Patents

Literature

676 results about "Caisson" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geotechnical engineering, a caisson (/ˈkeɪsən/ or /ˈkeɪsɒn/) is a watertight retaining structure used, for example, to work on the foundations of a bridge pier, for the construction of a concrete dam, or for the repair of ships. Caissons are constructed in such a way that the water can be pumped out, keeping the work environment dry. When piers are being built using an open caisson, and it is not practical to reach suitable soil, friction pilings may be driven to form a suitable sub-foundation. These piles are connected by a foundation pad upon which the column pier is erected.

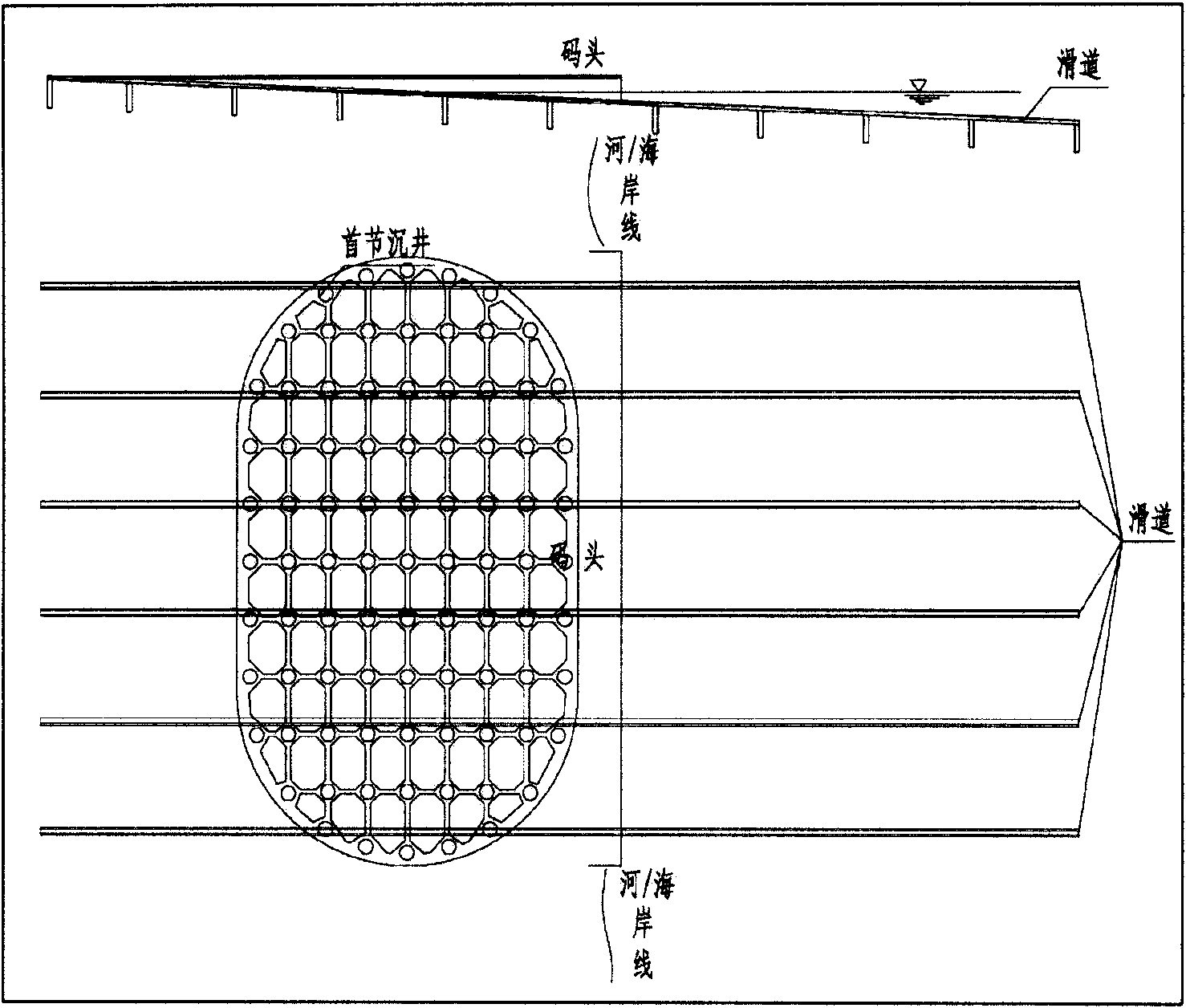

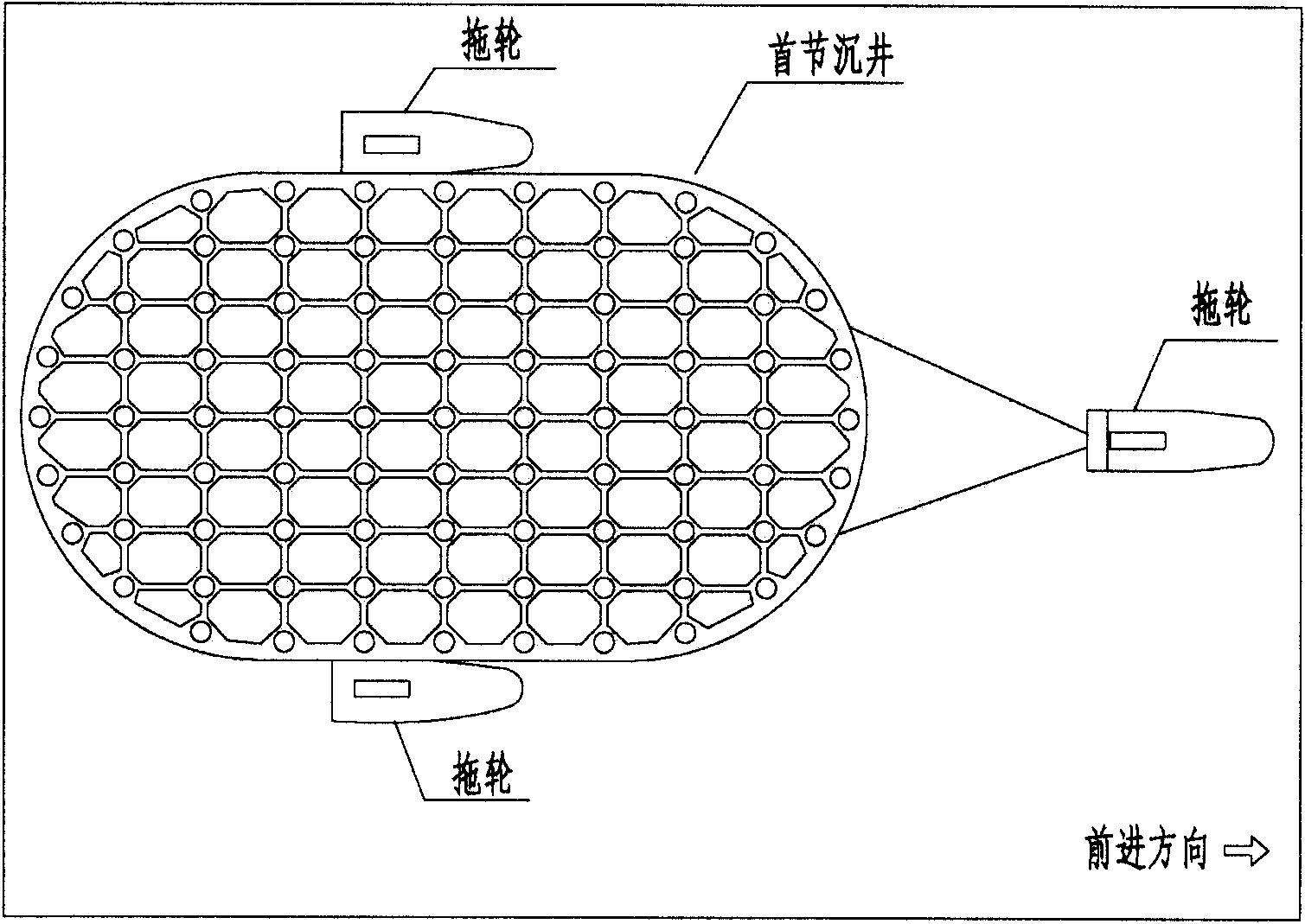

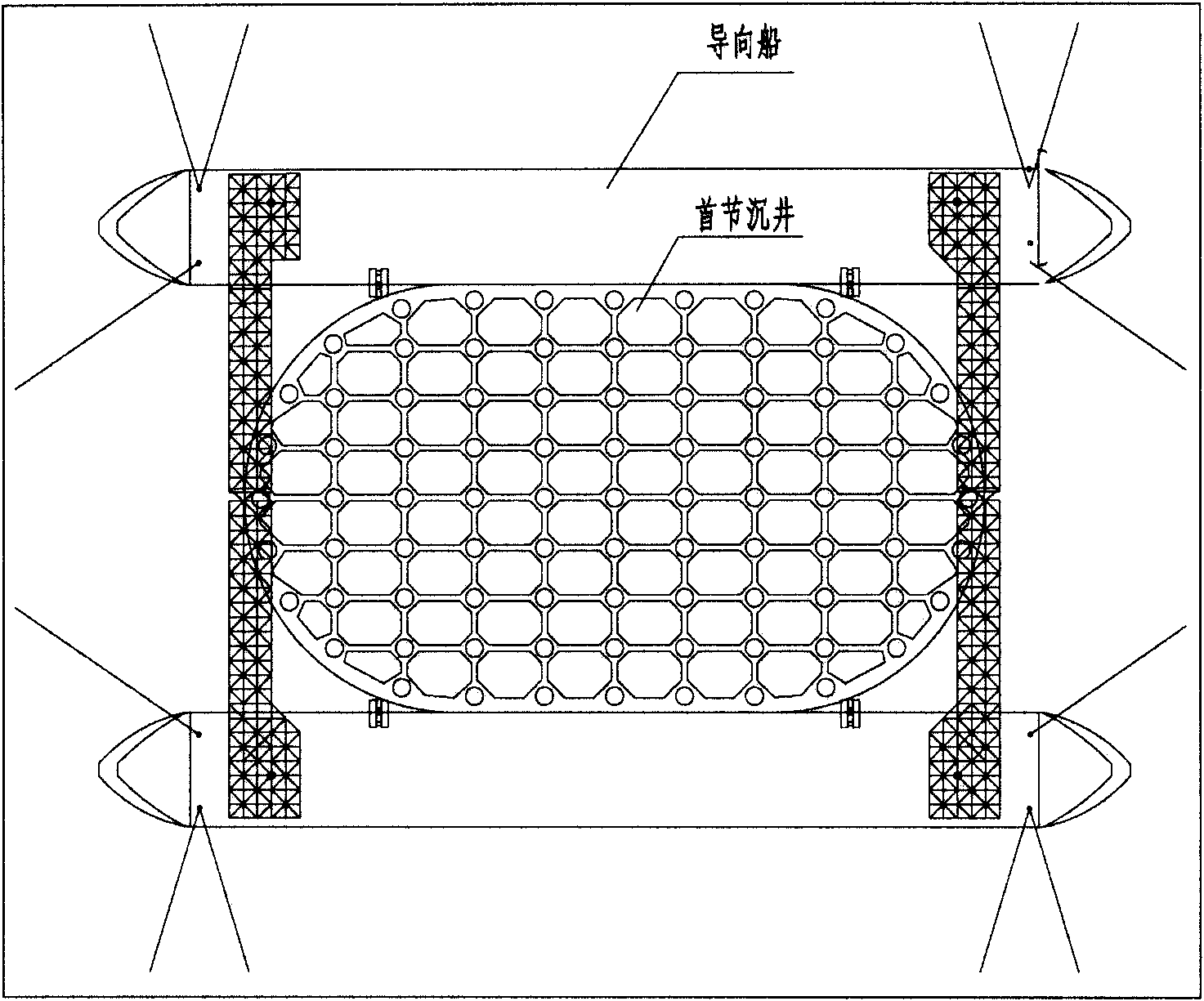

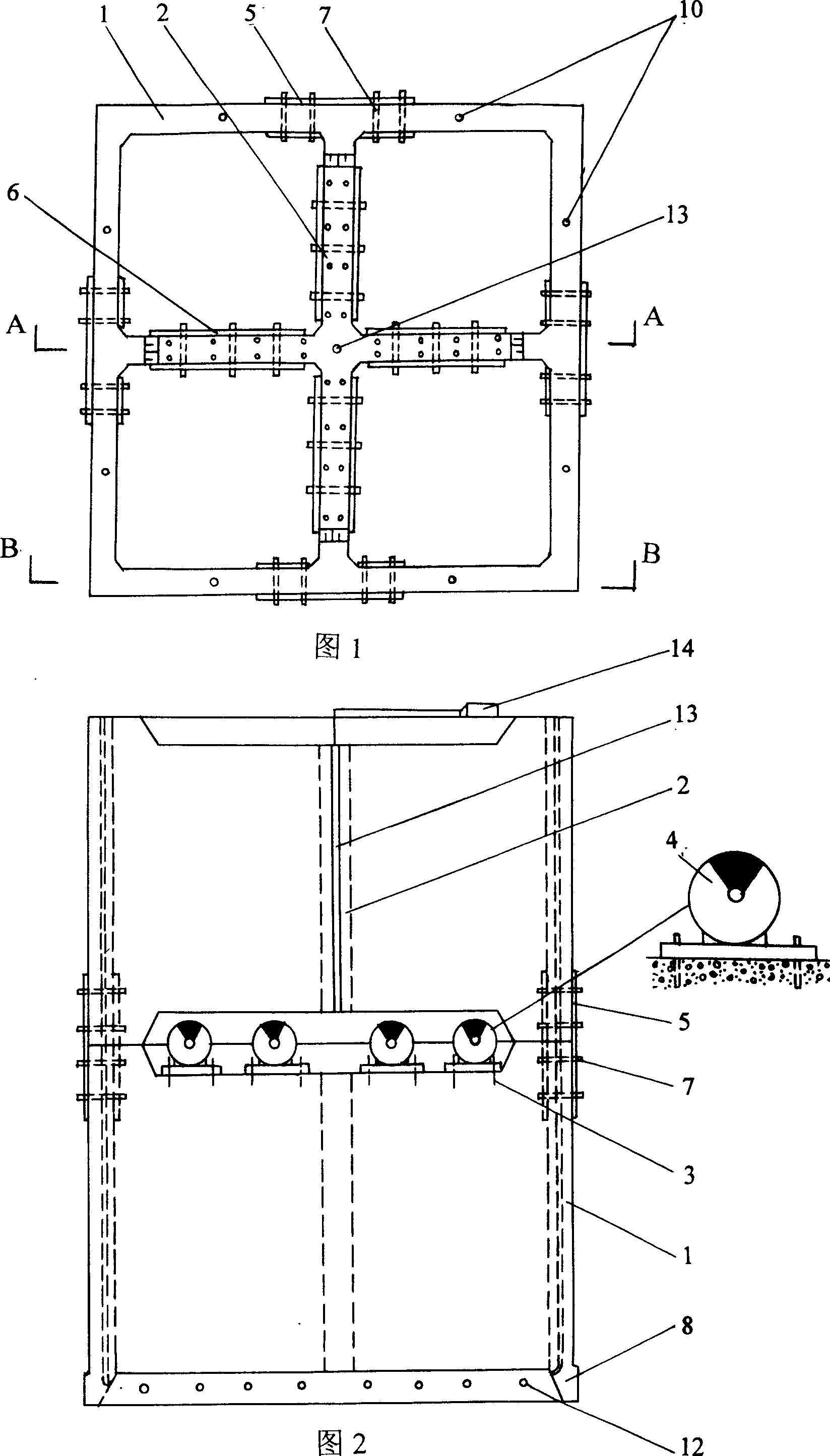

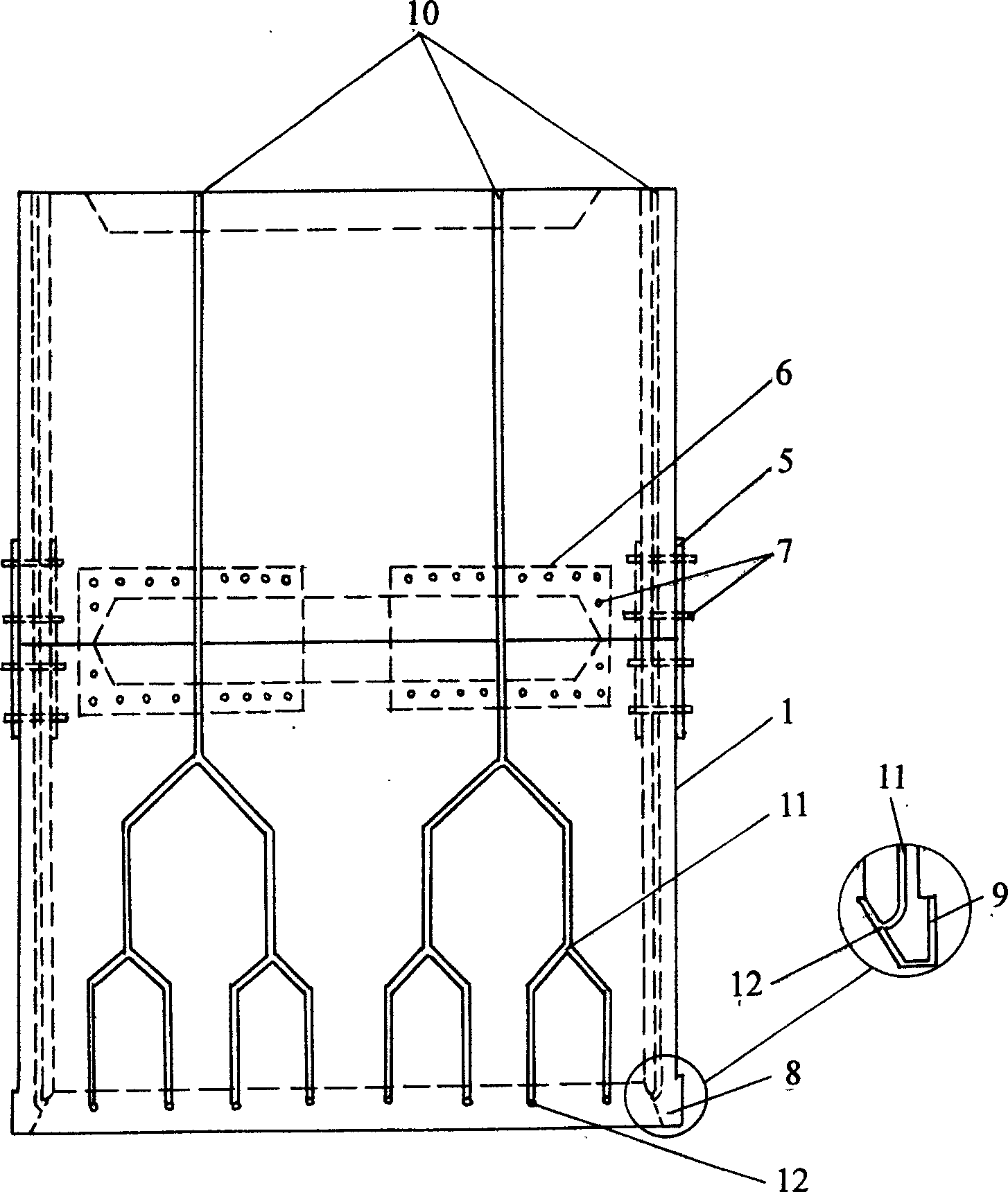

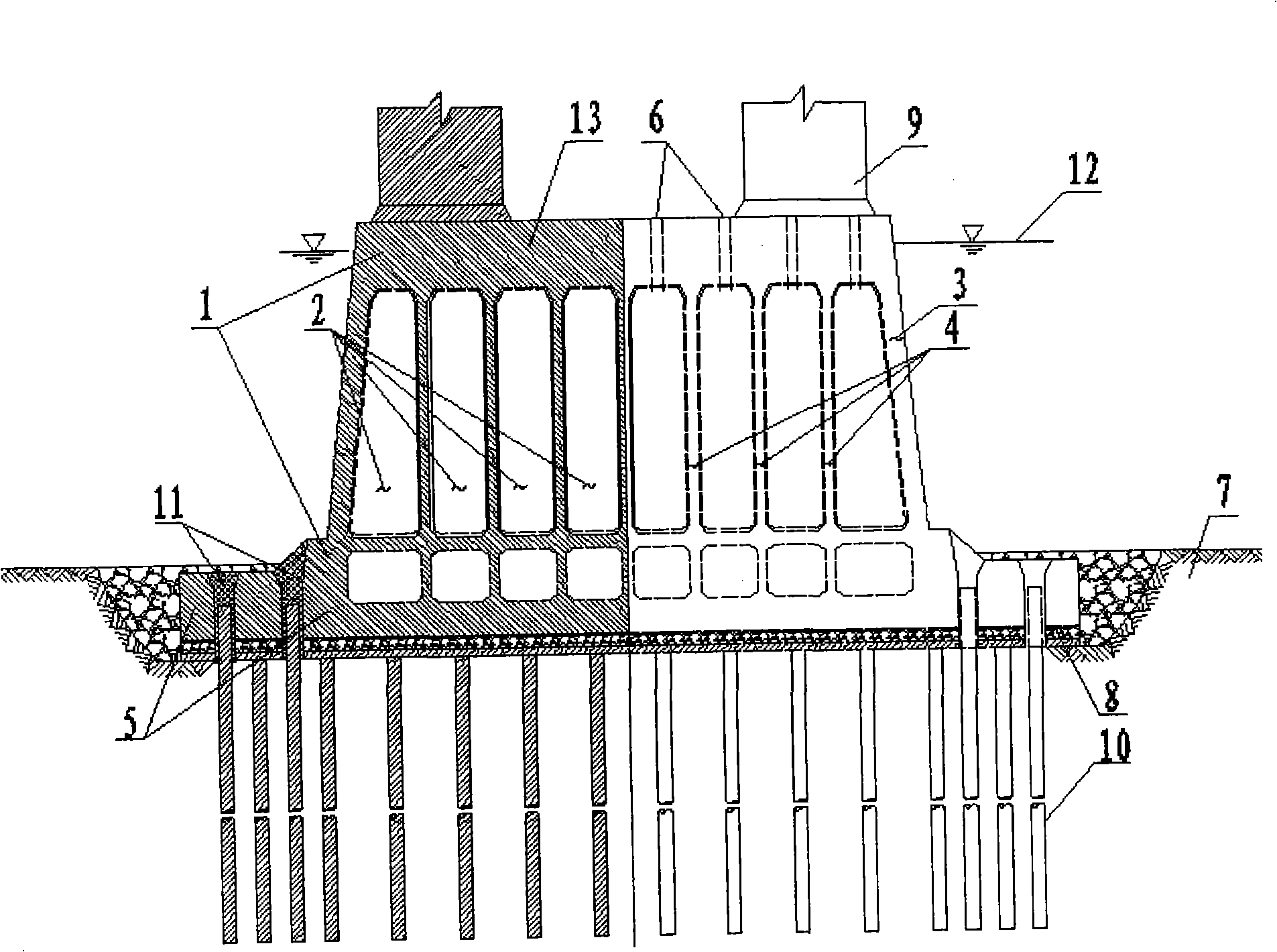

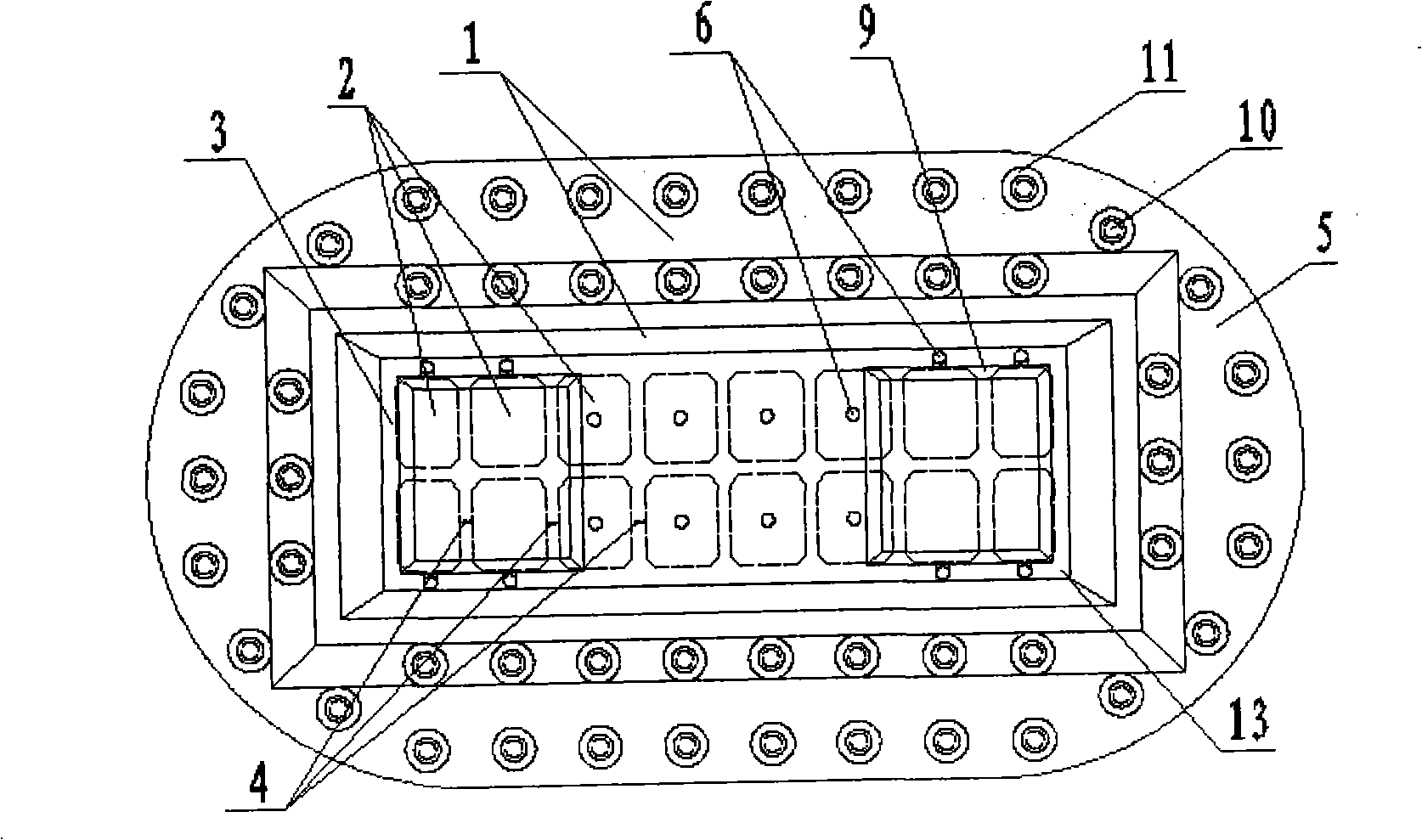

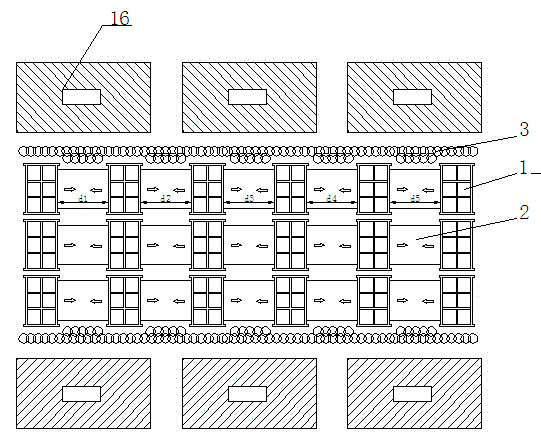

Bridge composite foundation consisting of open caisson and pile and construction method

