Patents

Literature

481results about How to "Increased shear capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

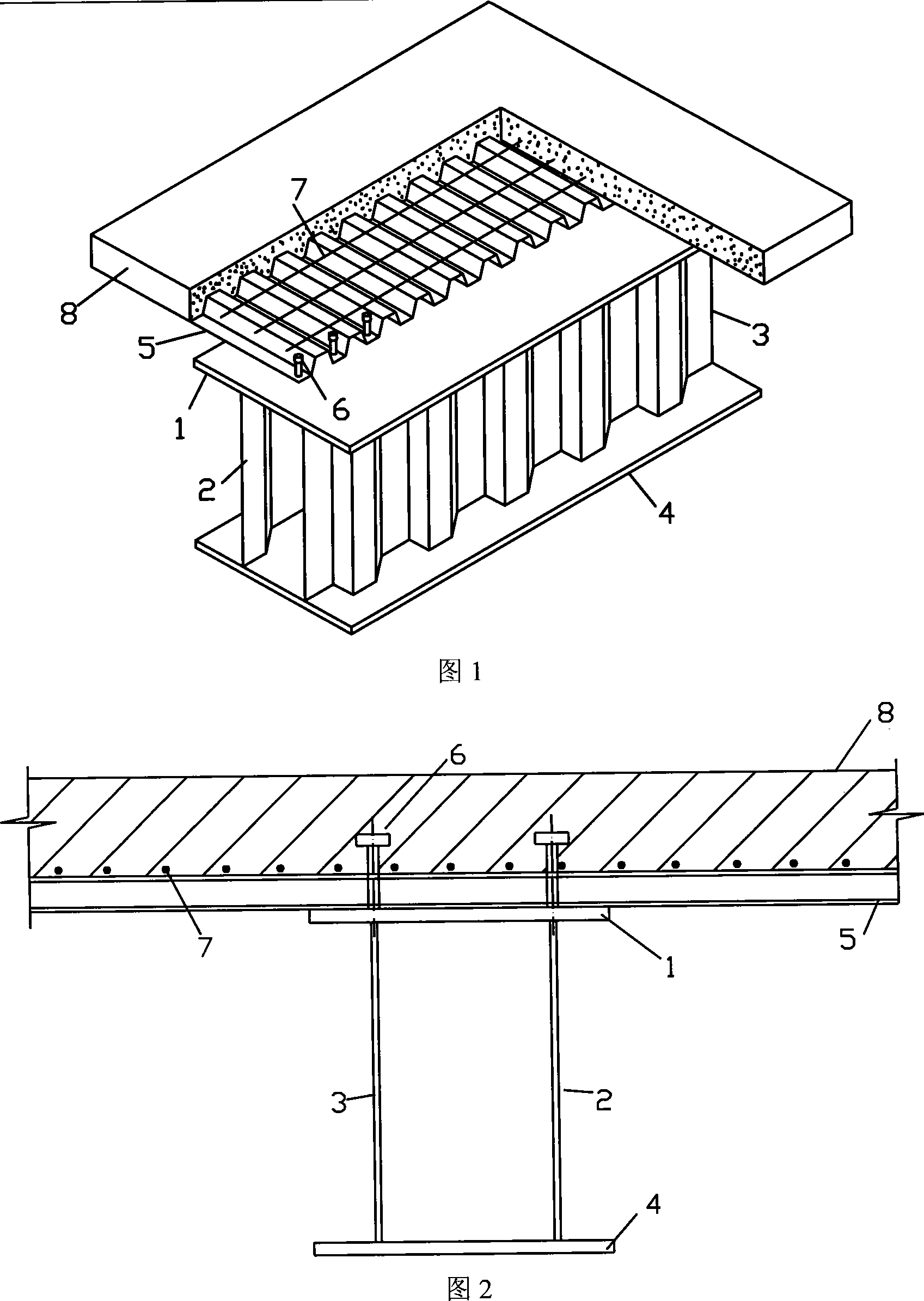

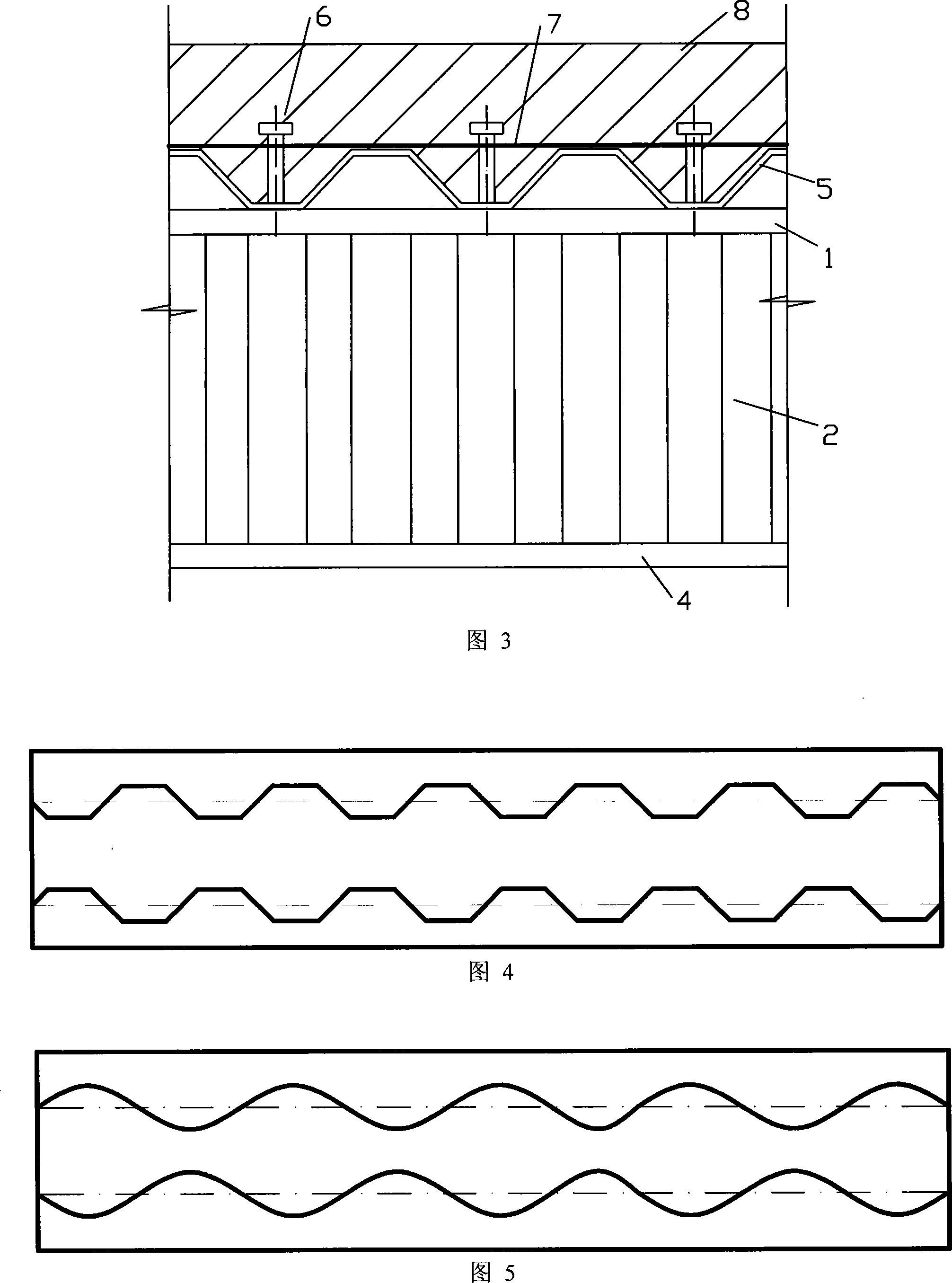

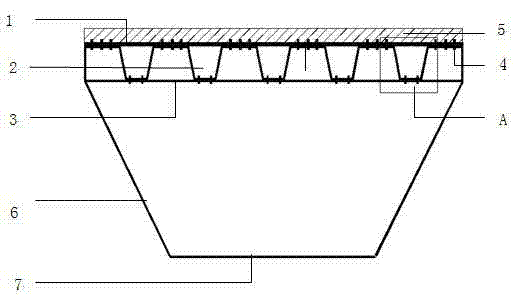

Double-ripple ventral shield steel case built-up beam

InactiveCN101220697APrecise positioningImprove mechanical propertiesFloorsLoad-supporting elementsSteel barSpandrel

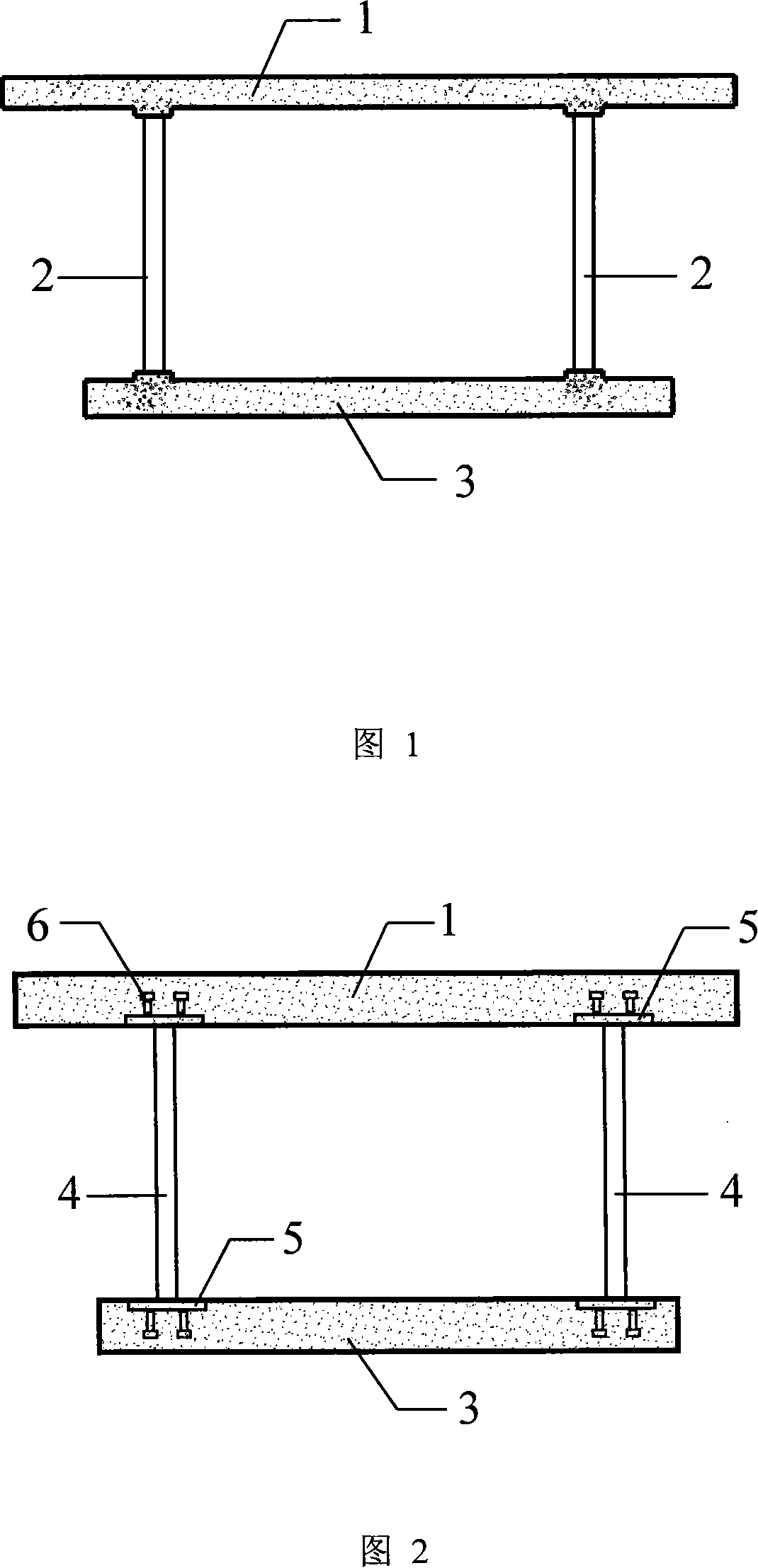

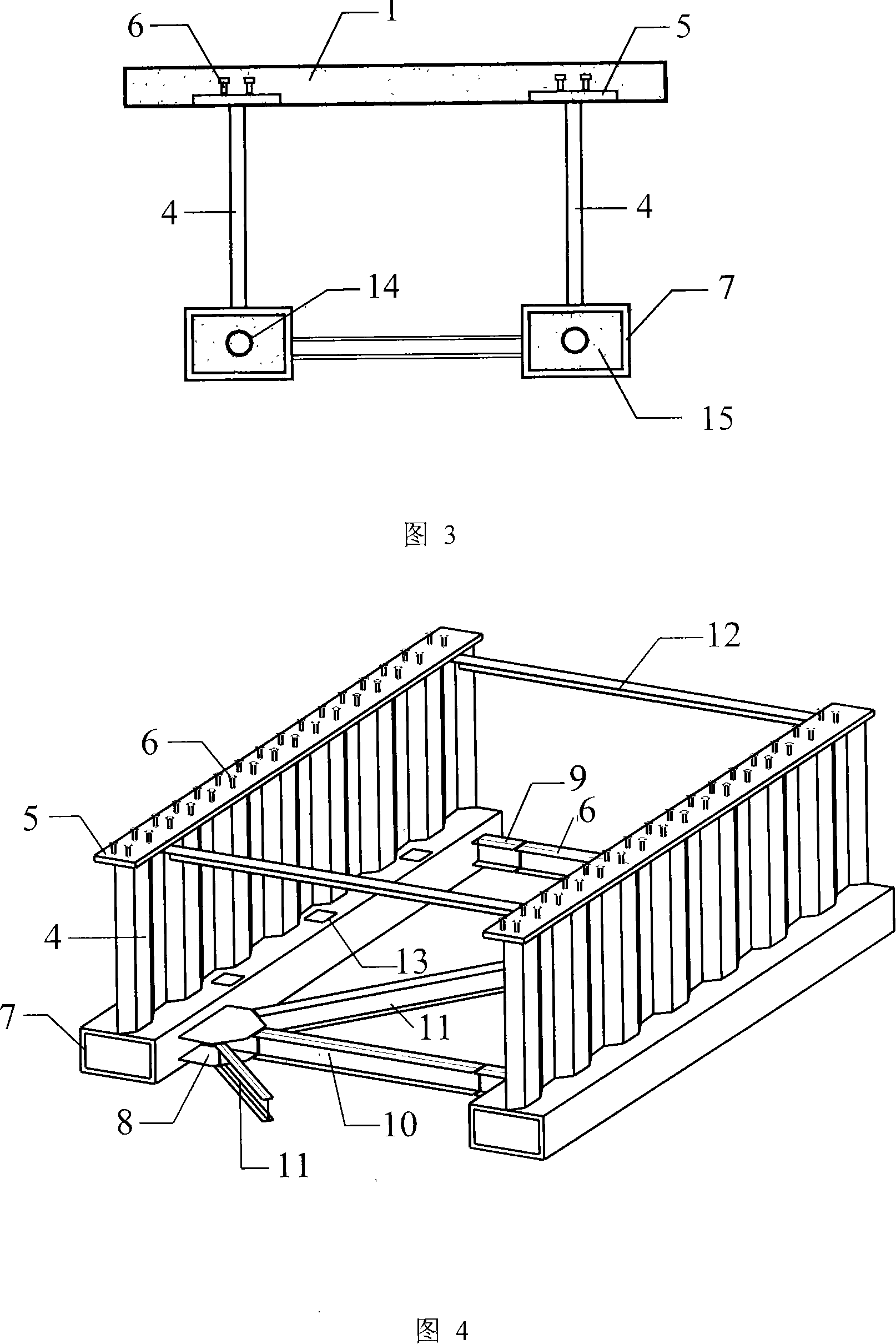

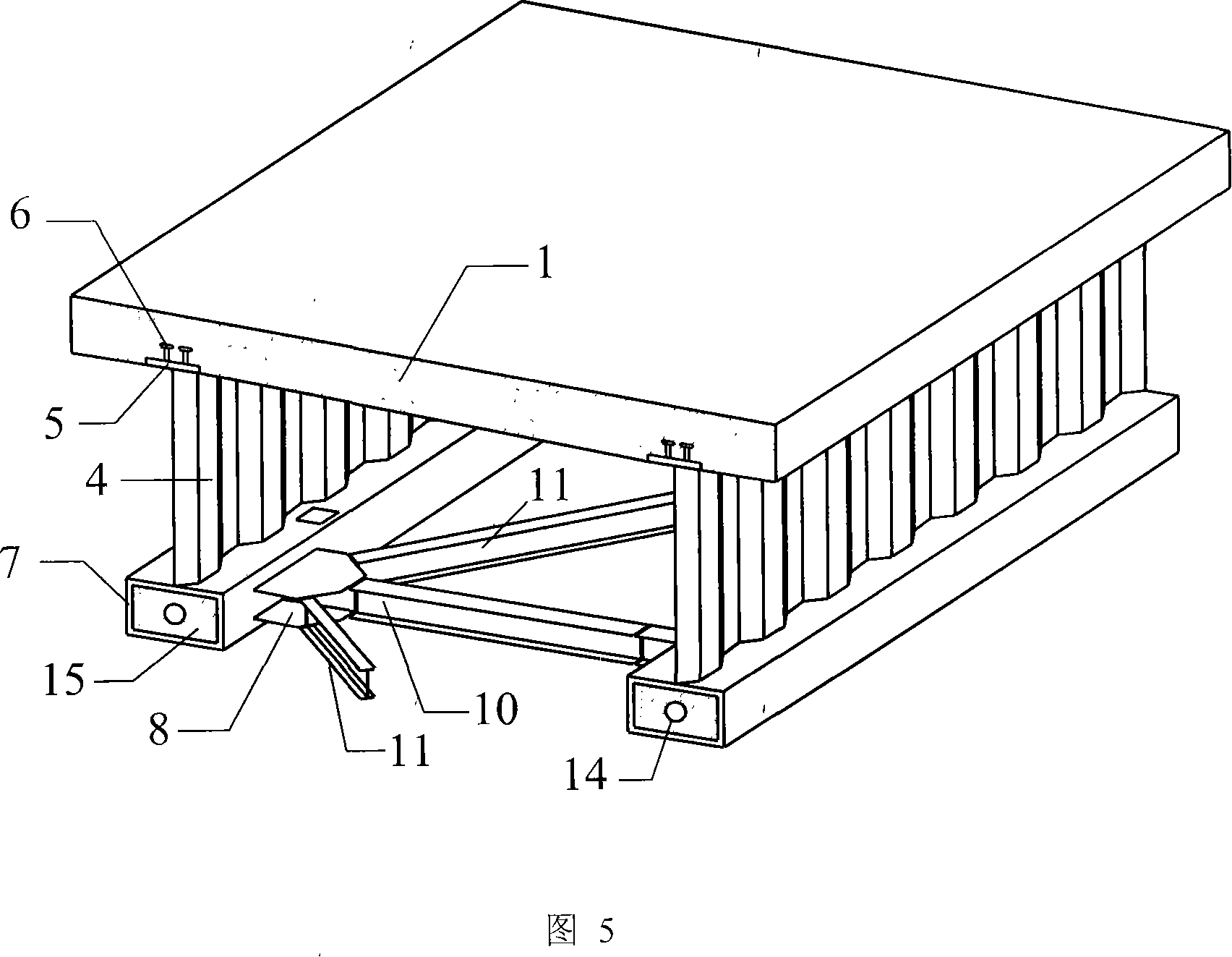

The invention belongs to the technical field of architectural profiles and particularly relates to a double corrugated web steel box composite beam. The sectional shape of the invention is composed of two symmetrically arranged corrugated webs, a top flange and a lower flange. The top flange is parallel with the lower flange, the web is vertical to the top flange and the lower flange, the web and the flange are connected by single-side fillet joint, and the web has periodically repetitive trapezoidal wave or sinusoid wave along the length direction. The top of the composite beam is a reinforced concrete wing plate and a profiling steel plate. The top flange, the reinforced concrete slab and the profiling steel plate are connected each other by male pins, and a transverse reinforcement can be additionally used for the connection between the reinforced concrete wing plate and the profiling steel plate. The invention can replace the traditional hot rolled flange beam, H-beam composite beam and welded steel box composite beam; furthermore, the invention has wider application than the flange beam and the H-beam composite beam, and can realize maximization to be used in special fields and special places, including the construction of wide-span industrial and civilian buildings and wide-span bridges, etc.

Owner:TONGJI UNIV

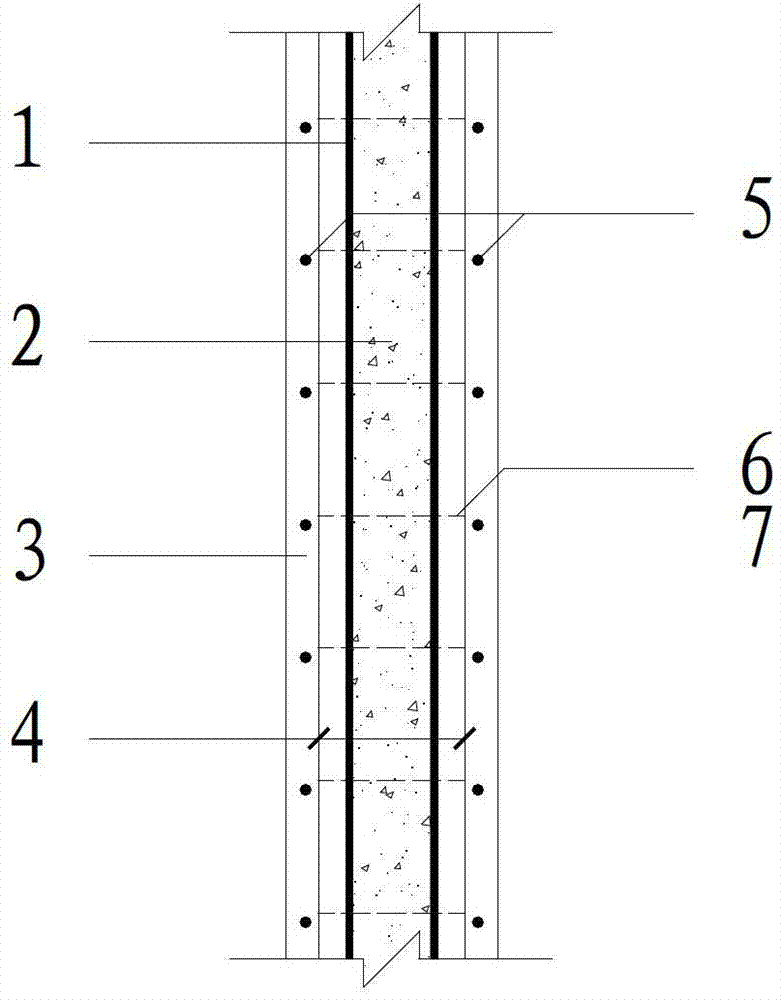

Section steel concrete- punched steel plate-concrete combined shear wall and method for producing the same

InactiveCN101457560AIncreased shear capacityIncrease the usable areaWallsShock proofingRebarSteel plates

The invention relates to a shear wall, in particular to a profile steel concrete-punching steel plate-concrete combined shear wall and a manufacturing method thereof. The shear wall is limited by a profile steel concrete column and formed by a steel plate combination structure which is covered with concrete outside and provided with holes; the shear wall is provided with the steel plate, and then two sides of the steel plate are configured with a reinforcing mesh formed by reinforcing steel bars which are distributed transversely and longitudinally, and a drawknot rib that passes through the holes is used for connecting the reinforcing meshes at the two sides of the steel plate together; finally, the concrete is poured. The profile steel concrete-punching steel plate-concrete combined shear wall can improve the carrying capacity, reduce the attenuation speed of rigidity and carrying capacity, lead the later period shakeproof performance of the wall to be relative stable, and weakens the damage caused by cutting and gliding at the bottom.

Owner:BEIJING UNIV OF TECH

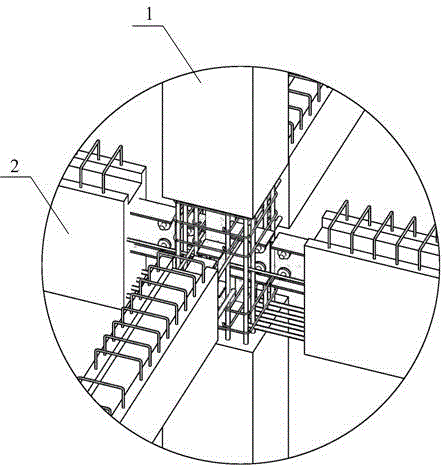

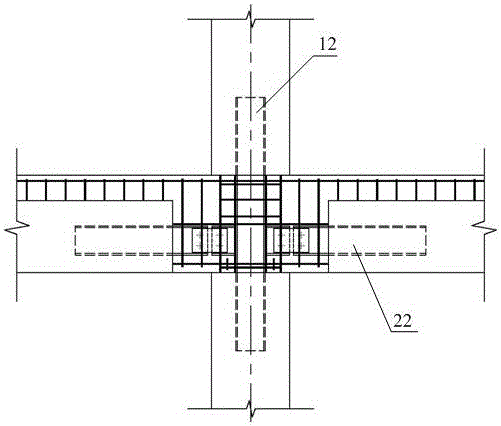

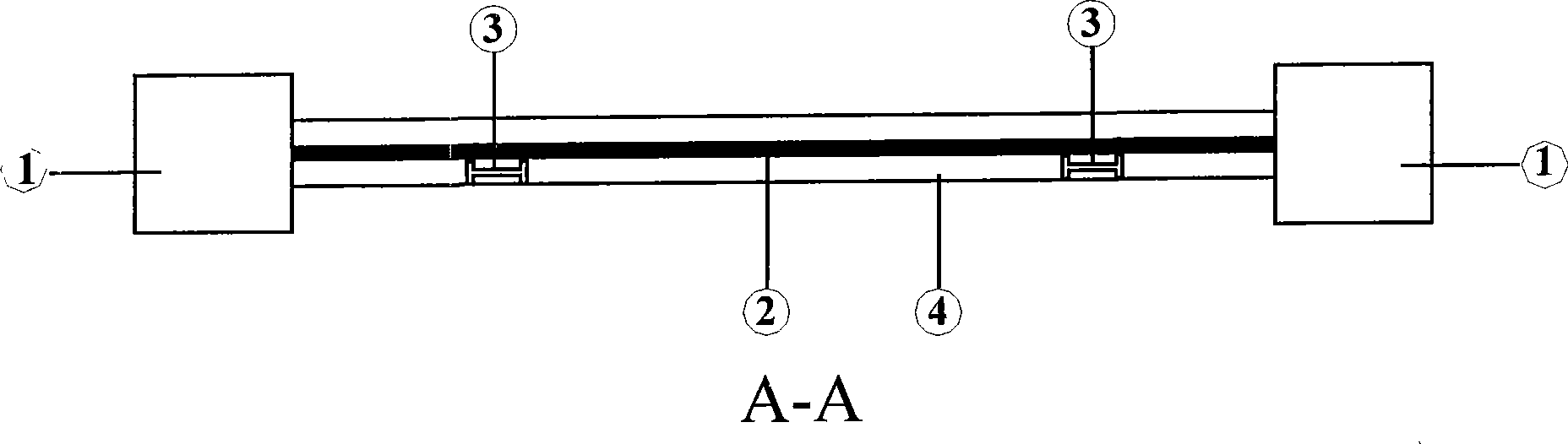

Steel bar truss stiffened steel concrete composite shear wall

InactiveCN104929281AImprove bearing capacityIncreased shear capacityWallsSheet steelReinforced concrete

The invention discloses a steel bar truss stiffened steel concrete composite shear wall, relates to a shear wall and belongs to the field of building structures. The steel bar truss stiffened steel concrete composite shear wall aims to solve the problems that an existing steel concrete shear wall is poor in anti-seismic property, prone to crack and complex in construction when connected with steel members. The steel bar truss stiffened steel concrete composite shear wall comprises a second stiffening member, concrete, a first stiffened steel body and a plurality of shearing-resistant connecting keys. The first stiffened steel body comprises a first stiffening member, two steel plates, a plurality of transverse steel bars and a plurality of steel bar trusses. Each steel bar truss comprises two erection steel bars and three longitudinal steel bars, wherein the three longitudinal steel bars are arranged in a triangular shape, and the steel bar trusses are arranged in parallel between the two steel plates in the horizontal direction. The erection steel bars are connected to the steel plates. The transverse steel bars are horizontally arranged between the two steel plates, and the transverse steel bars are connected with the steel bar trusses. The first stiffening member and the second stiffening member are provided with the shearing-resistant connecting keys, and the concrete is poured on the first stiffening steel body and the second stiffening member.

