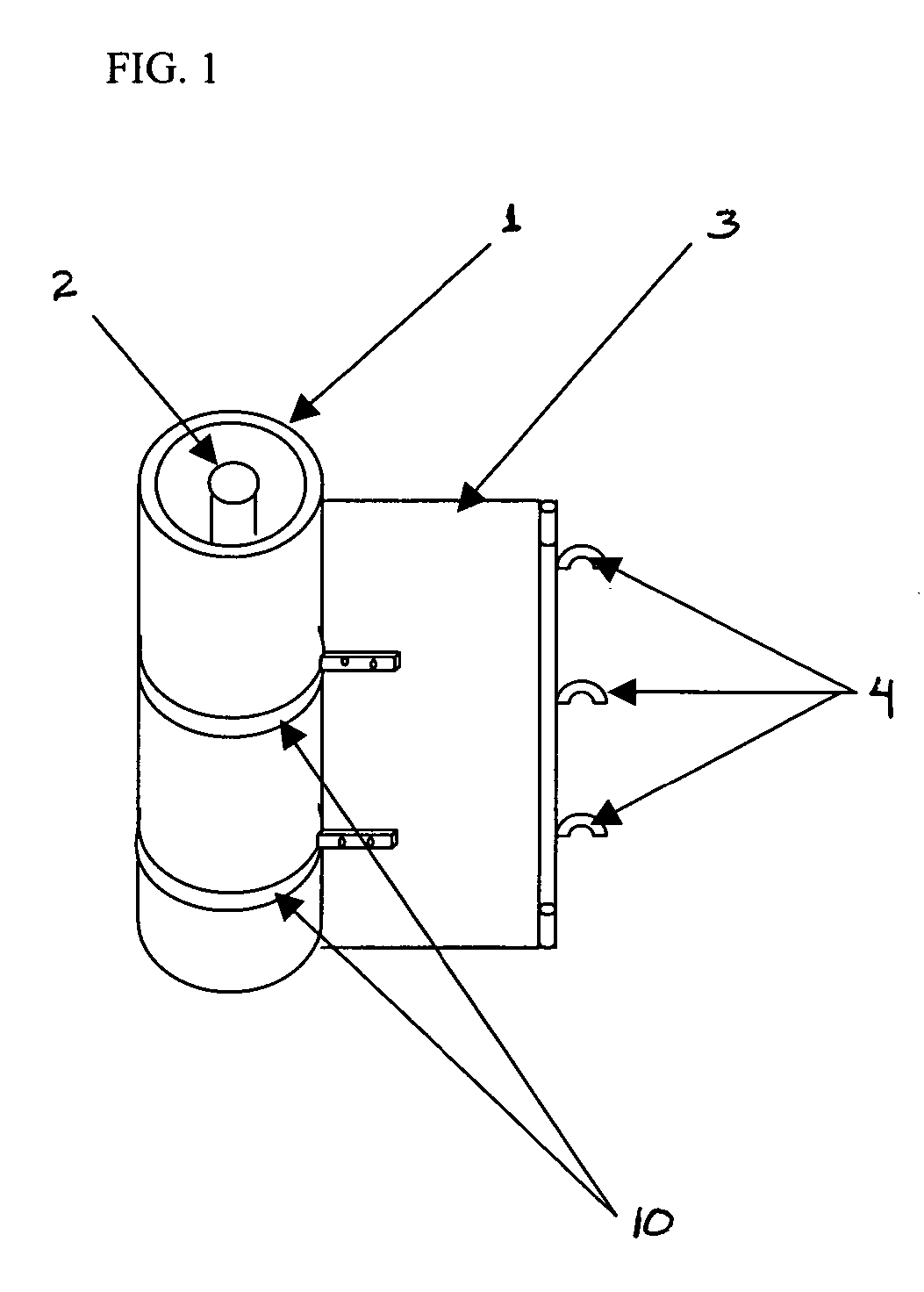

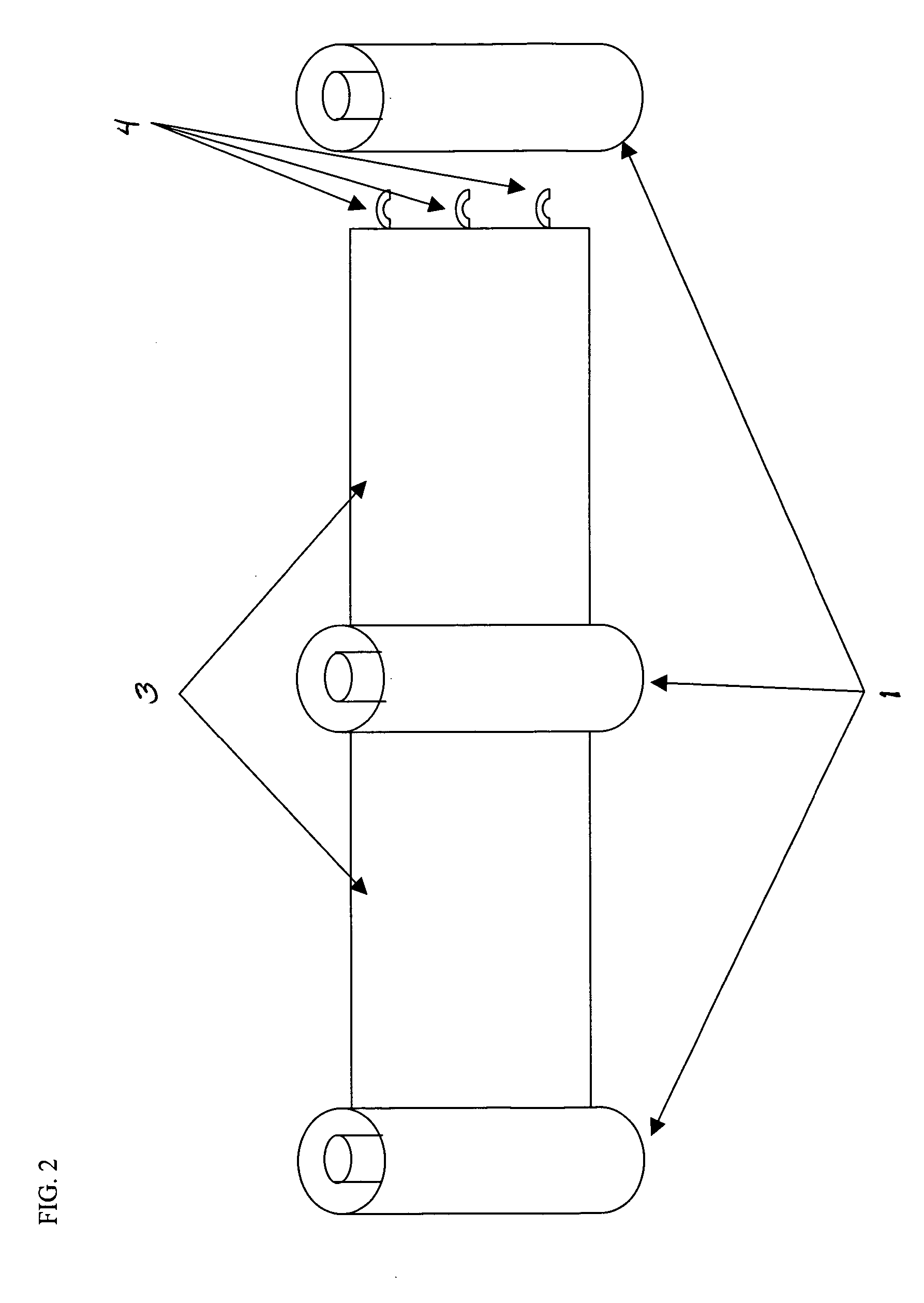

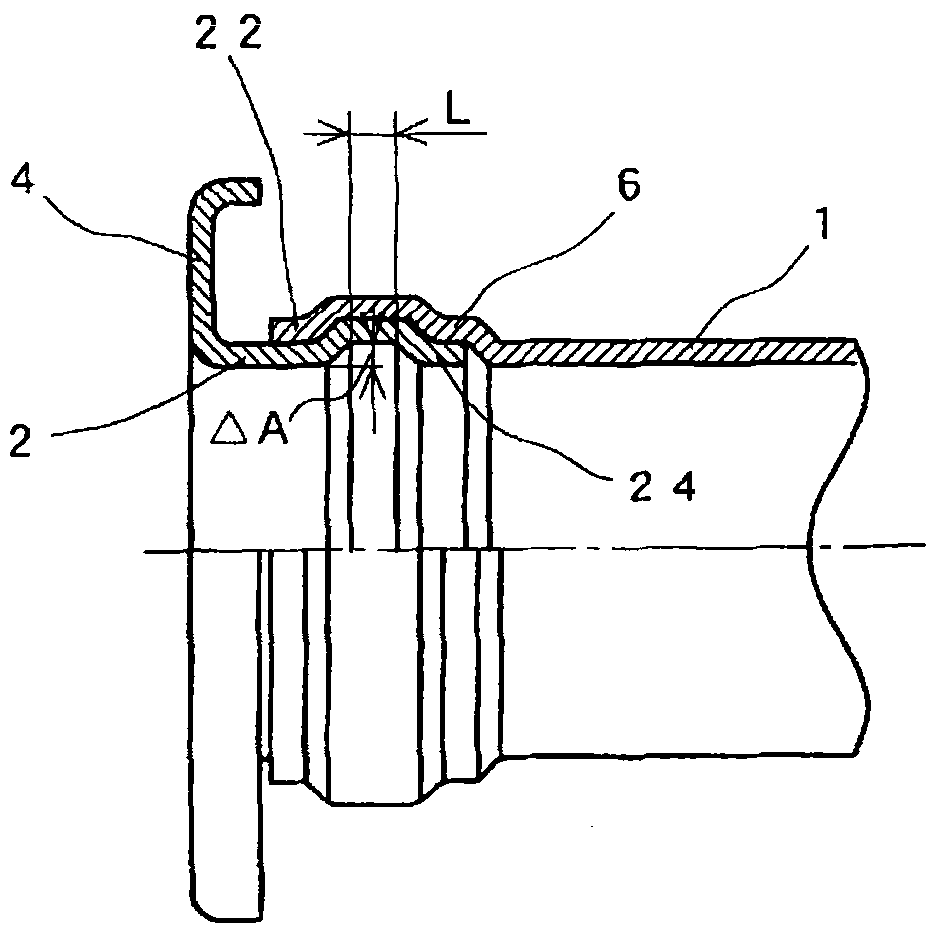

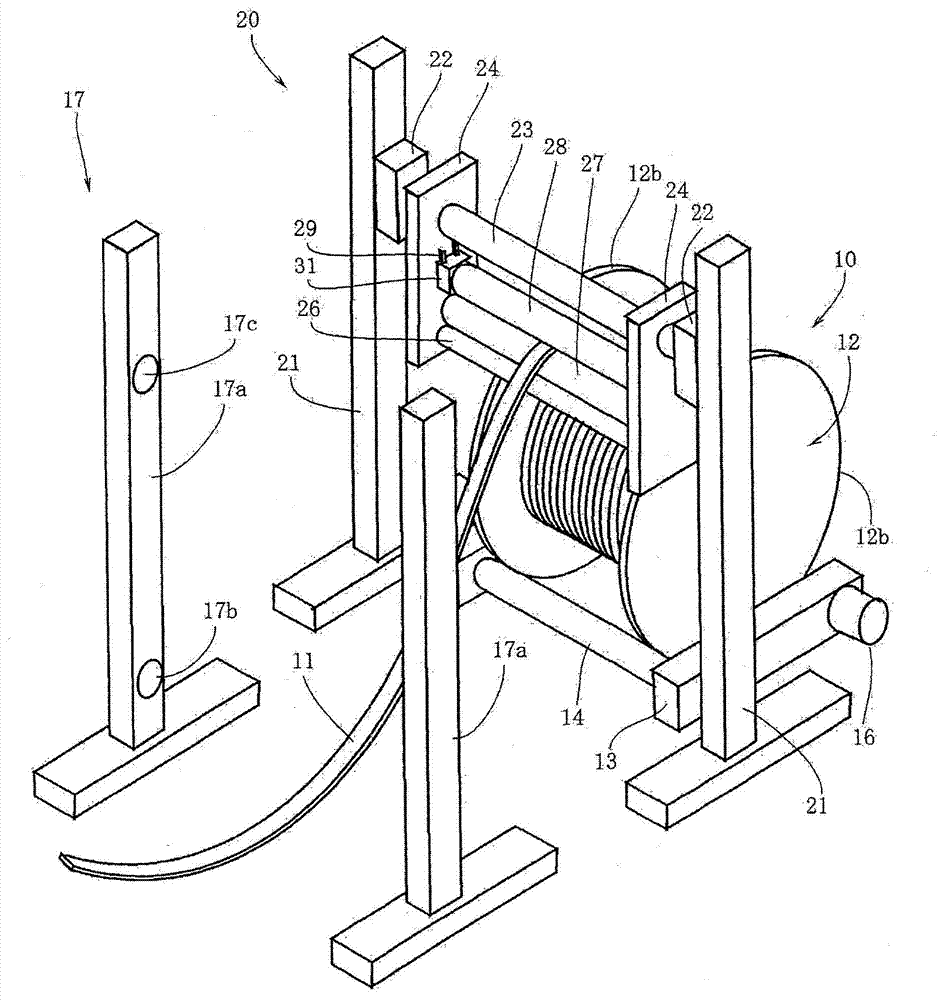

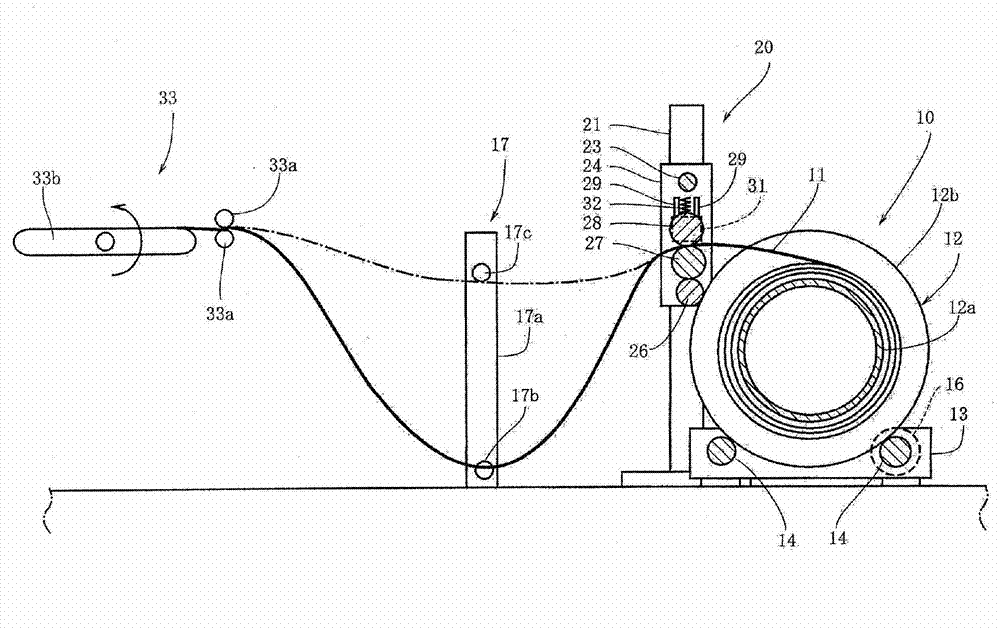

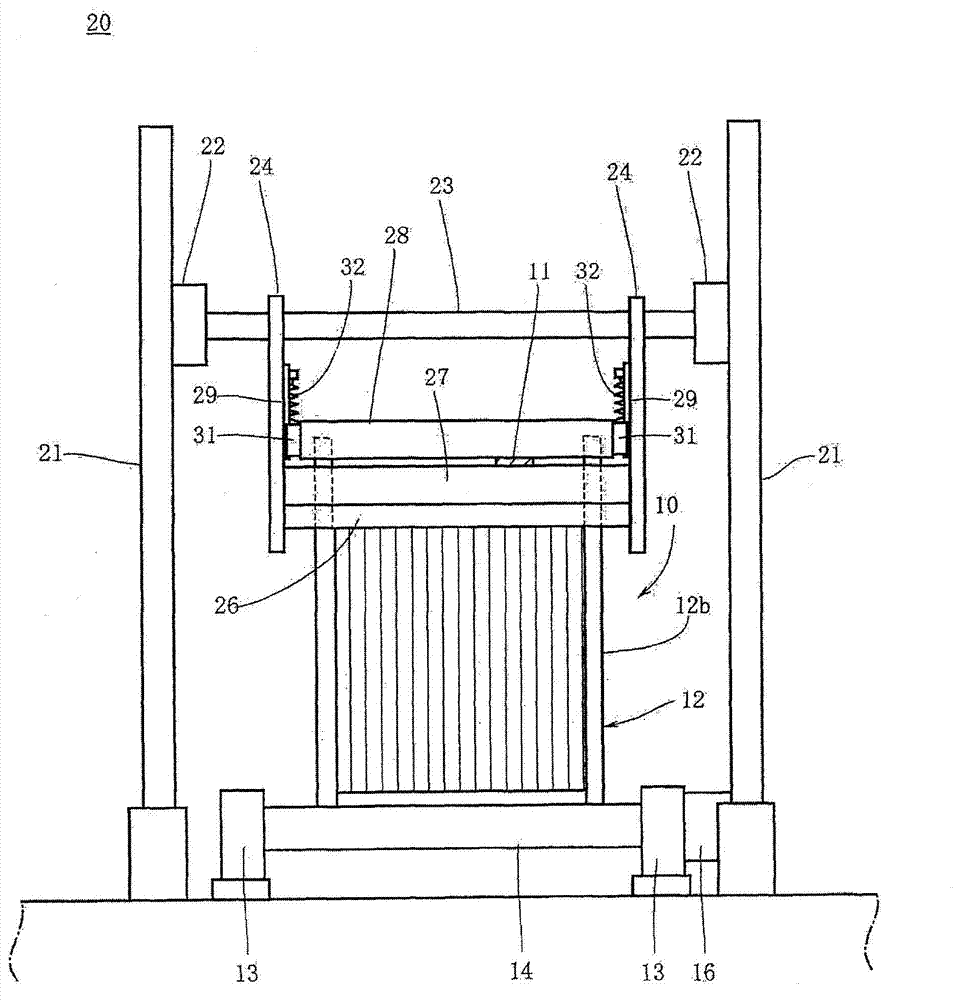

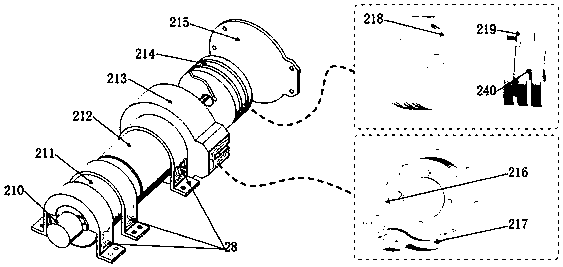

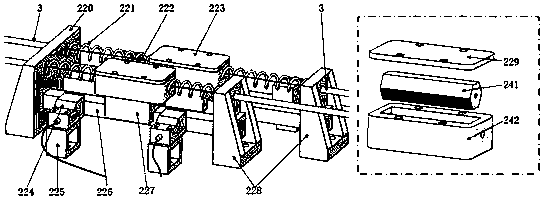

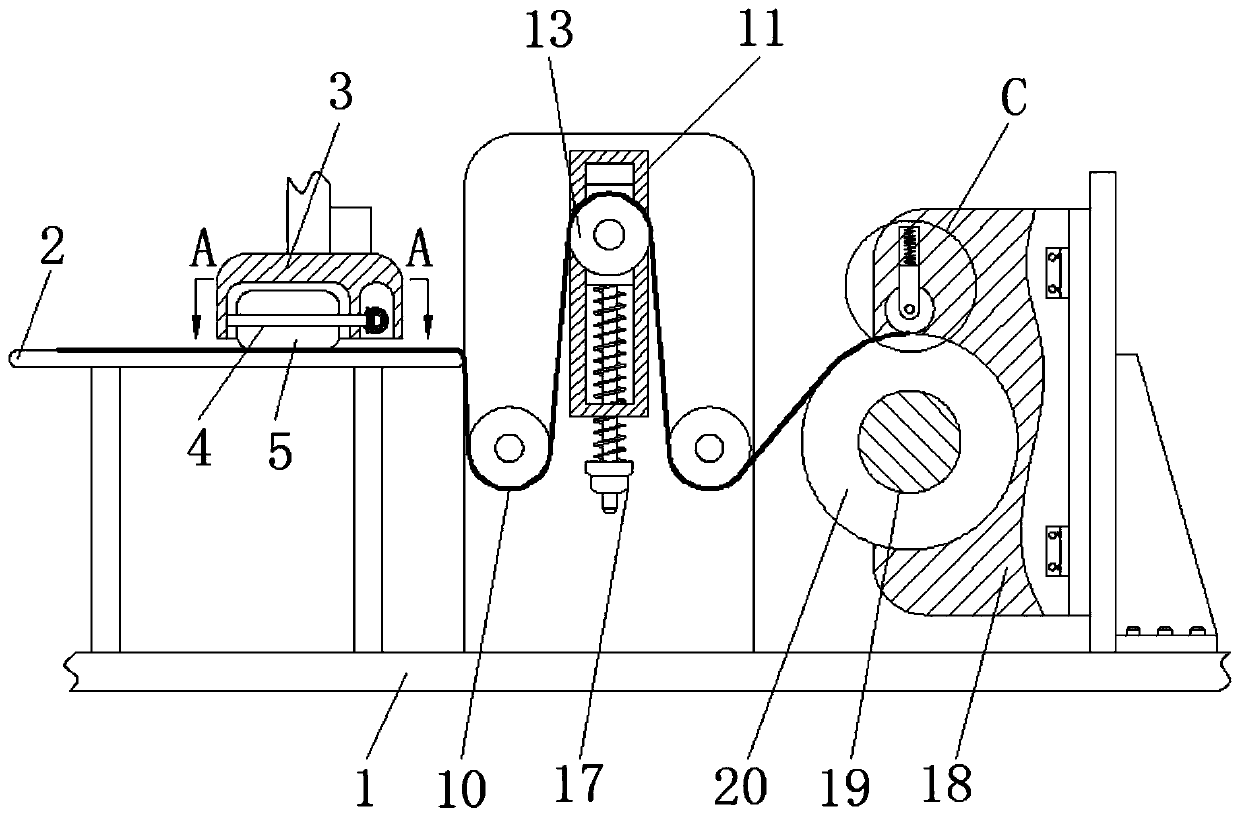

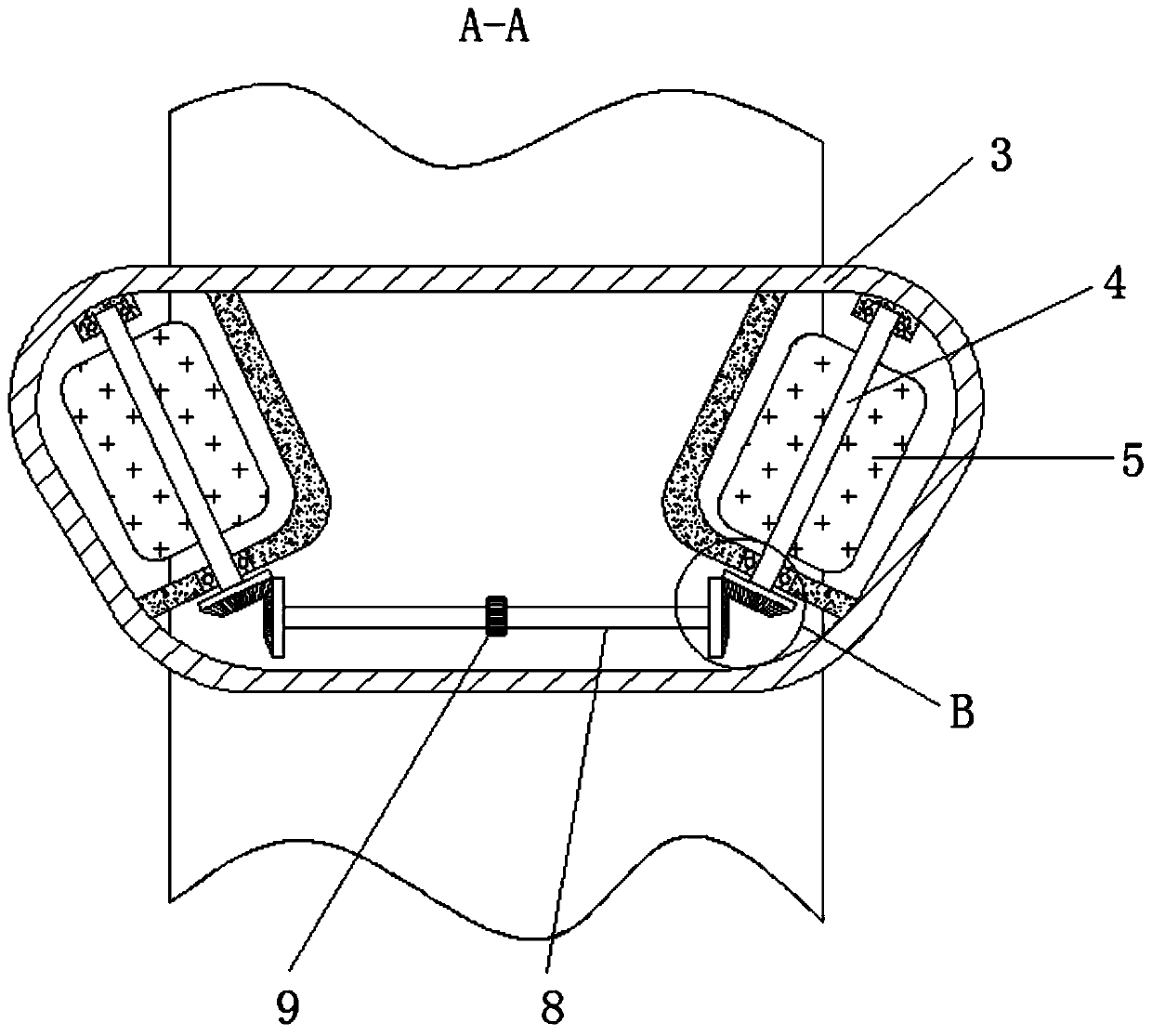

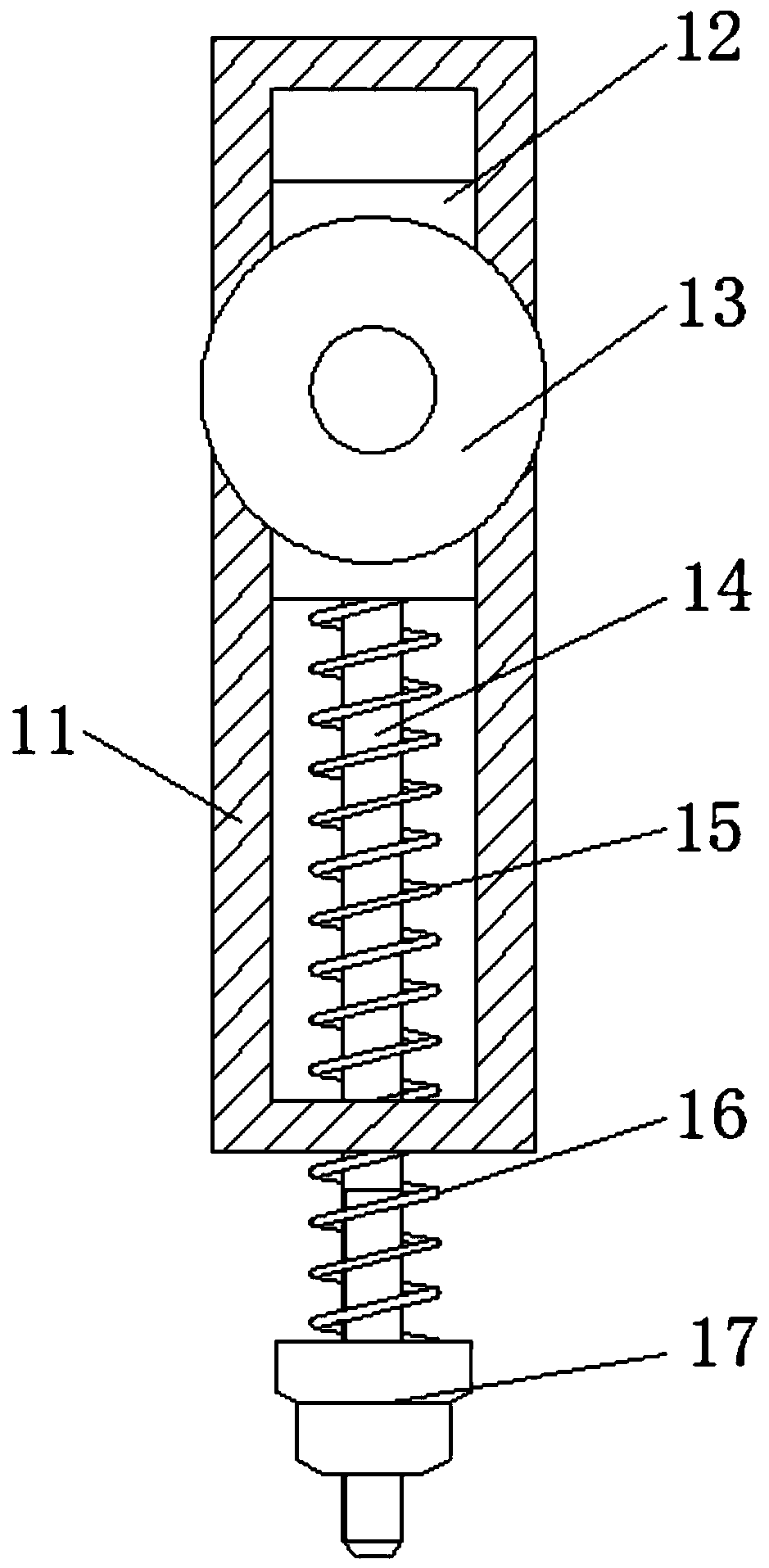

Slack preventing device for wire rod wound around spool, and slack preventing method therefore

ActiveCN103193106AAvoid slackNo slackFilament handlingInductances/transformers/magnets manufactureEngineeringMechanical engineering

The invention prevents a slack of a wire rod in a spool by preventing the wire rod fed by rotation of the spool from returning to the spool. A wire rod slack preventing device (20) is installed parallel to a wire rod feeding machine (10) feeding a wire rod (11) by rotating a spool (12), around which the wire rod (11) is wound, and has a reverse rotation roller (26) having a rotating axis which is parallel to a