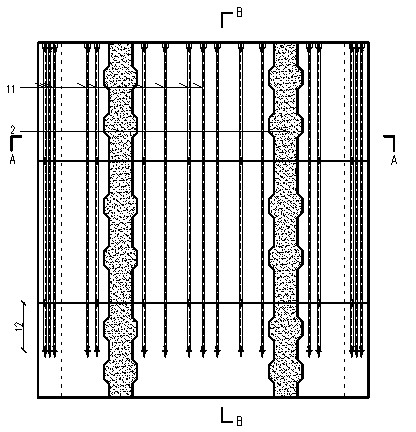

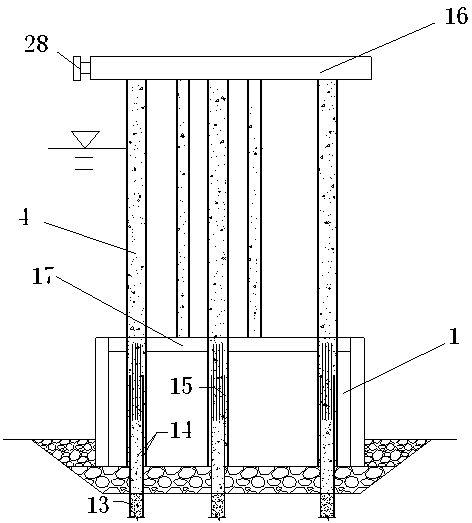

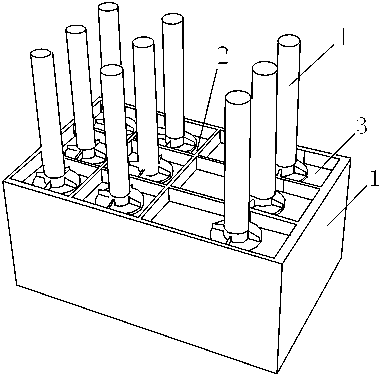

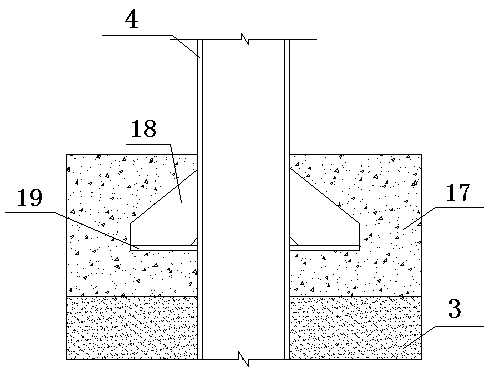

The invention discloses a bridge composite foundation consisting of an open caisson and a pile and a construction method and relates to bridge technology. The composite foundation consists of the open caisson and the pile. Open caisson partition walls have horizontal and longitudinal wall structures. A pile sinking preformed hole is reserved at the intersection of the open caisson partition walls. A steel pipe pile or a concrete driven pile sinks through the hole. The construction method comprises the following steps of: manufacturing the first section of the open caisson, floating the first section to a bridge position designed position, positioning the first section, filling water into an open caisson wall and the partition walls to sink the pile, heightening the section until the open caisson sinks to position, and casting concrete into the open caisson wall and the partition walls; after the open caisson sucks mud to sink, continuously heightening the section, and casting open caisson bottom sealing concrete when the open caisson is heightened to a designed standard height; riprapping the periphery of the open caisson to protect the open caisson, pumping water from the open caisson or coring the open caisson, and constructing an open caisson top plate; and after sinking the pile in the pile sinking preformed hole, casting the concrete into the pile sinking preformed hole to realize connection between the open caisson and the pile. The bridge composite foundation of the invention is suitable for a deep water soft soil foundation, takes the advantage of the open caisson having high rigidity and serving as a pile foundation construction space enclosing structure and exerts the characteristic of controlling sinking of the pile foundation.

