Patents

Literature

440 results about "Shear capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The shear capacity of vertical stirrups is the tension strength of one stirrup times the number of stirrups that interrupt potential cracks on a 45-degree angle from the tension steel. Thus, Vs = Avfyd/s. A U-stirrup has an area Av = 2(area of one stirrup leg).

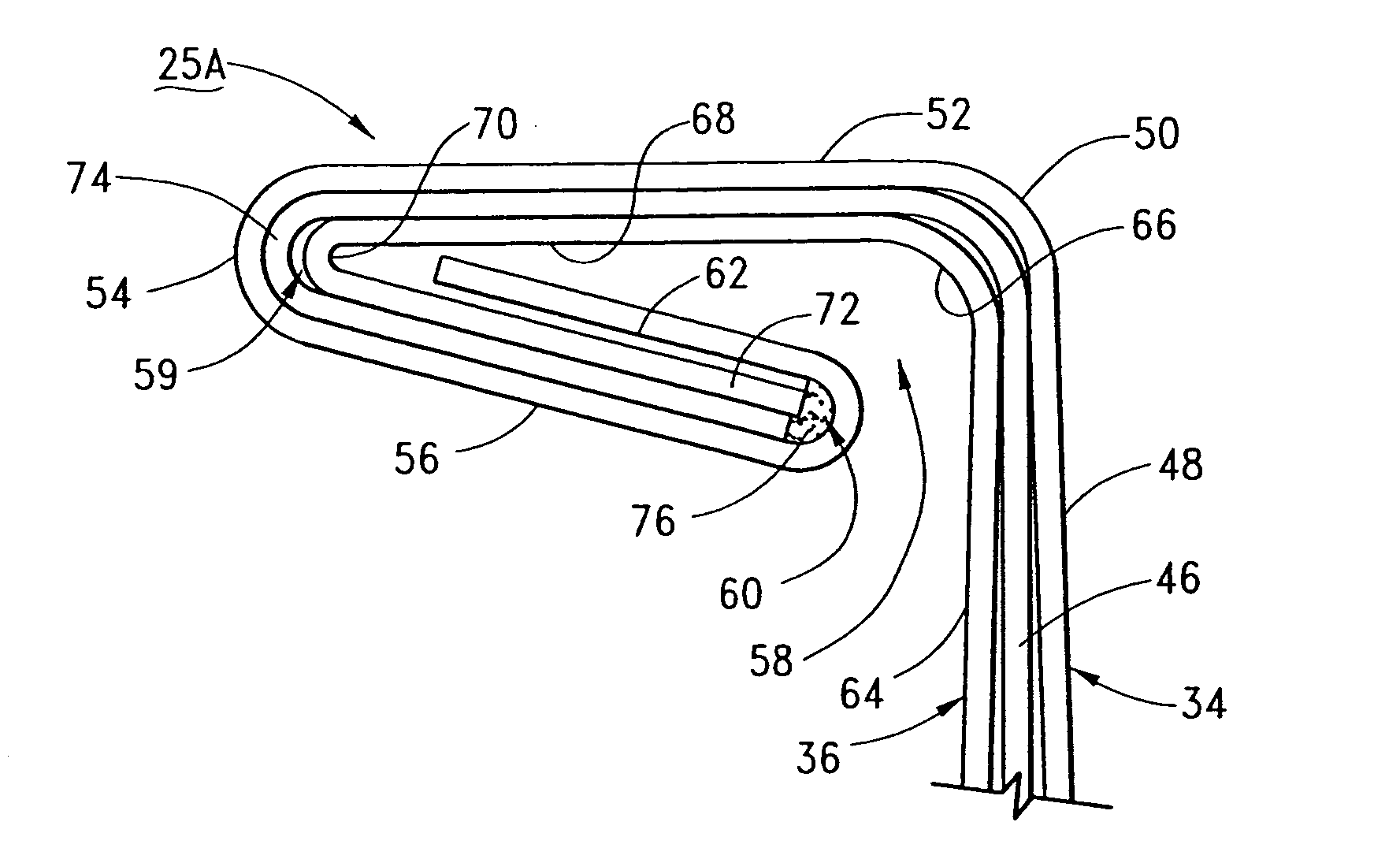

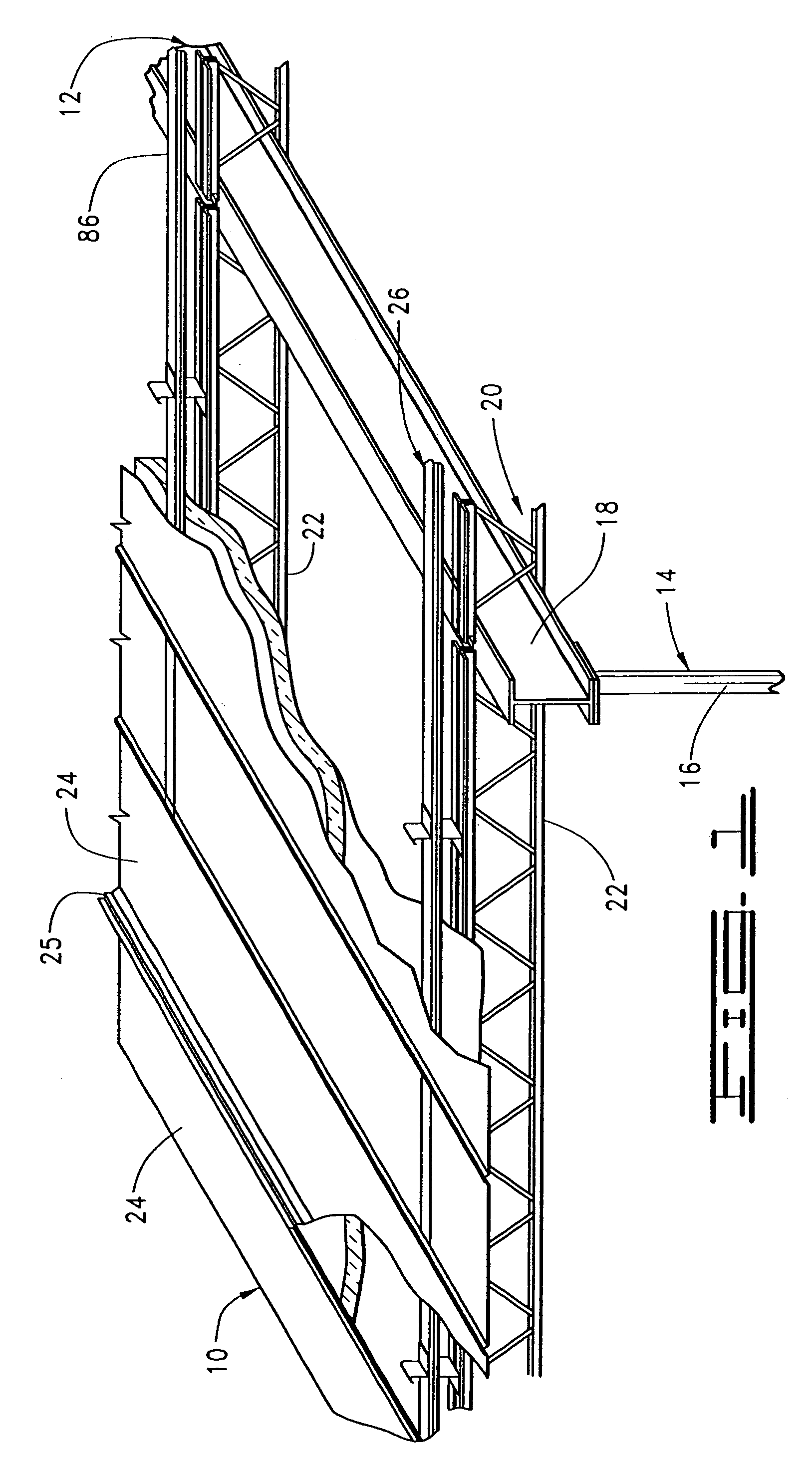

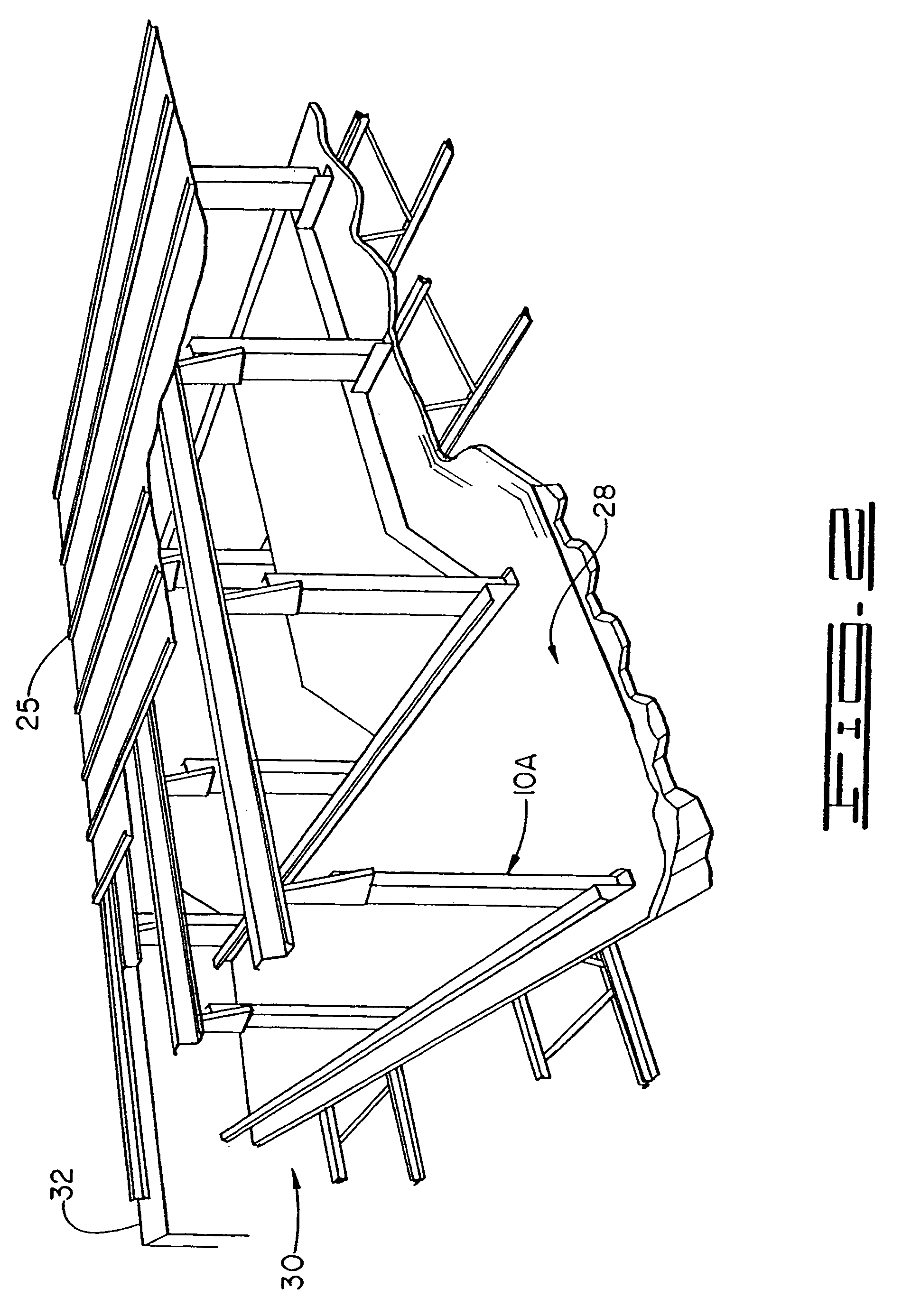

Standing seam roof assembly having increased sidelap shear capacity

InactiveUS6889478B1Improve clippingImprove the immunityRoof covering using slabs/sheetsRoof covering using tiles/slatesShear capacityEngineering

A standing seam roof assembly in which adjacently disposed roof panels are supported by underlying support structure in overlapping edge relationship and connected with standing seams, the roof assembly resistant to sideslipping when subjected to uplift forces and having roof panels with female sidelap portions having male insertion cavities, while adjacently disposed roof panels having male sidelap portion lockingly engaged the female cavities. The sidelap shear capacity of the roof panels is increased in one embodiment by backer plates disposed in pairs on opposing sides of the standing seams and fastened together to sandwich together the female and male sidelap portions so the standing seams have increased resistance to side slipping under wind uplift. In another embodiment, cinch plates are supported on the roof panels between the standing seams and connected to an underlying backer member that extends to and is connected to the underlying support structure.

