Wireline System

a wireline system and wireline technology, applied in the field of wireline systems, can solve the problems of potentially damaging the core quality of the hole, and achieve the effect of preventing rope slack and maintaining rope tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

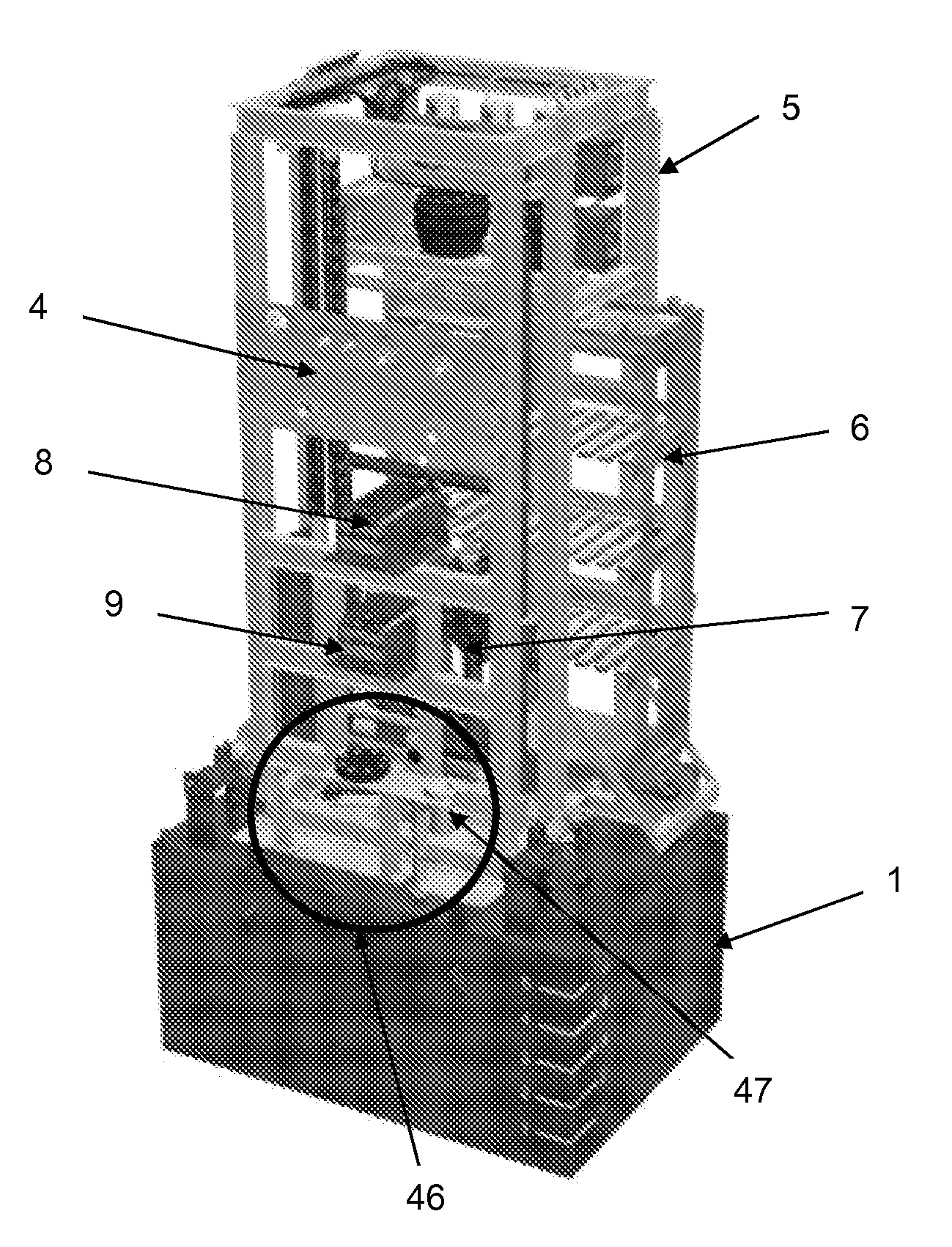

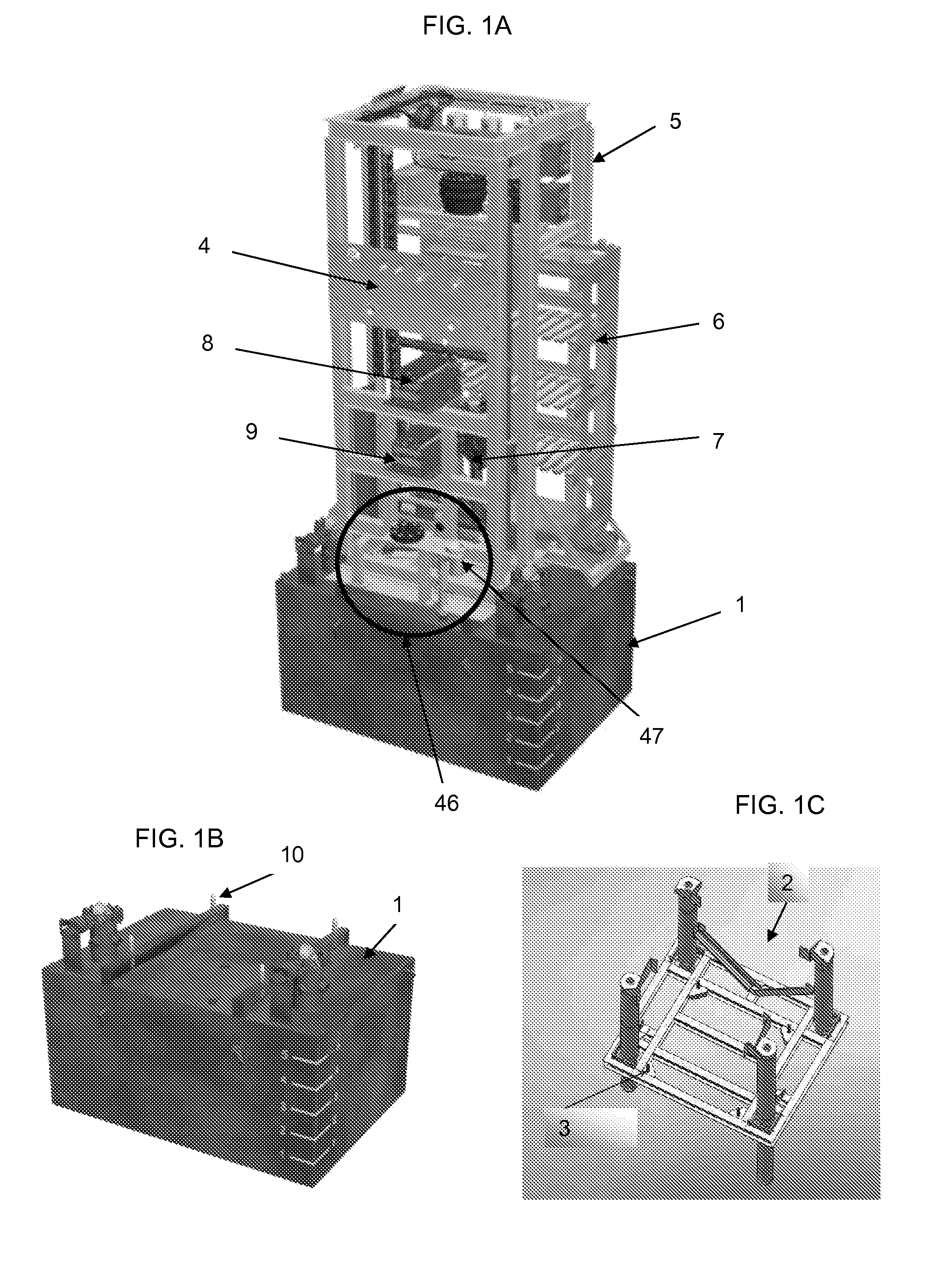

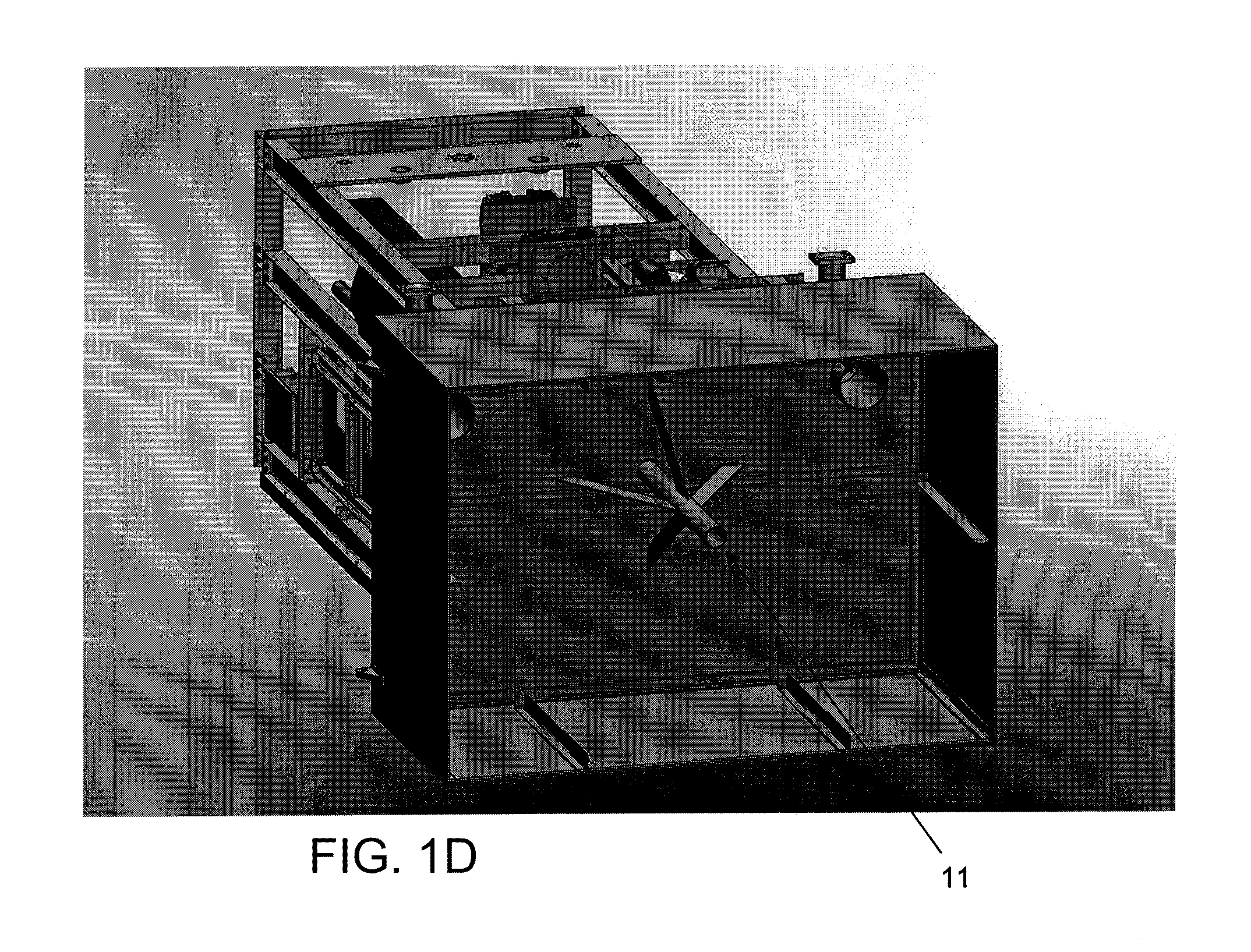

[0036]Referring now to the figures of the drawing in detail and first, particularly, to FIG. 1A thereof, there is seen an improved wireline assembly according to the invention, including an underwater foundation assembly 1 which rests on, engages with or penetrates into the surface of the seabed or water bottom. This structure may be, but is not limited to, a prior art gravity base, suction caisson, skirted mud mat or multi-legged jack up foundation, with legs being adjustable in length and may be single stage or multi-stage telescopic in nature, and may include foot pads of varying geometry and function, including rigidly or compliant, connected flat, convex or concave bearing plate assemblies, helical augers or expanding mechanical anchor assemblies. The illustrated foundation assembly 1 is a caisson which is also shown detached from the remainder of the wireline assembly in FIG. 1B. A jack up assembly 2 having pins 3 that align with a caisson attachment point is shown in FIG. 1C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com