Owner:HARBIN INST OF TECH

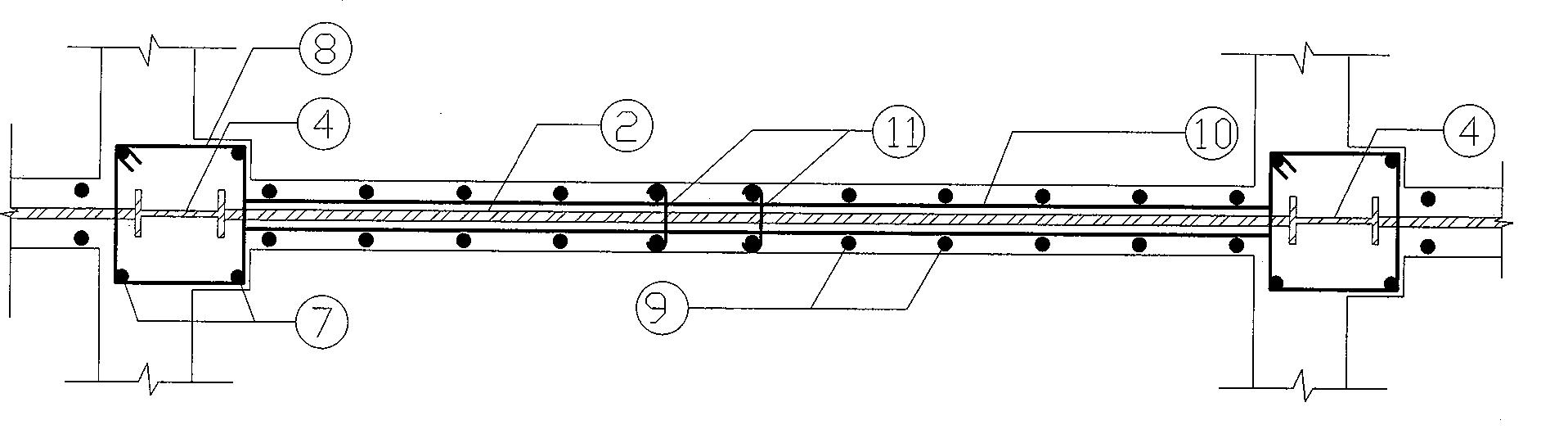

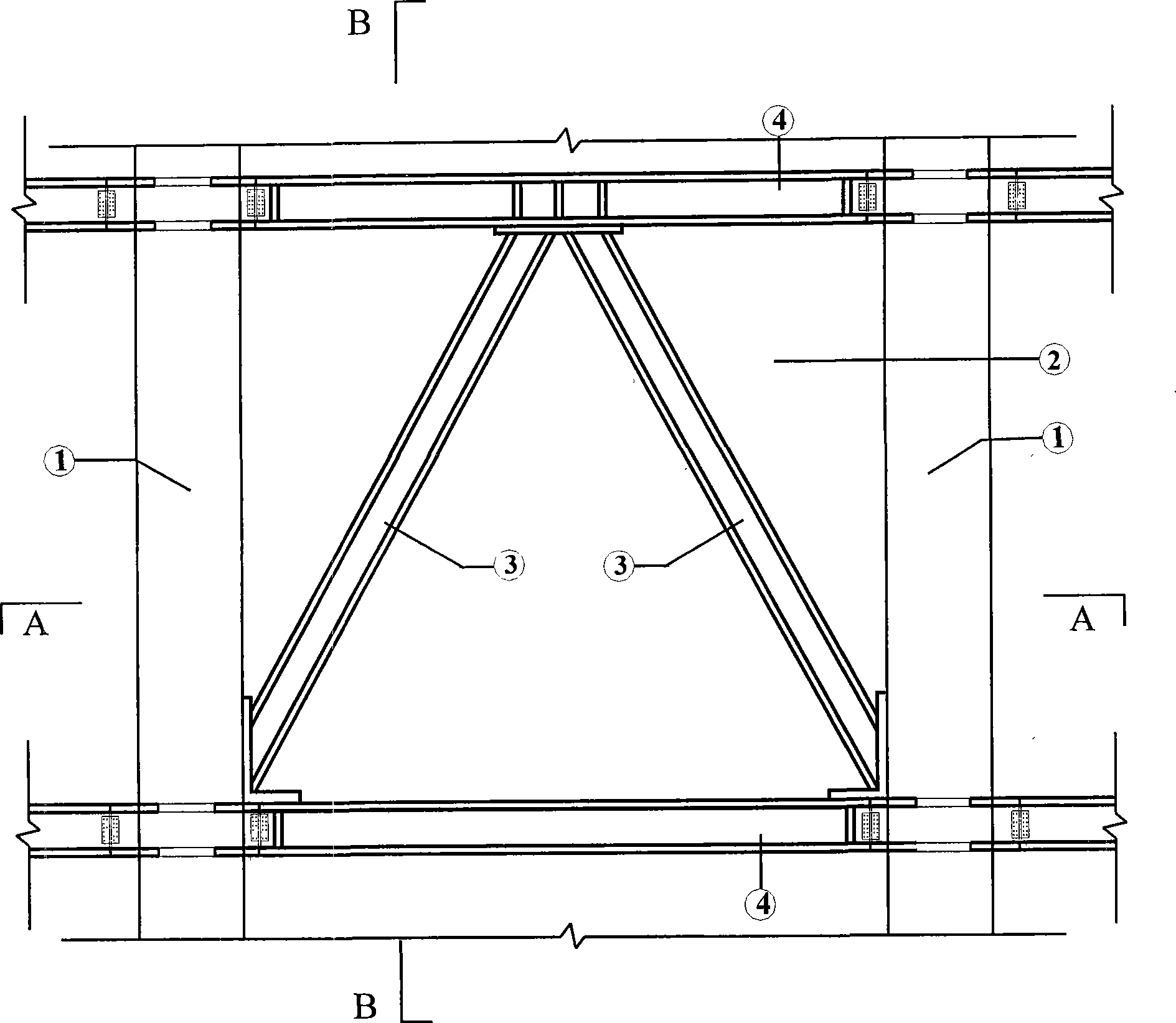

Lower edge open truss style corrugated steel web combination beam

InactiveCN101139812AImprove crack resistanceIncreased durabilityLoad-supporting elementsBridge materialsFalseworkCrack resistance

A truss-type corrugated steel web composite beam with an open bottom chord belongs to a bridge support member. The bottom chord opened and truss-type corrugated steel web composite beam comprises an upper wing edge concrete slab, a corrugated steel web and a bottom chord opened truss-type rectanglar steel tube concrete member. Compared with steel truss-type web composite corss section, the invention adopts the corrugated steel web with rather high shear strength to replace a steel web member, so as to guarantee quite high shear bearing capacity. The opened truss-type bottom chord is composed of two parallel-arranged rectanglar steel tubes arranged in parallel and internally cast concrete, as well as horizontal braces and batter braces between the rectanglar steel tubes. Moreover, the bottom chord adopts the steel tube concrete member to overcome the problem of rather high work volume that, in traditional composite cross section of corrugated steel web box beams and steel truss-type webs, such execution measures as scaffolding, formwork-support, concrete casting and etc. should be taken for lower wing edge concrete slabs. Meanwhie, the invention can effectively improve structure crack resistance, avoid crackage exposure and etc, and considerably increase structure durability. The bottom chord is a brace-connected open-type structure with advantages of simple structure and fast, smooth and convenient execution.

Owner:TSINGHUA UNIV

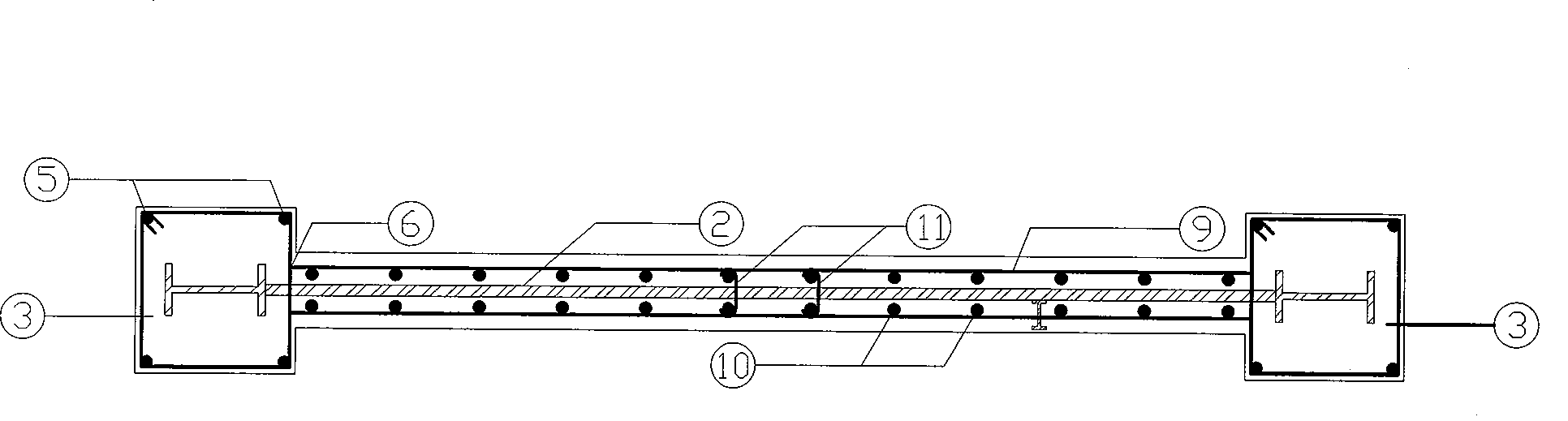

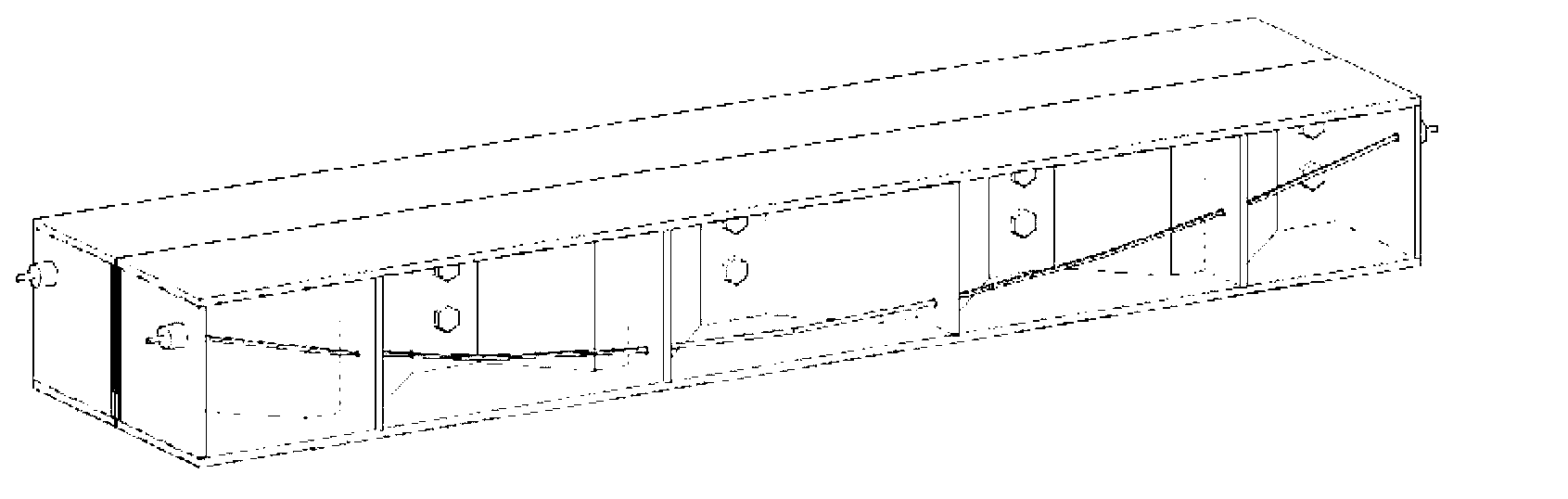

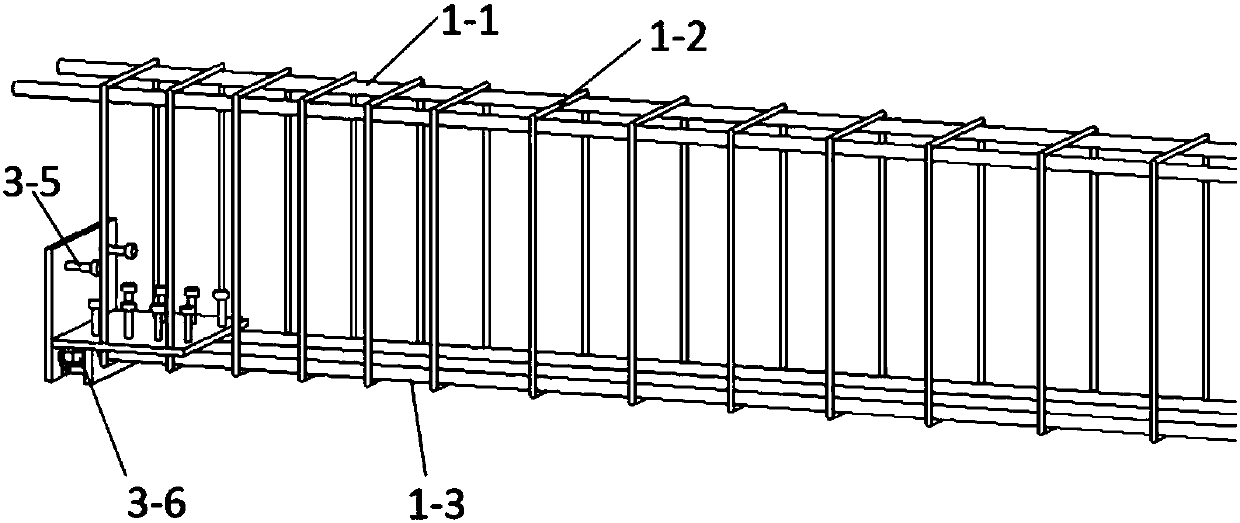

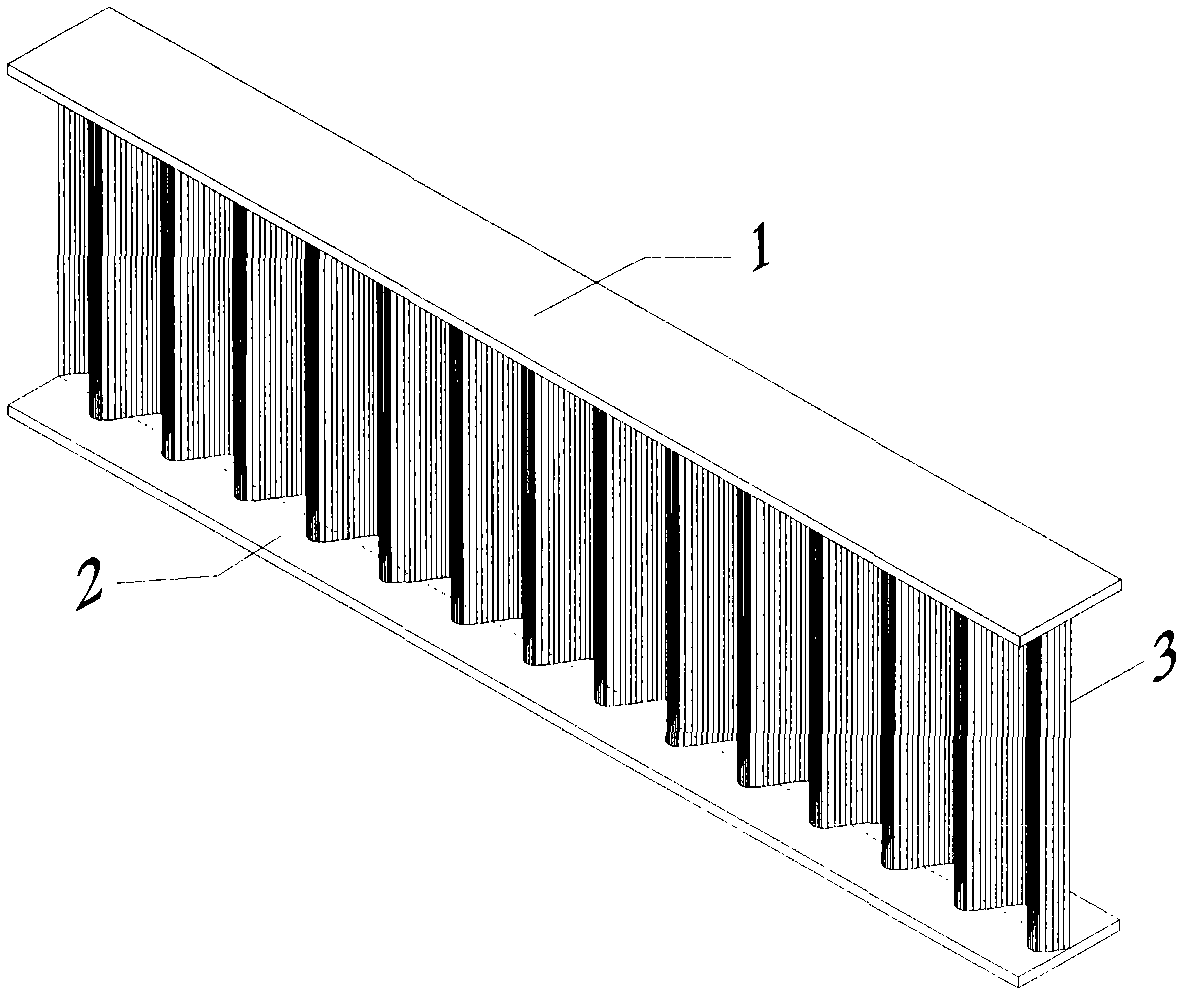

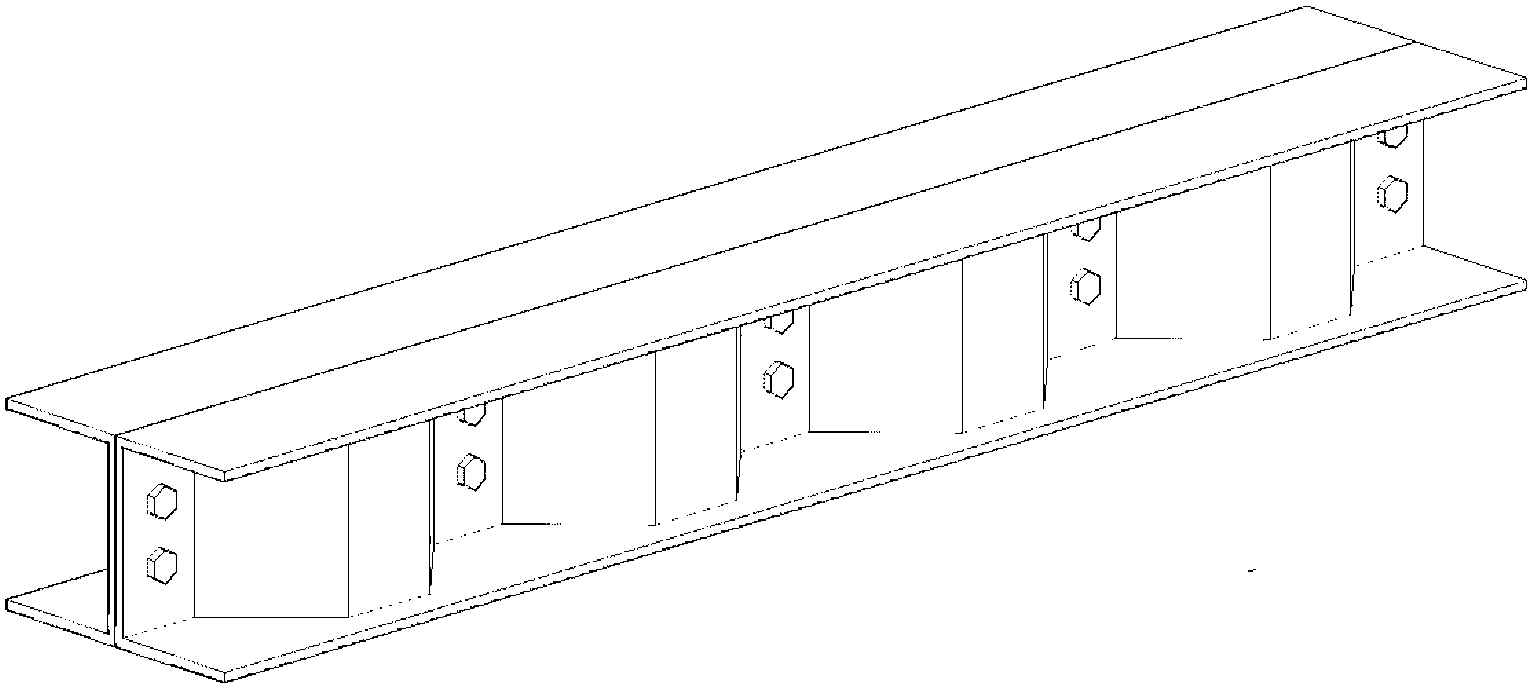

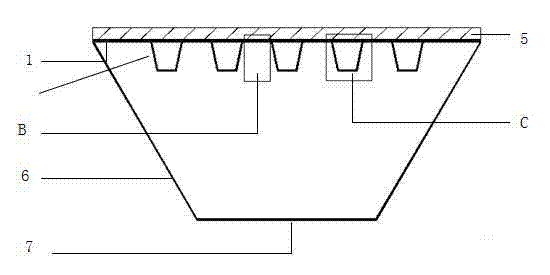

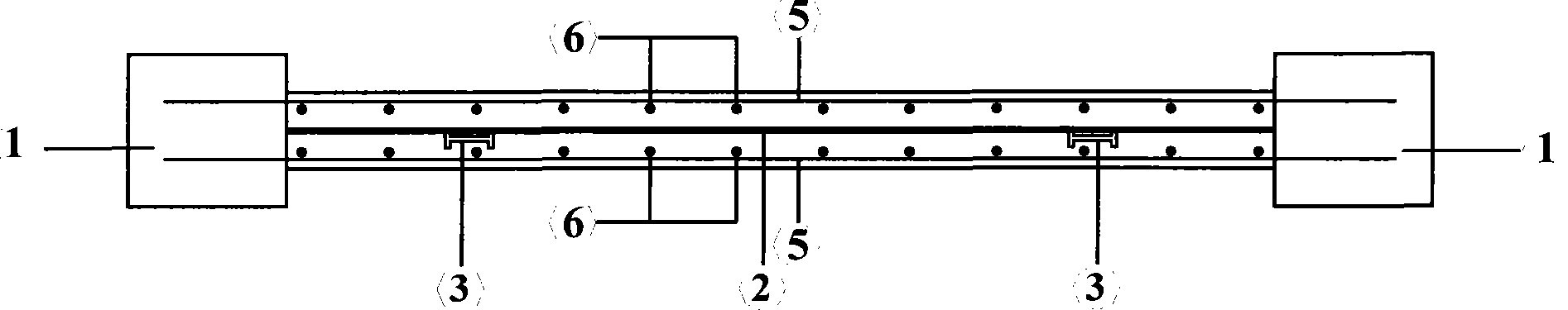

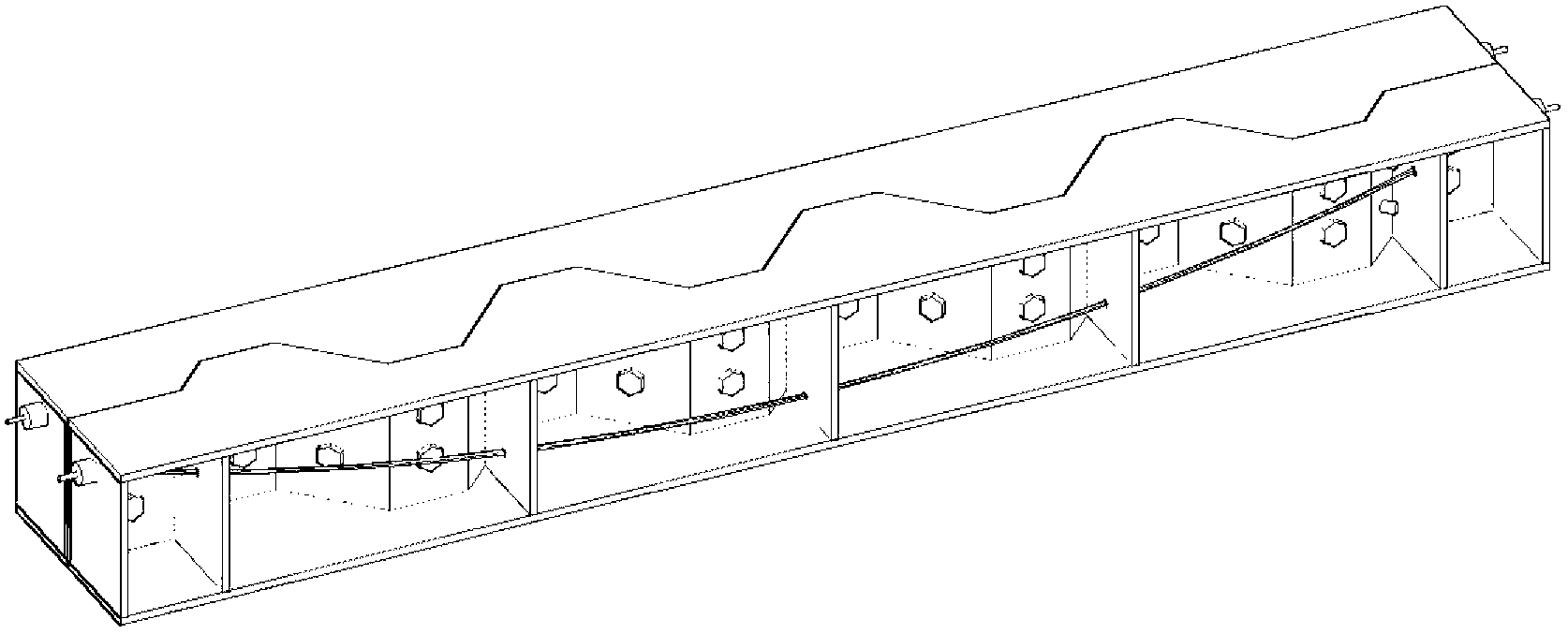

Assembling type pre-stress honeycombed ribbed web steel beam

ActiveCN103255877AImprove mechanical performanceImprove stabilityGirdersJoistsRepeating waveformsButt joint

The invention relates to an assembling type pre-stress honeycombed ribbed web steel beam and belongs to the technical field of a building section bar. The assembling type pre-stress honeycombed ribbed web steel beam is formed by assembling two butt-joint pre-stress ripple web ribbed steel channel beam webs through bolts. Each pre-stress ripple web ribbed steel channel beam is formed by a top flange, a web, a bottom flange, a pre-stress cable, transverse stiffening ribs, anchorage devices and beam end plates. A section die of the pre-stress ripple steel channel beam web is formed by the top flange, the bottom flange and the web; the section of the web is in a uniform or non-uniform periodically-repeated waveform; the transverse stiffening ribs are vertically placed among the two flanges and the web; the beam end plates are parallel to the transverse stiffening ribs and are arranged at the two ends of the beam; and the pre-stress cable is tensioned and then is fixed on the beam end plates through the anchorage devices. The assembling type pre-stress honeycombed ribbed web steel beam disclosed by the invention is a novel assembling type pre-stress steel beam which is applicable to an assembling type steel structure system, particularly a large-span multi-story assembling type steel structure system; and compared with a conventional assembling type beam, the steel beam has the advantages of light self weight, high bearing capability, great span and the like.