Owner:ENCON PROD INC

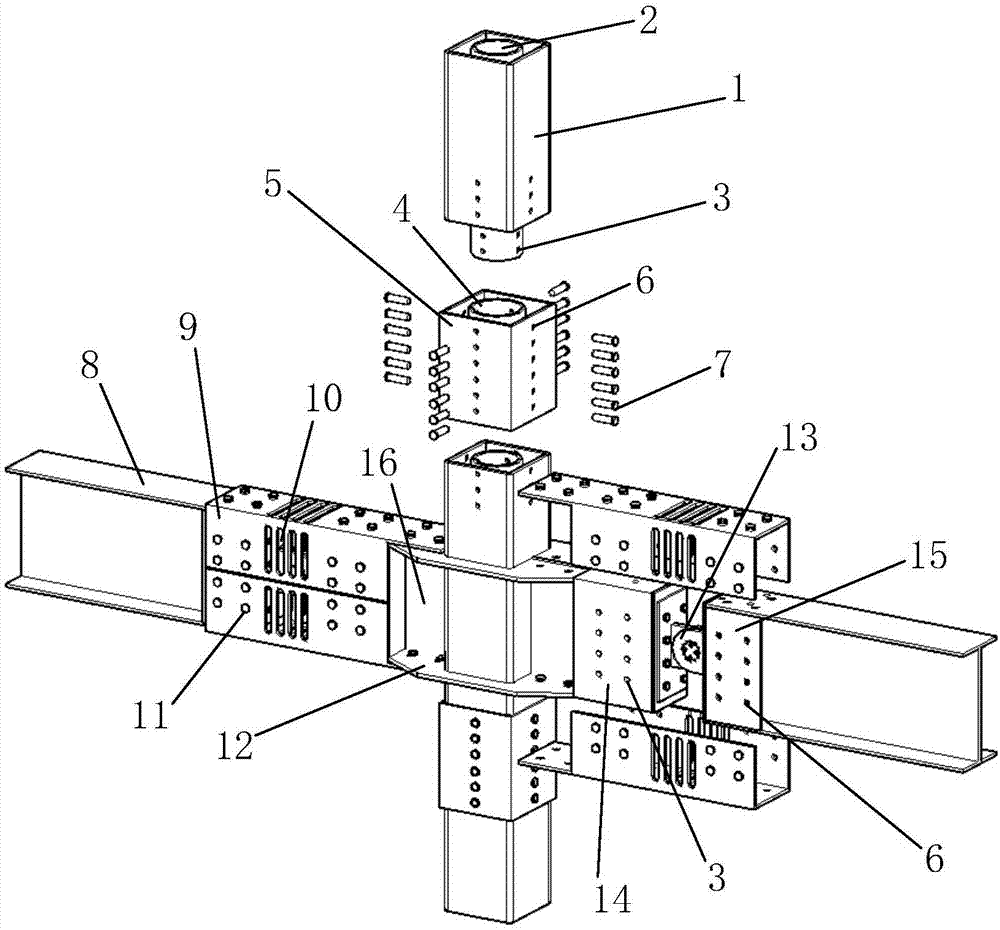

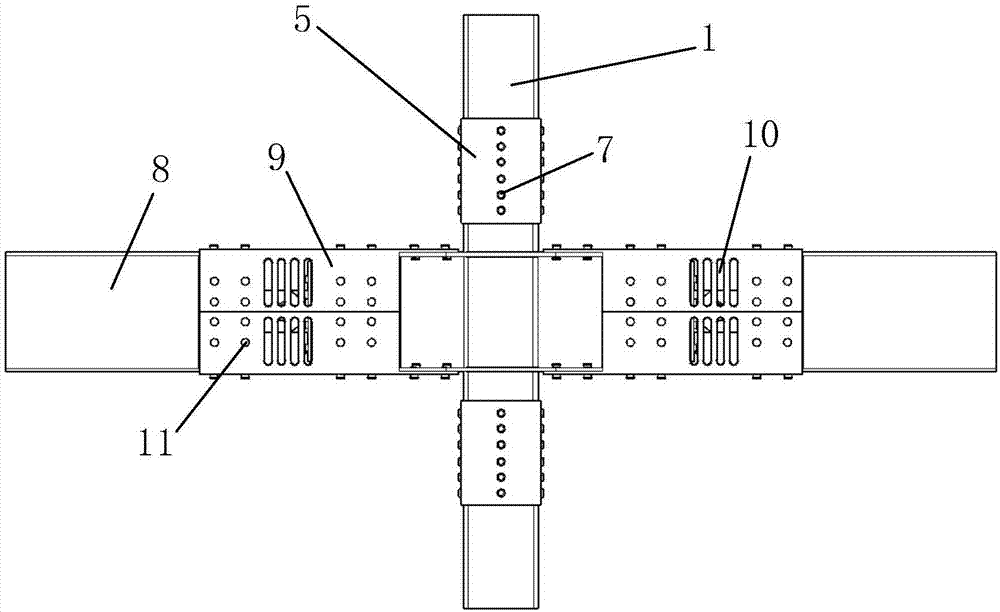

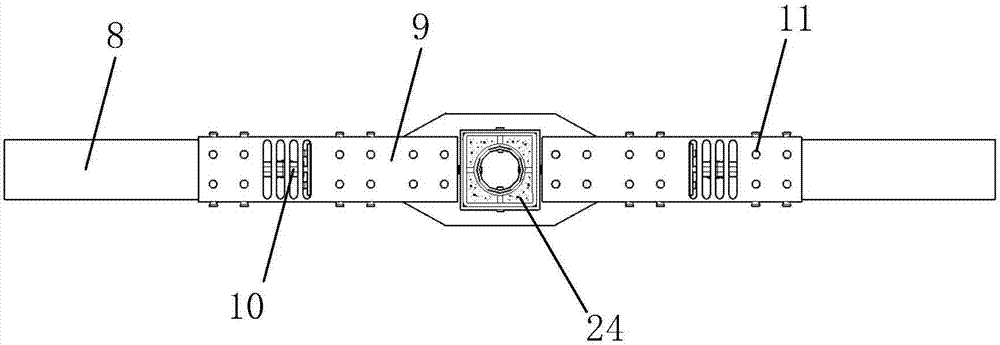

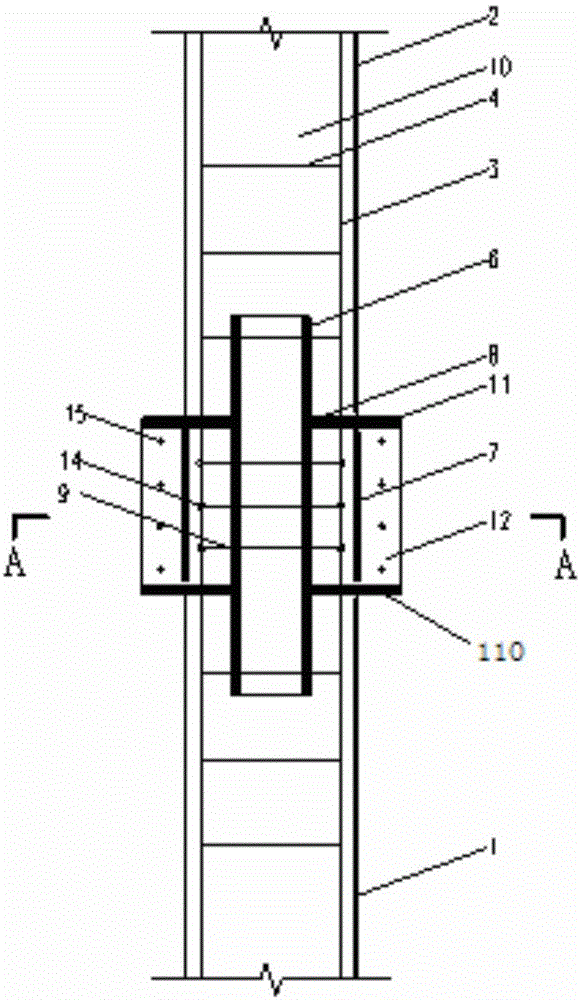

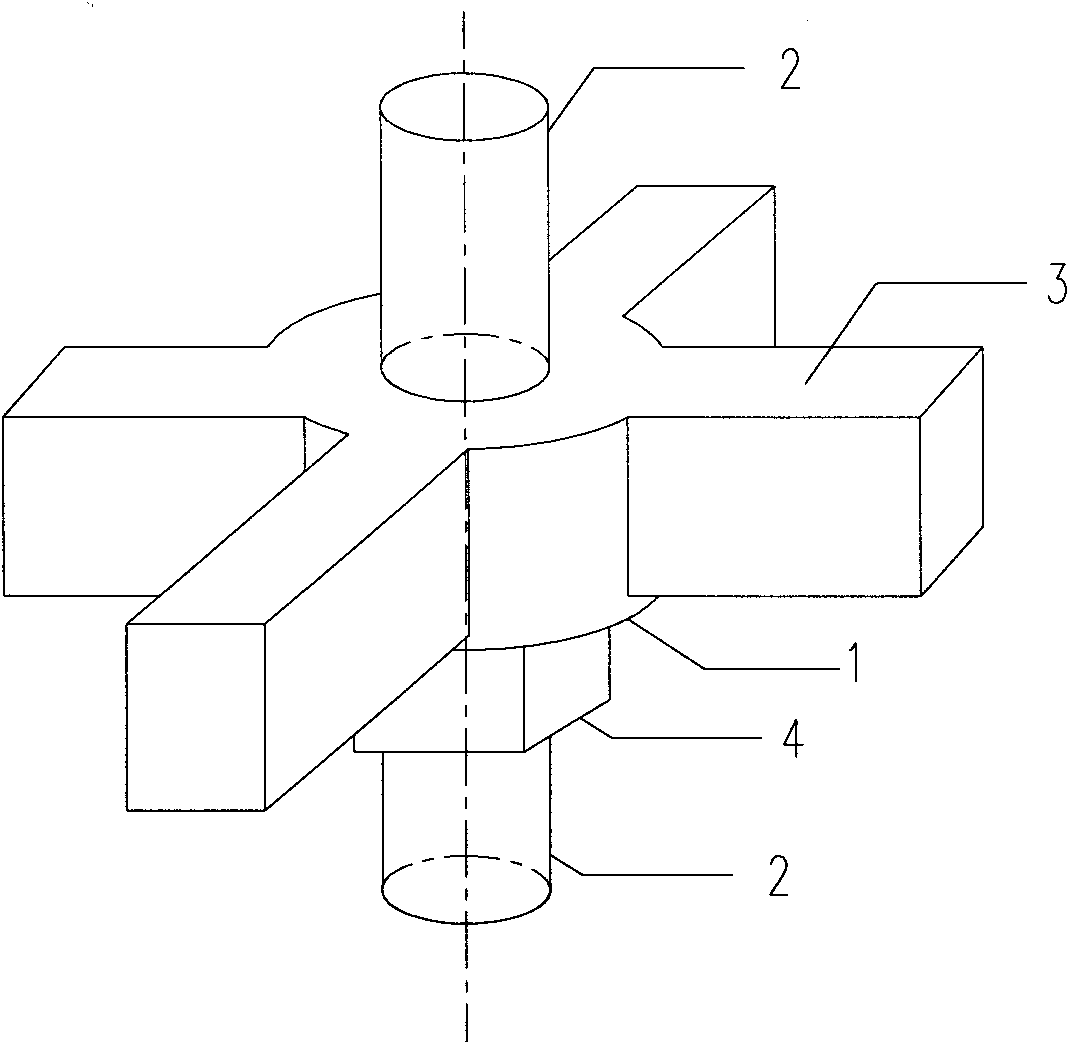

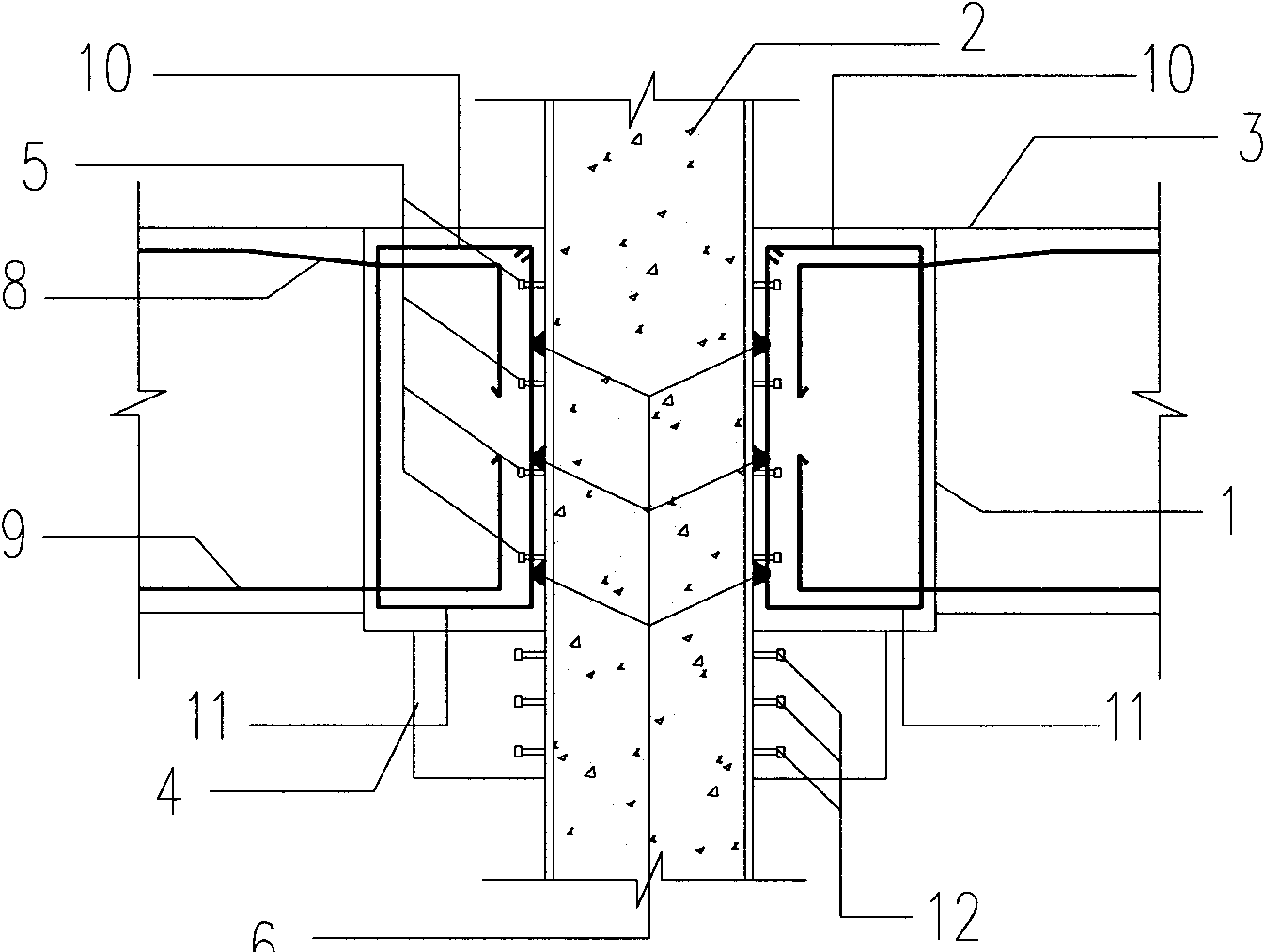

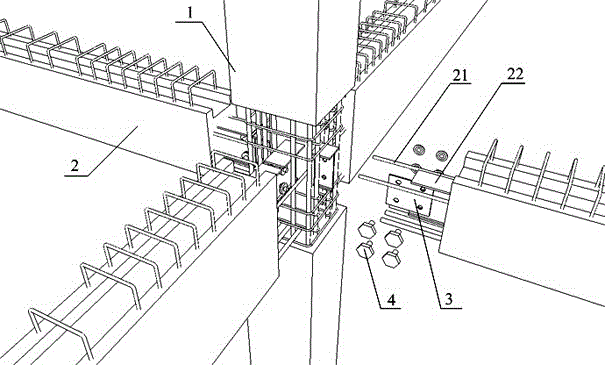

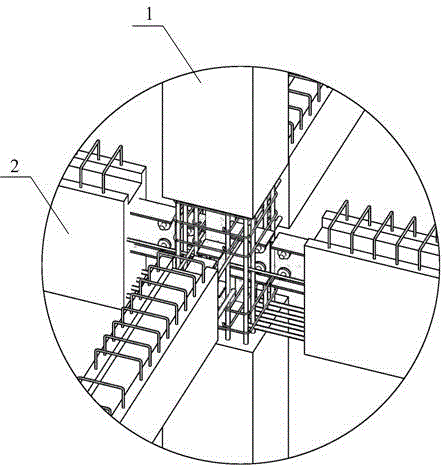

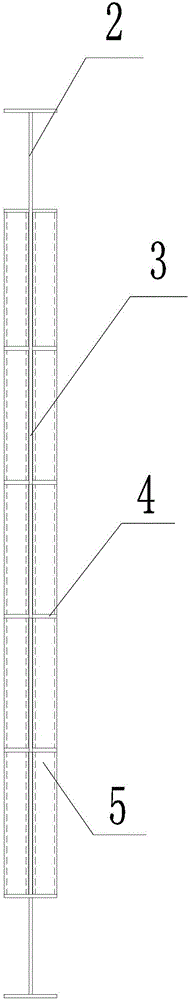

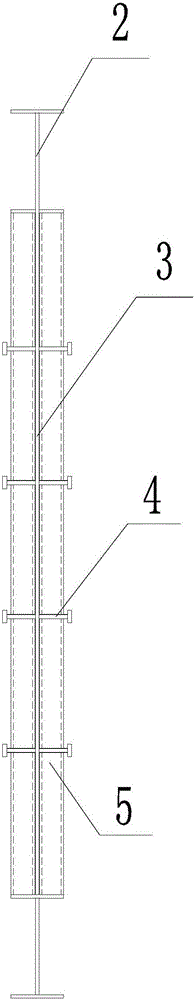

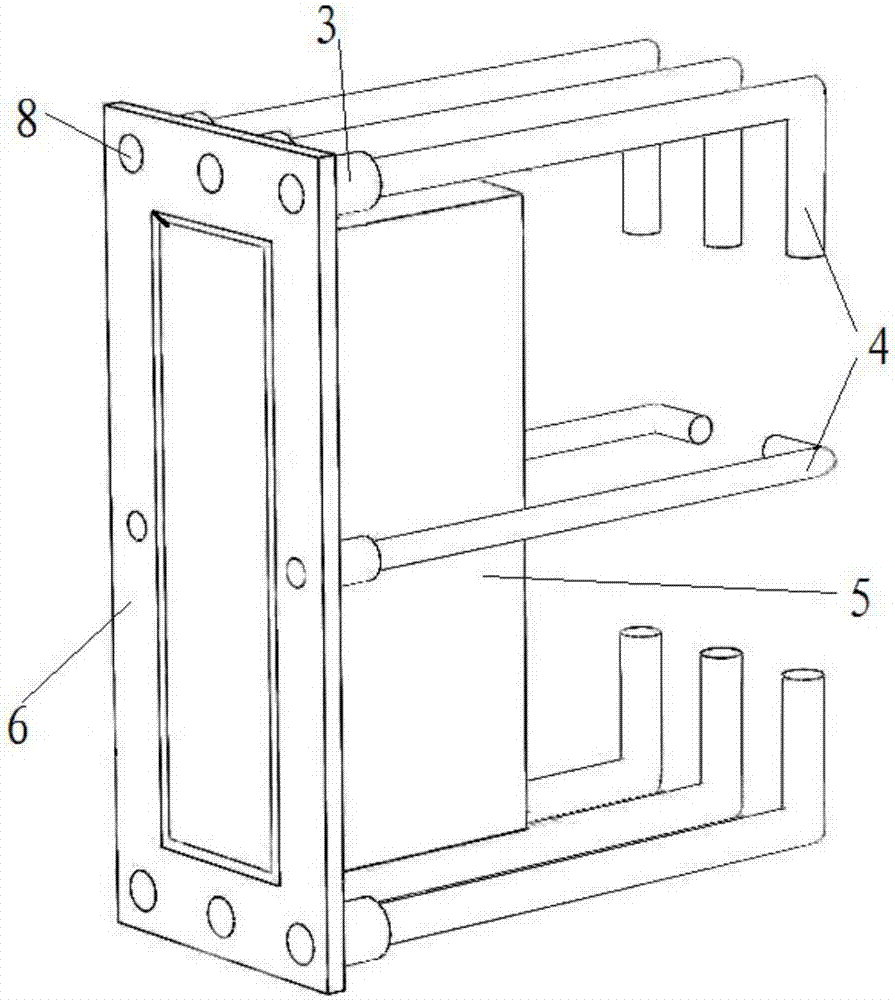

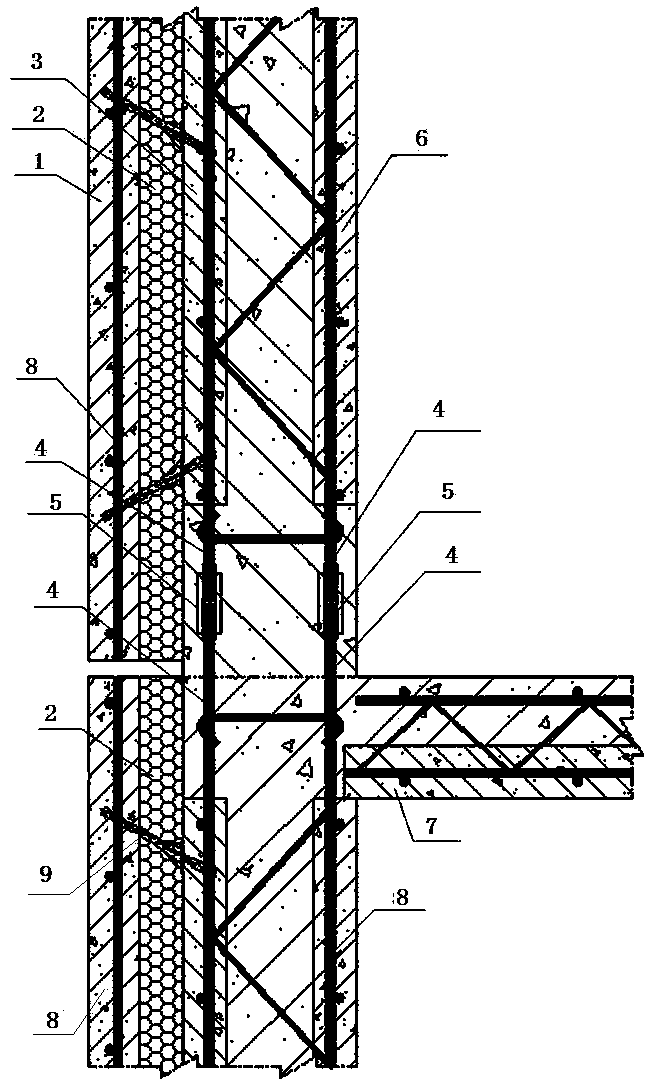

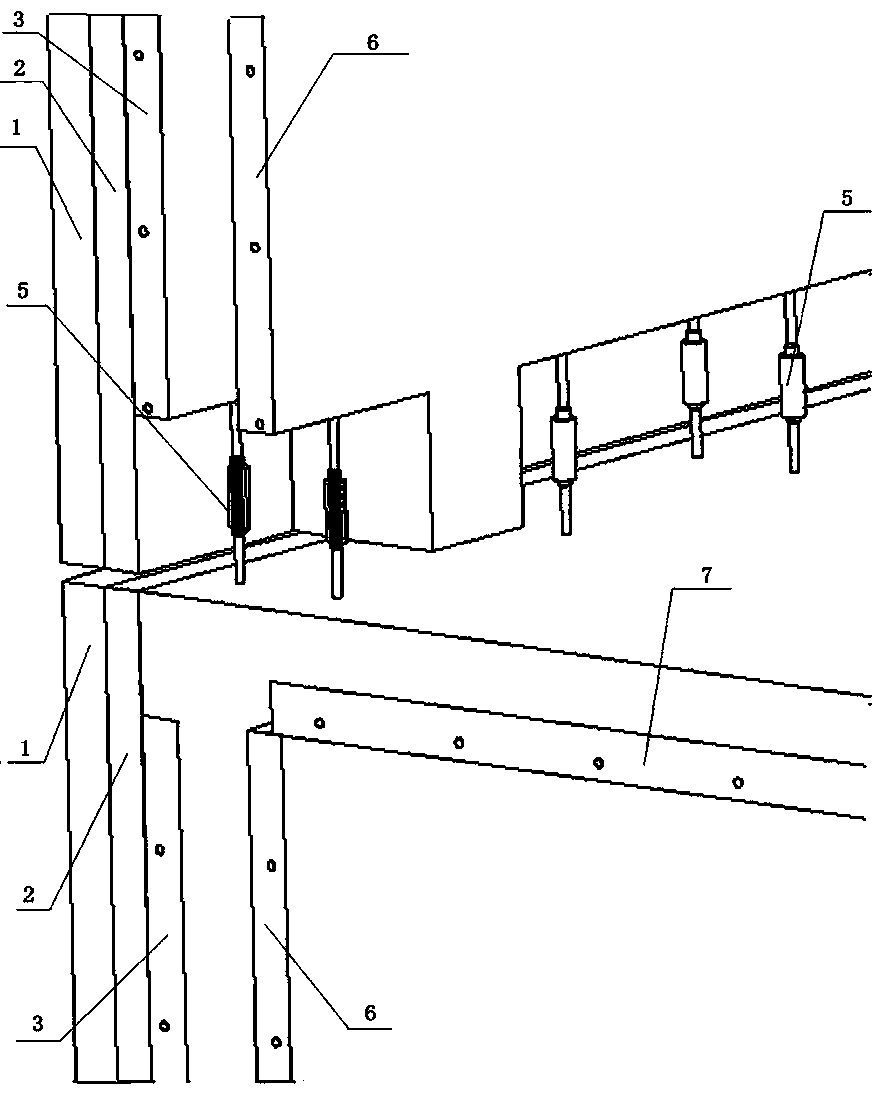

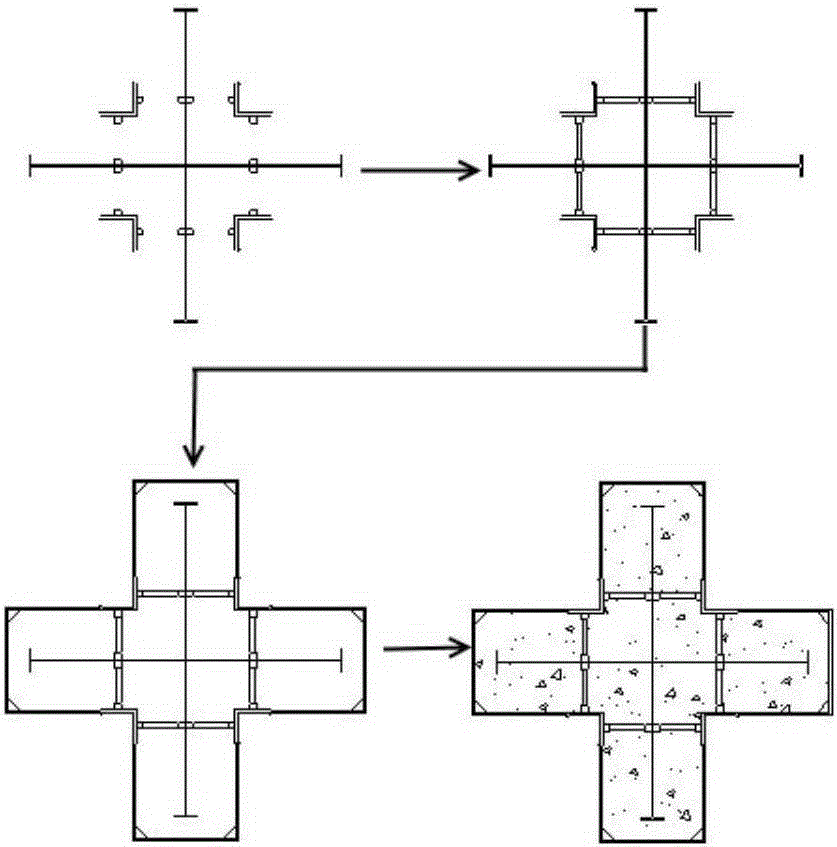

Double-sleeve steel-structure beam-column joint and installation method

ActiveCN107338872ASolve the destructiveSolve problems that are difficult to recover quicklyBuilding material handlingShear capacityEngineering

The invention relates to the technical field of structural engineering, in particular to a double-sleeve steel-structure beam-column joint and an installation method. The double-sleeve steel-structure beam-column joint comprises steel pipe columns and steel beams and further comprises inner sleeved steel pipes, circular sleeves, rectangular sleeves, a transfer connecting plate, energy dissipation steel plates, short beams and ratchet wheel connecting pieces, threaded holes are formed in the inner sleeved steel pipes, and bolt holes are formed in the circular sleeves, the rectangular sleeves and the steel pipe columns; and the inner sleeved steel pipes, the circular sleeves, the rectangular sleeves and the steel pipe columns are connected through long bolts, the steel pipe columns are further connected with the transfer connecting plate, the upper and lower sides of the transfer connecting plate are connected with the short beams through the upper energy dissipation steel plates and the lower energy dissipation steel plates correspondingly, and the short beams are further connected with the steel beams through the upper and lower energy dissipation steel plates and the ratchet wheel connecting pieces. According to the double-sleeve steel-structure beam-column joint and the installation method, by arranging multi-stage energy dissipation points ingeniously, the problems that the destructive effect of an earthquake on a building structure is large, and the building structure is difficult to recover rapidly are solved; and the joint columns are connected by adopting the core pipes, the double-sleeves and the long bolts, the bearing capacity is superior to the bearing capacity of an existing beam-column joint mode, and the shear capacity of the whole joint is enhanced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