rotating axis of the spool and rotating in a reverse direction to a rotating direction of the spool while being in contact with the spool, a forward rotation roller (27) having a rotating axis which is parallel to the rotating axis of the reverse rotation roller (26) and rotating in the same direction as the spool while being in contact with the reverse rotation roller (26), and a pinching roller (28) having a rotating axis which is parallel to the rotating axis of the forward rotation roller (27) and pinching the wire rod, which is fed out of the spool, together with the forward rotation roller (27). Further, a wire rod slack preventing method draws the wire rod which is fed out due to the rotation of the spool, while pinching the wire rod by the forward rotation roller (27), which rotates with the rotation of the spool, together with the pinching roller (28).

Owner:NITTOKU ENG CO LTD

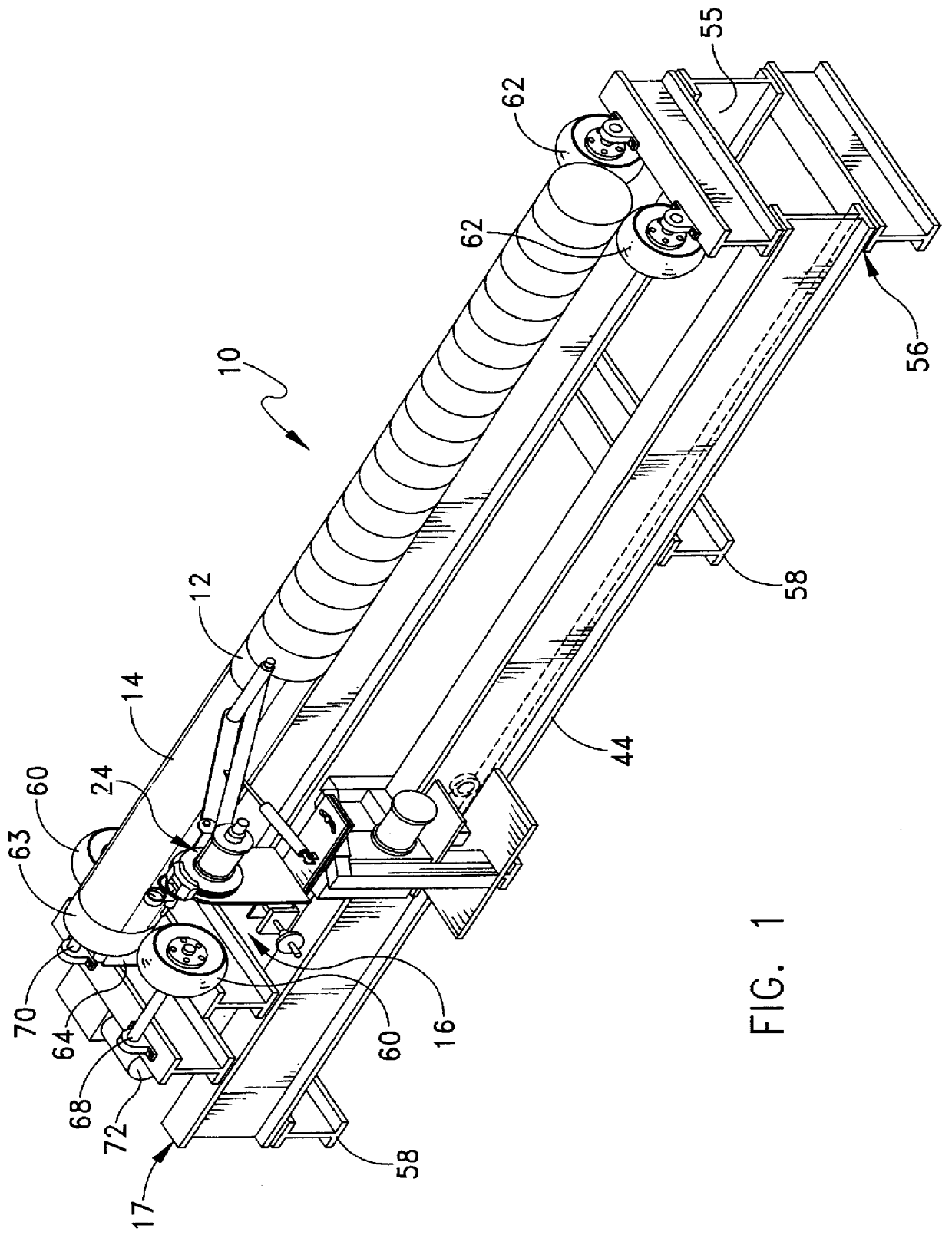

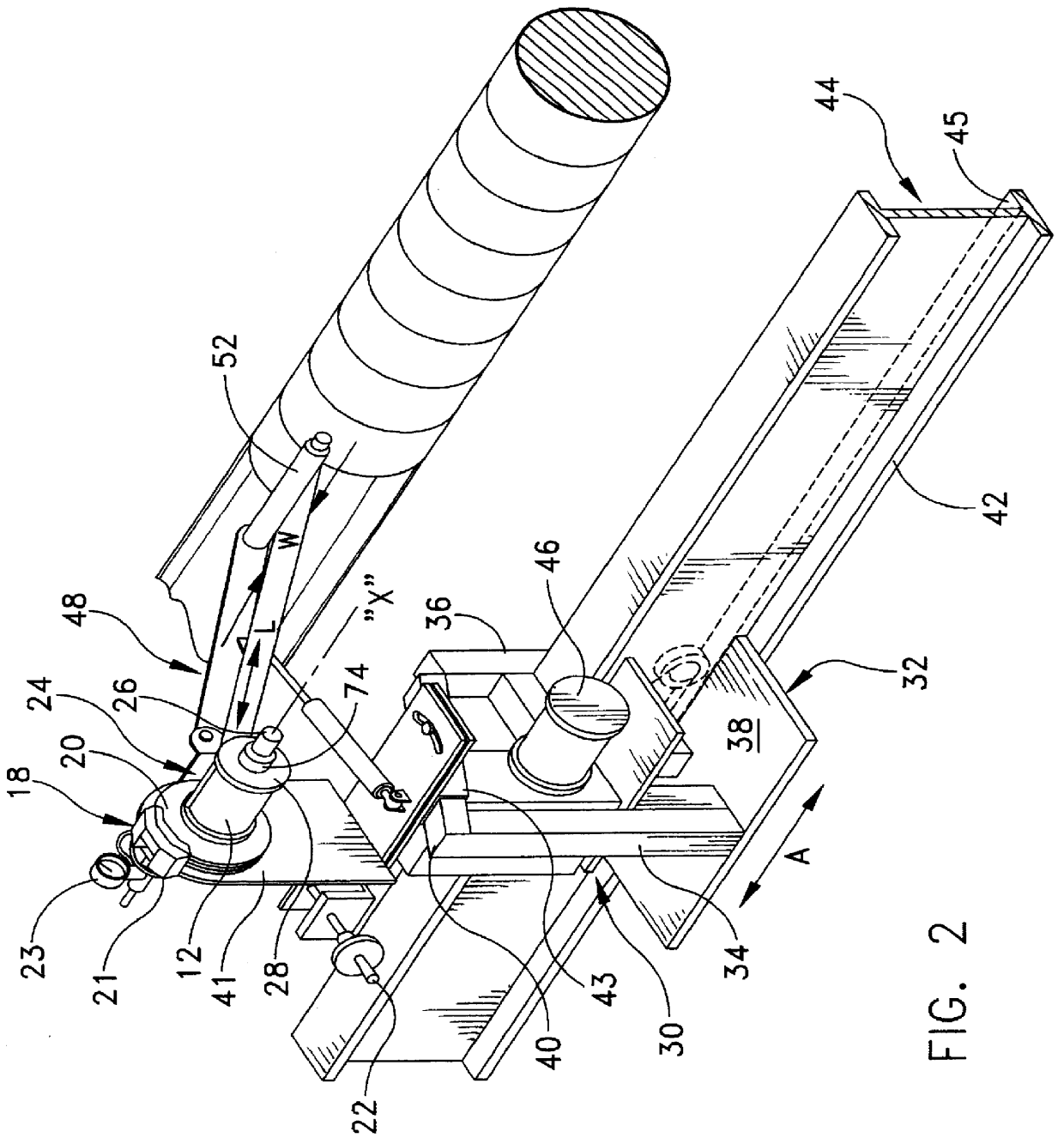

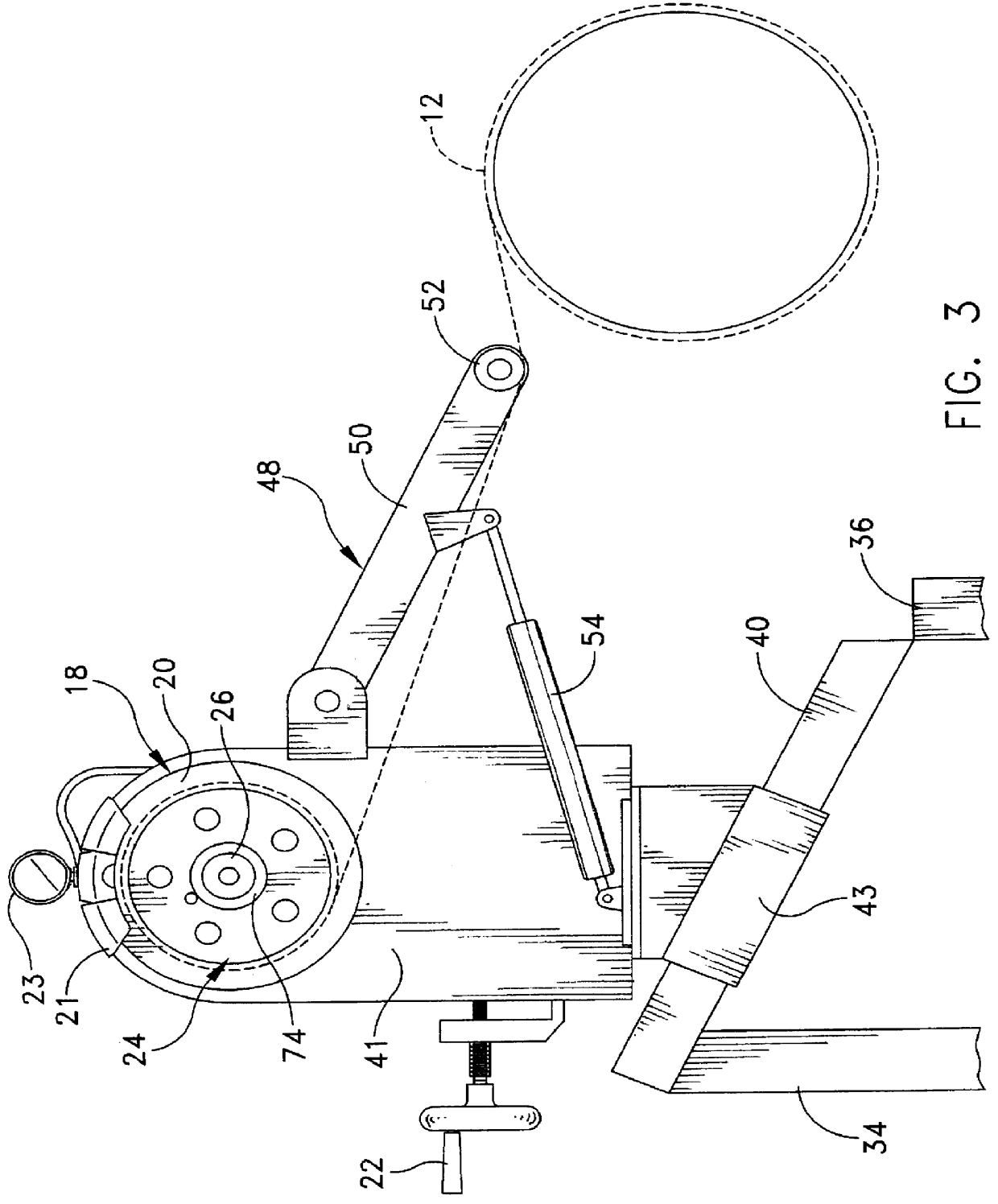

Machine for applying a protective material onto a pipe

A machine for applying one or more protective layers of material onto a tubular member, for example a pipe, in a substantially wrinkle free and continuous manner. The machine includes a brake tension unit for applying a constant tension to the protective material in order to neck down the material as it is applied onto the pipe, and a base unit for supporting and rotating the pipe. The constant brake tension unit preferably includes a conventional disc brake and a mounting arm for holding a core of material in engagement with the brake tension unit. Pressure applied to the rotor slows rotation of the rotor and the attached core which restricts the unwinding of the protective material from the core. Thus, as the material attempts to unwind from the core a preselected force is applied to resist the unwinding. The material is therefore placed under tension and, due to the nature of the protective material, the material elongates and necks down under the applied pressure. The brake unit may also include a tension arm for holding the protective layer against the pipe to prevent slack in the material as it is being applied.