Owner:CCCC HIGHWAY CONSULTANTS +1

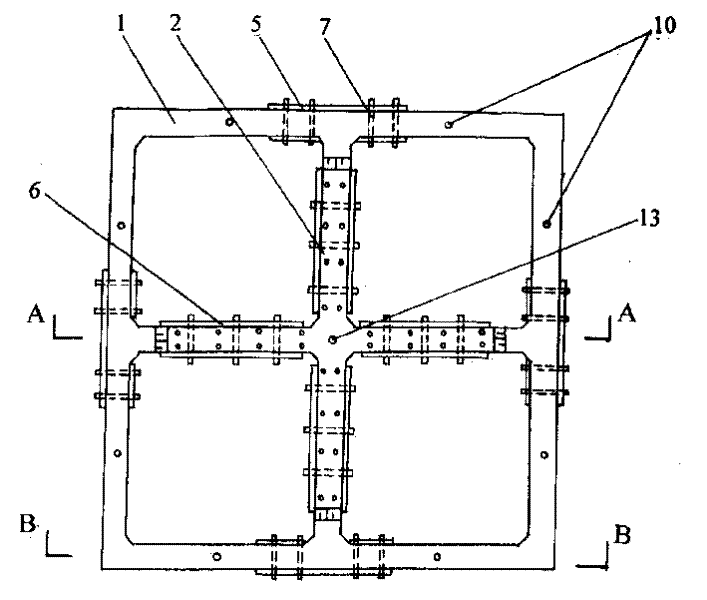

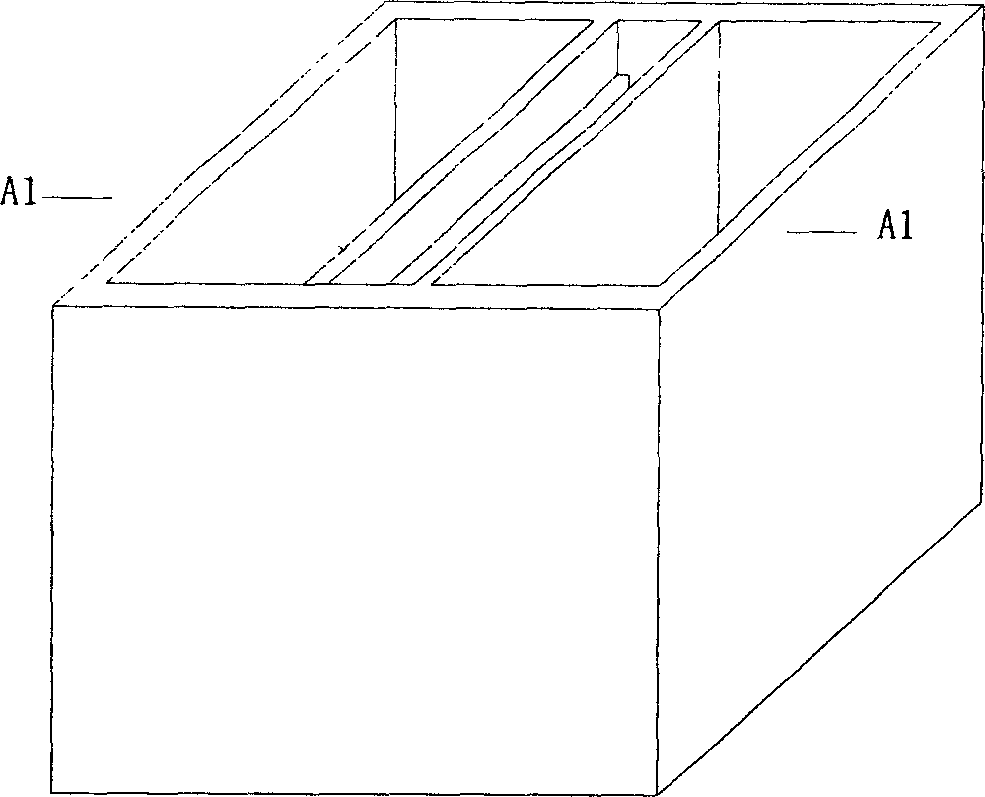

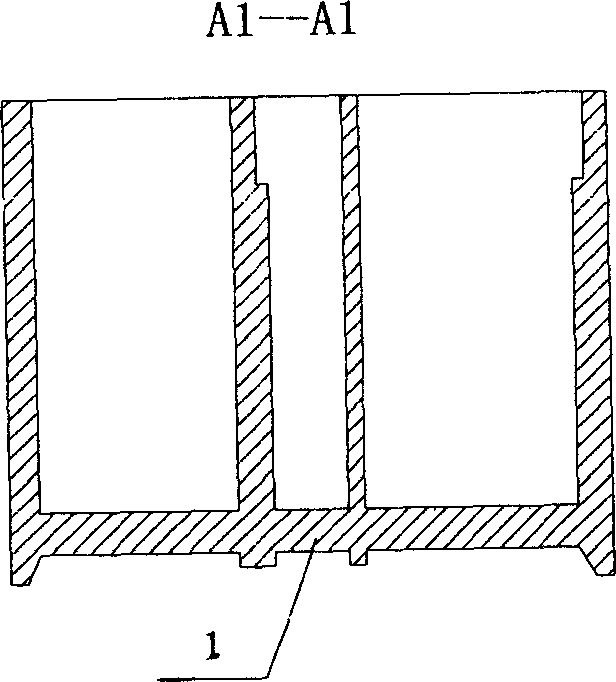

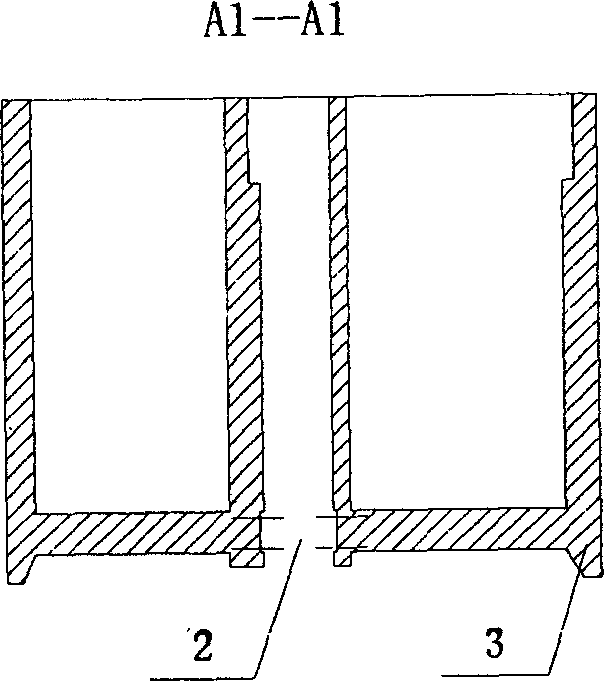

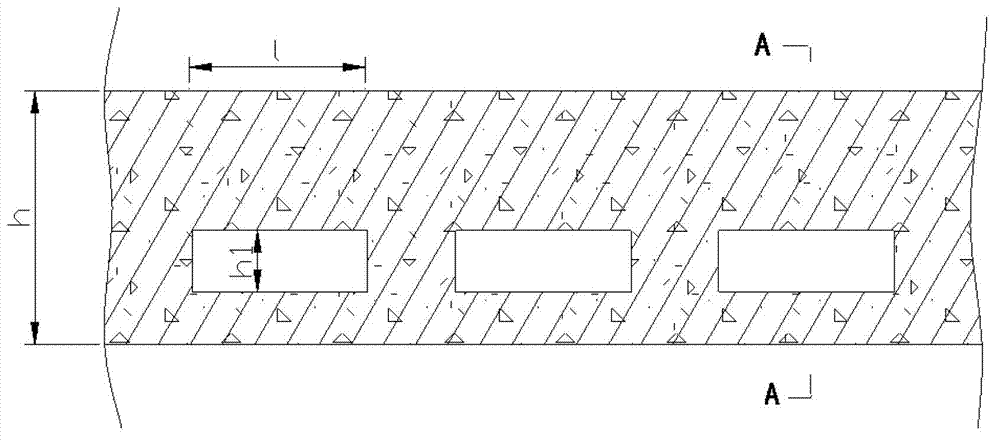

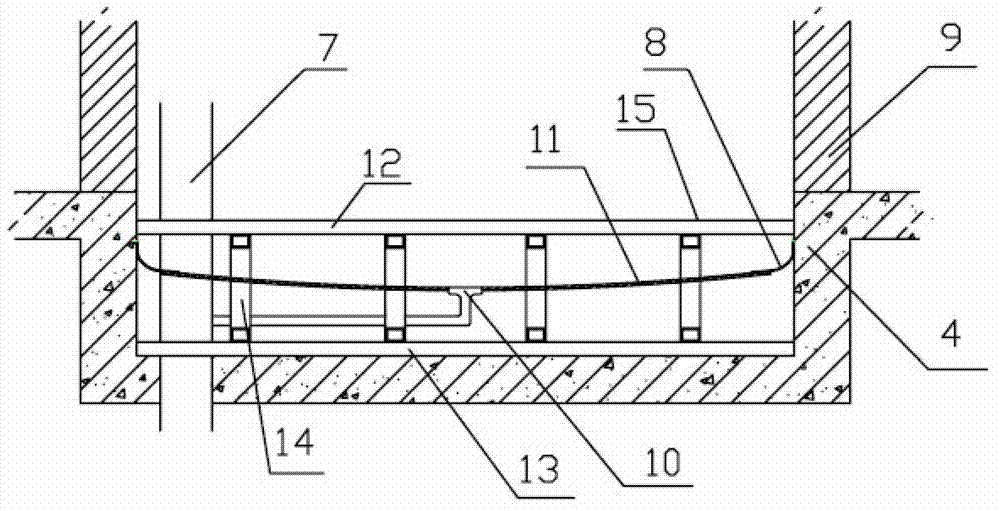

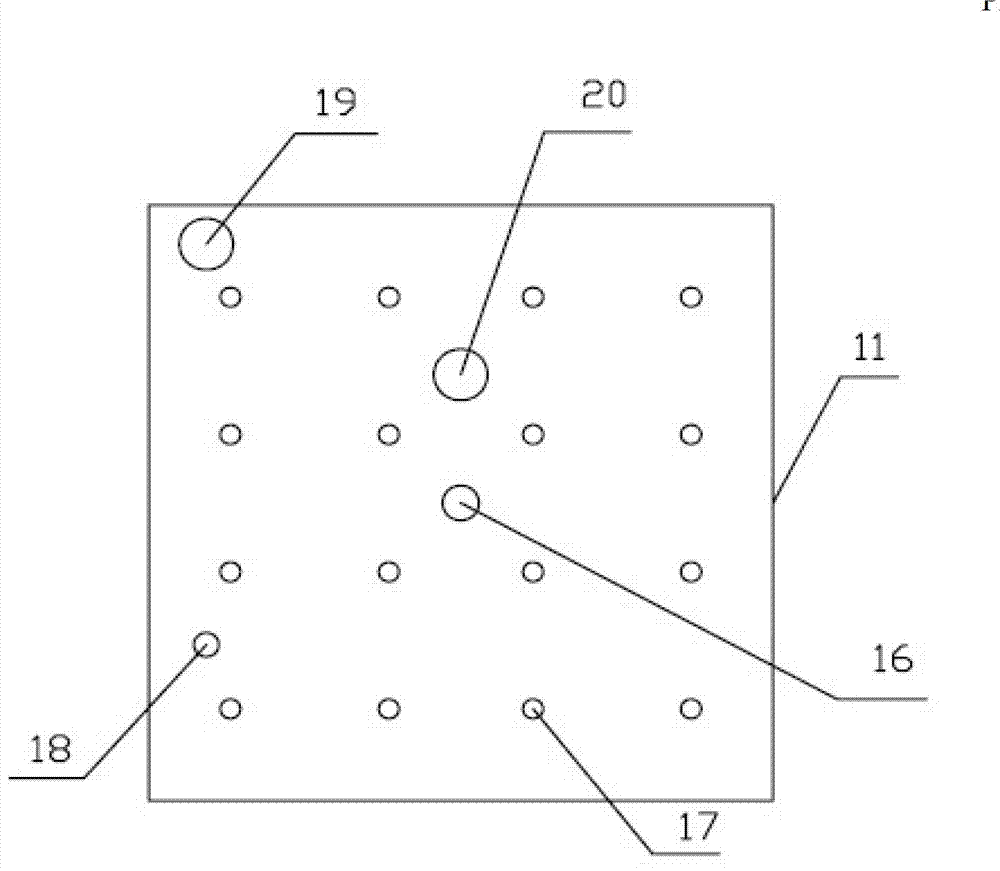

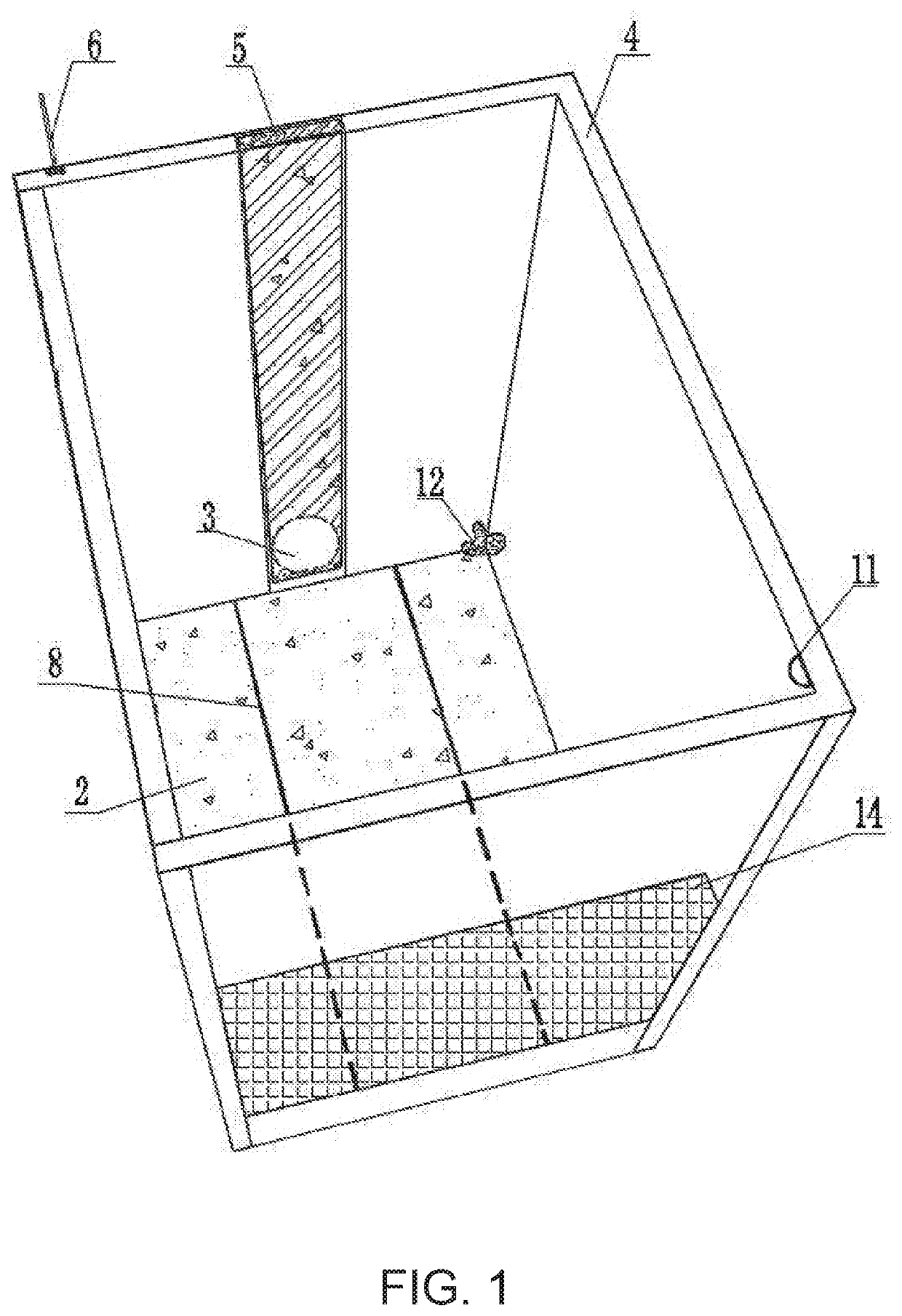

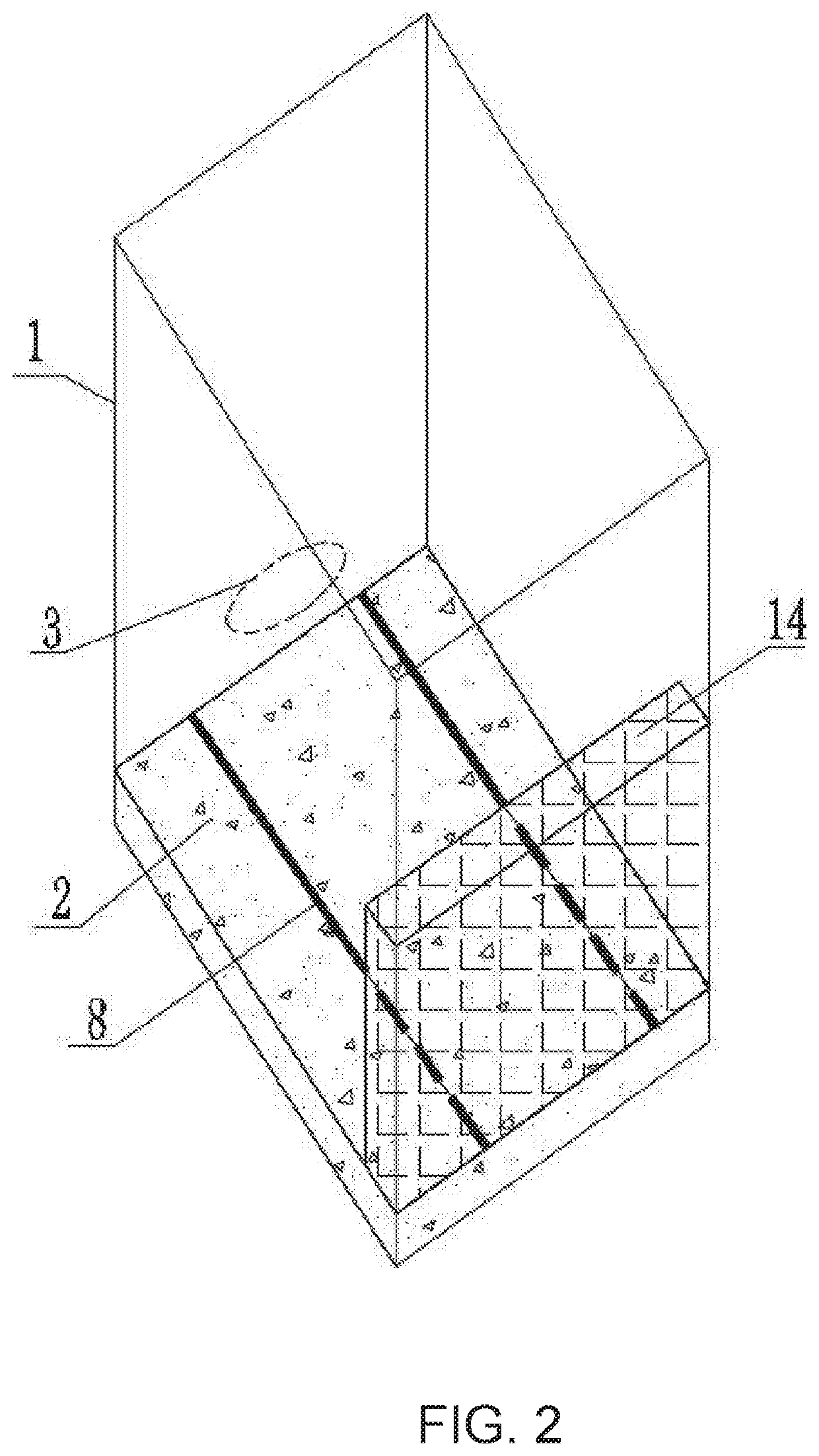

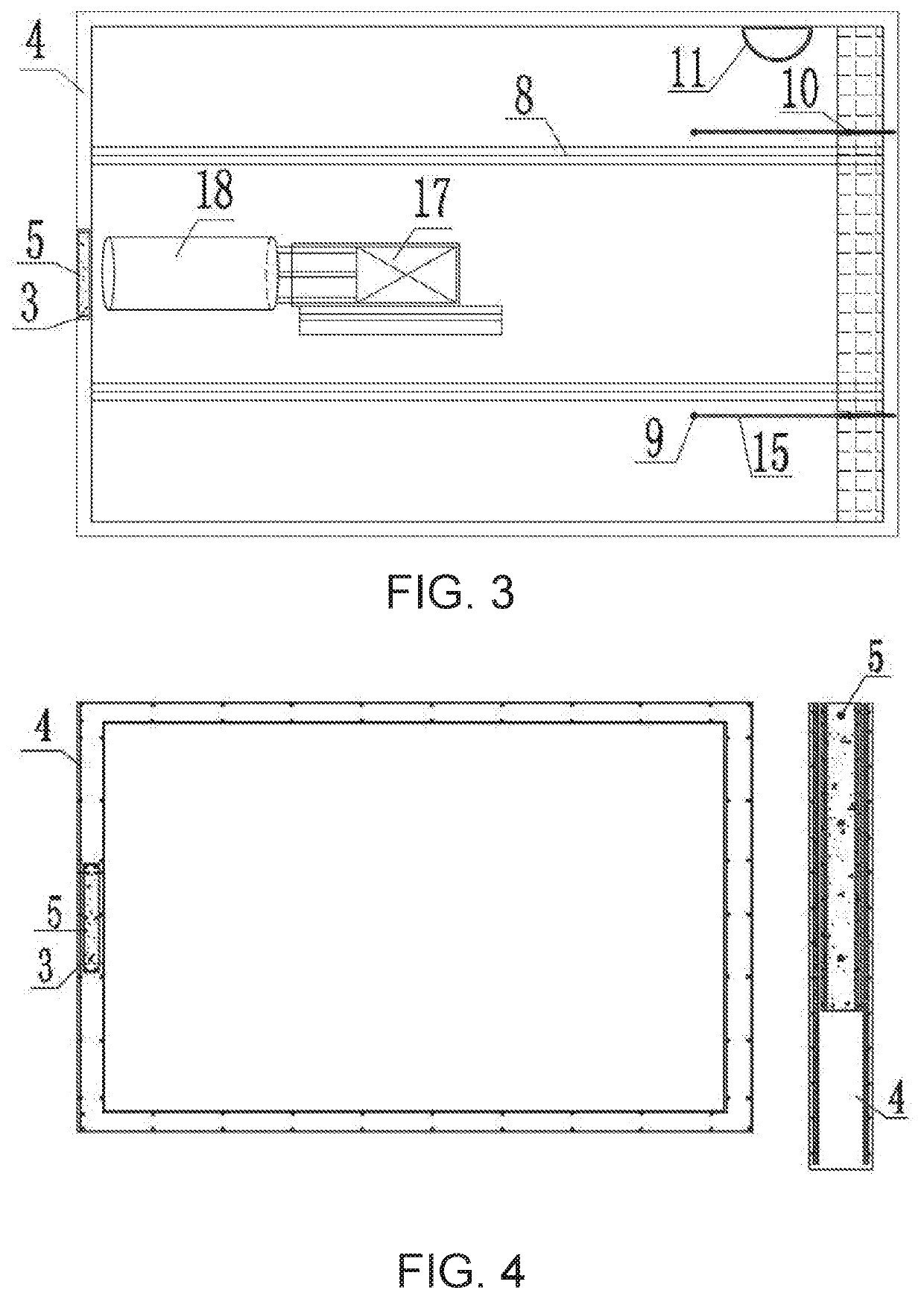

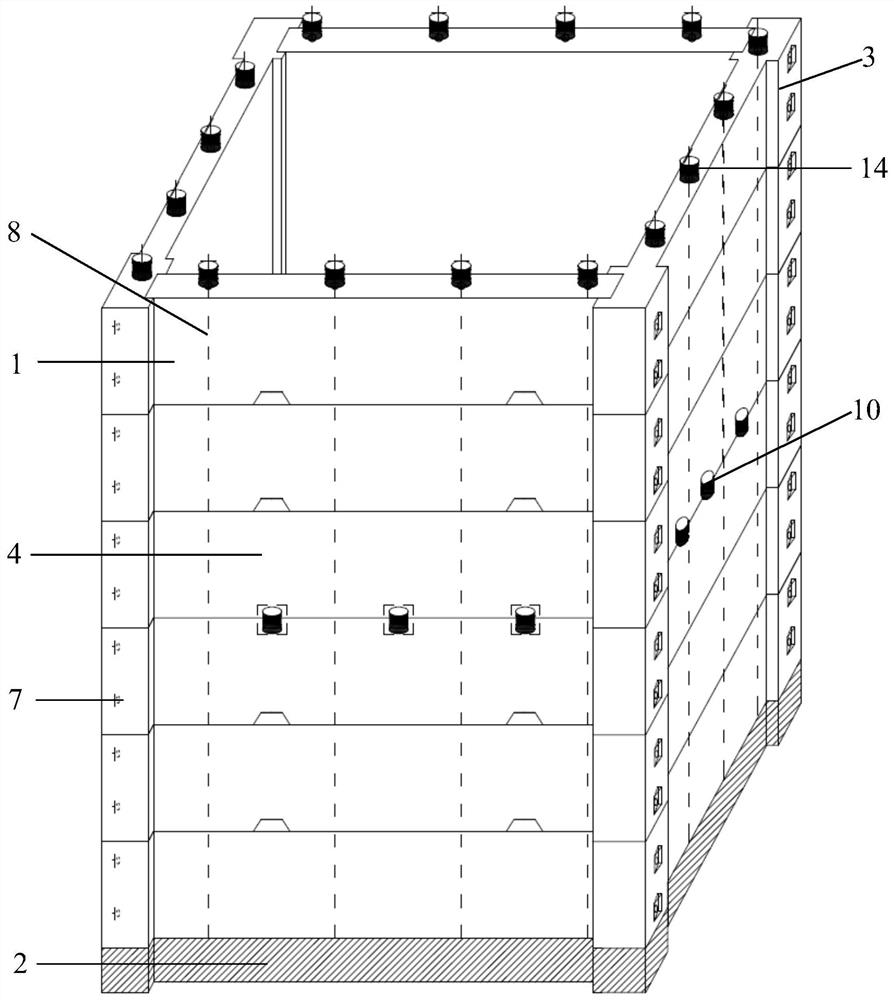

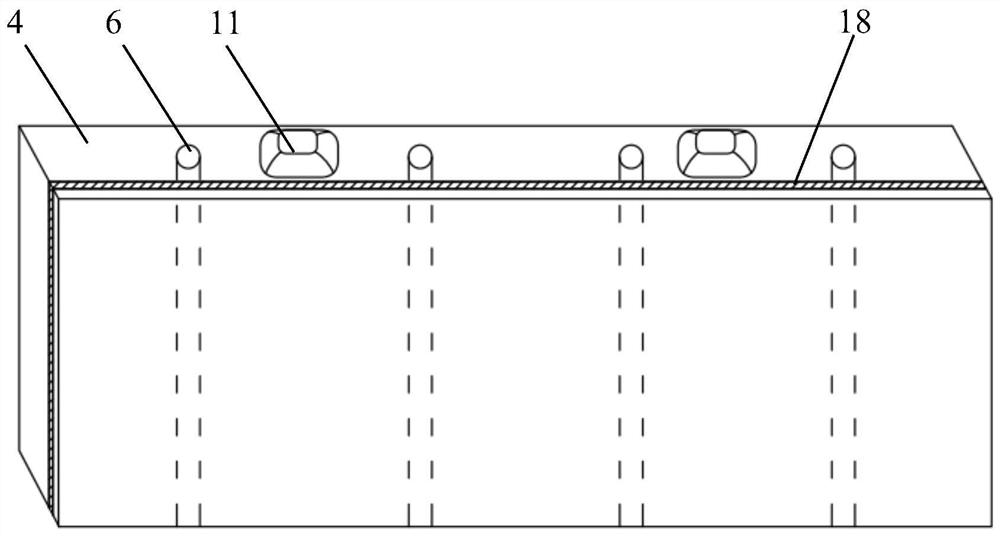

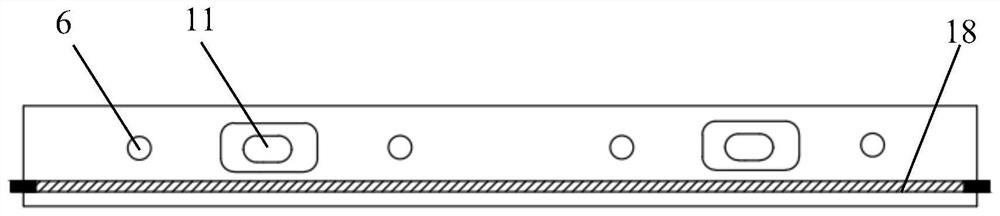

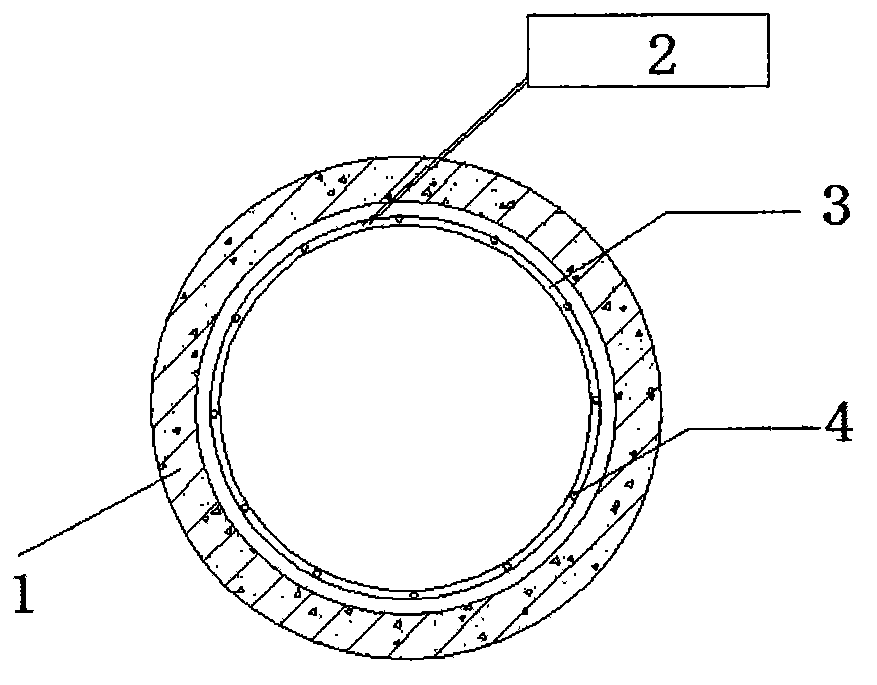

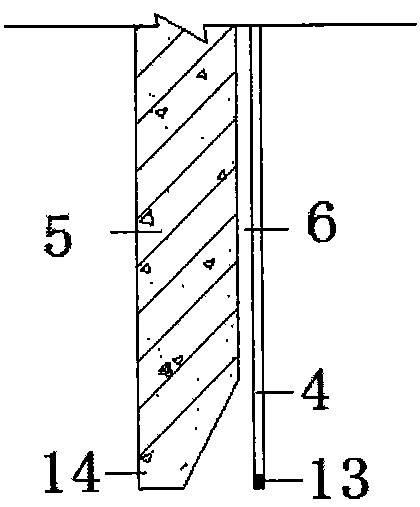

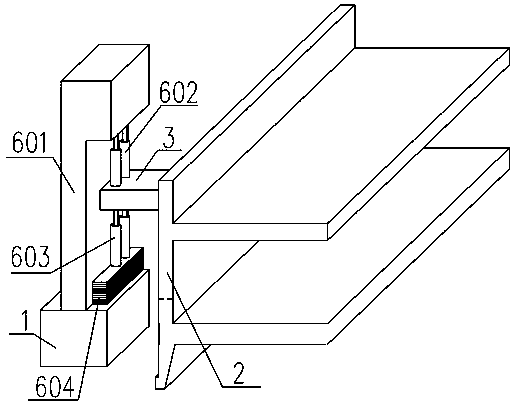

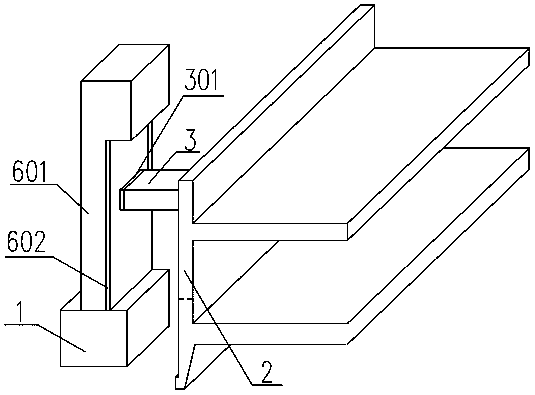

Caisson structure and fast construction method of opencaisson

The caisson structure contains caisson walls to constitute the caisson enclosure separated into several sections, and partition walls and crossbeams inside the caisson enclosure. There are edged feet in the lowest caisson section, steps on the containing partition walls between each two sections, vibrators inside the steps, built-in high pressure water pipe inside the caisson walls, branch pipes, built-in cable tubes communicated with the vibration controller, and clamping steel plates around the upper and the lower caisson enclosures and on two sides of the partitions to integrate the caisson structure. The fast construction method of open caisson includes sectional prefabrication, sectional installation and sectional stamping until reaching the designed height, and has fast construction speed and low cost.

Owner:王民寿

Late poured band type assembled pipe jacking working open caisson

InactiveCN102155025AImprove construction progressLower requirementArtificial islandsUnderwater structuresArchitectural engineeringSteel bar

The invention discloses a bidirectional prestressing type preassembled working open caisson which is applied to pipe jacking projects. The open caisson is rectangular and is formed by splicing prefabricated well pieces with U-shaped and straight sections. Cantilever ends at two sides of each U-shaped well piece are different in length; the horizontal U-shaped well pieces are spliced dissymmetrically according to the lengths of the cantilever ends at two ends; and the vertical adjacent U-shaped well pieces are spliced in a staggered way according to the sizes of the cantilever ends. All the vertical well pieces and the horizontal well pieces are connected through prestressed reinforcements. The vertical prestressed reinforcements are connected through connectors at the transversal abutted seams. The vertical prestressed reinforcements in the well pieces of the blade foot section are subjected to non-bonding treatment. Shear key structures are arranged on the sections of prefabricated well pieces at two sides of transversal abutted seams; and the well pieces provided with the shear key structures adopt a matching prefabrication method to ensure the mounting precision of the open caisson. When in prefabrication, the reinforcements are inserted into a prestressing duct. The bidirectional prestressing type preassembled working open caisson disclosed by the invention remarkably improves the filed casting efficiency of the open caisson, shortens the pipe jacking construction period, and accords with the architectural notion of 'low carbon economy and green construction'.

Owner:SOUTHEAST UNIV

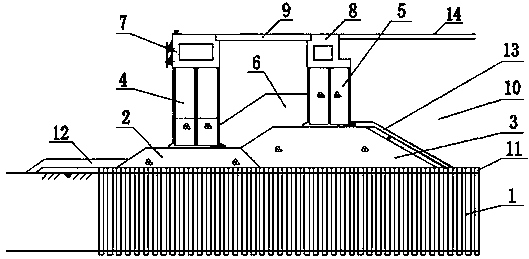

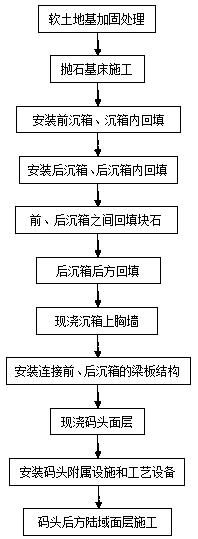

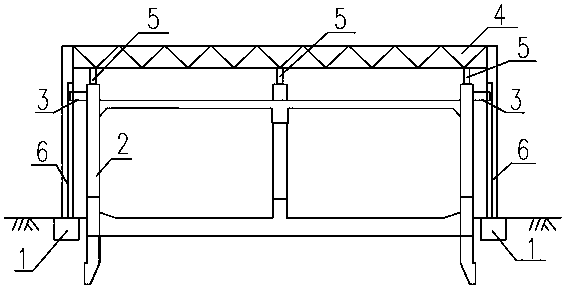

Deepwater open type wharf with combined foundation and method for constructing deepwater open type wharf

The invention discloses a deepwater open type wharf with a combined foundation. A foundation support system of the deepwater open type wharf comprises a caisson gravity structure system and a pile foundation structure system which are fixedly assembled and connected with each other, a caisson is fixed onto a submarine foundation bed in an implantation manner, the pile foundation structure system is of a concrete-filled steel pipe pile bundle structure comprising through long piles and non-through piles, steel pipe piles arranged along the insides of steel casings are driven into a rock-soil bearing stratum to form the through long piles, and the bottoms of the non-through piles are embedded into a top plate of the caisson to be fixedly connected with the top plate of the caisson, so that the wharf with the combined foundation which comprises an open type pile foundation and the gravity caisson is formed. The invention further provides a method for constructing the wharf. The method includes prefabricating the combined foundation on a land; processing the submarine foundation bed; positioning and sinking the combined foundation; manufacturing the through long piles; manufacturing an upper wharf face plate. The deepwater open type wharf and the method have the advantages that merits of the gravity structure and merits of a pile foundation structure are combined with one another, the problem of differential settlement is effectively solved, wharf apron mooring conditions are improved, and the wharf is high in bearing capacity and good in durability.

Owner:SHANGHAI UNIV

Steel cavity stranded caisson-pile inverse-way composite base and construction method

ActiveCN101294394AEffective control of settlementReduce settlementCaissonsBulkheads/pilesRiver bedEngineering

The invention relates to a composite foundation composed of a caisson with a steel cavity and piles constructed by the reverse operation method, and a construction method thereof, belonging to the bridge construction technology. The composite foundation comprises a caisson, a foundation bed, and piles. The caisson is composed of a steel cavity, an outer wall, an inner wall with a partition wall structure, a caisson cover, and a caisson bottom platform, wherein the caisson cover is preserved with water pumping and gas delivery holes, which are doubled as inspection holes. The caisson is arranged above the foundation bed and placed inside water, bridge piers are arranged on the caisson cover, the periphery of the caisson bottom platform is connected with the piles constructed by the reverse operation method, and the piles are inserted into the foundation bed and the sea bed or river bed through sinking pile preserved holes. After a foundation trench is excavated, a ship is located by riprapping to form the foundation bed, and the foundation bed is leveled by a platform type foundation bed riprapping leveling ship. The piles are connected with the caisson by pouring concrete in the preserved holes in the caisson. The inventive composite foundation utilizes the buoyancy force of the caisson steel cavity and considers the combined action of the piles, soil and the caisson to share partial external load by the sea bed or the river bed. The composite foundation optimizes the pile foundation design, reduces settlement during bridge service period, and reduces construction cost.

Owner:CCCC HIGHWAY CONSULTANTS

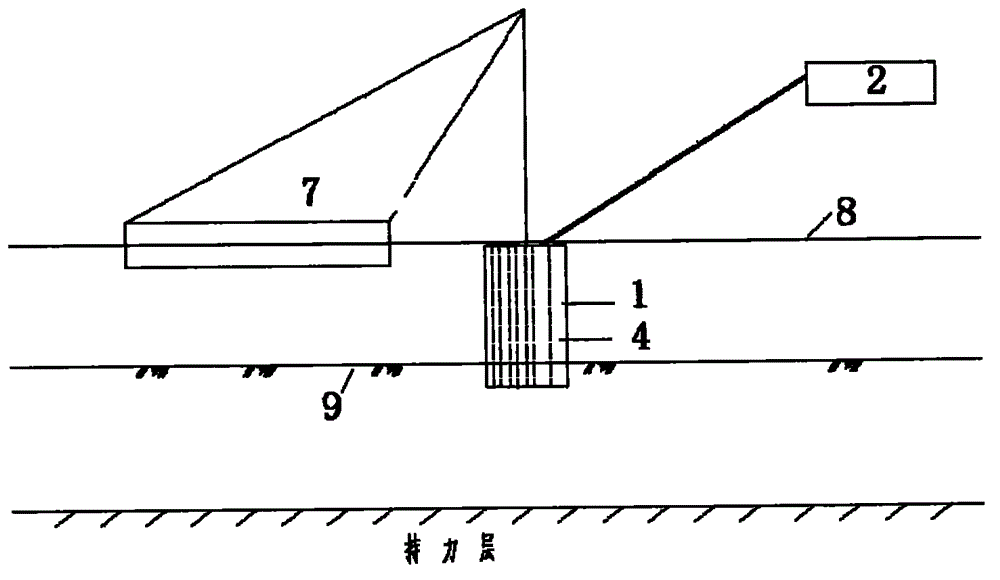

Ground caisson construction technology and ground caisson

InactiveCN1718942AConstruction safetyCheap constructionCaissonsBulkheads/pilesEngineeringHigh pressure water

The present invention relates to a land caisson construction process and land caisson. Said contruction process includes the following steps: firstly, completely closing or partial closing bottom plate of caisson, then sinking. Said land caisson is characterized by that the lower portion of periphery of the caisson is equipped with edge feet, several high-pressure water guns are vertically mounted on the bottom portion of caisson body, said water guns are communicated by water pipe.

Owner:大融合(广东)海洋休闲渔业发展有限公司

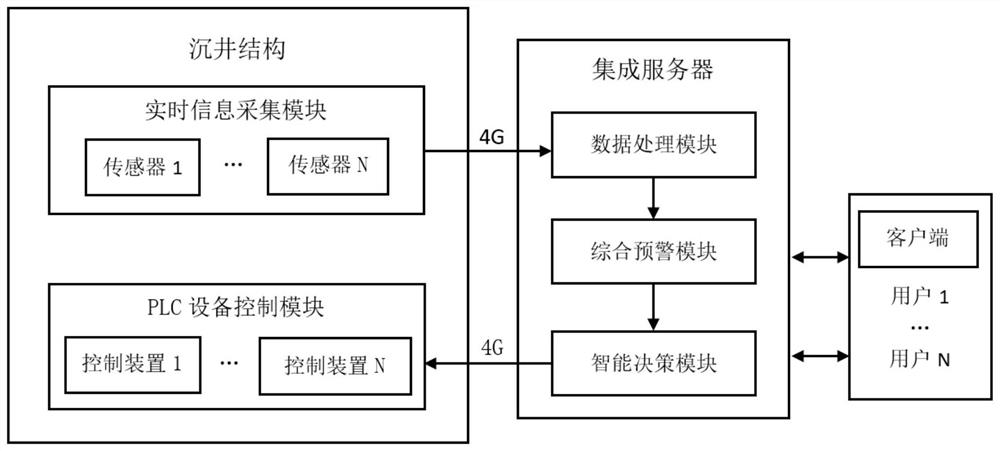

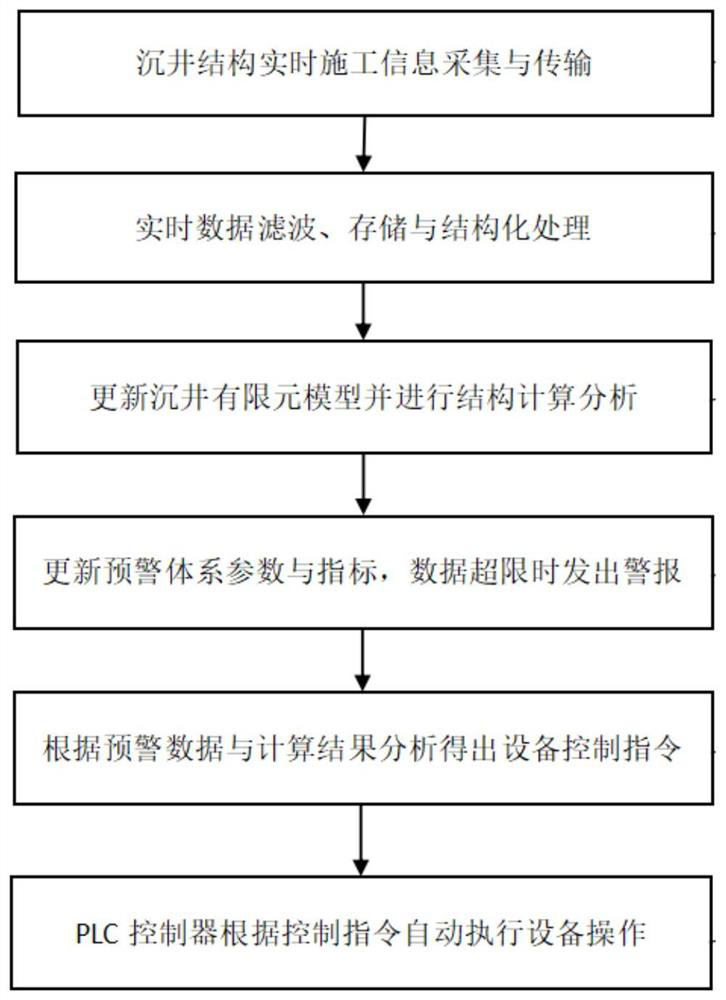

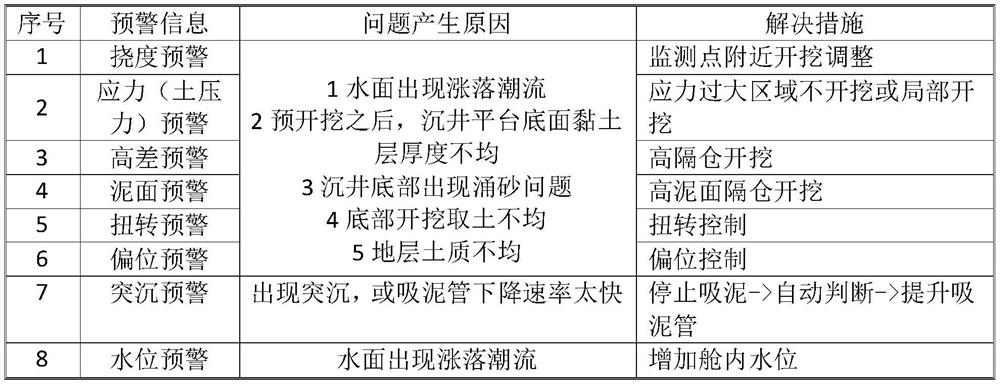

Whole-process intelligent control system and control method for large open caisson construction

ActiveCN111622252AOvercome the problem of being unable to intelligently control construction equipmentUnable to collect in real timeCaissonsTime informationField device

The invention discloses a whole-process intelligent control system and control method for large open caisson construction. The control system comprises a real-time information acquisition module, a data processing module, a comprehensive early-warning module, an intelligent decision module, a PLC device control module and a control system client. The real-time information acquisition module and the PLC device control module are installed on an open caisson structure, and the data processing module, the comprehensive early-warning module and the intelligent decision module are all integrated onan integrated server. According to the whole-process intelligent control system and control method, important parameters of each construction stage of an open caisson are monitored, so that the internal stress and the overall stability of the open caisson structure are mastered in time; and the construction site equipment is dynamically controlled according to the real-time monitoring data analysis result to adjust the posture of the open caisson, so that early-warning information is provided for safe construction, the basic construction is ensured to be smoothly carried out, and the purposesof construction guiding and feedback design are achieved.