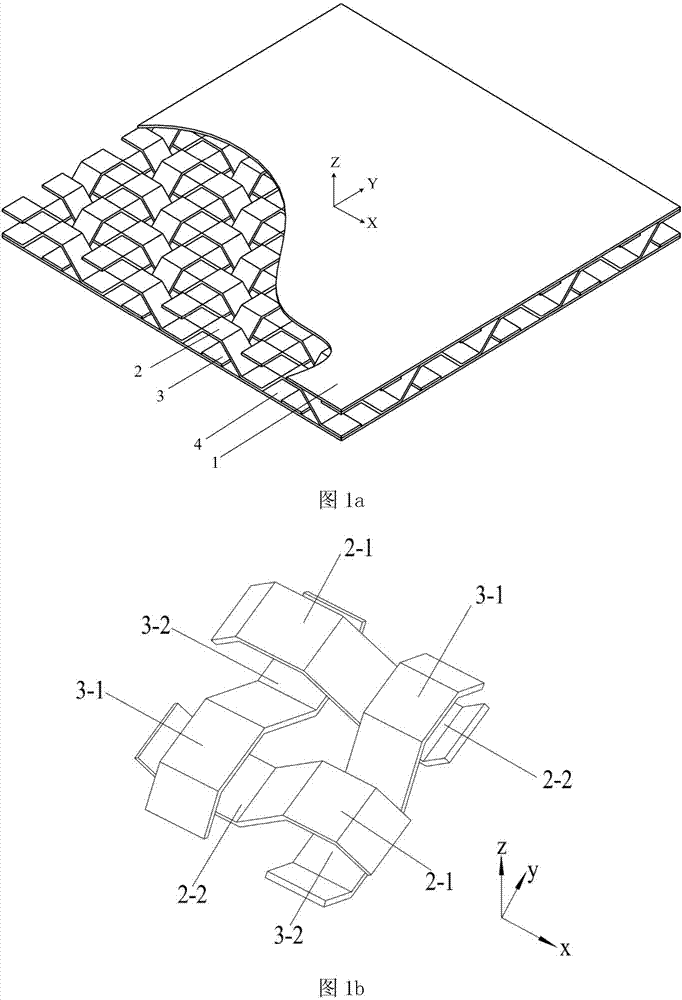

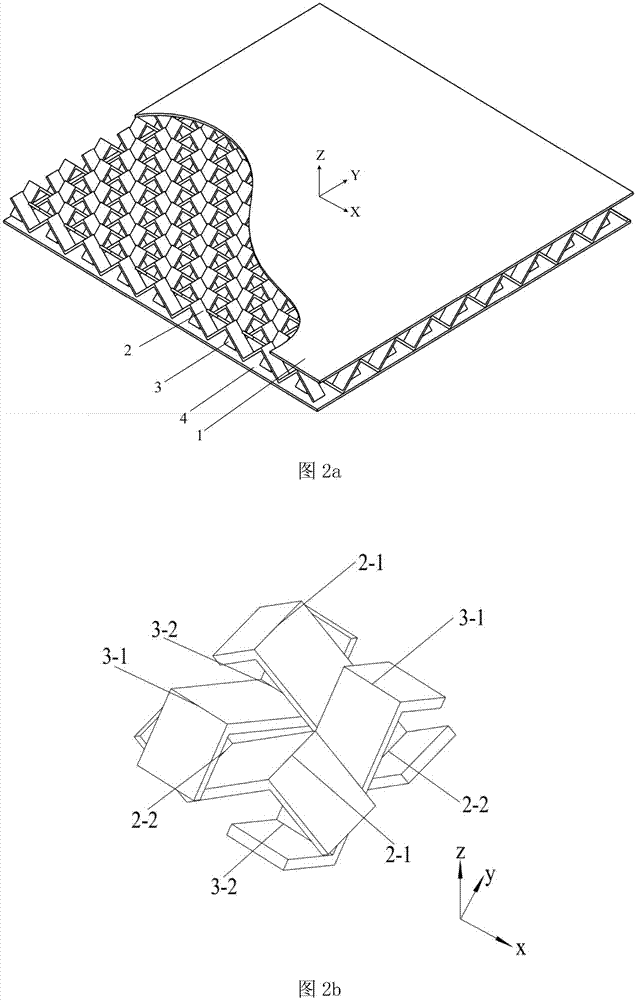

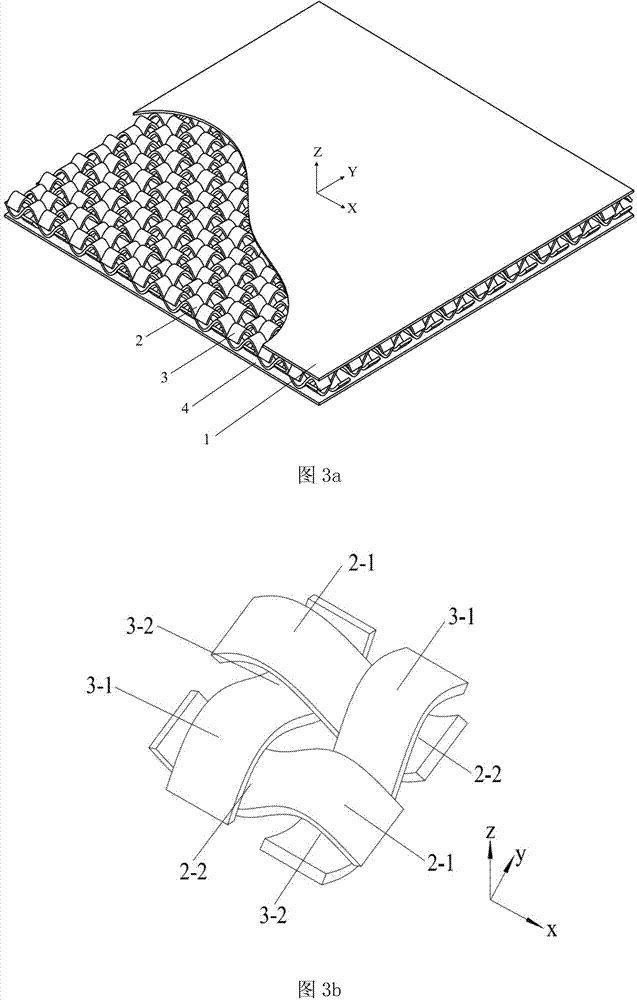

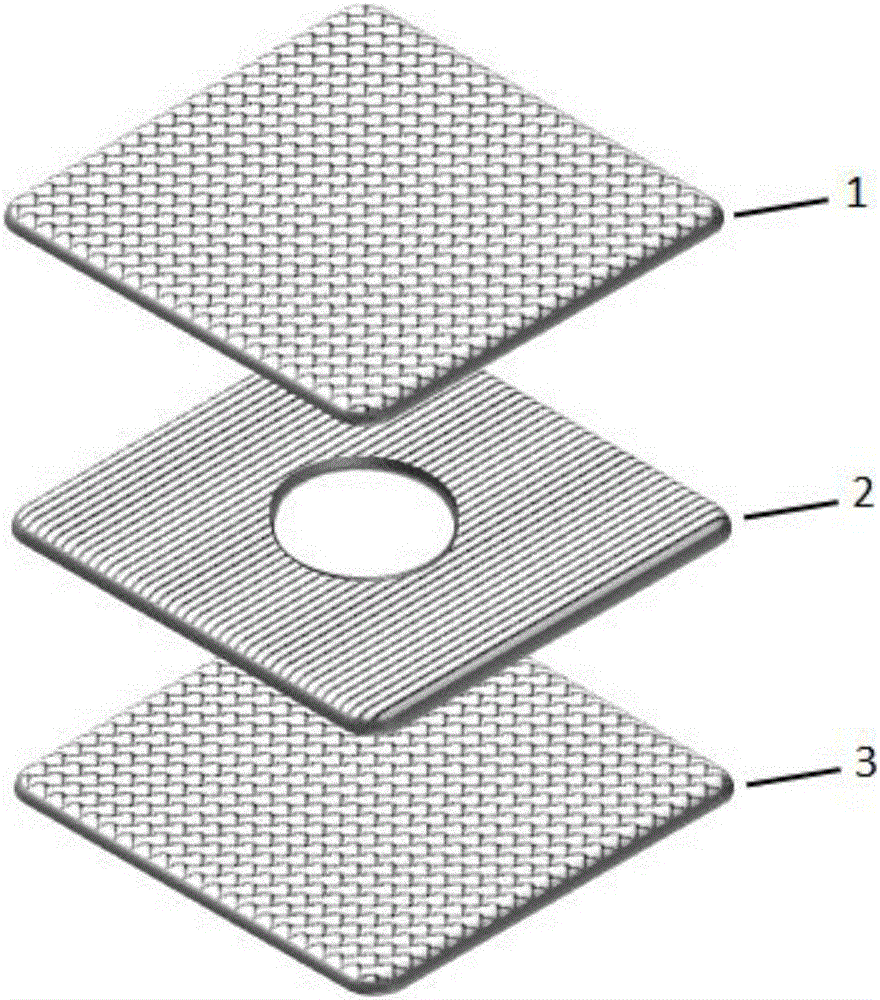

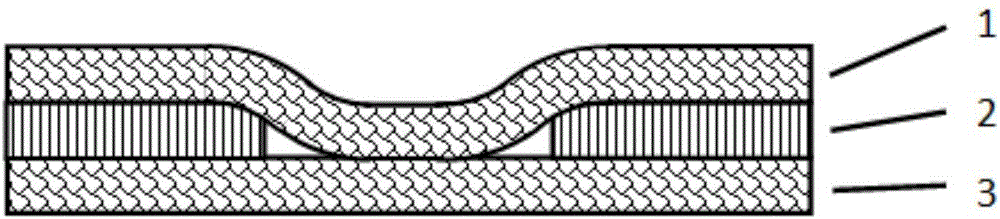

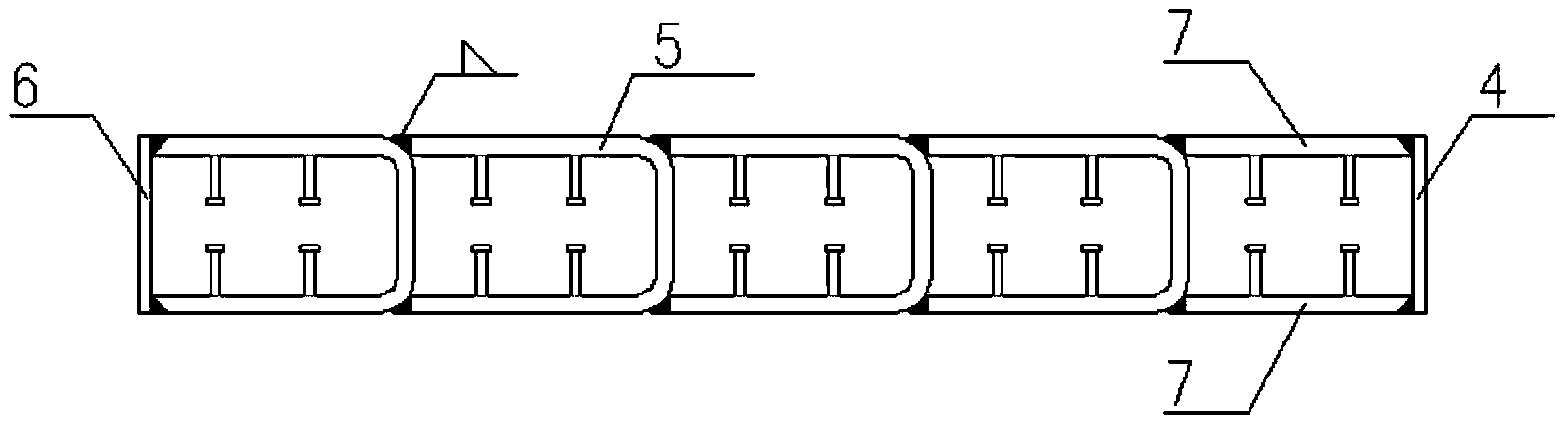

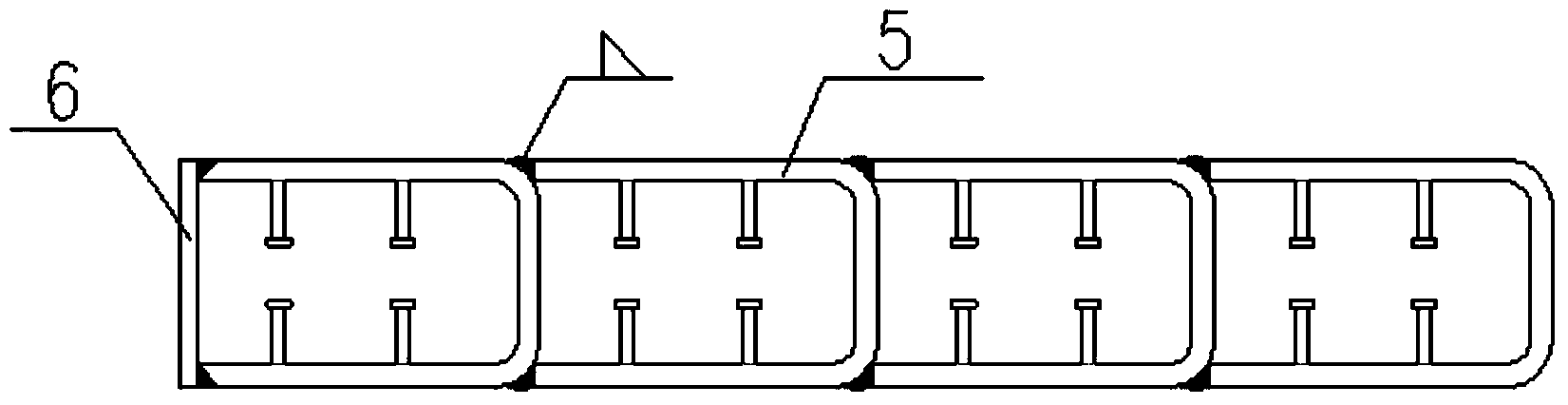

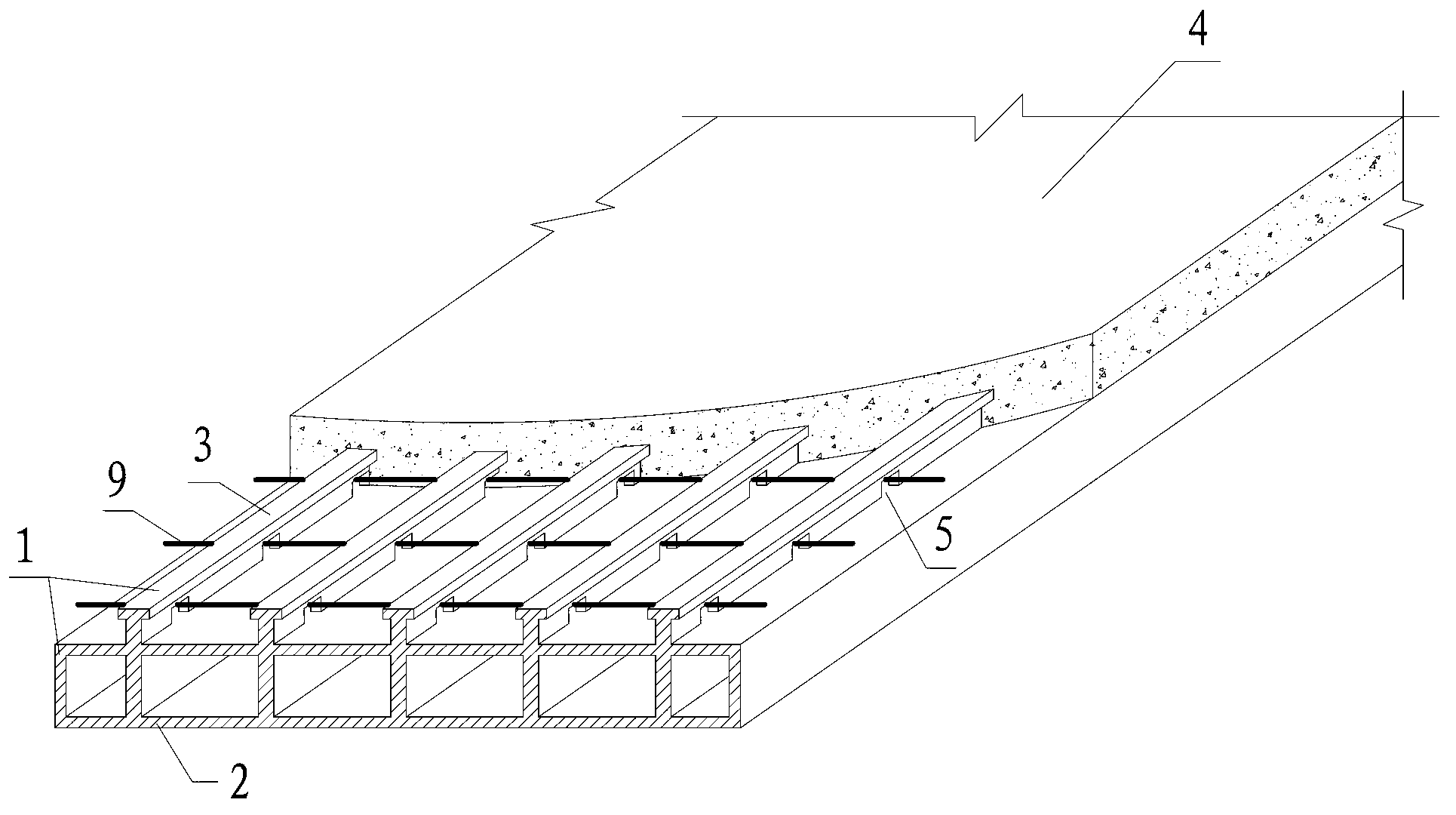

Light-weight orthogonal corrugated core sandwich composite structure and preparation method thereof

The invention discloses a light-weight orthogonal corrugated core sandwich composite structure and a preparation method thereof. The composite structure comprises an upper panel, a lower panel and an orthogonal corrugated core body arranged between the upper panel and the lower panel; compared with the traditional transverse isotropic corrugated core sandwich structure, in the orthogonal approximately-isotropic corrugated core sandwich composite structure disclosed by the invention, anti-shear capacities and anti-bending capacities in two in-plane orthogonal directions are approximately the same; in out-of-plane vertical directions, with the adoption of the design thinking and method of orthogonal corrugations, the anti-local buckling capacity of the orthogonal approximately-isotropic corrugated core sandwich composite structure is greatly enhanced compared with the transverse isotropic corrugated core sandwich structure, thus effectively avoiding the occurrences of local collapse and deformation along a corrugated surface; a gap formed by the orthogonal design of the core layer provides a space for multifunctional design for the structure, and functional components and parts can be placed, and sound absorption materials or other functional materials can be filled according to the needs of engineering applications, thus realizing multi-functionalization.

Owner:XI AN JIAOTONG UNIV

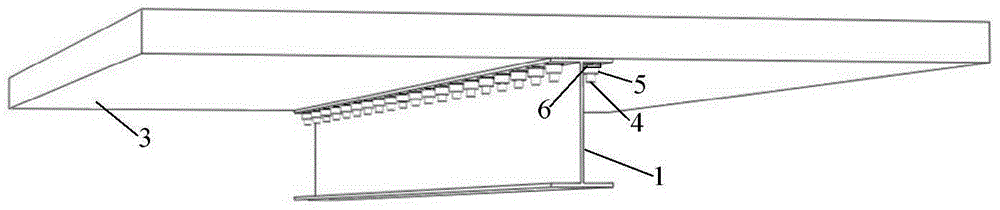

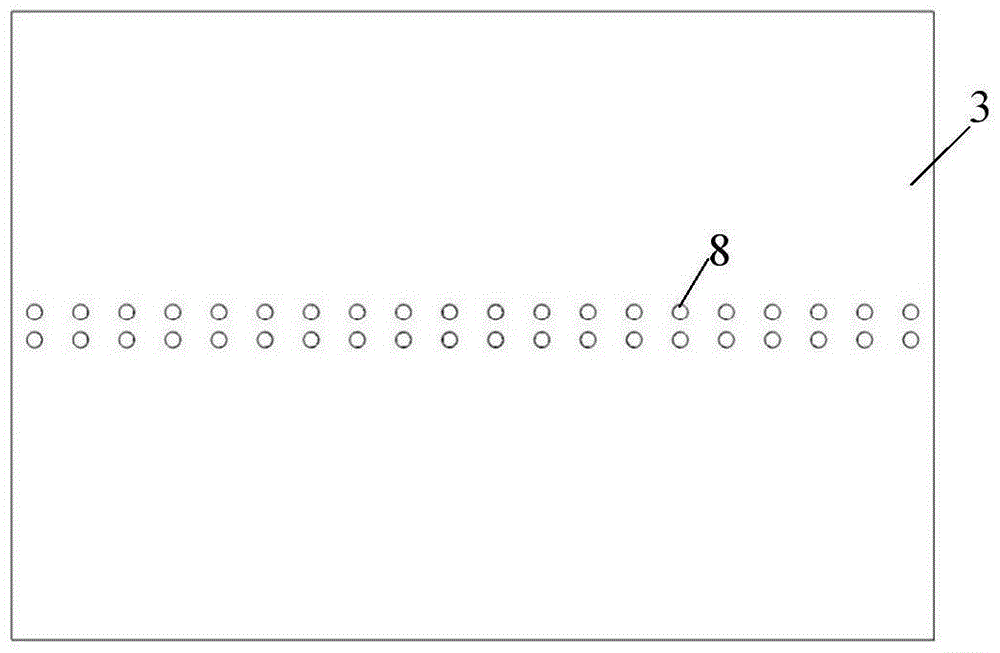

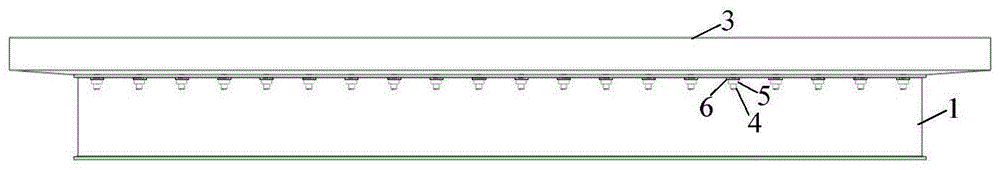

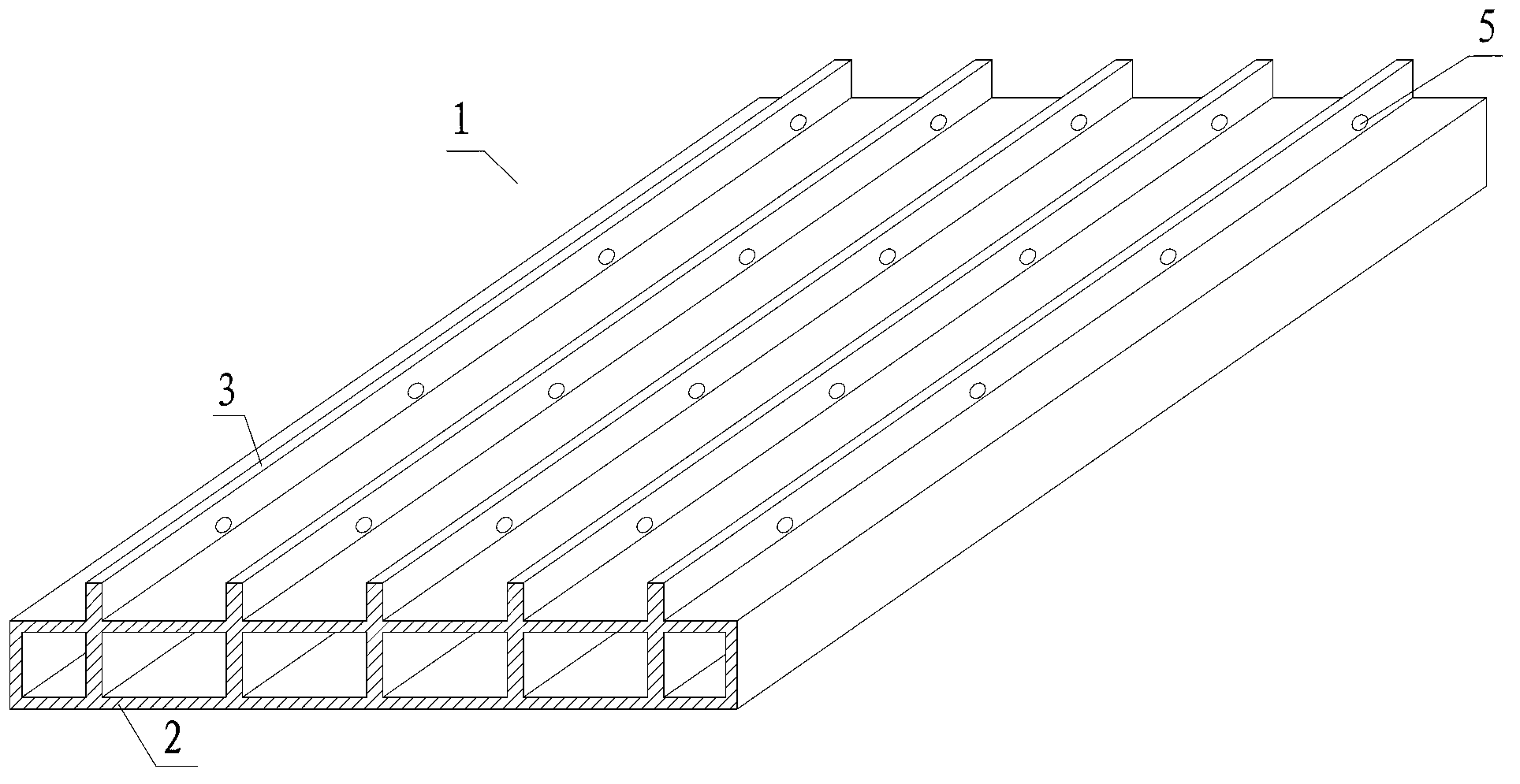

Prefabricated assembled steel-concrete composite beam connected by adopting high-strength bolt

InactiveCN105239720AImprove assembly efficiencyWork lessLoad-supporting elementsBridgesRebarPrecast concrete

The invention discloses a prefabricated assembled steel-concrete composite beam connected by adopting a high-strength bolt. The composite beam main comprises a steel beam, a prefabricated reinforced concrete slab and a shearing resistant bolt connection pair, wherein reasonable structural measures are reserved on the steel beam and the prefabricated concrete slab, and the shearing resistant bolt connection pair is adopted to connect the steel beam with the prefabricated concrete slab, so that compared with a situation that the beam-slab connection part is in rigid connection and the shear capacity is not substantially reduced, strong ductility and deformability can be obtained. When a prefabricated slab needs to be replaced, by detaching the nut of the shearing resistant bolt, the prefabricated slab is separated from the steel beam, so as to realize detaching and replacement of the prefabricated slab. All components adopted in the invention are assembled and connected on site, so that field welding work and template engineering can be reduced, the industrial assembly efficiency of buildings is improved, the function of detaching, separating and replacement of the beam-slab main body structure of the assembled composite structure can be achieved, and the novel architectural concept of capability of detachment and energy conservation and environment protection of building components can be embodied.