Owner:BEIJING UNIV OF TECH +1

Prefabricated concrete frame beam-column joint construction method

The invention discloses a prefabricated concrete frame beam-column joint construction method, and relates to connection of a prefabricated column and a superposed beam. High-strength bolt bars and threaded sleeves are pre-buried in the column side of the prefabricated column, and a column side key groove is pre-formed; a beam end key groove is pre-formed in the beam end of a prefabricated beam, and a connection plate is pre-buried; the construction method adopts the following steps that (1), mounting of the prefabricated column is completed; (2) the prefabricated beam is mounted from top to bottom, so that the high-strength bolt rods penetrate through bolt connection holes; (3), upper longitudinal ribs of the superposed beam are mounted, firstly connection of the upper longitudinal ribs ofthe superposed beam and the threaded sleeves is completed, and then tying of the upper longitudinal ribs of the superposed beam and stirrups of the superposed beam is completed; (4) a washer and a lock nut are connected to each high-strength bolt rod to form pretightening force; and (5), templates are supported on the two sides of the prefabricated beam, concrete is poured, and a post-cast concrete anti-shear key integrated with a post-cast part of the superposed beam is formed in each of the beam end key groove and the column side key groove. The prefabricated concrete frame beam-joint construction method can achieve easy, rapid and convenient on-situ connection of the prefabricated column and the superposed beam, and connection is stable and reliable.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

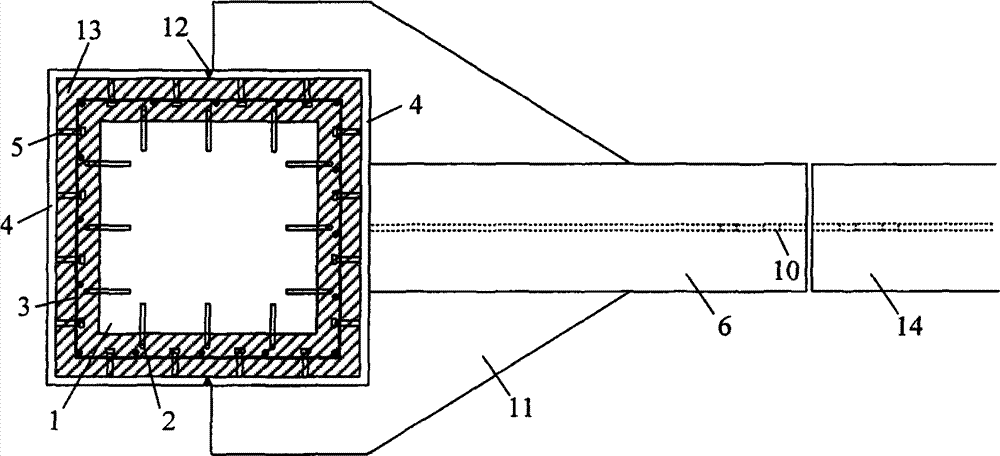

Connecting method of steel beam and existing reinforced concrete column

InactiveCN102966245AEasy to get materialsReduce wet work loadBuilding repairsReinforced concrete columnEngineering

The invention relates to a connecting method of a steel beam and an existing reinforced concrete column, which can be used for reinforced modification of an existing reinforced concrete structure, and belongs to the technical field of structural engineering. The method comprises the steps of: scabbling, planting bars and binding reinforced mesh pieces on the surface around with a node connection domain of the original reinforced concrete column; processing two pieces of channel steel and welding a stud connection piece inside; extending an extending bracket and external reinforcing plate on the channel steel connected to the steel beam; buckling the two pieces of channel steel and wrapping the original reinforced concrete column; welding in an abut manner; pouring node area concrete; and finally connecting the steel beam. The method overcomes the deficiencies of the conventional connection method, is simple in structure, quick and convenient to construct, good in stress performance of the connecting node, reliable in force transfer, and can efficiently prevent a node core area from cracking and being exposed. The core area concrete is wrapped by a steel plate so that the concrete is strongly constrained, and the quake-proof ductility of the node is good. The method has high practicality and wide application prospect.

Owner:TSINGHUA UNIV

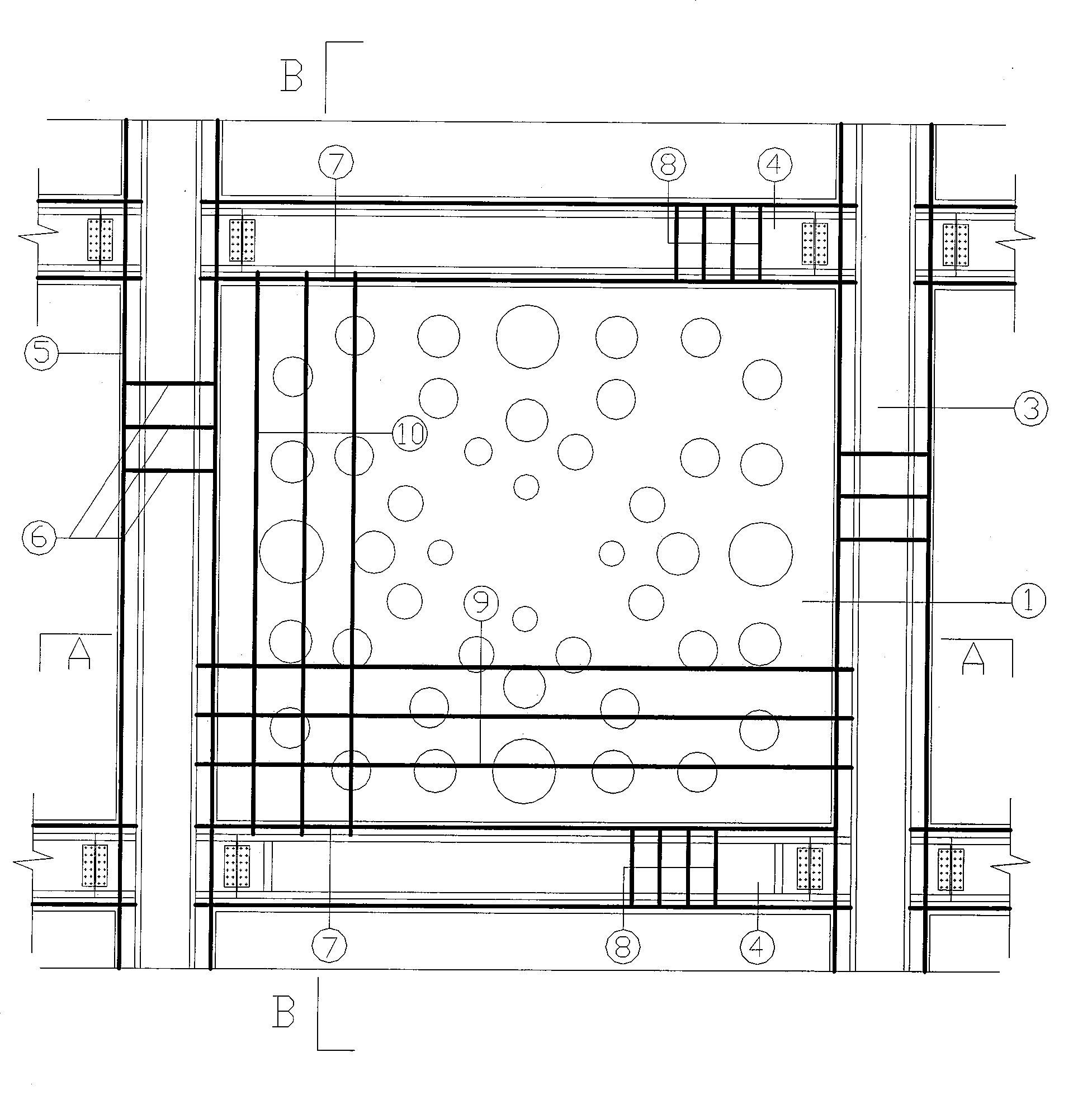

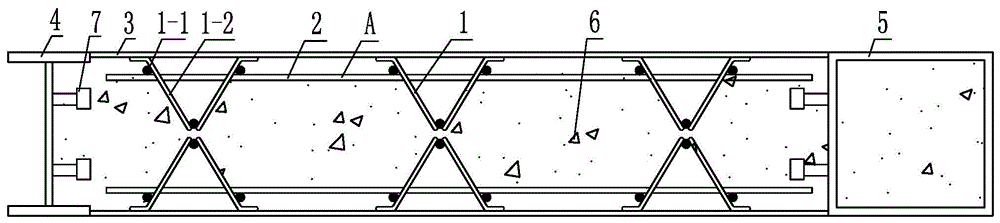

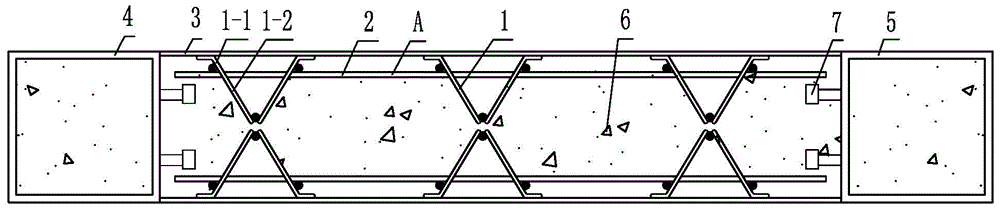

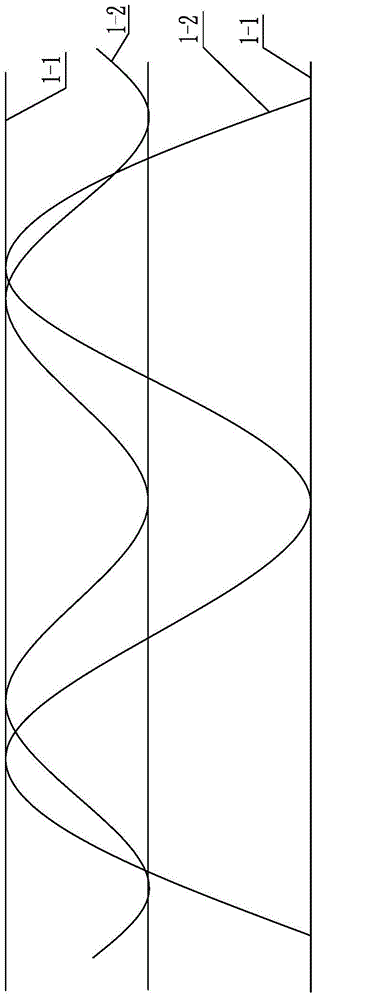

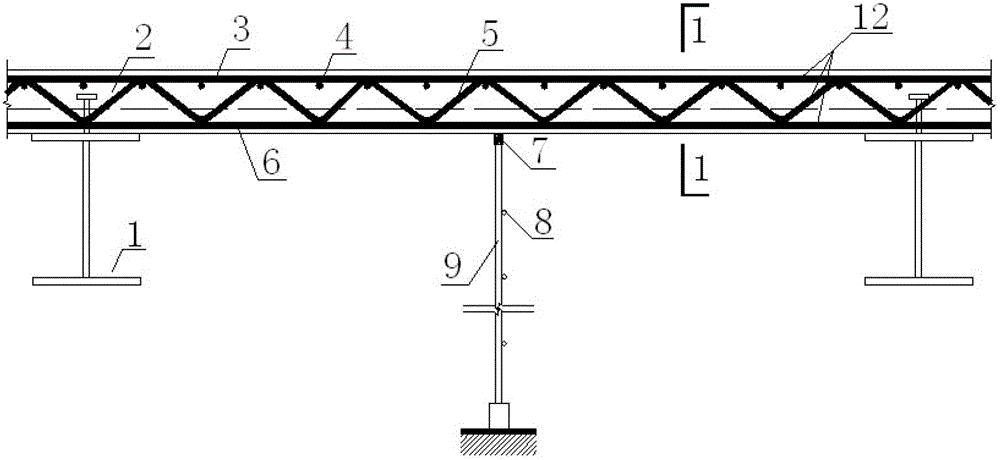

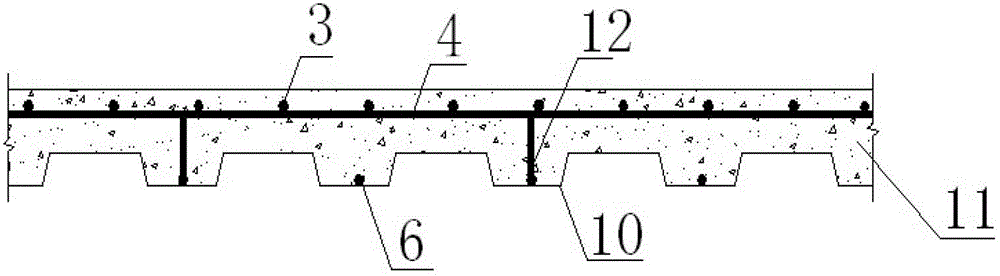

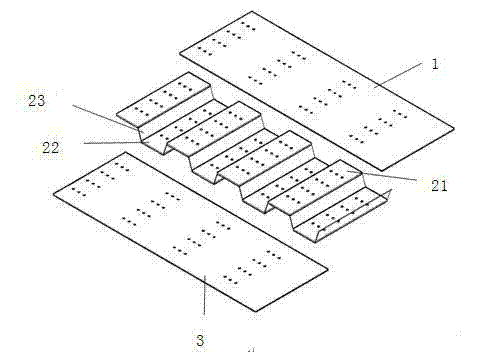

Composite floor with steel bar trusses, profiled steel plate and regenerated concrete, and manufacturing method for composite floor

InactiveCN102877582AIncreased shear capacityImprove ductilityFloorsBuilding material handlingSheet steelRebar

The invention relates to a composite floor with steel bar trusses, a profiled steel plate and regenerated concrete, and a manufacturing method for the composite floor. The composite floor mainly comprises the profiled steel plate, the regenerated concrete poured on the profiled steel plate, the inclined grid type steel bar trusses and transversely distributed bars, wherein the profiled steel plate is paved on a steel beam of a steel structure main body; the bottom of the profiled steel plate is fixedly connected with the steel beam; each inclined grid type steel bar truss is arranged on each wave groove or isolation groove of the profiled steel plate and consists of a snake-shaped steel bar, a plate bottom stressing bar and an upper longitudinal steel bar which are welded with one another; and the transversely distributed bars are arranged on the inclined grid type steel bar trusses and are connected to the inclined grid type steel bar trusses in a bound manner. By the composite floor, the anti-shearing bearing capacity of the inclined section of a composite plate can be improved; and the composite floor is suitable for industrial and civil buildings with relatively high requirements on the bearing capacity of floors.

Owner:BEIJING UNIV OF TECH

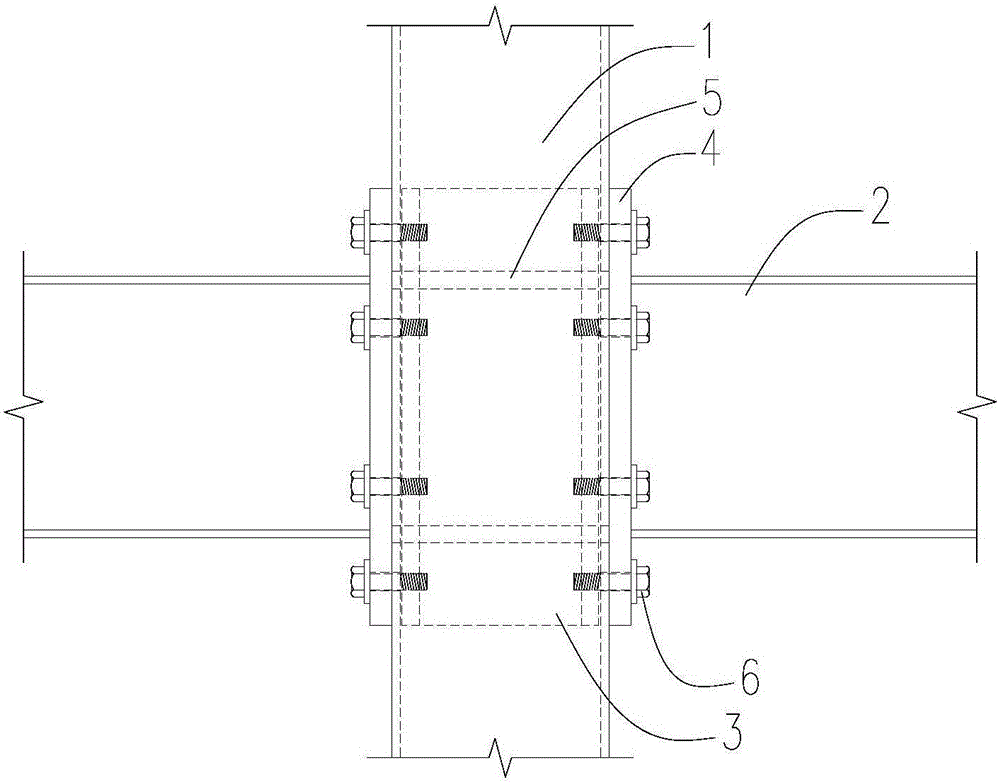

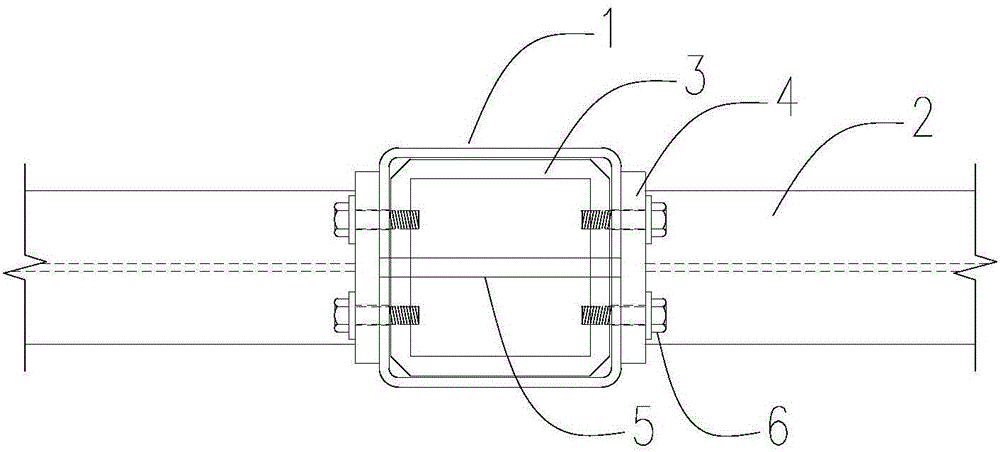

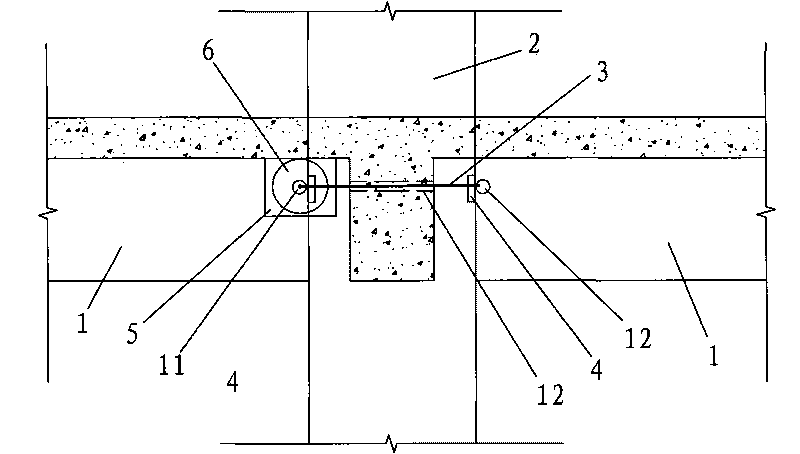

Rectangular steel pipe column and H-shaped steel beam inner sleeve type unilateral bolt connection node

ActiveCN105971118AEasy to fixIncreased shear capacityBuilding constructionsMaterials scienceBolt connection

The invention relates to a rectangular steel pipe column and H-shaped steel beam inner sleeve type unilateral bolt connection node. The structure is simple, the performance is good, the defect that a unilateral bolt is prone to be pulled out is overcome, and the assemblage degree is high. The node comprises a rectangular steel pipe column, H-shaped steel beams, a through pull rod and high-strength bolts; a steel sleeve is coaxially arranged in the rectangular steel pipe column, and extended end-plates are welded to the ends of the H-shaped steel beams; the steel sleeve is provided with positioning circular holes and tapping bolt holes; the extended end-plates and the rectangular steel pipe column are provided with multiple bolt holes in a paired mode in the axial direction of the rectangular steel pipe column, and a connecting wall panel and an opposite wall panel of the rectangular steel pipe column are each provided at least two positioning circular holes in the axial direction of the rectangular steel pipe column; the bolt holes are formed corresponding to the tapping bolt holes and the positioning circular holes on the same side, and the through pull rod penetrates through the positioning circular holes and is used for positioning the steel sleeve and the rectangular steel pipe column; the high-strength bolts sequentially penetrate through the bolts holes in the extended end-plates and the bolt holes in the rectangular steel pipe column to be fixedly connected with the corresponding tapping bolt holes in the steel sleeve.

Owner:CHANGAN UNIV

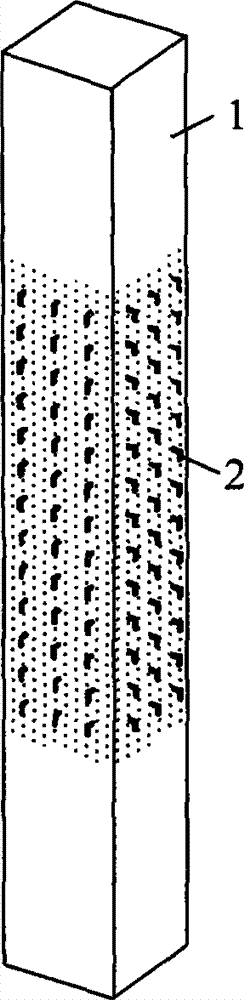

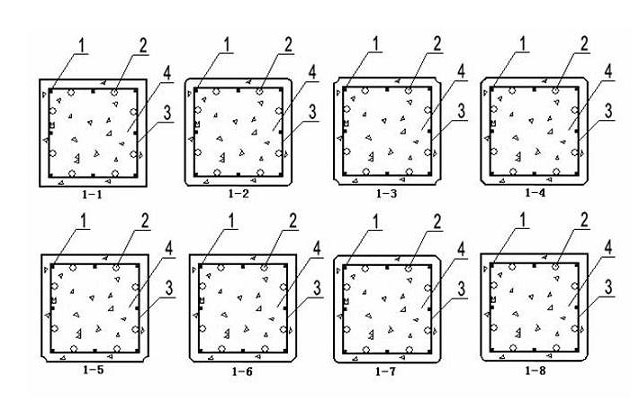

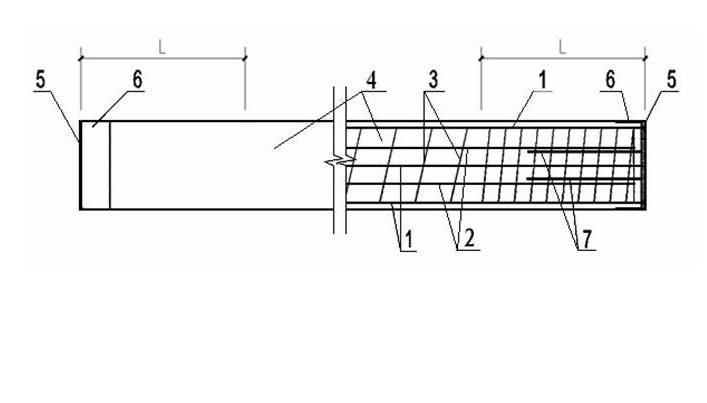

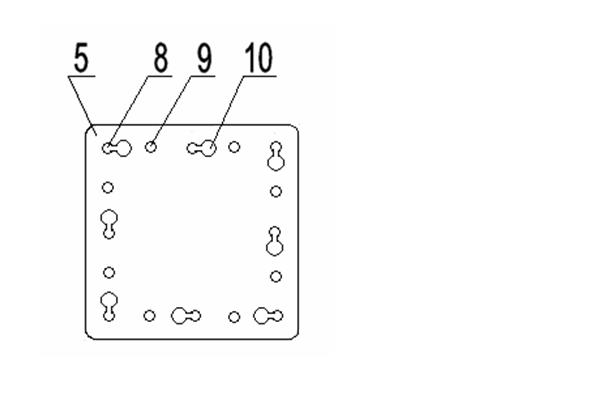

Anti-seismic prefabricated concrete solid square pile and production method thereof

ActiveCN102383418AImprove the forceReduce peak tensile stressMouldsMould auxillary partsPre stressPrecast concrete

The invention discloses an anti-seismic prefabricated concrete solid square pile which comprises main reinforced bars, hoop reinforcements, anchoring bars, pile caps and concrete. A cross section main body of a pile body is square; the main reinforced bars are formed by sequentially permutating and combining prestress main reinforced bars and general main reinforced bars and penetrate through the pile body along the longitudinal direction of the pile body; the hoop reinforcements are arranged on the outer edges of the main reinforced bars and are spirally squared; the pile caps are respectively arranged at two ends of the pile body and consist of end plates and skirt edges; the main reinforced bars and the hoop reinforcements are connected by welding or binding to form a steel reinforcement cage; two ends of the prestress main reinforced bars are fixedly arranged on the end plate by riveting or using a bolt connecting mode; the general main reinforced bars are separated from the end plate and are shorter than the prestress main reinforced bars; and the anchoring bars are respectively arranged at two ends of the pile body. The anti-seismic prefabricated concrete solid square pile with the structure simultaneously has high press bearing capacity, tensile bearing capacity, shear bearing capacity and flexural bearing capacity and is a concrete solid square pile suitable for industrial mechanical production and is used for high seismic fortification intensity.