Owner:CCCC SECOND HARBOR ENG +2

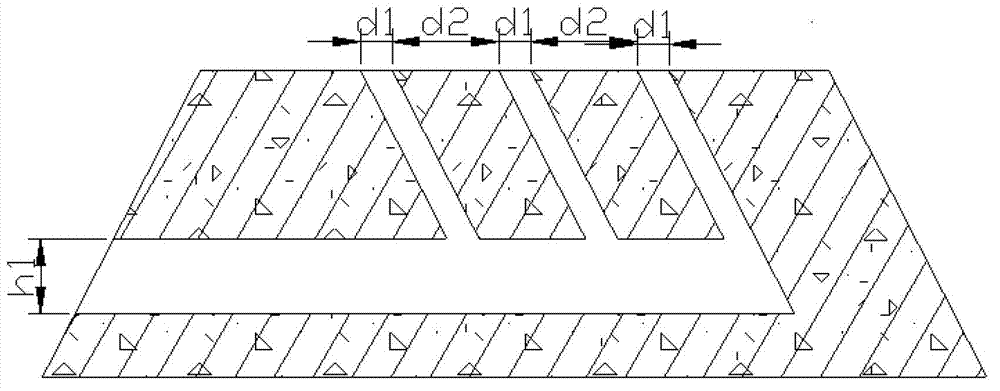

Opened backflow shutter type bulwark

InactiveCN103031821AReduced strength requirementsSafe berthBreakwatersQuaysWindow shutterEngineering

The invention discloses an opened backflow shutter type bulwark which comprises a bulwark body in a slope external structure. The bulwark body is characterized in that the bulwark body inside is a swash height chamber in a caisson structure. A plurality of opened channels are arranged on the lower part of the bulwark body on the coastal side in a length direction. The opened channels are connected with the swash height chamber. A shutter structure is arranged on the upper part of the bulwark body in the sectional direction of the bulwark body. The shutter structure is connected with the swash height chamber and forms a wave channel with the opened channels. According to the bulwark provided by the invention, the wave height is reduced by the gap of the shutter, energy is consumed by the swash height chamber, and the action force by wave on the bulwark is reduced by backflow of the opened channels.

Owner:HOHAI UNIV

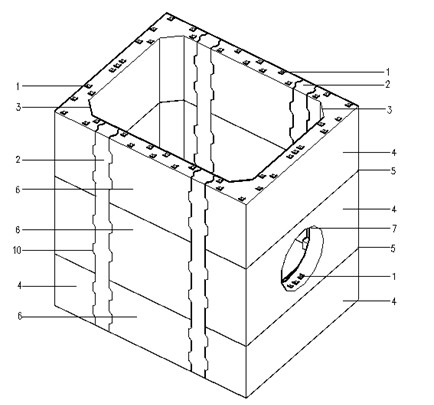

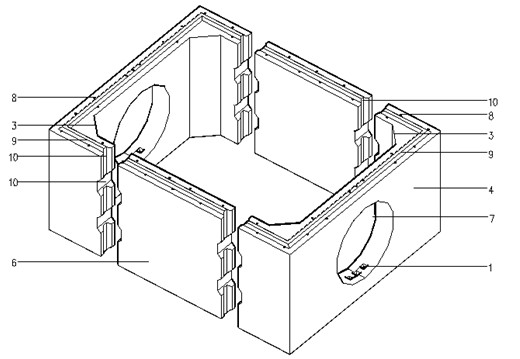

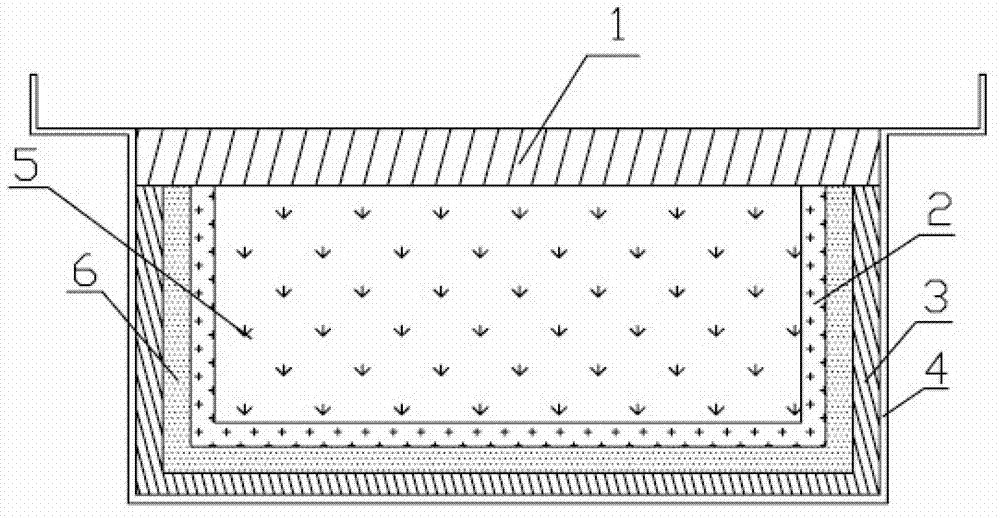

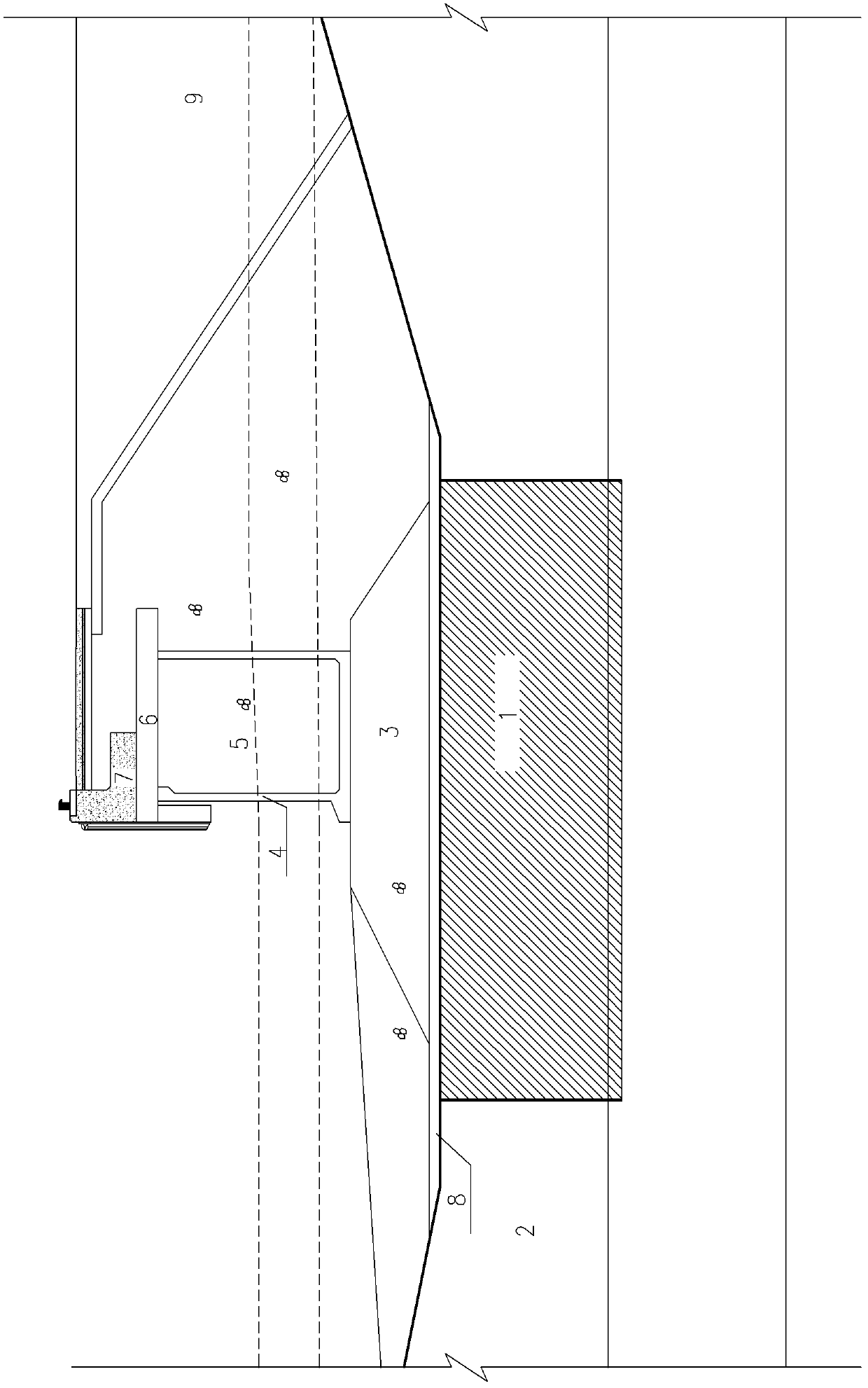

Frame for bathroom caisson, bathroom caisson and construction method

InactiveCN102767218ASolve the problem of water leakageNo leakage of water will occurDomestic plumbingBuilding material handlingLeaking waterArchitectural engineering

The invention relates to the technical field of building engineering, in particular to a frame for a bathroom caisson, a bathroom caisson and a construction method. The frame for the bathroom caisson comprises a support frame, a water collecting device, a floor drain device and a discharge pipe connection port. The support frame is in an aerial structure, and the water collecting device is arranged inside the aerial structure; the support frame is used for supporting the water collecting device which is used for collecting leaked water; and the discharge pipe connection port and the floor drain device which are arranged on the water collecting device are communicated to discharge the water collected by the water collecting device. The bathroom caisson comprises a caisson body and the frame for the bathroom caisson; a discharge reserve hole is arranged in the inner wall of the caisson body; the bathroom caisson is arranged in the caisson body through the frame; the discharge pipe connection port and the discharge reserve hole are communicated; and the water collecting device is connected with the inner wall of the caisson body. The framework for the bathroom caisson, the bathroom caisson and the construction method can solve the water leakage problem of the bathroom caisson.

Owner:卫青富

Ultrahigh ultra-large open caisson and construction method

PendingCN107447770AAvoid risk of collapseSave horizontal support systemCaissonsSupporting systemArchitectural engineering

The invention discloses an ultrahigh ultra-large open caisson and a construction method, and belongs to the technical field of municipal drainage, and aims to solve the problem that certain foundation pit collapse risk exists as an existing enclosure form of foundation pit construction is relatively high in cost and is long in construction period. The construction method for the ultrahigh ultra-large open caisson comprises the following steps of: firstly, arranging a waterproof curtain, a compaction grouting substrate and a cushion layer as preparatory measures, separately casting a first section of the open caisson and a second section of the open caisson in two steps until a complete open caisson structure is completed; then, performing open caisson construction; and finally, performing substrate concrete pouring. Through the construction method of manufacturing twice and performing open caisson construction once, a horizontal supporting system is saved, so that the foundation pit collapse risk is avoided; the open caisson is separately manufactured through two steps, so that the risk of a manufacturing process of manufacturing the ultrahigh ultra-large open caisson once is avoided, the construction period is shortened, and construction cost is reduced, and therefore, the popularization value is relatively high.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

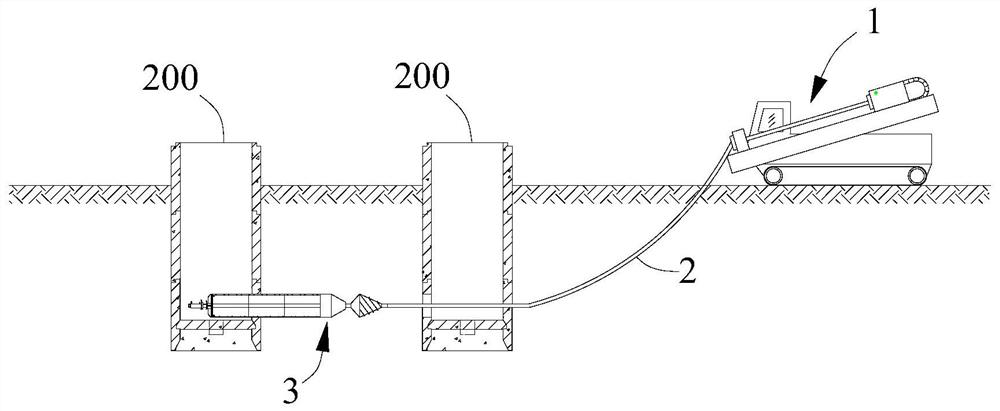

Rectangular working well with preset pipe jacking hole and sliding back wall in water-rich stratum and construction method thereof

ActiveUS20200248551A1Saving in capital investmentShorten the overall cycleProtective foundationPipe elementsPipeCaisson

A construction method of a rectangular working well includes steps of: (I) designing functional requirements for the rectangular working well; (II) constructing a caisson of an enclosing structure of the rectangular working well; (III) constructing an edge protector; (IV) excavating earthwork of the rectangular working well; (V) forming a back cover for the rectangular working well, and pre-embedding a sliding track, a pull ring and a back wall anchor; (VI) installing a ladder for entering the rectangular working well; (VII) preventing joint leakage; (VIII) installing a water-proof pressure plate at an entrance of the preset pipe jacking hole; (IX) constructing the sliding back wall; (X) lifting the sandwich concrete slab wall at a top of the preset pipe jacking hole; and (XI) performing pipe jacking. The structure system constructed by the present invention has many advantages such as clear function, safety, quickness, and flexible design.

Owner:INFRASTRUCTURE RENEWAL INST OF SOUTHERN CHINA +1

Construction method of deep foundation pit open caisson self-sinking support system

InactiveCN110805053AReduce the difficulty of excavationGuaranteed stabilityCaissonsSupporting systemPipe

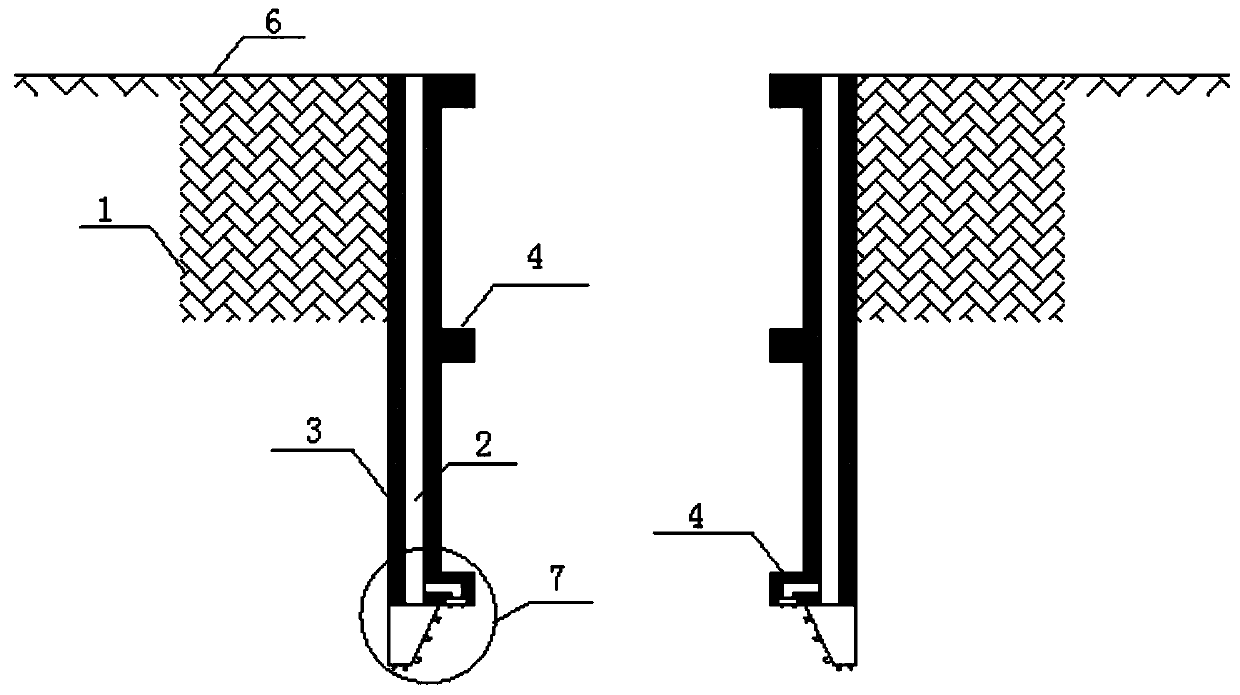

The invention discloses a construction method of a deep foundation pit open caisson self-sinking support system. The construction method comprises the following steps that after the pay-off, blade feet made by the cast-in-place are measured, spray heads are pre-buried in the blade feet, a first section ring beam is subjected to cast-in-situ manufacturing, a first section prefabricated open caissonwell body is installed, steel pipes are pre-buried in the open caisson well body, after the open caisson well body is connected with the blade feet, the soil body is cut by water injection and mud isdischarged, and the first section open caisson well body sinks to the designed elevation, after the ring beam is subjected to cast-in-place construction, the next section open caisson well body is installed, the water injection and sinking are carried out by adopting the same method as the first section open caisson well body, all the open caisson well bodies are installed in sequence, so that the open caisson well bodies of all the sections sink in place, and bottom sealing and mud drainage are carried out. According to the construction method of the deep foundation pit open caisson self-sinking support system, the open caissons are assembled in a prefabricated manner, the soil body is converted into the mud to be discharged outwards to enable the open caissons to sink automatically, thesoil pressure and the bottom water pressure at the peripheries are balanced by utilizing the mud in the open caisson, the excavation difficulty is reduced, and the stability in the sinking and excavation process is ensured.

Owner:WUHAN MUNICIPAL CONSTR GROUP

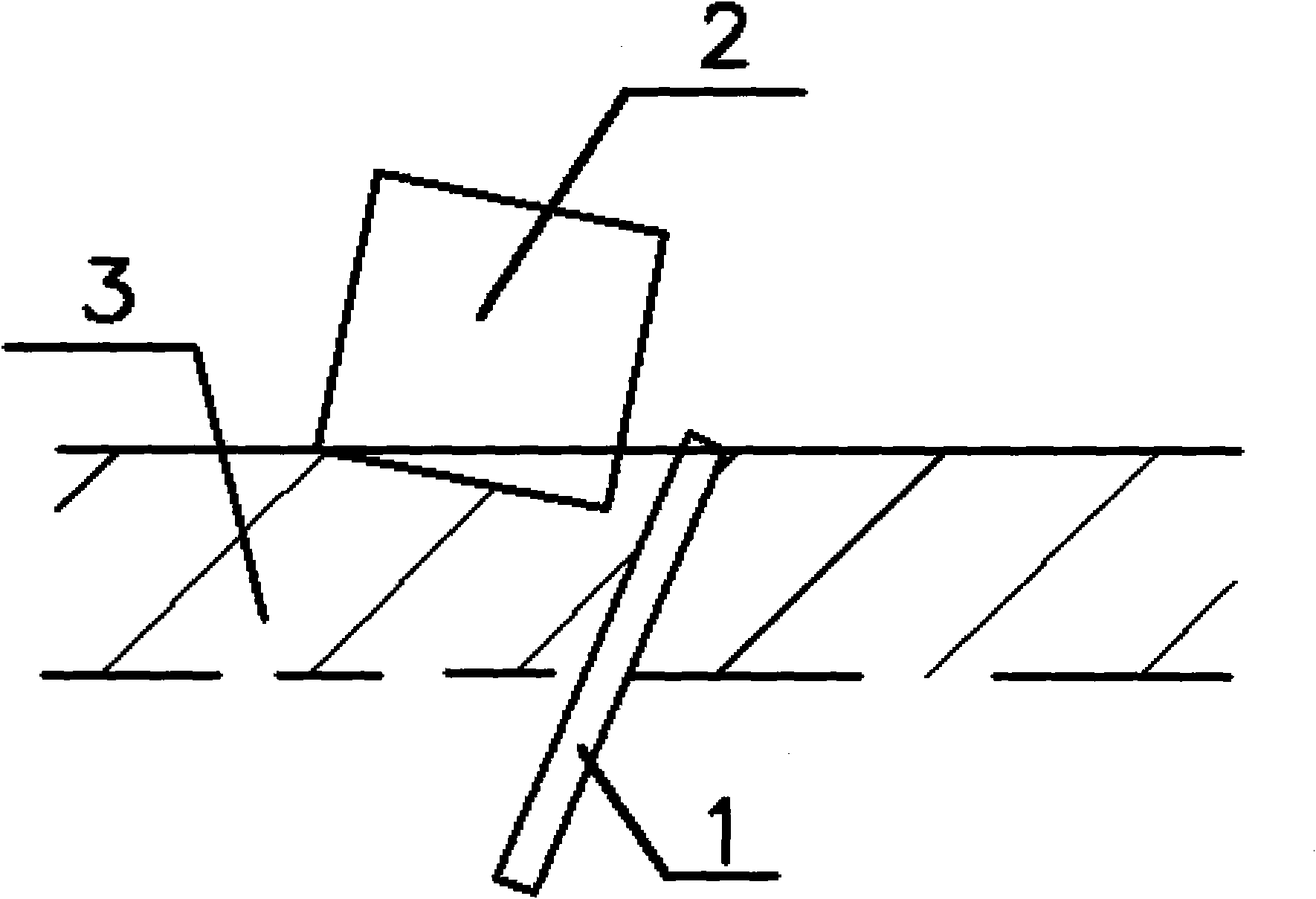

Open caisson deviation rectification construction method

The invention discloses an open caisson deviation rectification construction method, which is characterized in that quicklime piles are arranged at the positions where the open caisson needs to be jacked, and are obliquely infiltrated into the foundation soil, the rake rate of the quicklime pile is 75-90 degrees. The real-time monitoring is carried out during the process of the jacking of the open caisson, the construction is stopped when the jacking quantity of the open caisson reaches 8-10cm, and the construction of the quicklime piles can be carried out after three-dimensional back-stay soil body is stable. The construction of slip-casting is carried out after the construction of the quicklime piles is finished. The invention is characterized in that the material can be obtained in local, the price is low, the occupied field is small, no hydroelectric equipment is needed and the construction is quick, and the like.