Owner:HUNAN UNIV

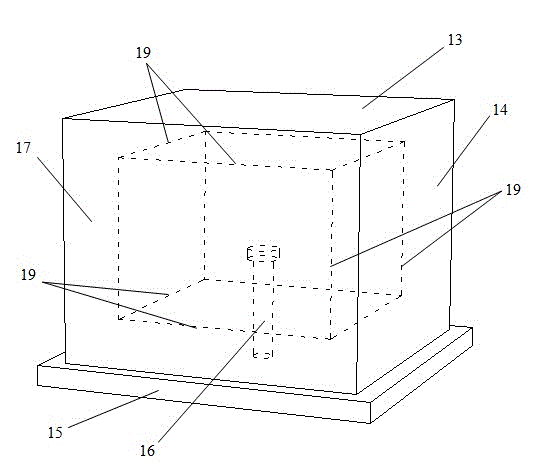

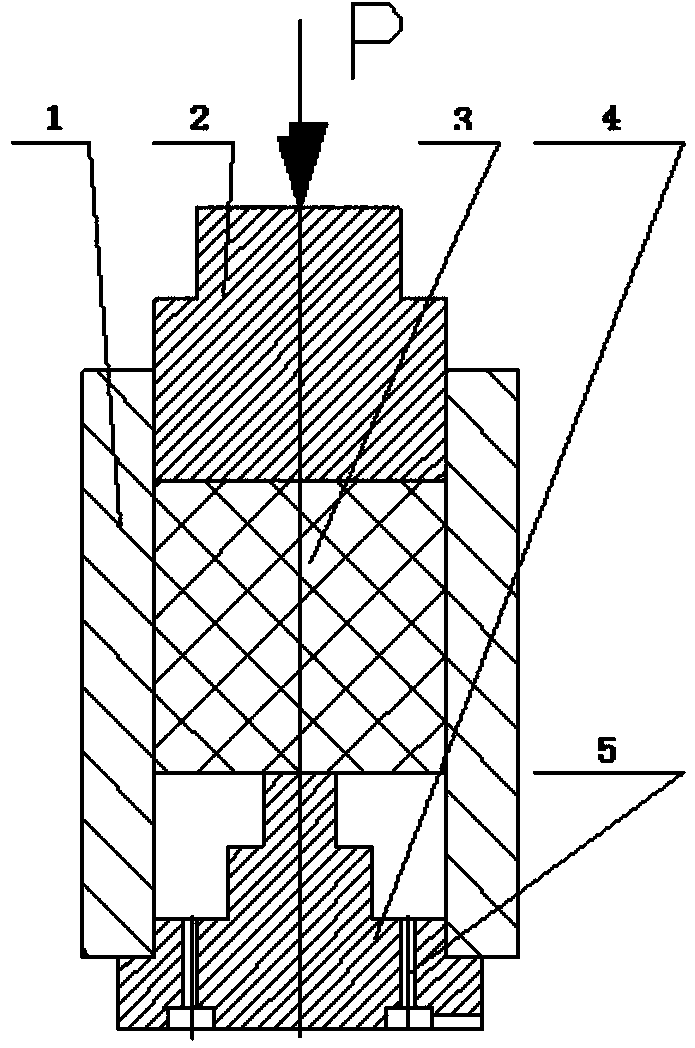

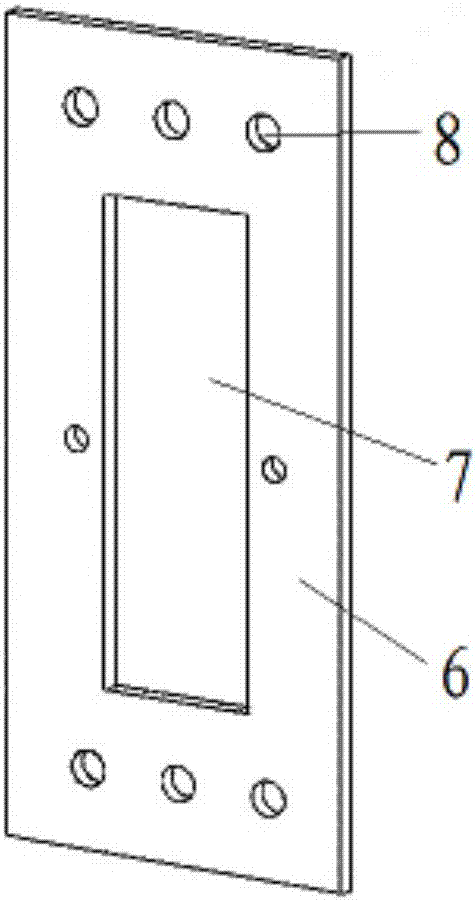

Test piece and method for shear capacity testing of steel-concrete interface shear connecting piece

InactiveCN102879282AAvoid uneven distributionAccurate measurementPreparing sample for investigationUsing mechanical meansSquare cross sectionArchitectural engineering

The invention discloses a test piece and a method for shear capacity testing of a steel-concrete interface shear connecting piece. The test piece comprises a steel plate, a concrete block, a stirrup and a shear connecting piece, and is characterized in that the number of the shear connecting piece is one, wherein the concrete block is cuboid and the cross section of the concrete block is square; the stirrup is a cuboid stirrup with a square cross section enclosed by a reinforcing steel bar; the stirrup is cast in the concrete block; the geometric center of the stirrup is overlapped with the geometric center of the concrete block; two opposite sides of the cross section of the stirrup are parallel with two opposite sides of the cross section of the concrete block; the concrete block is cast on the steel plate; the rod end of the shear connecting piece is welded to the steel plate; and the shear connecting piece is perpendicular to the steel plate and is positioned in the center of an interface of the steel plate and the concrete block. According to the test piece and the method, the influence of loading eccentricity can be corrected to achieve accurate shear capacity of a combined structure shear connecting piece; and the cohesion of the steel-concrete interface can be measured.

Owner:ZHEJIANG UNIV

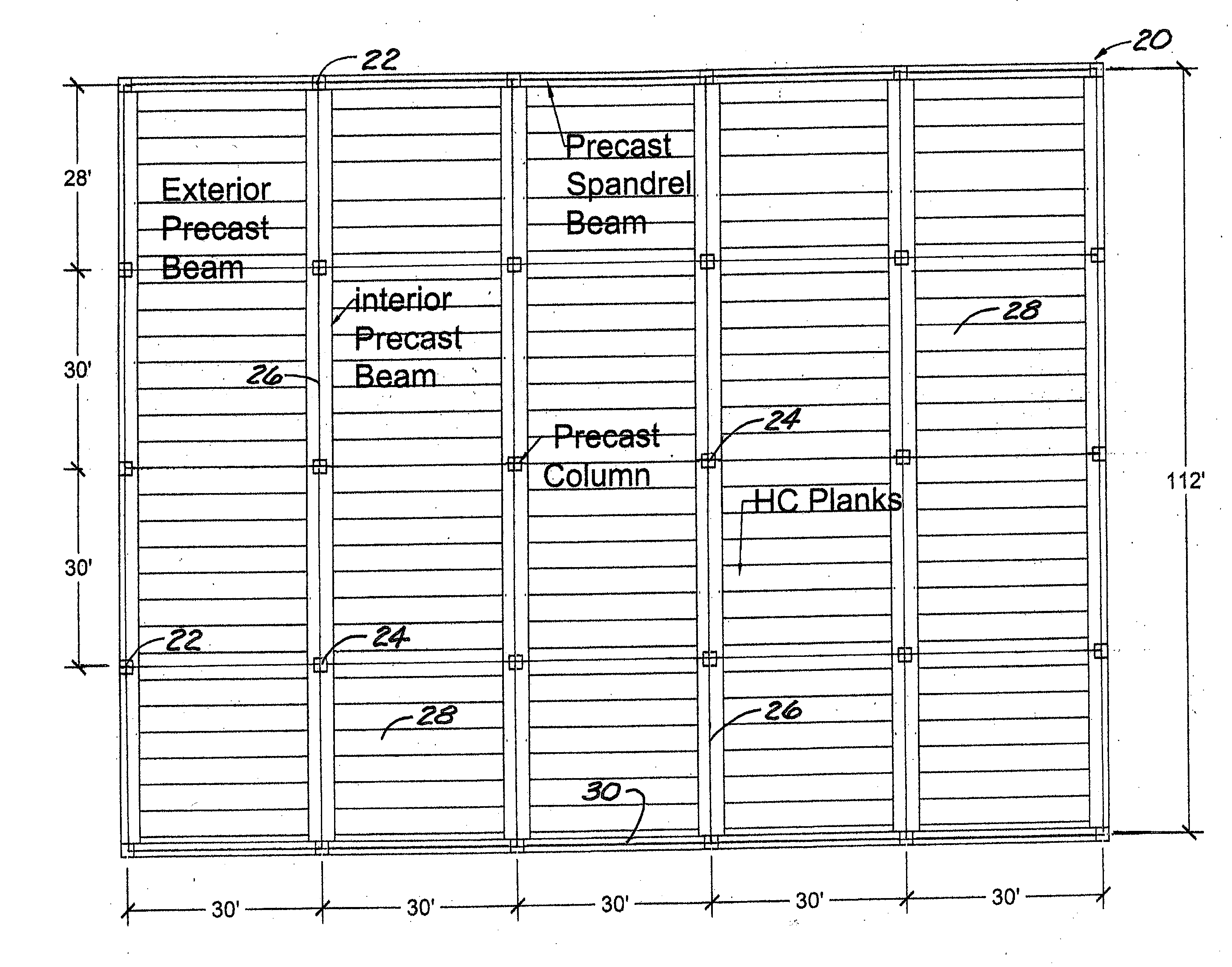

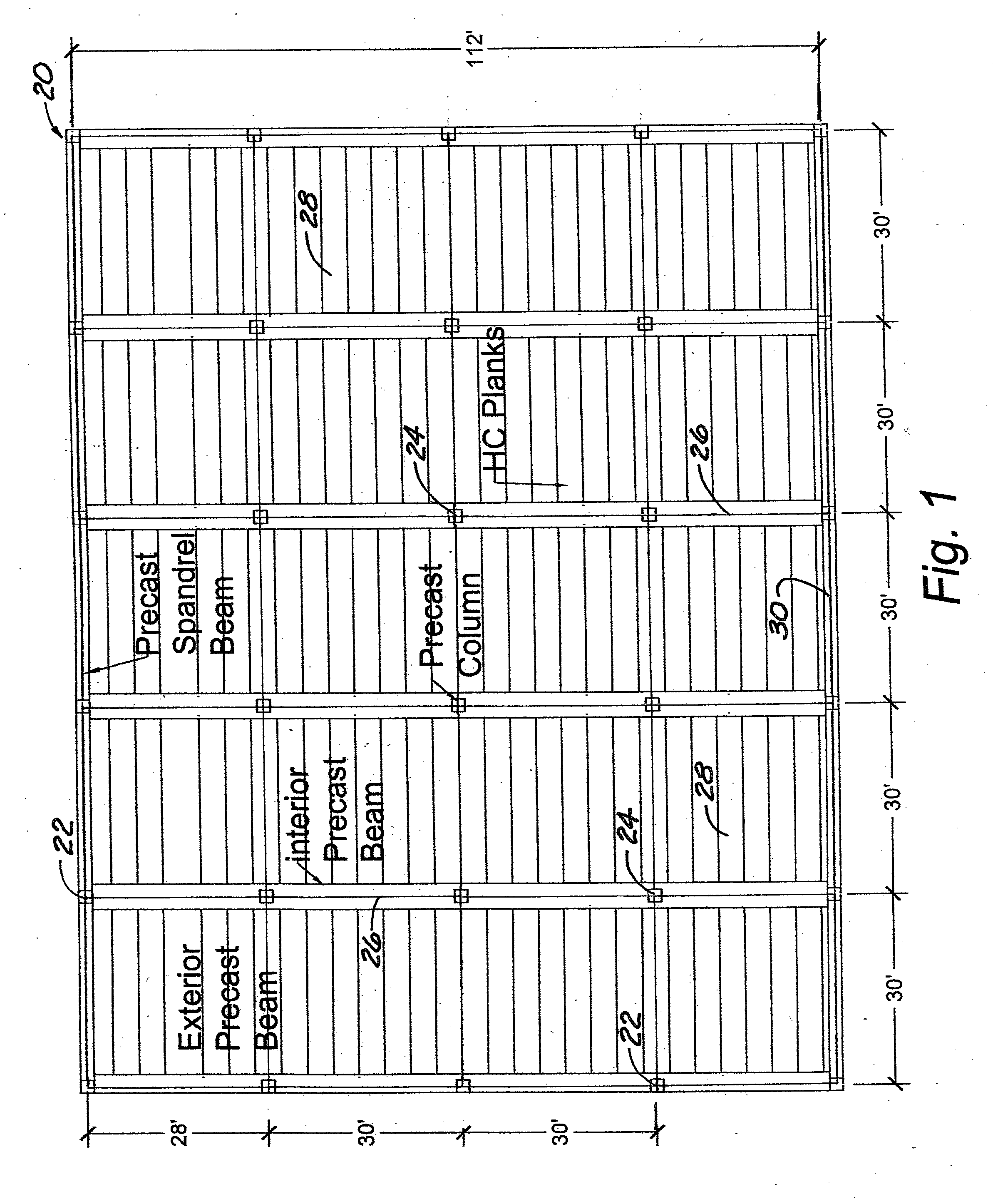

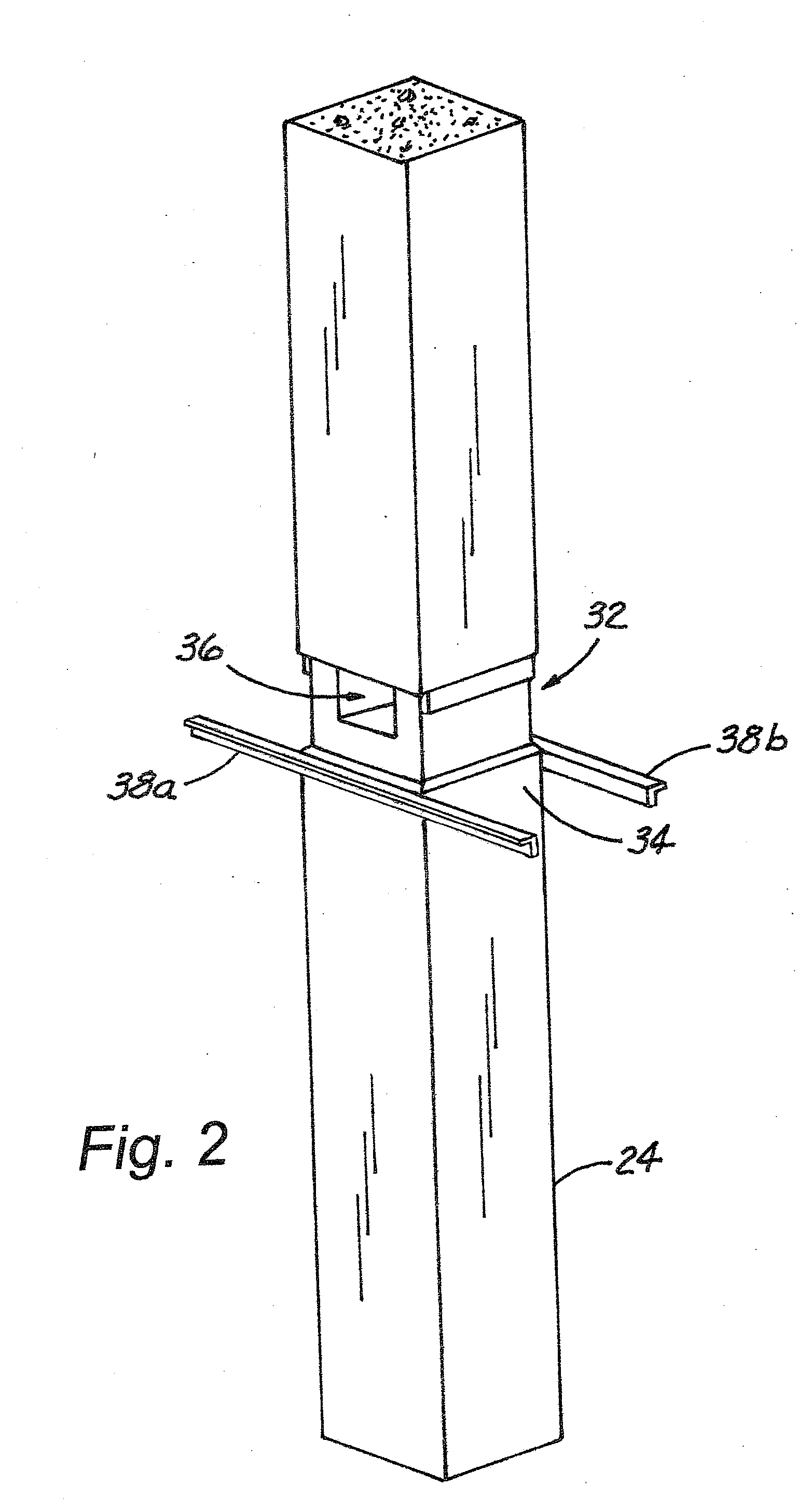

Shallow Flat Soffit Precast Concrete Floor System

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

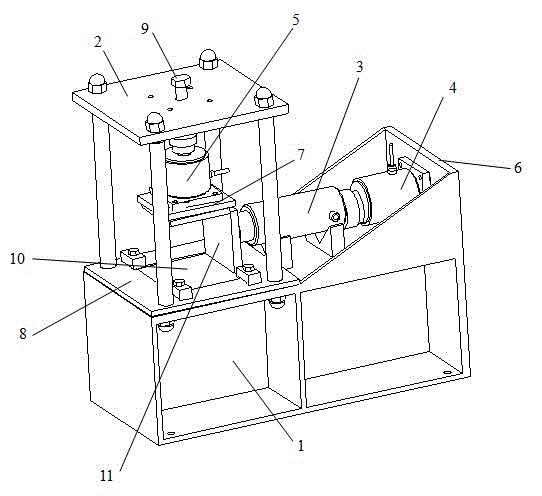

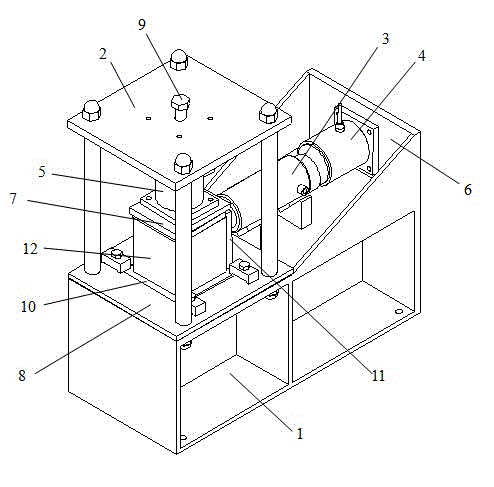

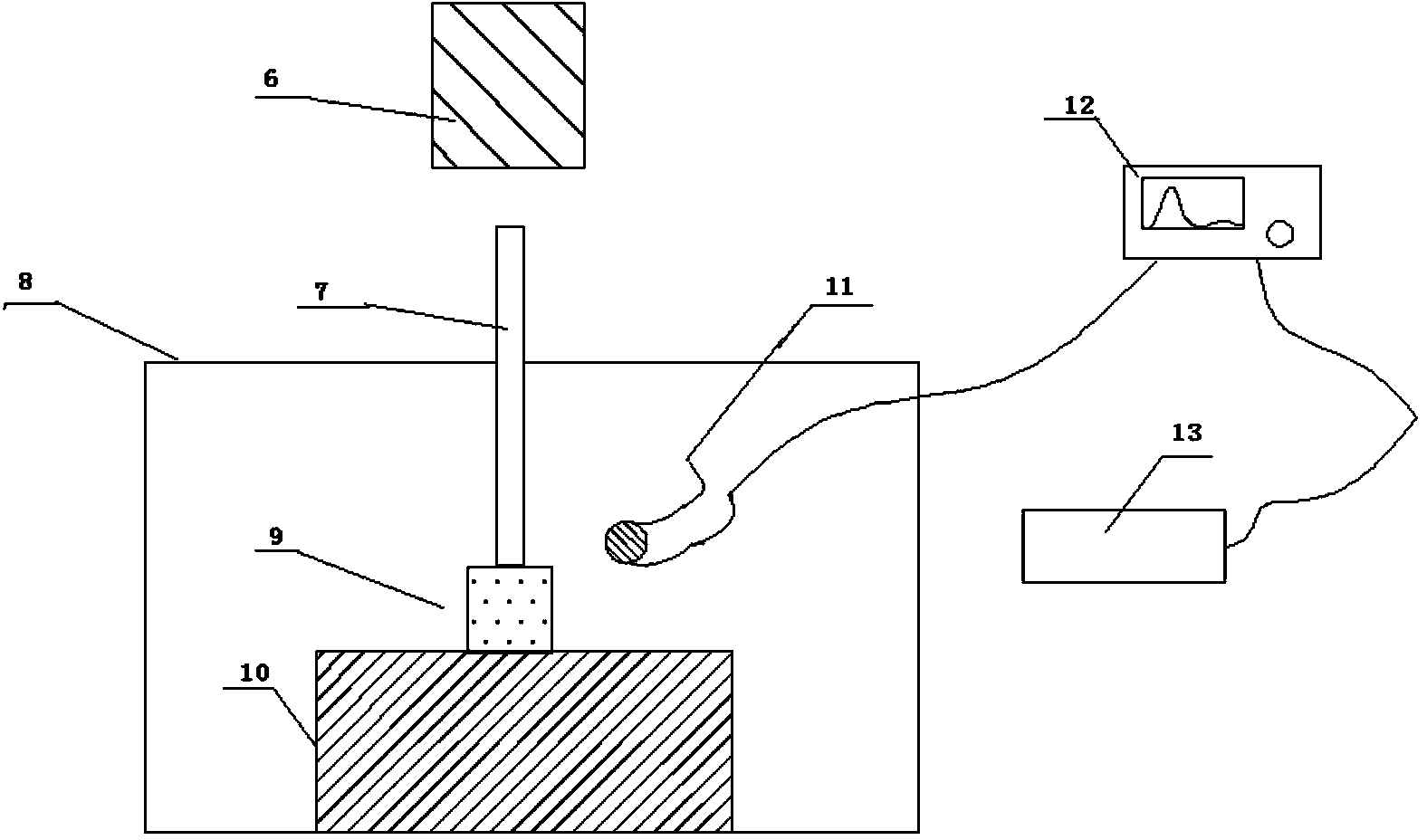

Experimental device for evaluating explosive loading impact safety of tail part of projectile body

The invention discloses an experimental device for evaluating the explosive loading impact safety of the tail part of a projectile body and solves the problem that in the prior art, the explosive loading impact safety of the tail part of the projectile body of a warhead cannot be accurately evaluated. The device comprises a limit barrel body, a drive press block, a shearing die and the like, wherein the drive press block is placed at the upper end of explosive loaded in the limit barrel body and used for applying certain pressure to the explosive; the shearing die is mounted at the bottom end of the limit barrel body in a sleeving manner and used for generating shearing acting force on the explosive. The experimental device is mainly used for experiment research on the self-response of the explosive loading of the tail part of the projectile body of the warhead under shearing action, has a simple structure and is convenient to operate, and can compare the anti-shear ability and the ignition response characteristic of the explosive loading under the same loading condition.