Owner:TEK RAP

Power cable winding device

InactiveCN108275512AAvoid slackGuaranteed cleanlinessFilament handlingCleaning using toolsBristlePower cable

The invention discloses a power cable winding device. A worm is meshed with a worm wheel, the worm wheel is fixedly connected with a take-up roller, and the worm wheel and the take-up roller are connected with a device body in a rotating mode; a wire inlet is formed in the left side of the device body, extrusion wheels are arranged on the upper portion and the lower portion of the right side of the wire inlet, the lower ends of the extrusion wheels are rotationally connected with a transverse plate, the transverse plate is fixedly connected with the device body, the upper ends of the extrusionwheels are connected with the lower end of a screw rod in a rotating mode, the left side of the screw rod is connected with a sliding groove in a sliding mode, the sliding groove is fixedly connectedwith the side wall of the device body, and the upper end of the screw rod is in threaded connection with a sleeve. The device drives the worm wheel and the take-up roller to rotate through rotation of the worm, and the left and right movable piston plates spray water in a water spraying cavity out of a spray head to clean a cable, and meanwhile, a rotating cleaning barrel drives bristles inside the cleaning barrel to further clean and dry the cleaned cable. The device is reasonable in structural design, and high in automation, and greatly improves the winding efficiency of the cable, achievesthe cleaning function, guarantees the cable cleaning, and reuses the cable.

Owner:山东博发智能科技有限公司

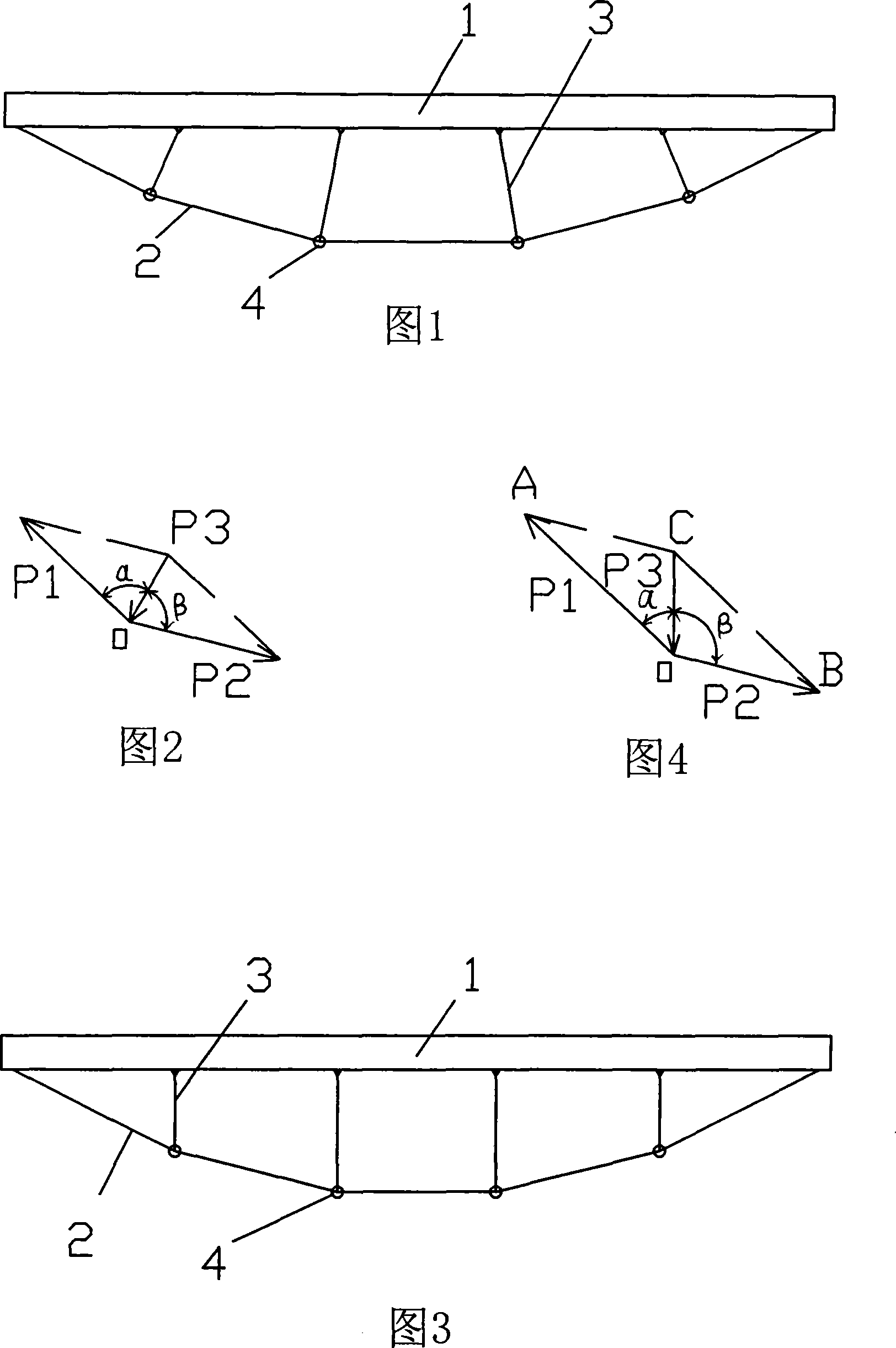

Beam string structure

The invention relates to a string beam, which comprises a rigid beam, a bracing cable and a plurality of bracing bars, the upper ends of the bracing bars are hinged with the rigid beam, the lower ends of the bracing bars are fixedly connected with the bracing cable through rope clamping devices, the both ends of the bracing cable after being stretched are respectively and fixedly connected with the both ends of the rigid beam, the bracing cable is formed into broken lines in an axle symmetrical way, the adjacent two broken lines form a broken line angle, the various turning points of the broken lines are positioned on the identical parabola, each bracing bar is respectively positioned on the angle bisector of the broken line angle. The string beam of the invention can avoid the loose bracing cable generated by the slipping of a pre-stressed rope at the position of the rope clamping device when being used, and the potential safety hazard is eliminated.