Owner:广东固易特种工程有限公司

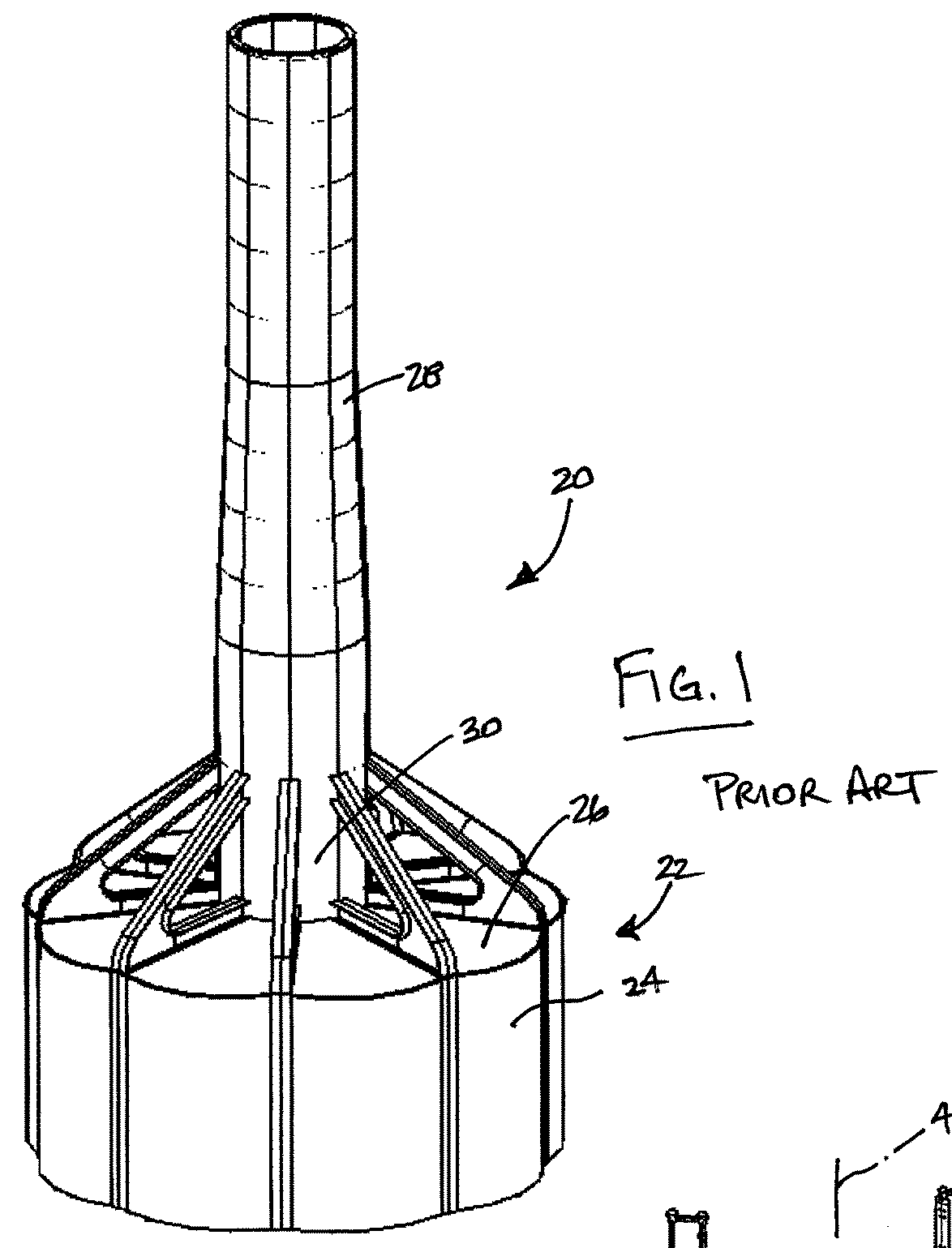

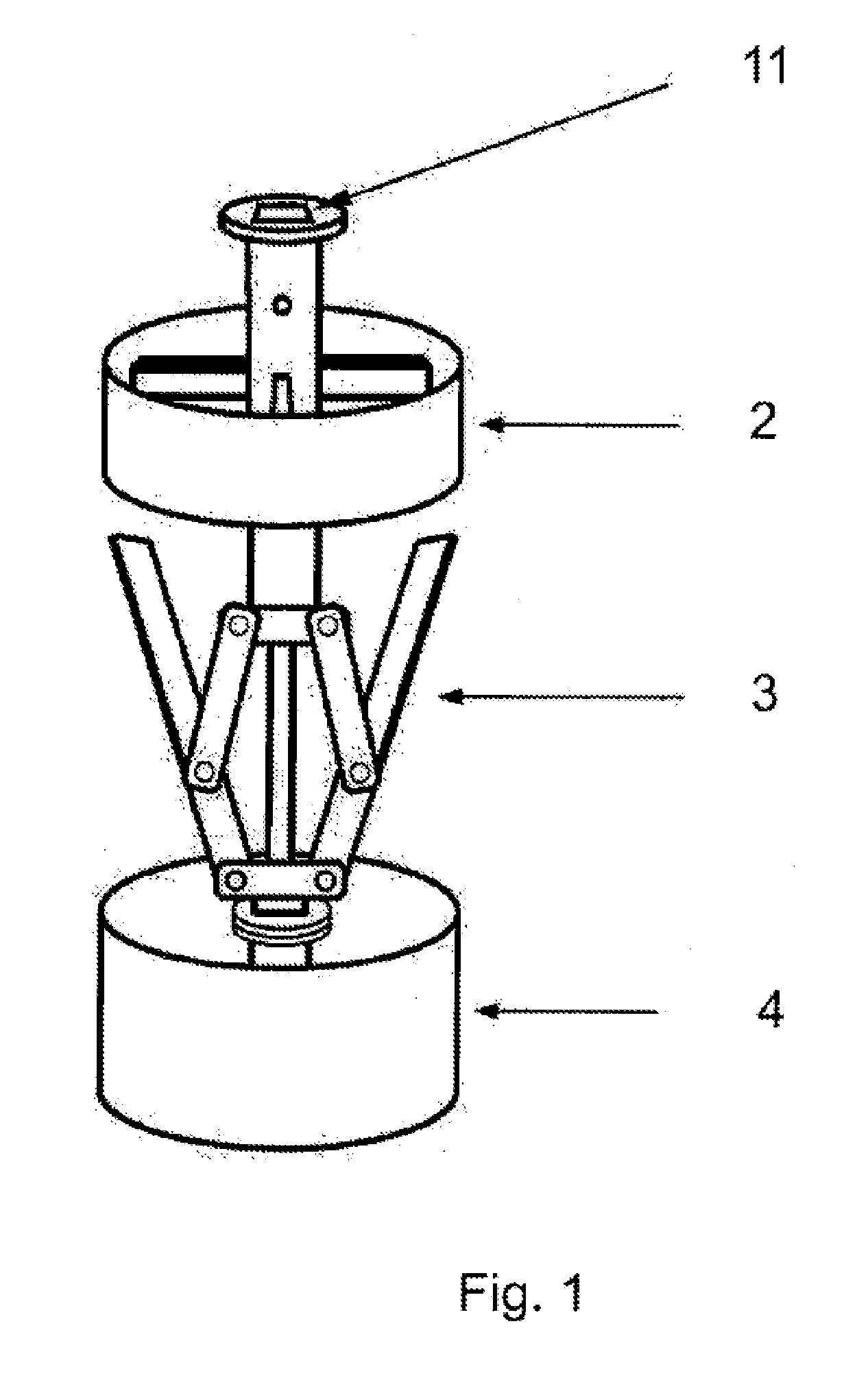

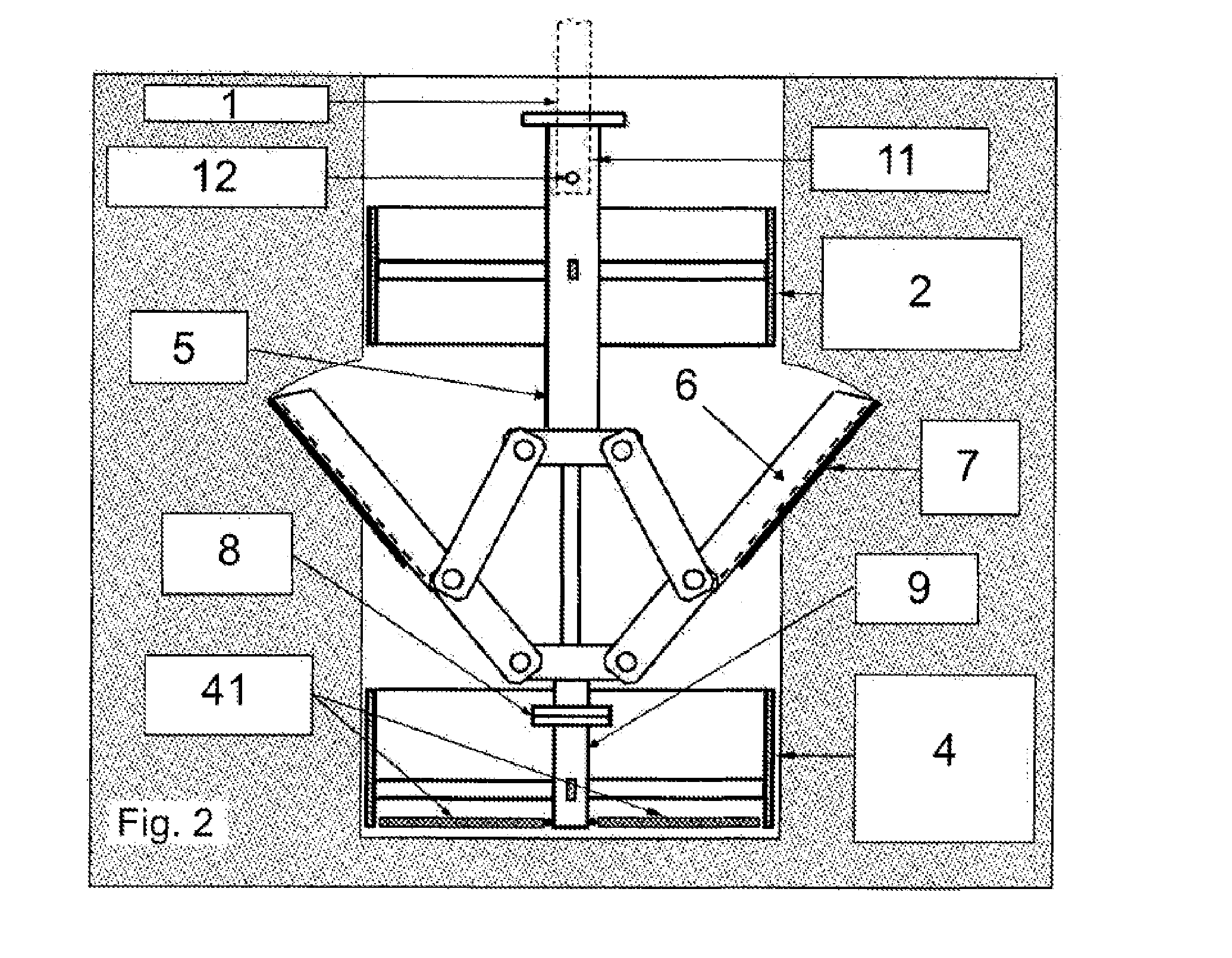

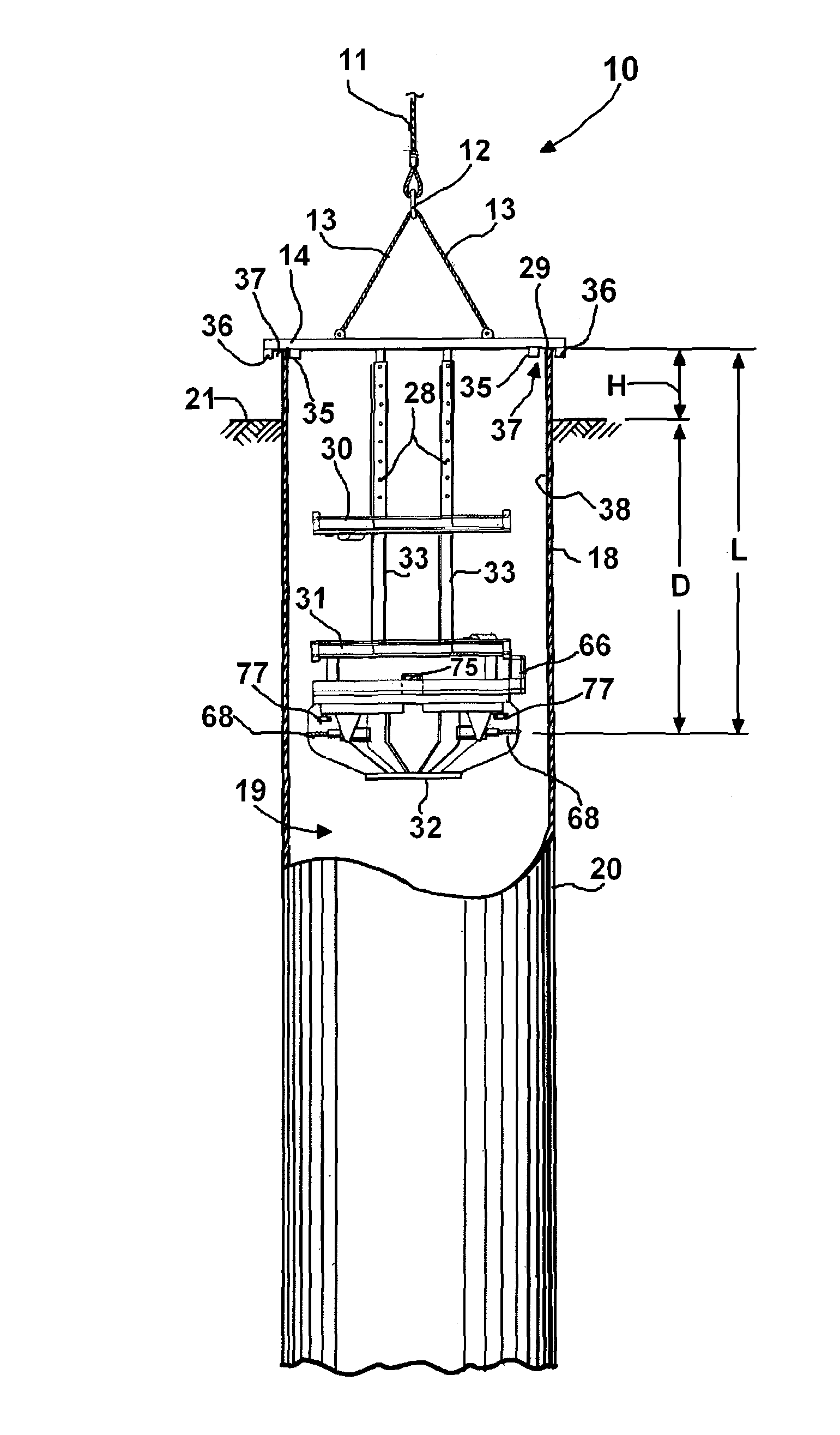

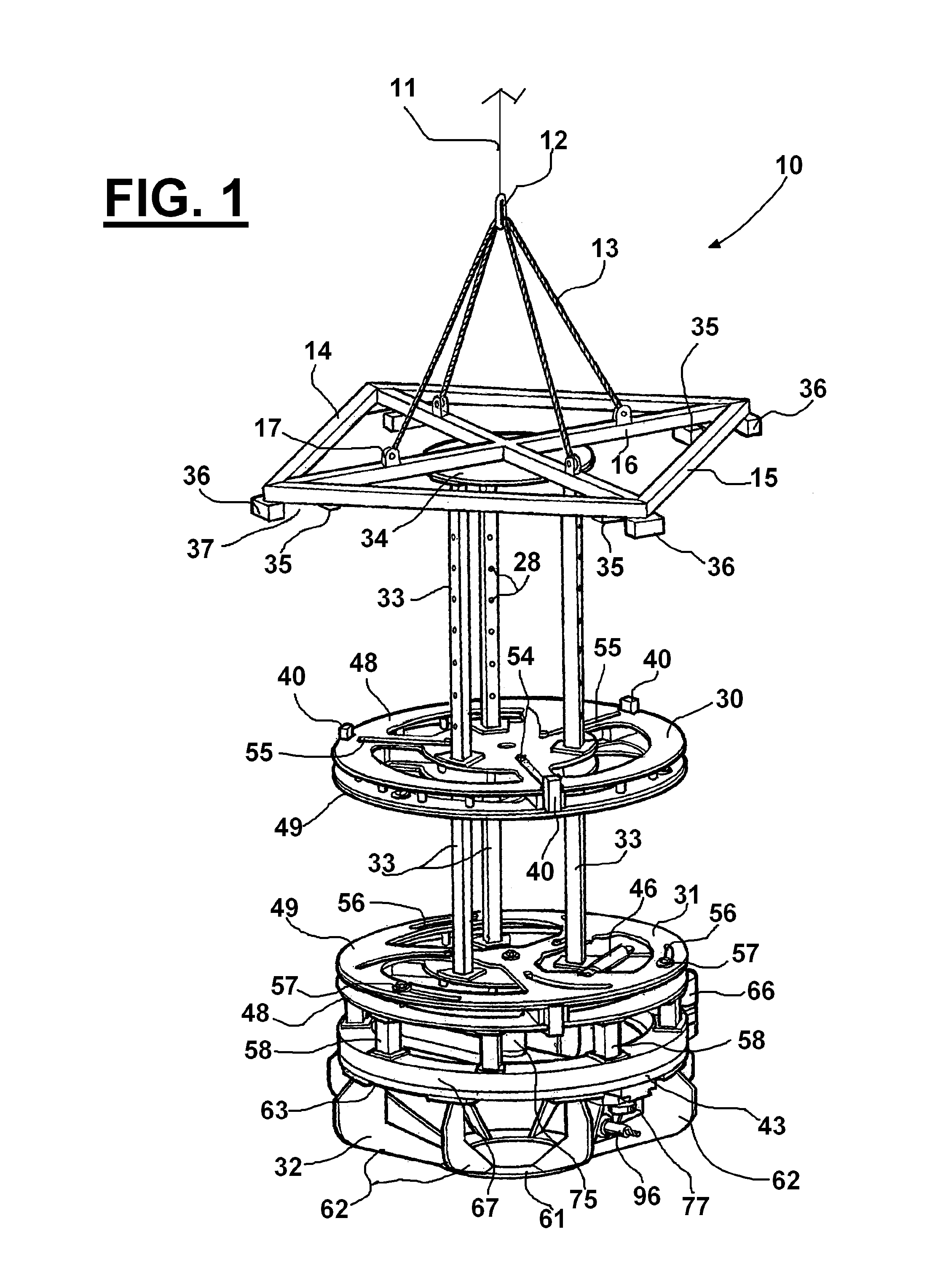

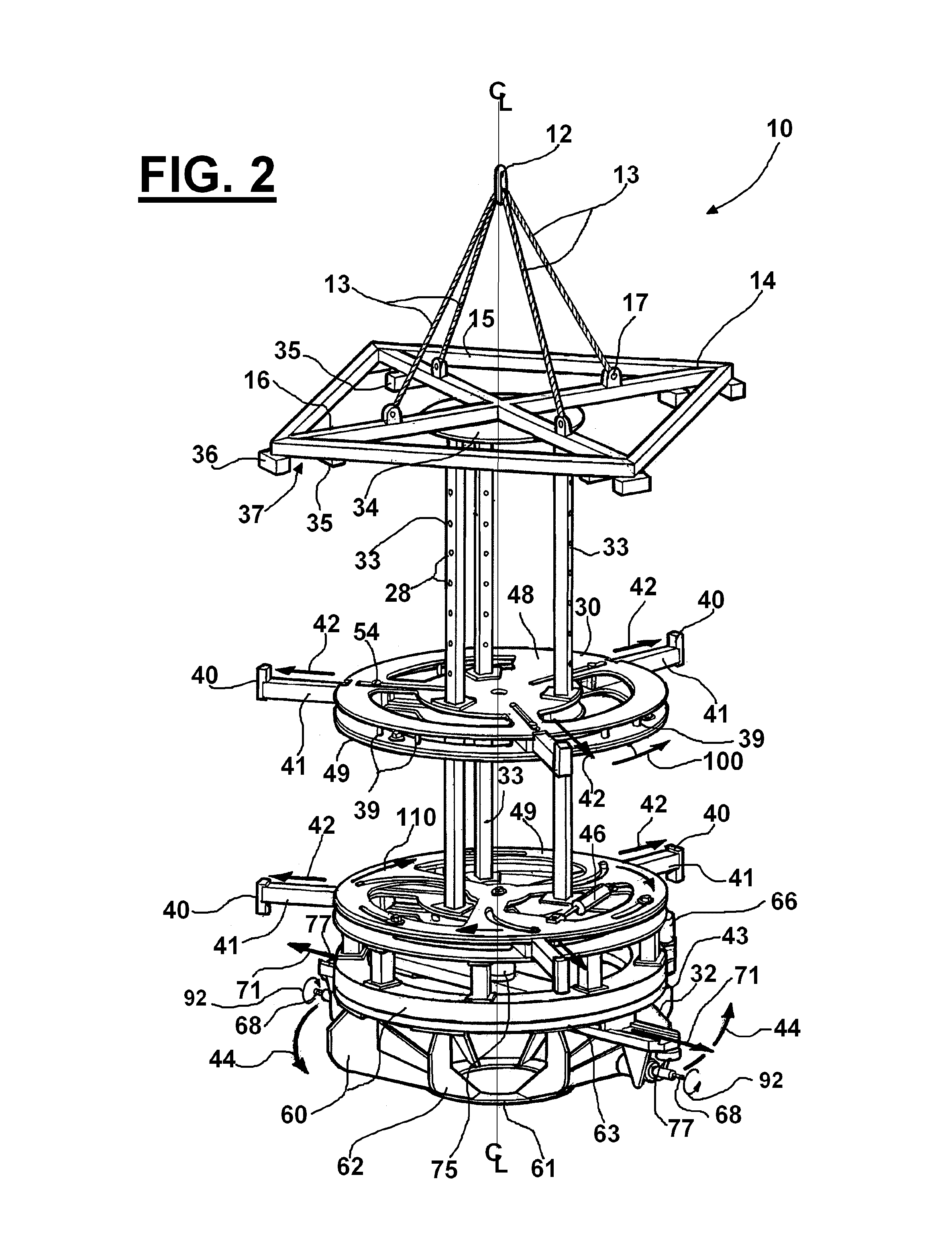

Method and apparatus for manufacturing marine foundation

ActiveUS20180266069A1Avoids deleterious tolerance stack-upsLess sensitivityArtificial islandsFoundation engineeringStructural engineeringEngineering