Owner:XIAN MODERN CHEM RES INST

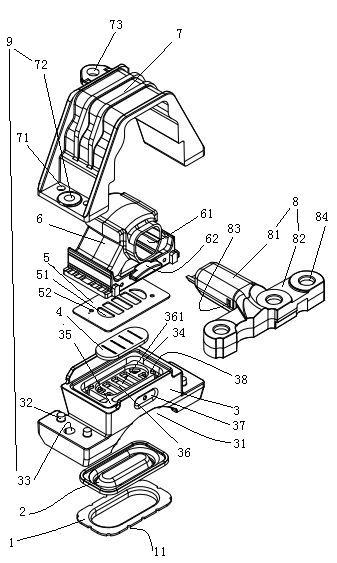

Hydraulic suspension of engine

ActiveCN102588501AImprove shock absorptionImprove shear resistanceSpringsJet propulsion mountingShear capacityEngineering

Owner:泛美汽车零部件(宁波)有限公司

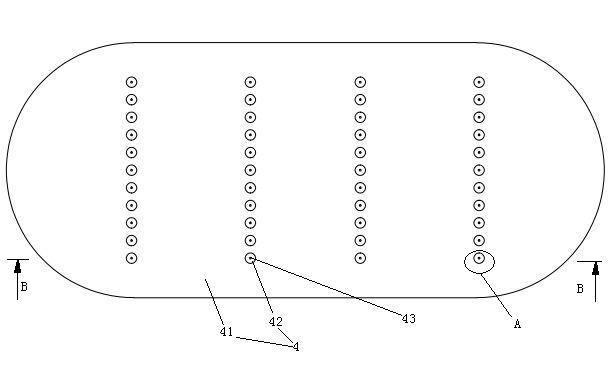

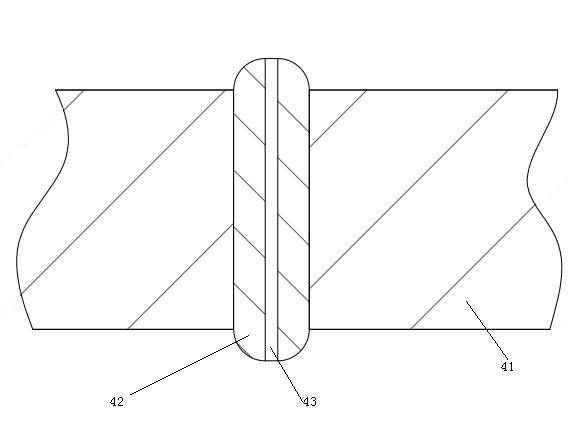

Structure for rapidly restoring hinge joint of hollow slab bridge and construction method thereof

InactiveCN105019365AReduce workloadQuality is not affectedBridge erection/assemblyBridge strengtheningBridge engineeringPositive pressure

The invention discloses a structure for rapidly restoring a hinge joint of a hollow slab bridge and a construction method thereof, which belong to the field of bridge engineering. The structure for rapidly restoring the hinge joint of the hollow slab bridge comprises a hinge joint crossing U-shaped bar, a sealing section, a coarse aggregate and a curing body, wherein the hinge joint crossing U-shaped bar is embedded upwards from the bottom surface of a hollow slab; the sealing section is arranged at the lower part of the hinge joint; the coarse aggregate is arranged on the sealing section; the curing body is formed by a high-expansion grout pressed to a coarse aggregate area and is used for enclosing the coarse aggregate; and a combined body of the coarse aggregate and the curing body is named as grouted aggregate concrete. According to the structure for rapidly restoring the hinge joint of the hollow slab bridge, the U-shaped reinforcing steel bar is used for resisting flexural-tensile stress in a transverse direction of the bridge and the grouted aggregate concrete is used for resisting the shear force between the slabs. An internal stress is generated in the grouted aggregate concrete through a high polymer formed by the high-expansion grout so that the shrinkage of the traditional hinge joint concrete is avoided; and through the internal stress, a positive pressure between a new concrete interface and an old concrete interface is increased, the bonding force between the interfaces is increased and the anti-shear capacity of the hinge joint is enhanced. The construction method for the structure for rapidly restoring the hinge joint of the hollow slab bridge, disclosed by the invention, is advantaged in that the construction speed is high; the hollow slab bridge can be rapidly opened for traffic; the curing effect of the structure is good; and standardized operation can be realized.

Owner:ZHENGZHOU UNIV

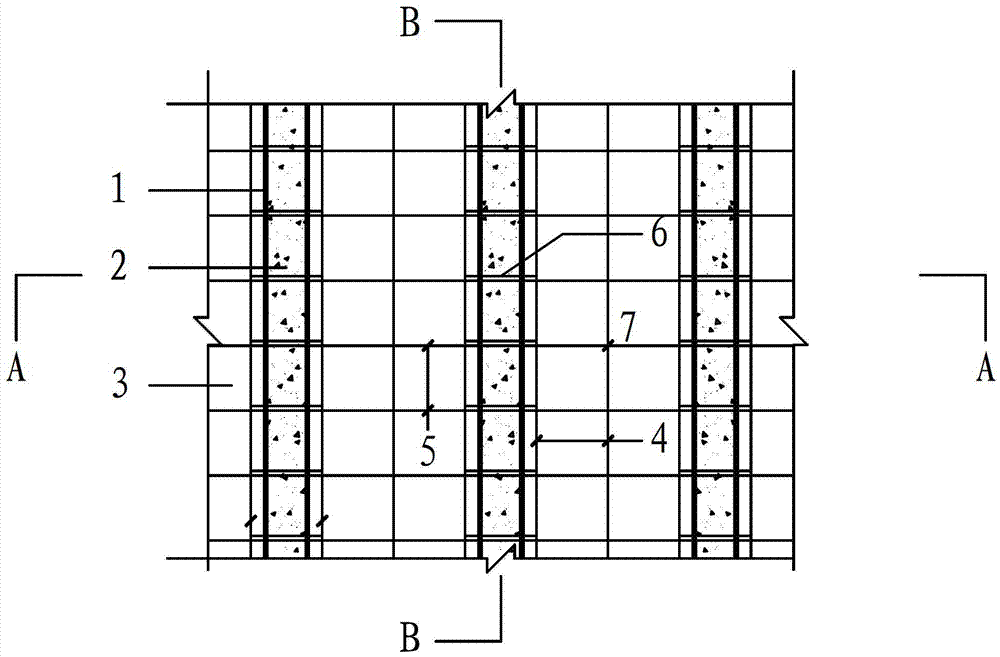

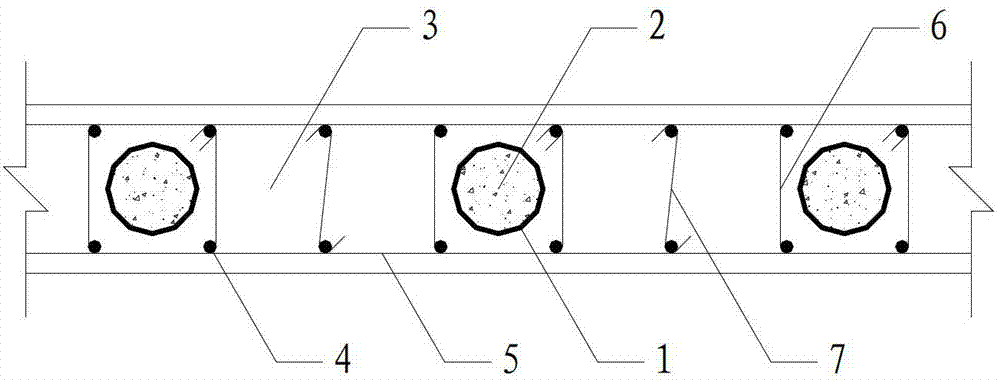

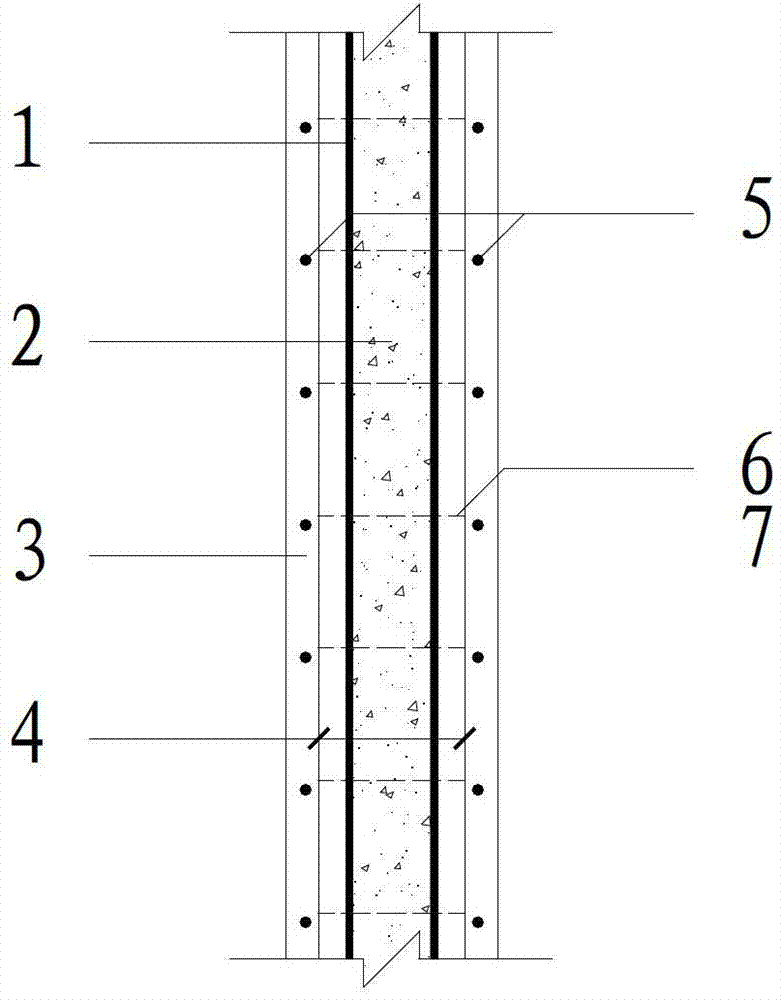

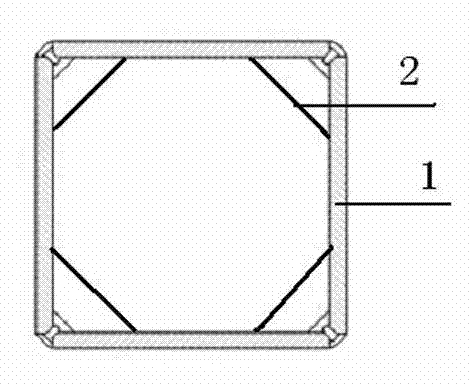

Concrete-filled steel tube combined shear wall and construction process thereof

InactiveCN102900169AHigh strengthImprove ductilityWallsBuilding material handlingReinforced concreteShear capacity

The invention relates to a concrete-filled steel tube combined shear wall and a construction process thereof. The shear wall comprises steel tubes which are distributed uniformly along the section of the shear wall, concrete filled into the steel tubes, concrete poured outside the steel tubes, square stirrups arranged outside the steel tubes, and vertically-distributed steel bars and horizontally-distributed steel bars which are arranged on front and rear sides of the steel tubes, tie steel bars which are tied between the steel tubes and the vertically-distributed steel bars and between the steel tubes and the horizontally-distributed steel bars, and longitudinal steel bars which are arranged at the positions of restraint members on edges of two sides of the steel bars. According to the concrete-filled steel tube combined shear wall, the steel tubes are embedded into the ordinary reinforced concrete shear wall, and the bearing capacity of the concrete is improved under the restraint action of the steel tubes, so that the sectional dimensions of the members are reduced, the dead weight of a structure is reduced, a seismic effect is reduced, and more usable areas are provided for buildings under the condition of the same design axial force; and anti-seismic properties of the flexural capacity, shear capacity, damage ductility and the like of the shear force are improved effectively by utilizing the high bearing capacity and high ductility of the concrete-filled steel tubes.