Owner:连云港固全新型建材有限公司

Closed metal support structure and construction method thereof

ActiveCN102505946AImprove efficiencyIncreased shear capacityUnderground chambersTunnel liningEngineeringRock tunnel

The invention relates to a closed metal support structure with an I-shaped section member of corrugated steel web plates. The I-shaped section member of the corrugated steel web plates comprises a top flange, a bottom flange and the corrugated steel web plates, wherein the corrugated steel web plates are welded with the top flange and the bottom flange. After each section of member is bent to be of a required shape of the support, the corrugated web plates are welded by an end plate, and the top flange and the lower flange are connected with a perforated cover board by bolts. According to the invention, after the corrugated steel web plates are connected by the end plate, the deformation of an axis of the support is generated; on the other hand, when the flanges bear an axial force, the axial deformation of the supported is adapted through adjusting the position of an adjusting screw in the hole, and the telescopic node connection manner is well adaptive to large deformation of soft rock. The closed metal support structure provided by the invention has the advantages of simple manufacturing and processing of the end plate and the cover board, convenience for installation, economy and reasonability, and capability of remarkably improving the comprehensive benefit. The closed metal support structure and the construction method thereof can be applied to the technical field of soft rock tunnel support.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

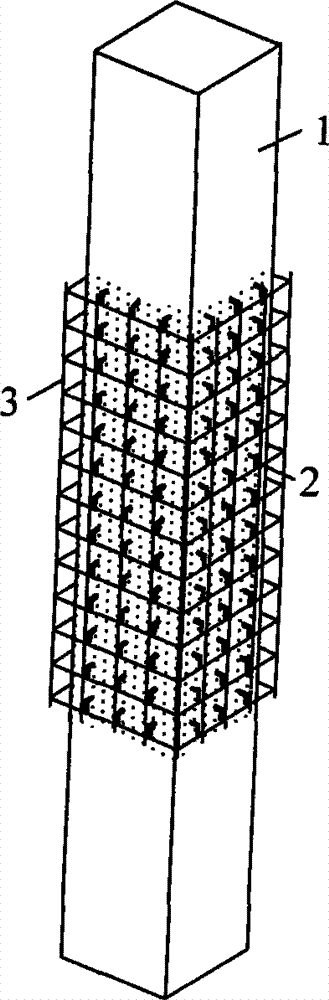

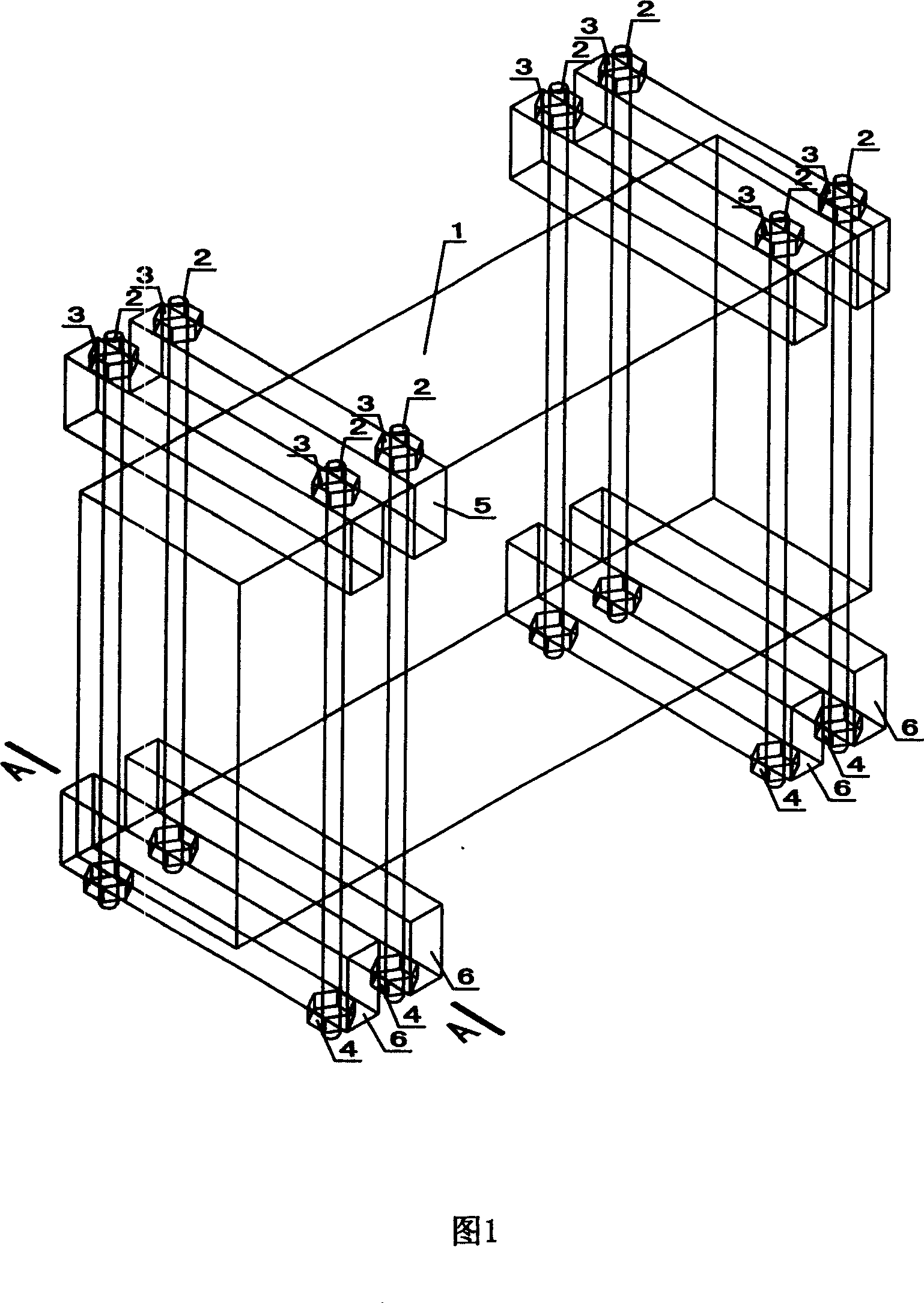

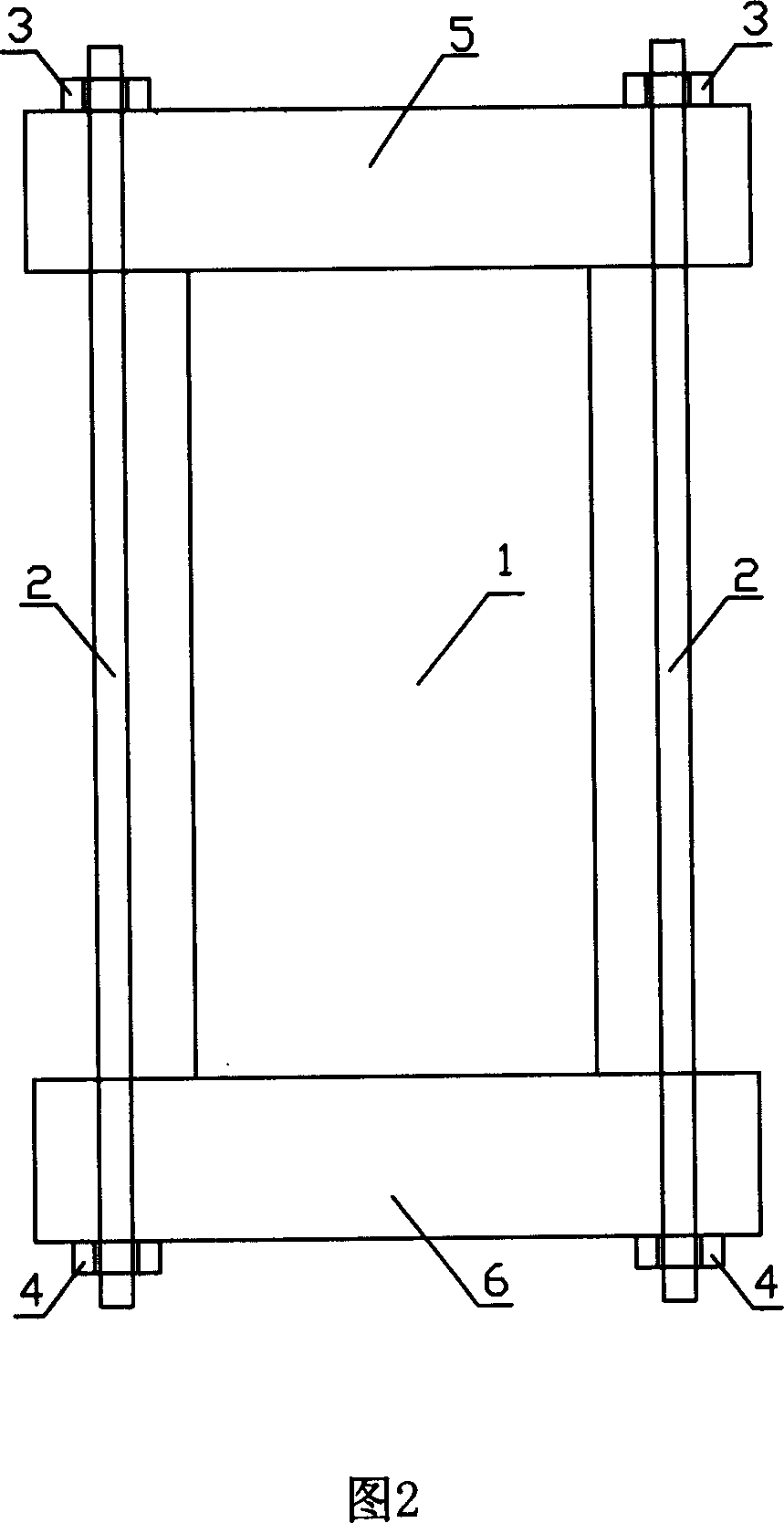

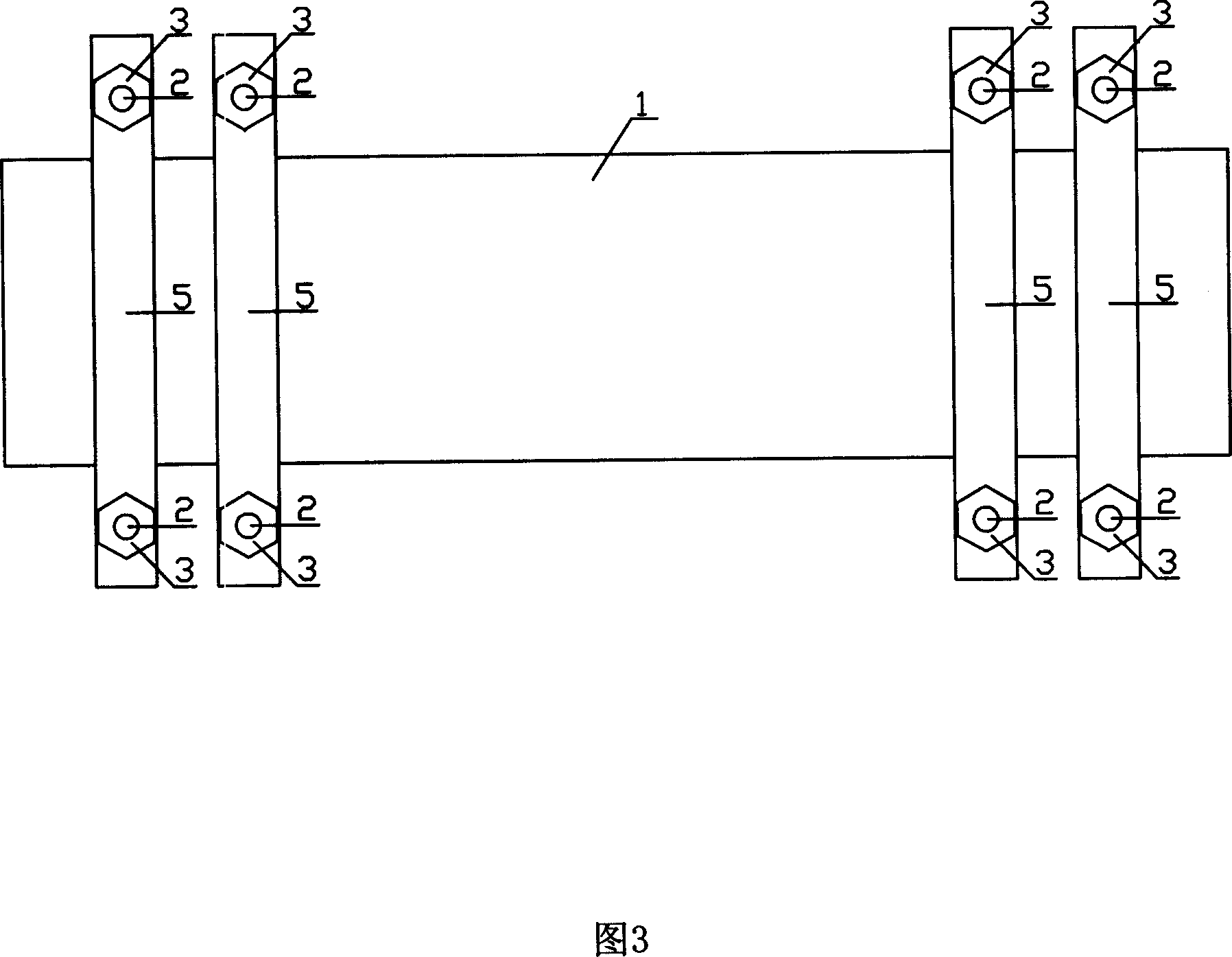

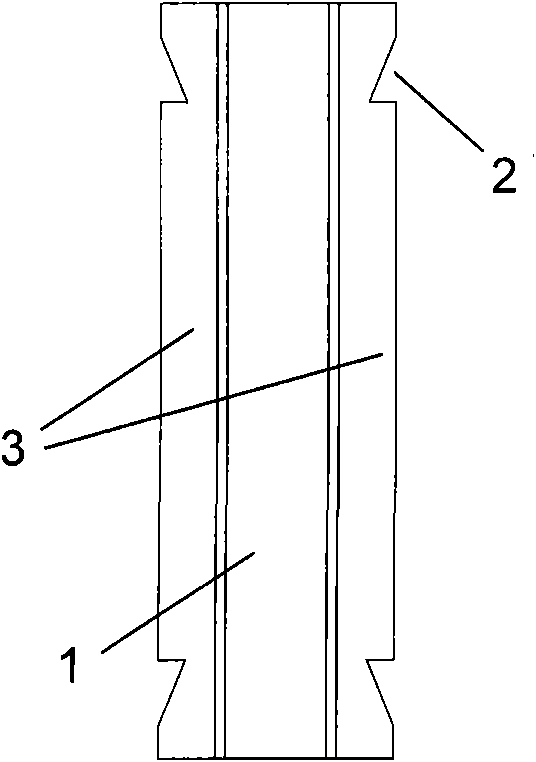

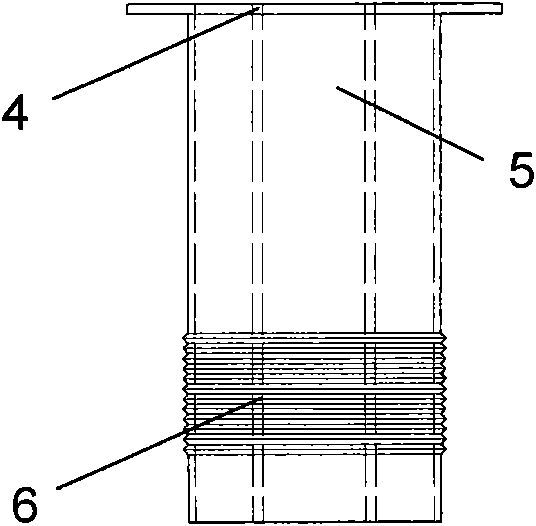

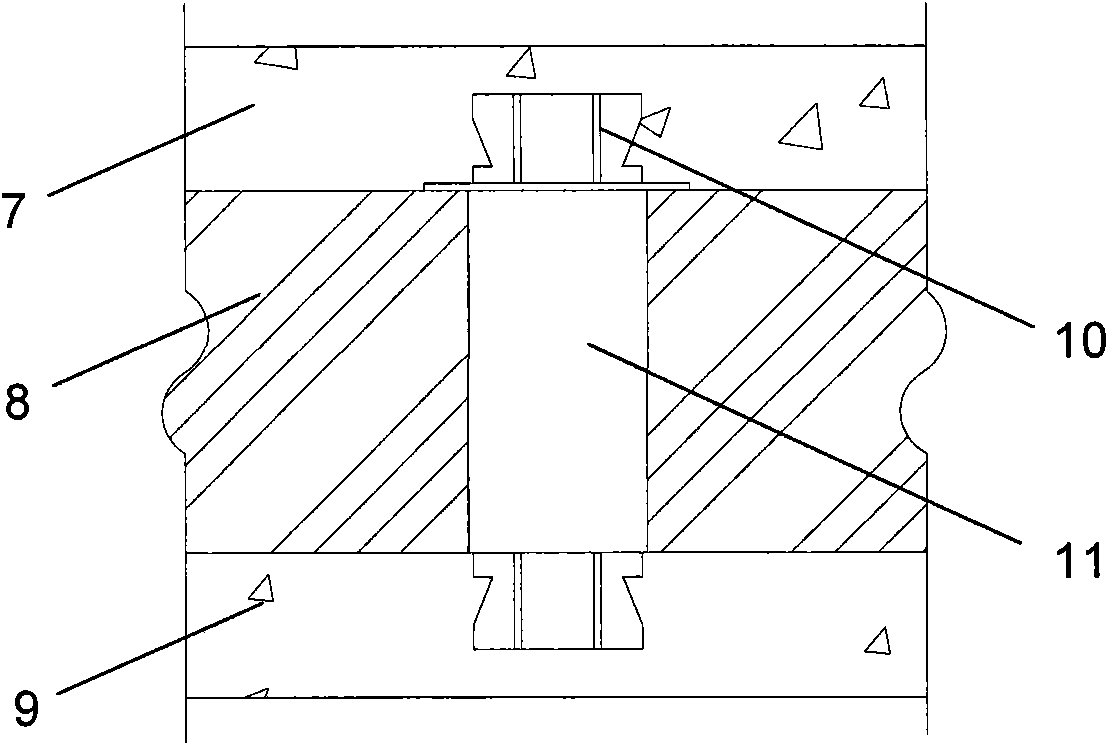

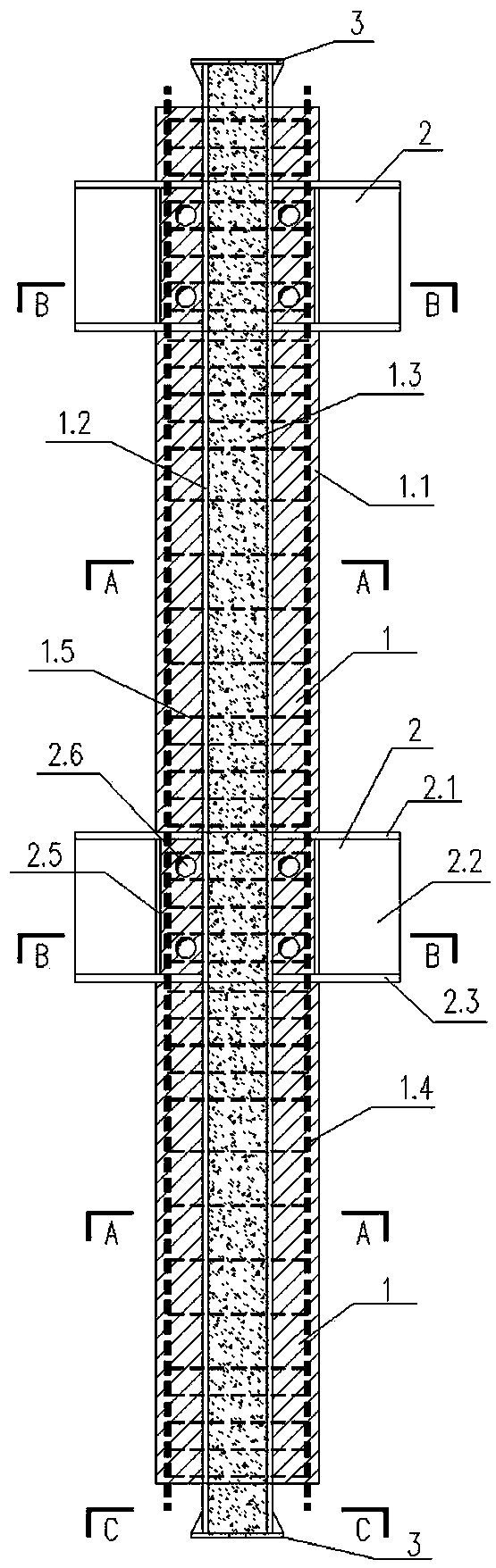

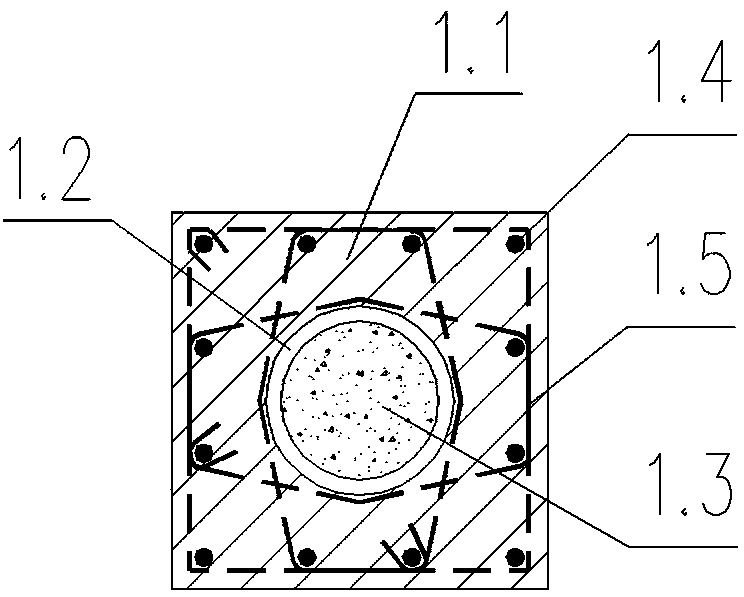

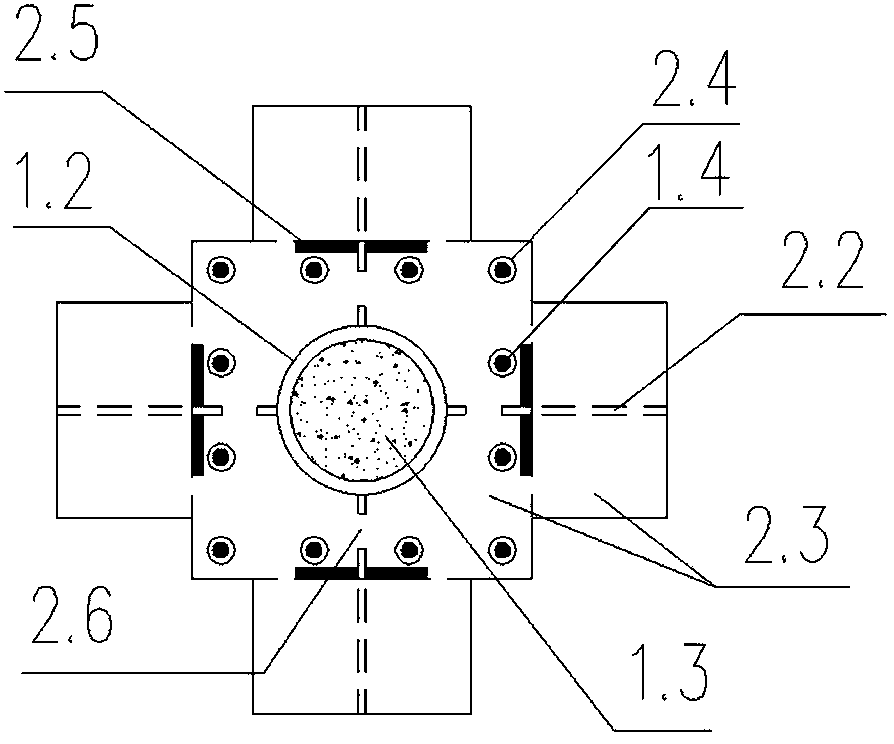

Prefabricated column and precast construction method thereof

ActiveCN104088397AFirmly connectedNo technical quality requirementsStrutsBuilding material handlingArchitectural engineeringRebar

The invention relates to a prefabricated column and a precast construction method. The prefabricated column comprises a lower prefabricated column and an upper prefabricated column matching the lower prefabricated column, a first vertical steel bar extending out of the upper and lower ends of the lower prefabricated column is arranged in the lower prefabricated column, the lower end of the lower prefabricated column is provided with a first connection member, the upper end of the lower prefabricated column is provided with a first steel pipe and a first flange plate welded to the top surface of the first steel pipe, a second vertical steel bar extending out of the upper and lower ends of the upper prefabricated column is arranged in the upper prefabricated column, the upper end of the upper prefabricated column is provided with a second connection member, the lower end of the upper prefabricated column is provided with a second steel pipe and a second flange plate welded to the top surface of the second steel pipe, the top of a second pre-embedded steel pipe is in a butt connection relationship with two auxiliary steel pipes, the first flange plate and the second flange plate are in a butt connection relationship by bolts, the first connection member is connected to the second connection member by threads, and the first vertical steel bar and the second vertical steel bar are bound by stirrups. The prefabricated column can be constructed simply, has a low price, and is suitable for buildings having high floor height and large column sectional area.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