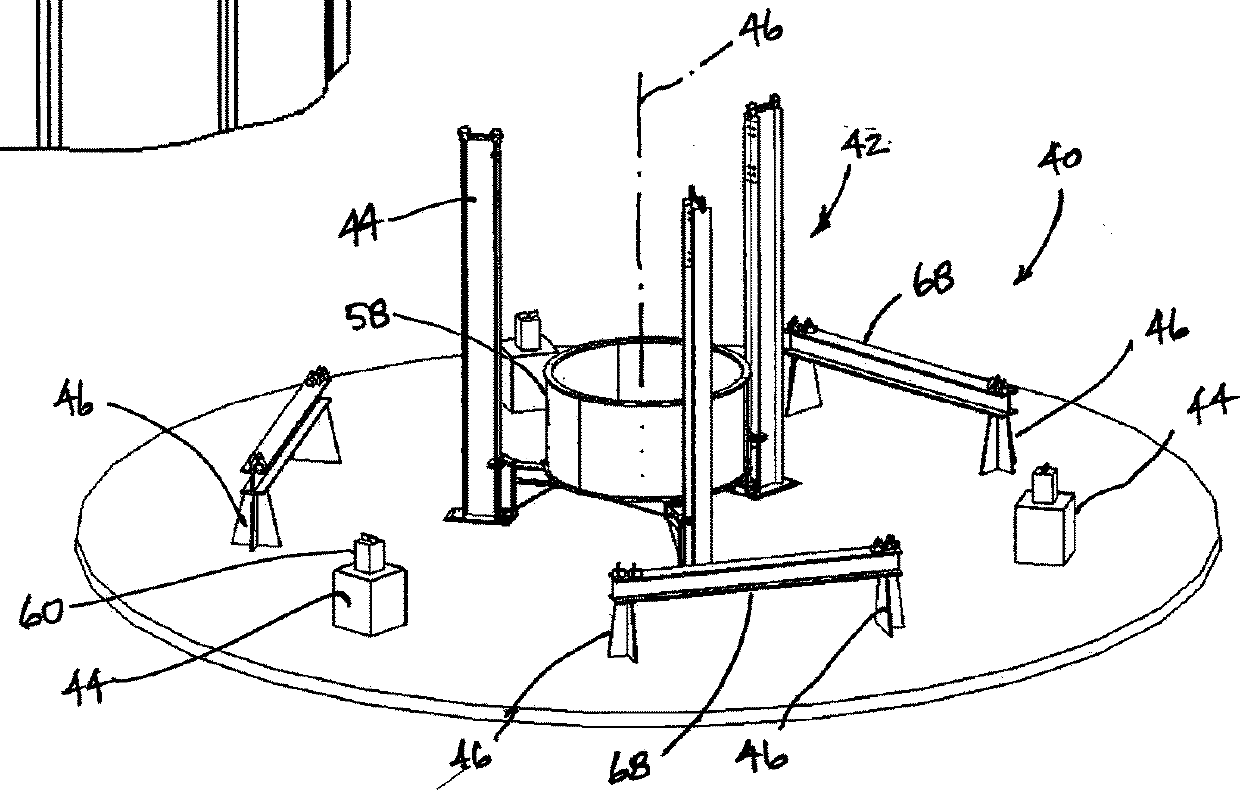

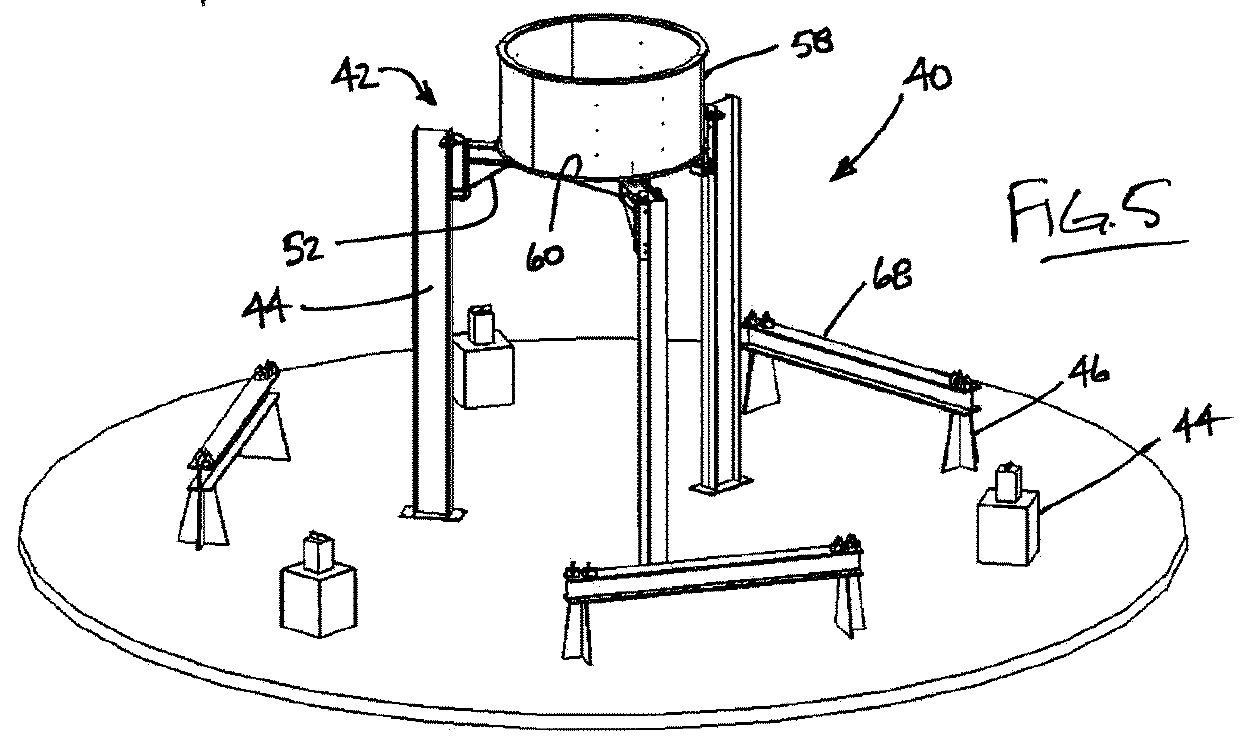

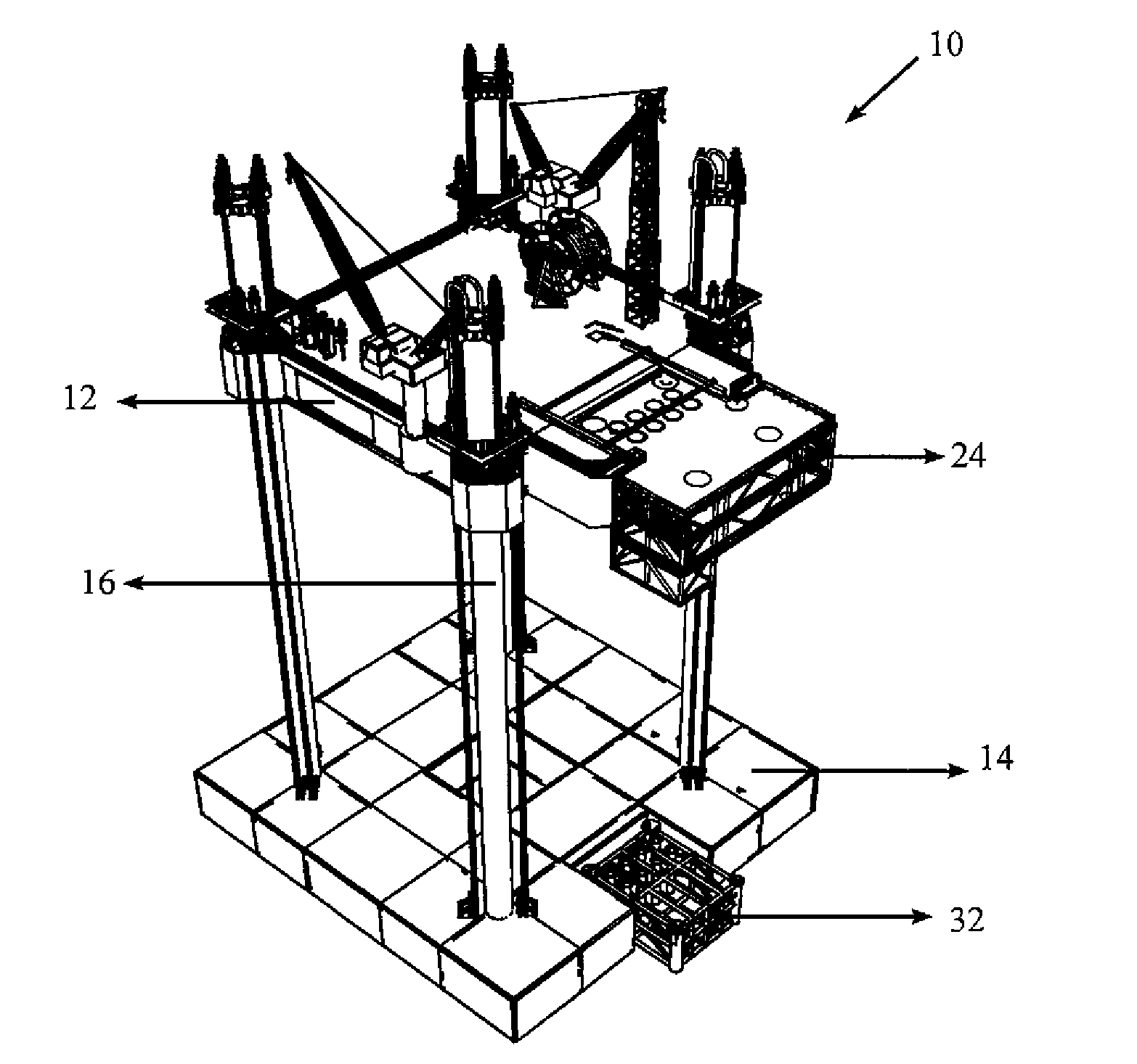

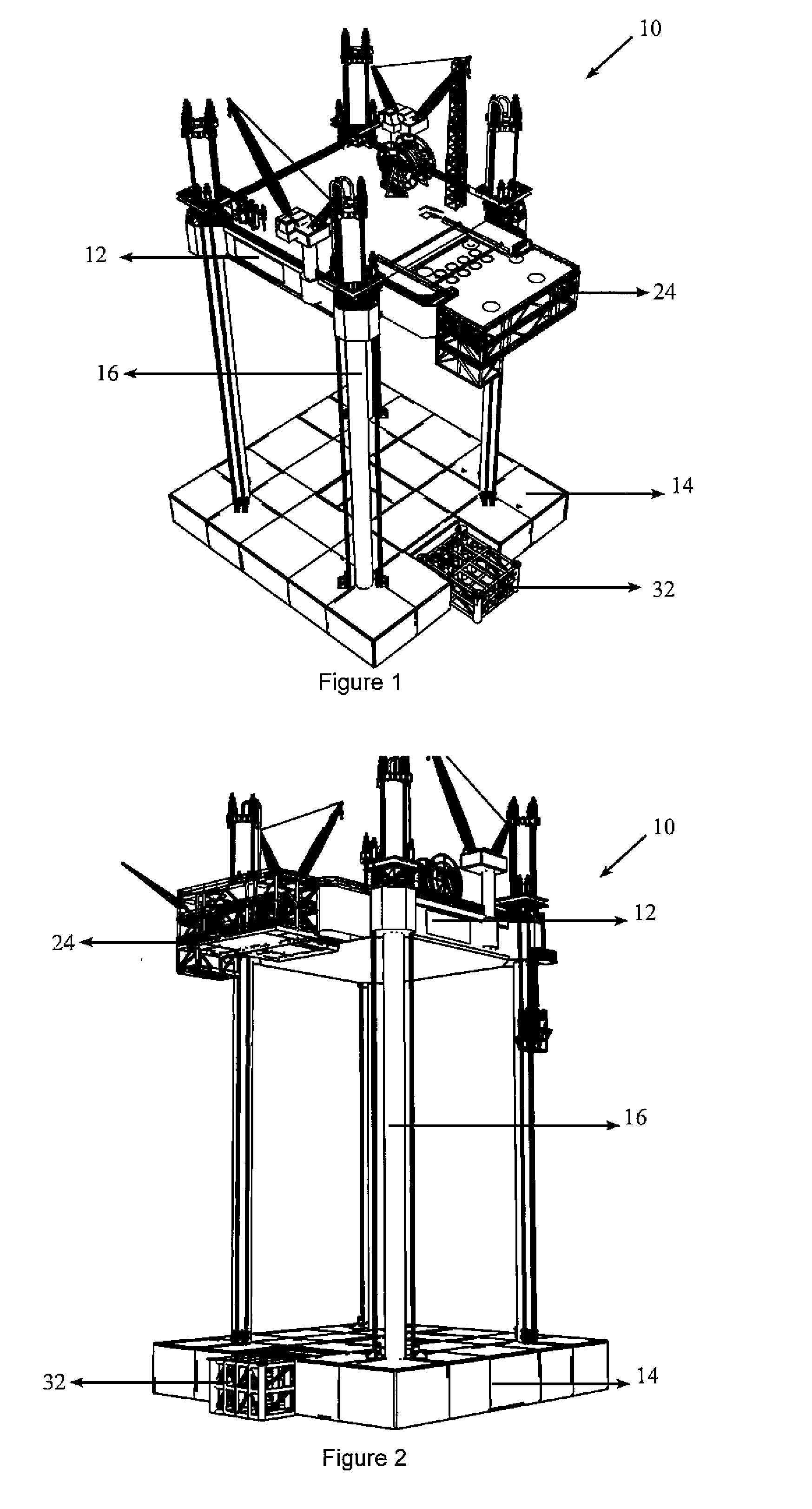

A method and fixturing apparatus for manufacturing a suction caisson foundation includes providing an elevated center support and peripheral supports, elevating the foundation's prefabricated thumb section atop the center support, and temporarily securing radial frame members about the circumference of the prefabricated thumb section with the each frame member resting atop a respective peripheral support. The skirt panels are then affixed to the frame members, and the frame members to the prefabricated thumb section to thereby become self-supporting. The center support is removed from the interior of the resulting bucket, as by raising the peripheral supports to unload the center support, and lowering and dismantling the center support, whereupon additional panels are affixed to the frame members to define the foundation's lid, and further shaft sections added atop the prefabricated thumb section to complete the foundation. Temporary beams bridging preselected framing members advantageously allow use of transportation crawlers.

Owner:GREAT LAKES TOWERS LLC

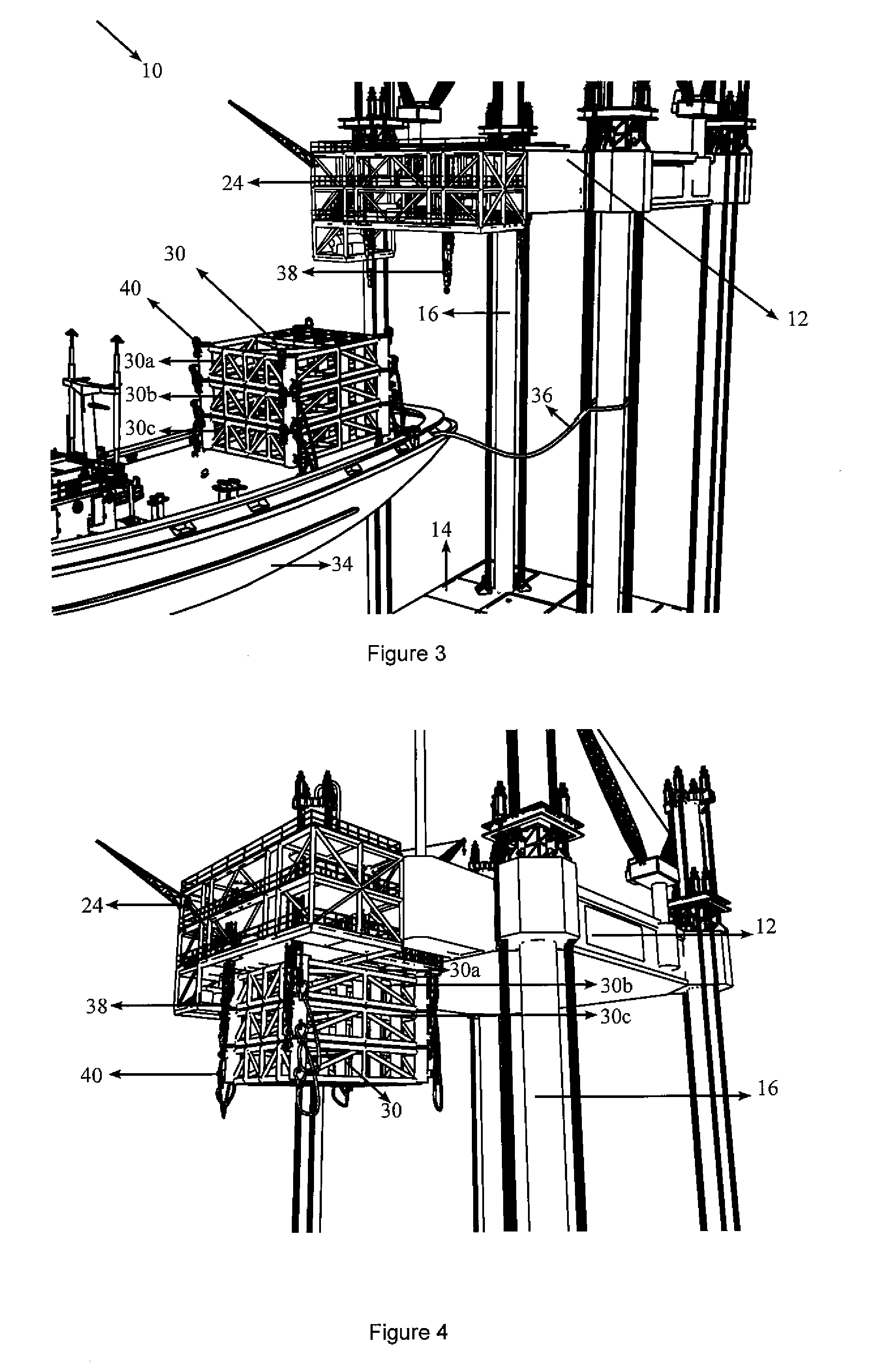

Offshore unit and method of installing wellhead platform using the offshore unit

InactiveUS20110168402A1Eliminate needArtificial islandsDrilling rodsOcean bottomElectrical conductor

An offshore unit includes a hull and / or a deck frame, a mat attached to at least one connecting leg or a spud can attached to each of at least one connecting leg or lower hull attached to at least one connecting means. A wellhead deck is removably attached to the hull and / or deck frame and a sub-sea clamp in conjunction with a caisson or a sub-sea conductor frame is removably attached to the mat or to the at least one connecting leg, where a spud can is attached to each of the at least one connecting leg, or to the lower hull. The offshore unit is relocatable and is a platform or a rig capable of performing drilling, production, construction, accommodation, hook-up and commissioning or a combination of any of these functions thereof. The offshore unit is a self-elevating mobile platform or submersible platform or semi-submersible platform.

Owner:DE RAJ ENERGY SDN BHD

Gravity wharf built on silt foundation and method for constructing gravity wharf

InactiveCN103374900AGuaranteed bearing capacityReduced skid resistanceBreakwatersQuaysWater levelSilt

The invention discloses a gravity wharf built on a silt foundation and a method for constructing the gravity wharf. The method for constructing the gravity wharf includes (1), designing a wharf structure and a foundation, reinforcing a composite foundation of the silt foundation by sand compaction piles and determining the bearing capacity, a sand pile replacement rate and a reinforcing range of the designed foundation of the wharf; (2), excavating a foundation trench, specifically, excavating the foundation trench until the depth of an excavated part of the foundation trench is smaller than a bottom elevation of the foundation trench and the difference between the depth of the excavated part of the foundation trench and the bottom elevation of the foundation trench is not smaller than one times the diameter of each sand compaction pile, constructing the sand piles, detecting the compactness of the sand piles after the sand piles are completely constructed, determining or re-determining the bottom elevation of the foundation trench, and secondarily excavating the foundation trench; (3), constructing a rock rip-rap foundation bed, performing rock rip-rap and leveling the top surface of the foundation bed; (4), mounting a precast caisson and enabling the top surface of the precast caisson to be higher than a construction water level; (5), performing rock rip-rap on the inside of the caisson; (6), constructing an upper structure of the wharf; (7), determining a rear backfill structural form and a backfill loading mode of the wharf, and performing rear backfill loading construction on the wharf. The gravity wharf and the method have the advantages that the bearing capacity of the foundation can be greatly improved, and influence of back-silting in a wharf construction procedure can be overcome.

Owner:CCCC THIRD HARBOR CONSULTANTS

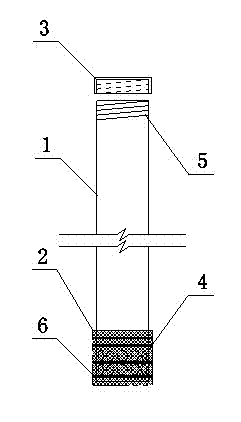

Open caisson sealing bottom water drainage device and construction method

The invention discloses an open caisson sealing bottom water drainage device and a construction method. The device comprises a well tube. A head sealing cover is connected with the top of the well tube. Water permeable holes are evenly formed in a tube wall on the lower portion of the well tube. Filter screens are arranged on the outer side of the tube wall of the lower portion of the well tube and at the bottom of the well tube, wherein the outer side of the tube wall is provided with water permeable holes. The head sealing cover is connected with the well tube through threads. The filter screen is a three-layer dense screen sheet and fixed on the lower portion of the well tube through an iron wire. The open caisson sealing bottom water drainage device has the advantages of being simple in manufacture, convenient to install, good in open caisson sealing bottom water draining and water sealing effect, low in investment cost and capable of improving project efficiency.

Owner:CHINA MCC17 GRP

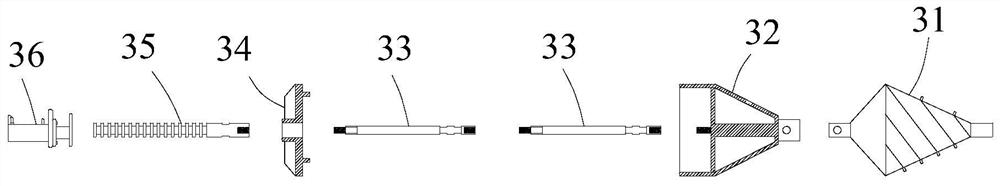

Jacking-pulling construction method

The disclosure provides a jacking-pulling construction method. The jacking-pulling construction method comprises the following steps of: well site production, that is, a pipe jacking-pulling working well is made by using a precast reinforced concrete pipe well through the undrained caisson construction, the bottom of the pipe jacking-pulling working well is sealed by using concrete underwater, andthe water level inside the well is more than 1 meter higher than the water level outside the well; guide hole drilling, that is, a directional drilling machine is connected to a first end of a jacking-pulling drill pipe, and a second end of the jacking-pulling drill pipe is connected to a guide bit, so as to drill a guide hole according to a predetermined trajectory; reaming stage, in which the guide bit is disassembled, a reverse drill bit is installed to the second end of the jacking-pulling drill pipe, and reverse reaming is performed along the hole through which the jacking-pulling drillpipe passes; and pipeline laying, that is, a front end fixing cap, a short force transmission rod, a rear anchor top plate, a rear anchor short rod, a hydraulic jack and a self-locking socket pipe areinstalled to the end of the reverse drill bit, and jacking-pulling installation construction is carried out on the self-locking socket pipe. The scheme provided by the disclosure achieves the effectsof high construction accuracy, short construction period and small construction area.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

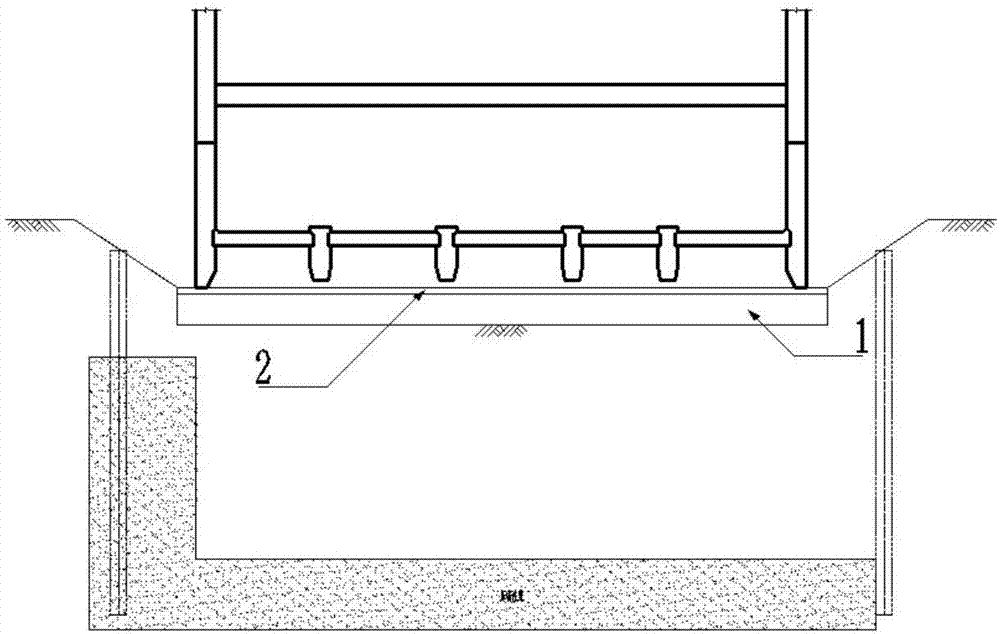

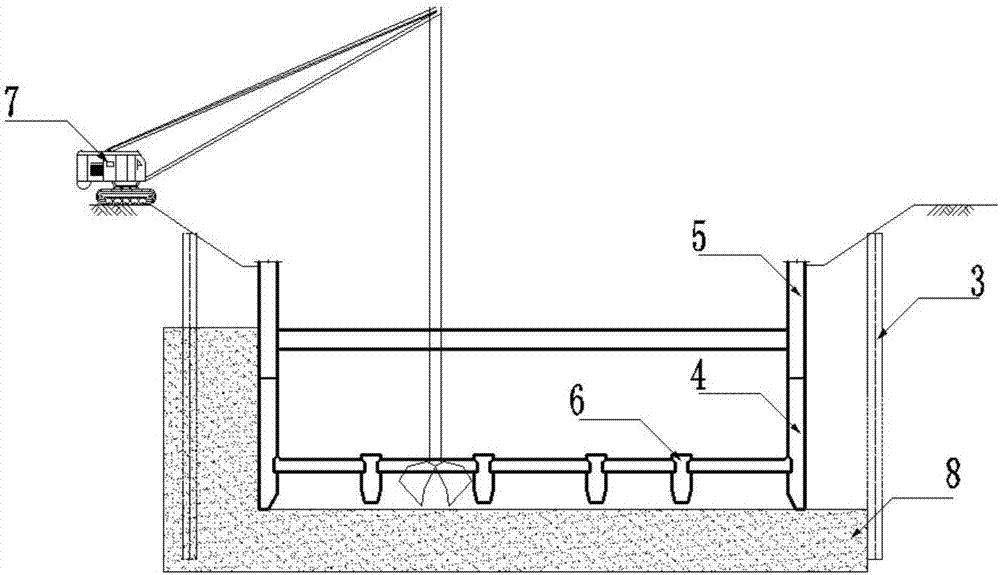

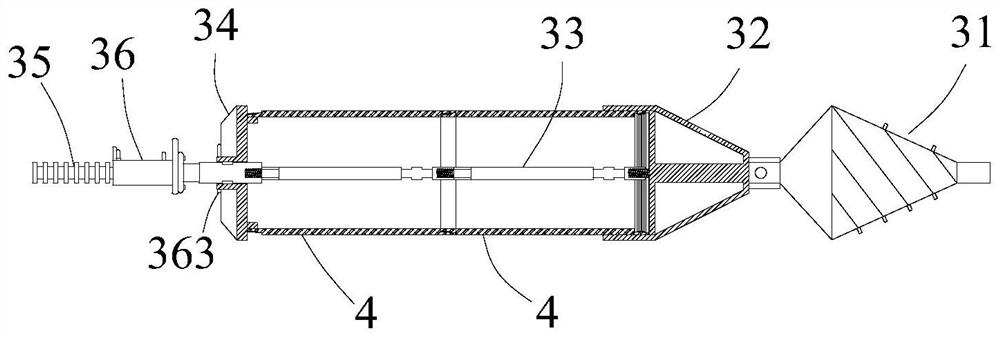

Construction method for cast-in-situ caisson formwork-supporting system

ActiveCN105672337AShorten the construction periodReduce the number of erectionsCaissonsSupporting systemArchitectural engineering

The invention relates to a construction method for a cast-in-situ caisson formwork-supporting system. The construction method comprises the following main construction steps: (1) excavation of a foundation pit; (2) laying of cushion layers; (3) building of a scaffold; (4) erection of first-section caisson formworks; (5) concrete pouring and maintenance; (6) detachment and sinking for the first-section caisson formworks; and (7) erection of second-section caisson formworks. The structure disclosed by the invention is convenient to disassemble and assemble, high in construction efficiency, capable of realizing cantilever formwork-supporting in a caisson and realizing the horizontal movements of the formworks, adaptive to caisson formwork-supporting systems with different heights, and high in economic and technical benefits.