Owner:TSINGHUA UNIV

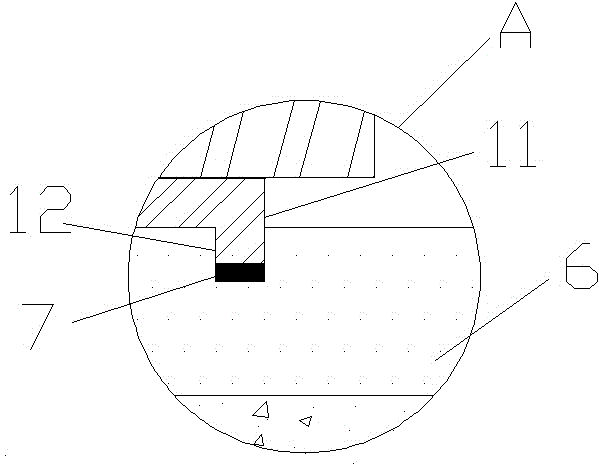

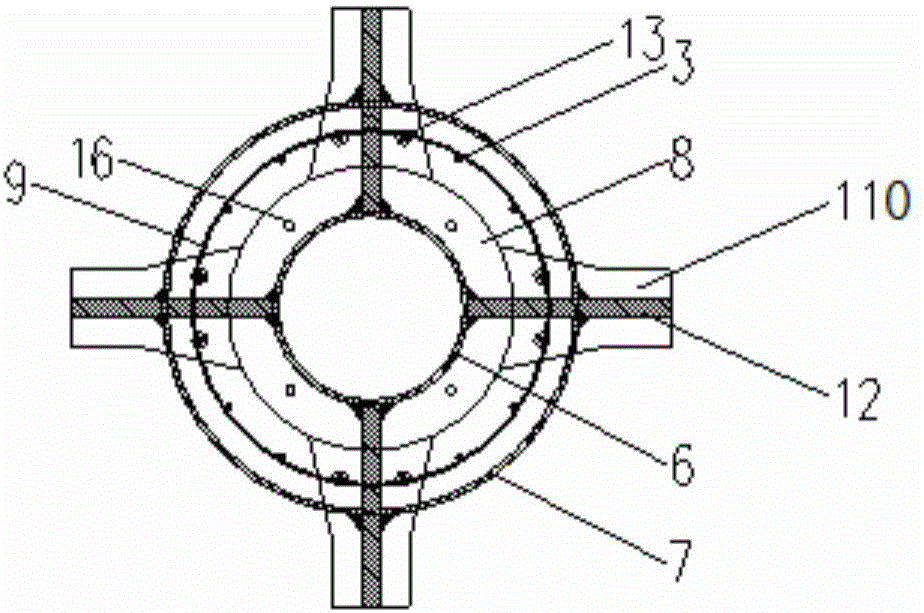

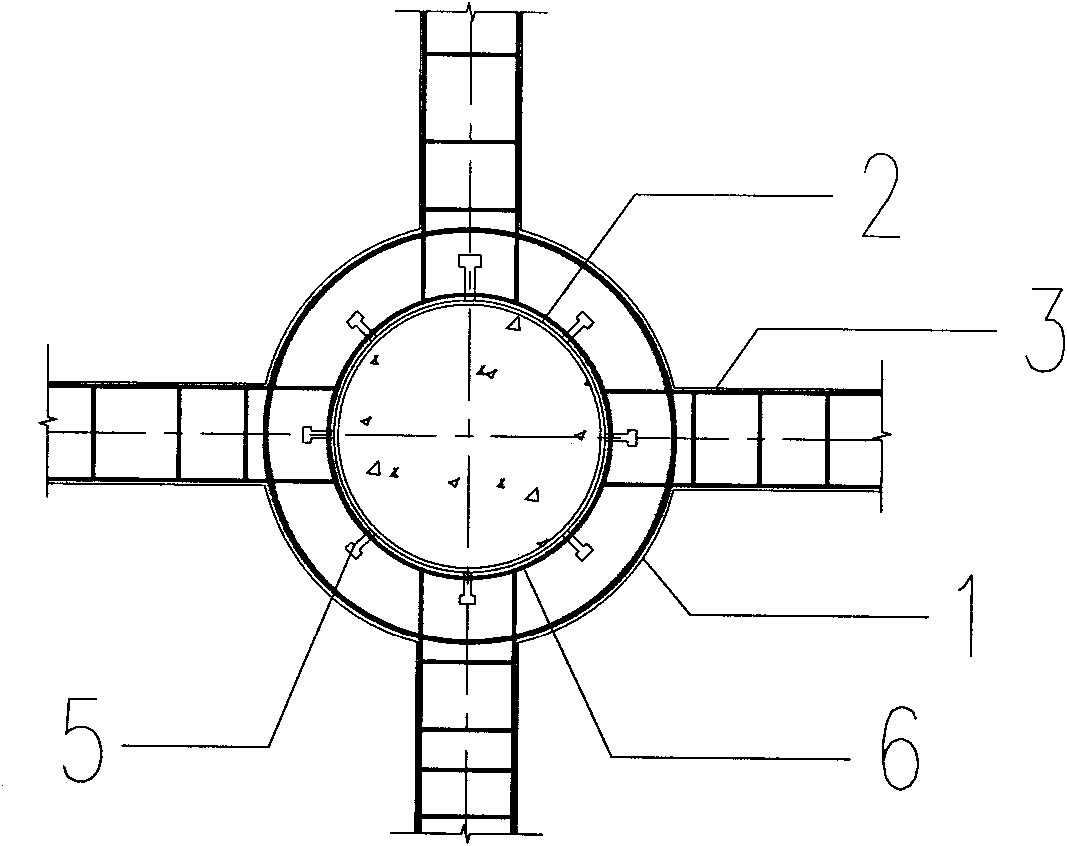

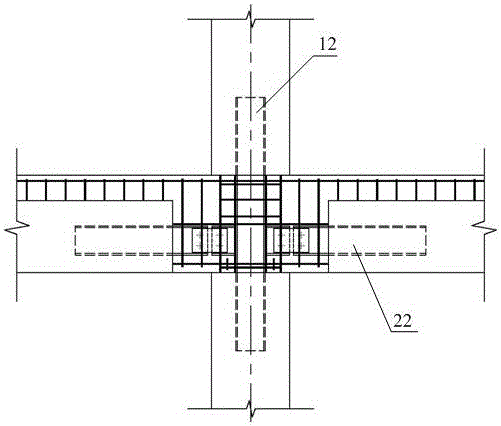

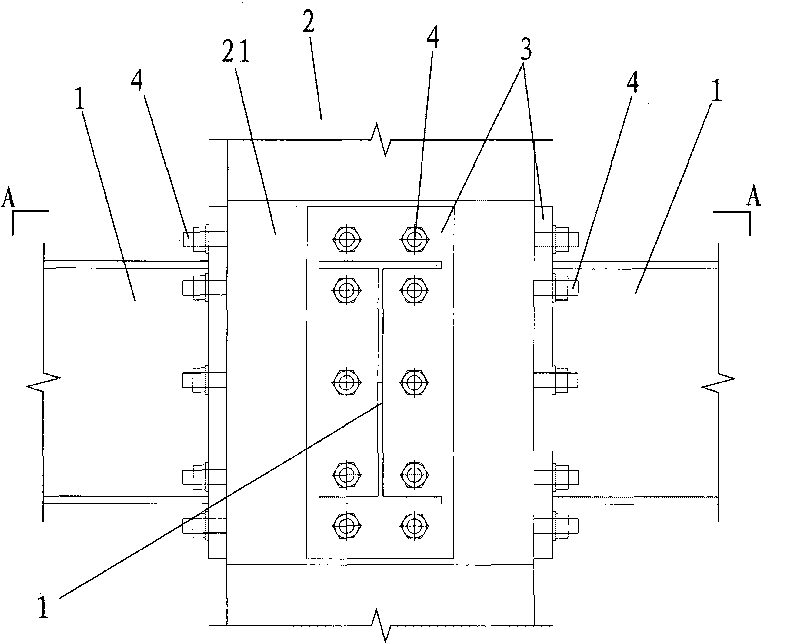

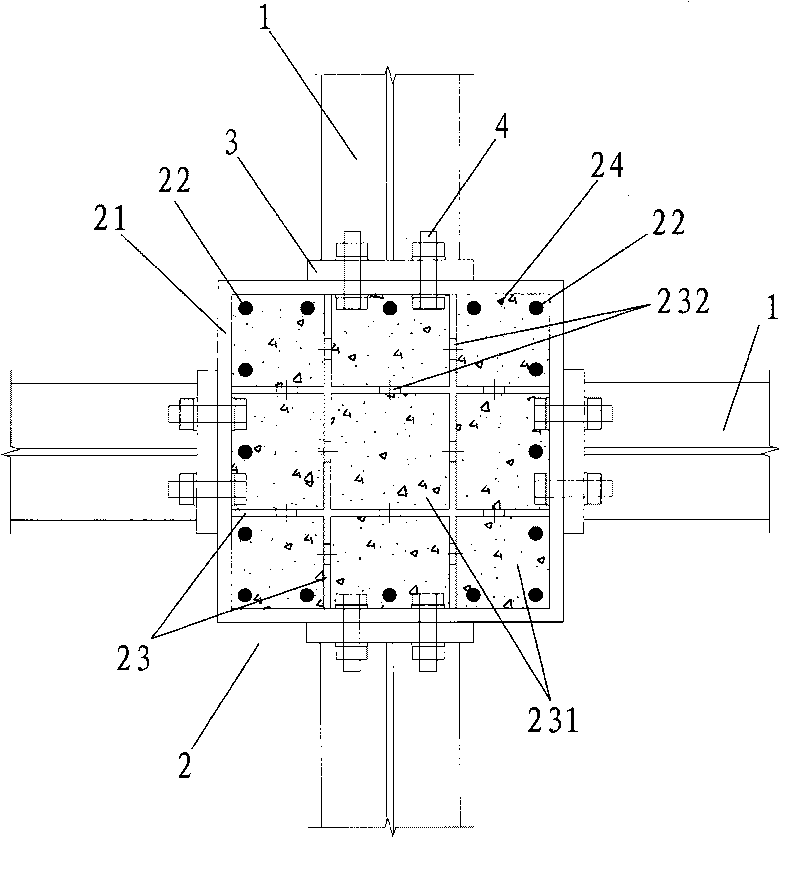

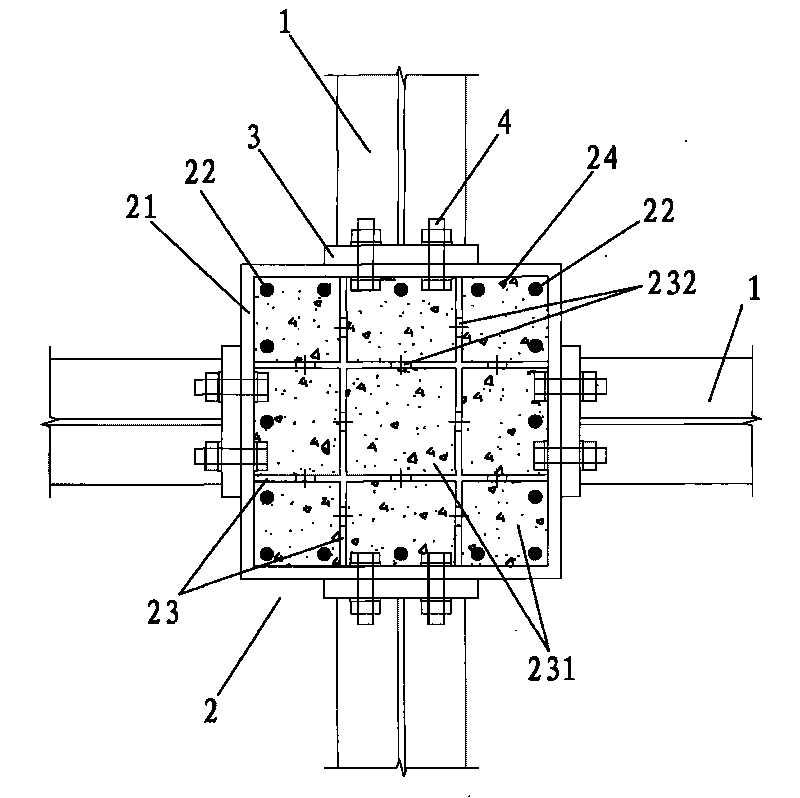

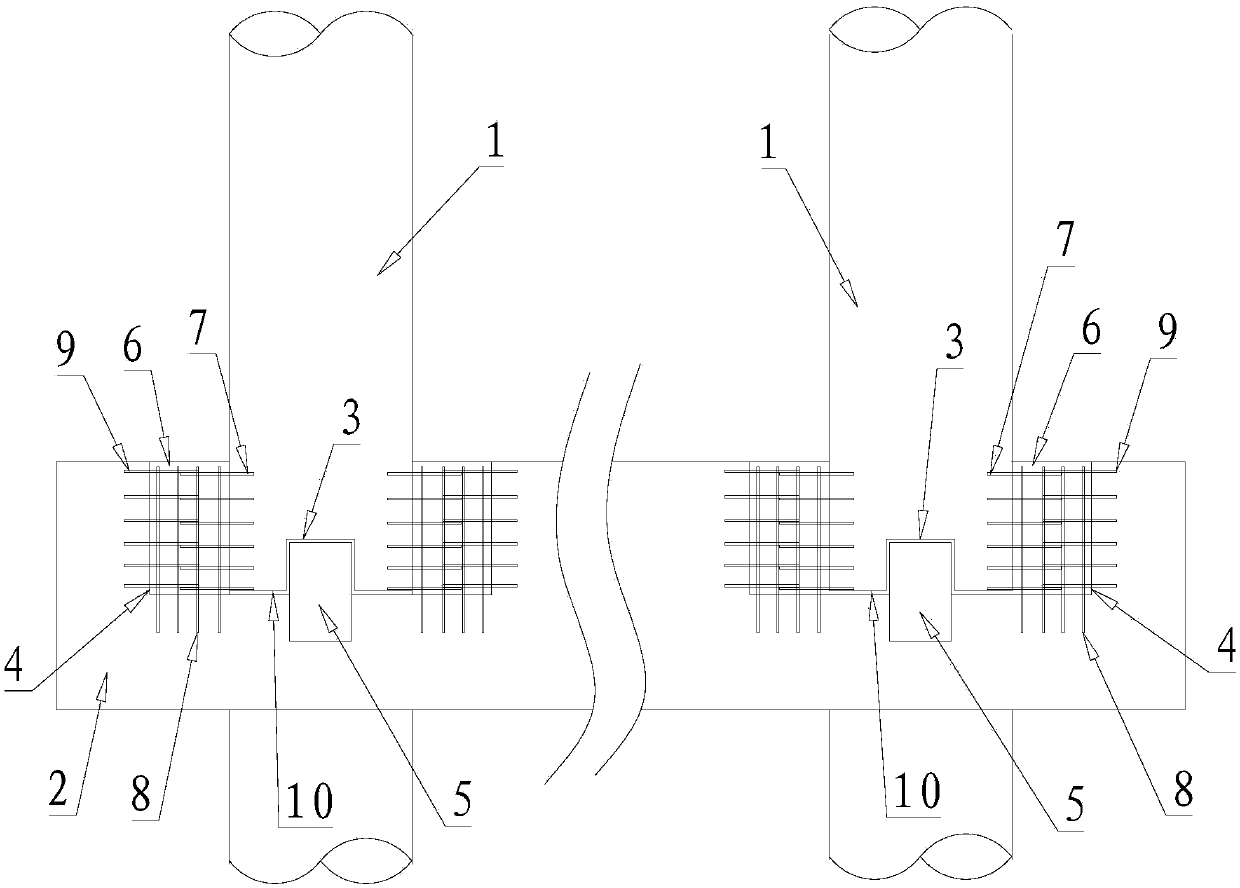

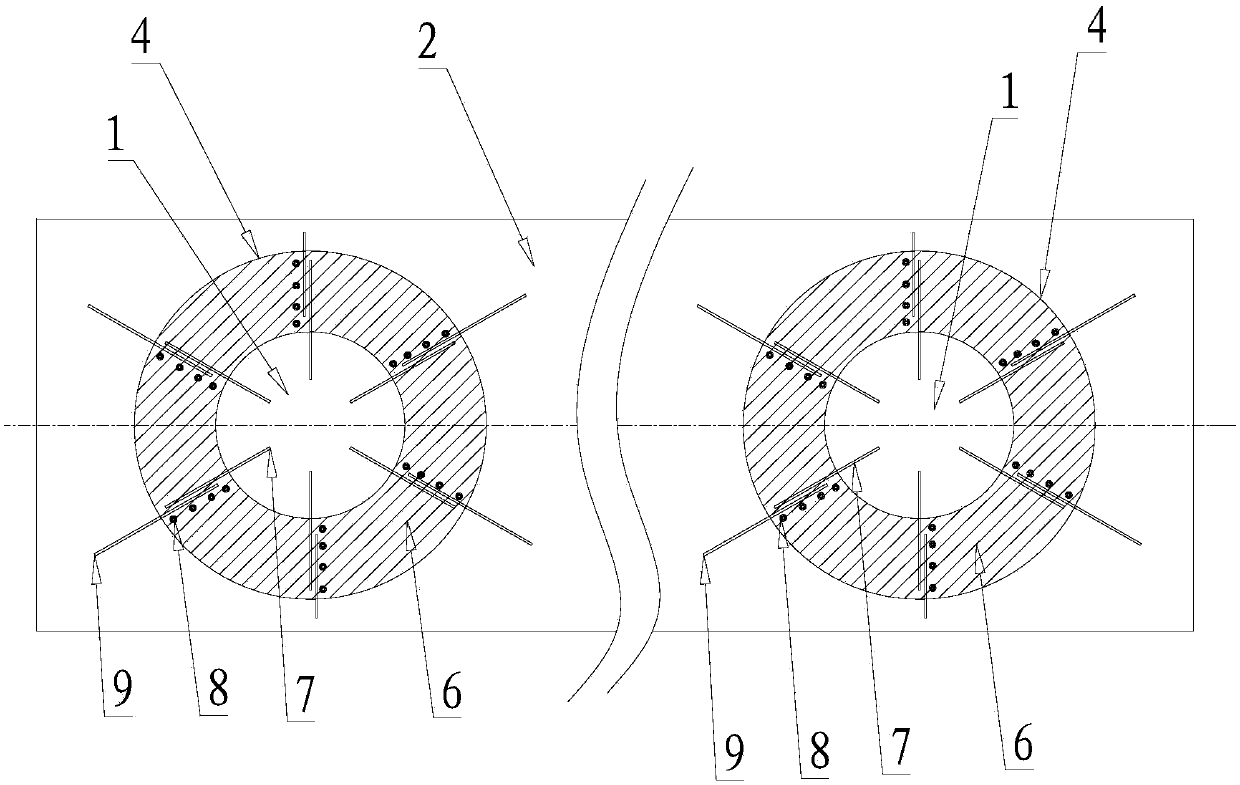

Circular steel tube constraining reinforced concrete-steel beam framework node for nodal-region composite steel tube

InactiveCN105672491AImprove bearing capacityImprove ductilityBuilding constructionsReinforced concrete columnShear capacity

The invention provides a circular steel tube constraining reinforced concrete-steel beam framework node for a nodal-region composite steel tube. The node comprises a first columnar circular steel tube, a second columnar circular steel tube, columnar longitudinal bars, columnar stirrups, a steel beam, a nodal-region inner-layer circular steel tube, a nodal-region outer-layer circular steel tube, outer reinforcing rings, nodal-region stirrups and concrete. The second columnar circular steel tube and the first columnar circular steel tube are located on the upper side and the lower side of the steel beam respectively. The steel beam directly transmits the shear force and the bending moment to the nodal-region inner-layer circular steel tube and then transmits the shear force and the bending moment to the core-region concrete, the condition that the nodal-region outer-layer steel tube directly bears the shear force is avoided to prevent the steel tube from being bent, and therefore the steel tube can fully play an annular constraining role to ensure the bearing capacity and the ductility of the node; the two ends of the nodal-region inner-layer circular steel tube stretch into an upper steel tube constraining reinforced concrete column and a lower steel tube constraining reinforced concrete column by a certain distance respectively, the integrity of the node is guaranteed, and the shear capacity and anti-seismic performance of the node are improved. The node is safe, reliable, good in integrity, clear in force transmission and convenient to construct and has the advantage on force bearing and the economic performance.

Owner:CHONGQING UNIV

Flexible fabric switch

ActiveCN105931909AImprove bending resistanceImprove shear resistanceElectric switchesLayersShear capacityIsolation layer

The invention discloses a flexible fabric switch, and belongs to the field of wearable electronic equipment. The flexible fabric switch comprises an upper conductive layer and a lower conductive layer, wherein an elastic isolation layer is arranged between the upper conductive layer and the lower conductive layer; one or more through holes are formed in the elastic isolation layer; and the upper conductive layer and the lower conductive layer are connected with conductive wires respectively. The flexible fabric switch is simple in structure; meanwhile, the upper conductive layer and the lower conductive layer can be in surface-surface contact for conduction; and in addition, the flexible fabric switch is light, thin and stable, and high in stability, fatigue resistance, bending resistance, and shearing resistance.

Owner:ZHUHAI ADVANPRO TECH

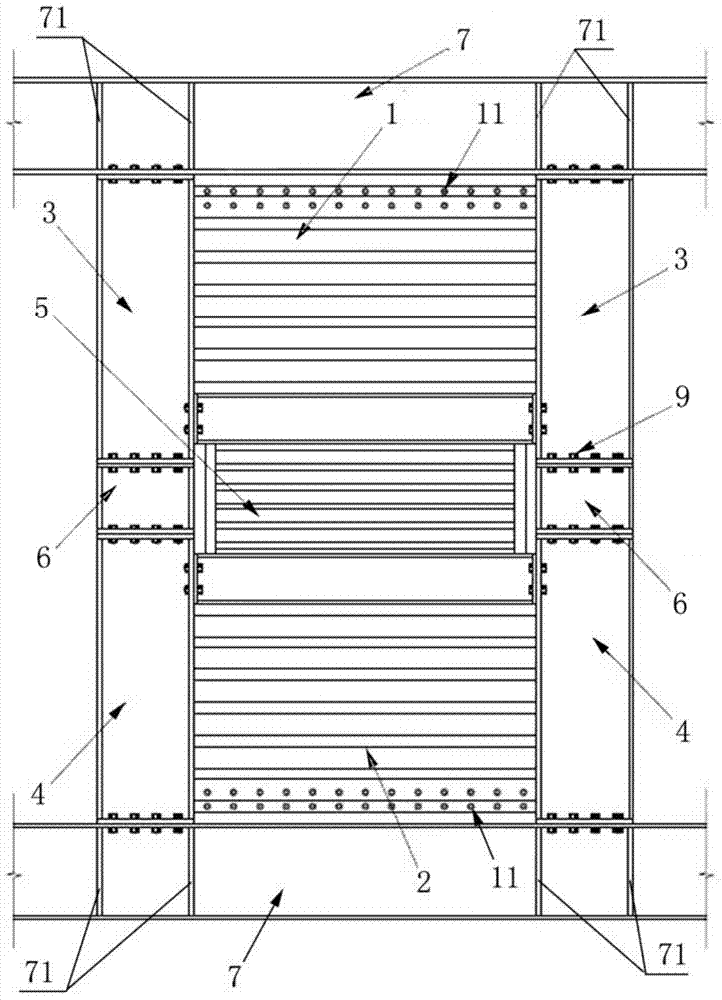

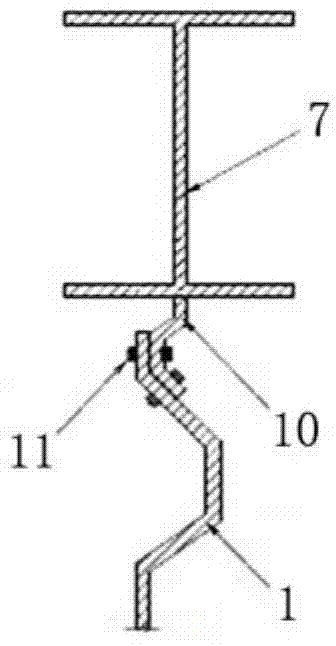

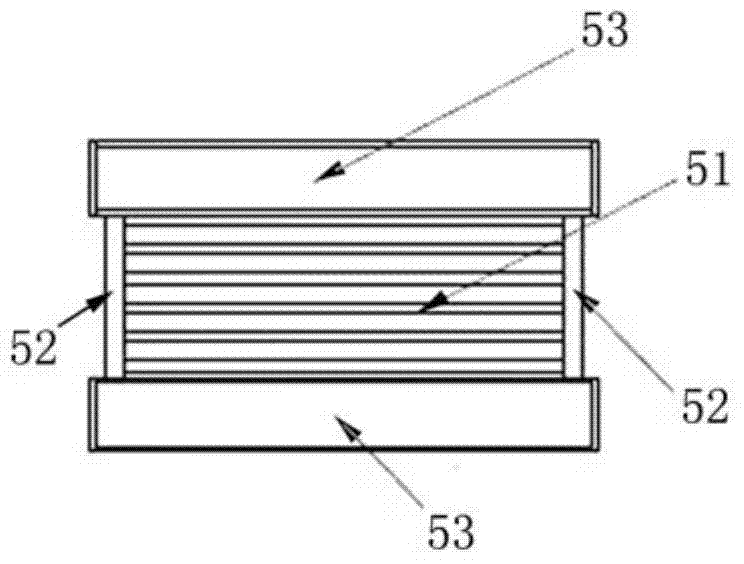

Beam through type corrugated steel plate energy consumption shear wall structure

ActiveCN104746774AIncreased shear capacityReduce building weightWallsShock proofingSheet steelShear capacity

The invention provides a beam through type corrugated steel plate energy consumption shear wall structure which comprises a first corrugated steel plate shear wall piece, a second corrugated steel plate shear wall piece, an upper edge steel column, a lower edge steel column, a corrugated steel plate energy consumption section and short steel columns on the left side and the right side of the corrugated steel plate energy consumption section. The corrugated steel plate energy consumption section and the short steel columns are located in the middle of a floor. The upper end and the lower end of the corrugated steel plate energy consumption section are connected with the first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece respectively. The first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece are connected with a floor beam through bolts respectively. The lower end of the upper edge steel column is connected with the upper ends of the short steel columns through bolts, and the upper end of the lower edge steel column is connected with the lower ends of the short steel columns through bolts. The upper end of the upper edge steel column and the lower end of the lower edge steel column are connected with the floor beam through bolts respectively. The first corrugated steel plate shear wall piece and the second corrugated steel plate shear wall piece are connected with the upper edge steel column and the lower edge steel column respectively. The corrugated steel plate shear wall pieces are adopted as a body of the shear wall structure, and therefore a building is small in dead weight, the material consumption is low, and the shear capacity of a wall body is improved.

Owner:TONGJI UNIV

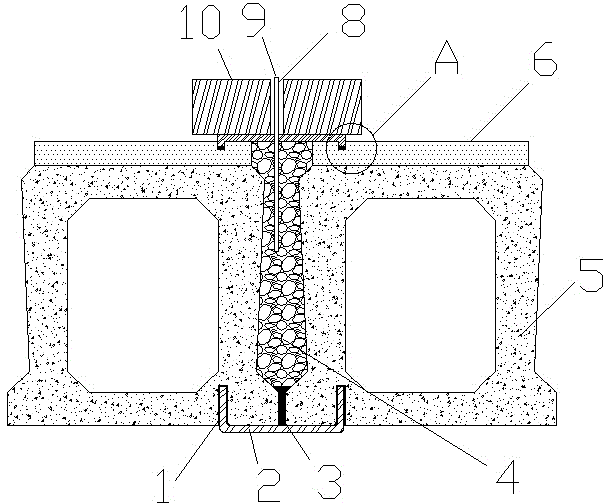

Connecting joint of ring beam of steel core concrete column used for topdown construction method foundation pit engineering

ActiveCN101775844ASolve the rebar crossing problemSolve the problem of low shear capacityStrutsExcavationsReinforced concreteShear capacity

The invention belongs to a connecting joint of a ring beam of a steel core concrete column used for topdown construction method foundation pit engineering in the underground structure of a fixed building. An underground structural beam (3) and a steel core concrete column (2) are connected by a reinforced concrete ring beam (1), a column end socket (4) is formed below the underground structural beam (3) and the steel core concrete column (2) in topdown construction method construction, the section size and the reinforcement of the column end socket (4) are the same as those of a permanent framework column after the topdown construction method execution is finished, the column end socket (4) and a contact position of the steel pipes of the steel core concrete column (2) are connected by using end socket connection studs (12), and the end socket connection studs (12) are welded on the outer walls of the steel pipes of the steel core concrete column (2) and arranged alternately along the outer perimeters of the walls of the steel pipes of the steel core concrete column (2). As optimization, a joint of a steel pipe column and the ring beam can also be provided with annular ribs (6) or studs (5). By adopting the joint, the penetration problem of reinforcing steel bars at the position of the joint of the beam column of the steel core concrete column can be completely avoided, and the problem of shear capacity of the concrete ring beam and the steel core concrete column can also be solved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

Deck installation structure of big-span steel bridge

InactiveCN1920176AReduce the elastic modulus differenceReduced risk of crackingBridge structural detailsPolymer modifiedShear capacity

The invention relates to a floor laying structure of large-span steel bridge, wherein it comprises: panel, waterproof adhesive layer, transition layer, waterproof adhesive layer and pitch laying layer; said transition layer uses polymer cement concrete; the pitch laying layer uses polymer modified pitch concrete; the transition layer is irrigated on the panel with welding nails; the surface of transition layer near to the pitch laying layer has longitudinal and transverse anti-slide grooves; the transition layer can reduce the flexible modulus difference interlayer, to reduce the steering stress and improve the adhesive strength between layers; the welding nails and the anti-slide grooves can improve the friction resistances of laying layer, reduce the horizontal deformation of maximum stress area, and avoid horizontal displacement.

Owner:SHENZHEN OCEANPOWER ENG TECH +1

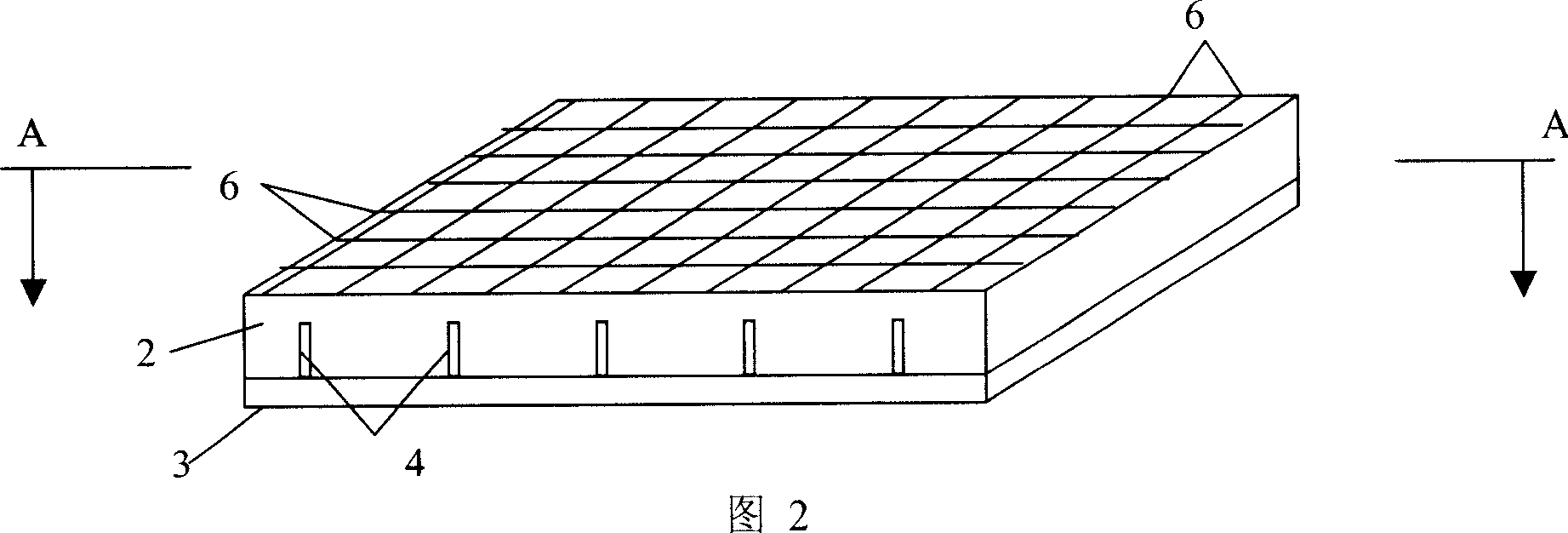

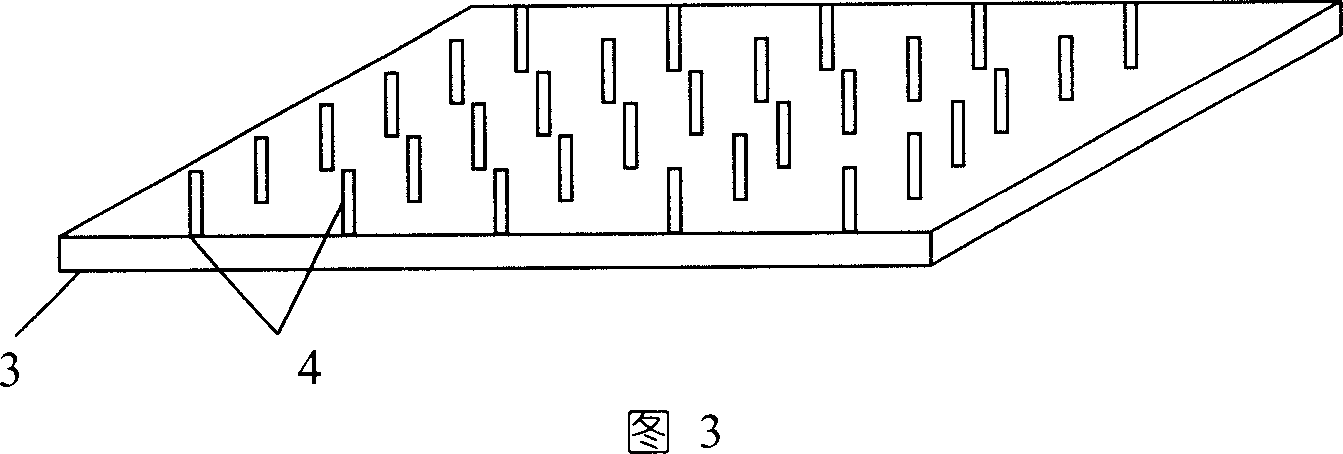

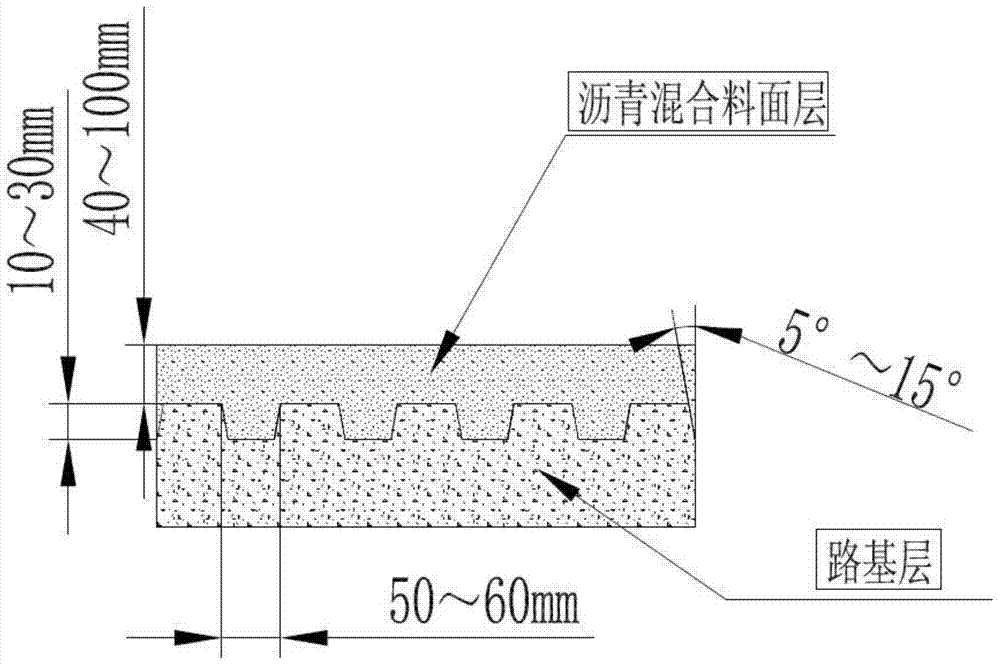

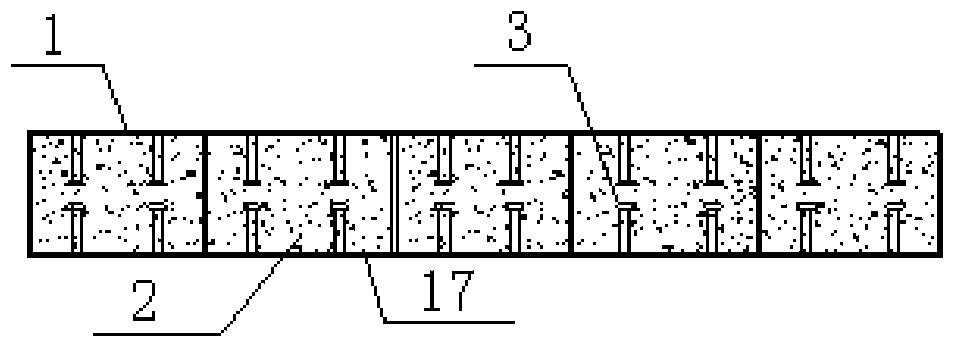

Surface treatment method for base course of asphalt pavement

InactiveCN103758004AImprove carrying capacityIncreased shear strengthIn situ pavingsRoads maintainenceShear capacityRoad surface

Belonging to the technical field of highways, the invention relates to a pavement construction method, particularly to a rolling construction method for an asphalt pavement roadbed. Based on the traditional asphalt pavement paving construction technologies, rolling moulding is further carried out to the base course surface, so that the traditional planar bonding contact of the original asphalt pavement surface and the base course is changed, the base course and a subcrust asphalt mixture are in an embedded compact combination state, so that the interlayer of the base course surface and the asphalt subcrust realizes a denticulate embedded bonding effect in an integral form of compact embedded combination. With the method provided by the invention, after construction, the shearing strength between the base course surface and the subcrust is greatly improved compared with the traditional planar bonding layer construction process, the anti-shear ability between the asphalt pavement and the base course is enhanced, and at the same time, the anti-shear deformation ability of the asphalt pavement is also improved. While the bearing capacity of the asphalt pavement is improved, the service life is also prolonged.