Owner:CHINA JINGYE ENG +5

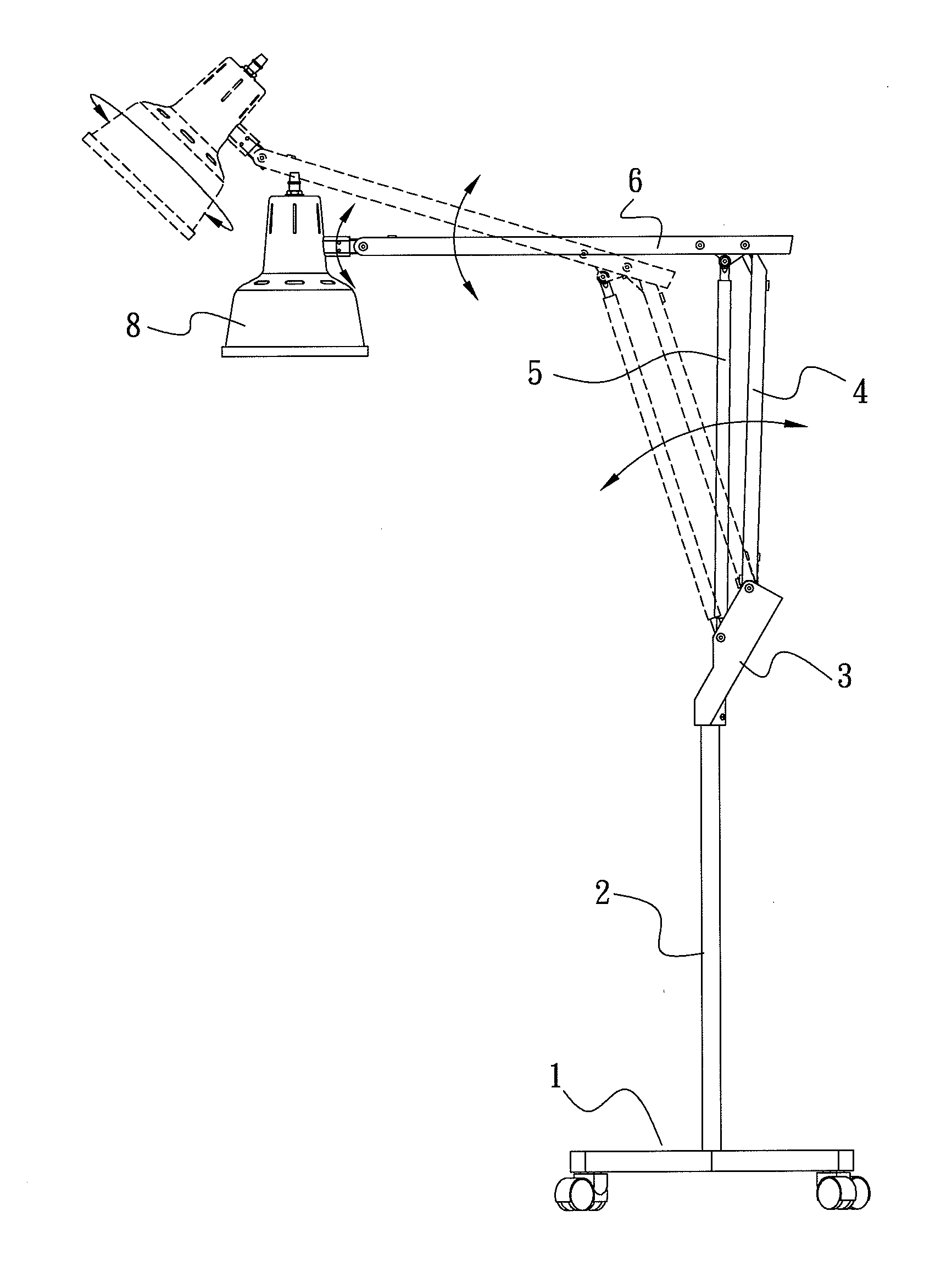

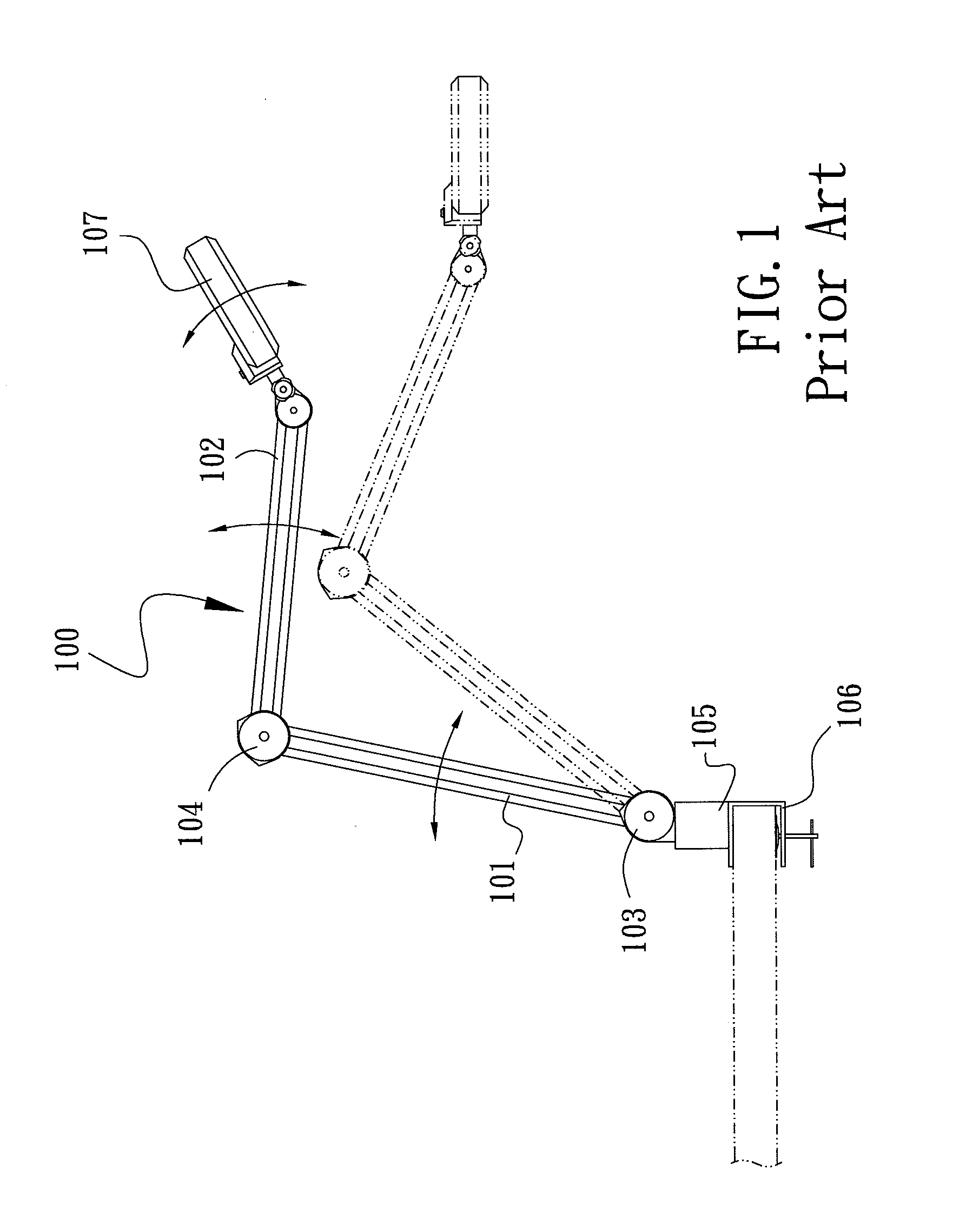

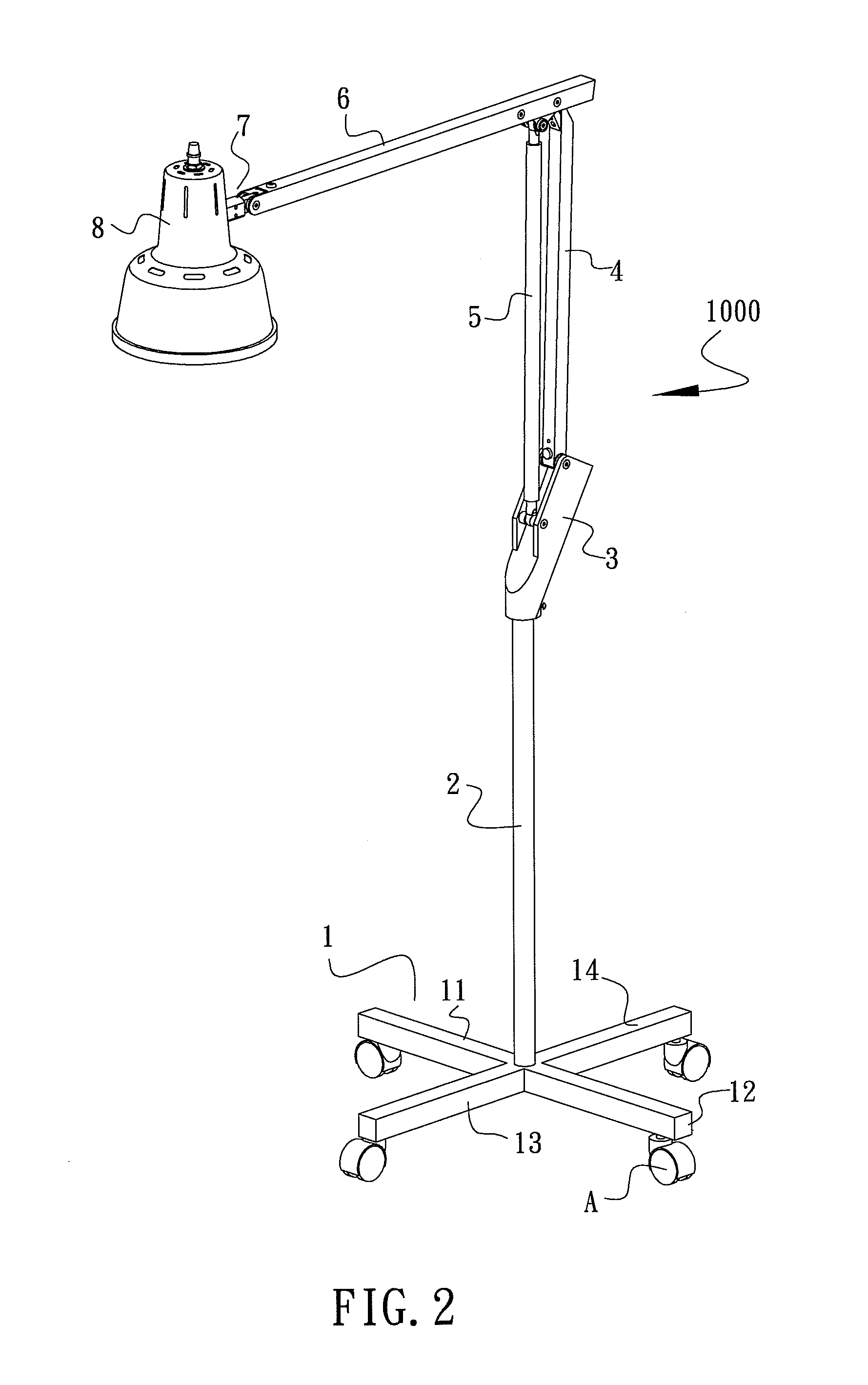

Adjustable sructure for lamp stand

InactiveUS20120063152A1Simple structureEasy to assembleLighting support devicesFree standingEngineeringMechanical engineering

An adjustable structure for lamp stand, in which a swivel mount is fitted to the upper portion of a base, thereby enabling ends of a first bar support and a telescopic link to be pin connected to the swivel mount, while the other ends are pin connected to a second bar support. A lamp swivel component is disposed on the end of the second bar support. Accordingly, relative positions between the first bar support, the second bar support and the telescopic link can be freely adjusted, while still providing stable support to the structure.

Owner:CHANG TSUNG CHANG

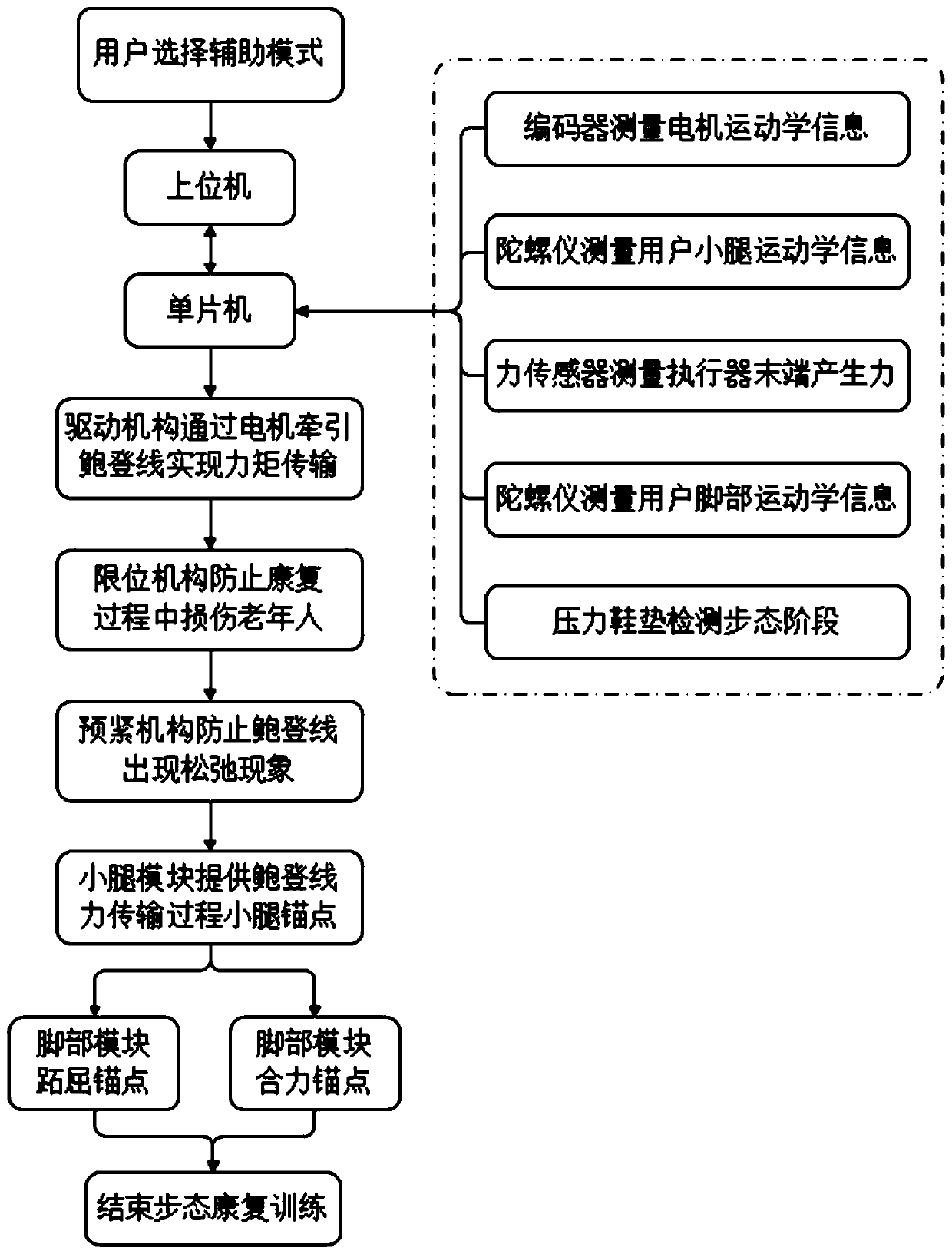

Flexible ankle rehabilitation robot system

ActiveCN110575350AGuaranteed uptimeAvoid injury hazardProgramme-controlled manipulatorDiagnosticsRobotic systemsGyroscope

The invention discloses a flexible ankle rehabilitation robot system. An execution module is connected with a foot module through a Bowden cable and a shank module, and a tension module for measuringtransmission force of the Bowden cable is arranged between the shank module and the foot module; a shank gyroscope is arranged on the shank module, a foot gyroscope and a pressure insole are arrangedon the foot module, a heel pressure sensor and a foot sole pressure sensor are arranged on the pressure insole, and the shank gyroscope and the foot gyroscope are arranged on the front face and the foot face of the shank of a user correspondingly; the pressure insole is located inside the foot module, sends a control instruction towards the execution module through an upper computer and receives sensing feedback information; the execution module transmits torque through the Bowden cable and the shank module to the foot module, so that ankle movement is assisted; and the shank gyroscope and thefoot gyroscope are mutually matched for detecting ankle motion information. The flexible ankle rehabilitation robot system is low in weight and achieves the gait training function for users with abnormal gaits of foot drop and strephenopodia.

Owner:深圳睿瀚医疗科技有限公司

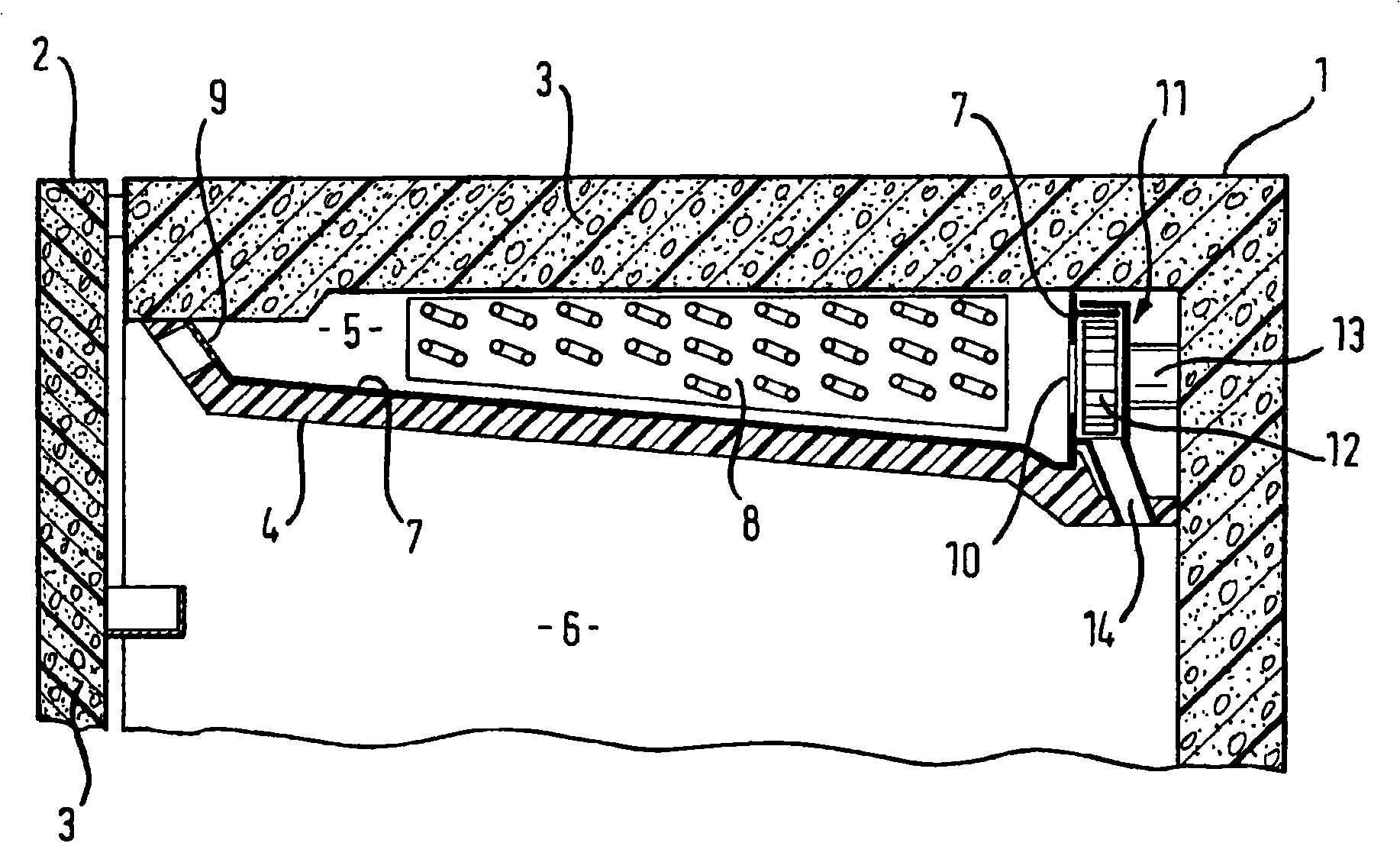

No-frost refrigeration device

The invention relates to an evaporator unit for a no-frost cooling device which comprises an evaporator, a support (7) which surrounds the evaporator, wherein a passage (10) which leads to an air channel (14) is formed in a wall (16) of the support (7), and a ventilator (11) which is mounted on the passage (10) such that vibrations are dampened and is supported by a wall element (15) of the air channel (14) which is opposite the passage (10). The wall element (15) is secured to the support (7) by means of vibration-dampening elements (20, 21).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

