Dock wall type wharf structure with deepwater soft soil foundation and construction method thereof

A soft soil foundation and wharf technology, which is applied in infrastructure engineering, quay walls, water conservancy projects, etc., can solve the problems that cannot meet the needs of gravity type wharves, and have higher requirements for foundation bearing capacity, so as to increase the land use area and improve the bearing capacity , save the effect of trestle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

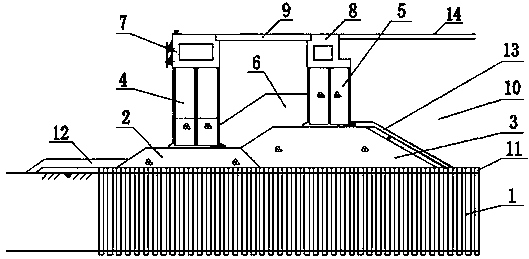

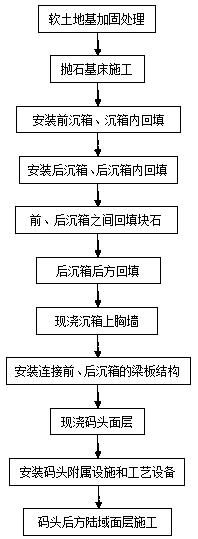

[0029] Such as figure 1 As shown, a deep-water soft soil foundation bank-type wharf structure, including reinforced soft soil foundation 1, riprap front foundation bed 2, riprap rear foundation bed 3, front caisson 4, rear caisson 5, riprap slope embankment 6 , the front breast wall 7, the rear breast wall 8, the beam-slab structure 9 and the backfill 10 behind the wall; the end of the reinforced soft soil foundation 1 near the deep water is provided with a pre-riprap foundation bed 2, and the top of the pre-riprap foundation bed 2 A front caisson 4 is provided, and a front breast wall 7 is arranged on the top of the front caisson 4; a post-riprap bed 3 is arranged behind the front bed 2 of the riprap, and the height of the bed 3 after the riprap is higher than the bed before the riprap. The height of the bed 2; after the riprap, the top of the foundation bed 3 is provided with a rear caisson 5, the top of the rear caisson 5 is provided with a rear parapet 8, and the rear of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com