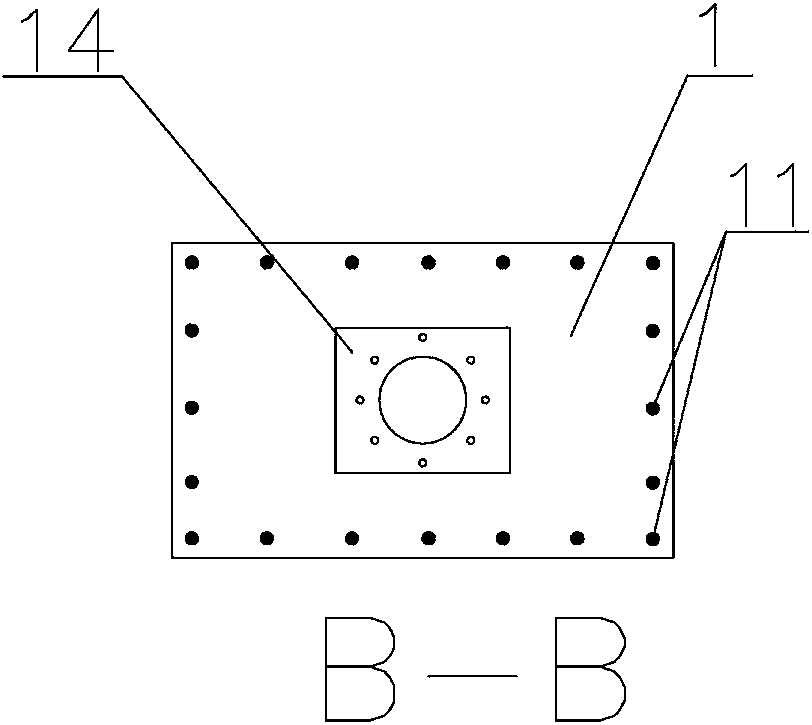

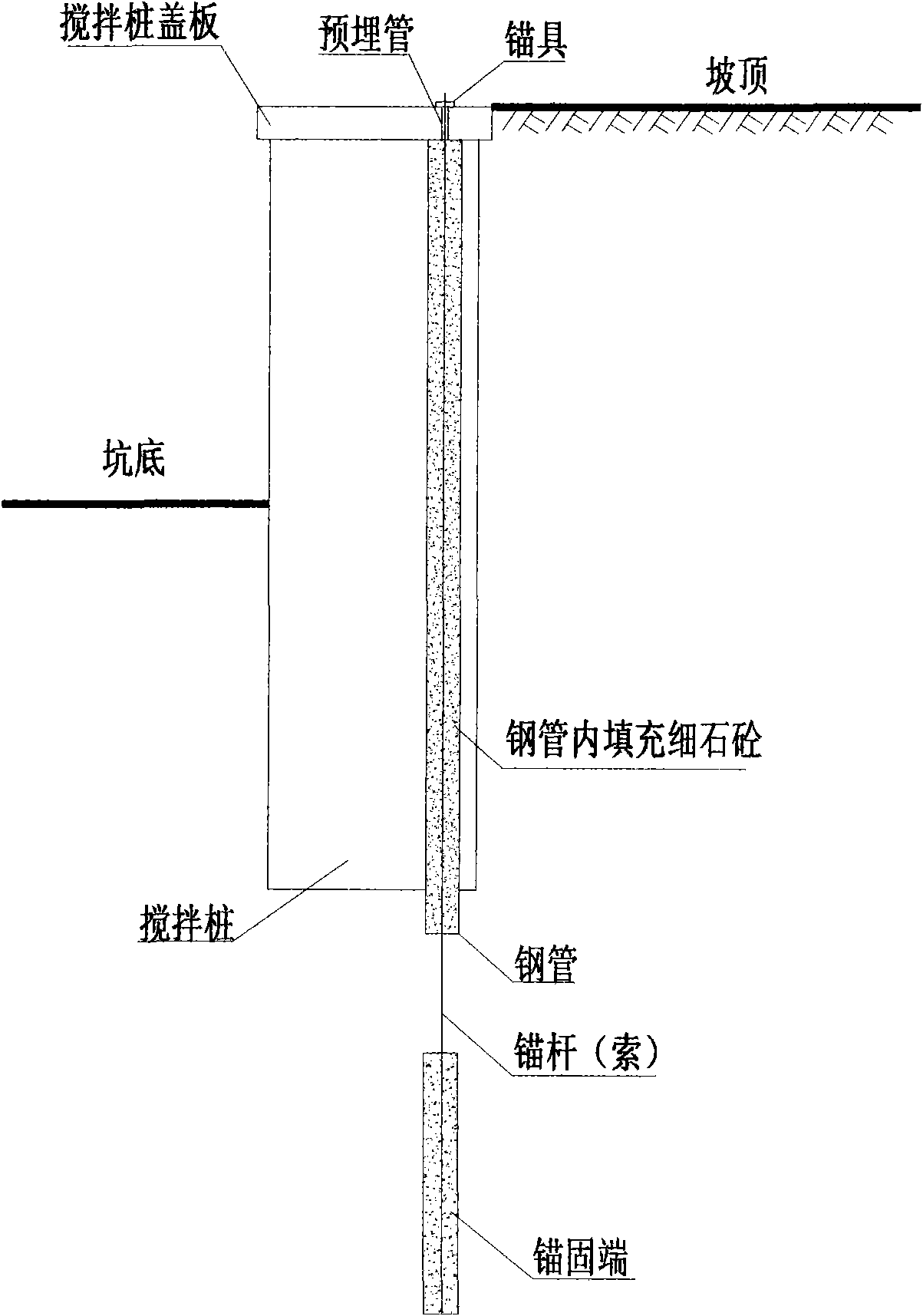

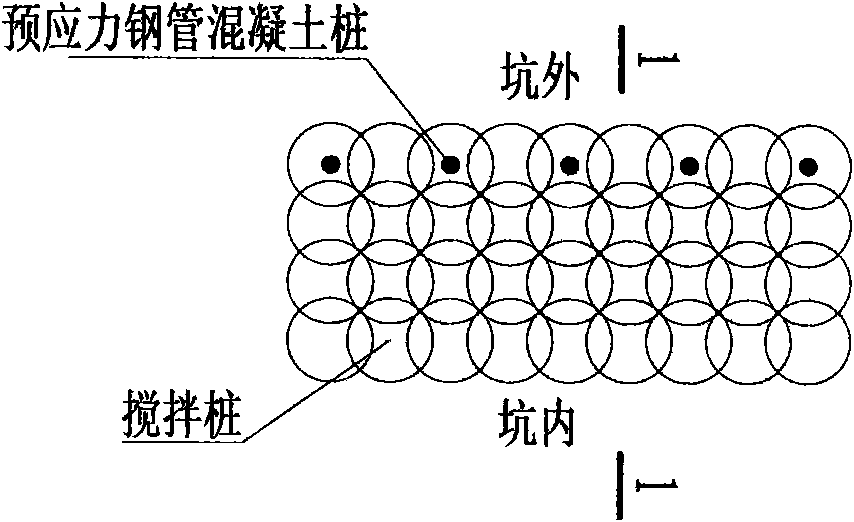

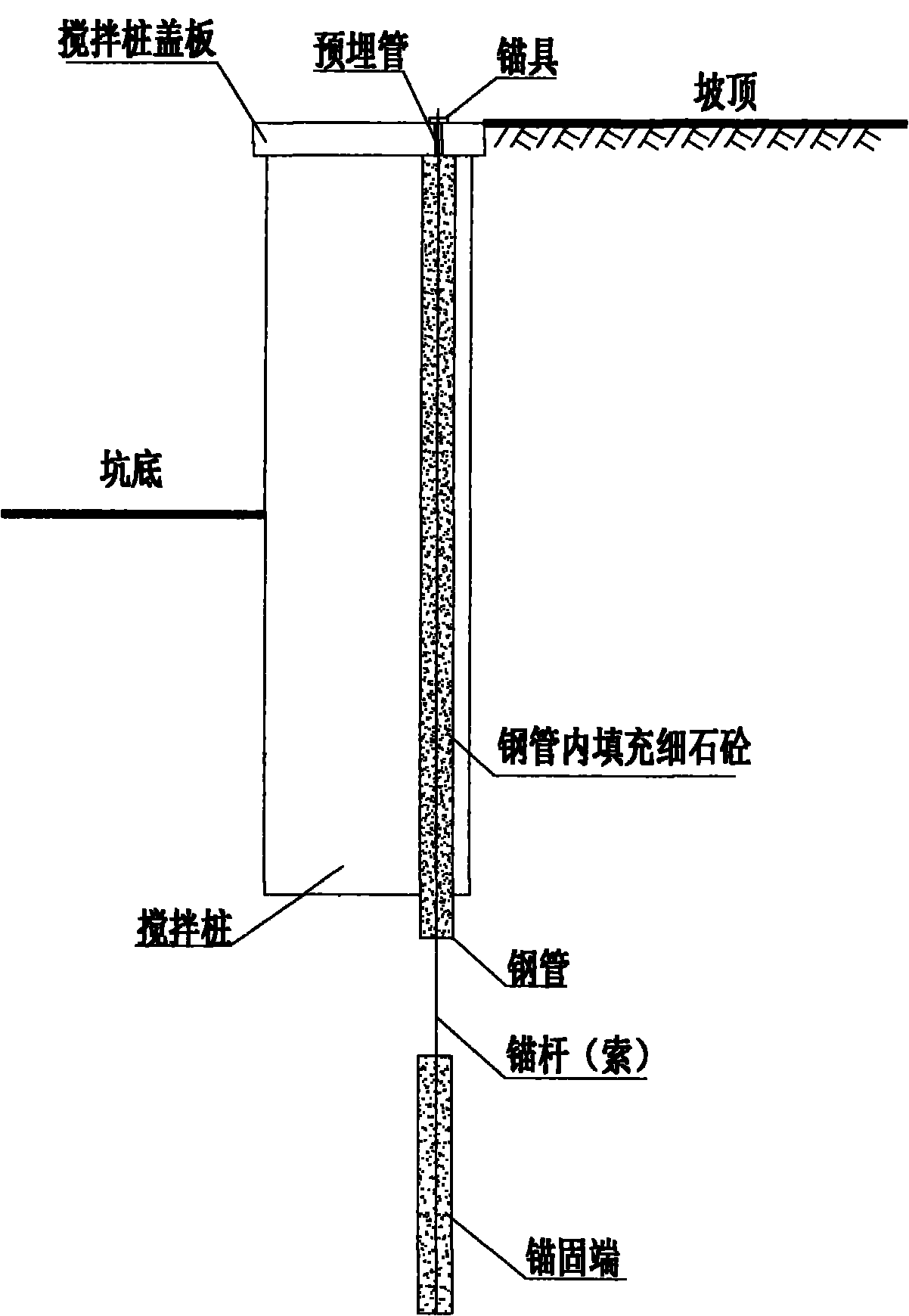

Deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method

InactiveCN101851925AImprove overturning resistanceImprove slip resistanceExcavationsBulkheads/pilesLow noisePre stress

The invention provides a deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method. The method comprises the following steps: (1) constructing the deep mixing pile; (2) grouting at an anchoring end; and (3) forming the micro pre-stressed steel pipe concrete pile. The method has the advantages that as the deep mixing pile is equipped with the micro pre-stressed steel pipe pile and an anchor rod or an anchor rope, the bending and shearing bearing capacity thereof is improved; the antidumping and anti-slip capability of the wall body of the mixing pile is improved under the condition of not exceeding a land red line; and meanwhile the combined support method has the advantages of short construction period, low noise, no pollution and no soil squeezing and is very beneficial to environmental protection during the construction process, thus being a novel combined support member and a method which are worth to be popularized and applied.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

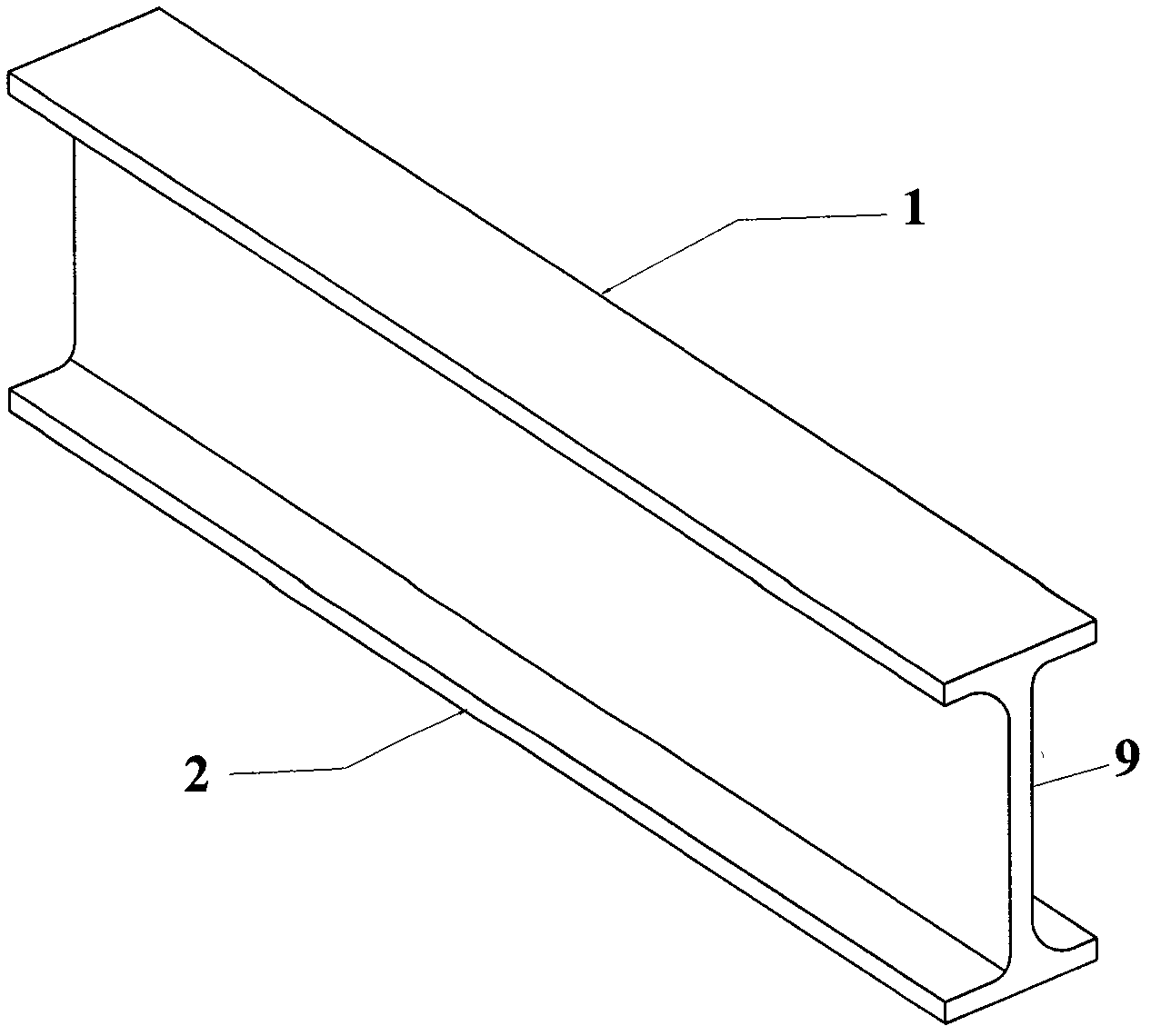

Fabricated honeycomb web steel beam

ActiveCN103233551AImprove mechanical performanceReduce thicknessGirdersJoistsRepeating waveformsSheet steel

The invention relates to a fabricated honeycomb web steel beam, and belongs to the technical field of building profiles. The fabricated honeycomb web steel beam is formed by web plates of two corrugated web steel channel beams, which are butted and assembled through a bolt. The section opening of each corrugated web steel channel beam is formed by an upper flange, a lower flange and a web plate; the sections of the web plates form even or uneven periodic repeated waveforms; the corrugated sections are rectangular curves, or arc angle rectangle curves, or trapezoidal curves or arc angle trapezoidal curves, or wedge curves, or arc angle wedge curves, or sine curves; the flanges are plain plates; each upper flange is parallel to each lower flange; the web plates are vertically located between the flanges as a whole; the outer sides of the corrugated curves of the web plates along the length direction are flush to a side boundary of each flange along the length direction; and the web plates are connected with the flanges by a single-side angle welding line. The fabricated honeycomb web steel beam is an innovation-type steel beam suitable for the fabricated steel structure system. Compared with the traditional fabricated beam, the fabricated honeycomb web steel beam has the advantages of light dead load, high carrying capacity, and good mechanical behavior.

Owner:BEIJING UNIV OF TECH +1

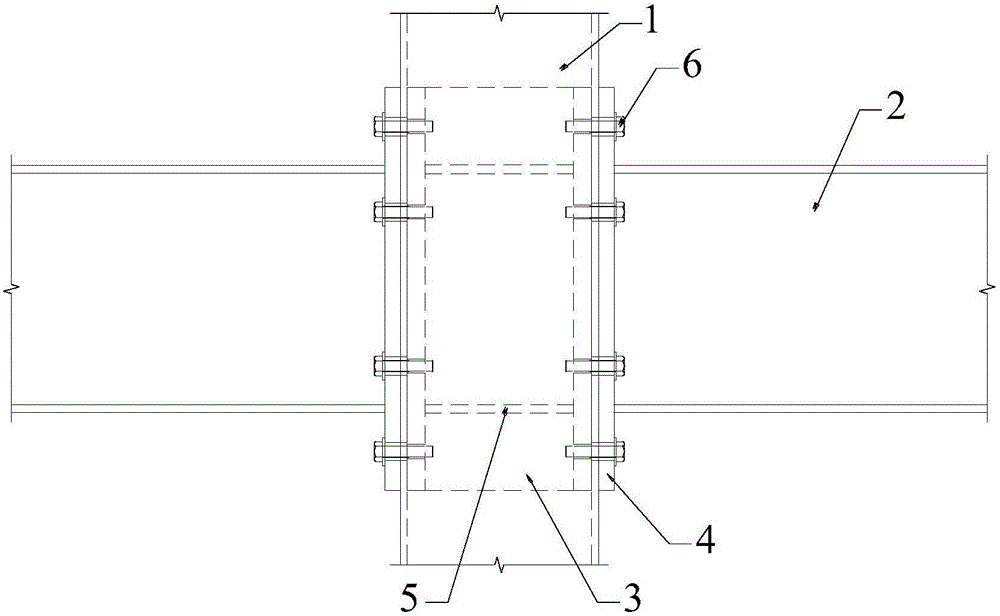

Prefabricated concrete frame structure and manufacturing method thereof

ActiveCN106149873AEnsure continuityEnsure integrityBuilding constructionsShear capacityAgricultural engineering

The invention discloses a prefabricated concrete frame structure which comprises prefabricated columns and prefabricated beams. Each prefabricated column is connected with one end of the corresponding prefabricated beam, a node area is formed at a joint of each prefabricated column and the corresponding prefabricated beam, each prefabricated beam is divided into an upper-layer column body and a lower-layer column body by the corresponding node area, each upper-layer column body and the corresponding lower-layer column body are connected through longitudinal reinforcing steel embedded in the prefabricated column in the corresponding node area, and column body longitudinal rebars are embedded in each prefabricated column and are continuous in the corresponding node area; beam end reinforcing steel is embedded at one end, connected with the corresponding prefabricated column, of each prefabricated beam, and the longitudinal reinforcing steel and the beam end reinforcing steel are connected through bolts. The invention further discloses a manufacturing method of the prefabricated concrete frame structure. Nodes of the prefabricated concrete frame structure are equivalent to cast-in-place concrete frame nodes in anti-seismic performance and energy dissipating capacity, anti-seismic concept design of 'strong nodes and weak components', 'strong shear capacity and weak bending capacity' and 'strong columns and weak beams' is realized, and construction process and difficulty can be reduced.

Owner:FOSHAN ELECTRIC POWER DESIGN INST +1

External transverse prestressed steel reinforced concrete beam

InactiveCN101025047AIncreased shear capacityImprove shear resistanceBuilding repairsGirdersPre stressConcrete beams

The invention discloses an external horizontal prestressed reinforced concrete beam whose upper and lower surfaces are oppositely equipped with multiple upper and lower press pieces respectively, the two sides of each of the upper and lower press piece are both equipped oppositely with at least a row of holes, where a pull rod runs through the upper and lower press pieces, and is strained and fixed between the upper and lower press pieces through upper and lower anchors at its two ends. As compared with the common reinforced concrete beam, the invention adds prestressed bars on the two sides of the reinforced concrete beam, increasing hoop reinforcement area and making the concrete in a pressed state by prestressing the pull rods, thus improving concrete shearing strength. And the invention reduces the size of the reinforced concrete beam, saving material and increasing construction use space, applied to reinforce the existing and new built reinforced concrete beams and.

Owner:SOUTH CHINA UNIV OF TECH

Concrete-filled steel tube combined shear wall and construction process thereof

InactiveCN102900169AHigh strengthImprove ductilityWallsBuilding material handlingReinforced concreteShear capacity

The invention relates to a concrete-filled steel tube combined shear wall and a construction process thereof. The shear wall comprises steel tubes which are distributed uniformly along the section of the shear wall, concrete filled into the steel tubes, concrete poured outside the steel tubes, square stirrups arranged outside the steel tubes, and vertically-distributed steel bars and horizontally-distributed steel bars which are arranged on front and rear sides of the steel tubes, tie steel bars which are tied between the steel tubes and the vertically-distributed steel bars and between the steel tubes and the horizontally-distributed steel bars, and longitudinal steel bars which are arranged at the positions of restraint members on edges of two sides of the steel bars. According to the concrete-filled steel tube combined shear wall, the steel tubes are embedded into the ordinary reinforced concrete shear wall, and the bearing capacity of the concrete is improved under the restraint action of the steel tubes, so that the sectional dimensions of the members are reduced, the dead weight of a structure is reduced, a seismic effect is reduced, and more usable areas are provided for buildings under the condition of the same design axial force; and anti-seismic properties of the flexural capacity, shear capacity, damage ductility and the like of the shear force are improved effectively by utilizing the high bearing capacity and high ductility of the concrete-filled steel tubes.

Owner:TSINGHUA UNIV

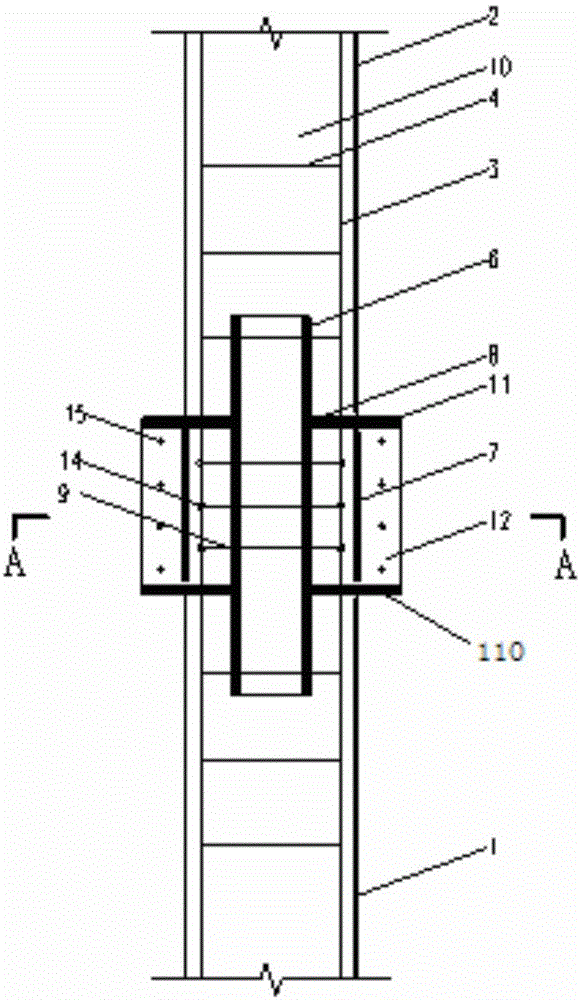

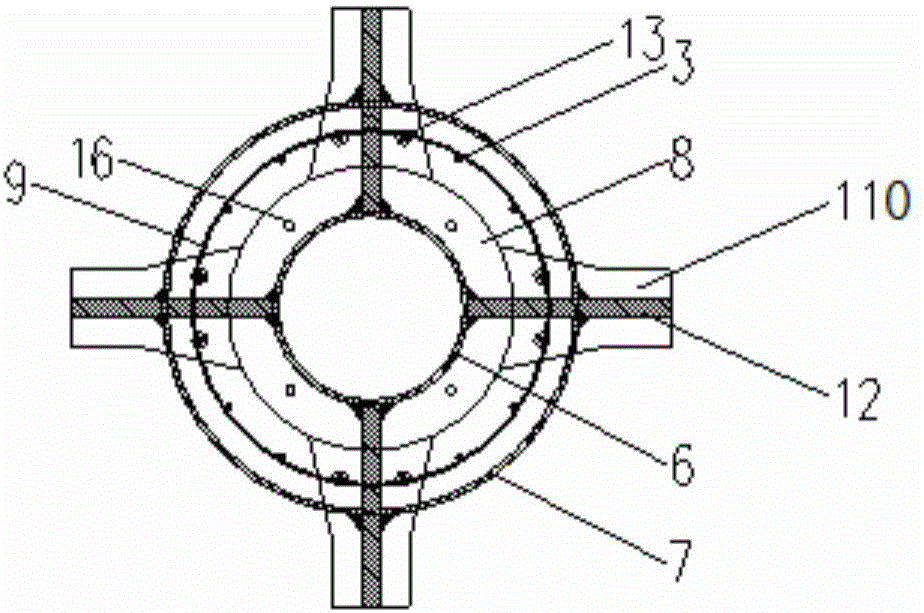

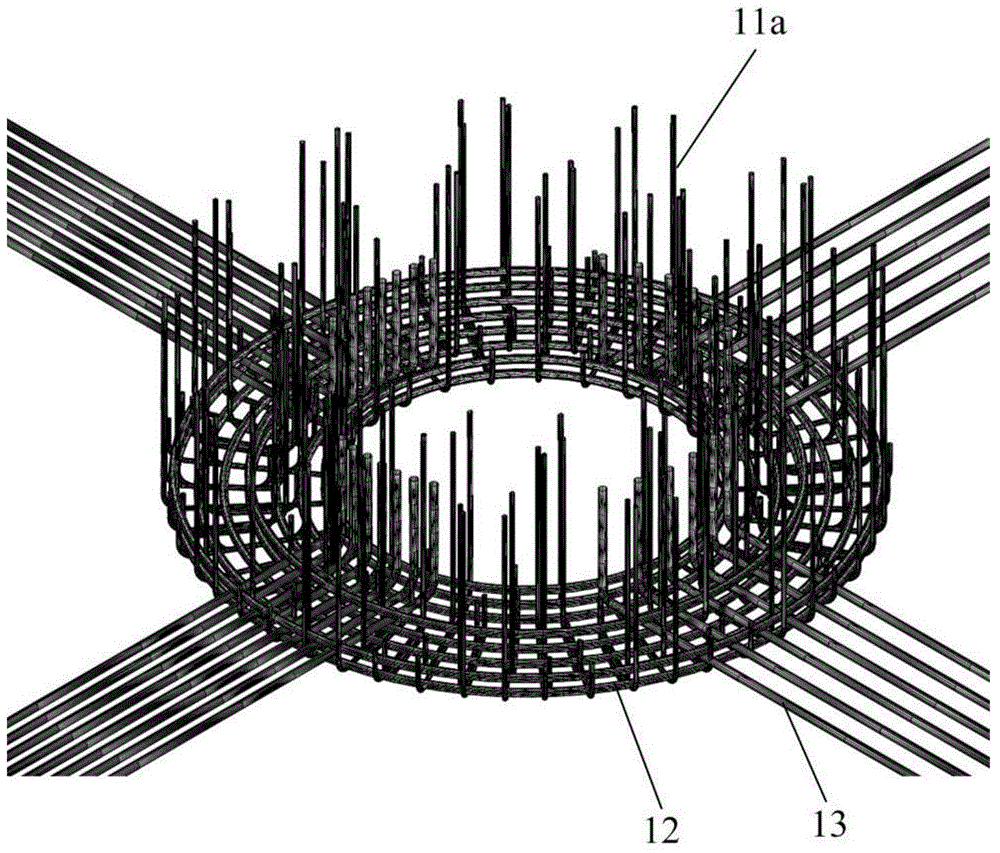

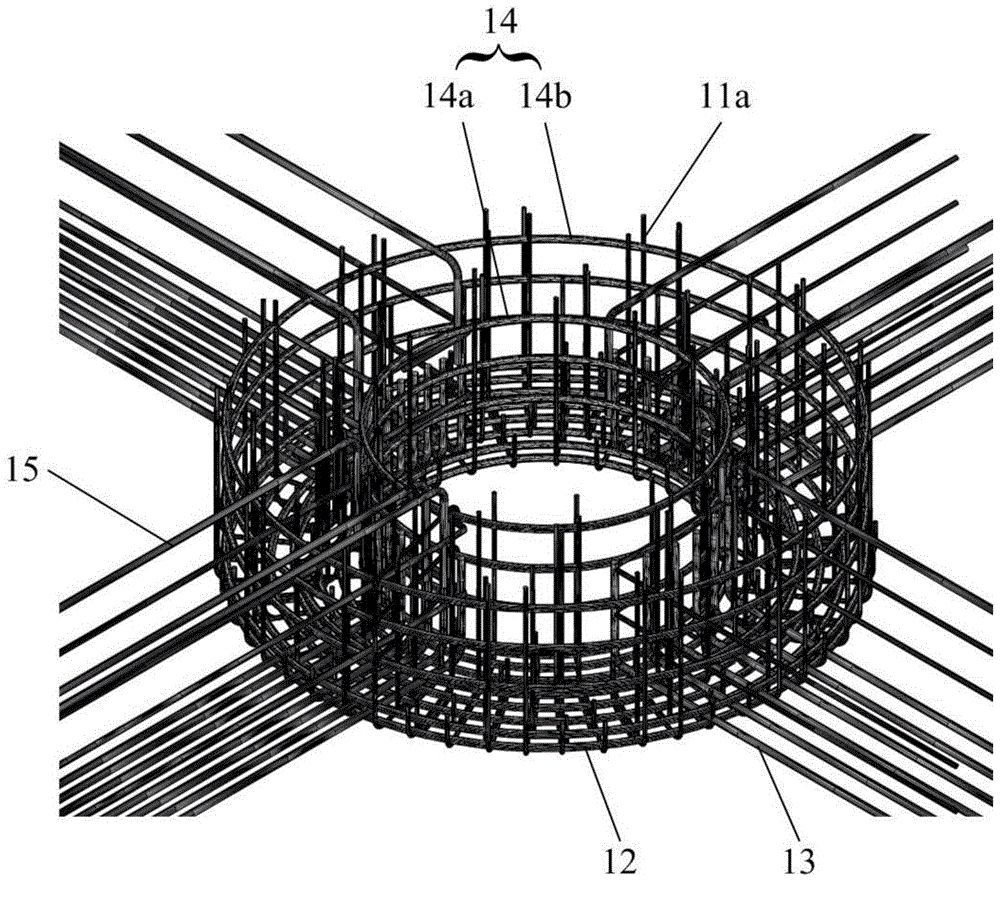

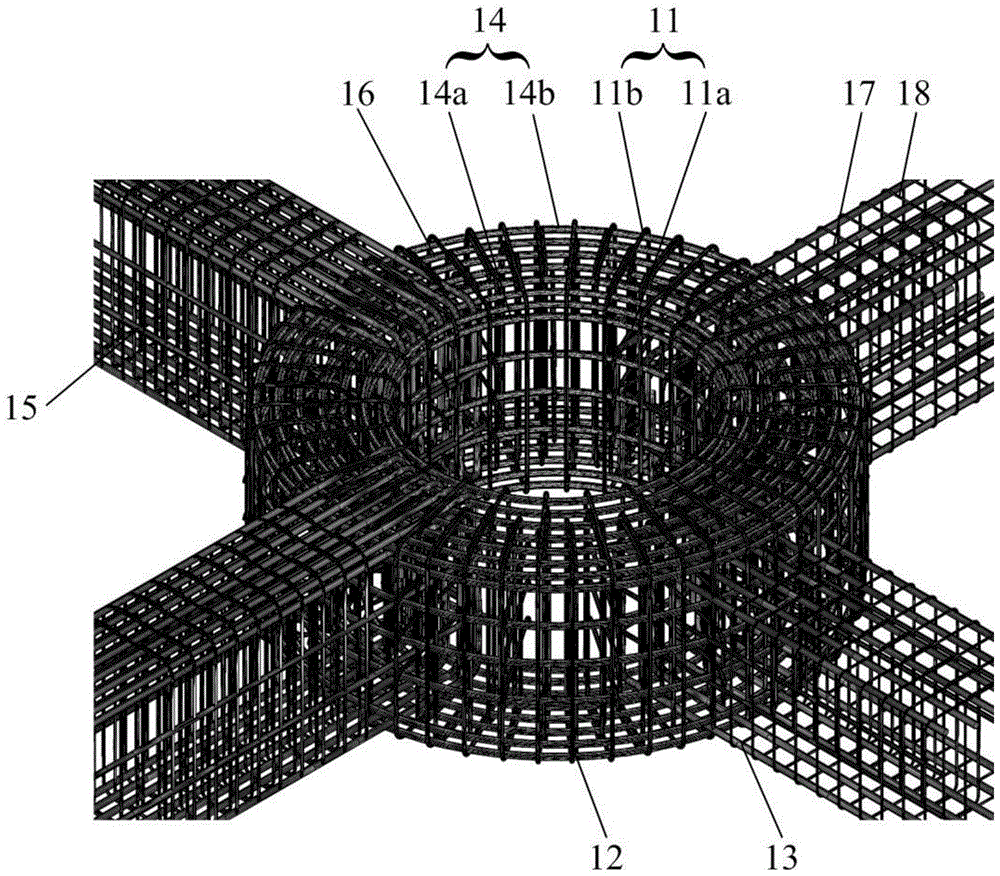

Circular steel tube constraining reinforced concrete-steel beam framework node for nodal-region composite steel tube

InactiveCN105672491AImprove bearing capacityImprove ductilityBuilding constructionsReinforced concrete columnShear capacity

The invention provides a circular steel tube constraining reinforced concrete-steel beam framework node for a nodal-region composite steel tube. The node comprises a first columnar circular steel tube, a second columnar circular steel tube, columnar longitudinal bars, columnar stirrups, a steel beam, a nodal-region inner-layer circular steel tube, a nodal-region outer-layer circular steel tube, outer reinforcing rings, nodal-region stirrups and concrete. The second columnar circular steel tube and the first columnar circular steel tube are located on the upper side and the lower side of the steel beam respectively. The steel beam directly transmits the shear force and the bending moment to the nodal-region inner-layer circular steel tube and then transmits the shear force and the bending moment to the core-region concrete, the condition that the nodal-region outer-layer steel tube directly bears the shear force is avoided to prevent the steel tube from being bent, and therefore the steel tube can fully play an annular constraining role to ensure the bearing capacity and the ductility of the node; the two ends of the nodal-region inner-layer circular steel tube stretch into an upper steel tube constraining reinforced concrete column and a lower steel tube constraining reinforced concrete column by a certain distance respectively, the integrity of the node is guaranteed, and the shear capacity and anti-seismic performance of the node are improved. The node is safe, reliable, good in integrity, clear in force transmission and convenient to construct and has the advantage on force bearing and the economic performance.