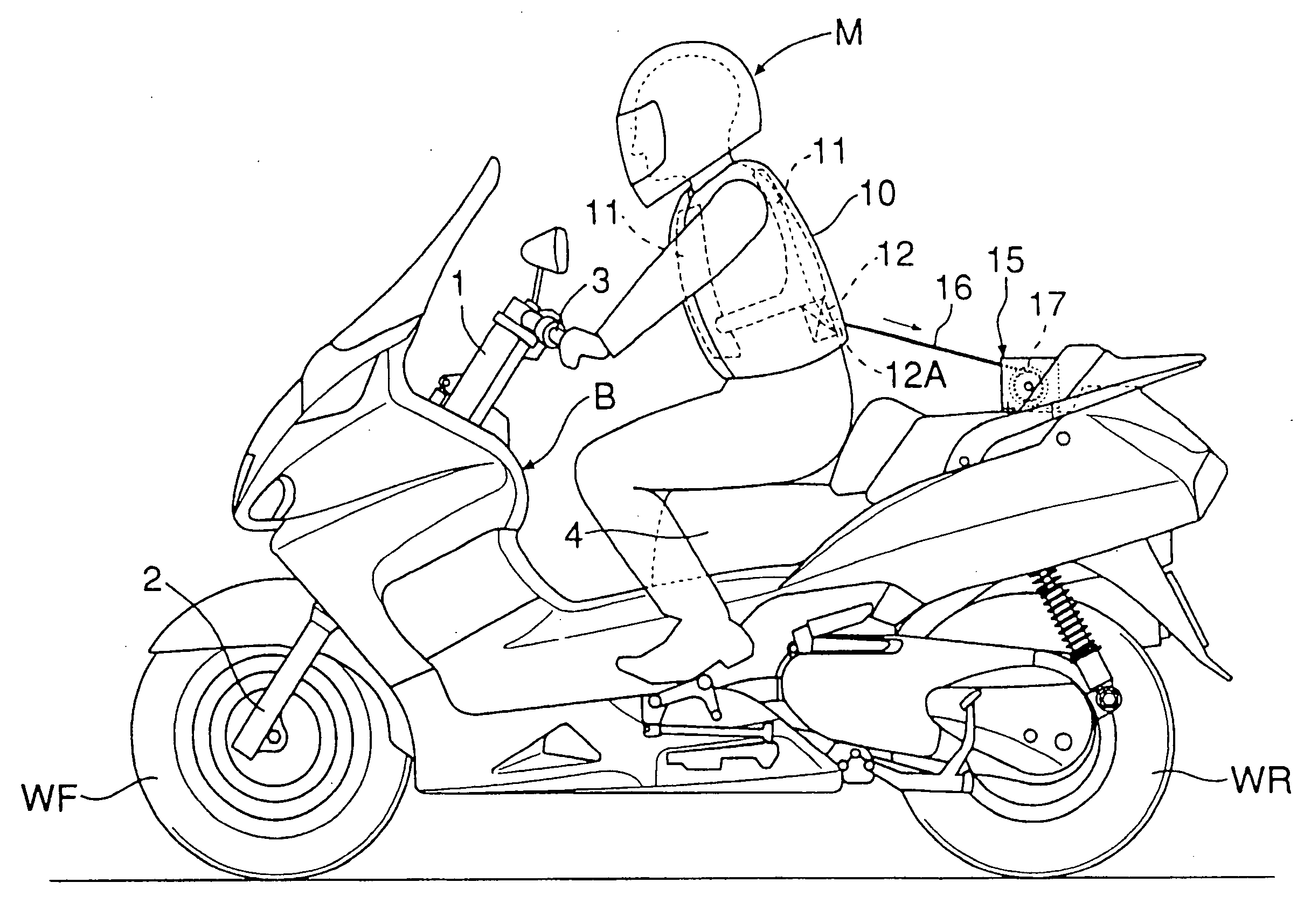

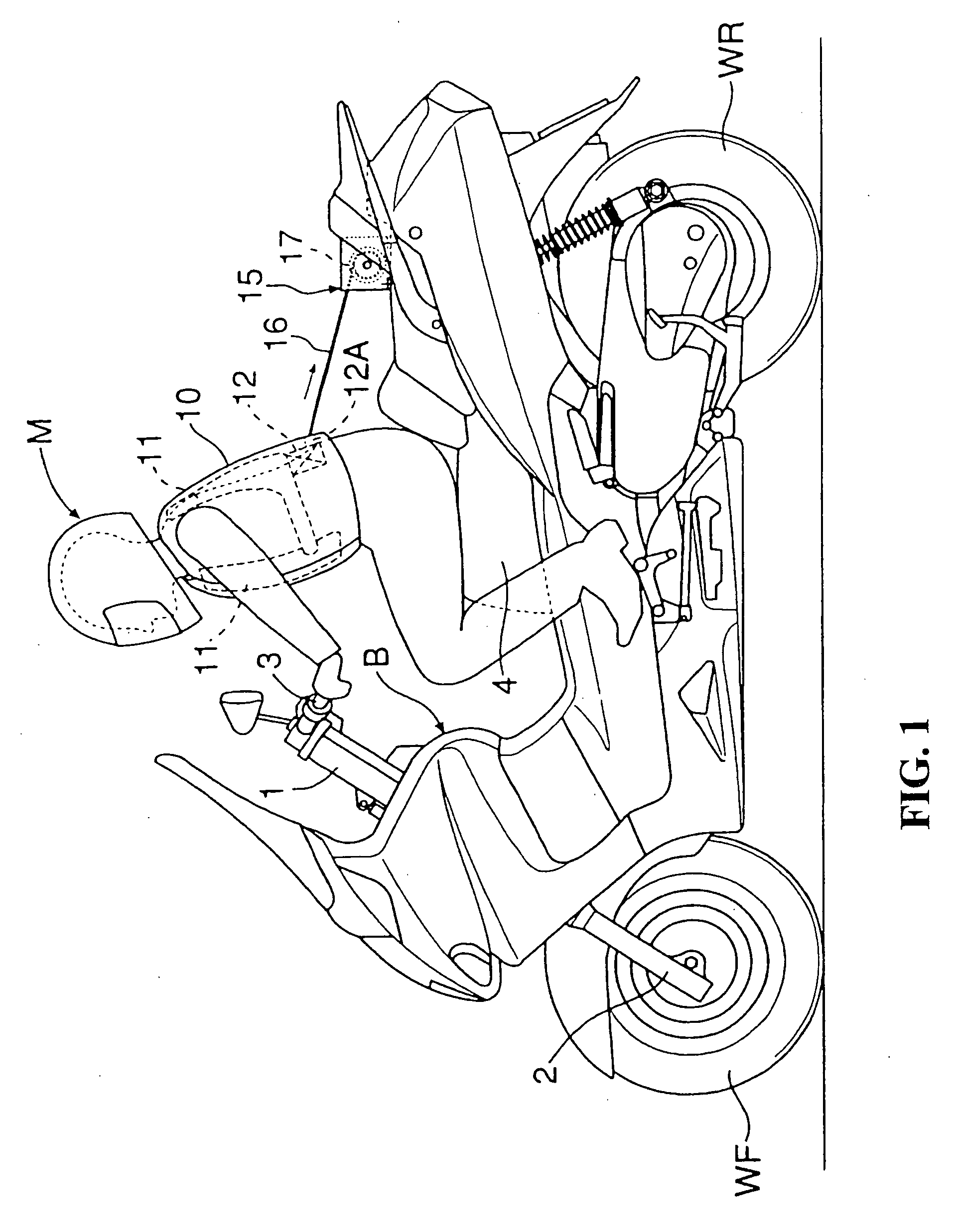

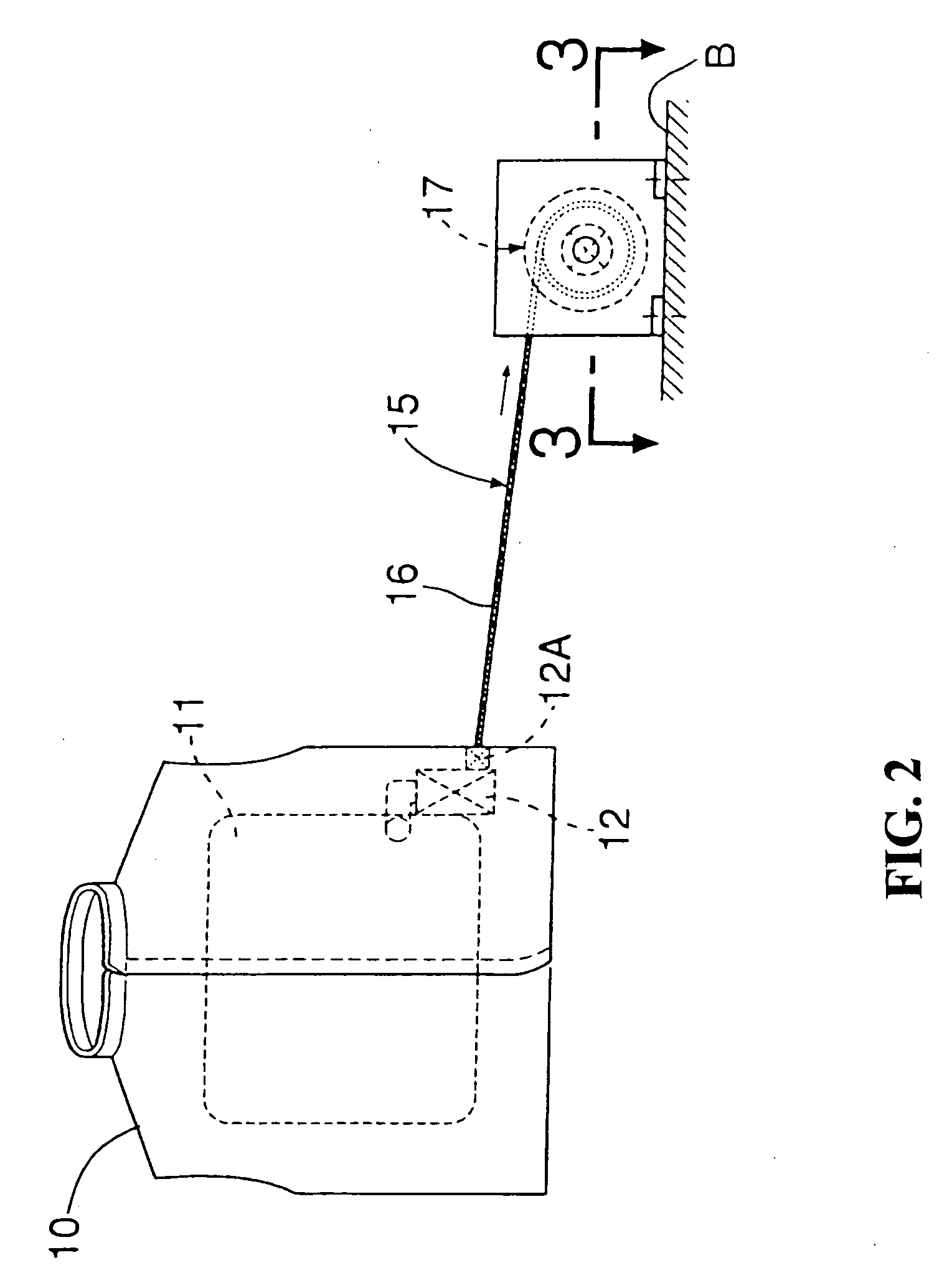

Rider separation detecting device

InactiveUS20070069507A1Quick checkGood lookingChemical protectionHeat protectionEngineeringConductor Coil

Owner:HONDA MOTOR CO LTD

Tension-adjustable textile fabric winder based on Hooke law principle

The invention relates to the technical field of textile fabrics, and discloses a tension-adjustable textile fabric winder based on a Hooke law principle. The tension-adjustable textile fabric winder based on the Hooke law principle comprises a support frame, wherein a cloth guiding plate is fixedly connected to the inner part of the support frame; an unfolding frame is movably connected to the toppart of the cloth guiding plate; an unfolding shaft is movably connected to the inner part of the unfolding frame; an unfolding wheel is fixedly connected to the outer part of the unfolding shaft; afirst bevel gear is fixedly connected to the outer part of the unfolding shaft; a second bevel gear is connected to the outer part of the first bevel gear in a meshing way; a rotary shaft is fixedly connected to the inner part of the second bevel gear; a main gear is fixedly connected to the outer part of the rotary shaft; and a fixed cloth guiding roller is movably connected to the inner part ofthe support frame. Through the cooperative use of the cloth guiding plate and the unfolding wheel, a fabric is fully ensured to be unfolded and spread on the surface of the cloth guiding plate in therotation process of the unfolding wheel, the fabric is effectively prevented from being wrinkled and imprinted, and the fabric is fully ensured to be wound flatly.

