Steel box beam orthotropic deck slab

A technology for orthotropic bridges and steel box girders, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as fatigue cracks, achieve the effects of eliminating welding fatigue cracks, avoiding excessive local deformation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

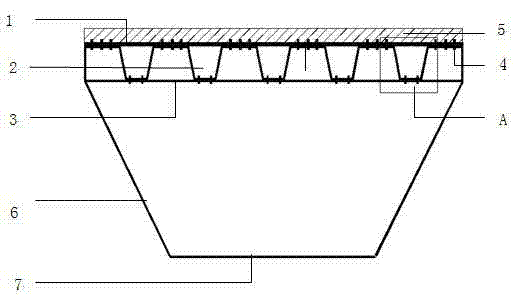

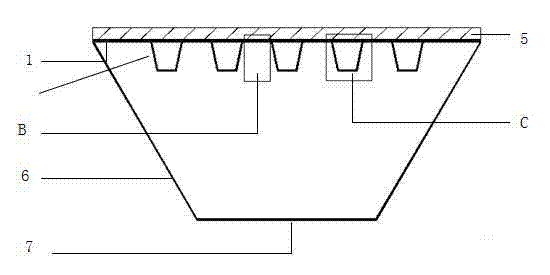

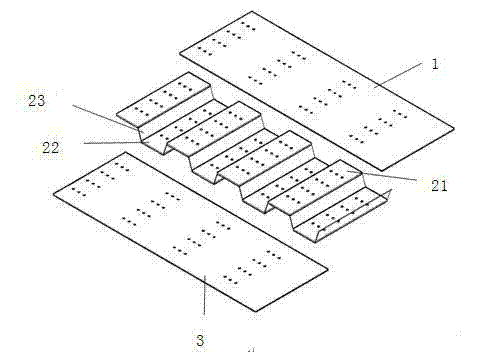

[0026] see figure 1 , the orthotropic steel bridge deck includes an upper roof 1, a corrugated steel plate 2 and a lower roof 3, the wave direction of the corrugated steel plate 2 is consistent with the direction of the transverse bridge, and the corrugated steel plate 2 is composed of crest surfaces 21 and trough surfaces staggered along the direction of the transverse bridge 22. It consists of a slope 23 connecting the crest surface 21 and the trough surface 22. The included angle between the inclined surface 23 and the crest surface (21) and the included angle between the inclined surface 23 and the trough surface 22 are not 90°, and the wave section of the corrugated steel plate 2 is a plurality of continuously arranged trapezoids. The upper top plate 1, the lower top plate 3 and the corrugated steel plate 2 are connected by high-strength bolts 4 . The high-strength bolts 4 expose about 3-5 centimeters on the upper side of the upper roof 1, as the shear bond between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com