Owner:CHONGQING UNIV

FRP connecting piece of prefabricated heat preservation wall body

The invention belongs to the technical field of civil engineering, and concretely relates to an FRP connecting piece of a prefabricated heat preservation wall body. The connecting piece consists of an FRP connection board and a plastic socket ring and is characterized in that the FRP connection board is fabricated by a pultrusion technique, a fiber layering is compositely laid by adopting unidirectional coarse roving, continuous fibrofelt and positive / negative degree multiple axial directional cloth. After pultrusion, the FRP connection board is cut by fixed length to fabricate an FRP connection board single piece, and mechanical processing equipment is used for cutting one or more than one anchoring rabbet at the end part of the connection board, and finally the melt ABS plastic is cast around the FRP connection board by a casting technique to obtain the finished product of the FRP connecting piece of the prefabricated heat preservation wall body; wherein, the connection board component in the connecting piece is used for connecting the concrete wall pieces at the two sides of a heat preservation board, while the ABS plastic socket ring is used for fixing the position of the connecting piece during concrete casting. The invention realizes a novel connecting system with an integral structural function, has the advantages of low heat conductivity coefficient, good corrosive nature, simple and convenient construction and the like, and has relatively extensive application prospect in the field of civil engineering.

Owner:TONGJI UNIV

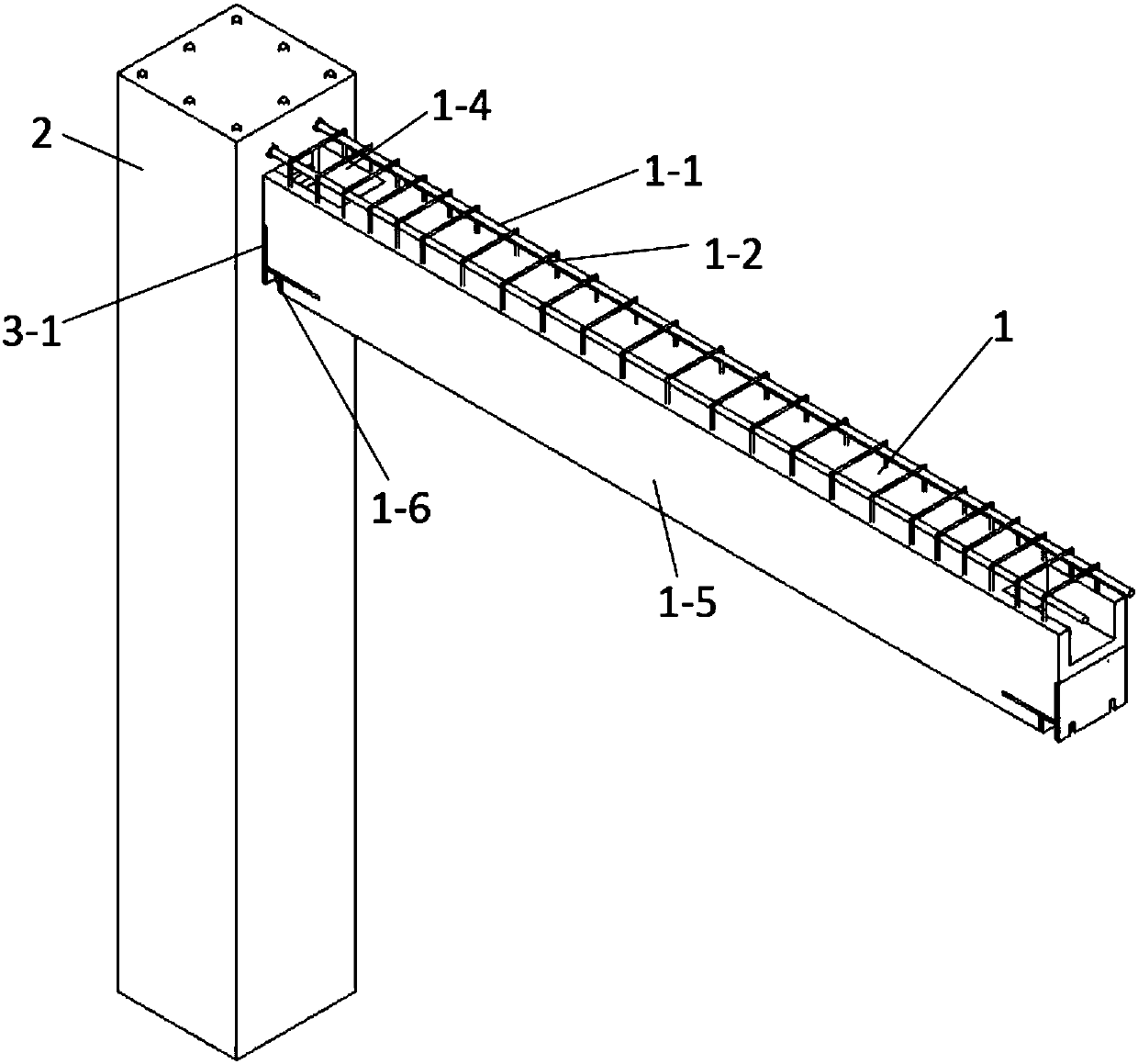

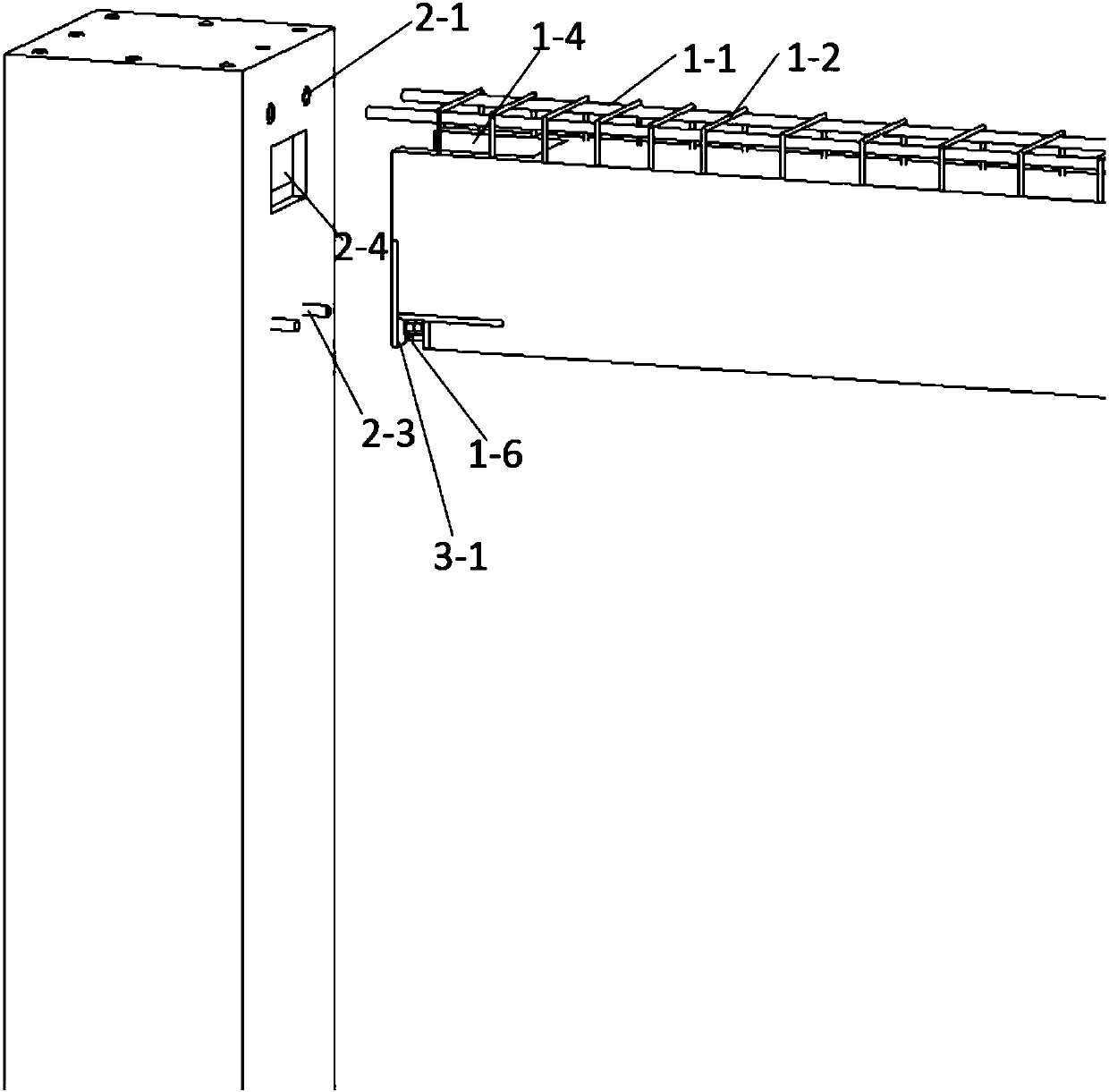

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

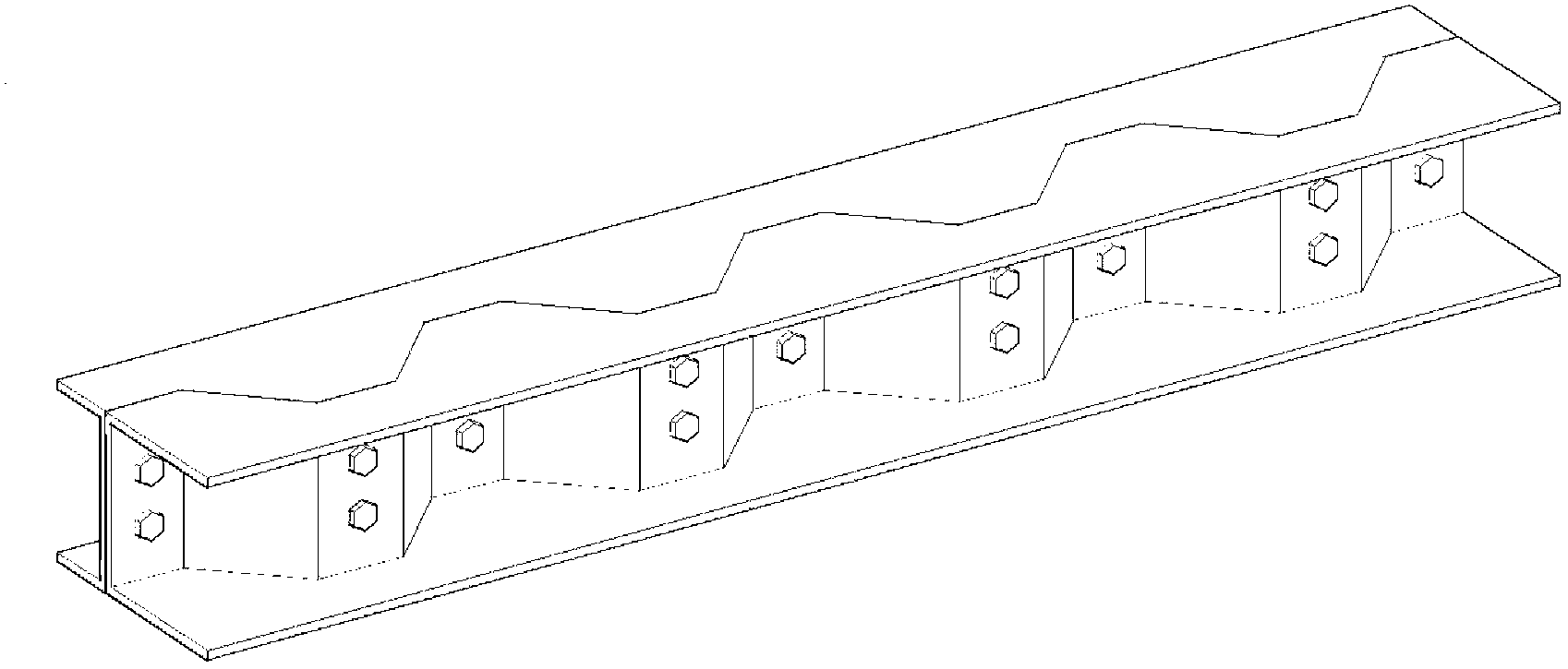

Steel box beam orthotropic deck slab

ActiveCN103614964AIncreased shear strengthDecreased shear capacityBridge structural detailsBridge deckEngineering

The invention discloses a steel box beam orthotropic deck slab. The steel box beam orthotropic deck slab comprises an upper top plate, a corrugated steel plate and a lower top plate which are sequentially connected from top to bottom. The corrugated direction of the corrugated steel plate is consistent with the transverse bridge direction. The corrugated steel plate is composed of crest surfaces, trough surfaces and inclined planes connected with the crest surfaces and the trough surfaces, wherein the crest surfaces, the trough surfaces and the inclined planes are staggered in the transverse bridge direction. Included angles of the inclined planes and the crest surfaces and included angles of the inclined planes and the trough surfaces are not 90 degrees, and the corrugated cross section of the corrugated steel plate is a plurality of continuously arranged trapezoids. The corrugated steel plate is utilized to serve as a longitudinal stiffening rib of a steel box beam deck top plate, the orthotropic slab formed by the upper top plate, the lower top plate and the middle layer corrugated steel plate is similar to a parallel chord truss with an inclined web member in the transverse bridge direction, pressure resistance stability and transverse flexural rigidity of the deck slab are improved, and excessive local deformation under the effect of a concentrated wheel load is effectively avoided. According to the steel box beam orthotropic deck slab, a traditional welding mode is abandoned, bolting is adopted completely, and the problem of fatigue cracking of welding cracks can be solved thoroughly.

Owner:SOUTHEAST UNIV

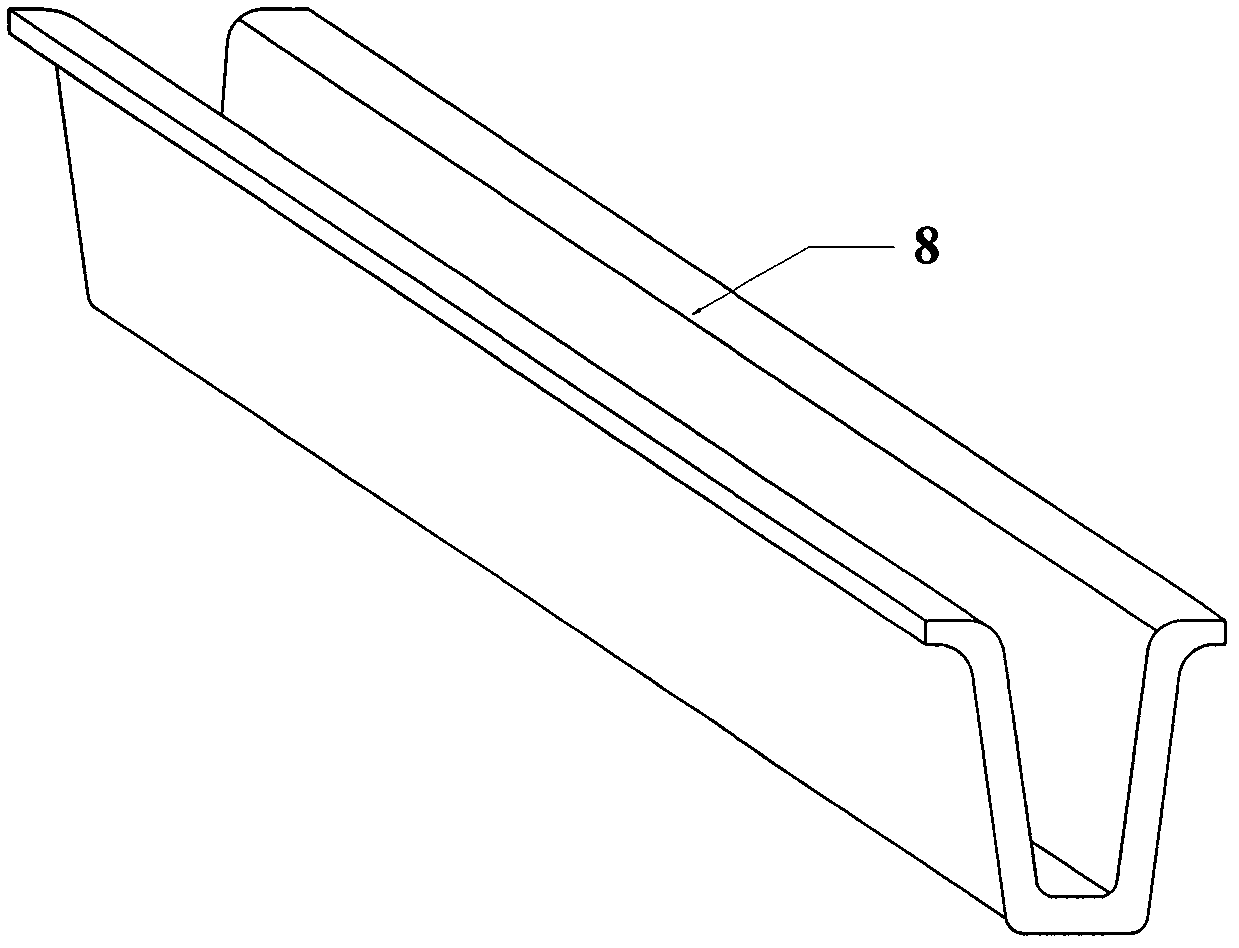

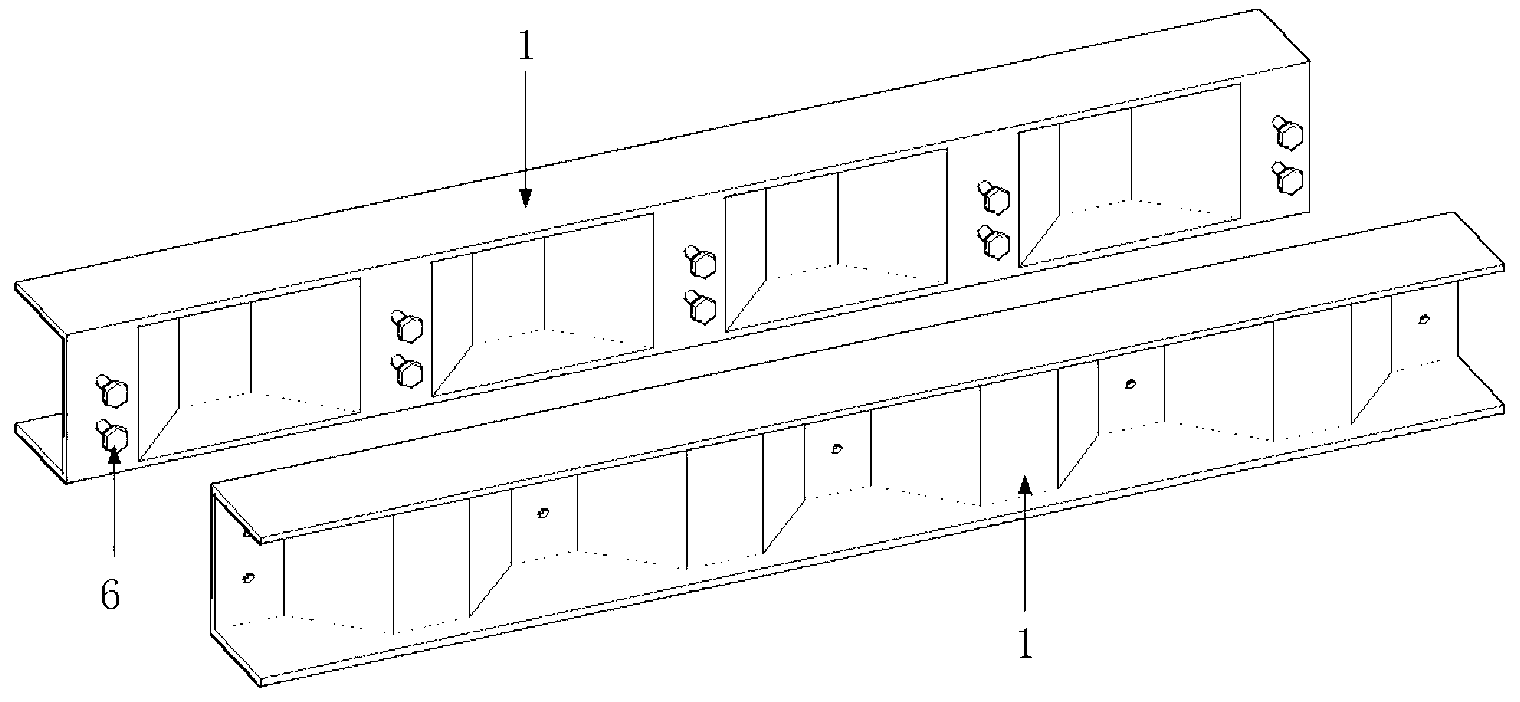

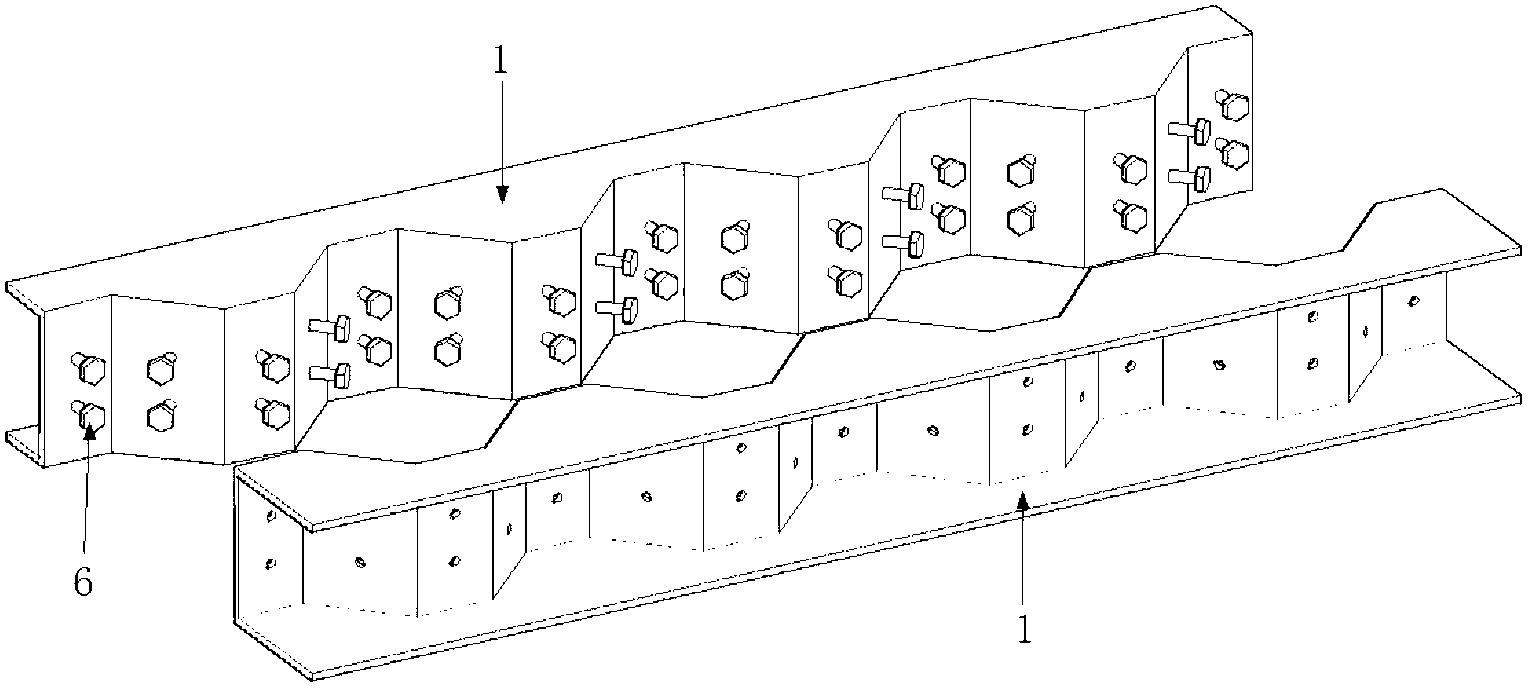

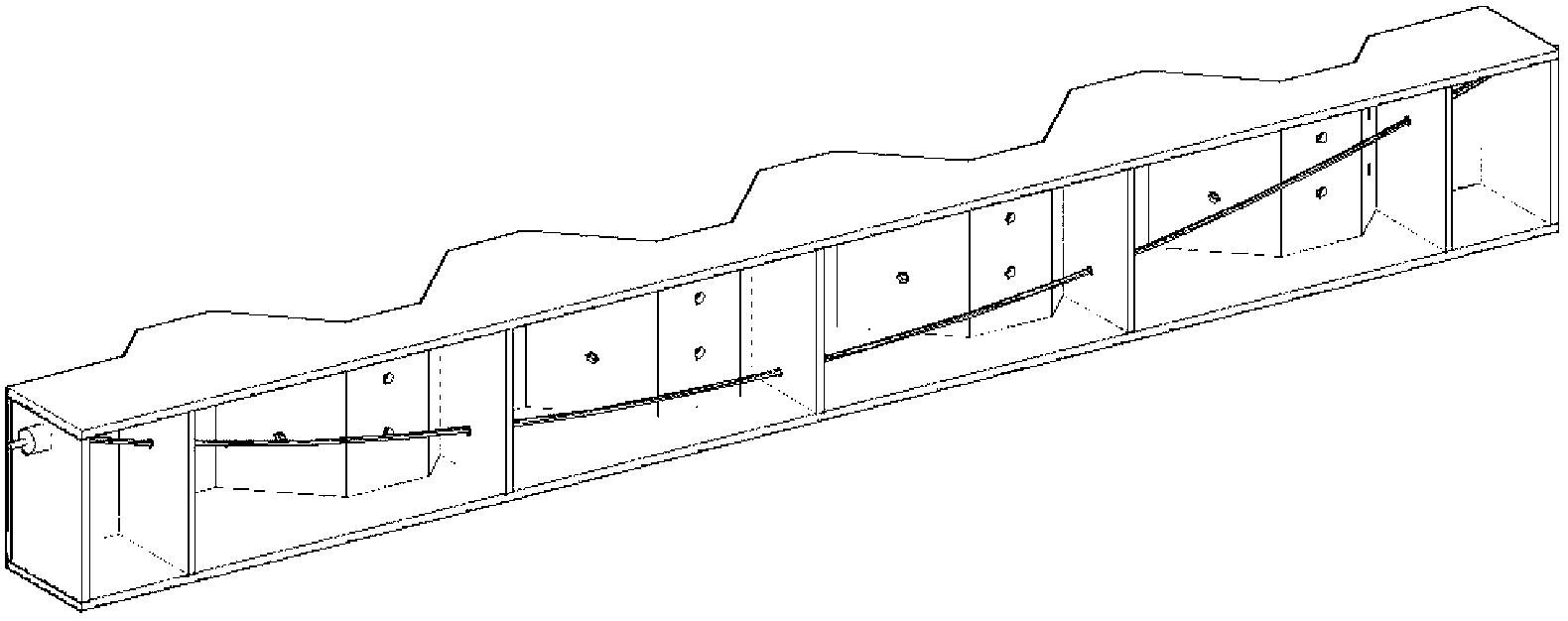

Assembly type ripple web plate occluded steel beam

ActiveCN103290992AImprove mechanical performanceReduce thicknessGirdersJoistsRepeating waveformsButt joint

The invention relates to an assembly type ripple web plate occluded steel beam which is prepared from two ripple steel channel beams assembled together through occlusion and butt joint of web plates and through bolts. A cross section mouth of each ripple steel channel beam is composed of an upper flange, a lower flange and one web plate, wherein the cross sections of the web plate form a uniform or nonuniform periodically-repeating waveform, the cross section of ripples of the web plate is a rectangular curve, an arc angle rectangular curve, a trapezoid curve, an arc angle trapezoid curve, a wedge-form curve, an arc angle wedge-form curve or a sine curve, the flanges are steel plates, one edge of each flange in a length direction is a waveform curve with a shape similar to that of the curve of the cross sections of the web plate, the upper flange is parallel to the lower flange, the web plate is perpendicular to and located between the upper flange and the lower flange, the waveform curve edges of the flanges are connected with the ripple cross sections of the web plate, and the web plate is connected with the flanges through single-sided angle welding. The assembly type ripple web plate occluded steel beam provided by the invention is applicable to innovative steel beams in an assembly type steel structure system; and compared with traditional assembly type steel beams, the assembly type ripple web plate occluded steel beam has the advantages of light weight, high carrying capacity and good bearing performance.