Owner:陕西秦塬纺织有限公司

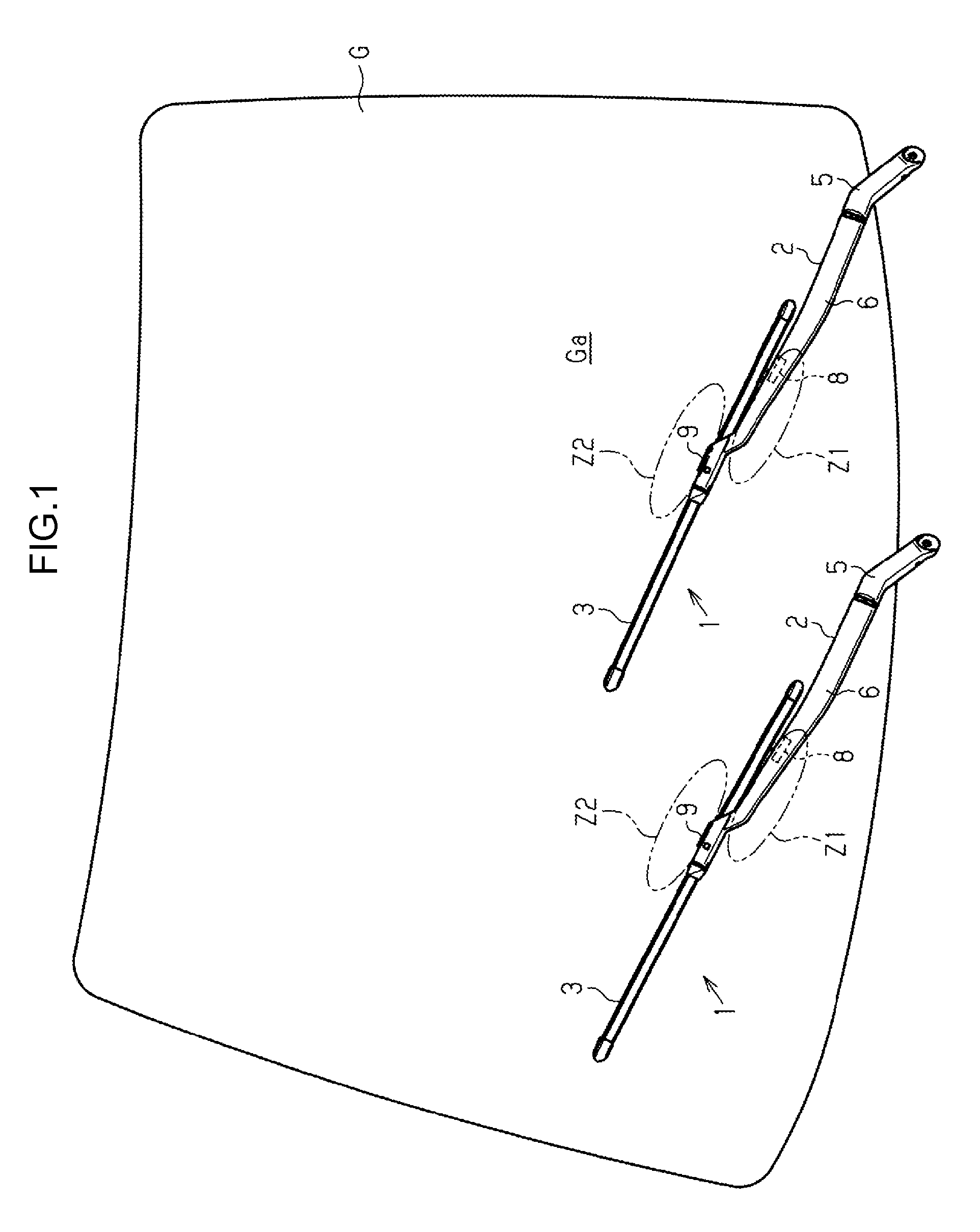

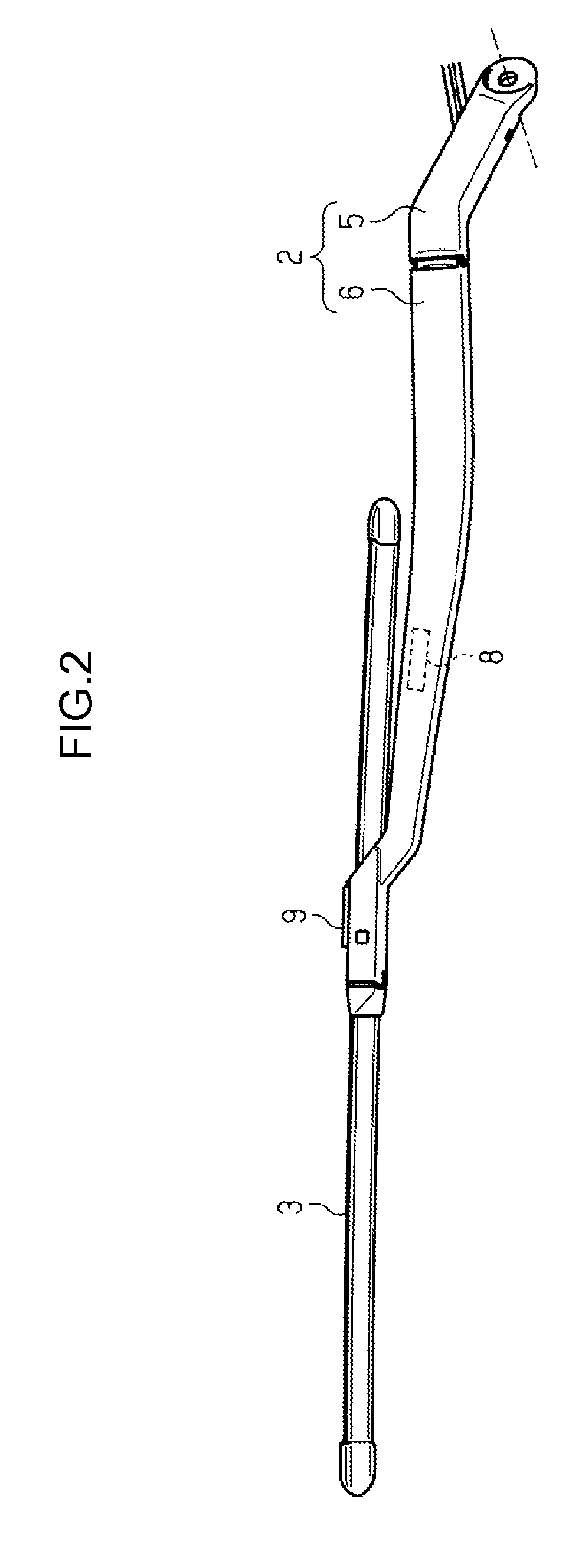

Vehicle wiper

ActiveUS20160121853A1Large tensile force can be suppressedStrong pullWindow cleanersVehicle cleaningWindshieldNozzle

A vehicle wiper comprises a retainer that is formed in an elongated shape open at the lower side facing toward a windshield, and that is provided so as to be capable of swinging about a shaft axis of a pivot shaft that is swung to-and-fro; a first nozzle member that is housed inside the retainer, and that is capable of ejecting washer fluid from an ejection portion; and 1 a retainer cover member that closes off an opening of the retainer, and that is formed with a window through which the ejection portion of the first nozzle member is externally exposed.

Owner:DENSO CORP

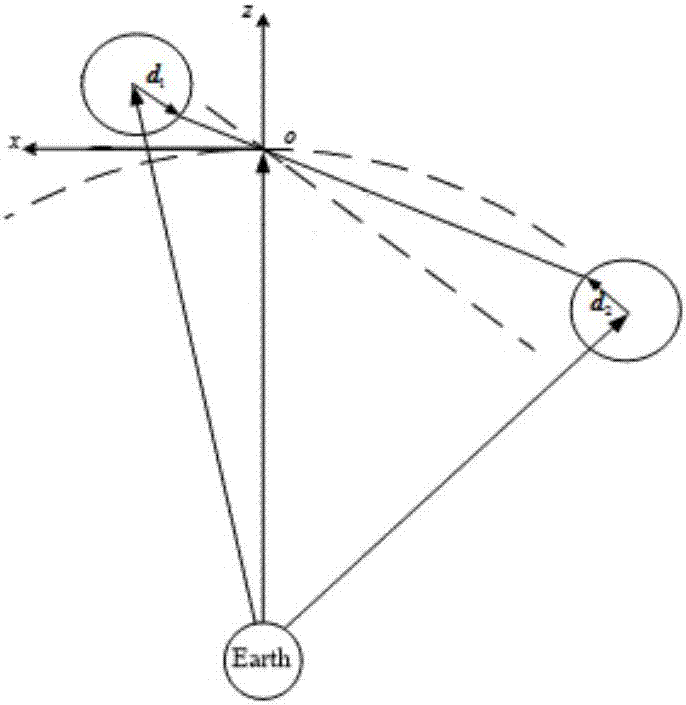

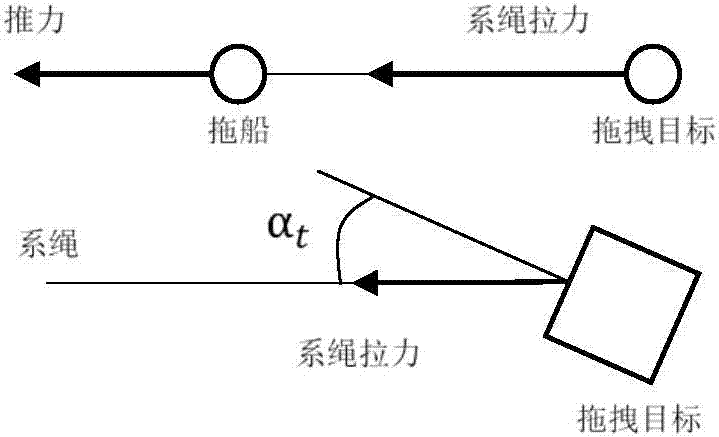

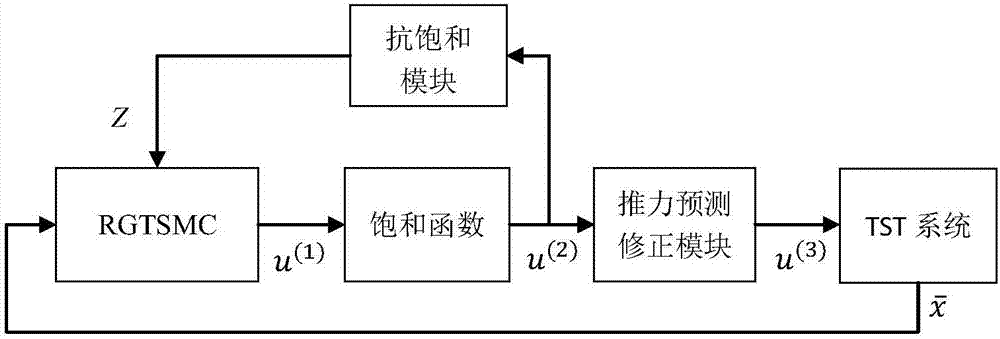

Dragged target attitude stability control method based on thrust control of tethered space tug

The invention provides a dragged target attitude stability control method based on thrust control of a tethered space tug. The method includes following steps: 1, performing a system hypothesis, wherein the tethered space tug is an integral body including a tug, a target, and an elastic-connection tie rope, and the tug and the target are located at two ends of the tied rope; 2, calculating a reference trajectory based on optimization; 3, deducing a robust global terminal sliding mode controller; and 4, adding an anti-saturation module and a thrust prediction and correction module. By the above steps, the robust global terminal sliding mode controller obtained in step 3 and the anti-saturation module and the thrust prediction and correction module obtained in step 4 are combined so that the designed dragged target attitude stability controller based on thrust control of the tethered space tug and the control method thereof are obtained, the controller designed by the method can satisfy the constraint demand, and the loosening of the tied rope is also prevented by the designed thrust prediction and correction module.

Owner:BEIHANG UNIV

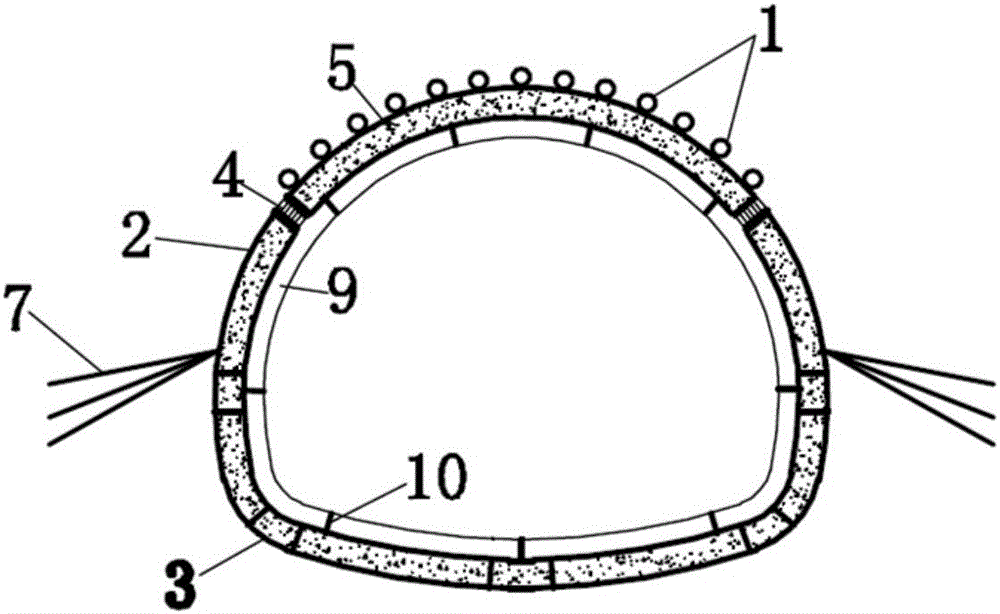

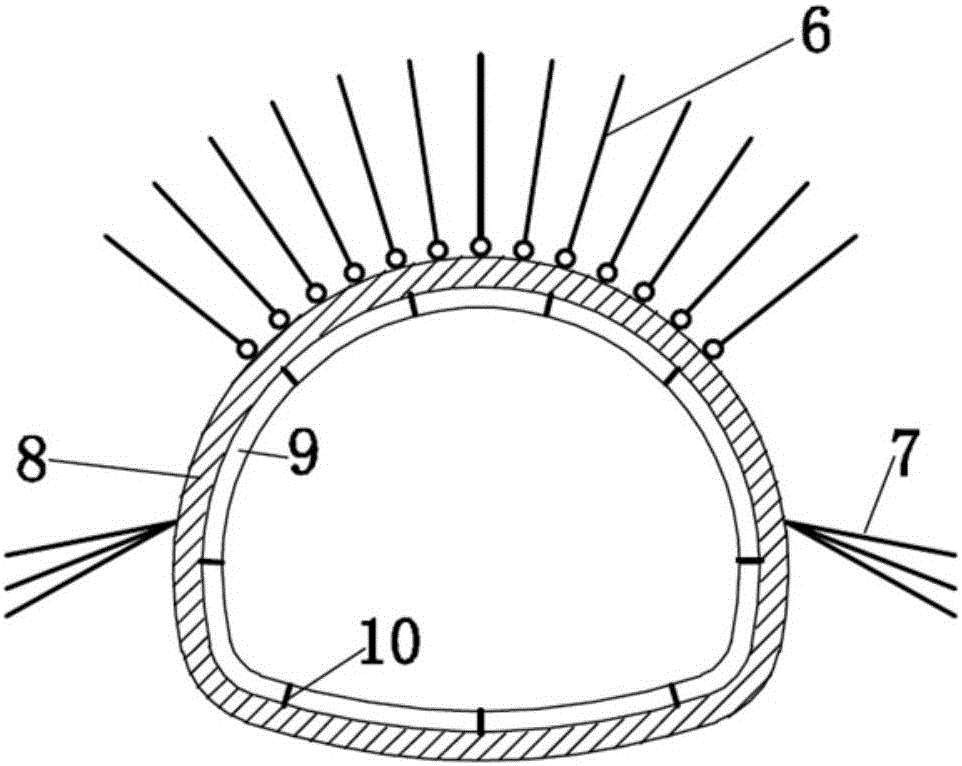

Novel shallow-buried tunnel support structure applicable to urban sensitive areas and construction method of novel shallow-buried tunnel support structure applicable to urban sensitive areas