Owner:ALATECH TECH

Linear steel tube bundle composite structure

The invention discloses a linear steel tube bundle composite structure. The linear steel tube bundle composite structure comprises a linear steel tube bundle assembly, wherein the linear steel tube bundle assembly comprises a plurality of steel tube units which are connected in sequence; cavities are formed in the steel tube units; concrete is poured into the cavities; studs are arranged on the side walls of the cavities; through holes are formed in partition plates between adjacent steel tube units. In the steel tube bundle composite structure, steel tube bundles are manufactured in factories and constructed by assembling in the field; the concrete poured in the steel tube bundles is integrated and conveniently poured without a support mold; the steel tube bundles and the concrete work synergistically through the studs; the linear steel tube bundle composite structure is reliable in composite function and high in bending resistance, compression resistance and shear capacity; industrial devices are used in all the processes for producing components of the steel tube bundle composite structure, so that the steel tube bundle composite structure is high in production speed and high in quality of products; meanwhile, a large quantity of labor is saved.

Owner:HANGXIAO STEEL STRUCTURE

Prefabricated concrete frame structure and manufacturing method thereof

ActiveCN106149873AEnsure continuityEnsure integrityBuilding constructionsShear capacityAgricultural engineering

The invention discloses a prefabricated concrete frame structure which comprises prefabricated columns and prefabricated beams. Each prefabricated column is connected with one end of the corresponding prefabricated beam, a node area is formed at a joint of each prefabricated column and the corresponding prefabricated beam, each prefabricated beam is divided into an upper-layer column body and a lower-layer column body by the corresponding node area, each upper-layer column body and the corresponding lower-layer column body are connected through longitudinal reinforcing steel embedded in the prefabricated column in the corresponding node area, and column body longitudinal rebars are embedded in each prefabricated column and are continuous in the corresponding node area; beam end reinforcing steel is embedded at one end, connected with the corresponding prefabricated column, of each prefabricated beam, and the longitudinal reinforcing steel and the beam end reinforcing steel are connected through bolts. The invention further discloses a manufacturing method of the prefabricated concrete frame structure. Nodes of the prefabricated concrete frame structure are equivalent to cast-in-place concrete frame nodes in anti-seismic performance and energy dissipating capacity, anti-seismic concept design of 'strong nodes and weak components', 'strong shear capacity and weak bending capacity' and 'strong columns and weak beams' is realized, and construction process and difficulty can be reduced.

Owner:FOSHAN ELECTRIC POWER DESIGN INST +1

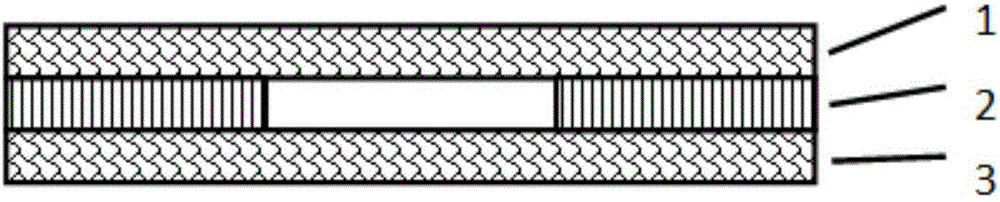

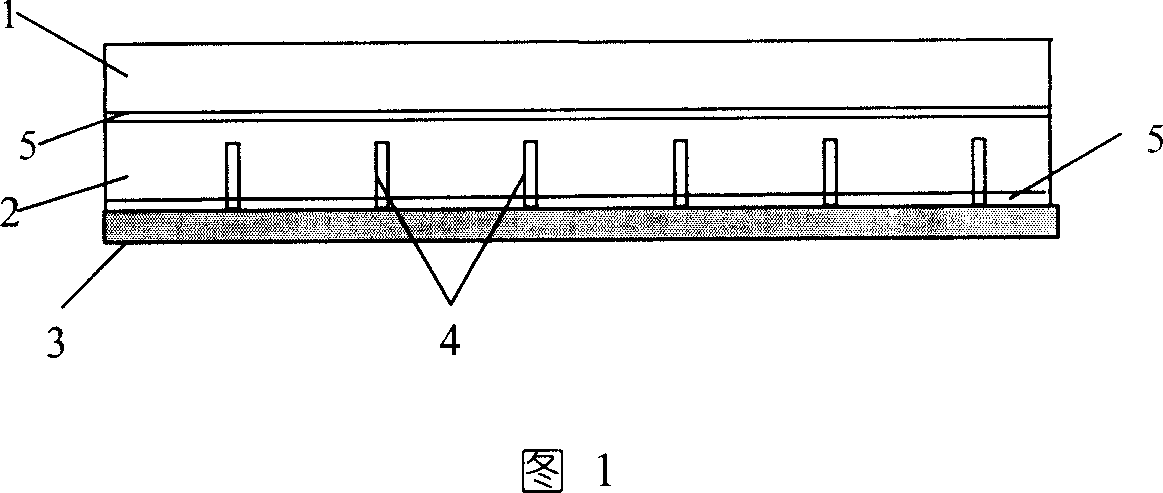

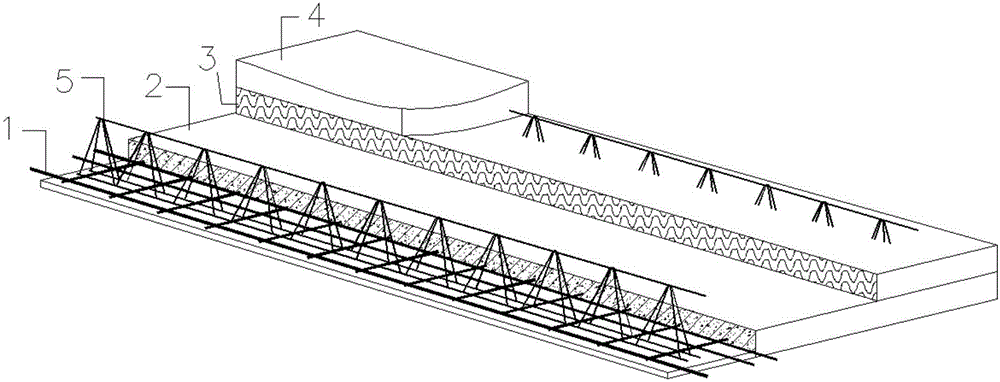

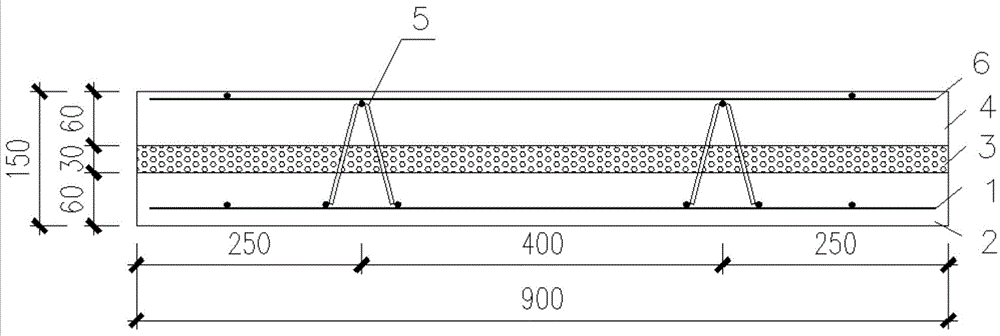

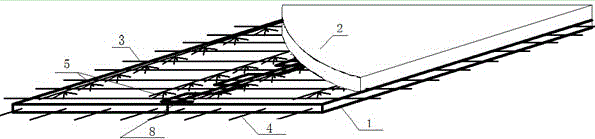

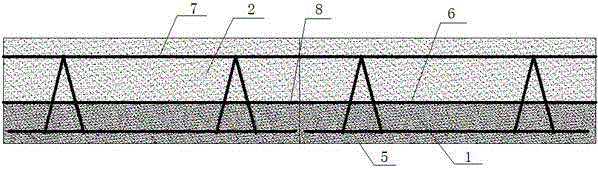

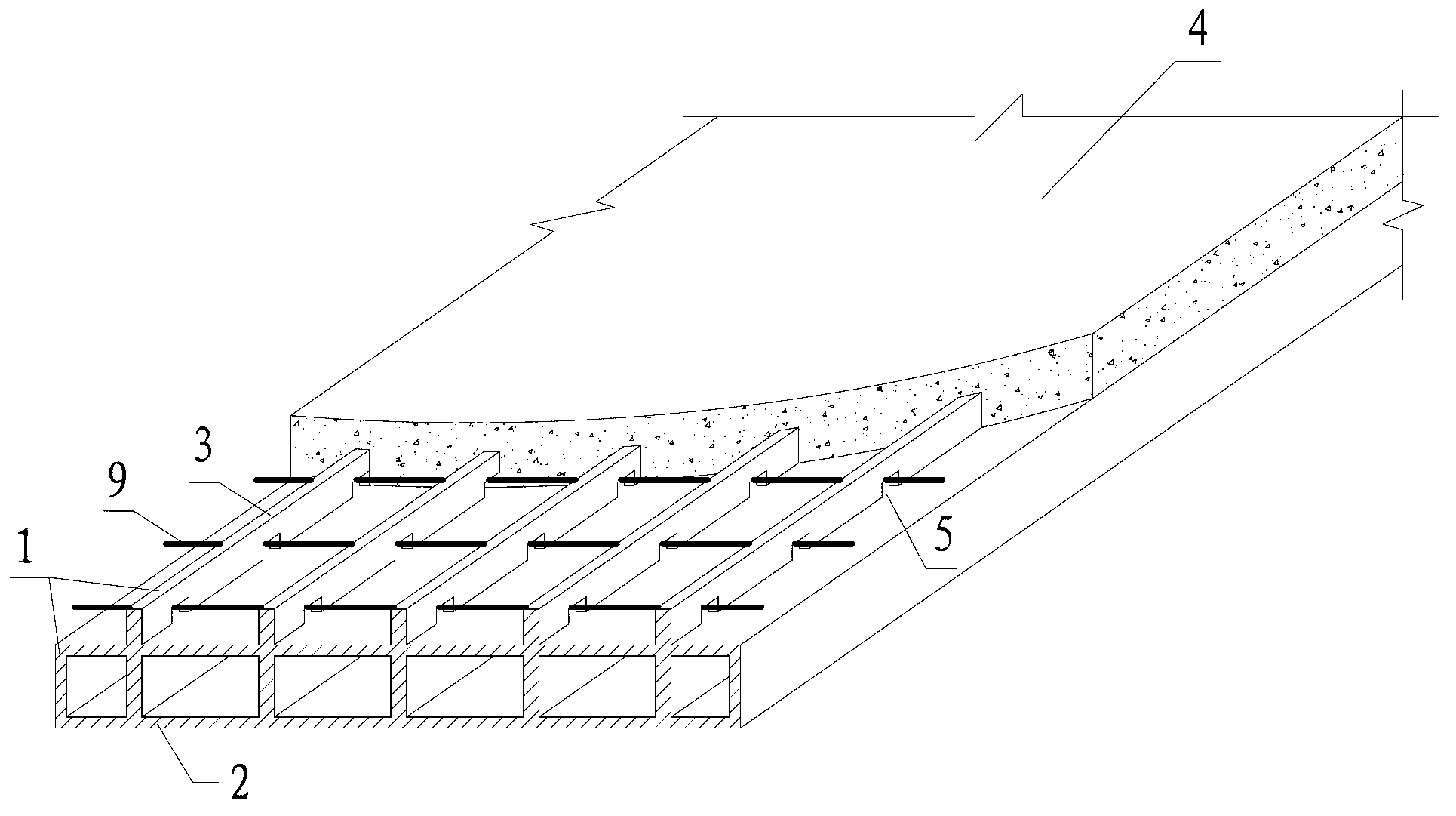

Composite floor slab based on polyphenyl granule fiber concrete sandwich insulation and construction method

InactiveCN106522440AImprove bearing capacityIncreased durabilityFloorsHeat proofingRough surfaceFiber

A composite floor slab based on polyphenyl granule fiber concrete sandwich insulation comprises a prefabricated bottom plate concrete layer, a polyphenyl granule fiber concrete prefabricated bottom plate insulation layer is arranged on the prefabricated bottom plate concrete layer, and a post-poured layer is arranged on the polyphenyl granule fiber concrete prefabricated bottom plate insulation layer. The invention further provides a construction method for the composite floor slab. The polyphenyl granule fiber concrete sandwich insulation layer is poured on the basis of a common steel bar truss composite floor slab, and the novel sandwich insulation composite floor slab is formed by combining the prefabricated bottom plate concrete layer, the polyphenyl granule fiber concrete insulation layer and the on-site post-poured layer; load bearing and heat insulation of the floor slab are integrated, later insulation treatment of a roof panel is omitted, and field operations are reduced; and the mode of combining a steel bar truss and a rough surface is further adopted, the steel bar truss penetrates through the three layers of the whole composite floor slab to tightly combine the three layers of the whole composite floor slab, and thus the bearing capacity, shear capacity and integrity of the composite insulation floor slab are improved.

Owner:西咸新区矩阵实业有限公司

Anti-buckling steel plate seismic shear wall provided with stiffening ribs

ActiveCN106013506AGuaranteed stabilityPrevent local bucklingWallsProtective buildings/sheltersHorizontal forceShear capacity

The invention discloses an anti-buckling steel plate seismic shear wall provided with stiffening ribs. The anti-buckling steel plate seismic shear wall comprises a steel plate wall, horizontal stiffening ribs, vertical stiffening ribs, steel columns and steel girders, wherein the steel plate wall is arranged in a frame formed by the steel columns and the steel girders, and the multiple horizontal stiffening ribs are uniformly fixed on two side wall surfaces of the steel plate wall at vertical intervals and horizontally welded on the steel plate wall; the multiple vertical stiffening ribs are fixed between the horizontal stiffening ribs at horizontal intervals and are vertically arranged, and upper ends and lower ends of the vertical stiffening ribs are welded with the horizontal stiffening ribs; a gap is reserved between each vertical stiffening rib and the steel plate wall. According to the anti-buckling steel plate seismic shear wall provided with the stiffening ribs, overall buckling and local buckling of the steel plate wall can be prevented, so that the steel plate wall can only yield, and the shear capacity and the severe earthquake energy dissipation performance of the steel plate wall are improved; the anti-buckling steel plate seismic shear wall is simple in structure and reasonable in stress, can bear horizontal force under the action of the earthquakes, and is convenient to construct and high in degree of industrialization.

Owner:HANGZHOU TONGMSK DESIGN CO LTD

Connection joint of core drum wall body and concrete beam and construction technology

PendingCN107119803AHigh quality connectionGuaranteed shear performanceBuilding constructionsConcrete beamsShear capacity

The invention relates to the technical field of architectural structures, in particular to a connection joint of a core drum wall body and a concrete beam and a construction technology. The connection joint comprises the core drum wall body and the concrete beam. A groove is formed in the core drum wall body. A bulge matched with the groove is arranged on the concrete beam. A pre-embedded part is pre-arranged in the core drum wall body. The pre-embedded part comprises connectors, wall body anchor bars, a filling part and a vertical plate. A through hole is formed in the vertical plate. One end of the filling part is inserted in the through hole and used for taking out the filling part to form the groove after the core drum wall body is poured. The inner side surface of the vertical plate is connected with the connectors. The connectors are connected with the wall body anchor bars. The position where the vertical plate is connected with the connectors is provided with connecting holes. Longitudinal bars are pre-arranged in the concrete beam. The longitudinal bars are connected with the connectors by penetrating through the connecting holes. According to the connection joint of the core drum wall body and the concrete beam and the construction technology, the groove is reserved under the condition that sliding formwork construction or creeping formwork construction of the core drum wall body is met, and the fact that the wall body is connected with the beam in a high quality mode and the shear capacity are ensured.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE +2

Small-section square girder and welding process thereof

ActiveCN102773590AResolve the breakSolve Weld CrackingElongated constructional elementsArc welding apparatusShear capacityWelding deformation

The invention discloses a small-section square girder and welding process thereof, belonging to welding technology and capable of solving the problem of low welding quality in case of small manual welding space. The small-section square girder has four girder plates with widths of 200-220mm and lengths smaller than or equal to 10m in paired arrangement to form a box-shaped inner cavity, in which are arranged reinforcement rib plates, flanges are welded at two ends of the girder plates, and inside and outside fillets are present between the girder plates and between the girder plates and the flanges. In welding, a to-be-welded part is cleaned before welding, a run-on plate and a run-off plate are assembled and welded, welding is carried out by use of an automatic welding cart, an inner cavity and an exposed welding seam alternate welding sequence is adopted during welding, an inner cavity backing welding seam is firstly formed, the backing welding seam for an exposed welding seam is then formed after the back gouging is strictly performed, the inner cavity and the exposed welding seam are sequentially formed, and a back-step welding method is adopted. According to the invention, welding deformation is controlled within an allowable range, torsion resistance and shearing resistance of the small-section square girder are improved, and stability and reliability of the girder are ensured.

Owner:SHANXI PINGYANG IND MACHINERY

Cast-in-place shear wall structure equivalent to prefabricated sandwiched superposed shear wall continuous steel bar

The invention provides a cast-in-place shear wall structure equivalent to a prefabricated sandwiched superposed shear wall continuous steel bar, the cast-in-place shear wall structure is formed by connecting a prefabricated superposed shear wall outer acanthus, an insulating layer, a prefabricated superposed shear wall intermediate plate, a lattice steel bar and a prefabricated superposed shear wall inner acanthus, the upper ends and the lower ends of the prefabricated superposed shear wall intermediate plate and the prefabricated superposed shear wall inner acanthus are all shorter than the prefabricated superposed shear wall outer acanthus and the insulating layer, and the steel bar extends out; in construction and installation, the downward extended steel bars of the upper layer prefabricated superposed shear wall intermediate plate and inner acanthus are respectively fixedly connected with the upward extended steel bars of the lower layer prefabricated superposed shear wall intermediate plate and inner acanthus, and concrete is cast between the intermediate plate and the inner acanthus to form a structure system containing the insulating layer and equivalent to the cast-in-place shear wall. The cast-in-place shear wall structure provided by the invention is insulating and energy-saving, strong in seismic capacity, structure strength and anti-shear capacity, the technical problem that the sandwiched superposed shear wall cannot be applied to the high-rise building is broke through, and the industrial production is realized.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

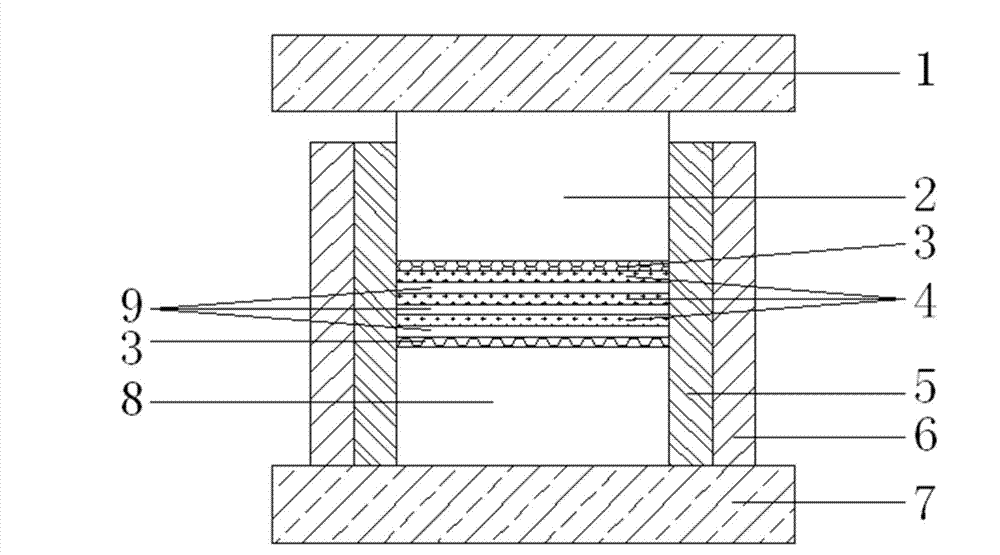

Method for manufacturing multi-layer amorphous alloy and crystal metal composite structure through diffusion welding

InactiveCN102886599AAvoid brittlenessImprove shear resistanceNon-electric welding apparatusShear capacityAlloy

The invention discloses a method for manufacturing a multi-layer amorphous alloy and crystal metal composite structure through diffusion welding. The method comprises the following steps of: cutting, grinding and cleaning an amorphous alloy sheet and a crystal metal sheet, assembling and fixing the amorphous alloy sheet and the crystal metal sheet so as to form a fixed workpiece, and welding the fixed workpiece in a vacuum diffusion furnace. According to the composite structure, extension of a shear band of an amorphous alloy material in the shearing process can be blocked, so that the problem that the pure amorphous alloy material has high brittleness is solved, and the shear resistance is improved. In addition, the welded amorphous alloy material can continuously keep the amorphous characteristics, compared with that of the pure amorphous alloy material, the shear resistance of the composite structure material is greatly improved, the toughness is improved, and the welded sheet is high in surface quality and reliable in connection.