Owner:CHINA RAILWAY CONSTR GRP BEIJING ENG CO LTD +1

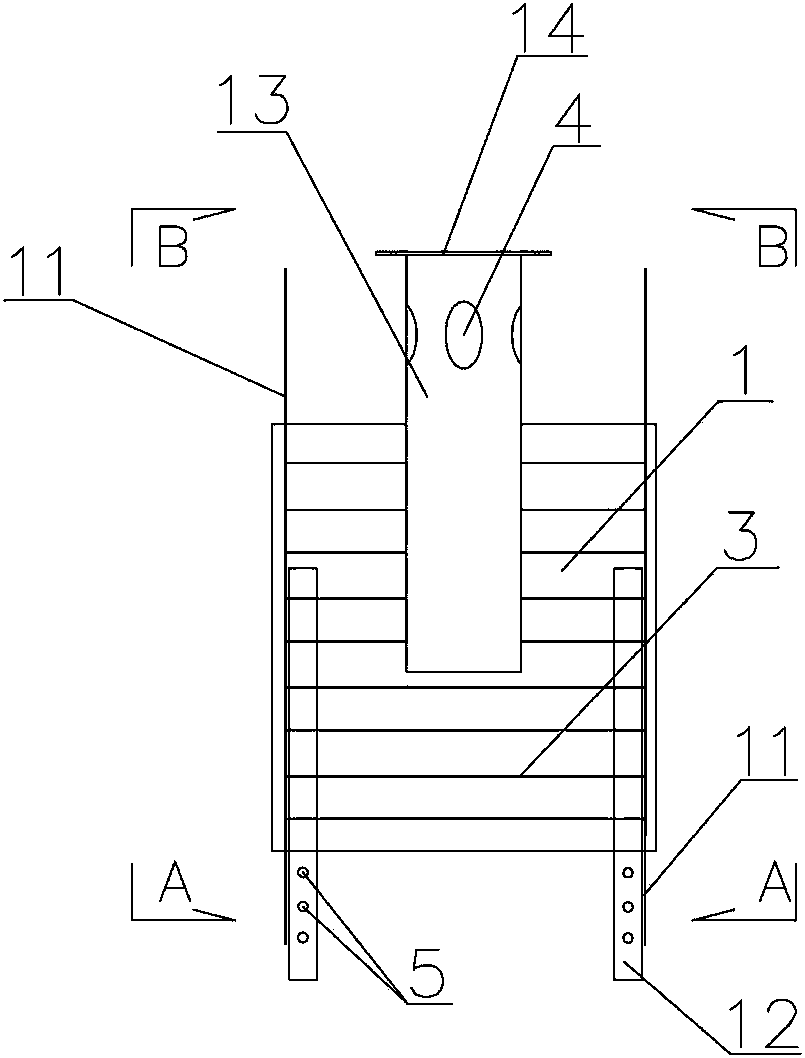

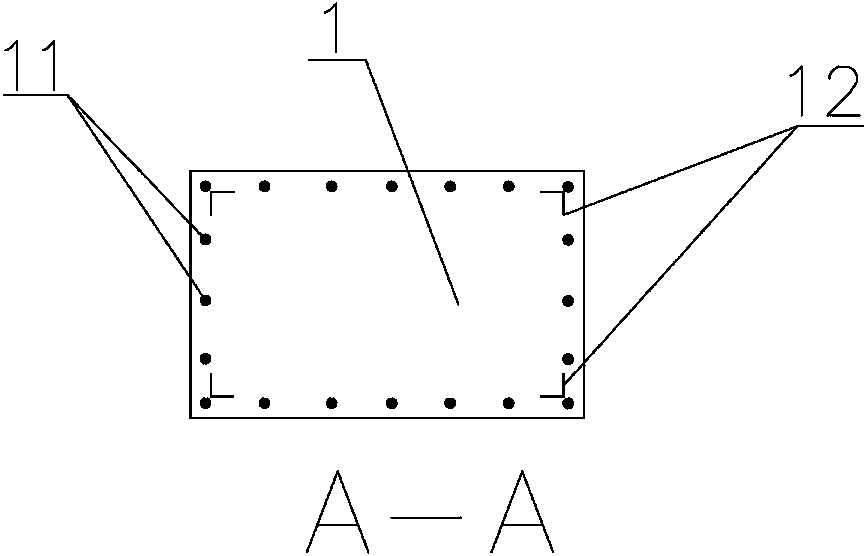

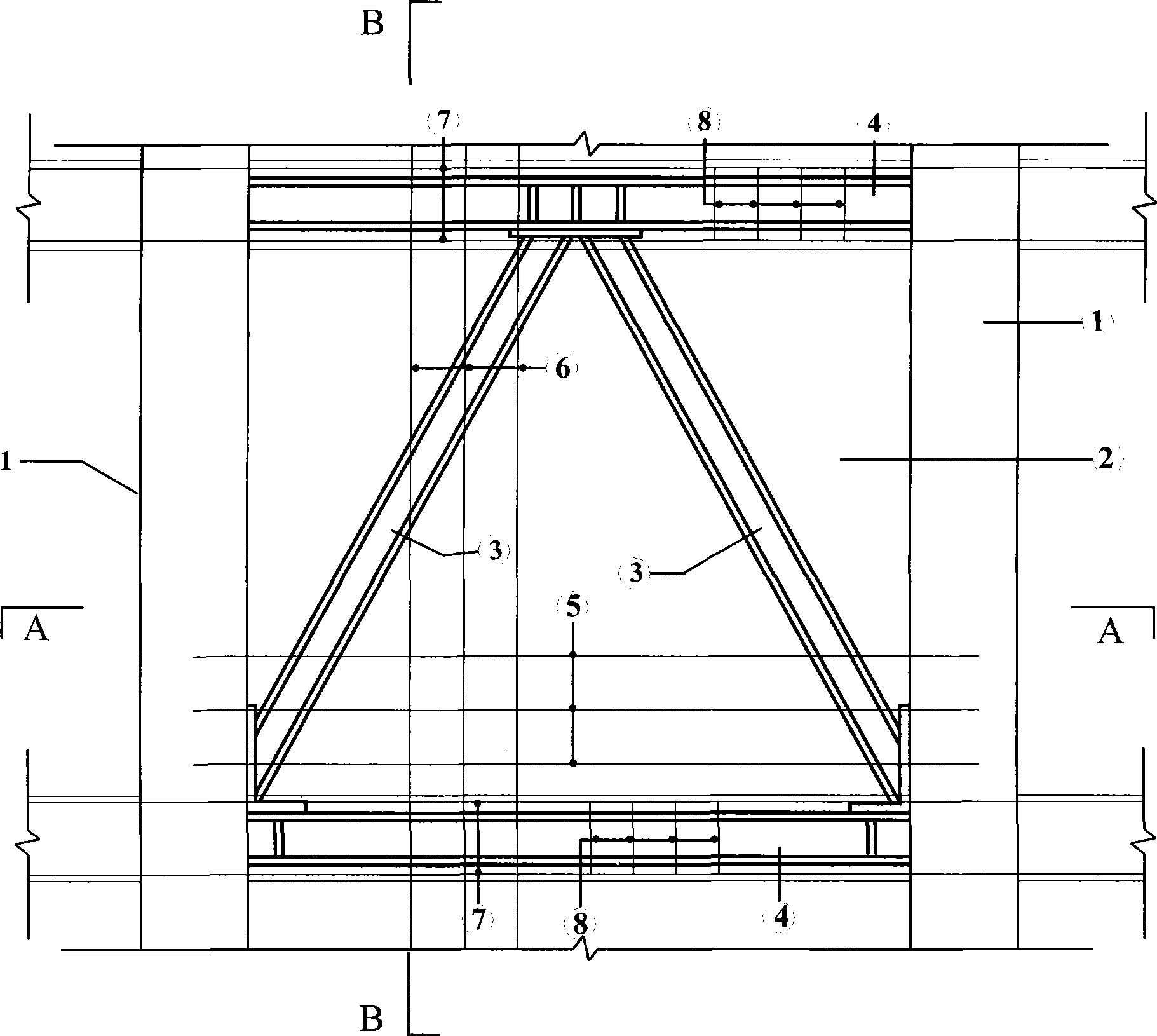

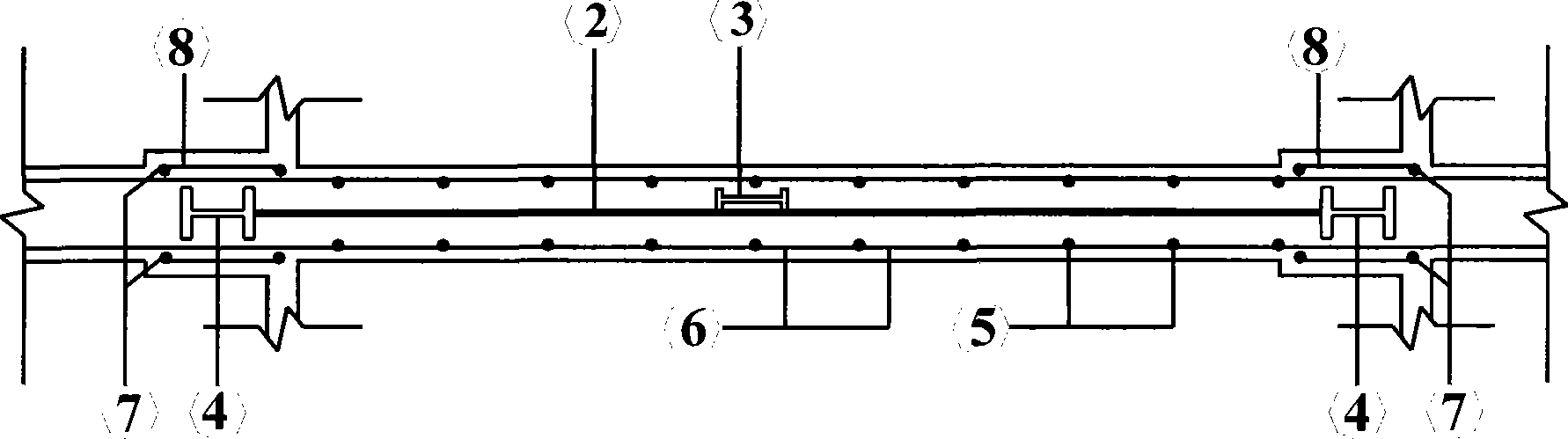

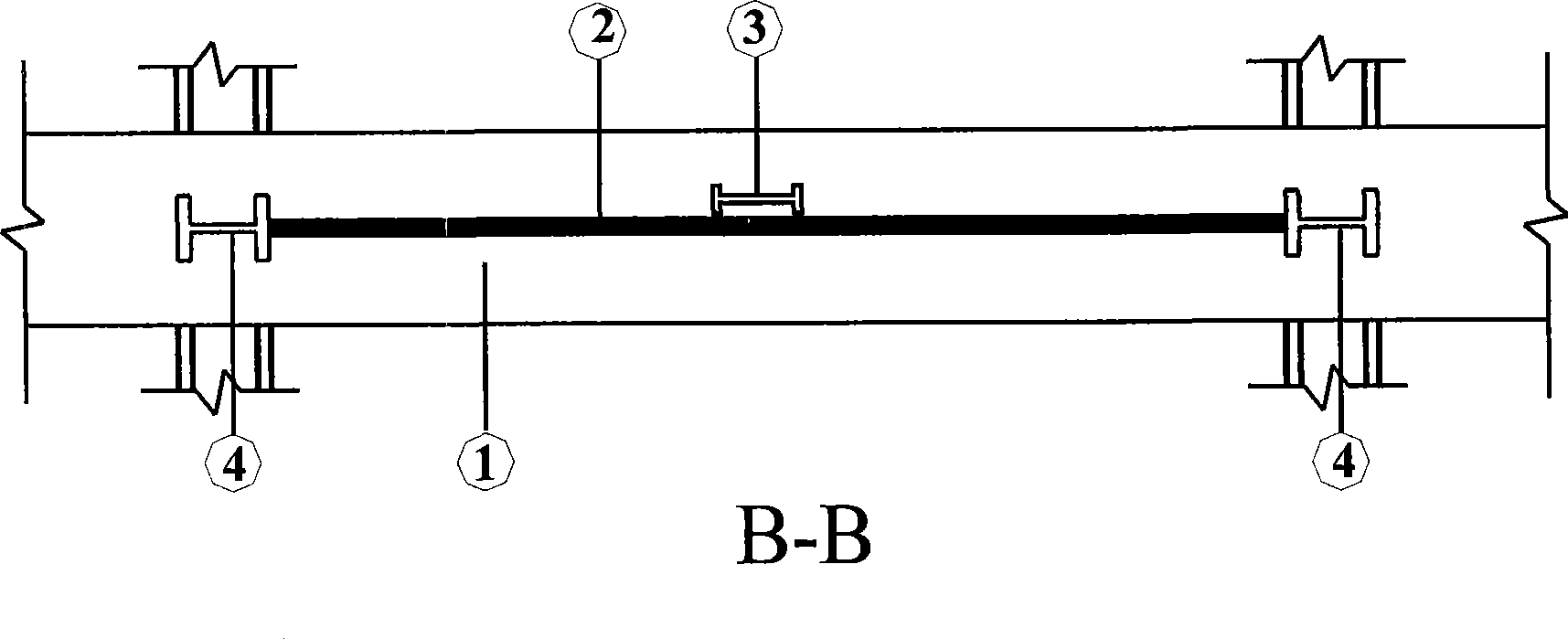

Steel tube concrete - steel support - steel plate external wrapping concrete shear force wall and manufacturing method thereof

InactiveCN101435235ASolving Out-of-Plane Instability ProblemsIncreased shear capacityWallsShock proofingSheet steelShock resistance

The invention discloses a steel pipe concrete-steel support-steel plate outer packed concrete shear wall and making method thereof, belonging to a shear wall and making method thereof. The shear wall is composed of steel pipe concrete frame columns (1) and concrete shear wall boards embedded with a steel plate (2), and is characterized in that the two ends of the shear wall are provided with steel pipe concrete frame columns (1), the frame beam is provided with a section steel beam (4), and the steel plate (2) embedded in the shear wall is provided with a steel support (3). Compared with the conventional shear wall, the shear wall of the invention has large initial rigidity, high bearing ability, slow attenuation for bearing force and rigidity, good whole shock resistance and energy consumption performance, stable shock resistance performance, and reduced bottom shearing sliding destroy.

Owner:BEIJING UNIV OF TECH

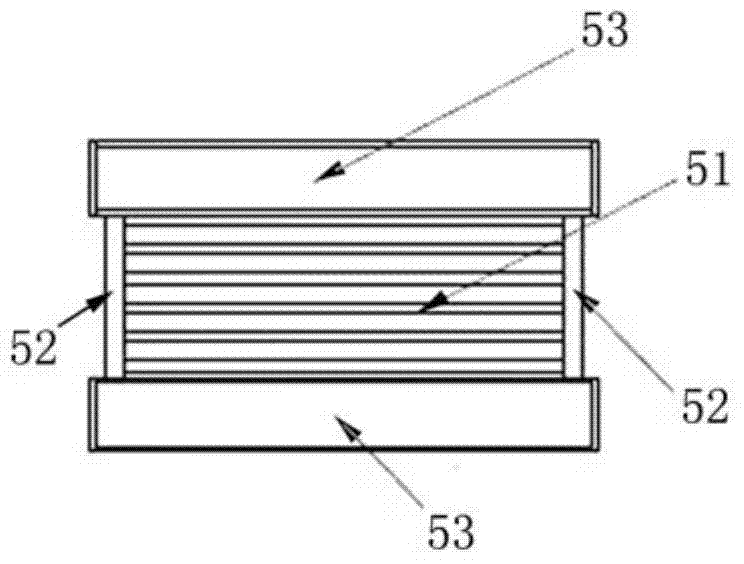

Beam through type corrugated steel plate energy consumption shear wall structure

ActiveCN104746774AIncreased shear capacityReduce building weightWallsShock proofingSheet steelShear capacity

The invention provides a beam through type corrugated steel plate energy consumption shear wall structure which comprises a first corrugated steel plate shear wall piece, a second corrugated steel plate shear wall piece, an upper edge steel column, a lower edge steel column, a corrugated steel plate energy consumption section and short steel columns on the left side and the right side of the corrugated steel plate energy consumption section. The corrugated steel plate energy consumption section and the short steel columns are located in the middle of a floor. The upper end and the lower end of the corrugated steel plate energy consumption section are connected with the first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece respectively. The first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece are connected with a floor beam through bolts respectively. The lower end of the upper edge steel column is connected with the upper ends of the short steel columns through bolts, and the upper end of the lower edge steel column is connected with the lower ends of the short steel columns through bolts. The upper end of the upper edge steel column and the lower end of the lower edge steel column are connected with the floor beam through bolts respectively. The first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece are connected with the upper edge steel column and the lower edge steel column respectively. The corrugated steel plate shear wall pieces are adopted as a body of the shear wall structure, and therefore a building is small in dead weight, the material consumption is low, and the shear capacity of a wall body is improved.

Owner:TONGJI UNIV

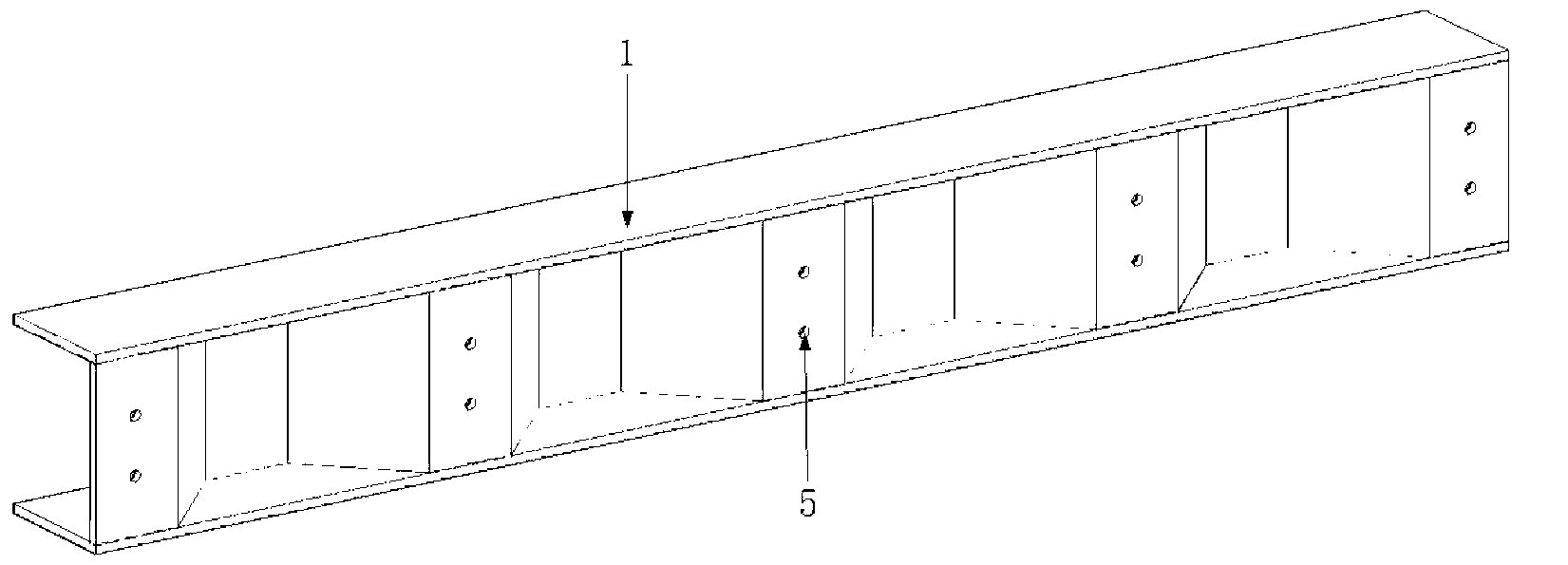

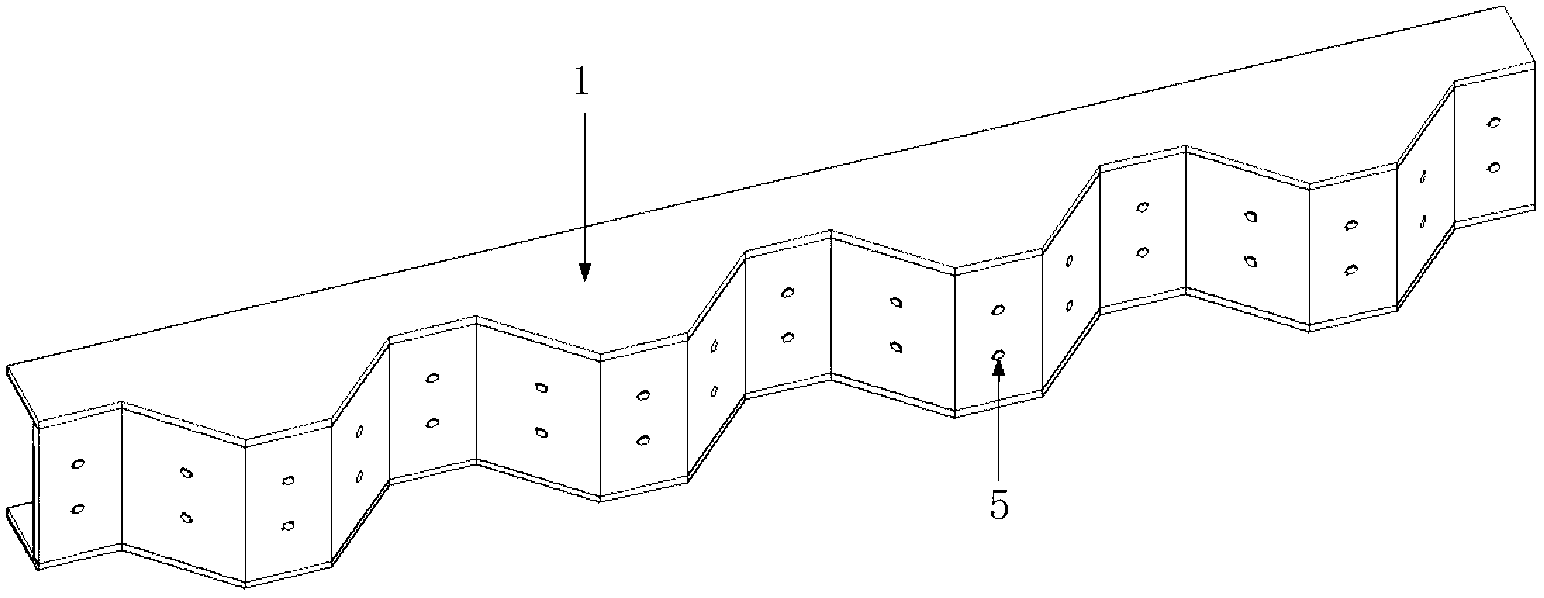

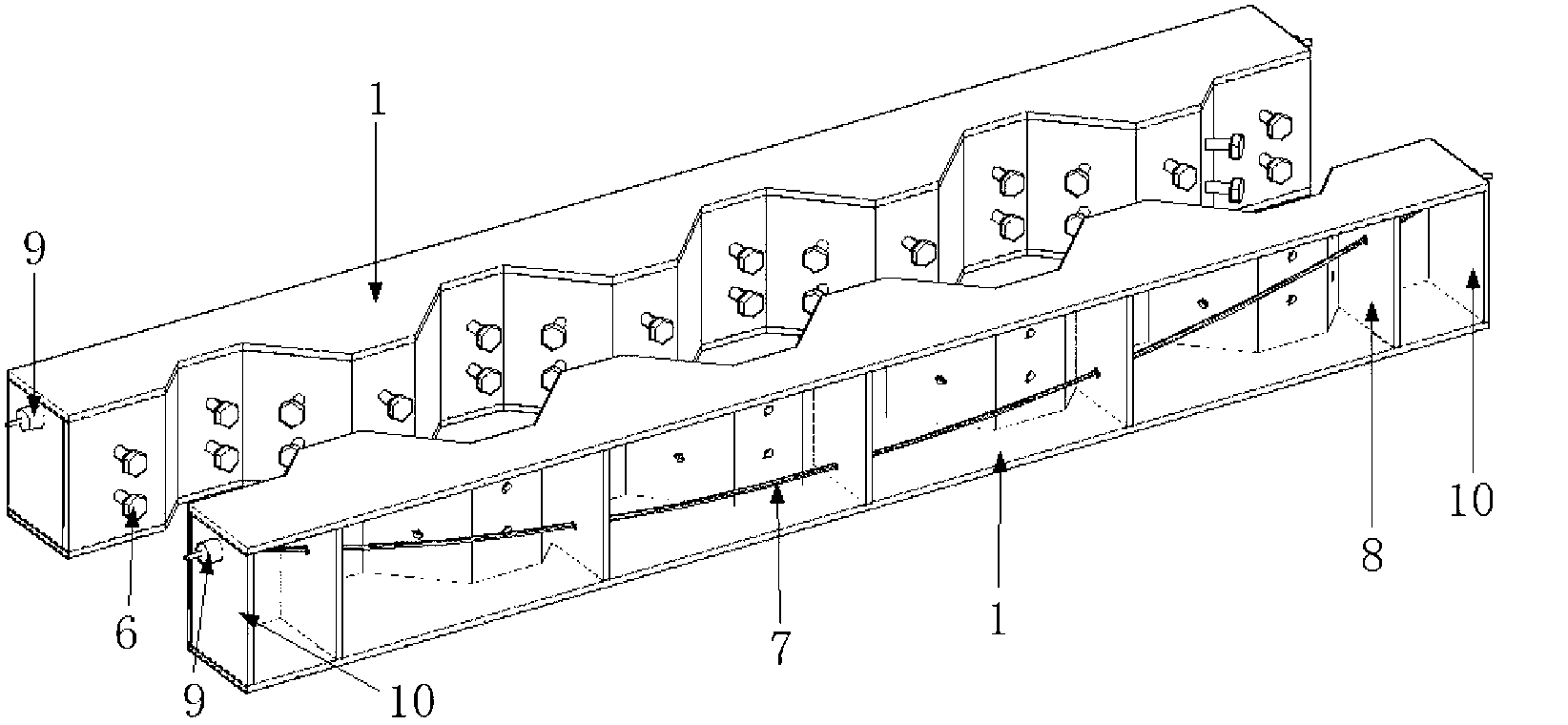

Assembled prestressed corrugated web occlusion steel girder

InactiveCN103216034AImprove mechanical performanceImprove carrying capacityGirdersJoistsButt jointWave shape

The invention relates to an assembled prestressed corrugated web occlusion steel girder. The steel girder is formed by assembling two prestressed corrugated steel channel beams through bolts, wherein webs of the steel channel beams are in occlusion and butt joint with each other. Each prestressed corrugated steel channel beam consists of a top flange, a web, a bottom flange, a prestressed cable, lateral stiffening ribs, anchorage devices and beam end plates, wherein the section opening shape of each prestressed corrugated steel channel beam is formed by the top and bottom flanges and the web, the section of the web is in a uniform or non-uniform periodic repeating wave shape, the lateral stiffening ribs are vertically positioned between the two flanges and the web, the beam end plates are arranged on the two ends of the beam and parallel to the lateral stiffening ribs, and the prestressed cable is fixed on the beam end plates through the anchorage devices after being tensioned. The steel girder is an innovative assembled prestressed steel girder which is suitable for assembled steel structural systems and particularly large-span multi-high-level assembled steel structural systems; and compared with a conventional assembled girder, the steel girder has the advantages of light weight, high bearing capability, large span and the like.