InactiveCN105781582AAvoid slackSolve the problem of water leakageUnderground chambersTunnel liningWater leakageStructure of the Earth

The invention belongs to the technical field of tunnel and underground engineering and particularly relates to a novel shallow-buried tunnel support structure applicable to urban sensitive areas and a construction method of the novel shallow-buried tunnel support structure applicable to the urban sensitive areas.The novel shallow-buried tunnel support structure comprises an advanced support, a primary support and a prefabricated tunnel lining which are sequentially arranged from outside to inside along the radial direction of a tunnel, wherein the primary support comprises a plurality of concrete-filled steel tube arches which are arranged at intervals along the longitudinal direction of the tunnel, a form is erected and form concrete is poured between every two adjacent concrete-filled steel tube arches, and the concrete-filled steel tube arches are formed by pouring early-strength concrete through adjustable prestressed steel tubes.The novel shallow-buried tunnel support structure applicable to the urban sensitive areas effectively solves the ubiquitous problems of excessive ground surface settlement, difficulty in deformation control, water leakage, lining cracking and the like in a current urban shallow-buried tunnel construction process so as to guarantee that ground surface buildings nearby the tunnel, pipelines along the tunnel and road traffic are not affected by underground engineering construction.

Owner:CHANGAN UNIV

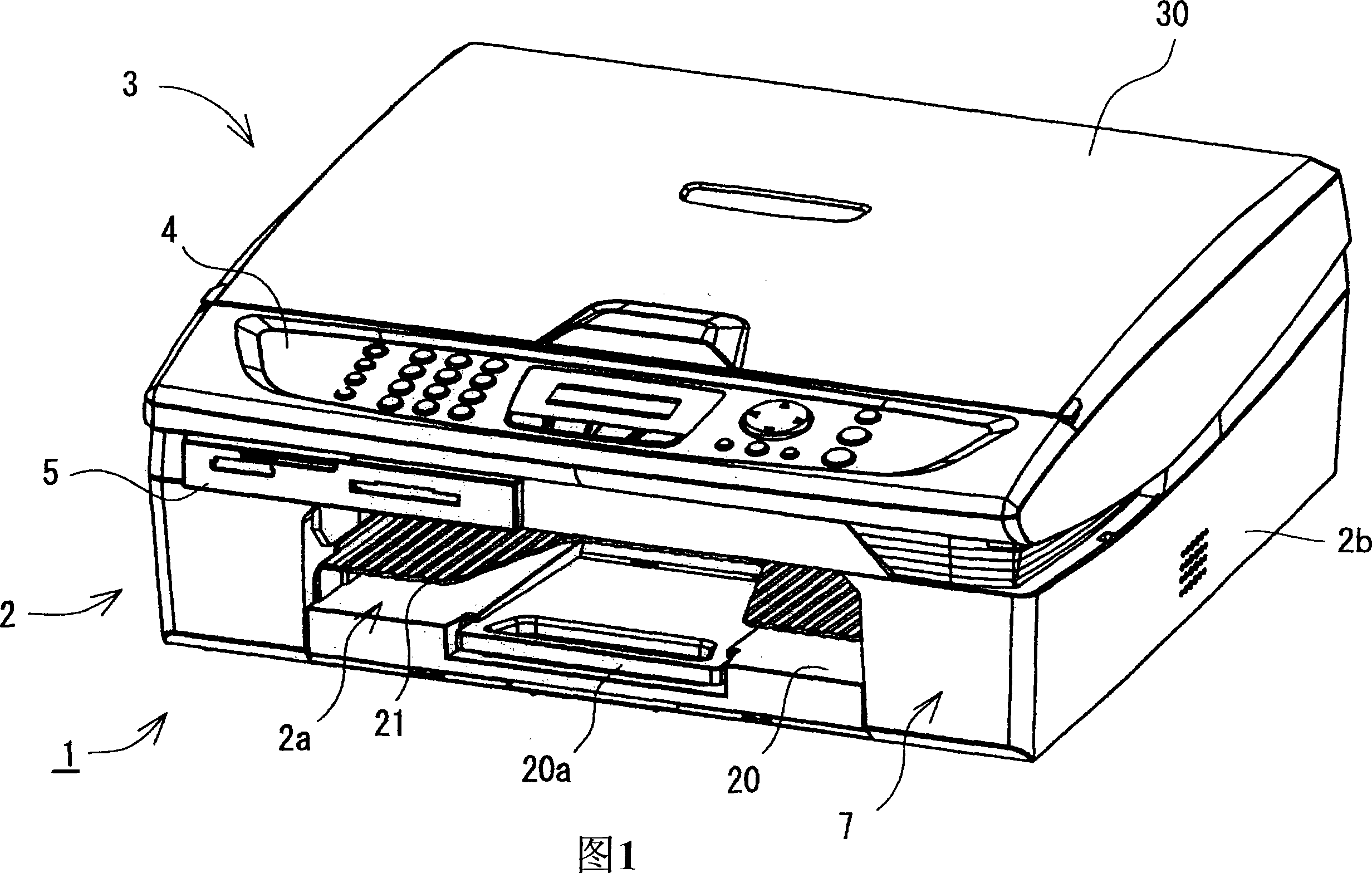

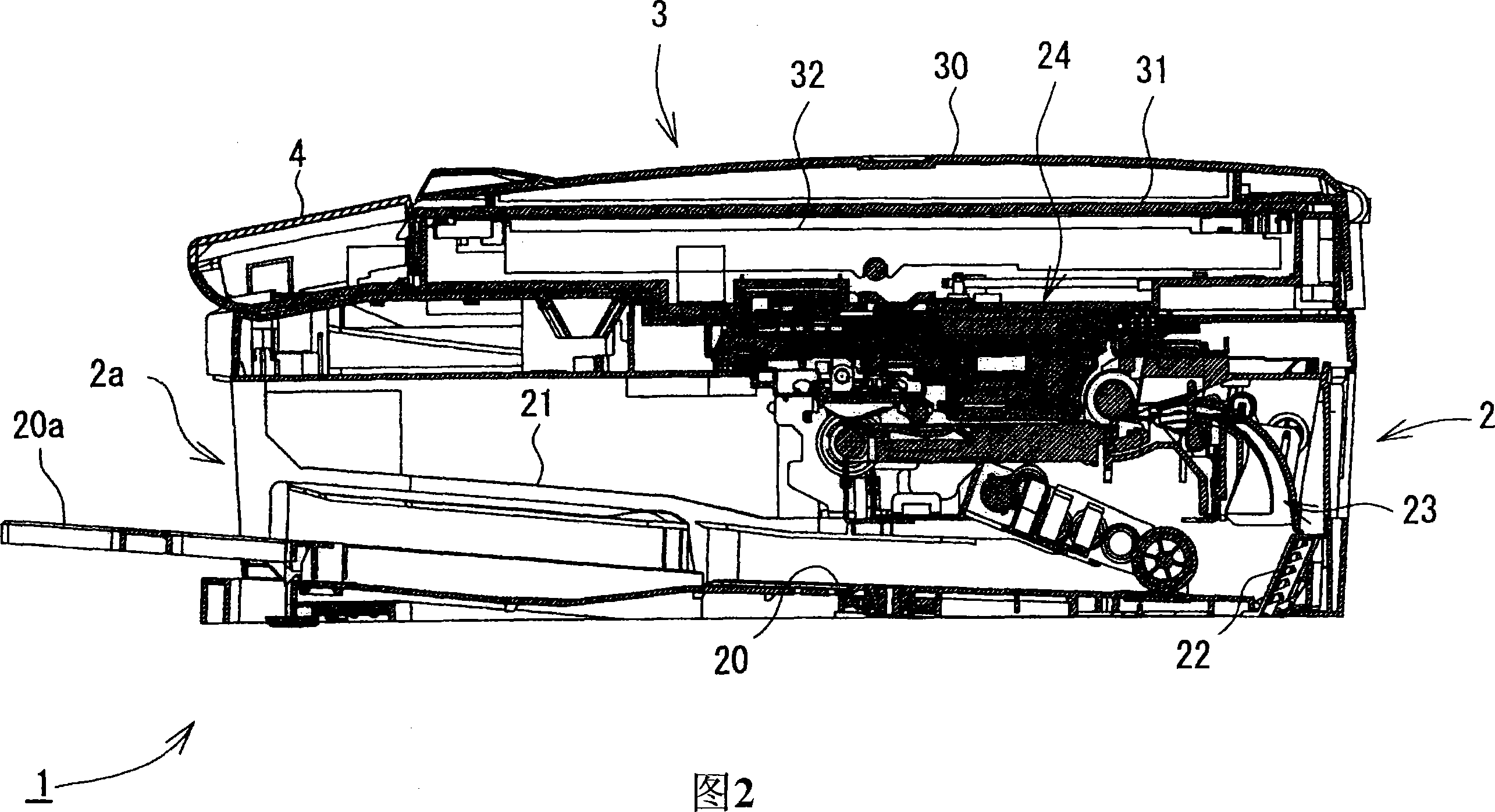

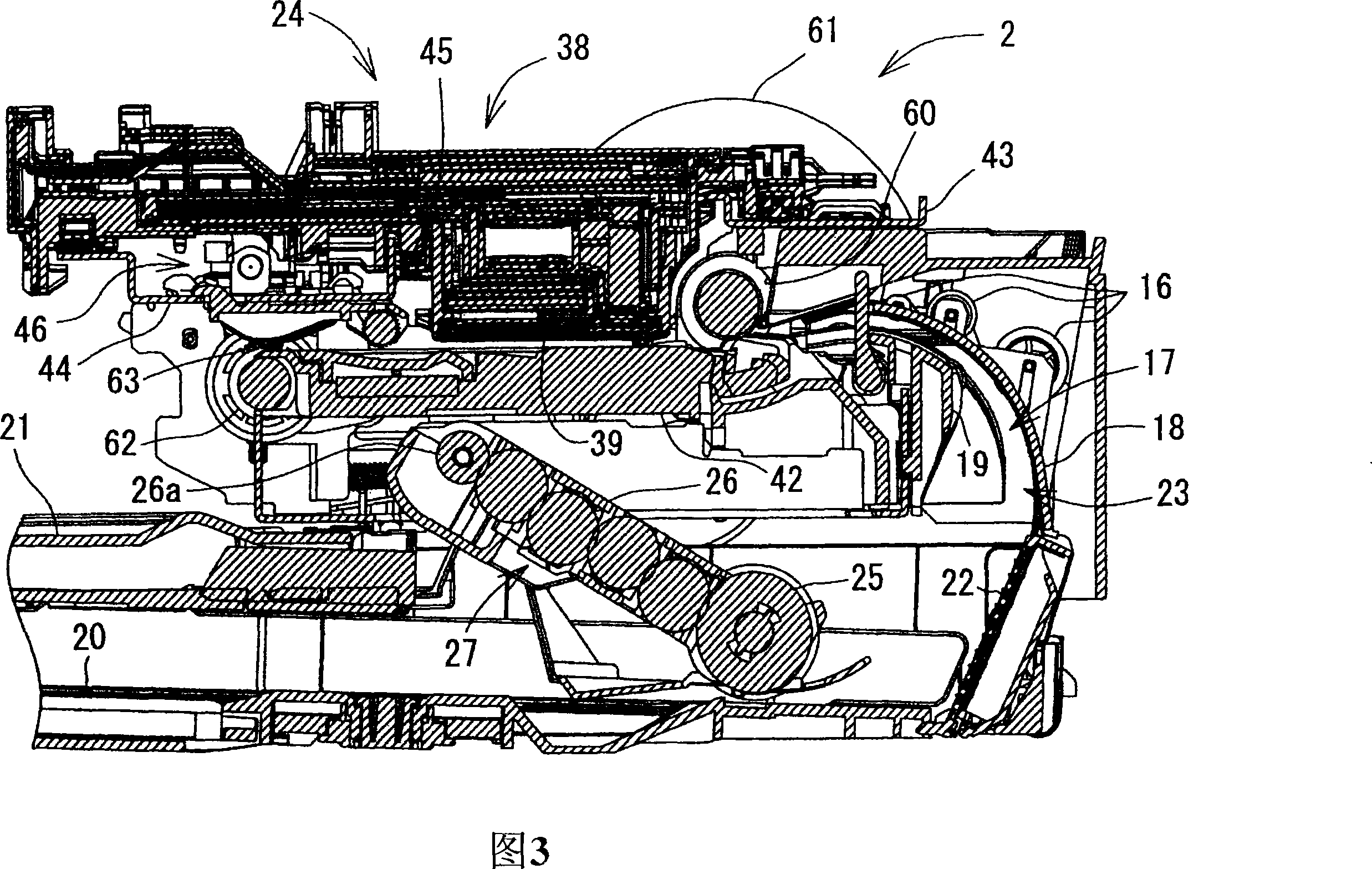

Image recording apparatus

ActiveCN101085575AAvoid bendingAvoid deflectionSpacing mechanismsOther printing apparatusReciprocating motionImage recording

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com