Owner:ZHEJIANG CHANHIGH MUNICIPAL GARDEN CONSTR CO LTD

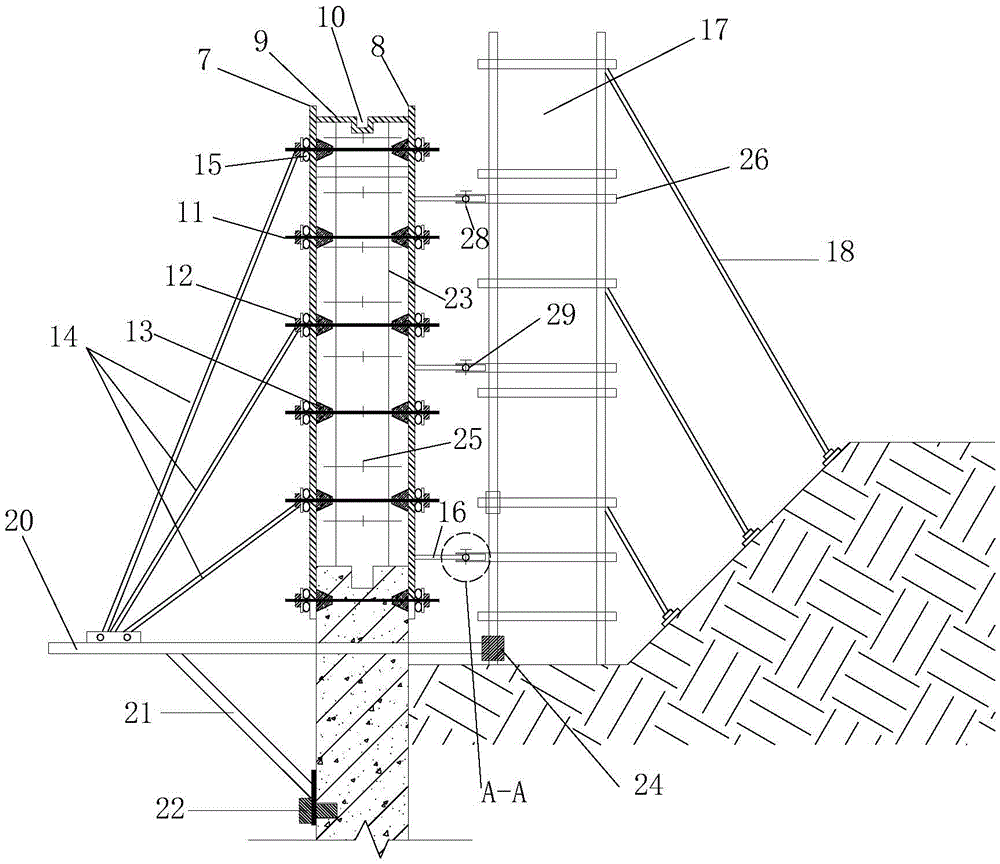

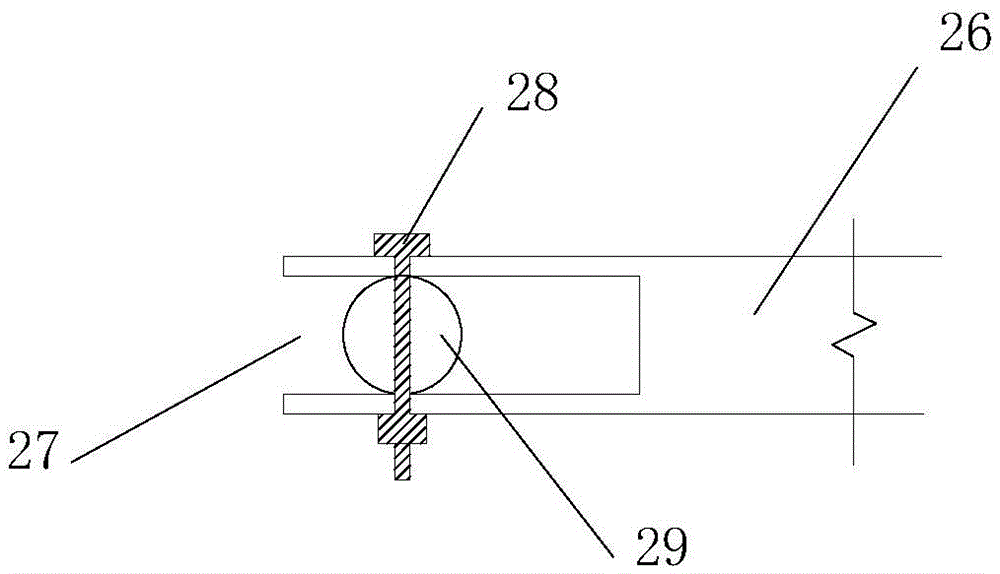

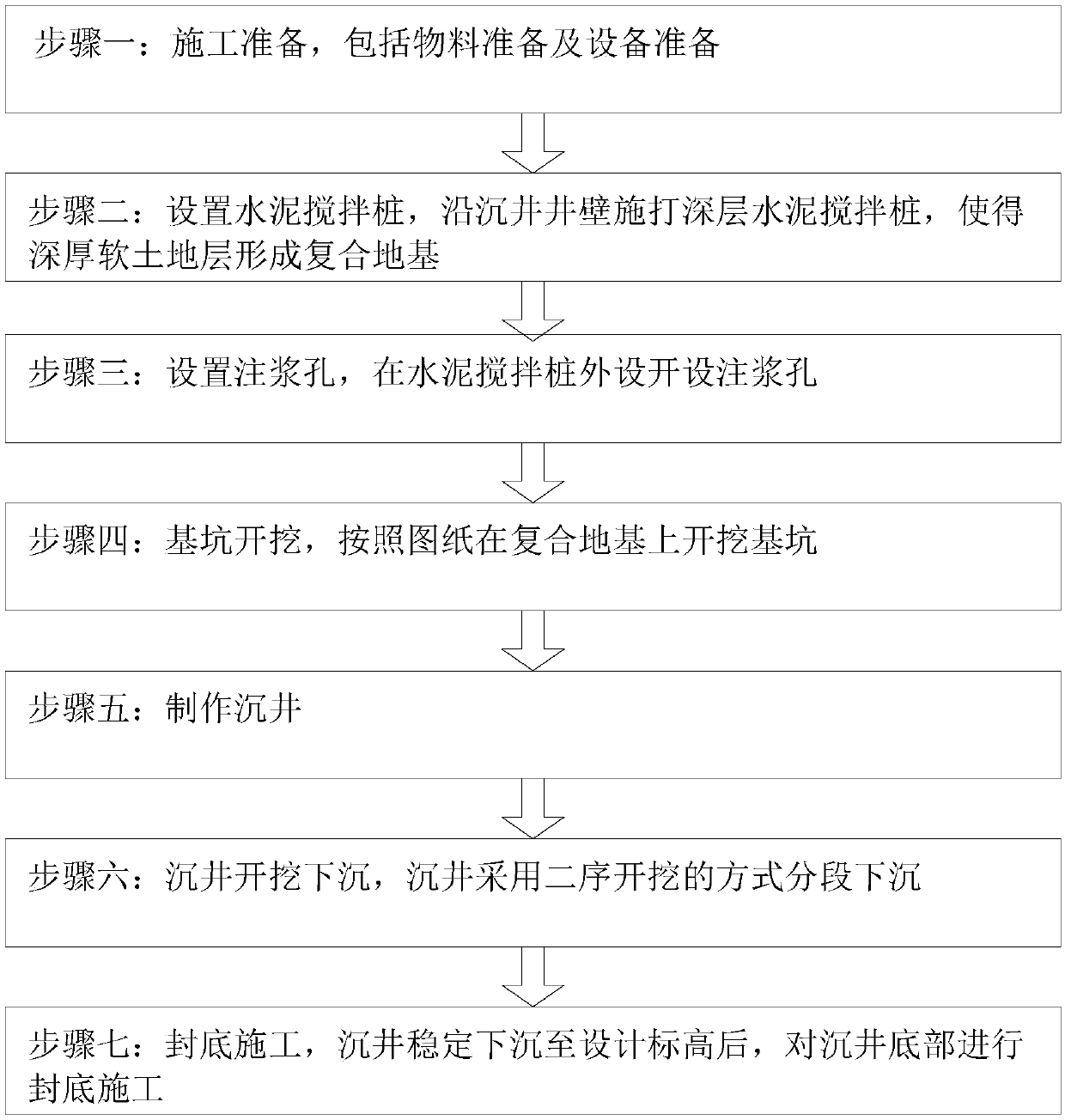

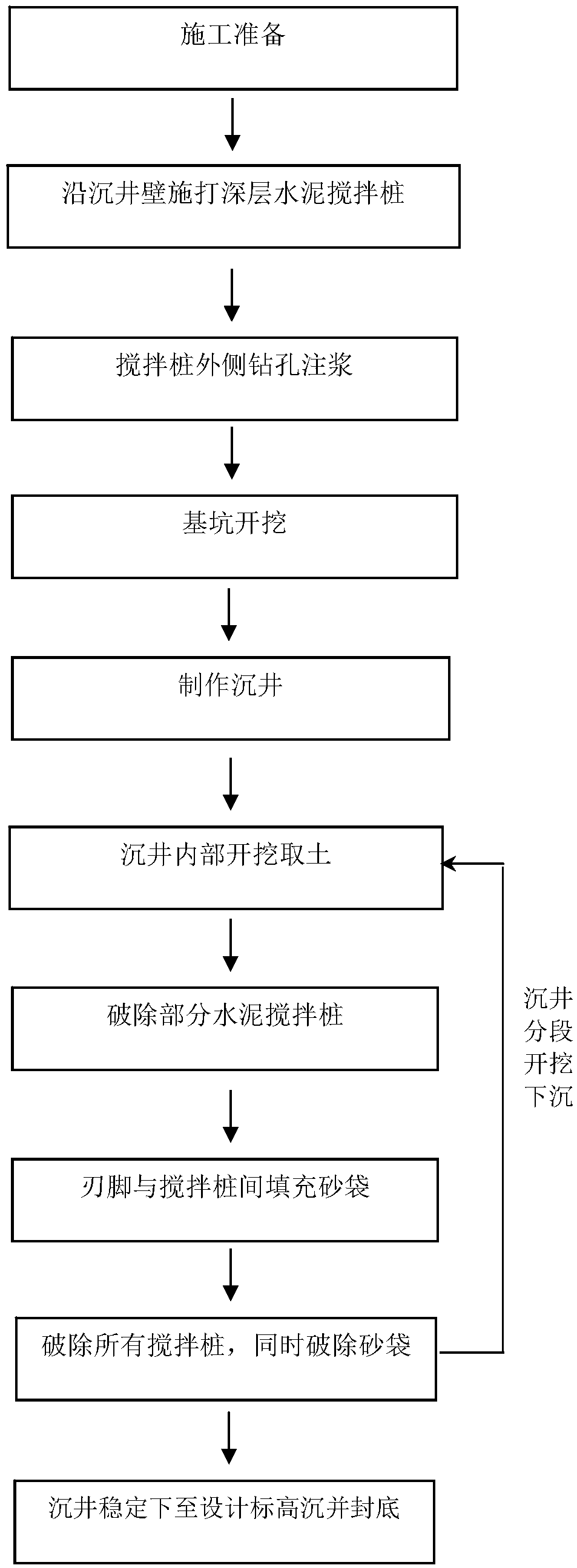

Construction method of large-diameter open caisson in deep and thick soft soil stratum

InactiveCN109695250AImprove construction qualityNo tilt deviation phenomenonExcavationsCaissonsMaterials preparationMaterials science

The invention discloses a construction method of a large-diameter open caisson in deep and thick soft soil stratum. The method comprises the following construction steps: performing construction preparation including material preparation and equipment preparation; arranging a cement mixing pile, and driving a deep layer cement mixing pile along the wall of the open caisson, so as to ensure that the deep and thick soft soil stratum forms a composite foundation; arranging a grouting hole, and forming the grouting hole in the exterior of the cement mixing pile; performing foundation pit excavation, and excavating a foundation pit in the composite foundation according to drawings; manufacturing the open caisson; performing open caisson excavation sinking, and adopting a secondary excavation mode to perform segmented sinking; performing bottom sealing, and performing bottom sealing on the bottom of the open caisson after the open caisson sink to a designed elevation. The method can preventsituations of excess of sinking of the open caisson and tilting of the open caisson, and has the advantages of low construction cost and construction difficulty, high safety and reliability and good construction quality which are not belong to the existing prior art.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

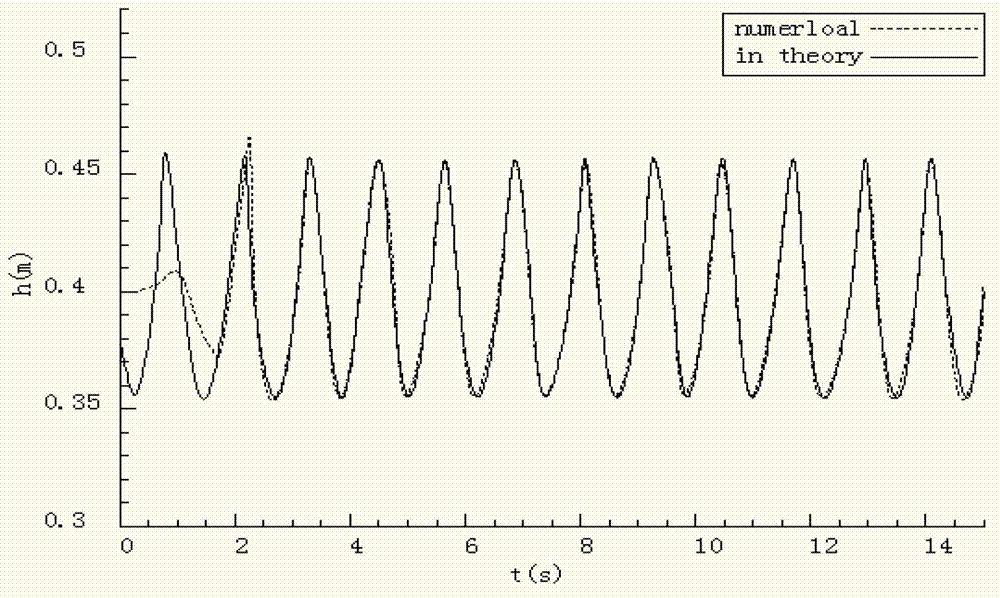

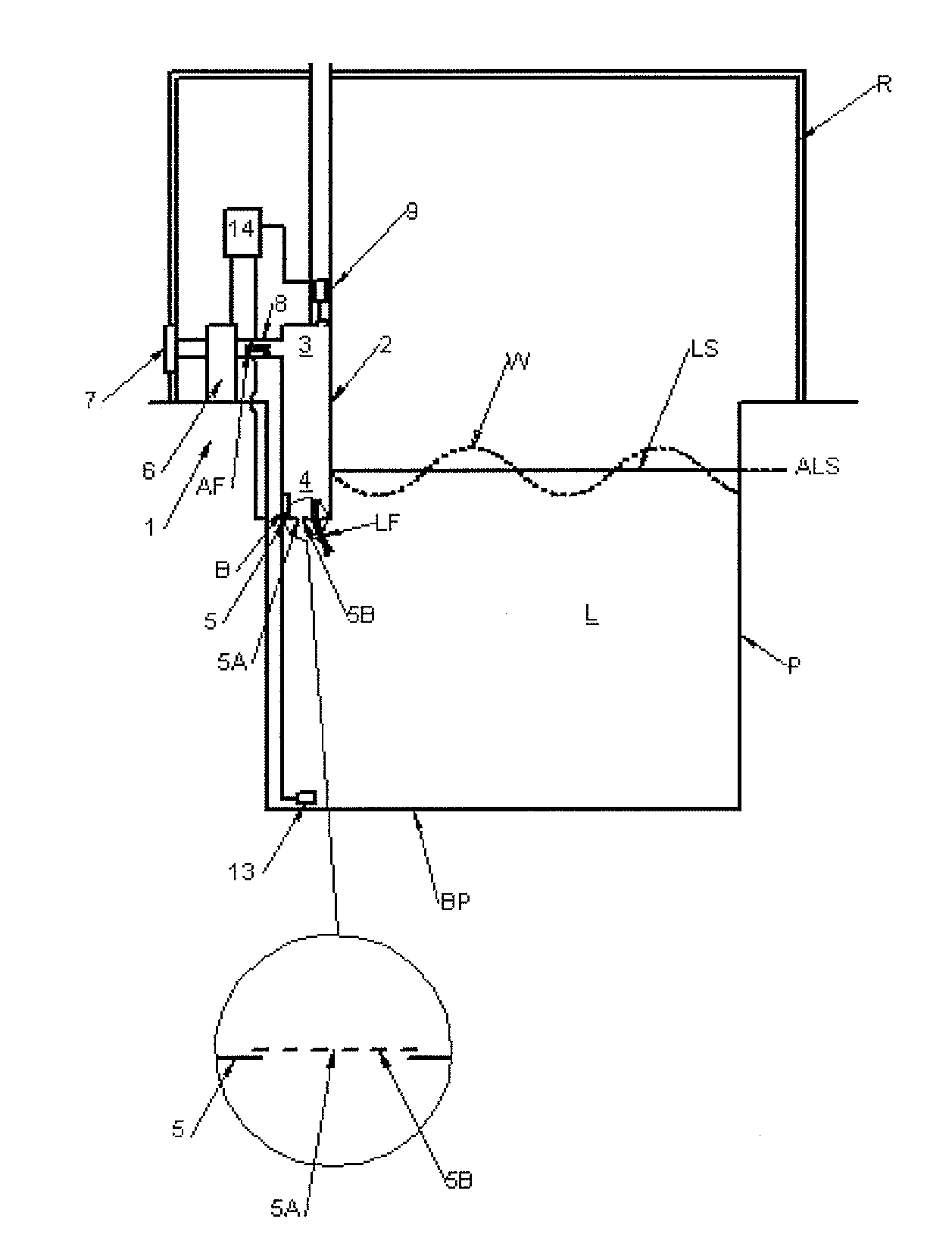

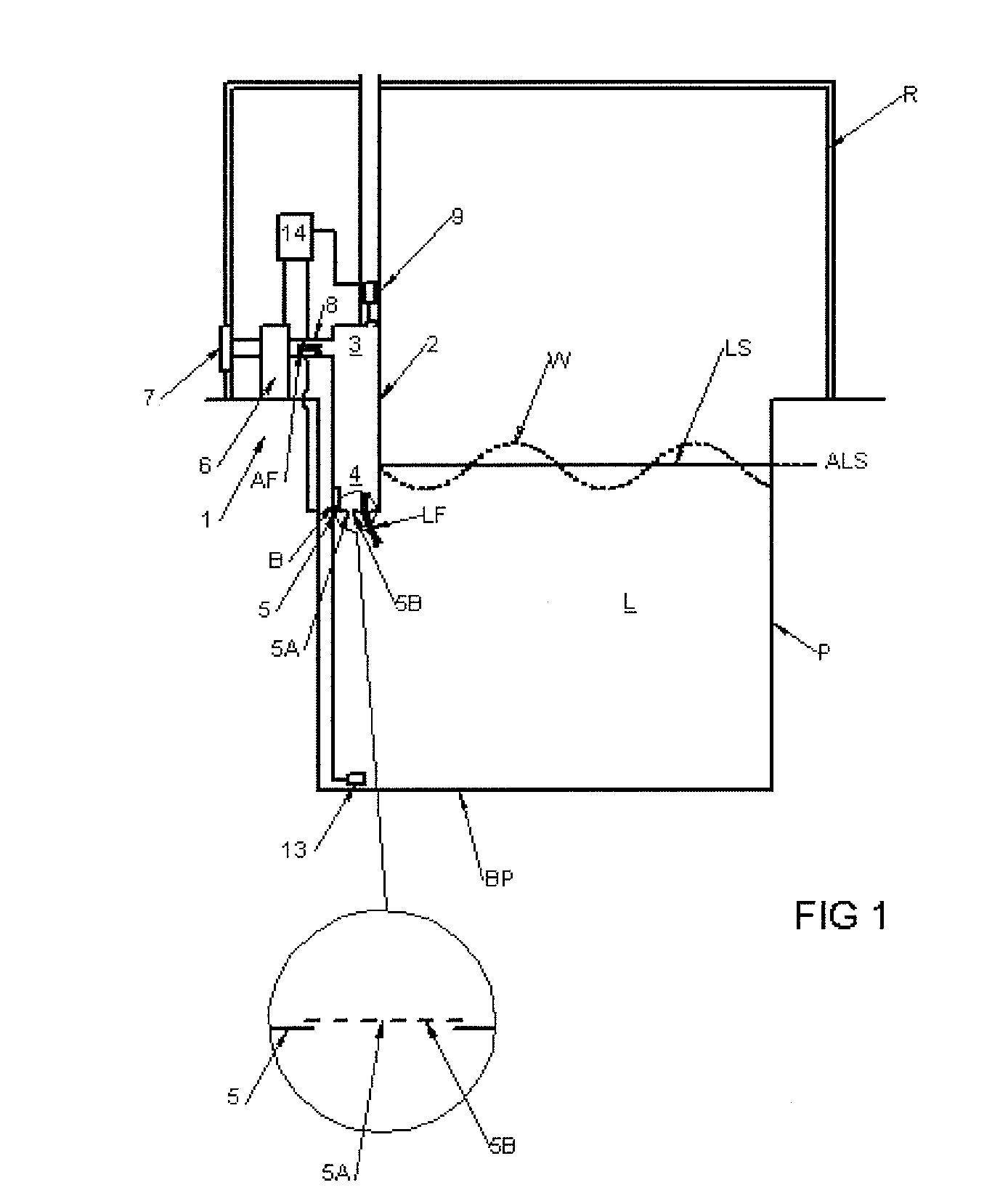

Wave making device

InactiveUS20100158611A1Reduce energy consumptionRapid exhaust of airWave producing pumpsPisciculture and aquariaExhaust valveEngineering

The wave making device comprises a caisson connected to an air blower and to a control valve mechanism comprising an exhaust valve adapted to move between a closed position and an open position, and a system adapted to move the exhaust valve and to maintain said exhaust valve into said position. The control valve mechanism is adapted to ensure continuously an air pressure within the caisson at least equal to the atmospheric pressure.

Owner:WOW!

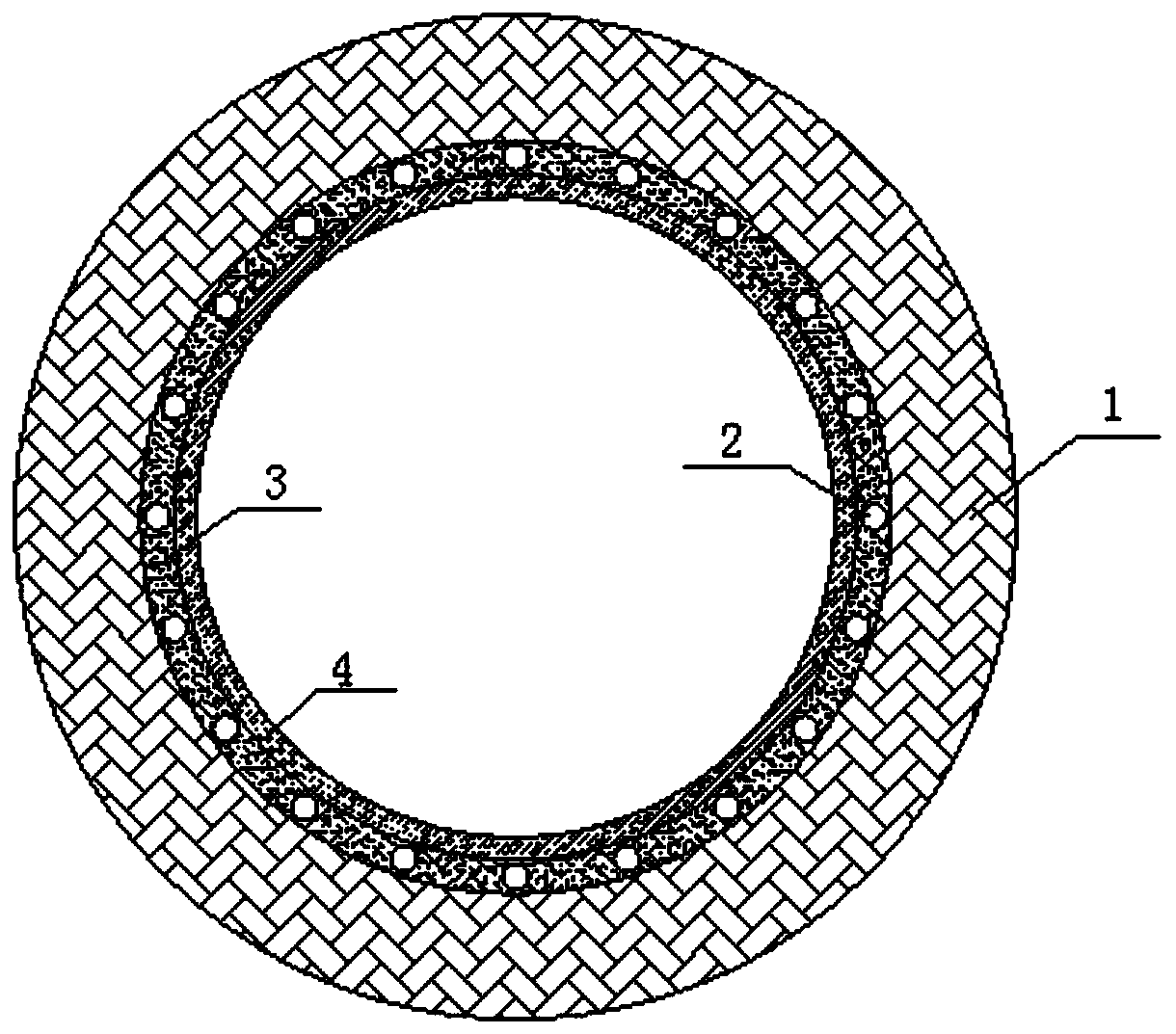

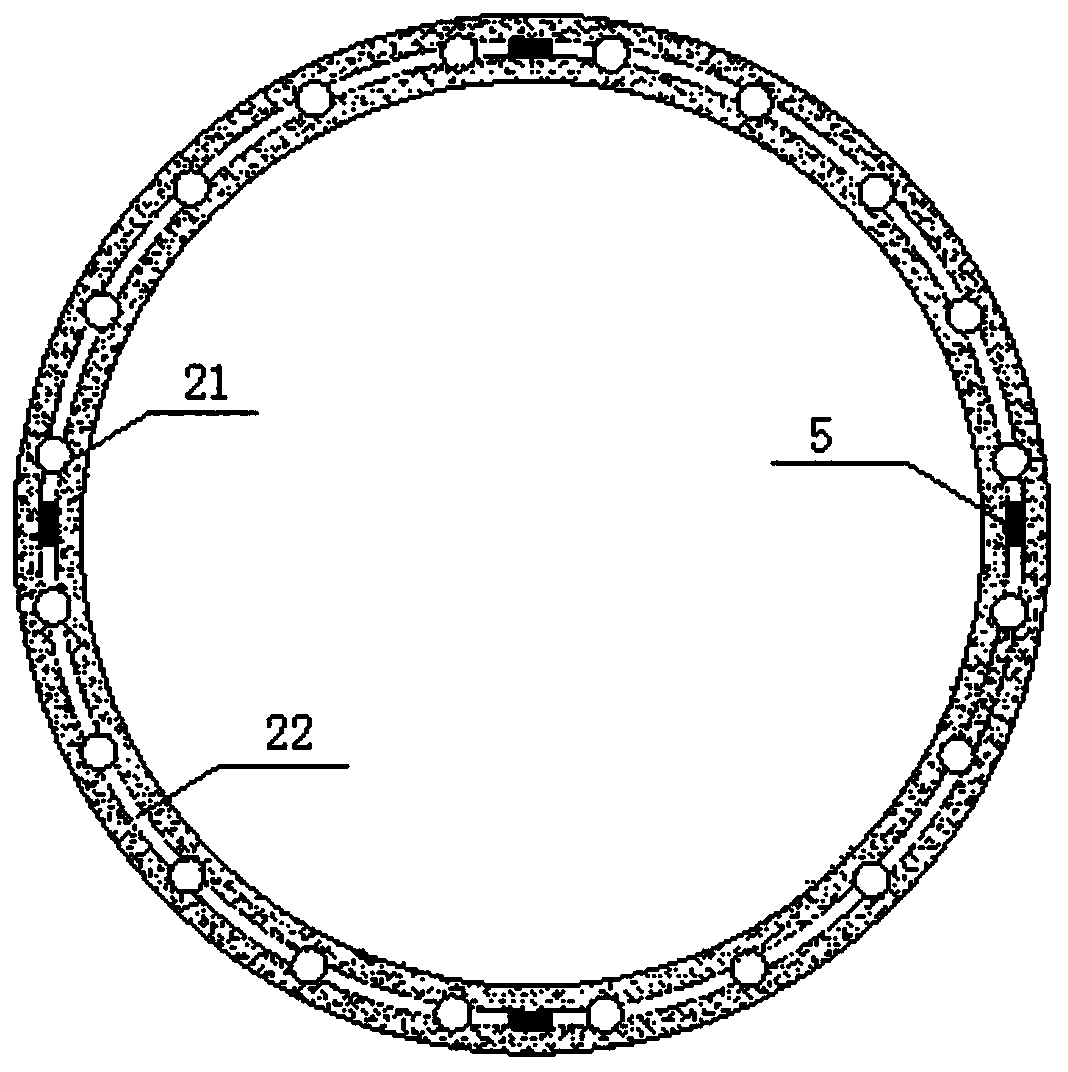

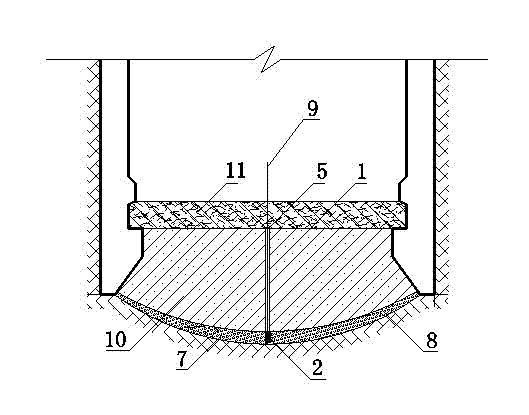

Fabricated open caisson structure and construction method thereof

The invention relates to a fabricated open caisson structure and a construction method thereof. A well wall structure is formed by vertical splicing of multiple segments of annular structures, each segment of annular structure is formed through end-to-end connection and closing of fabricated well piece structures, the adjacent fabricated well piece structures are connected through transverse connecting parts and longitudinal connecting parts to form a complete firm well wall structure, when the depth of the open caisson structure is large, the open caisson structure is segmented, each segmentis composed of one or multiple annular structures, the annular structures in each segment are connected and fixed, a bearing platform structure is arranged in each segment, and is in up and down symmetric, a jack is arranged between two bearing platform structure, during construction, the jacks play a role in pushing downwards the fabricated well piece structures, in the construction process, a center penetrating jack is arranged on the upper end of a steel strand, and is matched with the jacks between the bearing platform structures, sinking of the well wall structure is finished, the open caisson structure is not limited by the self weight, construction speed is high, the environment influence is small, and the cost is saved.

