Environment-friendly heat conduction insulating glue used by high-power LEDs and preparation method

A heat-conducting, insulating, high-power technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of reduced mechanical properties, reduced work efficiency, poor scattering performance, etc., to increase service life and improve work efficiency , the effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. A heat-conducting and insulating glue used in an environment-friendly high-power LED, which is made of the following raw materials in weight percentage:

[0033] Micron-sized high thermal conductivity powder 57.4%;

[0034] Epoxy resin 30%;

[0035] Curing agent 4%;

[0036] Solvent 7%;

[0037] Accelerator 0.6%;

[0038] Additive 1%;

[0039] The micron-level high thermal conductivity powder is selected from one of micron-level silver powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder.

[0040] Its preparation method adopts the preparation method of conventional heat-conducting and insulating glue.

Embodiment 2

[0041] Example 2. A heat-conducting and insulating glue used in an environment-friendly high-power LED, which is made of the following raw materials in weight percentage:

[0042] Micron-sized high thermal conductivity powder 53.5%;

[0043] Epoxy resin 18%;

[0044] Curing agent 10%;

[0045] Solvent 15%;

[0046] Accelerator 1.5%;

[0047] Additives 2%;

[0048] The micron-scale high thermal conductivity powder is selected from: any two of micron-scale silver powder, palladium powder, platinum powder, gold powder, C powder, AlN powder, and SiC powder or a mixture of three in any proportion.

[0049] Its preparation method is: under the constant temperature condition of temperature 26 ℃, the humidity is 52% under the condition of constant humidity to carry out the following operations: first weigh epoxy resin, solvent, curing agent, accelerator and Additives, after mixing, stir evenly to obtain a matrix for later use; then weigh the micron-sized high thermal conductivity ...

Embodiment 3

[0050] Example 3. A heat-conducting and insulating glue used in an environment-friendly high-power LED, which is made of the following raw materials in weight percentage:

[0051] Micron-sized high thermal conductivity powder 50%;

[0052] Epoxy resin 30%;

[0053] Curing agent 8%;

[0054] Solvent 9.8%;

[0055] Accelerator 1%;

[0056] Additives 1.2%;

[0057] The micron-scale high thermal conductivity powder is selected from any four of micron-scale silver powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder or a mixture of five in any proportion.

[0058] The preparation method is as follows: under the constant temperature condition of 28°C and the constant humidity condition of 60% humidity, the following operations are carried out: firstly weigh the epoxy resin, solvent, curing agent, accelerator and Additives, after mixing, stir evenly to obtain a matrix for later use; then weigh the micron-sized high thermal conductivity pow...

PUM

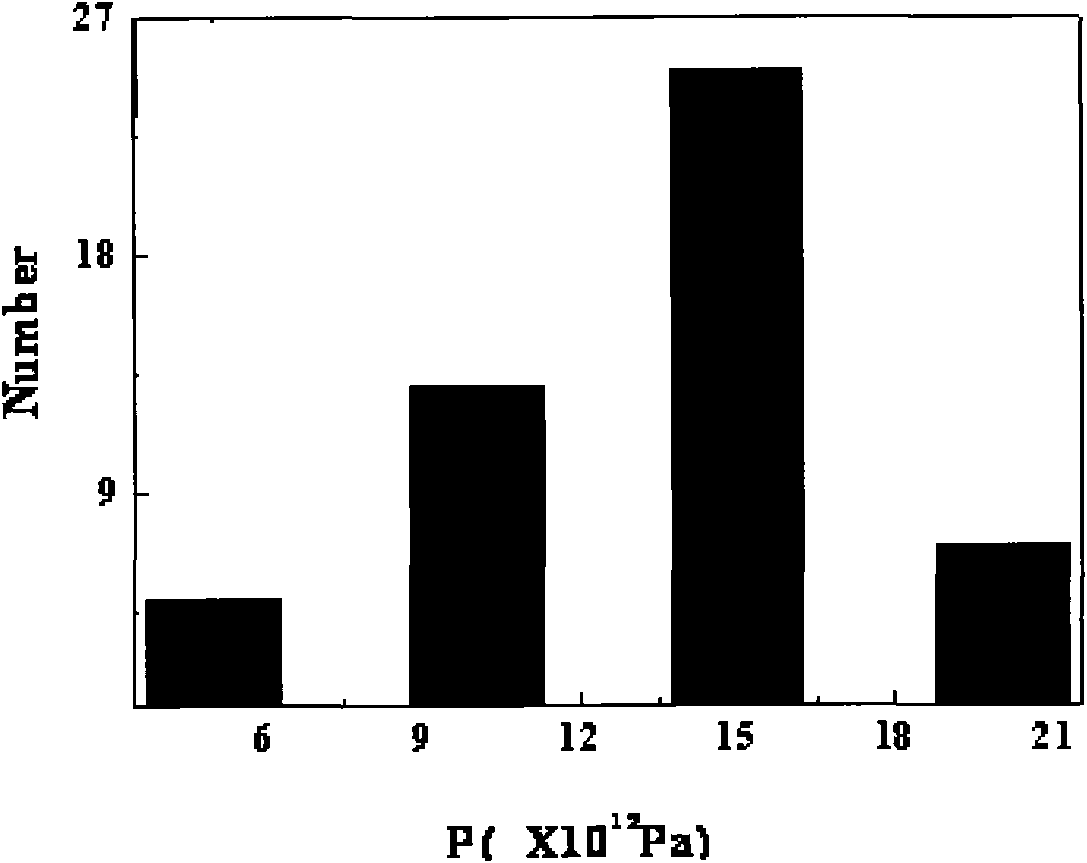

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com