Owner:HUAZHONG UNIV OF SCI & TECH

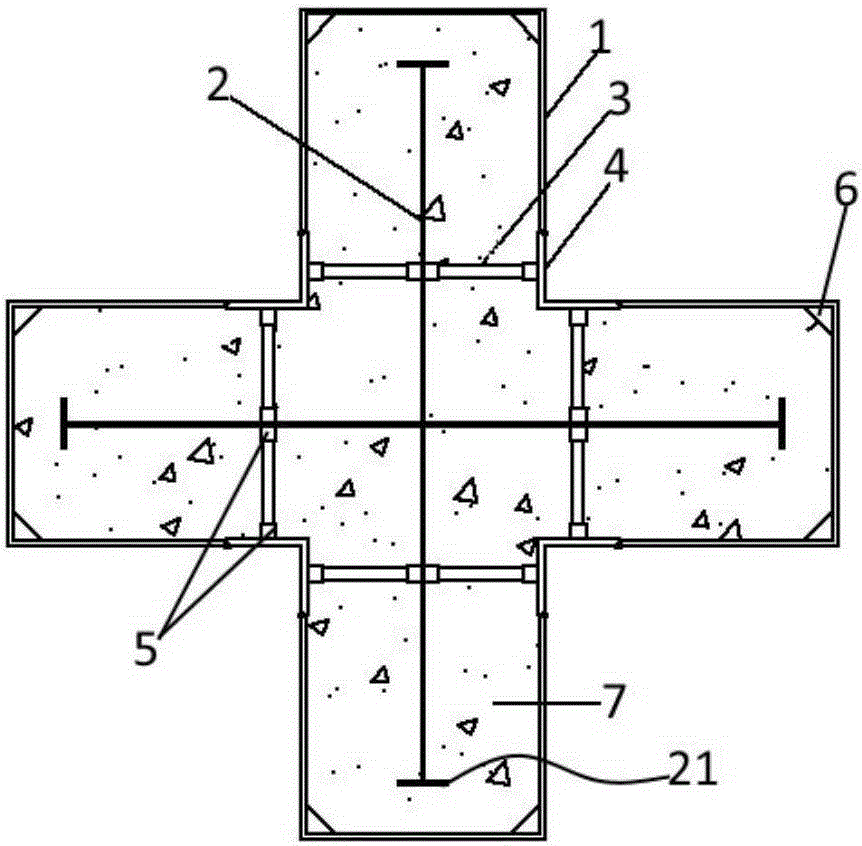

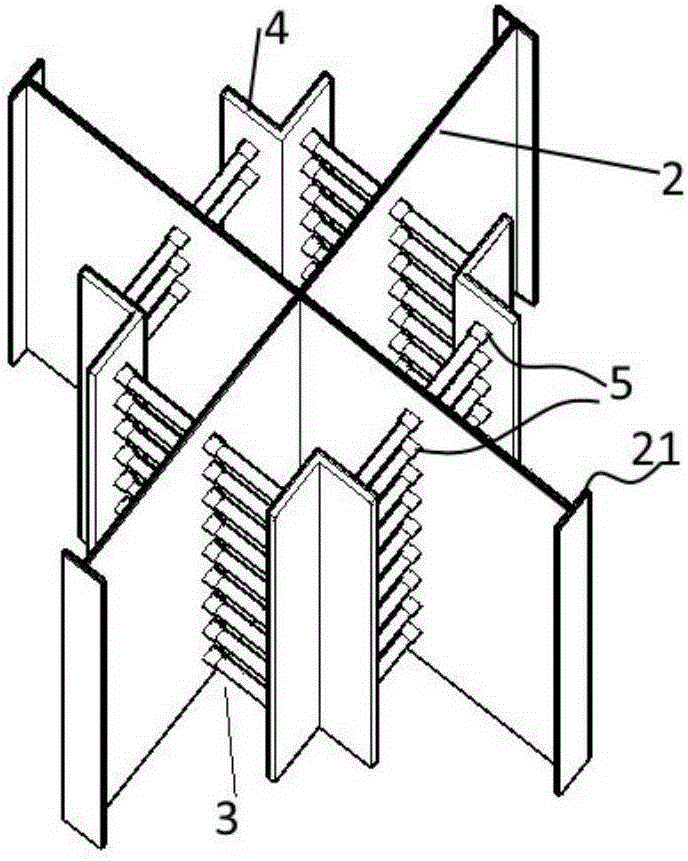

Inner truss system, shape steel-steel pipe concrete cross column and method for constructing same

InactiveCN105220833AEnhanced hoop effectIncreased load-bearing capacityStrutsPillarsShear capacitySteel tube

The invention discloses an inner truss system, a shape steel-steel pipe concrete cross column and a method for constructing the same. The shape steel-steel pipe concrete cross column comprises outer wrapping steel pipes, inner filled concrete and the inner truss system. The inner truss system comprises shape steel with a crossed transverse section, angle steel with an inverted-L-shaped transverse section, pressure sleeves and draw bars. The pressure sleeves are longitudinally arranged on web plates of the angle steel and the shape steel along a truss system, two ends of each draw bar are respectively fixedly connected with the corresponding pressure sleeve on the corresponding web plate of the shape steel and the corresponding pressure sleeve on the angle steel, and the angle steel is distributed to form quadrilaterals; the angle steel is fixedly connected with the outer wrapping steel pipes. The inner truss system, the shape steel-steel pipe concrete cross column and the method have the advantages that the bearing capacity and the shear capacity of column components can be improved by the steel pipes and the inner truss system, the ductility of the components can be obviously improved, and the anti-seismic capacity of structures can be enhanced; outer planar support effects can be realized by inner trusses for the web plates of the shape steel, accordingly, width-thickness ratios and height-thickness ratios of the web plates can be decreased, and the stability of the web plates can be improved.

Owner:HOHAI UNIV

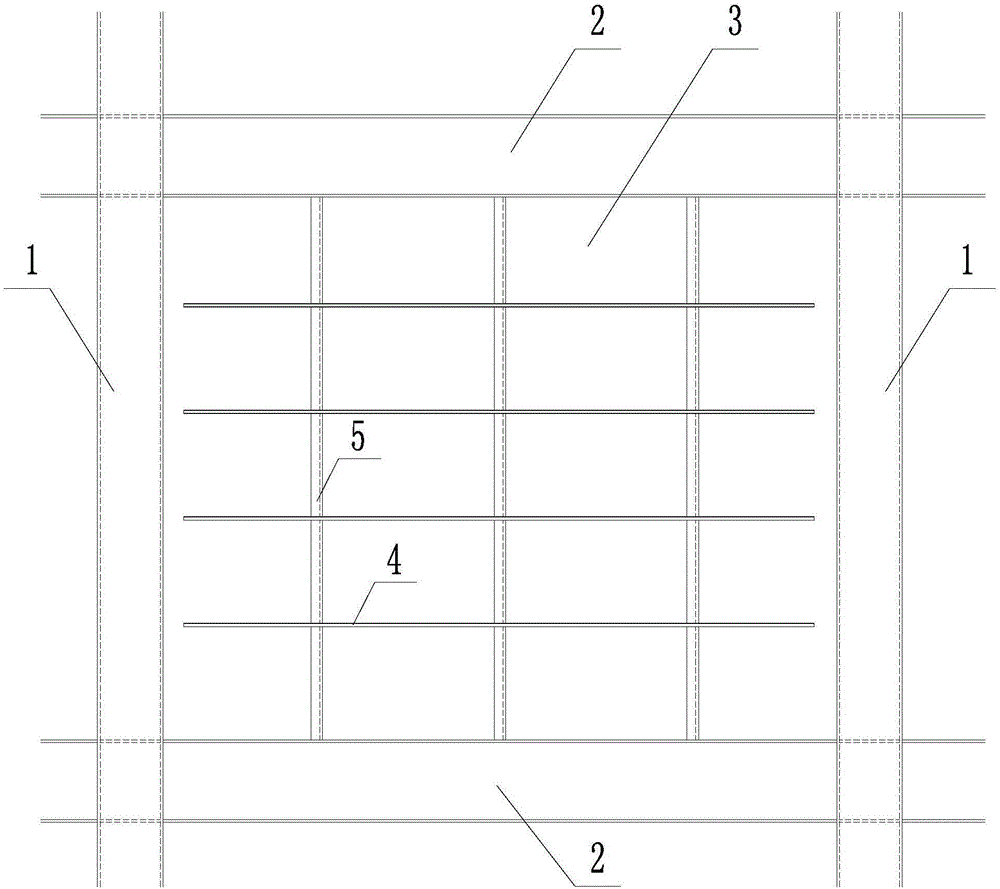

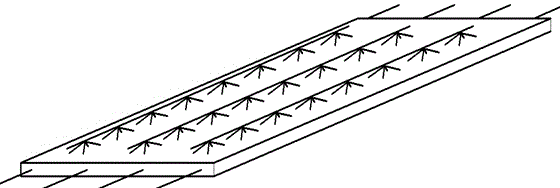

Assembly type composite floor slab

The invention provides an assembly type composite floor slab. The rigidity of a composite slab and the shear capacity of the combination surface can be improved, the production mode can be optimized, and construction can be convenient. The assembly type composite floor slab comprises a composite slab prefabrication bottom slab, a concrete composite layer and a plurality of trusses. Longitudinal pre-stress steel bars and transverse pre-stress steel bars are arranged in the composite slab prefabrication bottom slab, fold line steel bars are arranged on the joints of the composite slab, the concrete composite layer is poured on the composite slab prefabrication bottom slab, the bottoms of the trusses are embedded in the composite slab prefabrication bottom slab, and the tops of the trusses are higher than the upper surface of the composite slab prefabrication bottom slab and buried in the concrete composite layer.

Owner:山东隆和节能科技股份有限公司

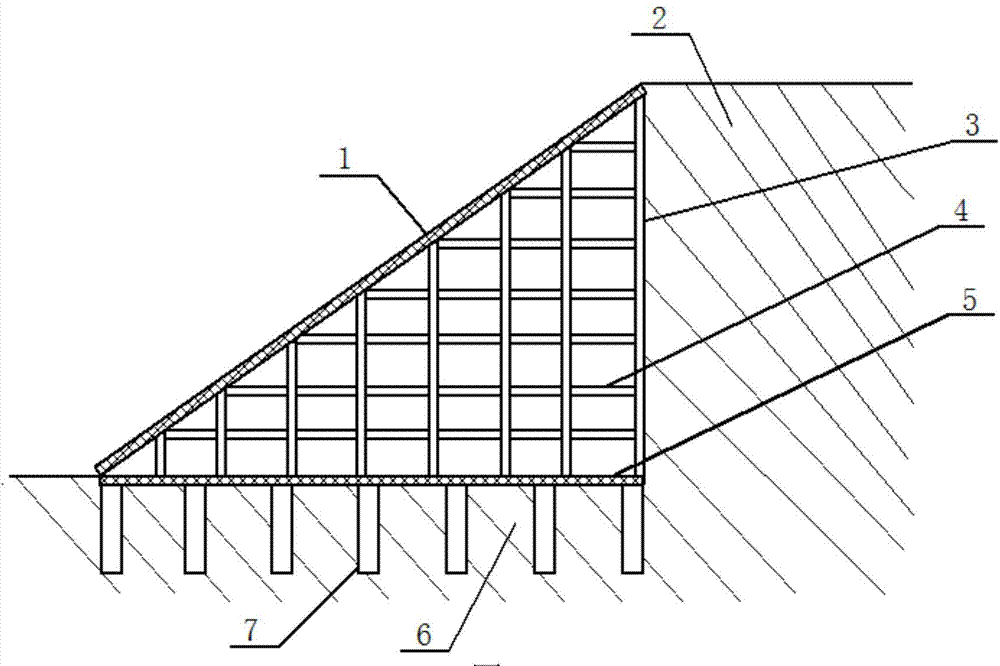

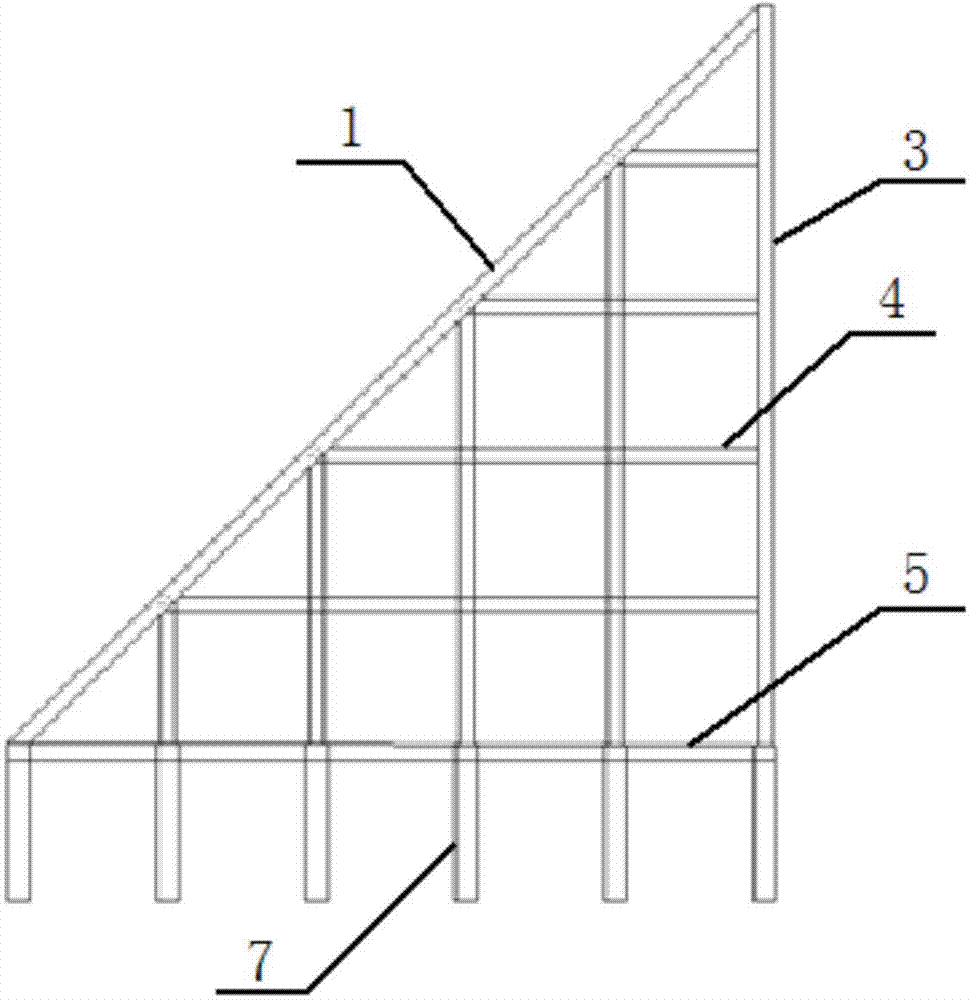

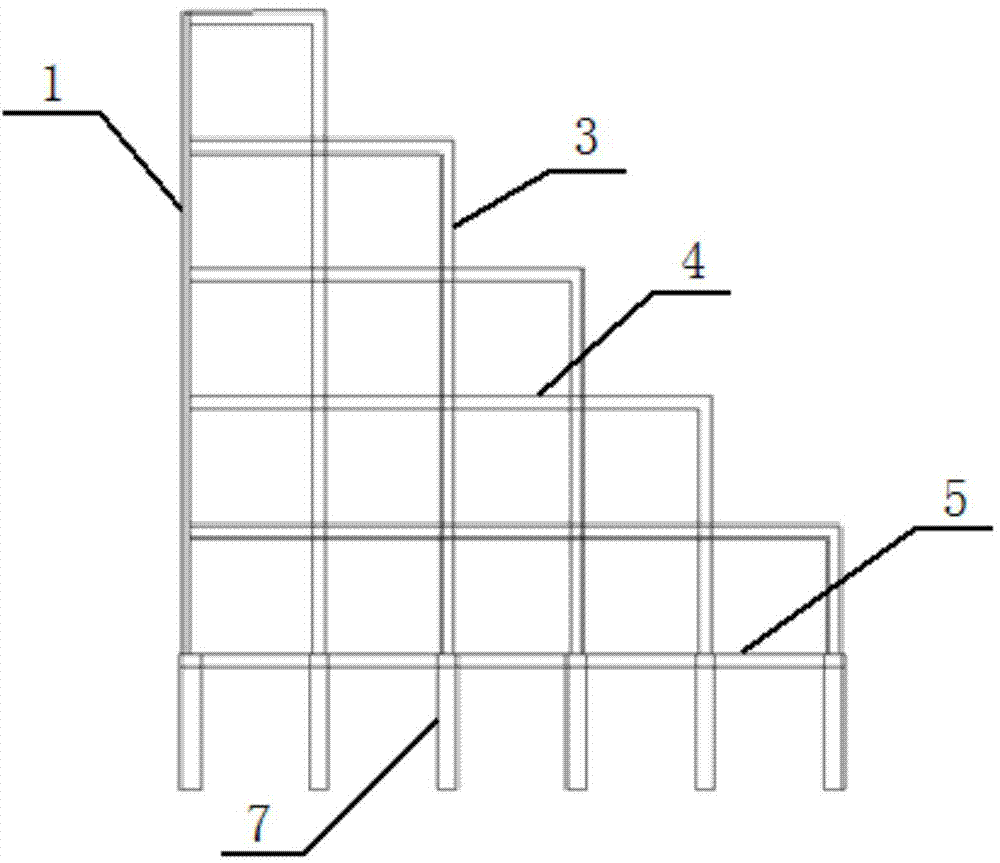

Three-dimensional continuous frame type reinforced concrete structure retaining wall

ActiveCN103485363AIncreased local pressureEnsure stabilityArtificial islandsExcavationsReinforced concreteShear capacity

The invention belongs to the field of construction engineering, and relates to a three-dimensional continuous frame type reinforced concrete structure retaining wall. The three-dimensional continuous frame type reinforced concrete structure retaining wall comprises piles which are fixedly connected through a ground beam. Columns are fixedly connected to a base plate, the columns are in rigid connection through girders so that a frame can be formed, and a shingle is arranged on the outer vertical face of the frame. The three-dimensional continuous frame type reinforced concrete structure retaining wall is simple in structure, the frame type structure is adopted, a frame body is rooted into a stable foundation supporting layer, the lateral pressure of a side slope soil layer is dispersed through the girders and the columns, the overlarge local pressure of a wall body can be avoided, anti-sliding capacity, shear capacity and bearing capacity are enhanced, the stability and the durability of the retaining wall are guaranteed, the potential risks of engineering can be greatly reduced, and the three-dimensional continuous frame type reinforced concrete structure retaining wall is suitable for enclosing and retaining side slope soil mass in loose sandy soil, recent fill and soil piling and filling areas which can not be closely grained easily.

Owner:HAINAN HENGXIN CIVIL ENG CONSTR

Ribbed FRP (fiber reinforced plastic) component and concrete composite bridge deck

InactiveCN103194970AIncrease contact areaIncrease mechanical bite forceBridge structural detailsFiberSurface layer

The invention discloses a ribbed FRP (fiber reinforced plastic) component and concrete composite bridge deck which comprises a ribbed FRP component and a later-poured concrete surface layer. The ribbed FRP component comprises two parts including an FRP baseplate on the lower portion and longitudinal FRP plate ribs on the FRP baseplate, at least one of the FRP baseplate and the longitudinal FRP plate ribs has a hollow section, and transverse through holes are arranged in the longitudinal FRP plate ribs. The longitudinal FRP plate ribs and the transverse through holes thereon increase contact area of the ribbed FRP component and concrete, improve anti-shearing capacity of a contact face and improve performance of a laminated face; the FRP baseplate or / and the longitudinal FRP plate ribs in hollow-section forms can lower material consumption, increase component stiffness and enable overall performance of the composited bridge deck to be substantially improved. The ribbed FRP component and concrete composite bridge deck is simple in structure, convenient to manufacture and construct, free of additional formworks and supports, and excellent in structural mechanics performance, and can effectively solve many problems of current composite bridge deck structures.

Owner:黄海林

Structure joint of novel reinforced concrete column-steel beam combined framework

InactiveCN101718118AIncrease stiffnessGood under pressureBuilding constructionsReinforced concrete columnShear capacity

The invention discloses a structure joint of a novel reinforced concrete column-steel beam (RCS) combined framework, which comprises a steel beam, a reinforced concrete column and high-strength connecting bolts, wherein the reinforced concrete column comprises a square-shaped steel plate barrel, longitudinal steel bars and a plurality of stiffened steel plates which are arranged in the square-shaped steel plate barrel and divide the square-shaped steel plate barrel into a plurality of cells in a cross sectional direction; the stiffened steel plates and the square-shaped steel plate barrel are welded into a whole; the longitudinal steel bars passes through the cells respectively; concrete is cast in the cells respectively; and the steel beam is connected to the outer barrel wall of the square-shaped steel plate barrel by connecting end plates and the high-strength connecting bolts. Compared with the prior art, the invention provides extremely high shear capacity for the square-shaped steel plate barrel and the stiffened steel plates in the square-shaped steel plate barrel in the joint area, thereby truly meeting the requirements for high-strength joints in the earthquake-resisting design. The joint dispenses with penetrating steel beams and penetrating connecting bolts and stirrups arranged in the core area of the joint. The joint has the advantages of simple structure and high construction operability, directly solves the difficult engineering problems of reinforcement binding and concrete casting in the core area of the RCS joint and has high practicability in engineering.

Owner:HUAQIAO UNIVERSITY

Splicing structure and splicing method of prefabricated bridge piers and prefabricated bearing platform

PendingCN108049305APrecise positioningShorten the construction periodBridge structural detailsFoundation engineeringShear capacityUltimate tensile strength

The invention provides a splicing structure and a splicing method of prefabricated bridge piers and a prefabricated bearing platform. By utilizing the joggling of hollow steel tubes in first concave grooves in the bottoms of the prefabricated bridge piers and concrete filled steel tube tenons enclosed by the inner walls of annular grooves in the top of the prefabricated bearing platform, on one hand, favorable positioning effects are achieved for the mounting, on the bearing platform, of the prefabricated bridge piers, and on the other hand, the shear capacity and the flexural capacity at splicing positions are improved; post-poured concrete is poured into the annular grooves to enwrap the splicing positions of the prefabricated bridge piers and the prefabricated bearing platform; the prefabricated bridge piers and the prefabricated bearing platform are connected into a whole; an overall stress structure is ameliorated; the splicing strength of the prefabricated bride piers and the prefabricated bearing platform is greatly improved, and is not less than the strength of a cast-in-place bridge pier. By adopting a way of splicing the prefabricated bride piers and the prefabricated bearing platform, the field pouring workload of concrete is effectively reduced; the field operation is facilitated; a road is not occupied; influences on an urban traffic environment during the operation are effectively relieved, and meanwhile, a construction period of a bridge is shortened.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com