Owner:BEIJING UNIV OF TECH

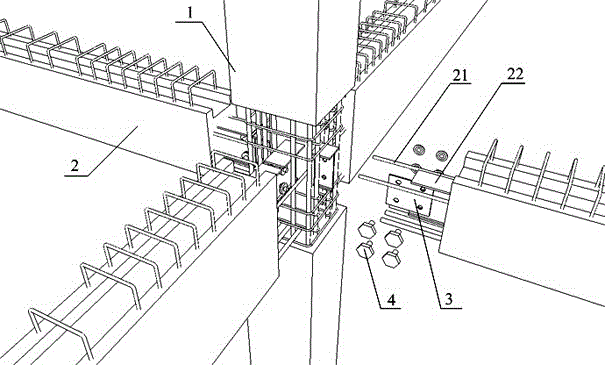

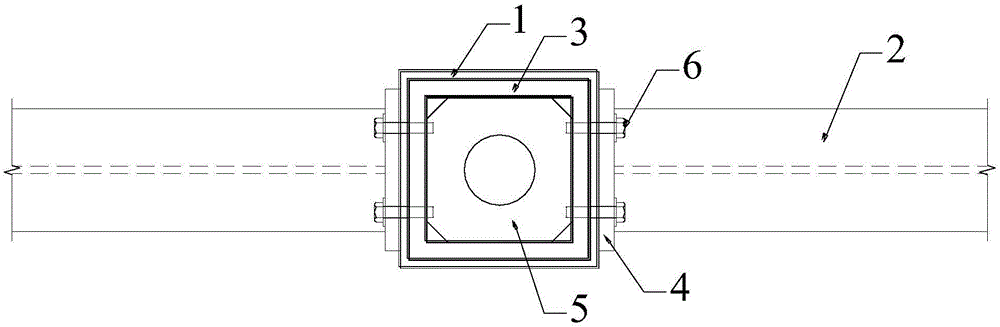

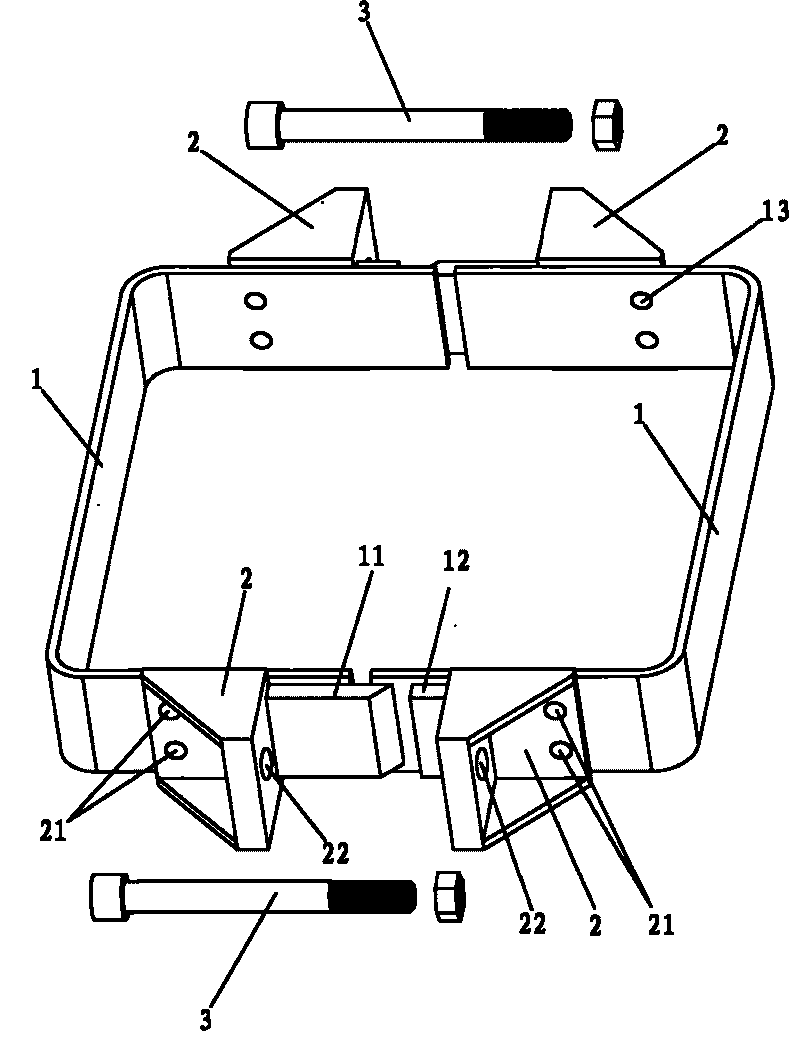

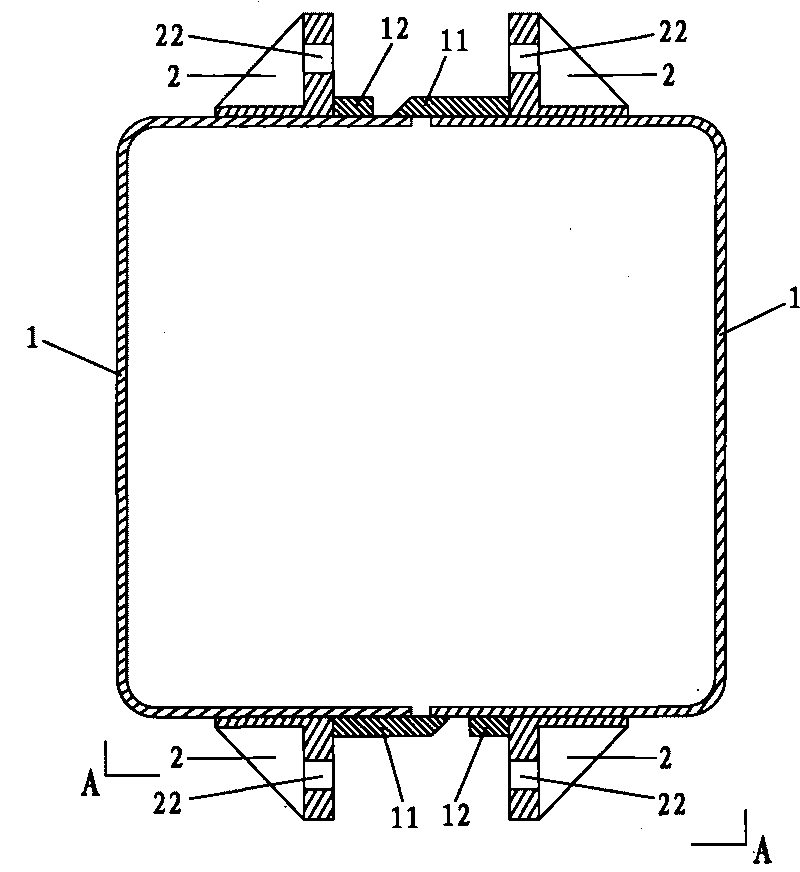

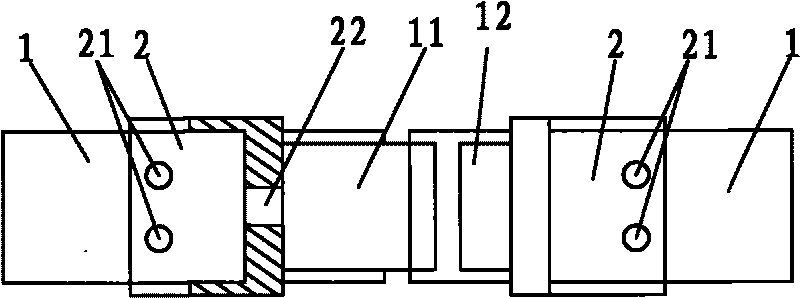

Inner sleeve type unilateral bolt connecting joint of steel tube column and H-shaped steel girder

The invention relates to an inner sleeve type unilateral bolt connecting joint of a steel tube column and an H-shaped steel girder which is simple in structure, good in performance and reliable in joint quality. The inner sleeve type unilateral bolt connecting joint comprises the steel tube column, the H-shaped steel girder, a steel sleeve, a transverse partition plate, externally-extended end plates and high-strength bolts, wherein the steel sleeve is arranged coaxially in the steel tube column; the transverse partition plate is fixed to a flange of the H-shaped steel girder in the steel sleeve in a coplanar mode; the externally-extended end plates are welded at the ends of the H-shaped steel girder; and the high-strength bolts penetrate through the externally-extended end plates. Tapping bolt holes are formed in the steel sleeve and matched with the high-strength bolts. A plurality of bolt holes are formed in a pair mode in the externally-extended end plates and the steel tube column in the axial direction of the steel tube column. At least two positioning circular holes are formed in a connecting wall plate and an opposite wall plate correspondingly by the steel tube column in the axial direction of the steel tube column. The bolt holes and the tapping bolt holes on the same side are formed oppositely. The positioning circular holes on the same side are formed oppositely. The high-strength bolts sequentially penetrate through the bolt holes in the externally-extended end plates and the bolt holes in the steel tube column and are connected with the tapping bolt holes corresponding to the steel sleeve, and are tightened and fixed according to the designed pretension force of the high-strength bolts.

Owner:CHANGAN UNIV

Novel pre-stressed steel plate hoop device and installation method thereof

InactiveCN101705662AIncreased shear capacityImprove the axial bearing capacityBridge structural detailsBridge erection/assemblySheet steelPre stress

The invention discloses a novel pre-stressed steel plate hoop device and an installation method thereof. The structure of the device comprises two U-shaped steel hoop plates that can compose a whole hoop, two suites of tensioning plates and tensioning bolts that can prestress the steel hoop. The device and the method have good technical reinforcement effect, and the structure has simple structure, convenient operation, low cost and has the advantages of environment protection and energy conservation.

Owner:HUAQIAO UNIVERSITY

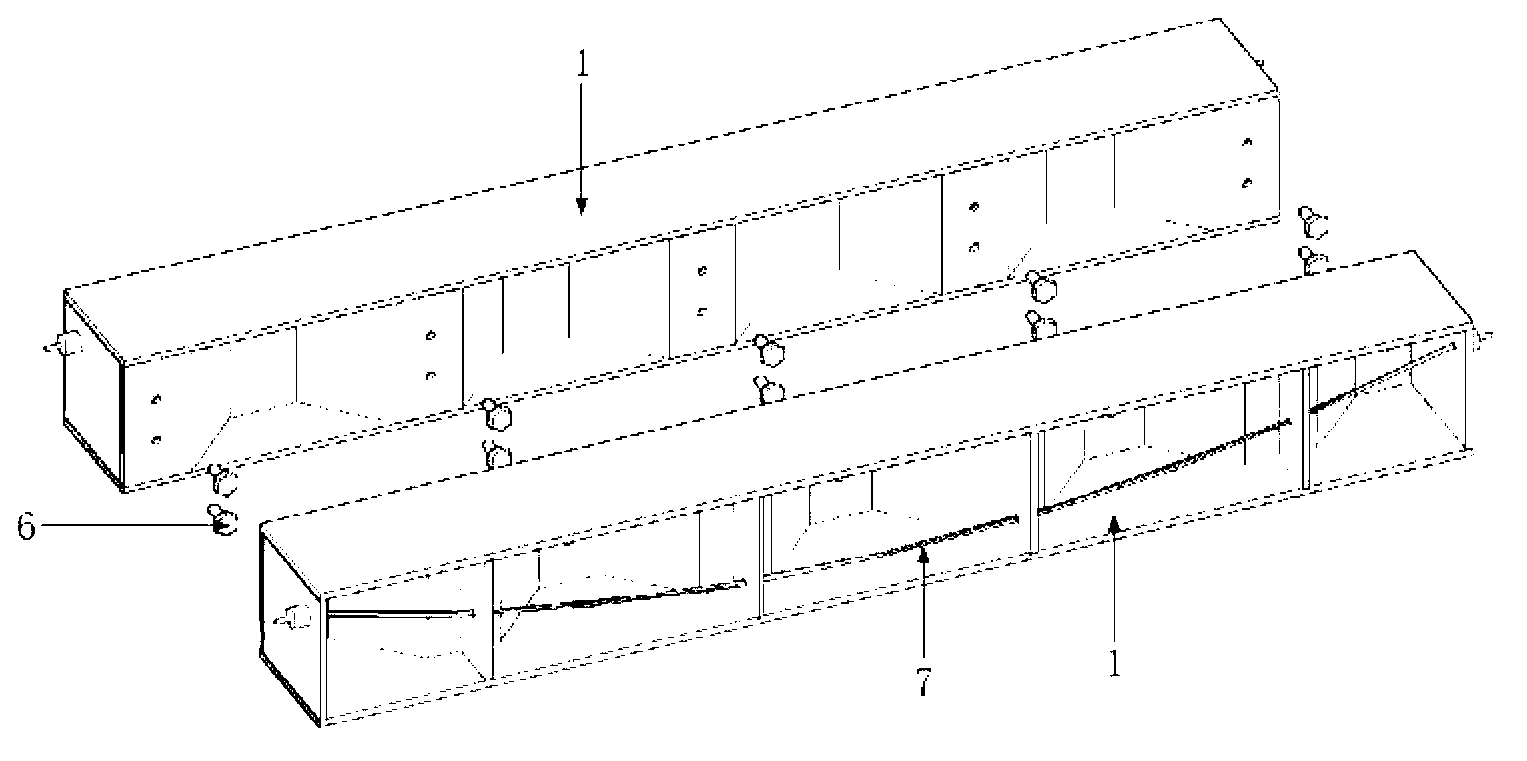

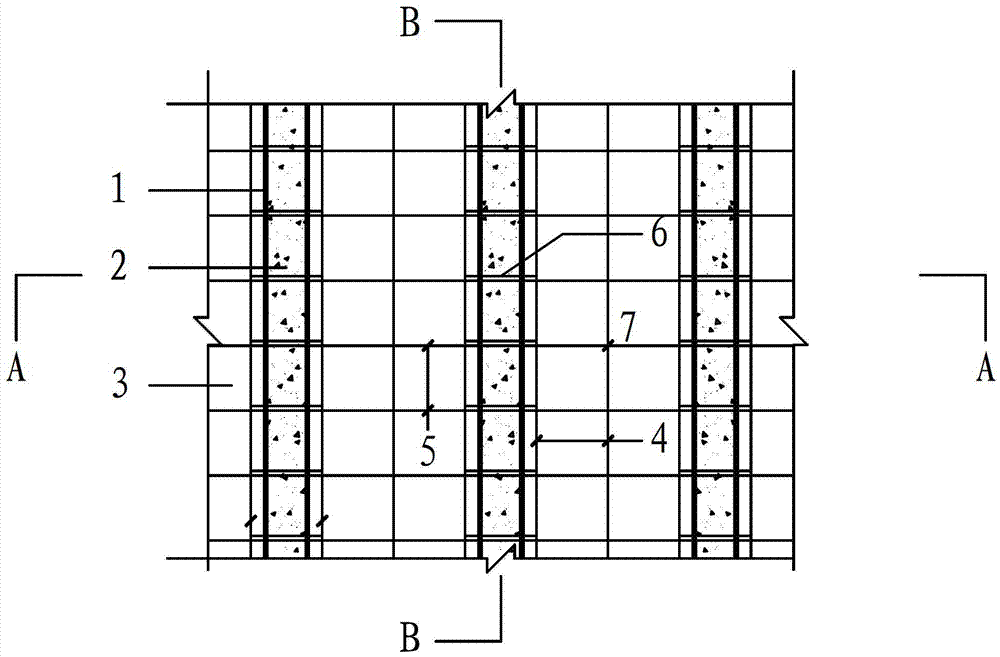

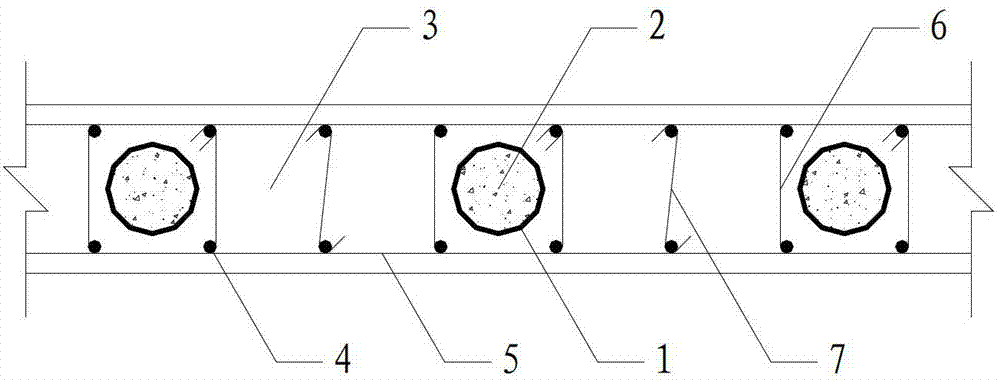

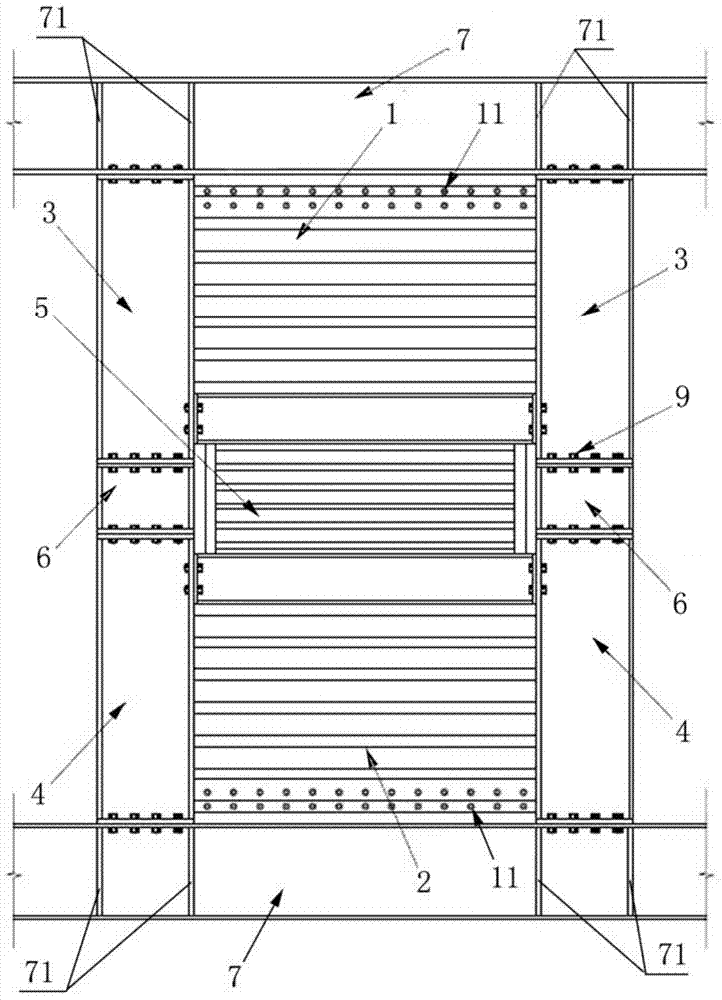

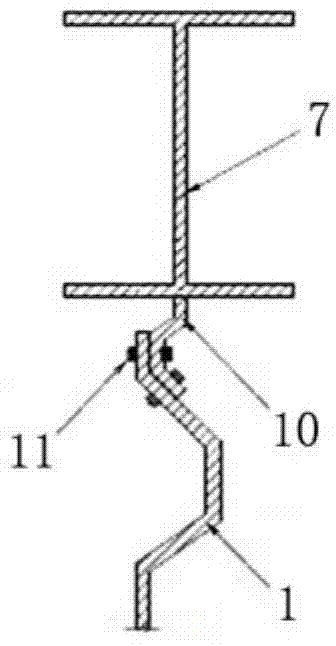

Steel tube concrete - steel support - concrete combined shear wall and manufacturing method thereof

InactiveCN101435234AIncreased shear capacityImprove ductilityWallsShock proofingSheet steelShock resistance

The invention discloses a steel pipe concrete-steep support-steel plate combine shear wall and making method thereof, belonging to the field of building construction. The steel pipe concrete-holed steel plate-concrete combine shear wall is characterized in that: the shear wall is composed of steel pipe concrete frame columns (1) and steel plate concrete shear wall boards, and the frame beam is provided with a section steel beam (3). A steel plate (2) embedded in the shear wall is provided with an opening, the two sides of the steel plate (2) are provided with steel bar nets composed of transverse steel bars (4) and longitudinal steel bars (5), and the steel bar nets at two sides of the steel plate (2) are tied by steel tie bars (7) at the opening on the steel plate (2). Compared with the conventional shear wall, the shear wall of the invention has large initial rigidity, high bearing ability, slow attenuation for bearing force and rigidity, good whole shock resistance and energy consumption performance, stable shock resistance performance, and reduced bottom shearing sliding destroy.

Owner:BEIJING UNIV OF TECH

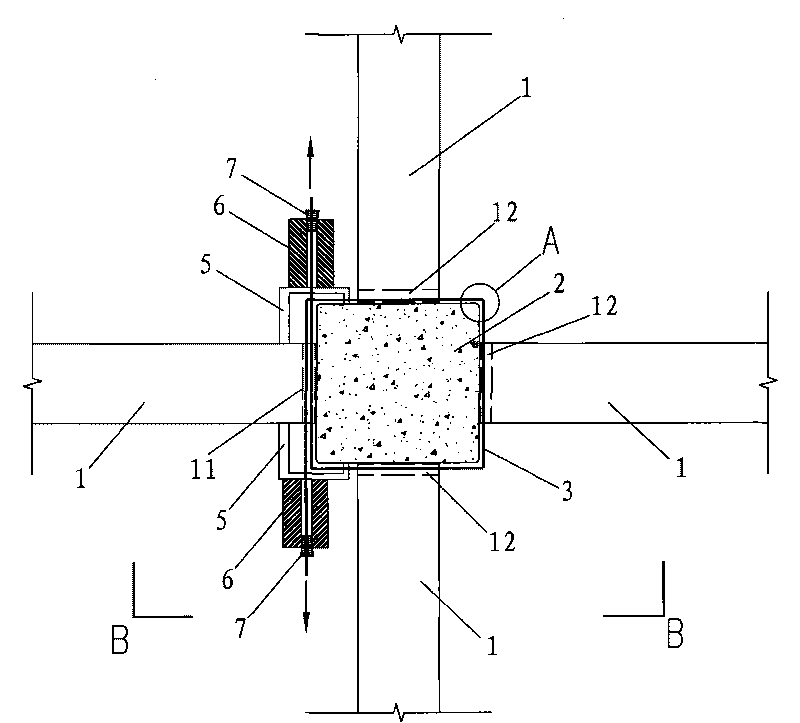

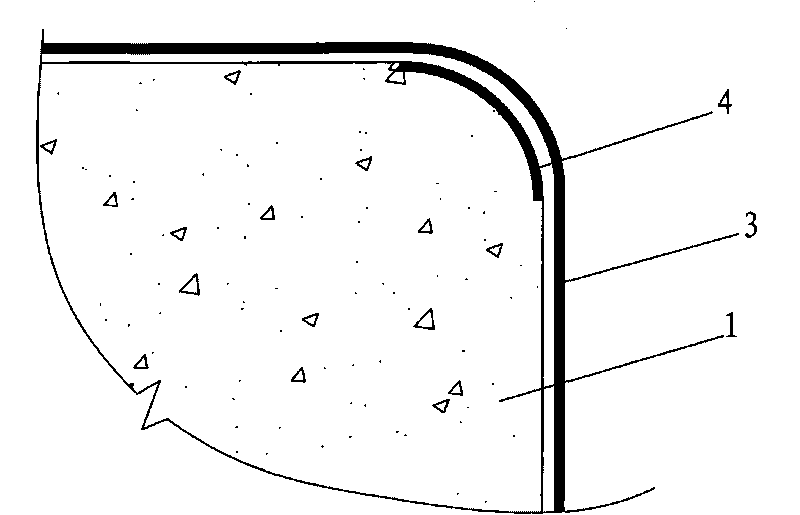

Construction method of constructing beam-column joint using ring beam

InactiveCN104947712AGuarantee the construction qualitySolve the problem of crossingArtificial islandsBuilding constructionsMultiple frameRebar

The invention discloses a construction method of constructing a beam-column joint using a ring beam, and relates to the technical filed of building construction. The construction method aims at solving the problems that the construction technology of rebar traversing in the position of the joint of the beam-column joint is complicated in an existing reverse building method, and harmful effect is caused to the joint structure when adjusting an original rebar structure on site. The construction method comprises the steps that 1 construction is conducted to form a concrete filled steel tubular column in the reverse building method, and a ring beam bottom cast is fixed to a bent surrounding the concrete filled steel tubular column; 2 multiple first U-shaped stirrups, ring beam bottom bars and lower rebars are erected in radial direction supported by the ring beam bottom cast; 3 multiple ring beam waist bars and multiple frame beam waist rebars are erected in the longitudinal direction of the axis of the concrete filled steel tubular column; 4 ring beam far bars and second U-shaped stirrups are erected, the first U-shaped stirrups and the second U-shaped stirrups can be put together and erected to form first annular stirrups, and the first annular stirrups are enclosed and fixed to the outer sides of the ring beam bottom bars, the ring beam waist bars and the ring beam face bars; fixing side formworks are installed, concreting is conducted, when a designed strength is reached, the formworks are removed, and construction of the beam-column joint is completed.

Owner:SHANGHAI NO 4 CONSTR

Reinforcement method of reinforced concrete beam column node

InactiveCN101748900AIncreased shear capacityImproved seismic performanceBuilding repairsRebarEarthquake resistant

The invention discloses a reinforcement method of a reinforced concrete beam column node. A steel strand is transversely wound on the core area of the reinforced concrete beam column node, a device for prestressing applies prestree to the steel strand, and a buckle is adopted to carry out butt joint anchoring treatment on two ends of the steel strand when the prestress of the steel strand reaches a preset level. By adopting the above scheme, the method has the advantages: (1) a closed prestress steel strand is adopted to form effective horizontal restrain to the concrete in core area so that the steel strand and the node area co-work to greatly improve the shear resisting bearing capability of the node core area and improve the earthquake resistant capability of the node; (2) the reinforced concrete beam column node has strong applicability and wide application aspect and is suitable for reinforcing namespace nodes; and (3) the reinforced concrete beam column node has favourable economical efficiency and convenient and quick construction.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com