Owner:北京中岩智泊科技有限公司

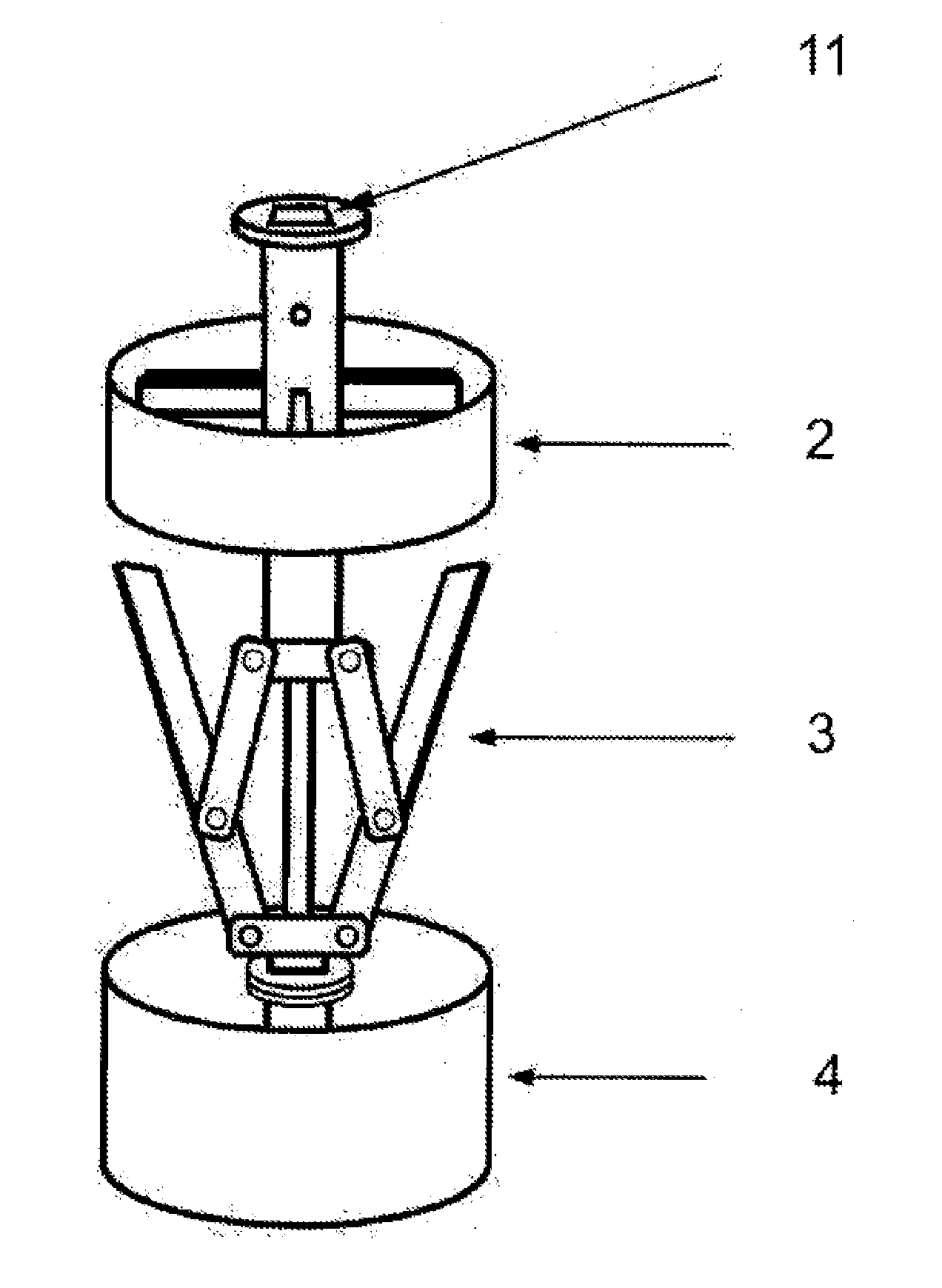

Device for enlarging caisson bases

The present invention relates to a device used to mechanically enlarge the base de caissons, so as to form a semi-spherical cavity in the base de the caisson formed, in which said device includes a socket in the upper extremity thereof for the engine shaft, a guide ring, a soil excavating mechanism and a recipient for collecting the excavated soil.

Owner:TEIXEIRA WILSON ROBERTO

Internal jacket leg cutter and method

ActiveUS9103088B2Increase feed rateReduce feed rateTube shearing machinesMetal working apparatusMechanical engineeringClassical mechanics

Owner:AES EOT EQUIP HLDG LLC

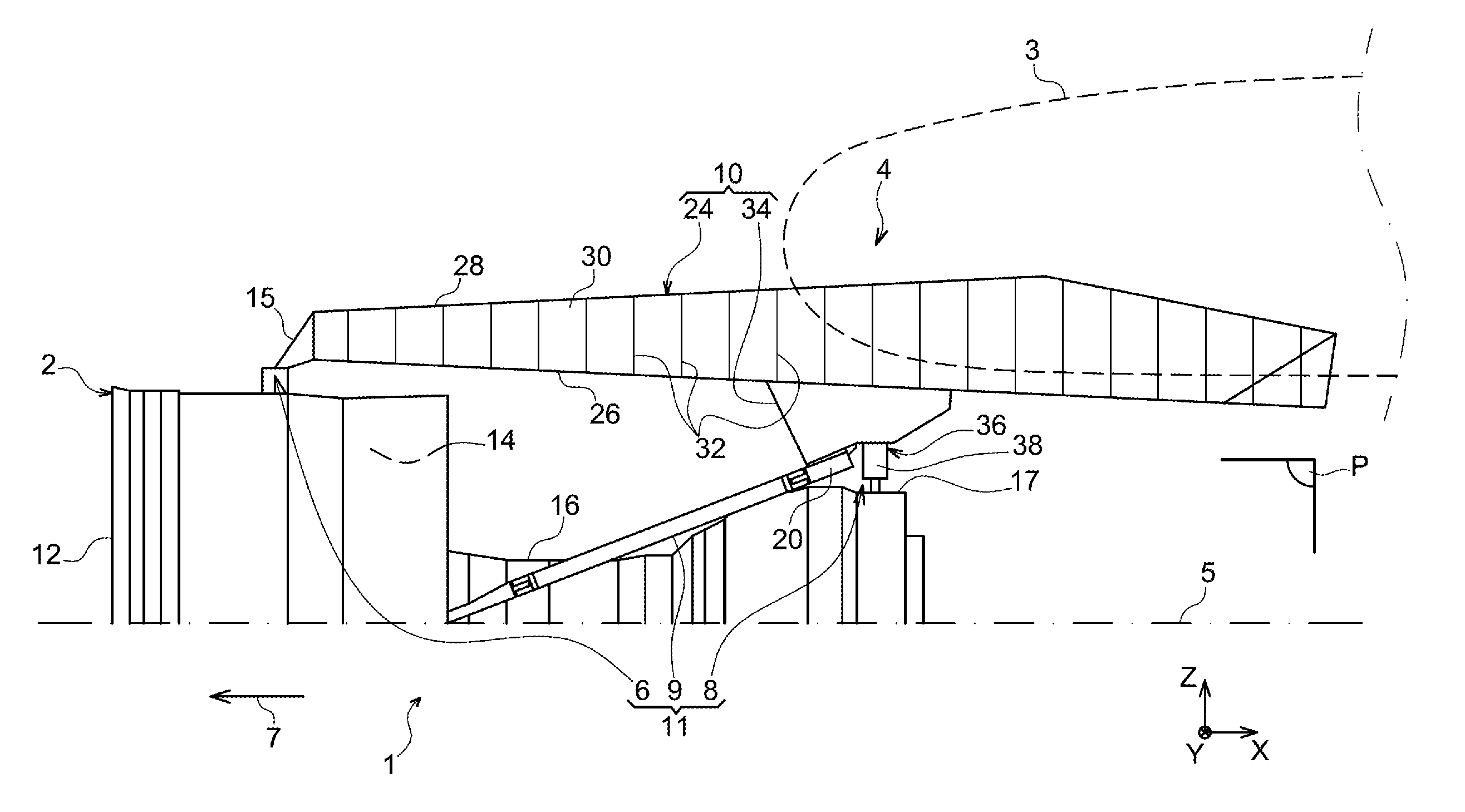

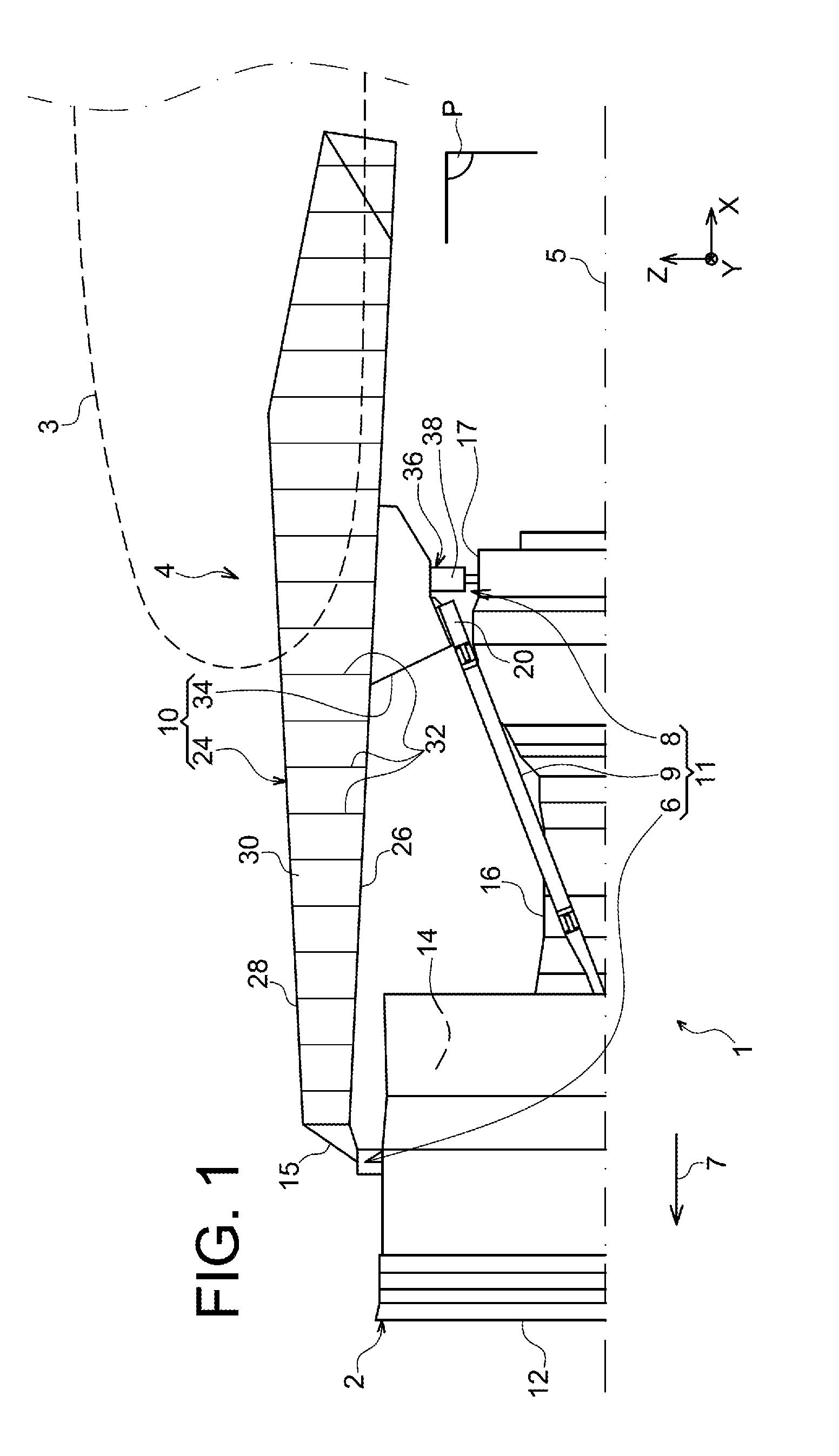

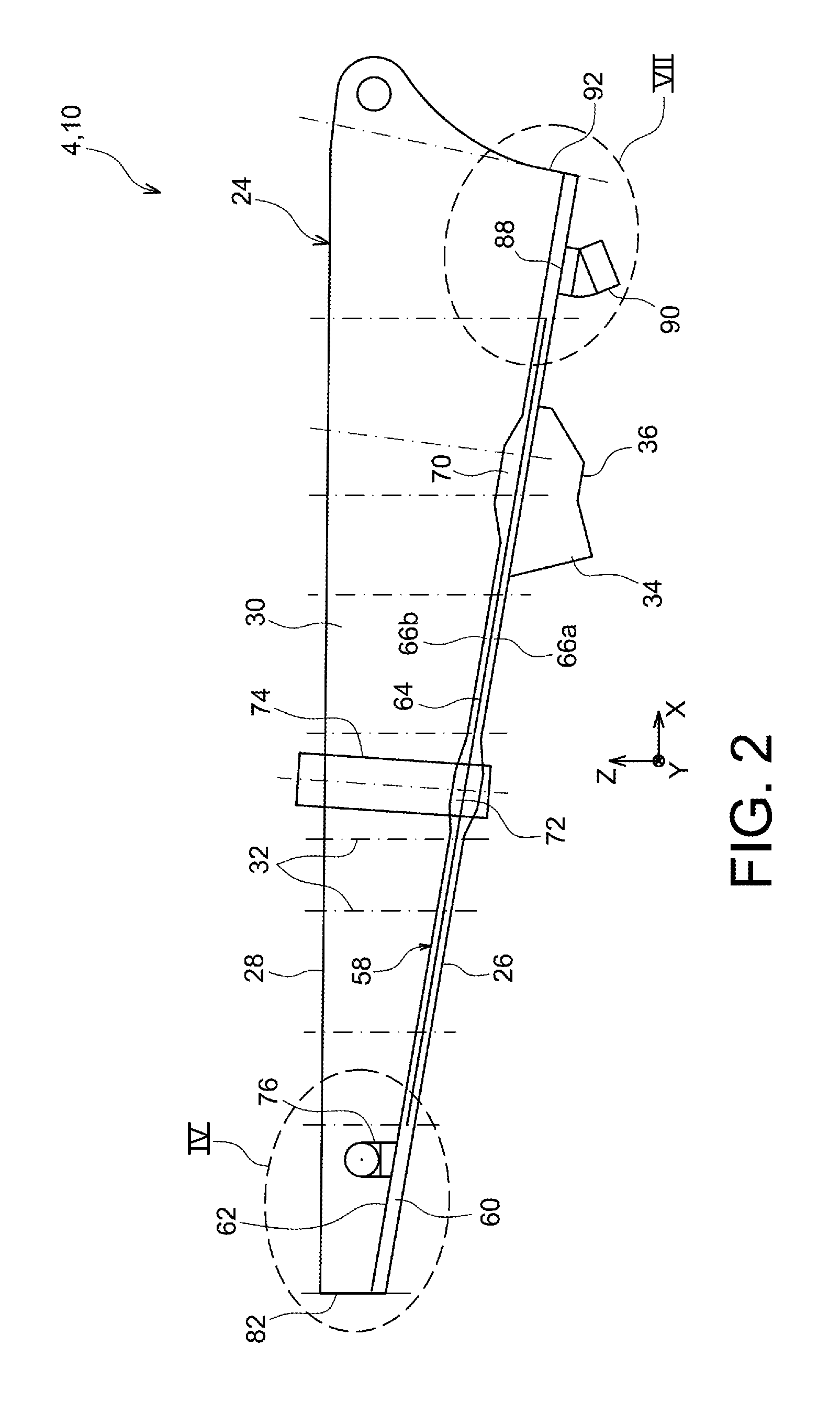

Aircraft propelling assembly including a duct forming a thermal barrier integrated in the caisson of the rigid structure of the engine mounting system

ActiveUS20150321765A1Simple and economical and effectiveAvoid disadvantagesPower plant constructionLaminated elementsEngine mountGuide tube

Housing a conduit of a thermal protection system of a rigid structure of an attachment pylon in an aircraft propulsion assembly within a box of the rigid structure, so as to take advantage of the volume within the rigid structure. The elements forming the conduits thus form an integral part of the rigid structure and can thus play a structural role.

Owner:AIRBUS OPERATIONS (SAS)

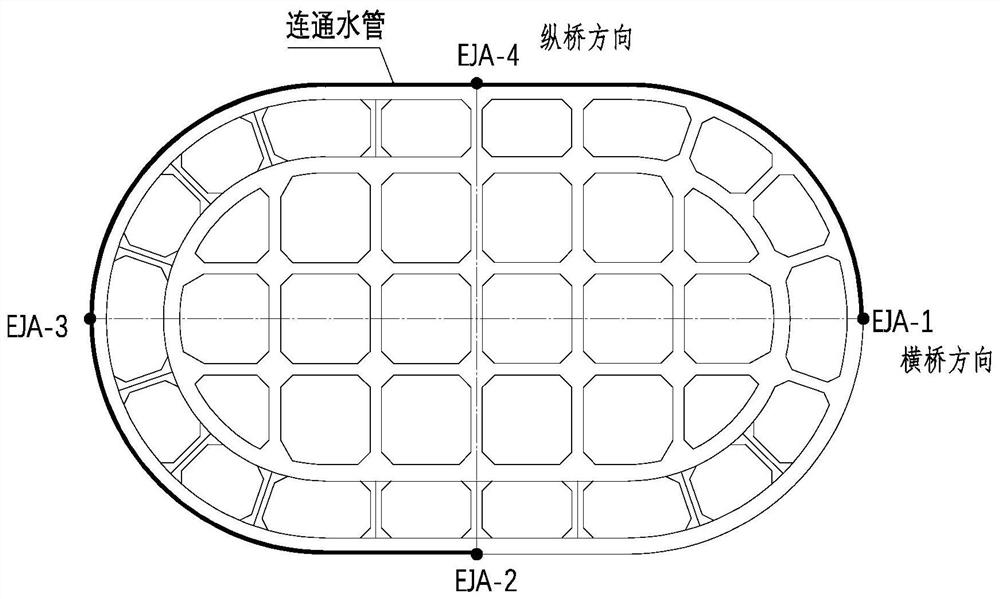

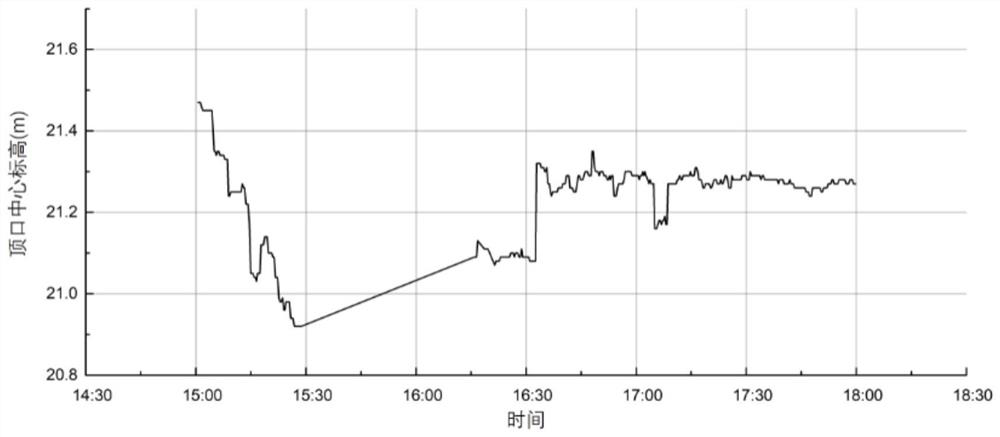

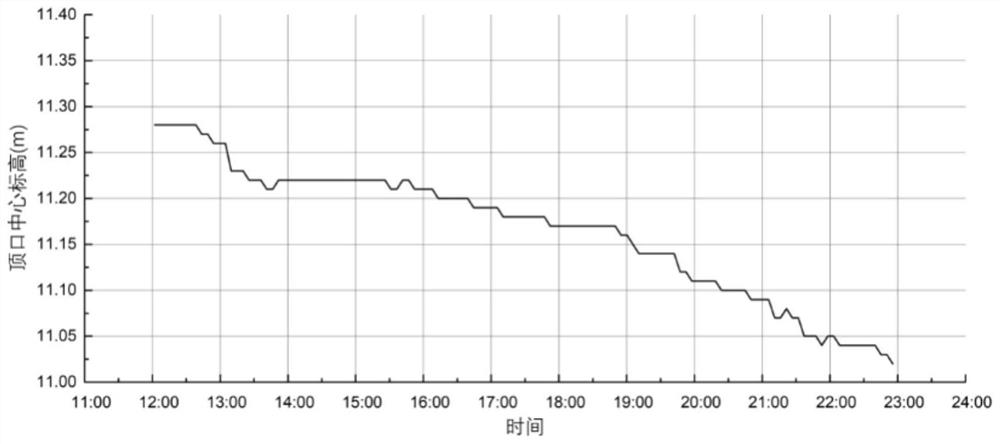

Open caisson geometric attitude testing method based on GPS-EJA

ActiveCN112902934AAccurate monitoringOvercoming the problem of severe distortionSurveying instrumentsIncline measurementAttitude testingMonitoring site

The invention relates to the technical field of bridge construction testing, and discloses an open caisson geometric attitude testing method based on GPS-EJA, which comprises the following steps: S1, marking more than four monitoring points on the top surface of an open caisson, and arranging a GPS observation station and an EJA transmitter at each monitoring point; s2, calculating the transverse slope rate and the longitudinal slope rate of the top face of the open caisson and measuring the distance between any two EJA transmitters through a measuring instrument; s3, randomly selecting one group of monitoring points from more than four monitoring points; s4, calculating a transverse inclination angle and a longitudinal inclination angle of the top surface of the open caisson and a distance between any two GPS observation stations, and performing rationality judgment; s5, performing calculation on the basis of the three-dimensional coordinate values acquired by the GPS observation stations which are judged to be qualified reasonably, and outputting geometric attitude parameters of the open caisson. According to the open caisson geometric attitude testing method, distortion data in the GPS monitoring process can be screened and removed, and the open caisson attitude can be automatically monitored.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Building dense region underground-space-building caisson construction method

The invention belongs to the technical field of underground architectural engineering, relates to a caisson construction method for developing an underground space at an old building dense region where an underground garage is not simultaneously built, and particularly relates to a building dense region underground-garage-building local caisson construction method. The method adopts interval caissons, an odd number of the caissons are disposed in the dense building group according to an adjacent building interval, a middle box body is sunk firstly, box bodies on two sides are symmetrically sunk then, and symmetrical forward tunneling is performed under protection of the caissons through the combination with a hidden digging method. The construction method can solve many problems of underground garage excavation construction in the building dense region well, and effectively eases a situation of a parking difficulty.

Owner:山东轨道交通勘察设计院有限公司 +1

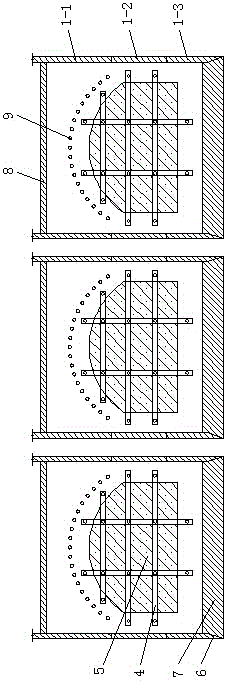

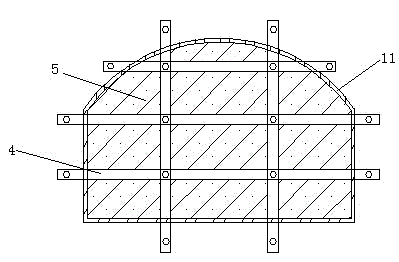

Dock wall type wharf structure with deepwater soft soil foundation and construction method thereof

PendingCN107700423AImprove bearing capacitySkip the trestleBreakwatersQuaysEngineeringStructural engineering

The invention discloses a dock wall type wharf structure with a deepwater soft soil foundation and a construction method thereof. The dock wall type wharf structure comprises a reinforced soft soil foundation, a riprap front foundation bed, a riprap rear foundation bed, a front caisson, a rear caisson, a riprap slope dyke, a front breast wall, a rear breast wall, a beam plate structure and behind-wall backfill. The riprap front foundation bed is arranged at the end, close to deep water, of the reinforced soft soil foundation, the front caisson is arranged on the top of the riprap front foundation bed, and the front breast wall is arranged on the top of the front caisson; the riprap rear foundation bed is arranged behind the riprap front foundation bed, the rear caisson is arranged on the top of the riprap rear foundation bed, the rear breast wall is arranged on the top of the rear caisson, and the behind-wall backfill is arranged behind the rear caisson; and the riprap slope dyke is arranged between the front caisson and the rear caisson, and the beam plate structure is arranged between the front breast wall and the rear breast wall. A dock wall type wharf can be directly built onthe deepwater soft soil foundation, the functions of the wharf and a circle levee are achieved, a trestle can be omitted, the land region using area can be increased substantially, and high value is achieved.

Owner:CCCC THIRD HARBOR CONSULTANTS

Novel water open caisson construction technology

ActiveCN104975612ASimple operation processReduce installation deviationCaissonsSoil propertiesSludge

The invention relates to a novel water open caisson construction technology. An open caisson is prefabricated in a land precast yard in one step, and a cutting edge angle is arranged on the bottom of the open caisson; a compressed air pipe is vertically arranged along the inner wall of the open caisson after prefabrication; high-pressure air nozzles are mounted on the pipe end; the upper part of the vertical compressed air pipe is connected by a compressed air parallel pipe; the open caisson is conveyed to a construction position, is hoisted by a floating crane or is positioned by a buoyancy tank; an air compressor is connected with the compressed air parallel pipe; the air compressor is started to convey compressed air to the compressed air pipe, and the open caisson slowly sinks; compressed air is ejected from the high-pressure air nozzles at the bottom; a soil body is cut by virtue of explosive force of the compressed air; and after being discharged, the compressed air rapidly moves towards the water surface in water, and cut soil upwards moves along with the compressed air, so that the inner wall of the open caisson and the soil body are isolated, and the open caisson sinks under the effect of self weight. The invention is applicable to a foundation with a uniform soil property, and is particularly applicable to a sludge or sandy foundation; the construction speed of the water open caisson can be greatly quickened; correction and leveling are facilitated; the apparatus is simple; the technology is simple and convenient; and the construction cost is reduced.

Owner:山东港通工程管理咨询有限公司

Soft soil area mud-water balance open caisson station counterforce and locking system

PendingCN110761328AEasy to assembleEasy to pourArtificial islandsUnderwater structuresButtressEngineering

The invention belongs to the technical field of underground engineering construction, and particularly relates to a soft soil area mud-water balance open caisson station counterforce and locking system. The soft soil area mud-water balance open caisson station counterforce and locking system comprises a counterforce truss, jacks and locking devices; the counterforce truss comprises a crossbeam andvertical columns, and the two ends of the crossbeam are fixed to the two vertical columns correspondingly; and the bottoms of the two vertical columns are fixed to the ground, and the opposite sidesof the two vertical columns are provided with the locking devices used for being matched with locking buttresses on an open caisson section side wall to lock an open caisson section. According to thesoft soil area mud-water balance open caisson station counterforce and locking system, the jacks are arranged on the lower part of the counterforce truss to apply sinking power to an open caisson structure and adjust the attitude of an open caisson; and the locking devices are arranged on the two sides of the open caisson section, and the locking devices are matched with the locking buttresses onthe open caisson section side wall to lock the open caisson section, so that the next section of open caisson structure is spliced and poured or the current open caisson section is monitored, the construction speed of the open caisson is increased, and safety is ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com